Patents

Literature

38results about How to "Small welding heat affected zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

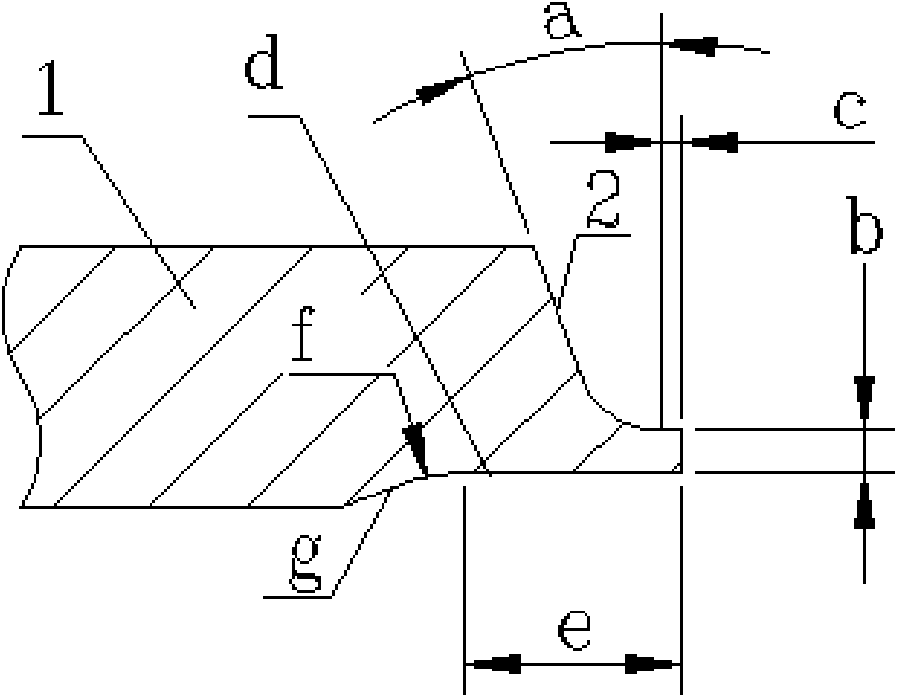

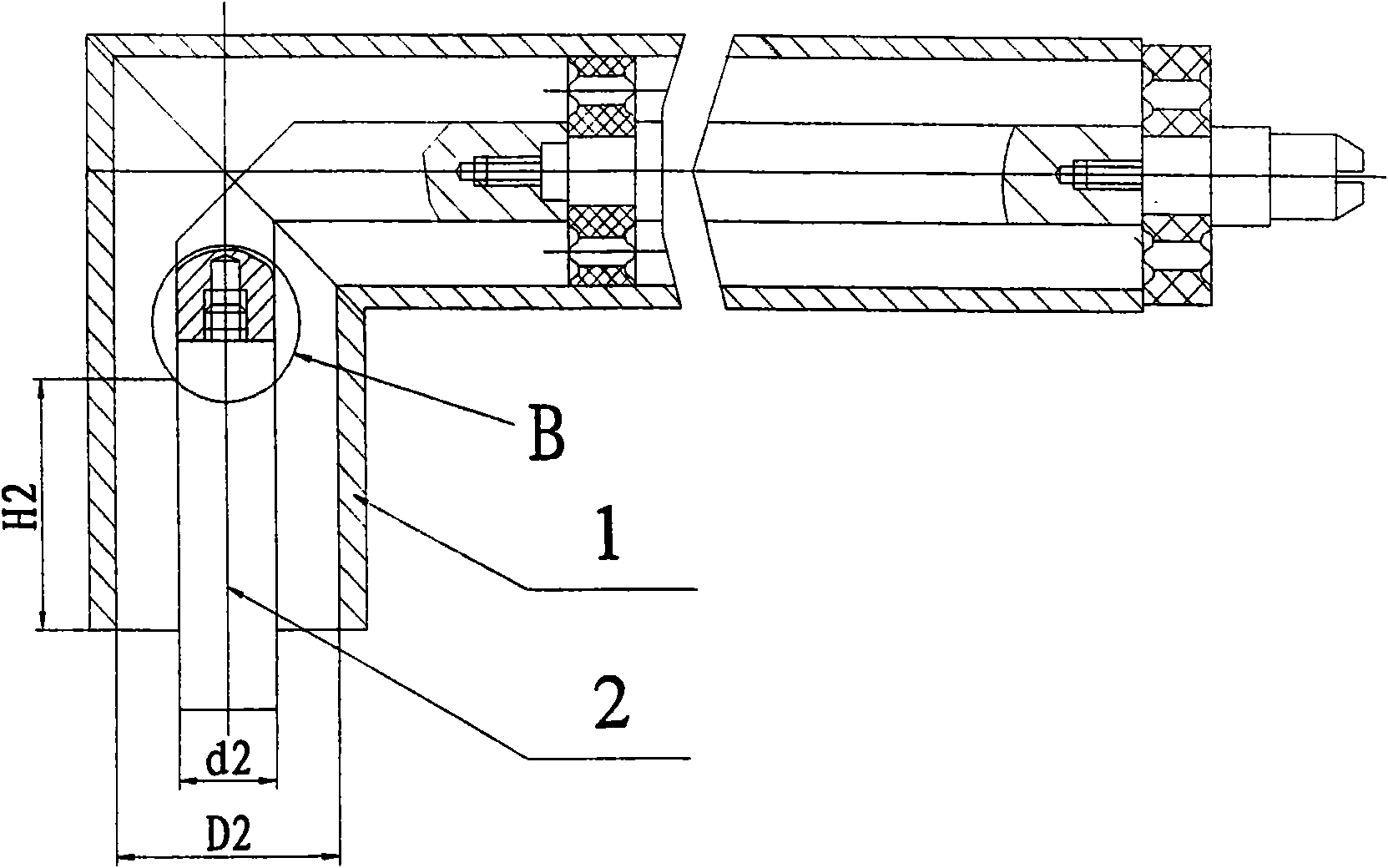

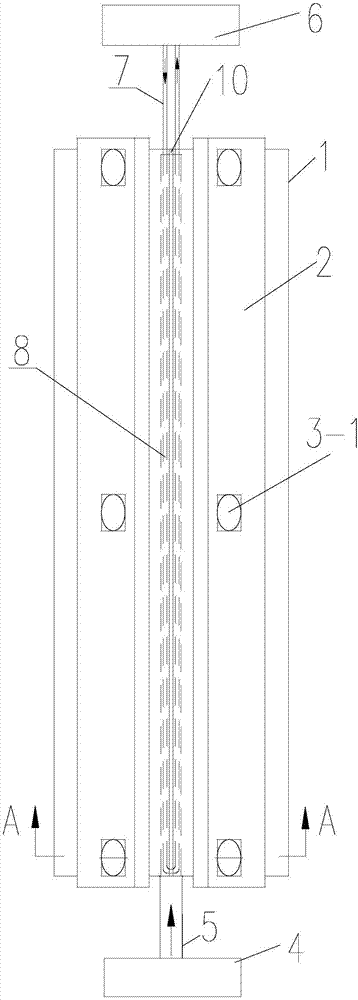

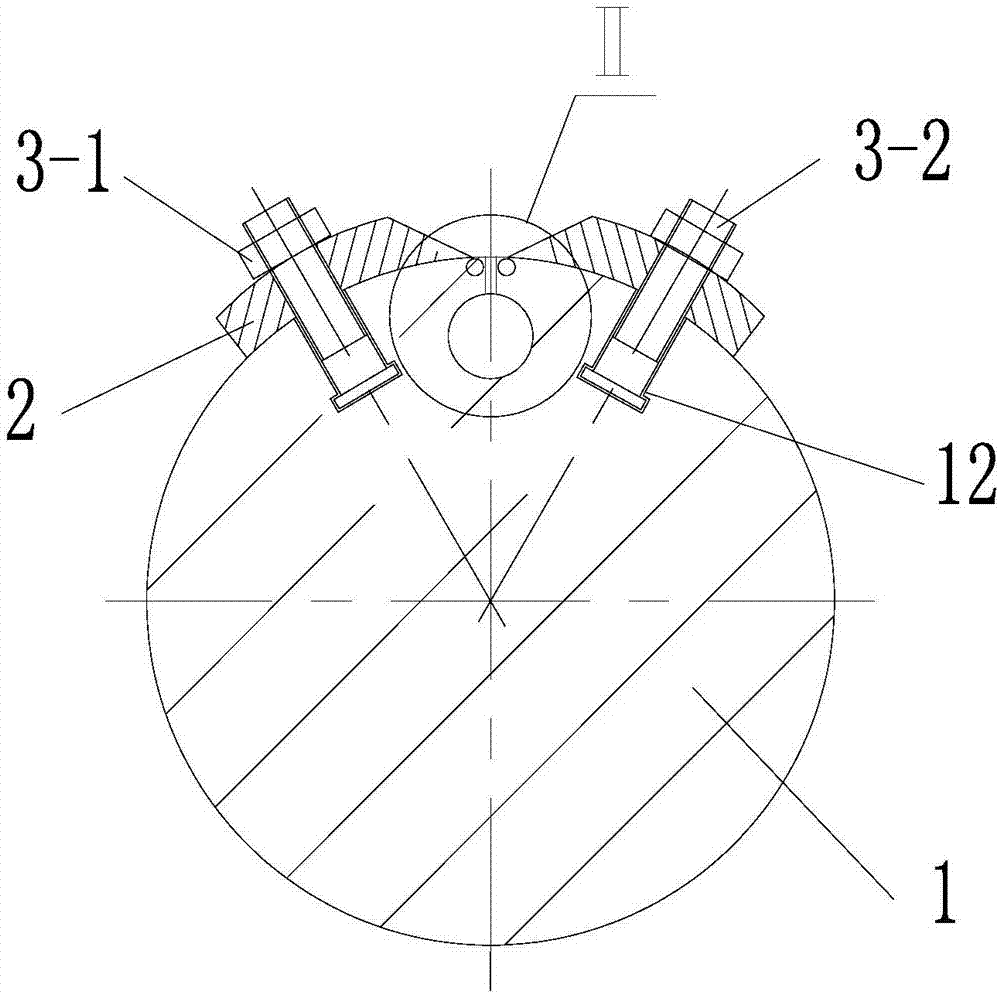

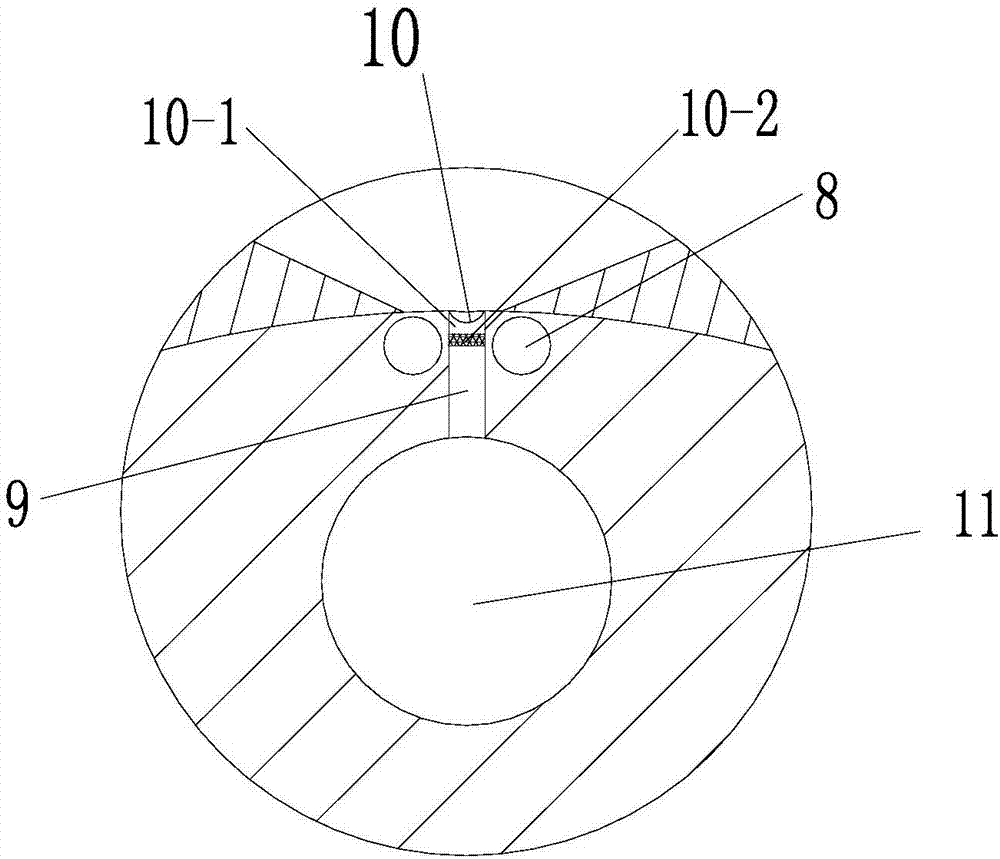

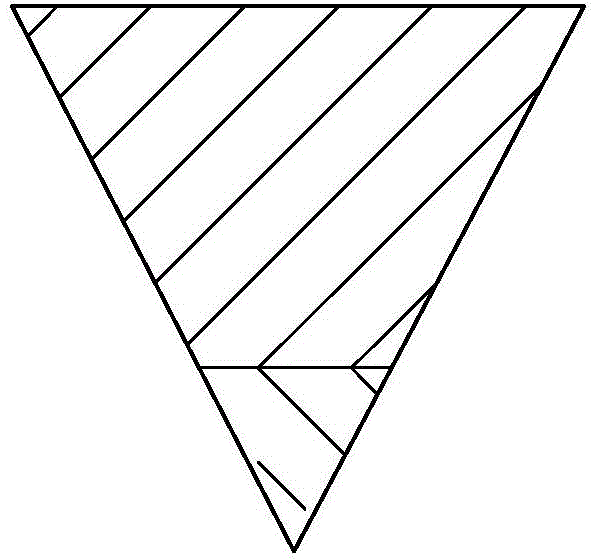

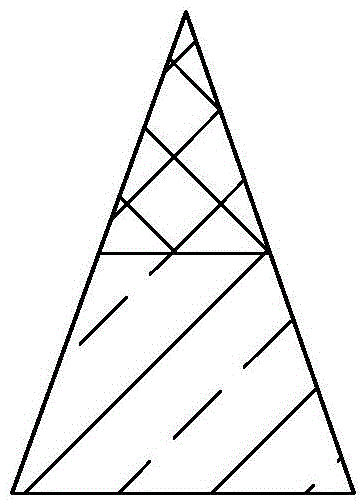

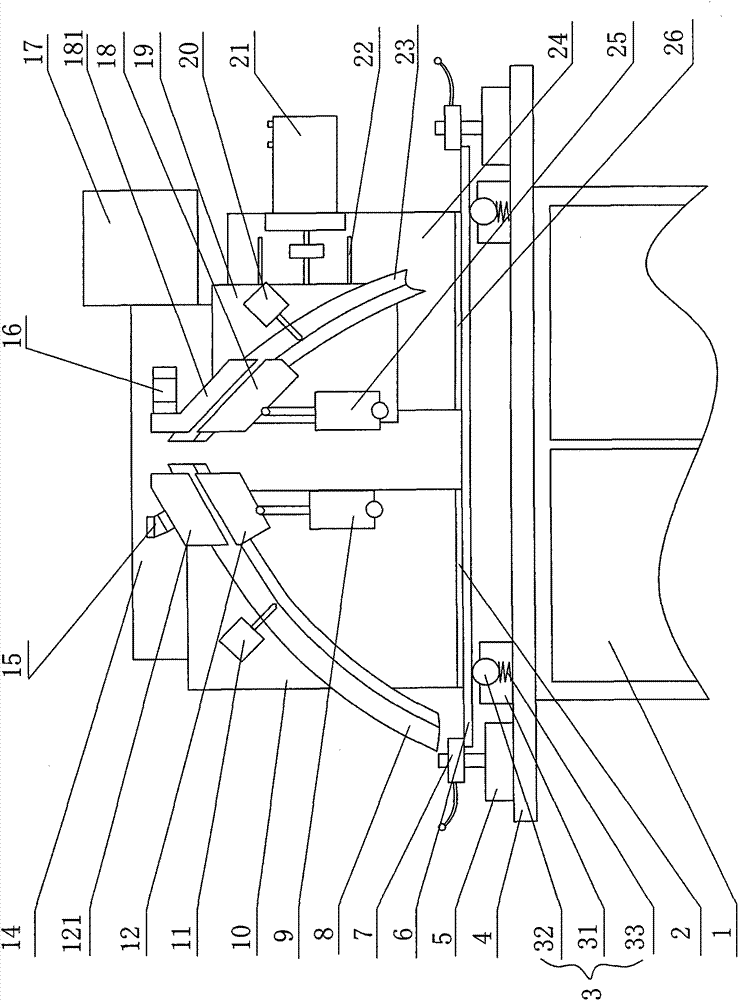

Stainless steel tube with welding bevel model, welding method and argon shield apparatus

InactiveCN101586699AGuarantee molding qualityGuarantee the quality of welding seam formationArc welding apparatusRigid pipesChemical industryPetroleum

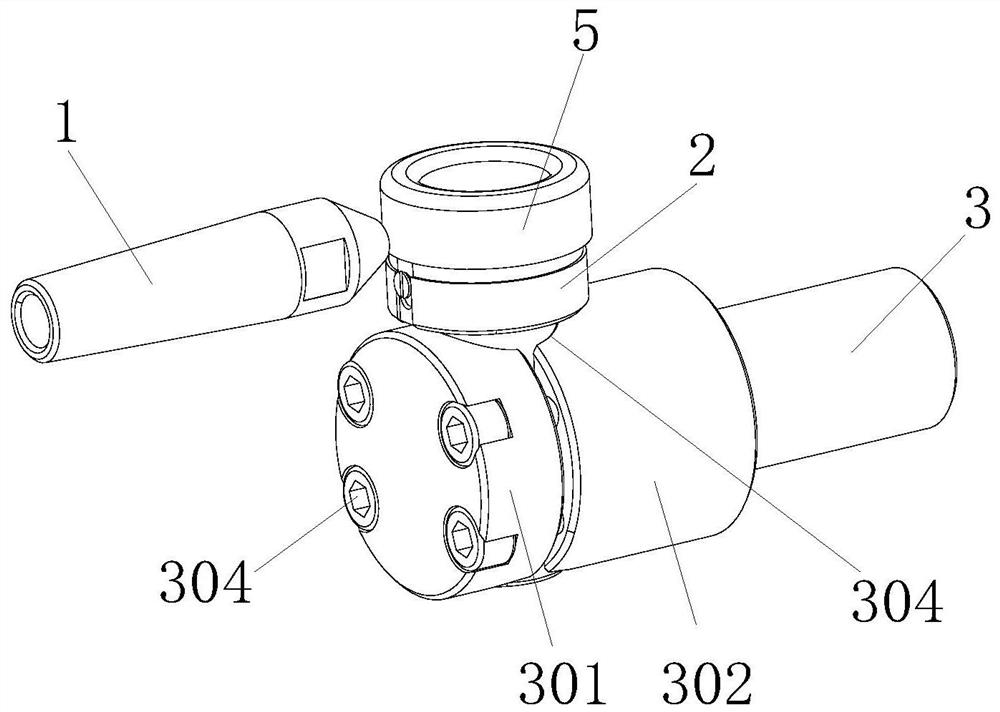

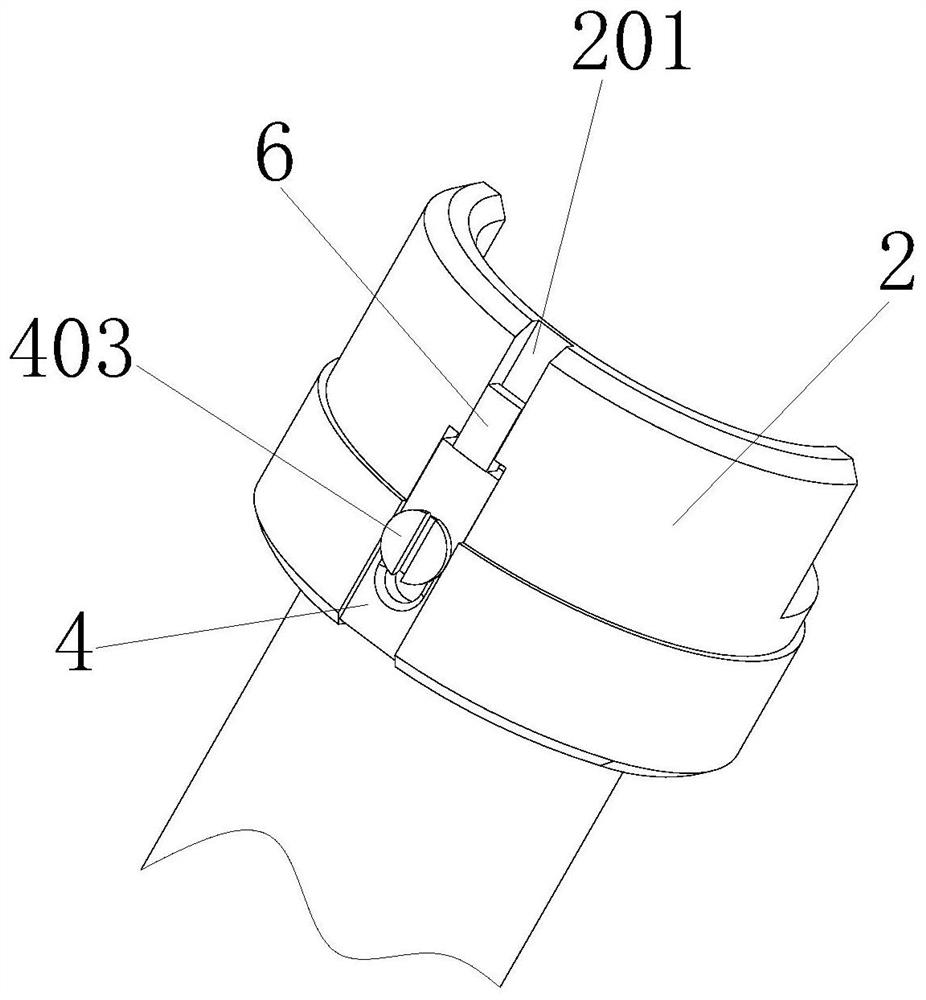

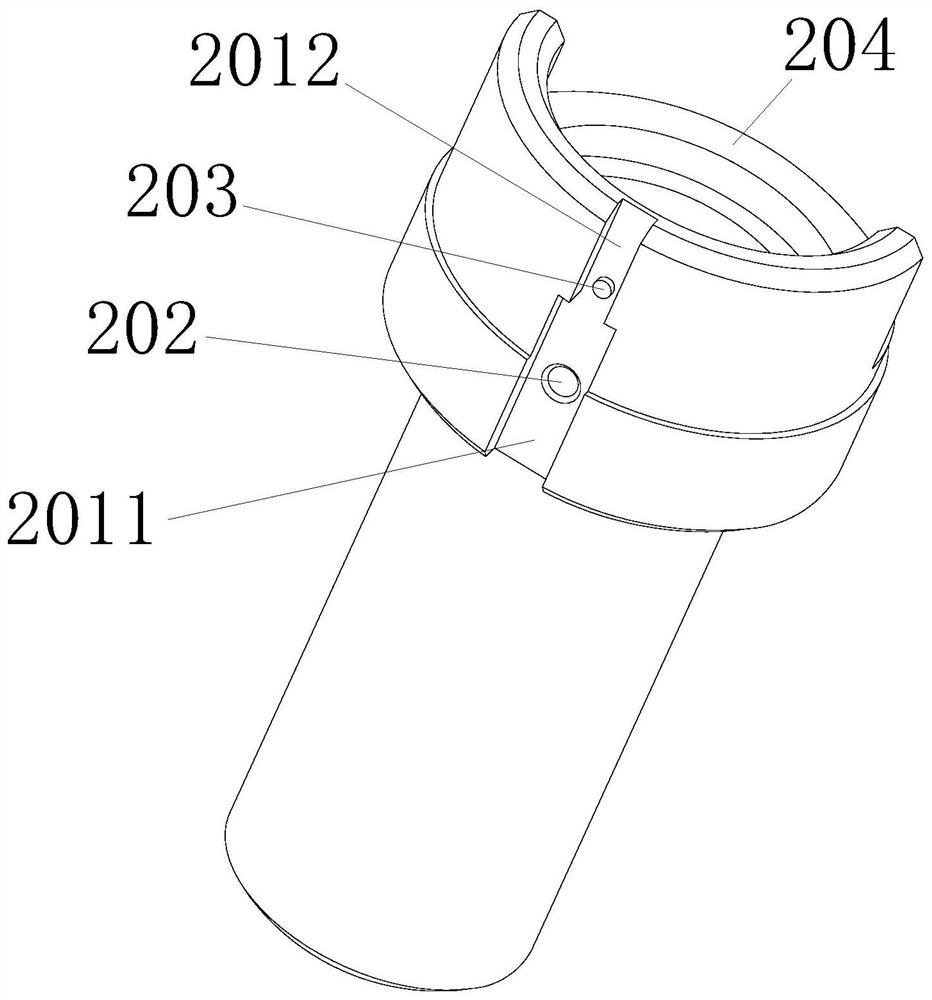

The invention discloses a stainless steel tube with welding bevel model. One end of the stainless steel tube is provided with an arc bevel. The arc bevels of the adjacent stainless steel tubes are jointed together to form a U shaped bevel. Meanwhile, the invention also discloses a welding method of the stainless steel tube and an argon shield apparatus used in the welding method. The invention has good weld joint molding effect and uniform weld joint reinforcement. The invention is mainly applied to the austenitic stainless steel welding in the fields of petroleum, chemical industry, metallurgy, machinery and naval construction.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

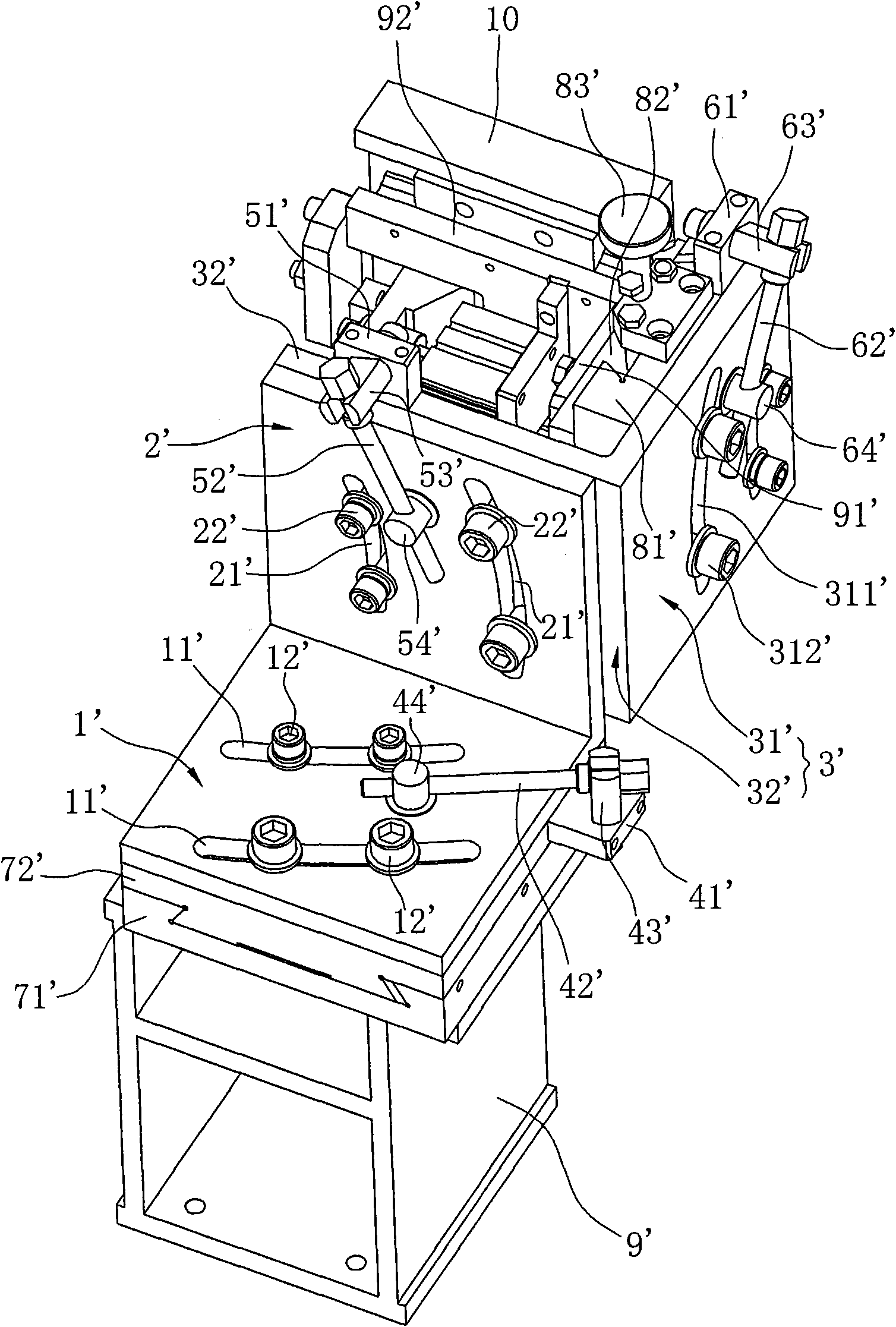

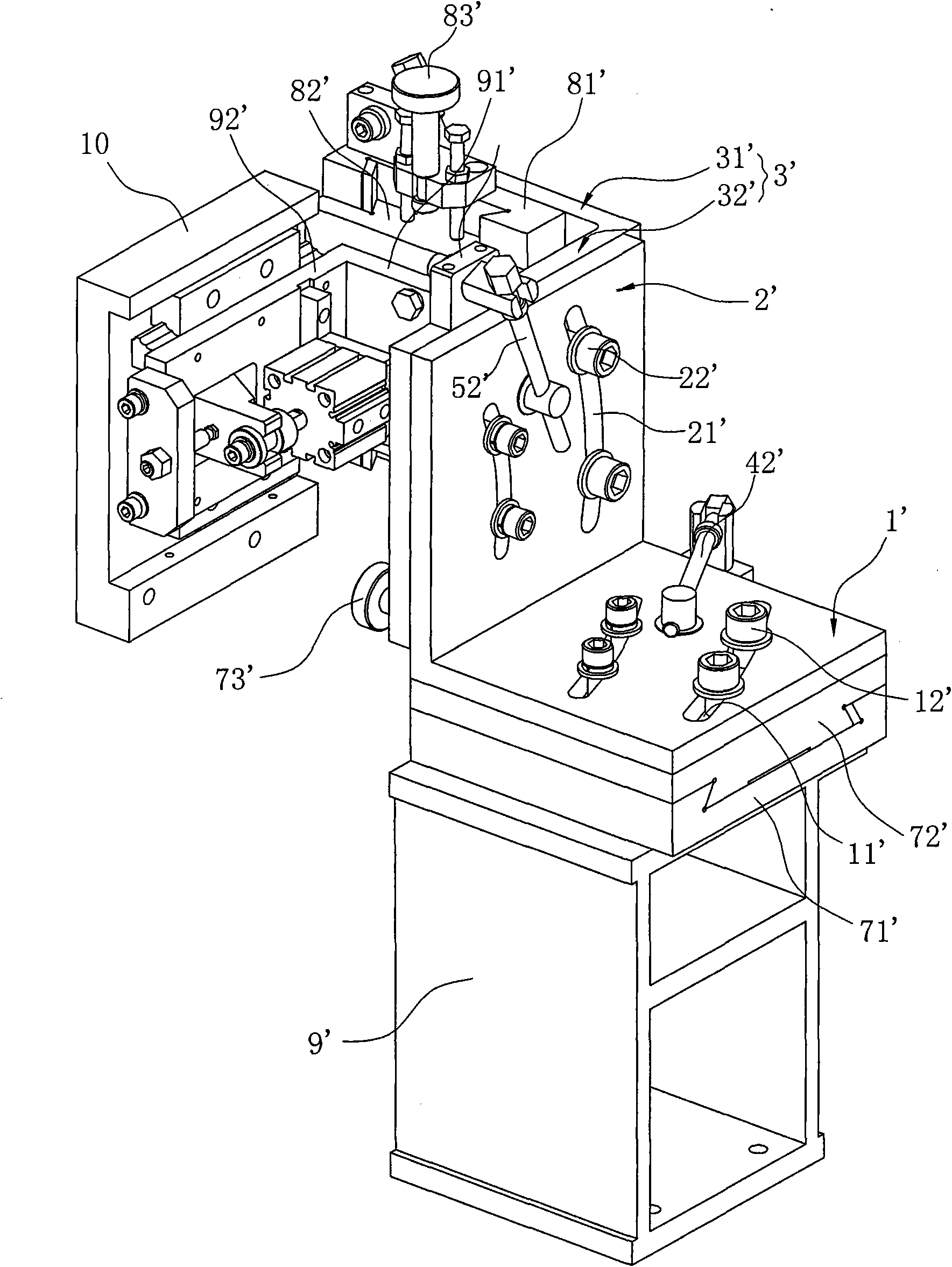

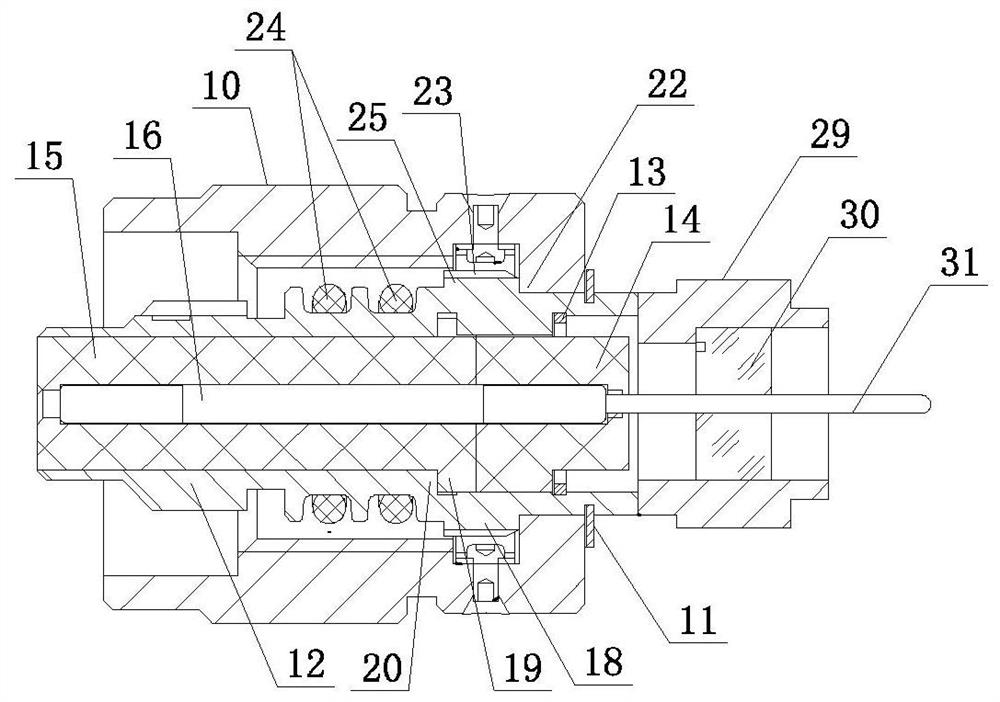

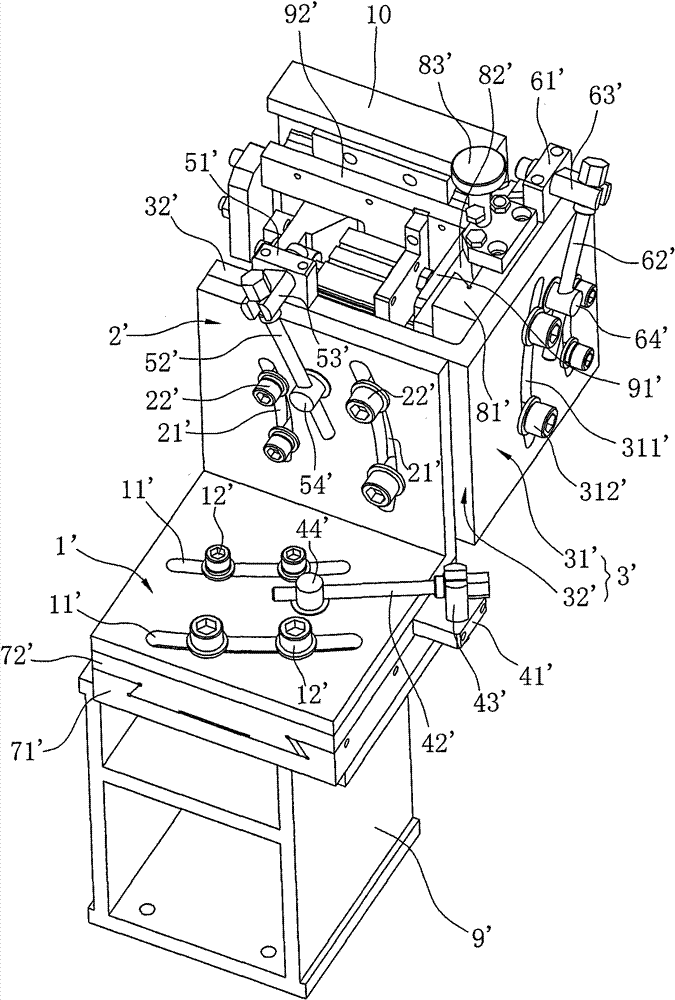

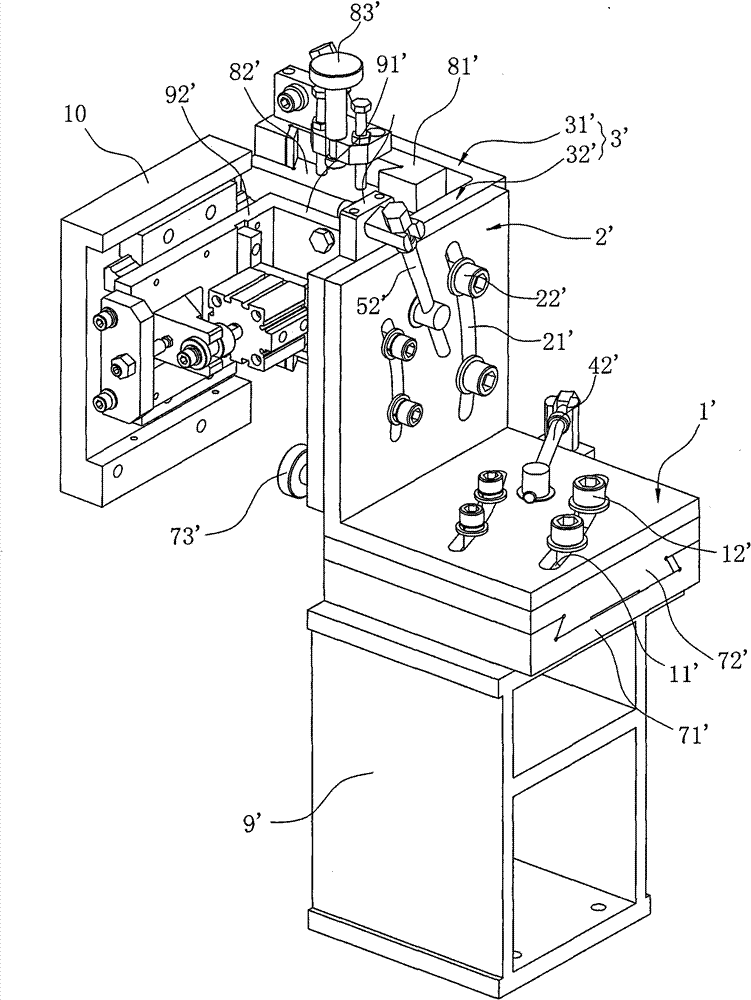

Flash butt welding machine for vehicle door corner welding

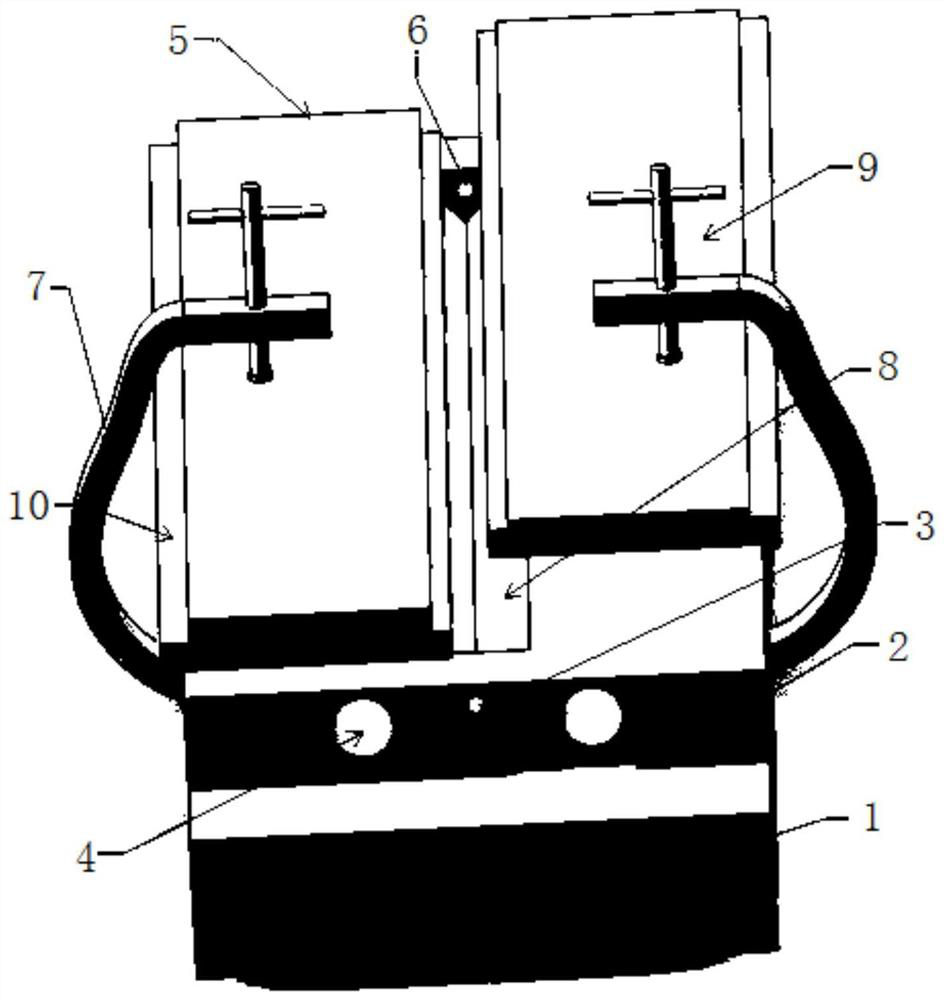

ActiveCN101979208AEffortless pushLabor-saving operationResistance welding apparatusButt weldingServo drive

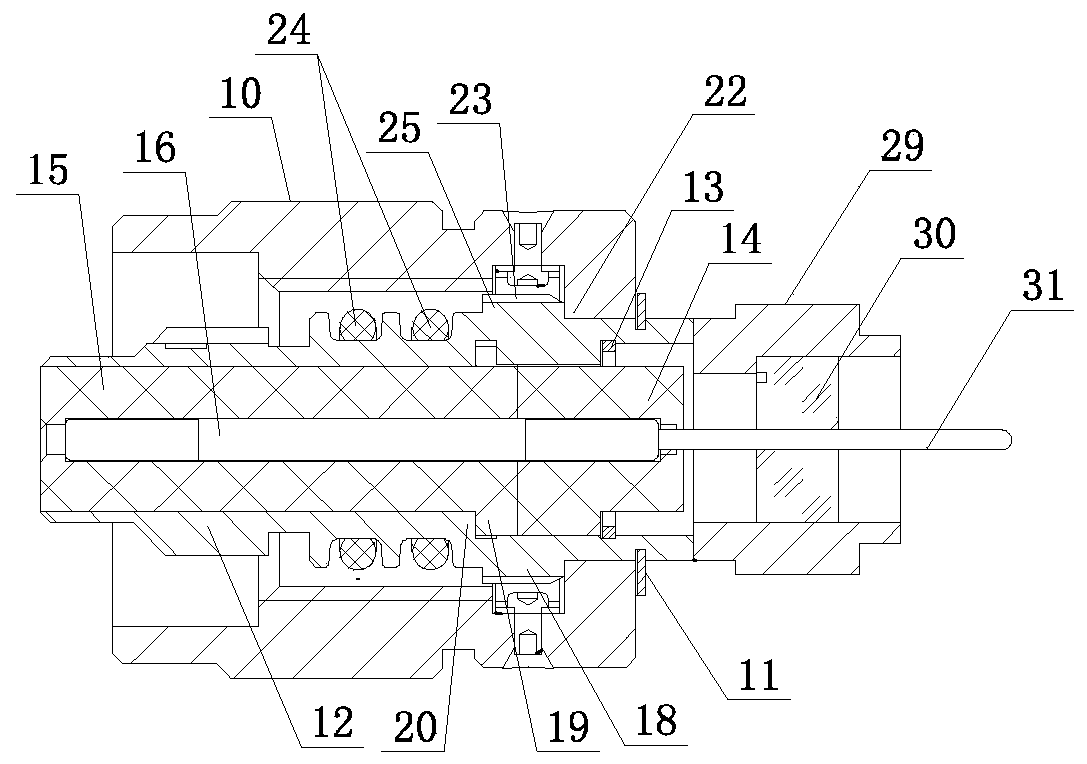

The invention discloses a flash butt welding machine for vehicle door corner welding, which comprises a base, clamping devices, an upsetting mechanism and an electric controller, wherein the clamping devices comprise a first clamping device for clamping a right welding piece and a second clamping device for clamping a left welding piece. The flash butt welding machine is characterized by also comprising a clamp adjusting device and an adjusting bottom plate capable of moving freely in a space, wherein the second clamping device is fixedly arranged on the adjusting bottom plate; an upsetting device comprises a guide rail seat, a moving component slipping along the guide rail seat and a servo driving device for driving the moving component to move; the first clamping device is fixedly arranged on the moving component; and a first insulating plate is arranged between the bottom of the clamp adjusting device and the base, and a second insulating plate is arranged between the bottom of theguide rail seat and the base. Compared with the prior art, the flash butt welding machine can randomly adjust the space placing position of the welding piece to ensure the welding quality and the appearance and profile requirements of a welded product; and the clamp adjusting device is convenient and simple in operation, and improves the welding efficiency.

Owner:NINGBO XINTAI MACHINERY

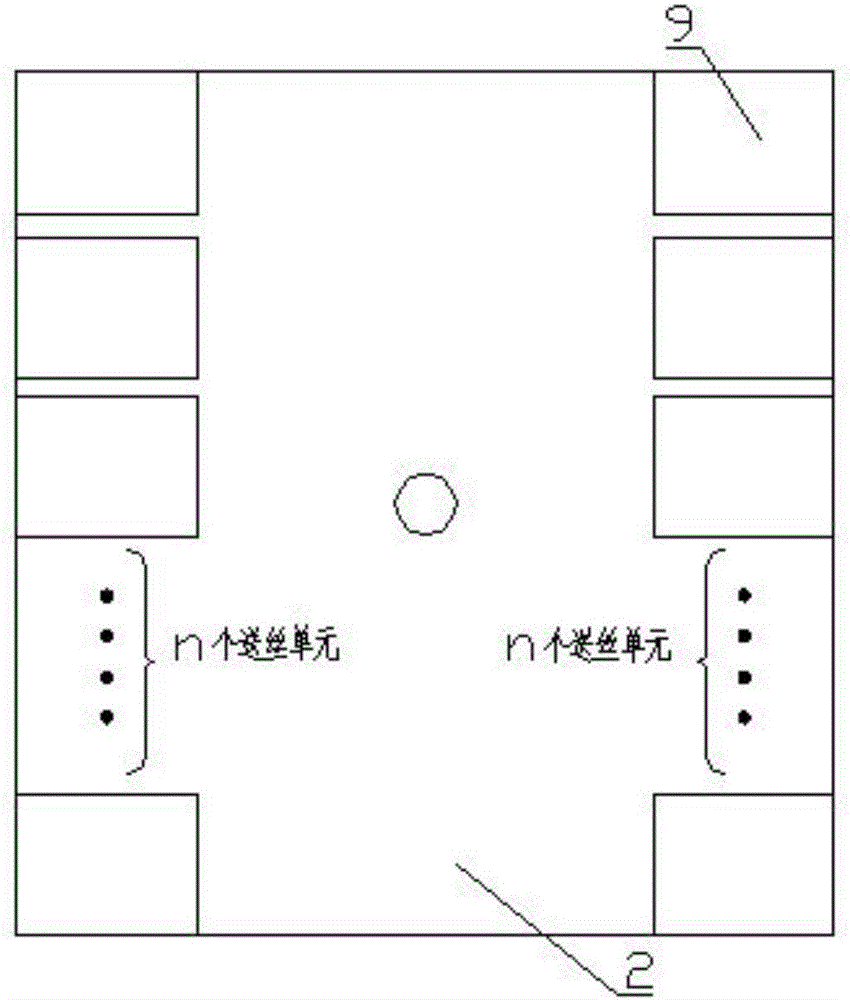

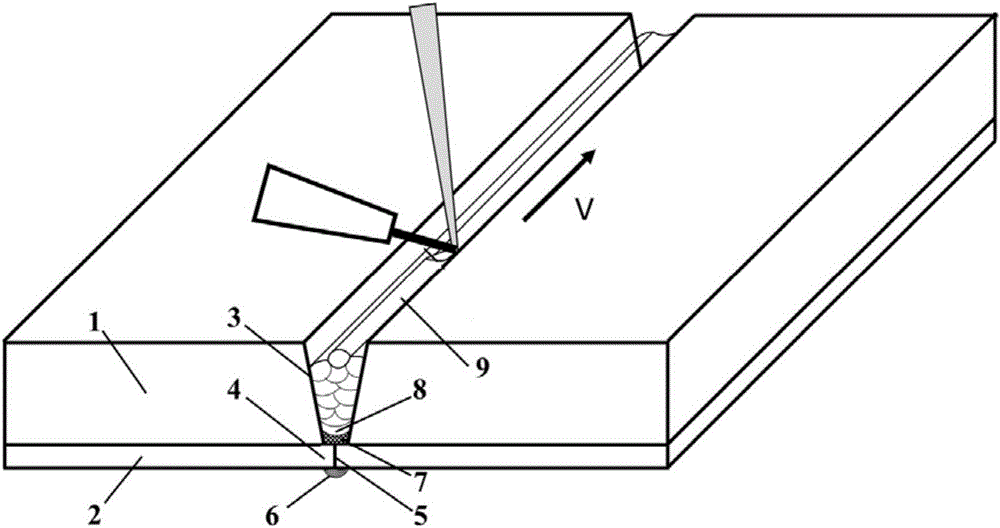

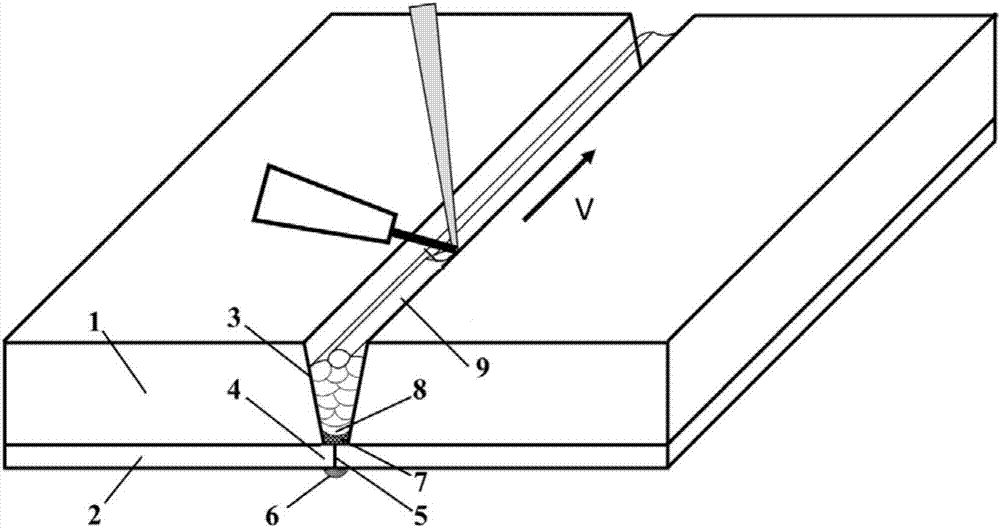

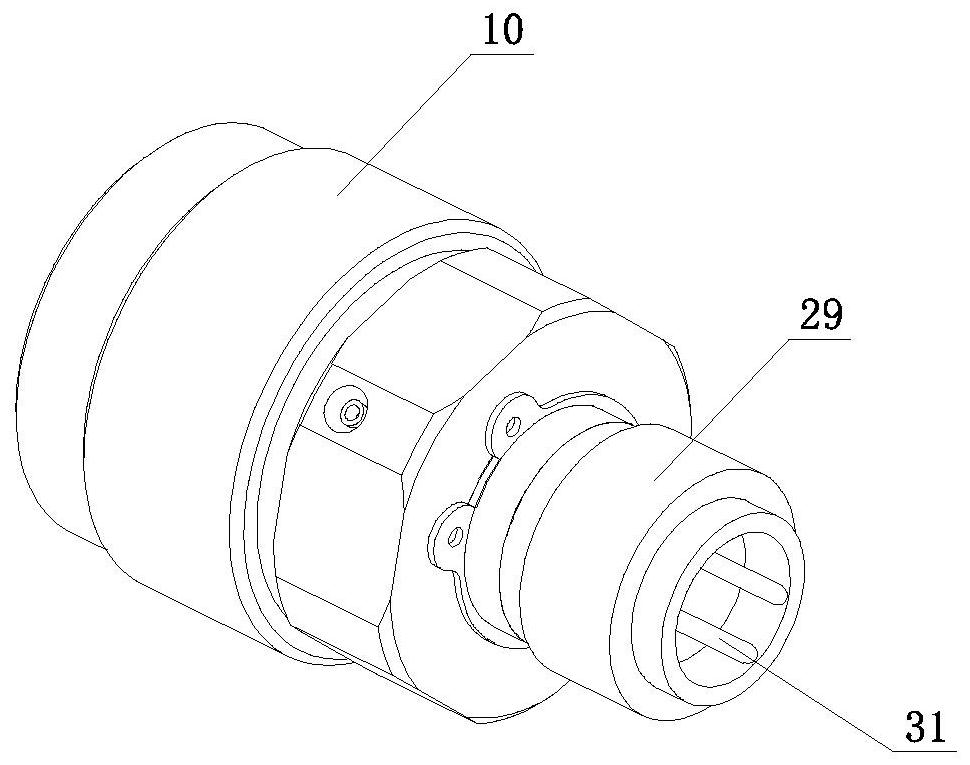

Fuse wire filled multifunctional controllable additive manufacturing device

InactiveCN106624323ARealize filler weldingFilling volume changeElectron beam welding apparatusSlagEngineering

The invention discloses a fuse wire filled multifunctional controllable additive manufacturing device. The fuse wire filled multifunctional controllable additive manufacturing device is composed of an electric control system, a vacuum chamber, an electronic gun, a high voltage power supply, a motion system, a wire feeding system and a particle feeding device. According to the device provided by the invention, metal particle included slag filling, particle included slag and wire rod mixed filling, single wire rod filling, multiple wire rod same material filling and multiple wire rod different material filling can be realized. By adjusting the wire feeding speed, the wire feeding mode and the filling amount of metal particles of each of wire feeding units, the filling material and the filling amount of a weld joint are changed; in an additive manufacturing process, the metal particles can be synchronously fed by virtue of the wire feeding system and the wire feeding system feeds the wires synchronously to realize metal particle included slag filling, and multiple wire rod same material same speed and multiple wire rod different material different speed addition, so that the components of the filling material of the weld joint are differently distributed, thereby realizing continuous processing of a functional gradient material.

Owner:NANJING UNIV OF SCI & TECH

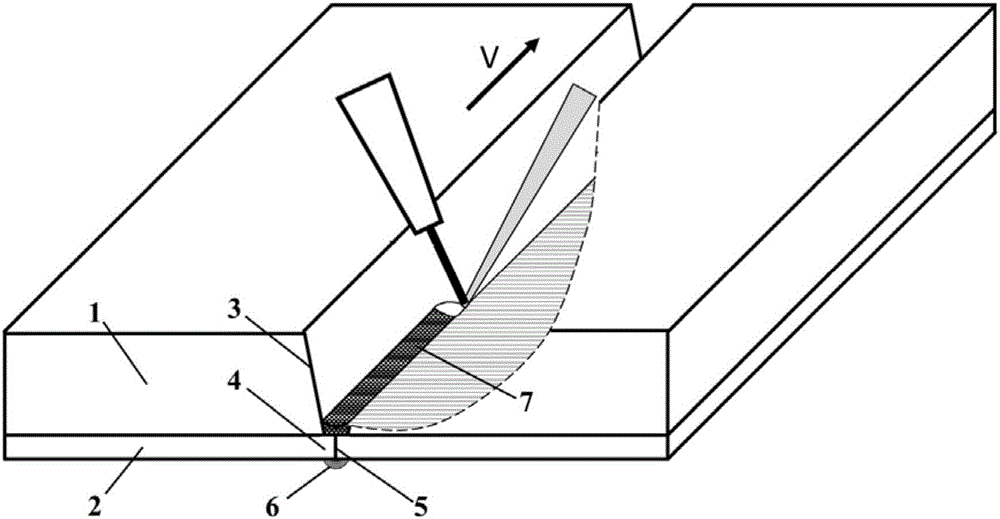

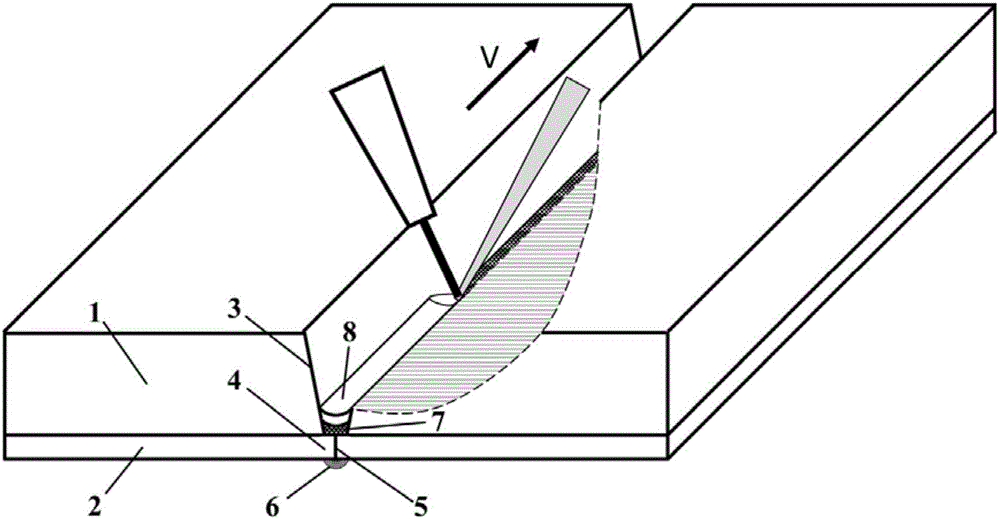

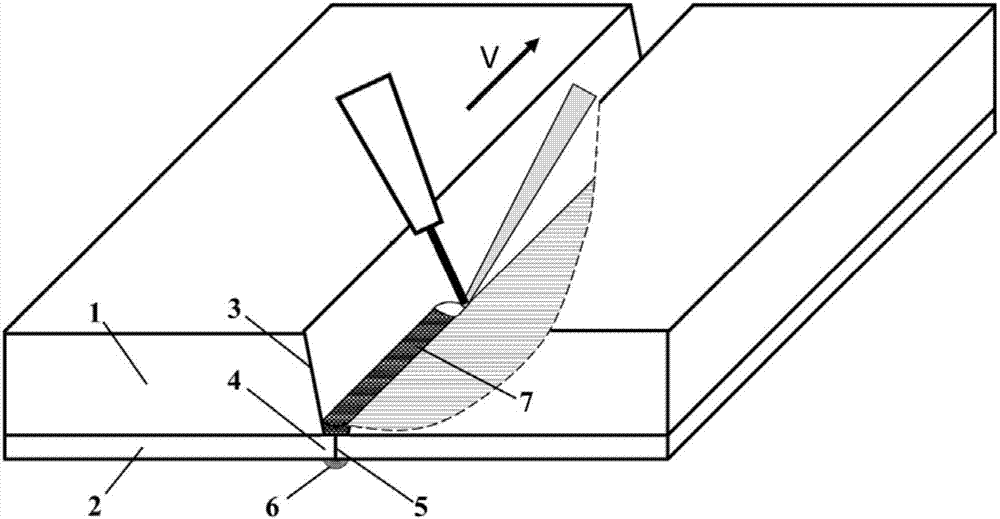

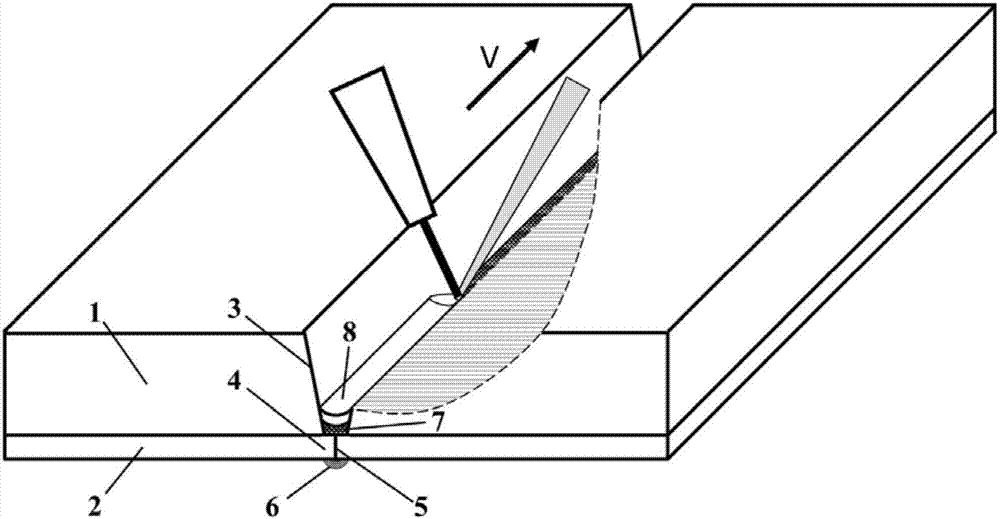

Laser preprocessing wire filling tungsten inert gas (TIG) welding method of titanium alloy and pure aluminum sheets

InactiveCN103084714AReduce lossesPromote homogenizationArc welding apparatusWelding/cutting media/materialsLaser processingTitanium

The invention provides a laser preprocessing wire filling tungsten inert gas (TIG) welding method of titanium alloy and pure aluminum sheets. Firstly, a titanium alloy sheet and a pure aluminum sheet are cleaned. Secondly, a to-be-welded part of the titanium alloy sheet undergoes liquid immersing processing. Thirdly, a laser is utilized to preprocess the to-be-welded surface of the lateral side of the titanium alloy sheet, wherein the surface of the lateral side of the titanium alloy sheet undergoes aluminizing so that a stable middle layer which is easy to combine is formed, and meanwhile, after laser processing, the to-be-welded surface of titanium alloy undergoes self cooling quenching. Finally, a welding wire with specific proportioning is utilized for TIG of titanium and the pure aluminum sheet, and the titanium alloy sheet and the aluminum sheet can be connected through the middle layer by welding. The laser preprocessing wire filling TIG welding method of the titanium alloy and pure aluminum sheets improves plasticity and toughness of a joint, operation is simple, cost is low, and connection effect is good.

Owner:东莞昶能镭射金属科技有限公司

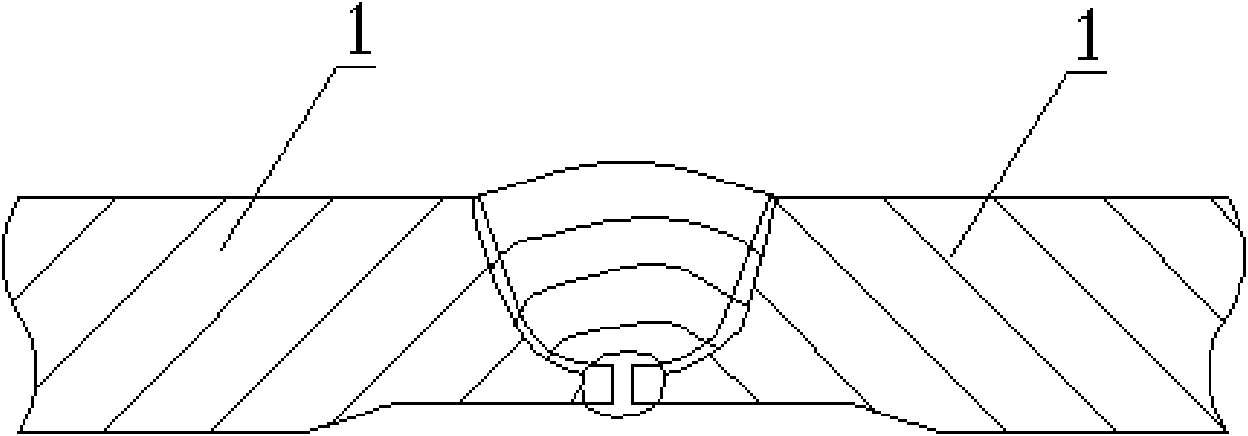

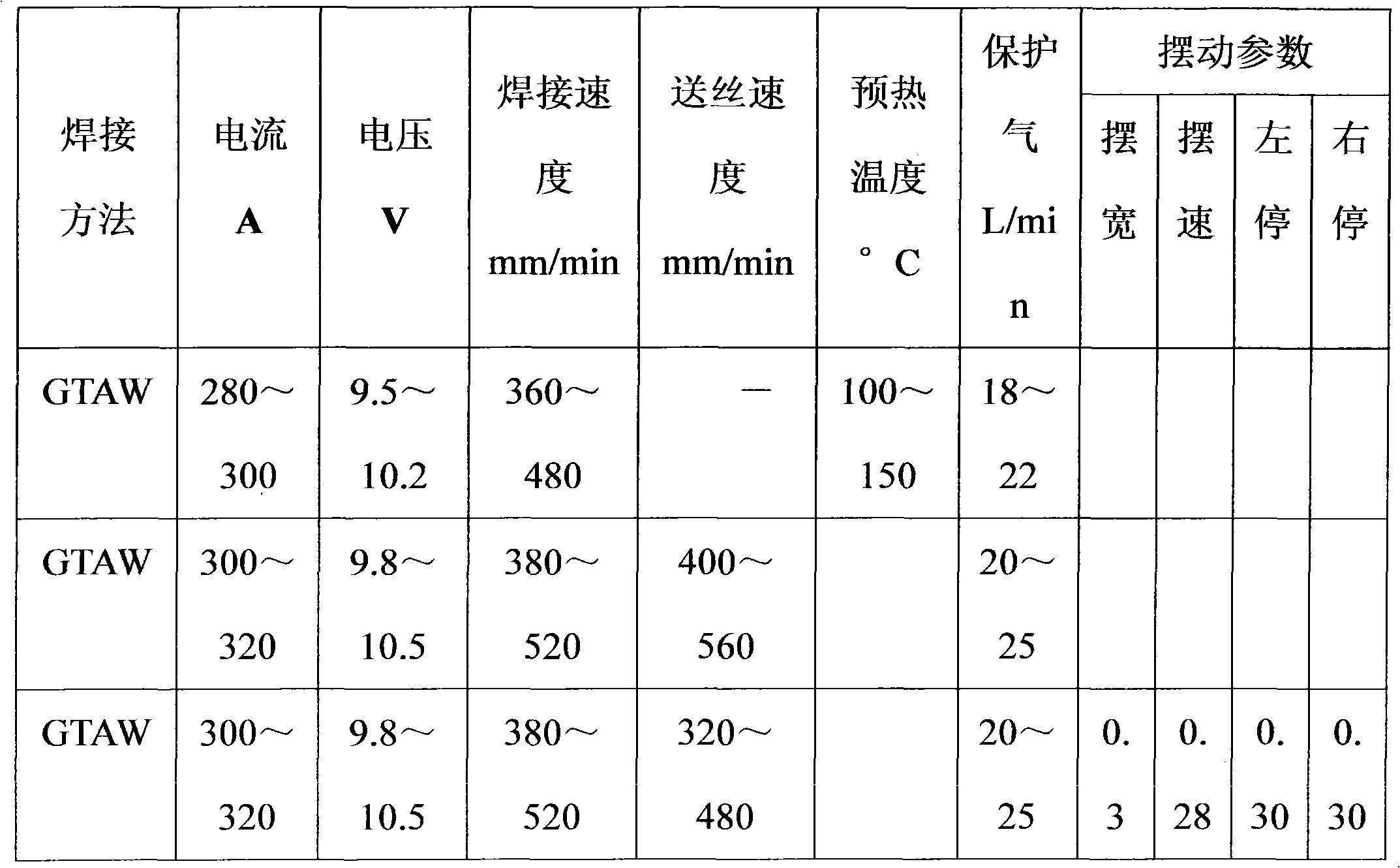

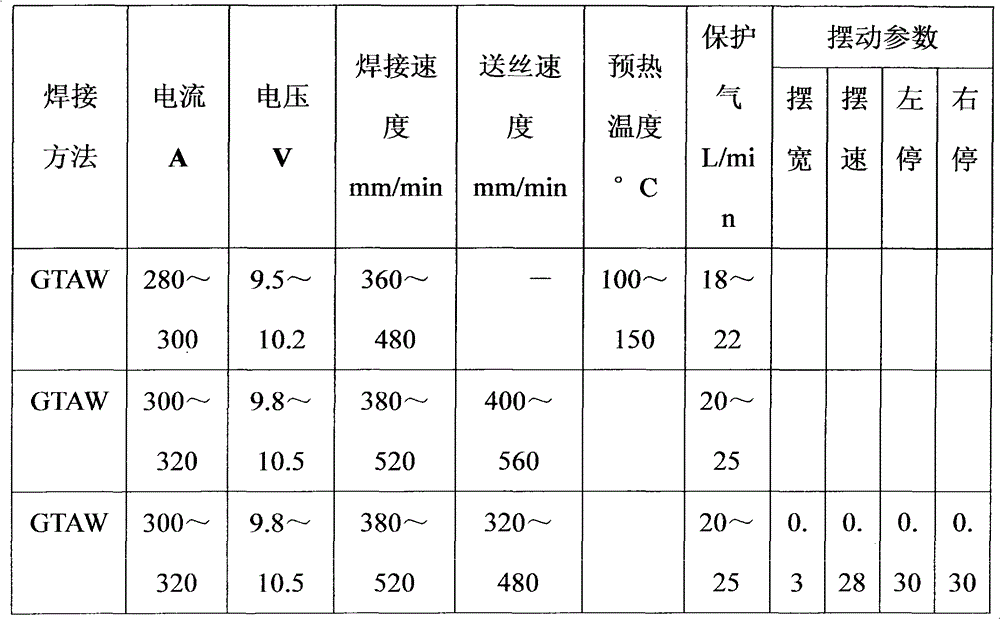

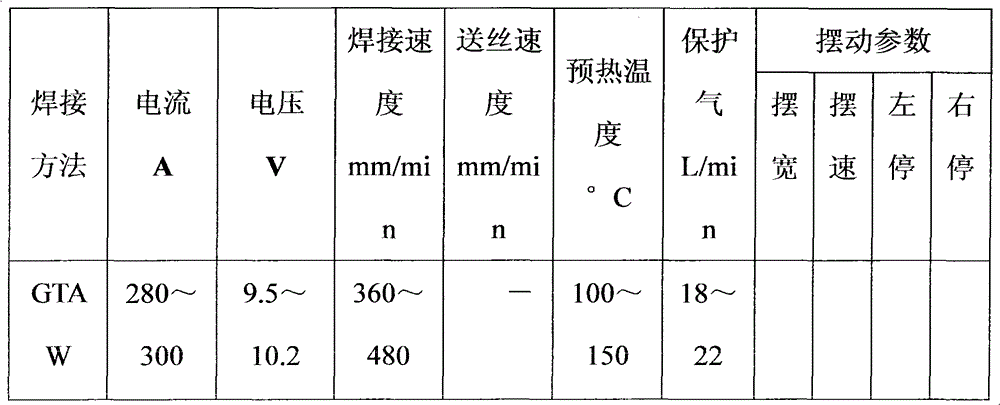

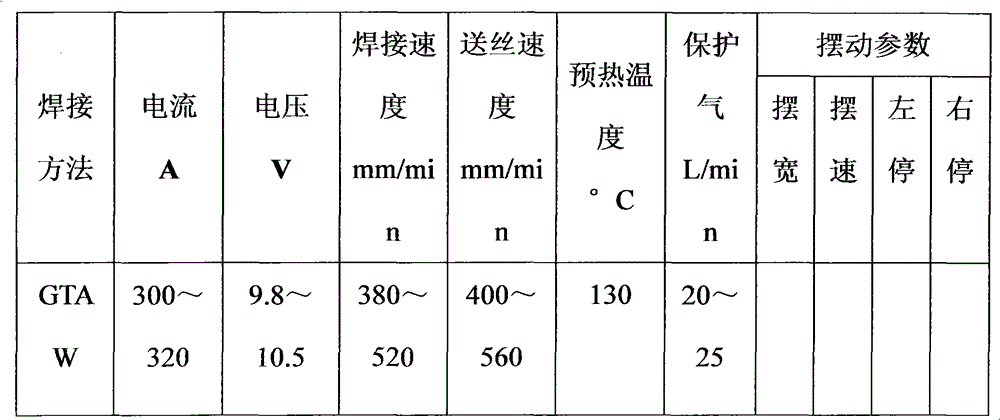

Automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of aluminum alloy butted circular seam

InactiveCN102079004AReduce distortionHigh degree of welding automationArc welding apparatusStainless steel wireAutomation

The invention relates to an automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of an aluminum alloy butted circular seam, which comprises the following steps of: before welding, cleaning greasy dirt at the periphery of a cylinder butted circular seam with acetone; removing an oxide film in the periphery of the cylinder butted circular seam by a stainless steel wire wheel; preheating before welding; debugging a control panel for controlling welding current and voltage, welding speed and wire feeding speed to match in real time; and welding by adopting an automatic TIG machine, wherein a welding wire is not added for back formation when a first layer is welded, a welding wire is added for filling when a second layer is welded, a welding wire is added when a third layer is welded, and a welding gun swings for cover surface forming. The automatic TIG welding method has the advantages of simple equipment, convenience in operation, stable welding, high welding speed, low production cost, fewer filled welding wires, fewer welding layers, small deformation, no need of correction after welding, attractive formed appearance and high welding seam quality and realizes welding automation.

Owner:陕西国德电气制造有限公司

Laser wire filling and butt welding method for titanium-steel composite plate with T2 red copper serving as transition layer

ActiveCN106112263AAvoid it happening againMitigation of Thermal Stress MismatchLaser beam welding apparatusButt weldingTitanium

The invention discloses a laser wire filling and butt welding method for a titanium-steel composite plate with T2 red copper serving as a transition layer. The method comprises the following steps: (1) machining two titanium-steel composite plates to be subjected to butt welding; (2) butting and assembling the two titanium-steel composite plates to be subjected to butt welding; (3) performing laser backing welding on a gap between titanium plates of the two titanium-steel composite plates to be subjected to butt welding to form a laser backing welding line; (4) covering the lower surface of the laser backing welding line with titanium welding wires by adopting laser wire filling welding to form a titanium wire welding line, and overlaying a layer of T2 red copper at the bottom of a V-shaped groove to form a transition layer welding line; (5) overlaying a first layer of steel welding bead on the upper surface of the transition layer welding line; and (6) overlaying a second layer of steel welding bead on the upper surface of the first layer of steel welding bead by adopting the laser wire filling method. According to the method, the problems of high welding heat stress and serious mismatch of heat stress between metal layers due to the formation of brittle intermetallic compounds in the butt welding process of the titanium-steel composite plate can be effectively solved.

Owner:XI AN JIAOTONG UNIV

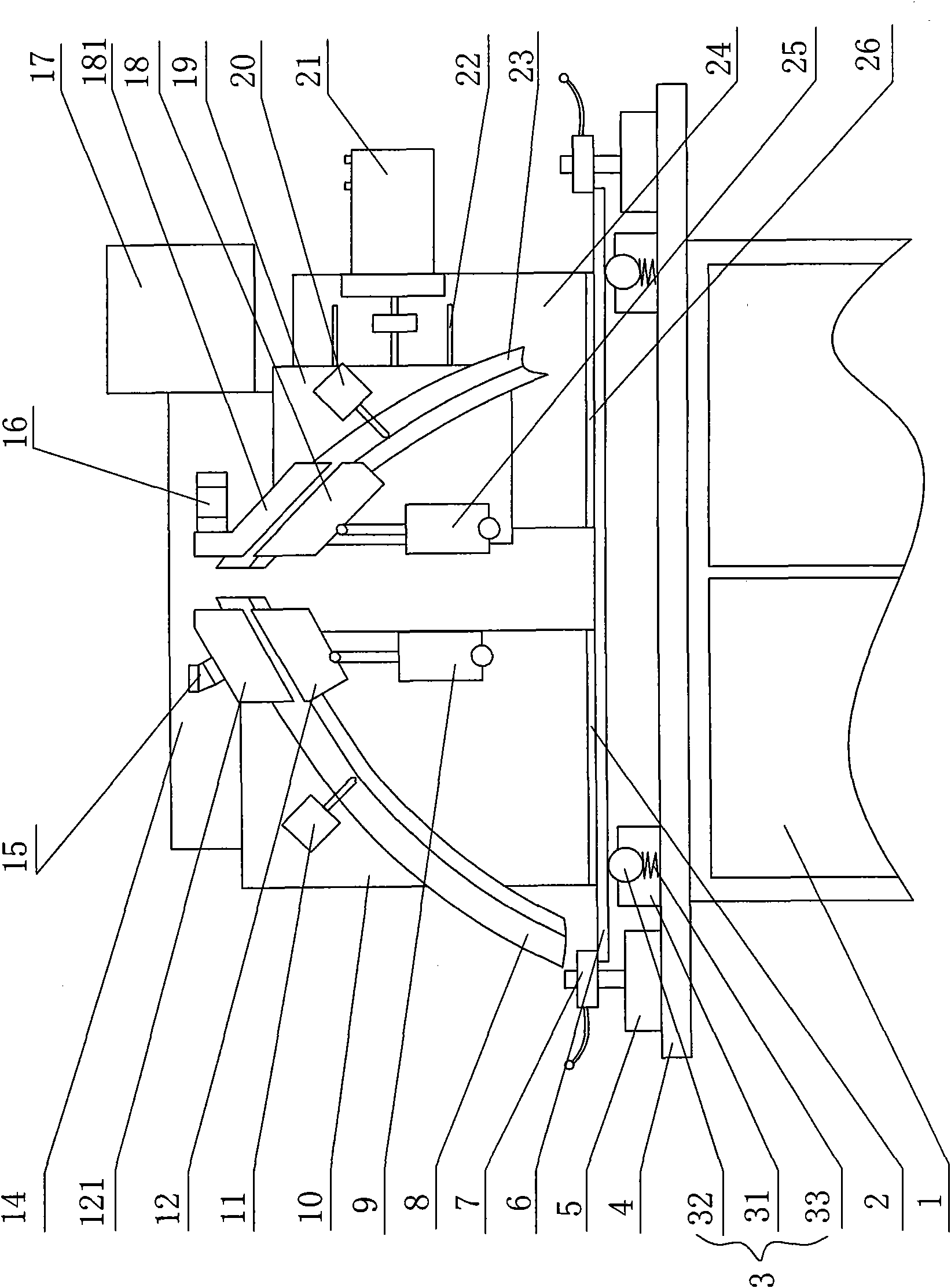

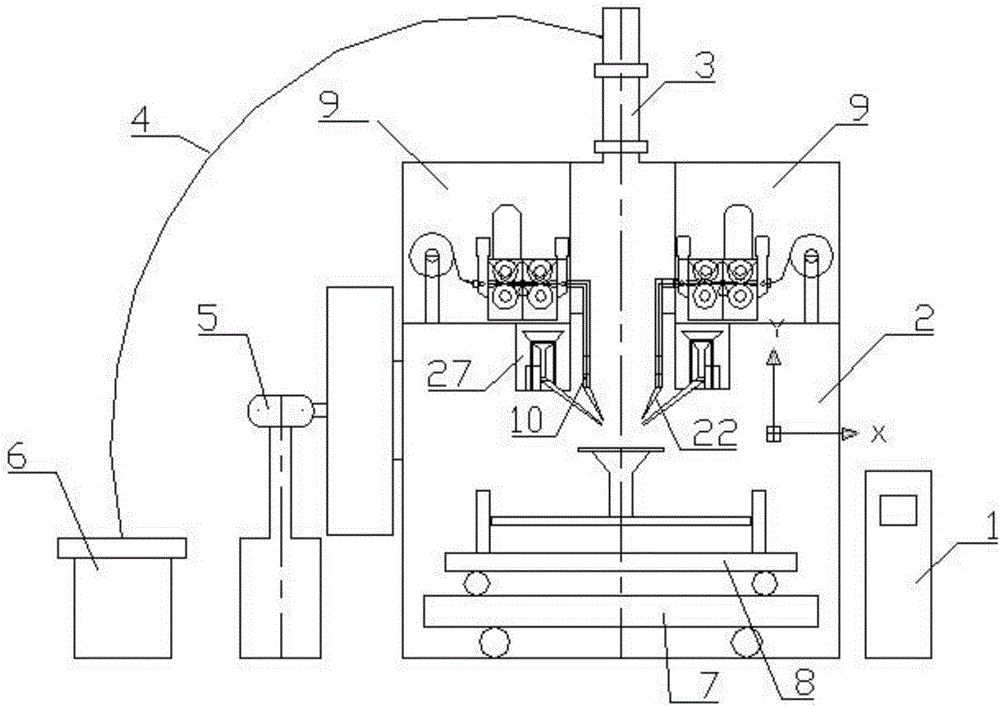

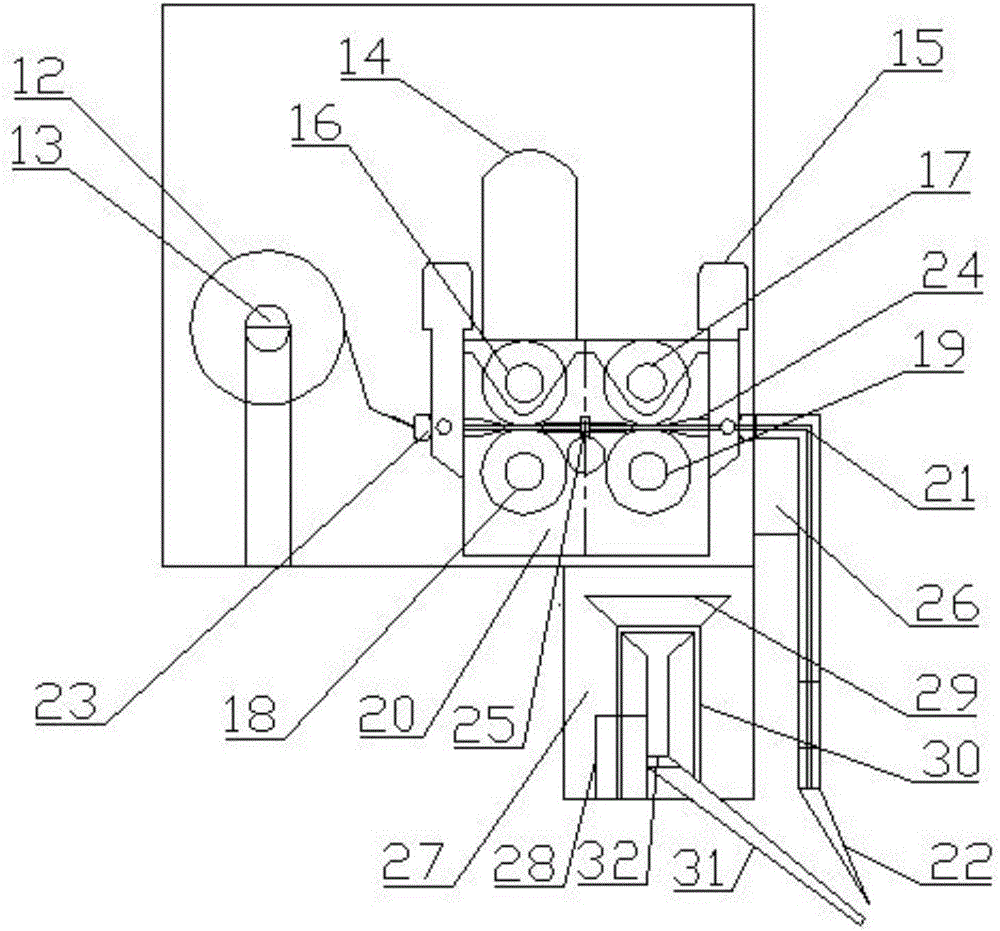

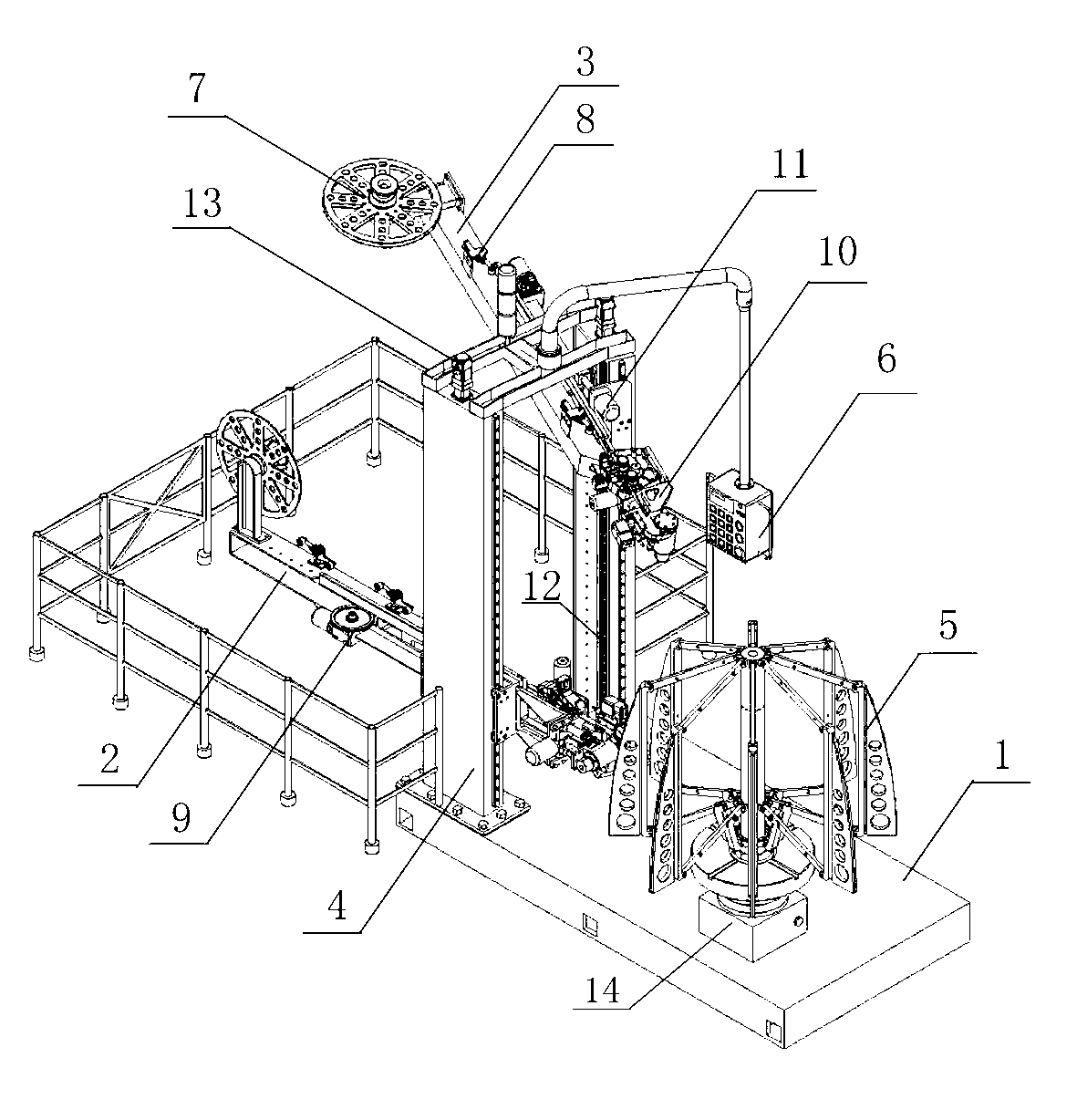

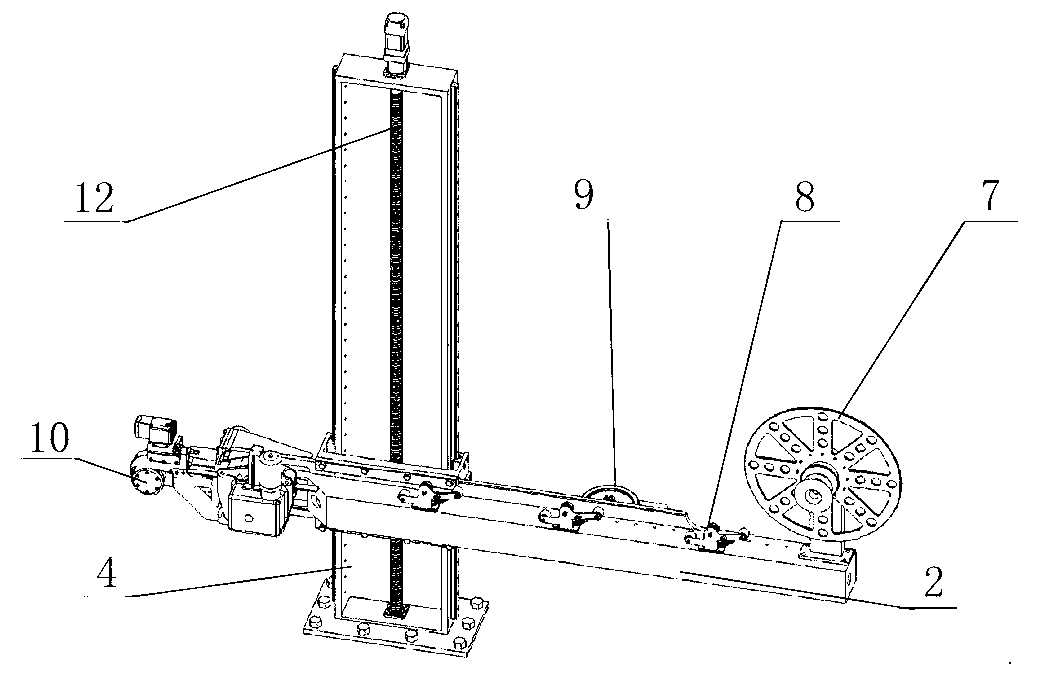

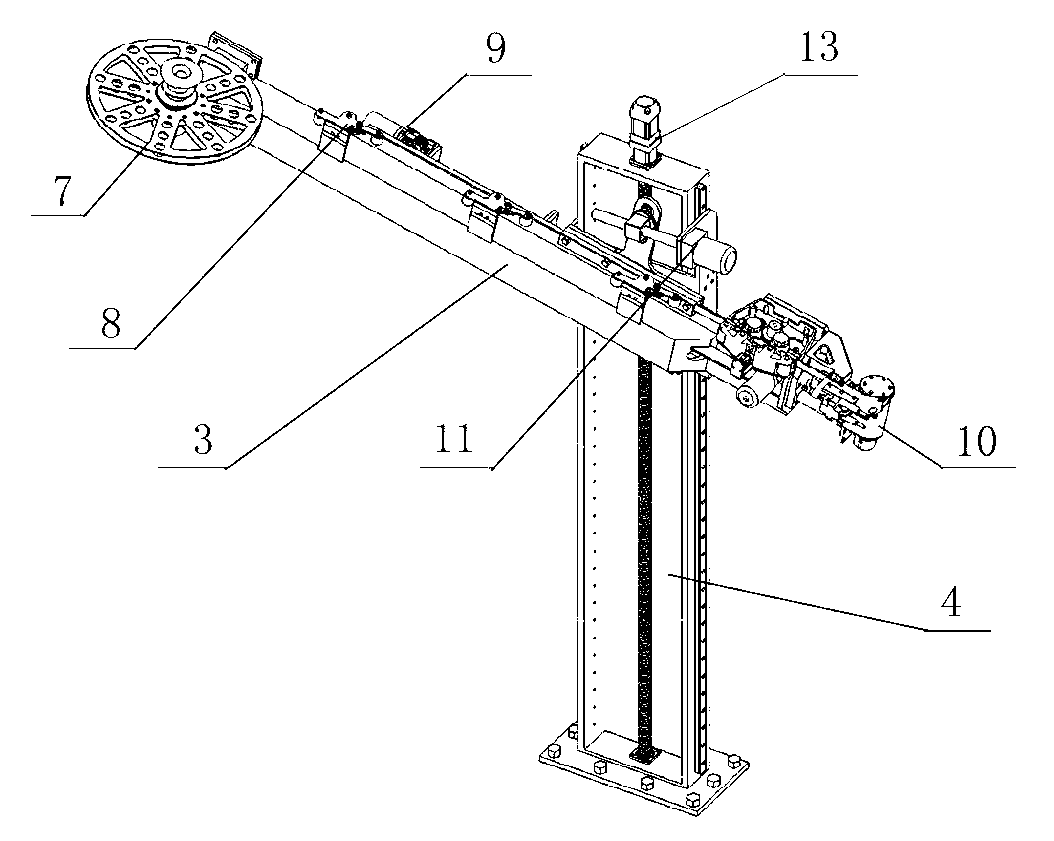

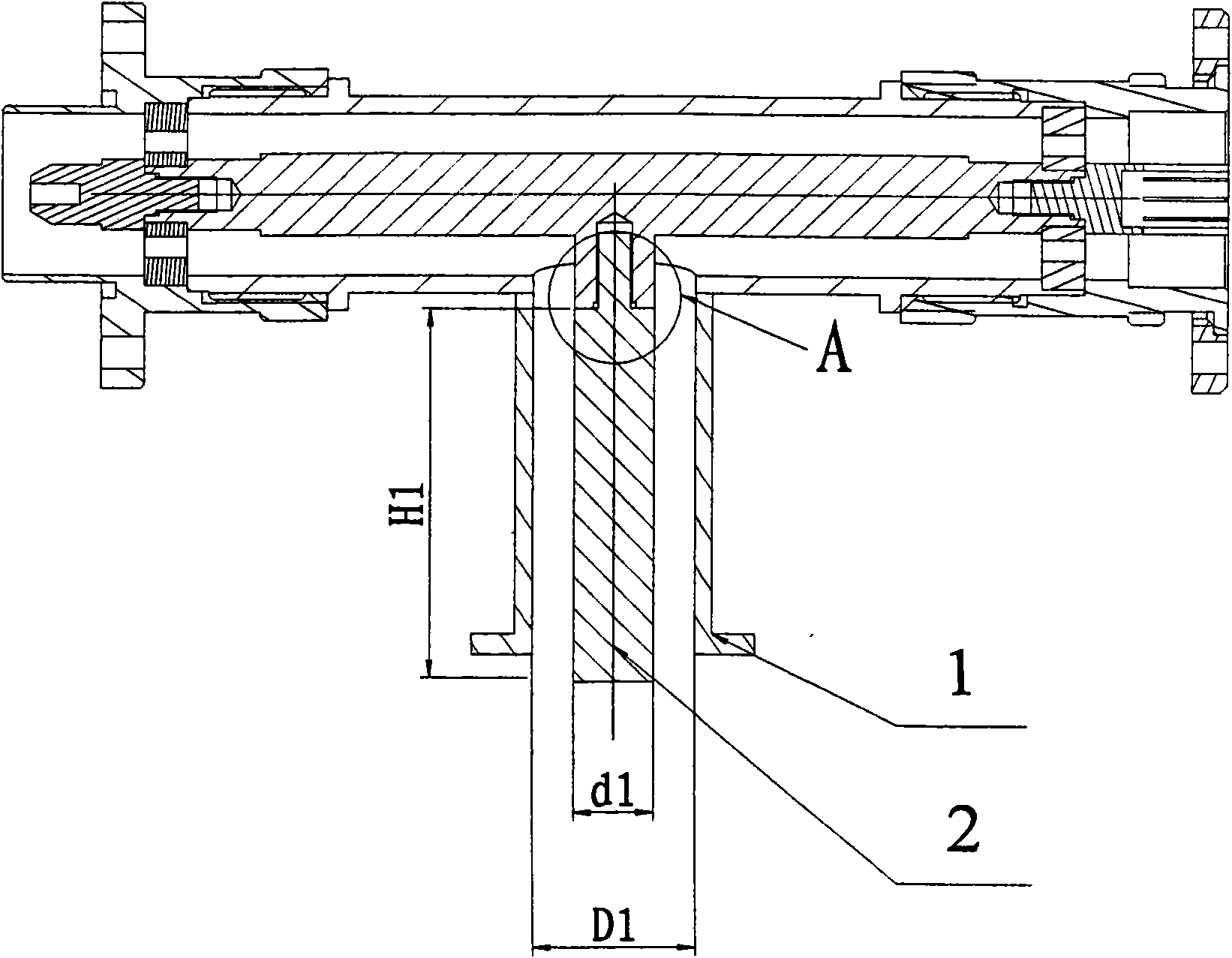

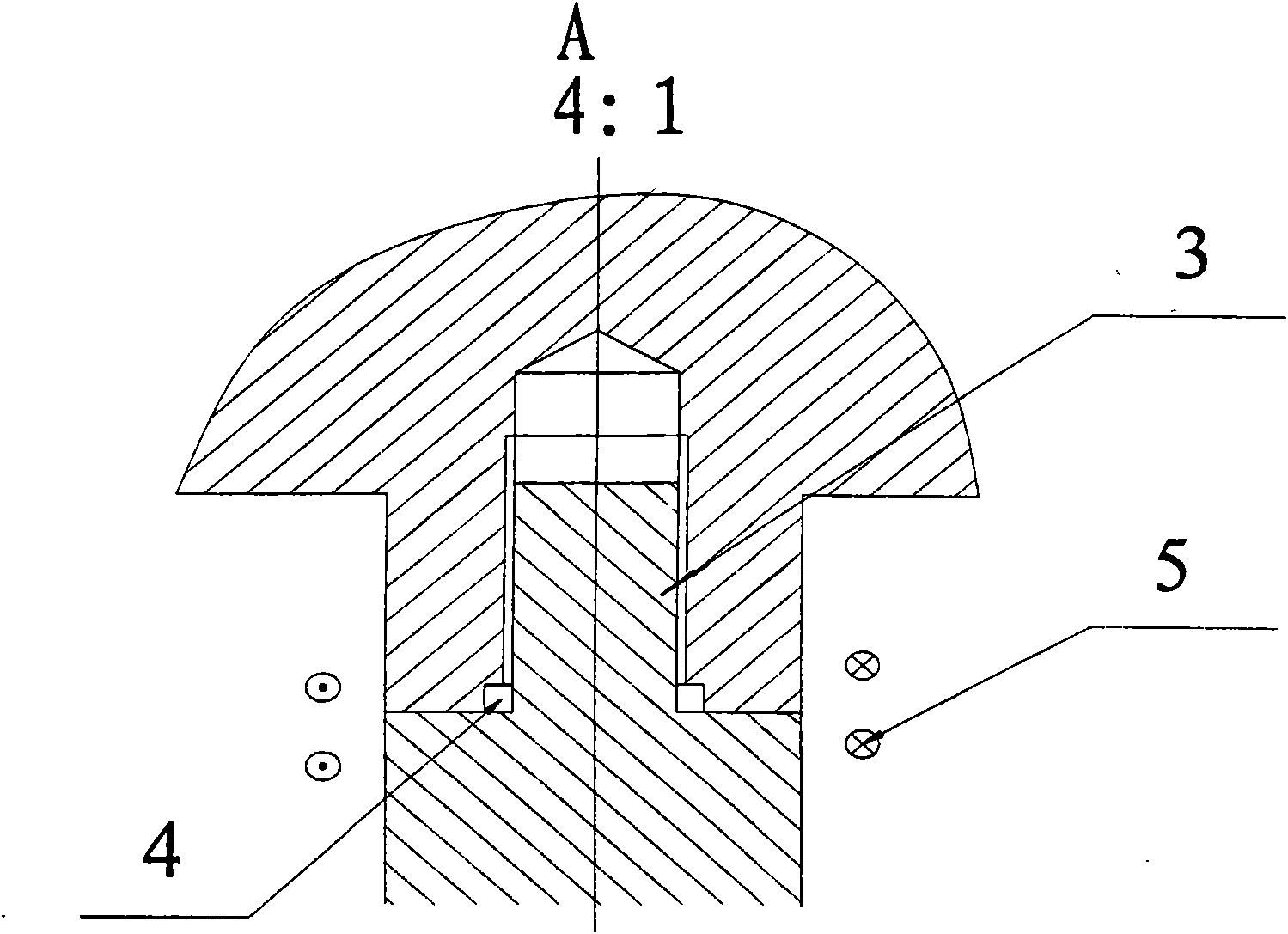

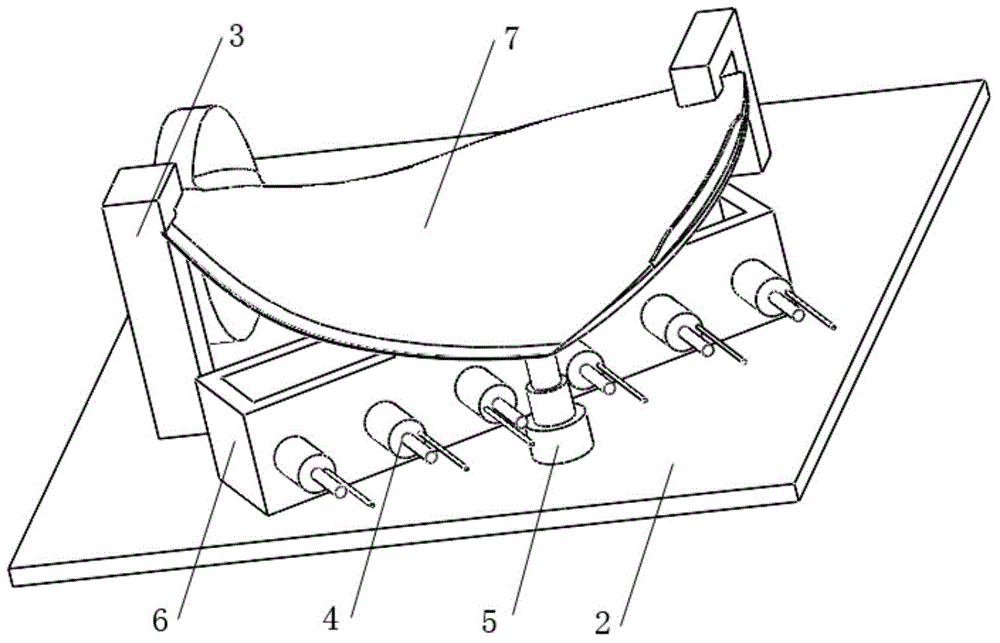

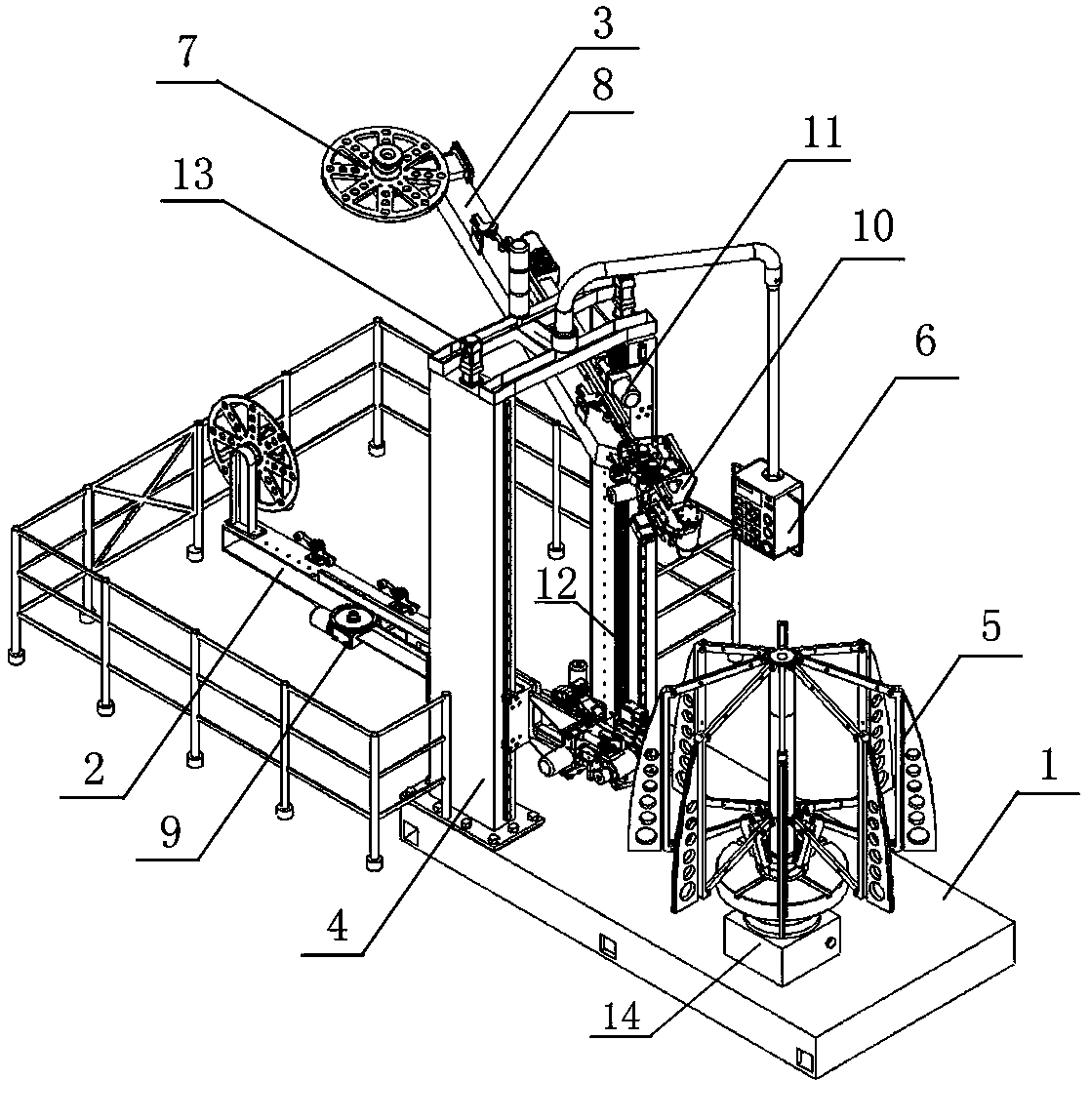

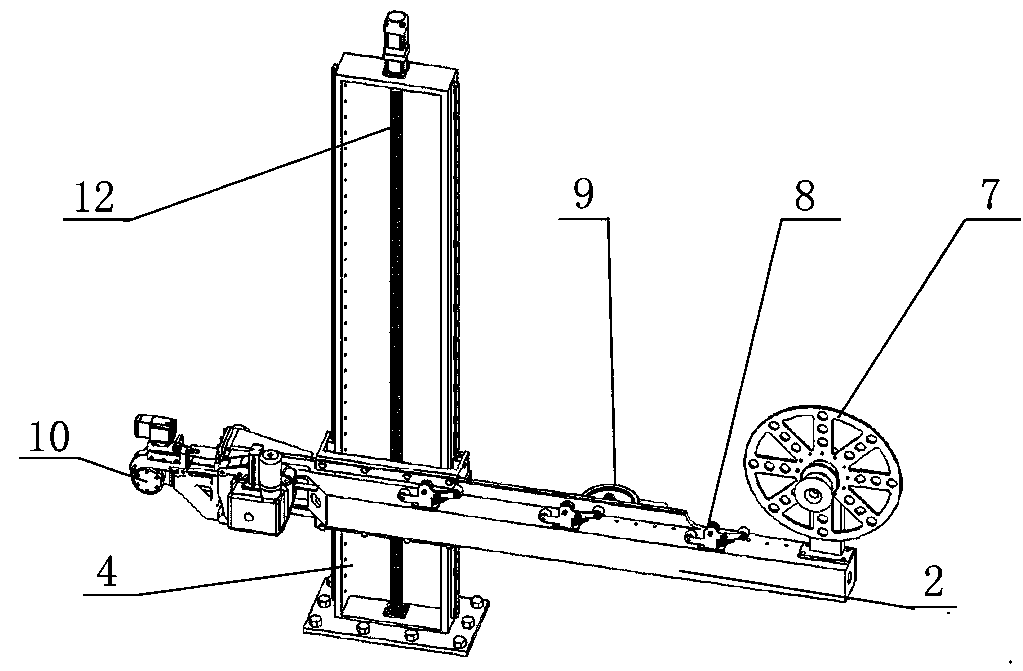

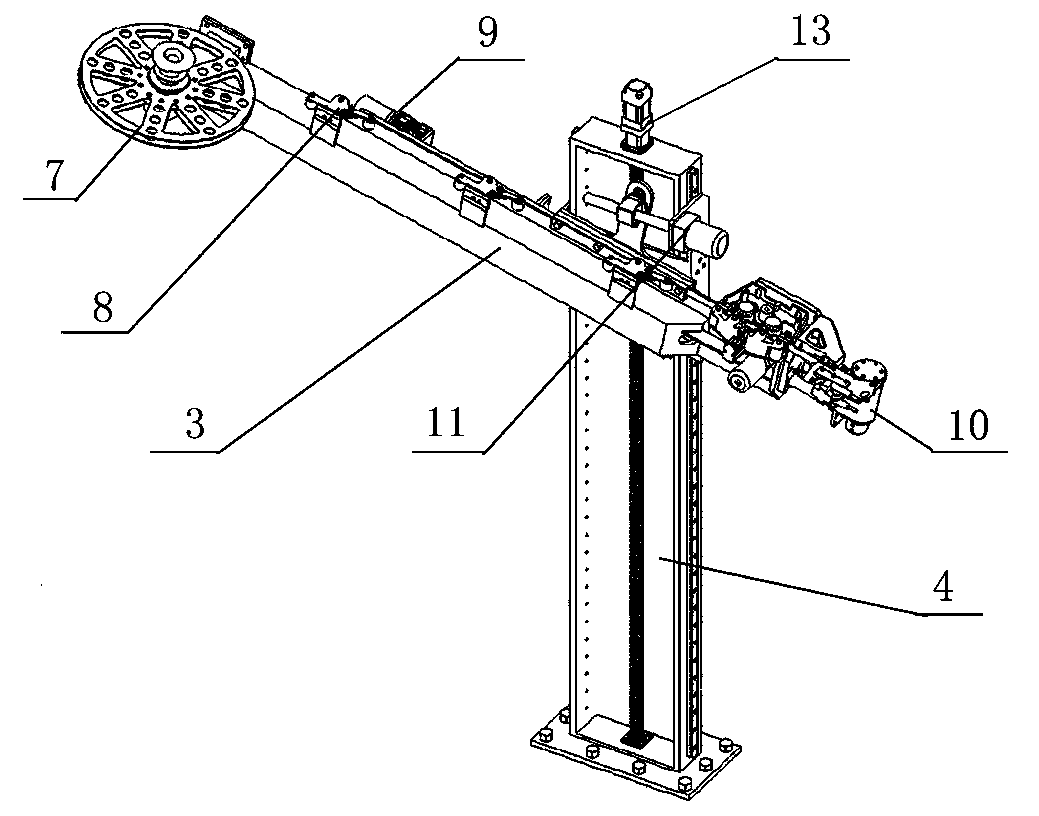

Rocket engine jet pipe brazing strip automatic rolling point welding machine and rolling point welding process

ActiveCN103192153ARealize full mechanizationFully automatedMetal working apparatusSolder feeding devicesEngineeringSpot welding

The invention relates to a rocket engine jet pipe brazing strip automatic rolling point welding machine and a rolling point welding process. The automatic rolling point welding machine comprises a body base, a rotating workbench, a tensioning pattern, a gate type support, a brazing strip disc, a controller, an angle adjusting mechanism, a longitudinal rolling point welding operating mechanical arm, an annular rolling point welding operating mechanical arm and the like. By the automatic rolling point welding machine, mechanical, automatic and intelligent longitudinal brazing strip and annular brazing strip rolling point welding are achieved on jet pipe components, welding efficiency is high, welding quality is good, welding point distances are adjustable, rolling point welding speed can be reach 3 points / second, and welding speed can reach more than 5 meters / second. The automatic rolling point welding machine has no noise, arc, splash, radiation and the like during welding, and is high in reliability, simple to operate, easy to maintain, and suitable for welding of rocket engine spraying pipes with the diameters of 260-1500mm.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

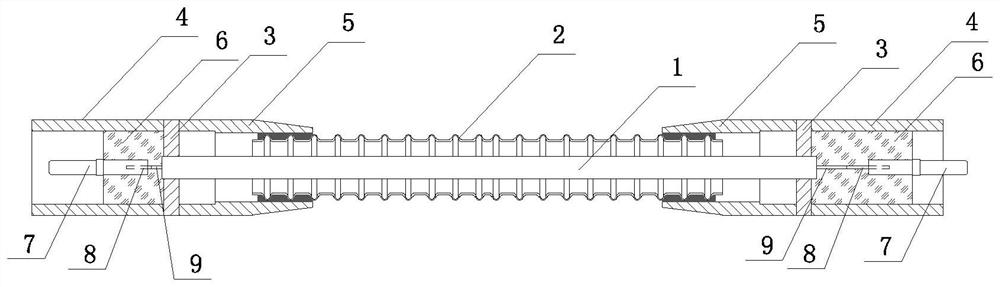

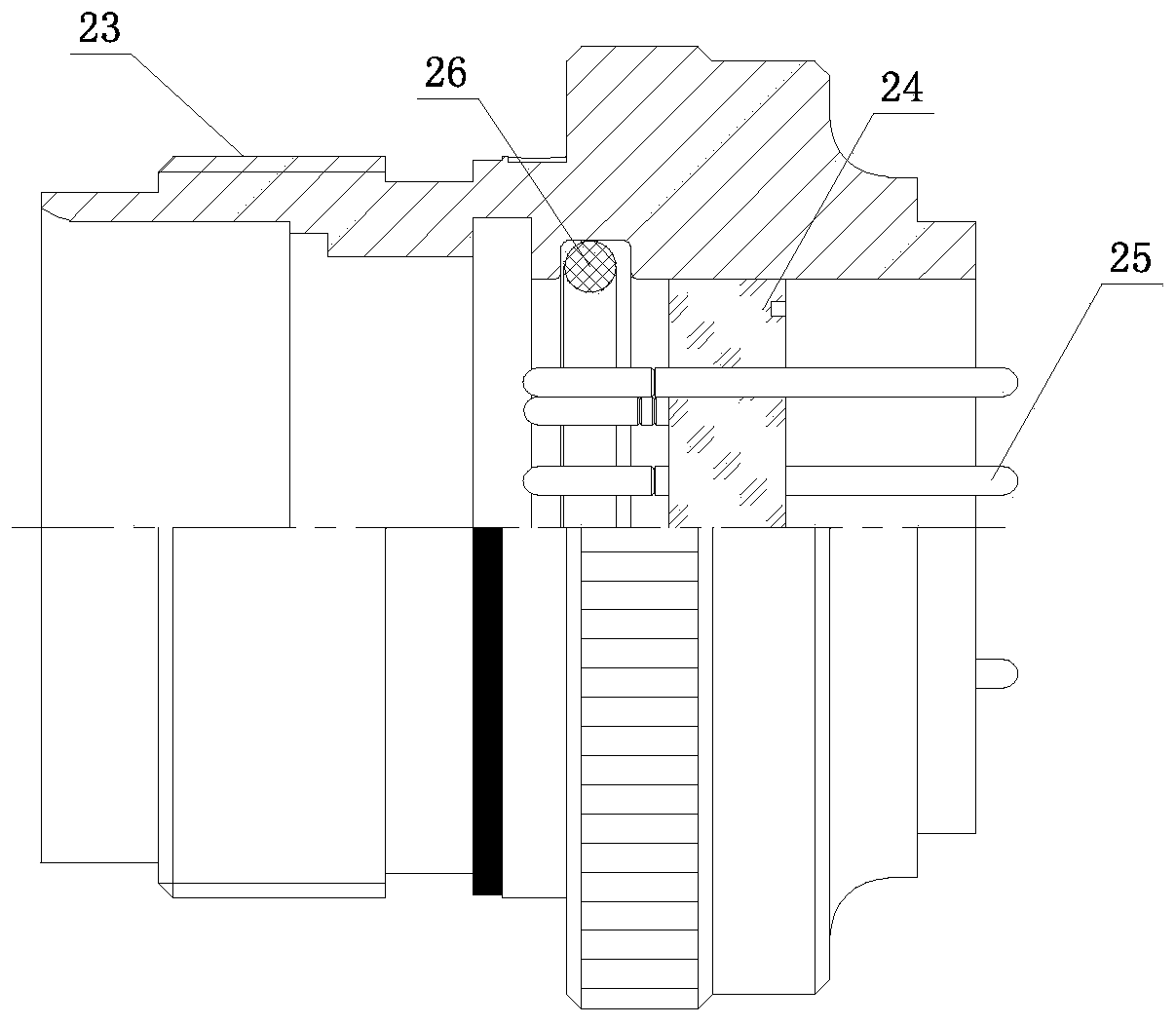

High-frequency induction brazing method for connection of deep cavity inner conductor of coaxial transmission line

ActiveCN101557066AImprove weld qualityGuaranteed long-term reliabilityLine/current collector detailsSoldering apparatusWeld seamSolder paste

The invention relates to a high-frequency induction brazing method for the connection of a deep cavity inner conductor of a coaxial transmission line. The coaxial transmission line consists of an inner conductor and a hollow outer conductor. The inner conductor is connected with two conductors to form a T shape or an L shape and the brazing method comprises the following steps: the connection ends of the two conductors are respectively provided with a threaded hole and a screw rod; a tool withdrawal groove at the joint of the threaded hole and the screw rod is provided with welding wires or coated with solder pastes; and the two conductors are screwed to lead an induction coil to be sleeved at the end joints of the deep cavity inner conductor or the joints between a supplementary conductor and the inner conductor. The welding conditions are as follows: the power, power rate and heating and electrifying time of a high frequency generator are respectively 5KW, 30-60 percent and 6-80 seconds. In the induction heating brazing, the local temperature of the weld joint of a workpiece can meet the requirement of the brazing temperature rapidly and solders are spread evenly. Compared with the integrative heating method, the heat absorbed by the workpiece has small heat input and centralized heat. The high-frequency induction brazing method utilizes the internal thermal conductance of the workpiece to cool water or assist water cooling, thereby rapidly realizing the brazing connection of the connection ends and high quality of weld seams.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

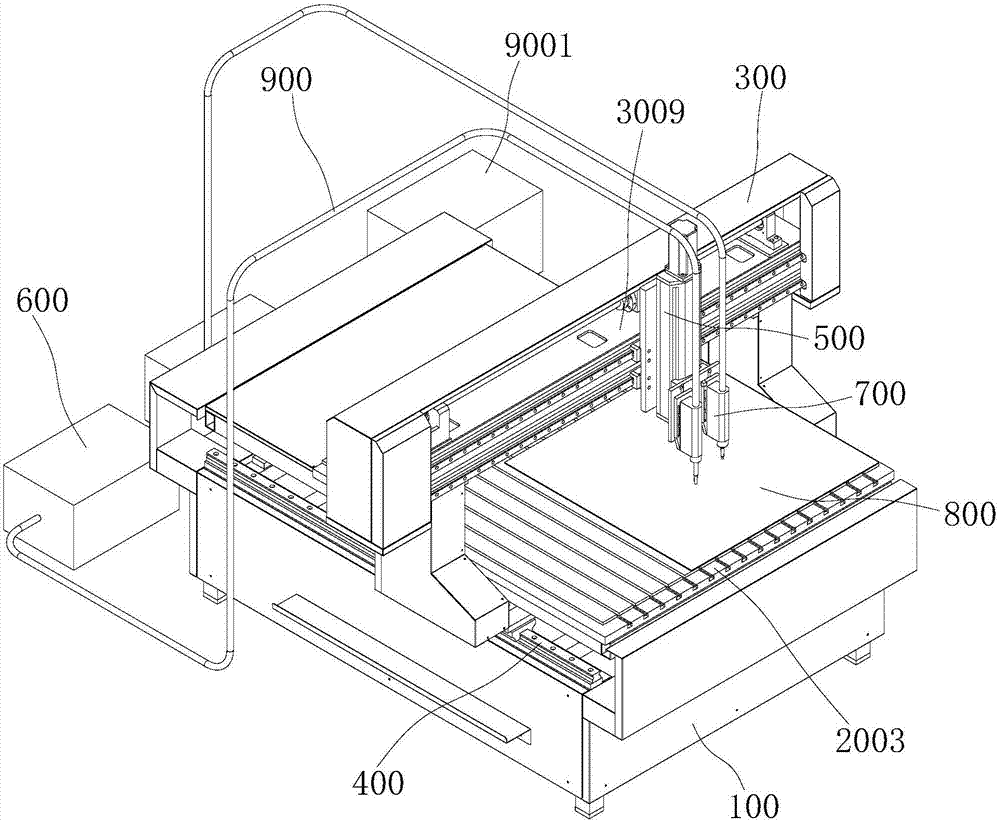

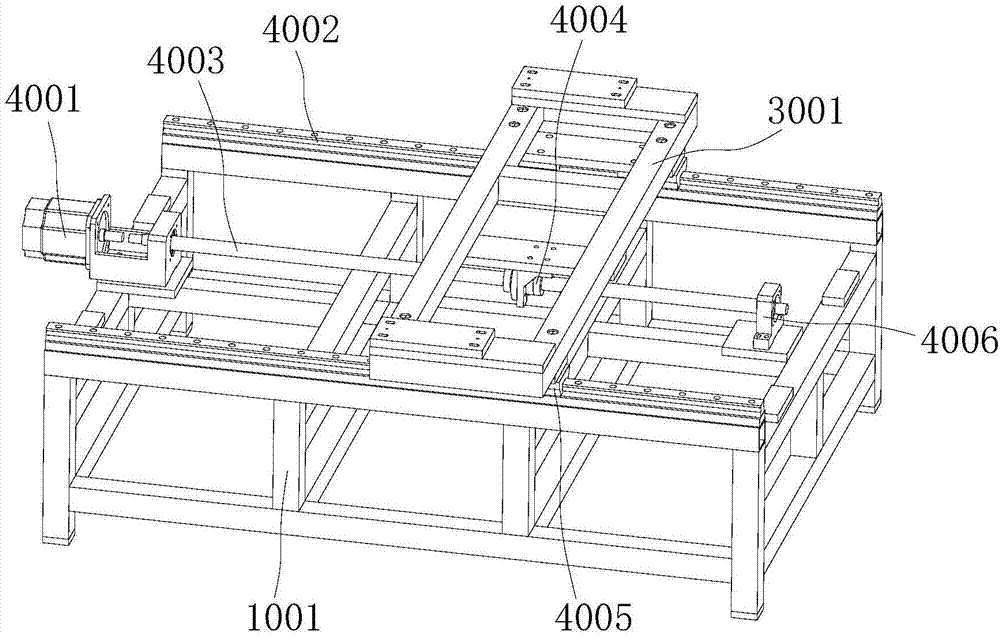

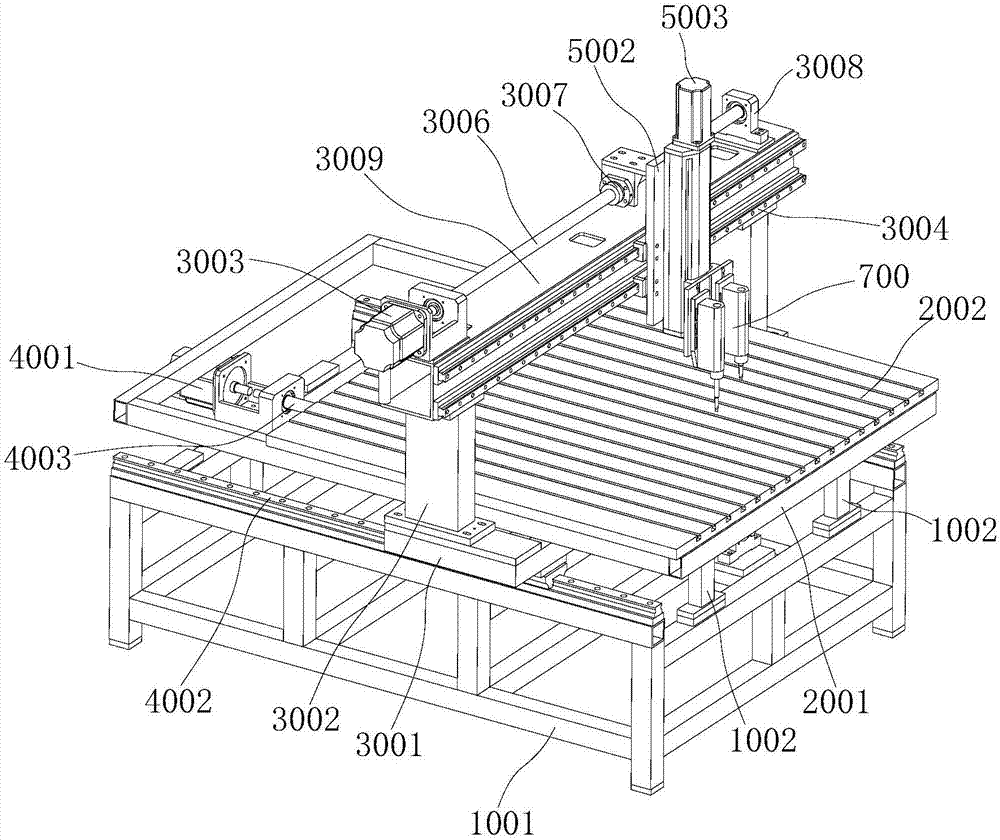

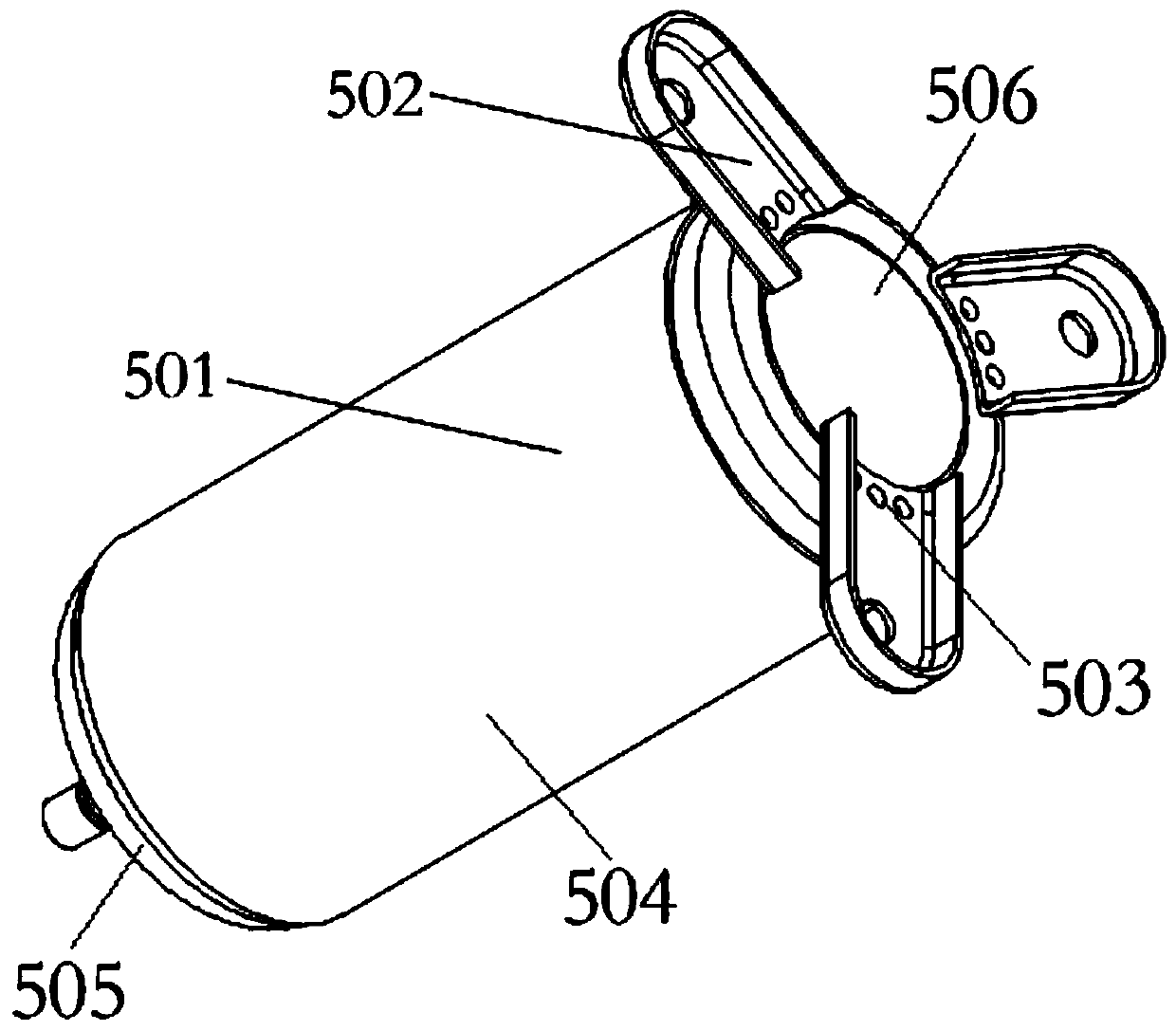

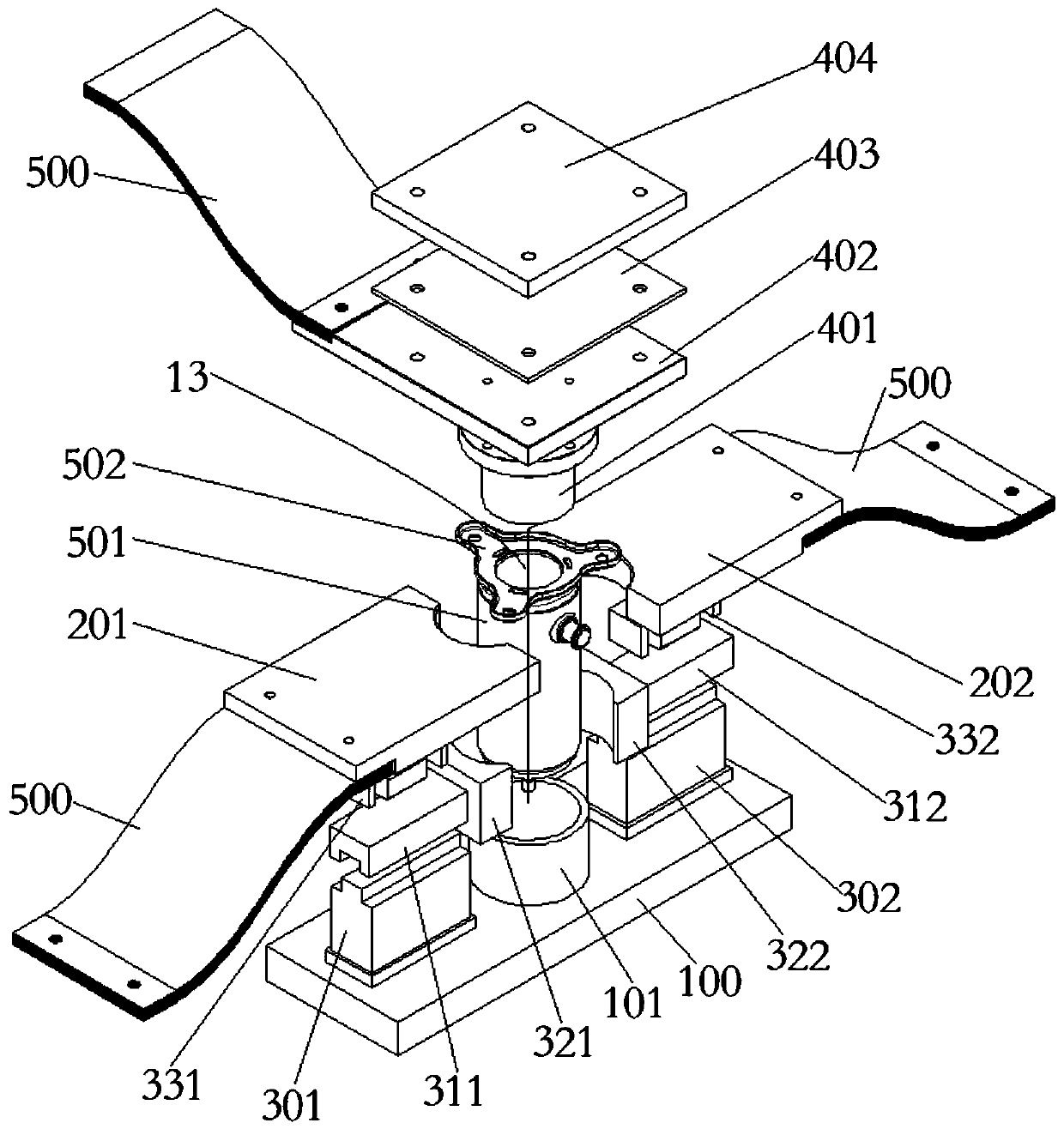

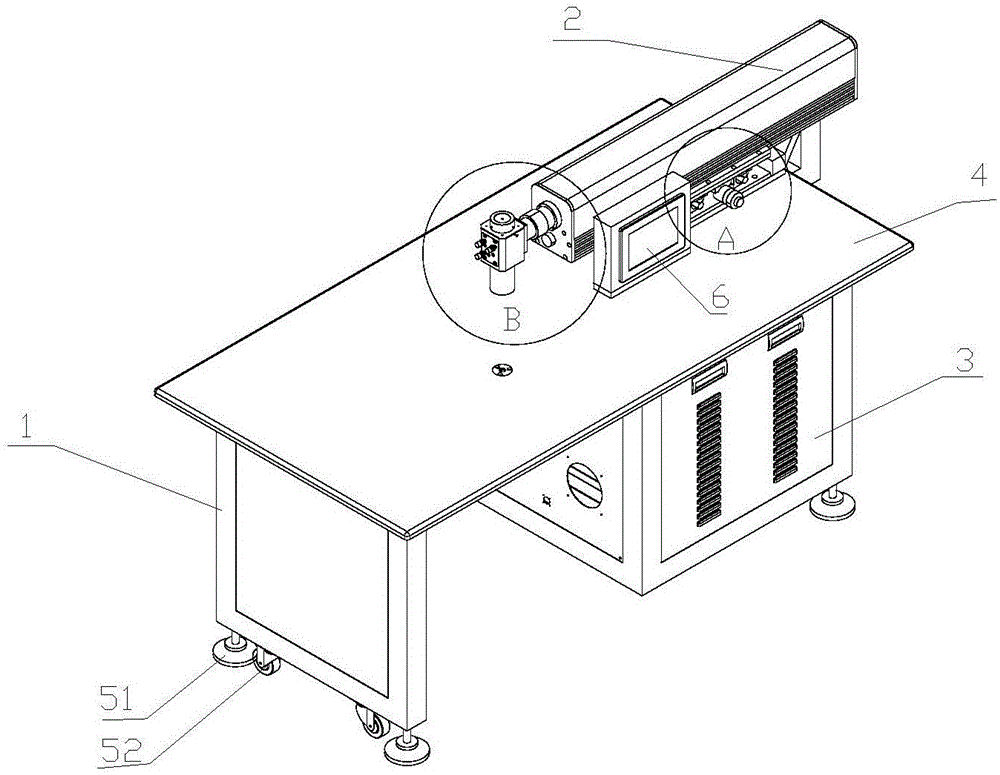

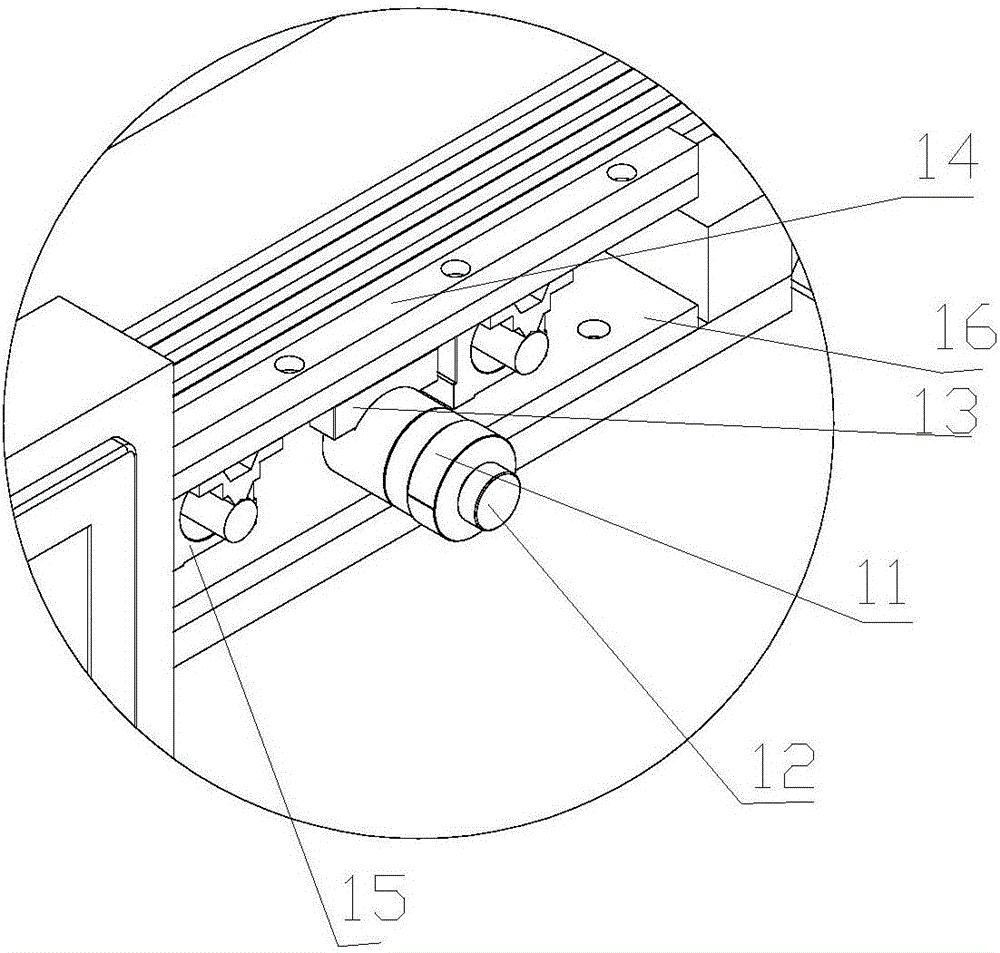

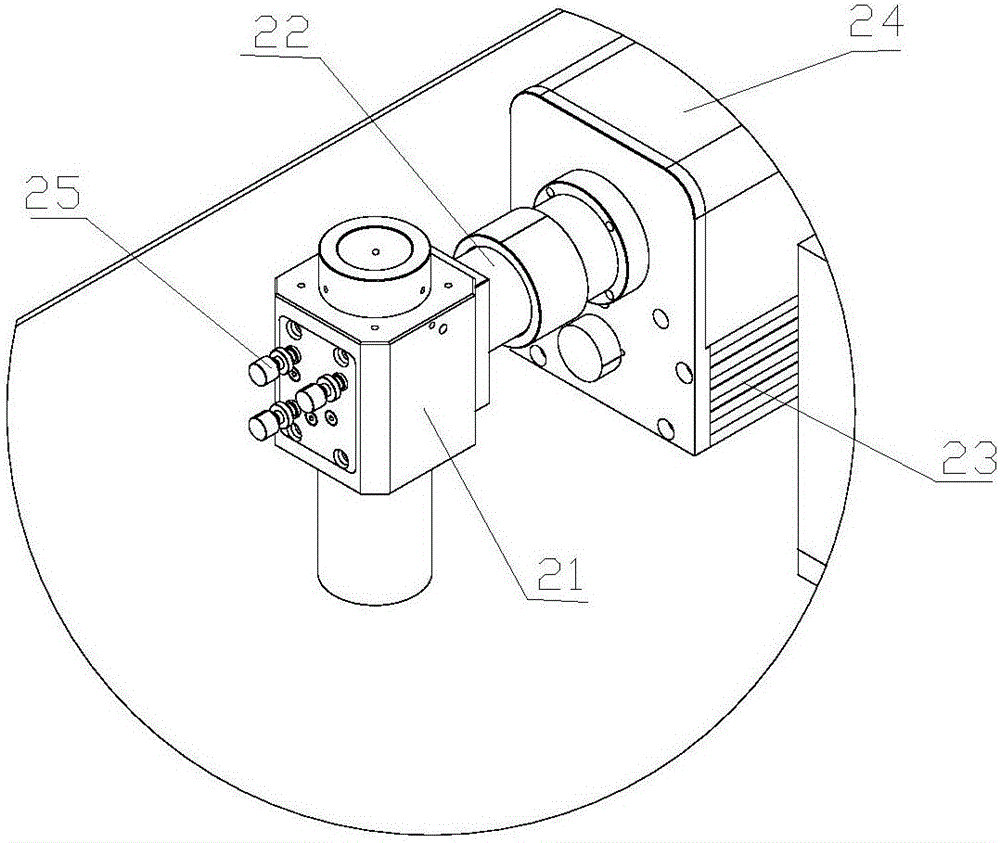

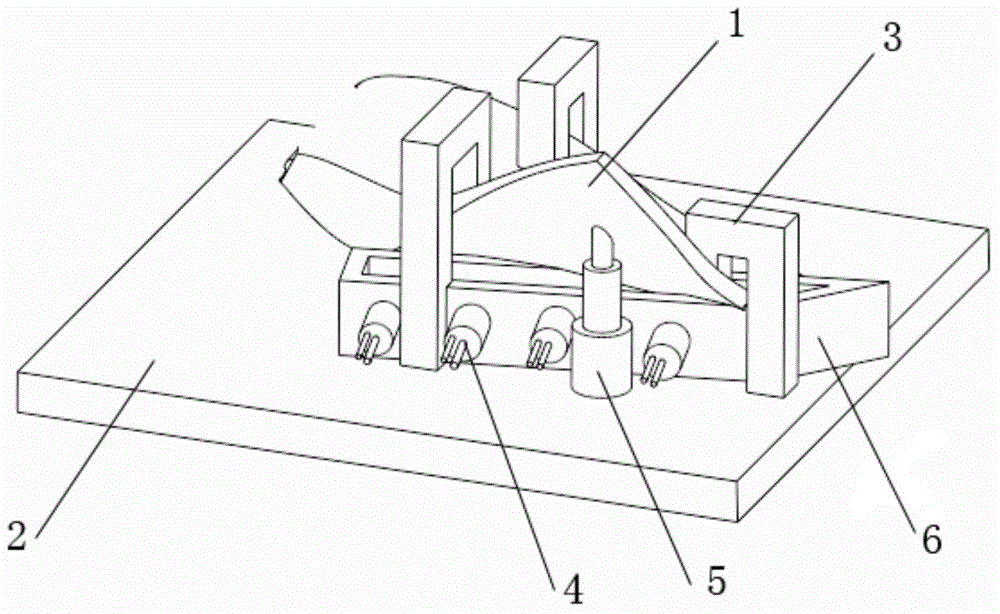

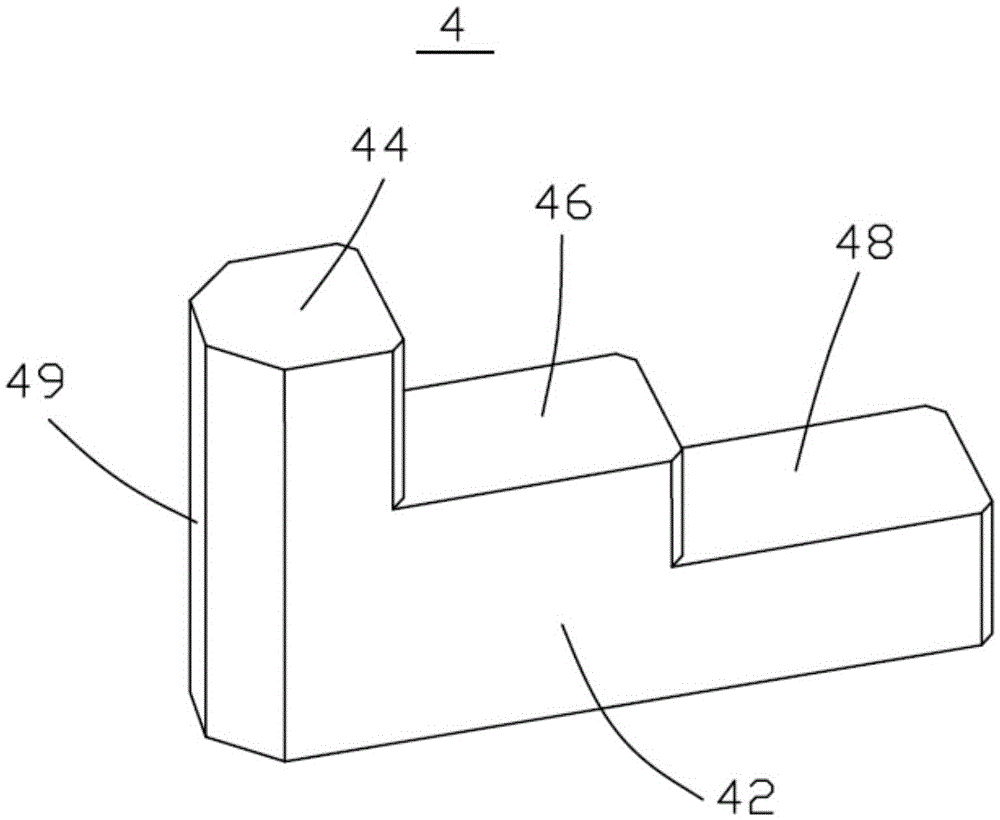

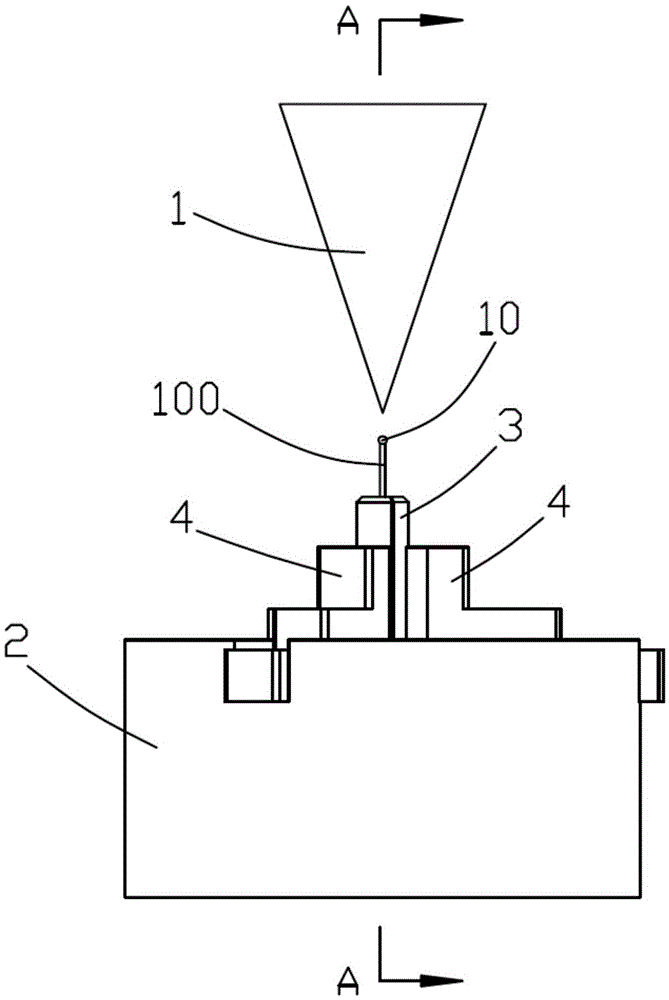

CNC stud welding dedicated machine

ActiveCN107322144ASmall welding heat affected zoneNo deformationWelding accessoriesManufacturing cost reductionHeat-affected zone

The invention discloses a CNC stud welding dedicated machine and relates to the technical field of welding machines. The CNC stud welding dedicated machine comprises a base, a working platform, an X-axis moving mechanism, a Y-axis moving mechanism, a plurality of Z-axis moving mechanisms, a nail feeding mechanism and a plurality of welding gun mechanisms, wherein the working platform is arranged on the base; sheet metal parts are arranged on the working platform; the Y-axis moving mechanism is arranged on the base; the X-axis moving mechanism comprises a cross beam; the cross beam is arranged on the Y-axis moving mechanism; the Z-axis moving mechanisms are arranged on the X-axis moving mechanism side by side; a plurality of welding gun mechanisms are mounted on each of the Z-axis moving mechanisms; each of the welding gun mechanisms comprises a gun cylinder and a welding gun chuck; and the nail feeding mechanism is positioned at the rear of the base and is connected with the gun cylinder of the welding gun mechanism through a nail feeding tube. The CNC stud welding dedicated machine has the following beneficial effects: welding heat affected zones on the welded sheet metal parts are small, and the sheet metal parts are free of deformation and color change, so that the welding quality is improved, the yield is greatly increased, the production efficiency of welding is improved and the manufacturing cost is reduced.

Owner:深圳市迈思克科技有限公司

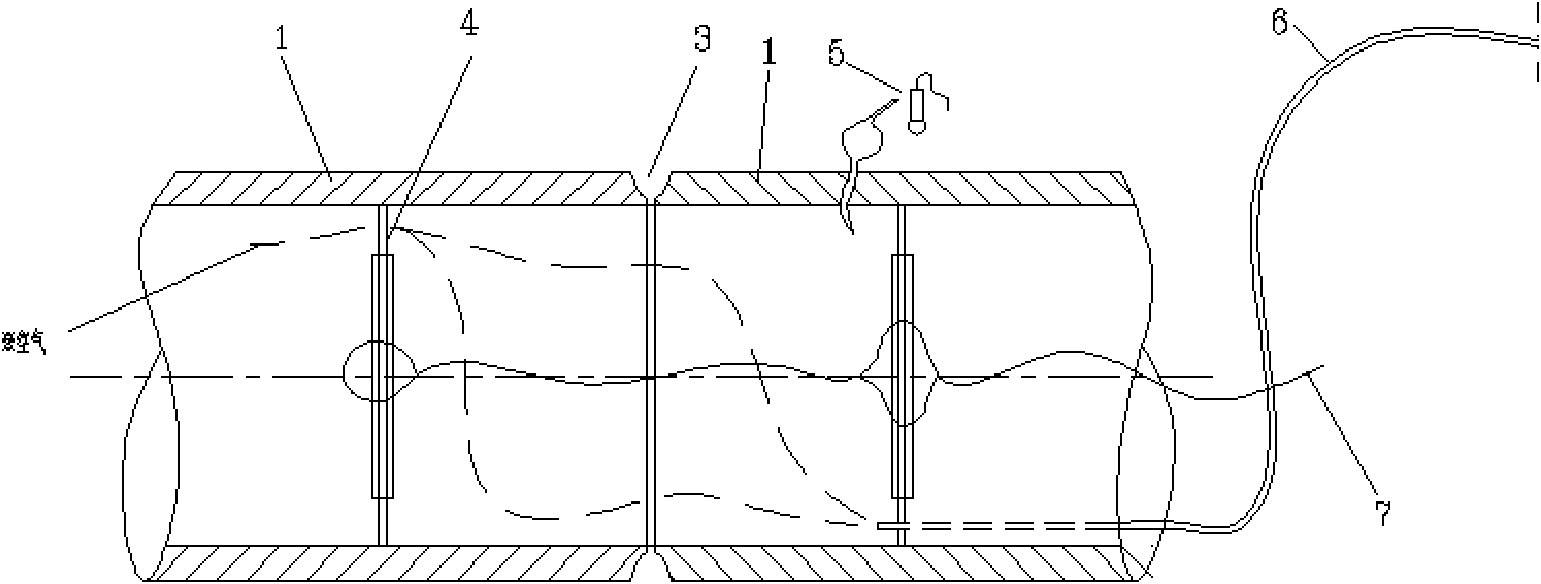

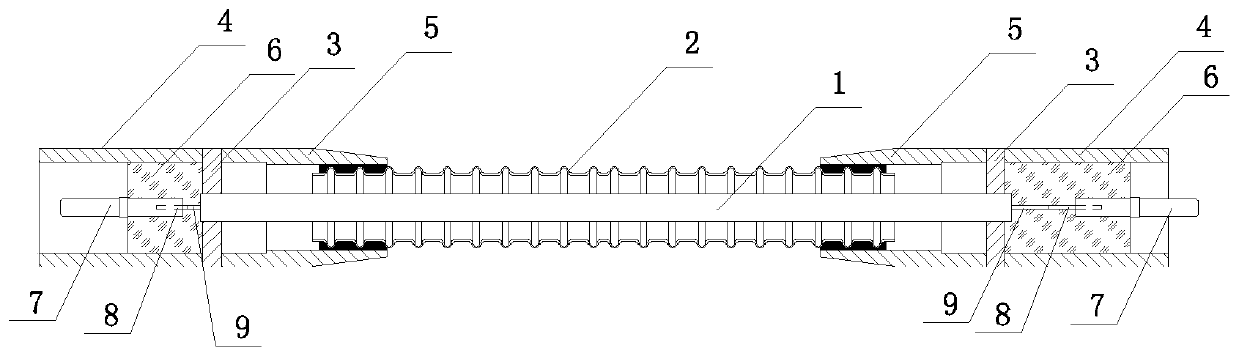

Control system and method for weld-forming of thin-walled pipe

ActiveCN107186342AIncrease stiffnessGuarantee the quality of back weld formationMetal working apparatusLaser beam welding apparatusControl systemPipe fitting

The invention discloses a control system and method for weld-forming of a thin-walled pipe. The control system comprises a welding tool used for weld-forming of the thin-walled pipe and a quality control device used for controlling the quality of longitudinal joints, welded by the welding tool, of the thin-walled pipe. The method comprises the following steps of 1, assembling the welding tool and the to-be-welded thin-walled pipe; 2, debugging the welding tool; 3, initializing the quality control device; 4, starting welding the to-be-welded thin-walled pipe; 5, acquiring real-time welding data of the thin-walled pipe; 6, judging whether the real-time welding data of the thin-walled pipe are abnormal or not; 7, judging whether the thin-walled pipe is defective or not; 8, judging whether the thin-walled pipe is deformed or not; and 9, carrying out stress relaxation on the thin-walled pipe. According to the control system and method for weld-forming the thin-walled pipe, the welding tool provides stable protective gas flow and double cooling measures for the to-be-welded thin-walled pipe, the welding quality of the to-be-welded thin-walled pipe is monitored in real time through the quality control device, so that the residual stress is eliminated, the fatigue life is prolonged, and the stress corrosion resistance is improved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Welding method of lower bend profile at bottom of high-speed rail train outer windshield

InactiveCN107414258ASolve the problem of low bending pass rateMeet the design requirementsArc welding apparatusHeat-affected zoneEngineering

The invention discloses a welding method of a lower bend profile at the bottom of a high-speed rail train outer windshield. The middle of an H-shaped profile is divided into two segments in T shapes, and after the two segments are bent correspondingly, a welding and welding tool installing and welding method is adopted for completing the welding method. According to the method, on one hand, the dimensional tolerance of the appearance after welding can meet the drawing requirement; on the other hand, the welding quality requirement of aluminum alloy welding is met; and an argon shield TIG welding machining tool, a friction stir welding machining tool and a pulse argon shield MIG welding machining tool are adopted in the welding method, finally the welding method of adopting the pulse argon shield MIG welding machining tool is determined by detecting the dimensional tolerance of parts through a welding strength test. The pulse MIG welding heat input quantity can keep the minimum quantity, the range of a heat effect area is small, and the weld joint strength meets the requirement of the aluminum alloy welding; the welding efficiency is high, and deformation is small; and the relative requirement for unevenness of welding clearances and welding faces is low, and 4mm plate butt-joint MIG welding can be within 1.5 mm.

Owner:CHANGZHOU HUBOLA JINCHUANG TRAFFIC EQUIP

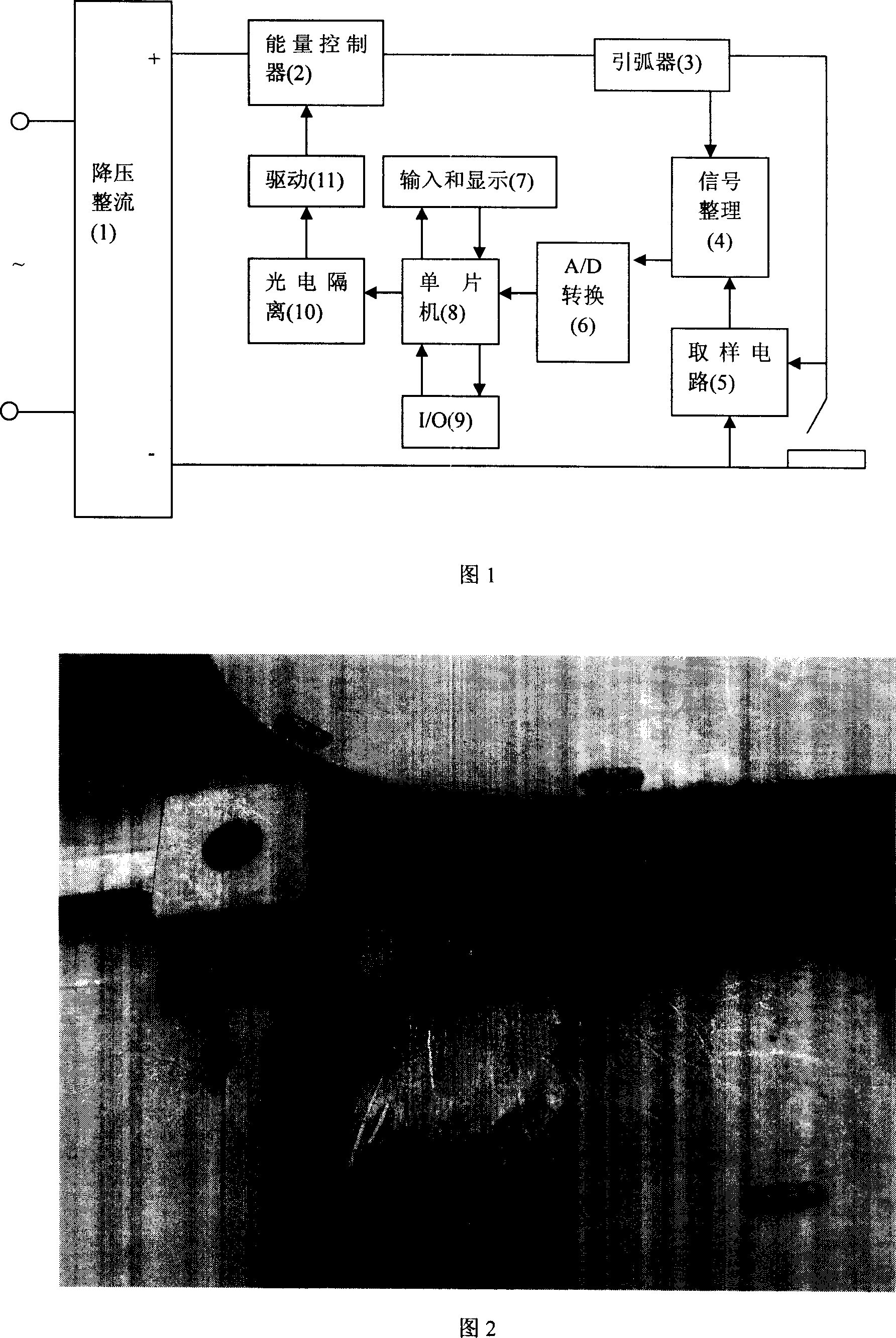

Micro-zone repair welding method for aluminum alloy defect

ActiveCN101011771AIncrease energy densityShort heating timeArc welding apparatusPulse energyMaterials science

The repairing welding for aluminum alloy defects starts with deciding defect location, trimming before the welding, degreasing for the repairing area, micro zone weld repairing using pulse energy, inspecting the working piece to make sure the repairing quality, till the nonexistence of leakage of the part. It also relates to the pulse energy micro bonding machine. Without affecting the dimension of the base metal, it can repair the defect, meeting the sealing requirement.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

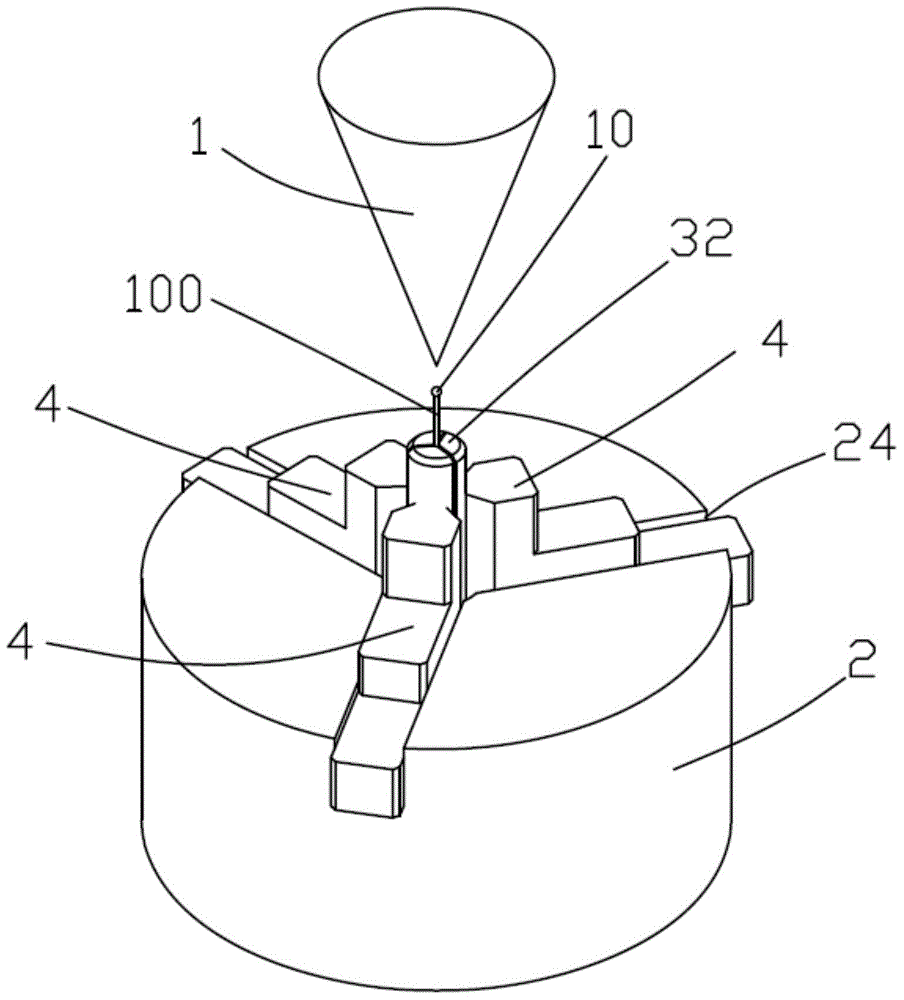

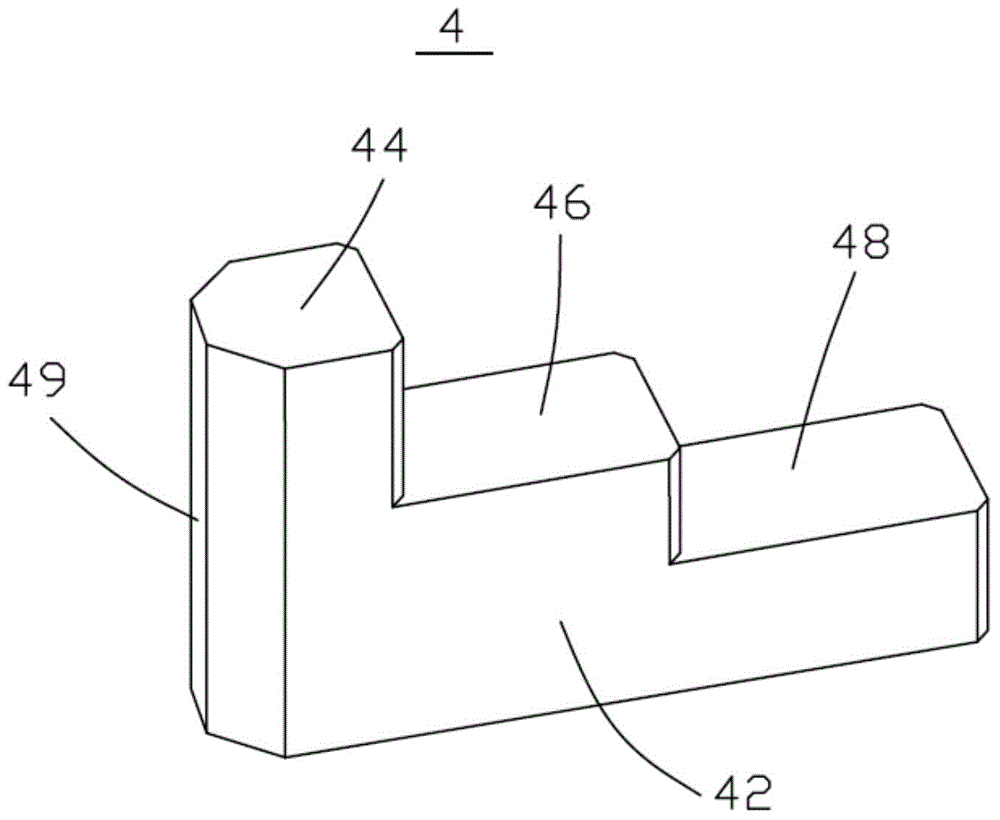

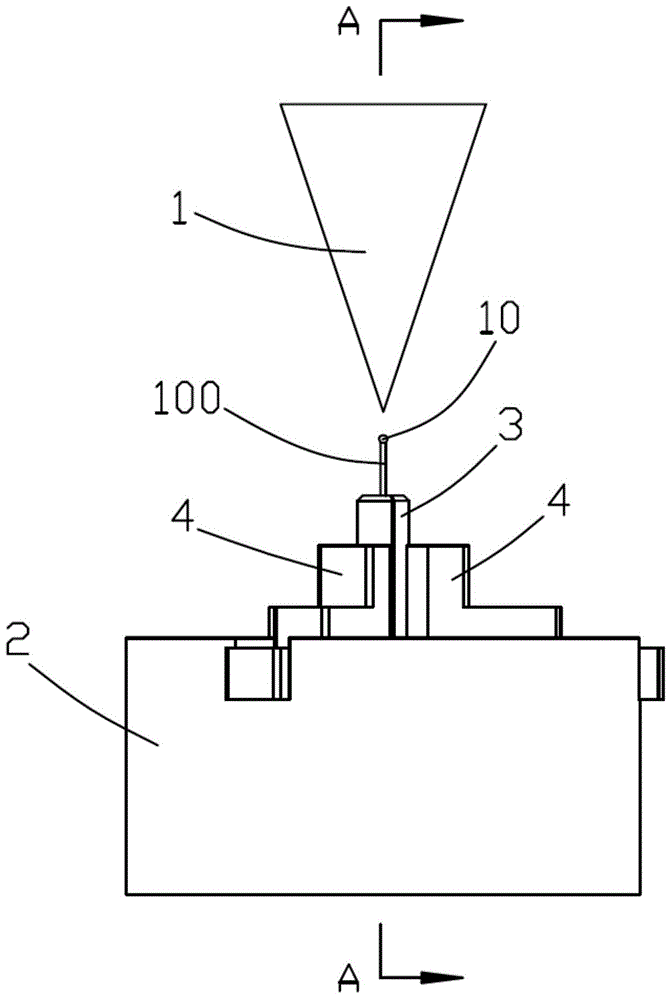

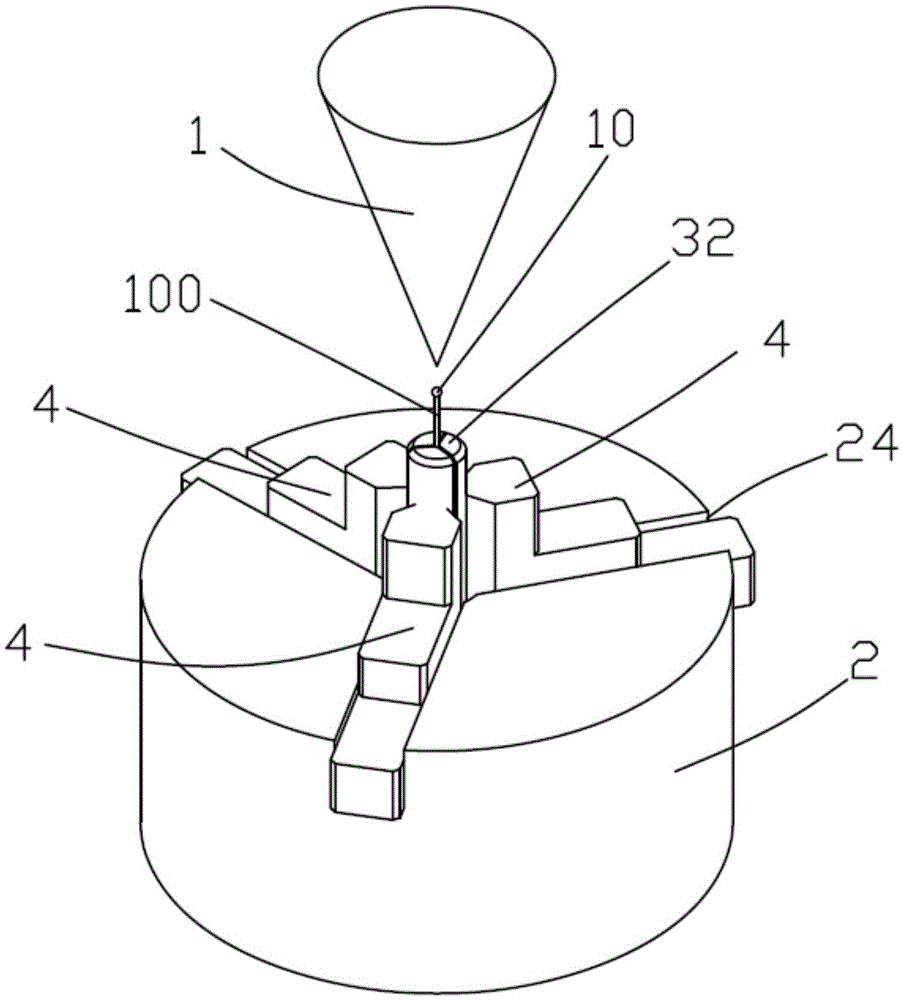

Laser welding device and method for melting ball on filament end face

ActiveCN104690424AImprove welding effectNo eccentricityWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneEngineering

The invention provides a laser welding device and method for a melting ball on a filament end face, wherein the device comprises a laser used for producing a laser beam, a circular truncated cone, a clamping piece used for clamping and fixing a filament, and a plurality of fixing blocks, wherein the clamping piece is vertically fixed in the center of the circular truncated cone, the plurality of fixing blocks are evenly distributed around the axis of the filament, are fixed on the circular truncated cone, and are abutted against the clamping piece, and the laser beam and the filament are coaxially arranged. The laser welding device and method guarantee that the melting ball is not eccentric when welded at the end part of a wire, the welding heat affected zone is small, no oxidation occurs after the welding, and the welding effect of the filament end face is effectively improved.

Owner:HANS LASER TECH IND GRP CO LTD

Laser wire-filled butt welding method for titanium-steel clad plate with t2 copper as transition layer

ActiveCN106112263BAvoid it happening againMitigation of Thermal Stress MismatchLaser beam welding apparatusButt weldingTitanium

Owner:XI AN JIAOTONG UNIV

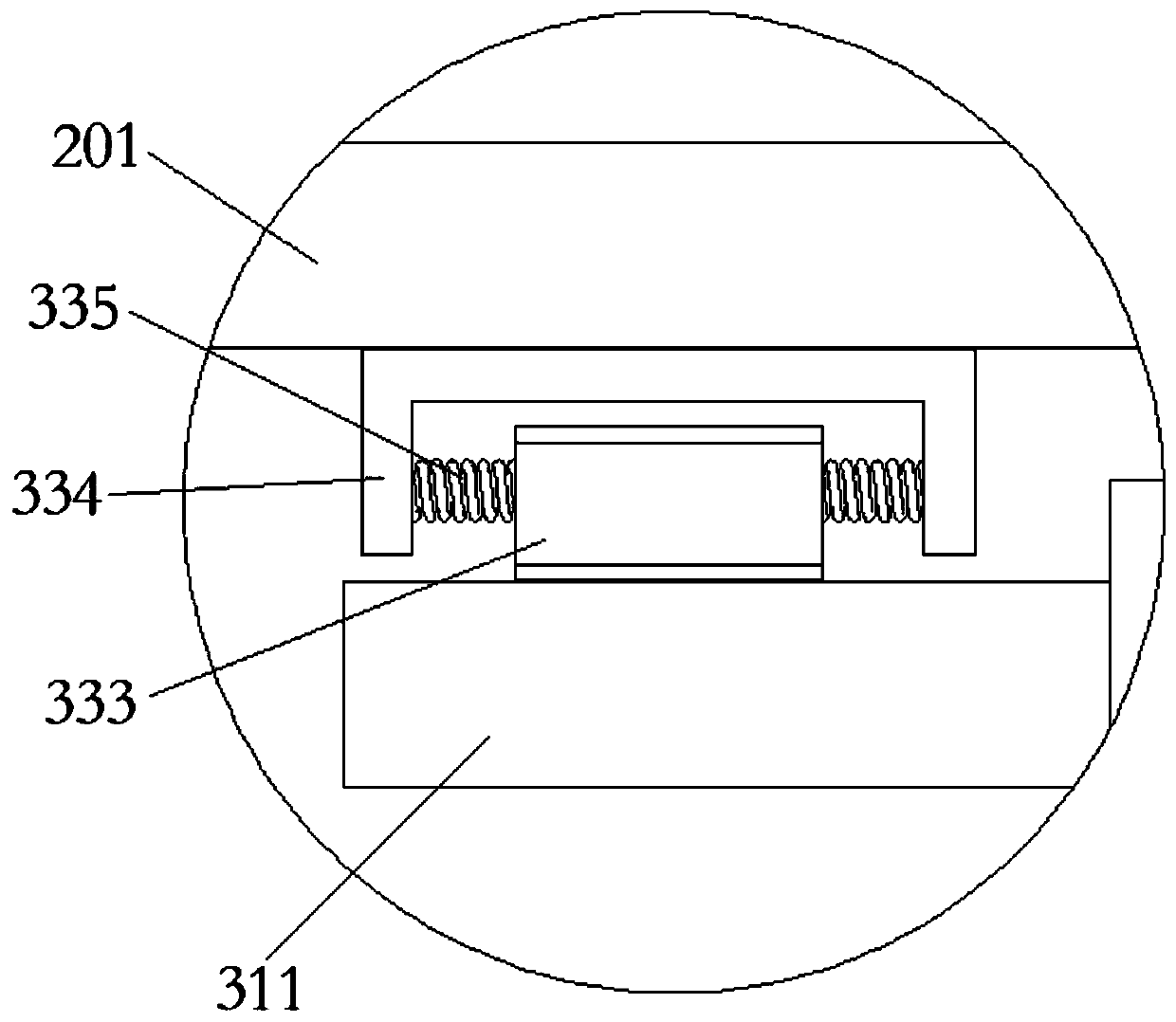

Welding tool equipment

PendingCN110116262AGuaranteed welding effectSmall welding heat affected zonePressure electrodesEngineeringHead moving

The invention provides welding tool equipment. The welding tool equipment comprises a base assembly, an upper electrode assembly and a lower electrode assembly. The base assembly is fixed. The upper electrode assembly comprises an upper electrode head. When the upper electrode head moves to the stroke end point in the direction of the base assembly, a welding space is formed between the bottom face of the upper electrode head and the base assembly. The lower electrode assembly comprises two or more lower electrodes. When the two or more lower electrodes move to the stroke end point towards thewelding space, the welding space is surrounded by the two or more lower electrodes, and the two or more lower electrodes are combined to form a lower electrode head. The welding pressure of the welding tool equipment is provided by the upper electrode head and the base assembly, the position of the lower electrode head can be freely arranged, and good practicality is achieved.

Owner:刘悦吟

Integrated type laser welding machine

InactiveCN106735896ASimple structureIngenious designLaser beam welding apparatusIntegrated designEngineering

The invention discloses an integrated type laser welding machine comprising an integrated machine frame, a laser welding device, a machine cabinet and a work panel. The laser welding device is connected to the top end of the integrated machine frame through a movement adjusting device. The machine cabinet is fixedly installed at the lower end of the integrated machine frame in an embedded manner. The work panel is fixedly connected to the middle portion of the integrated machine frame. A control unit is arranged in the machine cabinet and connected with a monitoring display terminal. The monitoring display terminal is fixedly arranged at the top end of the integrated machine frame. The laser welding device comprises a laser device, a transmitting optical fiber, a focus lens and a laser head, wherein the laser device, the transmitting optical fiber, the focus lens and the laser head are sequentially connected. According to the integrated type laser welding machine, the overall stability of the welding device is greatly improved in the welding process through integrated design, the welding efficiency and the quality of products are improved, the rejection ratio of the products is lowered, and the production cost is reduced.

Owner:深圳市耐恩科技有限公司

Blank blade correction method

ActiveCN104826895AThe orthopedic process is simpleSave production costShaping toolsHeat-affected zoneEngineering

The invention relates to a blank blade correction method. A cast blank blade is photographed, pictures are transmitted to a computer, the size of the blank blade is fit through a measuring scale and a three-dimensional number model, the blank blade is compared with a standard blade numerical model, and the deformation region and the deformation amount of the blank blade are determined; the blade is fixed to a steel plate platform and heated through a stacking heating wall and a heating burner, the blade is corrected multiple times through a jack via external force, and therefore the blank blade correction purpose is achieved; finally, the blade is delivered into a heat treatment furnace for relieving stress and shaping. By the adoption of the method, the correction process is simple, production cost is saved, a production period is shortened, a welding heat influence region is reduced, and product quality is improved.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

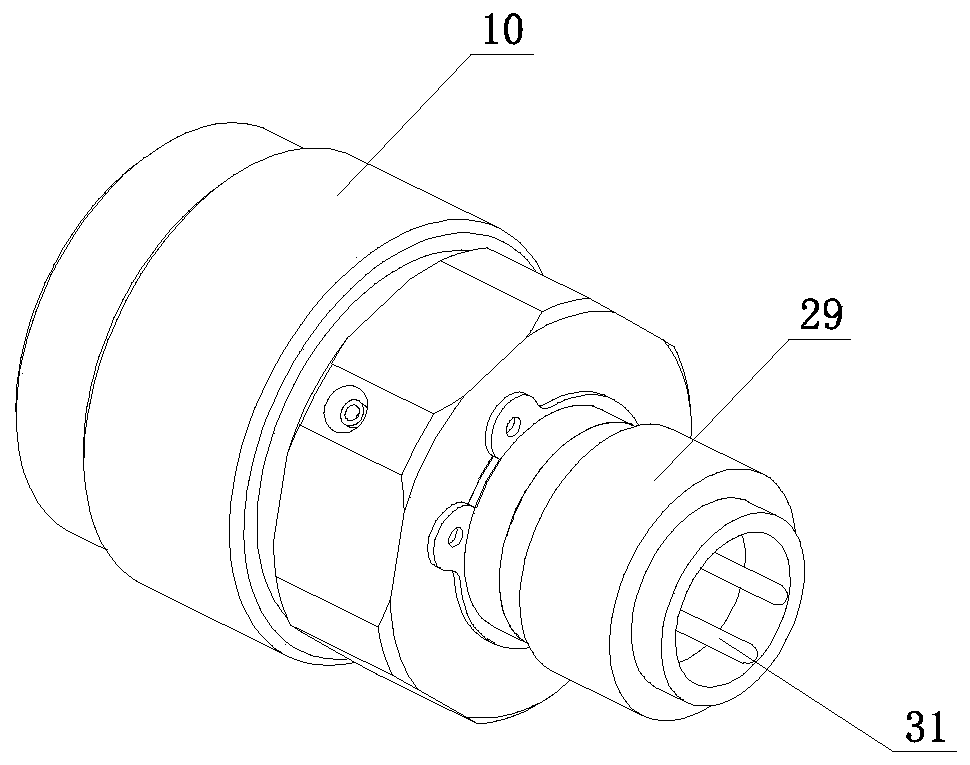

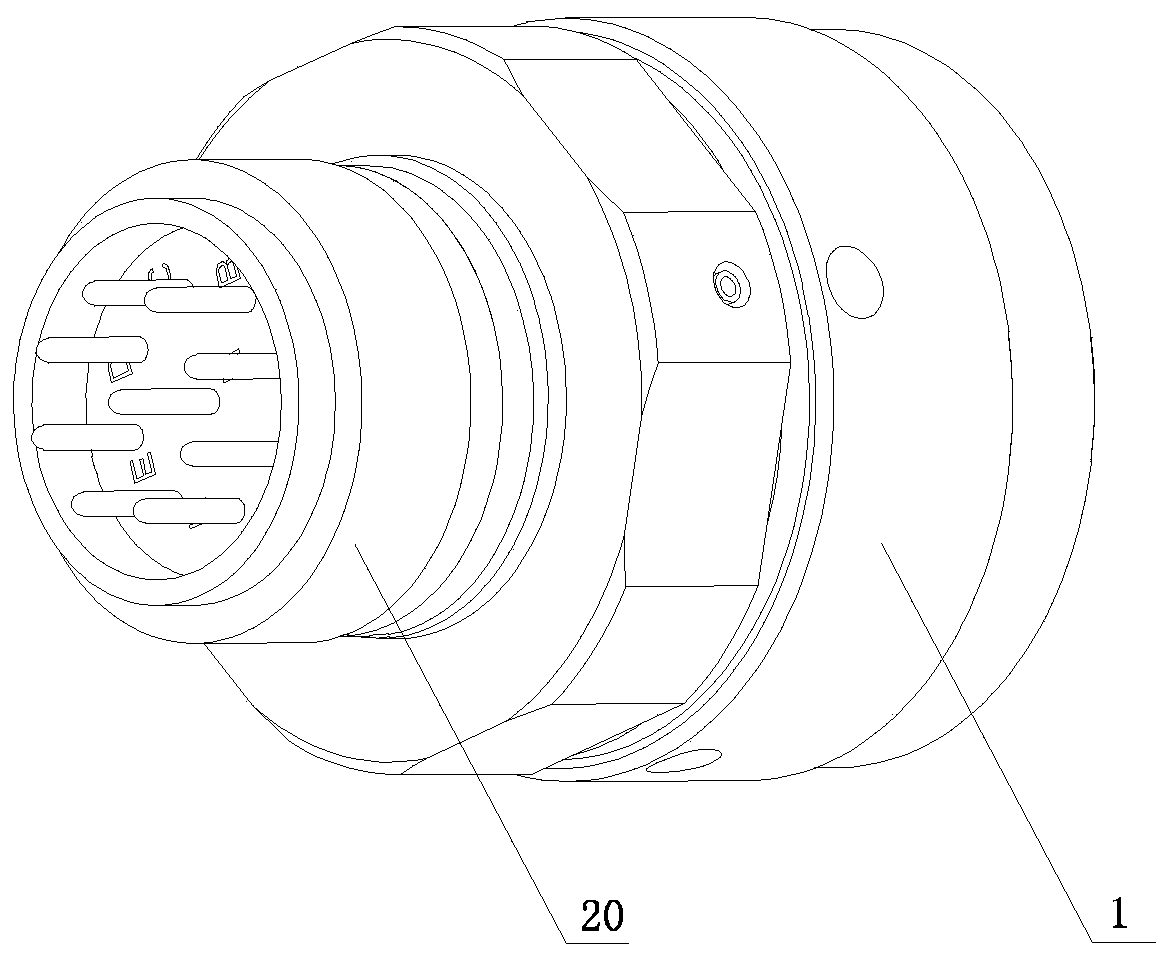

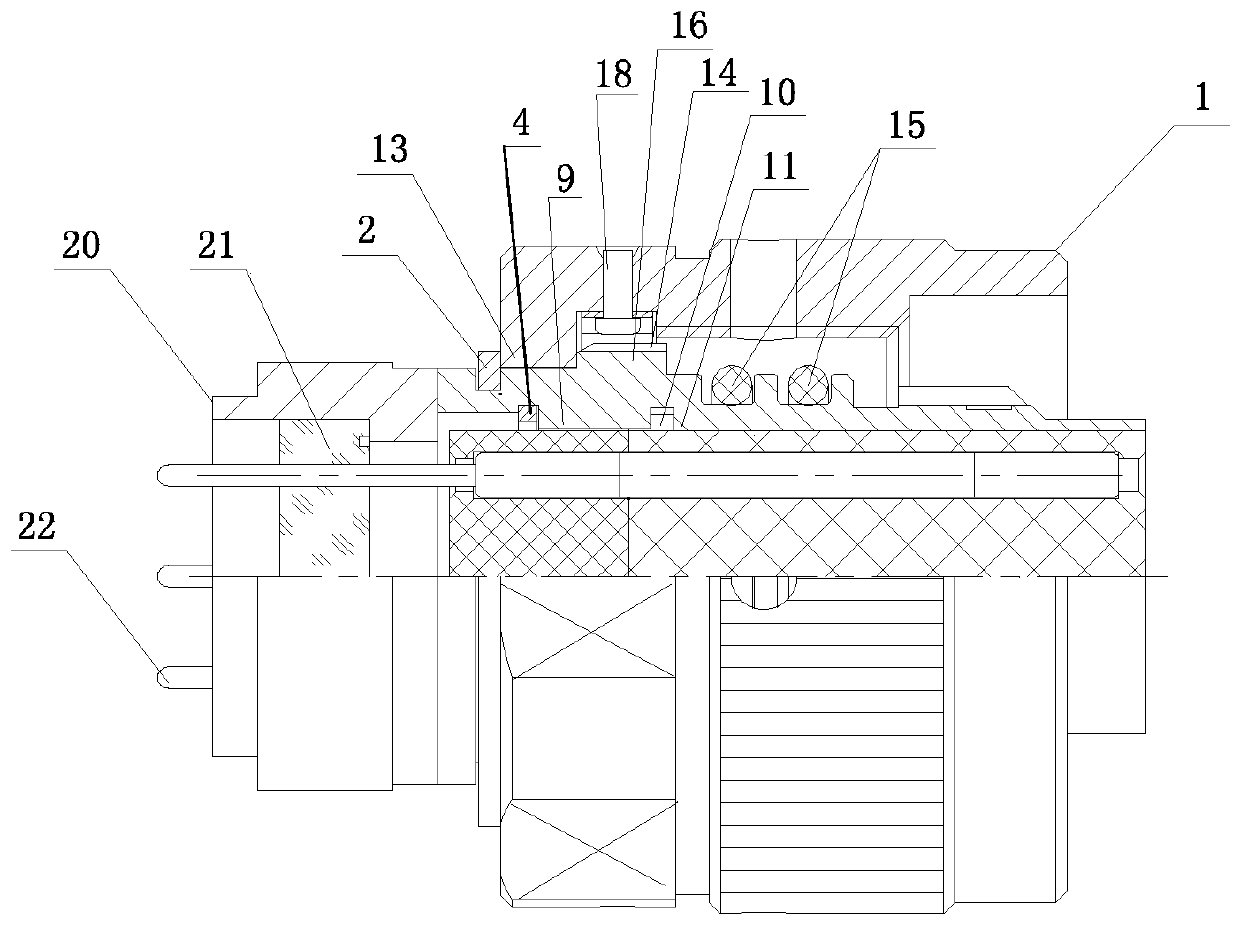

K1-type electrical connector assembly of mineral insulated cable for nuclear power

ActiveCN110380252AImprove corrosion resistanceNo maintenanceSoldered/welded conductive connectionsSecuring/insulating coupling contact membersNuclear powerButt joint

The invention relates to a K1-type electrical connector assembly of a mineral insulated cable for nuclear power, and the assembly comprises a cable assembly, and a plug and a socket which are respectively spliced with two ends of the cable assembly. The cable assembly is characterized in that the cable assembly comprises a mineral cable, a corrugated pipe wrapped outside the mineral cable, a positioning plate for fixing the mineral cable, and a stainless steel pipe welded with the positioning plate; the stainless steel pipe is internally provided with a glue pouring area and a switching jack contact piece; the switching jack contact piece is of a double-end jack structure, one end of the switching jack contact piece is electrically connected with the mineral cable core wire through a barewire, and the other end is plugged with the plug or the socket; the plug comprises a connecting nut, a spline housing, an insulator part, and a glass sintering part which is in butt joint with the double-end jack contact part; the socket is of an integrated structure formed by sintering a socket shell, a glass cake II and a double-end contact pin contact piece II through glass. The assembly provided by the invention is resistant to irradiation and aging and long in service life, and it is guaranteed that the product can still be used after being subjected to severe accident working conditionswhile the using requirements of a nuclear-grade K1-type electrical connector are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Stop tongue piece welding device and welding method thereof

ActiveCN113695724AGood welding size consistencyReduce laborResistance electrode holdersWelding/cutting auxillary devicesEngineeringPhysics

The invention relates to a stop tongue piece welding device and a welding method thereof. The welding device comprises an upper electrode and a lower electrode, wherein the lower electrode is matched with a base, the lower electrode is provided with a shell matched with a stop tongue piece, and the upper electrode is provided with an outer cone tightly matched with the surface of a resistance welding machine; and the lower electrode is provided with a sliding groove for storing the stop tongue piece, a positioning block for limiting the position of the stop tongue piece is installed in the sliding groove in a sliding manner, and a boss which abuts against the position of the stop tongue piece to focus welding energy is further arranged in the sliding groove. According to the stop tongue piece welding device and the welding method thereof, the positioning block and the boss are used for limiting the stop tongue piece, and operators are responsible for clamping parts, so that the labor amount is reduced, the stability and reliability of products are improved, and meanwhile the welding size consistency of the stop tongue piece is good; and according to the stop tongue piece welding device and the welding method thereof, traditional argon arc welding is replaced, the welding heat affected area is small after welding, and deformation is small.

Owner:安徽天航机电有限公司

Aero-engine turbine rear case support plate long crack A-TIG welding restoration method

ActiveCN110328492ANarrow grooveWeld seam cross-sectional area is smallArc welding apparatusAviationHeat-affected zone

The invention relates to an aero-engine turbine rear case support plate long crack A-TIG welding restoration method. The method includes the following steps: S1, grinding and cleaning; S2, coating a crack with soldering flux; S3, argon arc welding; S4, benchwork grinding; S5, stress relief heat treatment; and S6, inspection. The idea of performing active TIG welding (A-TIG) to restore the long crack of a rear case support plate of an aero-engine turbine is put forwards in the method, the heat input of a welded joint is low, welding heat affected zones are reduced, and the mechanical property of the welded joint is improved. The deformation amount of an intermediate case is greatly reduced compared with that in a TIG welding method. The engine maintenance cost is greatly reduced and the engine maintenance period is shortened.

Owner:PLA NO 5719 FACTORY

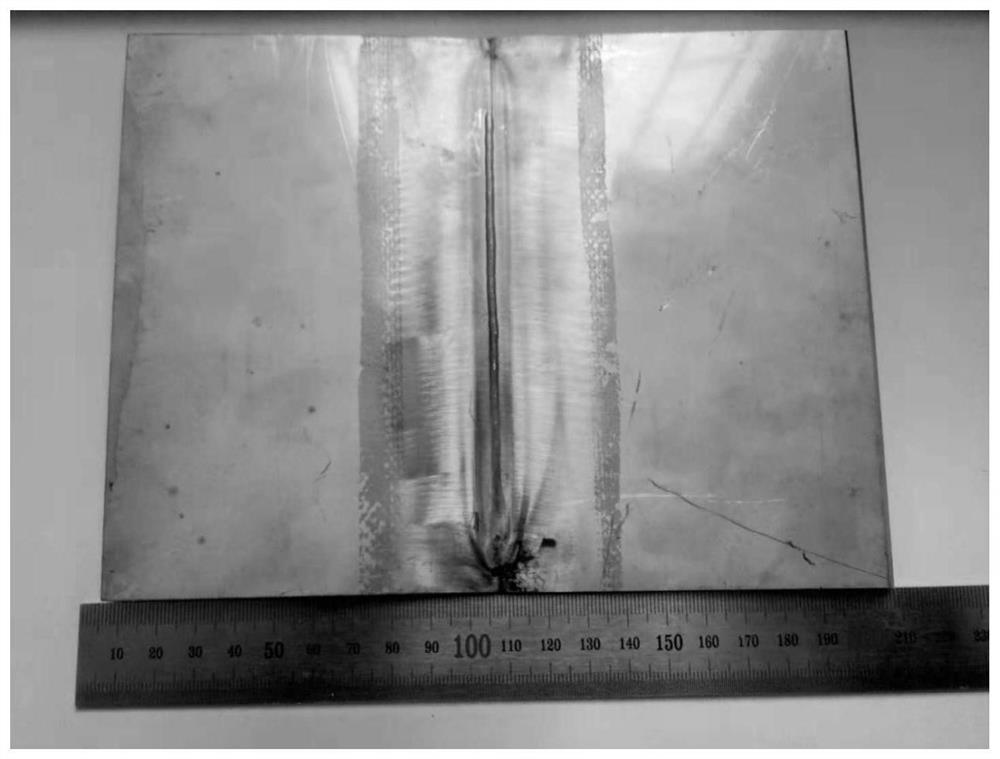

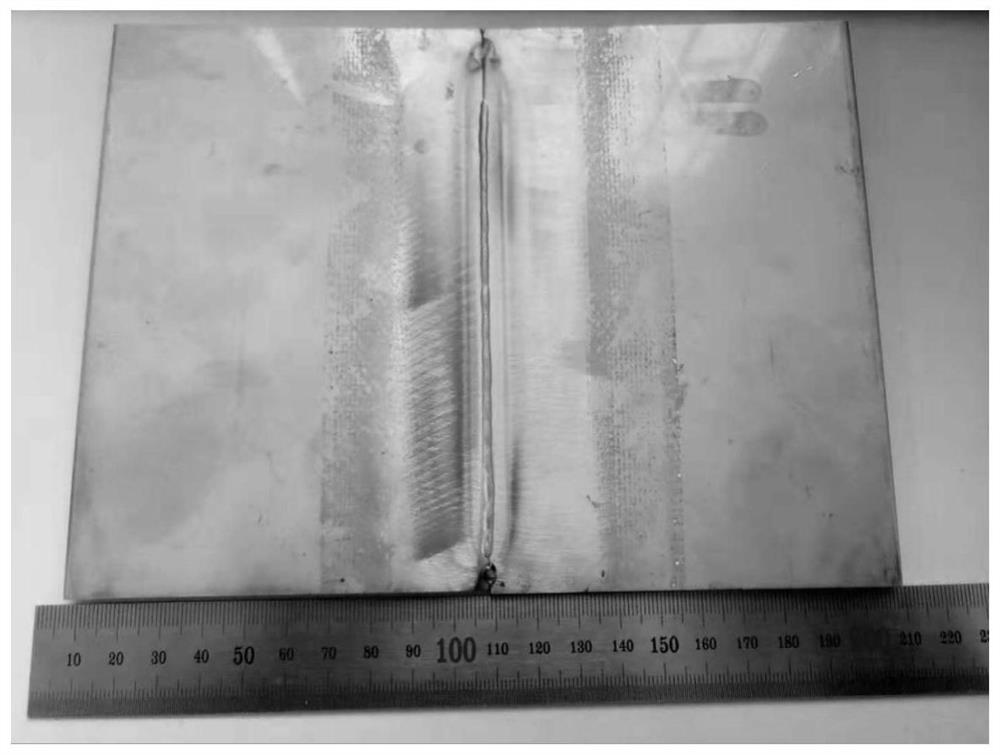

A 3-5mm stainless steel plate single side welding double side free forming welding method

ActiveCN109848525BReduce welding distortionReduce labor intensityArc welding apparatusHeat-affected zoneSS - Stainless steel

Owner:WUHAN UNIV OF TECH +1

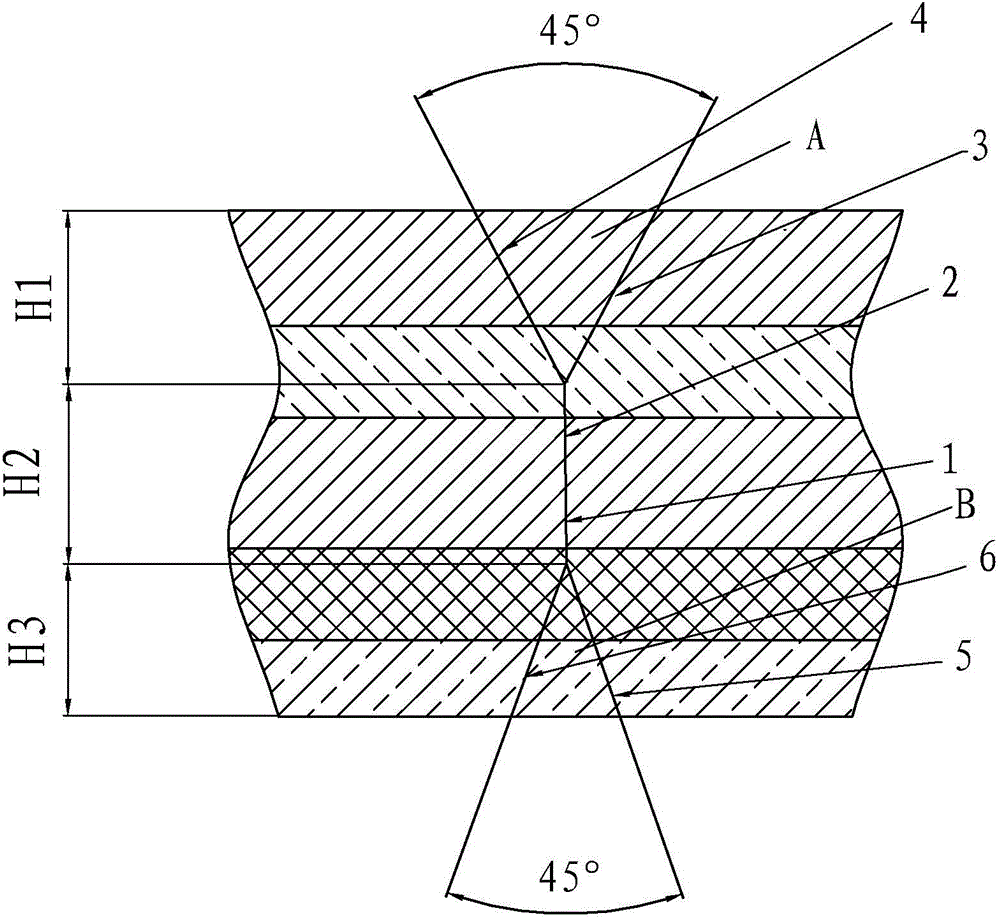

Welding method of metal layer shaped composite board

InactiveCN103537816BAchieve weldingFast welding speedWelding/soldering/cutting articlesMetal working apparatusSequence designMetallurgy

The invention relates to a welding method of a metal layer shaped composite board. The elding method of the metal layer shaped composite board is characterized by the following steps of 1, welded joint design, 2, wielding method design, 3, V-shaped strips preparation and filler wire selection and 4, welding sequence design. The wielding method design includes that the laser is utilized to weld I shaped grooves, middle truncated edge and weld grooves matching with the V-shaped strips; when the V shaped groove only has one layer of materials, the laser arc composite heat source is utilized to weld the weld grooves. The wielding method design includes welding the I shaped grooves and the middle truncated edge first and then the V-shaped grooves. Compared with the prior art, the welding method of the metal layer shaped composite board has the advantages that the welding method of the metal layer shaped composite board is high in welding quality, few in welding defects, is easy to operate and can increase welding efficiency.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

A K1 type electrical connector assembly for mineral insulated cables for nuclear power

ActiveCN110380252BImprove corrosion resistanceNo maintenanceSoldered/welded conductive connectionsSecuring/insulating coupling contact membersNuclear powerEngineering

The invention relates to a K1 type electrical connector assembly for a mineral insulated cable for nuclear power, comprising a cable assembly, a plug and a socket plugged into both ends of the cable assembly, the cable assembly includes a mineral cable, a corrugated tube wrapped outside the mineral cable, and a The positioning plate for fixing the mineral cable and the stainless steel tube welded with the positioning plate; the stainless steel tube is provided with a glue filling area and a transfer jack contact; the transfer jack contact is a double-ended jack structure, one end of which is connected to Mineral cable core wires are electrically connected, and the other end is mated with a plug or socket; the plug includes a connecting nut, a splined housing, an insulator part, and a glass sintered part mated with a double-ended socket contact; the socket consists of a socket housing, The glass cake II and the double-head pin contact II are made into an integrated structure through glass sintering; the invention is resistant to radiation, aging, and has a long service life. Remains usable after severe accident conditions.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

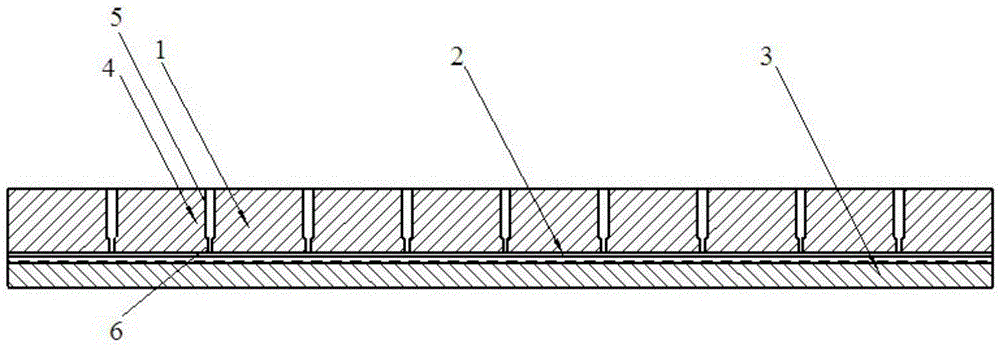

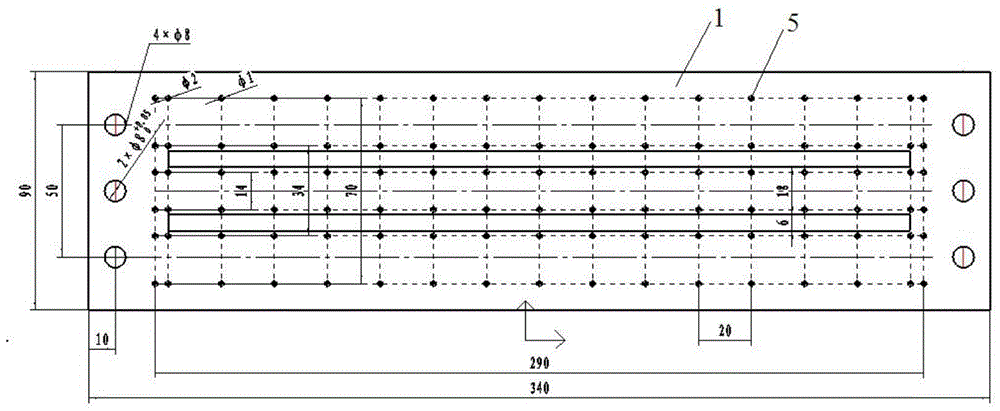

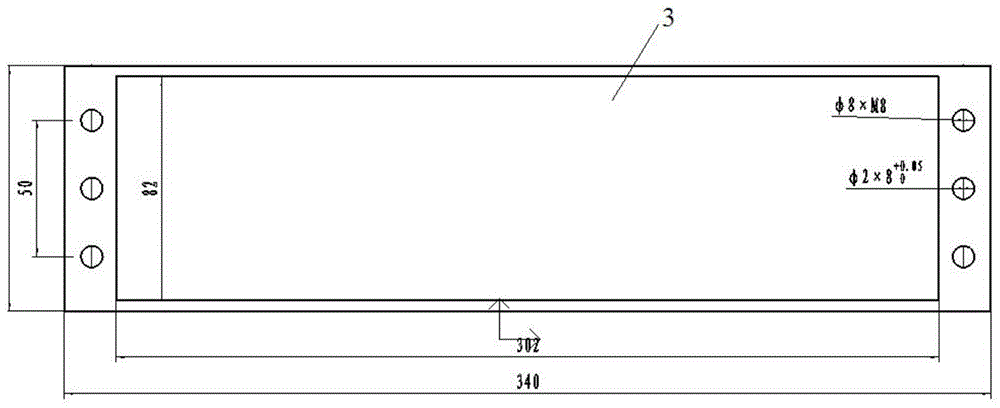

A method for processing stainless steel capillary cores on heat pipe plates

ActiveCN105057875BSmall welding heat affected zoneTightly boundElectron beam welding apparatusCopperElectron

The invention discloses a method for machining stainless steel capillary cores on a heat pipe plate. The method includes the following steps that firstly, a red copper template is provided and provided with through holes; secondly, the template, a stainless steel screen and the plate are sequentially stacked, the portions, corresponding to the through holes, of the stainless steel screen are exposed outside, and the template, the stainless steel screen and the plate are fixed together, so that a workpiece to be welded is obtained; and thirdly, the workpiece to be welded is welded through electron beams and the portions, corresponding to the through holes, of the stainless steel screen are welded to the heat pipe plate. By the adoption of the method, an electron beam welding process is adopted for machining the stainless steel capillary cores and the welding heat influence region is small; and the stainless steel screen and the heat pipe plate are combined tightly and the capillary effect is good.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Flash butt welding machine for vehicle door corner welding

ActiveCN101979208BEasy to operateRealize three-dimensional mobile adjustmentResistance welding apparatusButt weldingEngineering

The invention discloses a flash butt welding machine for vehicle door corner welding, which comprises a base, clamping devices, an upsetting mechanism and an electric controller, wherein the clamping devices comprise a first clamping device for clamping a right welding piece and a second clamping device for clamping a left welding piece. The flash butt welding machine is characterized by also comprising a clamp adjusting device and an adjusting bottom plate capable of moving freely in a space, wherein the second clamping device is fixedly arranged on the adjusting bottom plate; an upsetting device comprises a guide rail seat, a moving component slipping along the guide rail seat and a servo driving device for driving the moving component to move; the first clamping device is fixedly arranged on the moving component; and a first insulating plate is arranged between the bottom of the clamp adjusting device and the base, and a second insulating plate is arranged between the bottom of the guide rail seat and the base. Compared with the prior art, the flash butt welding machine can randomly adjust the space placing position of the welding piece to ensure the welding quality and the appearance and profile requirements of a welded product; and the clamp adjusting device is convenient and simple in operation, and improves the welding efficiency.

Owner:NINGBO XINTAI MACHINERY

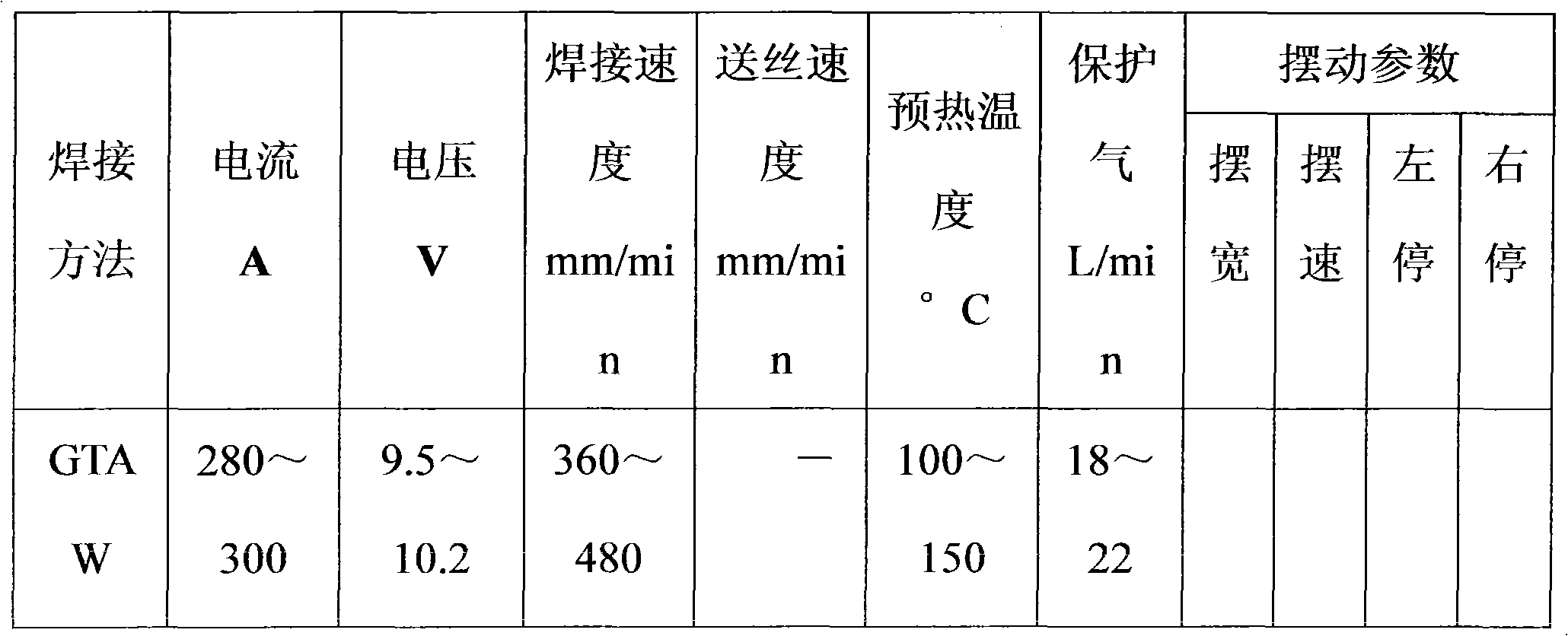

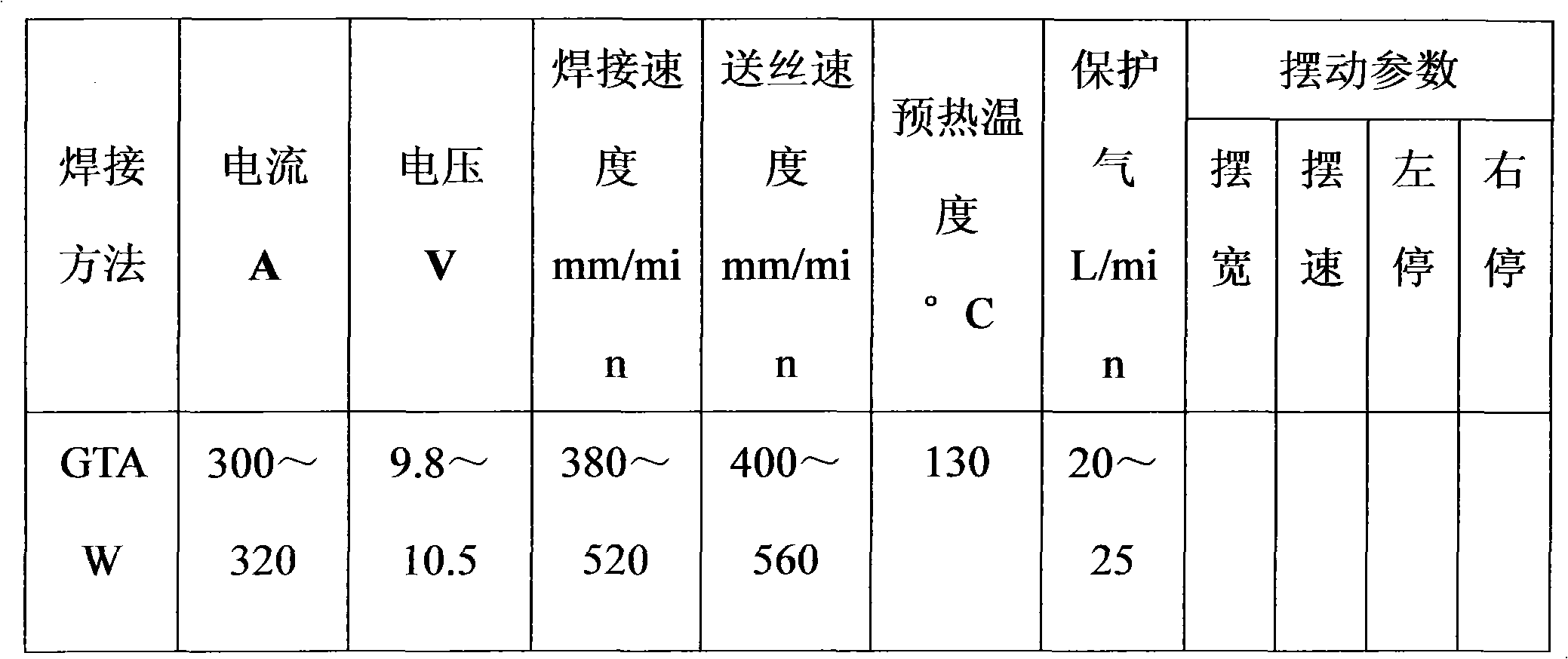

Automatic tig welding method for single-side welding and double-side forming of aluminum alloy butt ring seam without backing

InactiveCN102079004BReduce distortionHigh degree of welding automationArc welding apparatusSurface layerEngineering

Aluminum alloy butt circular seam without liner single-sided welding double-sided forming automatic TIG welding method, use acetone to clean the oil around the butt circular seam of the cylinder body before welding, and use stainless steel wire wheel to remove the inner oxide film around the butt ring seam of the cylinder body. Preheating, debugging the control panel to control the welding current, voltage, welding speed, wire feeding speed matching in real time, using automatic tungsten argon arc welding machine welding, welding the first layer without adding wire back forming, adding welding wire filling in the second layer, Three layers of welding wire are added, and the welding torch is oscillated to form the cover surface. The invention adopts simple equipment, convenient operation, realizes welding automation, stable welding, fast welding speed, low production cost, less filler wire, less welding layers, and less deformation after welding. No correction is required, the appearance is beautiful and the welding seam quality is high.

Owner:陕西国德电气制造有限公司

High-density connector resistant to nuclear grade environment

PendingCN110265830AEasy to replaceEasy maintenanceEngagement/disengagement of coupling partsCoupling protective earth/shielding arrangementsNuclear gradeHigh density

The invention relates to a high-density connector resistant to a nuclear grade environment. The high-density connector comprises a plug and a socket, wherein the plug comprises a connecting screw cap, a spline shell arranged in the connecting screw cap and limited by a check ring and a second limiting mechanism, and an insulator component arranged in the spline shell and limited by a clamp spring and a first limiting mechanism; the insulator component comprises an insulating pressing plate and a high insulator, and a double-head jack contact is arranged in the insulating pressing plate and the high insulator in a penetrating mode; a groove in the insulating pressing plate and a groove in the high insulator are communicated to form an anti-rotation groove, and the anti-rotation groove is matched with a key table in the spline shell to prevent rotation; an O-shaped sealing ring I and a ratchet are arranged outside the spline shell; a shielding strip is further arranged in the connecting screw cap and corresponds to the position of the ratchet; and the socket is composed of a socket shell, a glass cake II and a double-head pin contact which are integrally sintered together through glass. According to the connector, the insulation performance is improved, the properties of being resistant to irradiation, resistant to aging and resistant to saturation and steam, and long in service life can be realized, and the use requirements of K1 nuclear-grade environments can be met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

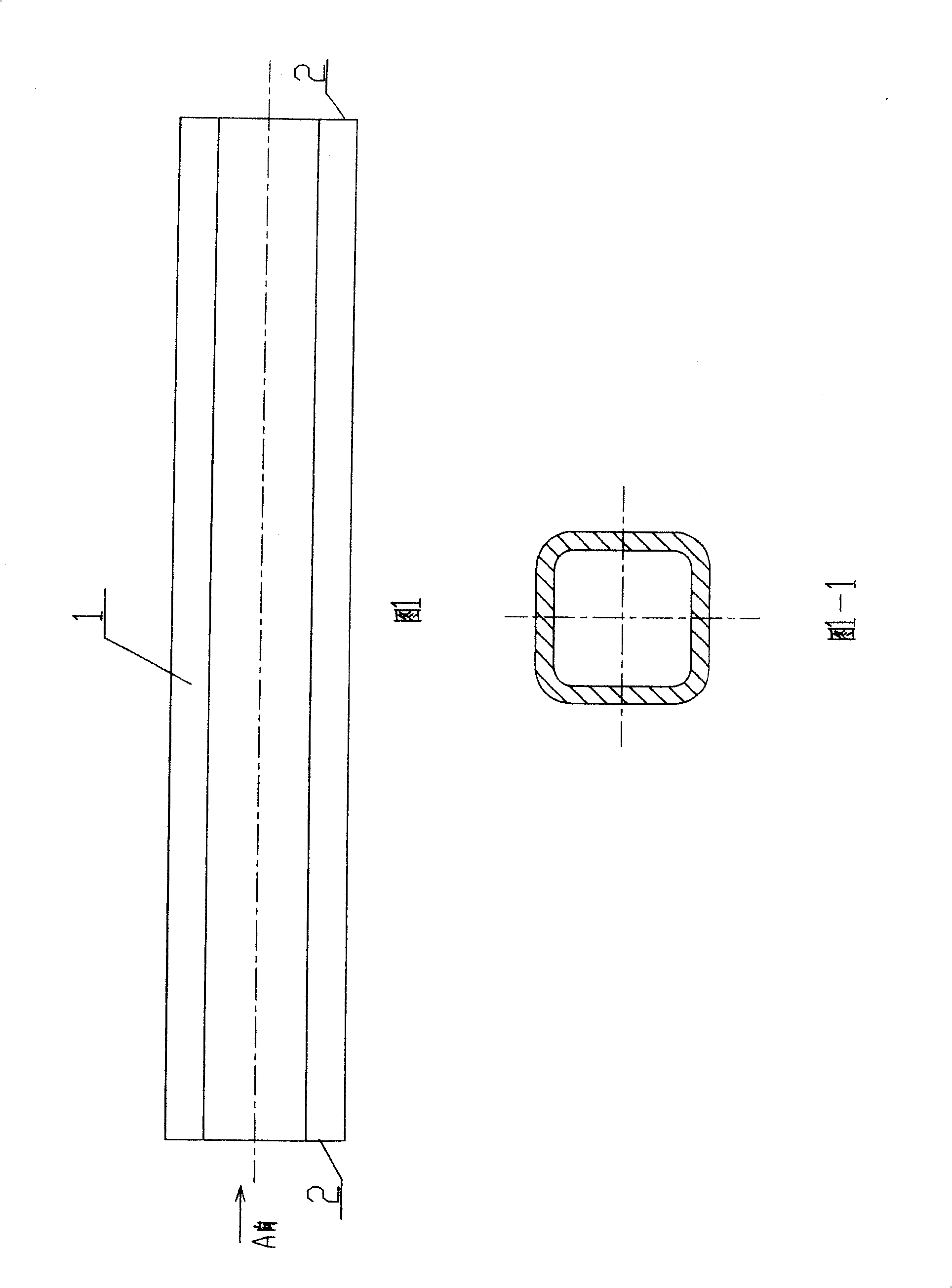

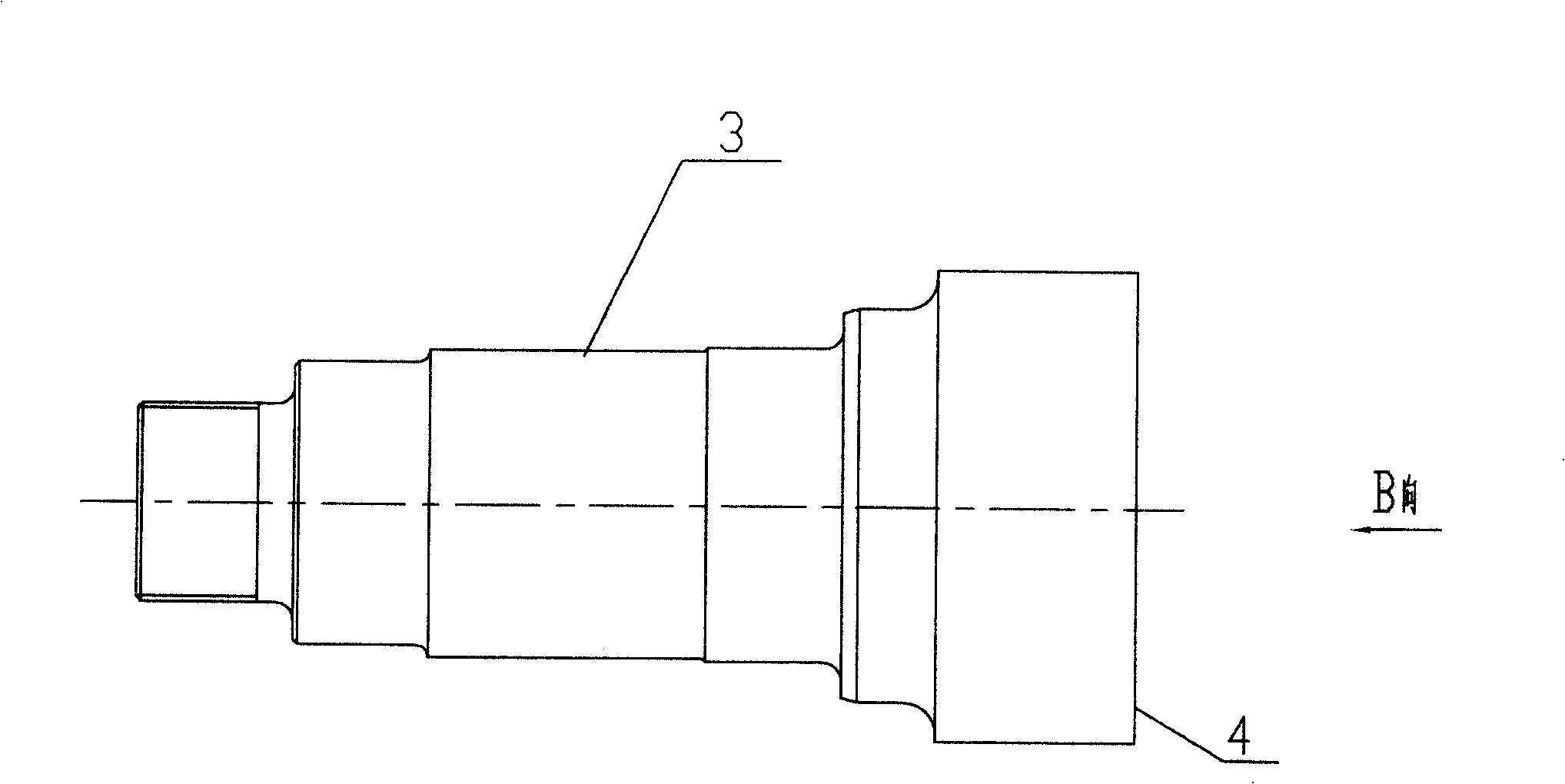

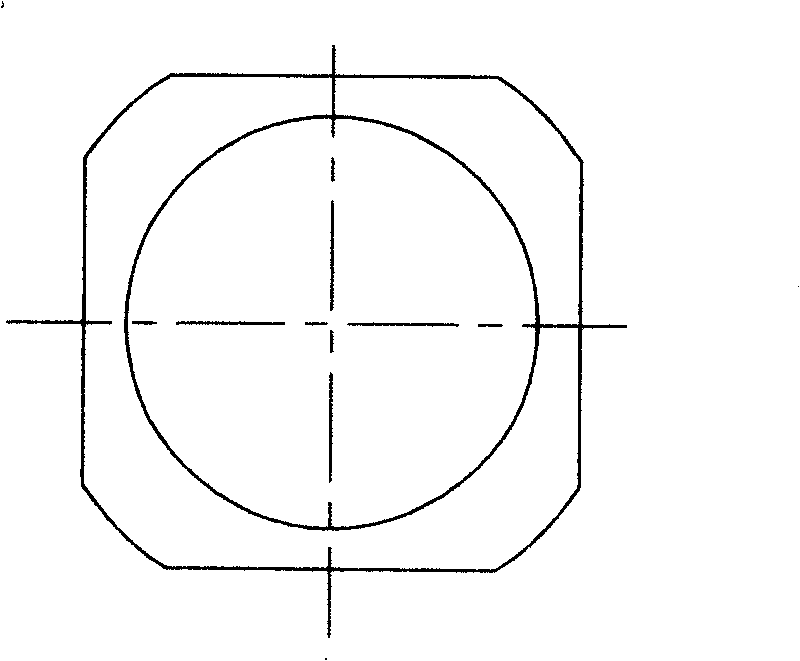

Vacuum electron beam welding process for square axle journal and axle pipe of support axle

ActiveCN100453241CReduce pollutionReduce labor intensityElectron beam welding apparatusMedium frequencyWeld seam

Owner:QINGDAO YUEK TRANSPORT EQUIP

Rocket engine jet pipe brazing strip automatic rolling point welding machine and rolling point welding process

ActiveCN103192153BRealize full mechanizationFully automatedMetal working apparatusSolder feeding devicesEngineeringSpot welding

The invention relates to a rocket engine jet pipe brazing strip automatic rolling point welding machine and a rolling point welding process. The automatic rolling point welding machine comprises a body base, a rotating workbench, a tensioning pattern, a gate type support, a brazing strip disc, a controller, an angle adjusting mechanism, a longitudinal rolling point welding operating mechanical arm, an annular rolling point welding operating mechanical arm and the like. By the automatic rolling point welding machine, mechanical, automatic and intelligent longitudinal brazing strip and annular brazing strip rolling point welding are achieved on jet pipe components, welding efficiency is high, welding quality is good, welding point distances are adjustable, rolling point welding speed can be reach 3 points / second, and welding speed can reach more than 5 meters / second. The automatic rolling point welding machine has no noise, arc, splash, radiation and the like during welding, and is high in reliability, simple to operate, easy to maintain, and suitable for welding of rocket engine spraying pipes with the diameters of 260-1500mm.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

Wire end melting ball laser welding device and method

ActiveCN104690424BImprove welding effectNo eccentricityWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneLight beam

The invention provides a laser welding device and method for a melting ball on a filament end face, wherein the device comprises a laser used for producing a laser beam, a circular truncated cone, a clamping piece used for clamping and fixing a filament, and a plurality of fixing blocks, wherein the clamping piece is vertically fixed in the center of the circular truncated cone, the plurality of fixing blocks are evenly distributed around the axis of the filament, are fixed on the circular truncated cone, and are abutted against the clamping piece, and the laser beam and the filament are coaxially arranged. The laser welding device and method guarantee that the melting ball is not eccentric when welded at the end part of a wire, the welding heat affected zone is small, no oxidation occurs after the welding, and the welding effect of the filament end face is effectively improved.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com