Patents

Literature

169 results about "Volumetric shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

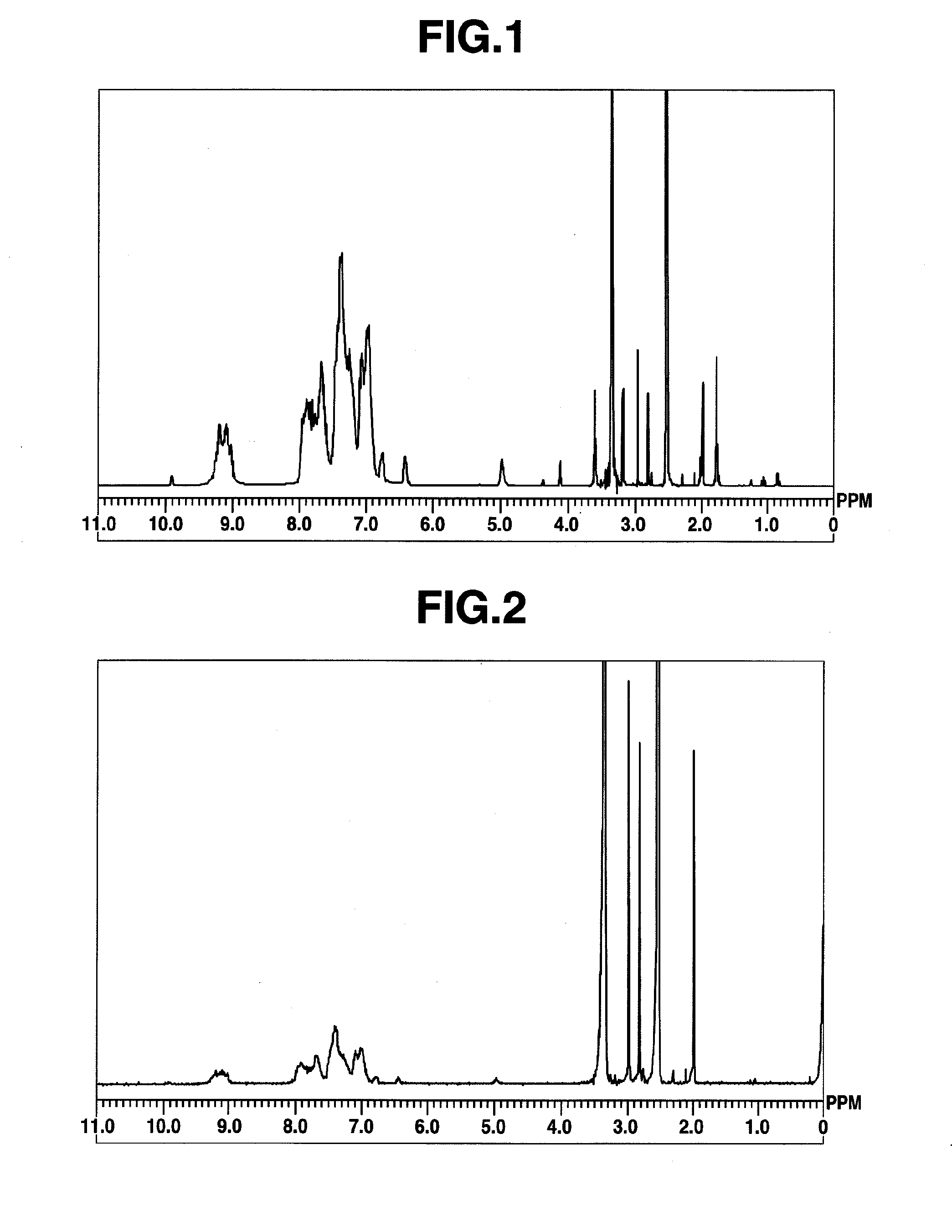

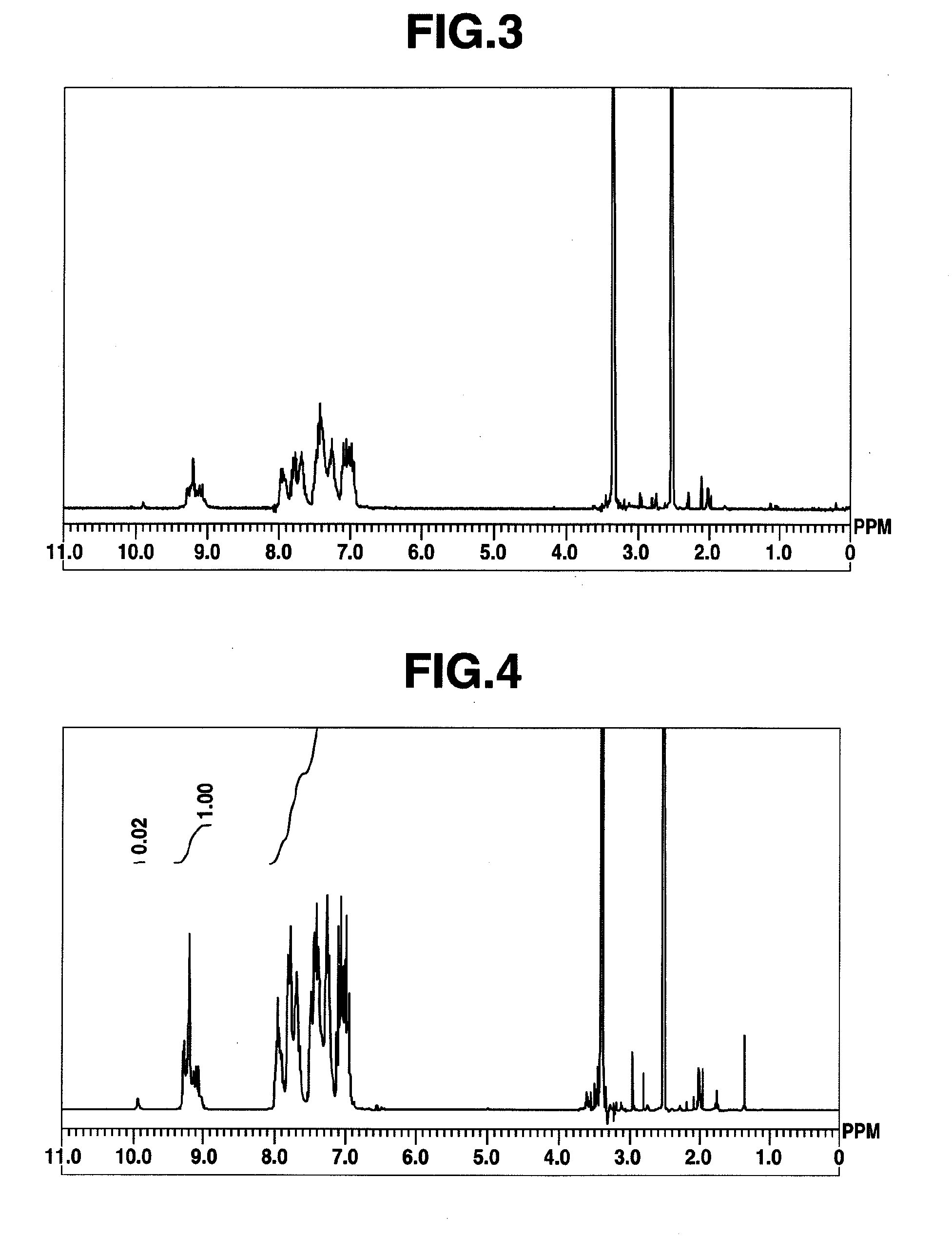

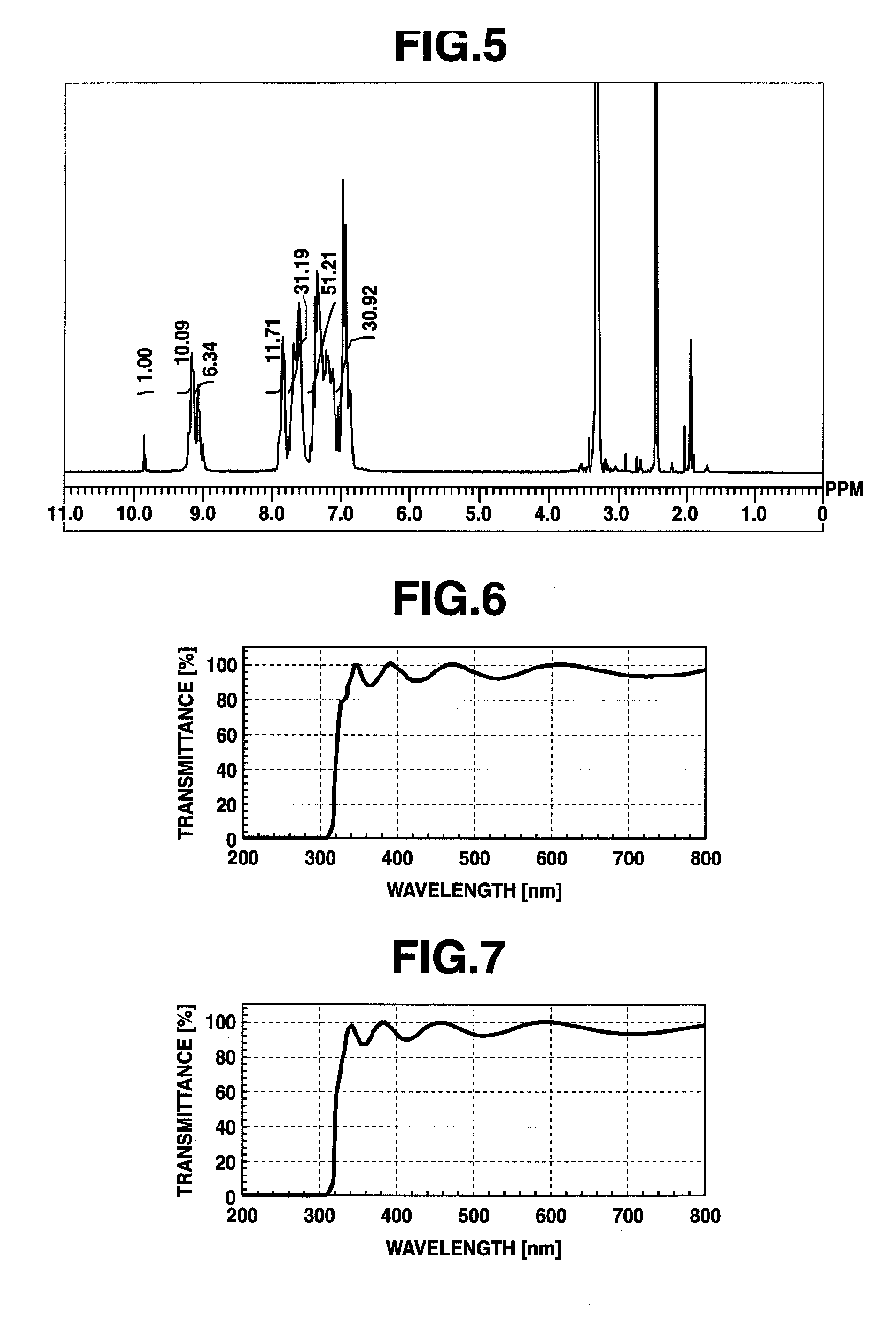

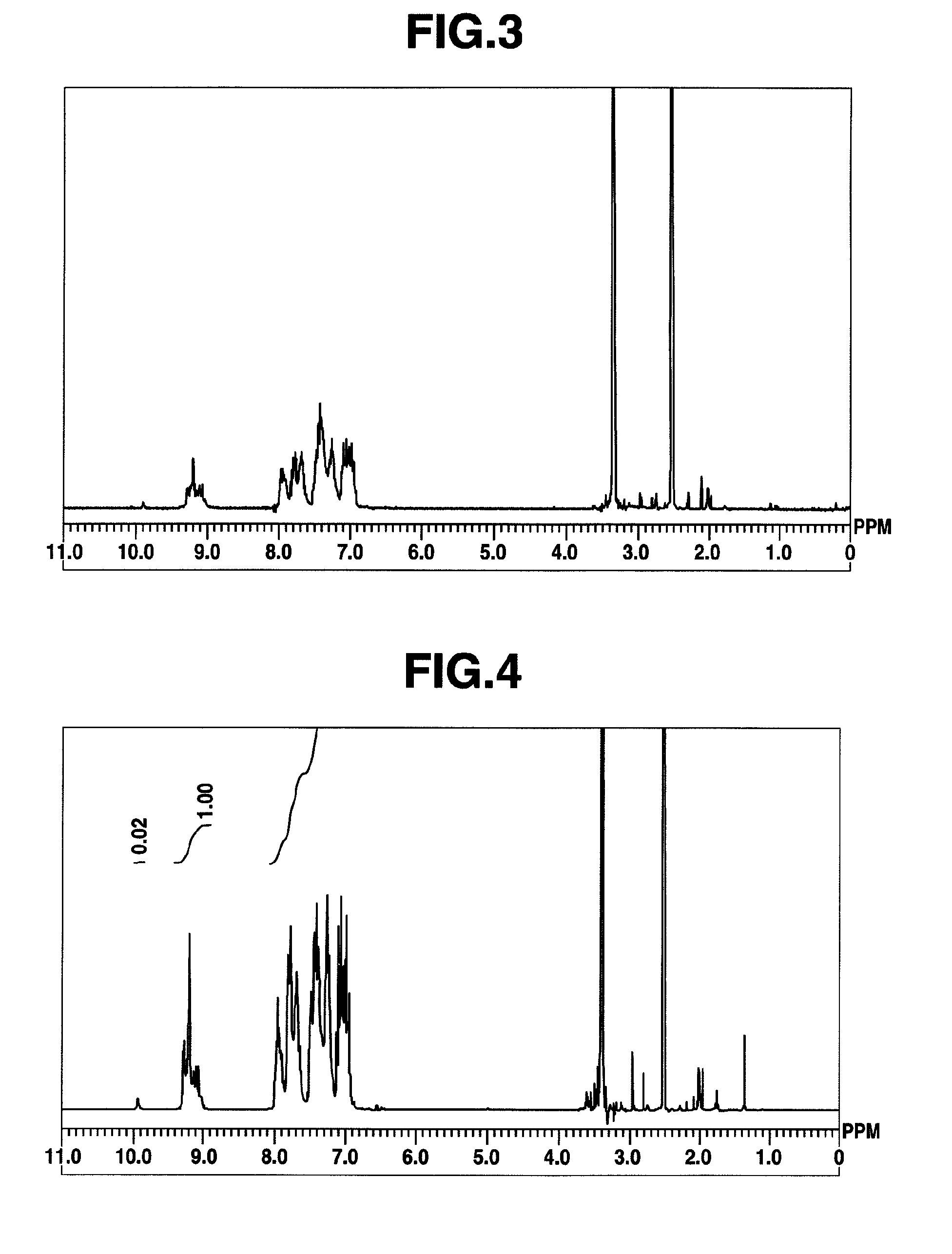

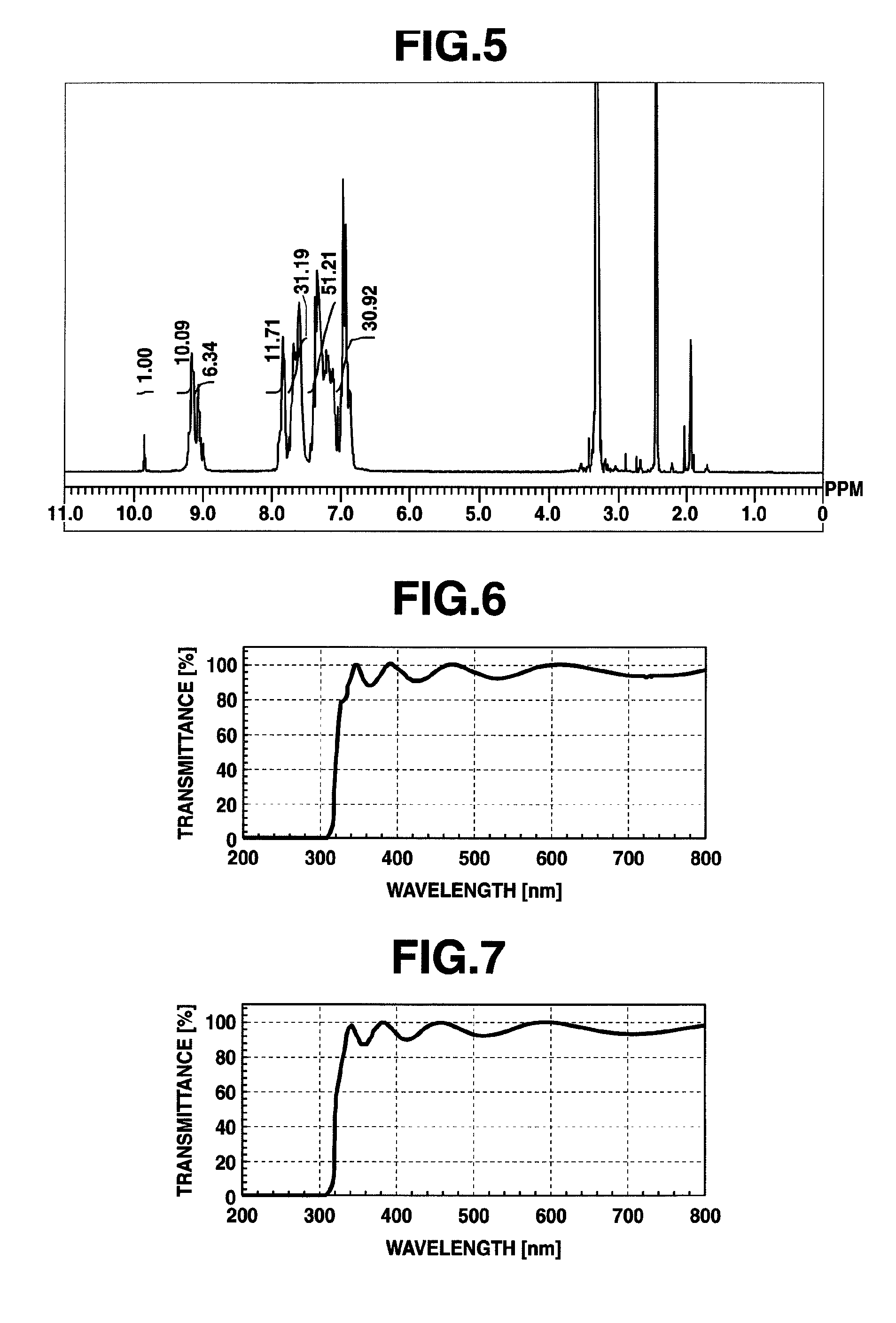

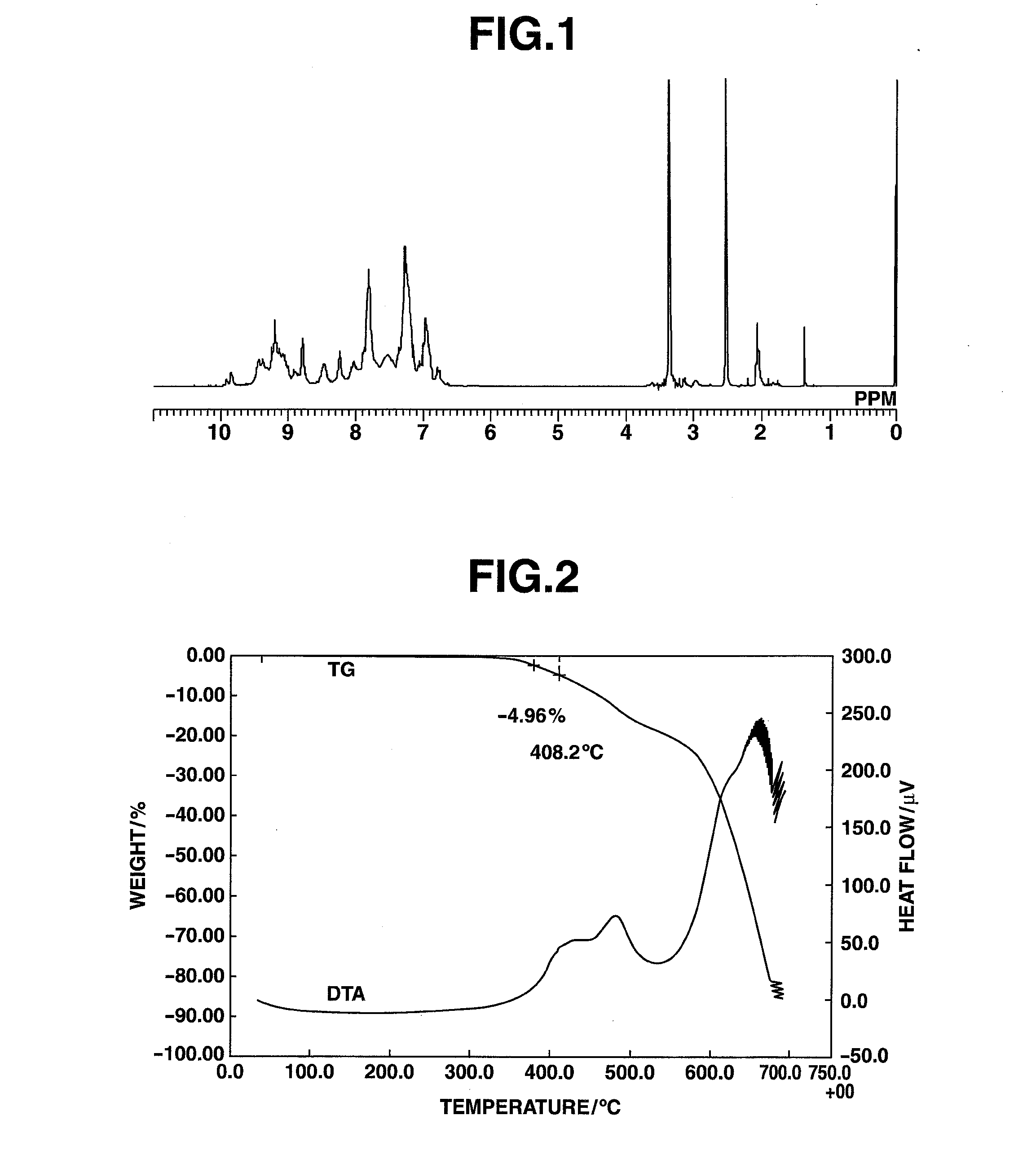

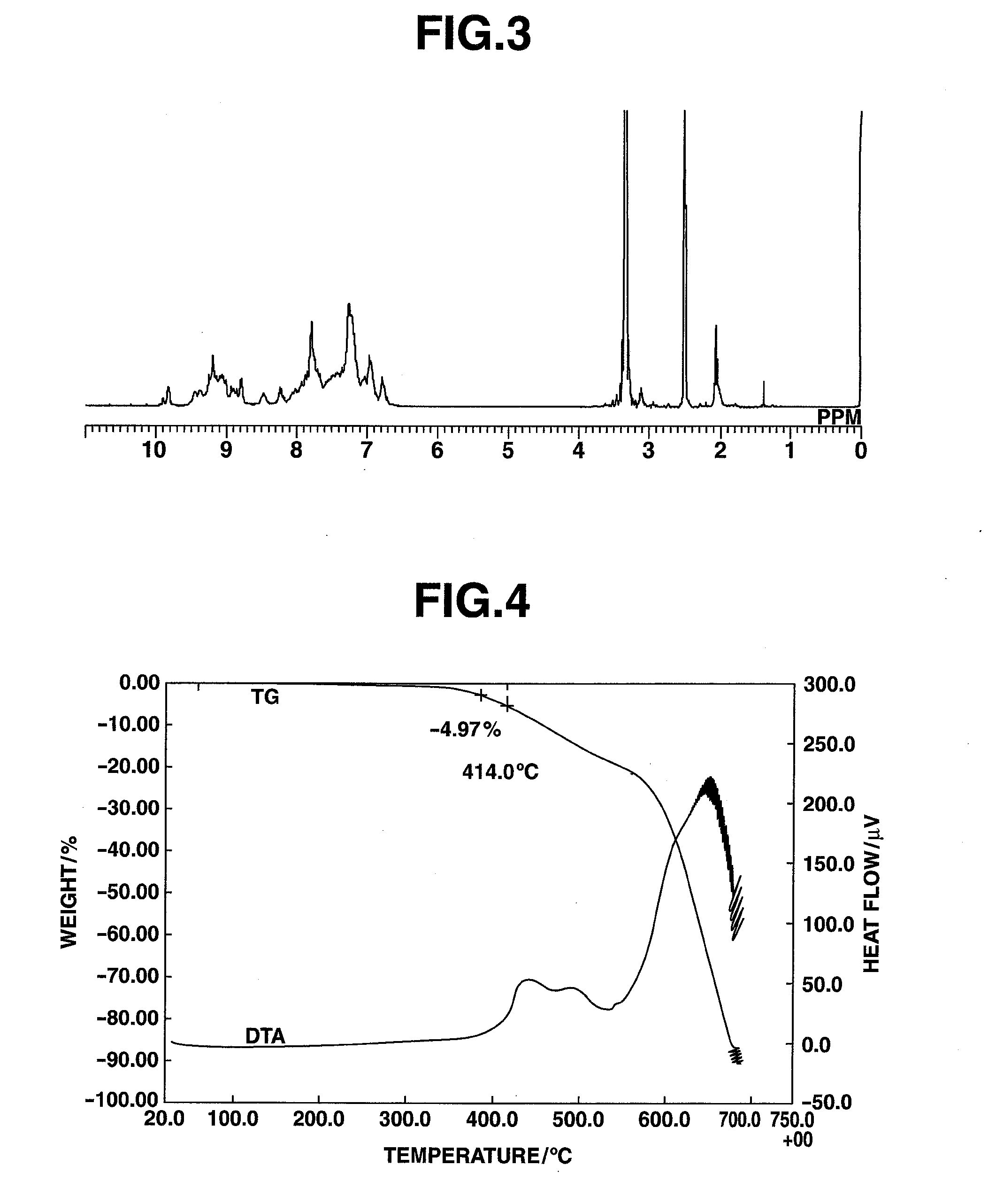

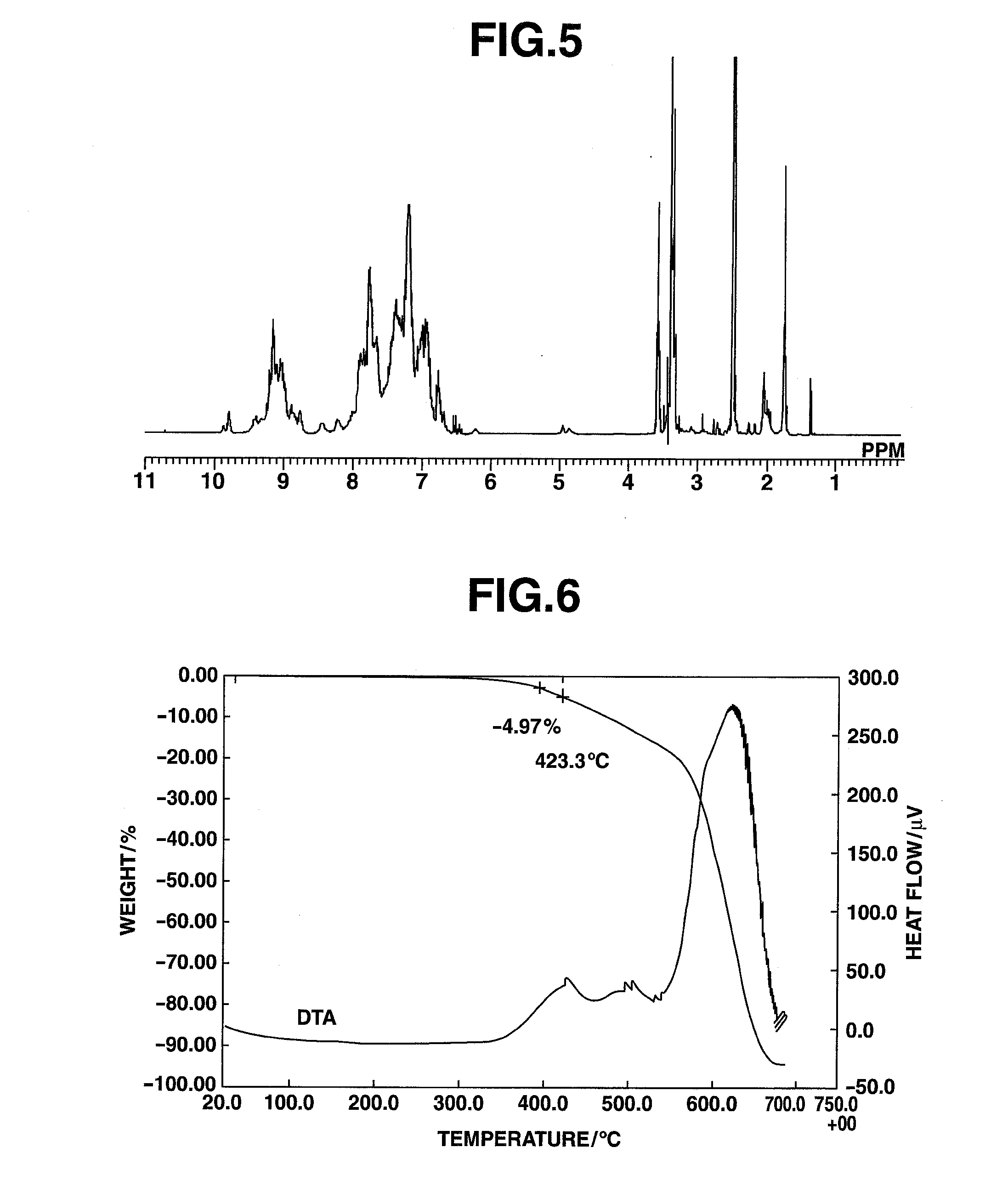

Triazine ring-containing polymer and film-forming composition comprising same

ActiveUS20120049308A1Improve heat resistanceLow volume shrinkageOrganic detergent compounding agentsOrganic chemistryPolymer scienceVolumetric shrinkage

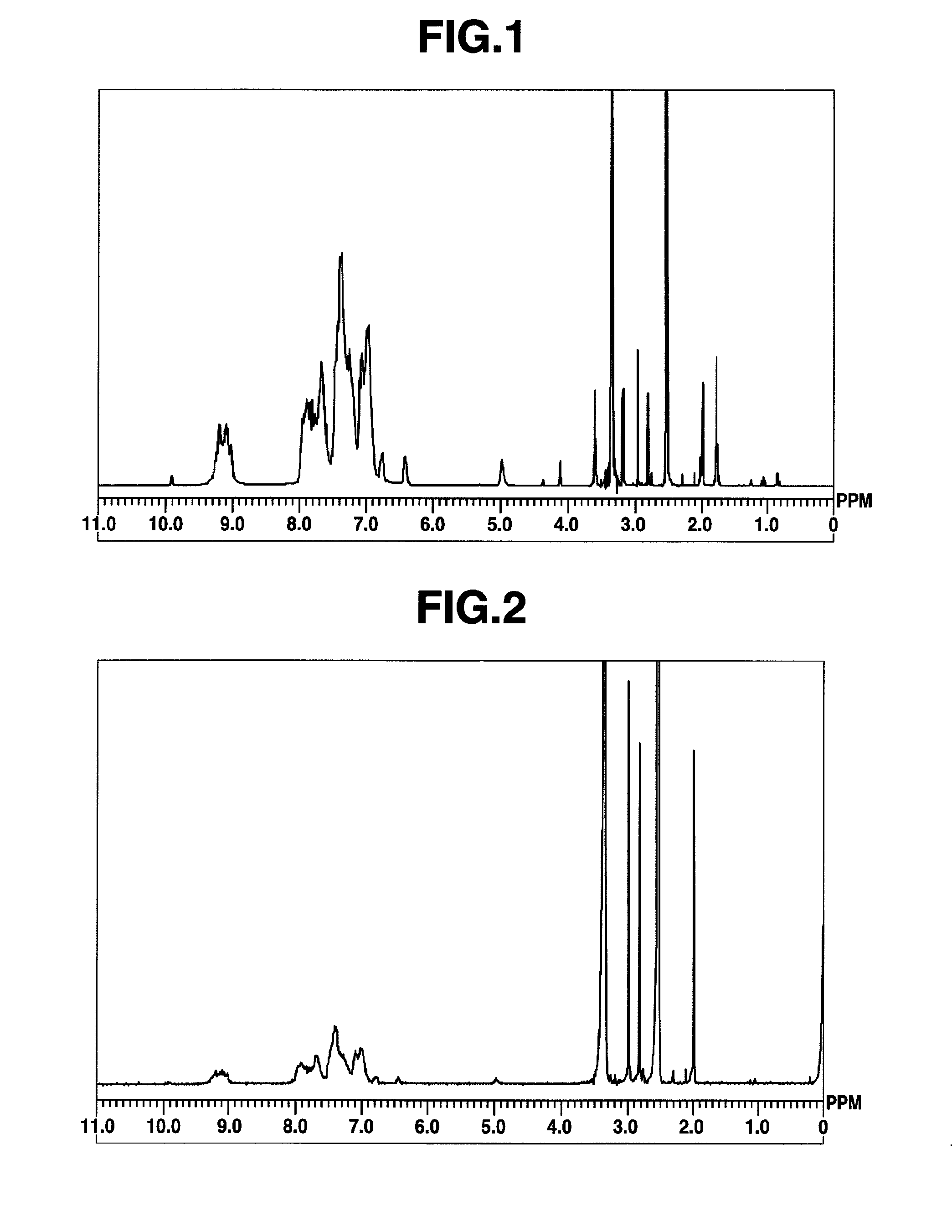

A polymer containing a triazine ring-containing repeating unit structure represented by, for example, formula (23) or (24), which alone can achieve high heat resistance, high transparency, high refraction index, high solubility and low volume shrinkage, without adding a metal oxide.

Owner:NISSAN CHEM IND LTD

Method for producing modified unsaturated polyester resins by low purity technical grade dicyclopentadiene

The present invention relates to a novel method of using industrial dicyclopentadiene of purity of 75 percent to 85 percent to prepare modified unsaturated polyester resin. In the preparation of the resin, the industrial dicyclopentadiene separated from the saturated or unsaturated dicarbonic acid or acidic anhydride and the distilled part of mixed C5 is used as the raw material. After hydrolysis and addition reaction, the diol or polyol of appropriate amount is added. The polymerization and dehydration reaction is done with the influence of acidic catalyst. When the mixture is condensed to the designated acid value, the inhibitor and cross-linking monomer of appropriate amount are added and then stirred to prepare the product. The present invention has the advantage that the cost of resin is lower than the common type unsaturated resin. At the same time, the air-drying performance, heat resistance, volumetric shrinkage rate and other performances are all superior to the common type unsaturated polyester resin. The product can be widely used in the fields of glass steel, mold, plastic clothing, sealing, and adhesive and so on.

Owner:泉州永悦新材料有限公司

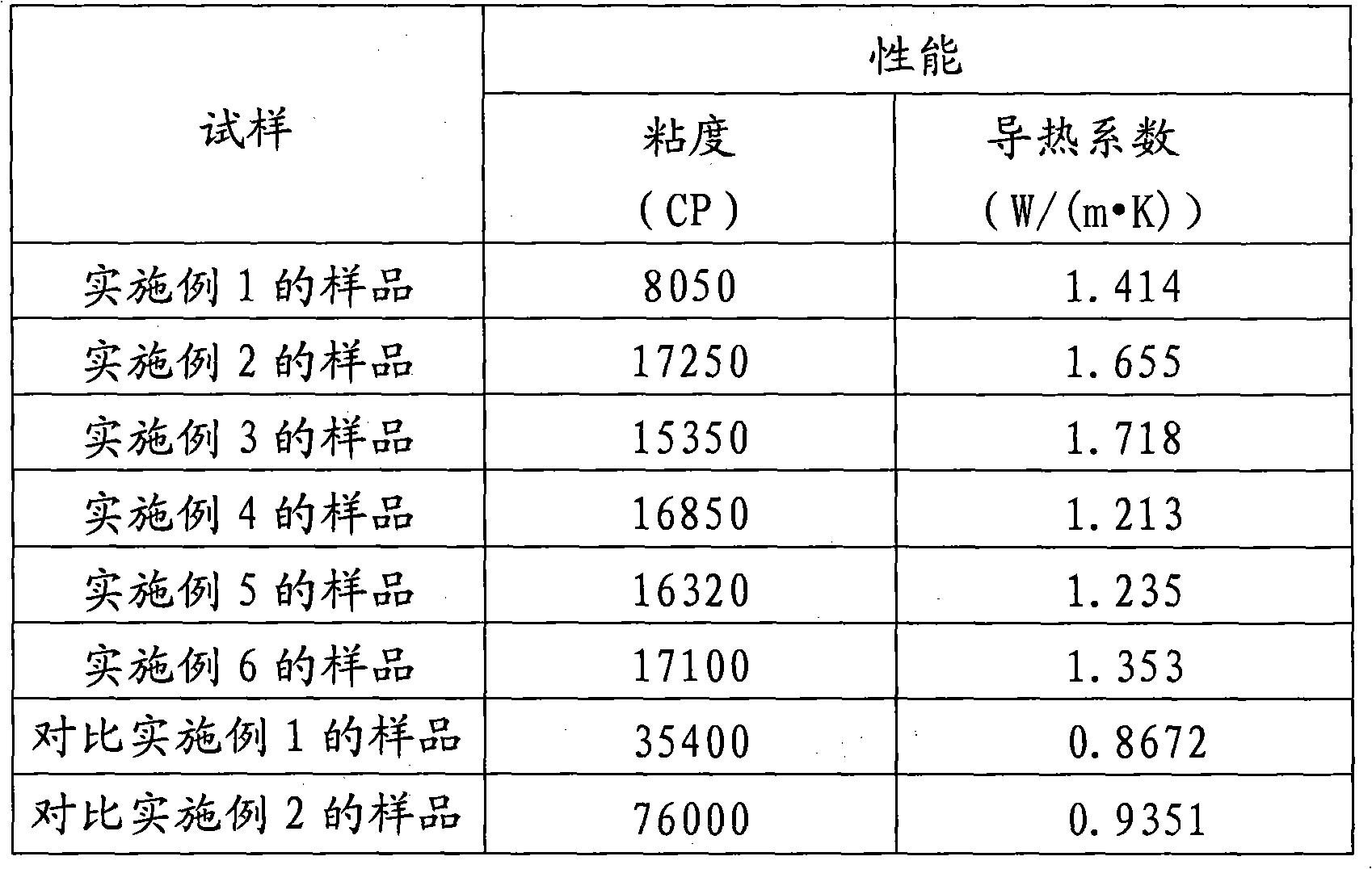

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

Low shrinkage thermosetting resin compositions and methods of use therefor

InactiveUS6963001B2Reduction tendencyReduce curingUrea derivatives preparationCarbamic acid derivatives preparationOrganic chemistryLow shrinkage

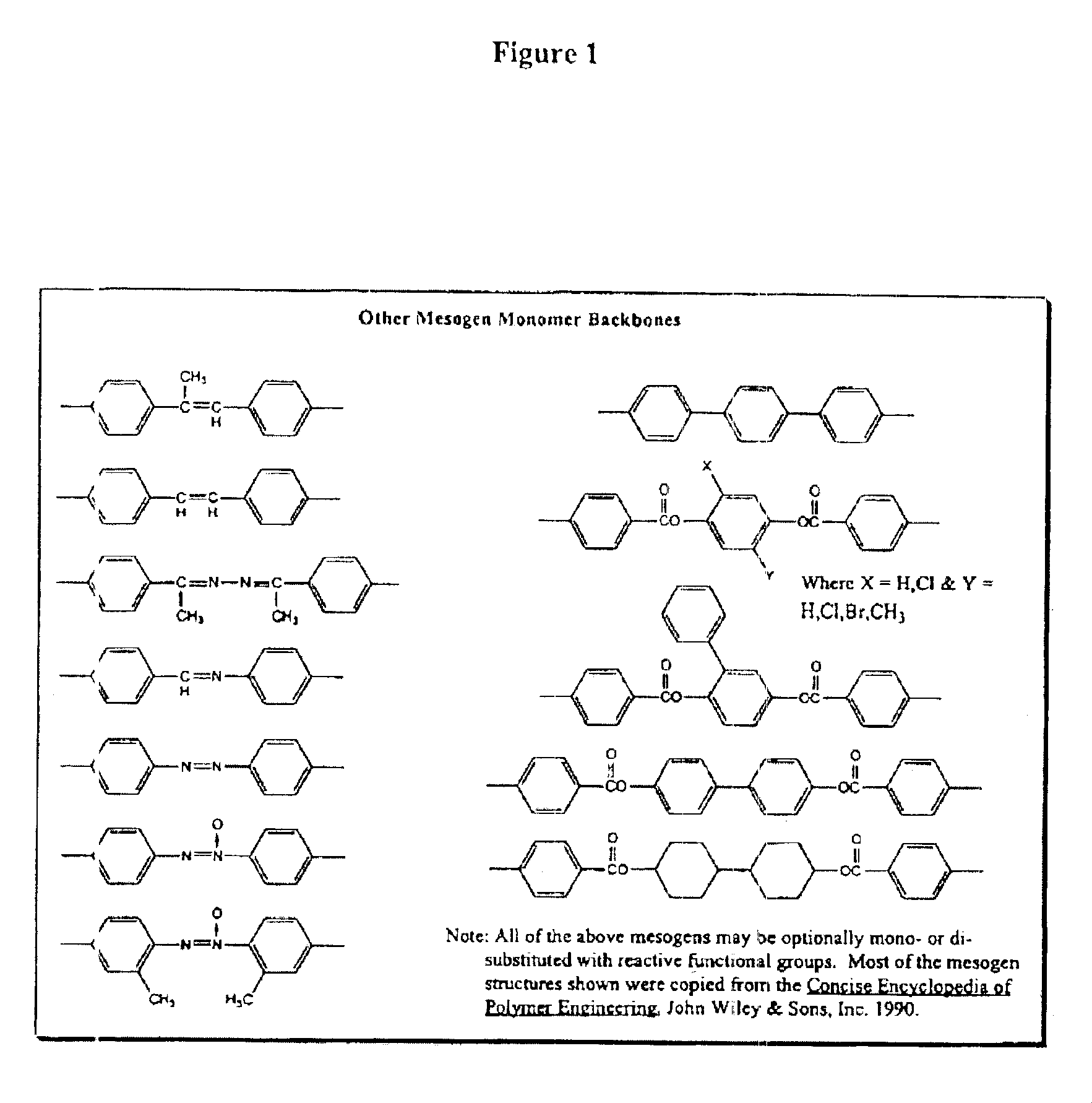

In accordance with the present invention, there are provided thermosetting resin compositions with a reduced propensity to shrink in volume upon cure and methods of use therefor. The compositions of the present invention include compounds having aromatic, rigid-rod like spacer groups between the crosslinkable moieties. As such, these compounds impart a degree of liquid crystal-like character to the thermosetting resin composition which results in lower shrinkage upon cure. This effect follows from the well-known expansion that occurs when liquid crystal-like materials pass from a nematic liquid crystal-like state to an isotropic state. Further provided by the present invention are low shrinkage die attach pastes and methods of use therefor.

Owner:HENKEL IP & HOLDING GMBH

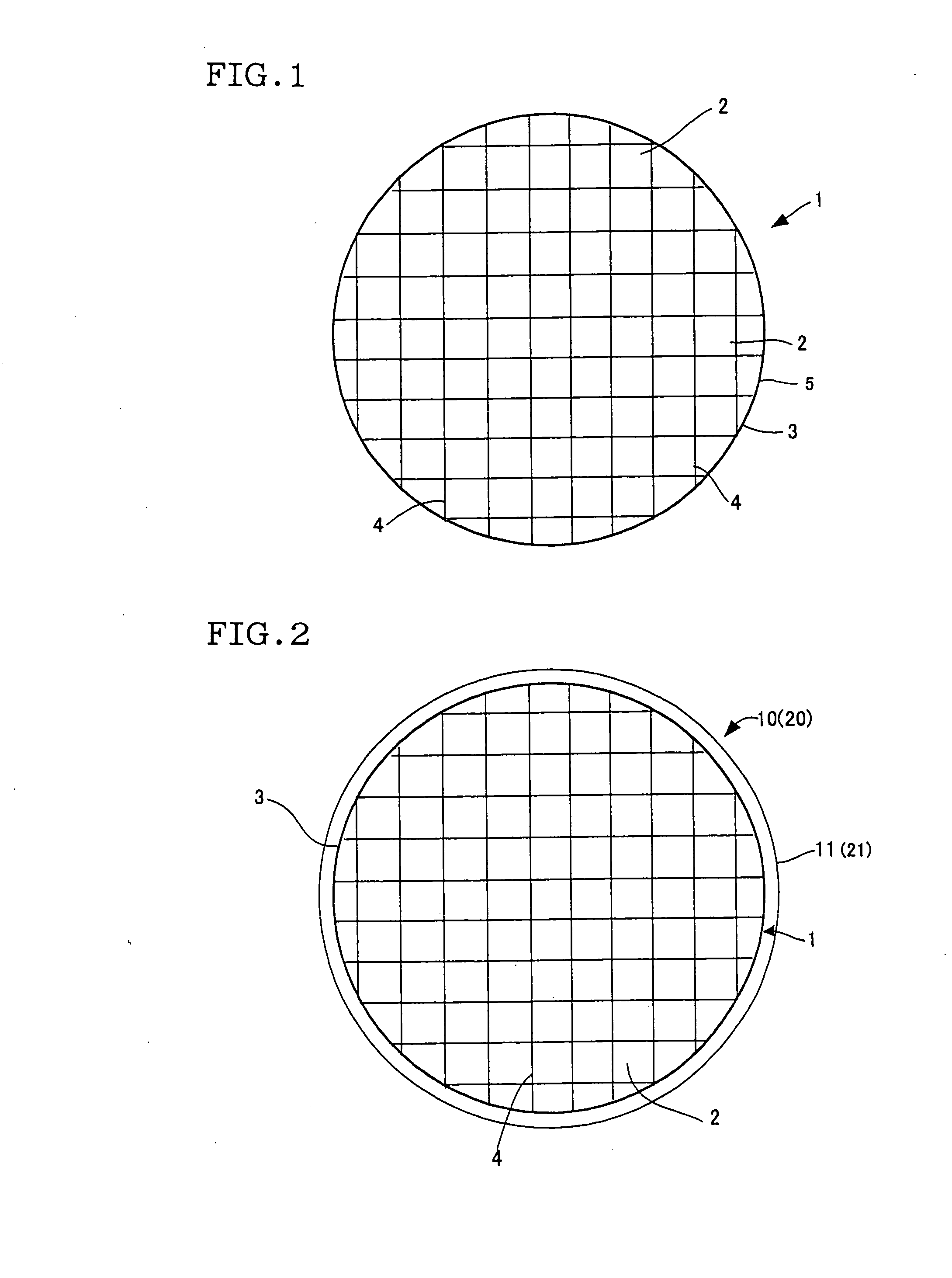

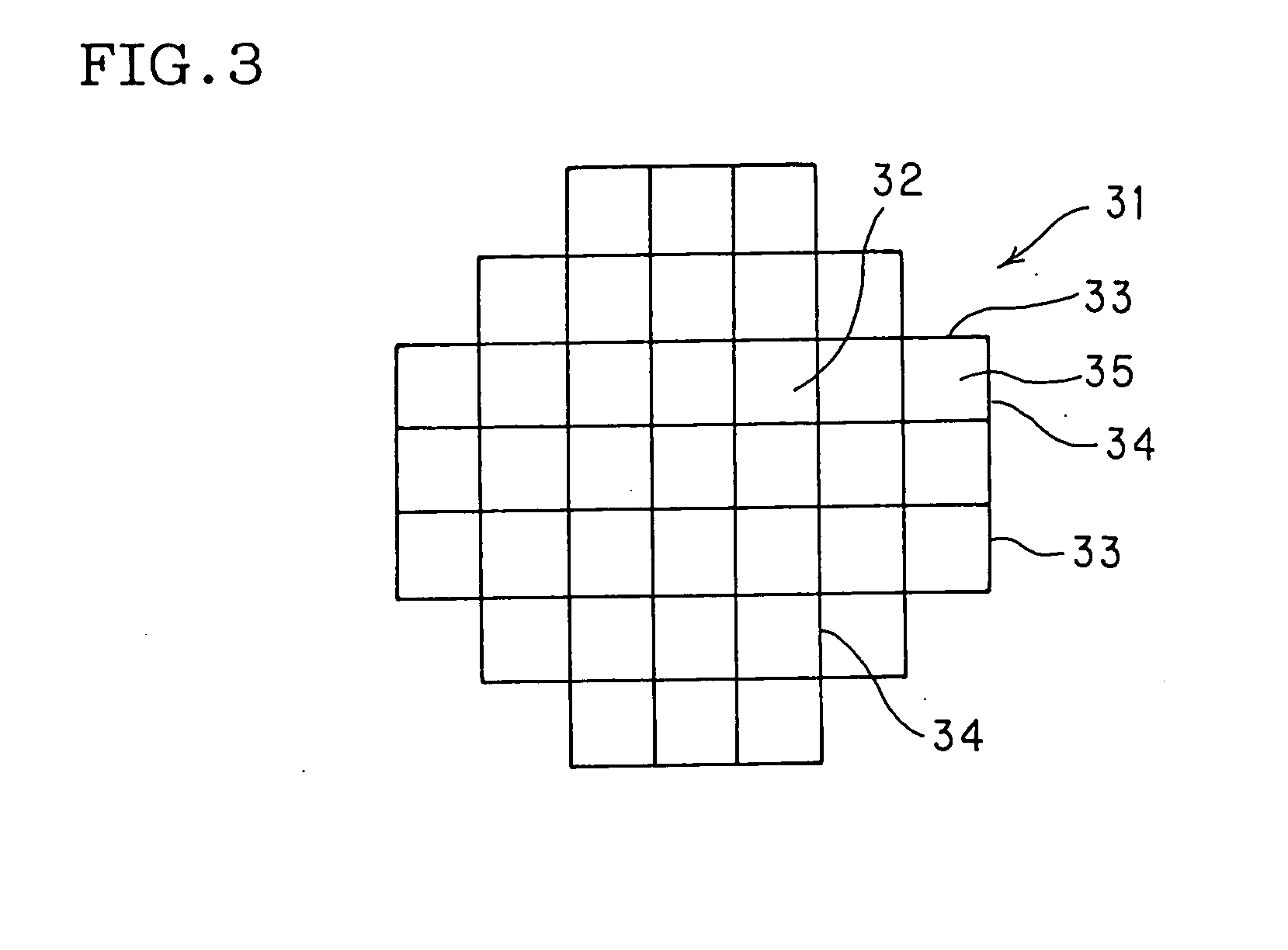

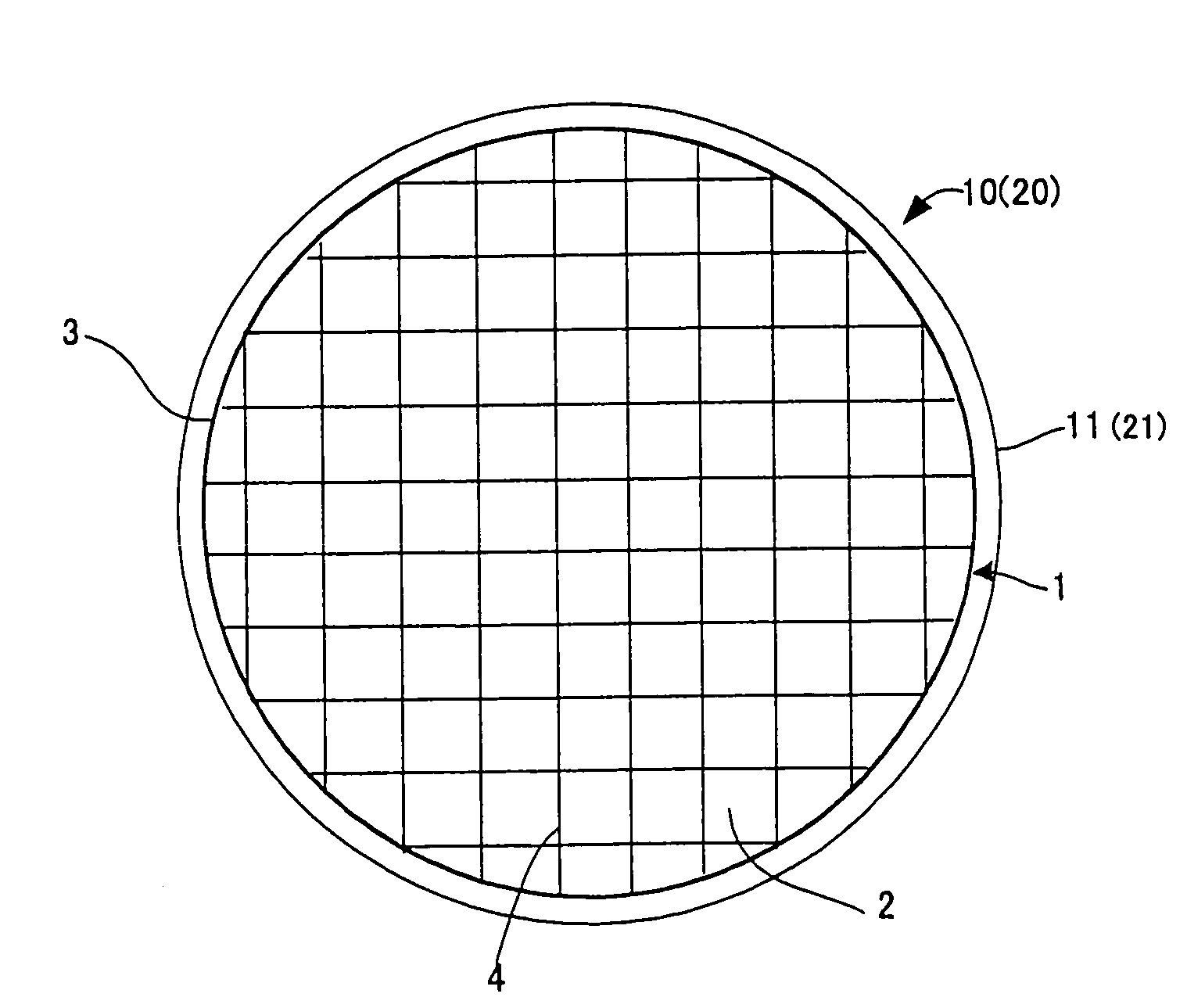

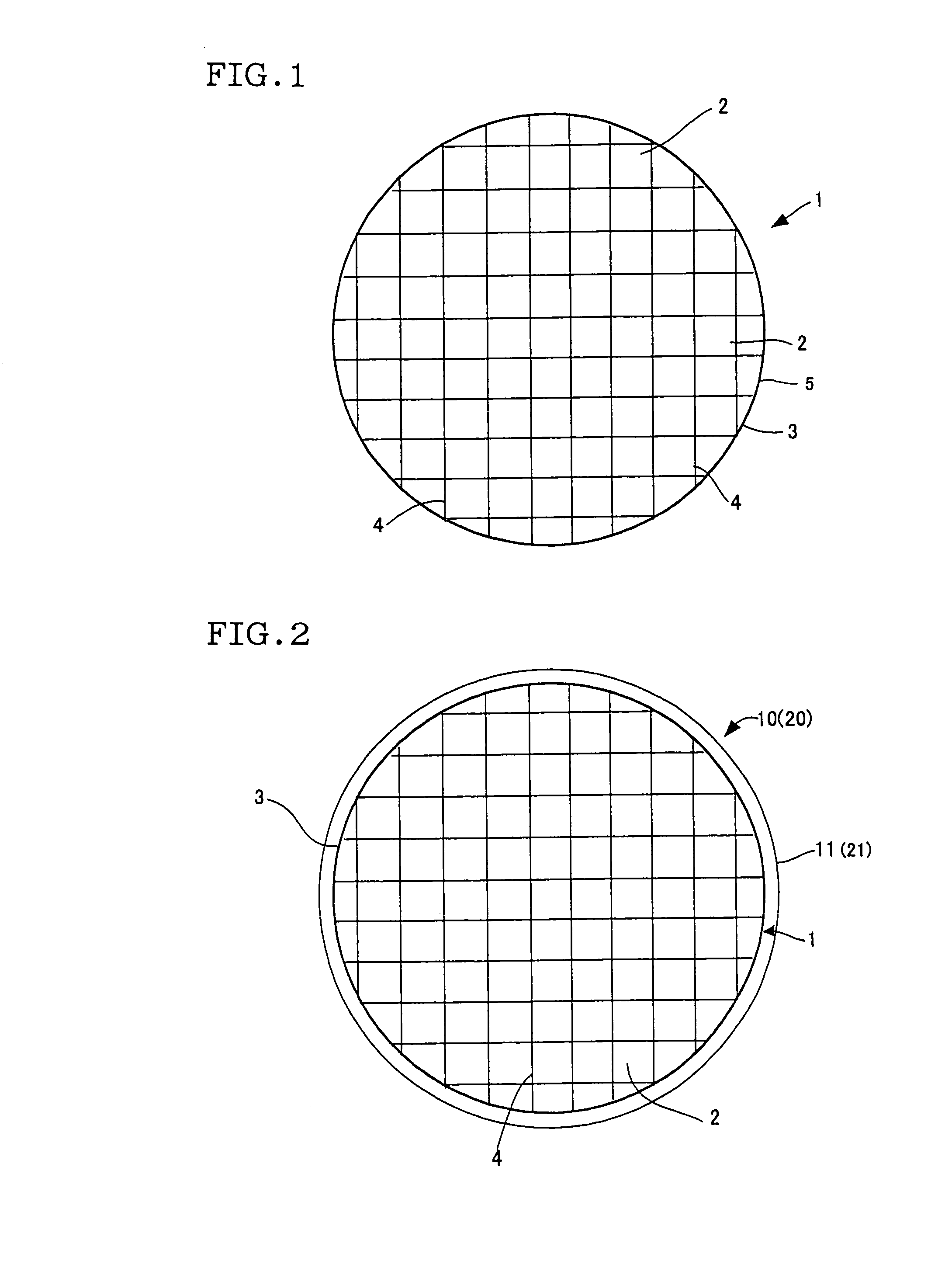

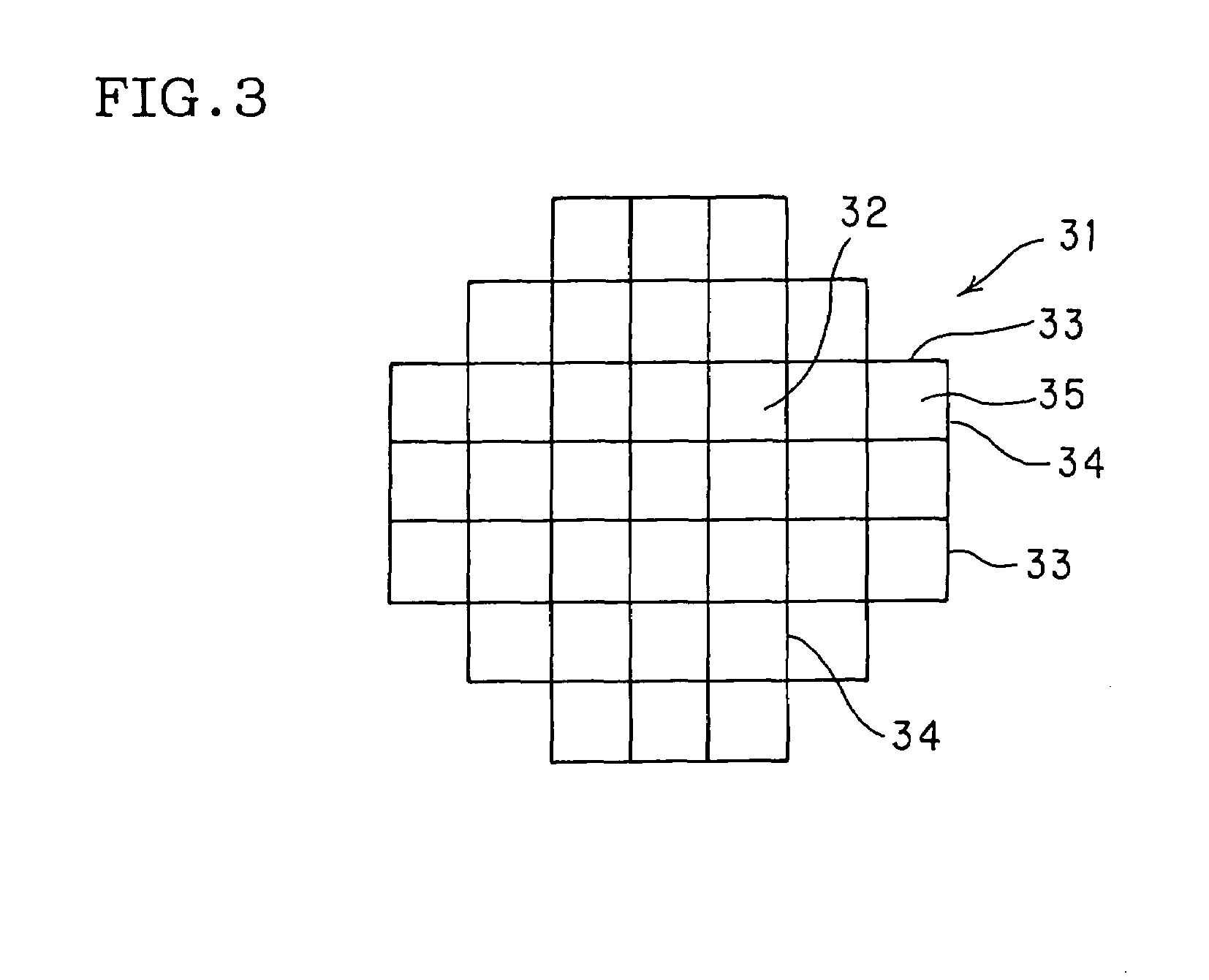

Honeycomb structure producing method, and honeycomb structure

ActiveUS20050255288A1Physical/chemical process catalystsDispersed particle filtrationVolumetric shrinkageStructural engineering

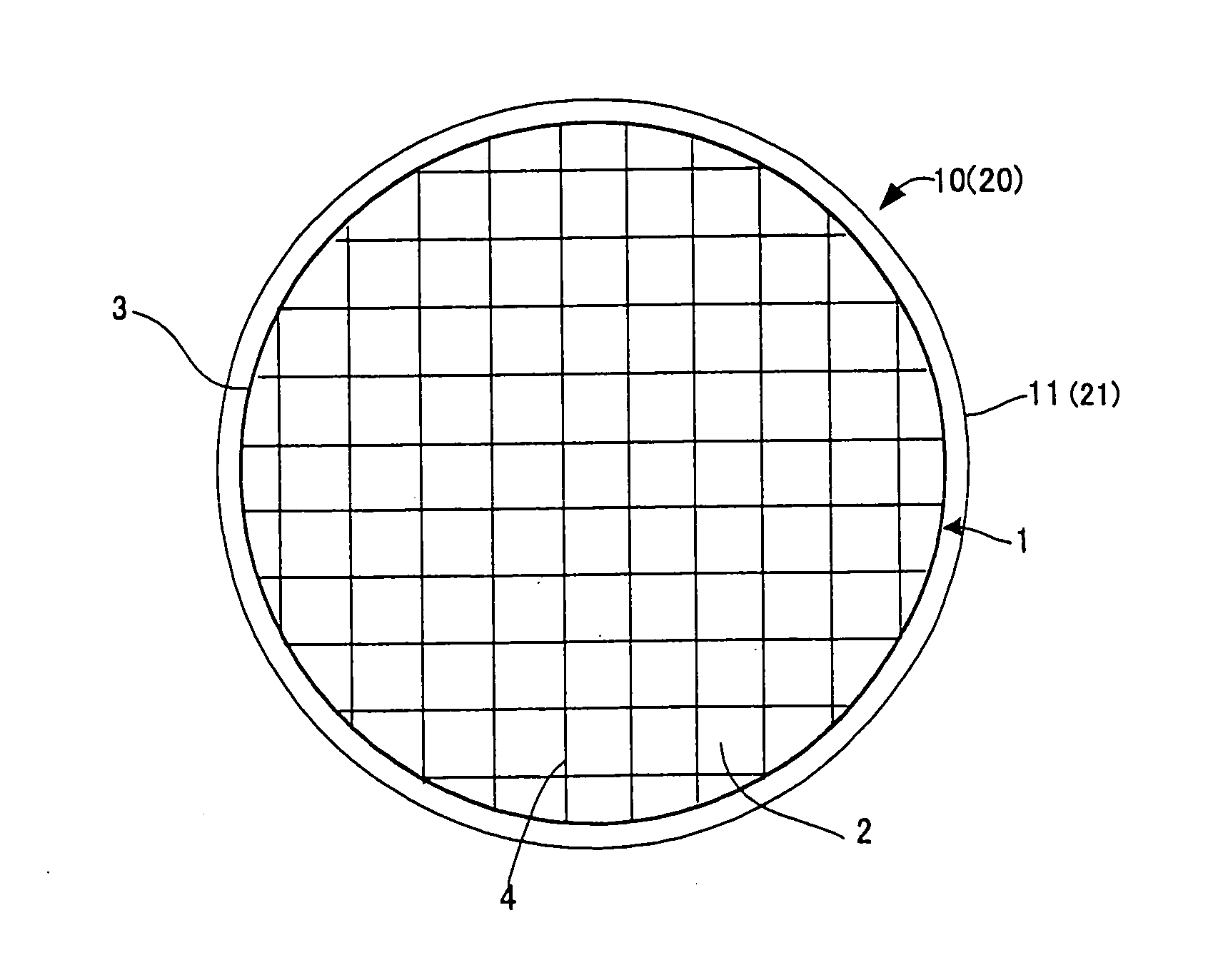

In a method for producing a honeycomb structure 20 which comprises disposing a material for forming outer wall 11 on the outer peripheral surface 3 of a cell structure 1 having a plurality of cells serving as fluid flowing channels to produce a cell structure being provided with a material for forming outer wall 10 and firing the resulting cell structure being provided with a material for forming outer wall 10, wherein a cell structure being provided with a material for forming outer wall 10 in which the absolute value of the difference between the volumetric shrinkage percentage (firing shrinkage percentage) before and after firing of the cell structure 1 and the firing shrinkage percentage of the material for forming outer wall 11 is not more than 0.5% is produced and fired. There is provided a method for producing a honeycomb structure which comprises providing an outer wall on the outer peripheral surface and firing it, according to which the outer wall hardly cracks during firing and high-strength and large-sized honeycomb structure can be produced, and further provided is a high-strength and large-sized honeycomb structure in which the outer wall hardly cracks during firing.

Owner:NGK INSULATORS LTD

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

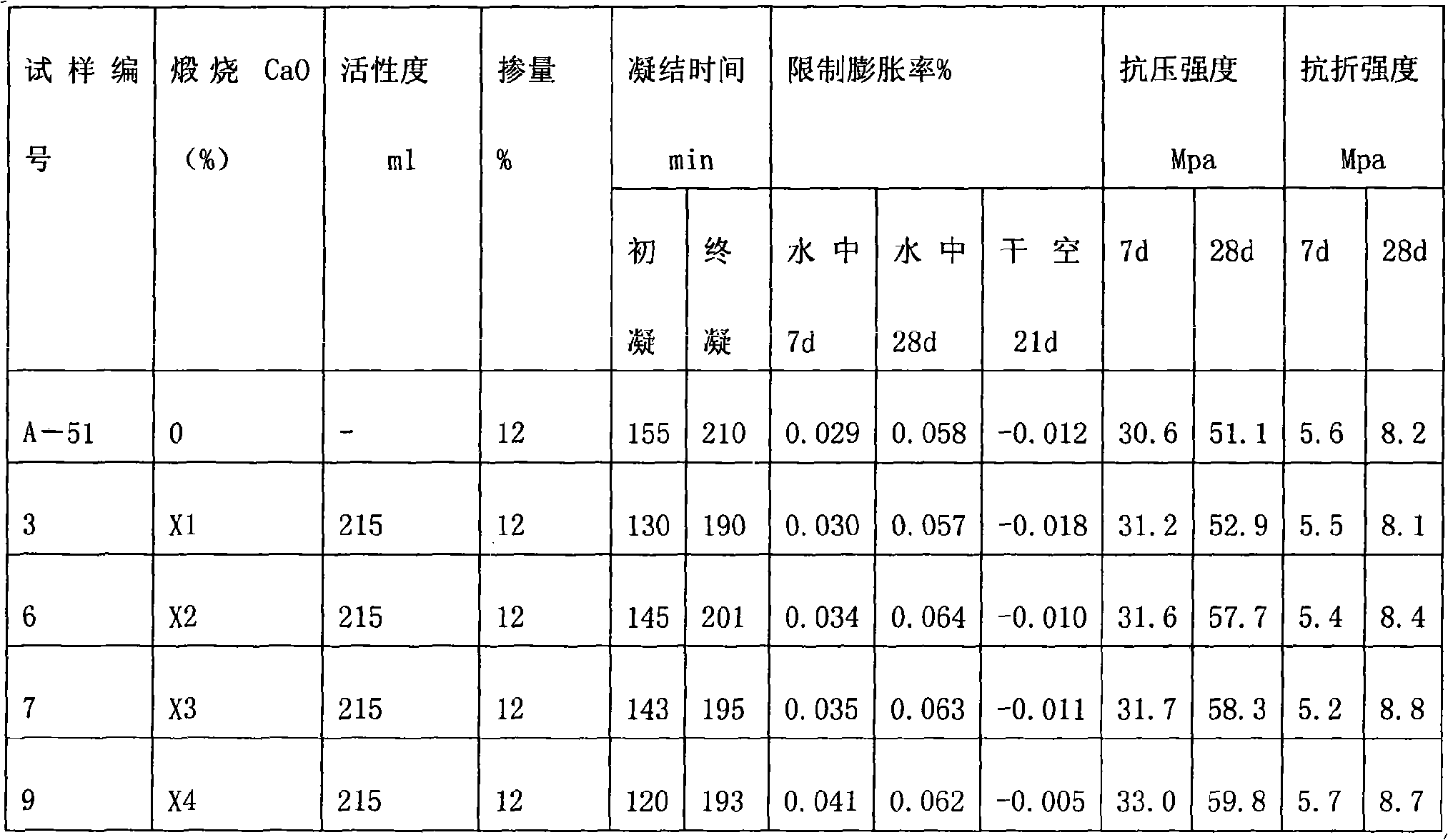

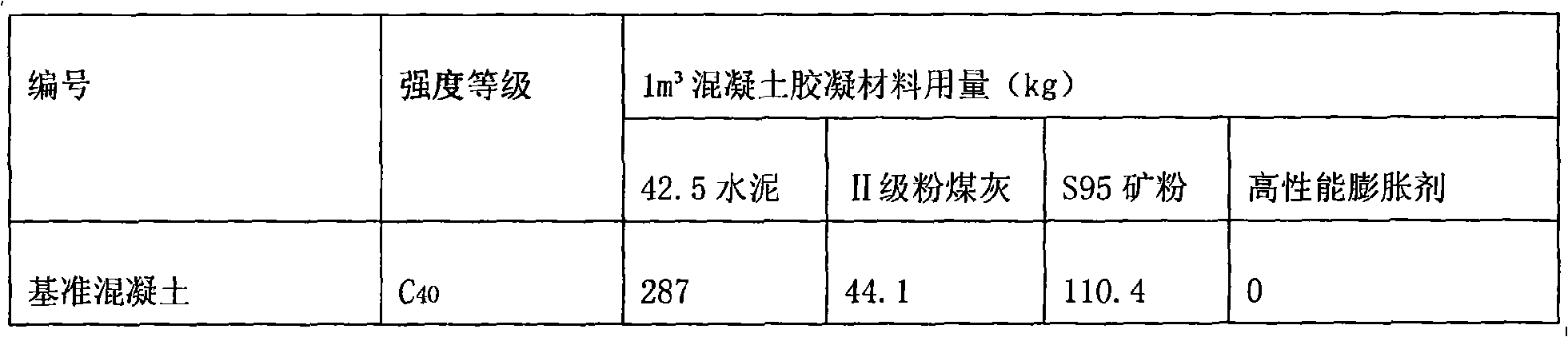

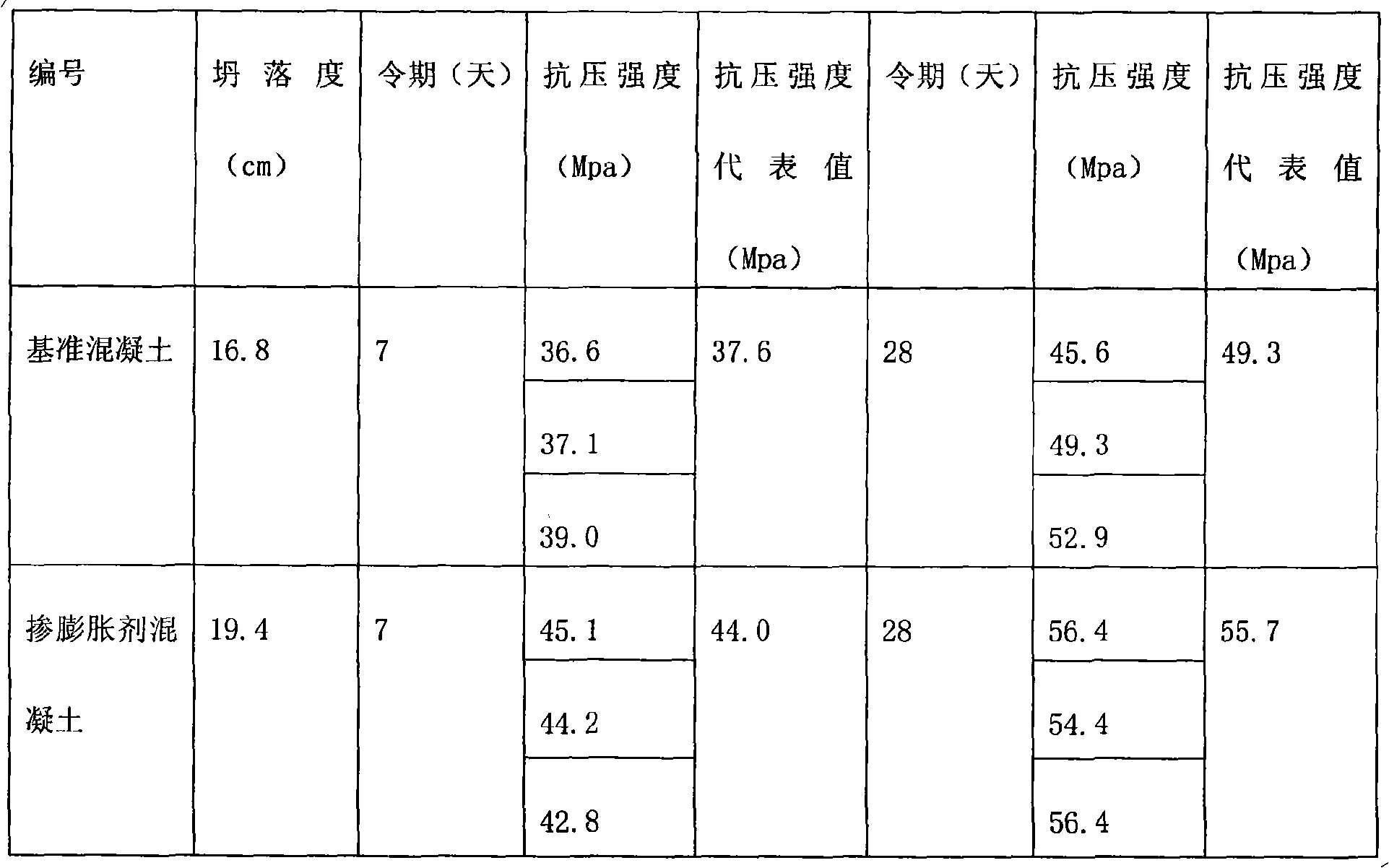

High-performance cement expansive material

The invention belongs to the technical field of building materials and relates to a high-performance concrete expansion agent which is composed of calcium clinker, aluminium material and calcium sulfate by mixing and matching, the calcium clinker contains magnesium oxide which is not more than 5 percent of the total weight, calcium oxide and magnesium oxide of 7 to 12 percent; the aluminium material and the calcium sulfate form ettringite. The high-performance expansion agent of the invention adopts the mutual action of three expansion sources of the CaO, the ettringite and the MgO and simultaneously carries out the utilization, the expansion of the three are appropriately combined to make up for deficiencies of each other, thereby obtaining the most appropriate expansion amount and the expansion exertion, better compensating the concrete shrinkage, improving the anti-crack effect of a product, overcoming the shortcoming of volumetric shrinkage and improving the durability of a building and the safety of the use.

Owner:蔡九德 +1

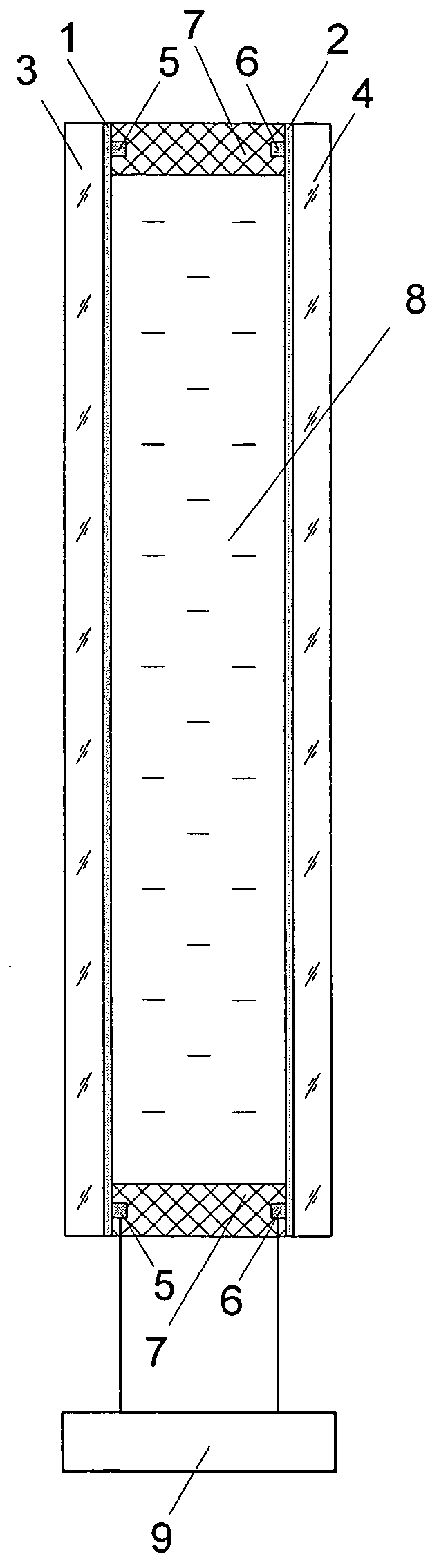

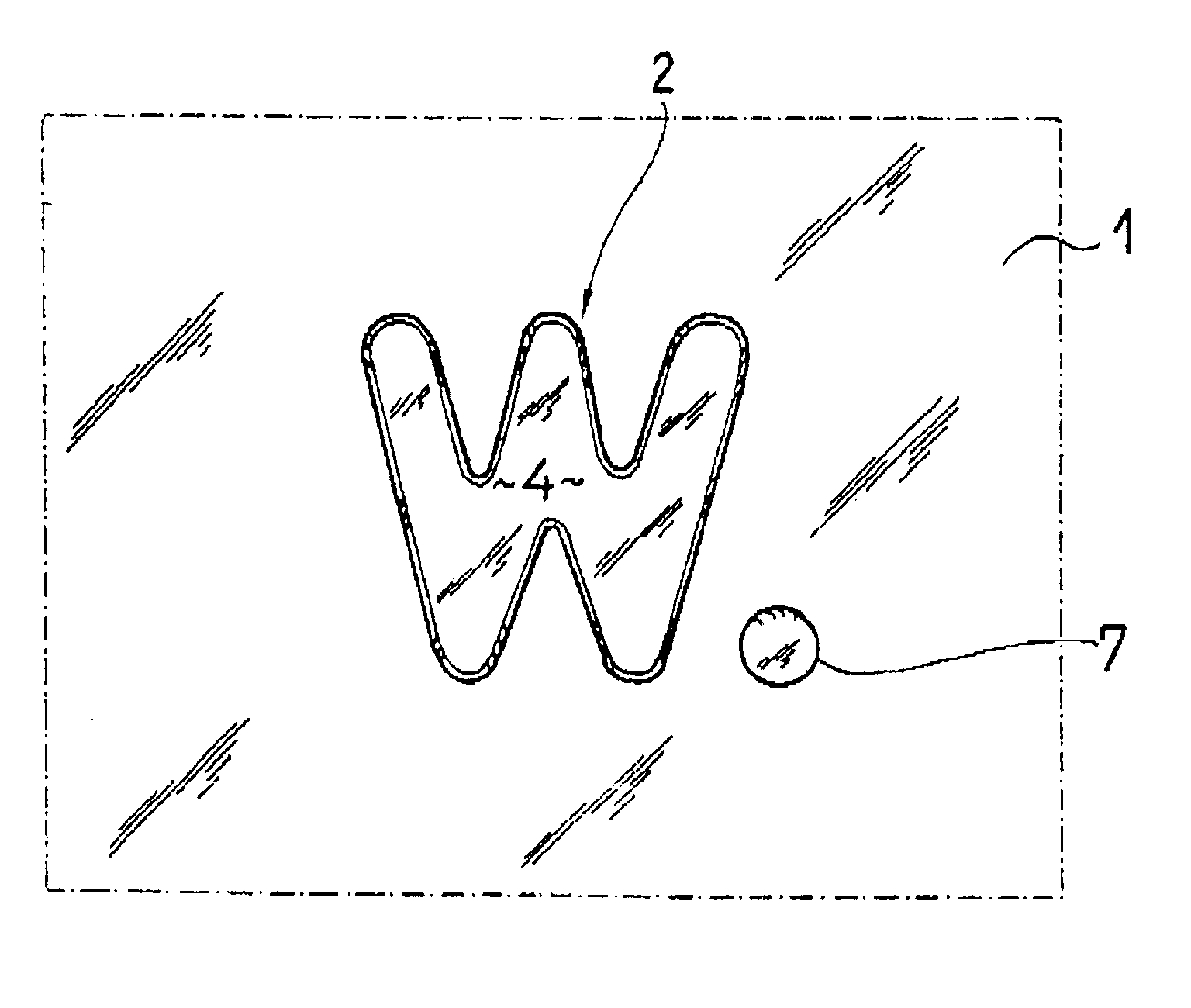

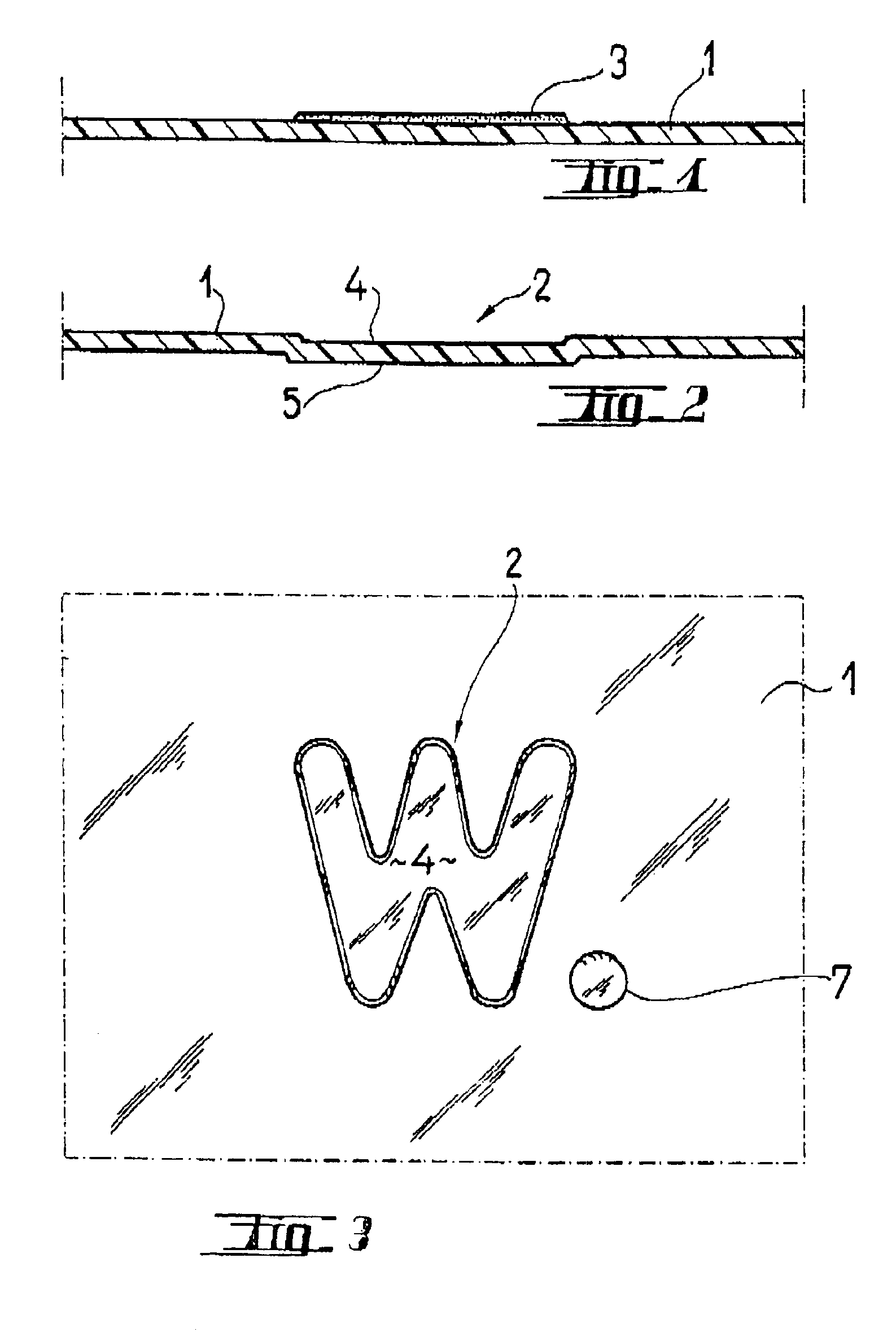

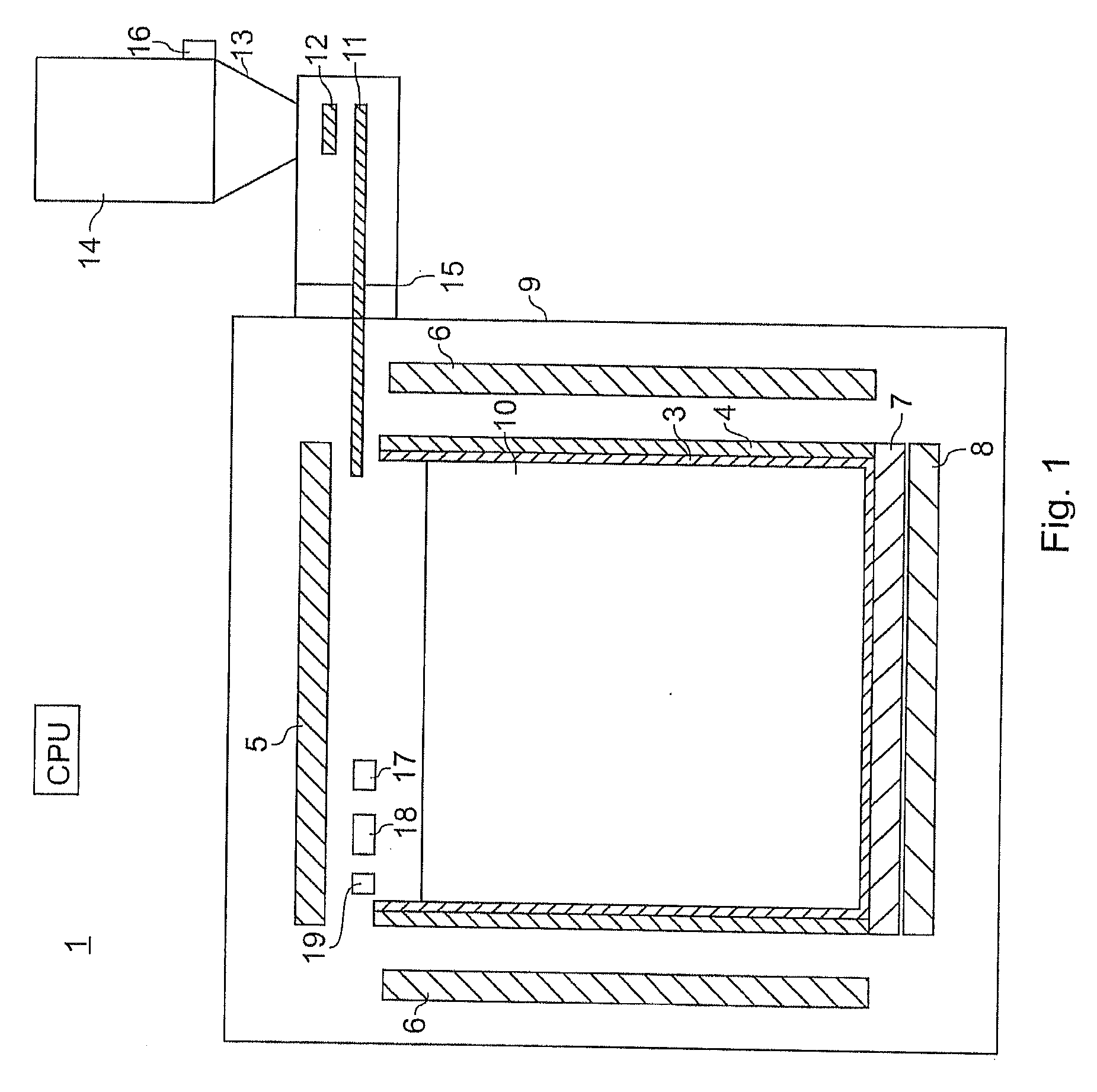

Method for producing an electrochromic device and said electrochromic device

InactiveUS20060050357A1Improve stabilityLong persistenceTenebresent compositionsNon-linear opticsVolumetric shrinkageEngineering

The invention relates to a method for producing electrochromic devices, in particular that having a large working surface area and which does not produce a volumetric shrinkage and can operate during a long maintenance of electrocoloured state of an electrochromic compound, high control voltages and polarity inversion. The inventive electrochromic device comprises at least two electrodes (1, 2), at least one of them being optically transparent. A closed sealed space is formed between said electrodes and filled with the electrochromic compound which is embodied in the form of a solid-like film. The inventive method for producing the electrochromic device consists in prefabricating an initial electrochromic compound in the form of a dispersed electrochromic system which contains at least a suspension and / or colloid. The dispersed medium of said system is embodied in the form of an electrochromic solution containing a liquid solvent, cathode and anode components, a disperse phase being embodied in the form of a finely dispersed polymer. Afterwards, the initial electrochromic compound is deaerated, thereby eliminating dissolved oxygen and air introduced by said finely dispersed polymer, and is used for filling the space between the electrodes.

Owner:AVELUM +1

Triazine ring-containing polymer and film-forming composition comprising same

ActiveUS8618243B2Improve heat resistanceLower the volumeOrganic detergent compounding agentsOrganic chemistryPolymer scienceVolumetric shrinkage

A polymer containing a triazine ring-containing repeating unit structure represented by, for example, formula (23) or (24), which alone can achieve high heat resistance, high transparency, high refraction index, high solubility and low volume shrinkage, without adding a metal oxide.

Owner:NISSAN CHEM IND LTD

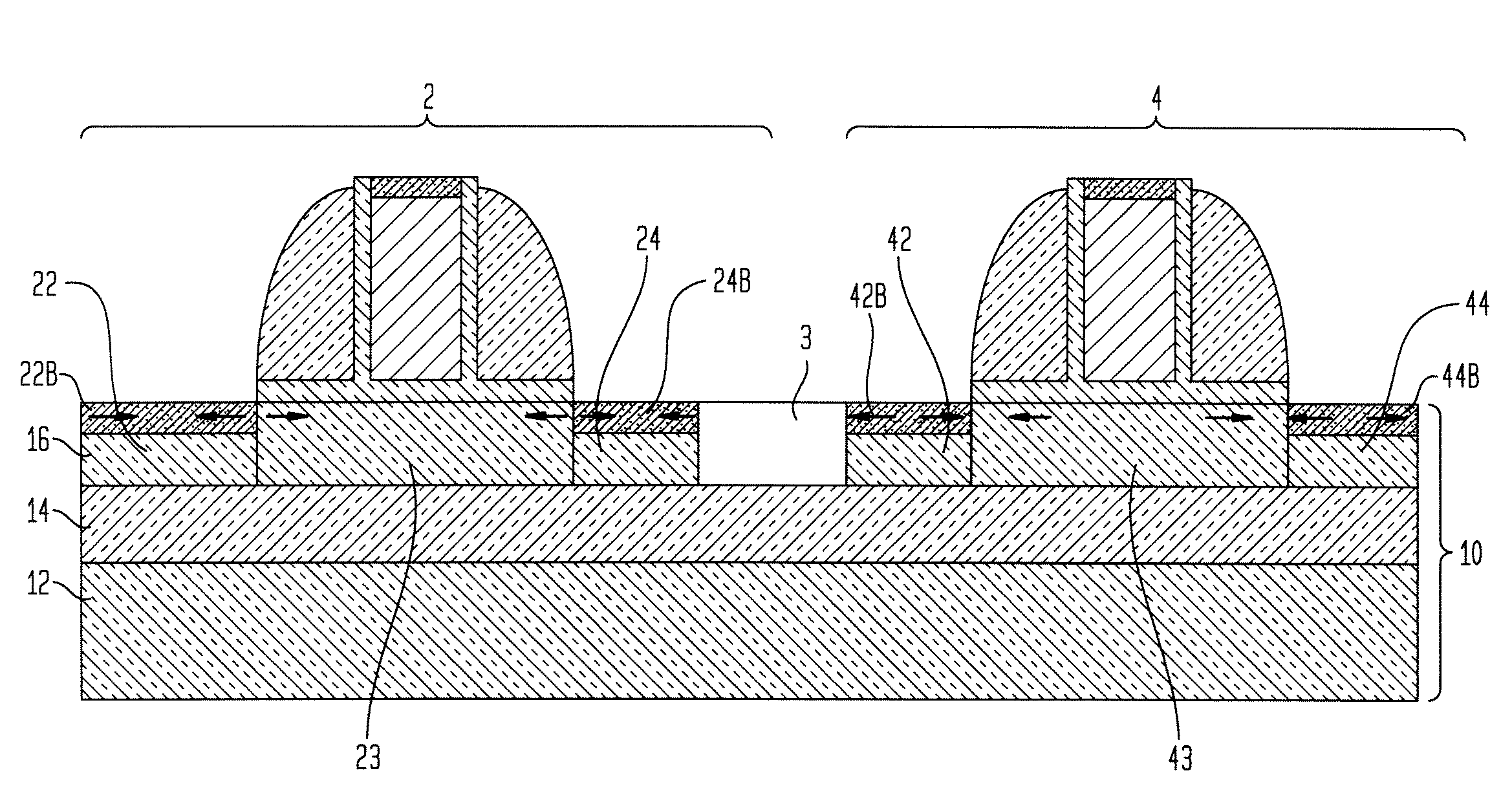

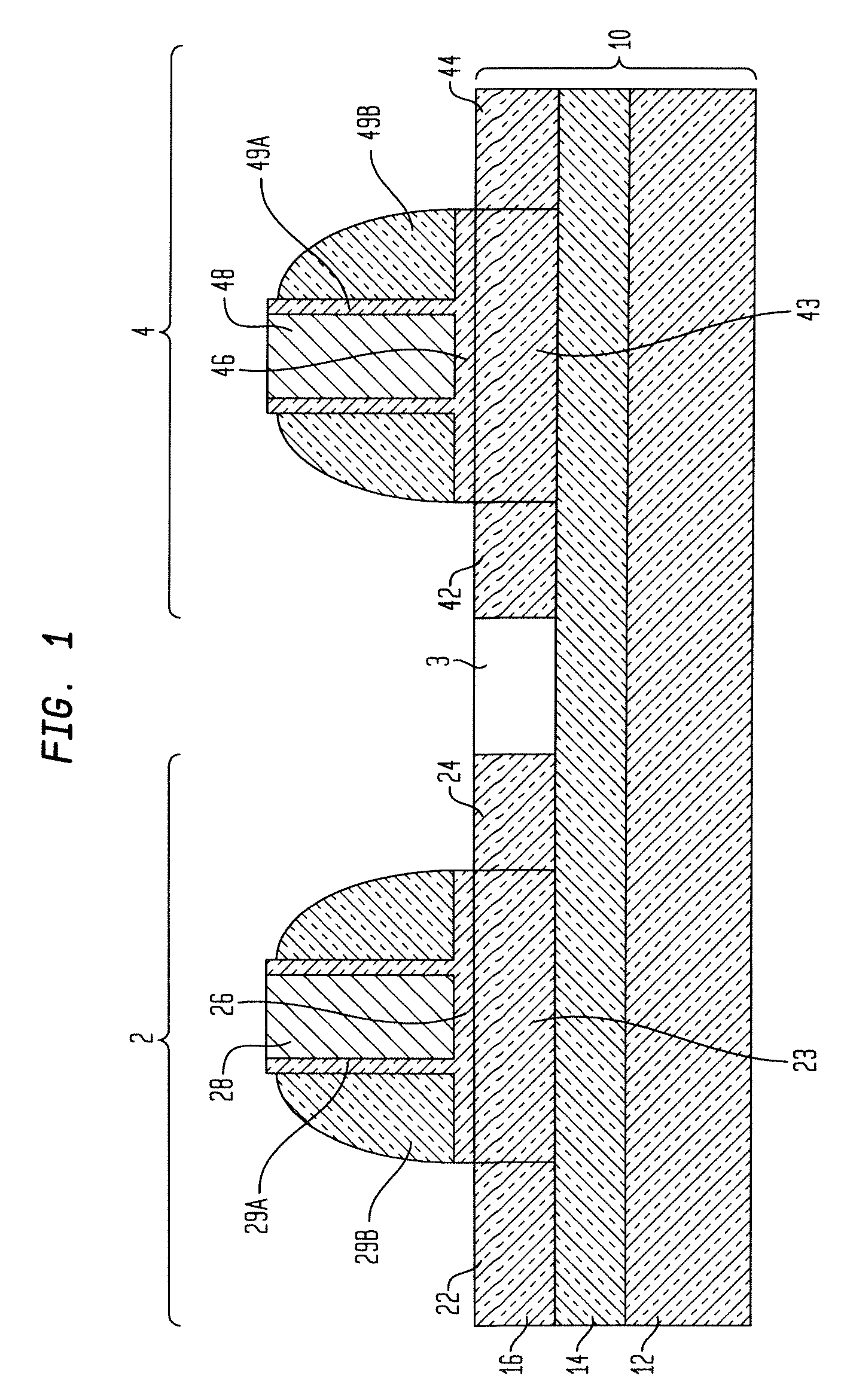

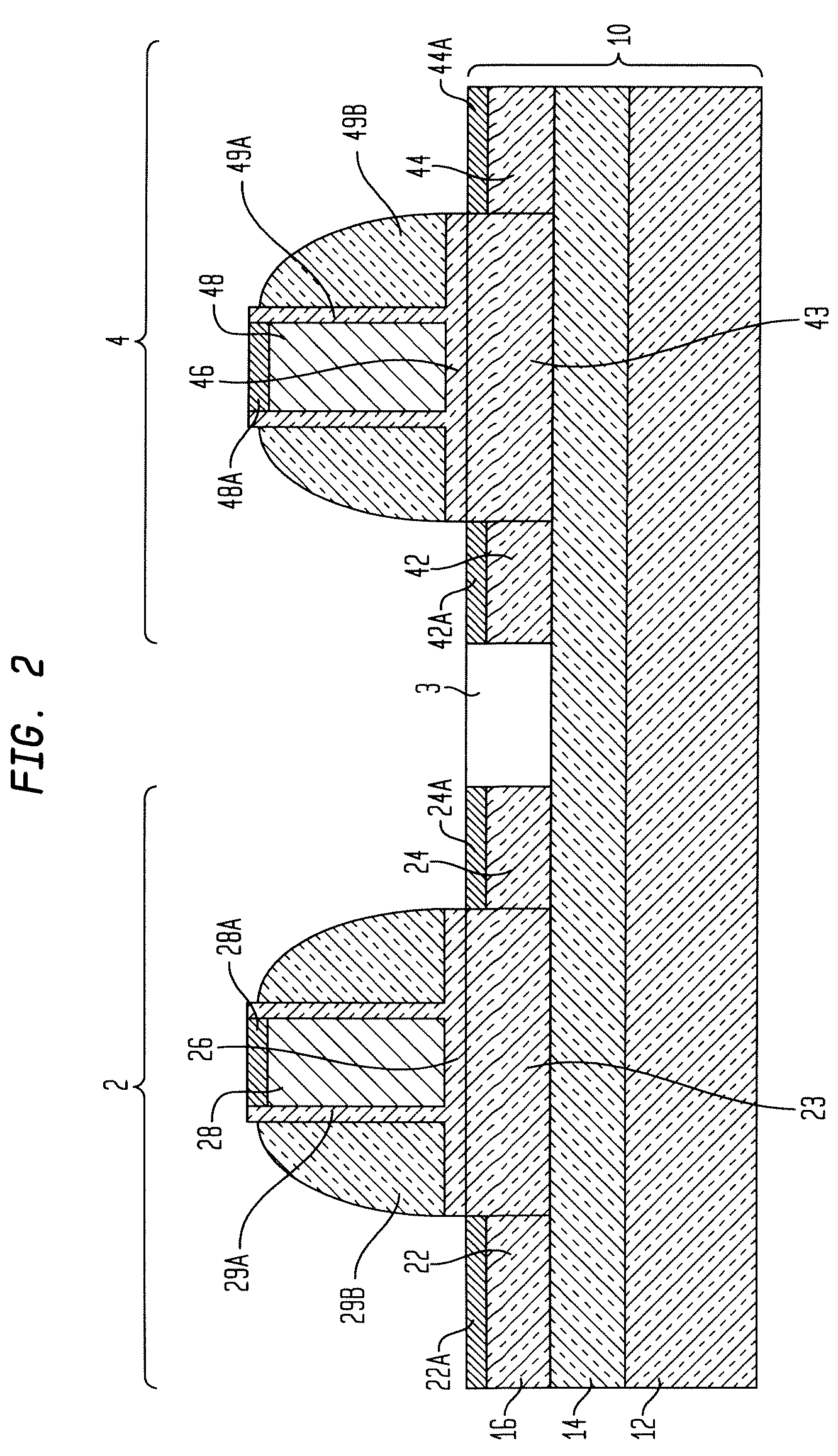

Methods for forming CMOS devices with intrinsically stressed metal silicide layers

InactiveUS7504336B2Improve mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesCMOSDevice material

Owner:INT BUSINESS MASCH CORP

Method for preparing brucite fiber reinforced SiO2 aerogel heat-insulating material

The invention discloses a preparation method for brucite fiber reinforcement SiO2 aerogel heat insulating material. Wherein, with industrial water glass or silicasol and natural brucite staple fiber as material, using high-energy ball grinding and chemical dispersion method to realize size refining for inorganic opacifier and even distribution before sol solidification; splitting the natural brucite staple fiber into nano diameter with chemical dispesion method as reinforcing material. This invention overcomes the volume shrinkage problem by substituting solvent and hydrophobisation treatment and fiber reinforcement. The materila has density as 0.20~0.50g / cm3 and thermal conductivity factor as 0.010~0.030w / m*k.

Owner:CHANGAN UNIV

Producing a textured effect in a plastic film, and plastic films having a relief pattern made by this method

InactiveUS6949290B2Increasing the thicknessRadiation applicationsLayered productsWrinkle skinLacquer

A method of manufacturing an imprinted effect in a plastic film, characterized by the following steps: (a) applying a hardenable mixture of lacquer and solvent subject to volumetric shrinkage in liquid form to a localized area of the plastic film, whereby the plastic film surface is for all practical purposes made insoluble by the solvent; (b) drying the lacquer-solvent material; (c) hardening the lacquer to a lacquer-laminate layer that is completely bound to a localized area of the surface; and (d) allowing the lacquer-laminate layer to shrink, with a simultaneous tightening of the laminated plastic film below the lacquer-laminate layer without formation of wrinkles.

Owner:SIEGWERK DRUCKFARBEN

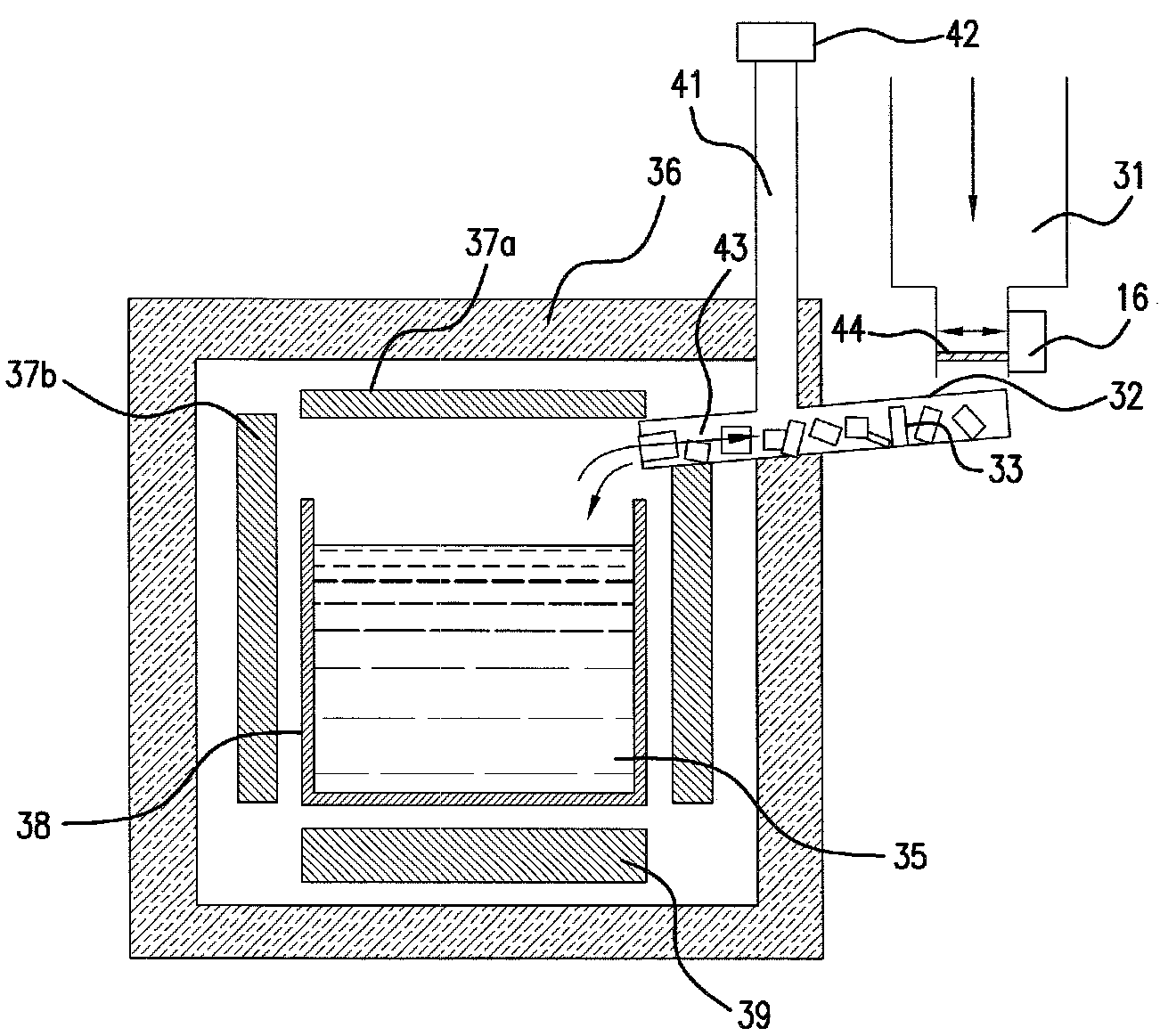

Method for producing a monocrystalline or polycrystalline semiconductore material

ActiveUS20090158993A1High filling levelShort melting timeAfter-treatment apparatusPolycrystalline material growthVertical gradientCrucible

The invention relates to a method for producing a monocrystalline or polycrystalline semiconductor material by way of directional solidification, wherein lumpy semiconductor raw material is introduced into a melting crucible and melted therein and directionally solidified, in particular using the vertical gradient freeze method.In order to prevent contamination and damage, the semiconductor raw material is melted from the upper end of the melting crucible. The molten material trickles downward, so that semiconductor raw material which has not yet melted gradually slumps in the melting crucible. In this case, the additional semiconductor raw material is replenished to the melting crucible from above onto a zone of semiconductor raw material which has not yet melted or is not completely melted, in order at least partly to compensate for a volumetric shrinkage of the semiconductor raw material and to increase the filling level of the crucible.In order to reduce the melting-on time and to influence the thermal conditions in the system as little as possible, the semiconductor raw material to be replenished is heated by the purposeful introduction of heat to a temperature below the melting temperature of the semiconductor raw material and introduced into the container in the heated state.

Owner:SCHOTT AG

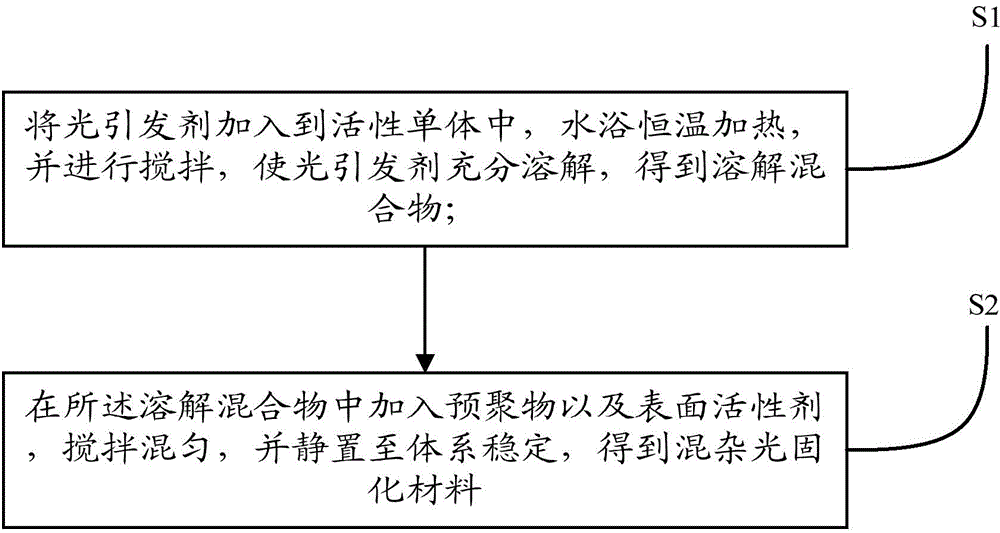

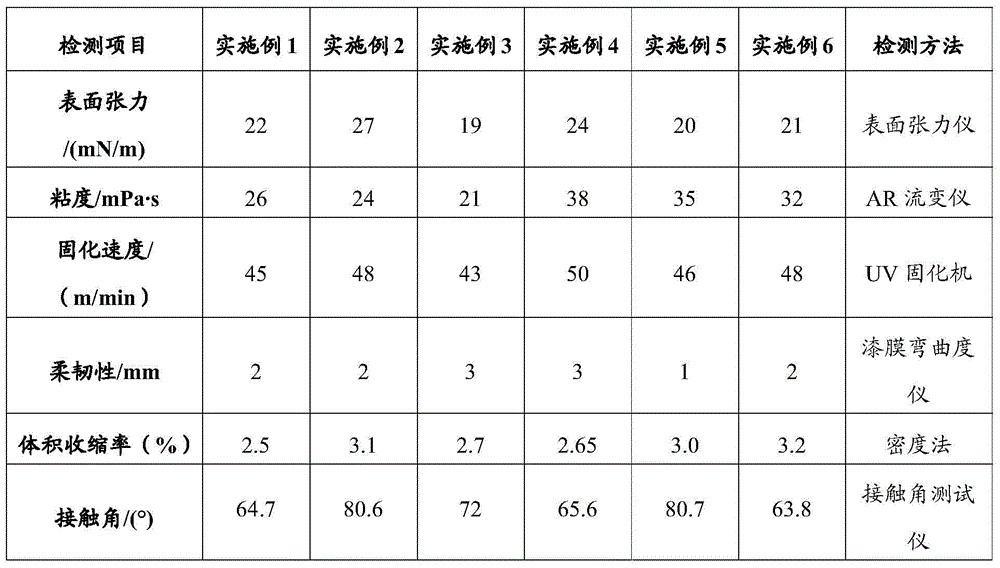

Hybrid light curing material for production of flexible plate as well as preparation method and application of hybrid light curing material

InactiveCN104804146AImprove curing efficiencyOvercoming pollutionAdditive manufacturing apparatusVolumetric shrinkagePhotoinitiator

The invention provides a hybrid light curing material for production of a flexible plate as well as a preparation method and application of the hybrid light curing material, and belongs to the technical field of radiation curing. The hybrid light curing material comprises the following raw materials by weight: 20 to 50 parts of one or more prepolymers, 30 to 50 parts of one or more active monomers, 3 to 5 parts of one or more photoinitiators, and 0.5 to 1 part of a leveling agent, is 20 to 30 cP in viscosity at 25 DEG C, 20 to 30 mN / m in surface tension at 25 DEG C, 40 to 50 m / min in curing speed while the light source linear power 200 W / cm, 1 to 3 mm in flexibility, and about 3 percent in volumetric shrinkage, and can meet the requirements of a 3-dimensional printing flexible plate. The defects of serious environmental pollution, high resource waste, complex production technology and the like in the conventional flexible platemaking technology are overcome.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

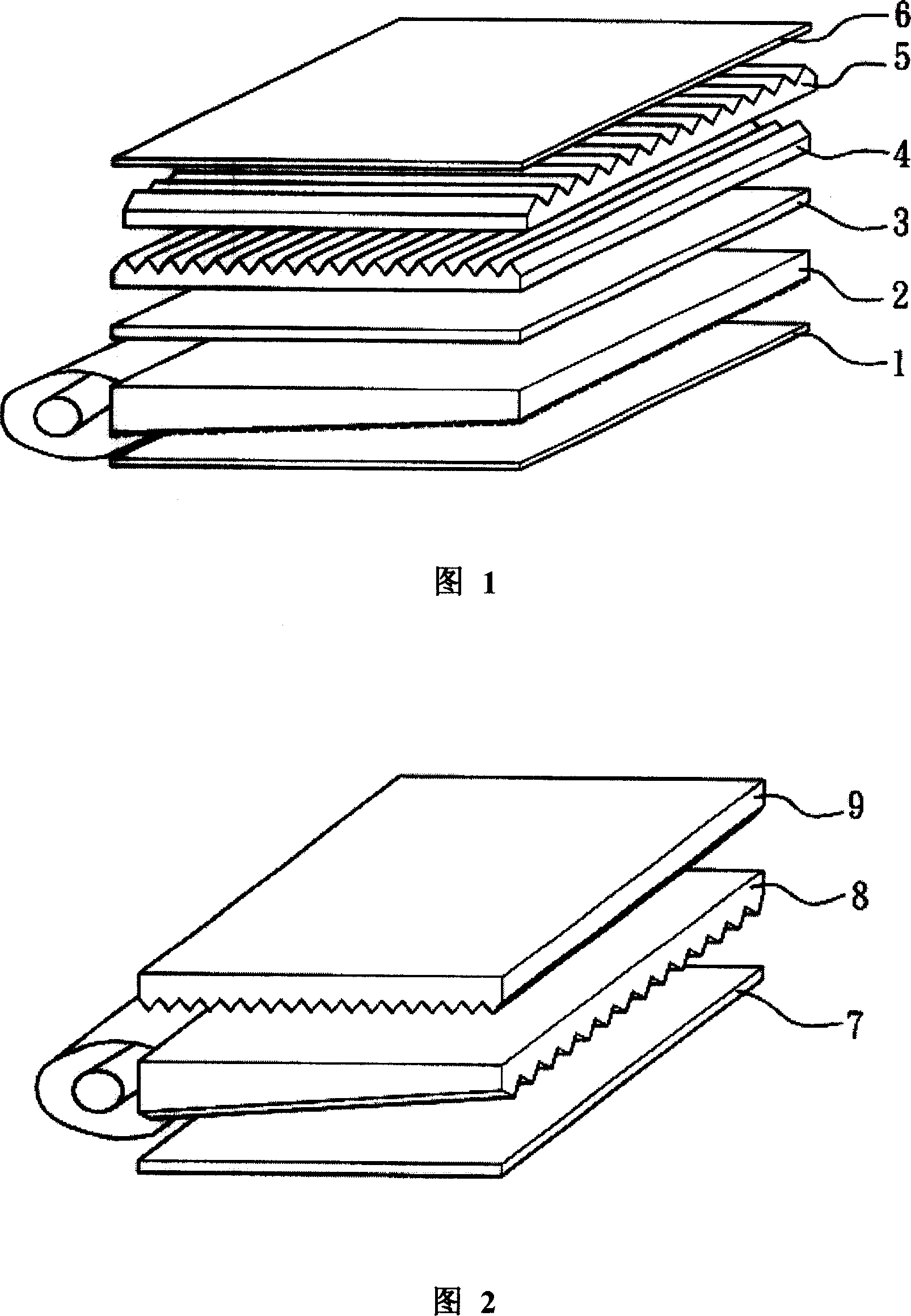

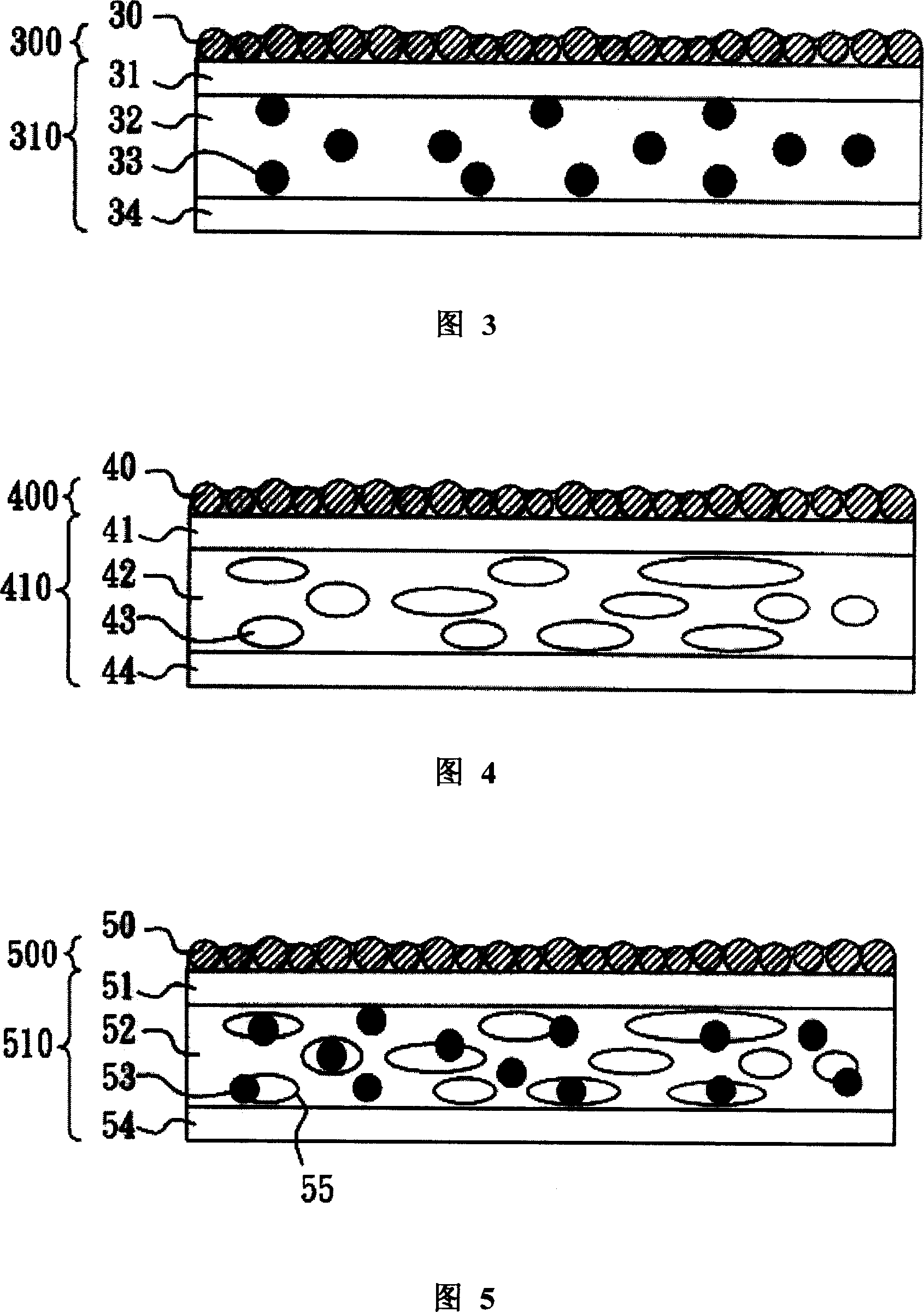

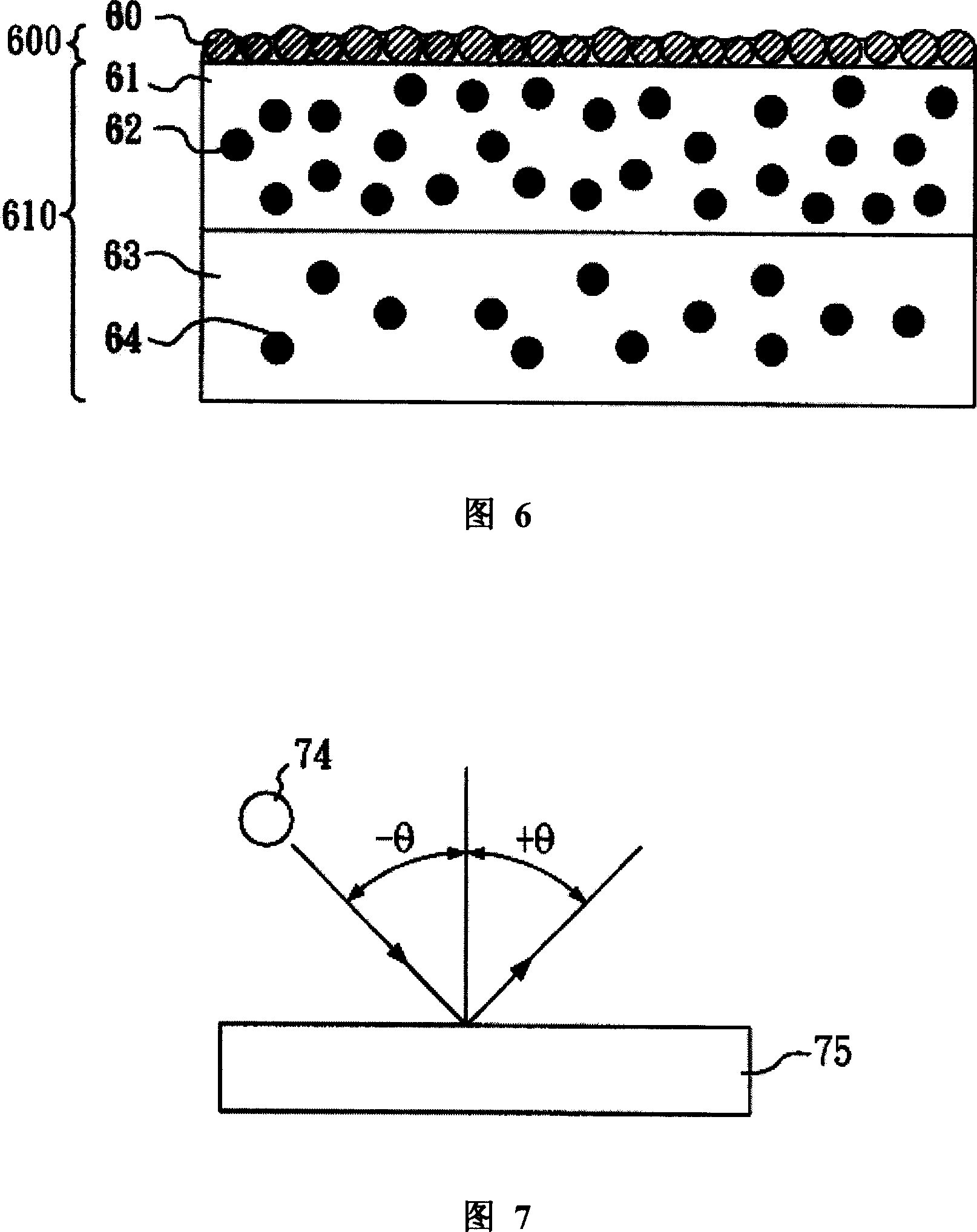

Antiscraping optical film and use thereof

InactiveCN101021644AImprove antistatic performanceExcellent hardness propertiesNon-linear opticsOptical elementsAntistatic agentLiquid-crystal display

The invention provides an anti-scratching optical film and its use. And its characters: at least a surface of its substrate is coated with antistatic anti-scratching layer whose surface resistivity is 108-1012 Ohm / sq and which has the hardness of pencil of 3H or above, according to the measurement by JIS K5400 standard method. And it has low volumetric shrinkage, unable to warp but having good antistatic performance and high hardness, applied to advertising lamp boxes or plane displays and other light source devices, especially applied to an LCD provided with ''V-channel'' light guide plate as anti-scratching reflective film at the bottom of the light guide plate.

Owner:长兴光学材料(苏州)有限公司

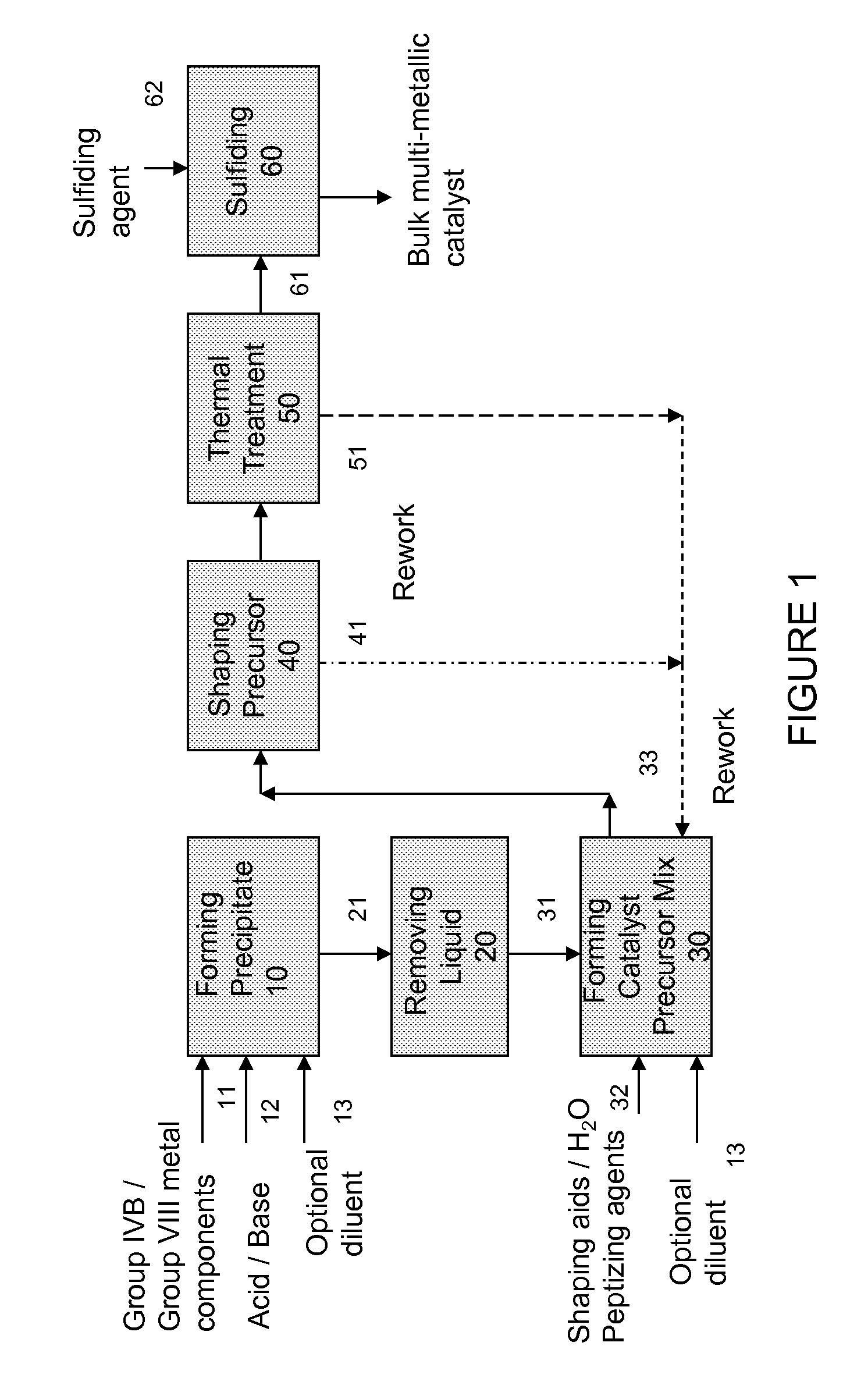

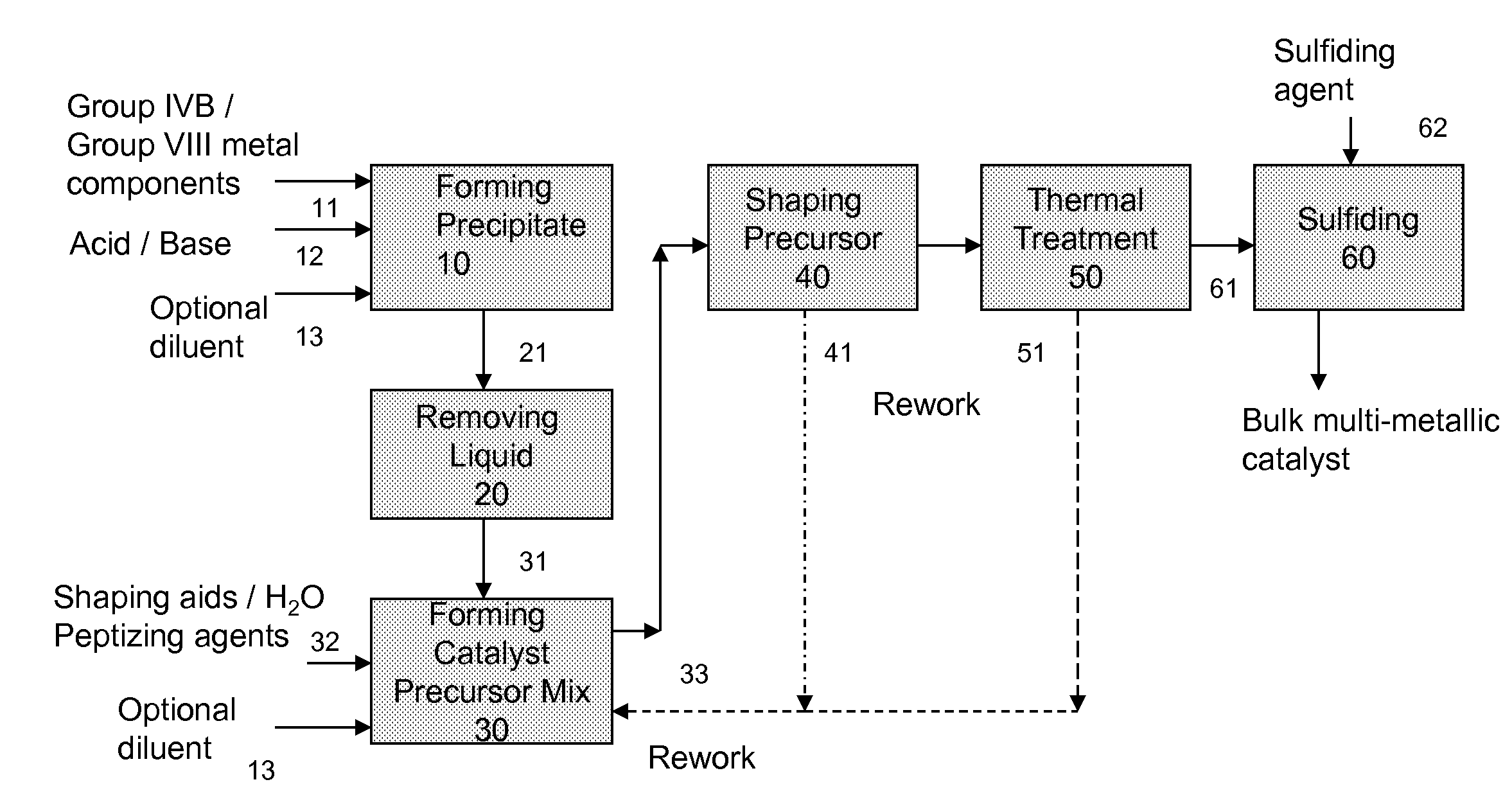

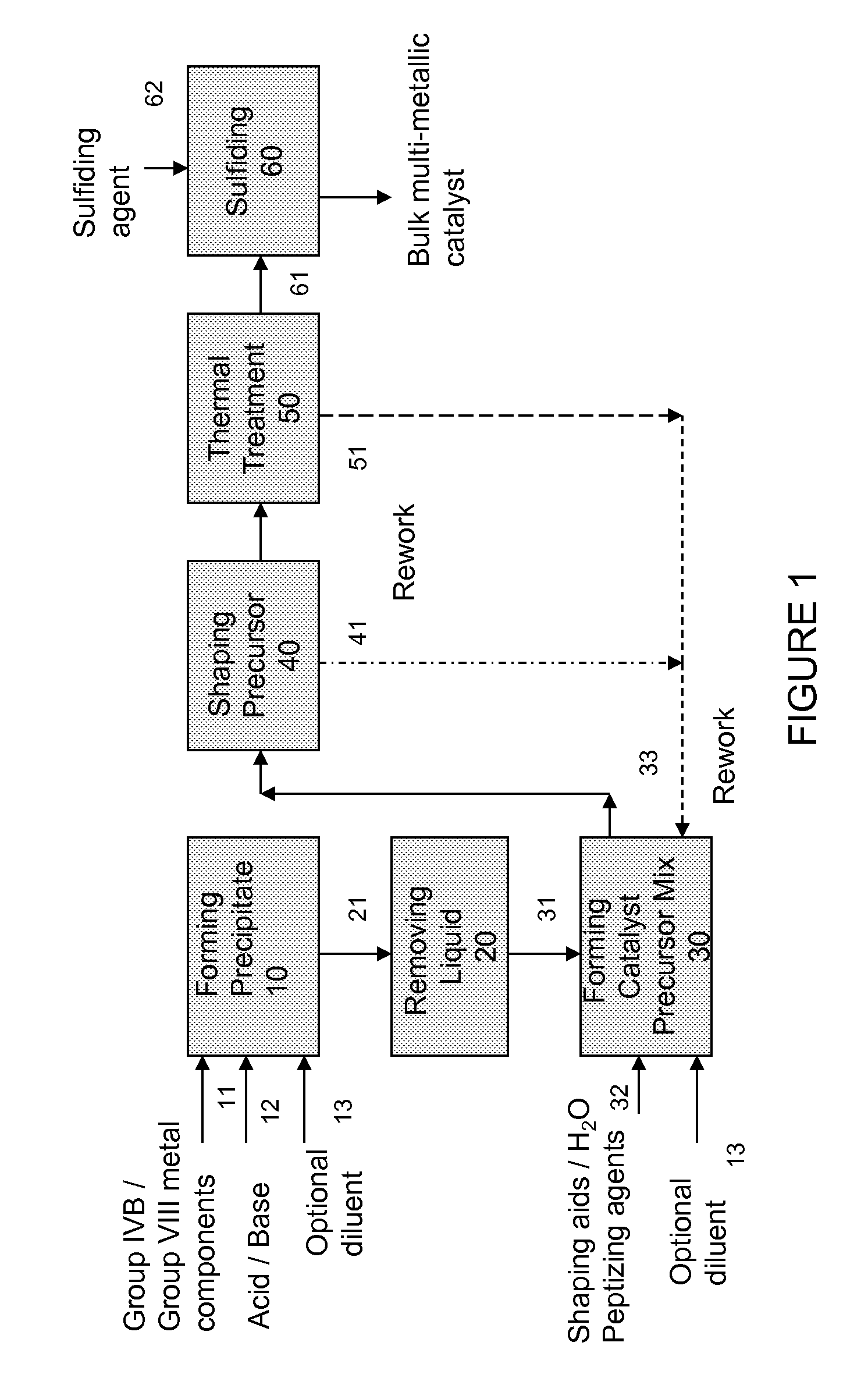

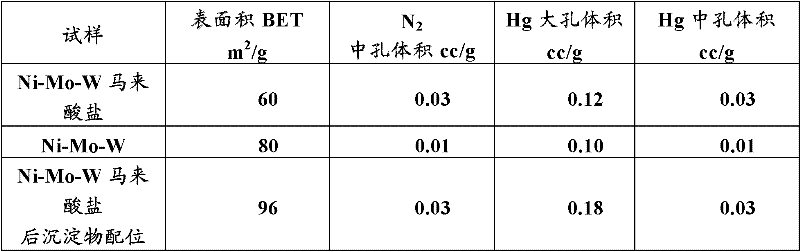

Hydroconversion multi-metallic catalyst and method for making thereof

ActiveUS7964525B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCompound (substance)Sulfidation

A stable catalyst with low volumetric shrinkage and a process for making the stable catalyst with low volumetric shrinkage is disclosed. The catalyst is made by sulfiding a catalyst precursor containing at least a Group VIB metal compound; at least a promoter metal compound selected from Group VIII, Group IIB, Group IIA, Group IVA and combinations thereof, having an oxidation state of either +2 or +4; optionally at least a ligating agent; optionally at least a diluent. In the process of making the catalyst, the catalyst precursor is first shaped then heat treated at a temperature of 50° C. to 200° C. for about 15 minutes to 12 hours, wherein the catalyst precursor still has a low (less than 12%) volumetric shrinkage after exposure to a temperature of at least 100° C. for at least 30 minutes, e.g., in sulfidation or in a hydrotreating reactor.

Owner:CHEVROU USA INC

Hydroconversion Multi-Metallic Catalyst and Method for Making Thereof

ActiveUS20100279855A1Lower the volumeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationVolumetric shrinkageOxidation state

A stable catalyst with low volumetric shrinkage and a process for making the stable catalyst with low volumetric shrinkage is disclosed. The catalyst is made by sulfiding a catalyst precursor containing at least a Group VIB metal compound; at least a promoter metal compound selected from Group VIII, Group IIB, Group IIA, Group IVA and combinations thereof, having an oxidation state of either +2 or +4; optionally at least a ligating agent; optionally at least a diluent. In the process of making the catalyst, the catalyst precursor is first shaped then heat treated at a temperature of 50° C. to 200° C. for about 15 minutes to 12 hours, wherein the catalyst precursor still has a low (less than 12%) volumetric shrinkage after exposure to a temperature of at least 100° C.

Owner:CHEVROU USA INC

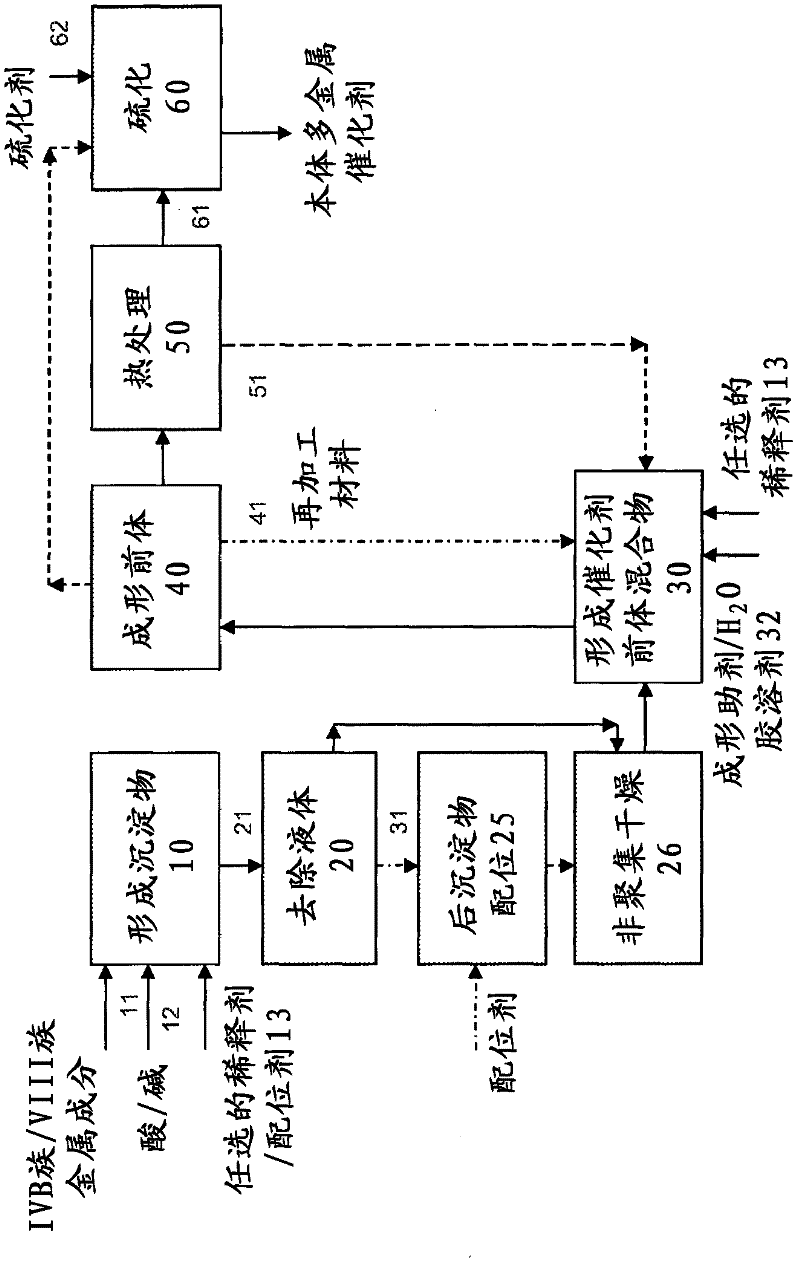

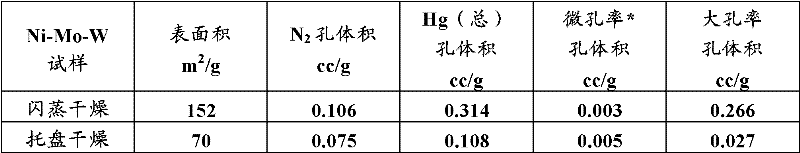

Hydroconversion multi-metallic catalyst and method for making thereof

ActiveCN102413933AGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsBoiling pointMetallic materials

A catalyst with low volumetric shrinkage and a process for making the stable catalyst with low volumetric shrinkage is disclosed. The catalyst is made by sulfiding a catalyst precursor containing at least a Group VIB metal compound; at least a promoter metal compound selected from Group VIII, Group HB, Group HA, Group IVA and combinations thereof, having an oxidation state of either +2 or +4; optionally at least a ligating agent; optionally at least a diluent. In one embodiment, the catalyst precursor is first shaped then heat treated at a temperature of 50 DEG C. to 200 DEG C. for 15 minutes to 12 hours, wherein the catalyst precursor has a low (less than 12%) volumetric shrinkage after exposure to at least 100 DEG C for at least 30 minutes, e.g., in sulfidation or in a hydrotreating reactor.; In one embodiment, the catalyst precursor has an essentially monomodal pore volume distribution with at least 90% of the pores being macropores, and a total pore volume of at least 0.08 g / cc. In one embodiment, the catalyst is suitable for hydrotreating heavy oil feeds having a boiling point in the range of 343 DEG C. (65O DEG F.) - to 454 DEG C. (850 DEG F.), an average molecular weight Mn ranging from 300 to 400, and an average molecular diameter ranging from 0.9 nm to 1.7 nm.

Owner:CHEVROU USA INC

Curable jettable liquid for flexography

A curable jettable liquid for manufacturing a flexographic printing plate comprising at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E' smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

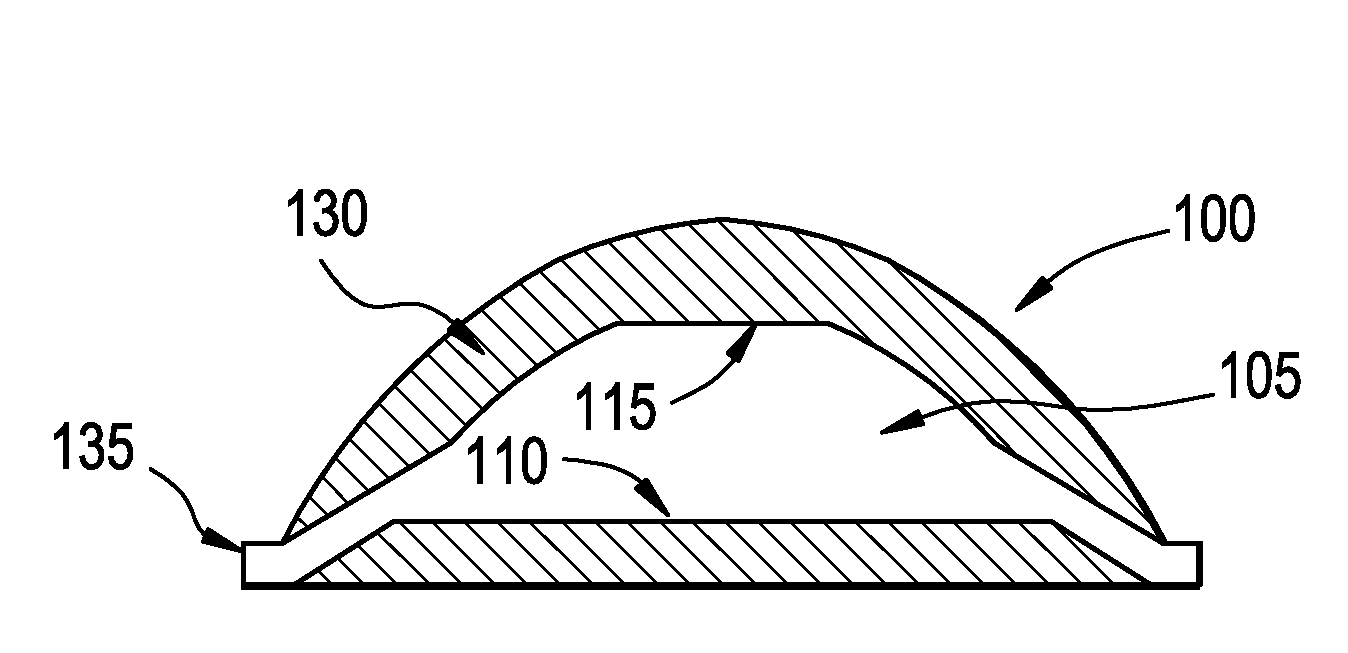

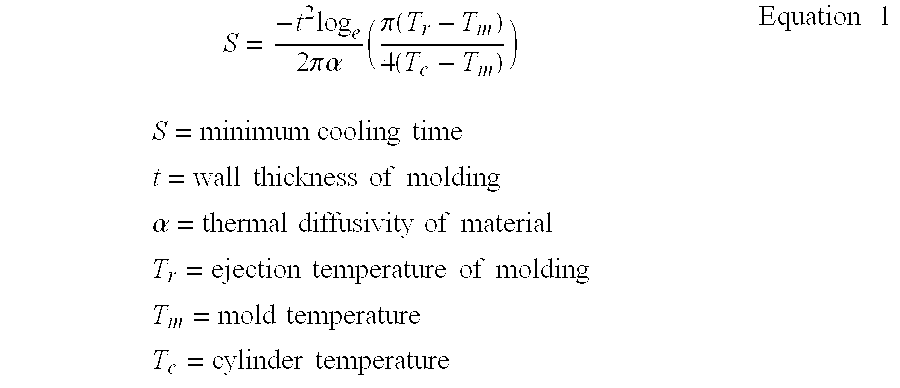

Over-molded thick wall parts

InactiveUS20080299340A1Substantial timeSignificant energy savingSynthetic resin layered productsOptical articlesVolumetric shrinkageEngineering

An over-molded thick wall part, an insert used in forming the over-molded thick wall part, and a method of forming over-molded thick wall parts. The insert includes at least two sides, wherein one of the sides includes a flat surface. With a flat surface, there is a tendency to form sink marks rather than internal shrinkage voids to compensate for the volumetric shrinkage of the resin. Therefore, the flat surface enables the insert to cool without forming voids within the interior of the insert that may adversely affect the aesthetics and / or usefulness of the of the over-molded thick wall part. The cooled insert is then encompassed within an over-molded outer component to form the thick wall part. By using a two step molding process to form the thick wall part, substantial time and / or energy savings may be achieved as compared to prior art methods of forming thick wall parts. Depending on the types of materials used to form the insert and the outer component of the thick wall part, various parts may be formed including lenses, handles, housings and the like.

Owner:SABIC INNOVATIVE PLASTICS IP BV

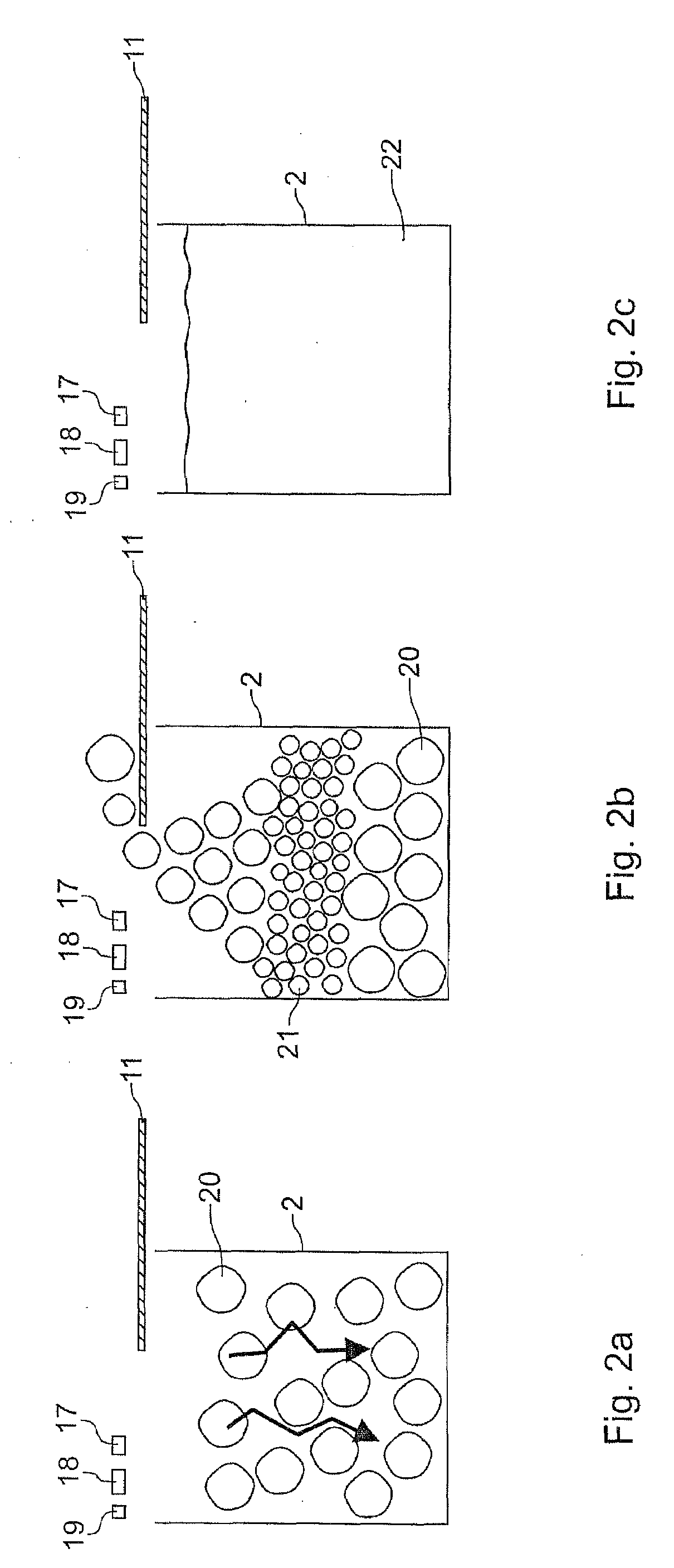

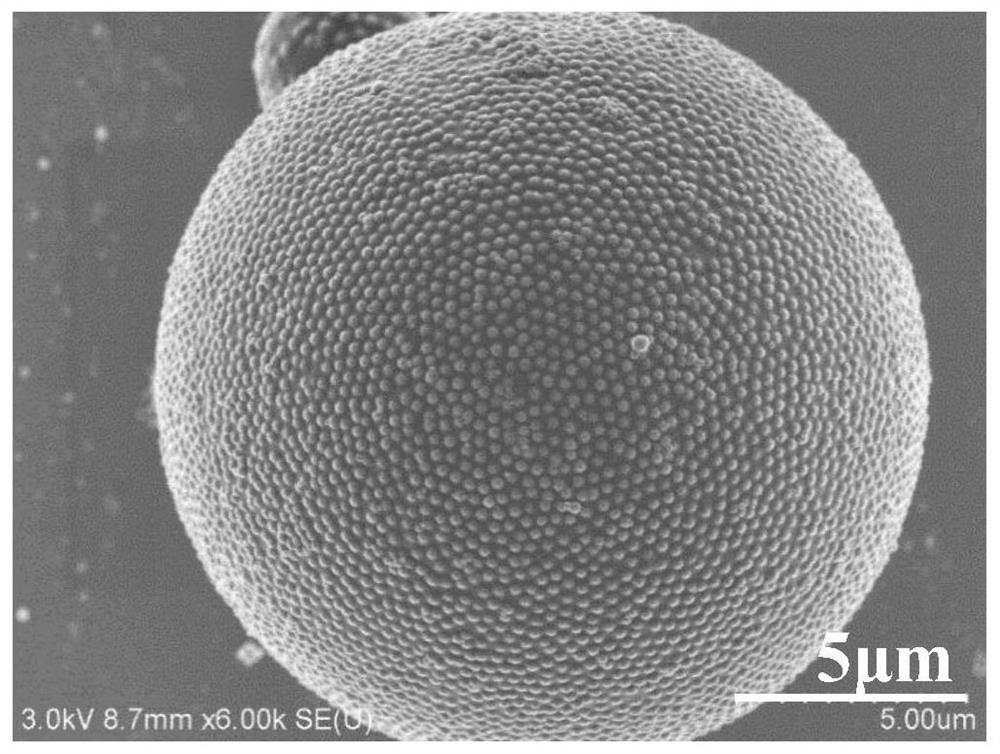

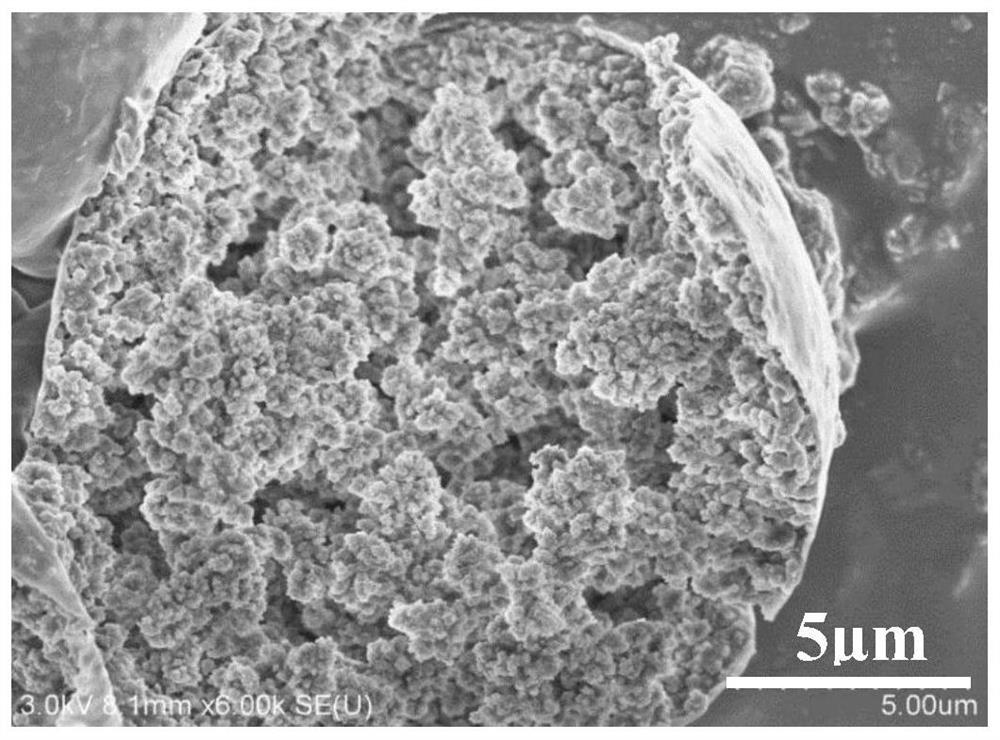

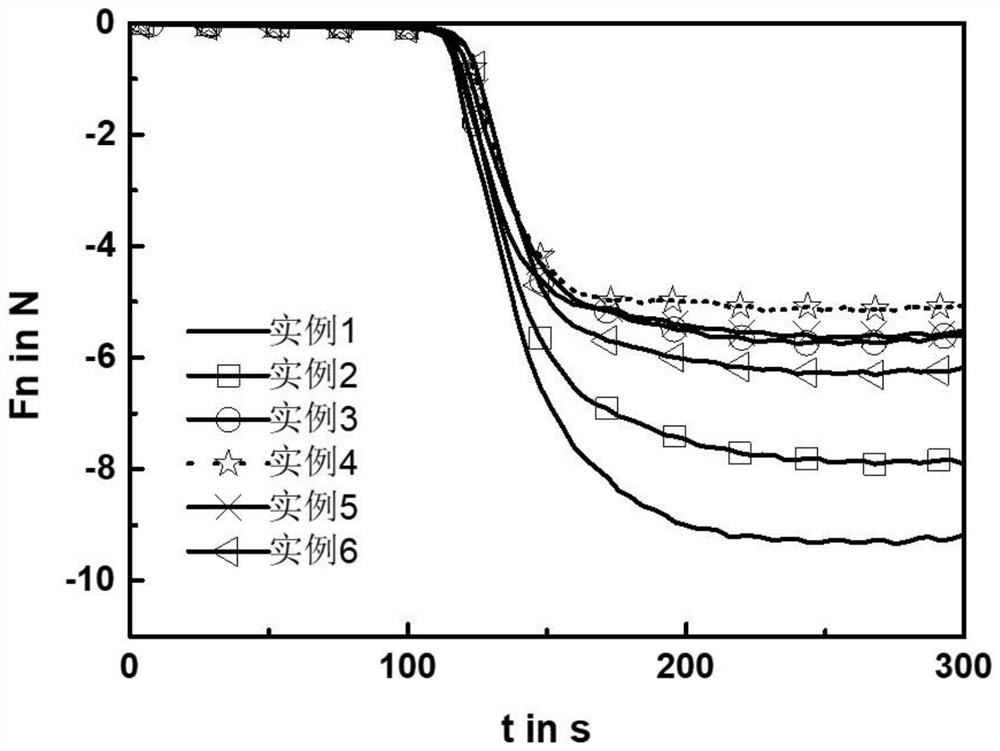

Method for reducing volume shrinkage of photocuring coating by using hollow/porous elastic microspheres

The invention discloses application of elastic hollow / porous microspheres in a coating, and particularly relates to the application of the elastic hollow / porous microspheres in the coating to prepare the coating containing the elastic hollow / porous microspheres and reduce the curing volume shrinkage rate of the coating. Through a linear laser confocal method shrinkage rate test, the curing volume shrinkage rate of the coating containing the elastic hollow / porous microspheres is reduced by 30%-65%, and the elastic hollow / porous microspheres account for 0.5-2.5 wt% of the total mass of the matrix resin and the monomers. The modified silicon dioxide particles are used as an emulsifier, so that the compatibility of the elastic hollow / porous microspheres in the coating is improved; and the elastic hollow / porous microspheres are used for reducing the volume shrinkage rate of the photocuring coating, only about 1.5 wt% of microspheres are added, the volume shrinkage rate of the cured material is reduced, and the coating is kept to have excellent comprehensive performance.

Owner:JIANGNAN UNIV

Honeycomb structure producing method, and honeycomb structure

ActiveUS7276276B2Physical/chemical process catalystsDispersed particle filtrationVolumetric shrinkageHigh intensity

In a method for producing a honeycomb structure 20 which comprises disposing a material for forming outer wall 11 on the outer peripheral surface 3 of a cell structure 1 having a plurality of cells serving as fluid flowing channels to produce a cell structure being provided with a material for forming outer wall 10 and firing the resulting cell structure being provided with a material for forming outer wall 10, wherein a cell structure being provided with a material for forming outer wall 10 in which the absolute value of the difference between the volumetric shrinkage percentage (firing shrinkage percentage) before and after firing of the cell structure 1 and the firing shrinkage percentage of the material for forming outer wall 11 is not more than 0.5% is produced and fired. There is provided a method for producing a honeycomb structure which comprises providing an outer wall on the outer peripheral surface and firing it, according to which the outer wall hardly cracks during firing and high-strength and large-sized honeycomb structure can be produced, and further provided is a high-strength and large-sized honeycomb structure in which the outer wall hardly cracks during firing.

Owner:NGK INSULATORS LTD

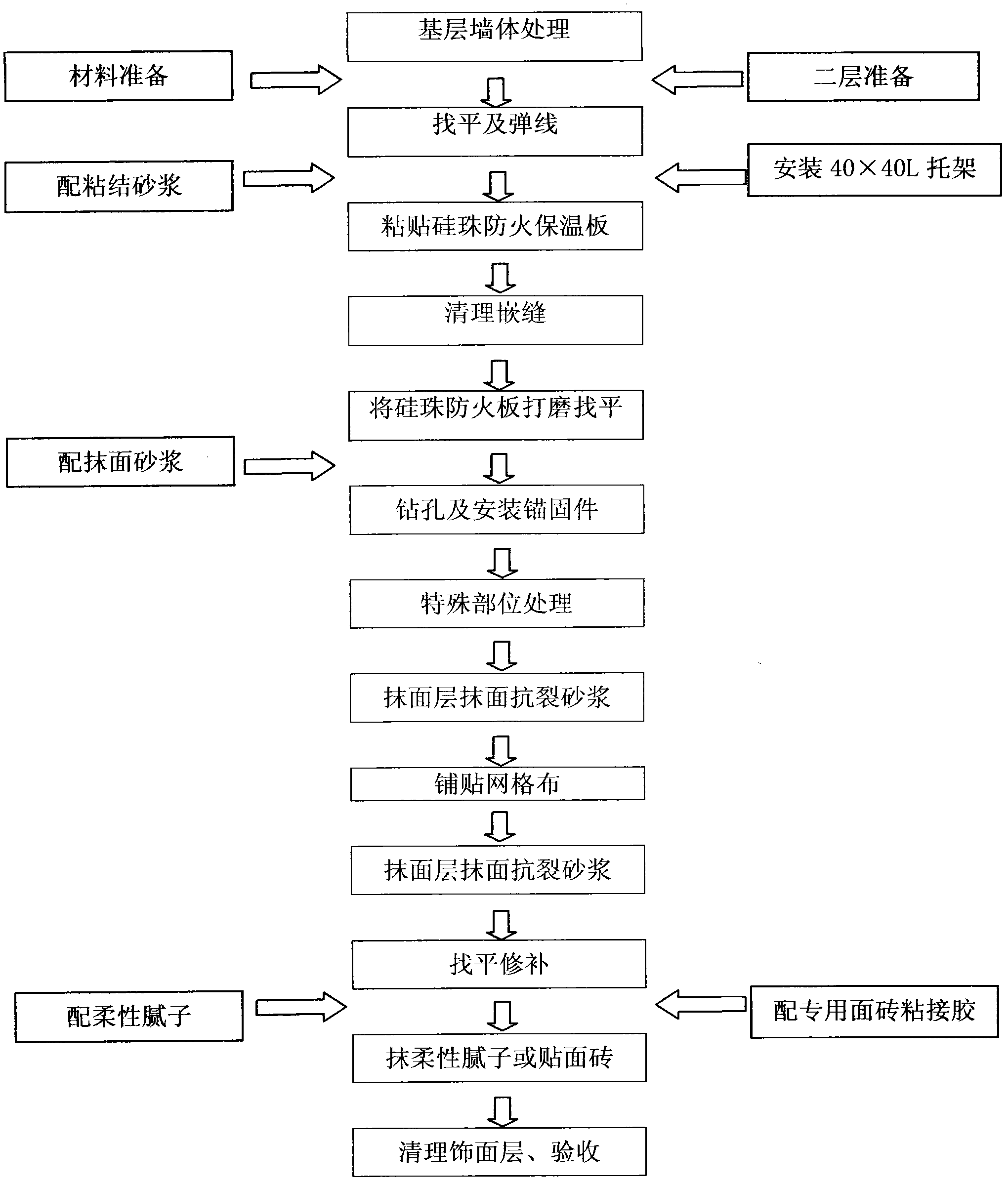

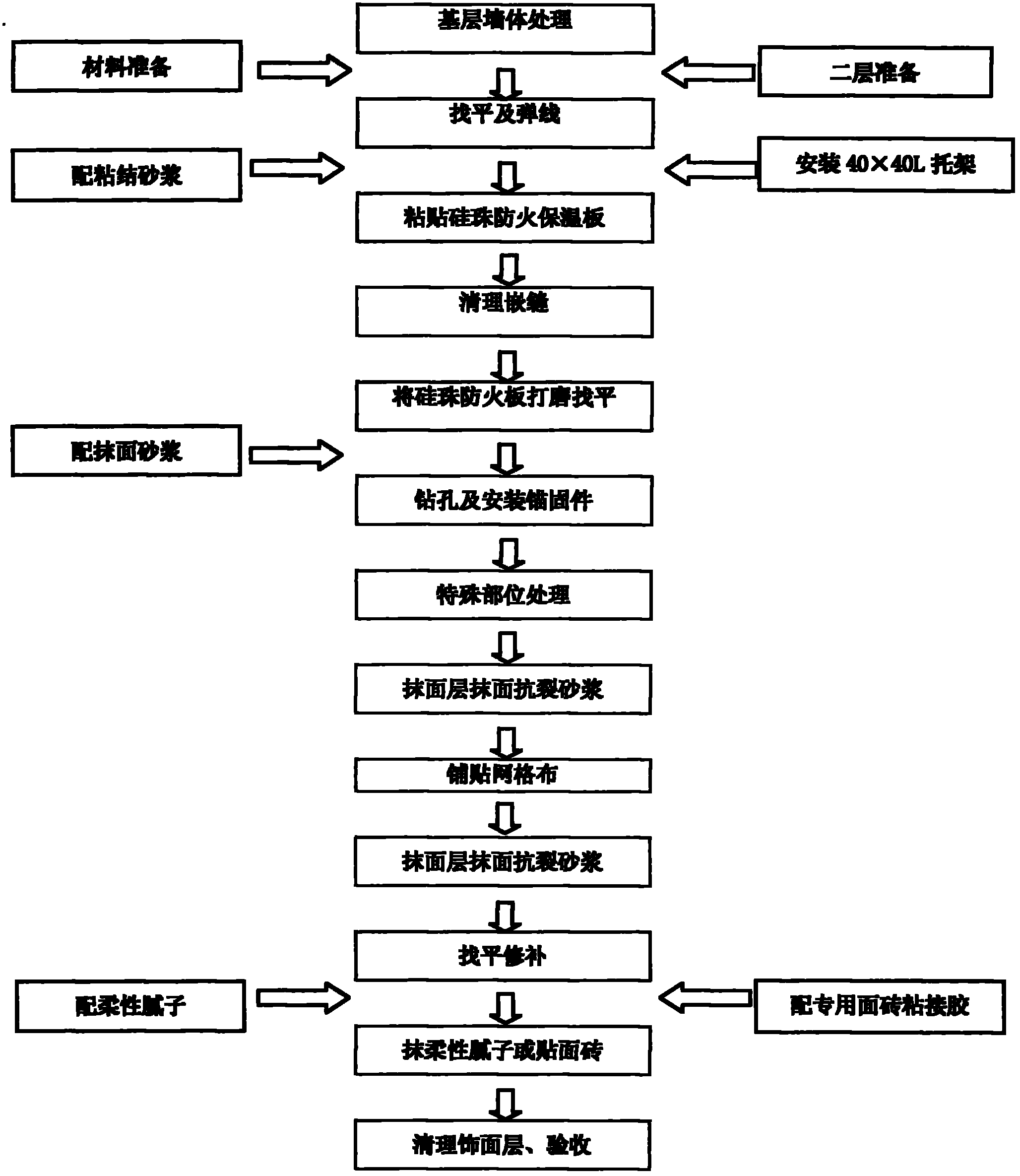

Inorganic heat-insulation fireproof plate

InactiveCN102619287ASolve easy pulverizationIncrease diversityHeat proofingBuilding material handlingPolymer scienceAging resistance

Disclosed is an inorganic heat-insulation fireproof plate, namely a silica bead fireproof heat-insulation plate. The fireproof plate is made of vitrified small balls and xonotlite, the weight ratio of the vitrified small balls to the xonotlite ranges from 1:2 to 1:5, in addition, waterproof materials with the weight ranging from 1% to 5% of the total weight of the fireproof plate and gel materials with the weight ranging from 8% to 10% of the total weight of the fireproof plate are added, and the fireproof plate is manufactured via working procedures including preparation, screening, pressure forming and drying. The vitrified small balls replace traditional common expanded perlite and traditional common polyphenyl particles to be used as lightweight aggregates of dry mixed heat-insulation mortar, shortcomings that the expanded perlite is high in water absorption and easy in pulverization and is high in volumetric shrinkage during slurry stirring, accordingly, low long-term strength, hollowing and cracking of a product are caused easily, and the like are overcome, defects of flammability, poor fireproof performance, harmful gas generation at a high temperature, low ageing resistance and weather fastness, high rebounding during construction and the like of the polyphenyl particles are also overcome, and comprehensive performances and construction property of the heat-insulation mortar are improved. In addition, the hydrophobic vitrified small balls cannot be degraded at a high temperature and are not easy to deform, and the flame retardant property of a polymer can be improved when the vitrified small balls are used as filling materials of the polymer.

Owner:QINGDAO FENGXIANG CHEM

Low shrinkage plugging mixture for ceramic filter, plugged honeycomb filter and method of manufacturing same

Disclosed are plugging mixtures for forming a ceramic honeycomb wall flow filter. The plugging mixtures exhibit a reduced percentage of volumetric shrinkage during the drying process and generally comprise an inorganic ceramic powder batch composition; an organic binder; a liquid vehicle; and a non-foaming volume transformation agent. Also disclosed are methods for forming plugged ceramic wall flow filters from such plugging mixtures and honeycomb articles produced therefrom.

Owner:CORNING INC

Pixel-to-barrier-uneveness-controllable ink

ActiveUS20060258774A1Decrease in ink volumeInhibition formationSurgical adhesivesDuplicating/marking methodsPolymer scienceVolumetric shrinkage

Disclosed is an ink, which has a viscosity and a volumetric shrinkage, controlled to 20˜80 cP and 10˜30%, respectively, by controlling an amount of each of: (a) a first monomer having a viscosity of 7˜1,600 cP and having one or two polymerizable functional groups; and (b) a second monomer having a viscosity of 30˜20,000 cP and having at least three polymerizable functional groups, in the presence of 0˜20 wt % of a solvent, and which can form a convex portion due to its surface tension controlled to 20˜40 mN / m, so as to compensate for its volumetric shrinkage, wherein the viscosity and the surface tension are measured at 25° C. A substrate, which is patterned or information-recorded with the ink, and a display device having the substrate are also disclosed.

Owner:LG CHEM LTD

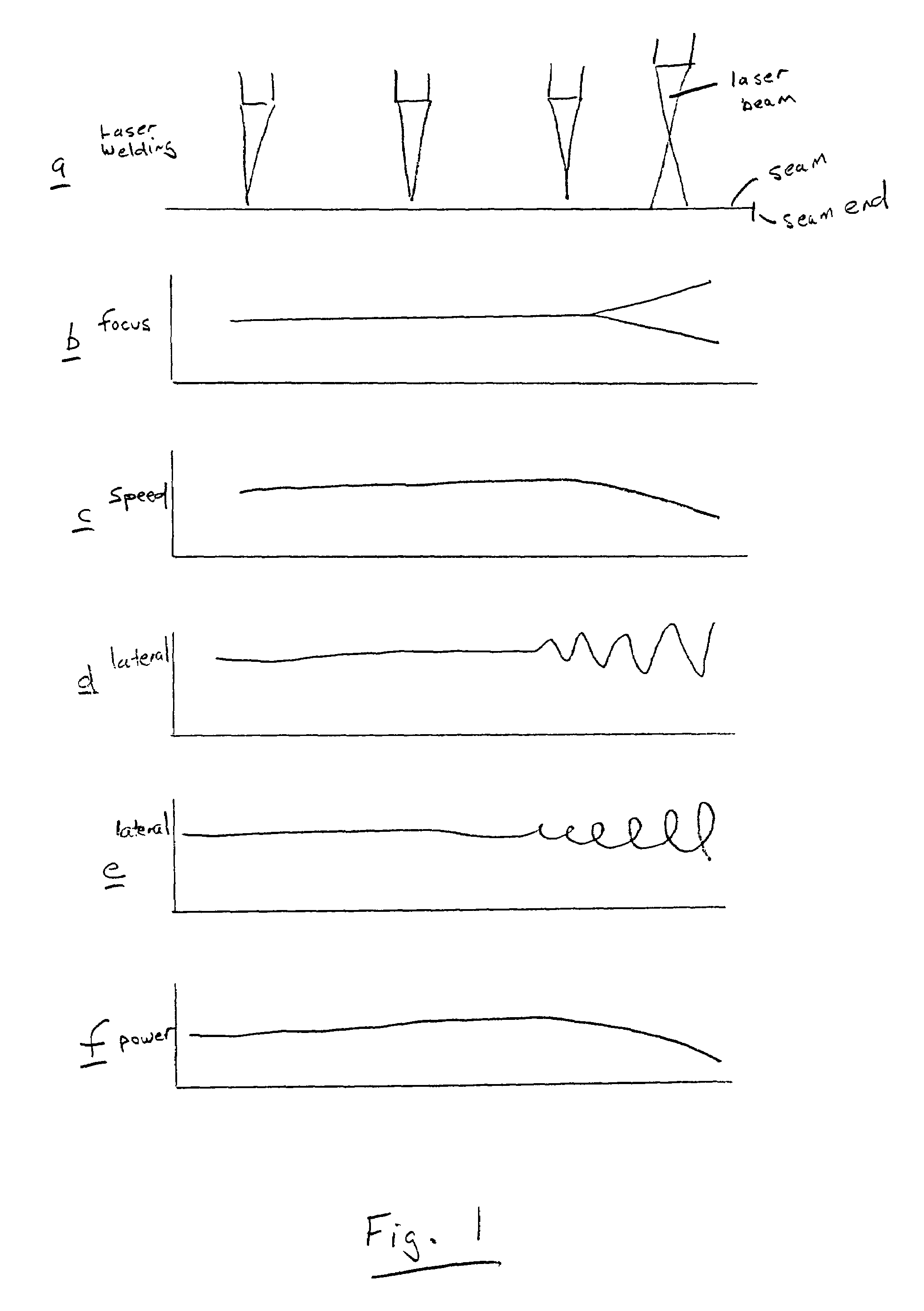

Process for laser beam welding with reduced formation of end craters

ActiveUS7091444B2Reducing end crater formationReduce formationLaser beam welding apparatusWeld seamOptoelectronics

During laser beam welding a so-called end crater forms at the end of the weld seam. The end crater is formed by the volume shrinkage of the solidifying melt after the laser beam reaches the seam end and is switched off or repositioned. The end crater acts as a geometric notch and decreases the mechanical characteristics, in particular the operational stability, of the weld seam so that holes or tears in the area of the end crater can occur. The task of the present invention is thus comprised of providing a process for reducing end crater formation. The task is solved in that towards the seam end the focus of the laser beam is distanced from the surface to be welded and / or a transverse movement of the beam occurs.

Owner:DAIMLER AG

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

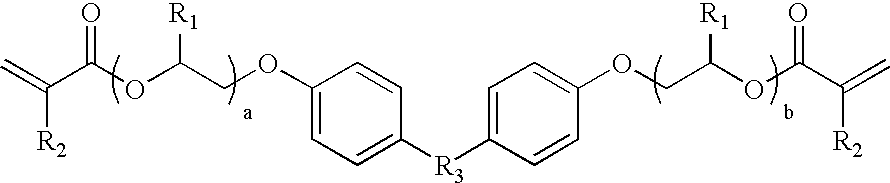

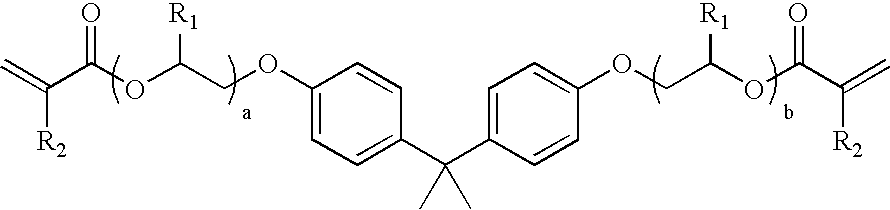

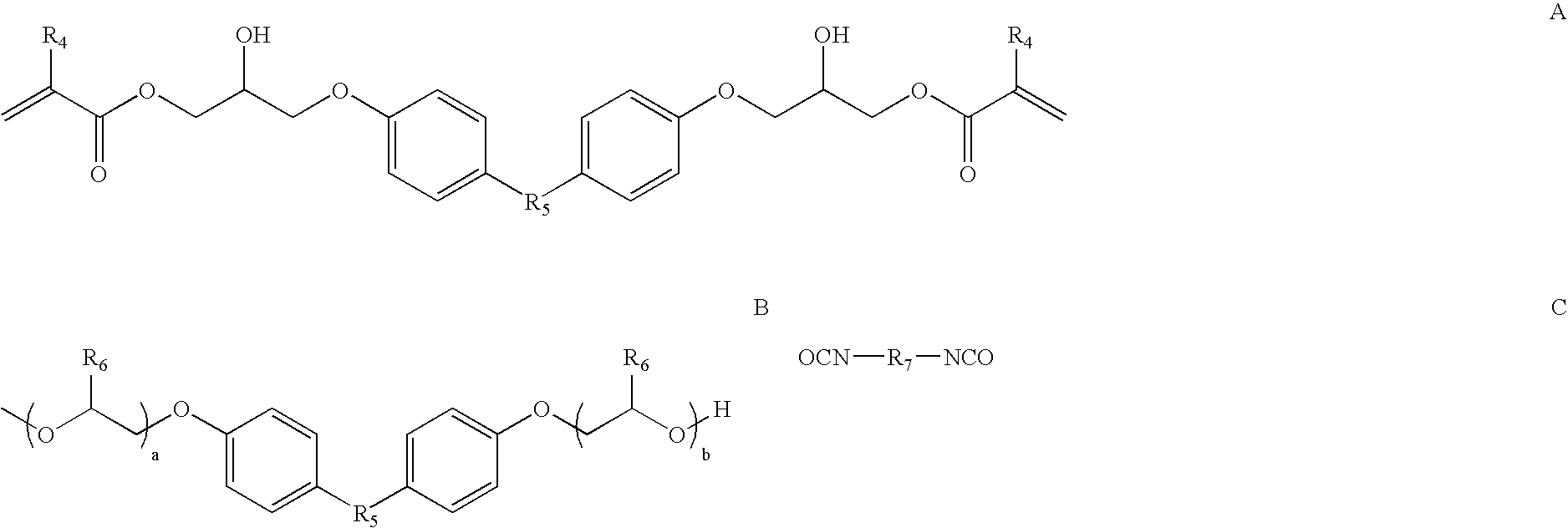

Low shrinking polymerizable dental material

A low shrinking polymerizable dental material, includes a mixture of a polymerizable di- or poly(meth)acrylate, an alkoxylated bisphenol dimethacrylate, a polymerizable monomer, a polymerization initiator and / or sensitizer, a stabilizer and a filler in a content of 70 to 85 per cent. The volumetric shrinkage during polymerization is less than 2.0 Vol.-%.

Owner:DENTSPLY RES DEVMENT

Preparation method of light-cured resin containing silicon nano gel for 3D printing and application of light-cured resin

InactiveCN106146754ALow shrinkageReduce shrinkage stressAdditive manufacturing apparatusLight cureOrganosilicon

The invention relates to light-cured resin, in particular to a preparation method of light-cured resin containing silicon nano gel for 3D printing and application of the light-cured resin. According to the resin, acrylate monomer and acrylic ester are used for modifying organo-siloxane, solution free radical polymerization is used for preparing organic silicon nano gel, the organic silicon nano gel of different structures, molecular weight and particle sizes is prepared by adjusting the structures and proportion of the monomer and organosilicone, and the optimal structure and proportion of the organic silicon nano gel are obtained. The light-cured resin with excellent comprehensive performance and containing the silicon nano gel for 3D printing is obtained by regulating the composition and proportion of the light-cured resin, and the light-cured resin has the advantages that the processing is easy, the water resistance is good, the volume shrinkage is small, and the material accuracy is high.

Owner:CHANGZHOU HUAKE POLYMERS

Triazine ring-containing polymer and film-forming composition containing same

ActiveUS20130289203A1Improve heat resistanceLower the volumeSolid-state devicesPolyamide coatingsPolymer scienceVolumetric shrinkage

A polymer containing a repeating unit structure having a triazine ring such as, for example, that which is represented by formula (25): can exhibit alone high heat resistance, high transparency, high refractive index, high solubility and low volume shrinkage; and can be used as a component in a film-forming composition as appropriate.

Owner:NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com