Method for rolling high-strength metal composite plate

A metal clad plate, high-strength technology, used in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of poor composite interface bonding performance, large residual stress, plate shape warpage, etc., and achieve good composite effect. , the effect of small residual stress and increased joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

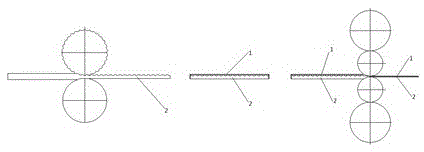

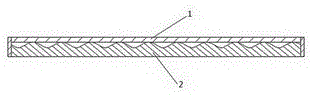

[0032] Such as figure 1 , 2 , using this method to prepare carbon steel-aluminum composite panels:

[0033] 1) Raw material processing, select low-alloy high-strength steel Q420 steel plate as substrate 2, the size is 120mm thick × 3000mm wide × 9000mm long, 4004 aluminum alloy plate is used as double plate 1, the size is 80mm × A substrate with sinusoidal corrugations on the composite surface is rolled by a rolling mill equipped with corrugated rollers. The corrugations of the substrate are continuously distributed on the substrate along the length direction. The height of the corrugations is s, the width of the corrugations is t, and the thickness of the metal layer of 4004 aluminum alloy is h 0 ,s / h 0 =0.6,2s / t=tanα,α=35 degrees;

[0034] 2) Composite slab blank, clean the composite surface of base plate 2 and double plate 1 to see the metal matrix, stack base plate 2 and double plate 1 in order, and use 15mm thick carbon steel plate around the stacked composite slab ...

Embodiment 2

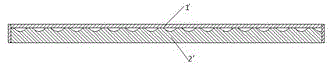

[0037] Such as figure 1 , 3 , using this method to prepare carbon steel-copper composite panels:

[0038] 1) Raw material processing, select Q345B carbon steel plate as the substrate 2ˊ, the size is 120mm thick × 1500mm wide × 3000mm long, TU2 copper plate is used as the double plate 1ˊ, the size is 40mm × wide 1500mm × long 3000mm, the Q345B carbon steel plate is passed through the corrugated roller The rolling mill rolls out the substrate with arc-shaped corrugated surface on the composite surface. The substrate corrugations are continuously distributed on the substrate along the length direction. The corrugation height is s, the corrugation width is t, and the metal layer thickness of TU2 copper plate is h 0 ,s / h 0 =0.5,2s / t=tanα,α=40 degrees;

[0039] 2) Composite slab blank, clean the composite surface of base plate 2' and double plate 1' to see the metal matrix, stack base plate 2' and double plate 1' in order, and weld 15mm thick carbon steel plate around the stacke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com