Weld joint of aluminum alloy member

A technology for aluminum alloy parts and welded joints, which is applied in the direction of welding/welding/cutting articles, vehicle parts, welding equipment, etc., and can solve problems such as insufficient strength of the welded part 105, reduced quality, difficulty in ensuring the thickness of the weld bead 107, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0043] Experimental examples related to the present invention are described below. In addition, this invention is not limited to an experimental example.

[0044] Soldering is carried out under the following conditions.

[0045] ○Test materials:

[0046] Aluminum casting parts: AC4CH-T5 (ISO Al-Si7Mg), thickness 8mm

[0047] ·Extension parts of aluminum alloy: 6N01-T5, thickness 3.5mm

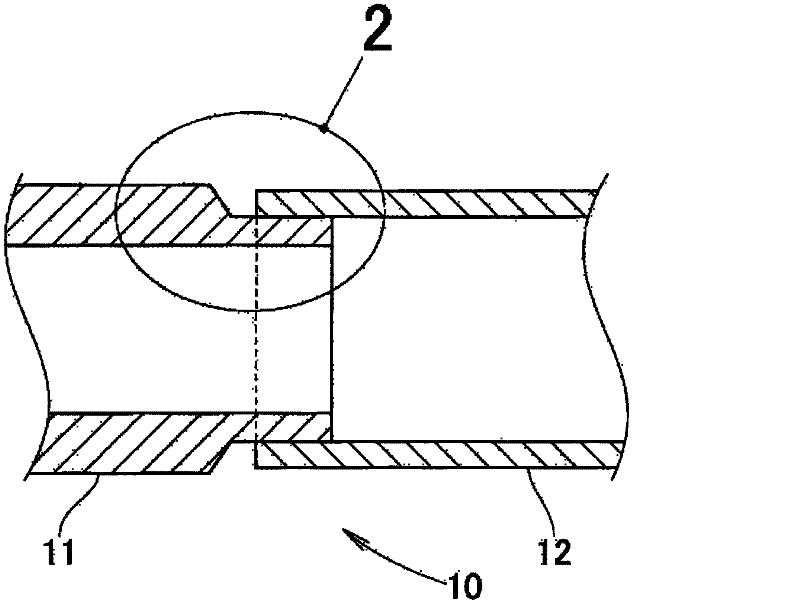

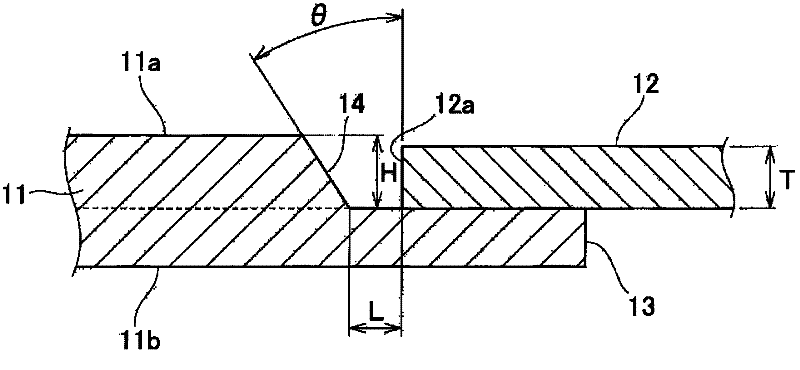

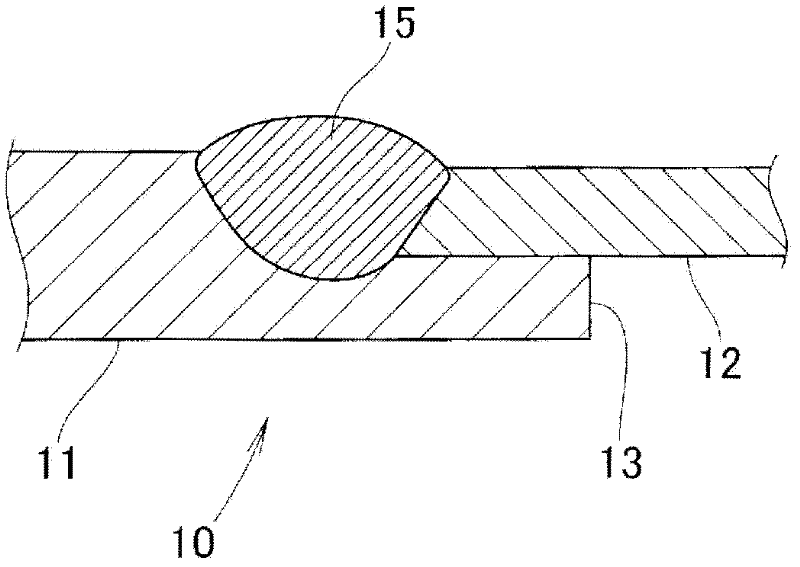

[0048] ○ Groove shape: figure 2 . Among them, the groove angle θ, the height H of the slope, and the root gap L are variables.

[0049] ○Welding conditions:

[0050] · Type: metal inert gas shielded welding

[0051] ・Filler wire: equivalent to A5356WY

[0052] ·Current: 230A

[0053] Rotation angle: 75°

[0054] ·Advance angle: 15°

[0055] · Welding speed: 70cm / min

[0056] ○: Verification of groove angle:

[0057] ·Height H of slope: 4.5mm

[0058] ·Root gap L: 5mm

[0059] Bevel angle θ: 10°, 15°, 30°, 45°, 50°

[0060] The joint efficiency was obtained for the obtained join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com