Patents

Literature

227results about How to "Desired characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

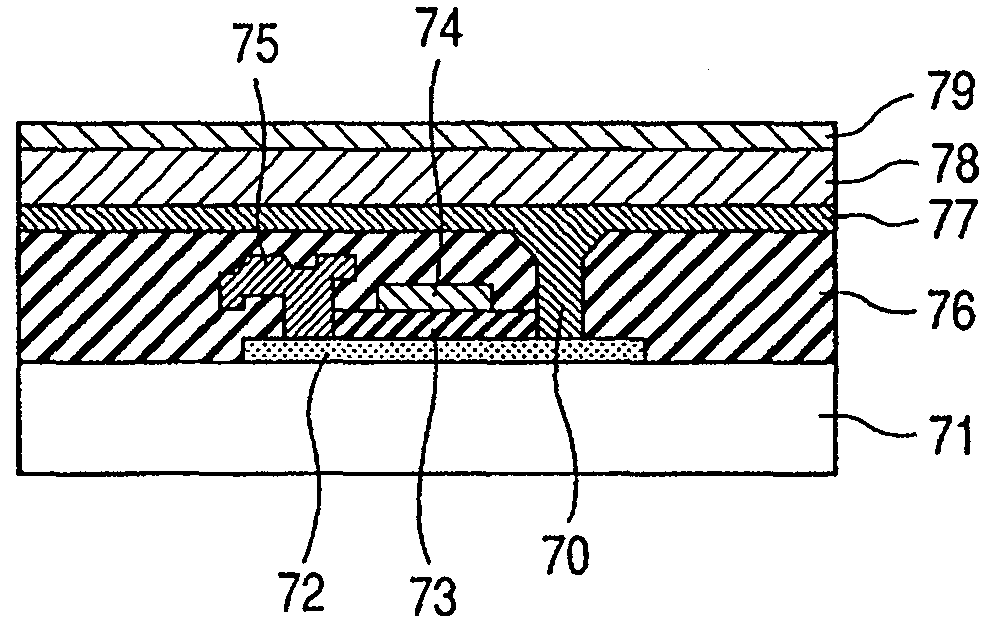

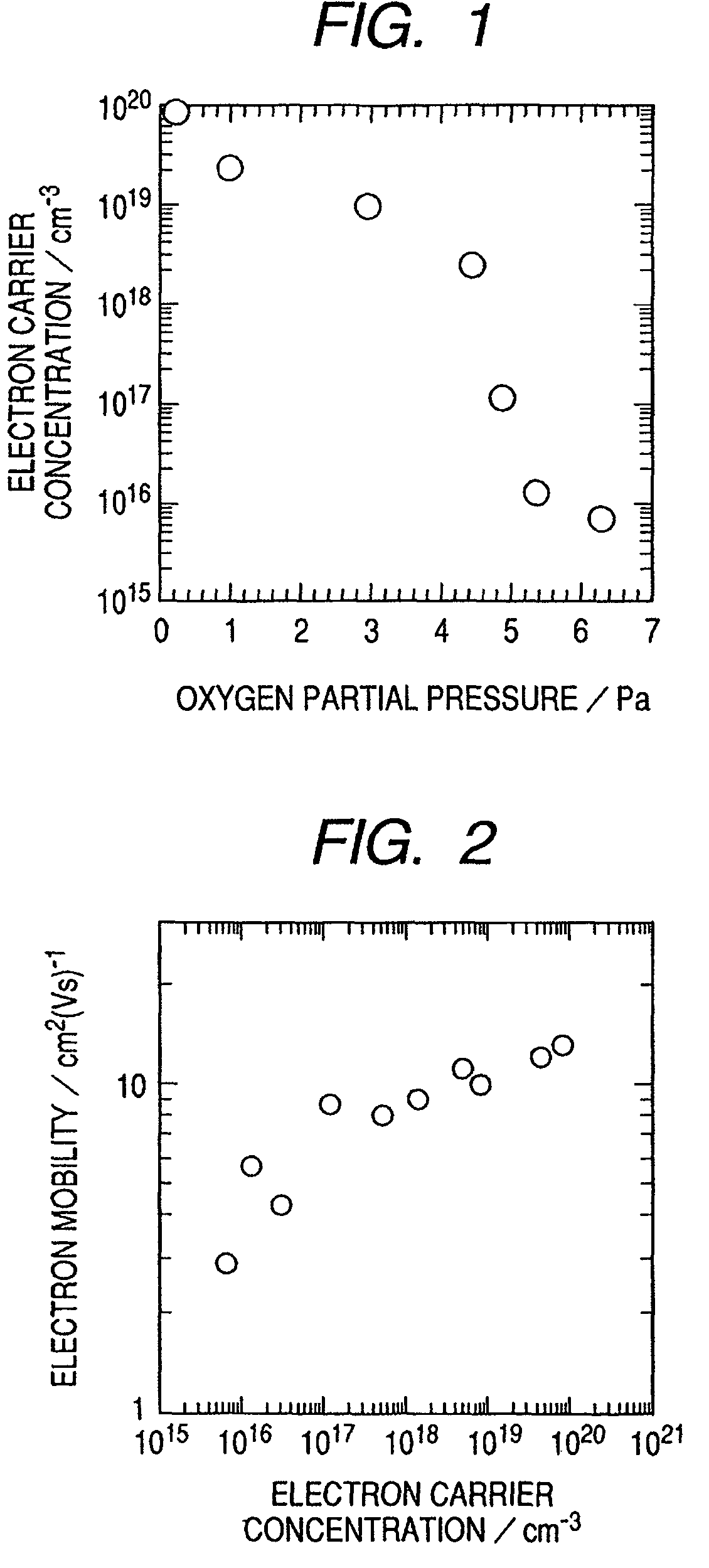

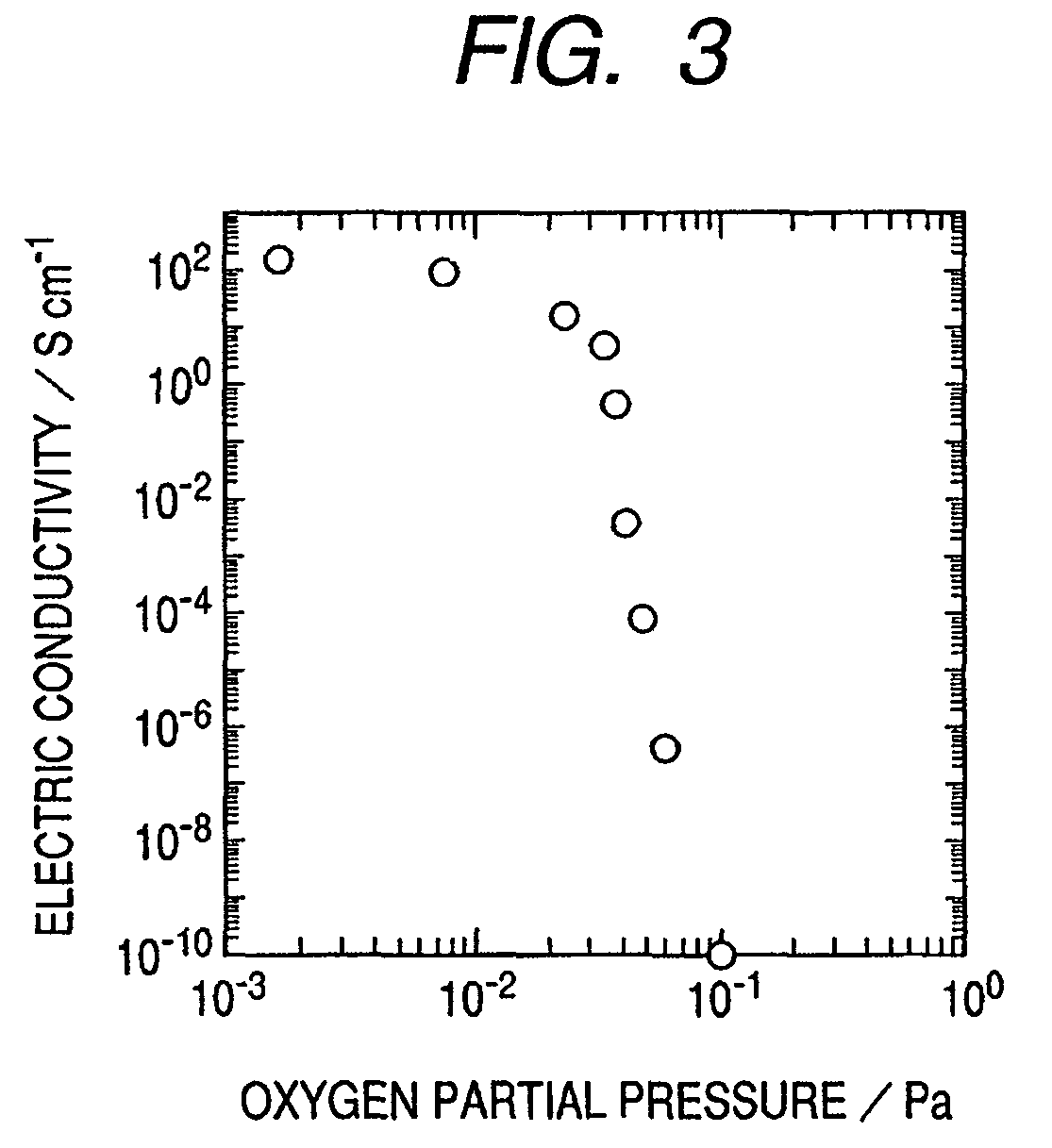

Light-emitting device

ActiveUS20060113549A1Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

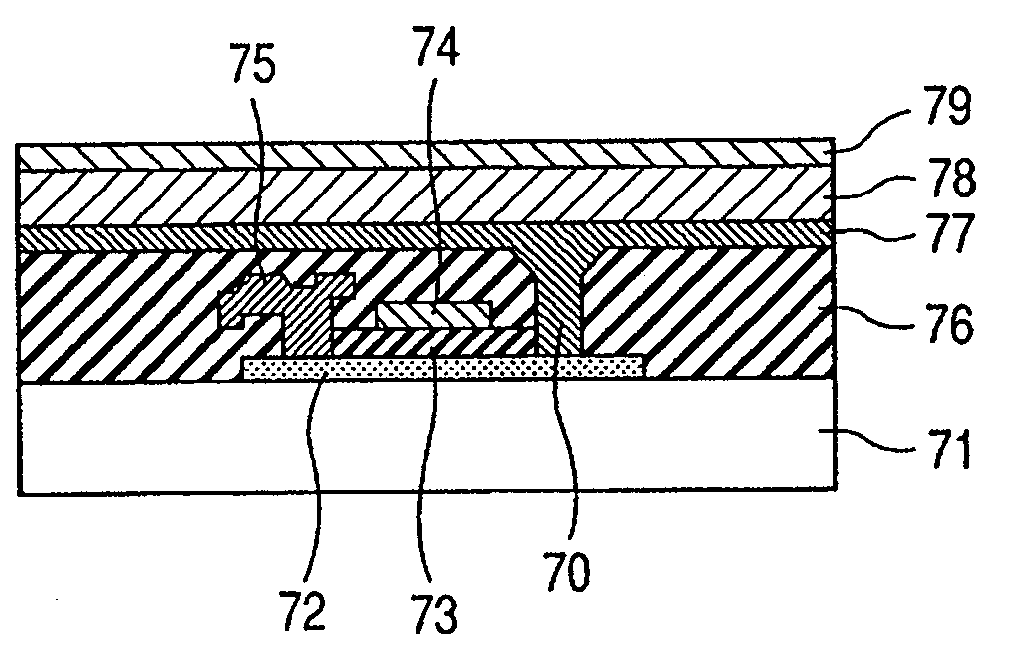

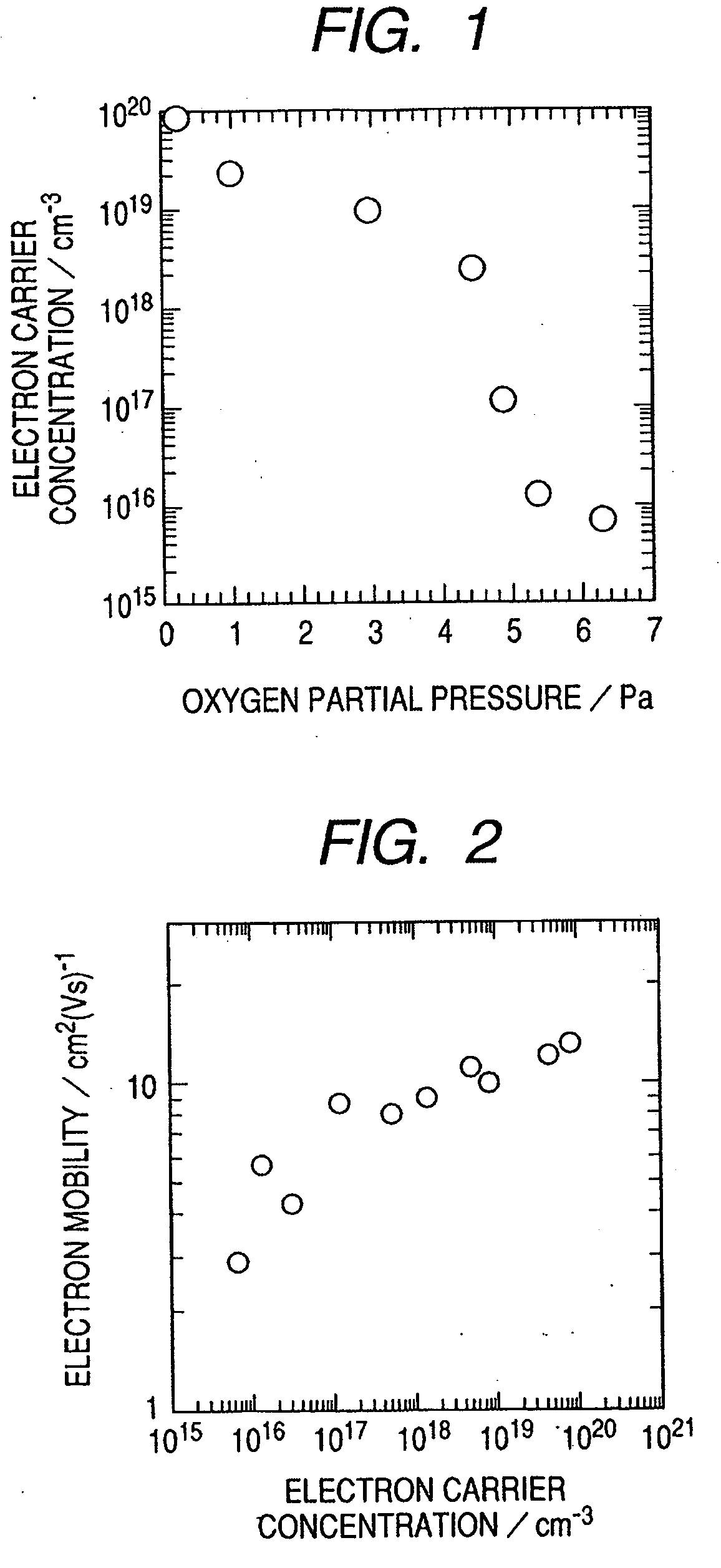

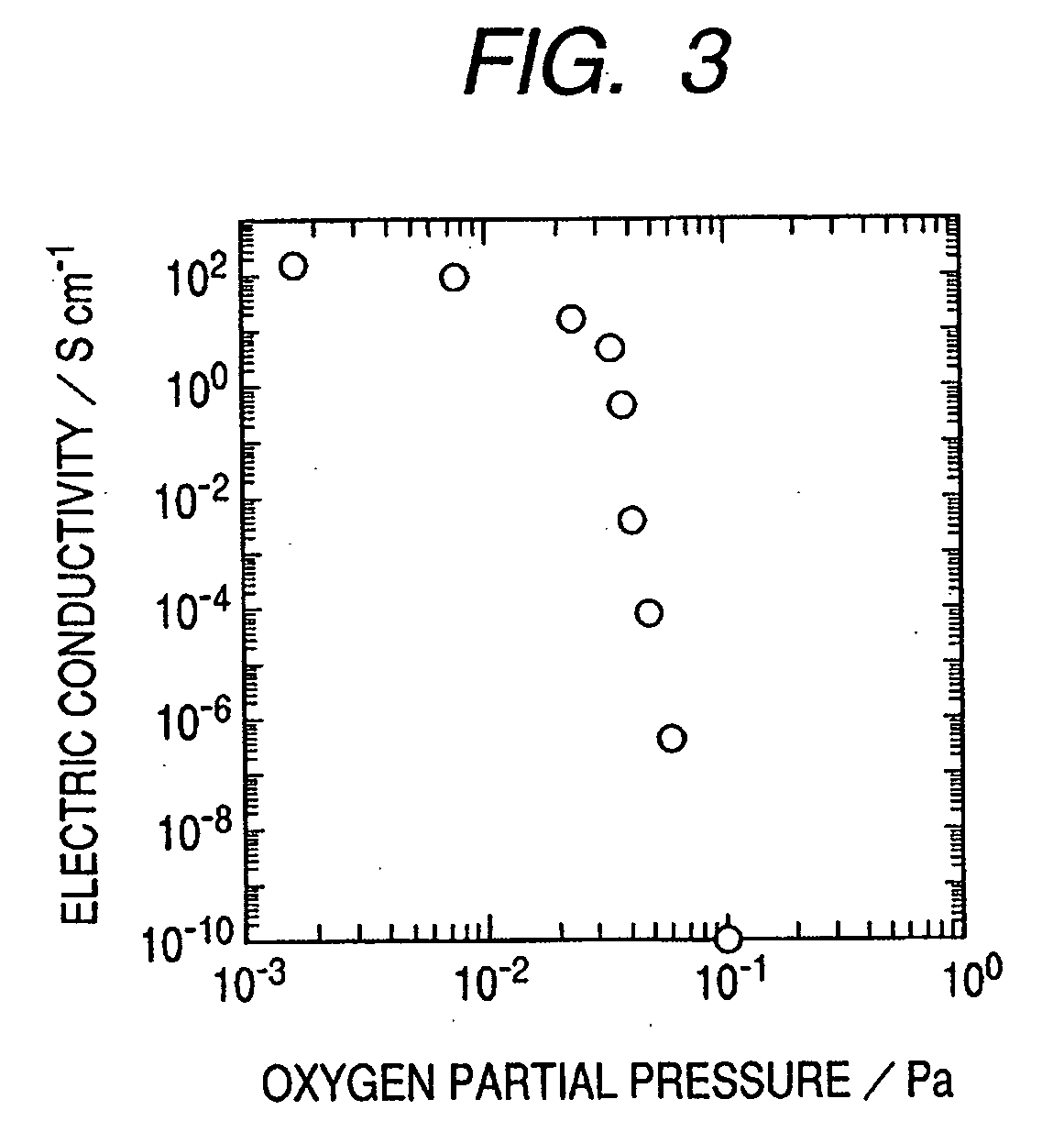

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

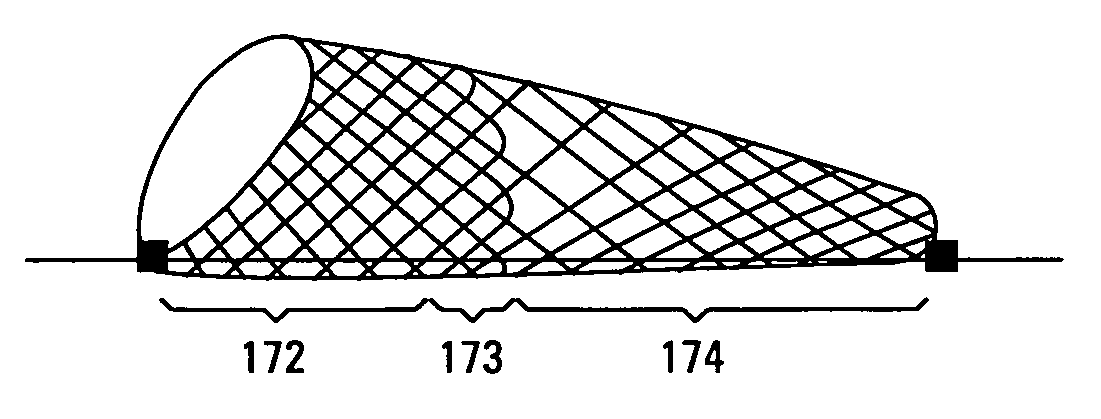

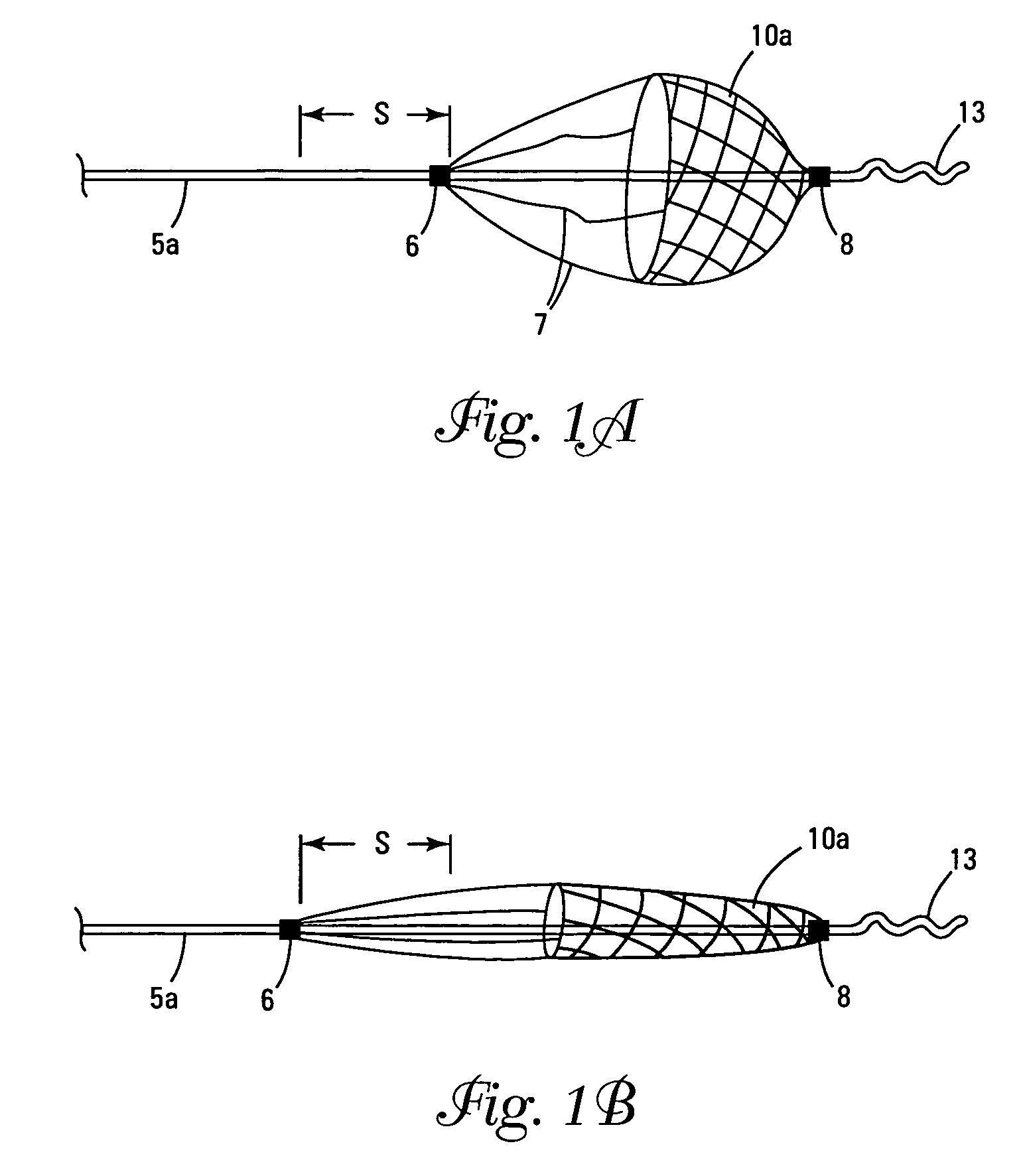

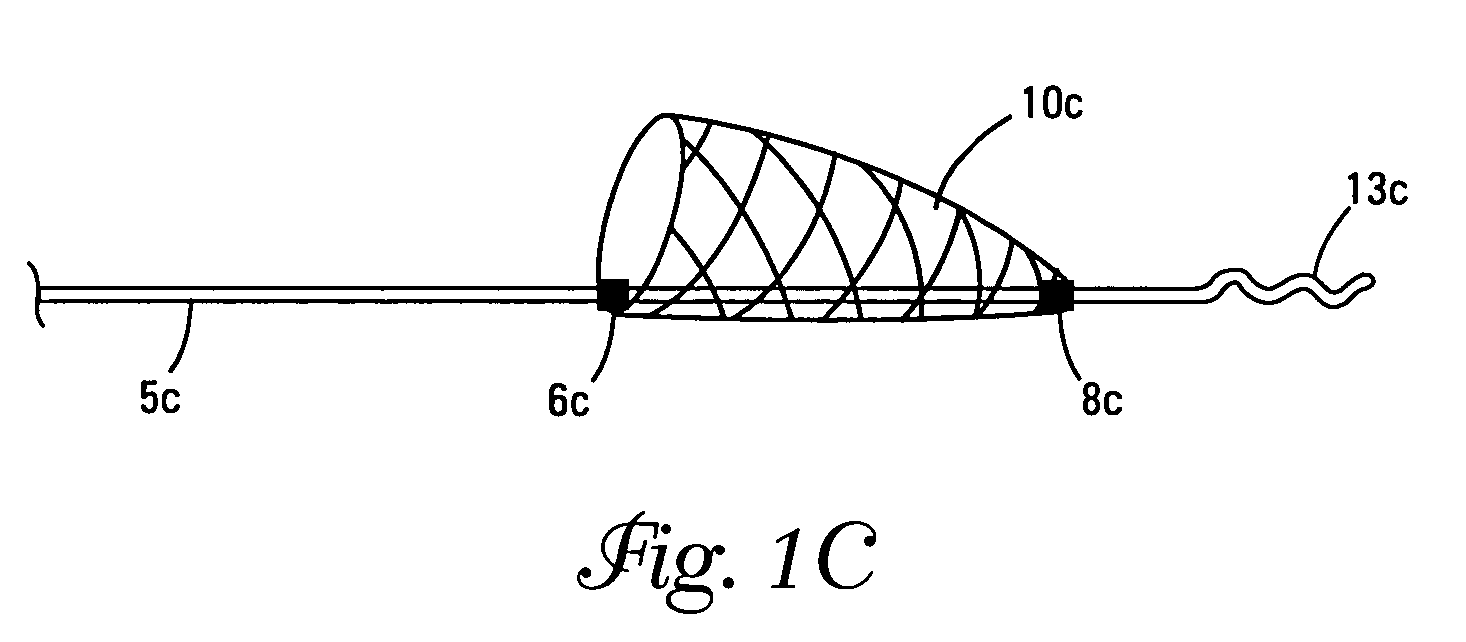

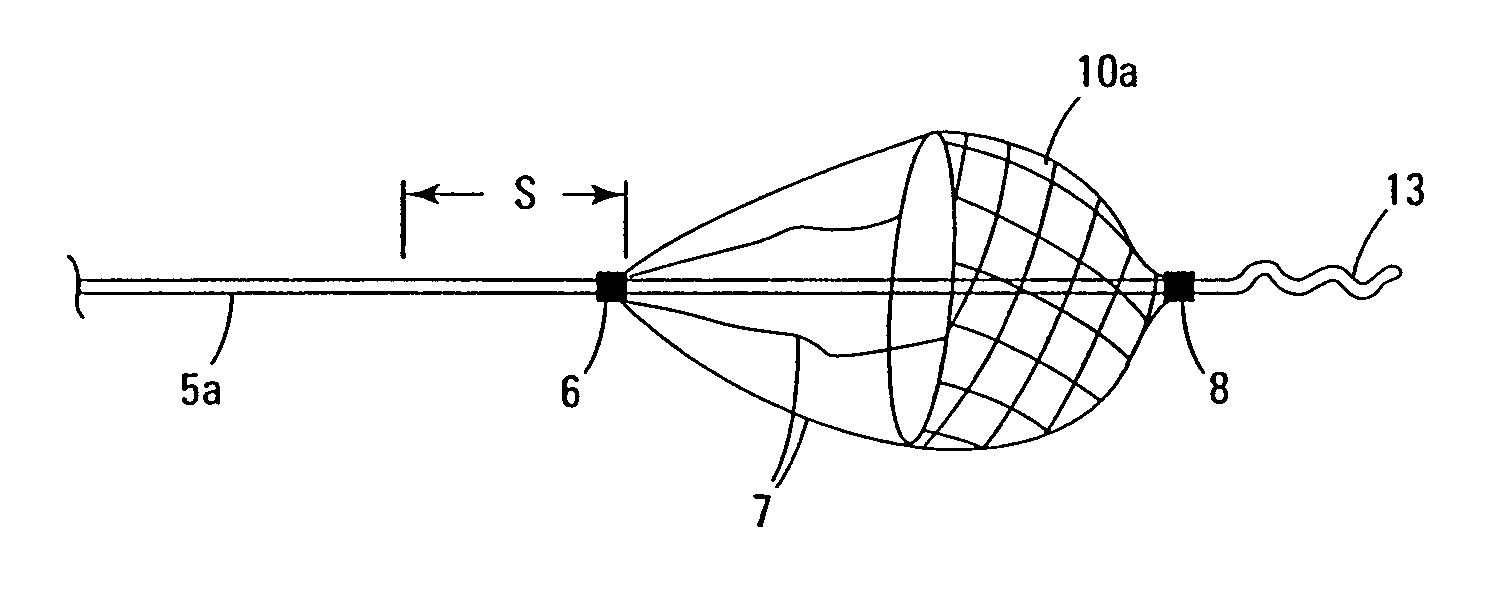

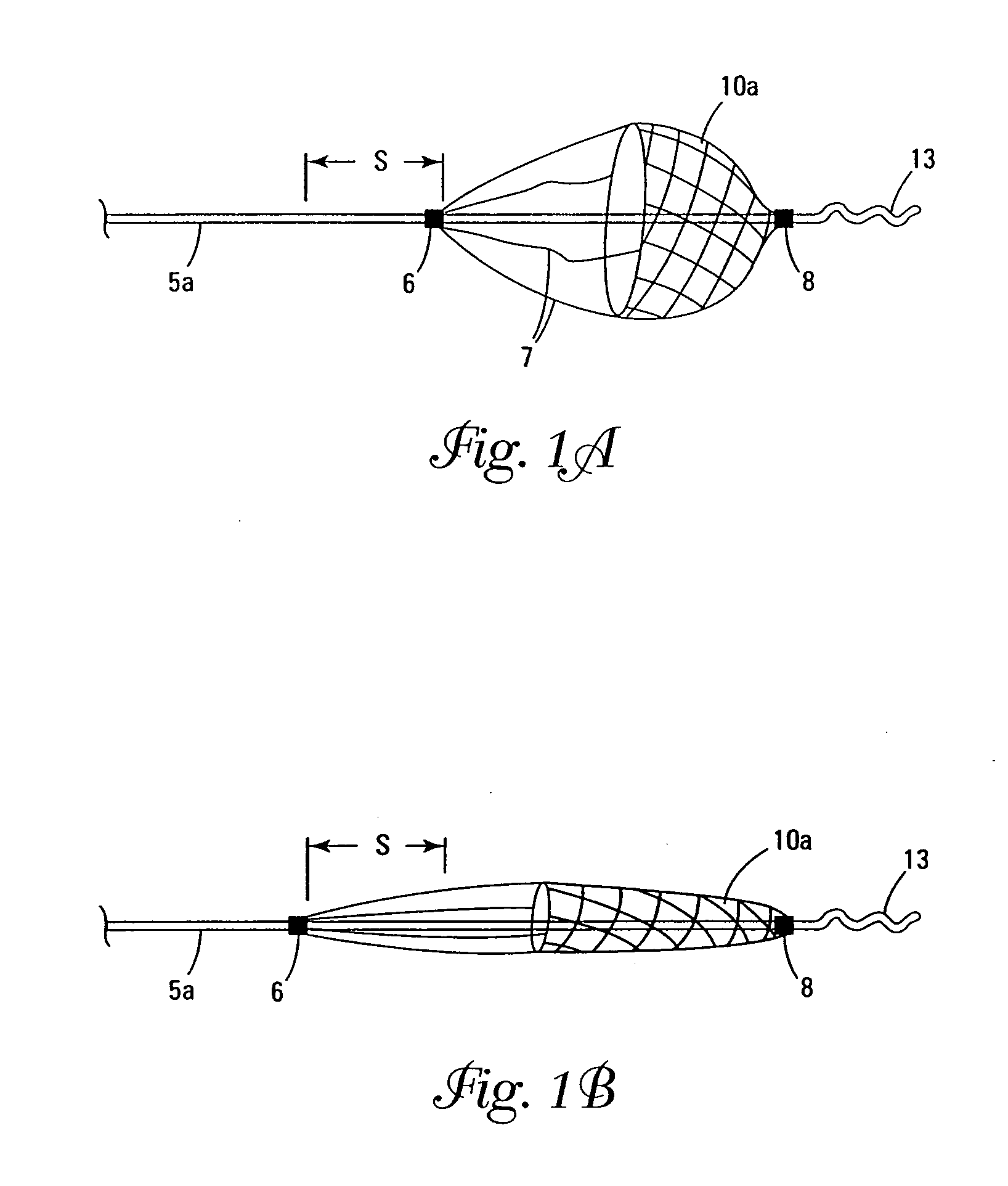

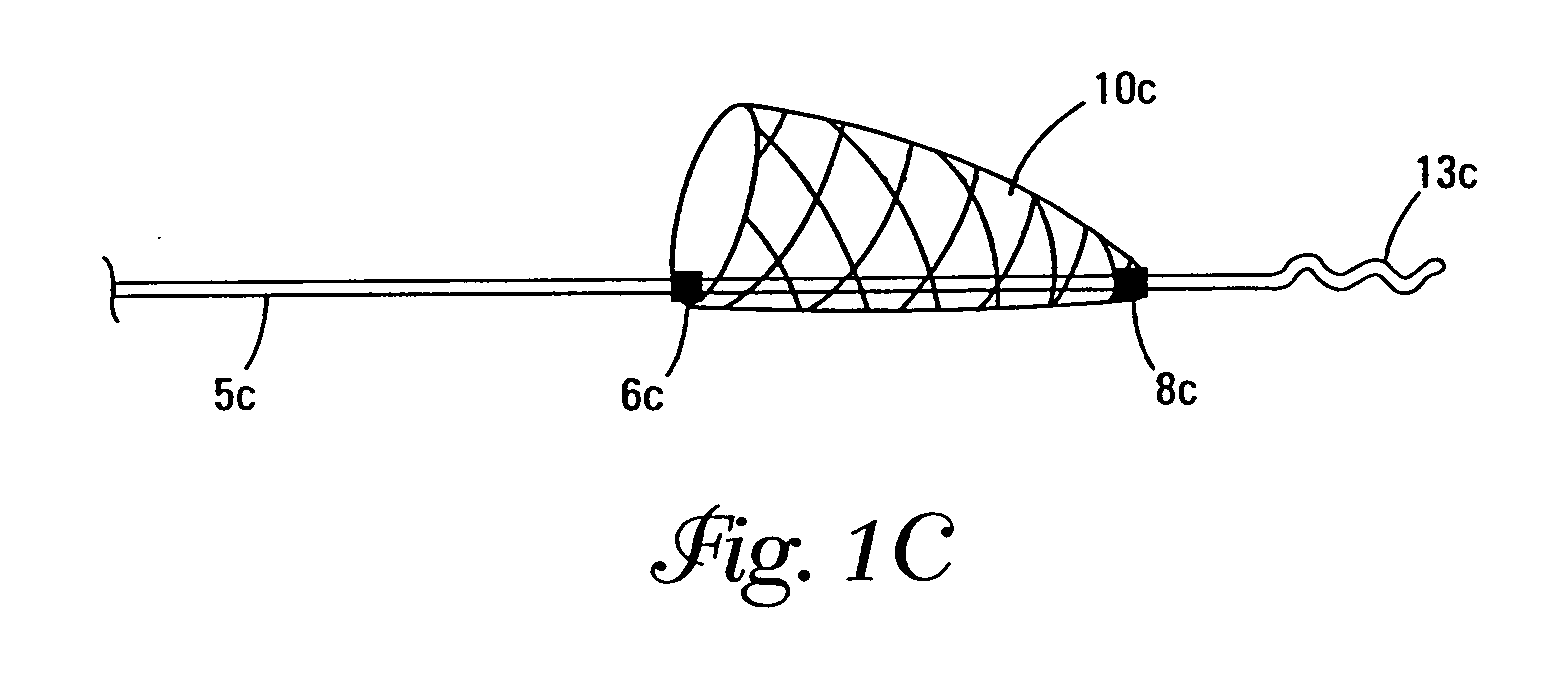

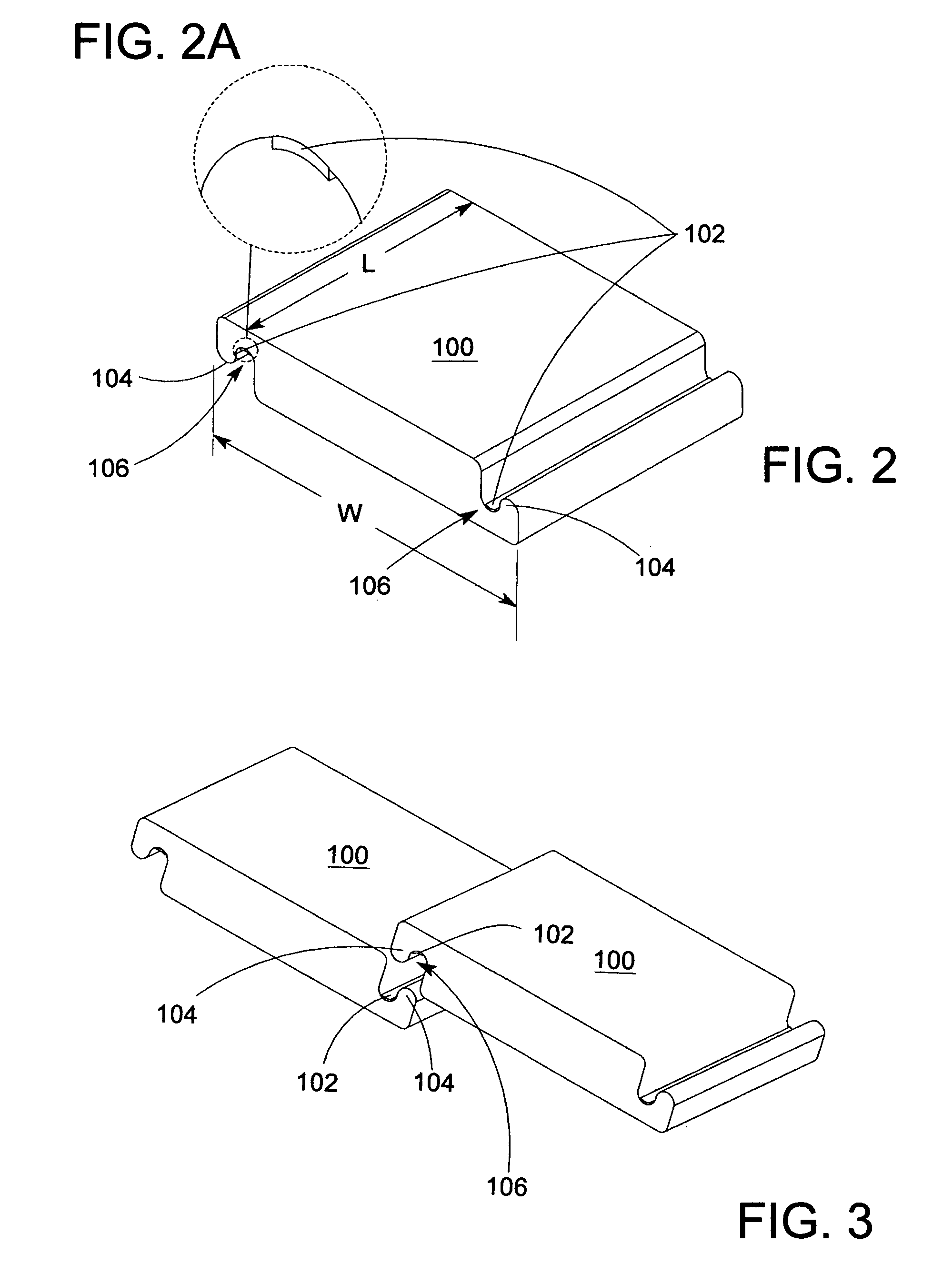

Embolic filters with controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained, and the filter element comprises a self-expanding material having pores. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size.

Owner:COVIDIEN LP

Embolic filters having multiple layers and controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter element is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size. The filter element has two or more filtering layers, each filtering layer having pores, each filtering layer being adjacent to at least one other filtering layer, and at least one of the filtering layers being made of a self-expanding material.

Owner:COVIDIEN LP

Light-emitting device

ActiveUS7872259B2Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

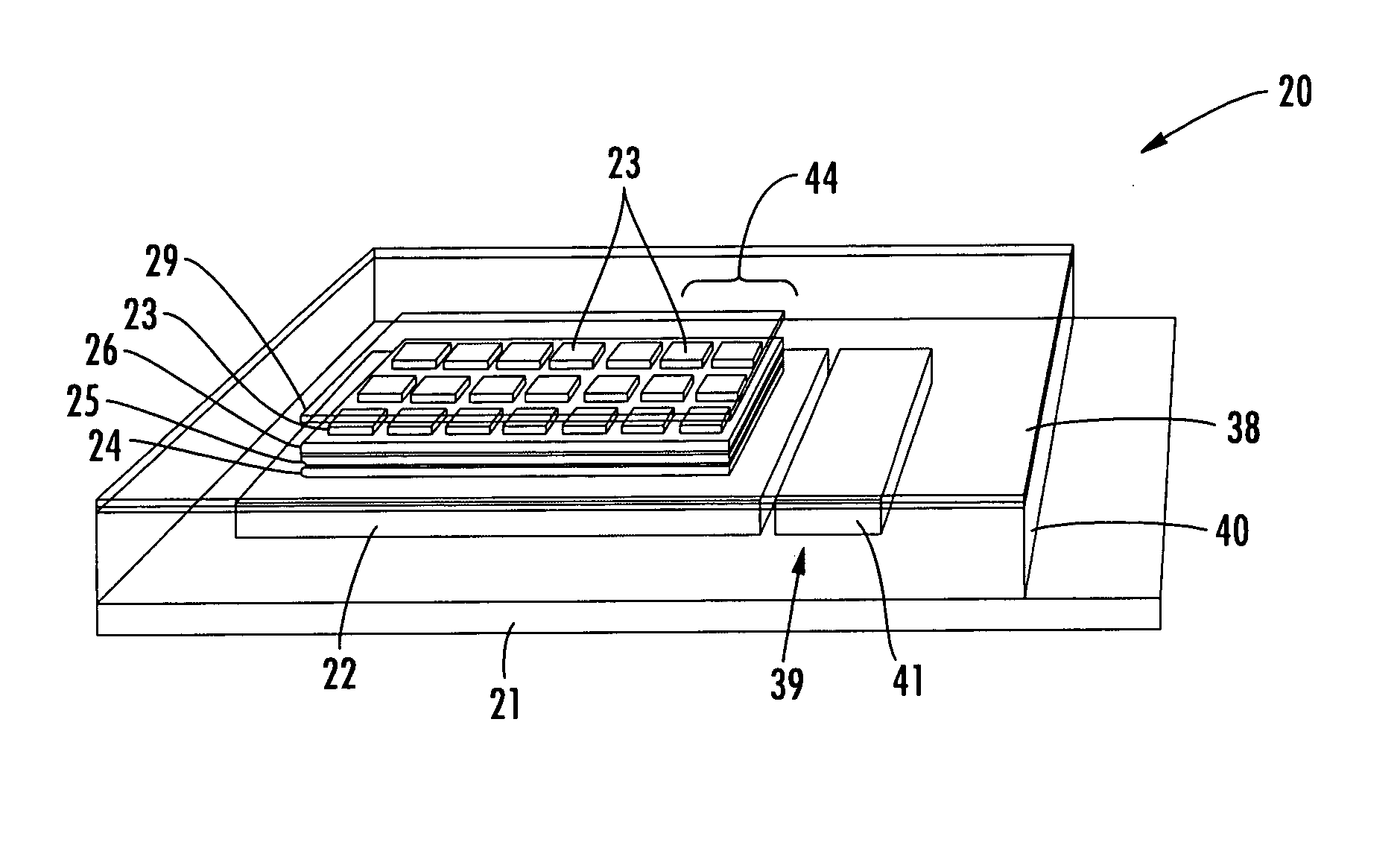

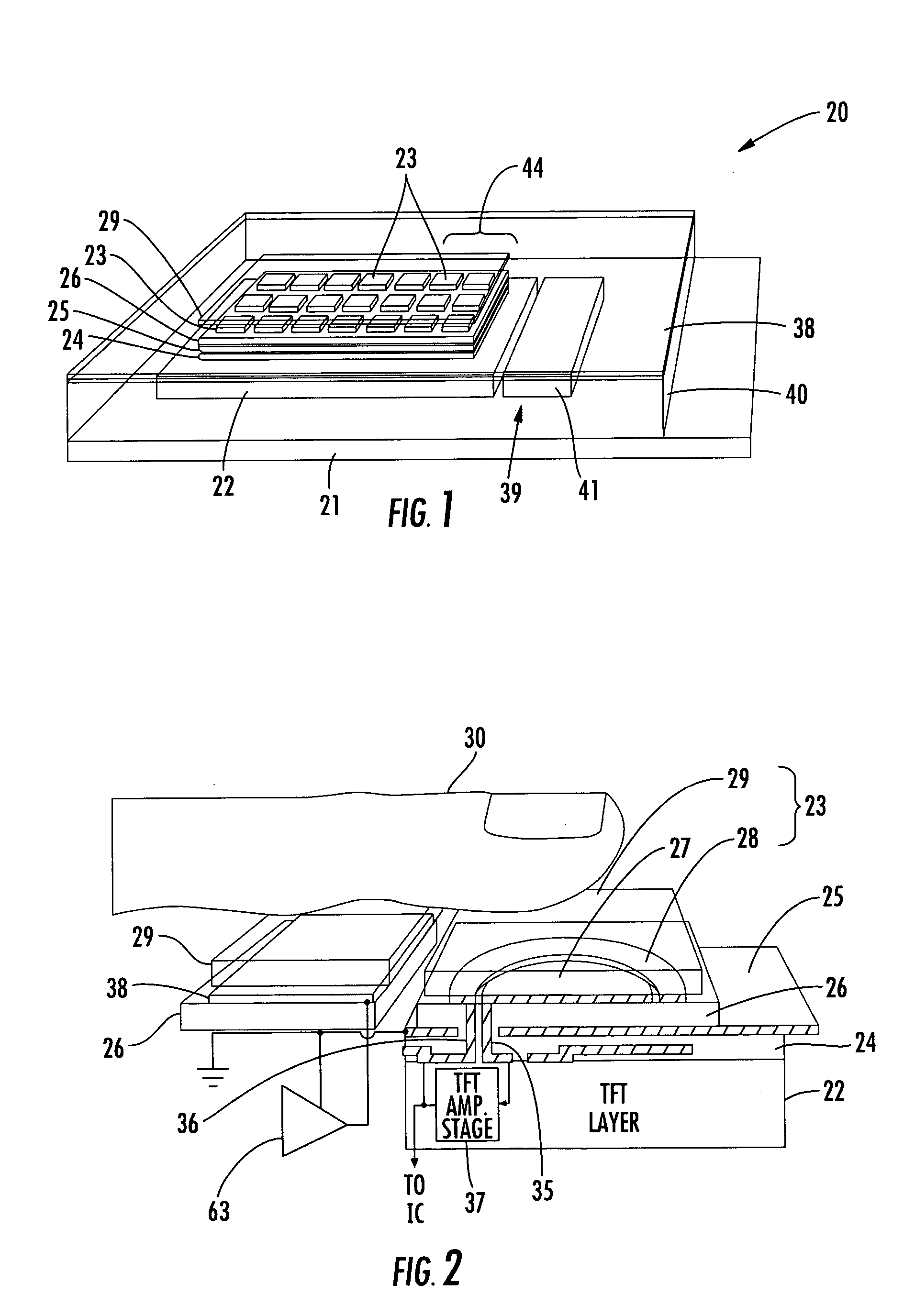

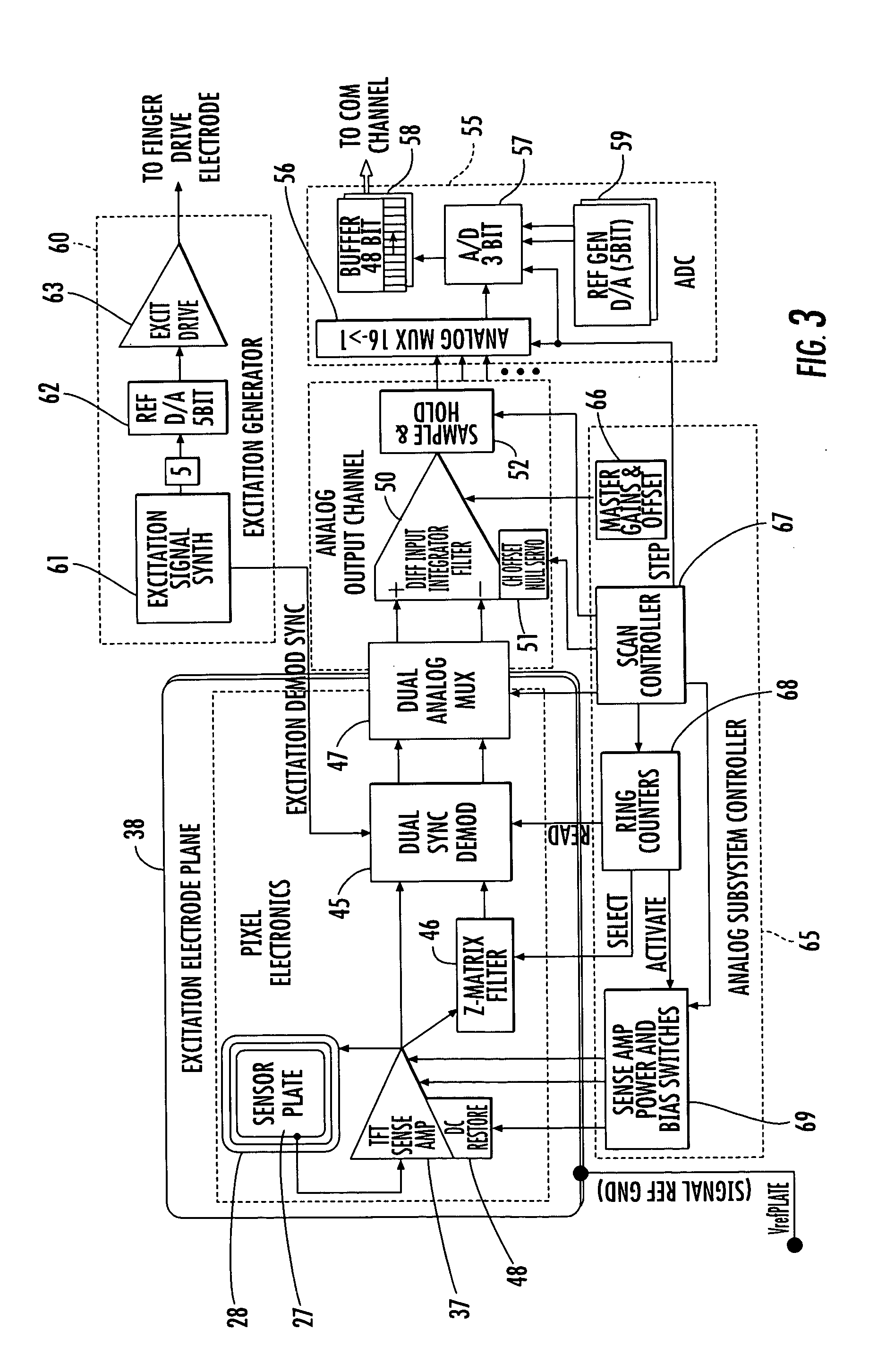

Finger biometric sensor with sensor electronics distributed over thin film and monocrystalline substrates and related methods

ActiveUS20050110103A1Desired characteristicSolid-state devicesPrint image acquisitionElectric fieldIntegrated circuit

A finger biometric sensor may include a thin film substrate, a thin film transistor (TFT) layer on the thin film substrate, and an array of electric field sensing electrodes adjacent the TFT layer for receiving a finger adjacent thereto. The TFT layer may include a plurality of TFTs defining a respective TFT amplifier stage for each electric field sensing electrode. The sensor may further include a finger excitation electrode adjacent the array of electric field sensing electrodes, and at least one integrated circuit adjacent the thin film substrate. The integrated circuit may include a monocrystalline substrate and processing circuitry adjacent the monocrystalline substrate and connected to the TFT amplifier stages.

Owner:APPLE INC

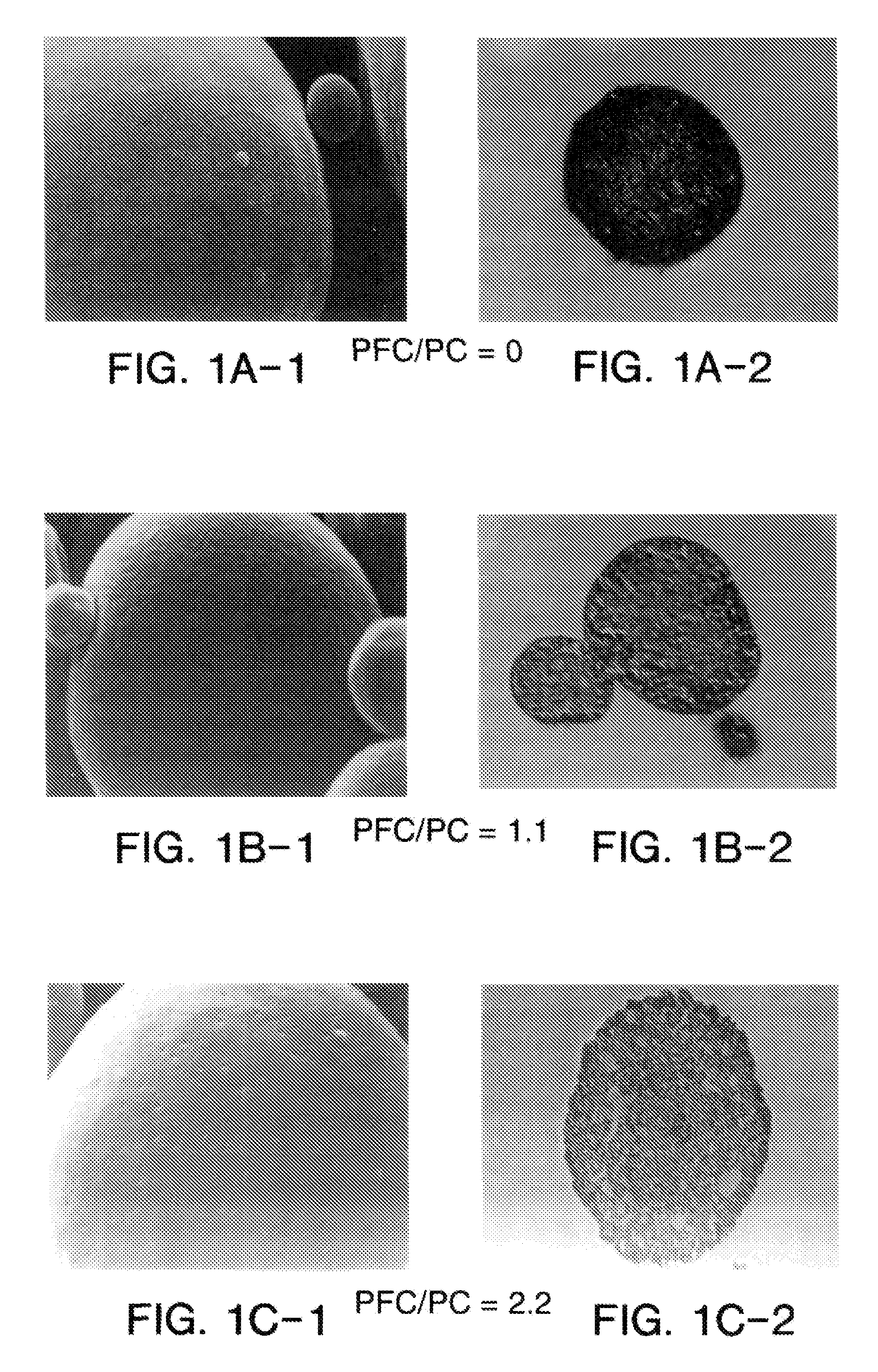

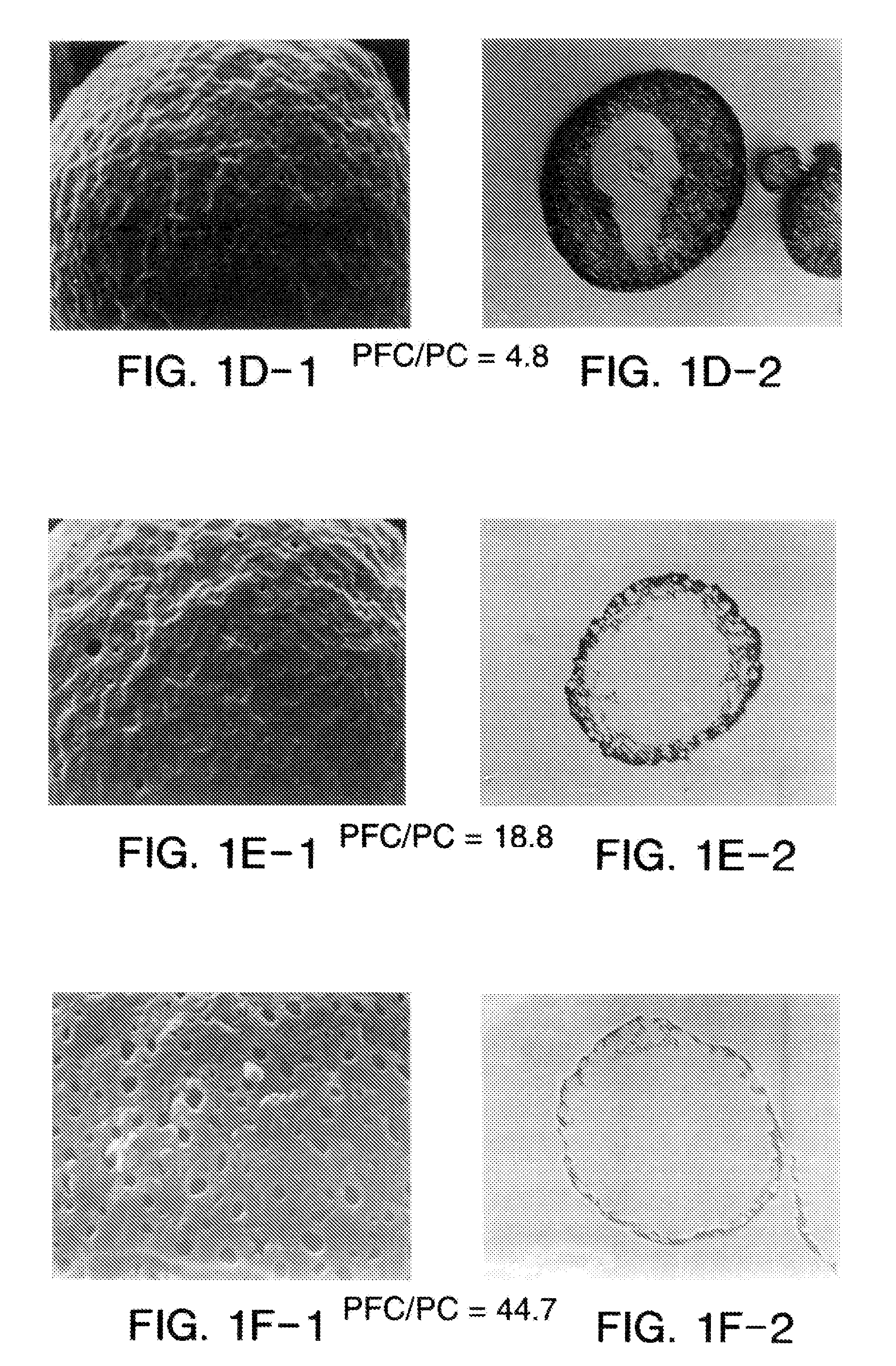

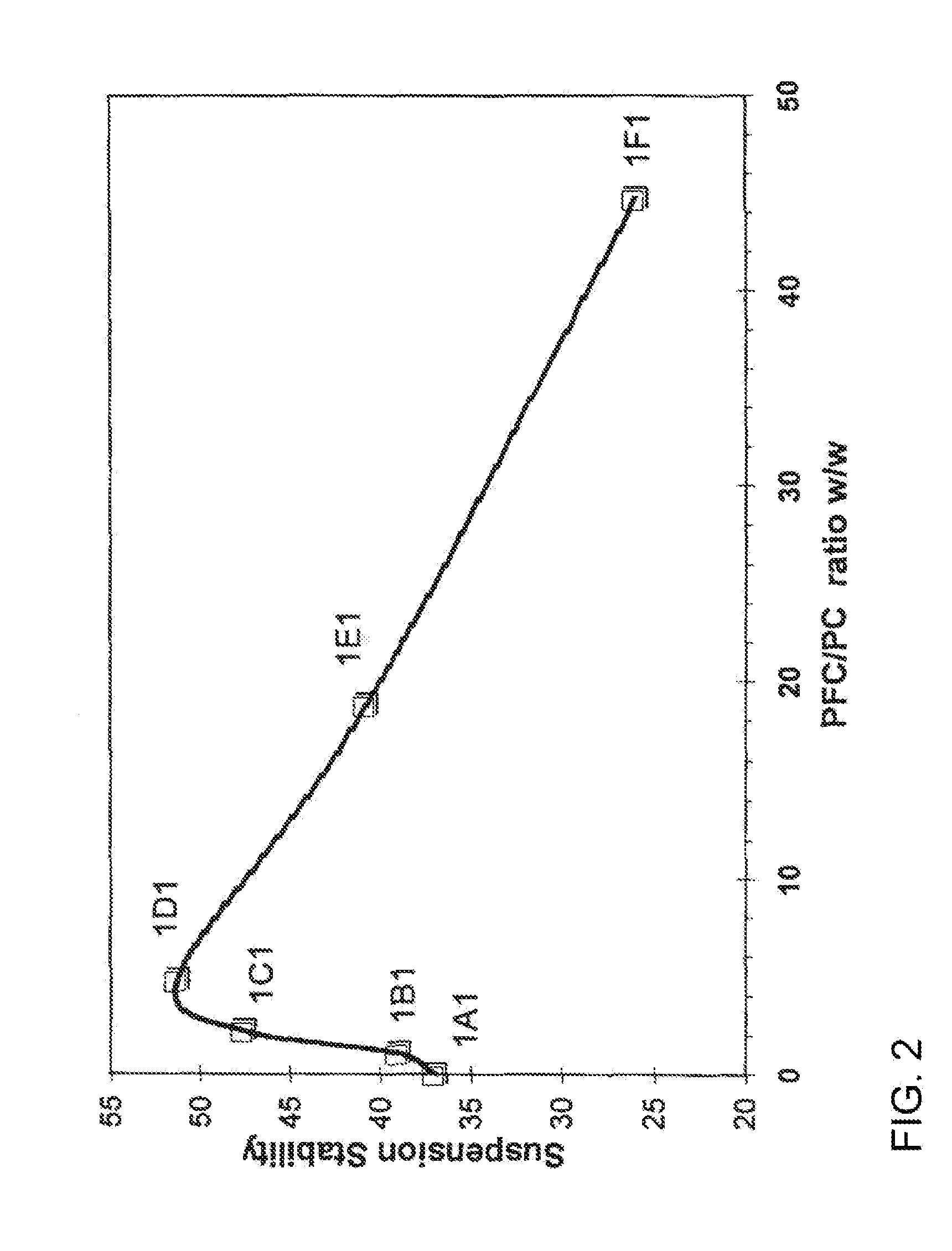

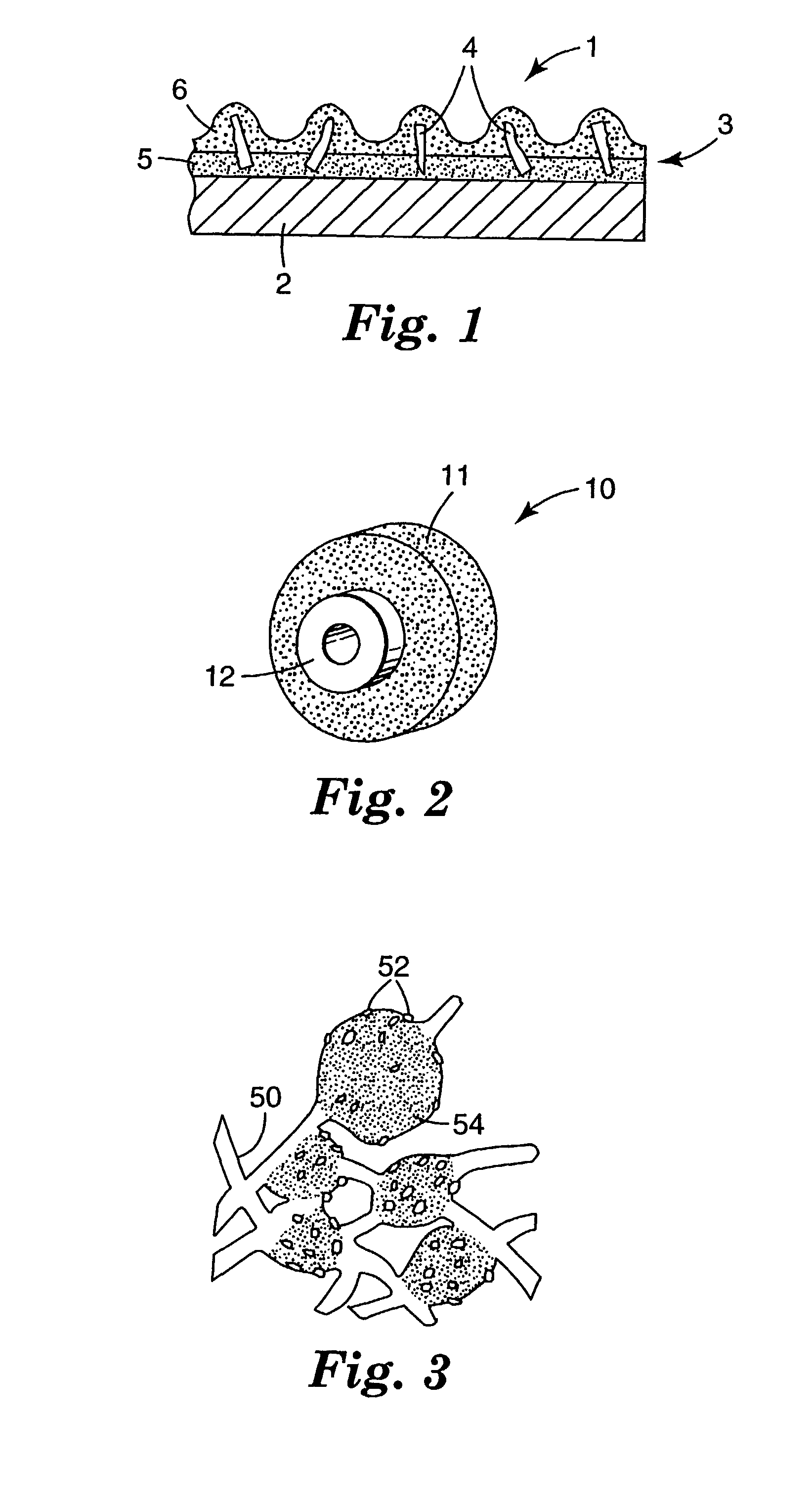

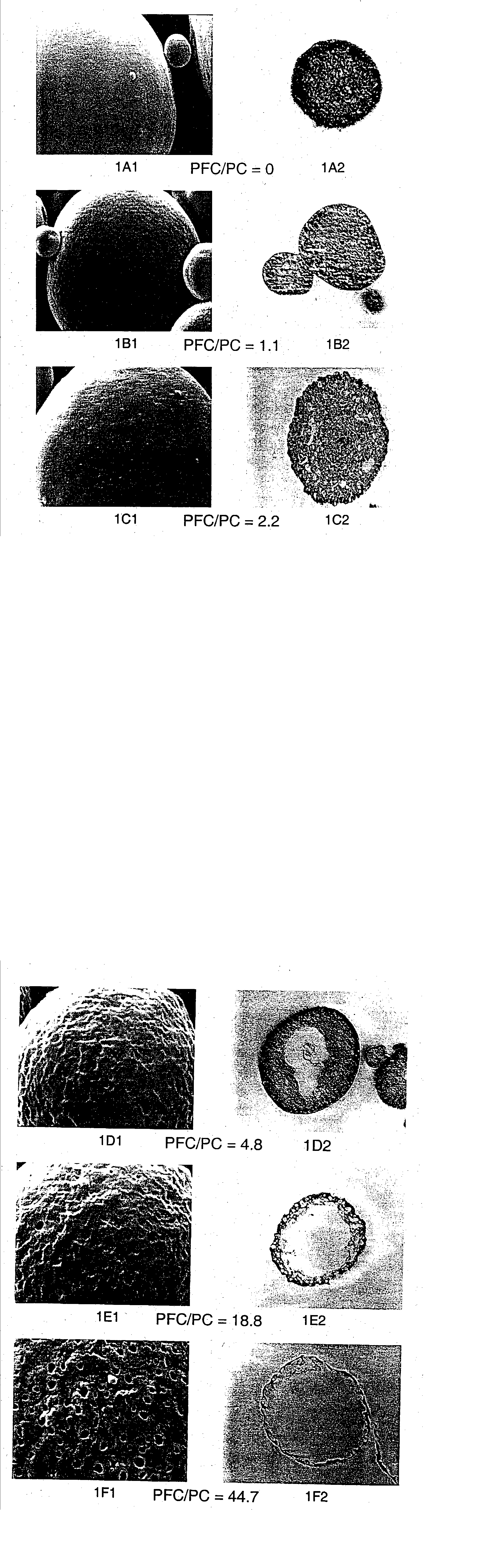

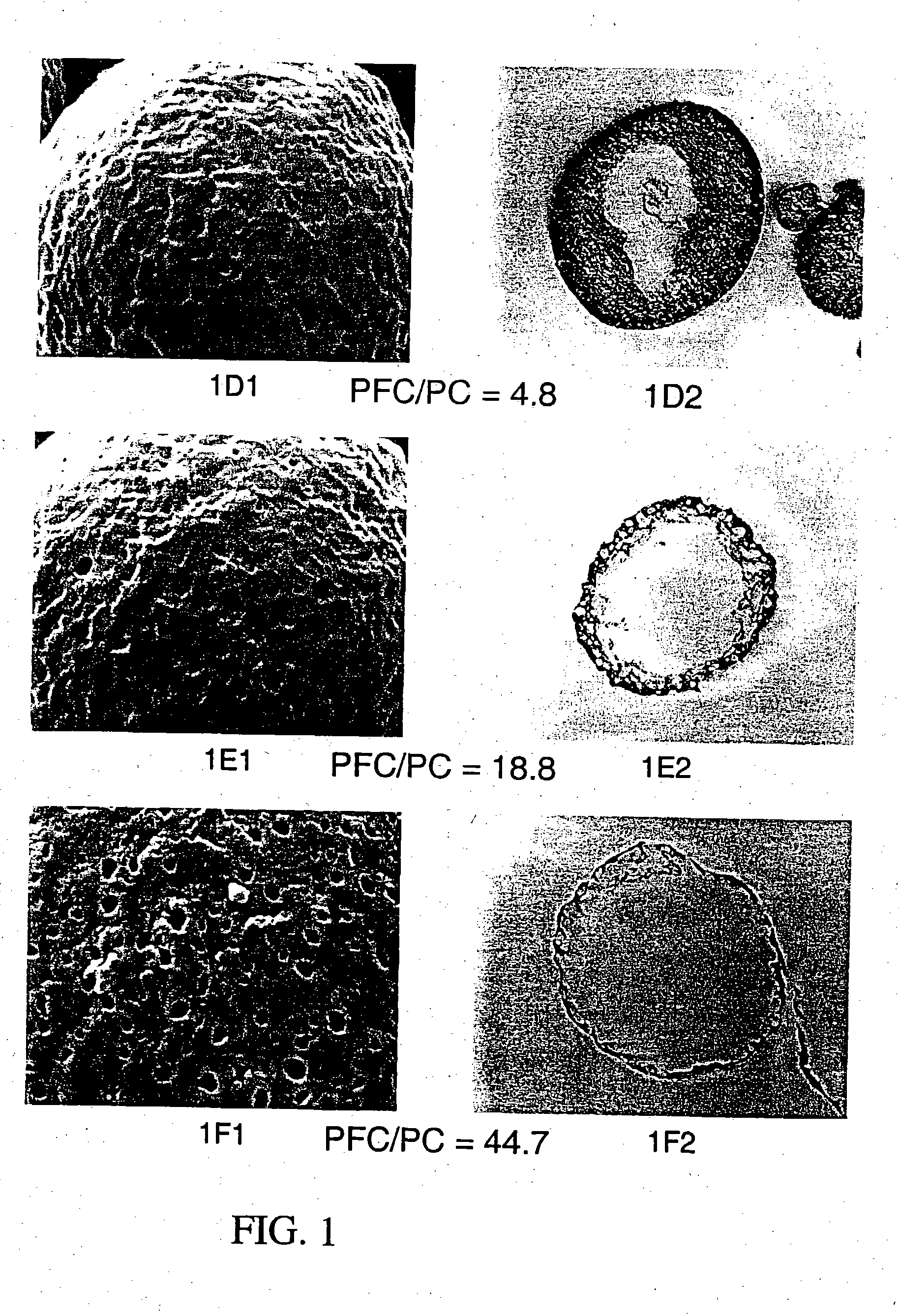

Engineered particles and methods of use

InactiveUS7306787B2Reduce deliveryLess attractivePowder deliveryOrganic active ingredientsNebulizerActive agent

Engineered particles are provided may be used for the delivery of a bioactive agent to the respiratory tract of a patient. The particles may be used in the form of dry powders or in the form of stabilized dispersions comprising a nonaqueous continuous phase. In particularly preferred embodiments the particles may be used in conjunction with an inhalation device such as a dry powder inhaler, metered dose inhaler or a nebulizer.

Owner:NOVARTIS AG

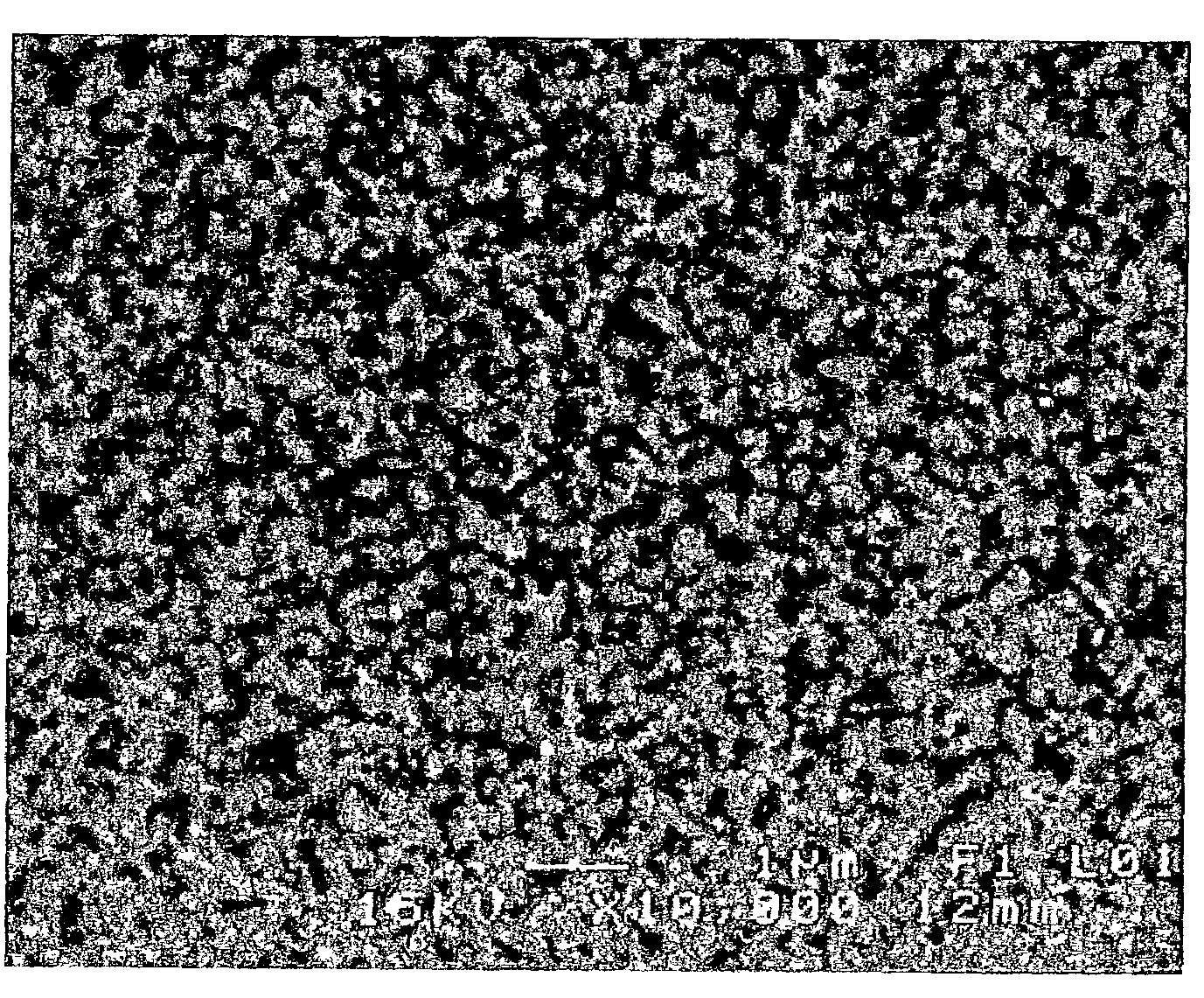

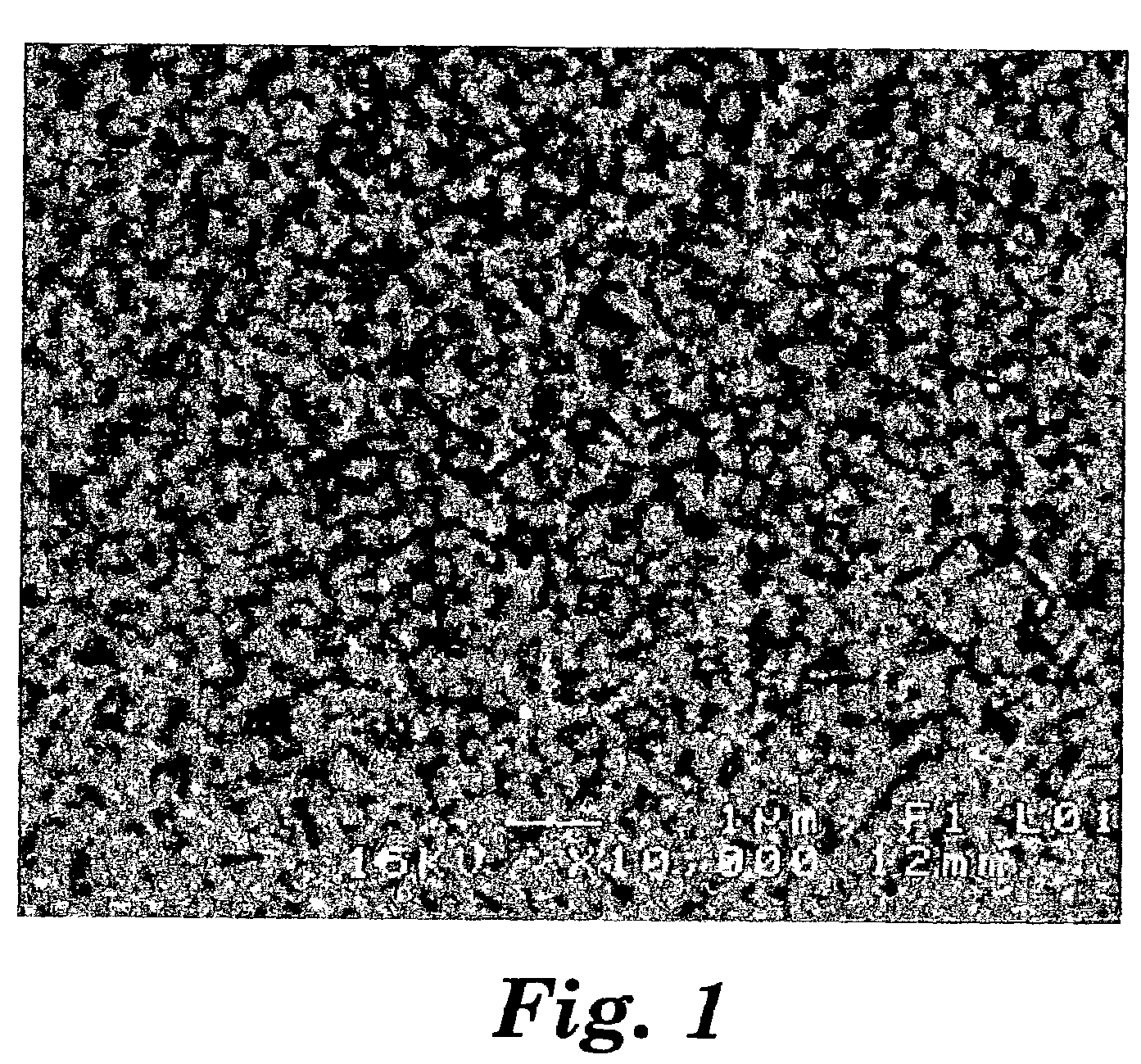

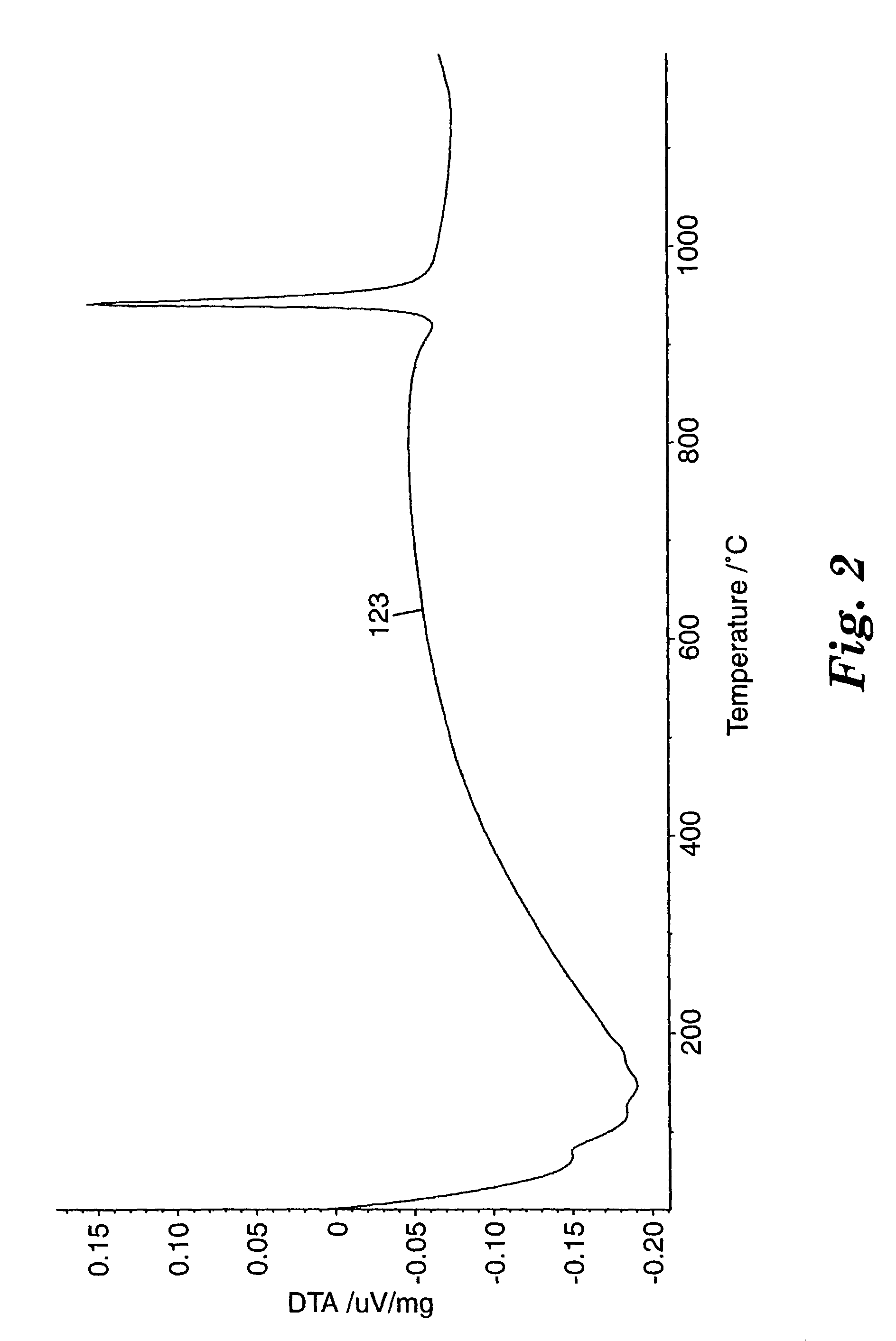

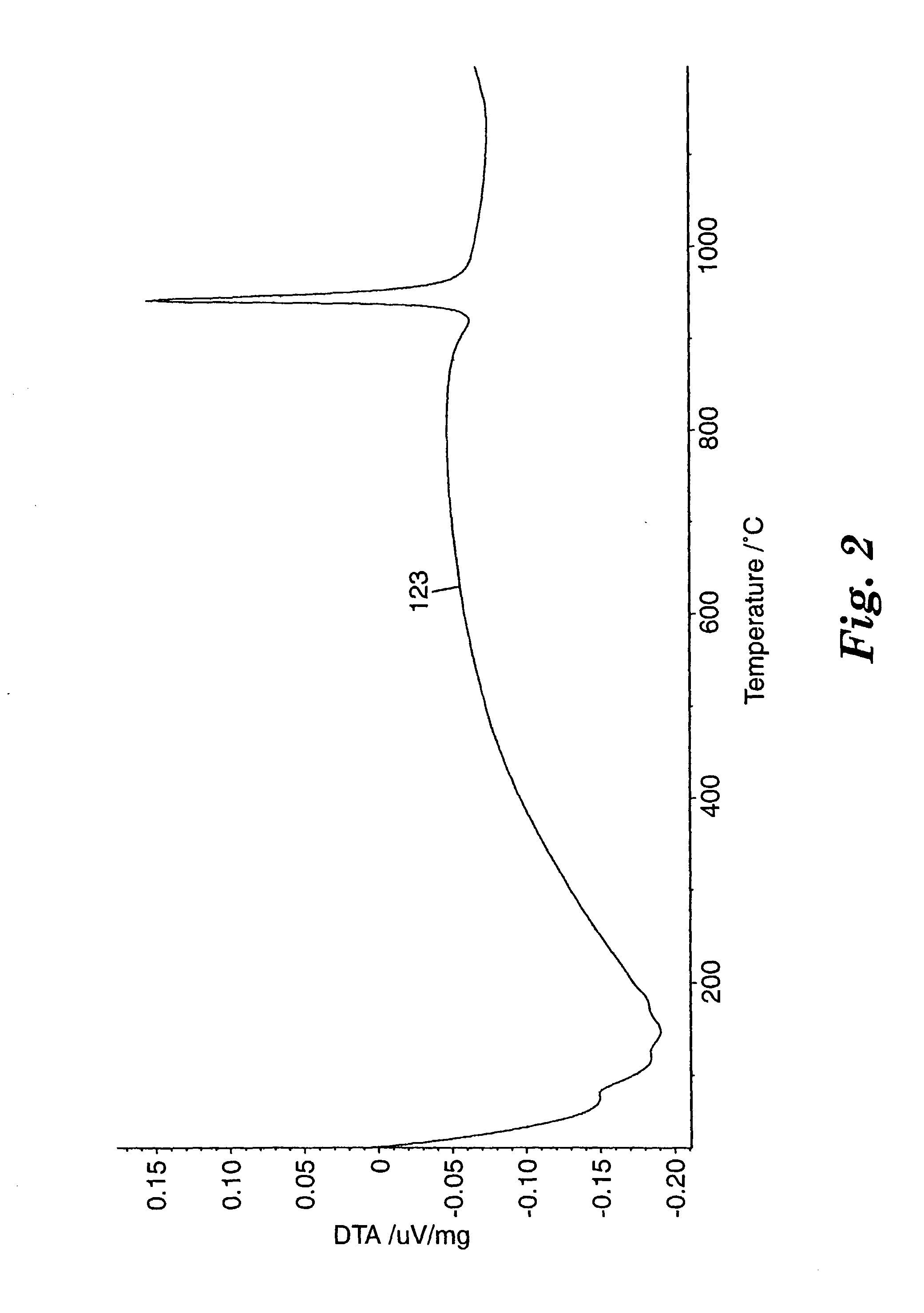

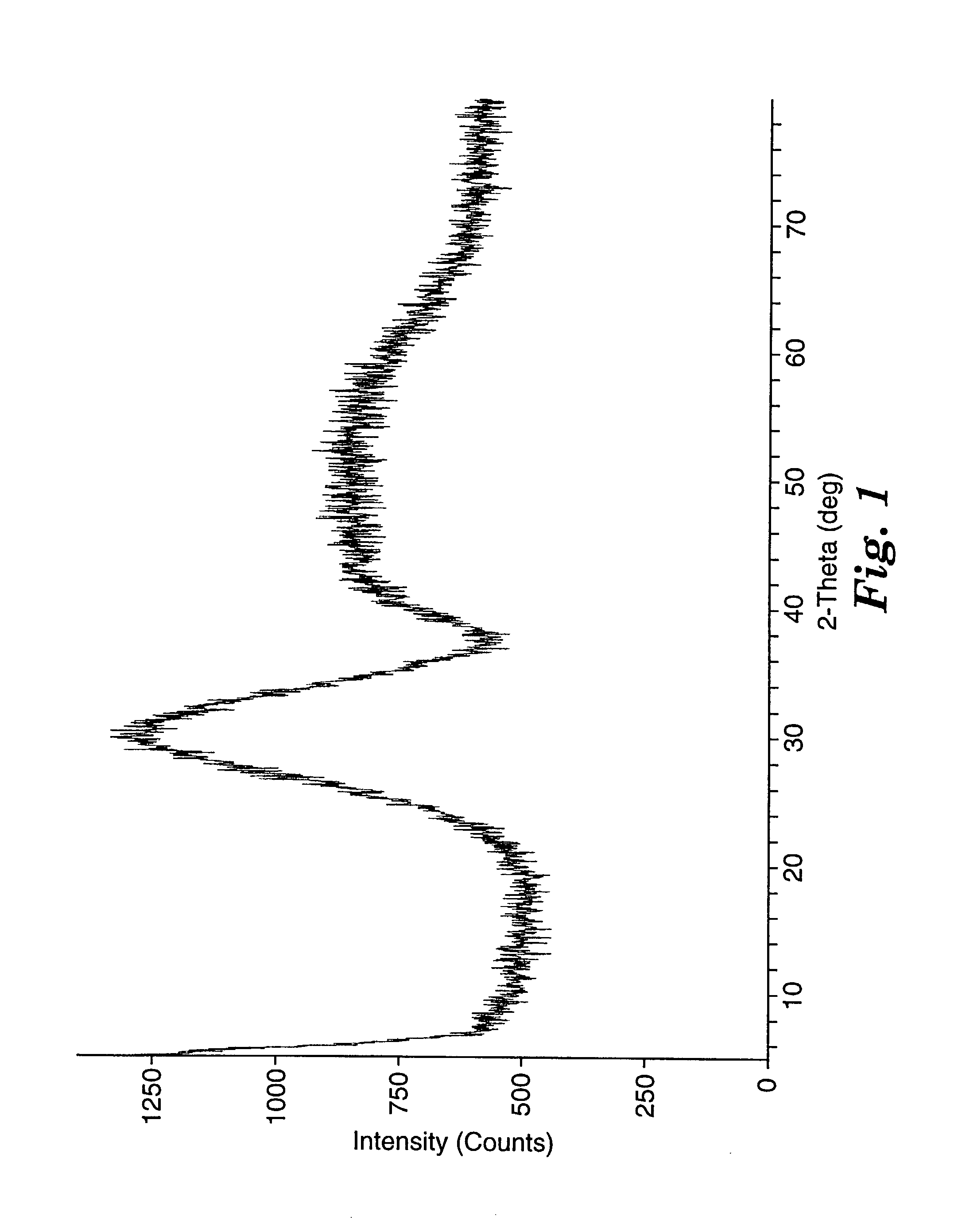

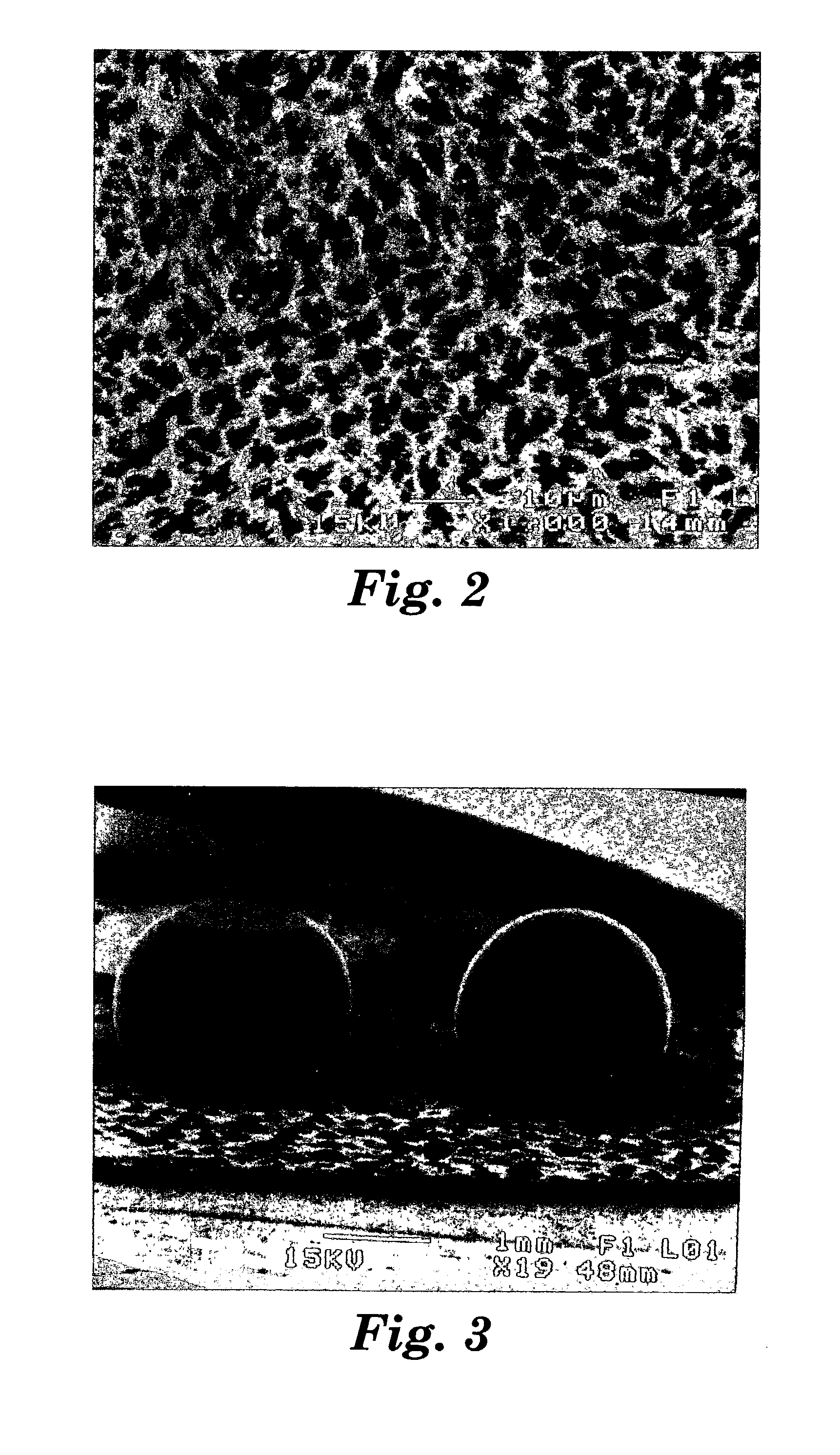

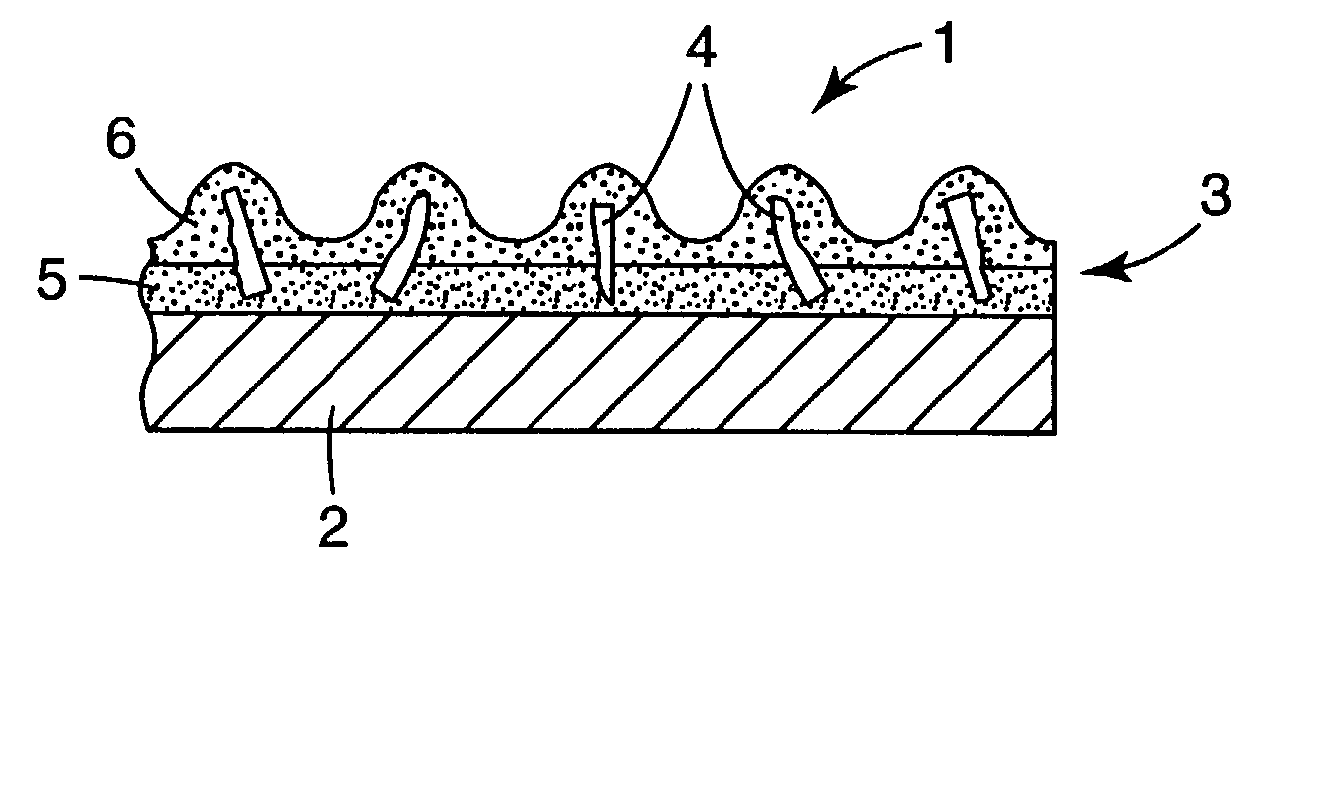

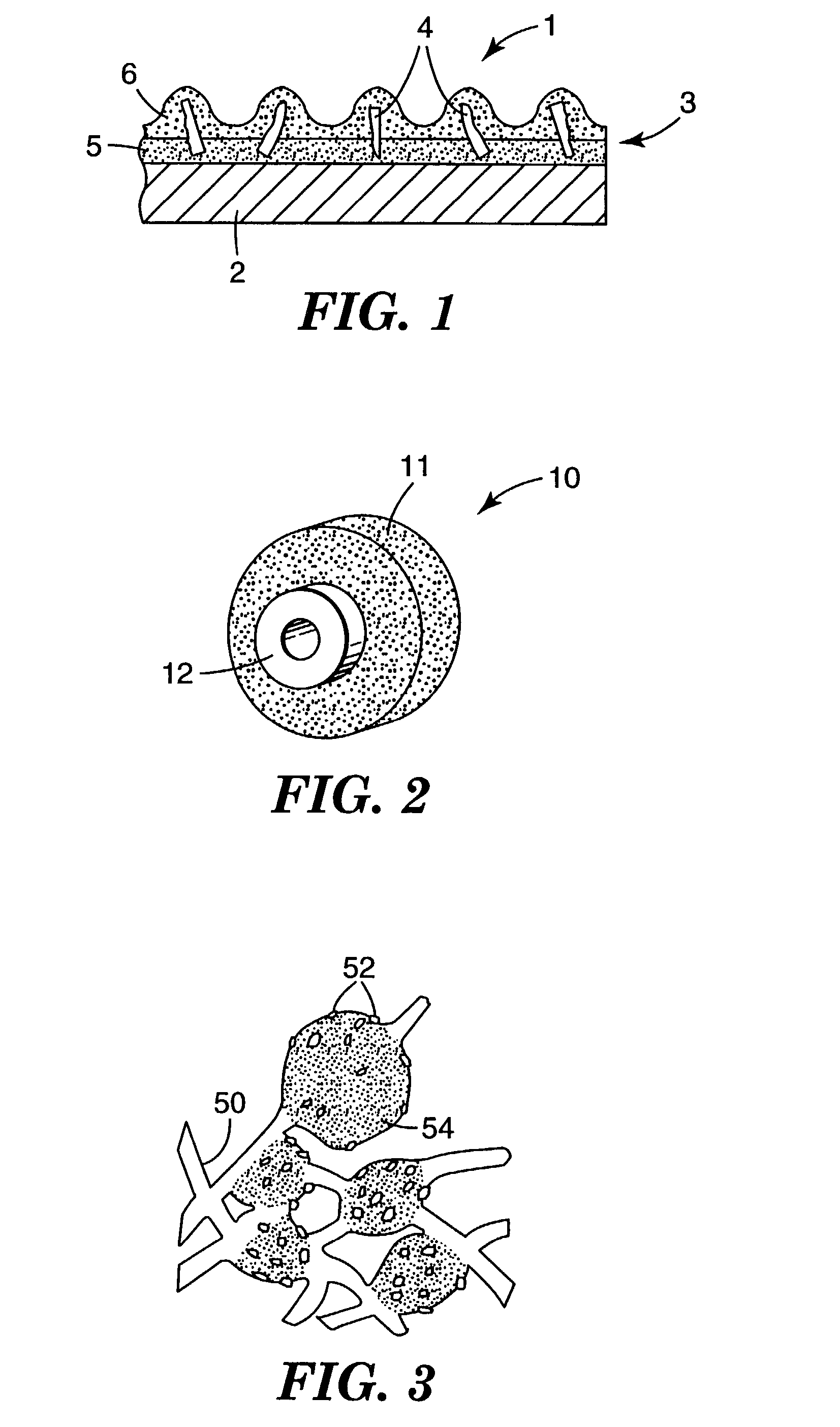

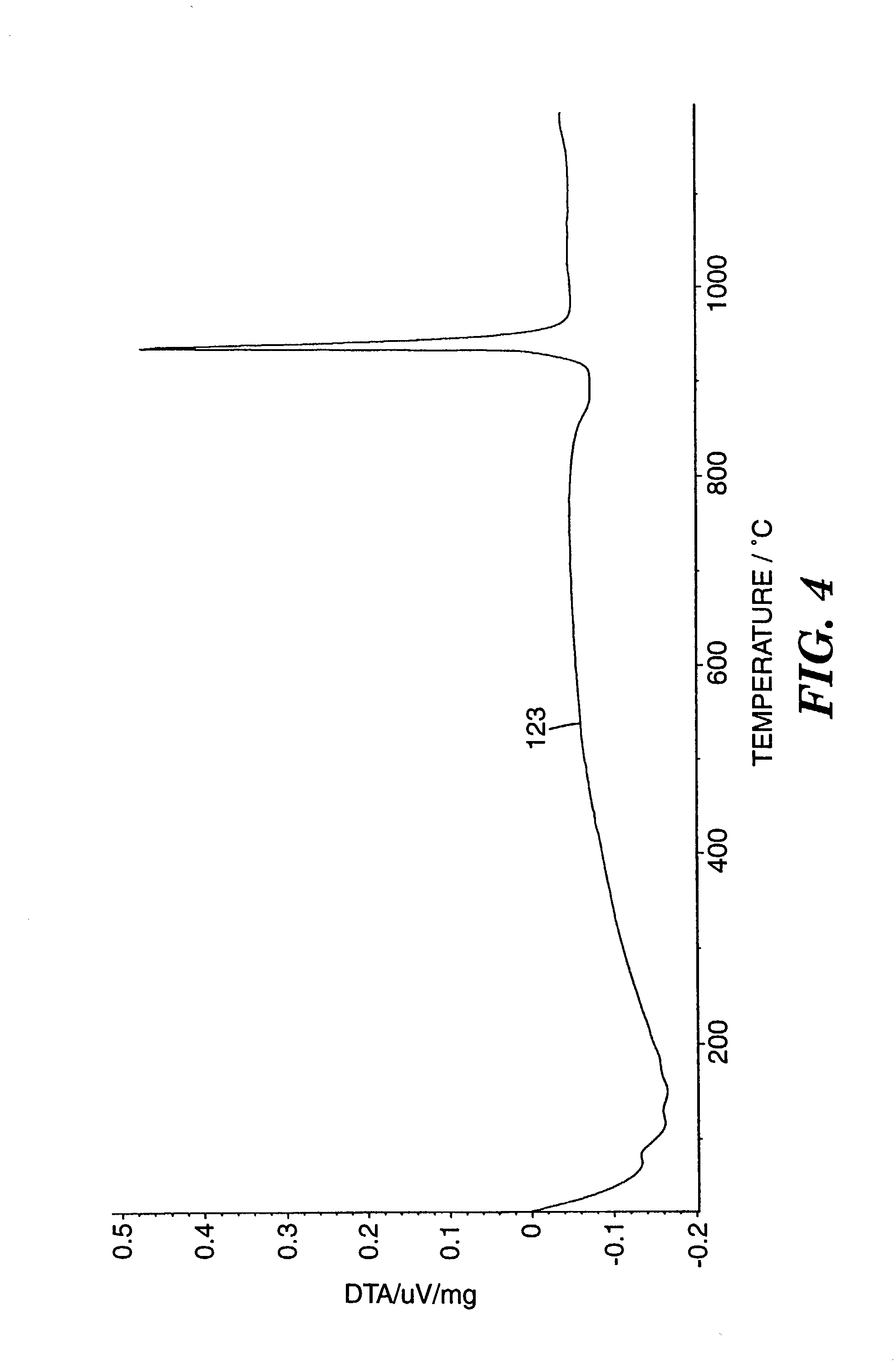

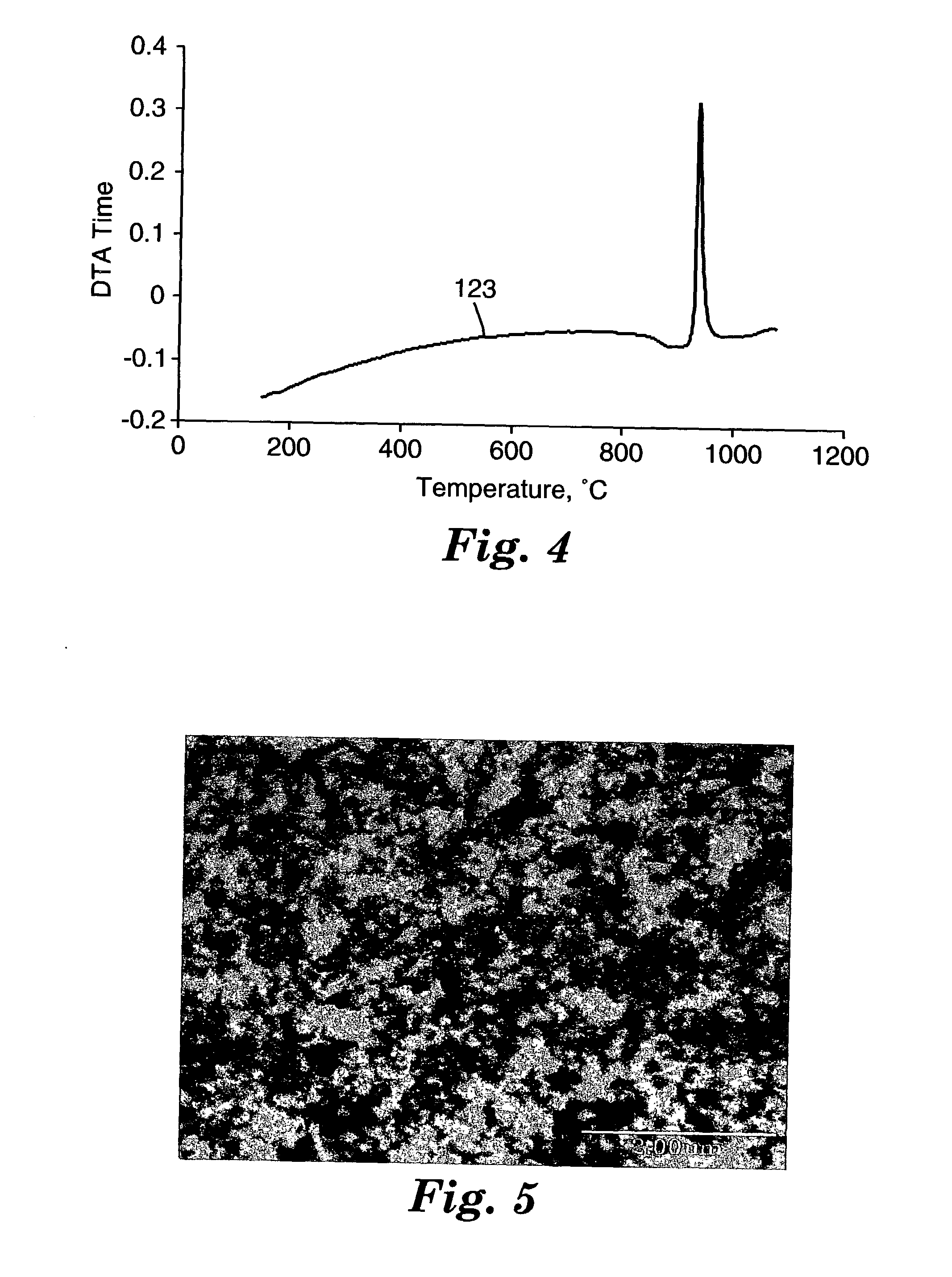

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

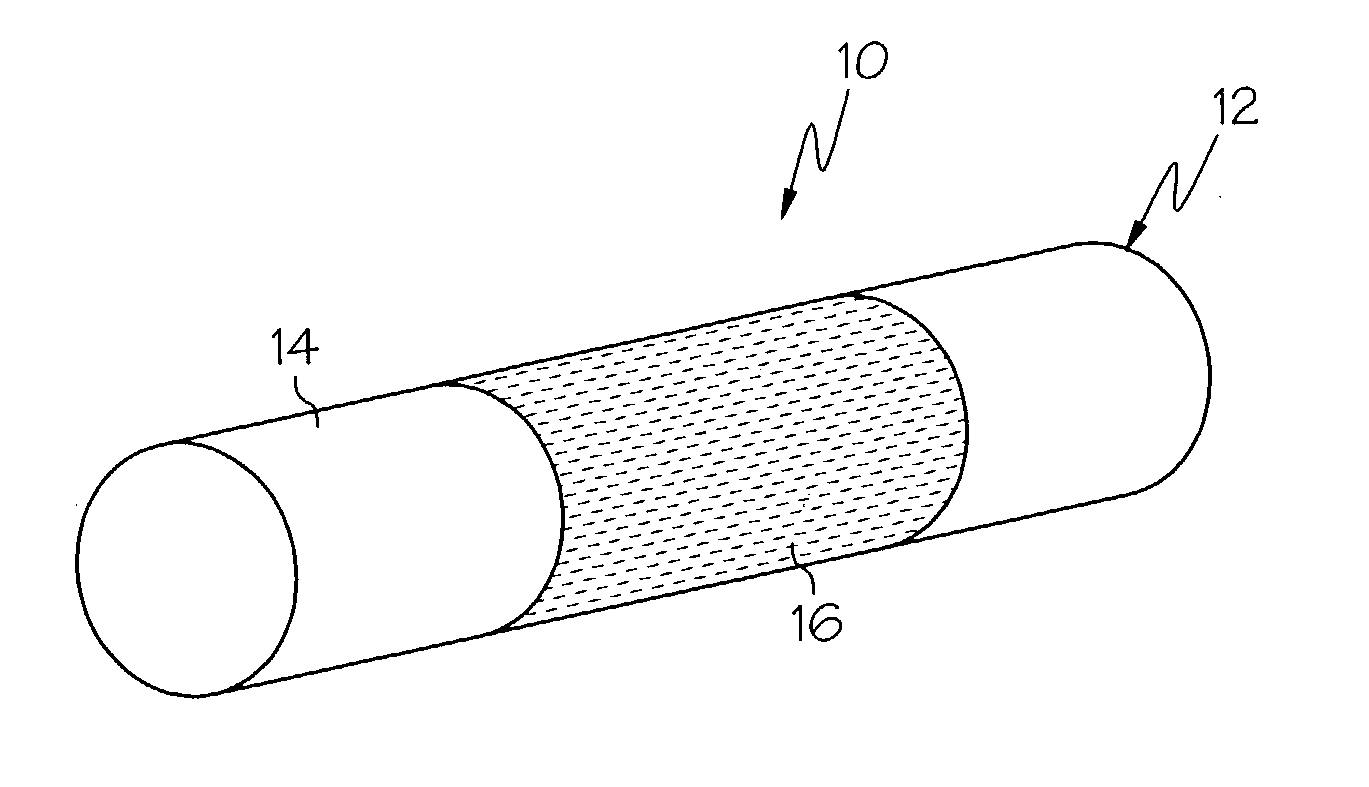

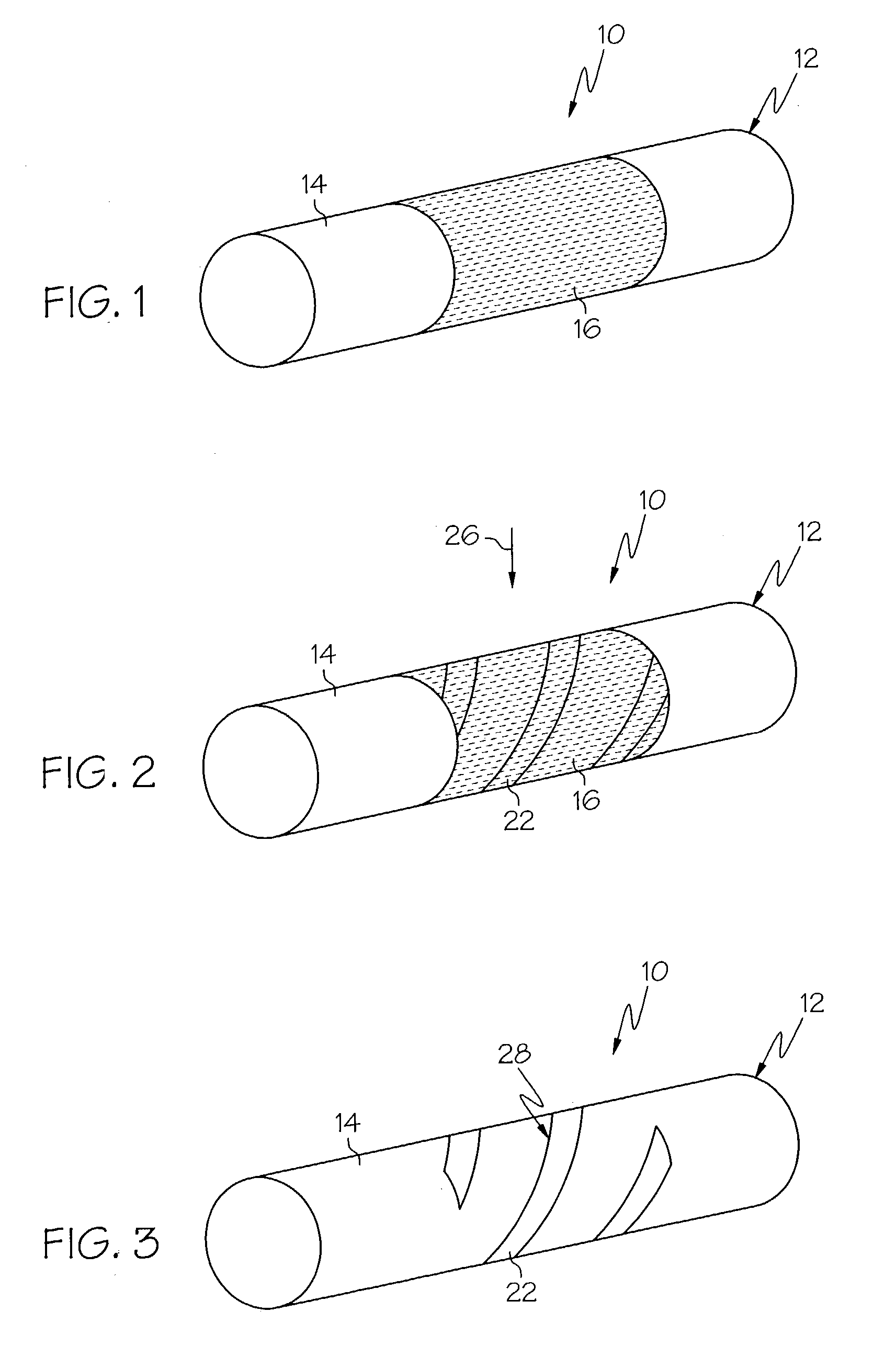

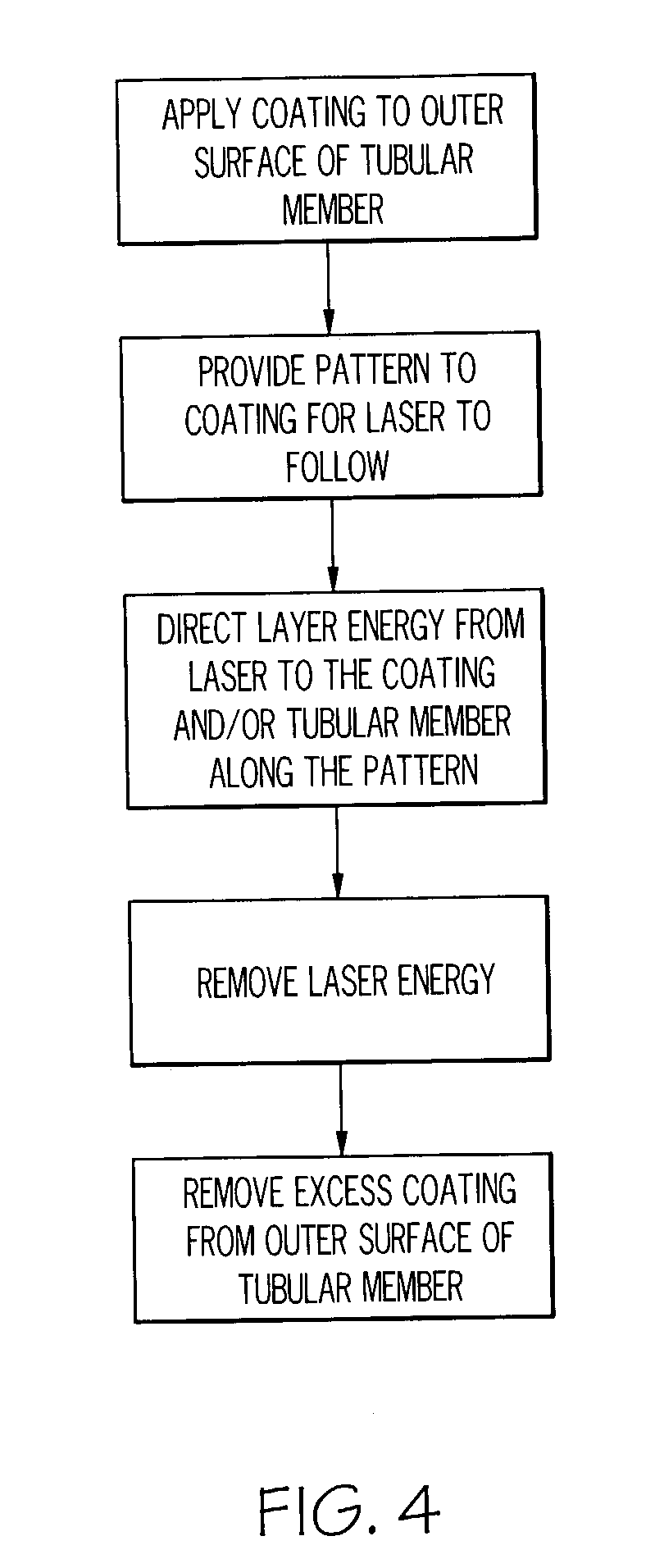

Laser sintering process and devices made therefrom

InactiveUS20040086674A1Improved and desired physical characteristicImproved engagement characteristicRadiation applicationsLayered productsMedical devicePolymer

Owner:SCI MED LIFE SYST

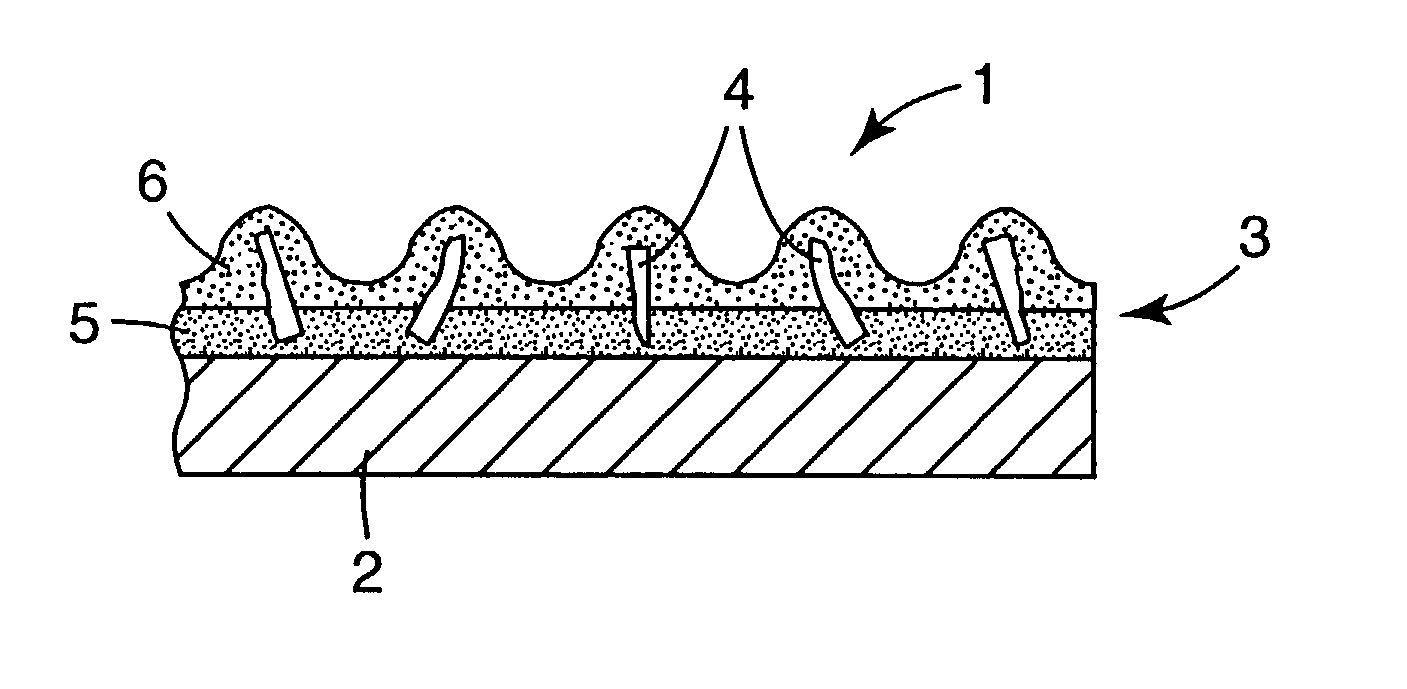

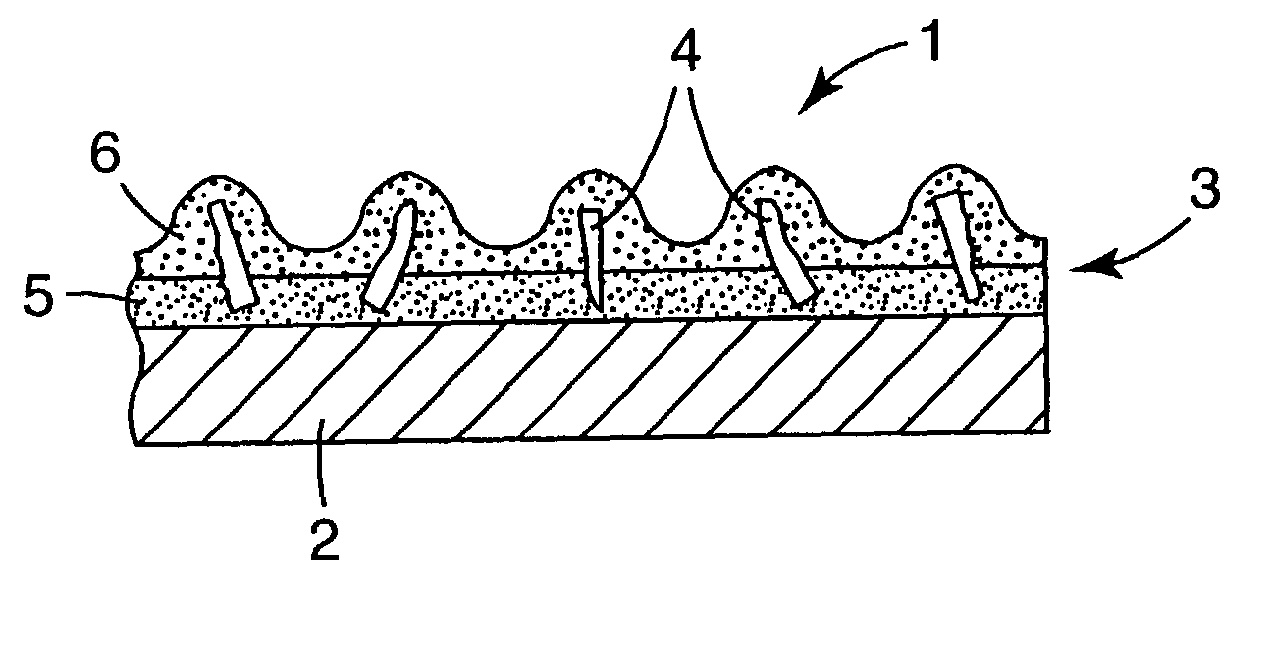

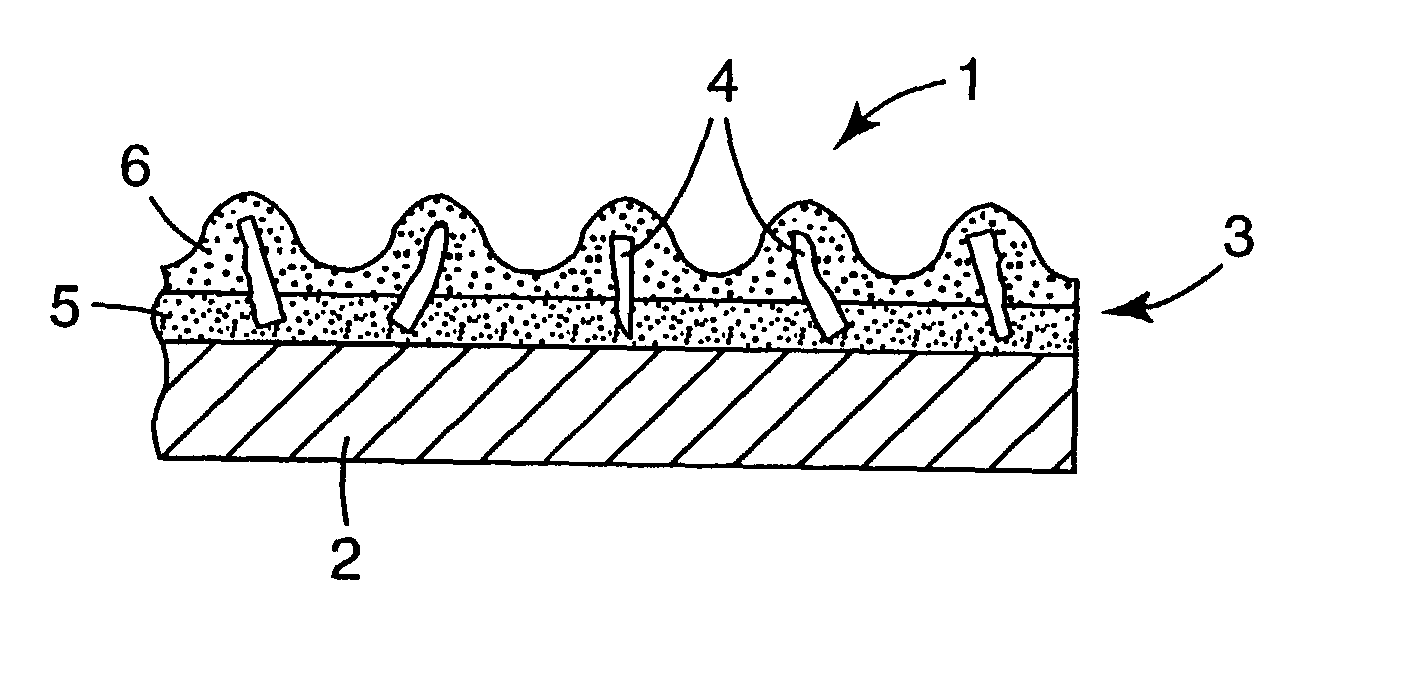

Nonwoven fabrics with advantageous properties

InactiveUS7060149B2Increasing the thicknessIncrease opening spacingEnvelopes/bags making machineryLaminationEngineeringNonwoven fabric

This invention relates to nonwoven fabrics with advantageous characteristics and the method to produce these fabrics. Advantageously, the fabrics of the subject invention have increased thickness (loft) compared to conventional nonwoven fabrics and have high air permeability and open space while maintaining softness and strength at the same basis weight.

Owner:THE PROCTER & GAMBLE COMPANY

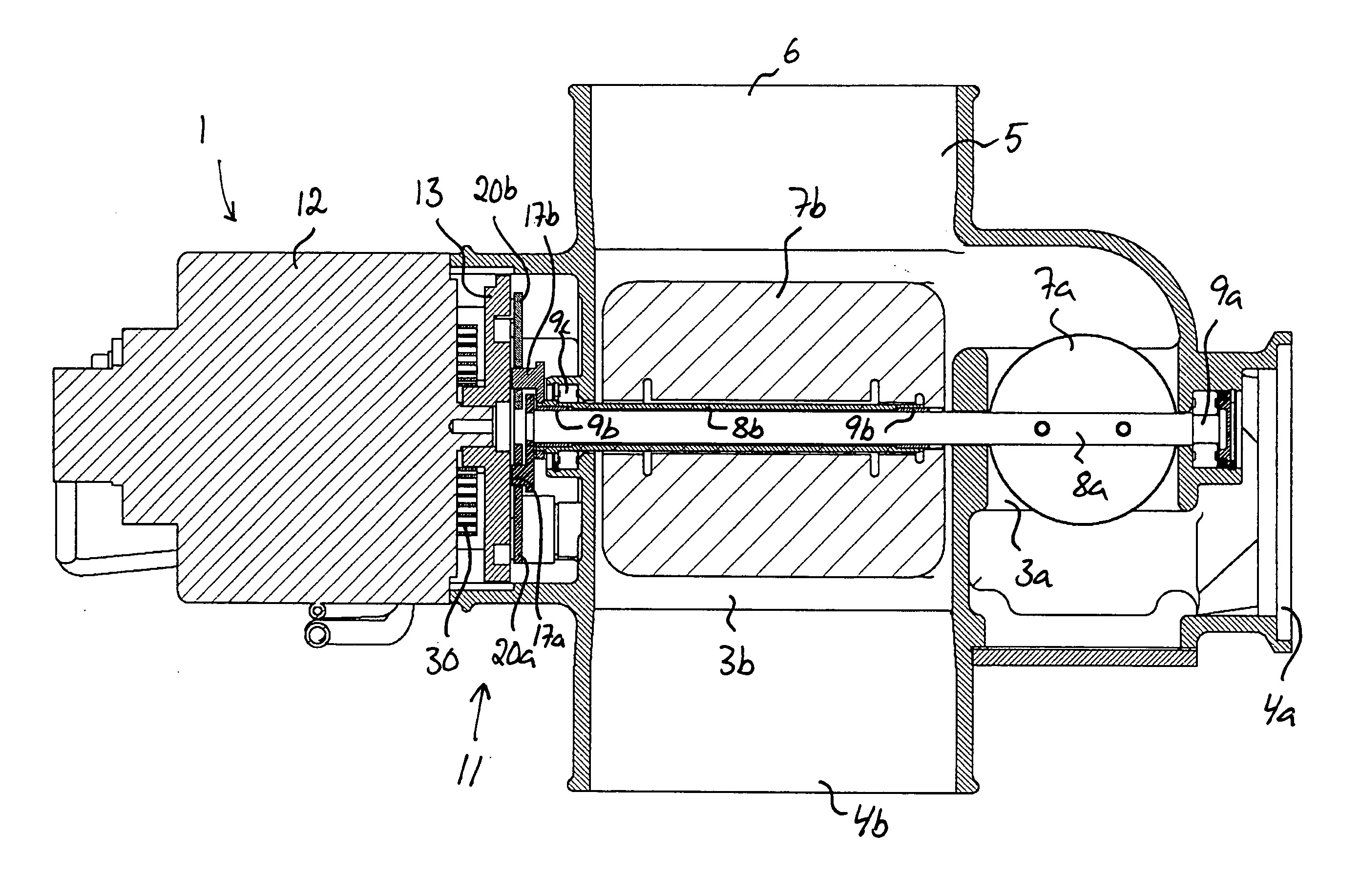

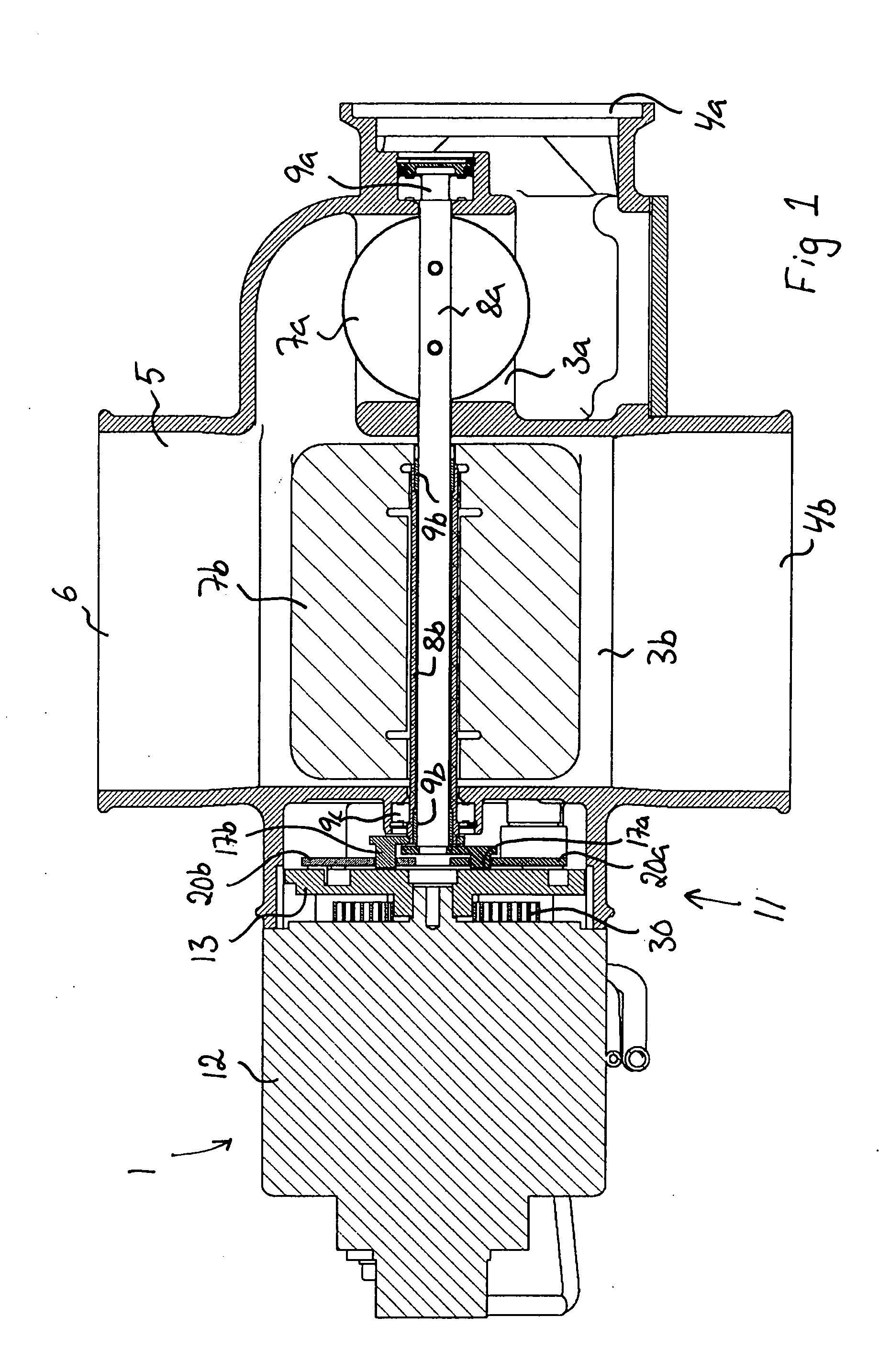

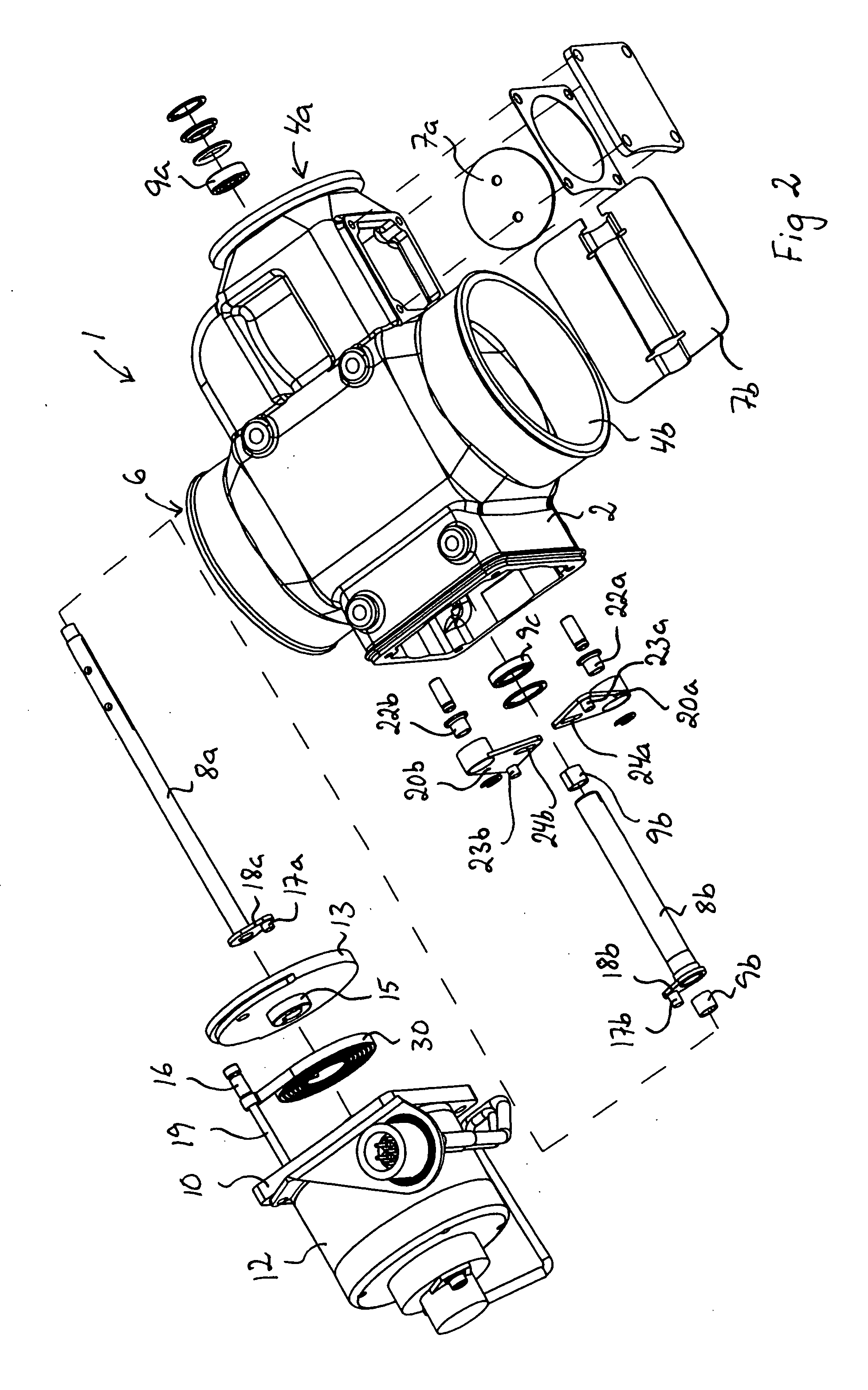

Valve device

InactiveUS20050241702A1Function increaseEasy to adjustInternal combustion piston enginesEngine operationsControl theoryMotion transfer

The invention relates to a valve device comprising a valve housing (2) with a first and a second flow channel (3a, 3b), and a first and second damper shaft (8a, 8b), which are rotatable relative to the valve housing (2). A first damper (7a) is arranged in the first flow channel (3a) fixed to the first damper shaft (8a) and a second damper (7b) is arranged in the second flow channel (3b) fixed to the second damper shaft (8b). A rotatable regulating member (13) is arranged to control the rotational position of the damper shafts (8a, 8b) via two motion transfer members (20a, 20b), the respective motion transfer member (20a, 20b) being in engagement with a guiding (21) of the regulating member (13) so that the rotational position of the motion transfer member and thereby the rotational position of the associated damper shaft (8a, 8b) is controlled by the rotational position of the regulating member via this guiding (21).

Owner:STT EMTEC AB

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

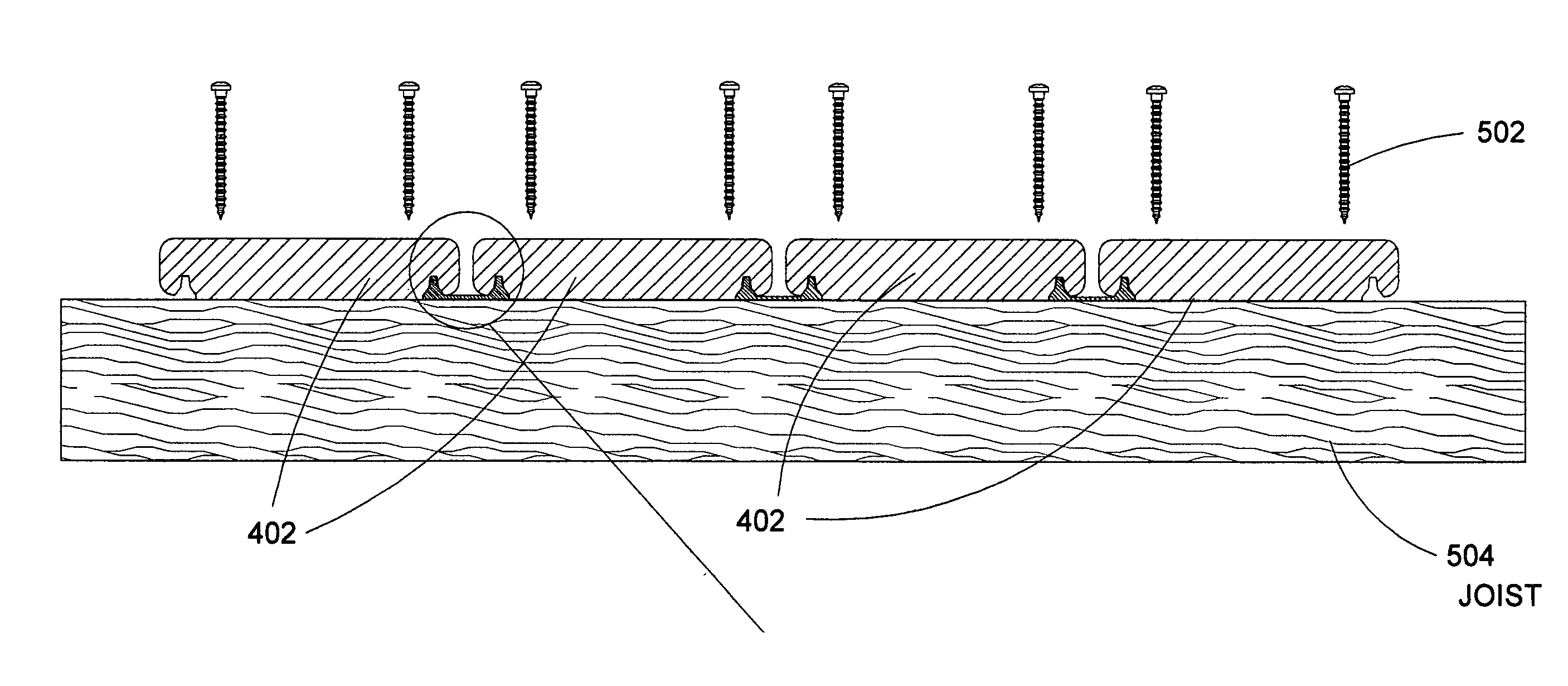

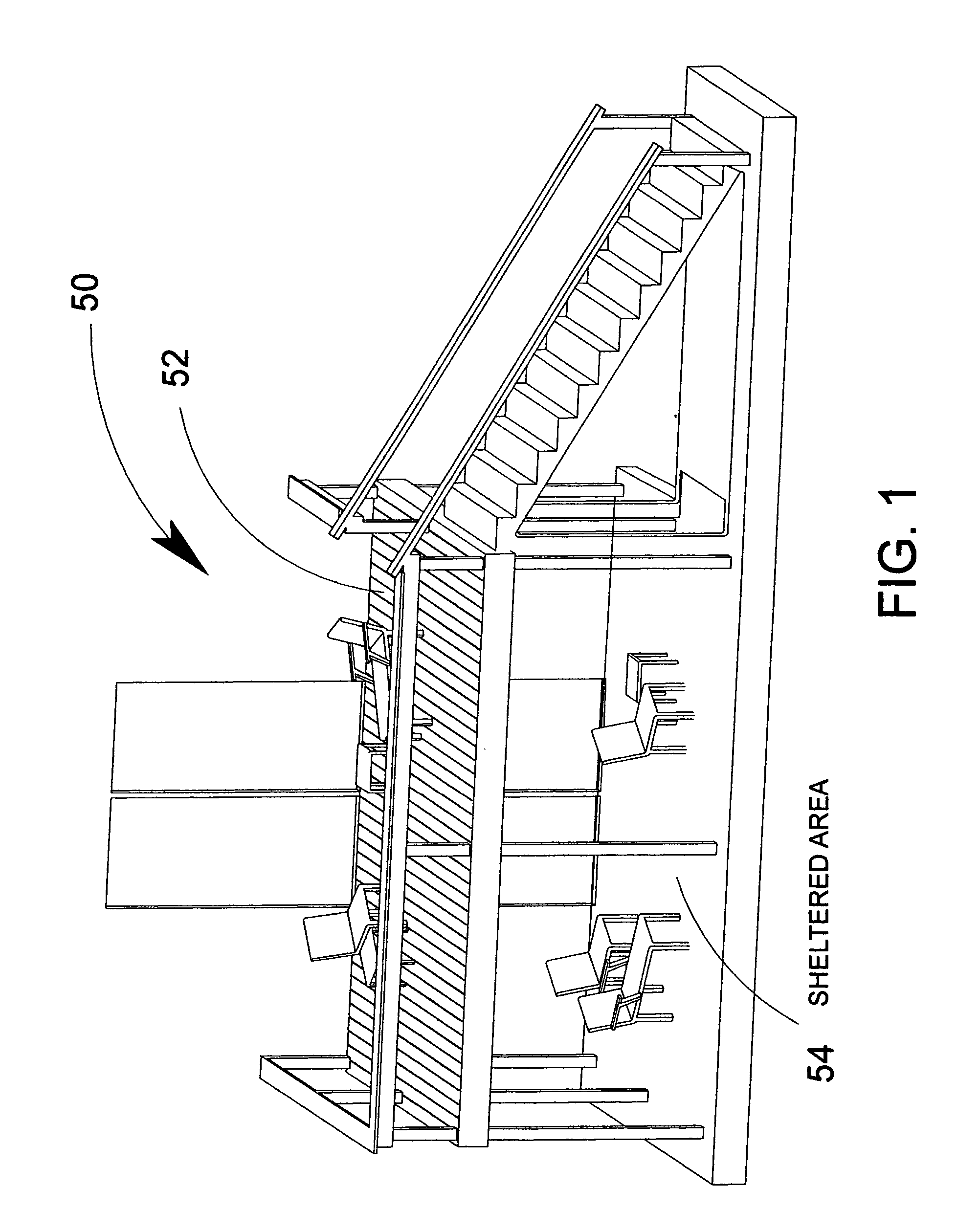

Synthetic boards for exterior water-resistant applications

InactiveUS20060156666A1Low costDesired characteristicCovering/liningsWallsEngineeringWater resistant

Specially configured synthetic boards are provided for use with conventional carpentry tools and techniques to form flat, water-tight surfaces such as decks, roofs, walls, boat decks, hulls, and the like. The boards are formed to their desired shape and scale by extruding mixtures of wood particles and thermoplastic materials through appropriate converging dies. In one configuration, the edges of the boards have complementary configured outwardly facing recesses that permit them to be joined to form the watertight surfaces, and in another configuration the boards have features that interact with separate plastic structures to provide water tightness.

Owner:CAUFIELD FRANCIS J

Magnetic disk using a glass substrate

InactiveUS6916558B2Suppress errorImprove recording densityBase layers for recording layersLayered productsMagnetic anisotropyMaterials science

In a magnetic disk having a glass substrate, an amorphous underlayer is formed on the glass substrate. A magnetic layer is formed on the amorphous underlayer. The glass substrate is provided with a texture formed to induce magnetic anisotropy in the magnetic layer. The amorphous underlayer contains a group IVa element on a glass substrate side and a group Va element on a magnetic layer side.

Owner:WD MEDIA SINGAPORE PTE

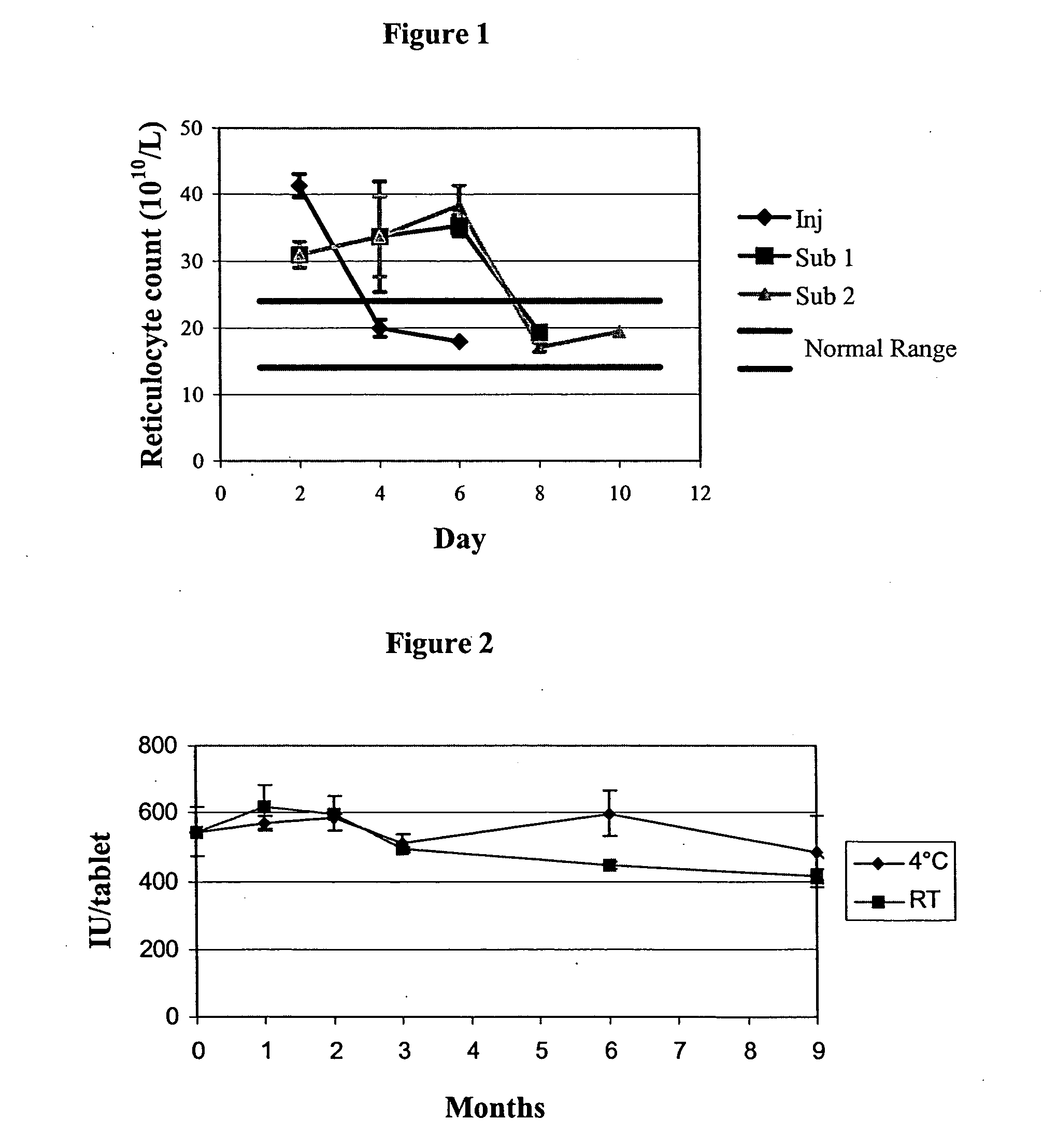

Method of preparing biological materials and preparations produced using same

InactiveUS20050019417A1Simple methodDesired characteristicOrganic active ingredientsSenses disorderMicroparticleSolid particle

Methods for preparing products containing moisture-sensitive materials, including biological materials such as proteins, peptides or live cells, comprising at least the steps: (i) providing a coating liquid comprising at least one active, a sugar polymer and a water soluble / miscible solvent; (ii) providing a quantity of microparticles comprising at least water soluble gel forming solid particles; (iii) fluidizing said quantity of microparticles within a processing chamber of a of a suitable apparatus to form a fluidized bed of said microparticles; (iv) spraying said coating liquid onto said fluidized bed from beneath the fluidized bed to coat said microparticles therewith under saturated moisture conditions; and (vi) allowing coated microparticles to dry, are described. Also described are compositions and uses.

Owner:PFIZER INC

Al2O3-rare earth oxide-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030126803A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesFiberThermal insulation

Al2O3-rare earth oxide-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

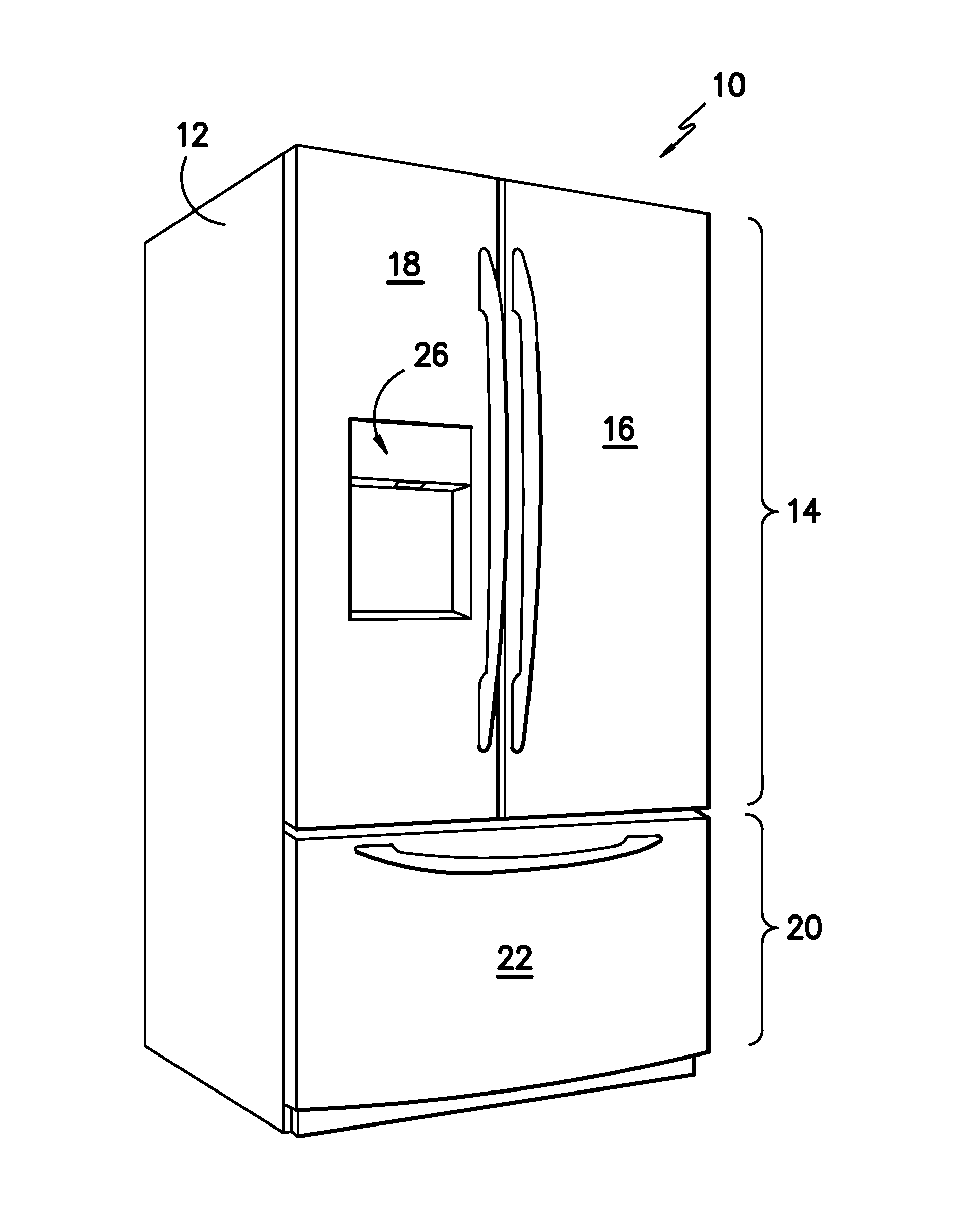

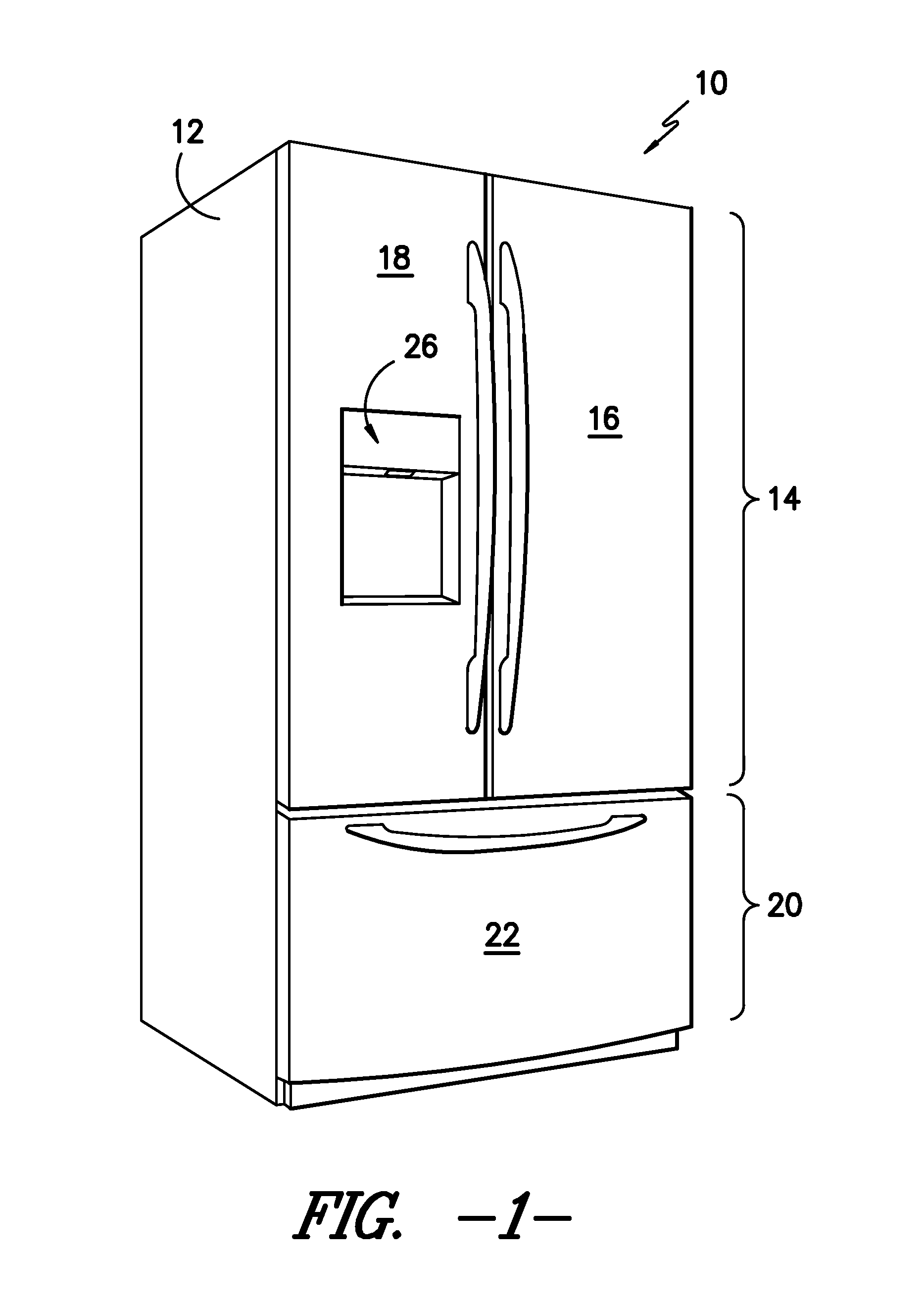

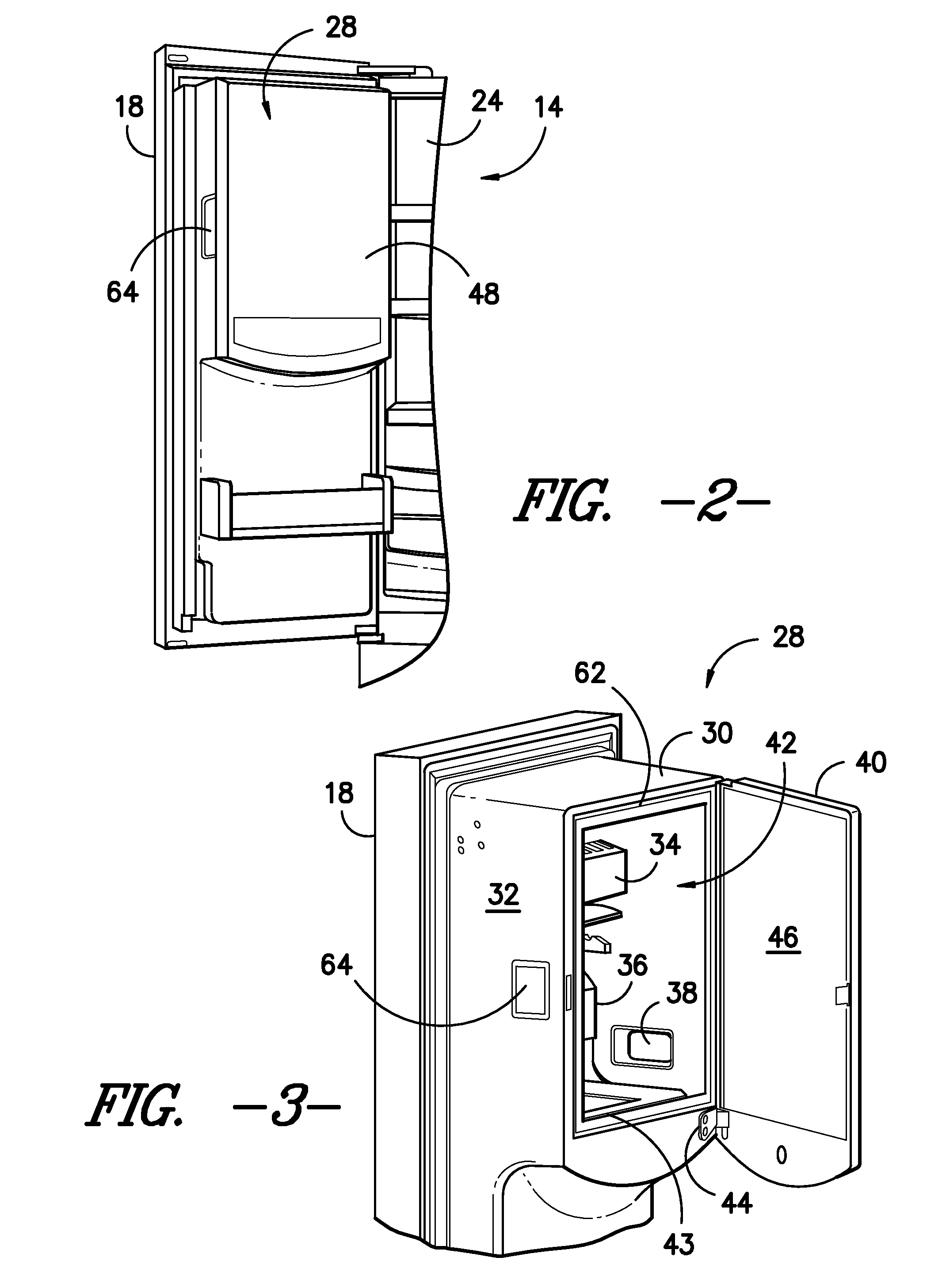

Fresh food compartment ice box door

InactiveUS20120279247A1Thin profileReduce sweatingLighting and heating apparatusDomestic refrigeratorsFresh foodEngineering

Owner:GENERAL ELECTRIC CO

Ceramic materials, abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030126802A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentGlass-ceramicMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

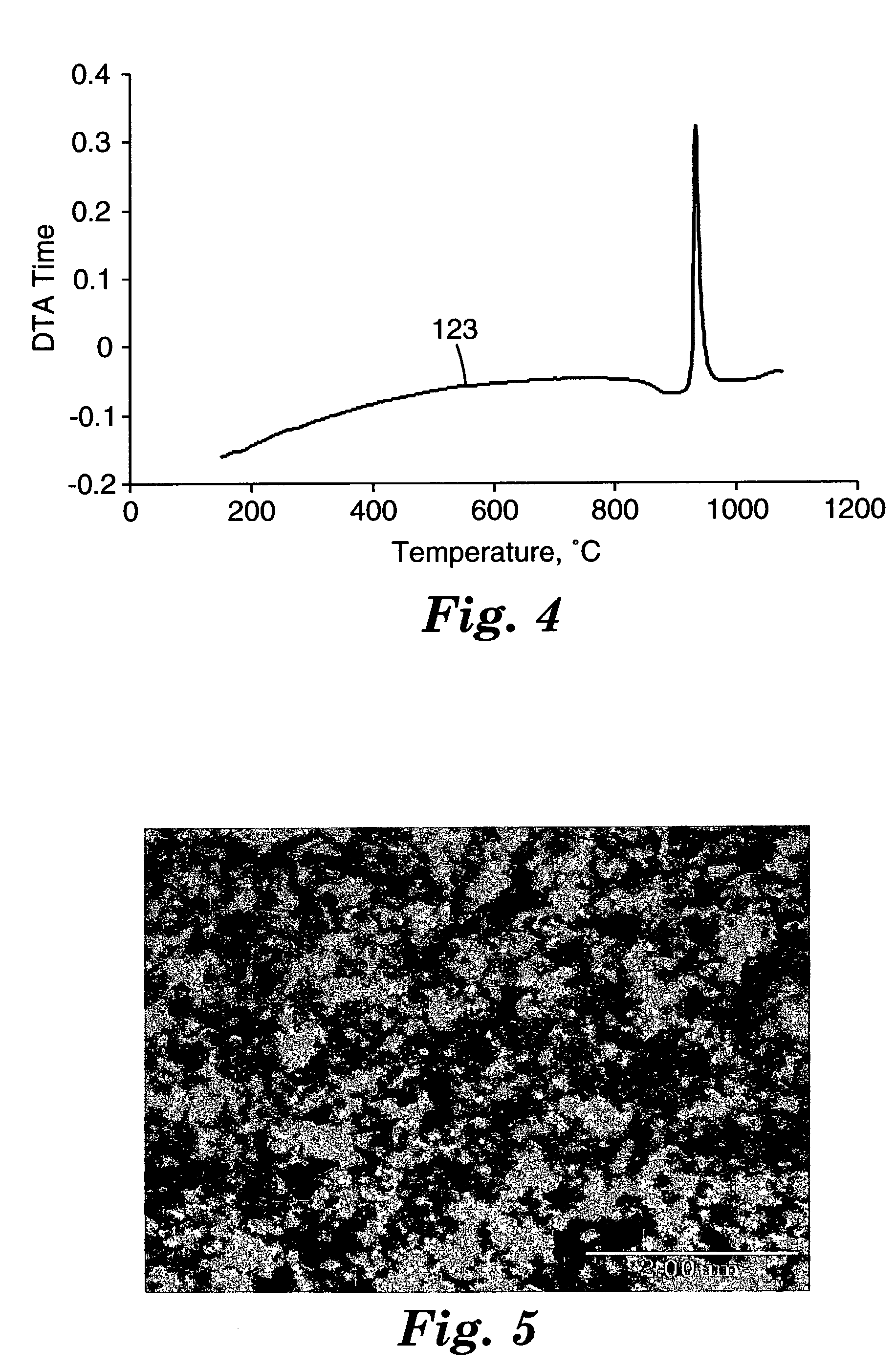

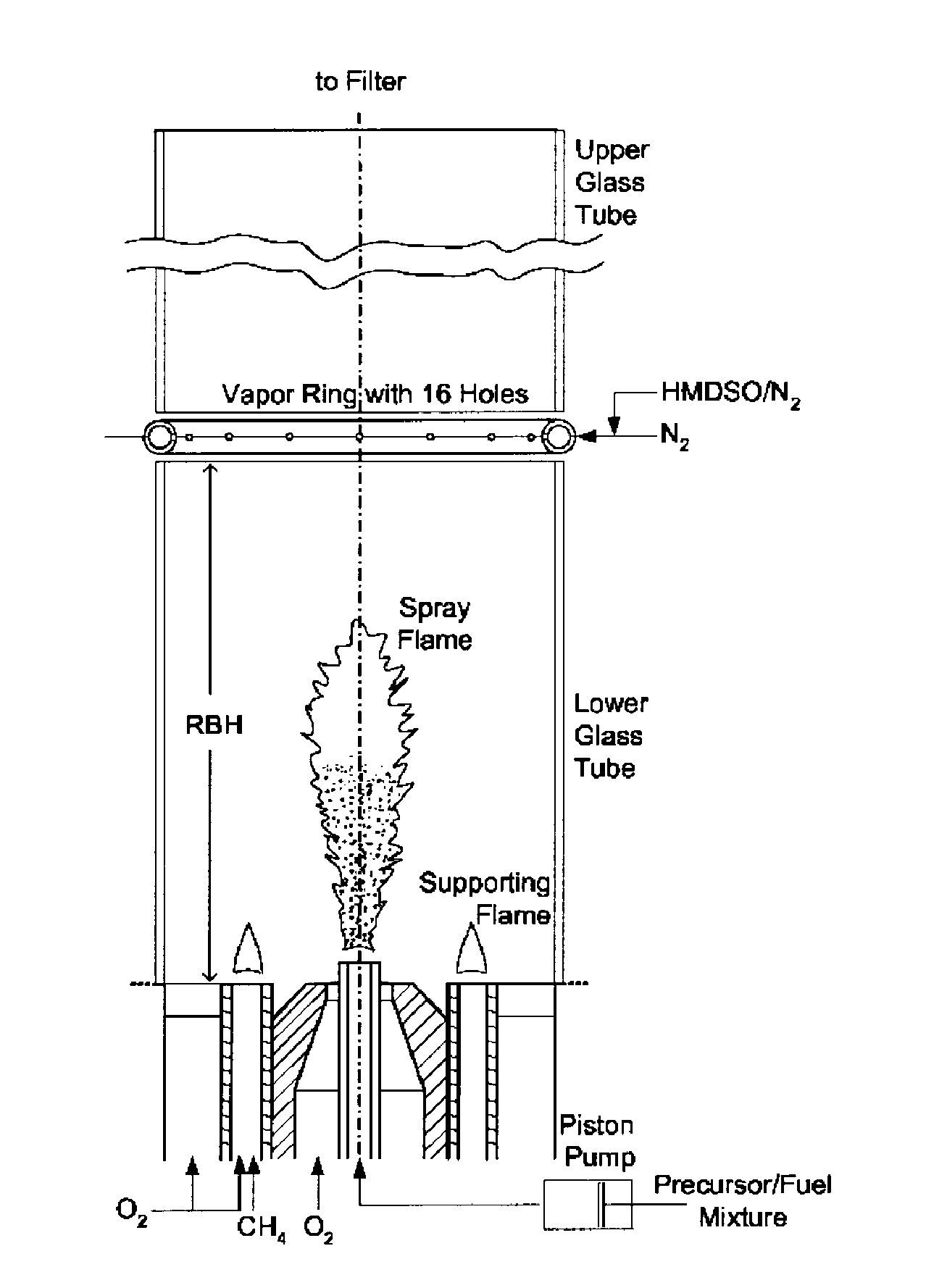

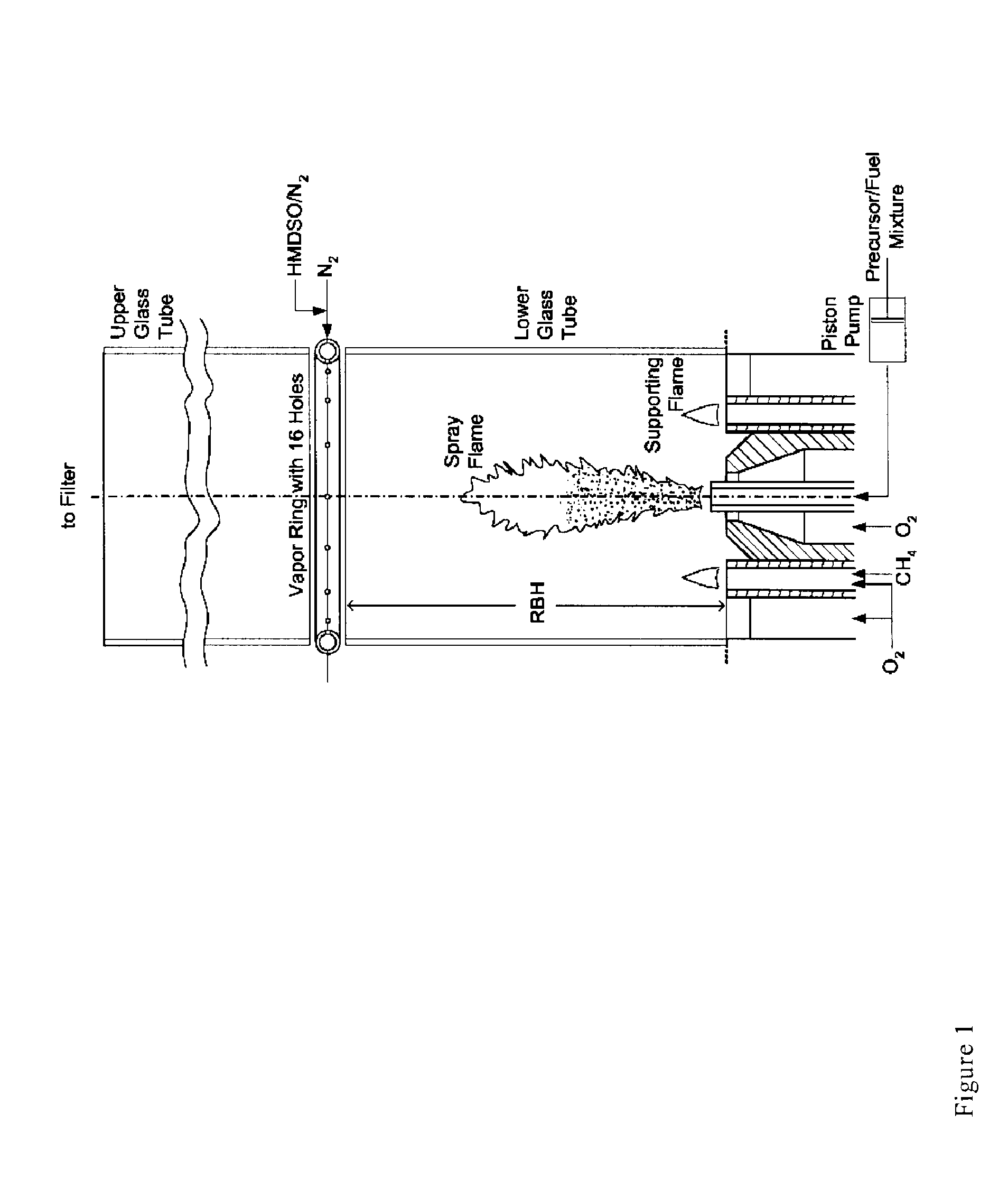

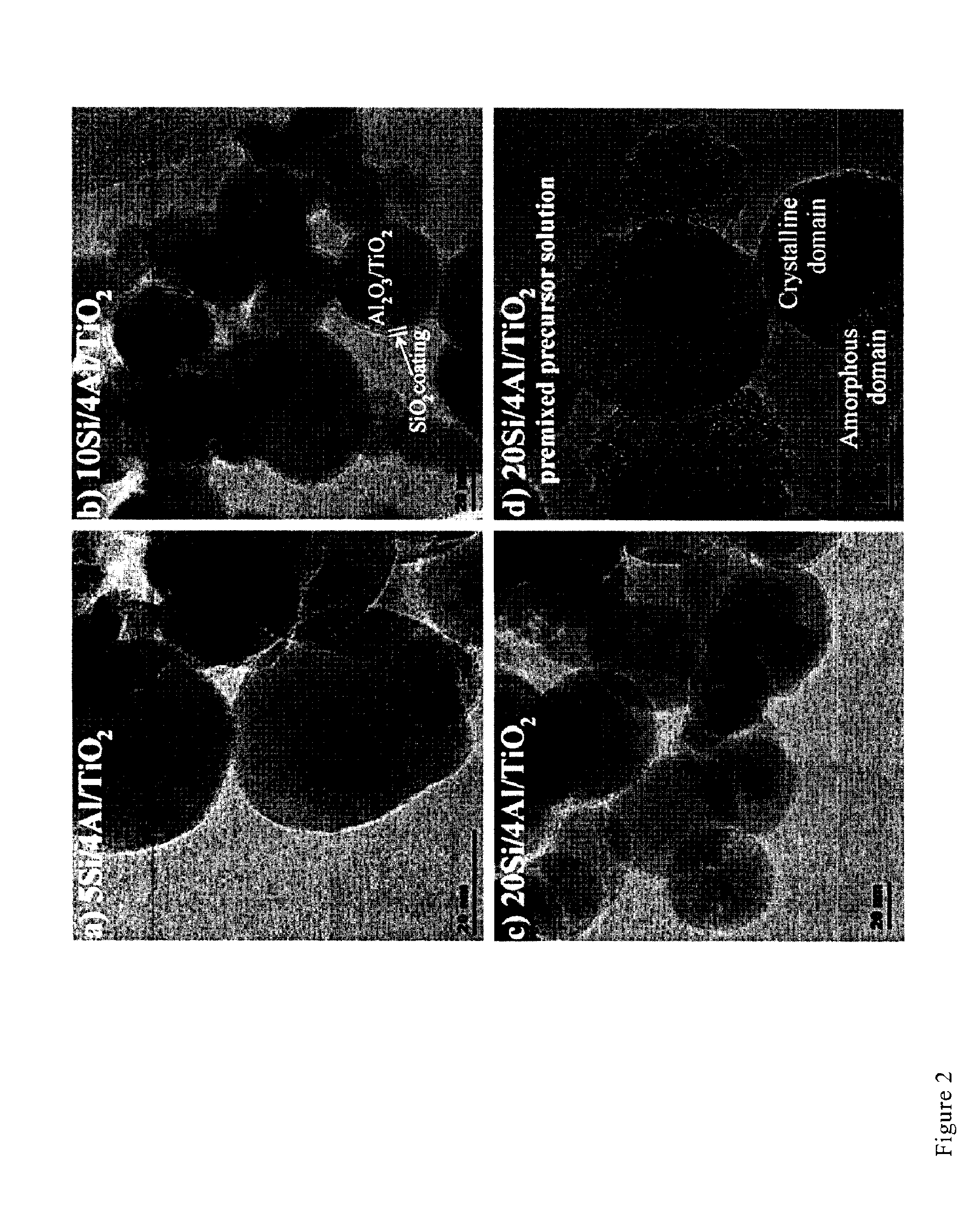

Gas phase production of coated titania

InactiveUS20090126604A1Not to wasteDesired characteristicPigmenting treatmentMaterial nanotechnologyGas phaseSpray pyrolysis

A flame spray pyrolysis process for the preparation of ultrafine titania particles coated with a smooth, homogeneous coating of one or more metal oxides is provided. The metal oxide coating is achieved by contacting the titania particles with a metal oxide precursor downstream of the titania formation zone, after the titania particles have formed. The process provides titania particles with a high rutile content and a smooth and homogeneous coating of a metal oxide.

Owner:TRONOX LLC

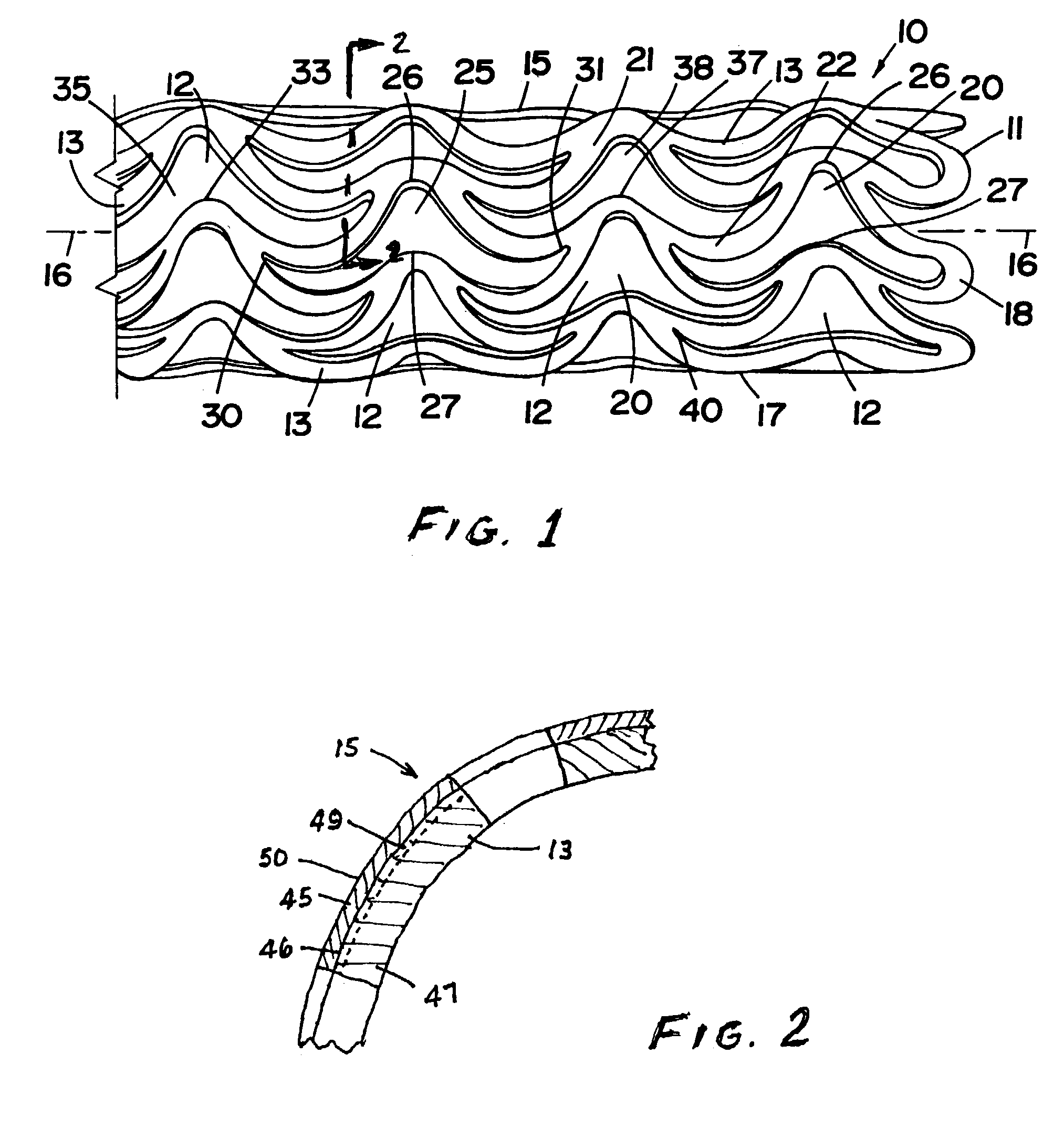

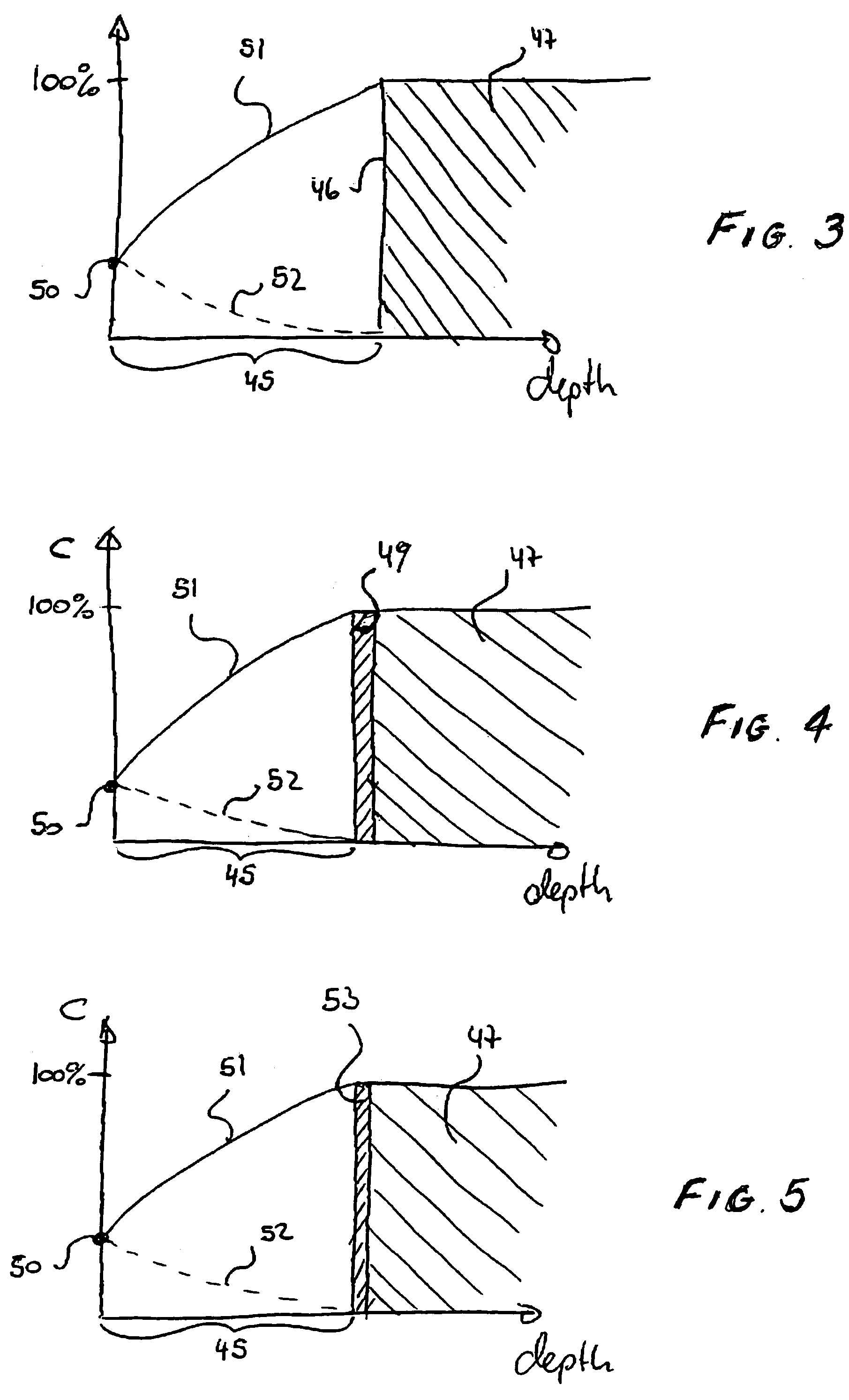

Metal stent with surface layer of noble metal oxide and method of fabrication

In a process for producing a biocompatible stent, a tubular substrate of the stent adapted for diametric expansion has a layer of a noble metal oxide formed over at least the outer surface of greater diameter of the substrate, the substrate being composed of a metal or an alloy thereof that is non-noble or less-noble than the layer's noble metal. An interface region adapted to prevent corrosion and to provide a firm bond between the surface of the substrate and the noble metal oxide layer is established, at least in part, by forming the noble metal oxide layer with a progressively varying concentration of noble metal-to-oxide with depth of the layer such that a surface of pure noble metal and negligible oxide of the layer is in closest proximity to the surface of the substrate. In one embodiment of the process, the interface region is established by forming the surface of pure noble metal and negligible oxide thereof in direct contact with the metal or alloy of the substrate surface. In another, the interface region is established by first creating an oxide of the substrate metal or alloy thereof at the substrate surface, and then forming the noble metal oxide layer as above, but in contact with the substrate metal or alloy oxide. Alternatively, the noble metal oxide layer has no progressively varying concentration but simply overlies an oxide of the substrate metal or alloy.

Owner:BOSTON SCI SCIMED INC

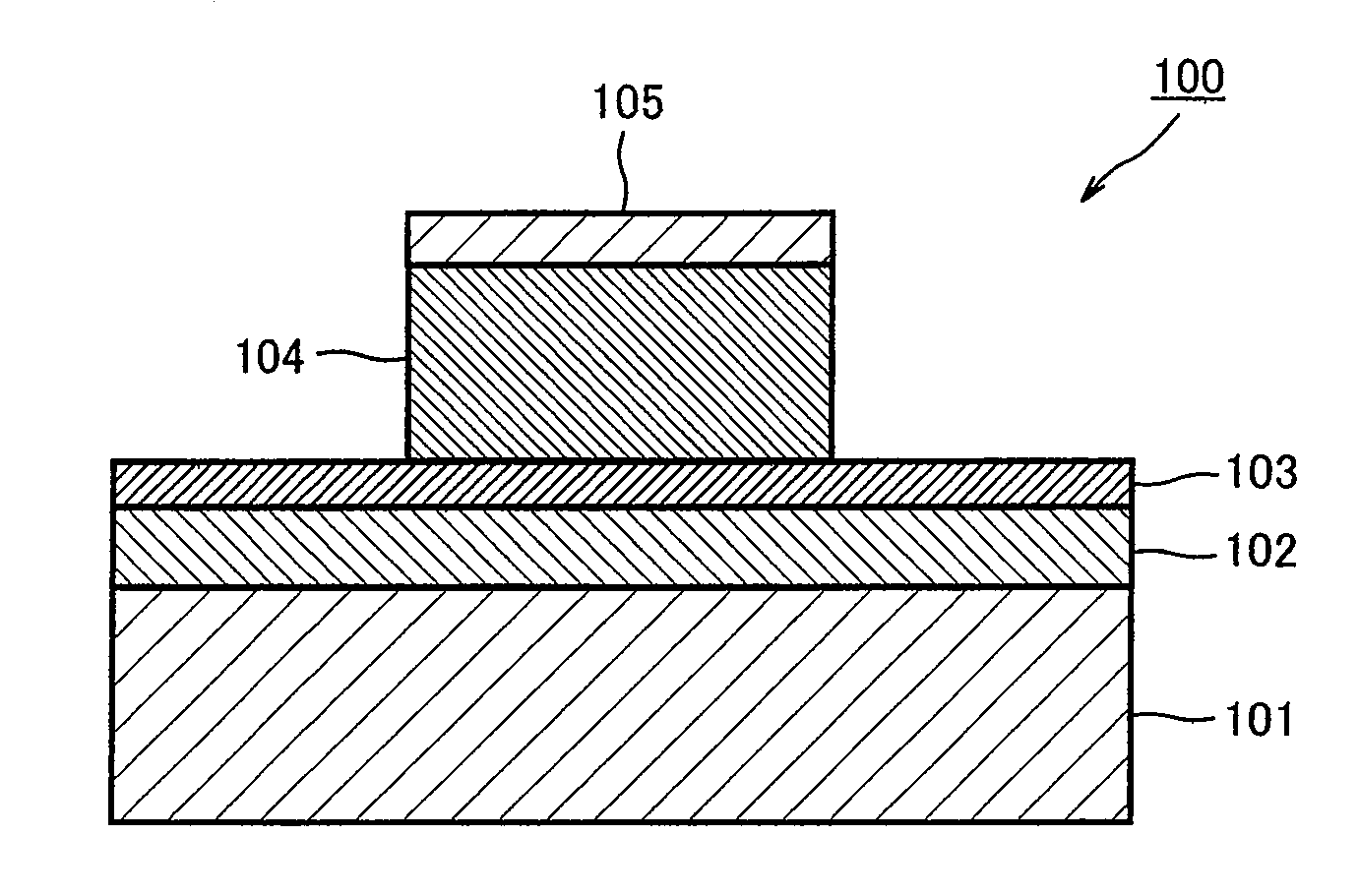

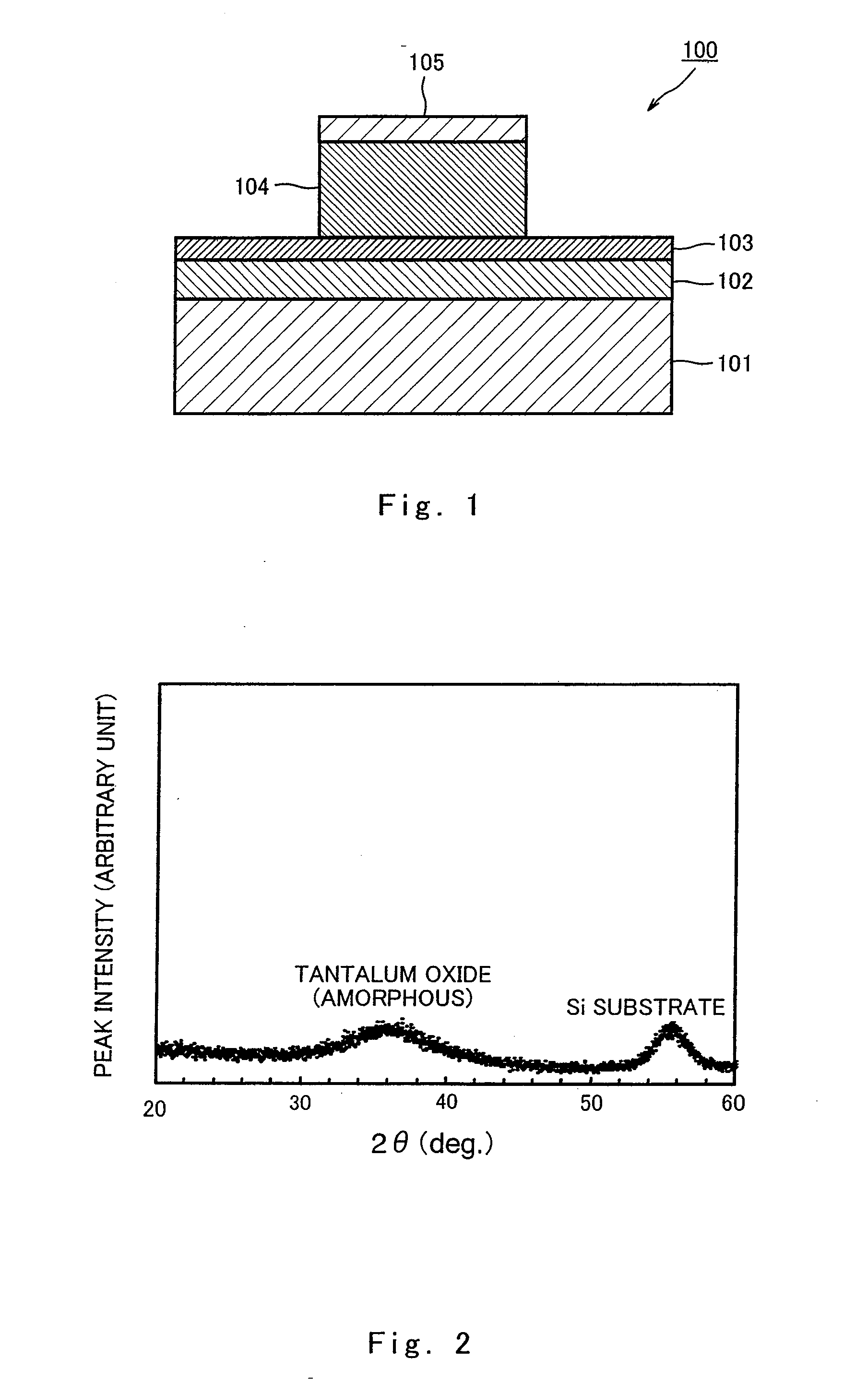

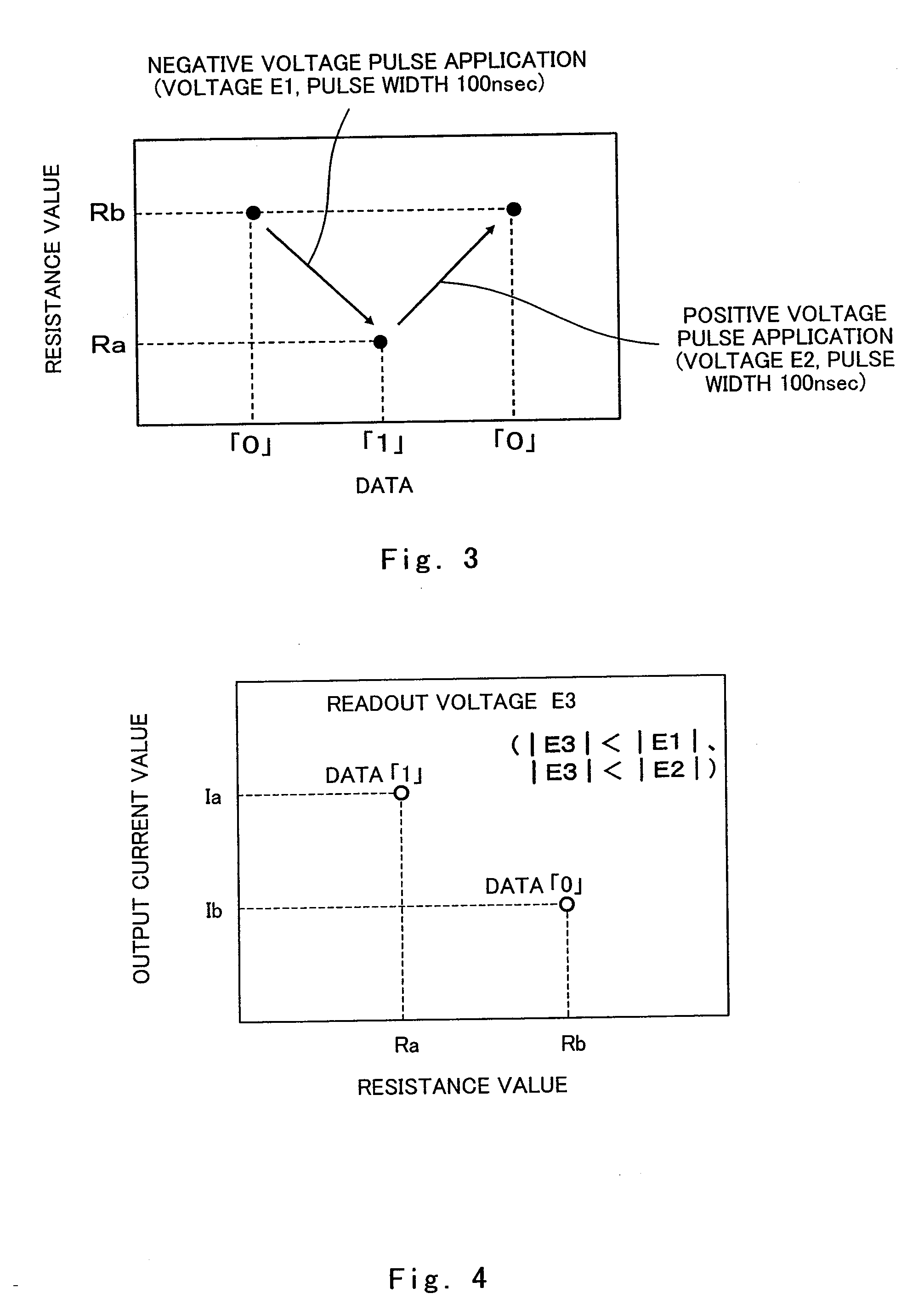

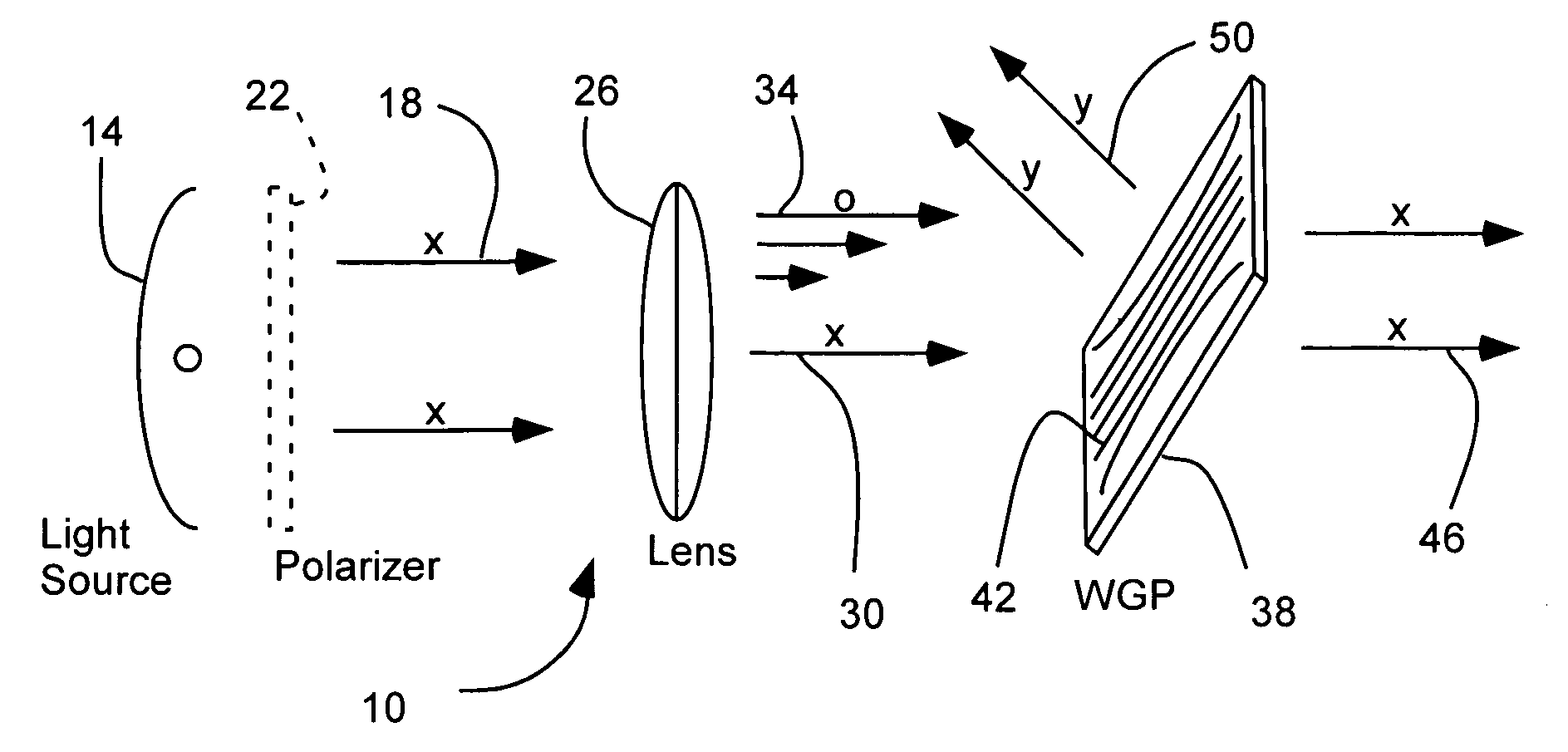

Nonvolatile memory element, nonvolatile memory apparatus, nonvolatile semiconductor apparatus, and method of manufacturing nonvolatile memory element

ActiveUS20090224224A1Stable characteristicsHigh affinitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsElectric signal

A nonvolatile memory element of the present invention comprises a first electrode (103), a second electrode (105), and a resistance variable layer (104) disposed between the first electrode (103) and the second electrode (104), a resistance value of the resistance variable layer varying reversibly according to an electric signal applied between the electrodes (103),(105), and the resistance variable layer (104) comprises at least a tantalum oxide, and is configured to satisfy 0<x<2.5 when the tantalum oxide is represented by TaOx.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

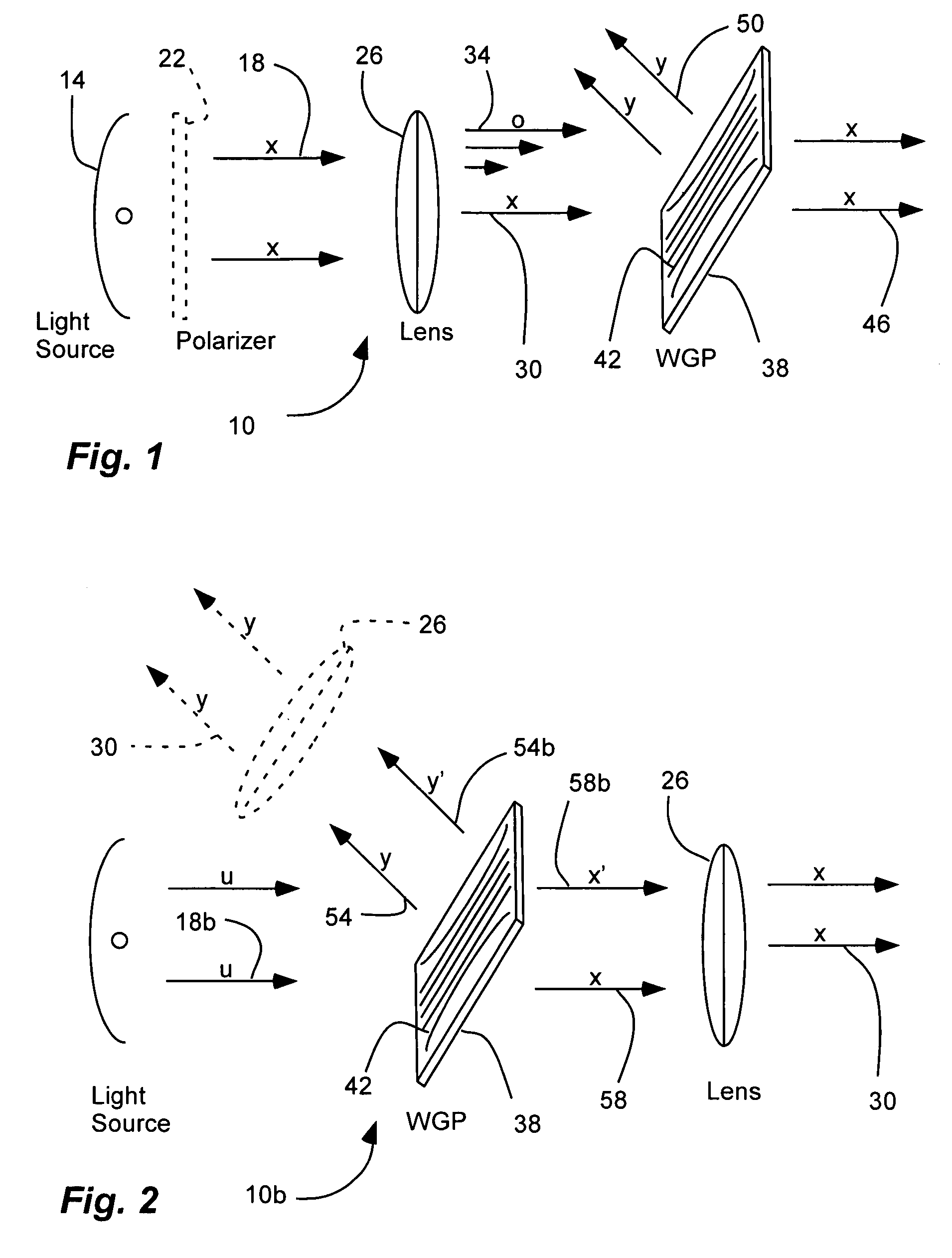

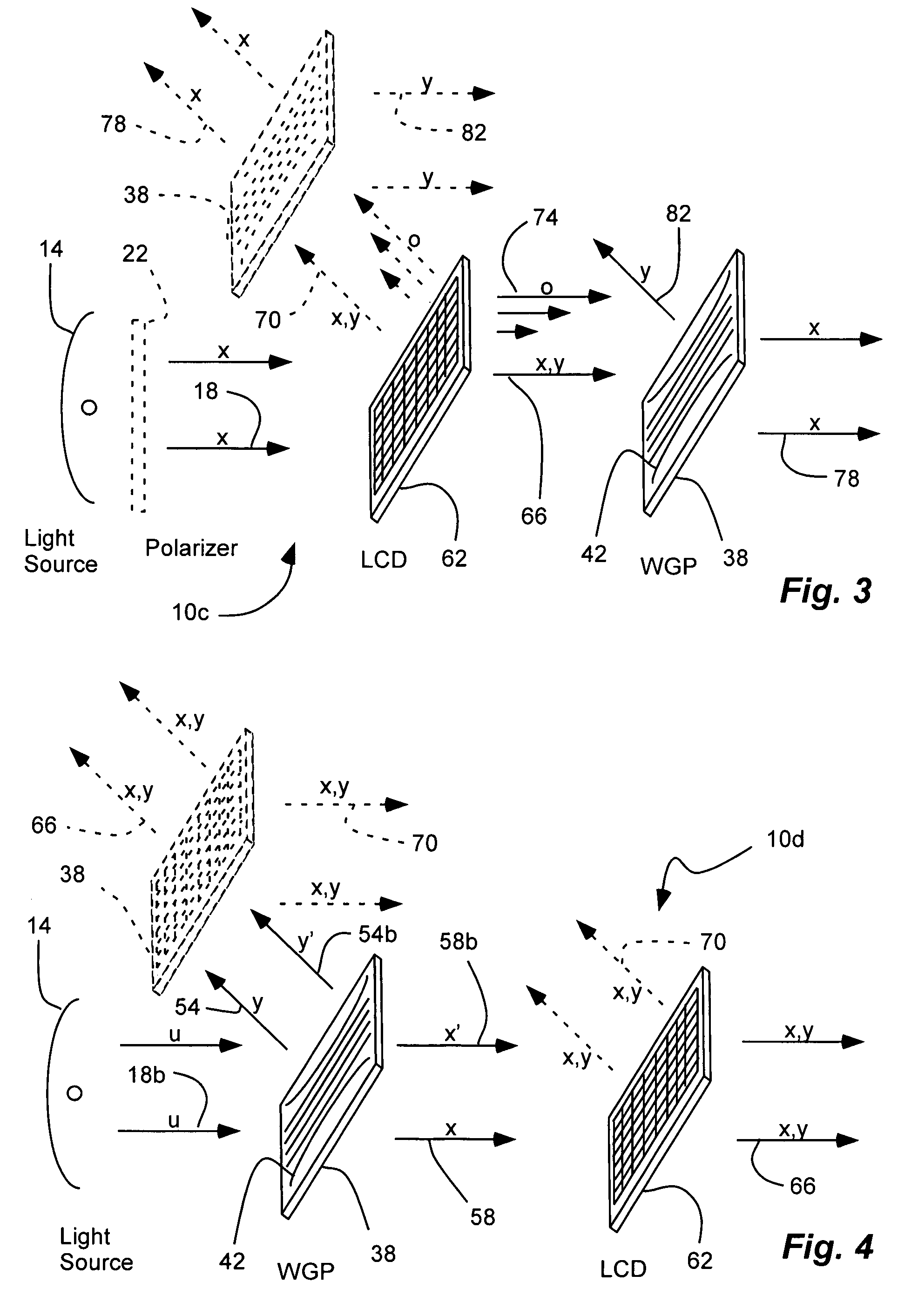

Method and apparatus for correcting a visible light beam using a wire-grid polarizer

InactiveUS7375887B2Desired characteristicUndesired characteristicPolarising elementsLight polarisation measurementWire gridLight beam

An optical system and method for providing a visible light beam with a desired characteristic includes a visible light source producing a visible light beam defining an optical train. An optical element is disposed in the optical train to create a modified beam, and that is capable of introducing an undesired characteristic that continuously transitions across at least a portion of the modified beam. A wire-grid polarizer is disposed in the optical train, and has a plurality of elongated elements with at least a portion that continuously transitions to a different characteristic. The wire-grid polarizer is positioned and oriented in the optical train with the different characteristic corresponding to the undesired characteristic of the modified beam to obtain a visible light beam with a desired characteristic substantially across the visible light beam.

Owner:MOXTEK INC

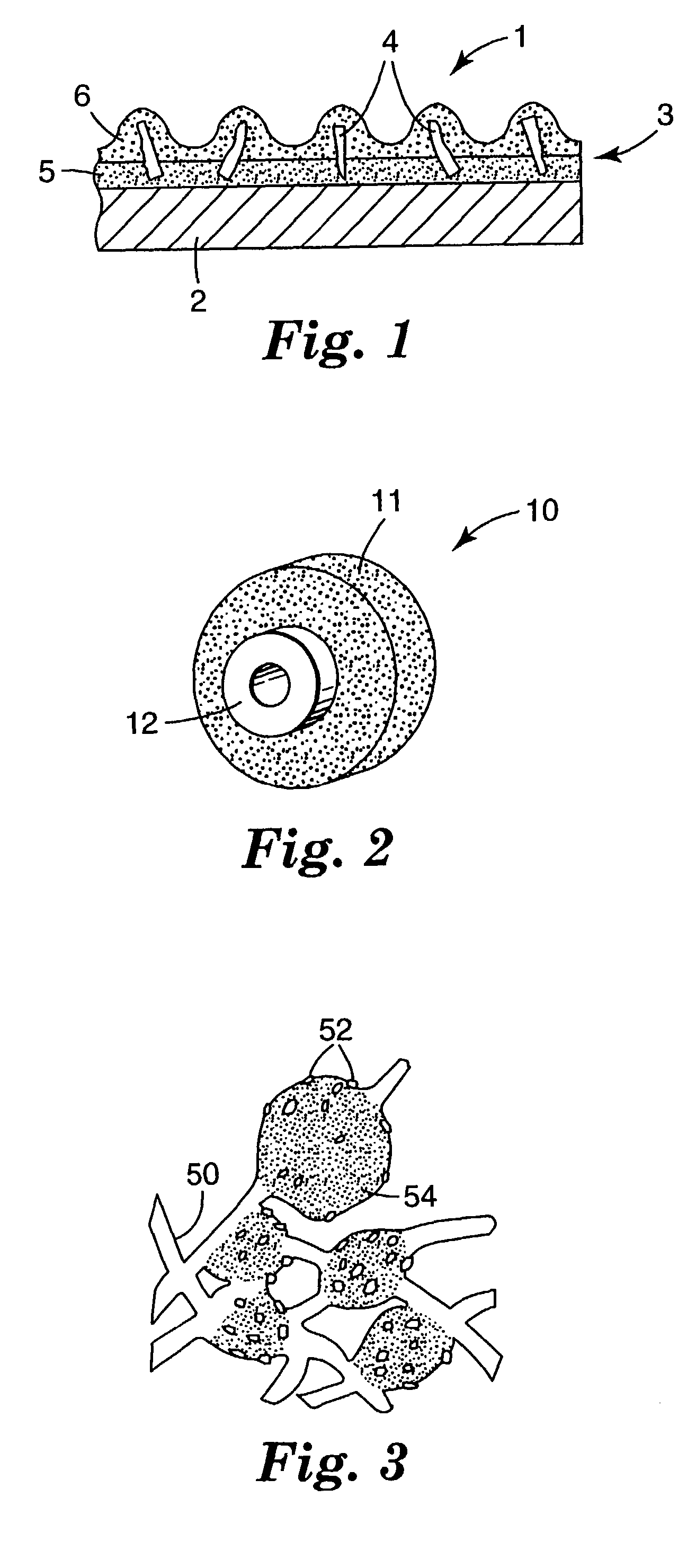

Abrasive particles and methods of making and using the same

InactiveUS20030110706A1Facilitates formation and homogeneityOxide formationPigmenting treatmentOther chemical processesOxideMetal

Abrasive particles comprising ceramic (including glasses, crystalline ceramics, and glass-ceramics) comprising (on a theoretical oxide basis) Al2O3 and at least one other metal oxide (e.g., REO and; REO and at least one of ZrO2 or HfO2) and methods of making the same. The abrasive particles can be incorporated into a variety of abrasive articles, including bonded abrasives, coated abrasives, nonwoven abrasives, and abrasive brushes.

Owner:3M INNOVATIVE PROPERTIES CO

Abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20030115805A1Facilitates formation and homogeneityOxide formationOther chemical processesInorganic pigment treatmentAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

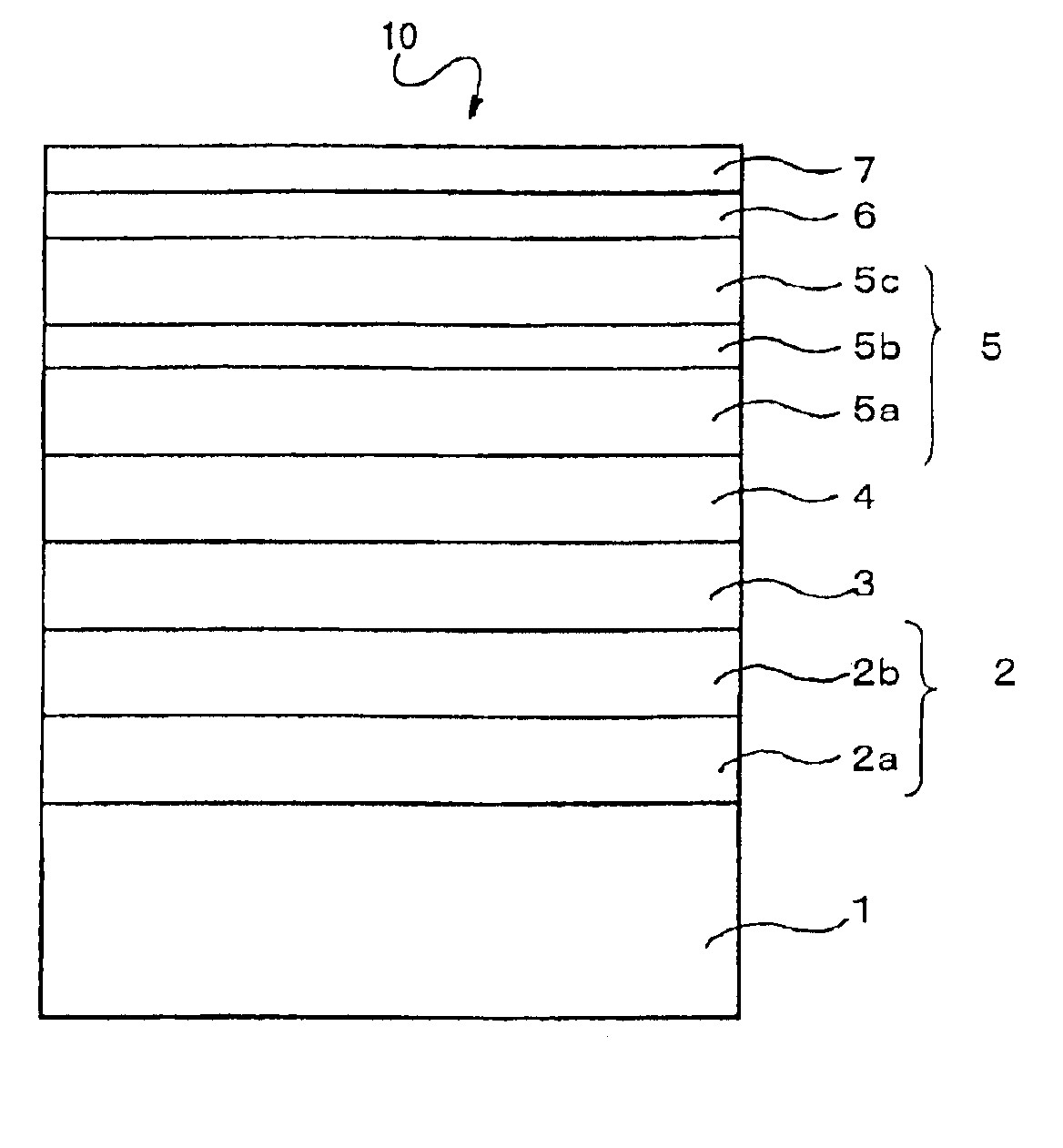

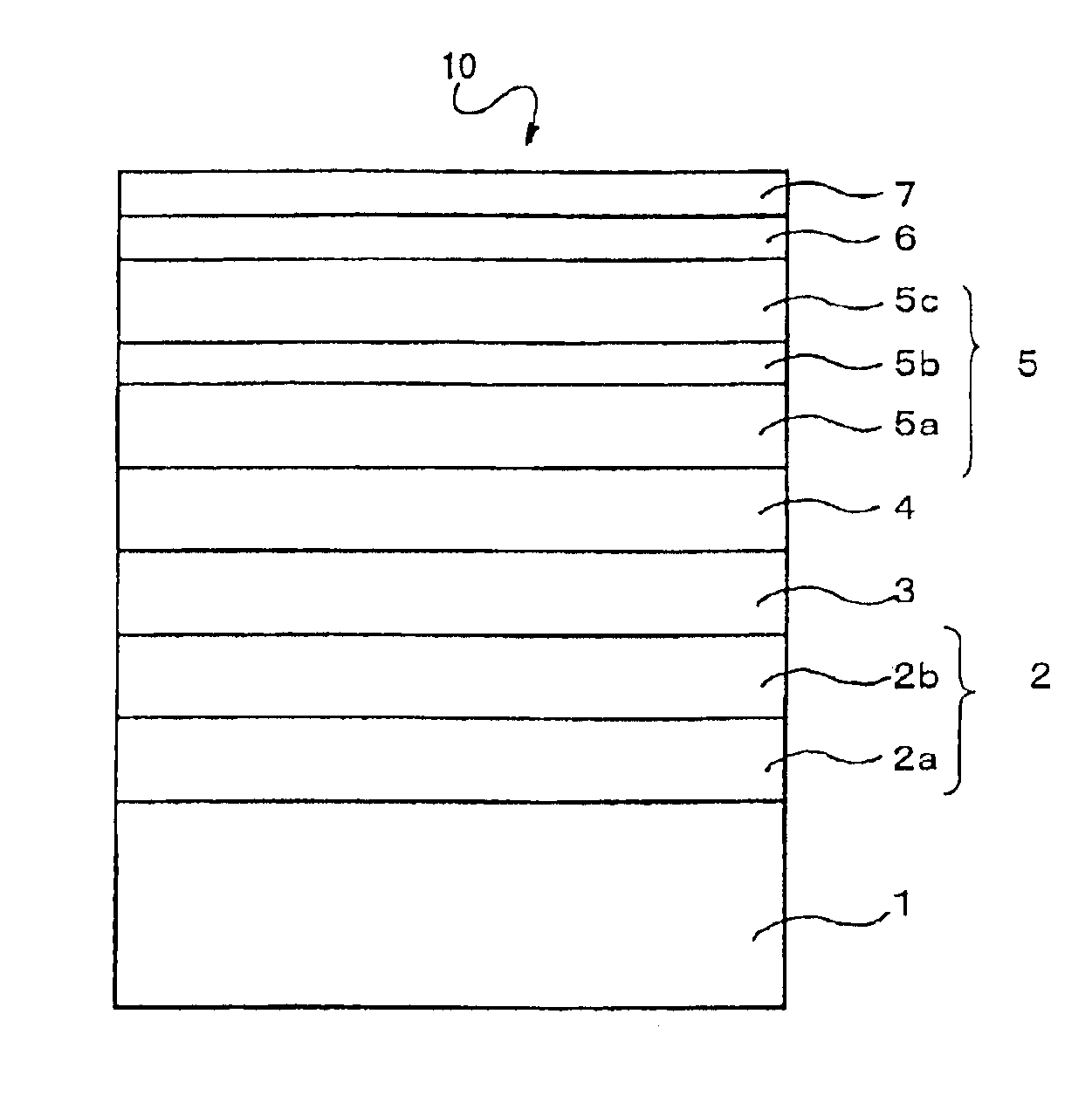

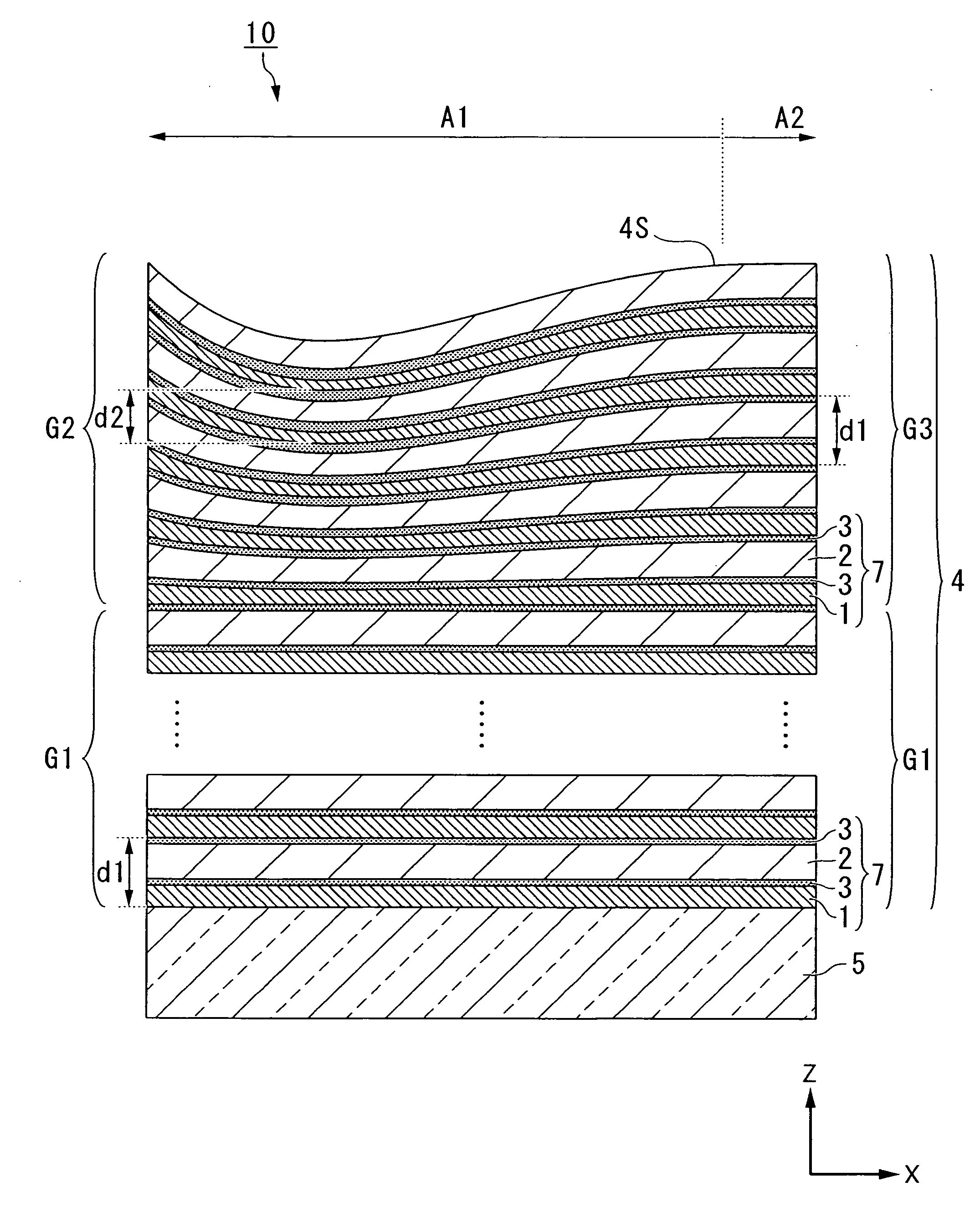

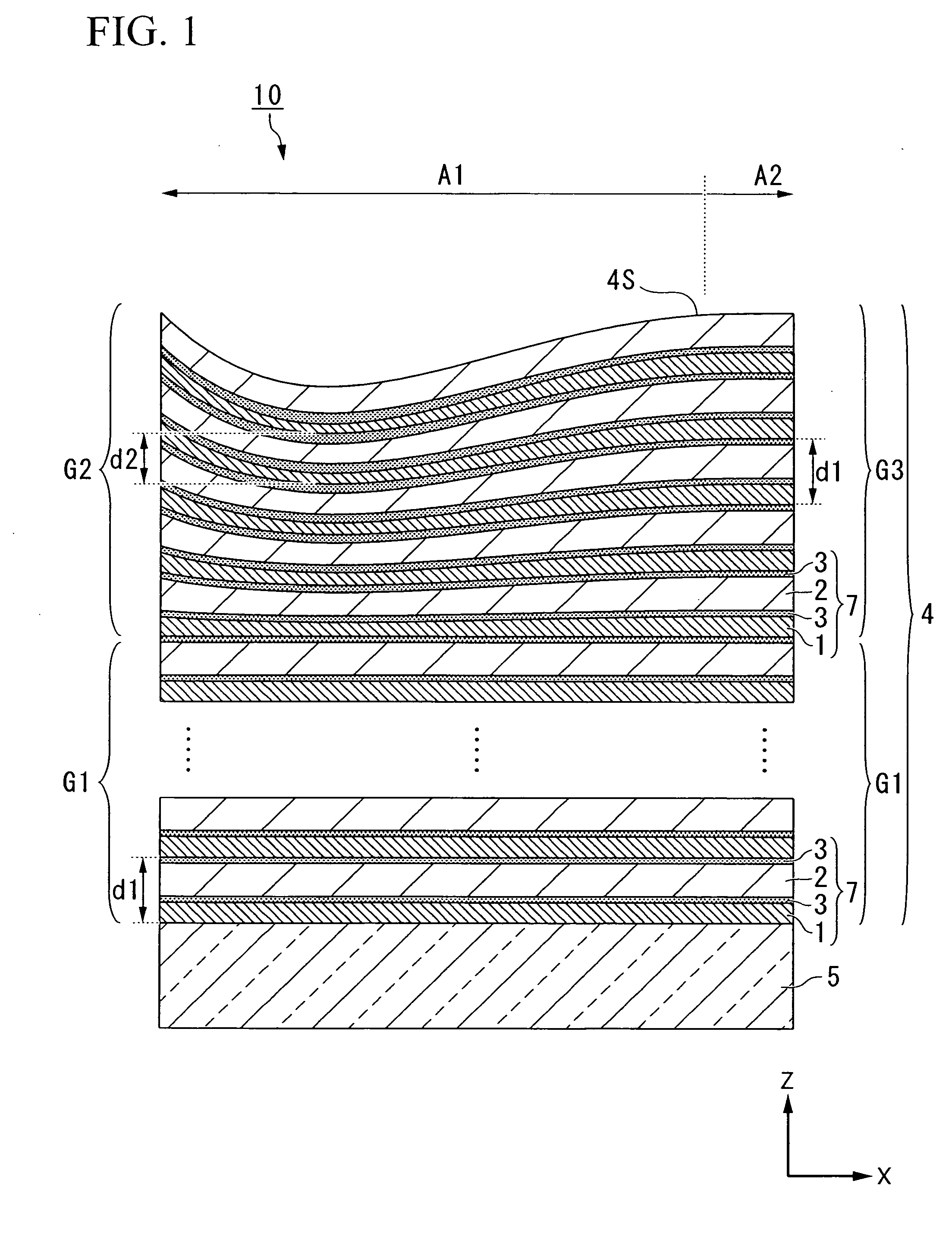

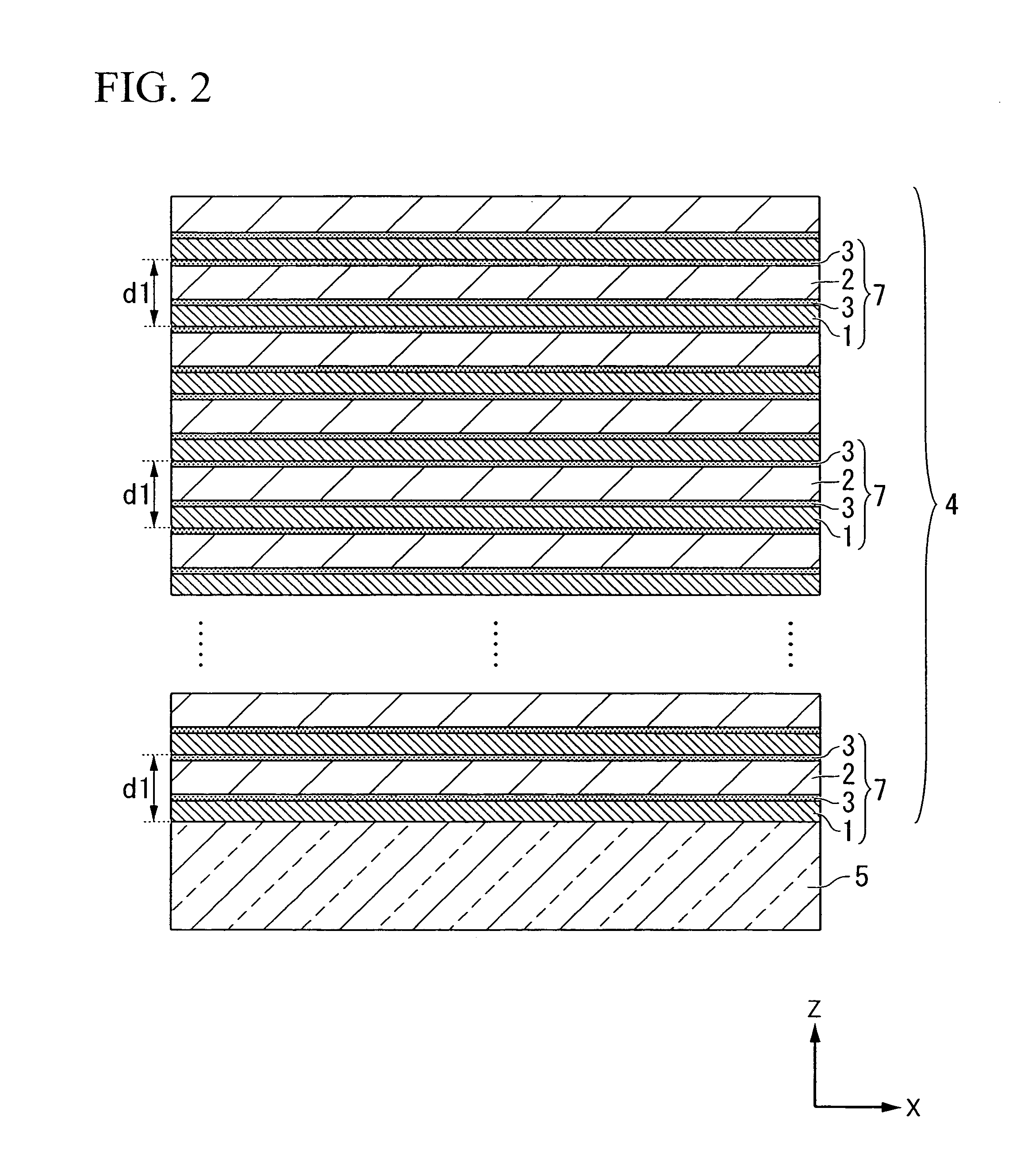

Multilayer-film reflective mirror, exposure apparatus, device manufacturing method, and manufacturing method of multilayer-film reflective mirror

ActiveUS20080259439A1Substrate can be favorably exposedDesired characteristicMirrorsRadiation/particle handlingOptoelectronicsExtreme ultraviolet

Multilayer-film reflective mirrors are disclosed. An exemplary such mirror has a base and a multilayer film formed on the base. The multilayer film includes multiple layer pairs. Each layer pair includes a respective first layer and a respective second layer, wherein the first and second layers are laminated together in an alternating manner. The multilayer film has first and second regions that reflect extreme ultraviolet light. A first group of layers is disposed in the first and second regions and has a first periodic length. A second group disposed in the first region has a second periodic length different from the first periodic length, and a third group disposed in the second region has a substantially same periodic length as the first periodic length.

Owner:NIKON CORP

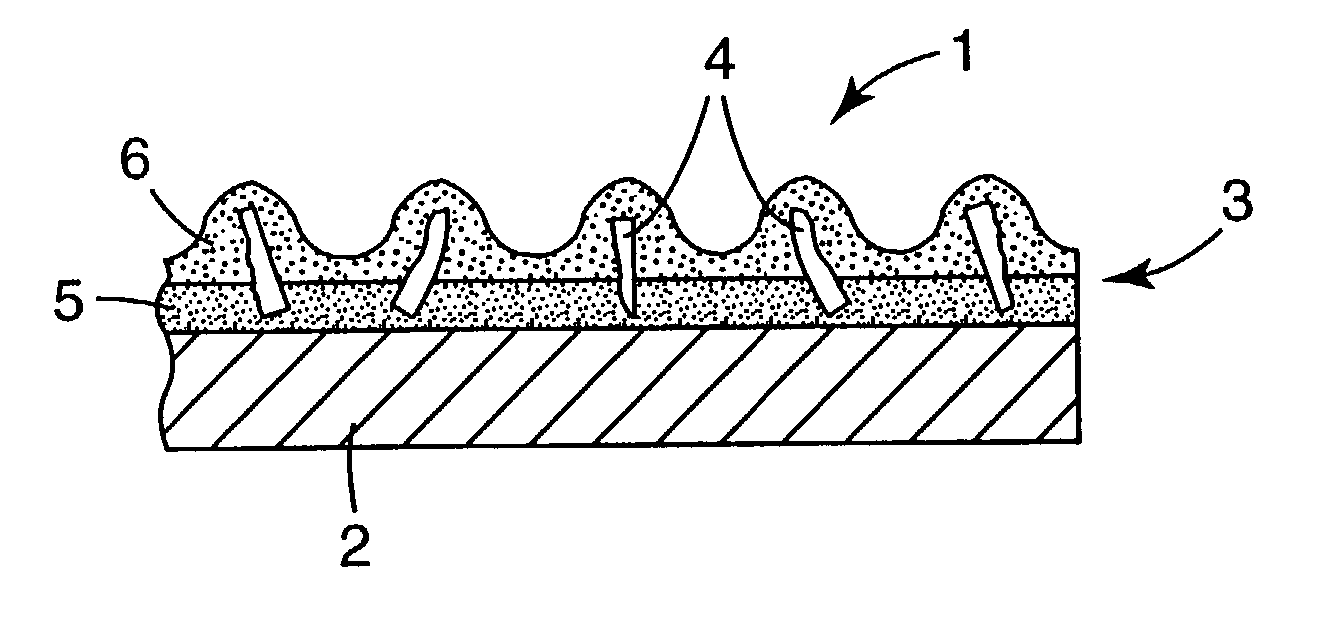

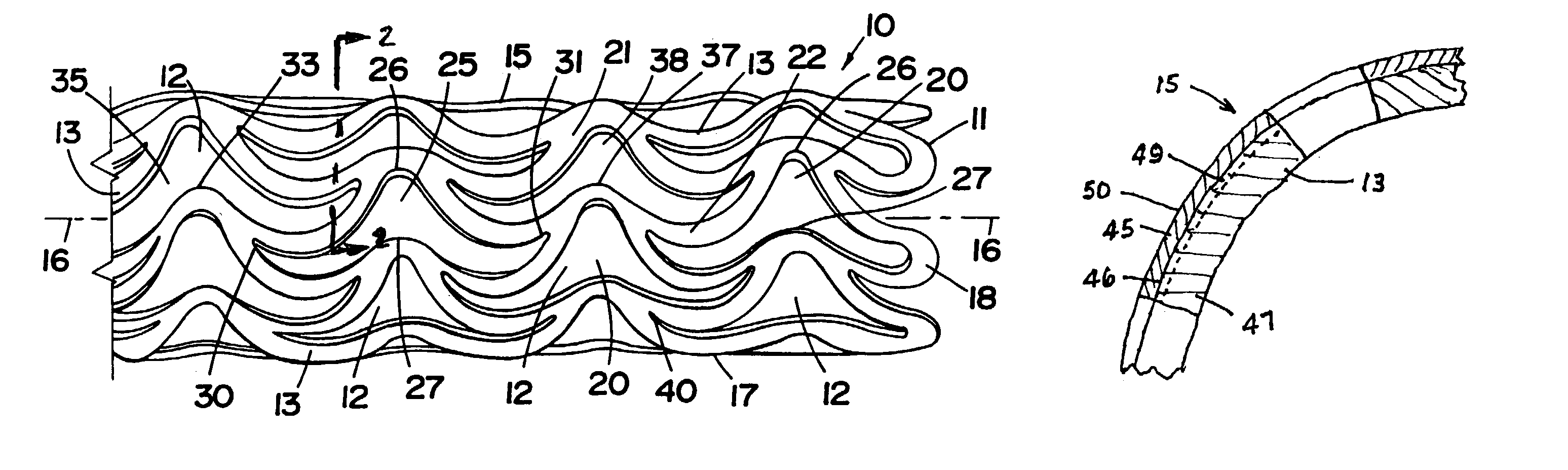

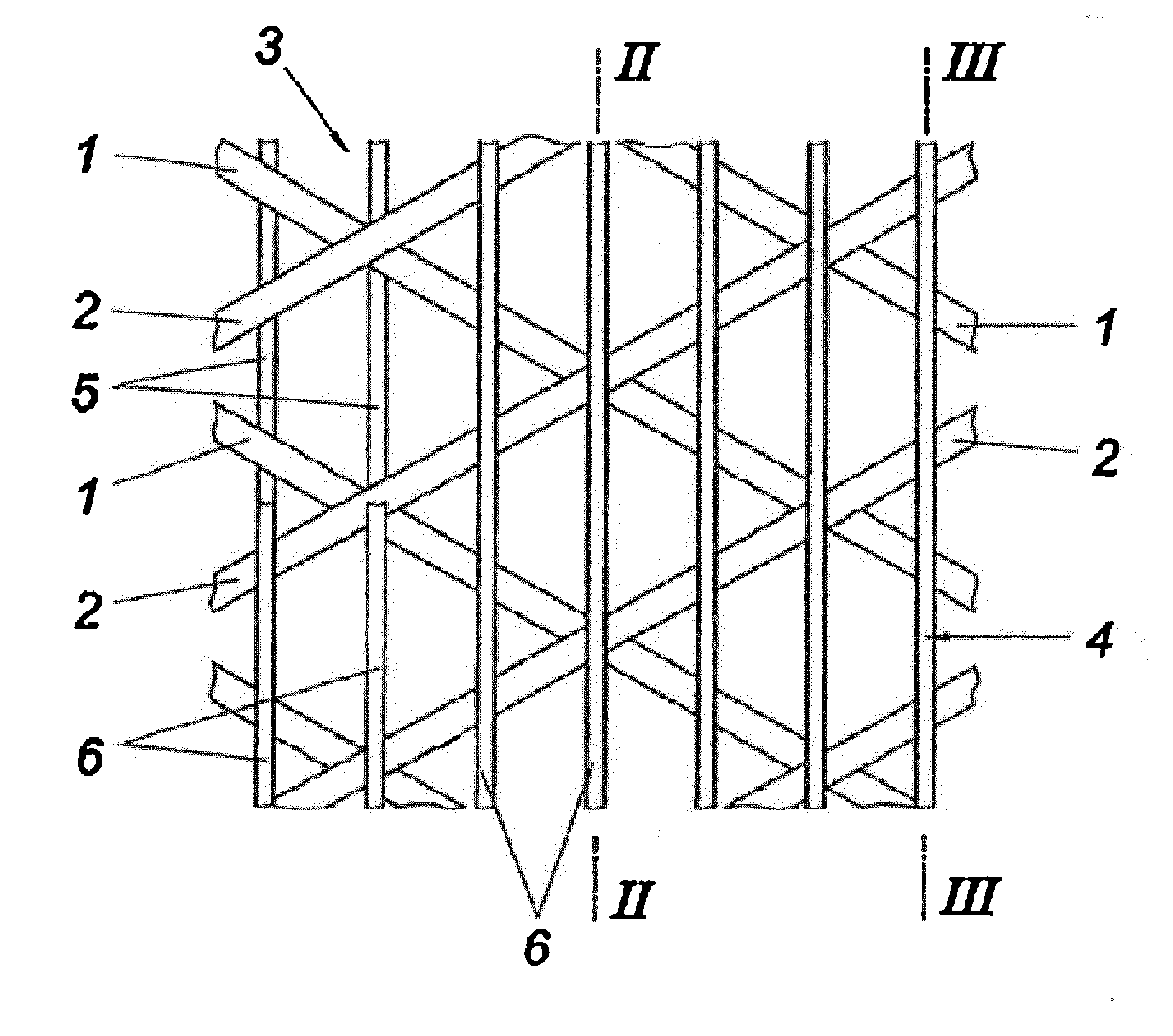

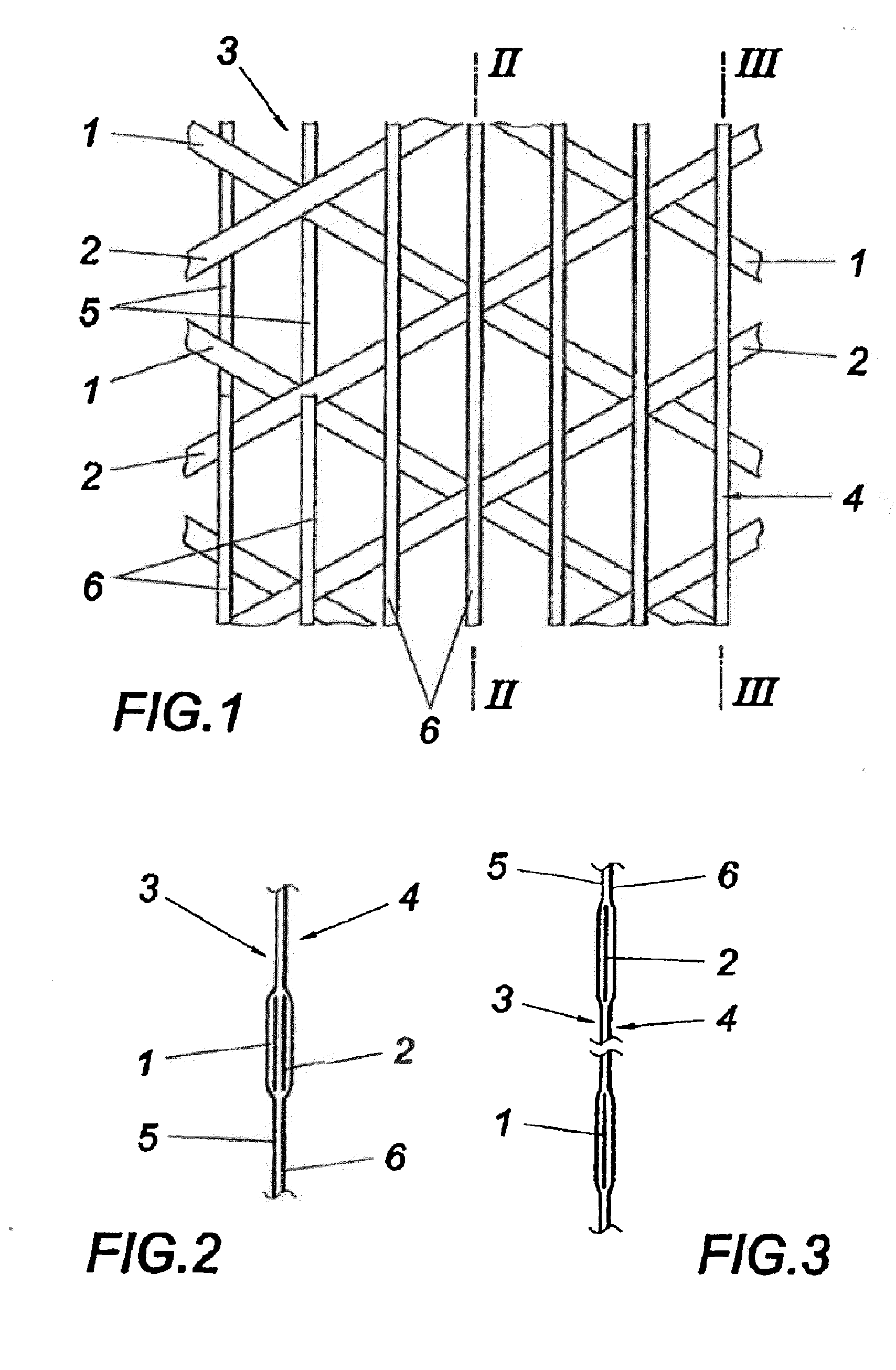

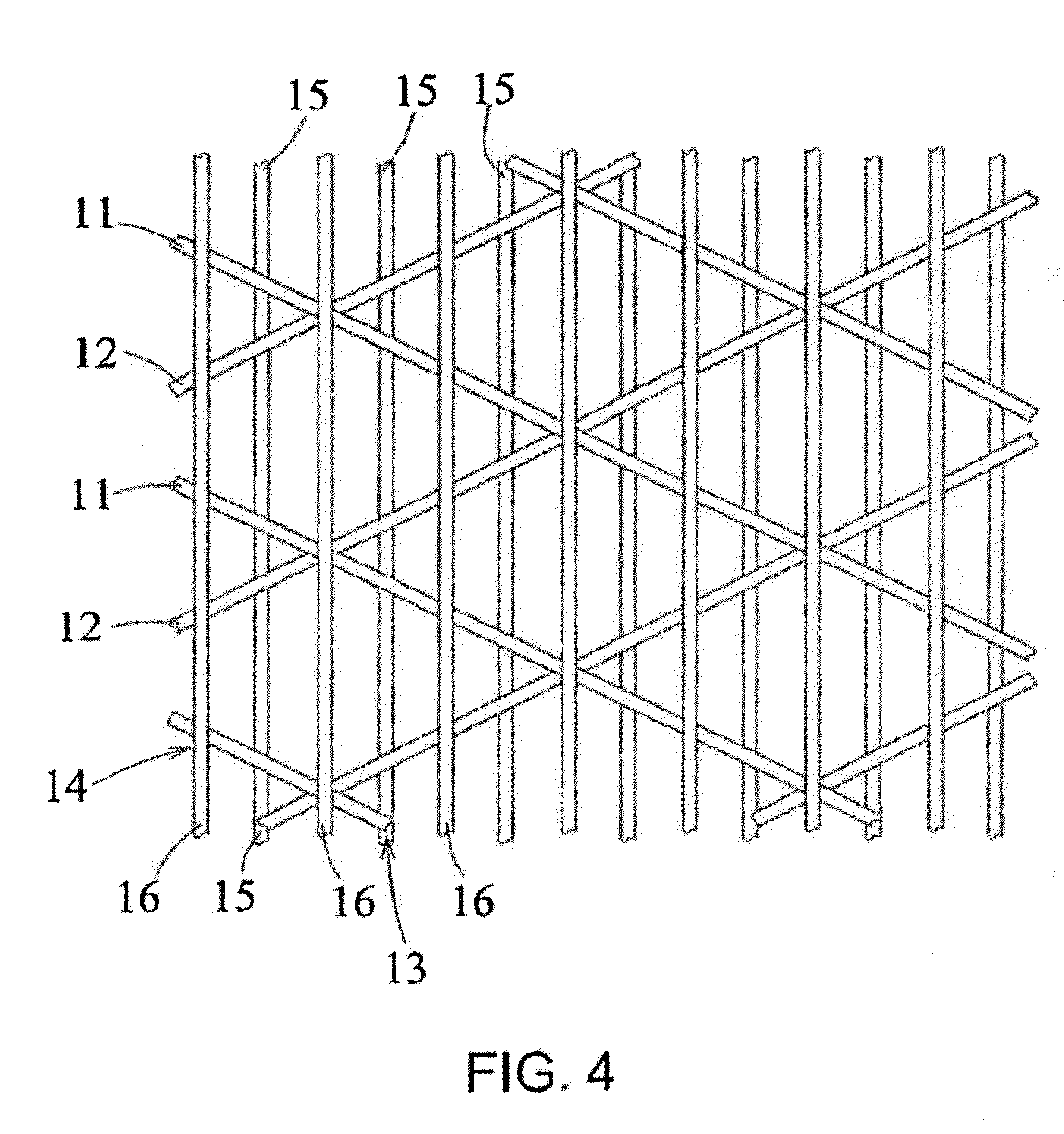

Open Mesh Material and Bags Made Therefrom

An open mesh material includes filaments (1, 2, 3, 4, 11, 12, 15, 16) that intersect one another. At least some of the filaments are composite filaments having a carrier portion of a relatively high melting point and a bonding portion of a relatively low melting point, the bonding portion of each composite filament being thermally bonded to other filaments at points of intersection. The material may be a non-woven fabric that contains at least two layers of weft filaments (1, 2, 11, 12) that may be bordered on one or both sides by a layer of warp filaments (3,4, 15, 16). When compared to other open mesh materials, the open mesh material disclosed herein has a superior combination of some or all of high strength, light weight, high dimensional stability, and openness. Also disclosed herein are articles can be made at least in part from the material including L-seam bags (20), form fill and seal (FFS) bags (1020), and multi-substrate bags (2,020). Methods of making those bags also are disclosed.

Owner:VOLM

Engineered particles and methods of use

InactiveUS20050074498A1Reduce deliveryLess attractivePowder deliveryOrganic active ingredientsNebulizerActive agent

Engineered particles are provided may be used for the delivery of a bioactive agent to the respiratory tract of a patient. The particles may be used in the form of dry powders or in the form of stabilized dispersions comprising a nonaqueous continuous phase. In particularly preferred embodiments the particles may be used in conjunction with an inhalation device such as a dry powder inhaler, metered dose inhaler or a nebulizer.

Owner:NOVARTIS FARMA

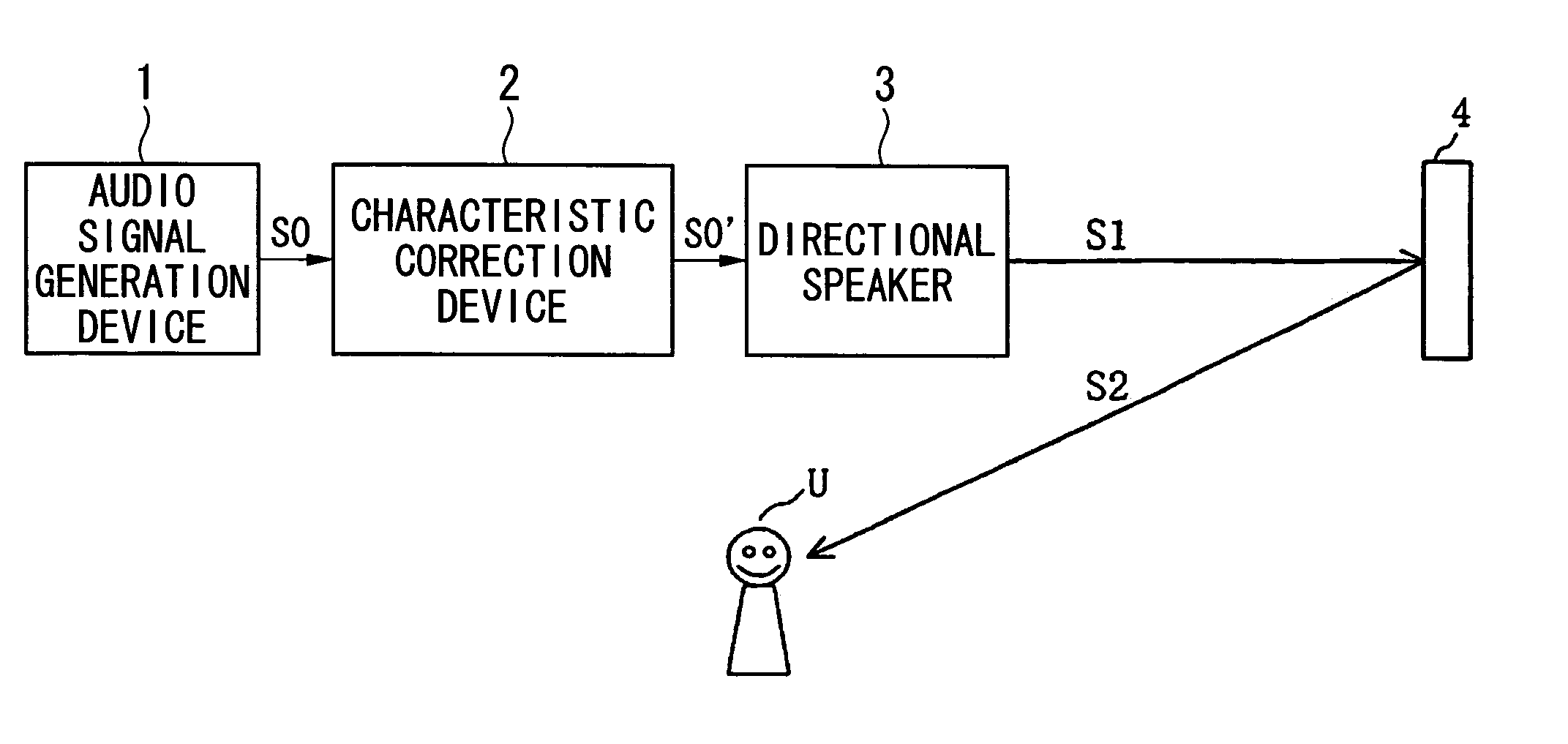

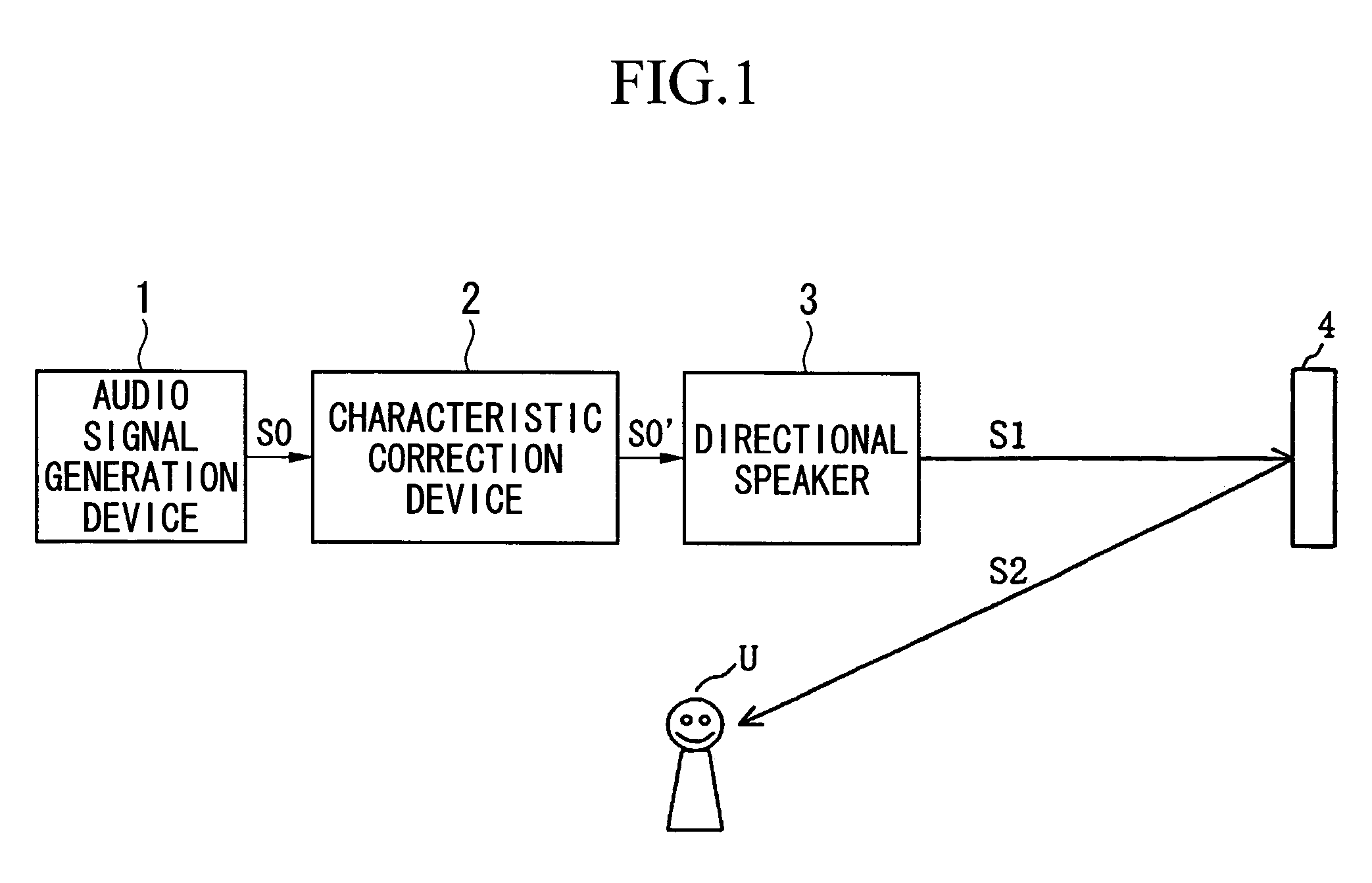

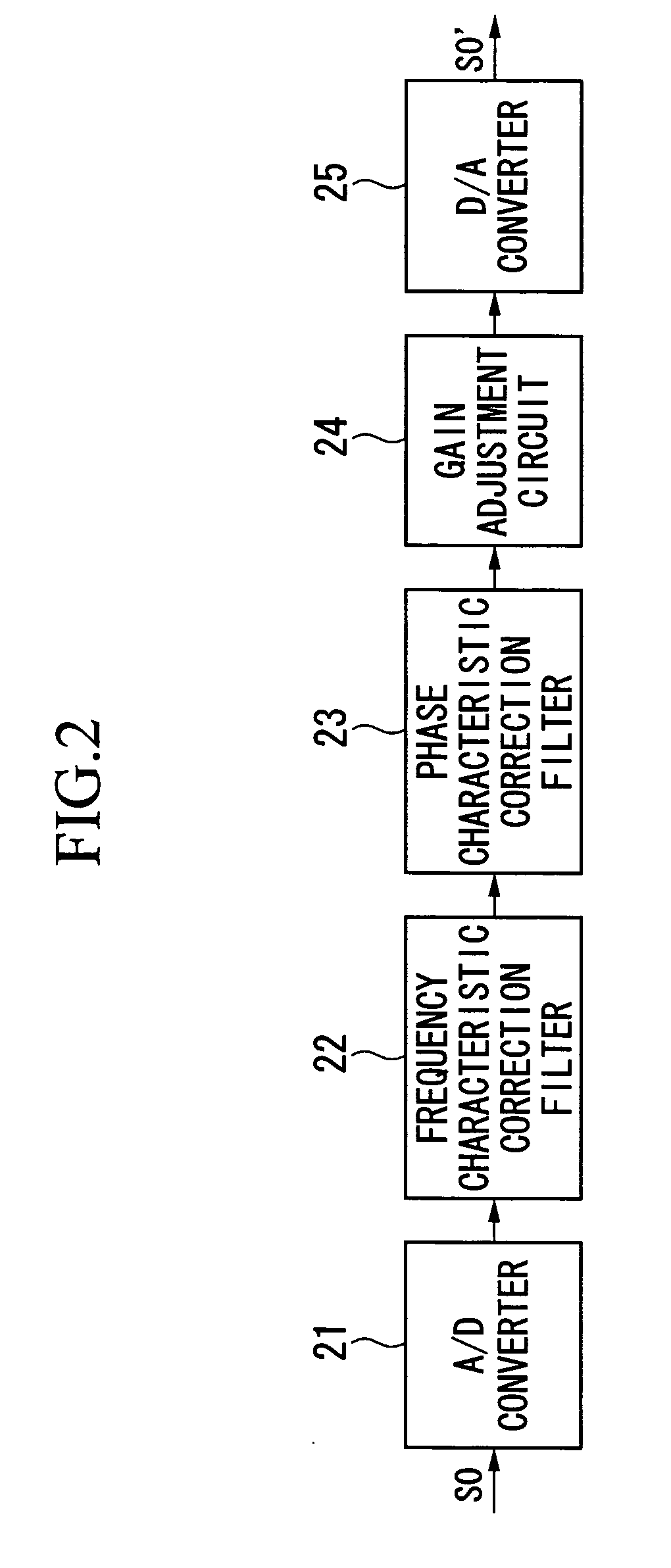

Audio characteristic correction system

An audio characteristic correction system adapted to an audio surround system in which a sound emitted from a directional speaker (an array speaker) is reflected on a wall surface or a sound reflection board so as to create a virtual speaker, at least one of frequency-gain characteristics, frequency-phase characteristics, and gain of an audio signal input to the directional speaker is corrected such that the sound reflected on the wall surface or the sound reflection board has desired audio characteristics at a desired listening position.

Owner:YAMAHA CORP

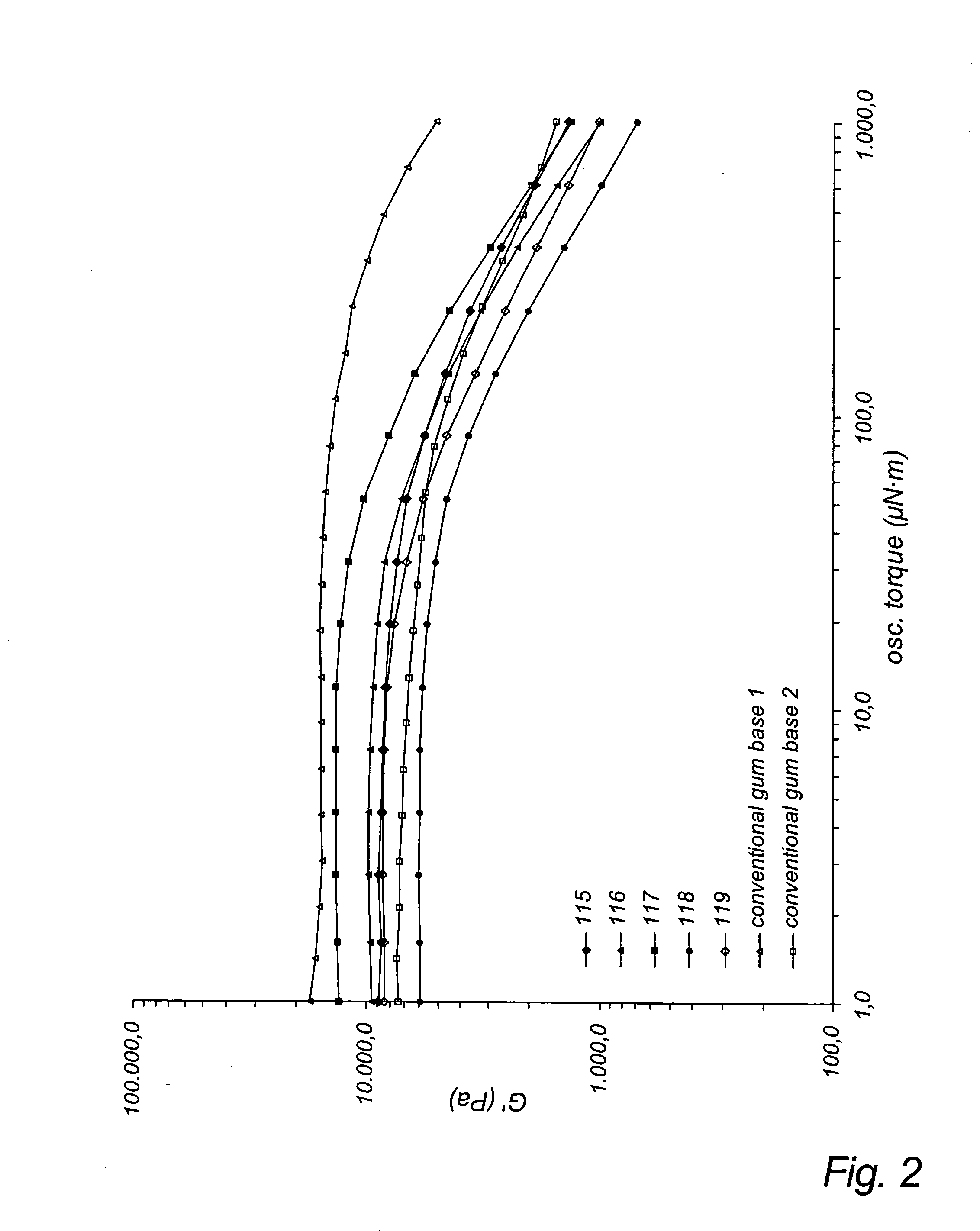

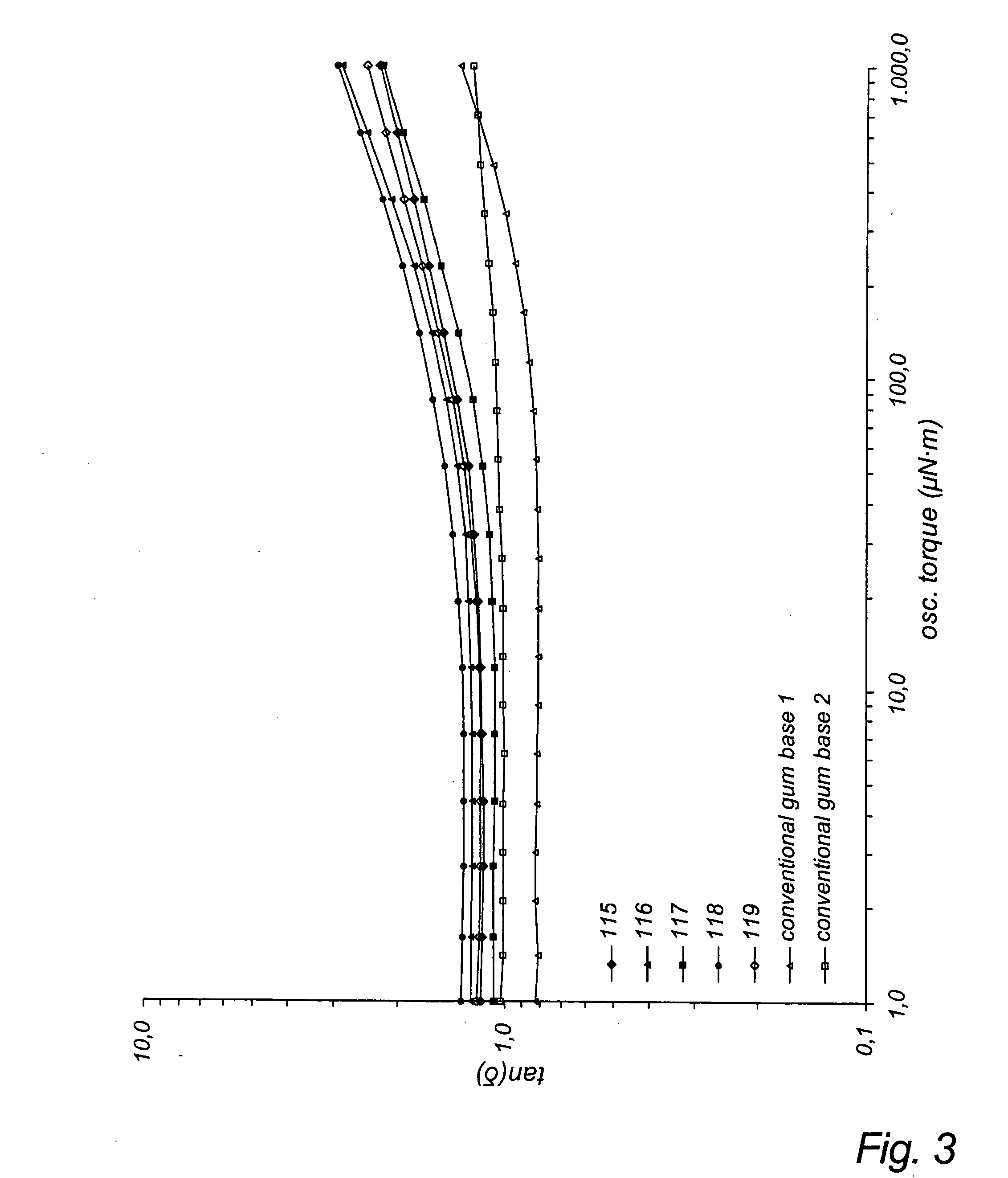

Degradable elastomers for chewing gum base

InactiveUS20040156949A1Impairing rheological propertyDesired characteristicConfectioneryChewing gumPolyesterChemistry

There is provided a novel degradable gum base comprising low molecular weight elastomer replacement compounds which are generally applicable for chewing gum formulations. In particular there is provided a gum base and a chewing gum comprising a polyester polymer obtainable by the polymerisation of two or more different cyclic ester monomers, wherein the cyclic ester monomers have a low glass transition temperature (Tg) and the polyester polymer has a glass transition temperature (Tg) in the range from (-20° C.) to (-80° C.).

Owner:GUMLINK AS

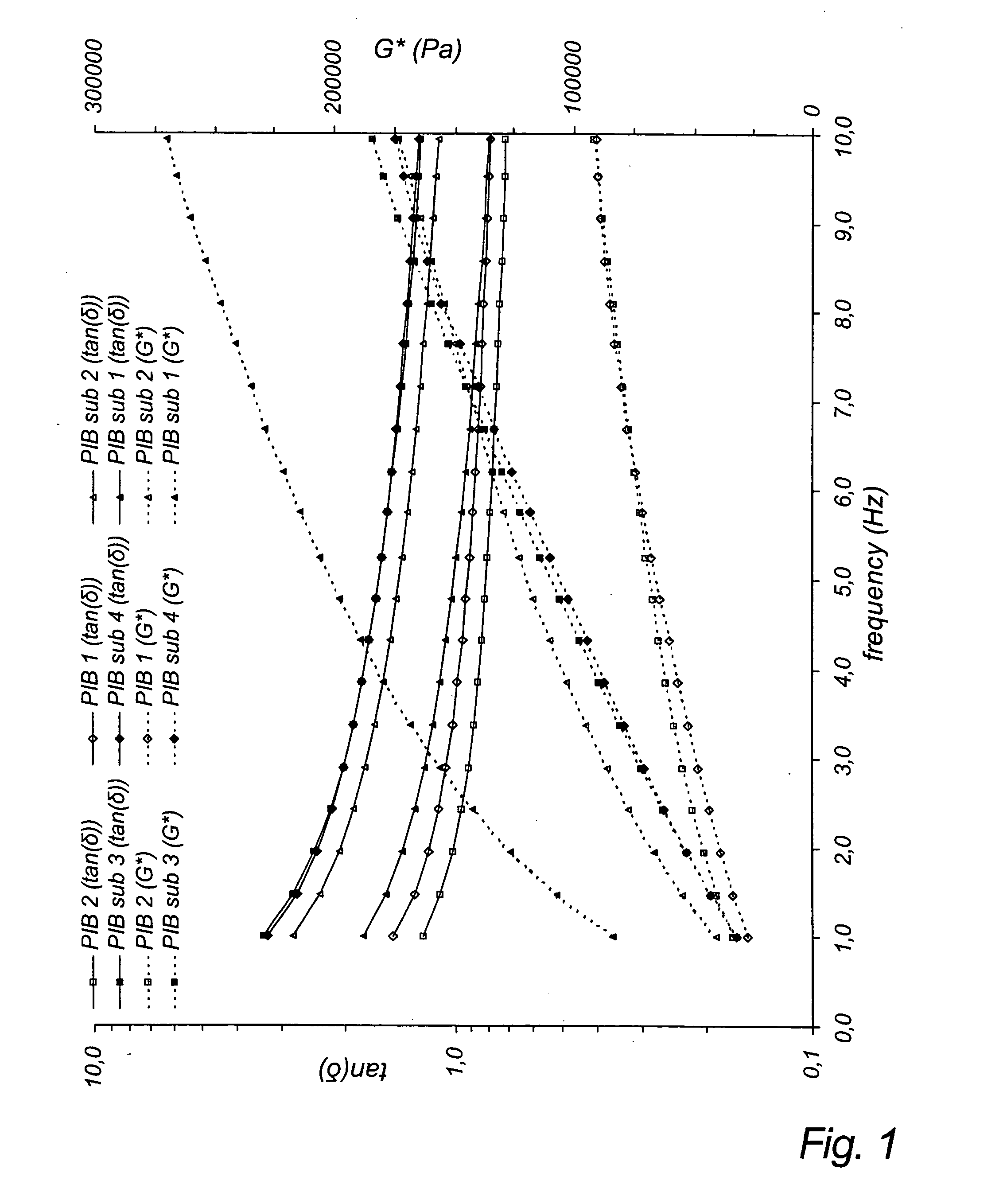

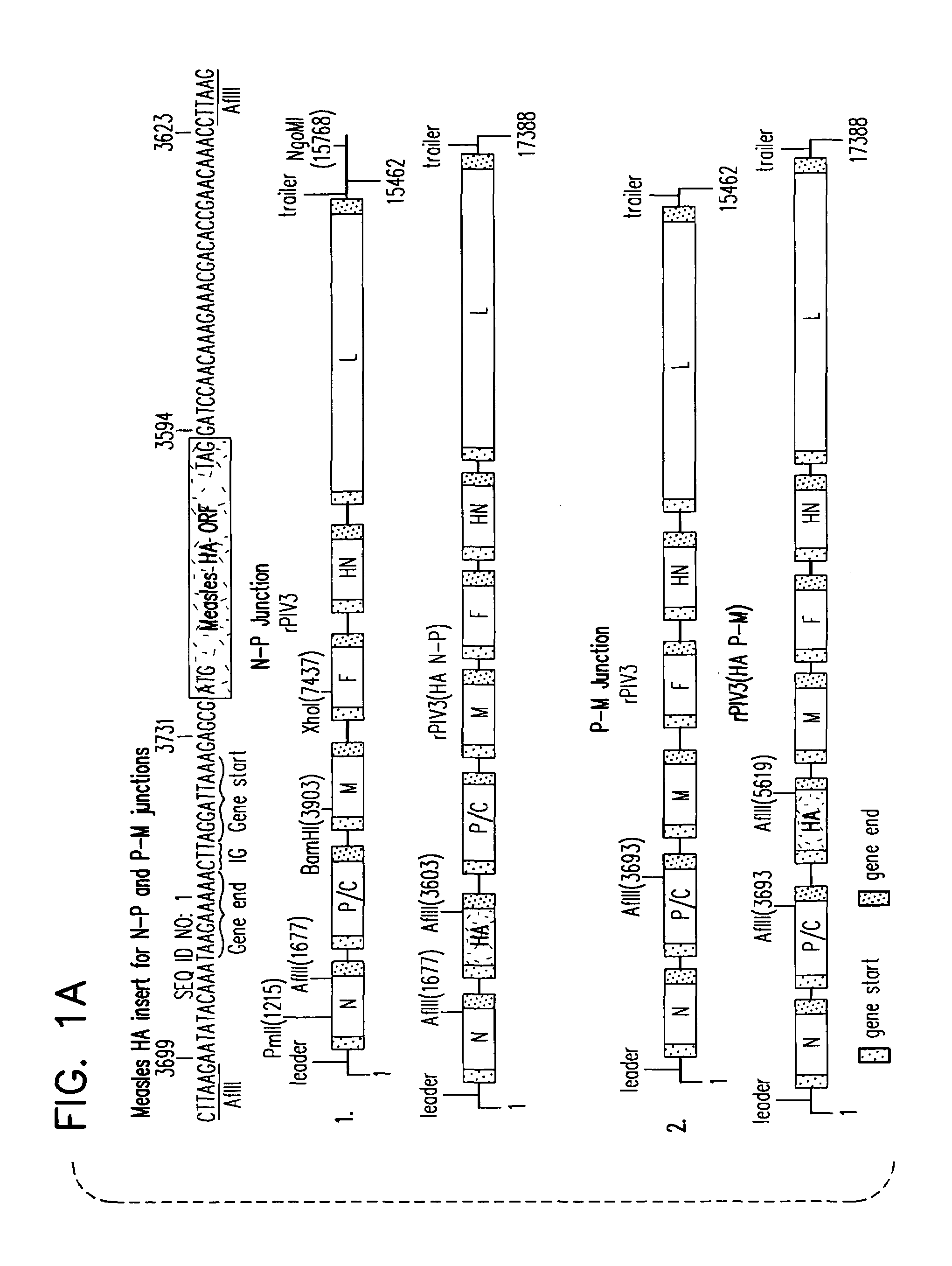

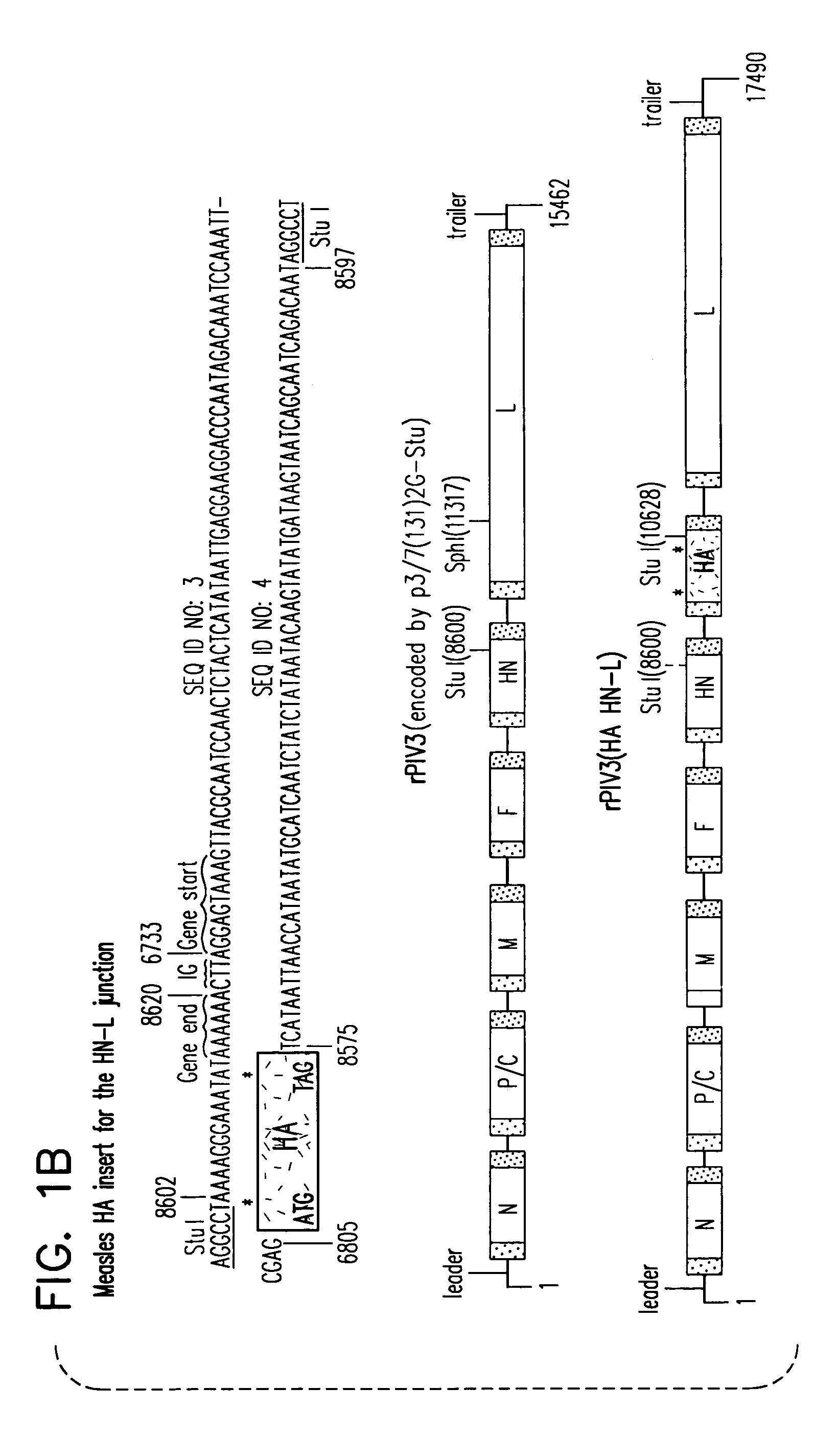

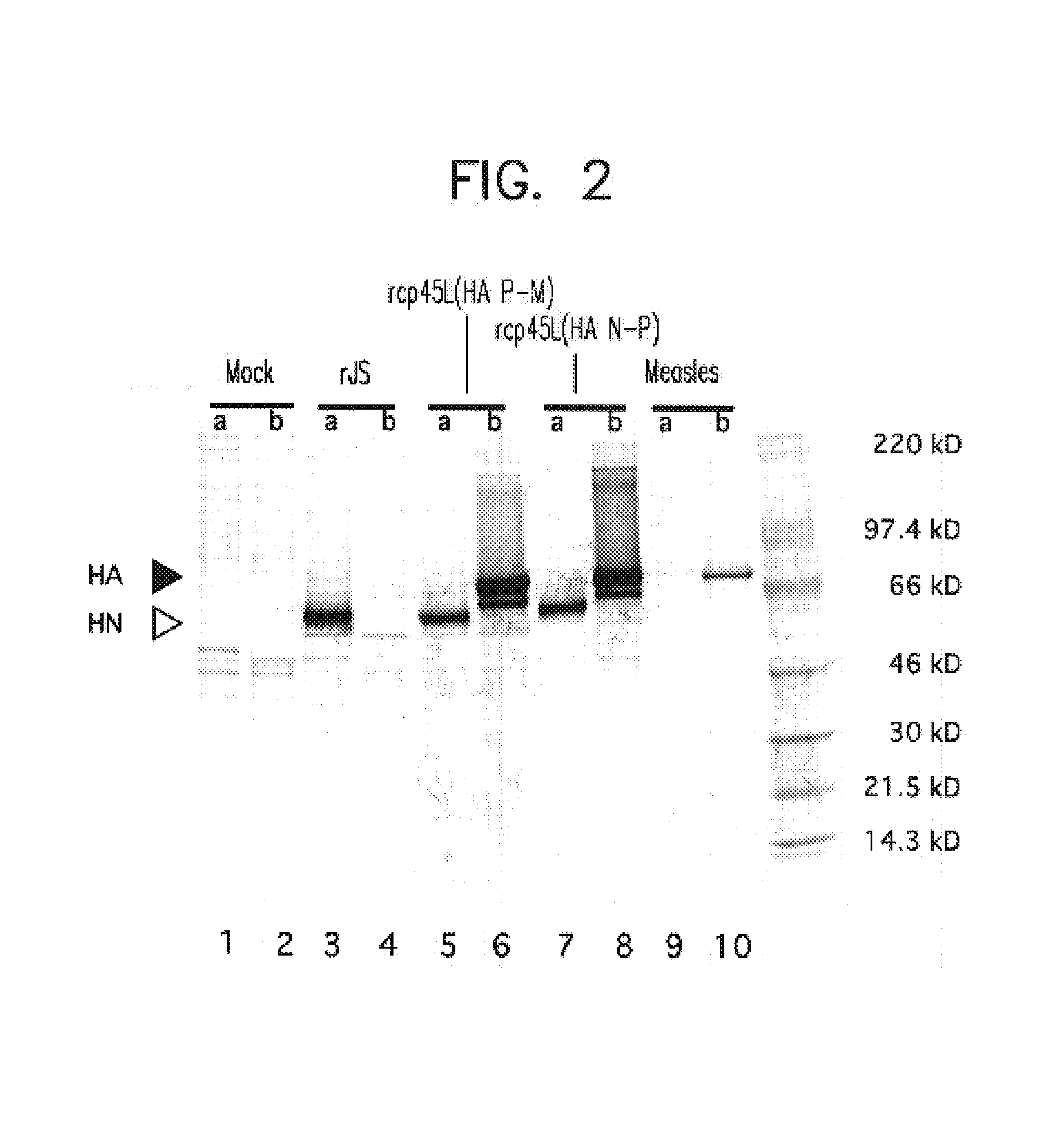

Construction and use of recombinant parainfluenza viruses expressing a chimeric glycoprotein

InactiveUS7250171B1Prone to infectionHigh titerSsRNA viruses negative-senseOrganic active ingredientsHeterologousEpitope

Chimeric parainfluenza viruses (PIVs) are provided that incorporate a PIV vector genome or antigenome modified to encode a chimeric glycoprotein incorporating one or more heterologous antigenic domains, fragments, or epitopes of a second, antigenically distinct HPIV. These chimeric viruses are infectious and attenuated in humans and other mammals and are useful in vaccine formulations for eliciting an immune responses against one or more PIVs, and, optionally against respiratory syncytial virus (RSV). Also provided are isolated polynucleotide molecules and vectors incorporating a chimeric PIV genome or antigenome which includes a HPIV vector genome or antigenome combined or integrated with one or more heterologous genome segment(s) encoding one or more antigenic determinant(s) of a heterologous PIV to encode a chimeric glycoprotein. In preferred aspects of the invention, the chimeric virus is attenuated for use as a vaccine agent by additional mutations or nucleotide modifications introduced into the chimeric genome or antigenome.

Owner:HEALTH & HUMAN SERVICES GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE

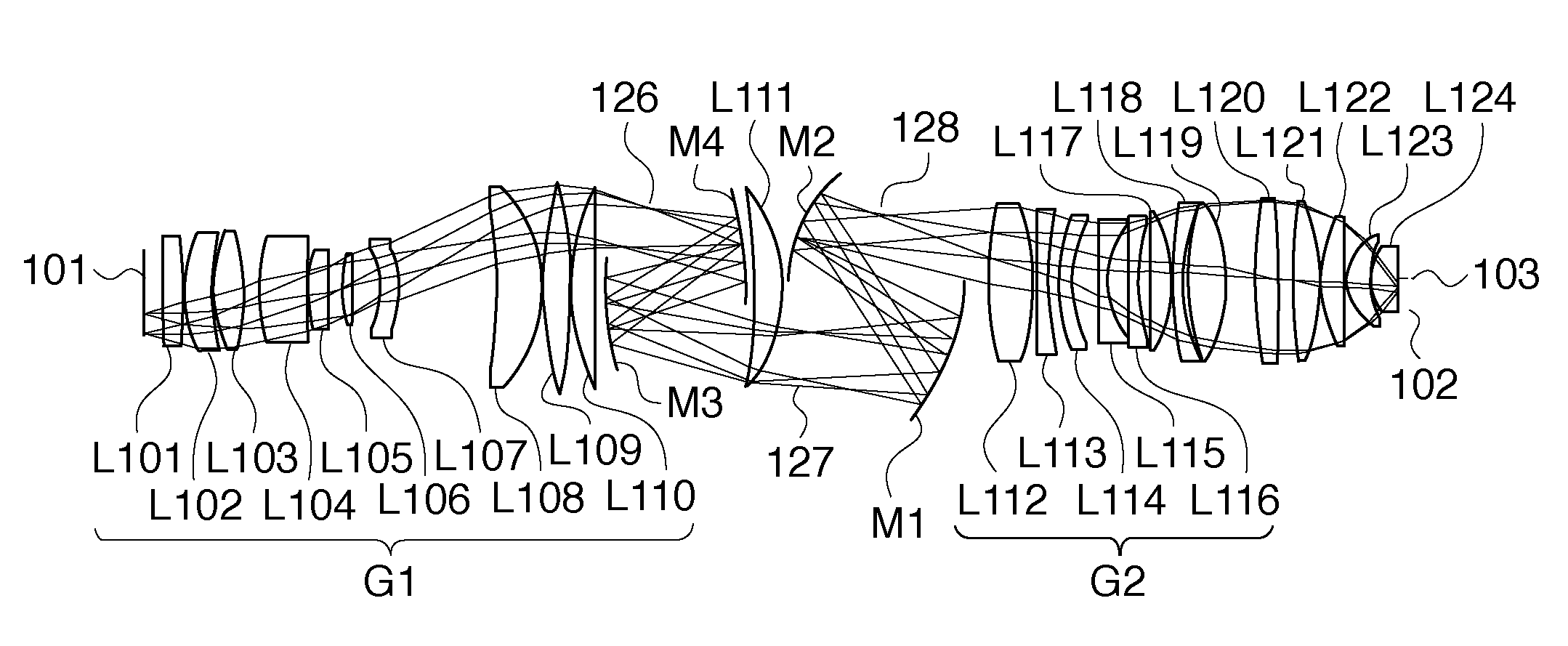

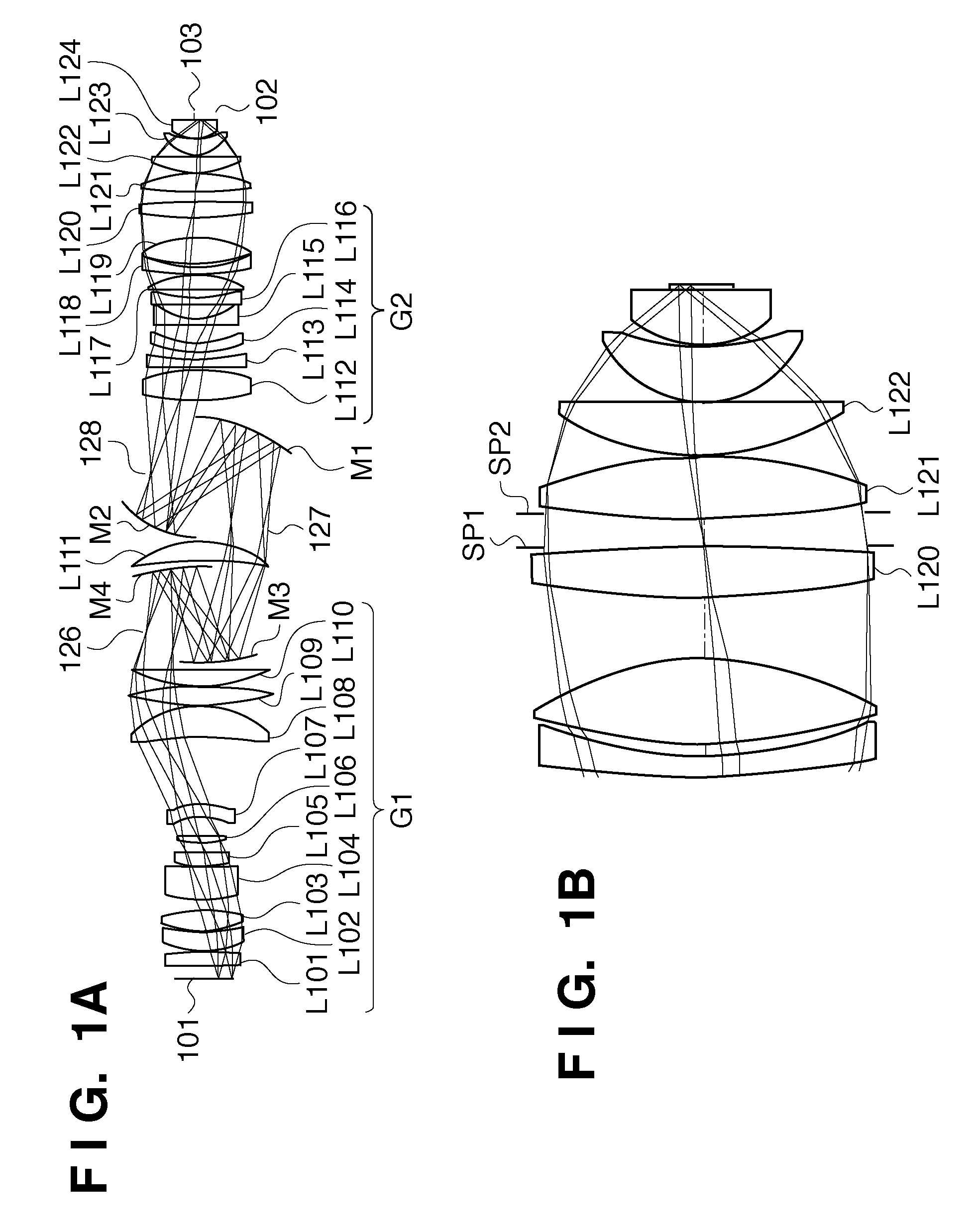

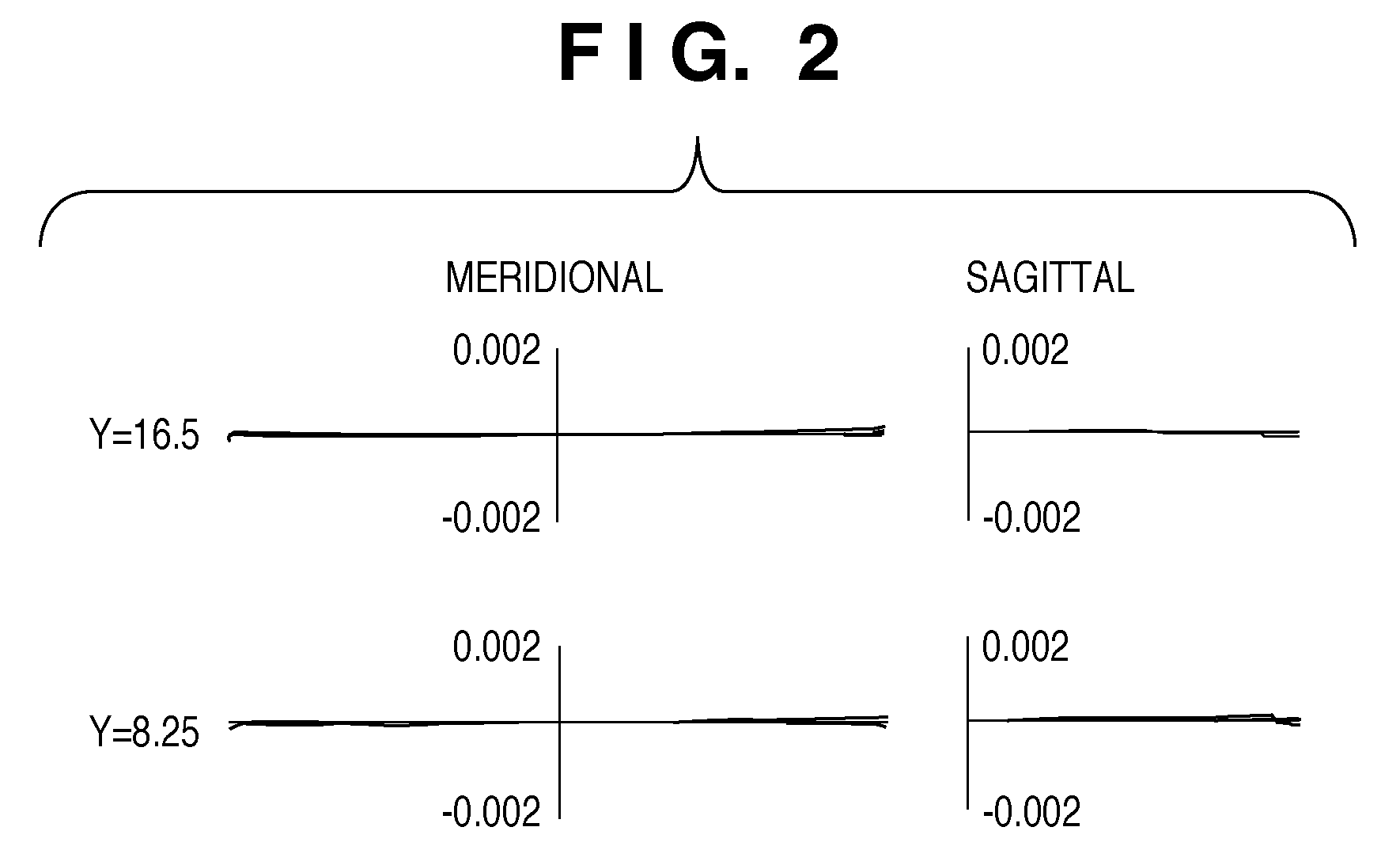

Projection optical system, exposure apparatus, and method of manufacturing device

InactiveUS20090080068A1Good optical performanceDesired characteristicPhotomechanical apparatusTelescopesEffective diameterImage-forming optical system

A projection optical system which projects an image of a first object onto a second object includes a plurality of lenses and a plurality of aperture stops for determining a numerical aperture. The plurality of aperture stops include a first aperture stop having an opening whose size can be changed, and a second aperture stop having an opening whose size can be changed. The first and second aperture stops are positioned nearer to the second object than a lens having the maximum effective diameter among the lenses included in an imaging optical system nearest to the second object. At least one of the first and second aperture stops is positioned at or near the pupil of the imaging optical system. The range of the numerical aperture determined by the first aperture stop is larger than the range of the numerical aperture determined by the second aperture stop.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com