Patents

Literature

1534 results about "Gel forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

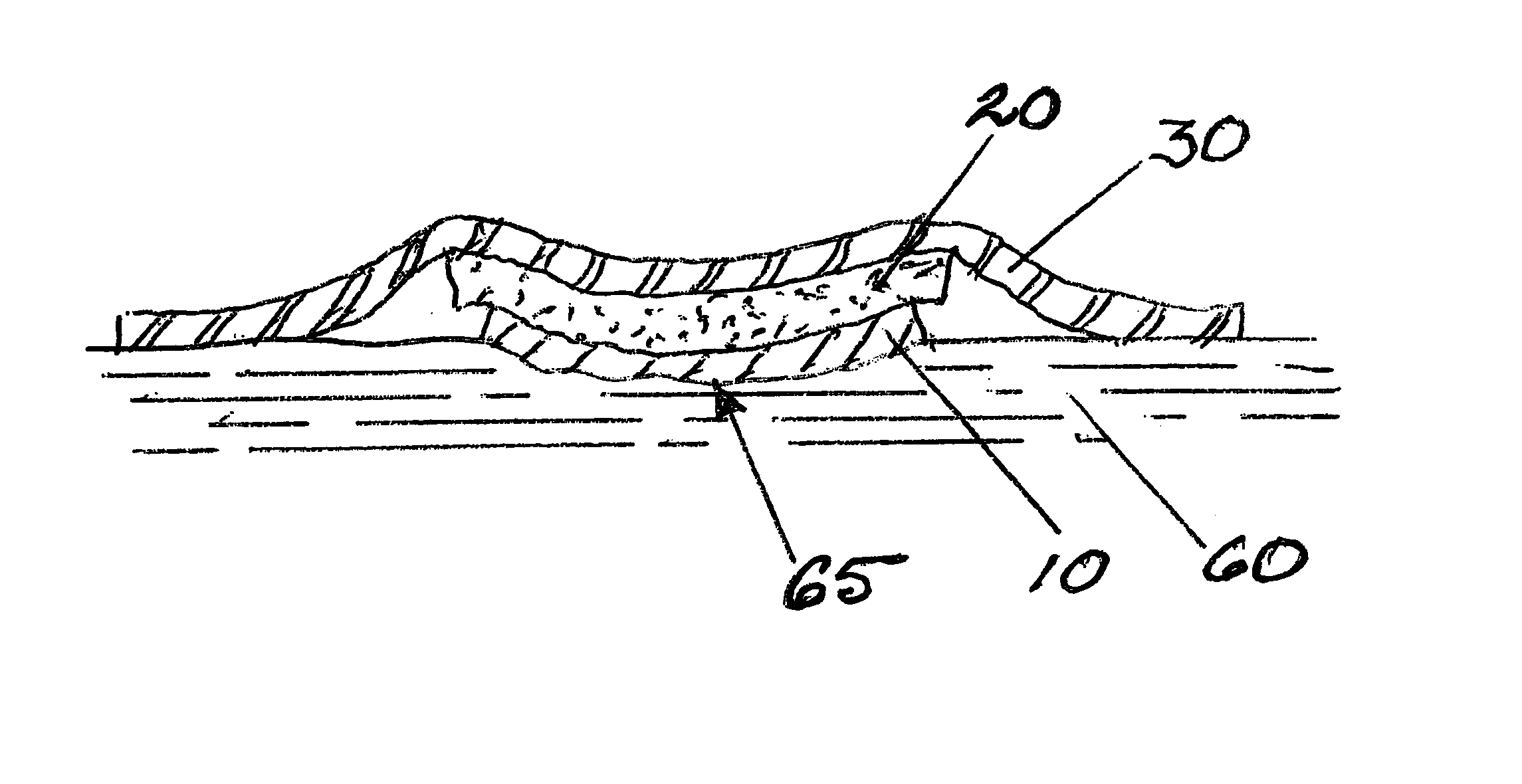

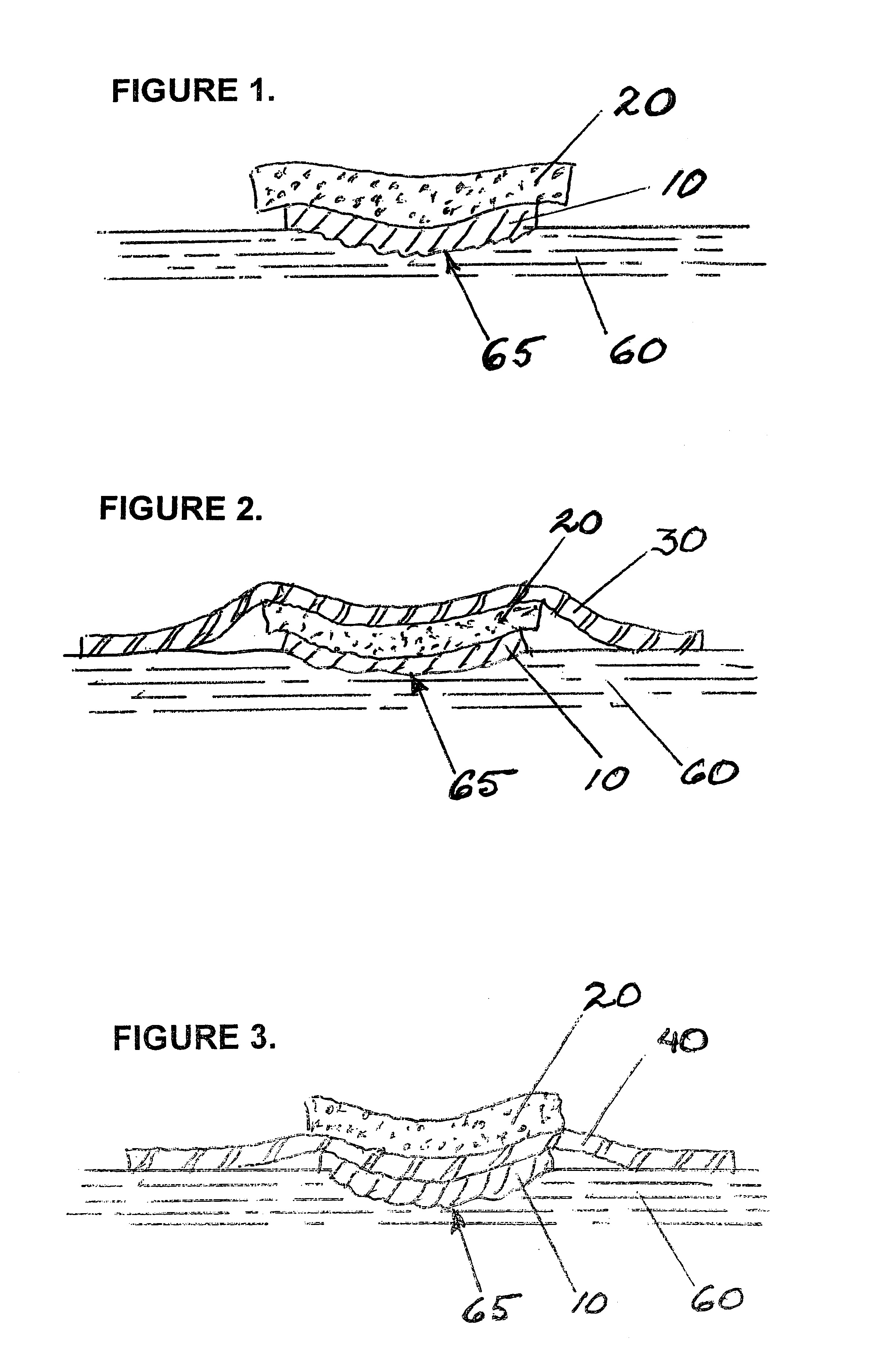

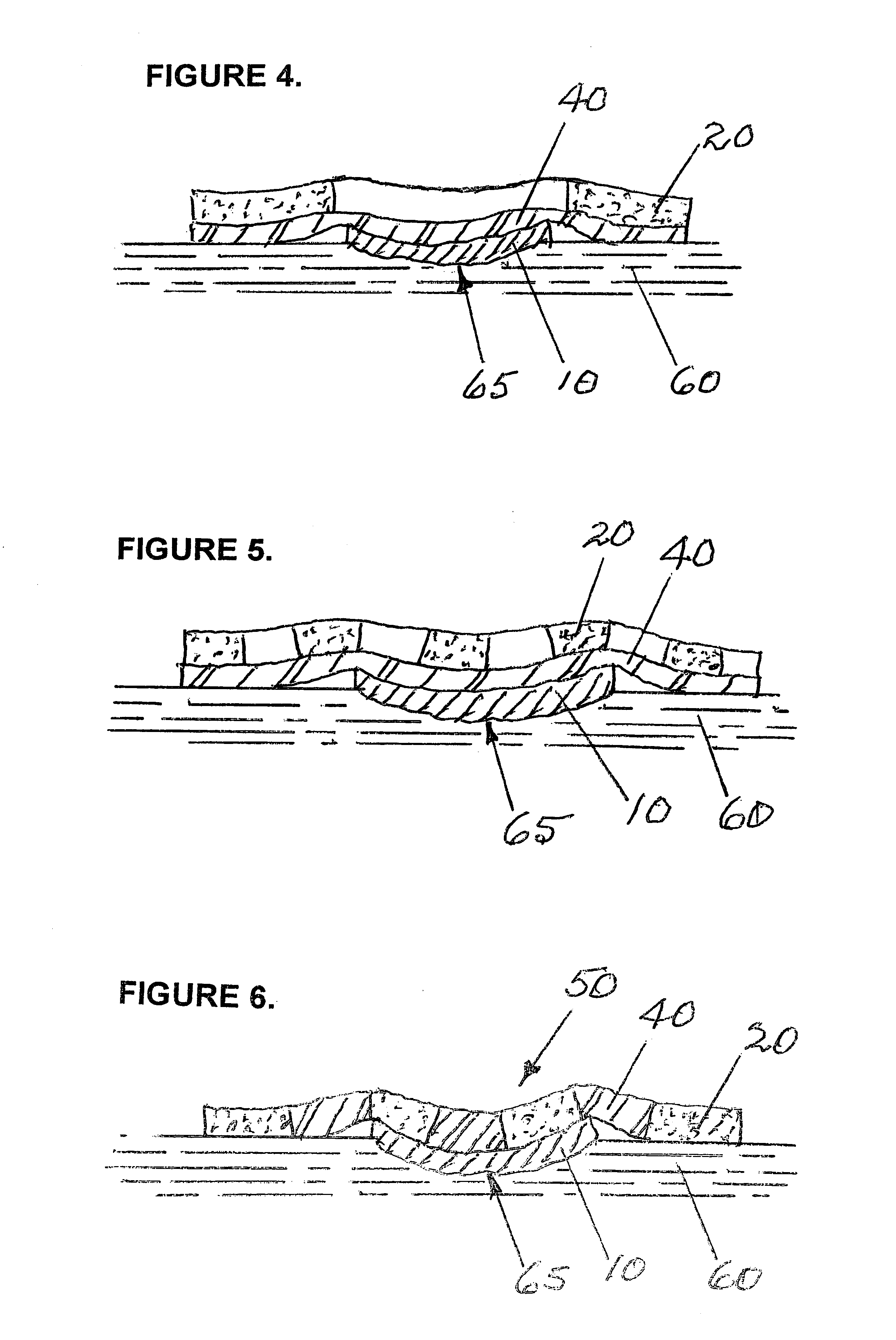

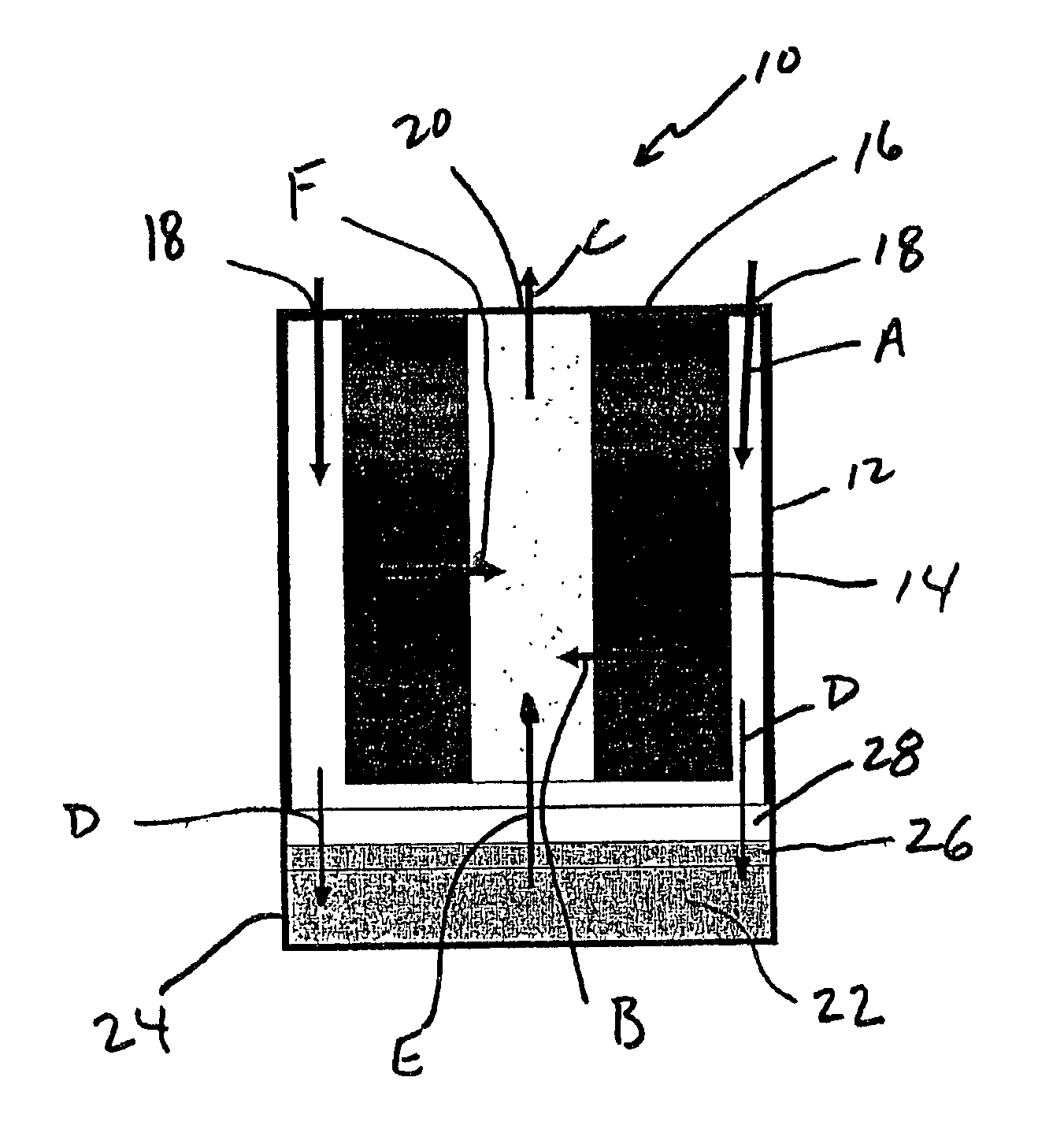

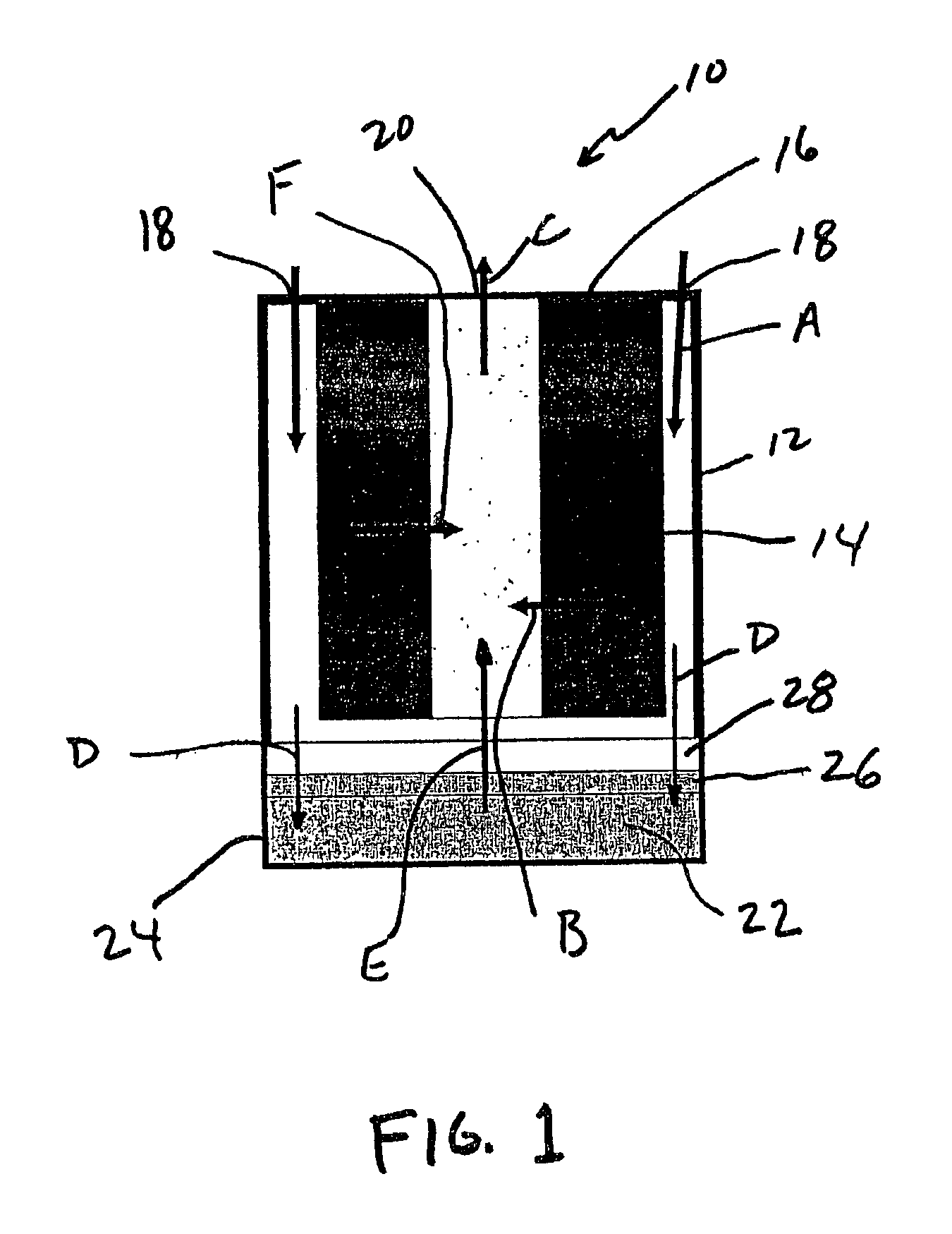

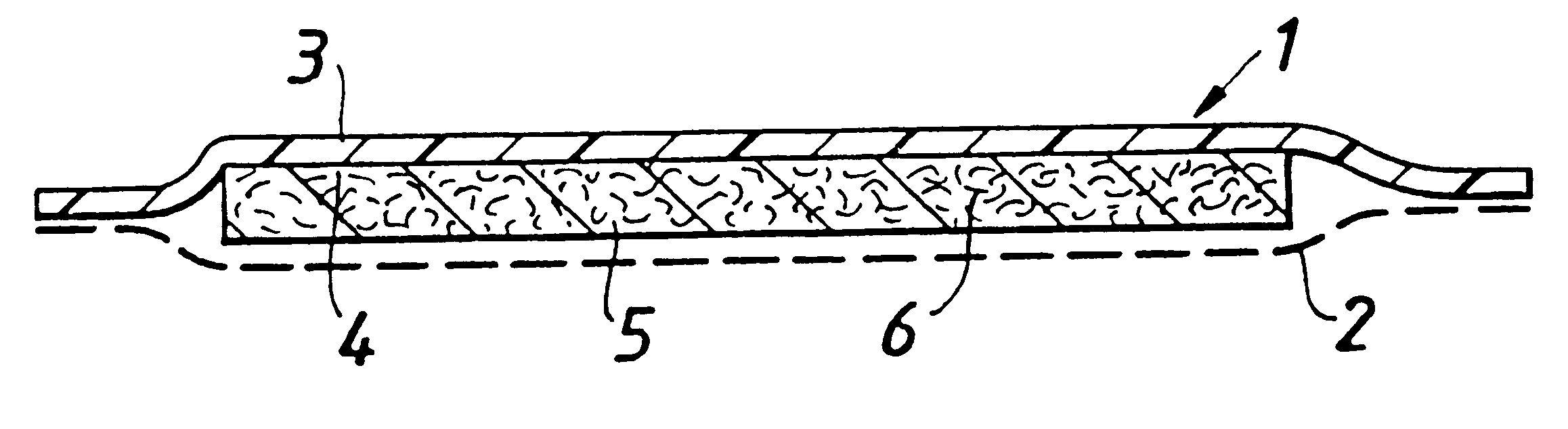

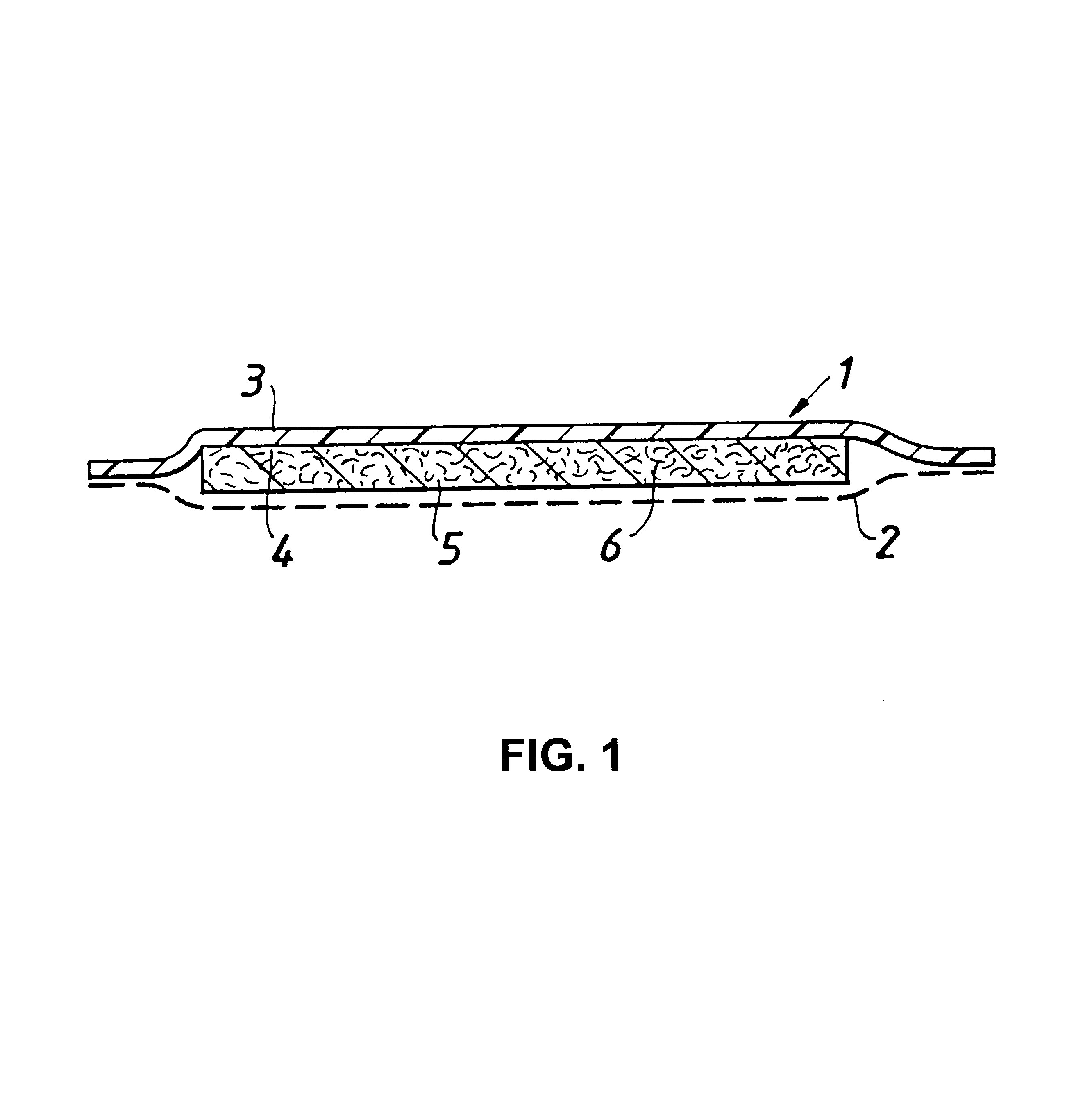

Bioabsorbable wound dressing

ActiveUS7041868B2Promote wound healingEasy to useAdhesive dressingsNon-surgical orthopedic devicesCell adhesionAdhesion process

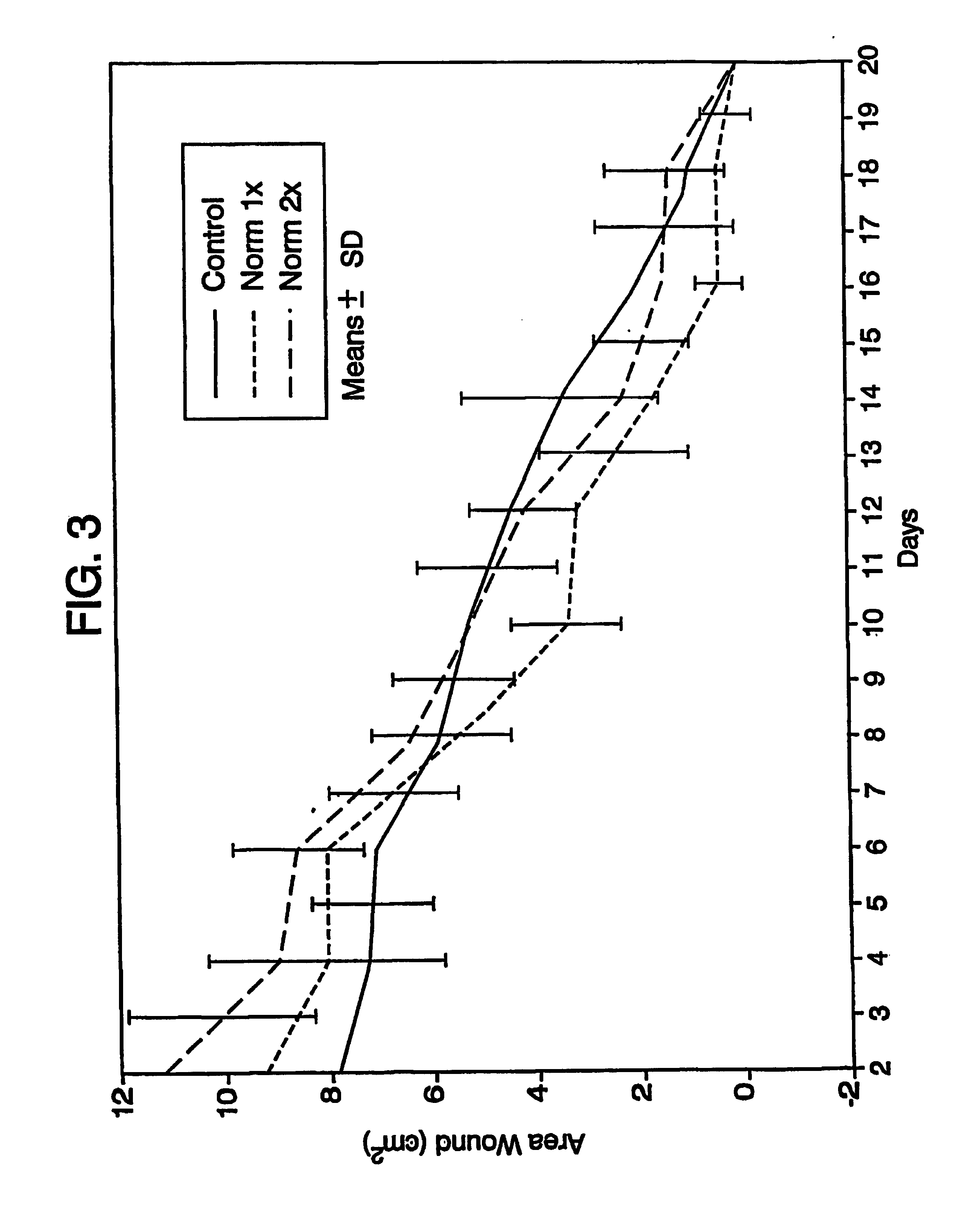

A wound dressing includes a first layer located adjacent the wound and which comprises a material that is bioabsorbable, porous and adapted for serving as a scaffold for cell attachment and proliferation; and a second layer which is in contact with the first layer and which comprises an absorbent, gel forming material adapted for serving as a barrier to cell adhesion and penetration. A method of treating a wound with the dressing is also disclosed.

Owner:AVENT INC

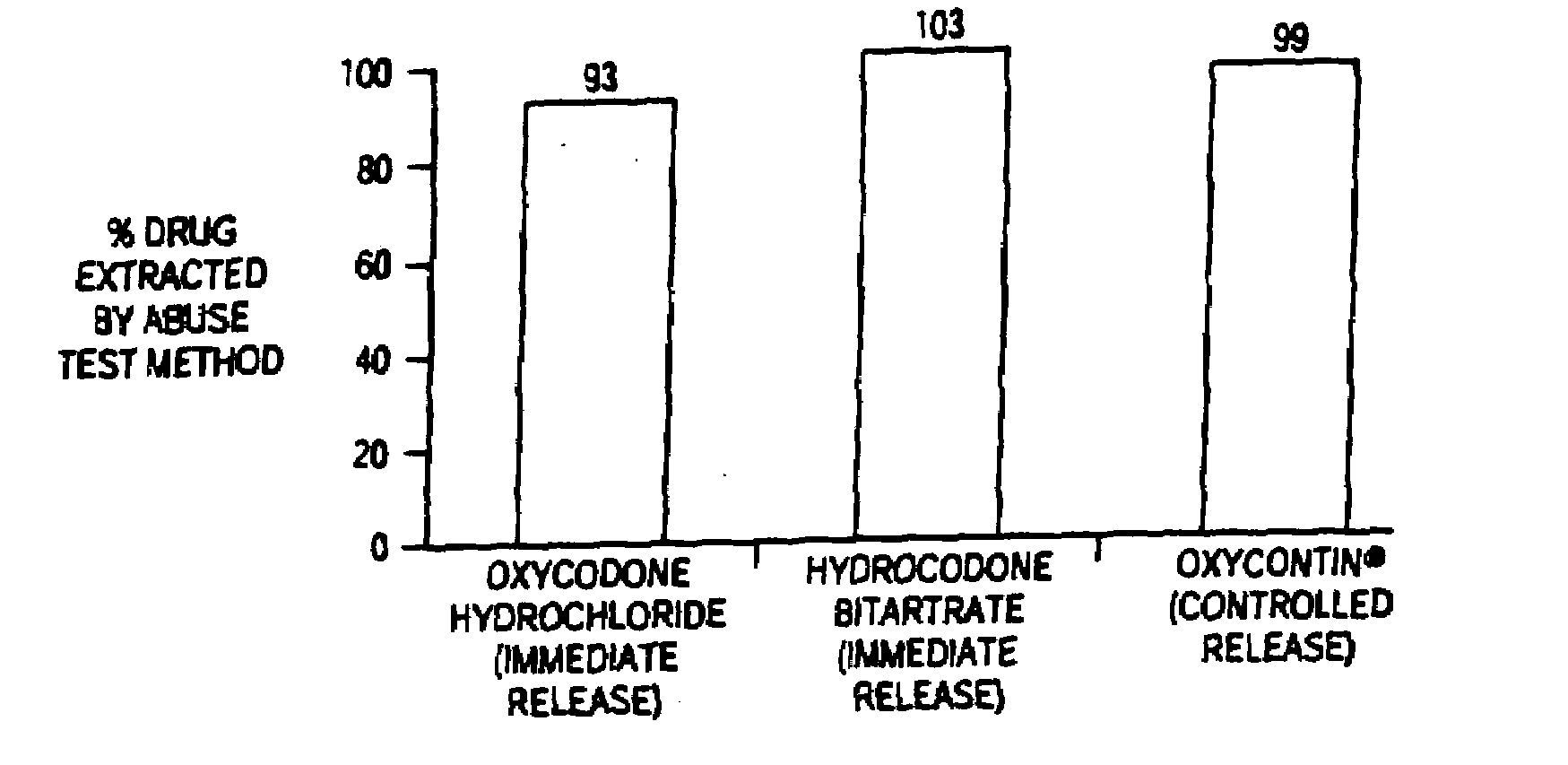

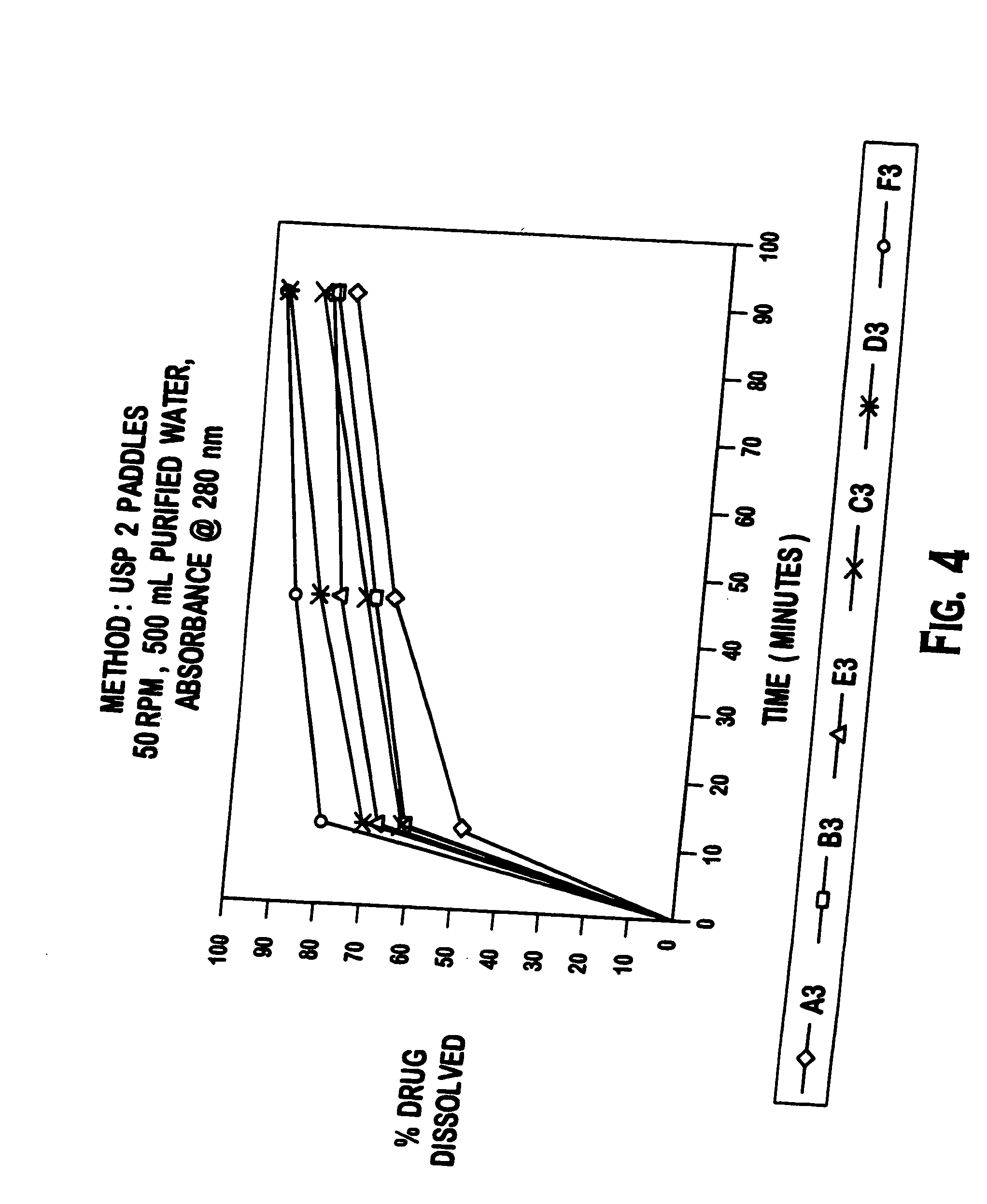

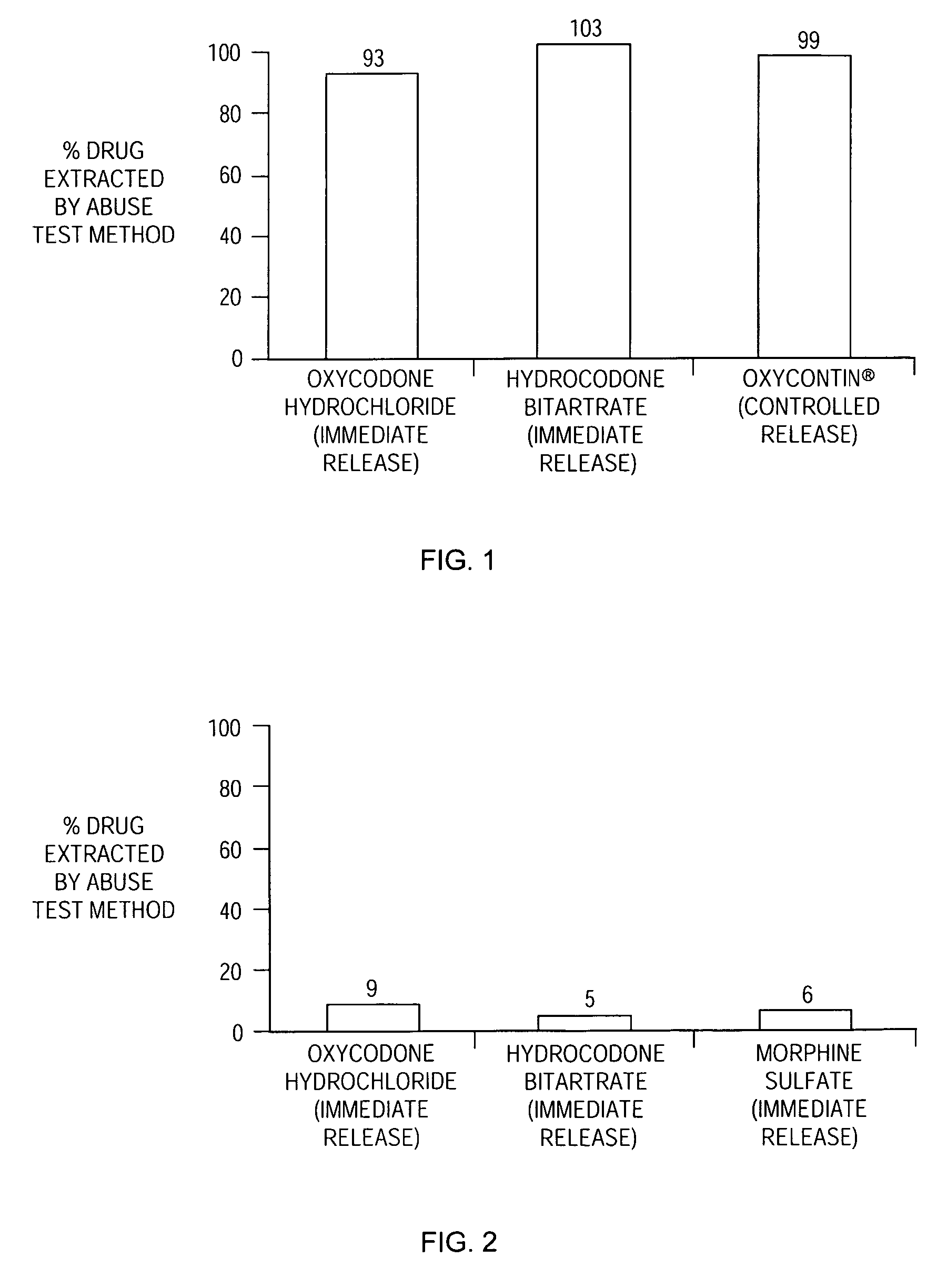

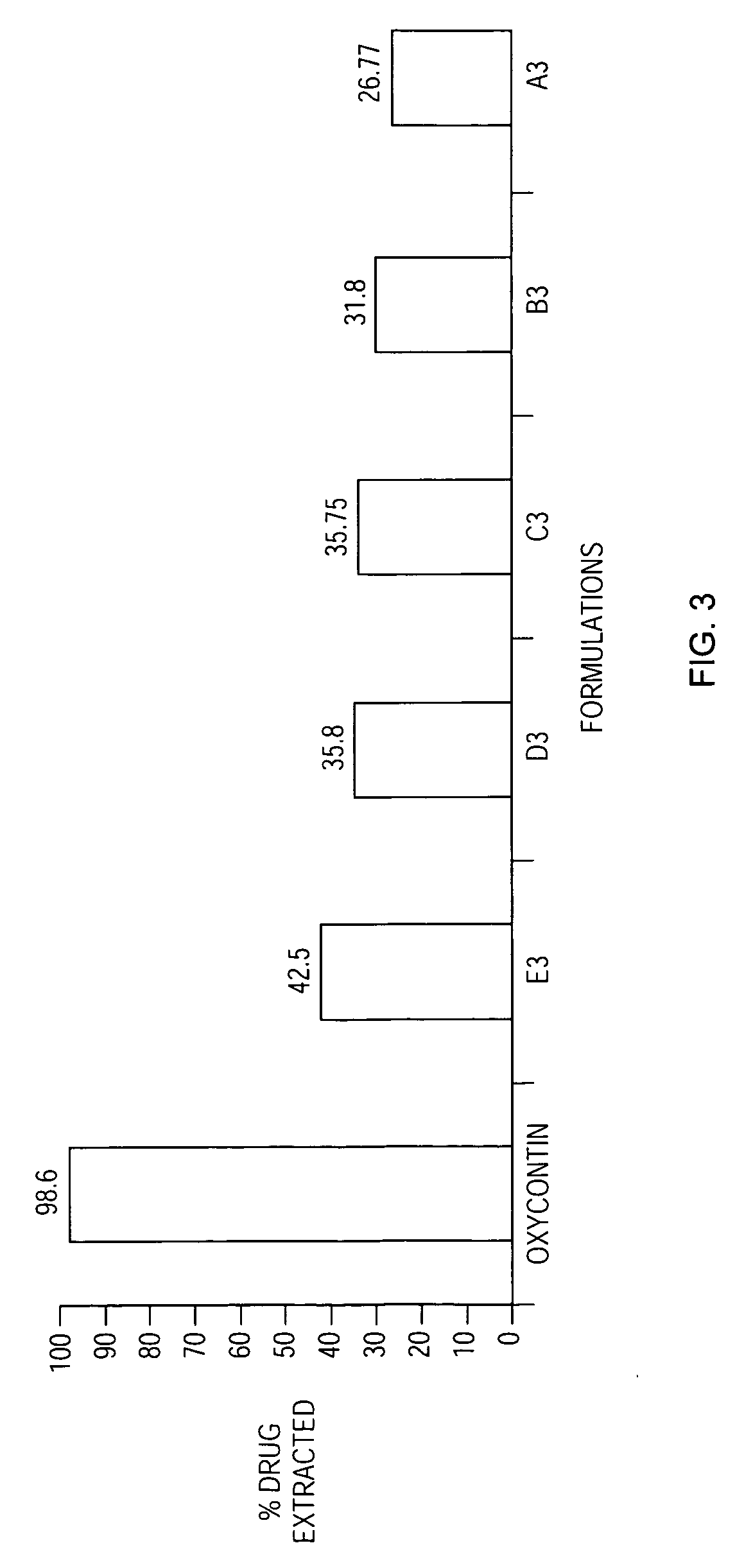

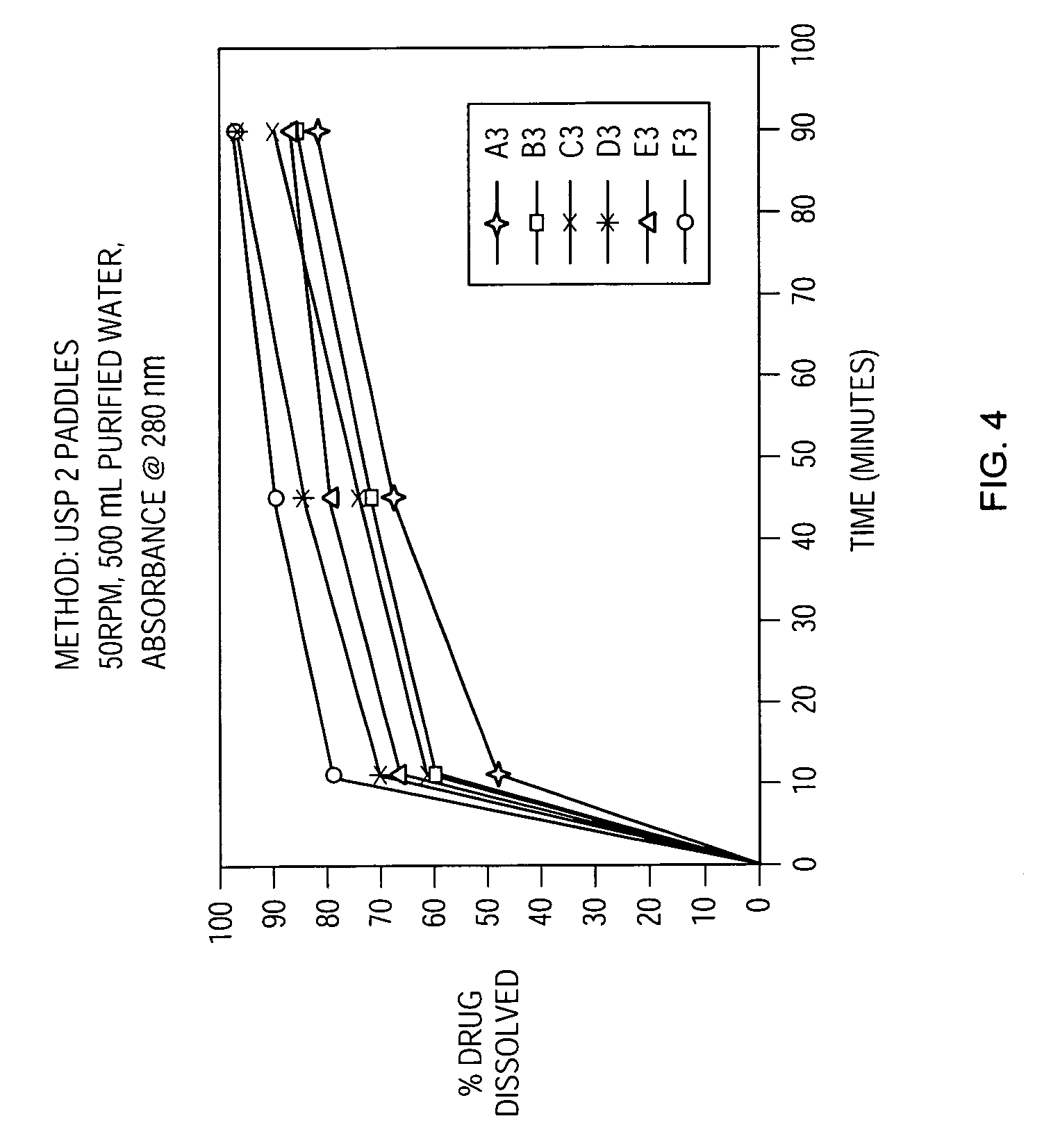

Methods and compositions for deterring abuse of orally administered pharmaceutical products

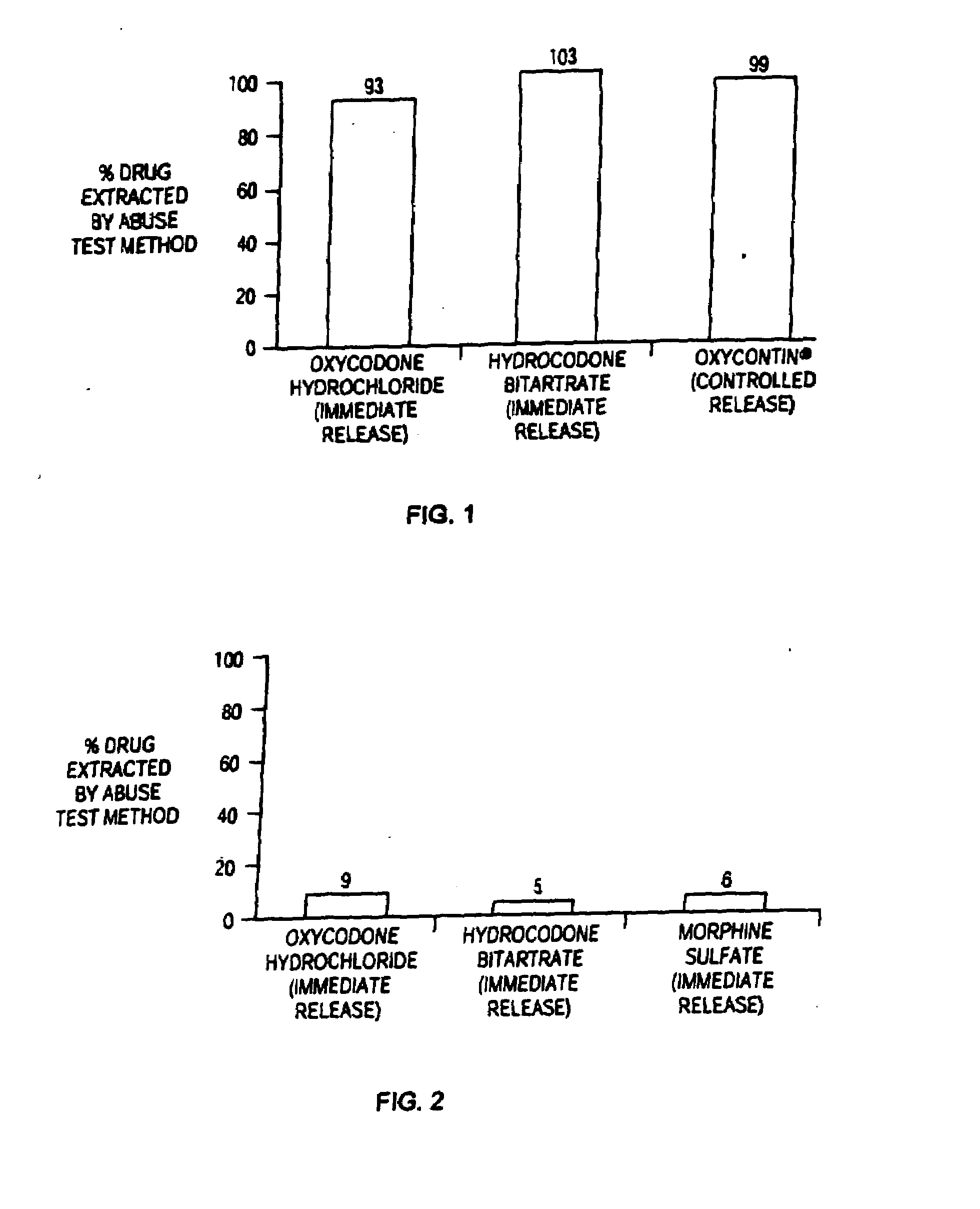

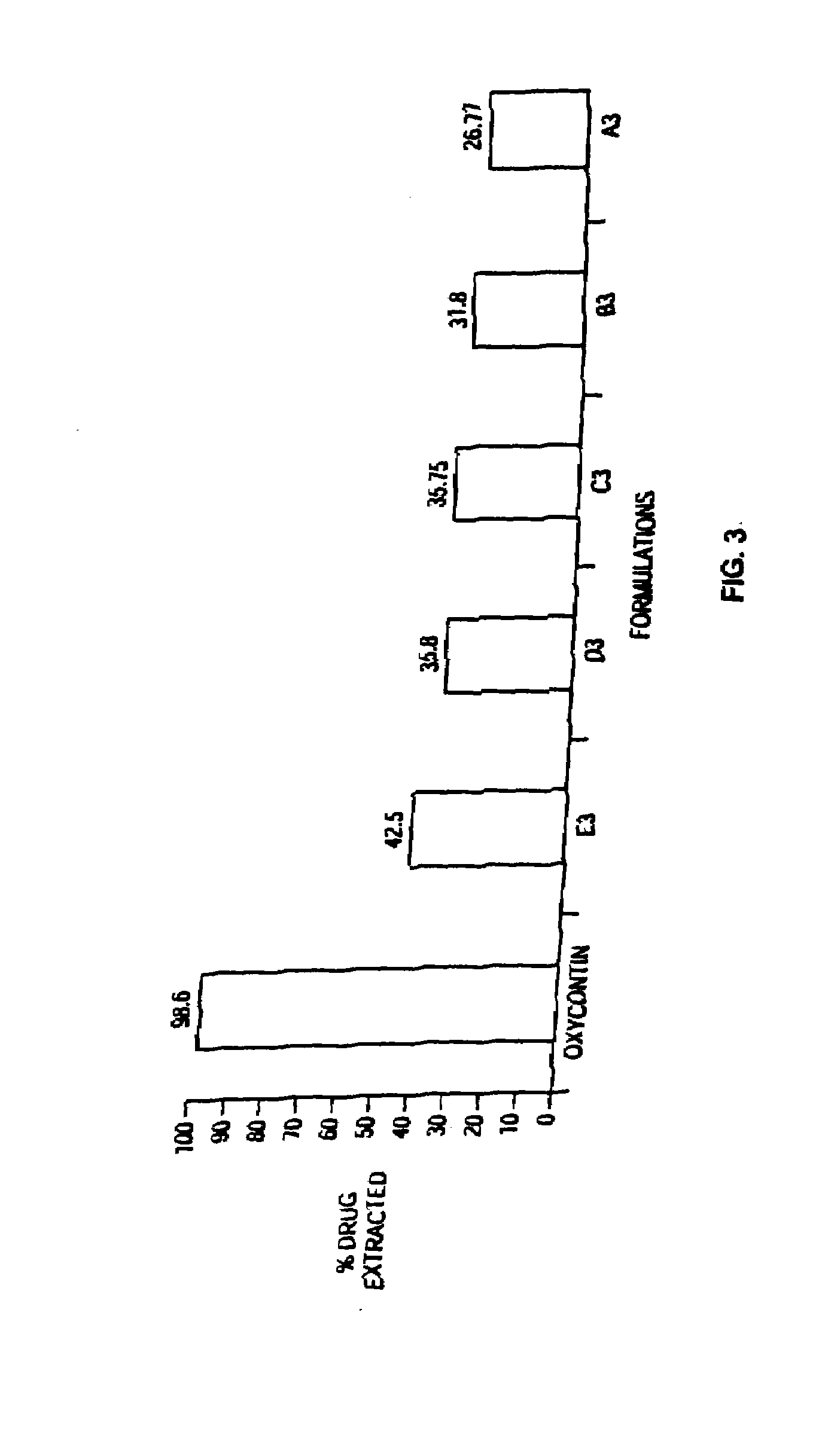

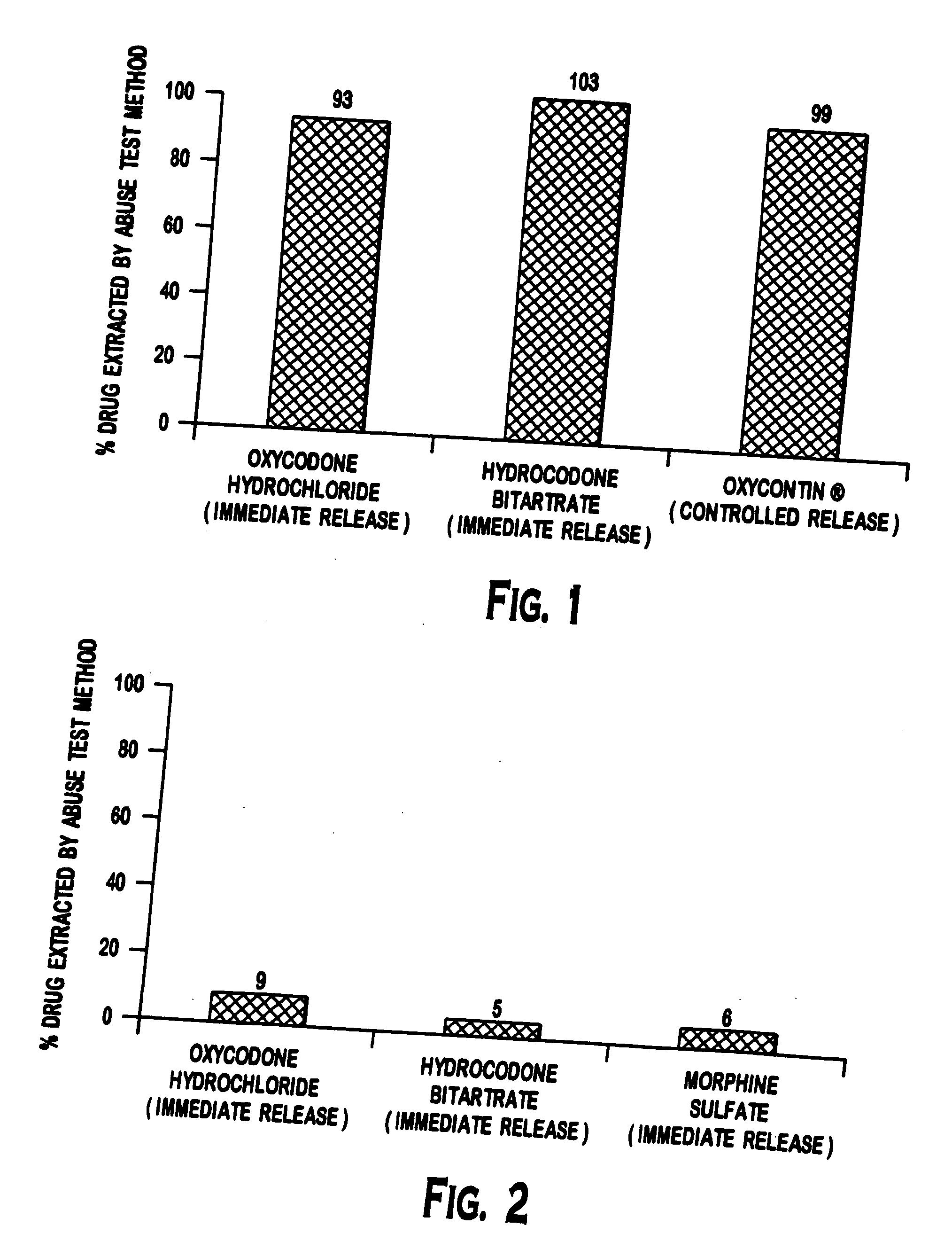

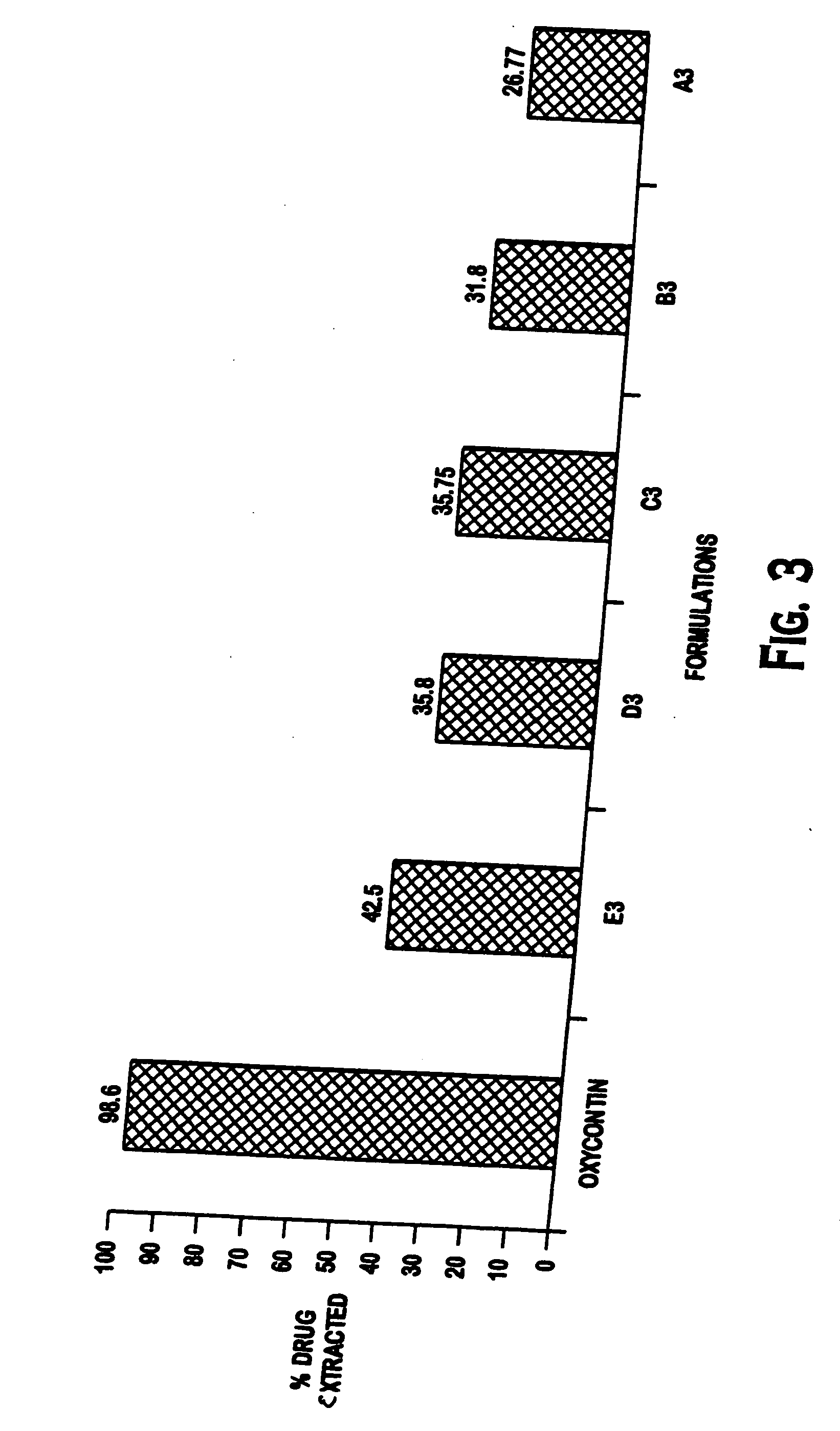

This invention relates to an abuse deterrent formulation of an oral dosage form of a therapeutically effective amount of any active drug substance that can be subject to abuse combined with a gel forming polymer, a nasal mucosal irritating surfactant and a flushing agent. Such a dosage form is intended to deter abuse of the active drug substance via injection, nasal inhalation or consumption of quantities of the dosage unit exceeding the usual therapeutically effective dose.

Owner:ACURA PHARMA

Methods and compositions for deterring abuse of orally administered pharmaceutical products

This invention relates to an abuse deterrent formulation of an oral dosage form of a therapeutically effective amount of any active drug substance that can be subject to abuse combined with a gel forming polymer, a nasal mucosal irritating surfactant and a flushing agent. Such a dosage form is intended to deter abuse of the active drug substance via injection, nasal inhalation or consumption of quantities of the dosage unit exceeding the usual therapeutically effective dose.

Owner:ACURA PHARMA

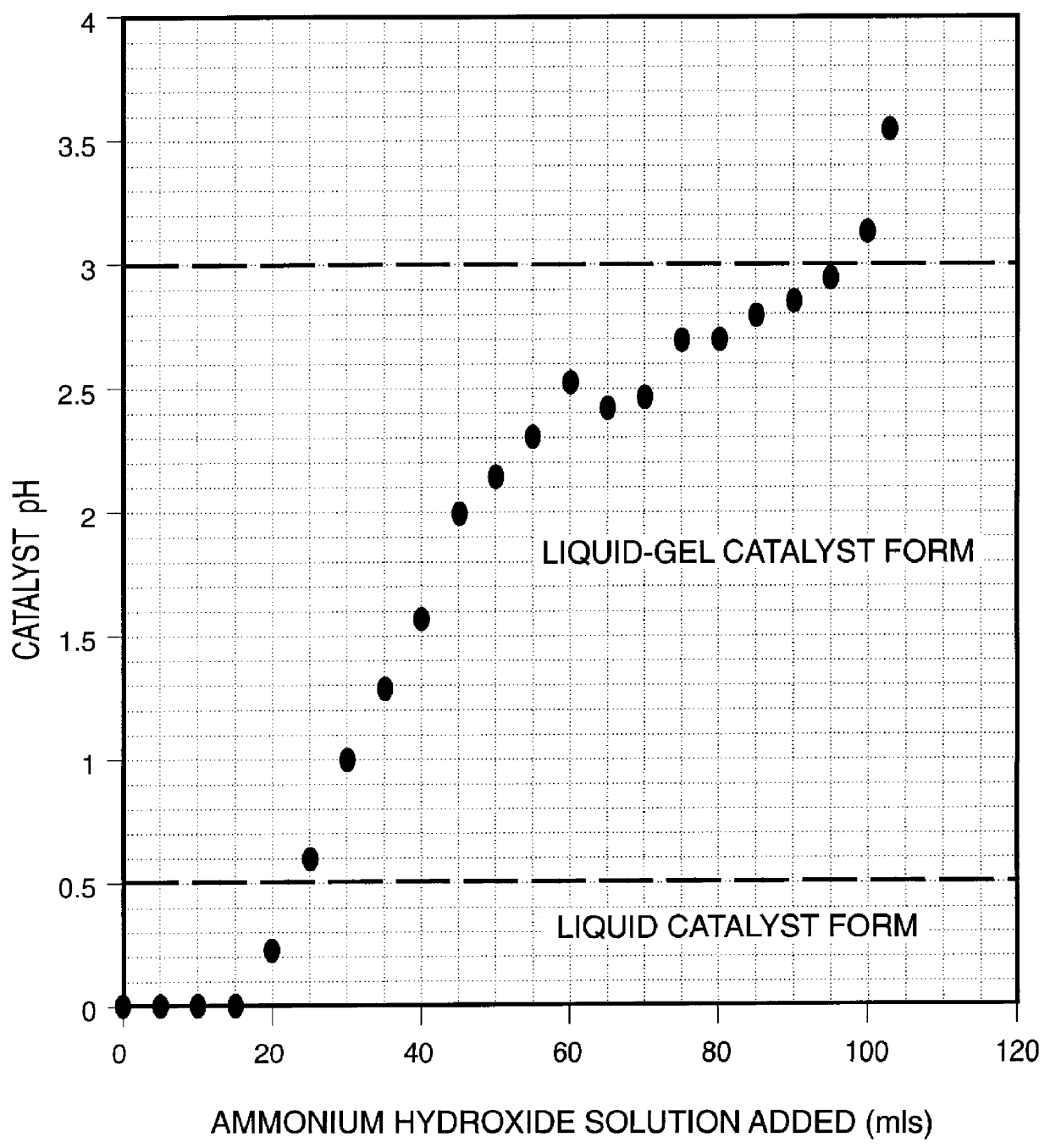

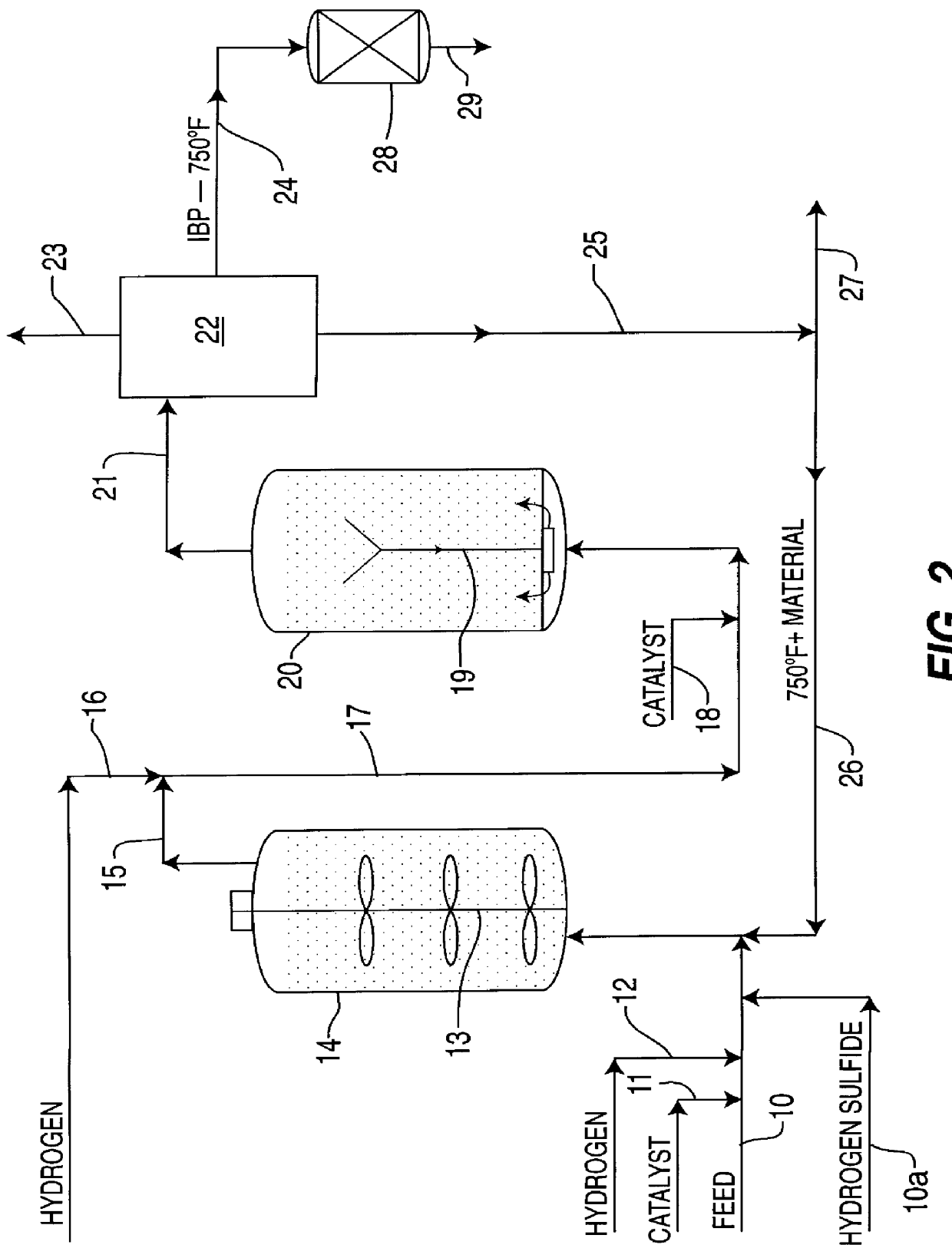

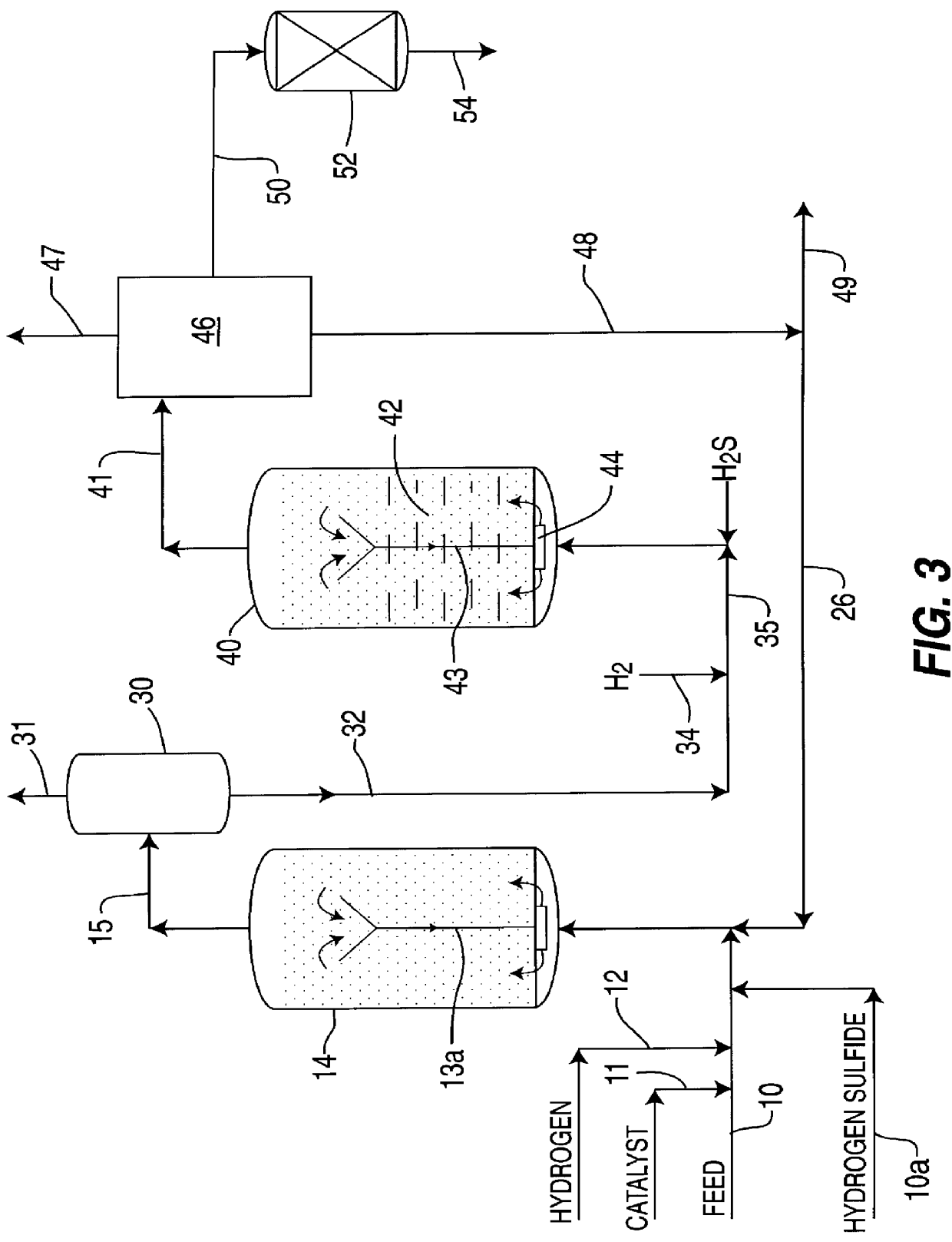

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

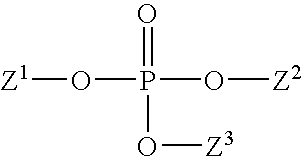

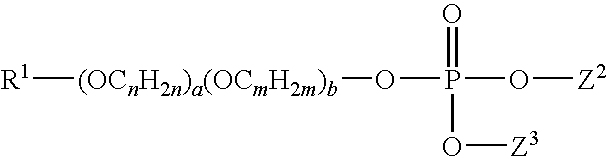

Slow release lubricant additives gel

A lubricant additive gel formed by the gellation of two or more lubricant additives for the slow release of the additive components into a fluid. The lubricant additive gel slowly releases into its component lubricant additives when contacted with the fluid such as an oil thereby serving as a lubricant fluid such as an oil thereby.

Owner:THE LUBRIZOL CORP

Methods and compositions for deterring abuse of orally administered pharmaceutical products

This invention relates to an abuse deterrent formulation of an oral dosage form of a therapeutically effective amount of any active drug substance that can be subject to abuse combined with a gel forming polymer, a nasal mucosal irritating surfactant and a flushing agent. Such a dosage form is intended to deter abuse of the active drug substance via injection, nasal inhalation or consumption of quantities of the dosage unit exceeding the usual therapeutically effective dose.

Owner:ACURA PHARMA

Composition and method for topical treatment of tar-responsive dermatological disorders

InactiveUS20070207222A1Reduced and no stickinessReduced and no and stainingAntibacterial agentsBiocideWaxDermatological disorders

The present invention relates to a composition including a wax and a therapeutically effective amount of tar for topical treatment of a tar-responsive dermatological disorder, the composition being in liquid or light gel form when at a temperature selected from room temperature and a temperature of skin of a mammal upon application of the composition to the skin of the mammal. The invention also relates to a method of treating a tar-responsive dermatological disorder by topically applying the composition to skin of a mammal, preferably a human, that is involved with the disorder.

Owner:TRISTRATA TECH

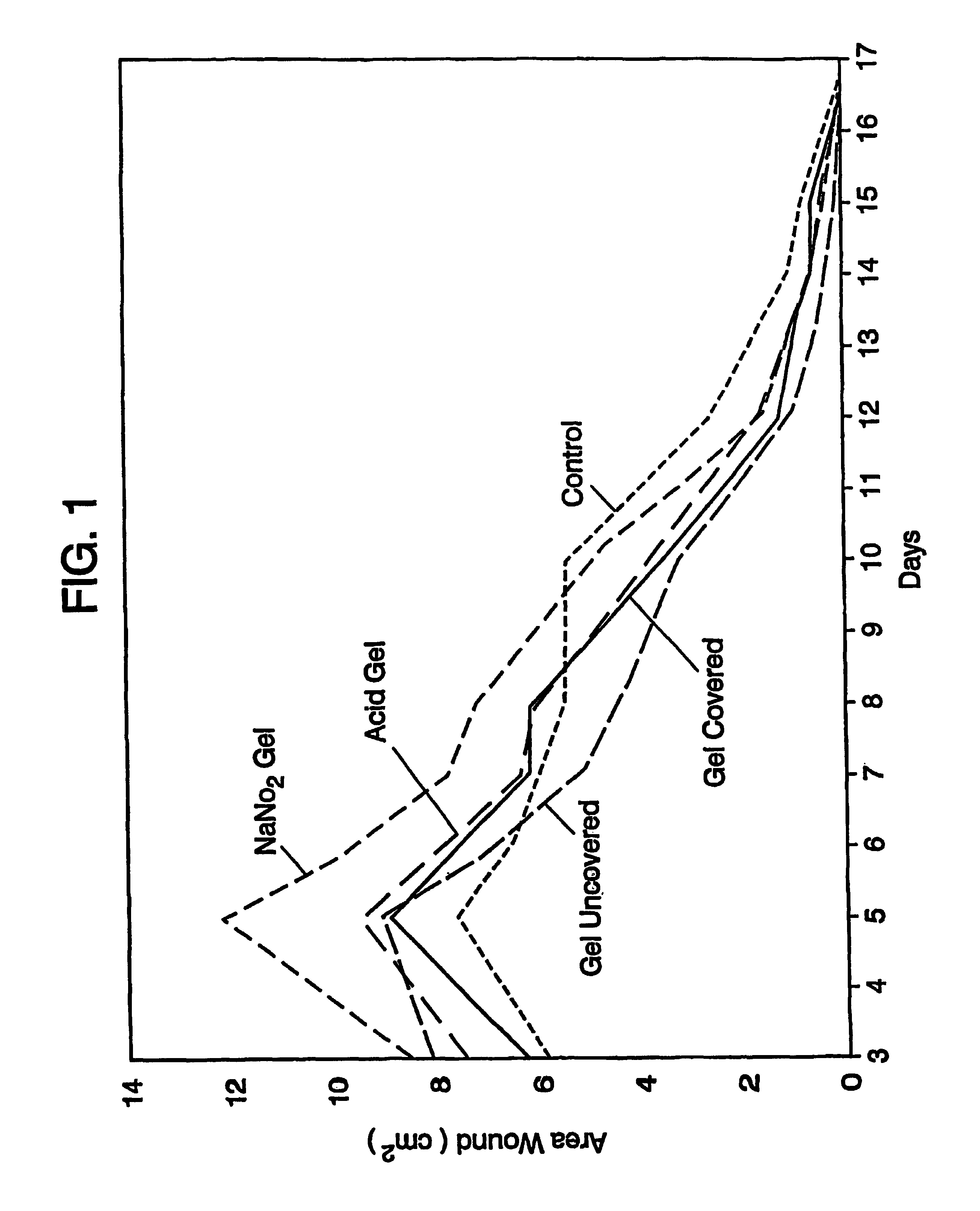

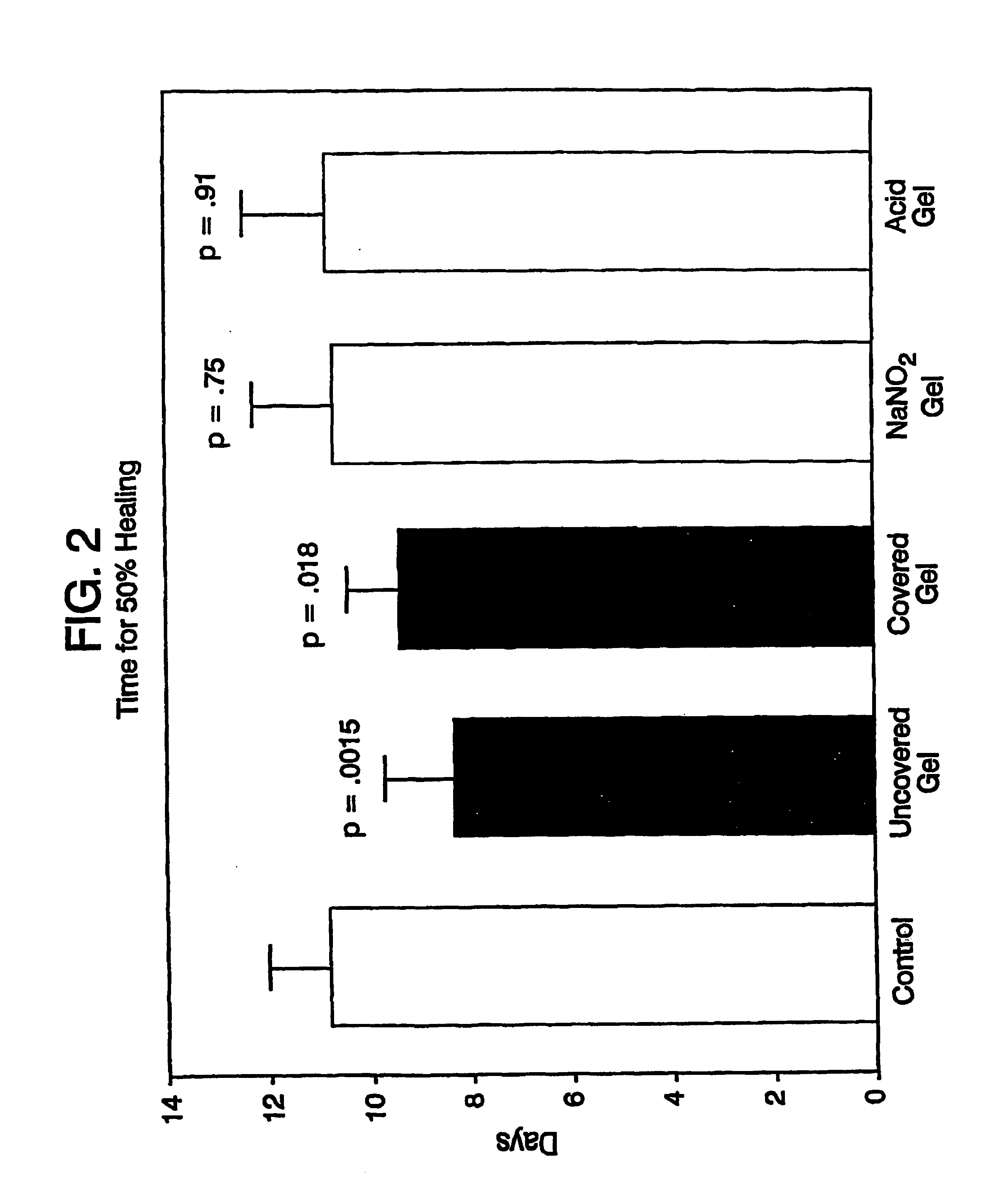

Systems and methods for topical treatment with nitric oxide

InactiveUS7048951B1Reduce skin irritationBiocideInorganic active ingredientsSandwich likeTransdermal patch

A simple, biocompatible system and procedure for generating nitric oxide (NO) is described. A mixture of powdered sodium nitrite, ascorbic acid, and maleic acid (or another organic acid of adequate strength) immediately generates nitric oxide (NO) on treatment with water. To slow down the NO generation, one may prepare an ointment from a nonaqueous medium (petrolatum, Vaseline™) and the three powdered ingredients, which on being applied topically on the skin will release NO as water permeates through this medium; alternatively, one may convert the aqueous sodium nitrite solution into a gel with hydroxyethylcellulose (or other gel-forming compound) and combine this gel with another gel obtained from aqueous ascorbic and maleic acids with hydroxyethylcellulose for topical application (on intact skin, burns intra-cavity, burns, intra-cavity, etc.). The two gels may be admixed immediately before use (possibly from a single container with separate chambers and dual nozzle, via pushing or squeezing the two gels through the nozzle), or may be applied in sandwich-like fashion (possibly as a transdermal patch) for further slowing down the delivery of NO.

Owner:NITRIC SOLUTIONS

Metal-containing composite materials

InactiveUS20060167147A1Robust processingStable materialPowder deliveryInorganic active ingredientsMetallic materialsMaterials science

The present invention relates to a process for the manufacture of metal-containing materials or composite materials, the process comprising the steps of encapsulating at least one metal-based compound in a polymeric shell, thereby producing a polymer-encapsulated metal-based compound and / or coating a polymeric particle with at least one metal-based compound; forming a sol from suitable hydrolytic or non-hydrolytic sol / gel forming components; combining the polymer-encapsulated metal-based compound and / or the coated polymeric particle with the sol, thereby producing a combination thereof; and converting the combination into a solid metal-containing material. The present invention further relates to metal-containing materials produced in accordance with the above process.

Owner:CINVENTION AG

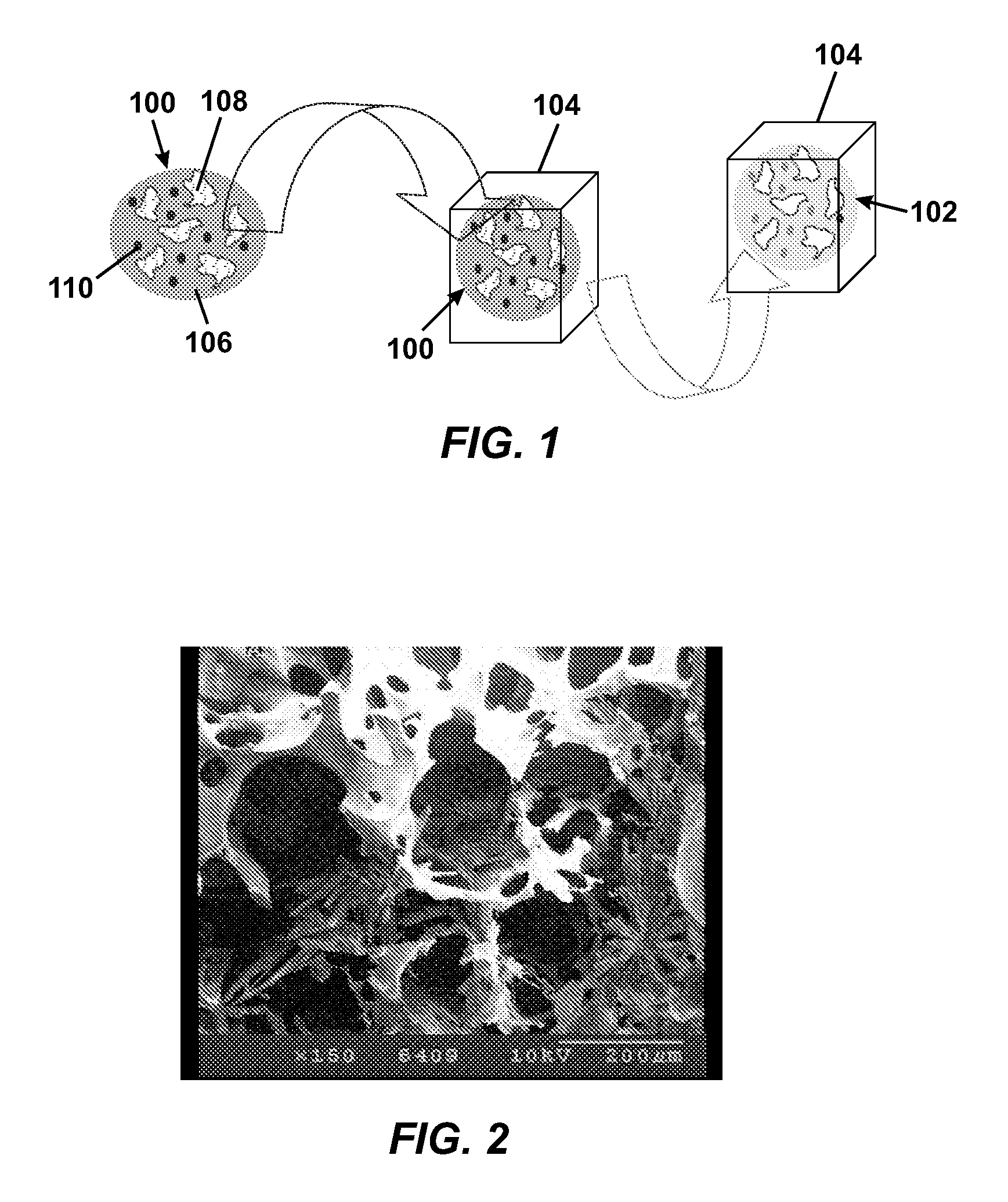

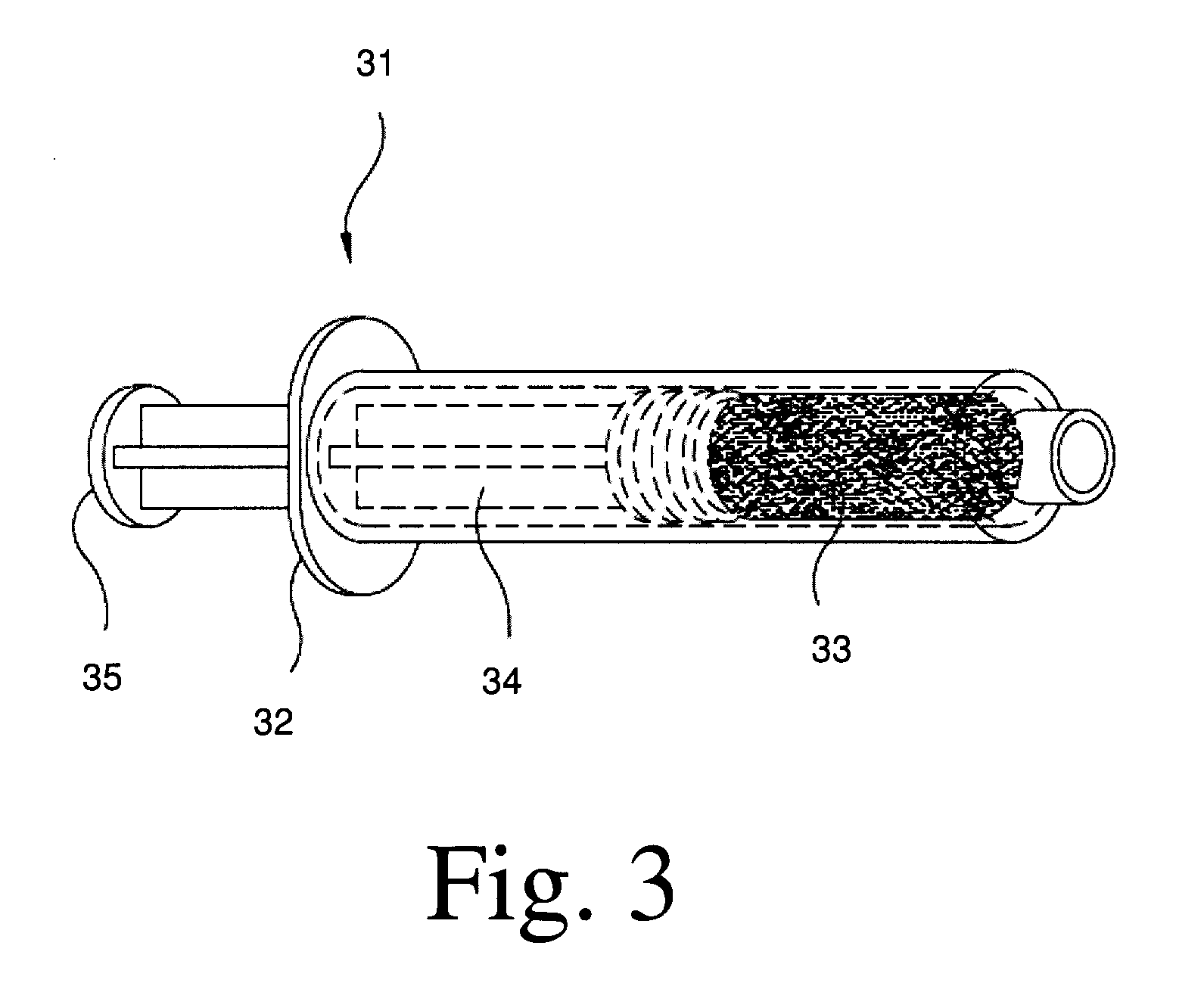

In-Situ Forming Porous Scaffold

A composition includes a viscous gel formed from a combination of a biodegradable polymer and a biocompatible solvent. The composition also includes a hydrophilic porogen, which may be incorporated in the viscous gel. The composition may form a porous scaffold in situ.

Owner:ALZA CORP

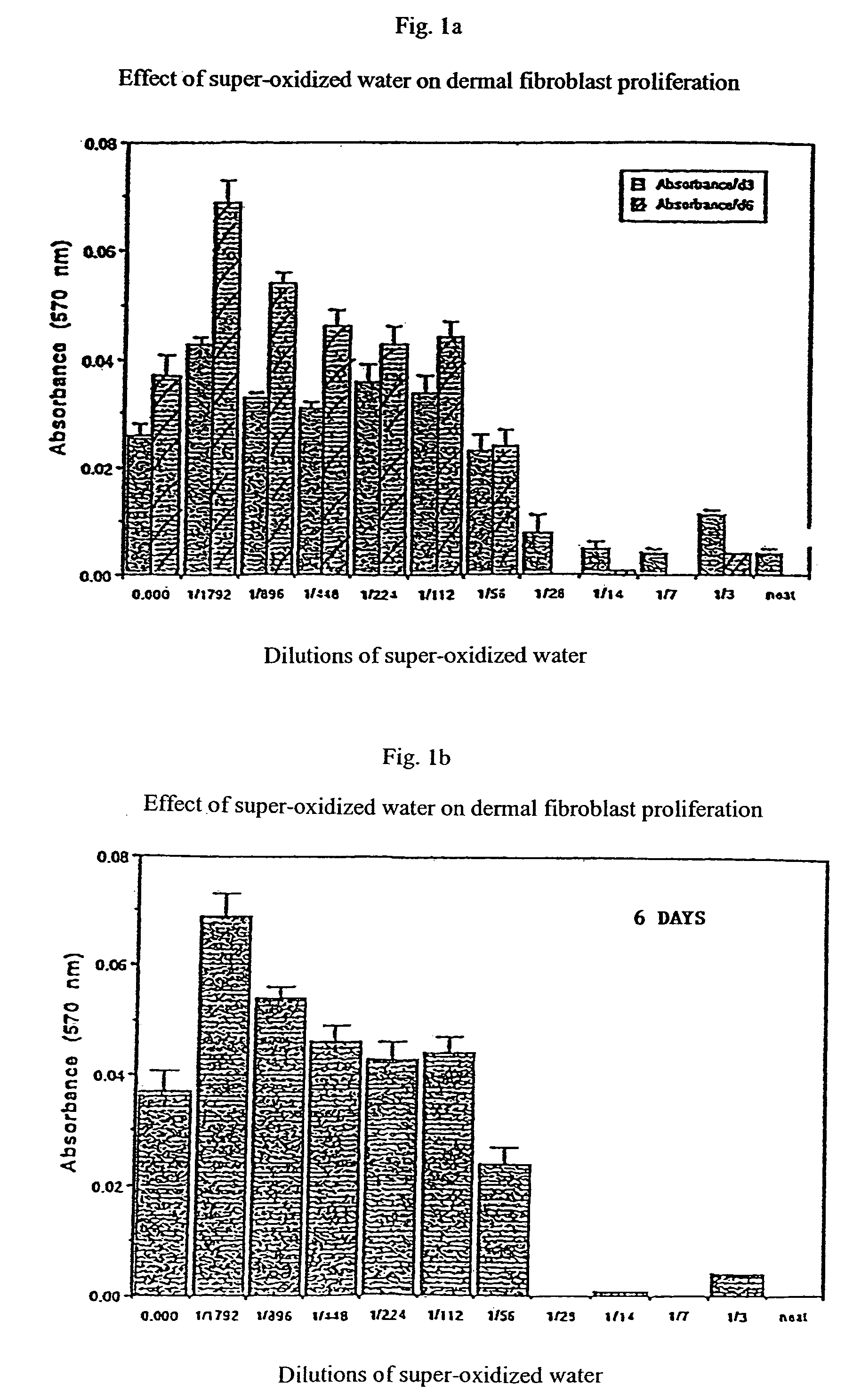

Wound and ulcer treatment with super-oxidized water

Super-oxidized water based on hypochlorous acid, such as is obtained by the electrochemical treatment of a saline solution, may be used in the treatment of leg ulcers or other open wounds. Preferably, the pH of the super-oxidized water is in a range of 4 to 7, and the water has a redox potential of >950 mV. Medicaments based on the super-oxidized water may be in liquid or gel form. The super-oxidized water is able to control the microbial population within the wound and at the same time permit cell proliferation.

Owner:STERILOX TECH INT +1

Abuse-resistant transdermal system

InactiveUS20070065365A1Complicates and preventsImprove solubilityOrganic active ingredientsIn-vivo testing preparationsAversive agentBULK ACTIVE INGREDIENT

An abuse-resistant transdermal system which contains, in addition to one or more active ingredients with potential for abuse, at least one gel-forming agent in quantities such that it forms a gel with a minimum quantity of an aqueous liquid, and contains as further agents which complicate or prevent abuse at least one emetic, and / or at least one dye as an aversive agent.

Owner:GRUNENTHAL GMBH

Storable water-microsphere suspensions for use in well cements and methods

Storable water-microsphere suspensions for use in well cements and methods of cementing well bores are provided. The storable water-microsphere suspensions are basically comprised of water, microspheres and an effective amount of a suspending agent selected from the group consisting of microfine or colloidal materials and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

Dressings

A wound dressing is provided which is made up of a backing layer, an apertured wound facing layer and an intermediate absorbent layer comprising fibers of material which upon contact with moisture will form a gel. The intermediate layer also includes a non-gel forming component, e.g., another fibrous material which can support the formed gels. The backing layer also has a water transmission rate which is greater than its moisture vapor transmission rate.

Owner:SMITH & NEPHEW INC

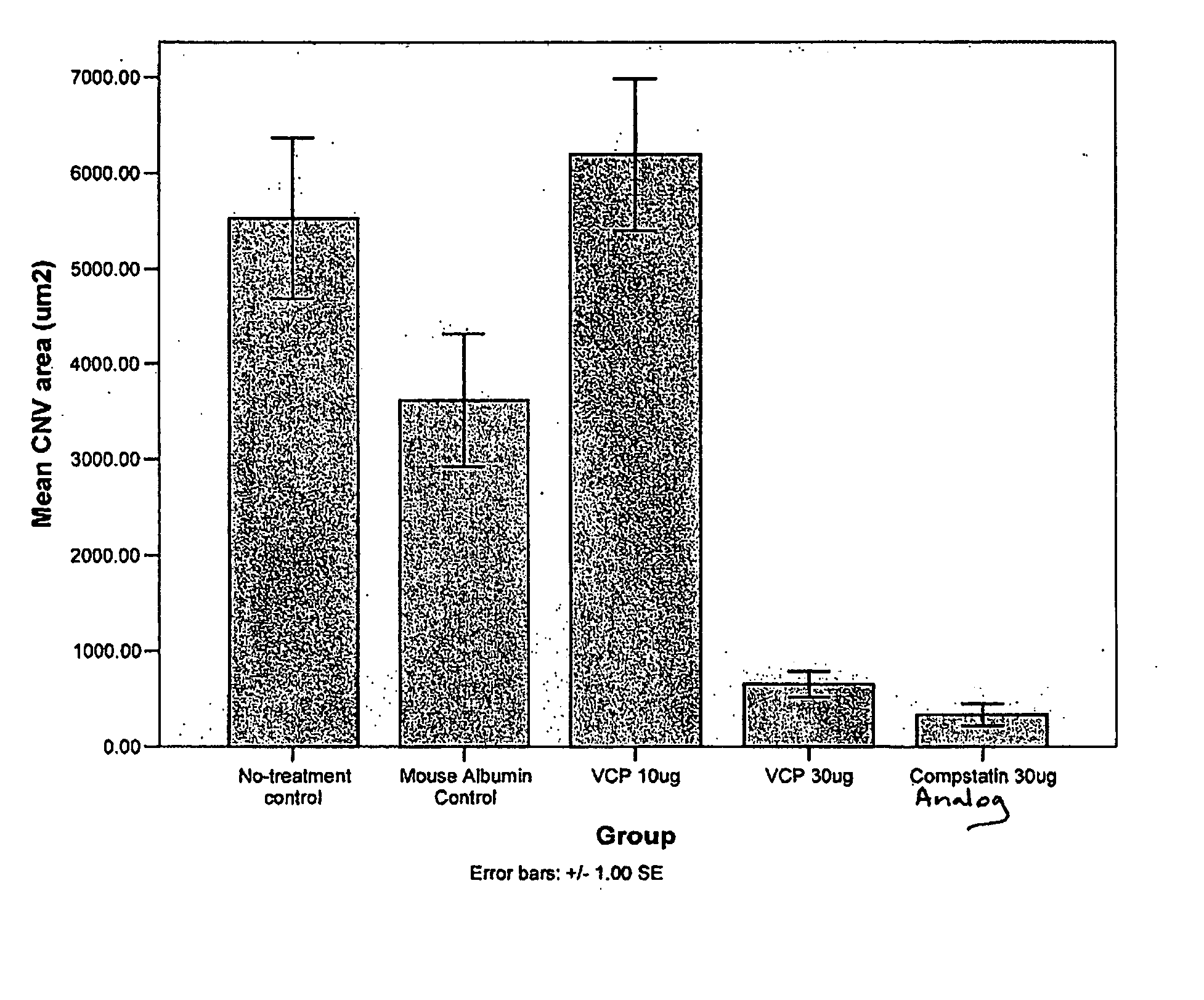

Compstatin and analogs thereof for eye disorders

ActiveUS20070238654A1Inhibit expressionImprove in vivo stabilityCompounds screening/testingOrganic active ingredientsDiseaseRetinal neovascularization

The present invention features the use of compstatin and complement inhibiting analogs thereof for treating and / or preventing age related macular degeneration and other conditions involving macular degeneration, choroidal neovascularization, and / or retinal neovascularization. The invention also provides compositions comprising compstatin or a complement inhibiting analog thereof and a second therapeutic agent. The invention also provides compositions comprising compstatin or a complement inhibiting analog thereof and a gel-forming material, e.g., soluble collagen, and methods of administering the compositions.

Owner:APELLIS PHARMA

Malleable multi-component implants and materials therefor

ActiveUS20090246244A1High viscosityEfficiently formedPeptide/protein ingredientsSkeletal disorderFiberMedicine

Described are implantable, malleable medical materials comprising mineral particles, insoluble collagen fibers, and a gel-forming polysaccharide component and / or another added gel-former. The malleable medical materials can be used treat bone or other tissue defects in patients, including in conjunction with biologically active factors such as osteogenic proteins. Also described are methods and materials that can be used to prepare the malleable medical materials.

Owner:WARSAW ORTHOPEDIC INC

Artificial tear replacement solution

InactiveUS7001607B1Reduce wearGood film formingHalogenated hydrocarbon active ingredientsSenses disorderConjunctivaConjunctival sac

A tear replacement solution that contains at least one water-soluble fluorosurfactant, water and a non-polar component, preferably in gel form, and a method for the external treatment for the eye of an mammal by applying the tear replacement solution to the eye, preferably by placing in the conjunctival sac.

Owner:PHARMPUR

Oral Care Compositions

InactiveUS20090269287A1Prevent significant water lossGood dispersionCosmetic preparationsToilet preparationsCarrageenanRelative humidity

Disclosed are oral care compositions, particularly thickened dentifrices in liquid, paste or gel form comprising a binding / thickening system that also function effectively as humectant agent thereby replacing a significant portion or all of traditional humectant components such as glycerin, sorbitol and other polyols. The binding / thickening system comprise select carrageenans that provide a water viscosity of at least about 20 mPa·s in a 1.5% solution at 25° C. and effective water-binding capacity to prevent significant water loss from the composition when exposed to air to cause unacceptable drying out. For example, the water-binding capacity of the carrageenan must be effective such that there is no more than about 0.75% water loss from a dentifrice composition when exposed to air for 30 minutes at room temperature conditions and 50% relative humidity. The present dentifrice compositions exhibit increased dispersibility in saliva during use, which provides for increased contact time of the composition with the user's teeth and oral cavity tissues such that the active dental agents contained therein are more rapidly available to effect their beneficial activity.

Owner:THE PROCTER & GAMBLE COMPANY

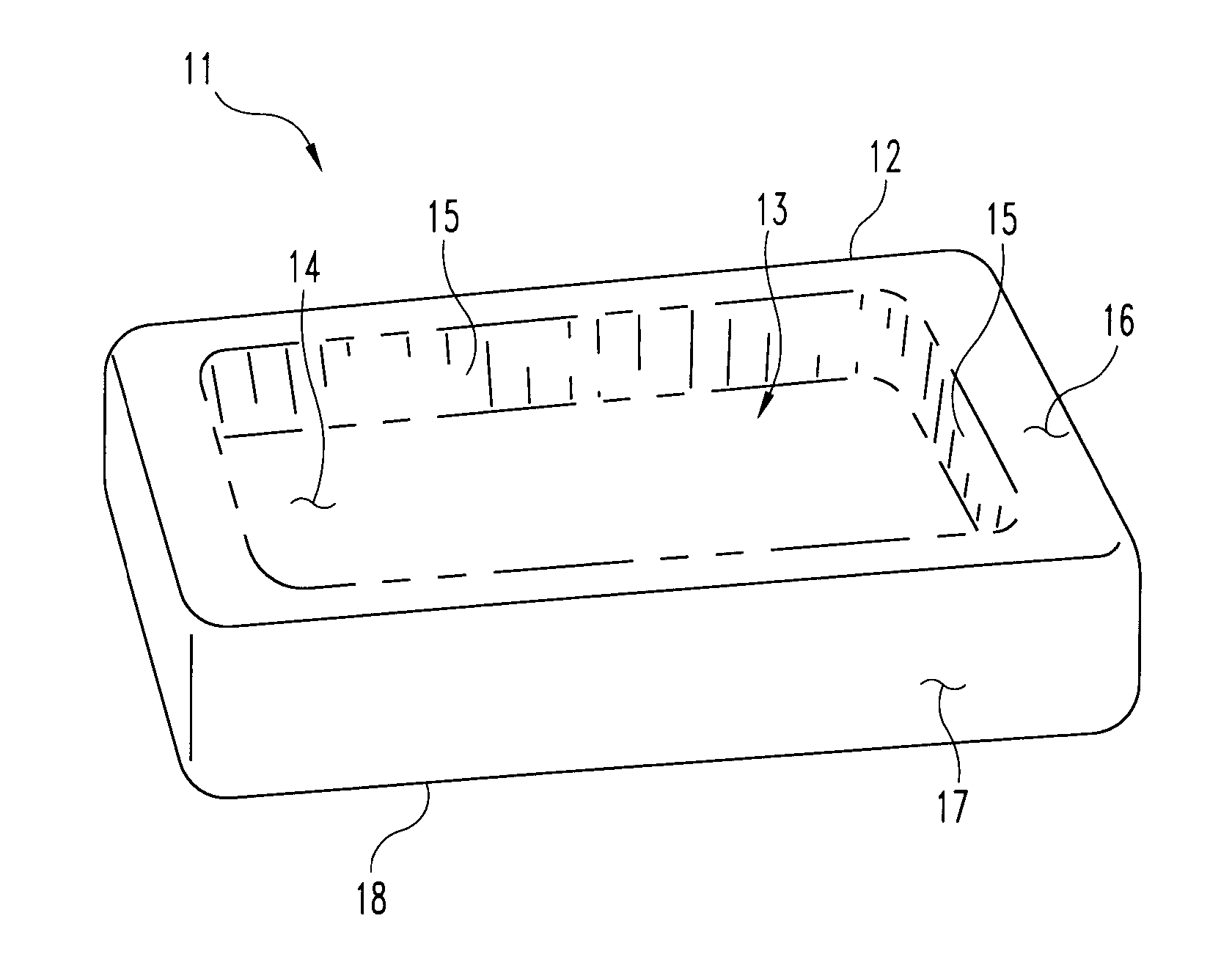

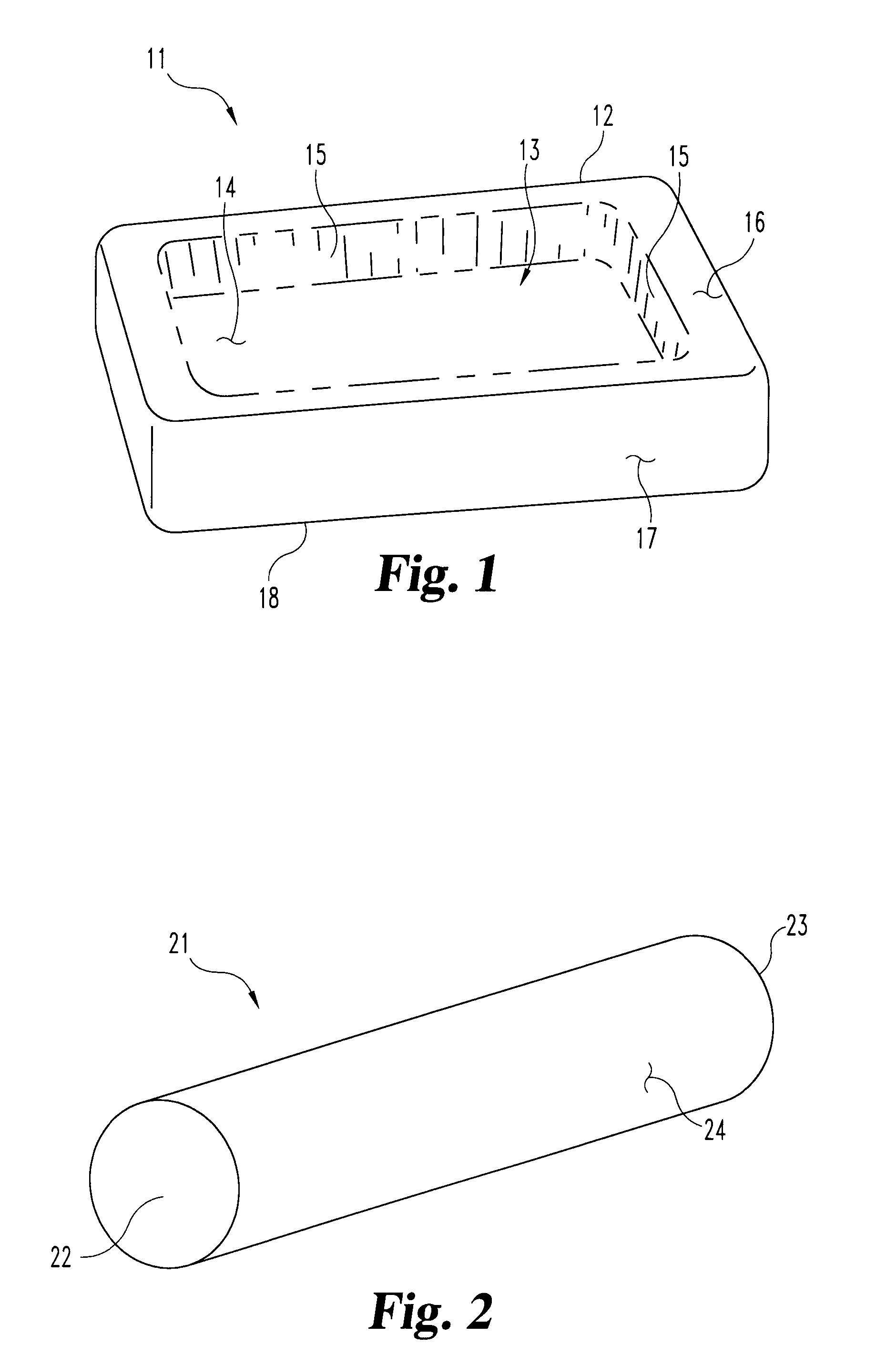

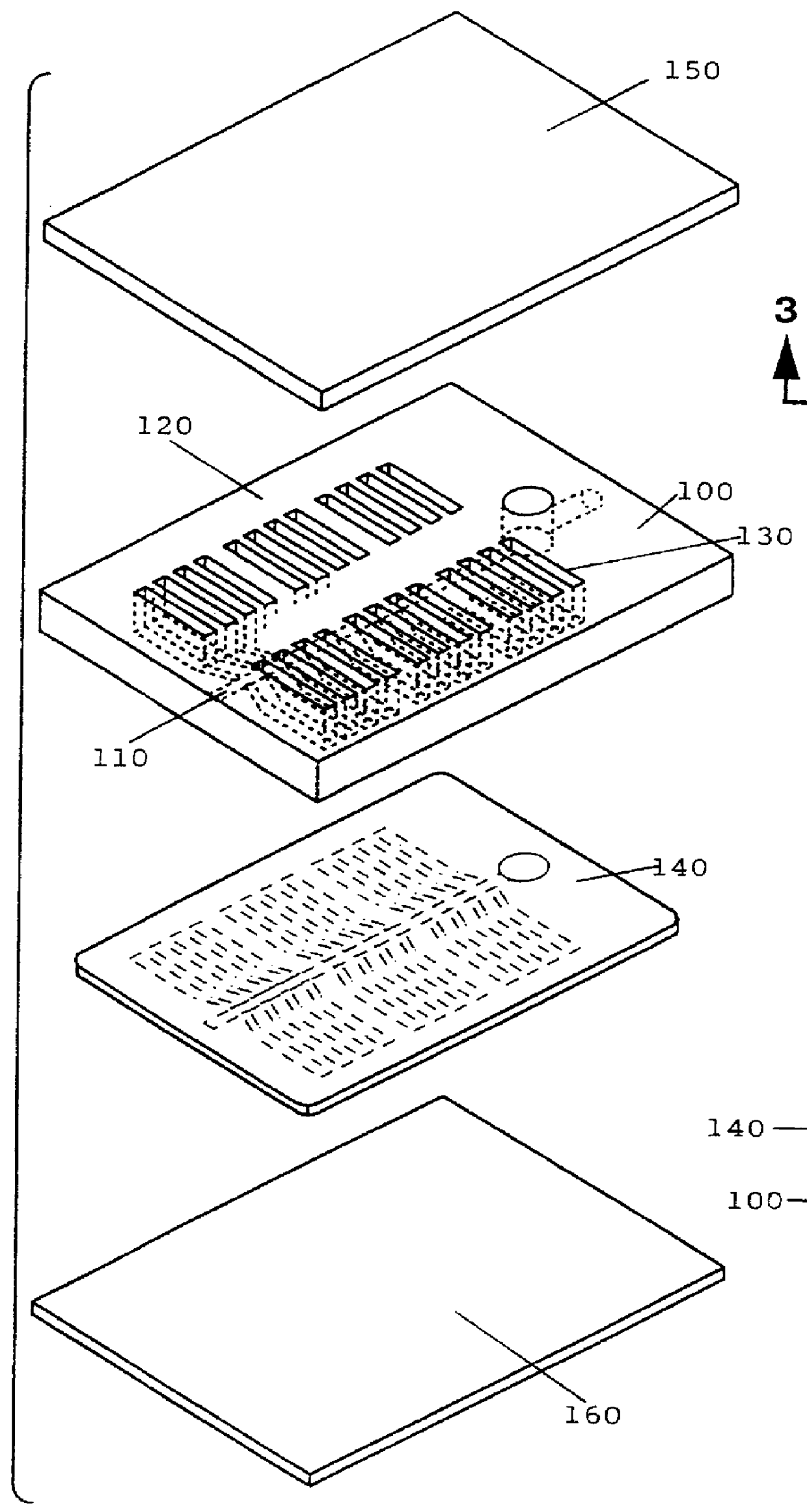

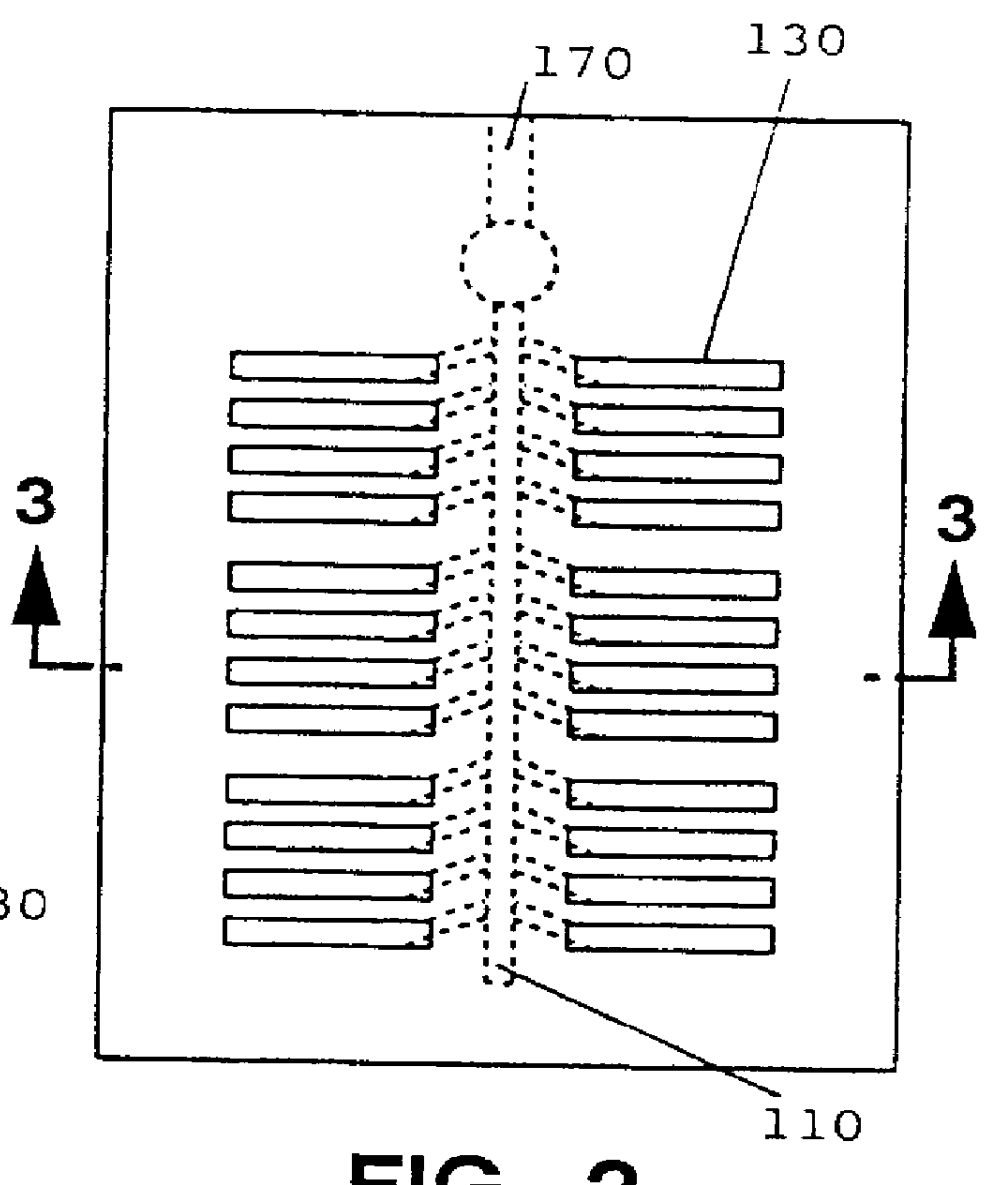

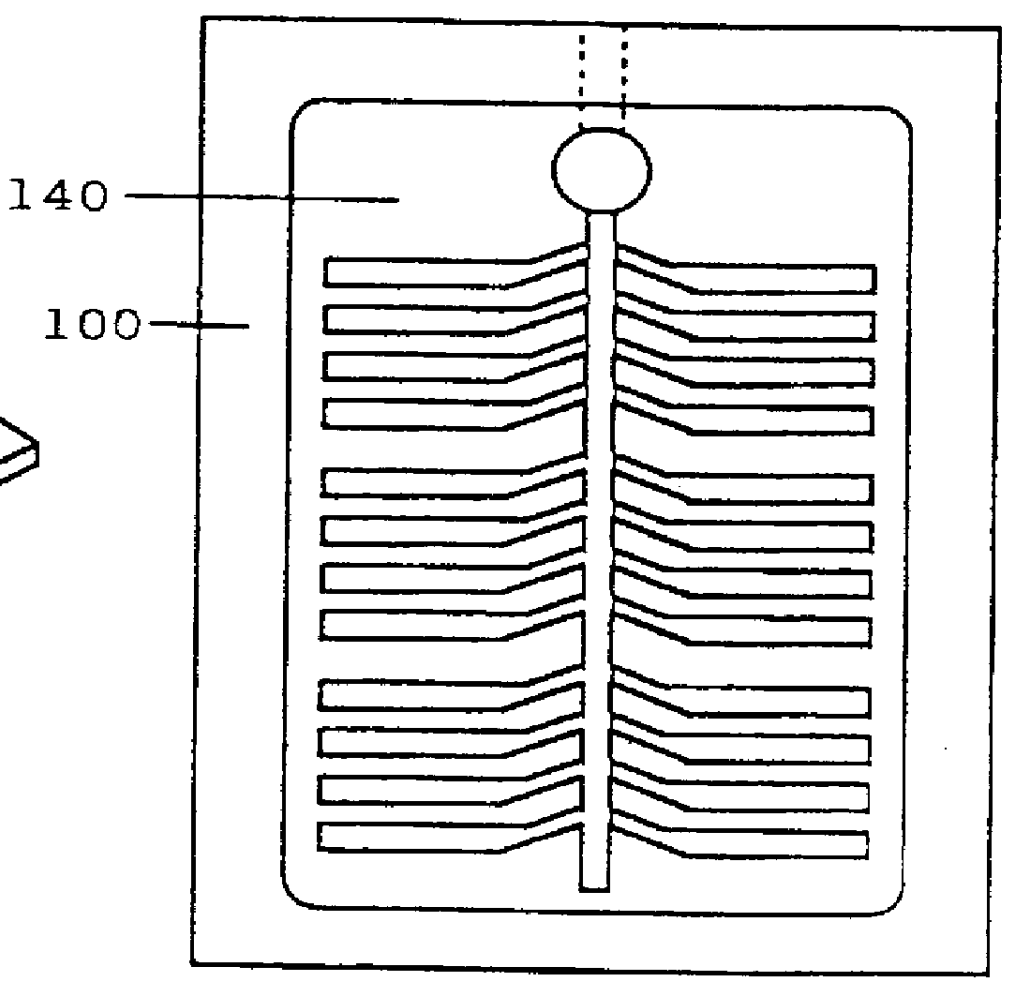

Comparative phenotype analysis of two or more microorganisms using a plurality of substrates within a multiwell testing device

InactiveUS6046021ABioreactor/fermenter combinationsBiological substance pretreatmentsEscherichia coliPlant cell

The present invention relates to growing and testing microorganisms in a multitest format which utilizes a gel forming matrix for the rapid screening of clinical and environmental cultures. The present invention is suited for the characterization of commonly encountered microorganisms (e.g., E. coli, S. aureus, etc.), as well as commercially and industrially important organisms from various and diverse environments (e.g., the present invention is particularly suited for the growth and characterization of the actinomycetes and fungi). The present invention is also particularly suited for comparative analysis of phenotypic differences between cell types, including strains of microorganisms that have been designated as the same genus and species, as well as other cell types (e.g., mammalian, insect, and plant cells).

Owner:BIOLOG

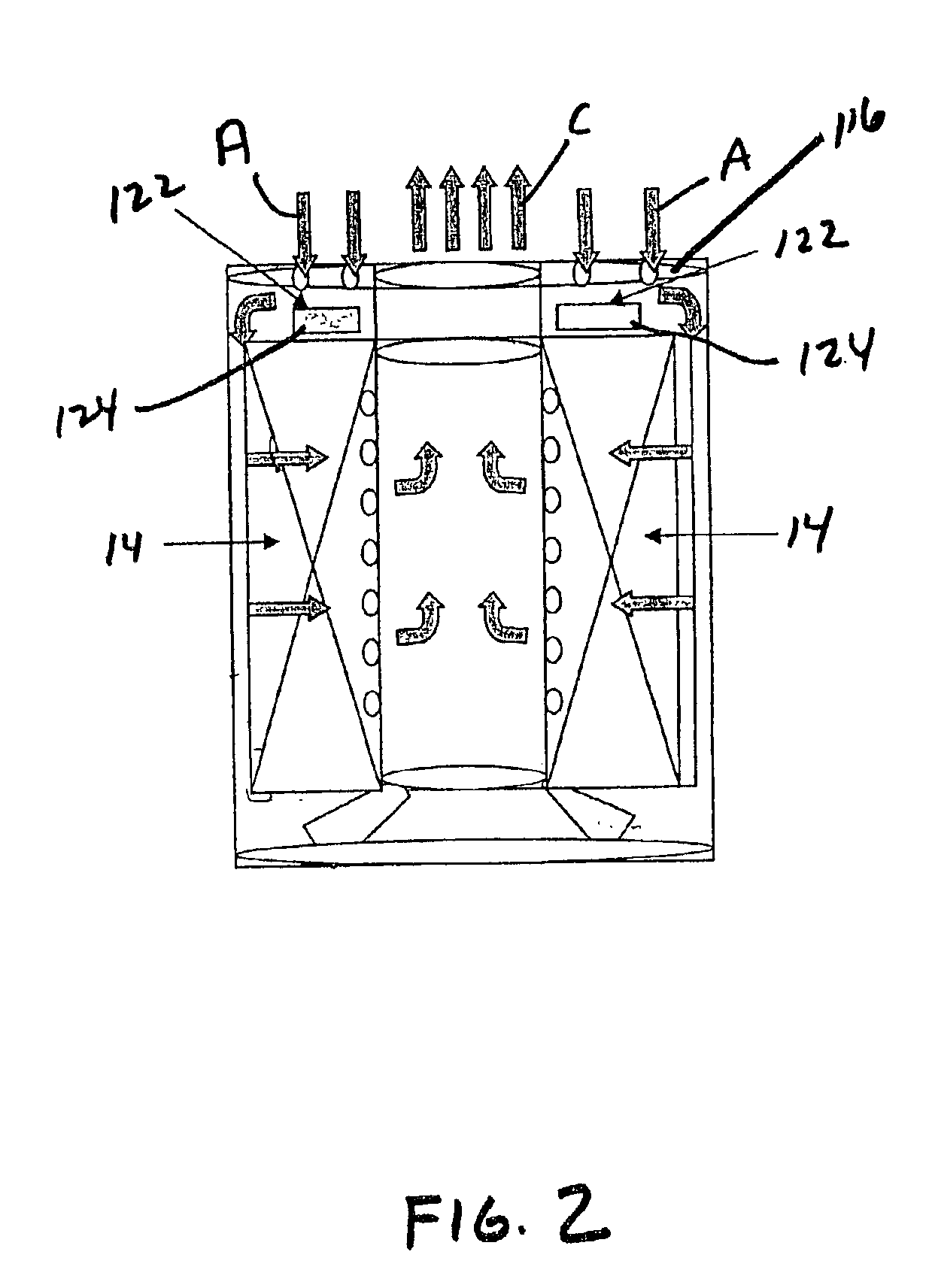

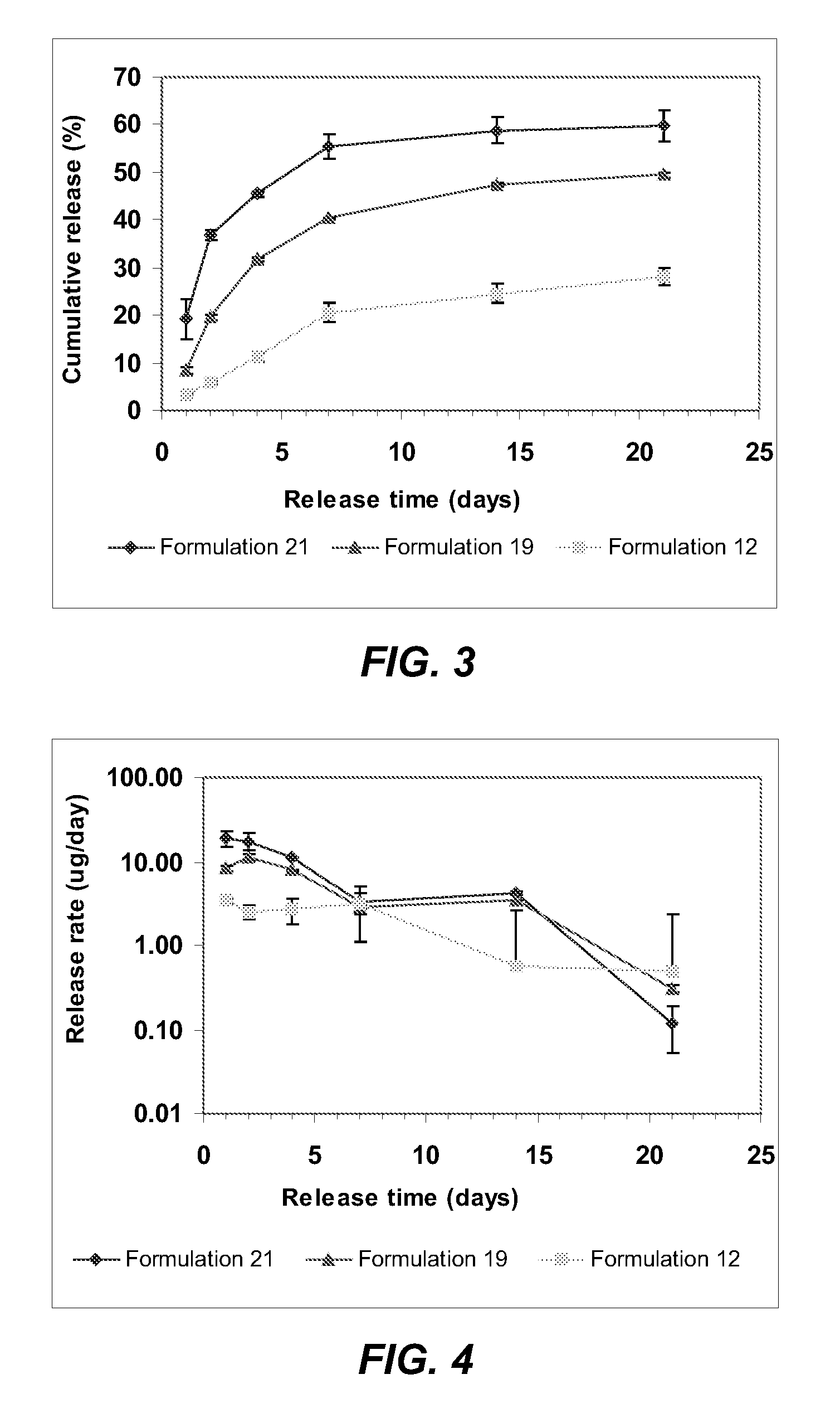

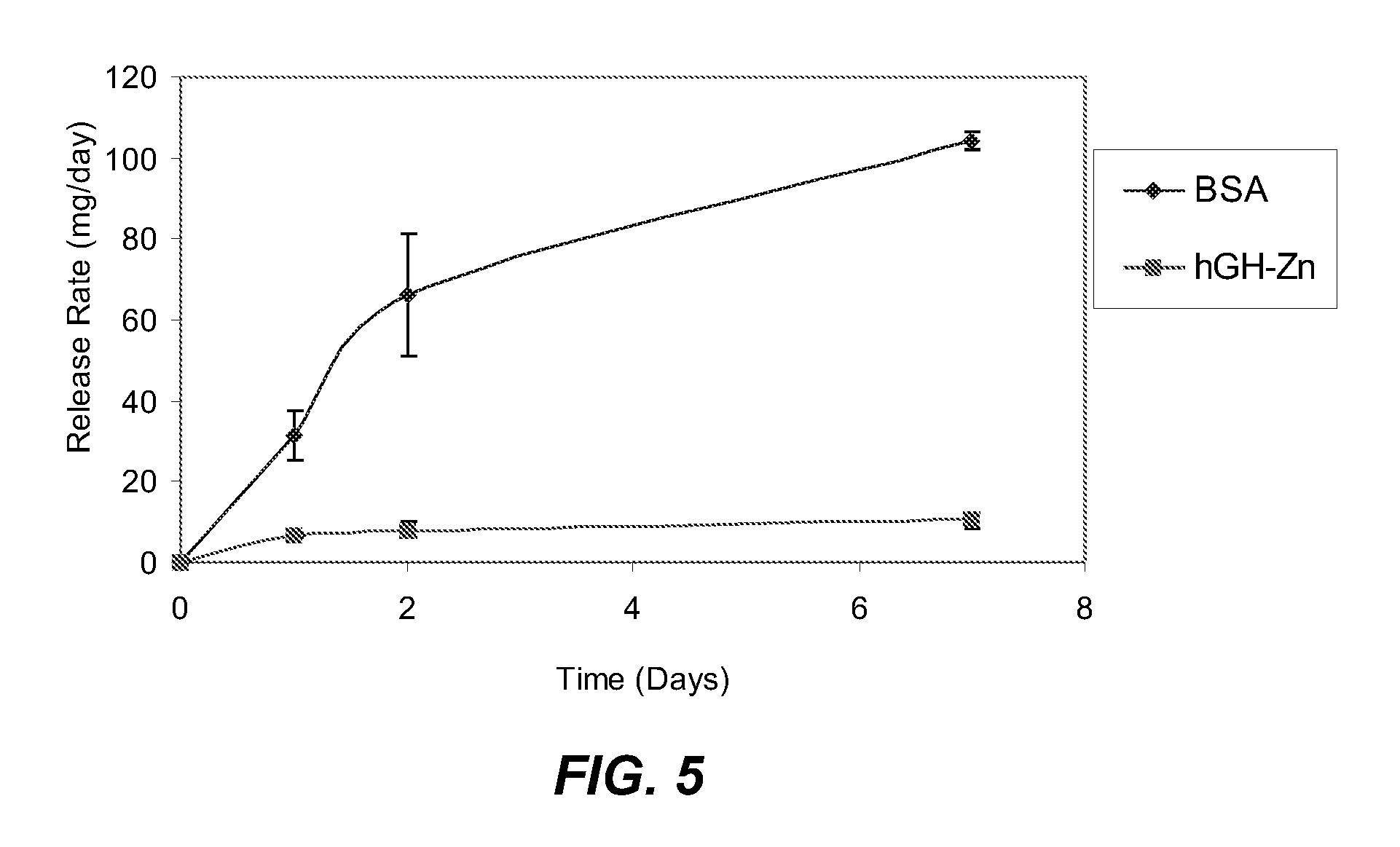

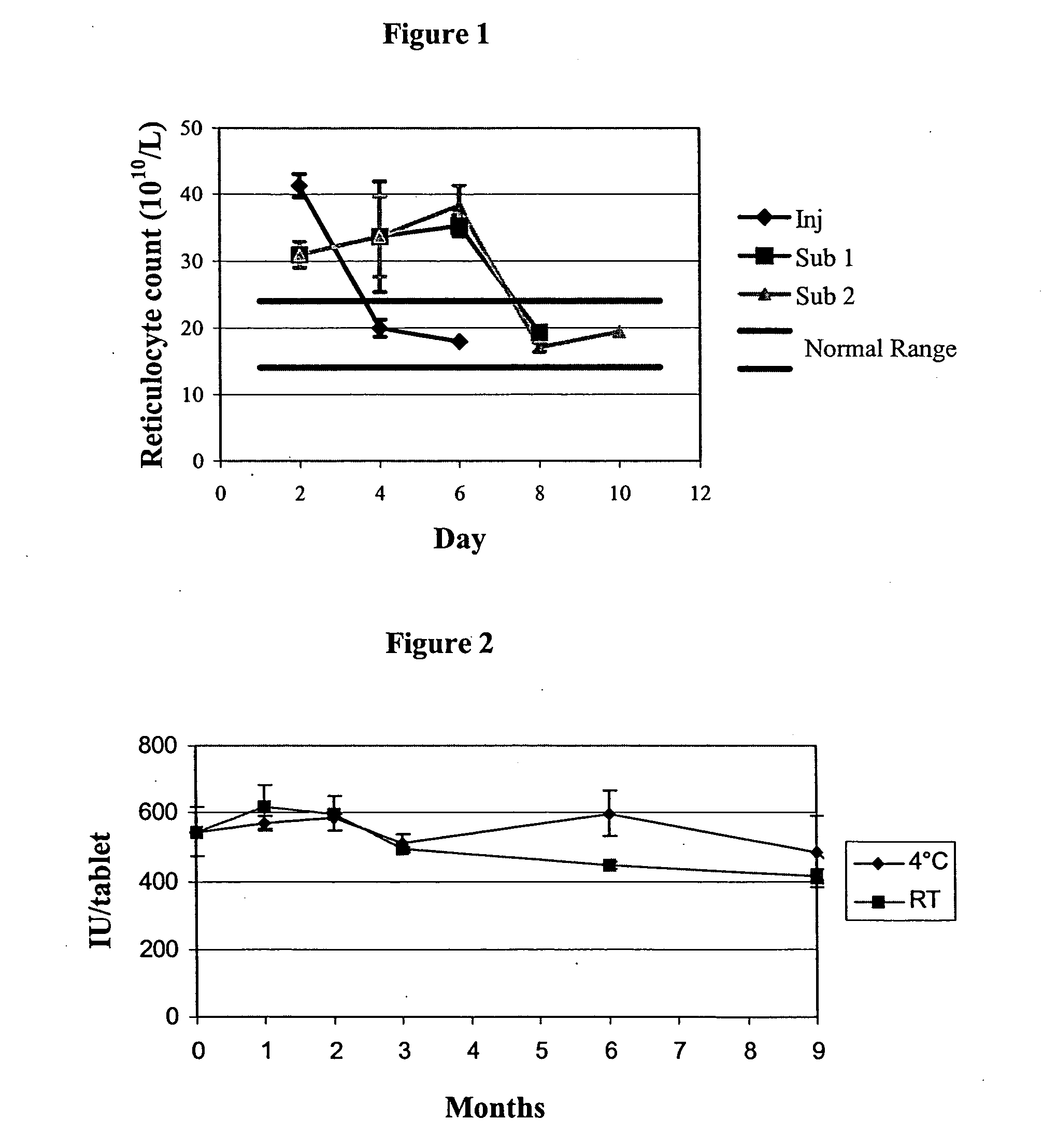

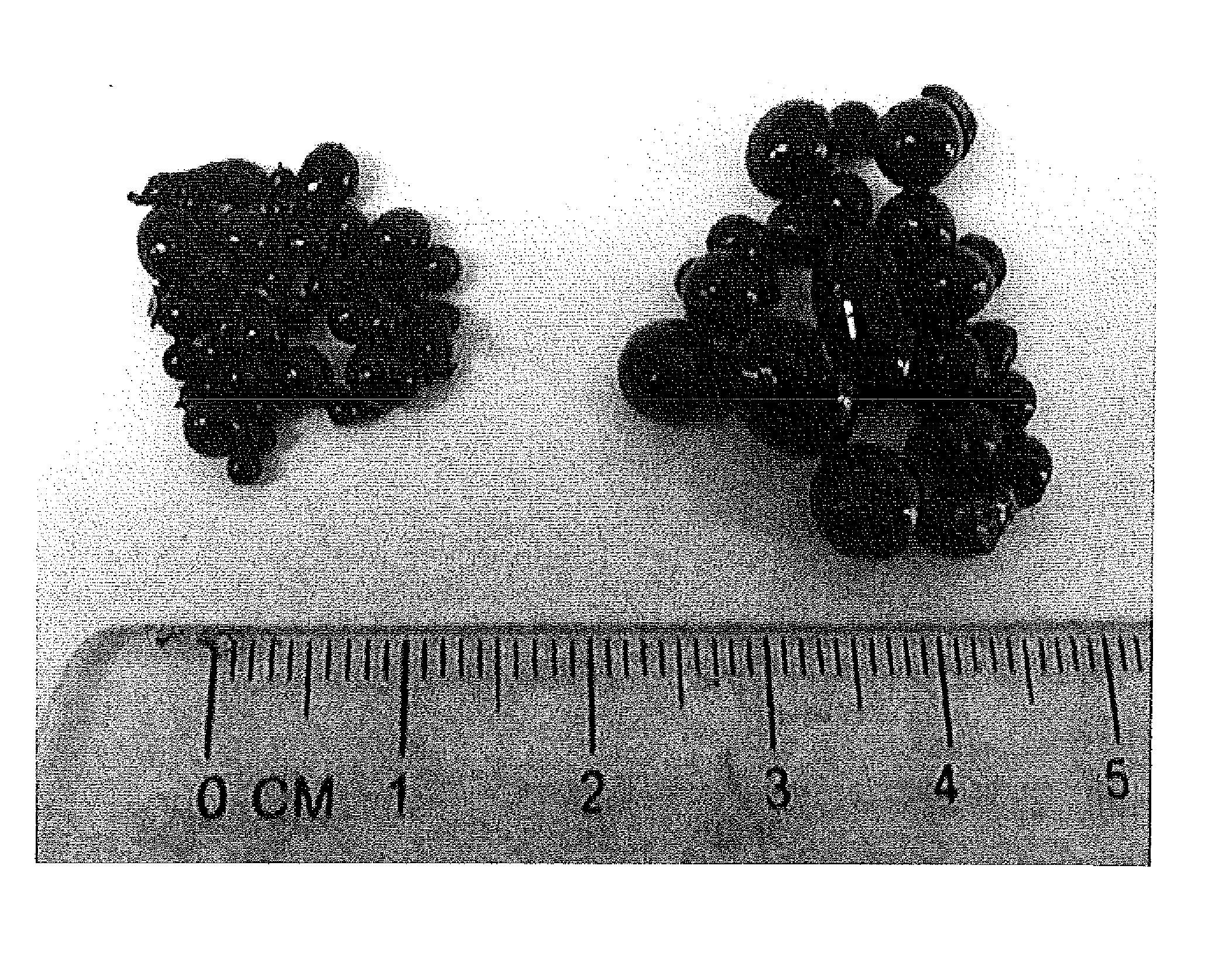

Method of preparing biological materials and preparations produced using same

InactiveUS20050019417A1Simple methodDesired characteristicOrganic active ingredientsSenses disorderMicroparticleSolid particle

Methods for preparing products containing moisture-sensitive materials, including biological materials such as proteins, peptides or live cells, comprising at least the steps: (i) providing a coating liquid comprising at least one active, a sugar polymer and a water soluble / miscible solvent; (ii) providing a quantity of microparticles comprising at least water soluble gel forming solid particles; (iii) fluidizing said quantity of microparticles within a processing chamber of a of a suitable apparatus to form a fluidized bed of said microparticles; (iv) spraying said coating liquid onto said fluidized bed from beneath the fluidized bed to coat said microparticles therewith under saturated moisture conditions; and (vi) allowing coated microparticles to dry, are described. Also described are compositions and uses.

Owner:PFIZER INC

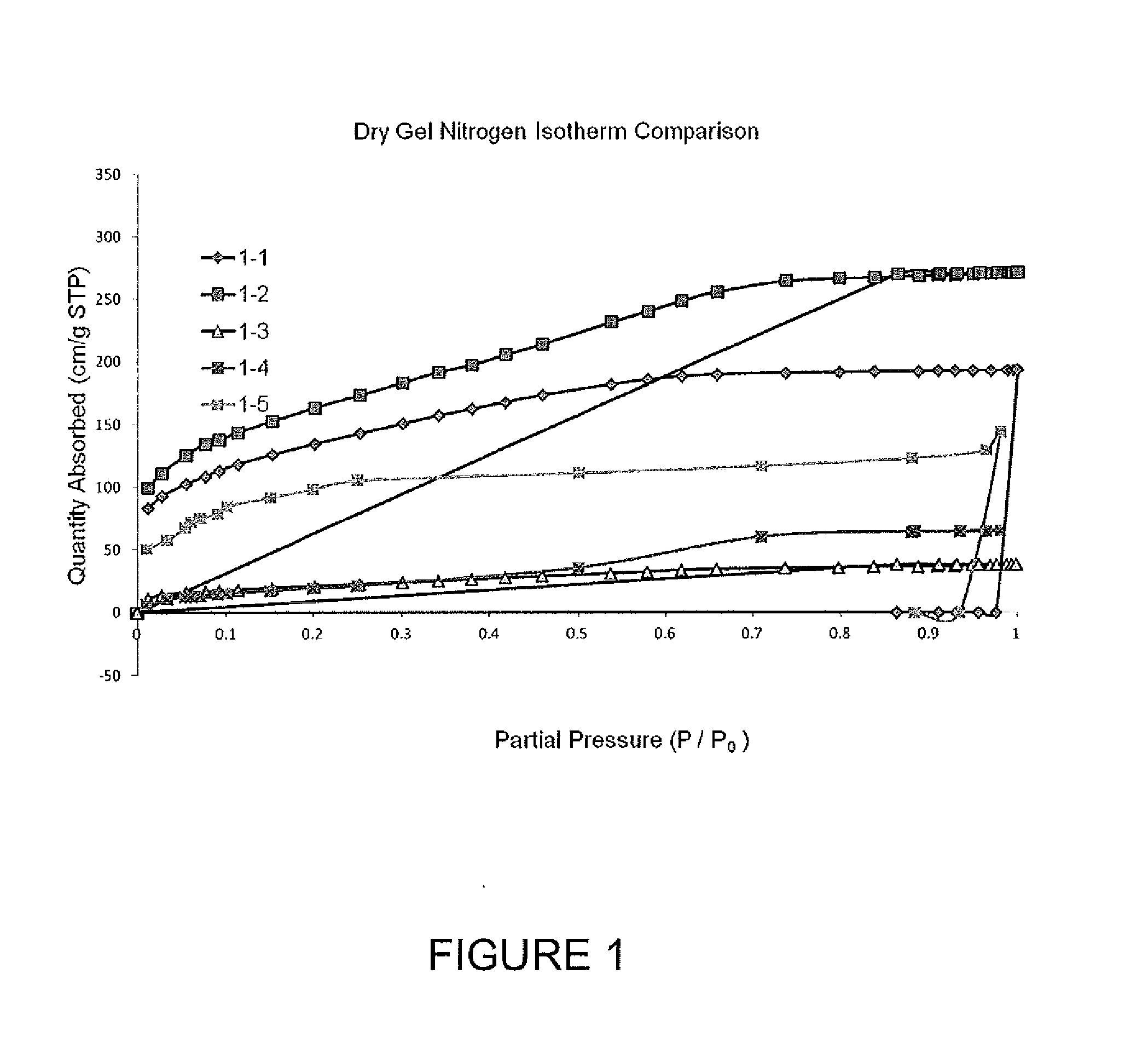

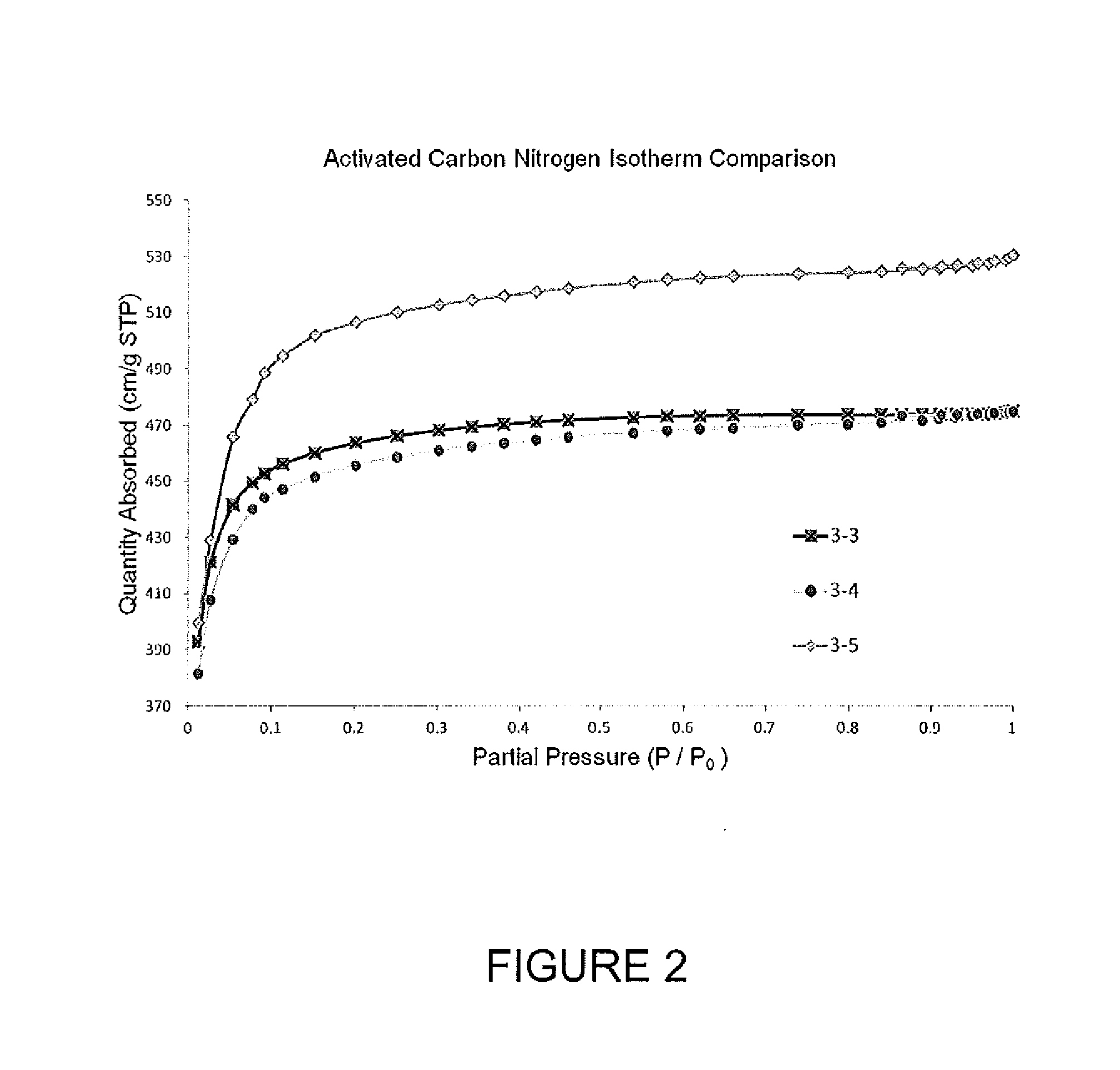

Preparation of polymeric resins and carbon materials

The present application is directed to methods for preparation of polymer particles in gel form and carbon materials made therefrom. The carbon materials can have enhanced electrochemical properties and find utility in any number of electrical devices, for example, as electrode material in ultracapacitors or batteries.

Owner:GEORGIA PACIFIC CHEM LLC

Biocolloid hemostatic prepared by aldehyde-modified sodium alginate and amine-modified gelatine

InactiveCN101716366AEasy to prepareRapid hemostasisAbsorbent padsBandagesFibrin glueBiocompatibility Testing

The invention relates to a biocolloid hemostatic prepared by aldehyde-modified sodium alginate and amine-modified gelatine. Sodium alginate and gelatine as raw materials; according to ratio, aldehyde-modified sodium alginate solution with the concentration of 5-25% and the same volume of amine-modified gelatine solution with the concentration of 5-40% are mixed; sodium alginate is modified by aldehyde through sodium periodate oxidation; and then gel is obtained by mixing with gelatine modified by ethanediamine. The adopted gelatine and sodium alginate are safe and stable, have good biocompatibility and can be absorbed and degraded by organism. Gel is rapidly formed through Schiff base reaction of aldehyde-modified sodium alginate and amine-modified gelatine, and the gel has the same gel-forming time as fibrin glue but better adhesion property and adhesion strength, can be acted on any part of body through simple local spraying or injection, and can be used as substitute product of fibrin glue.

Owner:TIANJIN UNIV

UV-stable, liquid or semisolid transdermal pharmaceutical preparation with light sensitive active ingredient

InactiveUS20050129756A1Improve stabilityGood effectOrganic active ingredientsBiocideSide effectAlcohol

The semisolid or liquid pharmaceutical preparation for transdermal administration contains at least one UV-light sensitive pharmaceutically active ingredient and at least one UV-absorbing substance, which is present in an amount that does not have pharmacological activity and in dissolved or dispersed form. This semisolid of liquid pharmaceutical preparation is preferably a hydroalcoholic gel, whose gel base includes water, alcohol, at least one gel-forming polymer and additional ingredients as needed. This pharmaceutical preparation is prepared with a UV-light sensitive pharmaceutically active ingredient, so that the application system has a high stability without the disadvantages of the known semisolid transdermal application forms. The injurious side effects, such as absorption of the UV-light protecting ingredient in the body, resulting from the intended light protection are reduced as much as possible.

Owner:SCHERING AG

Method for forming mould-free gel with metal sizing agents through 3D printing

The invention provides a method for forming mould-free gel with metal sizing agents through 3D printing. A 3D printing technology is combined with a gel forming technology, the metal sizing agents are prepared through a gel forming process, the sizing agents are adopted as the raw materials of 3D printing, then layered printing is carried out through 3D printing equipment according to a data model, the metal sizing agents are solidified fast by controlling the additive number of initiating agents and catalysts, the initiating agents and the catalysts are accumulated layer by layer to form a metal blank, and the metal blank is dried and sintered to obtain a metal part product with a large size and in a complex shape. The method can be used for manufacturing a part including a sealed cavity and a complex inner cavity, the part cannot be manufactured through a traditional gel casting forming mode, the blank is directly formed through the 3D printing technology, mould development cost is saved, the method has obvious advantages in single part production and small scale production, requirements for powder materials are low, the process is stable and reliable, the operability is strong, consumed time is short, efficiency is high, cost is low, and the industrialization of manufacturing the metal part with the large size and in the complex shape through the 3D printing technology is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Variable cohesive gel form-stable breast implant

ActiveUS20070135916A1Maintain formReduce and eliminate effectMammary implantsBreast implantSuperior pole

A variable cohesive gel form stabilizing implant is disclosed for augmentation or reconstruction of the breast. The prosthesis of this invention comprises an implantable shell or envelope (not limited to a single shell or envelope), filled with a biocompatible gel, or gels, having alterations in gel cohesiveness to maintain stable form, shape, and dimension after surgical implantation. The gel cohesiveness may increase, with increased volume or dimension of the prosthesis. The variable cohesiveness of the gel filler material may be altered by any means (i.e. chemical, fabrication, etc.). The variable cohesive gel form stabilizing implant has shape retention characteristics to maintain its form, thereby reducing or eliminating the undesirable effects of shell wrinkling, knuckling, scalloping or deformation, which can occur at the upper or lower pole of the prostheses, along the perimeter of the shell or at the base, post-implantation. Finally, the variable cohesive gel form stabilizing implant provides new control and possibilities for achieving and preserving the most natural breast shape.

Owner:ALLERGAN INC

Cosmetic treatment article comprising substrate and gel composition

InactiveUS20060104931A1Improve fitImprove adhesionBiocideCosmetic preparationsWater insolubleWater soluble

Disclosed are cosmetic treatment articles comprising: (1) a water-insoluble substrate; (2) a gel composition comprising: (a) a first gel forming composition comprising a water soluble polymeric gelling agent and (b) a second gel forming composition comprising a gel strengthening agent; and (3) preferably, a treatment composition comprising a rheology modifier. Further disclosed are cosmetic treatment articles comprising at least two different treatment compositions, each treatment composition being provided at one or more selected locations on the water insoluble substrate.

Owner:THE PROCTER & GAMBLE COMPANY

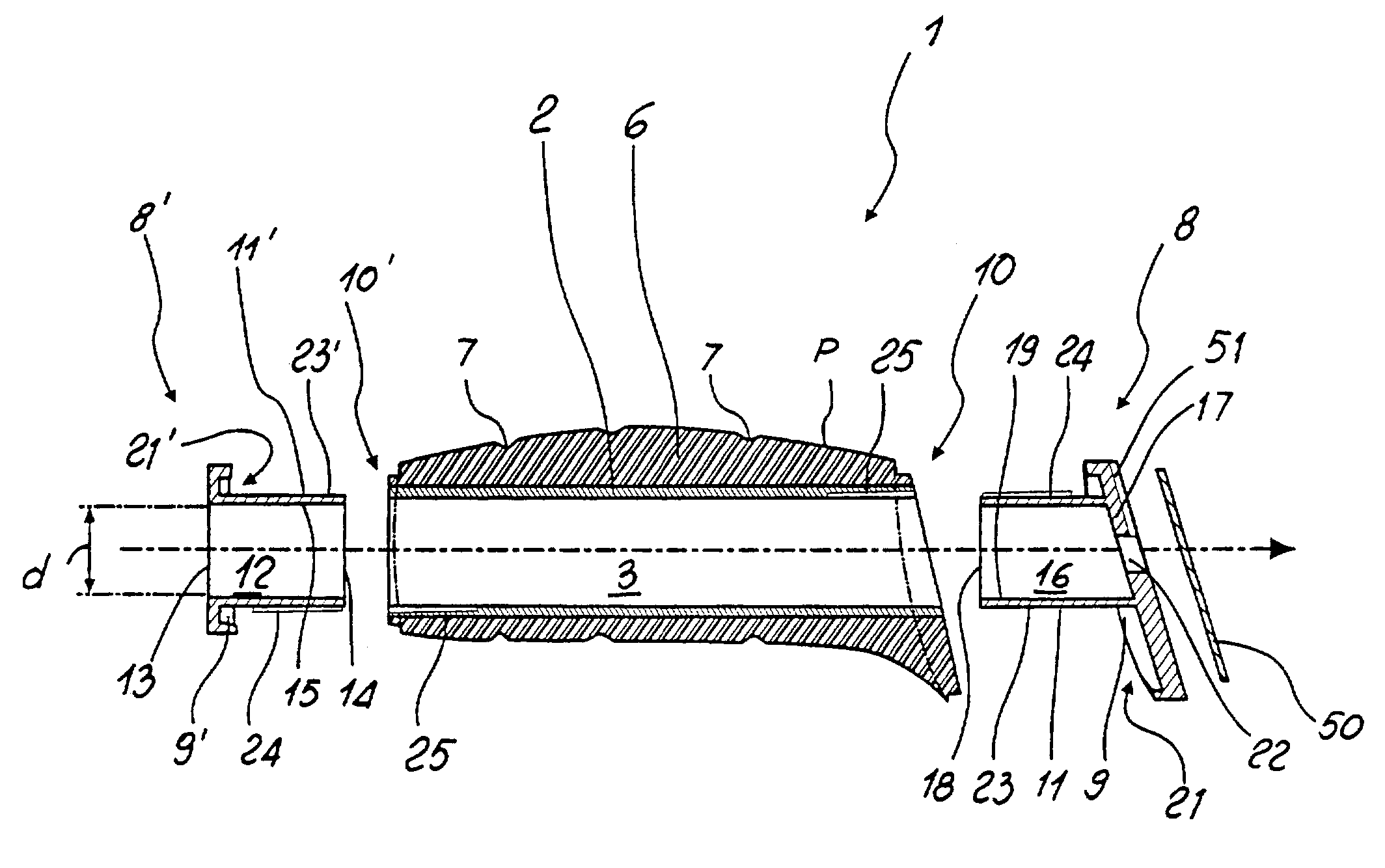

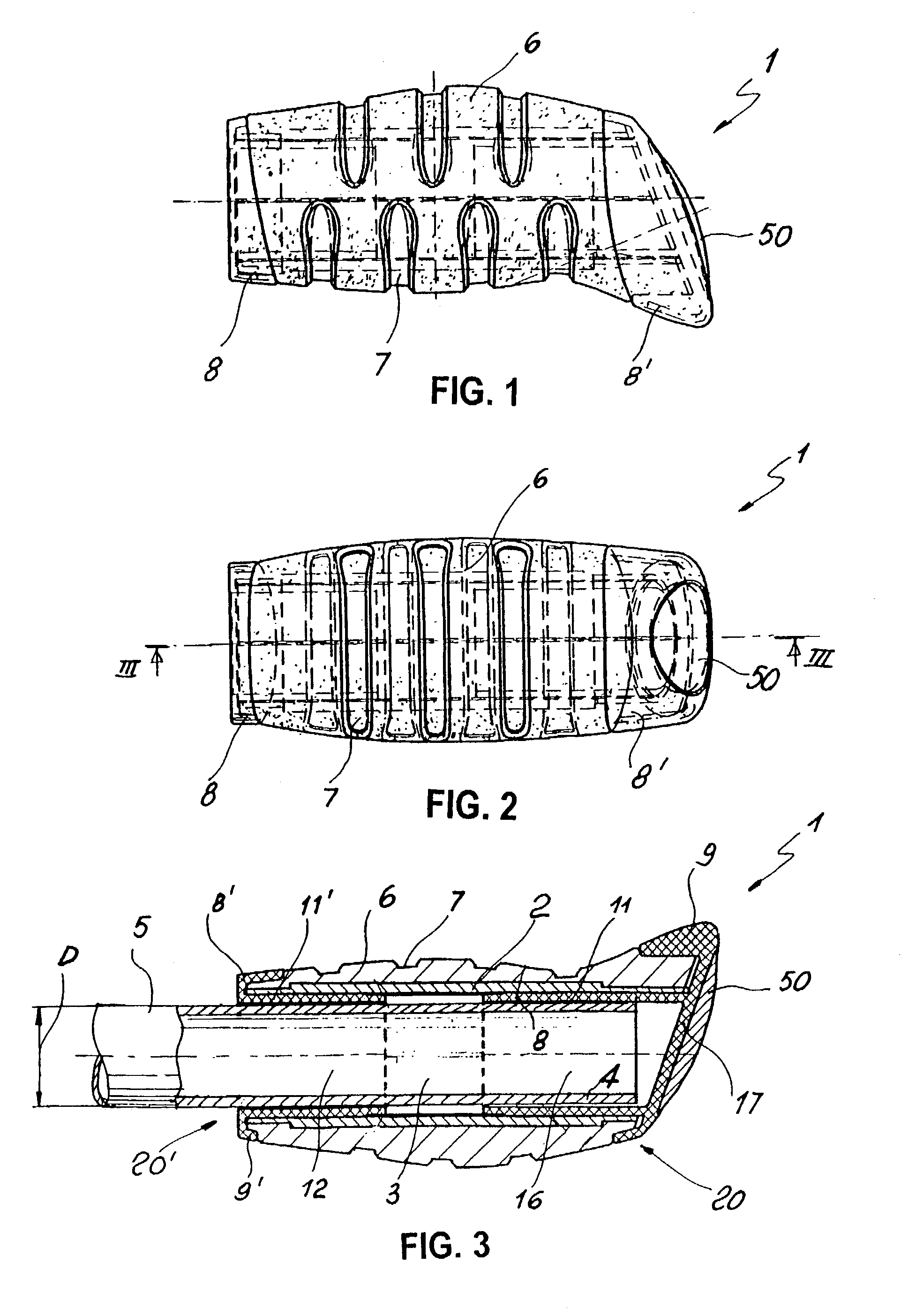

Handlebar grip, in particular for a bicycle

InactiveUS7219395B2Wide range of toleranceSimple structureTravelling carriersHoldersEngineeringSoft materials

Handlebar grip for a bicycle or similar vehicle, formed by a main rigid body of tubular shape supporting, fixed thereon, a covering of moderately soft material, in particular in gel form. Two terminal elements are provided at the ends of the grip, each of the elements being provided with an annular protection rim intended to line a corresponding end edge of the covering, and with an elastically deformable tubular lug to be inserted between an end section of the handlebar and the main body, compressed between the handlebar and the main body so as to ensure gripping engagement as a result of friction thereon.

Owner:SELLE ROYAL SPA

Storable water-microsphere suspensions for use in well cements and methods

Owner:HALLIBURTON ENERGY SERVICES INC

Disinfecting composition based on H2O2, acids and metal ions

The invention concerns an oxidising aqueous composition useful in particular for disinfection, hygiene and depollution purposes, and for surface treatment (particularly a metal surface to be stripped and / or passivated), and said composition, containing in water hydrogen peroxide, a RCO2H / RCO3H mixture (wherein R is a C1-C6 aliphatic radical with linear or branched hydrocarbon chain, saturated or unsaturated), a stabilising agent which is an acid and, as the case may be, Ag<+> ions. The invention is characterised in that it contains ions of at least one metal M which are ions of Ag<II>, Ag<III>, V<V>, Nb<V>, Ta<V>, Mo<VI>, W<VI>, Co<III>, In<III >or Tl<III>. Advantageously, said composition can be in gel form. The invention also concerns the method for preparing said composition.

Owner:DIGOL INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com