Patents

Literature

265results about How to "Strong blocking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

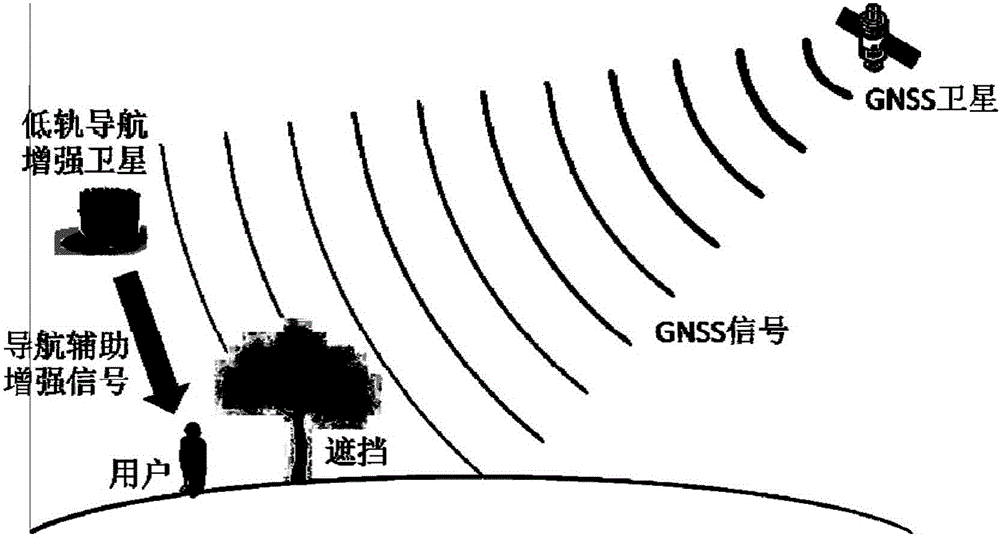

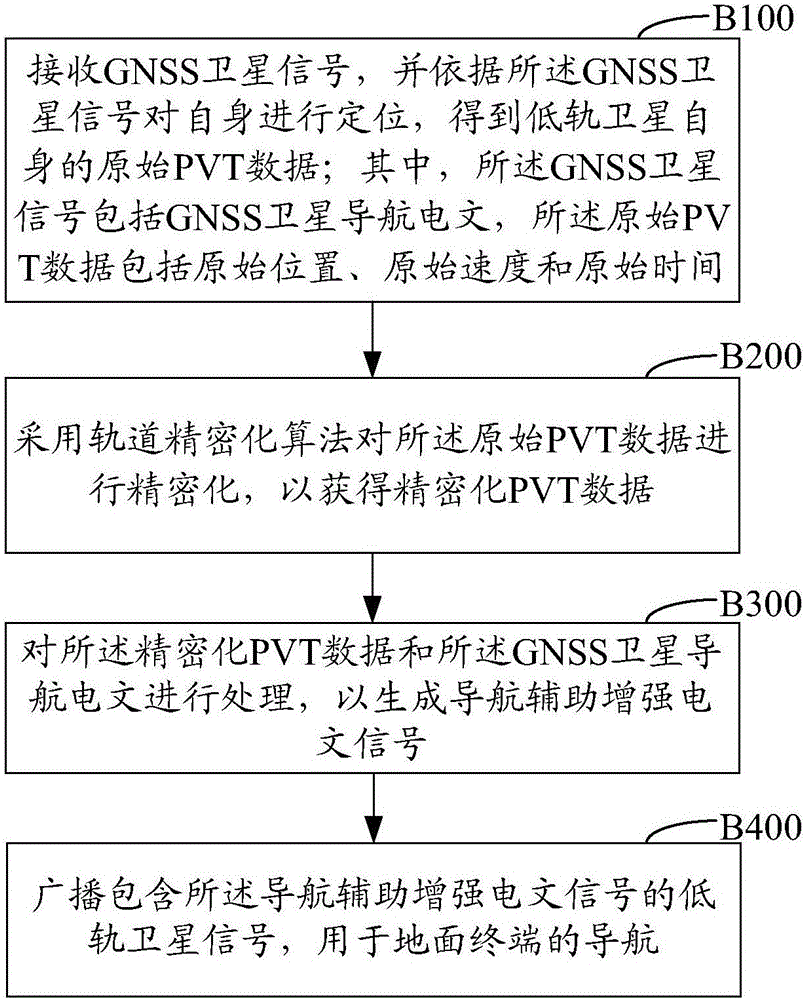

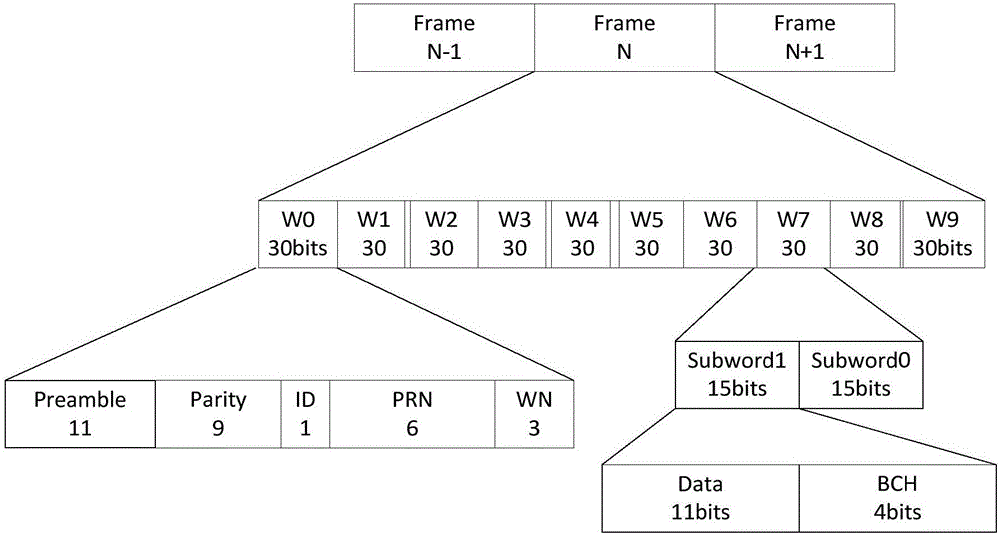

Assisted enhancement navigation method and device

ActiveCN106443739AIncrease signal strengthStrong anti-interferenceSatellite radio beaconingComputer terminalOrbit

Provided is an assisted enhancement navigation method and device. The method includes receiving a GNSS satellite signal and locating itself according to the GNSS satellite signal to obtain the original PVT data of the low-orbit satellite itself, wherein the GNSS satellite signal includes a GNSS satellite navigation message, and the original PVT data includes the original location, the original speed and the original time; making precision of the original PVT data by means of a track precision algorithm to obtain the precision PVT data; processing the precision PVT data and the GNSS satellite navigation message to generate a navigation assisted enhancement message signal; and broadcasting a low-orbit satellite signal containing the navigation assisted enhancement message signal for the navigation of a ground terminal. The assisted enhancement navigation method and device provided by the invention improve the precision of navigation.

Owner:TSINGHUA UNIV

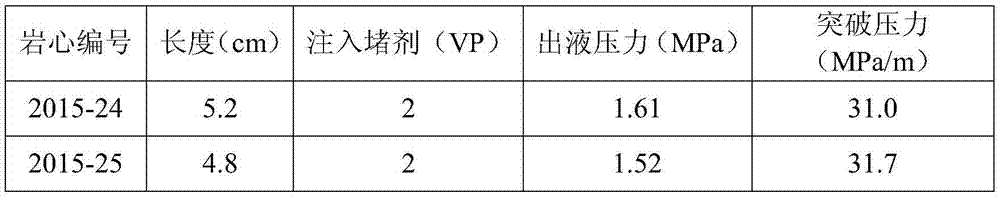

Fireflooding channeling sealing agent and preparation method thereof

ActiveCN105440233AHigh chemical activityHigh bonding strengthDrilling compositionNano al2o3Oleoresin

The invention provides a fireflooding channeling sealing agent and its preparation method. Raw materials for preparing the fireflooding channeling sealing agent contain, by weight, 0.5-3% of a melamine substance, 0.2-1% of phenol, 2-8% of aldehyde, 0.5-2% of a pH regulator, 0.2-1.2% of a nano-alumina oleoresin liquid XZ-LY102, 10-20% of ultrafine silicon dioxide and the rest of water. Sealing rate of the fireflooding channeling sealing agent can reach 93%; temperature resistance reaches 300 DEG C; the highest salinity tolerance reaches 150,000 mg / L; expriation data can reach 6 months and above under the steam condition of 300 DEG C; viscosity of a profile control agent before gel forming is 150-1,500 mPa.S; sealing strength can reach 31 MPa / m; and gel forming time can be controlled within 12-36h. By the use of the fireflooding channeling sealing agent, deep profile control of an oil layer can be realized.

Owner:PETROCHINA CO LTD

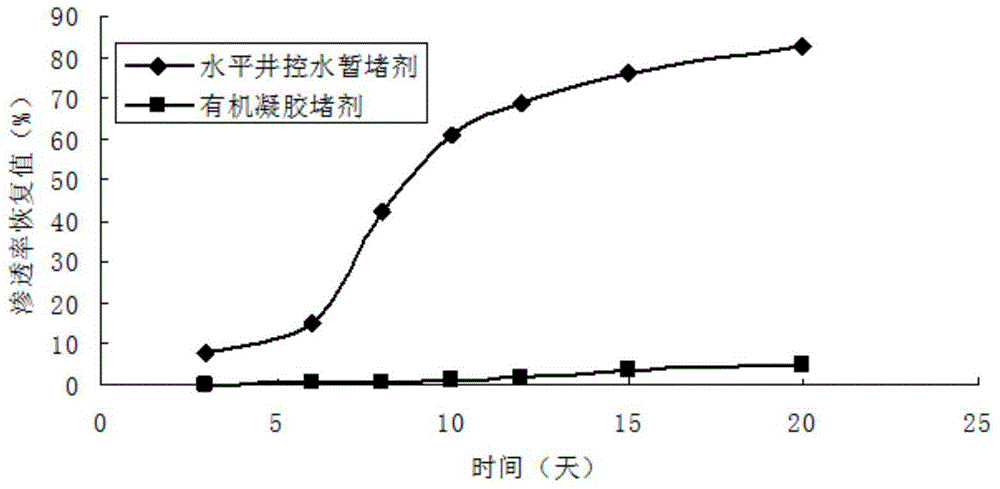

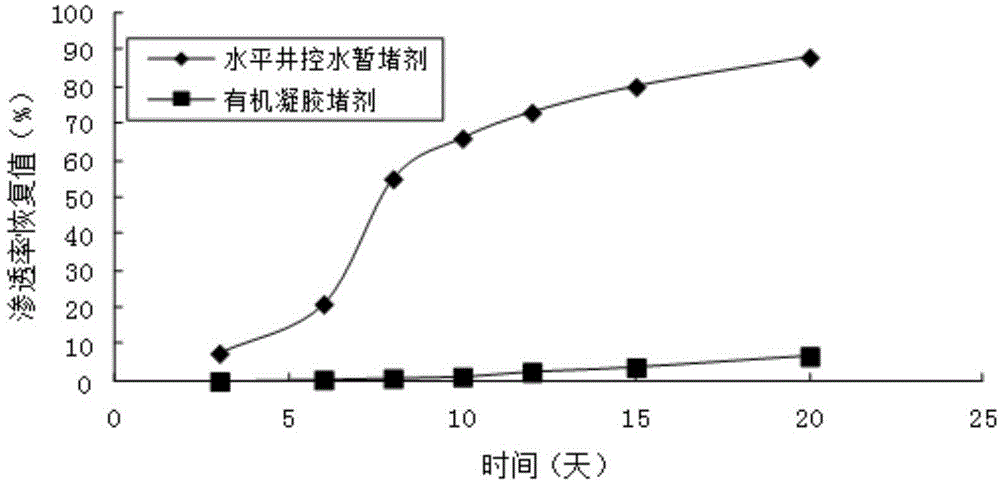

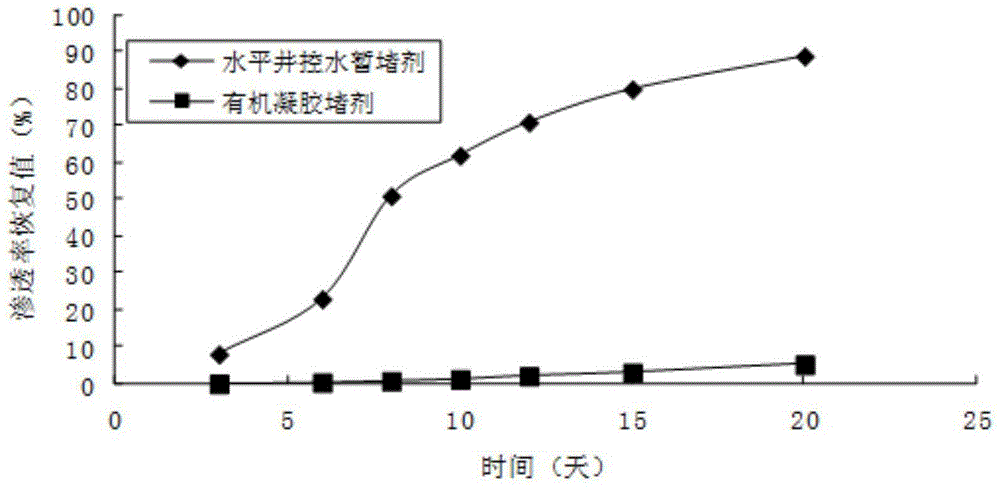

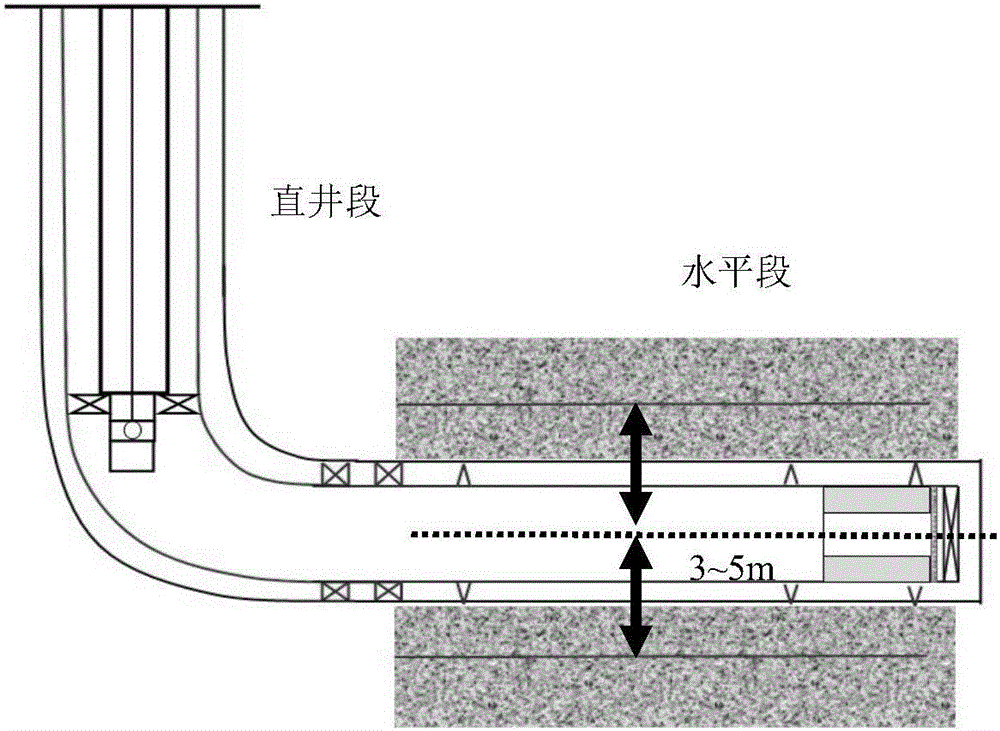

Temporary plugging agent for horizontal well water control, and preparation method and application thereof

ActiveCN104531115AReduce harmStrong blocking abilityDrilling compositionMass ratioMethylene bisacrylamide

The invention provides a temporary plugging agent for horizontal well water control, and a preparation method and application thereof. The temporary plugging agent for horizontal well water control comprises the following raw materials in parts by weight: 4-15 parts of acrylamide, 0.5-3 parts of polypropylene fiber, 1.5-4 parts of reinforcer, 0.5-1.0 part of composite crosslinking agent, 0.1-0.2 part of initiator and the balance of water, totaling 100 parts. The composite crosslinking agent is a mixture composed of polyethyleneglycol diacrylate and N,N-methylene-bis acrylamide in a mass ratio of 10:(1-4). The preparation method of the temporary plugging agent comprises the following steps: sequentially adding the acrylamide, polypropylene fiber, reinforcer and composite crosslinking agent into water, stirring uniformly, adding the initiator, and standing to react for 1-3 hours, thereby obtaining the temporary plugging agent. The invention also provides application of the temporary plugging agent in horizontal well water control. The temporary plugging agent provided by the invention has the characteristics of high gelling viscosity, controllable degradation time, thorough degradation and the like, can plug the high-permeability zone and implement adjustable degradation time, and can lower the damage to the reservoir.

Owner:PETROCHINA CO LTD

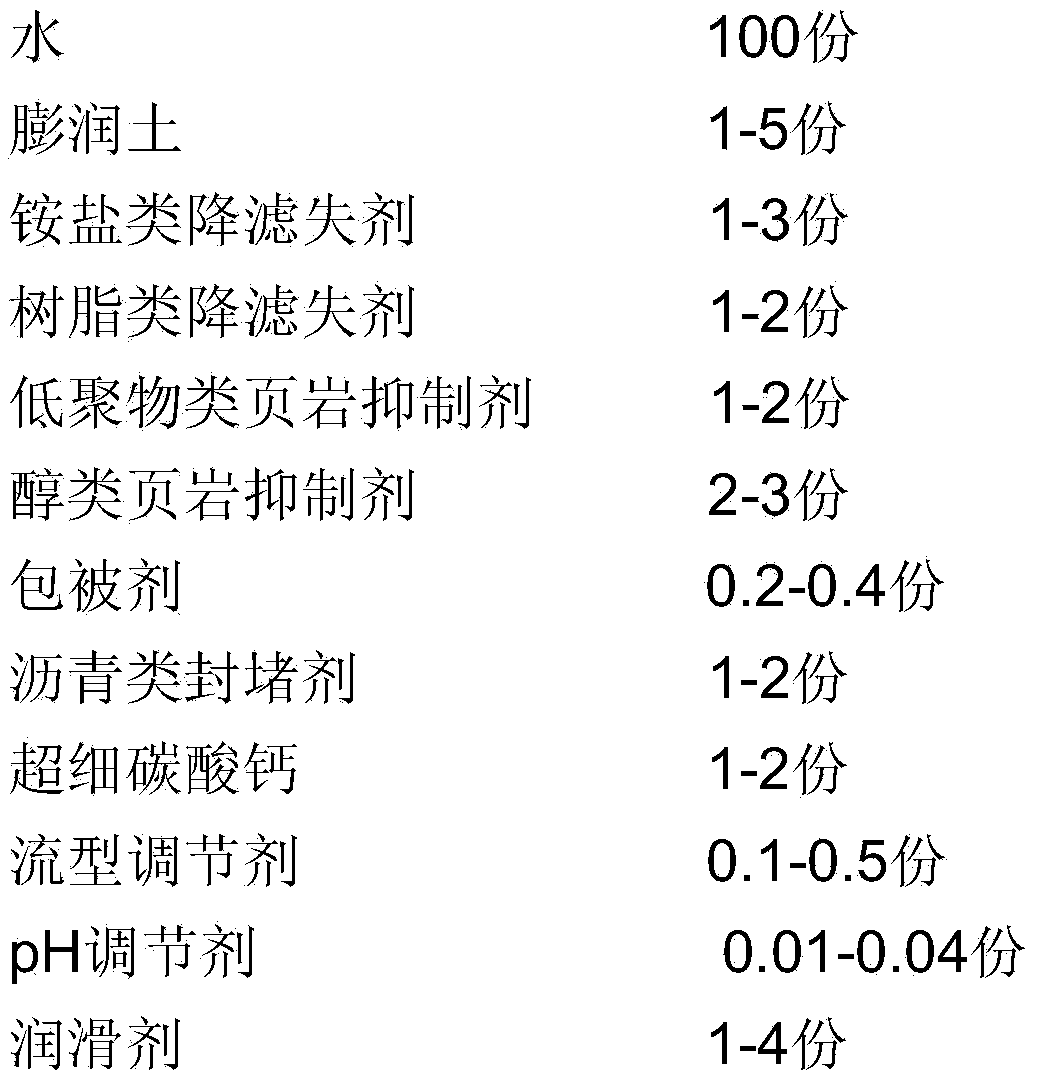

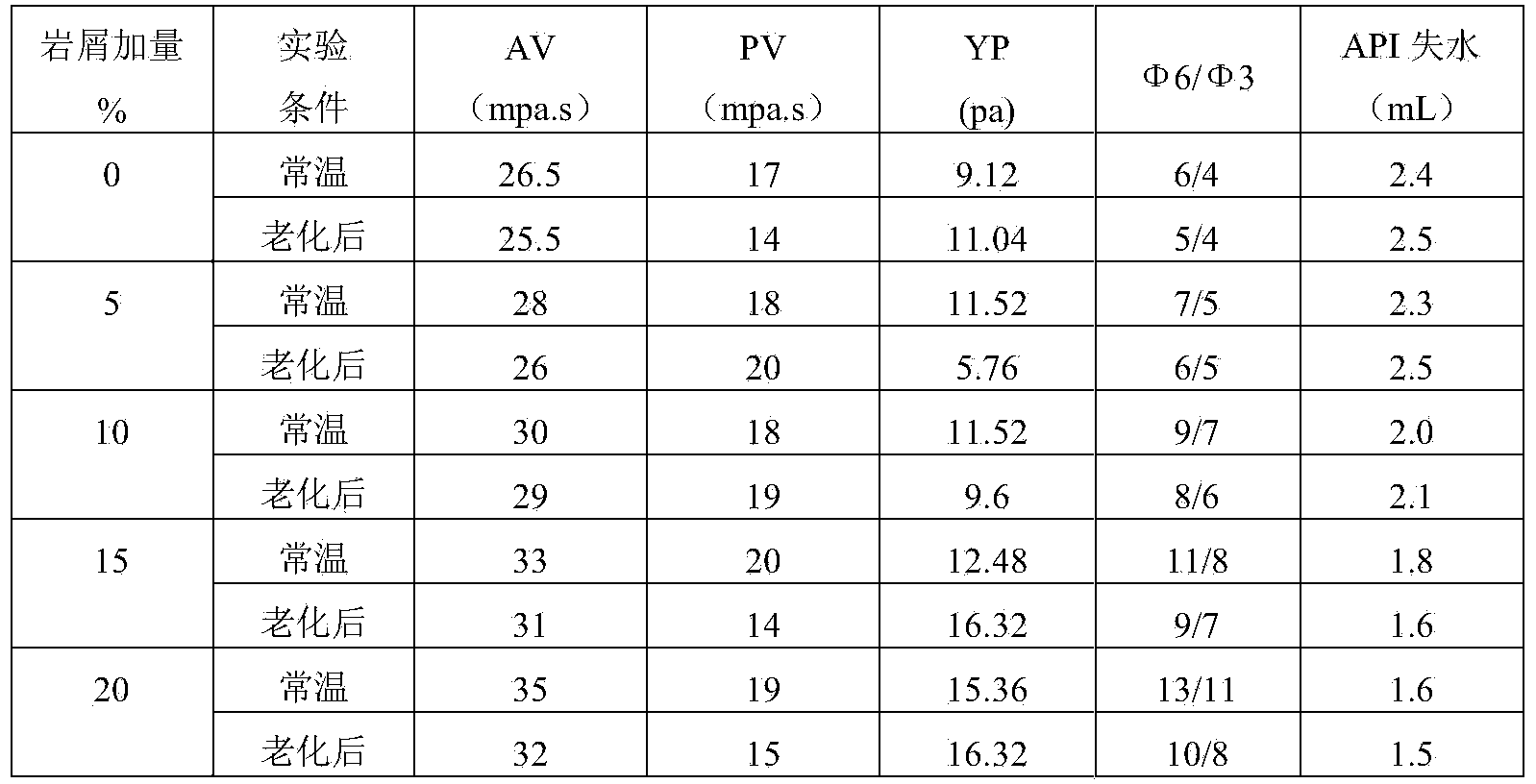

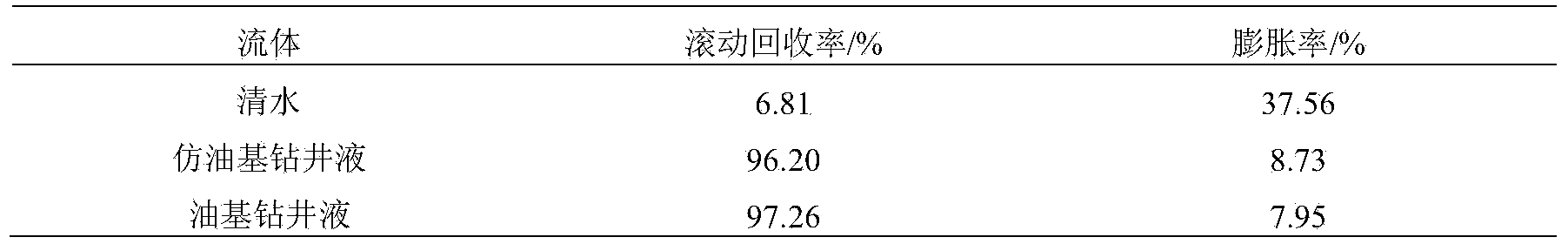

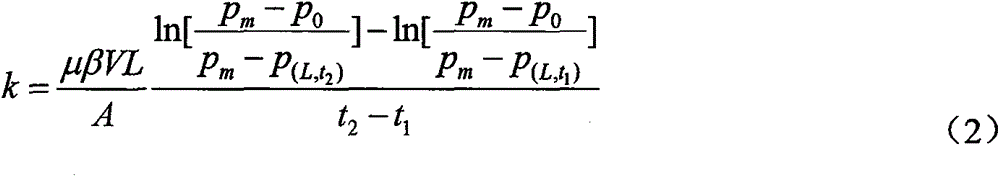

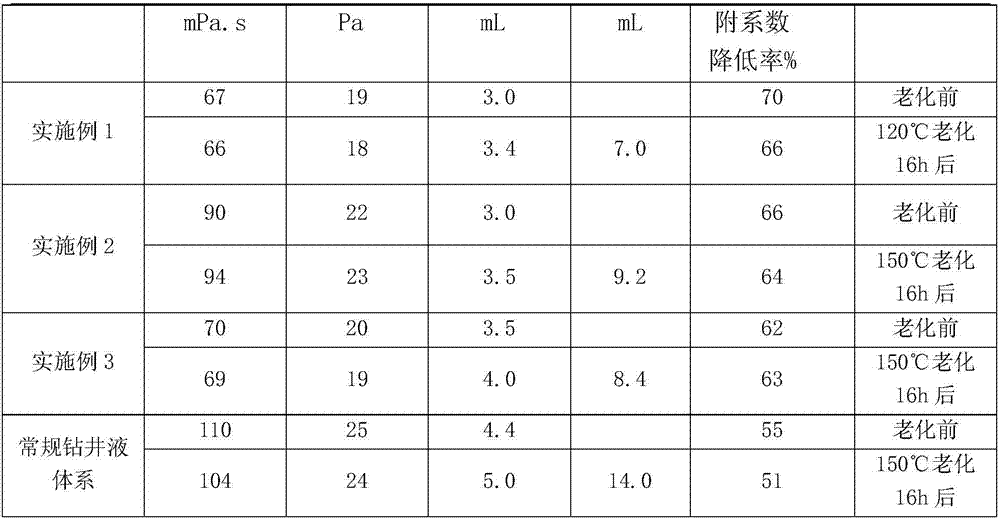

Oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity

InactiveCN104388065AEnhanced inhibitory effectStrong blockingDrilling compositionWater basedUltra fine

The present invention relates to an oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity. In the prior art, the existing amine compound-containing water-base drilling fluid provides the weak blocking capability for the mud shale micro-crack, and the lubricity can not completely meet the construction requirement. With the oil-base imitating drilling fluid of the present invention, the problems in the prior art are mainly solved. The oil-base imitating drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of bentonite, 1-3 parts of an ammonium salt filtrate reducer, 1-2 parts of a resin filtrate reducer, 1-2 parts of an oligomer shale inhibitor, 2-3 parts of an alcohol shale inhibitor, 0.2-0.4 part of a coating agent, 1-2 parts of an asphalt blocking agent, 1-2 parts of ultra-fine calcium carbonate, 0.1-0.5 part of a flow type adjusting agent, 0.01-0.04 part of a pH value adjusting agent, and 1-4 parts of a lubricant. According to the present invention, the oil-base imitating drilling fluid of the present invention is the water-base drilling fluid having the performance equivalent to the oil-base drilling fluid, the safe, rapid and efficient drilling construction in the mud shale stratum and the unconventional dense oil reservoir is ensured, and the new technical support is provided for the effective development of the oil and gas reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

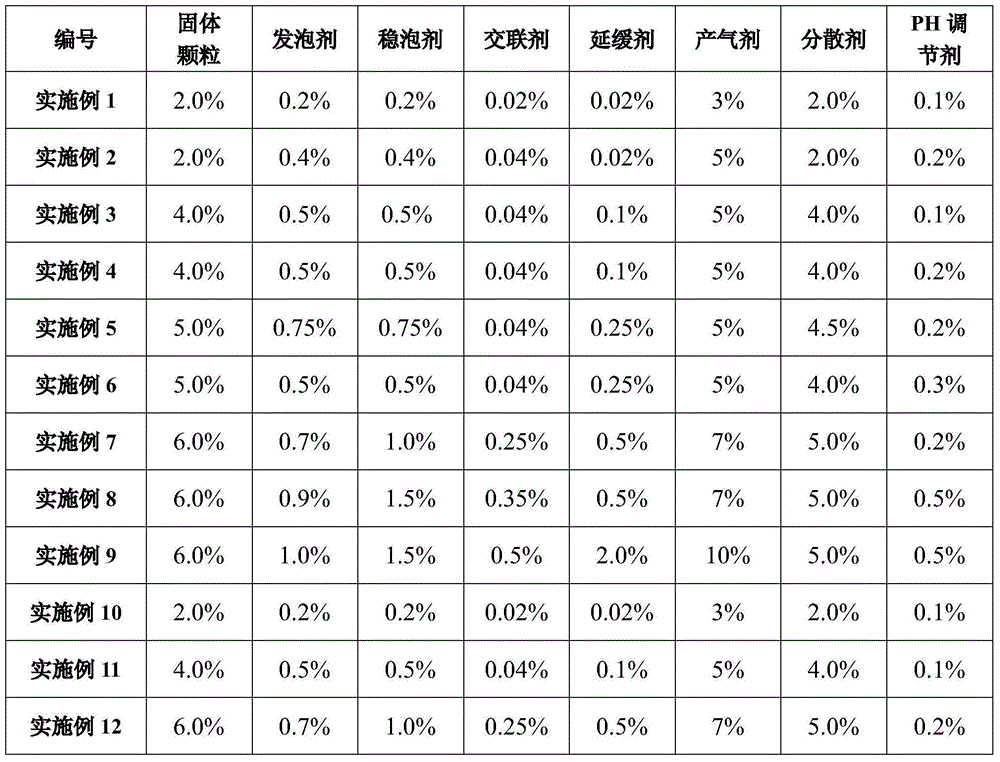

Three-phase self-foaming water-plugging agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

Clay foam stabilizing complex additive for foam flooding as well as preparation method and application of clay foam stabilizing complex additive

ActiveCN103694983AIncrease foam volumeExtended half-lifeFluid removalDrilling compositionHalf-lifeSolid particle

The invention relates to a clay foam stabilizing complex additive for foam flooding as well as a preparation method and an application of the clay foam stabilizing complex additive. The clay foam stabilizing complex additive comprises the following raw materials in parts by weight: 0.2-0.9 part of sodium dodecyl benzene sulfonate, 1-10 parts of clay particles and 100 parts of water, wherein the particle sizes of the clay particles range from 25mu m to 100mu m. The hydrophobic clay particles are added into the clay foam stabilizing complex additive for foam flooding, provided by the invention to ensure that the solid particles are attached on the surface of a liquid film and in a liquid film layer to form a rigid compact shell, so that the strength of the foam liquid film is enhanced, the liquid drainage of the liquid film is inhibited, the liquid film is prevented from thinning, and furthermore, the bubbling volume of the foam is increased, and the half-life period of the foam is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

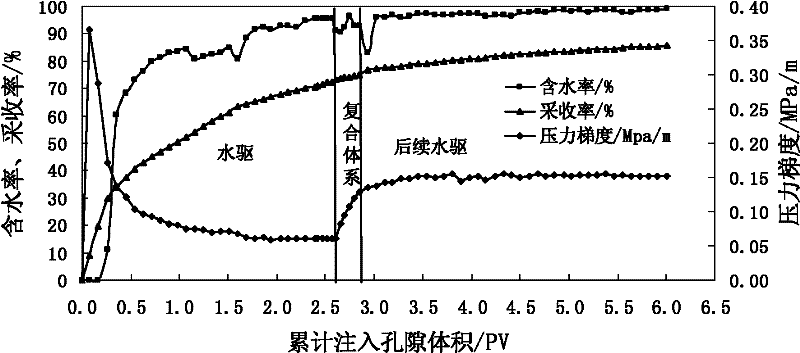

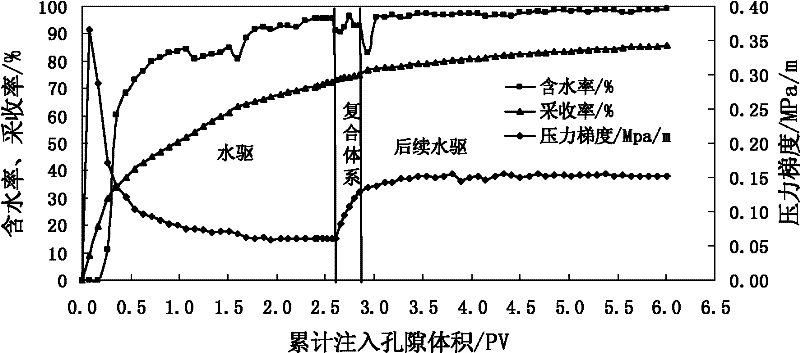

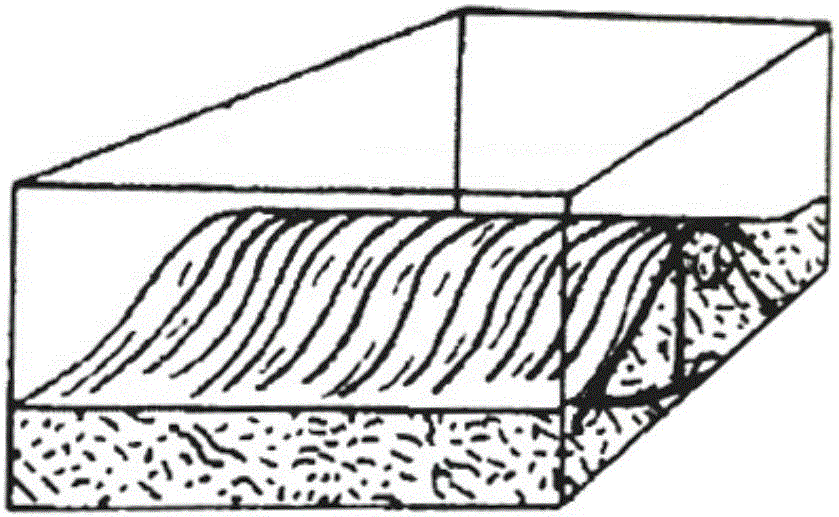

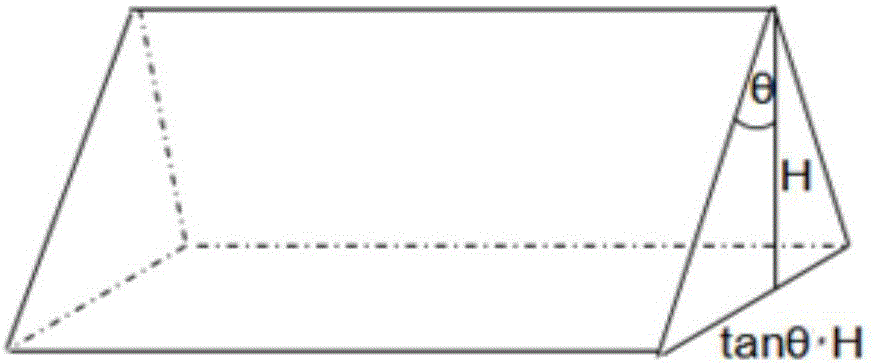

Composite profile control and oil displacement extraction method for thickened oil reservoir through water injection and exploitation

ActiveCN102251763AAlleviate conflicts in water injection developmentExpand the affected volumeFluid removalCross-linkPolymer science

The invention relates to a composite profile control and oil displacement extraction method for a thickened oil reservoir through water injection and exploitation. The method provided by the invention comprises the following steps: preparing a polymer and water into a polymer solution with the concentration of 500-5000mg / L; preparing a cross-linking agent and water into a cross-linking agent solution with the concentration of 500-5000mg / L; mixing the polymer solution and the cross-linking agent solution according to the mass ratio of (1:1)-(10:1) to obtain a polymer gel solution; preparing a movable micro-gel and water into a movable micro-gel solution with the concentration of 1000-5000mg / L; respectively injecting the polymer gel solution and the movable micro-gel solution into a well to form an oil displacement segmentation plug, wherein the polymer is partial hydrolysis polyacrylamide; the cross-linking agent is an organic chromium cross-linking agent; and the movable micro-gel is a copolymer of acrylamide and N-N methylene bisacrylamide. The method provided by the invention can obviously improve the anisotropism in storage layers, among the layers and on planes, relieves the water injection and exploitation contradictions of the oil reservoir, solves the problems of tonguing and fingering and obviously enlarges the swept volume of a displacing solution, thereby greatly improving the recovery ratio of crude oil.

Owner:PETROCHINA CO LTD

Heavy oil thermal recovery method using foamed gel to inhibit bottom water coning

ActiveCN106150466APrevent intrusionPlay the role of heat insulation protectionFluid removalSealing/packingNitrogenNitrogen gas

The invention discloses heavy oil thermal recovery method using foamed gel to inhibit bottom water coning and belongs to the technical field of oilfield exploitation and oilfield chemistry. The method includes the steps of firstly, injecting nitrogen into a producing well to form a front nitrogen slug when the period comprehensive water content of the producing well is larger than 90%; secondly, injecting a mixed system of nitrogen and a foamed gel solution to form a nitrogen-foamed gel main slug; thirdly, injecting nitrogen into the producing well to form a replacing nitrogen slug; fourthly, injecting steam, wherein the front nitrogen slug can push water of a shaft and a stratum in an area near the well to an oil layer and balance stratum pressure, the nitrogen-foamed gel main slug can effectively inhibit bottom water invasion, and the replacing nitrogen slug can replace a foamed gel blocking agent in a screen pipe and an area in near the shaft to prevent the blocking agent from solidifying near the shaft and blocking a steam injecting pipeline and an oil extraction pipeline. By the method, bottom water coning speed can be reduced, steam wave coefficient and utilization rate can be increased, and oil reservoir exploitation effect can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

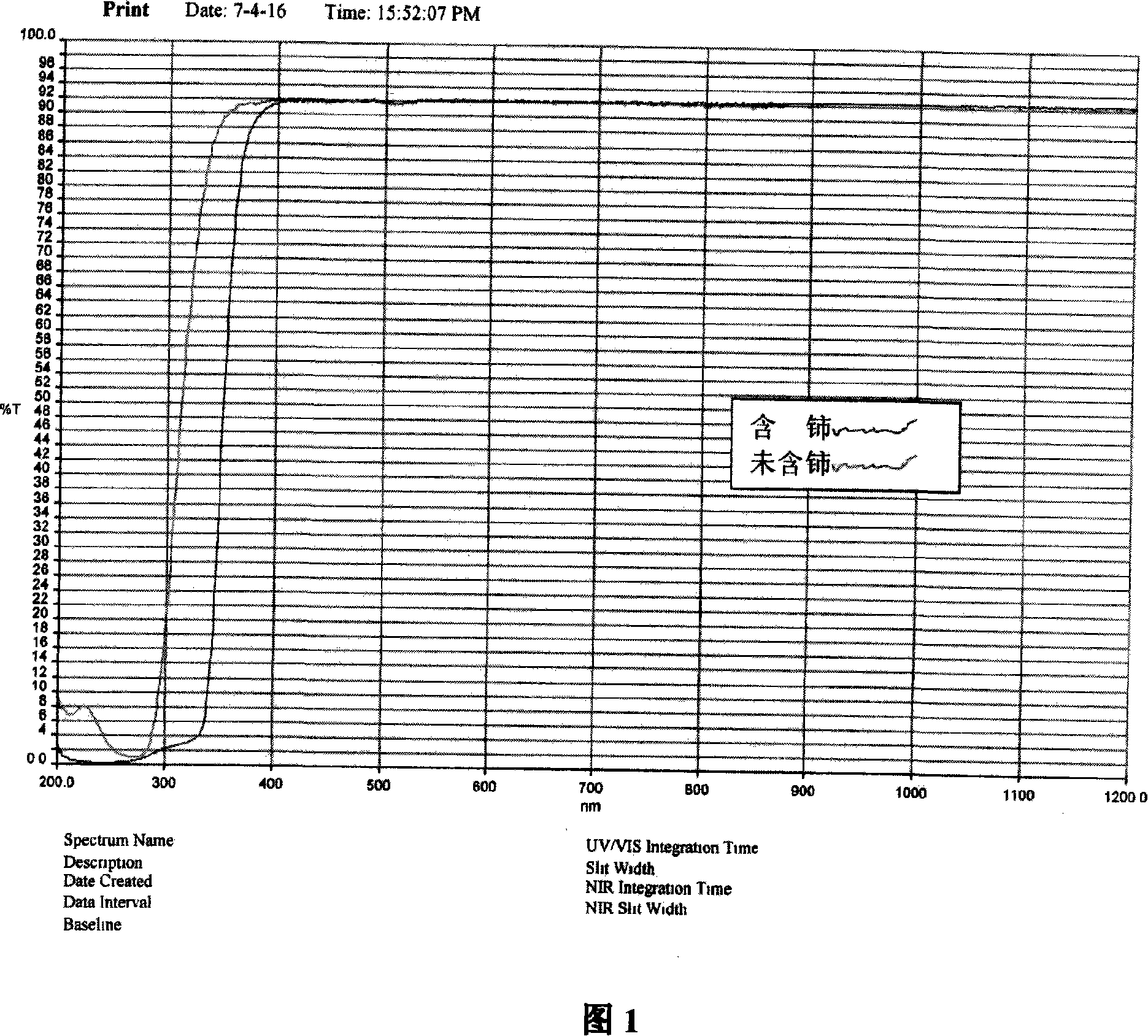

Ultraviolet blocking-up solar energy ultra-white configurated glass and method for manufacturing the same

The present invention is one kind of white figured glass capable of blocking ultraviolet ray for solar photovoltaic cell assembly with crystalline silicon cell and non-crystalline silicon electrode plates and its production process. The white figured glass is made of material with very low Fe element content and added CeO2, and has very low ultraviolet ray transmittance. Its production process includes sorting material, compounding material, mixing, smelting, rolling, annealing and other steps.

Owner:ZHEJIANG JIAFU GLASS CO LTD

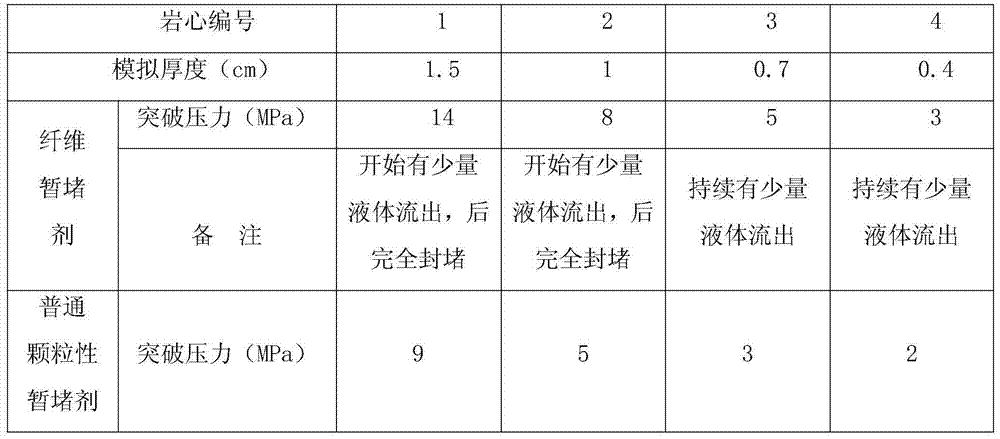

Fiber temporary plugging agent for acidizing and fracturing

The invention discloses a fiber temporary plugging agent for acidizing and fracturing. The fiber temporary plugging agent is prepared from 90-95 parts by weight of transport fluid and 0.8-2 parts by weight of temporary plugging fiber, wherein the transport fluid is prepared from the following raw materials in parts by weight: 0.2-0.6 part of guanidine gum, 0.1-0.5 part of bactericide, 0.3-0.7 part of viscosity stabilizing agent, 0.3-0.8 part of cleanup additive and 0.1-0.5 part of sodium carbonate. A dissoluble temporary plugging fiber is added to the transport fluid under a certain condition. The dissoluble fiber can form a high-density space network structure, so that the structure has strong plugging capacity. Thus, the strength of a temporary plugging layer is greatly improved. The fiber temporary plugging agent for acidizing and fracturing disclosed by the invention has the advantages of being good in plugging effect, easy to be automatically broken down after being fractured and acidized, and small in damage to a storage layer, and the success rate of construction is significantly improved.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

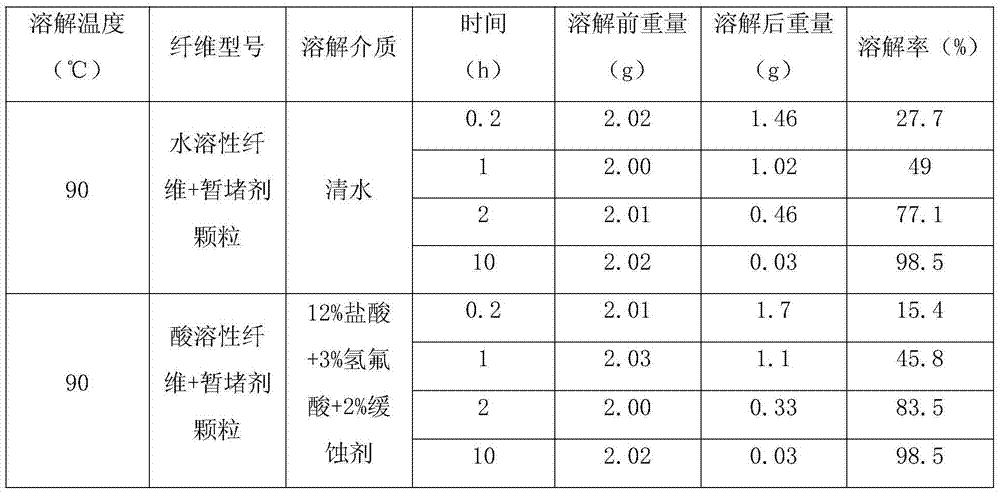

Ferric phosphate wastewater treatment process and treatment device

InactiveCN107082522ARealize resource processingIncreased efficiency of subsequent evaporationGeneral water supply conservationWater contaminantsPhosphatePhosphoric acid

The invention discloses a ferric phosphate wastewater treatment process and treatment device, wherein the treatment process comprises the following steps of (1) membrane concentration: ferric phosphate wastewater is subjected to membrane concentration to obtain concentrated water and fresh water, wherein the membrane concentration includes reverse osmosis and / or electroosmosis; (2) evaporation: the concentrated water is evaporated to recycle a nitrogen and phosphorus compound fertilizer; the evaporated concentrated liquid flow backs to the membrane concentration front end for circulation treatment; (3) resin treatment: the fresh water and evaporated condensed liquid are subjected to resin absorption treatment; resin absorption effluent is discharged in a standard reaching way or is reused for production; resin analytical liquid is subjected to membrane concentration treatment. Multistage reverse osmosis and resin absorption treatment are combined; ferric polyphosphate wastewater is subjected to desalination and ammonia and nitrogen removal step by step, so that the insulation capability of the whole treatment process on ammonia and nitrogen is higher; the ammonia and nitrogen discharging standard exceeding of effluent can be effectively avoided.

Owner:绍兴齐英膜科技有限公司

Oilfield development plugging agent

The invention provides an oilfield development plugging agent which is prepared from unsaturated resin emulsion, a curing agent and a coupling agent as raw materials, the unsaturated resin emulsion is formed by mixing 196 unsaturated polyester resin, an emulsifier and water, and the coupling agent is gamma-aminopropyl triethoxysilane. The plugging agent is suitable for the formation at the temperature of 30-90 DEG C, and the resin solution can be self curing at the temperature, and can be used for the permanent sealing of large holes or large cracks which do not need plugging releasing. The oilfield development plugging agent has strong plugging ability, salt resistance, wide applicable scope, long validity period and low cost. Compared with the blocking agent in other profile control systems, the oilfield development plugging agent has obvious advantages on plugging of oil reservoirs with large holes or large cracks, and is in line with the needs of oil field sites.

Owner:CHINA PETROLEUM & CHEM CORP +1

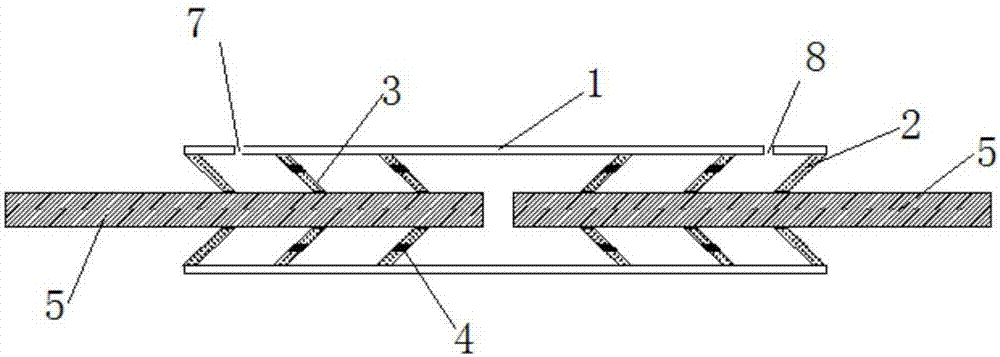

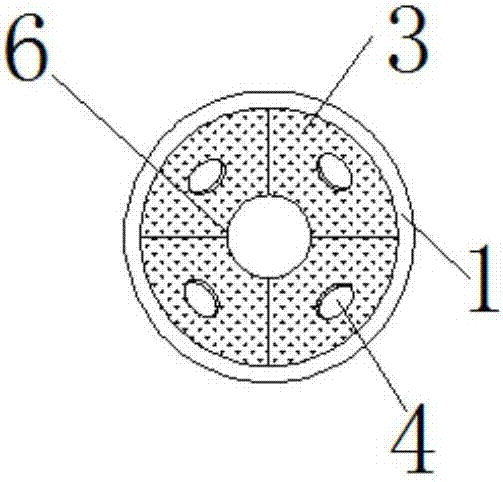

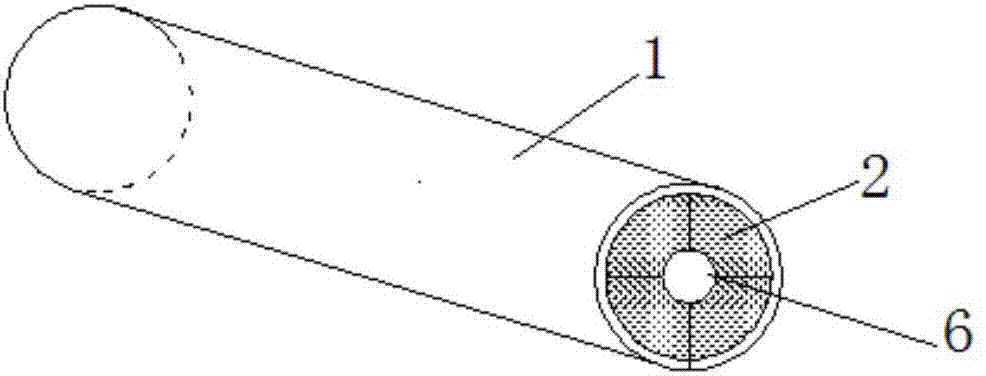

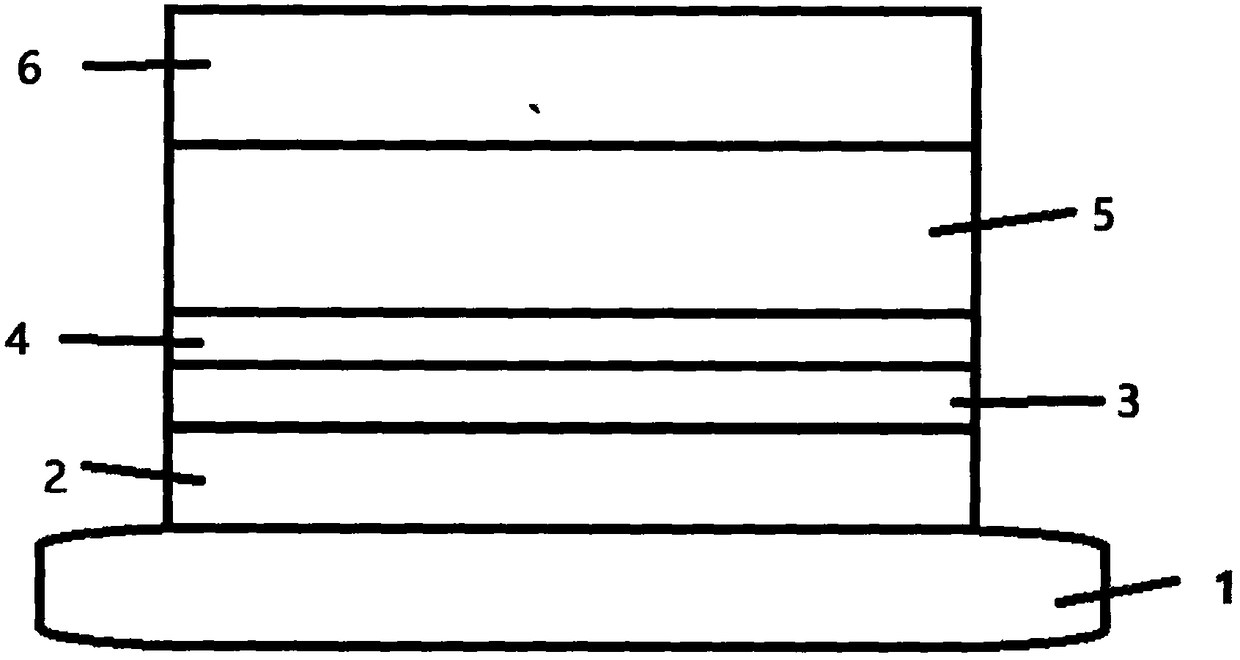

Steel tube sleeves used for prefabricated shear walls and columns and fabricating method for steel tube sleeves

The invention discloses a steel tube sleeves used for prefabricated shear walls and columns. The steel tube sleeves used for the prefabricated shear walls and the columns comprises a steel tube (1) and built-in barbs, wherein the four barbs (2) used for anchoring steel bars are circumferentially arranged on the inner walls at the two ends of the steel tube (1); n groups of the built-in barbs are evenly arranged in the axial direction of the steel tube, n is greater than or equal to 1 group, and the built-in barbs are symmetrically arranged toward the middle face of the steel tube. Compared with the prior art, the steel tube sleeves used for the prefabricated shear walls and the columns are simple in structure, convenient to install, simple in fabrication and low in cost, meanwhile, connecting requirements for the steel bars in constructional engineering can be met.

Owner:WUHAN UNIV OF TECH

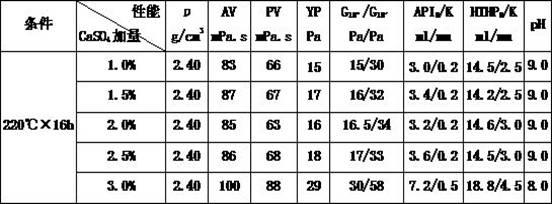

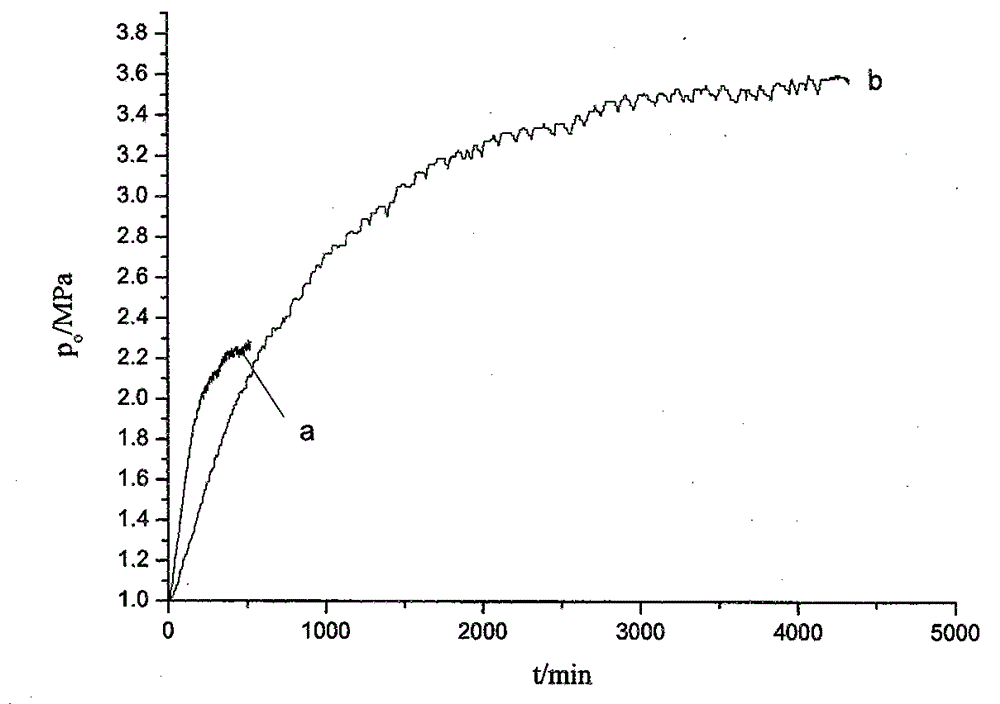

Saturated salt water drilling fluid for deep wells and extra-deep wells

InactiveCN102504773AMeet the requirements of drillingImprove rheologyDrilling compositionCelluloseFiltration

The invention relates to a saturated salt water drilling fluid for deep wells and extra-deep wells, which is used for drilling operation in petroleum fields under high-temperature and high-pressure environments and can overcome the defects of high solid concentration, complex formula and unstable properties of a drilling fluid system used in extra-deep well drilling. The invention adopts the technical scheme that the components of the raw materials for preparing the drilling fluid and the contents of the components are as follows: tap water: 90 to 100; bentonite: 2 to 6; Na2CO3: 4-8; maleic anhydride: 1 to 3; polyanion cellulose: 0.1 to 0.4; lignosulfonate: 5 to 9; sulfomethal phenolaldehy resin-lignosulfonate-humic acid copolymer: 7 to 11; emulsified asphalt: 2 to 5; C12-C18 straight chain paraffin emulsion: 3 to 6; emulsified paraffin: 2 to 5; Span 80: 0.2 to 0.5; CaO: 0.3 to 0.7; KOH: 0.3 to 0.7; KCl: 4 to 7; NaCl: 20 to 30; and barite for adjusting the density of the drilling fluid to 2.40 g / cm<3>. The drilling fluid has better rheological behavior under high temperature, has the advantages of good filtration properties, strong anti-pollution capacity, strong inhibitive capacity, good lubricity and strong shut-off capacity, and is used for extra-deep well drilling.

Owner:XINJIANG GRAND OILFIELD TECH

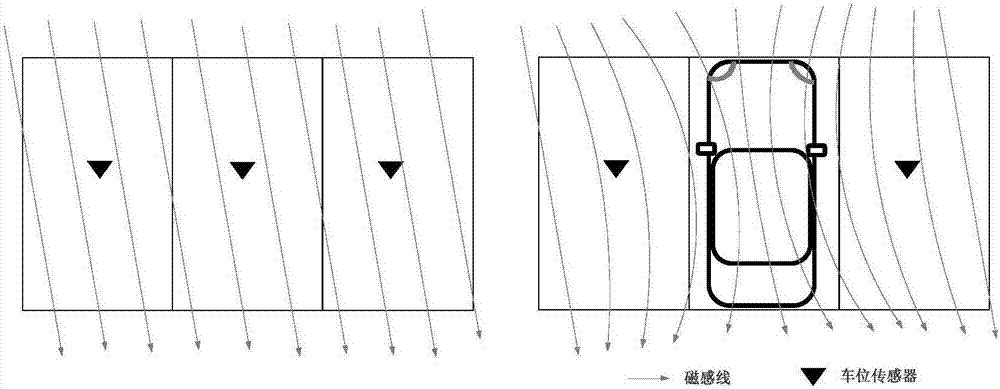

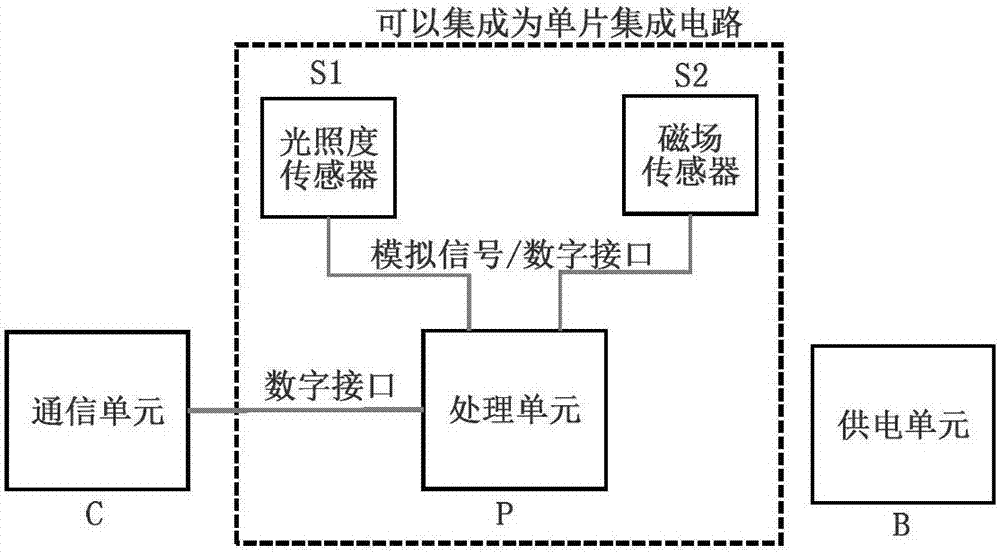

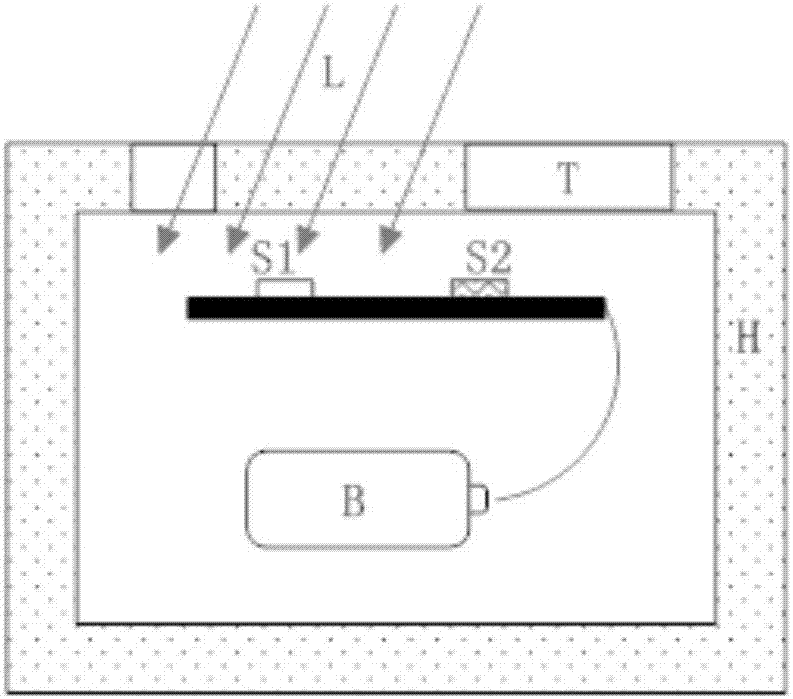

Composite parking stall detection method and device based on Iilluminance and terrestrial magnetism combined detection

ActiveCN106935037AResolve interferenceImprove detection accuracyDetection of traffic movementIndication of parksing free spacesIlluminanceTerrestrial Time

The invention discloses a composite parking stall detection method and device based on Iilluminance and terrestrial magnetism combined detection. According to the method, detection is carried out by combining illuminance and terrestrial magnetism; the method comprises detection for vehicle driving-in and driving-away events; in detection for a vehicle driving-in event, if a magnetic field is changed, the illuminance is decreased, and the decreased illuminance reaches a threshold, it is determined that a vehicle drives into a parking stall; and in detection for a vehicle driving-away event, the vehicle which is driven away disturbs the magnetic field, and if the magnetic field is changed while the illuminance is increased, it is determined that the vehicle drives away from the parking stall. According to the invention, terrestrial magnetic field disturbing and ambient light shielding effects of the vehicle body are utilized at the same time, the problem that adjacent parking stalls may interfere each other in a traditional pure terrestrial magnetism detection technology can be overcome, and the detection accuracy is improved substantially.

Owner:程萌

Method for protecting slope vegetation through plant fiber blankets

ActiveCN105123212AGuarantee the built effectEasy to buildExcavationsCultivating equipmentsFiberVegetation

The invention relates to a method for protecting slope vegetation through plant fiber blankets. The method for protecting slope vegetation through plant fiber blankets is applicable to fill roadbed slope protection during a construction period. According to the method, fill roadbed slopes are divided into two categories, according to one category, the fill roadbed slopes are formed slopes where roadbed filling is completed, and according to the other category, the fill roadbed slopes are non-formed slopes where roadbed filling is not completed. The operation that roadbeds are gradually filled and spreading is performed layer by layer is performed on the non-formed slopes, the plant fiber blankets are fixed, after filling of the all the roadbeds and covering of the plant fiber blankets are completed, plant seeds are sown on the surfaces of the plant fiber blankets, covering of thin soil is performed, and watering and curing are performed so that vegetation can be formed; the operations that grass seeds are sown on the total slopes, then the total slopes are covered with the plant fiber blankets, and curing is performed are adopted so that the vegetation can be built. By means of the method, the slopes can be greened as soon as possible, water and soil loss can be effectively controlled in the construction period, and the effectiveness of slope protection is enhanced in the construction period.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

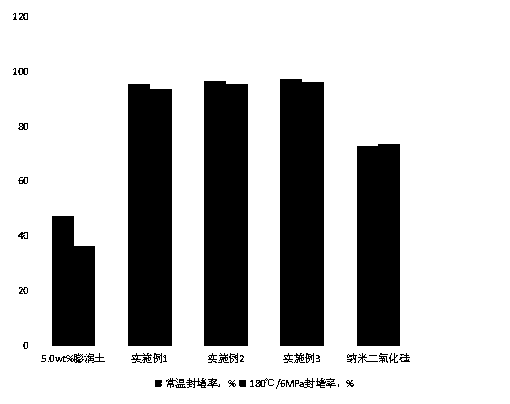

Nanofiber compound-based shale formation blocking agent for drilling fluid and preparation method

ActiveCN109810678AEffective blockingSimple methodDrilling compositionMicro nanoAcute toxicity testing

The invention relates to a nanofiber compound-based shale formation blocking agent for drilling fluid and a preparation method. The blocking agent is prepared from the following raw materials: bagasse, a dispersant, nano silica, nano graphite and deionized water. A nanofiber compound method is adopted to form the efficient blocking agent for effectively blocking nano pores and micro-nano cracks bycompounding various types of nano particles, the method is simple and reliable, and the prepared shale blocking agent has little influence on the performance of the drilling liquid, but has an obvious shale blocking effect. The blocking rate of base mud added with the amount of 3.0 percent by weight of a nanofiber compound in a shale core exceeds 96%, while under the conditions of high temperature and high pressure (180 DEG C / 6MPa), the blocking capacity remains basically unchanged (higher than 93%), and the treatment agent is non-toxic, has no adverse effects on environment, has acute toxicity EC50 which is greater than 60000, and is an efficient shale blocking agent.

Owner:CHINA PETROCHEMICAL CORP +3

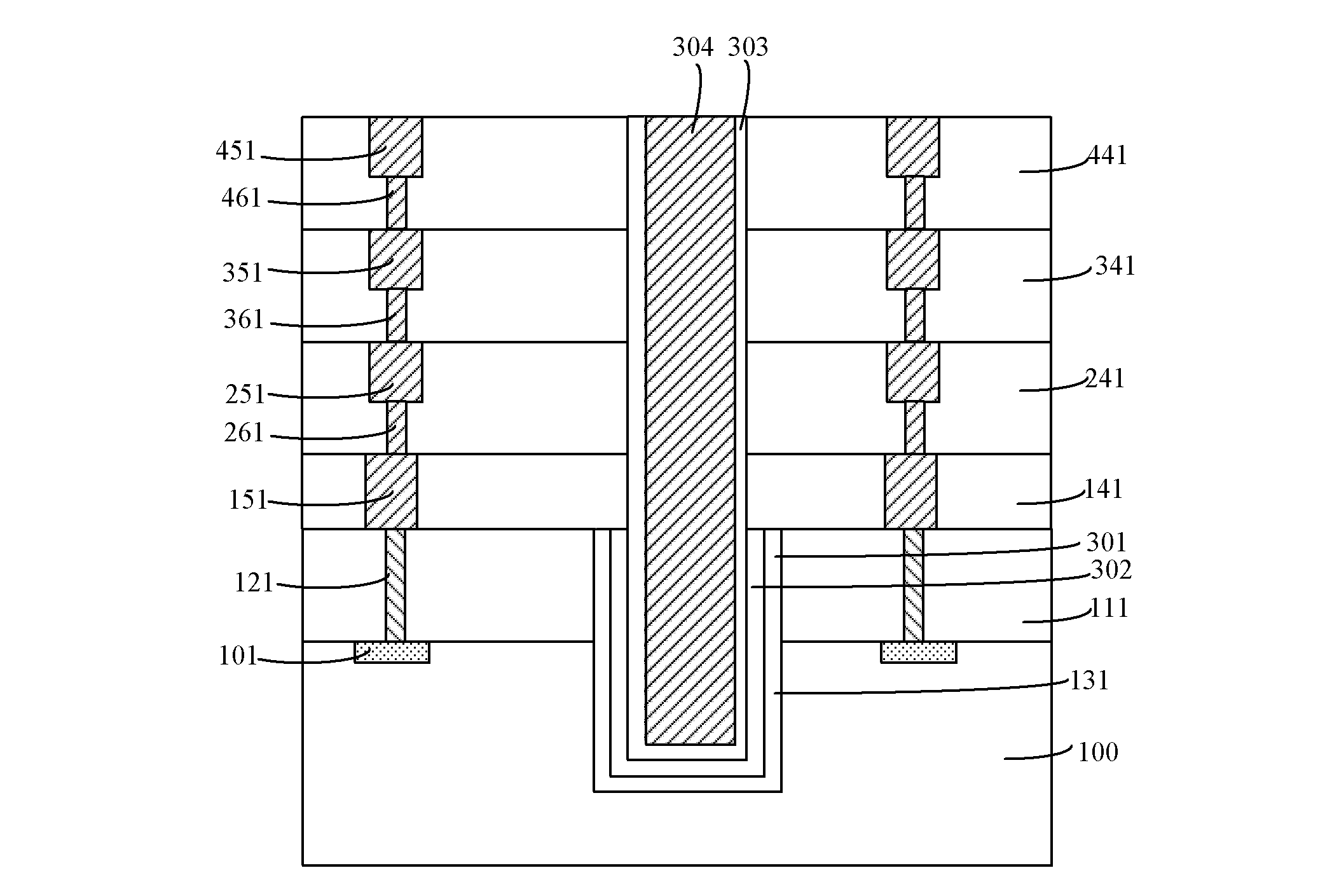

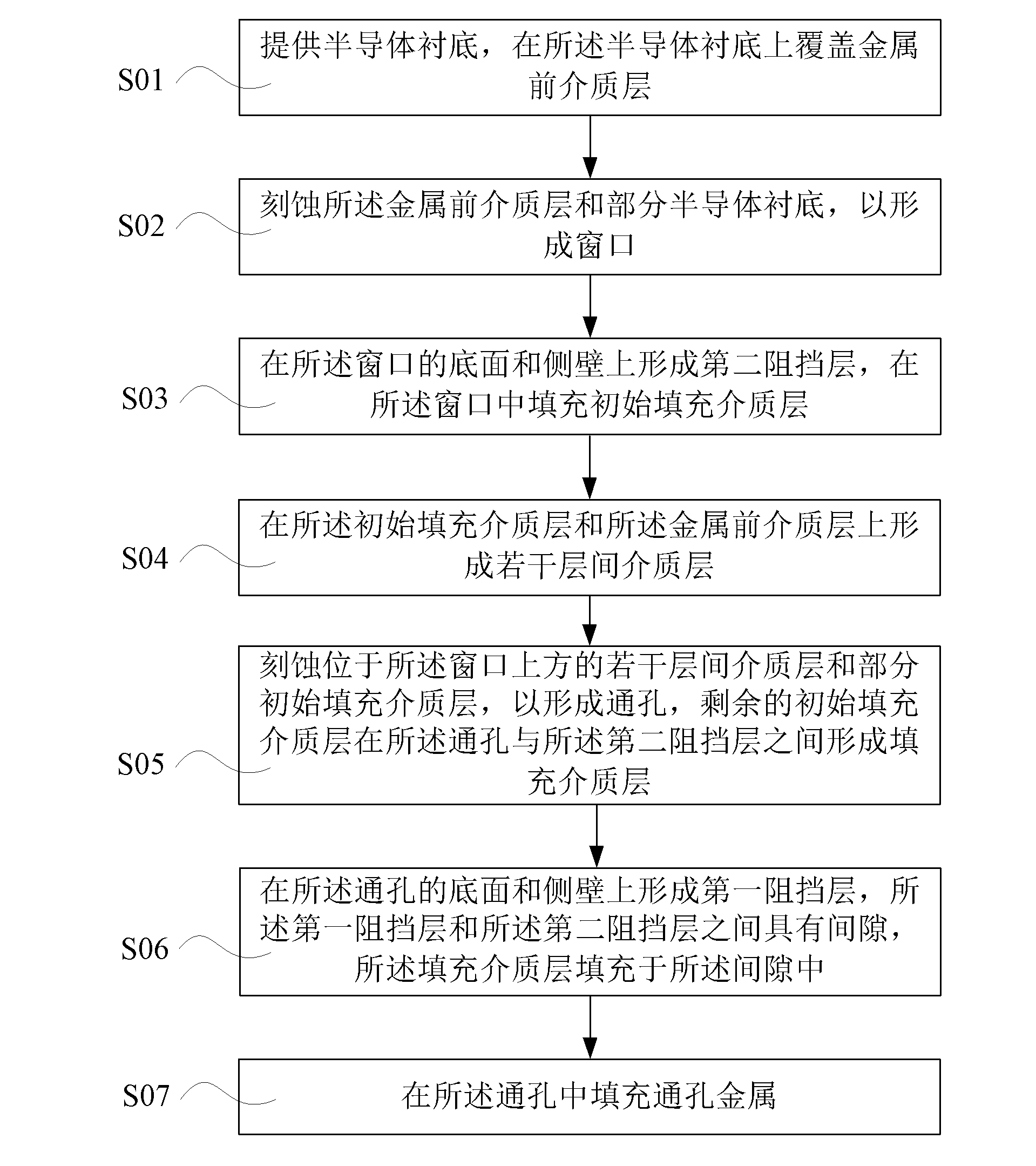

Through silicon via (TSV) structure and manufacturing method thereof

ActiveCN102623437AAvoid damageStrong blocking abilitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsEngineering

The invention relates to a TSV structure and a manufacturing method thereof, which include forming a window in a former medium layer and a semiconductor substrate, and forming a second blocking layer in the window before forming a plurality of interlayer medium layers; forming a through hole after forming the plurality of the interlayer medium layers, wherein the hole diameter of the through hole is smaller than that of the window after the second blocking layer is formed, accordingly, surplus initial filling medium layer forms a filling medium layer between the through hole and the window after the second blocking layer is formed; forming a first blocking layer and through hole metal in the through hole afterwards, so that a three layer isolating structure comprising the first blocking layer, the filling medium layer and the second blocking layer is formed between the through hole and the semiconductor substrate. The continuity of the isolating structure is improved, the problem of the degradation of semiconductor devices caused by the fact that conductive materials of the through hole metal diffuse into the semiconductor substrate is further effectively solved, and the reliability of semiconductor devices is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

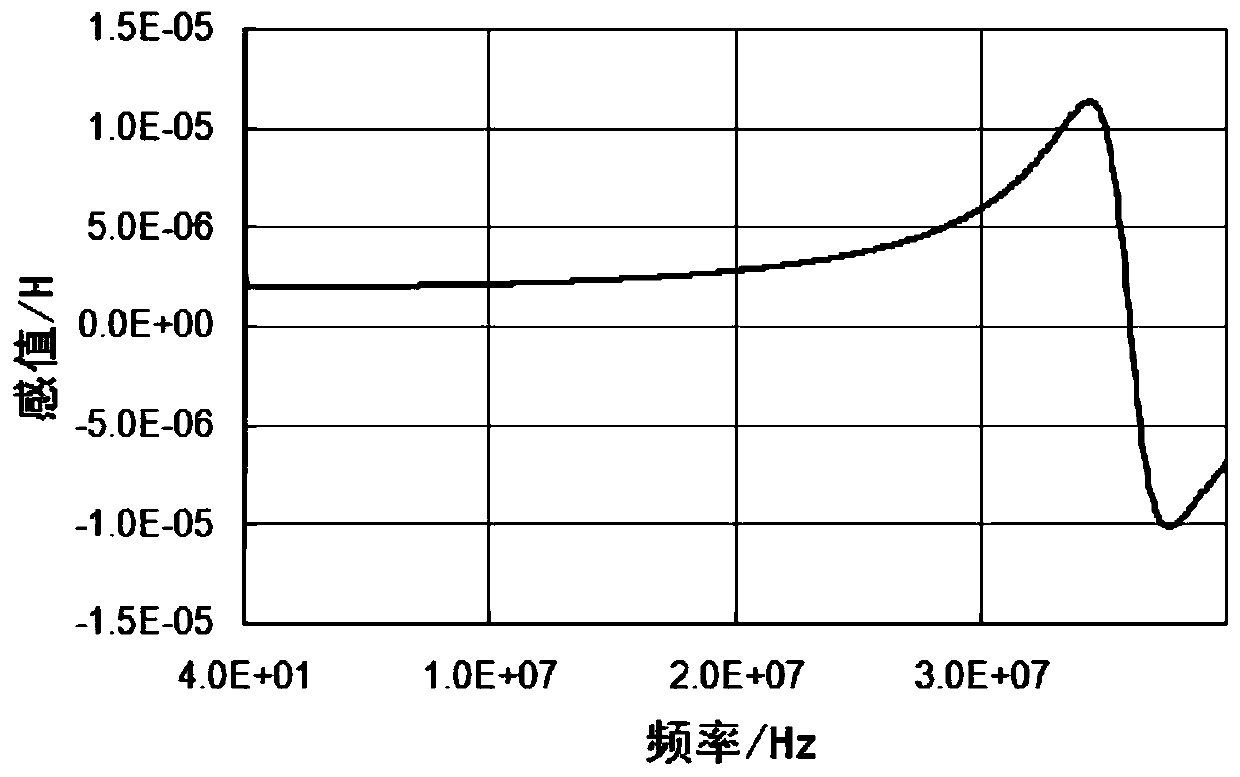

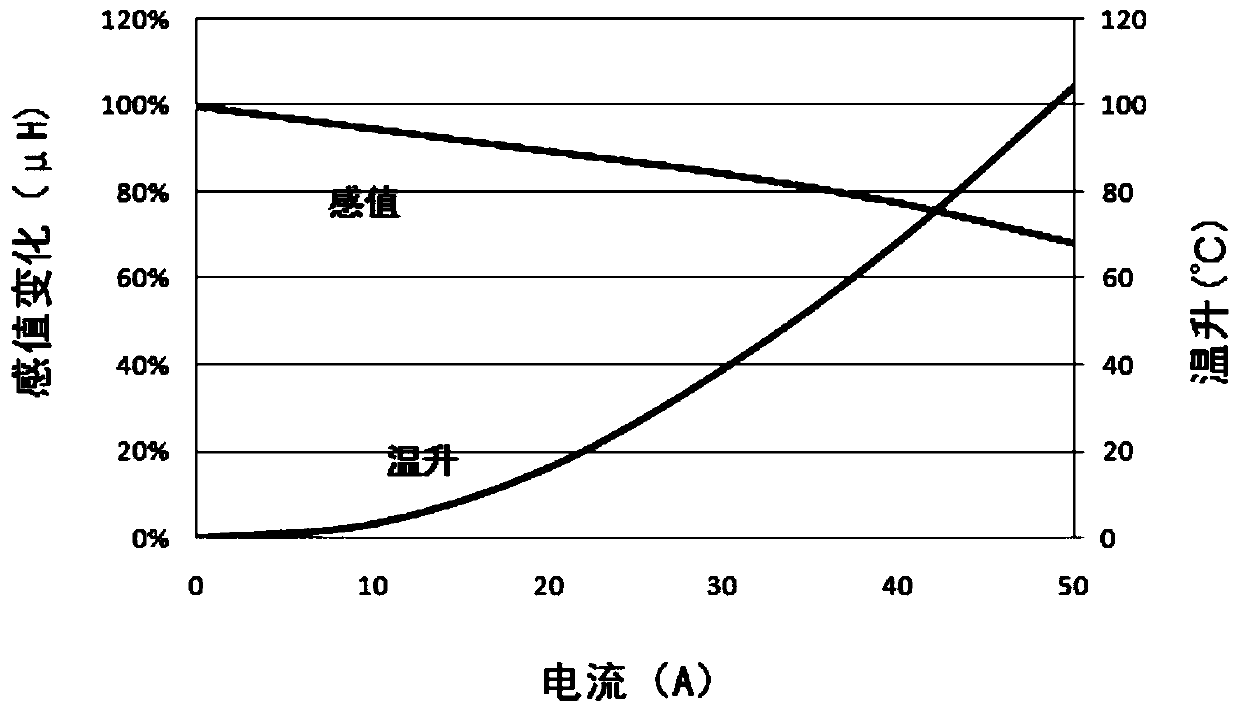

Soft magnetic powder used for high frequency mould pressing inductor as well as preparation method thereof

InactiveCN109754972AHigh resistivityLarge specific surface areaInductances/transformers/magnets manufactureMagnetic materialsInductorHigh resistivity

The invention discloses soft magnetic powder used for a high frequency mould pressing inductor as well as a preparation method thereof. The soft magnetic powder is prepared from a first main material,a second main material and an auxiliary material, the first main material is first metal soft magnetic alloy powder with the particle diameter of 1-10[mu]m, the second main material is second metal soft magnetic alloy powder with the particle diameter of 10-15[mu]m, the weight of the first metal soft magnetic alloy powder accounts for 60-99% of the weight of the soft magnetic powder, the weight of the second metal soft magnetic alloy powder accounts for 0-40% of the weight of the soft magnetic powder, and the weight of the auxiliary material accounts for 1-20% of the weight of the soft magnetic powder; and the soft material powder has the advantages of relatively high resistivity and relatively high saturation magnetization intensity, and usage frequency of the mould pressing inductor canbe improved.

Owner:NINGBO YUNSHENG ELECTRONIC COMPONENTS TECHNOLOGY CO LTD +1

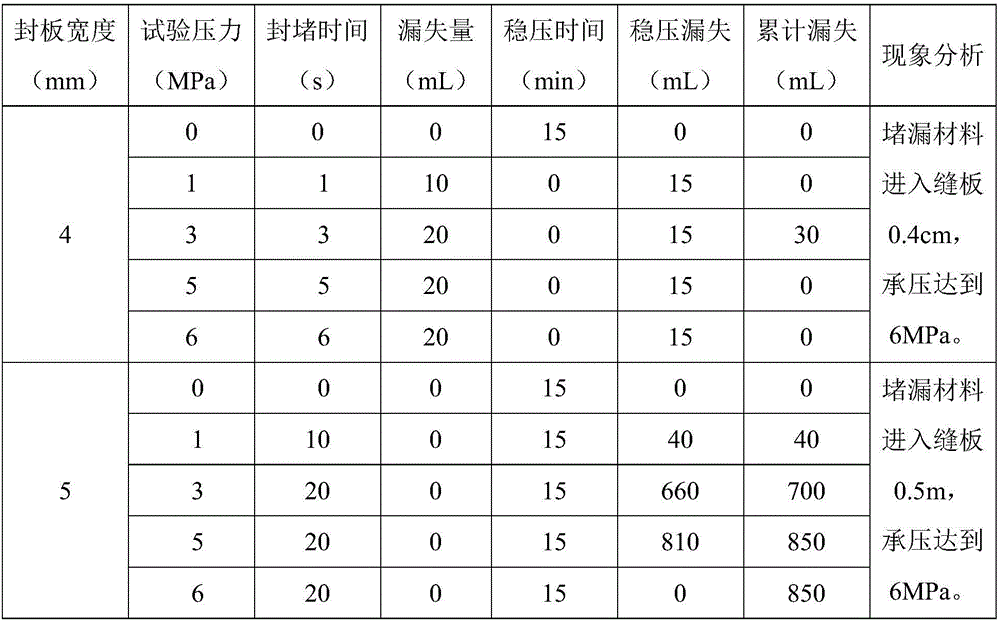

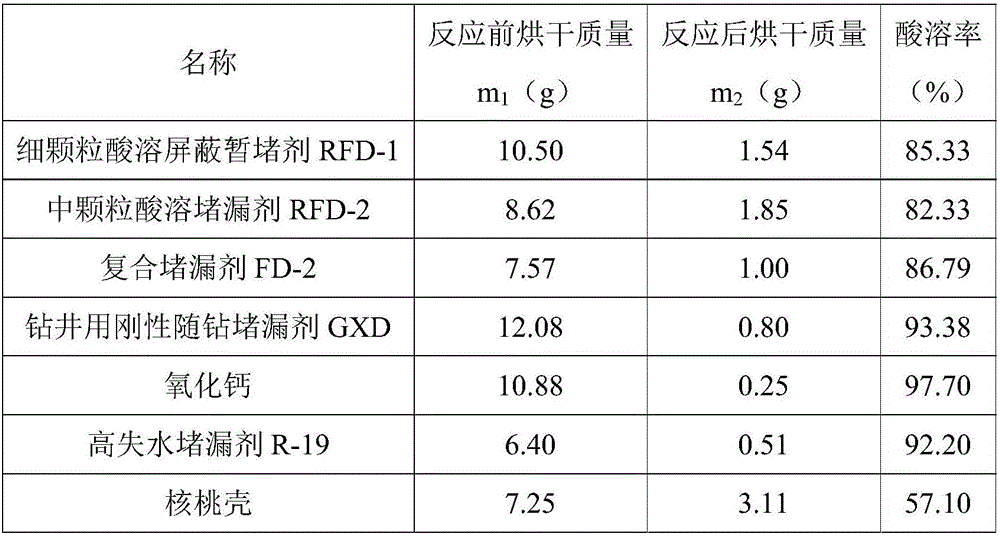

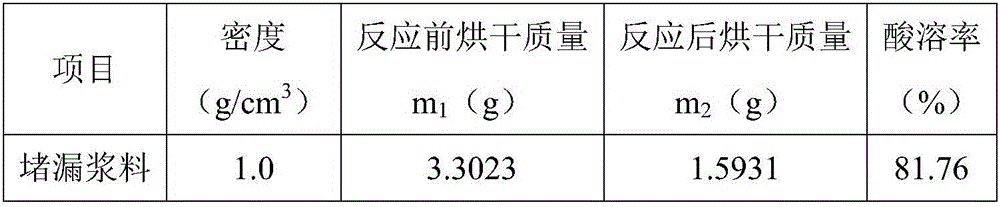

Plugging material and plugging slurry for protecting reservoir stratum with low fracturing fracture ability

The invention discloses a plugging material and plugging slurry for protecting a reservoir stratum with the low fracturing fracture ability. The plugging material is prepared from, by weight, 5-6 parts of walnut shell powder, 2-3 parts of a composite plugging agent, 1.5-2 parts of an agent for plugging while drilling, 4-5 parts of an acid soluble plugging agent, 4-5 parts of a high-dehydration-rate plugging agent and 0.2-0.3 part of calcium oxide. The natural plant inertia material, the fiber plugging agent and the acid soluble plugging agent are mixed according to the certain matching ratio to form the acid soluble plugging material in granule and fiber shapes. The material has the advantages that the bridging effect of a bridging material is good and the plugging success rate is high, and also has the advantages that the density is low, stratum pressure is effectively balanced, the stratum damage is small, the plugging property is strong and acid solubility is achieved. The plugging slurry prepared from the plugging material and water has the advantages of being low in density, high in pressure bearing capability, good in malignant leakage plugging effect, high in acid solubility and the like; the on-site preparation process is simple, construction is safe and reliable, and the purposes of reducing well leakage loss and protecting the reservoir stratum can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

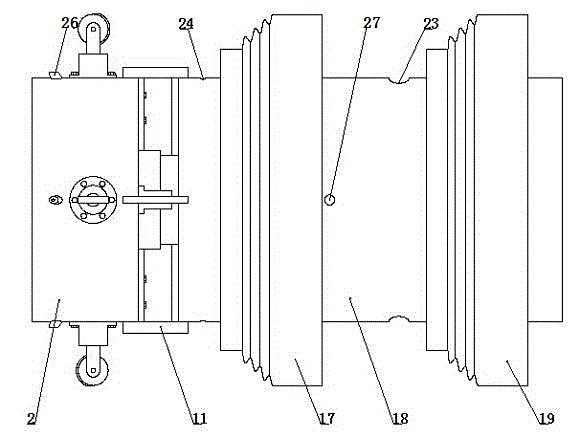

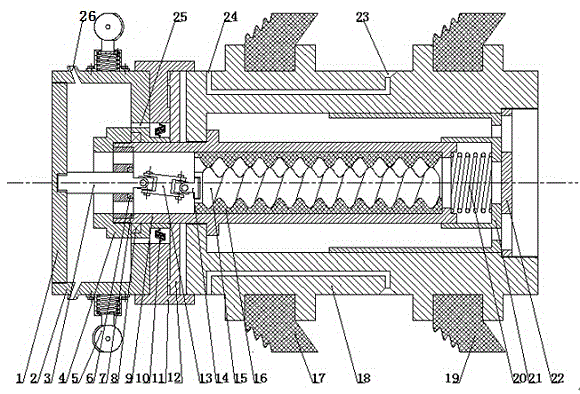

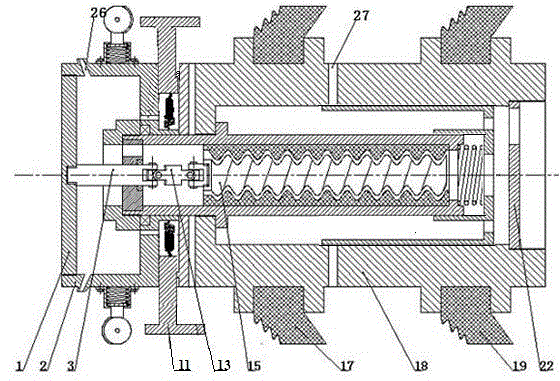

Novel plugging releasing and pipeline cleaning device

InactiveCN104959355AEasy to adjustImprove controllabilityHollow article cleaningUniversal jointEngineering

The invention relates to a novel plugging releasing and pipeline cleaning device which comprises a body, a first-level cup, a second-level cup, a motor shell, a rotating body and a scraper. The first-level cup and the second-level cup are embedded in grooves in the outer portion of the body, a valve seat is arranged between the body and the motor shell, and a compression spring is arranged between the valve seat and the motor shell. A valve deck is screwed to the rear end of the body, and a screw rod is arranged in stator rubber and connected with an input shaft through threads. One end of an output shaft is arranged in a positioning plate, and the other end of the output shaft is connected with a cover plate through threads. The output shaft and the input shaft are connected through a universal joint, the positioning plate is arranged inside the front end of the motor shell, and the rotating body is arranged outside the front end of the motor shell. A limiting end cover is screwed to the front end of the motor shell, and the scraper is arranged between the rotating body and a baffle and connected with the rotating body through a tension spring. By means of the novel plugging releasing and pipeline cleaning device, multi-level cleaning can be achieved on the wall of an oil conveying pipeline, adjustment is convenient, and controllability is high; pipeline cleaning and plugging releasing are achieved through the mutual act of the scraper and jet fluid, the pipeline cleaning effect is good, and the plugging releasing capability is high.

Owner:SOUTHWEST PETROLEUM UNIV

3D printing process method of high-strength aluminum-magnesium alloy

ActiveCN111872386ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingMaterials science

The invention relates to a 3D printing process method of a high-strength aluminum-magnesium alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-magnesium alloy raw materials are mixed evenly through heating and melting; then high-quality aluminum-magnesium alloy powder is prepared from the high-strength aluminum-magnesium alloy in a molten state through a gasatomization technology, and aluminum-magnesium alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is carried out according to 3D model data of parts in printing equipment with inert gas introduced, and a 3D printing product with the high-strength aluminum-magnesium alloy as a raw material is obtained. Compared with the prior art, as for the product printed through the process method, the relative density can reach 99% or above, the Vickers hardness can reach 110 HV or above, the tensile strength can reach 430 MPa or above, the elongation can reach 21%, through proper heat treatment, the Vickers hardness of a sample can reach 150 HV or above, the tensile strength can be further increased to 520 MPa or above, and the elongation is maintained at 17% or above.

Owner:TONGJI UNIV

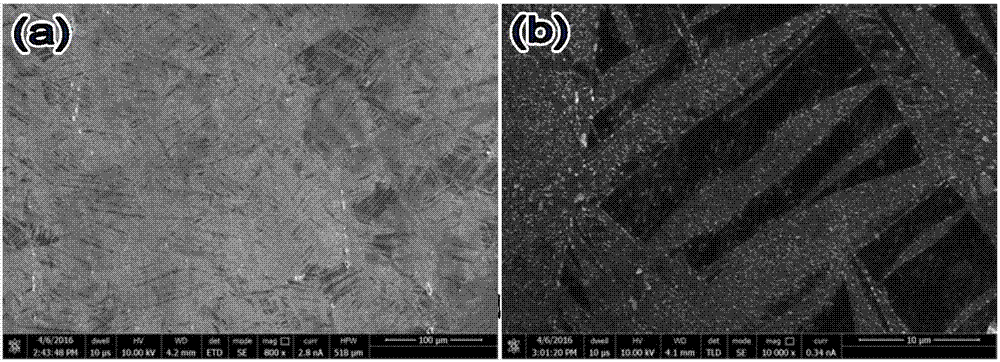

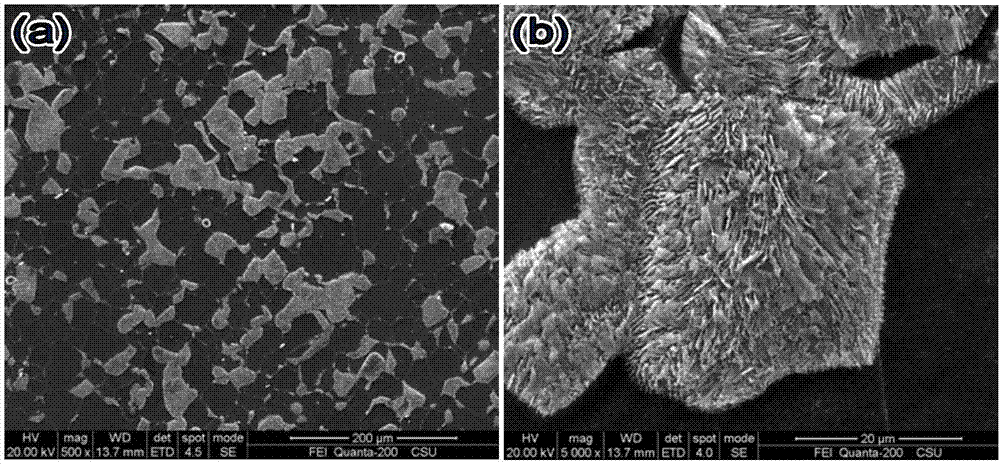

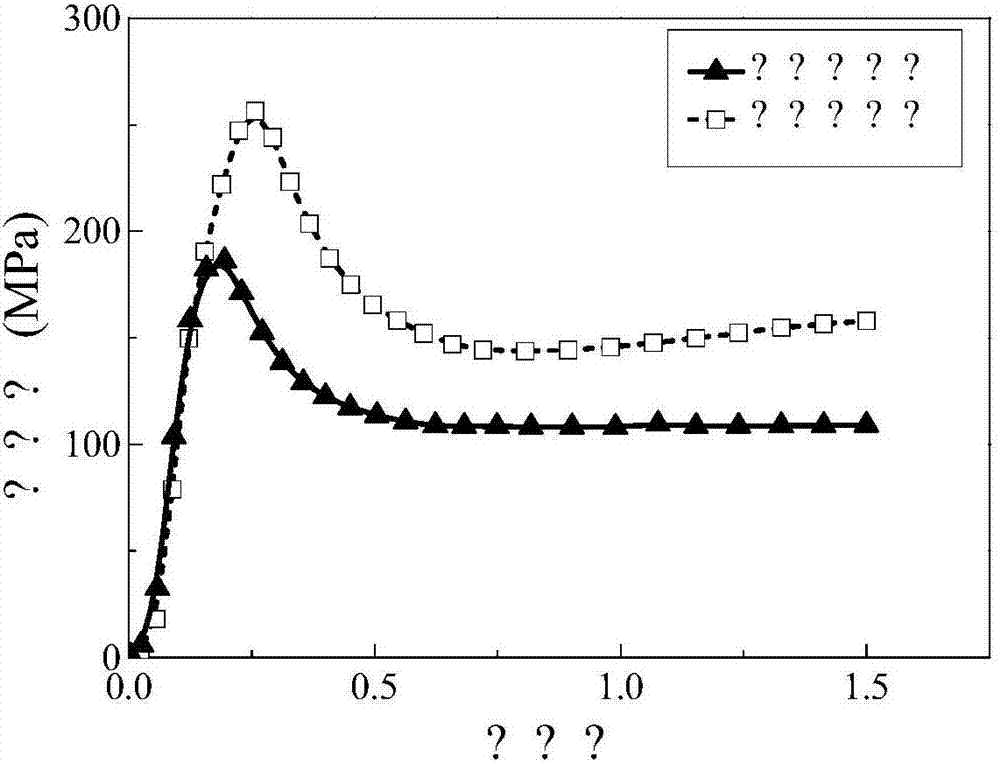

Method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance

InactiveCN107119246AImprove mechanical propertiesExcellent thermoforming propertiesCrystal twinningPre deformation

The invention provides a method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance. The method comprises the steps that Mg-Al-Zn magnesium alloy is subjected to pre-deformation treatment at 25 DEG C to 300 DEG C, twin crystal or low-angle crystal boundaries are introduced, and then aging treatment is conducted. According to the deformation heat treatment method, precipitation of a continuous precipitation phase of the Mg-Al-Zn magnesium alloy can be effectively promoted, and alloy tissue with a uniform, small and dispersively distributed precipitation phase is obtained finally; and alloy strength and plasticity are synchronously improved, and thermoforming performance and service performance of the alloy are improved. The method for improving the Mg-Al-Zn magnesium alloy thermoforming and service performance is reasonable in design, simple in equipment requirement, convenient to operate, low in cost and high in efficiency, distribution of the precipitation phase of the Mg-Al-Zn magnesium alloy is reasonably controlled, the thermoforming performance and service performance of the alloy are improved, and the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

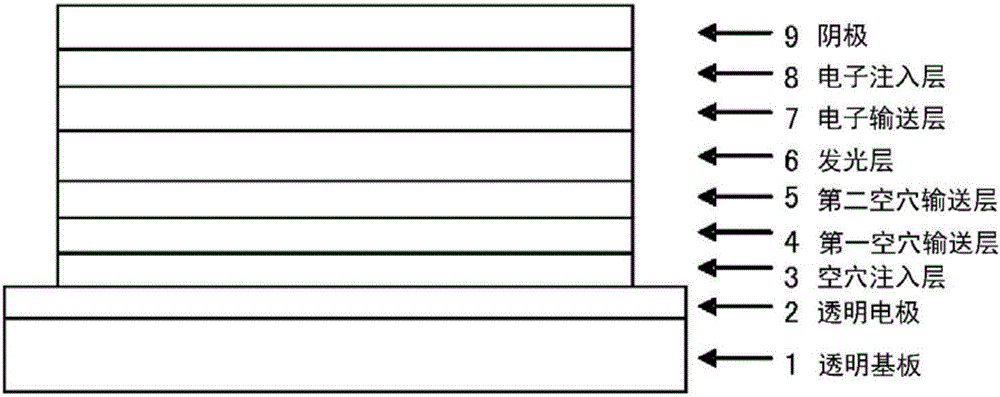

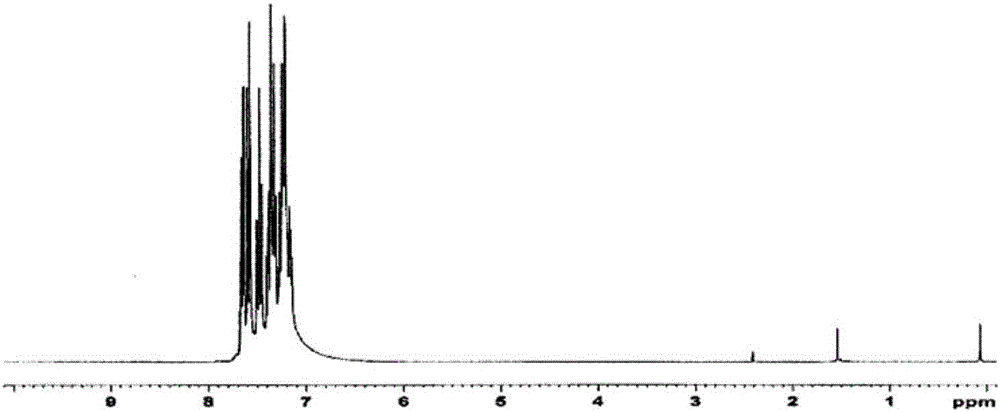

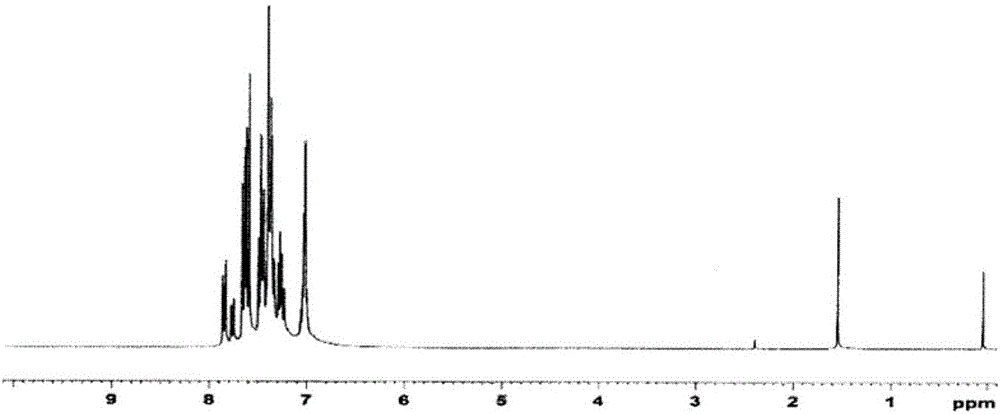

Organic electroluminescent element

ActiveCN106688119AExcellent hole injectionHigh hole mobilityOrganic chemistrySolid-state devicesOrganic electroluminescenceHole transport layer

This organic EL element comprises a positive electrode, a hole transport layer, a light emitting layer, an electron transport layer and a negative electrode in this order, and is characterized in that the hole transport layer contains an arylamine compound represented by general formula (1). In the formula, each of Ar1-Ar4 represents a monovalent aromatic hydrocarbon group or a monovalent aromatic heterocyclic group.

Owner:HODOGOYA CHEMICAL CO LTD

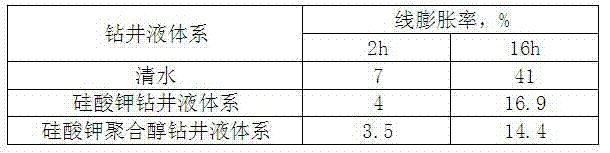

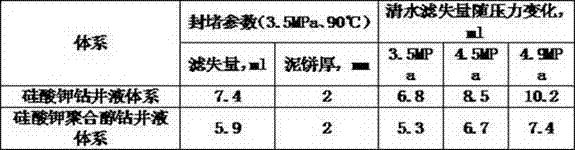

Potassium metasilicate polymeric alcohol water base drilling fluid

InactiveCN102391843AImprove rheologyGood water loss and wall buildingDrilling compositionWater basedSodium Bentonite

The invention relates to a potassium metasilicate polymeric alcohol water base drilling fluid for preventing collapse and tool sticking in oil and gas field drilling operation. The drilling fluid overcomes complex situations easily caused by high temperature and pressure under a deep well and a super deep well. A technical scheme is as below: raw materials for preparing the drilling fluid comprise 40-60 parts of sodium bentonite, 40-60 parts of powder instant potassium metasilicate, 3-6 parts of tackifier, 4-6 parts of fluid loss additive, 20-40 parts of plugging agent, 8-13 parts of KCl and 1000 parts of tap water, wherein a NaOH adjusting system has a pH of 11.5. A preparation method of the drilling fluid comprises the following steps: taking 1000g of tap water; adding sodium bentonite, powder instant potassium metasilicate, tackifier, fluid loss additive, plugging agent and KCl; adjusting a pH to 11.5 by a 40% NaOH and continuing stirring for 15 min to obtain the potassium metasilicate polymeric alcohol water base drilling fluid. The product of the invention has good rheological property, water loss wall-building property, strong inhibition, good plugging capability, good lubricity and good heat stability, and can satisfy requirements of safe well drilling under complex conditions.

Owner:SOUTHWEST PETROLEUM UNIV

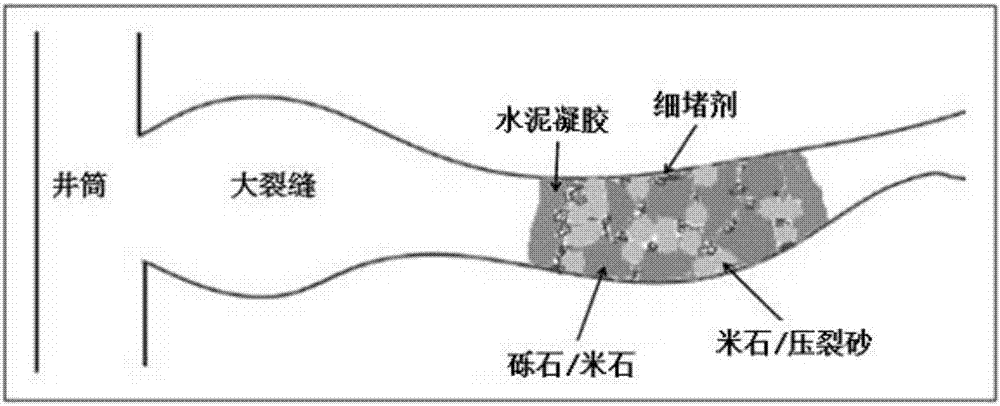

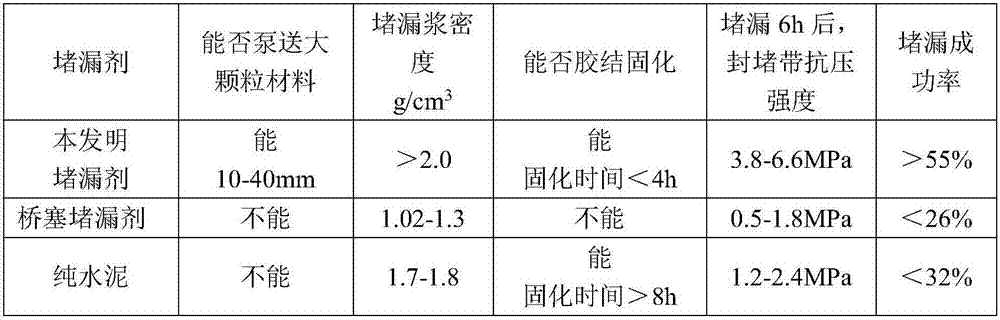

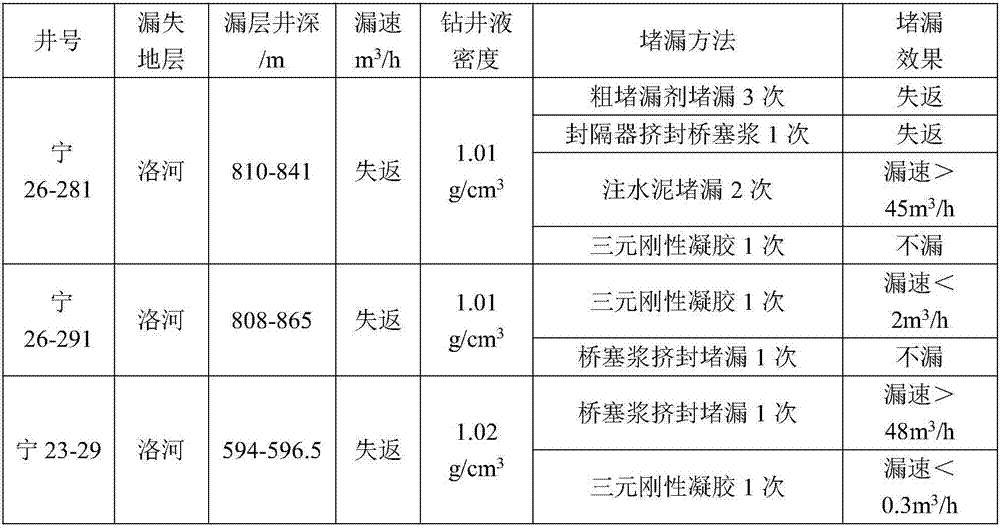

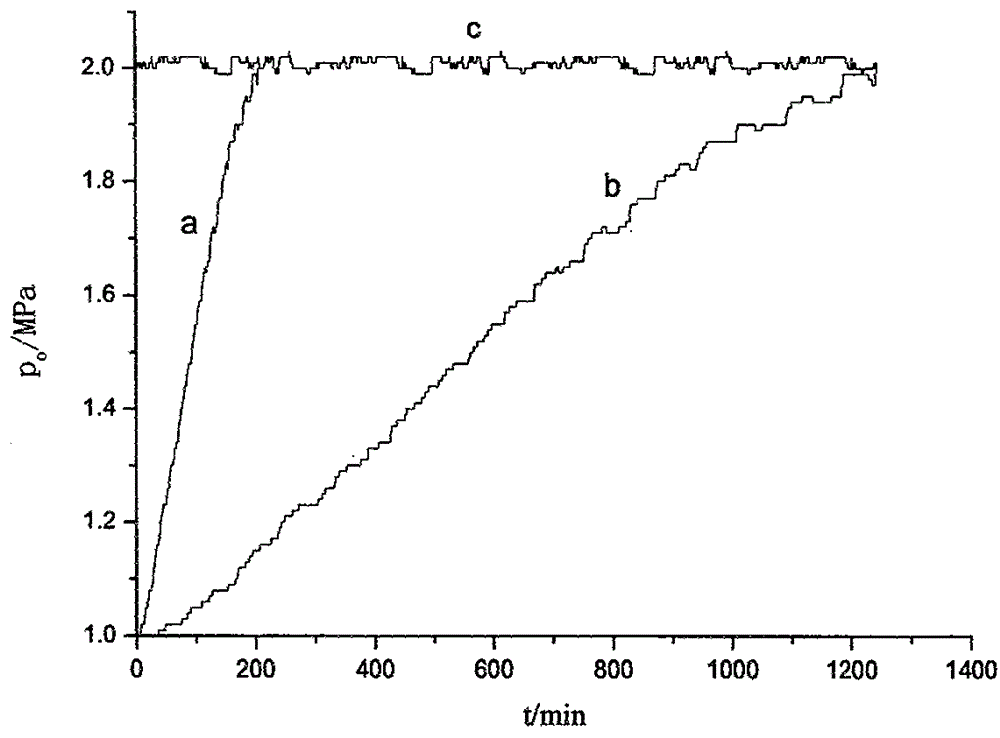

Lost circulation additive for plugging severe mud loss formation fracture and preparation method of lost circulation additive

ActiveCN107235691ALow costReduce manual labor intensityDrilling compositionGranolithicLost circulation

The invention provides a lost circulation additive for plugging severe mud loss formation fracture and a preparation method of the lost circulation additive. The lost circulation additive comprises the following components in percentage by mass: 45-56% of oil well grade-G cement, 8-12% of gravel, 12-15% of granolithic, 15-20% of fracturing sand, 6-9% of a thin plugging agent, 1-2% of a fluid loss agent and 2-4% of an admixture. According to the lost circulation additive disclosed by the invention, large fractures and large holes of the severe mud loss formation can be well plugged, the problem that the plugging agent cannot be bridged, remained, filled and reinforced in the large fractures can be well solved, and the requirements on drilling construction and environment friendliness are met. Moreover, the preparation method is simple, the operability is high, the severe mud loss plugging effect is obvious, the plugging operation cost is effectively reduced, and the plugging operation time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

3D printing process method of high-strength aluminum manganese alloy

InactiveCN111659889ALow costImprove qualityAdditive manufacturing apparatusTransportation and packagingManganese3D modeling

The invention relates to a 3D printing process method of a high-strength aluminum manganese alloy, and belongs to the technical field of 3D printing. The 3D printing process method comprises the stepsthat firstly, a high-strength aluminum manganese alloy is mixed evenly by heating and melting; then the melted high-strength aluminum manganese alloy is subjected to a gas atomization technology to prepare high-quality aluminum manganese alloy powder, and aluminum manganese alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is conducted according to three-dimensional model data of parts in printing equipment introduced with inert gas, and a 3D printing product with the high-strength aluminum manganese alloy as a raw material is obtained. Compared with the prior art, according to the product printed by the process method, the relative density can reach more than 99%, the Vickers hardness can reach more than 140 HV, the tensile strengthcan reach more than 440 MPa, the elongation can reach 20%, after proper hear treatment, the hardness of a sample can reach more than 180 HV, the tensile strength can be further increased to more than565 MPa, and the elongation is maintained at or above 19%.

Owner:TONGJI UNIV

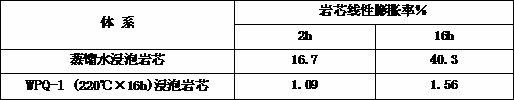

Aluminum-based anti-collapse agent for drilling fluid

InactiveCN104650826AStrong blocking abilityReduce moisture contentFlushingDrilling compositionAluminium hydroxideExpansion rate

The invention relates to an aluminum-based anti-collapse agent for drilling fluid. The efficient aluminum-based anti-collapse agent is synthesized through reaction of organic acids with aluminum-containing compounds under an acid condition at 25-105 DEG C, wherein the organic acids are gallotannic acid, citric acid, humic acid and oxalic acid; the aluminum-containing compounds are aluminum hydroxide, aluminum chloride, aluminum sulfate and aluminum nitrate. Aiming at a mudstone stratum, the aluminum-based anti-collapse agent can inhibit hydration expansion of clay and shale by virtue of the unique chemical property of organic acid-aluminum, pressure conduction in shale can be retarded, and the semipermeable membrane property of shale can be improved. By adopting the aluminum-based anti-collapse agent, the linear expansion rate of shale within 8 hours is less than or equal to 15%, a high / low water content shale sample can be effectively stabilized, the pore pressure transfer in mudstone can be reduced by more than 12 times, the induction osmotic pressure can be increased by greater than 50%, and the aluminum-based anti-collapse agent is excellent in anti-collapse property and beneficial for well wall stabilization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Environmentally-friendly drilling fluid with high plugging performance

InactiveCN107502320AImprove thermal stabilityImprove the lubrication effectDrilling compositionSodium BentoniteHexamethylenetetramine

The invention discloses an environmentally-friendly drilling fluid with high plugging performance. The drilling fluid comprises 2-6% of bentonite, 0.3-0.5% of sodium carbonate, 0.3-0.5% of an inhibitor, 0.2-0.5% of a coating agent, 0.1-0.3% of xanthan gum, 2-8% of a filtrate reducer, 2-5% of a plugging agent, 1-4% of calcium carbonate, 0.5-4% of a lubricant, and 25-250% of an inert weighting agent; and the nano plugging agent is formed by compounding of a product prepared from carbon spheres coated with AlOOH, acrylamide, N-isopropylacrylamide and hexamethylenetetramine and a vinyl acetate-ethylene copolymerization emulsion. The environmentally-friendly drilling fluid has the characteristics of high plugging performance, high lubricating performance, a good rheological property, strong ability of carrying rock debris, and friendliness to environments, and the environmentally-friendly drilling fluid is specially applied to environmental sensitive areas regions.

Owner:CNPC BOHAI DRILLING ENG

Golden yellow hfabric for shielding infrared thermal radiation

InactiveCN108130727AStrong blocking abilityEasy to keep warmFibre treatmentThermal radiationMaterials science

The invention discloses a golden yellow fabric for shielding infrared thermal radiation. By using a magnetron sputtering vacuum deposition method, a composite membrane layer is deposited on the surface of a fabric; the composite membrane consists of a medium layer, a metal silver membrane layer, a metal copper membrane layer, a nickel-chromium membrane layer and a protection layer; the metal copper membrane layer has the main contribution of a golden yellow color; a low-radiation effect for shielding infrared thermal radiation is mainly achieved by the metal silver membrane layer and the metalcopper membrane layer. By adopting the fabric, a large scale of fabrics have infrared thermal radiation shielding functions rapidly, and a relatively good thermal-insulating and heat-preservation effect can be achieved; in addition, magnetron sputtering vacuum membrane plating has no problem of chemical use, water pollution or air pollution, and is an environmental-friendly production mode.

Owner:GUANGDONG XINFENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com