Waste gas purifying system and waste gas purifying method

An exhaust gas purification system and oxidation catalyst technology, applied in chemical instruments and methods, charging systems, separation methods, etc., can solve the problems of filter melting, incomplete regeneration, and the inability to control the filter temperature at the optimal temperature, etc., to achieve The effect of preventing melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

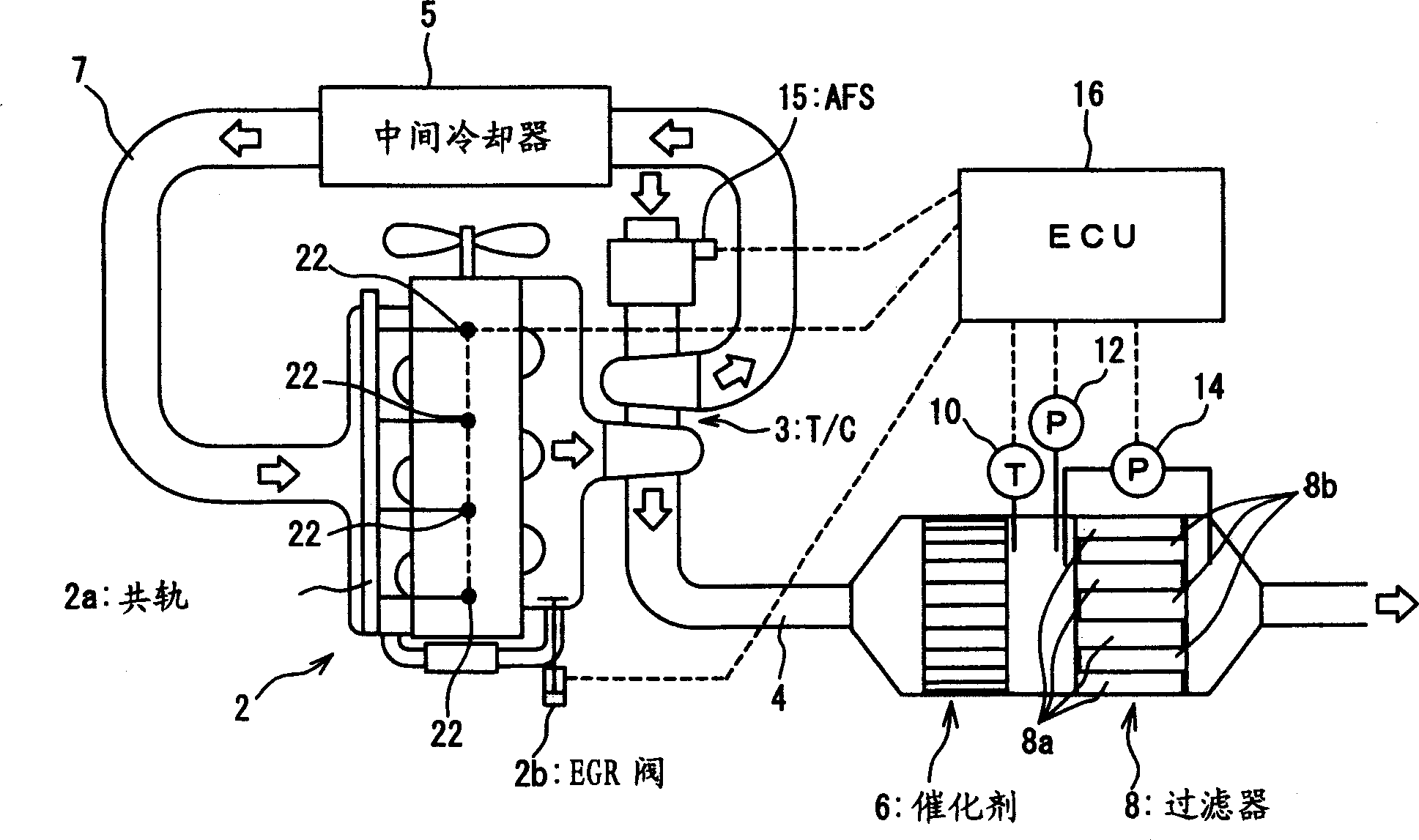

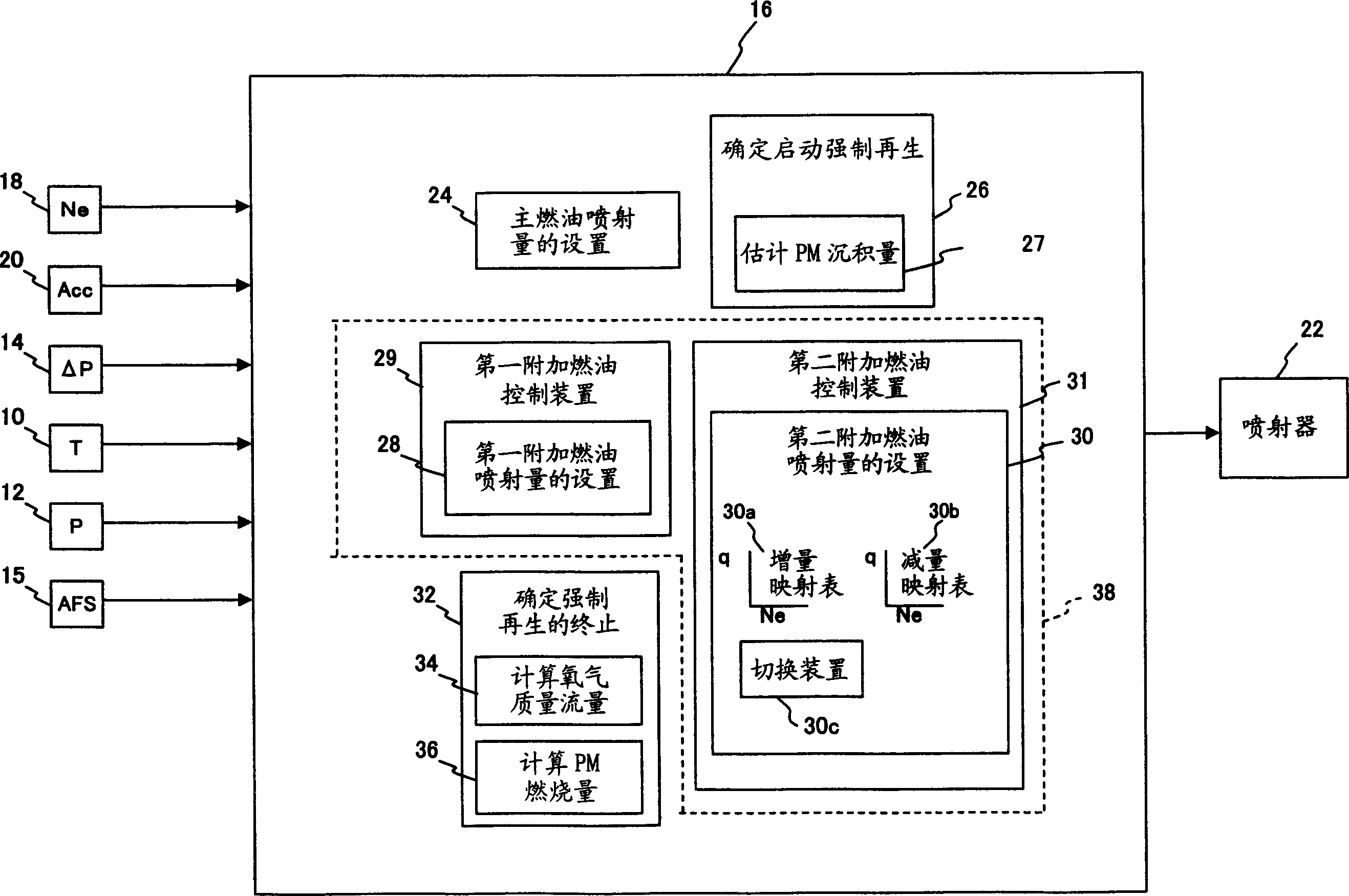

[0040] The exhaust gas purification system according to the embodiment of the present invention will be described below with reference to the accompanying drawings, wherein figure 1 It is a schematic diagram of the overall structure of the exhaust gas purification system. In this embodiment, the engine 2 is a diesel engine using diesel (HC) as fuel. The engine 2 is equipped with a common rail type fuel injection system in which fuel is stored in a high-pressure accumulator (common rail) 2a shared by a plurality of cylinders before being injected.

[0041] In the exhaust passage 4 of the engine 2, an oxidation catalyst (hereinafter simply referred to as "catalyst") 6 and a diesel particulate filter (hereinafter simply referred to as "filter") 8 are disposed in order from the upstream end of the exhaust gas flow. Furthermore, the turbocharger 3 is provided in the exhaust passage 4 , and the intercooler 5 is provided in the intake passage 7 .

[0042] Although not shown in deta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com