Method for preparing (Mn, Co) 3O4-Li2O coating through liquid phase sintering and application

A liquid phase sintering and coating technology, applied in structural parts, fuel cells, electrical components, etc., can solve the problems of increasing the preparation cost of protective coatings and the complexity of the preparation process, achieve good oxidation resistance, prevent vaporization and migration, Good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

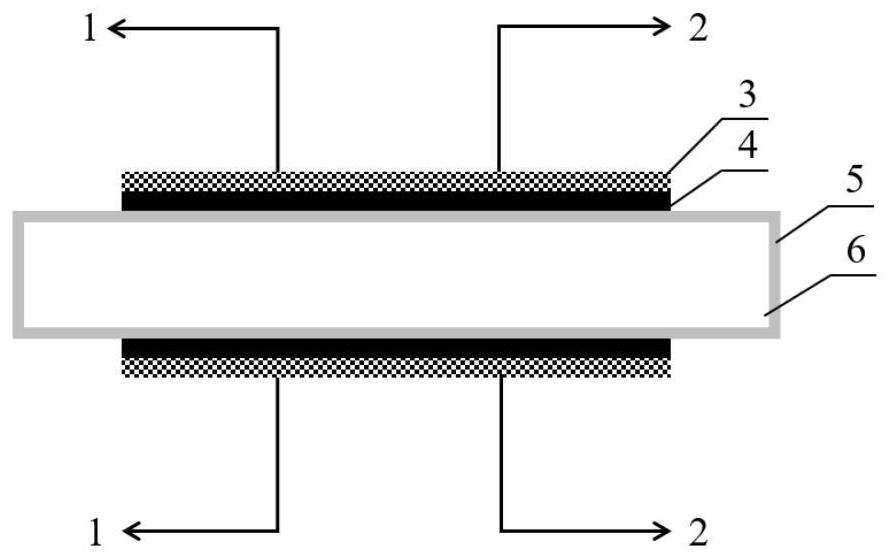

[0064] This embodiment provides a liquid phase sintering preparation (Mn, Co) 3 o 4 -Li 2 The method of O coating, the specific details are as follows:

[0065] S1: Based on the total molar percentage of the ingredients as 100%, the (Mn, Co) 3 o 4 Powder, LiNO 3 The ratio of metal atoms Mn / Co:Li is 95:5 and mixed evenly, using ethanol as solvent, heating, stirring and evaporating on a magnetic stirrer at 70°C, and then drying to obtain mixed powder.

[0066] S2: The mixed powder was oxidized and sintered at 600°C for 2 hours, ground in a mortar and sieved, and the (Mn,Co) 3 o 4 -Li 2 O powder and screen printing glue are mixed at a mass ratio of 10:8 and ground evenly.

[0067] S3: Screen printing (Mn, Co) on the metal connector substrate SUS 430 after sandblasting 3 o 4 -Li 2 O coating, dried in an oven at 80 °C to obtain an intermediate coating.

[0068] S4: 4% H at 900°C after the intermediate coating 2 +96%N 2 Pre-reduction in atmosphere for 24 hours, and oxida...

Embodiment 2

[0072] This embodiment provides a liquid phase sintering preparation (Mn, Co) 3 o 4 -Li 2 The method of O coating, the specific details are as follows:

[0073] S1: Based on the total molar percentage of the ingredients as 100%, the (Mn, Co) 3 o 4 Powder, LiNO 3 Mix uniformly according to the metal atom Mn / Co:Li ratio of 90:10, use ethanol as solvent, heat, stir and evaporate on a magnetic stirrer at 70°C, then dry to obtain a mixed powder.

[0074] S2: The mixed powder was calcined at 600°C for 2 hours, ground in a mortar and sieved with 200 mesh, and the (Mn,Co) 3 o 4 -Li 2 O powder and screen printing glue are mixed at a mass ratio of 10:8 and ground evenly.

[0075] S3: Screen printing (Mn, Co) on the metal connector substrate SUS 430 after sandblasting 3 o 4 -Li 2 O coating, dried in an oven at 80 °C to obtain an intermediate coating.

[0076] S4: 4% H at 900°C after the intermediate coating 2 +96%N 2 Pre-reduction in atmosphere for 24 hours, and oxidation i...

Embodiment 3

[0080] This embodiment provides a liquid phase sintering preparation (Mn, Co) 3 o 4 -Li 2 The method of O coating, the specific details are as follows:

[0081] S1: Based on the total molar percentage of the ingredients as 100%, the (Mn, Co) 3 o 4 Powder, LiNO 3 The ratio of metal atoms Mn / Co: Li is 98.5:1.5 and mixed evenly, using ethanol as solvent, heating, stirring and evaporating on a magnetic stirrer at 70°C, and then drying to obtain mixed powder.

[0082] S2: Calcinate the mixed powder at 600°C for 2h, grind it in a mortar and sieve it, and mix the (Mn,Co) 3 o 4 -Li 2 O powder and screen printing glue are mixed at a mass ratio of 10:8 and ground evenly.

[0083] S3: Screen printing (Mn, Co) on the metal connector substrate SUS 430 after sandblasting 3 o 4 -Li 2 O coating, dried in an oven at 80 °C to obtain an intermediate coating.

[0084] S4: 4% H at 900°C after the intermediate coating 2 +96%N 2 Pre-reduction in atmosphere for 24 hours, and oxidation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com