Welding method of metal layer shaped composite board

A welding method and composite plate technology, applied in the field of material processing, can solve the problems of limiting the promotion and application of metal layered materials, difficult layered material welding, inclusions and pores, etc., so as to reduce the heat affected zone of the weld seam and improve the welding efficiency. Efficiency and less welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

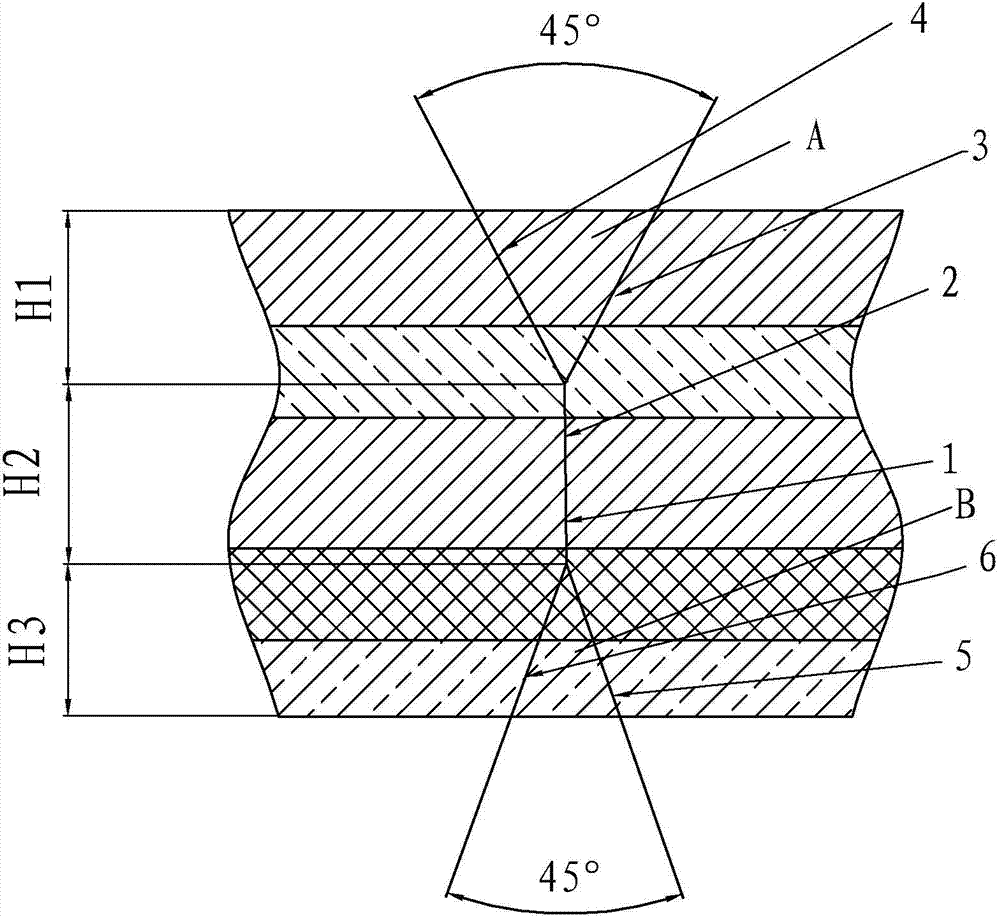

[0025] Example 1, such as figure 1 , figure 2 and image 3 As shown, the present embodiment welds a 40.0mm thick layered composite aluminum-aluminum alloy material with 5 layers, including the following steps:

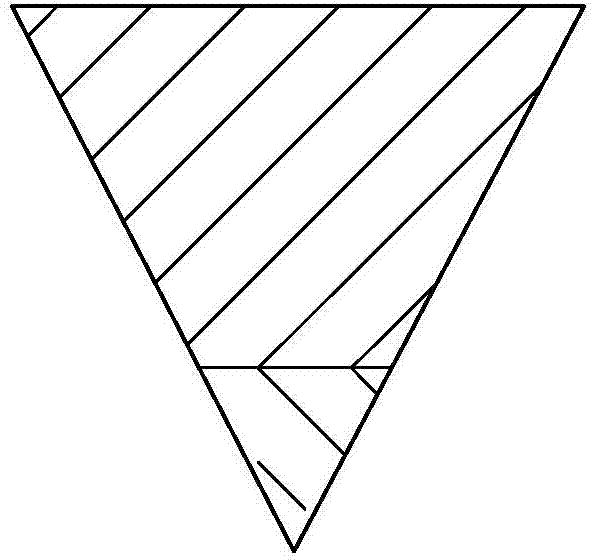

[0026] (1) Welding joint design: a layered aluminum-aluminum alloy composite plate with a thickness of 40.0mm and 5 layers with V-shaped grooves on both sides, an angle of 35°, and a blunt edge of 20.0mm in the middle. (2) Welding method design: the middle blunt edge and the weld bevel matching the V-shaped bar are welded twice by laser method, see figure 1 , where H1=10mm, H2=20mm, H3=10mm, angle 35°, 1 is the first weld, 2 is the second weld, 3 is the third weld, 4 is the fourth weld, 5 is the fifth weld, 6 is the sixth weld. (3) Preparation of V-shaped strips: The V-shaped strips and the base metal with V-shaped grooves are completely consistent in layer structure (two layers) and thickness (10.0mm). The preparation method is wire cutting, see figure 2 and ...

Embodiment 2

[0027] Example 2, such as Figure 4 As shown, in this embodiment, the layered composite aluminum-aluminum alloy material with a thickness of 15.0 mm and 2 layers is welded, including the following steps:

[0028] (1) Welding joint design: I-shaped grooves are made on a layered composite aluminum-aluminum alloy plate with a thickness of 15.0mm and 2 layers. (2) Welding method design: The I-shaped groove is welded on both sides by laser method. (3) Preparation of V-shaped strips and selective filler wires: I-shaped grooves do not need to prepare V-shaped strips and selective filler wires. (4) Welding sequence design: first weld one side, then weld the other side, see the specific welding sequence Figure 4 , where, H1=9mm, H2=6mm, 1 is the first weld, 2 is the second weld.

Embodiment 3

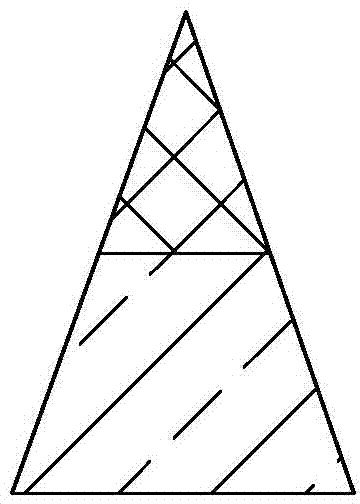

[0029] Example 3, such as Figure 5 As shown, the present embodiment is 30.0mm thick and has 3 layers of layered composite aluminum-magnesium-aluminum alloy materials for welding, including the following steps:

[0030] (1) Design of welded joints: a layered aluminum-magnesium-aluminum alloy composite plate with a thickness of 30.0mm has a V-shaped groove on one side, an angle of 30°, and a blunt edge of 20.0mm in the middle. (2) Welding method design: The blunt edge in the middle is welded on both sides by laser method, and the V-shaped groove is welded by laser arc composite heat source method. (3) Selection of filler wire: choose the aluminum alloy welding material that is consistent and matched with the base metal of the V-shaped groove for the filler wire. (4) Welding sequence design: first weld the blunt edge in the middle, and then weld the V-shaped groove. For the specific welding sequence, see Figure 5 , where H1=10mm, H2=8mm, H3=12mm, 1 is the first weld, 2 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com