Patents

Literature

246 results about "Arc energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

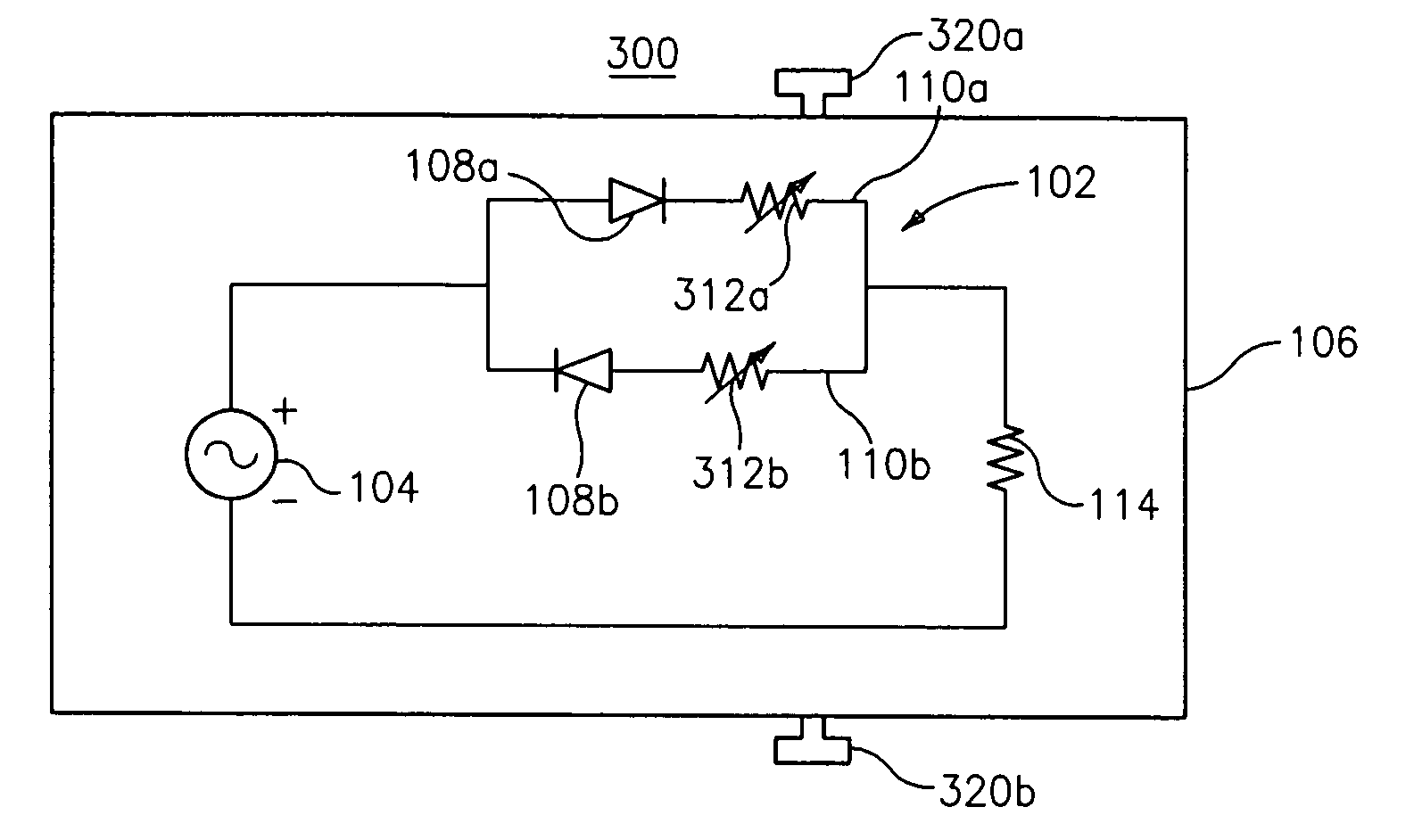

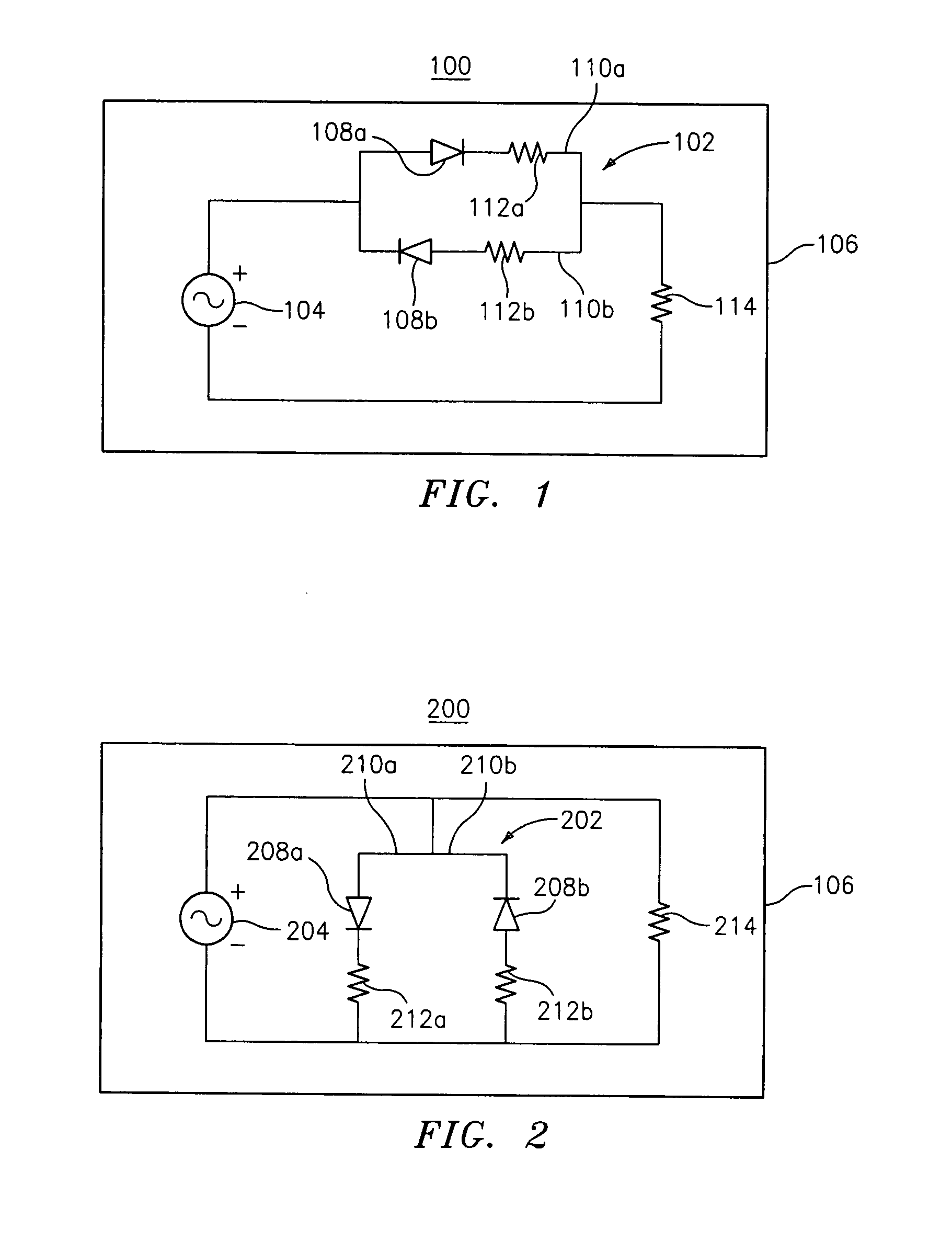

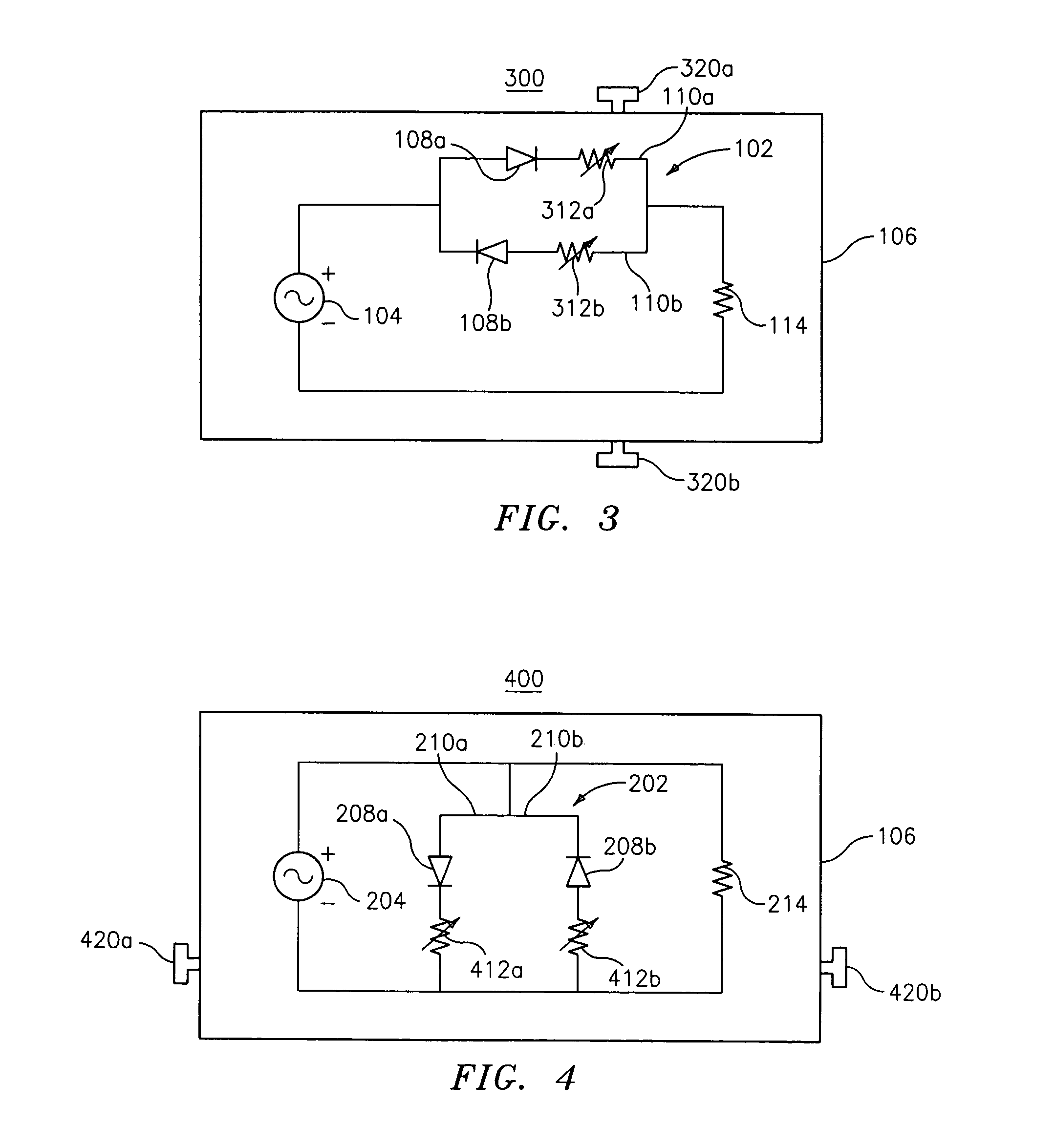

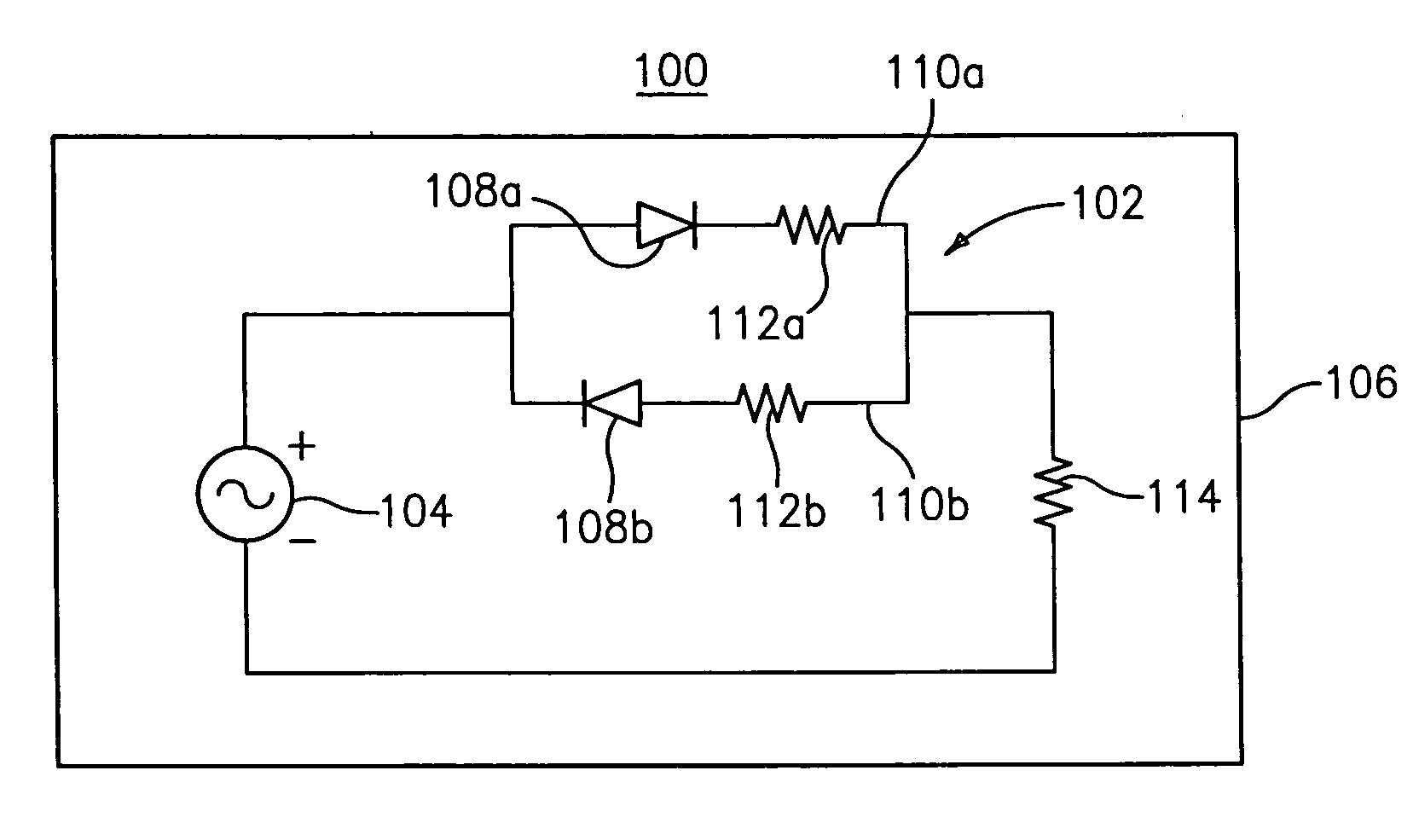

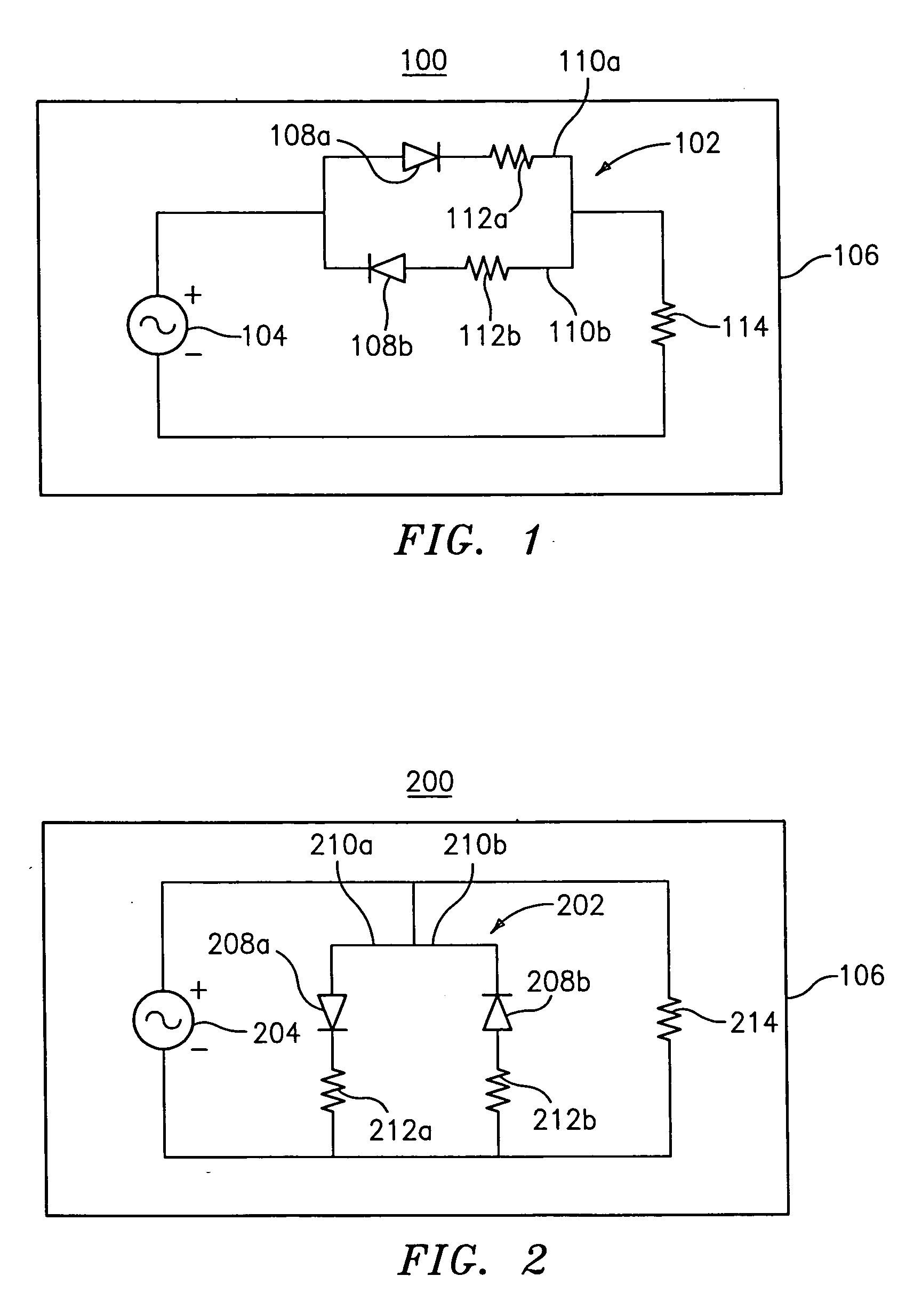

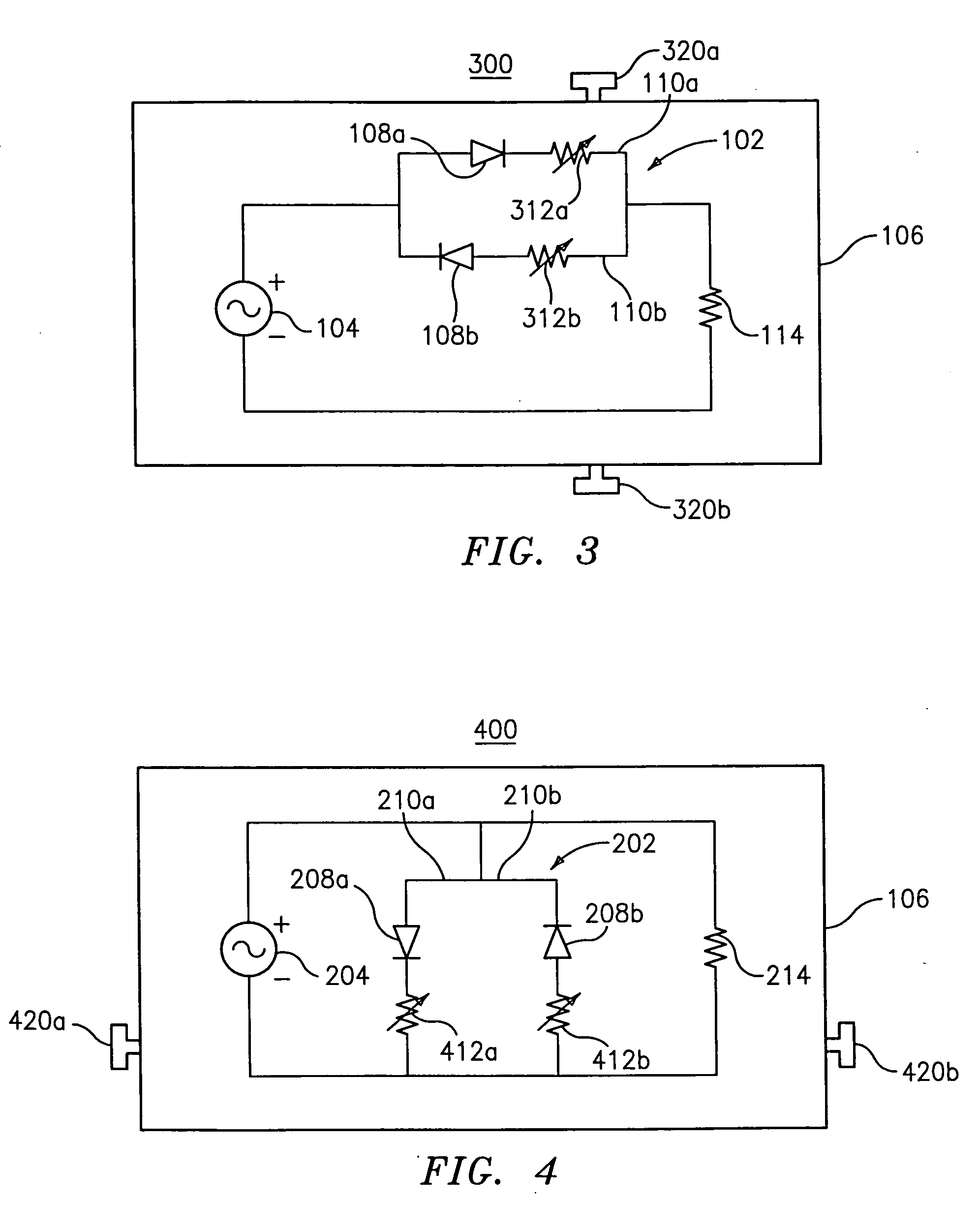

Circuit for controlling arc energy from an electrosurgical generator

ActiveUS7044948B2Quantity minimizationLimit thermal spreadSurgical instruments for heatingElectrosurgeryEngineering

A circuit is disclosed which minimizes the amount of tissue vaporized during a first half (positive half cycle) of an electrosurgical current cycle and minimizes the amount of current applied to tissue during a second half (negative half cycle) of the electrosurgical current cycle to control thermal spread. The circuit is preferably provided within an electrosurgical generator which is capable of controlling the amount of energy delivered to a patient during electrosurgery on a per arc basis.

Owner:COVIDIEN AG

Circuit for controlling arc energy from an electrosurgical generator

InactiveUS20060178664A1Quantity minimizationControl spreadSurgical instruments for heatingElectrosurgeryEngineering

A circuit is disclosed which minimizes the amount of tissue vaporized during a first half (positive half cycle) of an electrosurgical current cycle and minimizes the amount of current applied to tissue during a second half (negative half cycle) of the electrosurgical current cycle to control thermal spread. The circuit is preferably provided within an electrosurgical generator which is capable of controlling the amount of energy delivered to a patient during electrosurgery on a per arc basis.

Owner:COVIDIEN AG

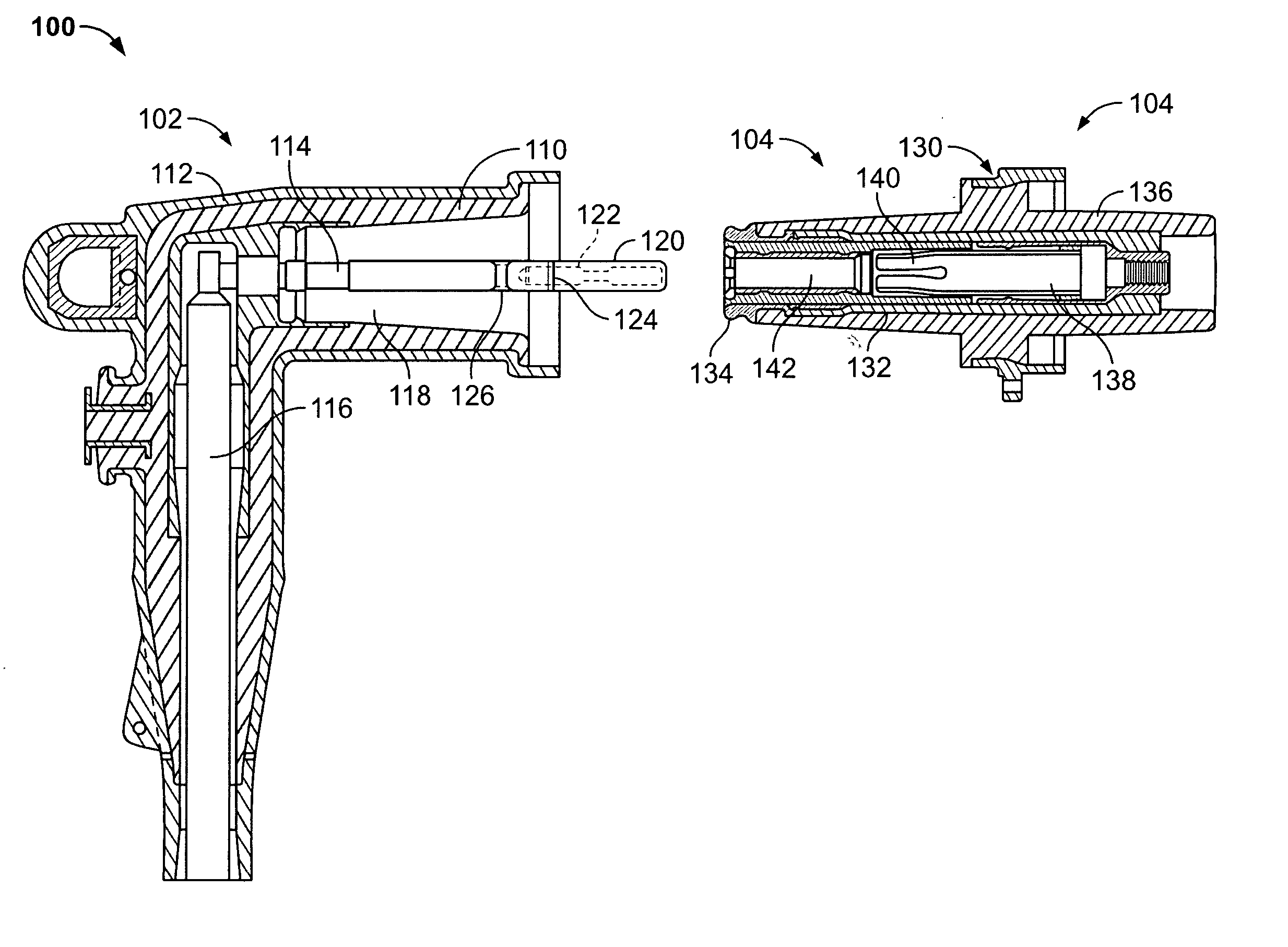

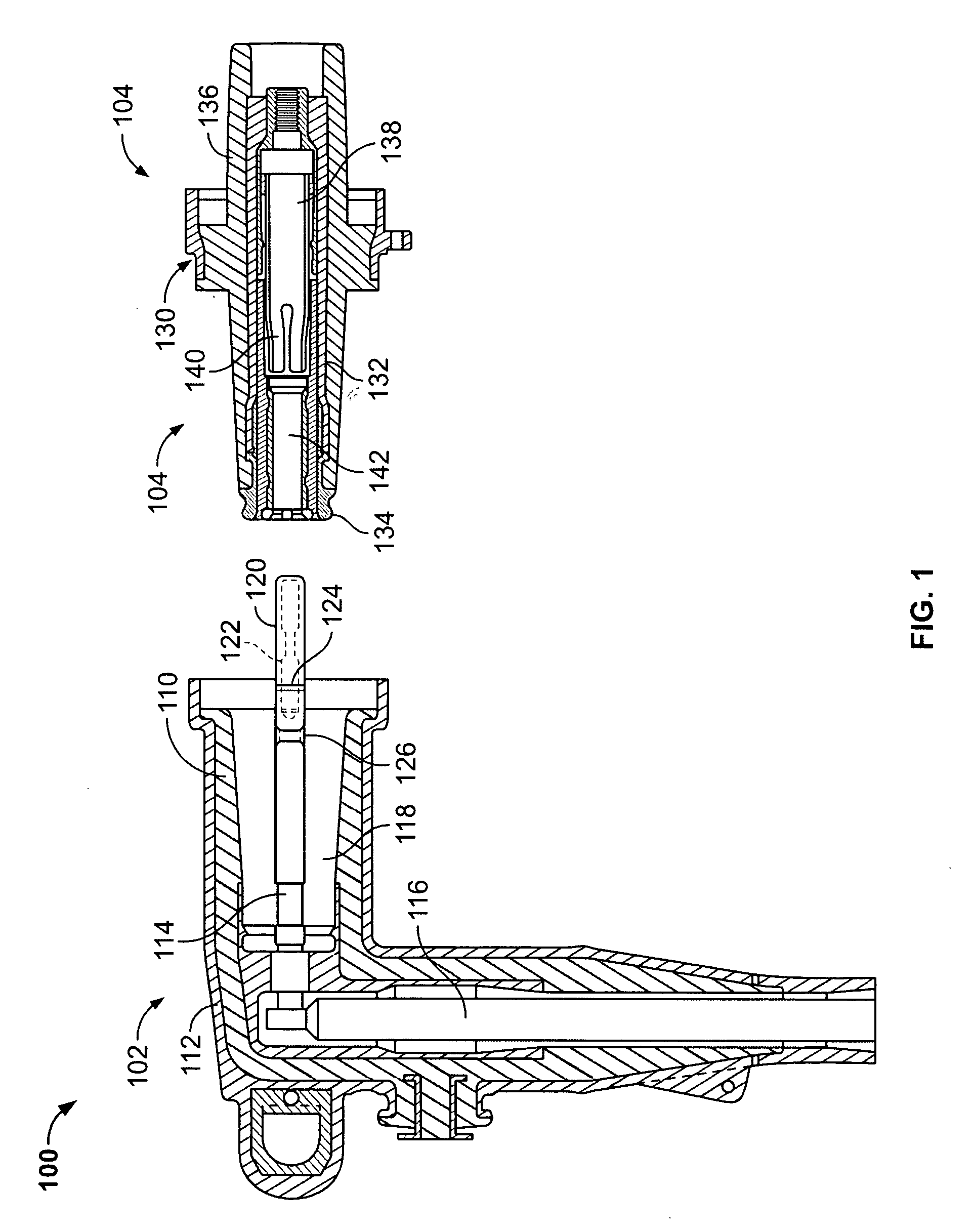

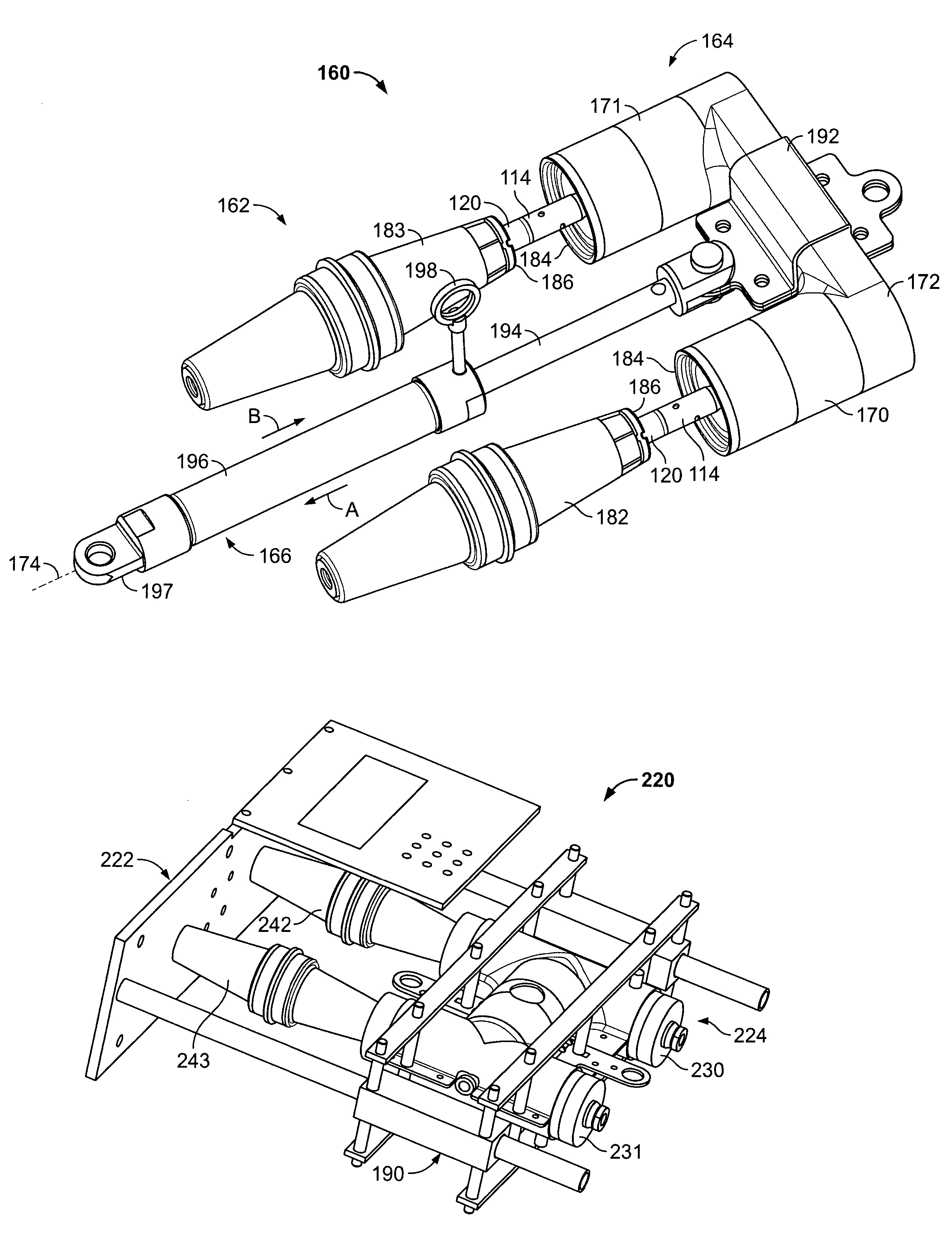

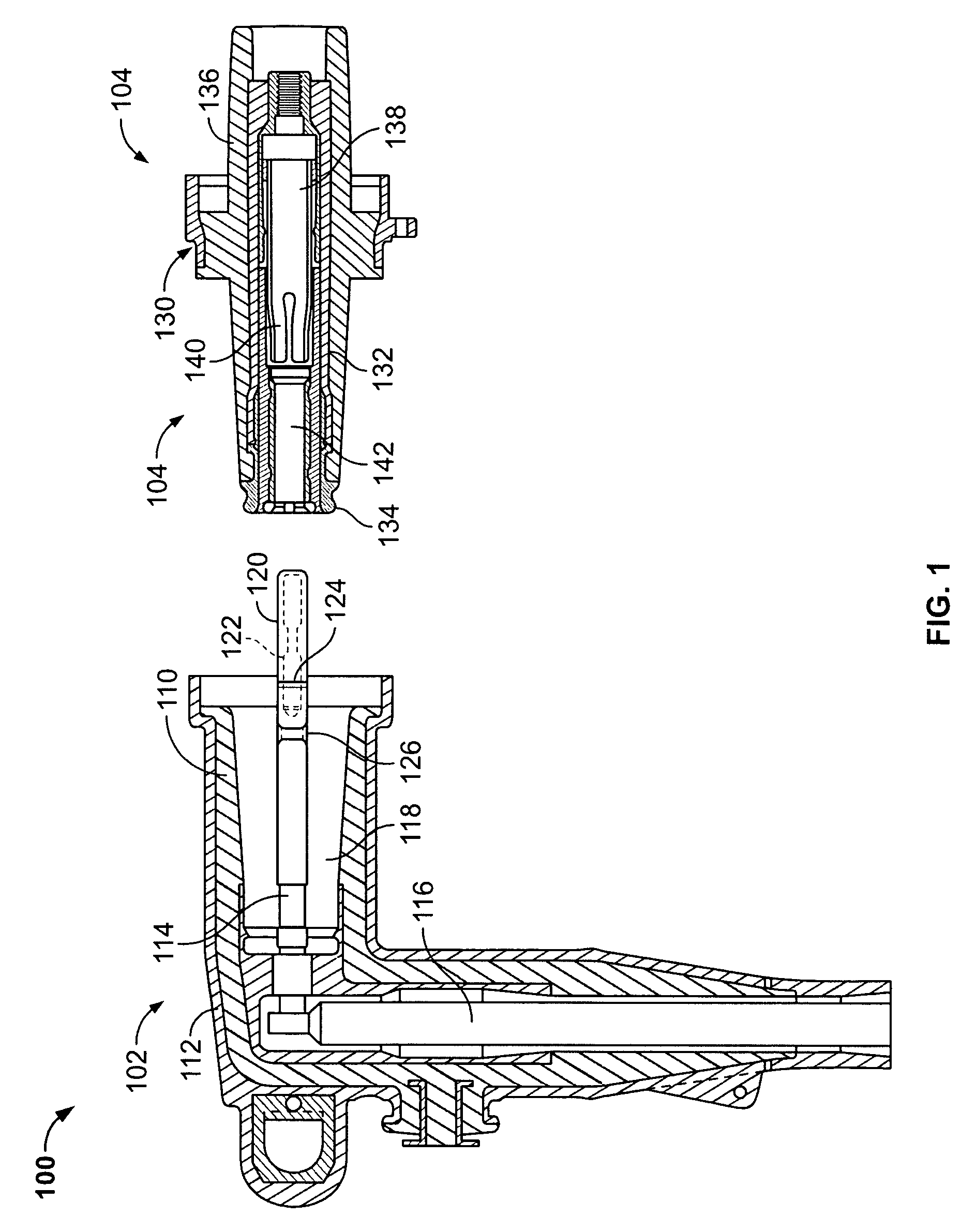

Apparatus, system and methods for deadfront visible loadbreak

InactiveUS20070032110A1Avoid separationOne pole connectionsCouplings bases/casesElectrical connectionEngineering

A loadbreak connector system and methods for visible break include first and second mating connector assemblies configured to make or break an electrical connection under energized circuit conditions, the first and second mating connectors selectively postionable relative to one another. One of the first and second mating connectors includes an arc follower, and the other of the first and second mating connectors includes an arc interrupter. The arc interrupter is configured to receive the arc follower, and the first and second meting connectors are positionable in an disconnected position wherein the arc follower remains engaged to and is located within the arc interrupter. Arc energy is distributed among multiple locations to reduce arc intensity.

Owner:EATON INTELLIGENT POWER LTD

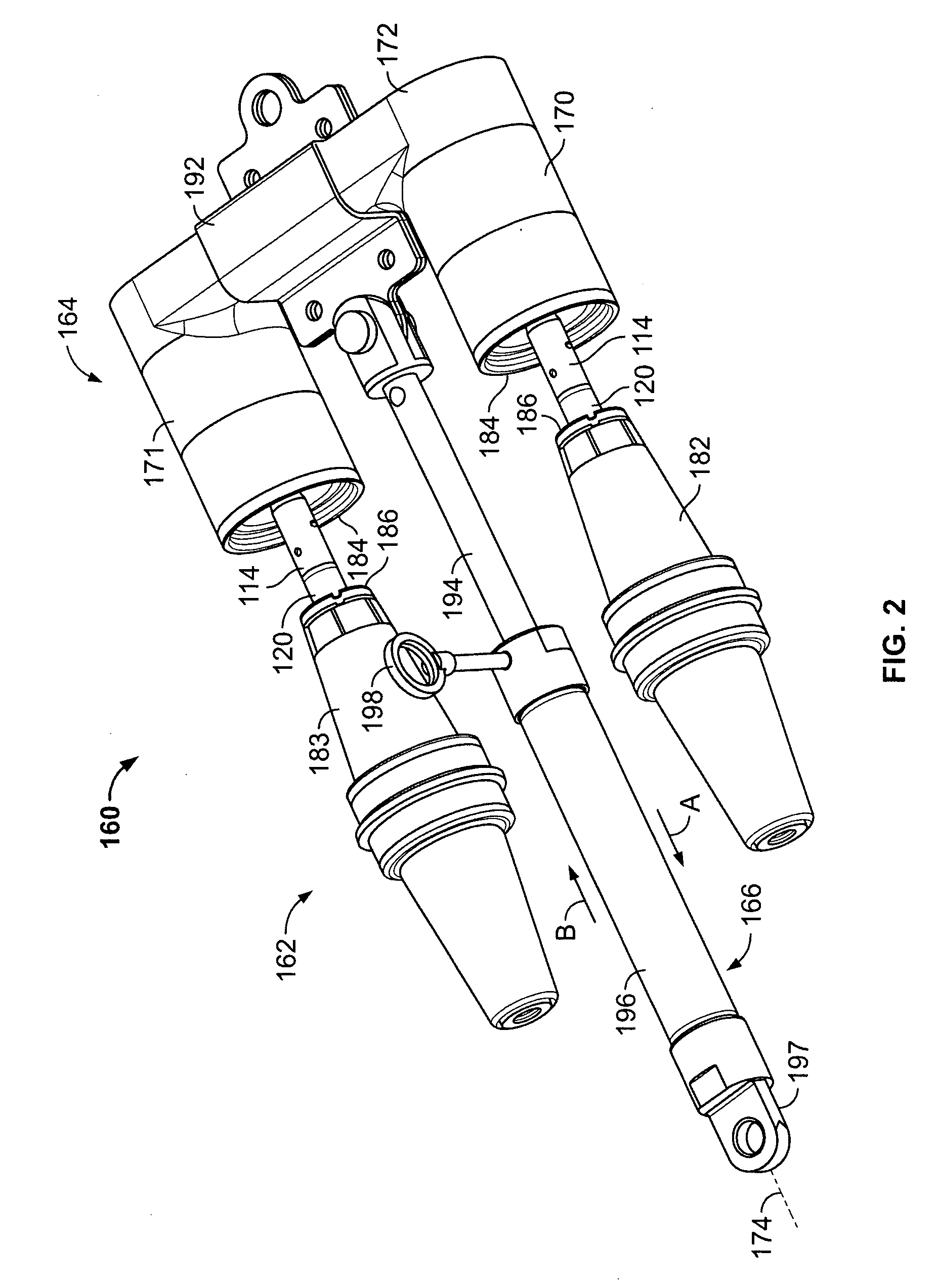

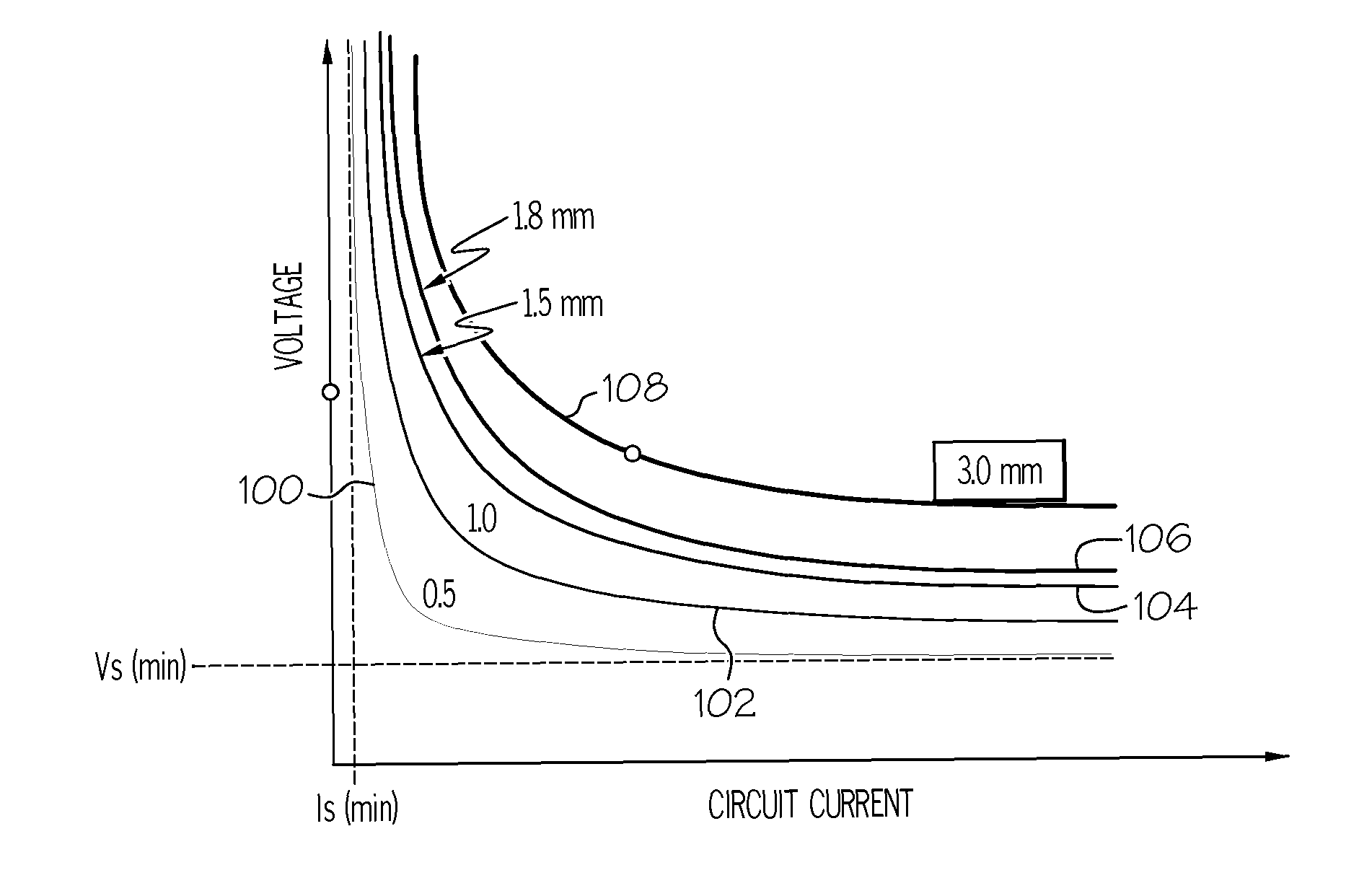

Hybrid high voltage DC contactor with arc energy diversion

InactiveUS20090168273A1Electric switchesEmergency protective arrangements for automatic disconnectionShunt DevicePulse control

Owner:HONEYWELL INT INC

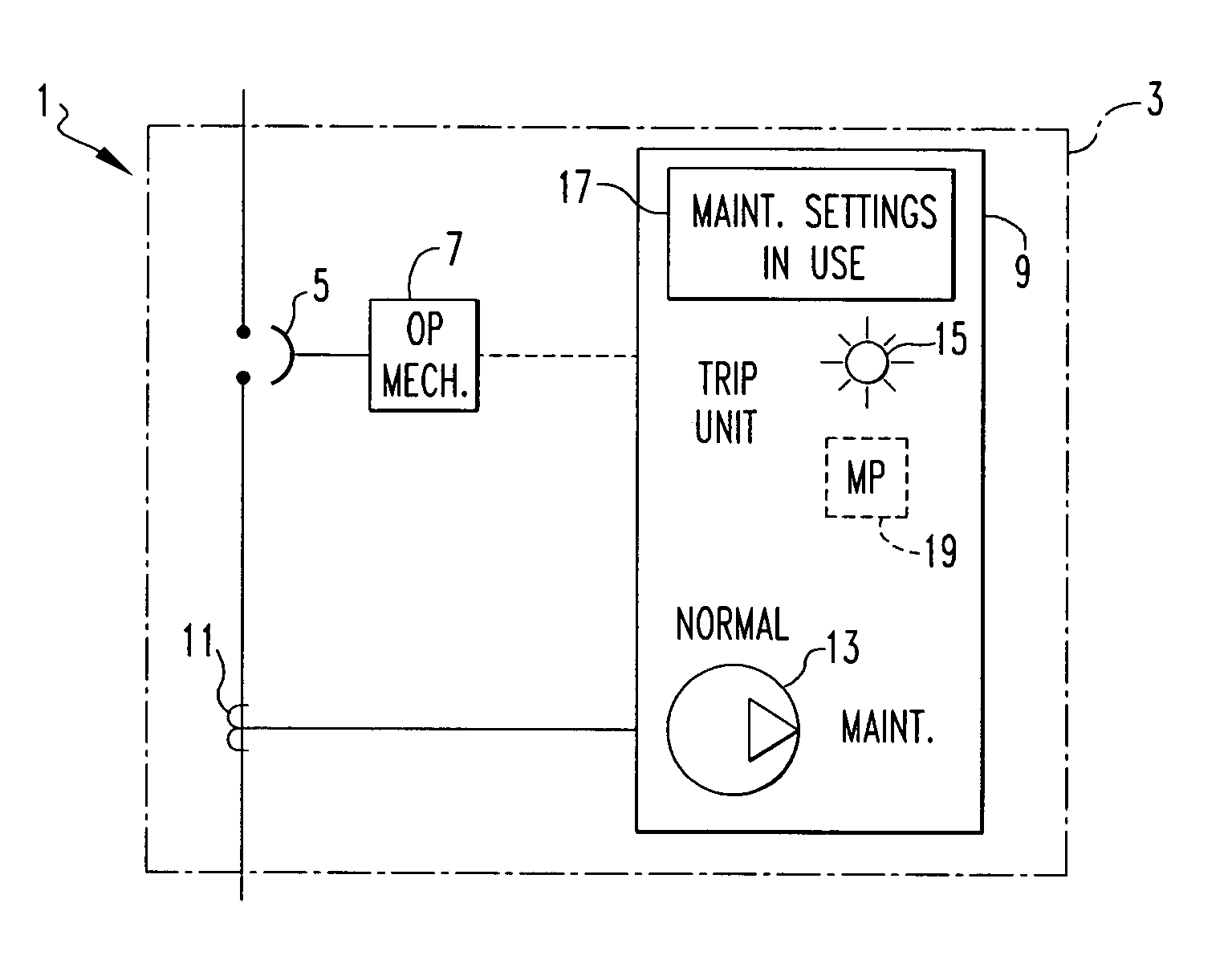

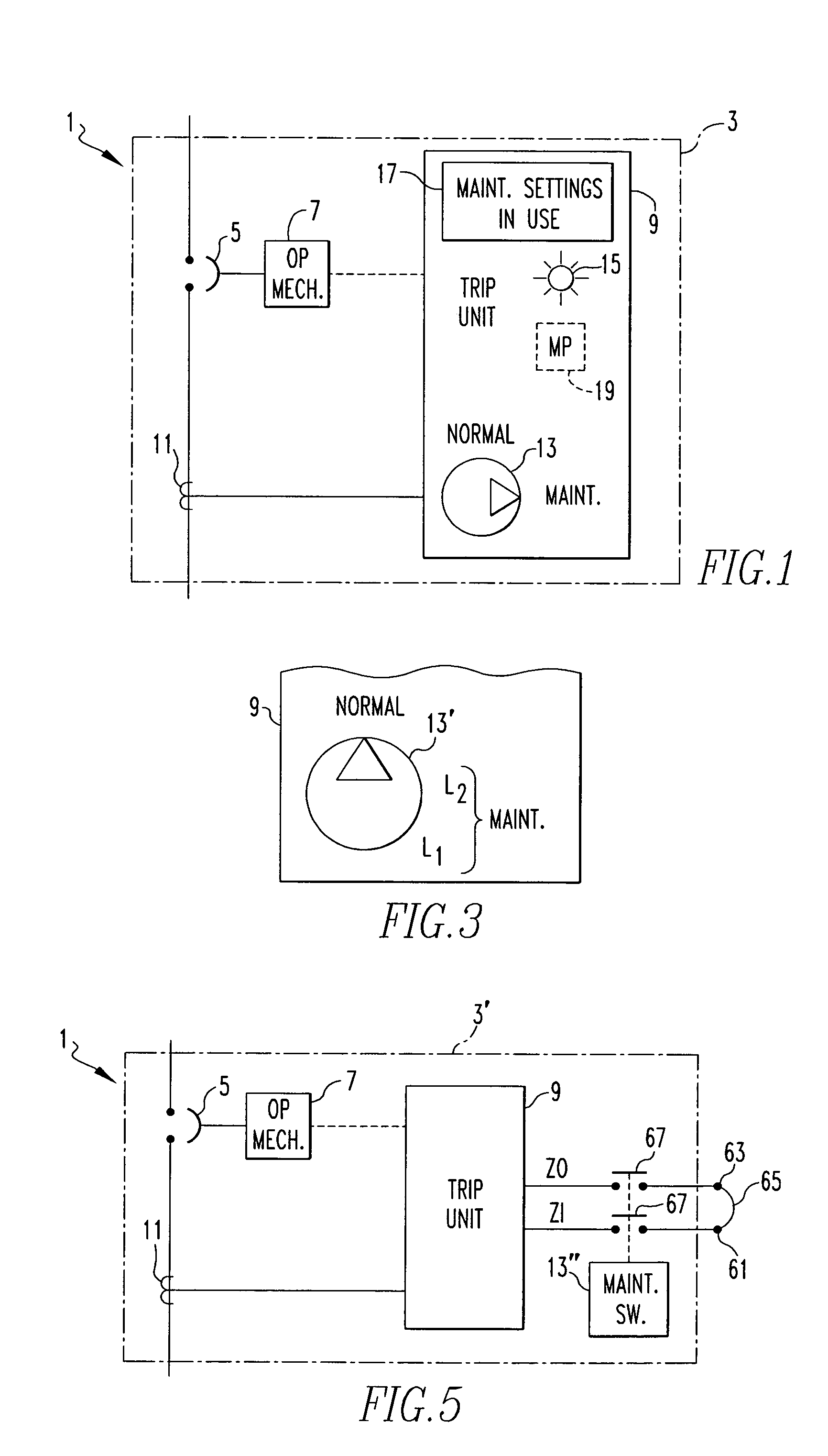

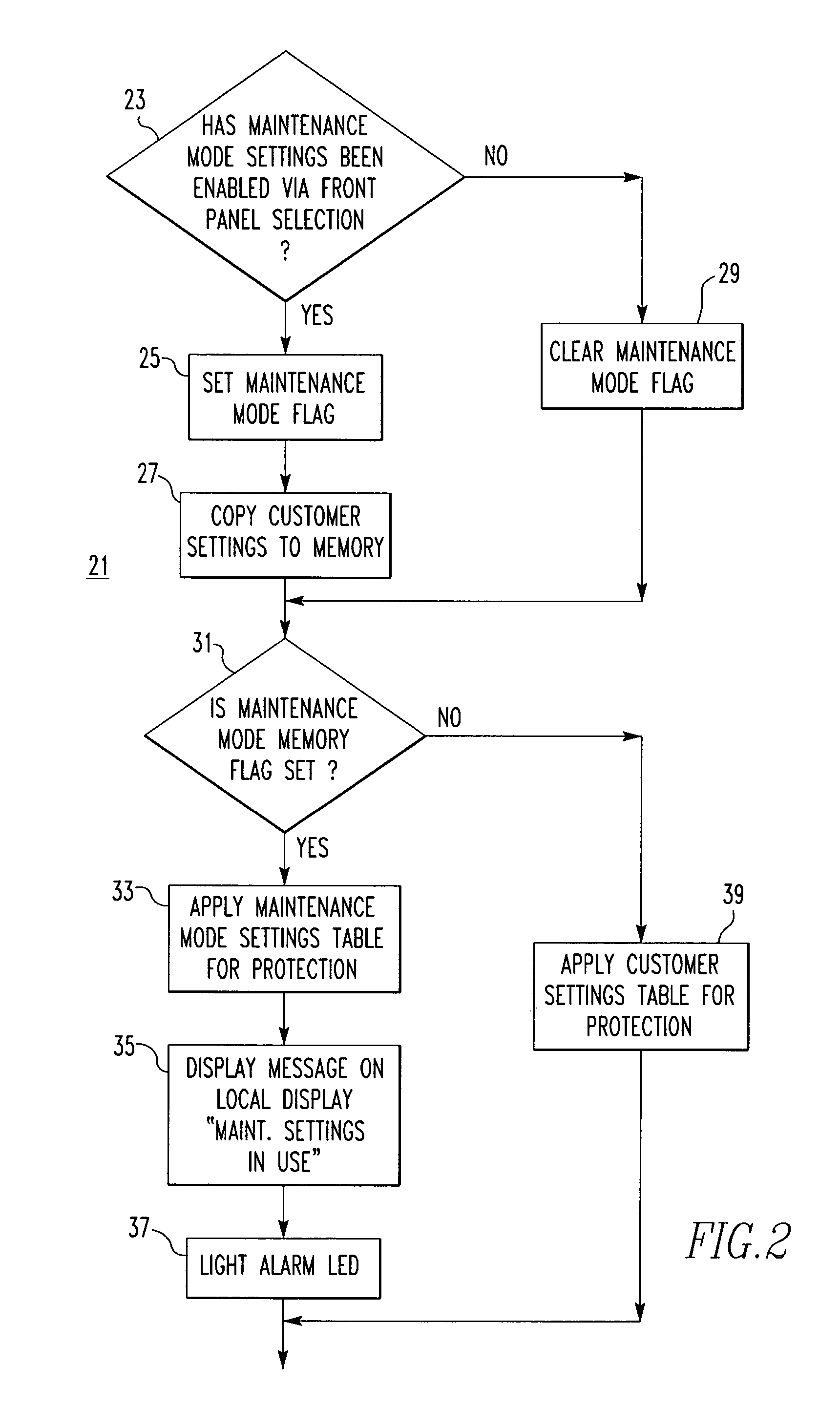

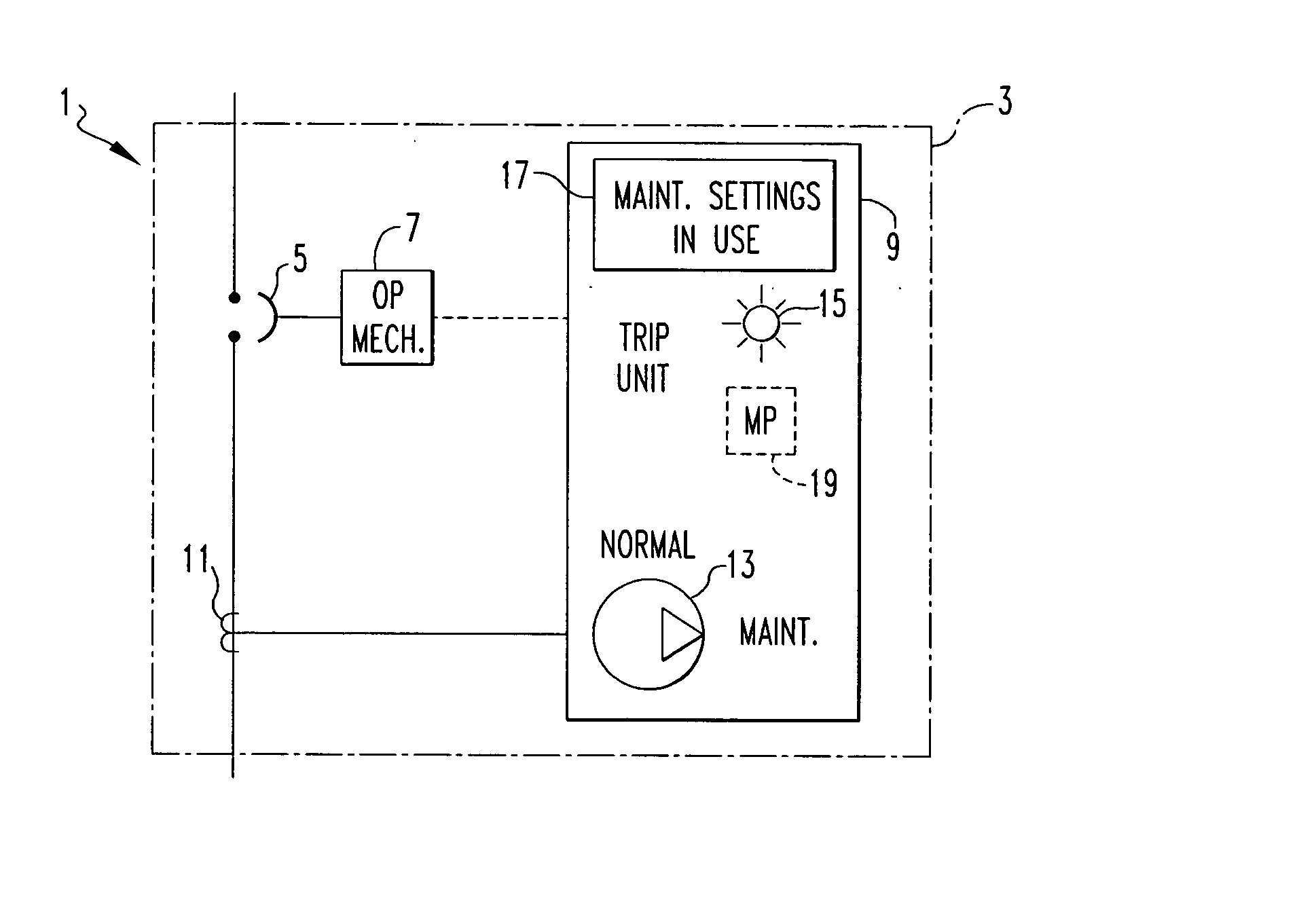

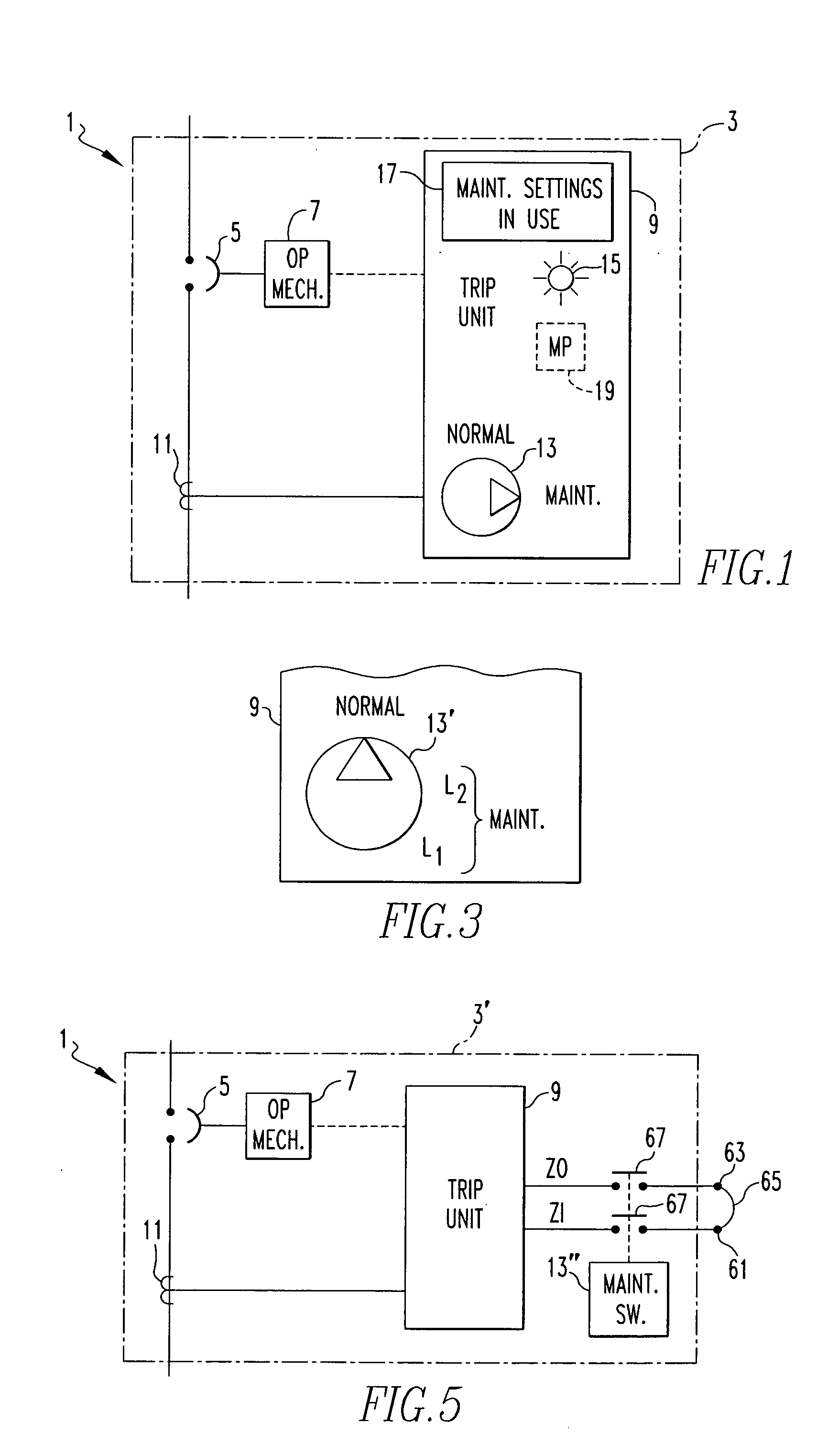

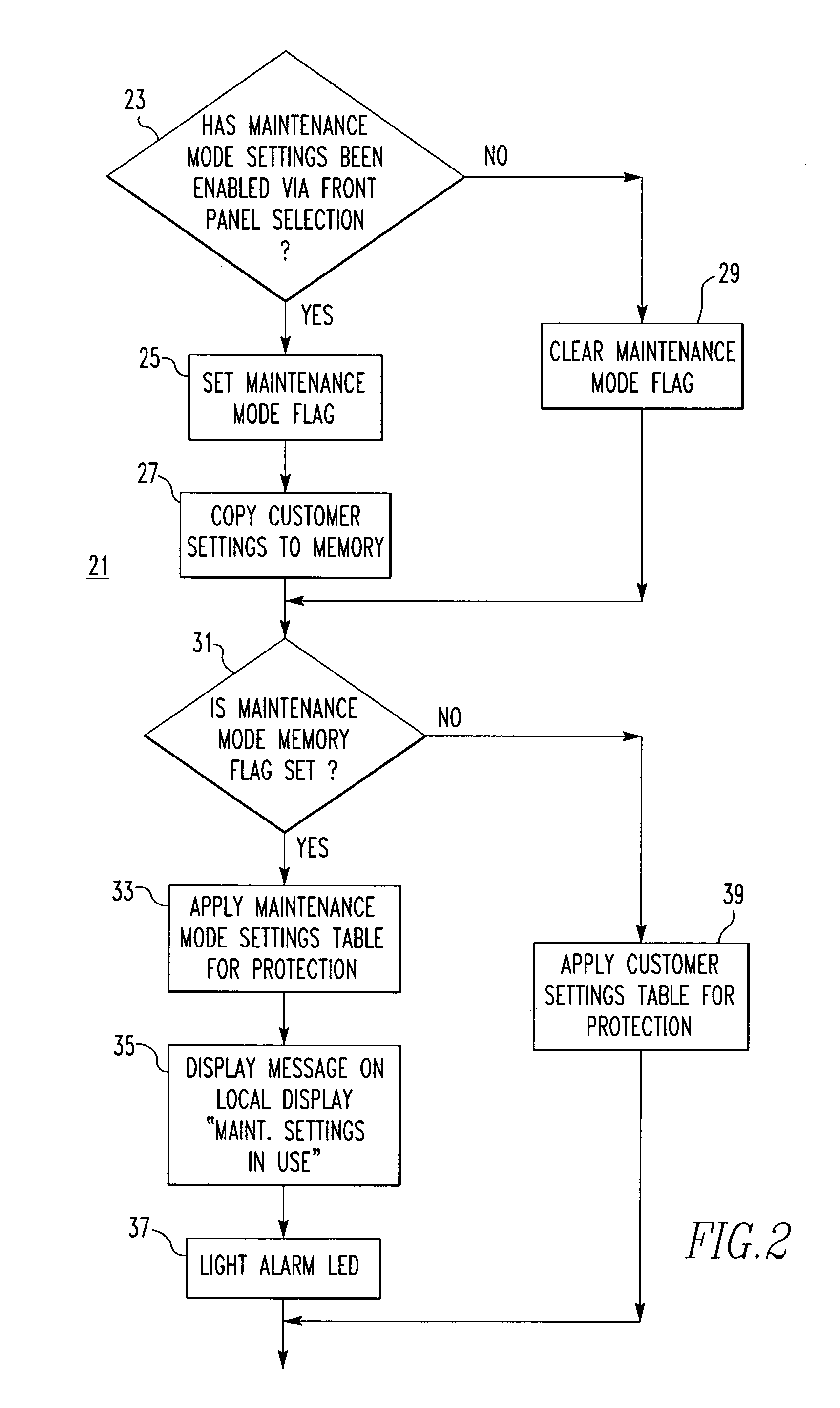

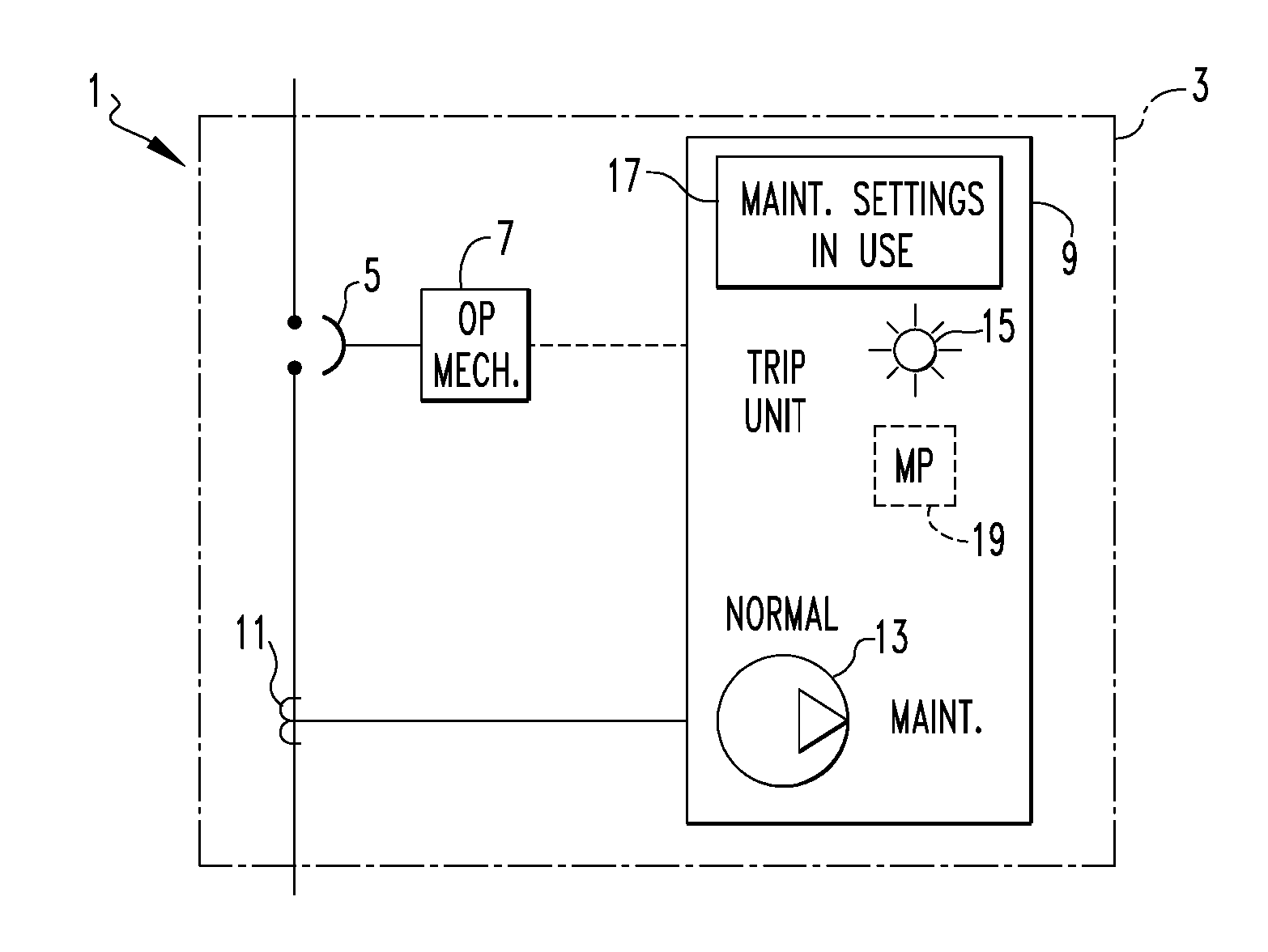

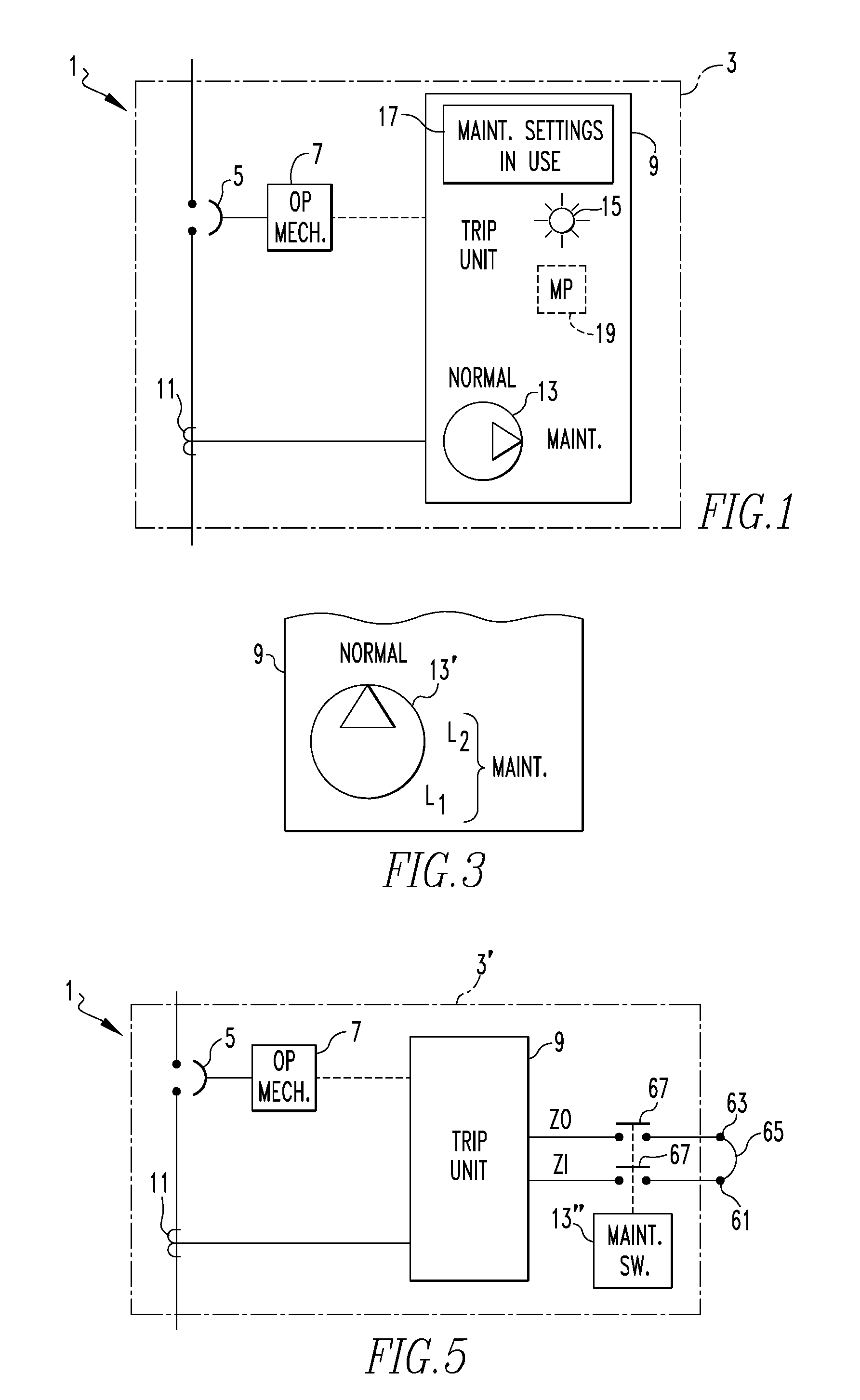

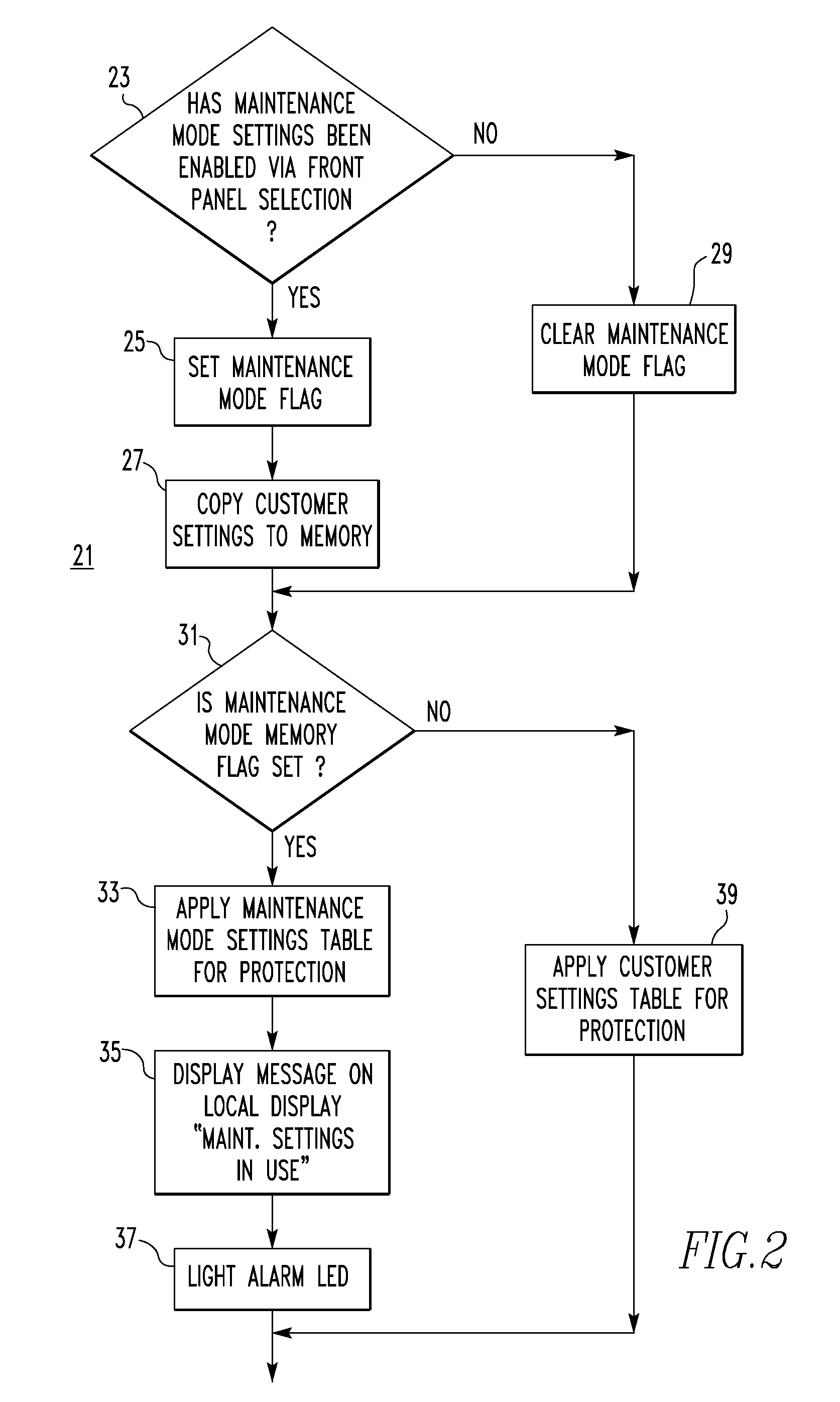

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

ActiveUS7203040B2Low levelReduce arc energyParameter calibration/settingProvisions for user interfaceLow voltage circuitsArc flash

Owner:EATON INTELLIGENT POWER LTD

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

ActiveUS20050219775A1Eliminate delaysLow levelParameter calibration/settingProvisions for user interfaceArc flashLow voltage circuits

Maintenance trip functions override the normal or specified trip functions of a low voltage circuit breaker to reduce pickup currents and / or time delays to effect faster trips, which reduces arc energy produced by faults during maintenance or testing on a live circuit breaker.

Owner:EATON INTELLIGENT POWER LIMITED

Apparatus, system and methods for deadfront visible loadbreak

InactiveUS7384287B2Avoid separationOne pole connectionsCouplings bases/casesElectrical connectionEngineering

A loadbreak connector system and methods for visible break include first and second mating connector assemblies configured to make or break an electrical connection under energized circuit conditions, the first and second mating connectors selectively postionable relative to one another. One of the first and second mating connectors includes an arc follower, and the other of the first and second mating connectors includes an arc interrupter. The arc interrupter is configured to receive the arc follower, and the first and second meting connectors are positionable in an disconnected position wherein the arc follower remains engaged to and is located within the arc interrupter. Arc energy is distributed among multiple locations to reduce arc intensity.

Owner:EATON INTELLIGENT POWER LTD

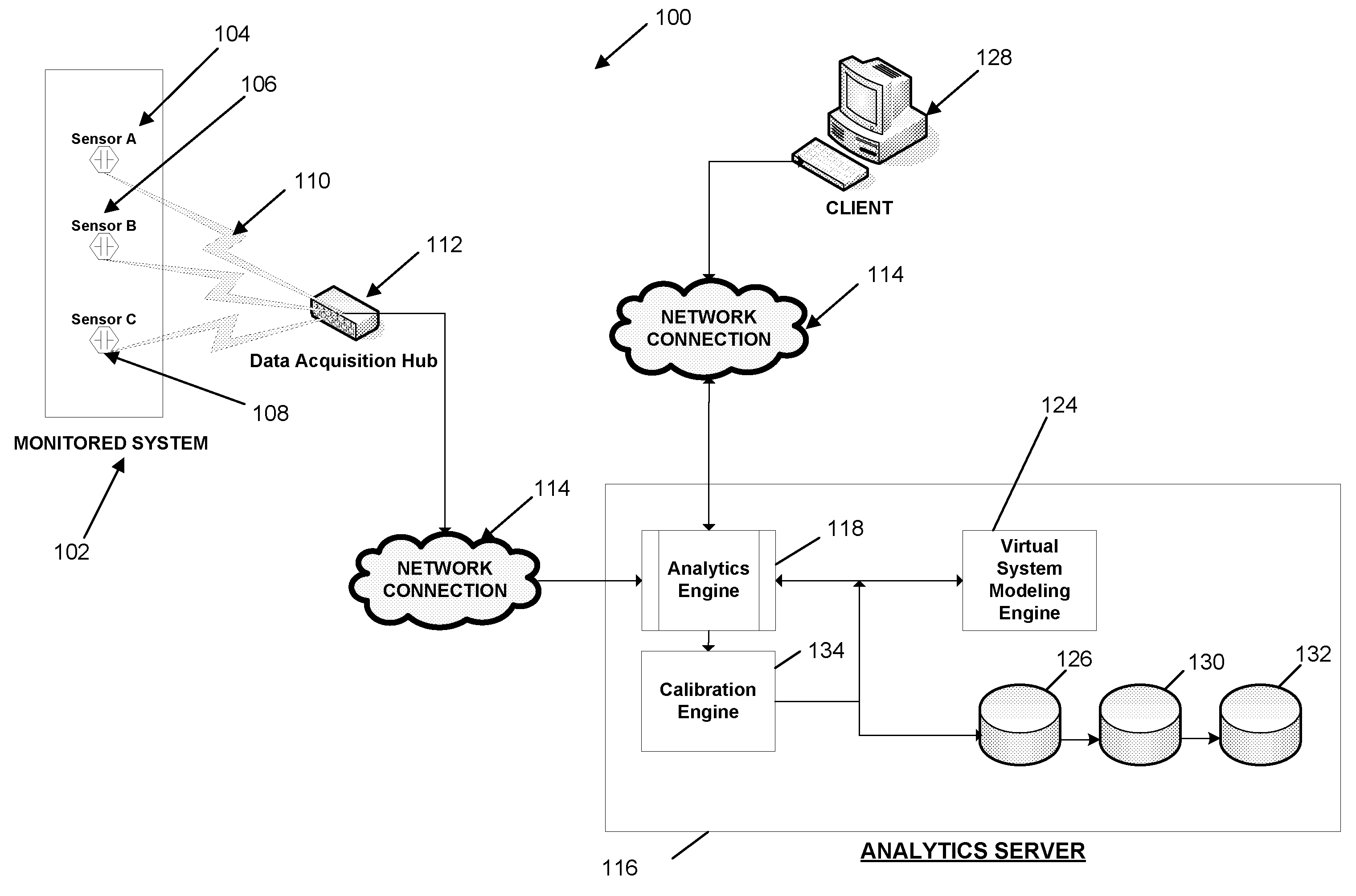

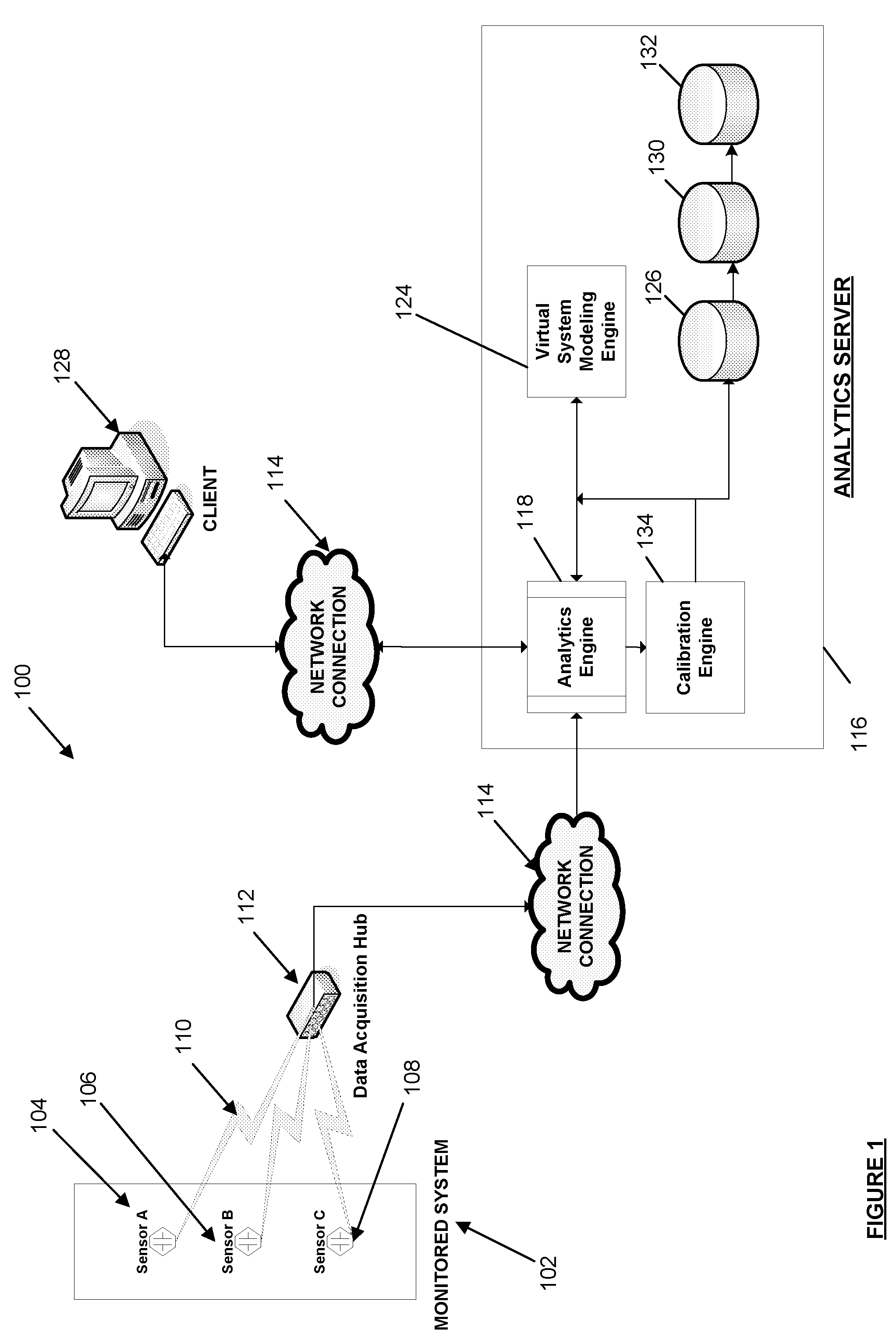

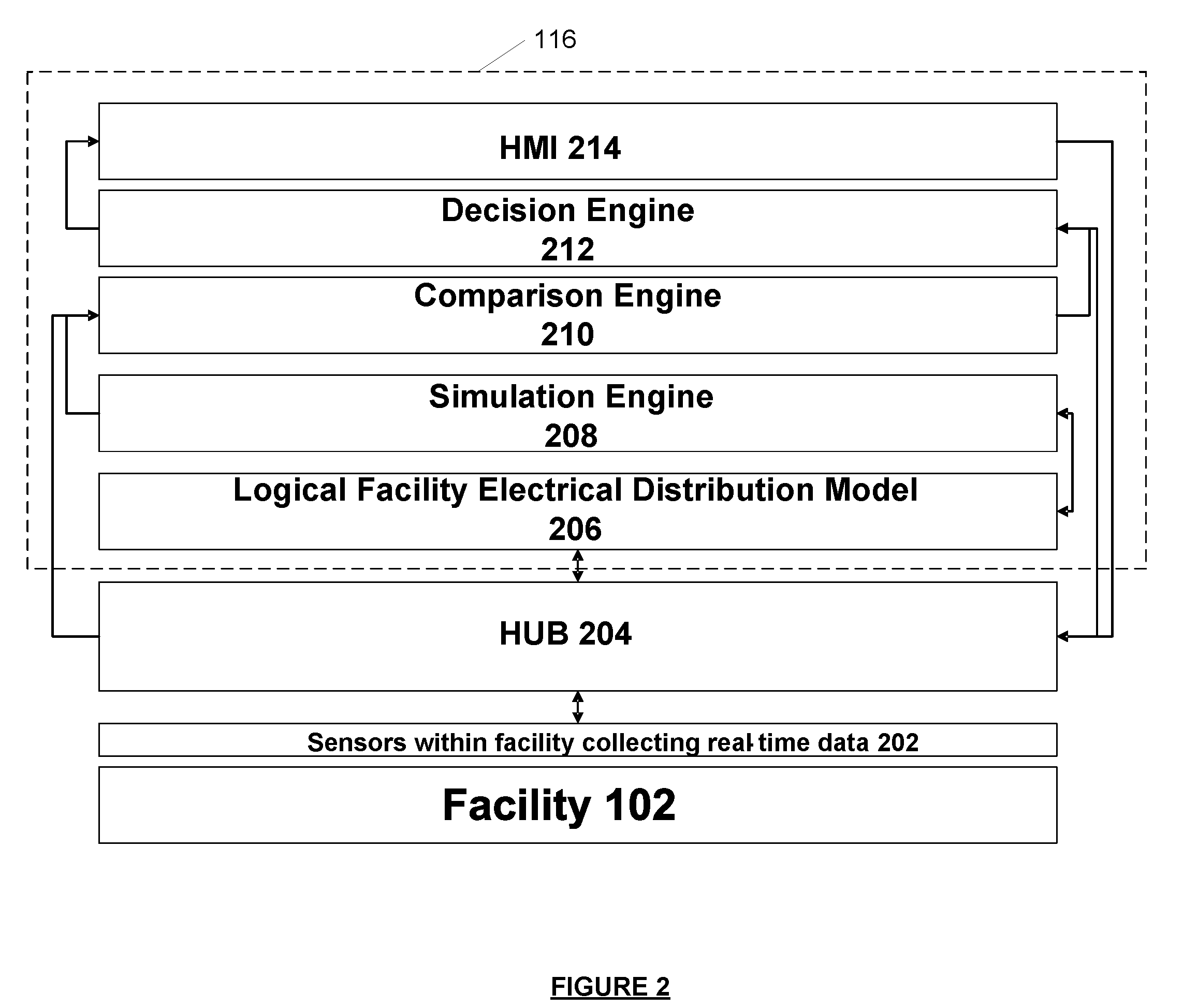

Method for predicting arc flash energy and ppe category within a real-time monitoring system

ActiveUS20090105998A1Analogue computers for electric apparatusComputation using non-denominational number representationArc flashElectric power system

A method for simulating an arc flash event on an electrical power system is disclosed. The virtual system model of the electrical system is modified to introduce a short circuiting feature. The standard to supply equations used in the arc flash event calculations is chosen. The arc flash event is simulated using the modified virtual system model in accordance with the chosen standard. The quantity of arc energy released by the arc flash event is calculated using results from the simulation. The report that forecasts an aspect of the arc flash event is communicated.

Owner:POWER ANALYTICS CORP

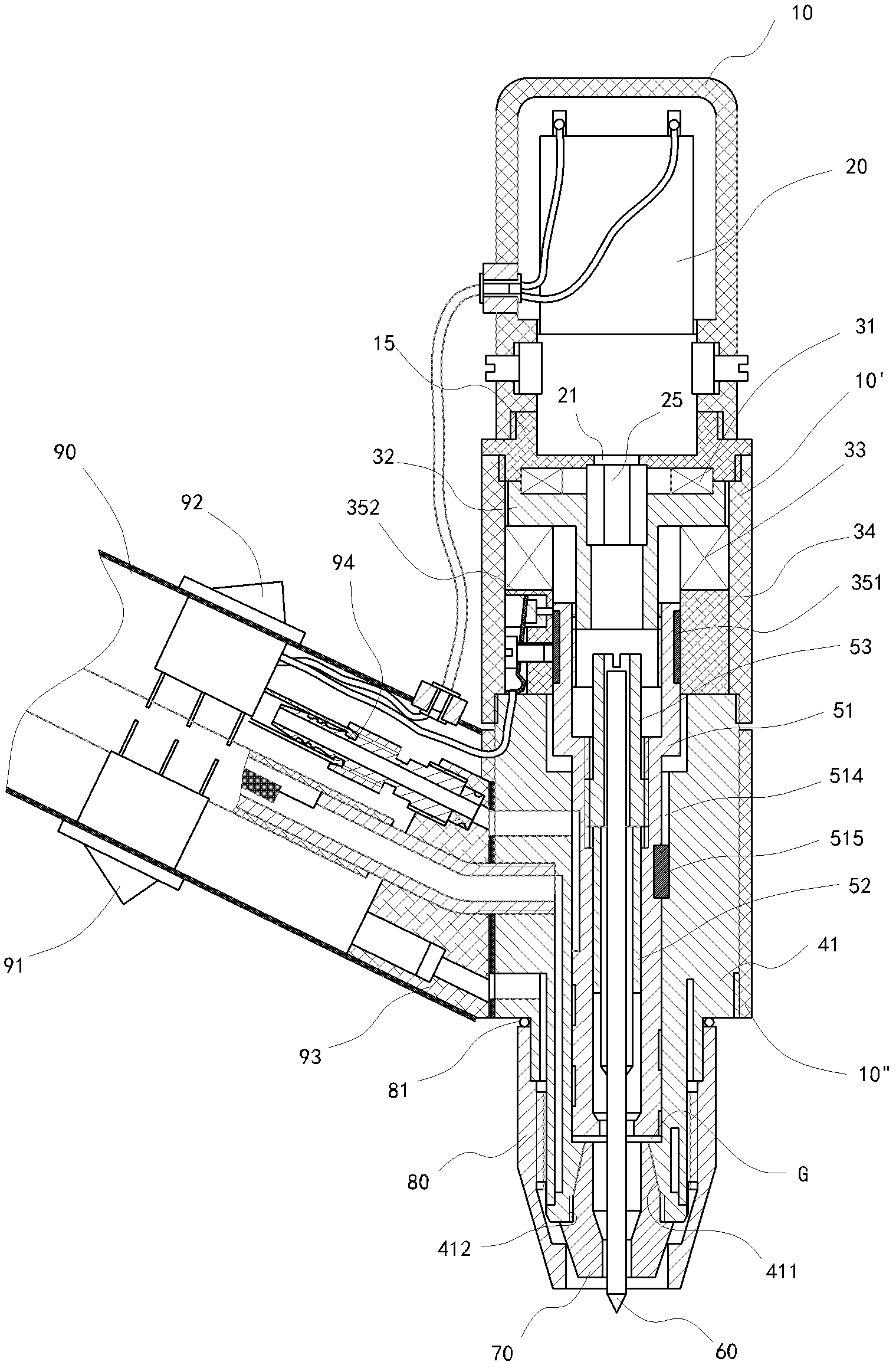

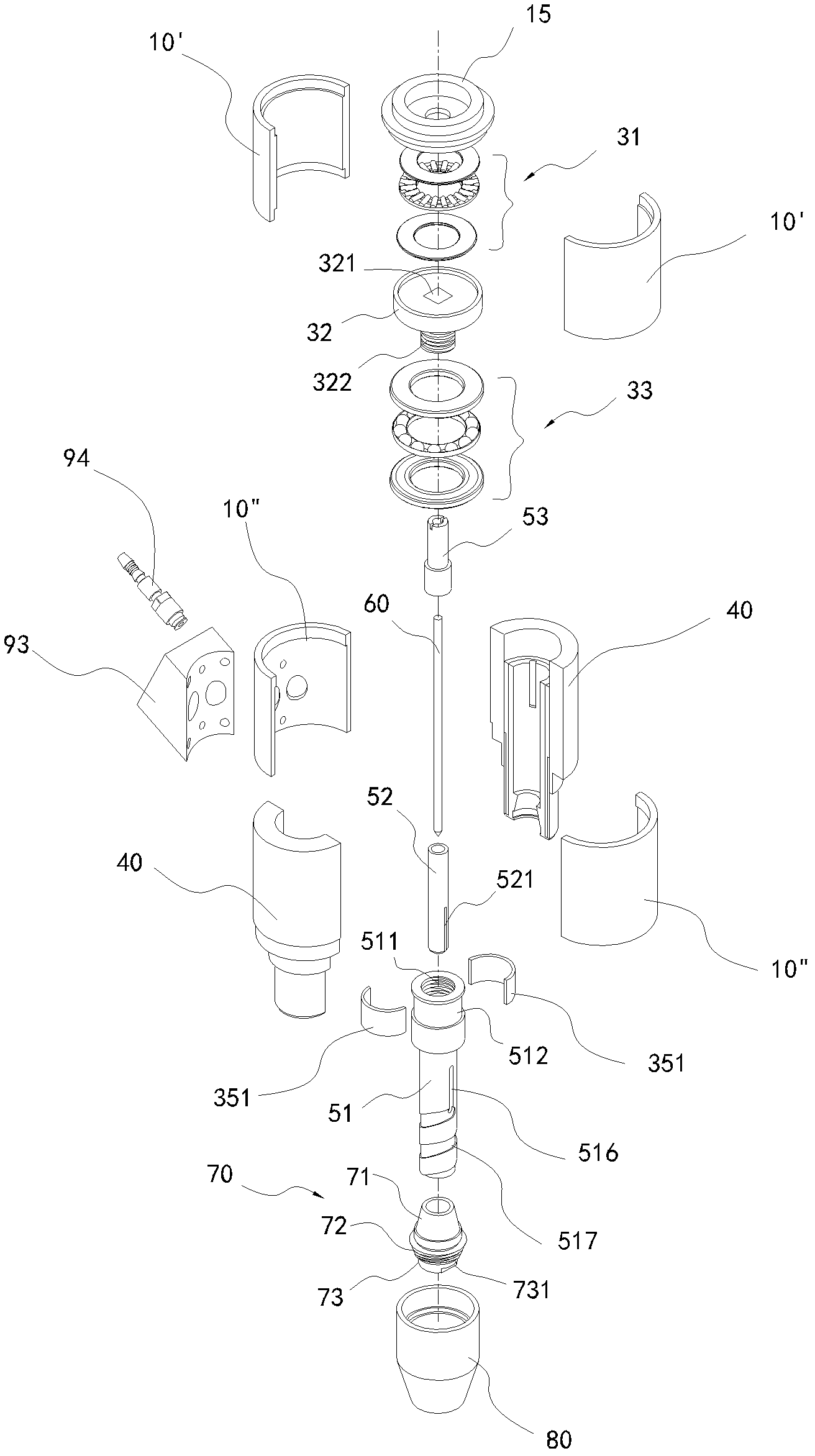

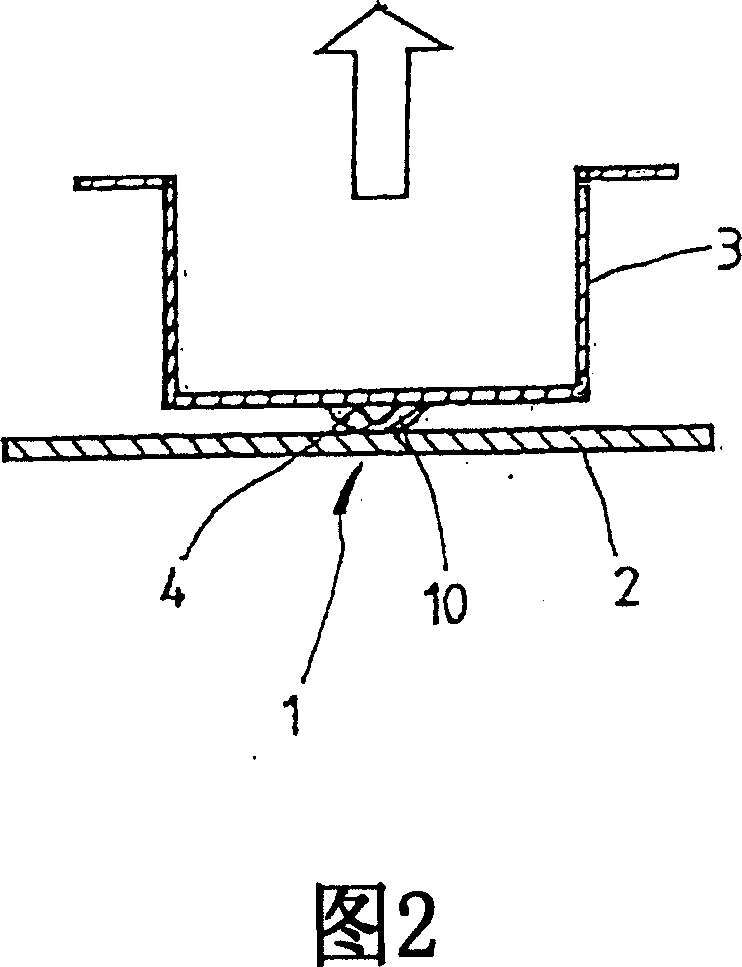

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

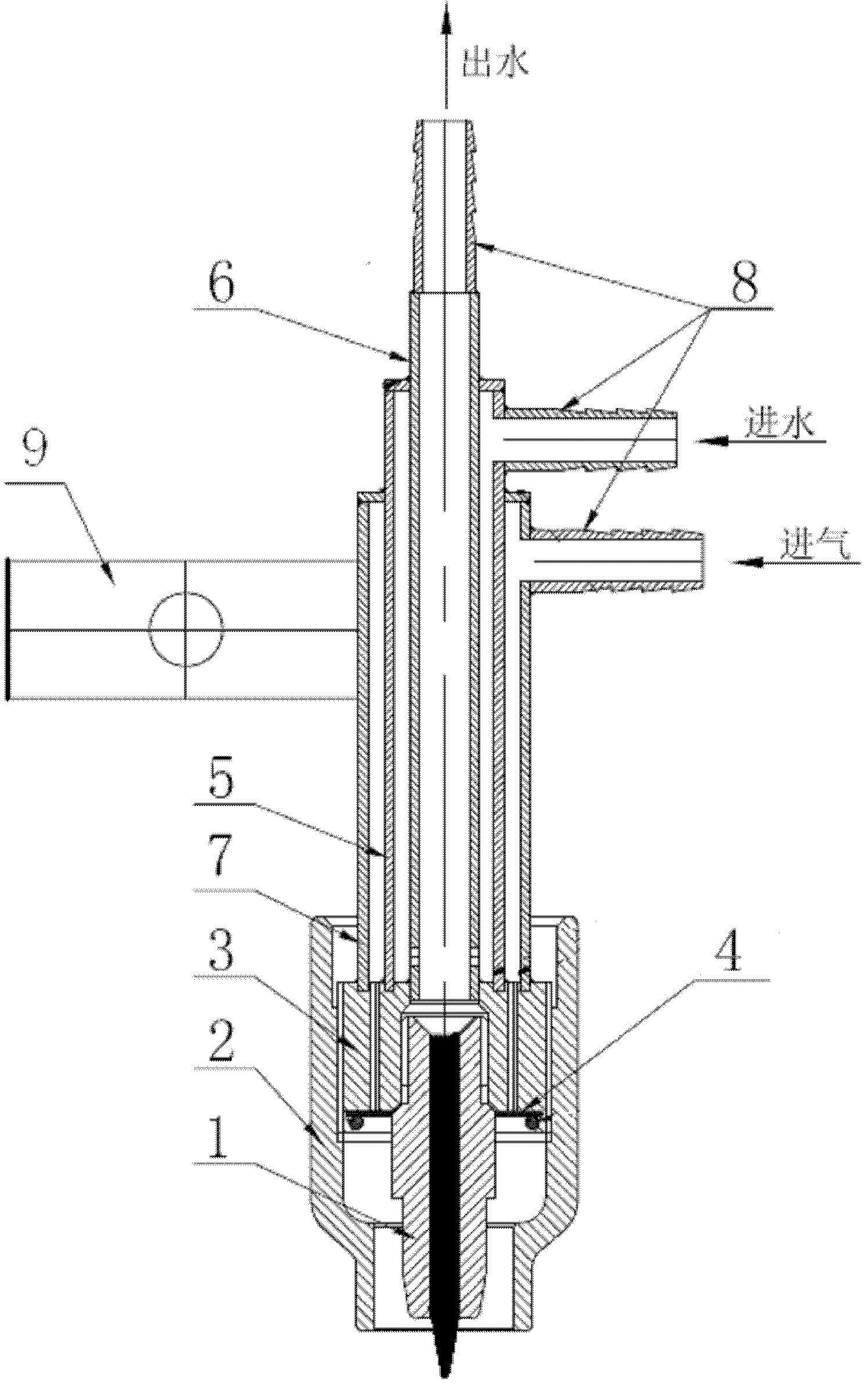

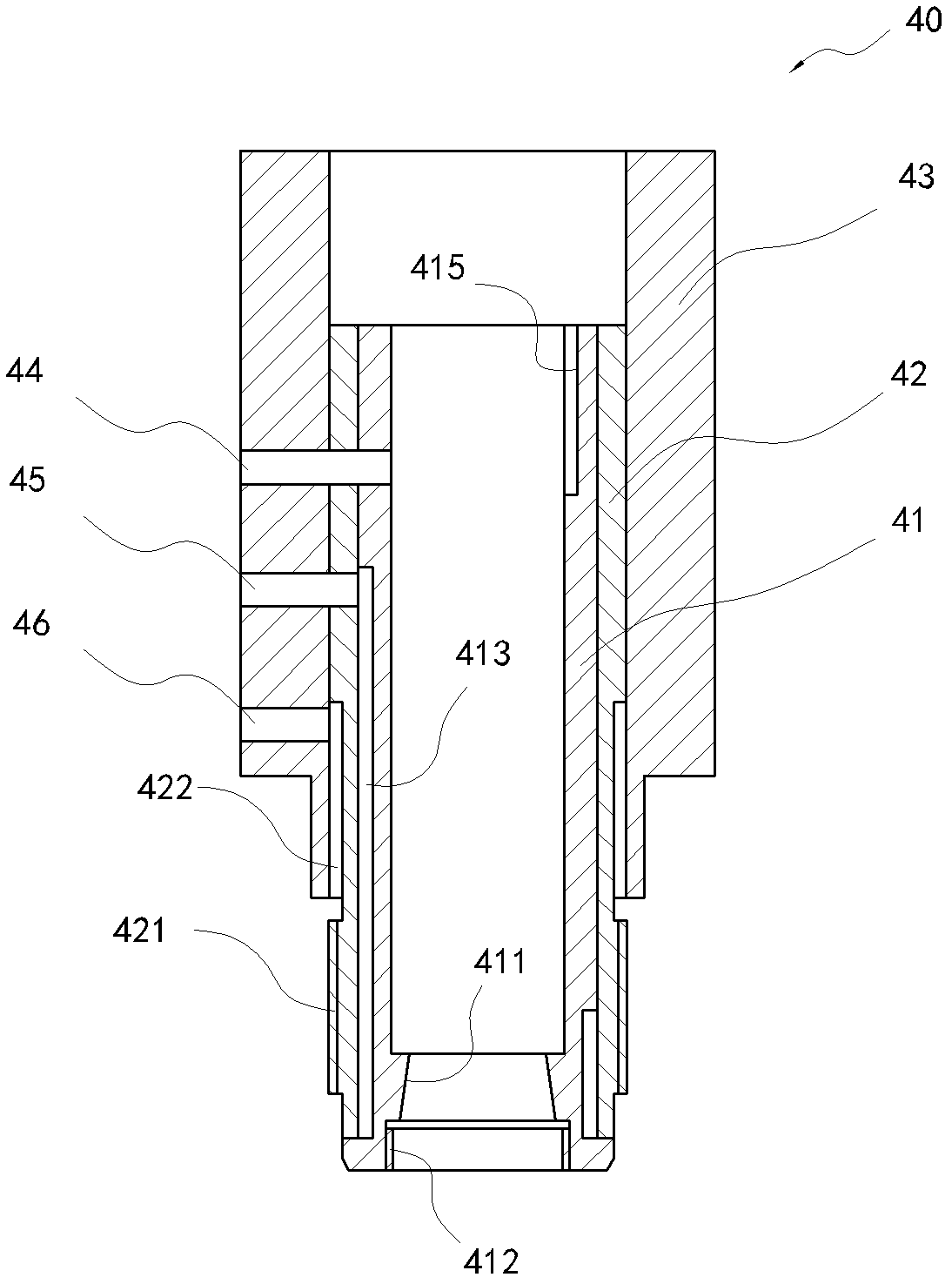

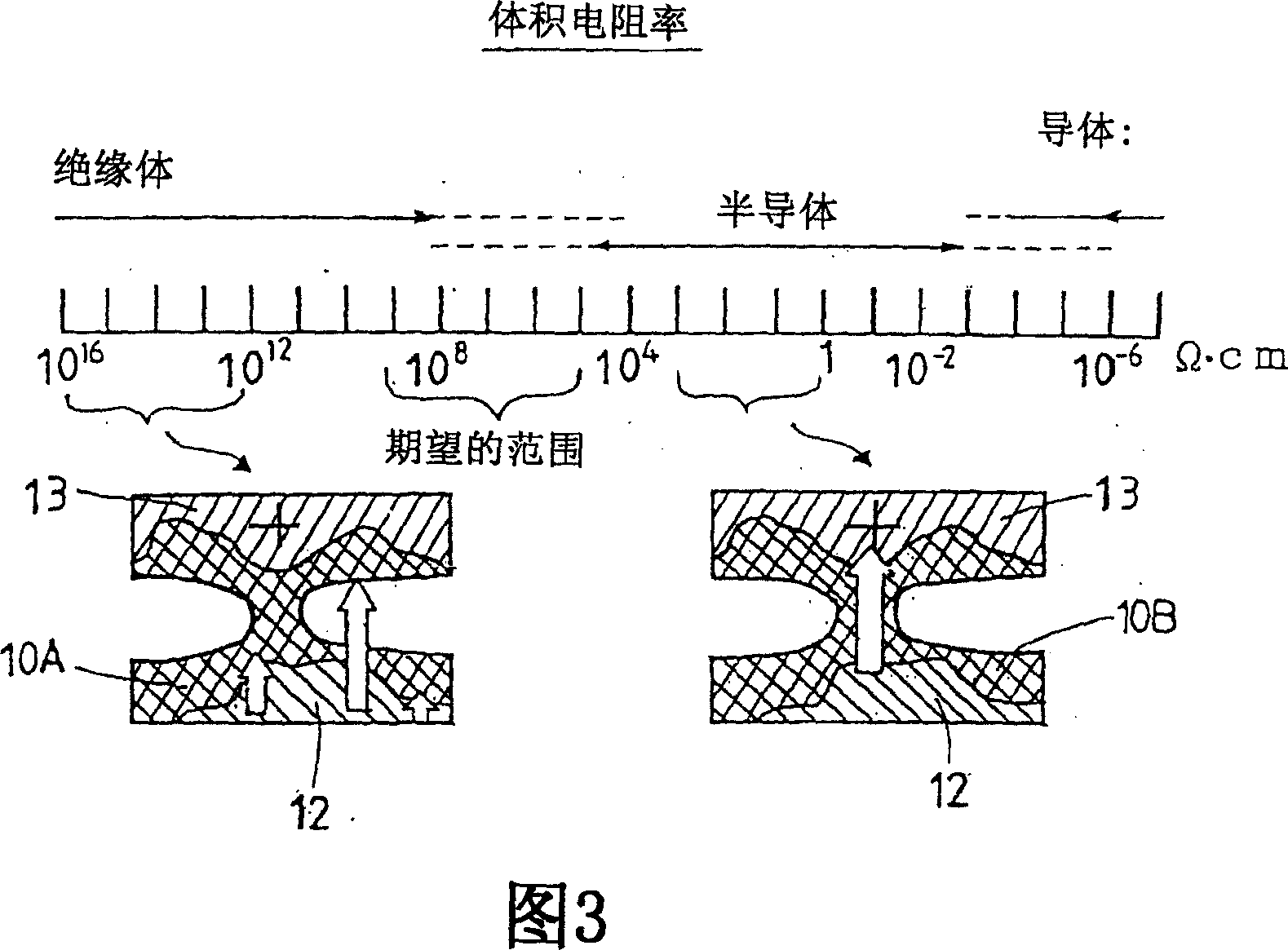

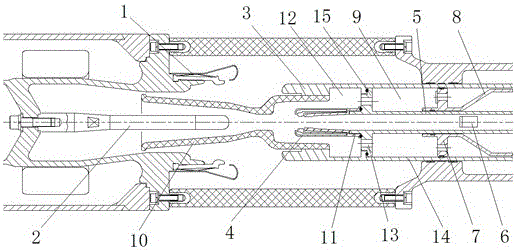

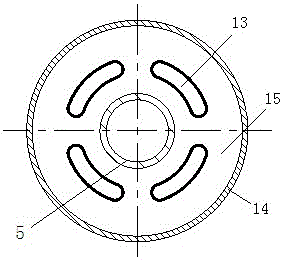

Condensation electric arc welding gun

InactiveCN102528249AIncrease energy densityAbility to control shapingElectrode supporting devicesElectrical conductorShielding gas

The invention discloses a condensation electric arc welding gun, which belongs to the technical field of welding equipment. A tungsten electrode is closely embedded in the center of an electrode holder; the electrode holder is sleeved in the center of a main connector through thread; the root part of the electrode holder is mutually engaged with the main connector by using an inclined surface, so that water cooling effect to the electrode and no leakage are guaranteed; a ceramic nozzle is sleeved on the periphery of the main connector through threaded connection; a protective gas laminar flow screen is a stainless steel wire net which is fixed on the other end face of the main connector through an O-shaped steel wire spring, so that protective gas forms laminar flow; a water outlet pipe, a water inlet bushing or a gas inlet bushing is provided with a cable connecting end; the water inlet bushing is coaxially sleeved outside a water outlet straight pipe; and the gas inlet bushing is sleeved outside the water inlet bushing, a water inlet passage is remained in the middle of the gas inlet bushing and the water inlet bushing, and the gas inlet bushing and the water inlet bushing are welded on the same end face of the main connector to form a water cooling passage and a gas protection passage. Apart from the ceramic nozzle, all the remaining materials are conductors. According to the condensation electric arc welding gun, the free electric arc energy intensity can be improved, and better capacity of controlling welding joint formation is achieved.

Owner:BEIJING UNIV OF TECH

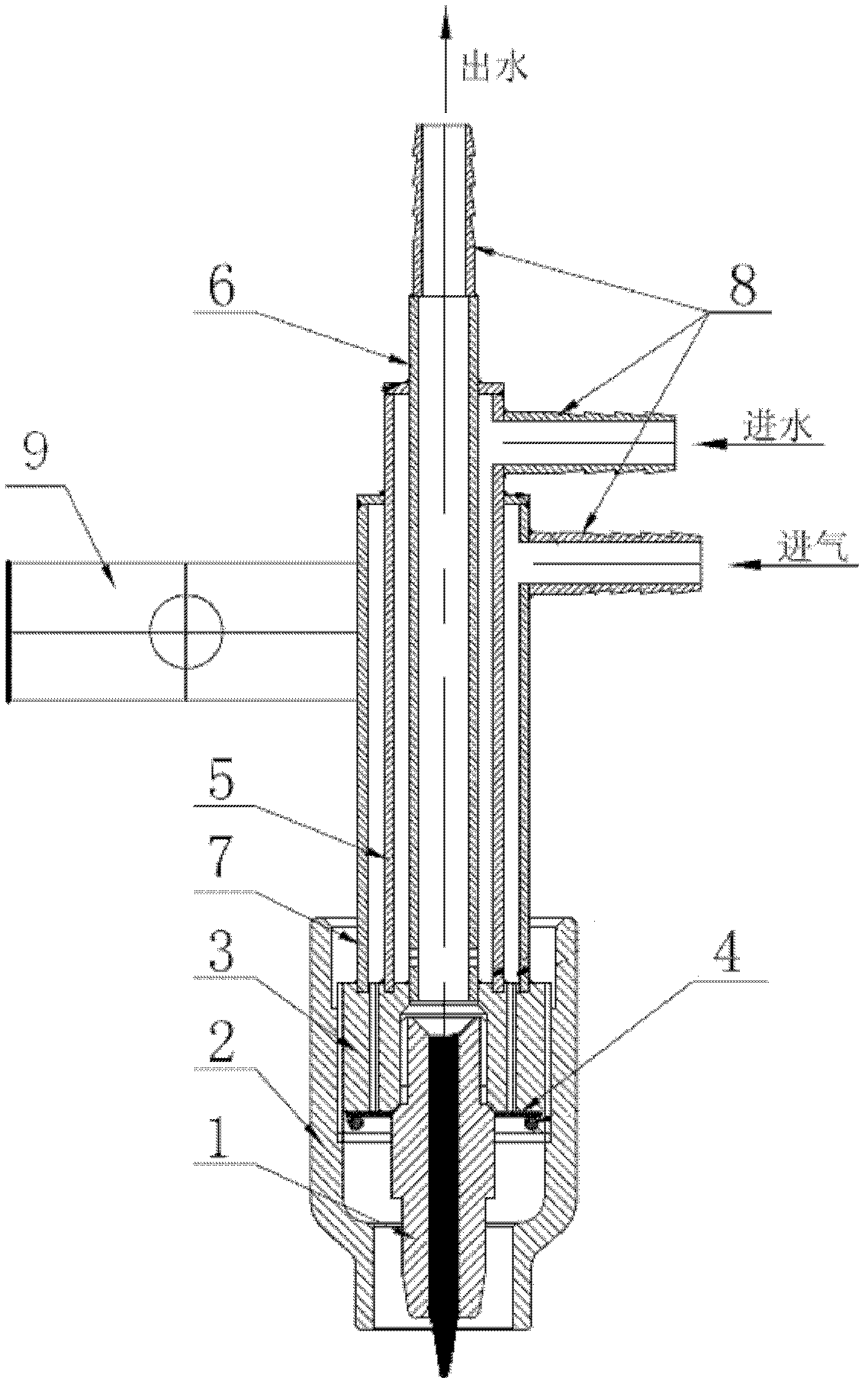

Welding machine with adjustable electric arc energy density

InactiveCN102248264ALower skill requirementsImprove stabilityElectrode supporting devicesWelding accessoriesEngineeringControl circuit

The invention relates to a welding machine with adjustable electric arc energy density, and the welding machine comprises a welding main machine, a gas supply system, a cooling water circulating system and a welding gun, wherein the welding gun comprises an upper insulating outer sleeve, a middle insulating outer sleeve, a lower insulating outer sleeve, a driving source, a tungsten rod regulating device, a cooling water clamping sleeve, a tungsten rod clamping sleeve, a tungsten rod, an electric arc nozzle, a protective gas nozzle, an operating handle and a control circuit; the tungsten rod regulating device comprises a rotating nut which is driven by the driving source and is limited by a limiting device; the cooling water clamping sleeve is formed by the way that an inner tube, a middle tube and an outer tube are brazed into a whole, the lower end of the inner tube is provided with a tapered bore and an internal thread which are matched with the electric arc nozzle, and a cooling water tank is formed on the outer side wall of the inner tube; the tungsten rod clamping sleeve is composed of the outer tube, the inner tube and a mandril, the outer tube is provided with the internal thread corresponding to the external thread of the rotating nut, especially an elongated slot which vertically extends for a certain length and a gas tank spirally surrounding the outer tube are arranged at one side close to the upper end of the outer tube, and the lower end of the elongated slot is communicated with the spiral gas tank to form a compression gas tank. The welding machine with adjustable electric arc energy density provided by the invention has the advantages of simple structure and convenience in operation.

Owner:茅鹏

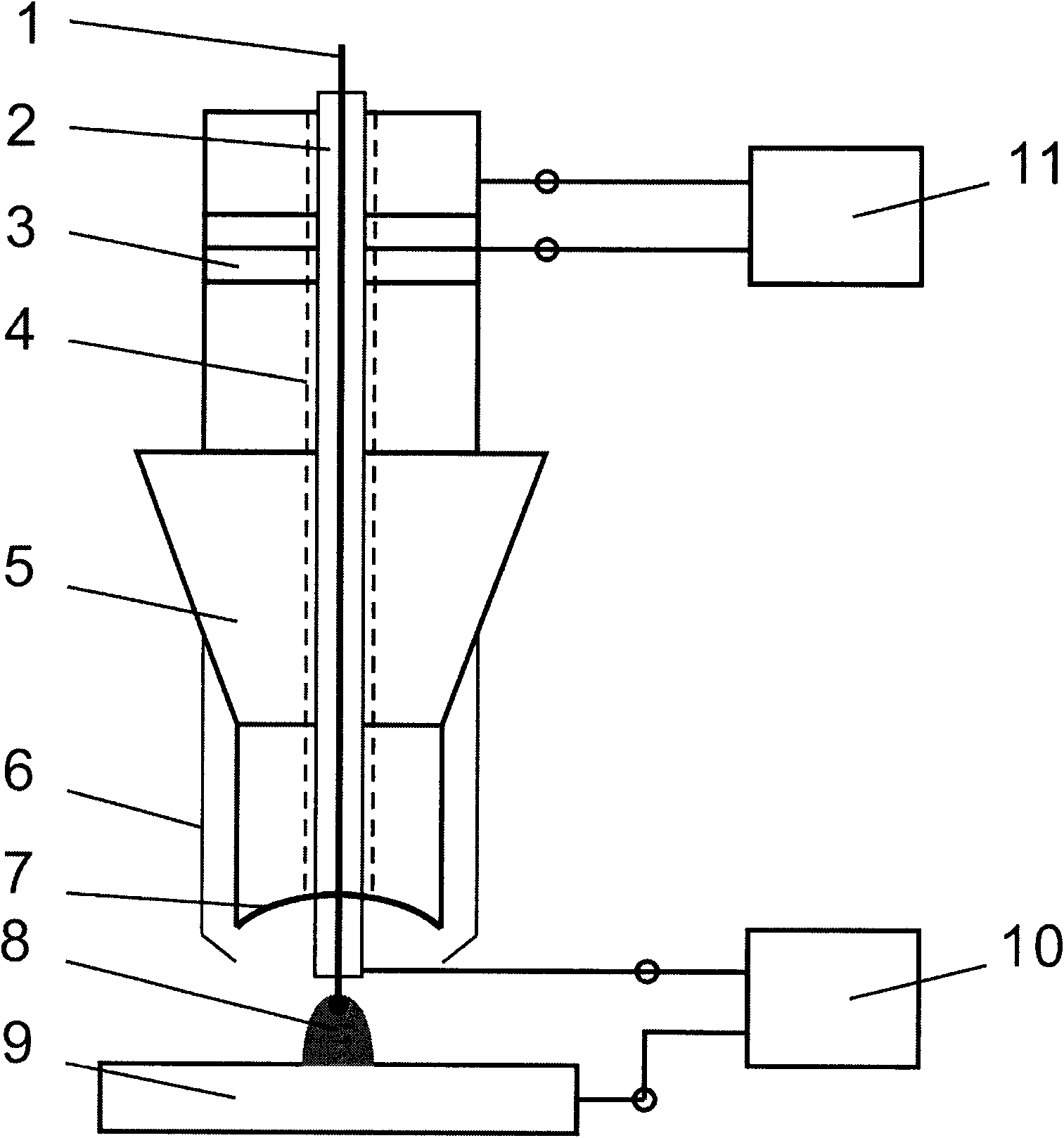

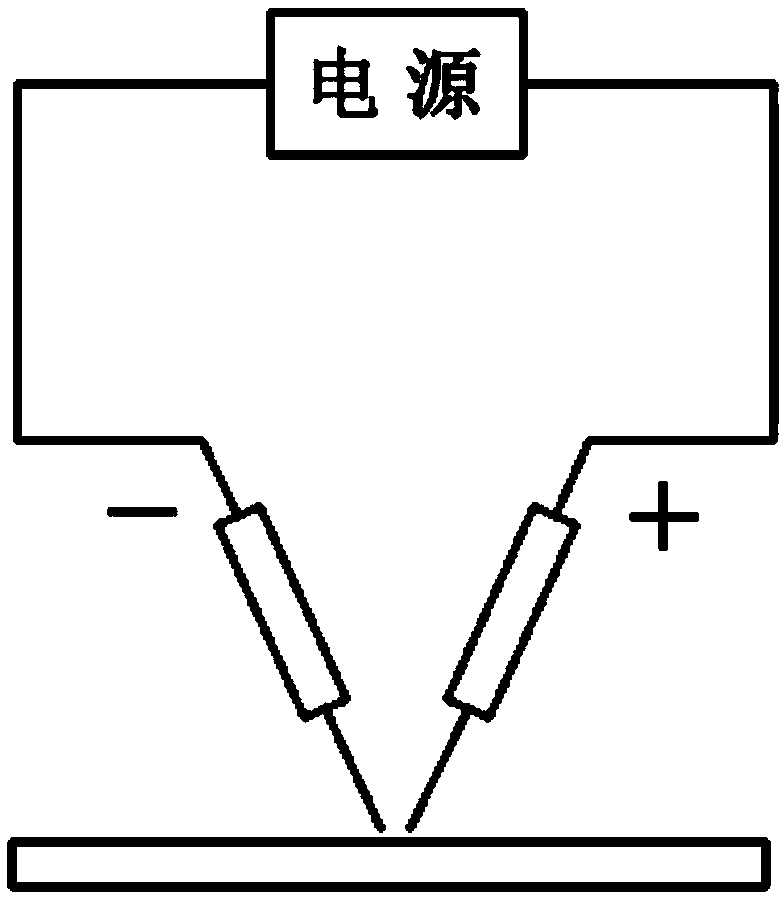

Welding device for compounding ultrasonic focusing sound field with molten pole arc welding

InactiveCN101947696AStrong penetrating powerEasy to shapeArc welding apparatusNon-electric welding apparatusUltrasonic sensorTransformer

The invention provides a welding device for compounding an ultrasonic focusing sound field with molten pole arc welding for improving the energy density of ultrasonic, changing the arc shape and the energy density and realizing high-efficiency high-quality welding. The welding device comprises a molten pole welding wire, a conductive pole, an ultrasonic transducer, an axle center through hole ultrasonic amplitude transformer, a welding nozzle, a focusing surface, a welding arc, a workpiece to be welded, a welding power supply and an ultrasonic power supply, wherein the molten pole welding wire passes through the conductive pole and is in sliding contact with the conductive pole, the ultrasonic power supply is connected with the ultrasonic transducer through a cable, the ultrasonic transducer is connected with the ultrasonic amplitude transformer through a bolt, and the focusing surface is positioned at the lower end part of the ultrasonic amplitude transformer. The invention ensures that the arc is compressed to improve the arc energy density, increase weld penetration and improve weld formation. The invention can change the arc shape and the heat generation characteristic and the transition form of molten metal, realizes the high-efficiency high-quality welding, and enlarges the application range of the arc welding.

Owner:HARBIN INST OF TECH

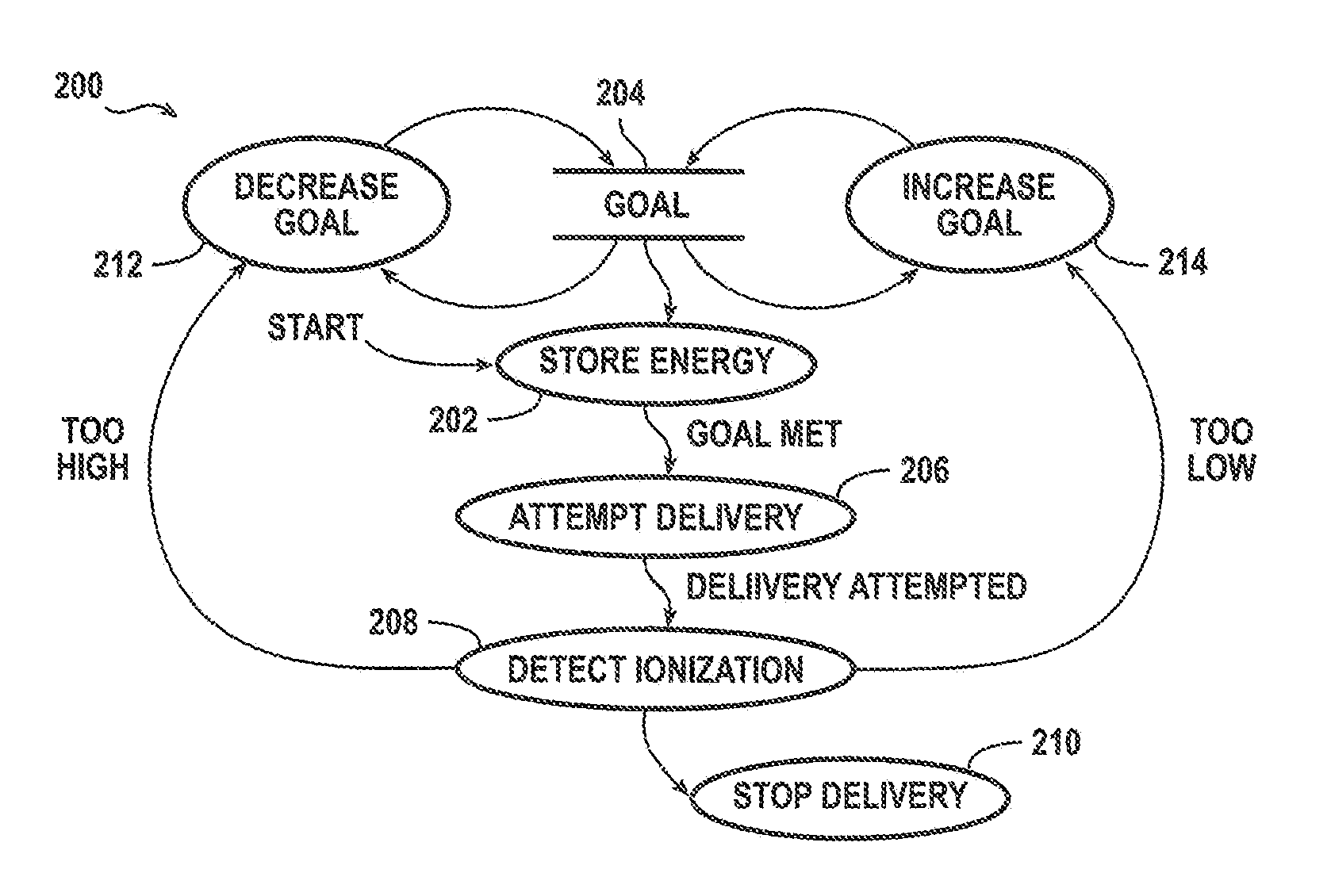

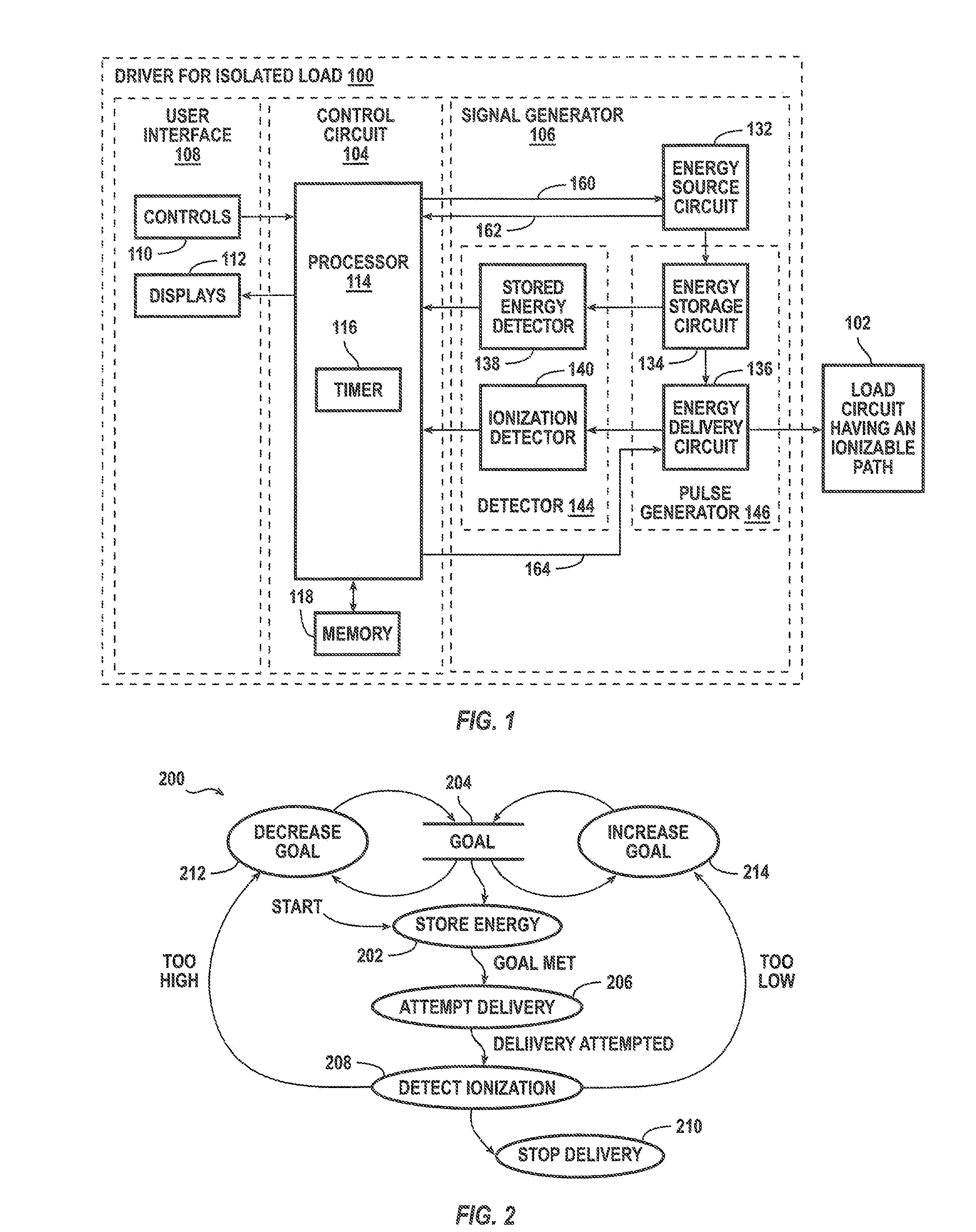

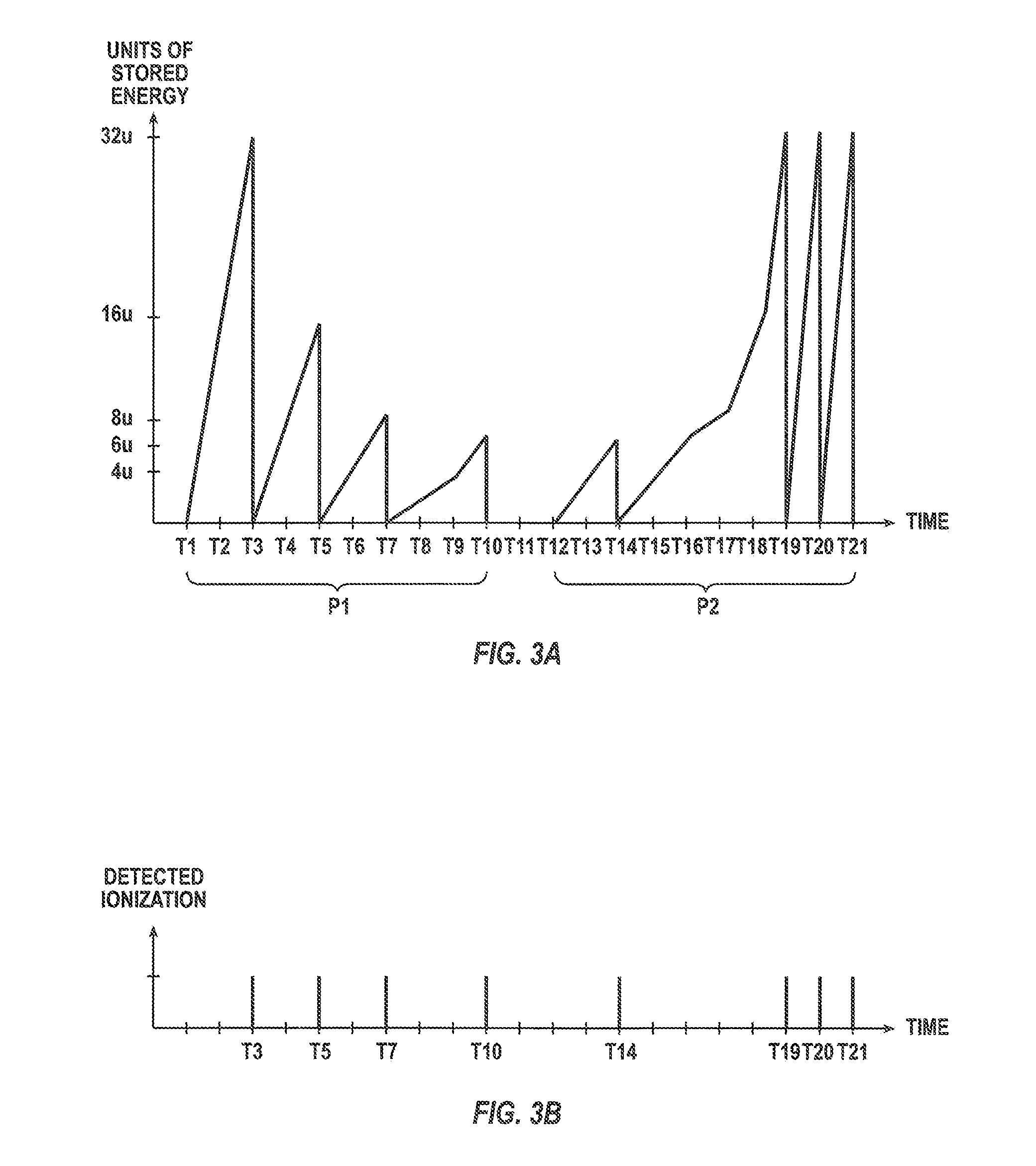

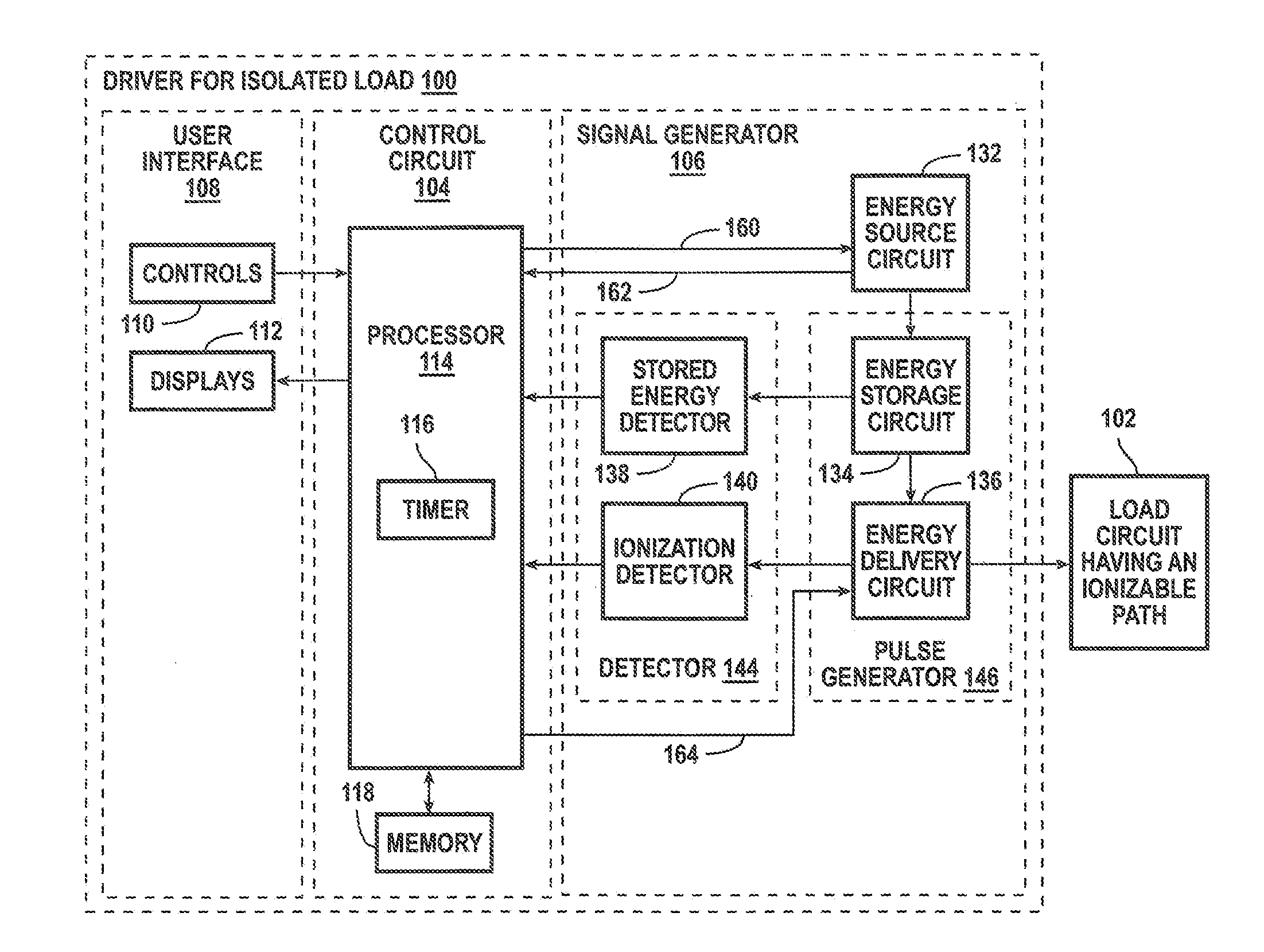

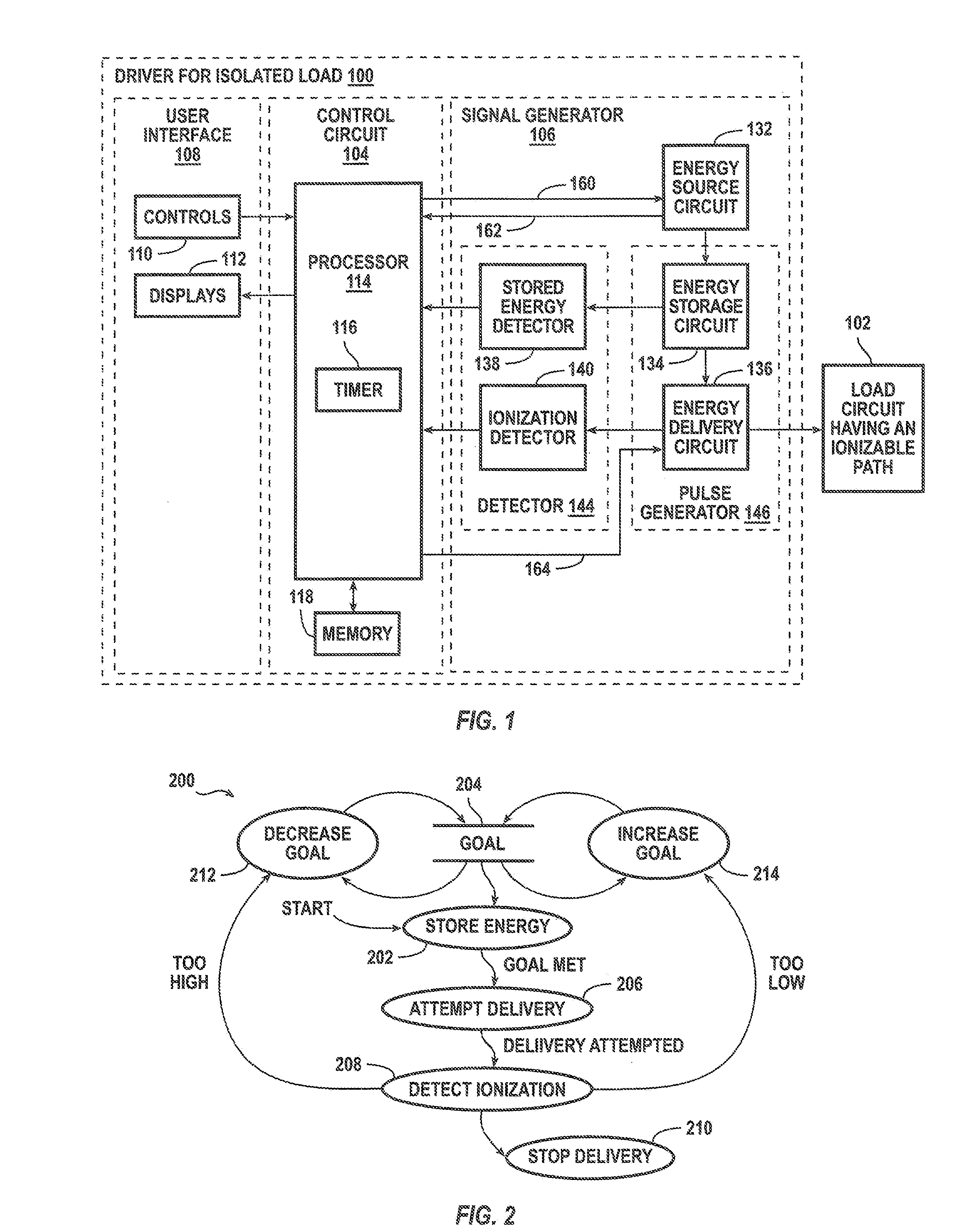

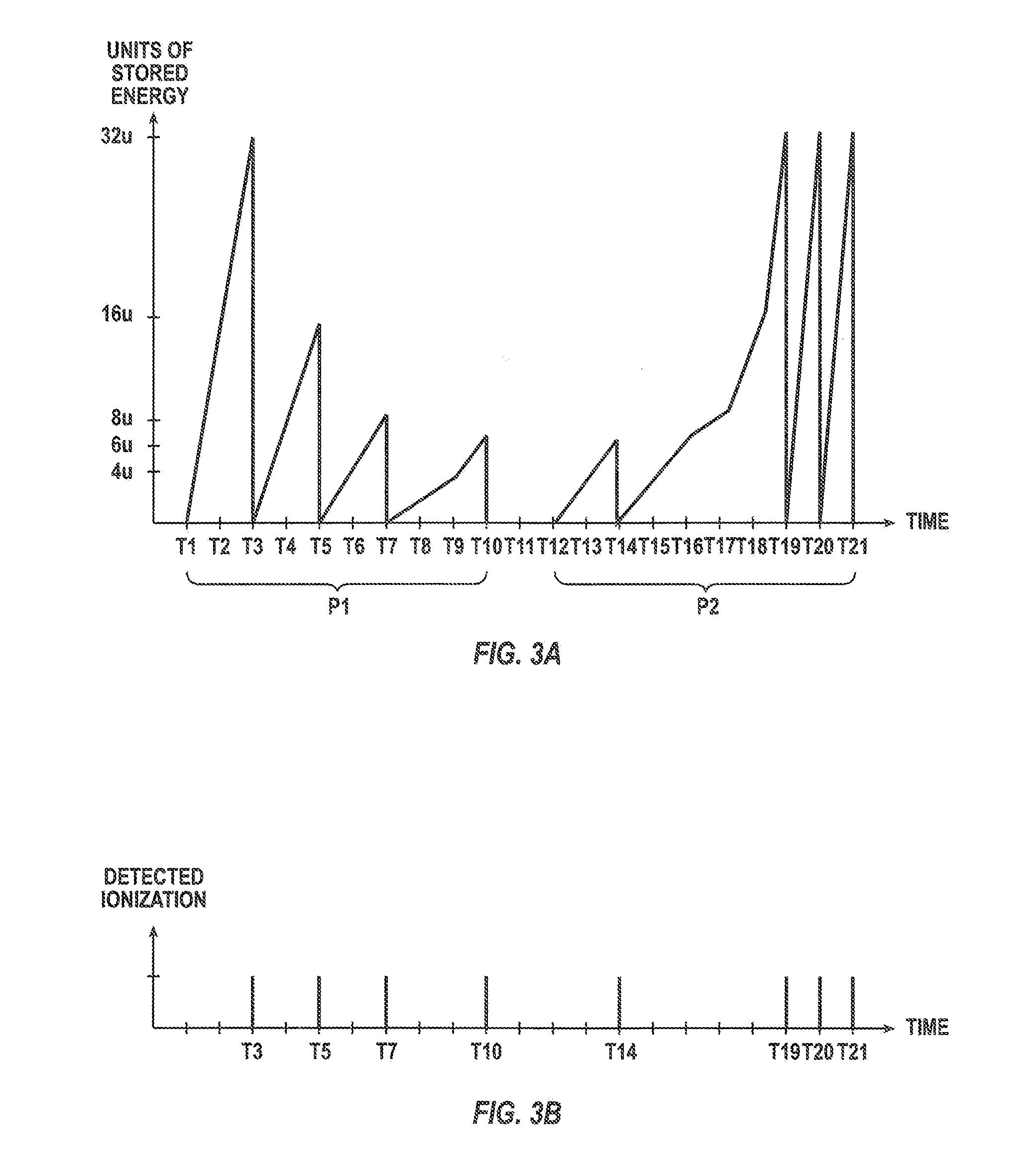

Systems and methods for ARC energy regulation

A driver provides a current through a load circuit that includes an ionizable path. The driver includes an energy sourcing circuit, an ionization detector, a controller, and a pulse generator. The controller determines, in response to the detector and by trial and error, a respective quantity of energy for each pulse of a plurality of pulses to be generated. For each pulse of the plurality, the pulse generator receives the respective quantity of energy from the energy sourcing circuit, provides in response to the quantity of energy a respective voltage to ionize the ionization path, and provides the current through the load circuit.

Owner:AXON ENTERPRISE INC

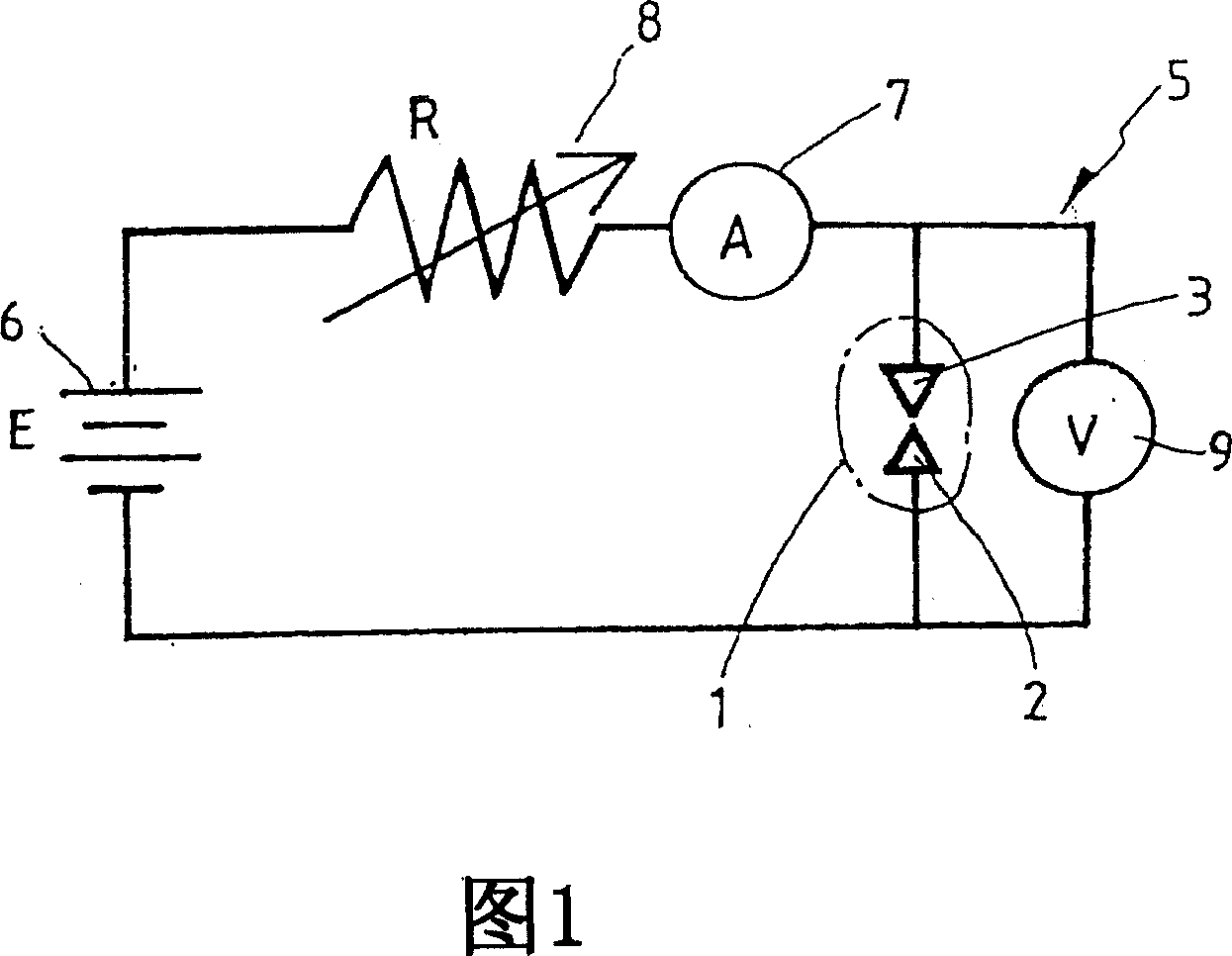

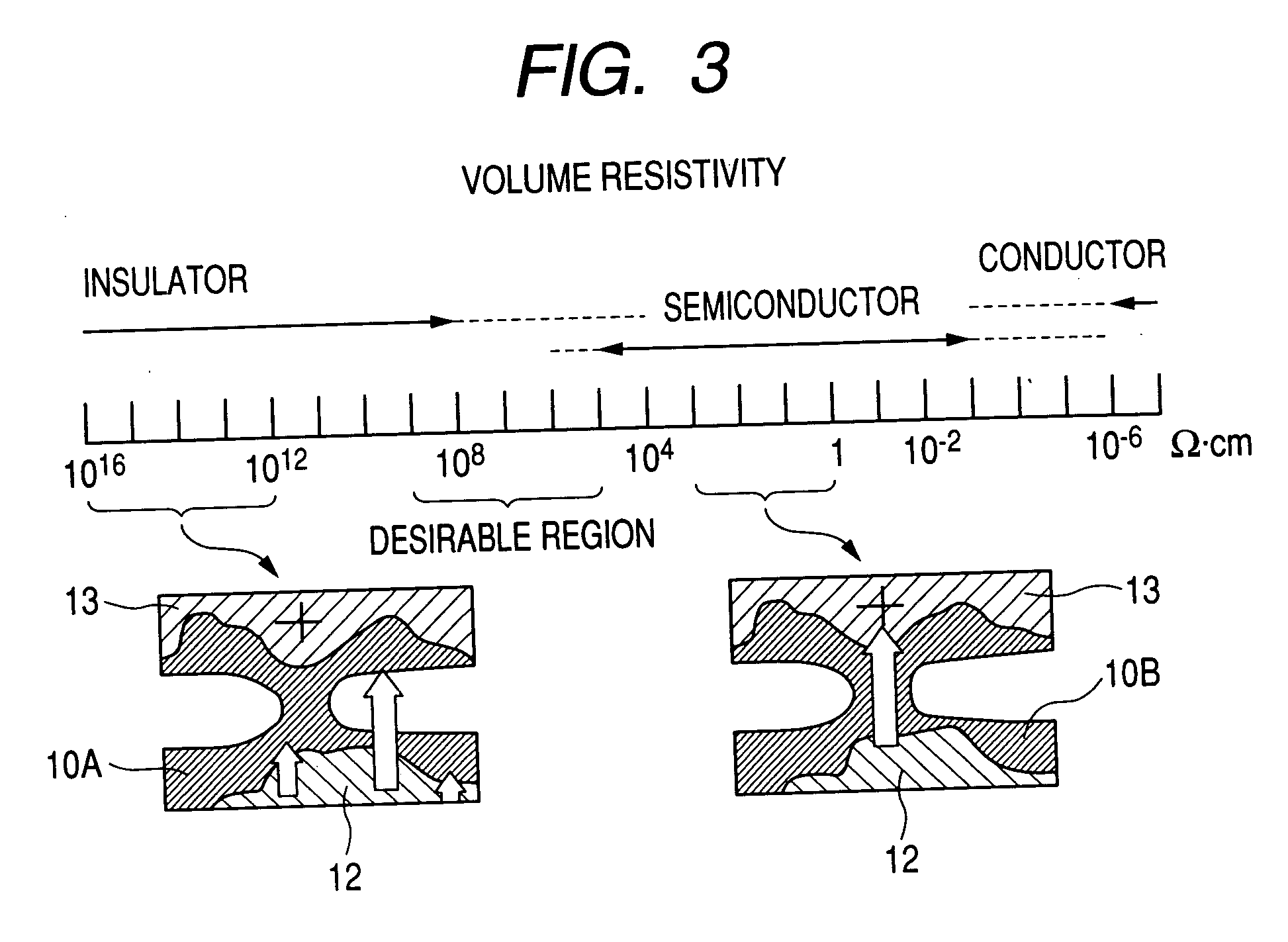

Method for inhibiting damage due to arc between electrical contacts

This method for inhibiting damage due to arc between electrical contacts involves the spreading of a grease composed of from 70% by weight to 95% by weight of a base oil and from 5% by weight to 30% by weight of a thickening agent and additives over a pair of electrical contacts in a circuit which causes terminals to move relative to each other so that they are disconnected from each other, whereby damage on the contact area due to arc occurring when the electrical contacts are isolated from each other is inhibited. As the thickening agent there is preferably used an organic bentonite. As the base oil there is preferably sued an ester oil, glycol oil or poly-alpha-olefin. The base oil preferably has a low density to reduce arc energy.

Owner:YAZAKI CORP

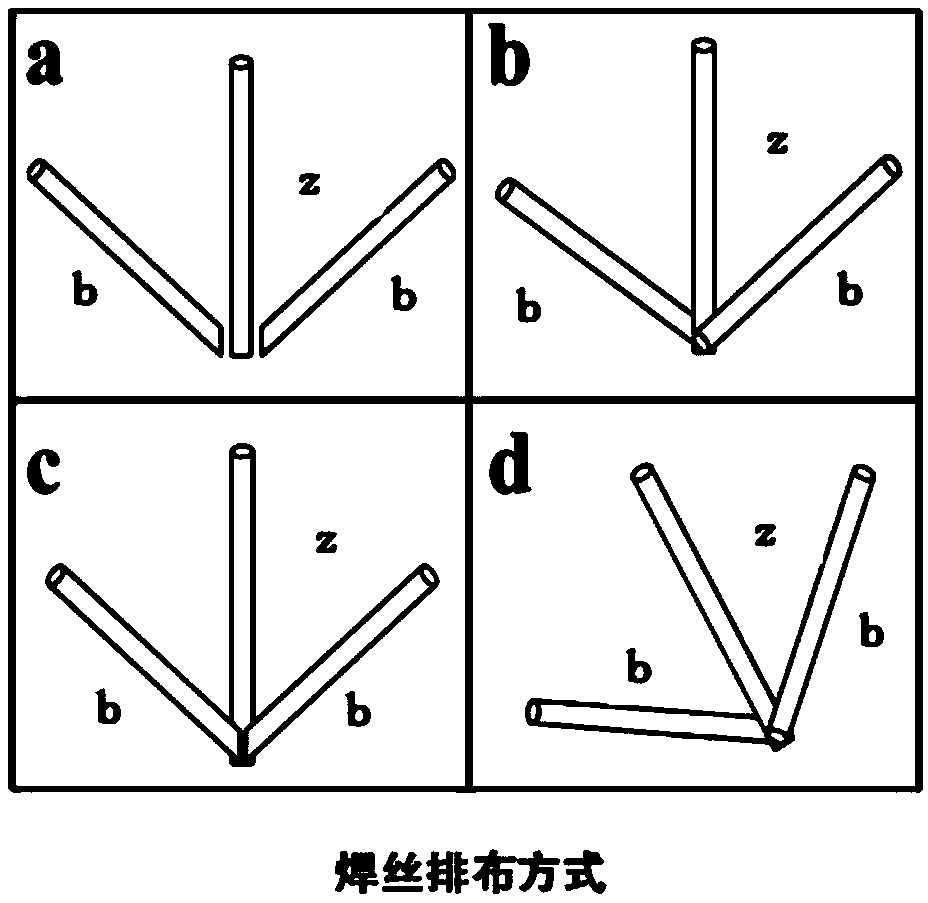

Three-wire gas shielded indirect arc welding method, device and application of method

ActiveCN109079287AIncrease heat inputHigh deposition coefficientArc welding apparatusWelding/soldering/cutting articlesEngineeringVolumetric Mass Density

Owner:DALIAN UNIV OF TECH

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

InactiveUS20070097582A1Low levelReduce arc energyParameter calibration/settingCircuit-breaking switches for excess currentsArc flashLow voltage circuits

Owner:SHIPP DAVID D +4

Systems and Methods for ARC Energy Regulation

A driver provides a current through a load circuit that includes an ionizable path. The driver includes an energy sourcing circuit, an ionization detector, a controller, and a pulse generator. The controller determines, in response to the detector and be trial and error a respective quantity of energy for each pulse of a plurality of pulses to be generated. For each pulse of the plurality, the pulse generator receives the respective quantity of energy from the energy sourcing circuit, provides in response to the quantity of energy a respective voltage to ionize the ionization path, and provides the current through the load circuit.

Owner:AXON ENTERPRISE INC

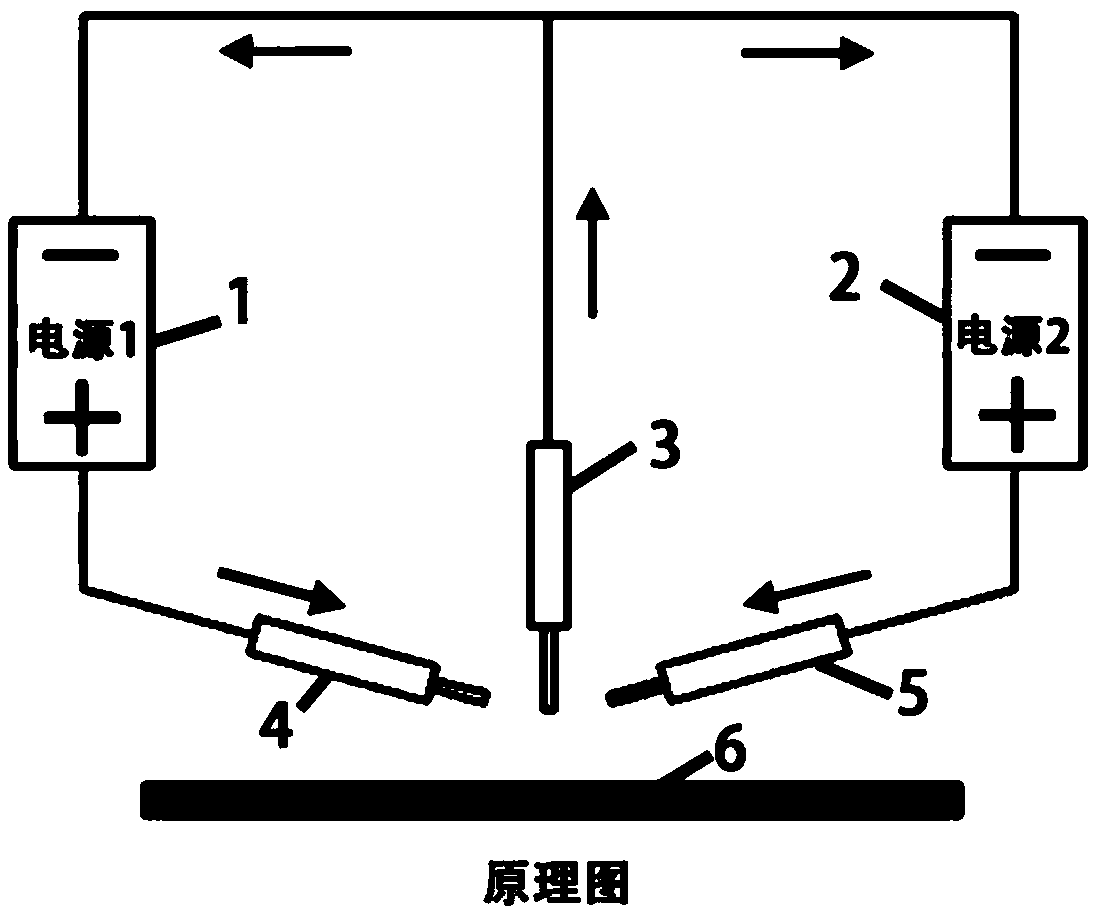

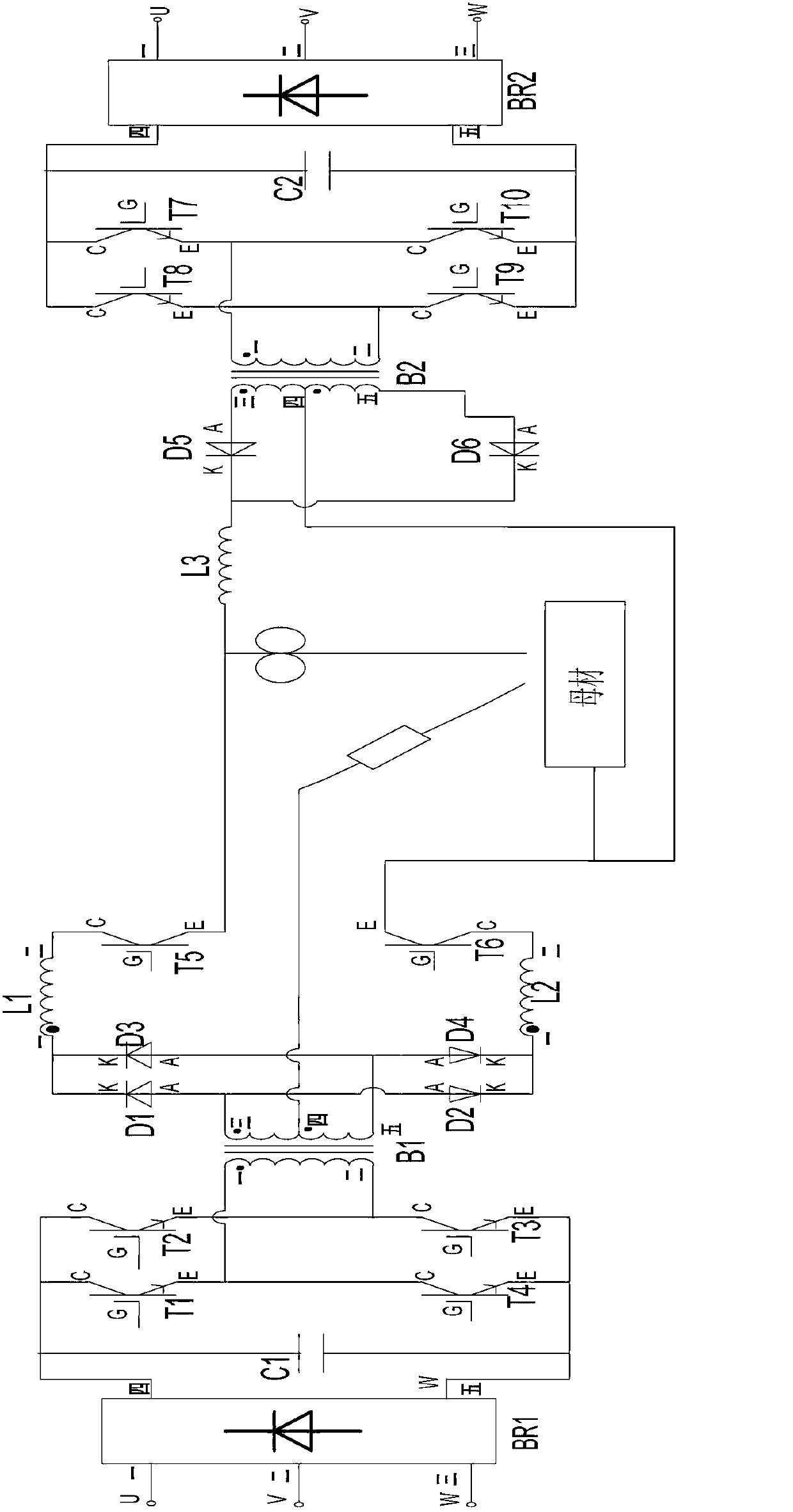

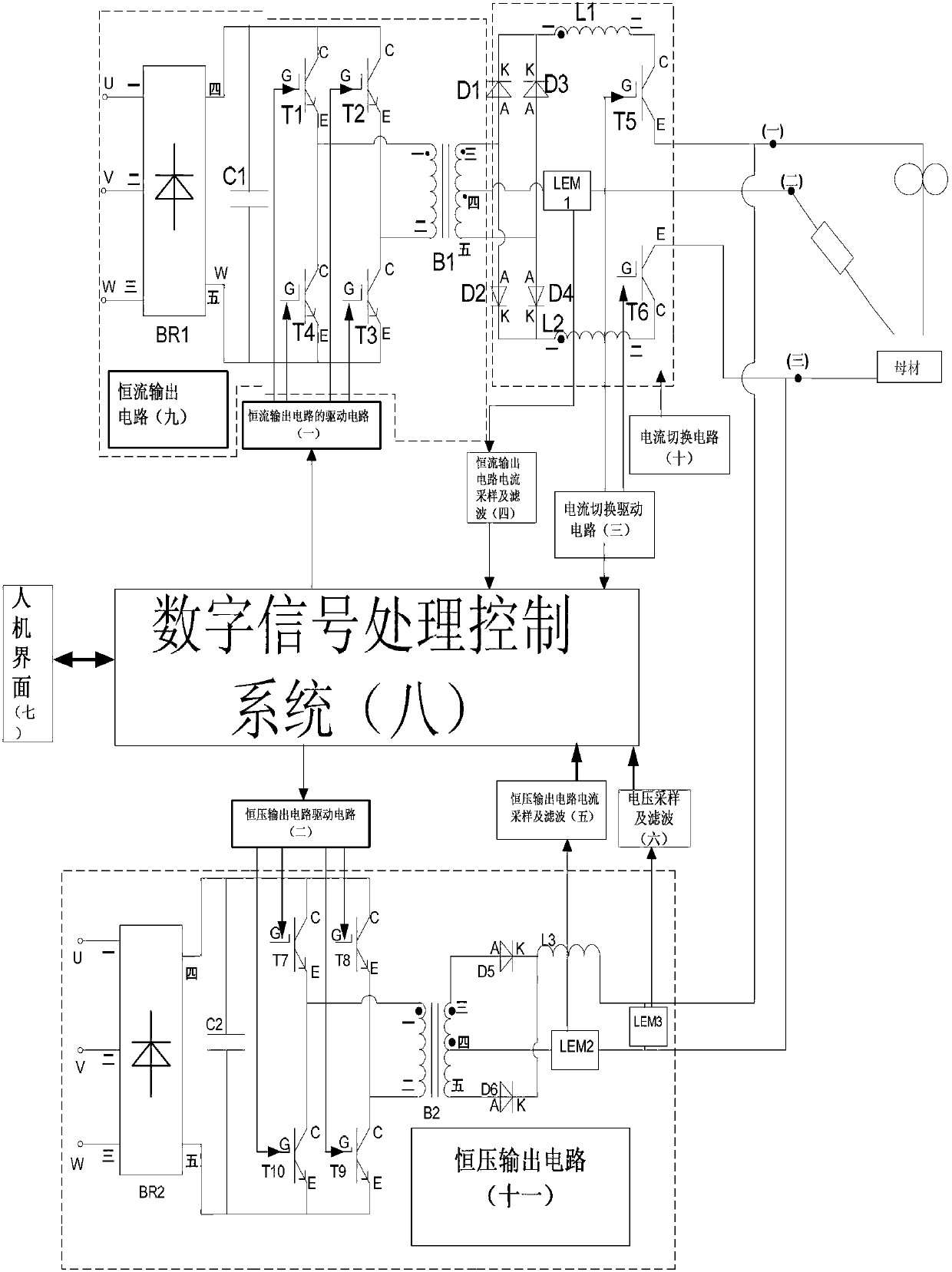

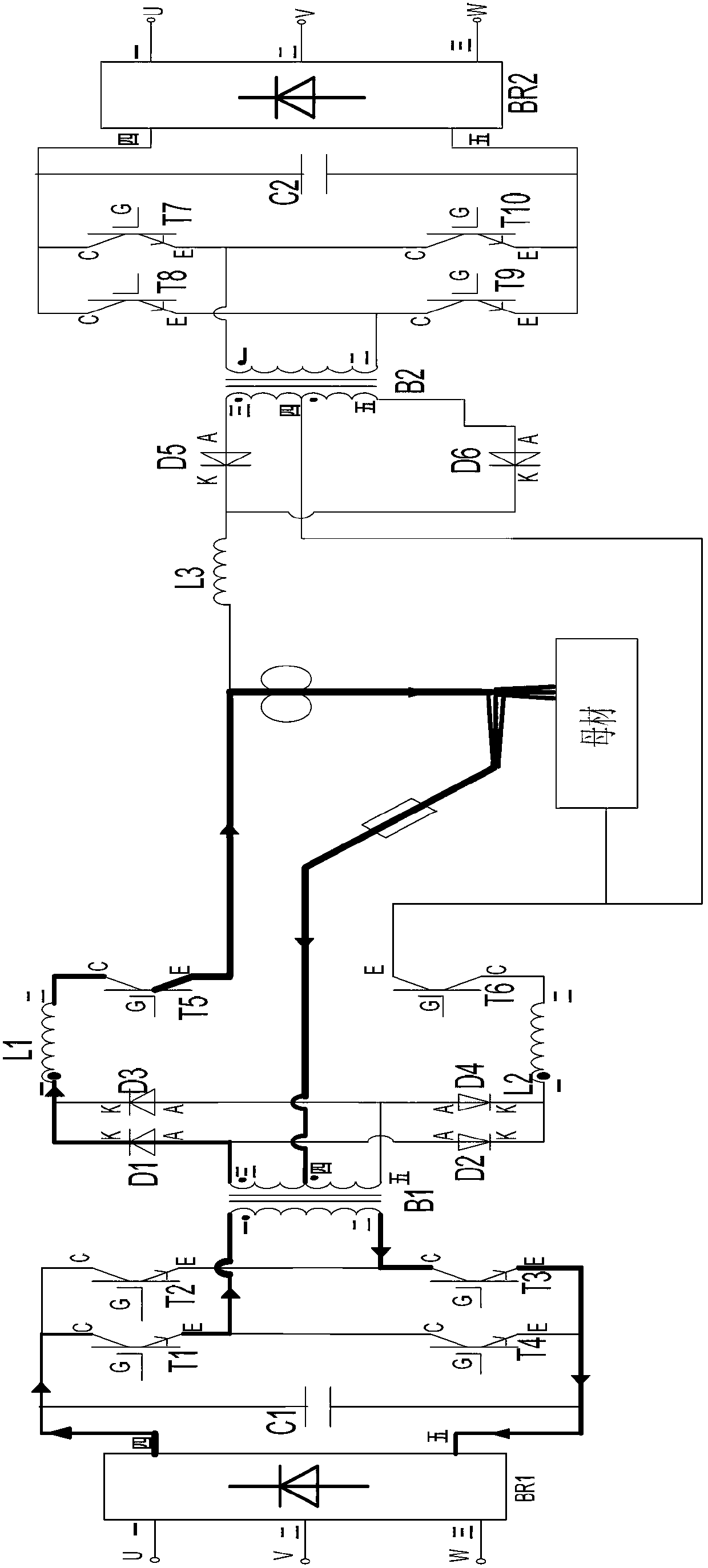

Double arc hybrid welding power supply device

ActiveCN103100783ALower the minimum thresholdHigh speed switchingArc welding apparatusWelding power supplyEngineering

The invention discloses a double arc hybrid welding power supply device, in which the power supply outputs current from different output terminals through the alternate conduction of a power switching device in a current switching circuit, thus ensuring that a welding arc burns among different electrodes; the switched current ratio is inversely proportional to the turn number ratio through replacing the turn number ratio of a double pack inductance in the current switching circuit; and the turn-on and turn-off in turns of two power switch tubes are fitted through the magnetic coupling effect of the double pack inductance, thus realizing a high-speed switching of the current output circuit, and a non-consumable electrode arc can switch between a tungsten electrode and a welding wire as well as between the tungsten electrode and a base metal in a high speed. Compared with the traditional double-consumable electrode welding wire arc welding process, the device disclosed by the invention can reduce the lowest critical value of the welding heat input; and compared with the simple hybrid welding of non-consumable electrode and consumable electrode, as the time switching radio of non-consumable electrode can be adjusted freely, the distribution radio of the non-consumable electrode energy, between the consumable electrode welding wire and the base metal, can be adjusted freely, thus improving the adaptation range of the welding process.

Owner:BEIJING UNIV OF TECH

Arc extinguishing chamber and breaker adopting arc extinguishing chamber

ActiveCN106356266ADoes not affect accessIncreased operating powerCircuit-breaking switch detailsPower flowArc energy

The invention relates to an arc extinguishing chamber and a breaker adopting the arc extinguishing chamber. The arc extinguishing chamber comprises a moveable end part, wherein the moveable end part comprises an air cylinder, a piston, a pull rod and a separating plate; the piston is arranged in the air cylinder; the air cylinder is separated into an expanding chamber and an air pressure chamber by the piston and the separating plate; a normal connected channel for connecting the expanding chamber with the air pressure chamber is arranged on the separating plate; and the area of the normal connected channel is only 15%-25% of the section area of the air cylinder, so that the process of the compressed air in the air pressure chamber entering the expanding chamber through the normal connected channel so as to be blown to the arc is not influenced, and the excessive arc energy is also prevented from being transferred to the air pressure chamber and resulting in the increasing of operation power. With such a structure, the arc extinguishing chamber can be used for effectively extinguishing arc when the current is broken on a circuit exceeding the limited voltage level in the prior art.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

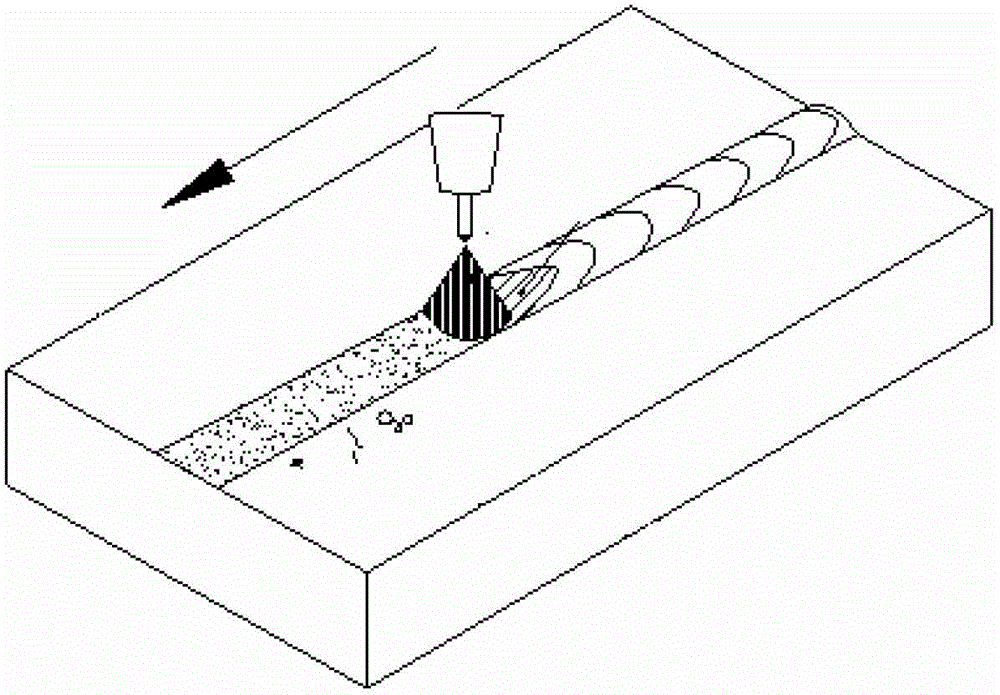

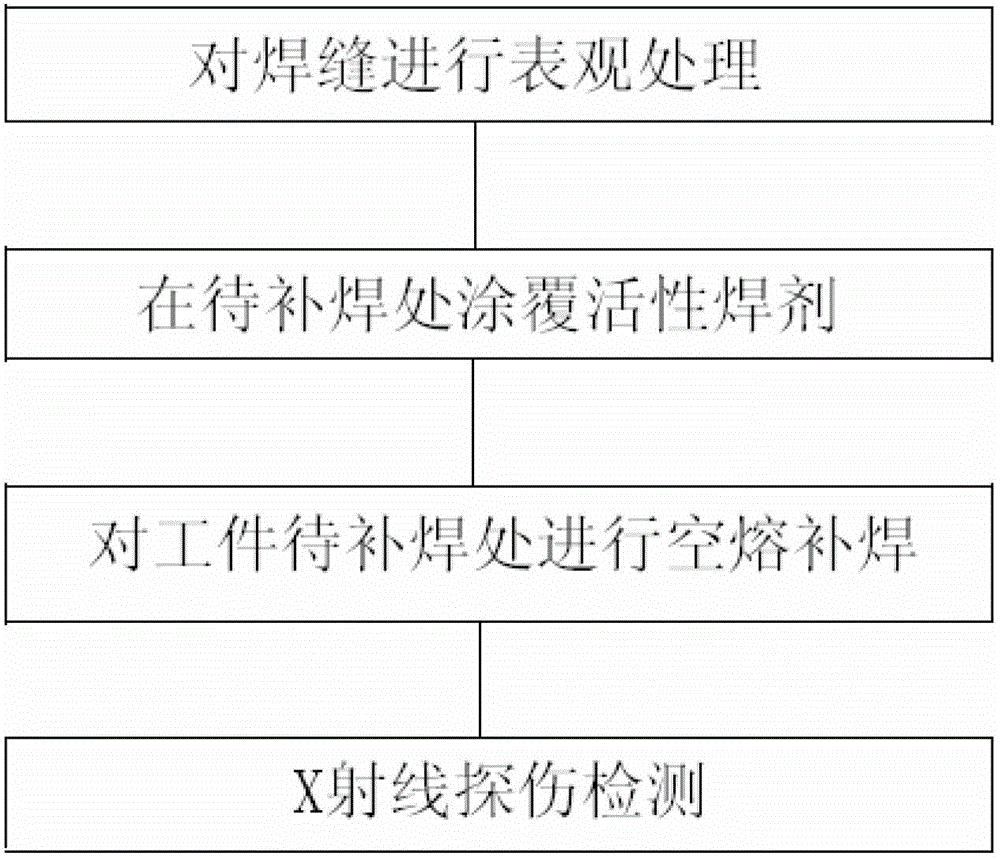

Argon tungsten-arc repair welding method based on activated flux

InactiveCN102717174AReduce the amount of repair welding deformationImprove welding efficiencyArc welding apparatusAlloyHigh intensity

The invention discloses an argon tungsten-arc repair welding method based on activated flux. The argon tungsten-arc repair welding method based on activated flux is suitable for low-alloy high-strength steel, low-alloy ultra-high-strength steel and stainless steel. The argon-arc welding activated flux of a low-carbon steel tungsten electrode is mixed into paste with acetone, and is coated at the part of a workpiece, which is to be repair-welded; argon tungsten-arc welding is adopted to carry out the repair welding treatment at the part of the workpiece, which is to be repair-welded and is coated with the activated flux; and when the workpiece is made by high-strength steel or ultra-high-strength steel, stress removal annealing treatment is carried on the whole repair-welded workpiece. The activated flux which is adopted during the repair welding process of the technology can improve the arc energy density; compared with the traditional repair welding technology, the method has the advantages that the weld heat input amount is reduced by about 50%, the repair welding deformation is reduced by about 40%, and the repair welding efficiency is improved to about 100%; the repair welding technological process with high efficiency, high performance and low deformation can be realized; and the method has the characteristics of simplicity and convenience in operation.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

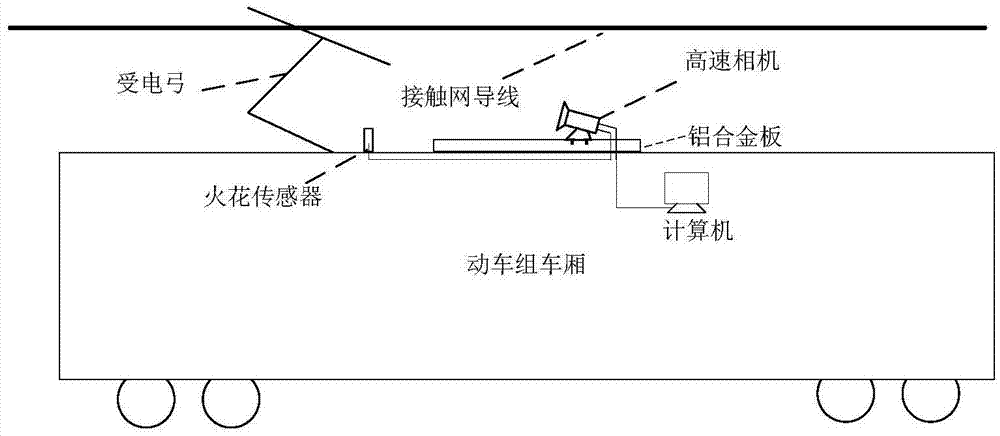

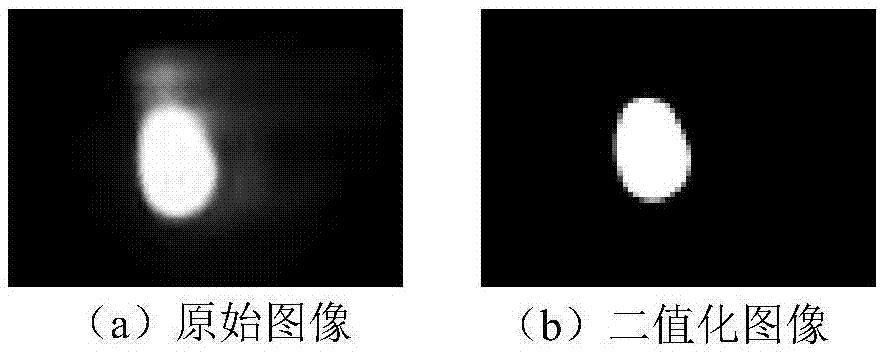

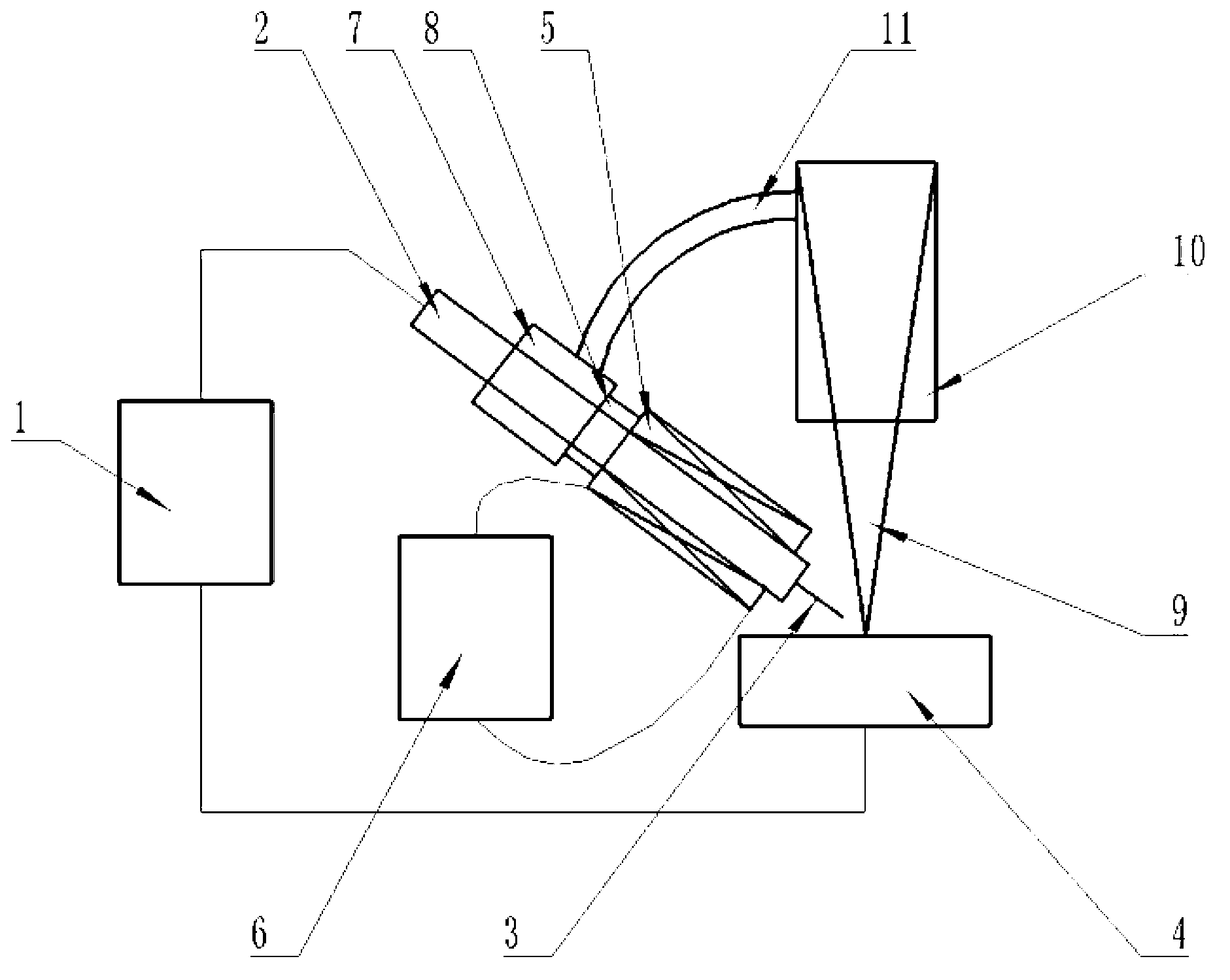

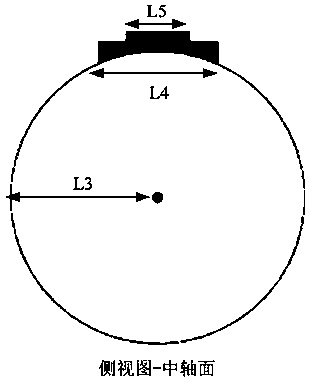

Pantograph arc energy measurement method

InactiveCN105445576AConducive to on-site online detectionElectrical testingUltimate tensile strengthArc energy

The invention discloses a pantograph arc energy measurement method used for the information management of the arcing image of the pantograph arc photographed by a high-speed camera. The method is characterized in that the arcing image of the pantograph arc is subjected to the binarization treatment to obtain the arc boundary perimeter. After that, the arc boundary perimeter is brought into a relevant empirical model to be processed, so that the pantograph arc energy can be obtained. According to the technical scheme of the invention, an effective means is provided for the quantitative measurement of the pantograph arc energy information at an operating site. According to the method, a user only needs to photograph the image of the pantograph arc by the high-speed camera in the non-contact manner, and then the information of the arc boundary perimeter in the arcing image of the pantograph arc is obtained. Meanwhile, based on the relationship between the arc boundary perimeter and the pantograph arc energy, the intensity information of the pantograph arc can be obtained. In this way, the user no longer needs to measure the voltage, the current and other information of the pantograph arc during the arcing process. the on-site and on-line detection of the pantograph arc energy is facilitated.

Owner:SOUTHWEST JIAOTONG UNIV

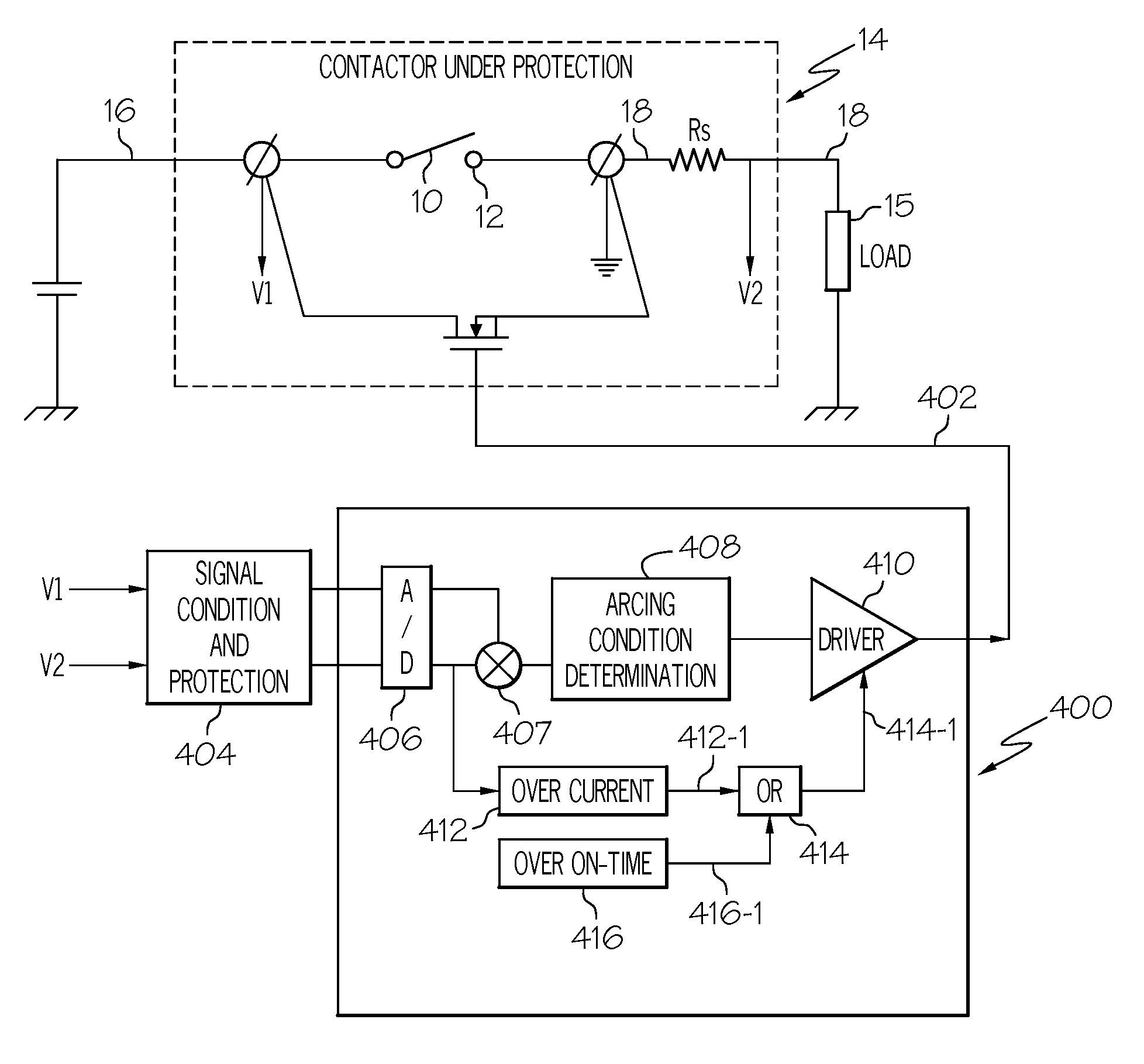

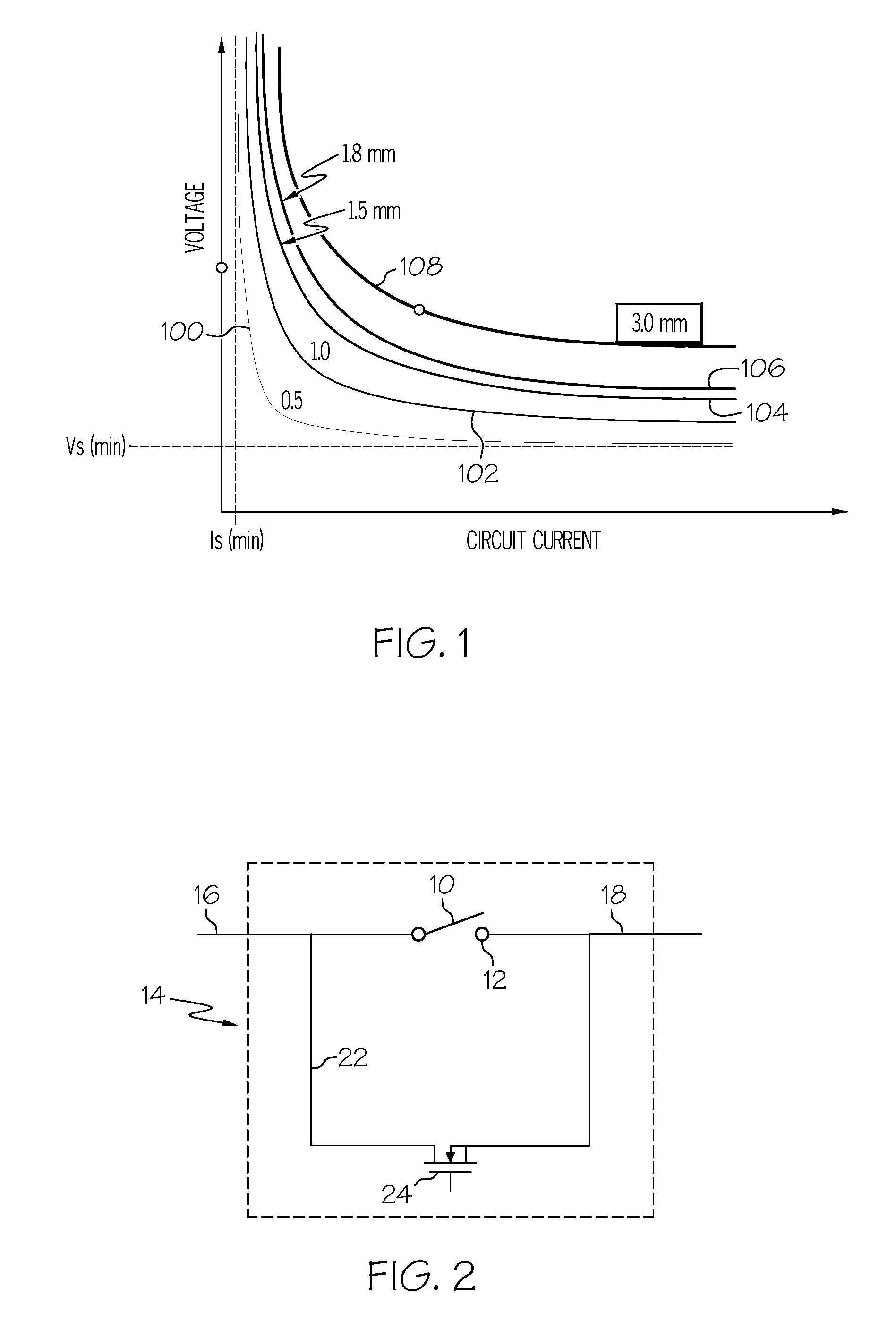

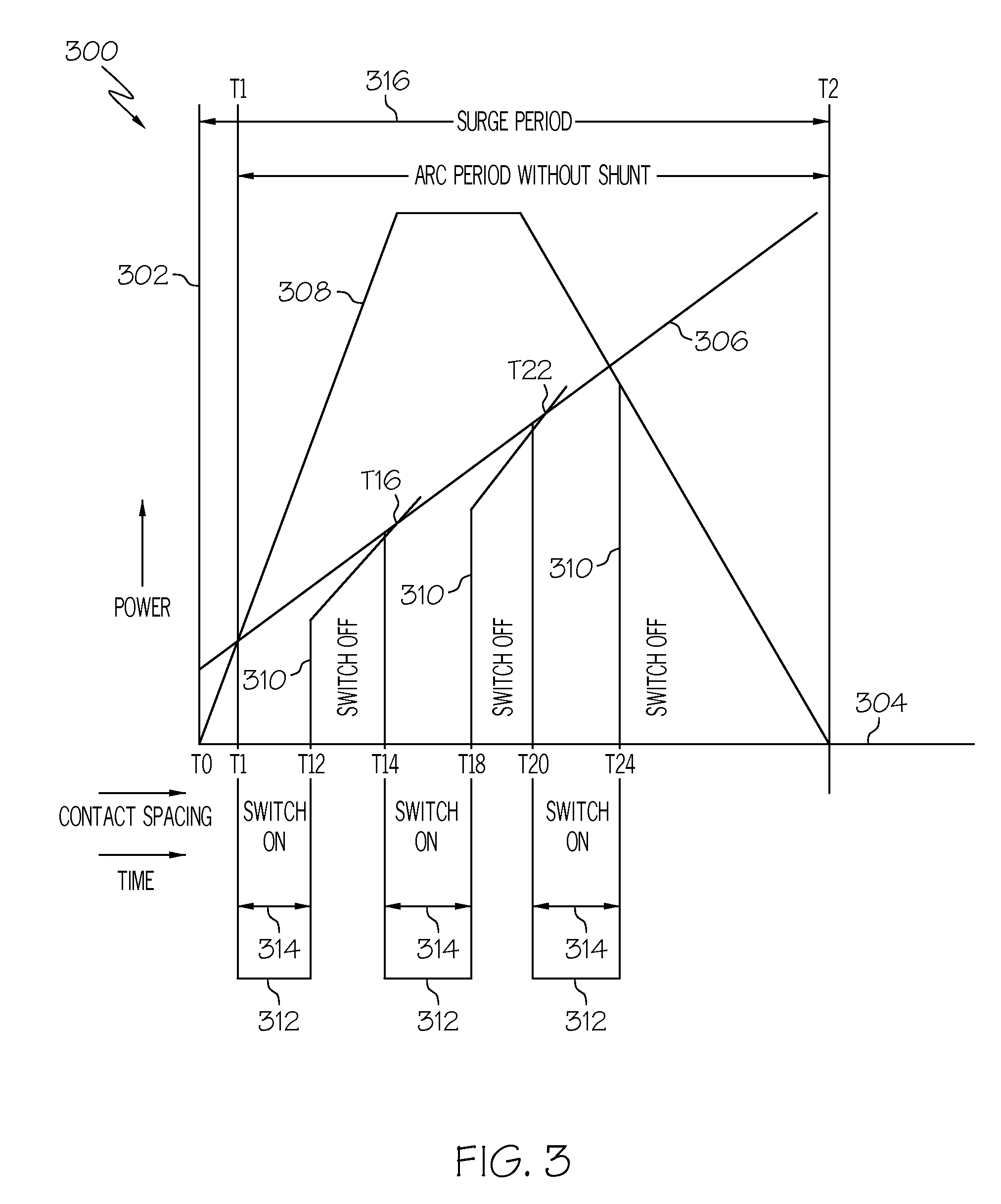

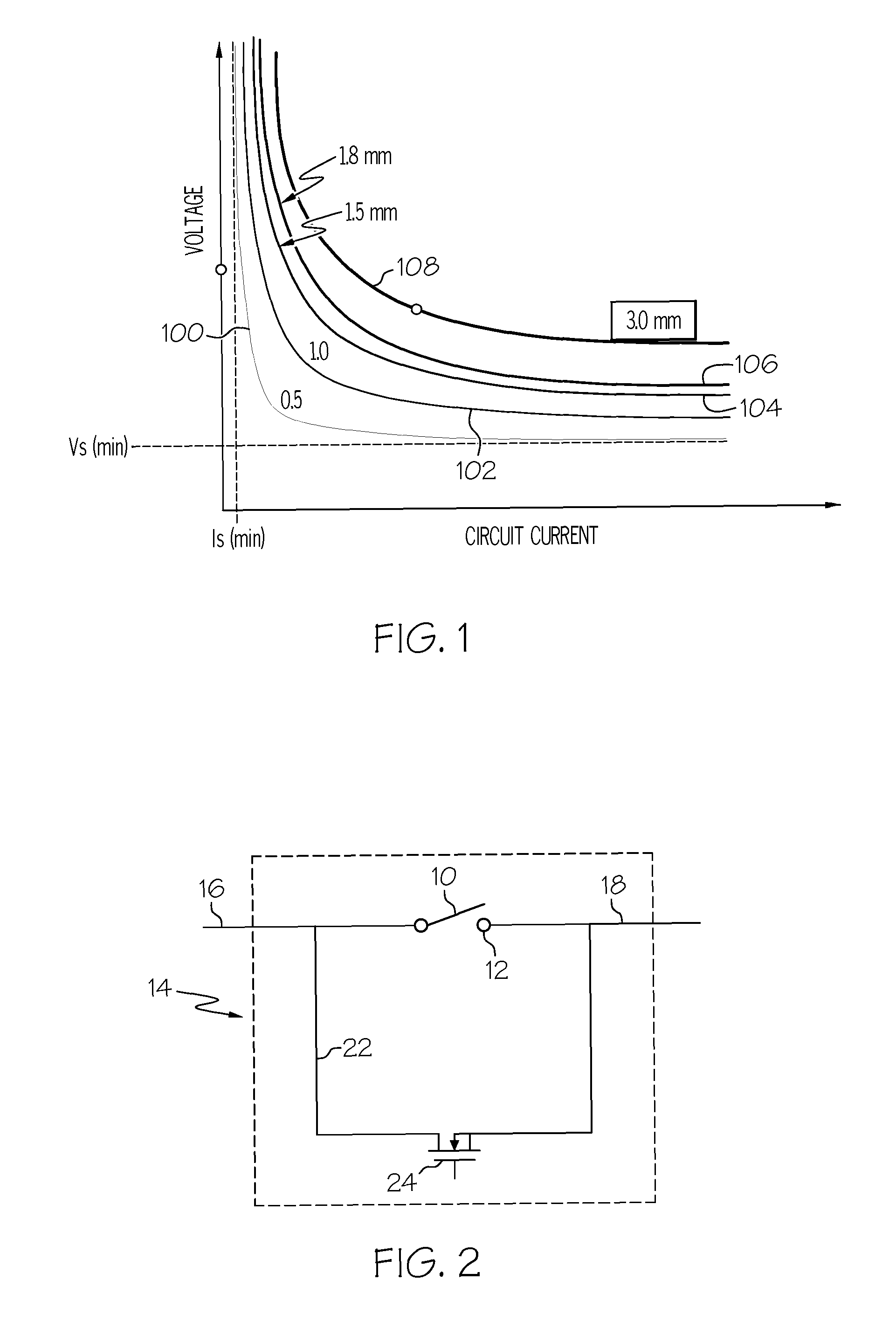

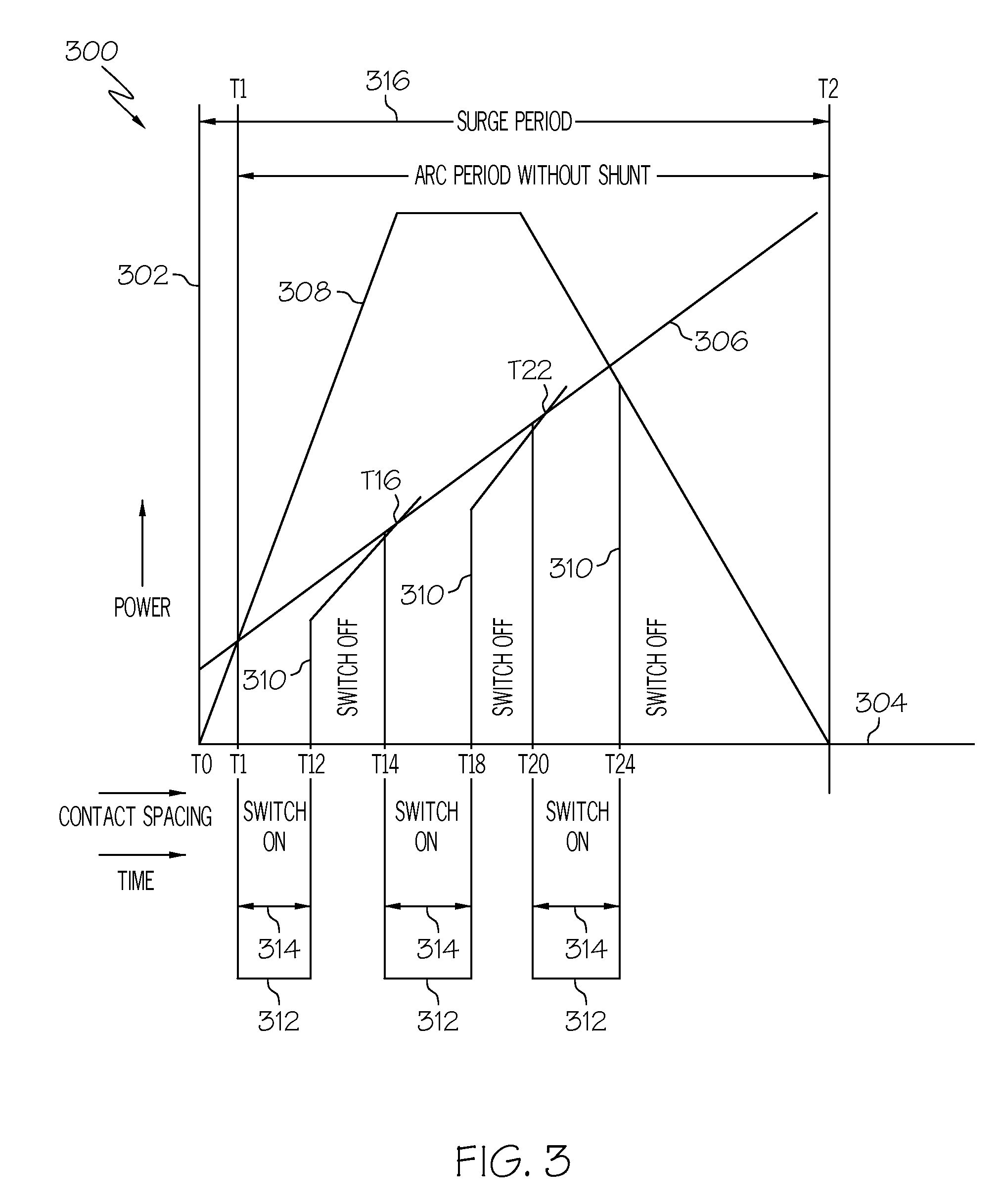

Hybrid high voltage DC contactor with arc energy diversion

InactiveUS7817382B2Electric switchesEmergency protective arrangements for automatic disconnectionShunt DevicePulse control

A contactor may operate to interrupt current in a circuit while the circuit is operating under load. A shunt is provided to by-pass surge power current around contacts to reduce arcing. The shunt includes a solid-state switch that may be operated in a series of pulses during movement of the contacts. The pulse control unit may detect a potential for arcing and then provide for periodic pulsing operation of the shunt. Because the solid-state switch may operate discontinuously, the contactor may be constructed with a switch that is selected on a basis of its pulse rating.

Owner:HONEYWELL INT INC

Switch cabinet and pressure relief structure thereof

ActiveCN107086484AReduce impactAvoid breakingSwitchgear arrangementsSubstation/switching arrangement casingsEngineeringSwitchgear

The invention relates to the field of switchgear, in particular to a switch cabinet and a pressure relief structure thereof. The switch cabinet comprises a cabinet body, wherein the cabinet body is provided with a pressure relief port, the pressure relief port is provided with pressure relief plates, each pressure relief plate comprises a pressure relief connection part and a maintaining connection part which is used for enabling the corresponding pressure relief plate to be connected on the cabinet body always, and the pressure relief port is provided with a foldable sheltering plate which is positioned on one side, facing the pressure relief port, of the pressure relief plate and used for sheltering one side, close to the maintaining connection part, of the pressure relief port; or the pressure relief port is provided with a guide plate positioned on one side, facing the pressure relief port, of the pressure relief plate, and the guide plate is provided with a guide surface which is used for guiding arcing energy inside the cabinet body to a region, far away from the maintaining connection part, on each pressure relief plate; or, a distance between the pressure relief connection part and the pressure relief port is less than a distance between the maintaining connection part and the pressure relief port, so that the pressure relief port is arranged eccentrically relative to the pressure relief plates, thereby solving the problem that potential safety hazards exist in the existing pressure relief structure.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

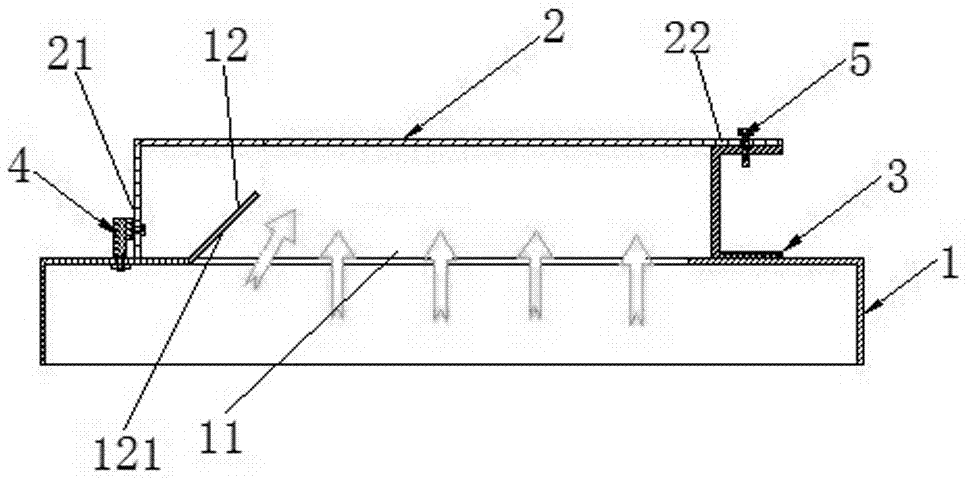

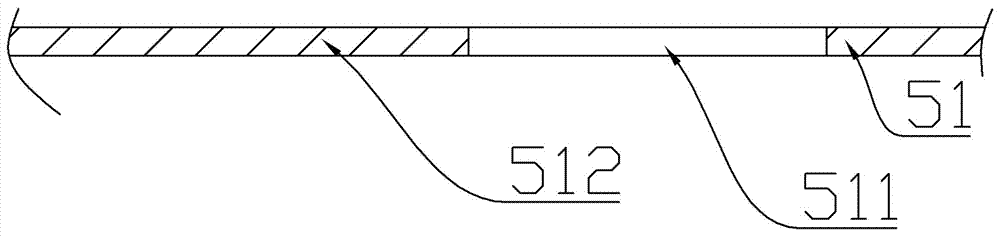

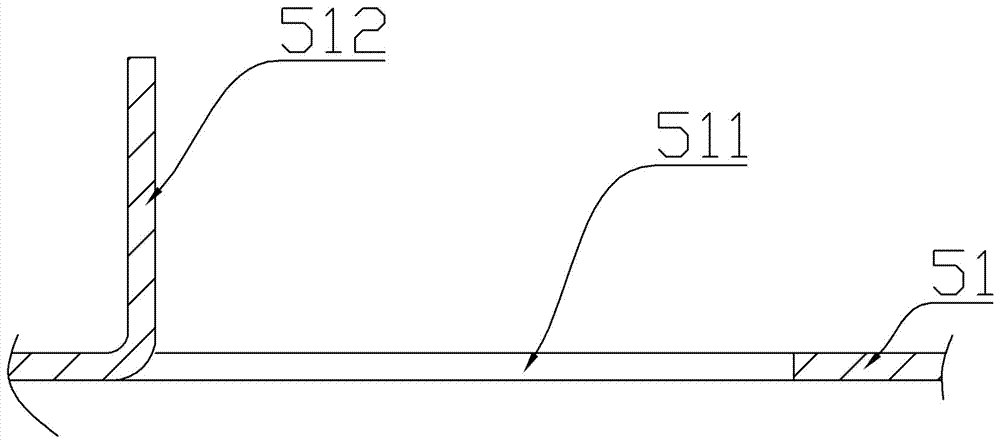

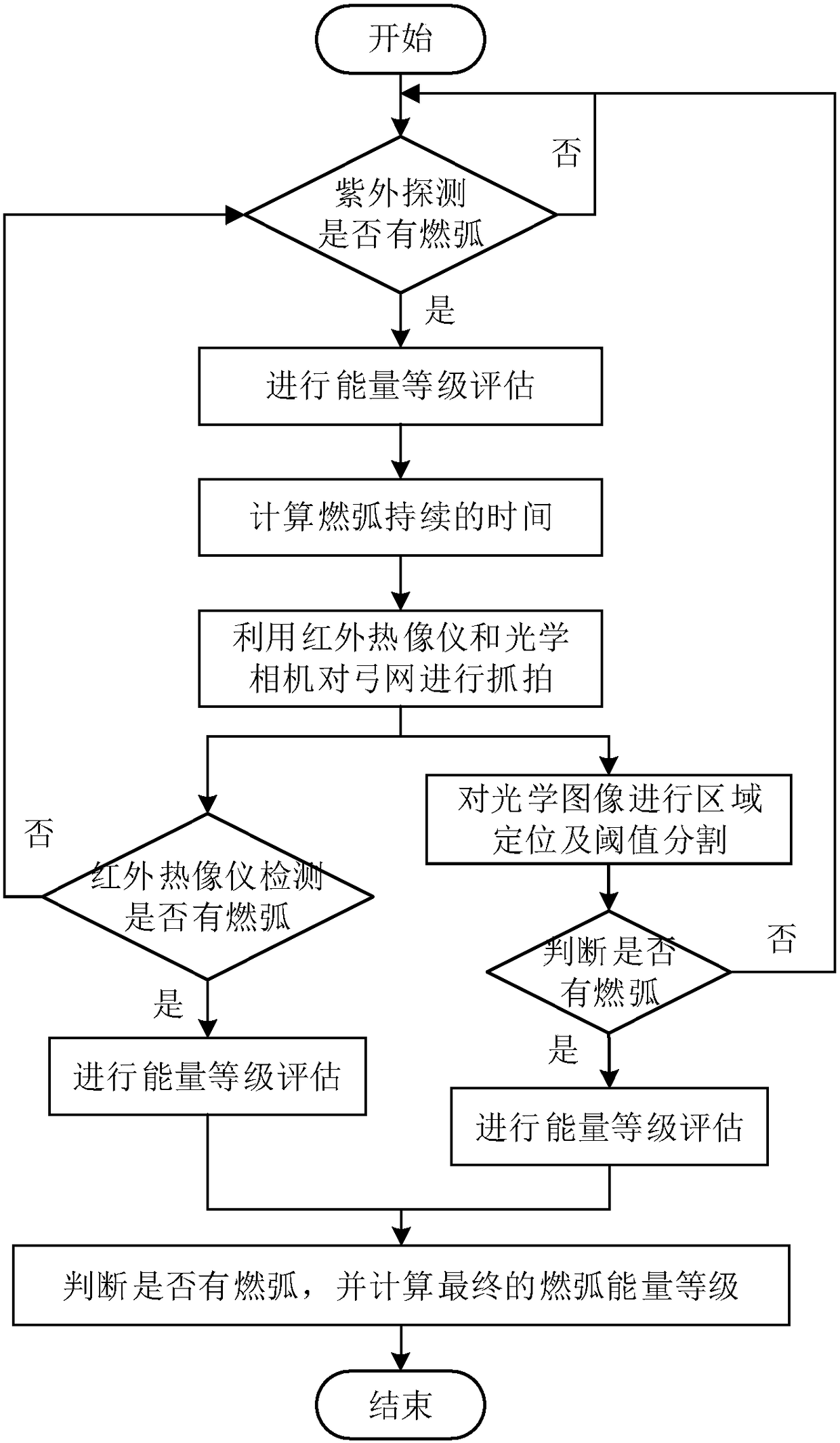

Arcing detection method based on fusion of ultraviolet images, infrared images and optical images

ActiveCN108333488AAccurate detectionDetection securityTesting using optic methodsHigh pressureArc energy

The invention discloses an arcing detection method based on fusion of ultraviolet images, infrared images and optical images. The method comprises the following step of S1, collecting ultraviolet bandsignals of a bow net; S2, performing energy level evaluation on arcing collected in step S1; S3, calculating the duration of arcing; S4, using a thermal infrared imager and an optical camera for capturing the bow net; S5, calculating the average temperature of the bow net in an effective area of the thermal infrared imager to determine whether or not there is arcing; S6, performing energy level evaluation on arcing detected by the thermal infrared imager; S7, performing regional positioning and threshold segmentation on the optical image; S8, evaluating the arcing energy level collected by the optical camera; S9, calculating the final arcing energy level. Detection and energy classification are conducted on arcing through the ultraviolet images, the infrared images and the optical image,whether or not there are two pieces of information including arcing and arcing energy is judged, and therefore the railway bow net and arcing of a high voltage line can be detected accurately, reliably and safely.

Owner:南京视道信息技术有限公司

Method for inhibiting damage due to arc between electrical contacts

InactiveUS20070075046A1Increased durabilityExtend your lifeHigh-tension/heavy-dress switchesAir-break switchesElectricitySodium Bentonite

This method for inhibiting damage due to arc between electrical contacts involves the spreading of a grease composed of from 70% by weight to 95% by weight of a base oil and from 5% by weight to 30% by weight of a thickening agent and additives over a pair of electrical contacts in a circuit which causes terminals to move relative to each other so that they are disconnected from each other, whereby damage on the contact area due to arc occurring when the electrical contacts are isolated from each other is inhibited. As the thickening agent there is preferably used an organic bentonite. As the base oil there is preferably sued an ester oil, glycol oil or poly-α-olefin. The base oil preferably has a low density to reduce arc energy.

Owner:YAZAKI CORP

Laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method and device with addition of high frequency magnetic field

InactiveCN103071937AReduced shieldingImprove laser utilizationArc welding apparatusLaser beam welding apparatusVolumetric Mass DensityEngineering

The invention relates to a laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method with the addition of a high frequency magnetic field. The method comprises the steps of: 1) first, respectively connecting anode and cathode of a TIG welding machine to a workpiece and a welding gun, and then, connecting an exciting power supply output end to an exciting coil, and clamping the welding gun on a welding gun clamping mechanism of a hybrid welding head to determine a welding travel path; 2) opening an exciting power supply to supply power to the exciting coil; and 3) opening a protective gas to weld and observing formation of weld. Compared with the prior art, the laser-TIG arc rangefinder hybrid welding method with the addition of the high frequency magnetic field provided by the invention has the beneficial effects that as the high frequency magnetic field is added, the pneumatic pressure and the electric current density of arc are effectively improved, so that the arc heat is distributed more centralized and the arc radius is reduced, therefore, the arc energy density and arc deflection are further improved. Improvement of the arc energy density and reduction of radius of an arc column of the arc are very beneficial for enhancing the stable combustion capacity and impacting penetration capacity of the arc during laser-TIG arc rangefinder hybrid welding.

Owner:鞍山煜宸科技有限公司

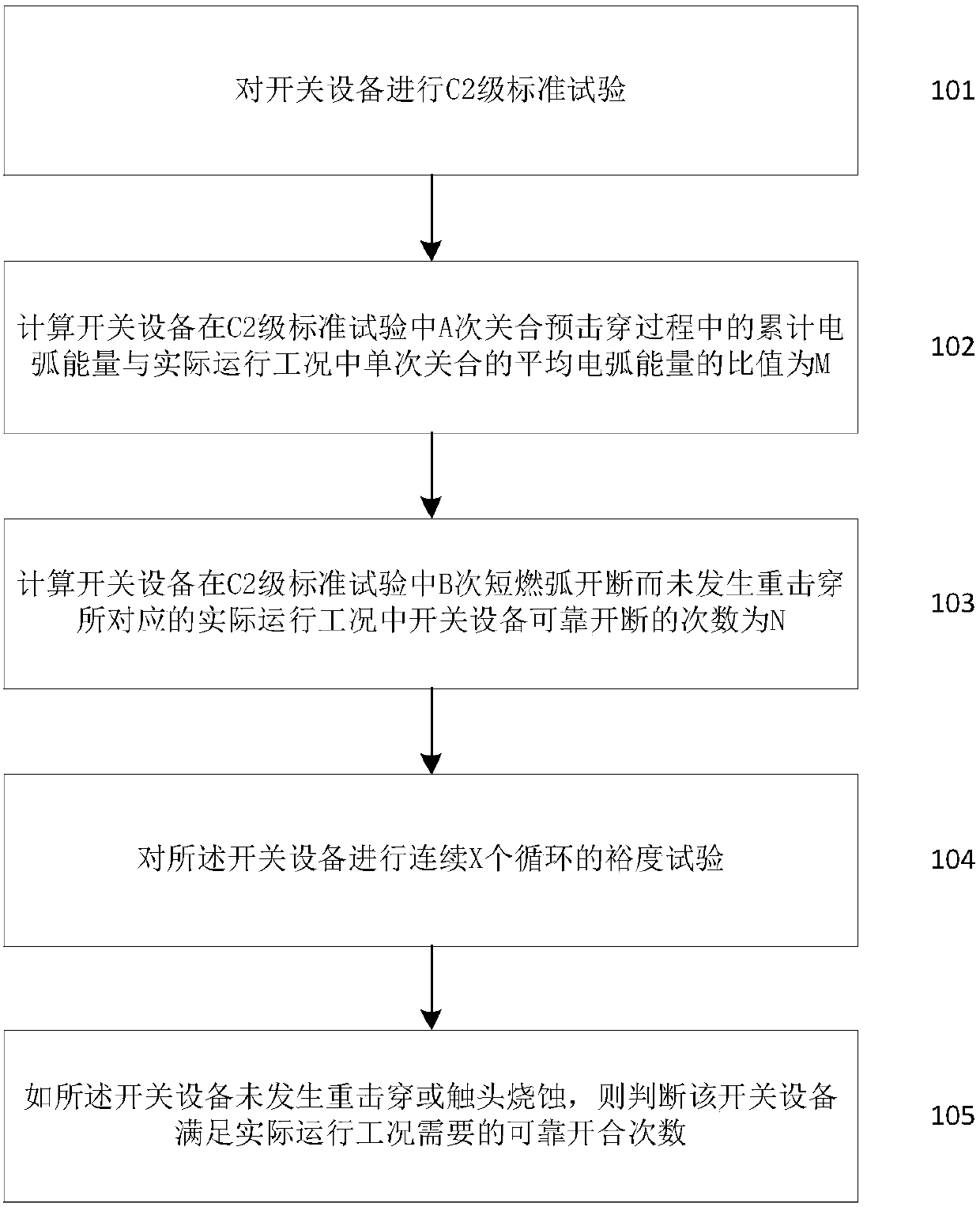

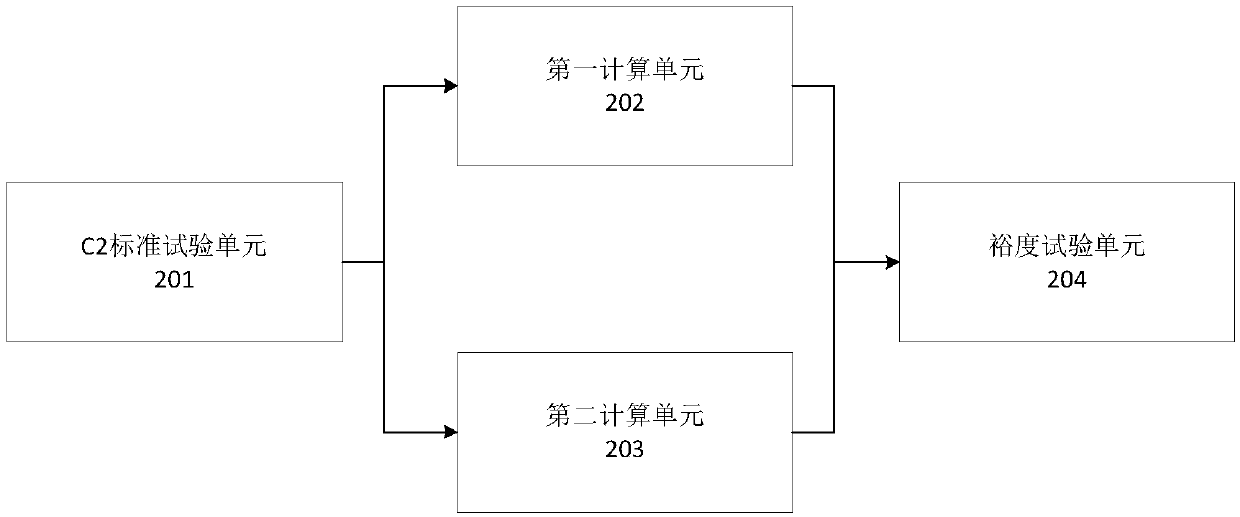

Test evaluation method and system of frequent-switching capacitive current switch equipment

ActiveCN108051736AMeet the needs of long-term safe operationCircuit interrupters testingElectrical resistance and conductanceSwitching frequency

The invention discloses a test evaluation method and system of frequent-switching capacitive current switch equipment. The method comprises steps that a C2-level standard test on to-be-evaluated switch equipment is carried out; the ratio of the cumulative arc energy in A switching pre-breakdown processes in the test to the average arc energy of a single switching in the actual operation conditionis calculated, and the reliable switching number of the switch equipment in the actual operation condition corresponding to B short arc breaks without severe breakdown in the test is further calculated; X cycle margin tests for the switch equipment are continuously carried out on the basis; if the switch equipment reliably breaks, the switch equipment is determined to satisfy the reliable switching frequency required by the actual operation condition; a closing resistor is added to a break to improve service life of a contact head of the switch equipment in the C2-level standard test. The method is advantaged in that whether the switch equipment can meet long-term safe operation demands in engineering can be verified.

Owner:CHINA ELECTRIC POWER RES INST +2

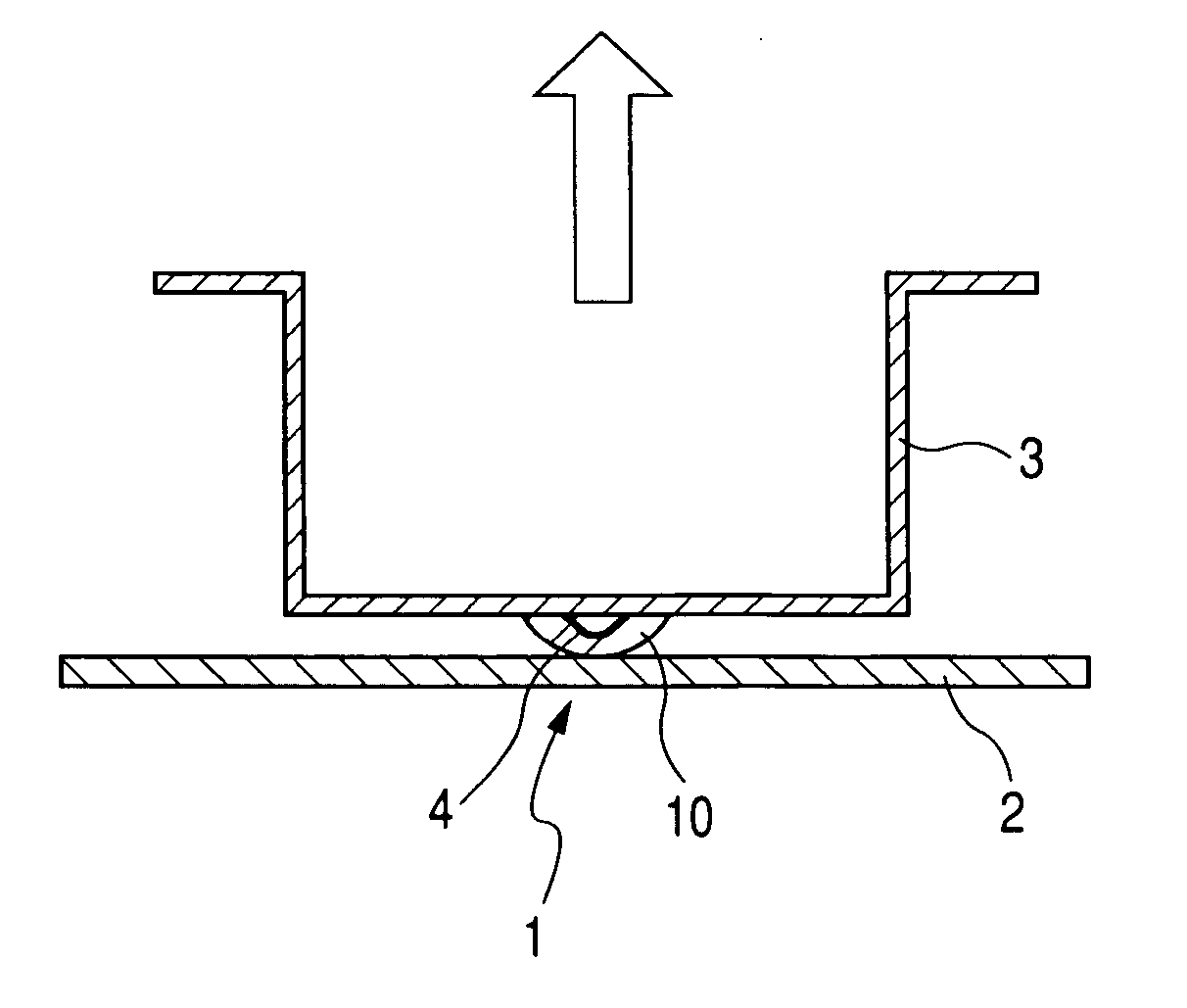

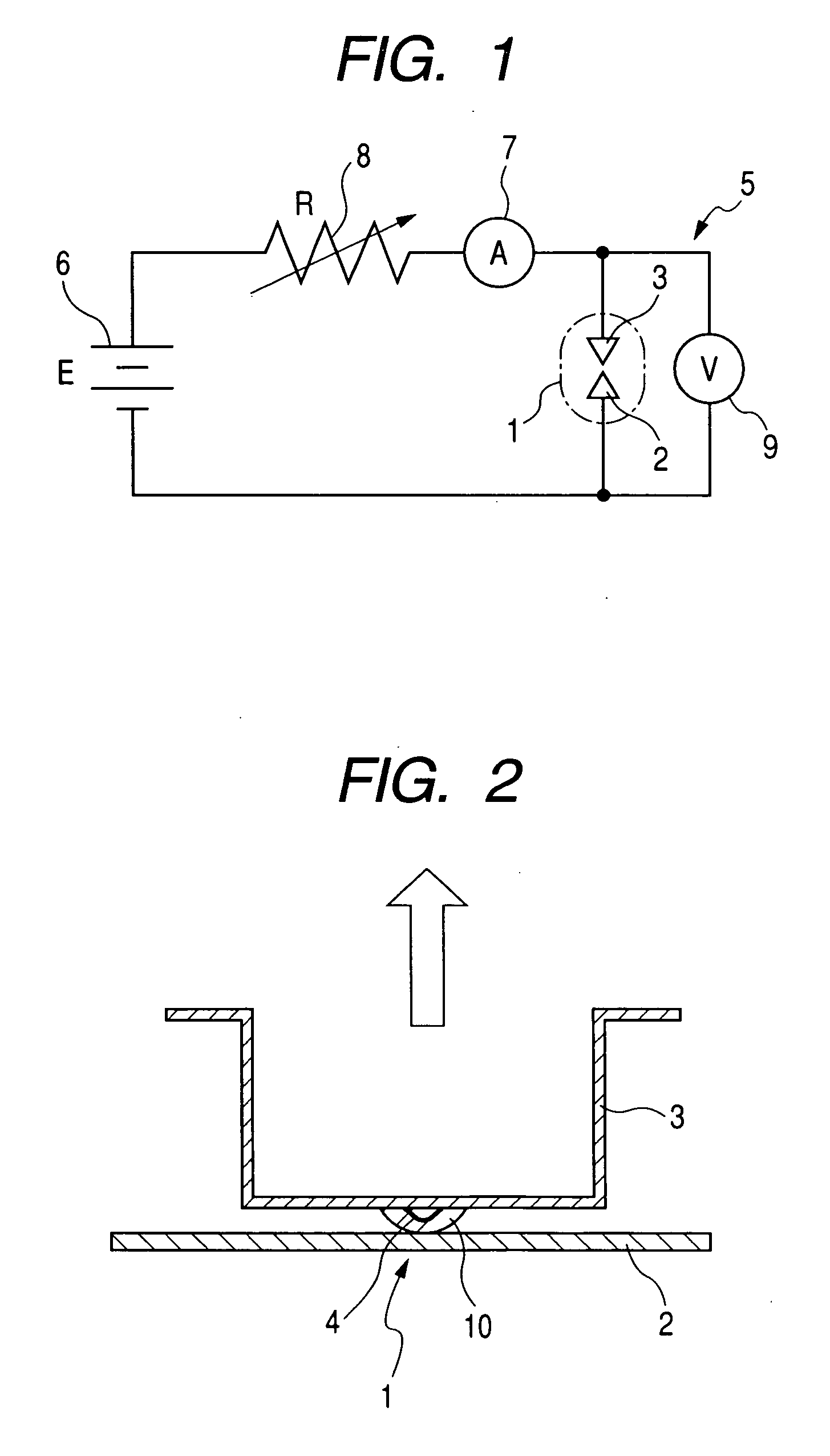

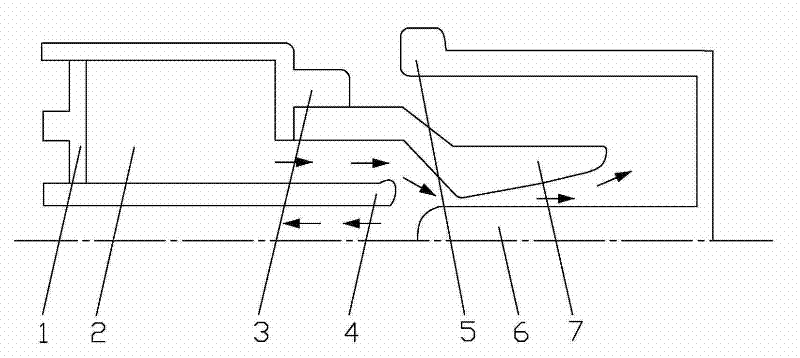

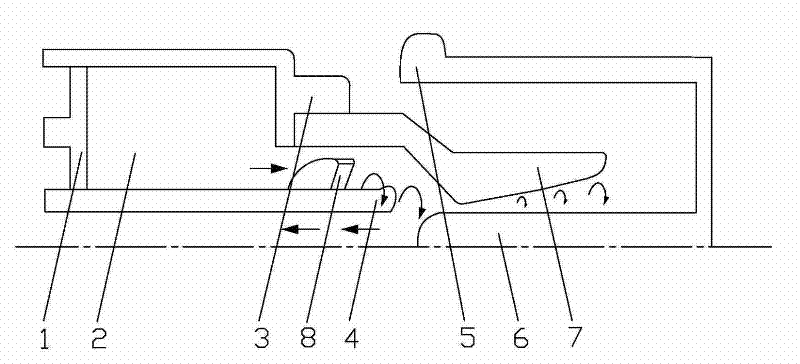

Gas rotation energy separation type high-voltage SF6 circuit breaker and energy separation method thereof

ActiveCN102364656AAccelerate offImprove breaking capacityHigh-tension/heavy-dress switchesAir-break switchesFan bladeArc energy

The invention belongs to the field of high-voltage SF6 circuit breakers, in particular to a gas rotation energy separation type high-voltage SF6 circuit breaker and an energy separation method thereof. The circuit breaker comprises a piston (1), an air cylinder (2), a movable main contact (3), a movable arcing contact (4), a static arcing contact (5), a static main contact (6) and a nozzle (7), wherein a vortex diversion mechanism (8) is fixedly arranged near the end part of the movable arcing contact (4) on the upstream of the nozzle (7), consists of a group of flow deflector units (9) with intersected structures and can consist of a fan blade type flow deflector (16) or a screw type flow deflector (21). By the circuit breaker and the method, SF6 gas which flows out of the air cylinder is subjected to vortex motion, temperature gradient variation along the radial direction is formed in the motion process, and arc energy is quickly dissipated; and the circuit breaker has a high arc temperature reduction speed, a high insulating property, high breaking capacity and high operation reliability and is convenient to mount and maintain.

Owner:SHENYANG POLYTECHNIC UNIV

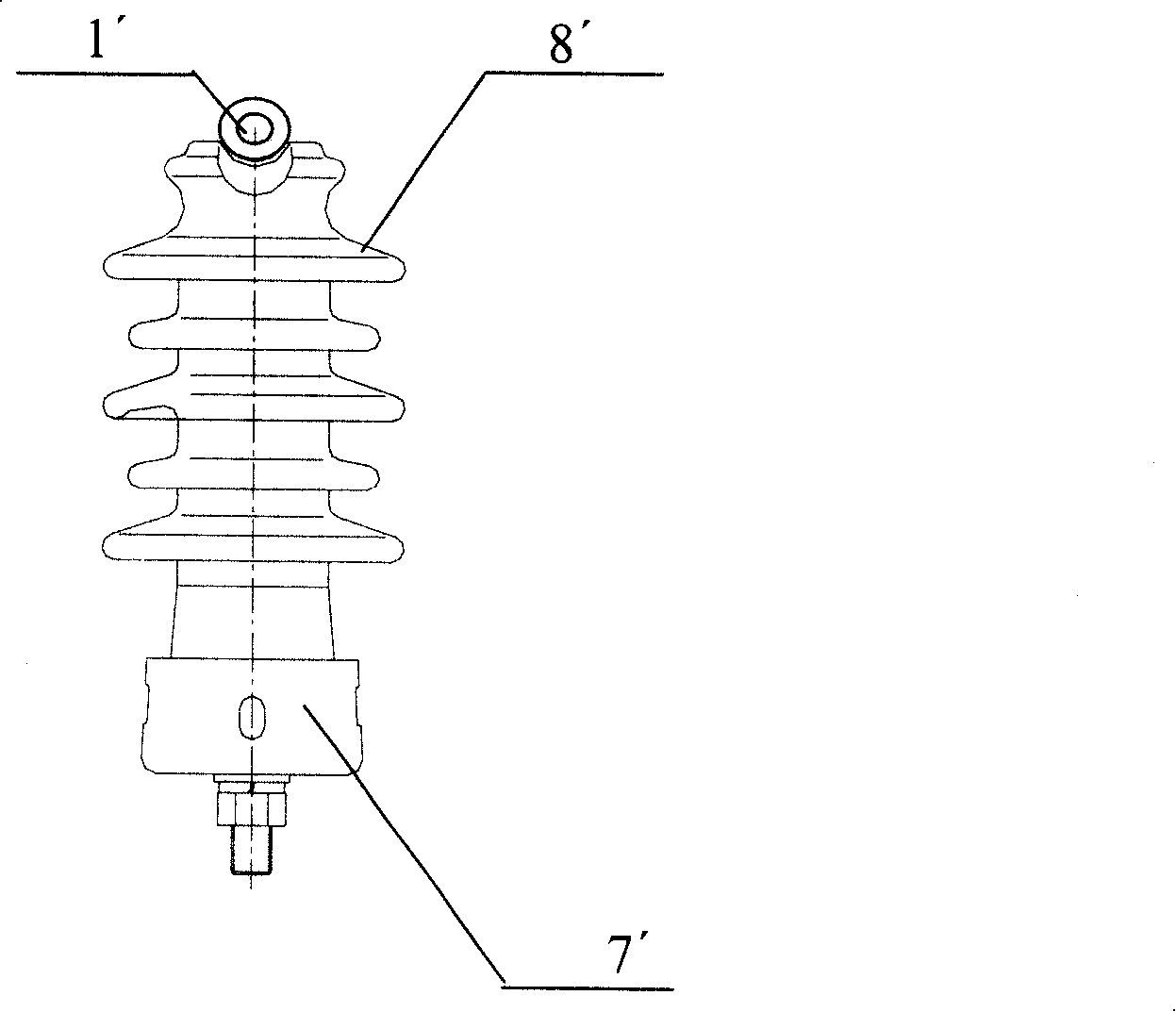

Lightning protection supporting insulator and insulated cable used with it

InactiveCN101174497AProtected from lightning damageGuaranteed safe operationInsulated cablesSupporting insulatorsElectric arcEngineering

The invention relates to a lightning-proof post insulator and a matching insulated cable, wherein, the lightning-proof post insulator comprises an insulator body, an upper flange, a lower flange, a discharge ring, a run-on tab, a built-in clip and an insulating boot. The invention is characterized in that the built-in clip is arranged at the top of the upper flange via a bolt with a pressure spring, enabling the insulated cable to be tightly pressed between the bottom of the built-in clip and the upper flange, and arranged on the discharge ring via the insulating boot from a top boot; part of the insulated cable arranged on the post insulator is bare, two insulated adhesive tapes are arranged at two ends of the bare cable and an aluminum armor tape is arranged in the middle. The invention has the advantages that part of the insulated cable close to the insulator is bared according to lightening breaking mechanism to the insulated cable; an arc root of a power frequency electric arc is transferred or fixed between the electric arc and the run-on tab via the discharge ring on the upper flange and the run-on tab on the lower flange of the lightning-proof post insulator; the electric arc energy of lightening short circuit is transferred away from the cable in a short time, thereby preventing the insulated cable from being damaged by lightening and ensuring safe operation of overhead insulated distribution network.

Owner:SHANGHAI ELECTRIC PORCELAIN WORKS CO LTD

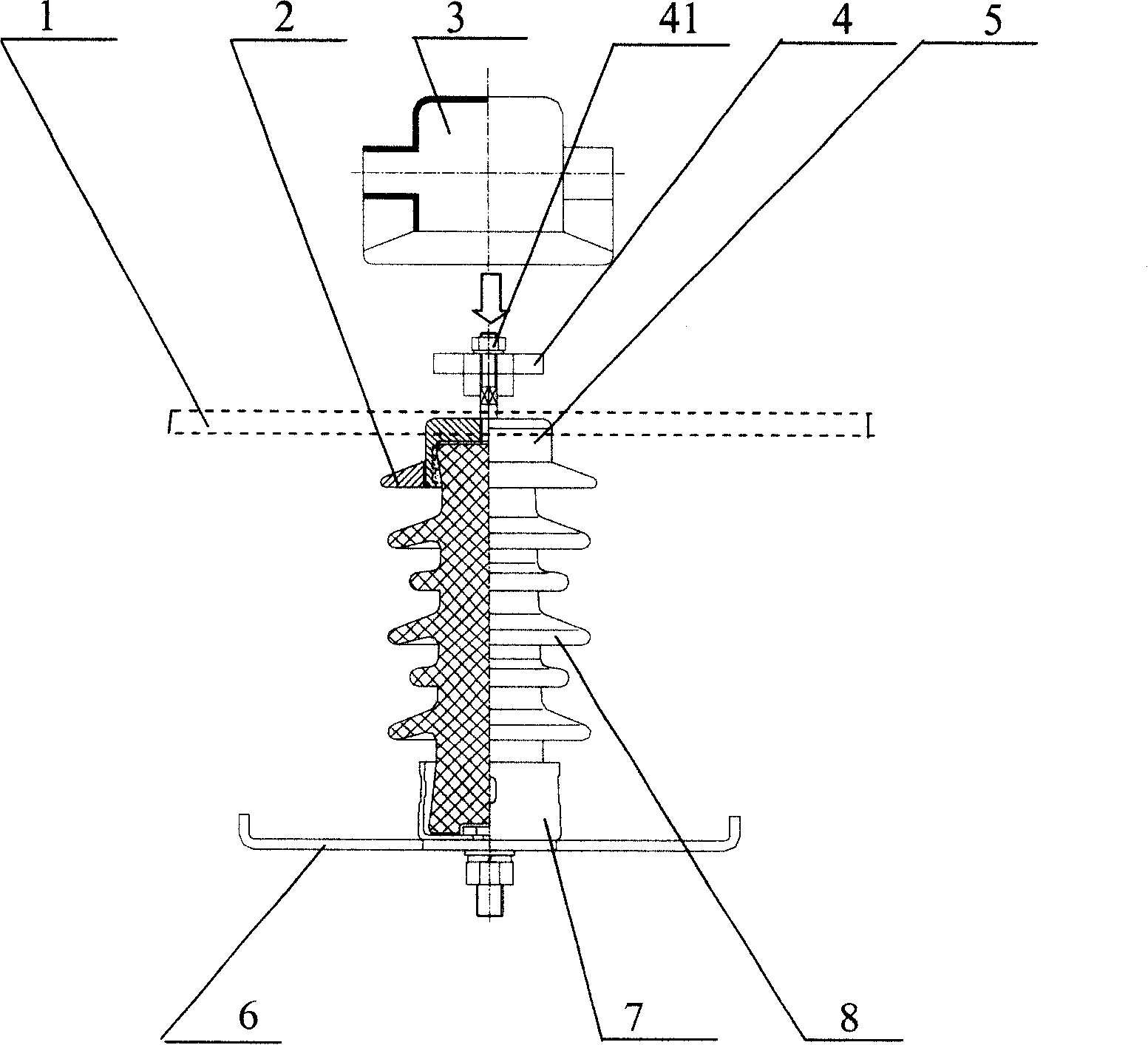

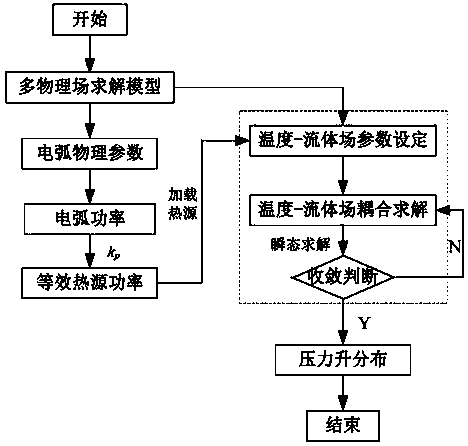

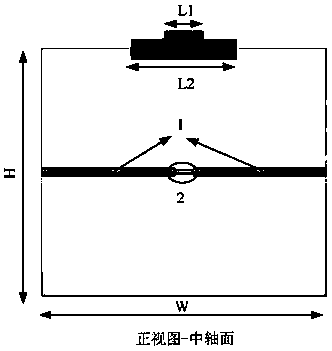

Switch cabinet internal short circuit arcing pressure rise calculation method based on arc energy thermal equivalence

PendingCN110188450ADesign optimisation/simulationSpecial data processing applicationsPressure risePhysical field

A switch cabinet internal short circuit arcing pressure rise calculation method based on arc energy thermal equivalence comprises the steps: simplifying a switch cabinet according to switch cabinet structure parameters, and obtaining a switch cabinet multi-physical-field solution simplification model; according to a result of a short-circuit explosion test, obtaining arc parameters, wherein the arc parameters comprise a short-circuit current instantaneous value I and an arc voltage U; calculating arc power P = U * I; calculating short-circuit explosion equivalent heat source power; setting temperature-fluid field calculation parameters, a gas model, boundary conditions and initial conditions; and carrying out coupling solution on the temperature-fluid field to obtain pressure rise distribution. The switch cabinet internal short circuit arcing pressure rise calculation method enables complex arc plasma in the switch cabinet to be equivalent to a heat source with a fixed size, and assumes that energy of an arc area is evenly distributed, and obtains the distribution law of short-circuit explosion pressure rise in the switch cabinet through temperature-fluid field coupling solution.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com