Steel tube sleeves used for prefabricated shear walls and columns and fabricating method for steel tube sleeves

A technology for shear walls and steel pipe sleeves, applied to structural elements, building components, building reinforcements, etc., can solve the problems of large amount of cutting and processing of steel sleeves, affect the promotion and application of projects, and increase the cost of processing and manufacturing, and achieve improvement Anchoring effect, simple structure, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

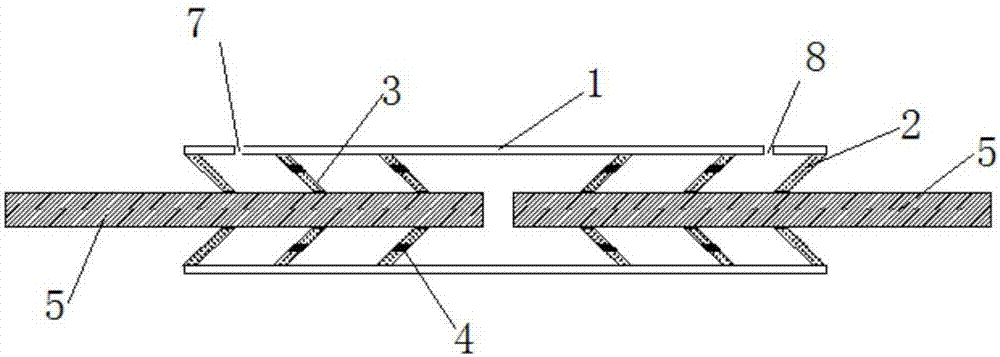

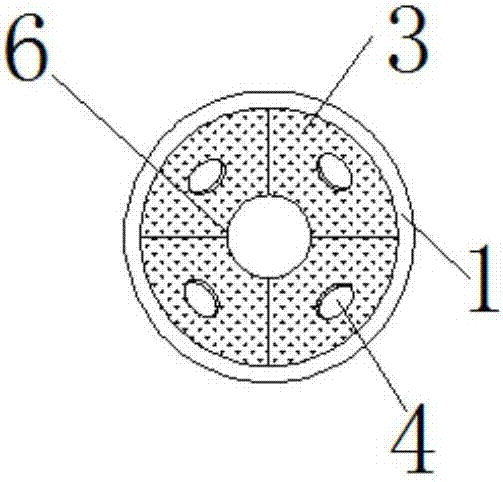

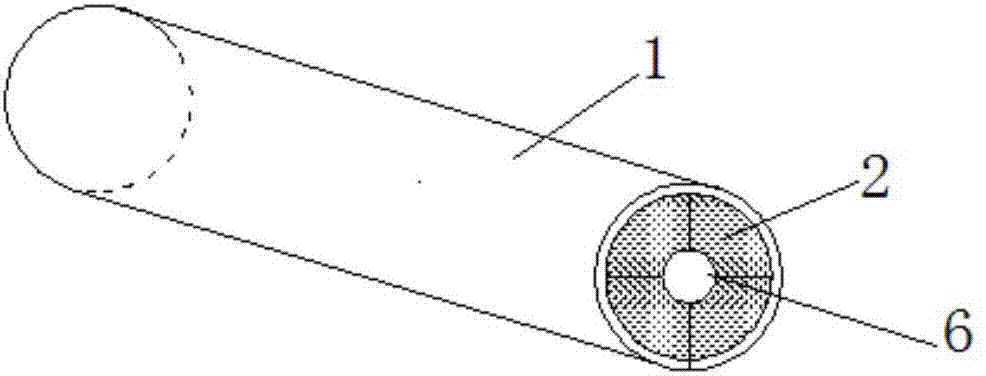

[0038] The invention provides a grouted steel pipe sleeve for the butt joint connection of stressed steel grout anchors between prefabricated components of a prefabricated concrete structure, which is made by direct casting or by the simple method described herein, which avoids the continuous rotation of the inner and outer corrugated ribs of the full grouted steel sleeve. The disadvantage of poor axial tension and compression ability also avoids the defects of large processing volume and low production efficiency of round steel cutting and processing semi-grouting sleeves with one end as a grout anchor steel bar and the other end as a straight thread connection steel bar. When in use, filling the gap with high-strength non-shrinkage cement-based grouting material can realize the grout-anchor steel bar butt connection joint that can meet the mechanical connection performance requirements of the steel bar stipulated in the national engineering code, and can be directly applied to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com