Patents

Literature

214 results about "Pickling Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional aluminum material corrosion-inhibition polishing pickling agent

The invention discloses a multifunctional aluminum material corrosion-inhibition polishing pickling agent. The multifunctional aluminum material corrosion-inhibition polishing pickling agent is prepared from the following components in parts by weight: 70-85 parts of inorganic acid, 3-8 parts of a compound organic corrosion inhibitor, 1-2 parts of an inorganic corrosion inhibitor, 2-4 parts of a surfactant, 1-3 parts of a complexing agent, 0.05-0.3 part of micro high-valent metal ion salt and 5-15 parts of a solvent. The multifunctional aluminum material corrosion-inhibition polishing pickling agent disclosed by the invention can be used for quickly and efficiently cleaning the surface of the aluminum material to achieve effects of removing oil, scrubbing, polishing, passivating and the like, thereby avoiding resource waste caused by an over corrosion phenomenon; after being pickled, the aluminum material can be restored to be bright and clean, so that the aluminum material is almost not corroded.

Owner:苏州禾川化学技术服务有限公司

Environment-friendly reaction type polishing brightener composition and preparation method and application thereof

The invention discloses an environment-friendly reaction type polishing brightener composition and a preparation method and application thereof and belongs to the field of fine chemical engineering. The components of the environment-friendly reaction type polishing brightener composition comprises, by mass, 5%-10% of polishing agent, 3%-6% of alcohol amine, 3%-5% of complexing agent, 1%-4% of surface activating agent, 0.5%-2.0% of brightener, 0.1%-0.5% of thickening agent, 0.5%-2% of corrosion inhibitor, 1%-3% of pickling agent and 75%-85% of water. The environment-friendly reaction type polishing brightener composition prepared is an upgraded replacement product of a traditional brightener, the cleaning and brightening effects on a stainless steel material are obvious, no corrosion is caused to a base material, and the composition is environment-friendly.

Owner:广东锴力环保新材料有限公司

Pole lug aluminum strip surface treatment passivation solution

The invention discloses a pole lug aluminum strip surface treatment passivation solution. The pole lug aluminum strip surface treatment passivation solution comprises chromium trioxide, nickel nitrate hexahydrate, a pickling agent, a film formation accelerant and water. By means of the pole lug aluminum strip surface treatment passivation solution, the passivation film compactness and the salt mist can be improved, and the bonding performance between a film and pole lug glue can be improved.

Owner:MAIKAIMEN ELECTRONICS TECH SHANGHAI

Environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements and application method thereof

The invention relates to the technical field of pickling agents, and particularly relates to an environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements and an application method thereof. The environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements is prepared from the following components by weight content in each liter of water: 5-60g of sulfuric acid, 5-10g of sulfamic acid, 20-100g of strong oxidant, 50-140g of fluoride, 20-70g of chloride, 3-8g of corrosion inhibitor, 10-20g of ethanol and 1L of water. The environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements disclosed by the invention is short in cleaning time, and good in cleaning effect, and can be used for cleaning at normal temperature, a cleaned stainless steel welding spot part is bright in color and luster, and the environment-friendly stainless steel pickling agent is convenient to use, and can be recycled, so that the cost is reduced, and pollution to the environment is reduced.

Owner:Dongguan Kaimeng Chemical Co Ltd

Method for carrying out deironing and whitening on kaolin

The invention discloses a method for carrying out deironing and whitening on kaolin. The method comprises the following steps of: carrying out acid leaching on kaolin by sulfuric acid serving as a pickling agent, carrying out reduction deironing on kaolin by organic reducing agents such as formaldehyde and acetaldehyde, which replace sodium hydrosulfite and serve as a brightening agent, filtering, washing and drying to obtain a whitened kaolin sample. The method disclosed by the invention has the characteristics of simple operating process, no generation of SO2 and H2S, less environmental pollution, low operating cost and good bleaching effect.

Owner:HEFEI UNIV OF TECH

Pickling agent for the chemical conversion coating of heat exchanger, method of pickling heat exchanger

InactiveUS20010018965A1Easy to useInorganic/elemental detergent compounding agentsChemical paints/ink removersCeriumPickling Agents

Owner:NIPPON PAINT CO LTD

Agent for preparing salted egg and the method for preparing salted egg by same

The composition of pickling agent contains (wt%) 10-90% of citric acid, 1-50% of potassium sorbate and 1-40% of sodium chlorite. When it is used, according to the ratio of pickling agent; salt; water; fresh egg =1:100-150:500:500-1000 the pickling agent can be dissolved into water, then poured into a container in which the fresh eggs ar held, and pickled at room temp. so as to obtained the invented pickled eggs.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Non-beany high protein meat-like vegetarian food and preparation method thereof

InactiveCN104207035AEfficient degradationNo beany smellFood preparationVegetarian ingredientsBiotechnologyRed yeast rice

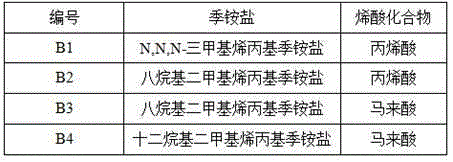

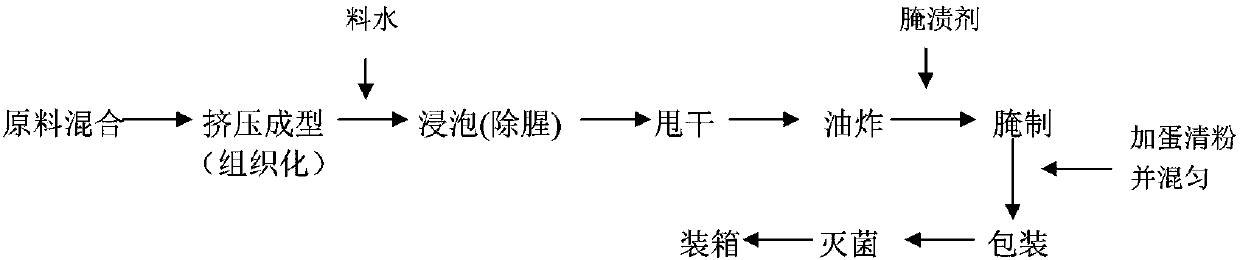

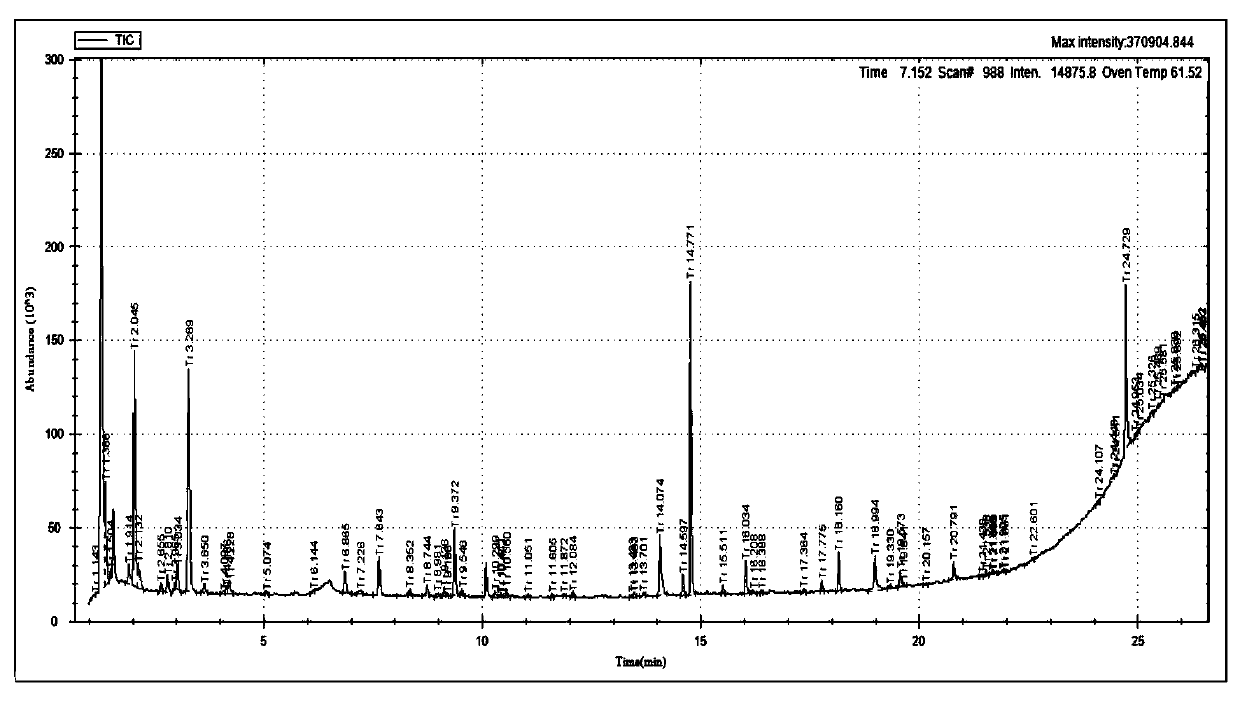

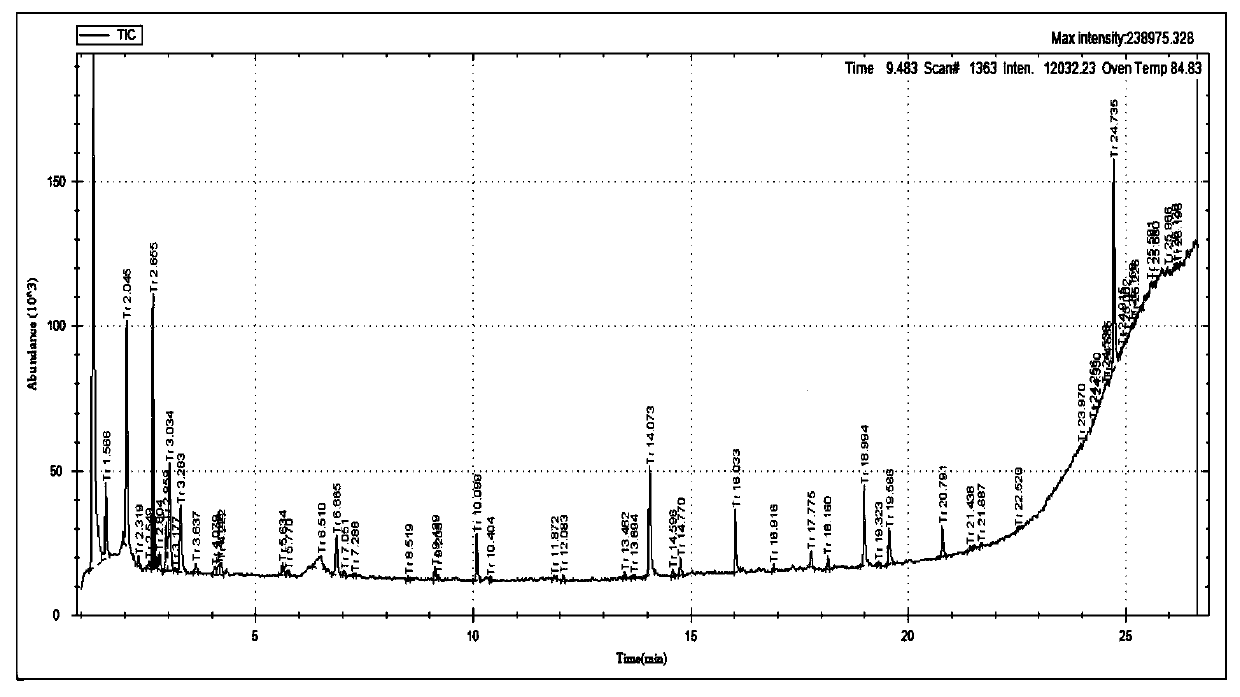

The invention discloses non-beany high protein meat-like vegetarian food and a preparation method thereof. The non-beany high protein meat-like vegetarian food is mainly prepared from, by weight, 45 to 55 parts of raw soybean meal, 11 to 17 parts of low temperature soybean meal, 10 to 20 parts of isolated soy protein powder, 15 to 25 parts of wheat gluten and 1 to 3 parts of red yeast rice powder. The method includes the steps of mixing all of the raw materials, adding water, stirring, and extruding for forming a strip semi-finished product; drying, soaking in seasoning water, dehydrating, spin-drying, frying at high temperature, pickling with a pickling agent, uniformly mixing after adding egg white powder, bagging, vacuumizing, and finally obtaining a finished product after performing high temperature sterilization. The relative content of beany flavor substances of volatile substances of the non-beany high protein meat-like vegetarian food is reduced to 14.76%, so that people can hardly taste the beany flavor.

Owner:河南中豫控股有限公司

Preparation method of ultrahigh-purity niobium oxide and prepared ultrahigh-purity niobium oxide

ActiveCN104445406AEasy to separateProcess technology is stableNiobium compoundsPhysical chemistryPickling Agents

The invention discloses a preparation method of ultrahigh-purity niobium oxide. The preparation method comprises the steps of acidity regulation, extraction separation, neutralization, precipitation, drying and calcining by taking a fluoroniobic acid solution as a raw material. In the extraction separation step, sec-octyl alcohol is used for extracting the regulated niflumic acid material liquid to obtain an organic phase; subsequently the organic phase is pickled by a pickling agent; finally the pickled organic phase is re-extracted by an anti-niobium agent to obtain the ultrahigh-purity niobium oxide. The invention also provides the ultrahigh-purity niobium oxide prepared by the method; the percentage composition of Nb2O5 is larger than or equal to 99.995%; the content of each impurity satisfies the regulations of the standard YS / T548-2007 on product grades F Nb2O5-048 and F Nb2O5-045.

Owner:JIUJIANG TANBRE

Environment-friendly type water-based pickling agent

The invention discloses an environment-friendly type water-based pickling agent. The environment-friendly type water-based pickling agent is characterized by comprising the following raw materials including, by weight percentage, 50%-80% of pure water, 15%-49% of organic acid and 1%-5% of surface active agent. According to the environment-friendly water-based pickling agent, the formula is simple, and the environment-friendly type water-based pickling agent is compounded from the organic acid and the biodegradable surface active agent; after use, an appropriate amount of alkali can be added to the environment-friendly type water-based pickling agent so that the environment-friendly type water-based pickling agent can be neutralized to be neutral, and then the environment-friendly type water-based pickling agent is directly discharged to a sewer; and in this way, bio-concentration, the increase of COD and other hazards are avoided, the water-based pickling agent is environmentally friendly and does not need independent treatment, and the use cost of an enterprise is reduced.

Owner:TIANJIN PRIMETECH CHEM

Method for processing original shape massive zymolysis chicken products

The invention relates to a food processing method, in particular to a processing method for producing fermented meat products by using chicken meat such as chicken breast, chicken legs with bones, chicken wing, etc. to serve as raw materials, which comprises the contents that: 1. the pickling agents used in the processing of original block type fermented chicken meat products are made by full mixing the common salt which makes up 1.5 percent to 2 percent (mass fraction, same as below) of the weight of chicken meat such as the meat of chicken breast, chicken legs, chicken wing, etc., 1.5 percent to 2 percent of cane sugar, 0.1 percent to 0.2 percent of starch sugar and 0.01 percent to 0.015 percent of sodium nitrite; 2. the spice formula of the original block type fermented chicken meat products is that: calculated by 100g chicken meat: soy sauce: 1kg to 1.5kg; mild aromatic Chinese spirits: 500g to 700g; pepper corn: 500g to 600g; cayenne pepper: 400g to 500g; bay leave: 600g to 700g; cummin seeds (powder): 500g to 600g; common fennel particles (powder): 450g to 550g; 3. the processing technique of the original block type fermented chicken meat is characterized in that the chicken meat which meets state sanitation and safety standards and is formed by cutting is added into and fully mixed with the invented pickling agents and spices and then pickled hermetically for 24 days to 36 days under the condition of 0 DEG C to 4 DEG C. After pickling, the pickled chicken meat is hung or placed horizontally to be fermented and dried for 24 hours to 36 hours under controlled temperature and humidity. The fermentation processing conditions are that: the temperature is 43 DEG C to 45 DEG C and the relative humidity is 80 percent to 90 percent.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Flavor dried radish product and its preparing method

InactiveCN101147550ACrispy tasteFit for consumptionFood preparationAdditive ingredientPickling Agents

The present invention relates to a kind of flavoured dried radish strips product. It is characterized by that its main components includes radish strips, salt, sugar, flavouring material and calcium preparation, and their weight ratio is 100:5-15:5-15:8-18:0.5-1. Its preparation method includes the following steps: (1), selecting fresh radish strips, cleaning, draining and drying; (2), adding sugar and salt to make impregnation treatment; (3), washing them by using clear water, draining and placing the radish strips in a container for standing-by; (4), preparing pickling agent; (5), making seal-pickling; and (6), opening and making sterilization treatment, packaging so as to obtain the invented product.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

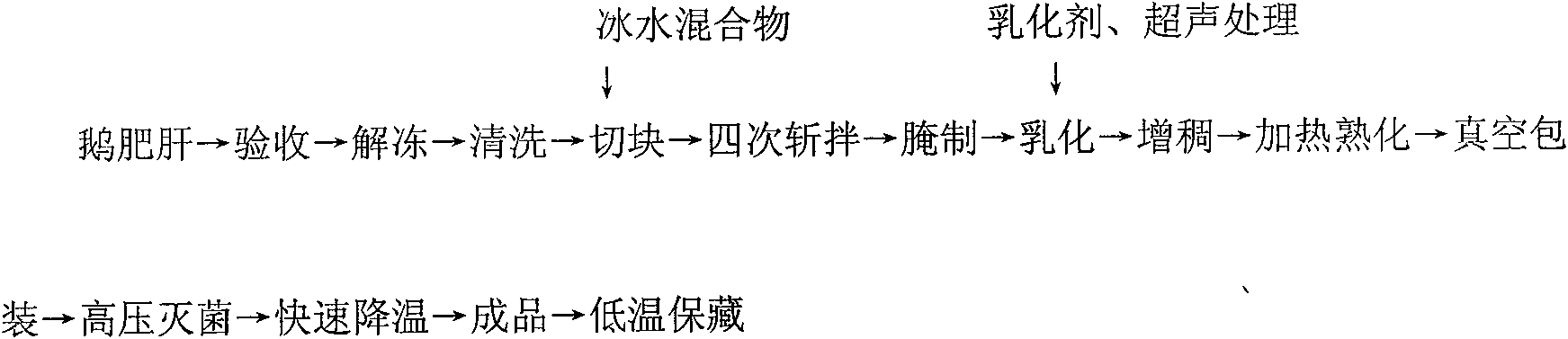

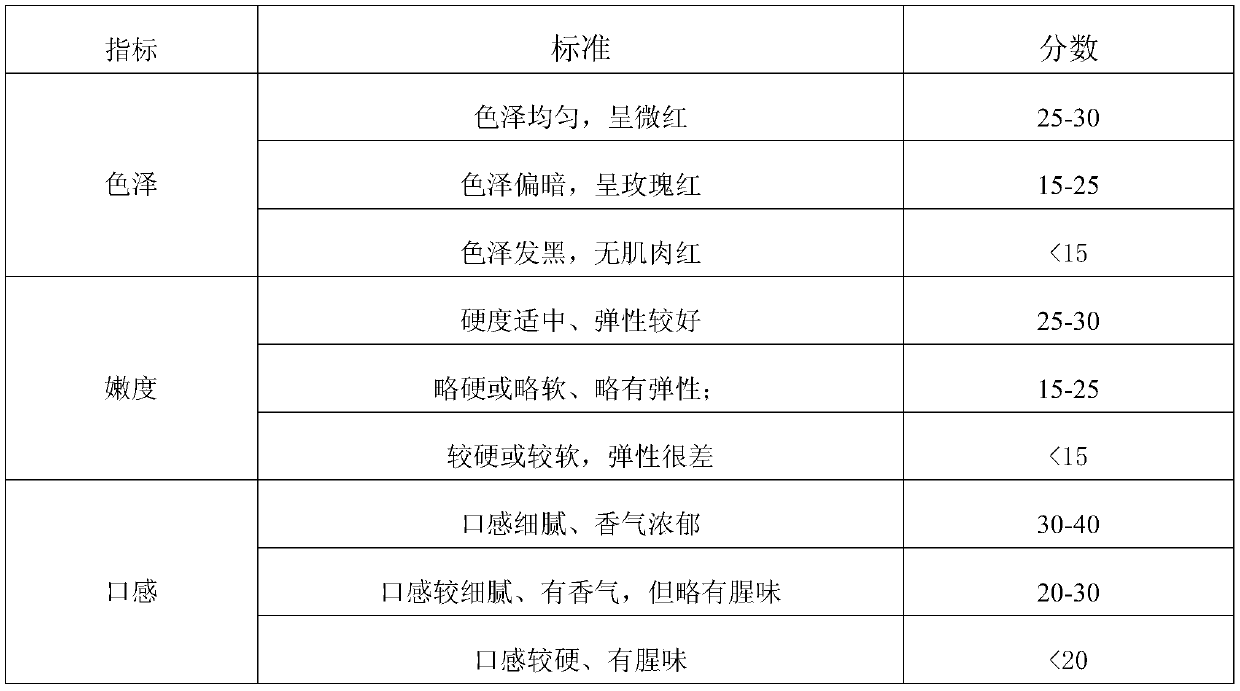

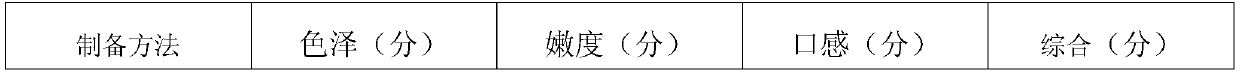

Process for stably processing foie gras without fat isolation and with low oxidation

InactiveCN101617807AAvoid churnAvoid breakingMeat/fish preservation by heatingMeat/fish preservation by freezing/coolingAdditive ingredientPickling Agents

The invention discloses a process for stably processing foie gras without fat isolation and with low oxidation, which comprises the following steps: slowly unfreezing goose livers serving as a raw material at a temperature of between 2 and 6 DEG C; cleaning the goose livers with a mixture of water and ice; mixing the goose livers under vacuum in a chopper for 10 to 15 minutes for four times; pickling the goose livers in a pickling agent for 24 hours at a temperature of between 0 and 4 DEG C; adding emulsifying agent; using 50 to 600w and 20 to 100 kHz ultrasonic waves to jointly process the goose livers to emulsify the pickled goose livers; thickening the emulsified goose livers and heating the goose livers at a temperature of between 90 and 100 DEG C to age the goose livers; canning the aged goose livers under vacuum; sterilizing the canned goose livers for 2 to 15 minutes at a temperature of between 100 and 120 DEG C; quickly decreasing the temperature to obtain the product; and storing the finished product in an environment at a temperature of 0 to 4 DEG C. The foie gras made by the process has rich nutrients, high quality, white color and luster, pure mouth feel, low fat oxidation, no fat isolation, little nutrient loss and long shelf life, and is widely applied to Chinese and western foods.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Pickling agent for the chemical conversion coating of heat exchanger, method of pickling heat exchanger

InactiveUS6528468B2Easy to useInorganic/elemental detergent compounding agentsChemical paints/ink removersCeriumPickling Agents

The present invention relates to a pickling agent for the chemical conversion coating of a heat exchanger which is capable of cleaning the complicated structure comprising fins and tubes of a heat exchanger in preparation for the successful formation of a chemical conversion film, a method of pickling a heat exchanger, a method of treating a heat exchanger comprising said pickling method, and a heat exchanger produced by using said treating method.The present invention provides pickling agent for the chemical conversion coating of a heat exchangerwhich comprises an acidic aqueous solutioncontaining nitric acid and / or sulfuric acid and at least one metal and / or metal oxoanion salt derived from any metal selected from the group consisting of iron, nickel, cobalt, molybdenum and cerium.

Owner:NIPPON PAINT CO LTD

Preparation method of instant pickled beef

ActiveCN109730238AIncrease elasticityImprove tendernessClimate change adaptationFood scienceCarrageenanPhosphate

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Efficient environment-friendly chemical cleaning method

ActiveCN104726881AEasy to transportLow costMetallic material coating processesLiquid wasteCleaning methods

The invention belongs to the technical field of metal surface chemical cleaning methods, and particularly relates to an efficient environment-friendly chemical cleaning method comprising a surface chemical cleaning method for boilers and other heat exchangers. The efficient environment-friendly chemical cleaning method comprises the processing steps of (1) performing sulfamic acid pickling, (2) performing water washing after pickling, (3) performing citric acid rinsing, (4) performing sodium nitrite passivation and (5) performing liquid waste treatment. The efficient environment-friendly chemical cleaning method utilizes a low-temperature pickling medium which is convenient to transport and facilitates field implementation, and uses a passivation agent with stable and good passivation effect at present to implement passivation. In addition, a passivation liquid used by the efficient environment-friendly chemical cleaning method can react with a pickling agent in a waste liquid pool to generate an innocuous product, so that independent treatment on the passivation liquid is omitted, and the dosage of sodium hydroxide for neutralization is reduced.

Owner:STATE GRID CORP OF CHINA +1

Method for rapidly and integrally pickling salted egg yolk

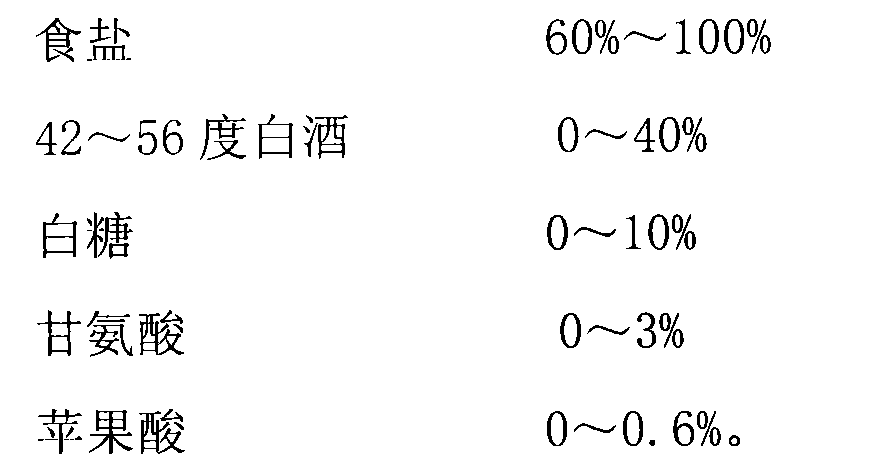

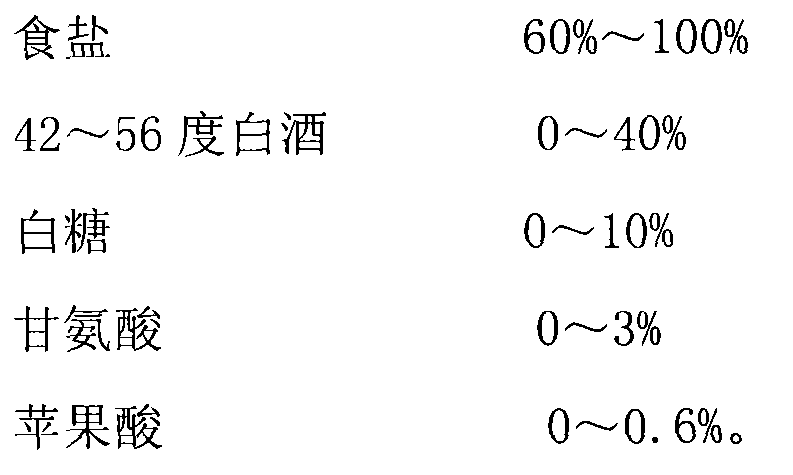

The invention relates to a method for rapidly and integrally pickling salted egg yolk, which is characterized by comprising the following steps of: fully mixing an egg yolk with a pickling agent in a pickling container; pickling; and carrying out heating concentration, maturing, oil pulverization and moulding treatment on the mixture to obtain the salted egg yolk. In the oil pulverization step, the mature salted egg yolk is subjected to grinding and pulverizing treatment. The pickling agent comprises the following components in percentage by weight: 60-100 percent of salt, 0-40 percent of white spirit, 0-10 percent of white sugar, 0-3 percent of glycine and 0-0.6 percent of malic acid. The invention has the advantages of large-scale production of salted egg yolk, simple production operation, high productivity and uniform quality, high oil pulverization performance and perfume and pure taste of the pickled salted egg yolk.

Owner:BEIJING UNIV OF AGRI

Pickling agent for stainless steel

The invention relates to a pickling agent for stainless steel. According to percentage by weight, the pickling agent consists of the following components: 23 to 30 percent of sulfuric acid; 4 to 6 percent of nitric acid; 7 to 14 percent of hydrochloric acid; 0.1 to 0.3 percent of corrosion inhibitor; 0.13 to 0.25 percent of additive; and the balance of water. The mass concentrations of the used acids are as follows: 95.0 to 98.0 percent of sulfuric acid; 65.0 to 68.0 percent of nitric acid; and 36.0 to 38.0 percent of hydrochloric acid. The components are uniformly mixed according to proportion. The corrosion inhibitor is hexamethylene tetramine, the additive is the mixture of sodium dodecyl sulfate and isooctyl phenol polyoxyethylene, the percentage by weight of the sodium dodecyl sulfate is 0.08 to 0.15 percent, the percentage by weight of the isooctyl phenol polyoxyethylene is 0.05 to 0.1 percent, and the effect is better when the temperature of each acid is 60 DEG C to 80 DEG C. The pickling efficiency of the pickling agent for stainless steel is increased by four to five times, the pickled surface is bright and clean, and the pickling agent for stainless steel is particularly suitable for pickling the surfaces of stainless steel with high Cr, Ni and Mo alloy contents to remove ferric oxide scales.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Raw leather pickling agent

The present invention relates to a pickling agent for pickling raw leather with hair. Its composition contains (by weight portion) 40-50 portions of sodium chloride whose grain size is 1 mm-2 mm and water content is less than 5%, 20-30 portions of sodium sulfate, 1.5-3 portions of dimethyl fumarate, 1.5-3 portions of white alum and 1.5-3 portions of sodium carbonate. The above-mentioned all ingredients are uniformly mixed so as to obtain the invented pickling agent. It can make raw leather with hair be smooth and have elasticity.

Owner:WEIFANG CHANGDA CHEM

Chinese style Lebanon sausage processing method

The invention discloses a convenient, rapid manufacturing method of Chinese libanom sausage, which comprises the following steps: 1) preparing pickling agent with 2% salt, 0.3% calcium chloride, 0.45% composite phosphate, 15-18g / 100kg beef sodium nitrite, 170-180g / 100kg beef sodium nitrite, 2) allocating condiment material with 100kg mother beef, 450-550g salt, 3.5-4.5kg sugar, 450-550g mustard, 0.8-1.2kg ginger and garlic (1: 1), 32-38g meat, 350-450g white pepper powder, 180-220g chili powder and 650-680g cumin powder, 3) cutting beef into blocks, pickling for 5-6 days, fermenting at 43 deg.c for 1-2 days, controlling moisture at 80-90% to reduce at 50-70% within 3-4 days, stopping manufacturing when the weight loss is 20-30%.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Efficient antirust mechanical oil cleaning agent

InactiveCN104877819AImprove rust resistanceEasy to cleanSurface-active non-soap compounds and soap mixture detergentsSalicylic acidChloramine

The invention discloses an efficient antirust mechanical oil cleaning agent which is prepared from the following raw materials in parts by weight: 5-9 parts of a pickling agent, 3-5 parts of monoethanolamine, 1-1.5 parts of a vitrification agent, 2-5 parts of phenyl salicylate, 5-10 parts of nano calcium carbonate, 2-4 parts of molybdenum disulfide, 7-14 parts of an antirust agent, 2-4 parts of glycerol monostearate, 5-8 parts of ferrous chloride, 6-8 parts of sodium dodecyl benzene sulfonate, 3-7 parts of magnesium nitrate, 4-6.5 parts of chloramine, 3-6 parts of kieselguhr, 4-15 parts of magnesium sulfate and 2-6 parts of dimethyl bis(isooctyl thioglycolate) tin. The efficient antirust mechanical oil cleaning agent has the beneficial effects of good cleaning performance and low cost; and the antirust capability is improved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Preparation method of low-alkali stomach-invigorating preserved egg

InactiveCN105918925AImprove the coagulation effectImprove solubilityFood scienceRoom temperaturePickling Agents

The invention discloses a preparation method of a low-alkali stomach-invigorating preserved egg. The preparation method comprises the following steps: step one, picking fresh duck eggs, cleaning, wiping the duck eggs, cleaning duck eggs by liquor (38 degrees), drying, and saving duck eggs for later use; step two, preparing a pickling agent; step three, pickling: soaking duck eggs into the pickling agent prepared in the step two, then transferring duck eggs and pickling agent to a pot, sealing the pot, carrying out pickling for 30 to 40 days at a temperature of 20 to 25 DEG C to obtain pickled duck eggs; step four, drying, sterilizing, and packing: drying the pickled duck eggs in the air, sterilizing the duck eggs for 1 to 3 minutes at a temperature of 130 to 160 DEG C, cooling to the room temperature, painting a layer of fresh-keeping membrane on the surface of duck eggs, and then carrying out vacuum packaging. The obtained preserved egg is low in alkali content and has the functions of invigorating and nourishing the stomach.

Owner:SUSONG XIANGYUAN POULTRY TRADE

Method for processing poor organic phase after solvent extraction indium extracting

InactiveCN103014338ASolve emulsification problemsSolve agingProcess efficiency improvementIndiumPickling Agents

Disclosed is a method for processing a poor organic phase after solvent extraction indium extracting. The method includes: A, poor organic phase regeneration, namely, mixing the poor organic phase after solvent extraction indium extracting with regenerant, standing for layering, and separating to obtain a regenerated organic phase, wherein the regenerant is a mixture of oxalic acid and hydrofluoric acid; B, dechlorinating, namely, mixing the regenerated organic phase with water, standing for layering, and separating to obtain a dechlorinated organic phase; and C, acid pickling, namely, mixing the dechlorinated organic phase with pickling agent sulfuric acid solution for acid pickling, standing for layering, and separating to obtain a purified organic phase. By the method, the poor organic phase is continuously purified and regenerated, so that impurities such as iron, arsenic, tin, silicon dioxide, antimony, chlorine entrained in the organic phase are eliminated, and the service life of the organic phase is prolonged. In addition, by the method, the rate of removal of chlorine in the poor organic phase is higher than 85wt%, and a condition for subsequent recovery of zinc in indium extracting residual liquid is provided.

Owner:ZHUZHOU SMELTER GRP

Pickle agent of salty eggs and the method for pickling the same

InactiveCN101061817AHigh nutritional valueIncrease oil outputEggs preservationSperanskiaAdditive ingredient

The invention relates to an agent for pickling salted eggs and method of pickling, wherein the agent comprises (by weight percentage) salt 18-20%, lemon acid 0. 05-1. 5%, spirit 0. 05-1. 5%, speranskia herb 0. 01-0. 02%, pine or cork tree extract 0. 01-0. 02%, and balancing water.

Owner:高邮市红太阳食品有限公司

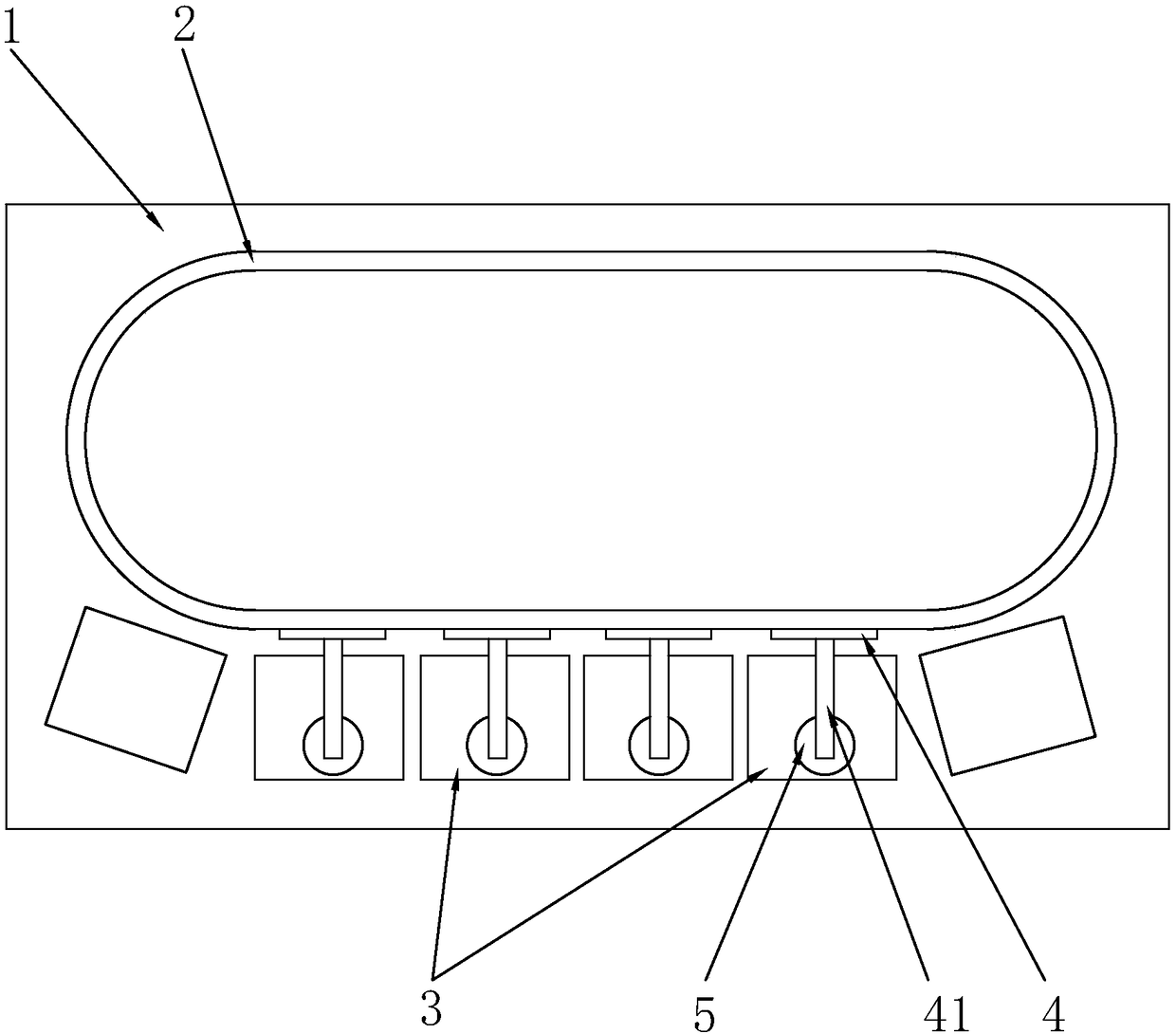

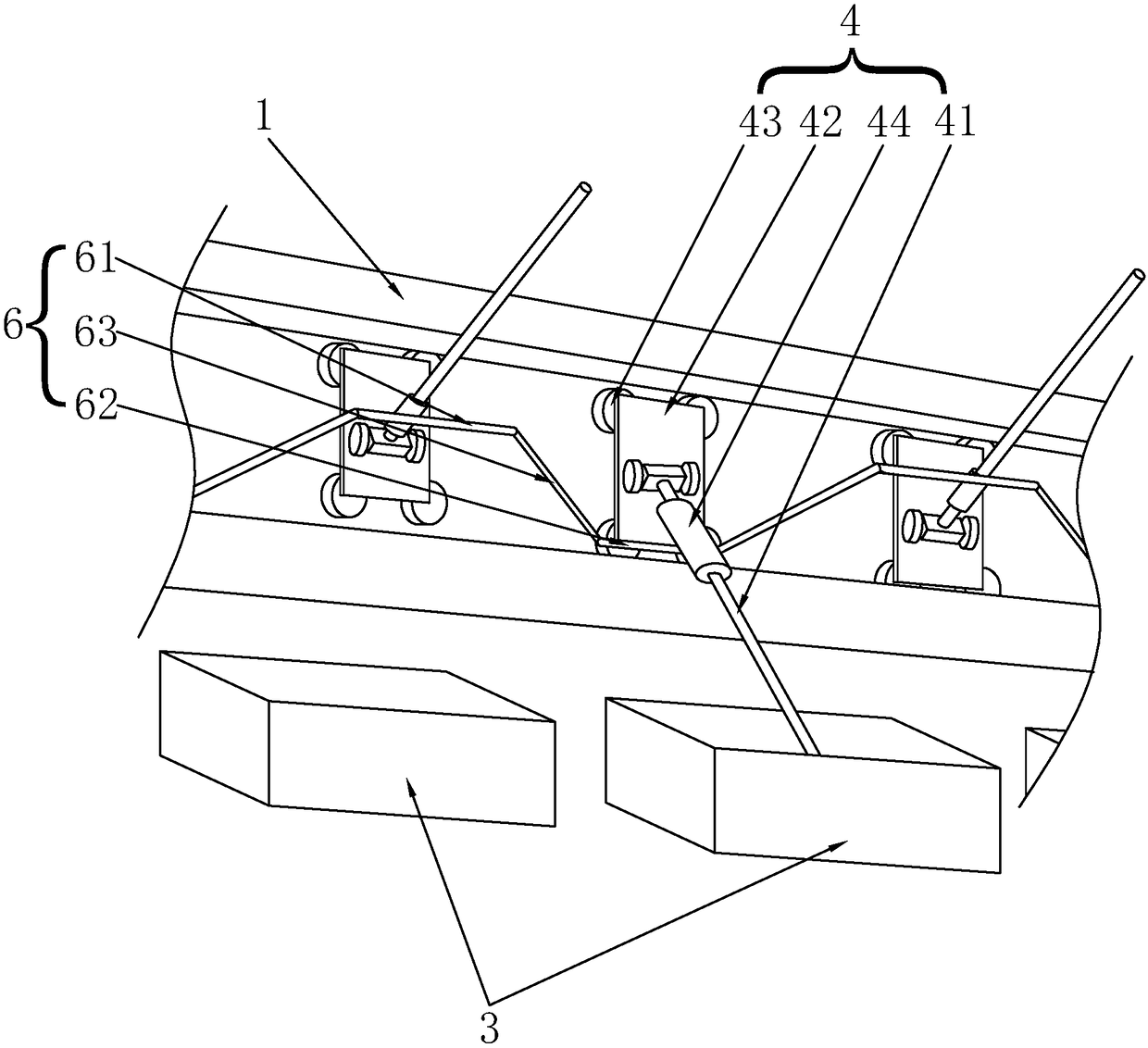

Automated rack plating line

InactiveCN108149308AImprove plating efficiencyImprove the plating effectElectrolysis componentsPickling AgentsEngineering

The invention discloses an automated rack plating line which comprises a rack, wherein a ring-shaped rail and a plurality of processing pools are arranged on the rack; the processing pools are sequentially arranged below the periphery of the ring-shaped rail, and sequentially filled with a deoiling agent, a pickling agent, an electroplating solution, a passivating solution and clear water; rack plating arm assemblies are slidably arranged on the ring-shaped rail, and comprise rack plating arms; the rack plating arms are used for hanging hardware and capable of swinging up and down; the rack plating arm assemblies slide along the ring-shaped rail; and the hardware is driven by the rack plating arm assemblies to sequentially pass through the processing pooled filled with the deoiling agent,the pickling agent, the electroplating solution, the passivating solution and the clear water. The automated rack plating line has the beneficial effects that through the ring-shaped rail, the processing pools filled with the deoiling agent, the pickling agent, the electroplating solution, the passivating solution and the clear water, as well as the rack plating arm assemblies, the hardware handling and electroplating process can be completed in an automated manner, and then the hardware electroplating efficiency and effect can be greatly improved. The automated rack plating line disclosed bythe invention is particularly suitable for the hardware being relatively large in size.

Owner:珠海市信豪工艺有限公司

Making method of fragrant and salted egg yolks

The invention discloses a making method of fragrant and salted egg yolks. The making method comprises the following steps: pickling cleaned fresh eggs till the appearances of egg yolks are preliminarily cured and formed; separating the egg yolks from egg white; moving the egg yolks into a breathable casing, then bundling and sealing the two ends of the casing to form an egg yolk string; placing a layer of dry powdery pickling agent containing table salt and perfume at the bottom of an egg yolk pickling container, tidily placing the egg yolk string on the pickling agent and then paving a layer of pickling agent again. A structure that one layer of pickling agent and one layer of egg yolk string are arranged in sequence is formed and is finally coated with a layer of pickling agent. The surface of the container is covered with a cover or a thin film for pickling till the egg yolks are completely pickled and wholly cured, so that the fragrant and salty egg yolks are obtained. The fragrant and salty egg yolks disclosed by the invention are short in pickling and maturing time and high in production efficiency; the low-salinity egg white can be obtained, so that wastes are reduced.

Owner:HEFEI UNIV

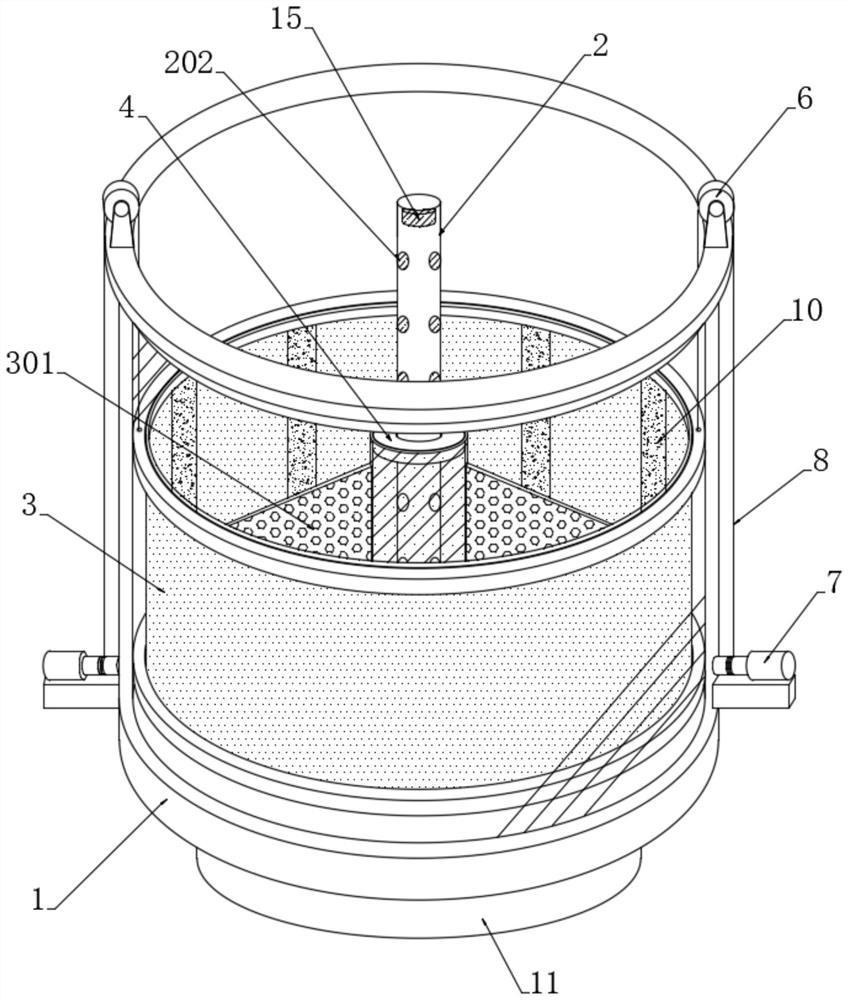

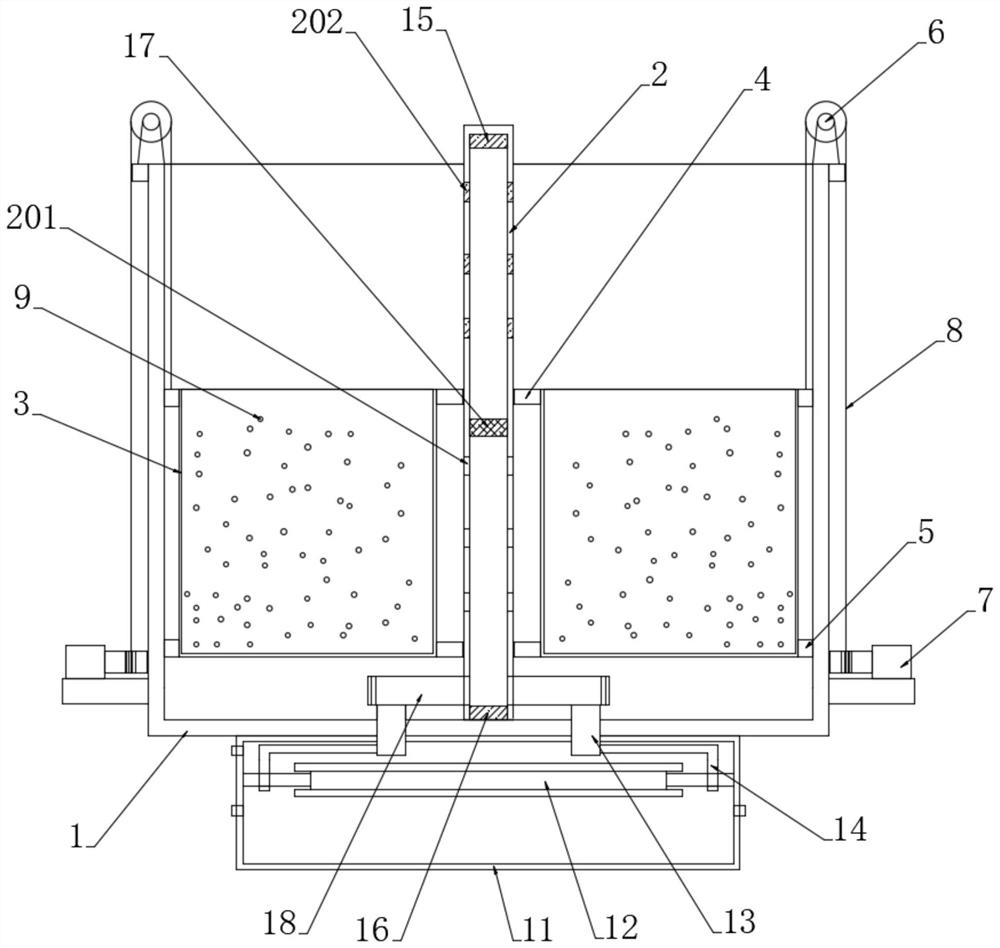

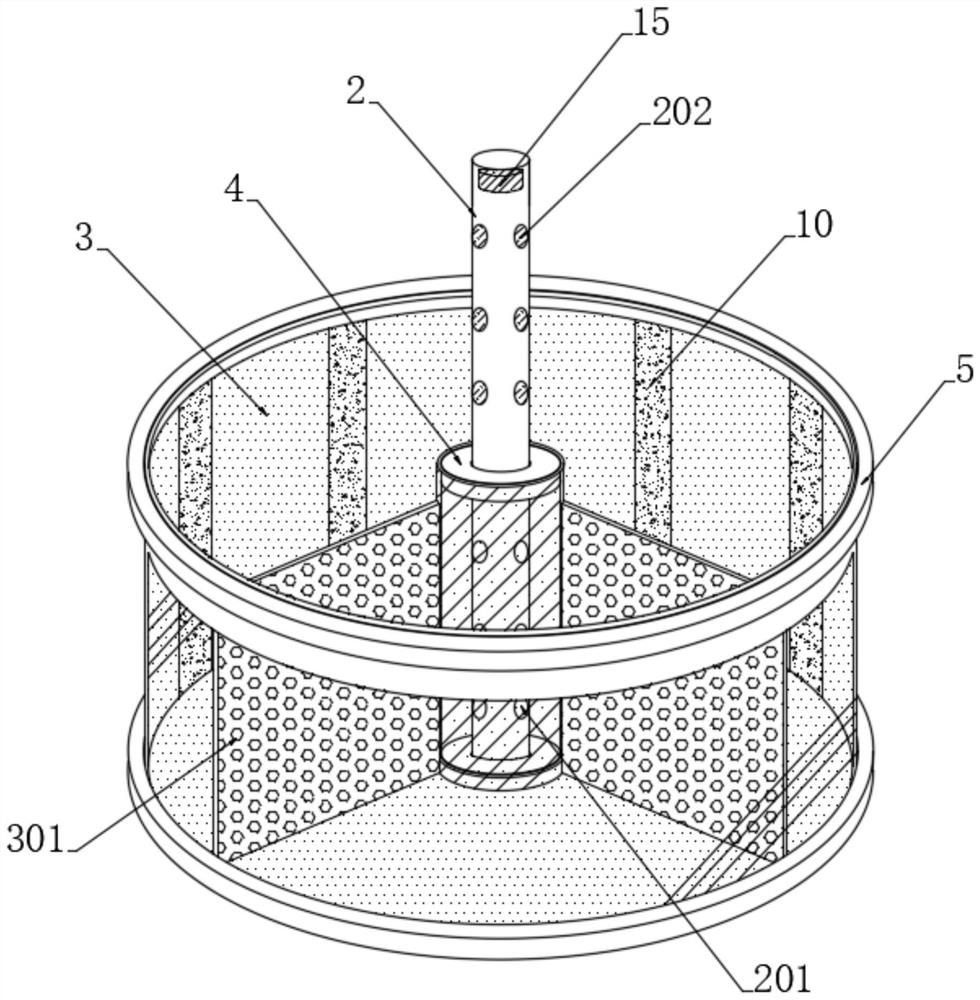

Polishing equipment for stainless steel products

ActiveCN111774942AEfficient removalImprove pickling and polishing effectEdge grinding machinesPolishing machinesPickling AgentsSS - Stainless steel

The invention discloses polishing equipment for stainless steel products, and belongs to the technical field of stainless steel production and processing. Through intermittent opening and closing cooperation of an upper electromagnet and a lower electromagnet, up-and-down lifting motion of a magnetofluid inside a jet-flow vertical pipe is achieved, therefore, a pickling agent is guided into the jet-flow vertical pipe, the extracted pickling agent is jetted into an annular polishing cavity through a lower jet-flow opening, fluid motion of the pickling agent is intensified, in addition, the multiple magnetic polishing particles are driven to do non-specification motion, the polishing equipment is simultaneously matched with intermittent opening and closing of a magnetic attraction plate, andthe motion of the magnetic polishing particles is intensified. Heat generated by the heating end of a semiconductor chilling plate is guided into the jet-flow vertical pipe and then diffuses into theannular polishing cavity along with the pickling solution, the pickling and polishing effect of the stainless steel products is effectively improved, oxide skin and the like at the gullies of the stainless steel products are effectively removed, and after polishing is completed and a polishing box is lifted upwards, the stainless steel products in a polishing box is dried through hot air flow andcold air flow.

Owner:揭阳市永乐五金电器厂有限公司

Natural antioxidative compound pickling agent and preparation method and application thereof

InactiveCN108185313AImprove food safetyNo side effectsFood ingredient as taste affecting agentNatural extract food ingredientsSide effectFreeze-drying

The invention discloses a natural antioxidative compound pickling agent and a preparation method and application thereof. The pickling agent comprises the following components in percentage: 30-60% ofsugar beet extract, 20-40% of salty essence, 10-15% of rosemary extract, 7-10% of onion powder and 3-5% of D-sodium isoascorbate. A specific preparation process comprises the following steps: (1) preparation of the sugar beet extract; (2) preparation of the salty essence: performing anticoagulation, diluting and centrifuging to obtain a hemoglobin solution, mixing and reacting the hemoglobin solution with histidine, tyrosine and chitosan oligosaccharide, and performing freeze drying to obtain the powdered salty essence; and (3) preparation of the onion powder; and mixing the raw and auxiliarymaterials proportionally to obtain the compound pickling agent applied to processing of meat products. The pickling agent conforms to the ideas of high edible safety and no toxic and side effects, the addition amount of the pickling agent to the meat products is 0.1-0.6% to achieve the effects of oxidation resistance, color development, bacteriostasis and flavor enhancing, and the safety of the meat products can be effectively ensured.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Mechanical antiwear restoration lubricant

The invention discloses a mechanical antiwear restoration lubricant which comprises the following components in parts by weight: 1-9 parts of wax solvent, 14-25 parts of pickling agent, 1-3 parts of phosphating solution, 1-3 parts of passivation solution, 1-3 parts of vitrification agent, 4-8 parts of calcium hydroxide, 7-10 parts of barium hydroxide octahydrate, 7-16 parts of sodium hydroxide, 5-16 parts of potassium nitrate, 7-15 parts of sodium nitrate, 2-4 parts of sodium sulfite, 1-3 parts of dispersant, 1-3 parts of thickener, 4-6 parts of flame retardant, 4-8 parts of stearic acid, 7-14 parts of stearate, 4-15 parts of stearamide, 1-3 parts of silicon oil and 4-10 parts of oleamide. The invention has the advantages of favorable use effect under high-temperature high-speed working conditions, no toxic or side effect and low manufacturing cost, and can be widely used.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Picking agent containing urea and method of producing it

InactiveUS20030004080A1Easy to handleLong-term stabilityOrganic detergent compounding agentsSurface-active detergent compositionsPickling AgentsHeat treated

A long-time stable pickling agent for the removal of an oxide layer on a stainless steel after heat treatment, such as welding, which pickling agent comprises nitric acid and fillers and constitutes of a pickling paste or pickling gel to be coated on the heat treated stainless steel, or of a pickling liquid to be sprayed on the steel. According to the invention, the pickling agent also comprises urea for reduced formation of nitrous fumes when the pickling agent is used.

Owner:AVESTA WELDING AKEITBOLAG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com