Patents

Literature

40results about How to "Long persistence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adjuvanted influenza vaccines for pediatric use

ActiveUS8506966B2Enhance immune responseHigh seroprotection rateSsRNA viruses negative-senseViral antigen ingredientsAdjuvantSeroconversion

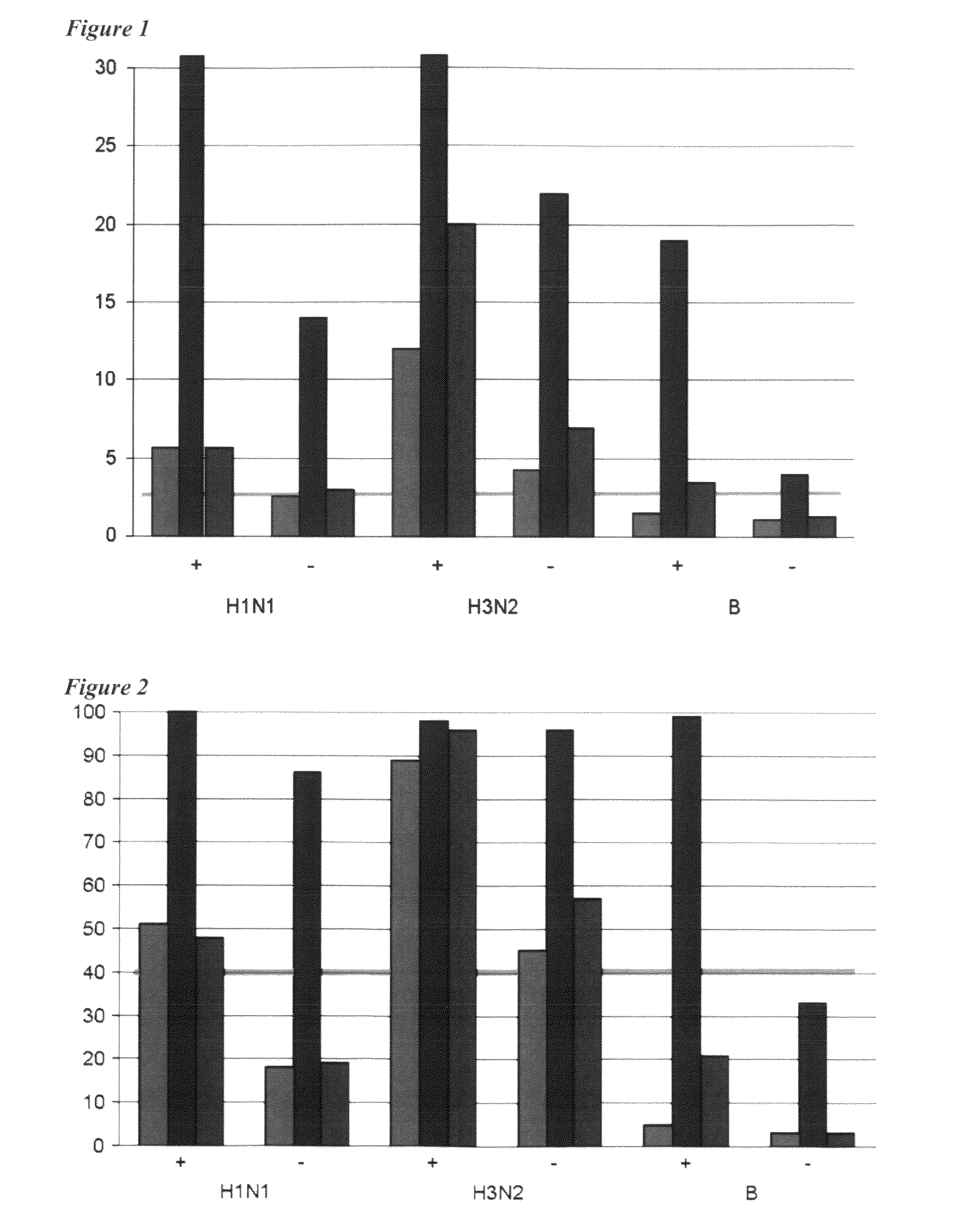

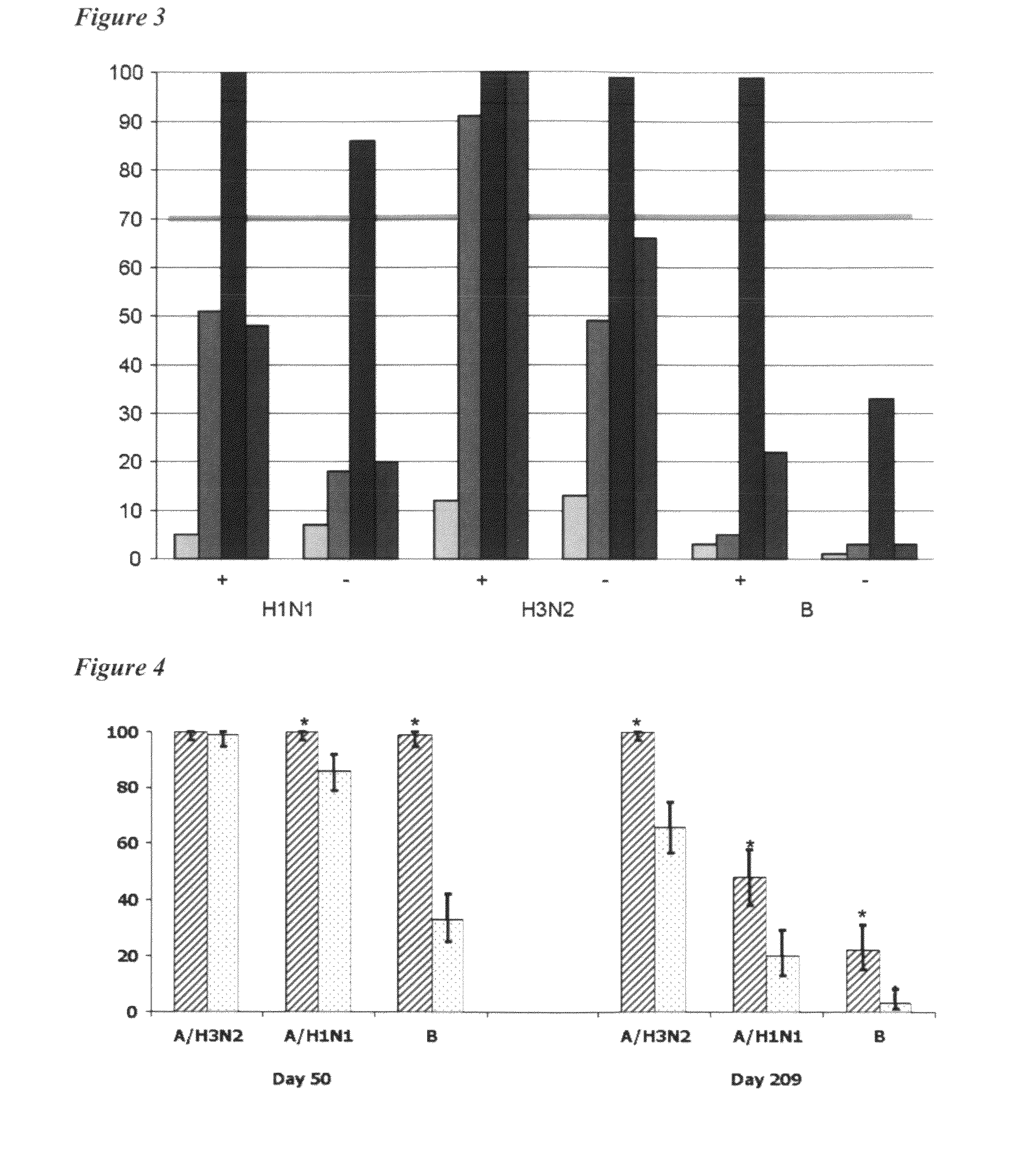

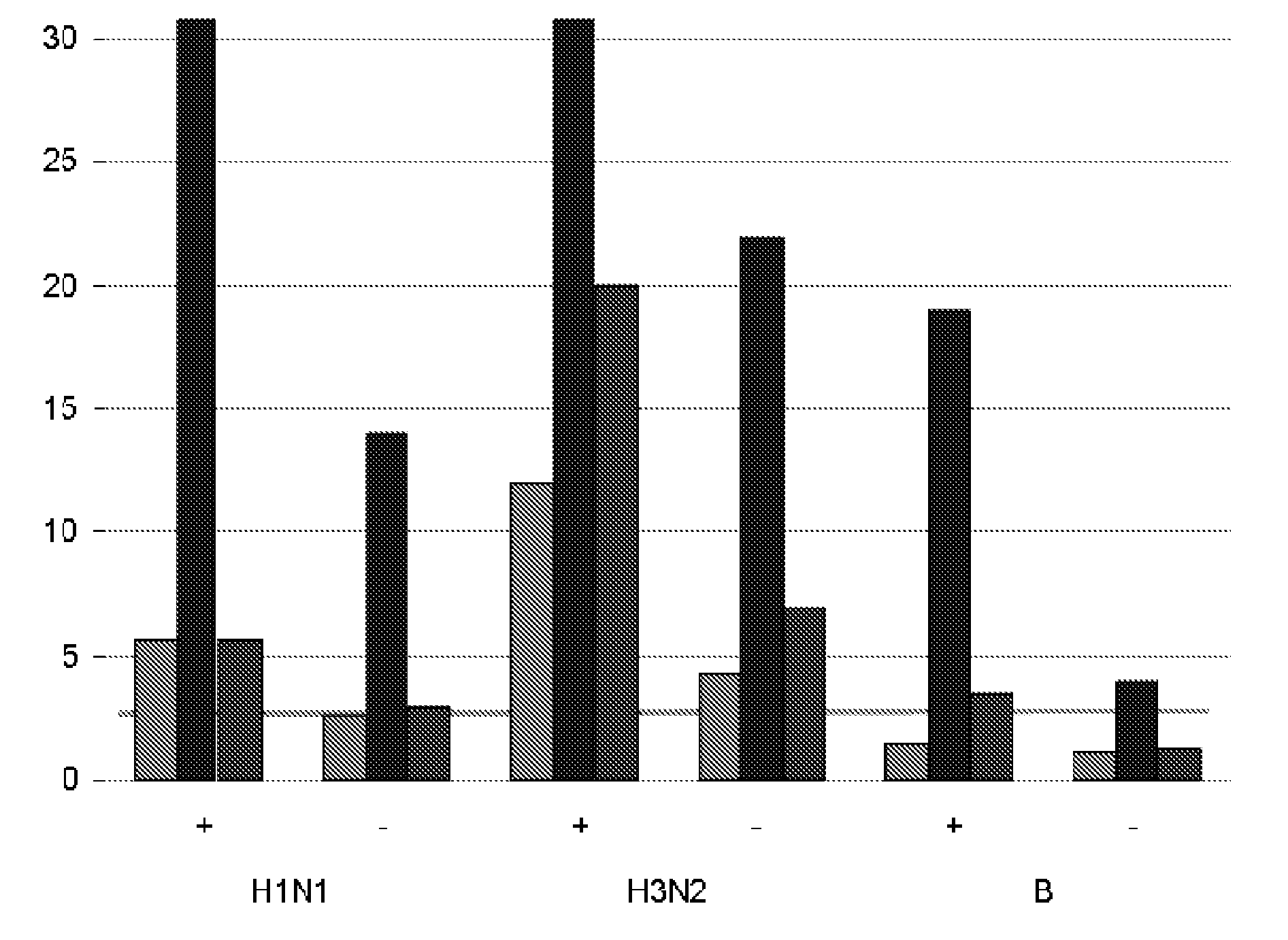

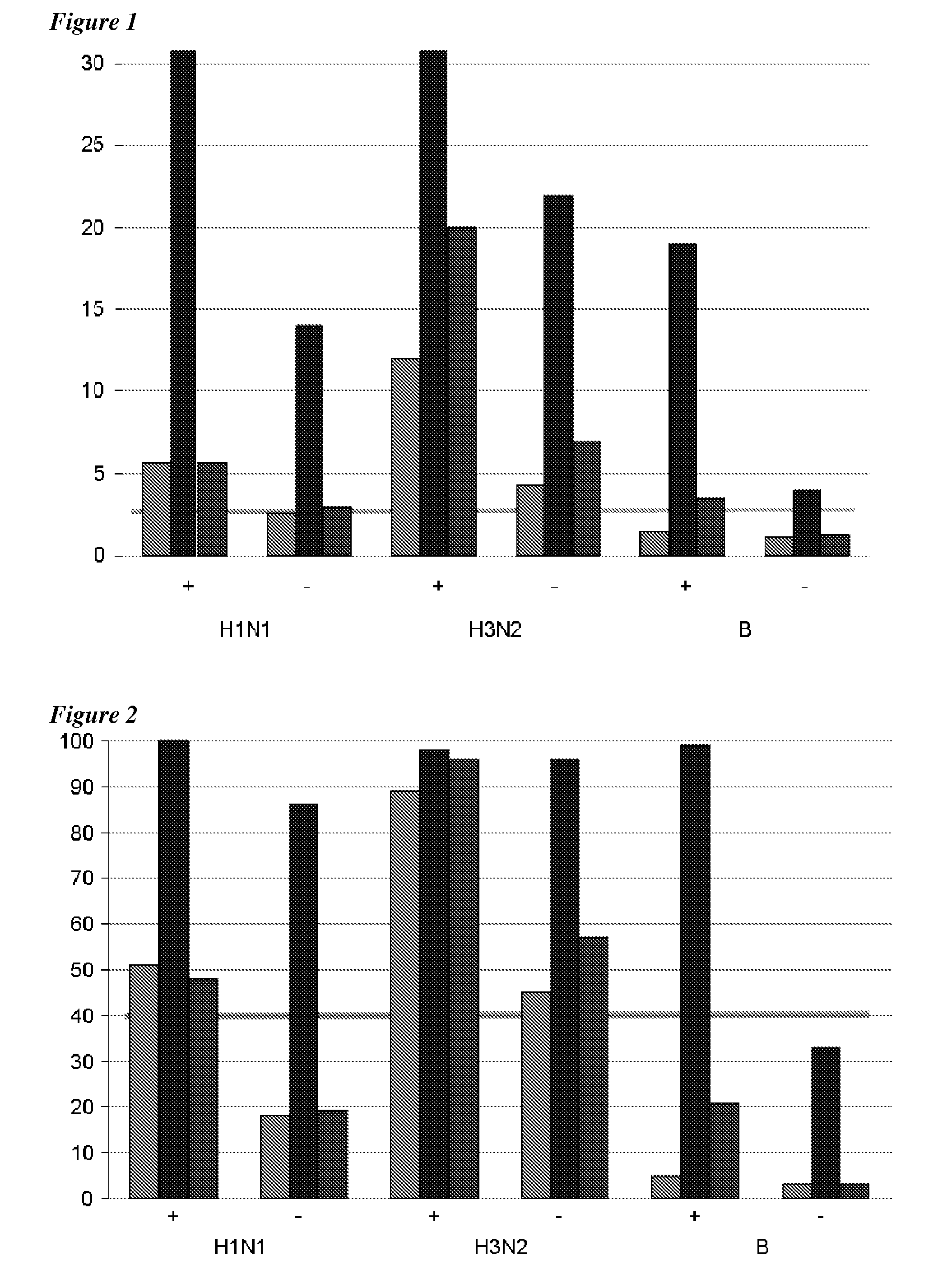

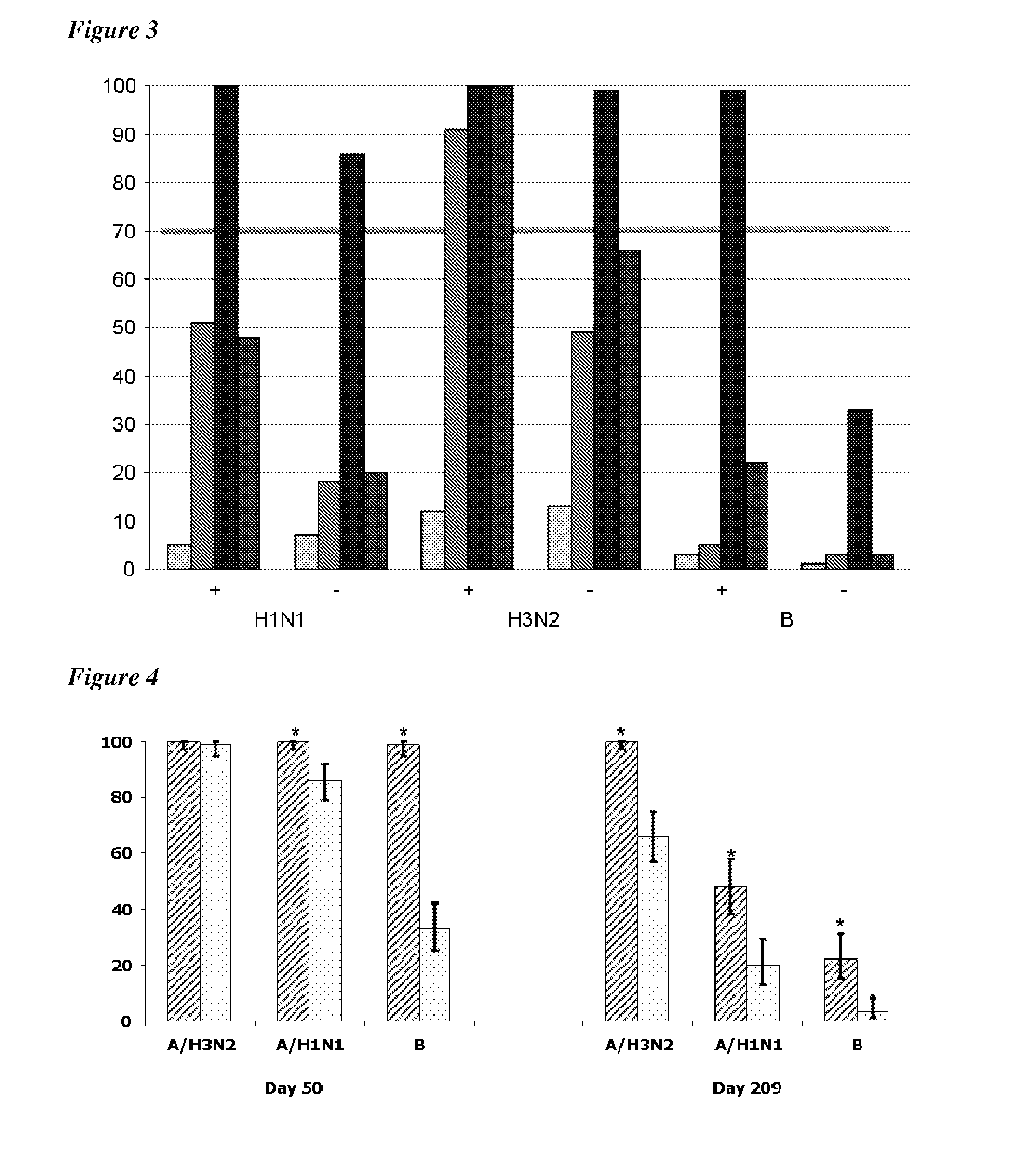

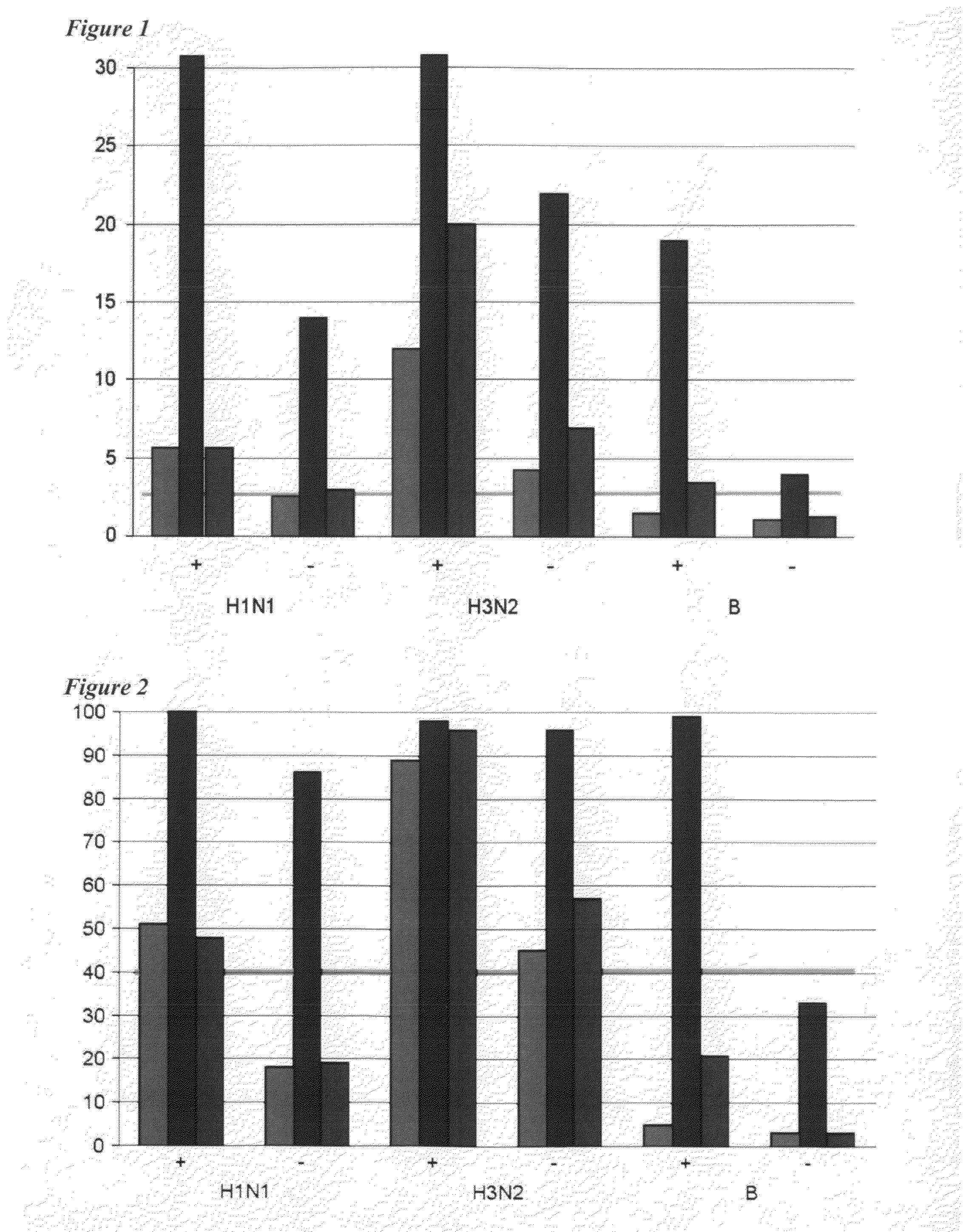

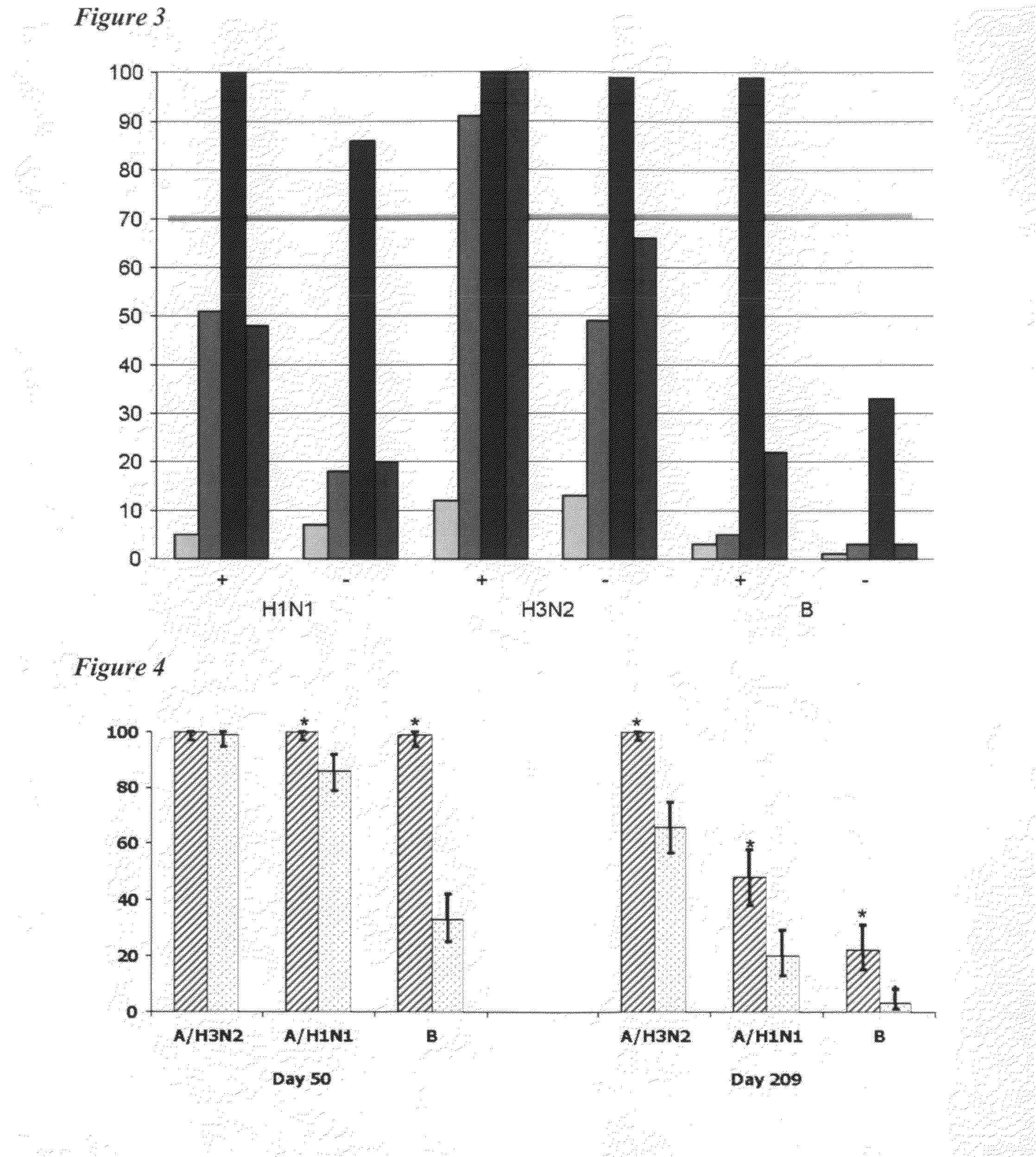

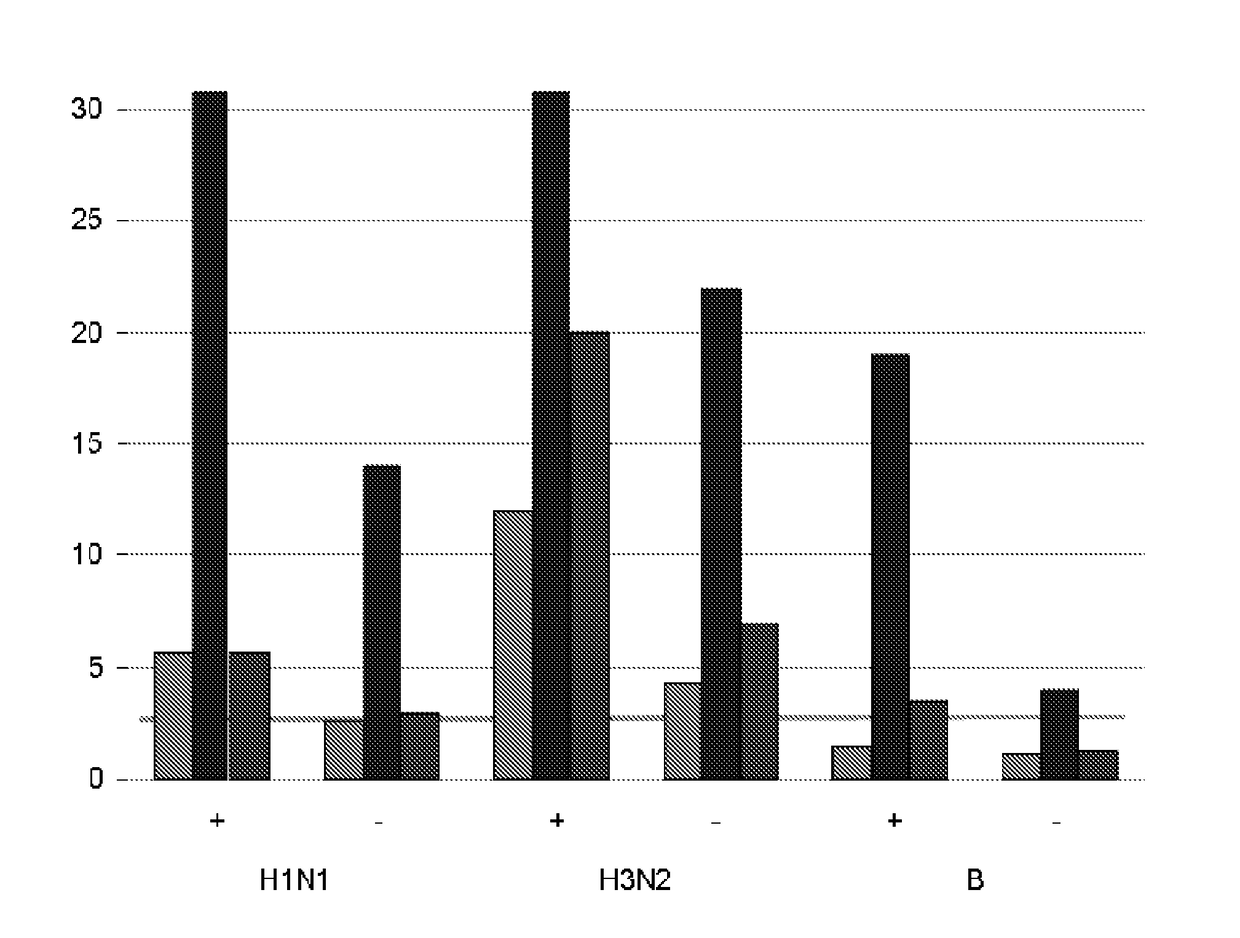

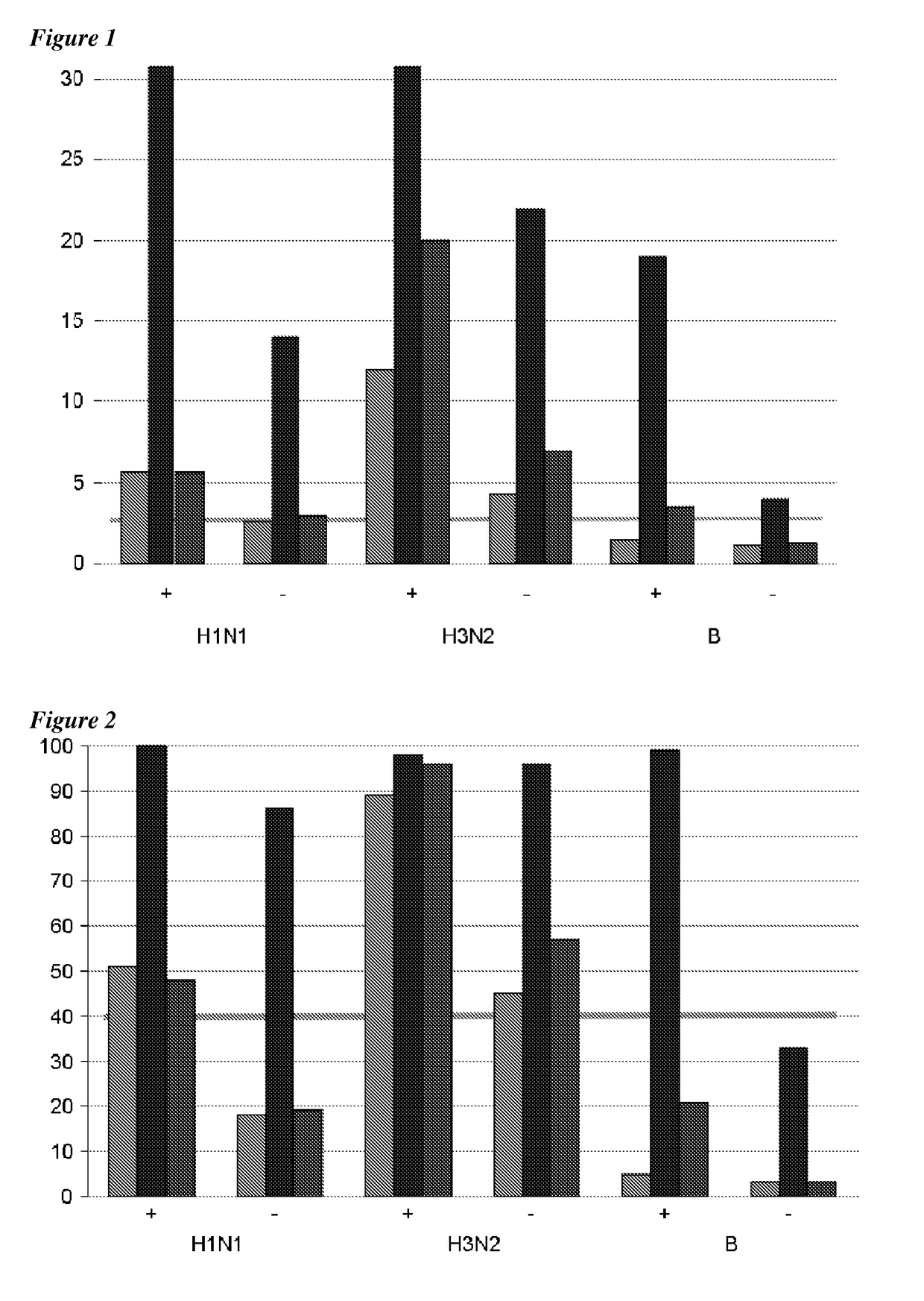

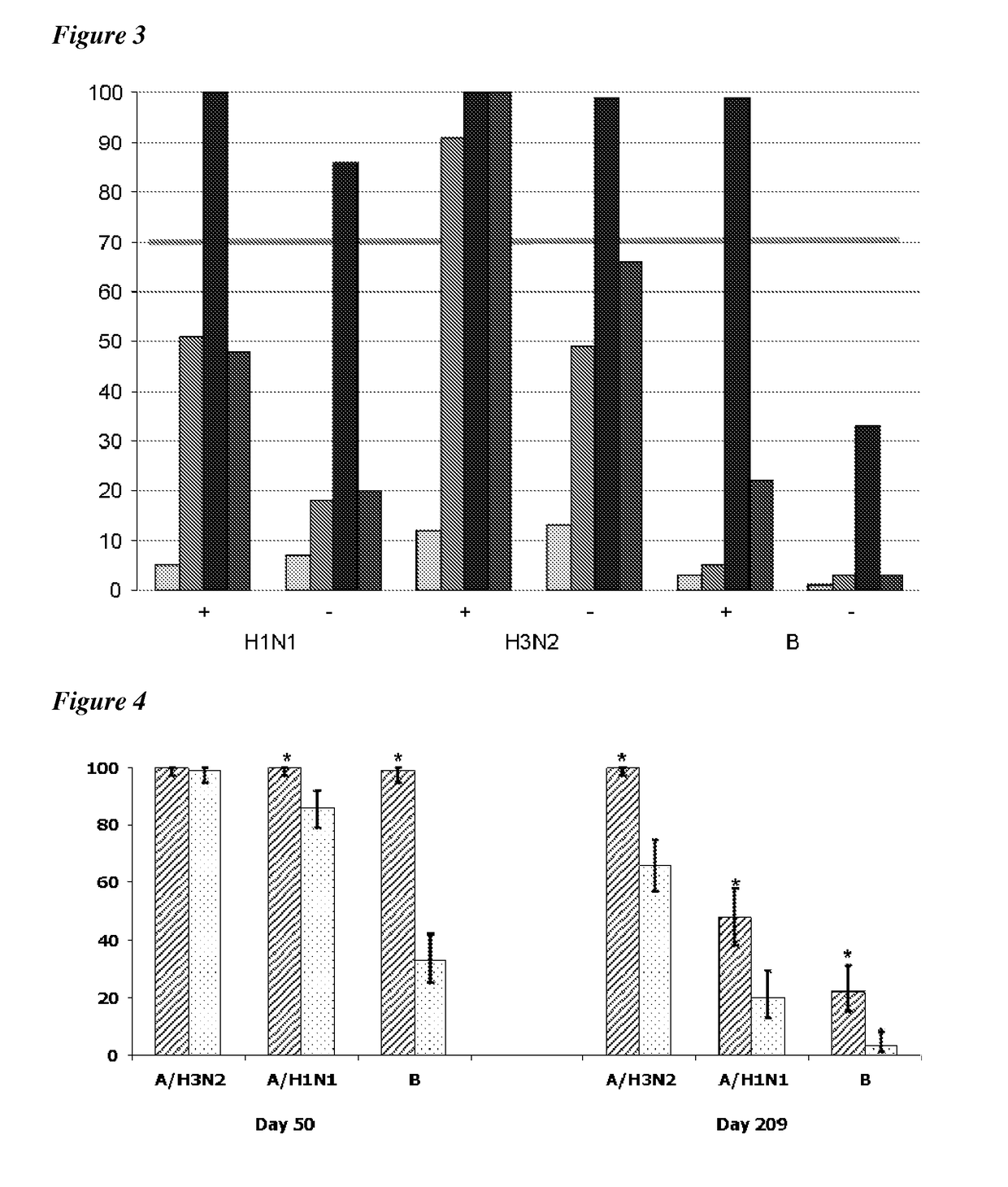

An influenza vaccine adjuvanted with a sub-micron oil-in-water emulsion elicits significantly higher immune responses in human pediatric populations. Compared to an existing unadjuvanted pediatric influenza vaccine, the adjuvanted vaccines provided herein can induce in children a longer persistence of high serum antibody titers and also longer seroconversion and seroprotection. The improvement in immune responses is seen for both influenza A virus and influenza B virus strains, but it is particularly marked for influenza B virus. Moreover, while the existing vaccine provides poor immunity in children after a single dose, the adjuvanted vaccine provides high seroprotection rates against the influenza A virus H3N2 subtype even after a single dose. Furthermore, the adjuvanted vaccine offers significantly better seroprotection against mismatched strains of influenza A virus.

Owner:SEQIRUS UK LTD

Adjuvanted influenza vaccines for pediatric use

InactiveUS20120027813A1Raise useful immune responseEnhance immune responseSsRNA viruses negative-senseViral antigen ingredientsInfluenza B virusesAdjuvant

An influenza vaccine adjuvanted with a sub-micron oil-in-water emulsion elicits significantly higher immune responses in human pediatric populations. Compared to an existing unadjuvanted pediatric influenza vaccine, the adjuvanted vaccines provided herein can induce in children a longer persistence of high serum antibody titers and also longer seroconversion and seroprotection. The improvement in immune responses is seen for both influenza A virus and influenza B virus strains, but it is particularly marked for influenza B virus. Moreover, while the existing vaccine provides poor immunity in children after a single dose, the adjuvanted vaccine provides high seroprotection rates against the influenza A virus H3N2 subtype even after a single dose. Furthermore, the adjuvanted vaccine offers significantly better seroprotection against mismatched strains of influenza A virus.

Owner:SEQIRUS UK LTD

Disinfecting composition based on H2O2, acids and metal ions

The invention concerns an oxidising aqueous composition useful in particular for disinfection, hygiene and depollution purposes, and for surface treatment (particularly a metal surface to be stripped and / or passivated), and said composition, containing in water hydrogen peroxide, a RCO2H / RCO3H mixture (wherein R is a C1-C6 aliphatic radical with linear or branched hydrocarbon chain, saturated or unsaturated), a stabilising agent which is an acid and, as the case may be, Ag<+> ions. The invention is characterised in that it contains ions of at least one metal M which are ions of Ag<II>, Ag<III>, V<V>, Nb<V>, Ta<V>, Mo<VI>, W<VI>, Co<III>, In<III >or Tl<III>. Advantageously, said composition can be in gel form. The invention also concerns the method for preparing said composition.

Owner:DIGOL INT LTD

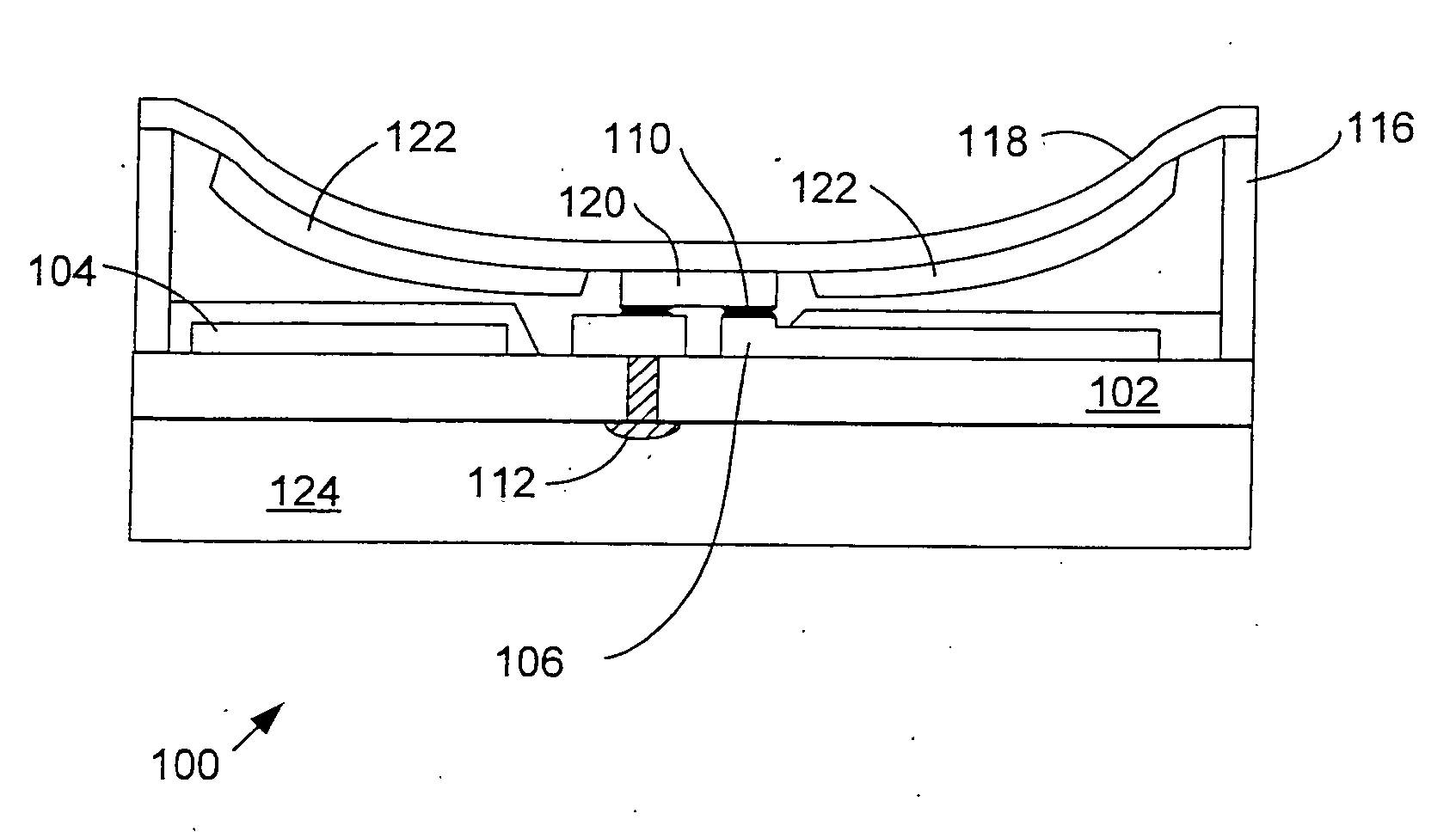

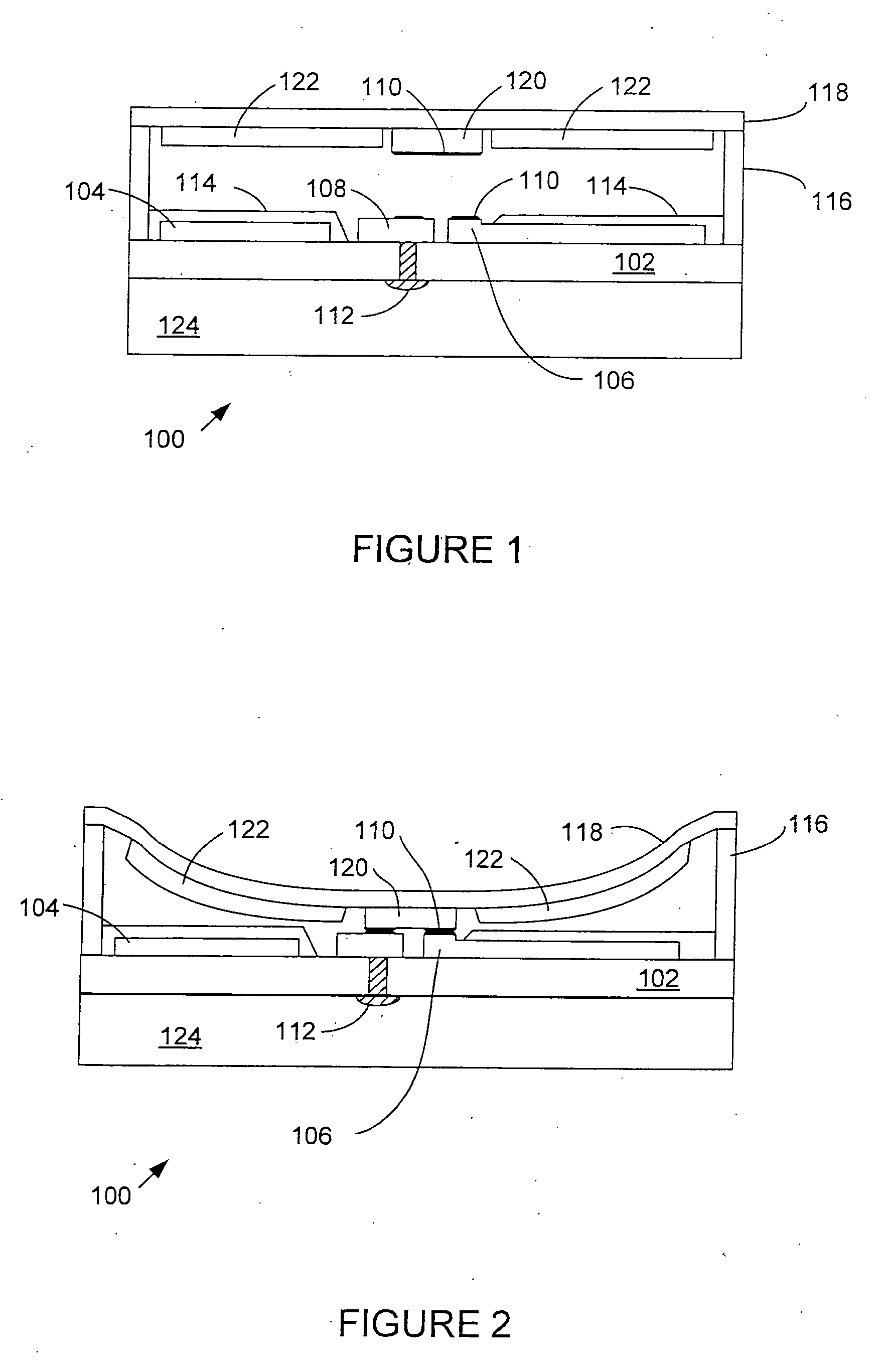

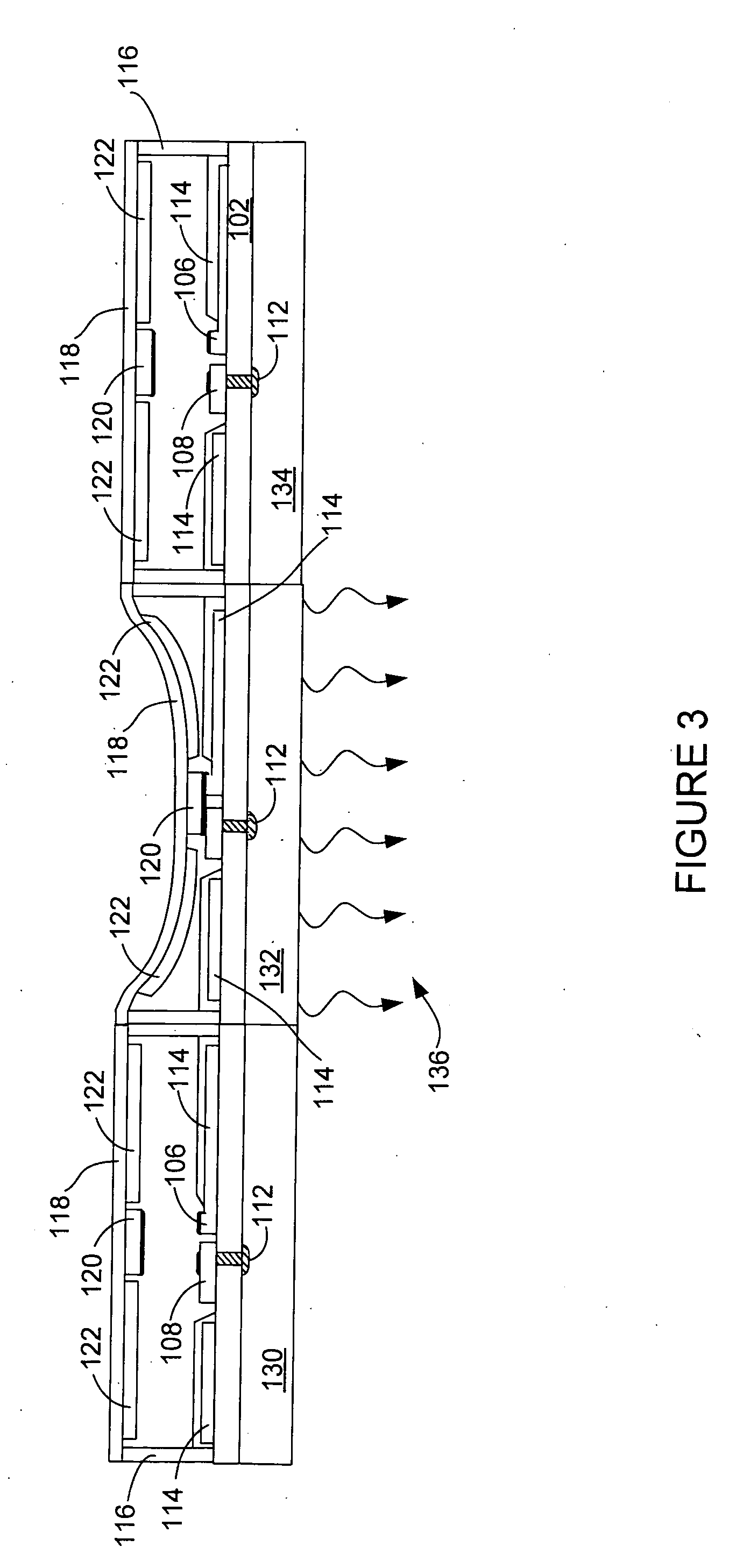

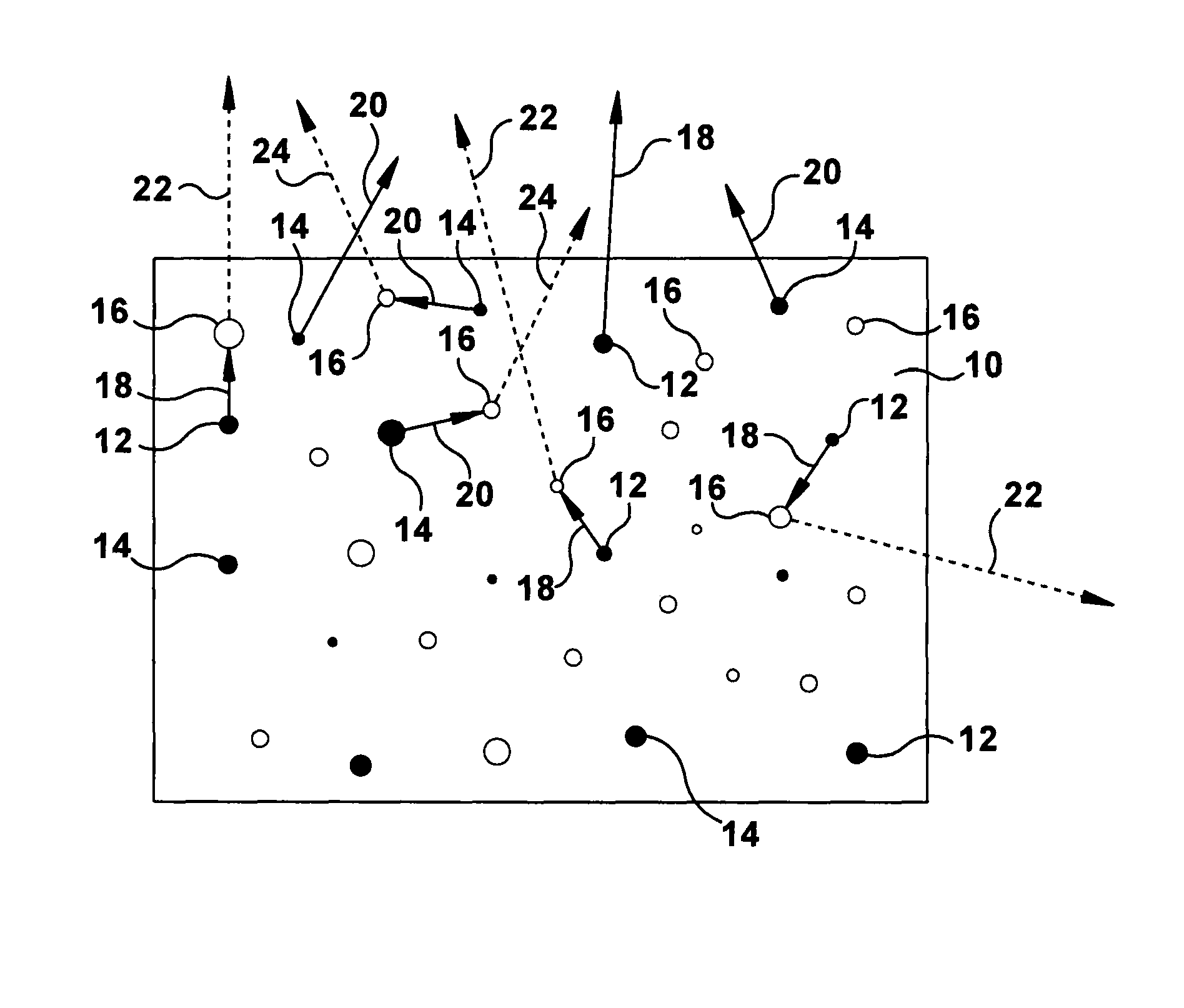

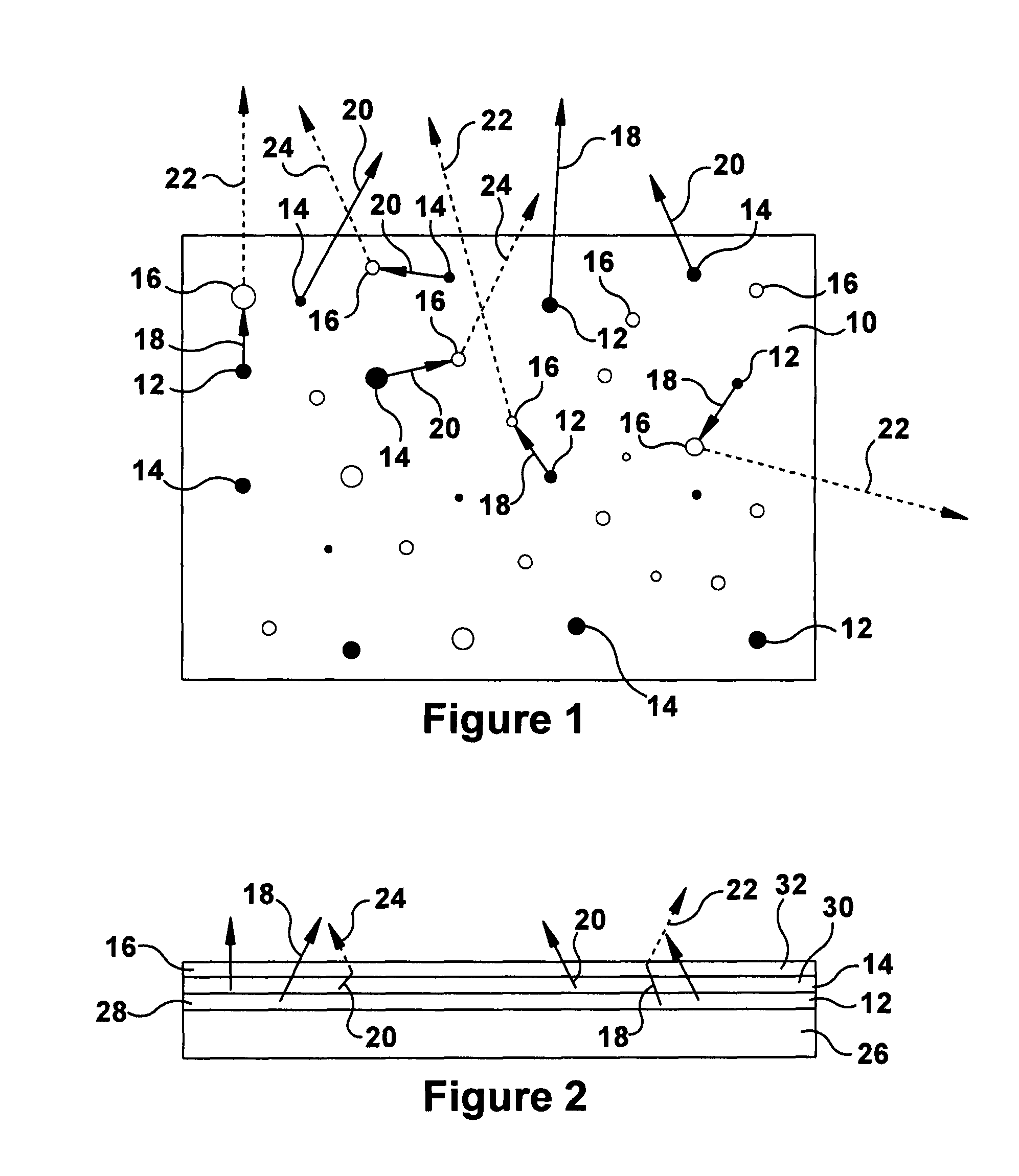

Micro-electromechanical display backplane and improvements thereof

InactiveUS20070002009A1Low costLow-cost techniqueElectrostatic/electro-adhesion relaysStatic indicating devicesDisplay deviceEngineering

A low cost, scalable backplane for electrophoretic displays comprising a multi-membrane plastic array of micro electromechanical (MEM) switches. Each switch controls the state of a pixel in the electrophoretic display device. Each switch may be latched to eliminate the need to constantly refresh the device and each switch may function as an enunciator

Owner:SEERTECH CORP

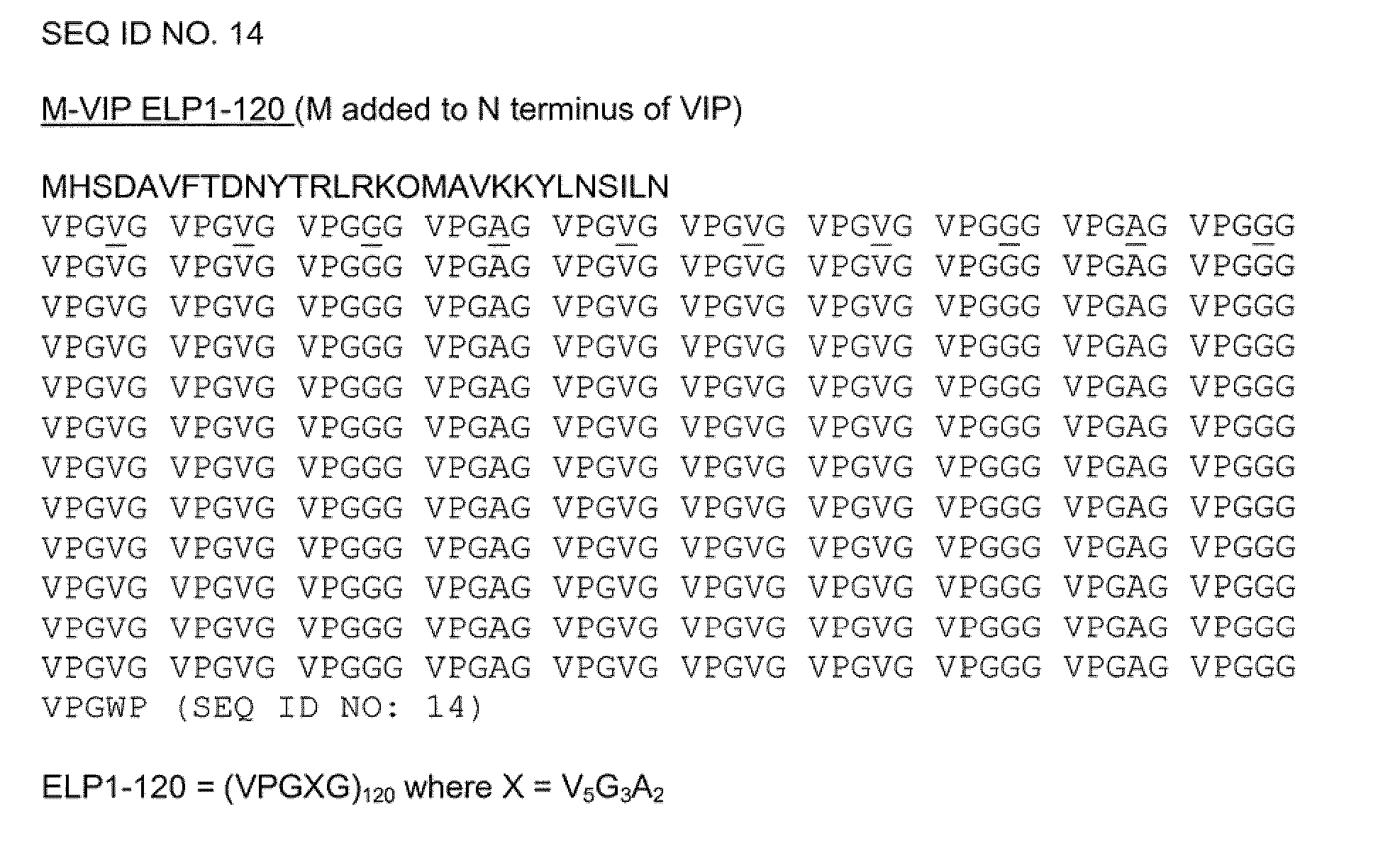

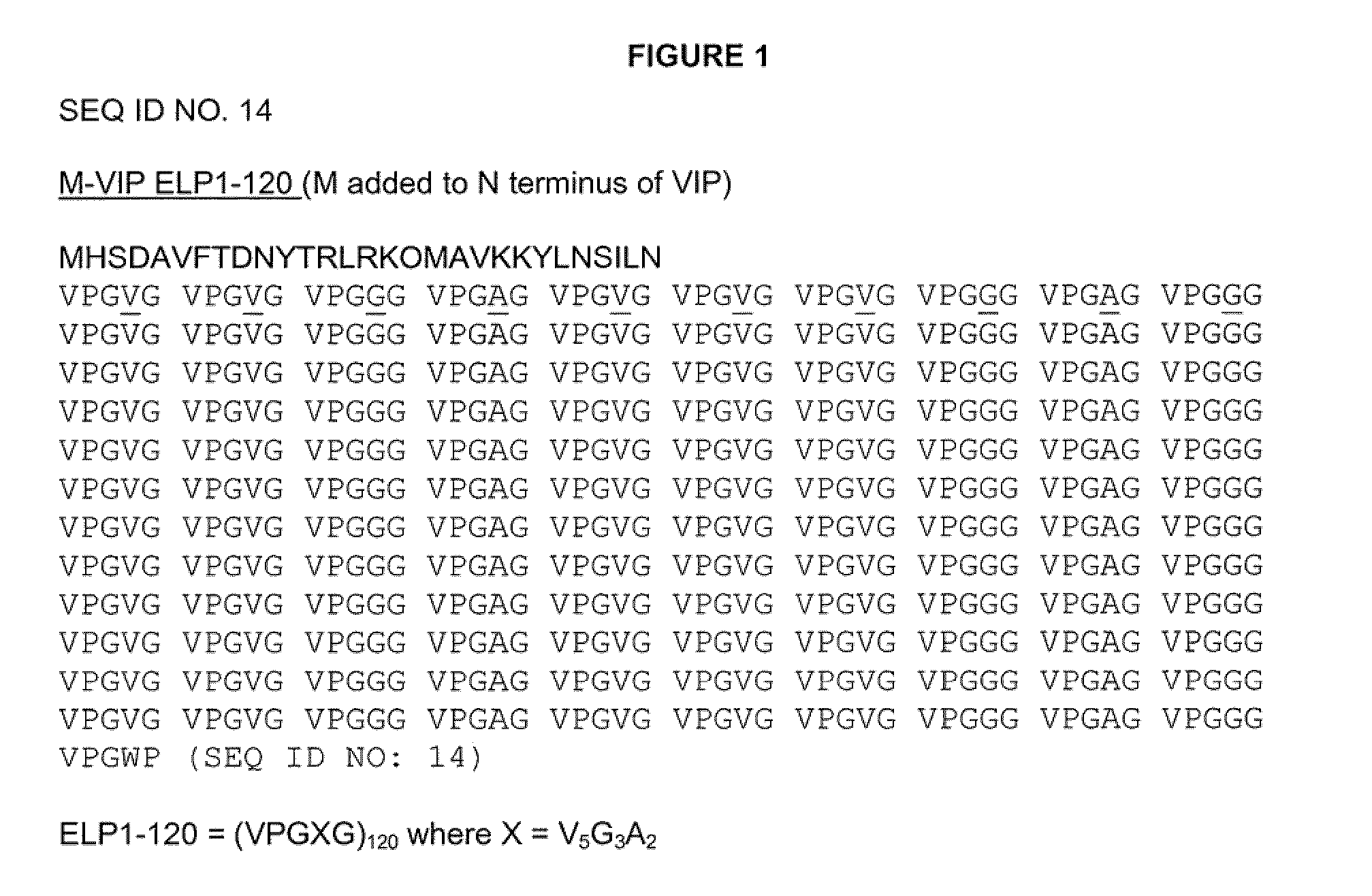

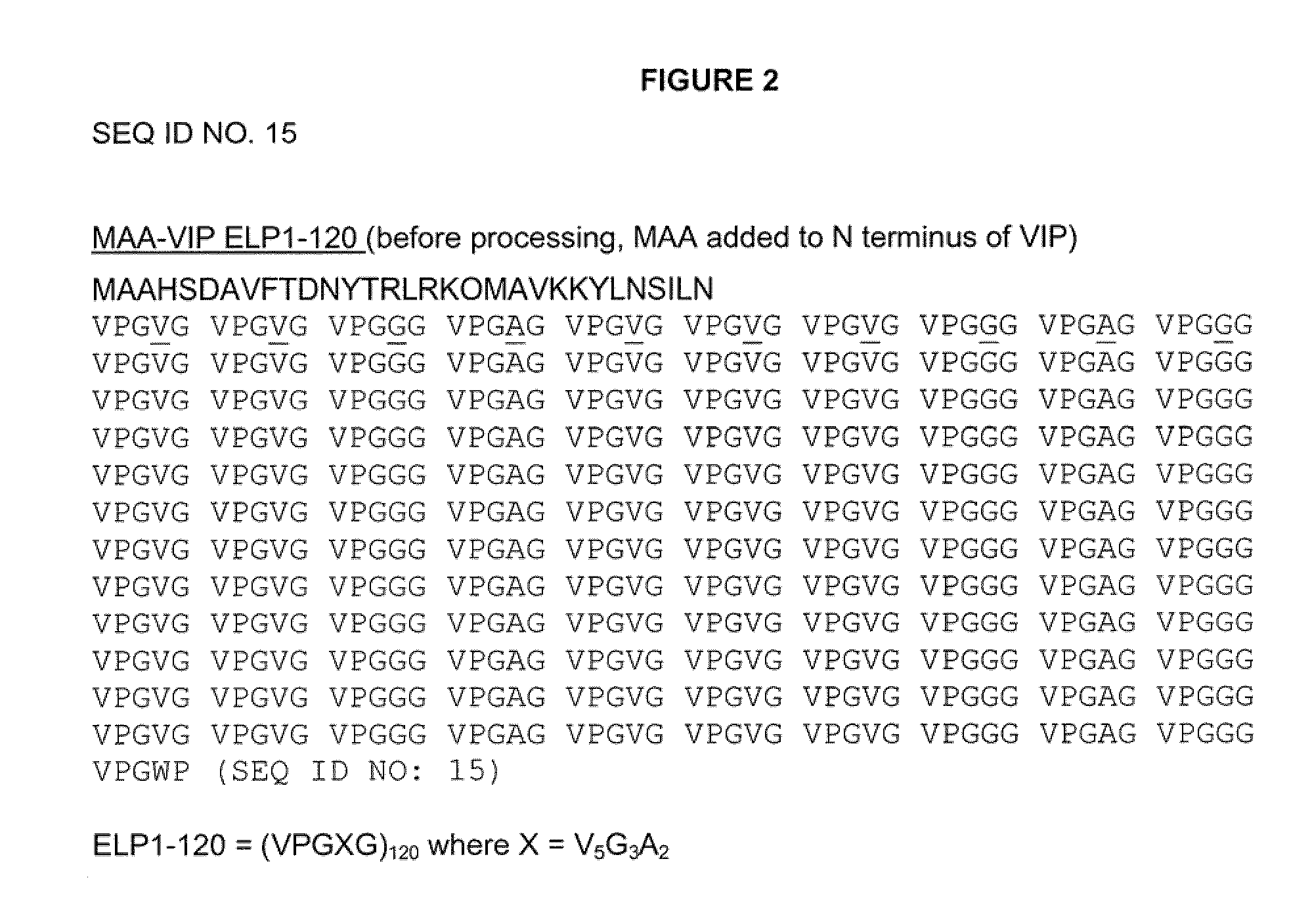

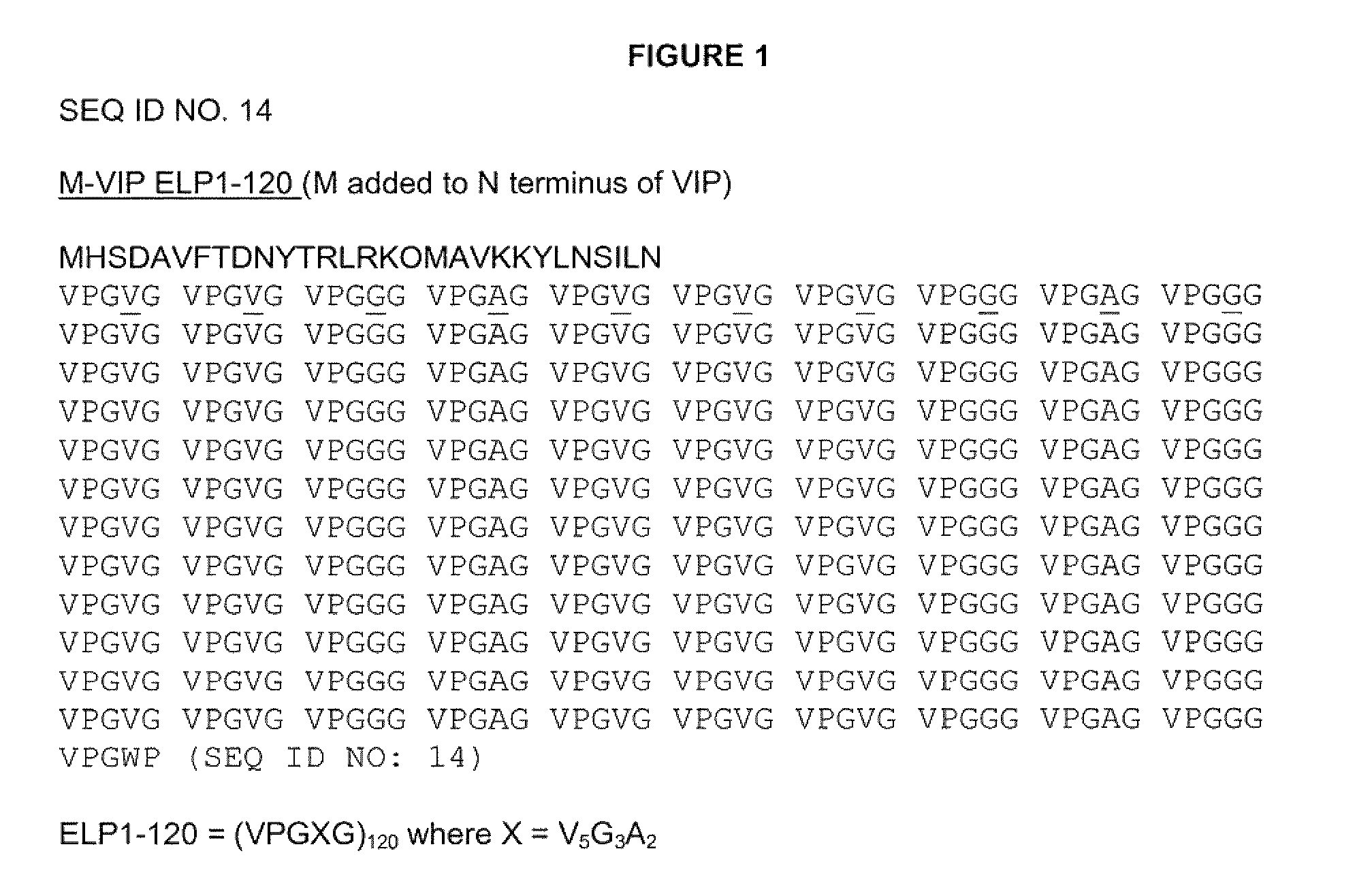

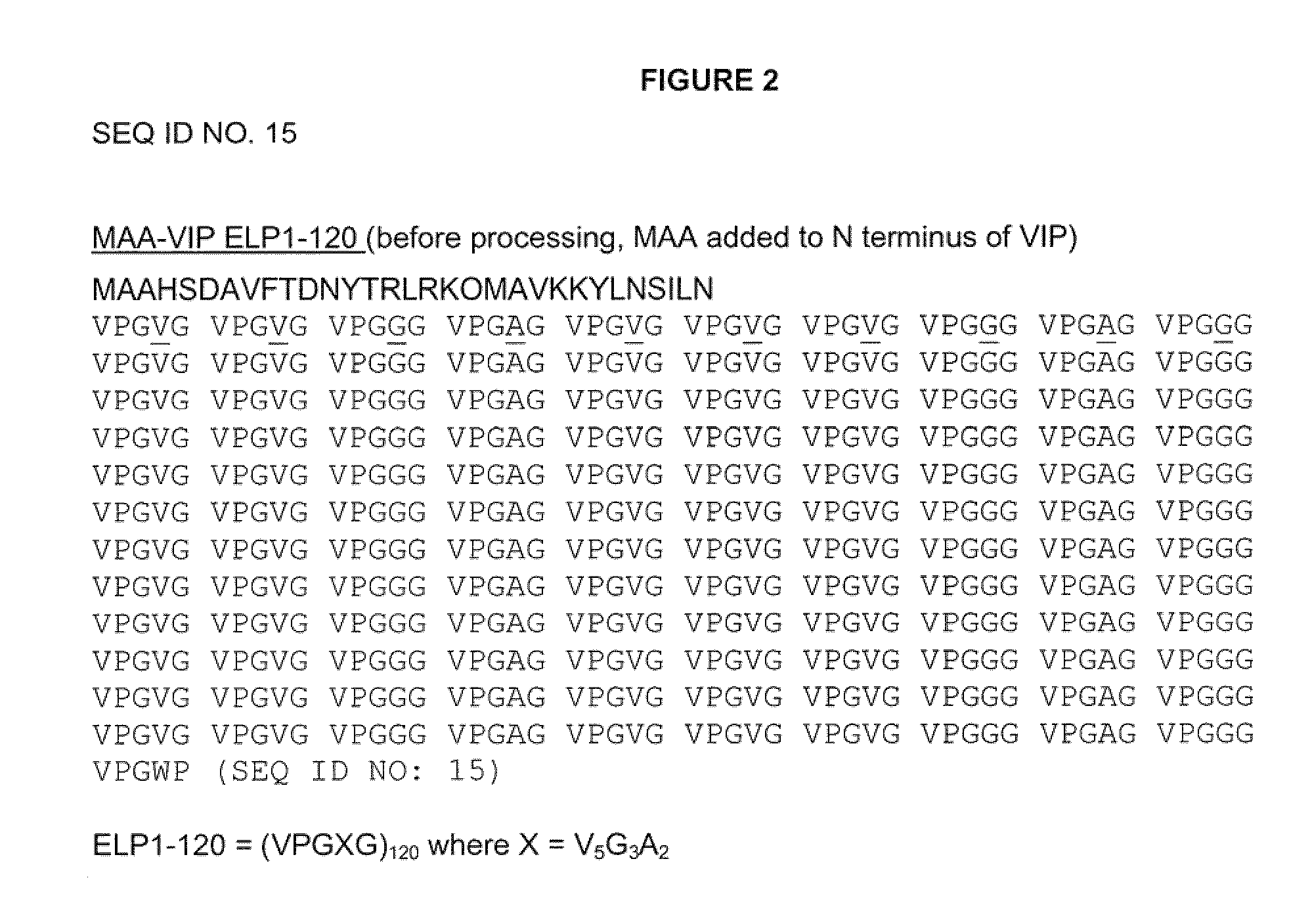

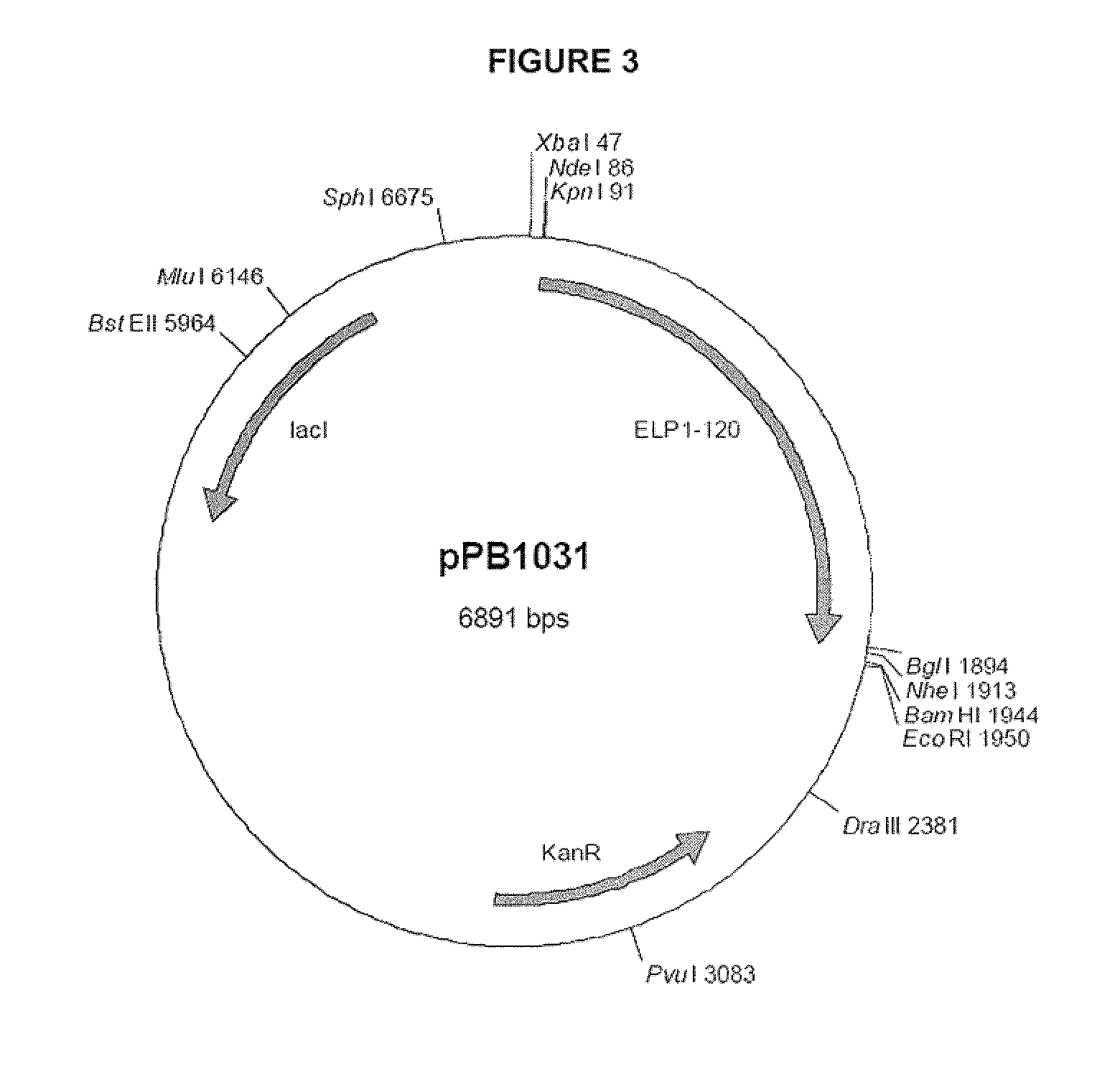

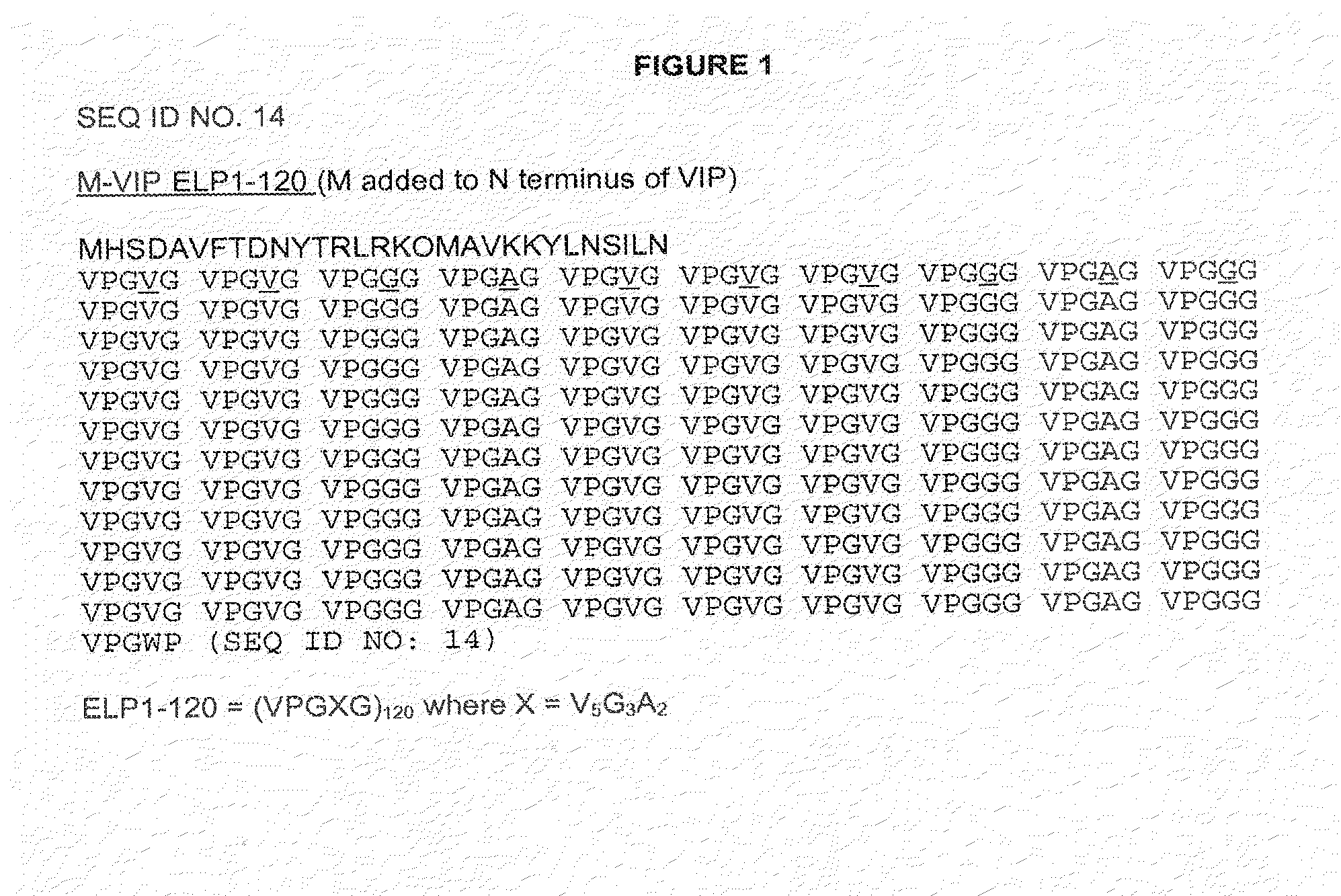

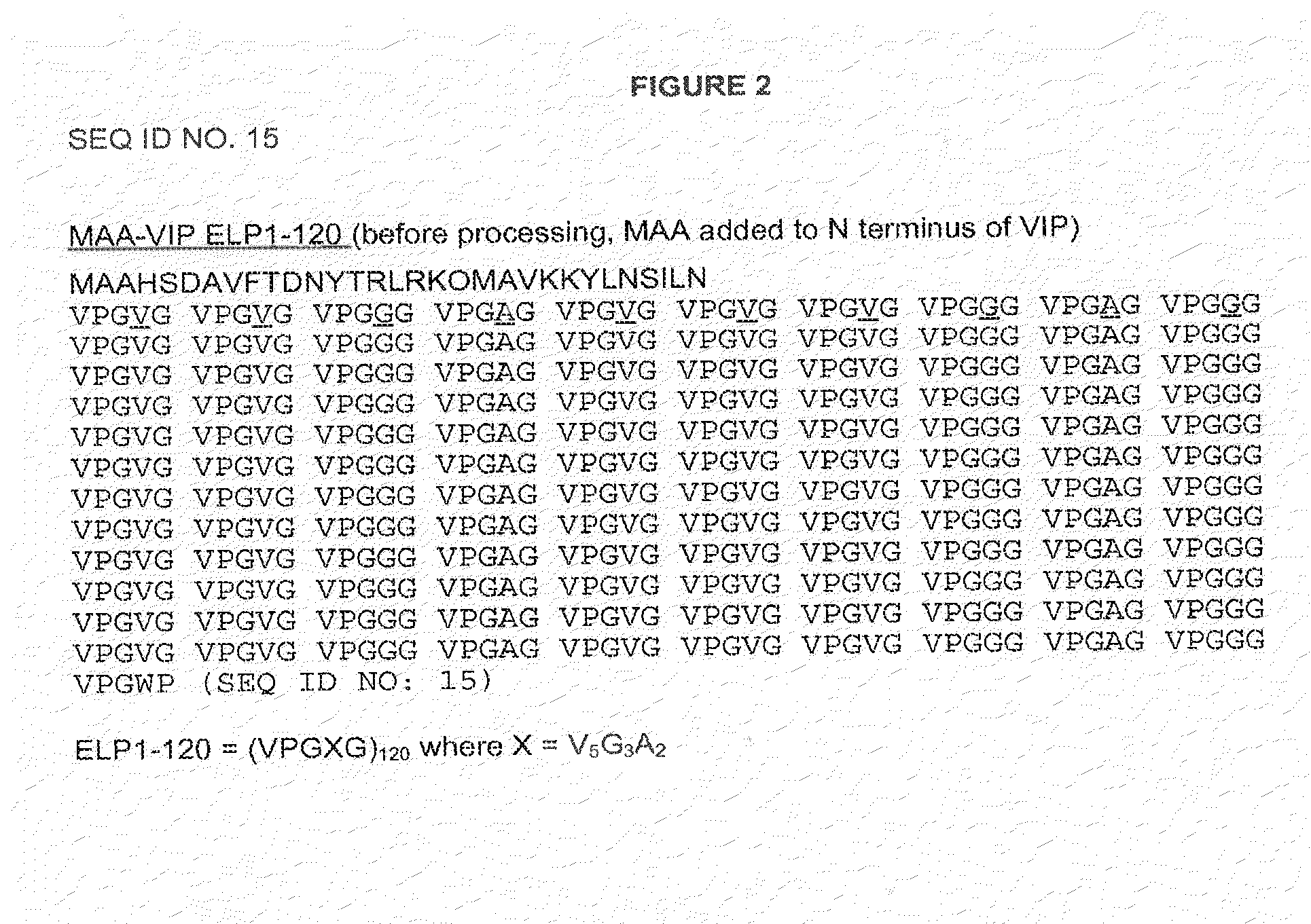

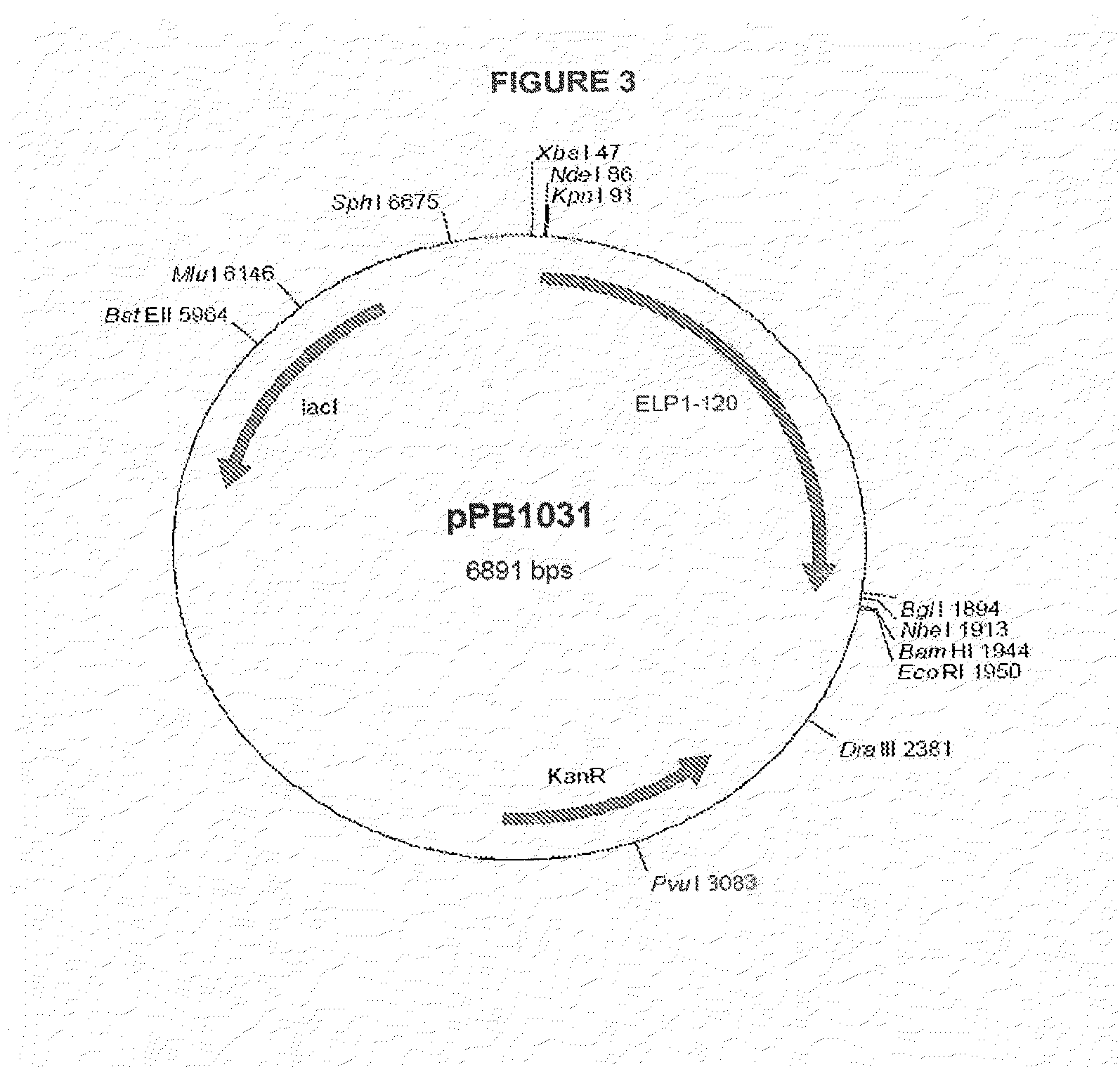

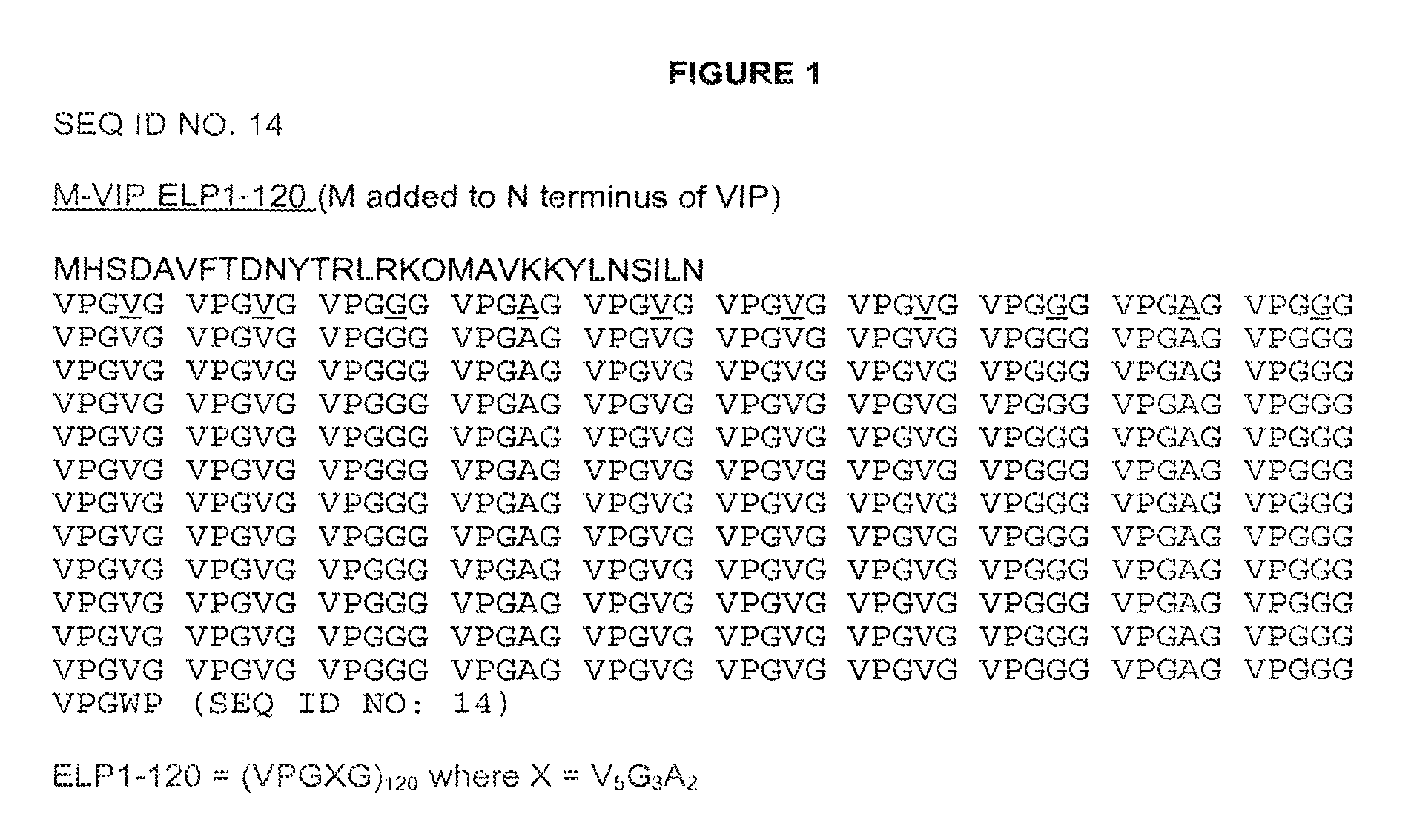

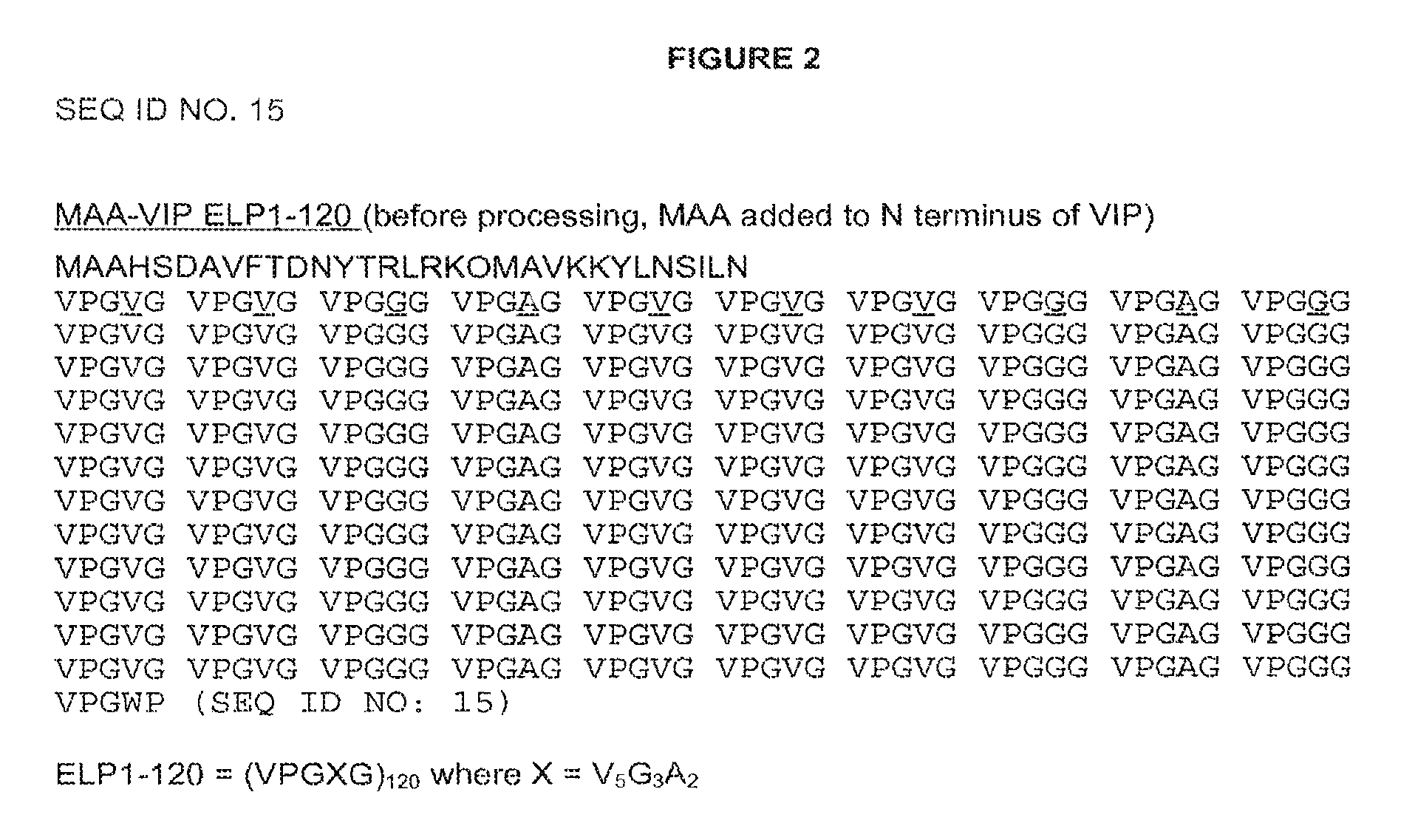

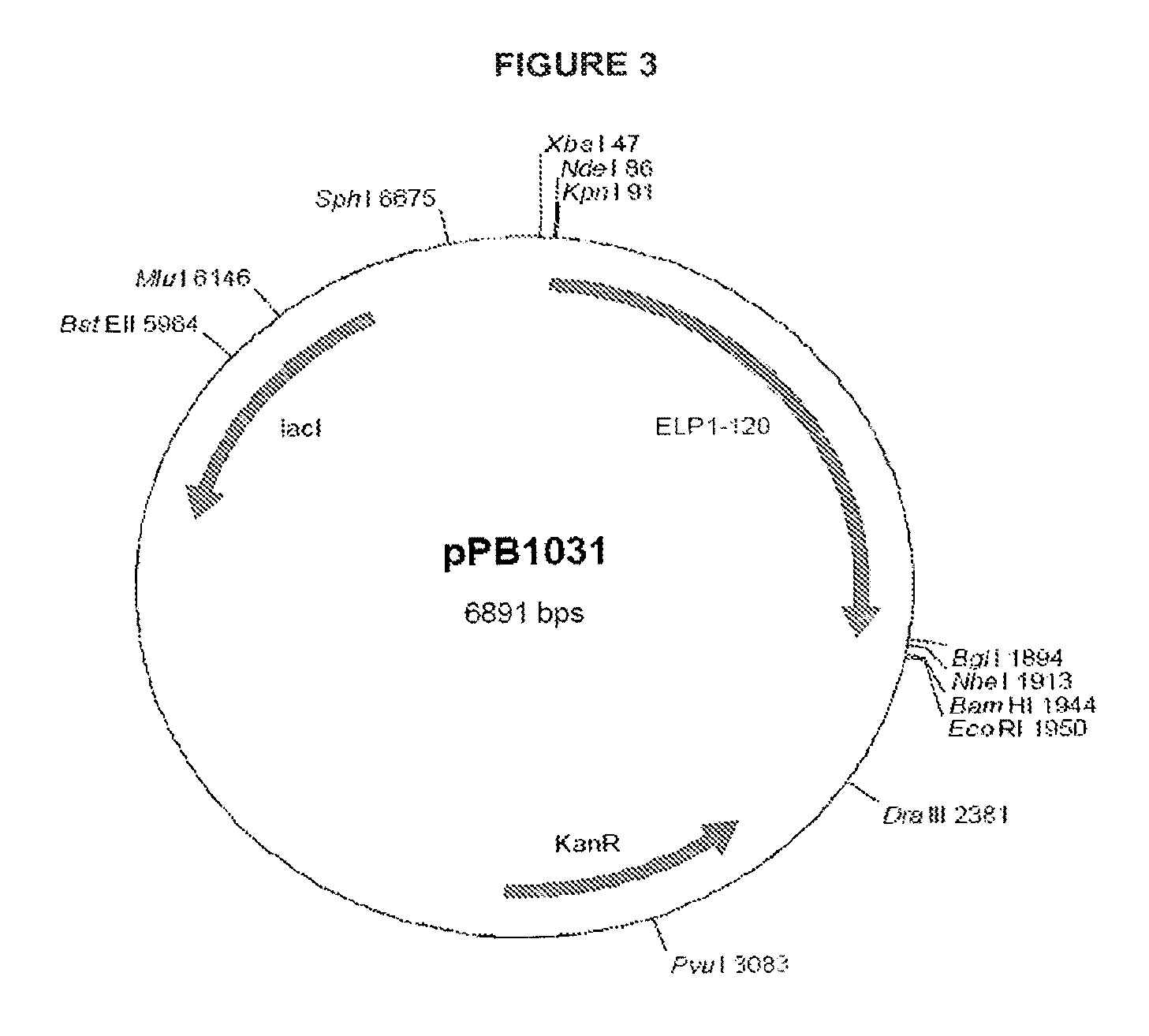

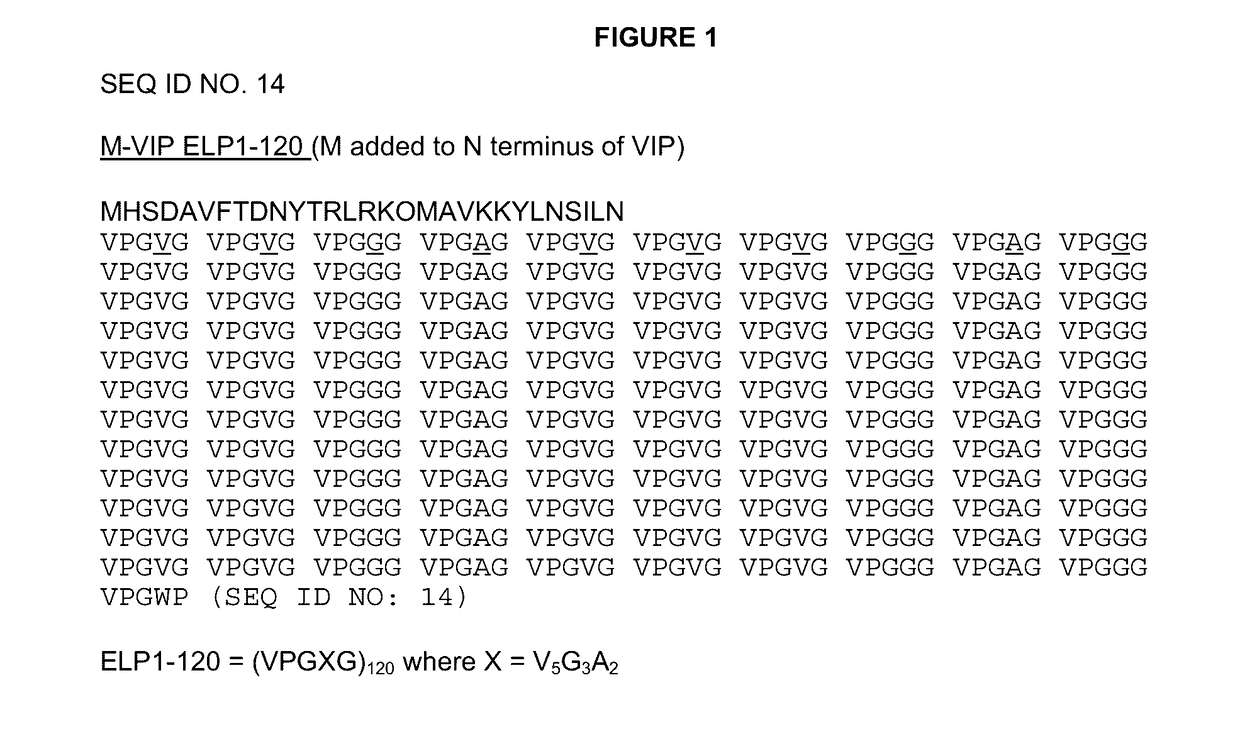

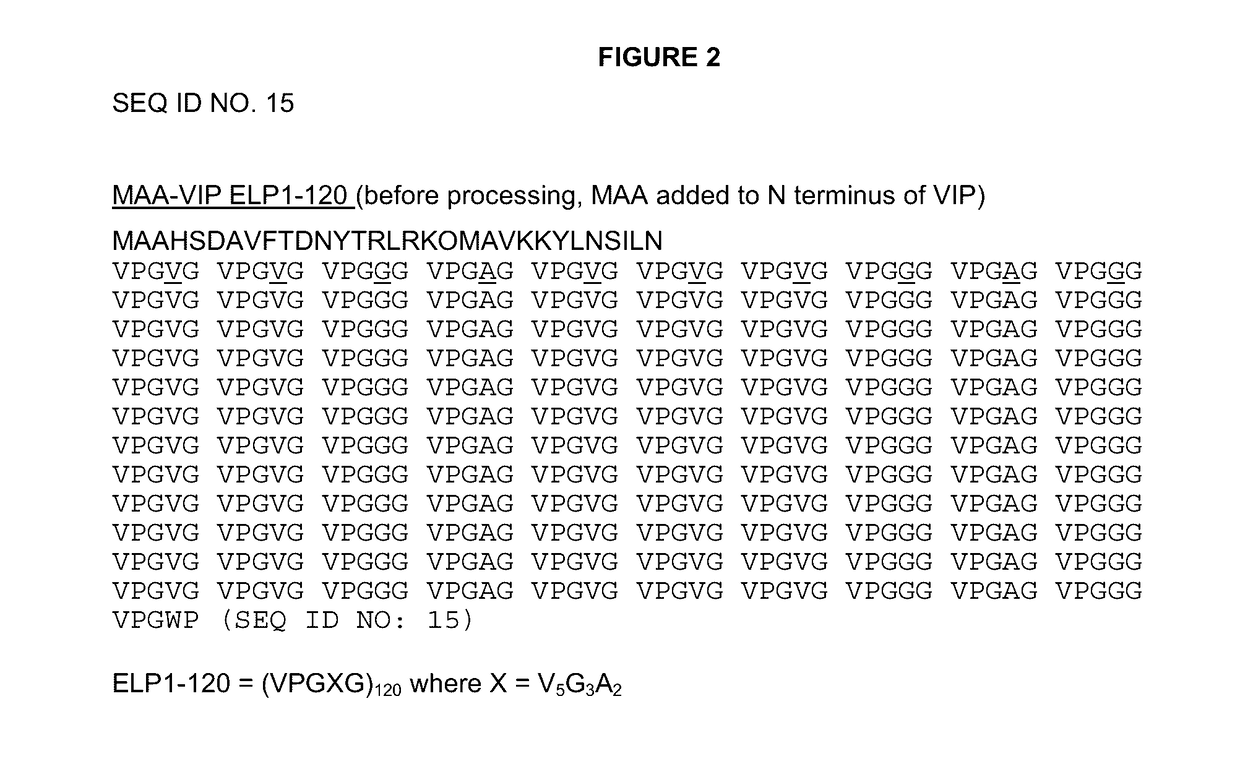

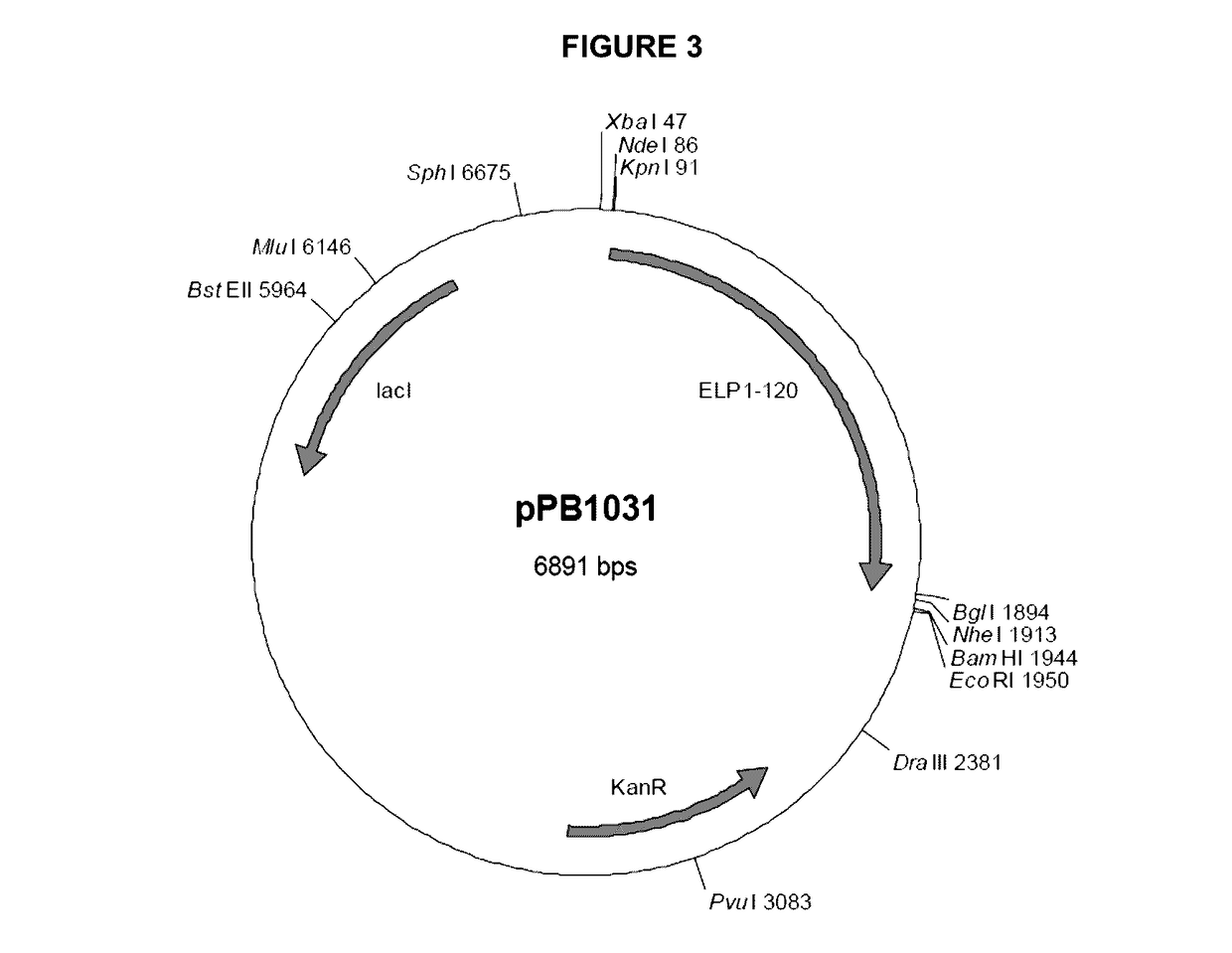

Modified vasoactive intestinal peptides

ActiveUS20110178017A1Increased circulatory half-life and persistenceAltered binding preferenceHormone peptidesPeptide/protein ingredientsDrugHalf-life

The present invention provides modified Vasoactive Intestinal Peptides (VIPs), encoding polynucleotides and vectors, as well as pharmaceutical compositions comprising the same. The invention further provides methods of making and using the modified VIP agents. In accordance with the invention the VIP exhibits an extended circulatory half-life, receptor-binding or biological potency, and / or altered receptor binding profile with respect to unmodified VIP.

Owner:PHASEBIO PHARMA INC

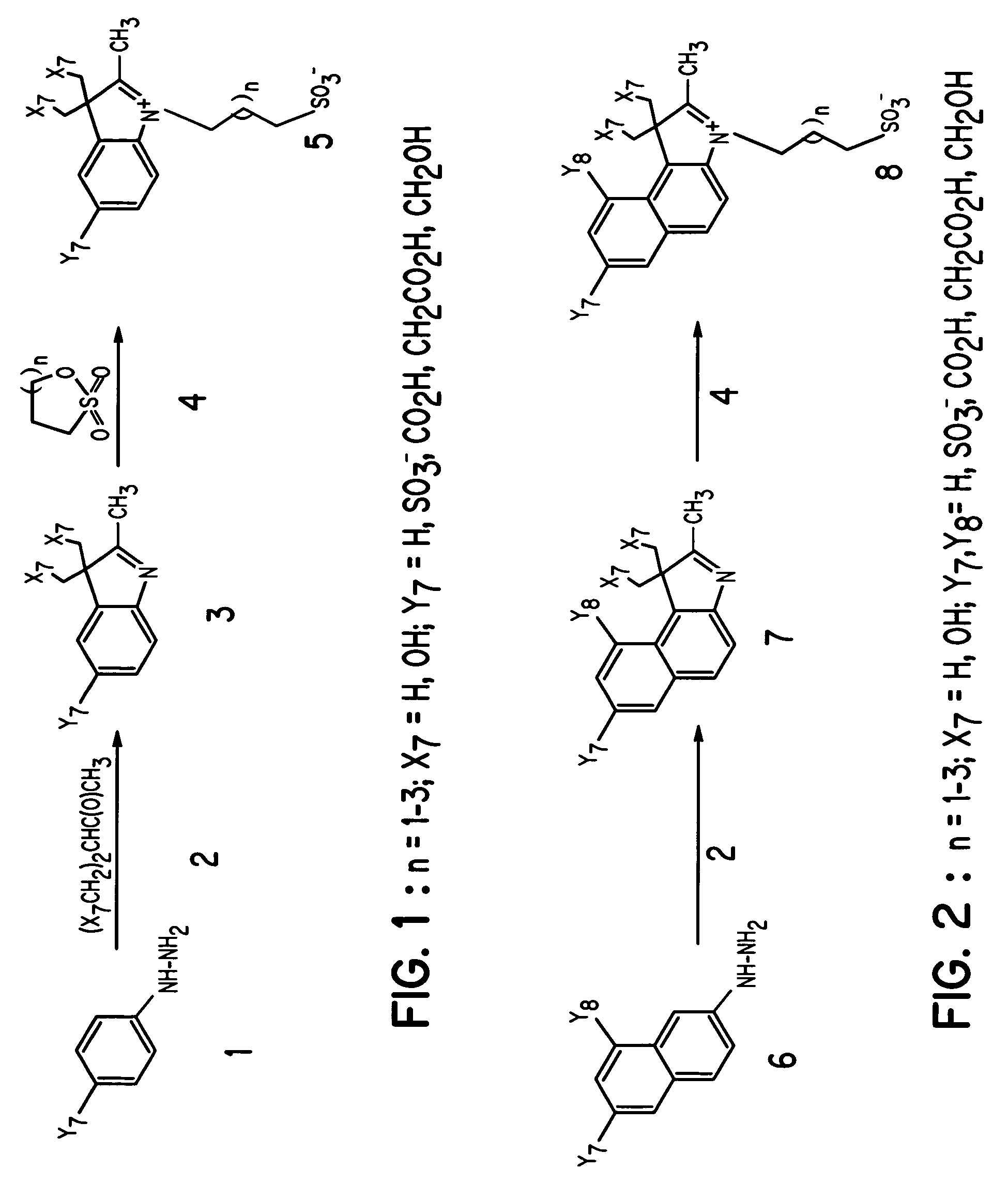

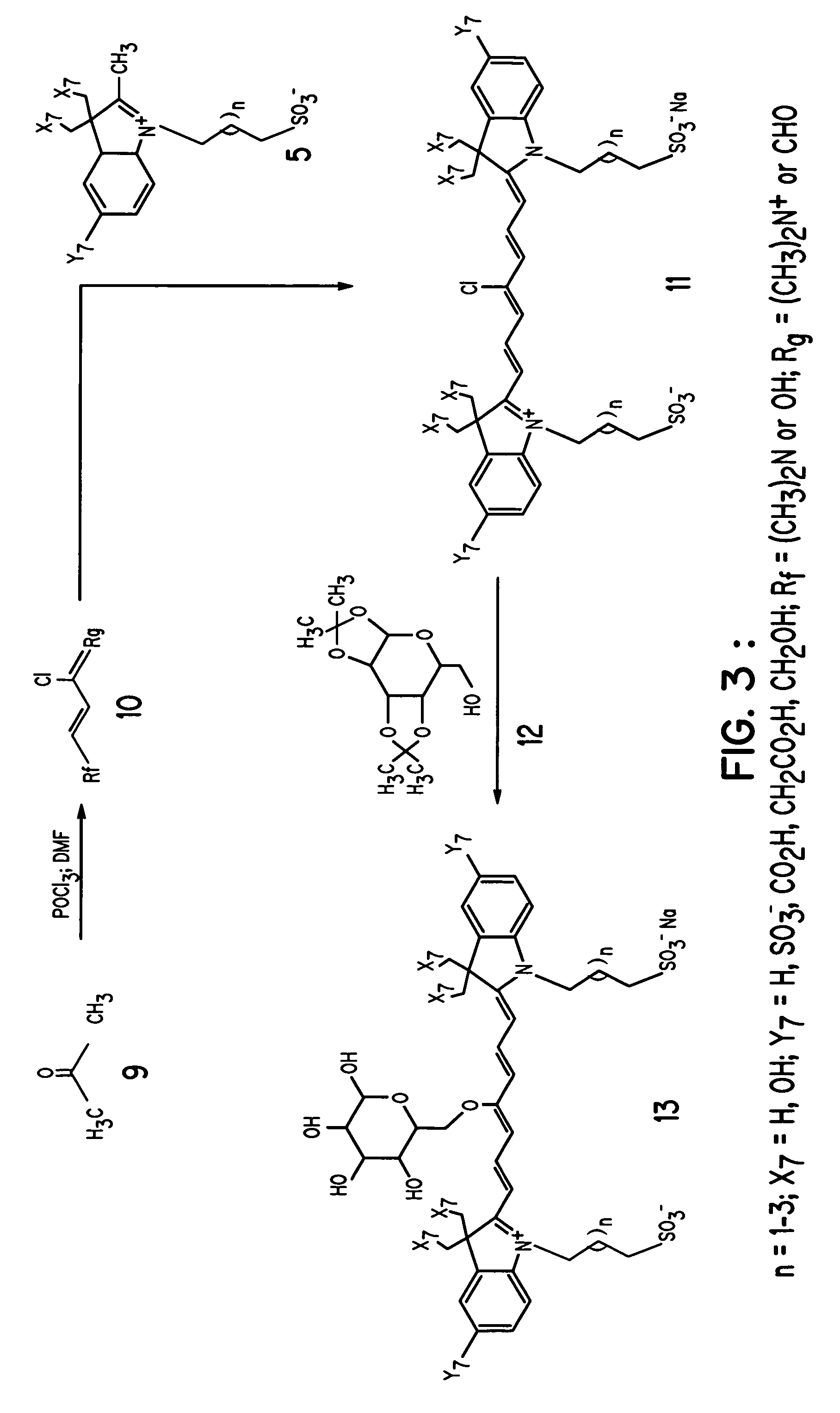

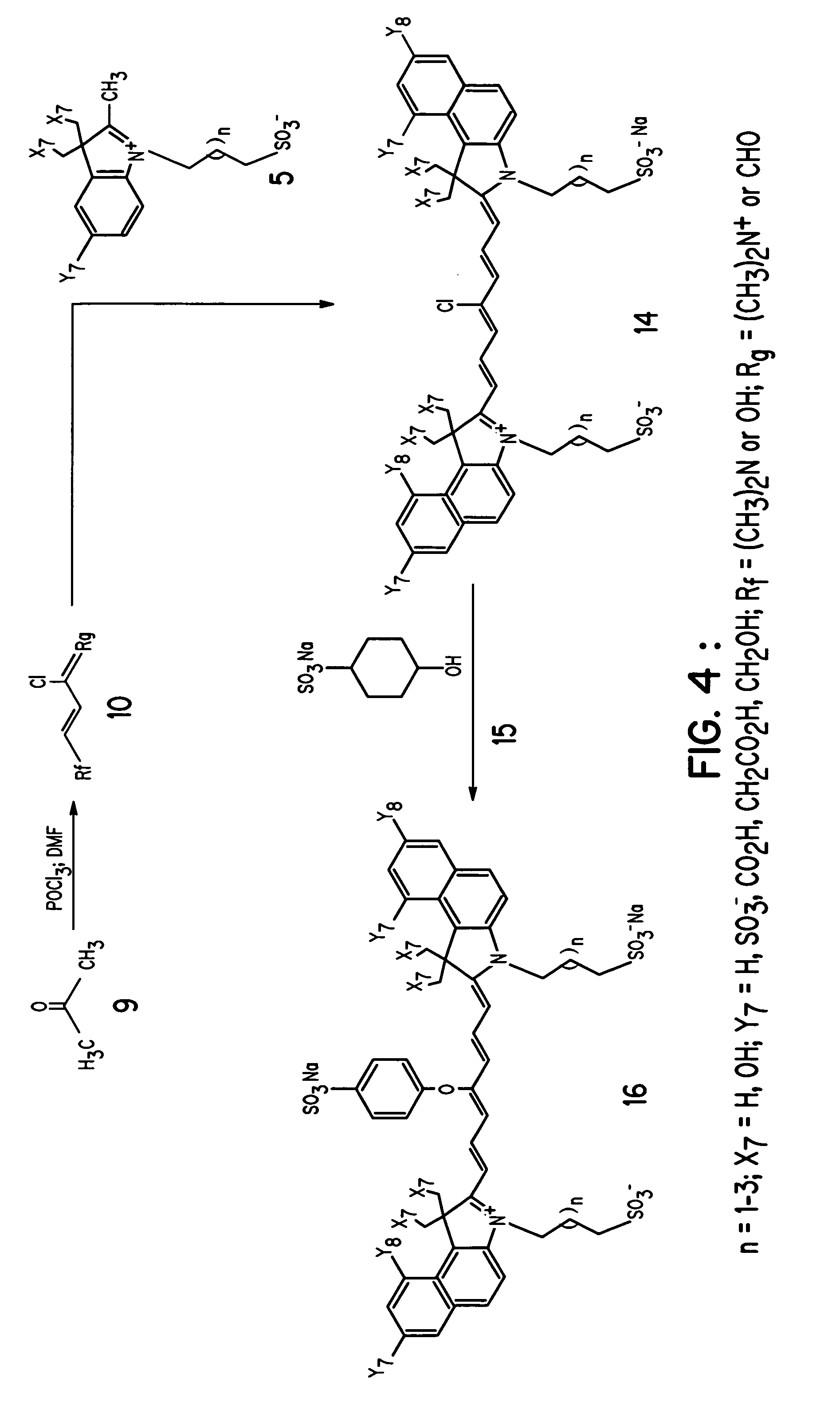

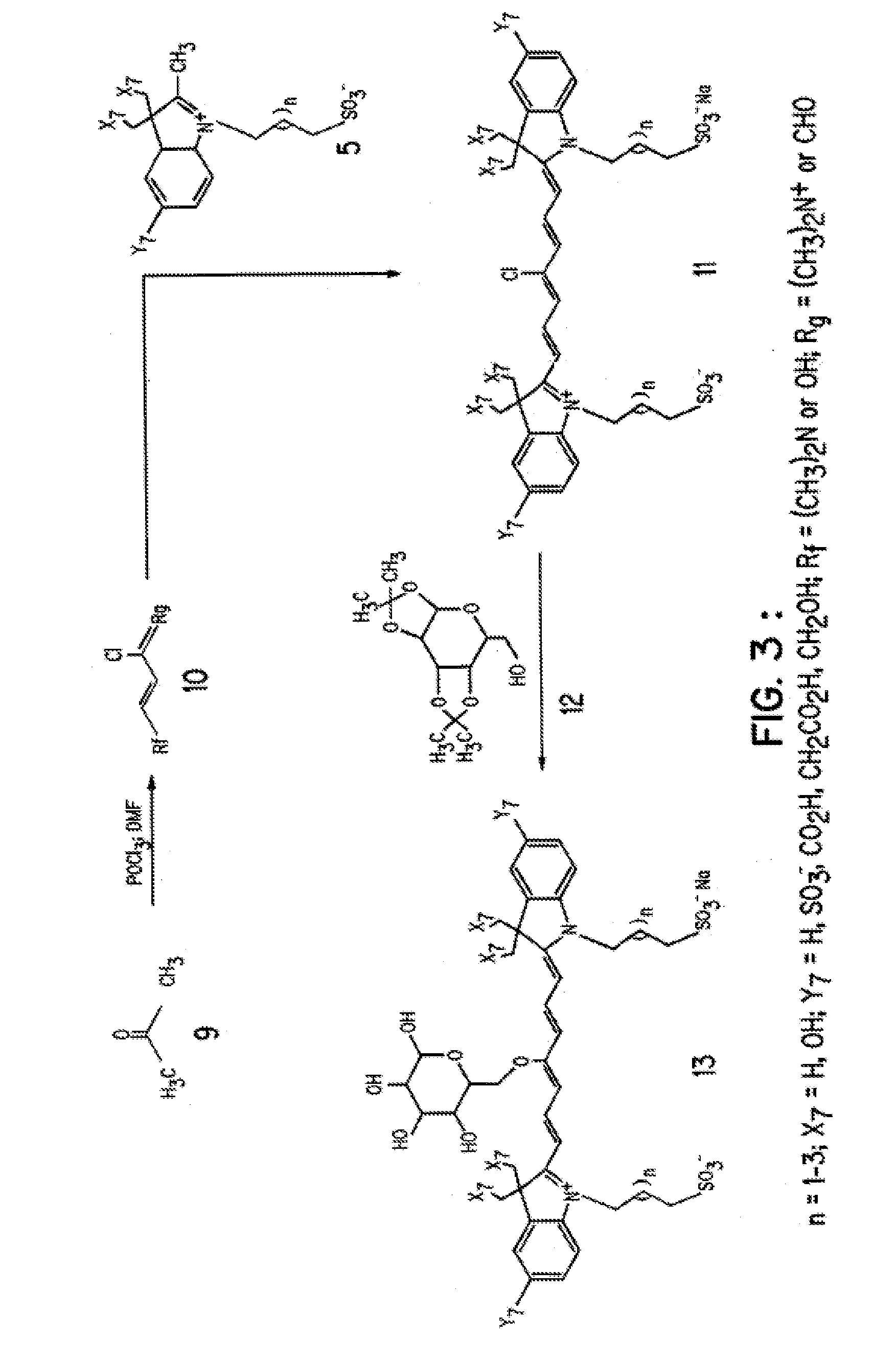

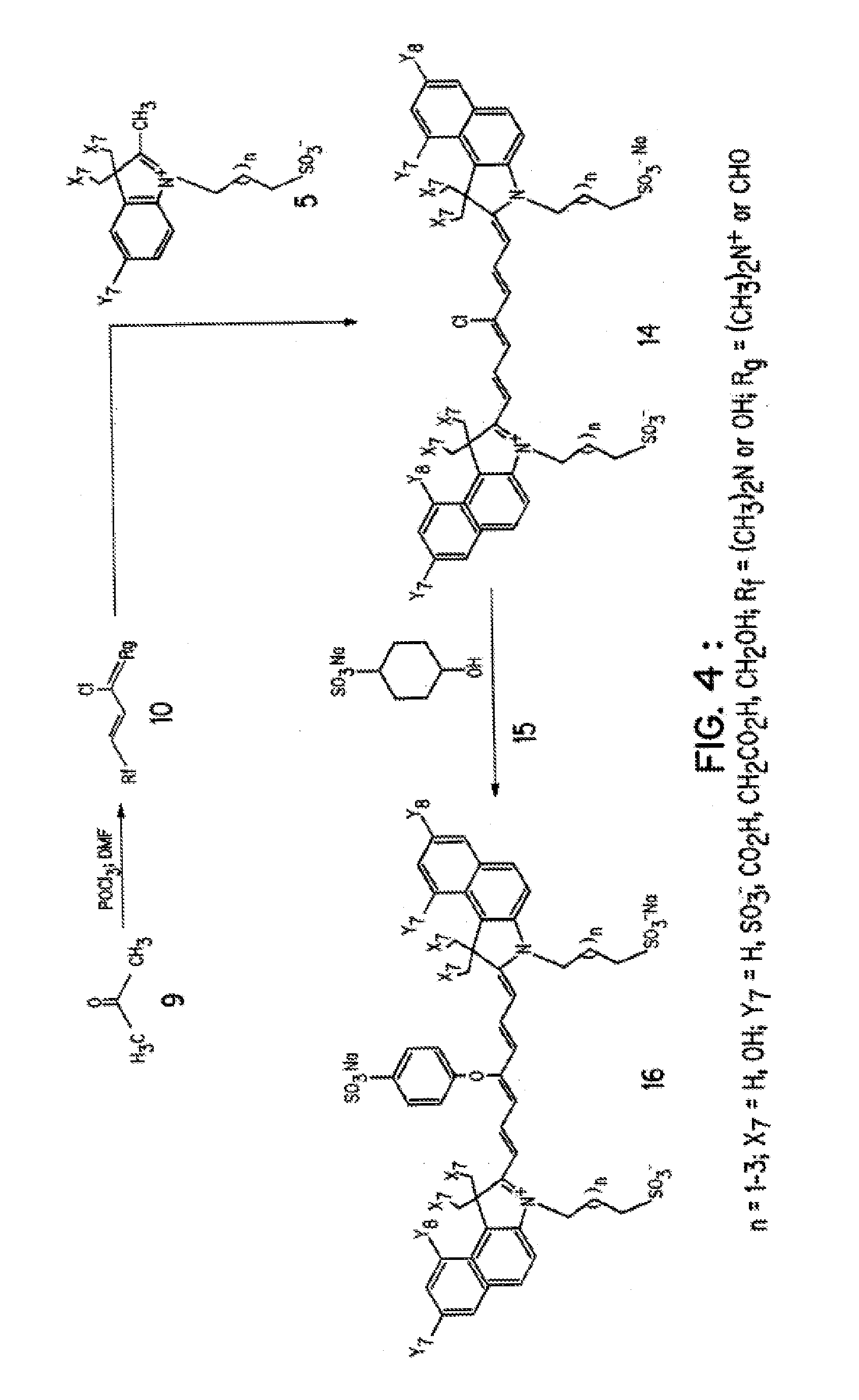

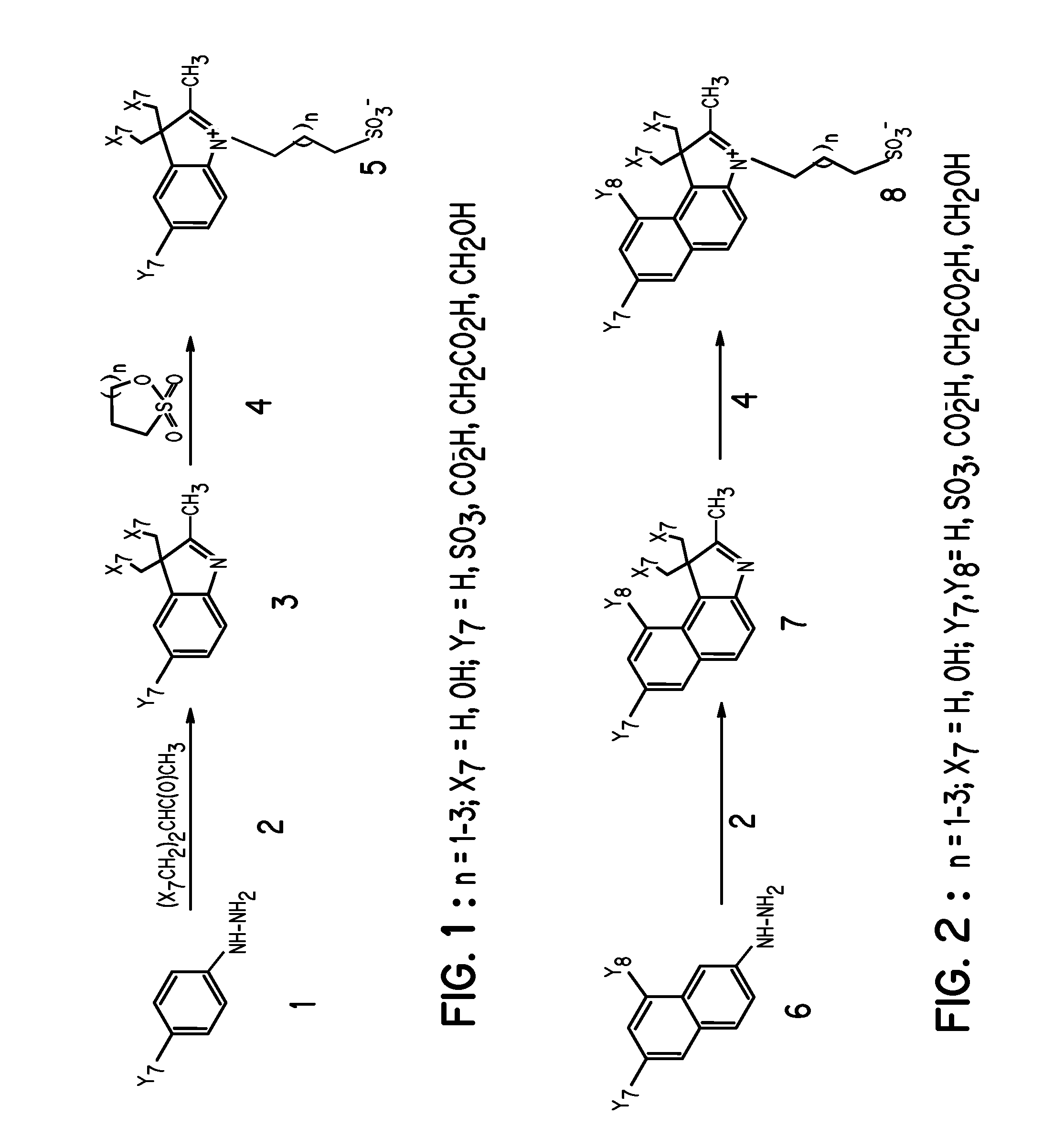

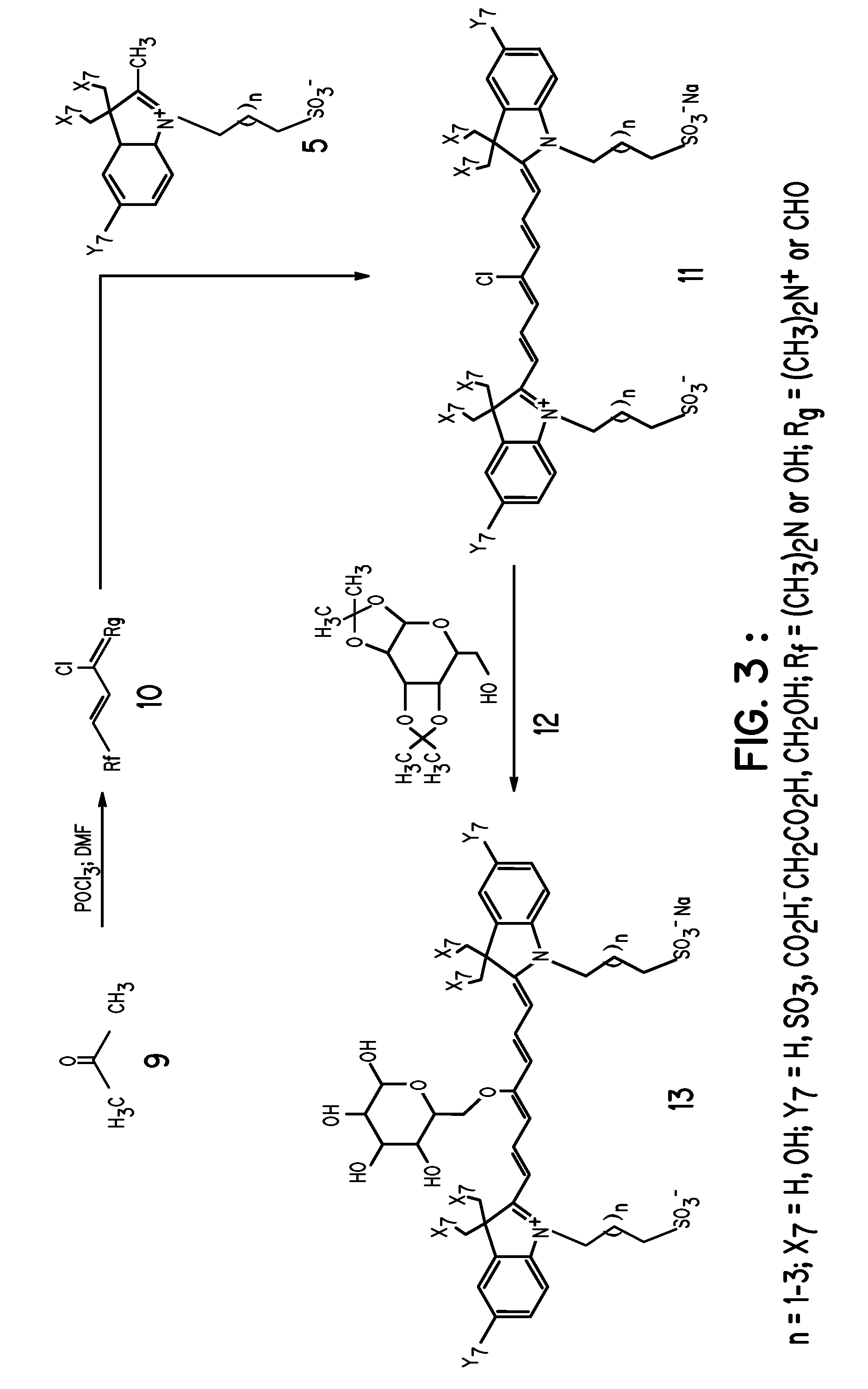

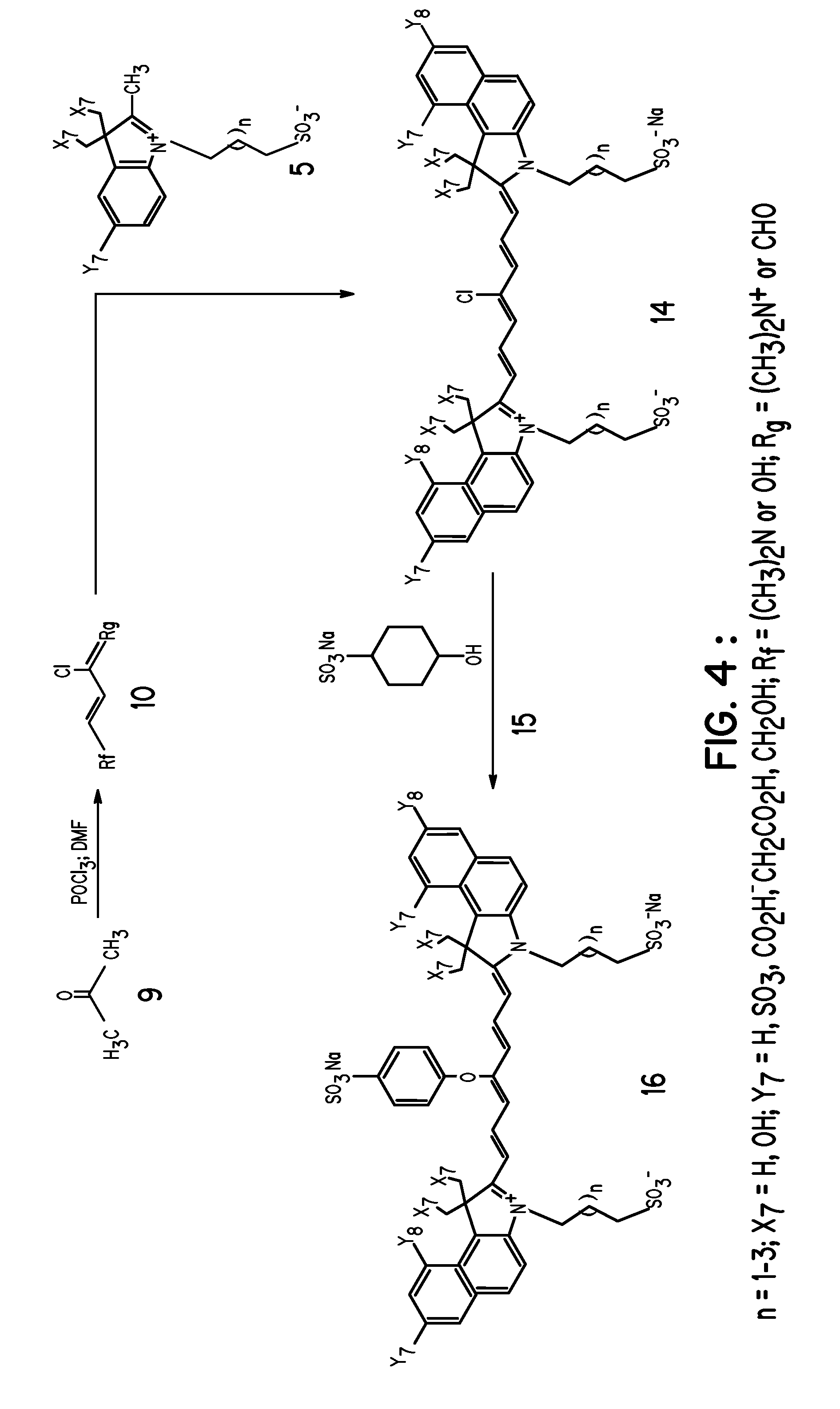

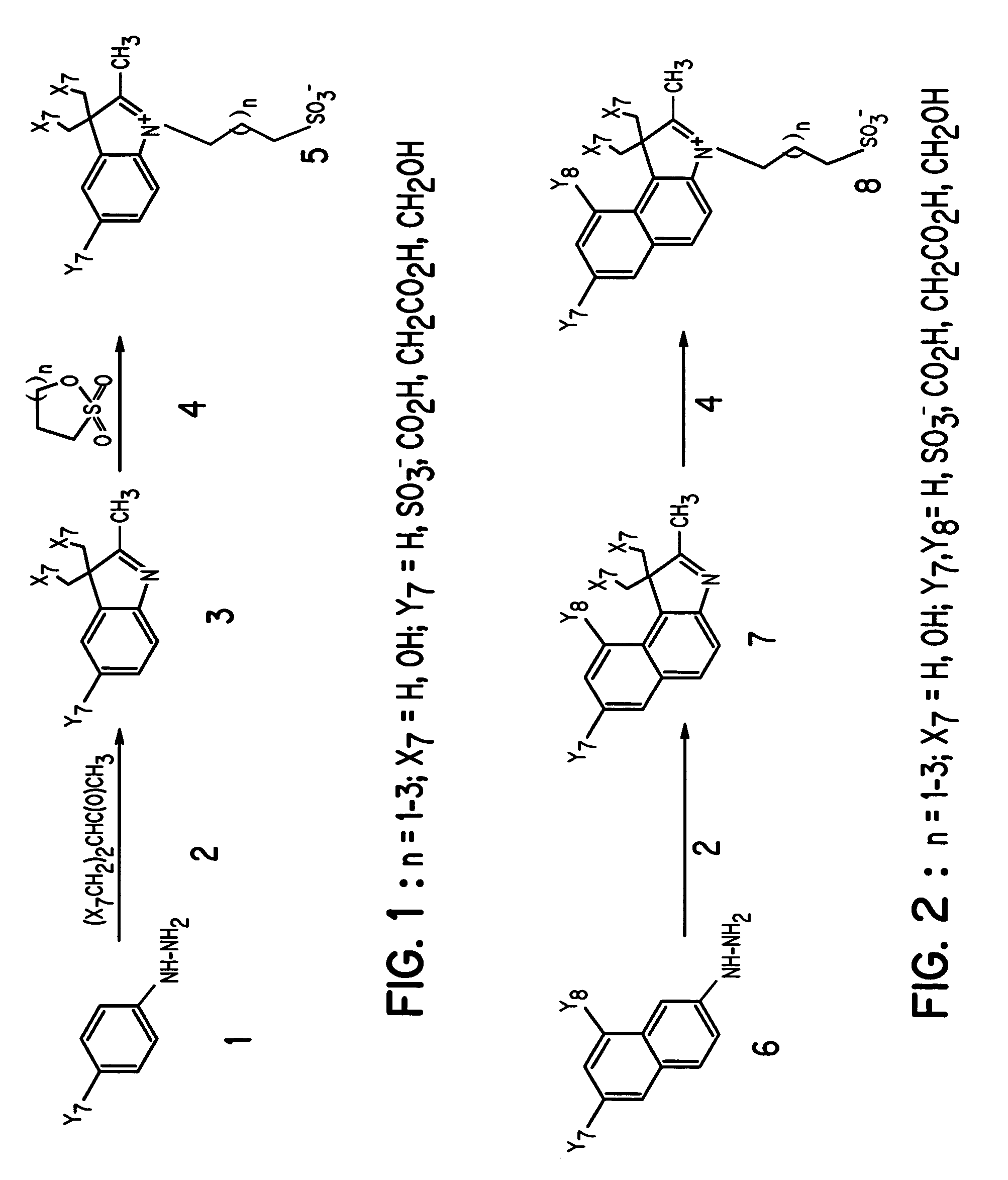

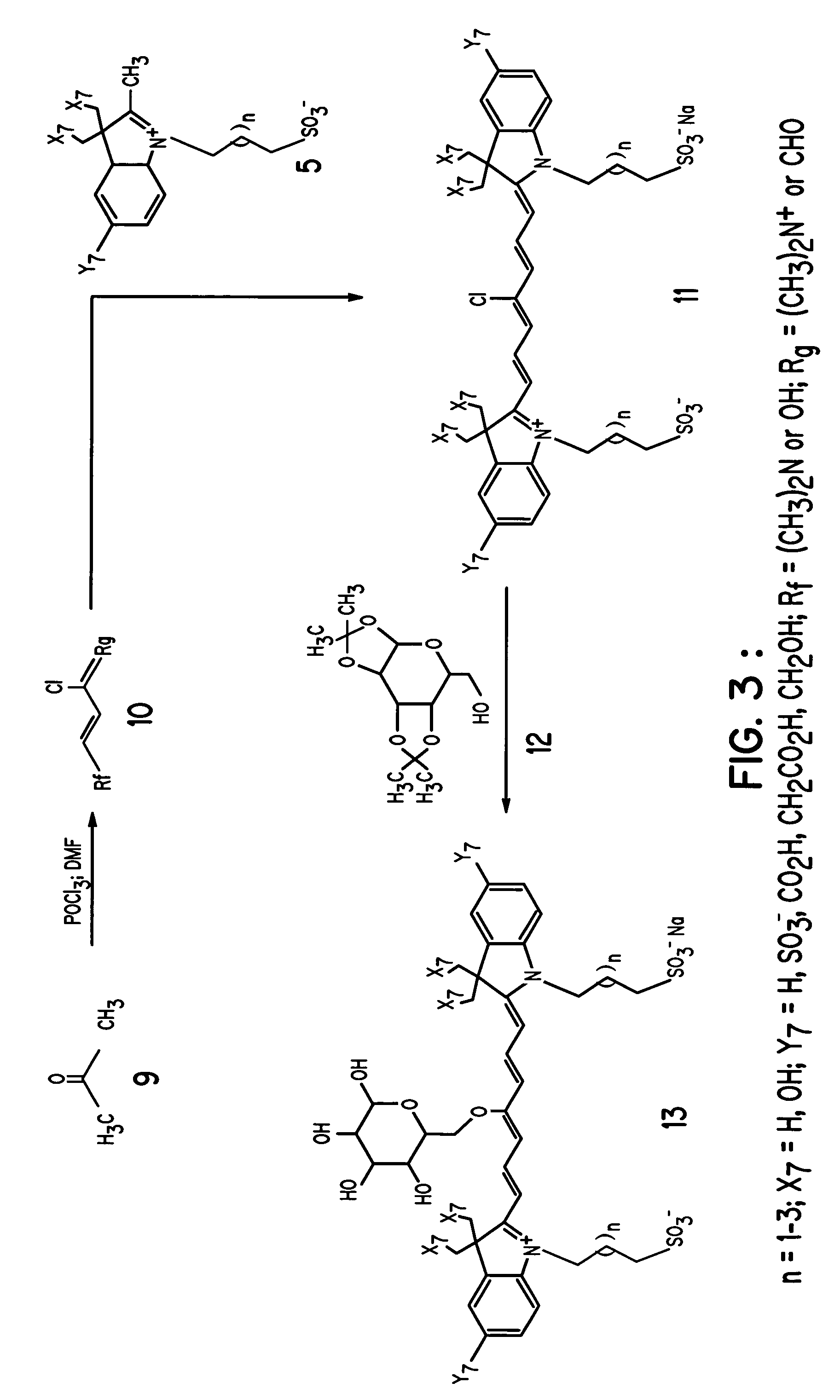

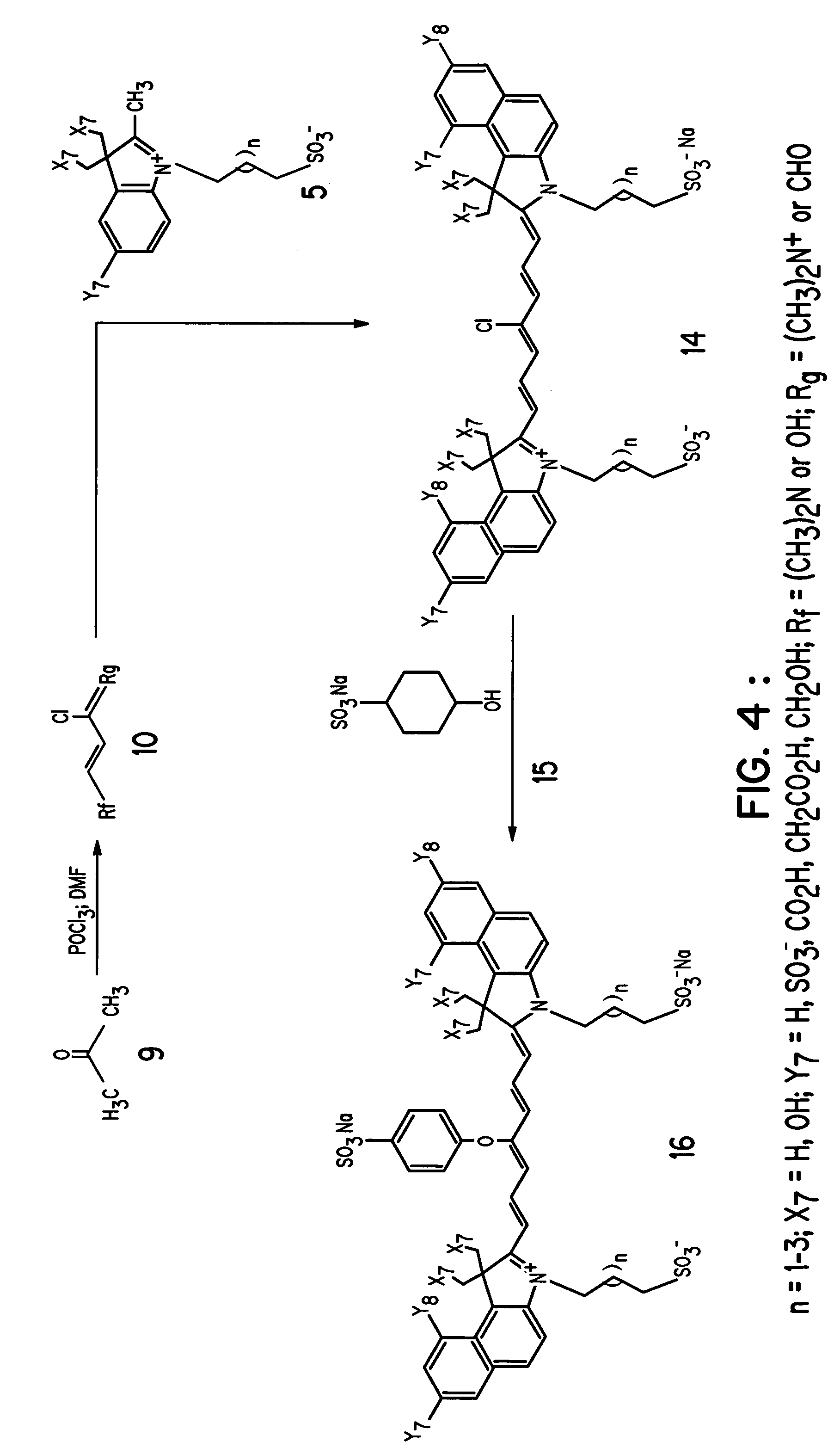

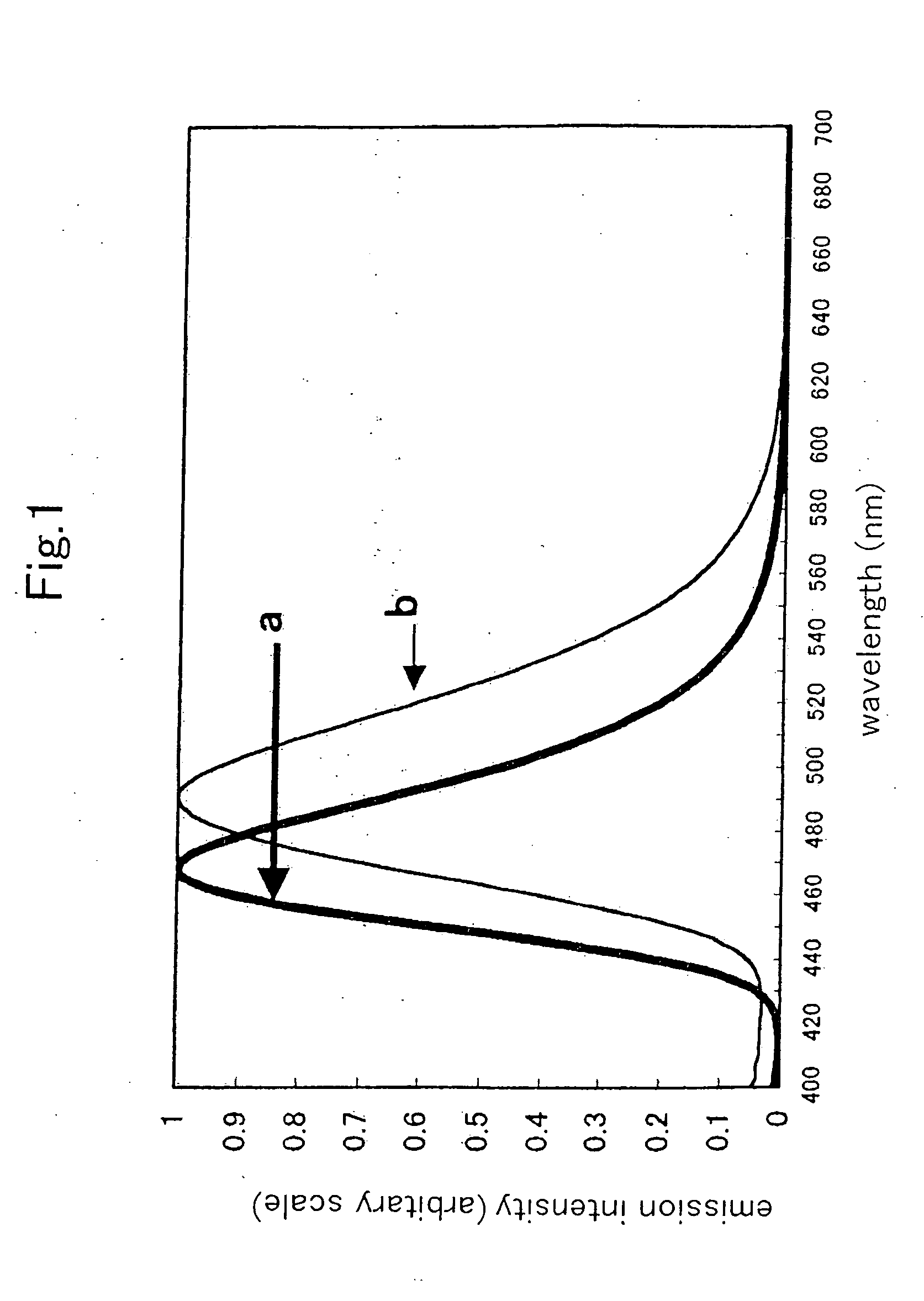

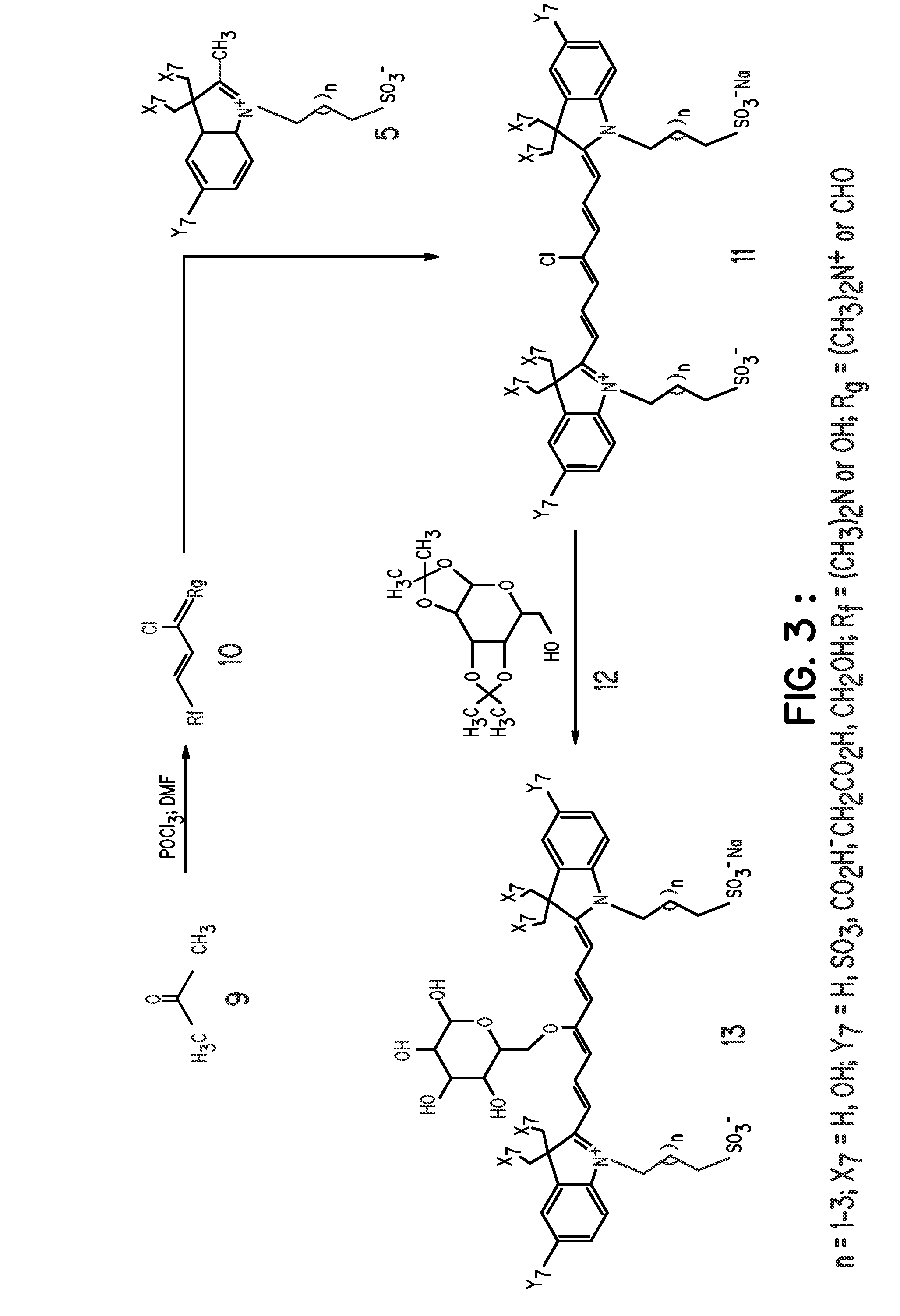

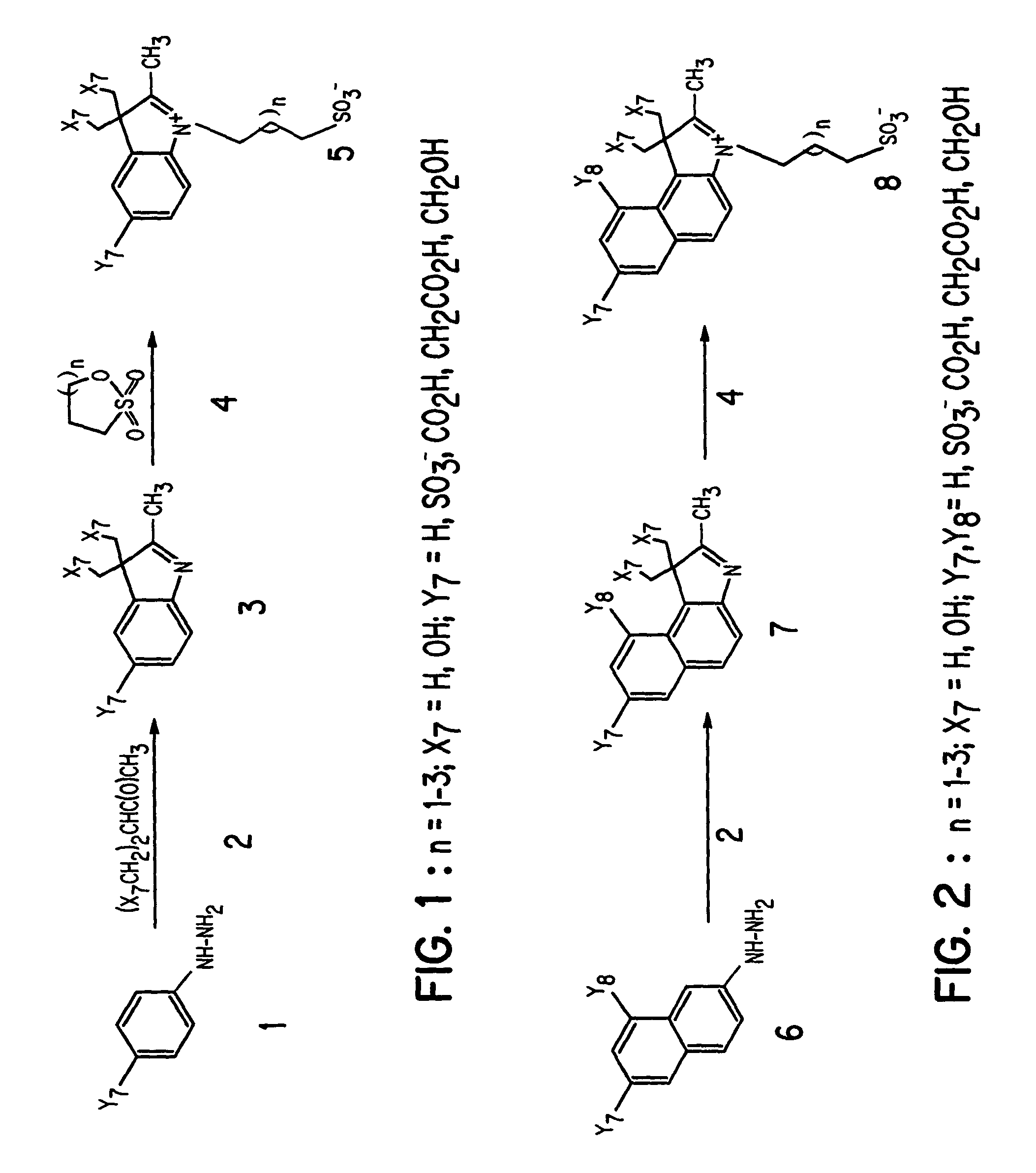

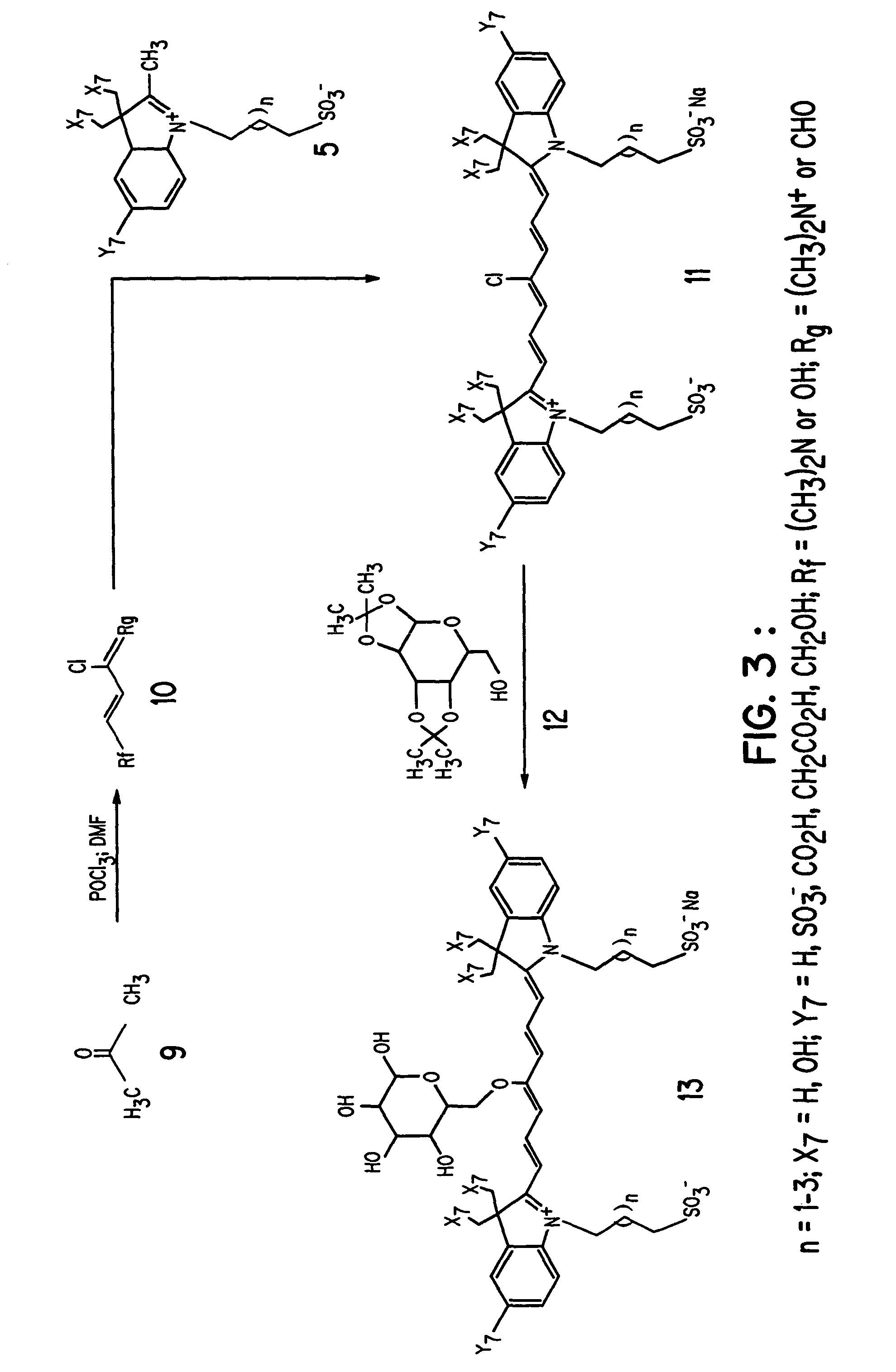

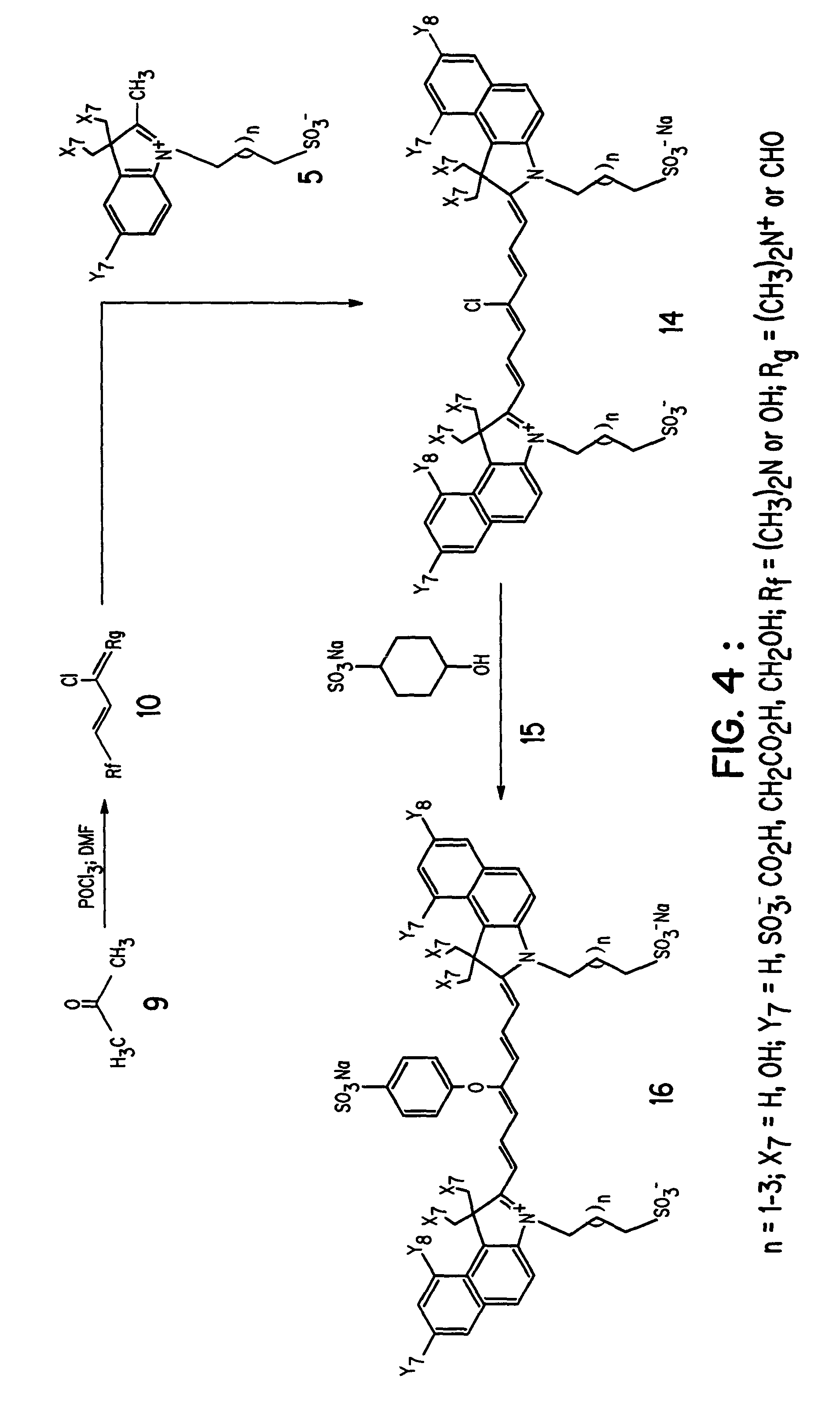

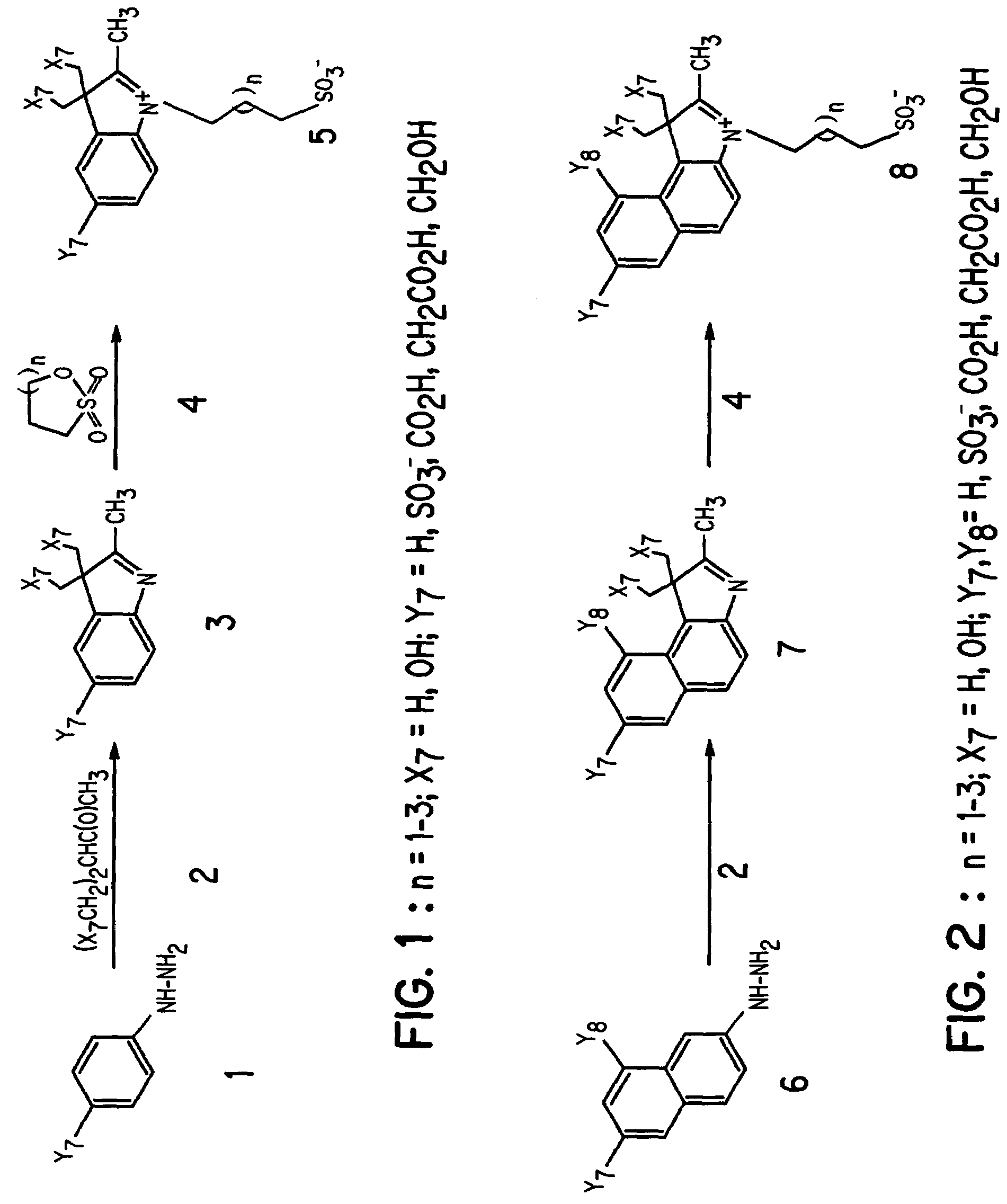

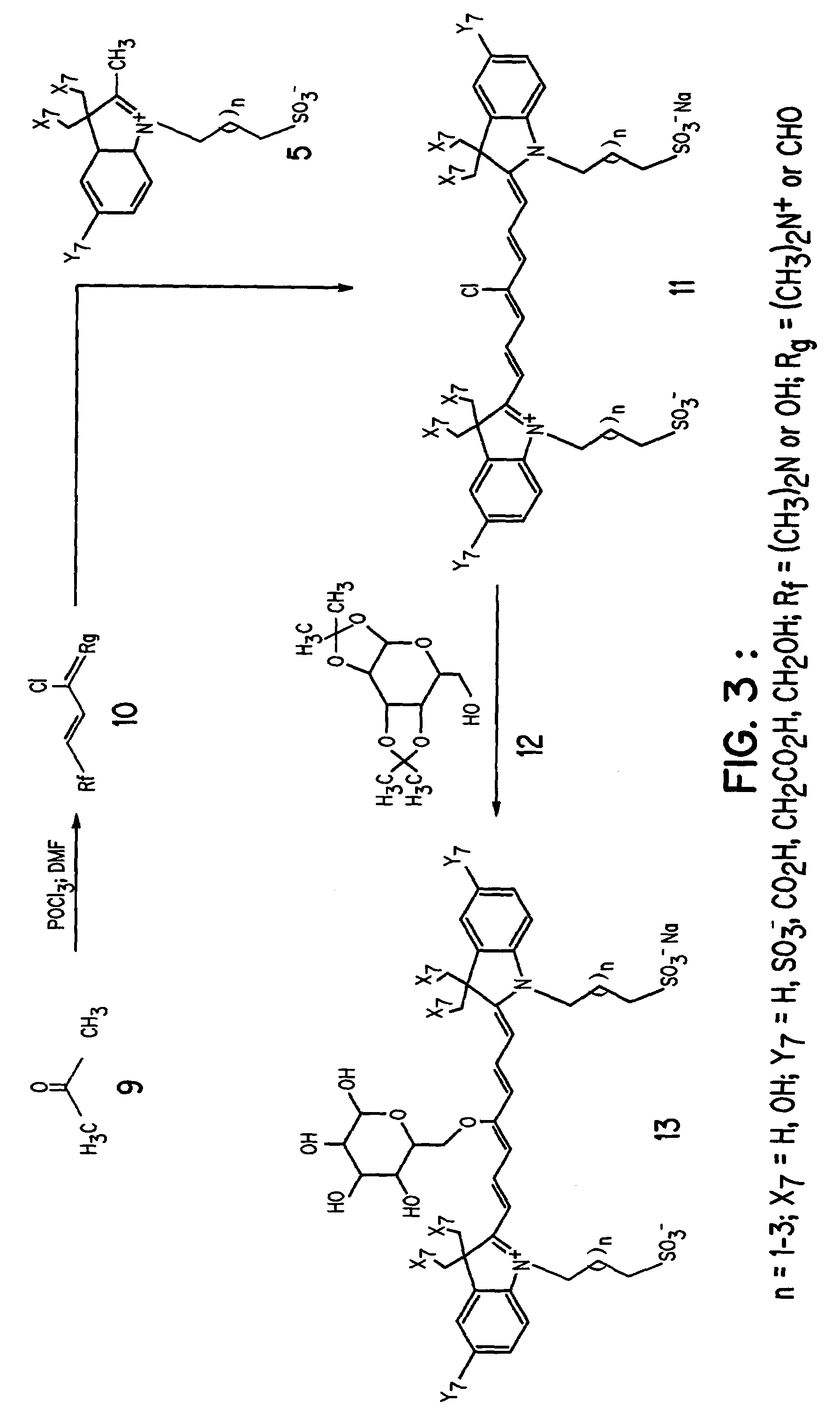

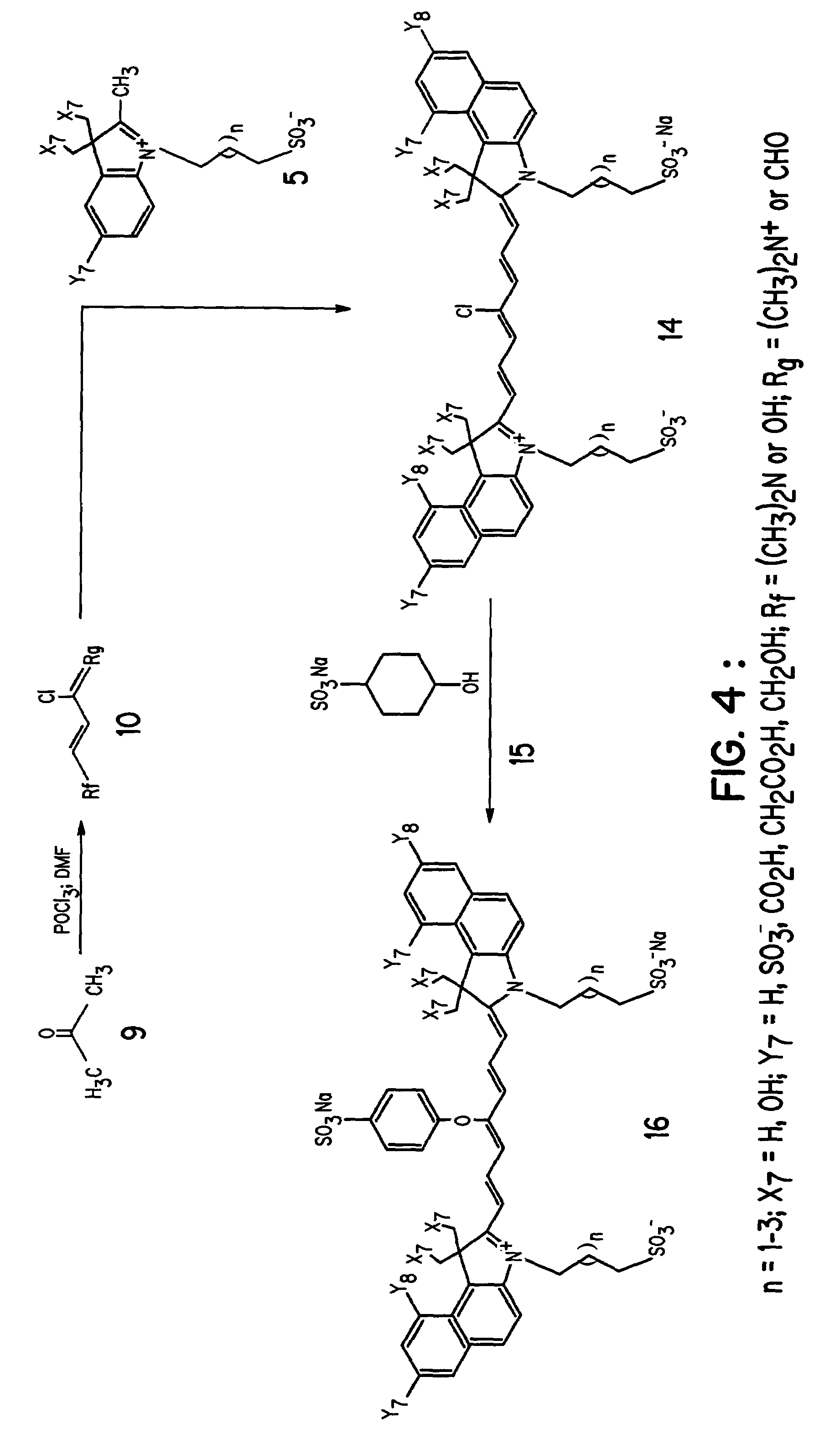

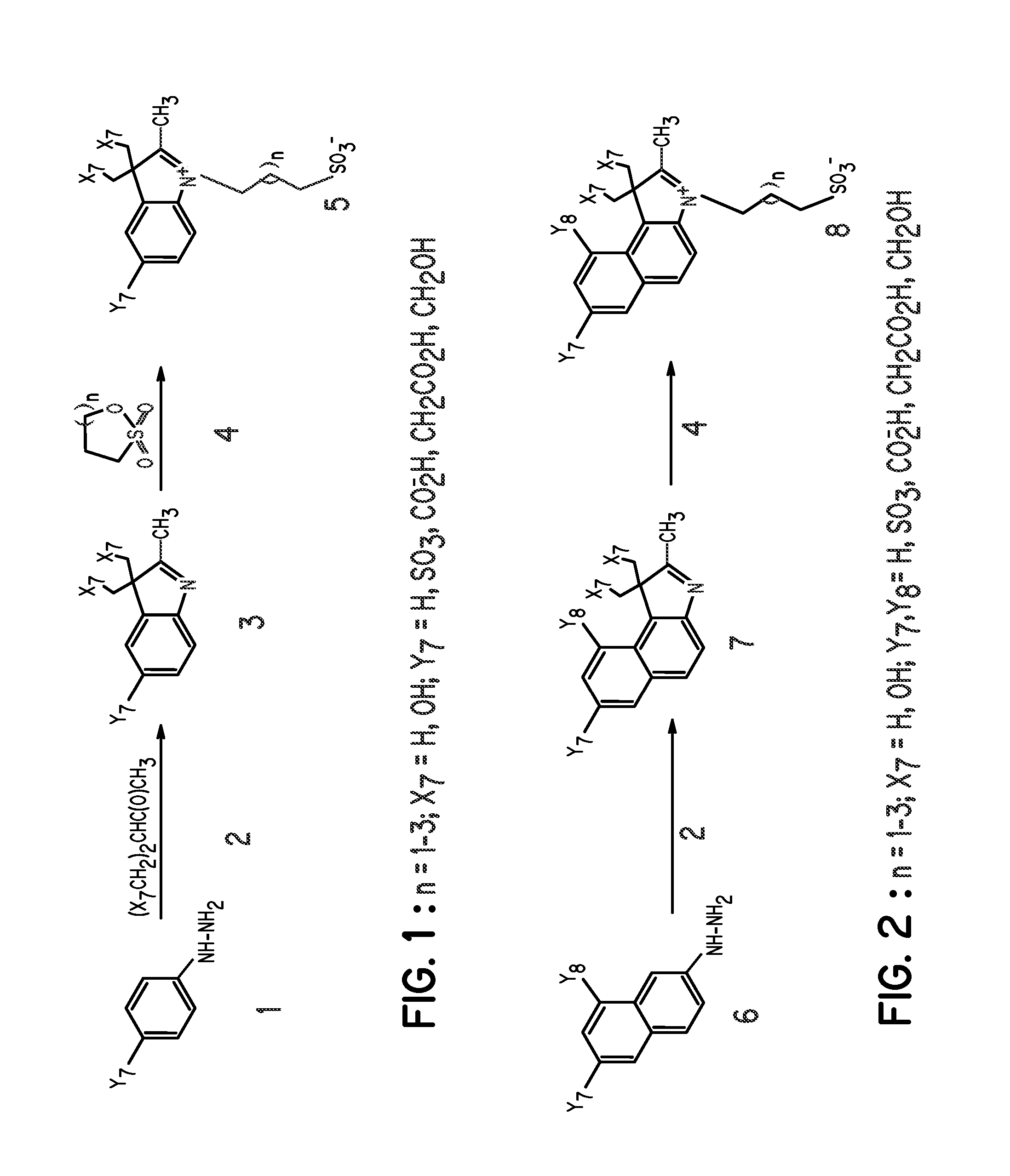

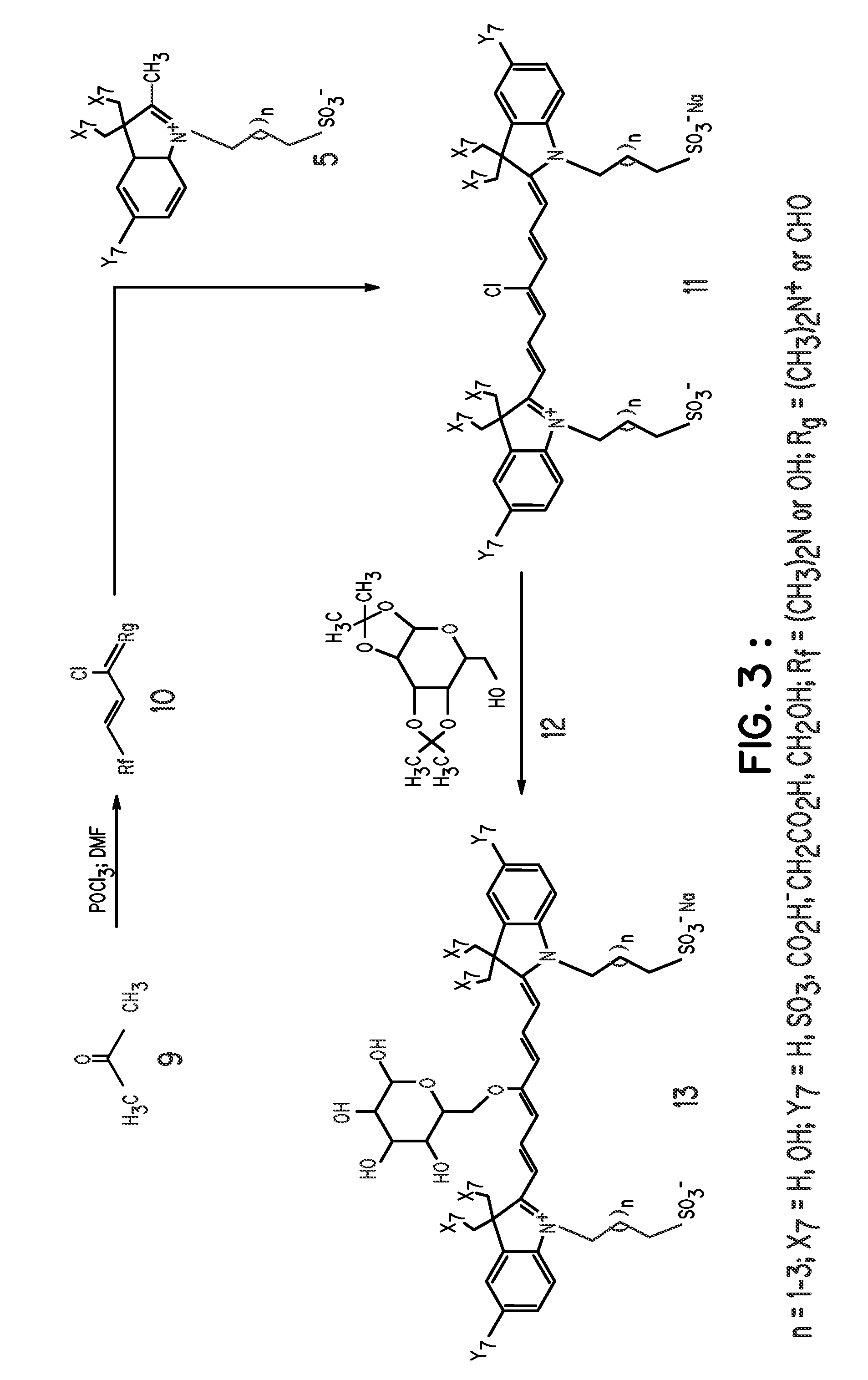

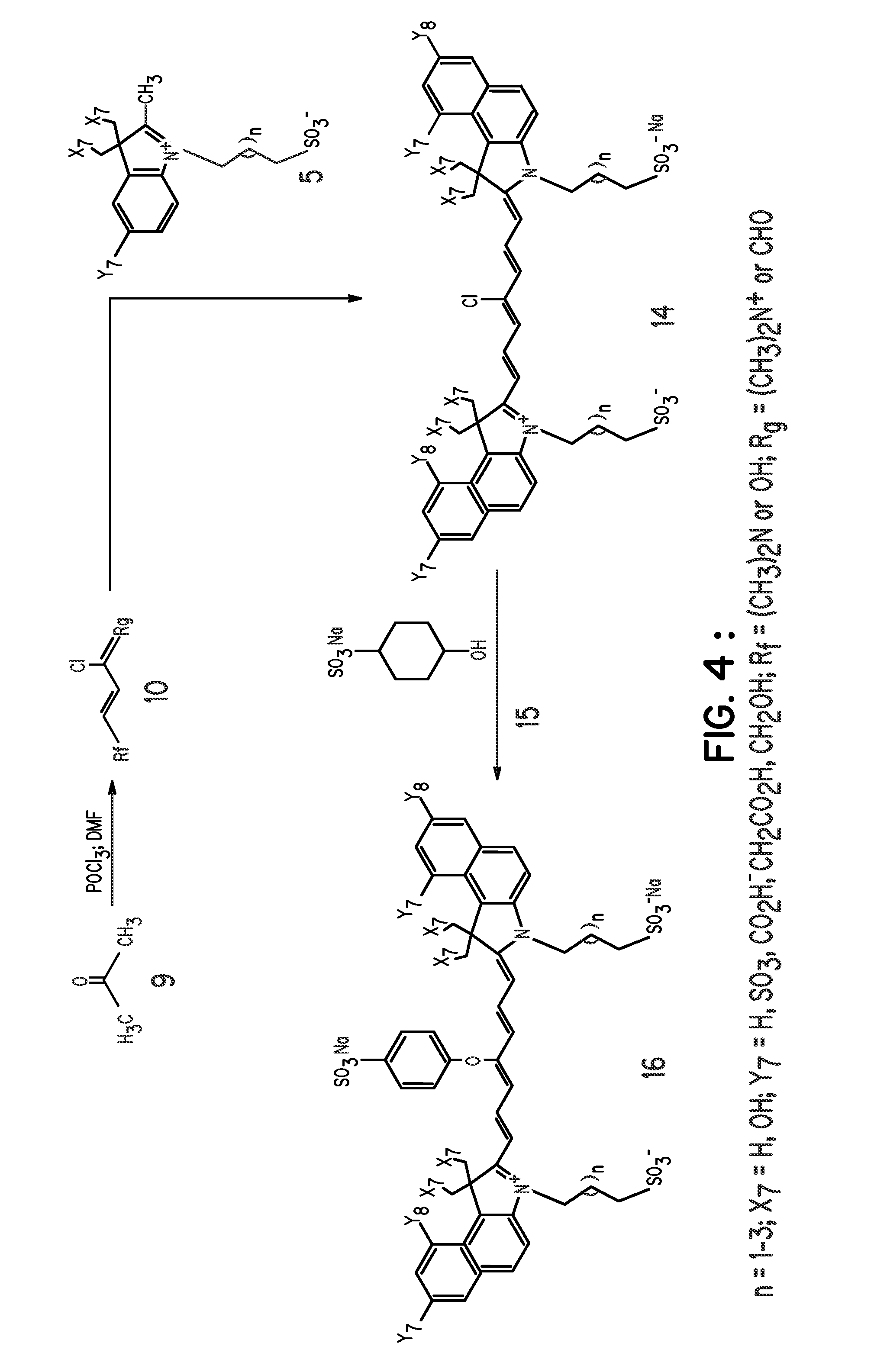

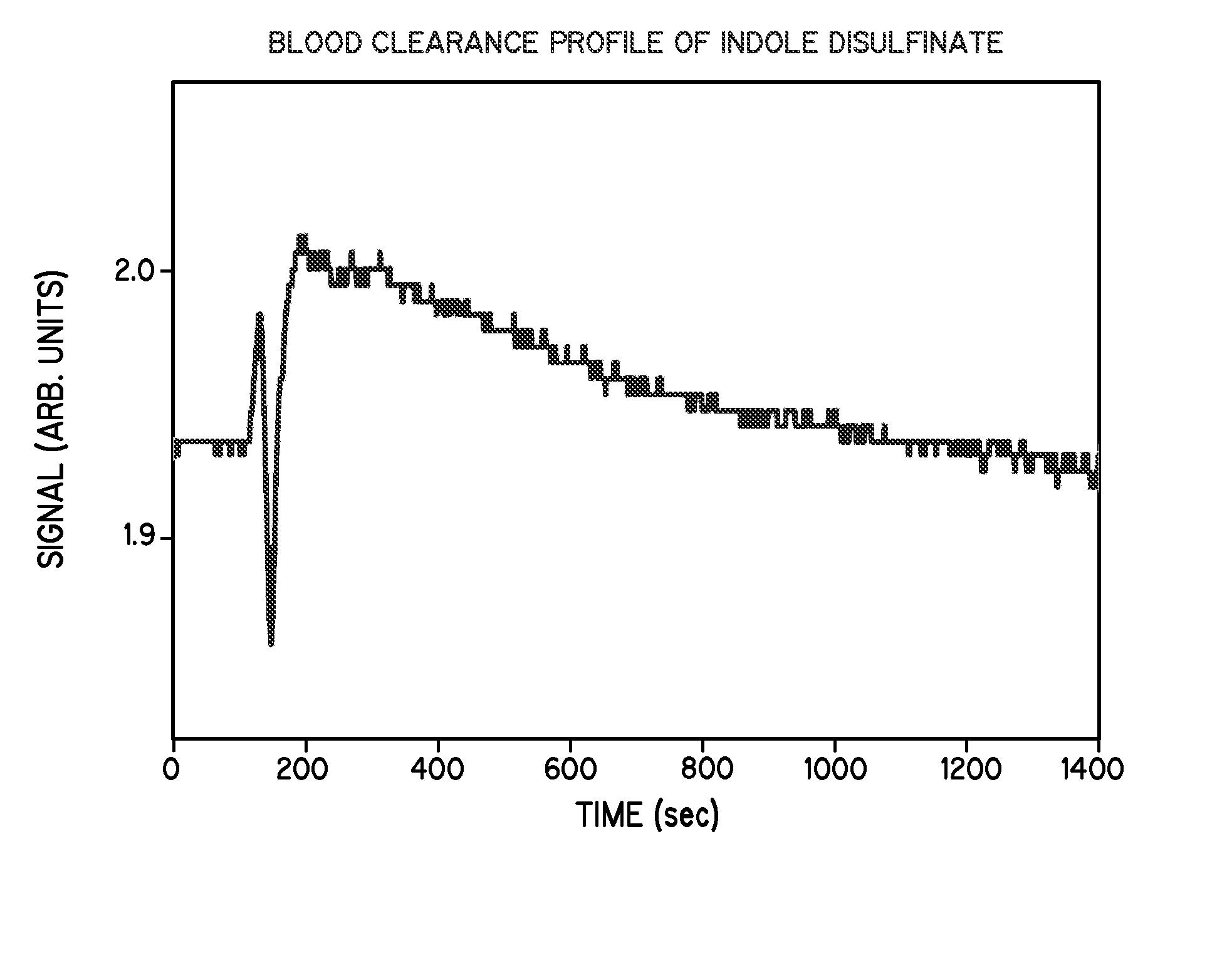

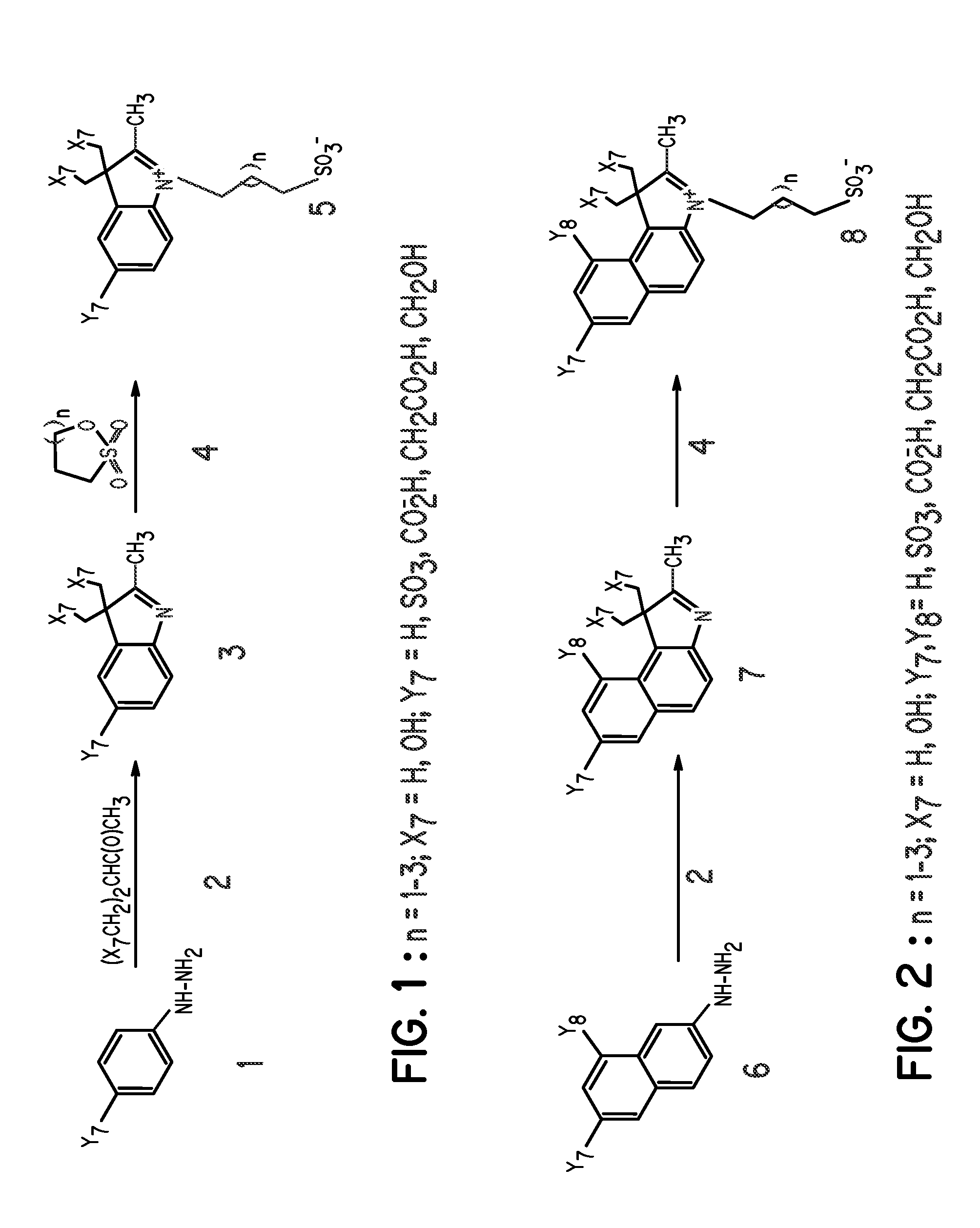

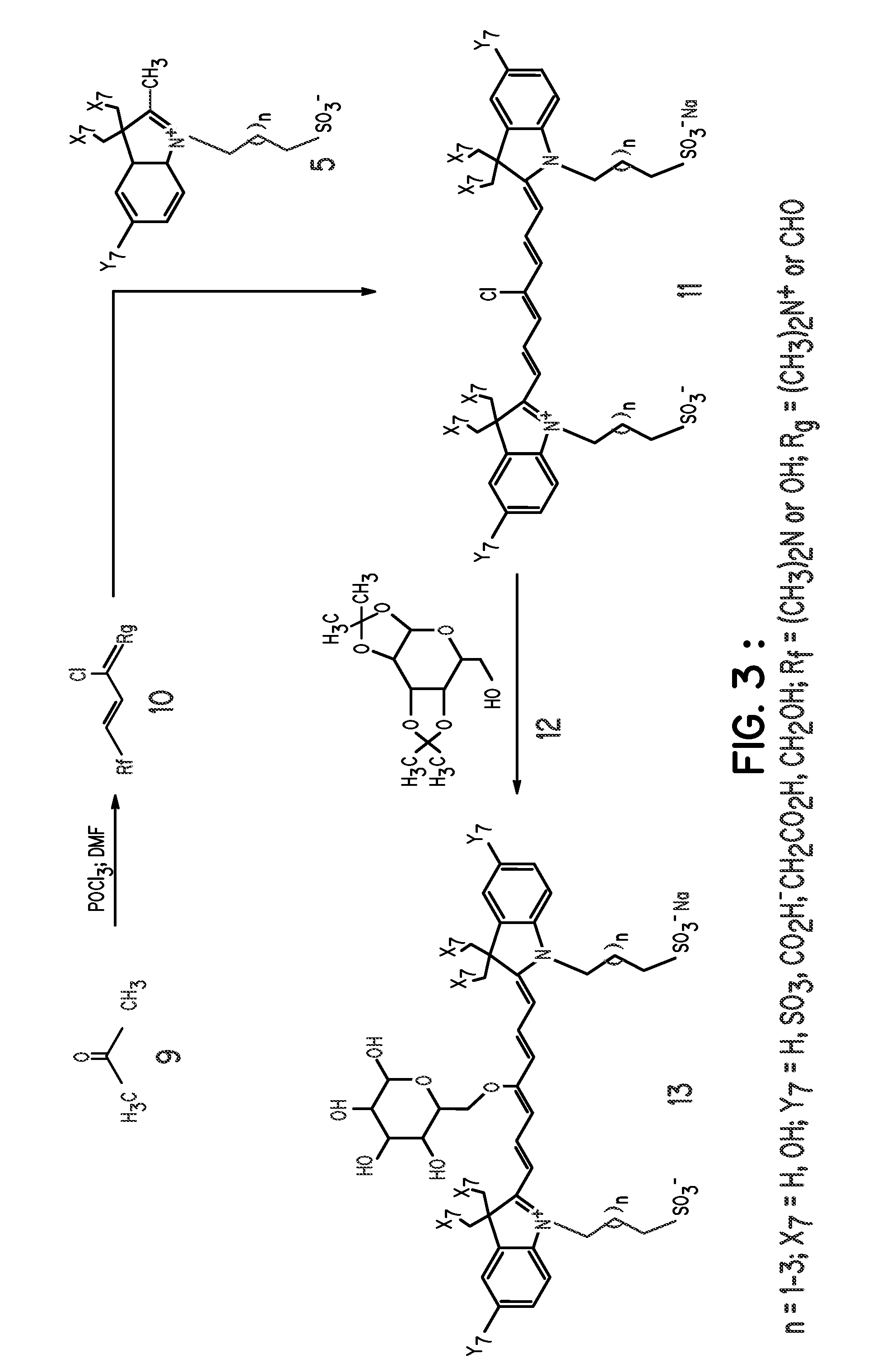

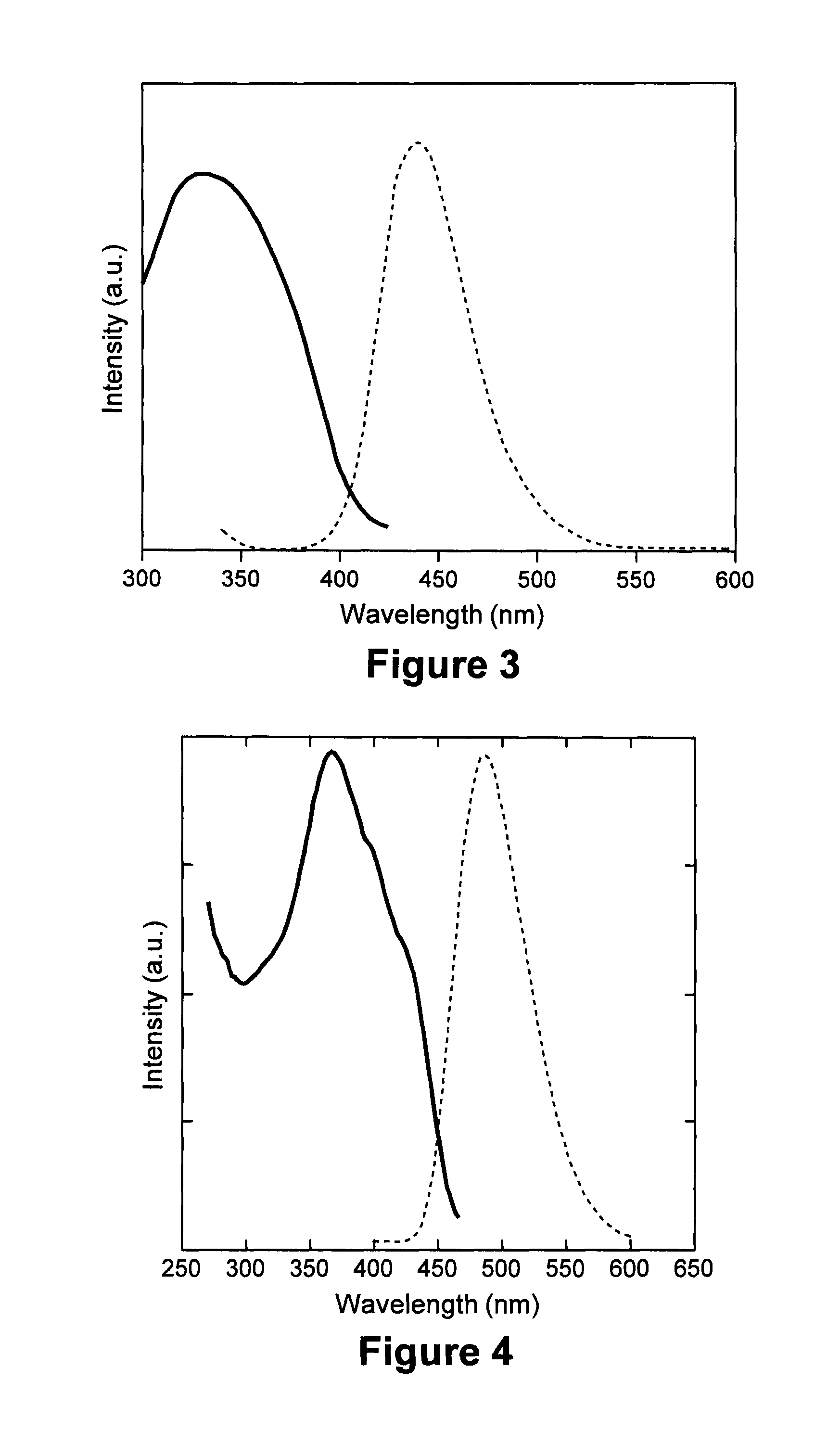

Light sensitive compounds for instant determination of organ function

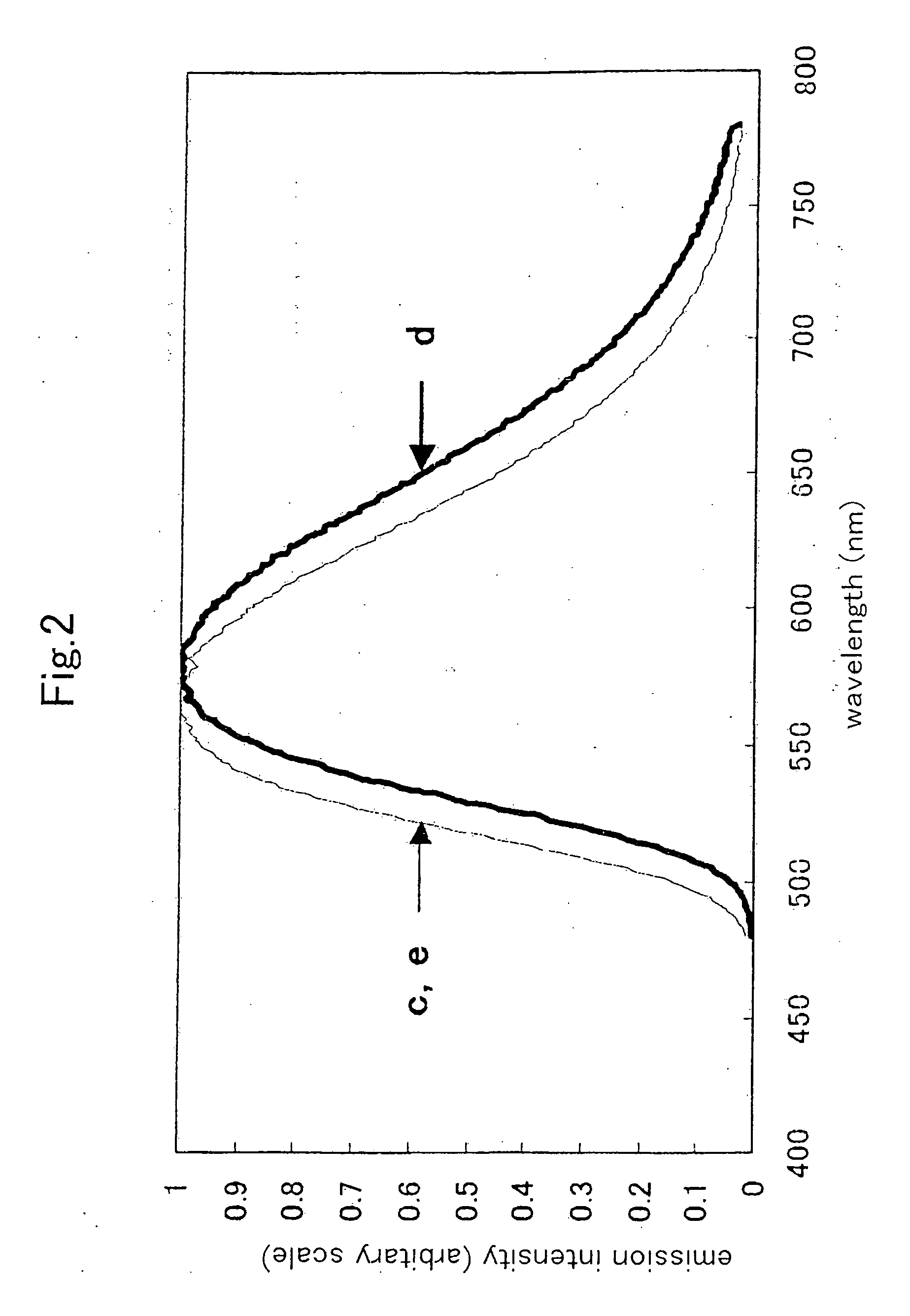

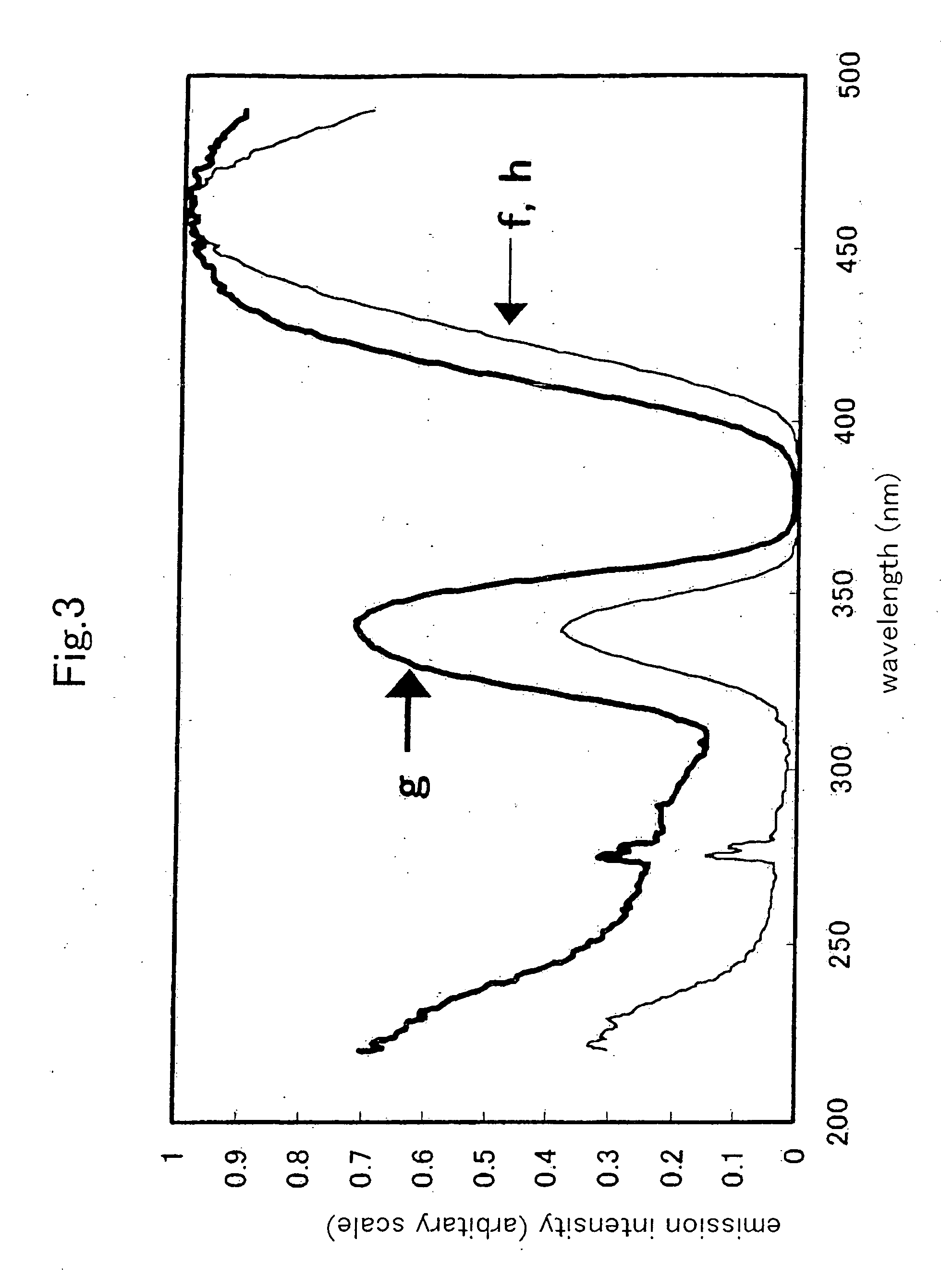

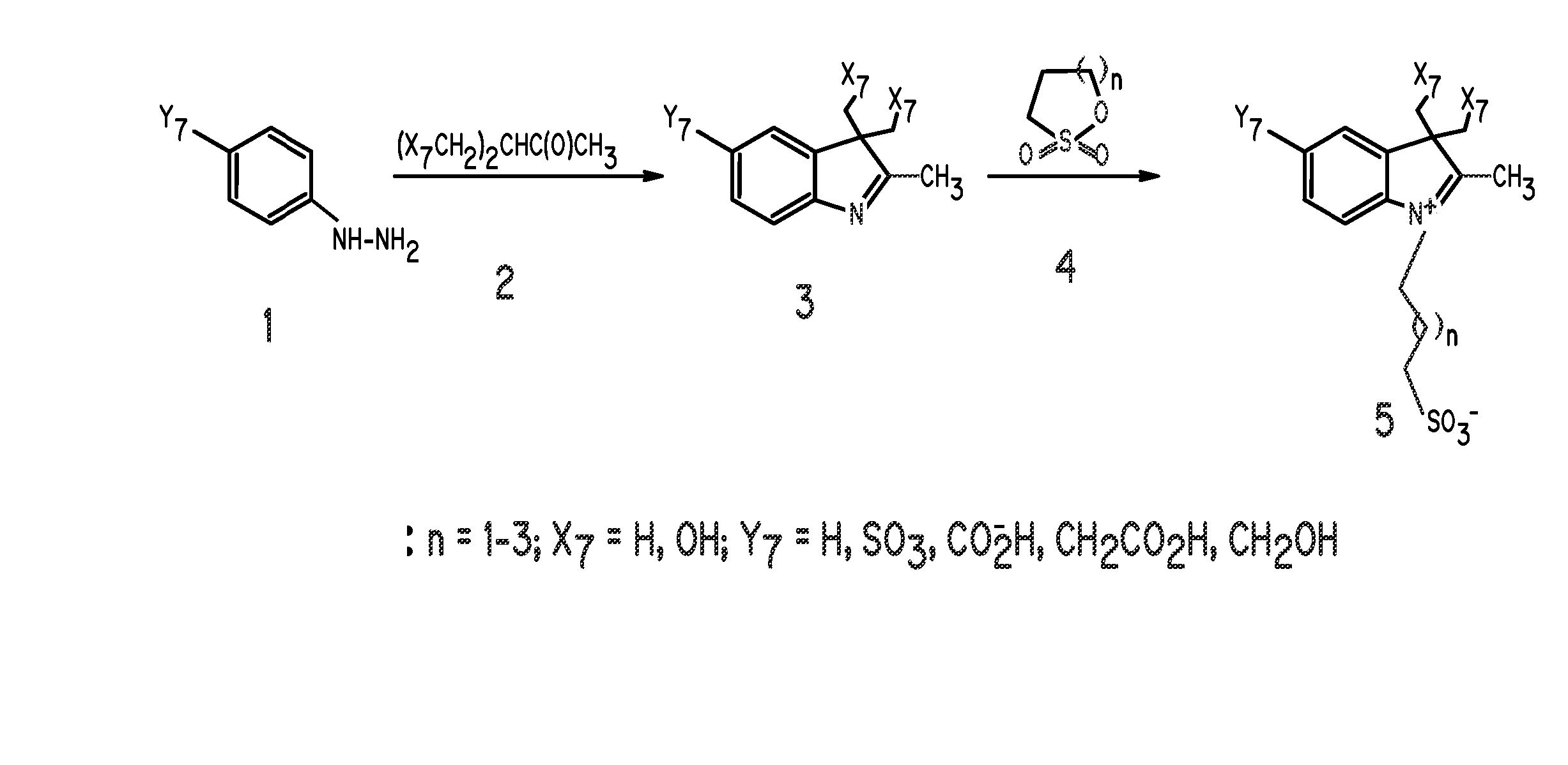

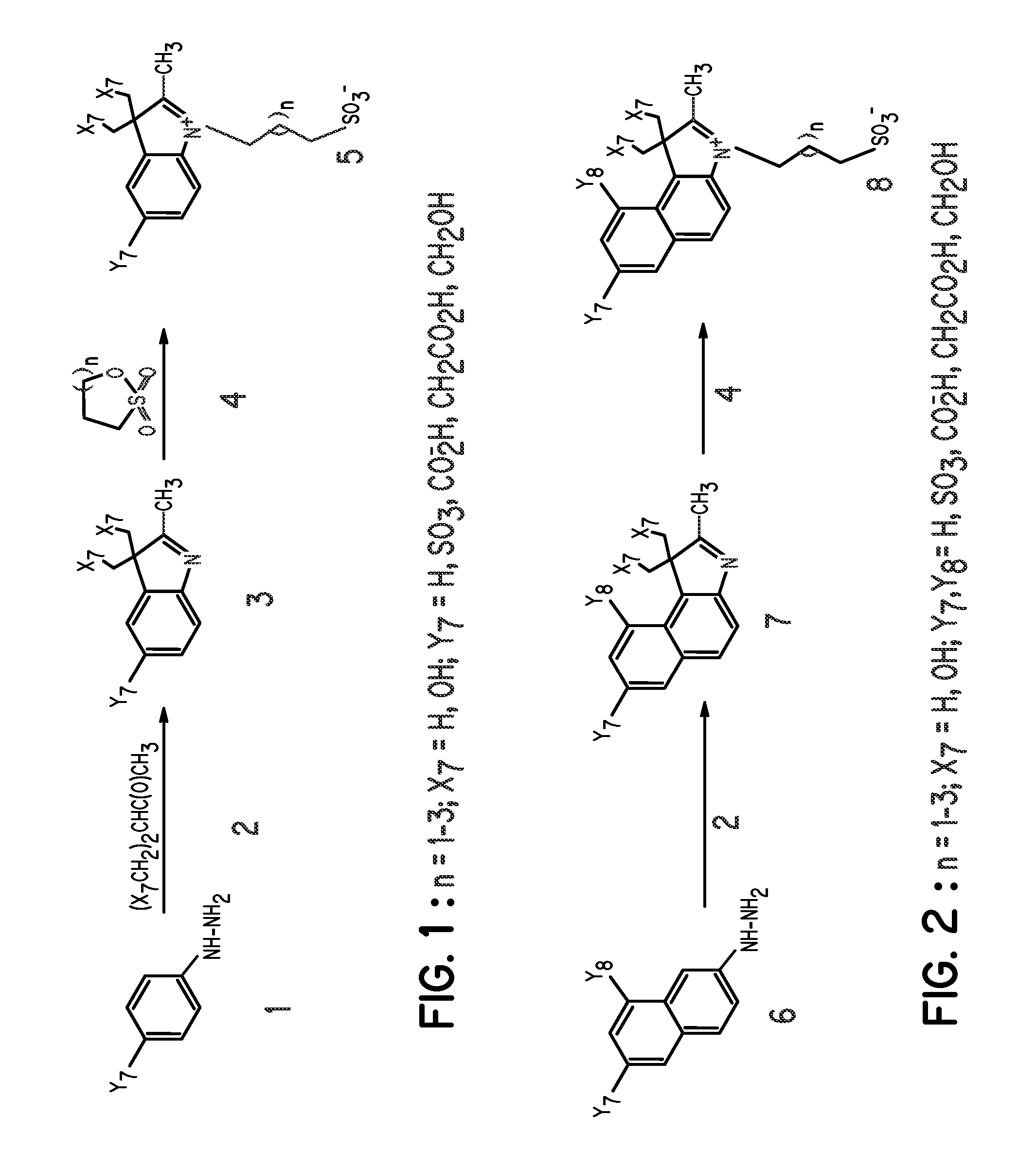

InactiveUS7175831B2Simple and efficient and effective monitoring of organ functionEasy to useUltrasonic/sonic/infrasonic diagnosticsBiocideDiseaseFluorescence

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

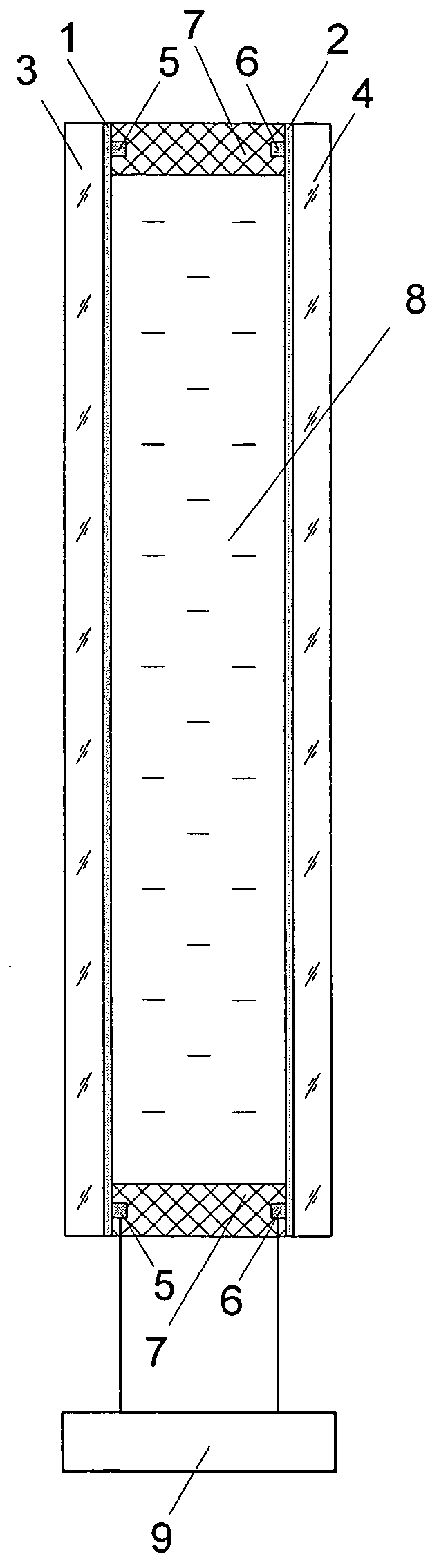

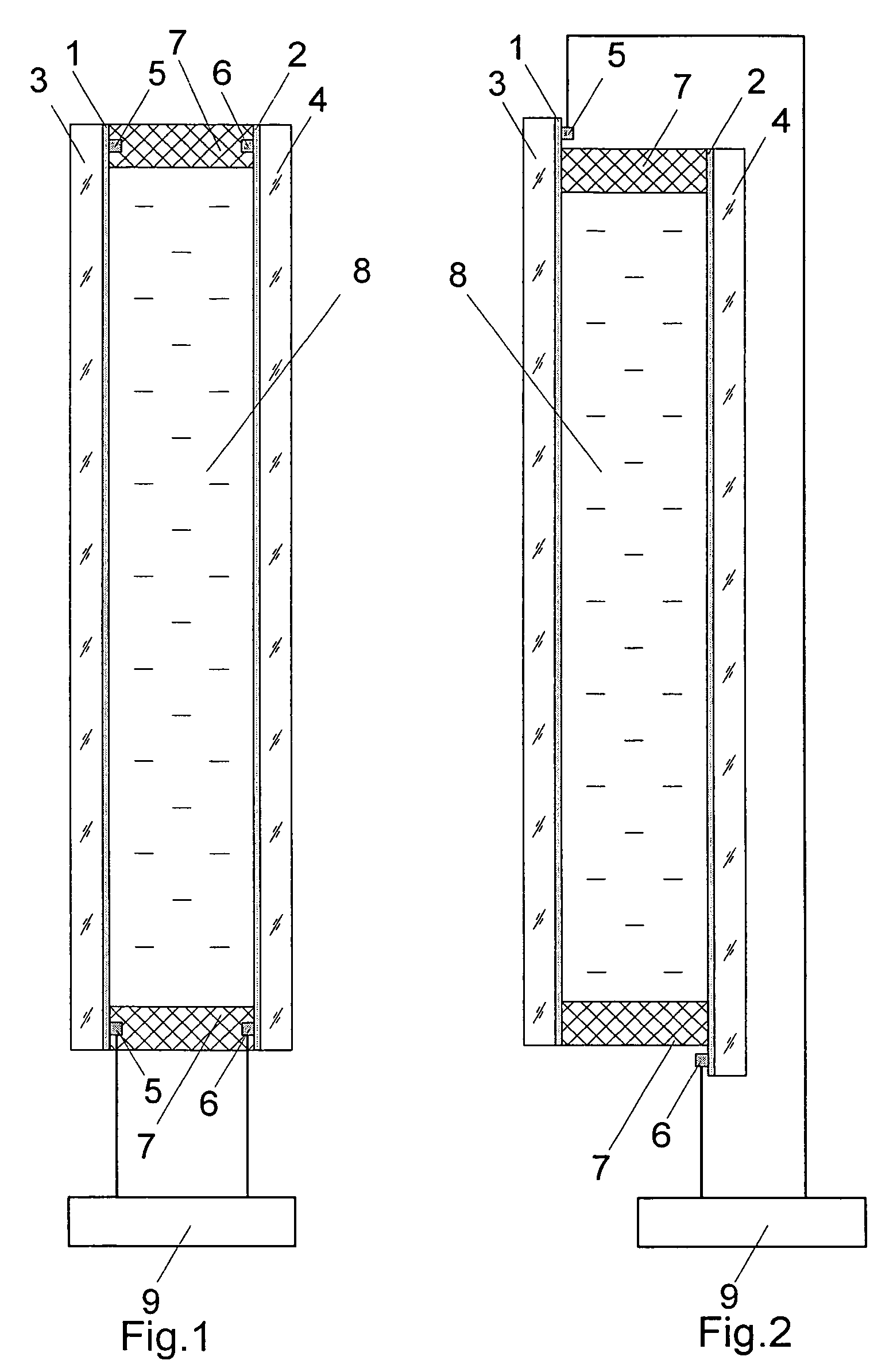

Method for producing an electrochromic device and said electrochromic device

InactiveUS20060050357A1Improve stabilityLong persistenceTenebresent compositionsNon-linear opticsVolumetric shrinkageEngineering

The invention relates to a method for producing electrochromic devices, in particular that having a large working surface area and which does not produce a volumetric shrinkage and can operate during a long maintenance of electrocoloured state of an electrochromic compound, high control voltages and polarity inversion. The inventive electrochromic device comprises at least two electrodes (1, 2), at least one of them being optically transparent. A closed sealed space is formed between said electrodes and filled with the electrochromic compound which is embodied in the form of a solid-like film. The inventive method for producing the electrochromic device consists in prefabricating an initial electrochromic compound in the form of a dispersed electrochromic system which contains at least a suspension and / or colloid. The dispersed medium of said system is embodied in the form of an electrochromic solution containing a liquid solvent, cathode and anode components, a disperse phase being embodied in the form of a finely dispersed polymer. Afterwards, the initial electrochromic compound is deaerated, thereby eliminating dissolved oxygen and air introduced by said finely dispersed polymer, and is used for filling the space between the electrodes.

Owner:AVELUM +1

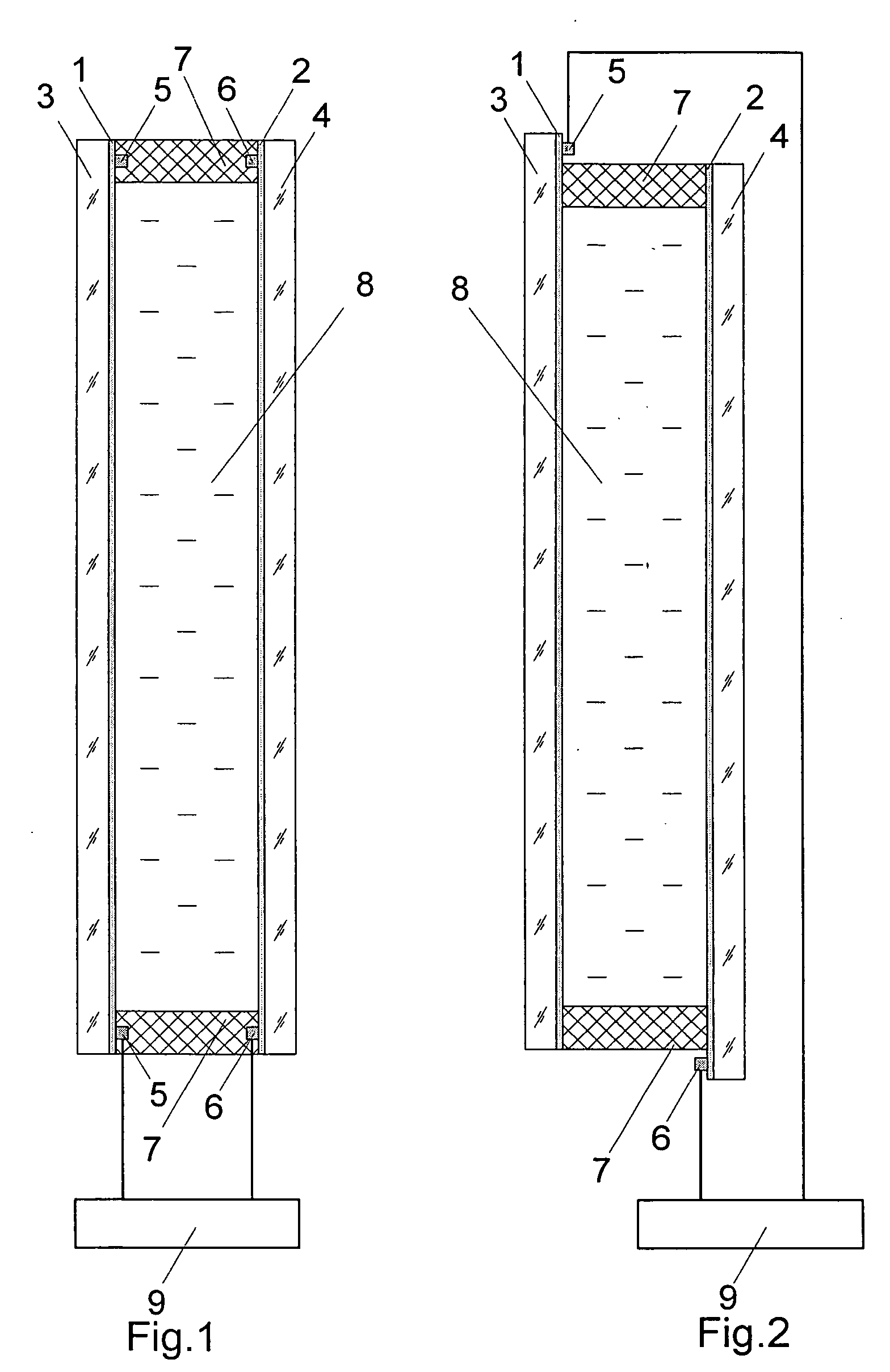

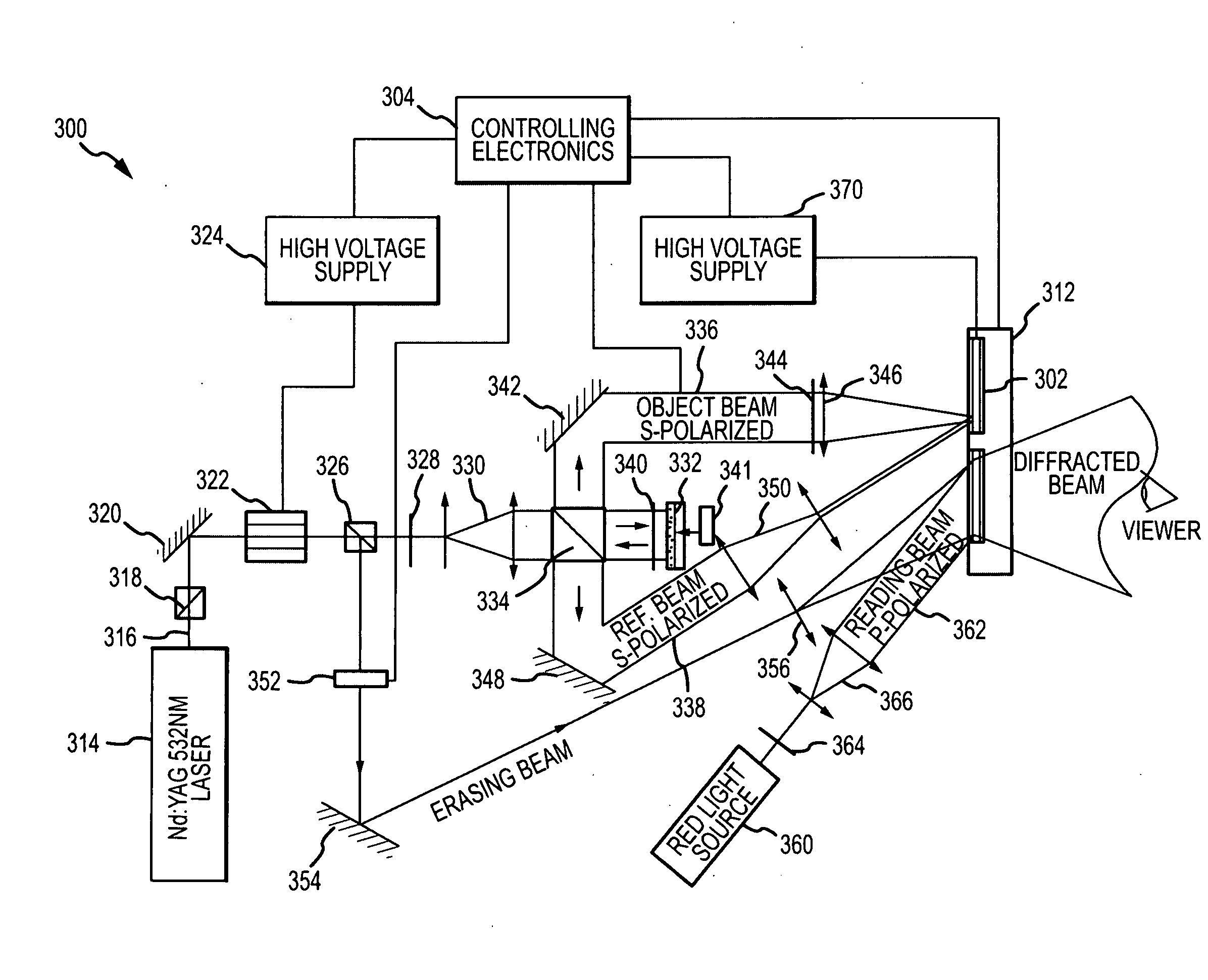

System and Method Using a Voltage Kick-Off to Record a Hologram on a Photorefractive Polymer for 3D Holographic Display and Other Applications

ActiveUS20090046333A1Shorten write timeImprove durabilityHolographic object characteristicsHologram recording materialLight beamMaximum efficiency

An updateable system and method of recording a hologram on a media simultaneously reduces the writing time and increases persistence without sacrificing diffraction efficiency. A voltage kick-off technique controls the bias electric field applied to a photorefractive polymer media in conjunction with the application of the writing beams and dark decay. Essentially the voltage kick-off technique applies a high electric field above the optimal field while the writing beams are on and reduces the electric field when the writing beams are off during dark decay. The voltage kick-off technique produced two separate unexpected results. First, when the writing beams are turned off and the electric field is lowered the diffraction efficiency continues to increase until it reaches a maximum efficiency that is within a few percent of that achieved by writing at the optimal field until steady-state is achieved. Second, the decay time constant is much larger than expected producing a much longer persistence without sacrificing diffraction efficiency or writing time.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Modified vasoactive intestinal peptides

ActiveUS9029505B2Increased circulatory half-life and persistenceAltered binding preferencePeptide/protein ingredientsPharmaceutical delivery mechanismHalf-lifeVasoactive intestinal peptide

The present invention provides modified Vasoactive Intestinal Peptides (VIPs), encoding polynucleotides and vectors, as well as pharmaceutical compositions comprising the same. The invention further provides methods of making and using the modified VIP agents. In accordance with the invention the VIP exhibits an extended circulatory half-life, receptor-binding or biological potency, and / or altered receptor binding profile with respect to unmodified VIP.

Owner:PHASEBIO PHARMA INC

Polysaccharide soft tissue fillers with improved persistence

ActiveUS20170143870A1Long persistenceEasy injectionPharmaceutical delivery mechanismTissue regenerationBiologyPolysaccharide

The present invention relates to polysaccharide soft tissue fillers comprising heparosan and processes for their preparation. The polysaccharide soft tissue fillers of the present invention are advantageously used in therapeutic or cosmetic applications such as for the filling of wrinkles.

Owner:MERZ PHARMA GMBH & CO KGAA

Adjuvanted influenza vaccines for pediatric use

ActiveUS20090220546A1Raising useful immune responseProvide immunitySsRNA viruses negative-senseViral antigen ingredientsSerum igeAdjuvant

An influenza vaccine adjuvanted with a sub-micron oil-in-water emulsion elicits significantly higher immune responses in human pediatric populations. Compared to an existing unadjuvanted pediatric influenza vaccine, the adjuvanted vaccines provided herein can induce in children a longer persistence of high serum antibody titers and also longer seroconversion and seroprotection. The improvement in immune responses is seen for both influenza A virus and influenza B virus strains, but it is particularly marked for influenza B virus. Moreover, while the existing vaccine provides poor immunity in children after a single dose, the adjuvanted vaccine provides high seroprotection rates against the influenza A virus H3N2 subtype even after a single dose. Furthermore, the adjuvanted vaccine offers significantly better seroprotection against mismatched strains of influenza A virus.

Owner:SEQIRUS UK LTD

Minimally invasive physiological function monitoring agents

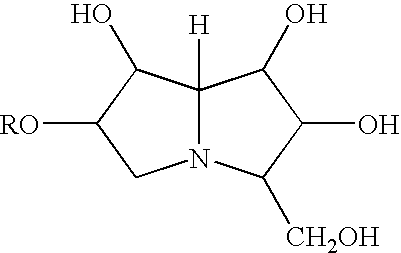

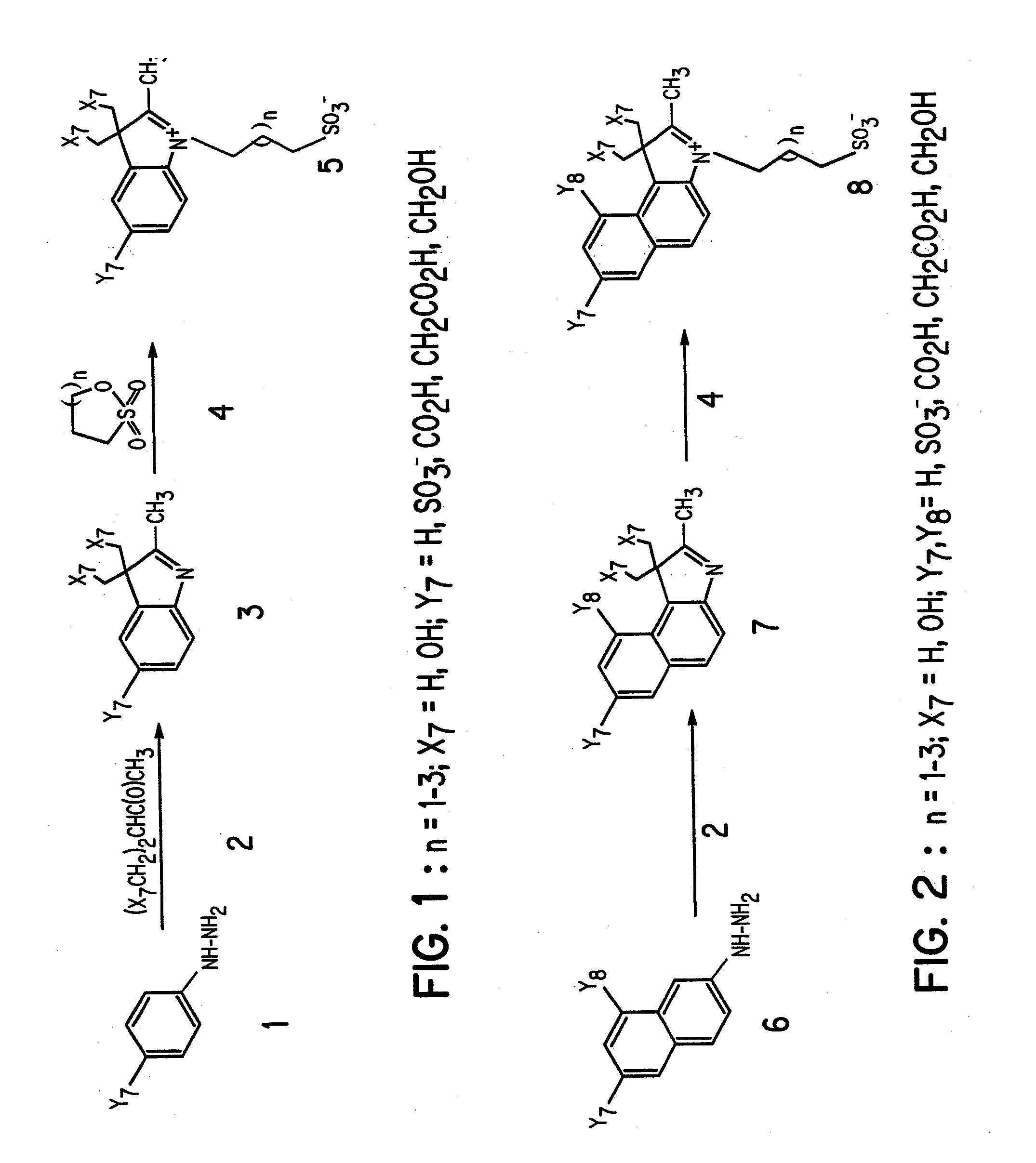

InactiveUS20090263327A1Easy to useRapid liver uptakeUltrasonic/sonic/infrasonic diagnosticsBiocideBenzeneFluorescence

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Light Sensitive Compounds for Instant Determination of Organ Function

InactiveUS20070140962A1Easy to useRapid liver uptakeUltrasonic/sonic/infrasonic diagnosticsMethine/polymethine dyesFluorescenceNormal blood volume

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Use of modified vasoactive intestinal peptides in the treatment of hypertension

ActiveUS20150111829A1Modified receptor binding profileLong persistenceOrganic active ingredientsConnective tissue peptidesHypertension medicationsVasoactive intestinal peptide

The present invention is based on the discovery that a VIP having a binding preference for VPAC2 can provide long-acting blood pressure control synergistically with concomitant anti-hypertensive therapies. Accordingly, methods and compositions useful for the treatment and / or amelioration of hypertension are provided.

Owner:PHASEBIO PHARMA INC

Hydrophilic light absorbing compositions for determination of physiological function

InactiveUS7297325B2Simple and efficient and effective monitoring of organ functionEasy to useUltrasonic/sonic/infrasonic diagnosticsBiocideFluorescenceNormal blood volume

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Liminous phosphor, fluorescent lamp, luminous display, and luminous molded product

InactiveUS20100038591A1Increase brightnessHigh purityDischarge tube luminescnet screensLuminescent compositionsChemistryMagnesium

There are provided a long persistent phosphor capable of keeping high persistent intensity and white persistence of especially satisfactory color purity after the phosphor is excited by ultraviolet irradiation and then the excited light is cut off, and a fluorescent lamp, a display item of long persistence and a formed product of long persistence in which the phosphor is used.A long phosphorescence persistent phosphor which comprises a mixture or mutual deposit of the first phosphor emitting long persistence in the first wave range by ultraviolet absorption, which is one or more than two of the following phosphors (i) and (ii), and a second phosphor which is excited by at least a part of emission of the first phosphor.Magnesium-strontium silicate phosphor (i) prepared by co-activating a complex-oxide containing Sr, Mg and Si as a matrix metal component with Eu and Dy.Strontium-aluminum silicate phosphor (ii) prepared by co-activating a complex-oxide containing Sr, Al and Si as a matrix metal component with europium Eu and Dy.The long persistent phosphor is used as a fluorescent screen to prepare a fluorescent lamp, applied to a displaying part to prepare a display item of long persistence or added to plastics and other materials and formed into a desired shape to prepare a formed product.

Owner:MITSUBISHI CHEM CORP

Novel Dyes for Organ Function Monitoring

InactiveUS20080056989A1Simple and efficient and effective monitoring of organ functionEasy to useOrganic chemistryIn-vivo radioactive preparationsFluorescenceNormal blood volume

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Minimally invasive physiological function monitoring agents

InactiveUS7556797B2Simple and efficient and effective monitoring of organ functionEasy to useUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsBenzeneFluorescence

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

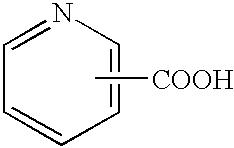

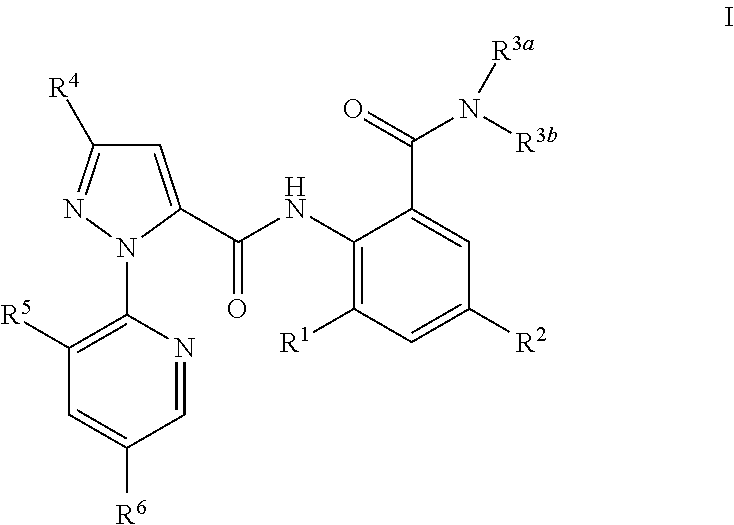

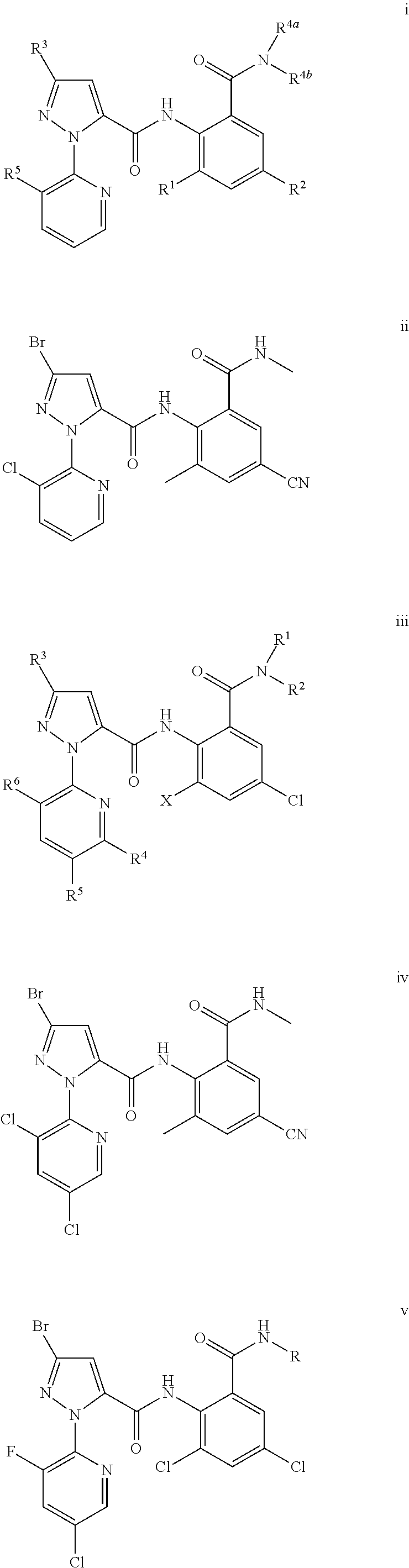

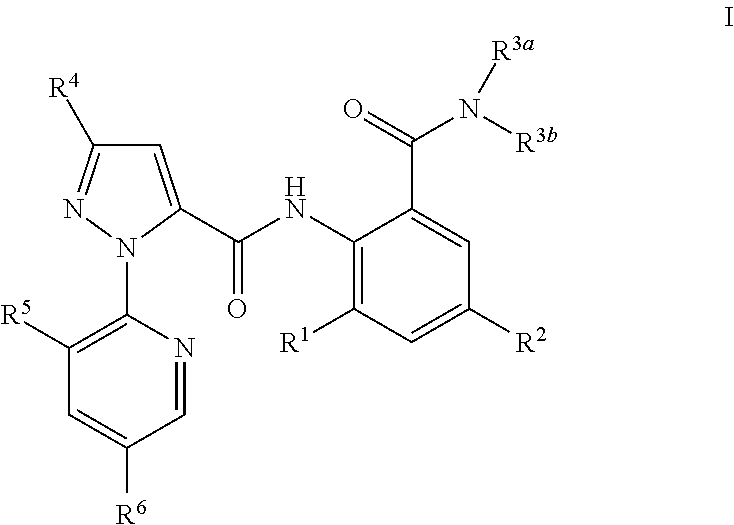

Polysubstituted pyridyl pyrazolecarboxamide and preparation method and use thereof

The present invention discloses a polysubstituted pyridyl pyrazolecarboxamide and its preparation method and use. The structure of the polysubstituted pyridyl pyrazolecarboxamide of the present invention is shown in the following General Formula I. The polysubstituted pyridyl pyrazolecarboxamide has the following advantages such as good insecticidal effect, low production cost; and it may be used in control of agriculture, forest or health pests, especially of resistant pests. For its preparation method, the yield is high, the number of steps is small, and the operation is simple.

Owner:GUANGDONG ZHENGE BIOLOGICAL TECH CO LTD

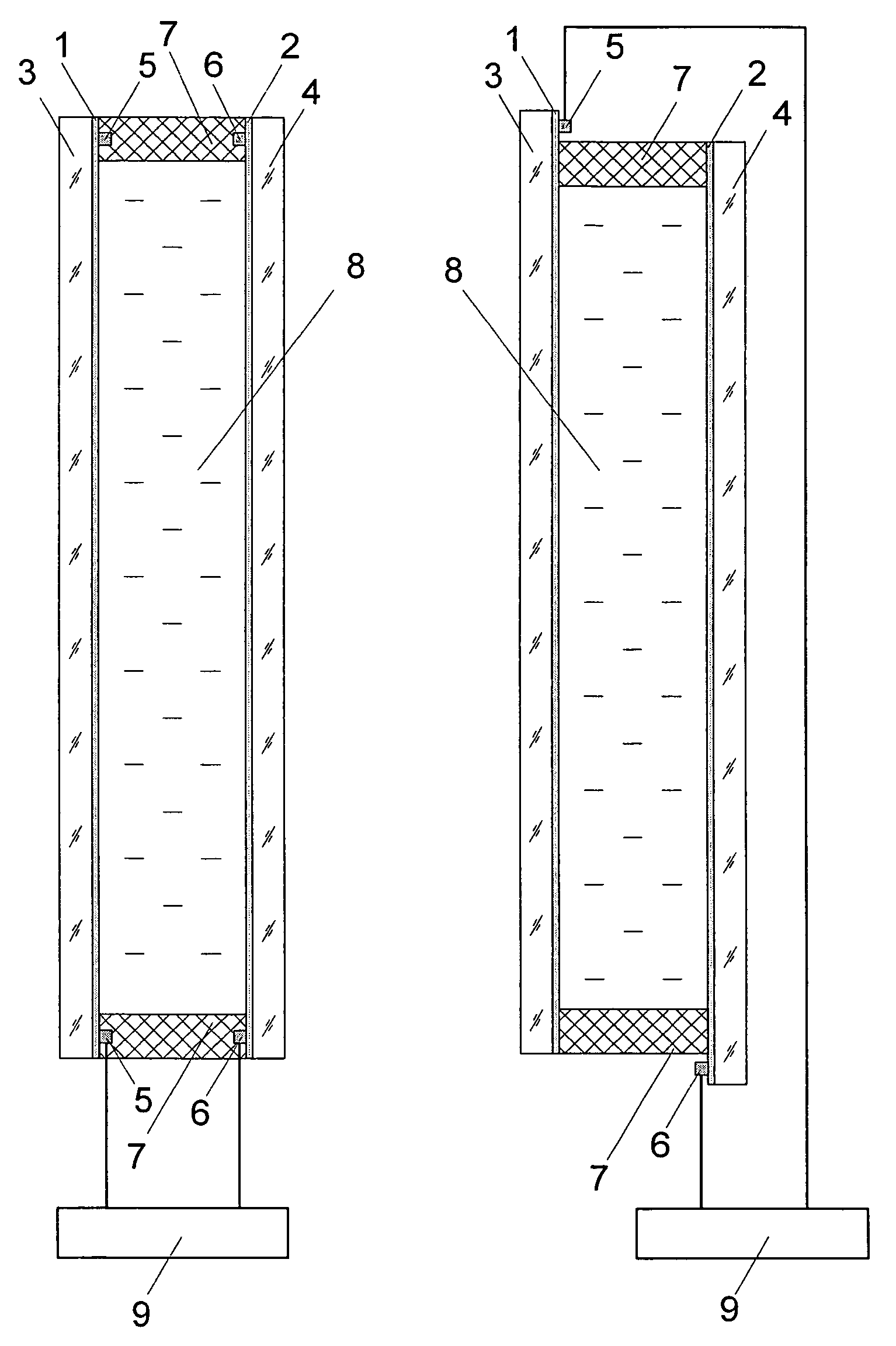

Method for producing an electrochromic device and said electrochromic device

InactiveUS7295361B2Improve stabilityLong persistenceTenebresent compositionsNon-linear opticsElectricityVolumetric shrinkage

The invention relates to a method for producing electrochromic devices, in particular that having a large working surface area and which does not produce a volumetric shrinkage and can operate during a long maintenance of electrocoloured state of an electrochromic compound, high control voltages and polarity inversion. The inventive electrochromic device comprises at least two electrodes (1, 2), at least one of them being optically transparent. A closed sealed space is formed between said electrodes and filled with the electrochromic compound which is embodied in the form of a solid-like film. The inventive method for producing the electrochromic device consists in prefabricating an initial electrochromic compound in the form of a dispersed electrochromic system which contains at least a suspension and / or colloid. The dispersed medium of said system is embodied in the form of an electrochromic solution containing a liquid solvent, cathode and anode components, a disperse phase being embodied in the form of a finely dispersed polymer. Afterwards, the initial electrochromic compound is deaerated, thereby eliminating dissolved oxygen and air introduced by said finely dispersed polymer, and is used for filling the space between the electrodes.

Owner:AVELUM +1

Use of modified vasoactive intestinal peptides in the treatment of hypertension

ActiveUS9561262B2Modified receptor binding profileLong persistenceOrganic active ingredientsConnective tissue peptidesHypertension medicationsVasoactive intestinal peptide

The present invention is based on the discovery that a VIP having a binding preference for VPAC2 can provide long-acting blood pressure control synergistically with concomitant anti-hypertensive therapies. Accordingly, methods and compositions useful for the treatment and / or amelioration of hypertension are provided.

Owner:PHASEBIO PHARMA INC

Dyes for organ function monitoring

InactiveUS7438894B2Easy to useRapid liver uptakeUltrasonic/sonic/infrasonic diagnosticsMethine/polymethine dyesFluorescenceNormal blood volume

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Hydrophilic light absorbing compositions for determination of physiological function in critically ill patients

InactiveUS20070269368A1Easy to useRapid liver uptakeUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsCritically illFluorescence

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

Hydrophilic light absorbing compositions for determination of physiological function in critically ill patients

InactiveUS20070269373A1Easy to useRapid liver uptakeUltrasonic/sonic/infrasonic diagnosticsBiocideCritically illFluorescence

Highly hydrophilic indole and benzoindole derivatives that absorb and fluoresce in the visible region of light are disclosed. These compounds are useful for physiological and organ function monitoring. Particularly, the molecules of the invention are useful for optical diagnosis of renal and cardiac diseases and for estimation of blood volume in vivo.

Owner:MALLINCKRODT INC

White persistent phosphor blend or layered structure

ActiveUS8404153B2High initial intensityLong persistenceNatural mineral layered productsLuminescent compositionsPhosphorLength wave

This disclosure features a blend, or use together in at least two layers of an article of manufacture, of a first persistent phosphor, a second persistent phosphor and a third phosphor. The first persistent phosphor has a formula I:Cax-y-z-aAaAl2-m-n-o-pOd:Euy,REz,Bm,Znn,Coo,Scp Iwhere the variables are defined in the disclosure. The second persistent phosphor has a formula II:Srx-y-z-aAaAl14-m-n-o-pOd:Euy,REz,Bm,Znn,Coo,Scp IIwhere the variables are defined in the disclosure. The third phosphor is a non-persistent phosphor that is excited at a wavelength in a range of 300-500 nm. Also featured is an article of manufacture including the blend or the phosphors present in at least two layers. Once the blend or layered structure comprising the three phosphors has been excited it can appear white in an absence of ambient light.

Owner:GE LIGHTING SOLUTIONS LLC

Use of modified vasoactive intestinal peptides in the treatment of hypertension

ActiveUS20170072021A1Modified receptor binding profileLong persistenceOrganic active ingredientsConnective tissue peptidesHypertension medicationsVasoactive intestinal peptide

The present invention is based on the discovery that a VIP having a binding preference for VPAC2 can provide long-acting blood pressure control synergistically with concomitant anti-hypertensive therapies. Accordingly, methods and compositions useful for the treatment and / or amelioration of hypertension are provided.

Owner:IMMUNOFORGE CO LTD

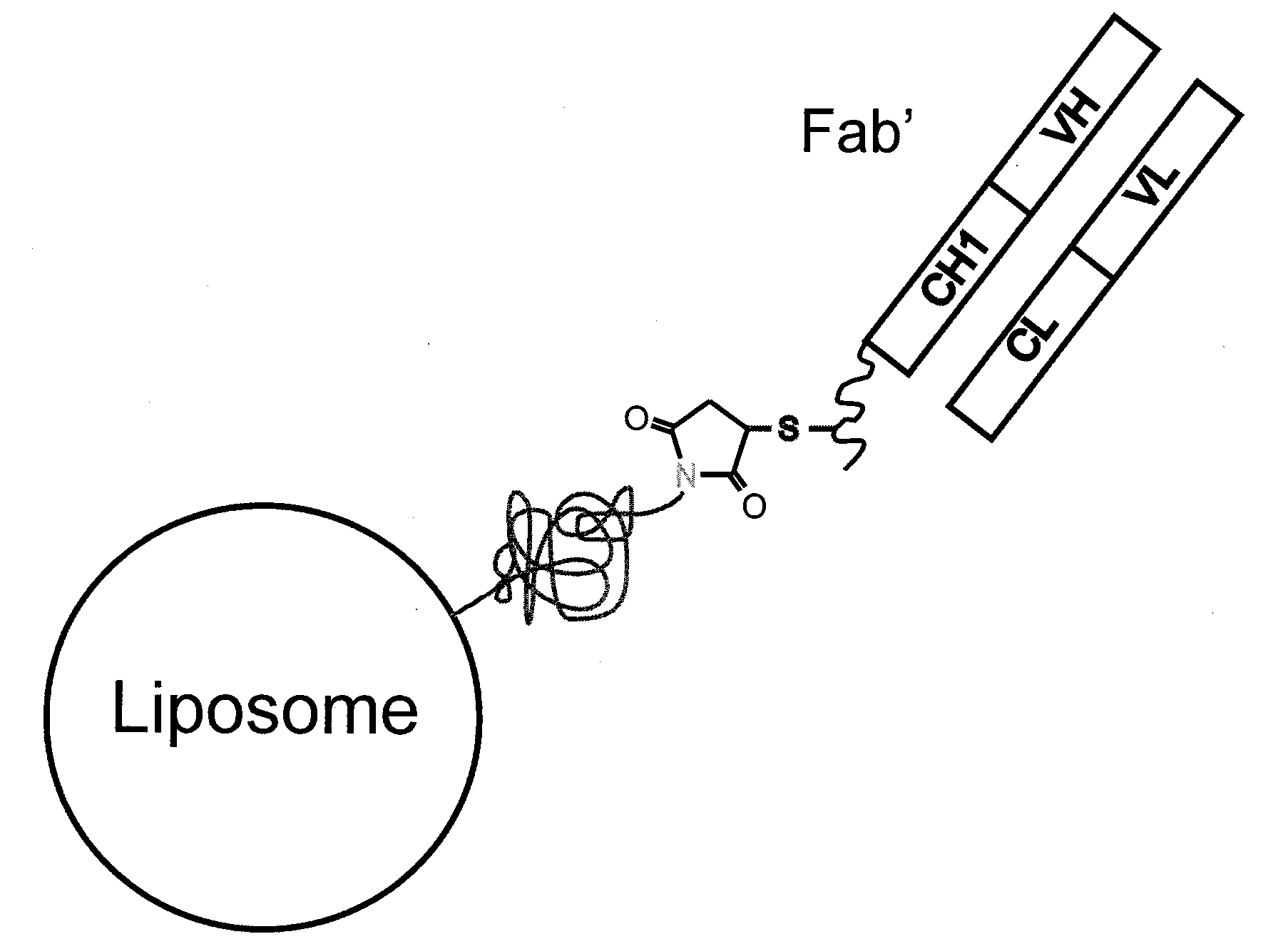

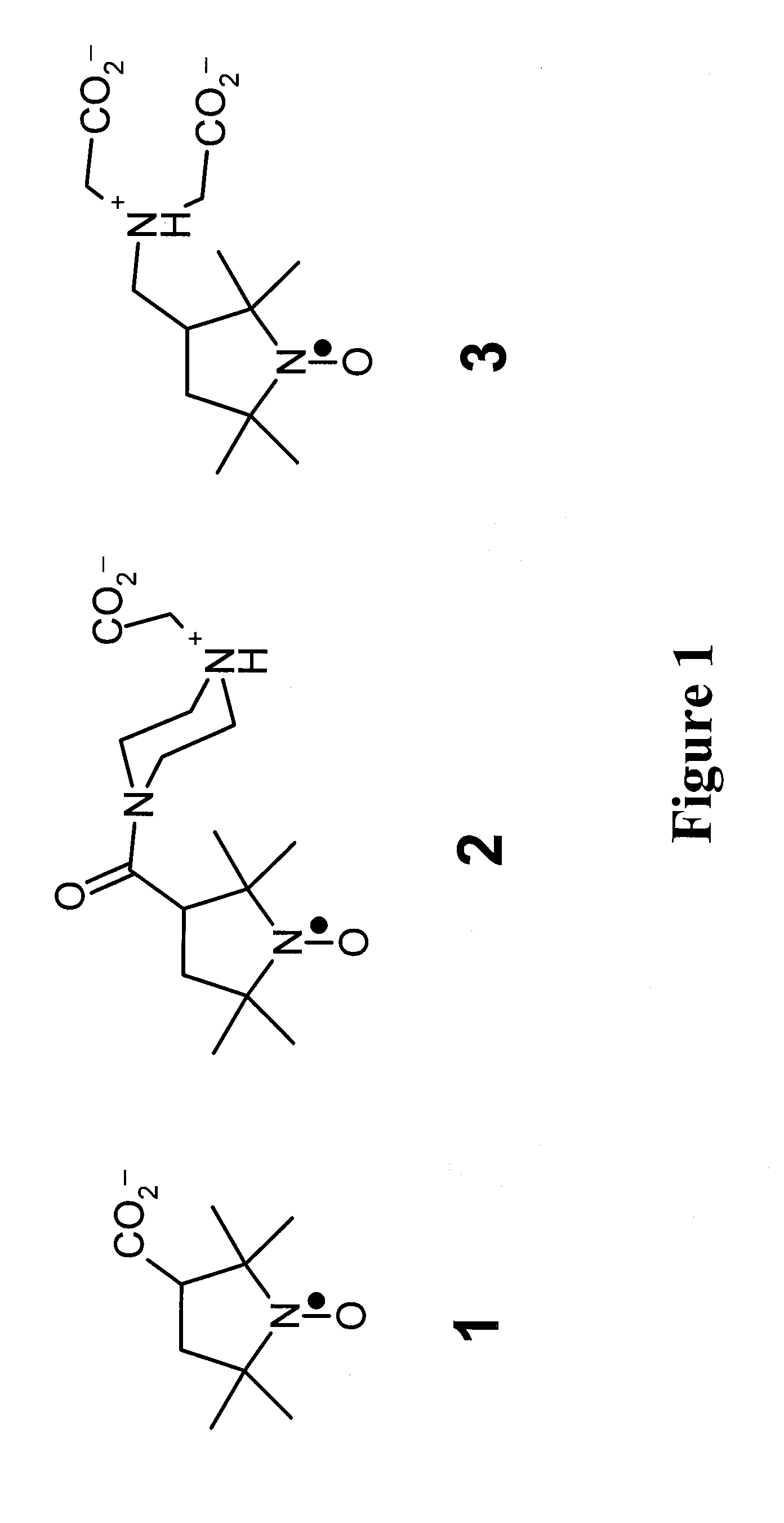

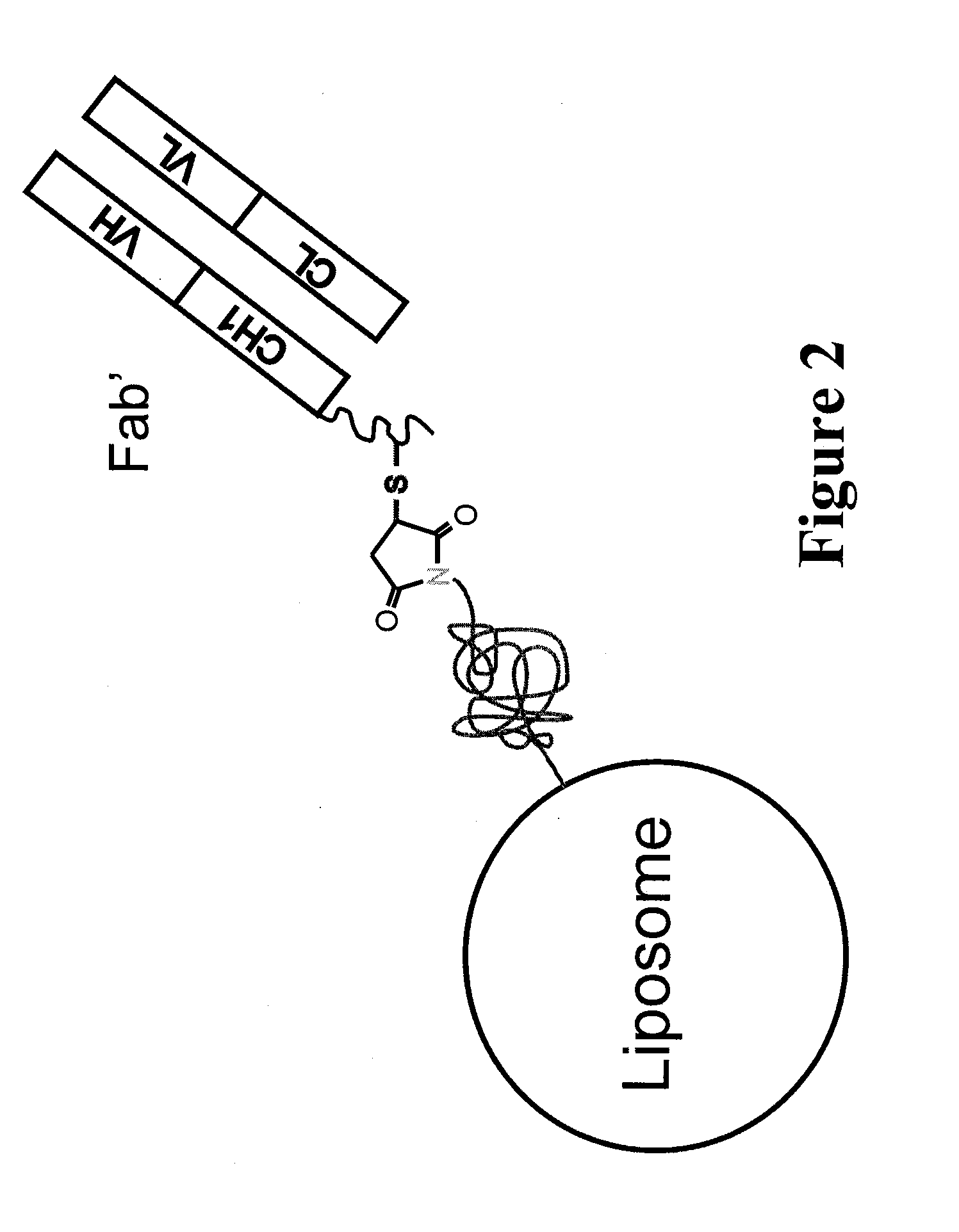

Targeted delivery of imaging probes for in vivo cellular imaging

ActiveUS20110165087A1Improve image contrastLonger signal persistenceBiocideDispersion deliveryLiposomeMedical physics

The present invention relates to nitroxide imaging probes that are isotopically modified or unmodified. Such nitroxide imaging probes may be included in liposomes that encapsulate self-quenching concentrations thereof, wherein the liposomes optionally comprise a targeting ligand specific to and having affinity for targeted tissue.

Owner:UNIV OF MARYLAND BALTIMORE

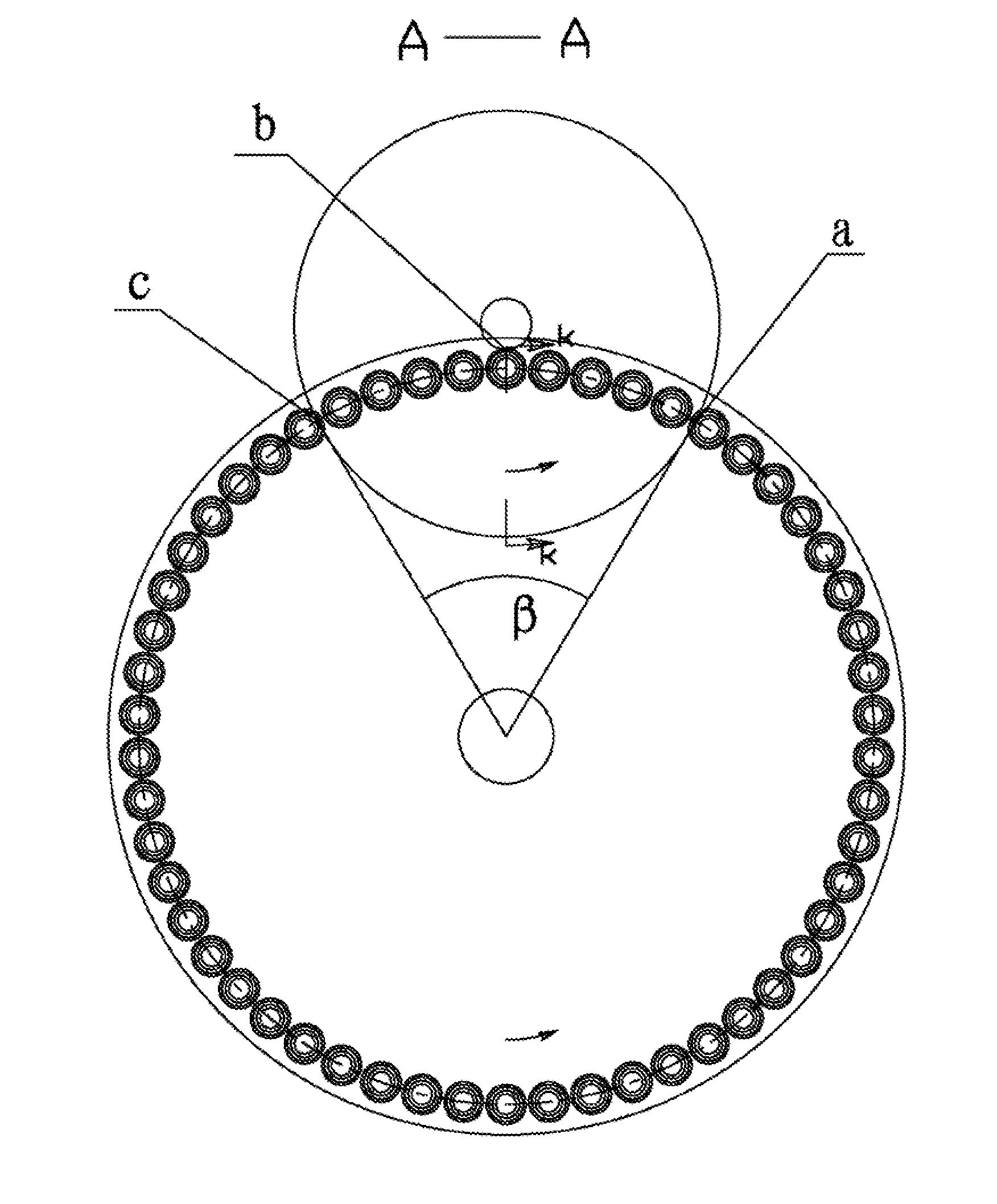

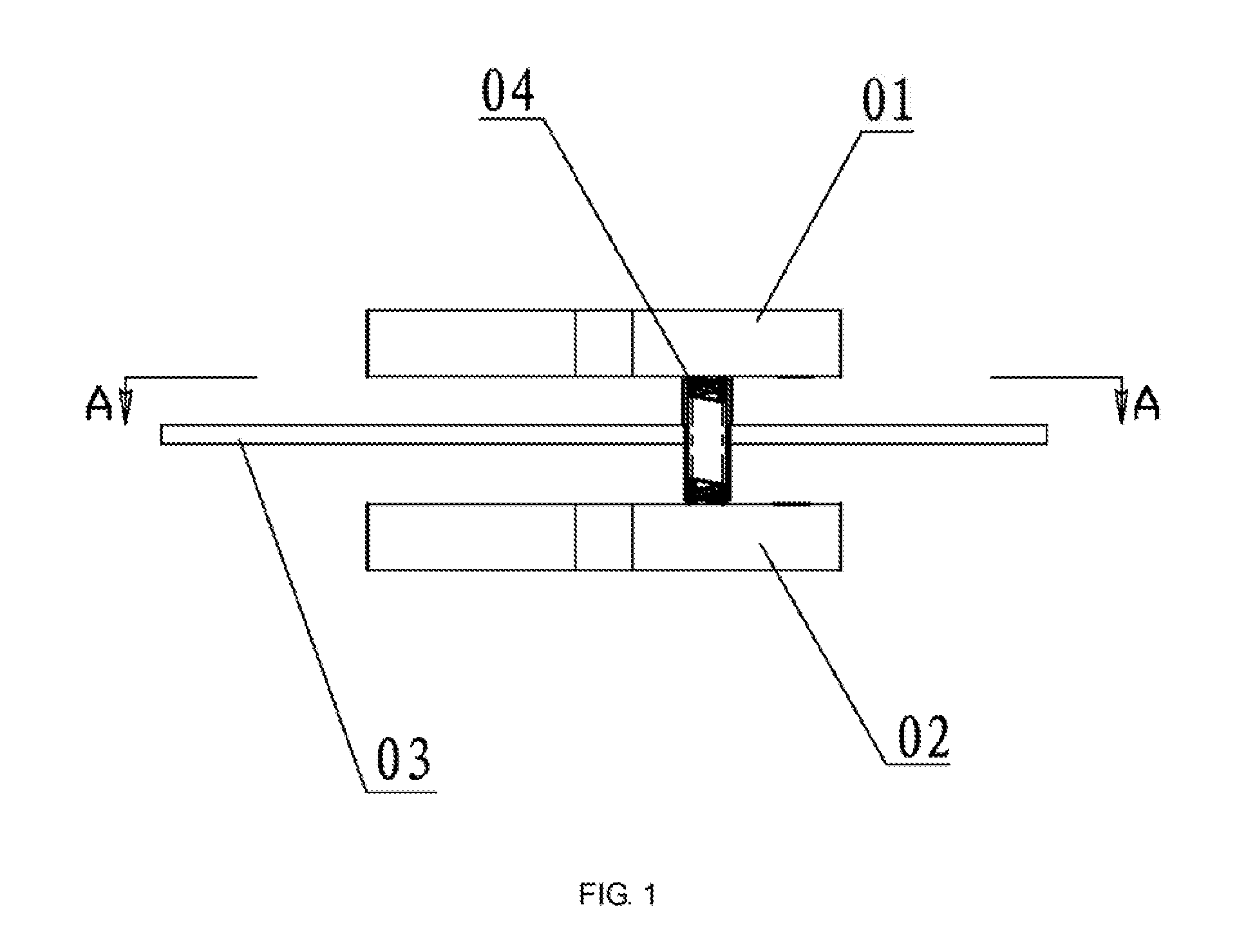

Method for grinding spring with high quality and high efficiency

ActiveUS20160297047A1Improve production efficiencyImprove stabilityGrinding drivesGrinding headsEngineeringGrinding wheel

Disclosed is a method for grinding a spring with high quality and high efficiency, comprising the steps as follows: firstly, at least one of an upper grinding wheel (1) and a lower grinding wheel (2) is configured to comprise an inner grinding wheel (21) and an outer grinding wheel (24), wherein the inner grinding wheel (21) is fitted in the outer grinding wheel (24); the inner grinding wheel (21) or the outer grinding wheel (24) is driven by a transmission mechanism, the inner grinding wheel (21) and the outer grinding wheel (24) rotating in opposite directions; after a complete spring is fed to a space between the upper grinding wheel (1) and the lower grinding wheel (2), the complete spring is moved back and forth in the plane of the grinding wheels; and then the upper grinding wheel (1) is moved downwardly such that two end faces of the spring are ground by the grinding wheels, and when the height of the ground spring meets the requirement, the upper grinding wheel (1) is stopped moving downwardly and is returned to the original point later. Then, the ground spring movement is stopped and it is moved away from the space between the two grinding wheels, i.e., the complete spring is removed. In this way, the spring is ground in a revolving state, which can improve the yield and quality of ground springs, save energy and protect the environment, and result in a low cost of grinding, a simple structure, low cost for manufacturing parts, long persistence in precision of mechanisms, and good stability.

Owner:SHAOXING JIADU SPRING MACHINE

Adjuvanted influenza vaccines for pediatric use

InactiveUS20180207258A1Enhance immune responseHigh seroprotection rateSsRNA viruses negative-senseViral antigen ingredientsSerum igeAdjuvant

An influenza vaccine adjuvanted with a sub-micron oil-in-water emulsion elicits significantly higher immune responses in human pediatric populations. Compared to an existing unadjuvanted pediatric influenza vaccine, the adjuvanted vaccines provided herein can induce in children a longer persistence of high serum antibody titers and also longer seroconversion and seroprotection. The improvement in immune responses is seen for both influenza A virus and influenza B virus strains, but it is particularly marked for influenza B virus. Moreover, while the existing vaccine provides poor immunity in children after a single dose, the adjuvanted vaccine provides high seroprotection rates against the influenza A virus H3N2 subtype even after a single dose. Furthermore, the adjuvanted vaccine offers significantly better seroprotection against mismatched strains of influenza A virus.

Owner:SEQIRUS UK LTD

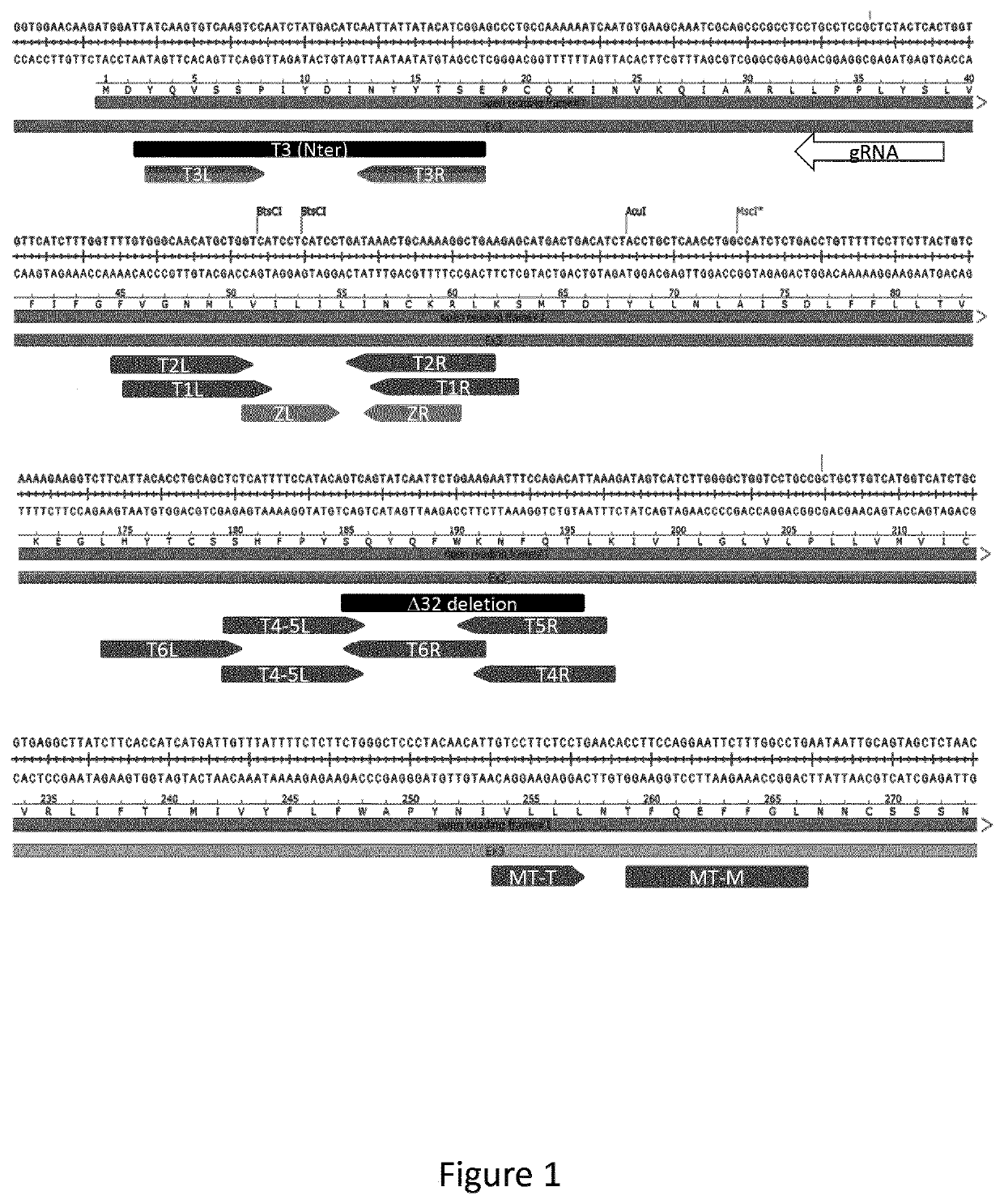

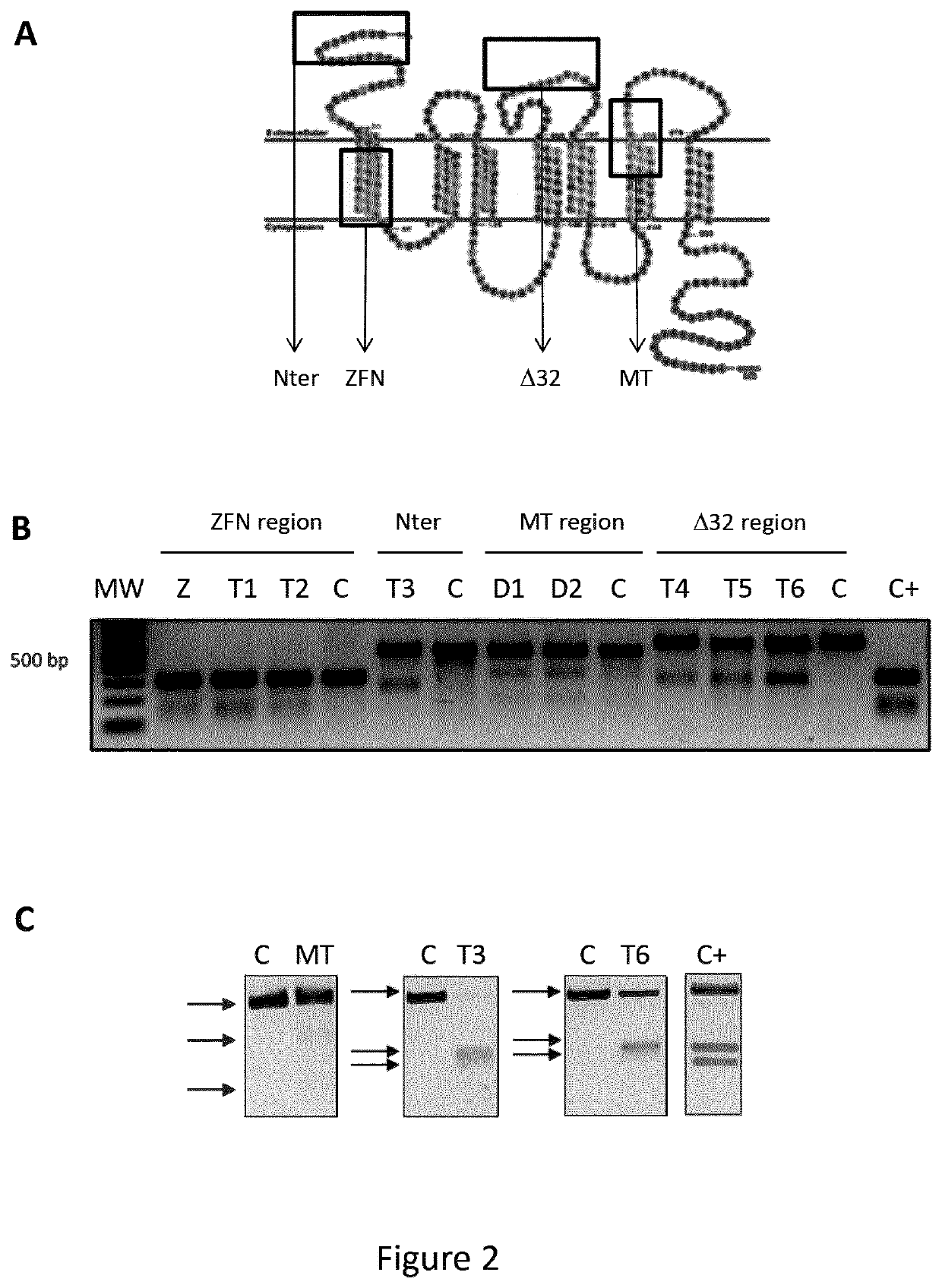

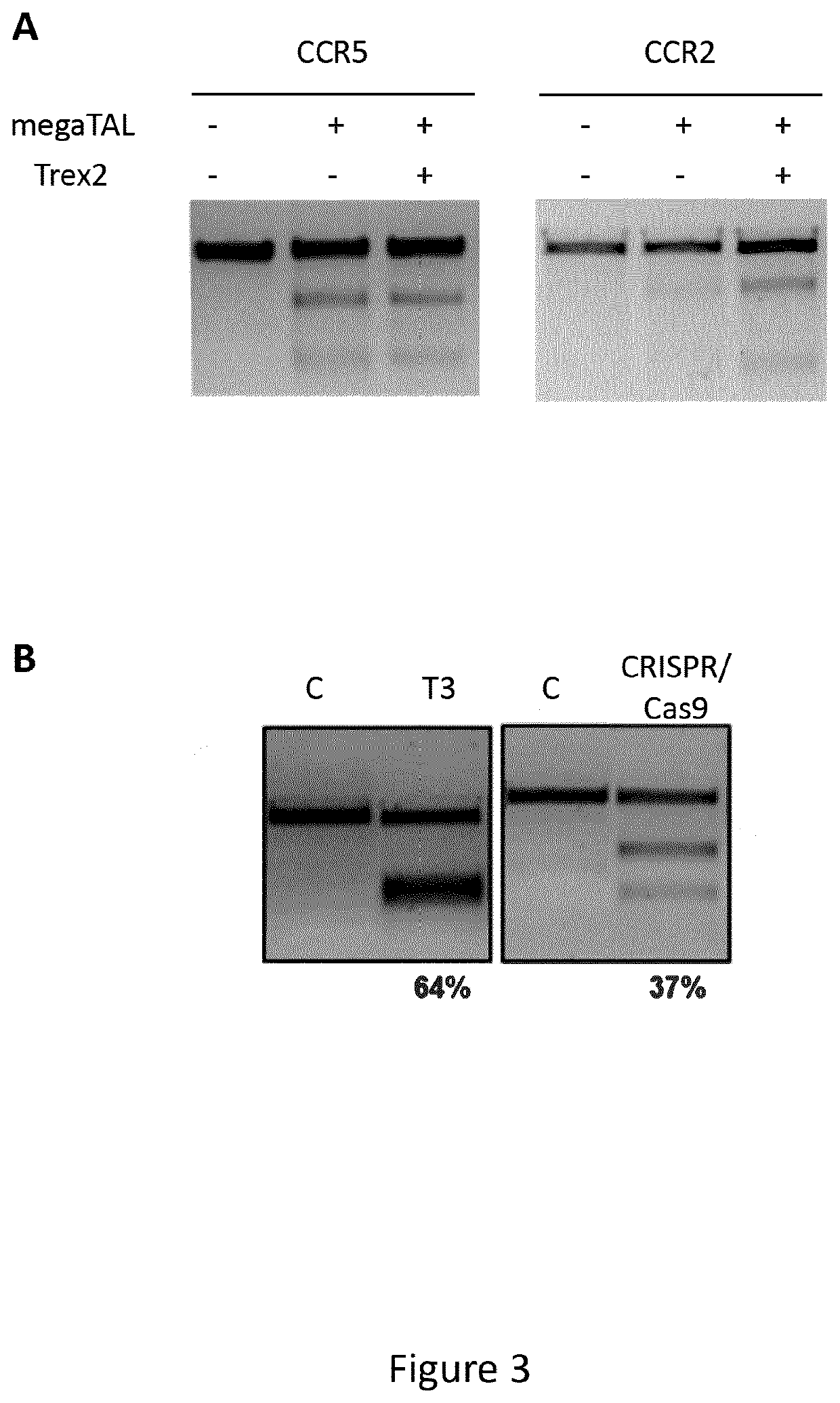

New sequence specific reagents targeting ccr5 in primary hematopoietic cells

PendingUS20200392459A1Improve efficiencyPrecision editingImmunoglobulin superfamilyPeptide/protein ingredientsHematopoietic cellNuclease

The invention pertains to the field of cell therapy and HIV treatments. It provides with highly specific reagents for reducing or inactivating expression of CCR5 in primate and human primary cells, especially under the form of TALE-nucleases. These reagents allow the production of safer primary hematopoietic cells made resistant to HIV, stem cells or differentiated cells, for their infusion into HIV patients.

Owner:ALBERT LUDWIGS UNIV FREIBURG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com