Patents

Literature

59results about How to "Little corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

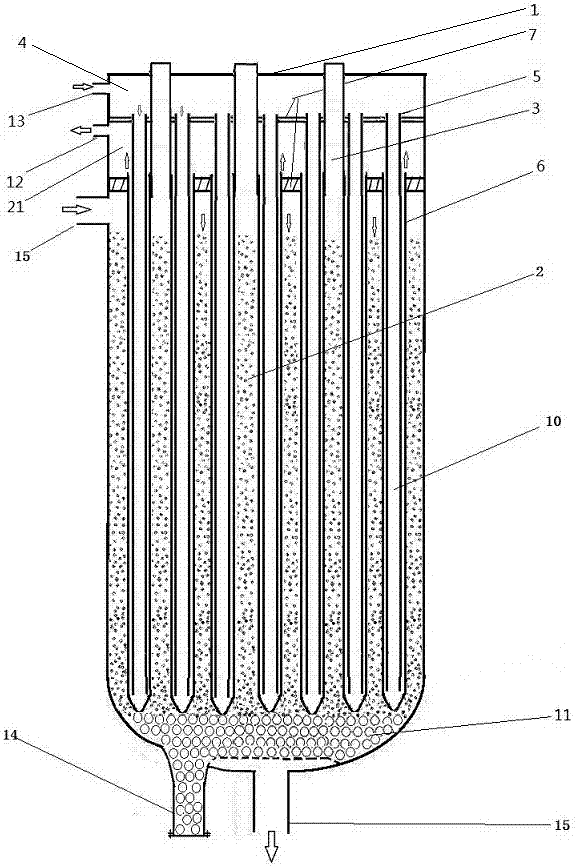

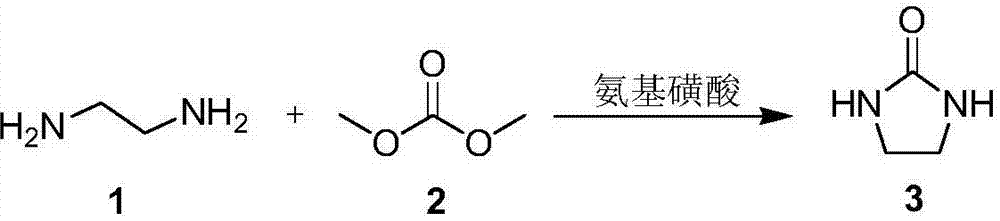

Solar and thermocompression vapor-compression distillation type water purifying device

ActiveCN102219273AIncrease temperatureEfficient use ofGeneral water supply conservationSeawater treatmentDistillationEngineering

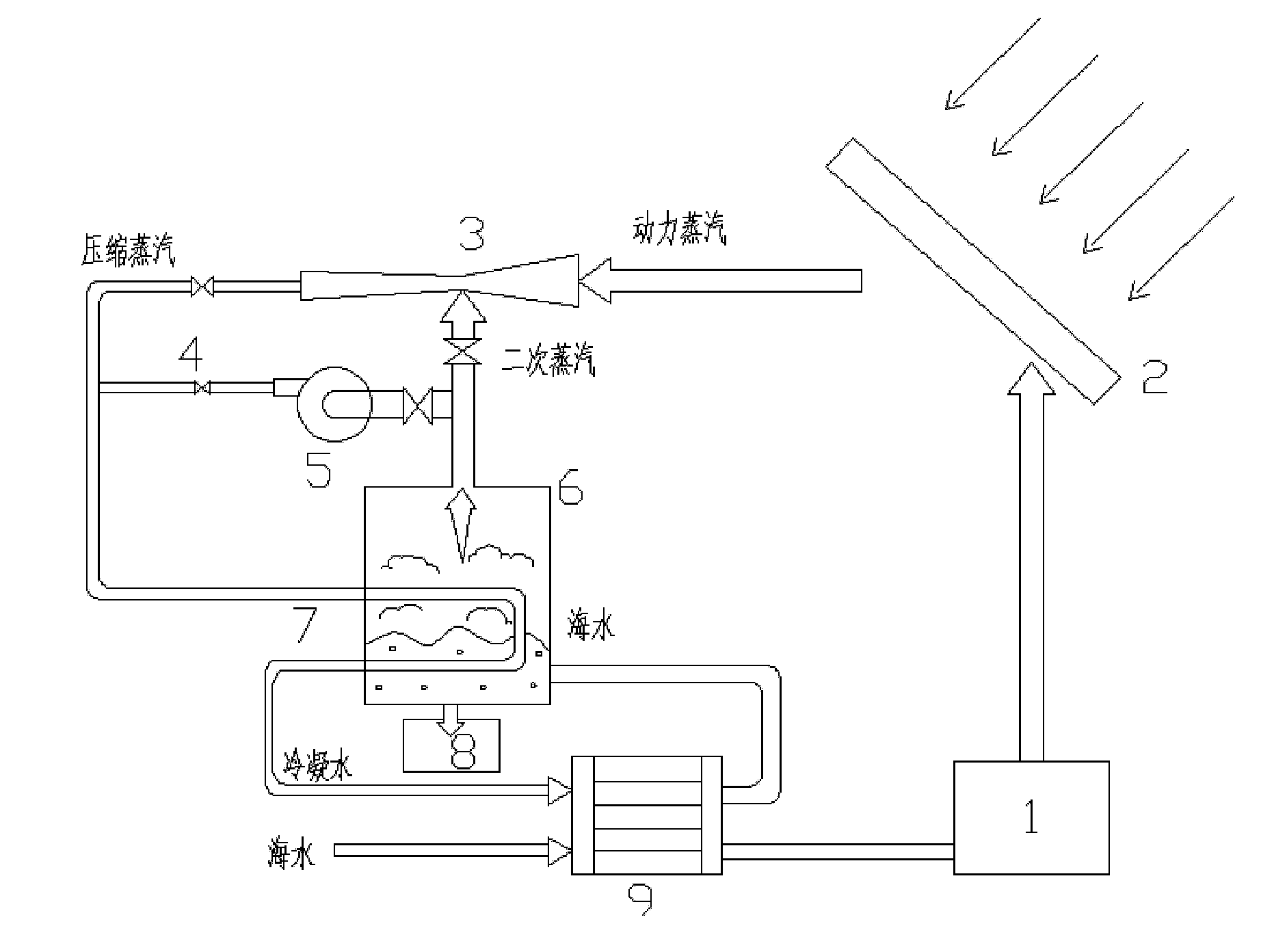

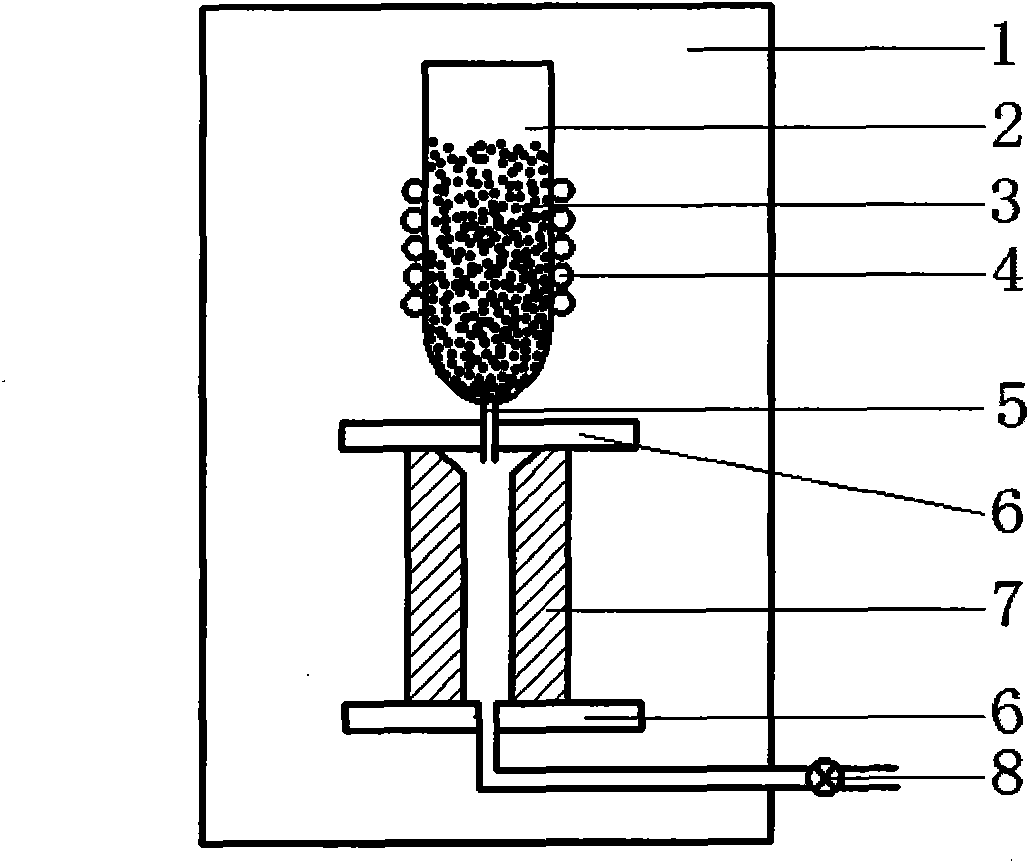

The invention discloses a solar and thermocompression vapor-compression distillation type water purifying device, belonging to the technical fields of novel energy and energy saving as well as emission reduction. The solar and thermocompression vapor-compression distillation type water purifying device comprises a fresh-water tank, a solar heat collector, a steam sprayer, a valve, a compressor, an evaporator, a heating chamber, a concentrate groove and a heat exchanger, wherein the solar heat collector is connected with the steam sprayer; an outlet of the evaporator and an inlet of the heating chamber are respectively connected with the steam sprayer; the heat exchanger is respectively connected with an outlet of the heating chamber and an inlet of the evaporator; and the compressor as a branch is connected with the steam sprayer in parallel and is adjusted by the valve. The invention has the benefits that the device has a compact technological structure, conventional energy sources are saved and the investment cost is reduced; by adopting low-pressure and corrosion and scale resistant measures, the temperature of a solution to be treated is prevented from being excessively high, the corrosion is greatly reduced and the service period of the equipment is prolonged. Particularly, the method is suitable for the aspects of freshening seawater, purifying sewage and the like and isa safe, pollution-free and energy-saving technology.

Owner:DALIAN UNIV OF TECH

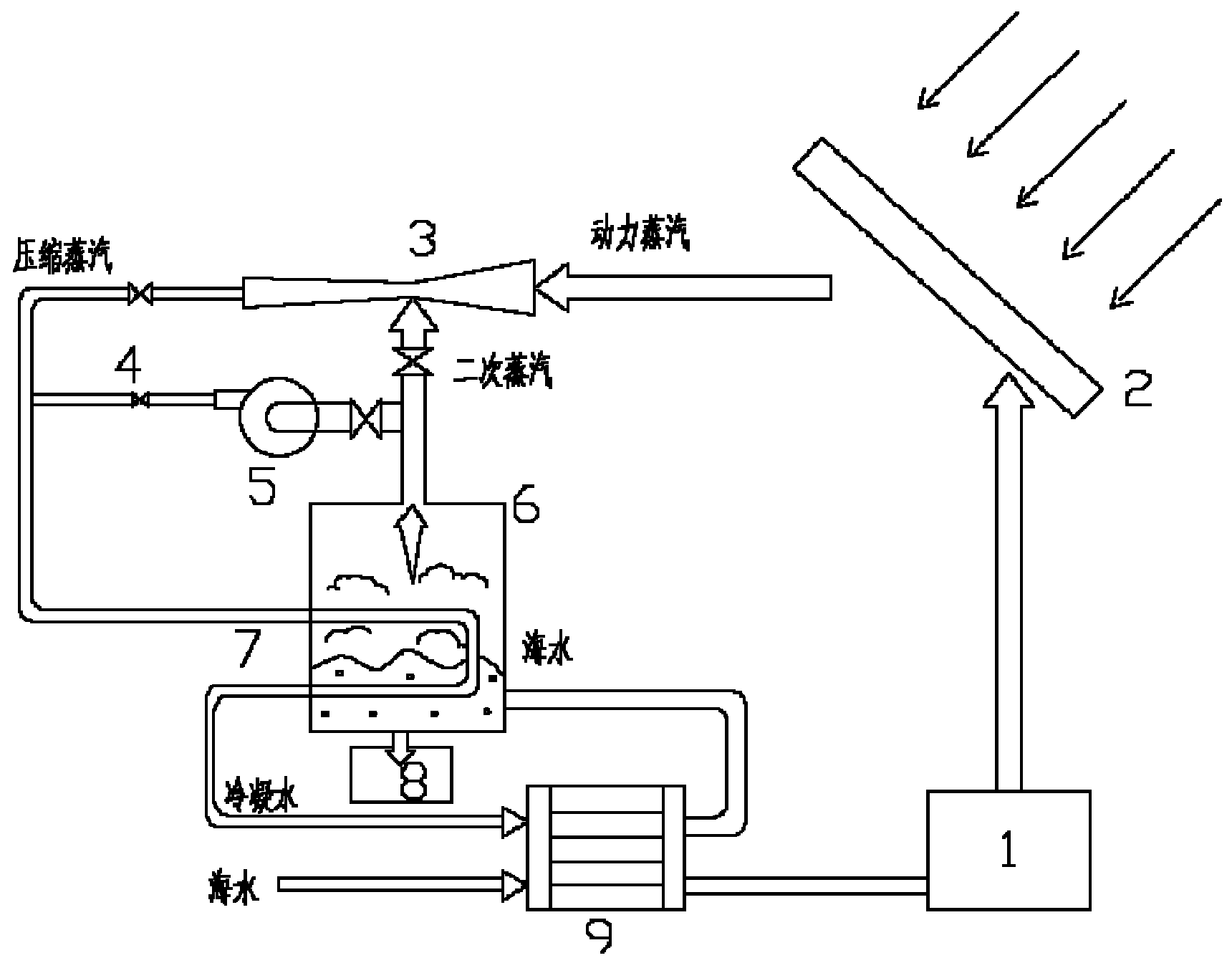

Preparation method for polycarboxylic acid series comb-shaped surface active agent

InactiveCN102199298AEnergy savingShort preparation timeTransportation and packagingMixingSolventSurface-active agents

The invention discloses a preparation method for a polycarboxylic acid series comb-shaped surface active agent, which comprises the following steps of: mixing two comonomers, an initiator, a chain transfer agent and a solvent under the protection of nitrogen, heating to a reacting temperature for polymerization to obtain an intermediate polymer; adding a graft compound, a catalytic agent and a dissolvant into the intermediate polymer, carrying out graft reaction at graft temperature, decompressing and removing part of solvent in a reaction system after reaction, and then precipitating the product with a precipitator; dissolving filter cakes with the solvent; precipitating the dissolved solution with the precipitator again, dissolving repeatedly, precipitating again and then refining, and finally decompressing and drying the product to the constant weight. The preparation method has the advantages of reasonable technology, simple operation, low preparation cost, mild reacting conditions and good product quality.

Owner:CHINA RES INST OF DAILY CHEM IND

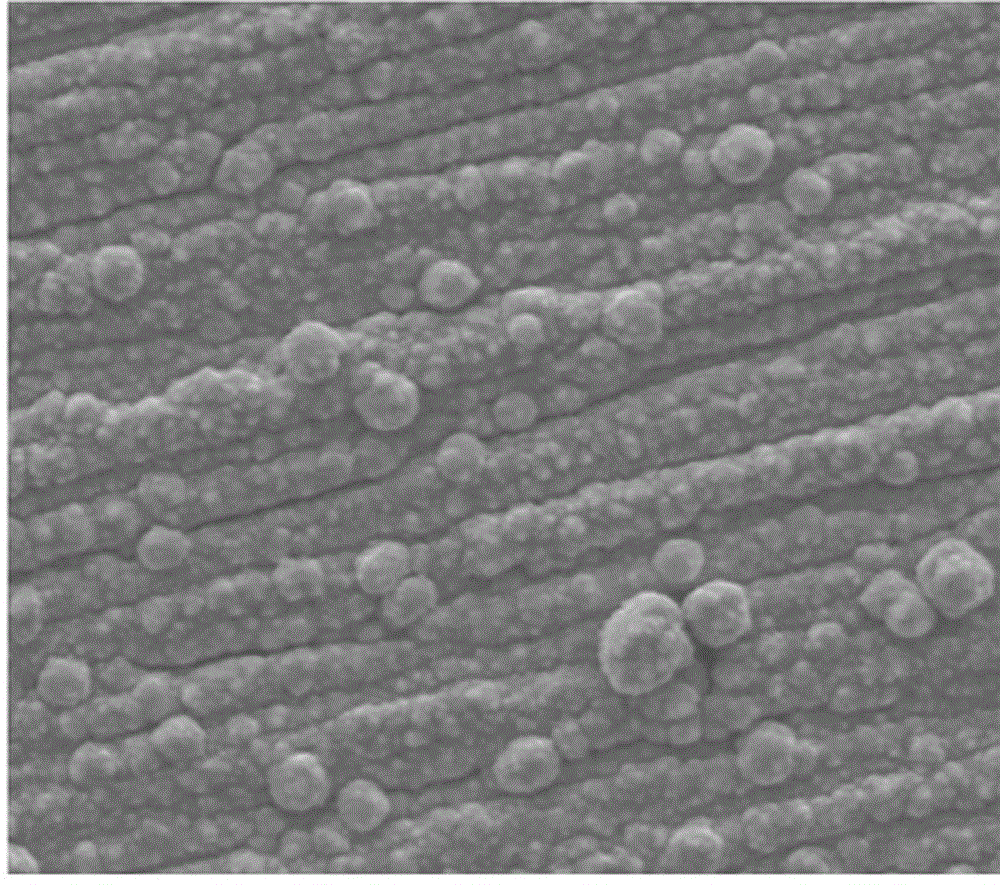

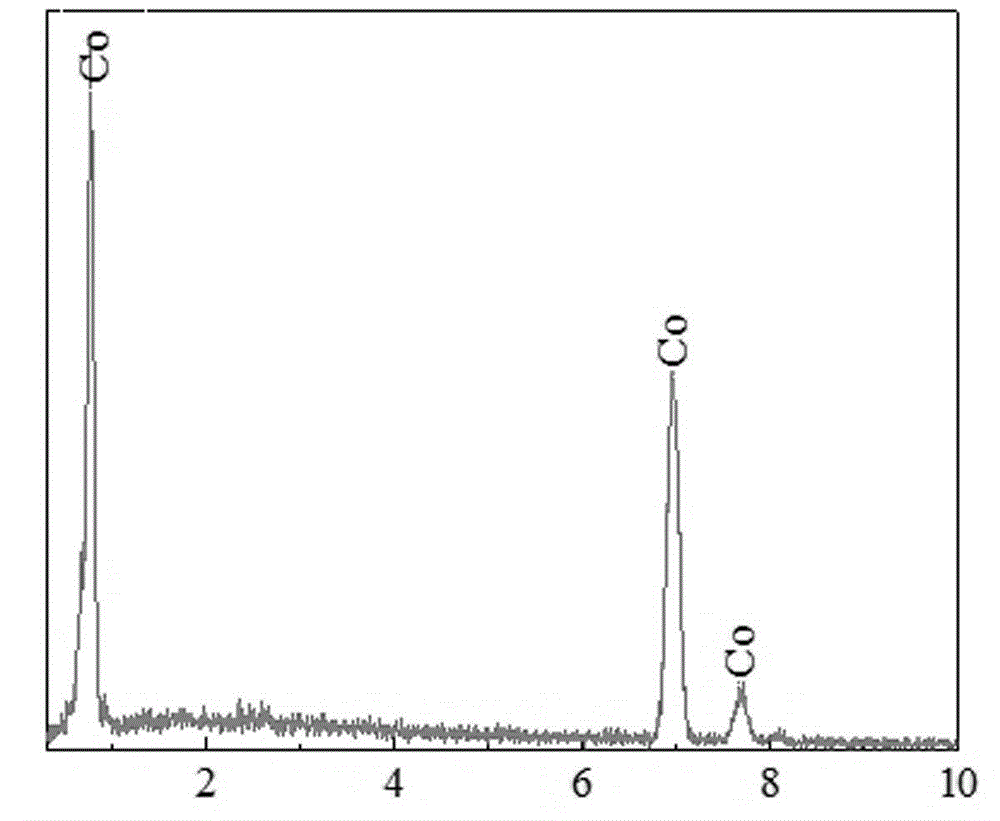

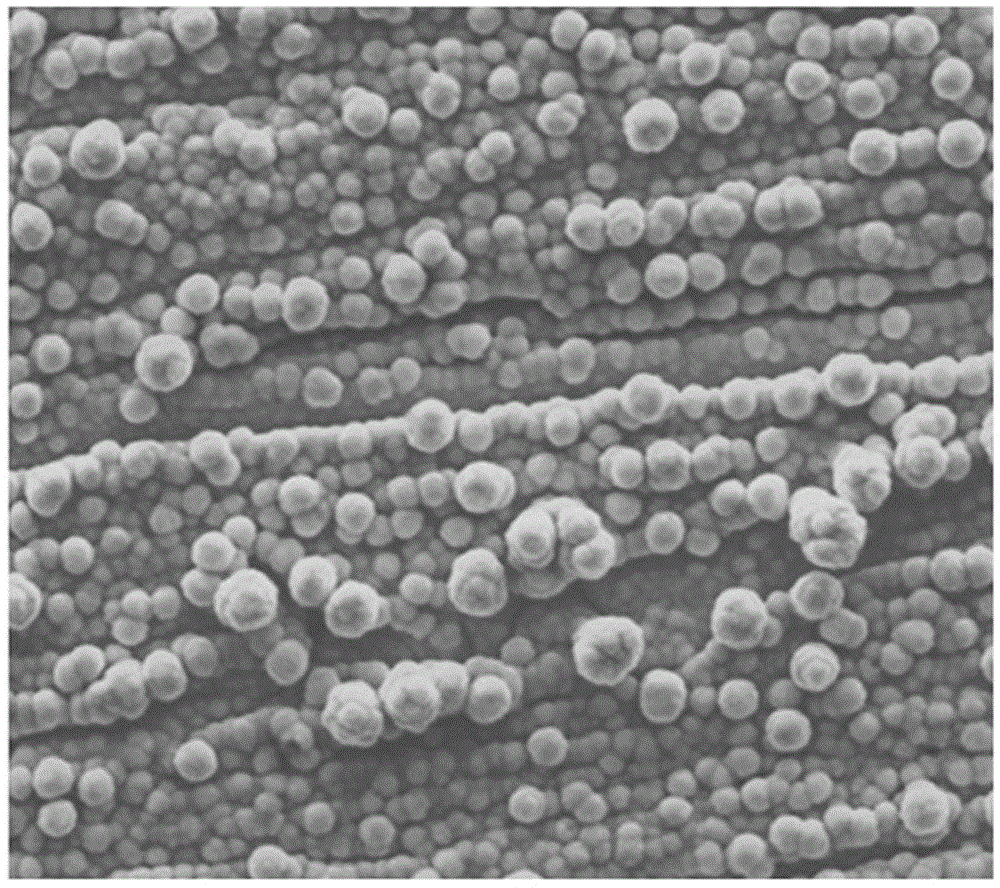

Degradable Mg-Zn-Y-Ca intravascular stent material and preparation method thereof

The invention relates to a degradable Mg-Zn-Y-Ca intravascular stent material and a preparation method thereof, which belong to the fields of design and manufacture of metal materials. The intravascular stent material is characterized by comprising the following chemical components in percentage by weight (wt%): Zn 1.00 to 4.00, Y 0.10 to 1.00, Ca 0.01 to 0.50 and the balance of Mg; the chemical components are subjected to sub-rapid solidification at (200+ / -10) K / S and heat treatment of heating at 320 to 420 DEG C and heat preservation for 20 to 30h; and the texture characteristic of the intravascular stent material is that: even and fine spherical quasicrystalline phases Mg3YZn6 are dispersed and distributed on an alpha-Mg matrix. The potential difference between the spherical quasicrystalline phases Mg3YZn6 and magnesium is lower so that the formation of a galvanic cell is restrained and galvanic corrosion is alleviated; the sphericity quasicrystal Mg3YZn6 has good corrosion resistance and can obviously enhance the corrosion resistant performance of magnesium alloy; and at the same time, the quasicrystal also has the characteristics of high hardness, low friction coefficient, low interface energy and the like and can greatly enhance the mechanical performance of the magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

Nitrile rubber production process

The invention relates to the technical field of rubber production, aiming to provide an improved nitrile rubber production process, which comprises polymerization, degassing and condensation. Raw materials including acrylonitrile, butadiene, desalinated and deoxidized water, condensed water and molecular weight regulators are fed into a polymerization position, convergence is carried out in a header pipe at the polymerization position, the converged mixture is pre-emulsified sequentially through a pipe pump and a pipe mixer, heat exchange is carried out through an ammonia-cooling heat exchanger for cooling, the cooled mixture, initiator emulsion and activator solution are sequentially fed into a plurality of reactors for polymerization to produce latex, the latex taken out of the reactorsand terminating defoamer solution are fed into a maturing reactor and are fully mixed when the rate of polymerization and conversion reaches 70 plus or minus 5 percent, and the mixture is then fed into a degassing tower to be degassed and into a condensation reactor for condensation. The problem of blockage of the heat exchanger can be avoided, the process is simple, the production process is stable and economical, the Mooney of rubber can be controlled easily, and the produced nitrile rubber has high quality.

Owner:NINGBO SHUNZE RUBBER

Prepn of cholrinated paraffin-70

InactiveCN1526796AAvoid pollutionAvoid destructionPetroleum chemical modificationParaffin waxTemperature control

The preparation of chlorinated paraffin-70 with liquid chlorine and solid paraffin as material includes mixing gasified chlorine and molten paraffin in the reactor, and three-stage substitution reaction in temperature controlled in 50-200 deg.c and controlled time to produce chlorinated paraffin-70. The product has no carbon tetrachloride contained, high chlorine content, high softening point and good use performance. The preparation process has low cost and no corrosion to apparatus.

Owner:JINGXIE CHEM PLANT MOUPING DISTRICT YANTAI

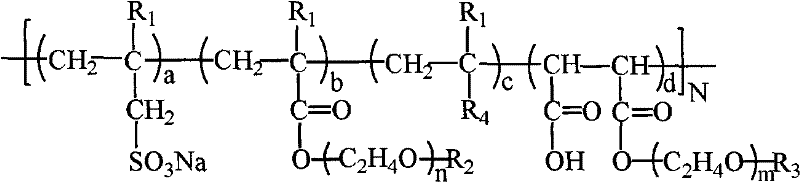

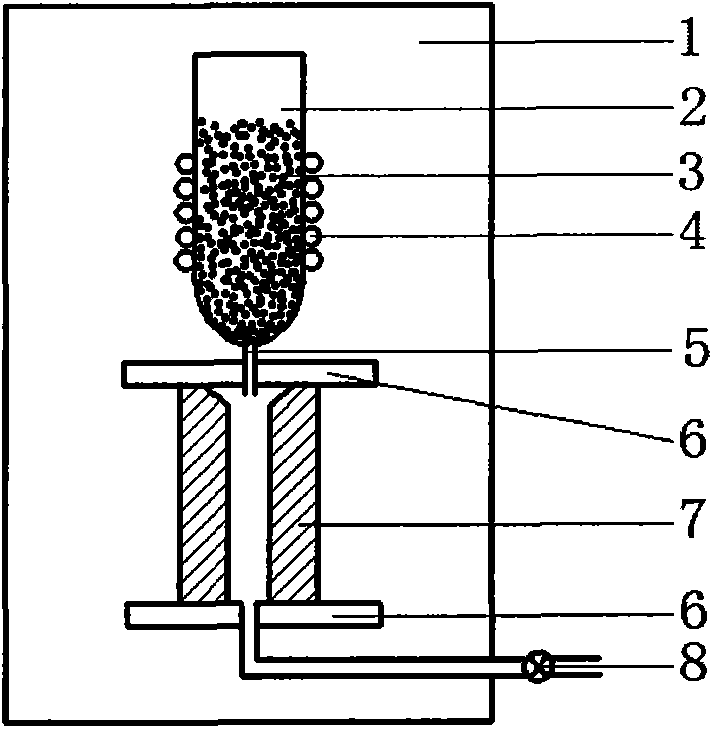

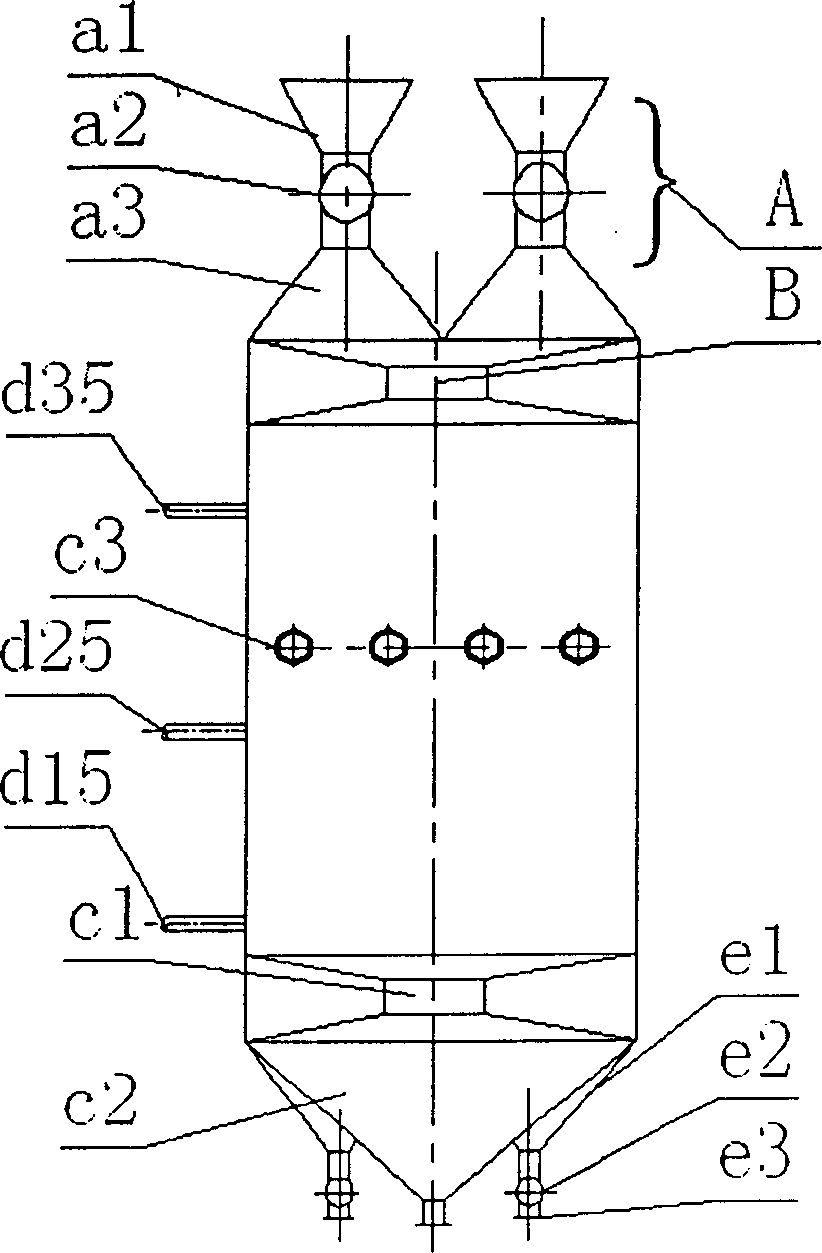

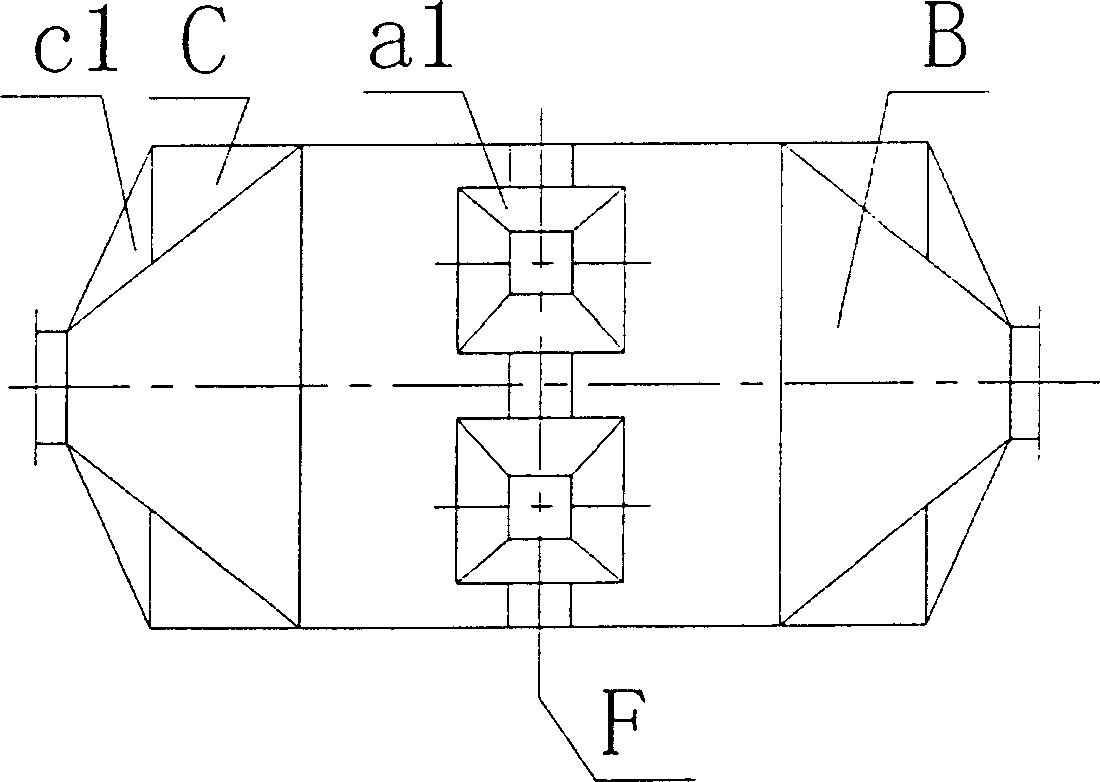

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

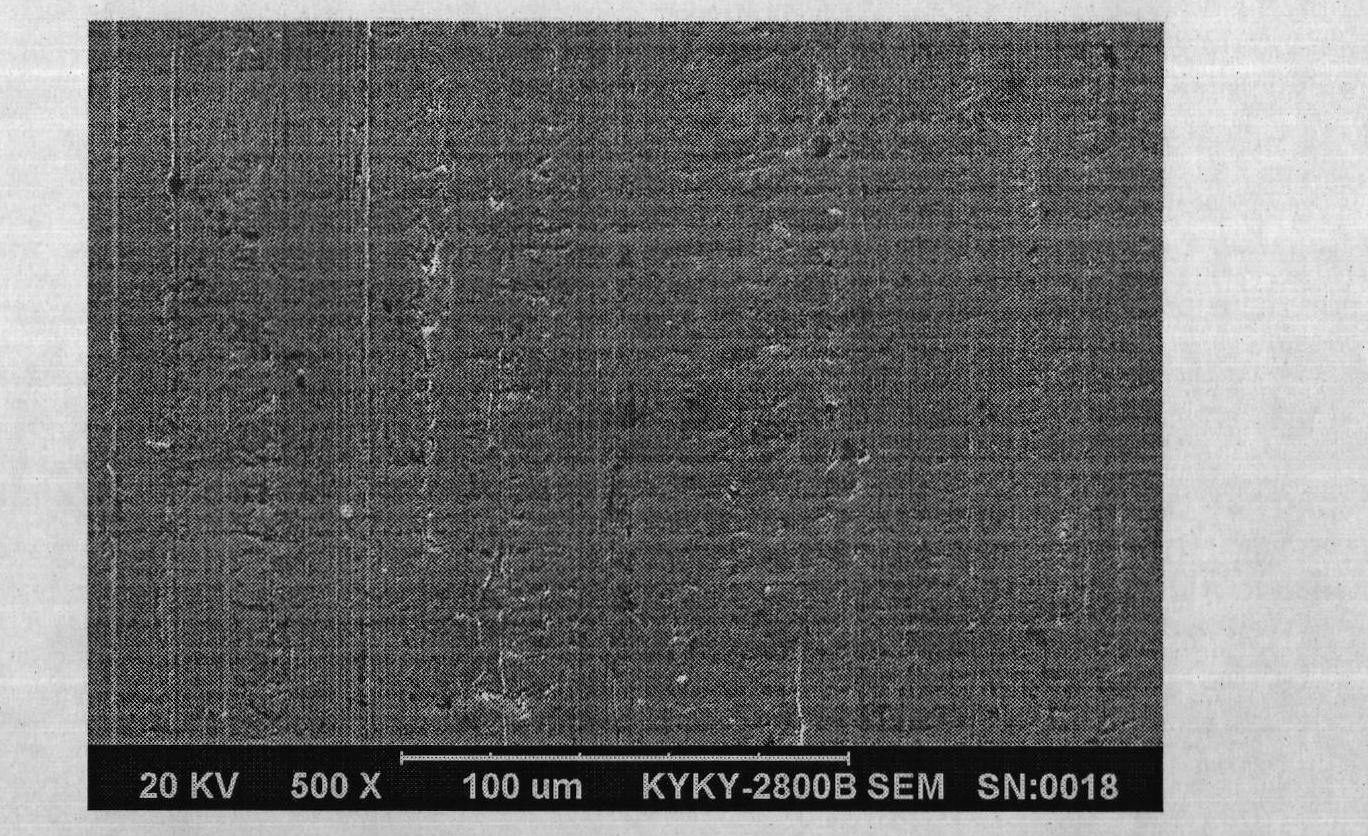

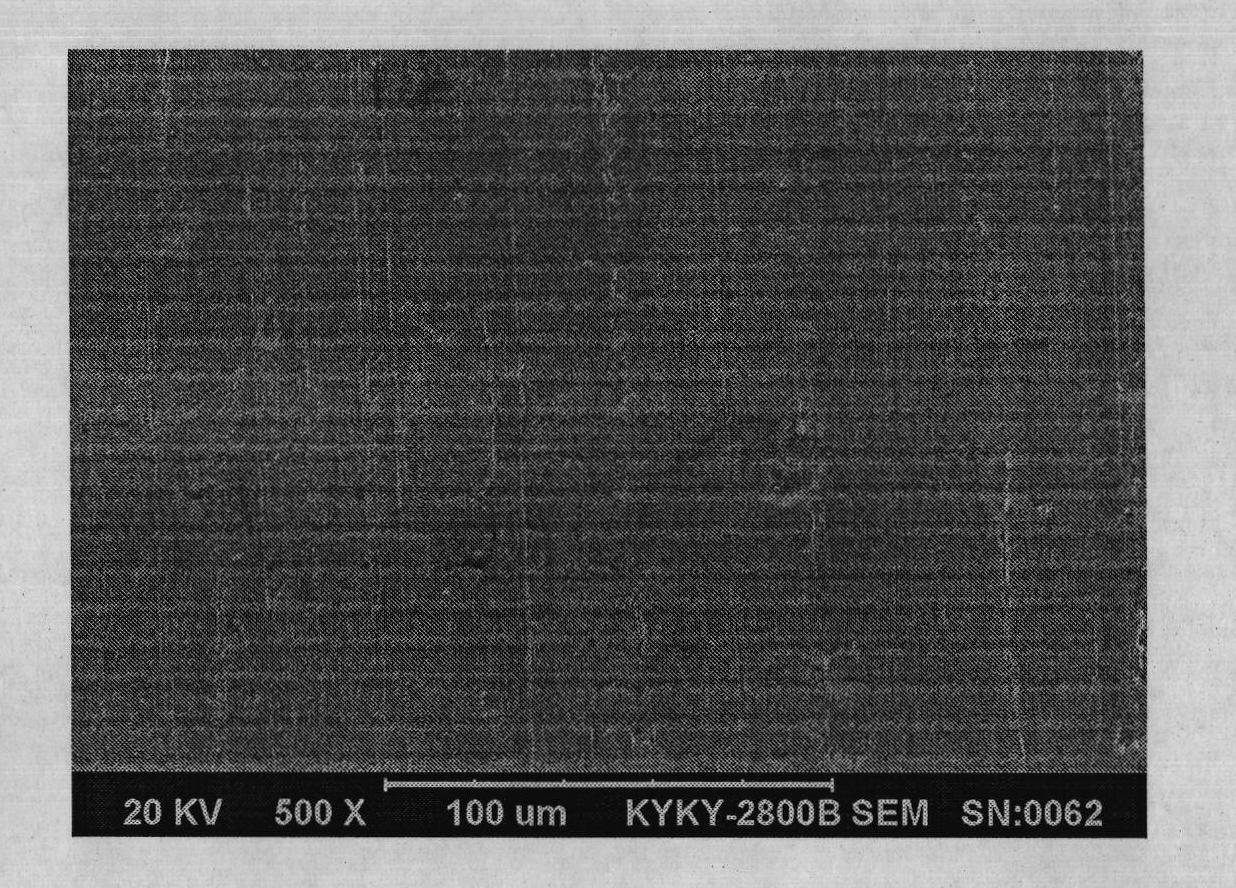

Bright electrochromism method for cold-rolled steel strip

InactiveCN102021623AImprove corrosion resistanceReduce concentrationAnodisationRare earthElectrochromism

The invention discloses a bright electrochromism technique for a cold-rolled steel strip. The technique is characterized by comprising the following steps: (1) electroplating a chromium layer, wherein the plating solution comprises the following components: 100-160 g / L of chromic anhydride, 1.5-3.0 g / L of NH4F, and 0.5-1.5 g / L of mixed rare-earth additive; the temperature of the plating solution is between 25 and 40 DEG C; the current density is between 25 and 70 A / dm<2>; and the electroplating time is between 10 and 20 s; and (2) electroplating and oxidizing the chromic layer, wherein the plating solution comprises the following components: 50-75 g / L of chromic anhydride, 0.8-2.5 g / L of NH4F, and 5-15 g / L of NaOH; the temperature of the plating solution is between 15 and 30 DEG C; the current density is between 8 and 20 A / dm<2>; and the electroplating time is between 2 and 6 s. In the invention, the performance advantages of the plating solution are fully used to obtain a uniform chromium-plated plate with bright plating layer and good quality, thus further improving the surface quality of the chromium-plated plate. Meanwhile, the method has the advantages of low corrosion to equipment, low temperature and effective reduction of energy consumption.

Owner:YANSHAN UNIV

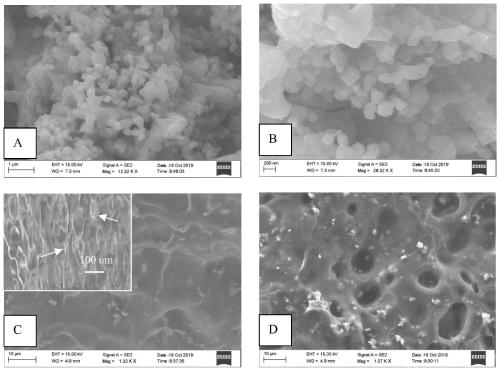

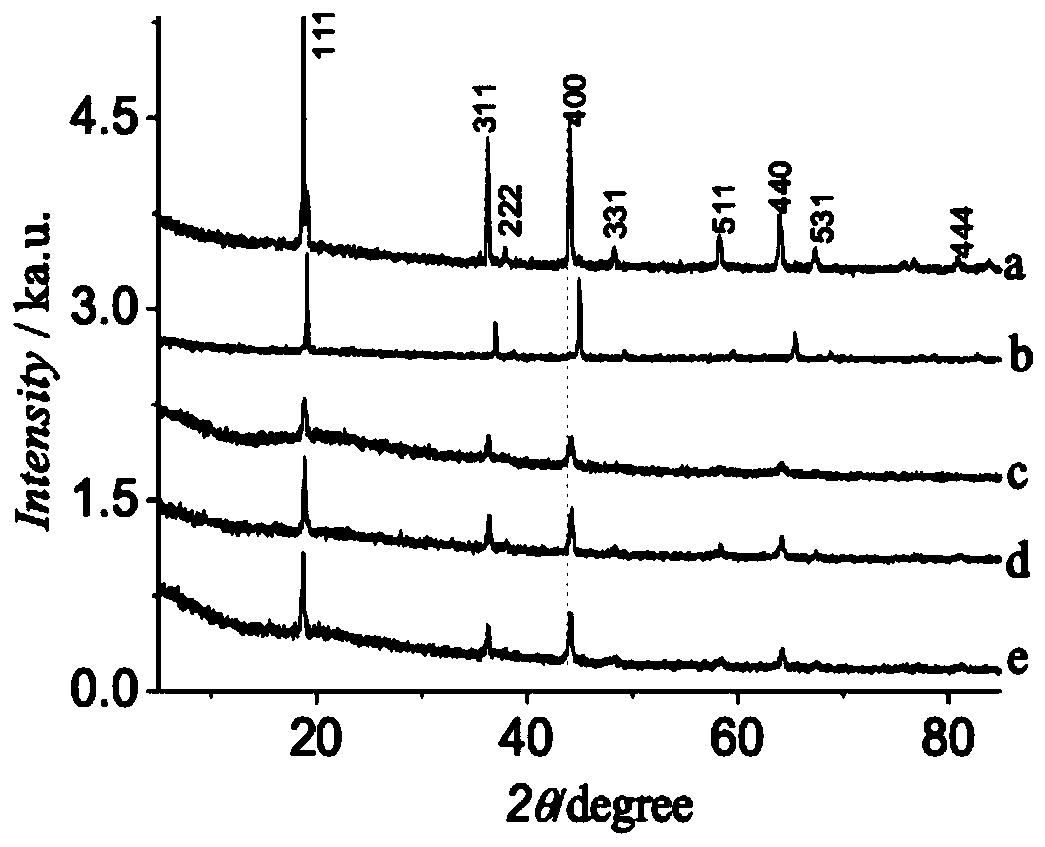

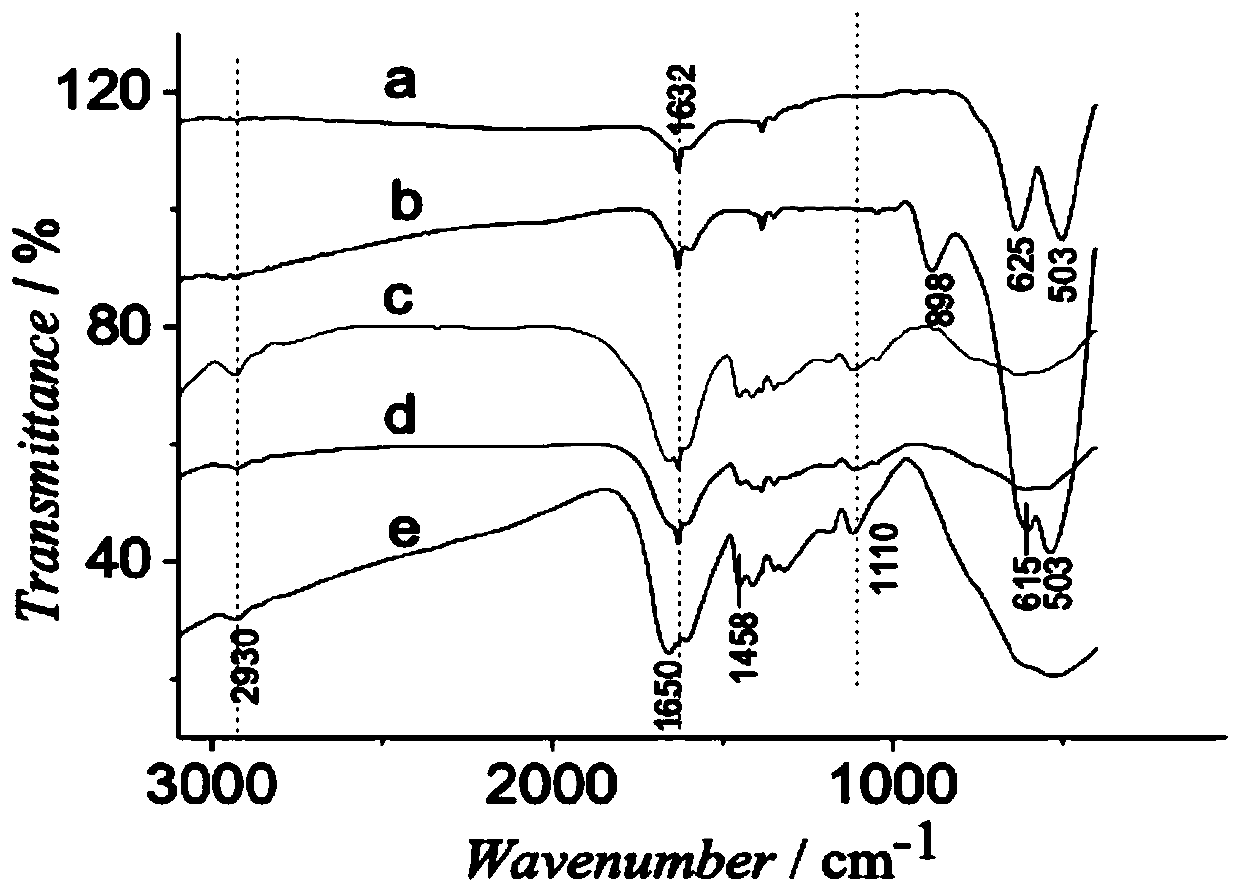

Preparation of conductive manganese-titanium lithium ion sieve/graphene composite hydrogel and application of conductive manganese-titanium lithium ion sieve/graphene composite hydrogel in extraction of lithium from salt lake brine

ActiveCN111250063AStable structureGood lithium adsorption capacityOther chemical processesDispersed particle separationManganeseIon exchange

The invention discloses preparation of conductive manganese-titanium lithium ion sieve / graphene composite hydrogel and an application of the conductive manganese-titanium lithium ion sieve / graphene composite hydrogel in extraction of lithium from salt lake brine. A manganese-titanium lithium ion sieve is prepared by adopting a sol-gel method, and manganese-titanium lithium ion sieve / graphene composite hydrogel (MnTi / GNs-LIPs) is prepared by adopting an in-situ thermal initiation polymerization method. According to the method, an adsorption-electrodeionization exchange method is adopted, the MnTi / GNs-LIPs adsorbent selectively adsorbs lithium in the salt lake brine and then is placed in a single weakly acidic solution, lithium is rapidly desorbed through electrodeionization exchange, and the purpose of recycling lithium in the salt lake brine in a classified mode can be achieved after repeated operation.

Owner:HEFEI UNIV OF TECH

Method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition

A method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition is characterized by comprising the steps of (1) mixing anhydrous urea, acetamide and anhydrous LiX uniformly and heating and stirring the mixture to form a colorless uniform liquid molten salt; (2) dissolving a transition metal chloride TMCl2 in low temperature molten salt and stirring and mixing the mixture uniformly to form a low temperature molten salt electrolyte; (3) with a copper sheet or stainless steel as a cathode and graphite as an anode, performing electro-deposition in the low temperature molten salt electrolyte at the electrolyzing temperature of 70-90 DEG C in a manner of constant potential and constant current to control the potential or cathode current density; and (4) when the electrolysis is finished, taking the copper sheet or stainless steel out and cleaning and drying it to obtain the transition metal and alloy thereof deposited on the surface of the cathode. The molten salt is low in price and is low in eutectic temperature so that the method is low in cost, is low in electrolysis temperature, is energy-saving, is less in pollution and is slight in corrosion on equipment.

Owner:NORTHEASTERN UNIV LIAONING

Pickling agent for stainless steel

The invention relates to a pickling agent for stainless steel. According to percentage by weight, the pickling agent consists of the following components: 23 to 30 percent of sulfuric acid; 4 to 6 percent of nitric acid; 7 to 14 percent of hydrochloric acid; 0.1 to 0.3 percent of corrosion inhibitor; 0.13 to 0.25 percent of additive; and the balance of water. The mass concentrations of the used acids are as follows: 95.0 to 98.0 percent of sulfuric acid; 65.0 to 68.0 percent of nitric acid; and 36.0 to 38.0 percent of hydrochloric acid. The components are uniformly mixed according to proportion. The corrosion inhibitor is hexamethylene tetramine, the additive is the mixture of sodium dodecyl sulfate and isooctyl phenol polyoxyethylene, the percentage by weight of the sodium dodecyl sulfate is 0.08 to 0.15 percent, the percentage by weight of the isooctyl phenol polyoxyethylene is 0.05 to 0.1 percent, and the effect is better when the temperature of each acid is 60 DEG C to 80 DEG C. The pickling efficiency of the pickling agent for stainless steel is increased by four to five times, the pickled surface is bright and clean, and the pickling agent for stainless steel is particularly suitable for pickling the surfaces of stainless steel with high Cr, Ni and Mo alloy contents to remove ferric oxide scales.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

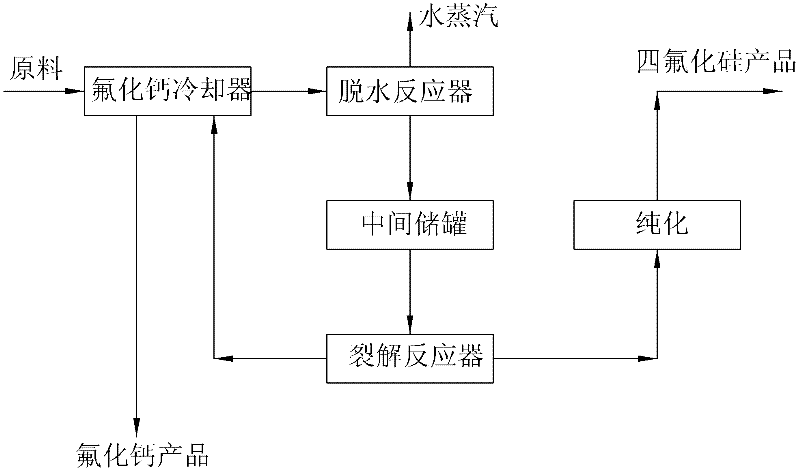

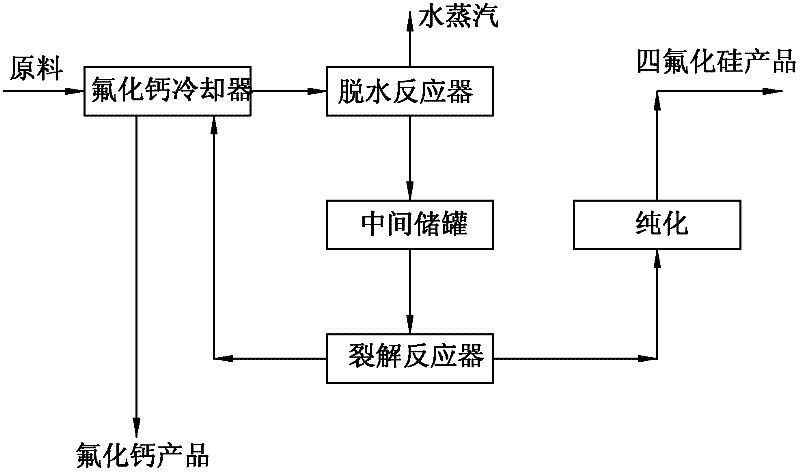

Method for preparing silicon tetrafluoride from calcium fluosilicate

InactiveCN102390835AHigh puritySimple processHalogenated silanesCalcium silicateSilicon tetrafluoride

The invention discloses a method for preparing silicon tetrafluoride. In the method, hydrated calcium fluosilicate is used as a raw material. The method is characterized by comprising the following steps of: preheating the hydrated calcium fluosilicate to 60-100 DEG C and drying under pressure of 0.05-0.5 MPaG and at the temperature of 100-220 DEG C for 60-150 minutes to obtain solid powdery calcium fluosilicate with moisture content of less than 1.5 percent by weight; feeding the calcium fluosilicate into an intermediate storage tank, then feeding into a cracking reactor, and pyrolyzing under the pressure of 0.05-0.5 MPaG and at the temperature of 220-420 DEG C for 60-150 minutes to obtain a silicon tetrafluoride rough product; and feeding the silicon tetrafluoride rough product into a sulfuric acid washing tower for washing to remove moisture so as to obtain a silicon tetrafluoride product with purity of 99 percent. The method has the advantages of simple technical process, capability of relieving corrosion to equipment, energy conservation, environmental friendliness, low cost and capability of improving purity of the silicon tetrafluoride.

Owner:SEDIN NINGBO ENG

Preparation method of O-3-chloro-2-propenylhydroxylamine

InactiveCN109438280AReduce the chance of collisionLittle pollutionOximes preparationWater bathsHydroxylamine

The invention belongs to the technical field of organic synthesis, and in particular relates to a preparation method of O-3-chloro-2-propenylhydroxylamine. The preparation method of the O-3-chloro-2-propenylhydroxylamine comprises the following steps: uniformly stirring hydroxylamine salt, water and acetone, adding a sodium hydroxide solution, reacting at room temperature for 1 to 2 hours, then adding 1,3-dichloropropene and a phase transfer catalyst, heating in water bath, controlling the temperature at 60 to 90 DEG C, reacting for 5 to 10 hours, standing still for stratification, separatingand collecting an oil phase, extracting the oil phase 2 to 3 times with an extractant, drying extract liquid with anhydrous sodium sulfate, and removing a solvent under reduced pressure to obtain theO-3-chloro-2-propenylhydroxylamine. According to the preparation method of the O-3-chloro-2-propenylhydroxylamine provided by the invention, acetone oxime is firstly prepared by taking the hydroxylamine salt and acetone as raw materials, and then 1,3-dichloropropene and the phase transfer catalyst are added for a reaction to prepare the O-3-chloro-2-propenylhydroxylamine; the O-3-chloro-2-propenylhydroxylamine prepared with the preparation method has the purity of 99% or more than 99% and the yield of 88% or more than 88%, and the method is suitable for industrial production.

Owner:江苏艾科维科技股份有限公司

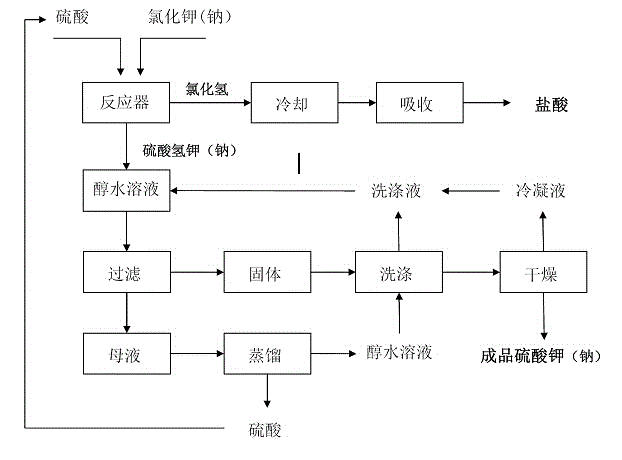

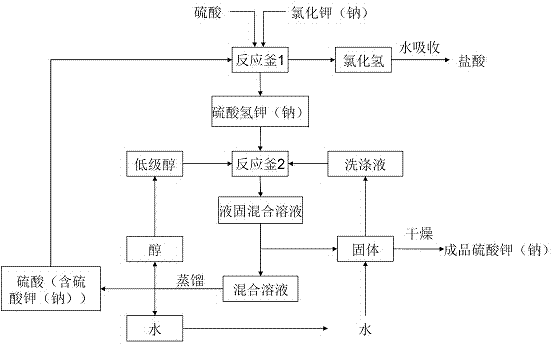

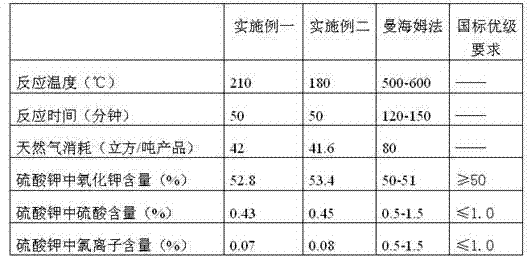

Method for producing potassium sulfate or sodium sulfate by potassium chloride or sodium chloride and sulfuric acid

InactiveCN104150510ALow reaction temperatureReduce energy consumptionChlorine/hydrogen-chlorideSulfate/bisulfate preparationHydrogen SulfatePotassium bisulfate

The invention discloses a novel method for producing potassium sulfate or sodium sulfate by potassium chloride or sodium chloride and sulfuric acid. According to the method, potassium chloride or sodium chloride and sulfuric acid react under heating to produce potassium sulfate or sodium sulfa and hydrogen chloride, potassium hydrogen sulfate or sodium hydrogen sulfate is degraded by an alcohol-water solution to produce potassium sulfate or sodium sulfate and sulfuric acid, a product is subjected to procedures such as centrifugal separation or centrifugal filtration, washing, drying and the like to obtain a finished product of potassium sulfate or sodium sulfate, and a mother solution is distilled and recovered to obtain an alcohol-water solution and sulfuric acid which are returned for recycling; and hydrogen chloride gas produced by the reaction is cooled, enters an absorption tower and is absorbed by water to prepare hydrochloric acid, or is cooled and purified for other application. When the method is used for preparing potassium sulfate or sodium sulfate, the reaction temperature is low, the equipment corrosion is weak, the reaction speed is high, short time is required, the product quality is stable, and a good comprehensive economic benefit is provided.

Owner:张秀贞

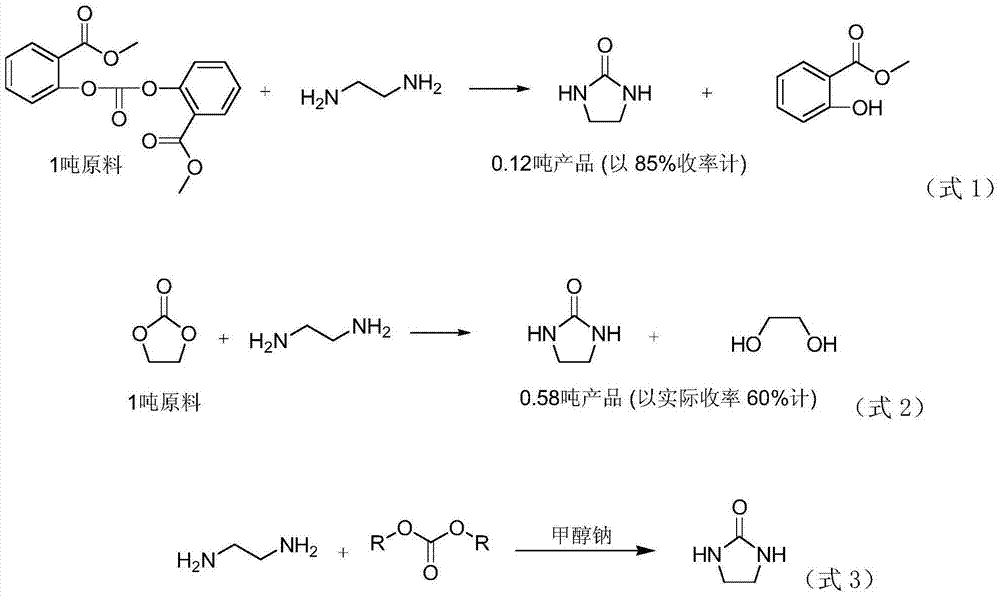

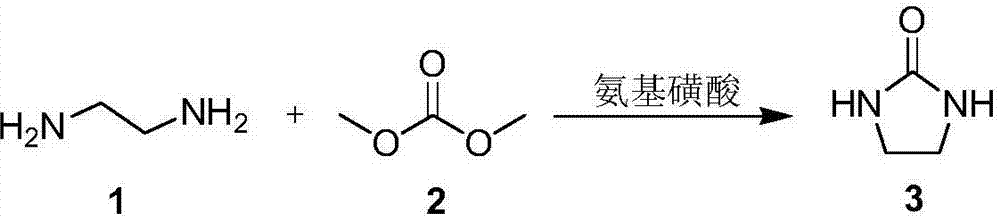

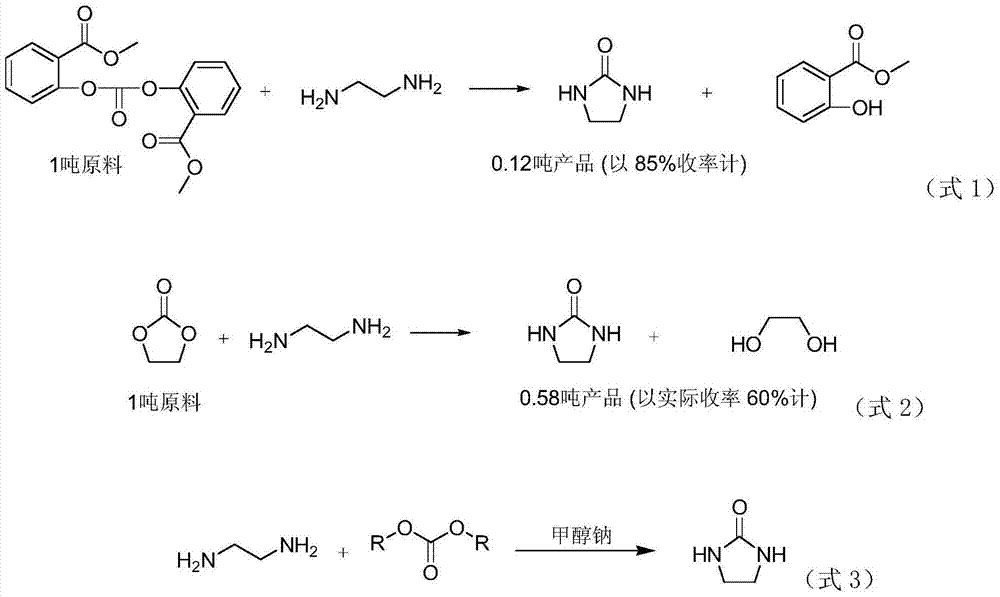

2-imidazolidone synthesis method

InactiveCN103497157ALow priceEasy to recycleOrganic chemistryChemical recyclingEthylenediamineAlcohol

The invention relates to 2-imidazolidone, and provides a 2-imidazolidone synthesis method simple in process and low in cost. The method includes: (1) sequentially adding a catalyst of sulfamic acid, a solvent of methyl alcohol, ethylenediamine and dimethyl carbonate into a heatable reactor for reacting at the temperature of 20-80 DEG C for 1-5 hours; (2) continuously raising the temperature to 120-180 DEG C, and reacting for 10-24 hours prior to generating a target product 2-imidazolidone; (3) after reaction is ended, filtering to remove the catalyst of sulfamic acid and remove the solvent of methyl alcohol so as to obtain a coarse product 2-imidazolidone; (4) refining the coarse product 2-imidazolidone obtained in the step (3) to obtain the product 2-imidazolidone. The defects that an existing synthesis process is carried out at high temperature under high pressure, high-corrosivity catalysts, toxic materials and high boiling solvent are used, atom utilization rate is low and the like are overcome.

Owner:XIAMEN UNIV +1

Method for producing casting cold-box resin

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

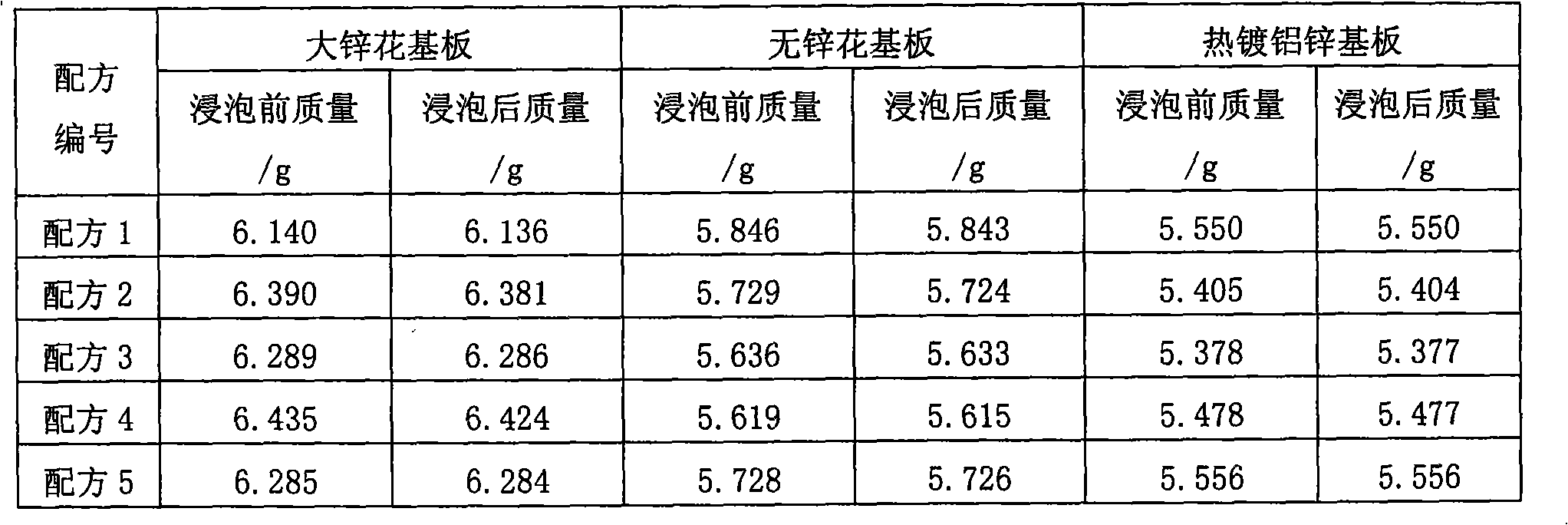

Paint remover for color-coated steel plates and using method thereof

ActiveCN101659806ALittle corrosionGood paint removal effectChemical paints/ink removersChemistryTriethanolamine

Owner:ANGANG STEEL CO LTD

Efficient metal rust remover

The invention relates to an efficient metal rust remover. The efficient metal rust remover is characterized by being composed of, by weight, 45-60 parts of hydrochloric acid, 4-5 parts of phosphoric acid, 0.4-0.6 part of hexamine, 0.4-0.6 part of lauryl sodium sulfate, 0.15-0.4 part of triethanolamine, 0.4-0.6 part of citric acid, 0.5-1.2 parts of oleic acid, 0.8-1.6 parts of oxalic acid, 3-6 parts of urotropin, 6-10 parts of fatty alcohol-polyoxyethylene ether, and 20-70 parts of water. The efficient metal rust remover is capable of removing rust efficiently and rapidly, does not burn or explode, is not volatile, and is low in substrate corrosion and price and convenient to use.

Owner:周仁勇

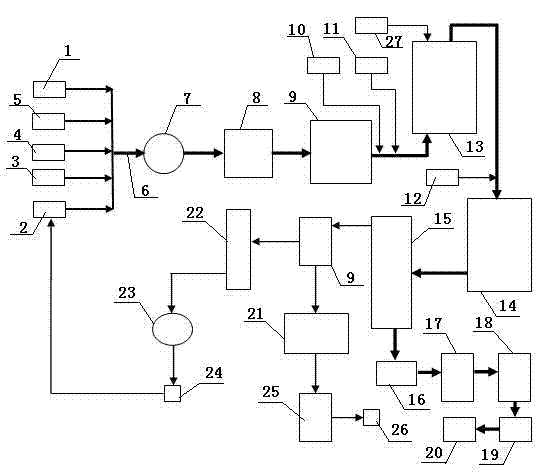

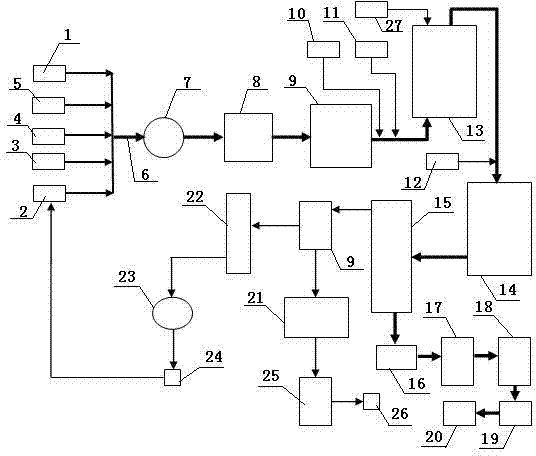

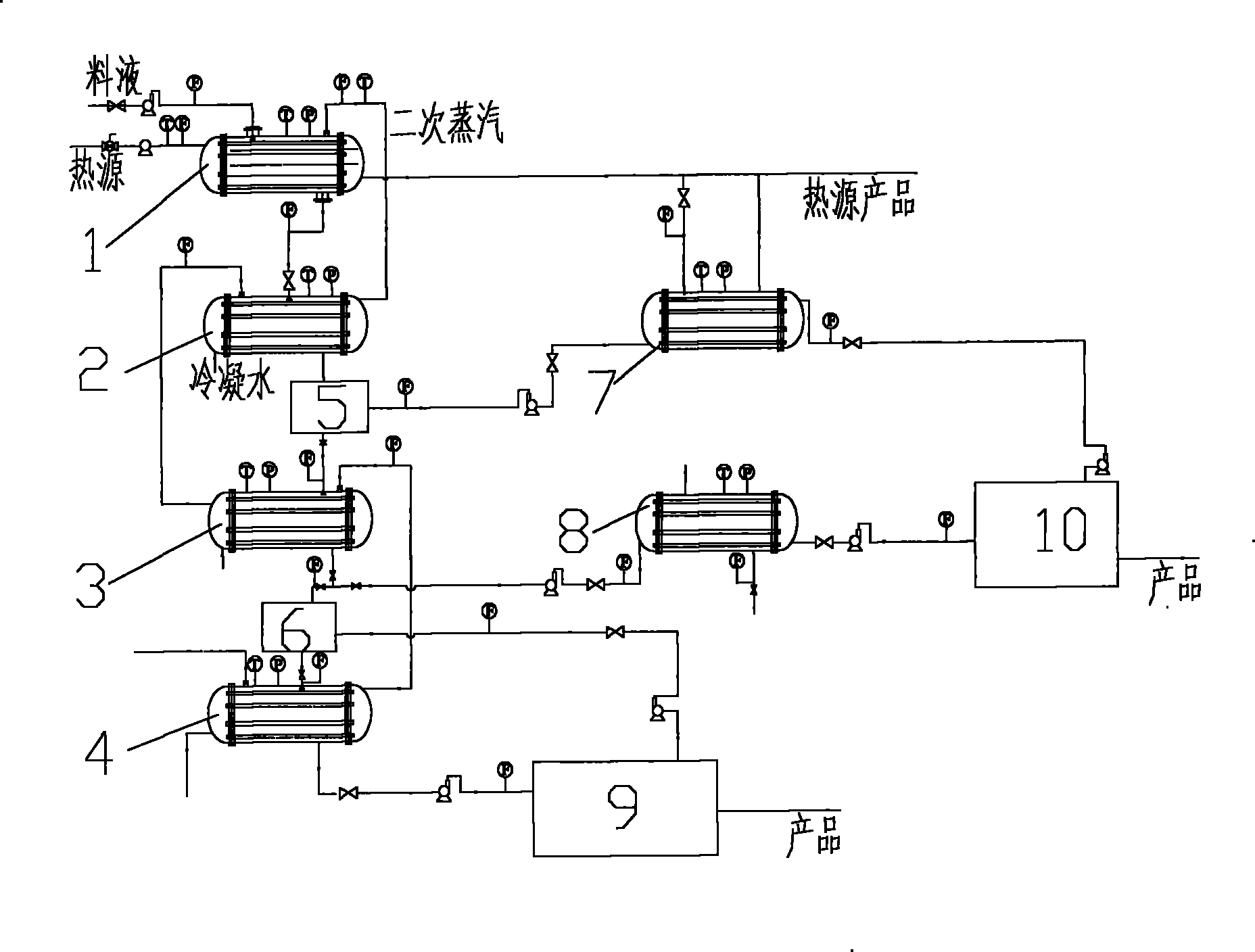

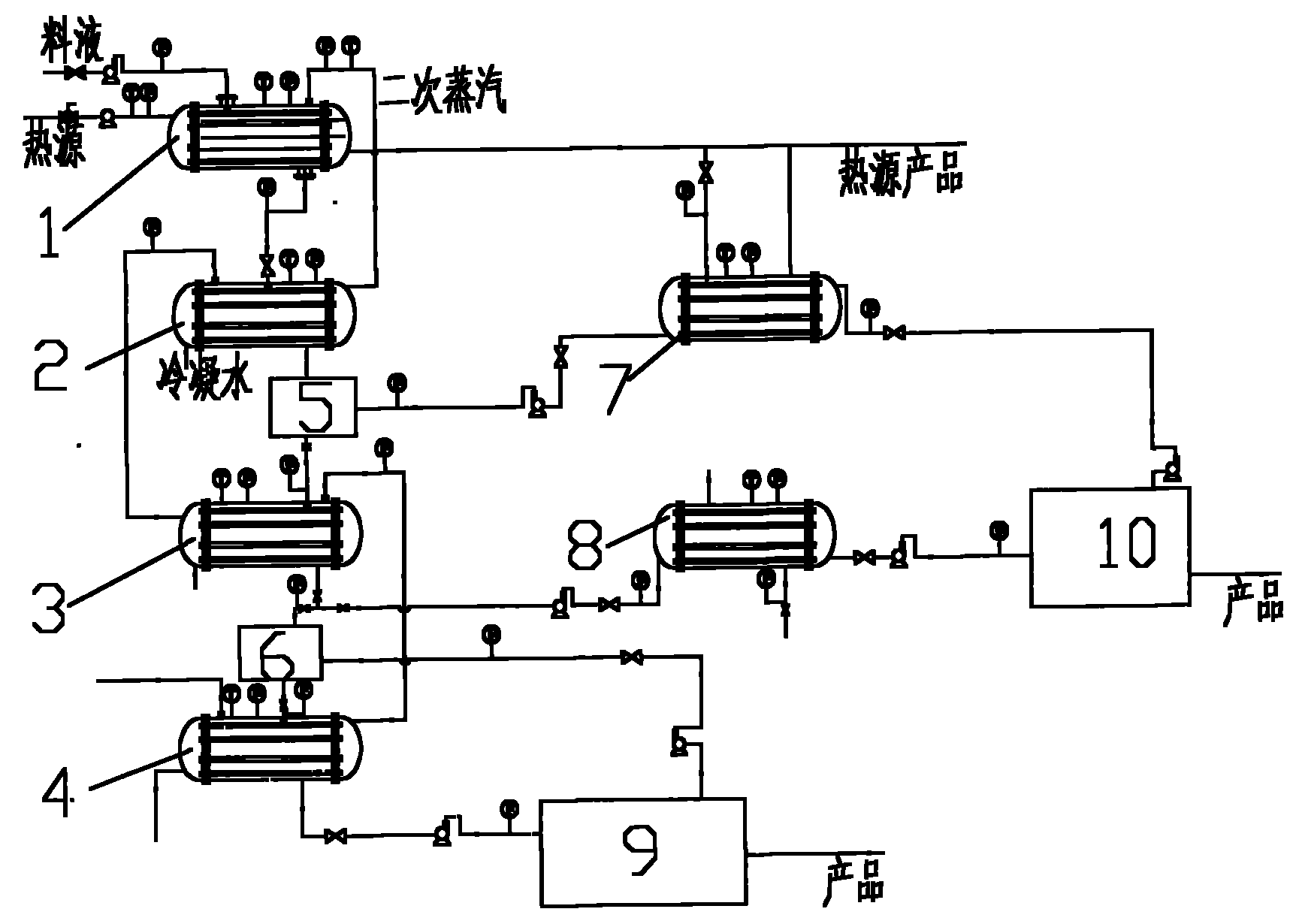

Low-temperature multiple-effect evaporation crystallization and filtration process

ActiveCN102151415AAvoid easy cloggingNo dischargeSolution crystallizationMultiple-effect evaporationRefluxFiltration

The invention relates to a low-temperature multiple-effect evaporation crystallization and filtration process belonging to the technical field of chemical engineering separation and energy conversation and emission reduction. The process is characterized in that processes of low-temperature multiple-effect evaporation, crystallization and filtration, granulation and the like are coupled to form aset of complete waste liquid emission free process for concentrating and extracting solute. The process comprises two loops, wherein a three-effect evaporator, a cooler, a crystallization filter and a heat exchanger form a loop; a four-effect evaporator and a crystallization filter form the other loop; low-temperature heat source or waste heat is utilized in one-effect evaporation, and secondary steam generated by the former one-effect is utilized in other effect evaporation; and heat required by the heat exchanger in a three-effect evaporation circulating loop is supplied by heat released bytemperature reduction of a heat source flowing from a one-effect evaporator. The invention has the advantages of reducing investment cost by adopting the low-temperature heat source or waste heat andthe secondary steam as heat sources, lightening corrosion because the concentration of a solution is not overhigh by adopting a reflux mode, being not easy to block a pipe, reducing operation cost, and being capable of completely separating out the solute without emitting waste liquid.

Owner:DALIAN UNIV OF TECH

Low temperature removal method for COS with relatively high concentration in gas

InactiveCN106975340ALow running costSolve the problems existing in desulfurizationGas treatmentDispersed particle separationHigh concentrationSulfur

The invention provides a low temperature removal method for COS with a relatively high concentration in gas. The low temperature removal method mainly comprises the following steps: process gas is maintained or heated to 30-80 DEG C and is introduced into hydrolysis desulfuration towers to be treated; the hydrolysis desulfuration towers are filled with a COS hydrolysis agent and an H2S oxidation desulfuration agent in a stacking or laminating manner; the H2S oxidation desulfuration agent can be subjected to sulfur-blowing thermal regeneration at 200-300 DEG C, and the performance of the COS hydrolysis agent is less or barely reduced after a thermal regeneration process; two or more hydrolysis desulfuration towers are arranged, can be connected in series or parallel for use and comprise vertical heating sleeves, and hydrolysis agent-desulfuration agent bed layers are arranged among the sleeves; and captured elemental sulfur is melted, gasified and blown out by the hydrolysis desulfuration towers during the thermal regeneration at 200-300 DEG C and is collected as sulfur by virtue of a regeneration condenser. The low temperature removal method has the beneficial effects that the desulfuration process is simple and reliable, the COS removal rate is easily maintained above 90% or even above 95%, the control is easy, the elasticity of processing quantity is high, and the method has strong adaptability to the degrees and fluctuation of contents of H2S and COS, and is safe and environment-friendly and low in operation cost.

Owner:淄博赢信达知识产权咨询服务有限公司

Method for producing potassium (sodium) sulfate at low temperature

InactiveCN104118890ALow reaction temperatureReduce energy consumptionChlorine/hydrogen-chlorideSulfate/bisulfate preparationHydrogen SulfateDistillation

The invention discloses a method for producing potassium (sodium) sulfate at a low temperature. The method comprises the following steps: performing heating reaction between potassium (sodium) chloride and sulfuric acid to generate potassium (sodium) hydrogen sulfate and hydrogen chloride, adding potassium (sodium) hydrogen sulfate into water to obtain a water solution of potassium (sodium) hydrogen sulfate, adding alcohol into the water solution, decomposing to generate potassium (sodium) sulfate and sulfuric acid, performing the processes of centrifuging (filtering) separation, washing, drying and the like to obtain finished potassium (sodium) sulfate, and performing distillation recovery on mother liquid to obtain alcohol, a water solution and sulfuric acid which can be reused, wherein hydrogen chloride gas generated in the reaction is cooled, then is absorbed by water in an absorption tower to obtain hydrochloric acid, or is cooled and purified for other uses. Potassium (sodium) sulfate is prepared by adopting the method, the reaction temperature is low, the equipment corrosion is low, the reaction speed is very high, the needed time is short, the product quality is stable, and good comprehensive economic benefits are achieved.

Owner:柳仁民

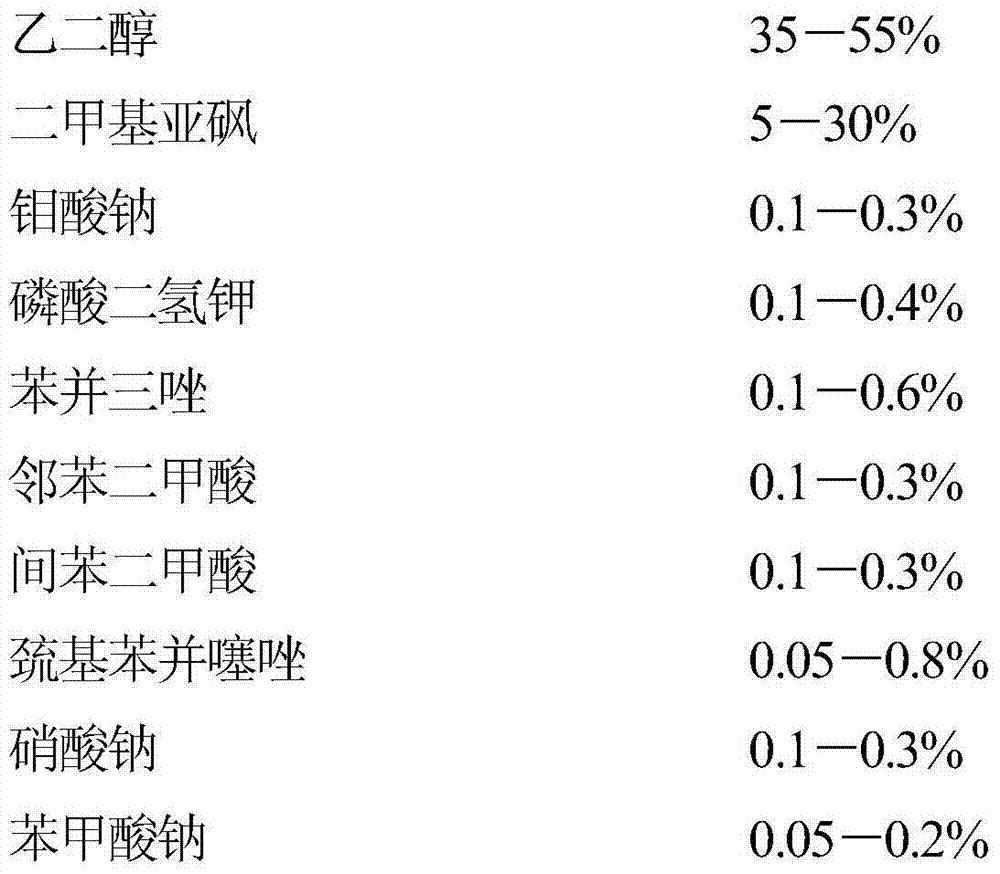

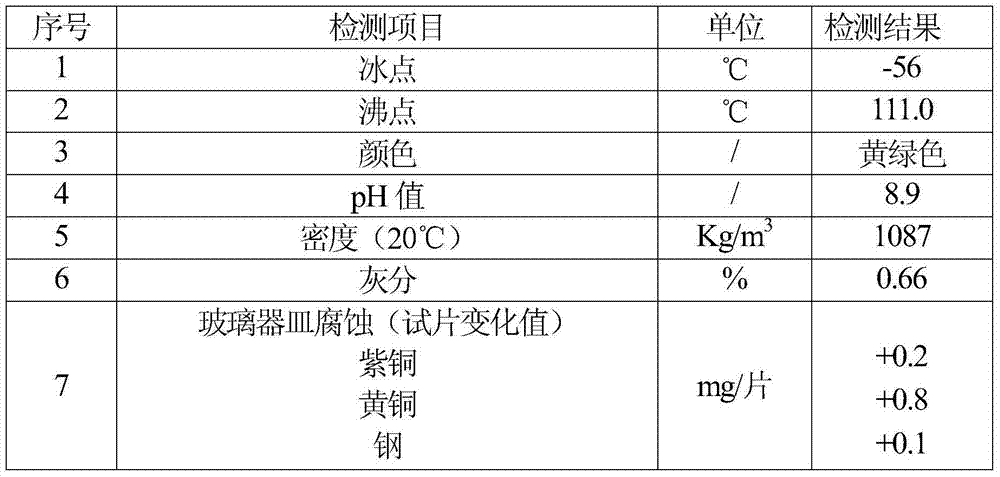

LNG vehicle anti-freezing liquid

ActiveCN104774595ALowering the freezing pointLittle corrosionHeat-exchange elementsPhosphatePotassium

The present invention relates to an LNG vehicle anti-freezing liquid, and provides a new special LNG vehicle anti-freezing liquid used for cold regions and having characteristics of excellent corrosion resistance, rust resistance, scale inhibition, high boiling point, and low freezing point. The LNG vehicle anti-freezing liquid is characterized by comprising, by weight, 35-55% of ethylene glycol, 5-30% of dimethyl sulfoxide, 0.1-0.3% of sodium molybdate, 0.1-0.4% of potassium dihydrogen phosphate, 0.1-0.6% of benzotriazole, 0.1-0.3% of phthalic acid, 0.1-0.3% of Isophthalic acid, 0.05-0.8% of mercapto benzothiazole, 0.1-0.3% of sodium nitrate, 0.05-0.2% of sodium benzoate, 0.1-0.5% of sodium hydroxide, 0.0005-0.0015% of fluorescein, and the balance of deionized water.

Owner:SHAANXI AUTOMOBILE GROUP

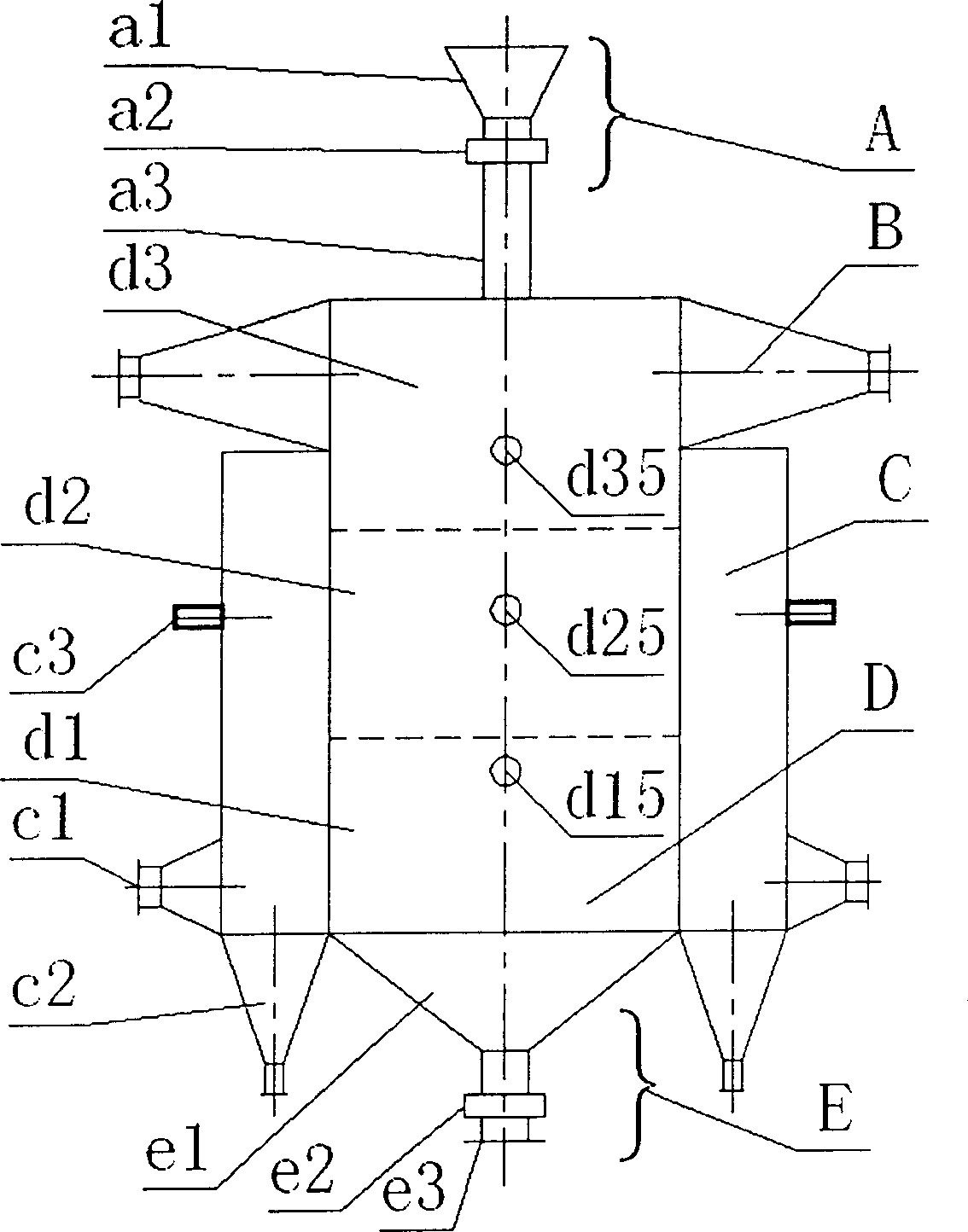

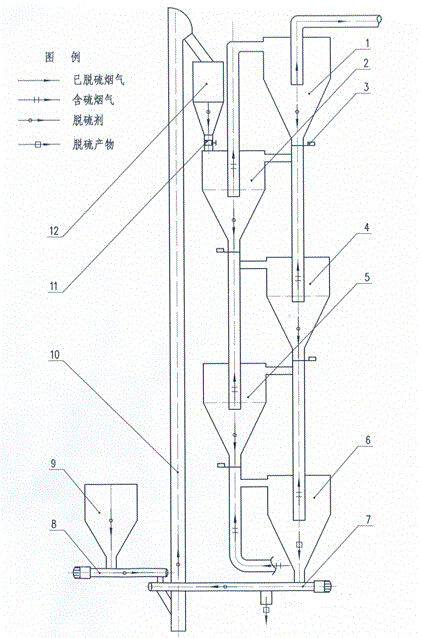

Cyclone cylinder flue gas dry-method catalytic desulfurization device and process

ActiveCN104474894AOvercoming airflow resistanceIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationThermodynamicsFlue gas

The invention relates to a cyclone cylinder flue gas dry-method catalytic desulfurization device and process; the device comprises at least two stages of cyclone cylinder bodies; a flap valve is arranged at a desulfurization product outlet at the bottom of the cyclone cylinder body; the desulfurization product outlet at the bottom of the first-stage cyclone cylinder body is communicated with a desulfurization product inlet at the upper part of the second-stage cyclone cylinder body; a flue gas outlet on the top of the second-stage cyclone cylinder body is communicated with a flue gas inlet at the upper part of the first-stage cyclone cylinder body; a flue gas outlet on the top of the first-stage cyclone cylinder body is communicated with a flue gas humidifier and a dust removing system; the desulfurization product outlet at the bottom of the last cyclone cylinder body is communicated with a spiral conveyor; the spiral conveyor is communicated with a feeding hole of a bucket elevator; the cyclone cylinder further comprises a desulfurization agent storage tank; the desulfurization agent storage tank is communicated with a variable speed spiral conveyor; the variable speed spiral conveyor is communicated with the feeding hole of the bucket elevator; the discharging hole of the bucket elevator is communicated with a high-level desulfurization agent tank; and the high-level desulfurization agent tank is communicated with the desulfurization product inlet on the top of the second-stage cyclone cylinder body through a feeder.

Owner:王在仕

Reverse flotation technology of phosphate ore in alkaline medium

The invention relates to a reverse flotation technology of phosphate ore in an alkaline medium. Crushed phosphate ore is crushed and evenly mixed with industrial lime, the mixture enters a grinder and water is added to perform size mixing. Thus, the ore is composed of materials and enters a reverse flotation roughing groove after the ore receives monomer separation. A reverse flotation collecting agent C5-9 soap is used for performing size mixing to carry out reverse flotation roughing and obtain a roughed foam mainly comprising carbonate gangue minerals and one part of roughed phosphorus concentrate products. The roughed foam enters a reverse flotation selection groove, and the industrial lime and the reverse flotation collecting agent C5-9 soap are added for performing size mixing. Reverse flotation selection is carried out and a foam product is tailings, and is discharged and piled up. The other part of the obtained products in the groove are phosphorus concentrate. The concentrate is combined and receives concentration, filtering and drying and the final phosphorus concentrate is obtained. The reverse flotation technology has the advantages of being simple in technological process, easy to operate and control, easy to stably operate, high in separation efficiency, superior in technologic index, high in quality of the obtained phosphorus concentrate, high in yield coefficient, low in cost of final product phosphorus concentrate and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

2-imidazolidone synthesis method

InactiveCN103497157BLow priceEasy to recycleOrganic chemistryChemical recyclingEthylenediamineAlcohol

The invention relates to 2-imidazolidone, and provides a 2-imidazolidone synthesis method simple in process and low in cost. The method includes: (1) sequentially adding a catalyst of sulfamic acid, a solvent of methyl alcohol, ethylenediamine and dimethyl carbonate into a heatable reactor for reacting at the temperature of 20-80 DEG C for 1-5 hours; (2) continuously raising the temperature to 120-180 DEG C, and reacting for 10-24 hours prior to generating a target product 2-imidazolidone; (3) after reaction is ended, filtering to remove the catalyst of sulfamic acid and remove the solvent of methyl alcohol so as to obtain a coarse product 2-imidazolidone; (4) refining the coarse product 2-imidazolidone obtained in the step (3) to obtain the product 2-imidazolidone. The defects that an existing synthesis process is carried out at high temperature under high pressure, high-corrosivity catalysts, toxic materials and high boiling solvent are used, atom utilization rate is low and the like are overcome.

Owner:XIAMEN UNIV +1

Solar and thermocompression vapor-compression distillation type water purifying device

ActiveCN102219273BIncrease temperatureEfficient use ofGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention discloses a solar and thermocompression vapor-compression distillation type water purifying device, belonging to the technical fields of novel energy and energy saving as well as emission reduction. The solar and thermocompression vapor-compression distillation type water purifying device comprises a fresh-water tank, a solar heat collector, a steam sprayer, a valve, a compressor, an evaporator, a heating chamber, a concentrate groove and a heat exchanger, wherein the solar heat collector is connected with the steam sprayer; an outlet of the evaporator and an inlet of the heating chamber are respectively connected with the steam sprayer; the heat exchanger is respectively connected with an outlet of the heating chamber and an inlet of the evaporator; and the compressor as a branch is connected with the steam sprayer in parallel and is adjusted by the valve. The invention has the benefits that the device has a compact technological structure, conventional energy sources are saved and the investment cost is reduced; by adopting low-pressure and corrosion and scale resistant measures, the temperature of a solution to be treated is prevented from being excessively high, the corrosion is greatly reduced and the service period of the equipment is prolonged. Particularly, the method is suitable for the aspects of freshening seawater, purifying sewage and the like and isa safe, pollution-free and energy-saving technology.

Owner:DALIAN UNIV OF TECH

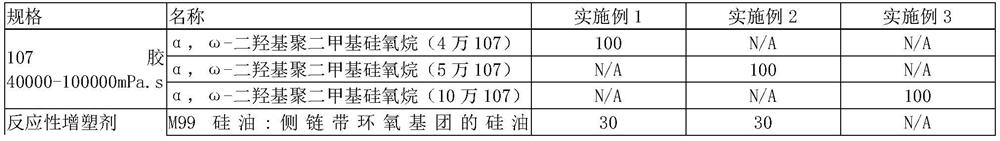

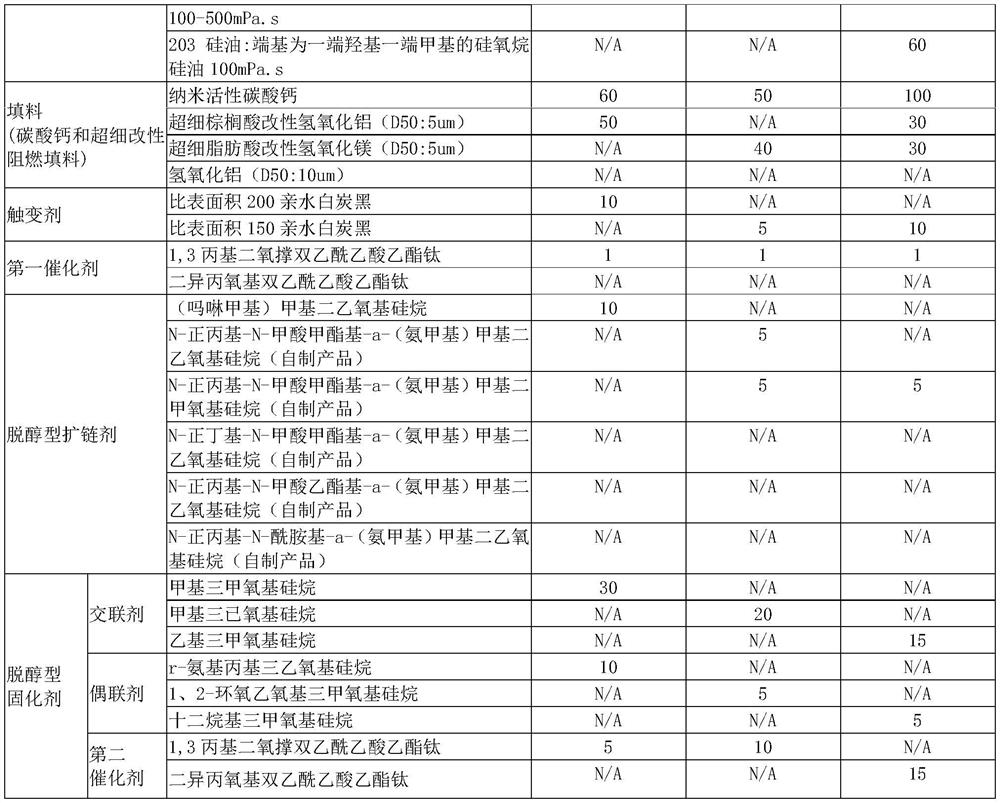

Preparation method of high-displacement dealcoholized flame-retardant fireproof sealant

ActiveCN113897171AGood chemical stabilityGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention belongs to the technical field of silicone rubber sealing materials, and particularly relates to a high-displacement dealcoholized flame-retardant fireproof sealant and a preparation method thereof. The high-displacement dealcoholized type flame-retardant fireproof sealant is prepared from the following raw materials in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 5 to 10 parts of dealcoholization type chain extender, 30 to 60 parts of reactive plasticizer, 50 to 100 parts of calcium carbonate, 40 to 90 parts of superfine modified flame-retardant filler, 25 to 55 parts of dealcoholization type curing agent, 5 to 20 parts of thixotropic agent and 1 part of first catalyst. The sealant provided by the invention has excellent chemical stability, weather aging resistance, thixotropy, constructability and the like. The sealant can be used as a sealing material of a building curtain wall, and has a wide application prospect.

Owner:CHENGDU GUIBAO SCI & TECH +1

Novel allantoin synthesis process

The invention discloses a novel technique for synthesizing allantoin, comprising the following steps that: alkali is added into a solvent of methanol or ethanol or water in a stirring state, methyl dichloroacetate or dichloroacetic acid are dropped to react, inorganic acid is added into the mixed solution to react, and a dihydroxy acetate solution is obtained after filtration, the obtained dihydroxy acetate solution is distilled, carbamide and the inorganic acid are added into the mixture, the mixture is stirred at a temperature of between 70 and 90 DEG C and reacts on the condition of heat preservation, and the reaction product is cooled to the room temperature, washed to be neutral and dried so that the product of the allantoin is obtained. The method takes the methyl dichloroacetate or the dichloroacetic acid as a raw material to synthesize the allantoin, lowers the production cost, has quality improvement and has a yield up to about 62 percent; meanwhile, a chloroacetic acid mother liquid is utilized indirectly to reduce the environment pollution caused by emission. The method does not pollute the environment, has simple and convenient operation and low energy consumption, and meets the requirements on energy conservation and emission reduction.

Owner:SHANDONG AILITONG NEW MATERIALS

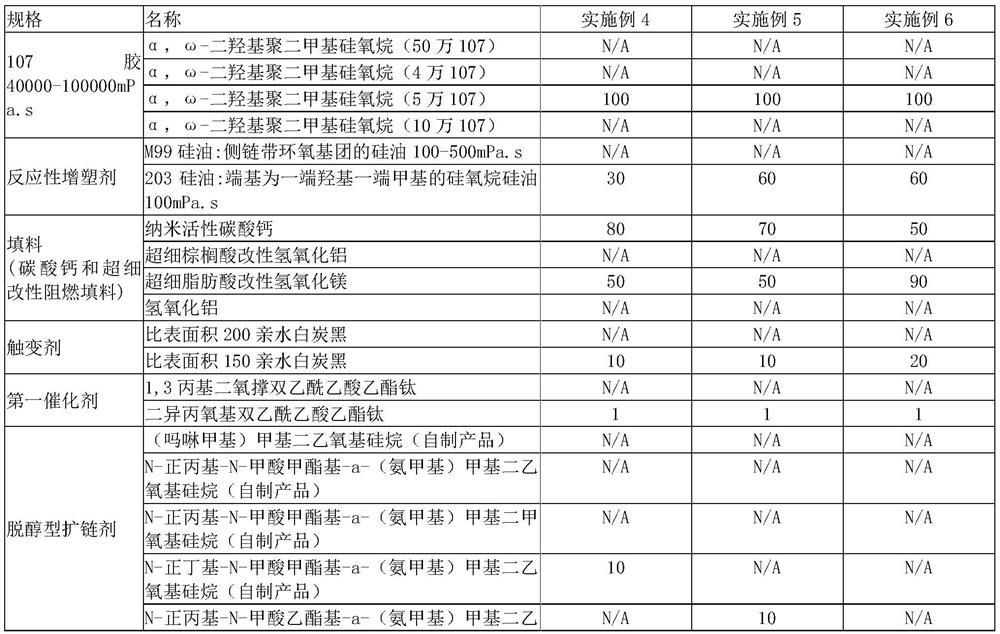

Blast furnace cloth bag ash resource utilization process method

PendingCN112158874AHigh yieldAvoid enteringZinc oxides/hydroxidesSolid waste disposalResource recoveryProcess engineering

The invention discloses a blast furnace cloth bag ash resource utilization process method, which uses blast furnace cloth bag ash as a raw material, and aims to realize resource recovery of chlorine,potassium and zinc and cyclic utilization of iron-containing and carbon-containing materials in a steel mill. The process method comprises a process step of recovering potassium and sodium by washingblast furnace cloth bag ash with water and crystallizing step by step, a process step of leaching zinc oxide with ammonia salt and a process step of recovering zinc oxide by evaporation, crystallization and calcination. According to the technological process, high-value utilization of the blast furnace cloth bag ash and cyclic utilization of the blast furnace cloth bag ash in the steel mill are achieved, energy conservation and emission reduction of iron and steel enterprises are promoted, and waste is turned into wealth.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

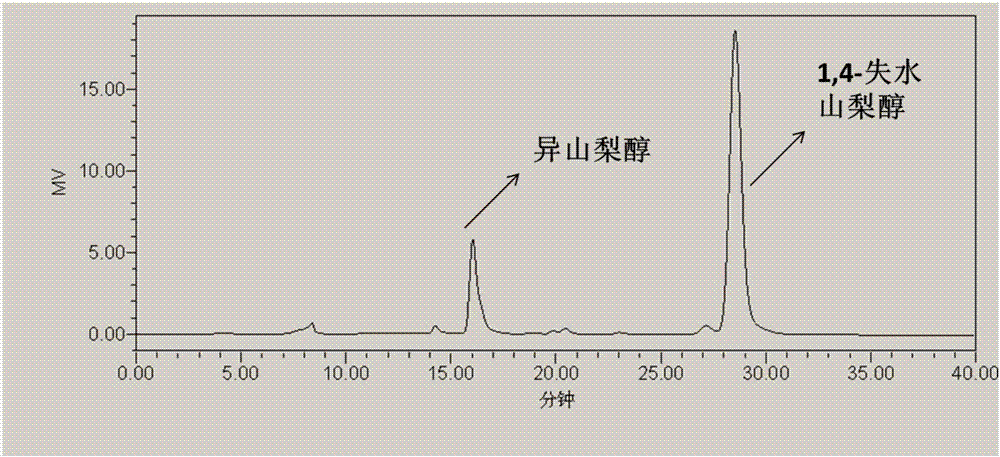

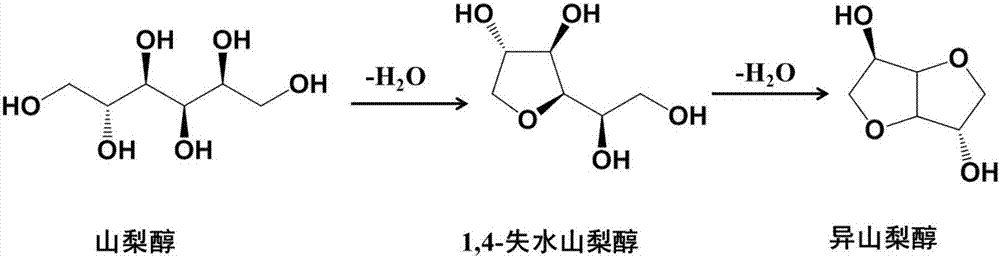

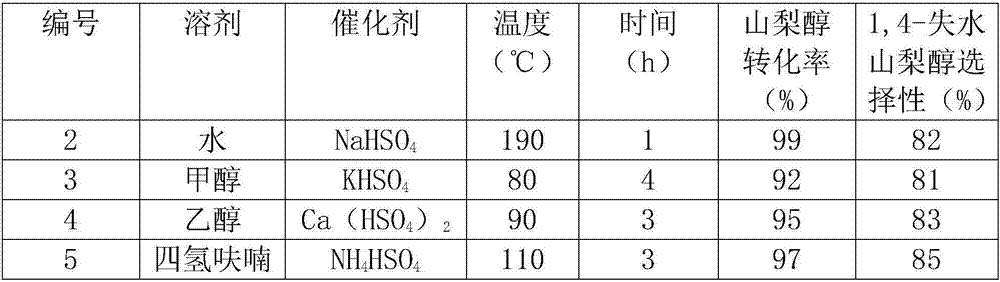

Method for preparing 1,4-sorbitan

The invention discloses a method for preparing 1,4-sorbitan. According to the method, sorbitol is used as a substrate, a molecule with strong polarity is used as a solvent, and 1,4-sorbitol is highly selectively prepared under the action of an acid salt catalyst. The method uses a combination of the special solvent and an acid salt, thereby realizing high selectivity of 1,4-sorbitol during dehydration of sorbitol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

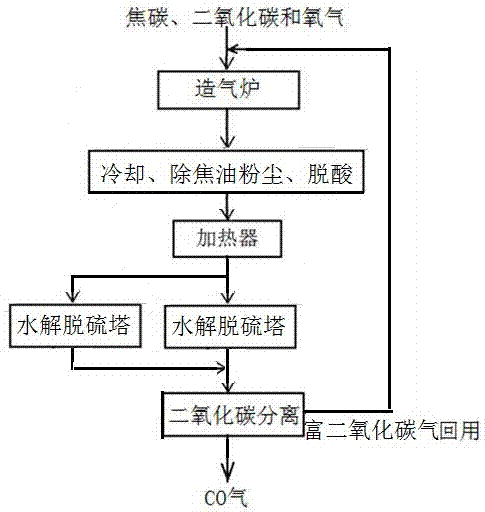

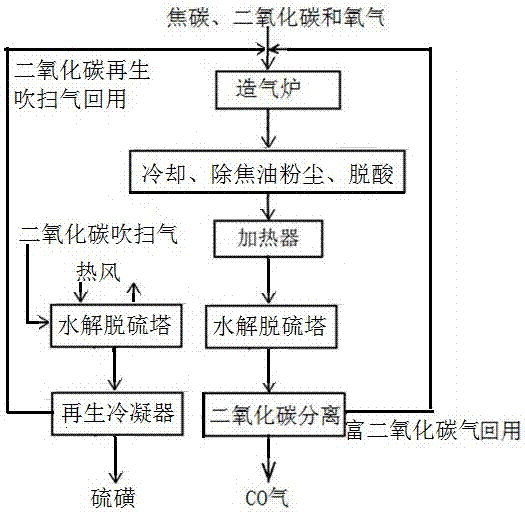

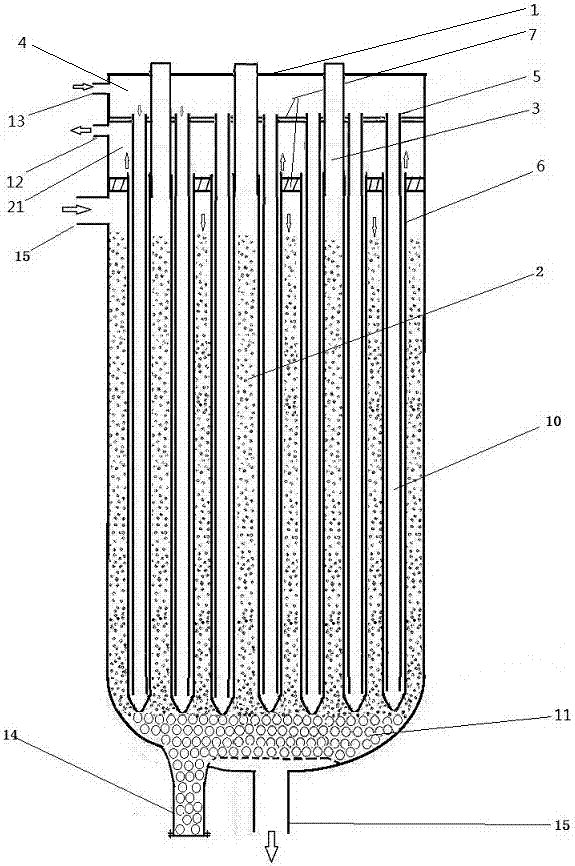

CO gas preparation process

InactiveCN106986341ALevel of contentStrong adaptability to fluctuationsEnergy inputSulfur preparation/purificationTarChemistry

The invention provides a CO gas preparation process. The CO gas preparation process mainly comprises the following steps: (1) preparing a raw gas from coke, CO2 and oxygen in a gas making furnace, recovering heat of the raw gas, and removing tar, dust impurities and strong acid ingredients; (2) maintaining or heating a process gas to 30-80 DEG C, removing majority of sulfide in a hydrolysis desulfurizing tower, wherein an organic sulfur hydrolyzing agent and an H2S oxidation desulfurizing agent are mixed or laminated in the tower; (3) separating CO2 from the process gas, removing the rest majority of sulfide at the same time to prepare the CO gas, and enabling the separated sulfur-containing CO2-rich gas to go back to the gas making furnace for recycling. The hydrolysis desulfurizing tower is provided with a vertical sleeve heating structure, a hydrolyzing agent-desulfurizing agent bed layer is arranged between sleeves; the hydrolysis desulfurizing tower melts, gasifies and blows out the captured elemental sulfur when the heat is regenerated at the temperature of 200-300 DEG C, and the elemental sulfur is collected by a regeneration condenser to obtain sulfur. The desulfurizing process of the process is simple and reliable, is easy to control, is large in elasticity of processing capacity, is strongly adaptive to high and low contents and fluctuation of H2S and COS, is safe and environment-friendly, and is low in operation cost.

Owner:淄博赢信达知识产权咨询服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com