Solid waste recovery and processing system of waste lead acid accumulator

A lead-acid battery and solid waste technology, applied in the field of solid waste recycling and processing systems, can solve the problems of animal and human hazards, difficult removal, insufficient combustion, etc., achieve major economic and social benefits, improve energy utilization, The effect of high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

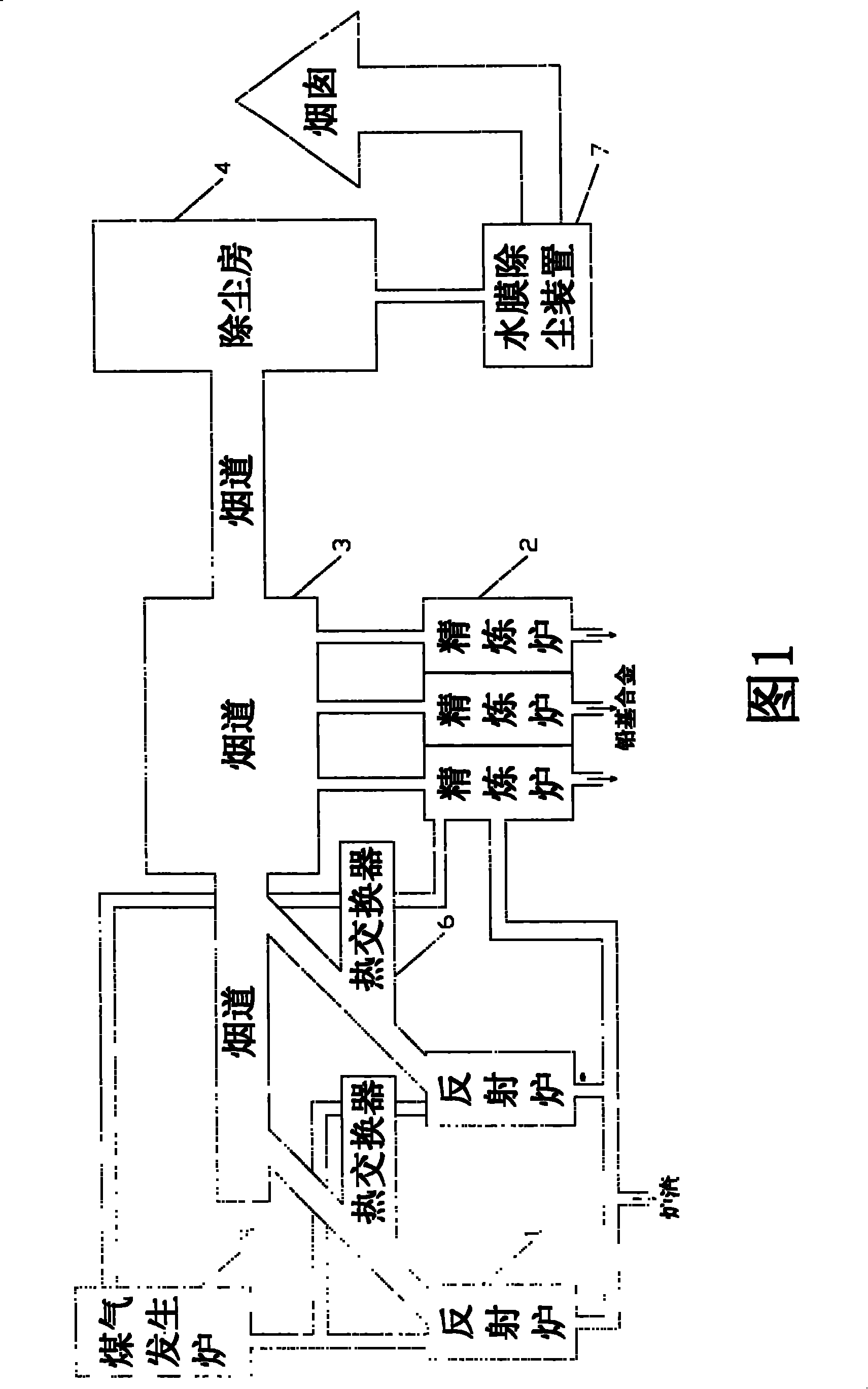

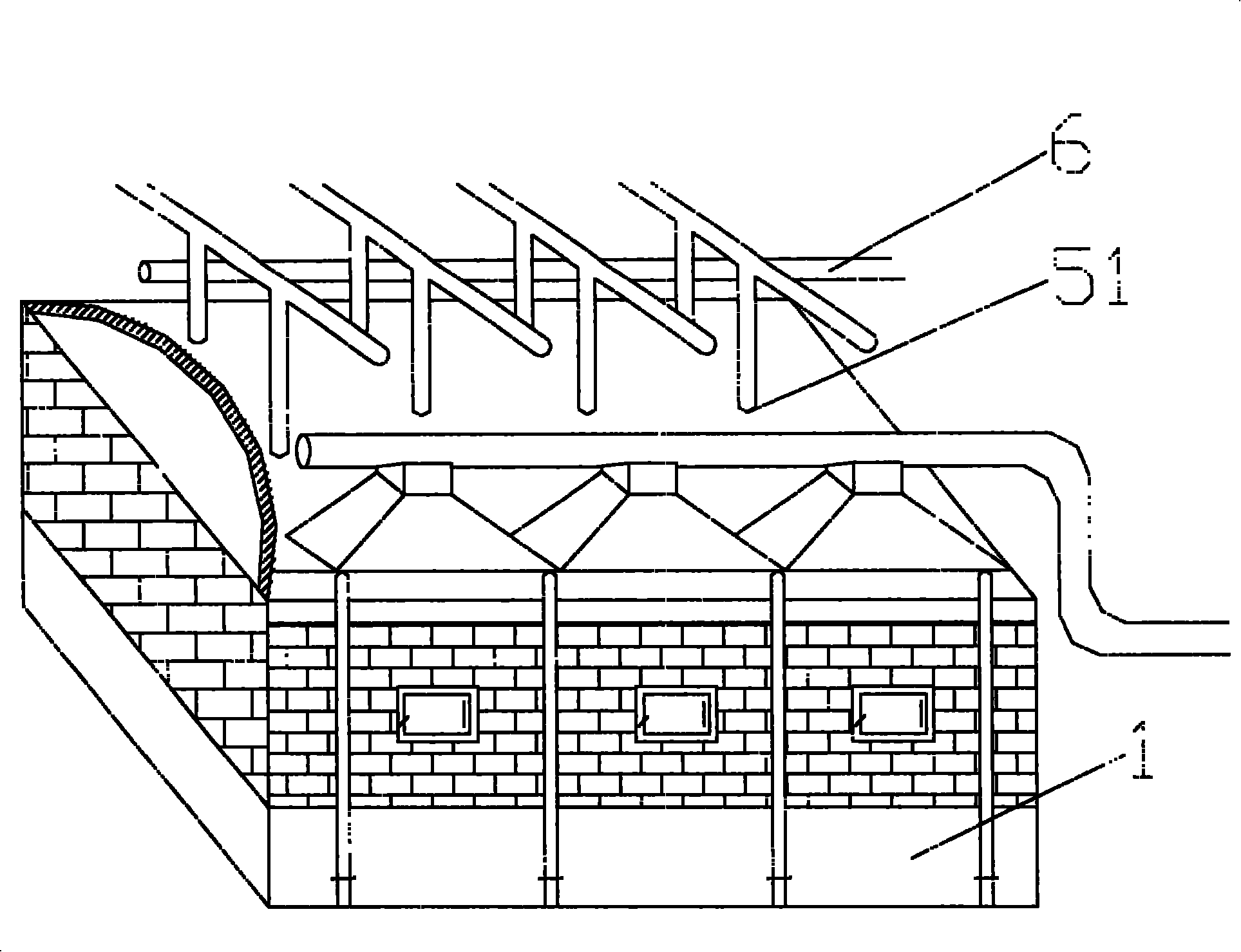

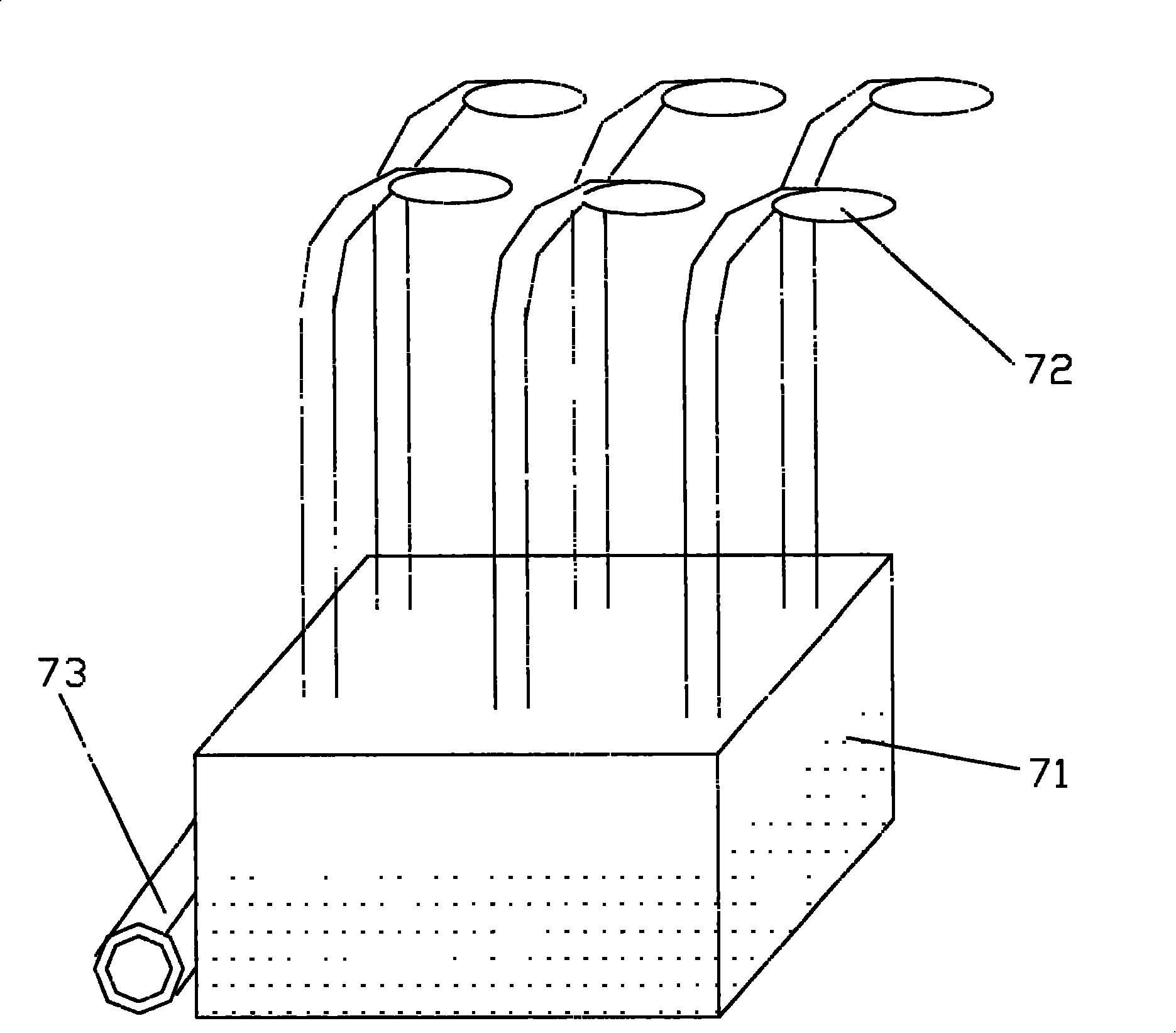

[0020] Fig. 1 is the structural representation of the solid waste recovery treatment system in the waste lead-acid storage battery of the present invention; Comprising reverberatory furnace 1, refining furnace 2, flue 3, dedusting room 4, described refining furnace 2 is connected in the rear end of reverberatory furnace 1, reflecting The smoke outlets of the furnace 1 and the refining furnace 2 communicate with the front end of the flue 3, and the dust removal room 4 communicates with the rear end of the flue 3, and also includes a gas generator 5, which is connected to the reverberatory furnace 1 and the refining furnace 2 connections. A heat exchanger 6 is also included, and the heat exchanger 6 is installed at the front end of the flue 3 close to the reverberatory furnace 1 . It also includes a water film dust removal device 7 connected to the rear end of the dust removal room 4 . Gas generator 5 uses gas combustion to provide firepower for reverberatory furnace 1 and refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com