Rolling compounding technology of ultrathin metal strip assisted by interlayer micro-nano particle spraying

A technology of micro-nano particles and auxiliary metals, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of poor plate shape and difficult bonding, and achieve uniform deformation, internal stress elimination, and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

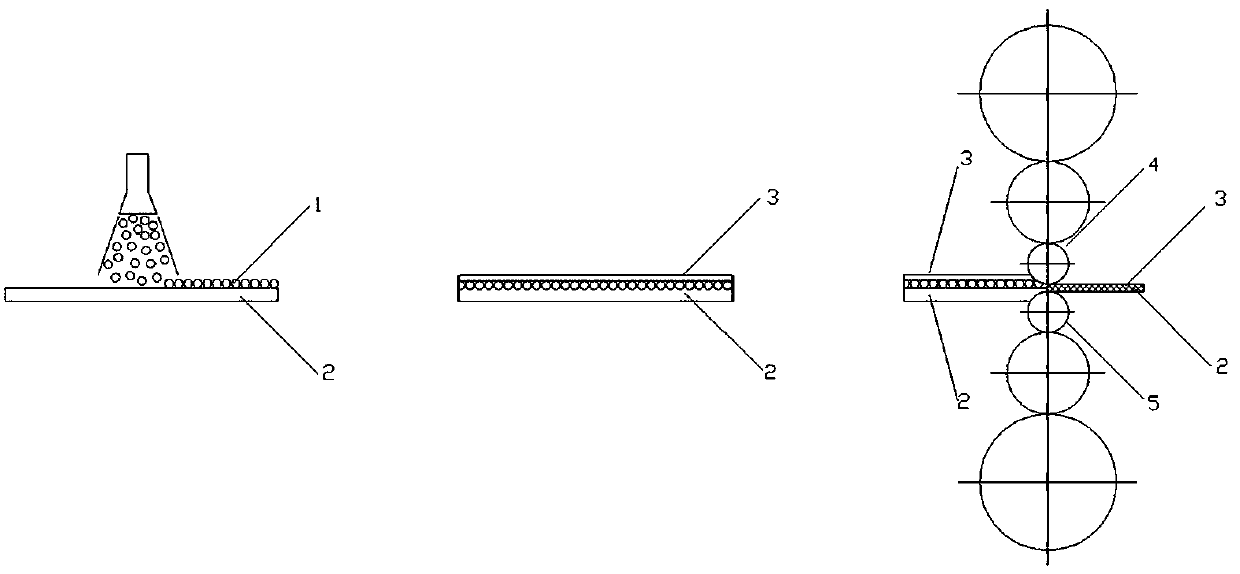

Method used

Image

Examples

Embodiment 1

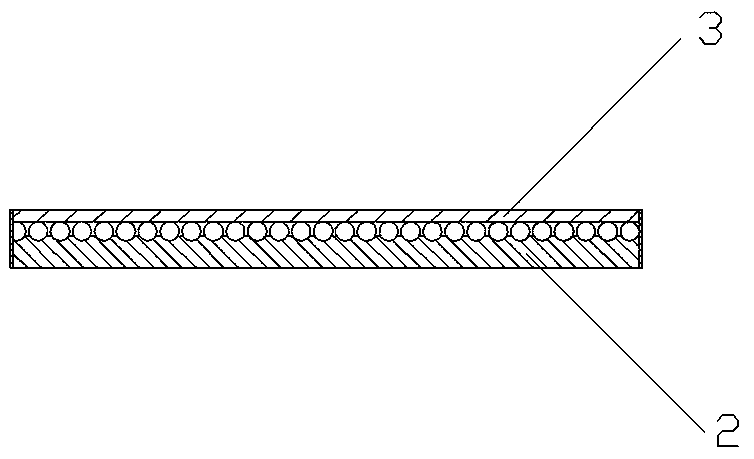

[0039]Select TU2 copper ultra-thin strip and SUS304 stainless steel ultra-thin strip. The size of the stainless steel ultra-thin strip is 0.05 mm thick × 40 mm wide × 100 mm long, as the substrate 2; the copper ultra-thin strip is 0.2 mm thick × 40 mm wide × 100 mm long, as the Double board 3;

[0040] (1) Surface treatment: Clean the surface of SUS304 stainless steel ultra-thin strip and TU2 copper ultra-thin strip with a grinder until the metal matrix is seen;

[0041] (2) Blank making: cold spraying process is adopted on the surface of SUS304 stainless steel ultra-thin strip to be compounded, the powder feeding rate is 0.6L / min, the moving speed of the spray gun is 1500mm / s, the spraying distance is 26mm, and copper micro-nano particles, particles The diameter is 38um. The polished surface buckle of SUS304 stainless steel ultra-thin strip and TU2 copper ultra-thin strip is stacked, and then sent to the press for compression, and the stacked composite ultra-thin strip is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com