Patents

Literature

1196results about How to "Avoid melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

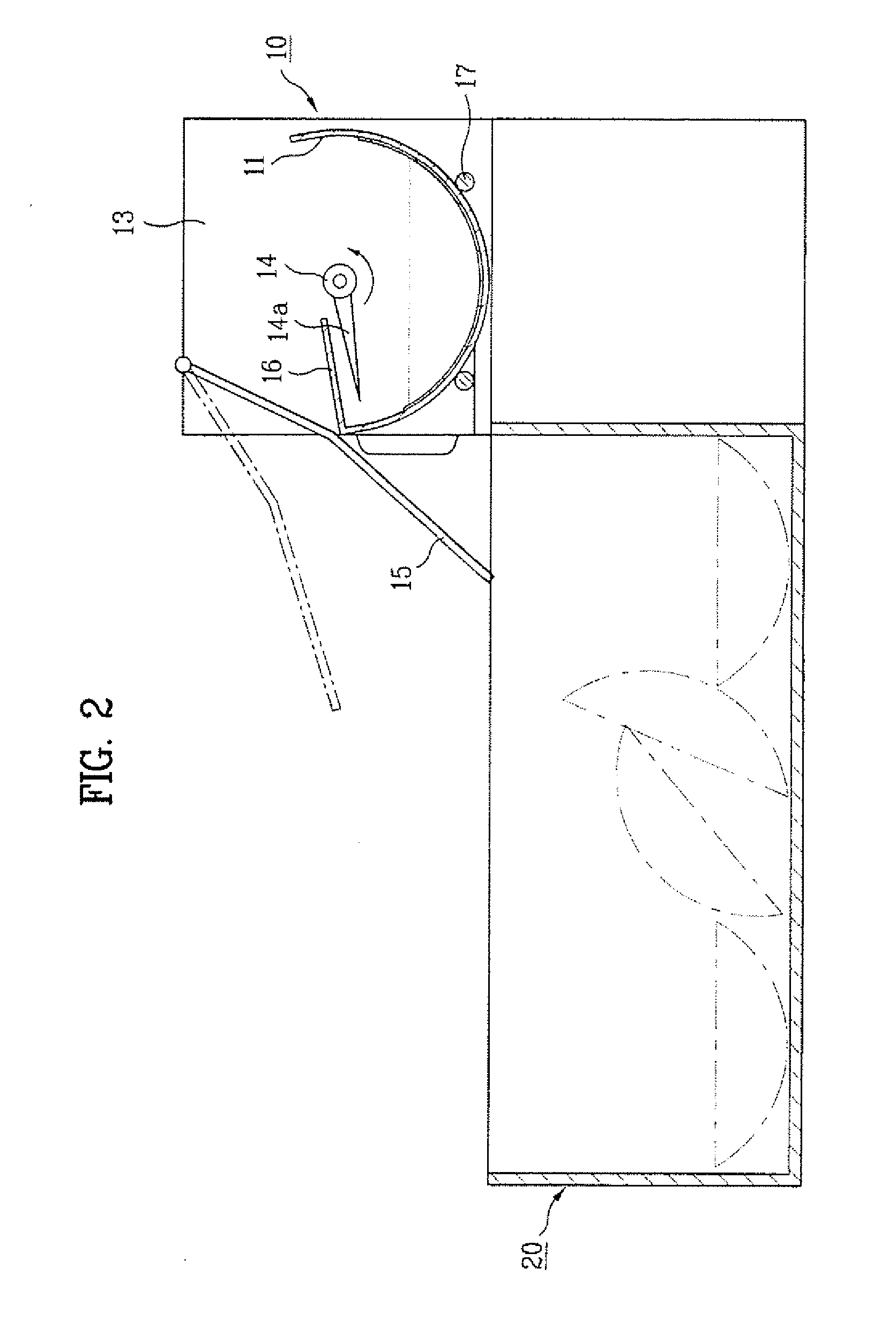

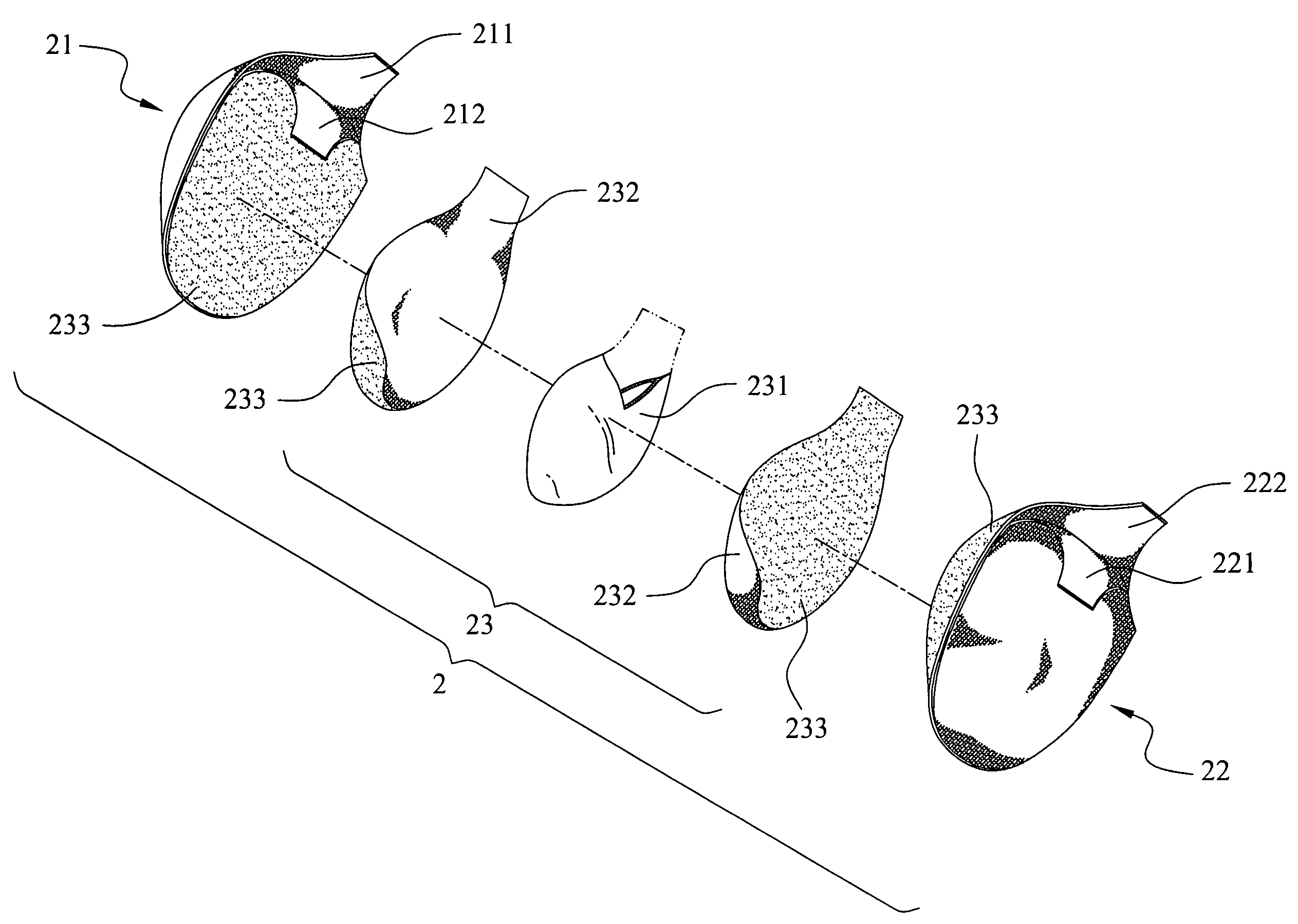

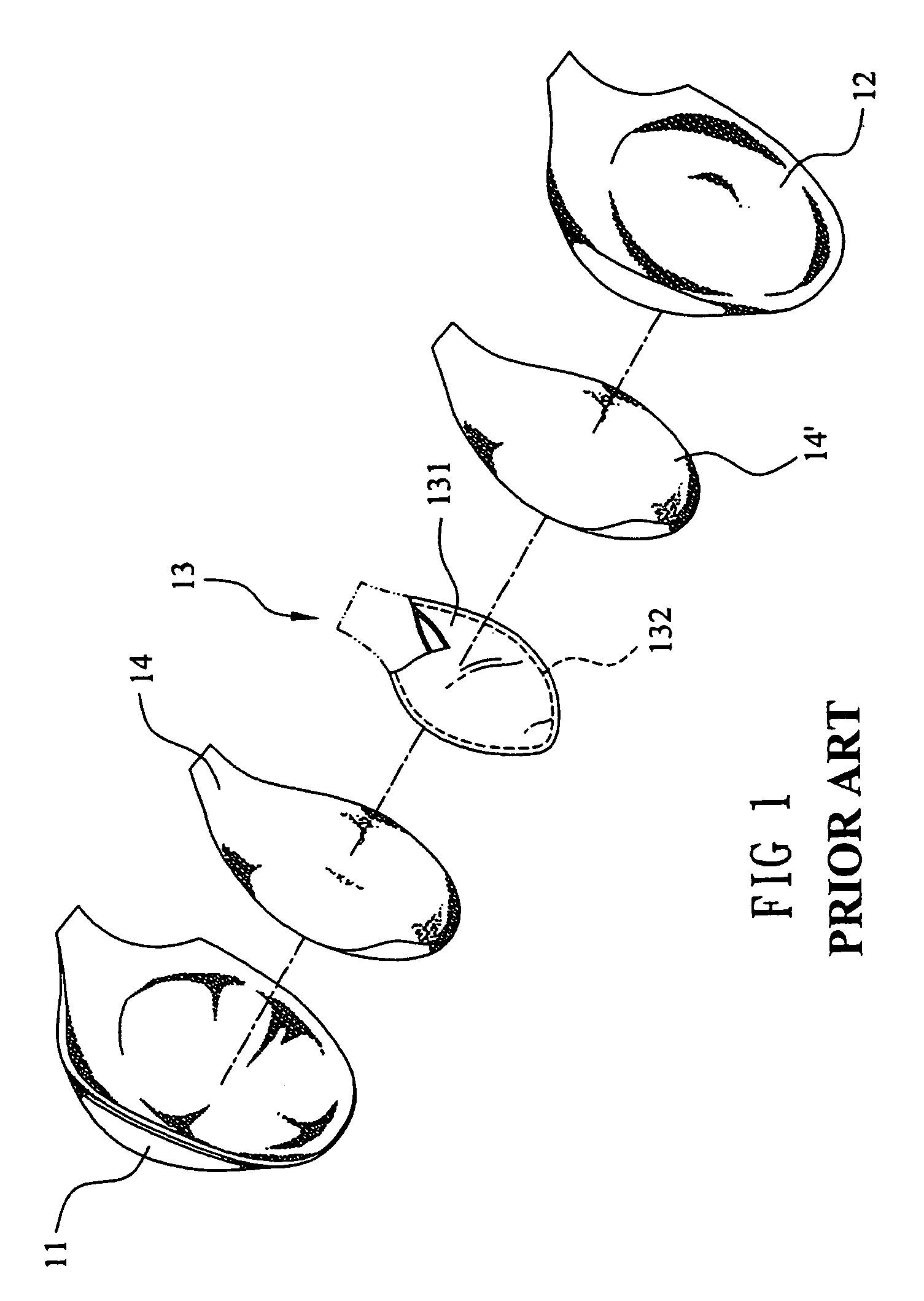

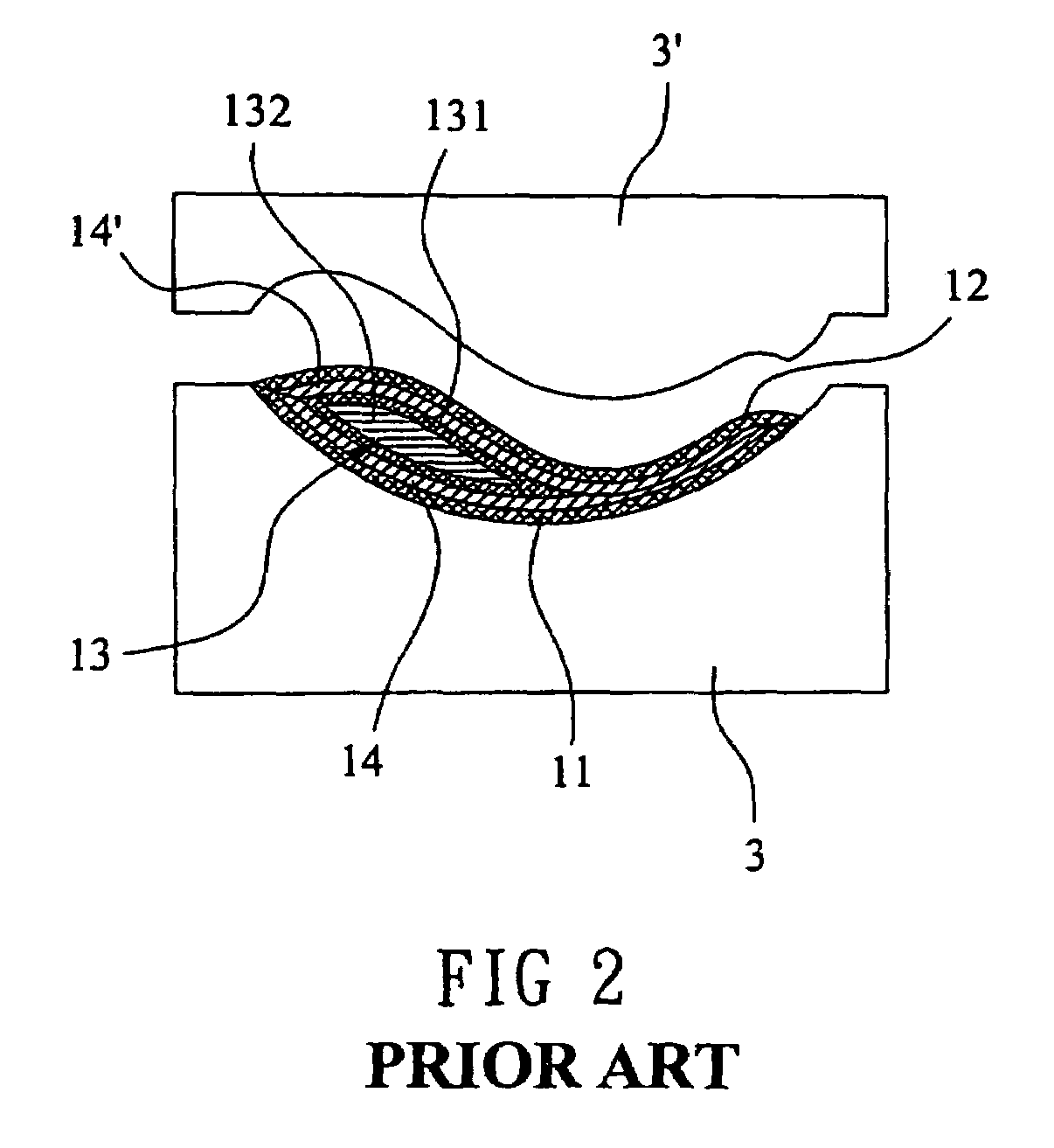

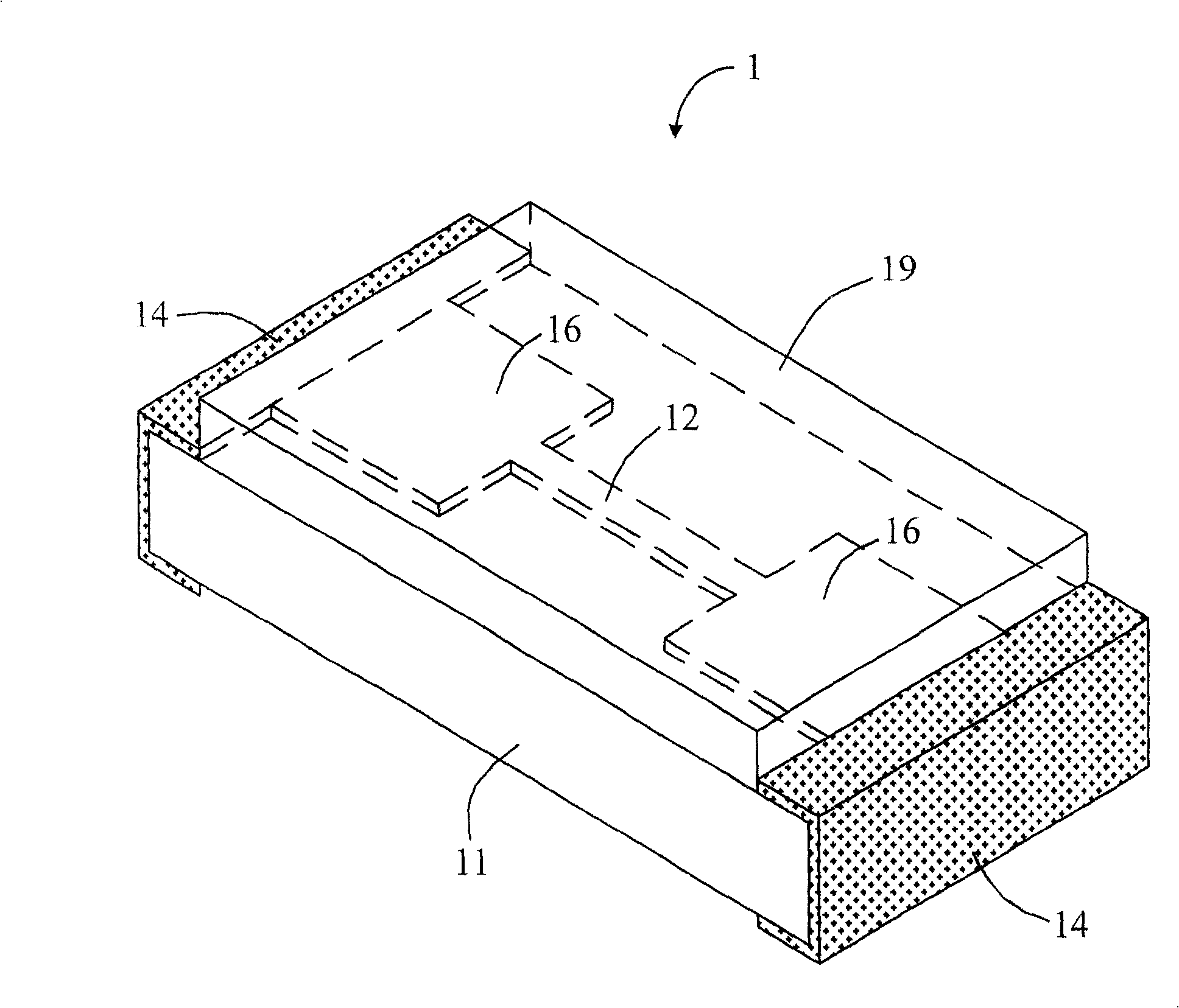

Method of cutting processed object

InactiveUS20060011593A1Precise cuttingPrevent unnecessary fracturesSolid-state devicesSemiconductor/solid-state device manufacturingClassical mechanicsLaser light

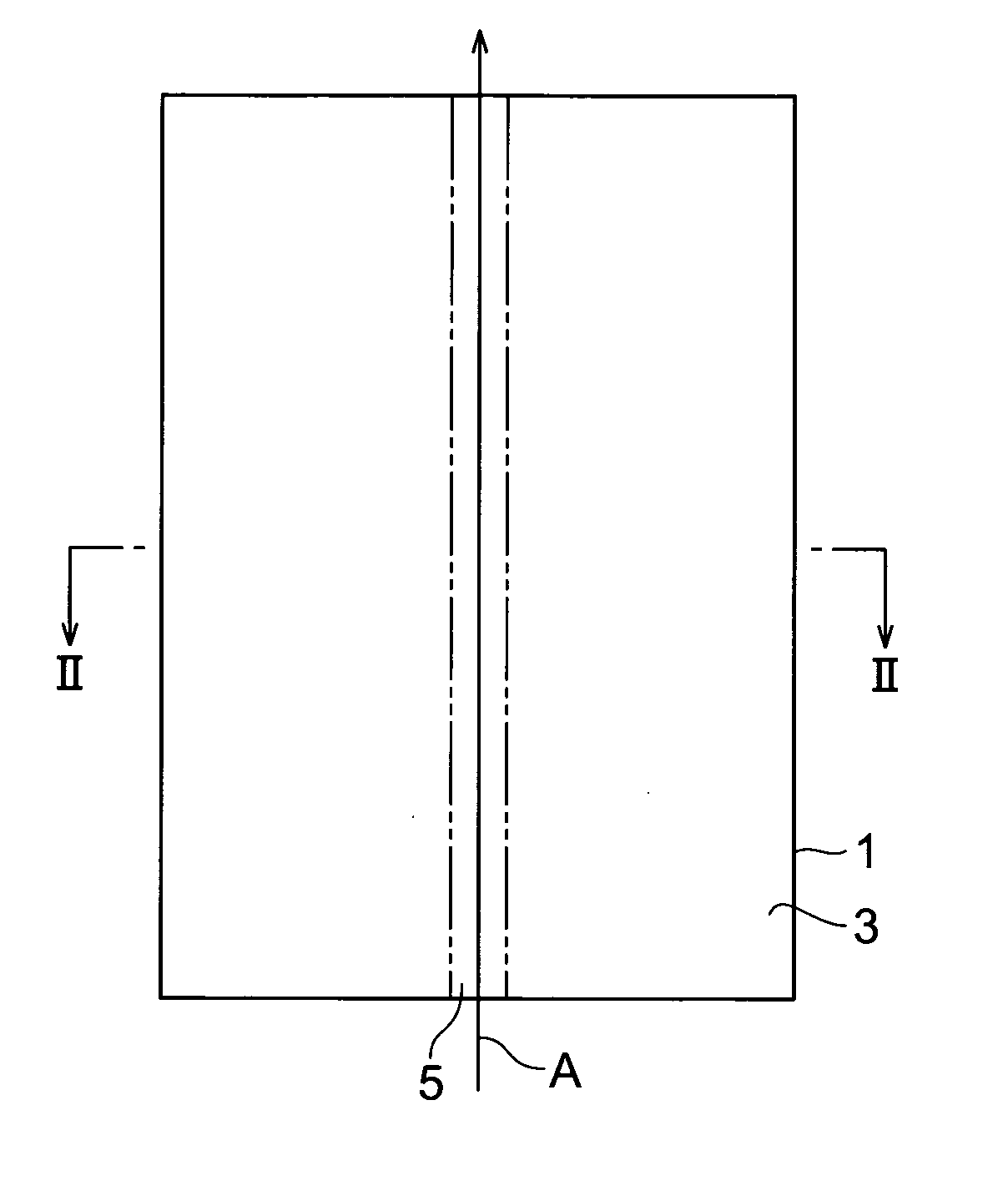

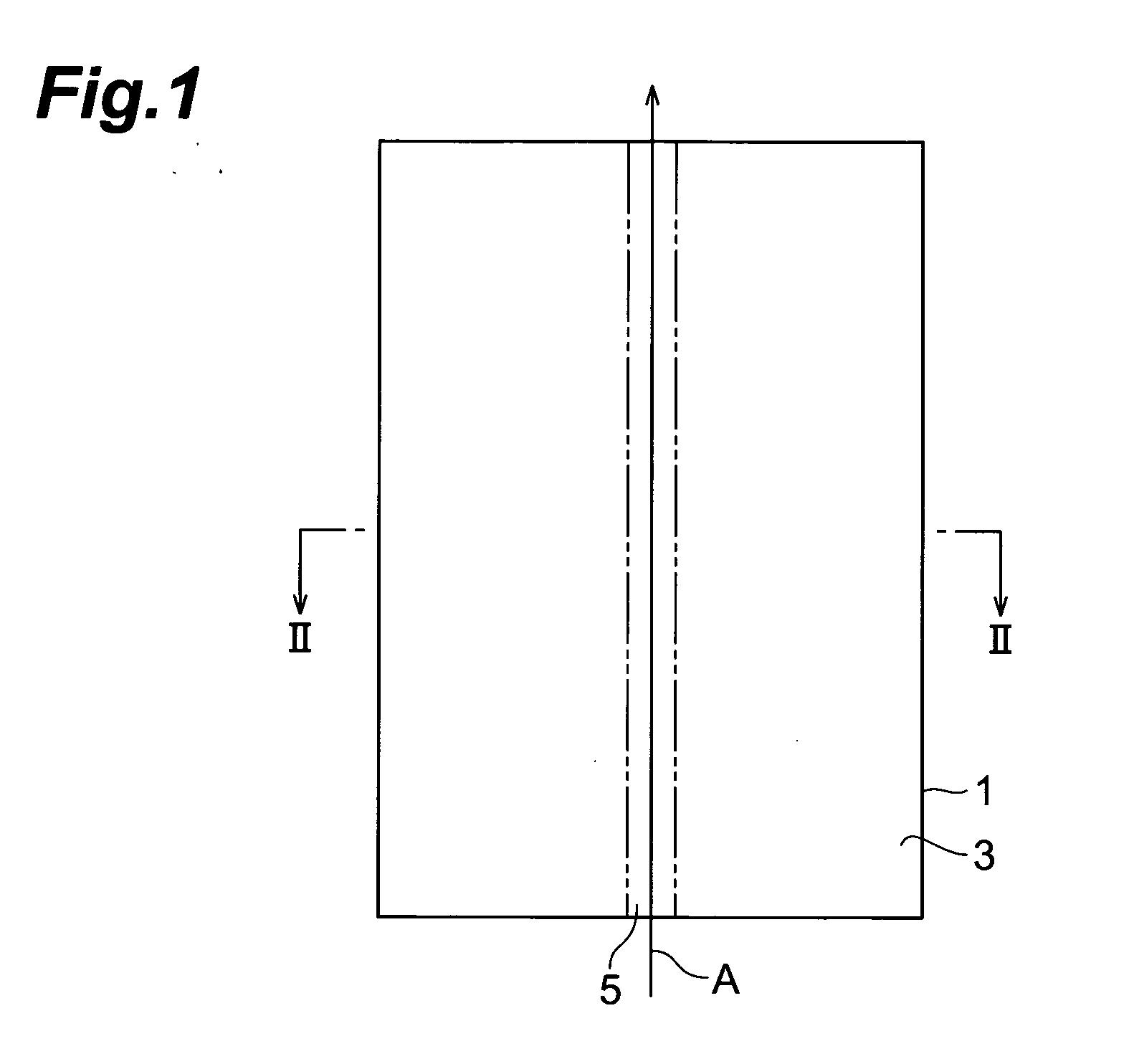

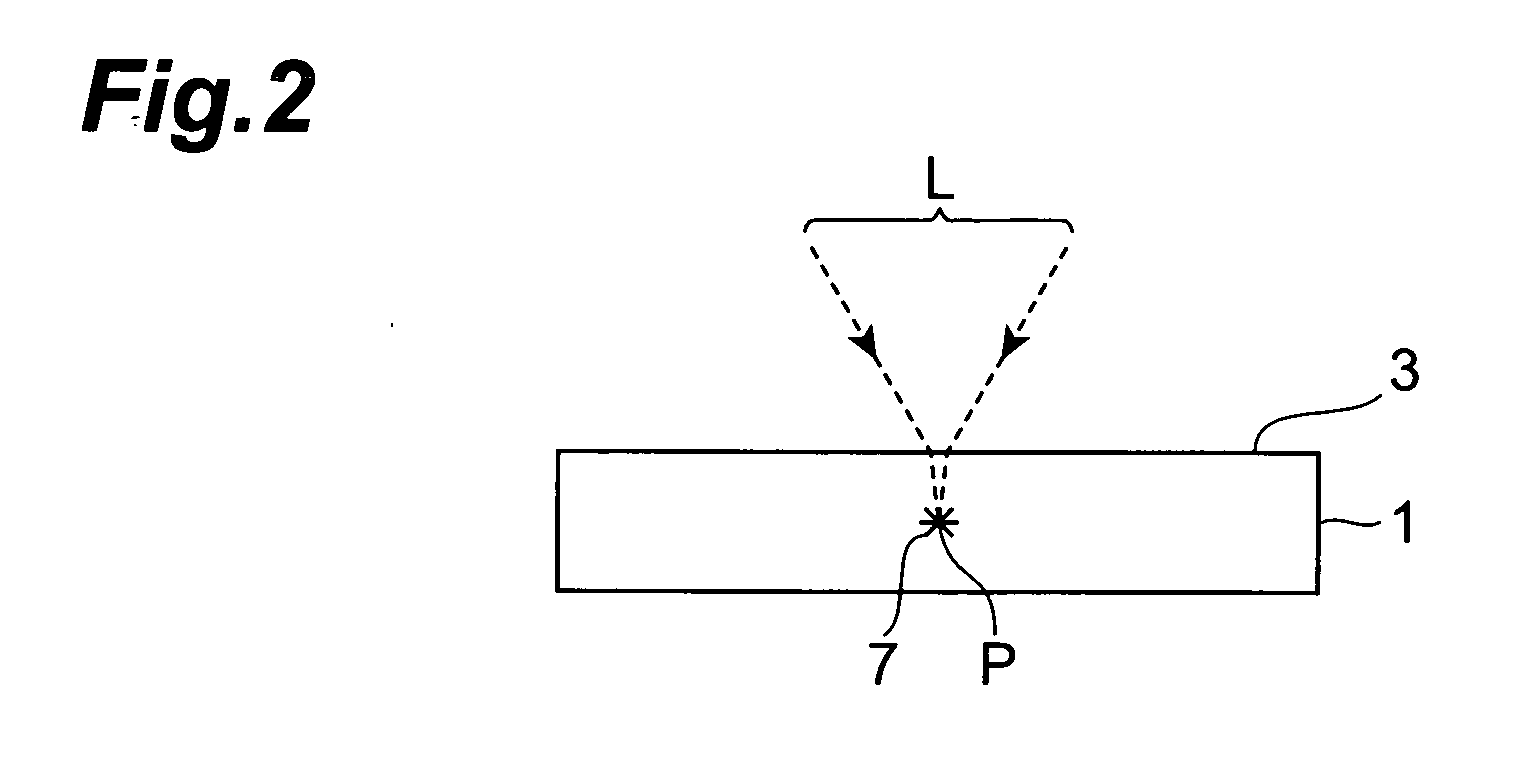

A method of cutting an object which can accurately cut the object is provided. An object to be processed 1 such as a silicon wafer is irradiated with laser light L while a light-converging point P is positioned therewithin, so as to form a modified region 7 due to multiphoton absorption within the object 1, and cause the modified region 7 to form a starting point region for cutting 8 shifted from the center line CL of the thickness of the object 1 toward the front face 3 of the object 1 along a line along which the object should be cut. Subsequently, the object 1 is pressed from the rear face 21 side thereof. This can generate a fracture from the starting point region for cutting 8 acting as a start point, thereby accurately cutting the object 1 along the line along which the object should be cut.

Owner:HAMAMATSU PHOTONICS KK

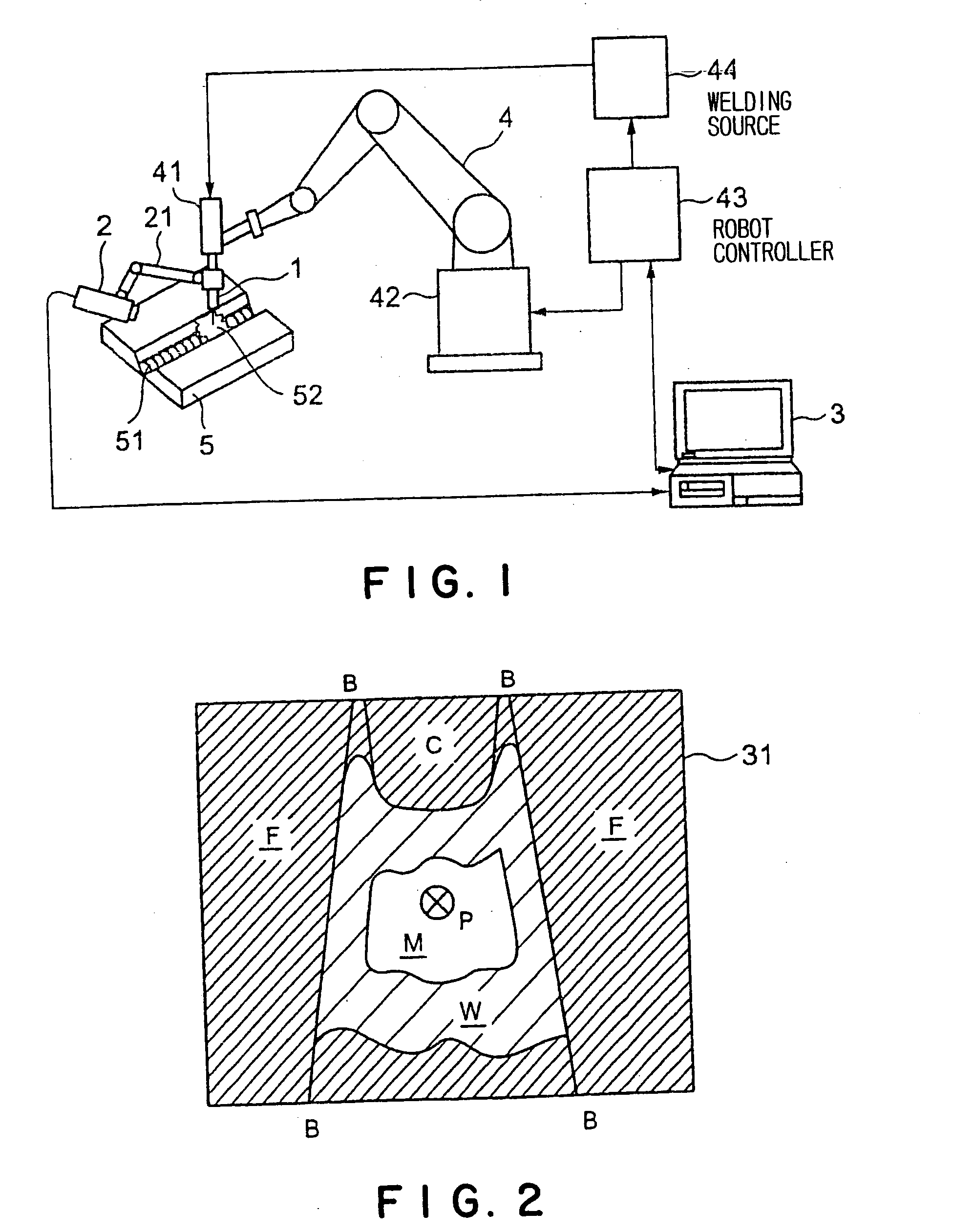

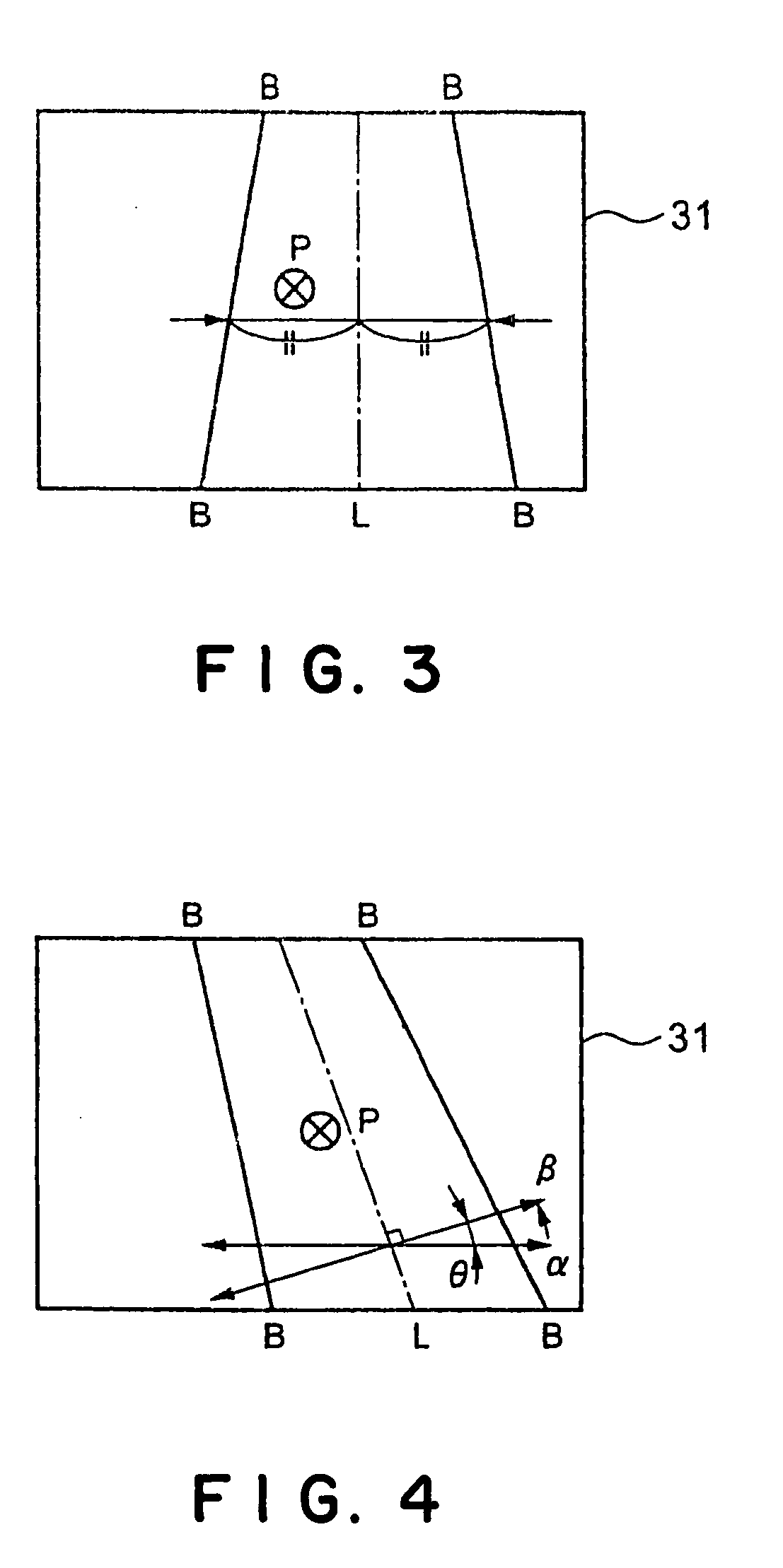

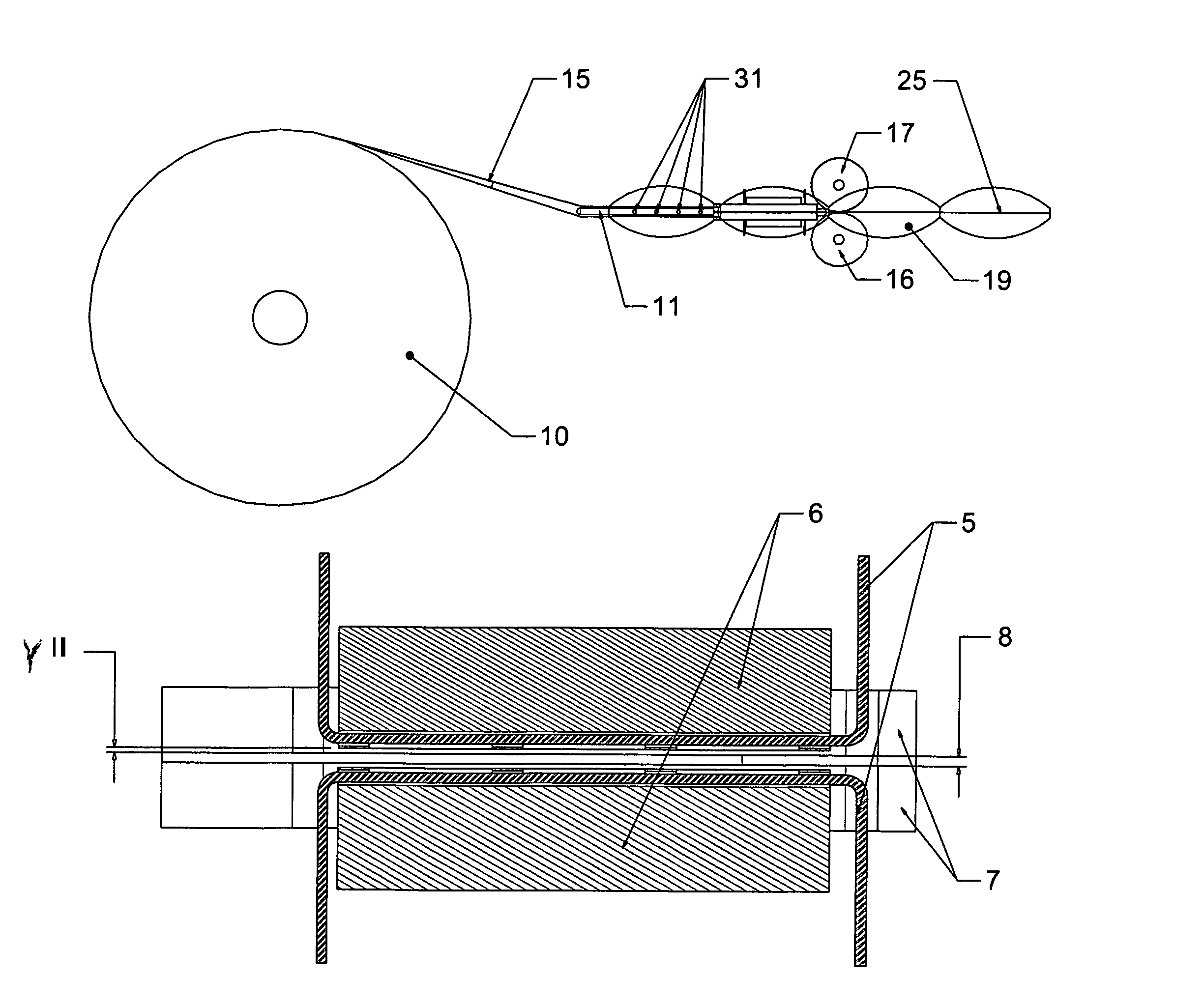

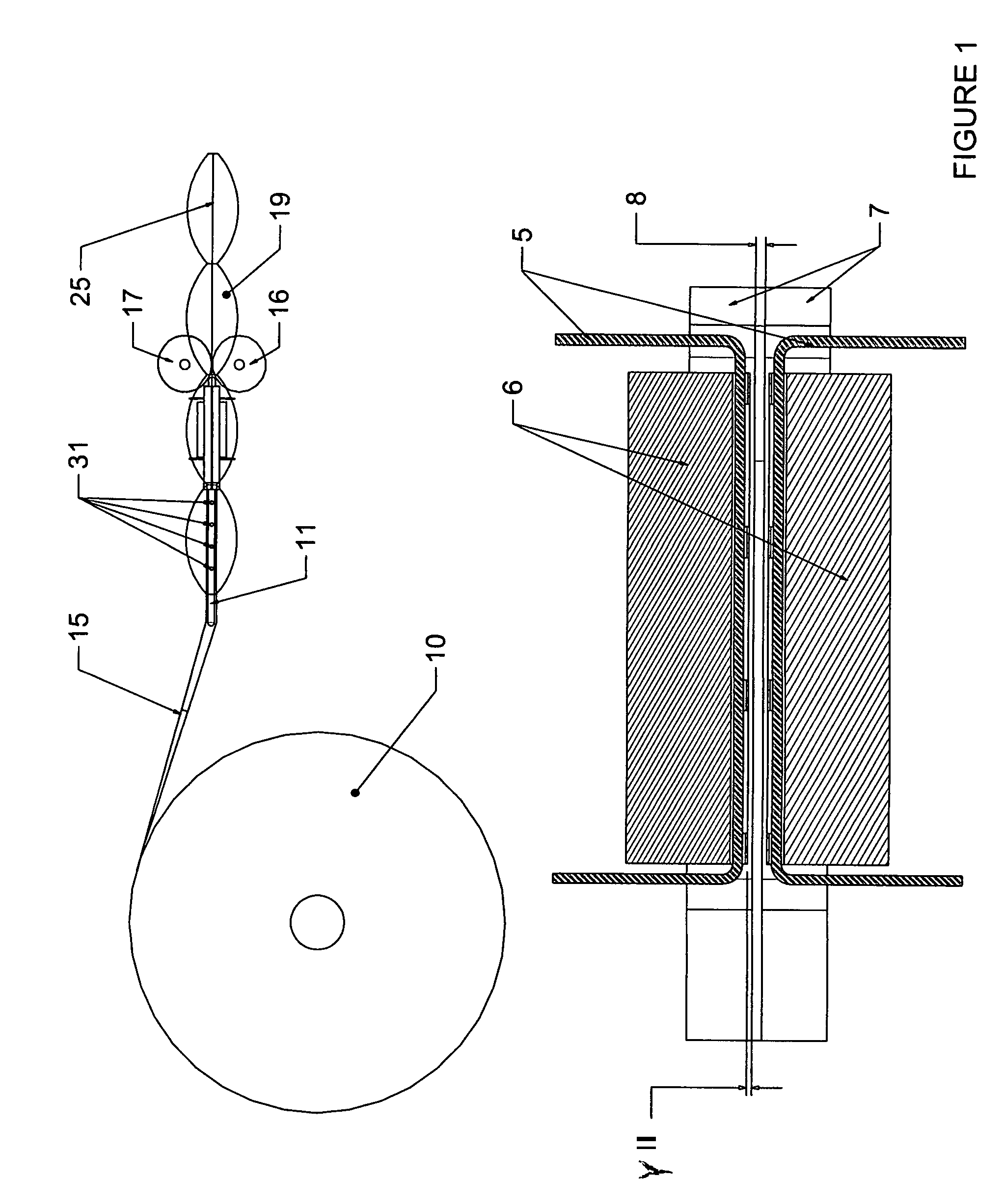

Automatic groove copy welder and welding method

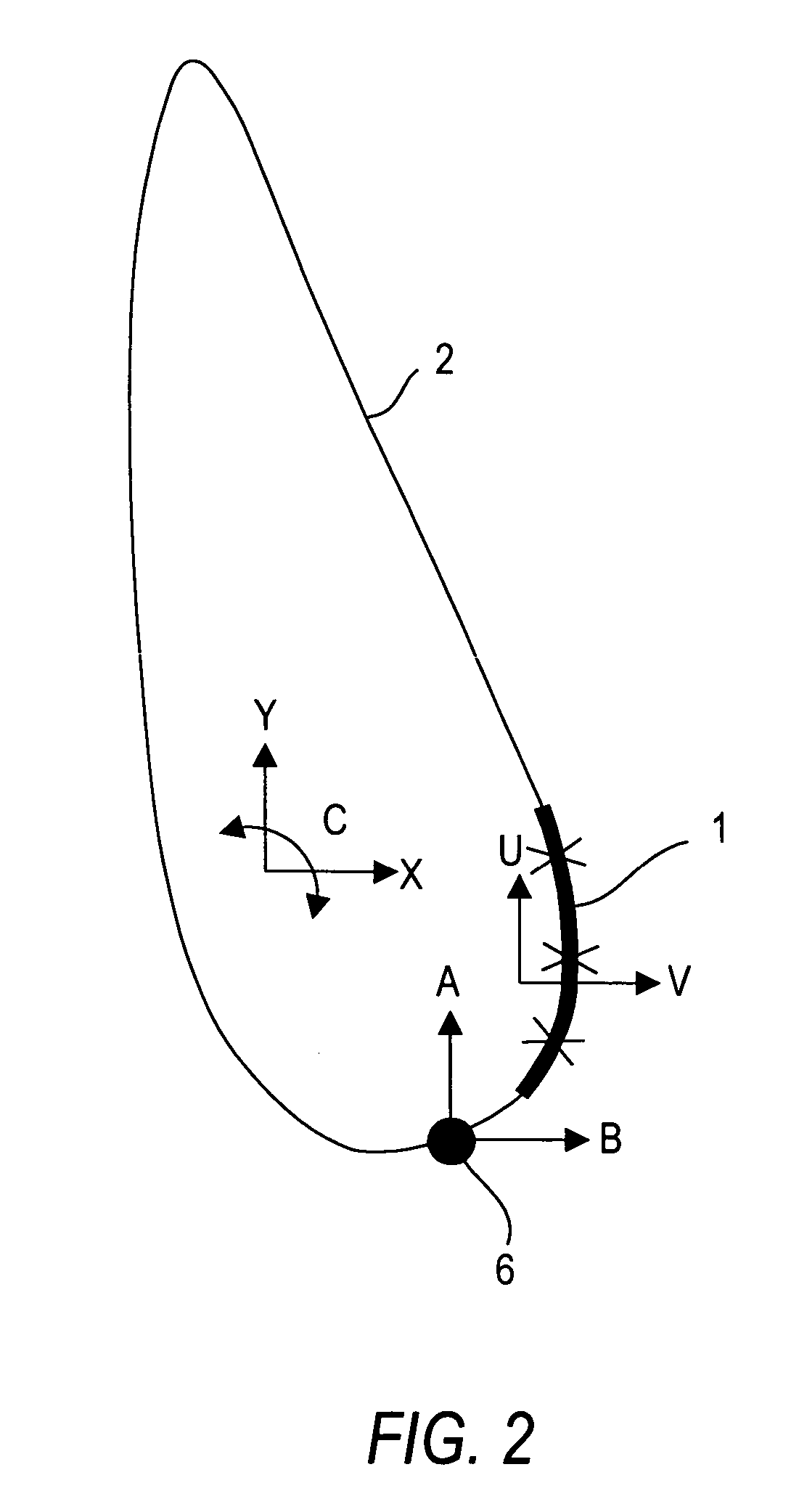

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

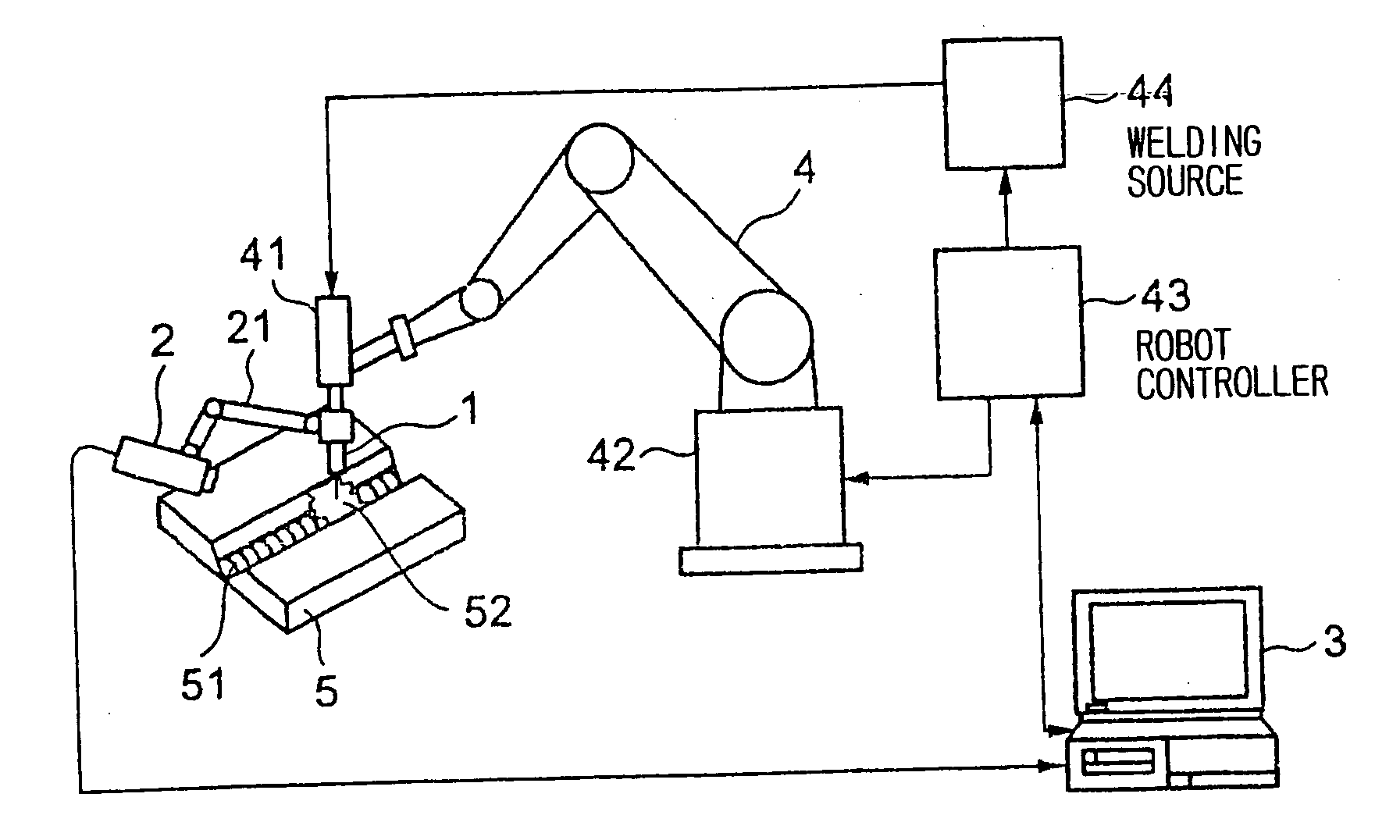

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

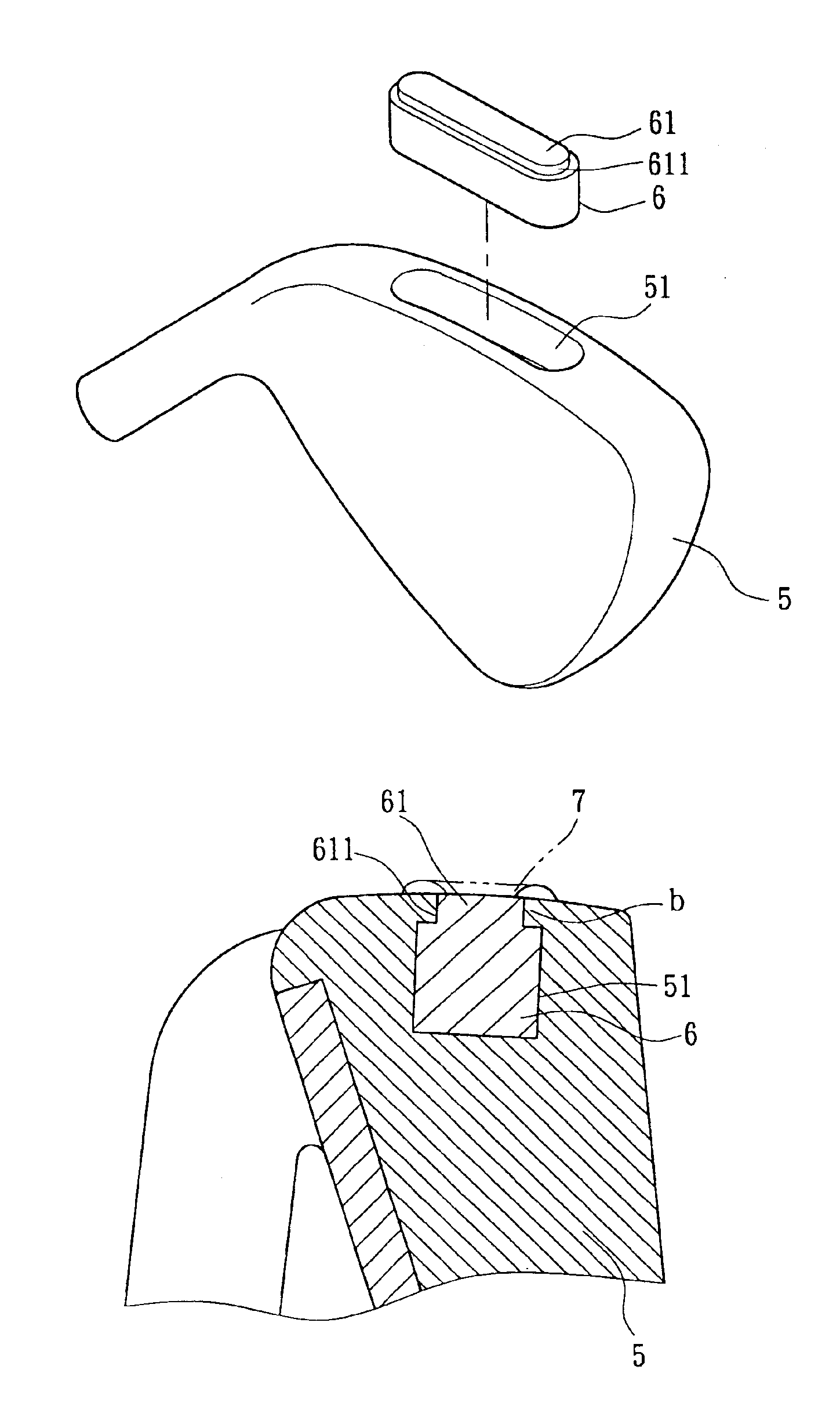

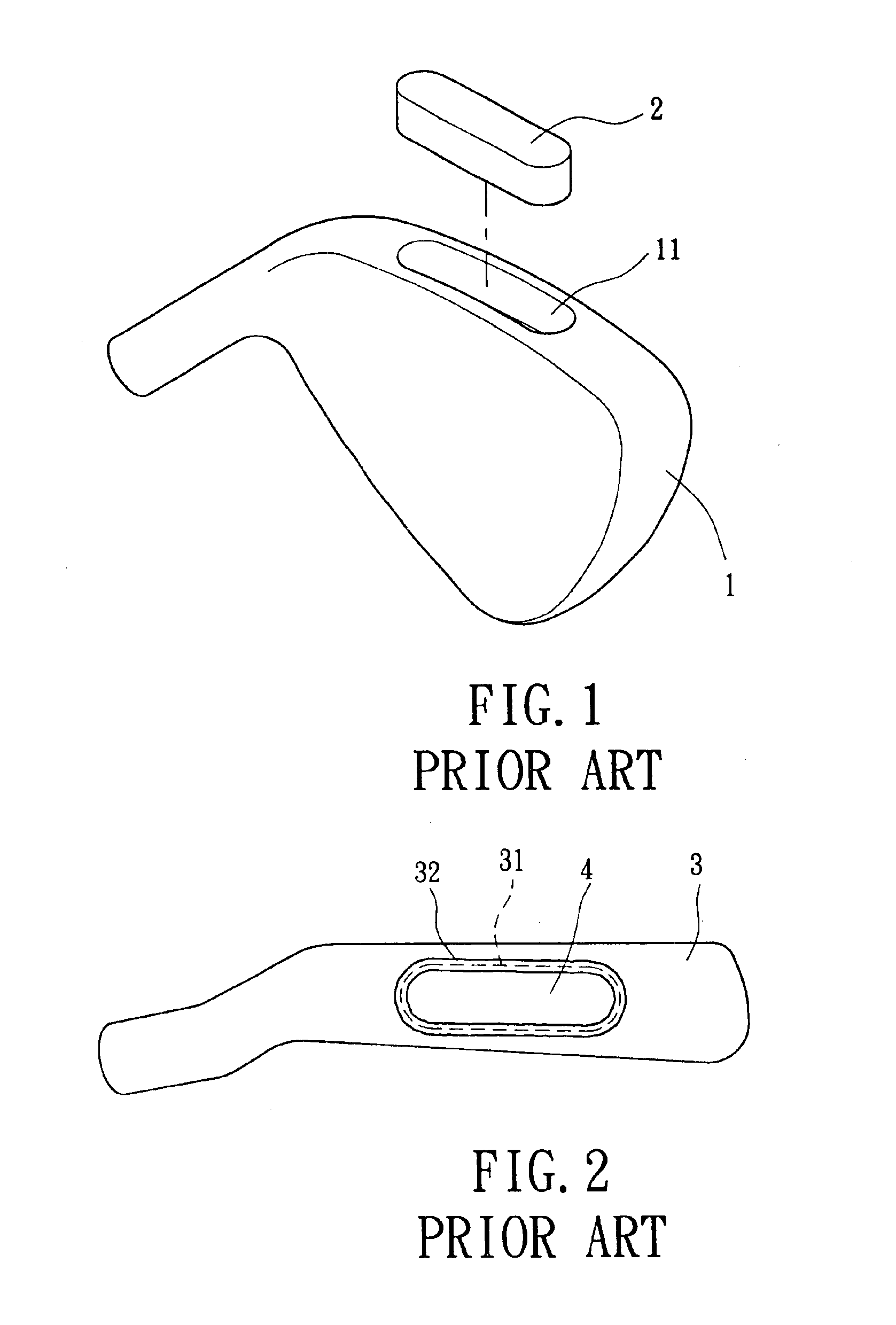

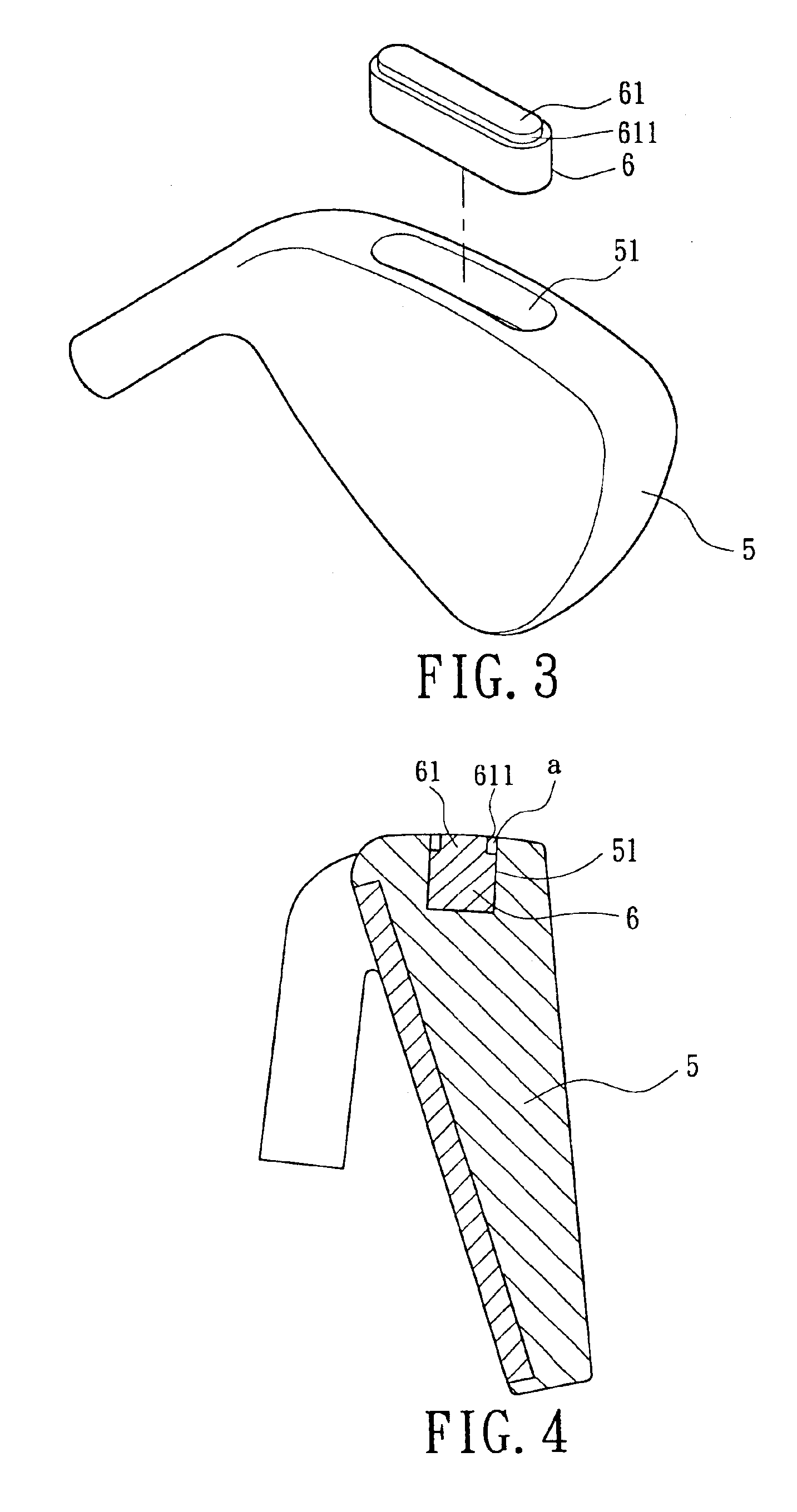

Weight number for a golf club head

A golf club head includes a golf club head body and a weight member. The golf club head member has a recession in which the weight member is mounted. The weight member is securely mounted in the recession of the golf club head body by a welding procedure that uses a welding material. The weight member is made of a material having a melting point higher than that of the golf club head body, avoiding melting of the weight member during the welding procedure. Only a portion of the golf club head body fuses with the welding material while using the welding material for proceeding with the welding procedure for the weight member.

Owner:FUSHENG PRECISION

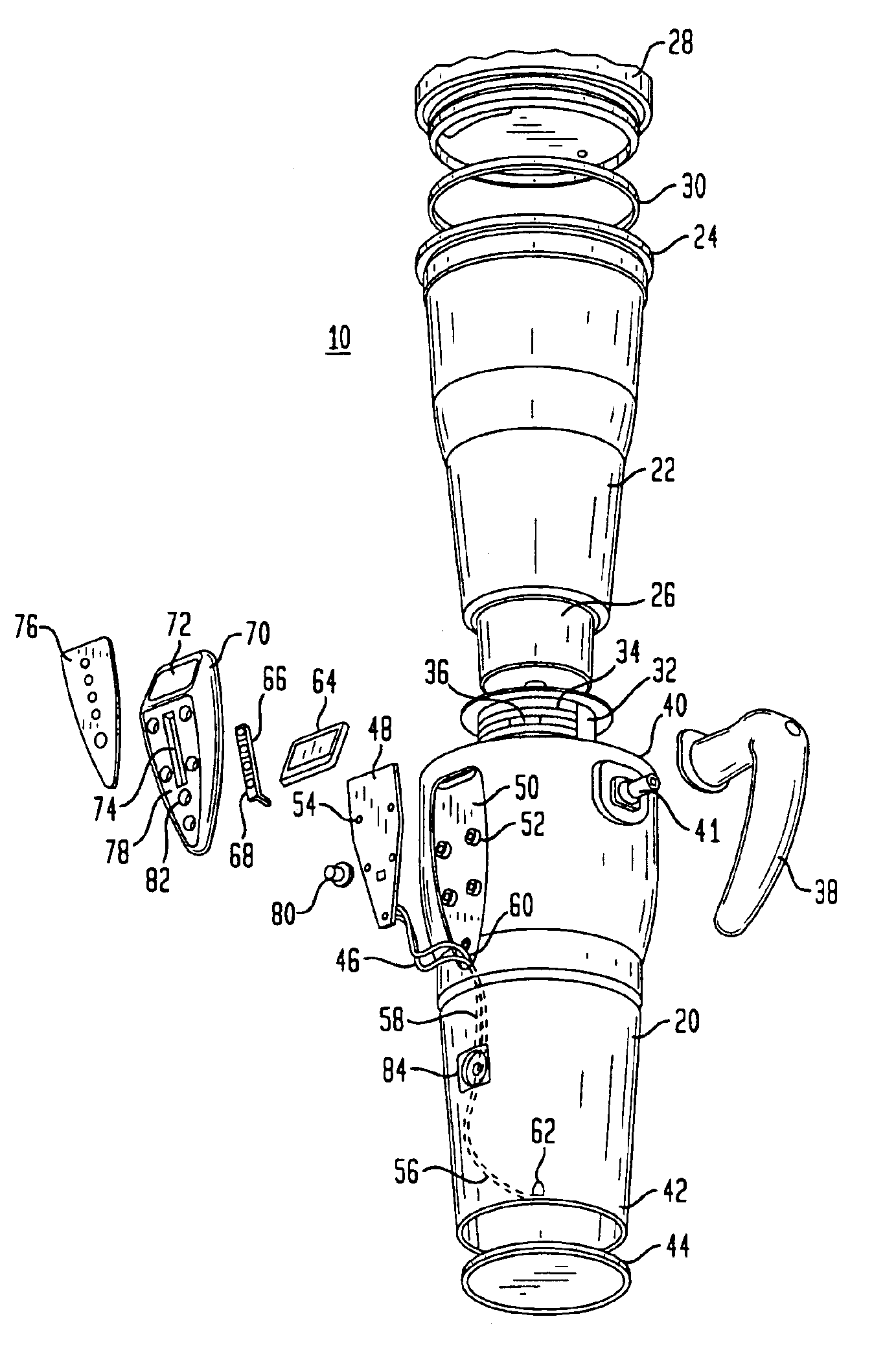

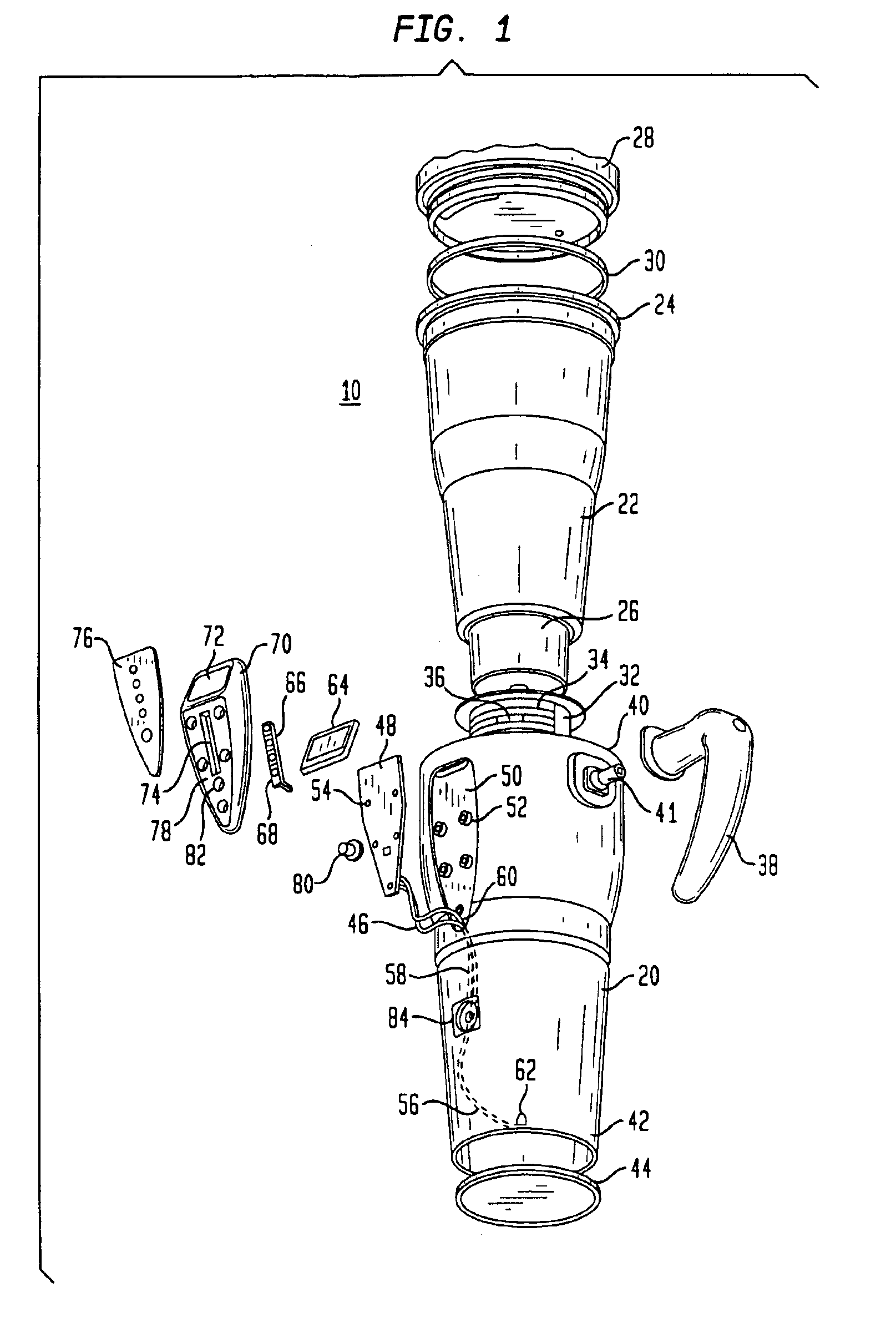

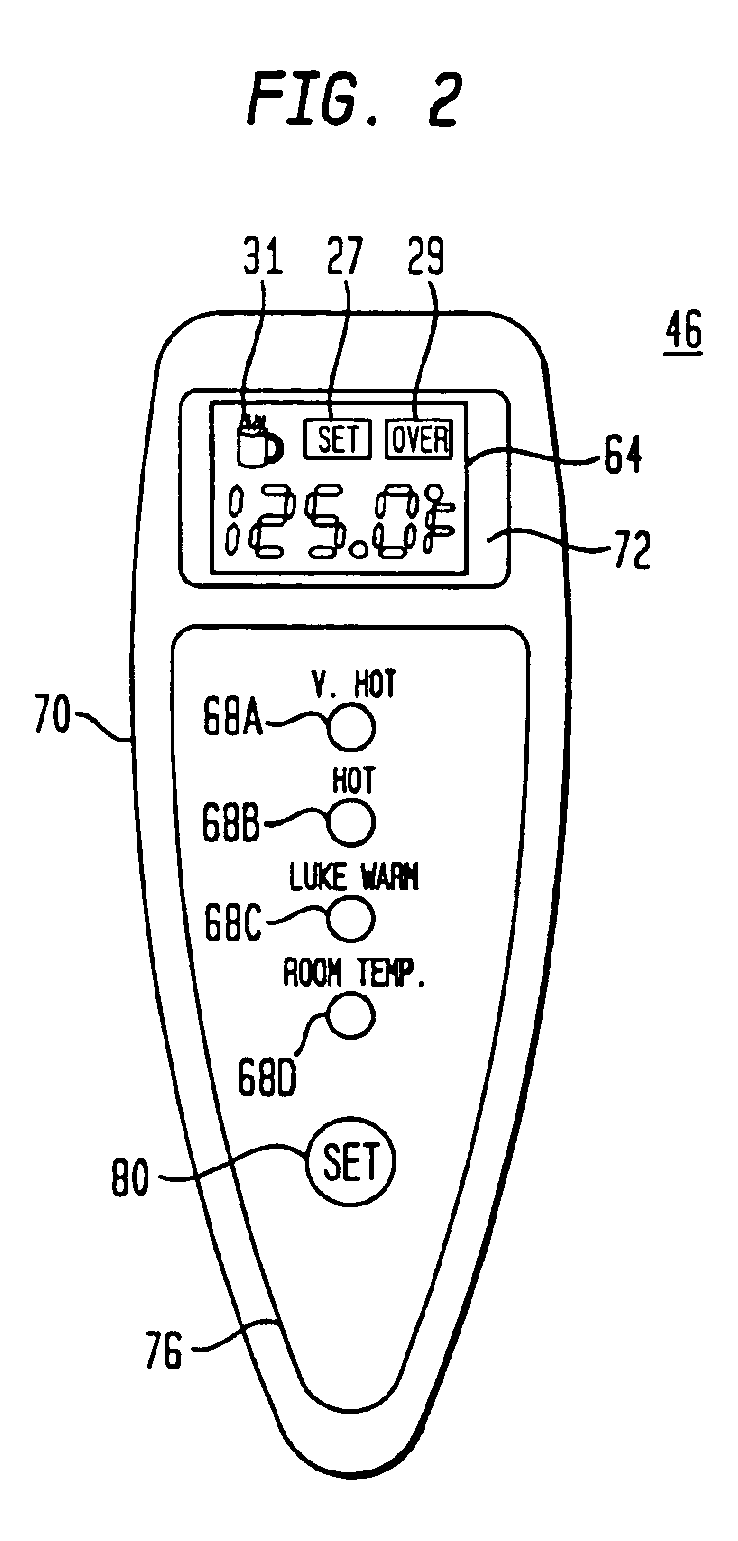

Electronic drinking mug

InactiveUS6864462B2Avoid meltingMinimize the possibilityElectric heatingBaking ovenEngineeringHeating element

An electronic drinking mug includes a heating element in thermal communication with the mug for heating a liquid contained in the mug, a temperture sensoring in communication with the heating element for monitoring a temperature of the liquid, a controller integrally attached to an outer surface of the mug and in communication with the temperature sensor and the heating element for selectively activating and deactivating the heating element so as to heat the liquid in the mug to a desired temperature. In operation, the controller receives temperature readings from the temperature sensor and deactivates the heating element when the monitored temperature of the liquid is greater than or equal to the desired user preset temperature of the liquid. A user interface is integrally attached to the outer surface of the mug and in communication with the controller for establishing the desired temperature of the liquid.

Owner:SOLAR WIDE INDAL

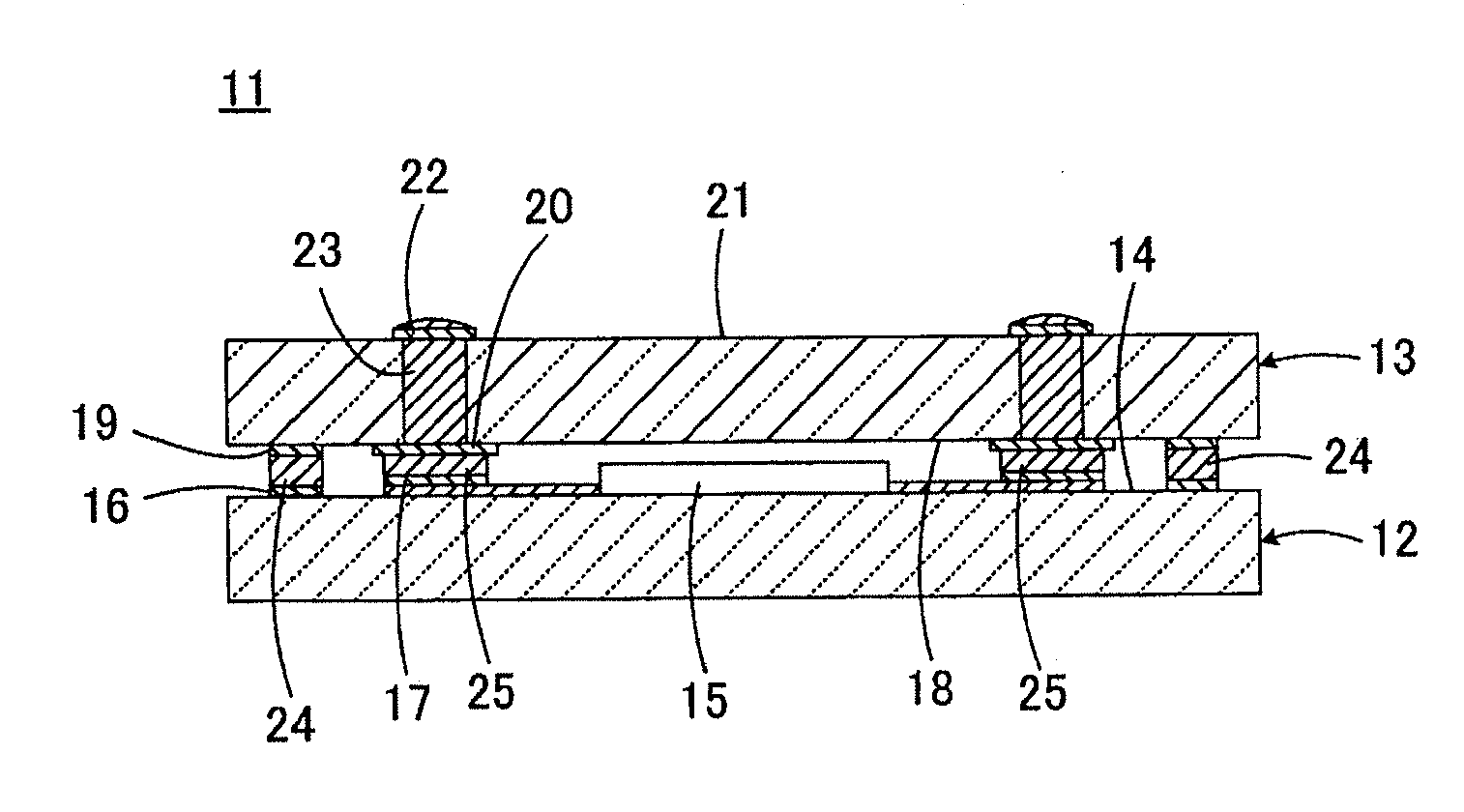

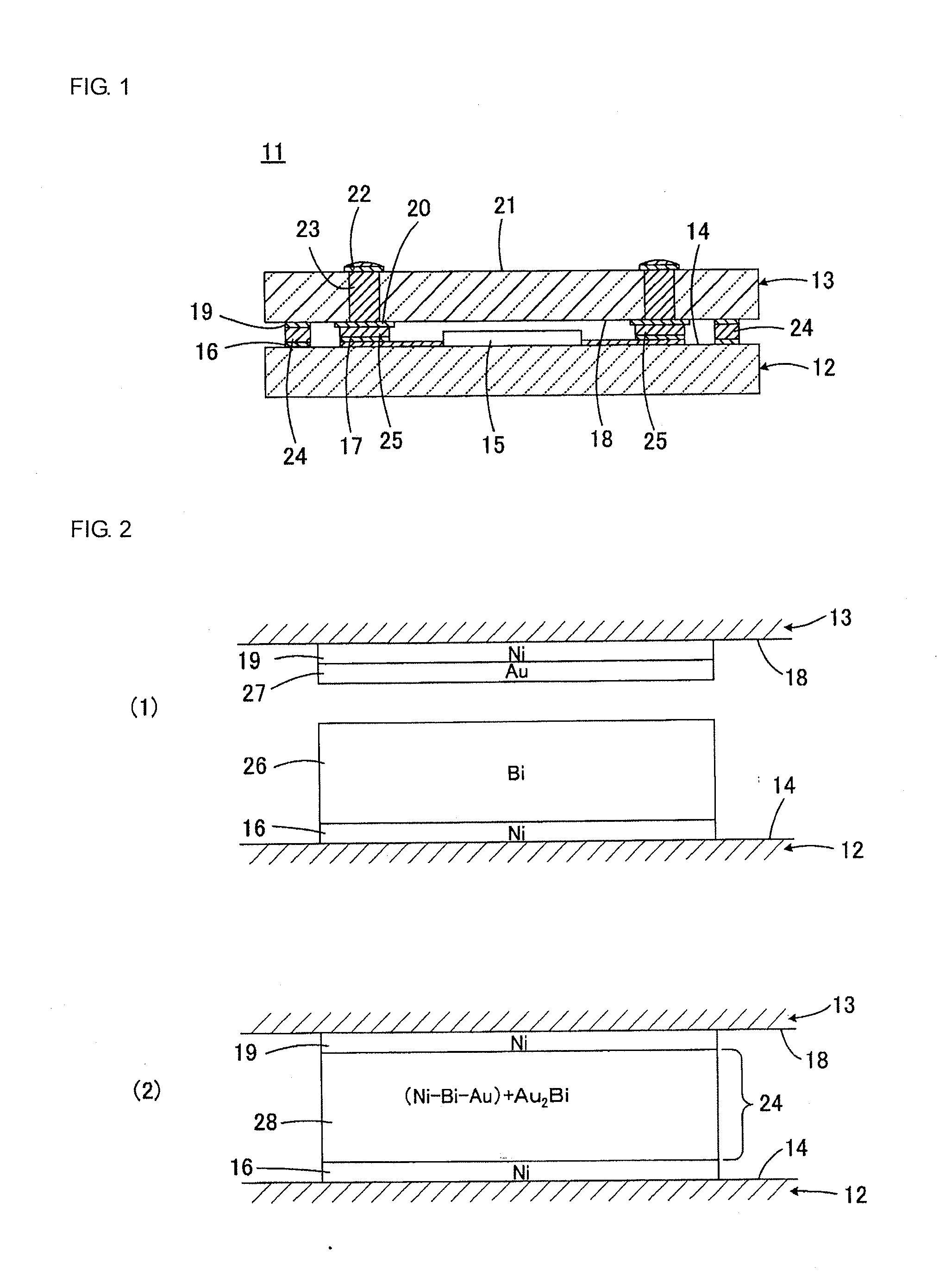

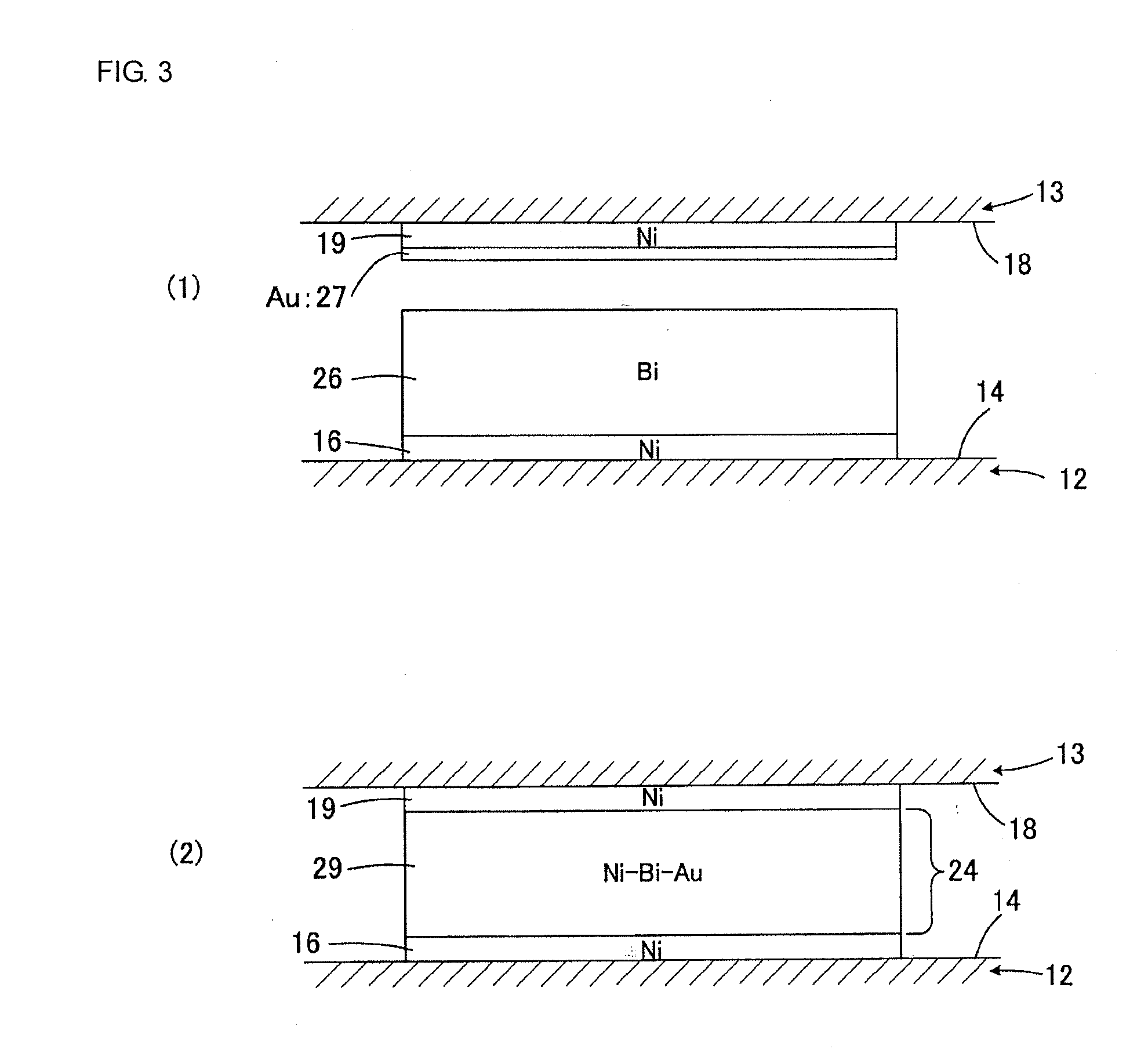

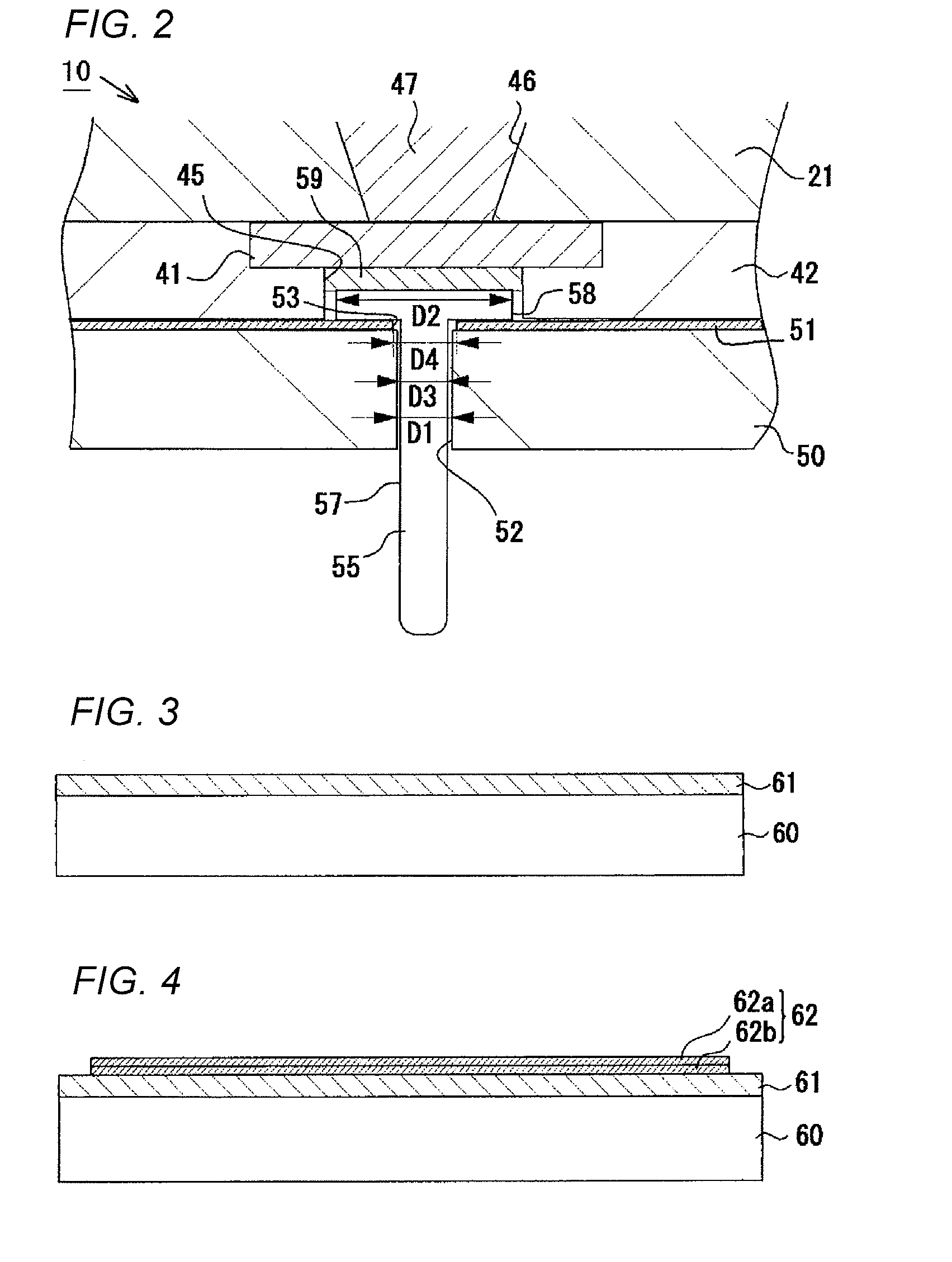

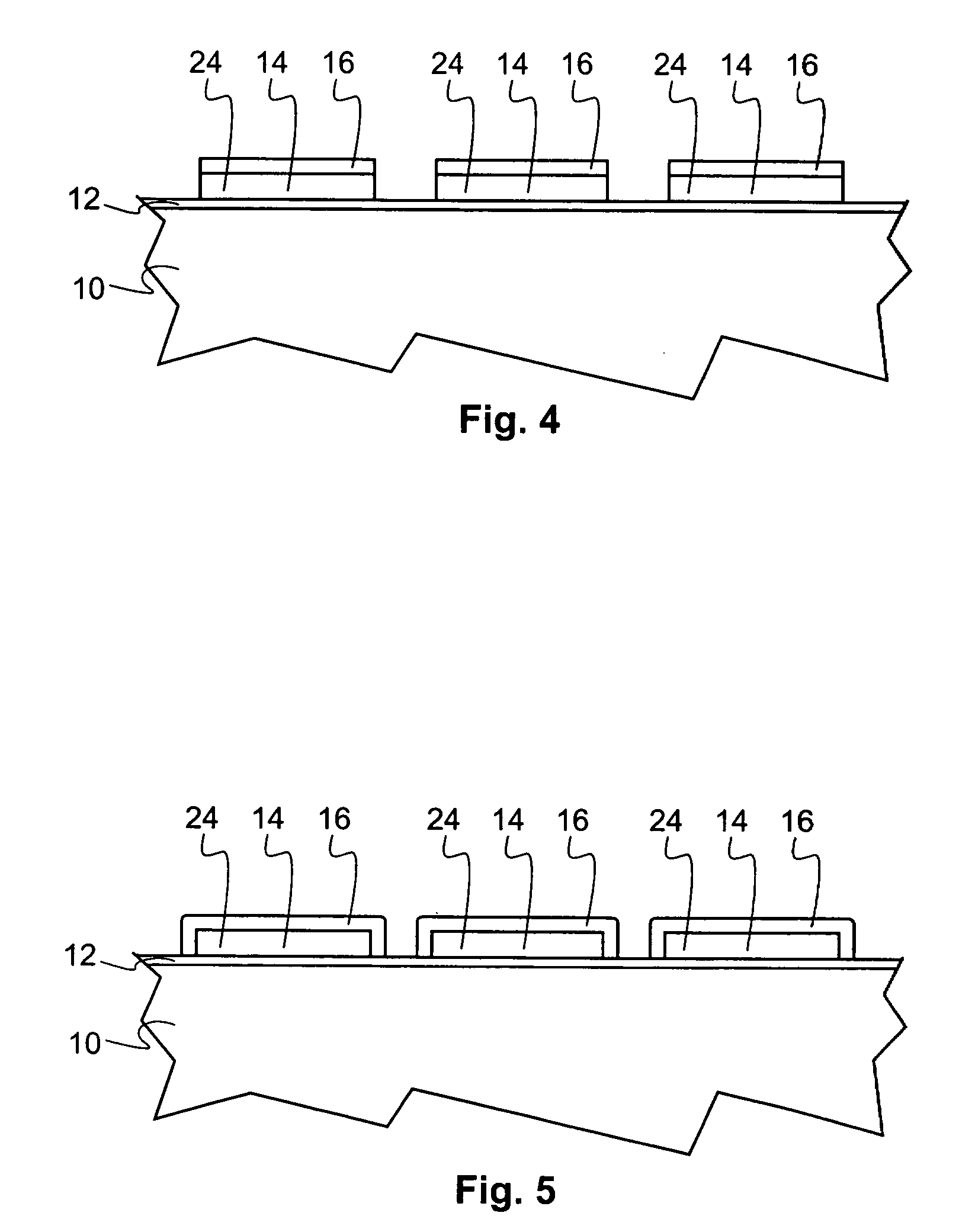

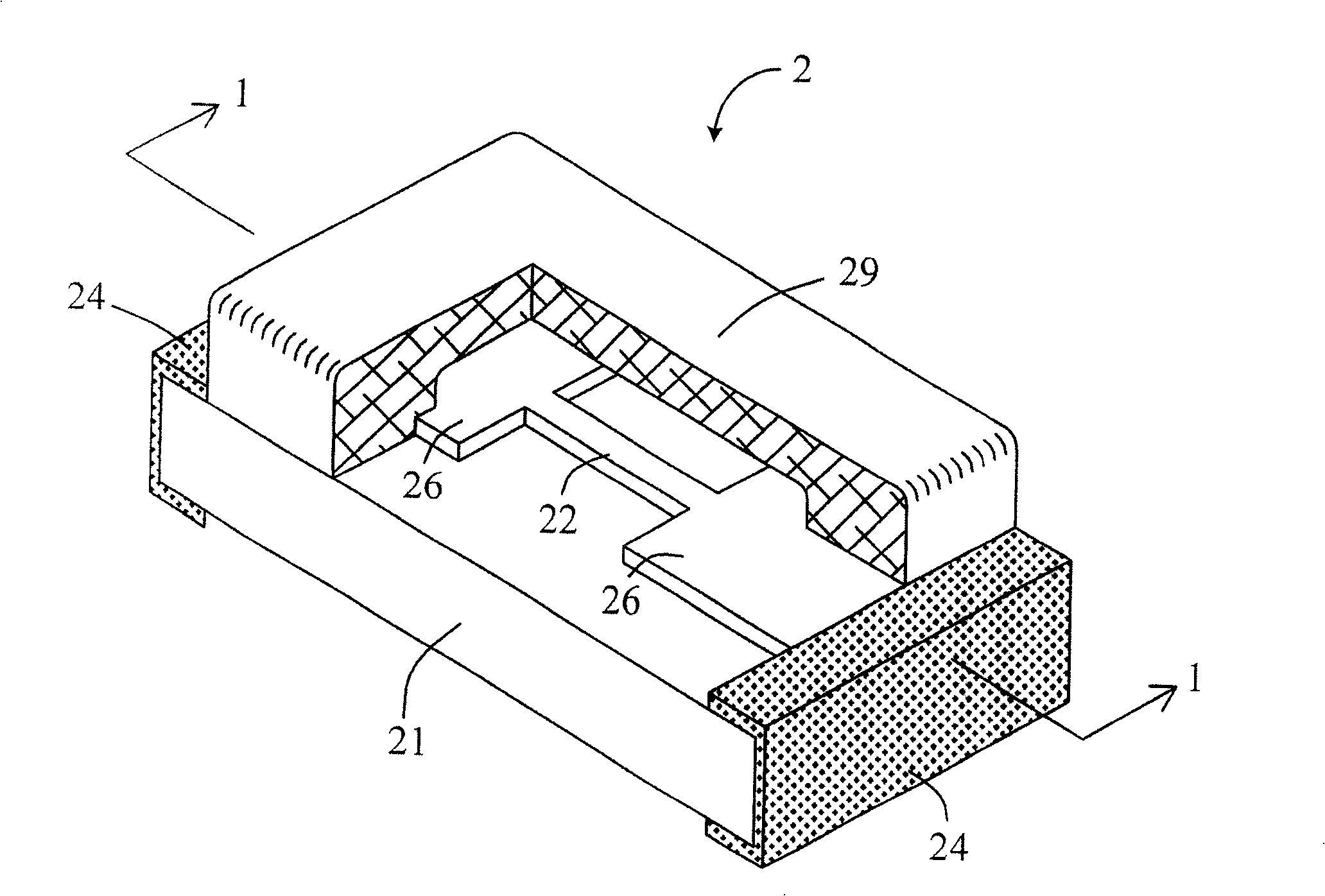

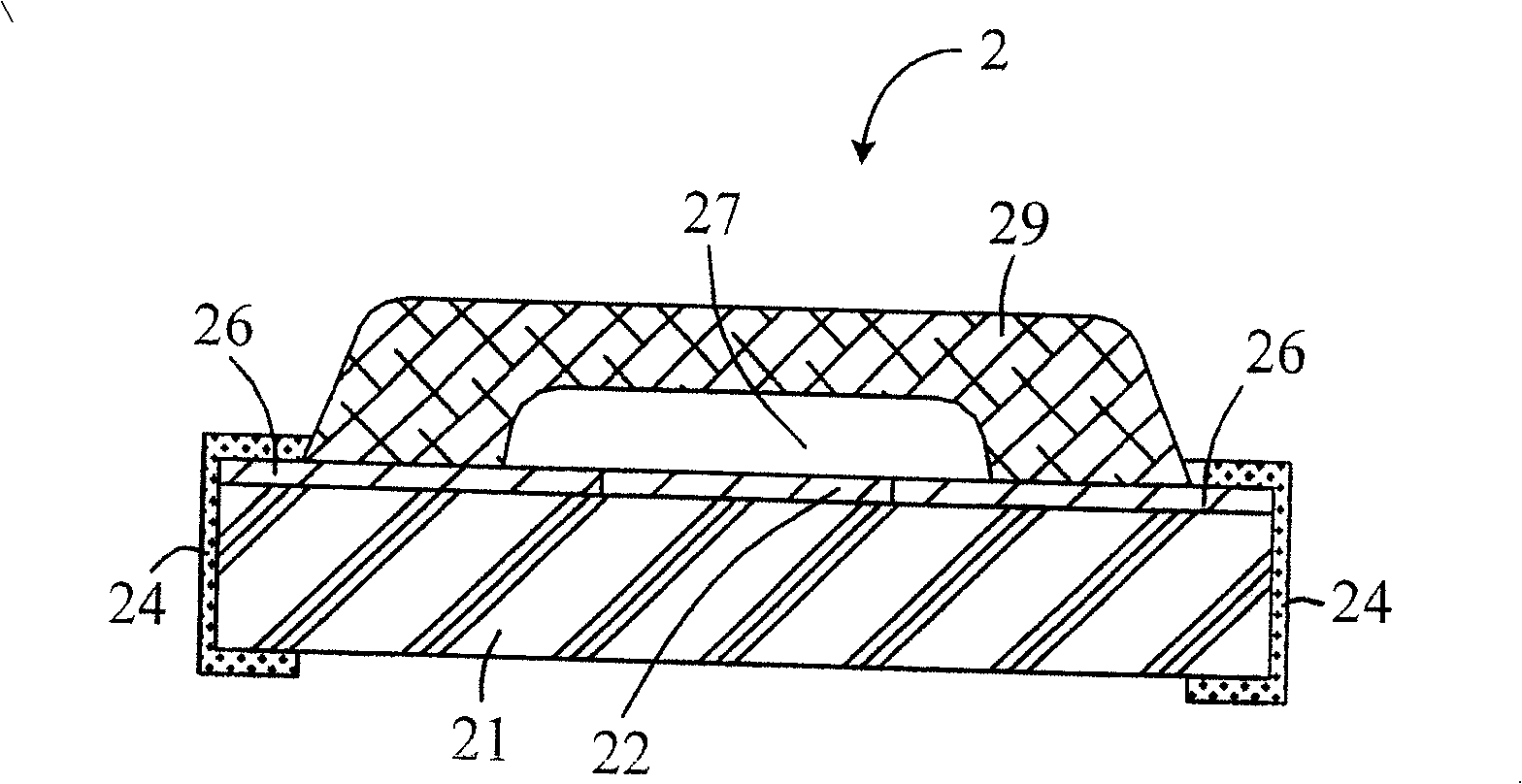

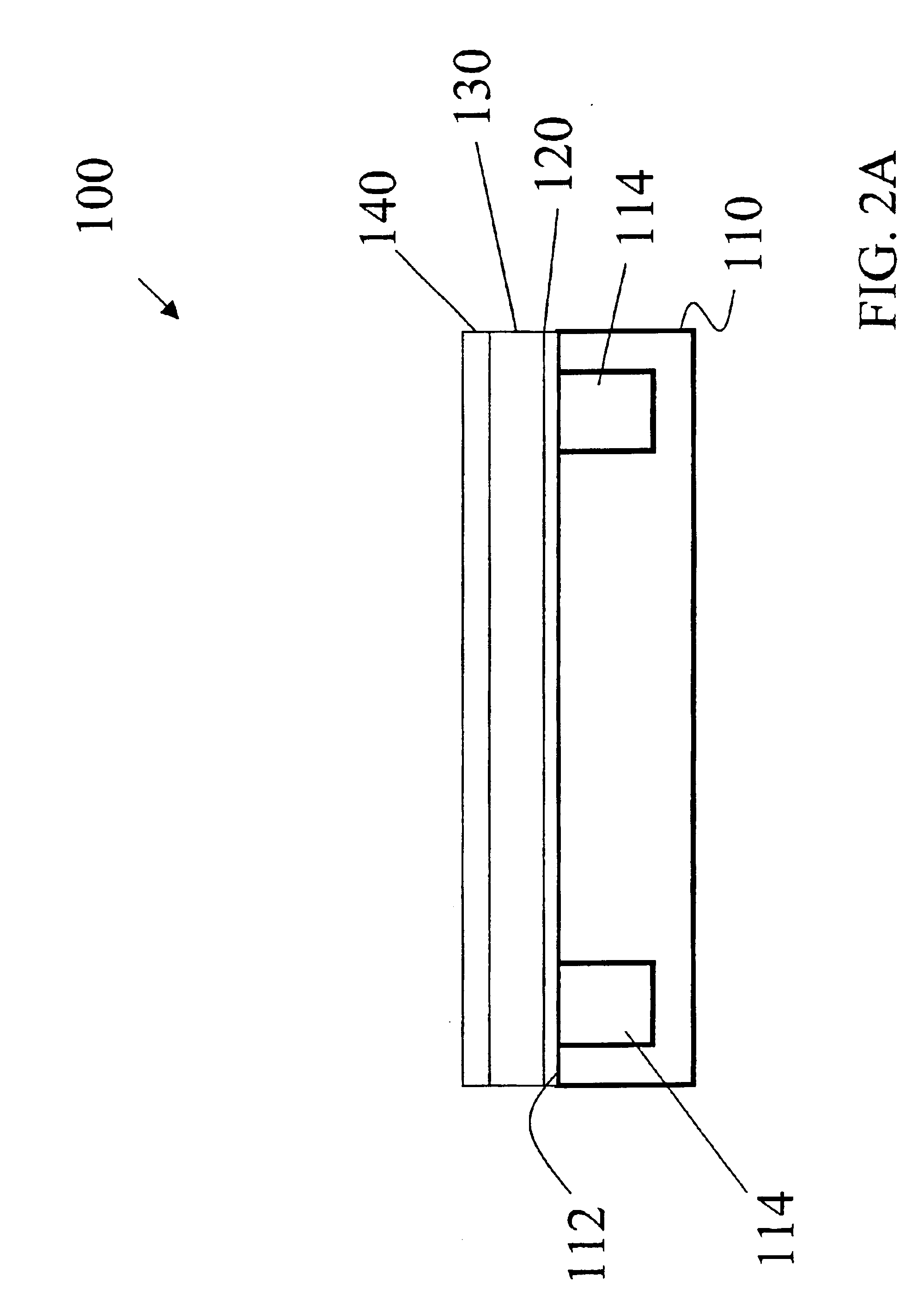

Electronic Component Device and Method for Manufacturing the Same

ActiveUS20110132655A1High speedShort timeImpedence networksSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component device having a first sealing frame formed on a main substrate and a second sealing frame formed on a cover substrate, both of which are composed of a Ni film. A bonding section bonds the first sealing frame to the second sealing frame. For example, a Bi layer is formed on the first sealing frame and an Au layer is formed on the second sealing frame, and then the first sealing frame and the second sealing frame are heated at a temperature of 300° C. for 10 seconds while applying pressure in the direction in which the first sealing frame and the second sealing frame are close contact with each other to form the bonding section. The bonding section is constituted by a mixed layer predominantly composed of a mixed alloy of a Ni—Bi—Au ternary alloy and Au2Bi.

Owner:MURATA MFG CO LTD

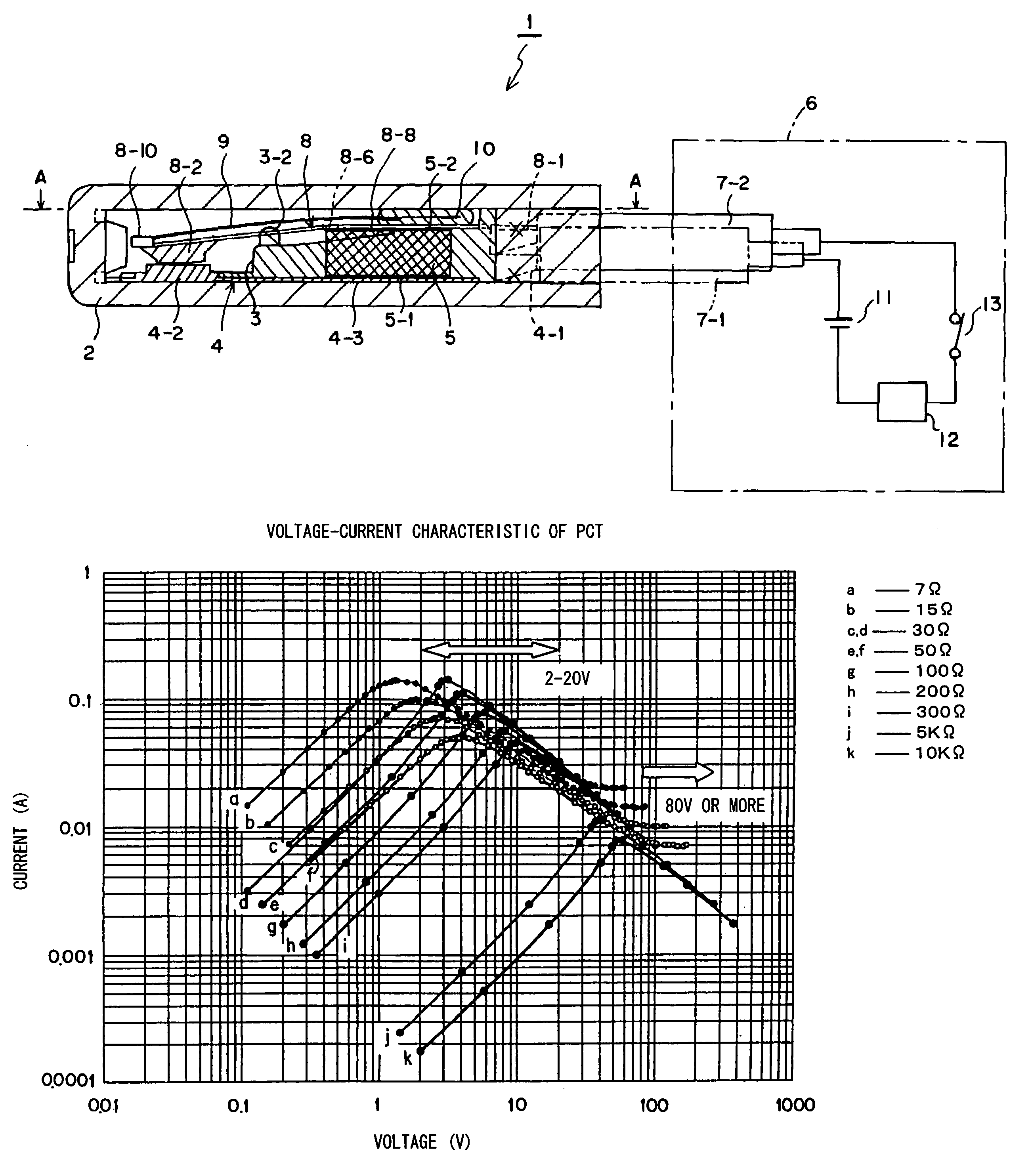

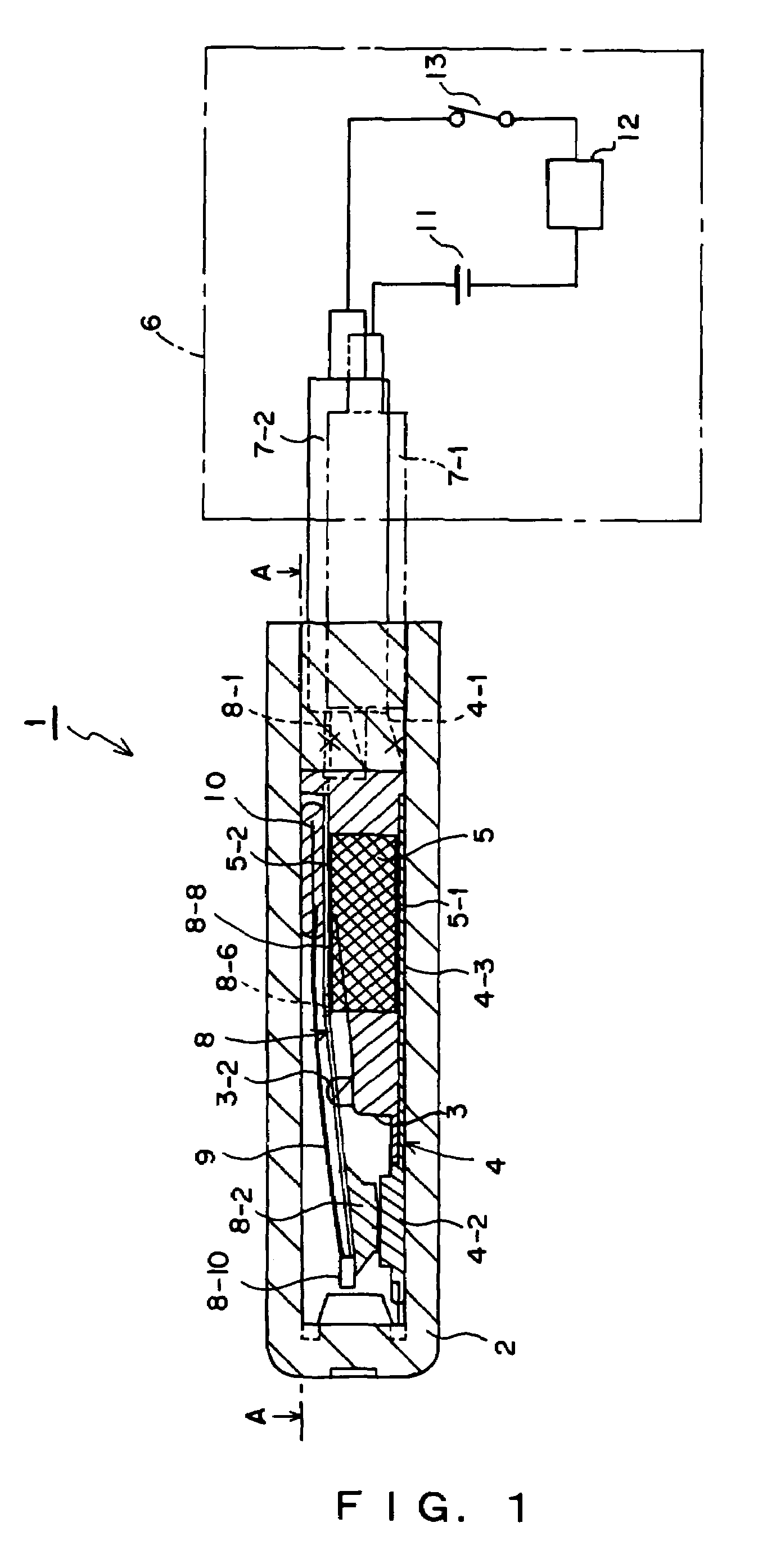

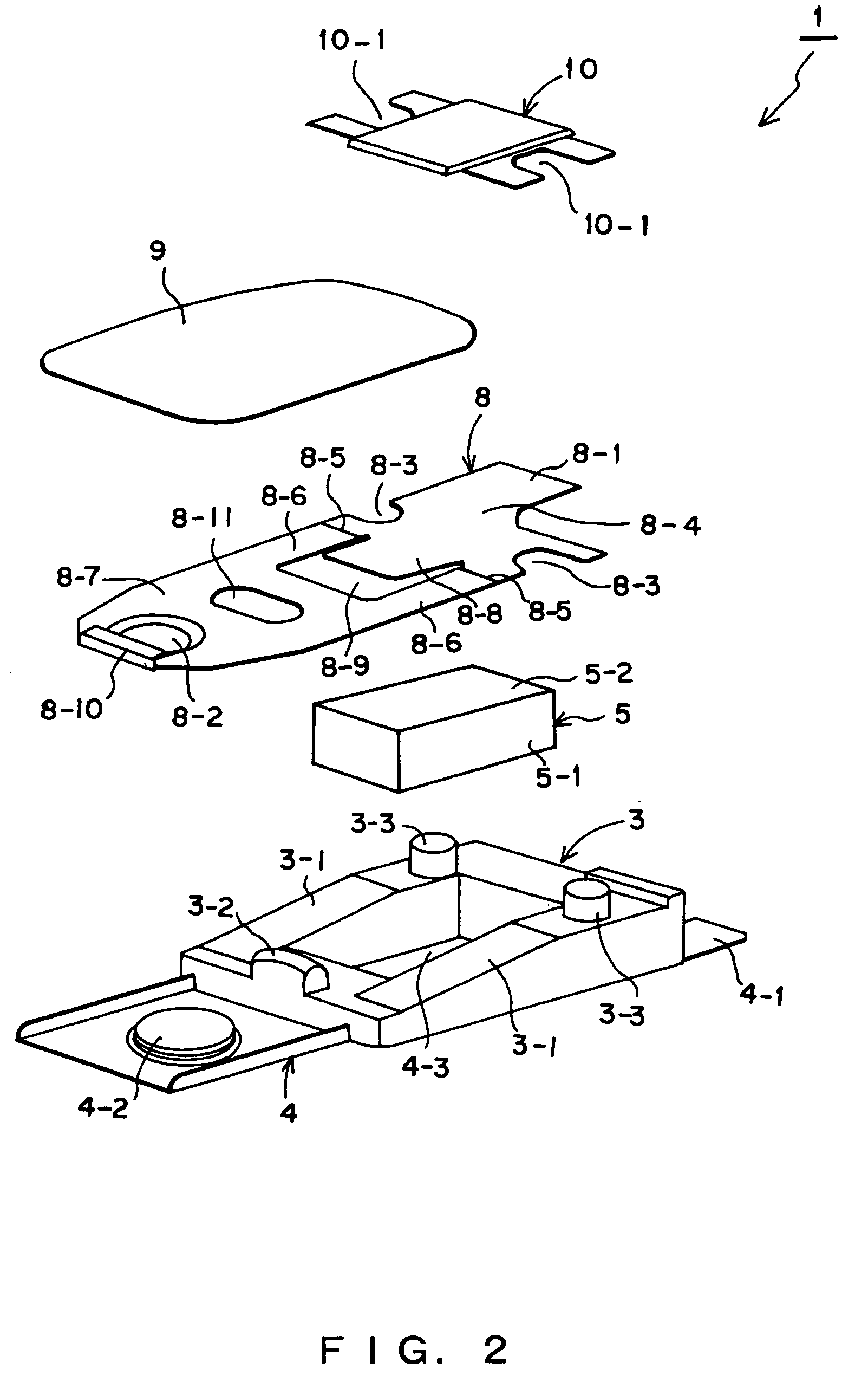

Direct current cutoff switch

ActiveUS7330097B2Inhibition continuesEasy to useProtective switch detailsElectrothermal relaysNonlinear resistorEngineering

In a direct current cutoff switch1, a PTC 5, which is a non-linear resistor, is parallel connected to a contact circuit composed of a fixed contact 4-2 and a movable contact 8-2 via electrodes 5-1. When the switch is closed, no current flows in the PTC 5 with a prescribed resistance value at 25° C., since voltage between both the electrodes 5-1 is almost “0”. When the switch is opened in order to cut off current, the contacts form a closed circuit since the PTC 5 is parallel inserted between the fixed contact 4-2 and the movable contact 8-2. For this reason, it is difficult for surge voltage to occur and an arc hardly occurs between both the contacts. The PTC 5 instantaneously heats due to passing current, reduces the resistance value and passes peak current. Then, the resistance value rises and becomes stable in a high value such that weak current which is negligible at 42V, which is rated voltage. Thus, current is substantially cut off.

Owner:UCHIYA THERMOSTAT

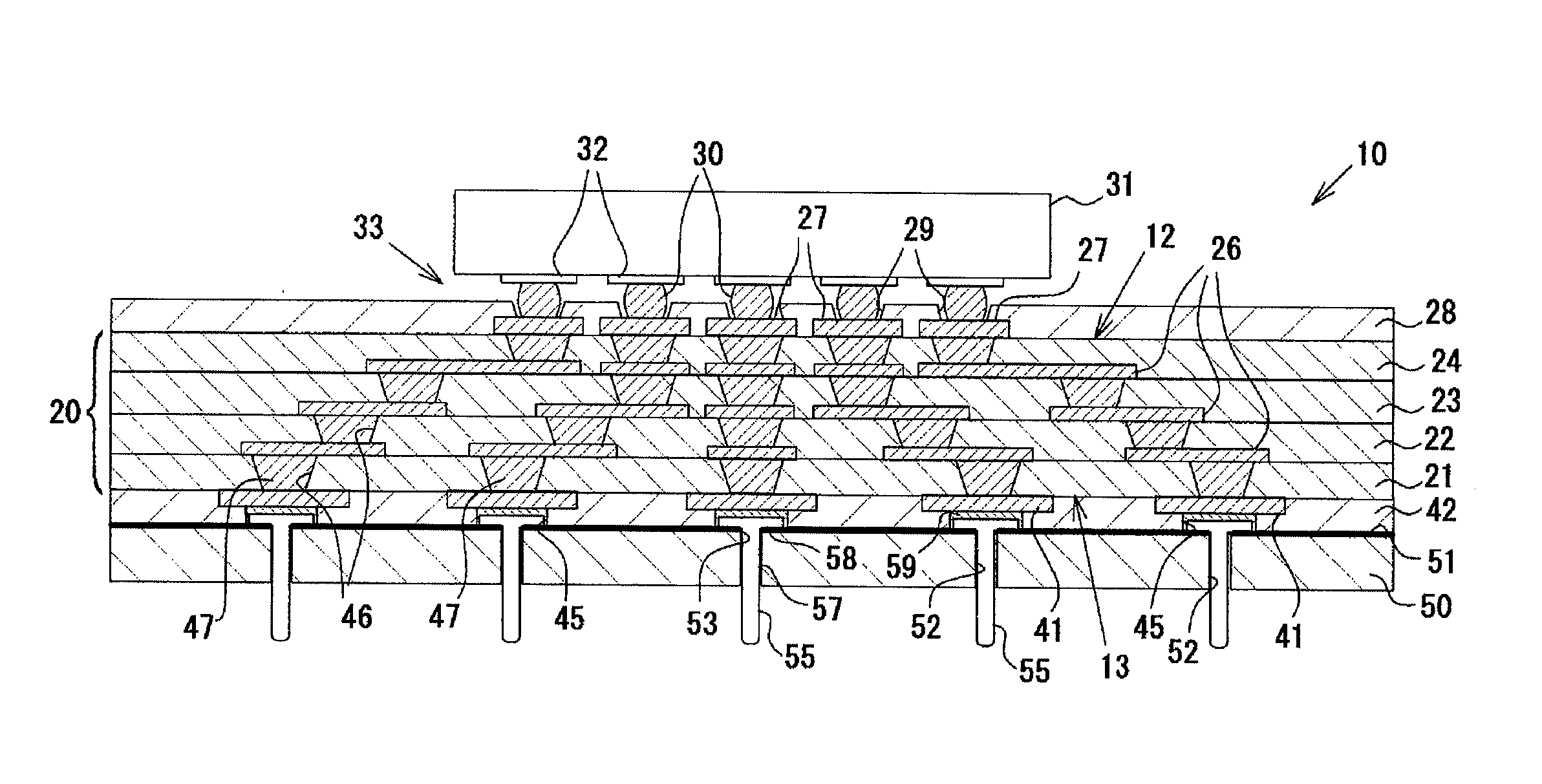

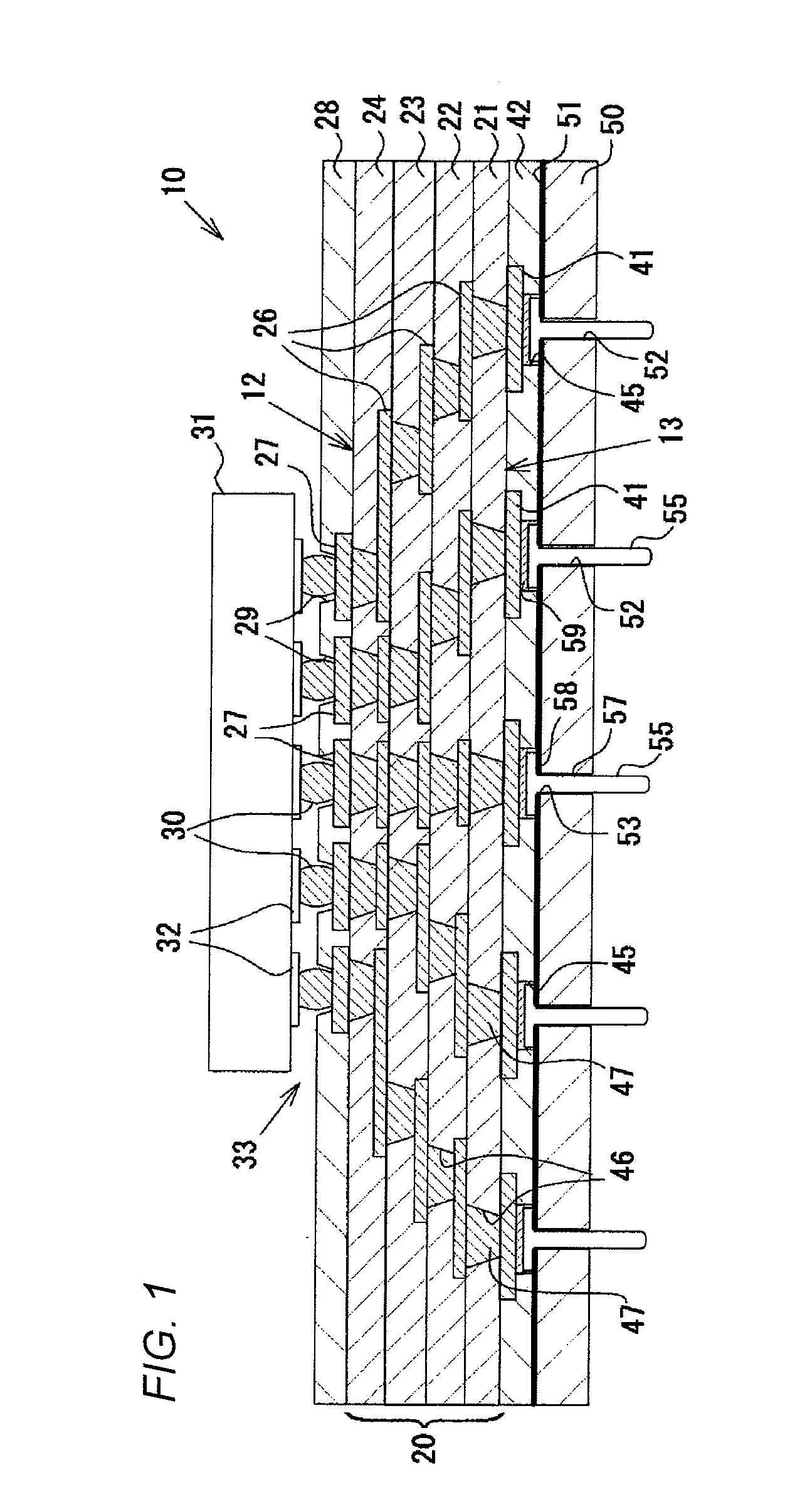

Multi-layer wiring board and method of manufacturing the same

InactiveUS20090242262A1Improve rigidityReduced areaElectrically conductive connectionsFinal product manufactureBiomedical engineering

A multi-layer wiring board without a core substrate includes: a multi-layer laminated structure; first terminals provided on a front surface of the multi-layer laminated structure; second terminals provided on a rear surface of the multi-layer laminated structure; terminal pins bonded to a corresponding one of the second terminals, wherein each of the terminal pins is formed in a nailhead shape that includes a shaft portion and a head portion, and a diameter of the head portion is larger than that of the shaft portion; and a reinforcing plate which has pin insertion openings formed at positions corresponding to the terminal pins and which is fixed to the rear surface, wherein the diameter of the pin insertion openings is smaller than the diameter of the head portion and is larger than the diameter of the shaft portion.

Owner:NGK SPARK PLUG CO LTD

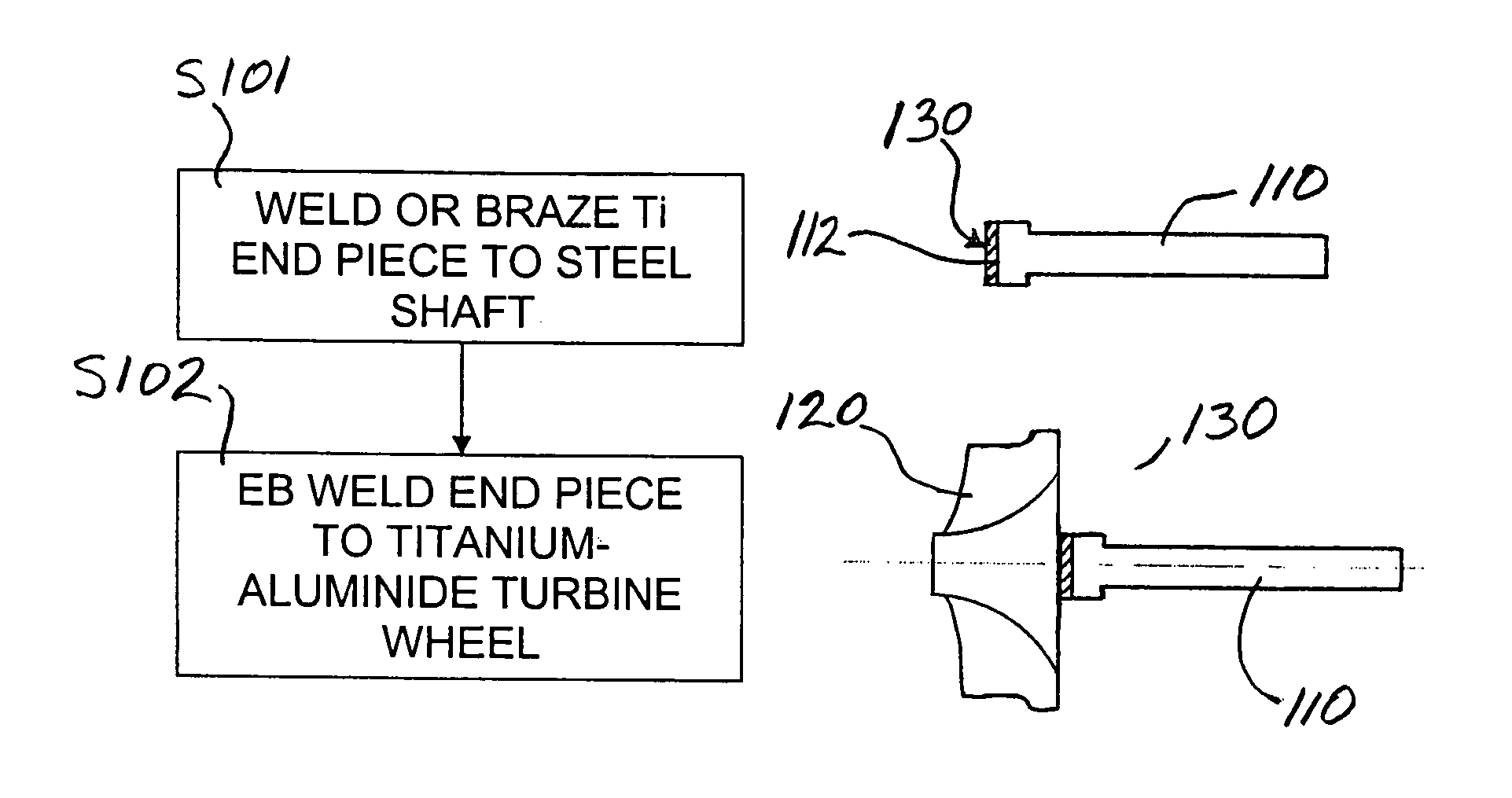

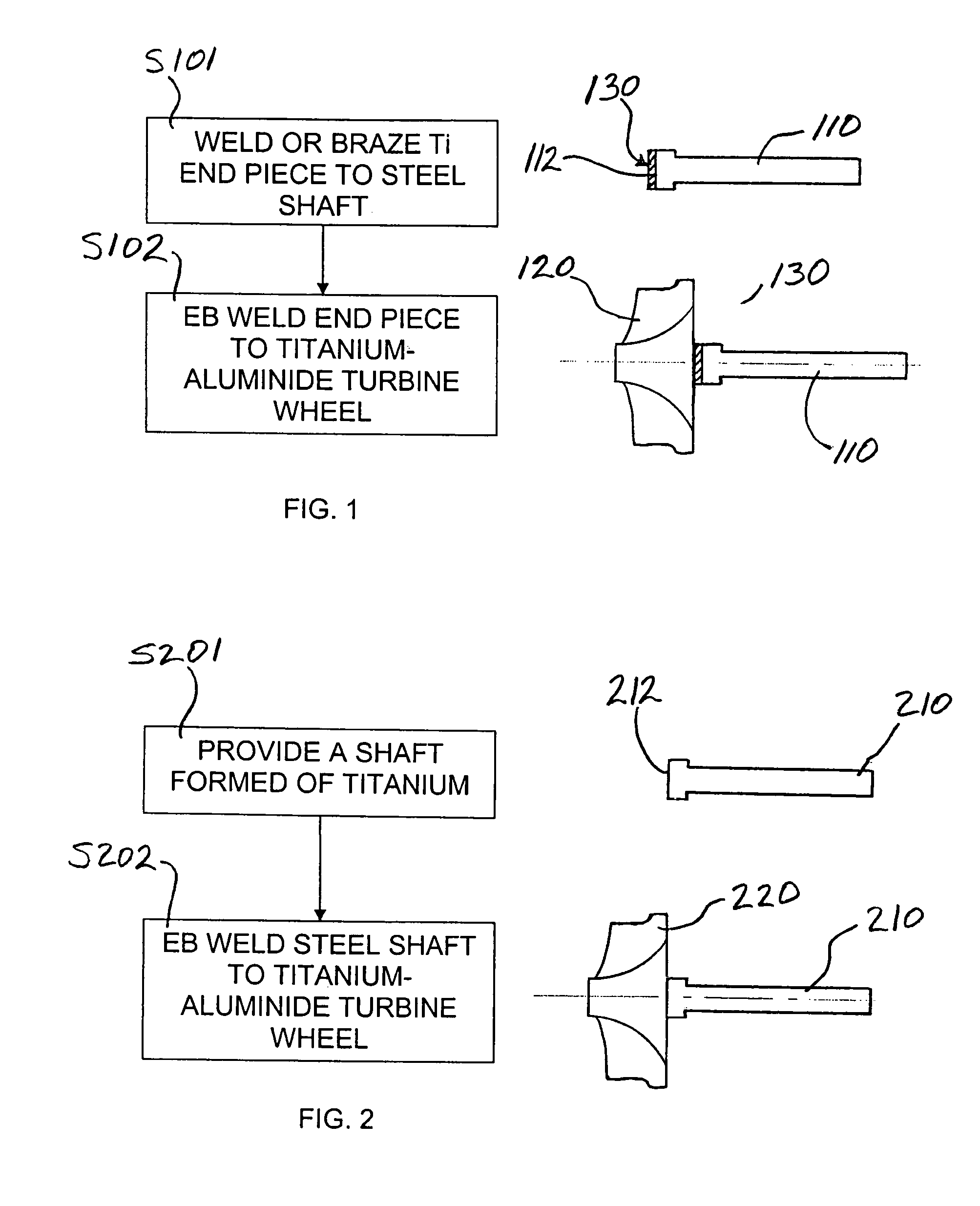

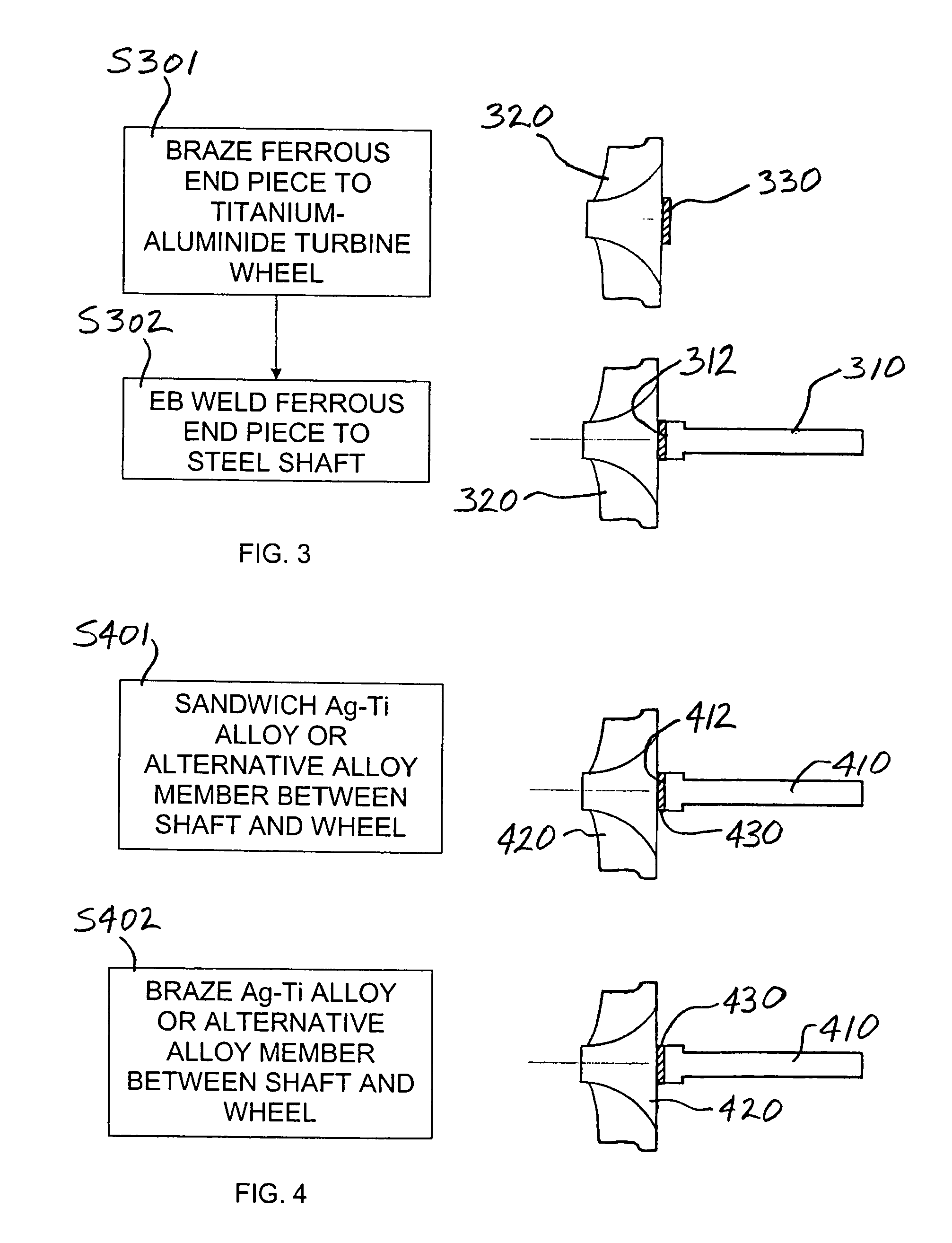

Titanium-aluminide turbine wheel and shaft assembly, and method for making same

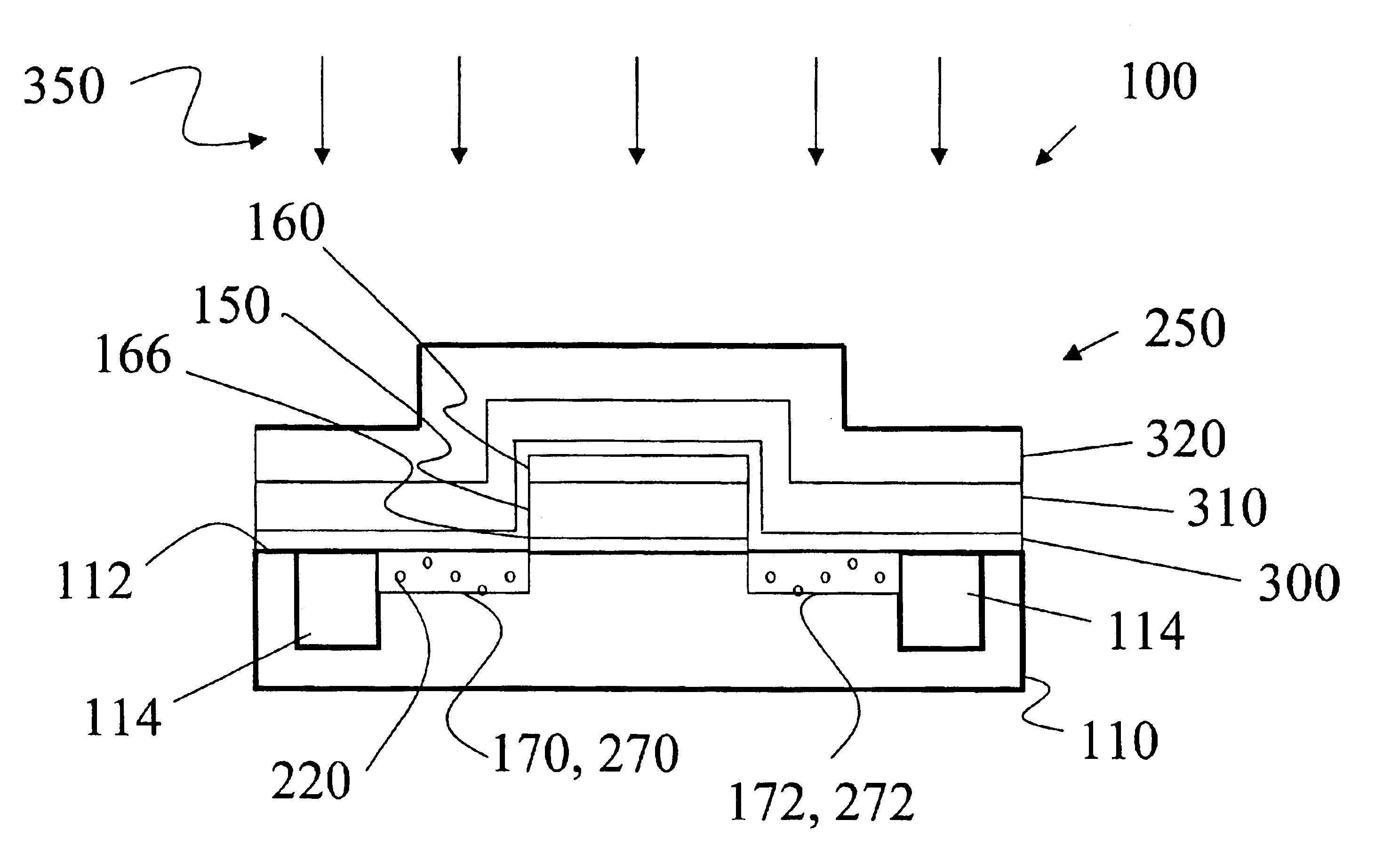

A titanium-aluminide turbine wheel (120, 220, 320, 420) is joined to the end of a shaft (110, 210, 310, 410) by utilizing a titanium surface on the end of the shaft to be joined to the wheel, and electron-beam welding the wheel onto the titanium surface on the shaft. A steel shaft (110, 310, 410) can have a titanium-containing end piece (130, 330, 430) mechanically joined (by brazing, bonding, or welding) to the end of the shaft, and the end piece can be directly electron-beam welded to the wheel. Alternatively, the shaft (210) can be formed as a titanium member and the end (212) of the shaft can be directly electron-beam welded to the wheel (220). In another embodiment, a ferrous end piece (330) is mechanically joined to the titanium-aluminide turbine wheel (320) and then the end piece is directly electron-beam welded to the end of a steel shaft (310). Alternatively, a silver-titanium alloy member (430) is sandwiched between the wheel (420) and a steel shaft (410) and is melted to join the parts together.

Owner:GARRETT TRANSPORATION I INC

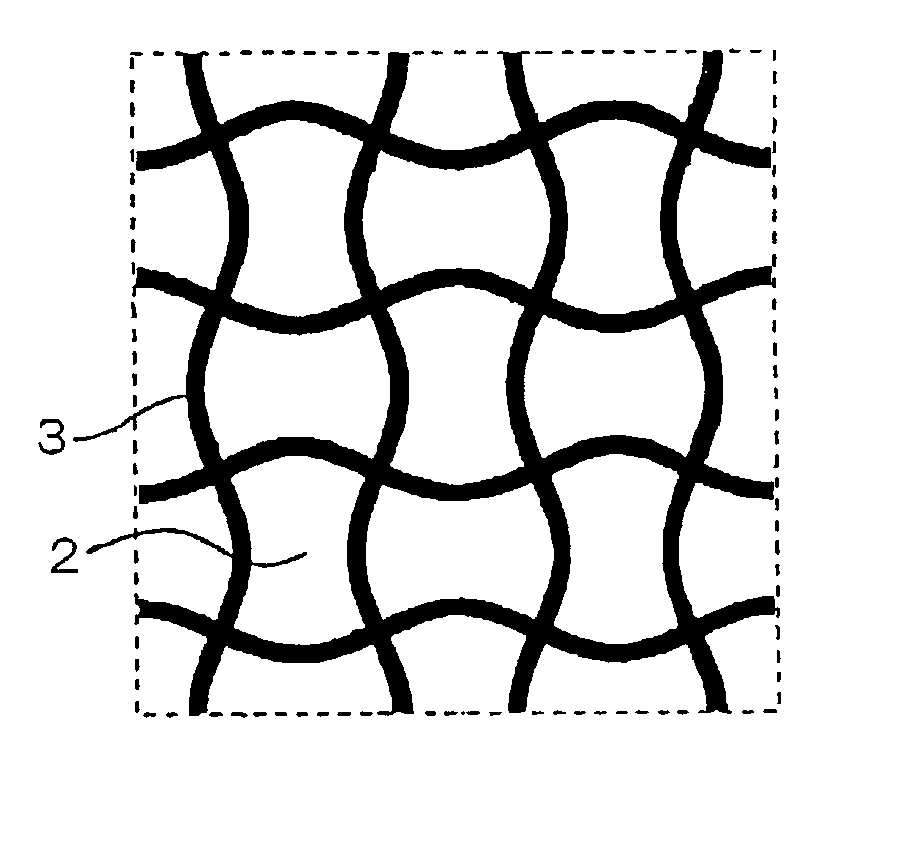

Ceramic filter and filter device

InactiveUS20020157358A1Increase pressure dropMechanical strengthCombination devicesAuxillary pretreatmentTemperature treatmentVacuum ceramic filter

Owner:NGK INSULATORS LTD

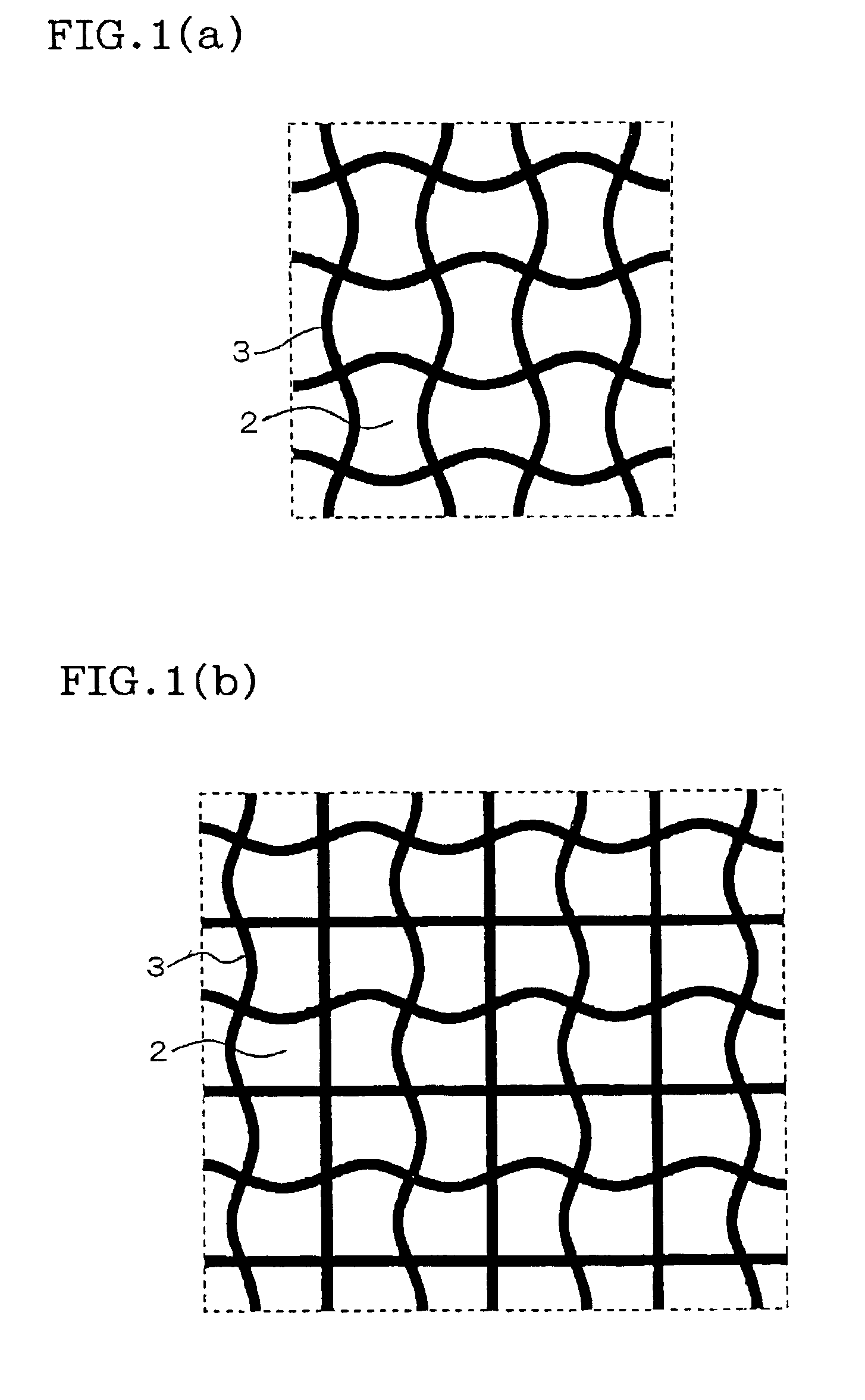

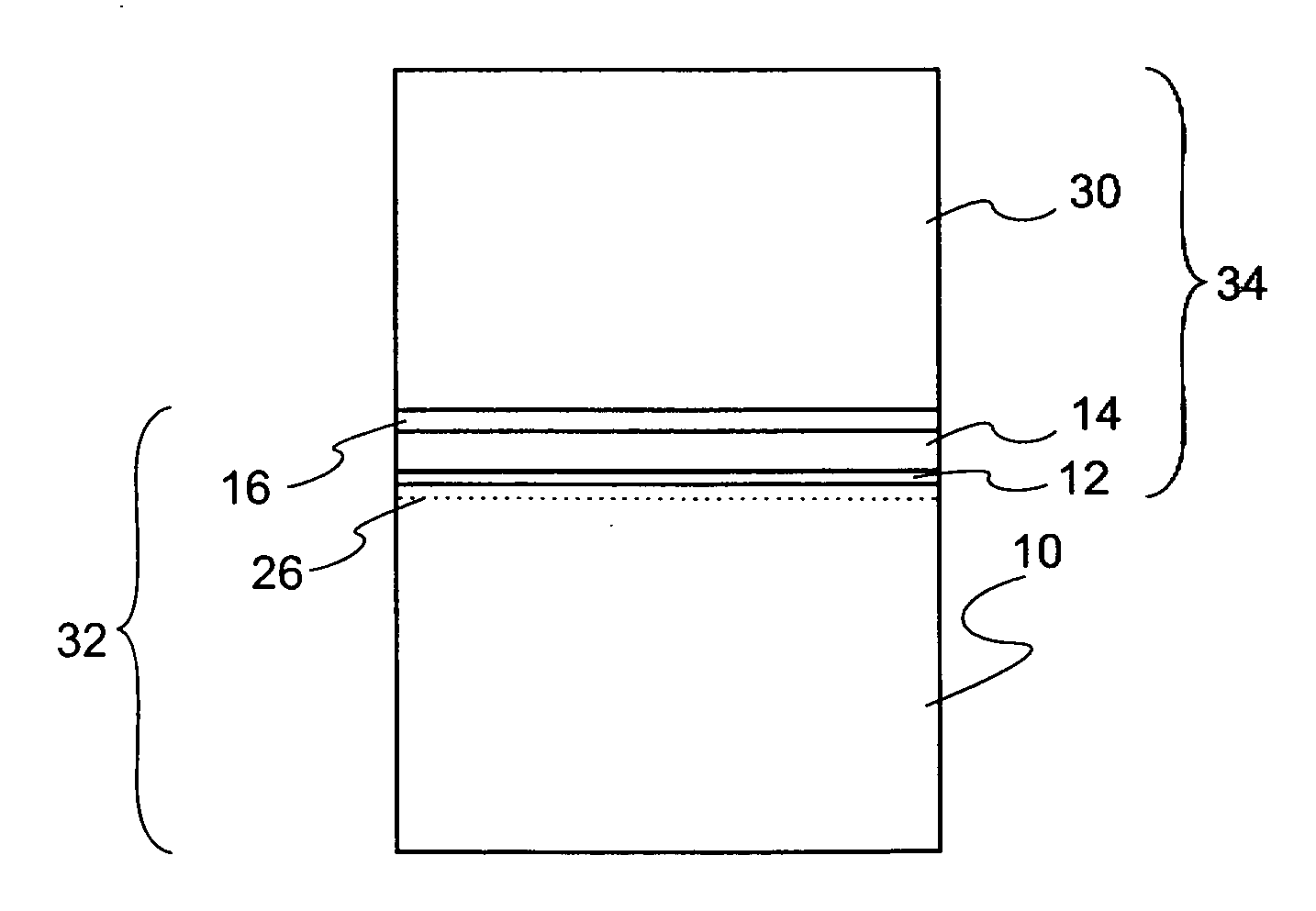

Relaxation of a strained layer using a molten layer

ActiveUS20060175608A1Freeze fastLarge diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesInterface layerComputer science

A method for making a crystalline wafer, in which an interface layer is associated with a support substrate. A first layer is associated with the interface layer in a strained state. The interface layer is melted sufficiently to substantially uncouple the first layer from the support substrate to relax the first layer from the strained to state to a relaxed state. The interface material is solidified with the first layer in the relaxed state to obtain a first wafer.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

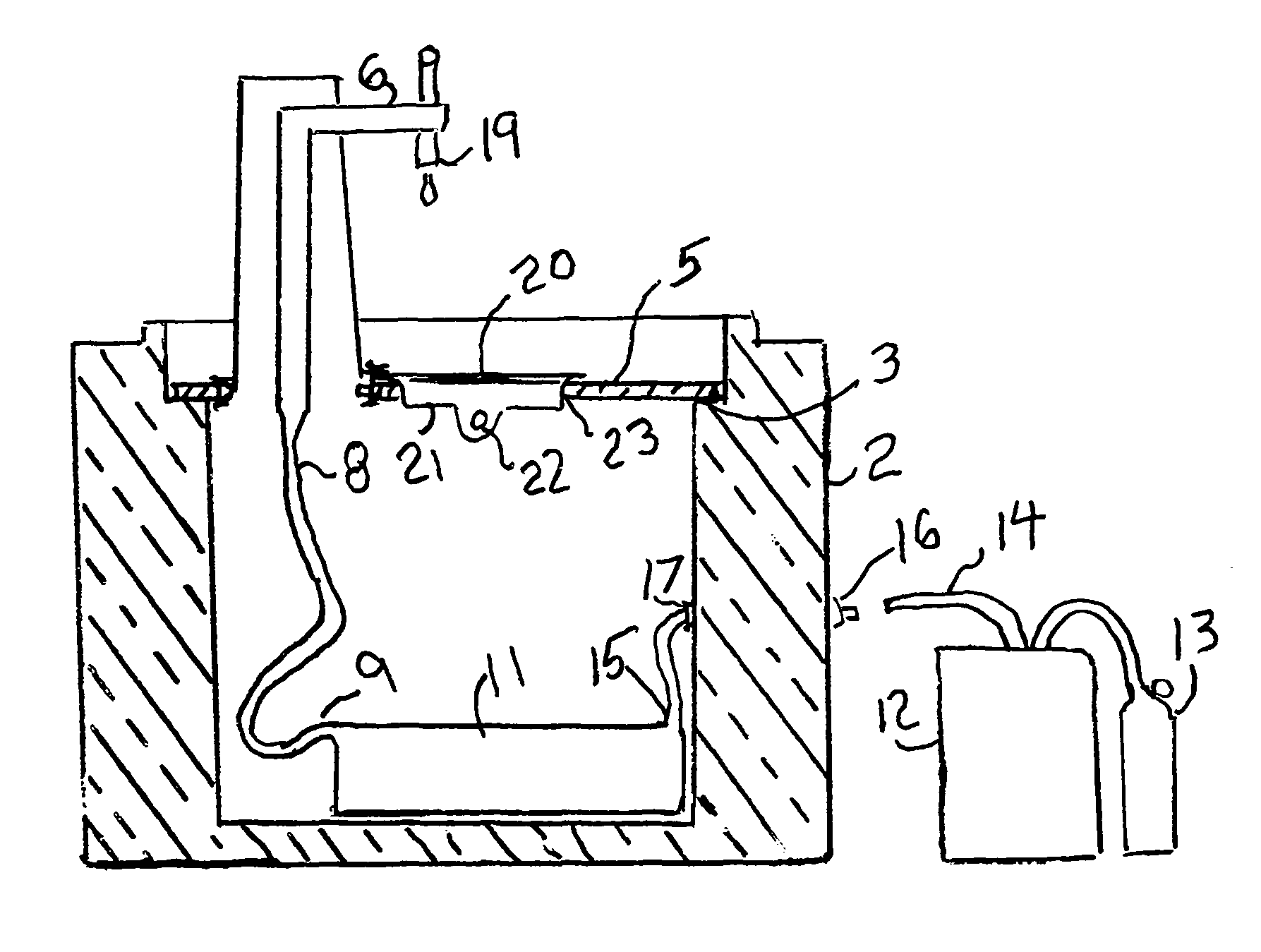

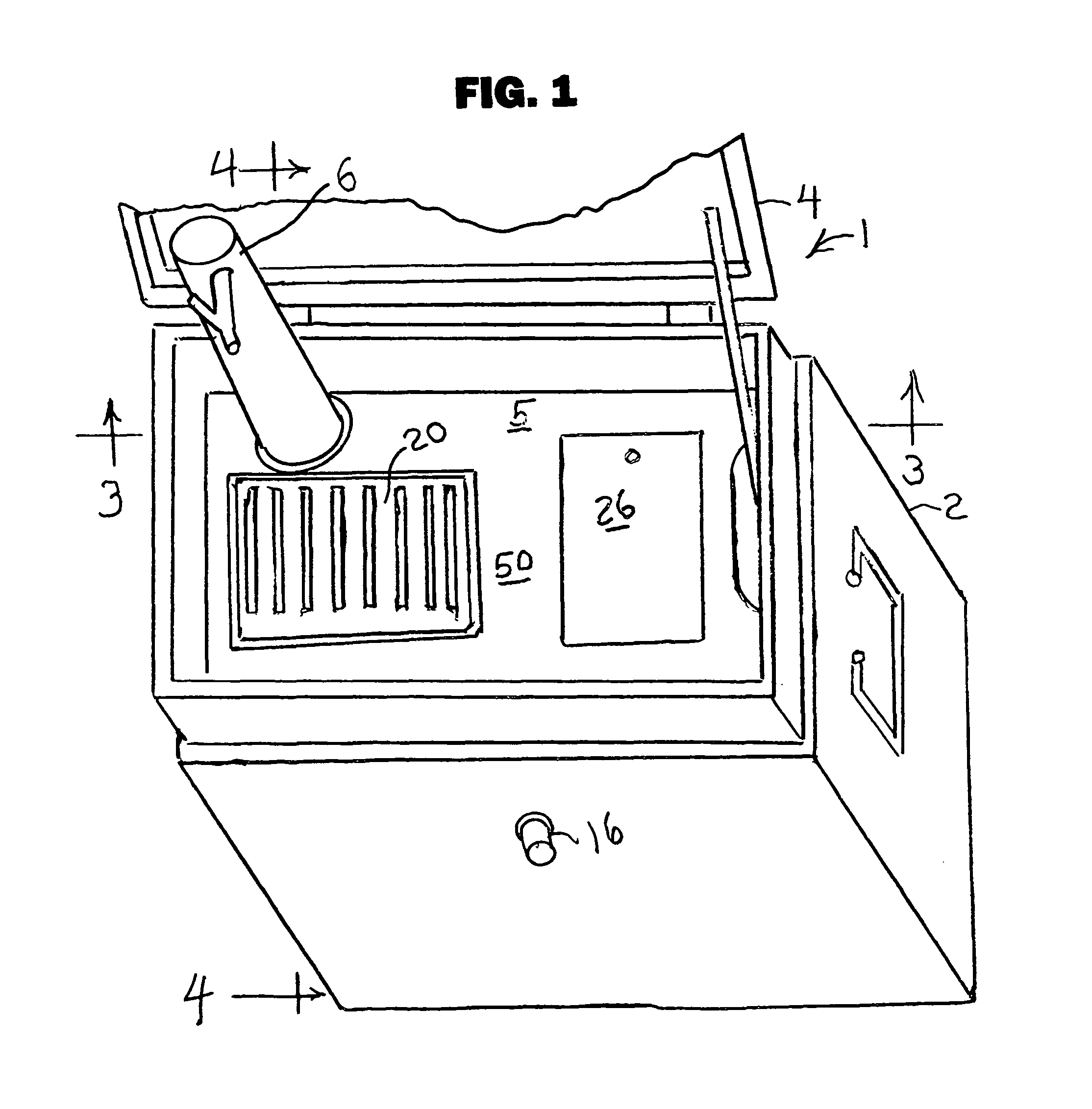

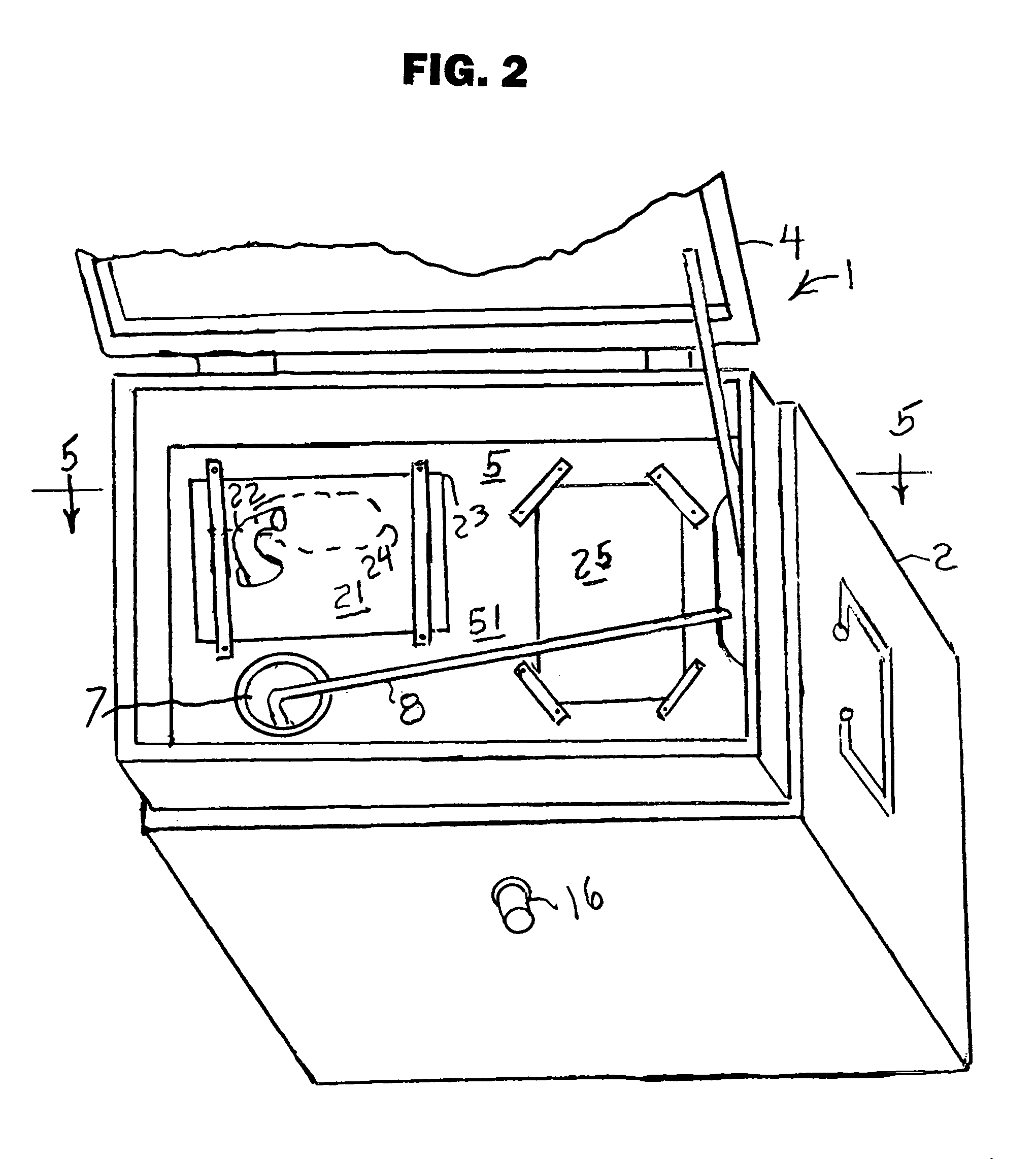

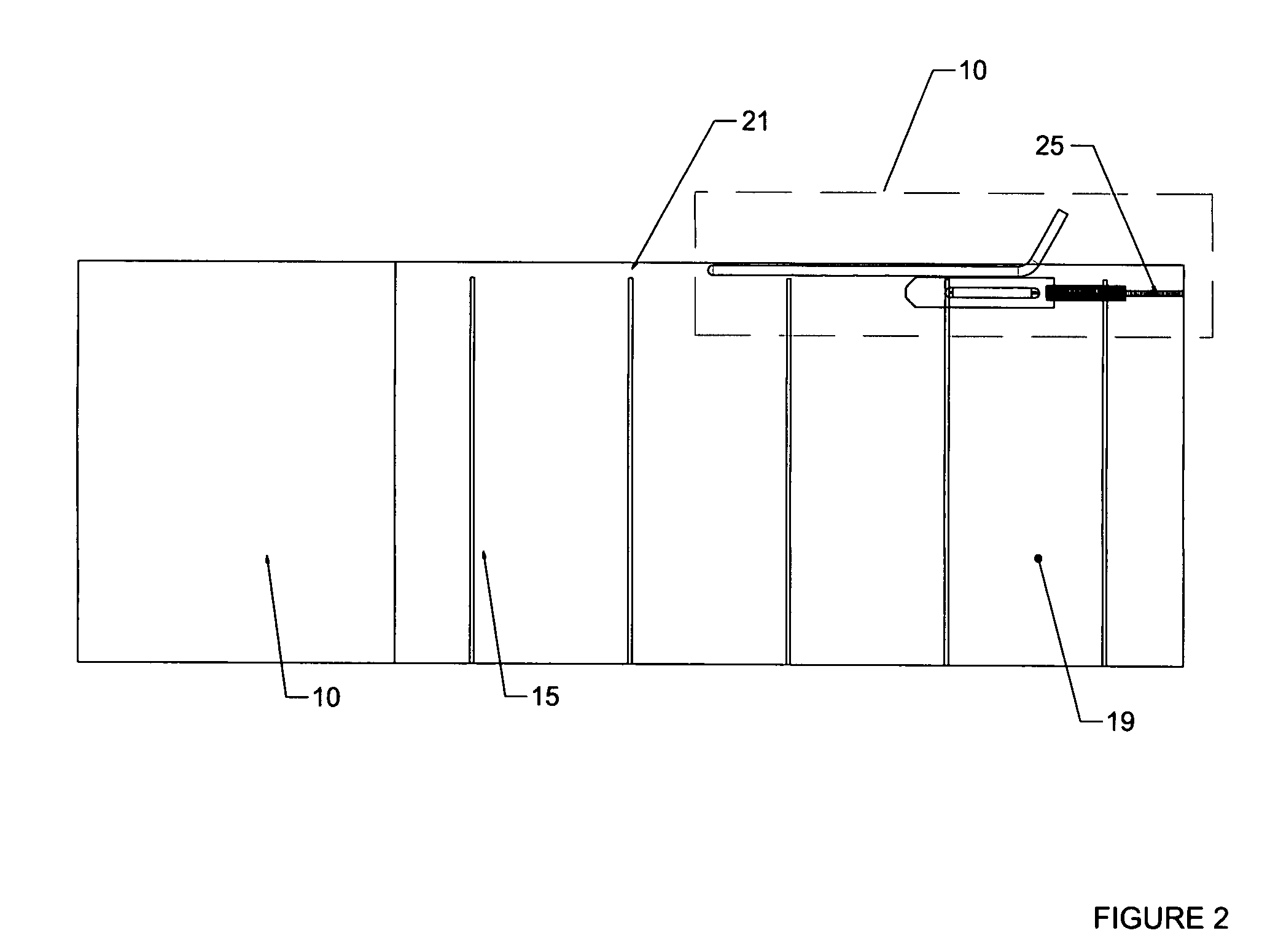

Portable draft bar

ActiveUS7861892B1Easily carrySafely transportTank vehiclesLiquid flow controllersCooling coilEngineering

A portable draft bar has an insulated chamber with an open top, an insulated cover for the open top, and a horizontal shoulder on the inside wall near the top. A rigid panel fits on the shoulder. At least one beverage tap mounted on the panel extends above the open top, with a drip tray below the tap outlet. A cooling coil within the chamber connects the tap inlet to a pressurized beverage container, with chamber ice cooling the coil. When not in use, the panel may be inverted and returned to the shoulder. With the cover in place and the container disconnected, the device is secure and transportable.

Owner:WHITE RICHARD W +1

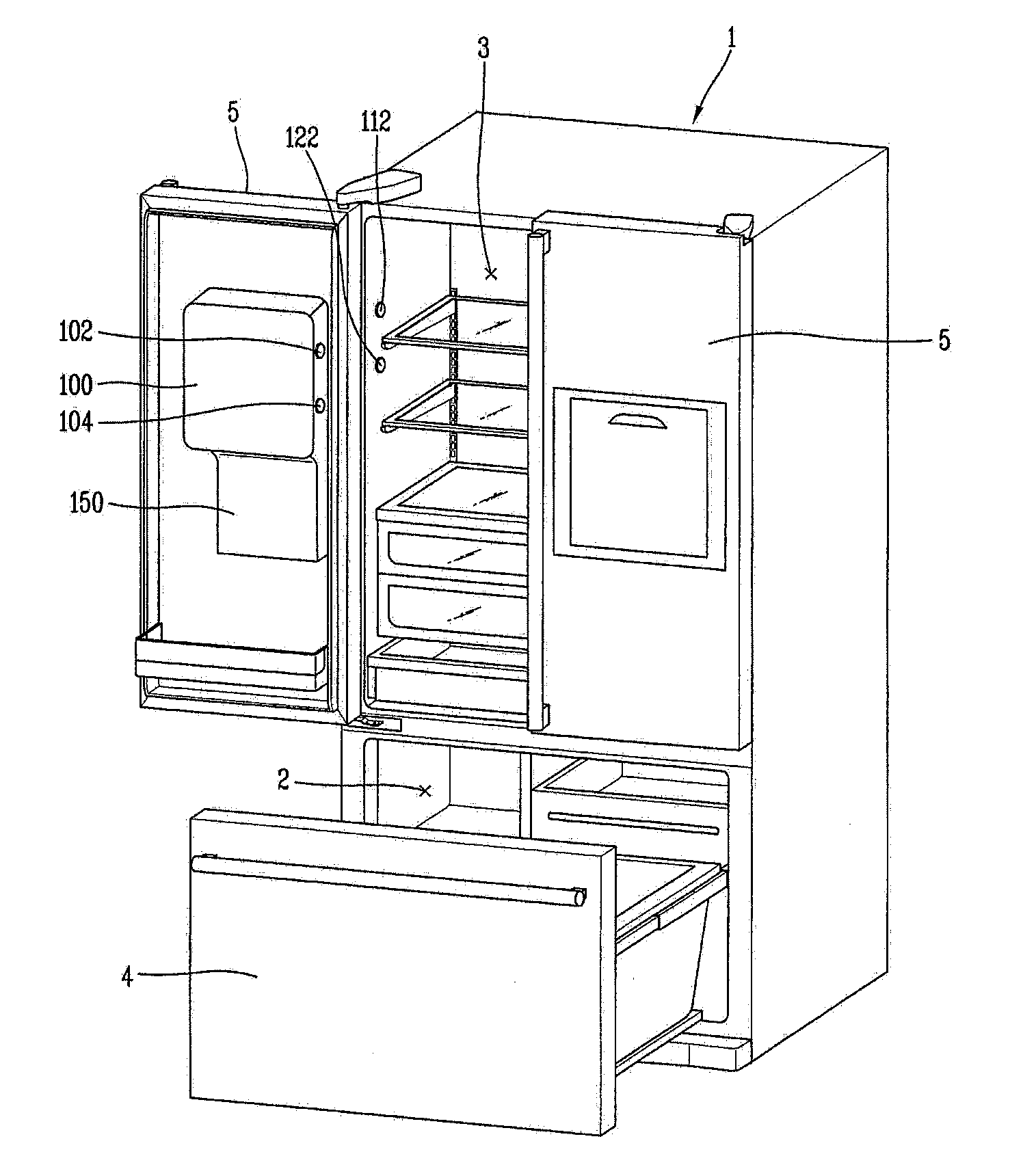

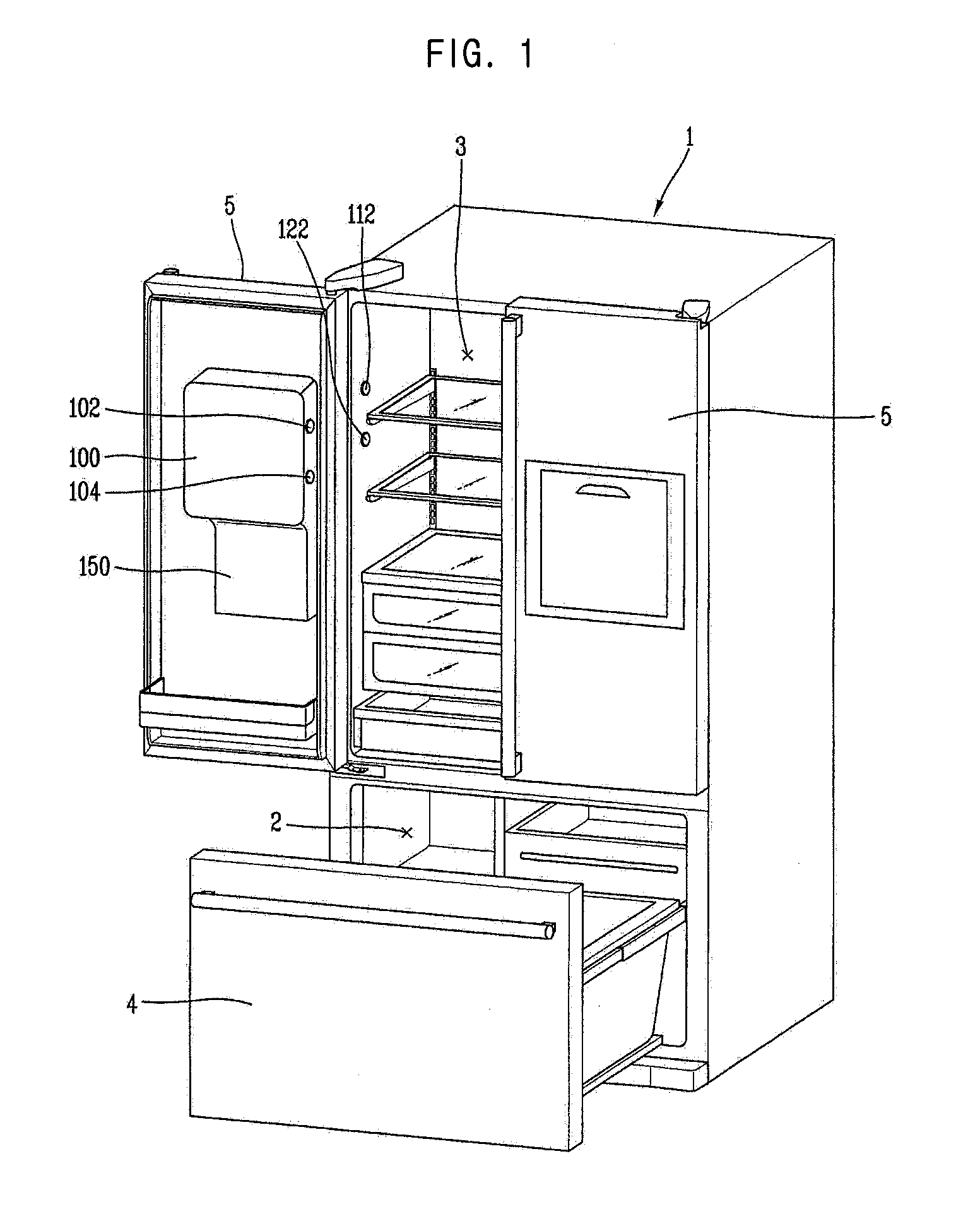

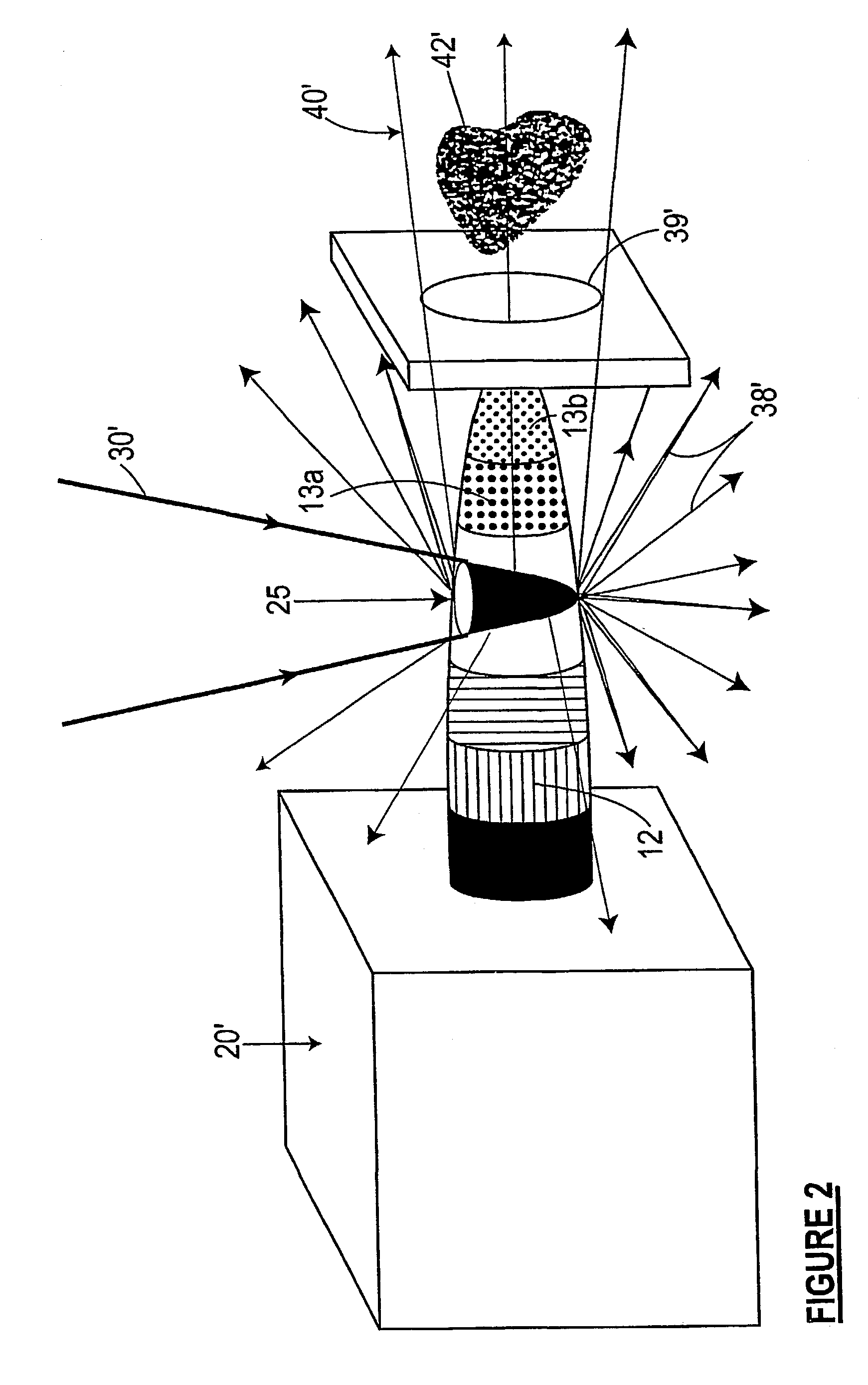

Refrigerator having ice transfer unit

InactiveUS20120023999A1Improve convenienceEffectively useLighting and heating apparatusIce productionFreezing chamberEngineering

A refrigerator includes: a refrigerator main body including a freezing chamber positioned at a lower portion thereof and a refrigerating chamber positioned at an upper portion thereof; an ice maker and an ice bank positioned at an inner side of the freezing chamber; an ice dispenser positioned at an inner side of the refrigerating chamber; a transfer flow path extending from the ice bank to the ice dispenser; an ice input unit supplying ice stored in the ice bank to the interior of the transfer flow path; and a blower blowing air to allow the ice supplied to the interior of the ice transfer flow path toward the ice dispenser.

Owner:LG ELECTRONICS INC

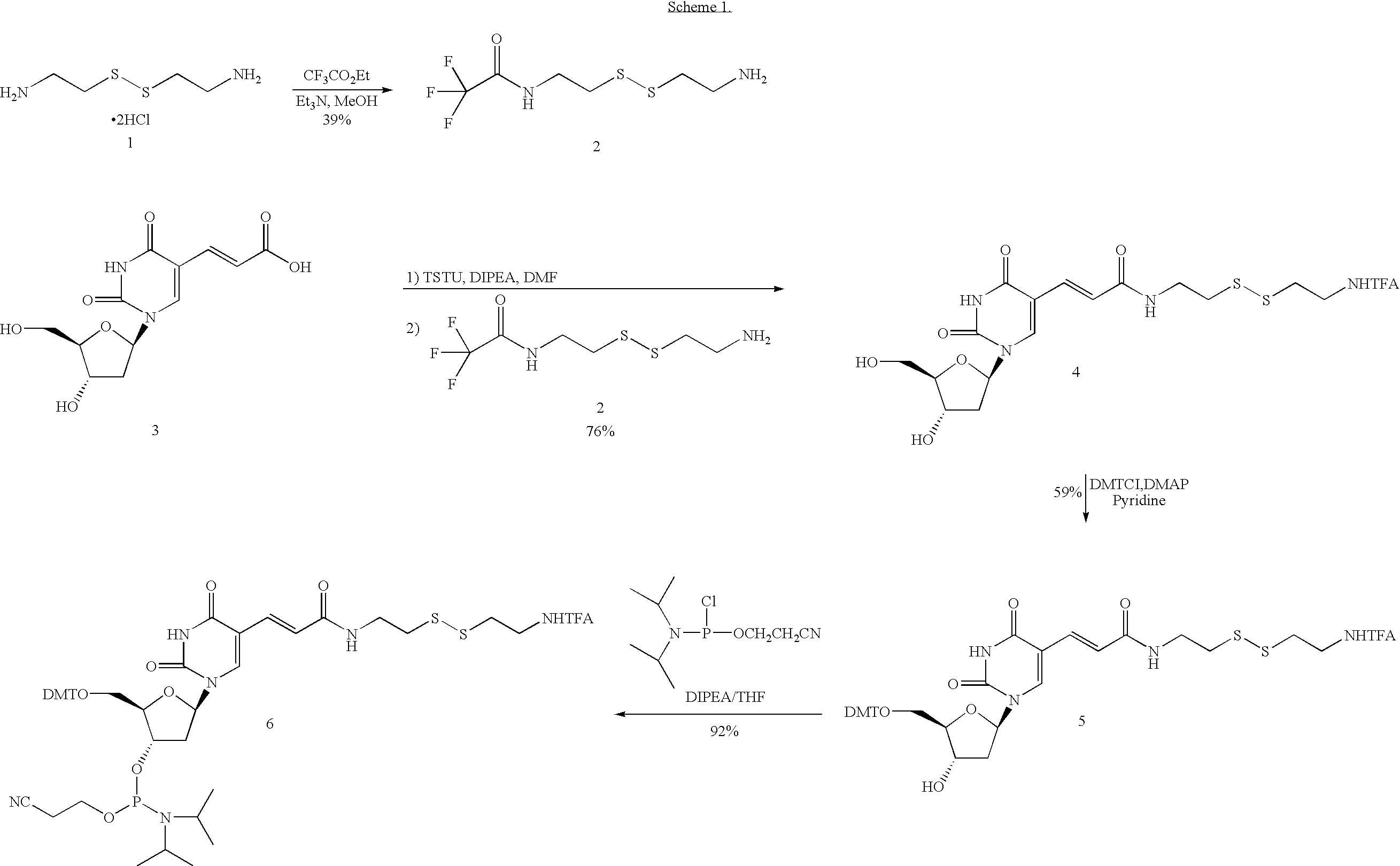

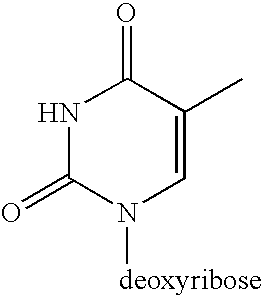

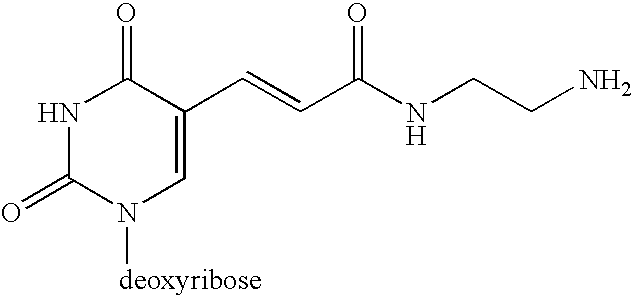

Immobilized probes

InactiveUS20050147973A1Easily and efficiently cleaved in aqueous mediaRapidly stabilise the duplexMicrobiological testing/measurementFermentationBiologySolid surface

The present invention provides a method for reversible covalent attachment of a probe to a solid surface via a flexible linker arm such that the probe can be circularized by ligation in the presence a complementary target nucleic acid and the resulting circular probe molecule detected. Detection can be by hybridization, primer extension, sequencing, PCR or other methods but is preferably by means of rolling circle amplification.

Owner:GE HEALTHCARE LTD

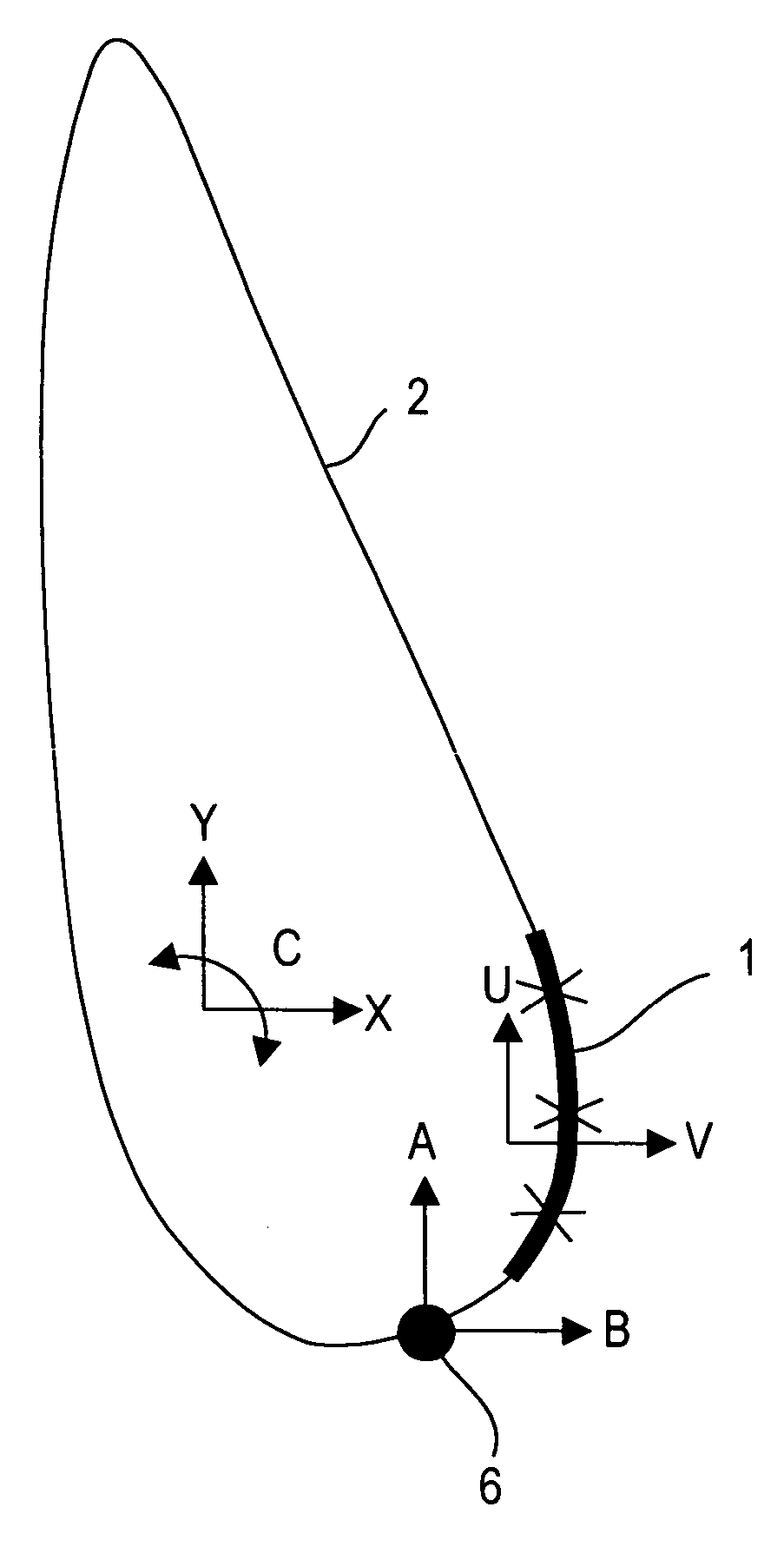

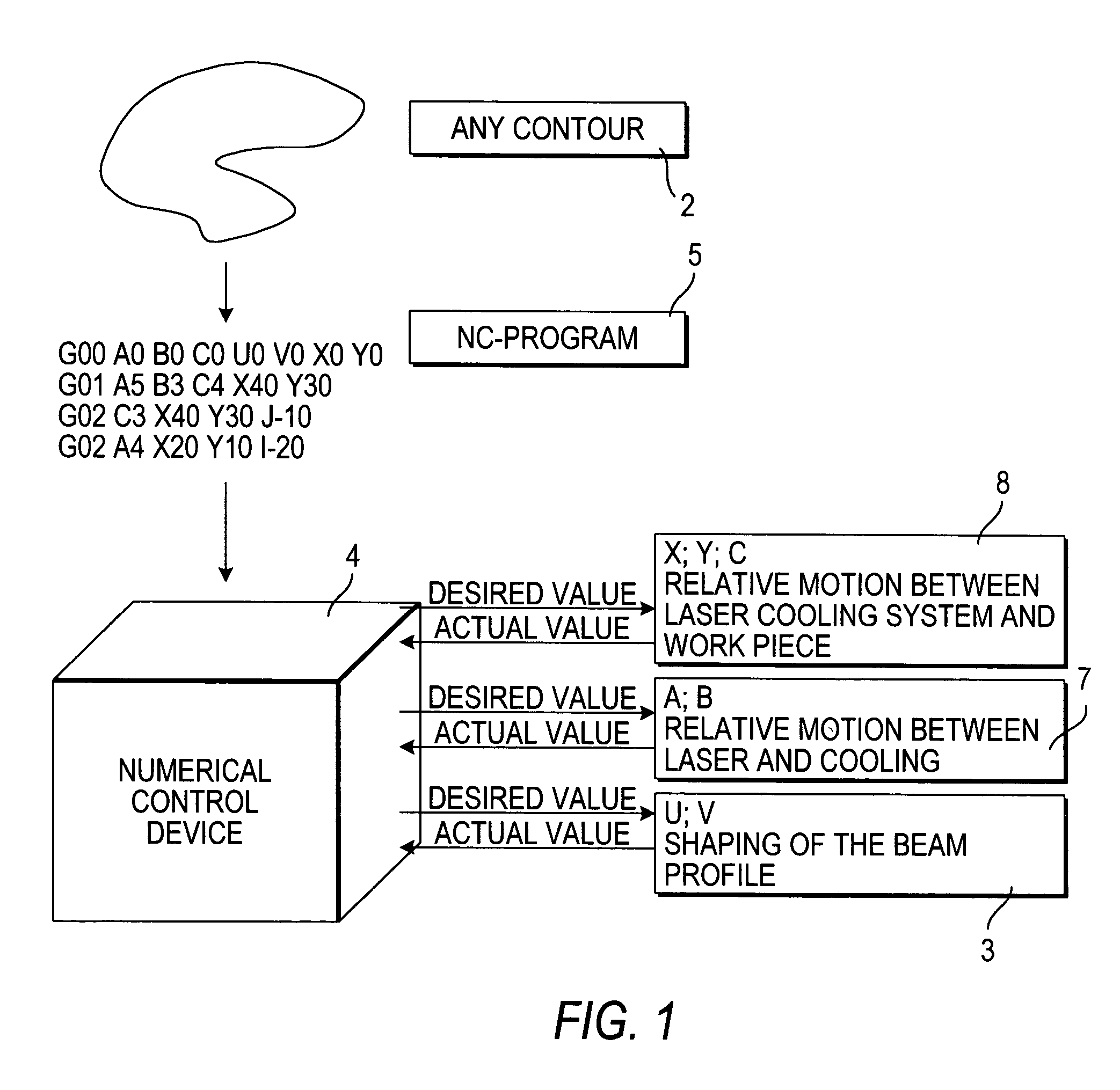

Method and device for cutting flat work pieces made of a brittle material

InactiveUS7014082B2Easy to cutAvoid meltingGlass severing apparatusWelding/soldering/cutting articlesFlat glassData control

The apparatus for cutting a flat glass work piece along a curved dividing line includes a laser generating a laser beam having a linear beam profile and an optical system with a scanner for producing a curvilinear focal point from the laser beam. The apparatus also moves a cold spot along the curved dividing line following the curvilinear focal point. A trajectory control device controls the position of the curvilinear focal point on the curved dividing line via actuators. A profile control device controls the contour of the curvilinear focal point according to trajectory data from the curved dividing line, so that all points of the curvilinear focal point lie on or coincide with the curved dividing line. The apparatus adjusts the length of the curvilinear focal point by adjusting scanning amplitude of the scanning motion.

Owner:SCHOTT AG

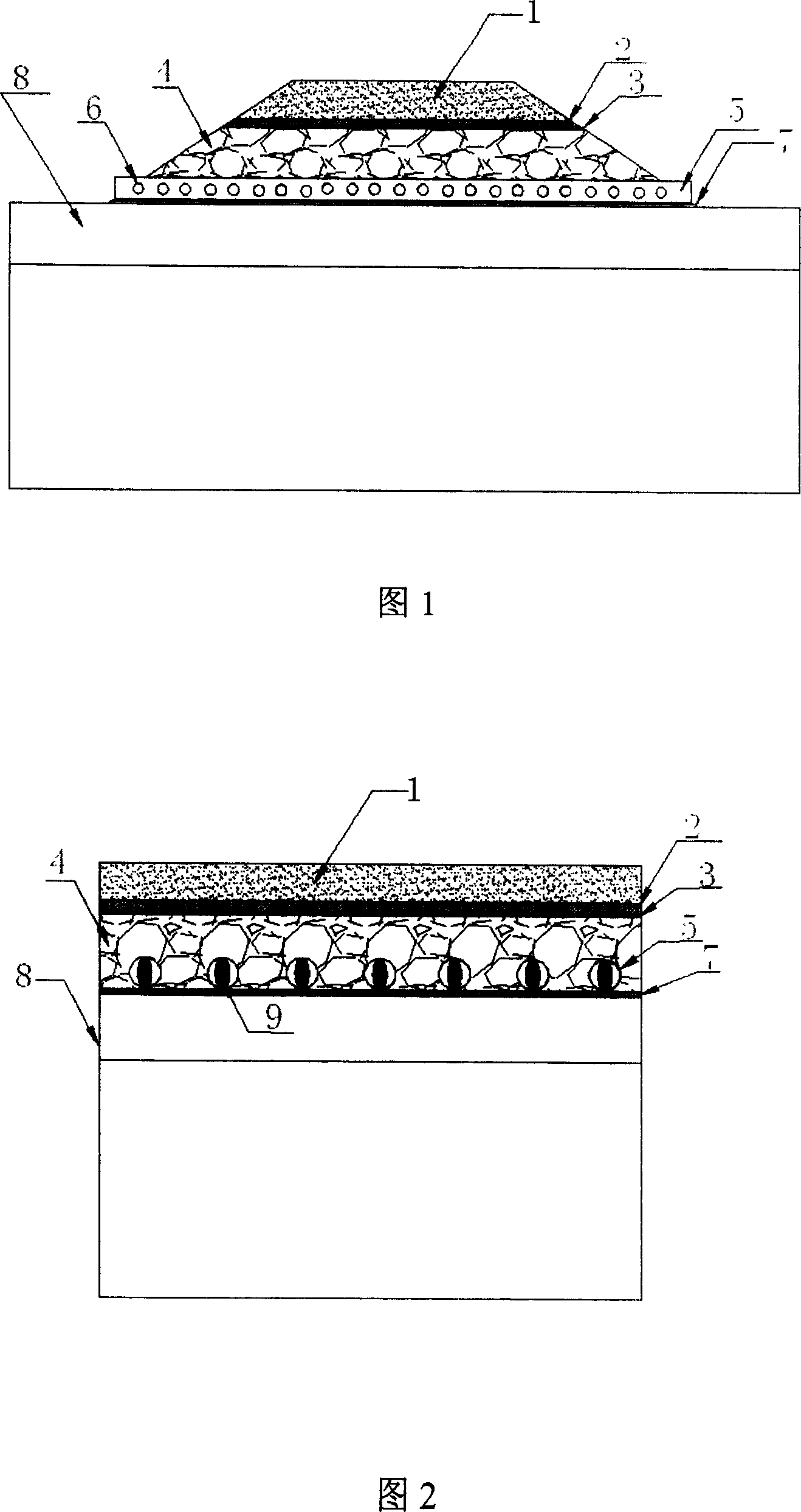

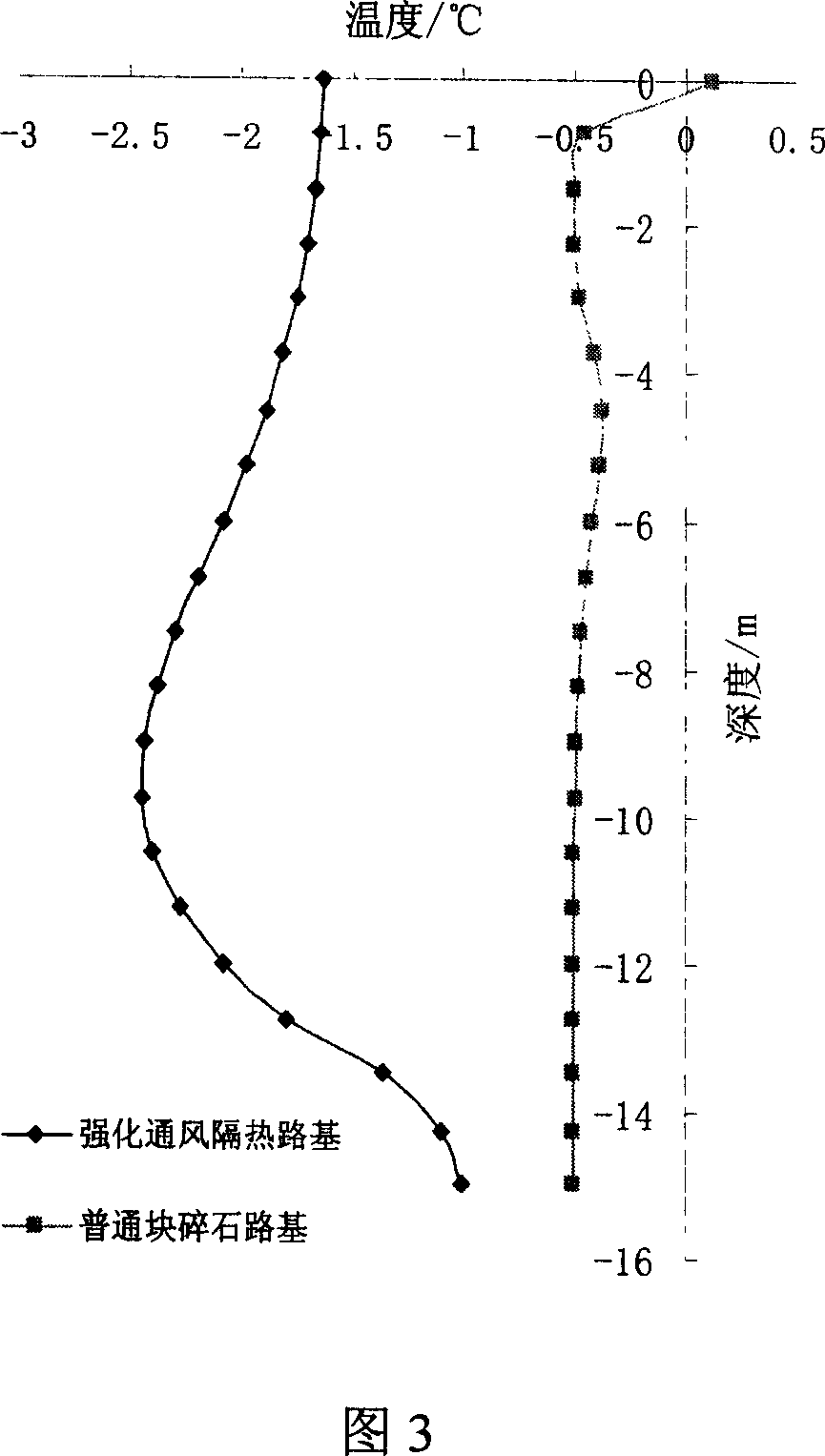

Reinforced ventilating heat-proof foundation

InactiveCN101012632AEnhance ventilation and convection cooling effectStrong ventilation and convection cooling effectRoadwaysCooling effectCrushed stone

The invention discloses a strengthening ventilation heat-insulation roadbed, characterized in that compacting sand-gravel-soil cushion is set on the compacting native surface; transverse concrete air ducts through wall with automatic air door controlled by temperature are set on the sand-gravel-soil cushion in a certain distance; crushed stone layer is set between air ducts through wall and above them; earthwork cloth is put on the horizontal crushed stone layer; heat insulation material is set on the earthwork cloth; and compacting embankment fill is filled on the heat insulation material. In the invention air ducts through wall are set in the crushed stone layer. In winter, by using lower temperature in frozen earth area and bigger wind speed through permeable hole of air duct the effect of convective cooling of air in the crushed stone layer is strengthened and there is strong ventilation cooling effect in air duct through wall itself. Two are combined with each other and are used by each other to decrease the temperature of frozen soil under the roadbed. In summer, the heat insulation material, the crushed stone layer and air duct through wall with air door controlled by temperature can play a role of thermal screen effect so as to prevent heat energy entering into embankment. At last storing cooling energy to the utmost is achieved; the temperature of frozen soil is decreased, the melting of frozen soil is avoided and the stability of embankment of frozen soil is ensured.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

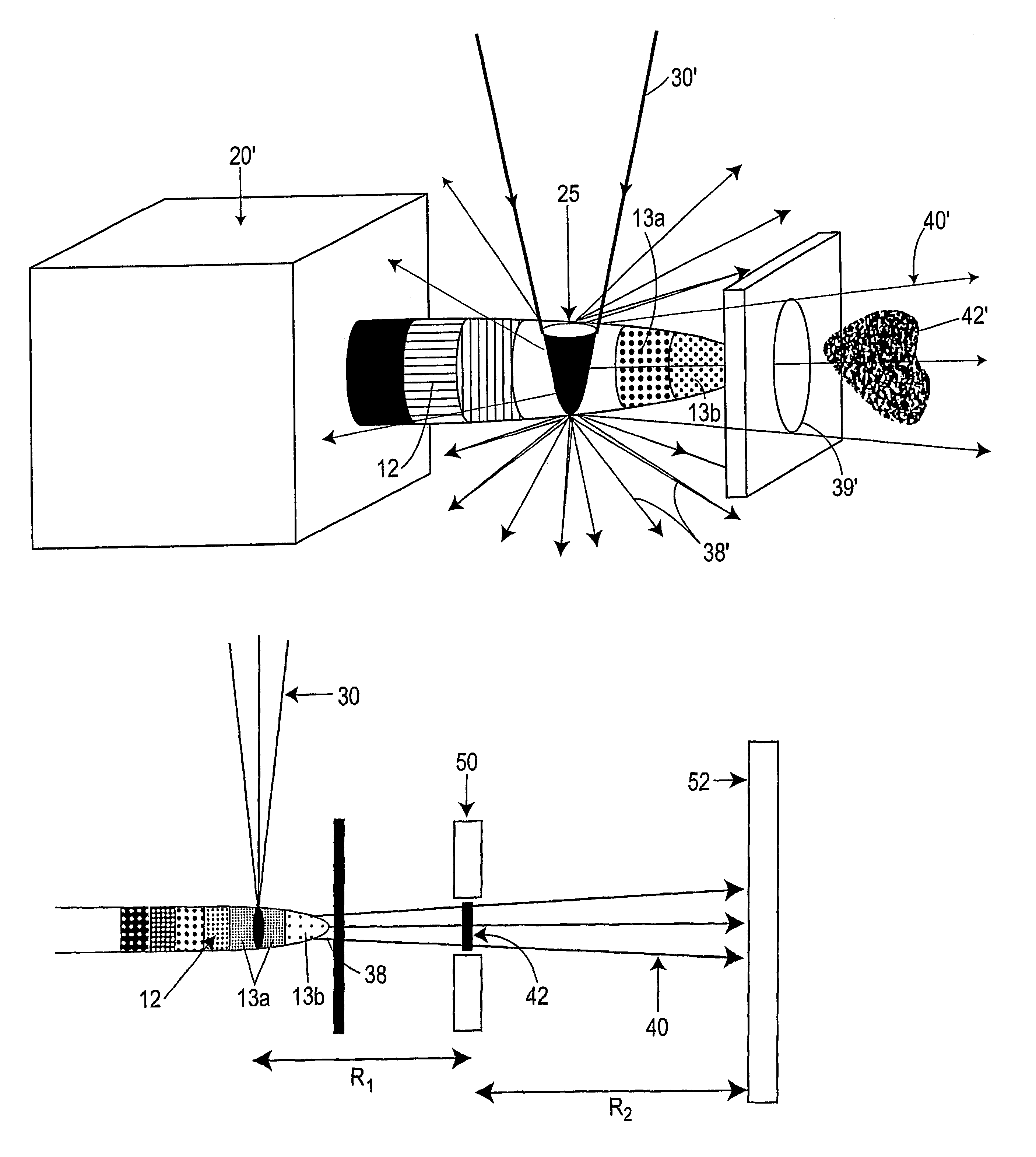

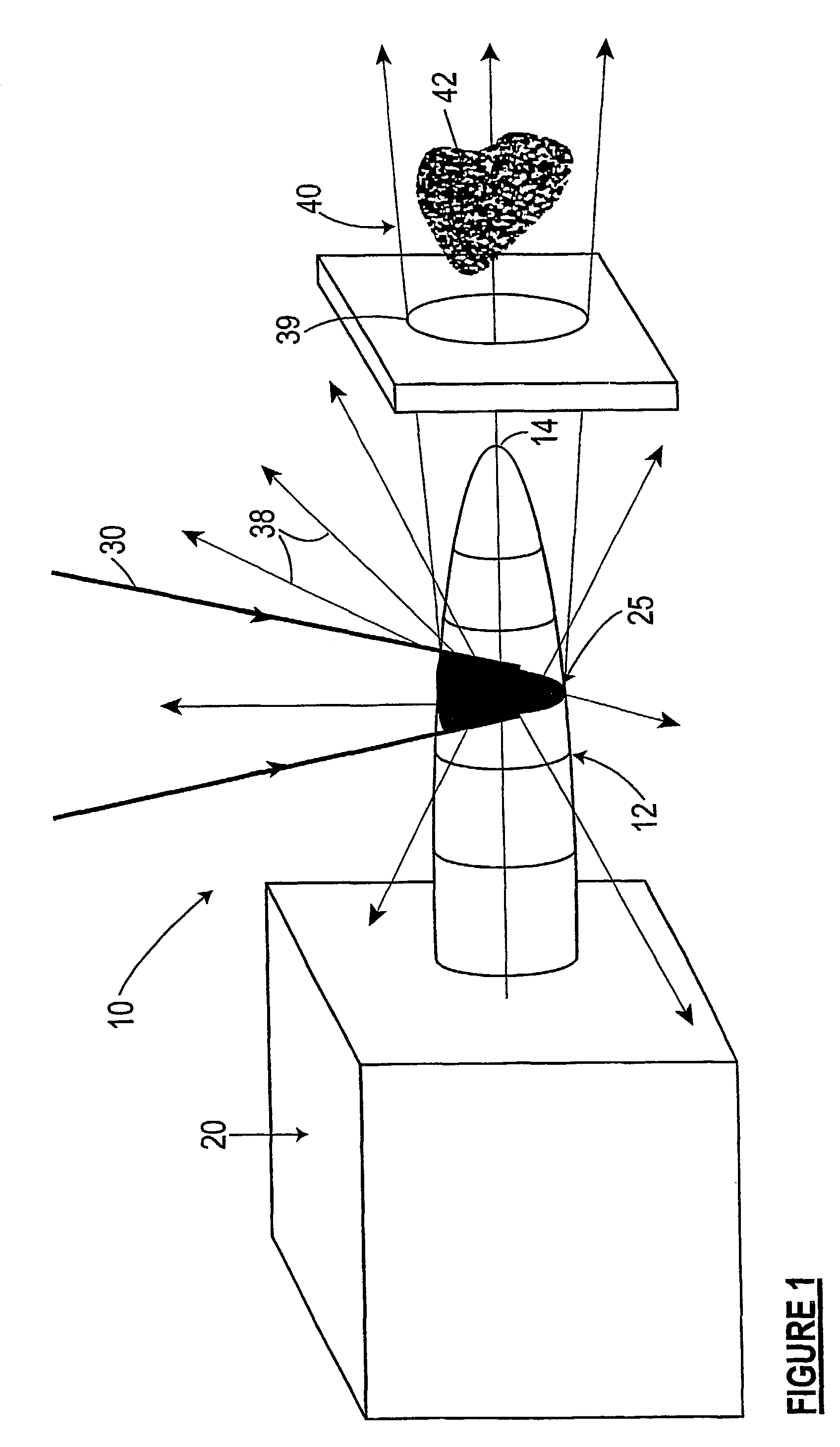

X-ray micro-target source

InactiveUS7050540B2Increase the amount of target material availableImprove efficiencyX-ray tube laminated targetsImaging devicesSoft x rayX-ray

X-ray generation apparatus including an elongated target body and a mount from which the body projects to a tip remote from the mount. The target body includes a substance that, on being irradiated by a beam of electrons of suitable energy directed onto the target body from laterally of the elongate target body, generates a source of x-ray radiation from a volume of interaction of the electron beam with the target body. The mount provides a heat sink for the target body.

Owner:XRT

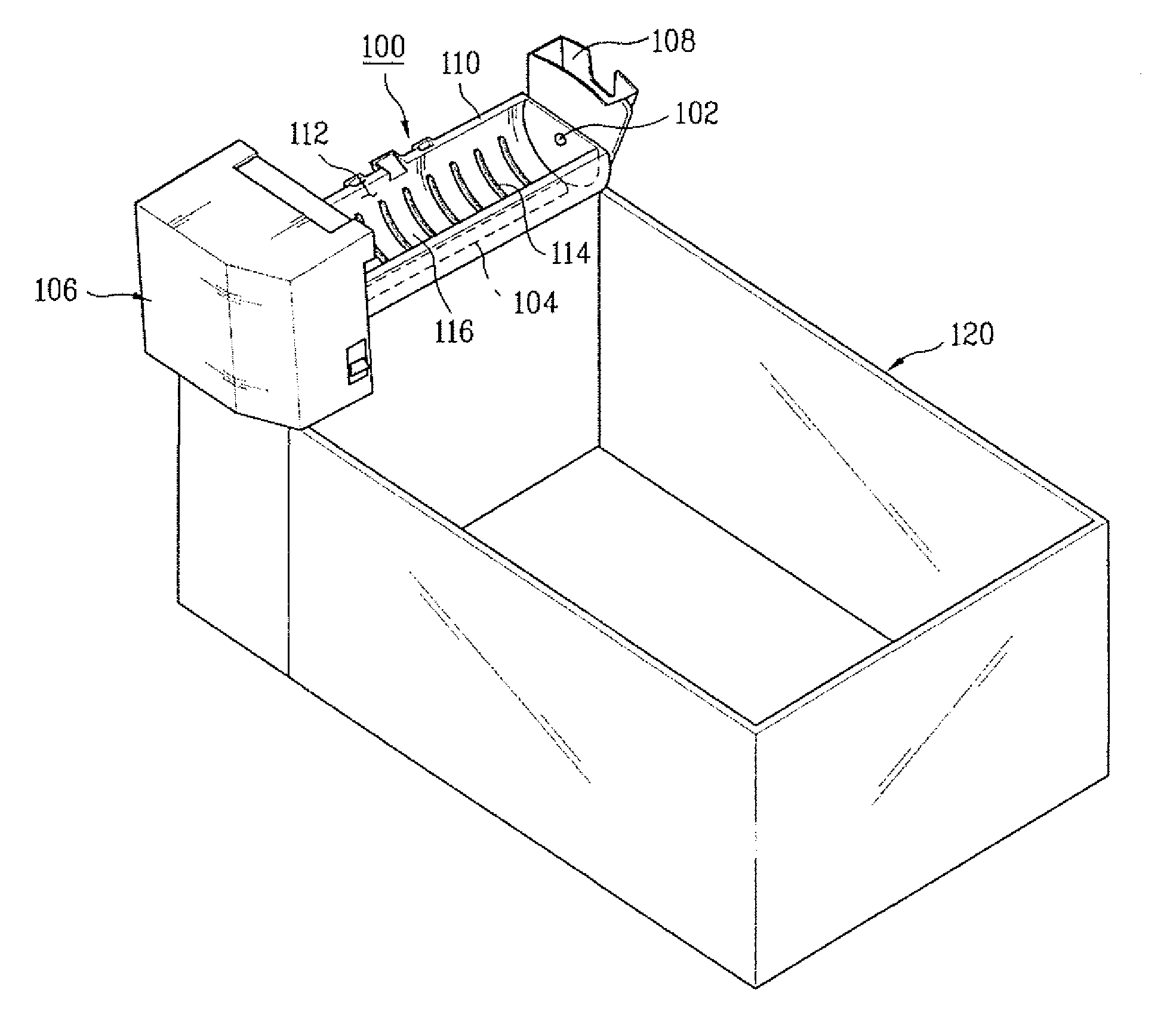

Icemaker and method for controlling the same

ActiveUS20070151282A1Simple structureQuantity minimizationLighting and heating apparatusIce productionIcemakerInjector

An icemaker and a method for controlling the same are disclosed. An object of the present invention is to provide an icemaker and a method for controlling the same, which has an improved structure to make a lot of ice in a short time. an icemaker includes an ice tray rotatable with at least one column of ice making chambers formed therein to make ice; an ejector rotatably provided in each ice making chamber to eject the ice formed in the ice making chamber; an operation device which rotates the ice tray; and a separation device which separates the ice from the ice tray. The separation device may be a heater which heats the ice. Preferably, the heater is operated until adhesive force which acts between the ice and the ice tray is smaller than pushing force in which the ejector pushes the ice.

Owner:LG ELECTRONICS INC

Method and apparatus for making dunnage

InactiveUS7490449B1Direct contact guaranteeHigh speedCapsMechanical working/deformationHeating elementNozzle

An apparatus for manufacturing dunnage including a plurality of rollers for pulling a web of material through the machine, a nozzle with at least one port through which gas or liquid flows, a plurality of ceramic elements in opposing positions such that the web of material can pass between the plurality of ceramic elements. A heating element is routed through each of the plurality of ceramic elements such that heat will radiate through openings in the top surfaces of the ceramic elements that will melt the portion of the material that is passing between the opposing ceramic elements. The apparatus may be equipped to manufacture multiple pieces of dunnage simultaneously.

Owner:EIBERT RALPH

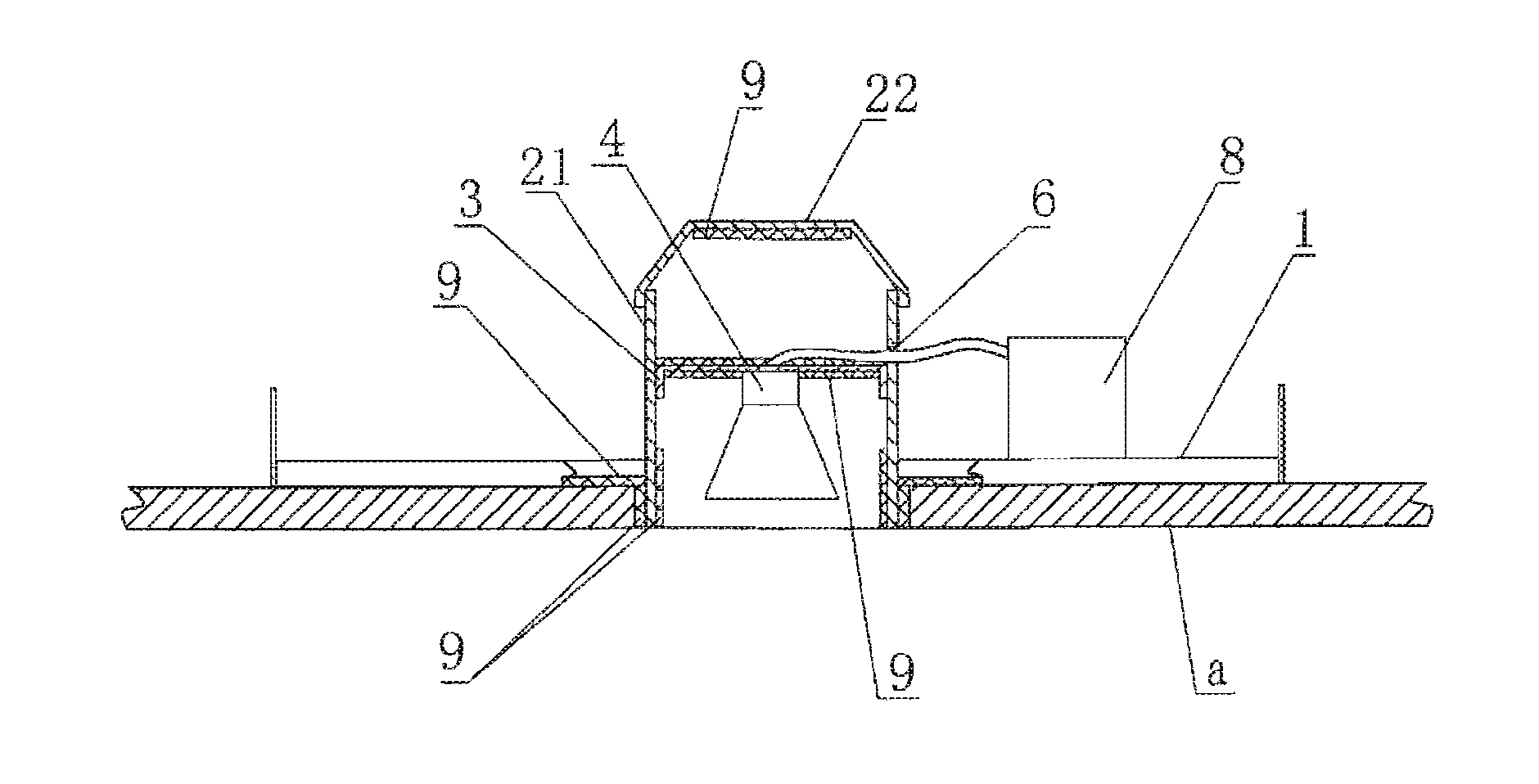

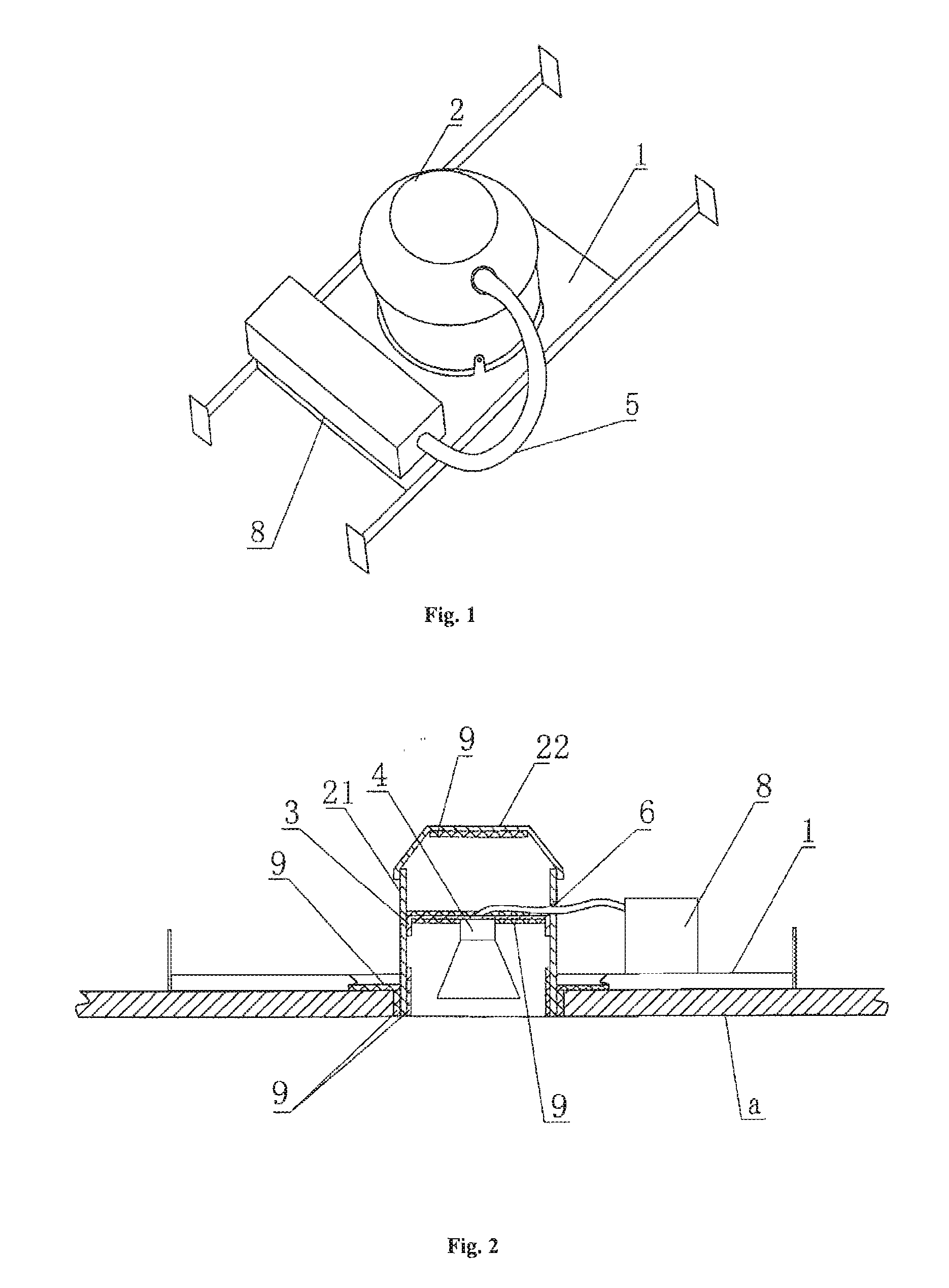

Fireproof light fixture

InactiveUS20100214790A1Prevent the spread of fireImprove cooling effectProtective devices for lightingFire rescueEngineeringElectric wire

A fireproof lamp, comprises a barrel cover (2) and a lamp holder (4) installed therein. A through hole (6) is provided on the barrel cover (2). A pipe (5) is installed in the through hole (6), and an electric wire connected with the lamp holder (4) is connected to a junction box (8) outside of the barrel cover (2). An expansion fireproof material (9) is provided inside the barrel cover (2).

Owner:WU NA

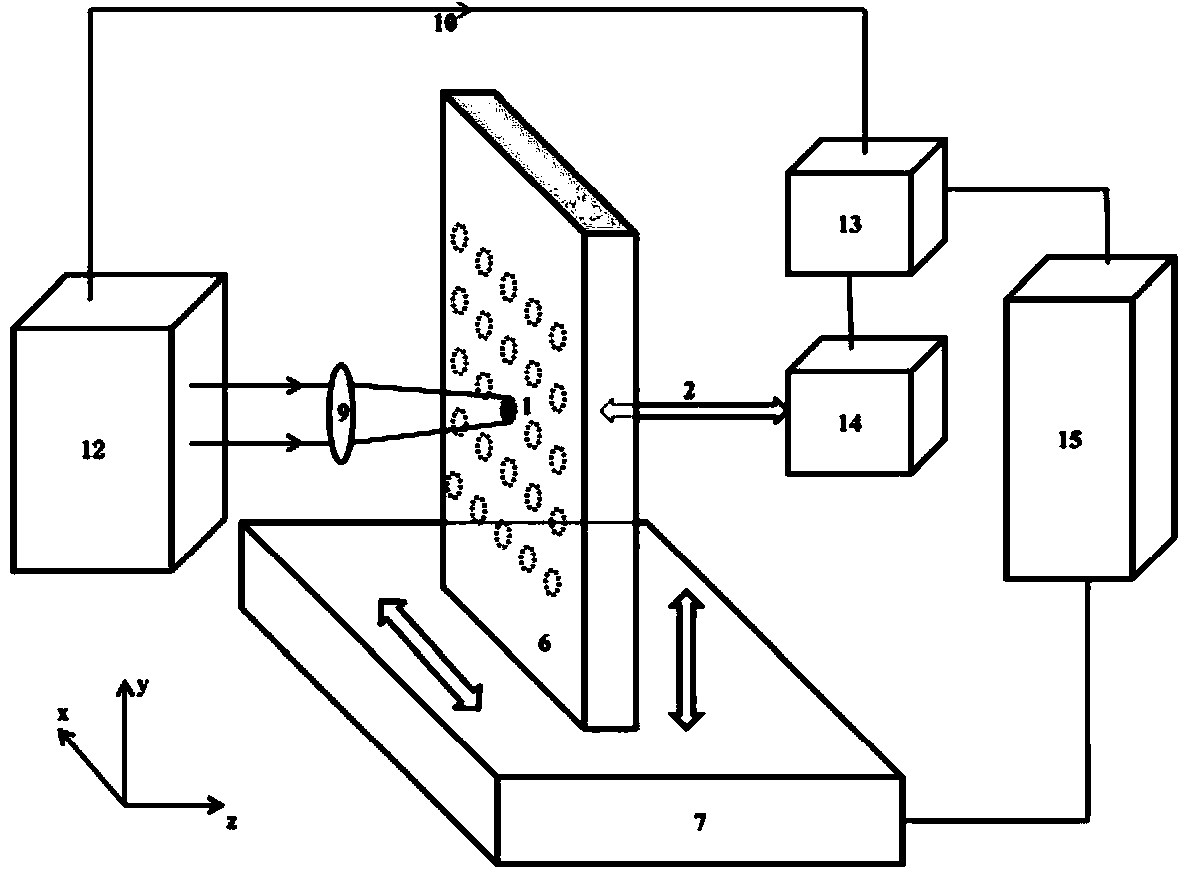

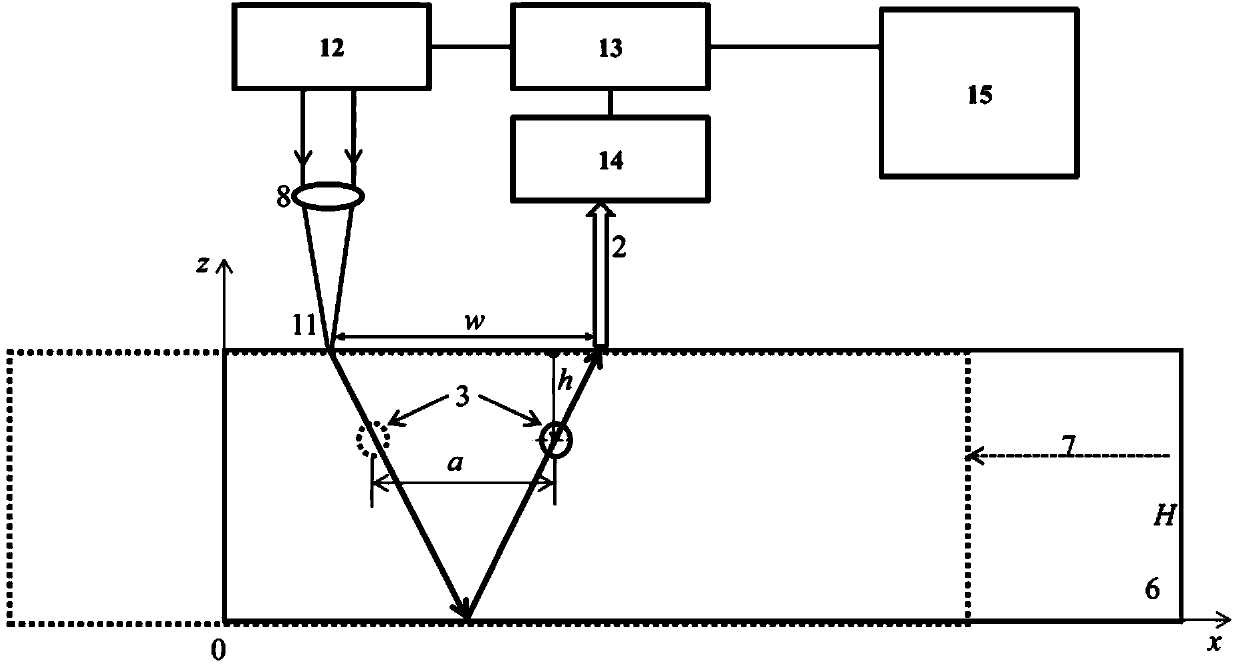

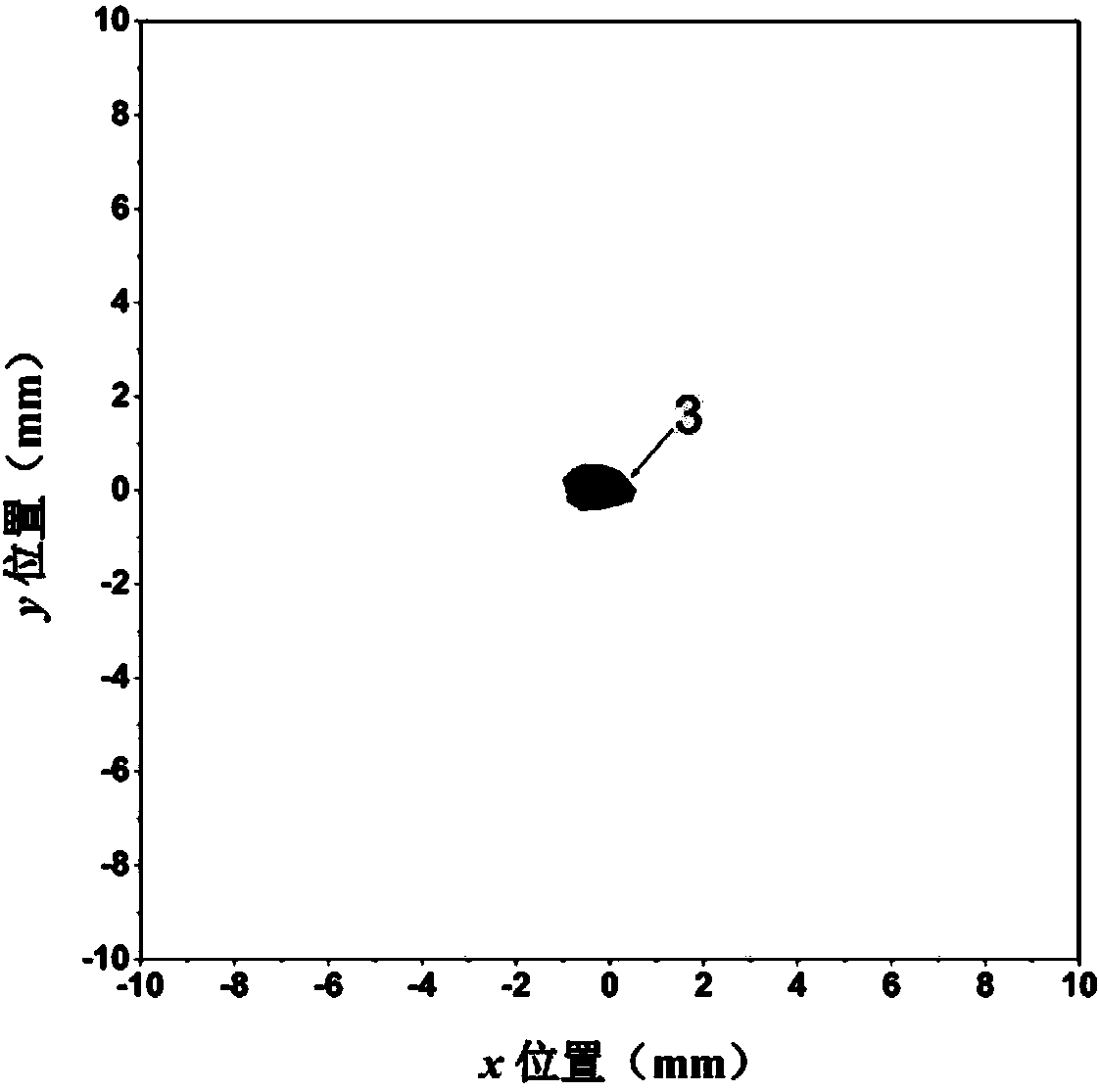

Full-optical laser ultrasonic measuring method for internal defect of material

InactiveCN103808802AAvoid meltingRealize non-destructive testingAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveNondestructive testing

The invention discloses a full-optical laser ultrasonic measuring method for internal defects of a material. The method comprises the following steps: firstly, measuring the two-dimensional position and the size of the internal defect of a measured object on an x-y plane, and subsequently measuring the depth of the internal defect of the measured object in the z direction. By adopting the method, the three-dimensional position and the size information of the internal defect can be obtained by scanning, and the method is high in precision and efficiency, and is applicable to non-destructive detection on various materials.

Owner:NANJING UNIV OF SCI & TECH

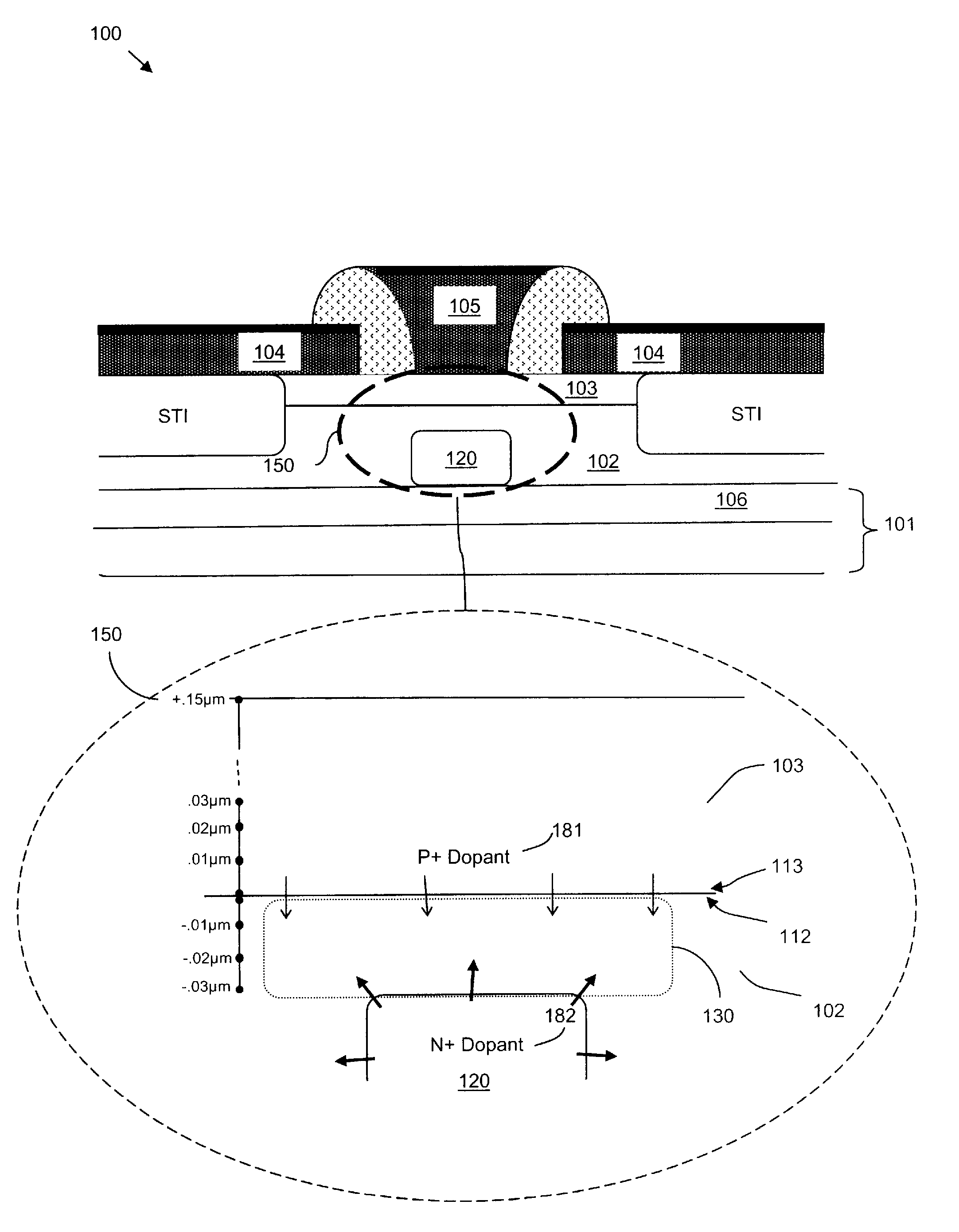

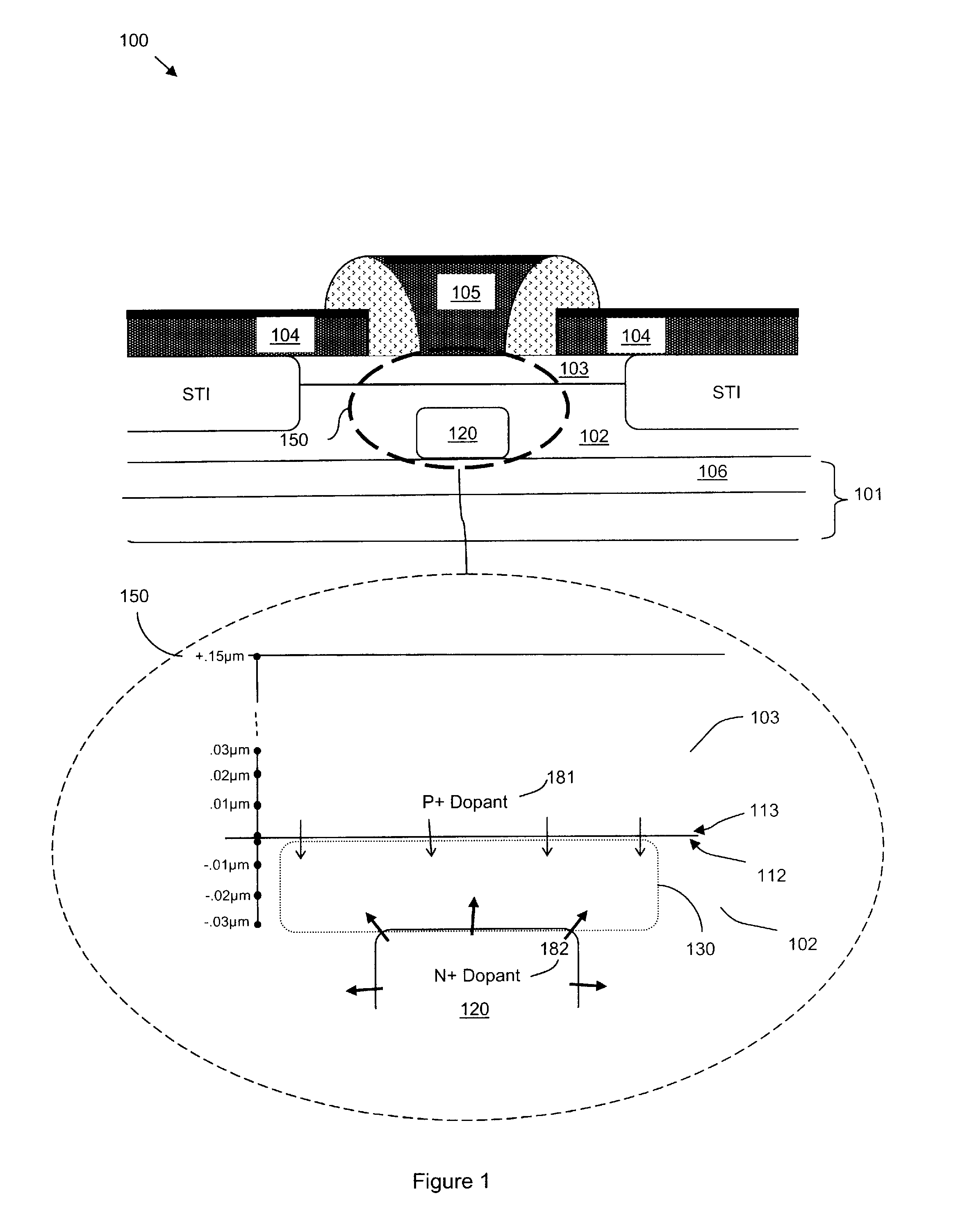

Silicon germanium heterojunction bipolar transistor structure and method

InactiveUS20080265282A1Minimizes unwanted defect-enhanced diffusionMinimize diffusionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureRapid thermal annealing

Disclosed is an improved semiconductor structure (e.g., a silicon germanium (SiGe) hetero-junction bipolar transistor) having a narrow essentially interstitial-free SIC pedestal with minimal overlap of the extrinsic base. Also, disclosed is a method of forming the transistor which uses laser annealing, as opposed to rapid thermal annealing, of the SIC pedestal to produce both a narrow SIC pedestal and an essentially interstitial-free collector. Thus, the resulting SiGe HBT transistor can be produced with narrower base and collector space-charge regions than can be achieved with conventional technology.

Owner:VEECO INSTR

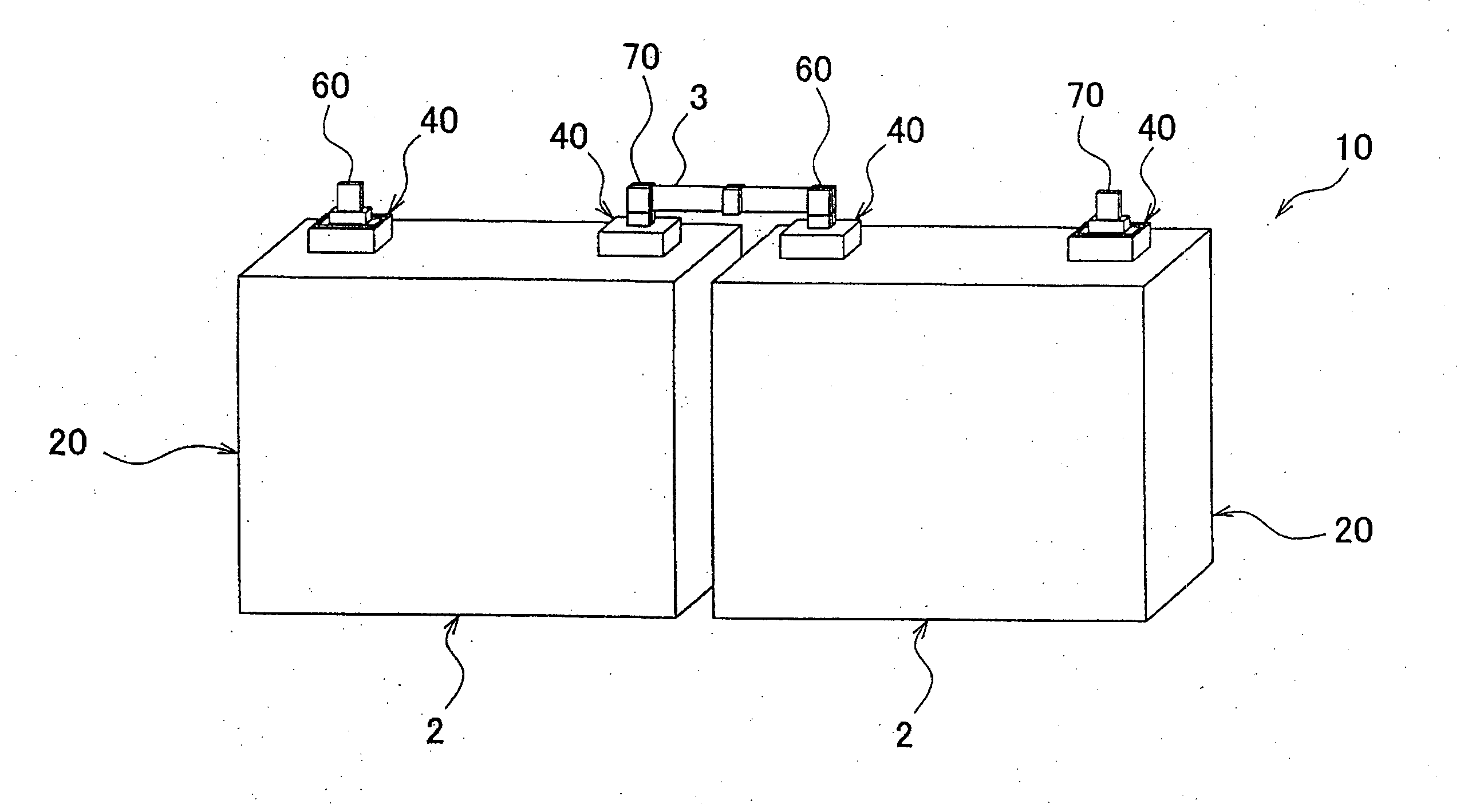

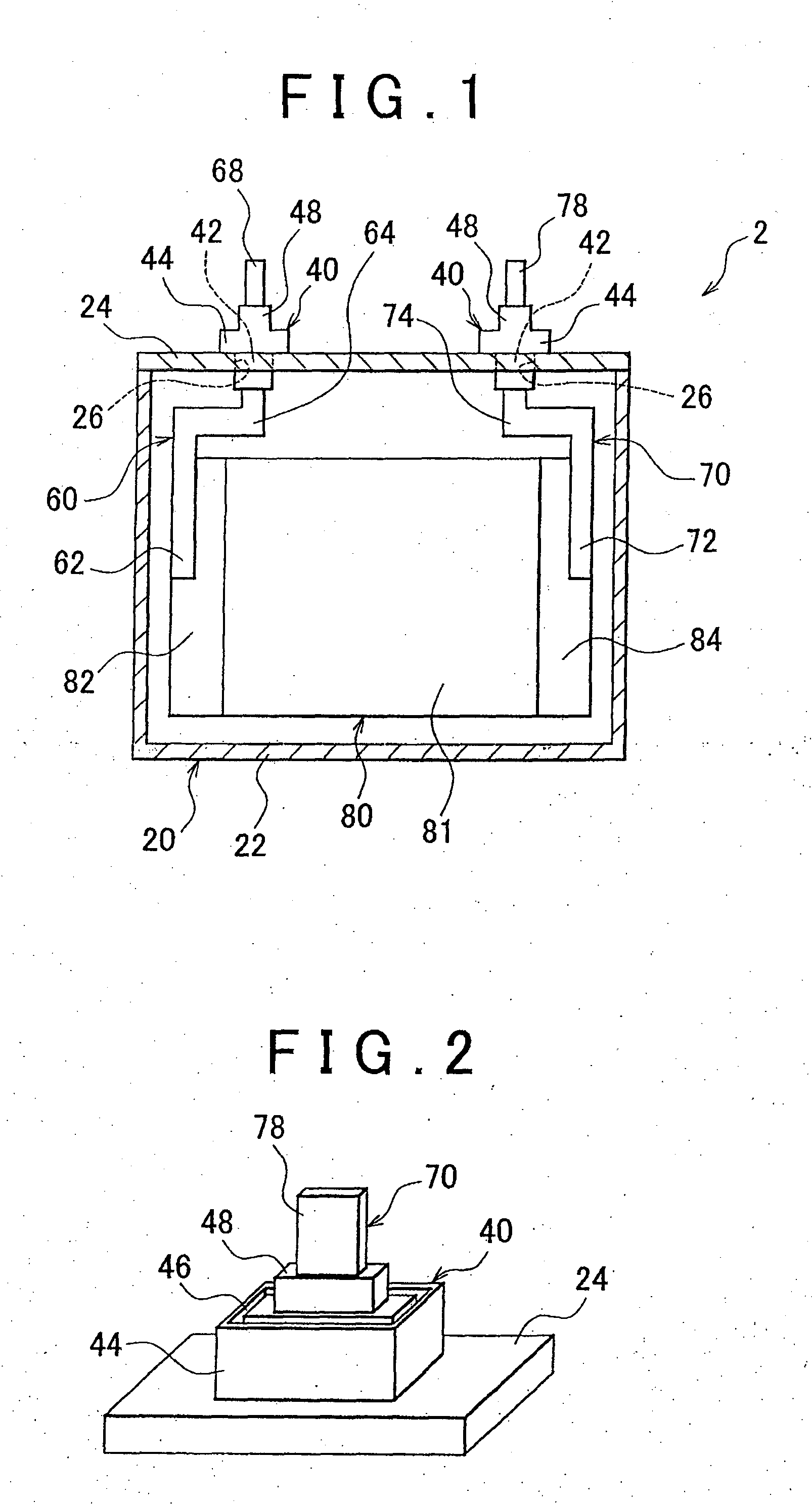

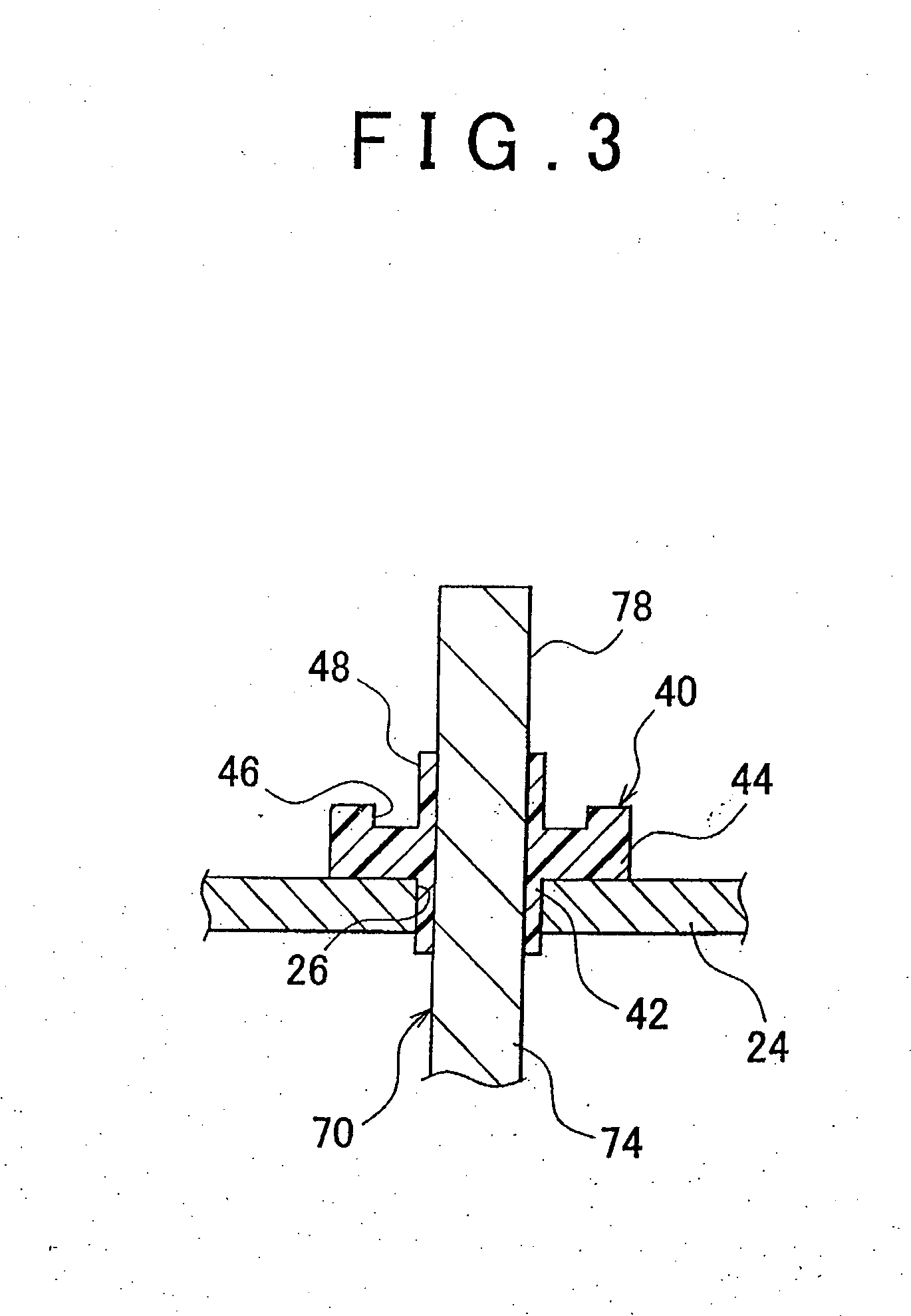

Battery cell and power supply

InactiveUS20100173190A1Avoid insulating propertiesWelding of the electrode terminal is preventedPrimary cell to battery groupingCurrent conducting connectionsBattery cellElectrical and Electronics engineering

A battery (2) includes an insulating member (40) fitted into a hole (26) in a case (20), and electrode terminals (60, 70), each being passed through the insulating member (40) and extended out of the case (20). The insulating member (40) includes: a first insulating portion (42) that isolates each of the electrode terminals (60, 70) from the inner surface of the hole (26) and closes the interface between each of the electrode terminals (60, 70) and the inner surface; and a second insulating portion (48) formed along the surface of each of the terminals (60, 70) at the outer end portion of the insulating member (40).

Owner:TOYOTA JIDOSHA KK

Integral thermo-press molding complex brassiere cup structure

Owner:CHEN CHIN TANG

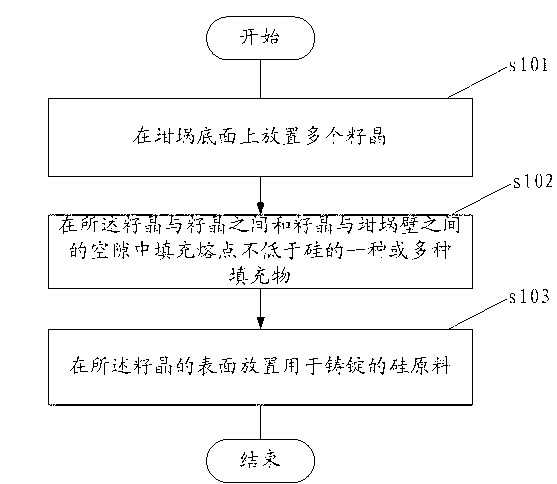

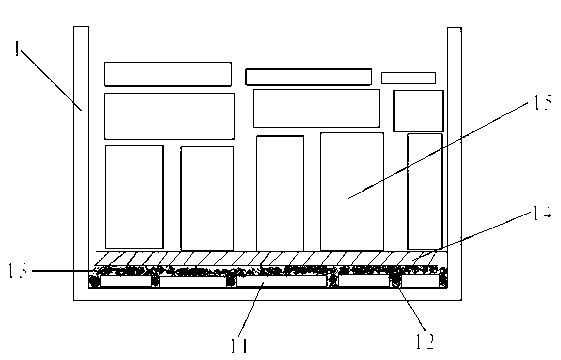

Charging method in monocrystalline silicon ingot casting, and monocrystalline silicon ingot casting method

ActiveCN102758242APrevent floatingAvoid meltingPolycrystalline material growthFrom frozen solutionsIngot castingFilling materials

The invention discloses a charging method in monocrystalline silicon ingot casting. The method comprises the steps that: a plurality of seed crystals are placed on a bottom surface of a crucible; one or more filling materials with a melting point no lower than that of silicon is filled in gaps among the seed crystals and between the seed crystals and a crucible wall; and a silicon raw material used in ingot casting is placed on the surface of the seed crystals. The invention also provides a monocrystalline silicon ingot casting method. With the method, when the silicon raw material is filled into the crucible, the filling materials with the melting point no lower than that of silicon is filled in gaps among the seed crystals and between the seed crystals and the crucible wall. Therefore, when the silicon raw material is molten, the molten silicon is prevented from entering the gaps among the seed crystals and between the seed crystals and the crucible wall, so that seed crystal floating and melting caused by the molten silicon are prevented. According to the value of silicon raw material thermal conductivity, a leveled charging method is adopted, so that temperature gradient during a monocrystalline silicon ingot casting procedure is increased. Therefore, molten silicon is prevented from contacting the seed crystals in a premature stage, and seed crystals can be prevented from melting too fast. Therefore, difficulty in controlling monocrystalline silicon ingot casting process can be prevented.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Chip fuse and its making method

The invention provides a chip type fuse and a method for the production thereof, which is characterized in that: electrical insulating materials are adopted as base plates of the fuse; fuse wires are arranged on the base plates; a protective layer is formed above the fuse wires and bound with the base plates at the periphery of the fuse wires, therefore, a hollow cavity is formed between the fuse wires and the protective layer; the hollow cavity is used for keeping the protective layer from being directly contacted with the fuse wires as well as to avoid the high heat and electric arcs generated by the fuse wires under the condition of excessive current loading from melting or destroying the protective layer. Moreover, the hollow cavity can also be in sealed status and gas which is less than one atmospheric pressure is sealed inside. In addition, a heat insulating layer and an electric arc damping layer are further arranged for the chip type fuse, so as to respectively reduce the response time and the strength of the electric arcs under the condition of excessive current loading. The invention also provides a method for the production of the chip type fuse, in particular to a method for forming the fuse wires and the hollow cavity. The chip type fuse and the method for the production thereof can avoid the high heat and electric arcs generated by the fuse wires under the condition of excessive current loading from melting or destroying the protective layer, so as to ensure the integrity and the use safety of the parts.

Owner:BESDON TECH CORP

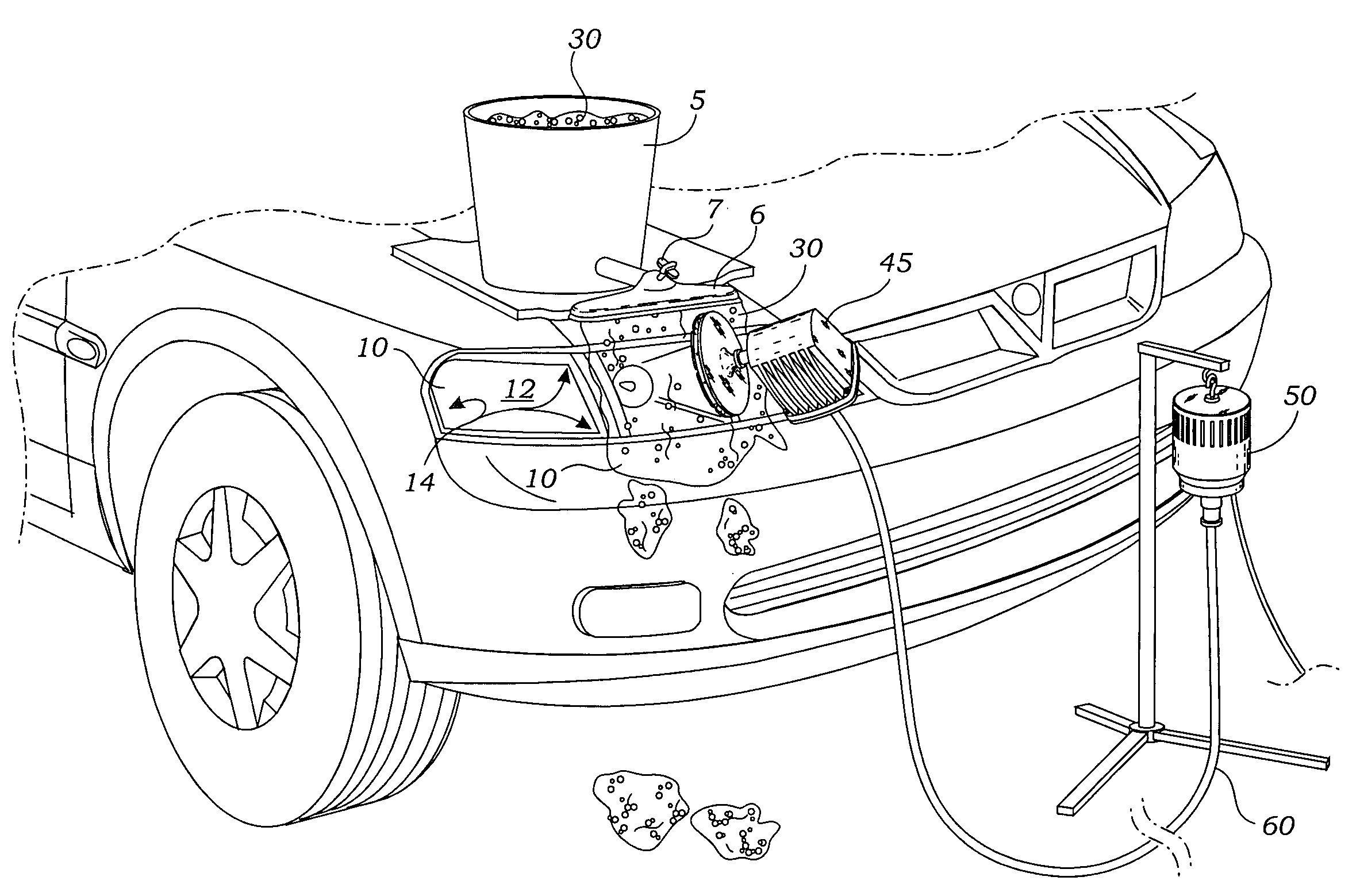

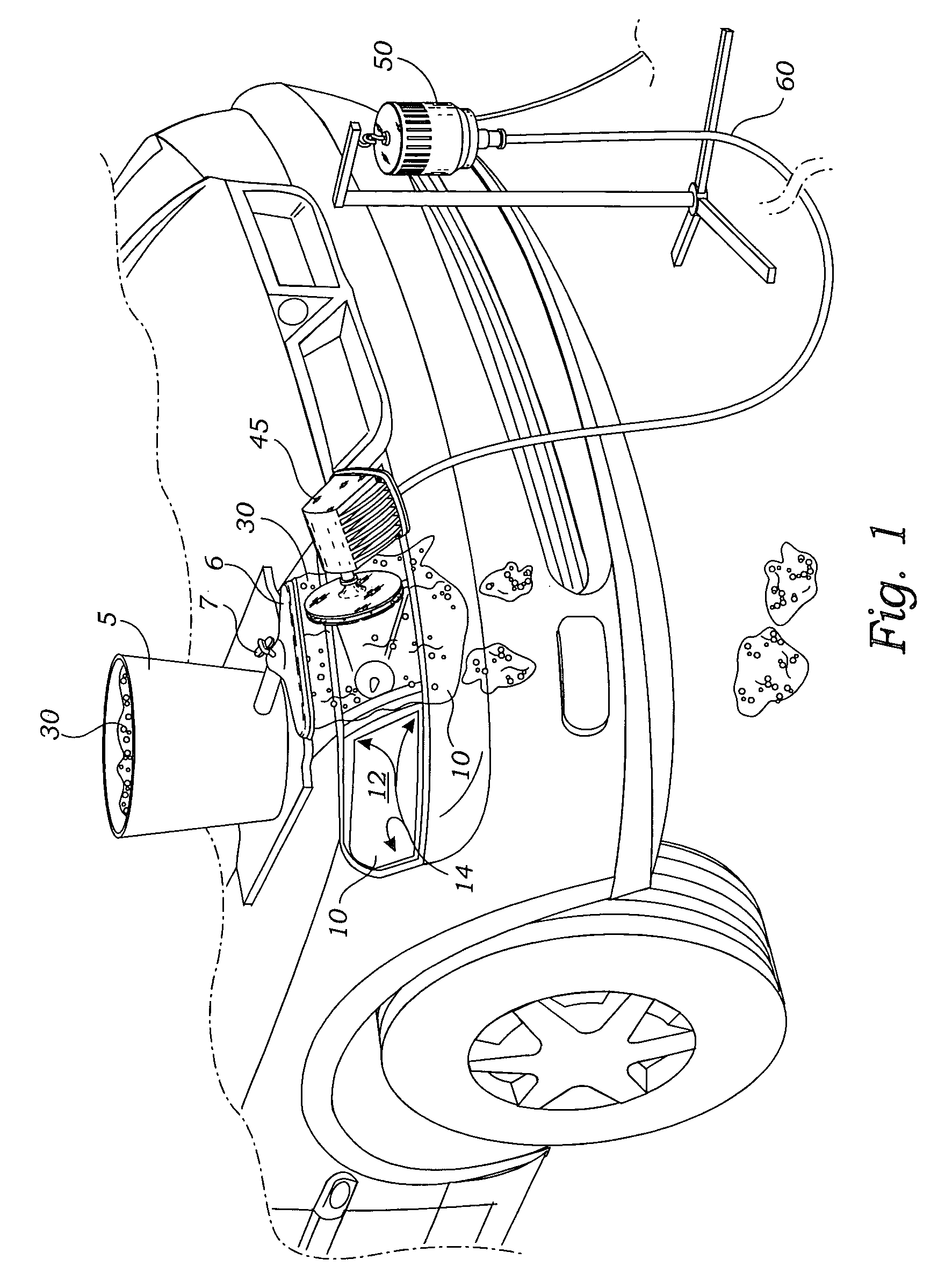

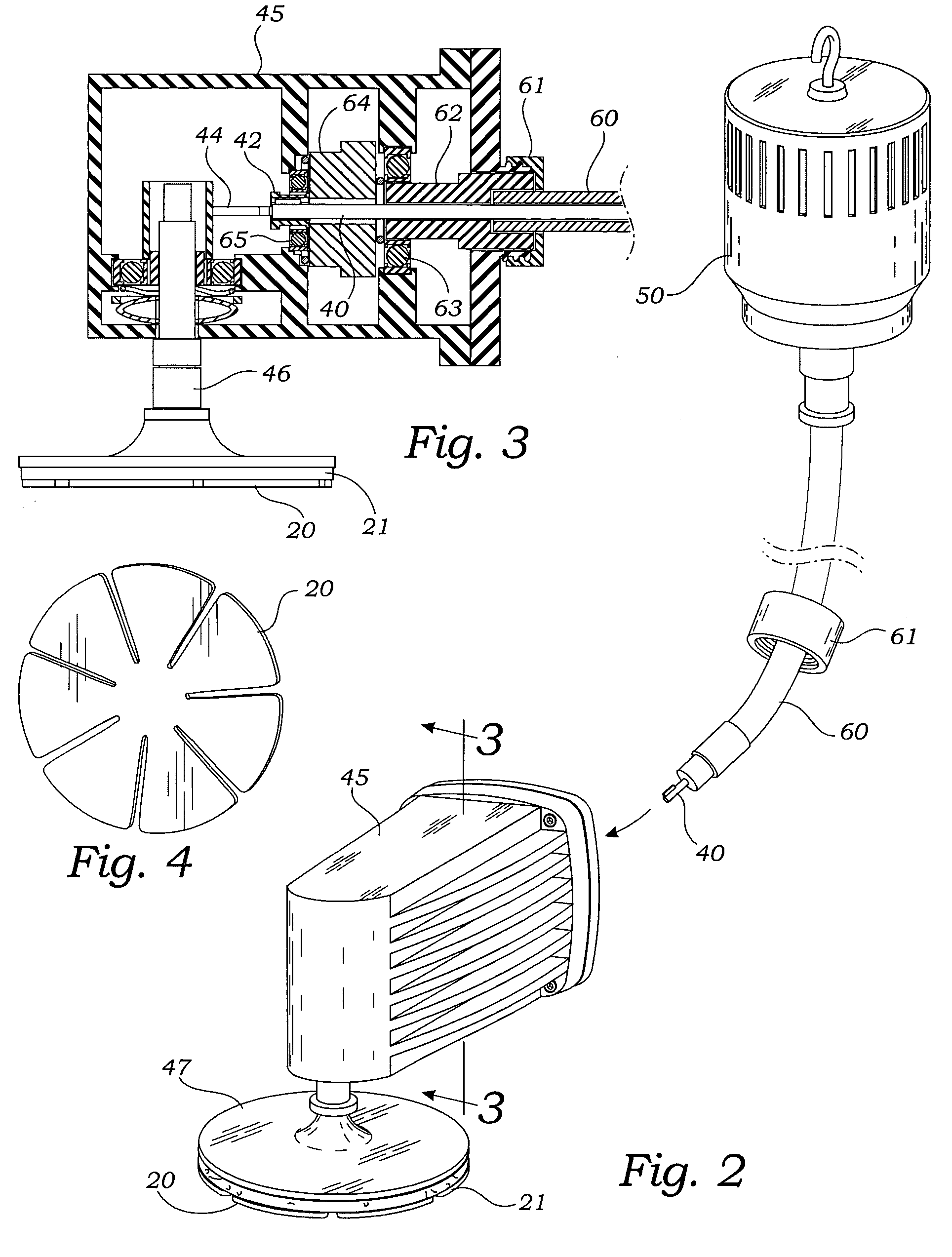

Headlight lens resurfacing apparatus and method

InactiveUS7404988B2Cost effectiveReduce labor costsDecorative surface effectsLayered productsCamera lensUltraviolet lights

Refinishing an exterior automotive lens having a damaged exterior surface in situ using a continuous movement and oscillating motion, with first, a 320 grit sanding disc, next a 600 grit sanding disc and finally a 1500 grit sanding pad while flushing the surface with water to prevent melting of the surface. Buffing the surface with a polishing compound until a high gloss is achieved. Finally, coating the surface with a transparent ultraviolet hardenable coating material, and hardening it by exposure to an ultraviolet light source. This method is accomplished using an oscillating tool having a remotely located drive.

Owner:KUTA TERRY MITCHELL

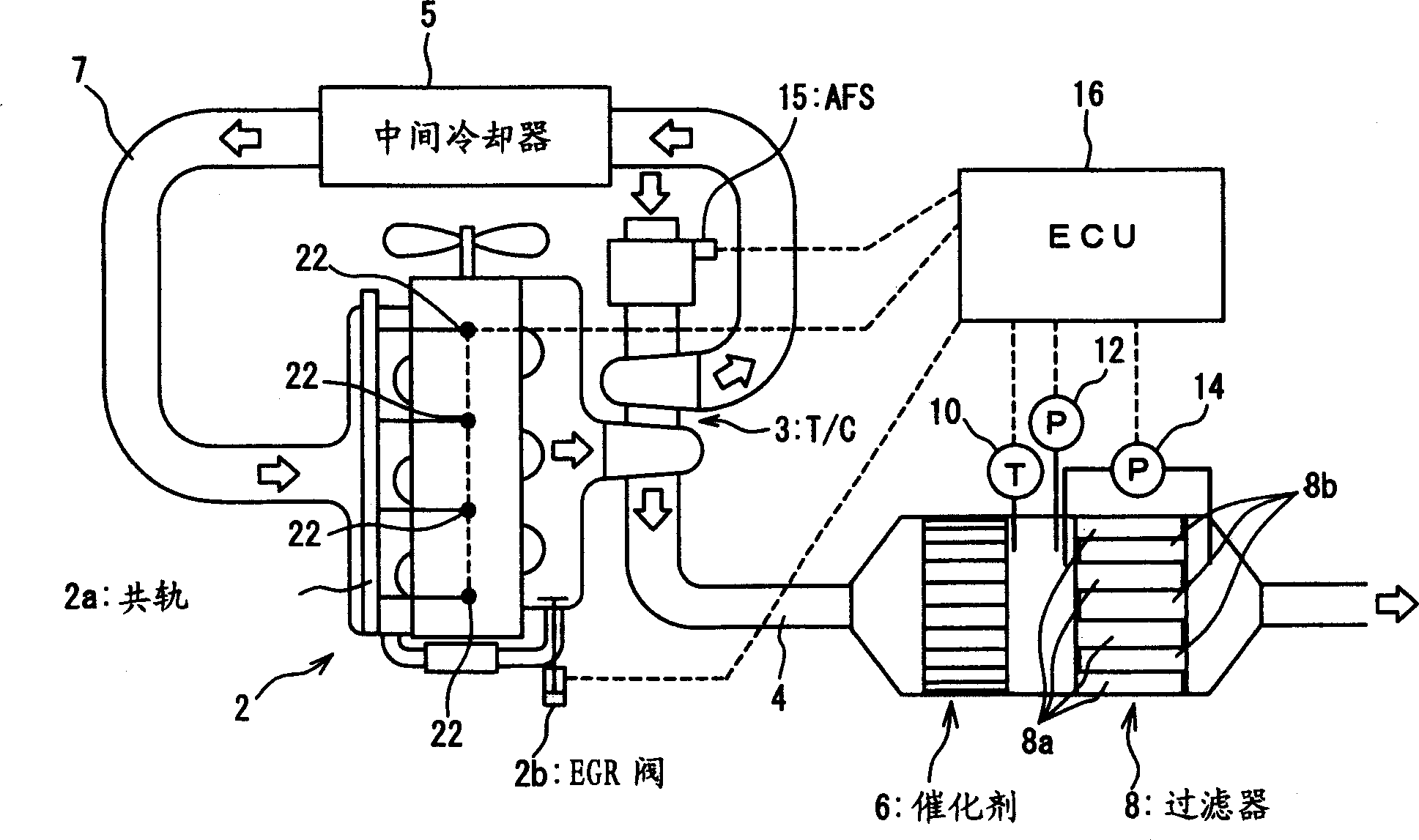

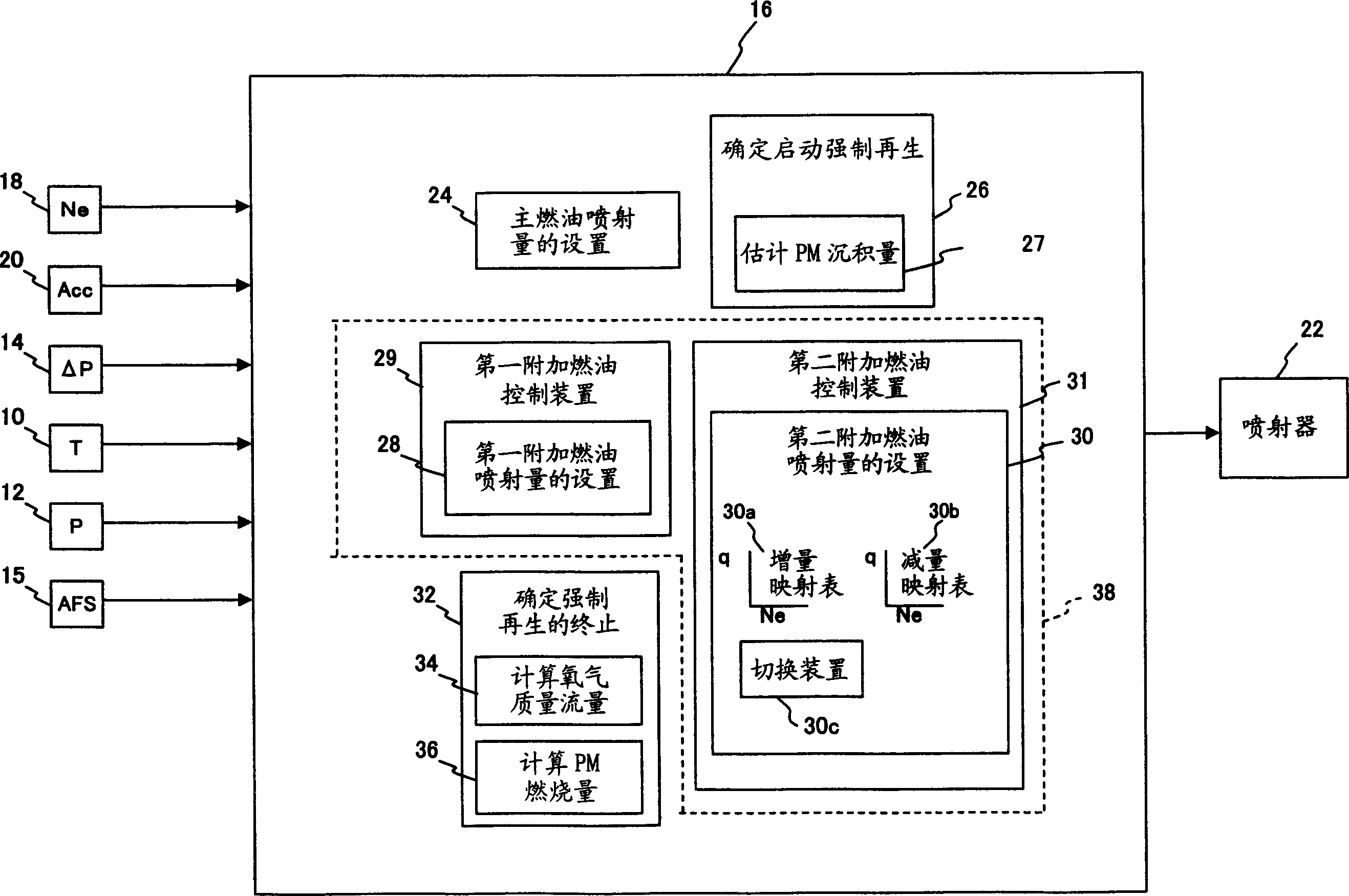

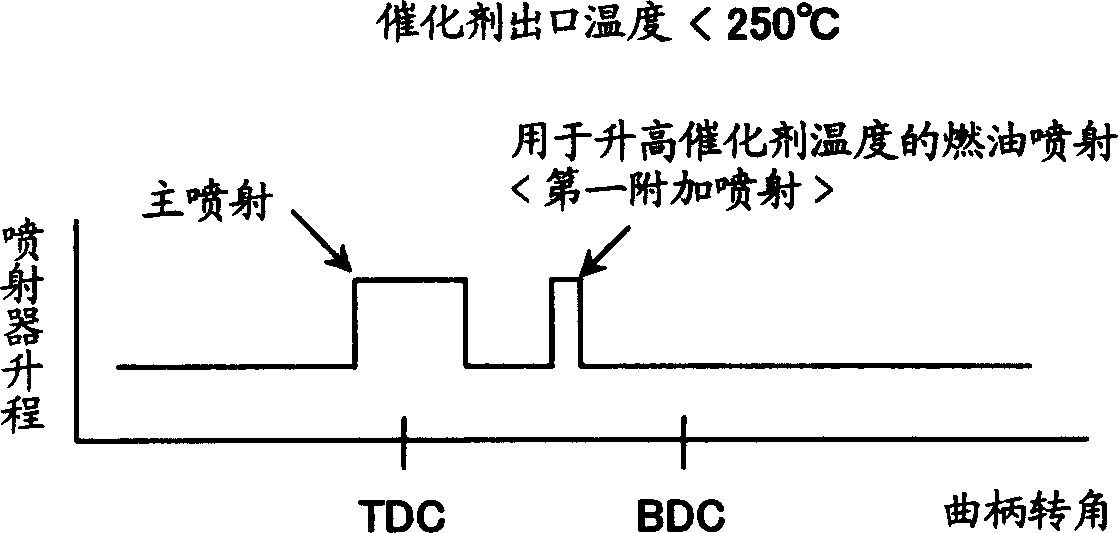

Waste gas purifying system and waste gas purifying method

InactiveCN1532381AStable temperatureAvoid meltingElectrical controlInternal combustion piston enginesExhaust fumesFuel injection

In regenerating a filter there are performed a first additional fuel injection involving additional injection of fuel into a cylinder after a main fuel injection in an engine to raise the temperature of an oxidation catalyst and a second additional fuel injection involving fuel injection after the first additional fuel injection to supply the oxidation catalyst with the fuel, a second additional fuel injection quantity is set in accordance with an engine speed and an engine load and is changed in accordance with an outlet temperature of the oxidation catalyst.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Back light module and liquid crystal display thereof

ActiveUS20120236228A1Easy to assembleLow costOptical light guidesIlluminated signsLiquid-crystal displayLight guide

This invention relates to a back light module and a liquid crystal display thereof. The back light module includes a rear panel, an LGP, a PCB, a plurality of LEDs and at least an elastic clamping fastener. The rear panel includes a base plate and at least a sidewall. The LGP is positioned on the base plate. The PCB opposite to the LGP is positioned on the sidewall of the rear panel. The LEDs are positioned on the PCB. At least an elastic clamping fastener successively passes through the rear panel and the PCB to fasten the rear panel and the PCB. In addition, the top of the elastic clamping fastener is higher than the surface of the LEDs. The back light module and the liquid crystal display thereof in this invention are simple in structure, convenient in assembly, and low in cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

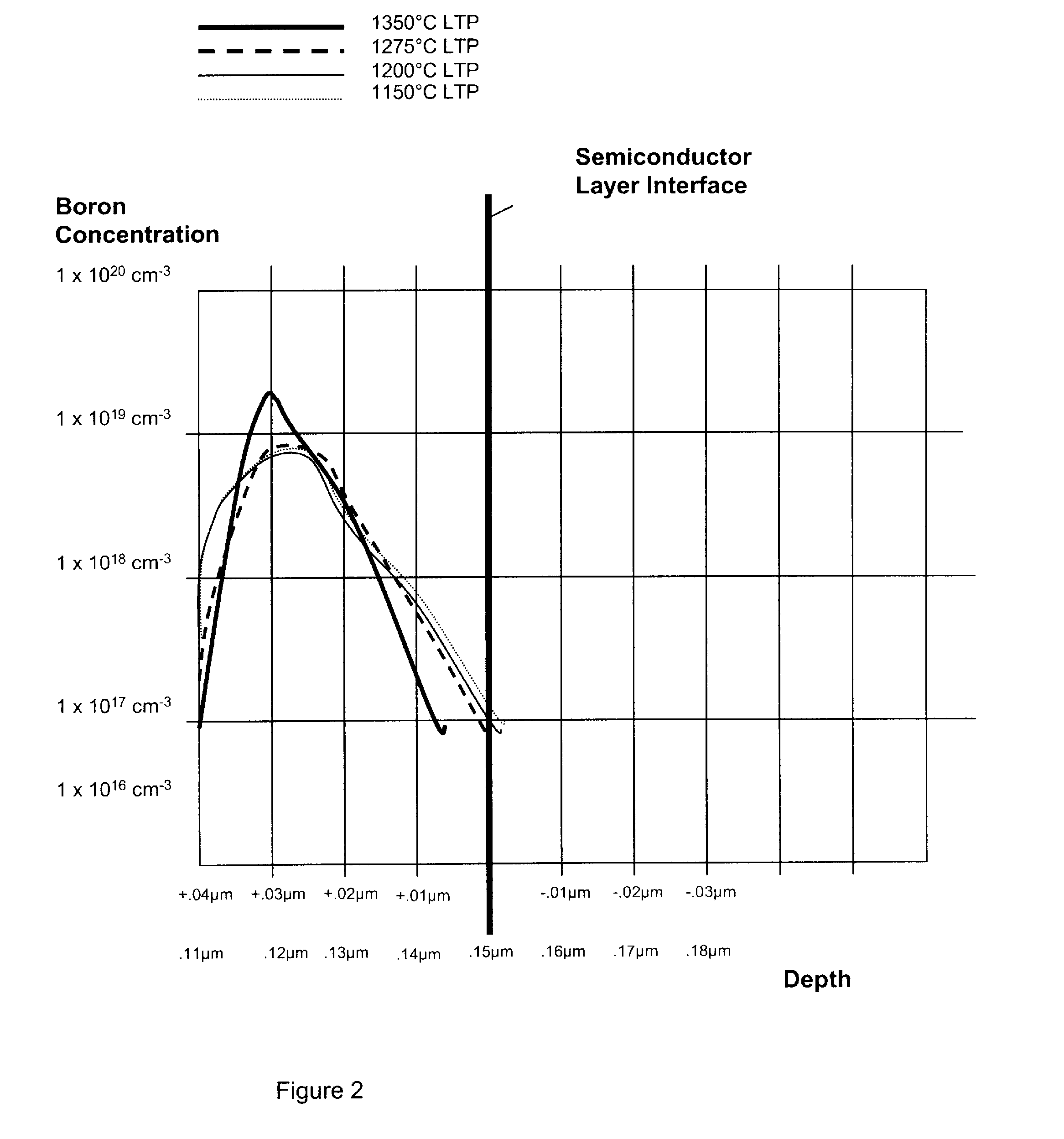

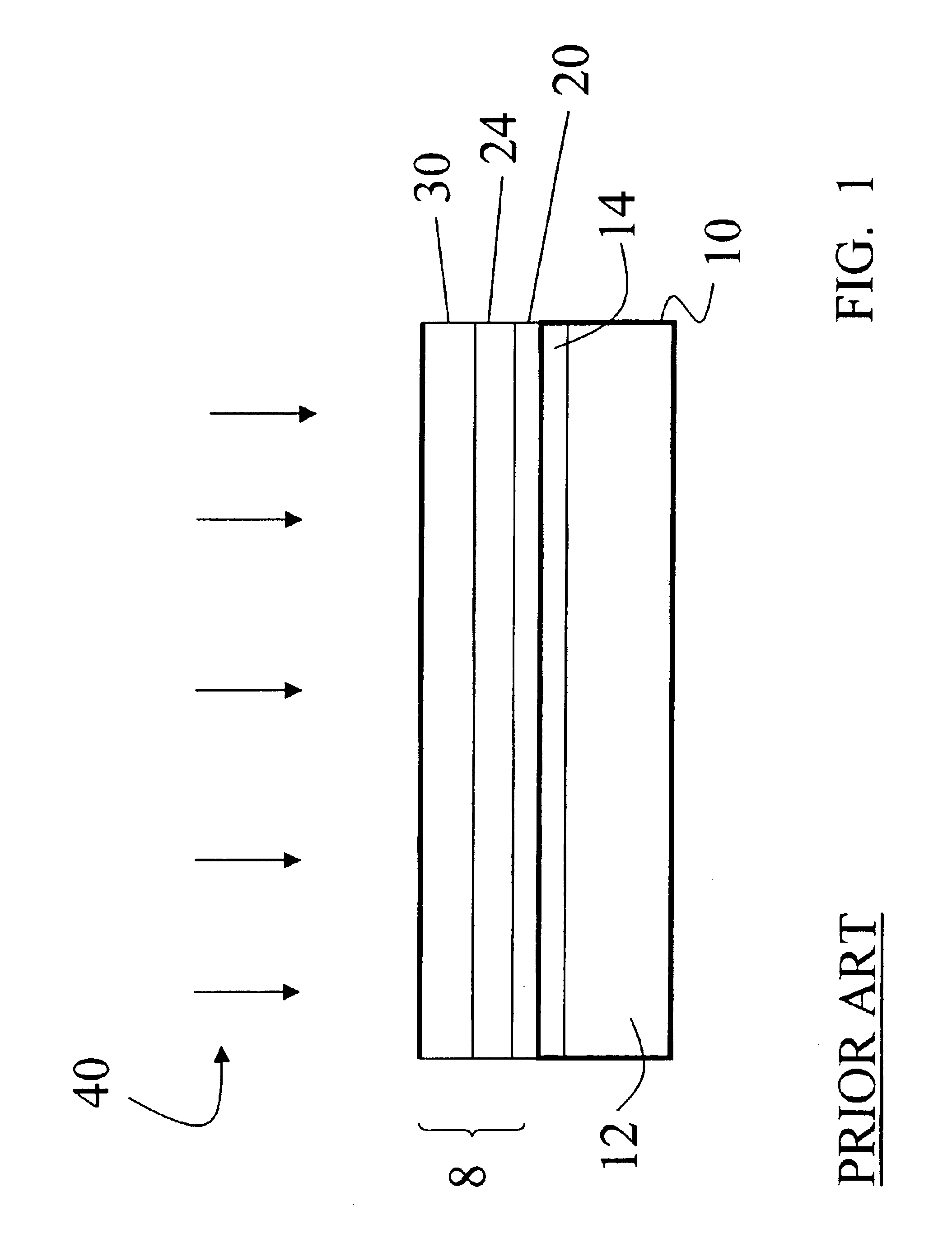

Method and system for laser thermal processing of semiconductor devices

InactiveUS6844250B1Avoid meltingSemiconductor/solid-state device manufacturingSemiconductor devicesDielectric layerSemiconductor

Methods and systems for performing laser thermal processing (LTP) of semiconductor devices are disclosed. The method includes forming a dielectric cap atop a temperature-sensitive element, and then forming an absorber layer atop the dielectric layer. A switch layer may optionally be formed atop the absorber layer. The dielectric cap thermally isolates the temperature-sensitive element from the absorber layer. This allows less-temperature-sensitive regions such as unactivated source and drain regions to be heated sufficiently to activate these regions during LTP via melting and recrystallization of the regions, while simultaneously preventing melting of the temperature-sensitive element, such as a poly-gate.

Owner:VEECO INSTR

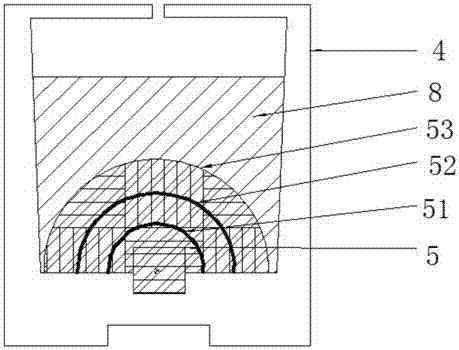

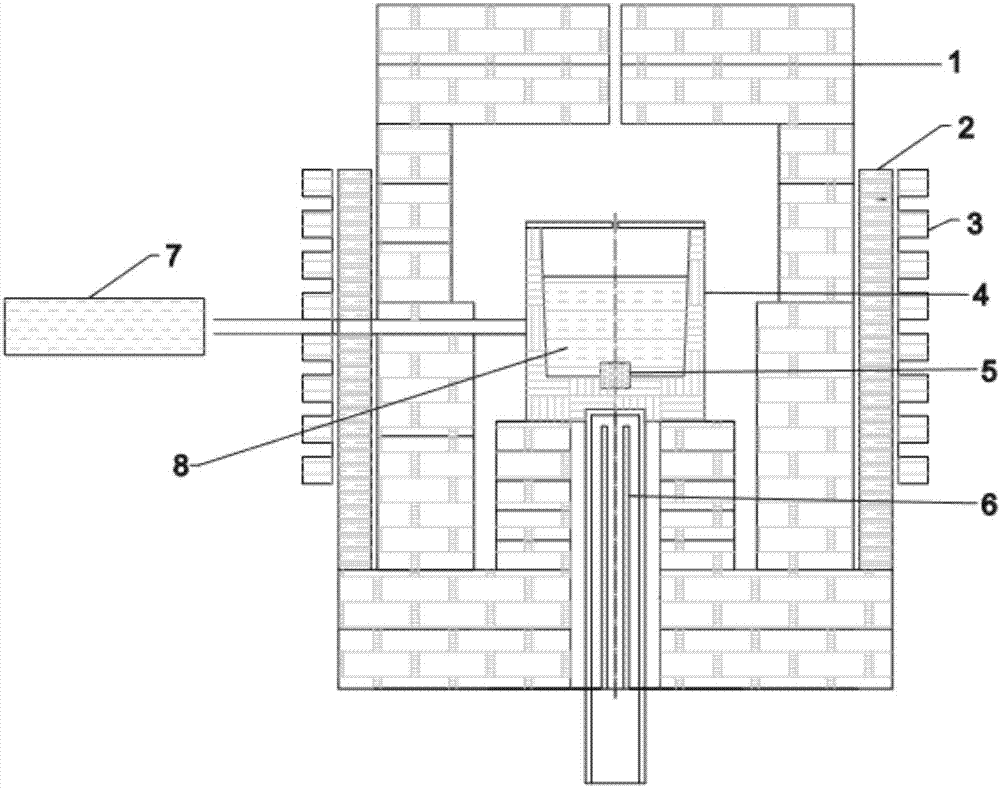

Growth equipment and growth method for large-size gallium oxide monocrystalline

InactiveCN107541776AReduce volatilityReduce decompositionPolycrystalline material growthUnder a protective fluidBrickCopper electrode

The invention relates to a piece of growth equipment and a growth method for large-size gallium oxide monocrystalline. The equipment comprises the following components: a zirconia insulating brick (1), a quartz cylinder (2), a water cooling copper electrode (3), an iraurita crucible (4), a heat exchanger (6), and an infrared thermometer (7). The method comprises the following steps: the iraurita crucible (4) is placed in the crystal growth furnace cavity formed by the zirconia insulating brick (1), the outside of the zirconia insulating brick (1) is provided with the quartz cylinder (2) and the water cooling copper electrode (3) in order, the heat exchanger (6) is placed at the bottom of the iraurita crucible (4), the infrared thermometer (7) is connected to the iraurita crucible (4), andthe iraurita crucible (4) contains a gallium oxide solution (8) and seed crystal (5). Compared with the prior art, heat exchange method is used for growing crystal, the efficiency is improved, and production cost is reduced; at the same time, grown crystal has the advantages of excellent quality, little stress, low dislocation density, good crystal perfection and optical homogeneity, improved utilization rate of the gallium oxide material, and simplified processing operation.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com