Hybrid light curing material for production of flexible plate as well as preparation method and application of hybrid light curing material

A hybrid light curing and flexographic technology, which is applied in the field of radiation curing, can solve the problems of hybrid light curing materials that have not yet been seen, and achieve the effects of reducing environmental pollution and waste of resources, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

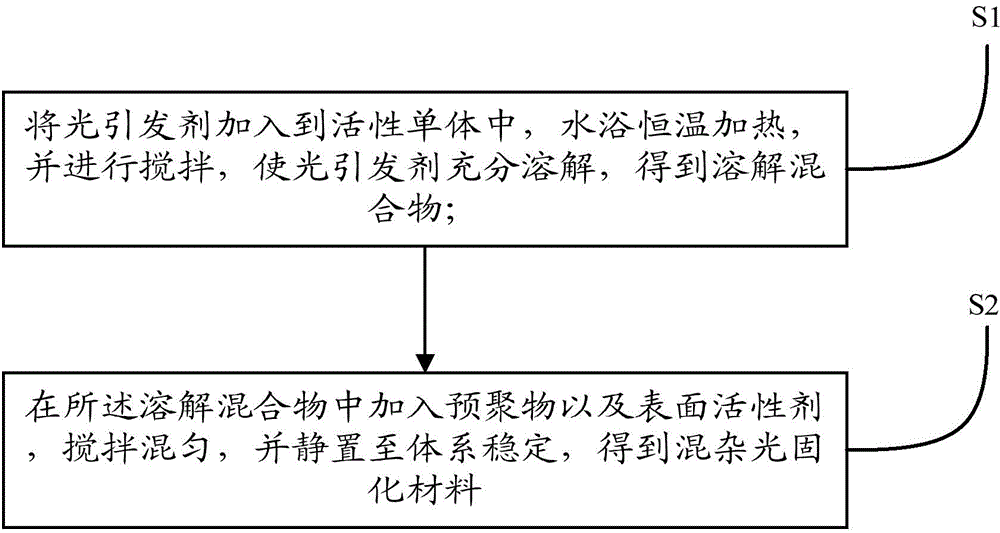

[0043] Please refer to figure 1 , the preparation method of the hybrid photocurable material provided by the invention comprises the following steps:

[0044] S1: Add the photoinitiator to the active monomer, heat in a water bath at a constant temperature, and stir to fully dissolve the photoinitiator to obtain a dissolved mixture;

[0045] In this step, preferably, the heating temperature is 40-50°C.

[0046] S2: Add the prepolymer and the leveling agent into the dissolved mixture, stir and mix, and let stand until the system is stable to obtain a hybrid photocurable material.

[0047] In this step, preferably, the stirring time is 30-60 min.

[0048] The equipment required for the preparation of the hybrid light-curing material of the present invention is an electromagnetic stirrer and ultrasonic dispersion equipment, and the process is simple and controllable. The light-curing material of the present invention is prepared and processed from commercially available prepoly...

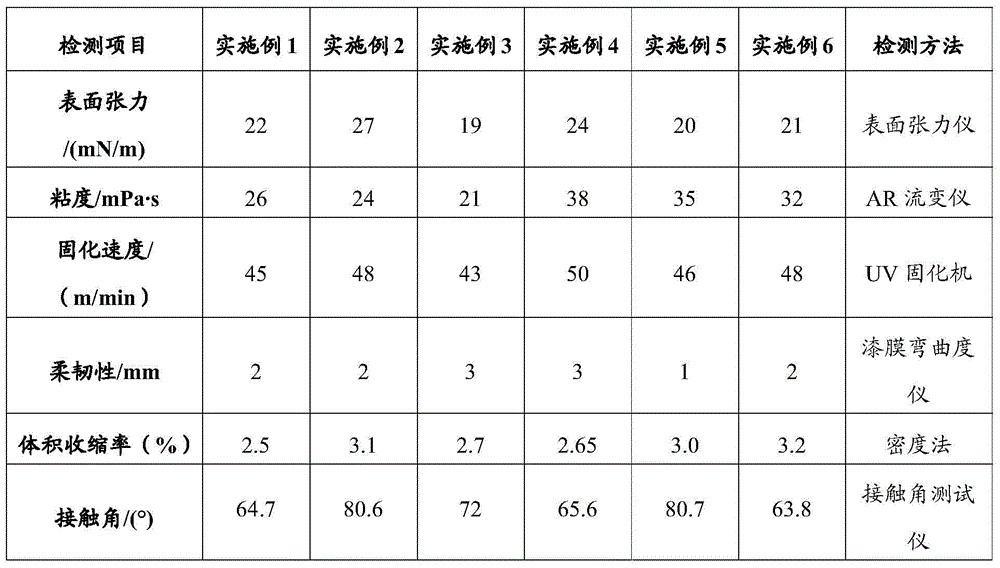

Embodiment 1

[0051] Add 5 parts of initiator to 50 parts of active monomer, heat in a water bath at 50°C, and stir to fully dissolve the photoinitiator to obtain a dissolved mixture; add 30 parts of prepolymer and 5 parts of auxiliary agent to the dissolved mixture (contains 1 part of leveling agent TEGO RAD 2700, and the rest are dispersants, such as modified acrylate block copolymers, alkene acid block copolymers or hyperdispersants with anchor groups, the same below) After stirring the mixture with a magnetic stirrer for 30 minutes to disperse, it is ready.

[0052] Wherein, wherein the prepolymer is a polyester acrylic resin, selected from V400 produced by Allnex Resin Co., Ltd., and the active monomer is a mixture of EOEOEA produced by Tianjiao Chemical Co., Ltd. and EM221 produced by Changxing Chemical Industry Co., Ltd., and the ratio is =2:3 (weight ratio), the initiator is JR-910 from Tianjin Jiuri Chemical Co., Ltd.

Embodiment 2

[0054] Add 5 parts of initiator to 45 parts of active monomer, heat at 40°C in a water bath, and stir to fully dissolve the photoinitiator to obtain a dissolved mixture; add 35 parts of prepolymer and 5 parts of auxiliary agent to the dissolved mixture After portioning, use a magnetic stirrer to stir the mixture for 30 minutes to disperse and obtain.

[0055] Among them, the prepolymer is polyester acrylic resin, which is selected from CN2302 produced by Sartomer Chemical Co., Ltd., and the active monomer is EOEOEA produced by Tianjiao Chemical Co., Ltd., EM221 produced by Changxing Chemical Industry Co., Ltd., and Tianjiao Chemical Co., Ltd. The mixture of TMPTA produced by Co., Ltd., the ratio is =2:3:1 (weight ratio), and the photoinitiator is selected from JR-910 and TPO of Tianjin Jiuri Chemical Co., Ltd., and the ratio is =1:1 (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Volumetric shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com