Process for stably processing foie gras without fat isolation and with low oxidation

A processing technology, a steady-state technology, applied in the field of food science, can solve the problems of oxidation, short product shelf life, easy segregation of product fat, etc., to prevent oxidation and loss, prevent fat oxidation and nutrient loss, and prevent liver rupture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

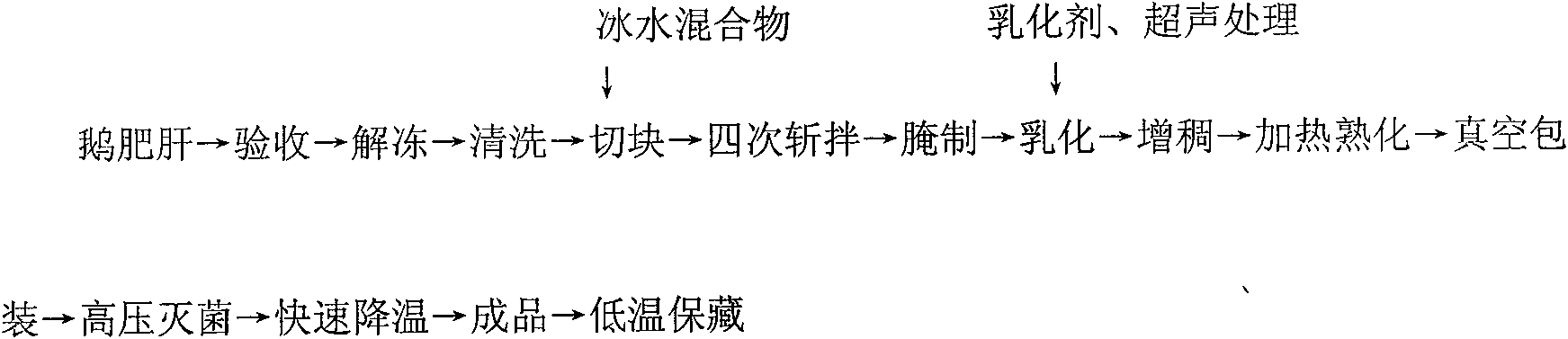

Method used

Image

Examples

example 1

[0025] 1. Select the frozen fresh foie gras and slowly thaw it at 5°C to remove the connective, blood clots in the liver tissue and the possible bile or exudate that may be attached to the liver.

[0026] 2. Cut the foie gras into pieces in the ice-water mixture state, weigh 5 kg of raw materials, and perform vacuum chopping and mixing for 4 times, each chopping and mixing for 10 minutes, so that the foie gras is homogenized into a paste.

[0027] 3. Add 250g of salt, 100g of white sugar, 250g of five-spice powder, 100g of chicken essence, 250g of green onion, 250g of ginger, 100g of sesame oil, and an appropriate amount of clean water to the goose fat liver that has been homogenized into a paste, mix well and marinate at 4°C 24 hours.

[0028] 4. Add 3g of emulsifier sucrose ester and 5g of casein, mix well and use 150W, 20kHz ultrasonic treatment for 20 minutes.

[0029] 5. Add 3g of sodium alginate, 4g of β-cyclodextrin, and 2g of guar gum, and stir well.

[0030] 6. Matu...

example 2

[0032] 1. Select the frozen fresh foie gras and slowly thaw it at 5°C to remove the connective, blood clots in the liver tissue and the possible bile or exudate that may be attached to the liver.

[0033] 2. Cut the foie gras into pieces in the ice-water mixture state, weigh 5 kg of raw materials, and perform vacuum chopping and mixing for 4 times, each chopping and mixing for 10 minutes, so that the foie gras is homogenized into a paste.

[0034] 3. Add 250g of salt, 100g of white sugar, 250g of five-spice powder, 50g of chicken essence, 300g of green onion, 300g of ginger, 150g of sesame oil, and an appropriate amount of clean water to the goose fat liver that has been homogenized into a paste, mix well and marinate at 3°C 24 hours.

[0035] 4. Add 4g of emulsifier monoglyceride and 6g of modified soybean lecithin, mix thoroughly and use 200W, 40kHz ultrasonic treatment for 15 minutes.

[0036] 5. Add 4g of starch, 5g of gum arabic, and 3g of carrageenan, and stir well.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com