Patents

Literature

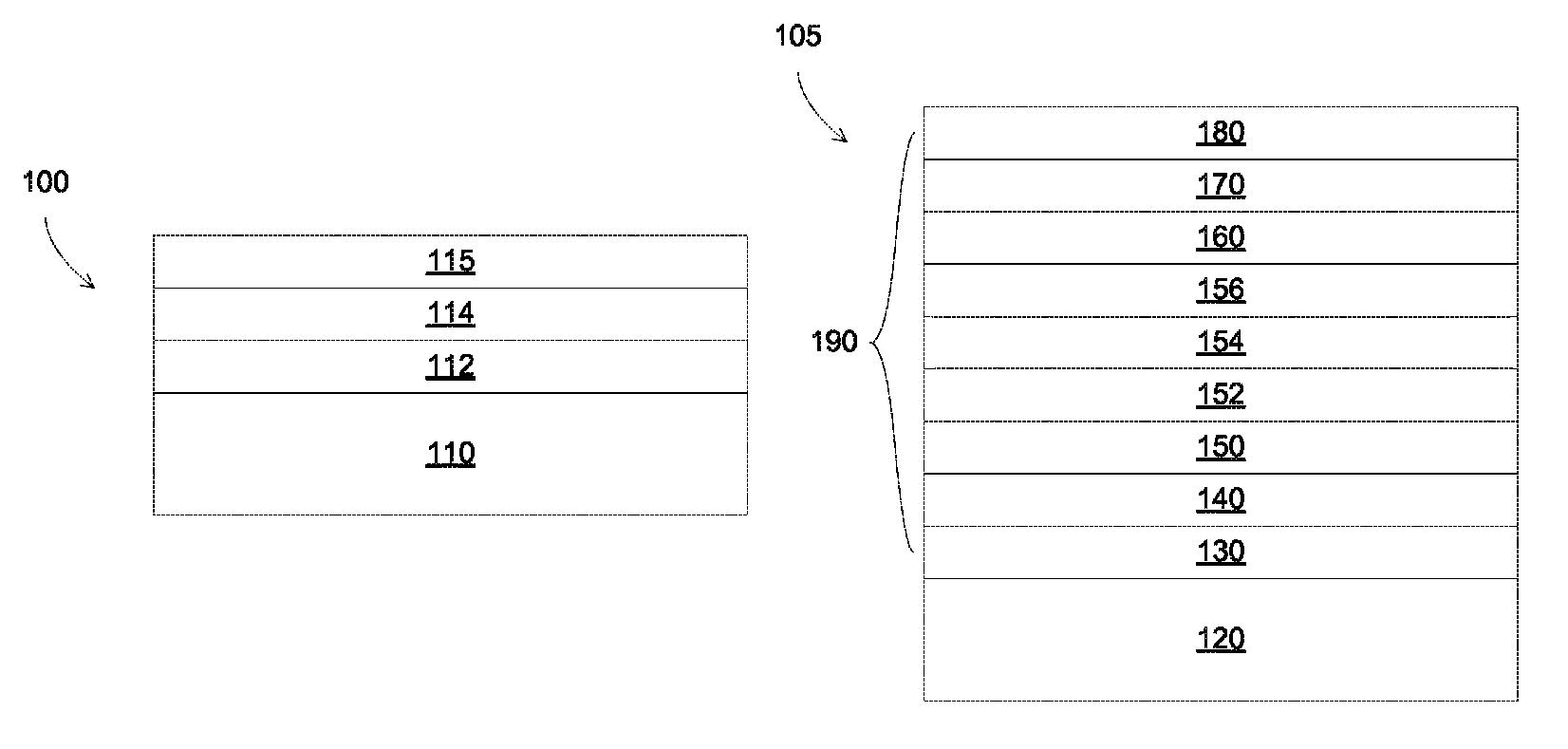

1171 results about "Bi layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

/bi·lay·er/ (bi´la-er) a membrane consisting of two molecular layers. Lipid bilayer, a fluid barrier to permeability, with polar head groups exposed and hydrophobic tails sequestered.

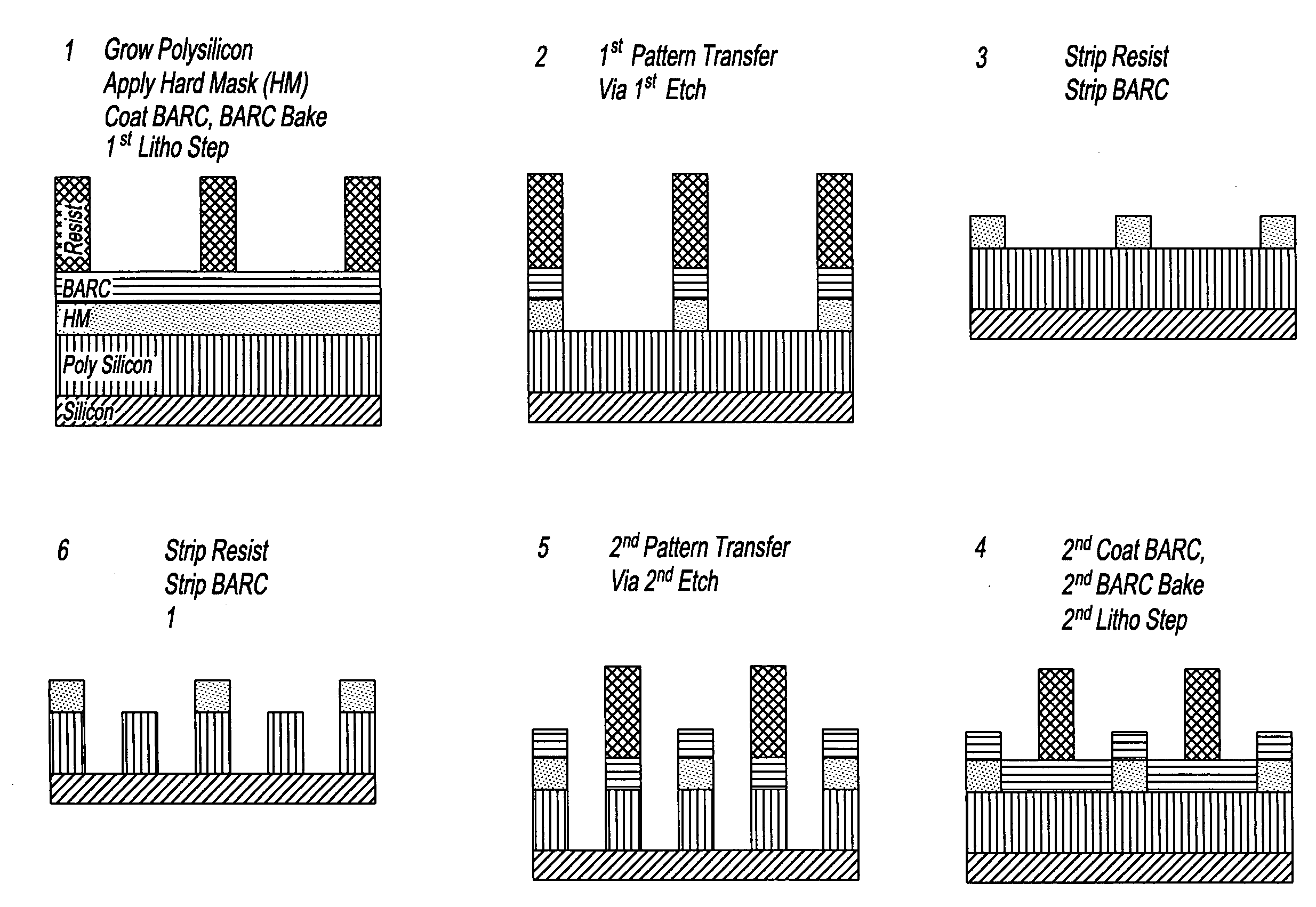

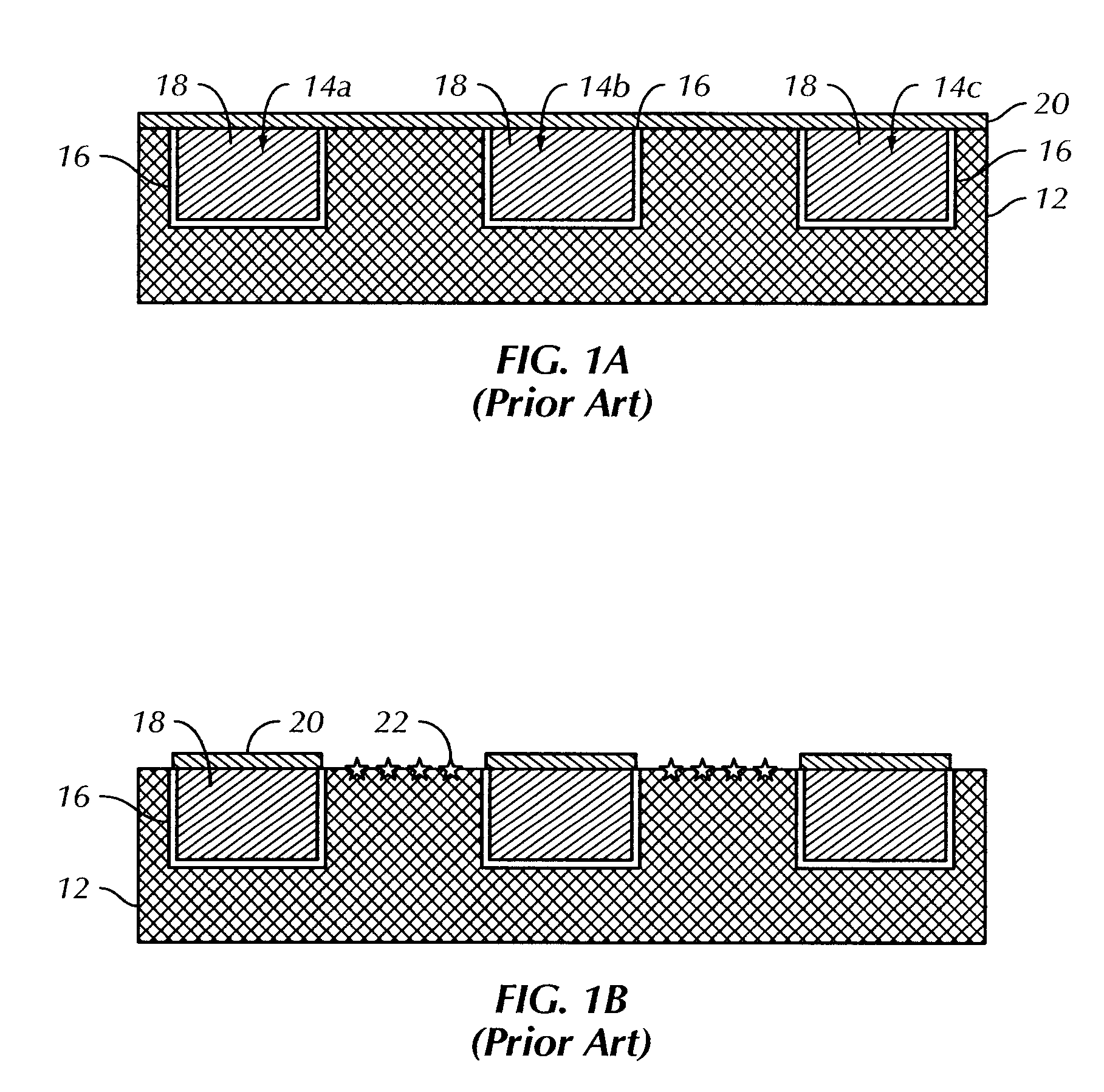

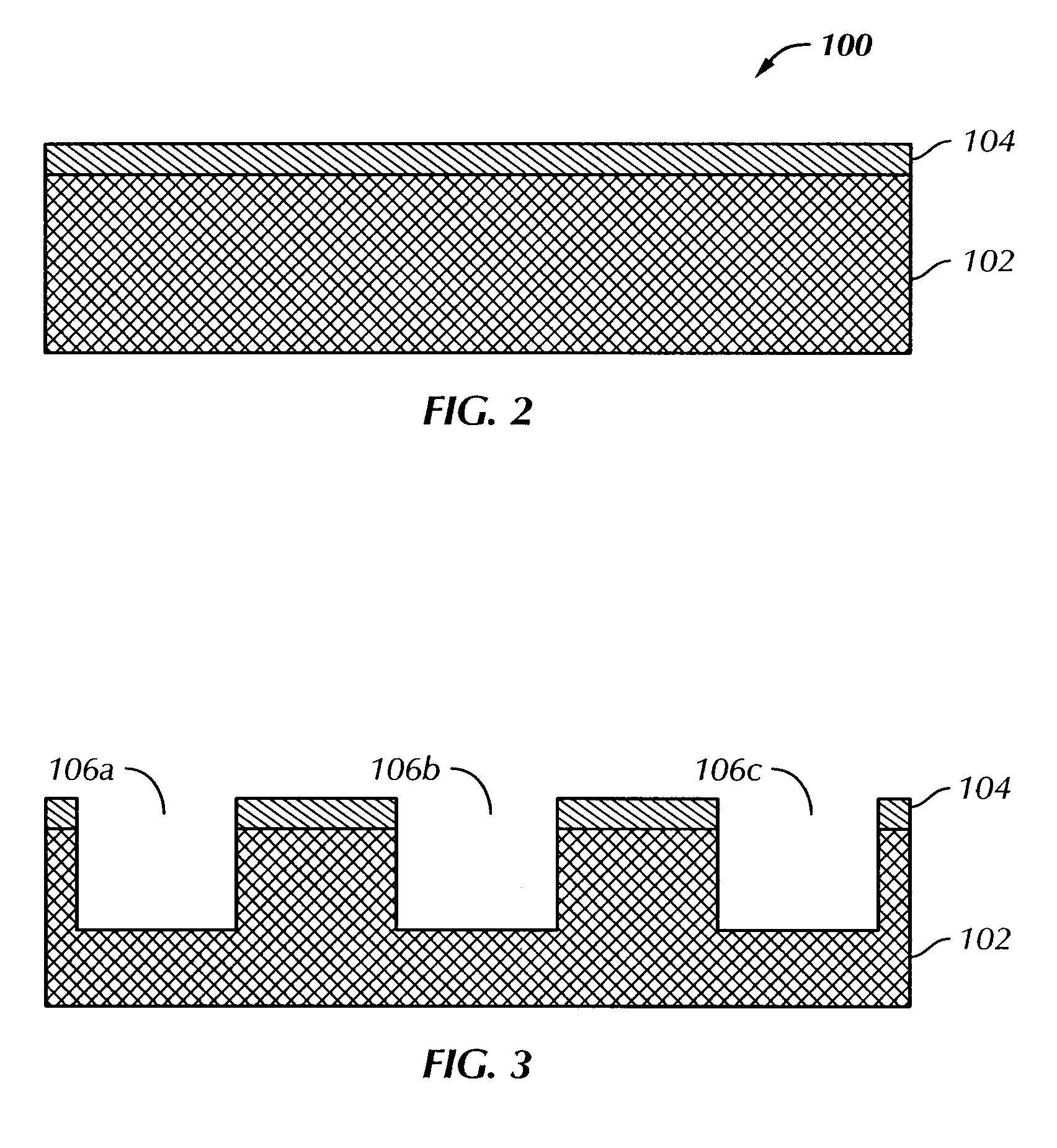

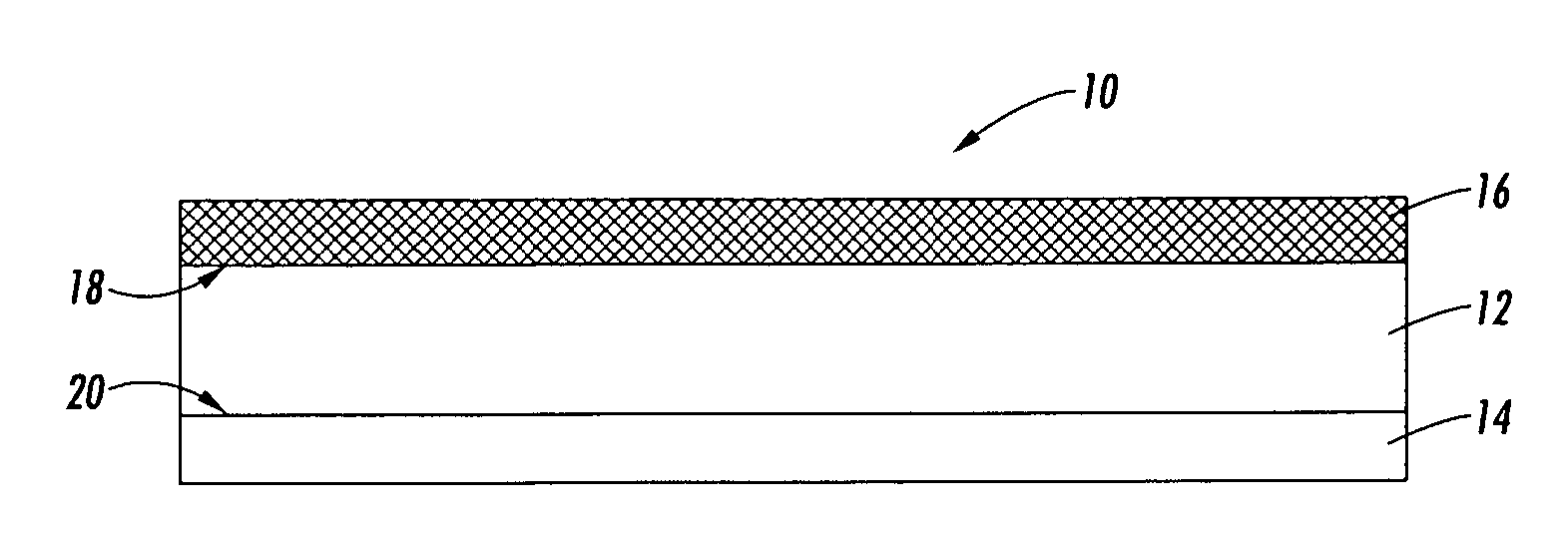

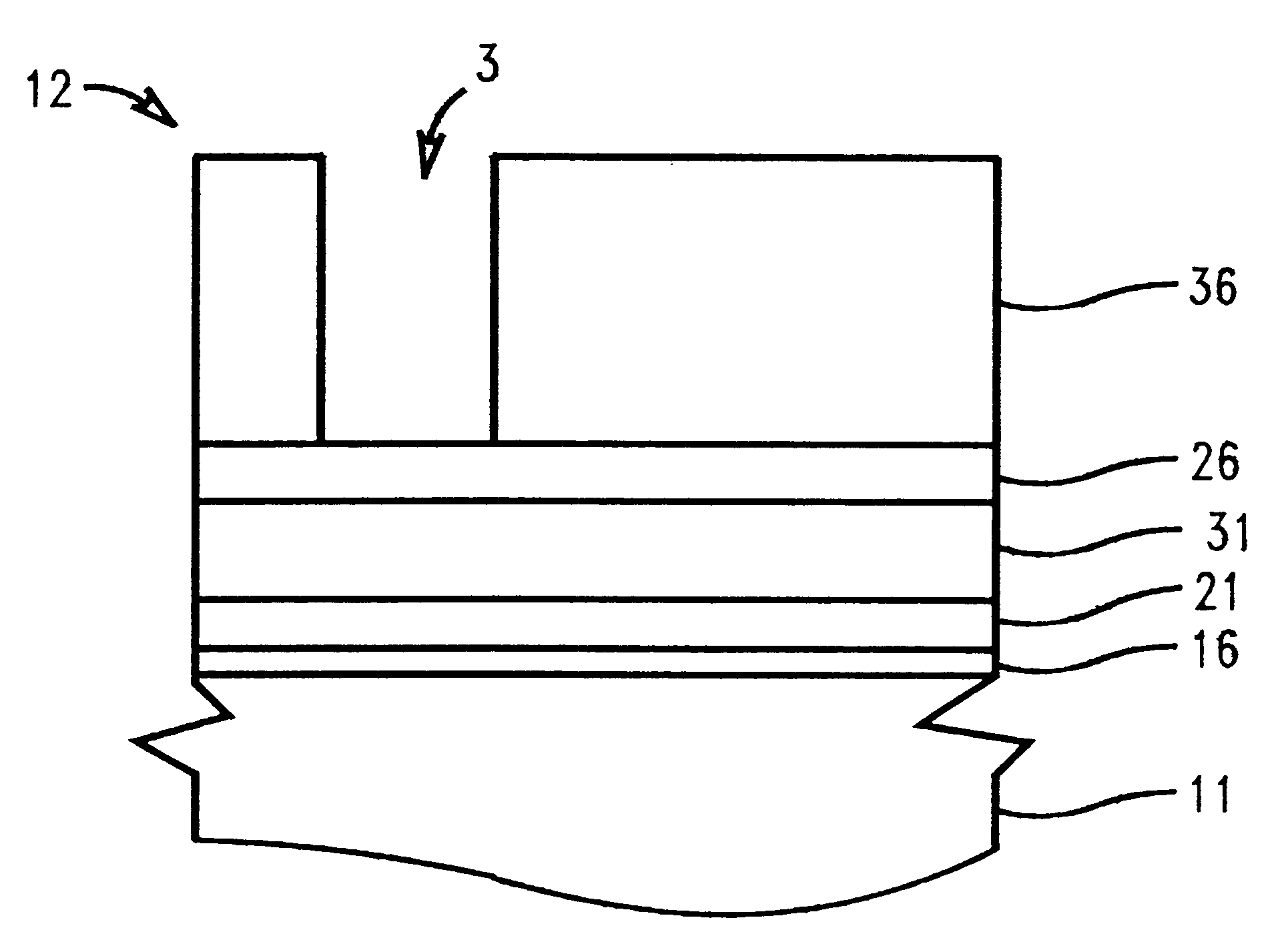

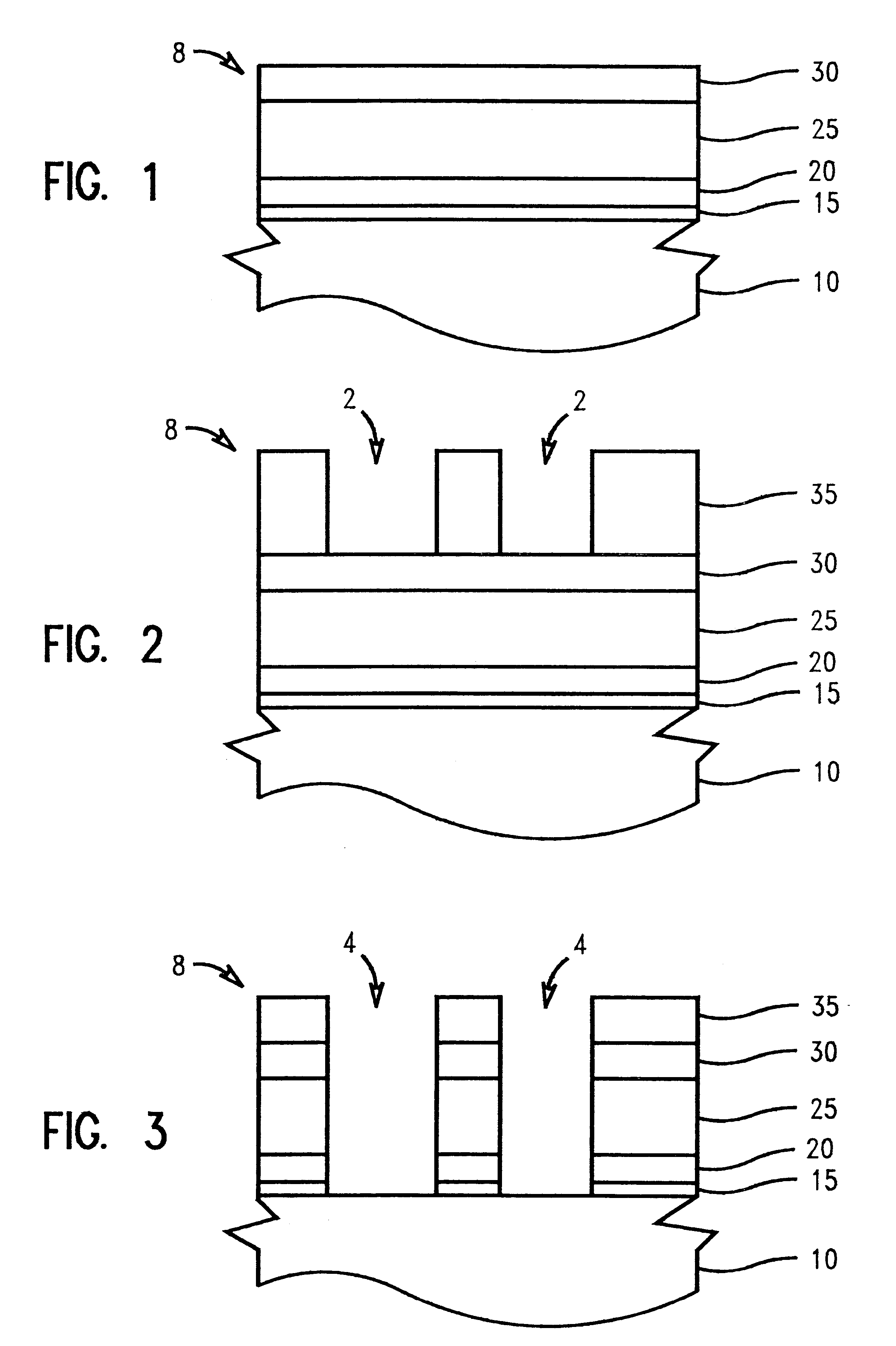

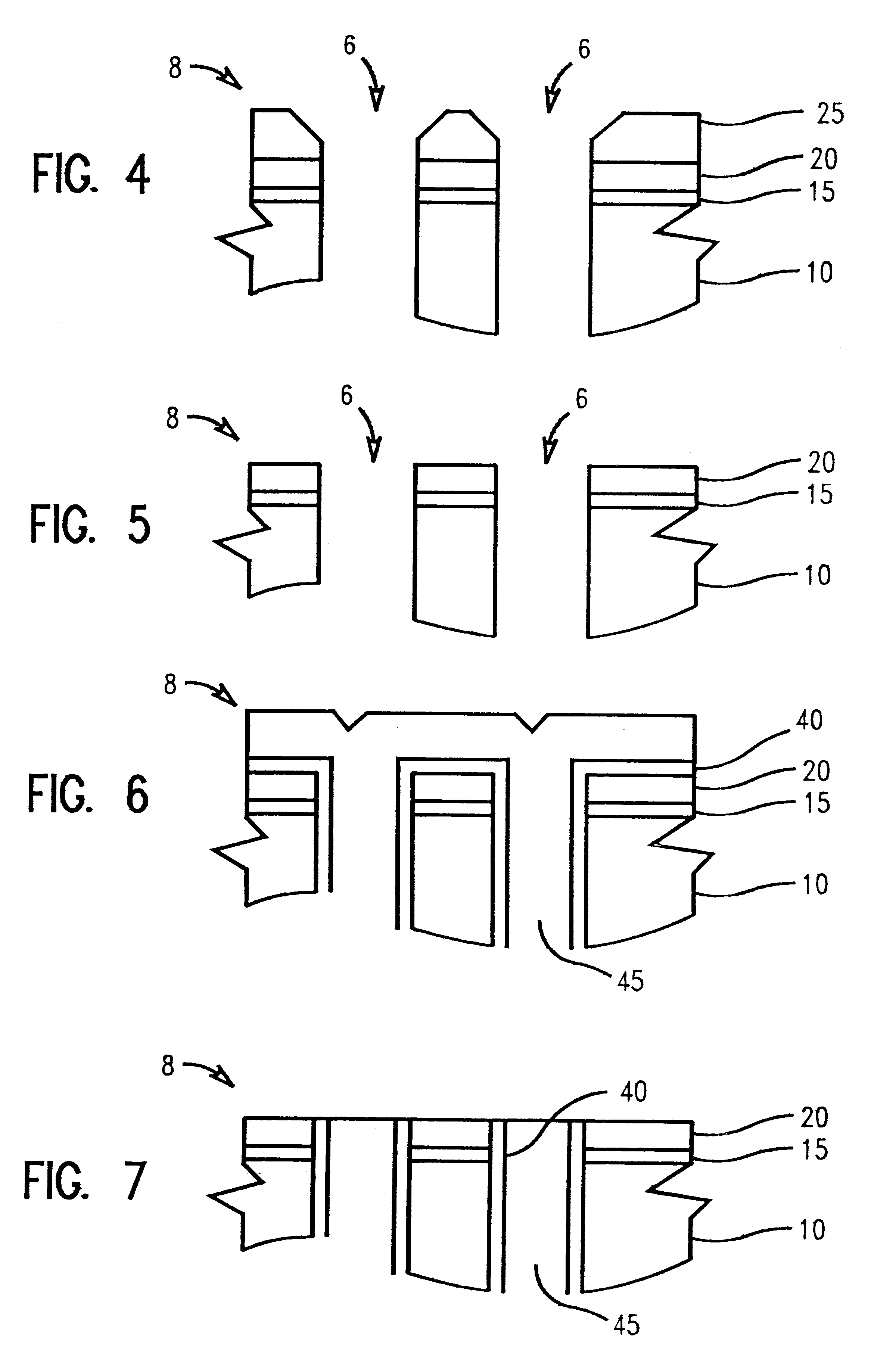

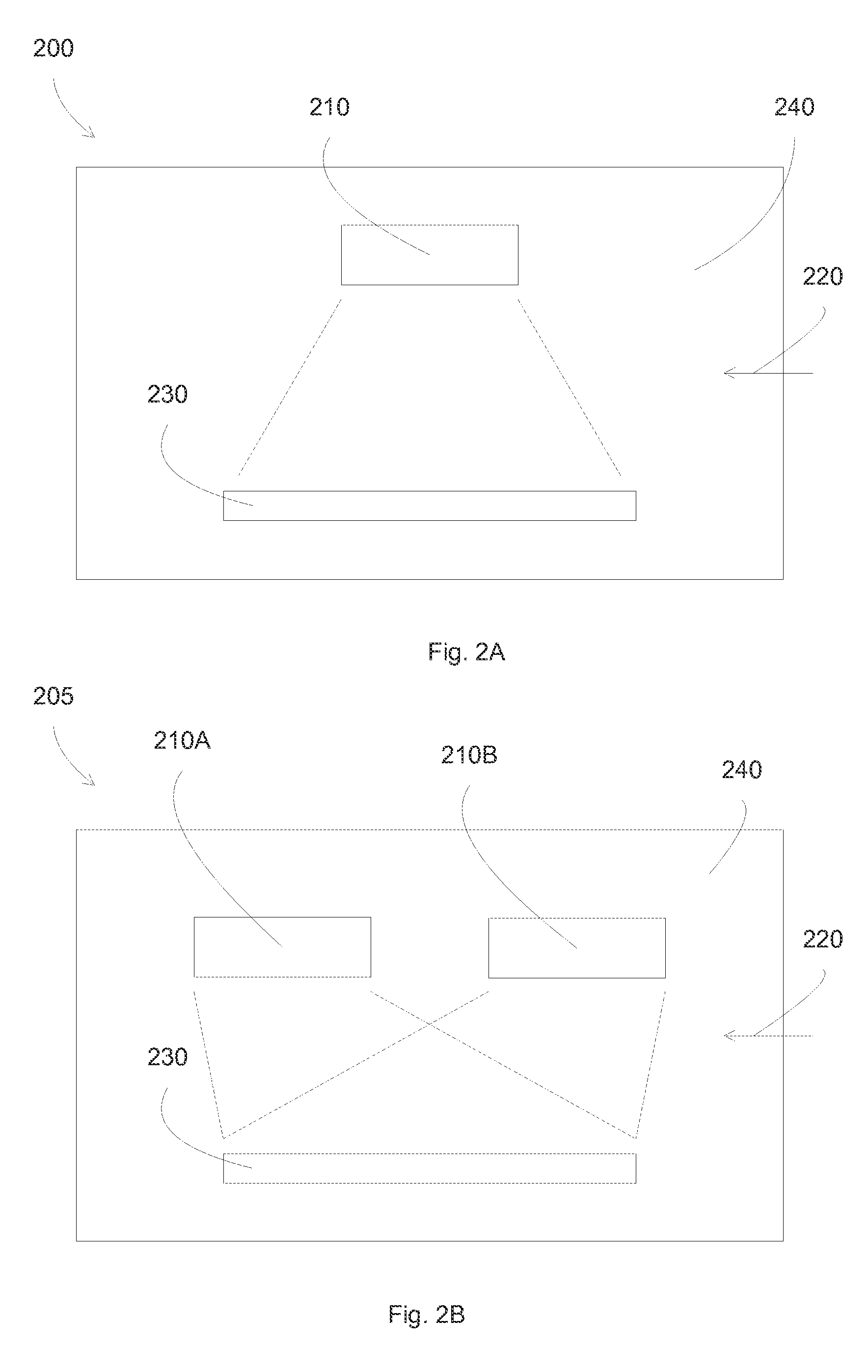

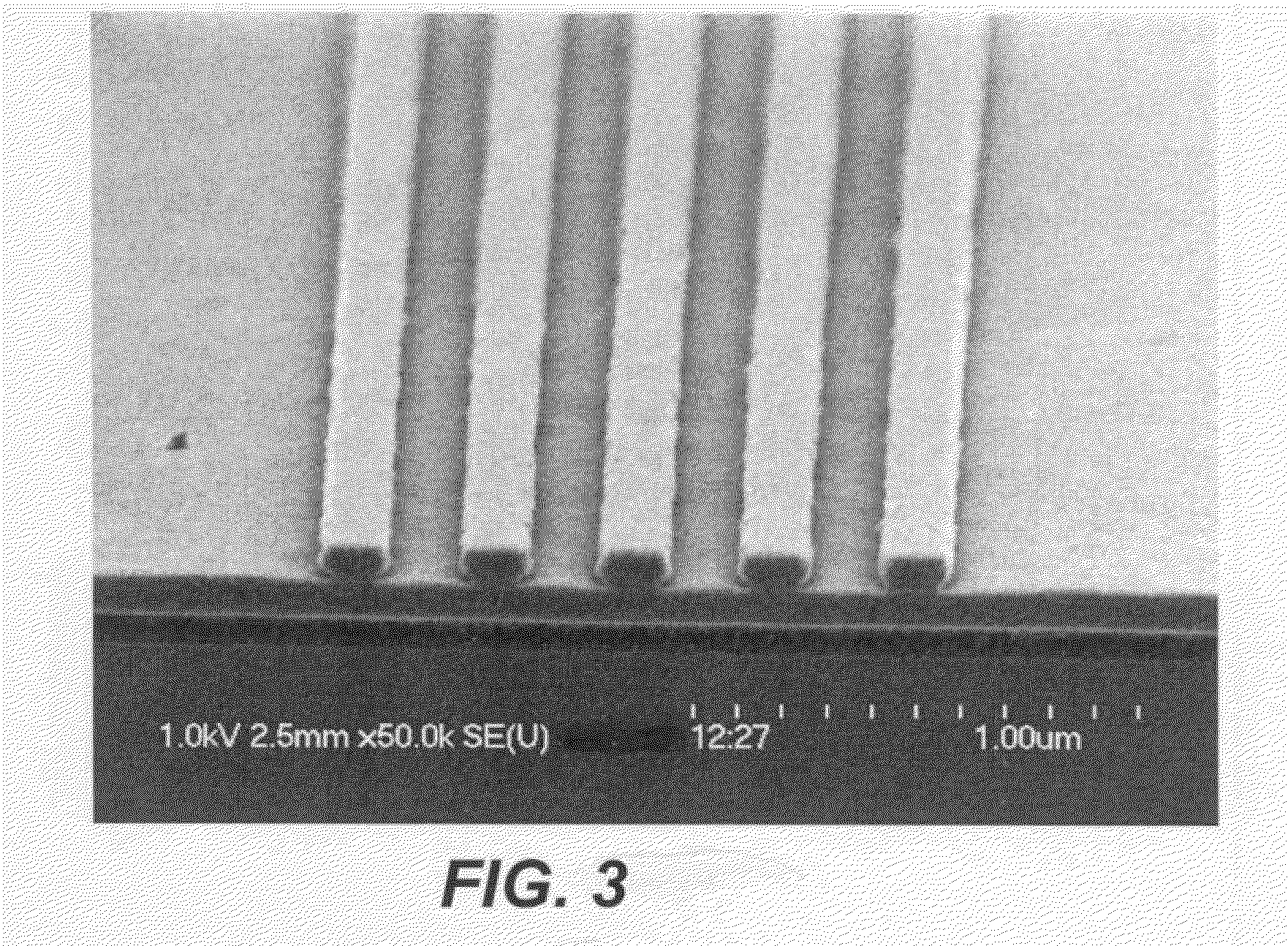

Device manufacturing process utilizing a double patterning process

InactiveUS20080199814A1Photomechanical apparatusSemiconductor/solid-state device manufacturingSolubilityAnti-reflective coating

Manufacturing semiconductor device by steps of:a) providing substrate with antireflective coating or underlayer,b) applying first photosensitive composition over substrate,c) exposing first composition to radiation to produce first pattern,d) developing exposed first composition to produce an imaged bilayer stack,e) rinsing the stack,f) applying fixer to the stack,g) applying optional bake,h) rinsing the stack,i) applying second optional bake,j) applying second photosensitive composition onto the stack to produce multilayer stack,k) exposing second composition to produce second pattern offset from first pattern,l) developing exposed second composition to produce multilayer stack, andm) rinsing multilayer stack;the photosensitive compositions have photoacid generator and substantially aqueous base insoluble polymer whose solubility increases upon treatment with acid and further comprises an anchor group, and the fixer is a polyfunctional compound reactive with anchor group, but does not contain silicon and the substrate stays within a lithographic cell from at least first coating step until at least after final exposure.

Owner:FUJIFILM ELECTRONICS MATERIALS US

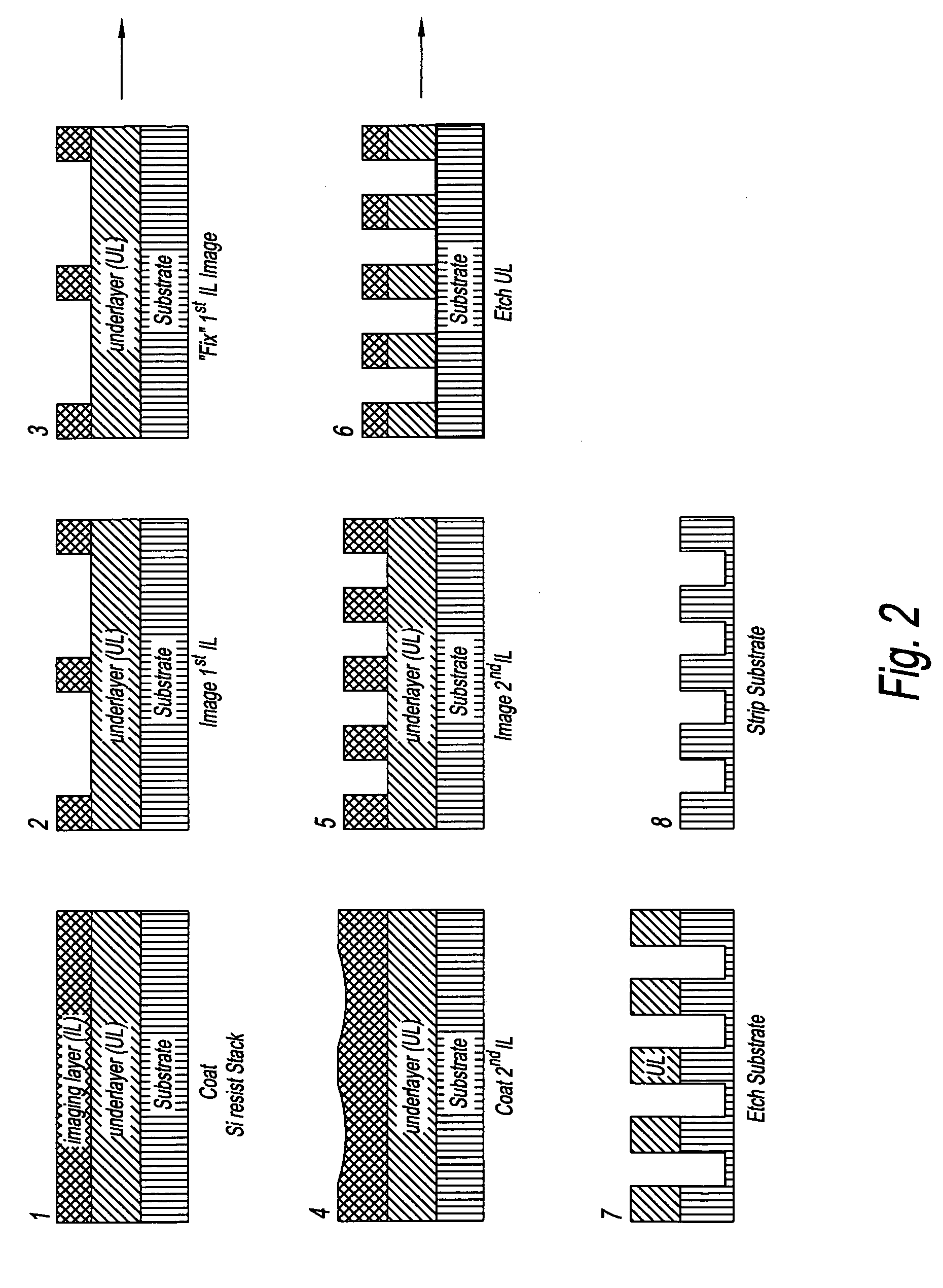

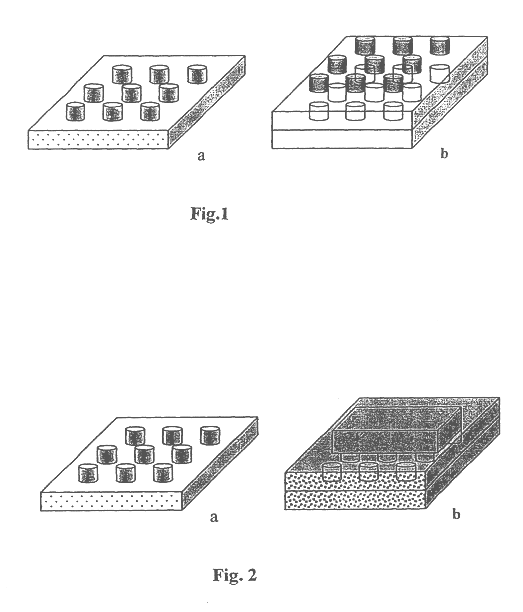

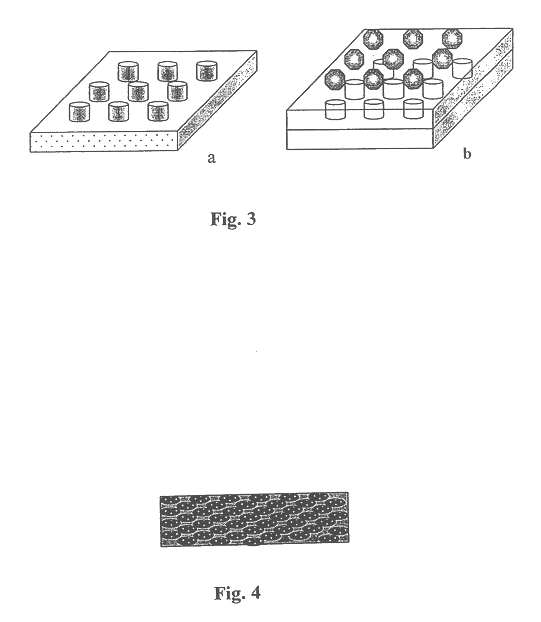

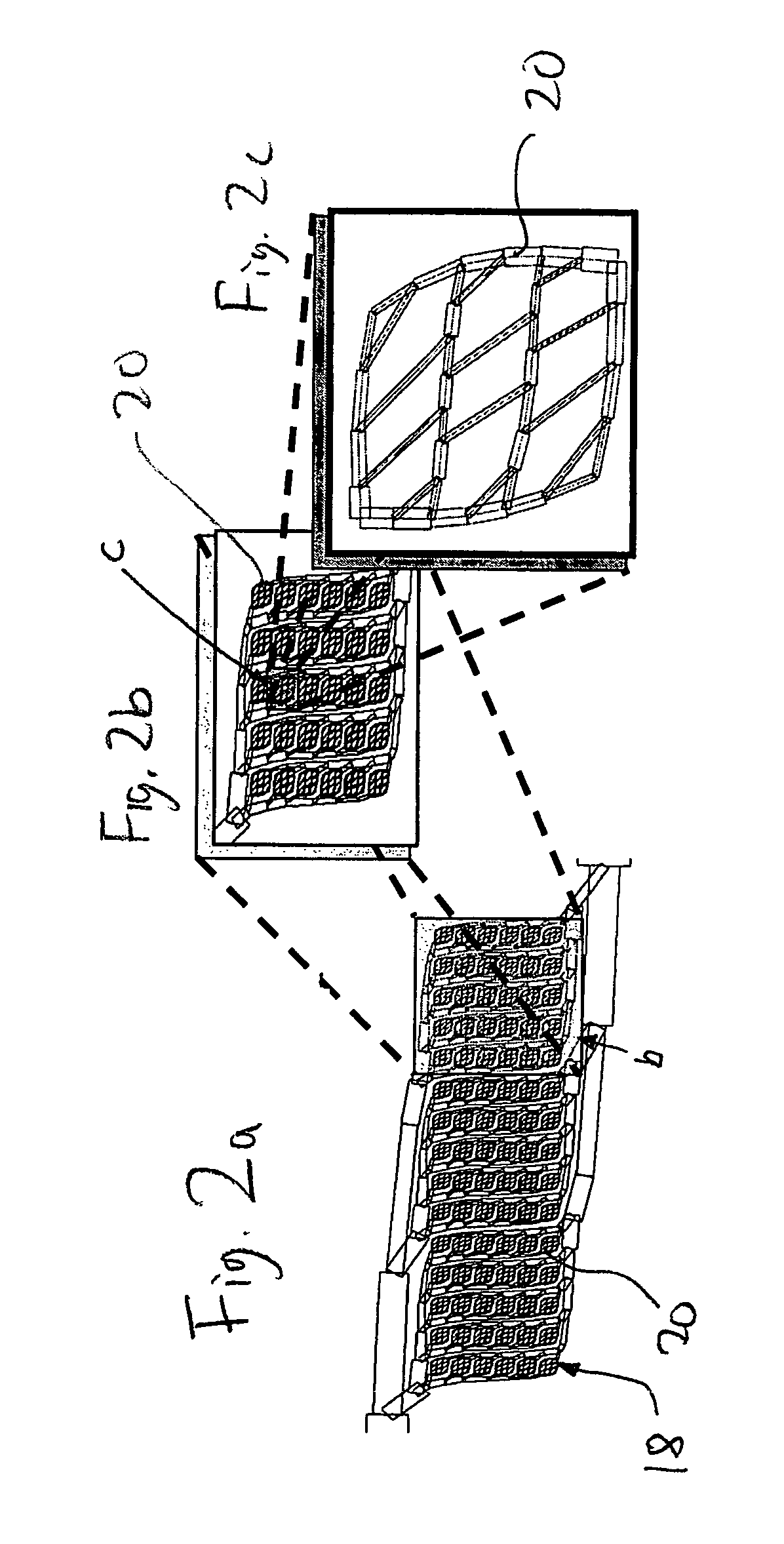

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

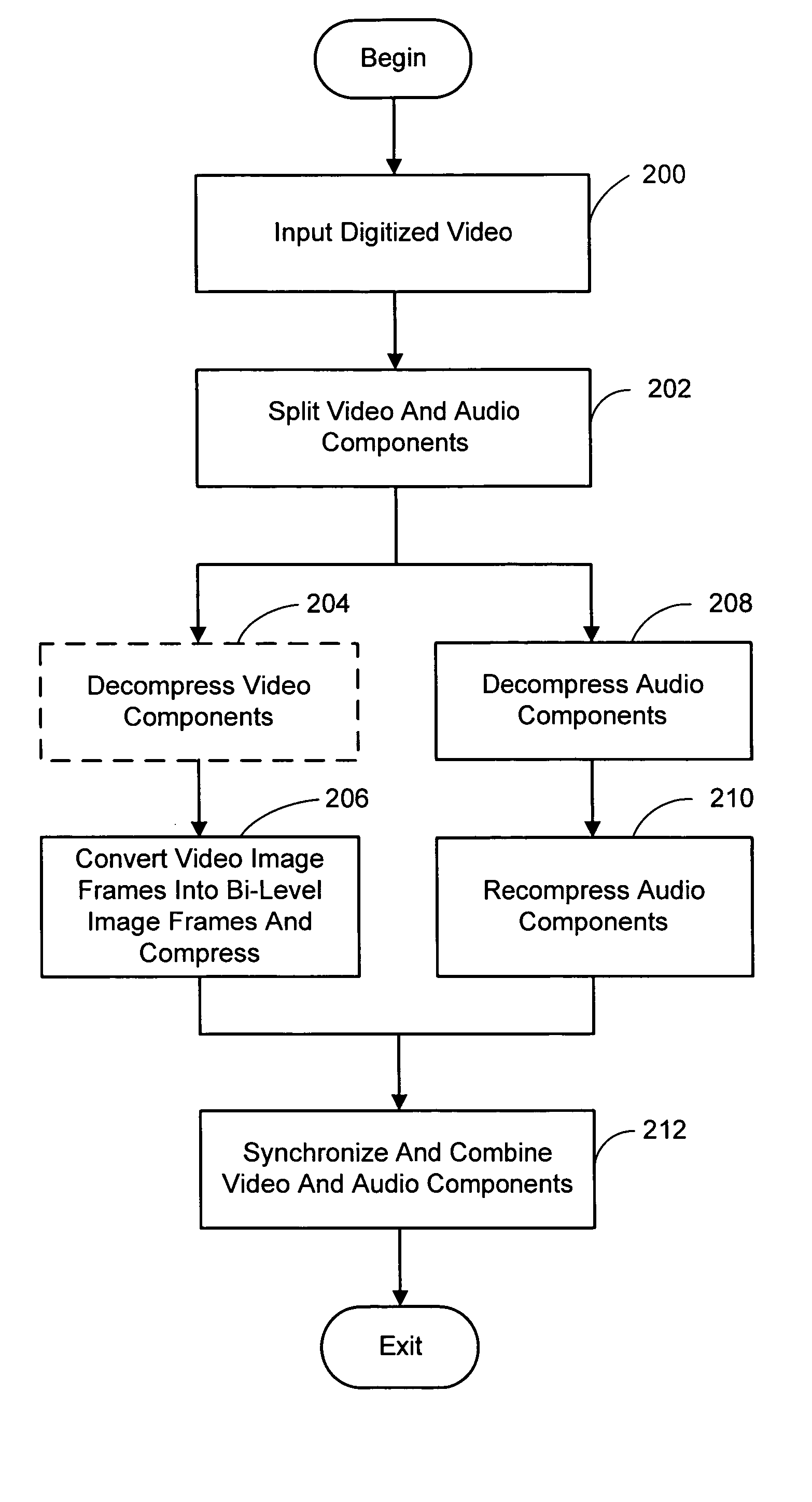

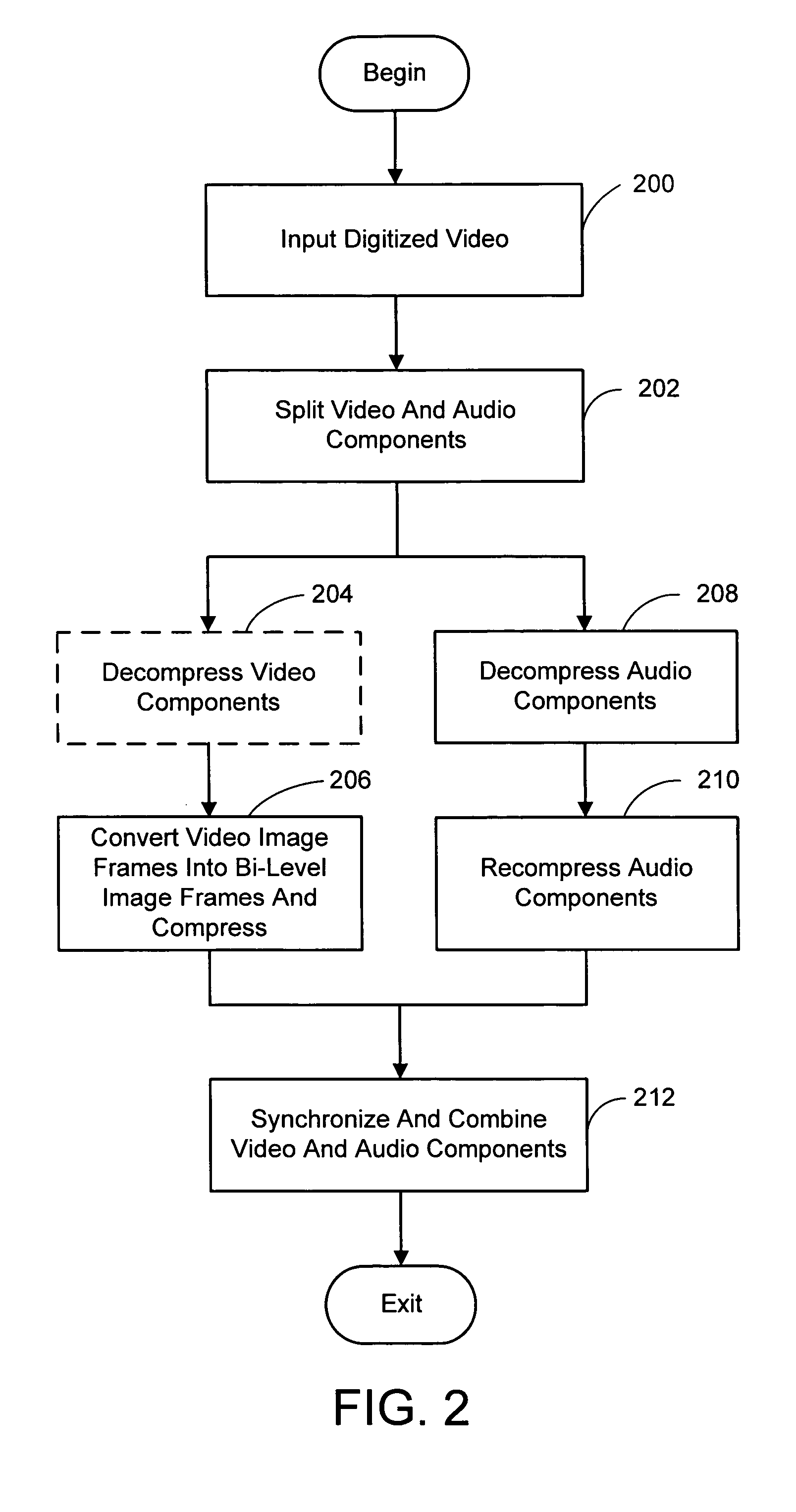

System and process for broadcast and communication with very low bit-rate bi-level or sketch video

ActiveUS20050041739A1Eliminating the unwanted backgroundColor television with pulse code modulationColor television with bandwidth reductionBi layerComputer graphics (images)

A system and process for broadcast and communication with bi-level or sketch video at extremely low bandwidths is described. Essentially, bi-level and sketch video presents the outlines of the objects in a scene being depicted. Bi-level and sketch video provides a clearer shape, smoother motion, shorter initial latency and cheaper computational cost than do conventional DCT-based video compression methods. This is accomplished by converting each color or gray-scale image frame to bi-level or sketch image frame using adaptive thresholding method, compressing bi-level or sketch image frames into bi-level or sketch video using adaptive context-based arithmetic coding method. Bi-level or sketch video is particularly suitable to such small devices as Pocket PCs and mobile phones that possess small display screen, low bandwidth connection, and light computational power.

Owner:ZHIGU HLDG

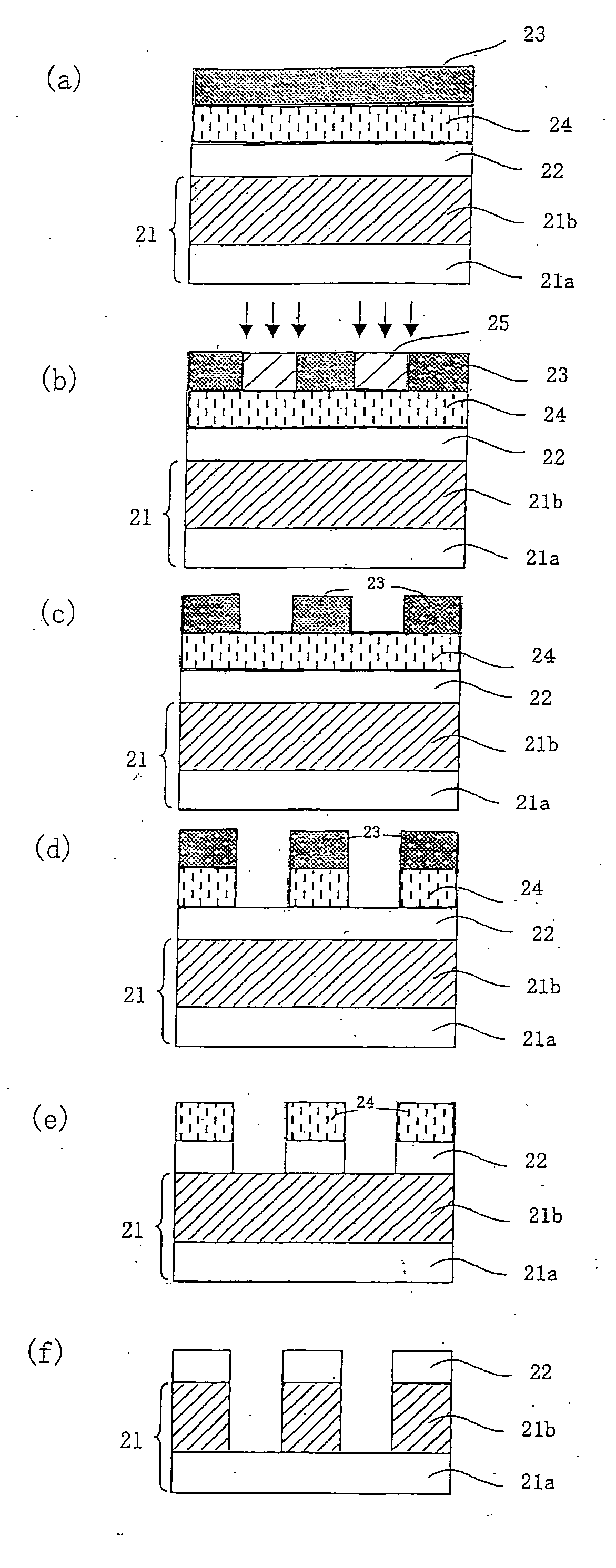

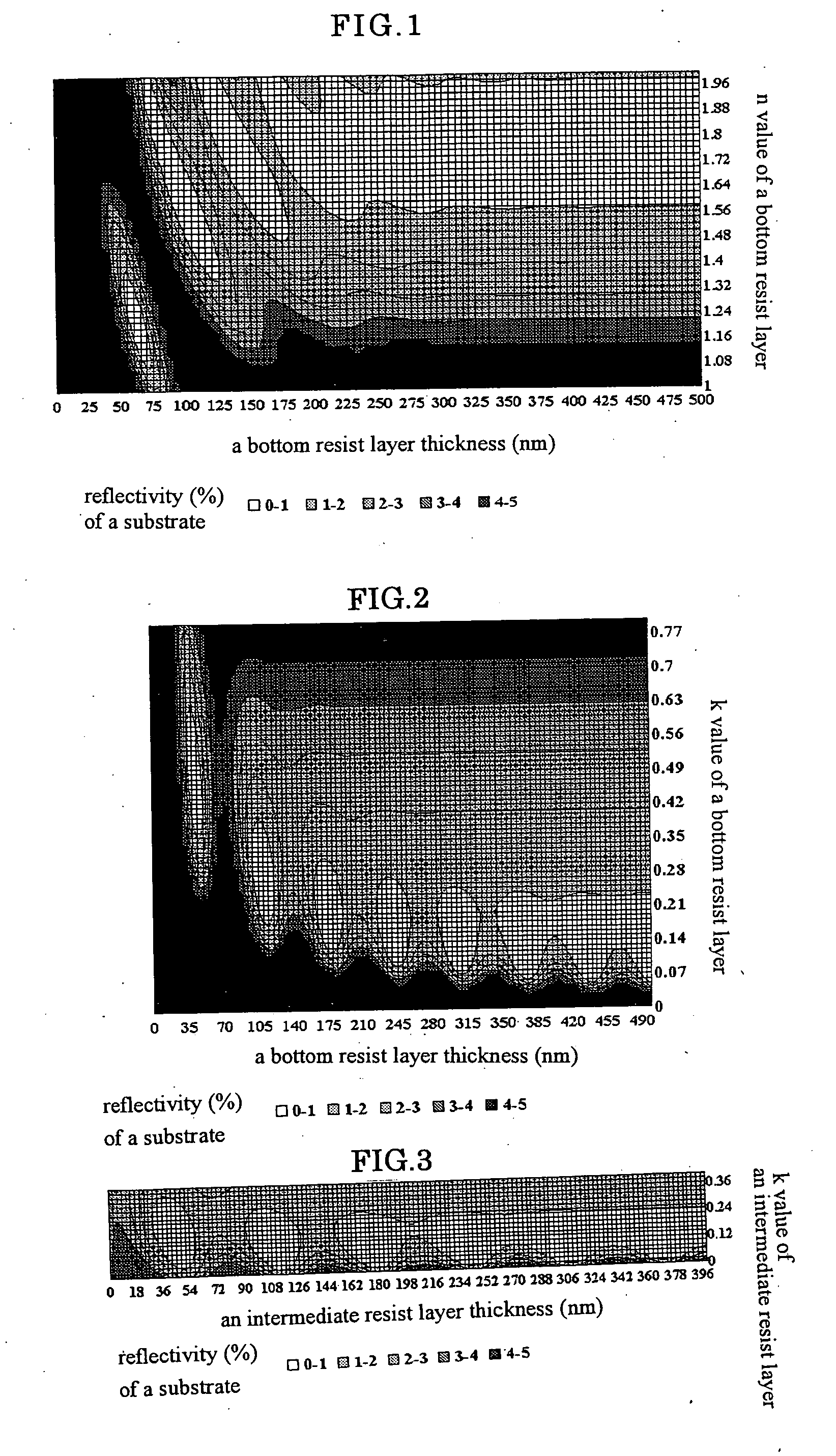

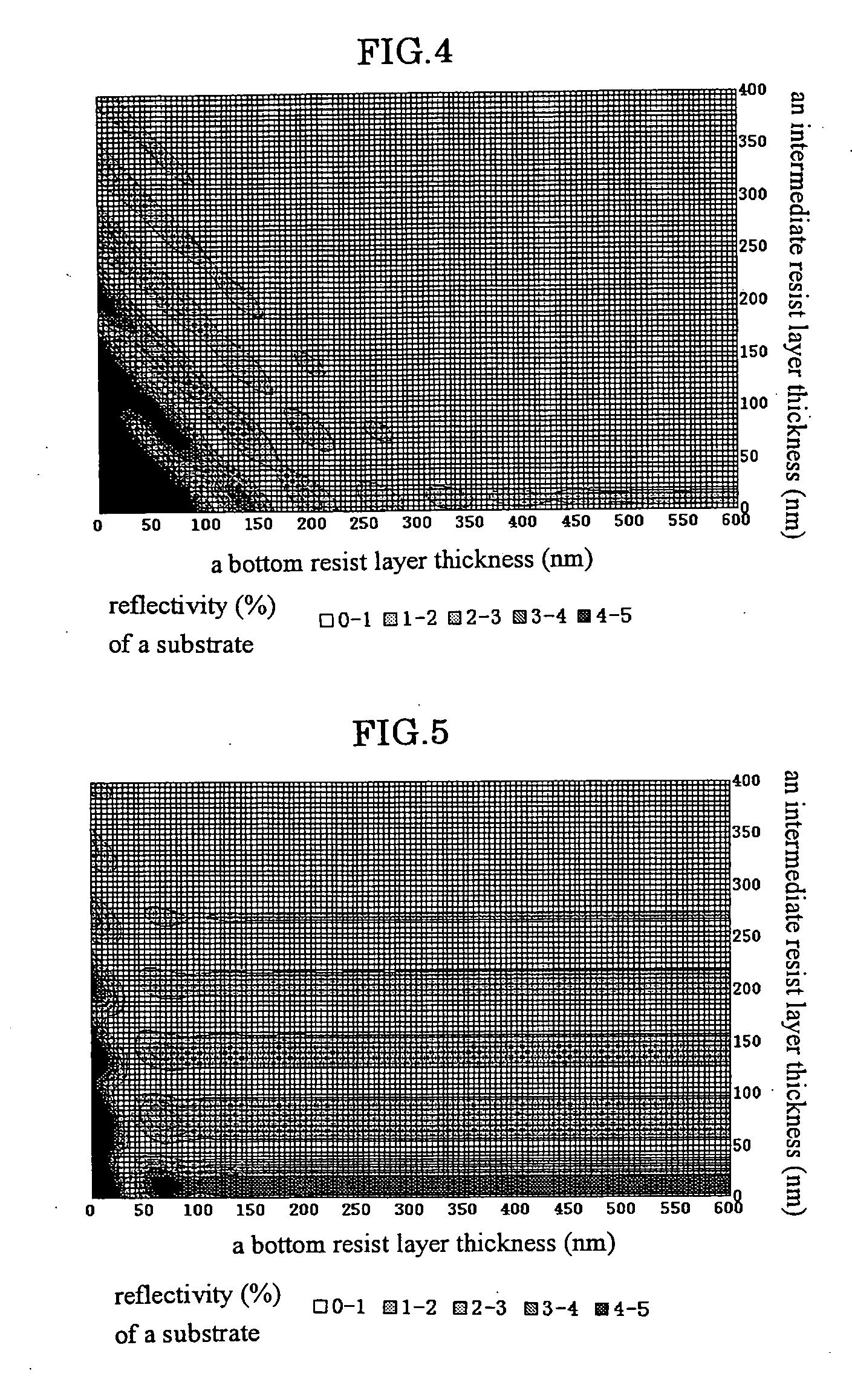

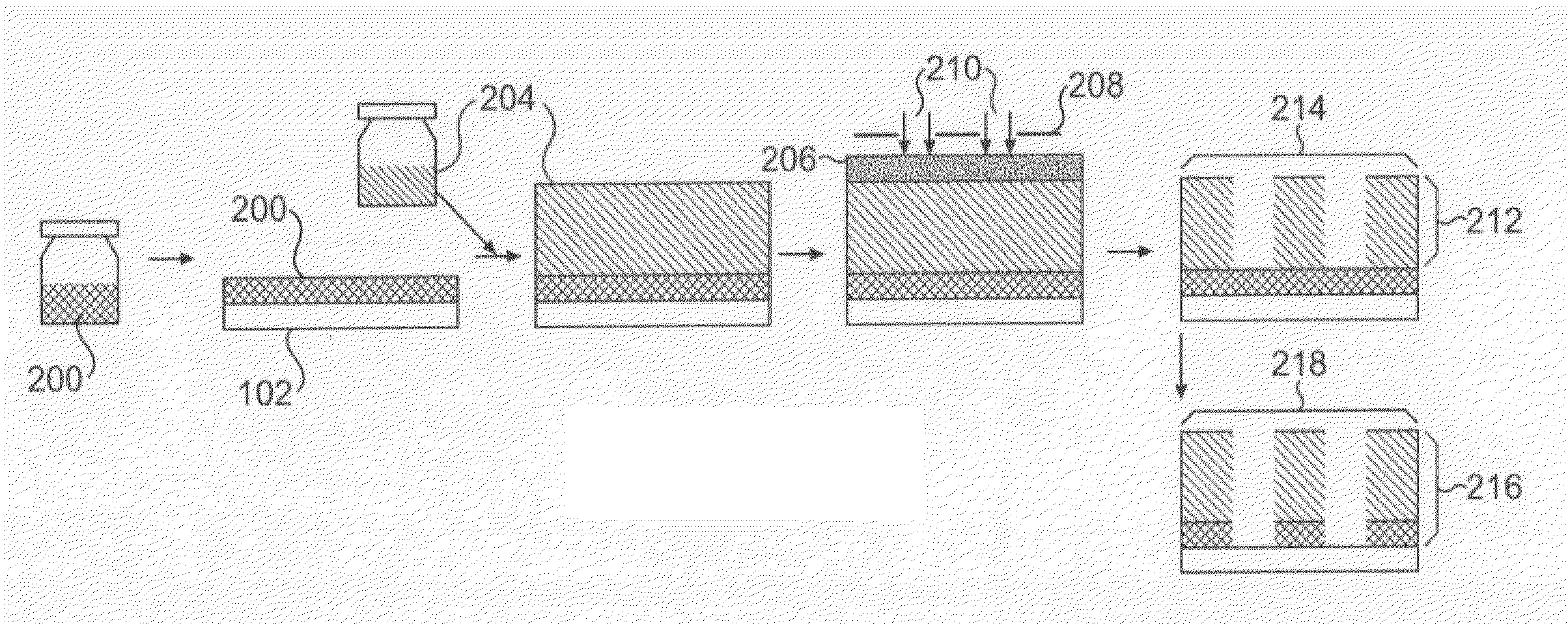

Bottom resist layer composition and patterning process using the same

InactiveUS20060234158A1Improve accuracyHigh precision formingPhotosensitive materialsSemiconductor/solid-state device manufacturingResistLithographic artist

There is disclosed a bottom resist layer composition for a multilayer-resist film used in lithography which comprises, at least, a polymer having a repeating unit represented by the following general formula (1). Thereby, there can be provided a bottom resist layer composition which shows an antireflection effect against an exposure light by combining with an intermediate resist layer having an antireflection effect if necessary, has a higher etching resistance during etching a substrate than polyhydroxy styrene, cresol novolac resin, etc., has a high poisoning-resistant effect, and is suitable for using in a multilayer-resist process like a bilayer resist process or a trilayer resist process.

Owner:SHIN ETSU CHEM IND CO LTD

Micromachined bilayer unit for filtration of small molecules

InactiveUS7776021B2Enhanced convectionFacilitated DiffusionBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationSmall molecule

Methods and materials for making an apparatus which duplicates the functionality of a physiological system id provided.

Owner:THE GENERAL HOSPITAL CORP +2

Shallow trench isolation (STI) with bilayer of oxide-nitride for VLSI applications

A reduction in parasitic leakages of shallow trench isolation vias is disclosed wherein the distance between the silicon nitride liner and the active silicon sidewalls is increased by depositing an insulating oxide layer prior to deposition of the silicon nitride liner. Preferably, the insulating oxide layer comprises tetraethylorthosilicate. The method comprises of etching one or more shallow trench isolations into a semiconductor wafer; depositing an insulating oxide layer into the trench; growing a thermal oxide in the trench; and depositing a silicon nitride liner in the trench. The thermal oxide may be grown prior to or after deposition of the insulating oxide layer.

Owner:QIMONDA +1

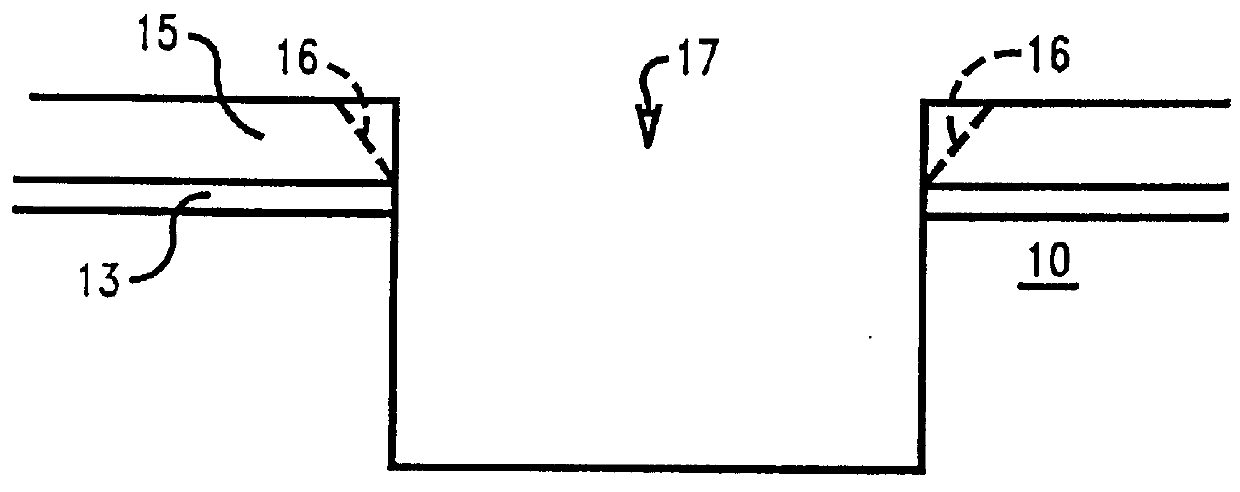

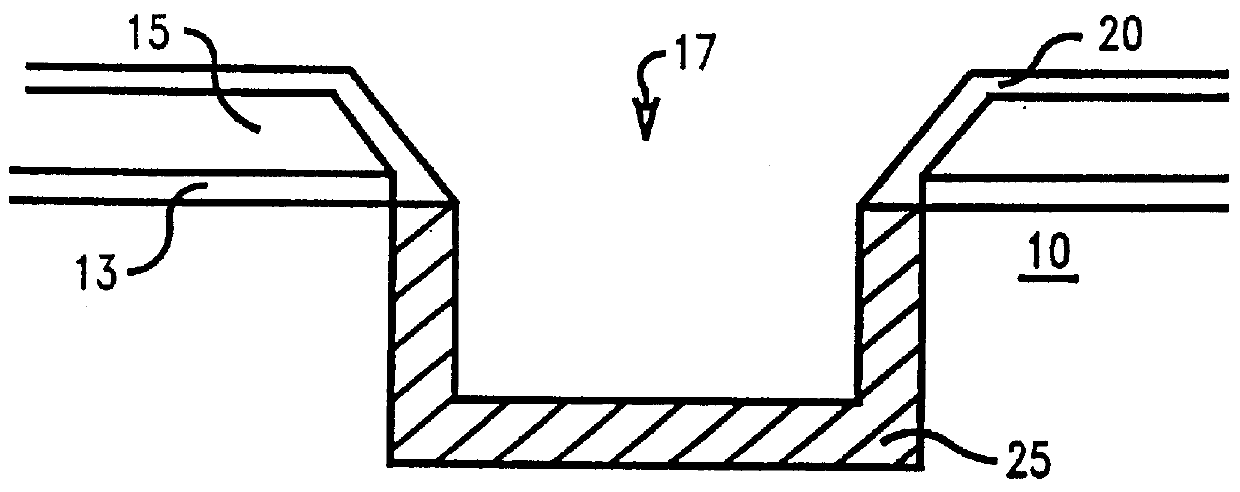

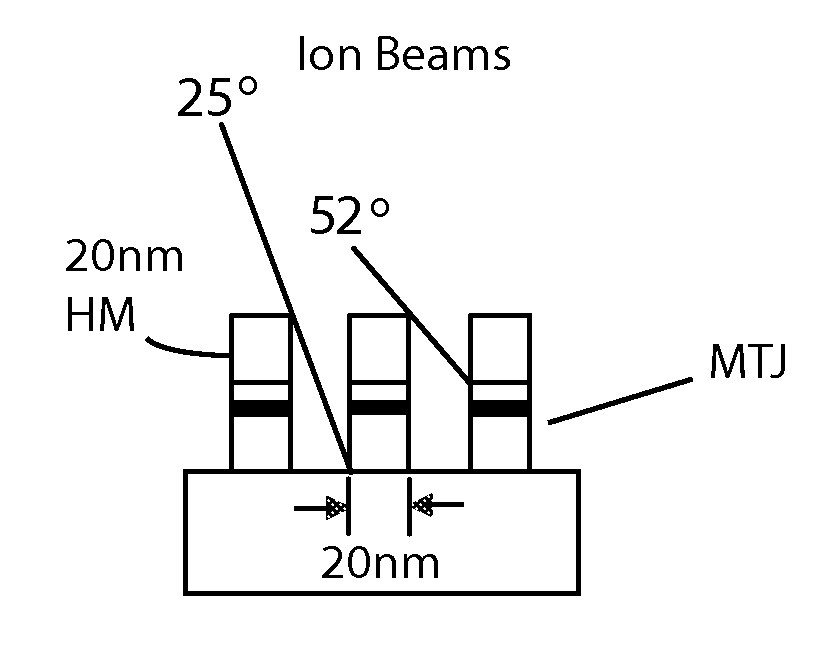

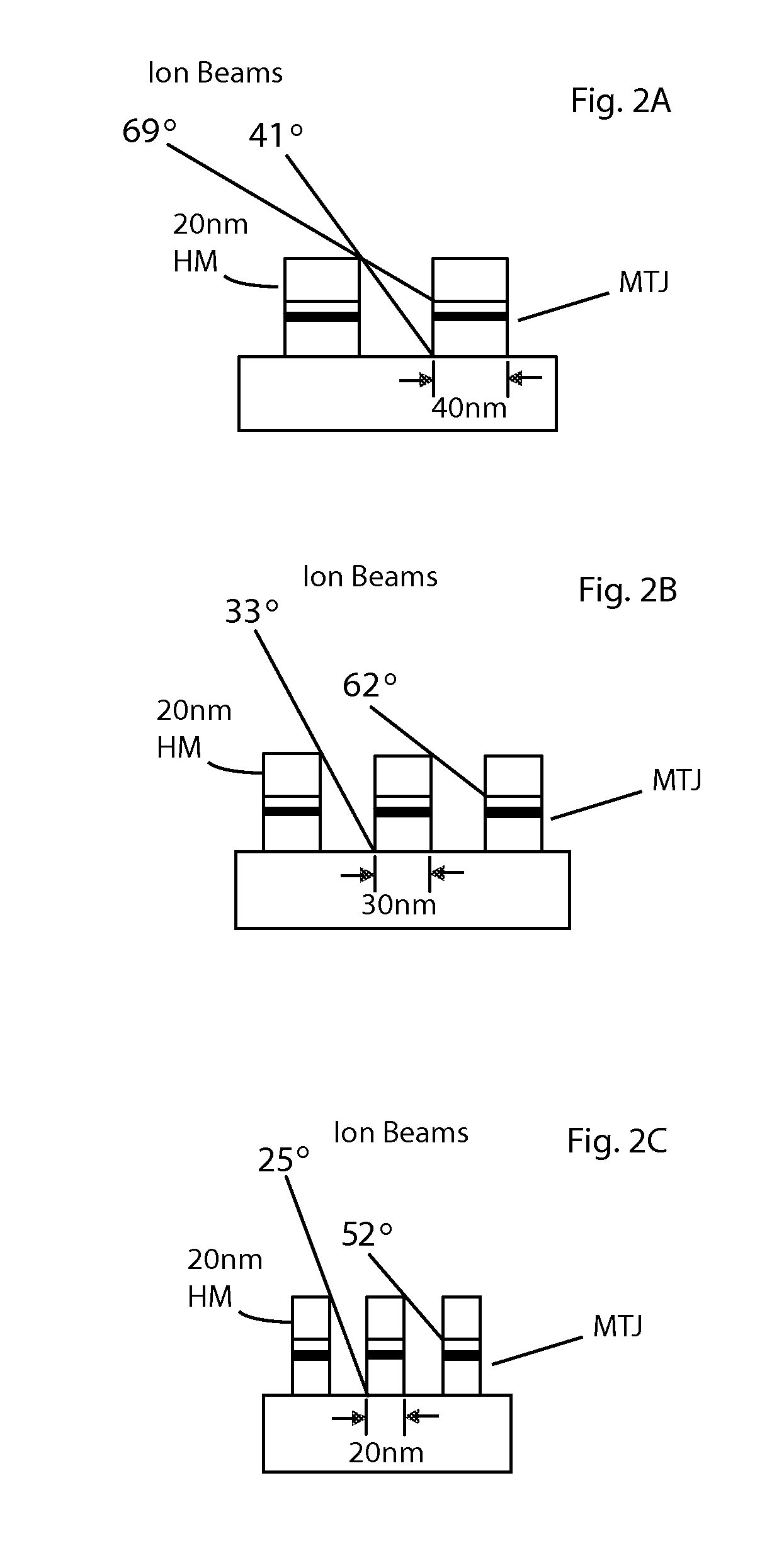

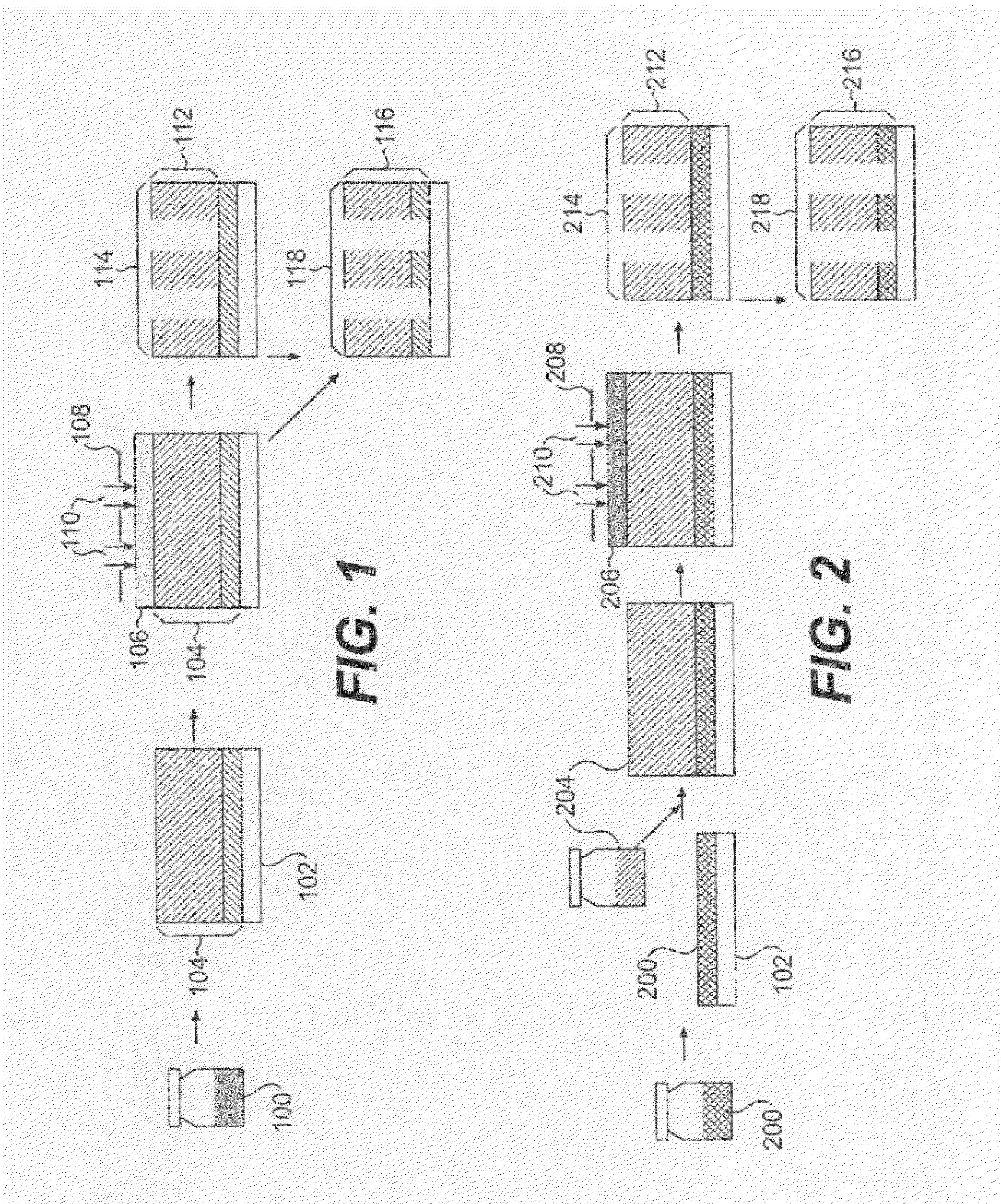

Fabrication method for high-density MRAM using thin hard mask

ActiveUS20150104882A1Increase incident IBE angleMaximum incidence angleSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentEtchingEngineering

Embodiments of the invention are described that use a thin metallic hard mask, which can be a bi-layer film, to increase the incident IBE angle for MTJ sidewall cleaning without losing the process margin for the subsequent interconnection process. The patterned metallic hard mask pads also serve as the top electrode for the MTJ cells. Using a thin metallic hard mask is possible when the hard mask material acts as a CMP stopper without substantial loss of thickness. In the first embodiment, the single layer hard mask is preferably ruthenium. In the second embodiment, the lower layer of the bi-layer hard mask is preferably ruthenium. The wafer is preferably rotated during the IBE process for uniform etching. A capping layer under the hard mask is preferably used as the etch stopper during hard mask etch process in order not to damage or etch through the upper magnetic layer.

Owner:AVALANCHE TECH

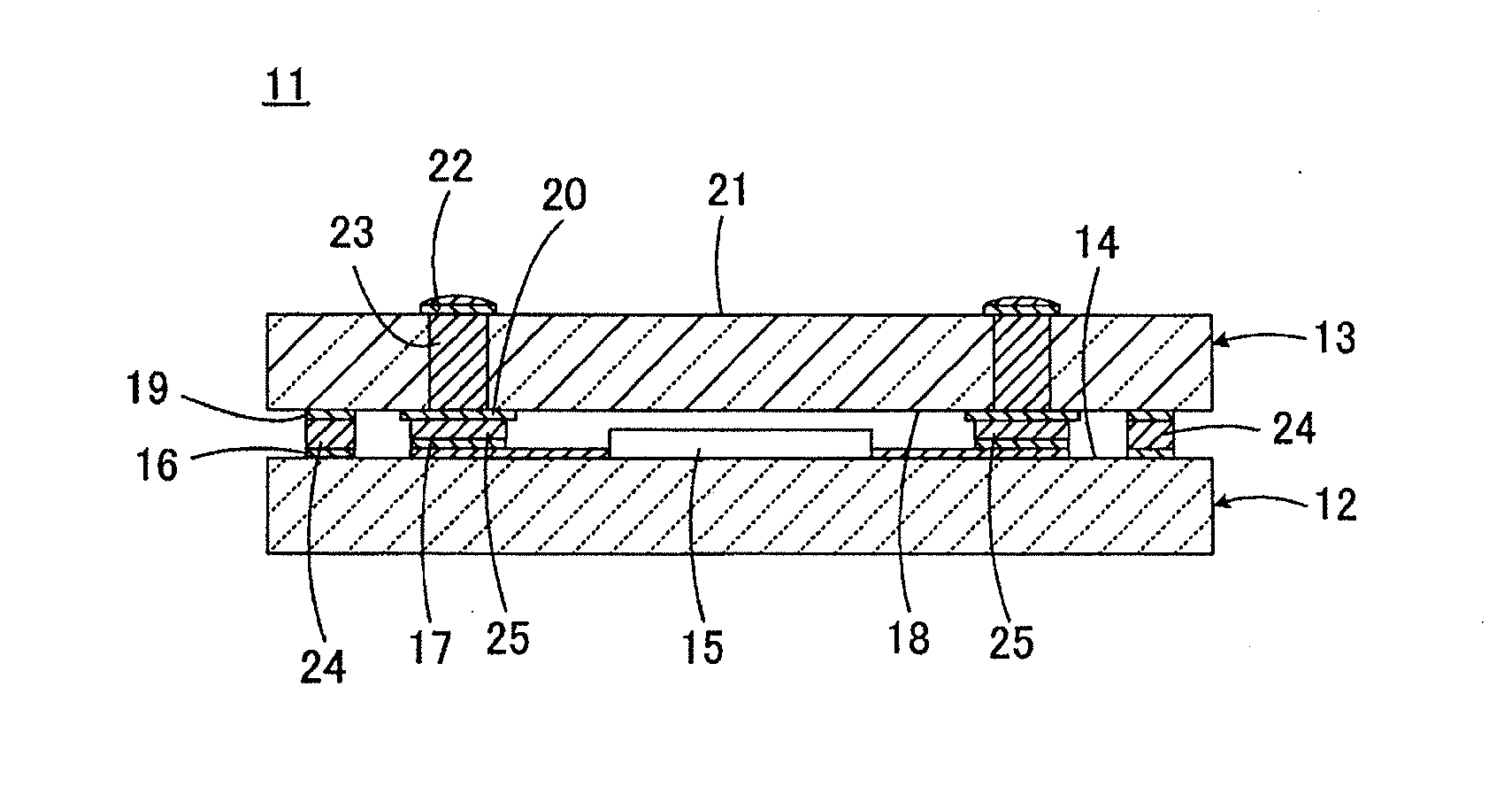

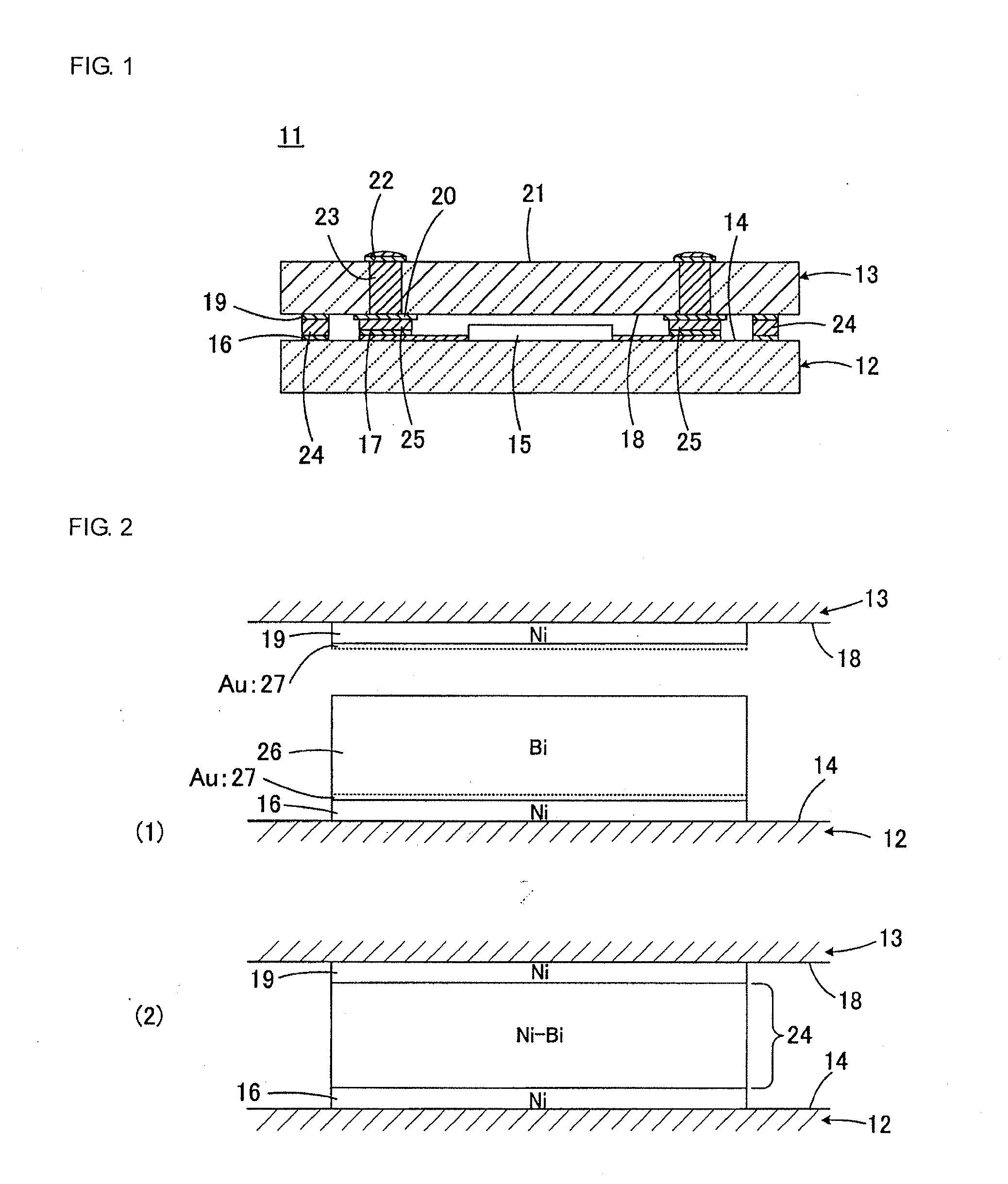

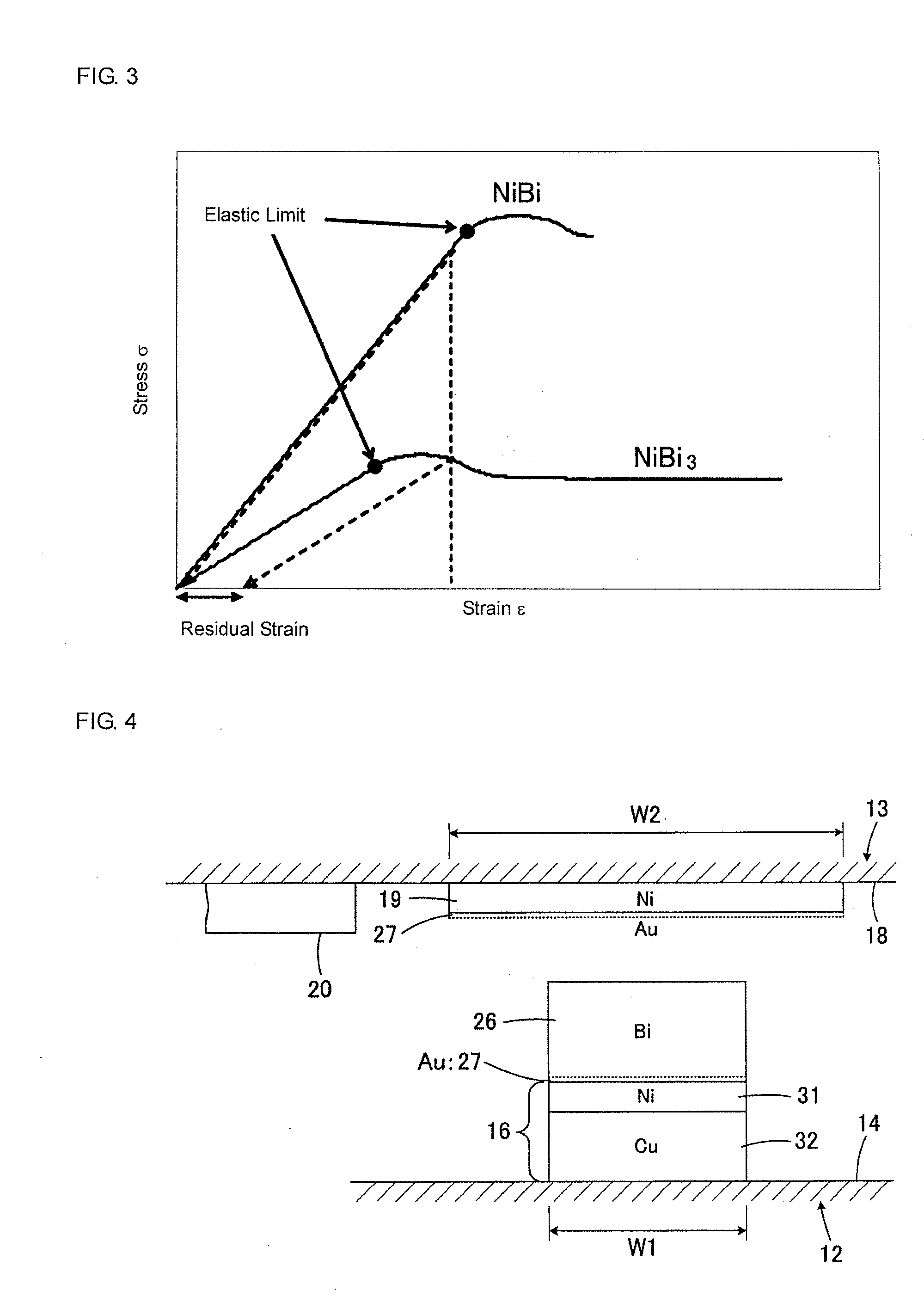

Electronic Component Device and Method for Manufacturing the Same

ActiveUS20110132656A1High speedLow production costSemiconductor/solid-state device detailsSoldering apparatusBi layerStructural engineering

An electronic component device having a first sealing frame formed on a main substrate and a second sealing frame formed on a cover substrate, the first and second sealing frames being composed of a Ni film. A bonding section constituted by a Ni—Bi alloy is formed between the first and second sealing frames. For example, a Bi layer is formed on the first sealing frame, and then the first sealing frame and the second sealing frame are heated at a temperature of 300° C. for at least 10 seconds while applying pressure in the direction in which the first sealing frame and the second sealing frame are in close contact with each other, and thus the bonding section, which bonds the first sealing frame to the second sealing frame, is formed.

Owner:MURATA MFG CO LTD

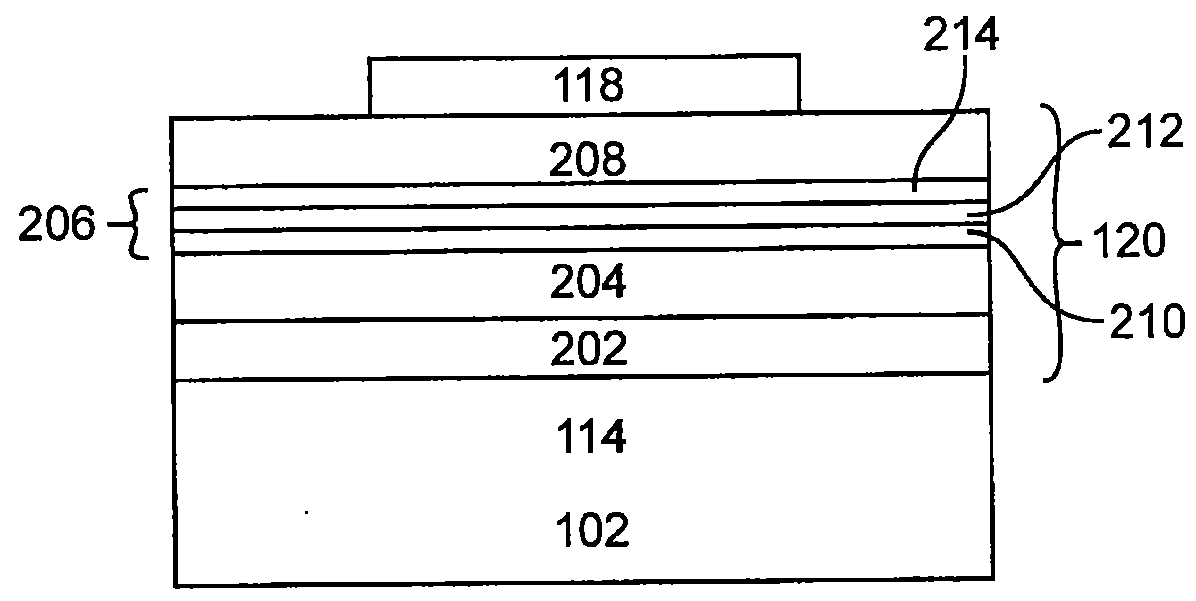

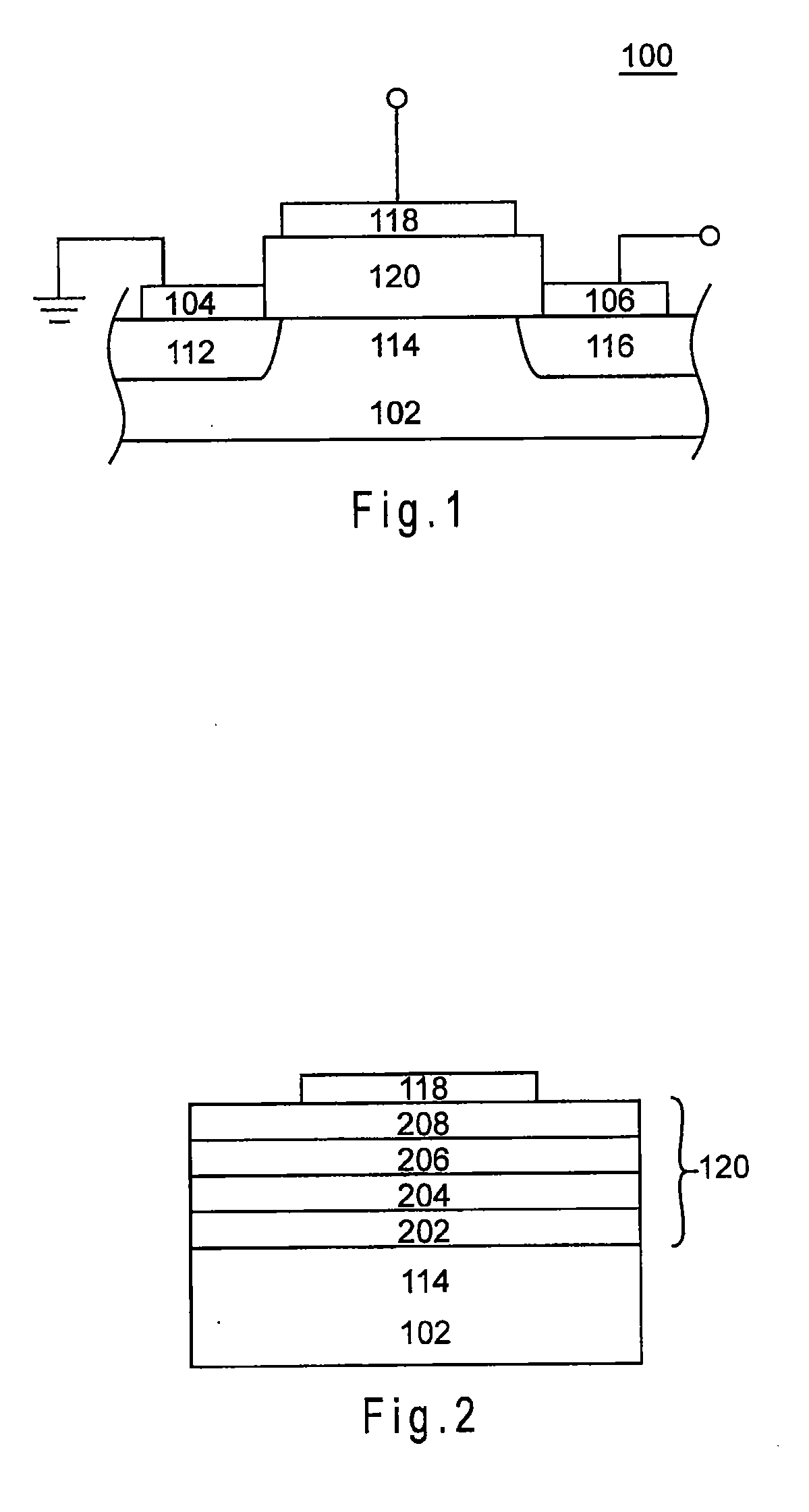

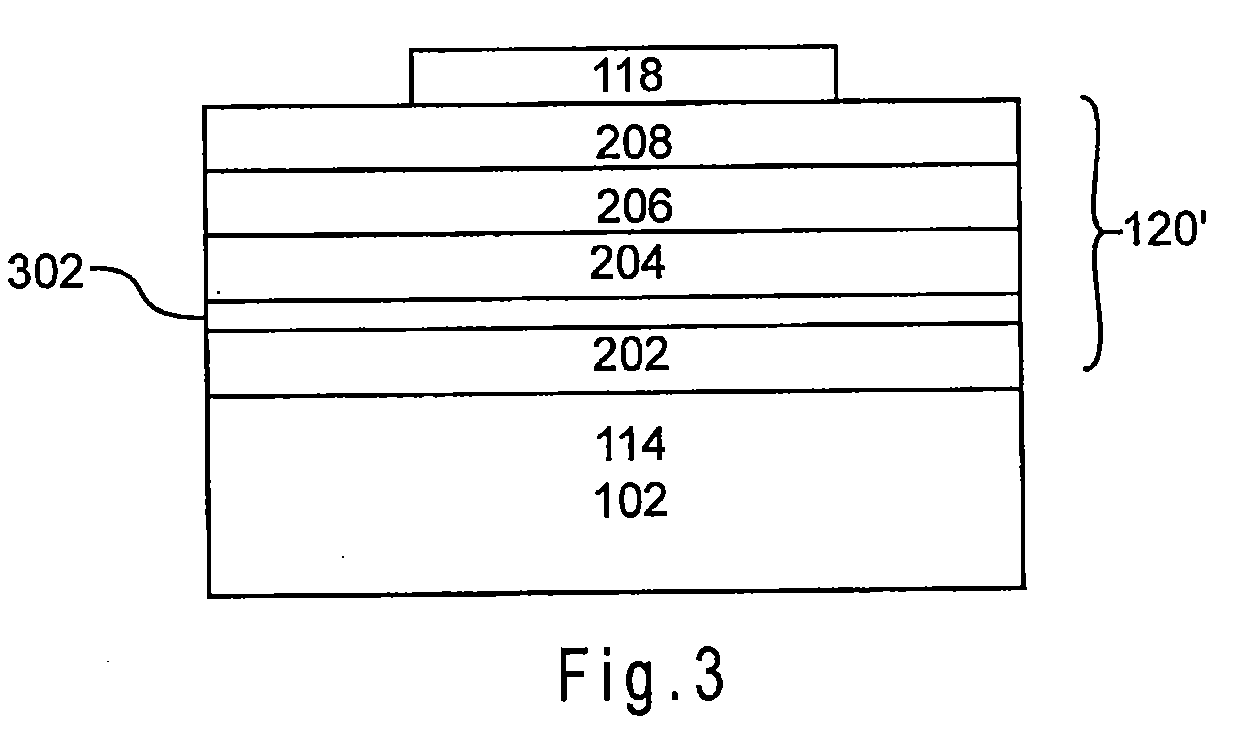

Electron blocking layers for electronic devices

Methods and apparatuses for electronic devices such as non-volatile memory devices are described. The memory devices include a multi-layer control dielectric, such as a double or triple layer. The multi-layer control dielectric includes a combination of high-k dielectric materials such as aluminum oxide, hafnium oxide, and / or hybrid films of hafnium aluminum oxide. The multi-layer control dielectric provides enhanced characteristics, including increased charge retention, enhanced memory program / erase window, improved reliability and stability, with feasibility for single or multi state (e.g., two, three or four bit) operation.

Owner:SANDISK TECH LLC

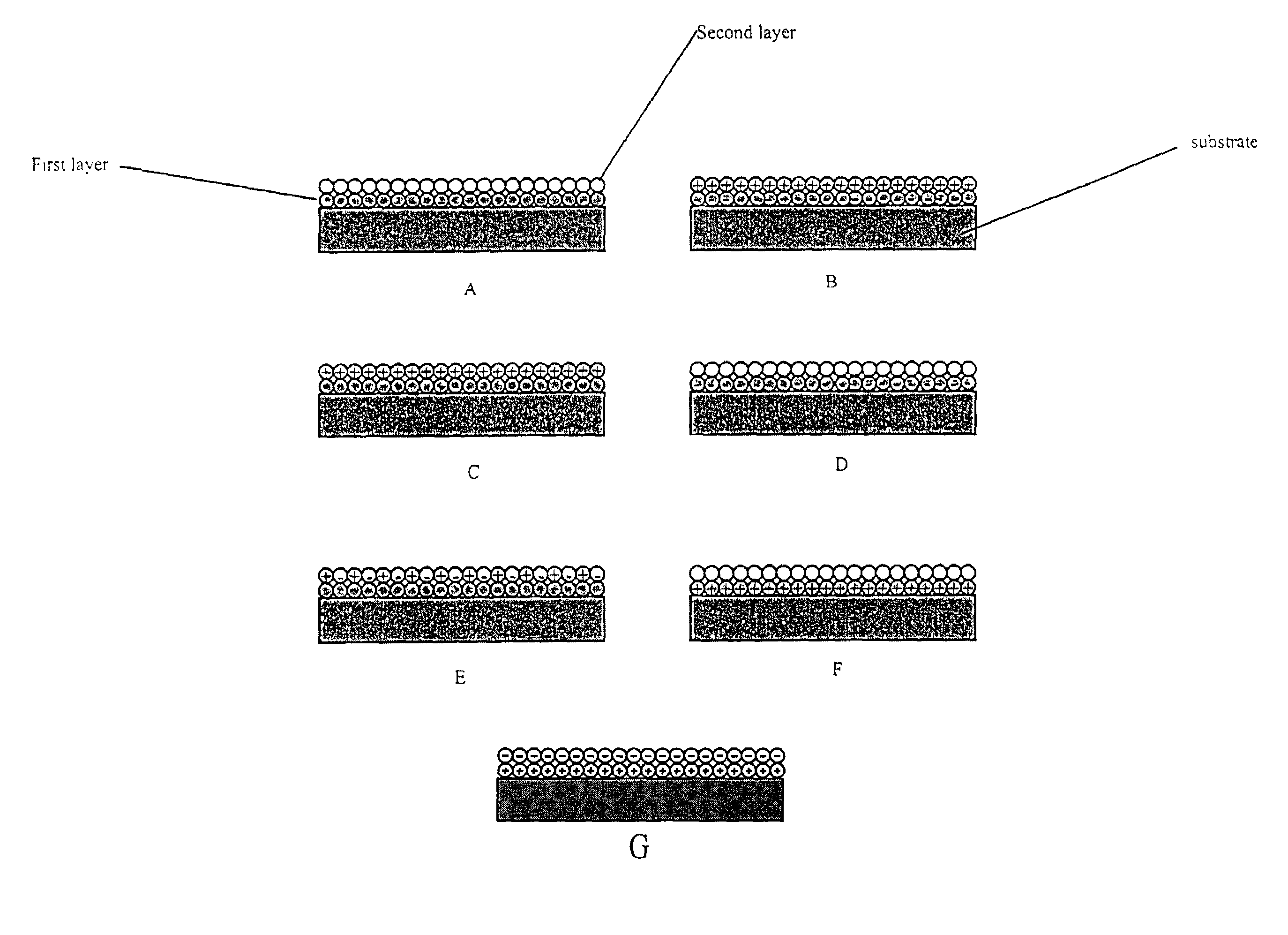

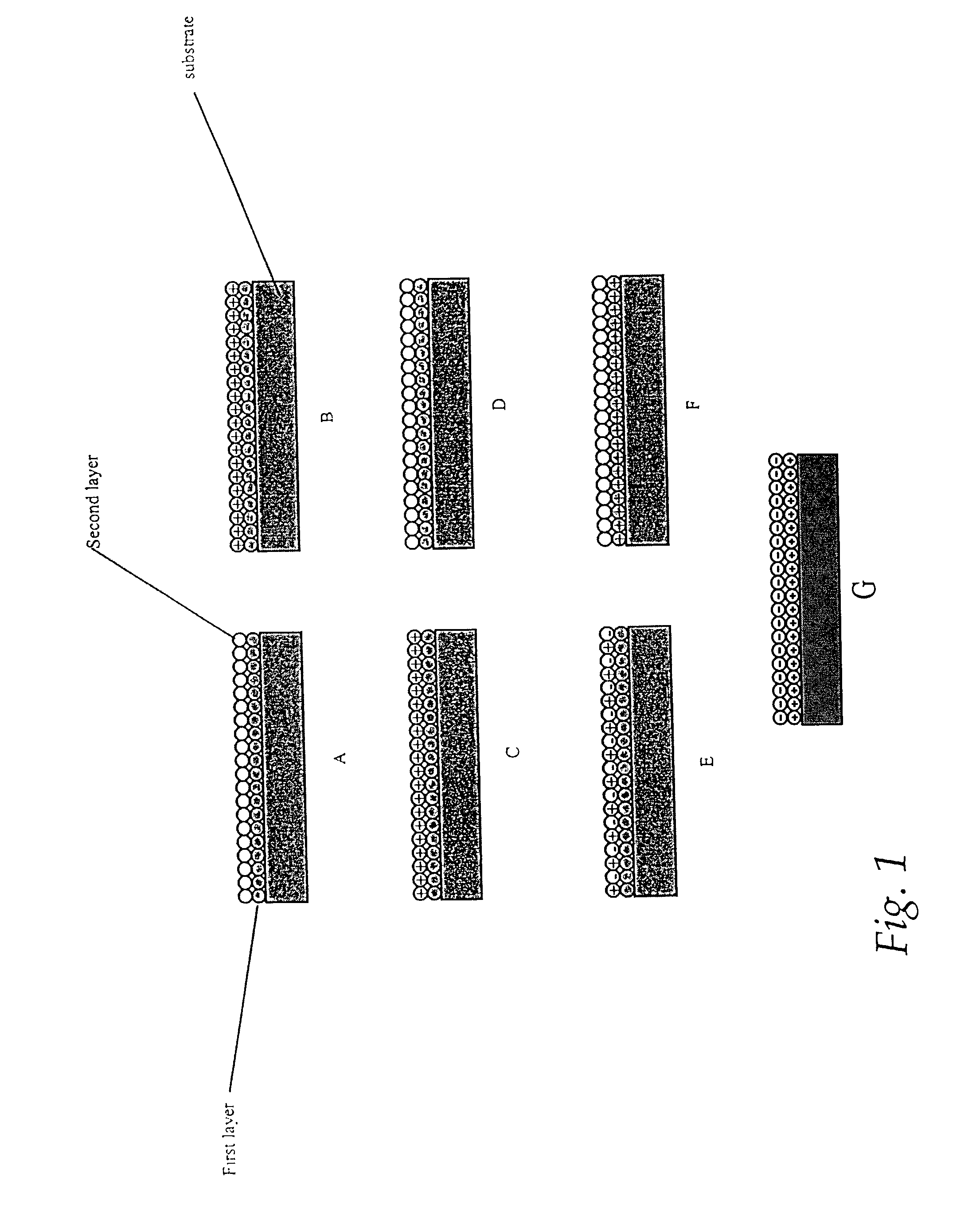

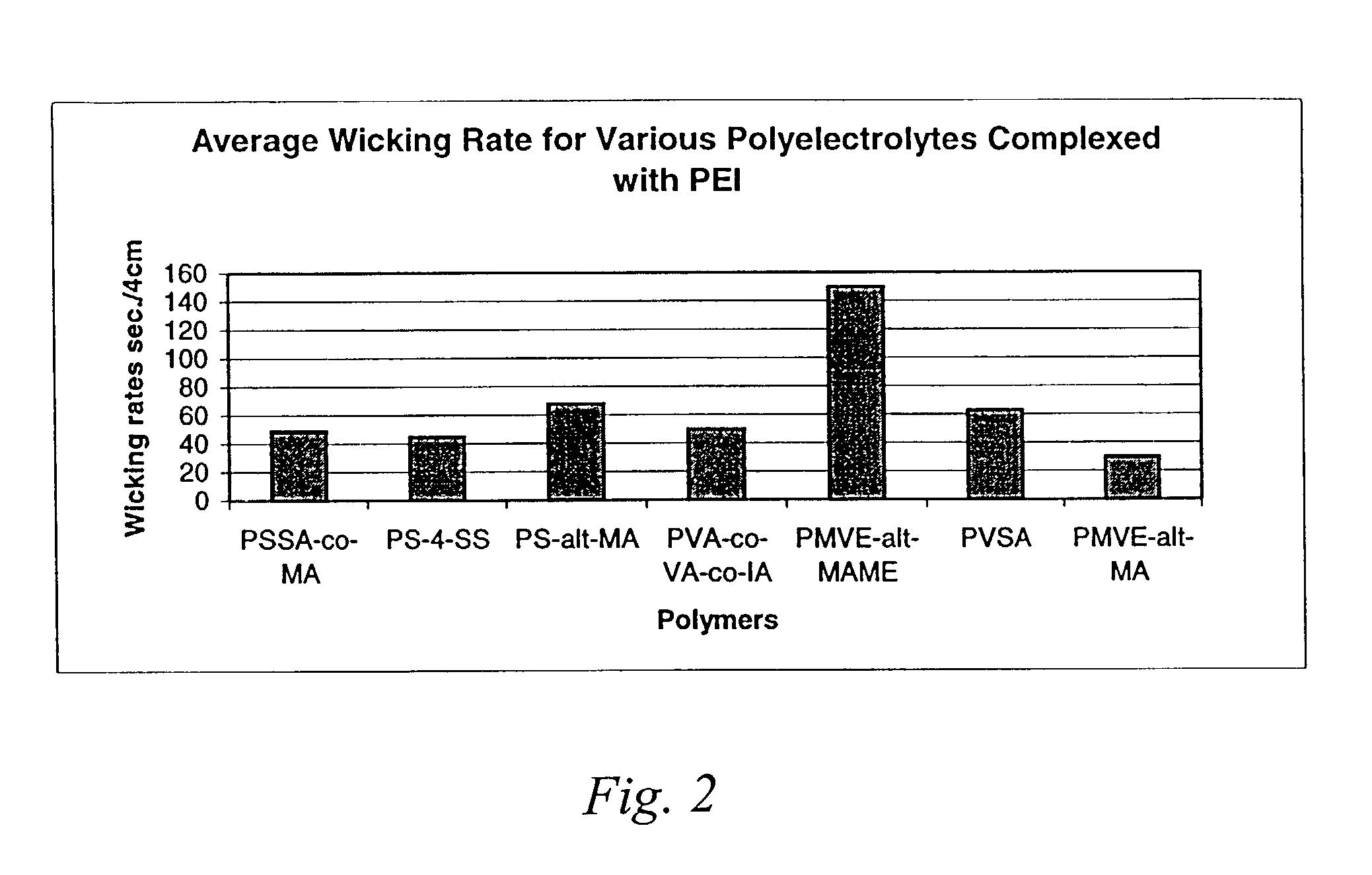

Multi-layer coated porous materials and methods of making the same

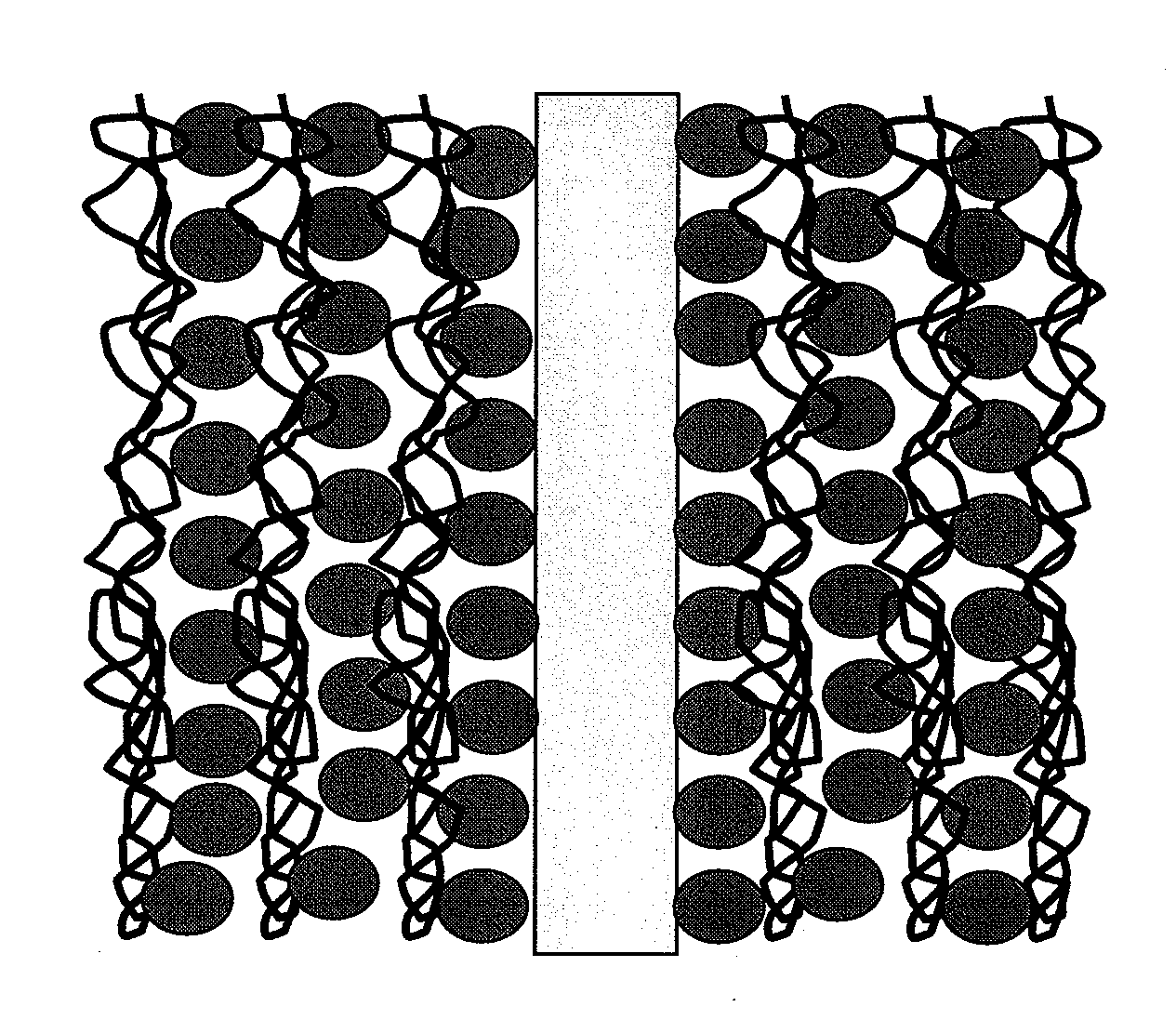

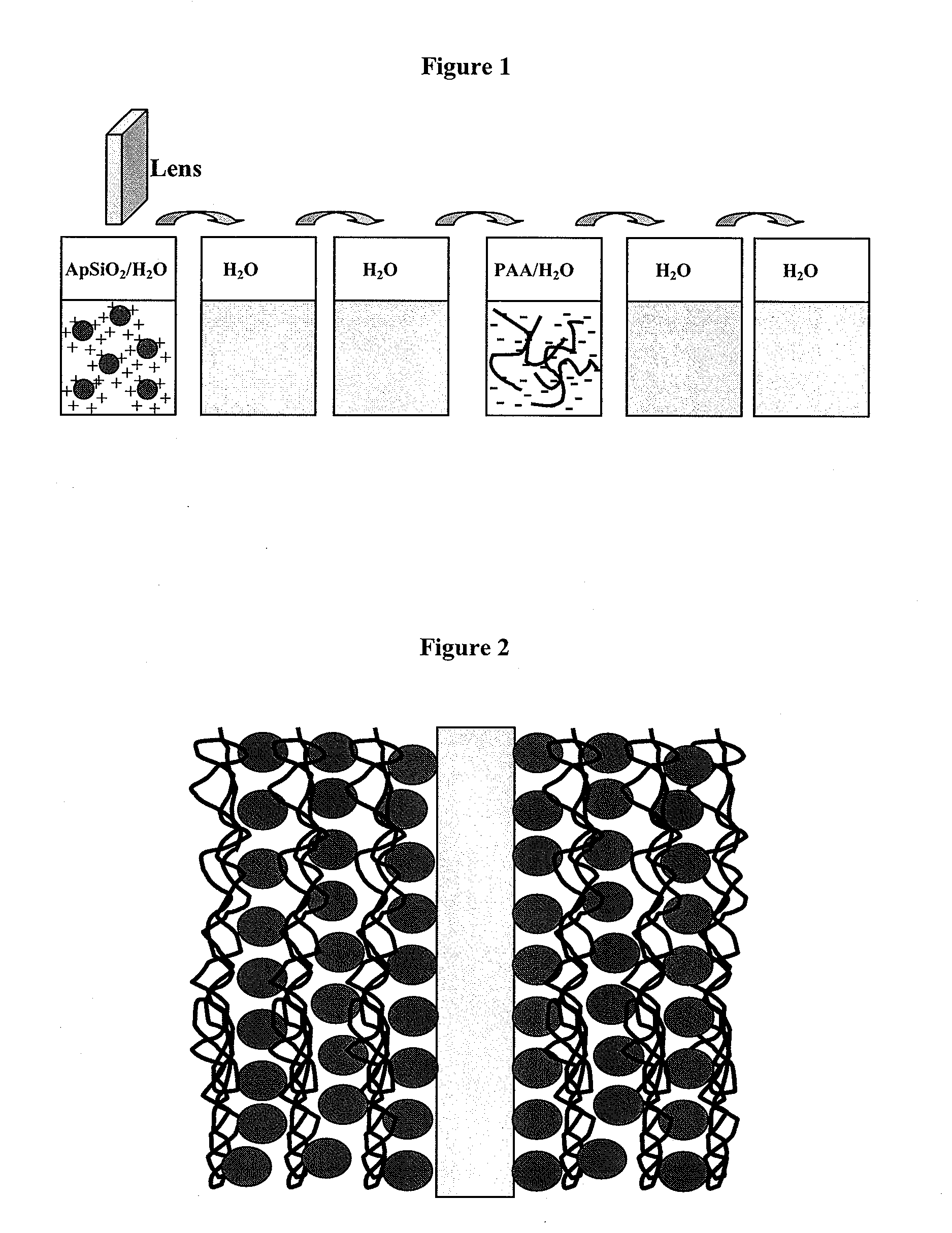

InactiveUS7094464B2Produced economically and consistentlyHighly functionalSemi-permeable membranesMaterial analysis by observing effect on chemical indicatorPolyelectrolytePorous substrate

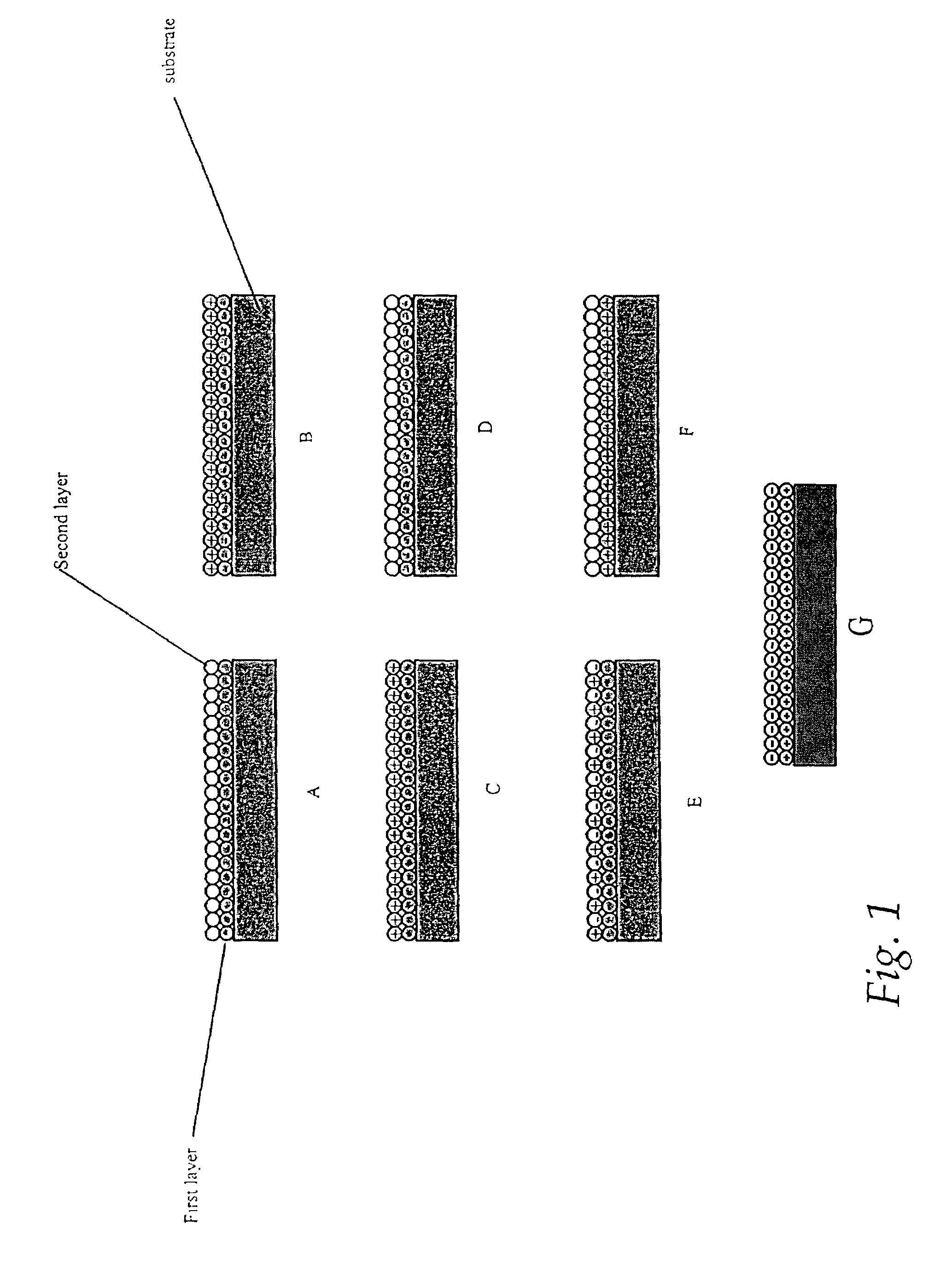

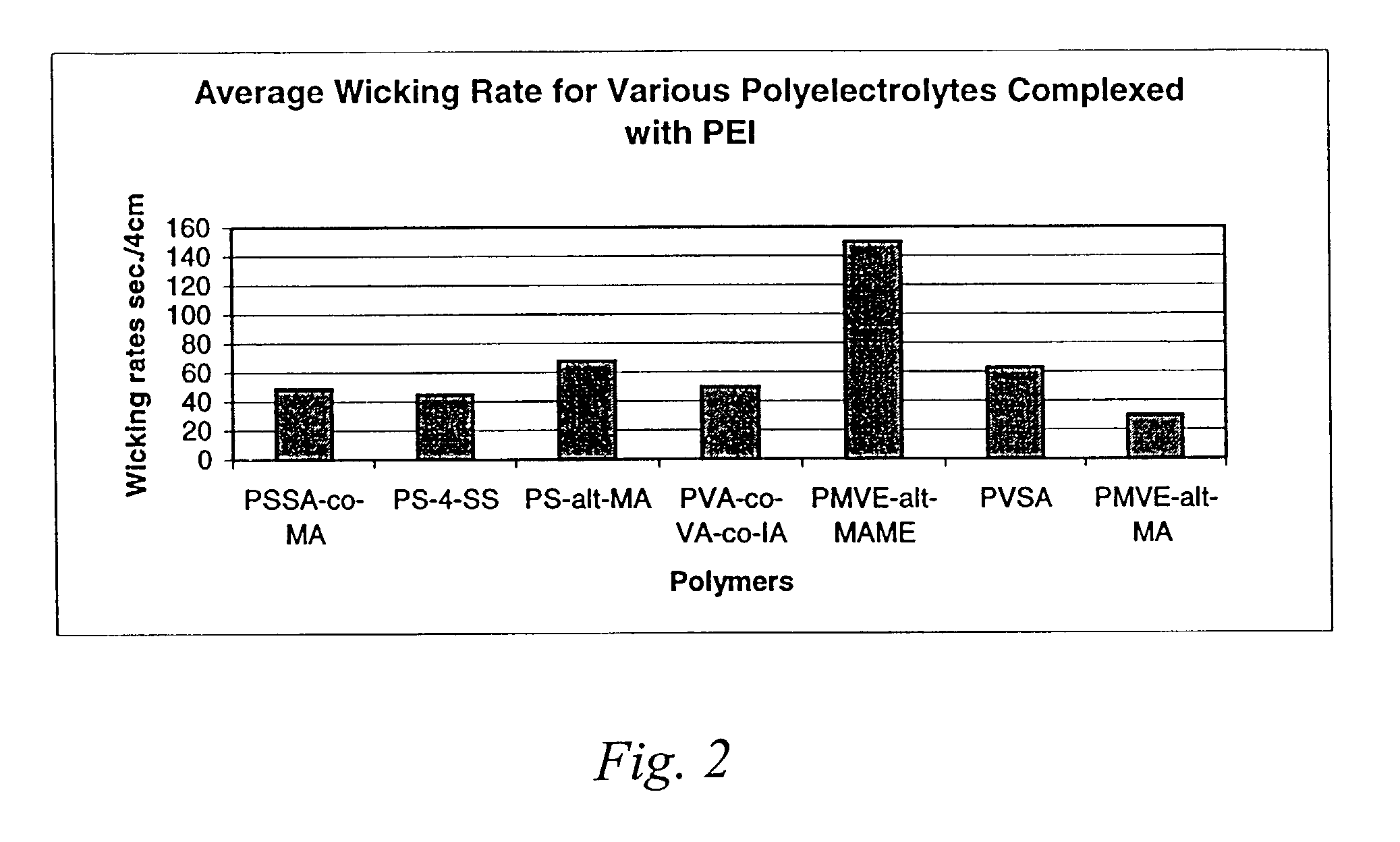

Multi-layer coated materials and methods of making them are disclosed. In a specific embodiment, a porous polymeric substrate is pre-activated and immersed in a polyelectrolyte solution to form a first layer having an electric charge and at least one functional group. The coated material is next immersed in a second solution of a material having an electric charge opposite of that of the first layer to provide a bi-layer coating. This process can be repeated to form multi-layer coatings on porous substrates.

Owner:POREX CORP

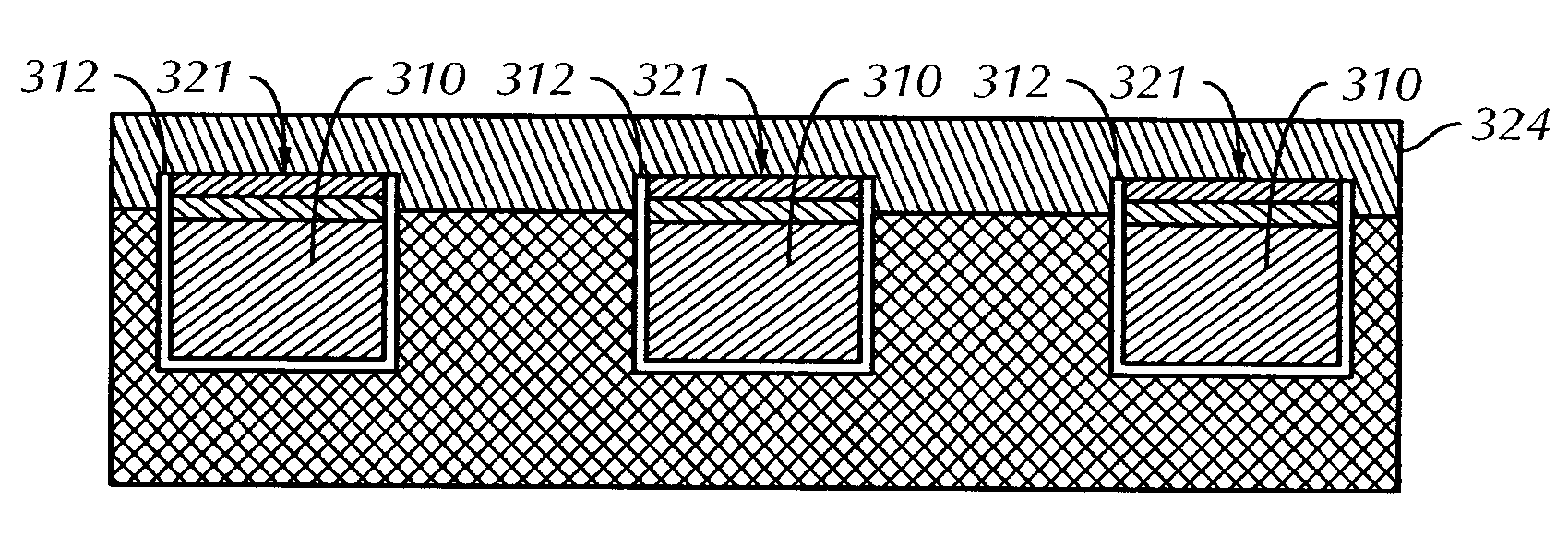

Interconnect structure with bi-layer metal cap

A structure and method of fabricating an interconnect structures with bi-layer metal cap is provided. In one embodiment, the method includes forming an interconnect feature in a dielectric material layer; and forming a bi-layer metallic cap on a top surface of the interconnect feature. The method further includes depositing a blanket layer of a dielectric capping layer, wherein the depositing covers an exposed surface of the dielectric material layer and a surface of the bi-layer metallic cap. The bi-layer metallic cap includes a metal capping layer formed on a conductive surface of the interconnect feature; and a metal nitride formed on a top portion of the metal capping layer. An interconnect structure is also described having an interconnect feature formed in a dielectric layer; a bi-layer metallic cap formed on a top portion of the interconnect feature; and a dielectric capping layer formed over the bi-layer metallic cap.

Owner:GLOBALFOUNDRIES INC

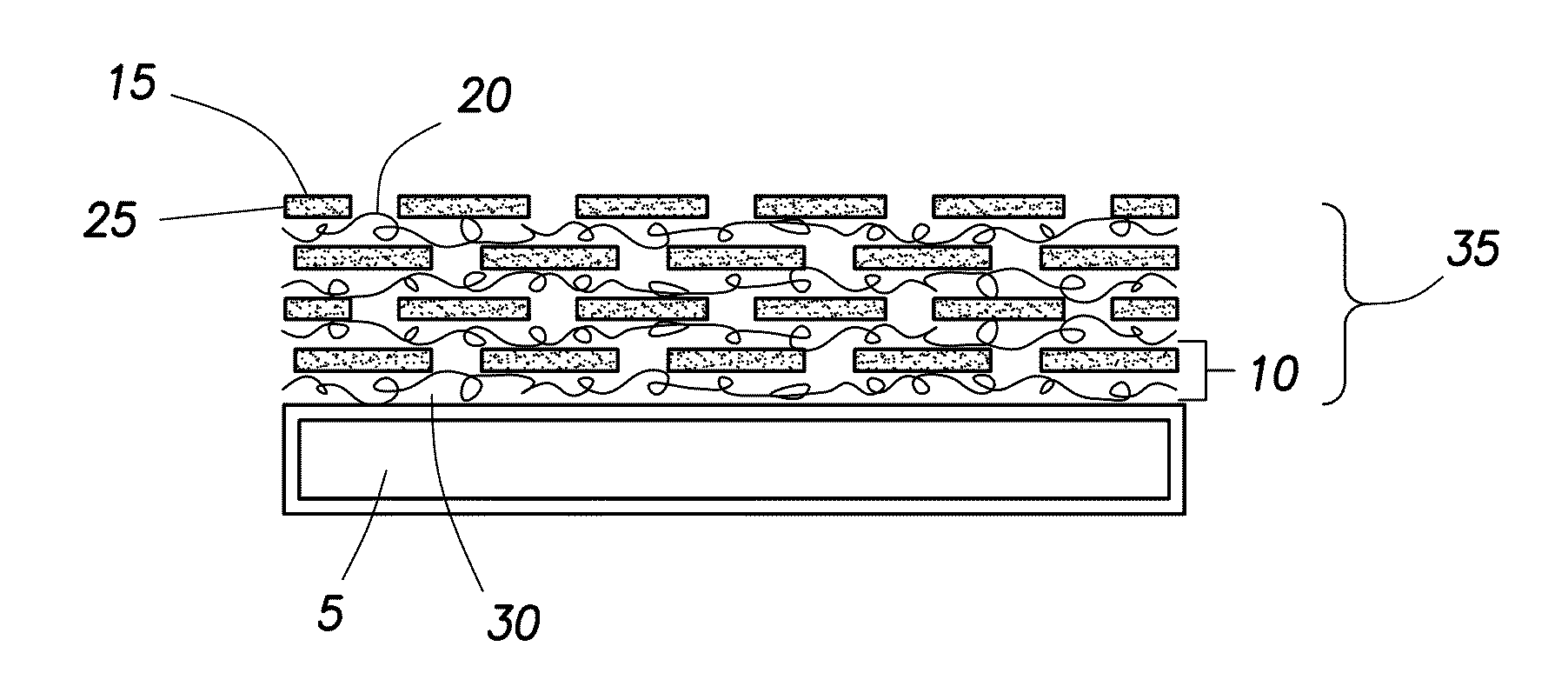

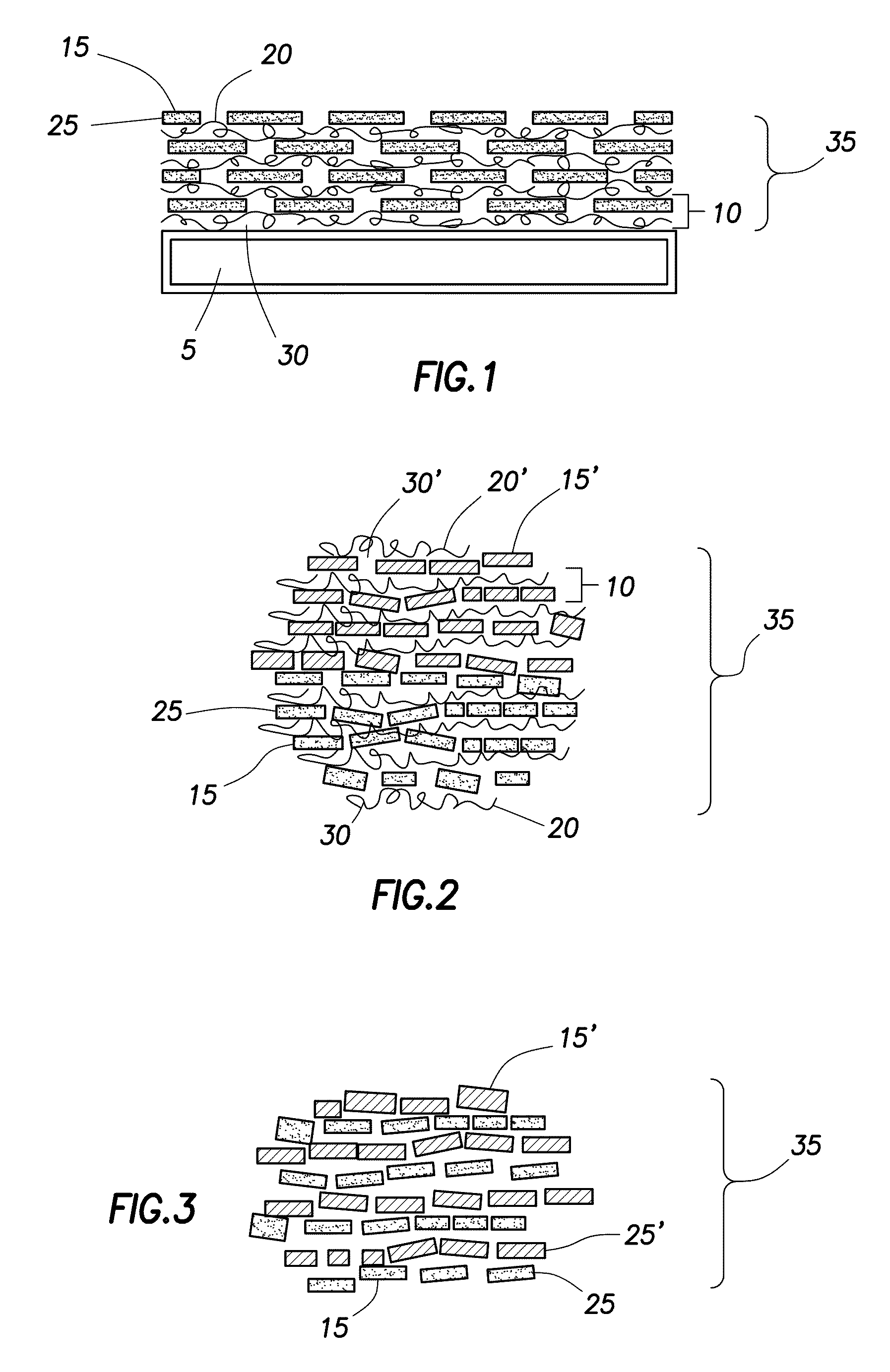

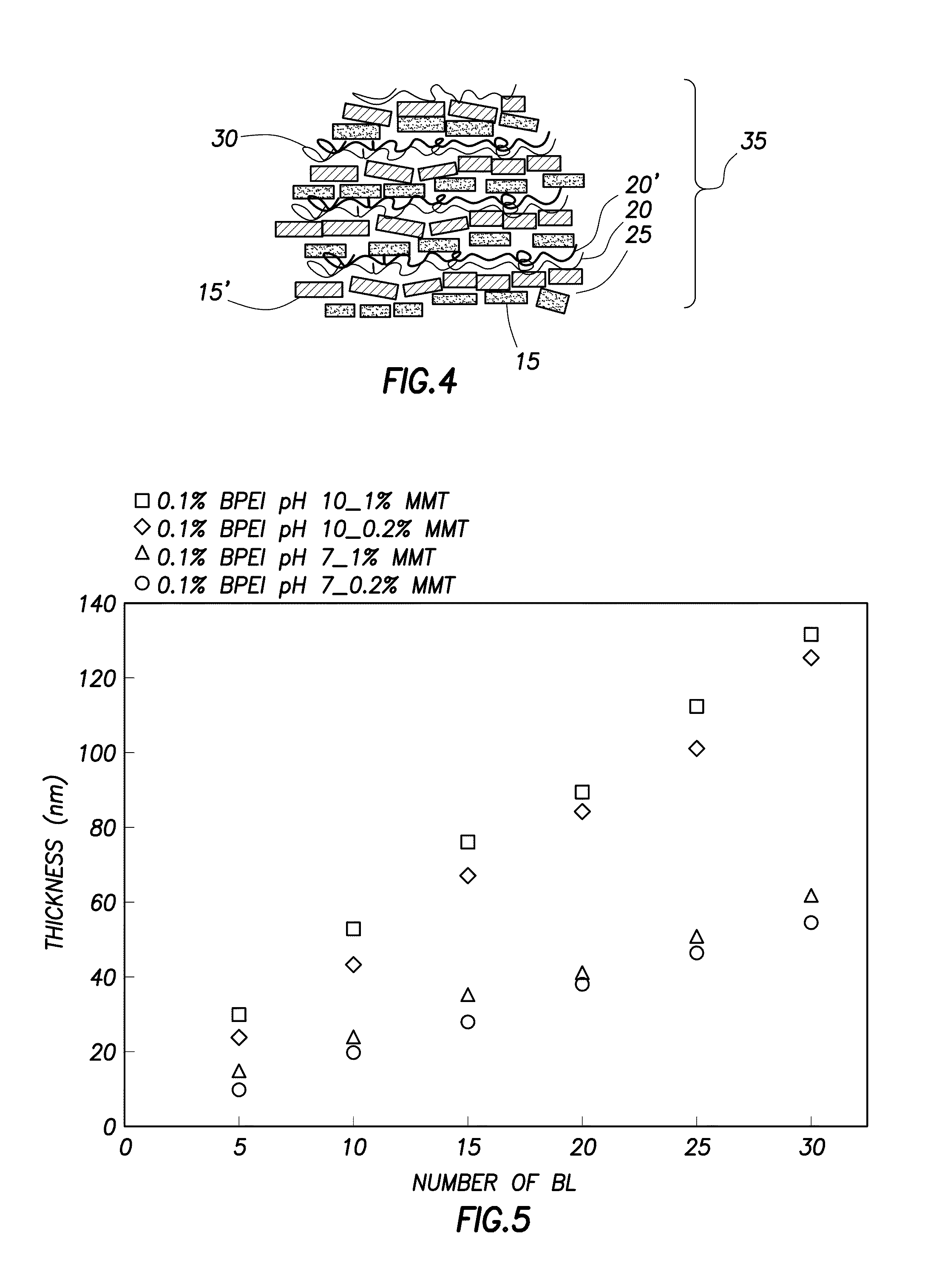

Multilayer Coating for Flame Retardant Foam or Fabric

A method includes coating a substrate to provide a flame resistant substrate. In an embodiment, the method includes exposing the substrate to a cationic solution to produce a cationic layer deposited on the substrate. The cationic solution includes cationic materials. The cationic materials include polymers, nanoparticles, or any combinations thereof. The method further includes exposing the cationic layer to an anionic solution to produce an anionic layer deposited on the cationic layer to produce a bilayer. The bilayer is the anionic layer and the cationic layer. The anionic solution includes layerable materials.

Owner:TEXAS A&M UNIVERSITY

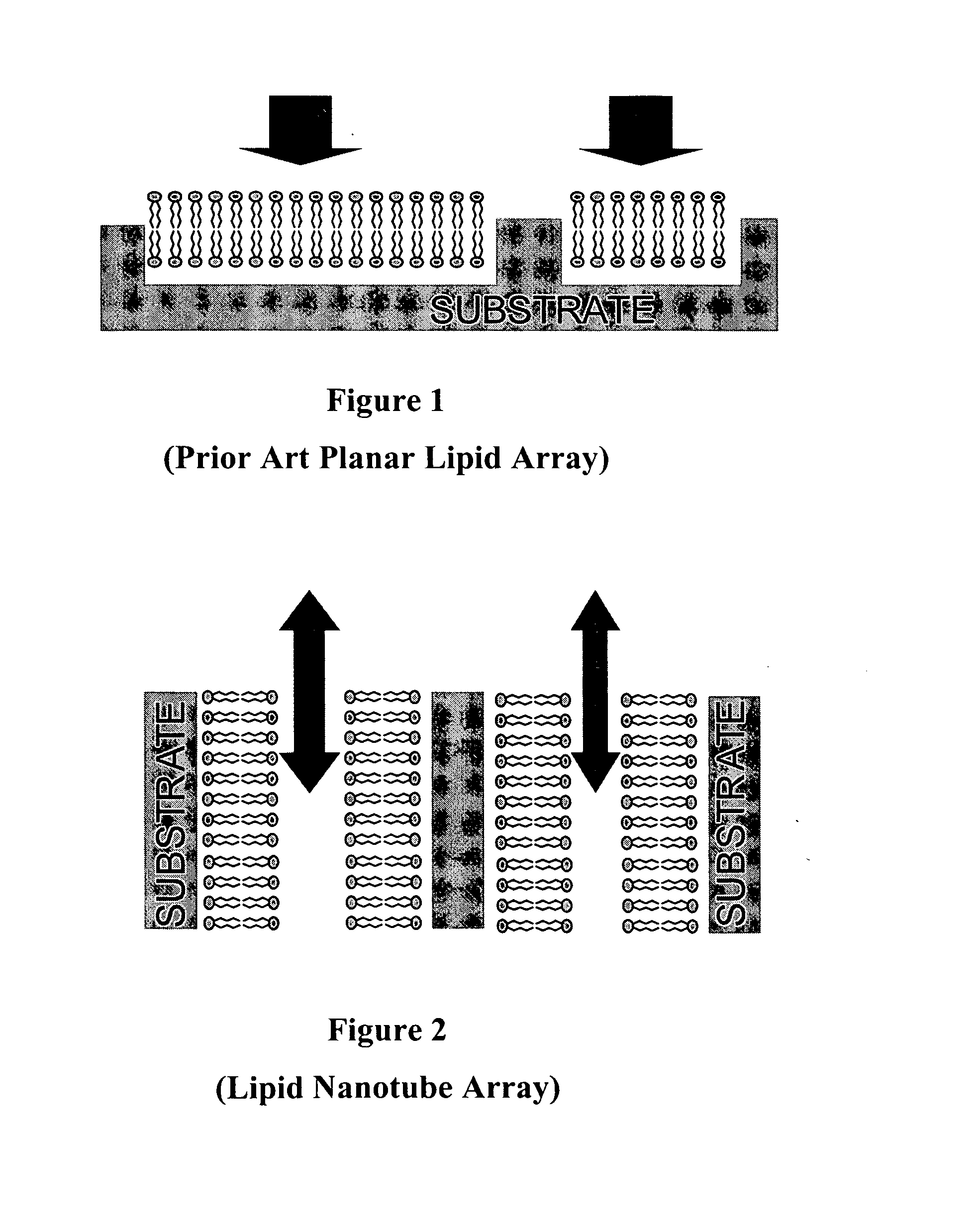

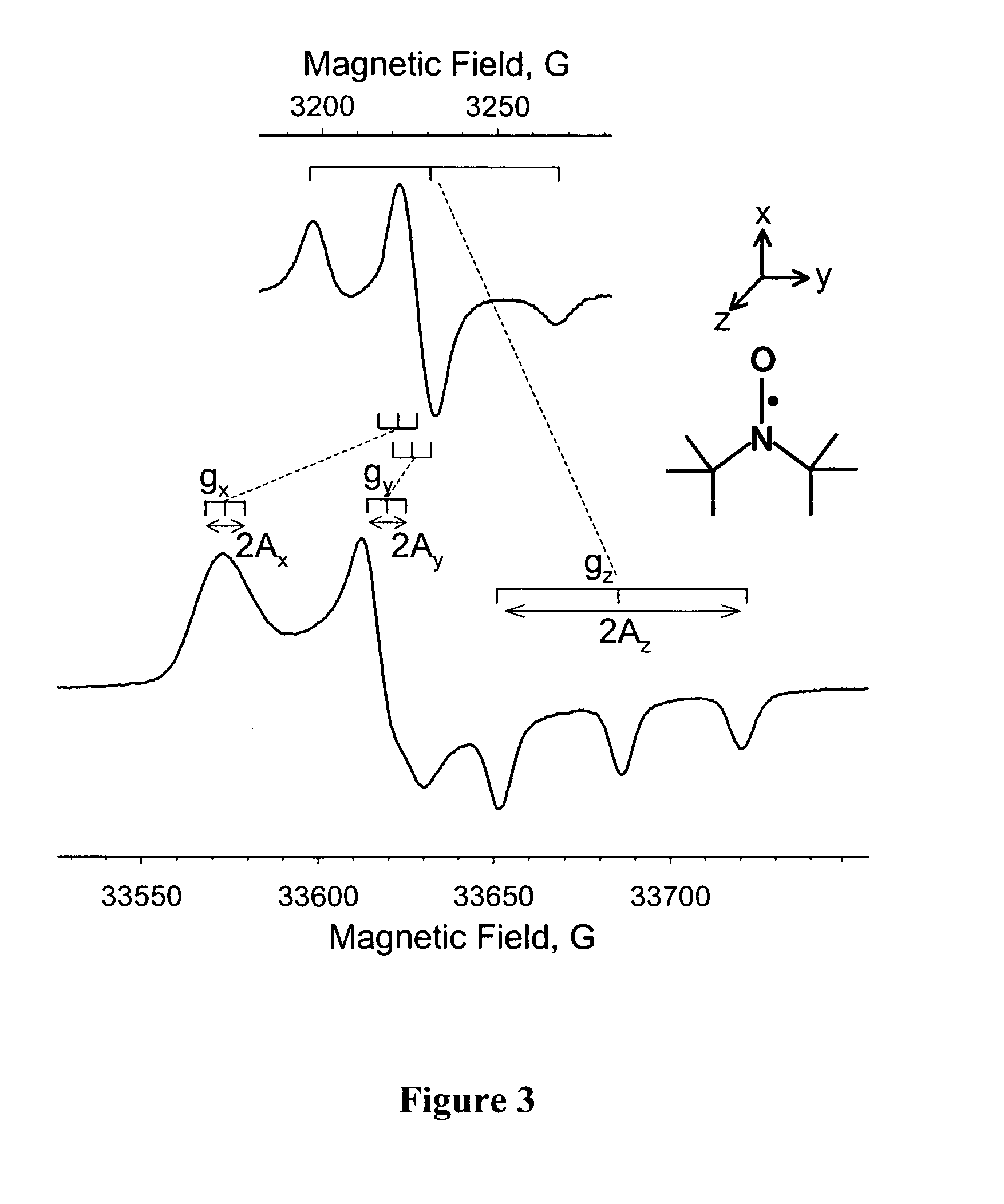

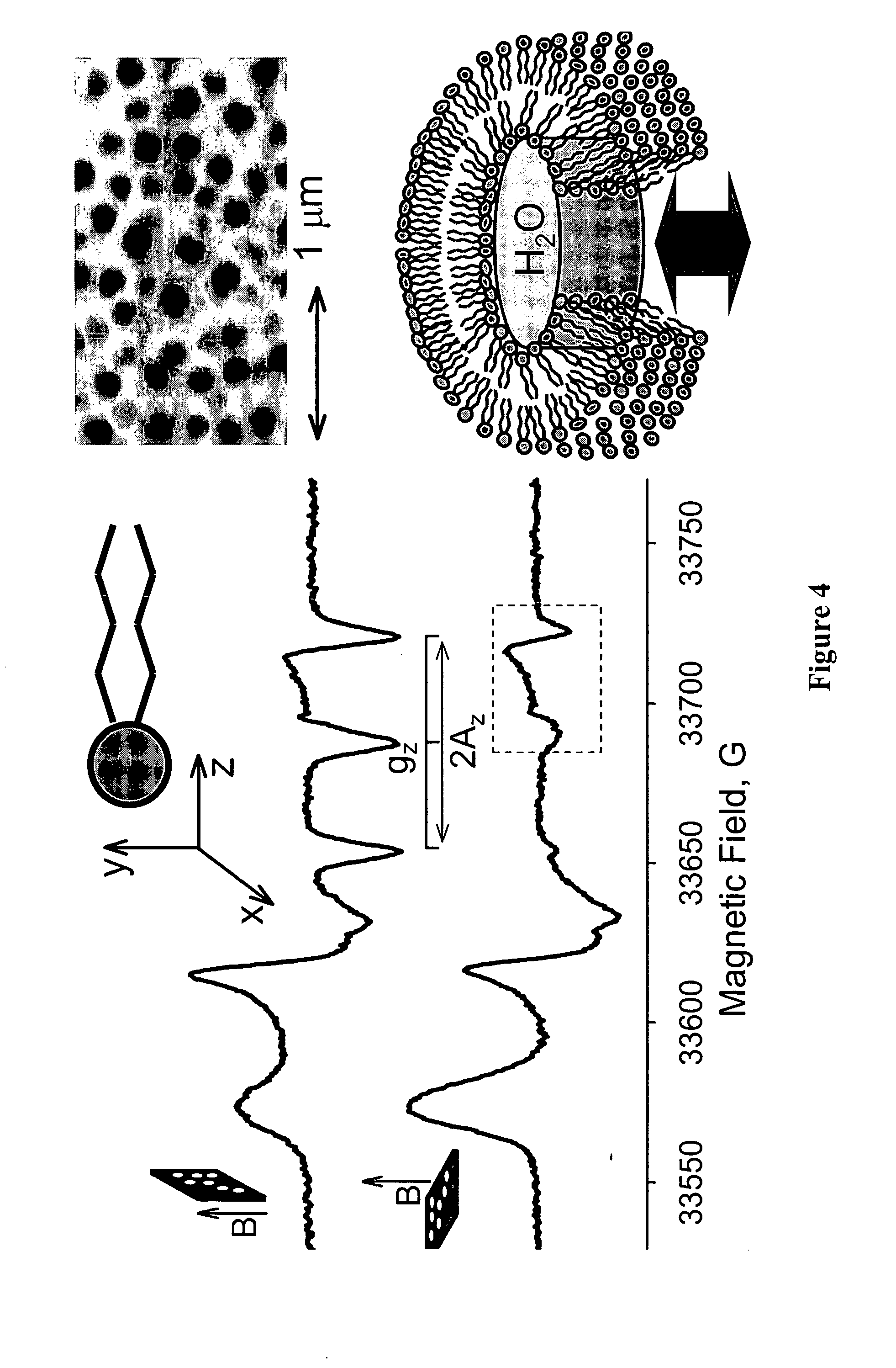

Nanotube structures having a surfactant bilayer inner wall coating

InactiveUS20080318245A1Increase surface areaProtect the surfaceBioreactor/fermenter combinationsMaterial nanotechnologyBi layerActive agent

Nanotubes and nanotube array structures comprise (a) a nanotube having an inner wall portion; and (b) a bilayer coating formed on the inner wall portions, with the bilayer coating comprised of surfactants. A secondary compound such as a protein, peptide or nucleic acid may be associated with the bilayer coating. The structures are useful for, among other things, affinity purification, catalysis, and as biochips.

Owner:NORTH CAROLINA STATE UNIV

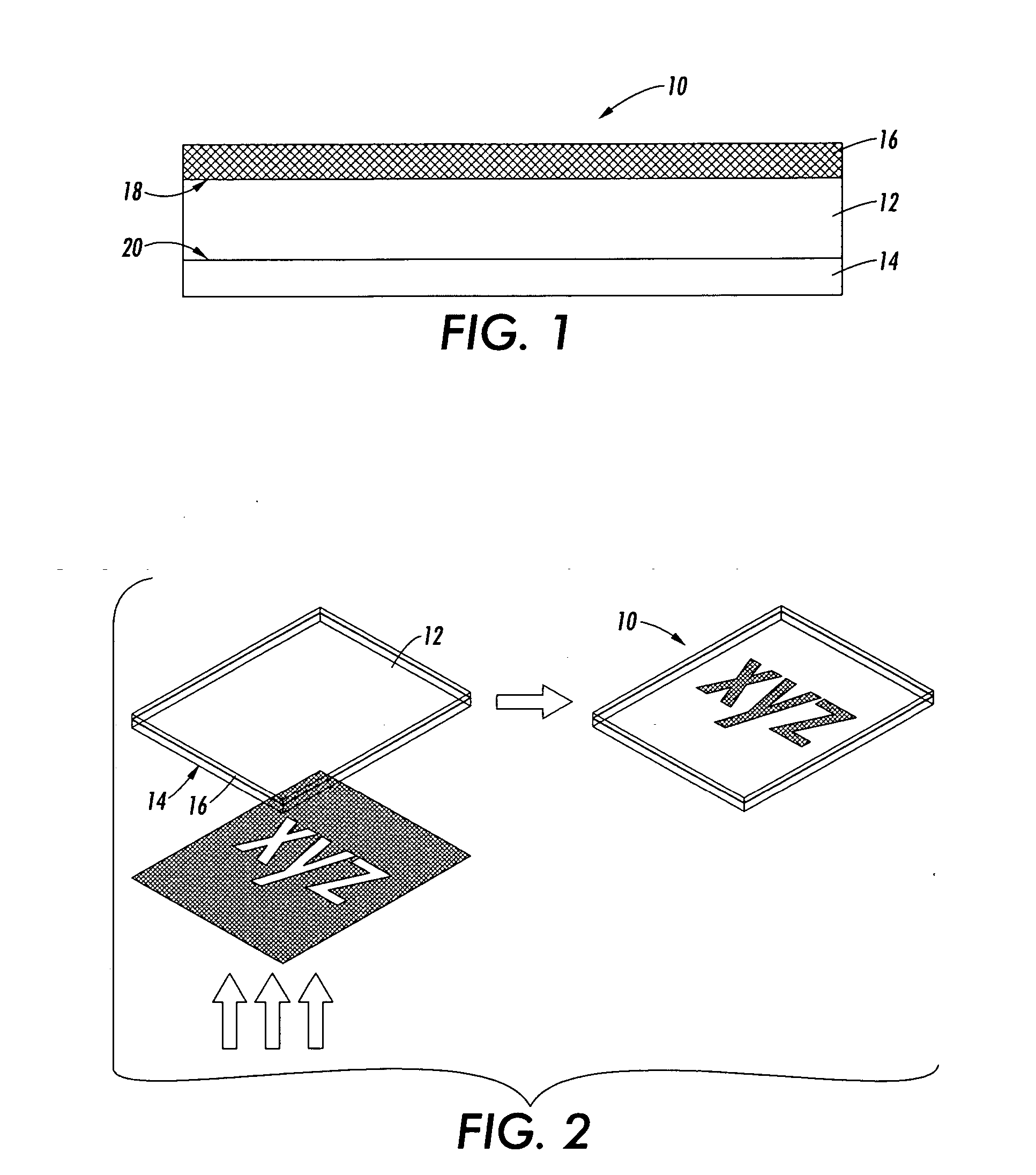

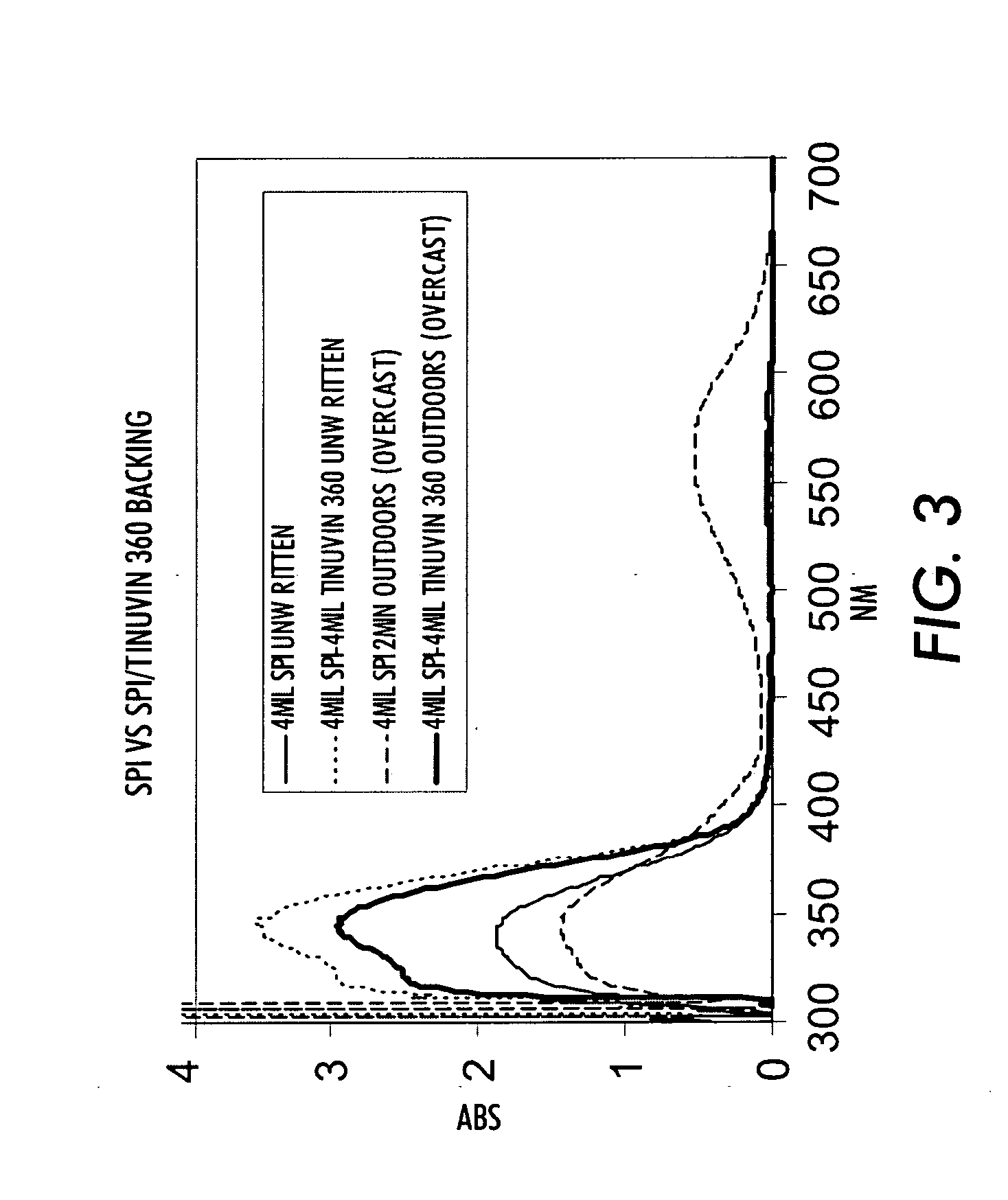

Dual-layer protected transient document

InactiveUS20060222972A1Photography auxillary processesRadiation applicationsProtection layerBi layer

Owner:XEROX CORP

Multi-layer coated porous materials and methods of making the same

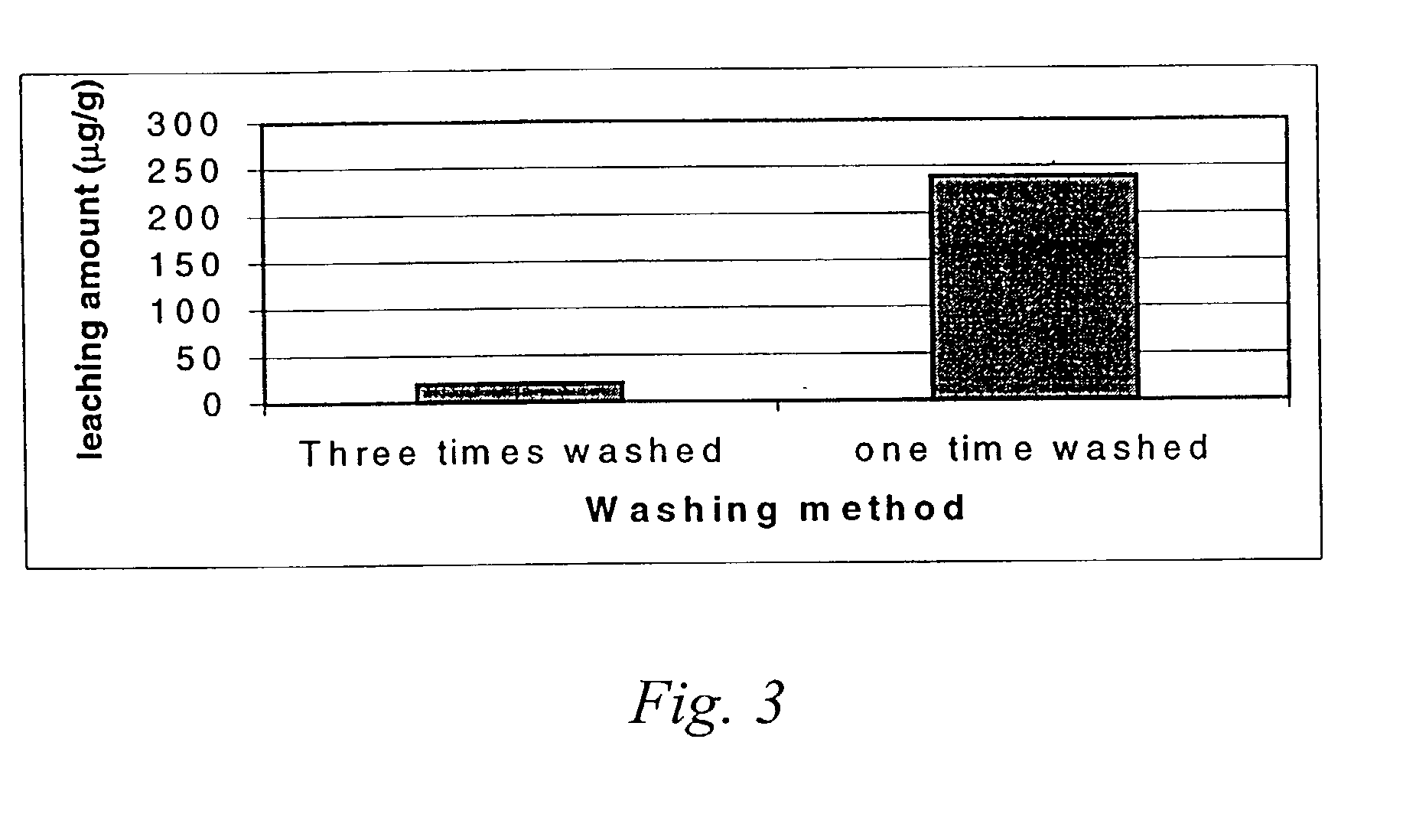

InactiveUS20030124332A1High density functional groupResistant to leachingSemi-permeable membranesMaterial analysis by observing effect on chemical indicatorPolyelectrolytePorous substrate

Multi-layer coated materials and methods of making them are disclosed. In a specific embodiment, a porous polymeric substrate is pre-activated and immersed in a polyelectrolyte solution to form a first layer having an electric charge and at least one functional group. The coated material is next immersed in a second solution of a material having an electric charge opposite of that of the first layer to provide a bi-layer coating. This process can be repeated to form multi-layer coatings on porous substrates.

Owner:POREX CORP

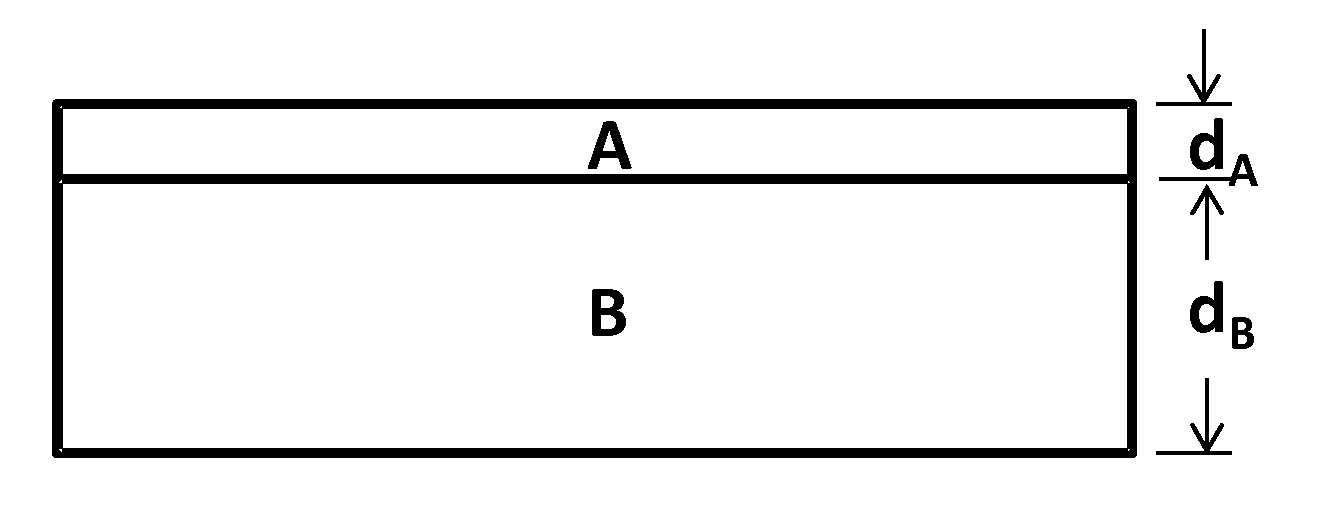

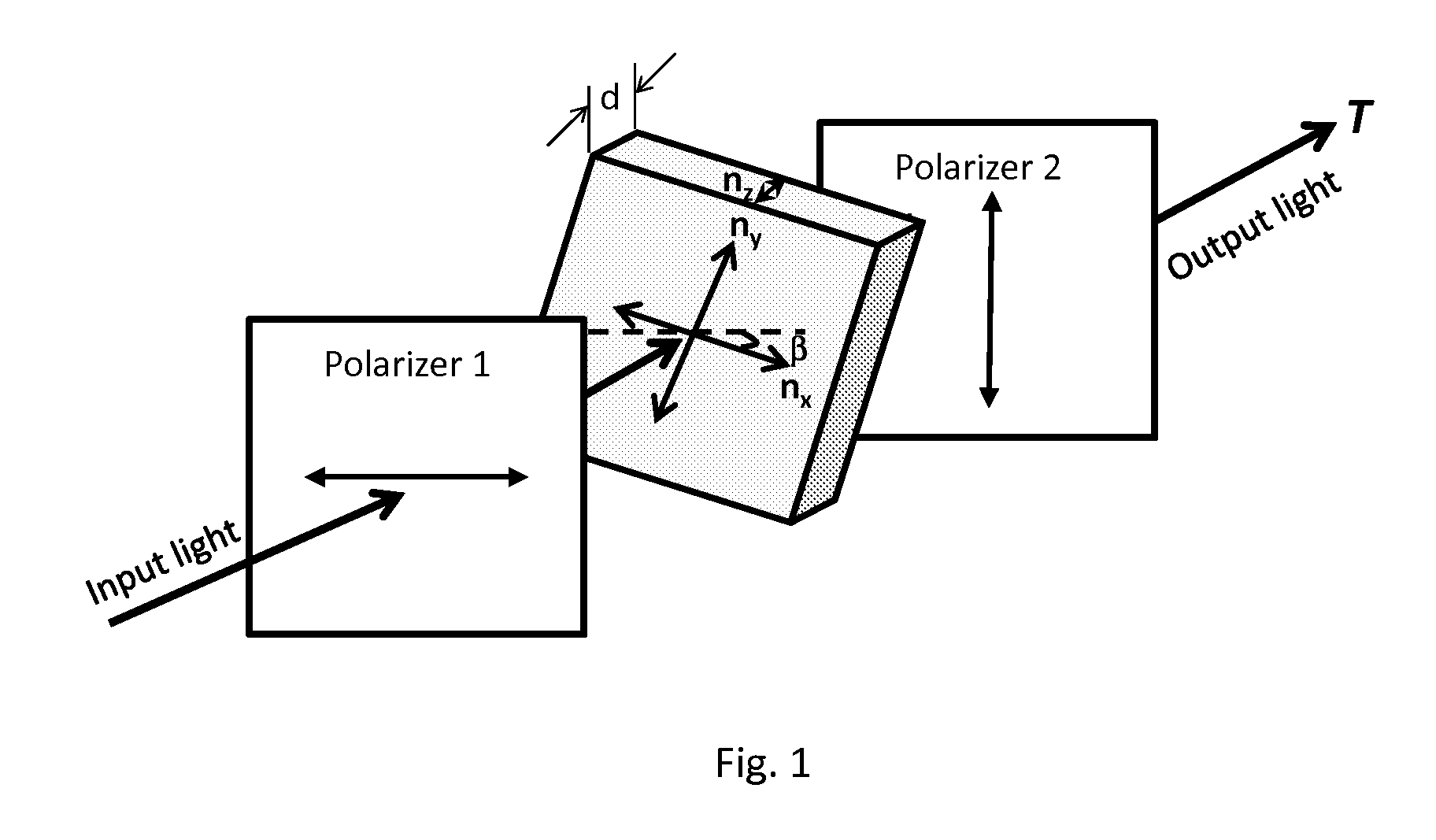

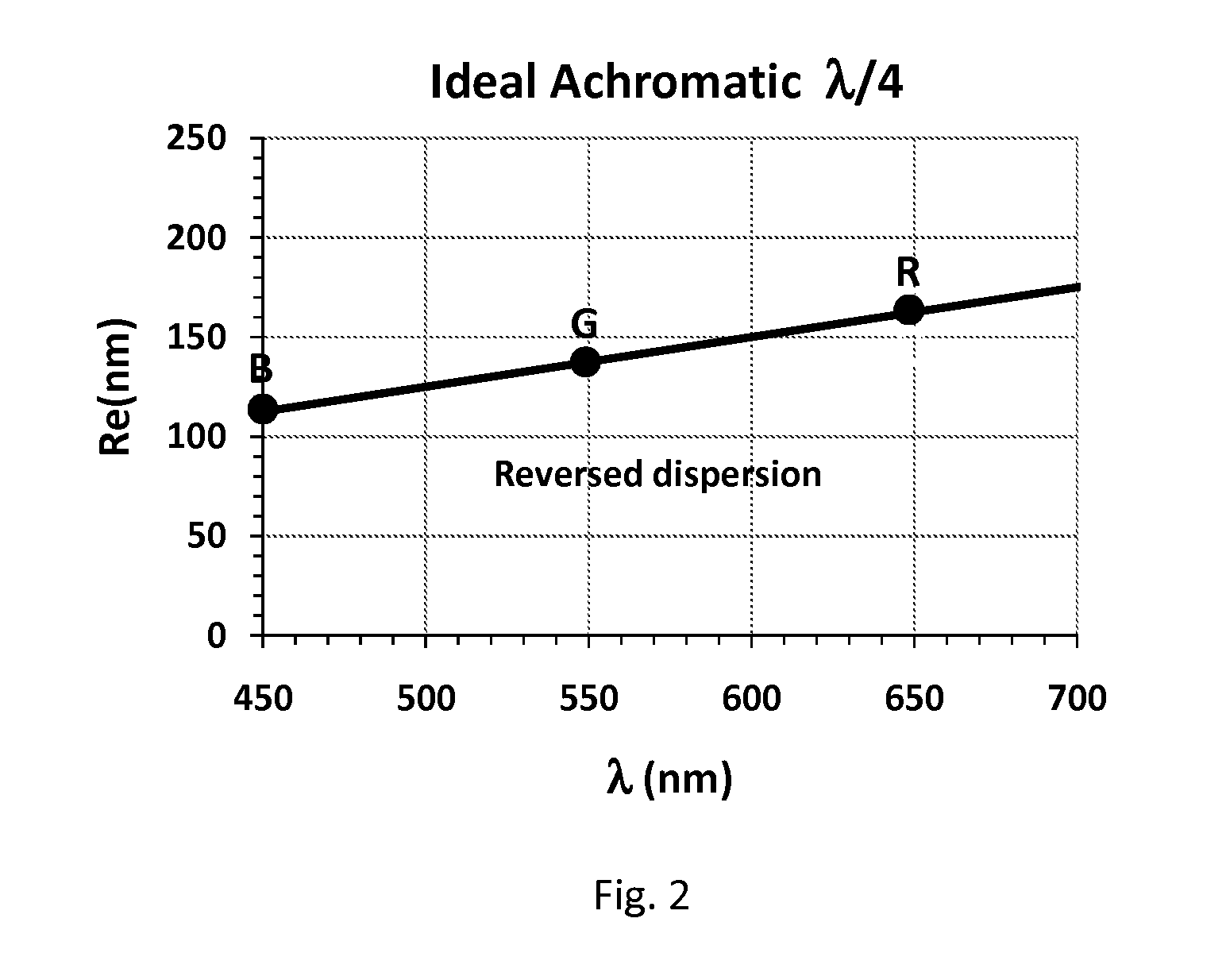

Multilayer cellulose ester film having reversed optical dispersion

InactiveUS20120003403A1High optical retardationReversed dispersionLiquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayColor shift

The present invention relates to a multilayer cellulose ester film having a reversed optical dispersion. The film can have an A-B bi-layer or an A-B-A tri-layer configuration. The cellulose ester material for layer A has a hydroxyl degree of substitution (DSOH) from 0 to 0.5, while the cellulose ester material for layer B has a DSOH from 0.5 to 1.3. By manipulating the thickness of layers A and B, and the film stretching conditions, desirable optical retardation and optical dispersion properties can be obtained. The film can be used as an optical waveplate in liquid crystal displays to improve viewing angle, contrast ratio, and color shift.

Owner:EASTMAN CHEM CO

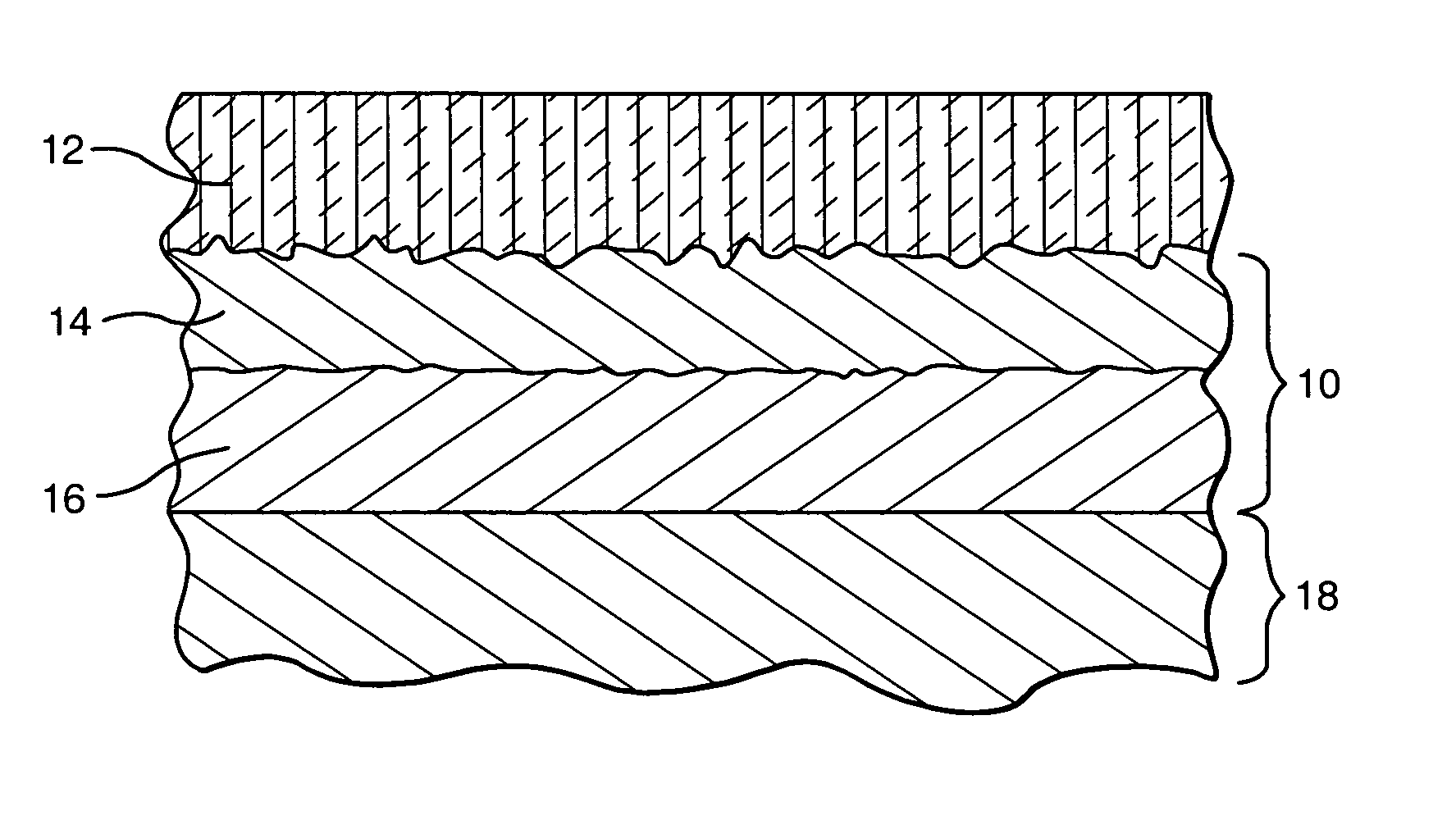

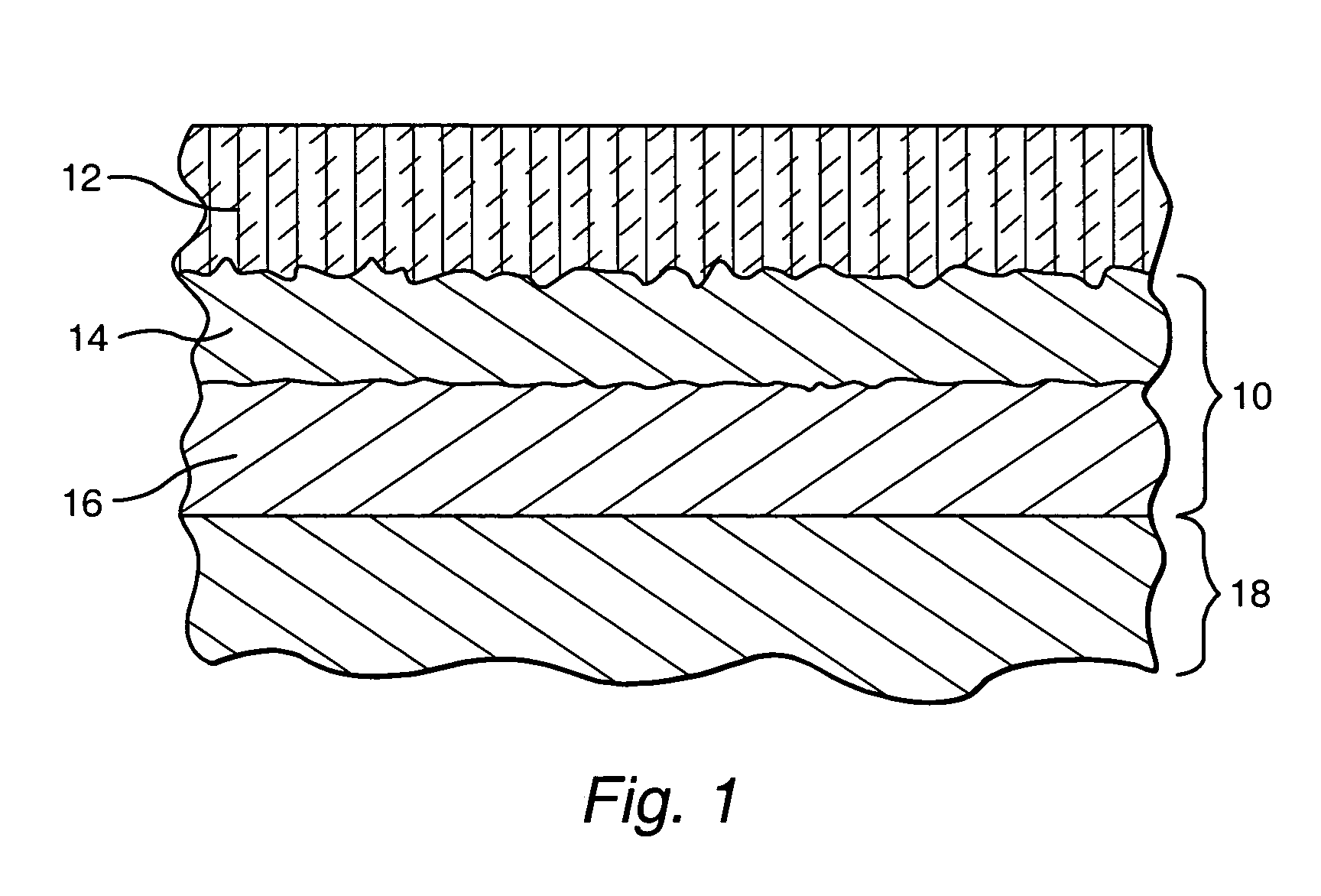

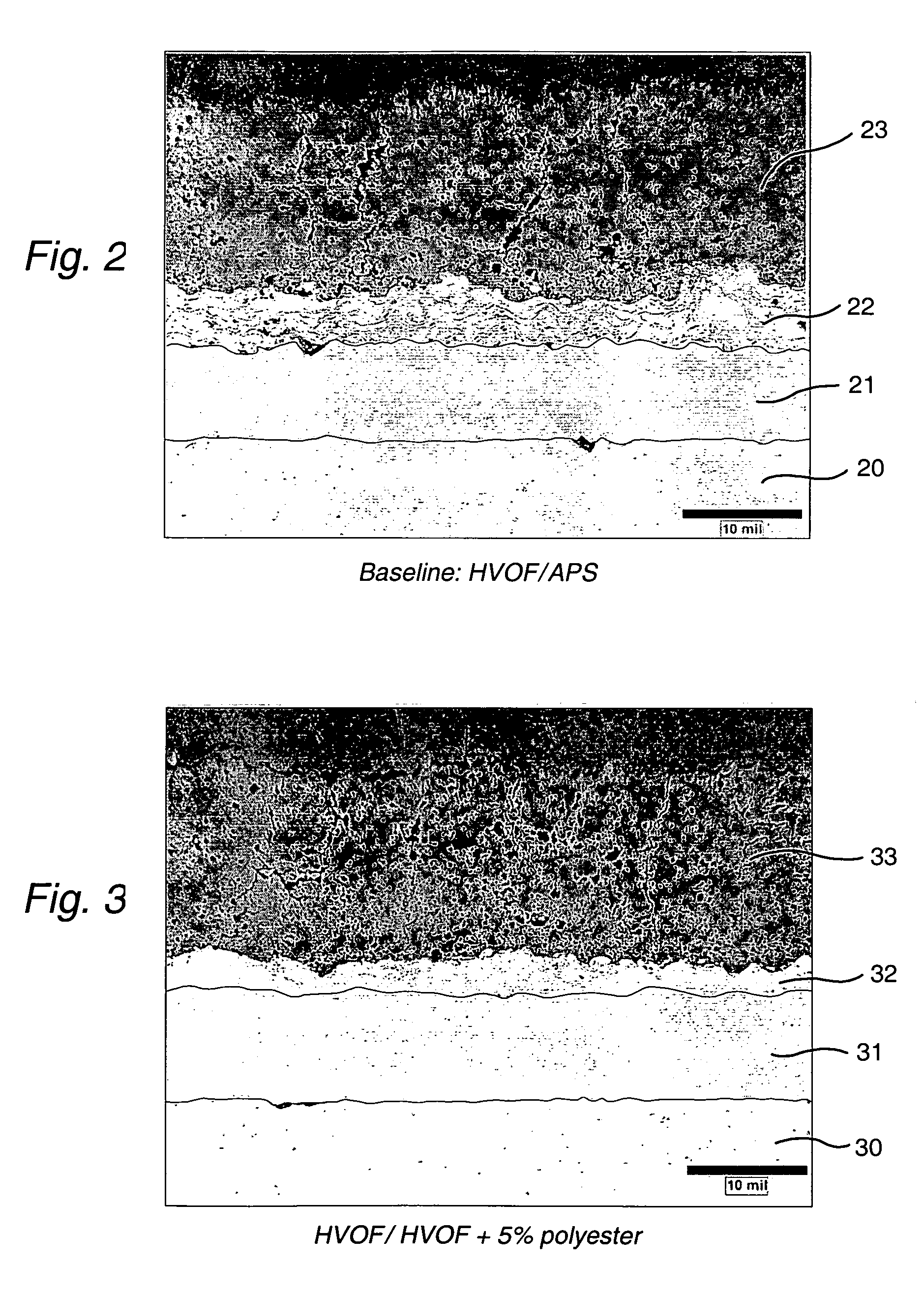

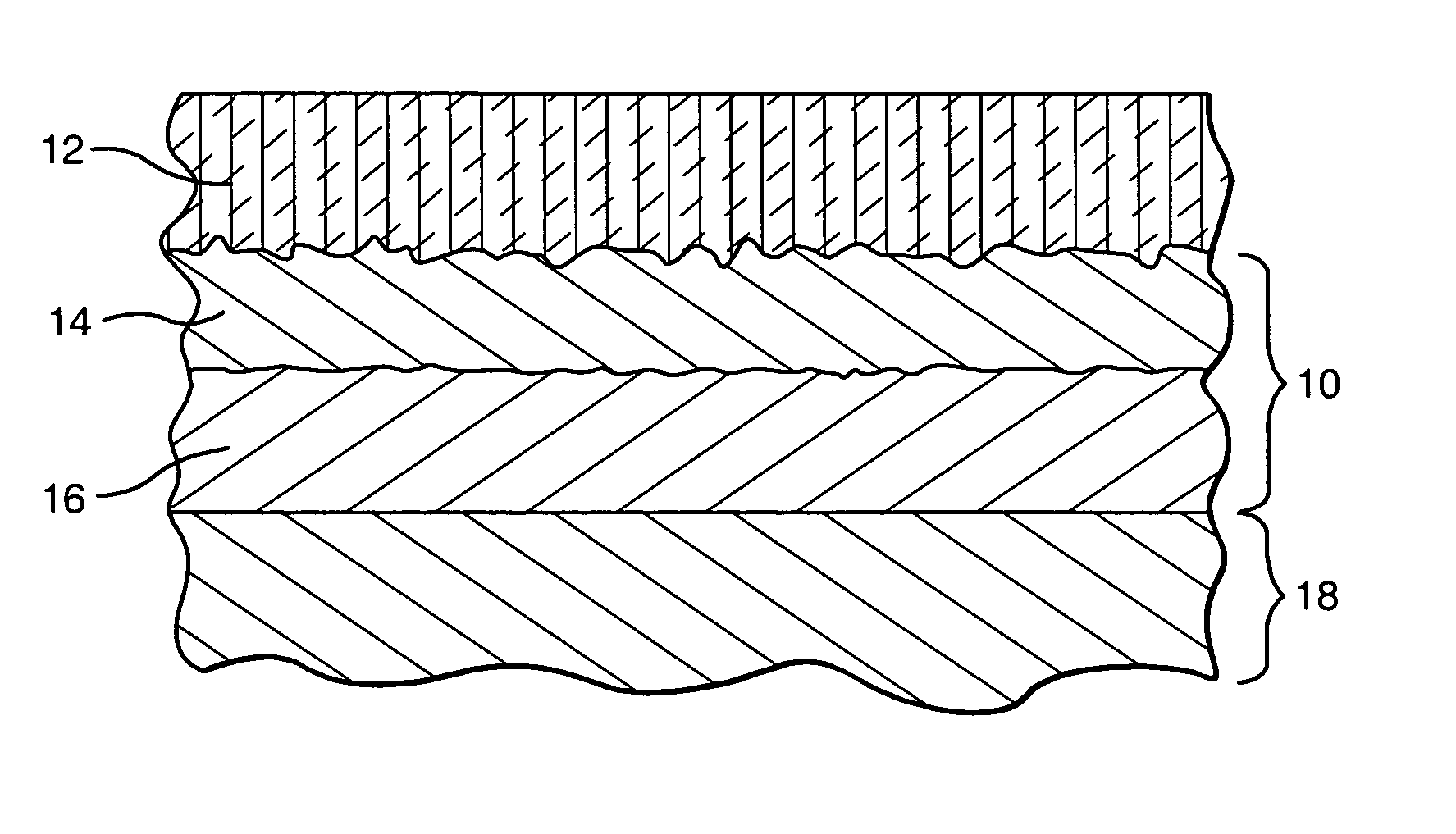

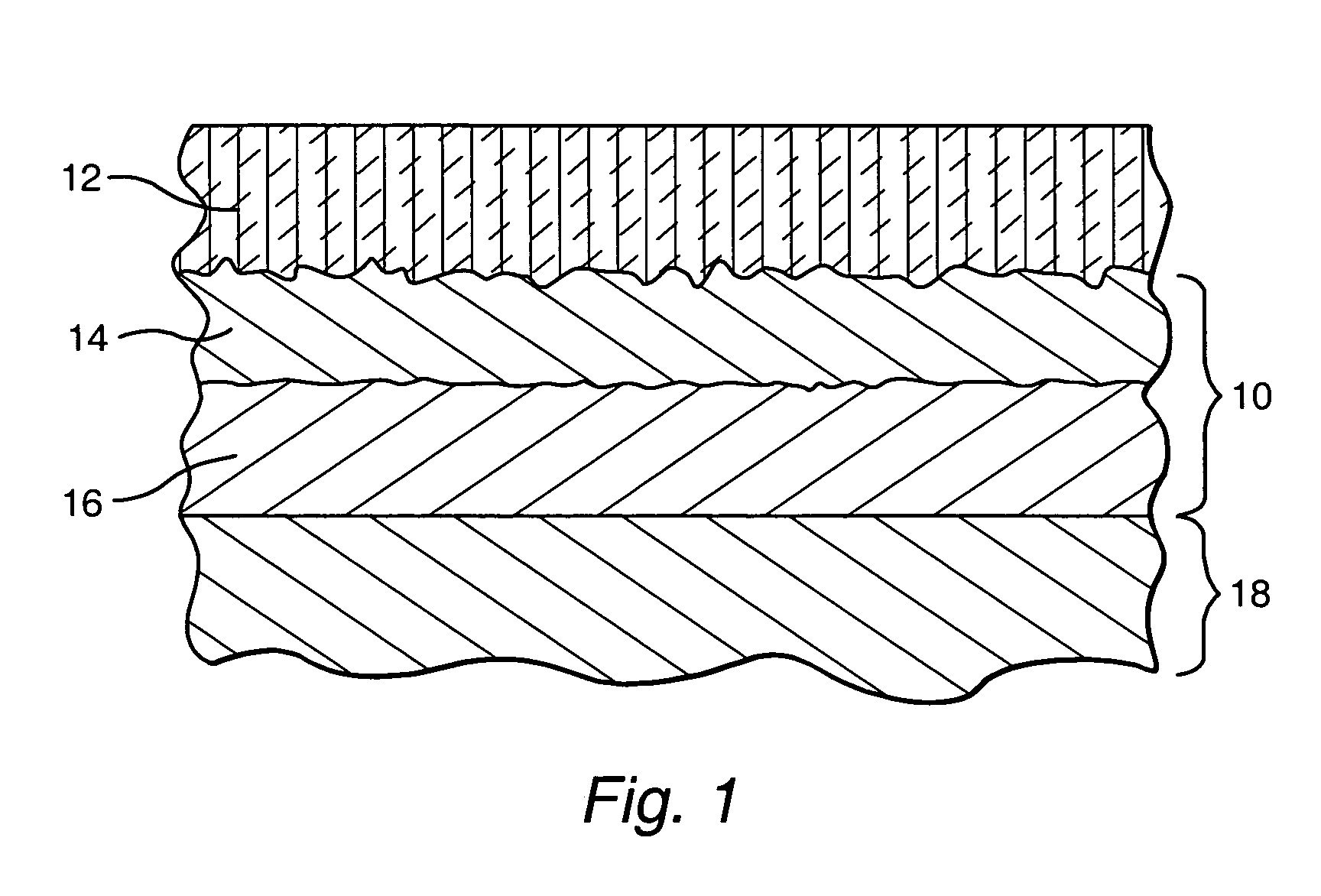

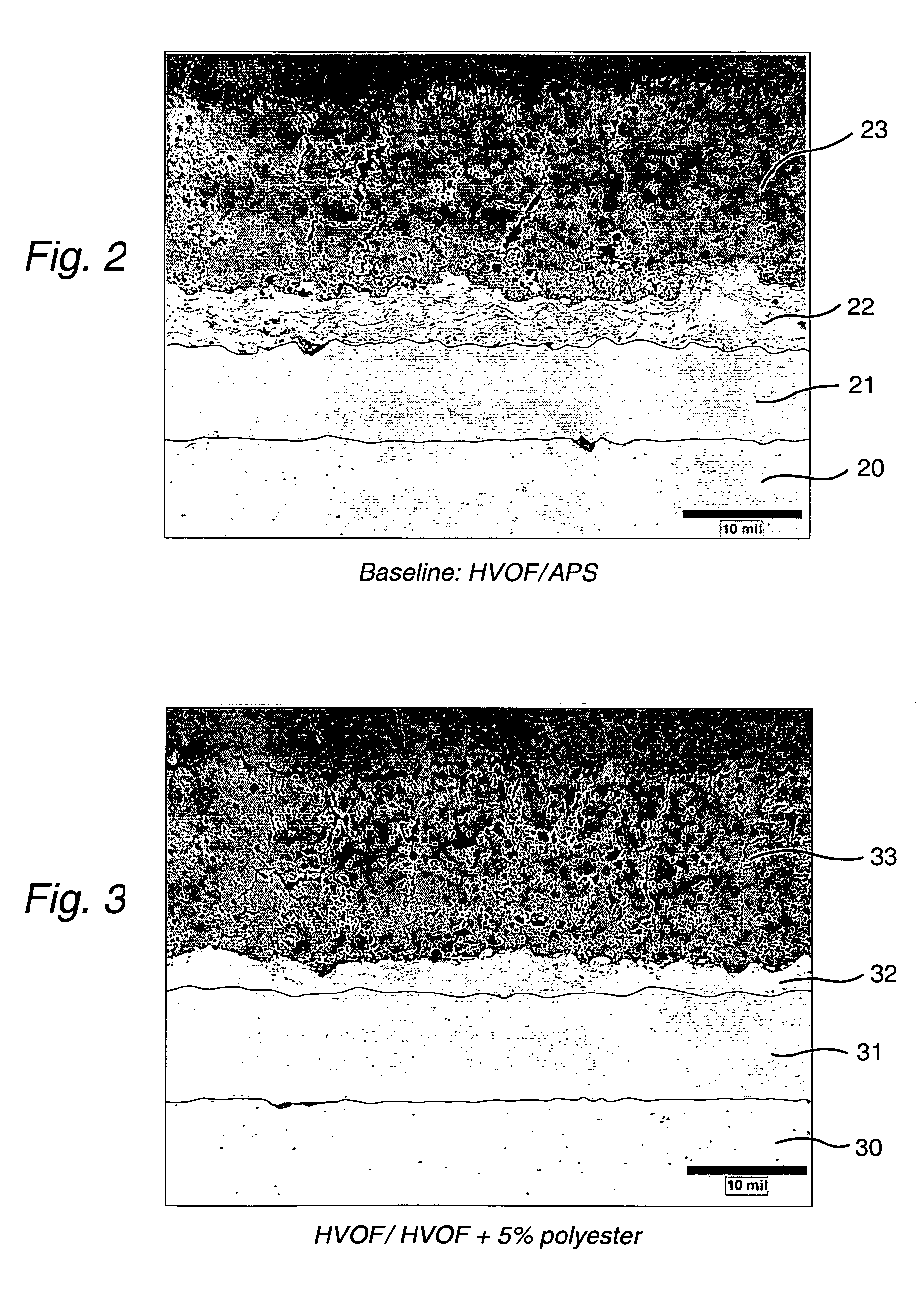

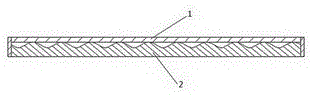

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS7150921B2Increase roughnessImprove ductilityMolten spray coatingPretreated surfacesPorosityPolyester

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine, and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate using high velocity oxy-fuel (HVOF) thermal spraying. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the thermal barrier coating (TBC). Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance.

Owner:GENERAL ELECTRIC CO

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS20050260434A1Increase roughnessImprove ductilityPropellersMolten spray coatingPolyesterPorosity

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine used to generate electricity and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate, with both layers being applied using high velocity oxy-fuel (HVOF) thermal spraying. In one embodiment, bond coatings in accordance with the invention can be used in combination with a thermal barrier coating (“TBC”). However, the invention can also take other forms, such as a stand alone overlay coating. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the TBC. Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance. Together, the layers enhance adherence to the substrate and improve the overall life of the coating system.

Owner:GENERAL ELECTRIC CO

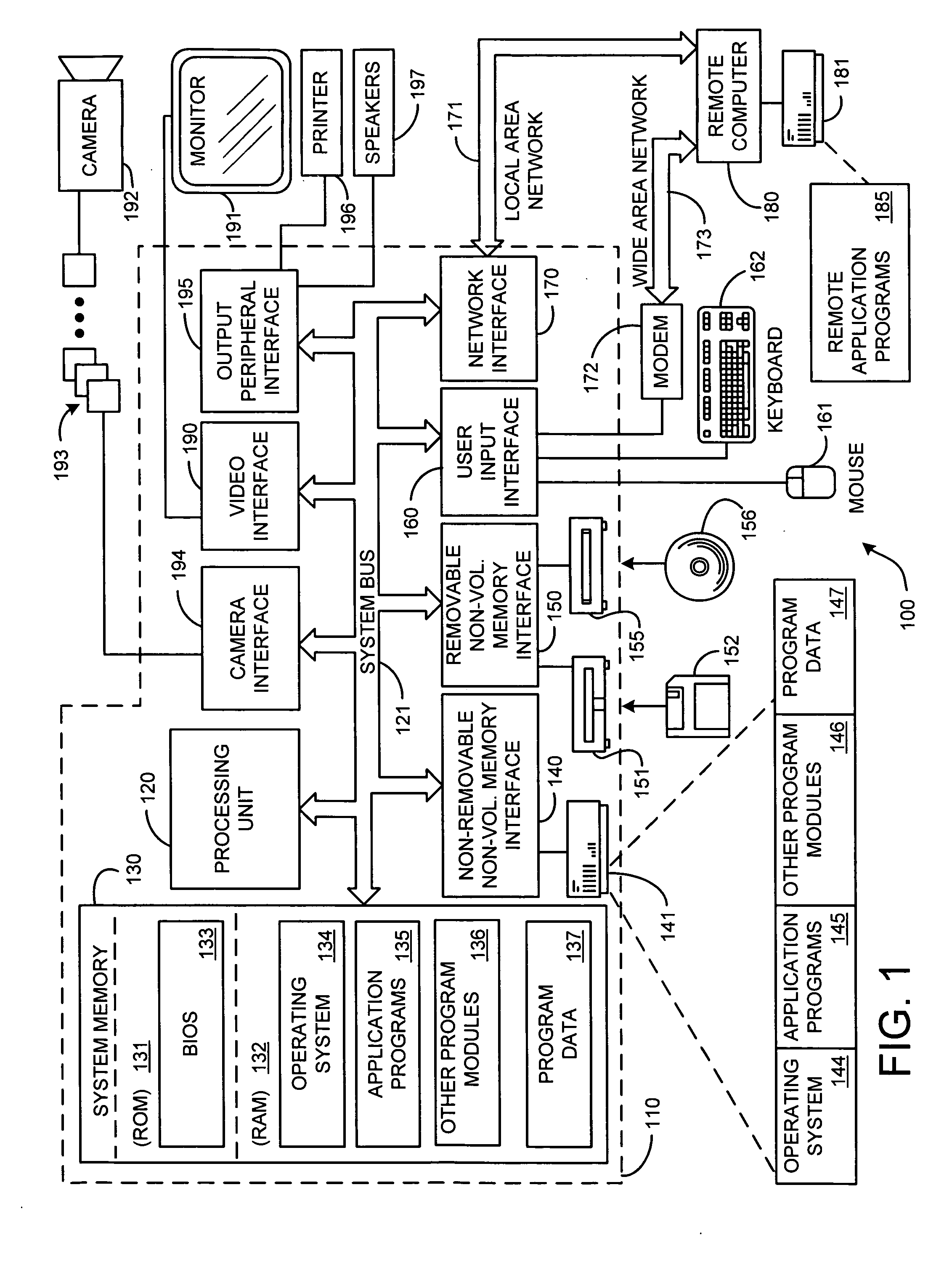

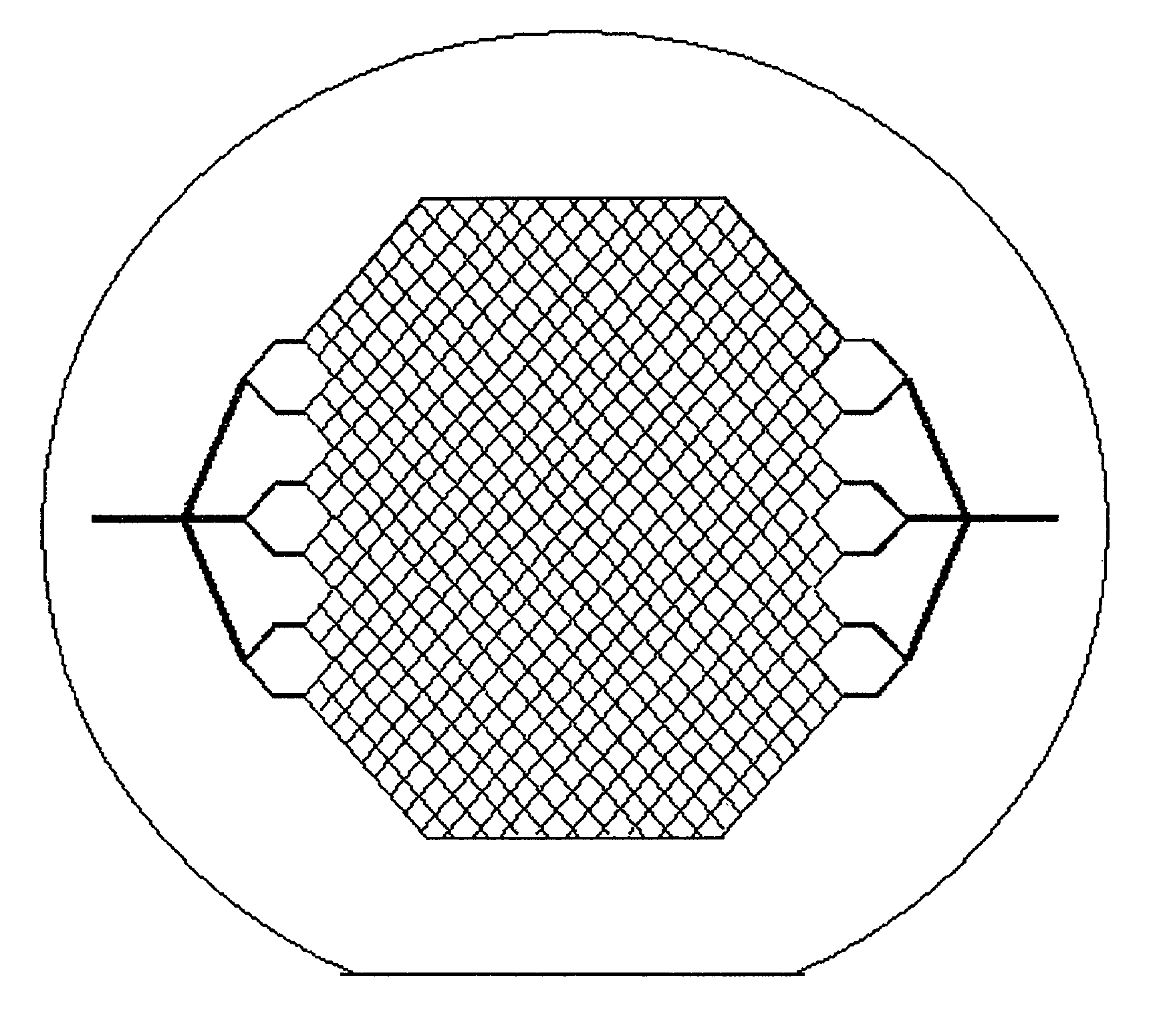

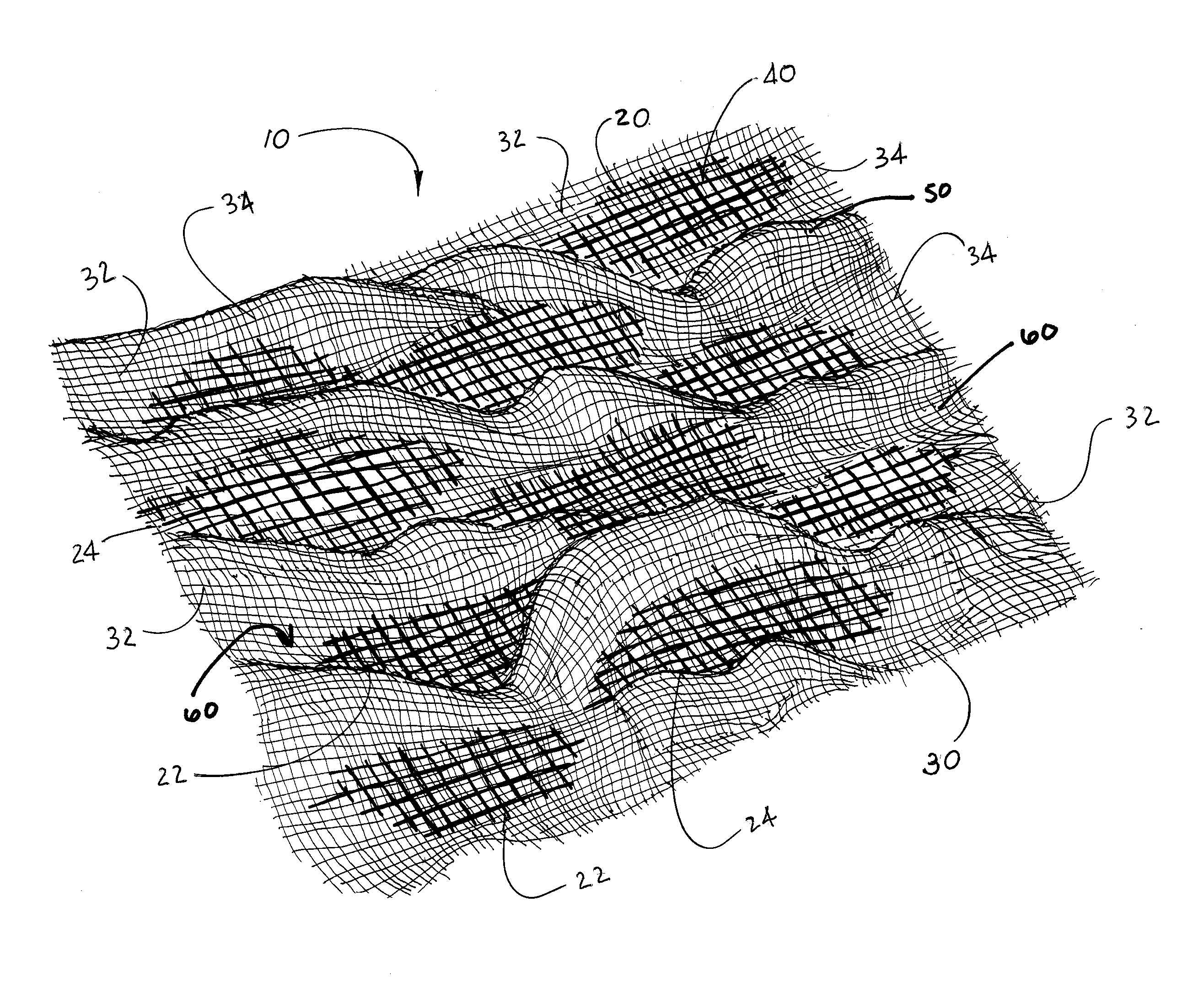

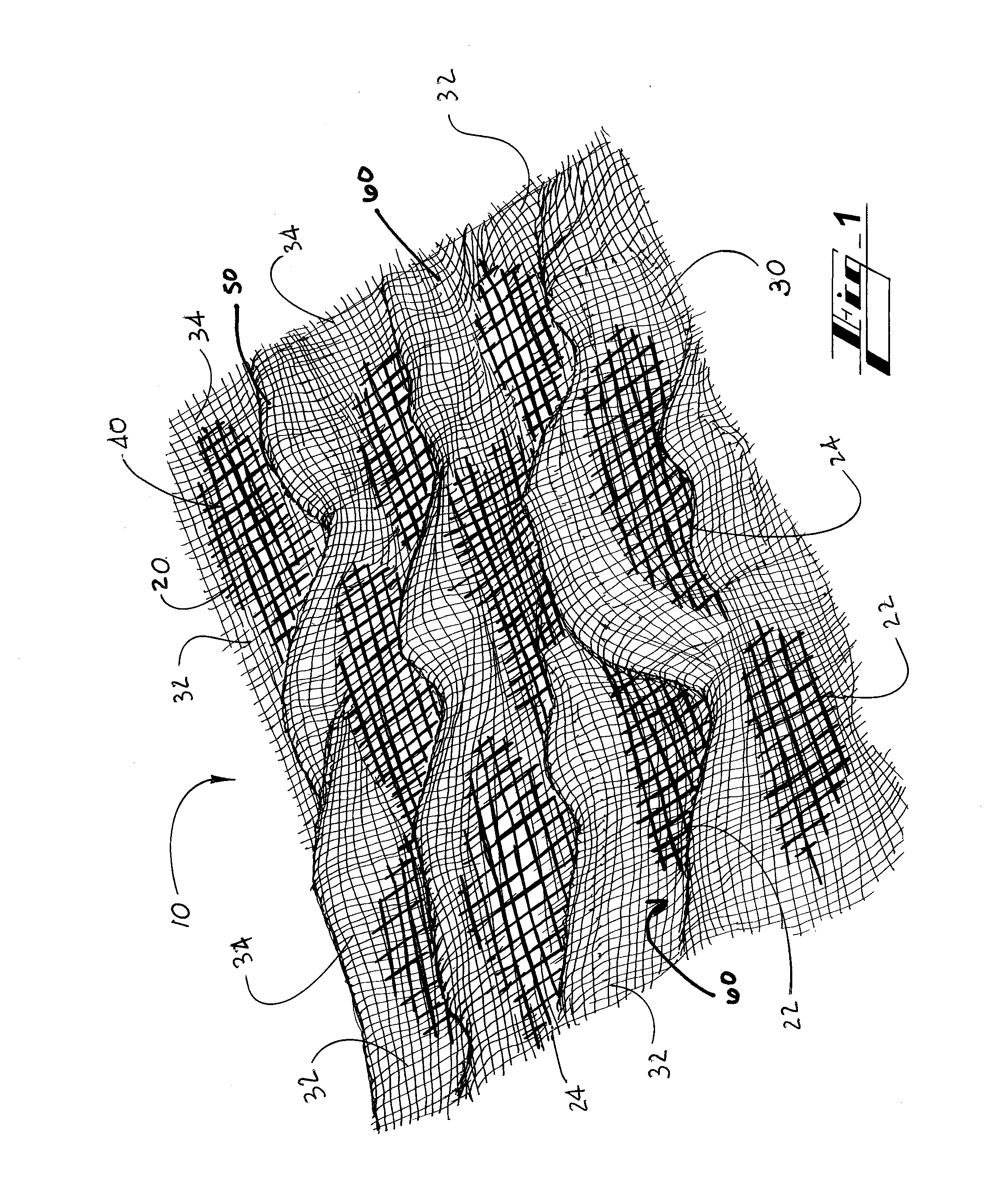

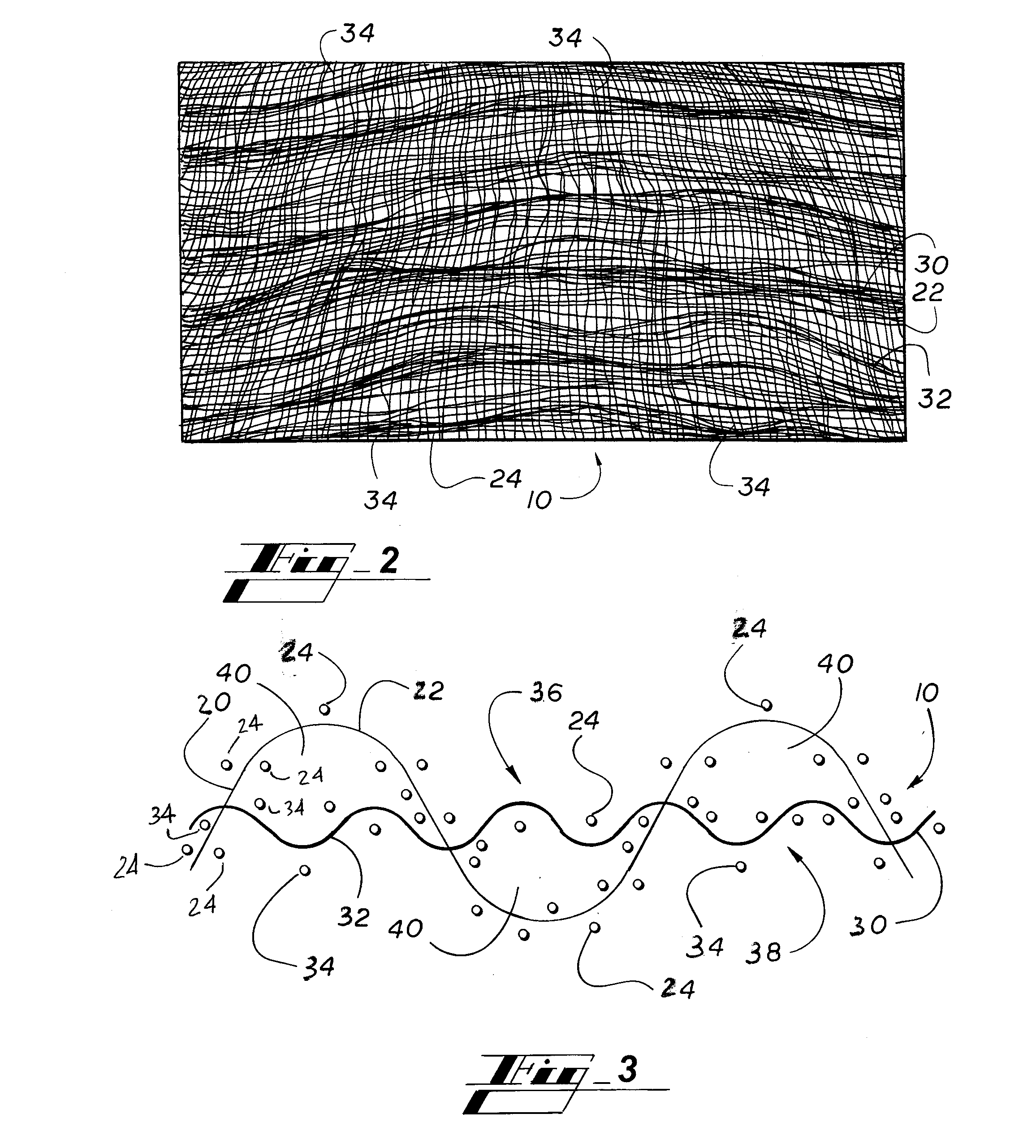

Turf reinforcement erosion control mat

A bi-layer, woven geotextile fabric has interwoven first and second layers. The first layer is over and under woven through the second layer in a pre-determined pattern so that the first layer has portions which face a first side of the second layer and portions which face a second side of the second layer. Monofilaments in the warp direction of the first layer have a pre-determined differential heat shrinkage characteristic that is greater than the monofilaments in the warp direction of the second layer. Closed cells defined by the pattern of the over and under weave are disposed on the first and second sides of the second layer. Shrinkage of the monofilaments in the warp direction of the first layer provide for a separation of a portion of the second layer from the first layer at the cells.

Owner:NICOLON CORP

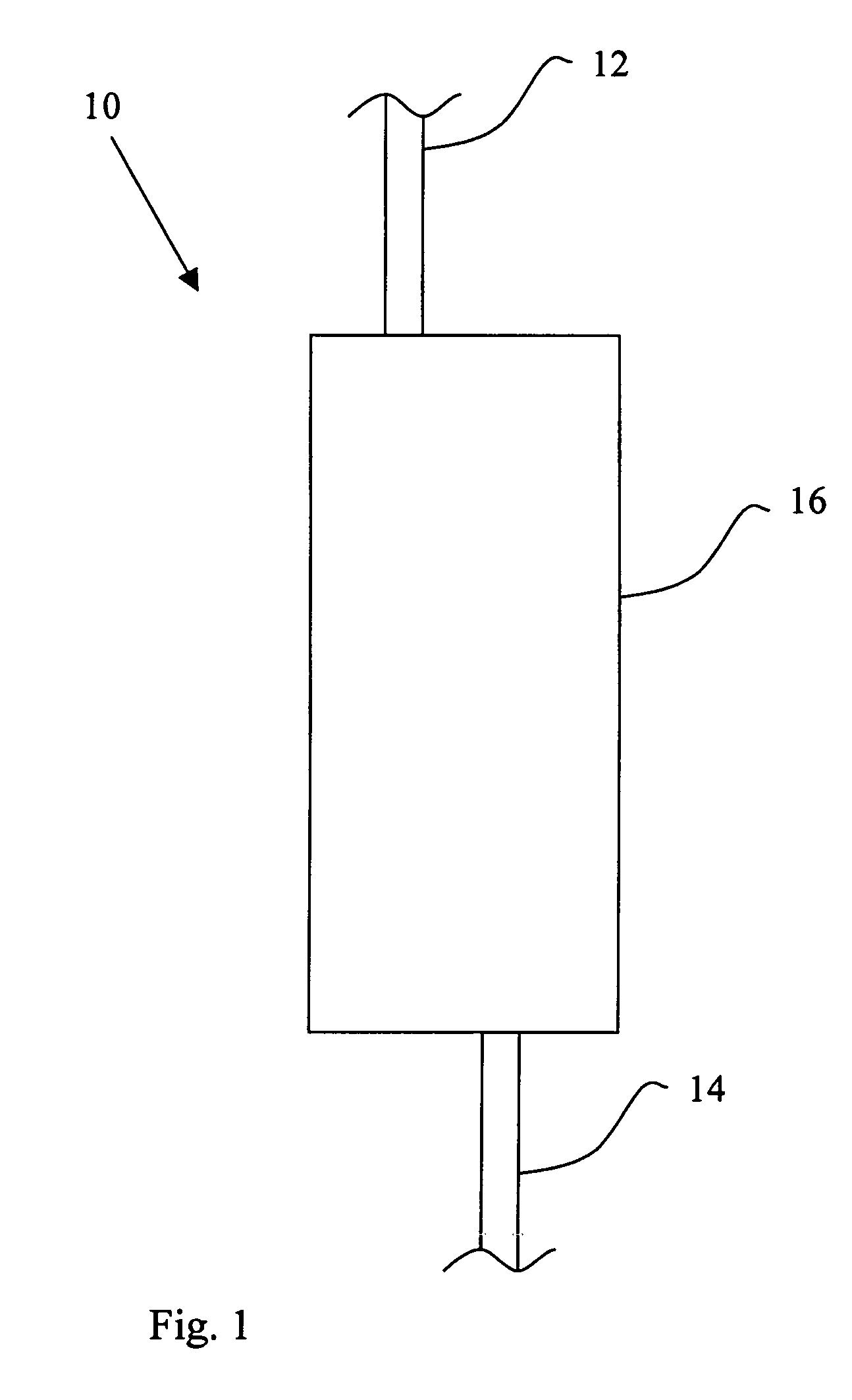

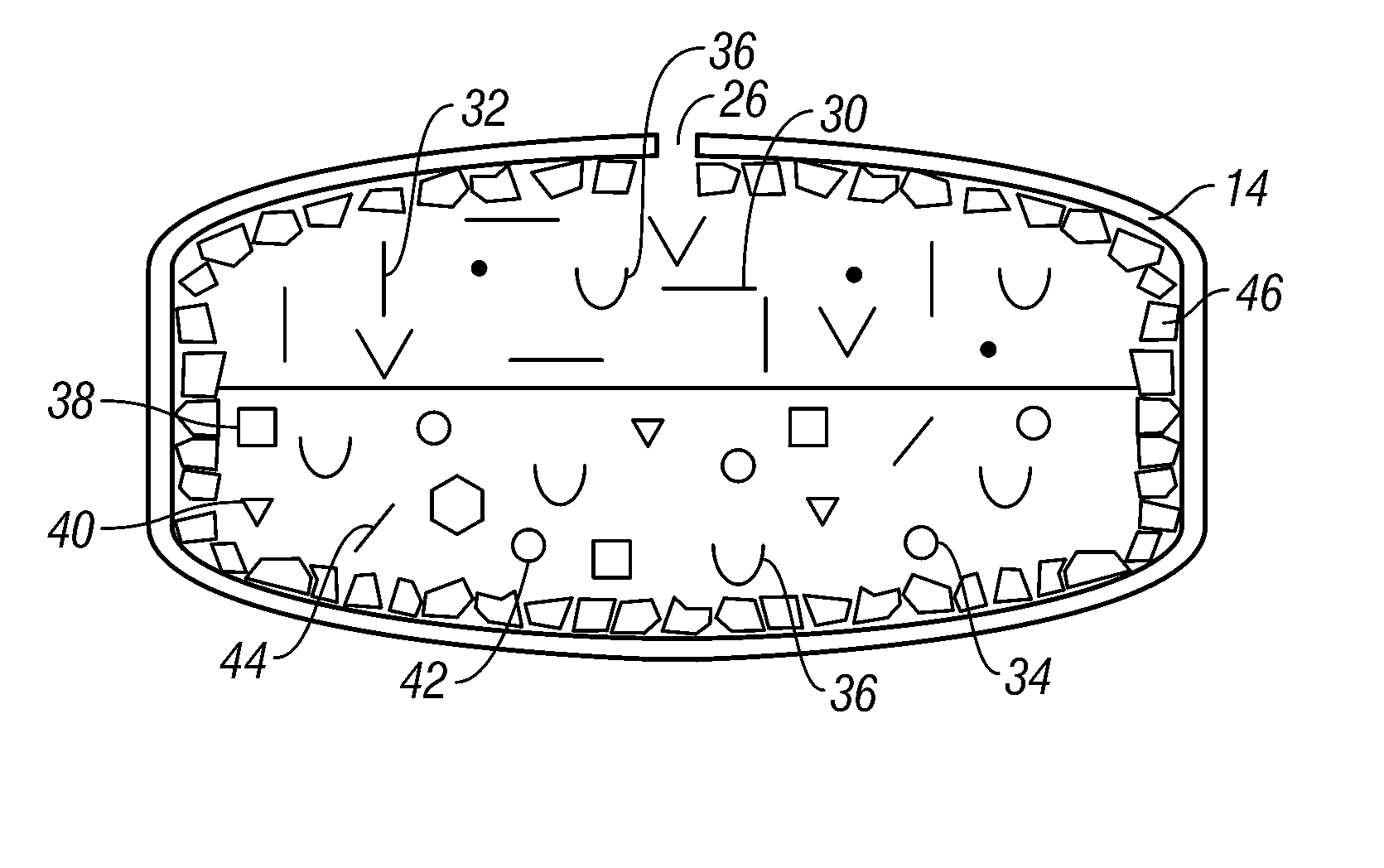

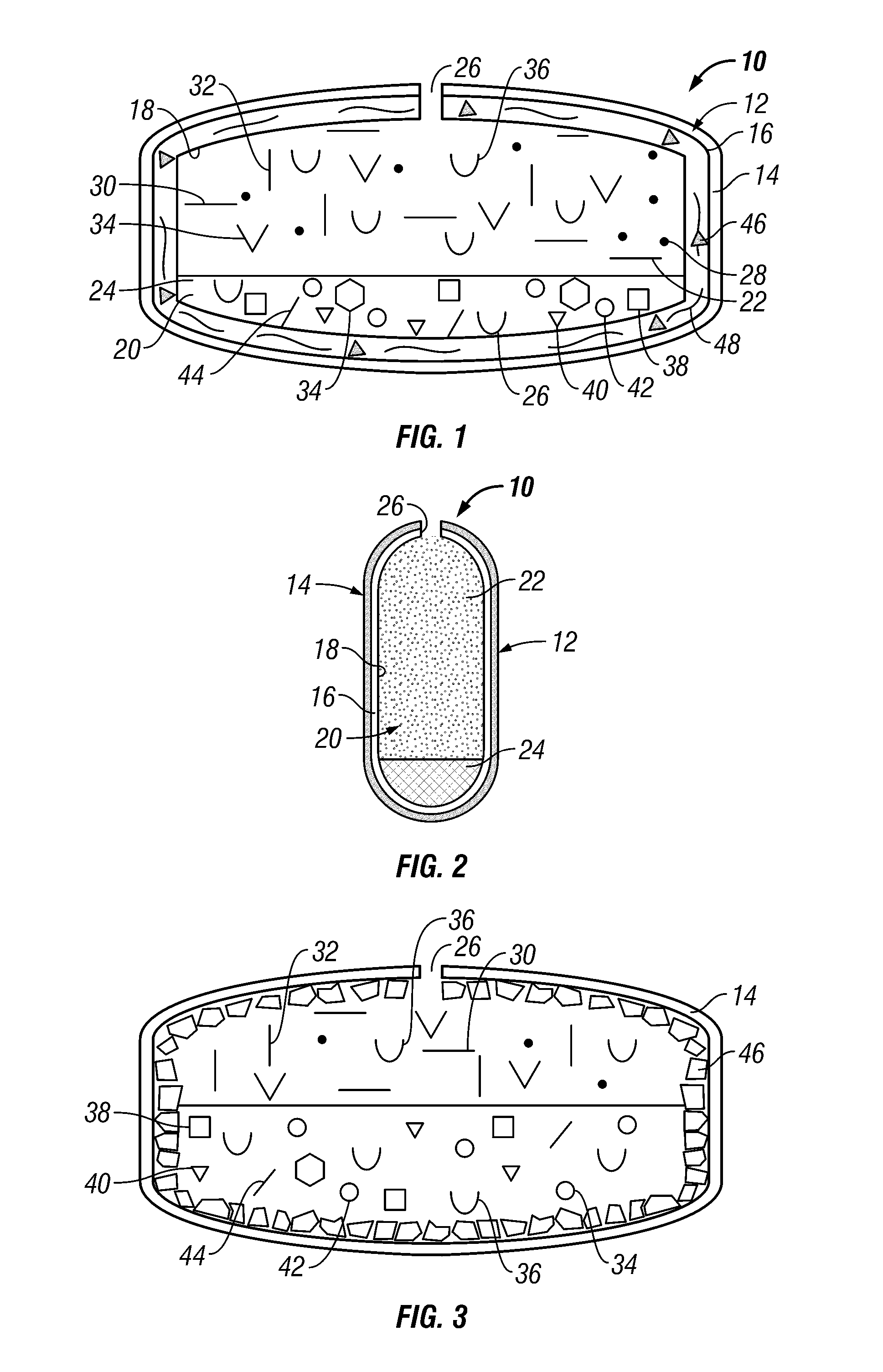

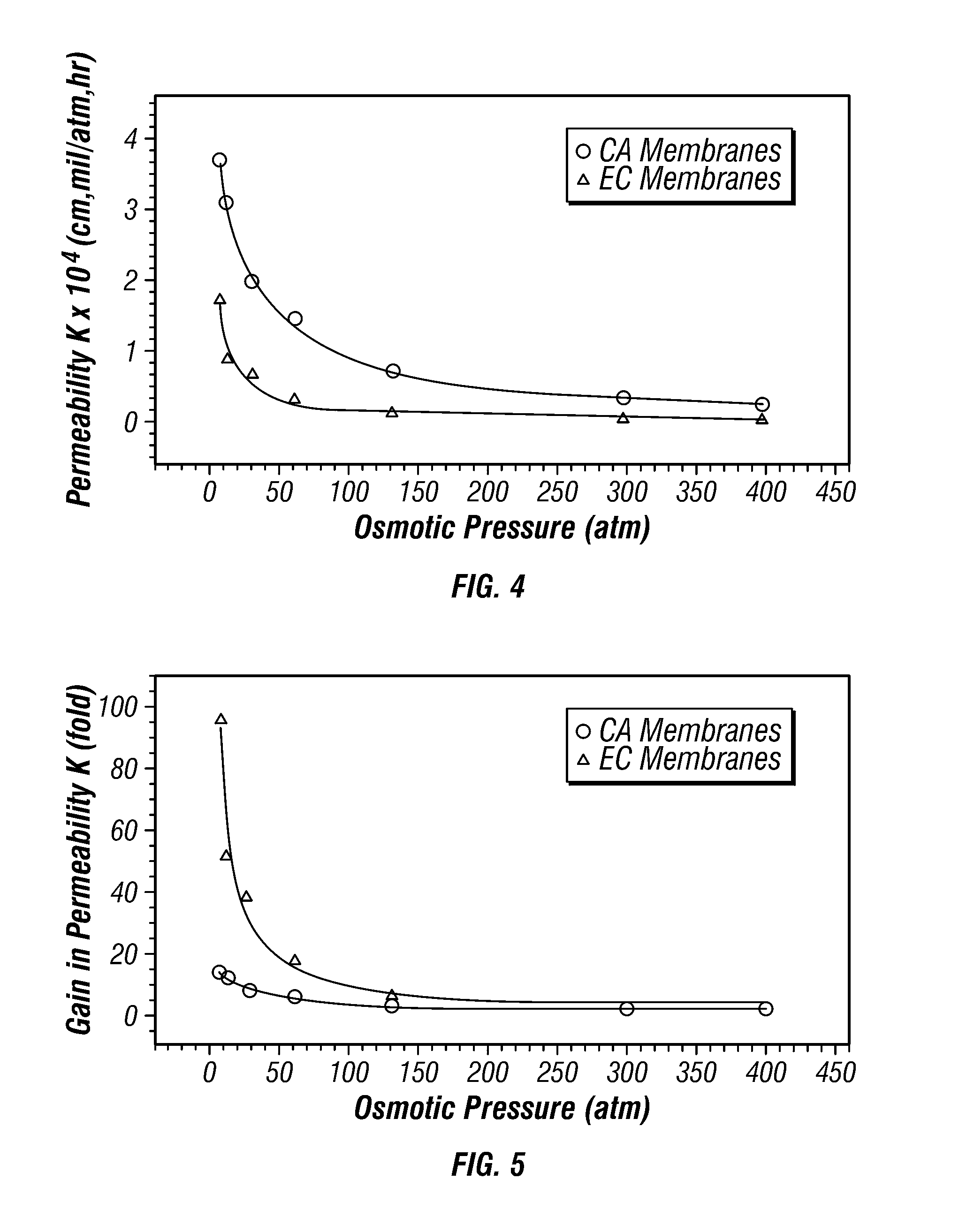

Volume Efficient Controlled Release Dosage Form

InactiveUS20070184112A1Easy loadingOrganic active ingredientsPharmaceutical non-active ingredientsBi layerActive agent

A dosage form that facilitates the controlled release of an active agent at a desired release rate or release rate profile includes a bi-layer membrane system and an osmotic core. The bi-layer membrane system includes a semipermeable membrane and an osmosensitive membrane and forms an internal compartment occupied by the osmotic core. The osmotic core includes an active agent composition and a light push layer. A passageway is formed through the bi-layer membrane system and permits expulsion of the active agent composition from the dosage form during operation. The bi-layer membrane system and the osmotic core are formulated and formed to provide controlled release of the active agent included in the active agent composition, while simultaneously facilitating increased loading of active agent within a dosage form of given dimension and increasing the delivery efficiency of such active agent relative to prior osmotic dosage forms including a push layer.

Owner:ALZA CORP

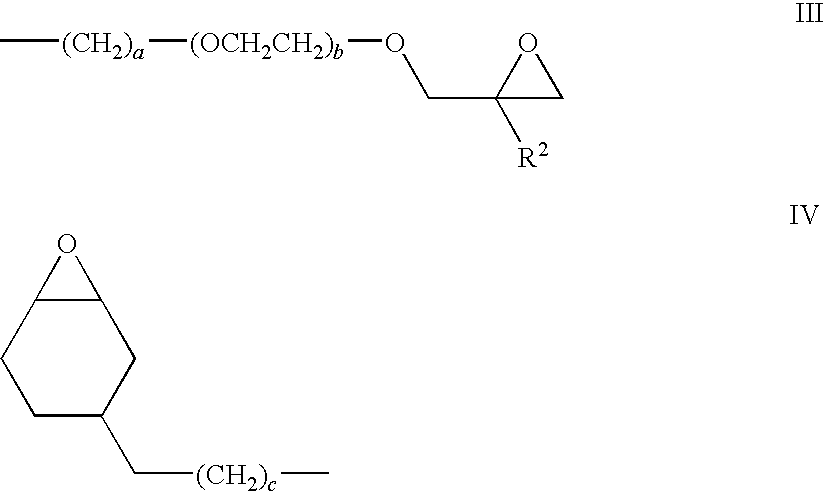

Process for Preparing Articles Having Anti-Fog Layer by Layer Coating and Coated Articles Having Enhanced Anti-Fog and Durability Properties

ActiveUS20100304150A1Improve mechanical durabilityEasy to depositSynthetic resin layered productsPretreated surfacesPolymer scienceAtmospheric pressure

Disclosed are processes for preparing articles having anti-fog properties, comprising providing a substrate having at least one main surface coated with an intermediate coating obtained by applying and at least partially curing an intermediate coating composition comprising at least one monoepoxysilane and / or an hydrolyzate thereof and at least one polyepoxy monomer comprising at least two epoxy groups, forming onto said intermediate coating at least one bi-layer, and curing said at least one bi-layer by heating at a temperature of 150° C. or less at atmospheric pressure and in the absence of added water steam. Also disclosed are articles made and / or makeable by these processes.

Owner:ESSILOR INT CIE GEN DOPTIQUE

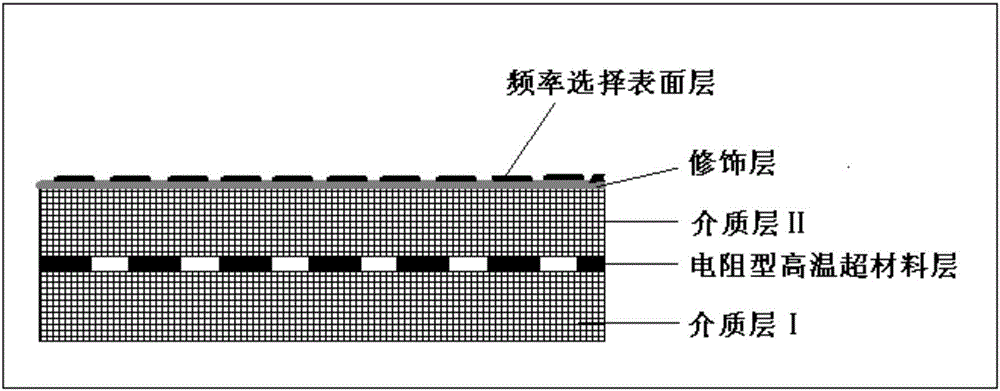

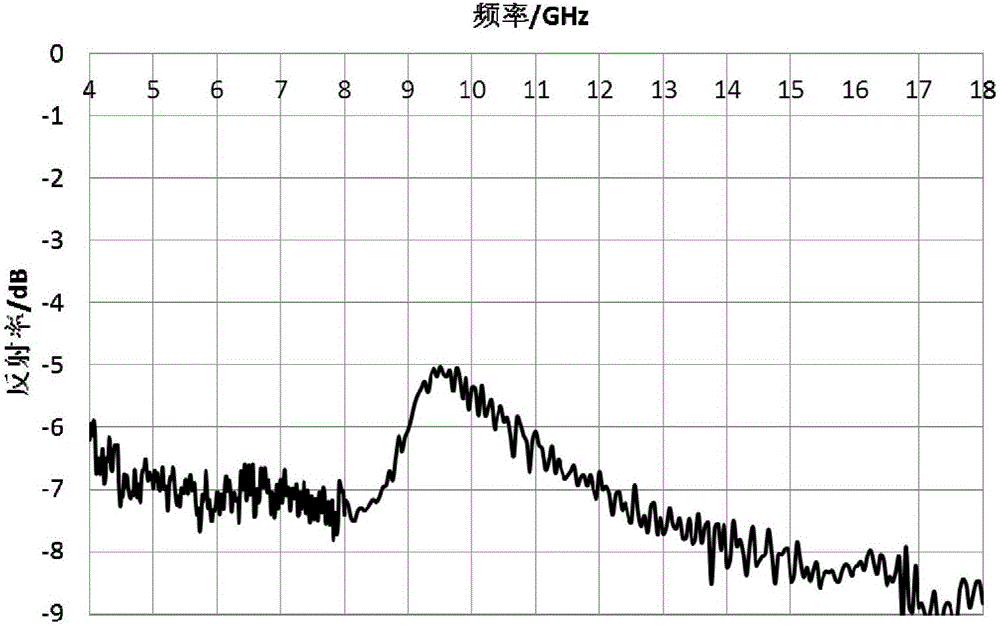

High temperature resistant radar and infrared compatible stealth material based on double-layer metamaterials and preparation method of stealth material

ActiveCN106427115ALow emissivity characteristicEasy to implement reflection functionLaminationLamination apparatusFiberLow emissivity

The invention discloses a high temperature resistant radar and infrared compatible stealth material based on double-layer metamaterials. The high temperature resistant radar and infrared compatible stealth material is of a layered structure sequentially comprises a dielectric layer I, a resistance-type high temperature metamaterials layer, a dielectric layer II, a decorative layer and a frequency selective surface layer from inside to outside, wherein both the dielectric layer I and the dielectric layer II are made of oxide fiber reinforced oxide-based composite materials, the resistance-type high temperature metamaterials layer mainly comprises a high temperature resistant resistor coating with periodic patterns, the decorative layer is made of glass coatings, and the frequency selective surface layer mainly comprises a high temperature resistant antioxidant and low infrared emissivity precious metal plating layer with periodic patterns. A preparation method is characterized in that the materials of the layers are prepared in a layered manner. The high temperature resistant radar and infrared compatible stealth material has high designability, the problem of radar and infrared compatible stealth contradiction can be effectively solved from the perspective of structural design by the aid of metamaterial technology, and the high temperature resistant radar and infrared compatible stealth material has good broadband wave-absorbing performance and low emissivity and can resist high temperature of 1000 DEG C or more.

Owner:NAT UNIV OF DEFENSE TECH +1

Multi-layer hard mask for deep trench silicon etch

InactiveUS6440858B1Minimize moisture sensitivityEnhanced vapor depositionSolid-state devicesSemiconductor/solid-state device manufacturingDielectricBi layer

A method of etching multiple films with a dual layer hard mask wherein one layer is totally removed and the other layer partially removed during deep trench etching of the silicon substrate. In particular, a method of deep trench etching silicon substrates comprising the steps of providing a semiconductor substrate capable of being etched, with HBr / NF3 / He / O2, having a layer of pad dielectric disposed depositing a layer of material capable of selective removability with respect to the pad dielectric, preferably BSG; depositing a layer of material having a slower etch rate than the semiconductor substrate and the layer of material capable of selective removability with respect to the pad dielectric, preferably, silicon oxide deposited by PECVD; patterning at least one of the layers, and etching the semiconductor substrate to form a trench and removing the layer of material having a slower etch rate than the semiconductor substrate, wherein trenches are of close proximity to each other.

Owner:IBM CORP

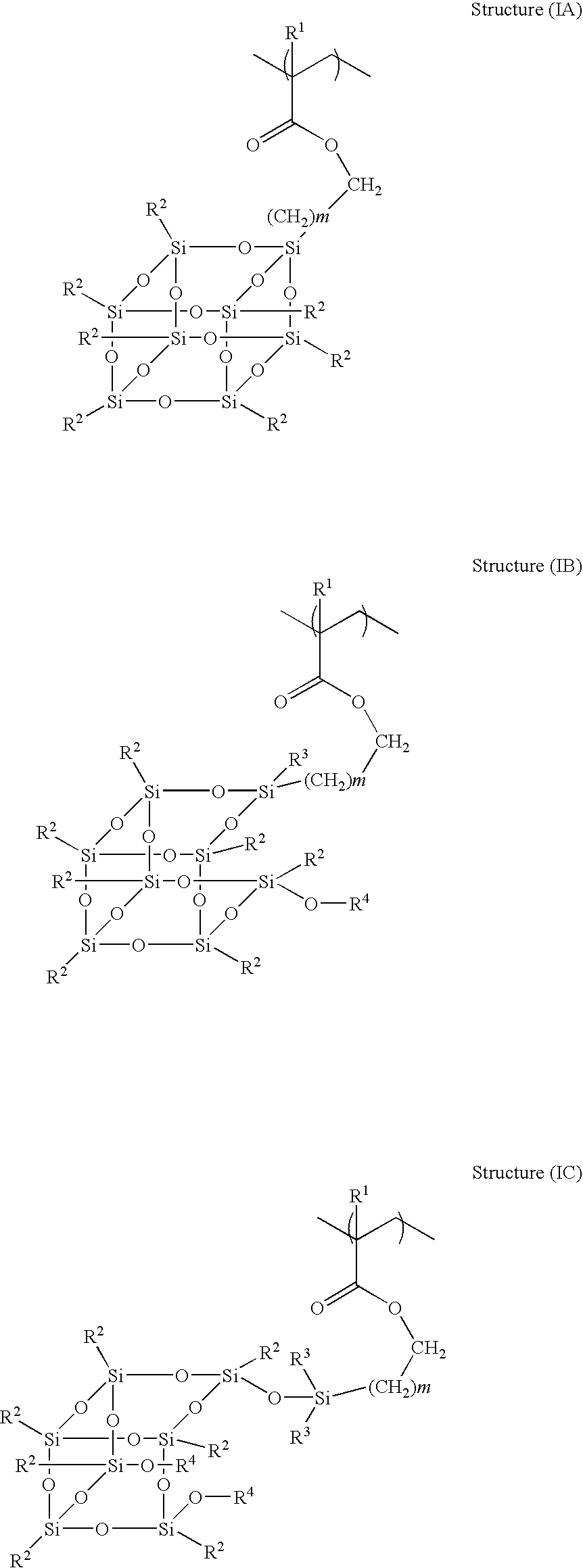

Copolymer, photoresist compositions thereof and deep UV bilayer system thereof

Novel copolymers suitable for forming the top layer photoimagable coating in a deep U V. particularly a 193 nm and 248 nm, bilayer resist system providing high resolution photolithography. Chemically amplified photoresist composition and organosilicon moieties suitable for use in the binder resin for photoimagable etching resistant photoresist composition that is suitable as a material for use in ArF and KrF photolithography using the novel copolymers.

Owner:ARCH CHEM INC

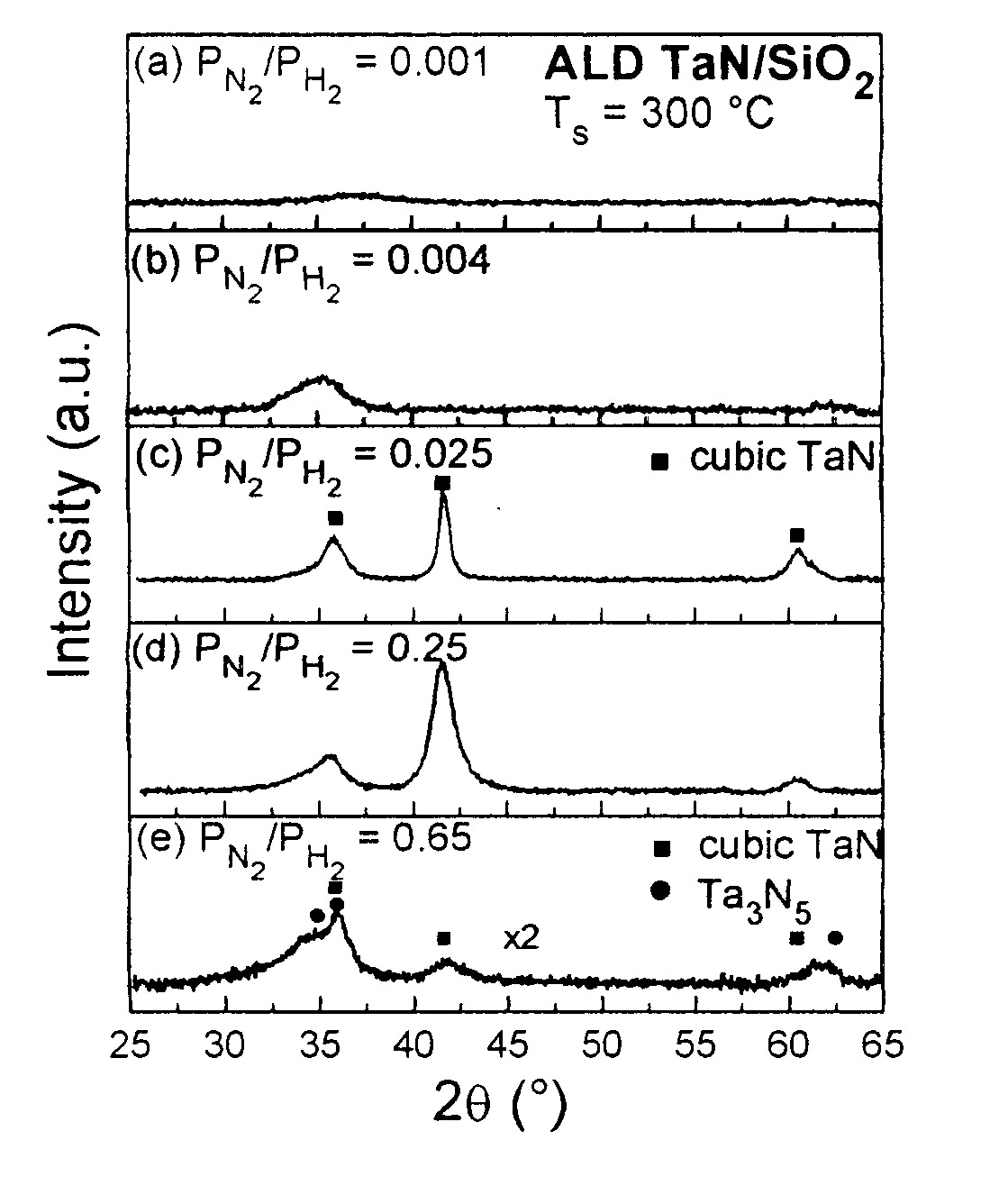

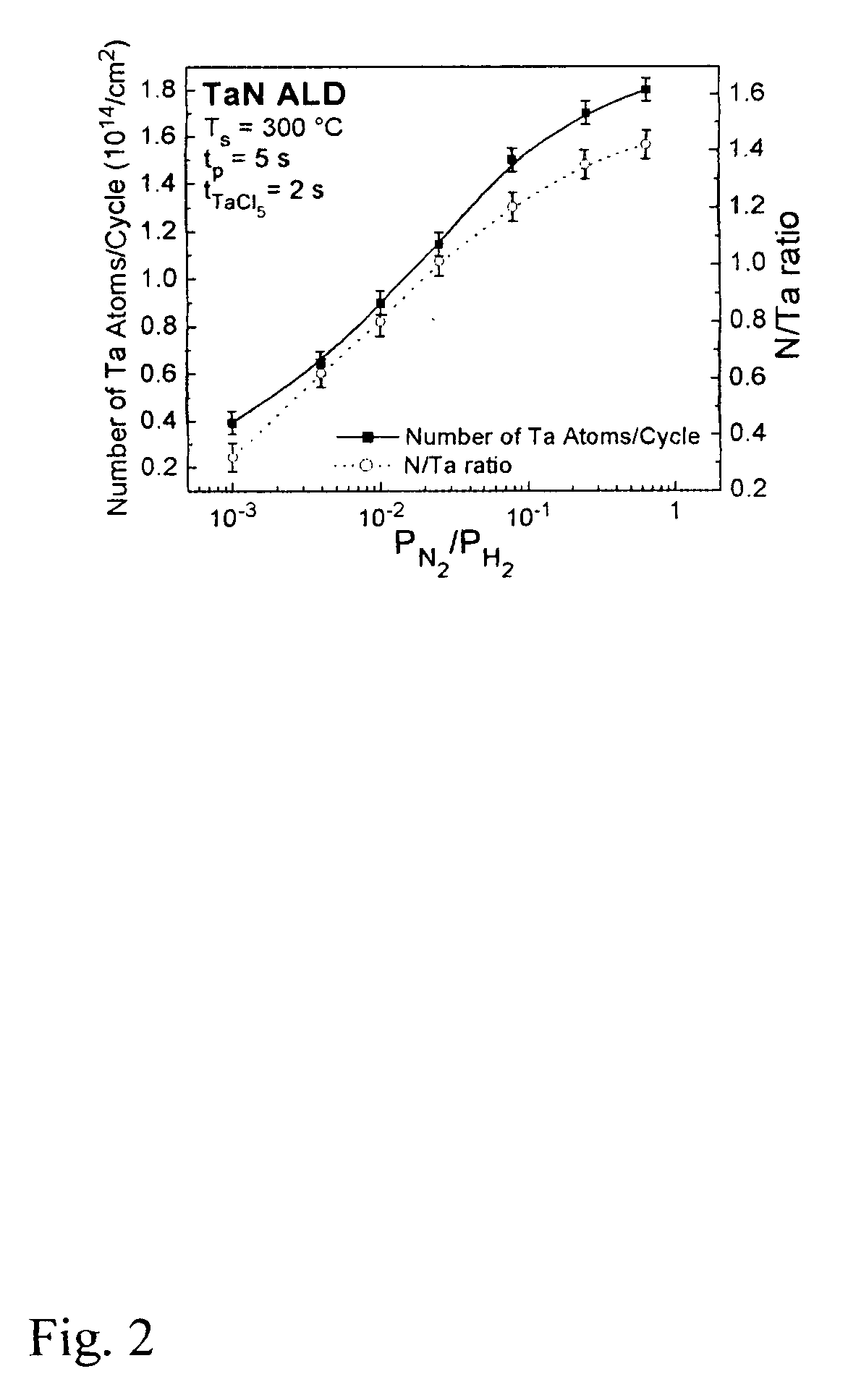

Plasma enhanced ALD of tantalum nitride and bilayer

InactiveUS20050095443A1Producing a copper diffusion barrierReliably producedSemiconductor/solid-state device detailsSolid-state devicesNitrogen plasmaBi layer

A method to deposit TaN by plasma enhanced layer with various nitrogen content. Using a mixture of hydrogen and nitrogen plasma, the nitrogen content in the film can be controlled from 0 to N / Ta=1.7. By turning off the nitrogen flow during deposition of TaN, a TaN / Ta bilayer is easily grown, which has copper diffusion barrier properties superior to those of a single Ta layer or a single TaN layer.

Owner:GLOBALFOUNDRIES INC

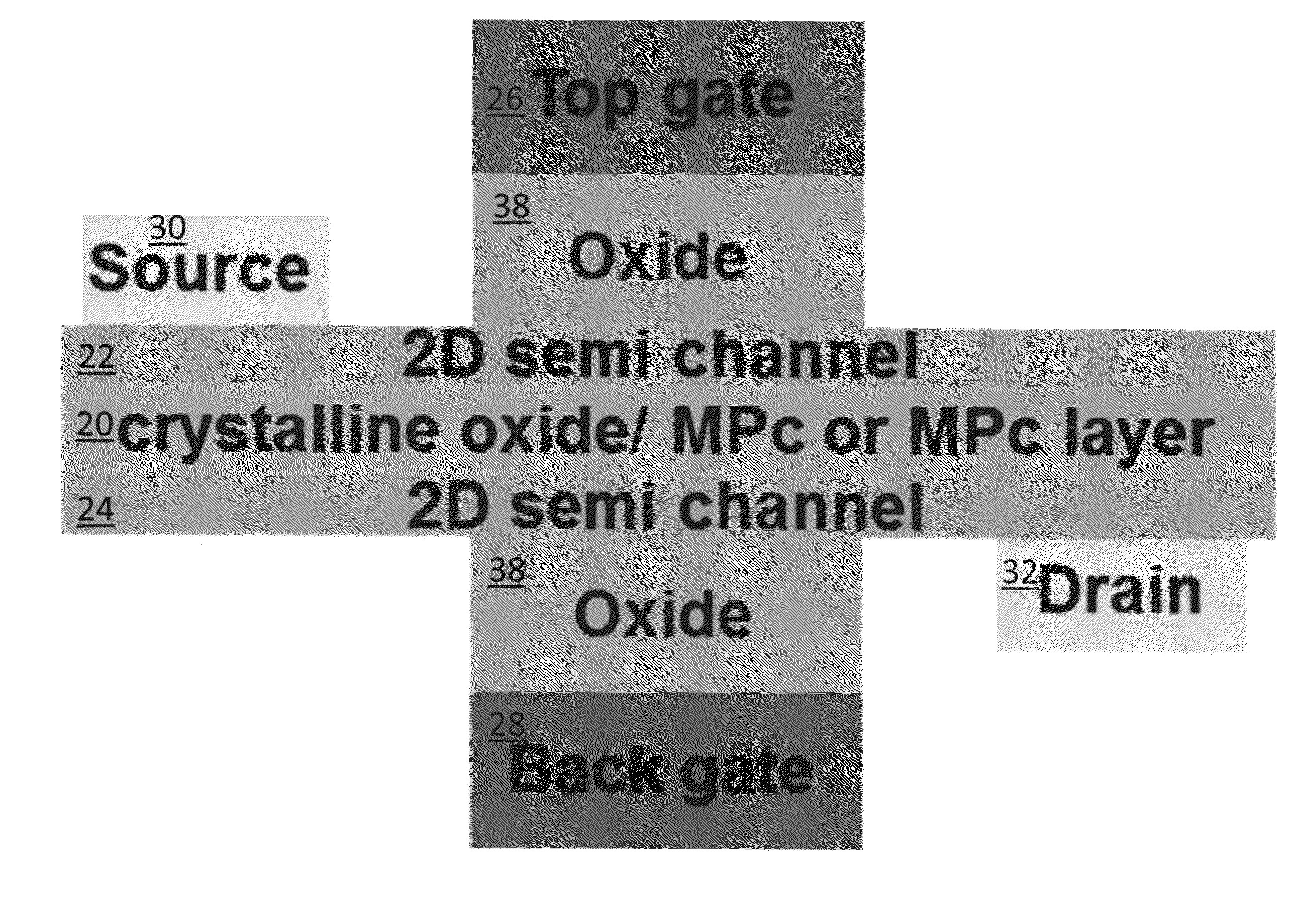

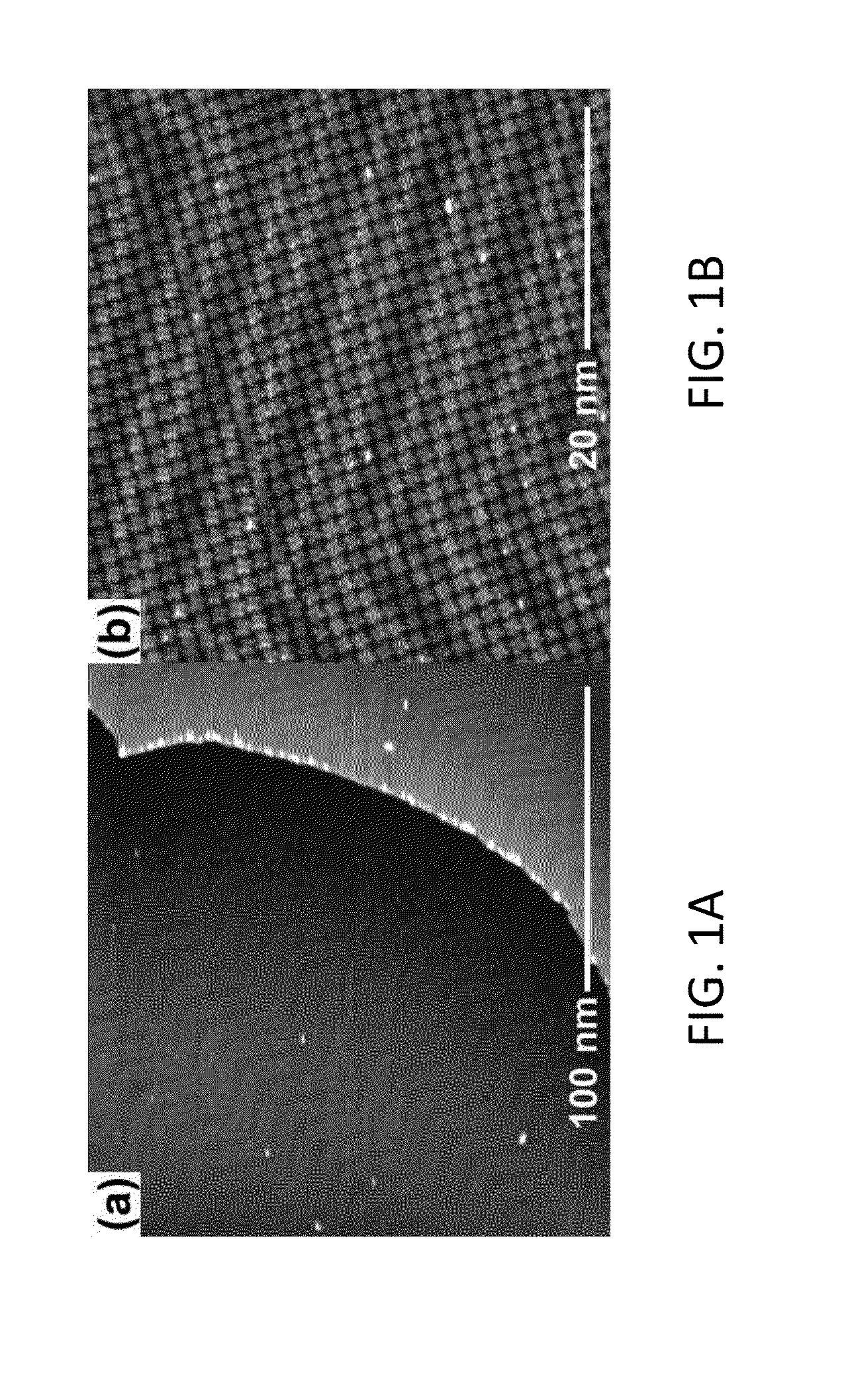

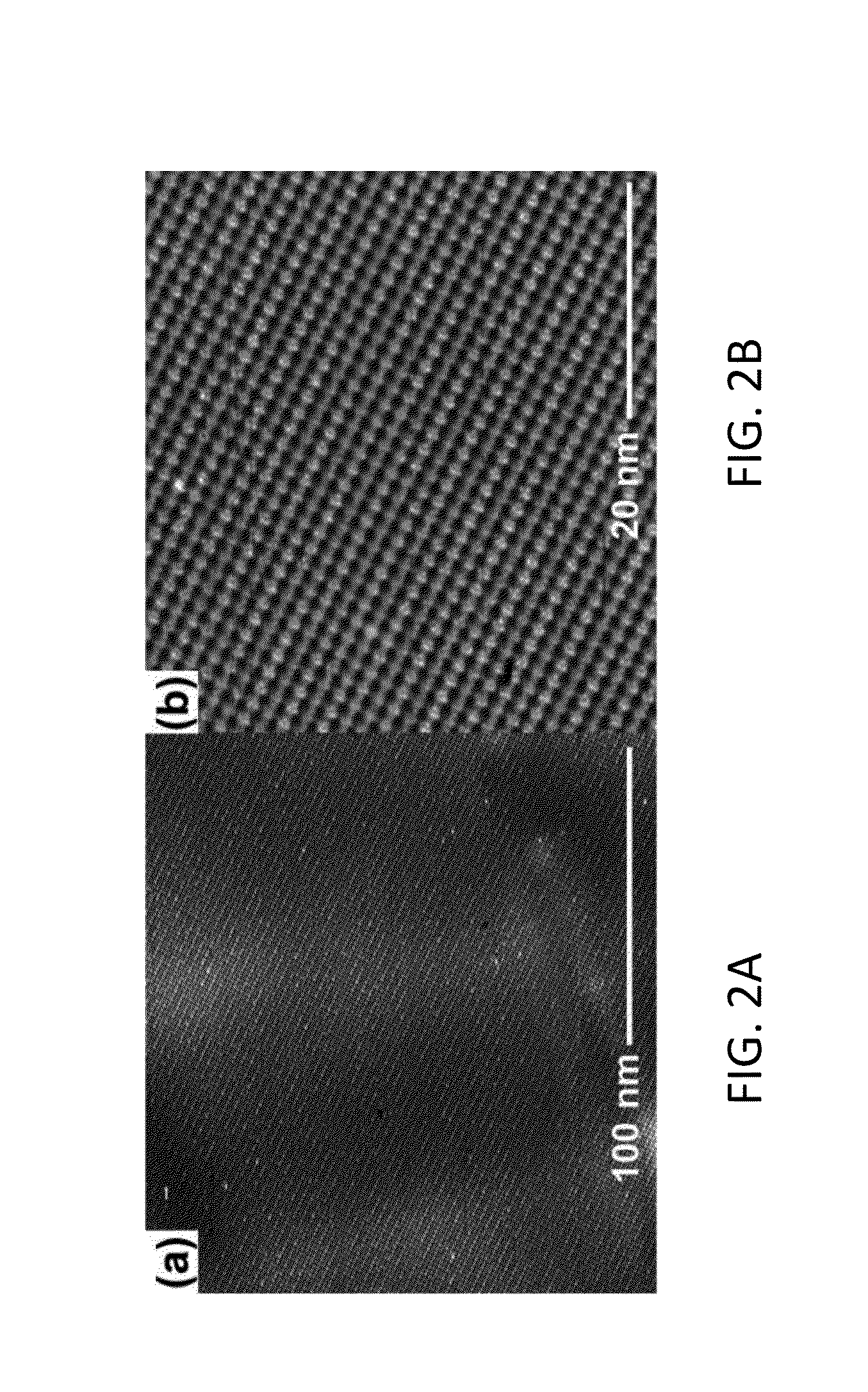

Method for passivating surfaces, functionalizing inert surfaces, layers and devices including same

ActiveUS20150221499A1Improve processingSemiconductor/solid-state device manufacturingSemiconductor devicesBi layerDevice material

The invention provides a method for passivation of various surfaces (metal, polymer, semiconductors) from external contaminants, and the functionalization of inert surfaces. The method of the invention can functionalize 2D semiconductor and other insert surfaces such as non-reactive metals, oxides, insulators, glasses, and polymers. The method includes formation of a monolayer, an ordered bilayer or an ordered multilayer of metal phthalocyanines (MPc). The invention also provides layer structure in a semiconductor device, the layer structure comprising one of an ordered monolayer, ordered bilayer or ordered multi-layer of metal phthalocyanine upon a surface, and one of an ALD deposited layer or 2D semiconductor on the one of a monolayer, ordered bilayer or ordered multi-layer of metal phthalocyanine.

Owner:RGT UNIV OF CALIFORNIA

Method for rolling high-strength metal composite plate

ActiveCN105478475ALimit deformation speedAddress stressAuxillary arrangementsMetal rolling arrangementsBi layerWave shape

The invention discloses a method for rolling a high-strength metal composite plate. The method is characterized in that a metal substrate and a cladding plate are selected, it is required that the deformation resistance of the metal substrate is larger than that of the cladding plate, the composite faces of the substrate and the cladding plate are cleaned, the substrate with the large deformation resistance is machined to obtain the substrate with a corrugated face on the composite face, the section of each corrugation is in an arc shape or a sinusoidal wave shape or an oval shape, and the height s of the corrugations, the width t of the corrugations and the thickness h0 of a metal layer with the large deformation resistance satisfy the conditions that s / h0 ranges from 0.1 to 0.8, 2s / t is equal to tan alpha, and alpha ranges from 10 degrees to 40 degrees; the substrate and the cladding plate are stacked and pressed in sequence, and a double-layer composite plate blank is obtained; and a composite plate strip is obtained after rolling is conducted according to the warm-rolling process or the hot-rolling process. By the adoption of the method, the problem of difference of metal plastic deformation caused by different degrees of deformation resistance of dissimilar metals is solved, and the curved surface of the substrate makes compensation for the difference, so that the rolled cladding layer and the rolled substrate layer are matched in length without buckling, and meanwhile the binding force between the substrate and the cladding plate is increased through traction on the cladding plate of the corrugations of the substrate.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-E glazing performance by seed structure optimization

ActiveUS9052456B2Improve thermal stabilityGood seed propertyOptical filtersFrom chemically reactive gasesBi layerLow emissivity

A bi-layer seed layer can exhibit good seed property for an infrared reflective layer, together with improved thermal stability. The bi-layer seed layer can include a thin zinc oxide layer having a desired crystallographic orientation for a silver infrared reflective layer disposed on a bottom layer having a desired thermal stability. The thermal stable layer can include aluminum, magnesium, or bismuth doped tin oxide (AlSnO, MgSnO, or BiSnO), which can have better thermal stability than zinc oxide but poorer lattice matching for serving as a seed layer template for silver (111).

Owner:GUARDIAN GLASS LLC

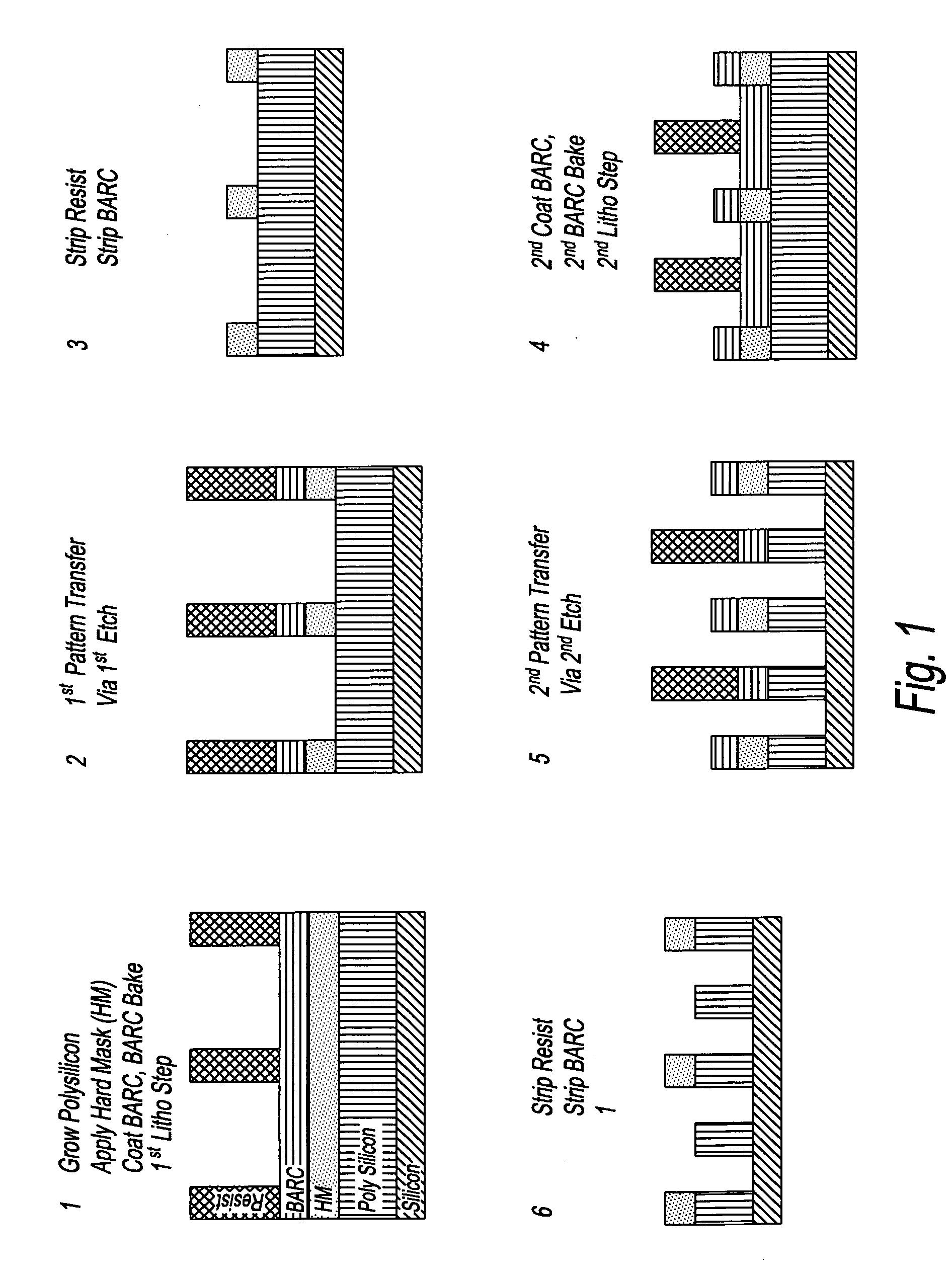

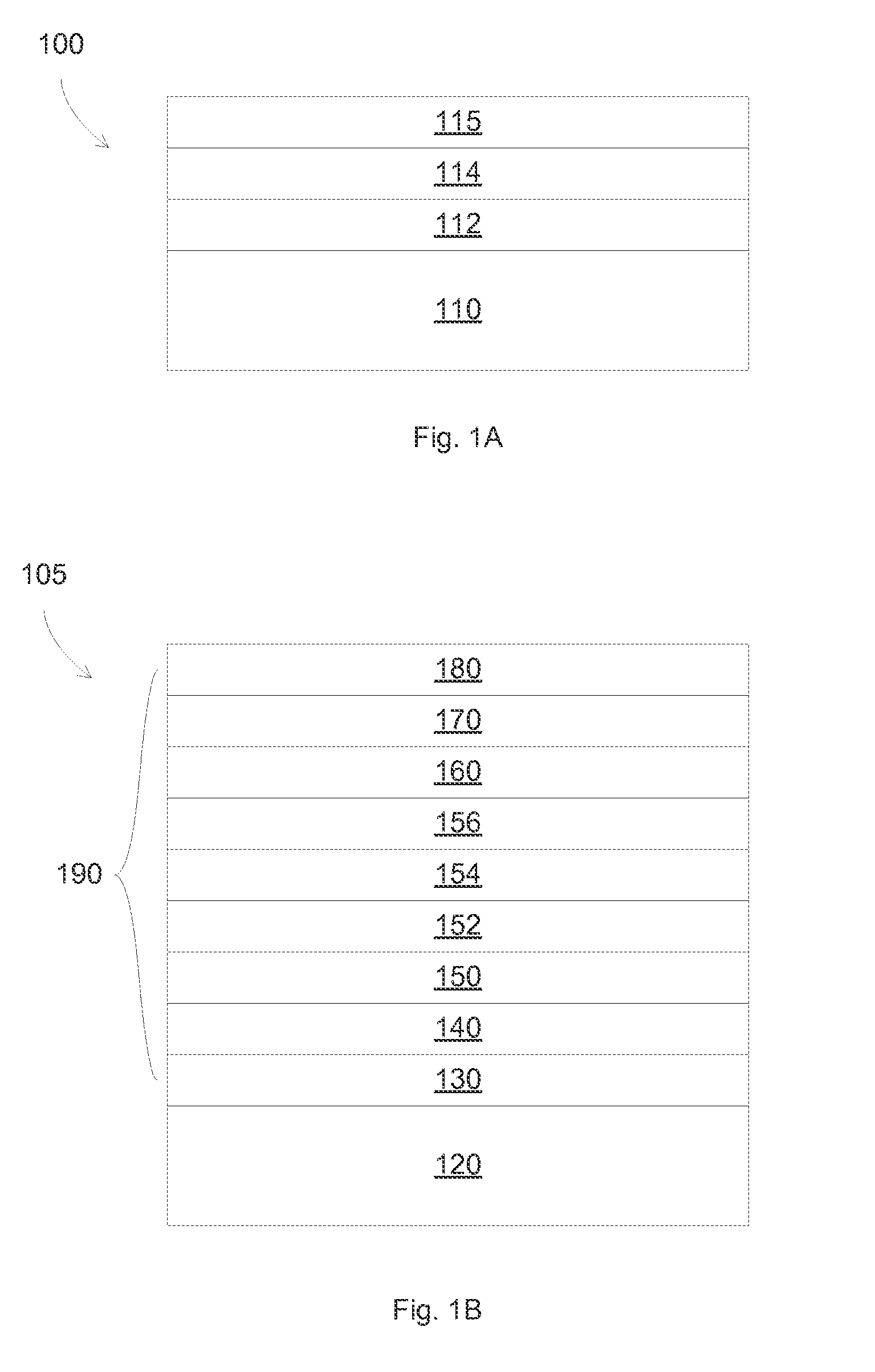

Self-segregating multilayer imaging stack with built-in antireflective properties

InactiveUS20100009132A1Reduce processing stepsVolume andPhotosensitive materialsRadiation applicationsResistAnti-reflective coating

A coating process comprises forming a patterned material layer on a substrate using a self-segregating polymeric composition comprising a polymeric photoresistive material and an antireflective coating material. The polymeric photoresistive material and the antireflective coating material that make up the self segregating composition are contained in a single solution. When depositing this solution on a substrate and removing the solvent, the two materials self-segregate into two layers. The substrate can comprise one of a ceramic, dielectric, metal, or semiconductor material and in some instances a material such as a BARC material that is not from the self segregating composition. The composition may also contain a radiation-sensitive acid generator and a base quencher. This produces a coated substrate having a uniaxial bilayer coating oriented in a direction orthogonal to the substrate with a top photoresistive coating layer and a bottom antireflective coating layer. The process may also include optionally coating a top coat material on the coated substrate. Pattern-wise exposing the coated substrate to imaging radiation and contacting the coated substrate with a developer, produces the patterned material layer wherein the optional top coat material and a portion of the photoresist layer are simultaneously removed from the coated substrate, thereby forming a patterned photoresist layer on the substrate. Alternatively, the optional top coat material, a portion of the photoresist layer and a portion of the bottom antireflective layers are simultaneously removed from the coated substrate by the developer, thereby forming a patterned photoresist layer on the substrate.

Owner:GLOBALFOUNDRIES INC

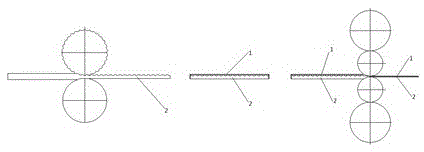

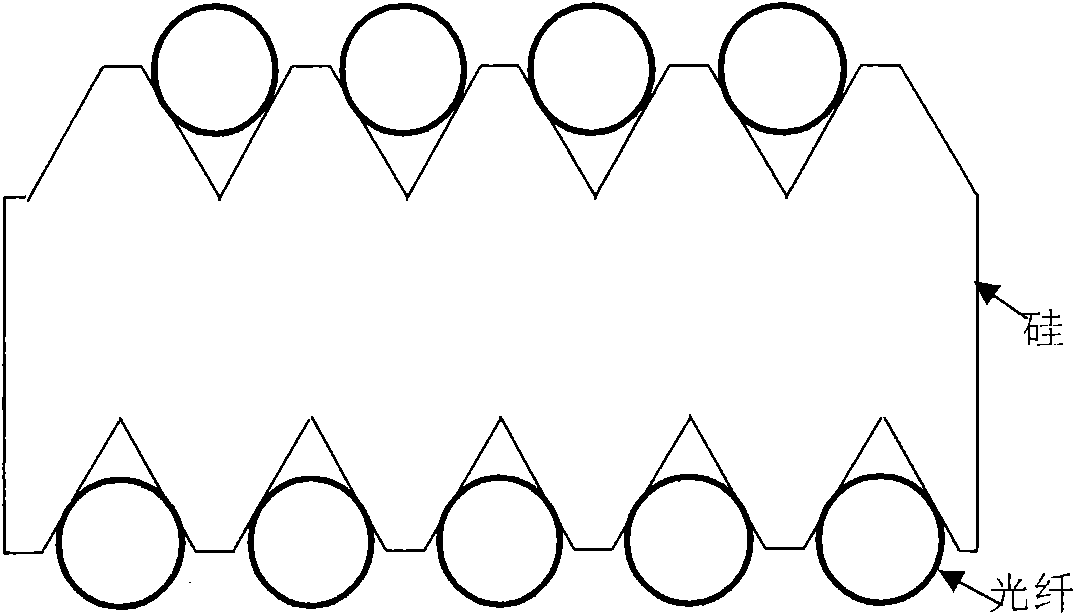

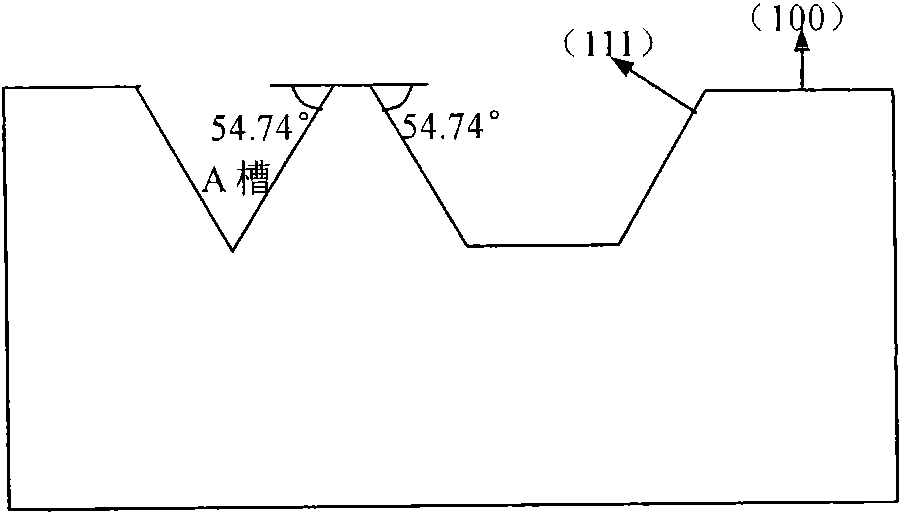

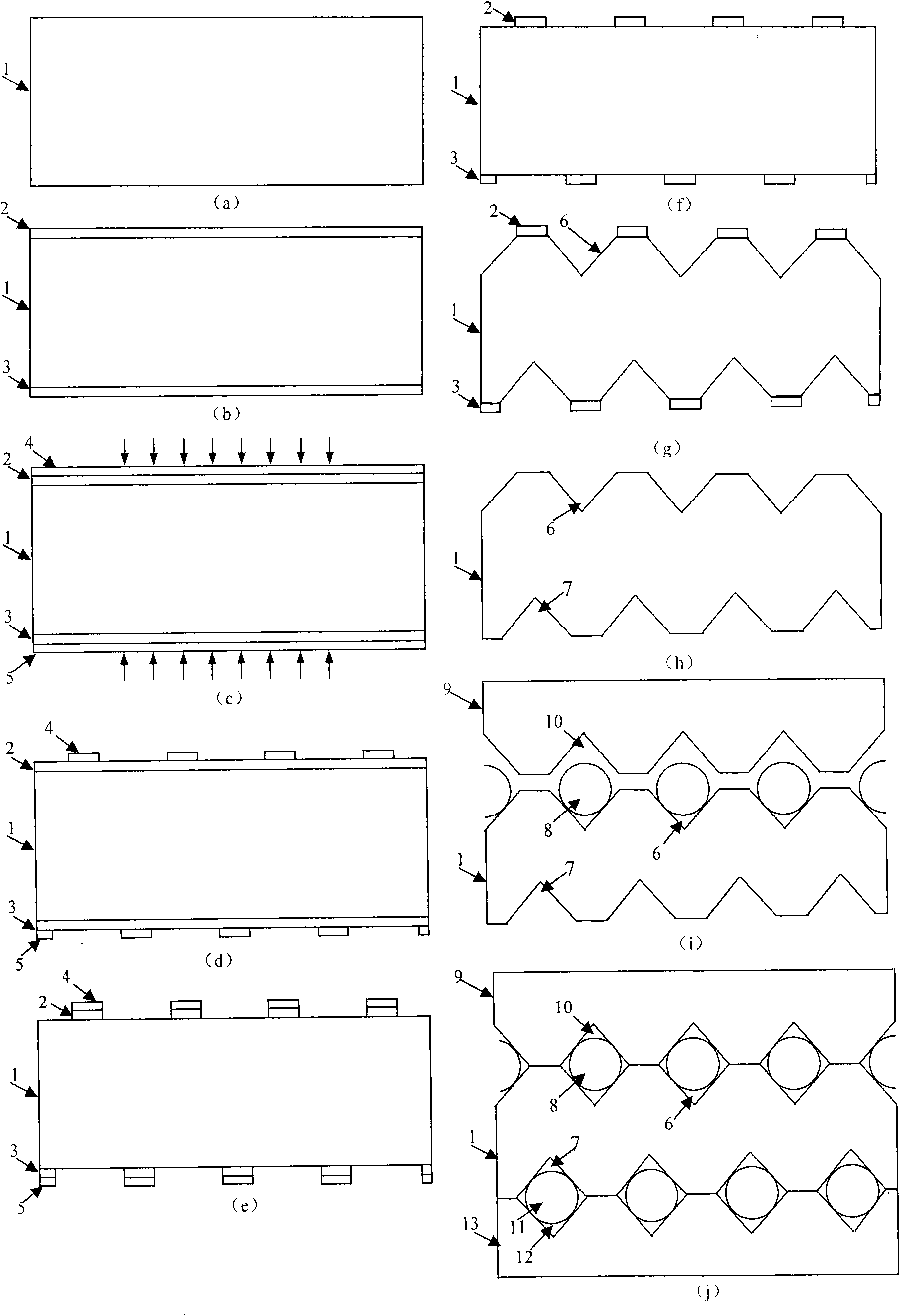

Two-dimensional double-layer fiber array and method for manufacturing same

InactiveCN101587205AHigh densityImprove practicalityPhotomechanical apparatusOptical waveguide light guideFiberFiber array

The invention relates to a two-dimensional double-layer fiber array and a method for manufacturing the same. The two-dimensional double-layer fiber array is manufactured on the same silicon chip; the fiber array is divided into an upper layer and a lower layer; a plurality of fibers can be placed in each layer; and each layer is fixed and protected by a cover plate. The double-layer fiber array applies double-side photoetching and anisotropic etching technology of a silicon process to manufacture a layer of the fiber array on the upper bottom surface and the lower bottom surface of the silicon chip respectively; each layer of the fiber array consists of at least one V-shaped groove; and the fibers are placed and fixed inside the V-shaped groove. The proposal, effectively improves the density of the fiber array and saves the space.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com