Welding method for Ti2AlNb-based intermetallic compound and dissimilar titanium alloy

A compound and titanium alloy technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems affecting the mechanical properties of the weld, affecting the performance of the weld, and asymmetry of the weld, so as to improve the welding heat cycle, The effect of reducing welding heat input and reducing high temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

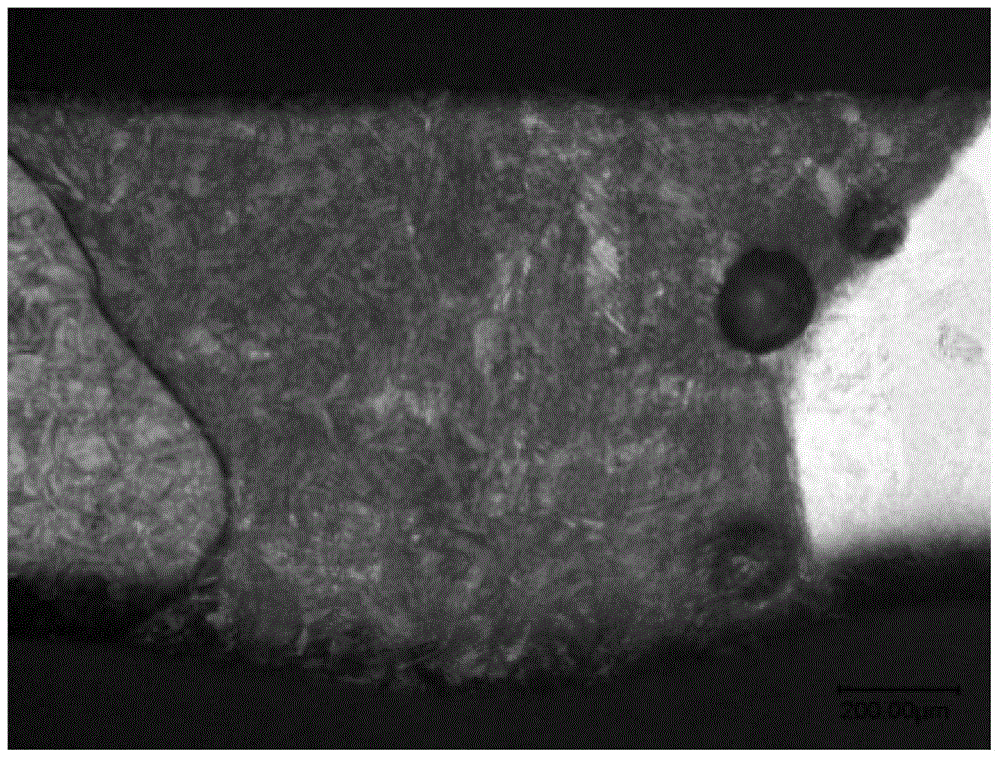

[0020] Specific embodiment one: a kind of Ti of this embodiment 2 The method for AlNb-based intermetallic compound and dissimilar titanium alloy welding, it is to carry out according to the following steps:

[0021] Step 1: Before welding, grind or clean the surface of the workpiece to be welded, and fix the polished or cleaned workpiece to be welded on the welding fixture; wherein, the workpiece to be welded is Ti 2 AlNb-based intermetallic compounds and dissimilar titanium alloys;

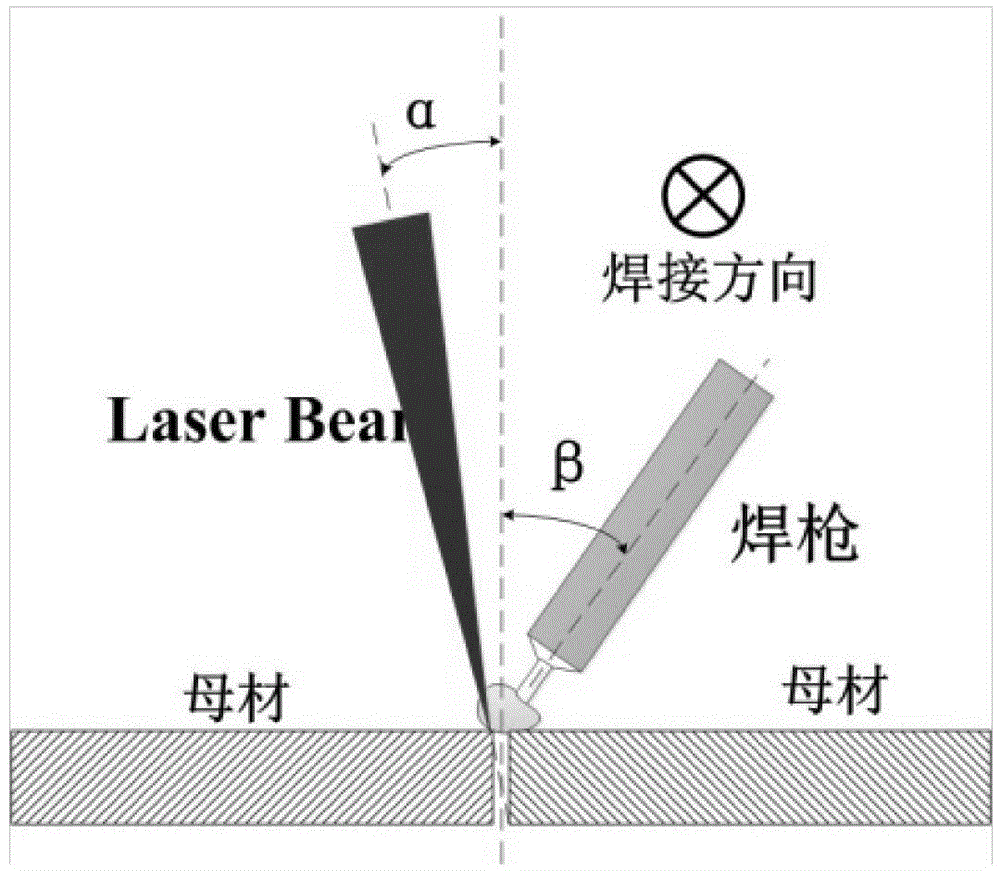

[0022] Step 2: Apply laser and TIG welding together on the area to be welded, and set the geometric parameters: the defocus amount is -3~﹢3mm;

[0023] Step 3: Set the welding parameters of laser-TIG hybrid welding: the arc current is 50-500A, the angle between the welding torch and the vertical direction is 10°-45°, the welding speed is 50-500mm / min, and the shielding gas is an inert gas; The power is 500~10,000W;

[0024] Step 4: Start the control switch, first pass in the shielding gas, and...

specific Embodiment approach 2

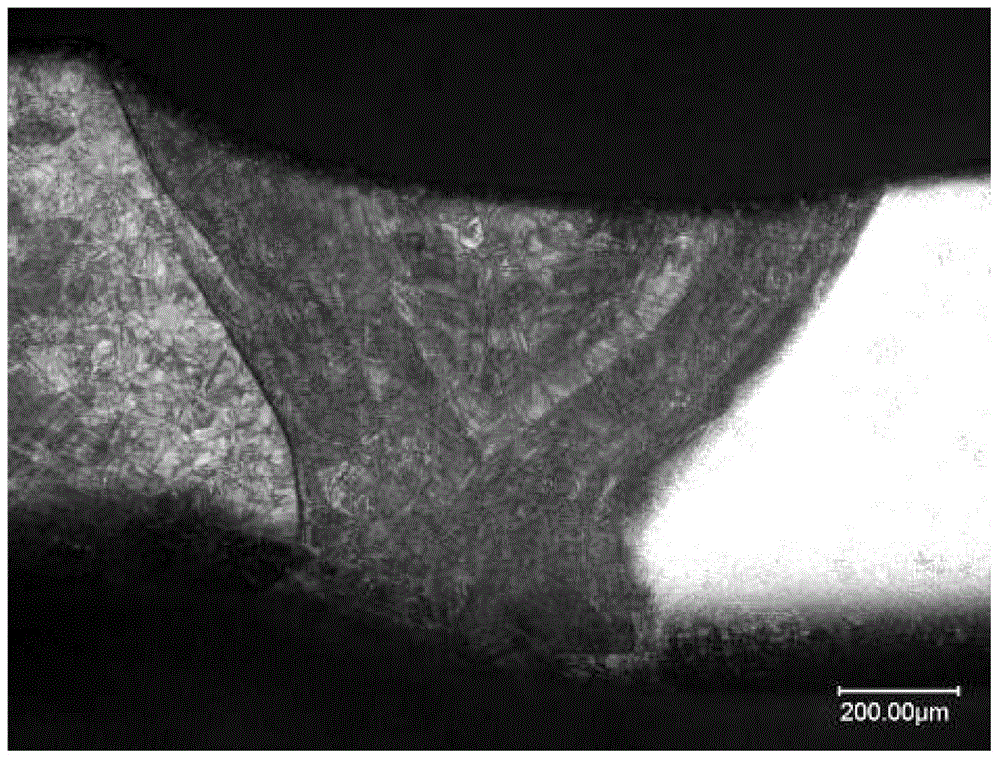

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the welding method adopts the parallel placement mode of laser and TIG electric arc perpendicular to the weld seam direction for welding, and the welding conditions are: the welding torch and the laser head are in the The same plane, and the plane is perpendicular to the direction of the weld, the laser head is located on the side of the workpiece with a relatively high melting point among the workpieces to be welded, and the focus of the laser beam is focused on the edge of the side of the workpiece with a relatively high melting point among the butt welded workpieces to be welded, The angle between the laser beam and the vertical direction is 5-30°; the welding torch of the TIG arc is located on the side of the workpiece with a relatively low melting point among the workpieces to be welded, and the welding torch is placed at the center of the weld gap. Others are the same as...

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is different from Embodiment 1 in that: the dissimilar titanium alloy is α titanium alloy or β titanium alloy or other dissimilar titanium alloys. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com