Stainless steel tube with welding bevel model, welding method and argon shield apparatus

A stainless steel pipe and welding bevel technology, which is applied to welding equipment, pipes/pipe joints/fittings, pipes, etc., can solve the problems of poor back forming effect, uneven weld reinforcement, affecting fluid performance, etc., and achieve inner wall cleaning , The inner wall weld reinforcement is uniform, and the effect of ensuring the quality of weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

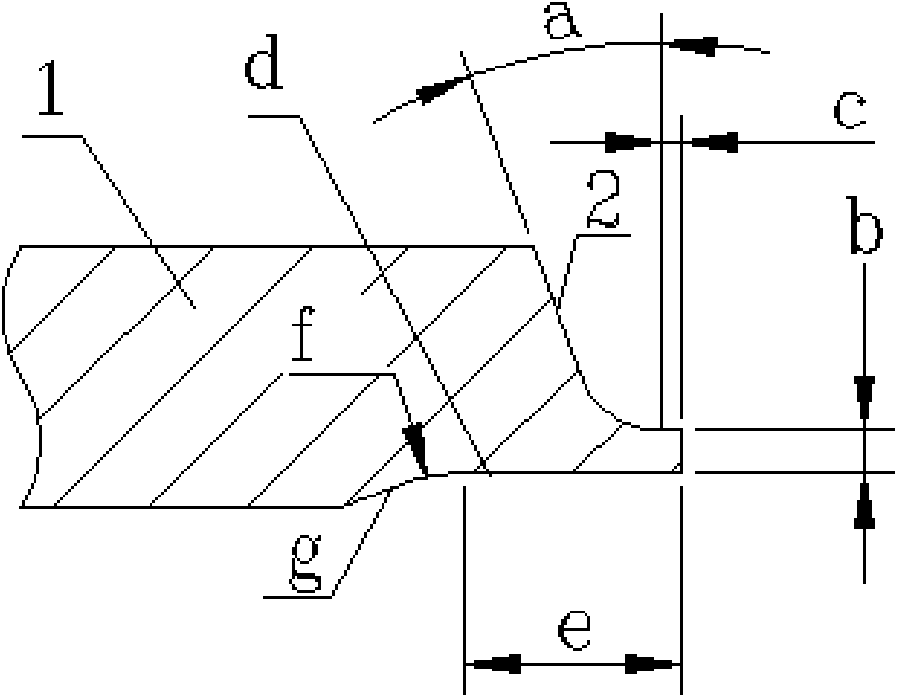

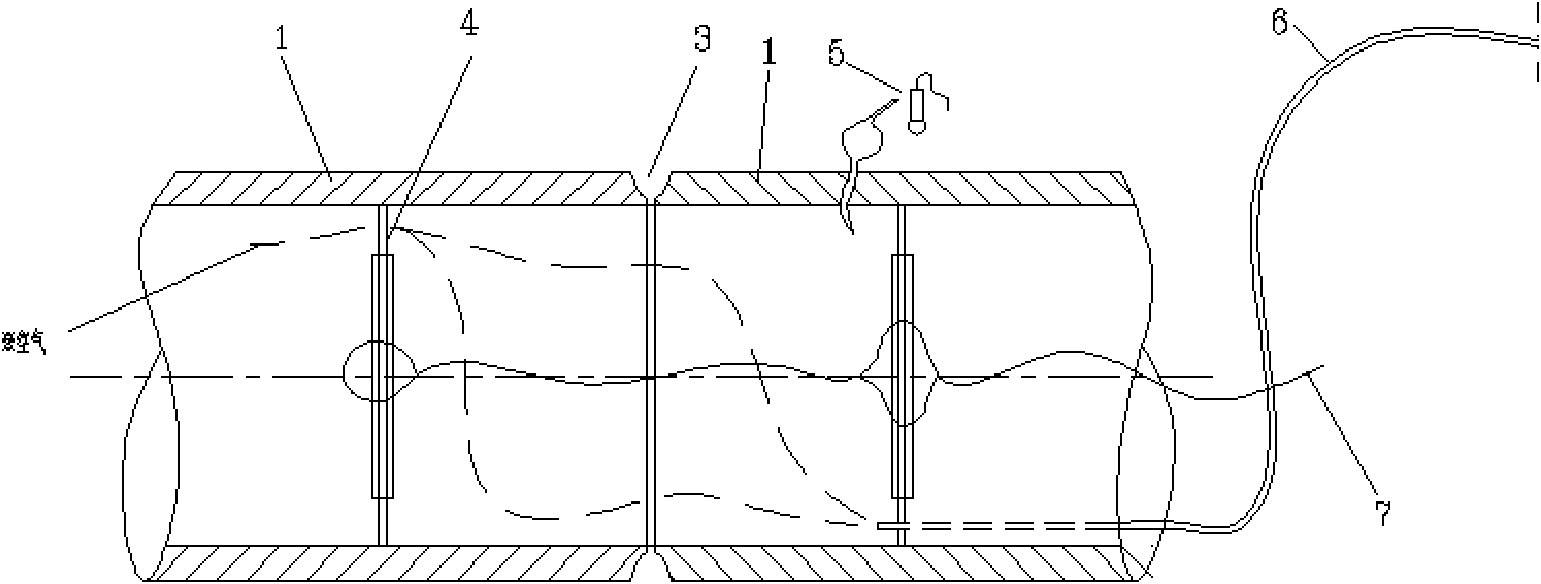

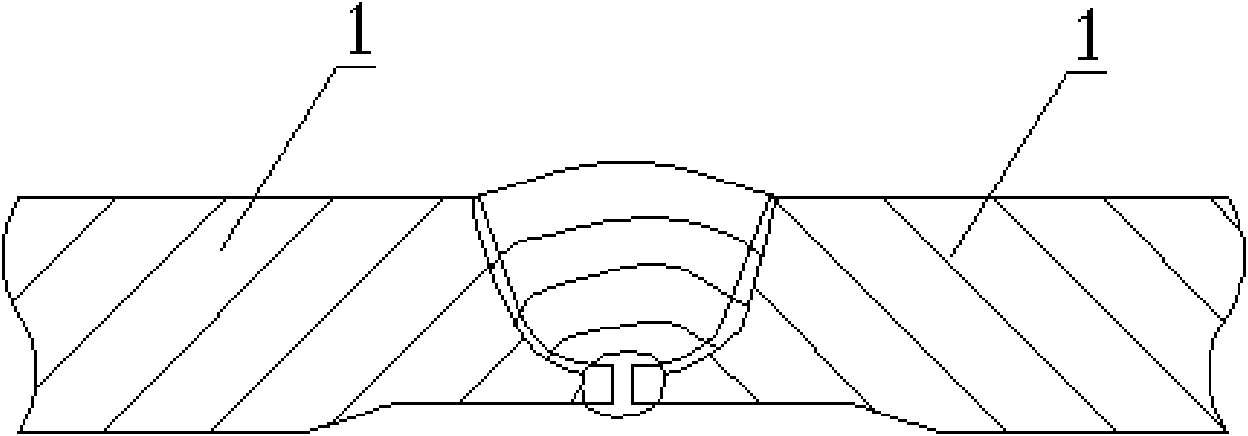

[0033] Such as figure 1 , figure 2 , image 3 As shown, a stainless steel pipe with a welded groove type, one end of the stainless steel pipe 1 has an arc-shaped groove 2 on the wall, and the arc-shaped grooves 2 of adjacent stainless steel pipes are put together to form a U-shaped groove 3. The groove angle a of the arc-shaped groove 2 is 20°, the thickness of the blunt edge of the arc-shaped groove is 2 mm, and the width of the blunt edge of the arc-shaped groove is 1 mm. The size of the item can ensure the quality of the weld seam of the steel pipe wall in the self-fluxing welding of the stainless steel pipe, especially the size of the blunt edge of the arc-shaped groove is increased to 2mm, so as to ensure that the self-fluxing metal of the stainless steel pipe base material is used to fill the welding The bottom weld seam ensures the forming quality of the weld seam on the inner wall of the stainless steel pipe. The inner wall of the steel pipe at the arc-shaped groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com