Patents

Literature

201results about How to "Reduce welding heat input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

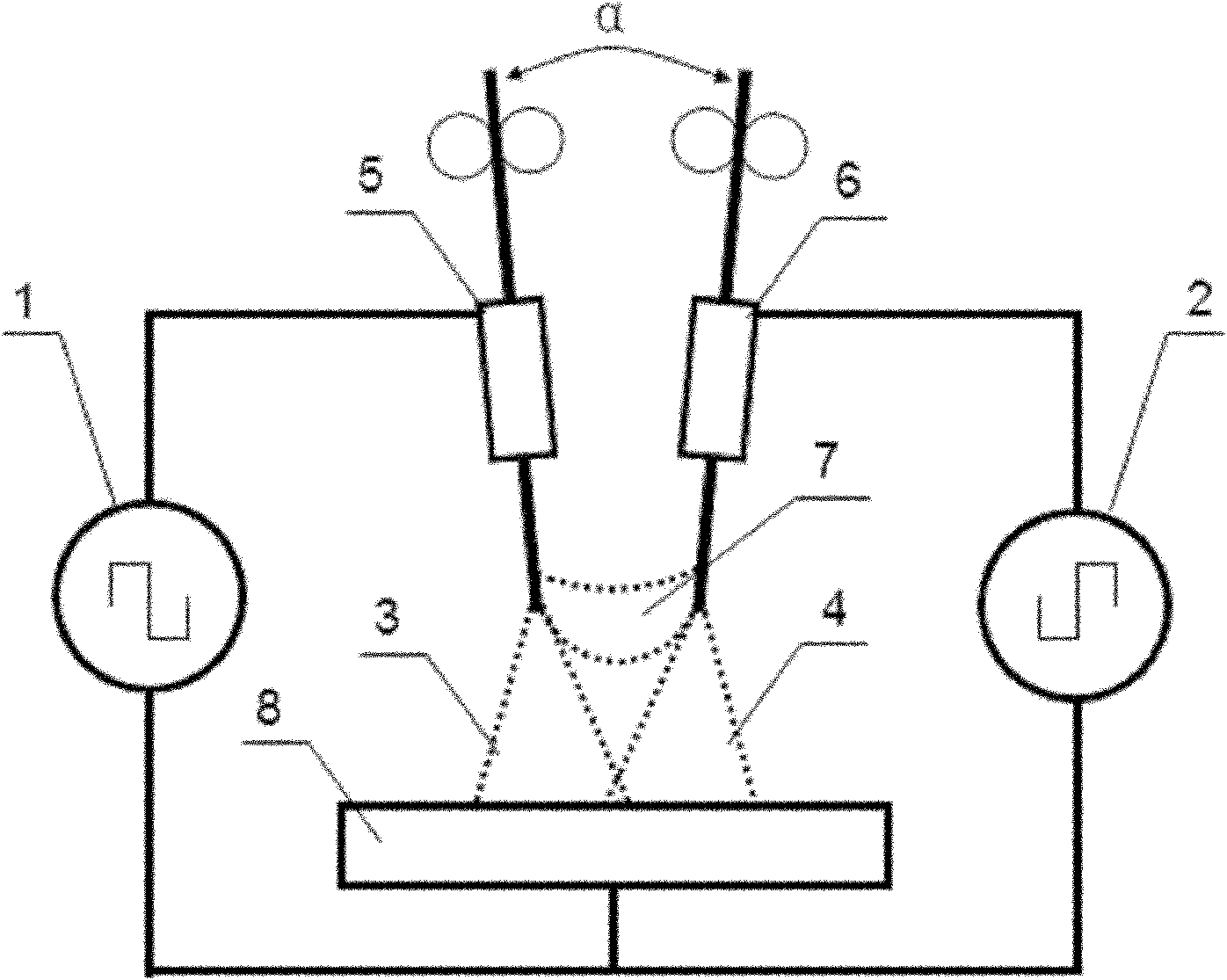

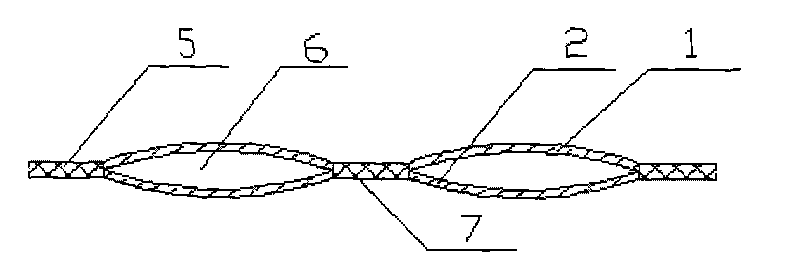

Dynamic twin-wire three-arc welding method

ActiveCN102069265AReduce welding heat inputAvoid electromagnetic interferenceArc welding apparatusPhase differenceEngineering

The invention provides a dynamic twin-wire three-arc welding method, belonging to the technical field of welding. The invention solves the problem that contradictions exist between improvement of deposition rate and reduction of heat input in the existing arc welding methods. The method is characterized in that a wire feeder is adopted to automatically feed a first welding wire and a second welding wire into two welding wire tips respectively and the included angle between the two welding wires is ensured to be 0-90 degrees; one output end of a first variable polarity power source is connected with one welding wire tip; one output end of a second variable polarity power source is connected with the other welding wire tip; after being connected with each other, the other output end of the first variable polarity power source and the other output end of the second variable polarity power source are connected with a workpiece to be welded; and the phase difference between output signals of the first variable polarity power source and the second variable polarity power source is 180 degrees. The welding method is efficient.

Owner:SHENZHEN RILAND IND

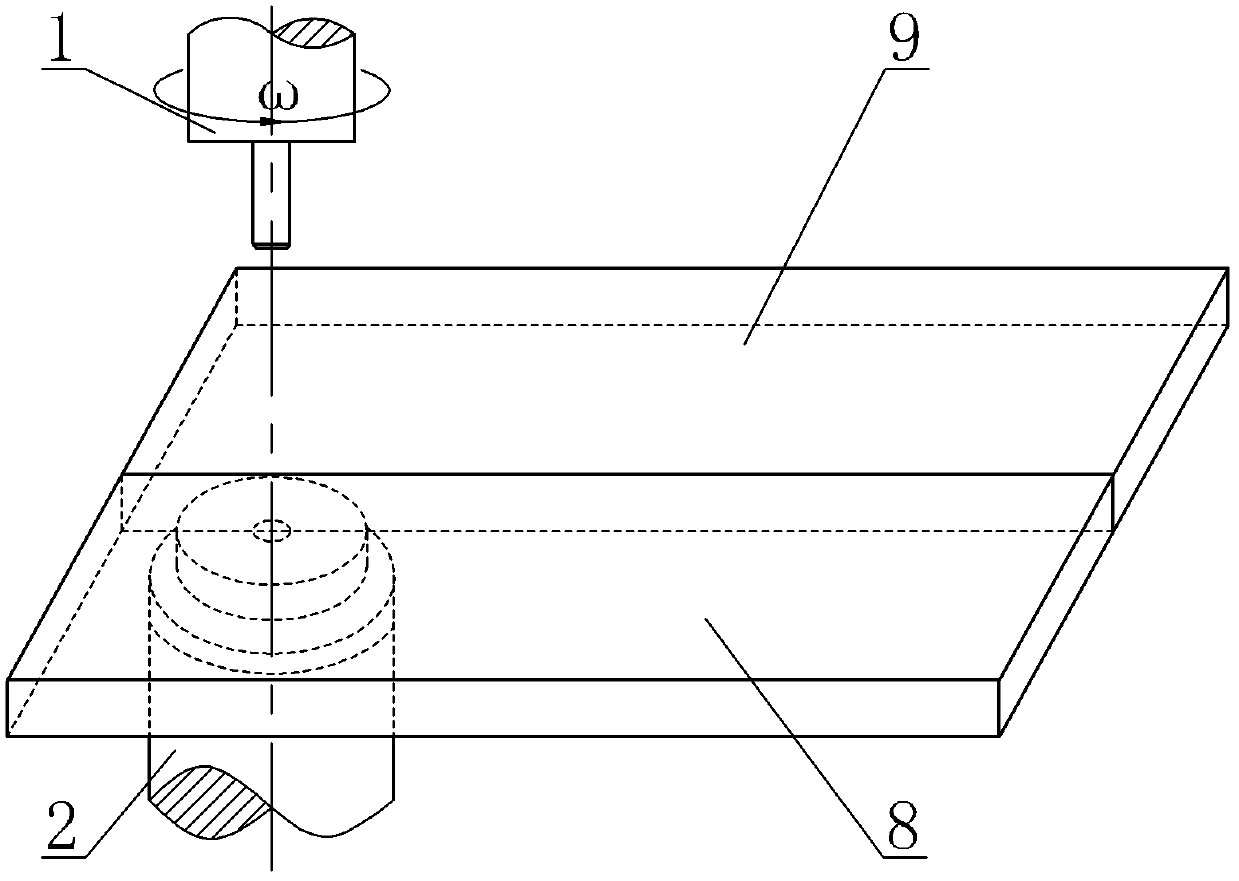

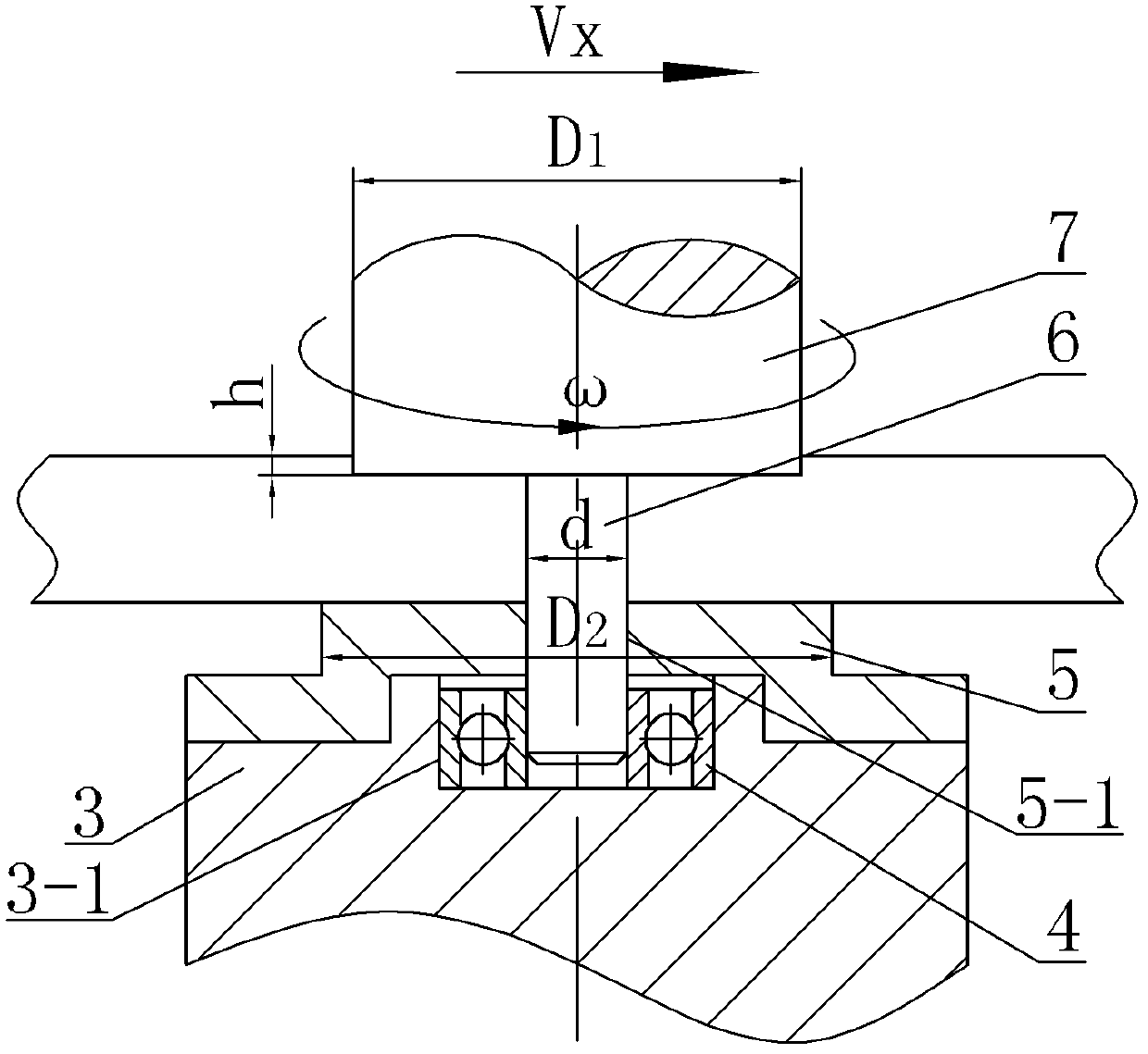

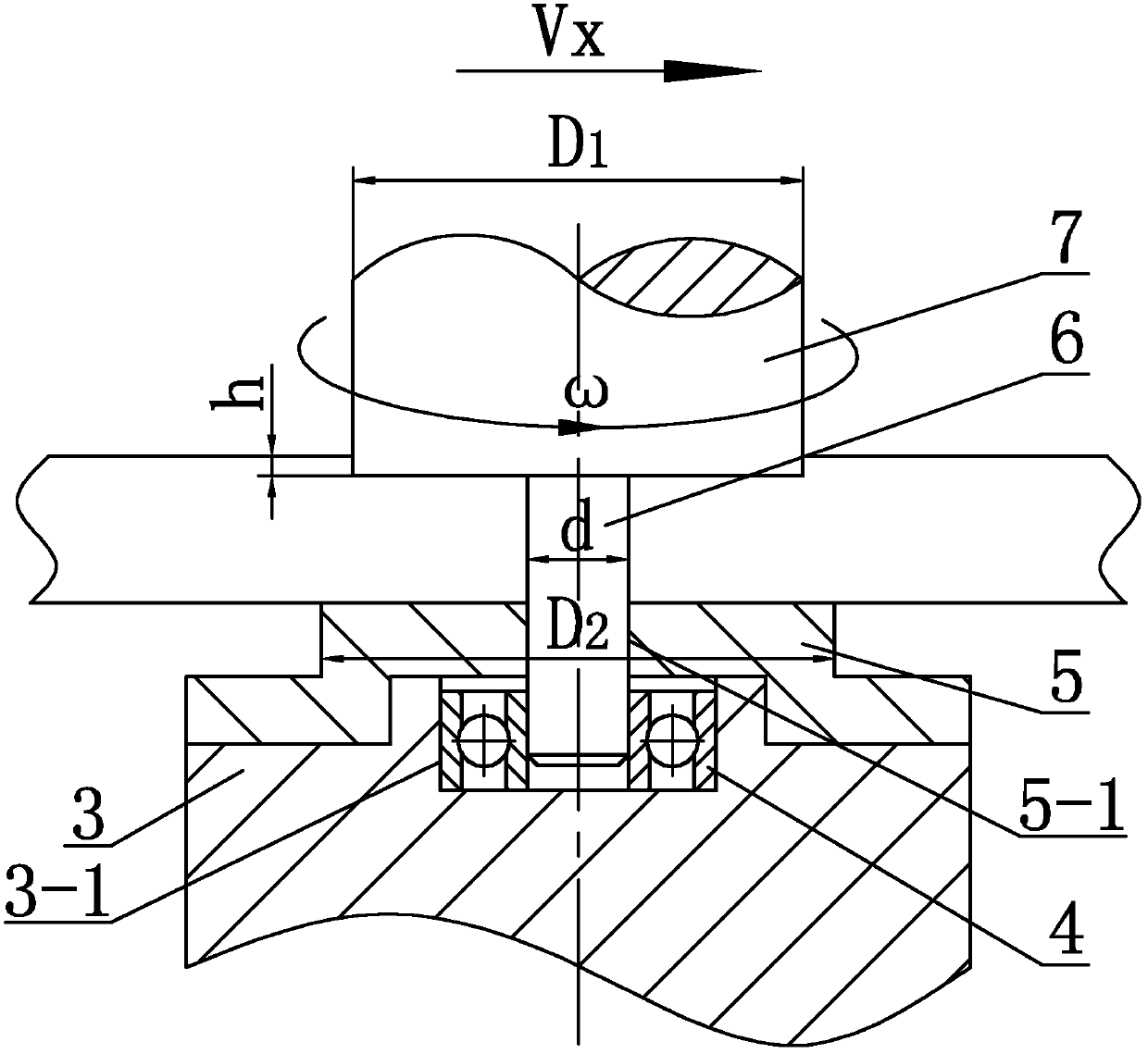

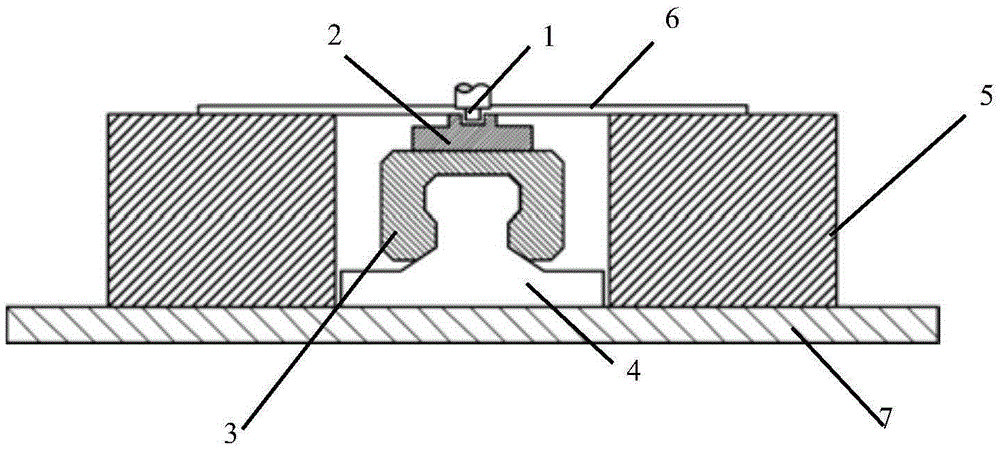

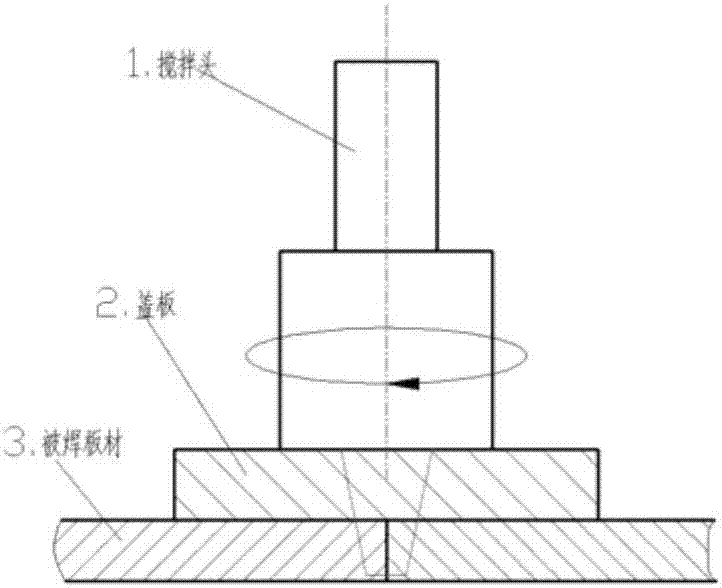

Self-sustaining friction stir welding stirring head with irrotational lower shaft shoulder and welding method of stirring head

InactiveCN102601515AAvoid rotating heatImprove carrying capacityNon-electric welding apparatusEngineeringMechanical property

The invention relates to a stirring head and a welding method, in particular to a self-sustaining friction stir welding stirring head with an irrotational lower shaft shoulder and a welding method of the stirring head, which solve the problems that welding heat input is increased as a lower shaft shoulder of an existing self-sustaining friction stir welding stirring head rotates to generate heat, weld formation is difficult, and the mechanical property of a welding joint is low. A circular groove is machined at the center of the upper end face of a support base, a radial positioning bearing is mounted in the circular groove, the lower shaft shoulder is fixedly mounted on the upper end face of the support base, a stirring pin is longitudinally machined on the lower shaft shoulder, and the lower portion of the stirring pin penetrates through the stirring pin and is mounted on the support base through the radial positioning bearing during welding. The welding method includes: firstly, determining the size of the stirring head; secondly, fixing workpieces to be welded; thirdly, positioning the stirring head before welding; fourthly, determining the rotation speed of the stirring head and the pressing depth of an upper shaft shoulder; and fifthly, determining welding speed and welding the first workpiece to be welded and the second workpiece to be welded. The stirring head and the welding method are used for friction stir welding.

Owner:HARBIN INST OF TECH

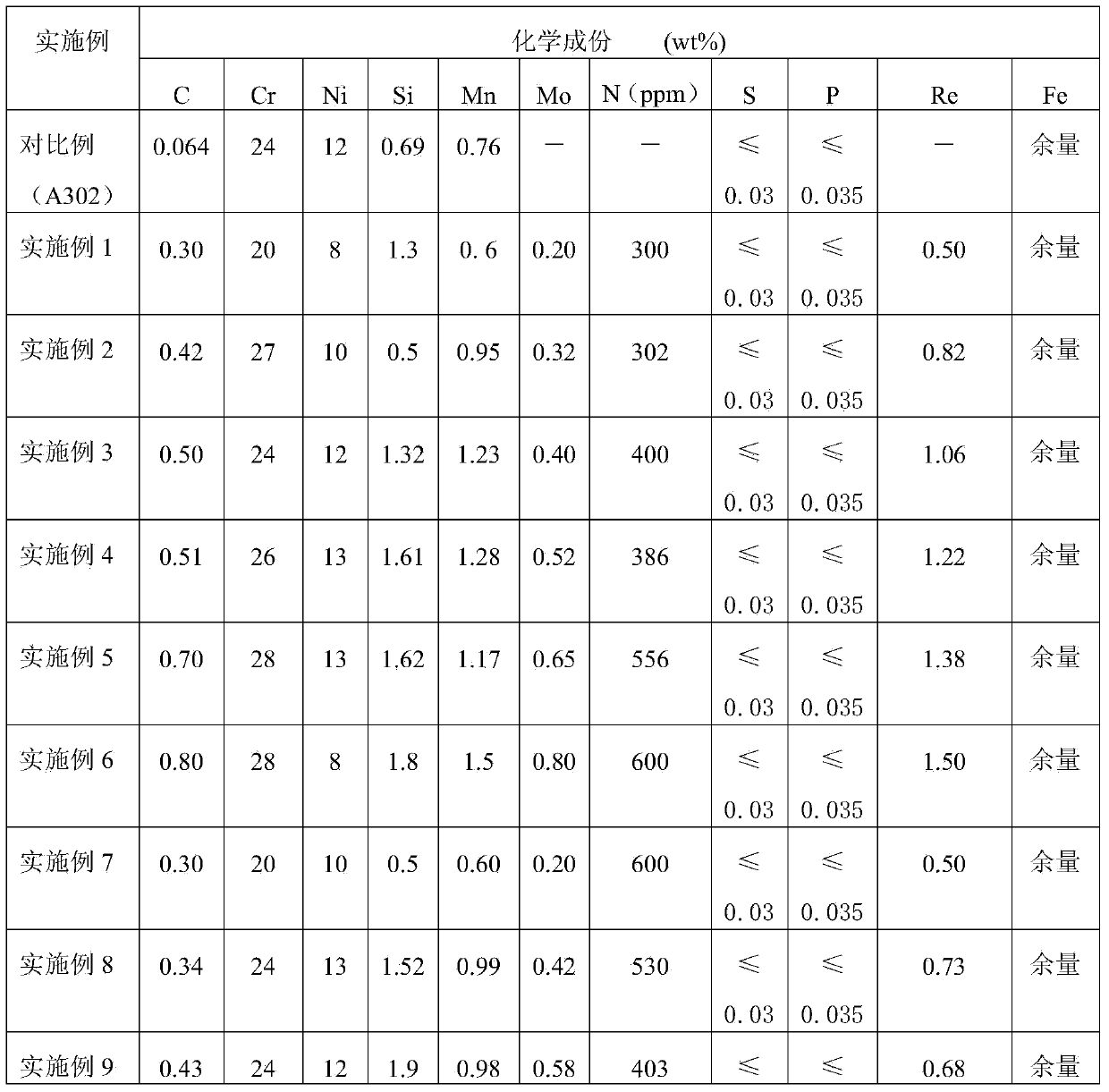

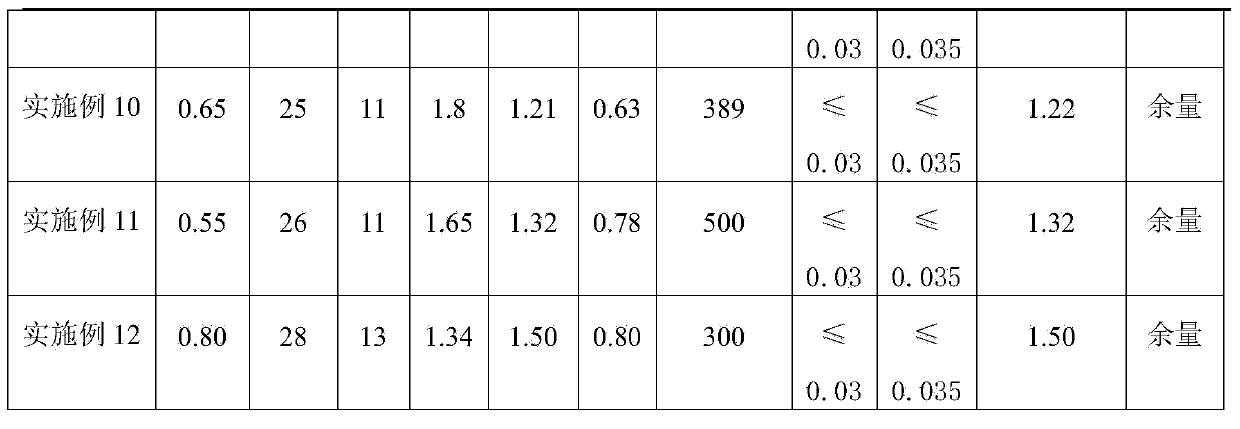

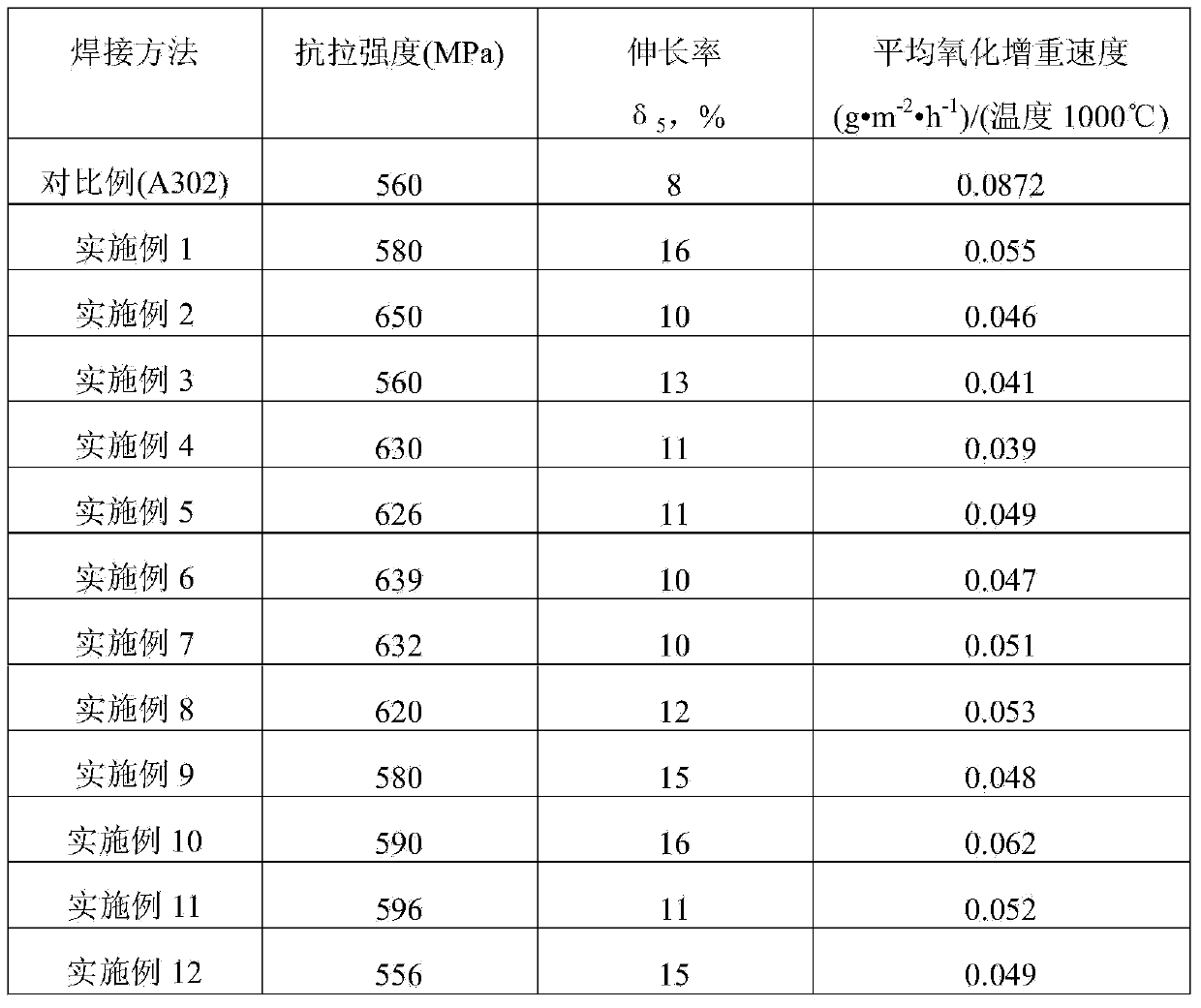

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

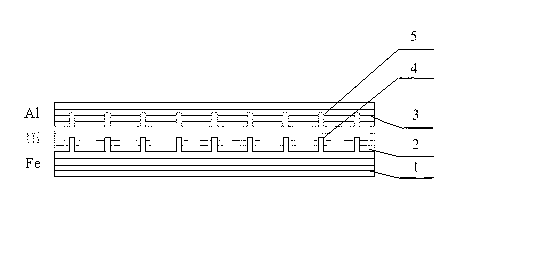

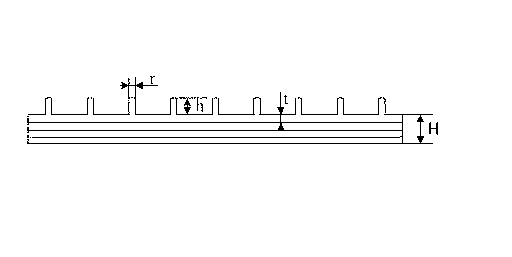

Connecting method for aluminum-steel dissimilar materials

ActiveCN103231203AReduce manufacturing costNo droplet transferArc welding apparatusMetal working apparatusOrganic solventCleansing Agents

The invention discloses a novel connecting method for aluminum-steel dissimilar joints and relates to a connecting method for aluminum-steel dissimilar materials. The connecting method is characterized in that alloy interlayer adding and mechanical inlaying are combined to achieve connection between aluminum-steel dissimilar materials. The method comprises the steps of cleaning the contact surface and the periphery of a part to be welded; using an organic solvent or a cleaning agent for wiping; surfacing uniformly-distributed columns on the contact surface of a steel part through steel welding wires; depositing a nickel base alloy layer on the contact surface of the steel part through nickel base alloy welding wires; surfacing uniformly-distributed nickel base alloy columns on the surface of the nickel base alloy layer through nickel base alloy welding wires; and surfacing an aluminum layer on the nickel base alloy surface, and performing further machining molding on an aluminum-steel joint. According to the connecting method, the defects of embrittlement of connecting joints, low connecting strength and the like caused by inter-metallic compounds during aluminum-steel welding are overcome, and the problem of failure of joints caused by overlarge differences of heat expansion coefficients of aluminum-steel materials is solved.

Owner:斯图加特航空自动化(青岛)有限公司

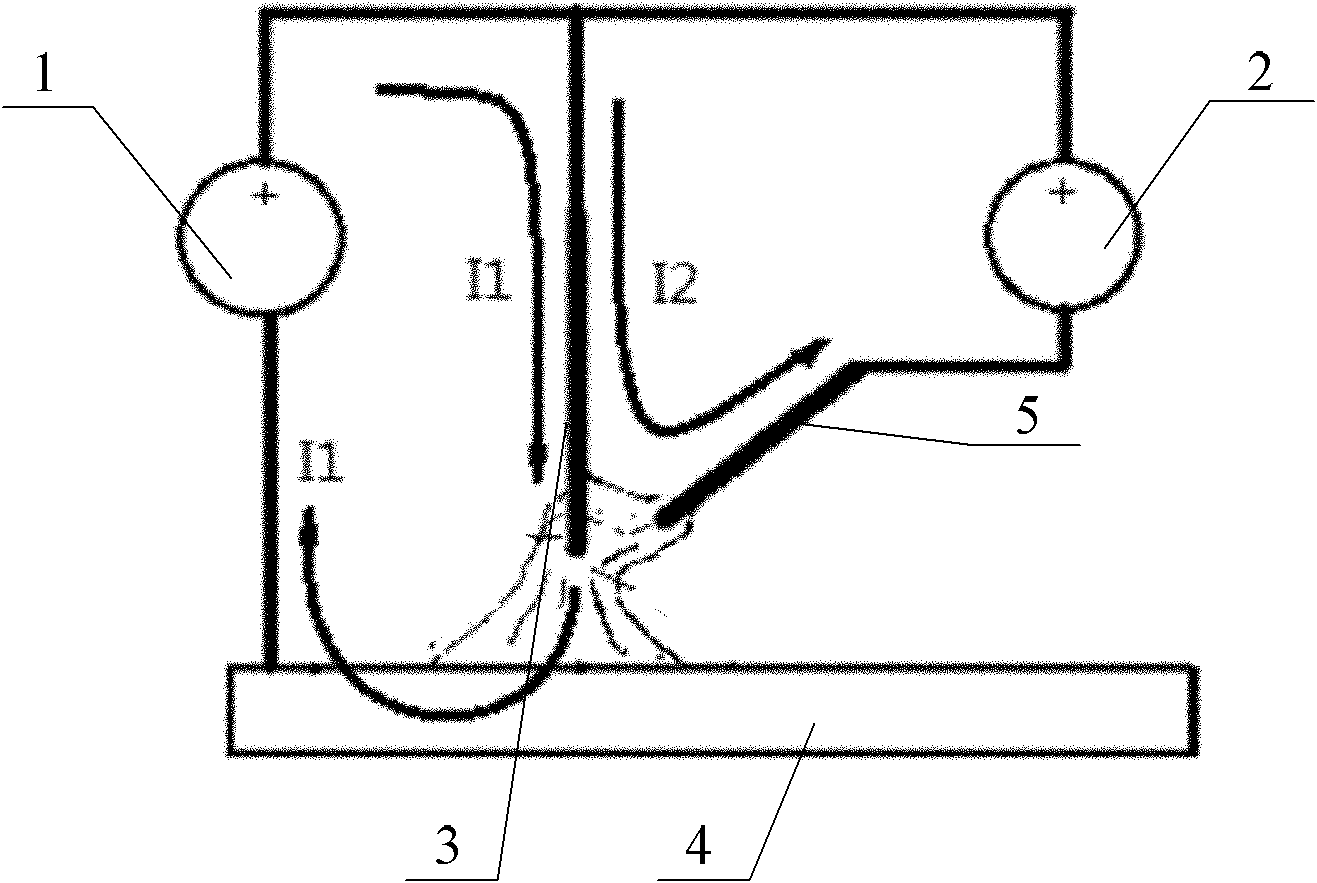

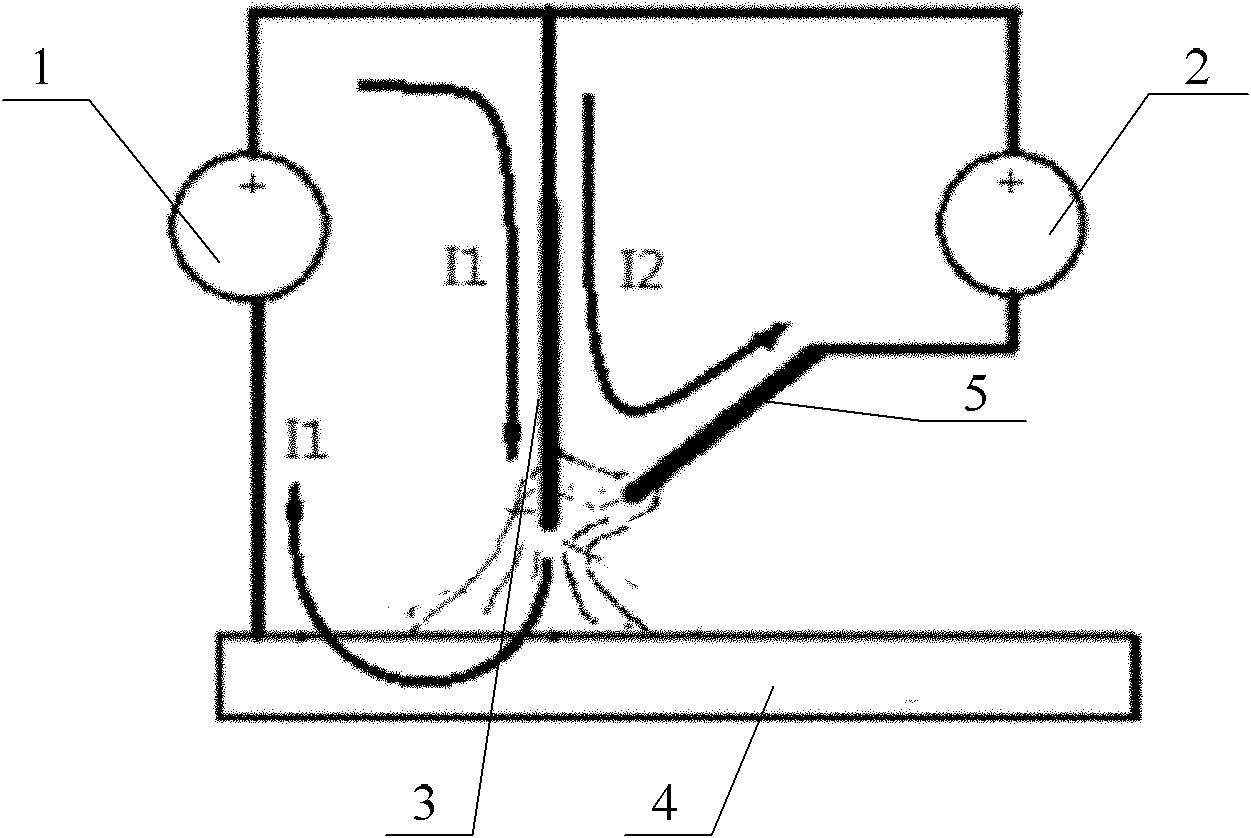

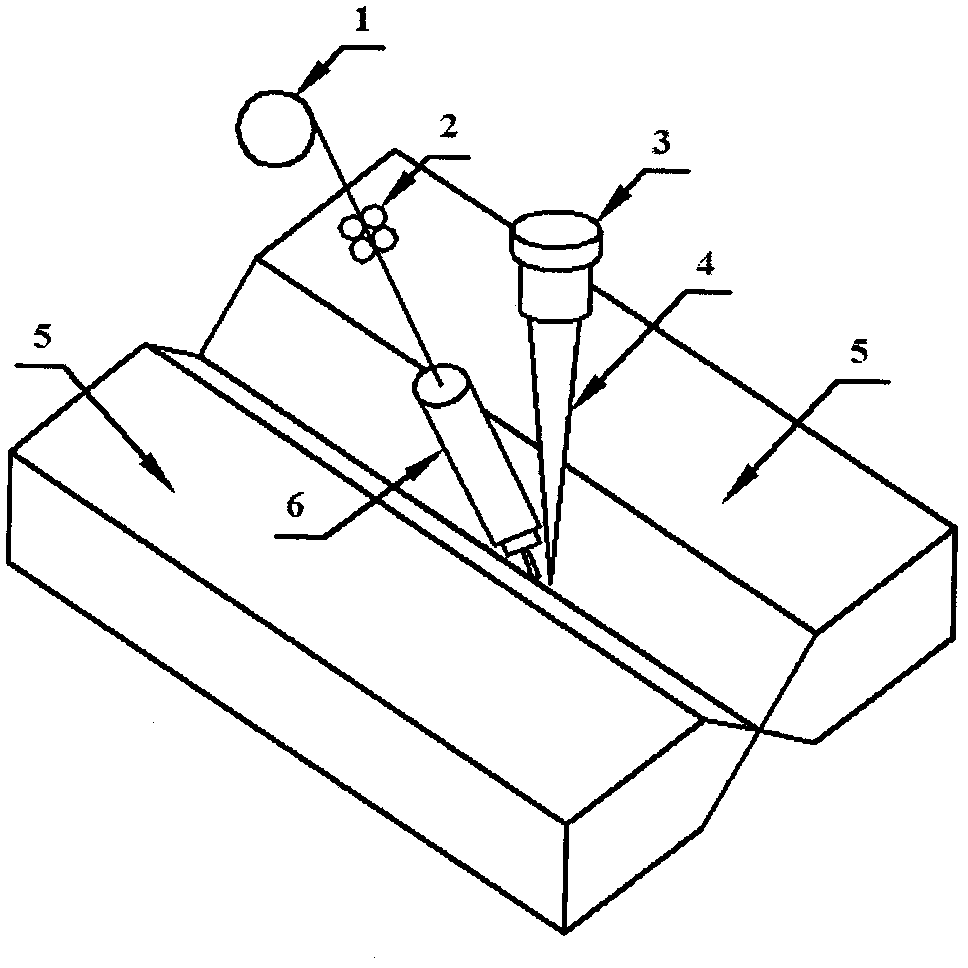

Electric arc welding method with high welding wire melting speed and low welding heat input

ActiveCN101972879AFast meltingReduce welding heat inputArc welding apparatusEngineeringAuxiliary electrode

The invention relates to an electric arc welding method with high welding wire melting speed and low welding heat input, belonging to the technical field of welding. The electric arc welding method solves the problem of the mutual contradiction between improving the melting speed of a welding wire and reducing the welding heat input in the consumable electrode electric arc welding method. The electric arc welding method is characterized in that: the homopolar output ends of a main power supply and an auxiliary power supply are connected with the head end of a main consumable electrode, and the other electrode output end of the main power supply is connected with a workpiece to be welded, and the other electrode output end of the auxiliary power supply is connected with the head end of an auxiliary electrode. The welding method comprises the following steps of: enabling the tail end of the main consumable electrode to be close to the part to be welded, of the workpiece to be welded, and forming a main electric arc between the tail end of the main consumable electrode and the surface to be welded, of the workpiece to be welded under the action of the main power supply; enabling the tail end of the auxiliary electrode to be close to the tail end of the main consumable electrode, forming an auxiliary electrode arc between the tail end of the main consumable electrode and the tail end of the auxiliary electrode under the action of the auxiliary power supply, and forming a composite electric arc between the main electric arc and the auxiliary electric arc so as to realize the welding. The invention is used as an electric arc welding method.

Owner:HARBIN INST OF TECH

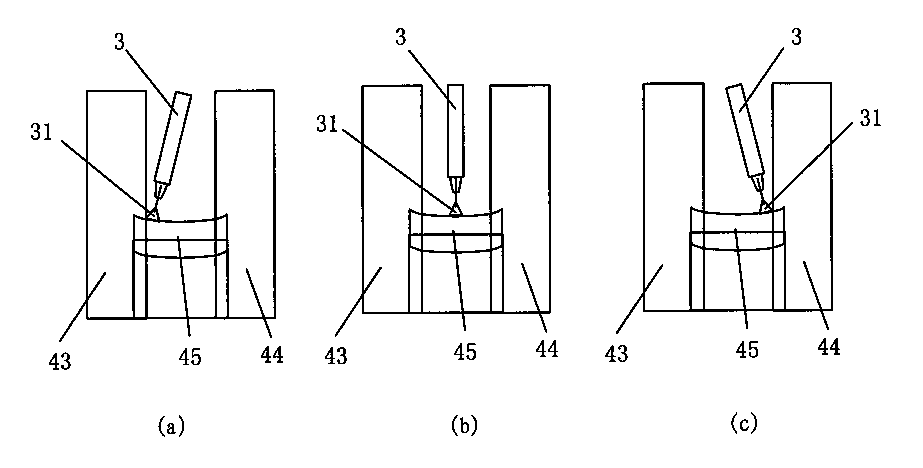

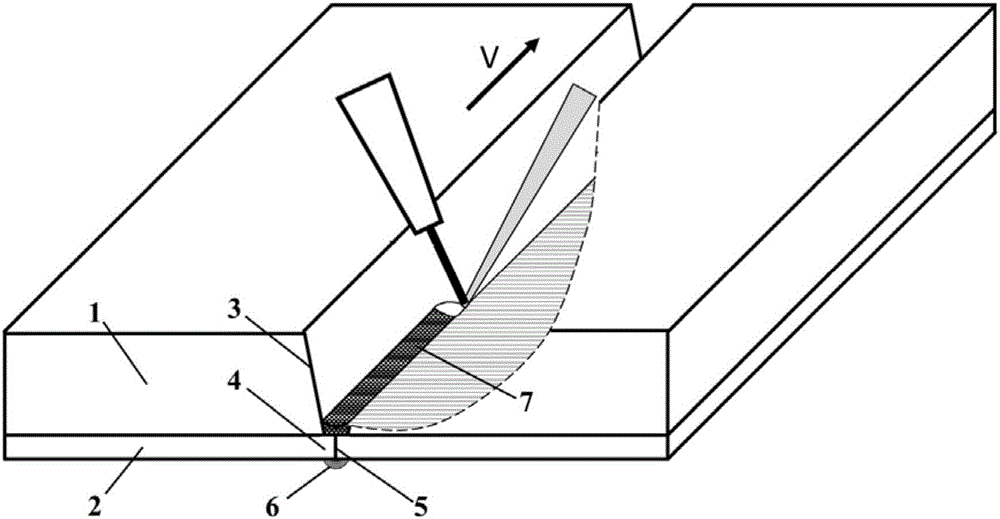

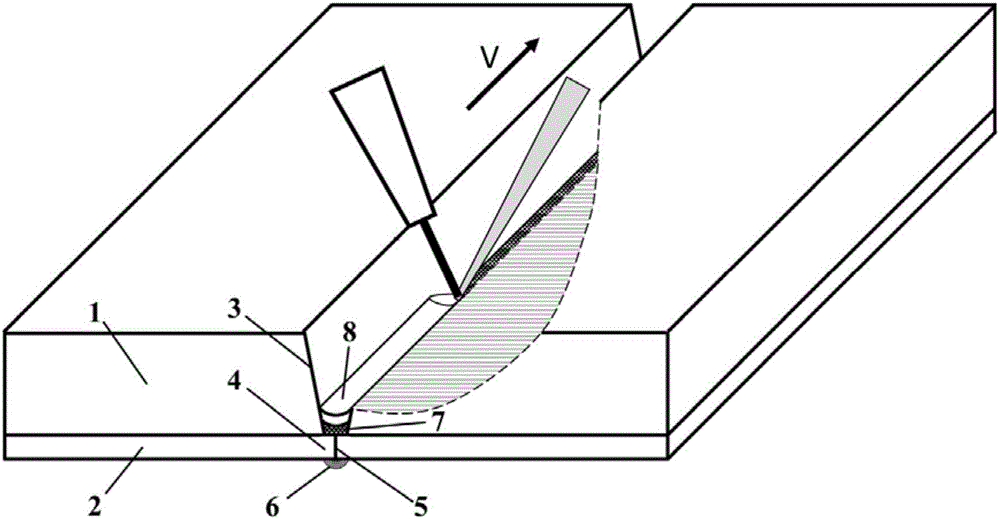

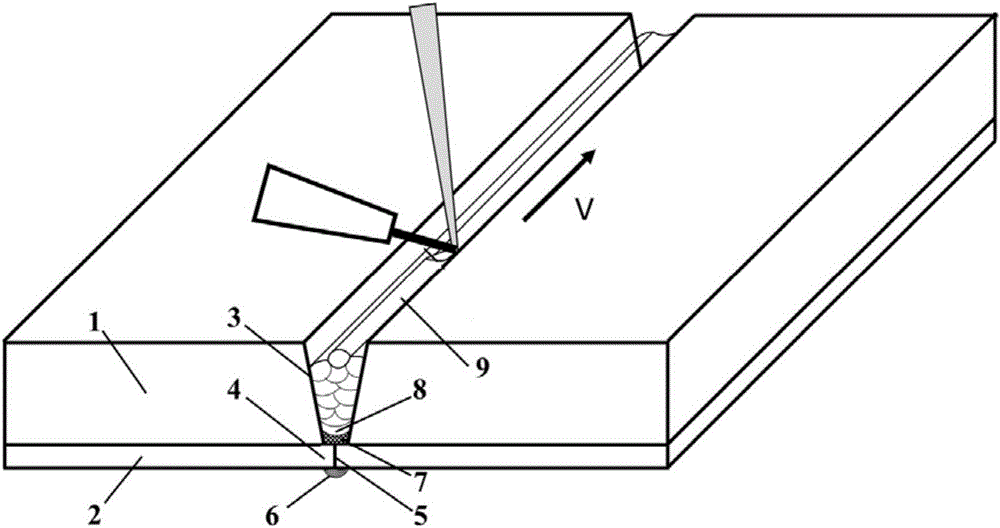

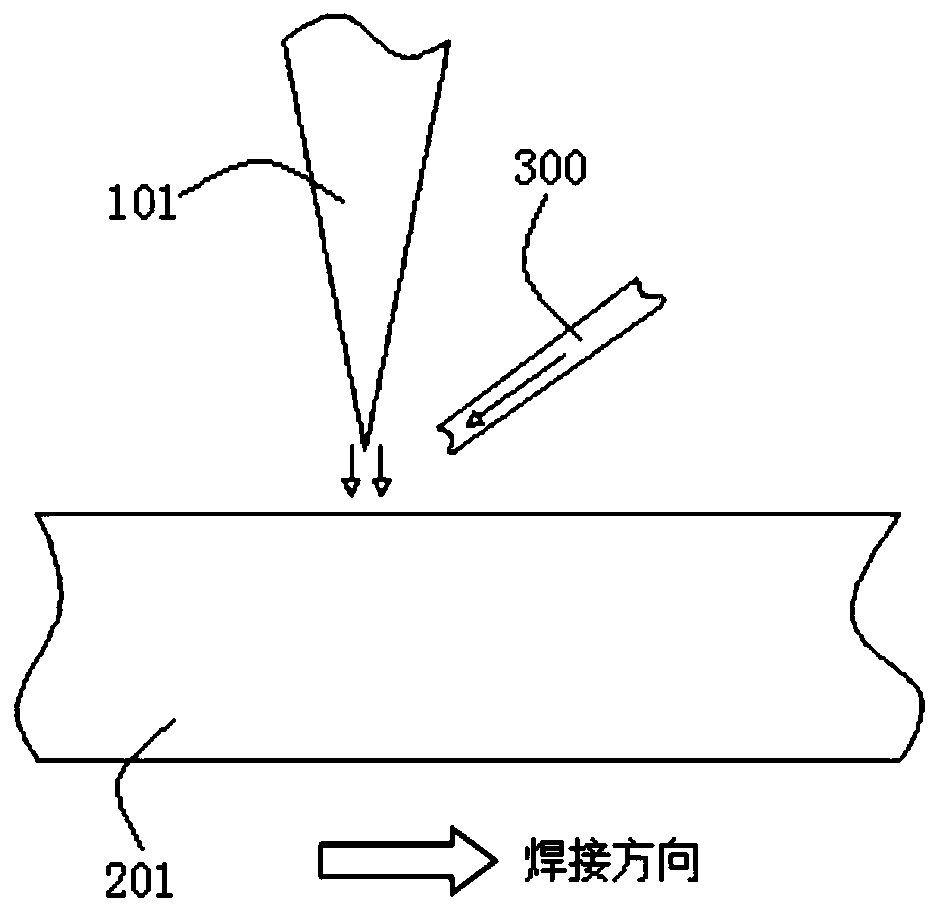

Laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method

ActiveCN102922153ASuppression of drippingEliminate undercut defectsLaser beam welding apparatusVertical planeArchitectural engineering

The invention provides a laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method, relates to a transverse welding method and solves the problem of the existing welding method that fused metal flows down when transverse welding is carried out in a vertical plane so as to cause undercut and deviation of a central line of a welding line. The laser guide GMAW electric arc compound transverse welding method is carried out by the following steps of: 1, carrying out oil-removing and oxidization-film-removing treatment on a work piece to be welded; 2, filling a welding wire; and 3, starting a laser device and a GMAW electric arc welding machine. With the adoption of the laser guide GMAW electric arc compound transverse welding method, the flowing of the fused metal can be controlled under the condition with a large welding current, so that the undercut defect of the welding line is eliminated and the central line of the welding line is rightly centered. The laser guide GMAW electric arc compound transverse welding method is applicable to the field of metal transverse welding engineering.

Owner:哈尔滨工大焊接科技有限公司

Method for overlaying wear-resistant layer of blade shroud of turbine working blade

InactiveCN102107314APromote maturityExtend working lifeArc welding apparatusPower flowWear resistant

The invention discloses a method for overlaying a wear-resistant layer of a blade shroud of a turbine working blade. In the method, manual tungsten electrode argon arc welding is used, and the specific process parameters meet the requirements that: welding wires are selected from a T800 cobalt-based wear-resistant alloy welding wire which is researched according to a B50TF193 standard of AmericanGeneral Electric Company and an S-6 cobalt-based wear-resistant alloy welding wire which is researched according to an American metal society standard AMS5788; the diameters are phi 1.6mm and phi 1.2mm respectively; a mark and the diameter of a tungsten electrode are WCe20 and phi 2.0mm; the diameter of a nozzle is phi 12mm; welding current is between 20 and 25A; and the flow rate of protective gas is between 10L / min and 12L / min. By the method, the condition of incomplete penetration or over-melting of a Z-shaped gear switching part R is avoided, the problem of overheating of welding is also solved, and the occurrence probability of welding cracks is greatly reduced or avoided. The method completely meets the requirements of the wear-resistant layer in a high-temperature working state after welding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

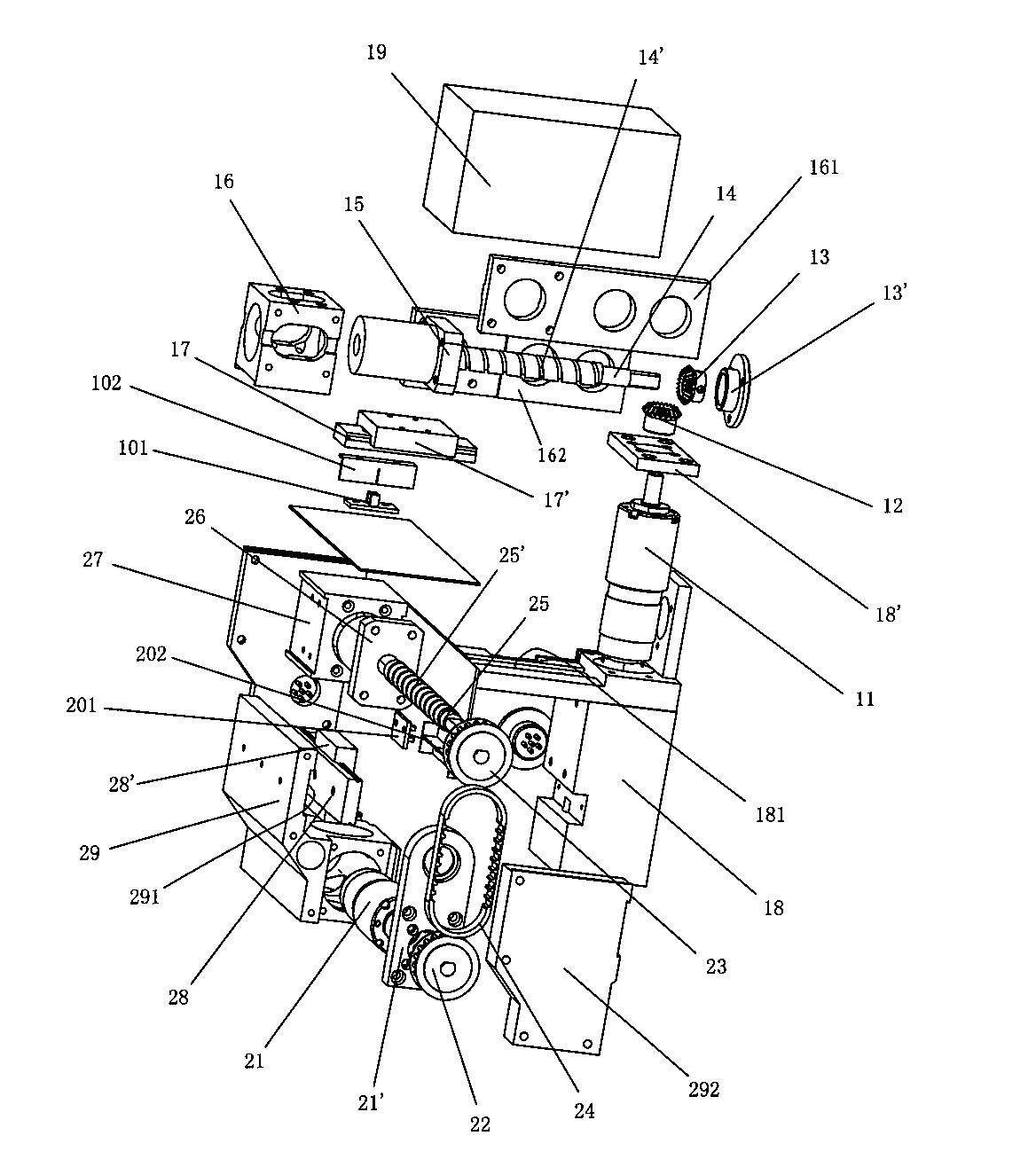

Welding gun swinging device for vertical electrogas welder

ActiveCN102423827AStrong penetrating powerImprove mechanical propertiesArc welding apparatusLinear motionReciprocating motion

The invention provides a welding gun swinging device for a vertical electrogas welder, which comprises a horizontal sliding mechanism for leading a welding gun to carry out linear motion along the direction of a vertical weld seam and a serrated swinging mechanism for leading the welding gun to swing in a groove clearance of the vertical electrogas welder, wherein the serrated swinging mechanism on which the welding gun is mounted is arranged on the horizontal sliding mechanism. Thus, the invention has the beneficial effects that a welding electric arc can move back and forth and be welded between a forming cushion plate on the back surface of the weld seam and a water-cooled forming slide block on the front surface of the weld seam as well as between a left side plate and a right side plate of a groove of the vertical electrogas welder; the side wall of the weld seam can be effectively ensured to be fully fused with a welding pool; the depth of a weld penetration can be remarkably increased, so that the mechanical property of the weld seam can be remarkably improved; and even if the melting speed of a welding wire is improved and the welding heat input is reduced, the side wall of the weld seam can still be fully fused with the welding pool to avoid interruption or mutation, even crack.

Owner:SHENZHEN RILAND IND

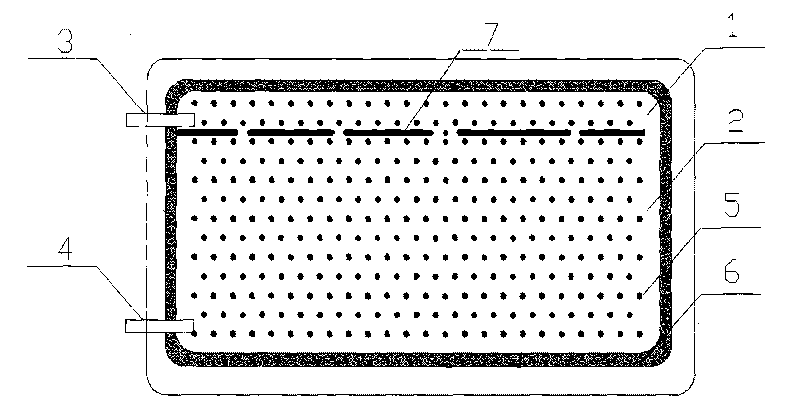

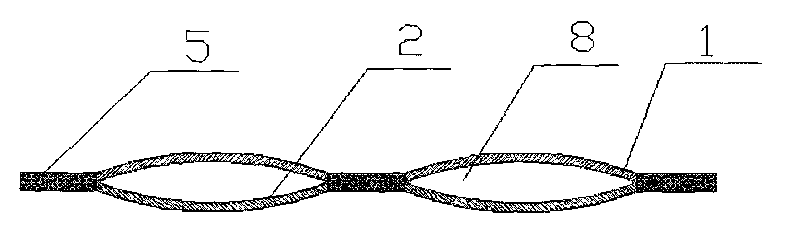

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

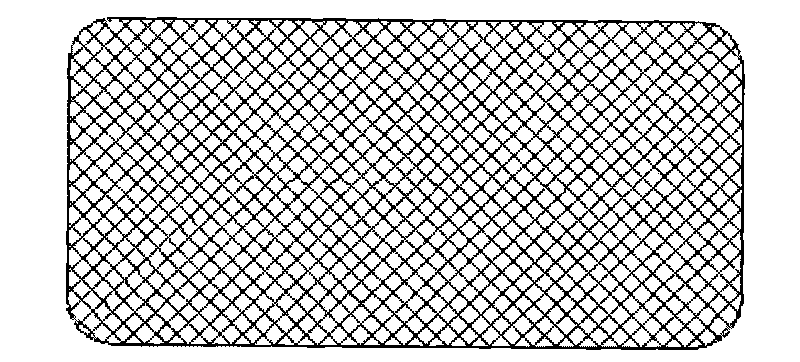

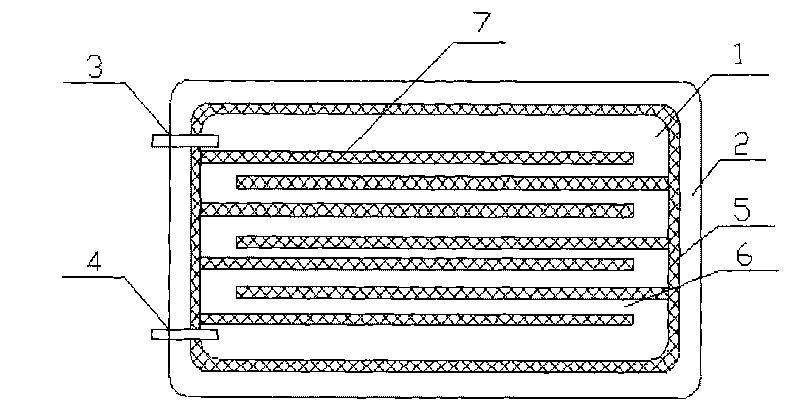

Stainless steel snakelike flow channel cold plate and processing molding method thereof

InactiveCN101691977AReduce pollutionLow soldering temperatureShaping toolsArc welding apparatusElectrical resistance and conductanceCold plate

The invention discloses a stainless steel snakelike flow channel cold plate and a processing molding method thereof. The snakelike flow channel cold plate adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a water-cooling resistance welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel snakelike flow channel cold plate by using an electric arc welding method; and then the snakelike flow channel cold plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

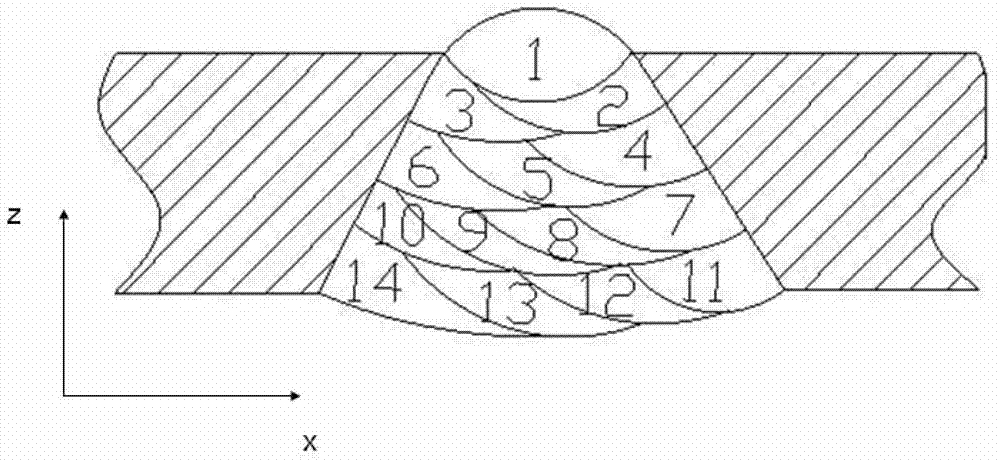

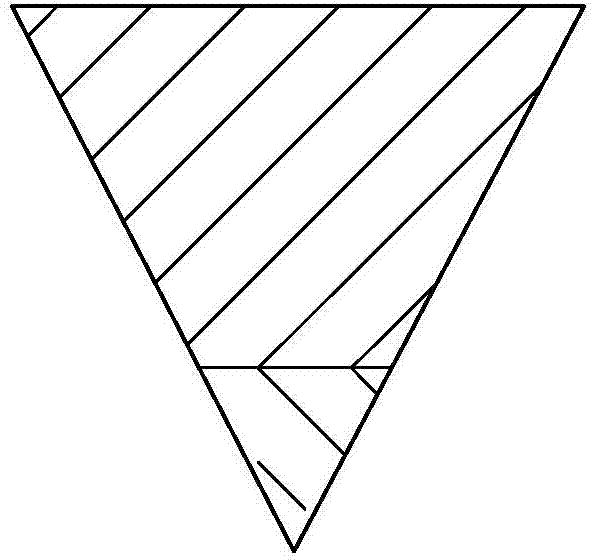

Manual arc welding bottoming layer Z-shaped arc extinction method and application thereof in Q460 high-strength steel horizontally-fixed steel pipe butt welding

ActiveCN102922085AFusion wellNo accumulationArc welding apparatusTubular articlesShielded metal arc weldingButt welding

The invention discloses a manual arc welding bottoming layer Z-shaped arc extinction method and application of the manual arc welding bottoming layer Z-shaped arc extinction method in Q460 high-strength steel horizontally-fixed steel pipe butt welding. An arcing point is located at a position of a root part of a groove 2 to 3mm close to a truncated edge, an electric arc is lightly led to an oblique rear part of a fusing tank along the groove after being struck and then transversely swung to the other side of the groove after a pause, act extinction is carried out towards the oblique rear part of an arcing point after fusing of the groove at the side is good through observation, and a running track of an end of a welding rod is Z-shaped. As the fusing tank can be well observed in a welding process, welding defects of a bottoming layer can be reduced and technical support is provided to ensure welding quality of the bottoming layer of a butt joint. With the adoption of the arc extinction method, shaping of the root part of a welding seam can be effectively controlled and a good welding seam structure can be obtained.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

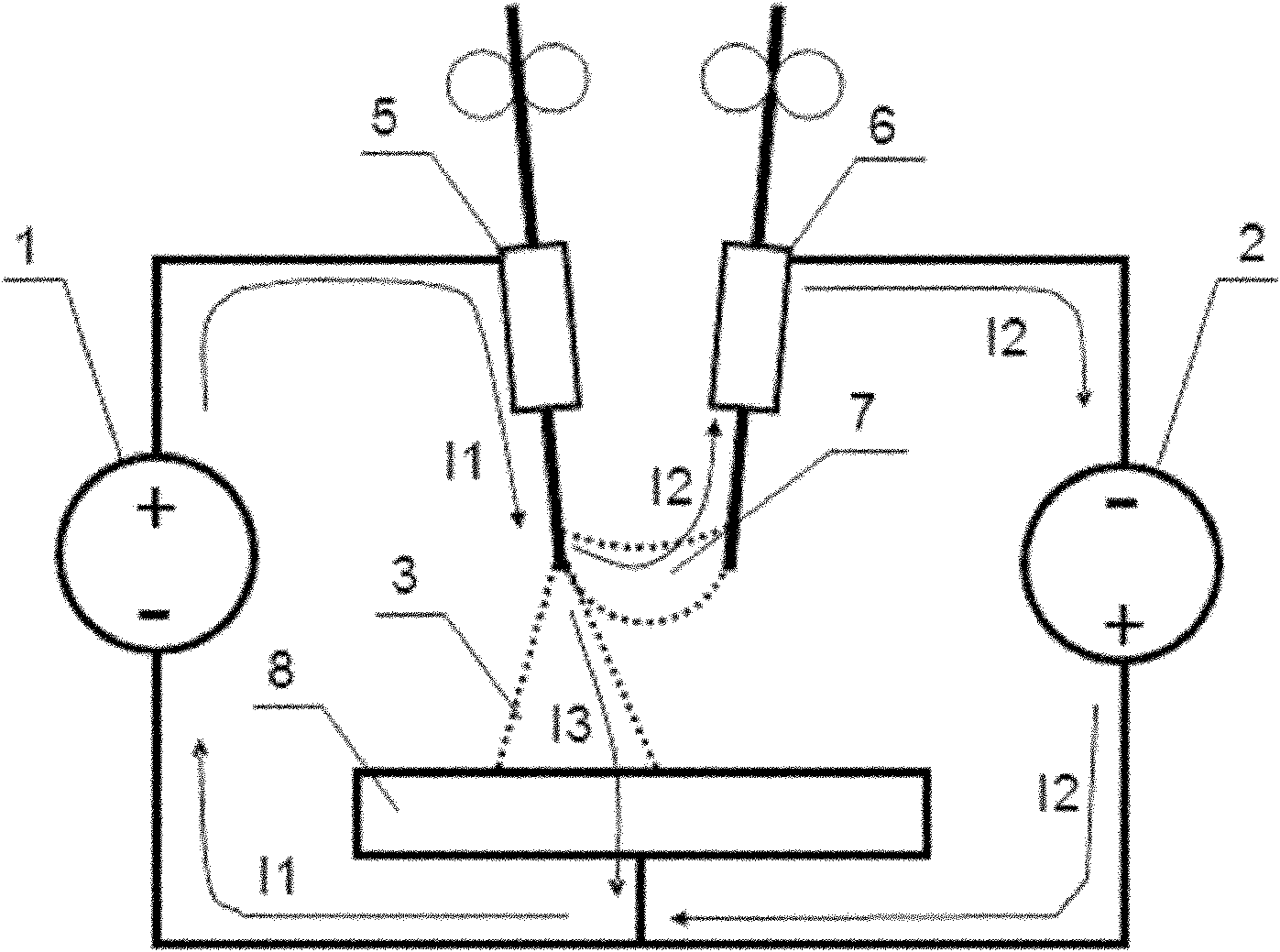

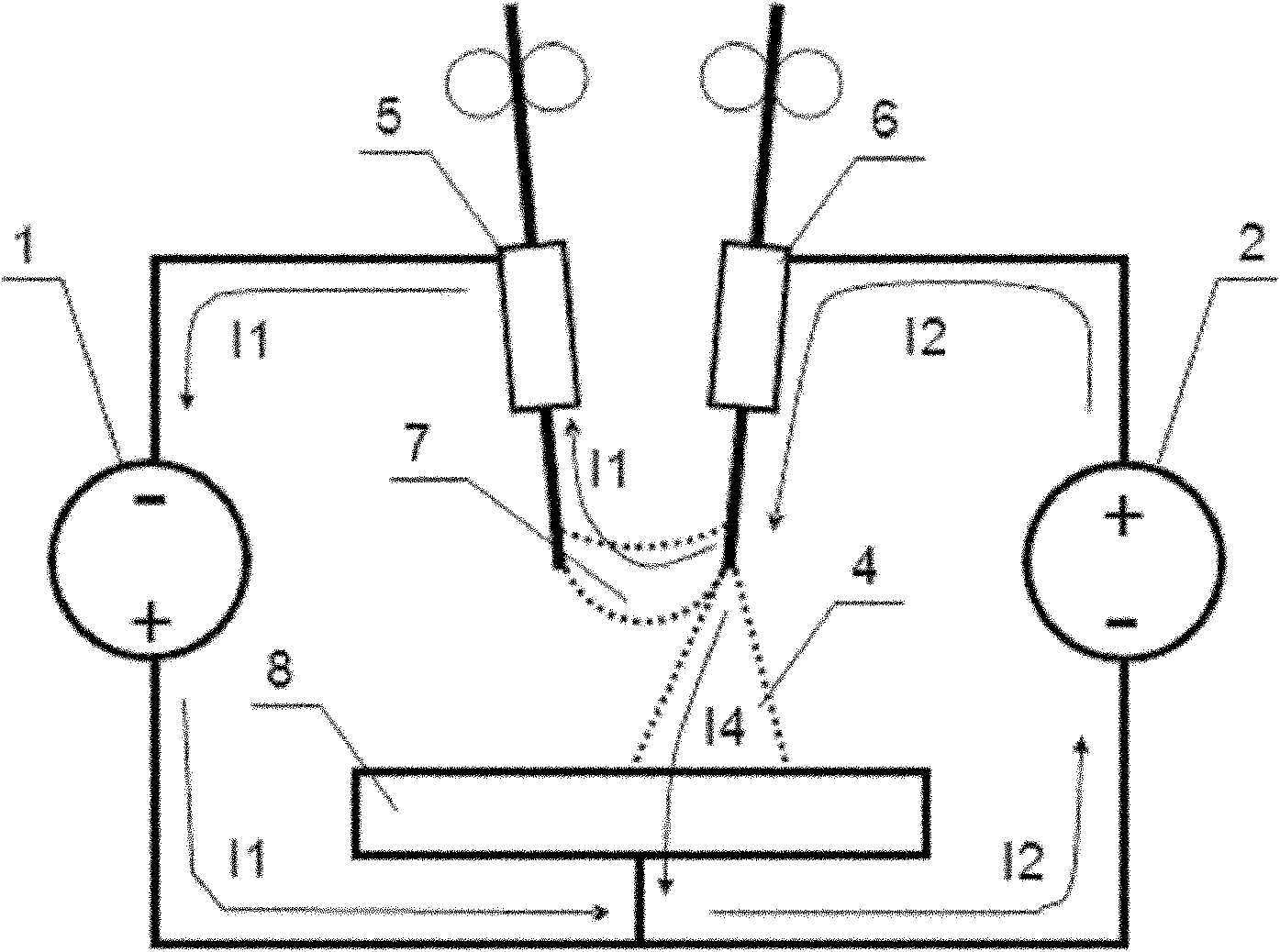

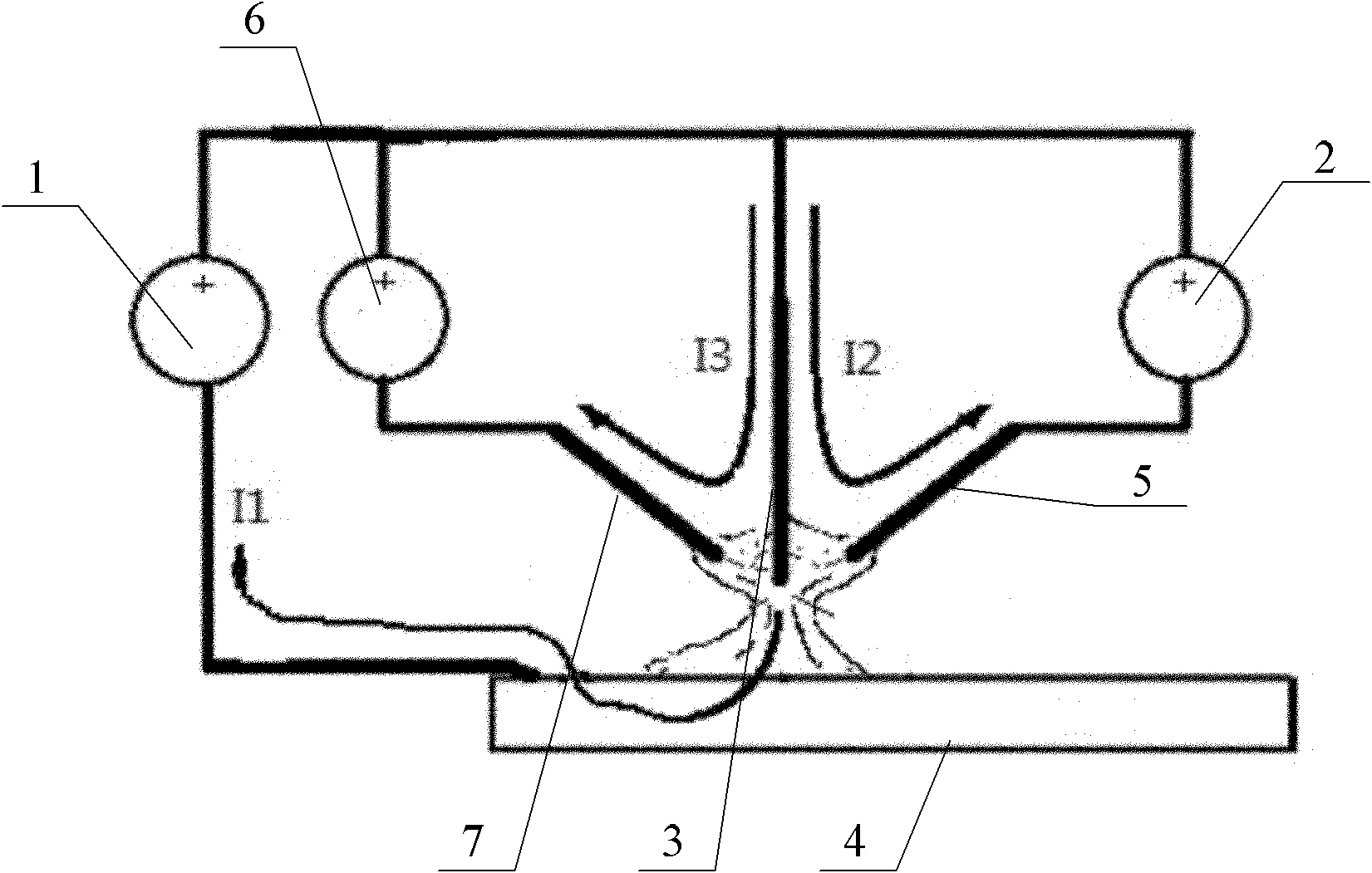

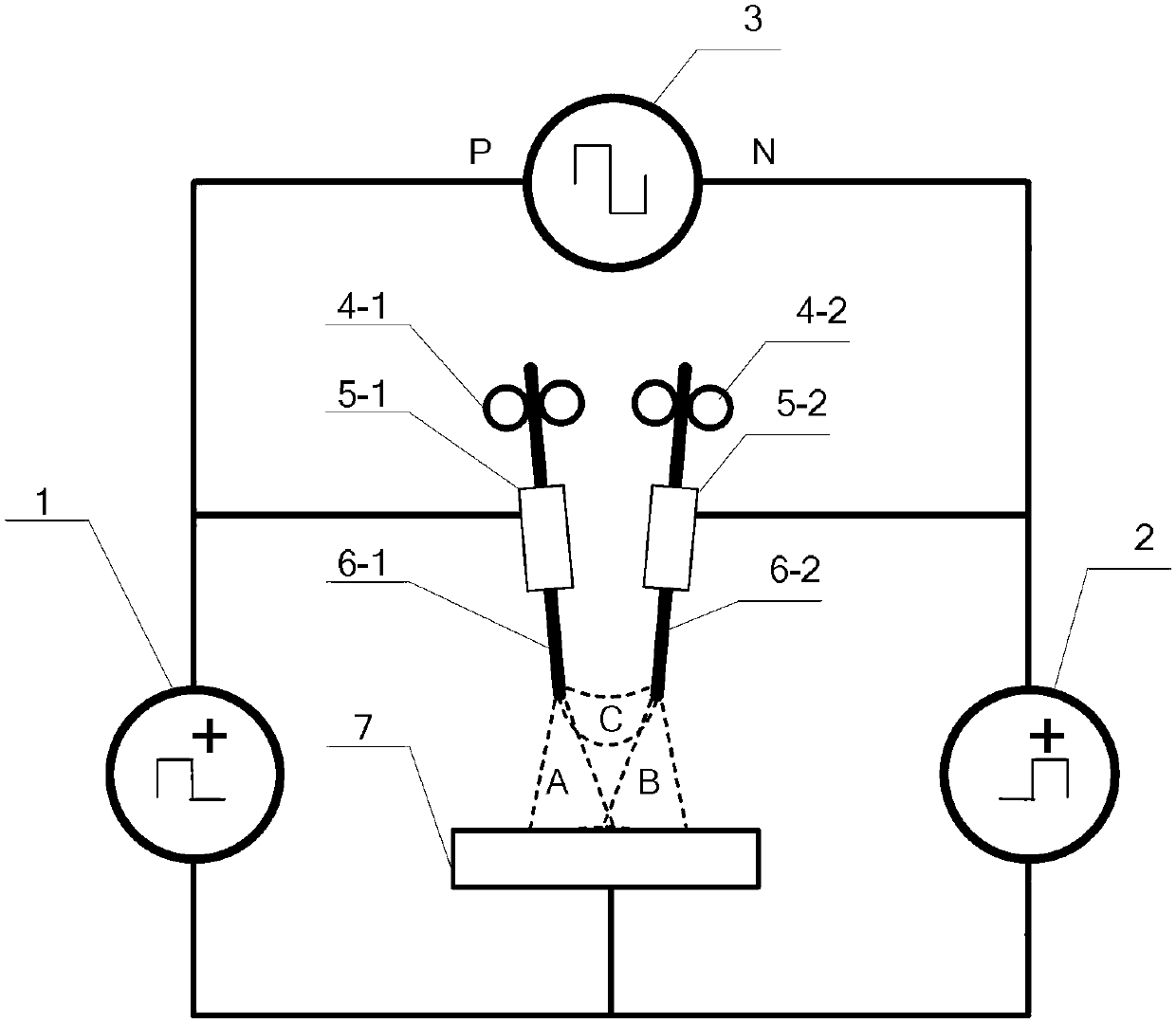

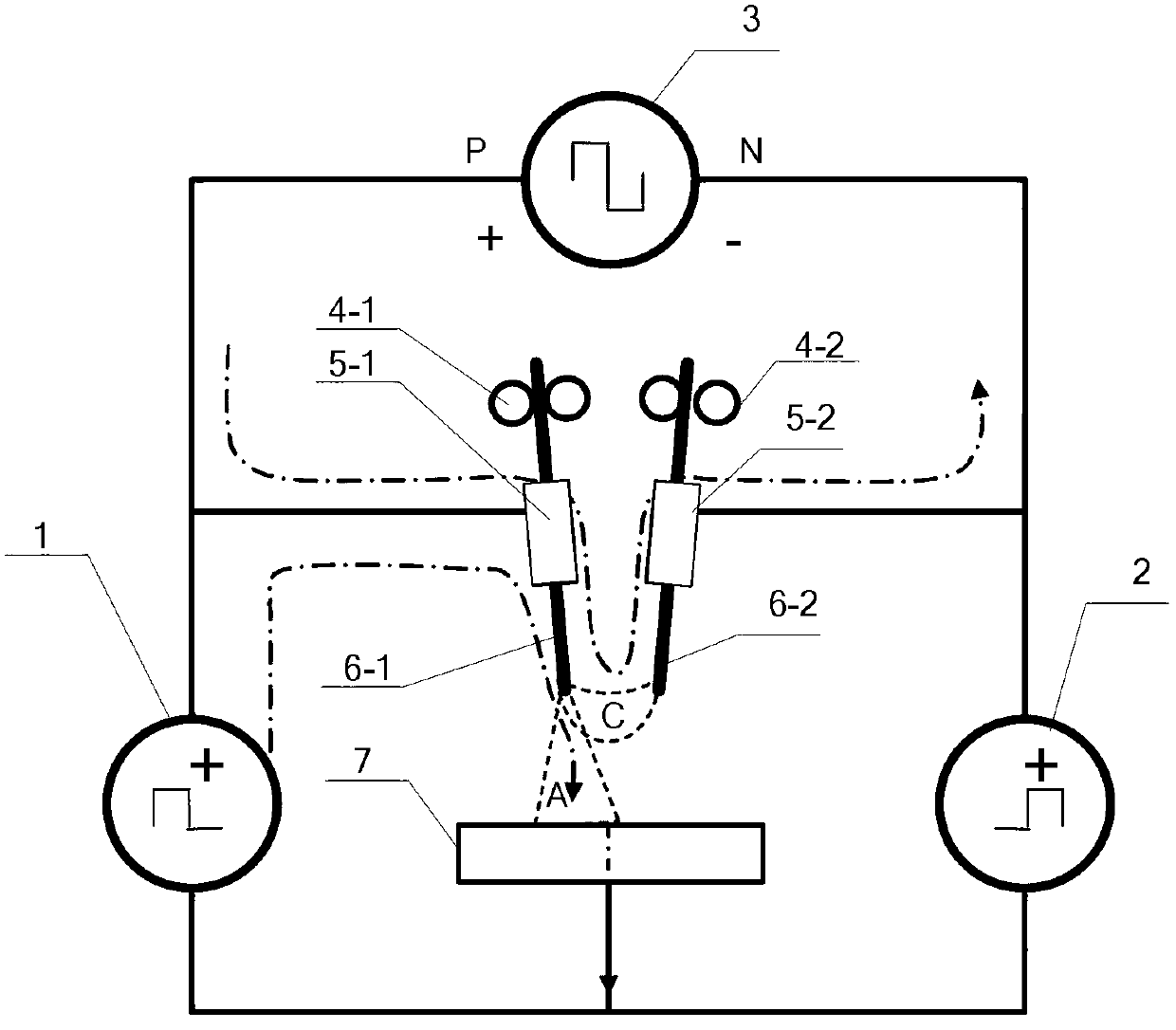

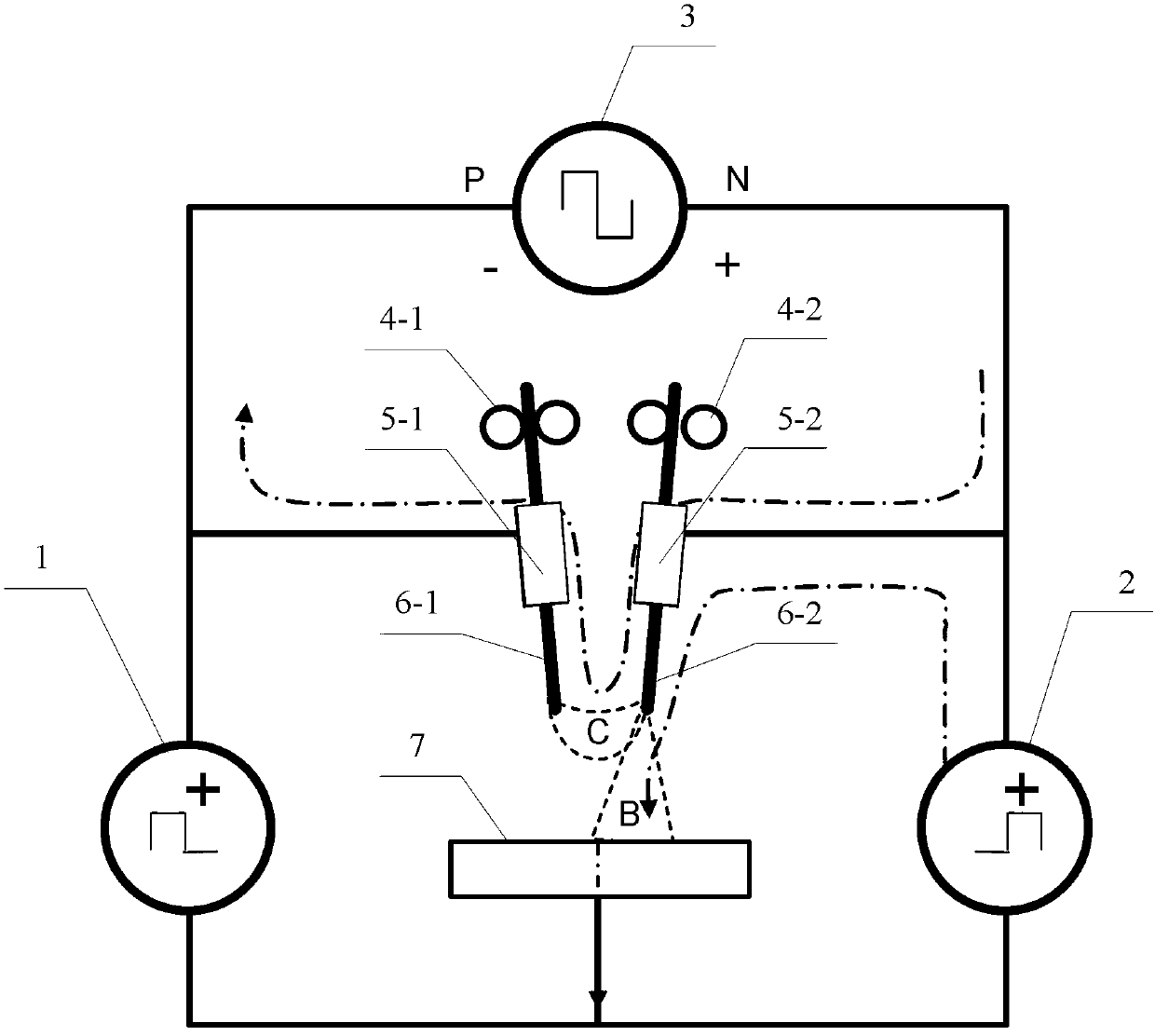

Multi-state double-wire electrical arc welding device and welding method

ActiveCN103341681AFlexible adjustment ratioGuaranteed PenetrationArc welding apparatusWelding power supplyPulse power supply

The invention provides a multi-state double-wire electrical arc welding device and welding method to solve the problem that in an existing electrical arc welding method, due to the fact that a fixed proportional relationship exists between the welding wire deposition rate and the weld heat input, contradictions exist between welding wire deposition rate increase and weld heat input reduction, and belongs to the technical field of consumable electrode electrical arc welding. The device comprises a first direct-current pulse power supply, a second direct-current pulse power supply, a welding power supply with the alterable polarity, a first wire sending mechanism, a second wire sending mechanism, a first contact tube, a second contact tube, a first welding wire and a second welding wire. In the welding process, the first direct-current pulse power supply, the first welding wire and a workpiece to be welded form a left electrical arc welding circuit, the second direct-current pulse power supply, the second welding wire and the workpiece to be welded form a right electrical arc welding circuit, and the welding power supply with the alterable polarity, the first welding wire and the second welding wire form a shunt circuit. The multi-state double-wire electrical arc welding device and welding method are used for electrical arc welding.

Owner:HARBIN INST OF TECH

Laser auxiliary consumable electrode arc additive connecting method for high-temperature alloy

ActiveCN106862771AReduce adverse effectsReduce welding heat inputLaser beam welding apparatusHeat-affected zoneManufacturing technology

The invention discloses a laser auxiliary consumable electrode arc additive connecting method for a high-temperature alloy, and belongs to the technical field of welding. According to the method, the laser arc composite welding technology and the additive manufacturing technology are combined, through the coupling function of laser photoinduced plasmas and consumable electrode arcs, stable globular transfer under small current is achieved, layer-by-layer accumulation of micro weld passes is achieved through accurate control over the width and depth of each welding line, a welding connector is formed, the heat input of each welding line is smaller, the welding heat affected zone is narrower, the high-temperature staying time of a melting pool is short, and the solidification speed is increased; the obtained melting pool is narrowed and becomes shallow, chemical components and structures are more uniform, and air holes, cracks and other defects are easier to control; and grain is finer, welding stress and residual deformation are small, the comprehensive performance of a high-temperature alloy welding connector is obviously improved, the component service life is prolonged, and high cost performance is achieved.

Owner:济南英维新材料科技合伙企业(有限合伙)

Laser wire filling and butt welding method for titanium-steel composite plate with T2 red copper serving as transition layer

ActiveCN106112263AAvoid it happening againMitigation of Thermal Stress MismatchLaser beam welding apparatusButt weldingTitanium

The invention discloses a laser wire filling and butt welding method for a titanium-steel composite plate with T2 red copper serving as a transition layer. The method comprises the following steps: (1) machining two titanium-steel composite plates to be subjected to butt welding; (2) butting and assembling the two titanium-steel composite plates to be subjected to butt welding; (3) performing laser backing welding on a gap between titanium plates of the two titanium-steel composite plates to be subjected to butt welding to form a laser backing welding line; (4) covering the lower surface of the laser backing welding line with titanium welding wires by adopting laser wire filling welding to form a titanium wire welding line, and overlaying a layer of T2 red copper at the bottom of a V-shaped groove to form a transition layer welding line; (5) overlaying a first layer of steel welding bead on the upper surface of the transition layer welding line; and (6) overlaying a second layer of steel welding bead on the upper surface of the first layer of steel welding bead by adopting the laser wire filling method. According to the method, the problems of high welding heat stress and serious mismatch of heat stress between metal layers due to the formation of brittle intermetallic compounds in the butt welding process of the titanium-steel composite plate can be effectively solved.

Owner:XI AN JIAOTONG UNIV

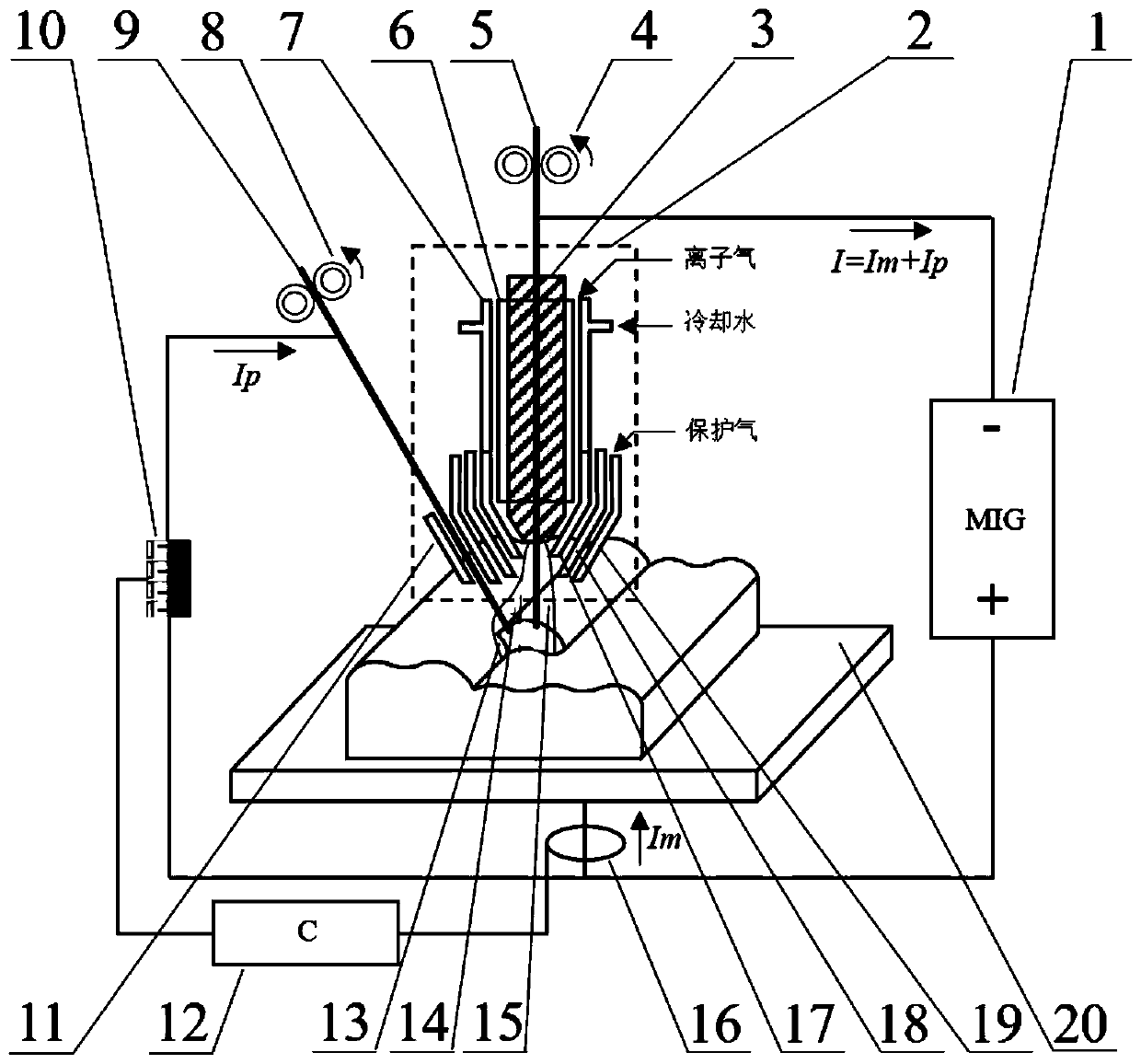

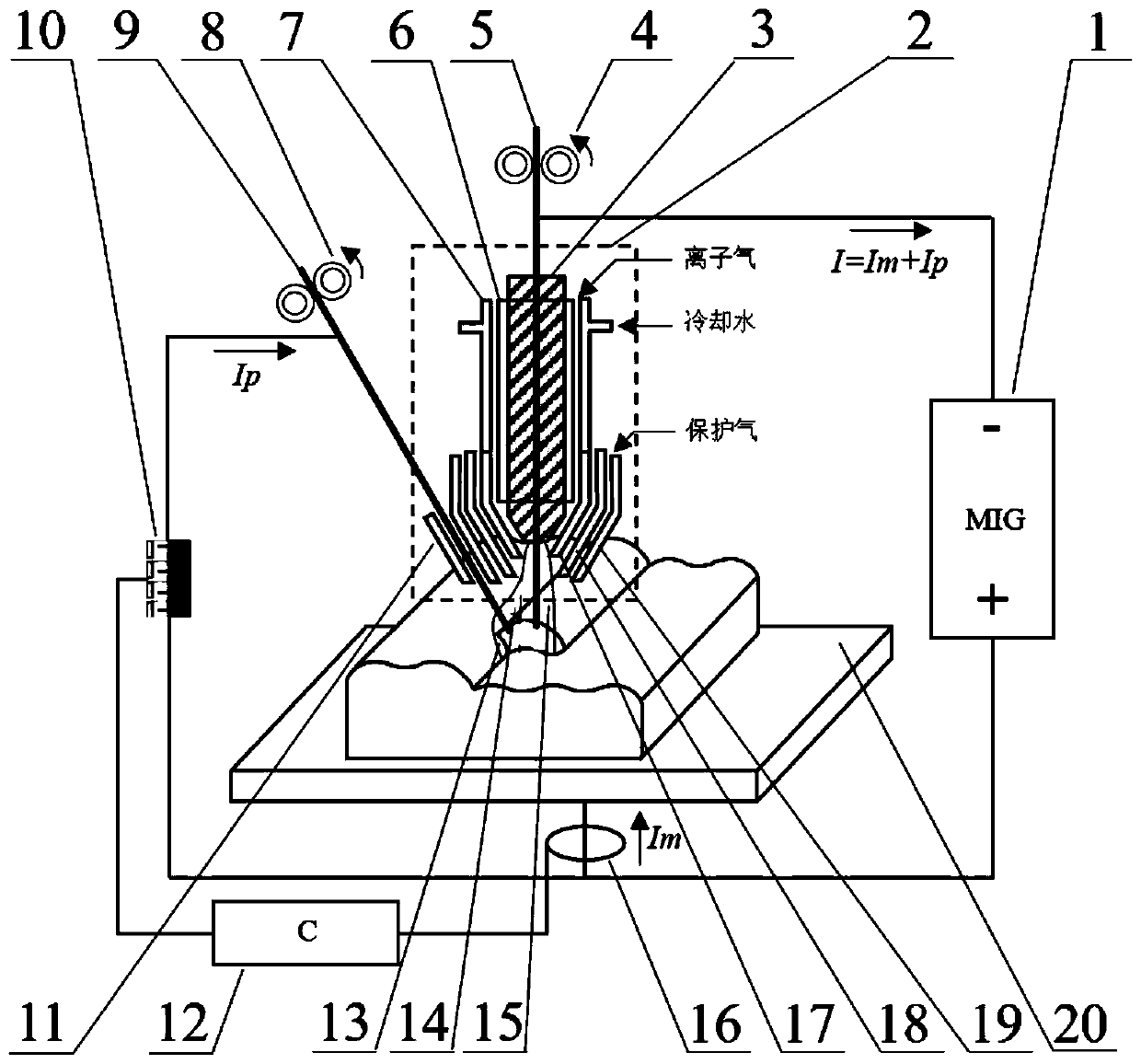

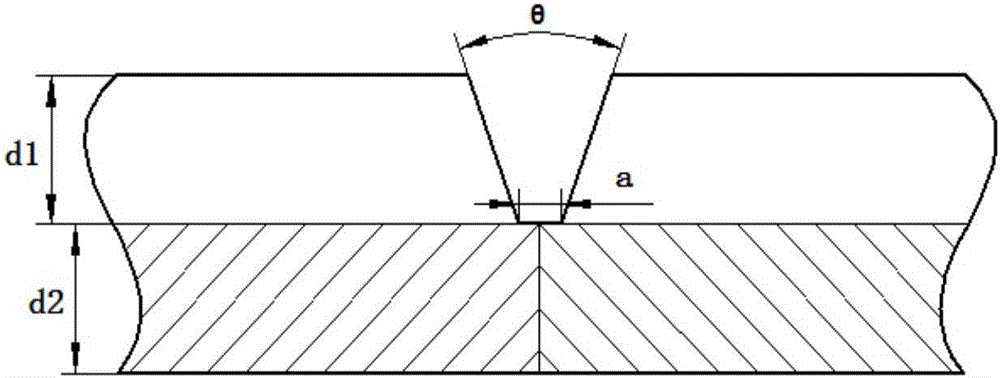

Additive manufacturing device and method for plasma arc gradient material of bypass hot wire consumable electrode

ActiveCN111168263AImprove Additive Deposition EfficiencyReduce welding heat inputAdditive manufacturing apparatusWelding apparatusElectric arcWelding power supply

The invention provides an additive manufacturing device and method for a plasma arc gradient material of a bypass hot wire consumable electrode. The device consists of an MIG welding power supply, a bypass hot wire consumable electrode plasma arc welding gun, an IGBT shunt controller, a workpiece, a current sensor and a current controller, wherein the MIG welding power supply, the bypass hot wireconsumable electrode plasma arc welding gun, the workpiece and the current sensor define a closed circuit; the MIG welding power supply, the bypass hot wire consumable electrode plasma arc welding gun, the workpiece, the IGBT shunt controller and the current controller define a closed circuit. The additive manufacturing device efficiently improves conventional electric arc welding basically, is controllable in heat input, is high in welding electric arc restraint intensity, and has the characteristics of low cost, high efficiency, high stability and the like of electric arc additive manufacturing.

Owner:HARBIN ENG UNIV

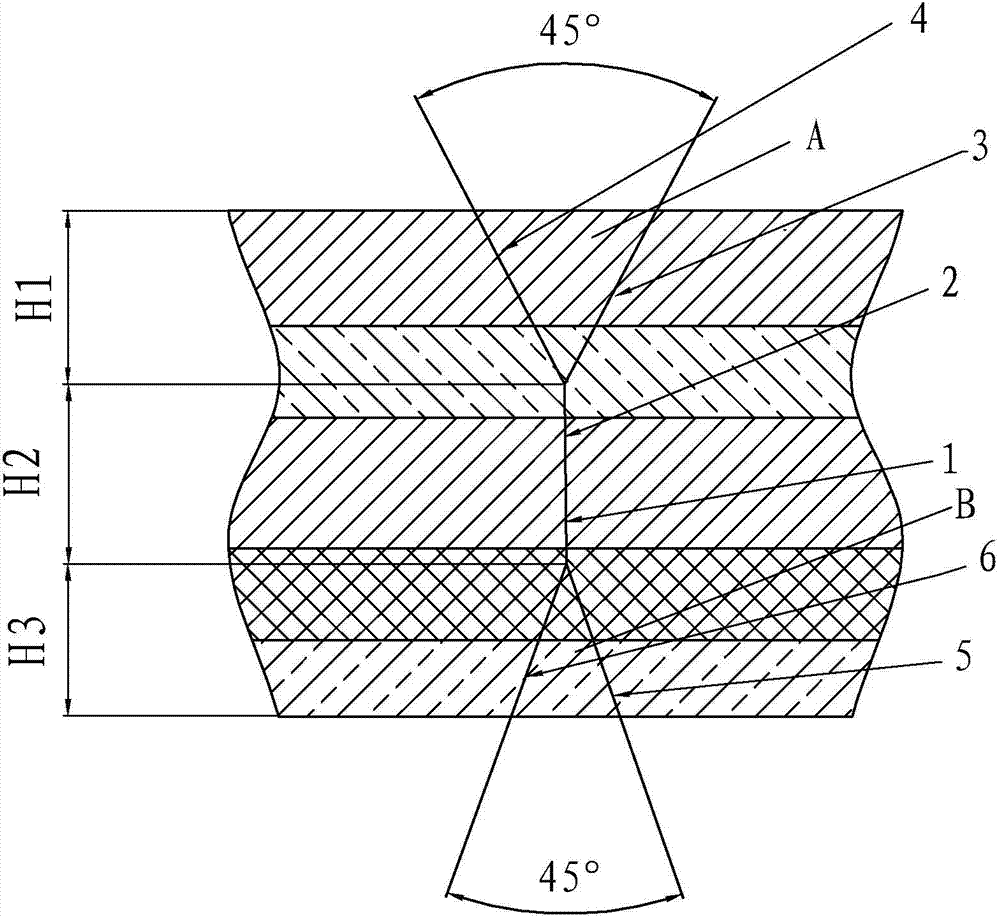

One-sided welding double-sided molding welding method for titanium steel composite pipe

ActiveCN106425104AGood for fusion transitionLow costWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyTitanium

The invention provides a one-sided welding double-sided molding welding method which is suitable for welding a titanium steel composite pipe. The one-sided welding double-sided molding welding method aims at solving the problems that in existing titanium steel composite pipe welding, operation of the welding process is complicated, the accumulated heat input is large, it is necessary to prepare special welding consumables, and the welding efficiency is low. The one-sided welding double-sided molding welding method for the titanium steel composite pipe comprises the following steps that (1), a flat bottom groove with a blunt edge is machined at the pipe end of the titanium steel composite pipe to be welded; (2), a welding area is cleaned; (3), a titanium alloy layer of the titanium steel composite pipe is welded through a laser welding method; (4), acetone is used as a binder so that evenly-mixed transition layer metal powder can be made into paste, the groove bottom is evenly welded, pressing is conducted, and drying is conducted; and (5), transition layer metal is molten through laser energy, the transition layer is formed firstly, and then filling of the steel metal layer is conducted through electric arc welding. By the adoption of the method, one-sided welding double-sided molding welding of the titanium steel composite pipe is achieved, and the welding quality of the titanium steel composite pipe is improved.

Owner:SOUTHWEST JIAOTONG UNIV

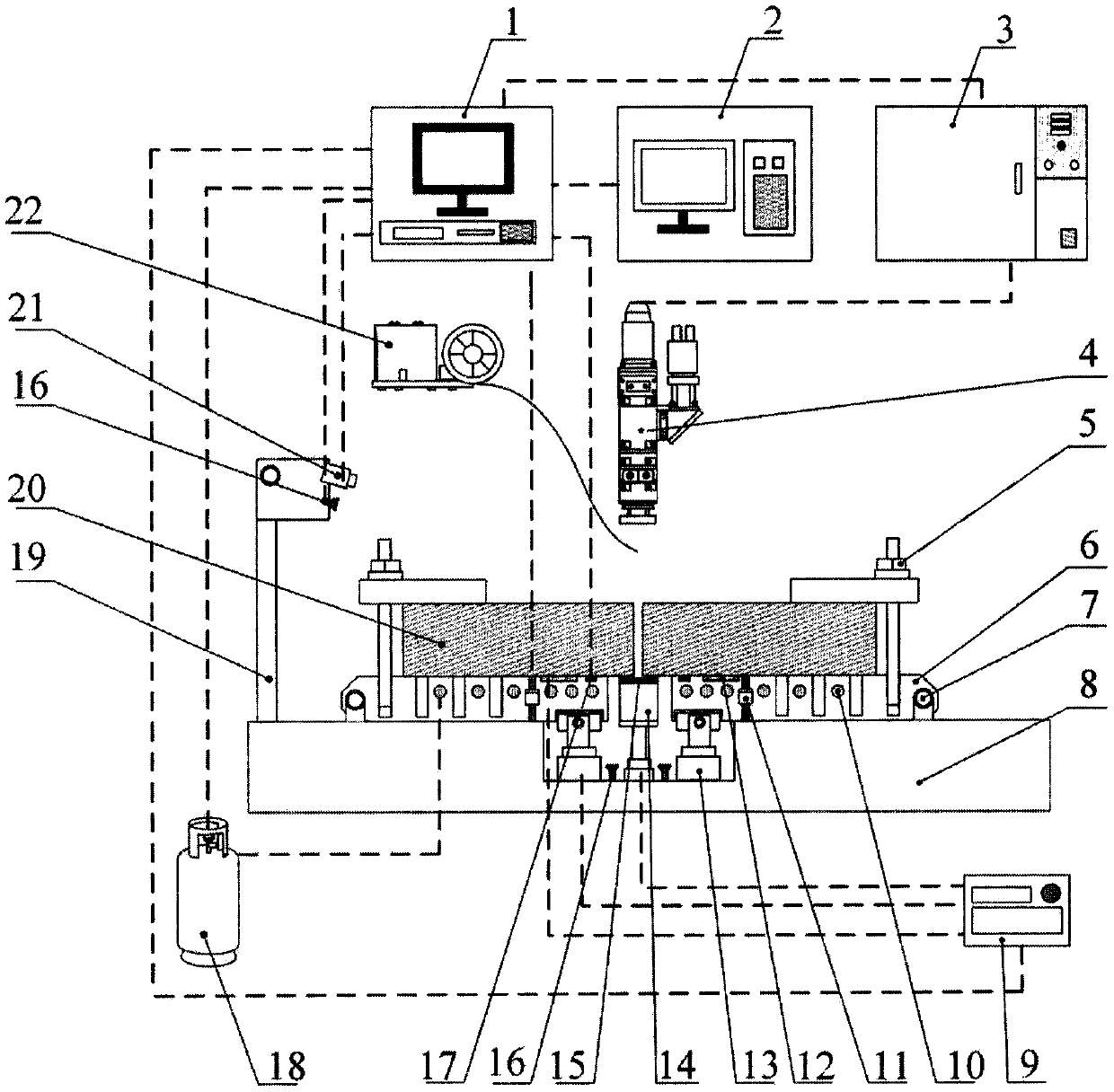

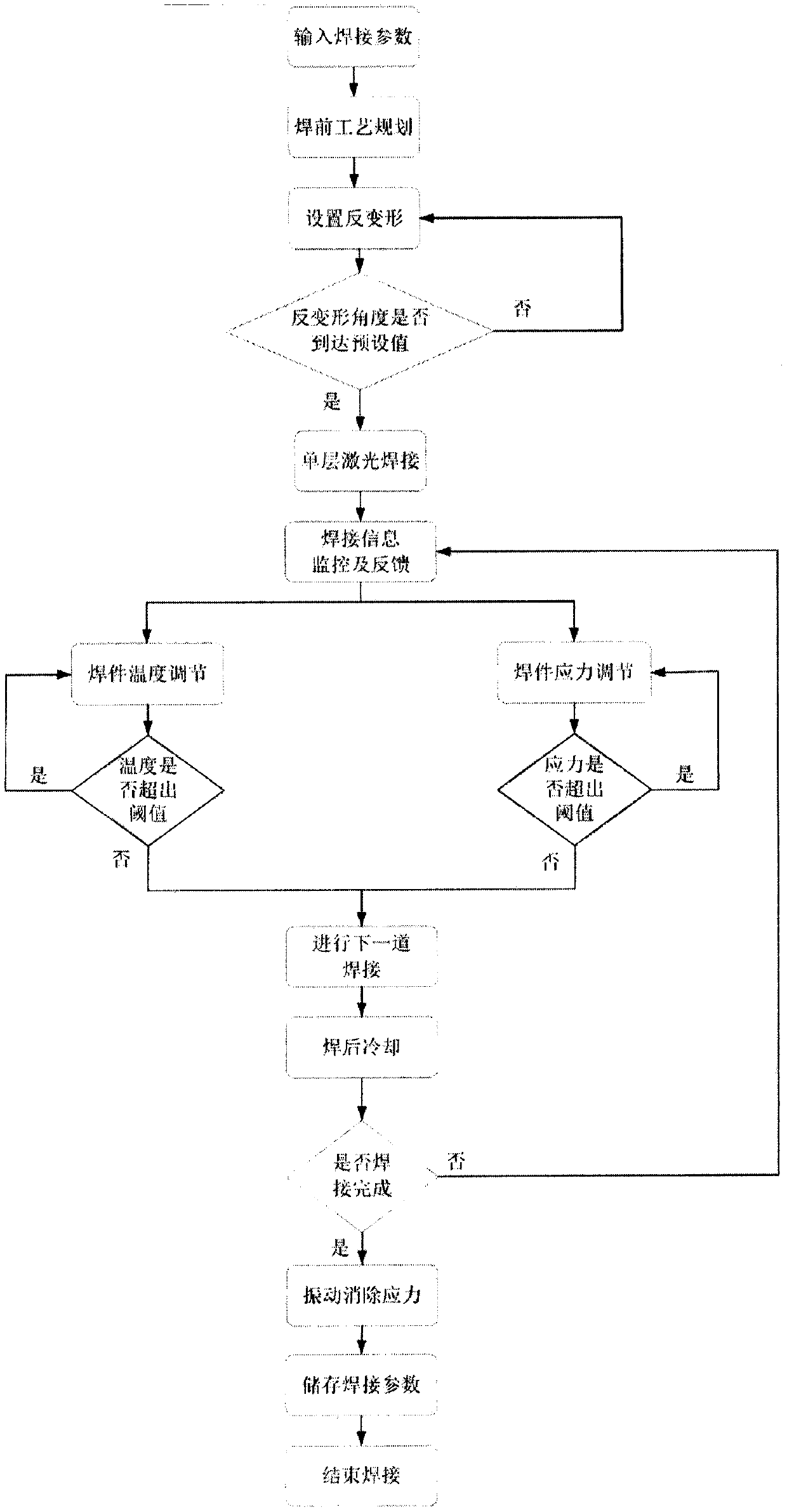

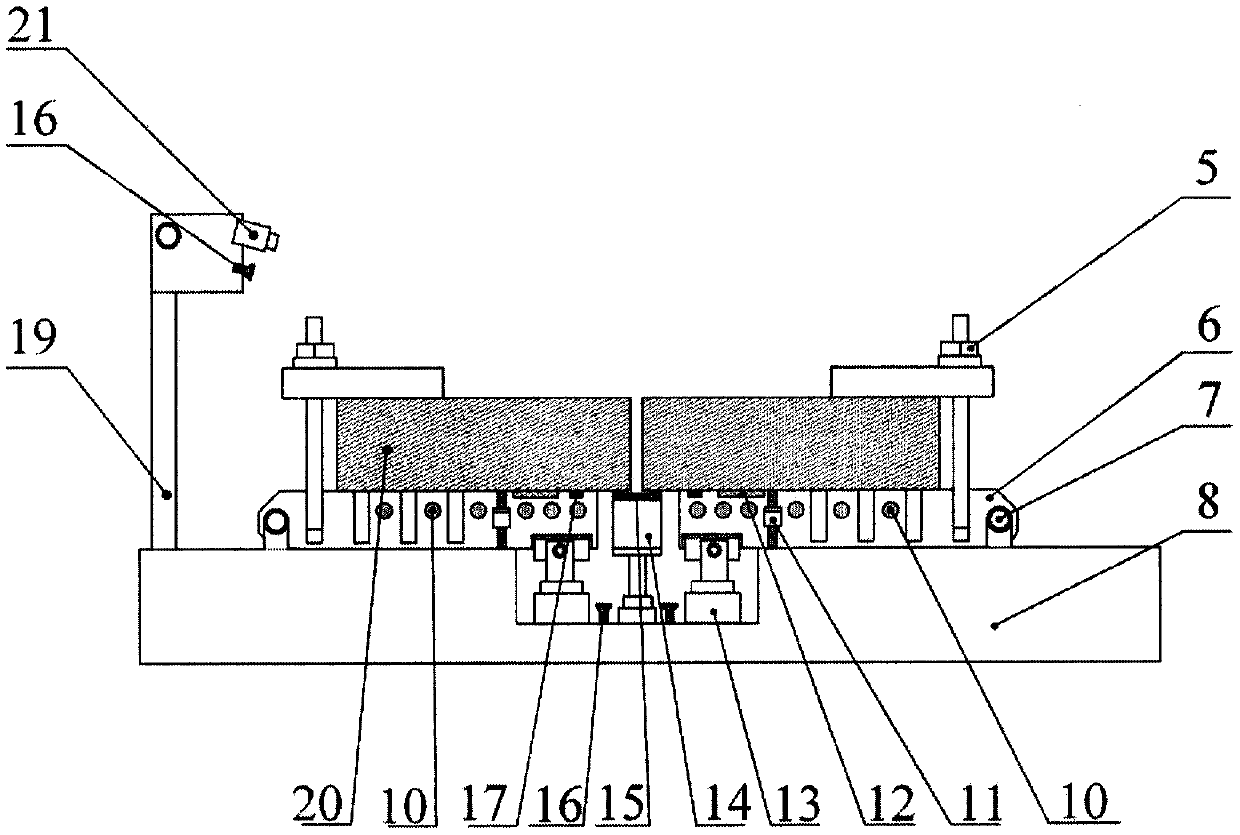

Intelligent real-time temperature control and shape control device and method for thick plate laser welding

ActiveCN110102895AFast welding speedReduce welding heat inputLaser beam welding apparatusComputer control systemTemperature control

The invention discloses an intelligent real-time temperature control and shape control device and method for thick plate laser welding. A computer control system, a before-welding planning system, a laser welding system, a monitoring and feedback system, a self-adaption water cooling system, an anti-deformation adjustment system and a self-adjusting vibration system are included. The before-welding planning system presets process parameters and an anti-deformation angle according to a welding material and the welding part size; the monitoring and feedback system is used for monitoring the temperature, anti-deformation and stress in the welding process and feeding back the temperature, anti-deformation and stress to the computer control system in real time; the self-adaption water cooling system conducts self-adaption control over the temperature and heat accumulation in the welding process; the anti-deformation adjustment system adjusts the anti-deformation angle; and the self-adjusting vibration system adjusts the vibration frequency and amplitude of a vibrating piece, and the stress in welding process and after welding is further reduced. By means of the intelligent real-time temperature control and shape control device and method, the temperature, deformation and stress conditions in the thick plate laser welding process can be monitored and regulated in real time, the deformation and stress after welding are greatly reduced, and it is ensured that high-quality thick plate laser welding parts are obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electron beam welding method for aluminium alloy pistons of high-power diesel engine

The invention relates to an electron beam welding method for aluminium alloy pistons of a high-power diesel engine. The method is characterized by comprising the following steps: washing and assembling the pistons, and ensuring the assembling clearance to be 0-0.03mm; carrying out weld preheating treatment on the assembled pistons; transferring the pistons after preheating treatment to a vacuum chamber the vacuum degree of which is higher than 5*10<-4>mba, and carrying out pulsed electron beam welding by utilizing 150kV high-voltage electron beam welding equipment or 60kV high-voltage electron beam welding equipment; adopting corresponding electron beam welding parameters according to the welding penetration; modifying weld seams by modification welding after welding; and finally carryingout heat treatment. By utilizing the method provided by the invention, the electron beam penetrability in aluminium alloy piston welding is greatly improved, the weld heat input is reduced, the weld seams with high depth-to-width ratio (40:1) can be obtained, the problems of spalling of cast iron rings and collapse of internal cooling oil channels during welding in aluminium alloy piston welding are solved, and the porosity of the weld seams is ensured to be less than 1%. The method has the characteristics of simple process and high yield.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

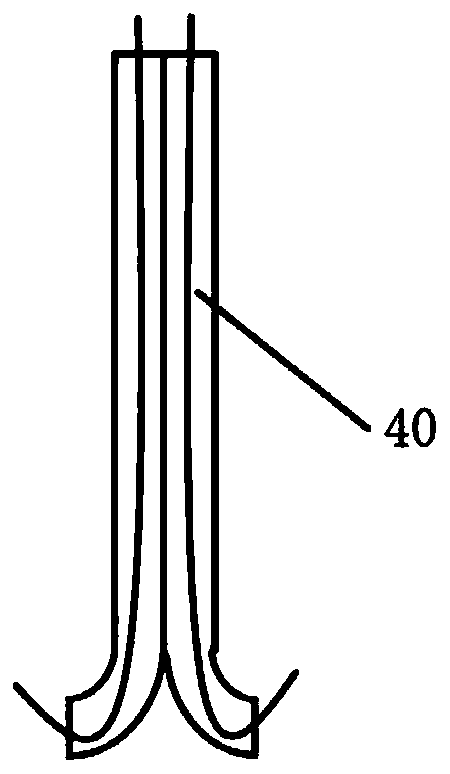

Twin-wire electrogas welding water-cooled welding torch

InactiveCN103071899ASimple structureReduce manufacturing costElectrode supporting devicesWater coolingElectrogas welding

The invention relates to a welding torch for arc welding, in particular to a twin-wire electrogas welding water-cooled welding torch, which comprises a first water-cooled welding torch and a second water-cooled welding torch which are mutually insulated, and an adjusting device for a distance between welding wires. The twin-wire electrogas welding water-cooled welding torch is characterized in that the adjusting device for the distance between the welding wires comprises a substrate and a feed screw nut mechanism arranged on the substrate; the first welding torch is fixed with the substrate; the second welding torch is fixed with a nut of the feed screw nut mechanism through a fixing plate; and the second welding torch is positioned above the first welding torch. The distance between the two welding torches is adjustable, an adjusting range for a welding condition is widened, proper current, voltage, welding speed and distance between the welding wires can be selected according to the thickness and materials of plates to be welded, and high quality welding lines are efficiently completed.

Owner:刘振英

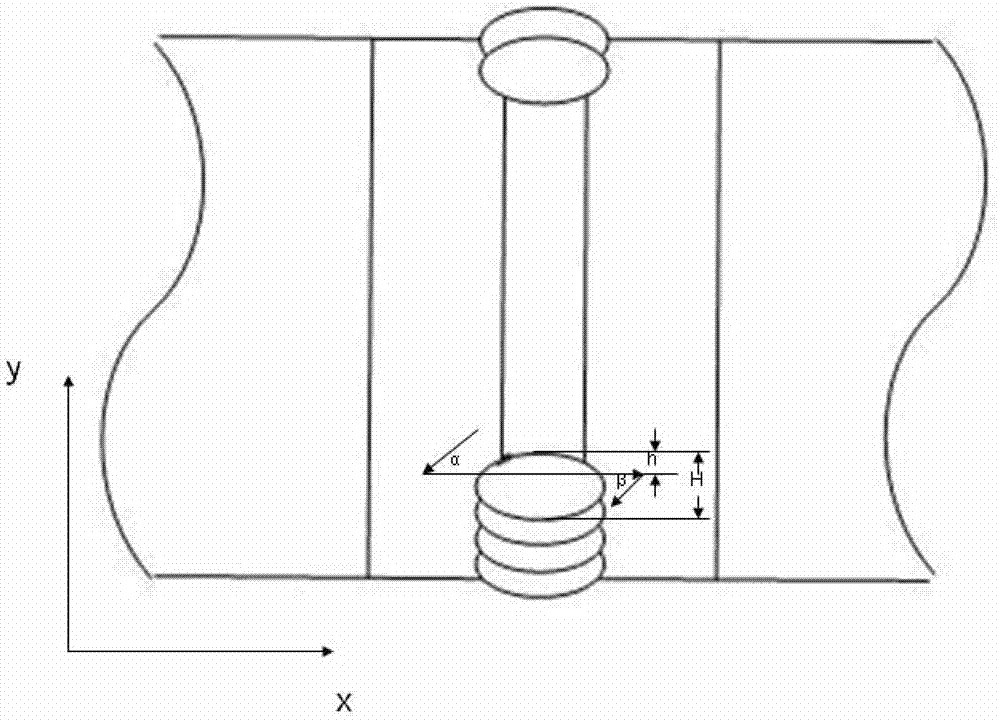

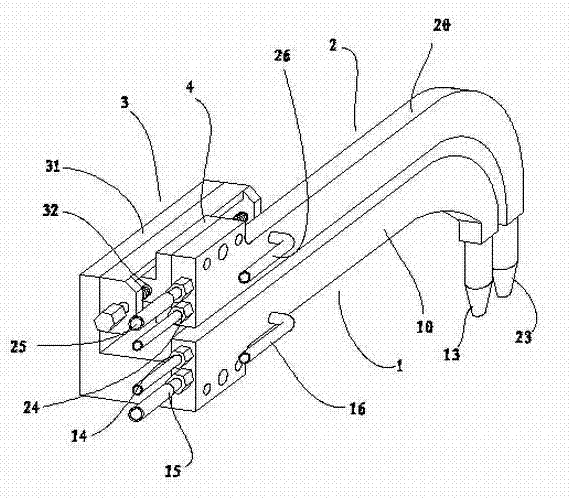

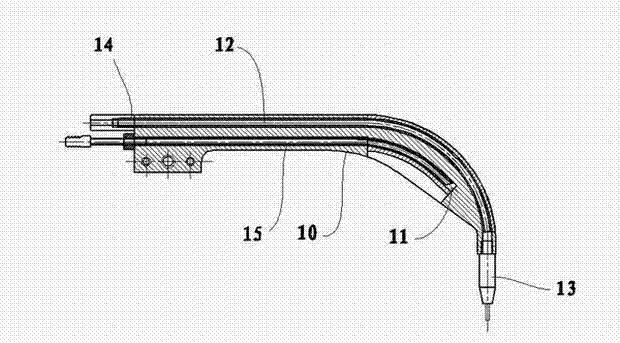

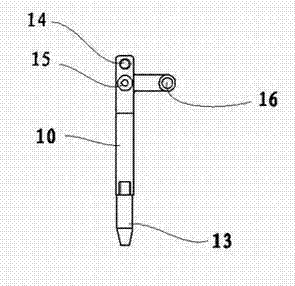

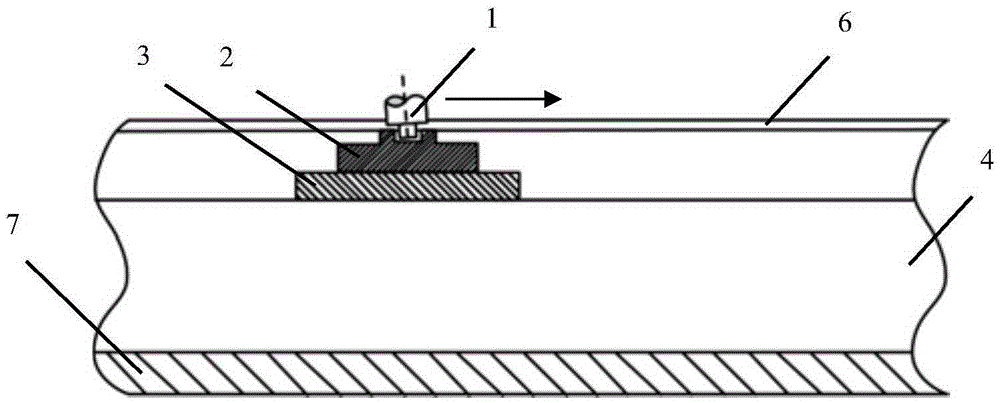

Stationary shaft shoulder assistant supporting inclined penetration friction-stir welding device and method

ActiveCN105382405AReduce the likelihood of breakageAvoid problems prone to void defectsNon-electric welding apparatusFriction weldingEngineering

The invention discloses a stationary shaft shoulder assistant supporting inclined penetration friction-stir welding device and method, relates to a friction-stir welding device and method, and aims at solving the problem that an existing friction-stir welding method is difficult in avoiding a non-welding-on defect, or the problem that although the non-welding-on defect can be avoided, overlarge thermal input and other defects are caused. The friction-stir welding device provided by the invention comprises a long-needle stirring head, a stationary shaft shoulder with a blind hole, a translation sliding block, a linear guideway and a positioning clamping apparatus. During welding, the liner guideway, a welded workpiece and the positioning clamping apparatus are stationary, and the long-needle stirring head, the stationary shaft shoulder and the translation sliding block move along a welding direction, so as to realize a welding process. The stationary shaft shoulder assistant supporting inclined penetration friction-stir welding method provided by the invention comprises the following steps: 1, assembly of the device; 2, fixing of the long-needle stirring head and the stationary shaft shoulder; 3, friction-stir welding. The device and the method, provided by the invention are used for friction-stir welding.

Owner:HARBIN INST OF TECH

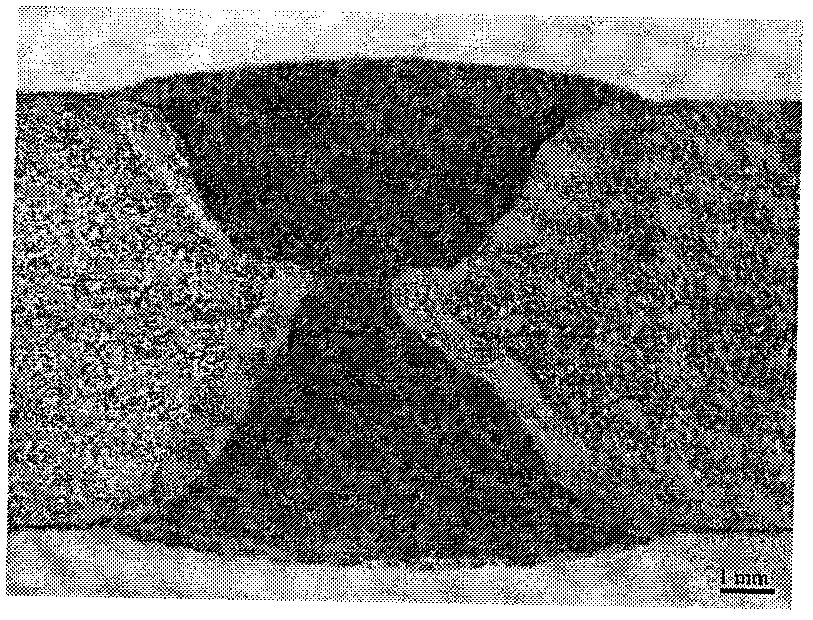

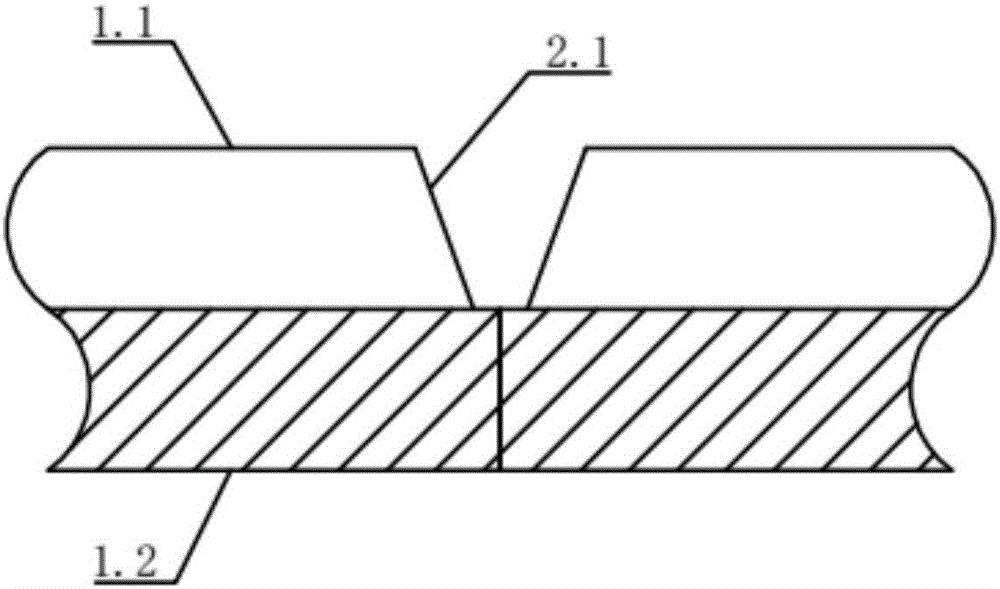

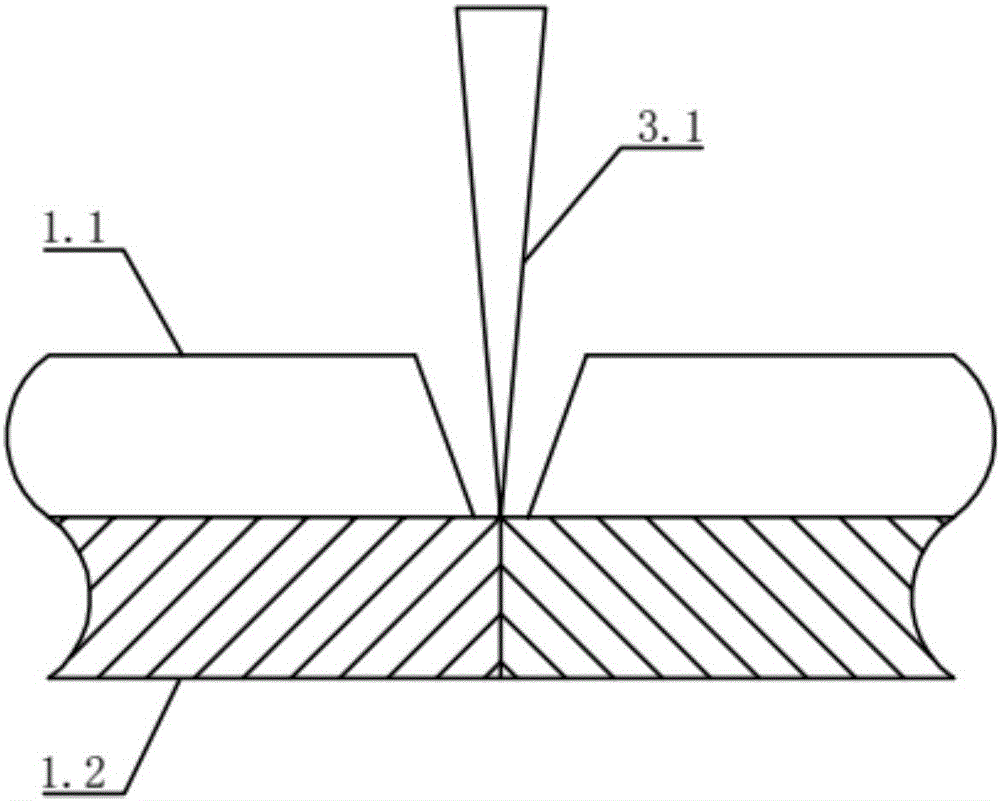

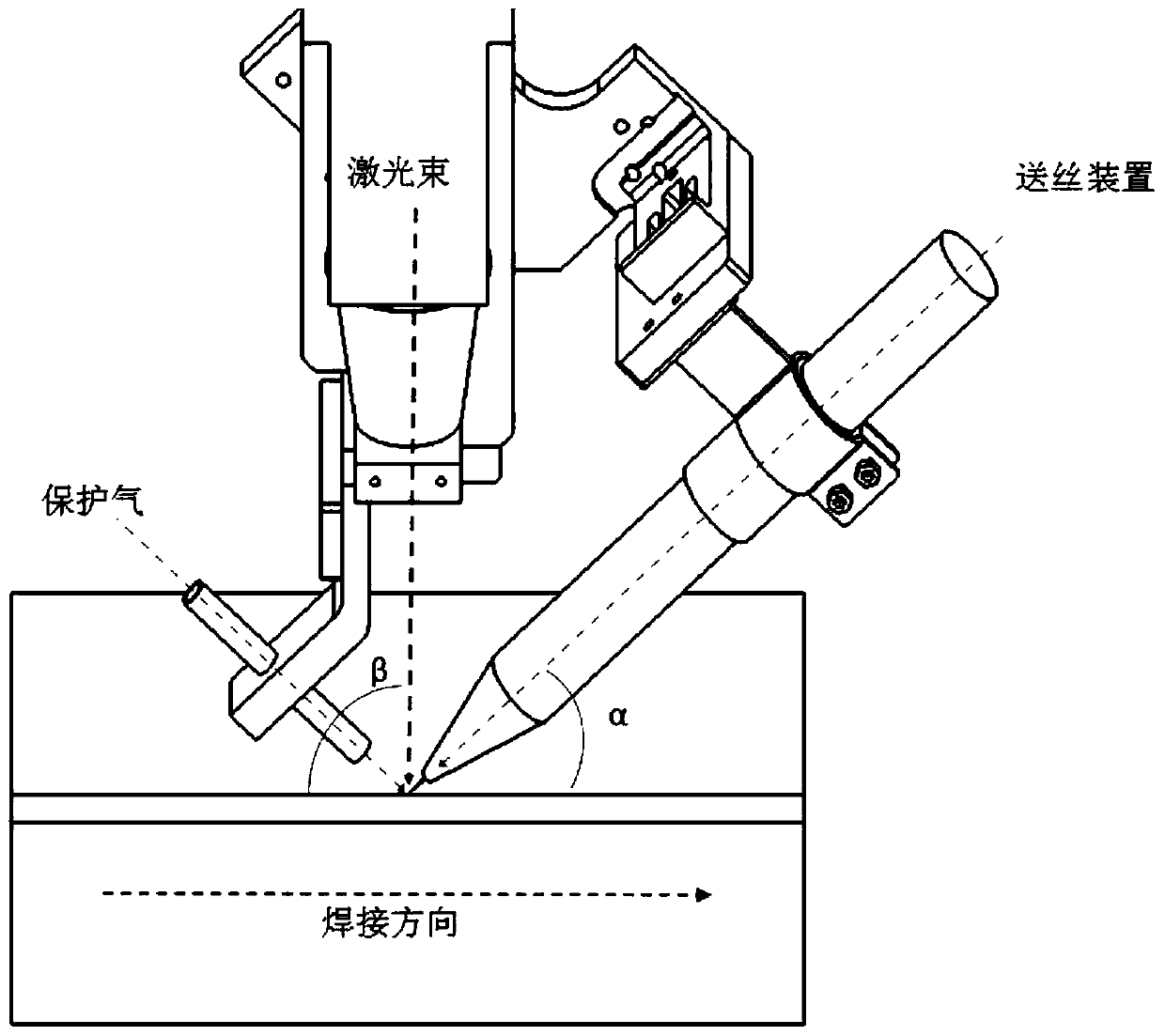

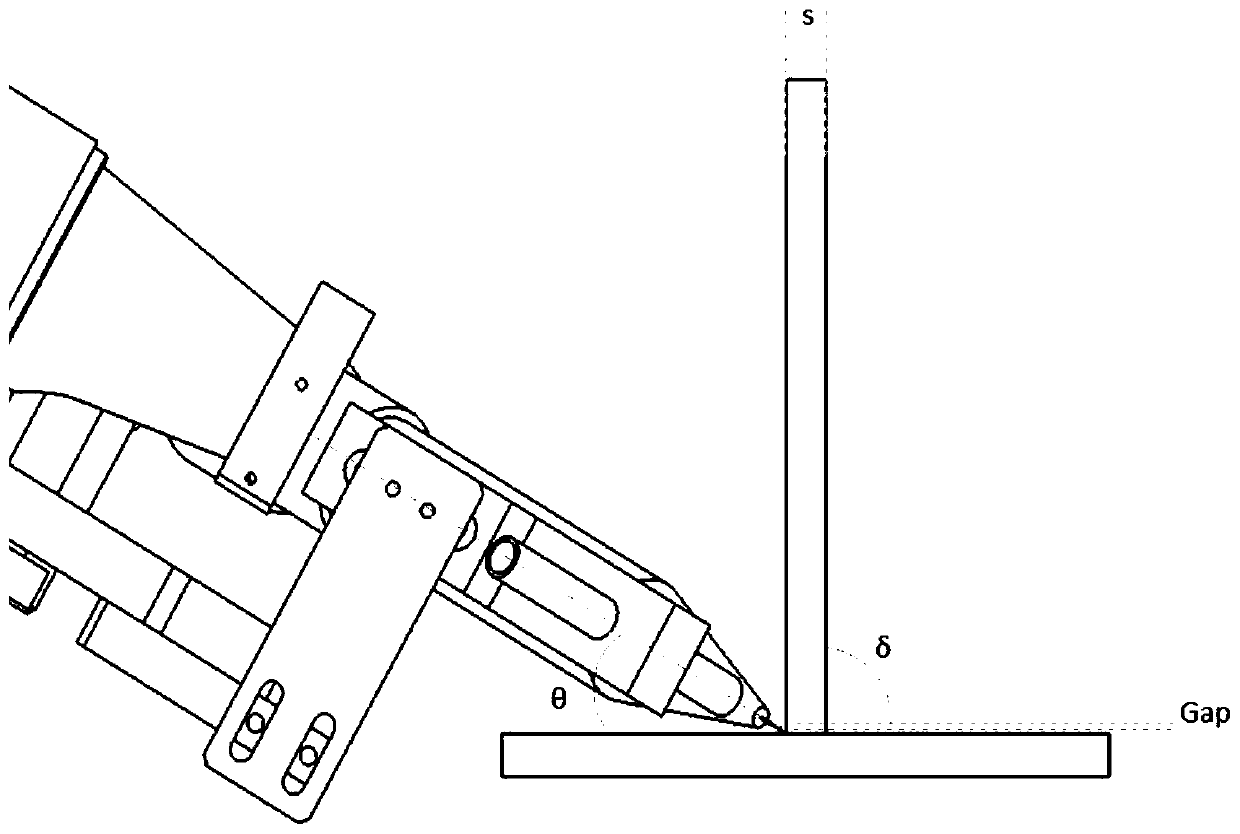

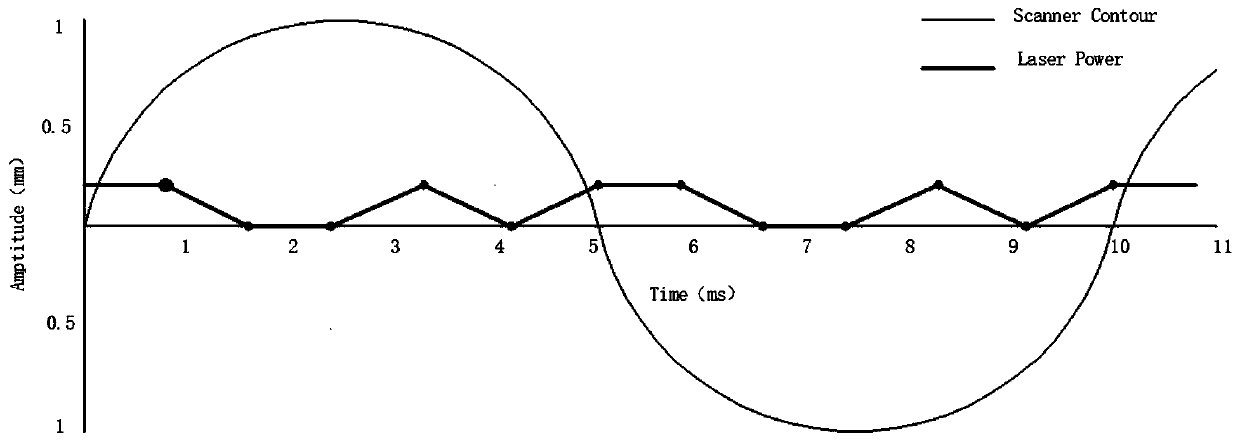

Swinging laser filler wire welding method of medium-thickness plate T-shaped joint fillet welding seam

The invention relates to the technical field of welding, and discloses a swinging laser filler wire welding method of a medium-thickness plate T-shaped joint fillet welding seam. In the medium-thickness plate T-shaped joint fillet welding process, by means of a laser beam which periodically swings in the welding direction and with the assistance of a filler wire, fillet welding seam welding is carried out, wherein the swinging direction is perpendicular to the welding direction. According to the swinging laser filler wire welding method of the medium-thickness plate T-shaped joint fillet welding seam, in the welding process, the laser beam swings periodically in a "I" shape and perpendicular to the welding direction, and a molten pool is uniformly stirred so as to widen the width of the welding seam, so that the large-size, large-penetration, high-efficiency and low-deformation welding process is achieved, and the adaptability of laser welding to plate gaps and the sensitivity of welding throat thermal cracks can be remarkably improved compared with a single laser.

Owner:NANJING ZHONGKE RAYCHAM TECH

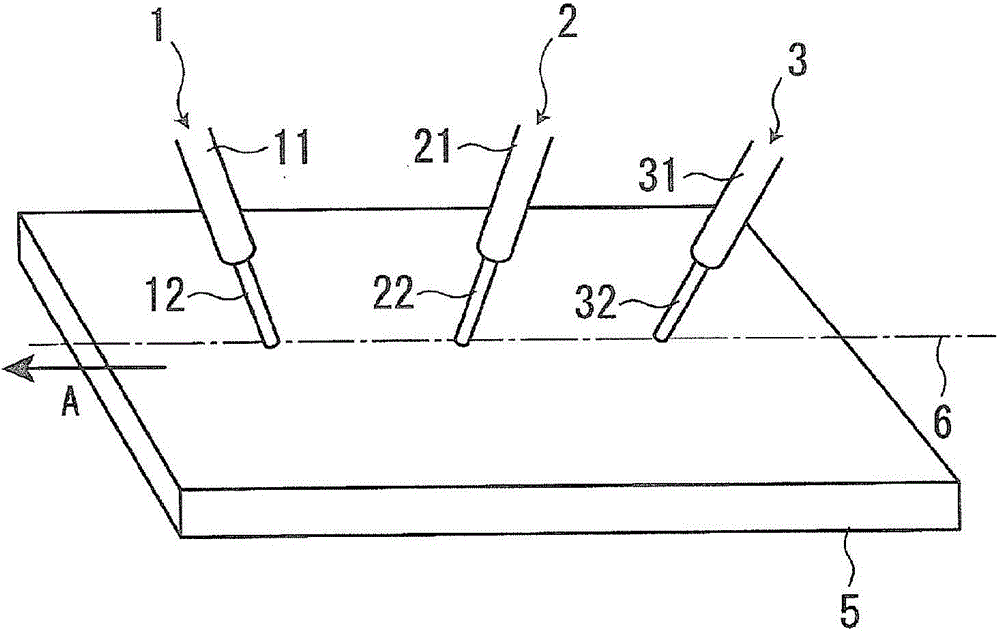

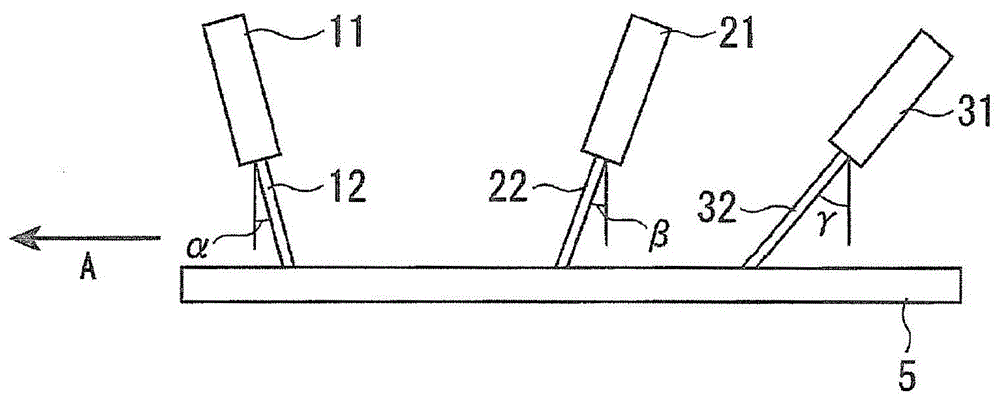

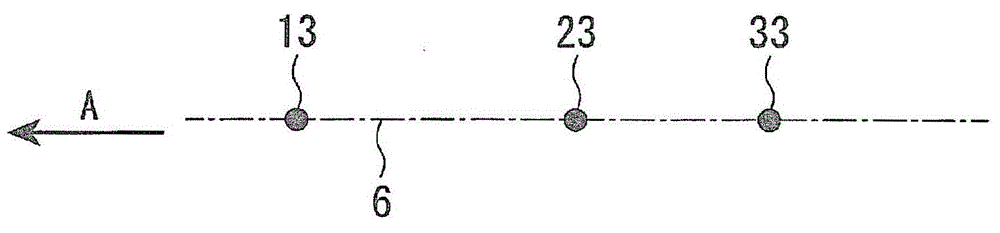

Submerged arc welding method for steel sheets

InactiveCN103958109AReduce welding heat inputEnsure penetrationArc welding apparatusWelding/soldering/cutting articlesSheet steelEngineering

Owner:JFE STEEL CORP

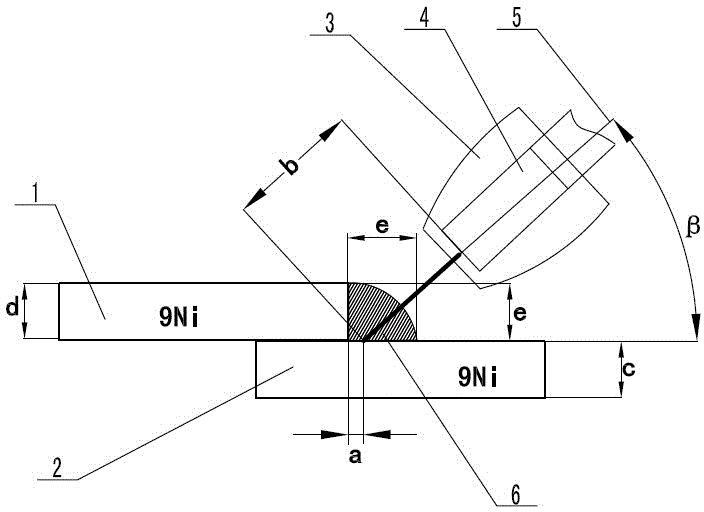

Welding technique for base plate of LNG low-temperature tank

InactiveCN104625359ASatisfy the pressure bearing capacity requirementsHigh hardnessArc welding apparatusDomestic vesselsFillet weldCurrent range

The invention discloses a welding technique for a base plate of an LNG low-temperature tank and belongs to the technical field of welding of LNG low-temperature tanks. According to the welding technique, two 9Ni steel plates with the thicknesses ranging from 6 mm to 9 mm are made to be in lap joint in the horizontal direction and overlap to form an overlap joint, the end face is cleaned, a preparation for welding is made, and then submerged-arc welding is conducted by means of alternating current, wherein the arc voltage ranges from 25 V to 29 V, the welding current ranges from 260 A to 290 A, the wire extension length ranges from 25 mm to 35 mm, the welding speed ranges from 22 in / min to 25 in / min, the welding wire angle ranges from 55 degrees to 65 degrees, and a full fillet weld with a welding foot with the length ranging from 6 mm to 9 mm is formed. By the adoption of the welding technique, submerged-arc welding of the base plate of the LNG low-temperature tank can be achieved, the problems that during submerged-arc welding, a lap fillet weld is poorly formed, hot cracks are formed during welding, and burning through occurs easily during welding are solved, the two 9Ni steel plates with the thicknesses ranging 6 mm to 9 mm can be welded in a single-pass mode at a time during actual operation, and welding efficiency is remarkably improved.

Owner:SINOPEC TENTH CONSTR

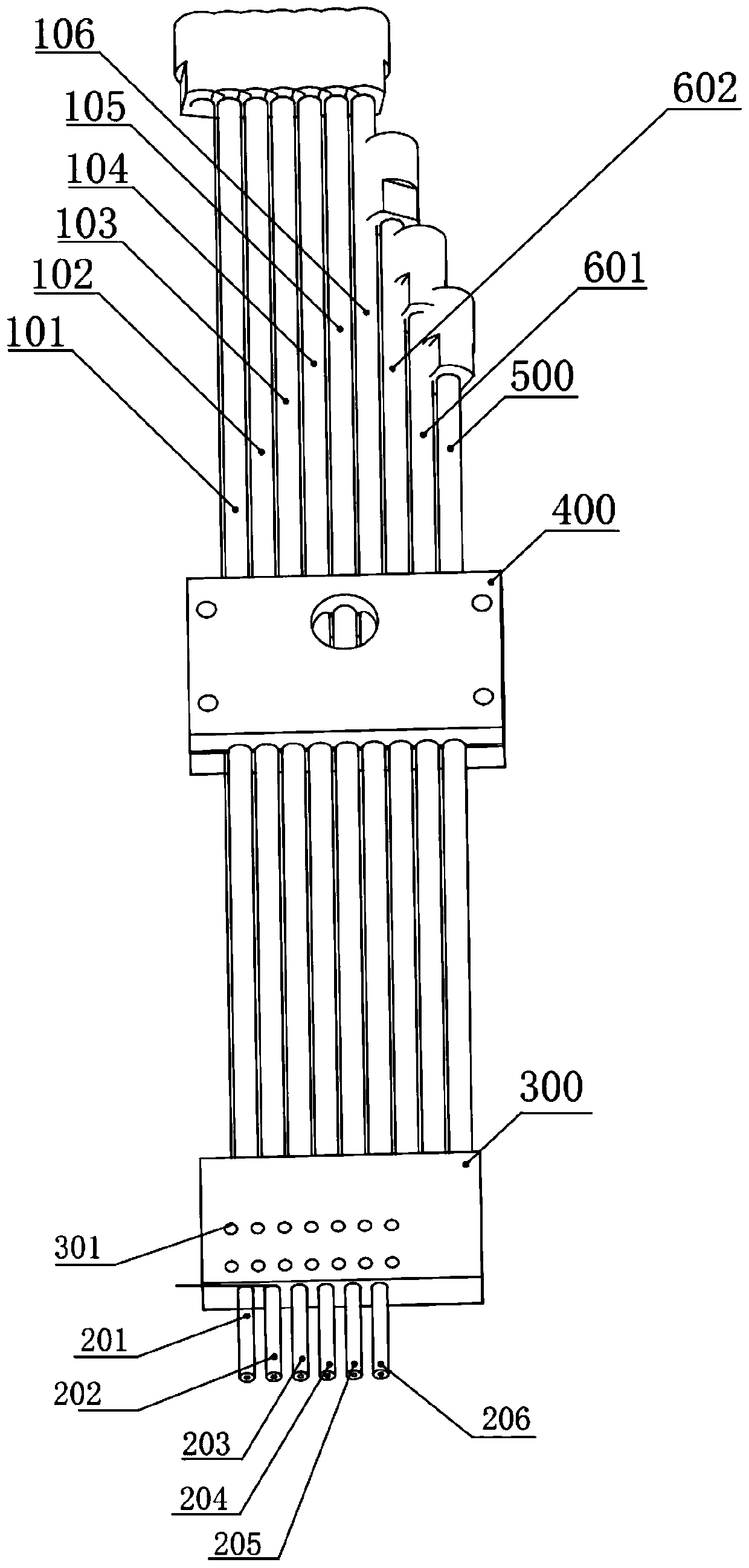

Multi-power-supply parallel multi-wire high-efficiency electric arc welding device and application thereof

InactiveCN110788447AWith bending propertiesFusion wellArc welding apparatusWelding power supplyEngineering

The invention discloses a multi-power-supply parallel multi-wire high-efficiency electric arc welding device and application thereof. The device comprises a plurality of independent welding power supplies, a plurality of independent wire feeding mechanisms, a multi-wire welding gun which can be densely arranged, and contact tubes, wherein the welding power supplies, the wire feeding mechanisms, the multi-wire welding gun and the contact tubes are sequentially connected. The independent welding power supplies can be constant in voltage or current. Welding wires are driven by the independent wire feeding mechanisms respectively. The contact tubes can be multi-wire integrated contact tubes with bent channels or multiple embedded type contact tubes. The welding wire distribution mode of the multi-wire welding gun which can be densely arranged is determined according to requirements of the welding technology. In the welding process, the welding device is suitable for common welding wires and also suitable for cable welding wires and single welding wire and cable welding wire combinations. According to the device, the welding efficiency can be greatly improved, the welding production efficiency is greatly improved, the welding joint quality is improved, the consumption of welding materials is effectively reduced, and the device is especially suitable for narrow gap welding of thick-wall materials.

Owner:南京引力工业焊接技术研究院有限公司

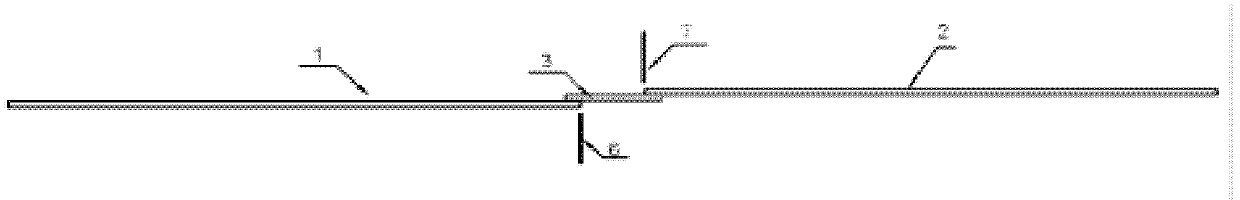

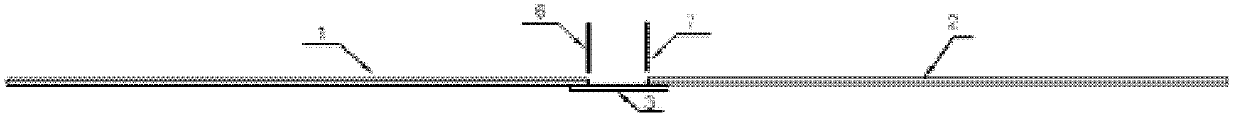

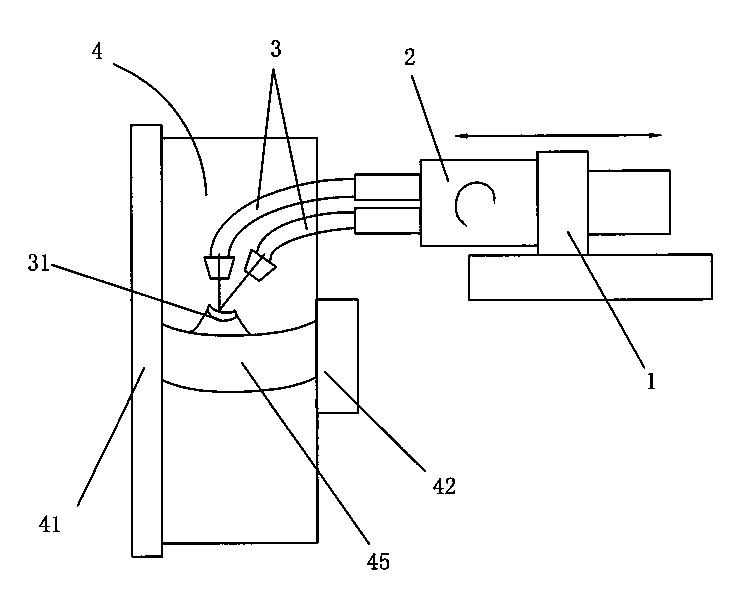

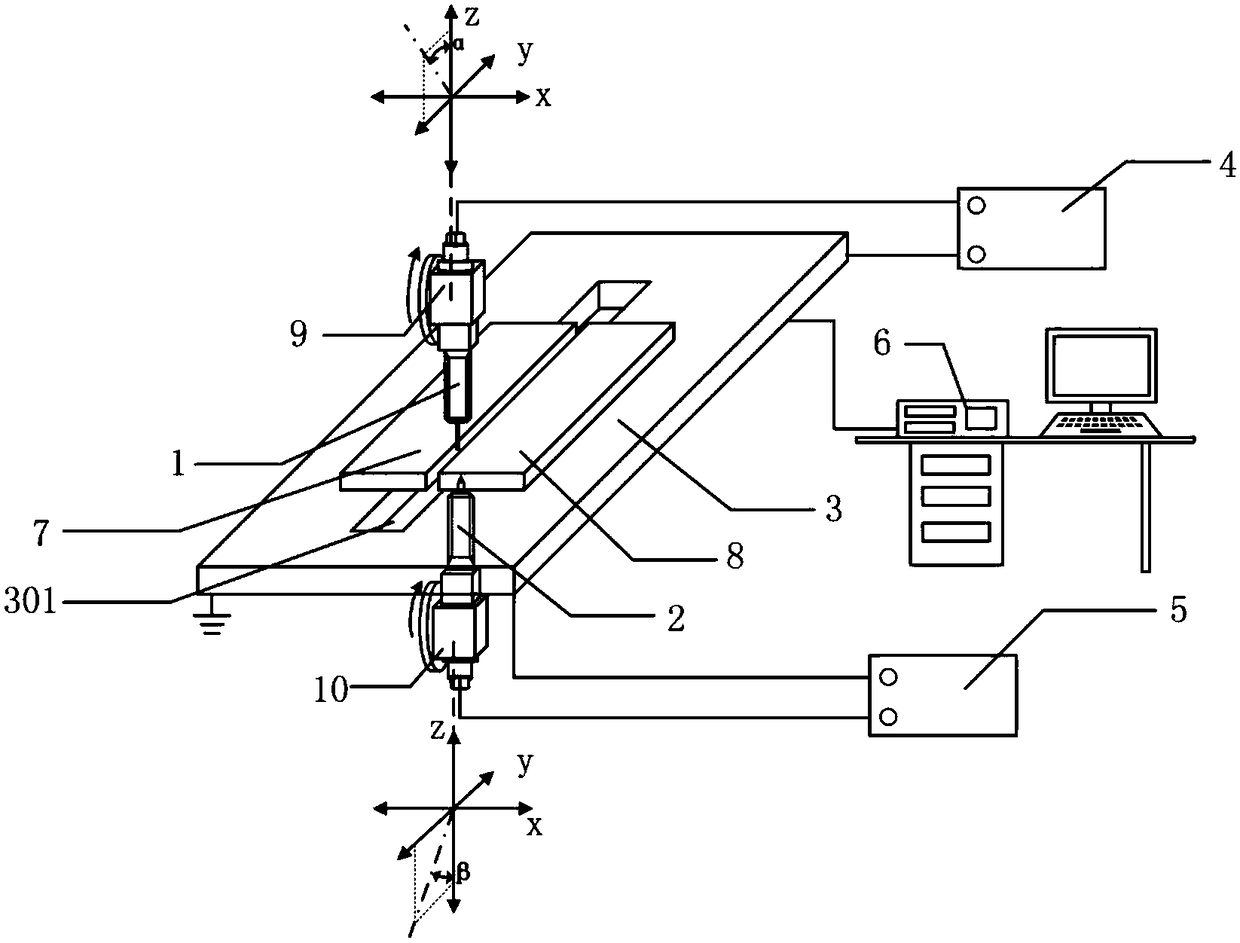

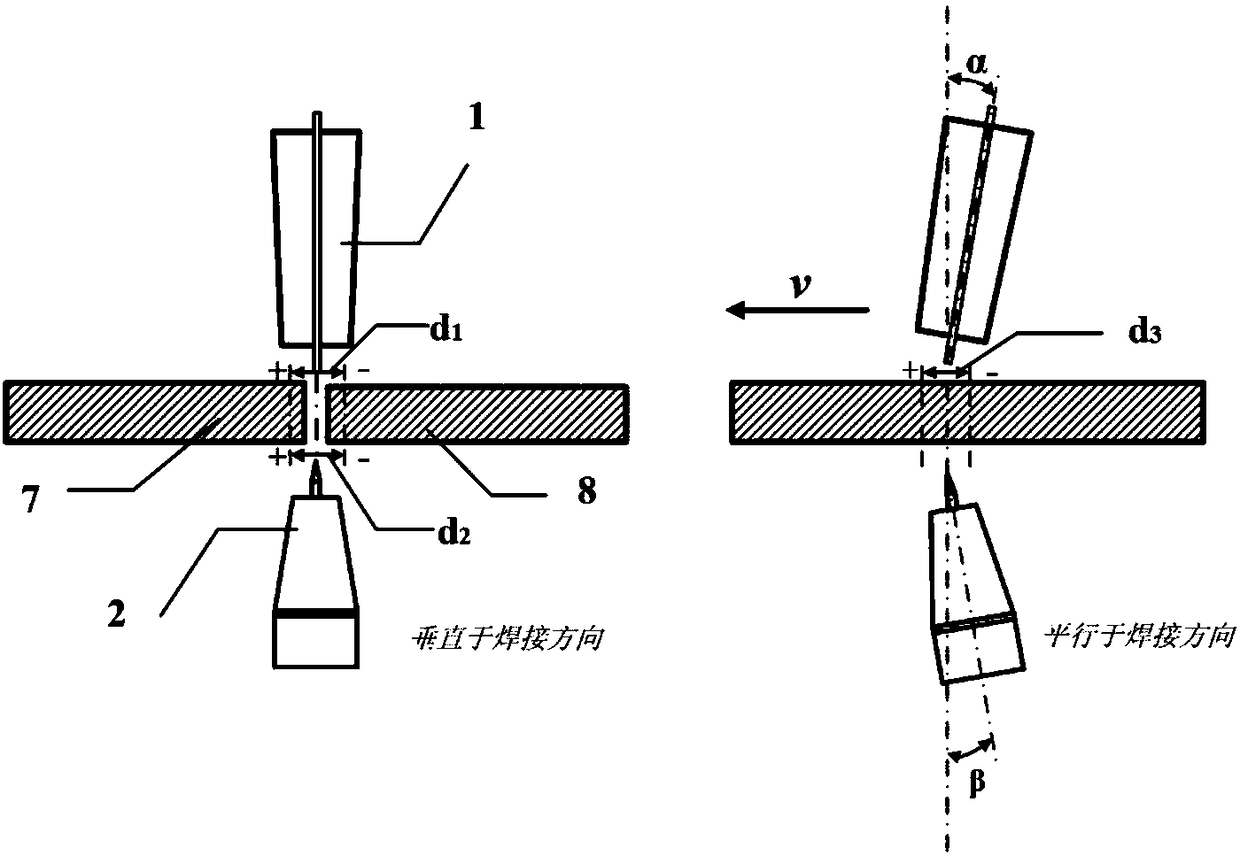

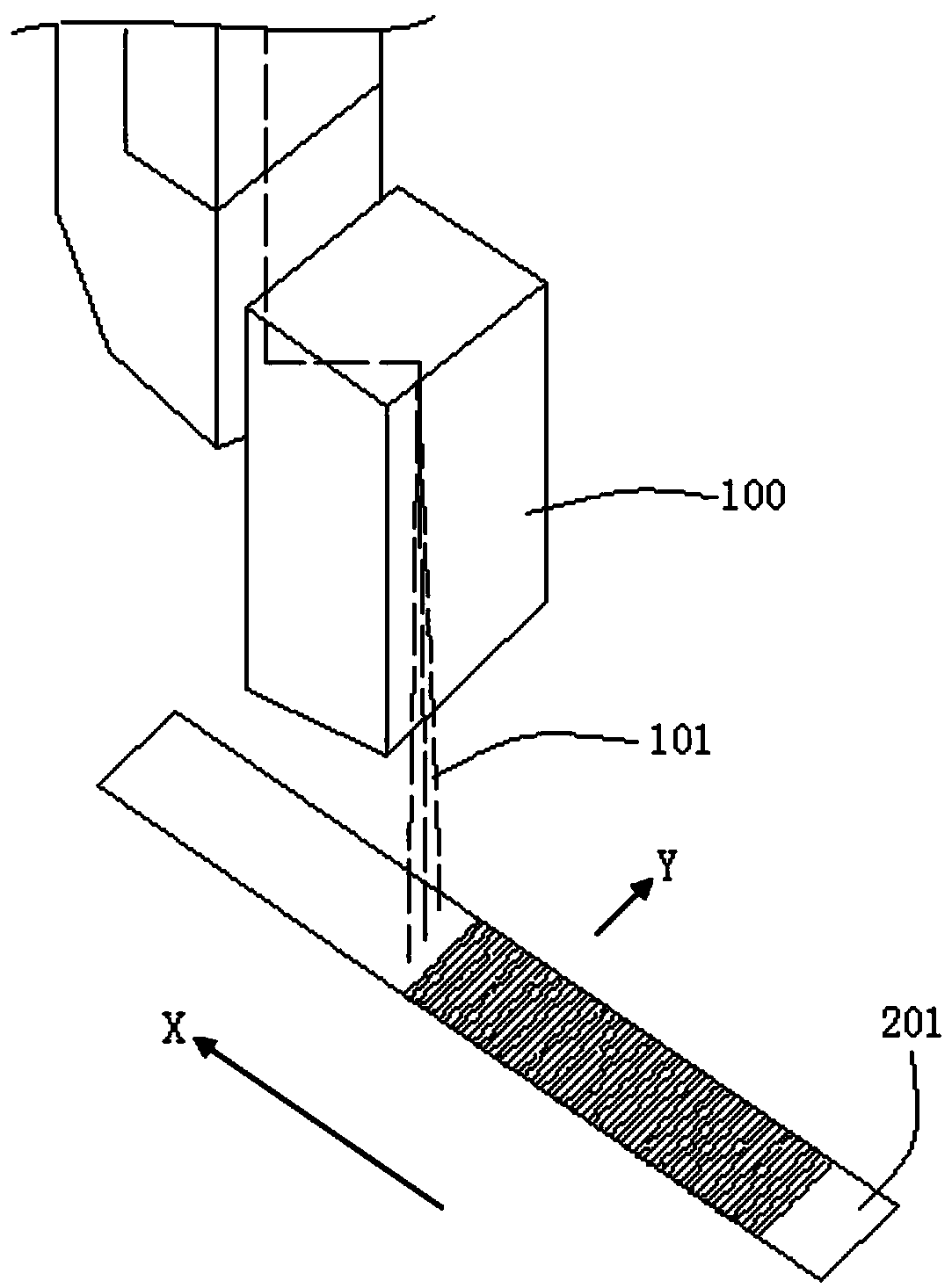

Double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials

ActiveCN108436234AImprove welding qualityControl soldering temperatureArc welding apparatusWelding/soldering/cutting articlesThree-dimensional spaceHeat losses

The invention discloses a double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials, and belongs to the field of metal material welding. Whenwelding the large thermal conductivity mismatched metal materials, the method adopts two heat sources to simultaneously heat the front and back sides of joints and optimizes energy distribution of the joints by controlling energy parameters and positional parameters of the two heat sources, side heat input of high thermal conductivity metal is increased, the heat loss caused by the higher thermalconductivity is compensated, the low thermal conductivity metal side welding temperature is controlled, and the problem of large thermal conductivity mismatched metal material welding forming is solved and the joint welding quality is improved. The preheating effect of the joints is obtained by tilting the two heat sources on the front and back sides at a certain angle in the welding direction, and the single-pass welding double-sided forming of the joints is realized under auxiliary measures such as no chamfering and pre-weld preheating. The welding device can effectively adjust and controlthe heat distribution of the joints by precisely controlling the position of the welding heat sources in the three-dimensional space, and efficient and reliable connection of the large thermal conductivity mismatched metal materials is realized.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy laser welding method

PendingCN109702342AFast welding speedSolve problemsWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingUltimate tensile strength

The invention relates to an aluminum alloy laser welding method. A laser spot performs swing movement in a welding seam width direction at a set frequency while a laser welding head runs in a length direction of a welding seam, and laser deep penetration welding is performed on an aluminum alloy base material, wherein a laser processing power at the middle position of the welding seam is larger than a laser processing power at the edge position of the welding seam. The aluminum alloy laser welding method adopts a laser deep penetration welding technology, has the advantages of large energy density, small welding heat input, high welding speed and the like and can well solve the problems and the defects existing in the aluminum alloy welding process in the prior art. For the aluminum alloylaser welding method, by being combined with the deflection movement of a laser beam, adopting different laser processing powers in a width direction of the welding seam and adopting a relatively large power at the middle position of the welding seam for processing, the energy is concentrated so as to ensure the weld penetration depth and the strength of the welding seam; and by adopting a relatively small power at the edge position of the welding seam for processing, obvious edge biting and ablation marks can be ensured not to occur on the edge of the welding seam, and good welding seam effect is achieved.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Welding method of metal layer shaped composite board

InactiveCN103537816AFast welding speedReduce welding heat inputWelding/soldering/cutting articlesMetal working apparatusWelding defectSequence design

The invention relates to a welding method of a metal layer shaped composite board. The elding method of the metal layer shaped composite board is characterized by the following steps of 1, welded joint design, 2, wielding method design, 3, V-shaped strips preparation and filler wire selection and 4, welding sequence design. The wielding method design includes that the laser is utilized to weld I shaped grooves, middle truncated edge and weld grooves matching with the V-shaped strips; when the V shaped groove only has one layer of materials, the laser arc composite heat source is utilized to weld the weld grooves. The wielding method design includes welding the I shaped grooves and the middle truncated edge first and then the V-shaped grooves. Compared with the prior art, the welding method of the metal layer shaped composite board has the advantages that the welding method of the metal layer shaped composite board is high in welding quality, few in welding defects, is easy to operate and can increase welding efficiency.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

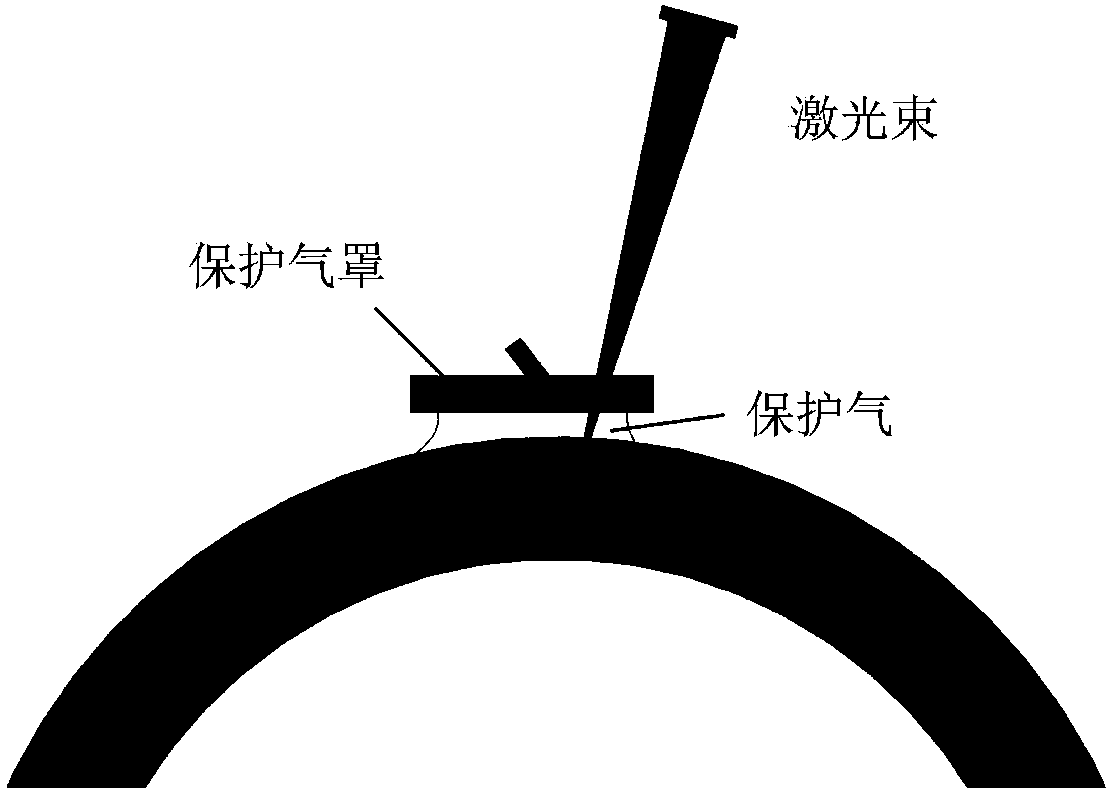

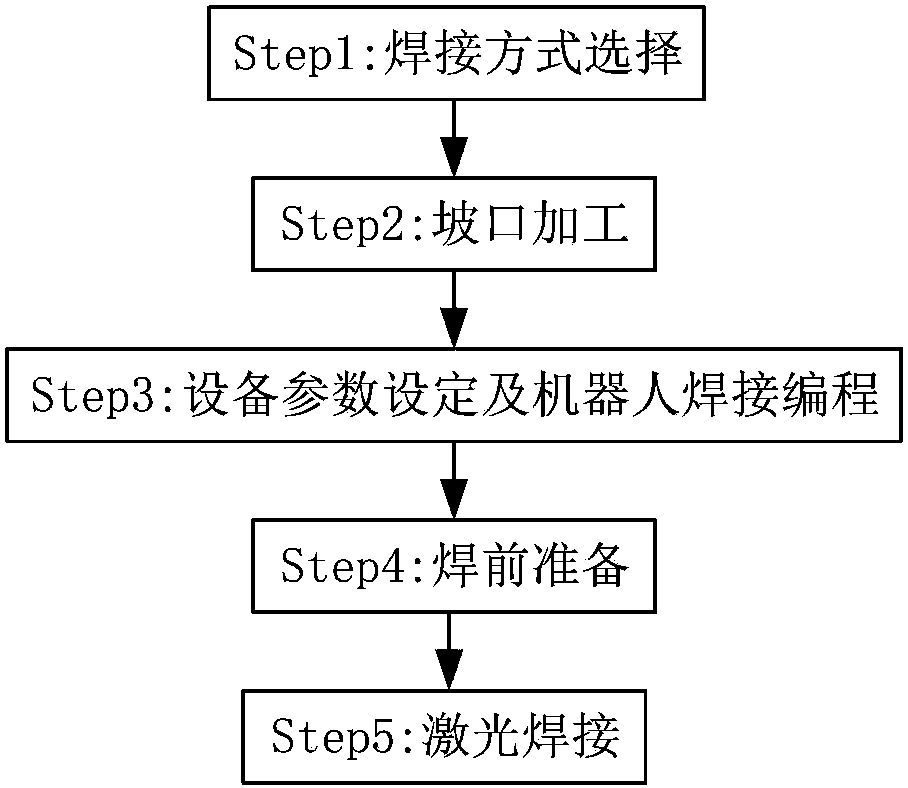

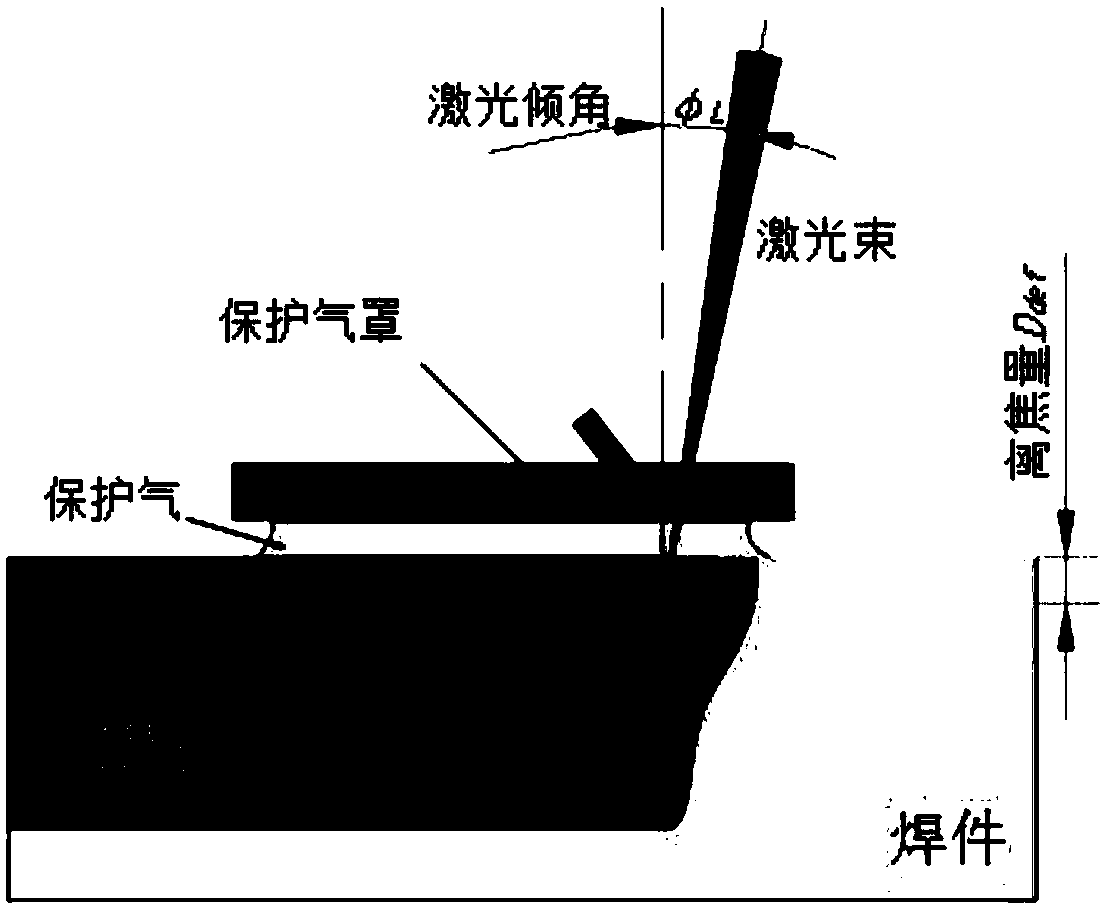

High-grade pipeline steel laser welding method

InactiveCN107081528AHigh energy density of laserImprove welding efficiencyLaser beam welding apparatusOptoelectronicsMode selection

The invention discloses a high-grade pipeline steel laser welding method and belongs to the technical field of advanced manufacturing. The method comprises the following steps of welding mode selection, groove machining, equipment parameter setting, welding robot welding programing, pre-welding preparation and laser welding. The high-grade pipeline steel laser welding method is quite suitable for one-step forming of long and straight welding seams of medium-thick material and backing weld of large-pipeline-diameter large-wall-thickness pipelines, and has the advantages of high laser energy density, high welding speed, low heat input, small deformation, high welding efficiency and the like.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

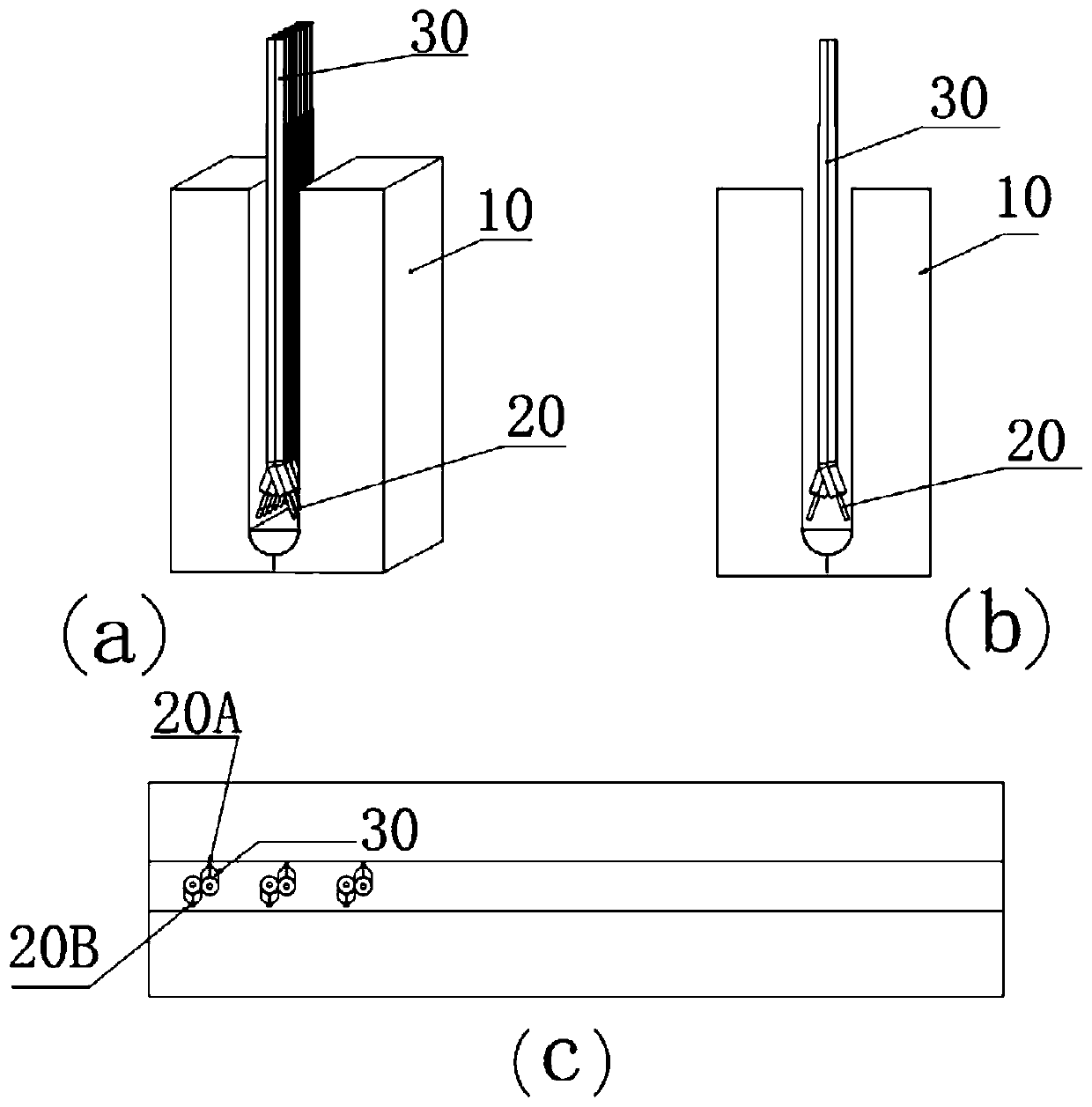

Thin plate and friction stir welding method for ultra-thin plate

InactiveCN107138849AHigh strengthReduce welding heat inputMetal working apparatusNon-electric welding apparatusButt jointWeld seam

The invention provides a thin plate and a friction stir welding method for the ultra-thin plate. The method comprises the processes that firstly, the upper surface and the butt joint surface of a welded plate and oxidation layers of the upper surface and the lower surface of a cover plate are cleaned up, and the welded plate is assembled in a butt-joint manner; secondly, the welded plate is covered with the cover plate made of a material the same as that of the welded plate, the accumulated value of the thickness (t1) of the cover plate and the thickness (t2) of the welded plate ranges from 2 mm to 5 mm, the width of the cover plate is larger than that of a shaft shoulder of a stirring head, and the length of the cover plate is equal to that of the welded plate; and thirdly, the stirring head for welding is selected, it is required that a pin of the stirring head is equal to (t1+t2)-(0.1-0.2), and appropriate welding parameters are selected for welding; and fourthly, the cover plate is removed through the machining manner till a welding seam is in flush with the welded base material. Compared with traditional friction stir welding, the friction stir welding of the ultra-thin plate can be achieved, the problem that the welding seam is thinned in the friction stir welding is avoided completely, the appearance of the welding seam is level, the post-welding deformation is small, and the joint connecting quality is reliable.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com