Method for inhibiting damage due to arc between electrical contacts

A technology of electrical contacts and arcs, which is applied in the field of damage caused by arcs, can solve the problems of durability degradation, electro-corrosion or melting of electrical contacts, and achieve the effects of preventing melting, improving durability, and reducing the duration of arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

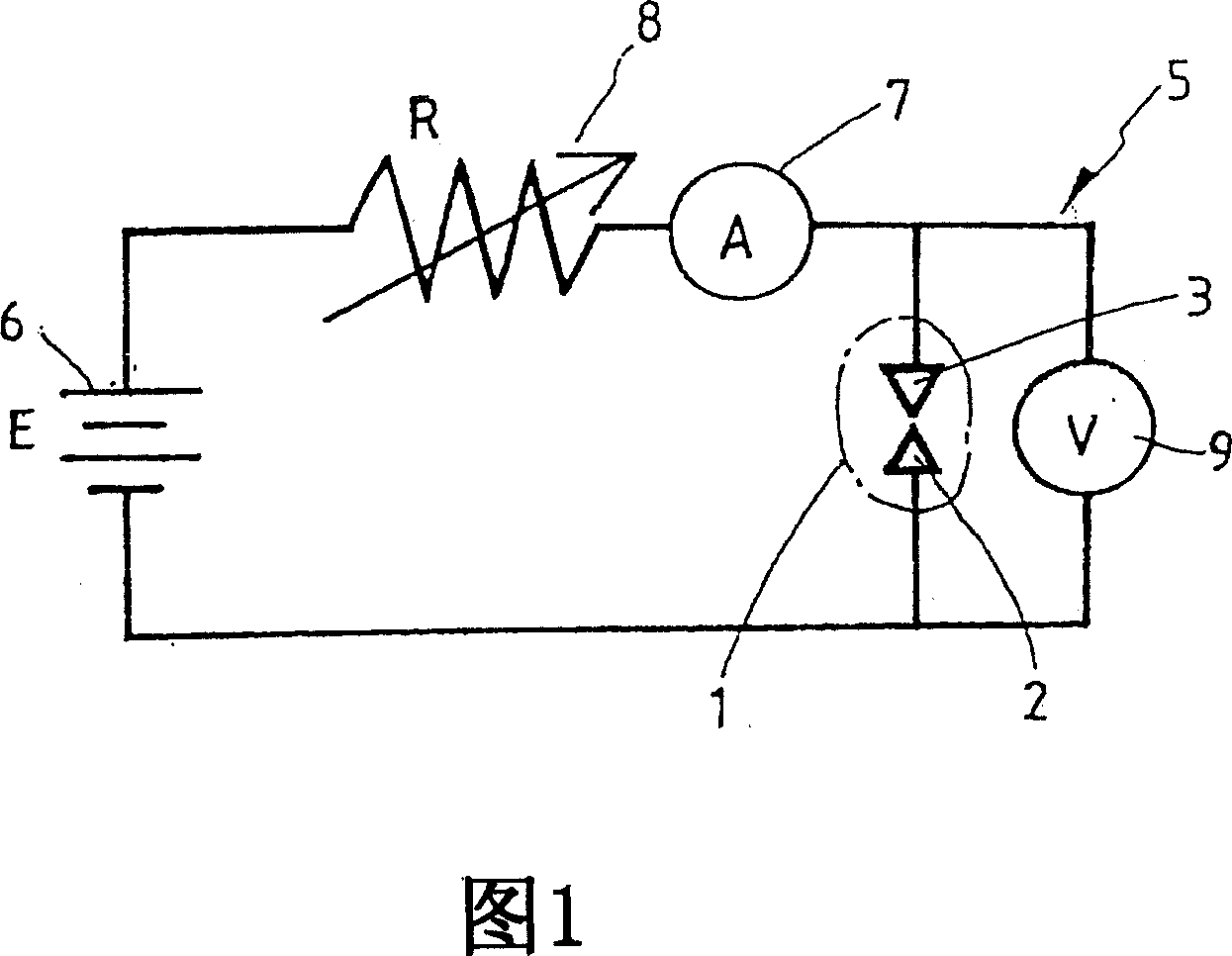

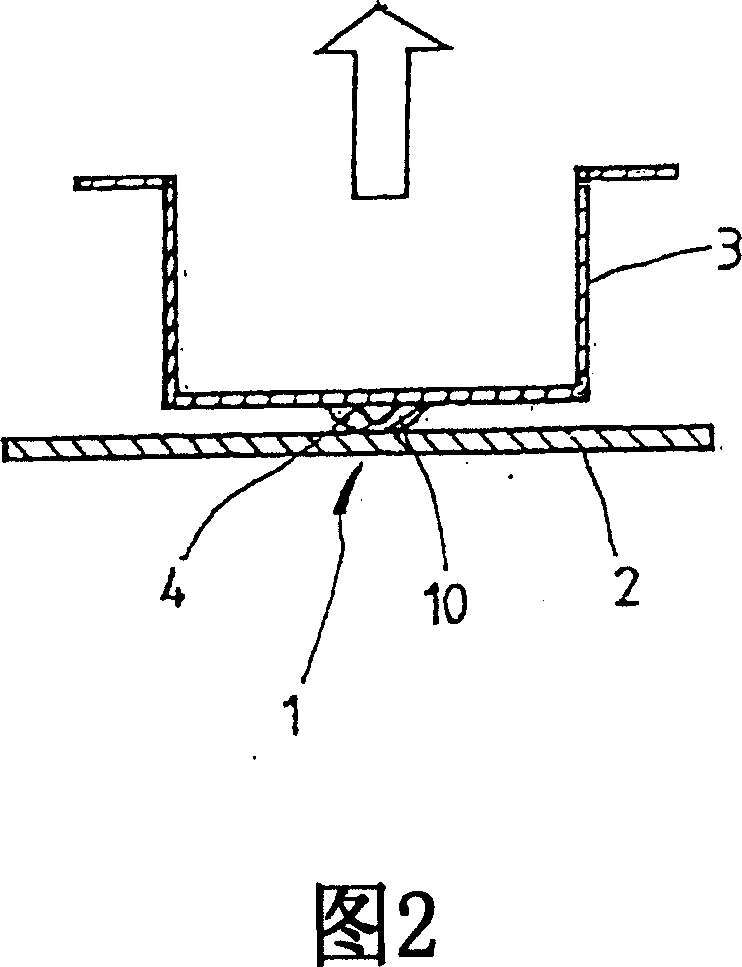

[0025] The method of preventing damage due to arcing between electrical contacts according to the present invention can be applied to a circuit in which a pair of terminals are moved relative to each other so that the electrical contacts thereof are disconnected. The method of preventing damage due to arcing between electrical contacts according to the present invention will be verified with reference to FIGS. 1 to 5 .

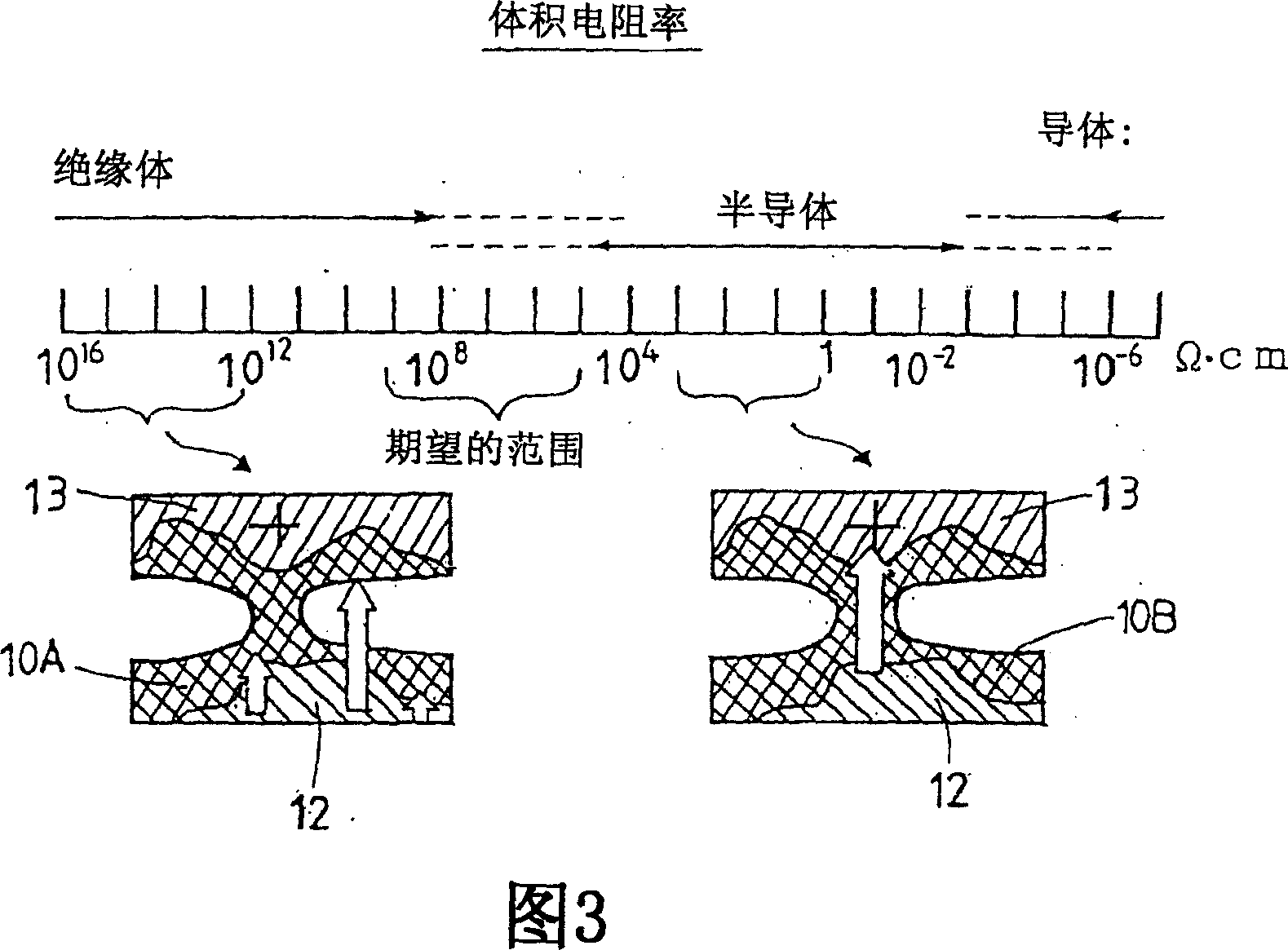

[0026]In particular, the method for preventing damage due to arcing between electrical contacts according to the present invention is characterized in that, before the electrical contacts are connected to each other, the base material other than fluorine-based oil is used from 70% to 95% by weight. Grease consisting of oil and from 5% to 30% by weight of thickeners and additives, distributed over terminal electrical contacts and their adjacent areas, so that when the electrical contacts are connected to each other and disconnected from each other, said electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com