Fireflooding channeling sealing agent and preparation method thereof

A technology of fire-flooding sealing channeling agent and regulator, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of low sealing strength of foam-type water blocking agent, very sensitive curing speed to temperature, and gel particles. The problems such as the inability to inject the plugging agent to achieve the effect of adapting to a wide range of reservoir types, excellent adsorption characteristics and strong plugging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a fire flooding sealing agent. In terms of weight percentage, the raw materials for preparing the fire flooding sealing agent include:

[0027] Melamine: 0.5%;

[0028] Guaiacol: 0.2%;

[0029] Formaldehyde: 2%;

[0030] Oxalic acid: 0.5%;

[0031] Liquid XZ-LY102 for nano-alumina oily resin: 0.2%;

[0032] Ultrafine silica: 10%; average particle size 10-20nm;

[0033] The balance is oilfield sewage.

[0034] The specific preparation process is:

[0035] (1) Add melamine, guaiacol, liquid XZ-LY102 for nano-alumina oleoresin and oxalic acid into oilfield sewage above 50°C, fully stir and dissolve for 20-30min at a stirring speed of 50-200r / min, and obtain a mixture solution;

[0036] (2) Add formaldehyde (formaldehyde solution with a mass concentration of 37-40%) and ultrafine silicon dioxide to the above mixed solution in sequence, and continue stirring for 30 minutes to obtain a fire flooding sealing agent.

Embodiment 2

[0038] This embodiment provides a fire flooding sealing agent. In terms of weight percentage, the raw materials for preparing the fire flooding sealing agent include:

[0039] Benzomelamine: 3%;

[0040] Methylguaiacol: 1%;

[0041] Formaldehyde: 8%;

[0042] Glacial acetic acid: 2%;

[0043] Liquid XZ-LY102 for nano-alumina oily resin: 1.2%;

[0044] Ultrafine silica: 20%; average particle size 10-20nm;

[0045] The balance is oilfield sewage.

[0046] The specific preparation process is:

[0047] (1) Add benzomelamine, methylguaiacol, liquid XZ-LY102 for nano-alumina oleoresin and glacial acetic acid to the oilfield sewage above 50°C, fully stir and dissolve for 20-30min, and the stirring speed is 50-200r / min, to obtain a mixed solution;

[0048] (2) Add formaldehyde (formaldehyde solution with a mass concentration of 37-40%) and ultrafine silicon dioxide to the above mixed solution in sequence, and continue stirring for 30 minutes to obtain a fire flooding sealing a...

Embodiment 3

[0054] This embodiment provides a fire flooding sealing agent. In terms of mass percentage, the raw materials for preparing the fire flooding sealing agent include:

[0055] Melamine: 2%;

[0056] Eugenol: 0.5%;

[0057] Herotropine: 4%;

[0058] Oxalic acid: 1%;

[0059] Liquid XZ-LY102 for nano-alumina oleoresin: 0.6%;

[0060] Ultrafine silica: 15%; average particle size 10-20nm;

[0061] The balance is oilfield sewage.

[0062] The specific preparation process is:

[0063] (1) Add melamine, eugenol, liquid XZ-LY102 for nano-alumina oleoresin, and oxalic acid to oilfield sewage above 50°C, fully stir and dissolve for 20-30min, and the stirring speed is 50-200r / min to obtain a mixed solution;

[0064] (2) Add urotropine and superfine silicon dioxide to the above mixed solution in sequence, and continue stirring for 30 minutes to obtain a fire flooding sealing agent.

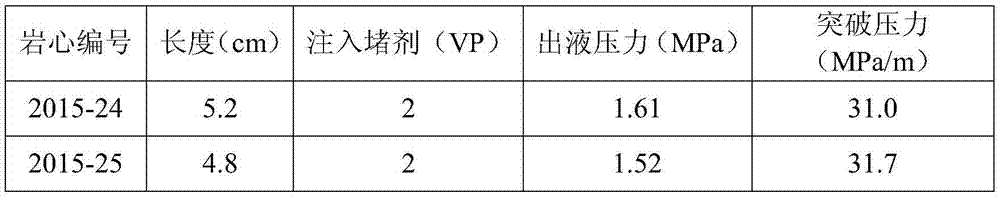

[0065] The fire flooding channeling agent prepared above was subjected to a core single-pipe simulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com