Method of preparing biological materials and preparations produced using same

a biological material and preparation technology, applied in the field of biological material preparation, can solve the problems of insufficient fluidisation rate, inability to elucidate, and extreme temperature sensitiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Stabilization of Microorganisms

Example 1A

Eight litres of live Bifidus culture was obtained from an original 3000 L liquid culture from Sine Pharmaceutical Co., Ltd. # 905, Xinjinqiao Rd., Pudong, Shanghai, P. R. China. Data supplied from the manufacturer established that 3000 L of fermentation liquid contains a total of 3×1016 CFU (colony forming units) and yields approximately 8.3 kg of freeze dry material containing a total of 2.16×1014 CFU of Bifidus; that is, after freeze drying, there is reduction of approximately 99% live bacteria population.

After arrival in the laboratory a sample of the culture was tested for stability at 4° C. At time zero 2.43×1016 CFU / 3000L was recorded. After storage for fourteen days under 4° C., the count was reduced to 1.5×1014 CFU / 3000L; that is, about one in 1500 cells survived after two weeks storage at 4° C.

The liquid culture, containing various sugar additives (as described below) was processed according to the invention in the following m...

example 1b

Further batches of Bifidobacterium bifidum 6-1 were imported from Sine Pharmaceutical Co., Ltd. # 905, Xinjinqiao Rd., Pudong, Shanghai, P. R. China. The culture used in Example 1A was thought to contain some waste material which may contribute to instability of the bacteria in the final bioencapsulated solid micro capsules. Accordingly, the culture used in the present example had all waste material removed, was concentrated and resuspended in buffer solutions. The culture was assayed on arrival from the manufacturer and a sample was also assayed just prior to use. Results indicated a bacterial count of 4.1×108CFU / L.

4 kg BatchSINE RX6Hydrogel core 6Pregel Maize Starch3.10 kgEgg Albumin0.40 kgCoating Liquid 6Bifidus 8.2 × 108 CFUMannitol0.10 kgGlycerol0.30 kgSodium Alginate0.06 kgSodium phosphate buffer0.04 kgPurified water to 1.00 kg.SINE RX7Hydrogel core 7Pregel Maize Starch2.44 kgGelatin0.52 kgStarch0.60 kgEgg Albumin0.20 kgCoatinq Liquid 7Bifidus 4.2 × 108 CFUMannitol0.05 kgGl...

example 2

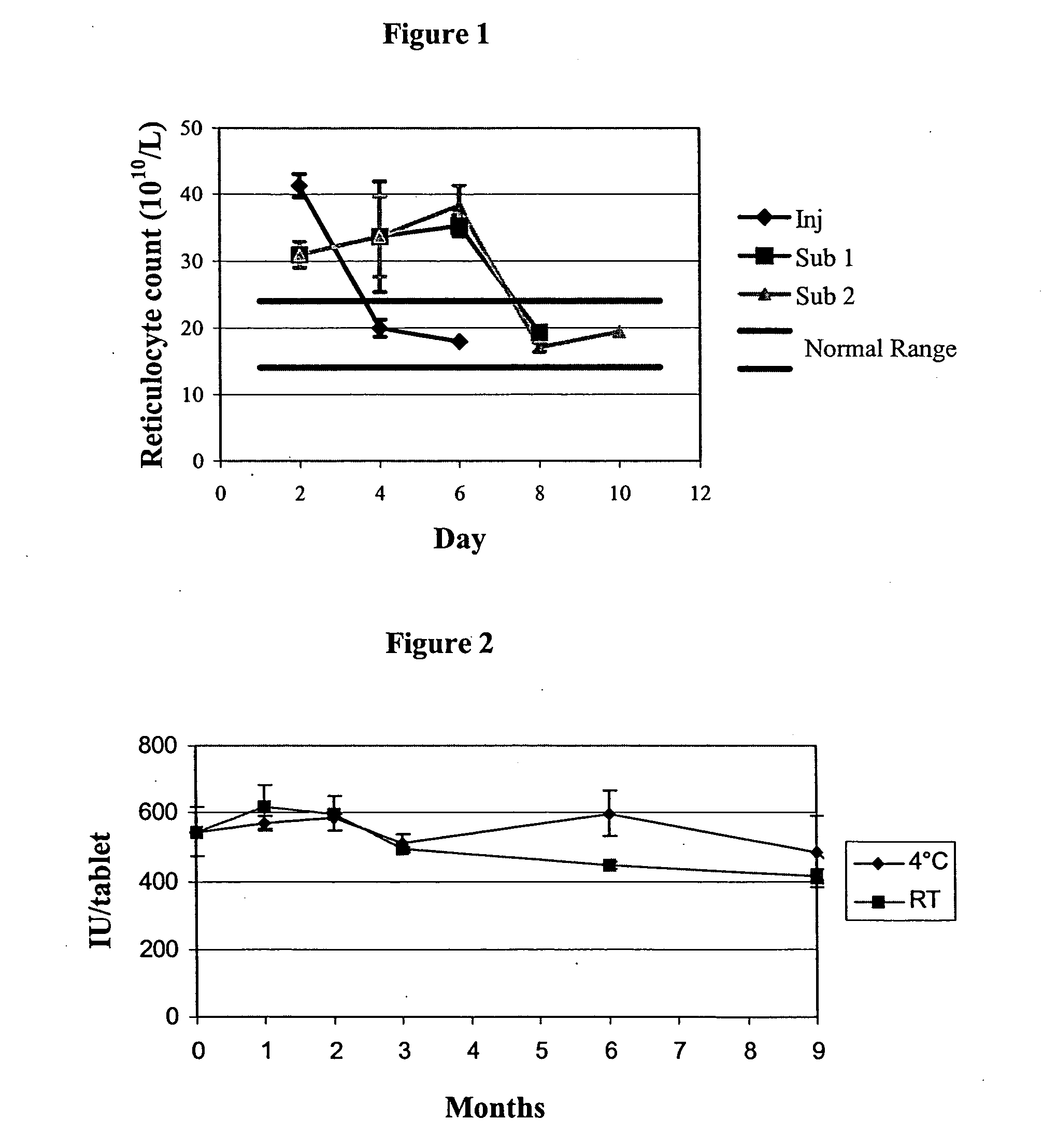

Stabilization of Enzymes

Enzymes are biological proteins which have applications in a variety of industries; for example, they are used in food processing, as animal feed additives, and as human and animal medications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com