Micro-zone repair welding method for aluminum alloy defect

An aluminum alloy and micro-area technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of poor accessibility and flexibility, arc energy loss, low arc energy density, etc., and achieve visual Good performance and accessibility, meet the requirements of sealing performance, and the effect of small welding heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

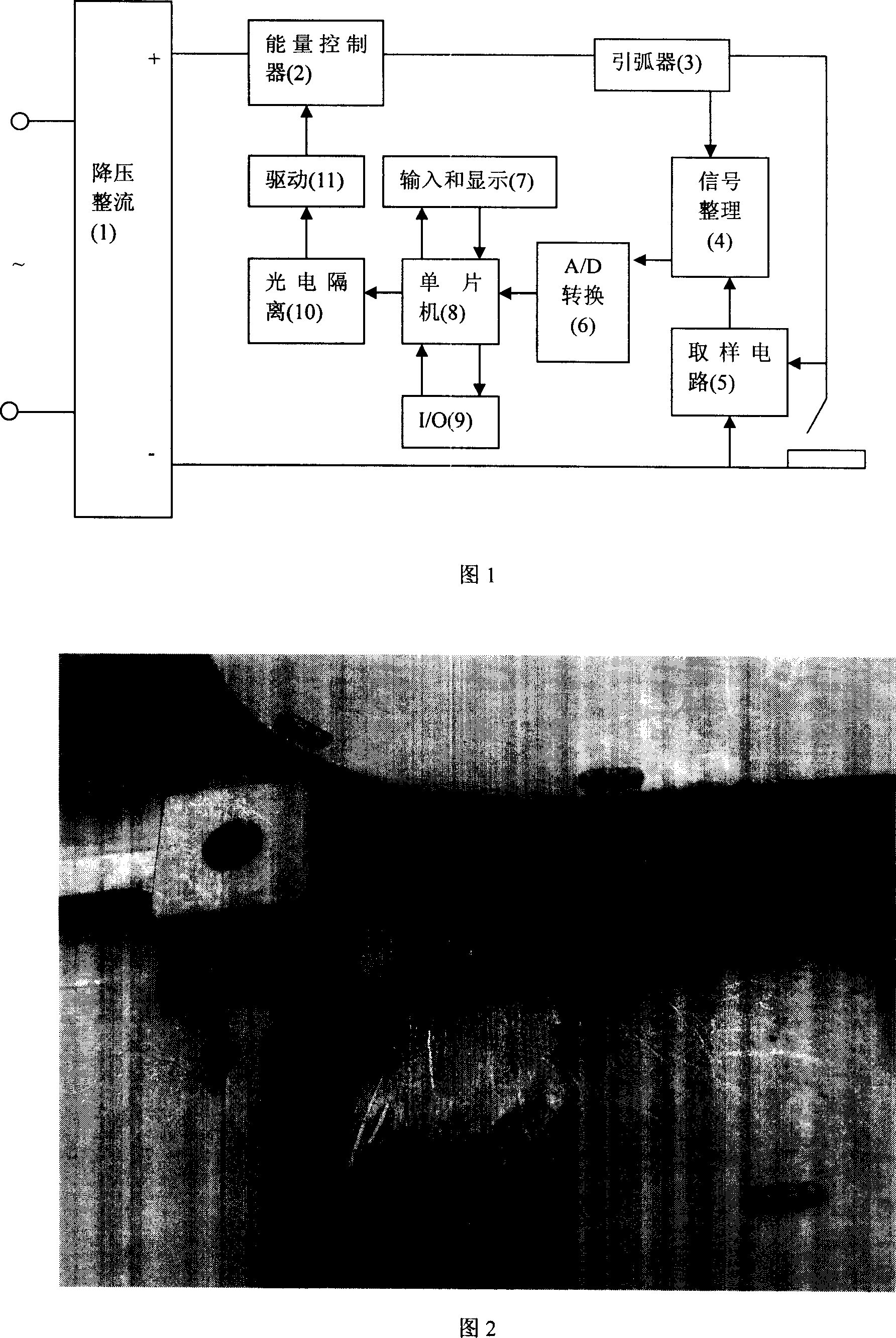

[0024] Embodiment 1, as shown in Figure 1, the pulse energy micro-area welding machine consists of a step-down rectifier circuit 1, an energy controller 2, an arc starter 3, a signal sorting circuit 4, a sampling circuit 5, an A / D conversion circuit 6, Input and display circuit 7, single-chip microcomputer 8, I / O circuit 9, photoelectric isolation circuit 10 and power drive circuit 11 constitute; The input terminal of the arc starter 3, the input terminal of the sampling circuit 5 is connected to the step-down rectifier circuit 1 and the arc starter 3, and the output of the arc starter 3 and the sampling circuit 5 is connected to the signal finishing circuit 5 and the A / D conversion circuit 6. The single-chip microcomputer 8, the output of the single-chip microcomputer 8 is connected to the energy controller 2 through the photoelectric isolation circuit 10 and the driving circuit 11.

[0025] The step-down rectifier circuit 1 rectifies the alternating current and supplies it t...

Embodiment 2

[0026] Embodiment 2, the workpiece shown in Figure 2, after brazing, there is a local leak at the tenon, which is repaired by the process of the present invention:

[0027] (1) Check the workpiece with water pressure or air pressure method to determine the location of the defect;

[0028] (2) According to the size and location of defects, etc., the welding repair area shall be repaired before welding;

[0029] (3) Degrease and degrease the welding repair area;

[0030] (4) Perform welding repair in the welding repair area with a pulse energy micro-area welding machine;

[0031] (5) Carry out post-weld finishing on the welding repair area;

[0032] (6) Carry out leak detection on the workpiece by water pressure or air pressure method to confirm the quality of welding repair;

[0033] (7) If there is still leakage after welding repair, repeat steps (2) to (6) until there is no more leakage. After the above-mentioned steps, the workpiece meets the sealing requirements after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com