Method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition

A technology of transition group metals and low-temperature molten salts, which is applied in the field of preparation of transition group metals and their alloys by electrodeposition of low-temperature molten salts, and the preparation of transition group metals and their alloys, which can solve the problems of poor electroplating layer quality, low current efficiency, and hydrogen evolution reaction and other problems, to achieve the effect of light equipment corrosion, low energy consumption, and low electrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

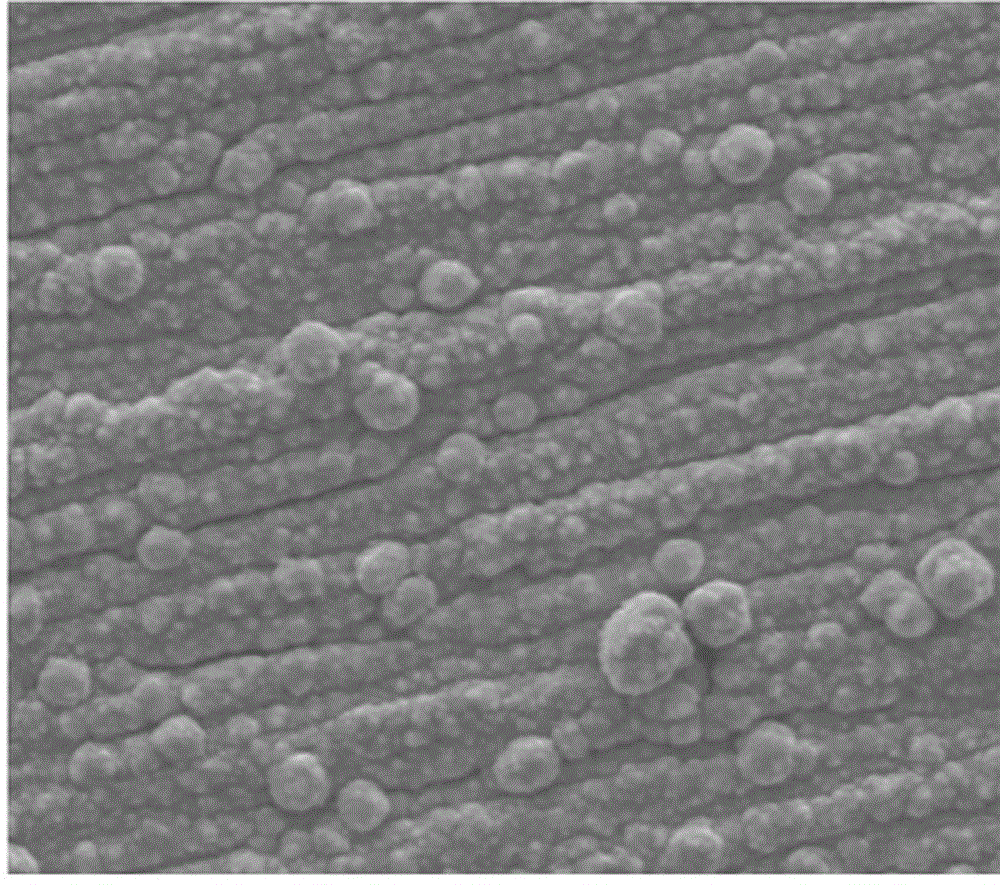

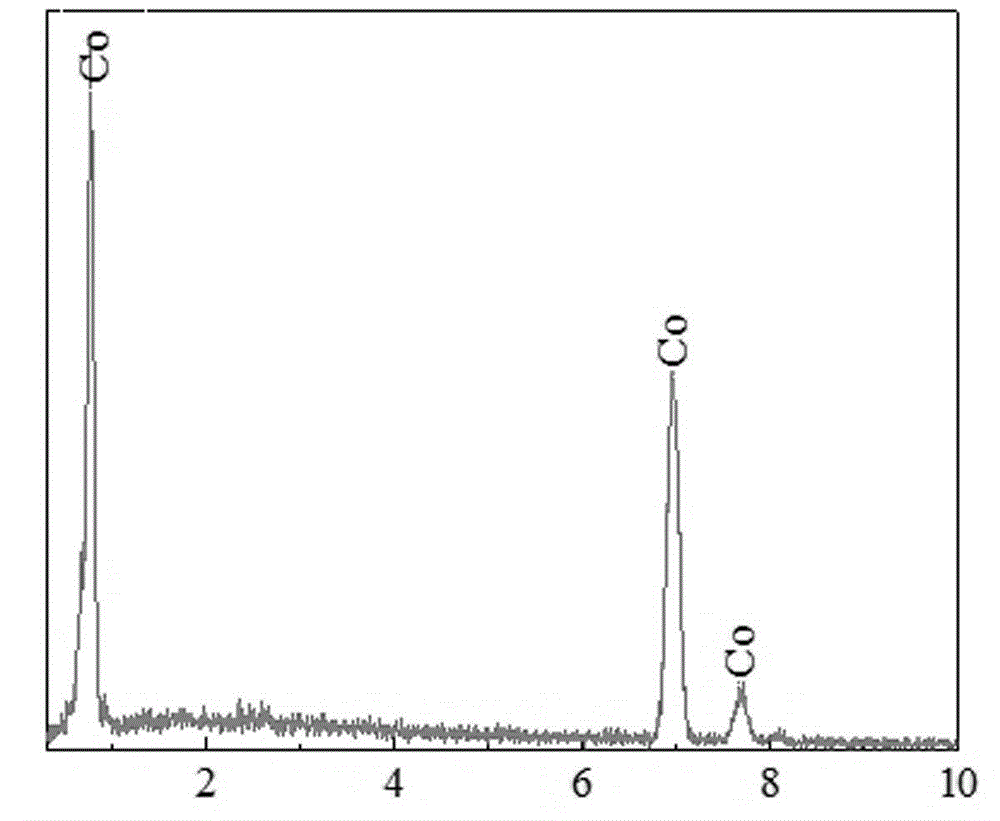

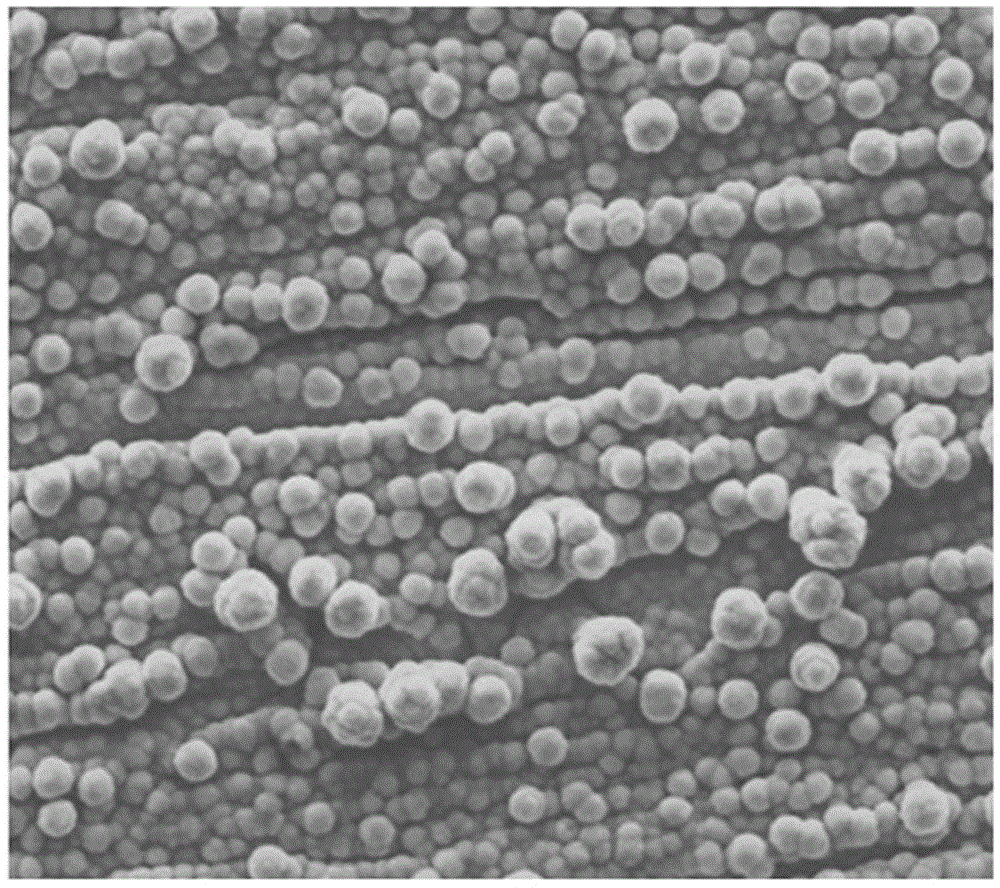

[0038] The method for preparing metal cobalt by low-temperature molten salt electrodeposition is characterized by comprising the following steps.

[0039] 1) Fully mix the anhydrous urea, acetamide and anhydrous LiBr that have been vacuum-dried, and heat and stir to form a colorless uniform liquid molten salt. The mass ratio of urea to acetamide and LiBr is: 35.2:50:14.8.

[0040] 2) the transition metal chloride CoCl 2 Dissolve in the low-temperature liquid molten salt prepared in the above steps, and stir and mix uniformly to form a low-temperature molten salt electrolyte; wherein the molten salt and CoCl 2 The mass ratio is: 100:1.

[0041] 3) With the treated copper sheet as the cathode and graphite as the anode, the electrolysis temperature is 70°C, the constant potential method is used, and the control potential is -0.7V (vs.Ag) and the low-temperature melt prepared in step 2) Electrodeposition in salt electrolyte for 1h.

[0042] 4) after the electrolysis, take out the...

Embodiment 2

[0044] The method for preparing metallic nickel by low-temperature molten salt electrodeposition is characterized by comprising the following steps.

[0045] 1) Fully mix the anhydrous urea, acetamide and anhydrous LiBr that have been vacuum-dried, and heat and stir to form a colorless uniform liquid molten salt. The mass ratio of urea to acetamide and LiBr is: 35.2:50:14.8.

[0046] 2) the transition metal chloride NiCl 2 Dissolve in the low-temperature liquid molten salt prepared in the above steps, and stir and mix uniformly to form a low-temperature molten salt electrolyte; wherein the molten salt and NiCl 2 The mass ratio is: 100:2.

[0047] 3) With the treated copper sheet as the cathode and graphite as the anode, the electrolysis temperature is 80°C, the constant potential method is used, and the control potential is -0.8V (vs. Electrodeposition in salt electrolyte for 2h.

[0048] 4) Take out the copper sheet after the electrolysis and clean it with ethanol first, t...

Embodiment 3

[0050] The method for preparing metallic iron by low-temperature molten salt electrodeposition is characterized by comprising the following steps.

[0051] 1) Fully mix the anhydrous urea, acetamide and anhydrous LiCl that have been vacuum-dried, and heat and stir to form a colorless uniform liquid molten salt. The mass ratio of urea to acetamide and LiCl is: 40.45:50:9.55.

[0052] 2) the transition metal chloride FeCl 2 Dissolve in the low-temperature liquid molten salt prepared in the above steps, and stir and mix uniformly to form a low-temperature molten salt electrolyte; wherein the molten salt and FeCl 2 The mass ratio is: 100:3.

[0053] 3) With the treated copper sheet as the cathode and graphite as the anode, the electrolysis temperature is 90°C, the constant potential method is used, the control potential is -0.9V (vs.Ag) and the low-temperature melt prepared in step 2) Electrodeposition in salt electrolyte for 3h.

[0054] 4) After the electrolysis, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com