Patents

Literature

129results about How to "Short melting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-containing titanium-based amorphous solder for braze welding Si3N4 ceramic and preparation method thereof

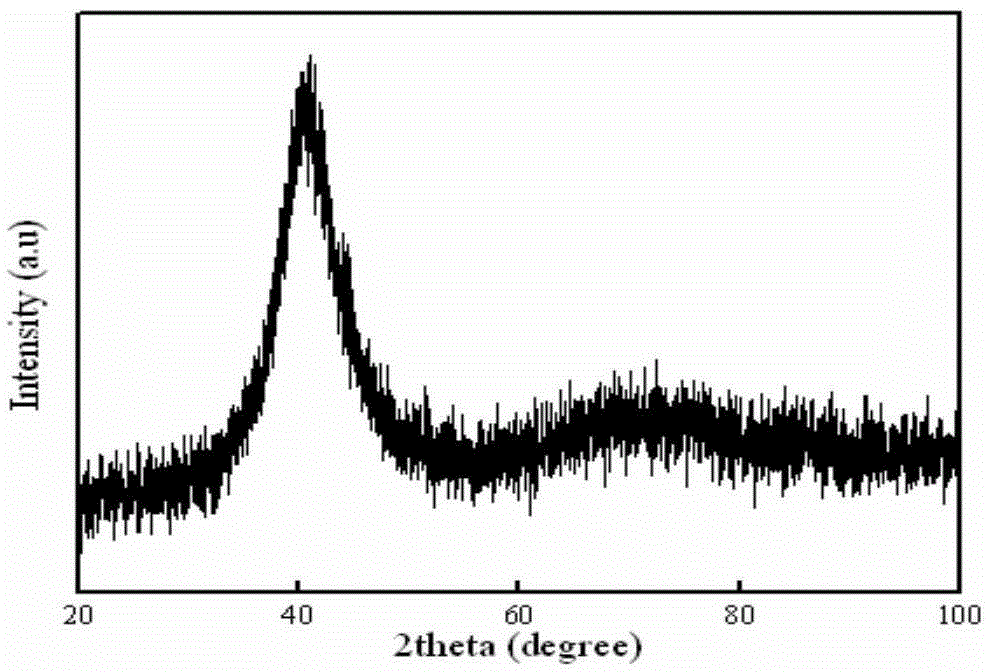

The invention relates to braze welding Si3N4 ceramics containing the boron Ti-based amorphous solder and the preparation method thereof, and belongs to the brazing material in the field of amorphous state and metallurgy. The ingredients of the brazing material consist of the following according to the mass percent: Zr of 12.0-28.0 percent, Ni of 12.0-28.0 percent, Cu of 12.0-28.0 percent, and B of 0.05-0.5 percent, and the remains is Ti. The melting scope of the brazing material ranges 1,150K to 1,250K, and the brazing temperature is from 1,273K to 1,373K. The Ti-Zr-Ni-Cu-B amorphous braze vacuum braze welding Si3N4 ceramics, which is produced by the rapid solidification technology, has superior high-temperature performance to Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder. The tie-in high-temperature bend strength reaches 145MPa under 673K DEG,108MPa under 773K DEG, and still 93MPa under 873K DEG.

Owner:JIANGSU UNIV OF SCI & TECH

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

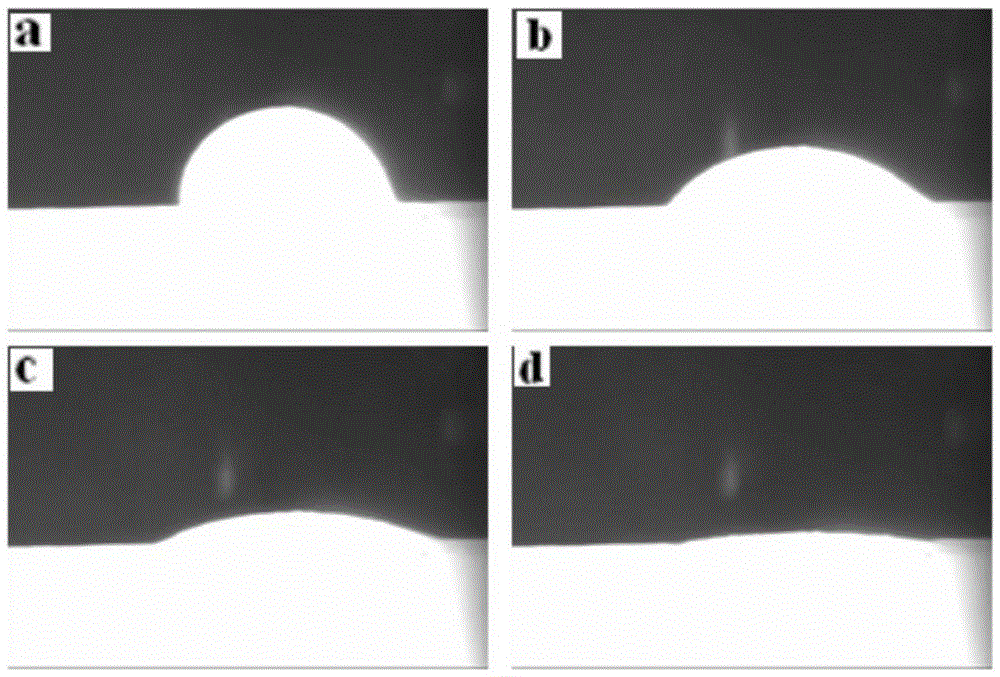

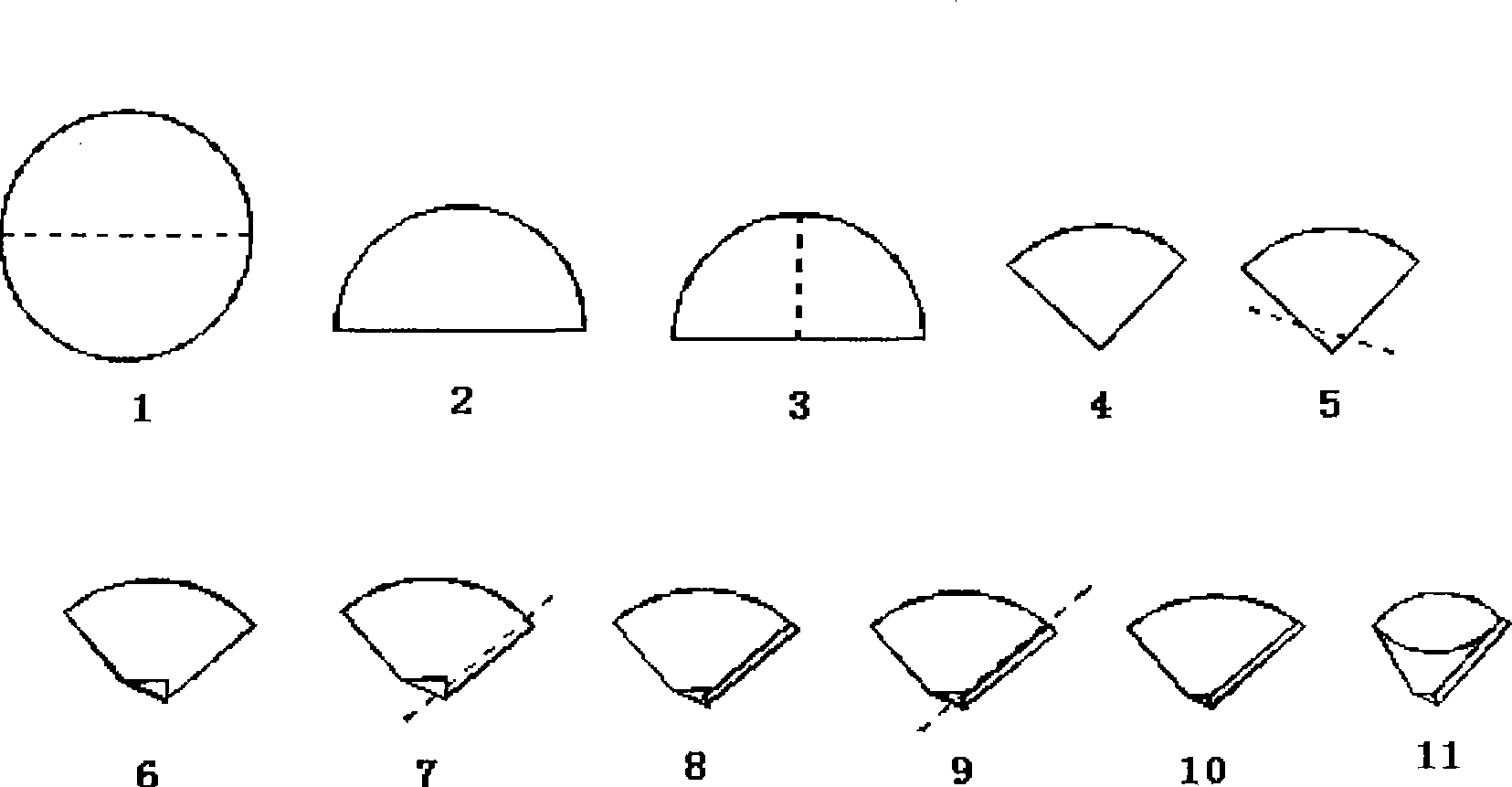

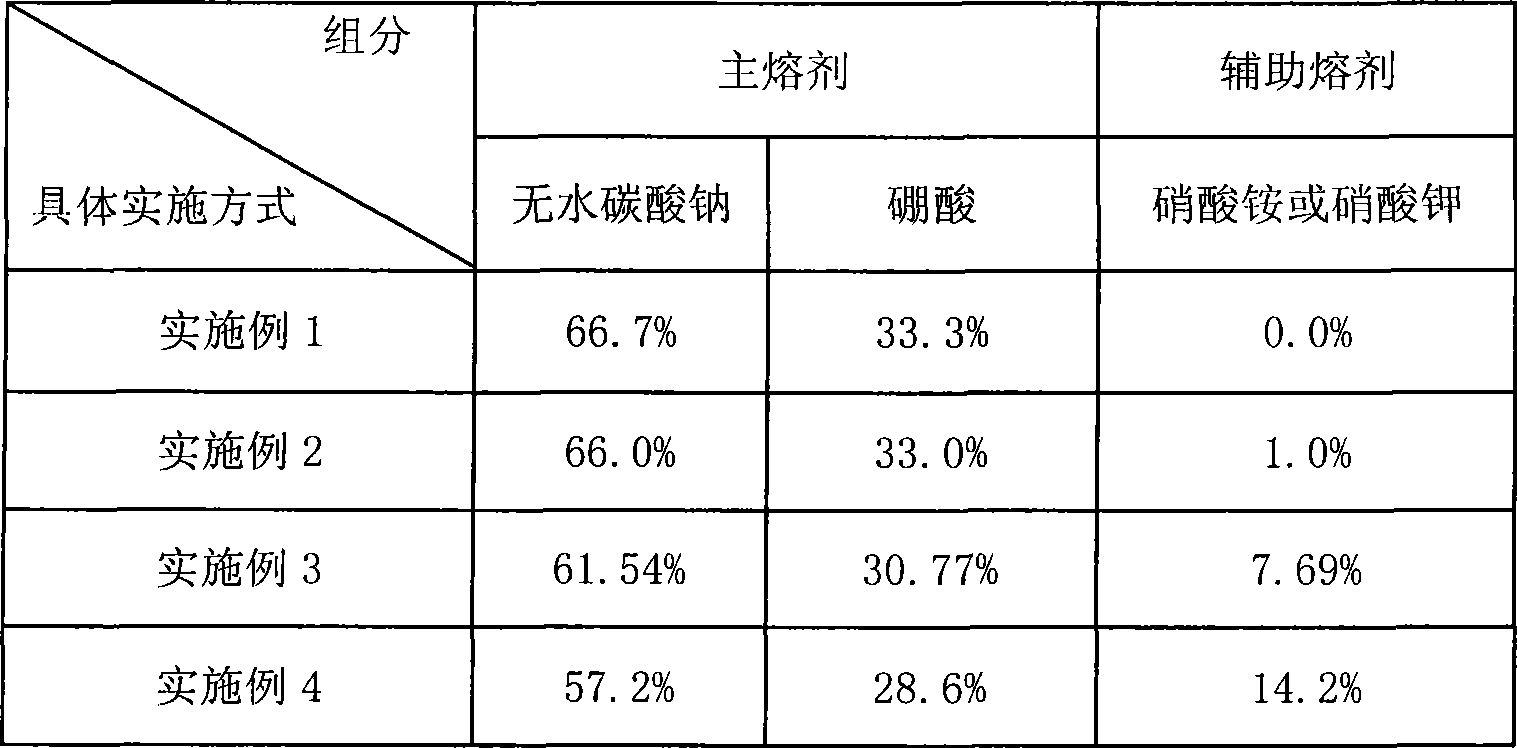

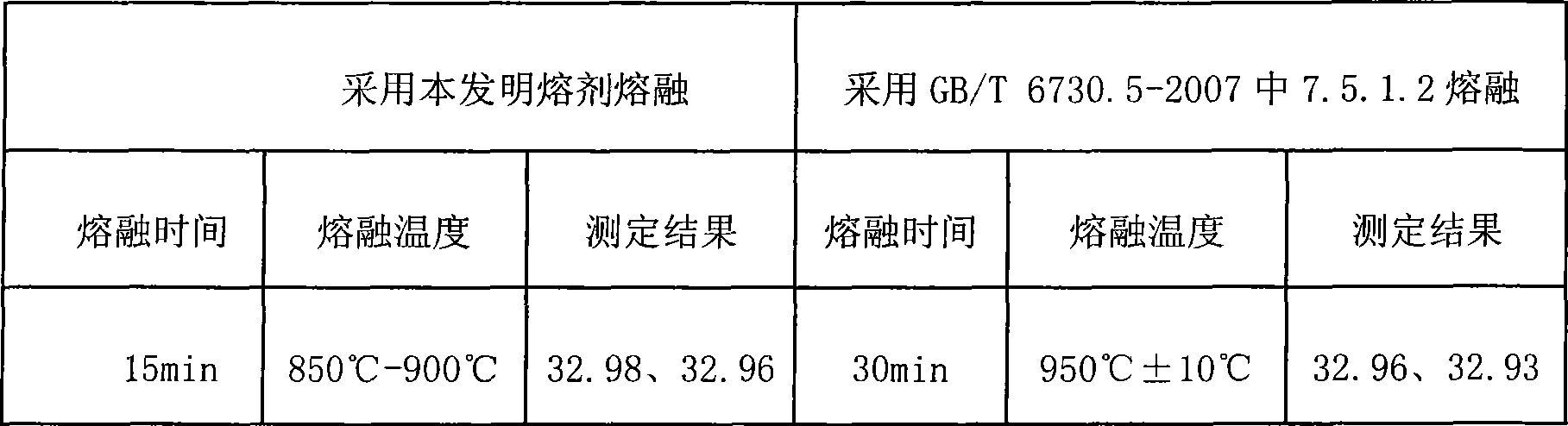

Fusion metallurgy sample analysis fusing agent and its preparation and use method

InactiveCN101368886ALess materialEasy to preparePreparing sample for investigationDecompositionMagnetite

The invention discloses an analysis fluxing agent for melting metallurgical samples, and a preparation and using method thereof; the analysis fluxing agent is prepared with a main fluxing agent and an auxiliary fluxing agent, wherein, the contents of anhydrous sodium carbonate and boric acid reach 85.80% to 100%; the content of the auxiliary flux agent nitrate ammonium or potassium nitrate is 0 to 14.20%; the invention can be used to melt and decompose vanadium-titanium magnetite, vanadium-titanium-bearing slag, high-titanium slag, metallurgical auxiliary material, refractory material, vanadium slag, non-ferrous metal ores and other metallurgical samples; the flux agent of the invention has the advantages of less material adoption, simple preparation method, low cost, simple operation, short melting time, as well as good melting and decomposition effect; the melted samples are of easy acid leaching and decomposition, wide application and convenient using.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

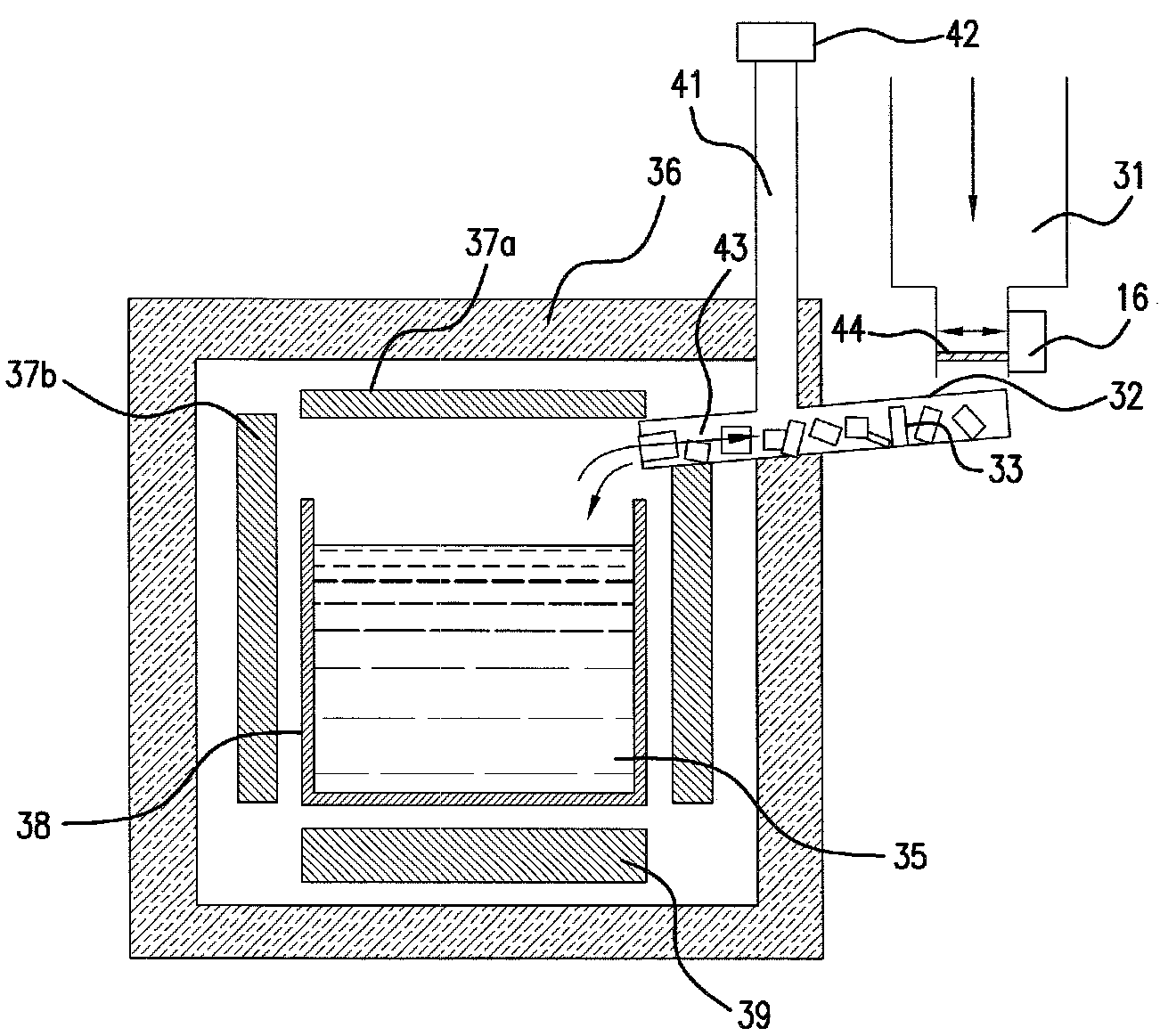

Method for producing a monocrystalline or polycrystalline semiconductore material

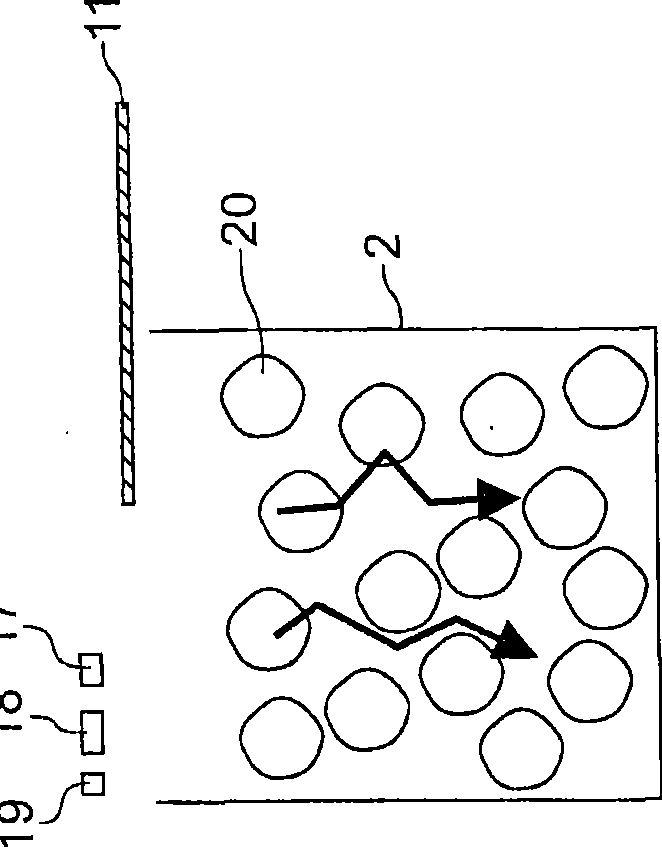

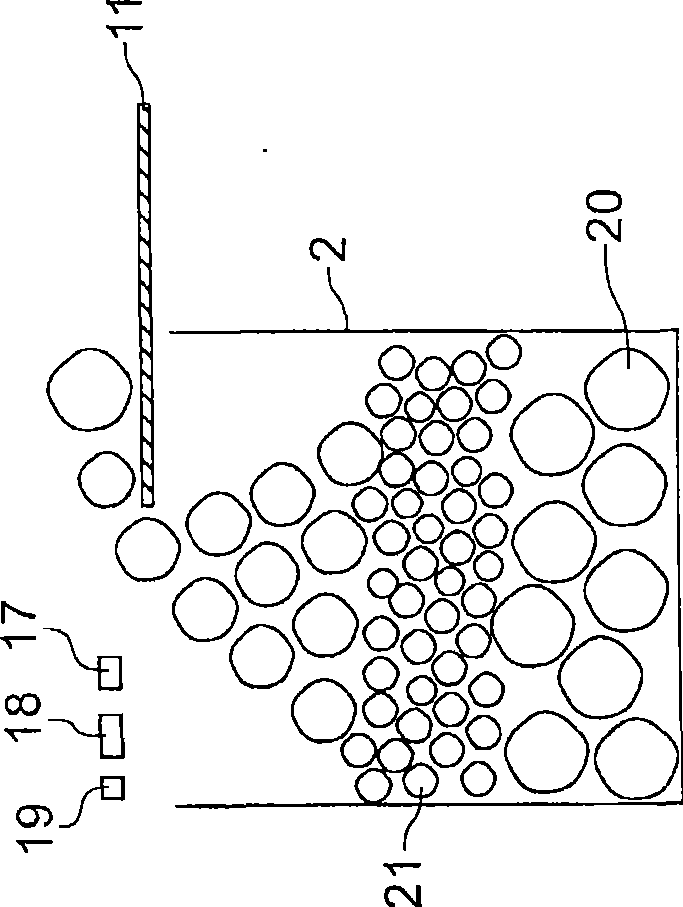

ActiveUS20090158993A1High filling levelShort melting timeAfter-treatment apparatusPolycrystalline material growthVertical gradientCrucible

The invention relates to a method for producing a monocrystalline or polycrystalline semiconductor material by way of directional solidification, wherein lumpy semiconductor raw material is introduced into a melting crucible and melted therein and directionally solidified, in particular using the vertical gradient freeze method.In order to prevent contamination and damage, the semiconductor raw material is melted from the upper end of the melting crucible. The molten material trickles downward, so that semiconductor raw material which has not yet melted gradually slumps in the melting crucible. In this case, the additional semiconductor raw material is replenished to the melting crucible from above onto a zone of semiconductor raw material which has not yet melted or is not completely melted, in order at least partly to compensate for a volumetric shrinkage of the semiconductor raw material and to increase the filling level of the crucible.In order to reduce the melting-on time and to influence the thermal conditions in the system as little as possible, the semiconductor raw material to be replenished is heated by the purposeful introduction of heat to a temperature below the melting temperature of the semiconductor raw material and introduced into the container in the heated state.

Owner:SCHOTT AG

Polyvinyl chloride powdery plastic dipping composition

The invention relates to a polyvinyl chloride powdery plastic dipping composition, and belongs to the technical field of processing and application of high-molecular materials. The polyvinyl chloride powdery plastic dipping composition is characterized by comprising the following components (in parts by weight): 100 parts of polyvinyl chloride, 2-15 parts of polyvinyl chloride paste resin, 35-65 parts of plasticizing agent, 1-7 parts of stabilizing agent, 1-6 parts of epoxidized soybean oil, 2-10 parts of lubricating agent and 0-10 parts of filler, wherein polyvinyl chloride is suspension method polyvinyl chloride resin, the polymerization degree is 500-800, and the grain diameter is 50-200 micrometers; the polymerization degree of the polyvinyl chloride paste resin is 1000, and the grain diameter is 5-20 micrometers. Compared with the prior art, the polyvinyl chloride powdery plastic dipping composition disclosed by the invention achieves shorter melting and plasticizing time and better leveling property of a plastic dipping product by requiring the polymerization degree of polyvinyl chloride resin powder and the granular size of the composition.

Owner:CHINA PETROLEUM & CHEM CORP

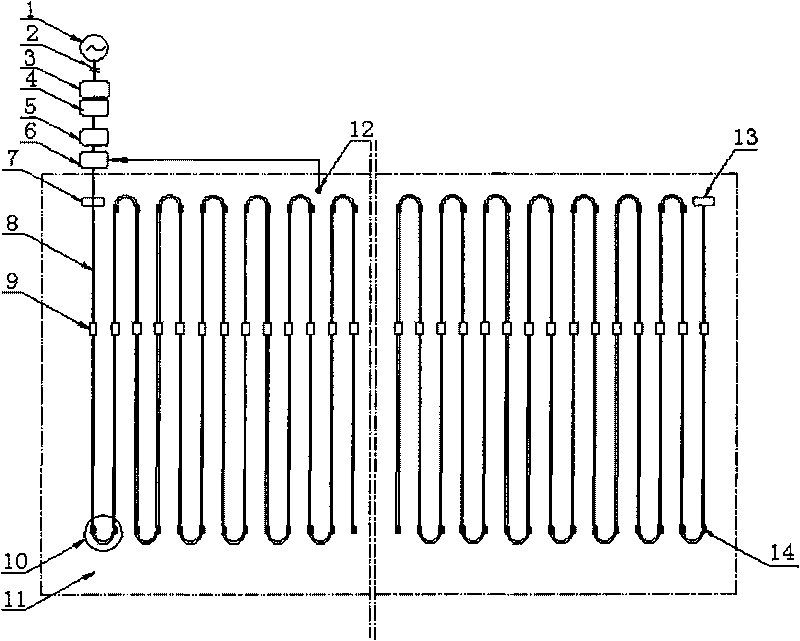

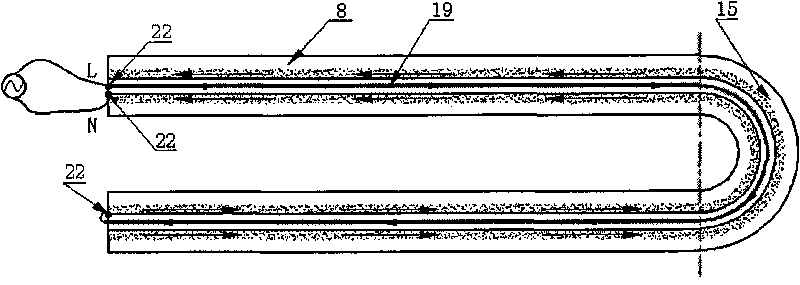

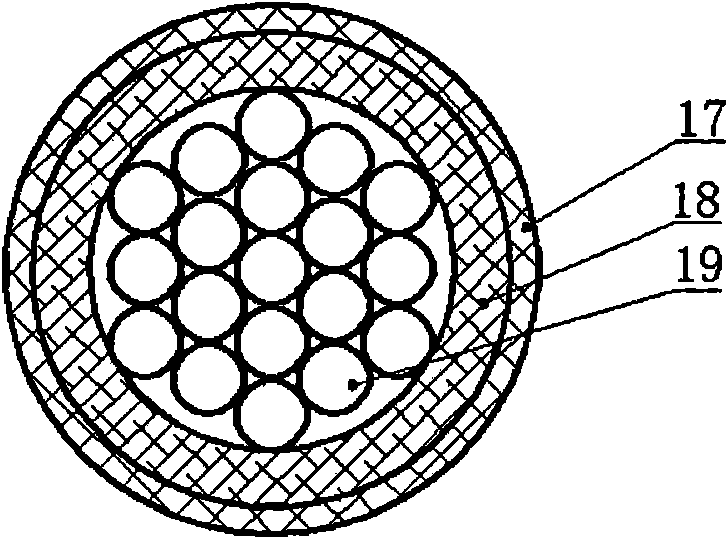

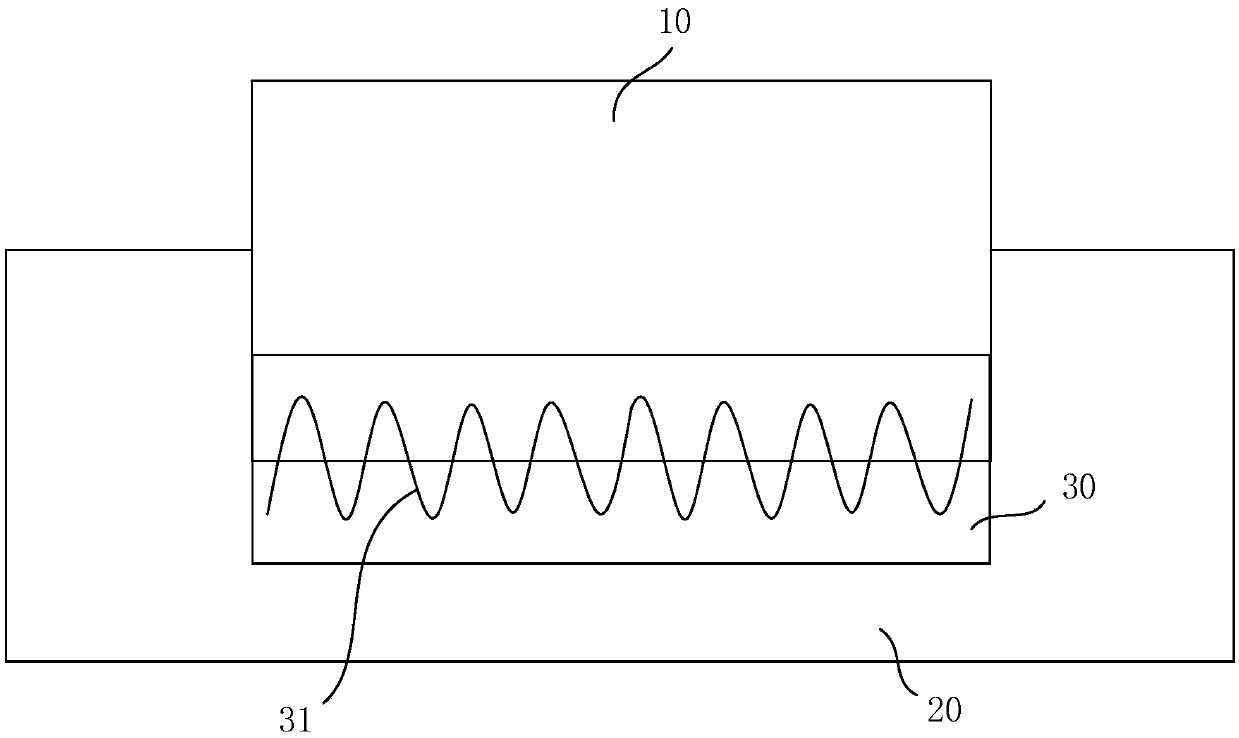

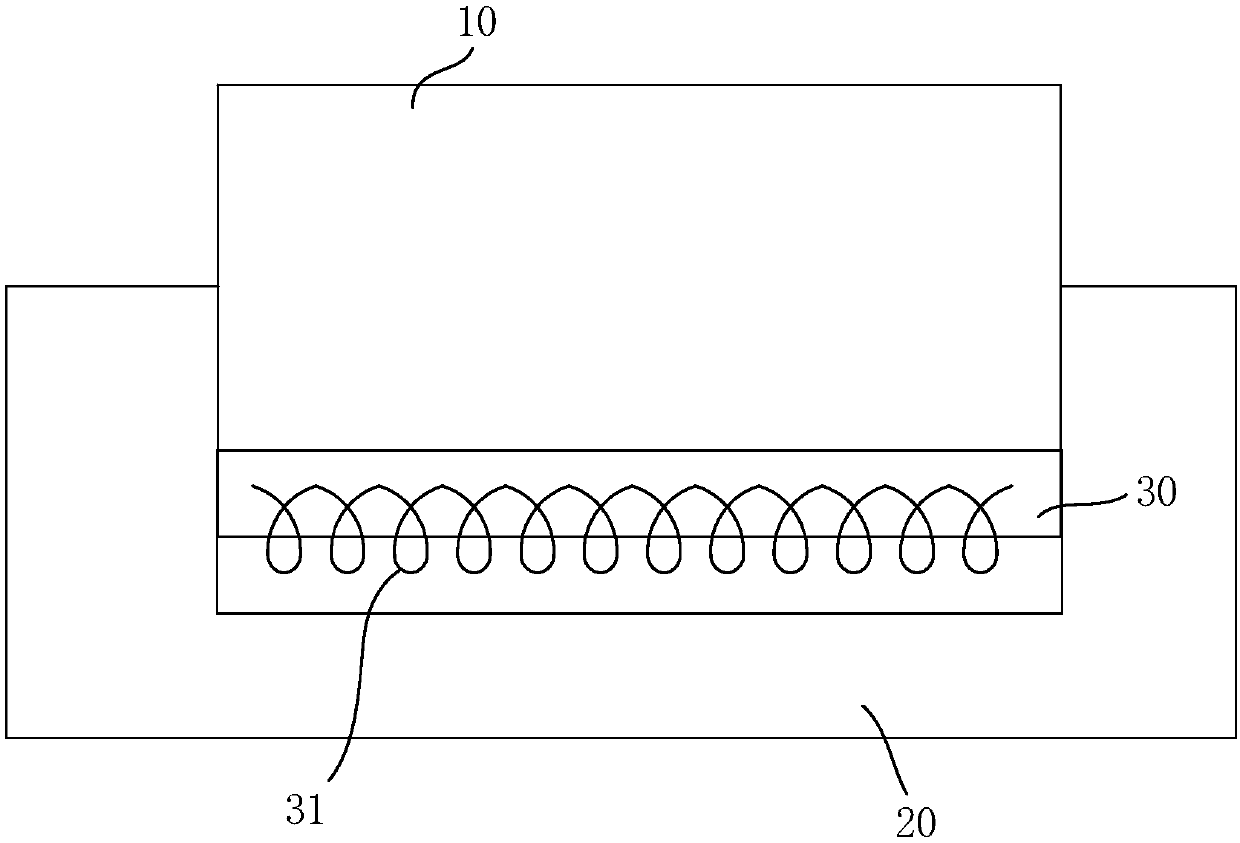

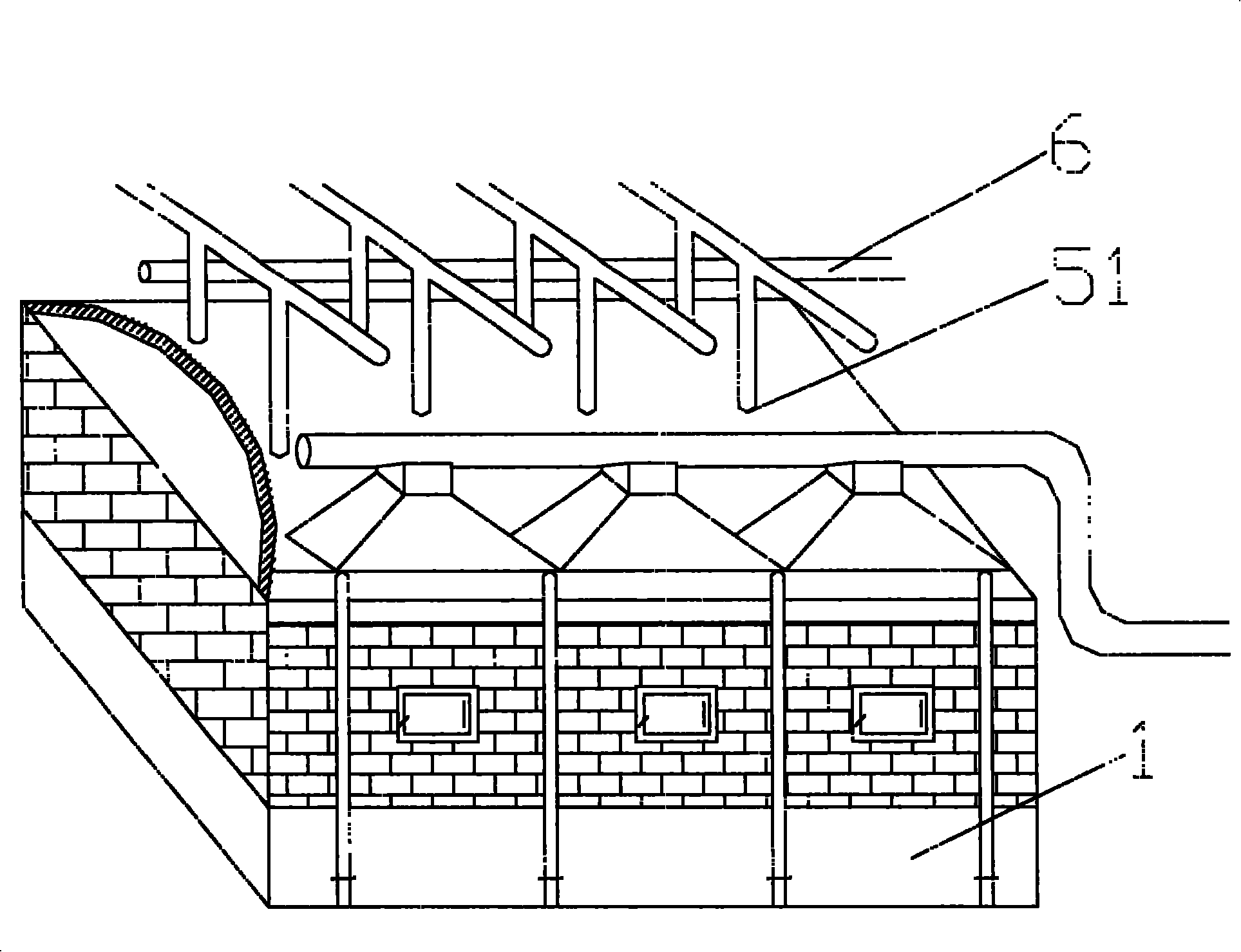

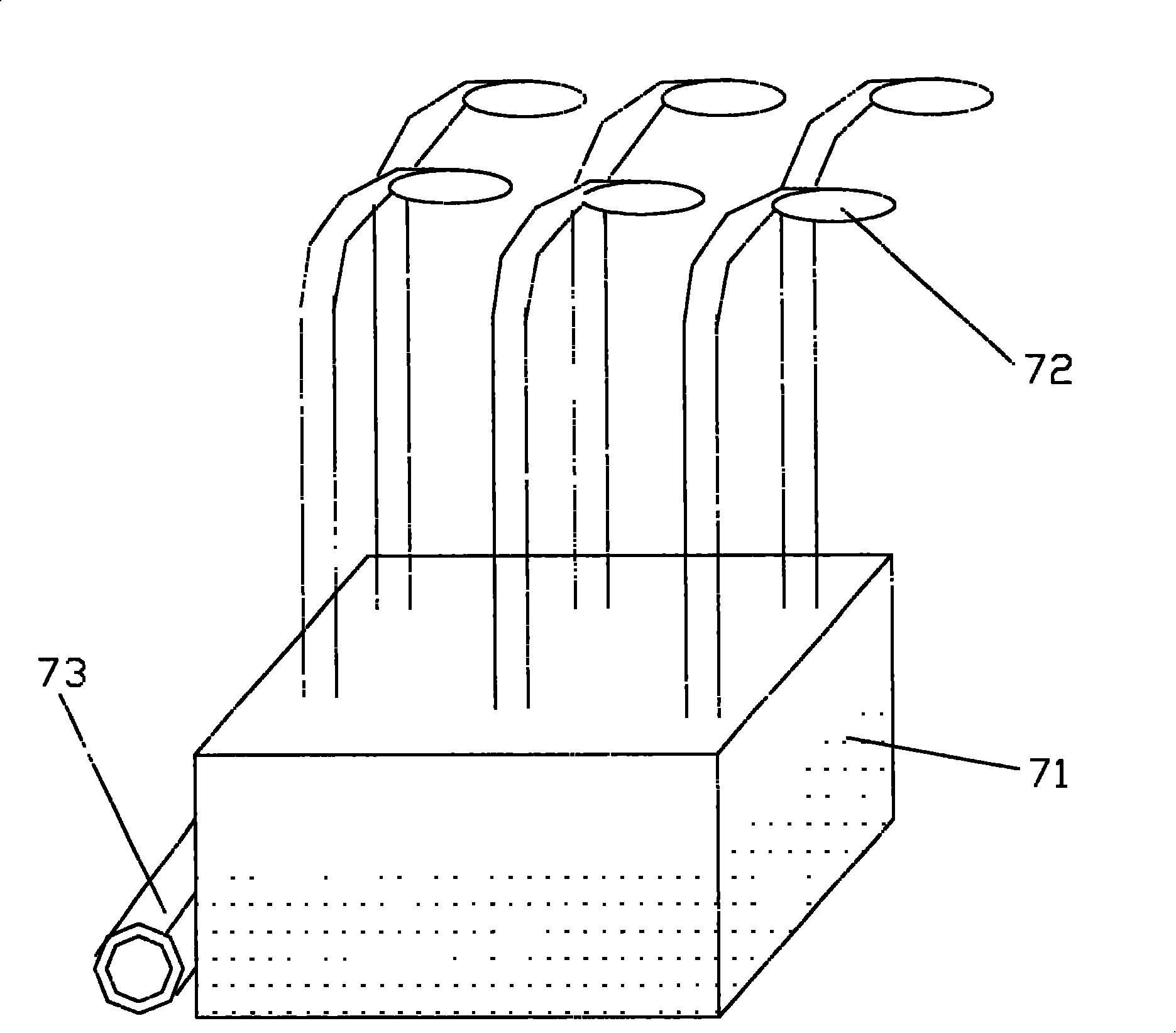

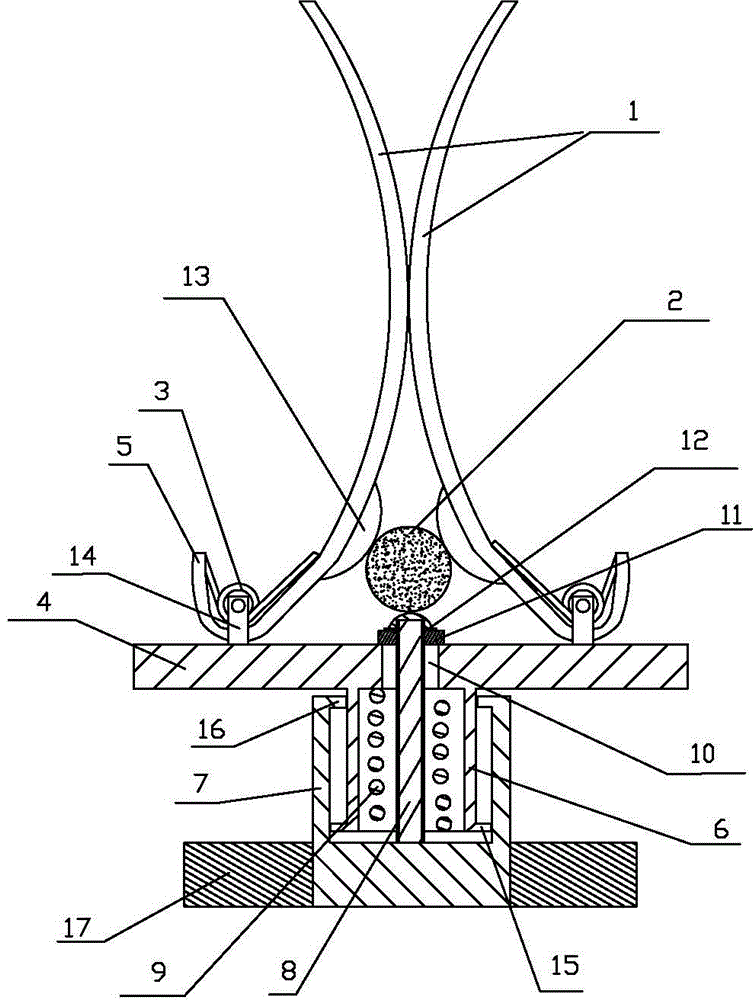

Method and system for heating and melting snow and ice on road surface under current surface effect

ActiveCN101718070AHigh mechanical strengthWill not disconnectPaving detailsRoad surfaceAlternating current

The invention relates to a method and a system for heating and melting snow and ice on the road surface under the current surface effect. The system comprises an alternating-current power supply, an input cable, a three-phase transformer, a three-phase balancer, an electrical switch, a temperature control device, a snow and ice melting sensor, a power supply terminal box, highly-ferromagnetic iron pipes, a transitional connecting tube, a high temperature wire, an electrical switch (3), a U-shaped bent-pipe wire penetrating part, an end terminal box, a grounding protector and a cathode protector. A U-shaped surface action heating element which is formed by connecting a plurality U-shaped highly-ferromagnetic iron pipes is energized under the surface effect and the proximity effect to efficiently emit heat to rapidly melt the snow and the ice on the road surface. The U-shaped highly-ferromagnetic iron pipes are buried in the teinforced concrete or asphalt road surface. The U-shaped surface action heating element has high mechanical strength and quite long service life, can be used permanently, is not easy to be subjected to the wire disconnection, is very easy to repair when being damaged, needs only one power supply point, can not affect the three-phase power supply balance, can be heated uniformly, adjusted randomly in temperature and constructed and installed conveniently with least labor, has high degree of automation, does not need electric insulation, is safe, reliable and economical and can not pollute the environment.

Owner:WUXI HENGYE ELECTRICAL HEATER EQUIP

High-temperature amorphous solder for soldering Si3N4 ceramics

InactiveCN101823188AGood flexibilityImprove wettabilityWelding/cutting media/materialsSoldering mediaRoom temperatureFlexural strength

The invention discloses high-temperature amorphous solder for soldering Si3N4 ceramics, belonging to the technical field of soldering materials. The high-temperature amorphous solder of the invention for soldering the Si3N4 ceramics comprises the following components by weight percent: 35.0% to 45.0% of Ti, 20% to 30% of Zr, 0.1% to 0.3% of B and Cu in balancing amount, wherein the melting temperature of the solder ranges from 1,100K to 1,200K, and the soldering temperature thereof is 1,223K to 1,373K. The Si3N4 ceramics is prepared by vacuum-soldering the Ti-Zr-Cu-B high-temperature active amorphous solder on the basis of the rapid solidification technology, and the maximal room-temperature strength of the Si3N4 ceramics reaches 245MPa; and the high-temperature performance thereof is much higher than that of the Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder, particularly, the high-temperature bending strength of the ceramic connector is 165.5MPa at the testing temperature of 673K.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing fluorine phosphorus composite opacifying glass

The invention discloses a method for preparing a fluorophosphate composite opaque glass, which comprises the following steps: 1) raw material preparation: 50 to 65 portions of silica, 0.5 to 6.5 portions boron oxide, 2 to 5 portions alumina, 10 to 17.5 portions calcium oxide, 0.5 to 6 portions of magnesium oxide, 0.5 to 2 portions of zinc oxide, 5 to 10 portions of sodium oxide, 5 to 8 portions of phosphorus pentoxide, 0.5 to 2 portions of sodium fluosilicate and 1 portion of calcium nitrate. The materials form the raw material after evenly mixing; 2) the raw material is melted under the temperature ranging from 1,300 DEG C to 1,480 DEG C and a clarification; the material then is extruded and pulled for shaping; an annealing is followed and the material is then cooled to a normal temperature. After a polishing and a cutting, the fluorophosphate composite opaque glass is obtained. The method for preparing the fluorophosphate composite opaque glass in the invention has the advantages of not only preventing the environment pollution by fluoride, but also saving energy.

Owner:ZHEJIANG UNIV

Composite livestock and birds depilator, its preparation method and application method

InactiveCN1826913AMeet health requirementsShort melting timeOther chemical processesPoultry processingWaxLivestock

The invention discloses a new composite poultry depilatory and the method for making and using the same, mainly to solve problem of difficulty to remove small hair from pig head, hog hoofs, and other poultries. The product comprises rosin glycerine cream, animal oil and fat and ceresin wax, and is characterized by high hair removing rate, safe, non toxic and convenient usage.

Owner:NANJING YURUN FOOD

Preparation method for pelletizing and producing yellow phosphorus by phosphorus ore concentrate

The invention provides a preparation method for pelletizing and producing yellow phosphorus by a phosphorus ore concentrate which comprises the following components in terms of producing 1000 Kg of yellow phosphorus: 7100-8500 Kg of phosphorus ore concentrate powder, 1800-2000 Kg of coke dust, 1800-3300 Kg of silica powder, 130 Kg of humic acid and 65 Kg of sodium hydroxide. The preparation method is as follows: grinding formula components by a ball mill; adding a binder composed of the humic acid and the sodium hydroxide, and evenly stirring; processing into a compound pellet by a ball pressing and forming machine; dying by a chain plate dryer; and sending into a yellow phosphorus electric furnace to prepare into a yellow phosphorus finished product. The invention fully utilizes powder phosphate ores and low-grade phosphate ores; the phosphorus ore concentrate powder obtained by mineral separation is produced into a pellet by the binder, and then the pellet is prepared into yellow phosphorus by the electric furnace. Compared with the existing phosphorus preparation by a phosphorus ore concentrate, the invention lowers cost by one time, reduces CO emission by about 35%, reduces electricity consumption by about 40%, improves capacity by 2 times and reduces materials by about 40%. Thus, the invention is an excellent method for solving the problems of high energy consumption, high emission and high pollution for yellow phosphorus production in China.

Owner:瓮安烨烨磷化工实业有限公司

Method for welding battery tabs and busbar

The invention discloses a method for welding battery tabs and a busbar, and belongs to the technical field of laser welding. The method comprises the following steps: attaching the battery tabs to thebusbar and keeping the battery tabs relatively fixed; selecting a laser welding device, wherein the diameter of a transmission optical fiber core of the laser welding device is less than or equal to30 microns, the optical amplification ratio of a laser beam is 1: (1-3), and the output power of a laser is 500-2000W; and carrying out curve track welding on laser beam spots along to-be-welded areasof the battery tab and the bus bar, wherein the welding speed is more than or equal to 50 mm / s. By adopting smaller laser beam spots and higher welding speed, the welding time of a welded workpiece is short, few intermetallic compounds are generated, the welding strength between the workpieces is high, and the electric conductivity is high. The welding track of the curve stripes is adopted for laser welding, so that the welding track is increased, and the connecting area of welding seams is increased. The welding method reduces the welding cost of a battery module.

Owner:HANS LASER TECH IND GRP CO LTD

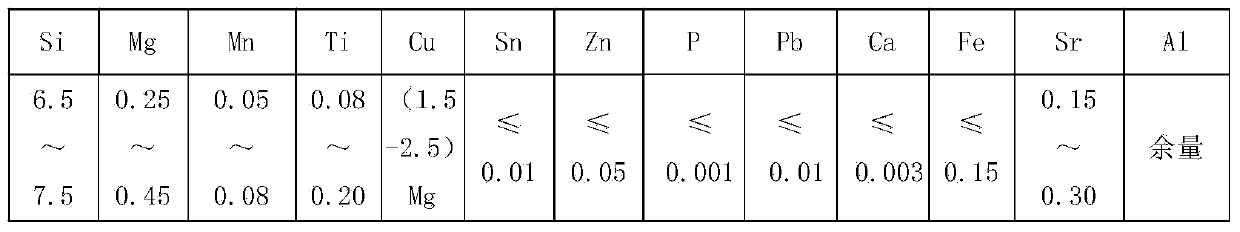

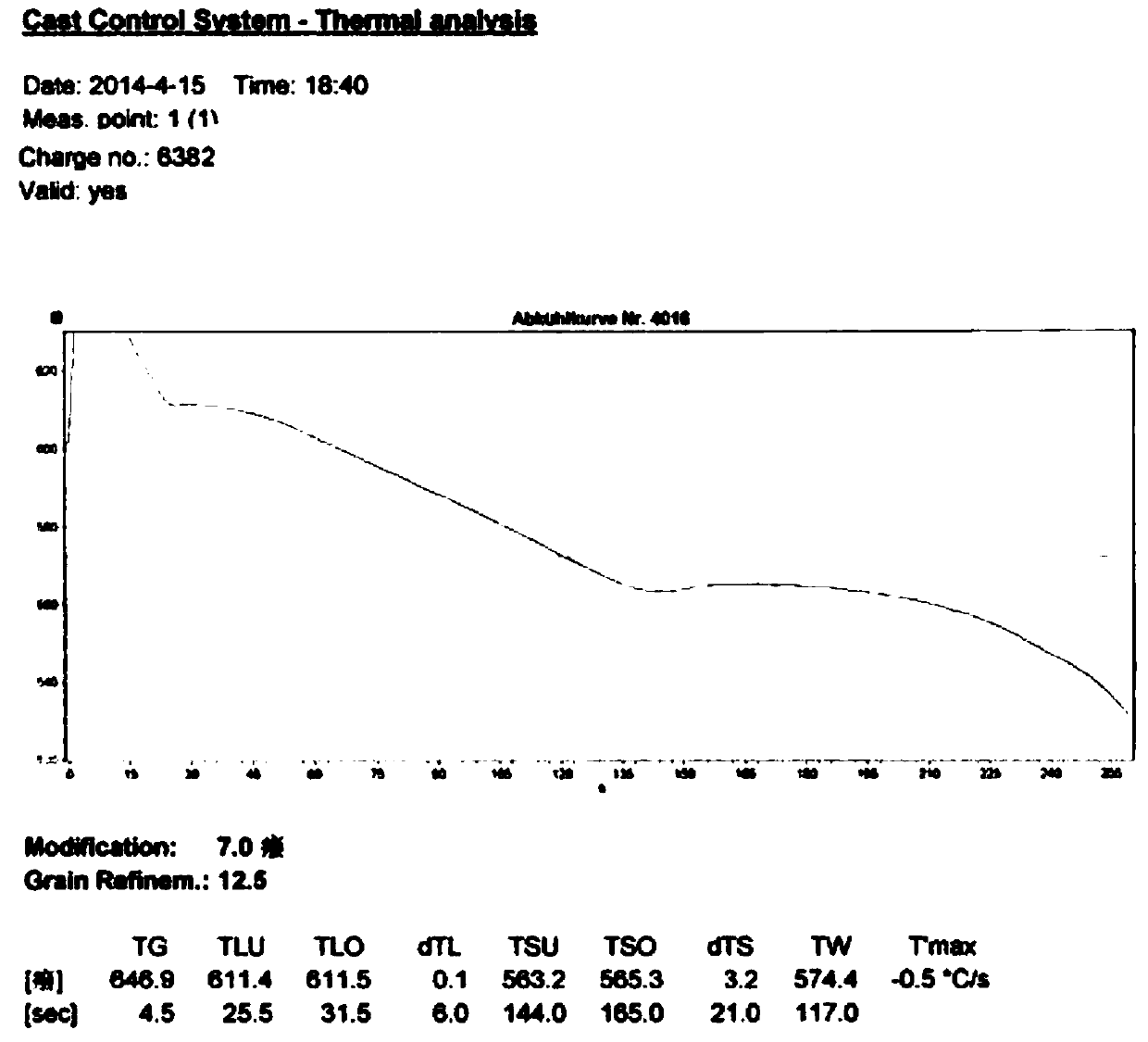

Hypoeutectic Al-Si alloy material for all-aluminum engine of high-grade car and preparation method of hypoeutectic Al-Si alloy material

The invention relates to a hypoeutectic Al-Si alloy material for an all-aluminum engine of a high-grade car and a preparation method of the hypoeutectic Al-Si alloy material. The hypoeutectic Al-Si alloy material with high strength and high toughness is researched by adding Cu and Mn strengthening elements and a Sr modification element, improving an industrial silicon melting process and adopting a process for removing gas and residues in a furnace and a casting process and a technology for detecting refinement and modification of alloy on line through thermal analysis. The hypoeutectic Al-Si alloy material has the tensile strength of 338-345Mpa and the elongation rate of 8.5-9.2% and can be completely applied to the all-aluminum engine of the high-grade car at home and abroad.

Owner:天津新立中合金集团有限公司

Innocent treatment method for arsenic containing mixed salt

The invention relates to an innocent treatment method for arsenic containing mixed salt. The method comprises the following steps of: (1) uniformly mixing arsenic containing mixed salt and slag or / and cullet, and controlling the content of arsenic in the mixed material at1.0-4.8wt% to obtain a mixed material; (2) feeding the mixed material into a furnace, heating to 1150-1250 DEG C, and insulating and melting for 0.4-2.4 hours to obtain melt; and (3) pouring the melt to a die to prepare solid or entering into water for water-quenching while the melt is still hot to obtain particle arsenic containing solid. The method for treating the arsenic containing mixed salt is free from environmental hidden danger, and free from secondary pollution, and the whole process is simple in flow, short in processing time, simple and convenient to operate, low in energy consumption, and suitable for industrialized production.

Owner:锡矿山闪星锑业有限责任公司

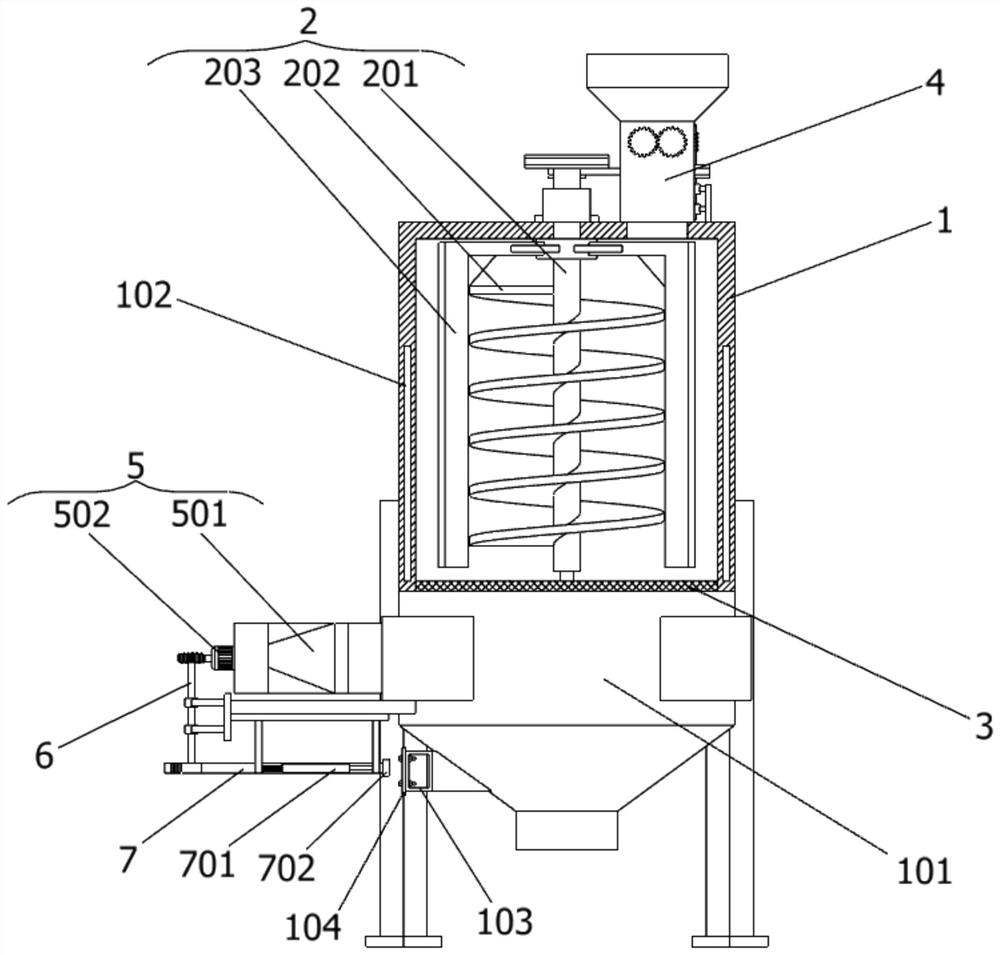

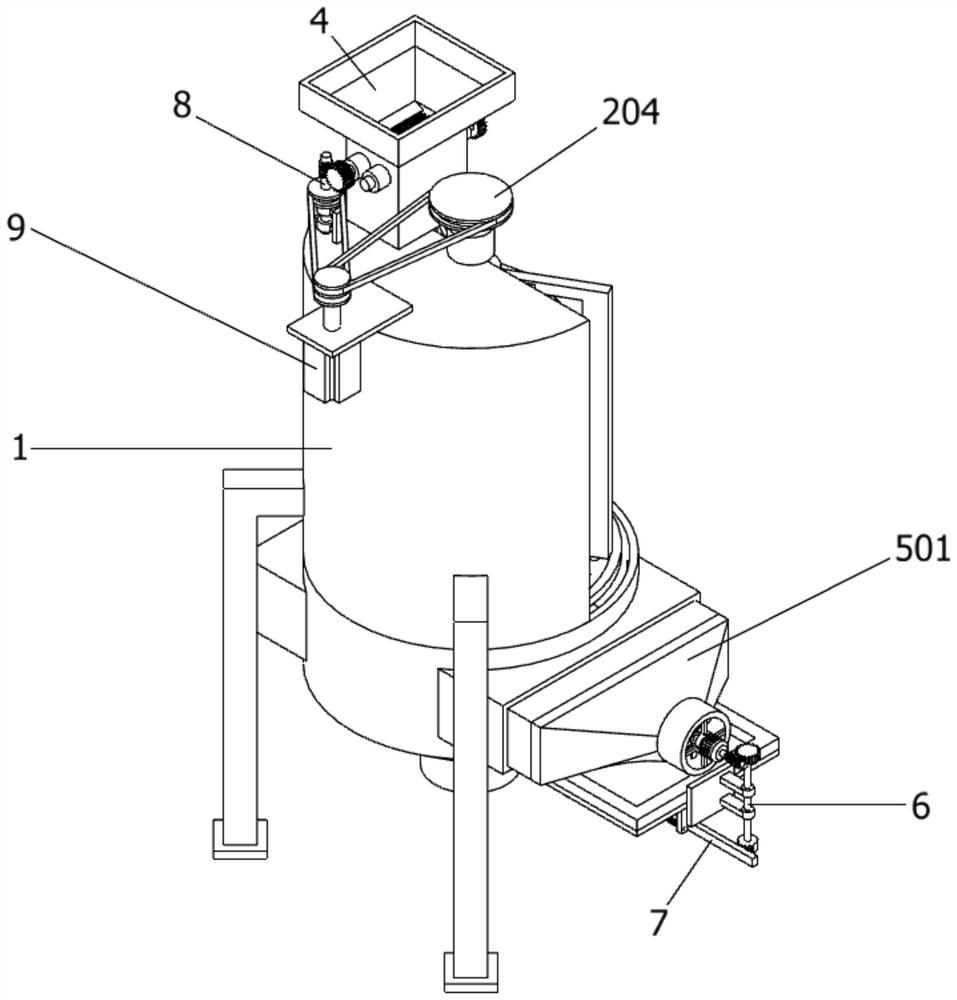

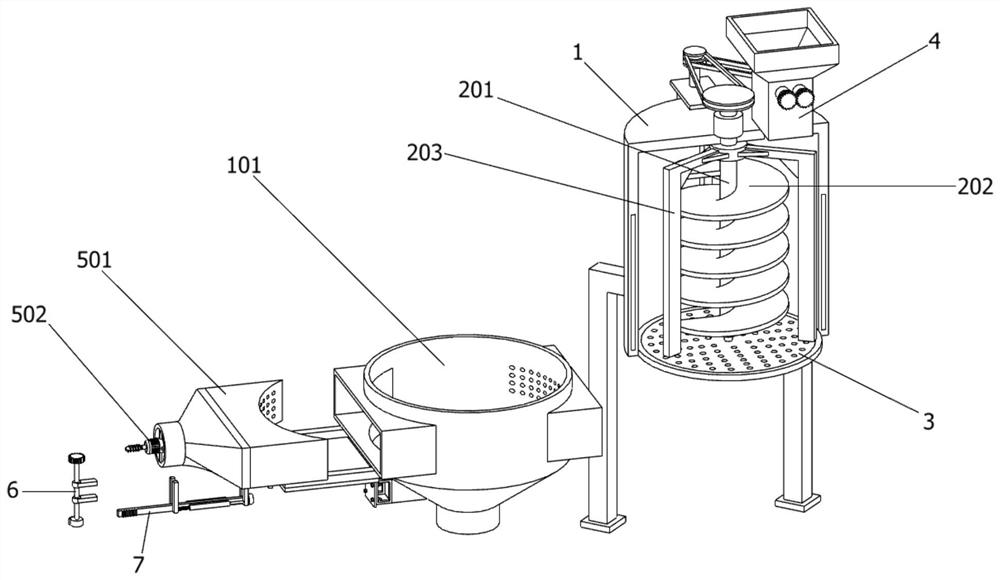

Environment-friendly granulator for recycling waste plastics

InactiveCN112917751AImprove melting efficiencyShort melting timePlastic recyclingGrain treatmentsElectric machineryProcess engineering

The invention provides an environment-friendly granulator for recycling waste plastics, belongs to the technical field of granulators, and aims to solve the problem that when the granulator downwards extrudes molten plastics, the extruded molten plastics have relatively high viscosity and easily adhere to the inner wall of a discharging receiving hopper. The environment-friendly granulator for recycling the waste plastics comprises a barrel body, wherein a rotary driving mechanism is arranged at the upper end in the barrel body, and a screen is mounted at the lower end in the barrel body; and a crushing hopper is arranged on the right side of the top end surface of the barrel body, and a cooling mechanism is arranged on the lower portion of the left side of the barrel body. Through the arrangement of the cooling mechanism, an air blowing motor is started, a double-end rotating shaft of the air blowing motor drives air blowing fan blades and a second worm to rotate correspondingly, external air is blown into an air blowing cover through the rotating air blowing fan blades, then air is evenly blown away to the granular molten plastics in the cut-off and falling process through air blowing holes in the air blowing cover, so that the granular molten plastics are rapidly cooled, and the granular molten plastics are not prone to adhering to the inner wall of the discharging receiving hopper.

Owner:田峰

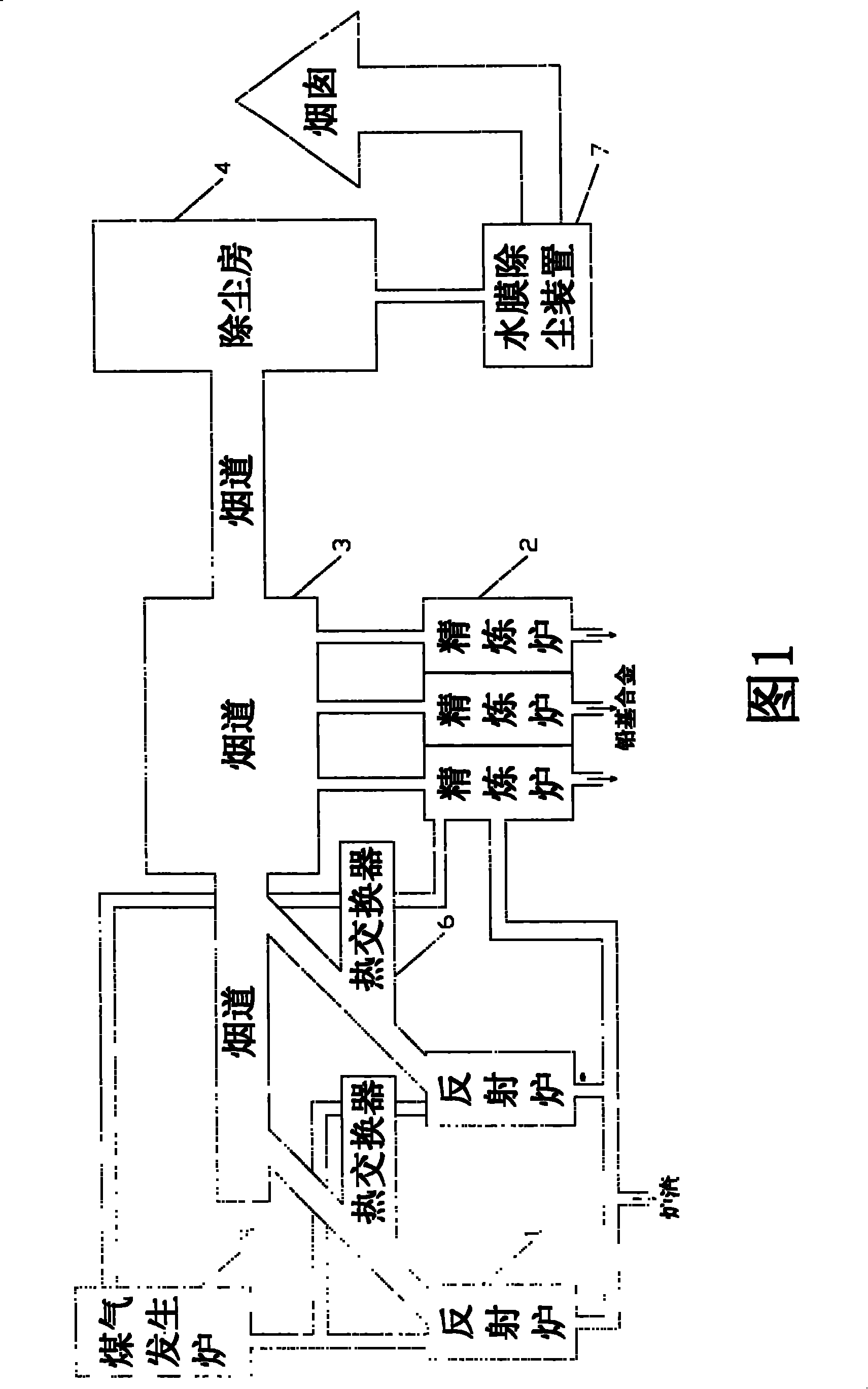

Solid waste recovery and processing system of waste lead acid accumulator

InactiveCN101197459AFully meltedBurn fullySolid waste disposalWaste accumulators reclaimingAtmospheric airReverberatory furnace

The invention discloses a system for recovering the solid waste in old and waste lead-acid storage batteries, comprising a reverberator, a finery, a flue, a dust removal house and a coal gas producer, wherein the finery is connected to the back end of the reverberator; the outlet flues of the reverberator and the finery are communicated with the front end of the flue; the dust removal house is communicated with the back end of the flue; the coal gas producer is connected with the reverberator and the finery. The invention adopts the gas combustion in the coal gas producer to heat both the reverberator and the finery and adopts a plurality of coal gas nozzles to provide enough fire to thoroughly smelt lead containing materials, with the fire in the front moving constantly backward to thoroughly smelt lead containing materials at the back, thereby saving energy resource; a heat exchanger is arranged for secondary combustion to provide big fire, thereby the smelting takes less time for completely smelting the lead containing materials; as cloth-bag dust removal followed by the dust removal of water film is adopted, the dust is completely removed, so the discharged gas causes no pollution to the atmosphere. The invention allows the lead containing solid waste to be burnt thoroughly and the dust to be removed completely.

Owner:许兴义

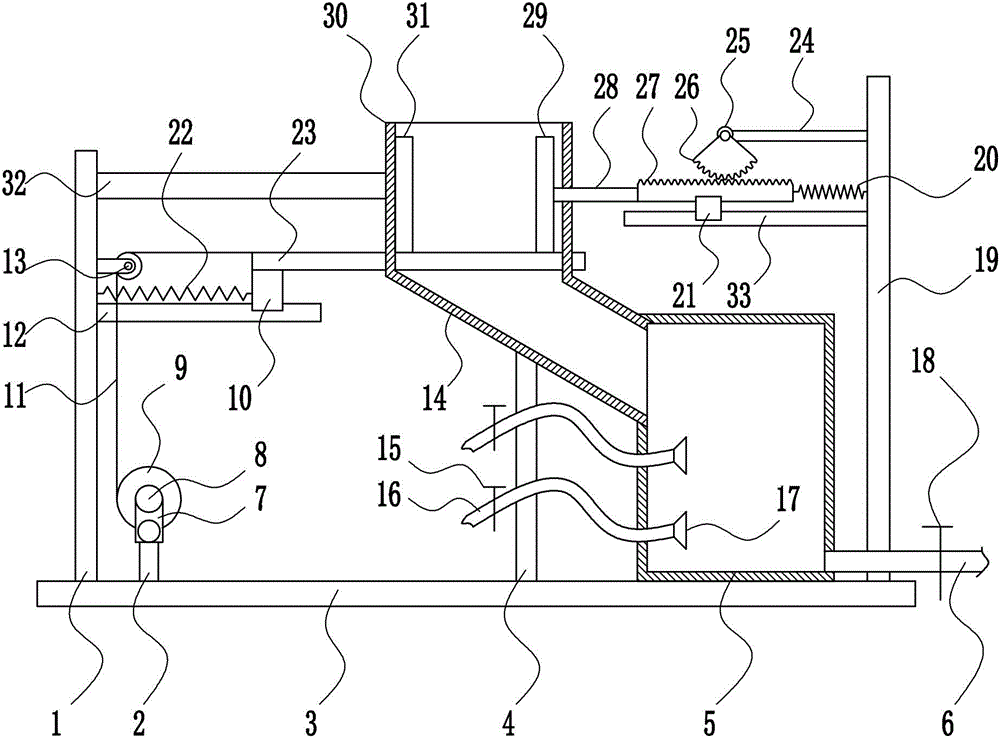

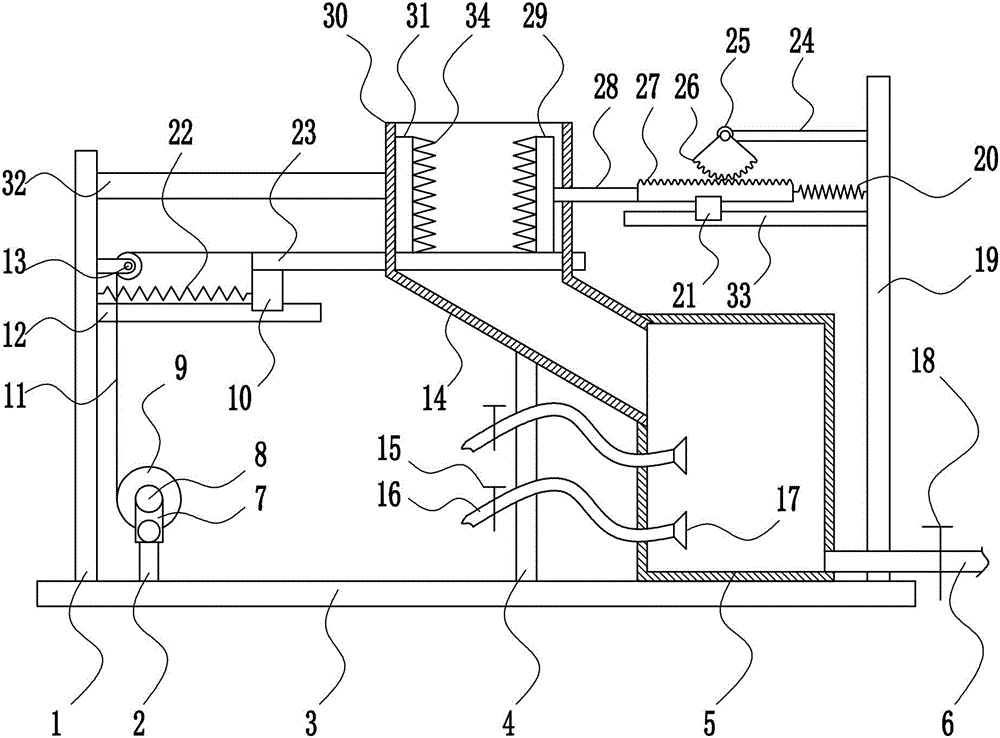

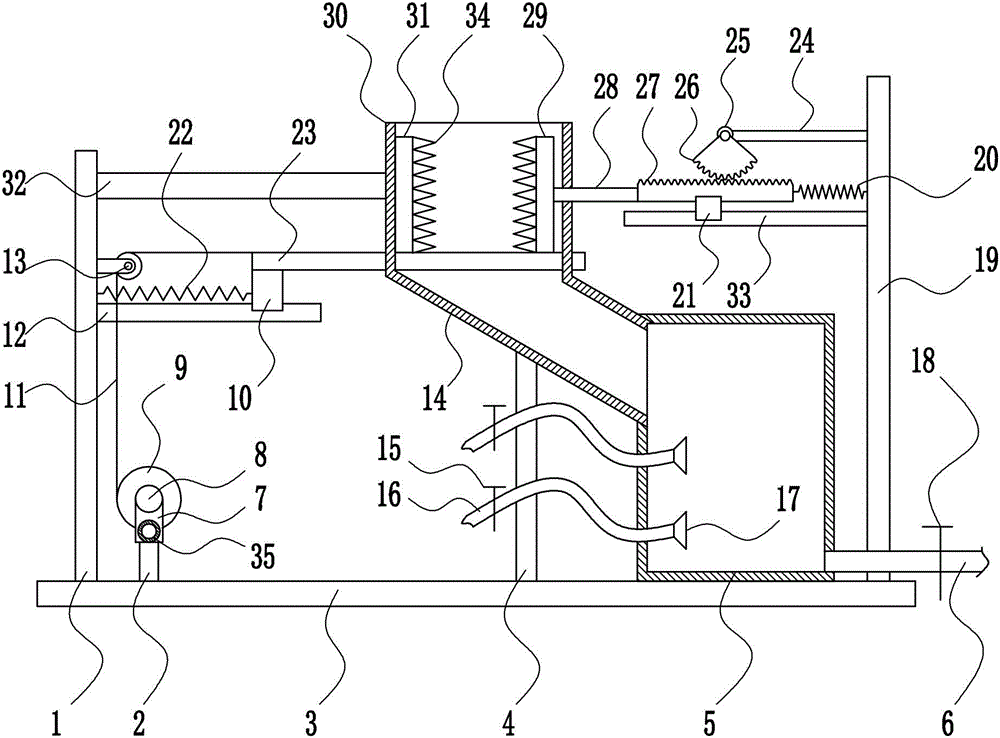

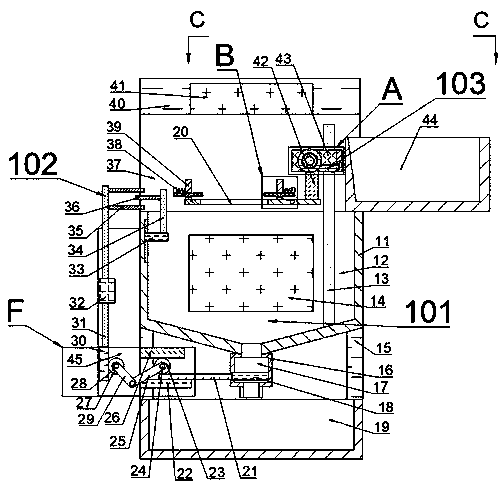

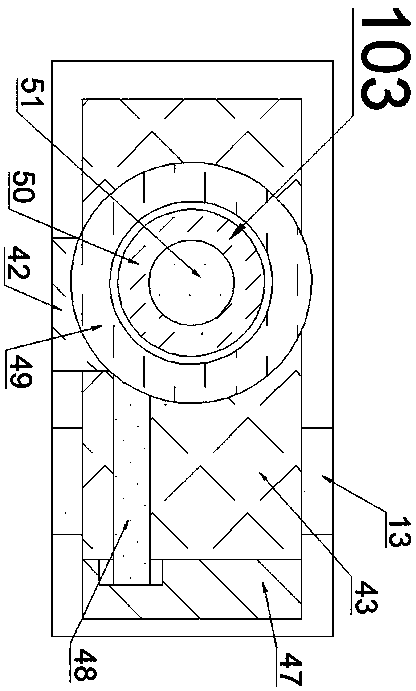

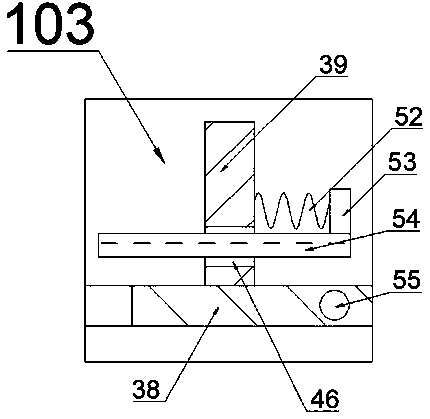

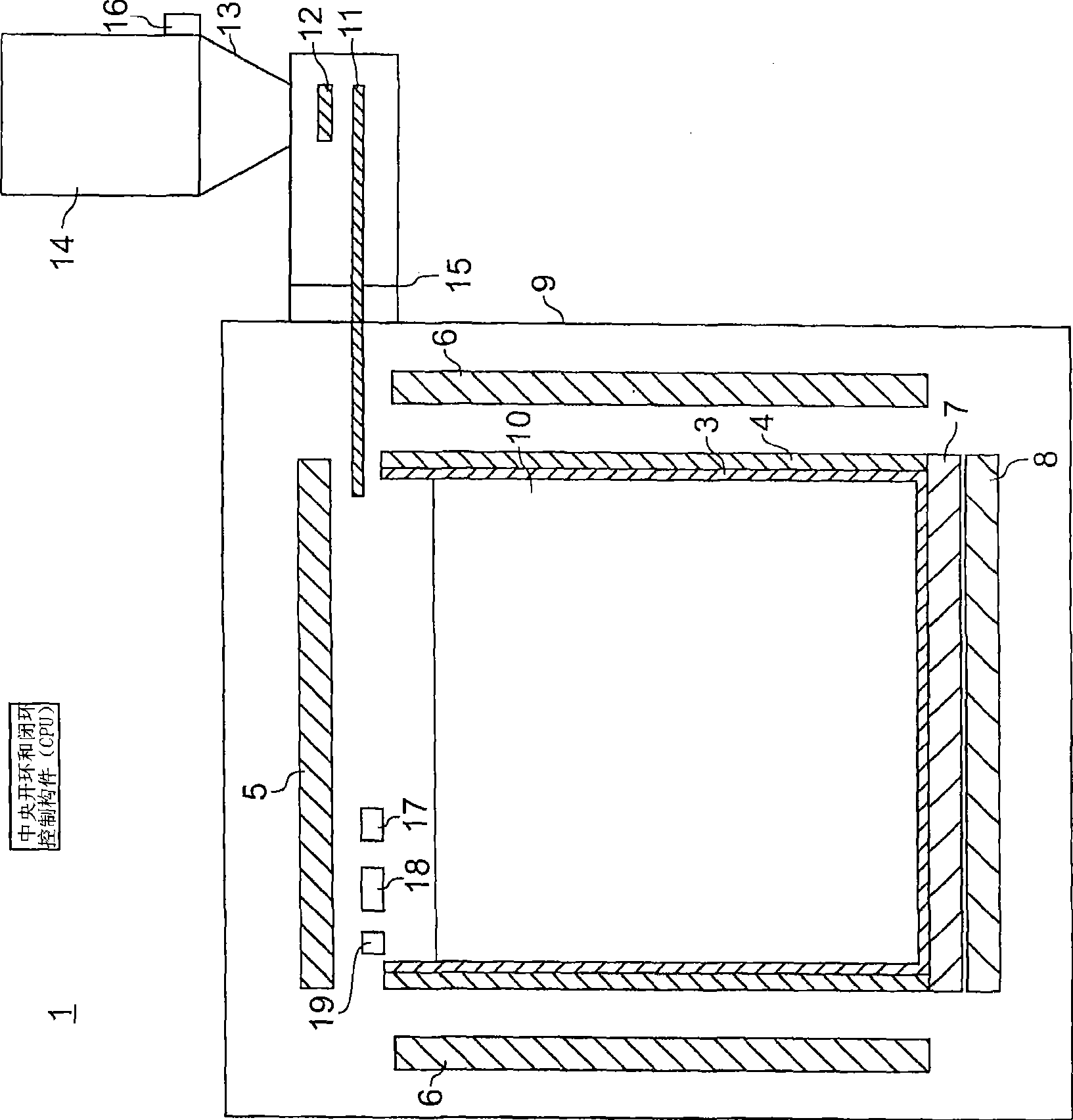

High-temperature melting equipment for preparing nano glass powder

InactiveCN106348571AImprove the crushing effectSpeed up the fallCharging furnaceGlass furnace apparatusConductor CoilNanotechnology

The invention relates to high-temperature melting equipment and in particular relates to high-temperature melting equipment for preparing nano glass powder. Aiming at solving the technical problems, the invention provides the high-temperature melting equipment for preparing the nano glass powder, which is simple to operate, rapid in melting speed and uniform in melting. In order to solve the technical problems, the high-temperature melting equipment for preparing the nano glass powder, provided by the invention, comprises a left frame, a first bearing seat, a bottom plate, a bracket, a melting box, a discharging pipe, a rocking handle, a first rotary shaft, a winding wheel, a first slide block, a pull wire, a first slide rail and the like; the left frame is welded at the left end of the top of the bottom plate; a left side of the top of the bottom plate is connected with the first bearing seat through a connection manner of a bolt. The high-temperature melting equipment for preparing the nano glass powder has the effects of simplicity in operation, short melting time and uniform melting; a worker can realize rapid melting of glass raw materials through utilizing the equipment; the high-temperature melting equipment is simple and convenient to operate and time and labor are saved.

Owner:徐州启迪双创科技企业孵化器有限公司

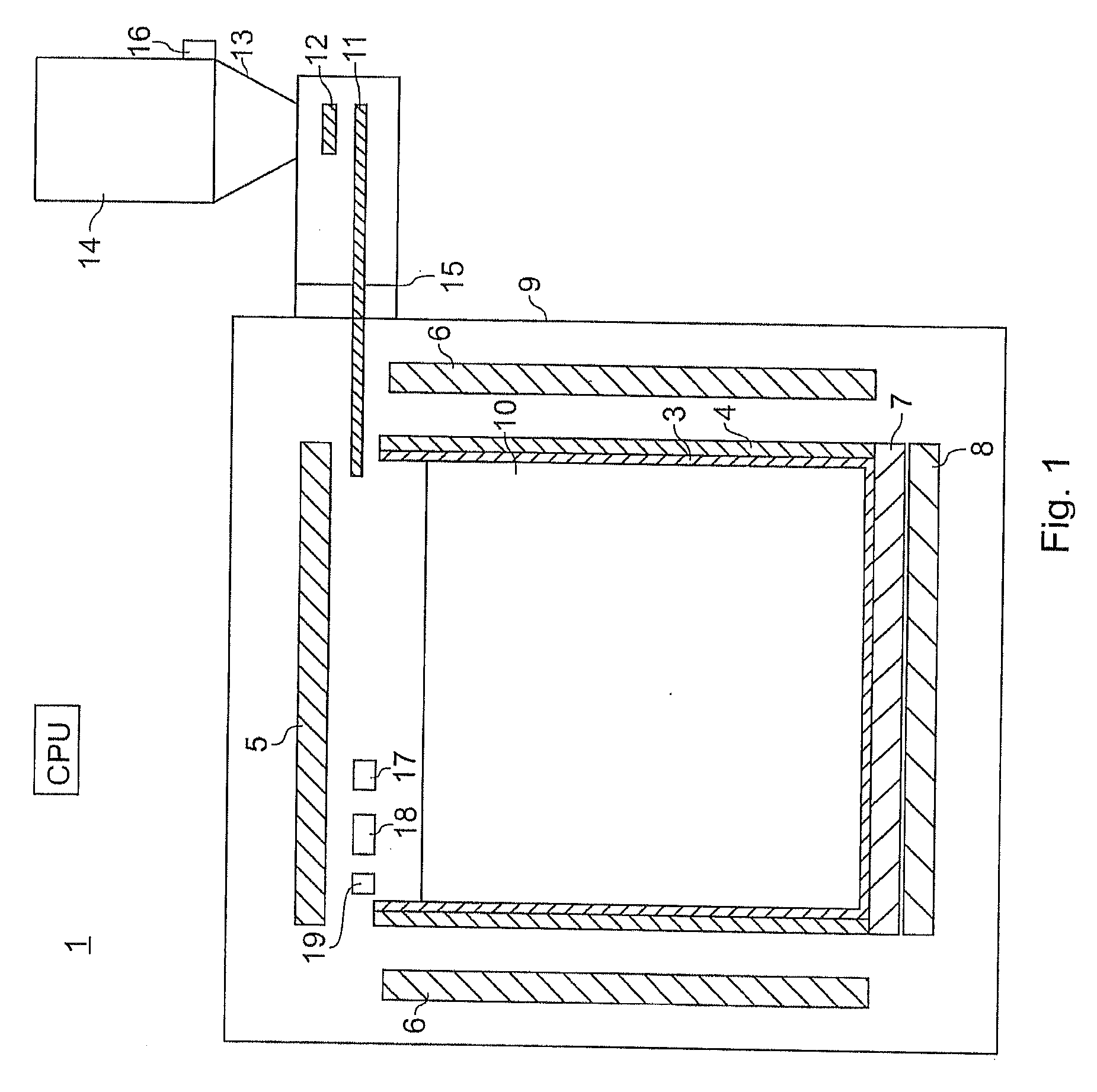

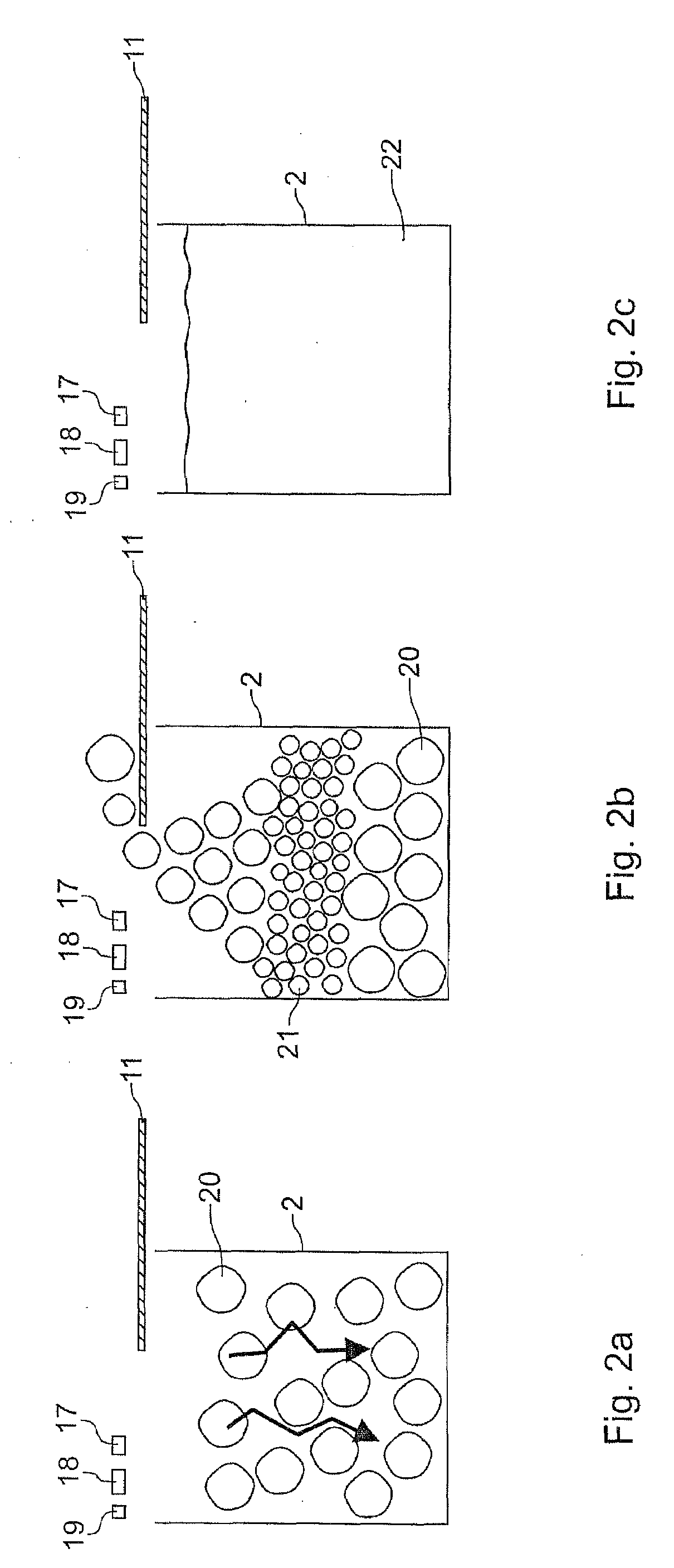

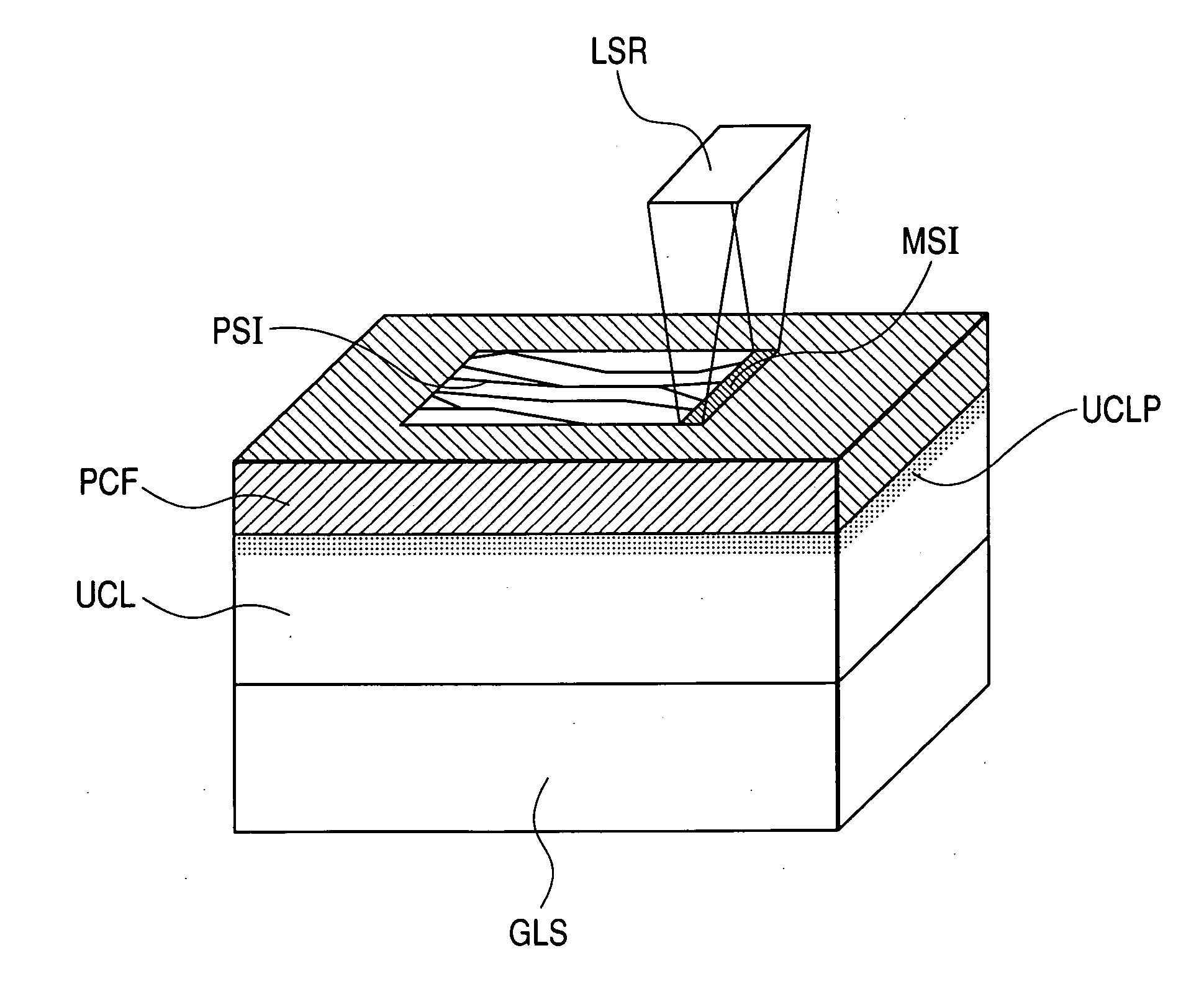

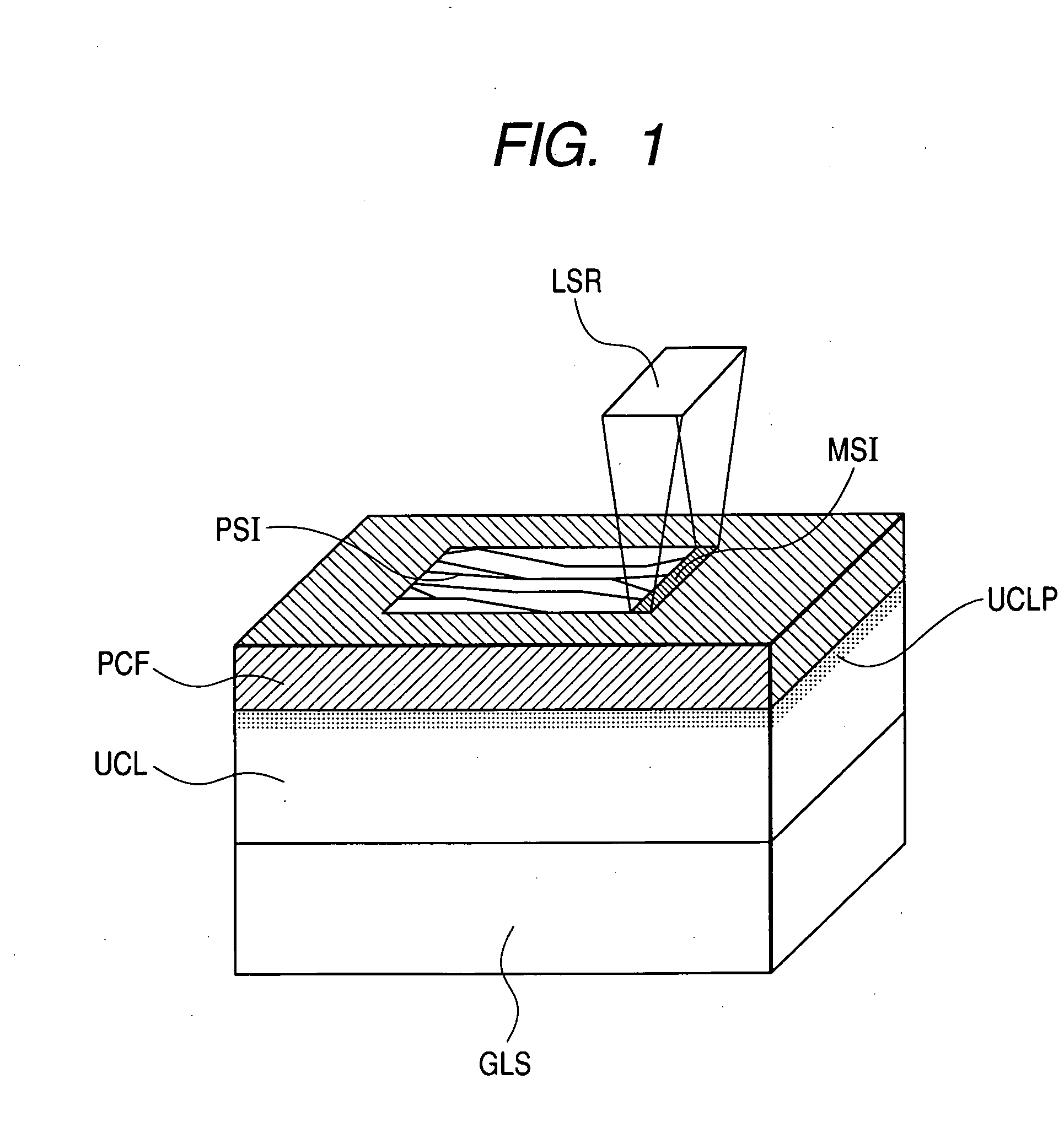

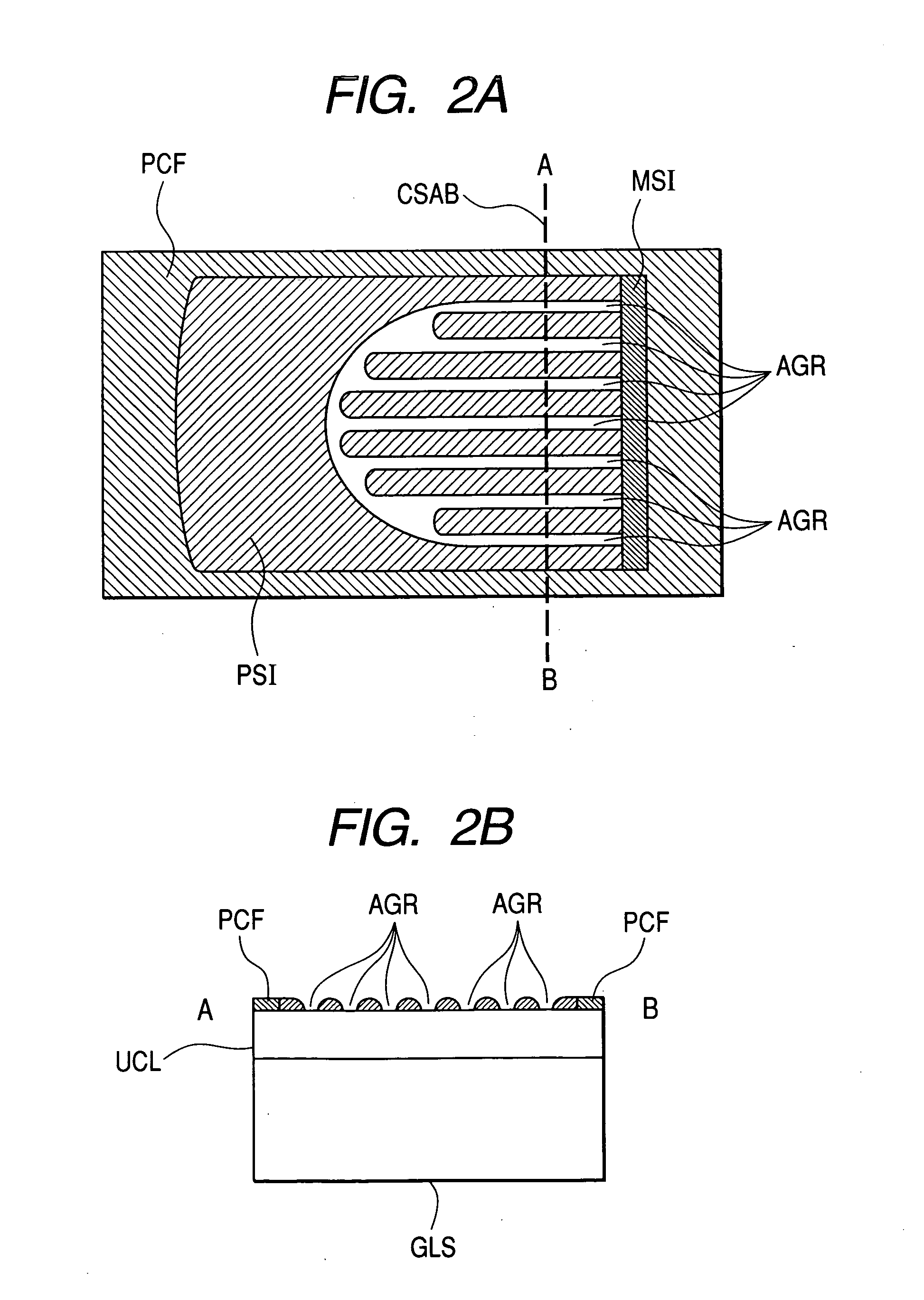

Thin film semiconductor circuit, manufacturing method thereof, and image display apparatus utilizing the same thin film semiconductor circuit

InactiveUS20060001051A1High manufacturing yieldQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingRe crystallizationPolycrystalline silicon

Agglomeration of a polycrystalline silicon film is eliminated at the time of obtaining a high quality polycrystalline silicon film by forming a silicon layer on an insulating film substrate and conducting long-term melting and re-crystallization. For this purpose, a layer or a plurality of layers of an underlayer UCL are provided on an insulating substrate GLS, the area near the surface in contact with a precursory silicon film PCF provided on this underlayer UCL is formed as an insulating film UCLP showing a film composition to improve the wettability of the melted silicon layer, and thereafter a high quality polycrystalline silicon film PSI is formed through elimination of agglomeration by melting of the precursory silicon film PCF using a laser beam LSR.

Owner:HITACHI DISPLAYS

Compound type poultry depilating agent as well as preparation method and application method thereof

The invention relates to a compound type poultry depilating agent prepared from the following components in parts by weight: 65-75 parts of food grade glycerol ester of rosin, 22.5-29 parts of food grade paraffin, 0.5-1.5 parts of food grade silicone grease and 5-10 parts of animal fat. The materials adopted in the invention meet specifications in national food safety, a product after poultry is processed completely meets specifications in the national safety standard, and the product is clean and non-toxic and can completely meet health requirements of consumers. The depilating agent disclosed by the invention has the advantages of low melting point, short melting time, easiness for operation and applicability to large-scale production.

Owner:HUAIBEI BAODI POULTRY IND

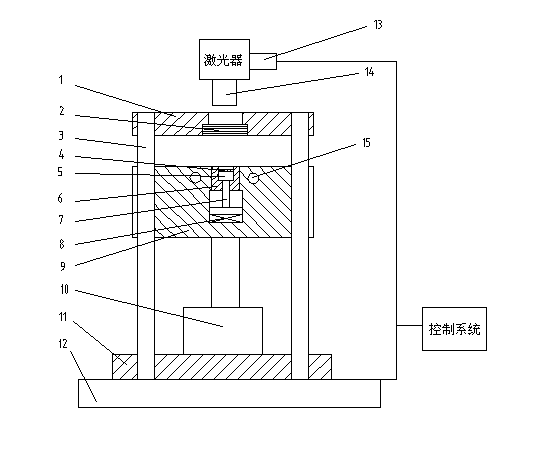

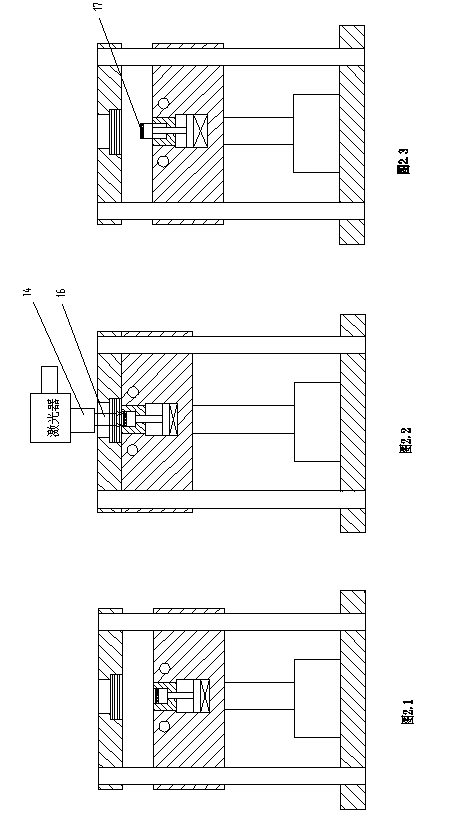

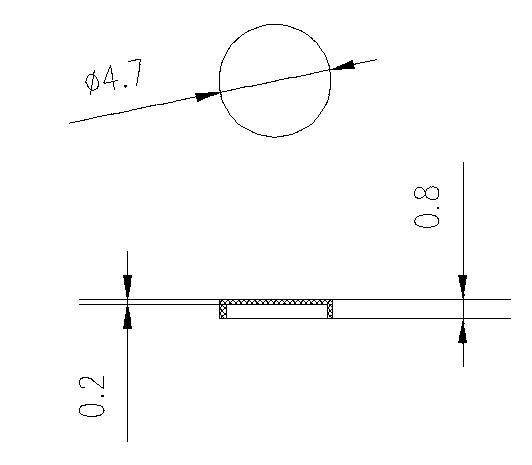

Small plastic part laser melting extrusion molding method and apparatus thereof

The invention discloses a small plastic part laser melting extrusion molding method and an apparatus thereof, relates to the high-precision small plastic part molding processing field, and especially relates to an infrared laser melting and die extrusion molding based small plastic part molding method and an apparatus thereof. Traditional high-precision small plastic parts have the disadvantages of high injection molding processing cost, difficult control of the quality of the an injection part, and severe wastes of plastic raw materials and energy. In the invention, infrared laser rapid heating melting and molding die extrusion molding processing technologies are adopted for the high-precision thermoplastic small plastic part. The small plastic part laser melting extrusion molding method and the apparatus thereof have the advantages of high molding precision, good molding quality, high efficiency and low cost, are suitable for the batch automatic molding processing of high-precision small plastic parts, and have high application values.

Owner:盐城动益汽车配件有限公司

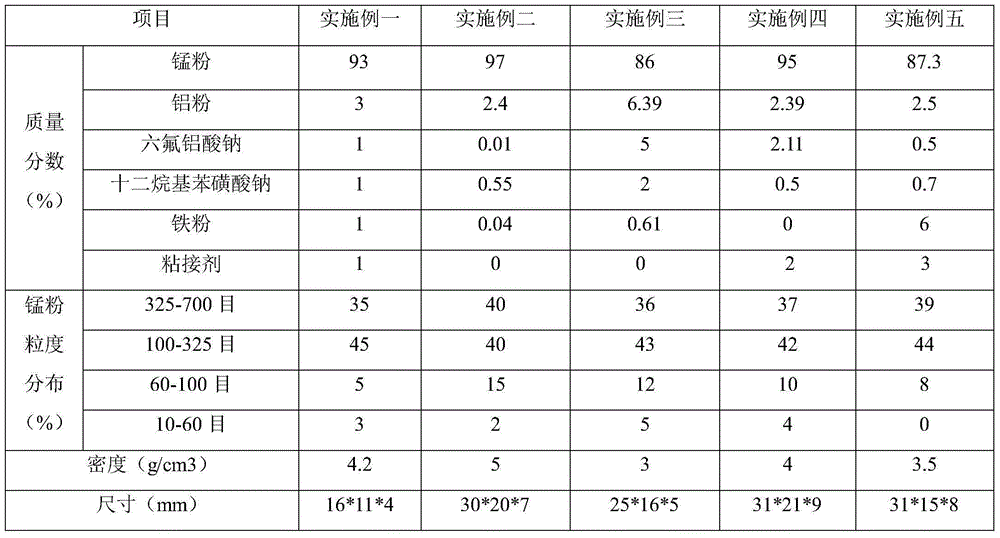

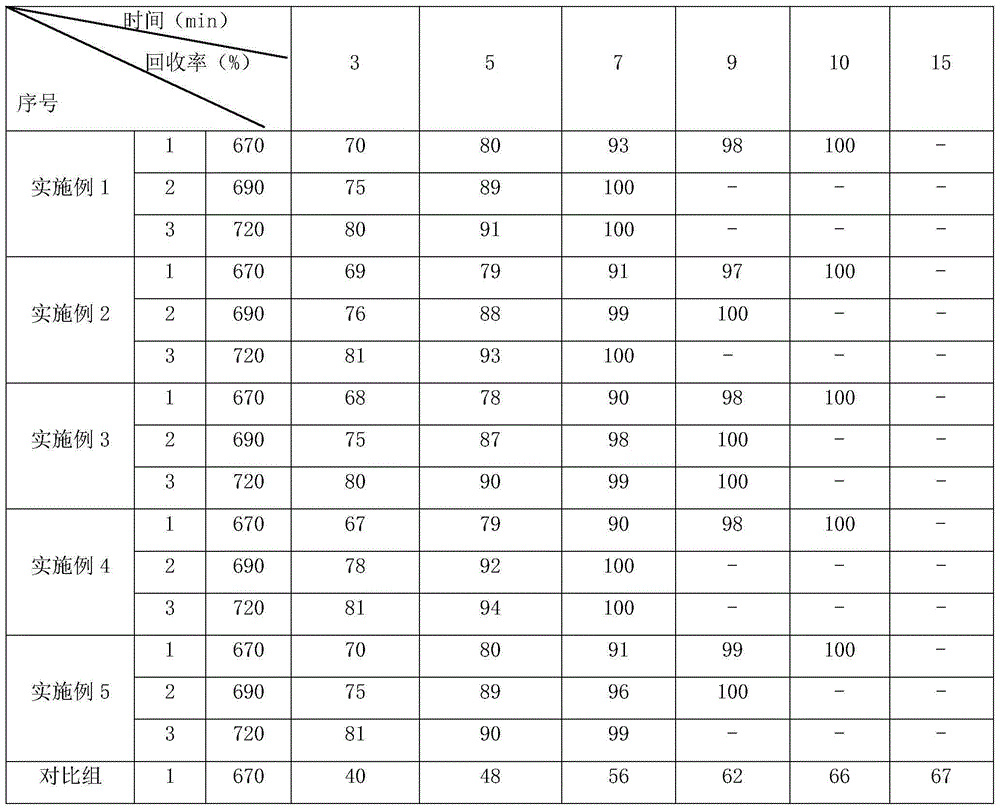

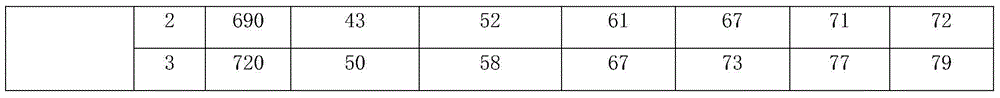

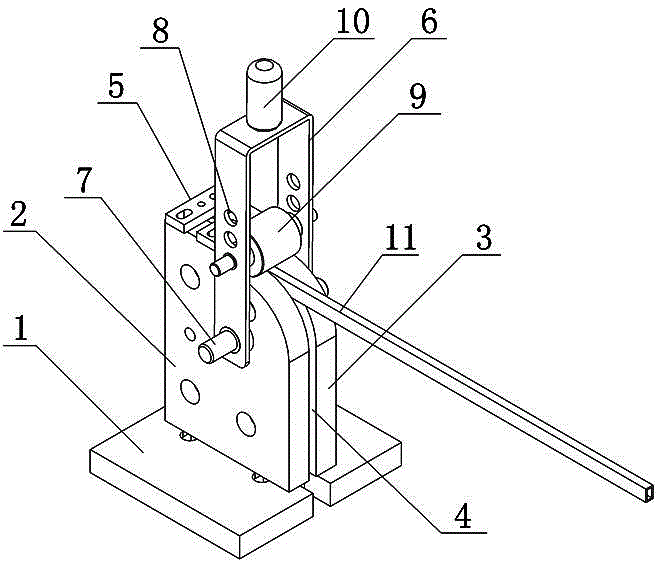

High-content manganese additive used for producing aluminum alloy and preparing method of high-content manganese additive

The invention discloses a high-content manganese additive used for producing aluminum alloy and a preparing method of the high-content manganese additive. The manganese additive in a cake shape or rugby shape and formed by pressing raw material powder. The raw material powder comprises manganese powder, aluminum powder, iron powder and fluxing agents. The manganese powder, the aluminum powder, the iron powder and the fluxing agents are crushed under protection of inert gas, and the high-content manganese additive further comprises a surfactant. According to the high-content manganese additive, by mass, the manganese powder accounts for 86%-97%, the aluminum powder accounts for 2.39%-6.39%, the iron powder accounts for 0%-6%, the fluxing agents account for 0.01%-0.05%, and the surfactant accounts for 0.5%-2%. The density of the formed high-content manganese additive ranges from 3.0 g / cm<3> to 5.0 g / cm<3>. The method includes the steps of 1, crushing, 2, material preparing, 3, material mixing, 4, pressing, 5, drying, 6 packaging and the like. When the high-content manganese additive is dissolved into molten aluminum, the melting temperature is low, the melting time is short, and the recovery rate of manganese is high.

Owner:CHONGQING RUNJI YUANDONG NEW MATERIAL TECH

Bending processing method for small-caliber thin-wall waveguide tube

The invention relates to a bending processing method for a small-caliber thin-wall waveguide tube, comprising the following steps: S1, filler refining: S11, material preparation: preparing the following components in parts by weight: 22-28 parts of Pb, 10-14 parts of Sn, 47-53 parts of Bi, and 11-15 parts of Cd; S12: heating for smelting: putting into a heating kettle for heating and smelting, sufficiently stirring during smelting, adding mica sheet and rosin, pouring into the container in molten state, and cooling for crystallization in room temperature to obtain low-melting-point alloy filler; S2, filler filling: S21, fixing a waveguide tube; S22, melting the low-melting-point alloy filler; S23, smearing machine oil; S24, filling; S3, bending formation; S4, filler recovery; S5, waveguide tube cleaning, thus obtaining the waveguide tube after bending formation. The bending processing method has the advantages of being short in production cycle, good in bending formation effect and recyclable in filler.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

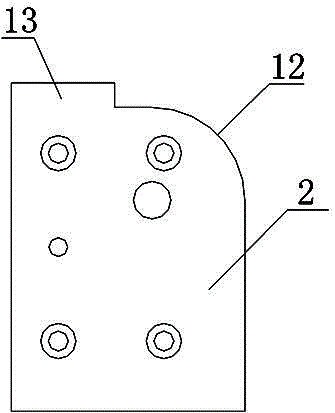

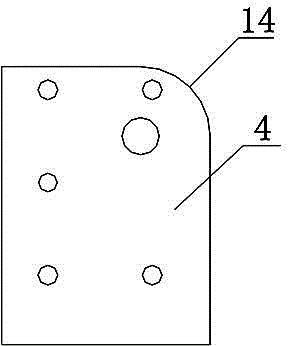

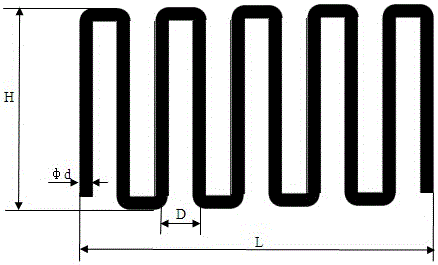

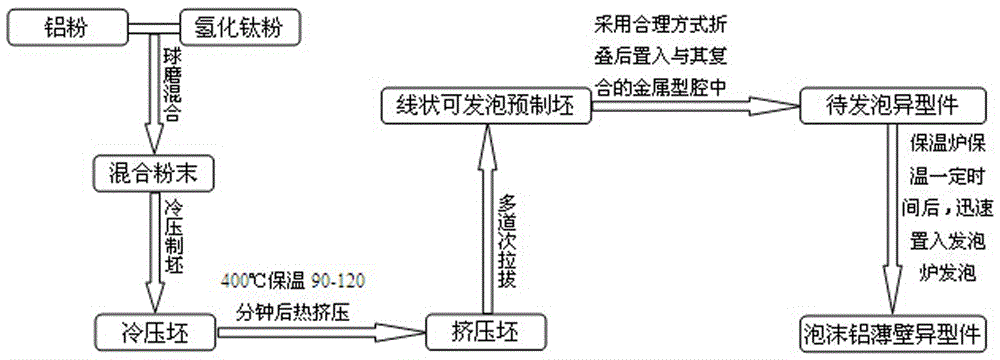

Preparation method of novel thin-walled and special-shaped foamed aluminum part

The invention relates to a preparation method for a novel thin-walled and special-shaped foamed aluminum part, and belongs to the technical field of porous metal materials. A three-step forming technique is adopted based on preparation of a foaming preformed blank, namely a multi-pass drawing procedure is added based on traditional cold-pressing and hot-extruding procedures, and the linear foaming preformed blank with the diameter being 2-5 mm is prepared. In the preparation process of the thin-walled and special-shaped part, the linear foaming preformed blank with the proper diameter is selected according to the wall thickness of the special-shaped part and the density requirement for a core foam body, the linear foaming preformed blank with the proper diameter is placed in a metal cavity combined with the linear forming preformed blank after being folded in a reasonable folding way, and then the linear foaming preformed blank with the proper diameter and the metal cavity are placed into a holding furnace together for heat-preservation foaming; and the procedure of preparing a plurality of small-size foaming preformed blanks required by a multi-blank foaming method by consuming a large amount of time is not needed any more. By adoption of the preparation method for the novel thin-walled and special-shaped foamed aluminum part, the production efficiency is greatly improved, the production cost is reduced, and the preparation method has extremely positive significance for promoting the industrialization process of thin-walled and special-shaped foamed aluminum parts.

Owner:SHENYANG POLYTECHNIC UNIV

Waste PCB component disassembly and soldering tin recovery device

InactiveCN110977083AGuaranteed stabilitySimplify the Solder Recycling ProcessHeating appliancesPrinted circuitsHeating oilHeating effect

The invention discloses a waste PCB component disassembly and soldering tin recovery device. The device comprises a heating box; a heating cavity with an upward opening is formed in the heating box; asoldering tin heating device for heating and melting soldering tin is arranged in the heating cavity; a soldering tin recovery device for recovering the soldering tin is arranged on the left side endsurface of the heating cavity; a component disassembly device is arranged on the upper side of the heating cavity; the component disassembly device is used for shifting PCBs into the heating cavity for heating; and an overturning device for overturning the PCBs is arranged in the component disassembly device. Oil is adopted to heat the PCBs; the soldering tin recovery mechanism can melt the soldering tin in the heating box to reach a certain quantity for automatic recovery; the liquid level of the heated oil is maintained in a certain range to guarantee the stability of the heating effect ofthe PCBs; and the device can recover components and the soldering tin from waste PCBs to greatly simplify the recovery process of the soldering tin on the PCBs.

Owner:QUZHOU CHAOYUE ENVIRONMENTAL PROTECTION TECH CO LTD

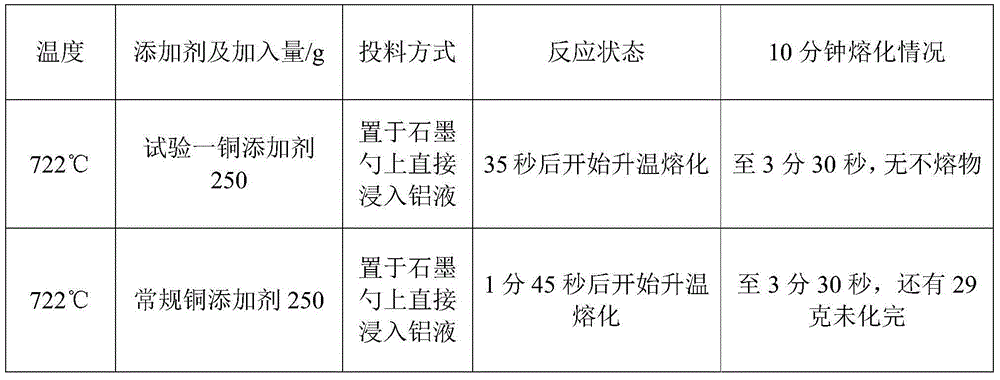

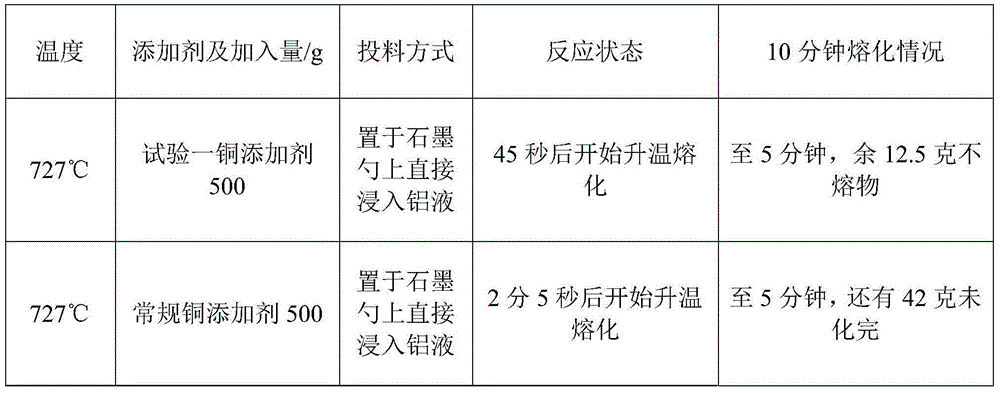

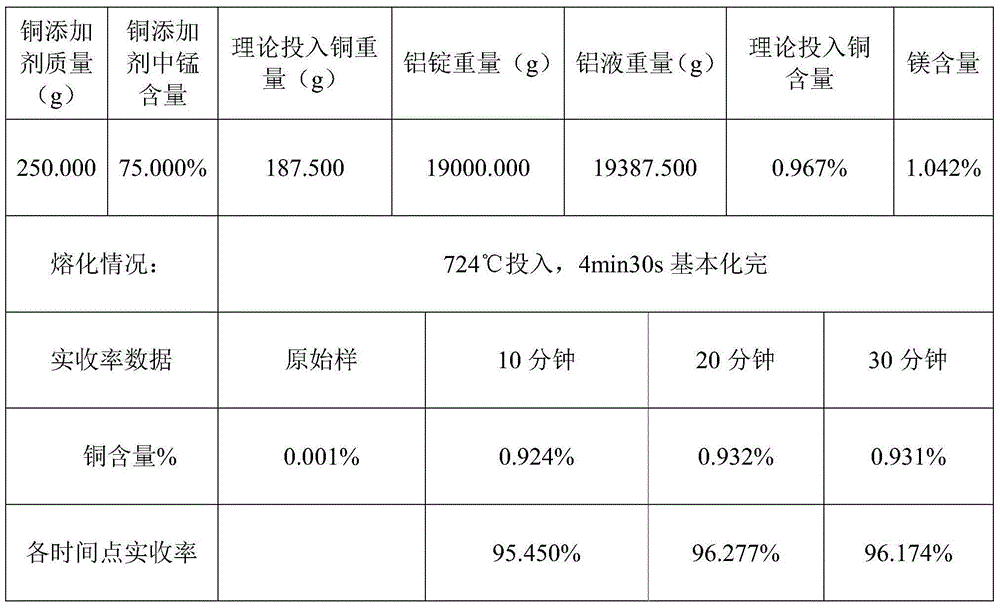

Copper additive for high magnesium aluminum alloy casting and preparation method thereof

The invention provides a copper additive for high magnesium aluminum alloy casting and a preparation method thereof, and relates to an additive for high magnesium aluminum alloy casting and a preparation method thereof. The copper additive aims to solve the technical problems that in a high magnesium aluminum alloy casting process, an existing copper additive is low in melting speed or not molten and low in casting yield, the melting temperature is high, time is long, and energy consumption is large. The copper additive is prepared by electrolytic copper powder and a fluxing agent. The method includes the steps that 1, the electrolytic copper powder and the fluxing agent are weighed; 2, the electrolytic copper powder and the fluxing agent which are weighed in the step 1 are evenly mixed and then are pressed to be in a circular cake shape under the condition that the hydraulic pressure ranges from 6 MPa to 7.5 MPa, and the copper additive for high magnesium aluminum alloy casting is obtained. The preparation method of the copper additive for high magnesium aluminum alloy casting is simple, and the copper additive has the advantages that the copper additive can be used at a lower smelting temperature, the melting time is short, the casting yield is high, energy is saved, and transport and storage are convenient to conduct. The method is applied to the field of preparing the copper additive for high magnesium aluminum alloy casting.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

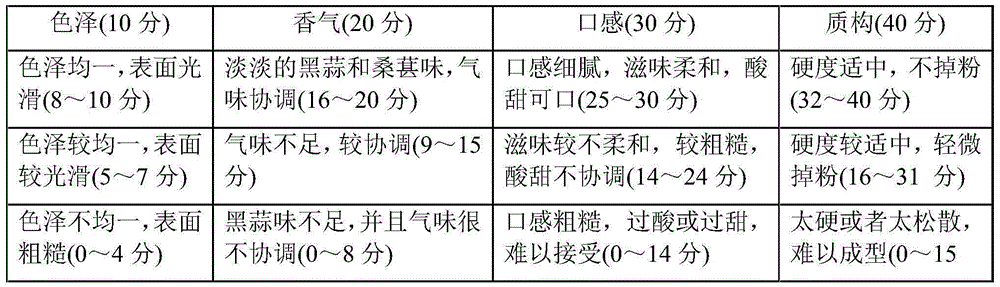

Black garlic and milk chewable tablet and preparation method thereof

The invention discloses a black garlic and milk chewable tablet and a preparation method thereof. The chewable tablet is prepared from the following raw materials in percentage by weight: 12 to 18 percent of black garlic, 6 to 9 percent of blackberries, 6 to 9 percent of black mulberries, 6 to 9 percent of black medlar, 8 to 15 percent of milk powder, 30 to 35 percent of sweetening agent, 9 to 15 percent of wetting bonding agent, 0.5 to 1 percent of acid agent, 4 to 6 percent of filling agent and 0.5 to 1 percent of lubricating agent. The method comprises the process of raw material pretreatment, soft material manufacturing, wet granulating, drying, tabletting, sterilizing, packaging and the like. The black garlic and milk chewable tablet provided by the invention is delicate in taste, fresh and cool in flavor, better in texture and convenient to carry, melts quickly after being chewed in mouth, and the preparation process of the chewable tablet is simple, free of high-heat treatment, and the active ingredients of black food such as the black garlic, the blackberries, the black mulberries, and the black medlar are reserved in maximum, so the demands of consumers on health food are met, and convenience is brought for fast-paced life.

Owner:XUZHOU UNIV OF TECH

Preparation method of high-performance glass fiber

The invention discloses a preparation method of high-performance glass fiber. The preparation method comprises the following steps: weighing a compound of silicon, aluminum, magnesium, calcium, zirconium, titanium, ferrum, cerium, yttrium, niobium, lithium, bismuth and boron, wherein the water-soluble compound is not less than 10% of the total molar quantity of all the compounds; then adding deionized water, and by taking zirconium oxide grinding balls as a grinding medium, sequentially performing ball grinding, spray drying, calcination, isostatic pressing treatment, fusing, wire drawing and other processes. The water-soluble compound evenly coats the surfaces of other compounds in a manner of ions through ball grinding mixing and spray drying, then nanoscale particles can be obtained after calcination. Under the high specific surface energy action of the nanoparticles and isostatic pressing, all the components are closely contacted, and the fusion temperature and fusion time of the glass can be obviously reduced, so that the energy consumption needed in the production of the glass fiber can be reduced.

Owner:CHINA JILIANG UNIV

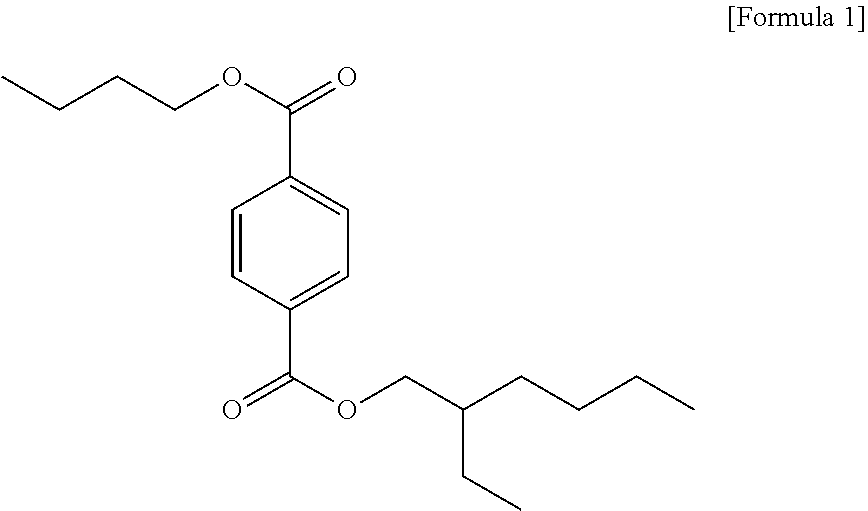

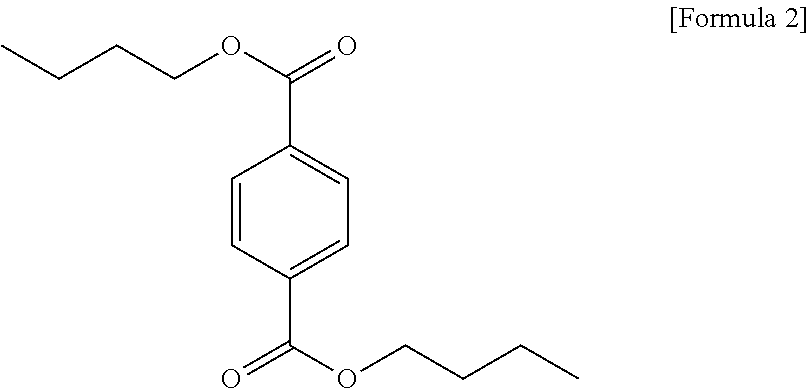

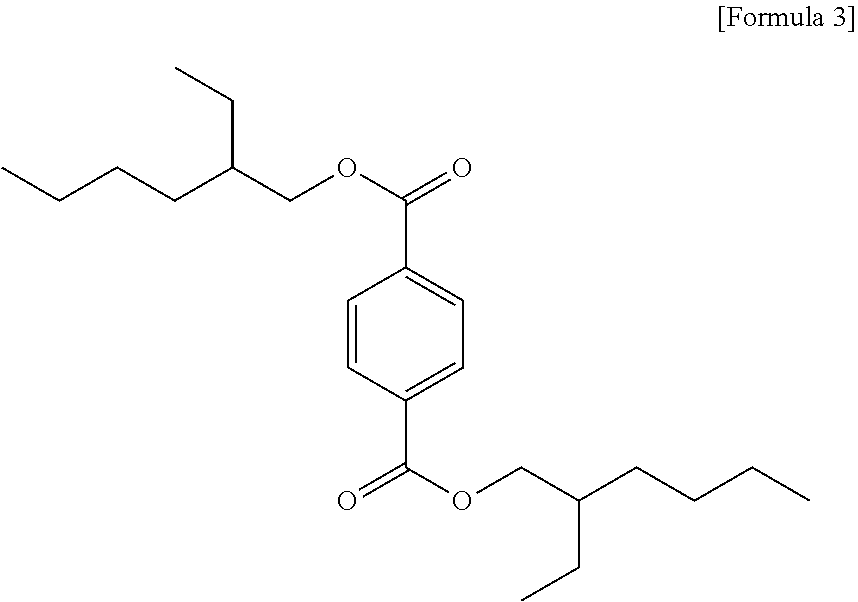

Ester plasticizer composition

ActiveUS20150007750A1Fast absorptionShort melting timeOrganic chemistryMixingHigh absorptionPlasticizer

Disclosed is an ester plasticizer composition, as a plasticizer composition, which comprises a hybrid alkyl-substituted terephthalate compound and a non-hybrid alkyl-substituted terephthalate compound as active ingredients, improves workability due to high absorption speed for the resins and short melting time, and thus may imparts a uniform foaming property upon being applied to wallpaper formulation.

Owner:LG CHEM LTD

Electrical equipment connector lead temperature measuring device prepared by adopting fusible alloy

ActiveCN104655314AGood warningStandard melting pointThermometers using physical/chemical changesNarrow rangeCoil spring

The invention discloses an electrical equipment connector lead temperature measuring device prepared by adopting a fusible alloy. The electrical equipment connector lead temperature measuring device comprises a left arc elastic clamping piece and a right arc elastic clamping piece. The electrical equipment connector lead temperature measuring device is characterized in that semi-circular curved sections of the lower ends of the arc elastic clamping pieces are both provided with coil springs enabling lower end clamping openings of the left and right arc elastic clamping pieces to be clamped tightly; the middle of a base plate surface of a round seat plate is provided with an overtemperature sign cylinder the outer side of which is sleeved by a cylindrical seal cap; the center of the cylindrical seal cap is provided with a core rod sleeved with a compression spring; the part, passing through a central through hole of the round base plate, of the core rod is sleeved with a fusible alloy ring; a heat conduction screw cap is screwed tightly on the upper end of the core rod. The device can be installed under the condition that a high-voltage power transformation device runs with power, furthermore, because the fusible alloy is adopted as a temperature test material, the device has the advantages of accurate fuse point, narrow range, response sensitivity and short fuse time; moreover, the fuse point can be adjusted according to seasons, the influences by natural temperature rise can be eliminated, and the fault temperature rise can be judged more accurately; the device is easy to install, is flexible and convenient to use, and has an obvious warning effect.

Owner:STATE GRID CORP OF CHINA +1

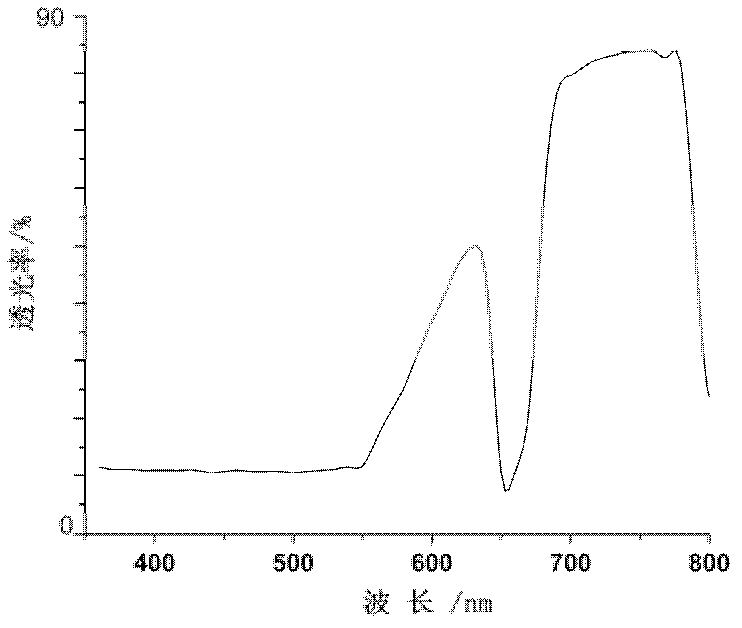

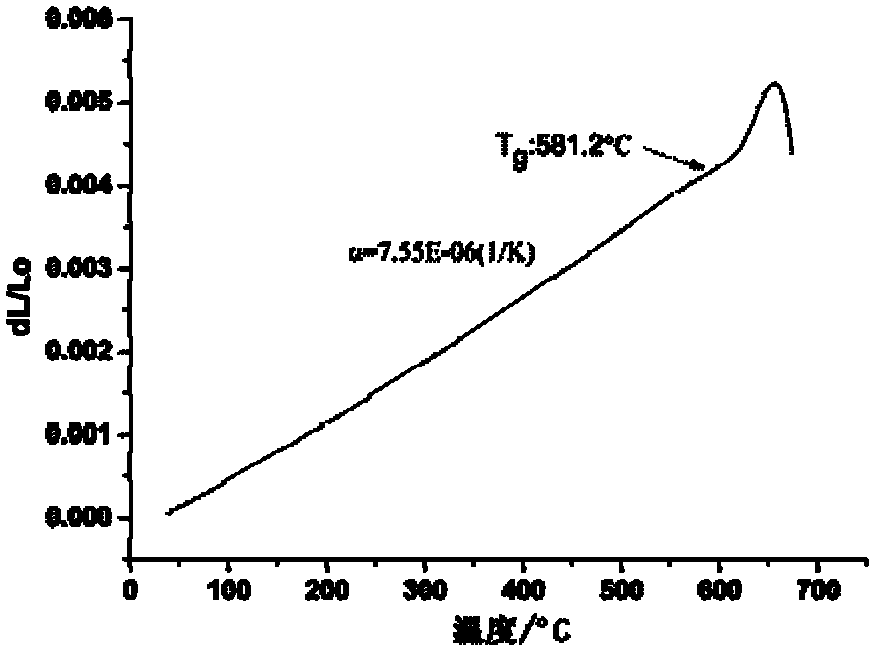

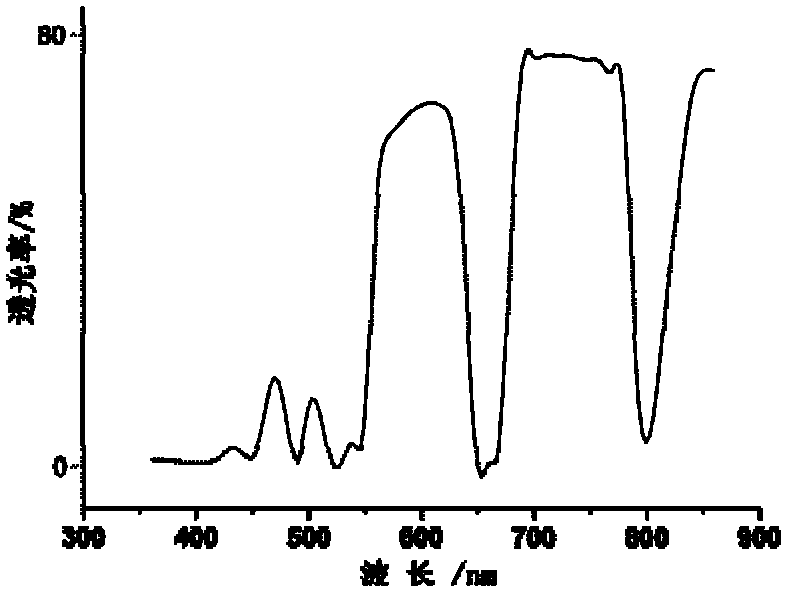

Preparation method of bismuth-containing paramagnetic Faraday optical rotation glass

InactiveCN102627404AExpand the scope of formationReduce high temperature viscosityHeat stabilityRare earth

The invention discloses a preparation method of bismuth-containing paramagnetic Faraday optical rotation glass. The preparation method comprises the following steps of: firstly, uniformly mixing Er2O3, Bi2O3, B2O3, Al2O3, SiO2, Sb2O3 and ZrO2 to obtain a batch; secondly, fusing the batch to obtain molten glass, dropping the molten glass into a graphite mould, thermally insulating at 550 DEG C for 3 hours, and cooling to room temperature to obtain the bismuth-containing paramagnetic Faraday optical rotation glass. According to the invention, the bismuth-containing paramagnetic Faraday optical rotation glass is prepared by adopting a fusing and pouring method, owing to bismuth oxide with large molecular weight and low melting point, a forming range of the glass is expanded and the fusing temperature is reduced. The prepared Faraday magneto-optical glass has high content of rare earth erbium oxide, excellent glass forming property, remarkable Faraday effect and large Verdet constant, and the test sample has high light transmittance in a visible light range, and excellent heat stability and chemical stability. The preparation process has the advantages of simple operation process, low founding temperature, small high-temperature viscosity in the glass fusing process, short fusing time, excellent forming property, low cost, energy conservation and environmental friendliness and is suitable for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing a monocrystalline or polycrystalline semiconductor material

InactiveCN101463497AControl temperature conditionsSpeed up meltingPolycrystalline material growthFrom frozen solutionsVertical gradientCrucible

The invention relates to a method for producing a monocrystalline or polycrystalline semiconductor material by way of directional solidification, wherein lumpy semiconductor raw material is introduced into a melting crucible and melted therein and directionally solidified, in particular using the vertical gradient freeze method. In order to prevent contamination and damage, the semiconductor raw material is melted from the upper end of the melting crucible. The molten material trickles downward, so that semiconductor raw material which has not yet melted gradually slumps in the melting crucible. In this case, the additional semiconductor raw material is replenished to the melting crucible from above onto a zone of semiconductor raw material which has not yet melted or is not completely melted, in order at least partly to compensate for a volumetric shrinkage of the semiconductor raw material and to increase the filling level of the crucible. In order to reduce the melting-on time and to influence the thermal conditions in the system as little as possible, the semiconductor raw material to be replenished is heated by the purposeful introduction of heat to a temperature below the melting temperature of the semiconductor raw material and introduced into the container in the heated state.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com