Laser root welding robot inside pipeline

A robot and pipeline technology, applied in laser welding equipment, pipeline systems, motor vehicles, etc., can solve the problems of low welding efficiency, large volume and weight, and low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

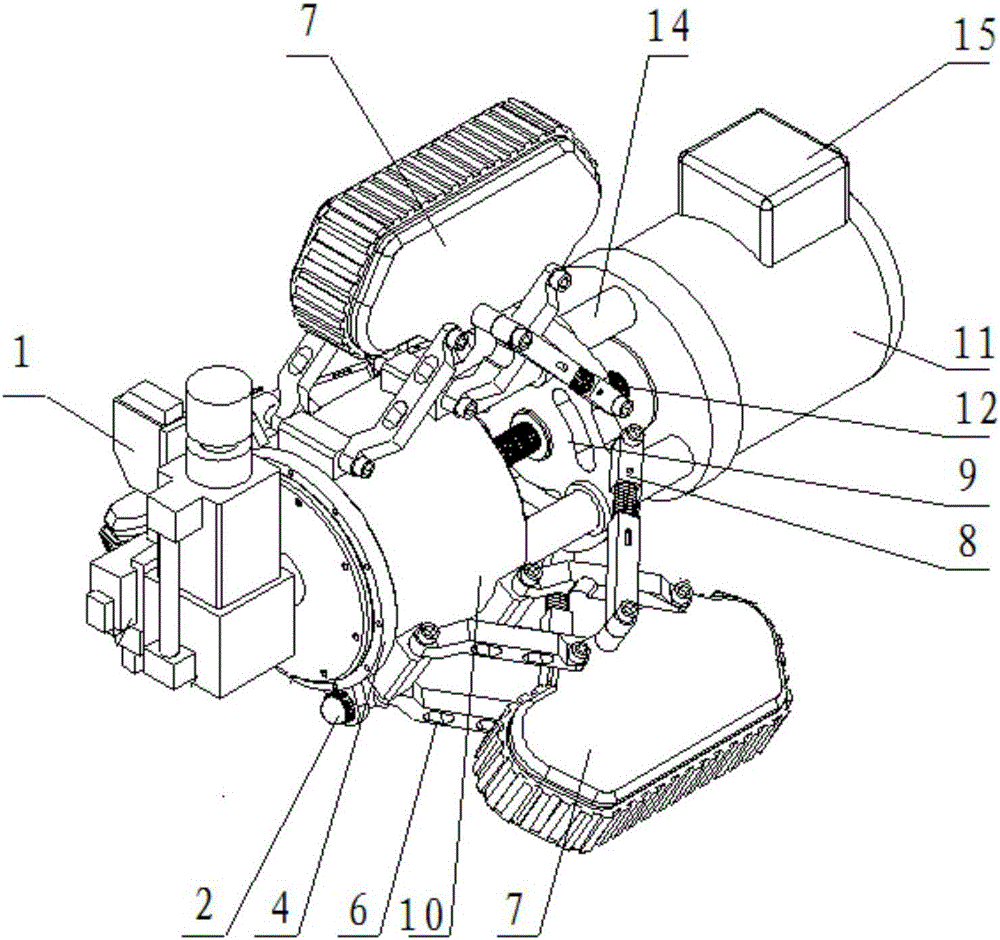

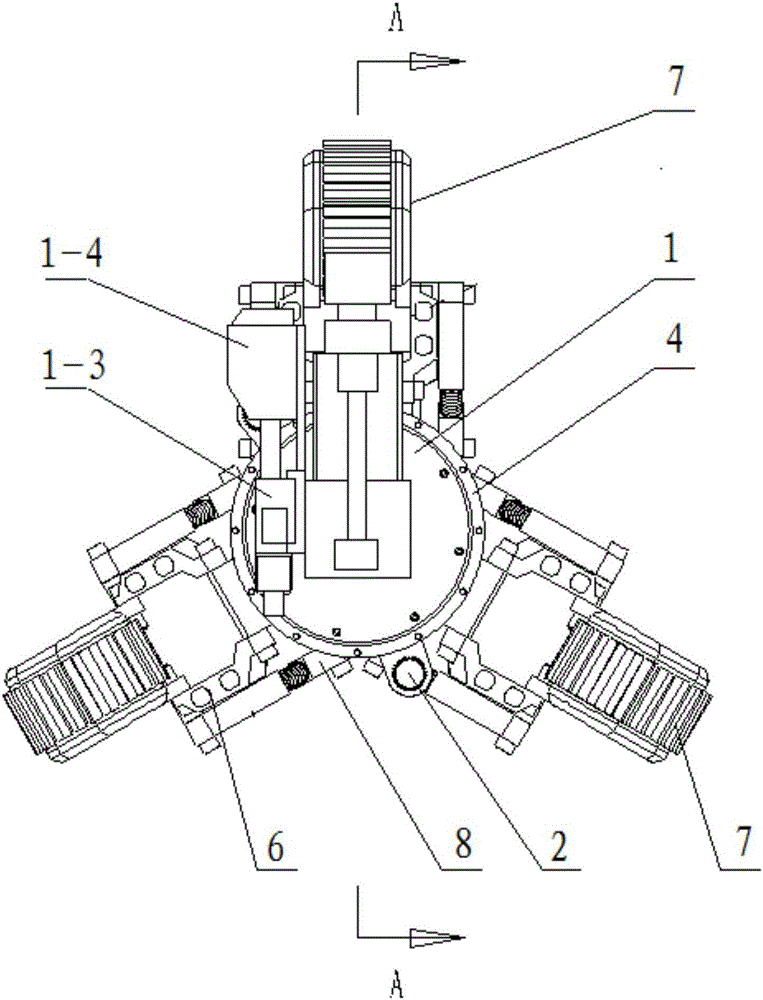

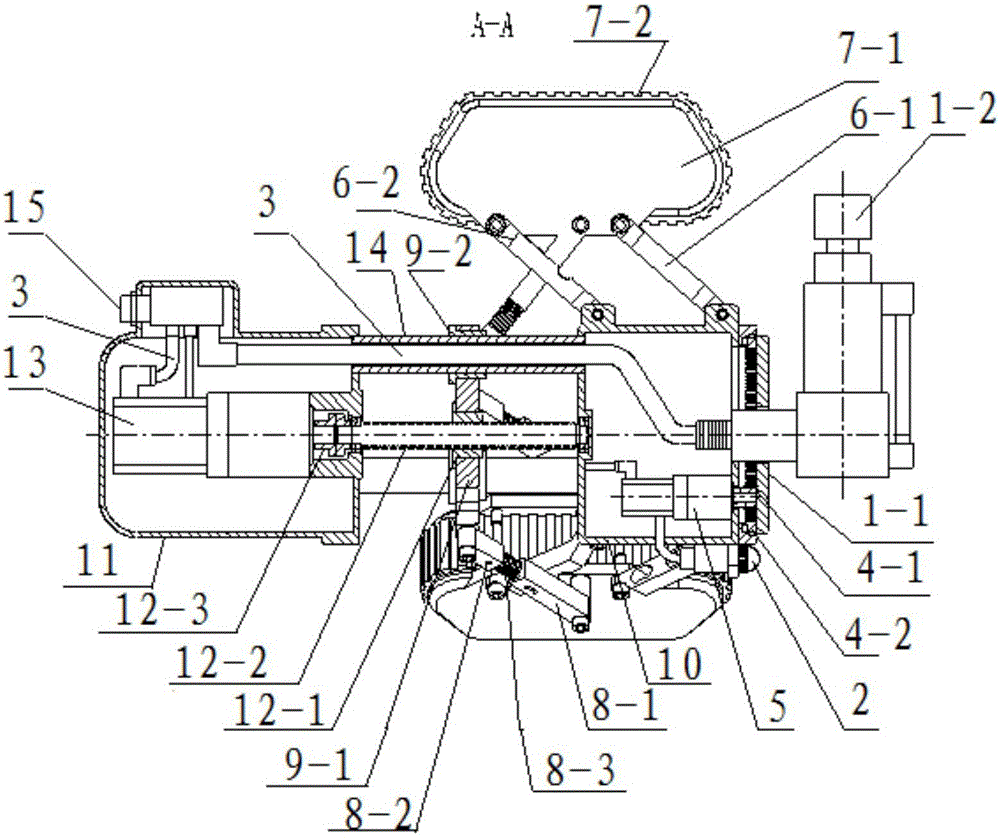

[0020] see Figure 1-5 , a pipeline internal laser follow-up welding robot provided by an embodiment of the present invention includes: an industrial computer, a weld seam welding device 1, a first transmission device 4, a front end frame 10, a first reduction motor 5, a connecting device 6, a crawler walking Device 7, pushing device 8, driving device 9, second transmission device 12, hollow guide rod 14, rear end frame 11, second reduction motor 13, cable 16 and cable terminal box 15.

[0021] The first transmission device 4 is connected to the seam welding device 1 .

[0022] The front end frame 10 is connected with the first transmission device 4 .

[0023] The first deceleration motor 5 is arranged in the front end frame 10 , and the first deceleration motor 5 is connected with the first transmission device 4 .

[0024] One end of the at least three sets of connecting devices 6 is movably connected with the front base 10 .

[0025] The at least three sets of crawler-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com