Patents

Literature

444results about How to "Address stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-ductility low-shrinkage anti-cracking concrete for bridge deck pavement and preparation method thereof

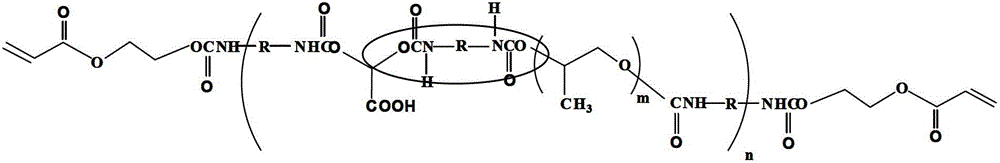

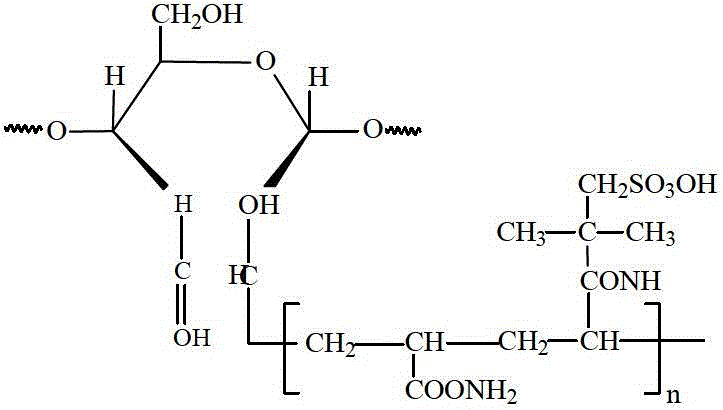

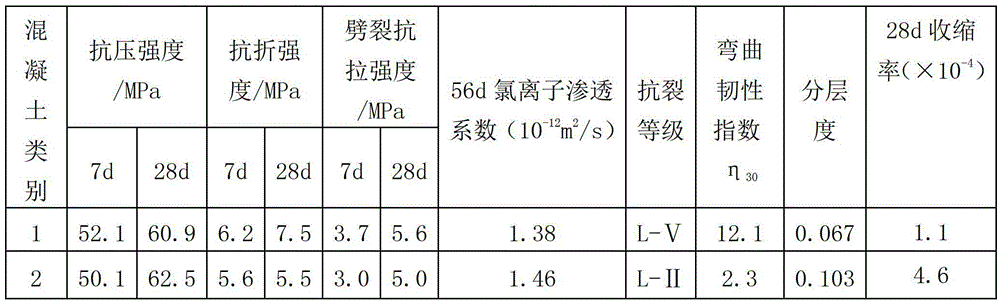

The invention belongs to the field of concrete structural materials, and discloses a preparation method for high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement. The high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement is characterized by comprising the following components in proportion: 135-155 kg / m<3> of water, a cementing material, 600-800 kg / m<3> of fine aggregate, 950-1150 kg / m<3> of coarse aggregate, 2.0-3.0 kg / m<3> of shrinkage-reducing ductility-increasing component,10-20 kg / m<3> of internal curing agent, 3.0-5.0 kg / m<3> of water reducing agent and hybrid fiber, wherein the cementing material comprises 320-380 kg / m<3> of cement and 20-40 kg / m<3> of coal ash in proportion; and the hybrid fiber comprises 0.8-1.0 kg / m<3> of organic polymer fiber and 40-50 kg / m<3> of steel fiber in proportion. According to the concrete and the preparation method for the concrete disclosed by the invention, reinforcement meshes on the bridge deck pavement layer can be cancelled.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

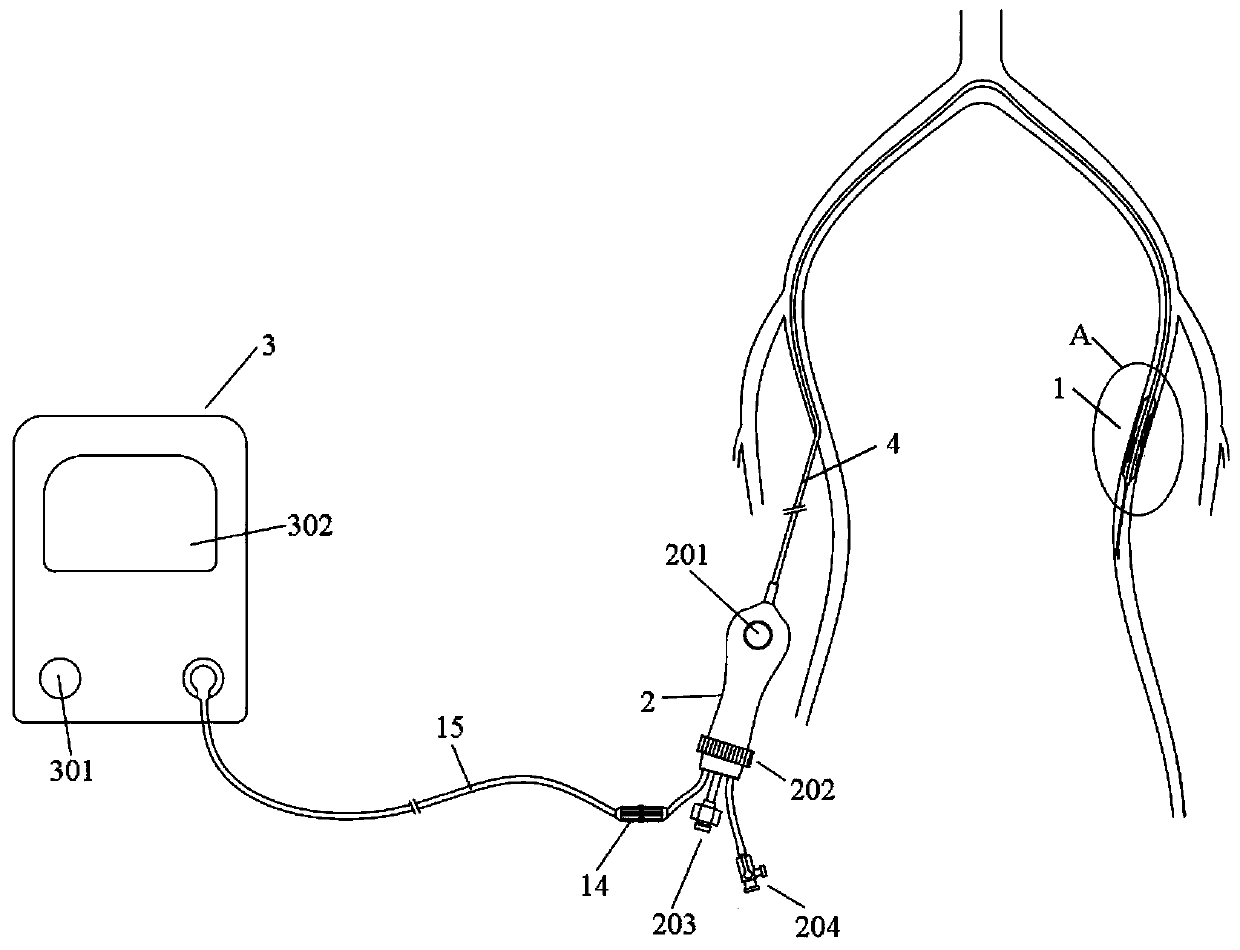

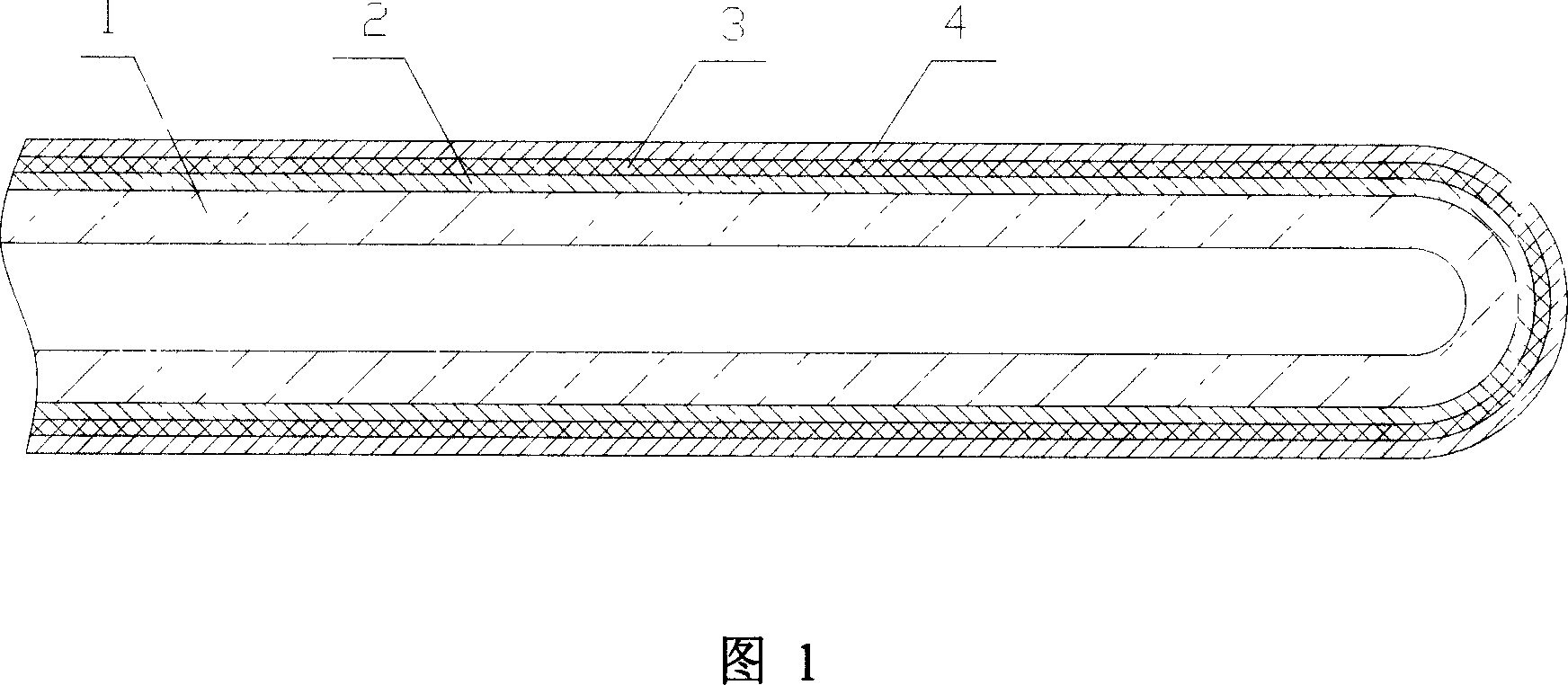

Vascular recanalization system for cardiovascular stenosis lesions

InactiveCN111568500AAchieve recanalizationAddressing injuries, such as dissectionsSurgeryMedical devicesStenotic lesionRestenosis

The invention relates to a vascular recanalization system for cardiovascular stenosis lesions. The vascular recanalization system comprises a balloon, an energy generation controller and a catheter. The catheter comprises a main body tube, one end of the catheter is connected with the energy generation controller, and the main body tube at the other end of the catheter is connected with one end ofthe balloon; wherein the balloon mainly comprises a balloon main body, an inner tube and an electrode pair, and the inner tube is arranged in the balloon main body; and the energy generation controller can send out and regulate a vibration signal with a specific frequency to enable the electrode pair to generate a vibration wave. The system further has a drug delivery function, can inhibit increase of endovascular membranes after recanalization and avoid restenosis after recanalization, thereby achieving the function of long-term treatment of stenotic lesions. For many vascular diseases needing to be implanted with stents, the purpose of achieving long-term patency rate without stent implantation is achieved, and therefore real intervention implantation-free is achieved.

Owner:苏州汇禾医疗科技有限公司

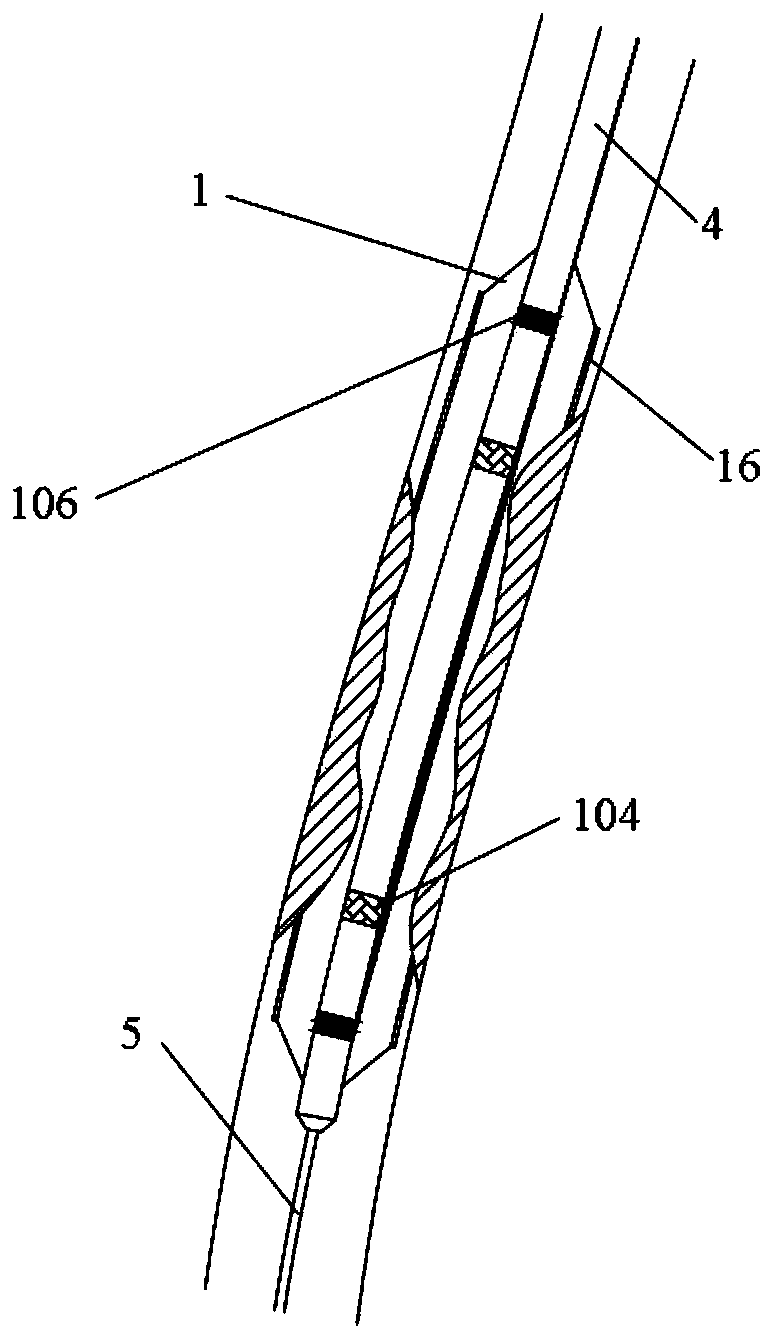

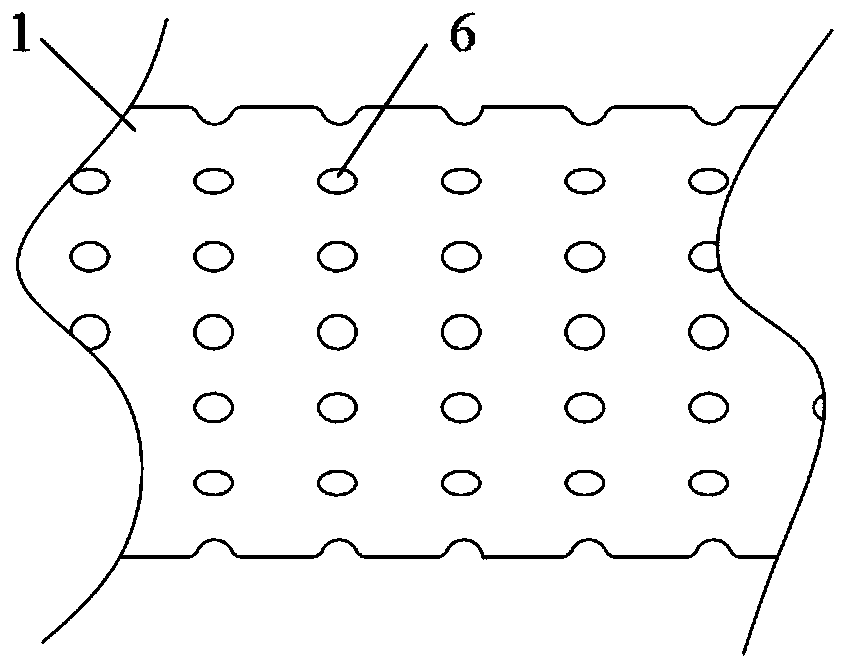

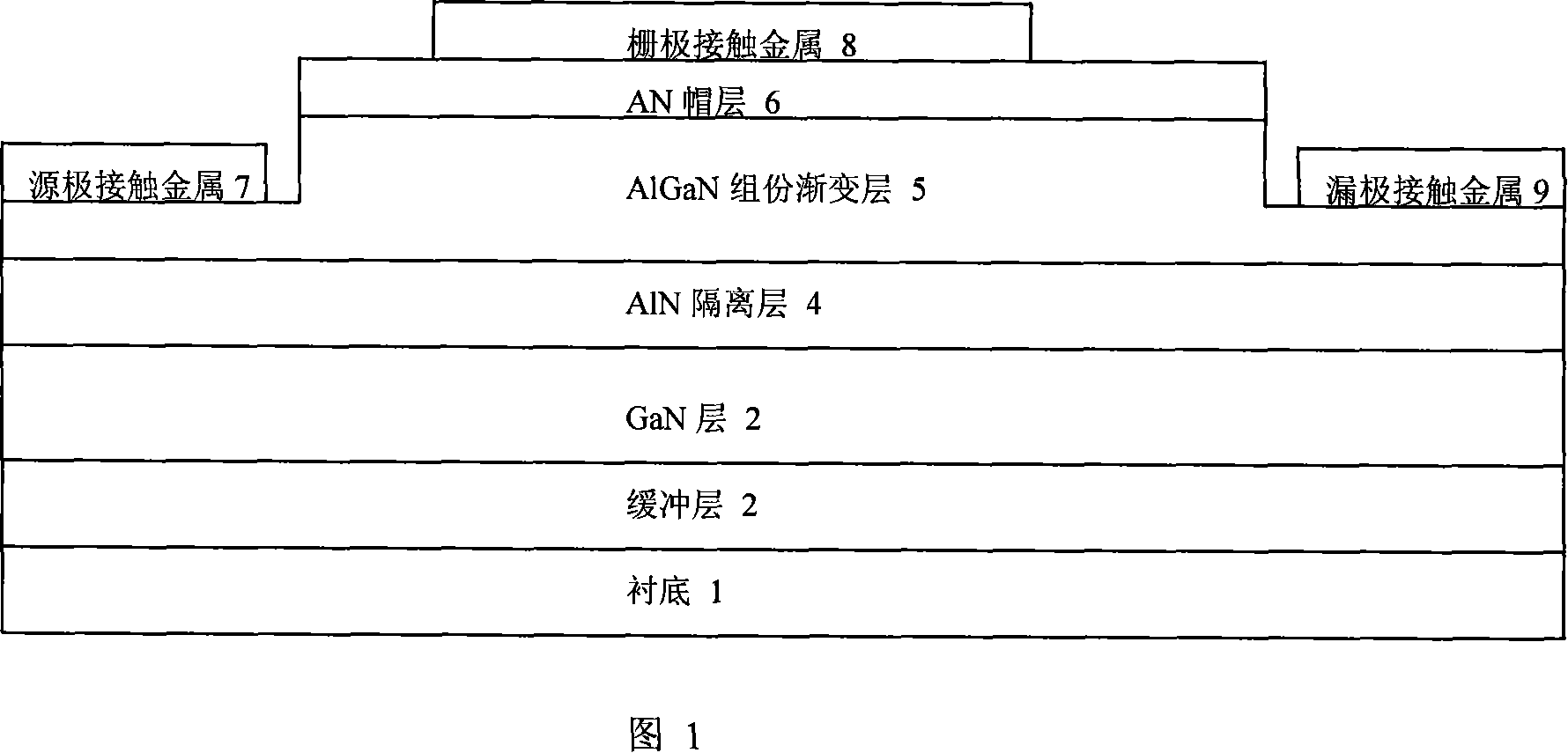

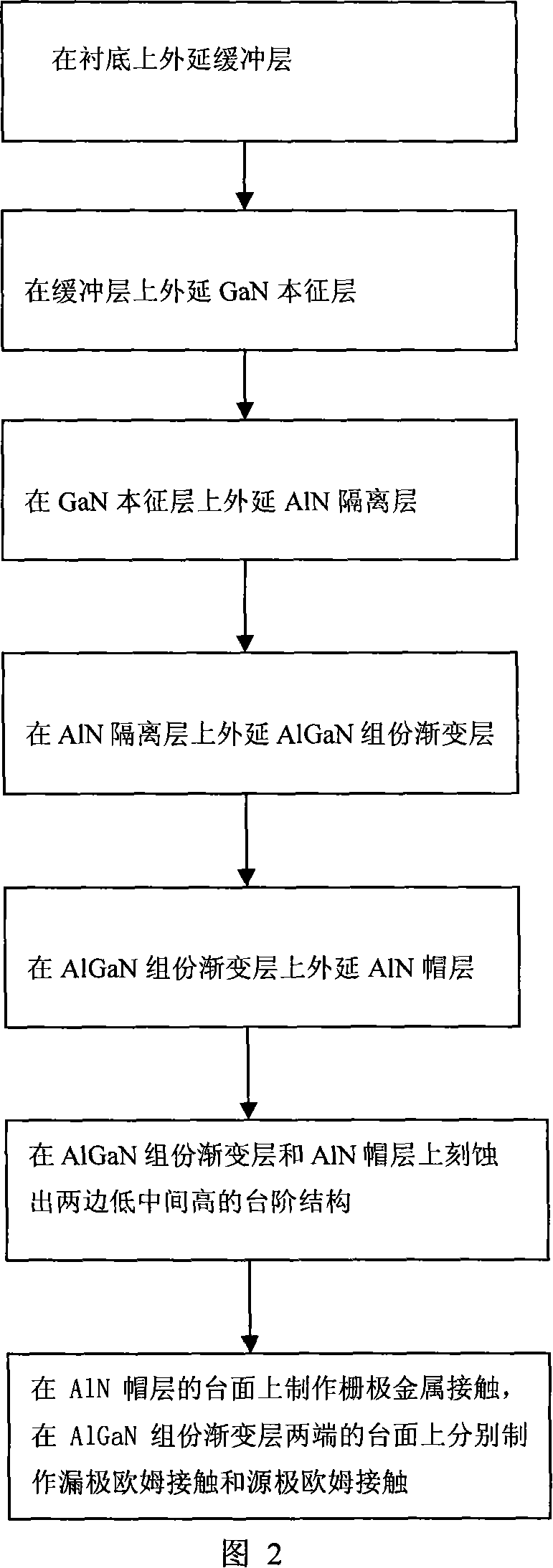

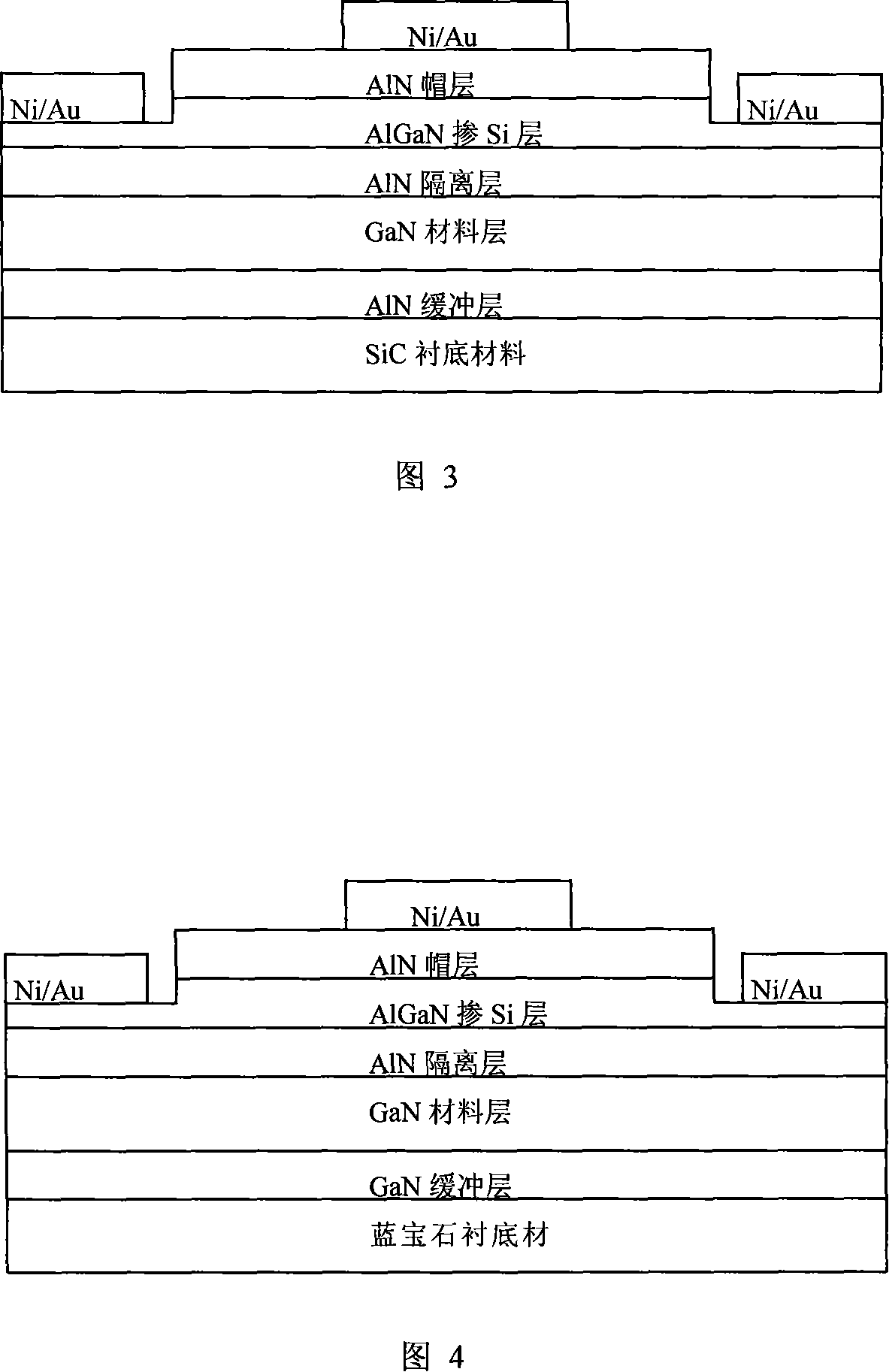

GaN device based on component-gradient GaN MISFET and preparing method thereof

InactiveCN101132022AReduce leakage currentAvoid secondary growthSemiconductor/solid-state device manufacturingSemiconductor devicesMicrowaveOhmic contact

The present invention discloses a GaN device based on component-gradual-changed GaN MISFET and its processing method. The device includes substrate (1), buffer layer (2), intrinsic GaN layer (3), AlN isolating layer (4) and source (7), drain (8), gate (9), in which component-gradual-changed AlGaN layer (5) and AlN cap layer (6) are orderly set on the AlN isolating layer. The process of the device includes: the GaN or AlN buffer layer are orderly extended on sapphire or silicon carbide substrate; the intrinsic GaN layer is deposited; the AlN isolating layer is deposited; the component-gradual-changed AlGaN is deposited; the AlN cap layer is deposited; two sides of the AlN cap layer on top and parts of two sides of component-gradual-changed AlGaN layer are separately etched to form a step structure which is high in central and low in two sides; ohmic contacts of the source and the drain and metal contact of the gate are separately made on different steps of the structure. The present invention has low drain current and high gate voltage, and can be used to process high power microwave devices.

Owner:XIDIAN UNIV

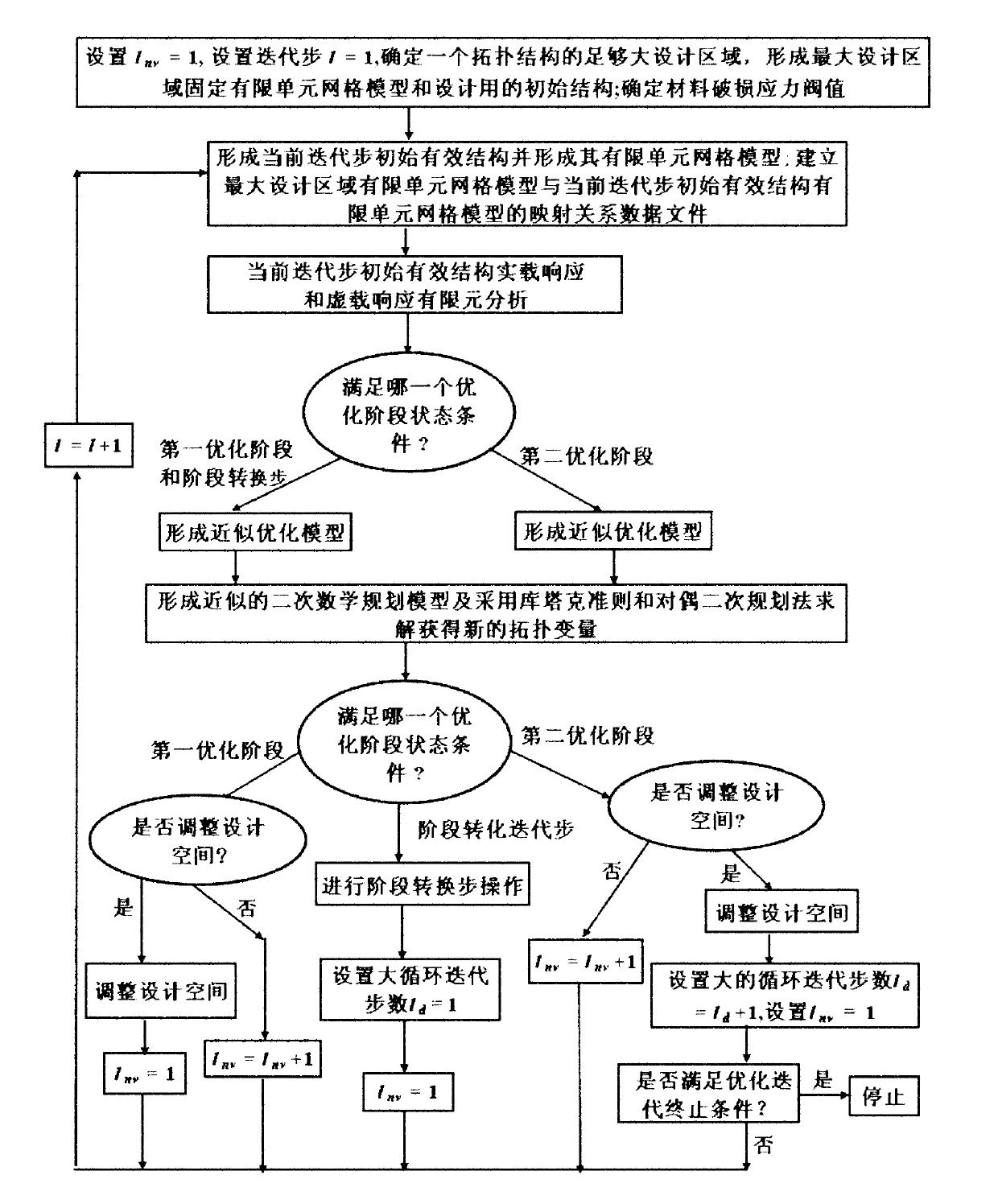

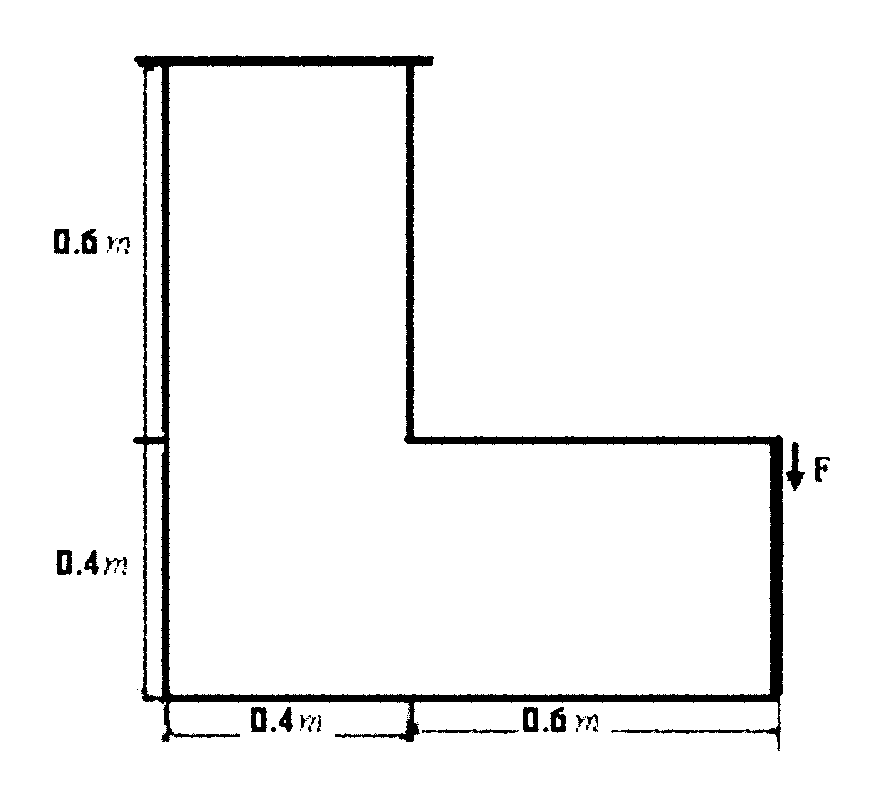

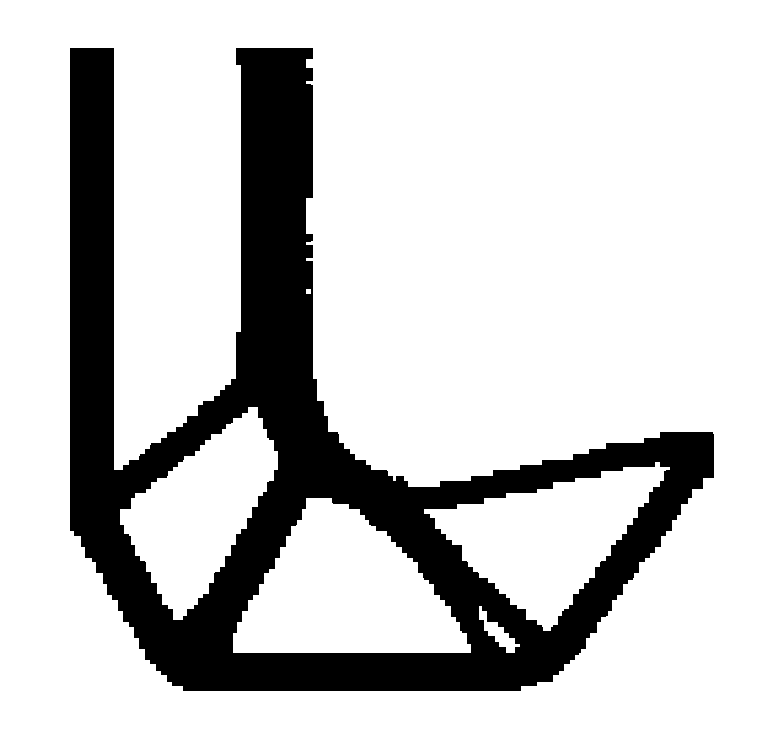

Material breakage constraint-based continuum structure topology design modeling and optimization design method

InactiveCN102043883AReduced maximum stress fluctuationsAddress stressSpecial data processing applicationsStress concentrationStress level

The invention discloses a material breakage constraint-based continuum structure topology design modeling and optimization design method, which is used for solving (a) problems of stress concentration and singularity, and (b) a problem of maximum stress fluctuation and a problem of high analyzed and calculated quantity in different degrees in the prior art. In the method, effective stress constraint relaxation is adopted to treat the phenomenon of stress singularity. In the process of optimizing problem approximation modeling, a q1 norm metrical function of the structural stress serves as a penalty function, all unit stress constraints are replaced by q2 norm metrical function constraint of the structural stress, the most potential active unit stress constraints and the introduced volume constraints, and the local stress level is controlled by combining variable constraint limit. The optimization process of the method is divided into two optimization stages and a conversion stage, and the design space is automatically expanded and reduced. A quadratic programming method is utilized to solve each stage, a pure optimized structural topology in black / white distribution can be obtained, and the method has high optimization design efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of wall thickness controllable directional solidification casting mould

InactiveCN103231025ASolve the problem of precise control of temperature fieldImprove the quality of directional solidificationFoundry mouldsFoundry coresSuperalloyDirectional solidification

The invention discloses a preparation method of a wall thickness controllable directional solidification casting mould. The preparation method comprises the steps of: firstly, designing an initial casting mould in three-dimensional software; then, placing the initial casting mould into casting software to finish stress calculation, and determining the optimal casting mould wall thickness; next, placing a secondary casting mould into a directional crystal growth simulation environment to carry out radiative heat transfer calculation, analyzing a temperature field distribution rule and a thermal field change rule, changing the wall thickness and giving a wall thickness close to a directional solidification growth temperature gradient rule; repeating the radiative heat transfer calculation and stress check, and revising the design until the final three-dimensional design of the casting mould is determined; and manufacturing the casting mould based on a rapid manufacturing method for a rapidly-molded ceramic casting mould. The method is used for solving the problem that the casting mould affects the growth of a directional crystal in the direction solidification process of a complex high-temperature alloy structure, thus a directional crystal blade can be more easily obtained, higher-quality directional crystal products can be obtained, and problems such as crack and stress deformation caused by hot stress and other stresses are avoided to a certain extent.

Owner:XI AN JIAOTONG UNIV +1

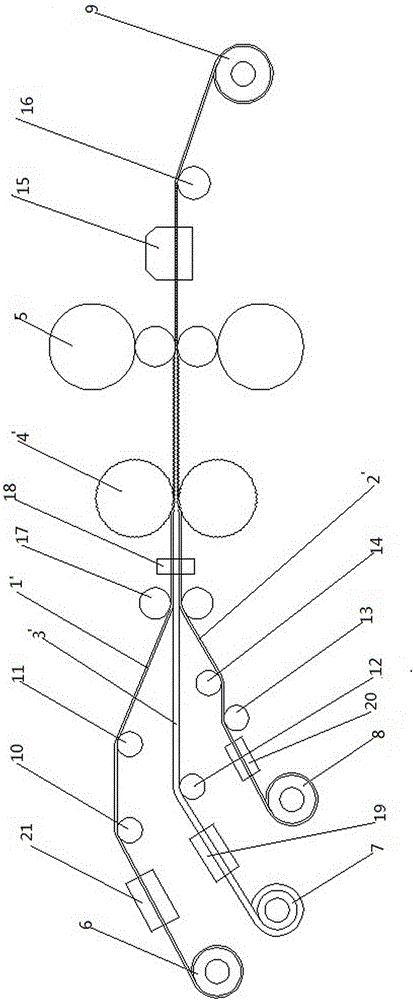

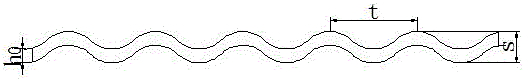

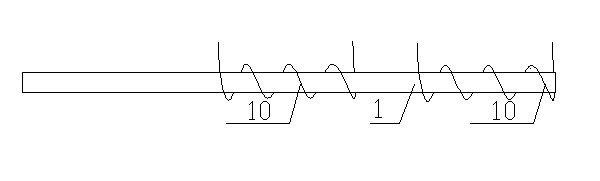

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

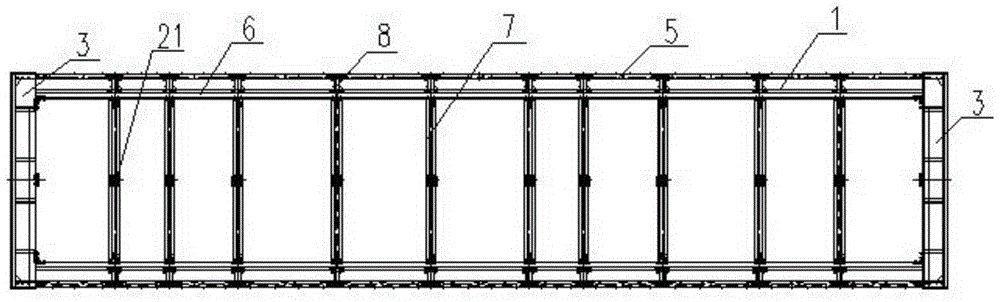

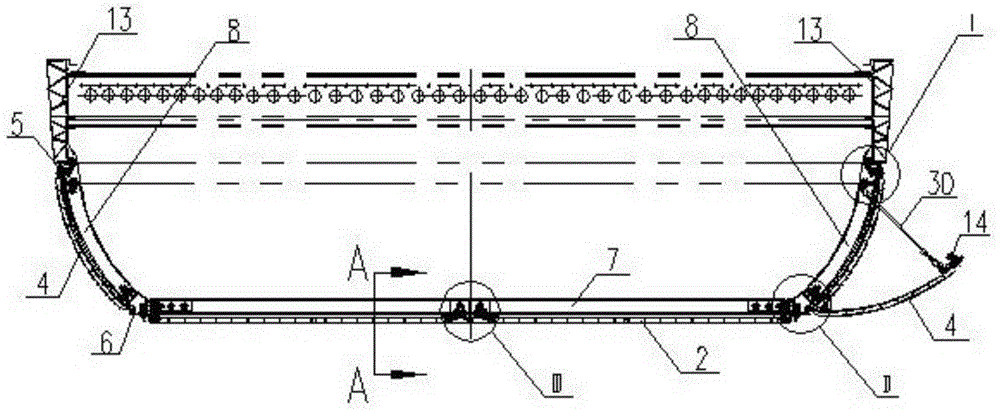

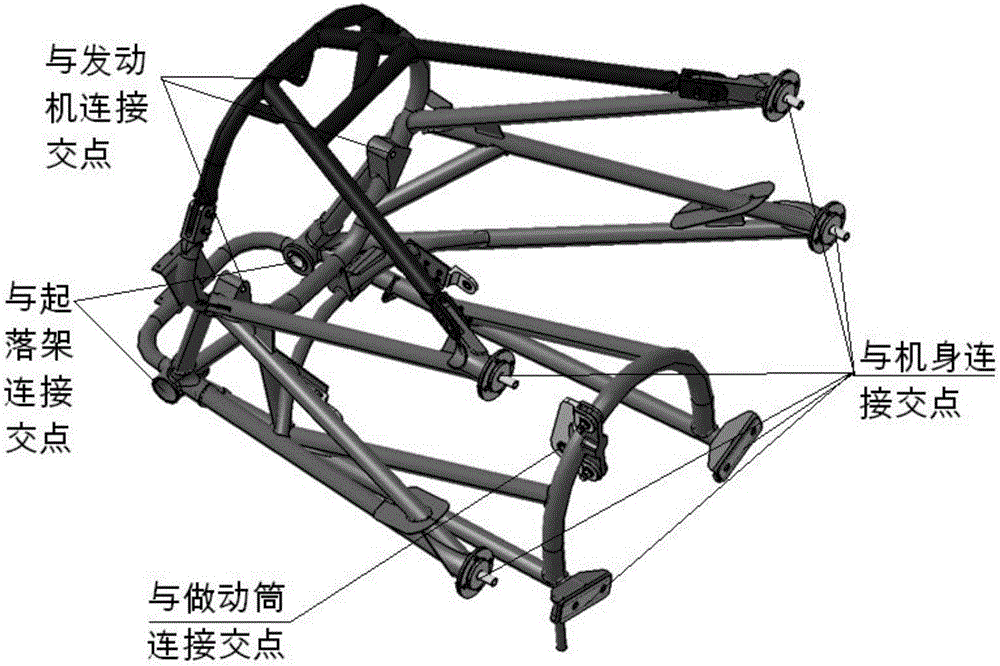

Integral equipment bay

ActiveCN104875760AHigh degree of commercializationShorten the time occupied by the assembly stationAxle-box lubricationRailway bodiesEngineering

The invention relates to an integral equipment bay which comprises a framework, a bottom plate, an end plate and an apron board, wherein the bottom plate, the end plate and the apron board are all fixedly arranged on the framework; the framework consists of an upper edge beam, a lower edge beam, multiple cross beams, multiple camber beams arranged between the upper edge beam and the lower edge beam, and end part brackets arranged at two ends; the upper edge beam and the lower edge beam are arranged along the vehicle length direction, and the multiple cross beams are arranged along the vehicle width direction; the upper edge beam, the camber beams, the lower edge beam, the cross beams and the end part brackets are fixedly connected with one another by virtue of fastening pieces; the upper edge beam is fixedly arranged on a vehicle body edge body by virtue of a fastening piece. <0}{0><}0{>According to the integral equipment bay, an overall equipment bay module can be preassembled by virtue of toolings offline; during entrucking, the overall equipment bay module is connected with the vehicle body edge beam, so that the entire car assembling table bit occupation time is shortened, and the entire car assembly efficiency and the equipment bay commercialization degree are greatly improved.

Owner:CRRC QINGDAO SIFANG CO LTD

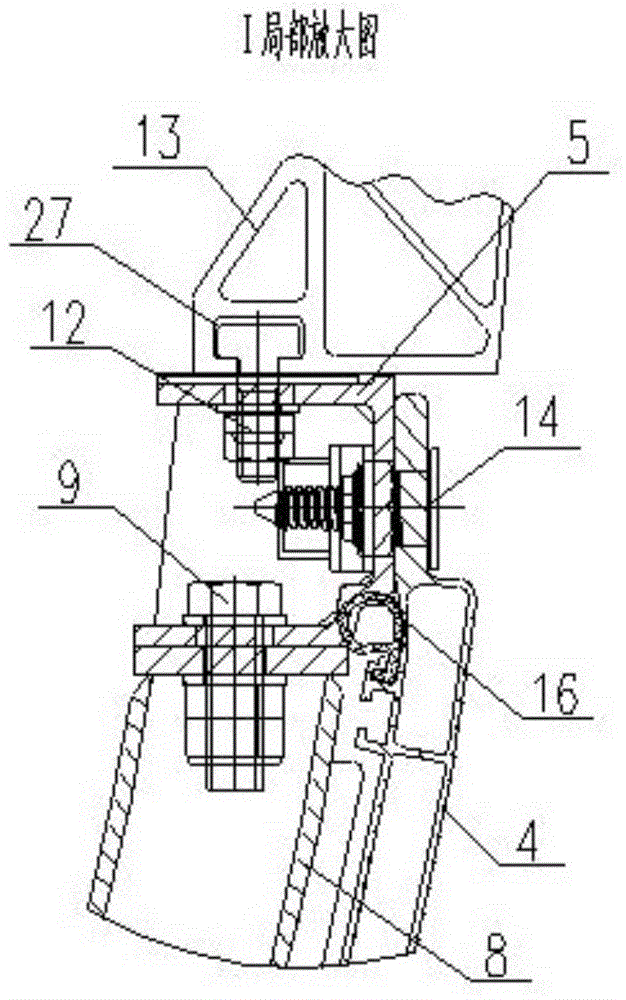

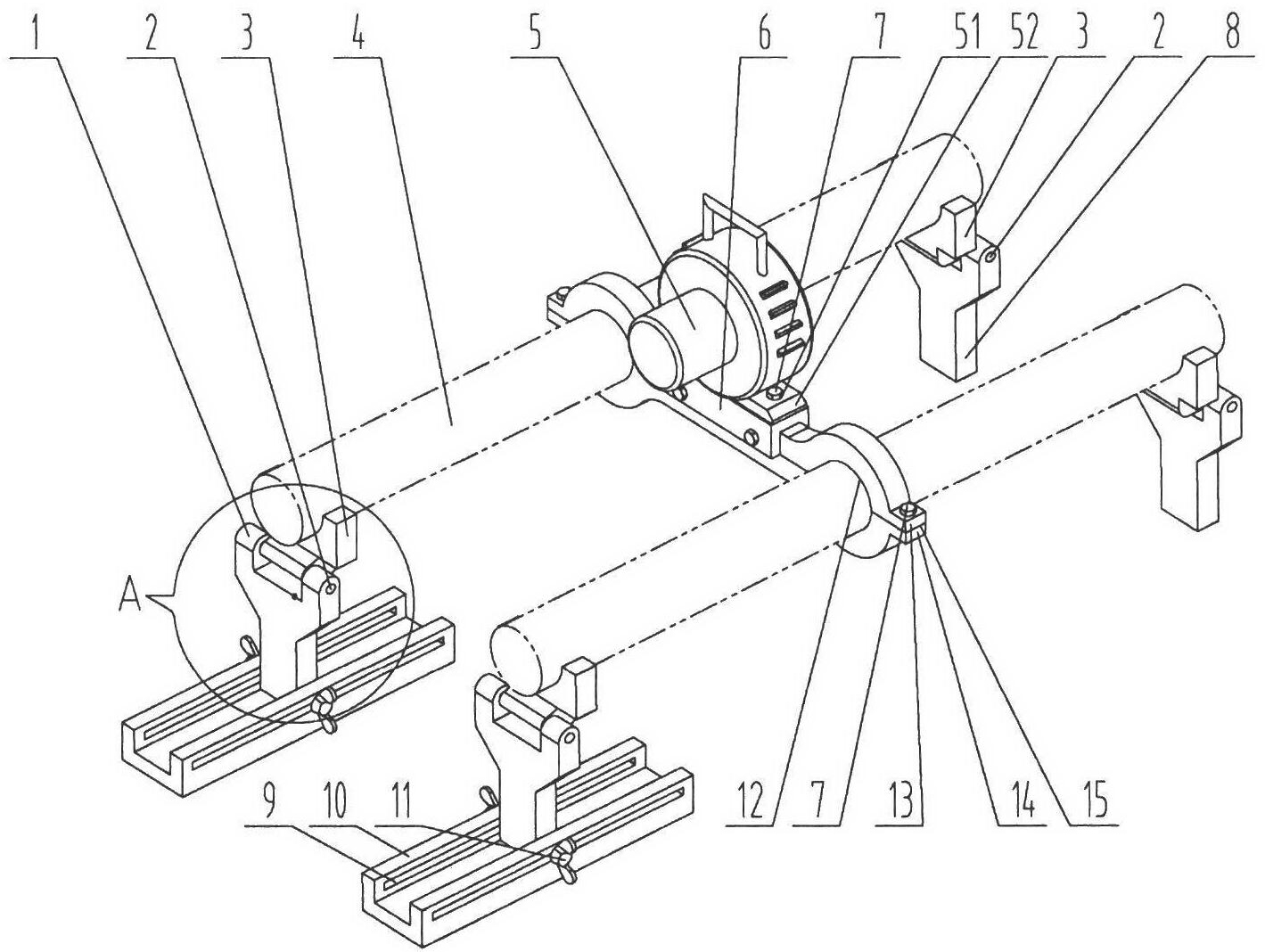

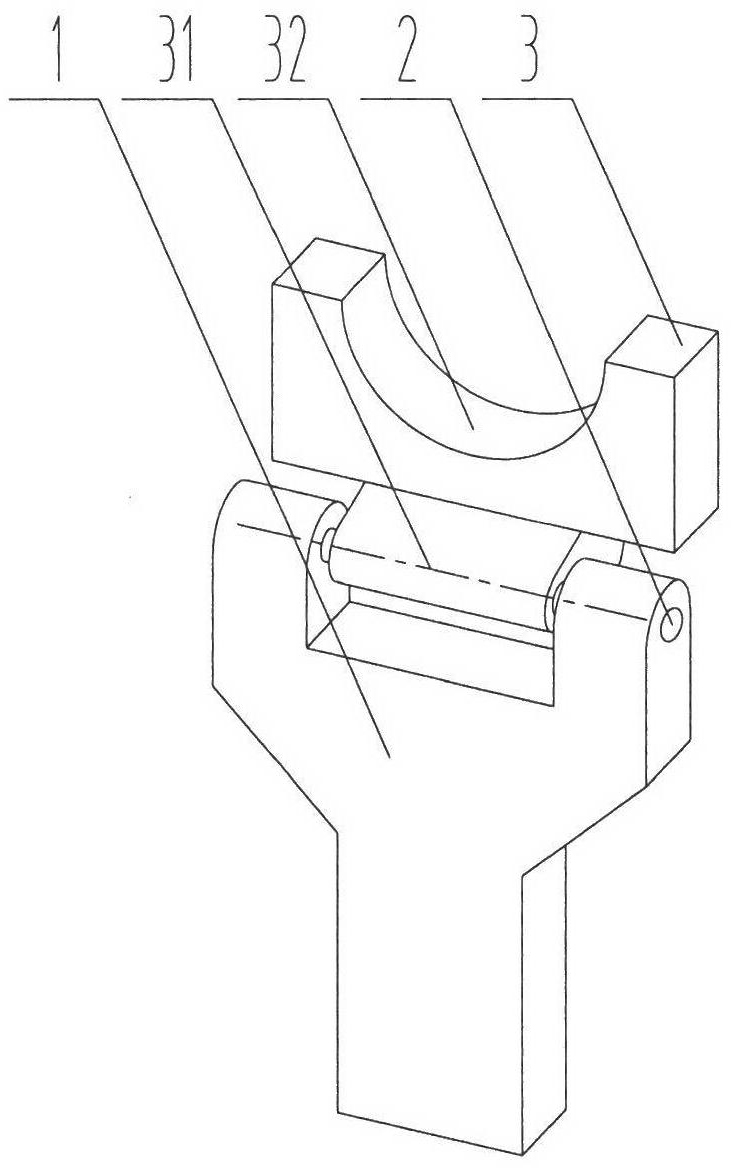

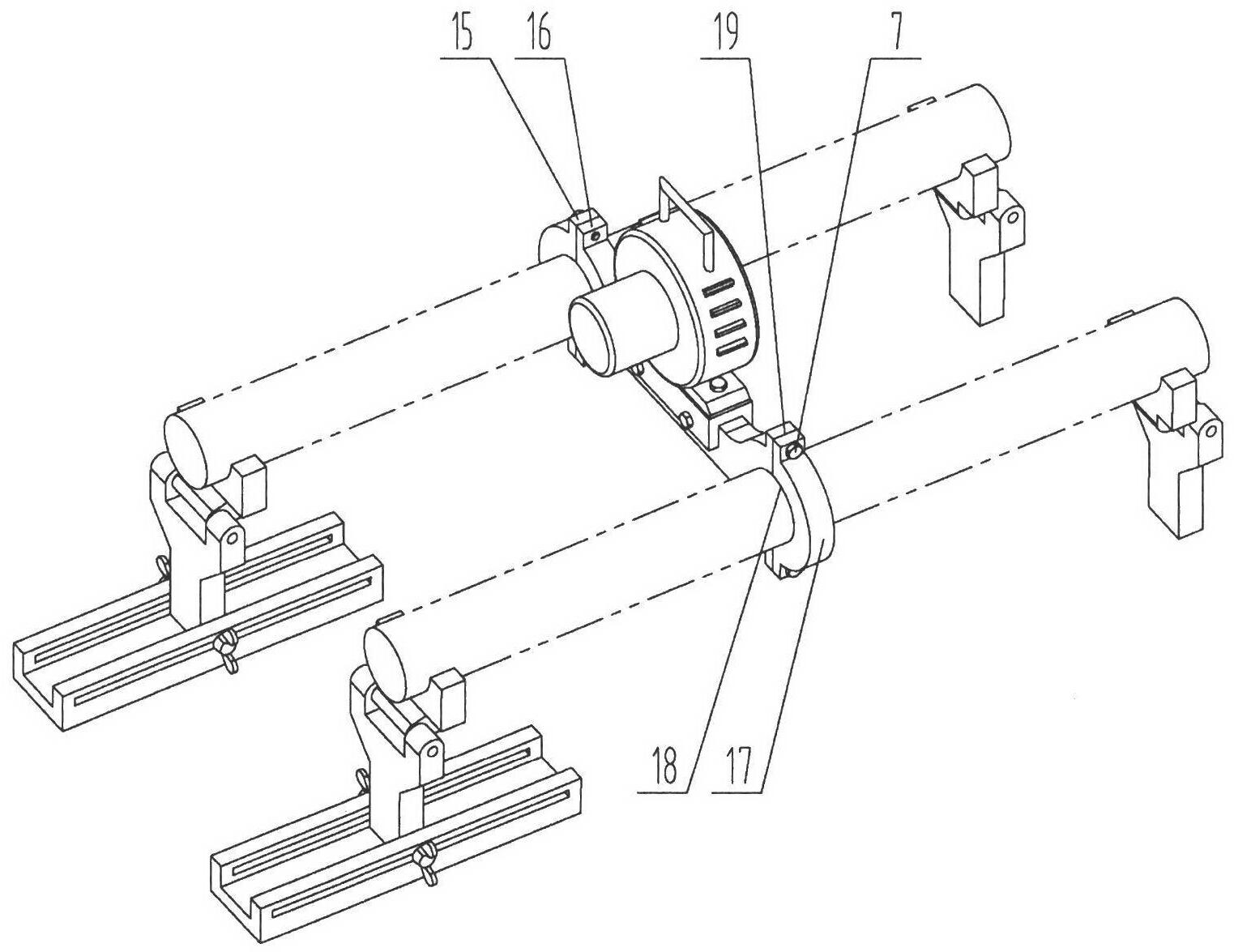

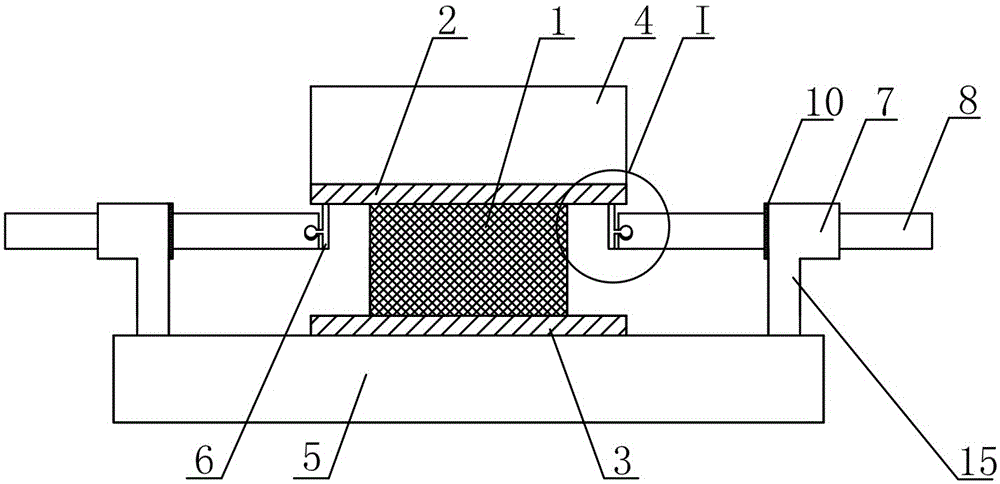

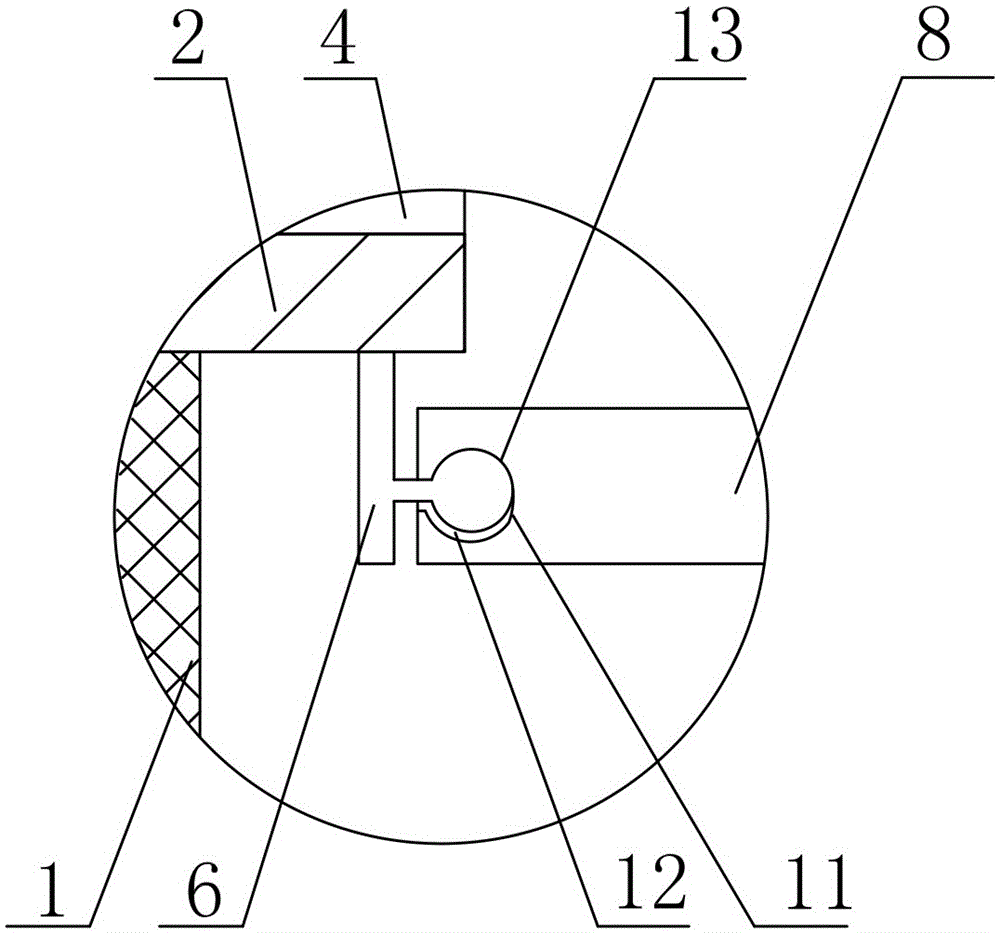

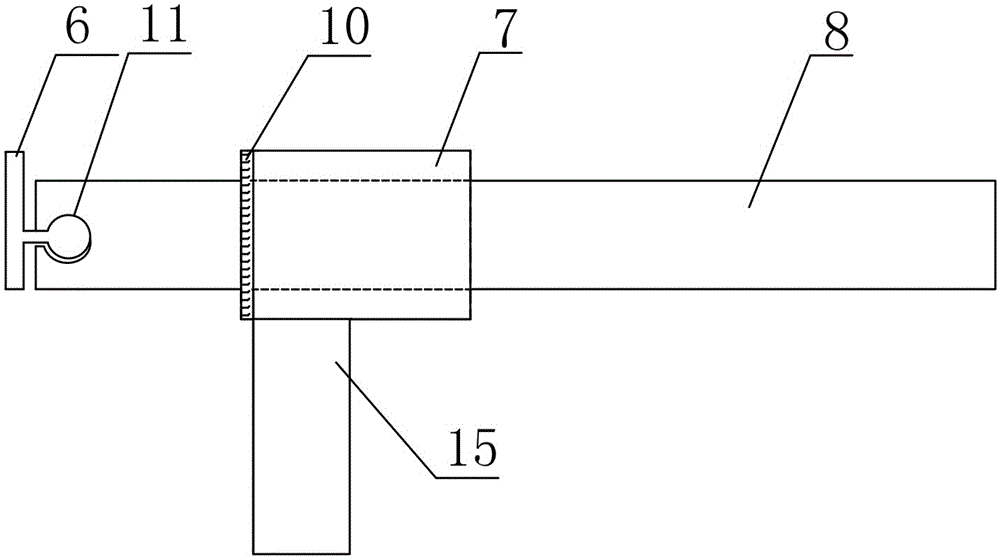

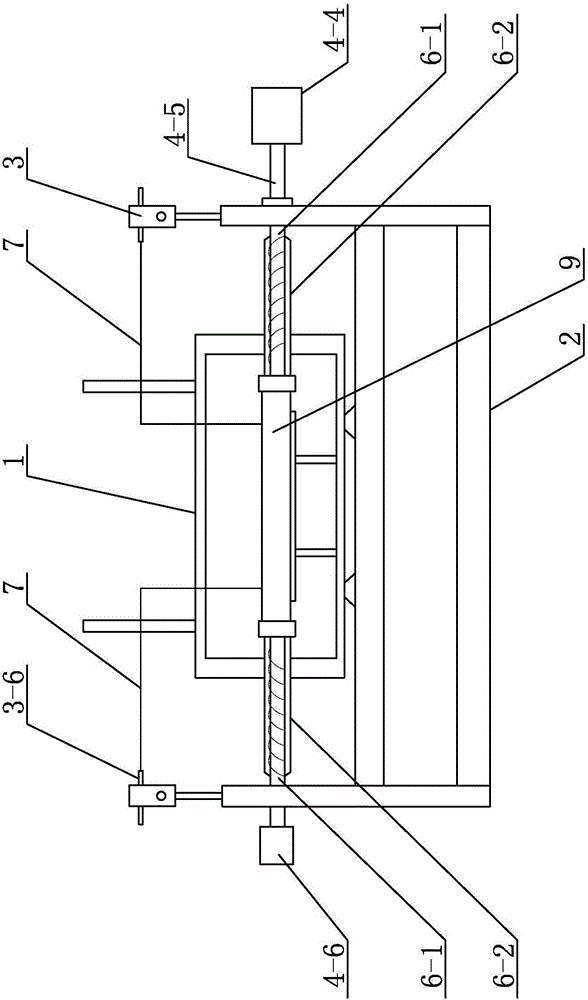

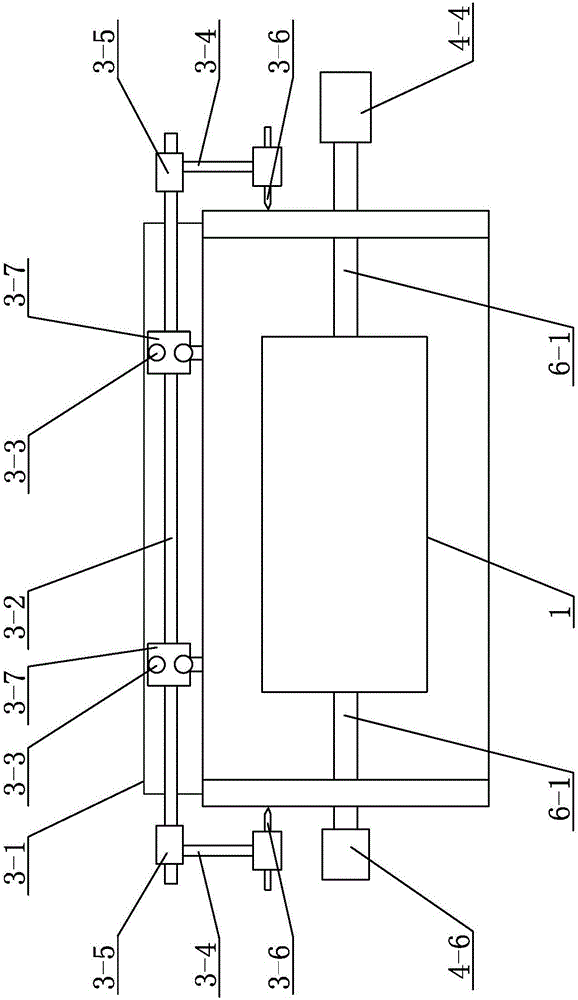

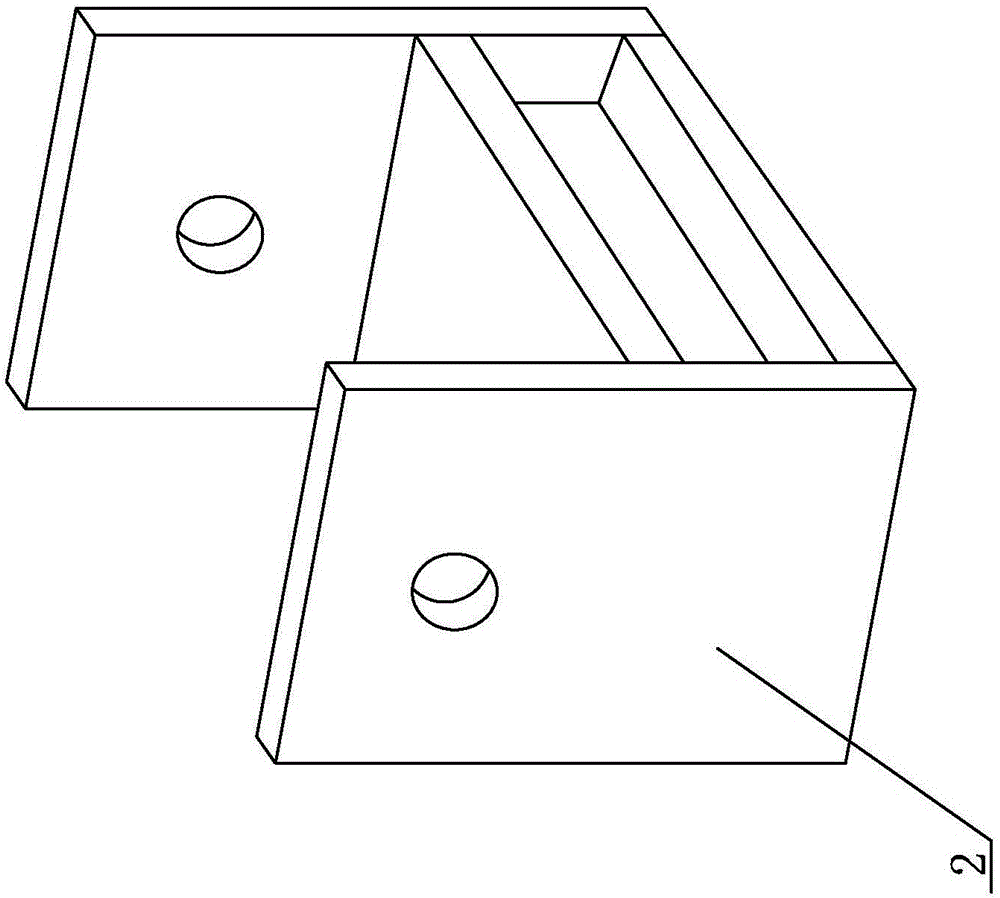

Vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and use method thereof

InactiveCN102321793AAddress effectivenessAddress stressFurnace typesHeat treatment furnacesMedium frequencyEngineering

The invention relates to a vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and a use method thereof. The apparatus comprises a vibration exciter, a support block for clamping and supporting a workpiece, and a support mechanism connected with the support block. The support mechanism comprises a pair of support frames comprising a left support frame and a right support frame, and a support seat for installing the left support frame and the right support frame, wherein the left support frame and the right support frame right are arranged relatively. Thesupport block respectively forms rotatable connections with the left support frame of the support mechanism and the right support frame of the support mechanism. The apparatus further comprises a vibration exciter base for installing the vibration exciter, wherein the vibration exciter base is arranged on the middle portion of the workpiece, the vibration exciter, the vibration exciter base and the workpiece synchronously vibrate during vibratory stress relief. According to the present invention, a simply supported beam form is adopted, the flexural vibration type primary resonance is generated by the shaft type parts under the excitation of the vibration exciter at the natural frequency adopted for shaft flexural vibration; in the prior art, the dynamic stress generated by the apparatus does not reach the requirement of residual stress decreasing, with the apparatus provided by the present invention, the problem in the prior art is solved; the deformation amounts on both ends of the shaft are substantially improved; the dynamic stress distribution of the shaft is uniform so as to effectively reduce the residual stress of the shaft part.

Owner:GUANGXI UNIV

Semiconductor silicon material water base cutting liquid

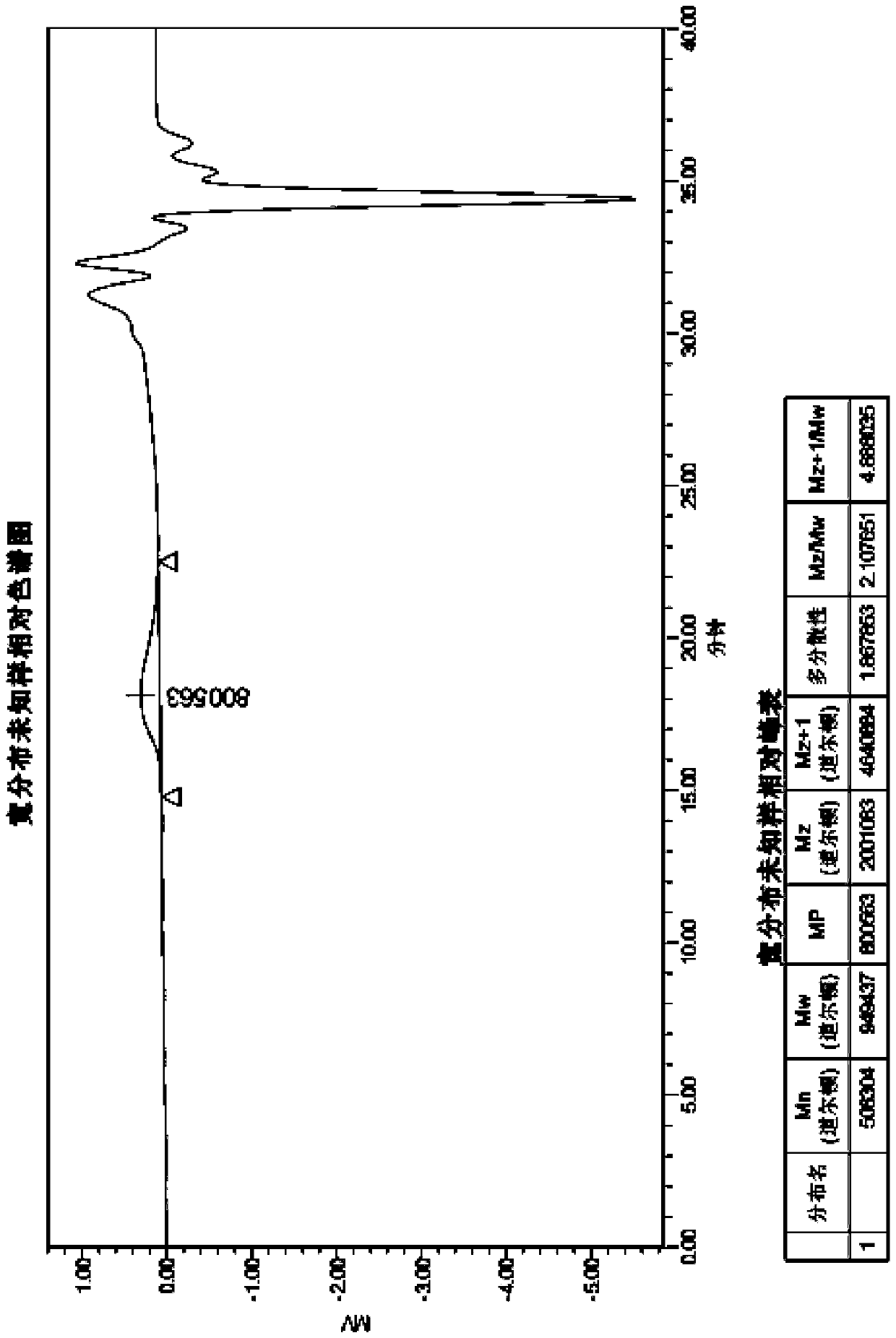

The alkaline water-base cutting liquid for silicon wafer and other semiconductor material consists of polyglycol of molecular weight 200-1000 in 30-90 weight portions, pH regulator 9-30 weight portions, chelating agent 1-10 weight portions and deionized water for the rest. The present invention has the beneficial effects of homogeneous stable chemical splitting effect coexisting with the mechanical effect, less stress, lowered damage of the semiconductor material, raised chip cutting efficiency and quality, simple post-treatment, and avoiding the chemical bonding and adsorption on the surface of silicon wafer.

Owner:HEBEI UNIV OF TECH

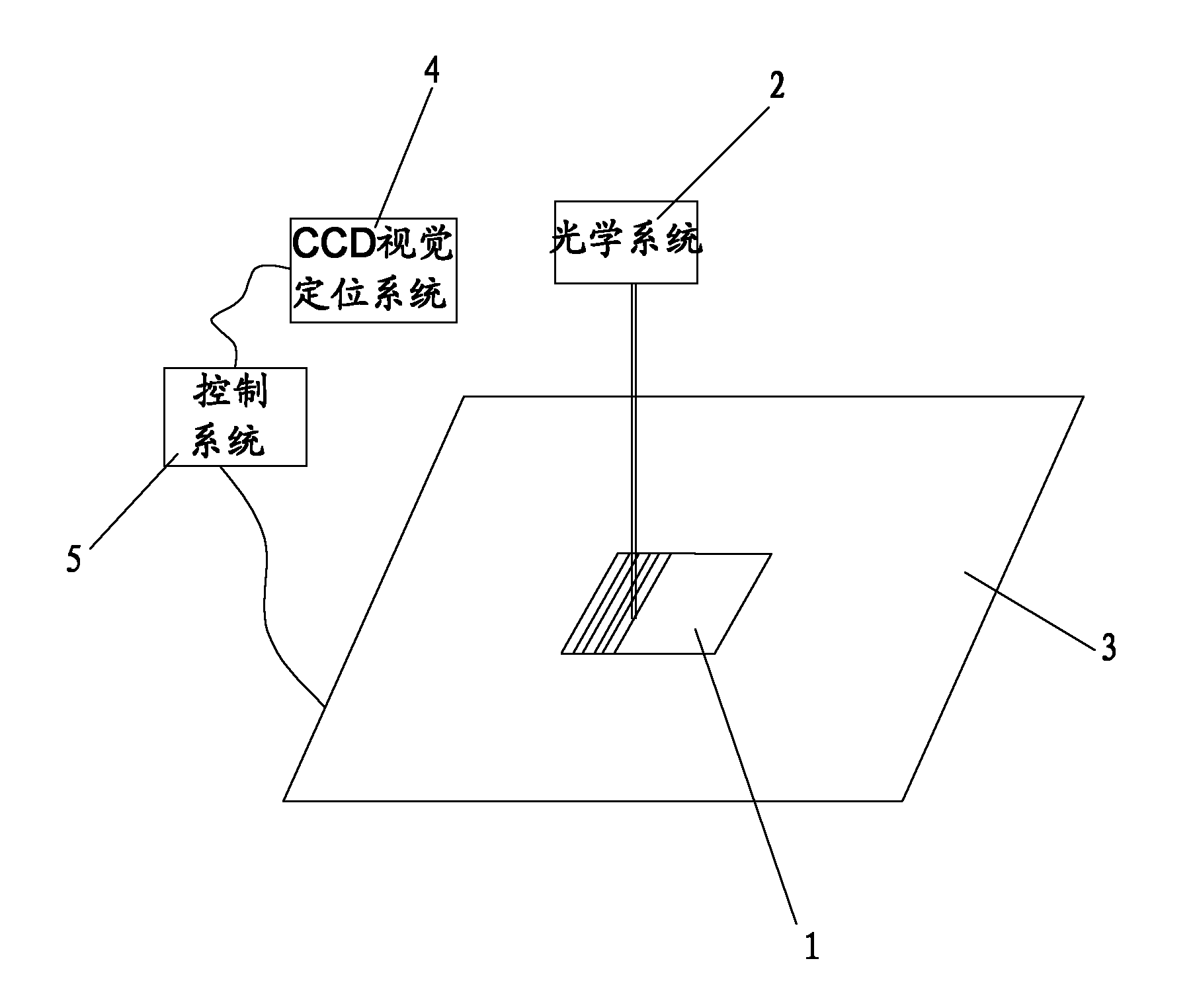

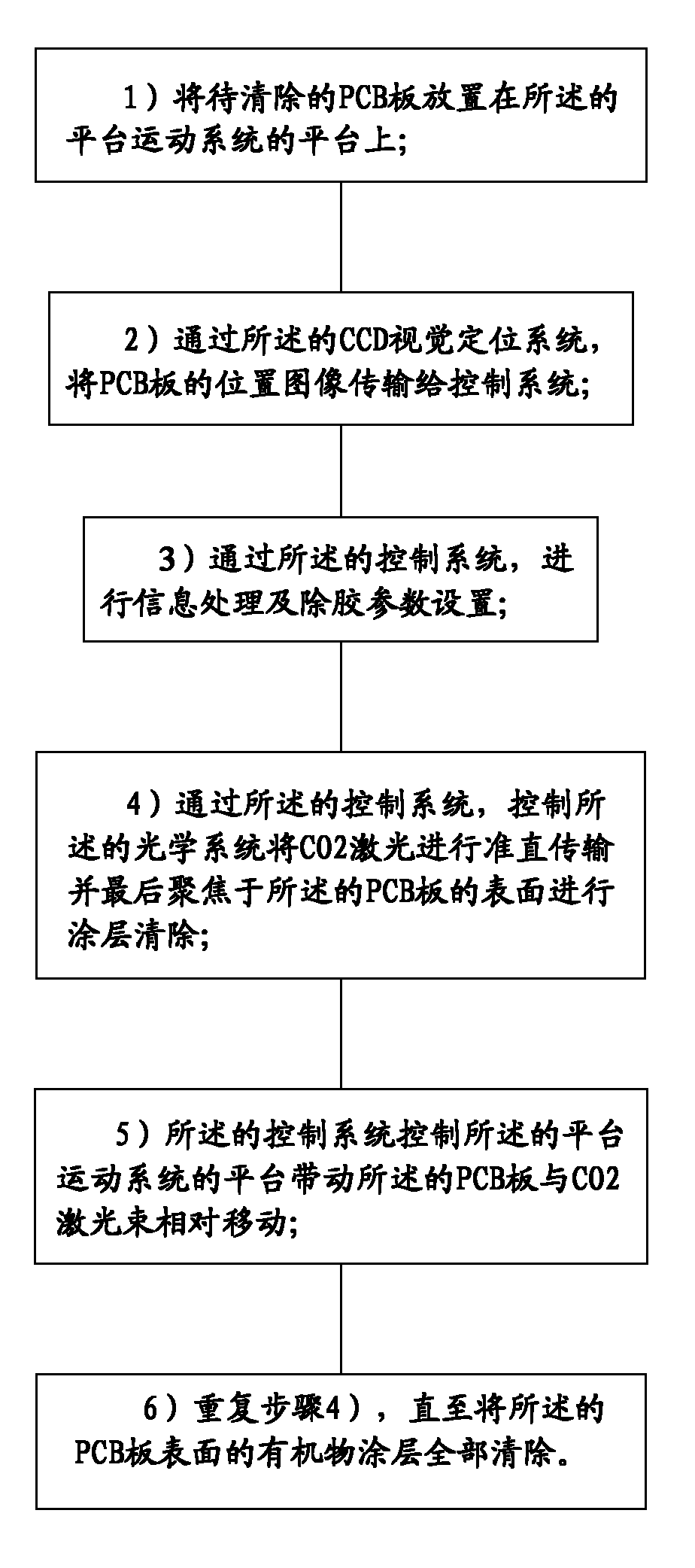

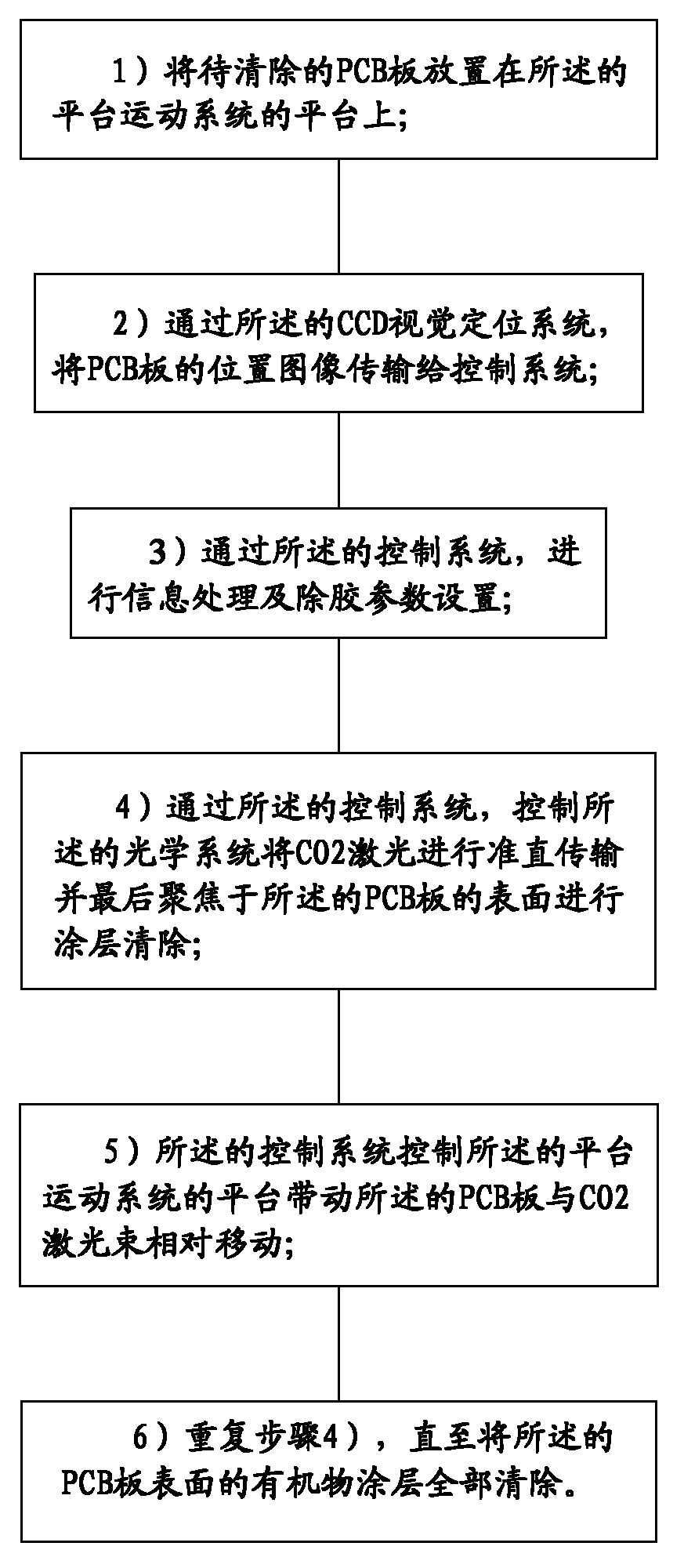

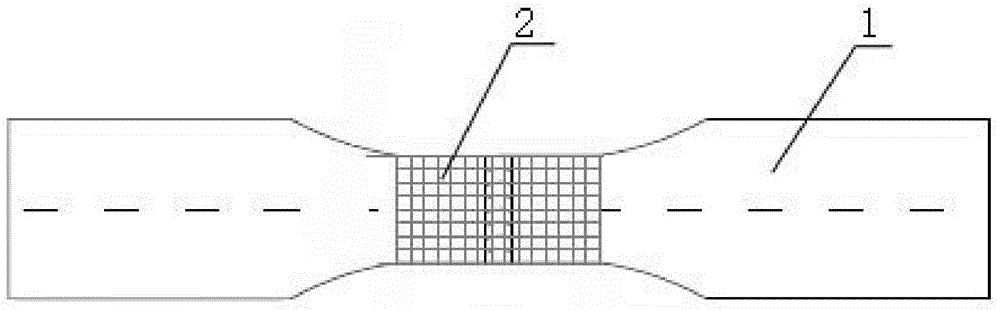

Device and method for degumming in SMT (surface mounting technology) industry

InactiveCN102164461AAvoid quality impactAddress stressPrinted circuit assemblingCleaning processes and apparatusCarbon dioxideMotion system

The invention discloses a device and a method for degumming in SMT (surface mounting technology) industry, which are used for removing a coating layer on a PCB (printed circuit board) board. The device comprises an optical system, a platform motion system, a CCD (charge coupled device) visual positioning system and a control system, wherein the optical system is used for performing the alignment transmission on CO2 (carbon dioxide) lasers and finally focusing on material surface and is used for walking along the laser track within the region through optical scanning; the control system is used for controlling the optical system, the platform motion system and the CCD visual positioning system; the platform motion system is used for performing the laser spanned degumming process through the matching motions of a numerical control platform along X and Y directions; the PCB board is arranged on the numerical control platform of the platform motion system; and the optical system is arranged above the numerical control platform of the platform motion system. By using the method and device provided by the invention, the defects of mechanical degumming, such as the influence of the mechanical degumming on the quality of the product, are avoided, the stress problem of the mechanical degumming is solved and the better degumming effect is achieved.

Owner:HANS LASER TECH IND GRP CO LTD +1

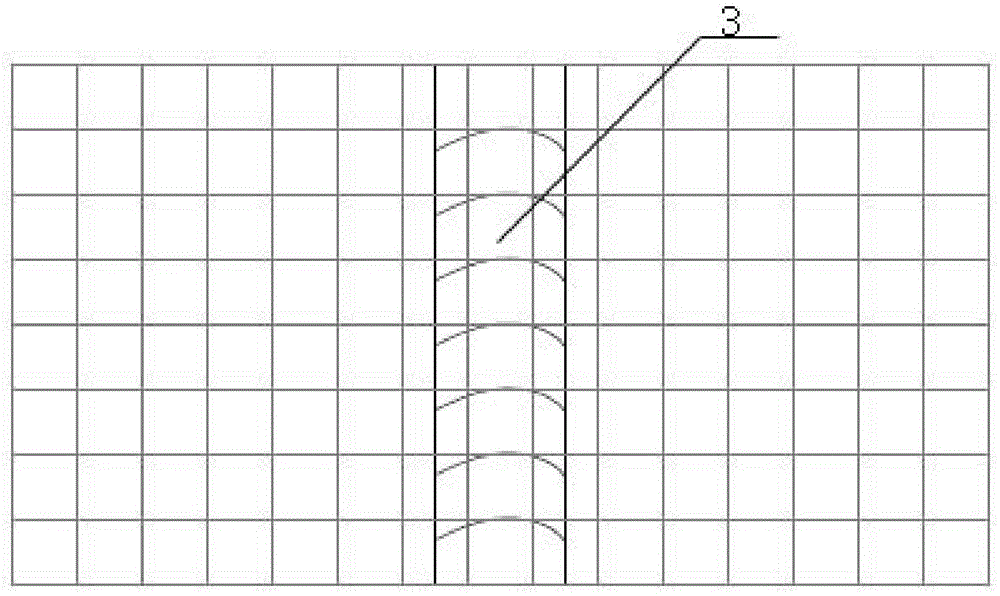

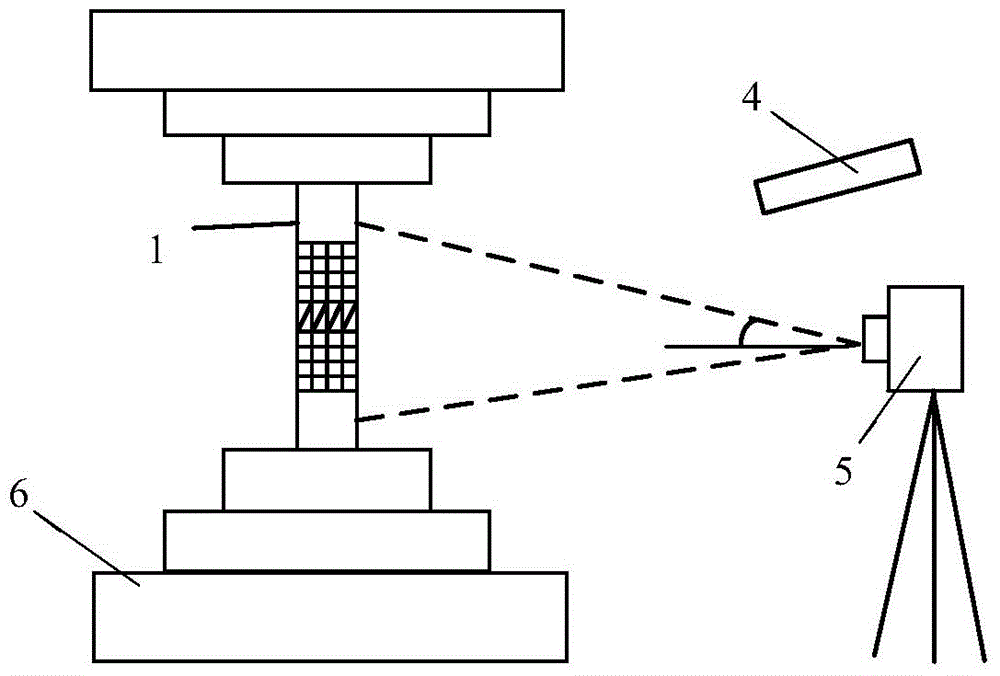

Welded member fatigue stress and strain real-time non-contact type monitoring method

InactiveCN104964886AAvoid conversionHigh precisionMaterial strength using repeated/pulsating forcesWeld seamStress–strain analysis

The present invention discloses a welded member fatigue stress and strain real-time non-contact type monitoring method. According to the method, the welded member welding seam and a certain surrounding area are subjected to grid division with a certain interval, each grid intersection point is adopted as an infinitesimal body as the stress and strain analysis unit, the feature information of the pixel points of all infinitesimal bodies in the area to be measured during the fatigue load acting process are extracted through a machine vision monitoring system when the fatigue load acts on the member, the collected member image is subjected to pixel point matching, the relation between the stress and strain change law and the image feature is established so as to obtain the feature change of the infinitesimal body during the fatigue load acting process, and finally the strain value and stress distribution law and the stress strain evolution law during the fatigue process are obtained. The method of the present invention is used for solving the monitoring problem of the stress and strain status distribution and evolution law of the welded member in the steel structure under the fatigue load acting.

Owner:SOUTHEAST UNIV

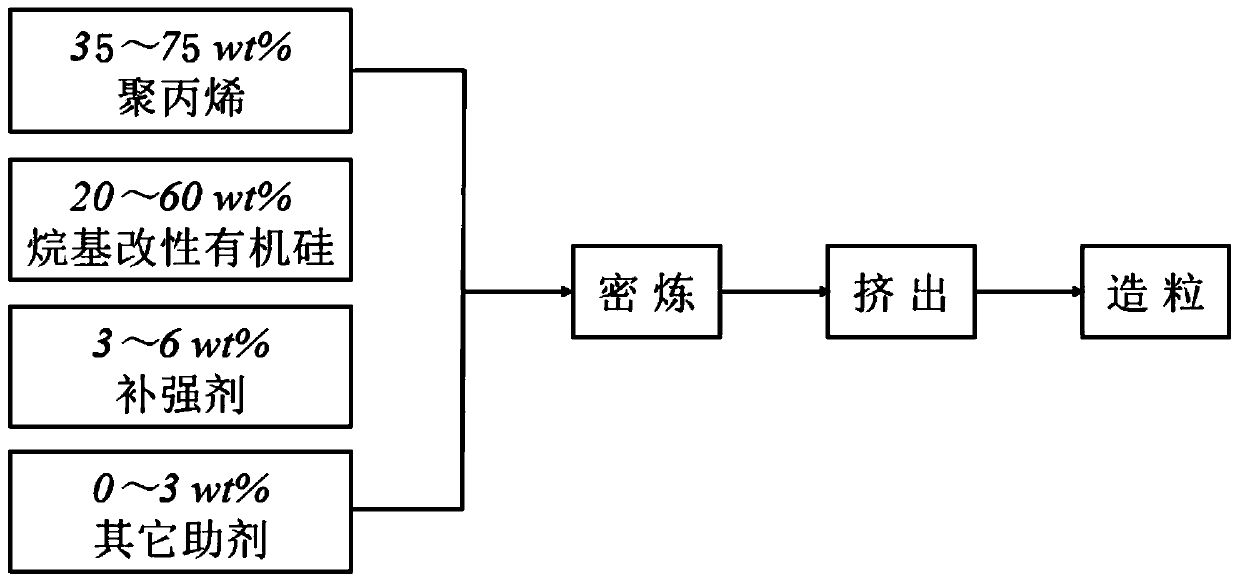

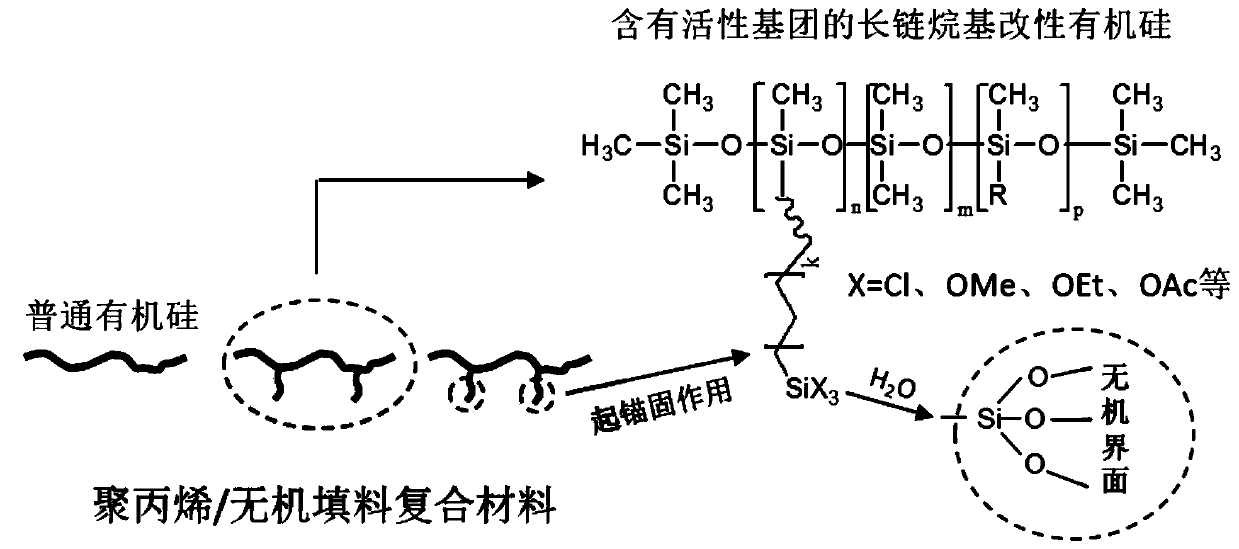

Silicone master batch with long-lasting scratch resistance, and preparation method thereof

The invention discloses a silicone master batch with long-lasting scratch resistance, and a preparation method thereof. The raw materials of the master batch contain modified silicone, the modified silicone is an active group-containing long side chain-grafted high molecular weight polysiloxane, and the raw materials also contain polypropylene, a reinforcing agent, an anti-aging agent and other assistants. The raw materials are internally mixed at 200-220 DEG C, and then are extruded and granulated under certain conditions by a twin-screw extruder to obtain the silicone master batch with long-lasting scratch resistance. The silicone master batch prepared by the invention contains the active group-containing long side chain-grafted high molecular weight polysiloxane, so the problems of unabiding scratch resistance and stress whitening of common silicone are well solved, the plastic processing performance is improved, and the device wearing is reduced. The preparation method of the invention has the advantages of simple process, environmental protection, safety, good repeatability, and easiness in industrialization. The silicone masterbatch prepared in the invention is mainly used for preparing a scratch-resistant automotive interior polypropylene composite material.

Owner:CHENGDU GUIBAO SCI & TECH

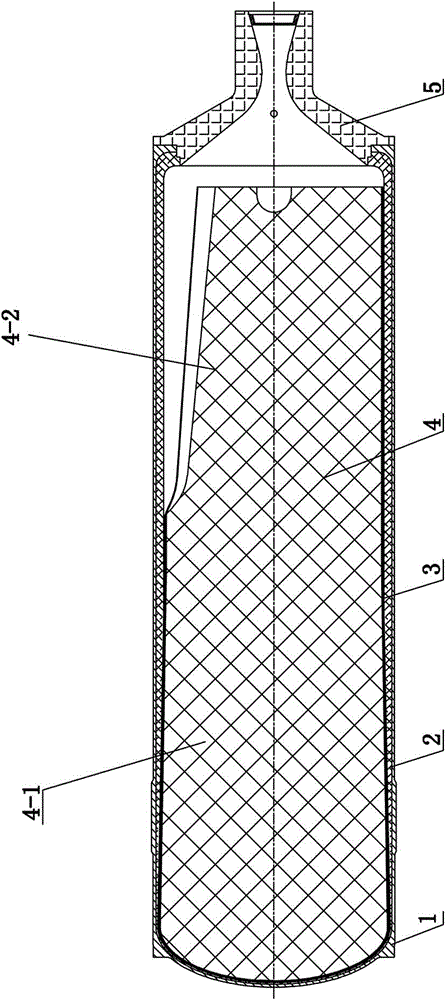

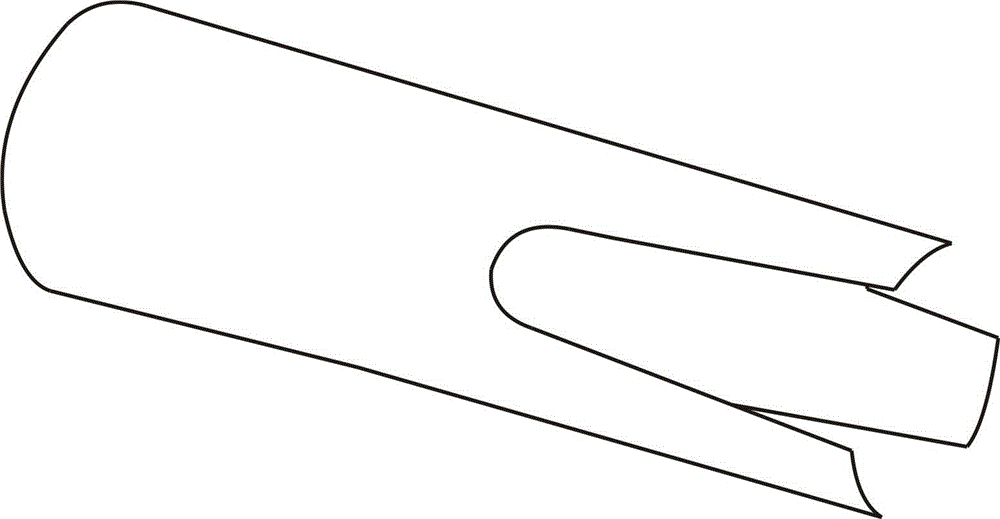

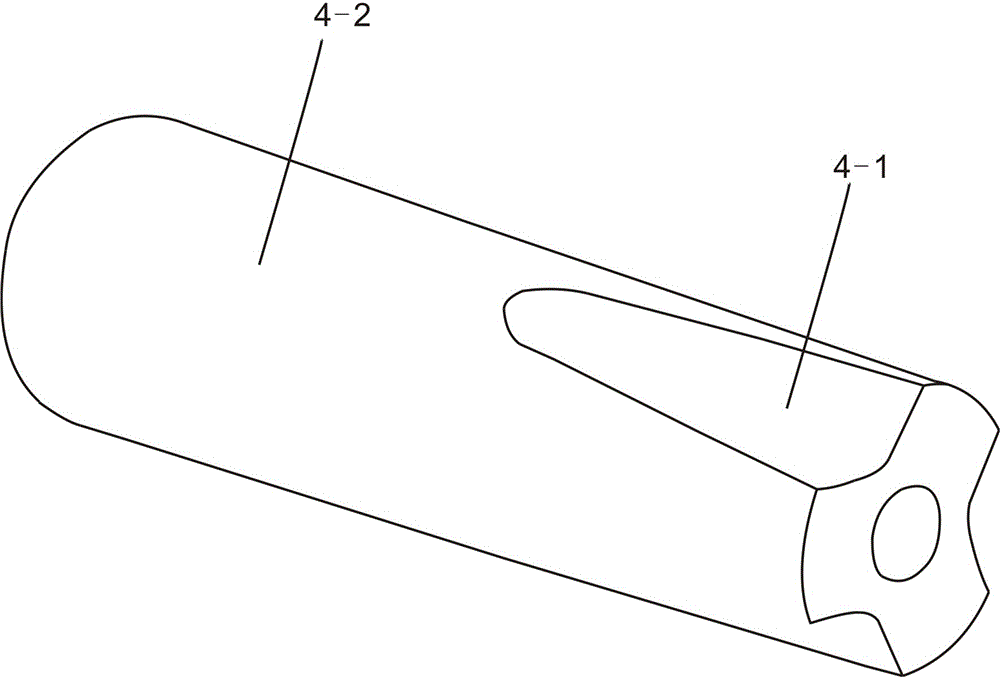

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Wire cutting liquid of semiconductor material

InactiveCN1618936AReduce wire breakage rateAddress stressSemiconductor/solid-state device manufacturingBase-materialsSemiconductor materialsCooling effect

A linear cutting liquid for semiconductor material is prepared from polyethanediol 10-10000, amine soda, penetrant, ether-alcohol as activating agent, chelating agent and deionized water. Its advantages are less corrosion to cutting wire, no filings deposit on the surface of Si chip, high penetrating, lubricating and cooling effect and low cost.

Owner:刘玉岭

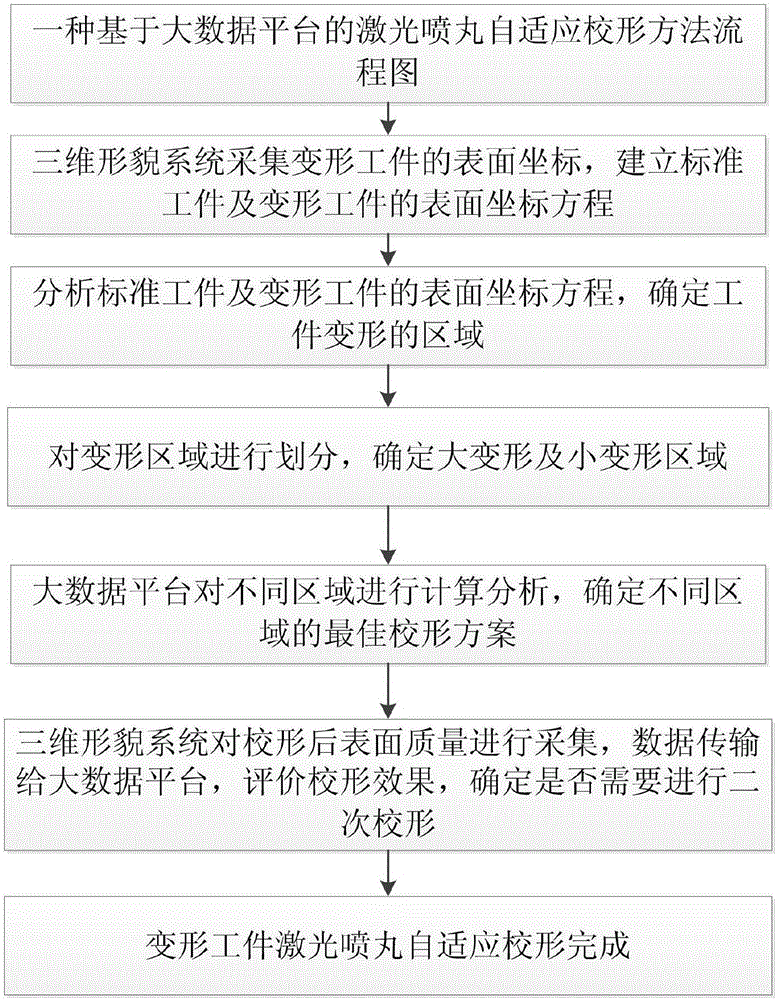

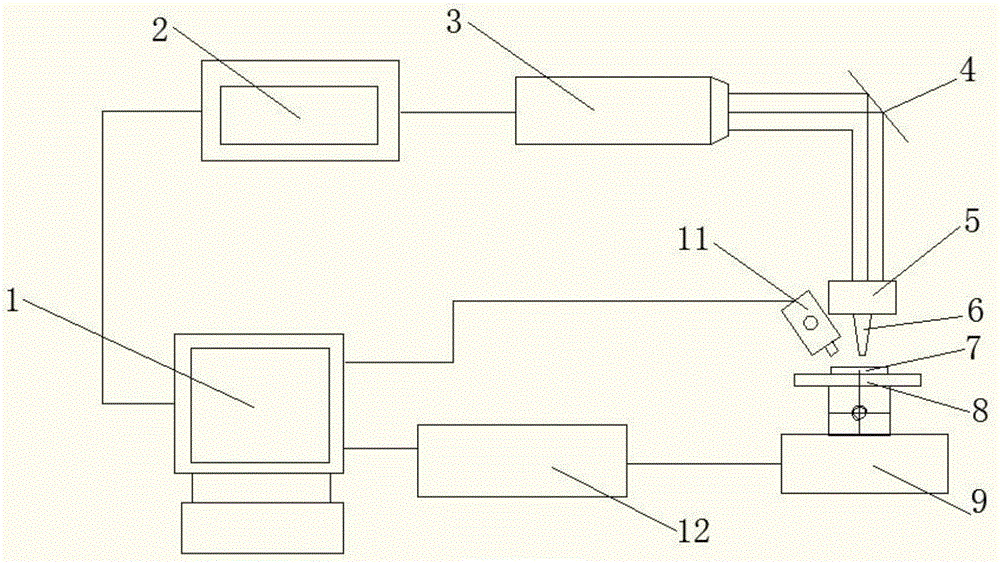

Self-adaption laser shot blasting shape correcting device based on large data platform and method

InactiveCN106216843ASolve the flatnessAddress stressLaser beam welding apparatusThree dimensional shapeData entry

The invention discloses a self-adaption laser shot blasting shape correcting device based on a large data platform and a method. The method comprises the following steps: (1) surface curvature data of a calibrated workpiece and a workpiece needing to be corrected the shape is input to respectively build three-dimensional curvature models; (2) an optimal shape correcting scheme is calculated through a laser shot blasting shape correcting large data platform in a self-adaption manner; (3) the shapes of the workpieces are corrected according to the optimal shape correcting scheme; the surface curvature detection is performed for the shape-corrected workpieces through a three-dimensional shape measurer; and data is input in the large data platform; and (4) the shape correcting effect is estimated through the large data platform to determine if secondary shape correction is needed; and if so, the steps (1-3) are repeated until the final machining requirements are reached, so that the self-adaption laser shot blasting shape correction of the workpieces is realized.

Owner:GUANGDONG UNIV OF TECH

Thermo-couple composite protective sleeve and making method thereof

InactiveCN1924532AImprove thermal conductivitySensitiveThermometers using electric/magnetic elementsUsing electrical meansAlloyLiquid metal

This invention relates to heat couple protection tube and its process method. The heat couple compound protection tube comprises basic tube cylinder and coating, which is characterized by processing the end of the cylinder into arc surface, wherein, the basic cylinder is made of metal and the coating layer is composed of metal combination layer, middle transmission layer and surface work layer; the metal combination layer is of metal ceramics materials or alloy materials similar to the basic cylinder metal property; the surface coating is of oxidation ceramics materials and the middle coating is of metal ceramics materials and oxidation mixture.

Owner:BAOSHAN IRON & STEEL CO LTD

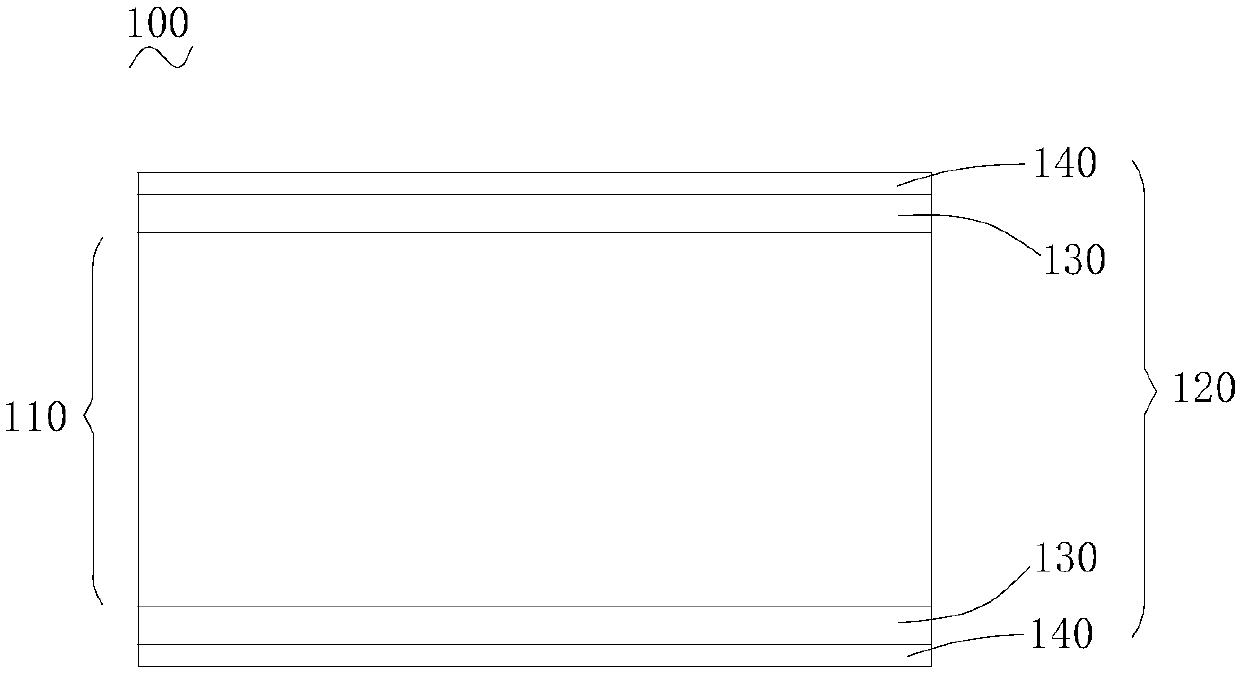

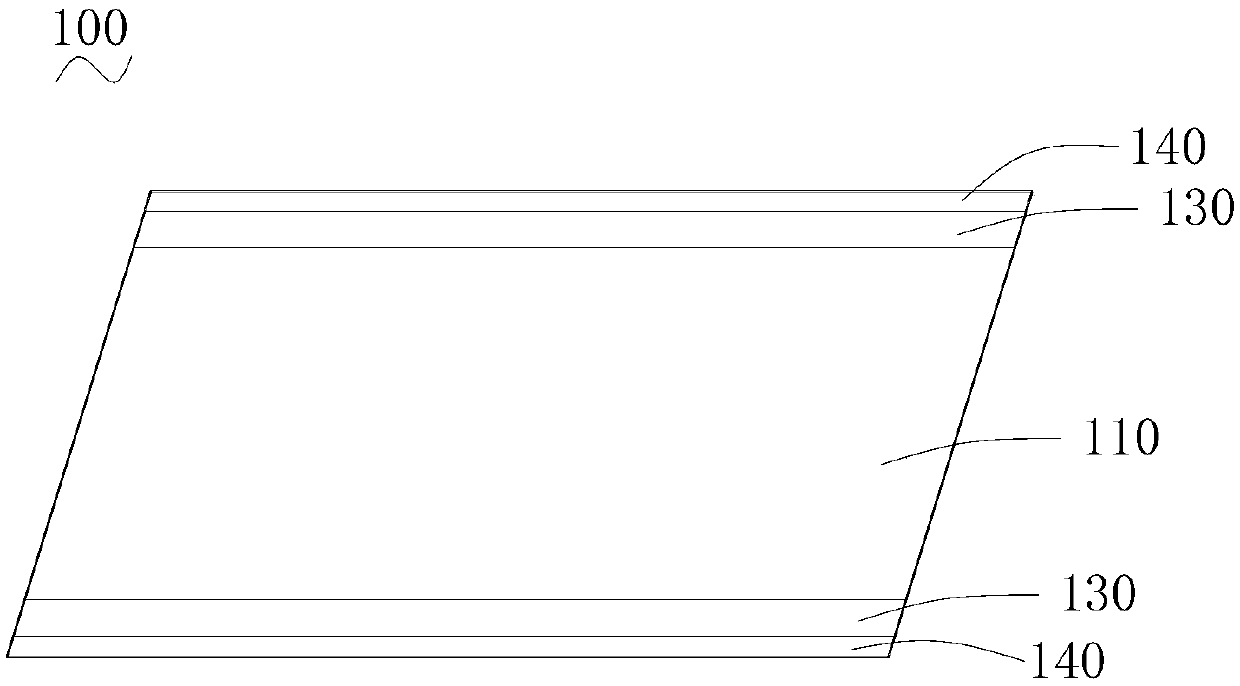

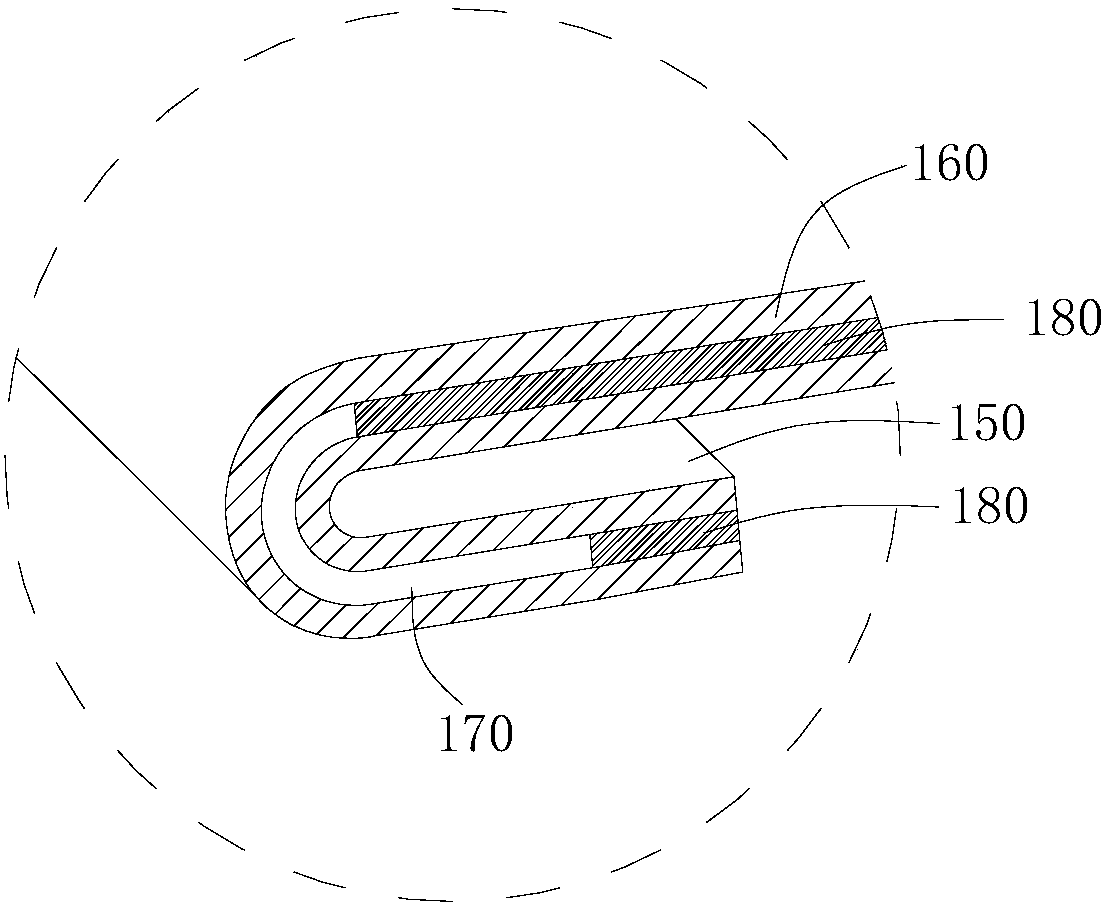

Flexible display module

The invention relates to a flexible display module. The flexible display module is provided with a bent zone and an extending zone located at the end of the flexible display module. The flexible display module comprises a first superposed layer and a second superposed layer which are superposed, and the first superposed layer and the second superposed layer are non-fixedly connected in at least part of bent zone and are fixedly connected in the extending zone. On one hand, the first superposed layer and the second superposed layer are non-fixedly connected in the bent zone, so that when the flexible display module is bent, the first superposed layer and the second superposed layer can be freely bent in the bent zone, and the stress problem caused by a bonding material to the two superposedlayers during traditional bending is avoided; on the other hand, the first superposed layer and the second superposed layer are fixedly connected in the extending zone, and relative slippage of the superposed layers during bending is avoided. The whole flexible display module is not likely damaged in the bending process.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Perforation cartridge case manufacturing process

The invention discloses a perforation cartridge case manufacturing process which comprises the following steps of (1) medium frequency heating: performing the medium frequency heating on round steel with a medium frequency furnace, and heating the round steel to 1150 DEG C to 1200 DEG C, (2) round steel blanking, (3) cake upsetting: allowing the middle of the head of the round steel to form a spherical concave, (4) stamping forming: keeping the stamping temperature higher than 1100 DEG C, and ensuring that the final forging temperature is higher than 850 DEG C, (5) normalizing, (6) cold pressing, (7) shape finish turning, (8) groove milling, and (9) oil stain and burr removal, and surface electroplating. The perforation cartridge case manufacturing process effectively solves the technical problems of nonuniform heating, high stamping rejection rate, and greater internal stress of a perforation cartridge case material.

Owner:宁波宇恒能源科技有限公司

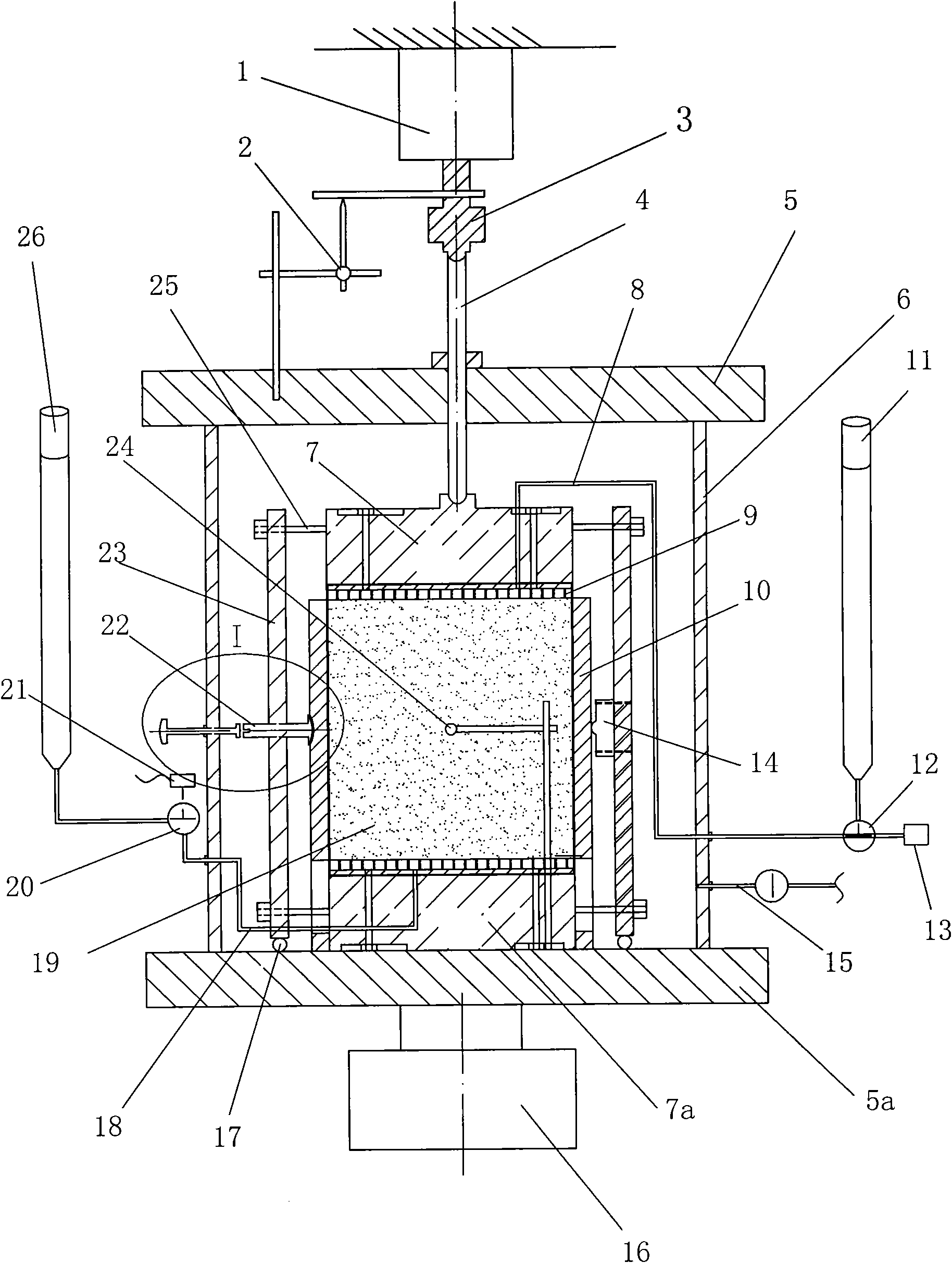

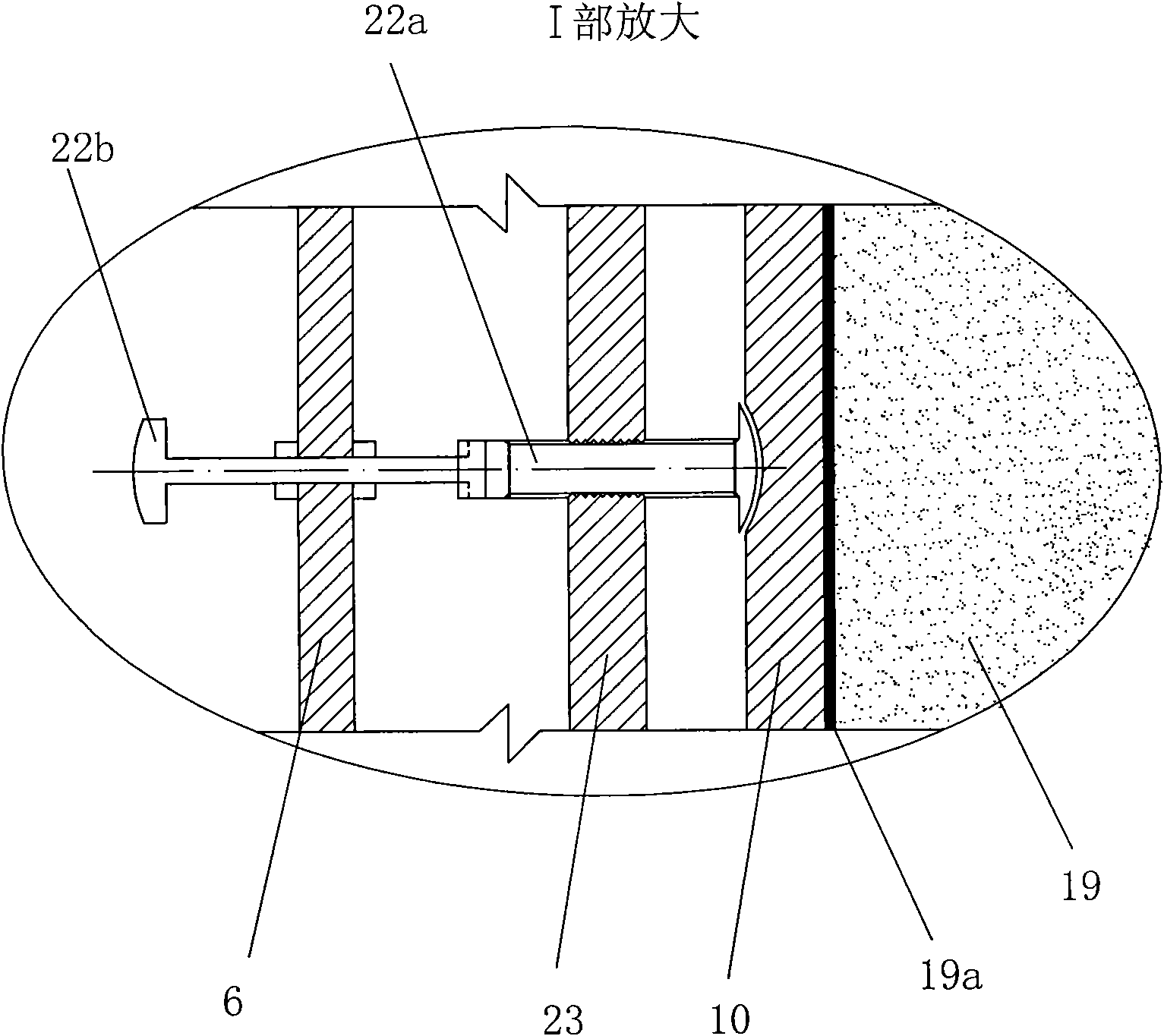

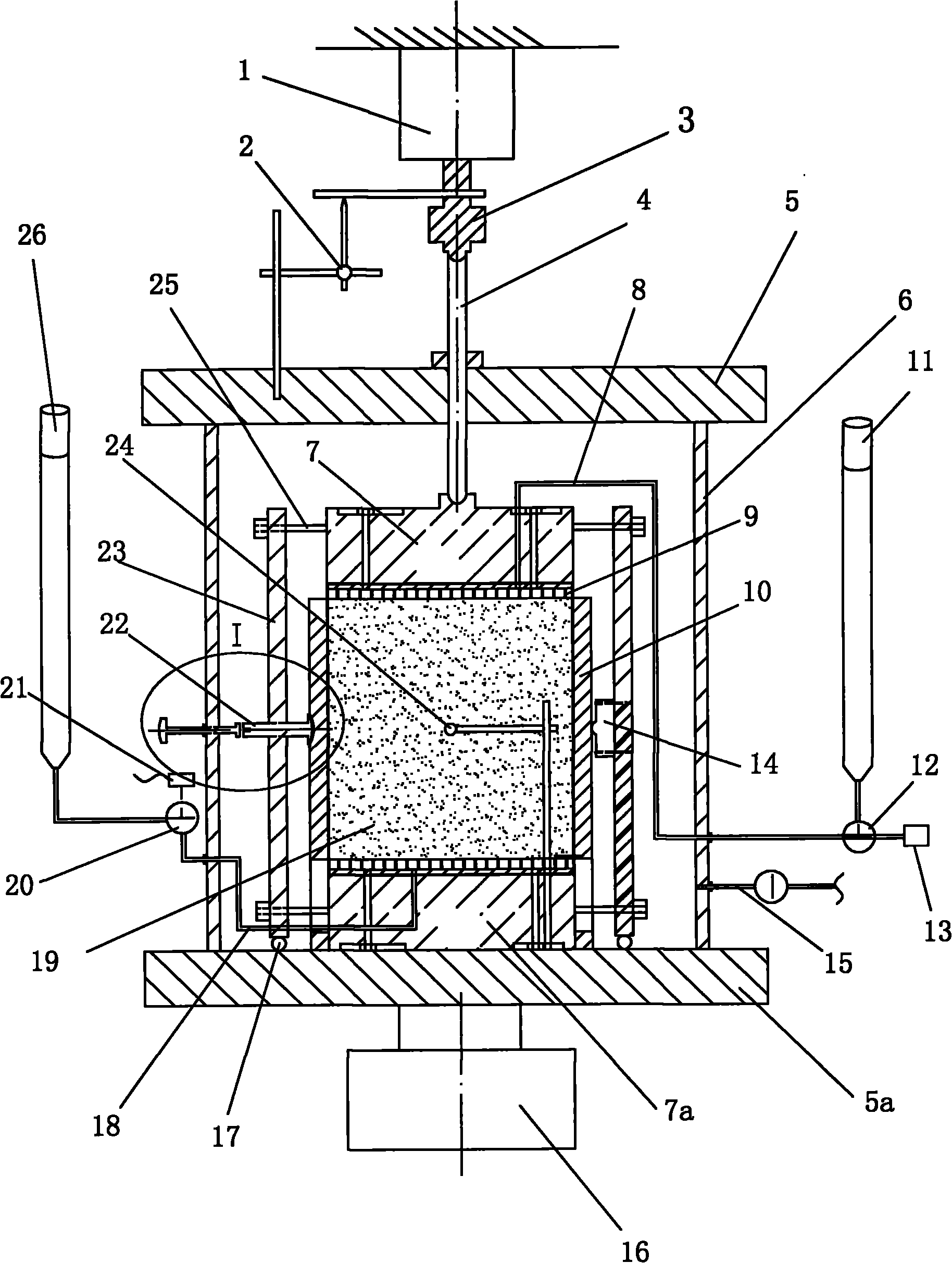

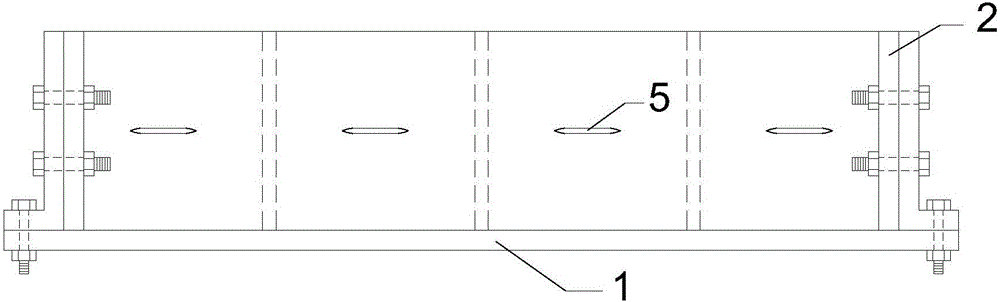

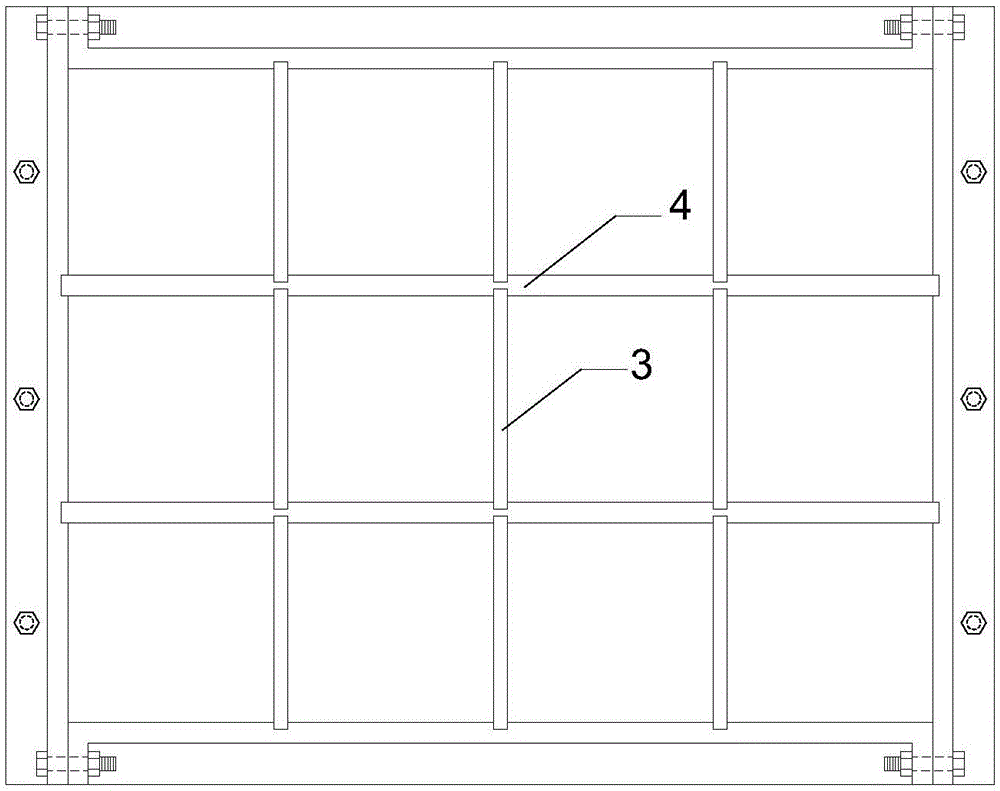

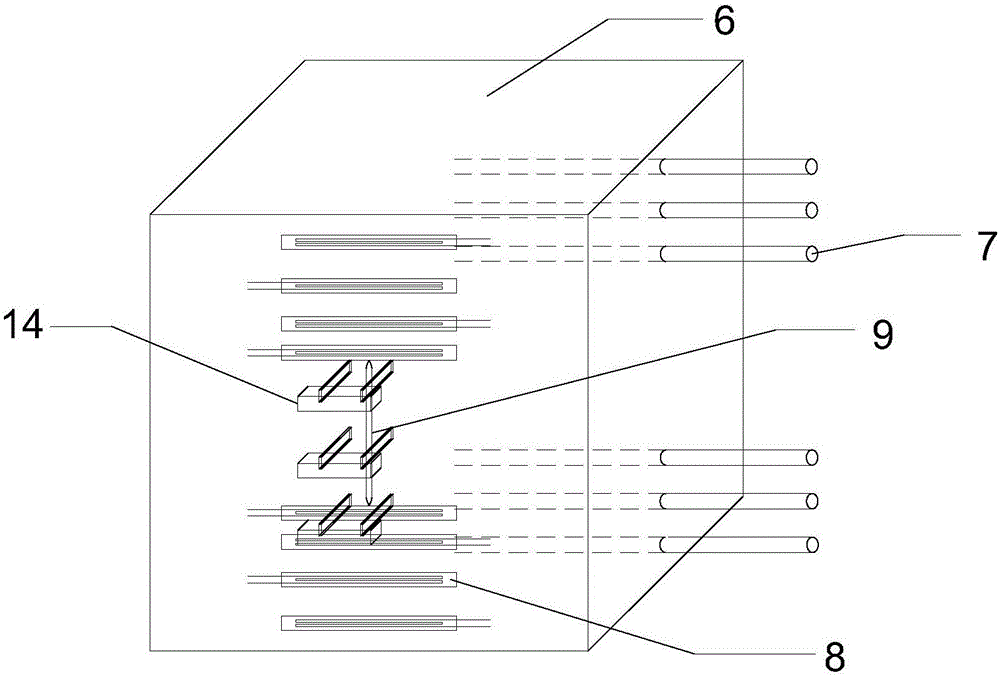

Cement soil plane strain tester

InactiveCN101881715AAchieve mechanical propertiesGuaranteed accuracyMaterial strength using tensile/compressive forcesHydraulic cylinderPrincipal stress

The invention relates to a cement soil plane strain tester; a shell (6) is connected between an upper and a lower covers (5 and 5a) to form a pressure chamber; the upper cover (5) is provided with a sliding top rod (4) connected with a piston rod of a hydraulic cylinder (1); the lower end of the top rod (4) is connected with a loading plate (7); a sample side pressure plate (10) is arranged between the upper loading plate (7) and a lower loading plate (7a); the cement soil plane strain tester is characterized in that a. the pressure chamber is internally provided with a counter-force frame (23); b. one end of the counter-force frame is provided with an adjusting screw rod (22) which is contacted with the sample side pressure plate (10); c. the upper and the lower loading plates are respectively provided with drain pipes (8 and 18) which are connected with flow meters (11 and 26); and d. the piston rod is provided with sensors (2 and 3), and the counter-force frame is internally provided with a sensor (14). The cement soil plane strain tester has the advantages that the mechanics characteristics of cement soil plane strain can be tested in a room, the problems of regulation and control of principal stress and accuracy thereof can be solved by using the adjusting screw rod to adjust the contact between the pressure plate along the direction of the principal stress and a sample, and the problem of contact between the sample and the pressure plate after consolidation and deformation of the principal stress can be also solved.

Owner:ANHUI & HUAI RIVER WATER RESOURCES RES INST

Test apparatus and method for simulating hydraulic fracture of concrete under high water pressure

InactiveCN106501089AConvenience for pouring concrete samplesAddress stressPreparing sample for investigationMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention discloses a test apparatus and method for simulating the hydraulic fracture of concrete under a high water pressure. The apparatus comprises a concrete sample, a water pressure supply system and a data acquisition system, the concrete is provided with a crack in advance, and the water pressure supply system comprises an electrically controlled pressure pump. The method comprises the following steps: 1, making a die; 2, pouring the sample; 3, carrying out demolding curing; 4, loading the sample; and 5, testing: introducing water into the crack through the electrically controlled pressure pump, and gradually improving the water pressure until the concrete sample is destroyed; and 6, analyzing the hydraulic fracture: replacing the concrete sample, repeating step 4 and step 5, and analyzing the phenomenon and the mechanism of the hydraulic fracture of the concrete sample according to a result obtained after several tests. The water pressure and deformation parameters are fast to acquire.

Owner:HOHAI UNIV

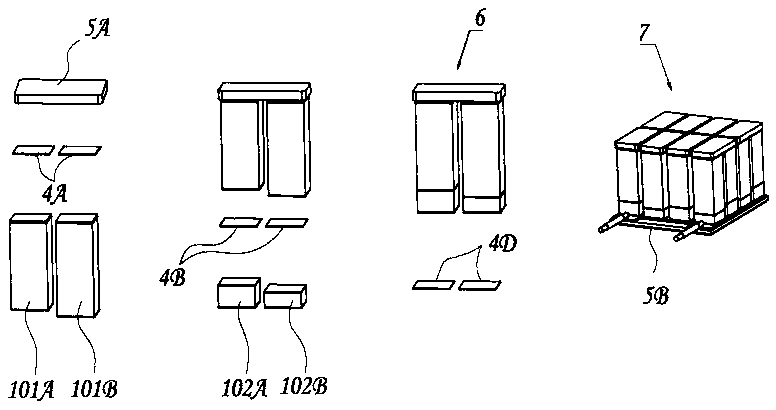

Wide-temperature range thermoelectric generation device with multi-segmented structure and preparation method

ActiveCN107681044AImprove integrityReduce thermal stressThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentTwo temperatureThermoelectric element

The invention relates to a wide-temperature range thermoelectric generation device with a multi-segmented structure and a preparation method thereof. The thermoelectric generation device is formed bycombining at least two types of thermoelectric materials with excellent thermoelectric properties in different temperature zones along the temperature gradient direction; high-temperature terminal electrodes and low-temperature terminal electrodes are used for being connected with P-type single thermoelectric elements and N-type single thermoelectric elements in a diversion manner; and barrier layers and connection layers are arranged between the high-temperature terminal electrodes or the low-temperature terminal electrodes and the corresponding single thermoelectric elements and between thesingle thermoelectric elements of two adjacent temperature segments. According to the wide-temperature range thermoelectric generation device with the multi-segmented structure and the preparation method thereof, maximization of the energy conversion efficiency of the whole temperature zone can be achieved, and the reliability of the thermoelectric generation device is high.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

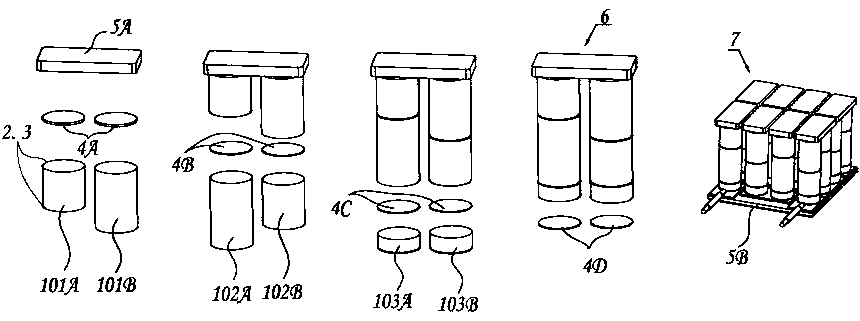

Small-section square girder and welding process thereof

ActiveCN102773590AResolve the breakSolve Weld CrackingElongated constructional elementsArc welding apparatusShear capacityWelding deformation

The invention discloses a small-section square girder and welding process thereof, belonging to welding technology and capable of solving the problem of low welding quality in case of small manual welding space. The small-section square girder has four girder plates with widths of 200-220mm and lengths smaller than or equal to 10m in paired arrangement to form a box-shaped inner cavity, in which are arranged reinforcement rib plates, flanges are welded at two ends of the girder plates, and inside and outside fillets are present between the girder plates and between the girder plates and the flanges. In welding, a to-be-welded part is cleaned before welding, a run-on plate and a run-off plate are assembled and welded, welding is carried out by use of an automatic welding cart, an inner cavity and an exposed welding seam alternate welding sequence is adopted during welding, an inner cavity backing welding seam is firstly formed, the backing welding seam for an exposed welding seam is then formed after the back gouging is strictly performed, the inner cavity and the exposed welding seam are sequentially formed, and a back-step welding method is adopted. According to the invention, welding deformation is controlled within an allowable range, torsion resistance and shearing resistance of the small-section square girder are improved, and stability and reliability of the girder are ensured.

Owner:SHANXI PINGYANG IND MACHINERY

Slide bar type tensile limiting-displacement vibration isolation support

ActiveCN105064528AImprove stabilitySimple structureShock proofingEarthquake intensityVibration isolation

The invention discloses a slide bar type tensile limiting-displacement vibration isolation support which comprises a vibration isolation rubber pad, an upper steel sheet and a lower steel sheet. The upper steel sheet and the lower steel sheet are anchored to an upper structure and a lower structure. The slide bar type tensile limiting-displacement vibration isolation support is characterized in that the two sides or the periphery of the bottom of the upper steel plate are / is symmetrically provided with slide bars and tensile limiting-displacement mechanisms composed of pull rods and sleeves, wherein the pull rods are provided with sliding grooves; the slide bars are fixedly connected with the upper steel sheet, the sleeves are anchored to the lower structure through bases, and the slide bars are circular rod pieces arranged on a vertical plate; the sliding grooves are clamp grooves formed in one ends of the pull rods and matched with the slide bars, and the sliding grooves are formed in the slide bars in a sleeving mode and connected with the slide bars in a sliding mode. Compared with the prior art, the slide bar type tensile limiting-displacement vibration isolation support is simple in structure and high in horizontal shearing resistance and vertical tensile deformation resistance, the stability of the support is greatly improved, the problems of toppling and ultralimit of tensile stress of the vibration isolation support possibly generated by vibration isolation of a high-rise building are well solved, and the slide bar type tensile limiting-displacement vibration isolation support is especially suitable for application and popularization of laminated rubber vibration isolation supports of high-rise buildings in earthquake regions of high earthquake intensity.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

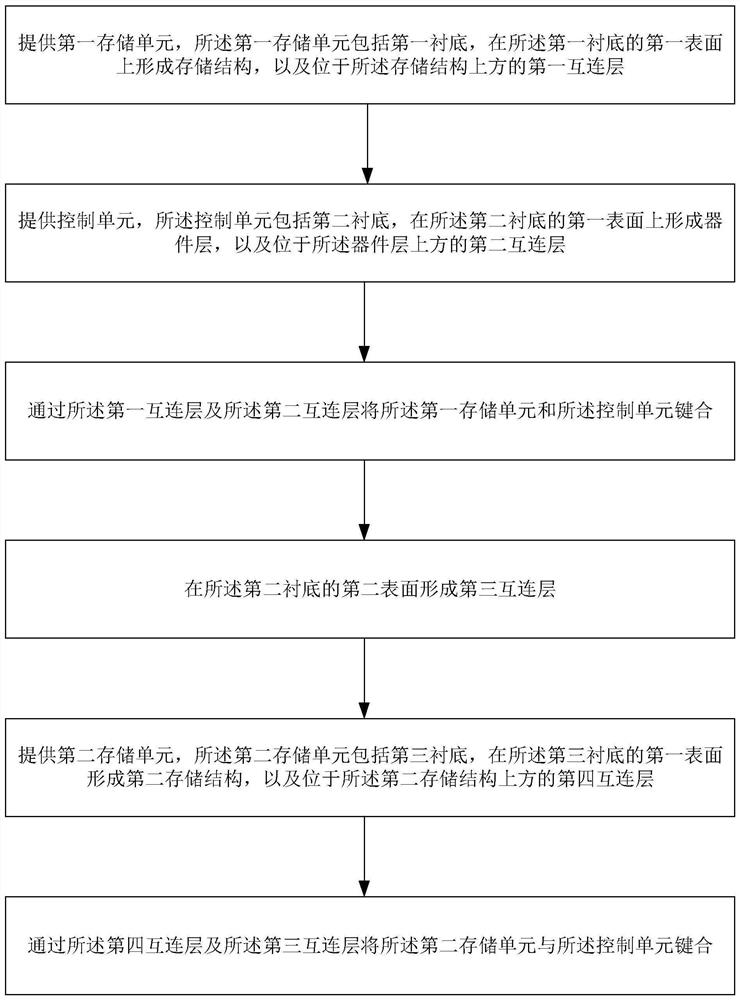

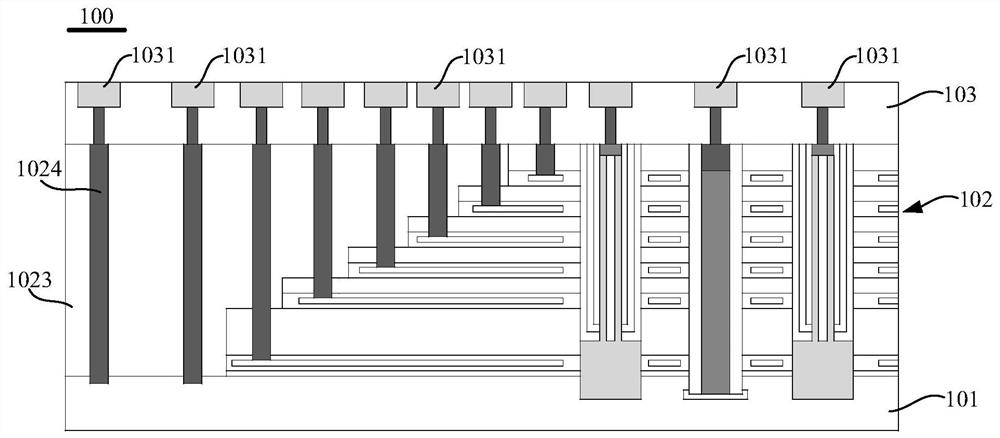

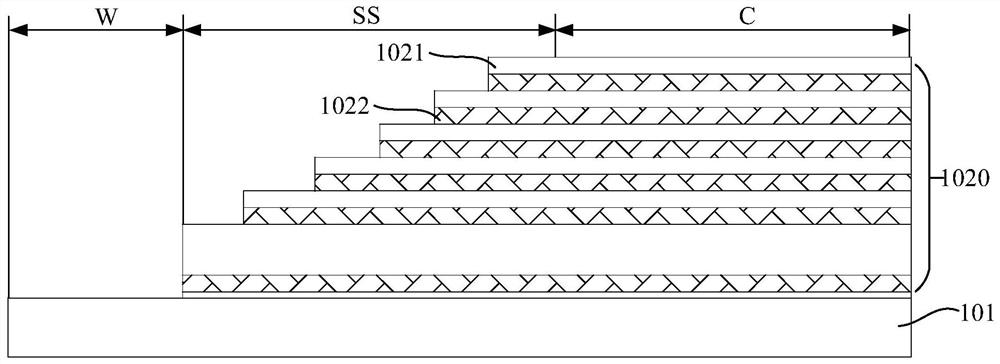

Three-dimensional memory device and forming method thereof

ActiveCN112614853AAchieve bondingSimple processSolid-state devicesSemiconductor devicesControl cellStructural engineering

The invention provides a three-dimensional memory device and a forming method thereof. A memory unit is bonded with a control unit, and then another memory unit is bonded on the back surface of a substrate of the control unit, so that bonding of at least three units is realized. Therefore, wafer-level bonding is realized, the process is simpler, the stress problem can be effectively solved while the number of storage layers is increased, the structure is more stable, and the risk of structural collapse is reduced. After the memory unit and the control unit are bonded, the bonding pads on the two sides are led out, the bonding pads can be led out from the sides of the two memory units, the bonding pads can also be led out from the two sides of one memory unit and the two sides of the control unit, and a control circuit of the control unit is used for controlling the memory unit accessed during memory. The pad leading-out mode is added, and the number of bonding pads per unit area is increased. The number of bonding pads per unit area is increased, the access hit rate of the memory unit can be improved, and therefore the memory period of the memory unit can be greatly shortened.

Owner:YANGTZE MEMORY TECH CO LTD

Machine-spraying quick-demulsifying solidification film formation creep waterproof coating and preparation method thereof

ActiveCN103525307AGood adhesionIncrease viscosityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses a machine-spraying quick-demulsifying solidification film formation creep waterproof coating and a preparation method thereof, belonging to the technical field of waterproof coating. The waterproof coating is formed from the components A and B by atomization mixing in air and dehydration curing, wherein the component A comprises the following components in percentage by weight: 5-20% of thermoplastic elastomer polymer, 20-50% of asphalt, 30-50% of water, 1-5% of emulsifier, 5-20% of rubber latex and 0-20% of filler; the component B consists of the following components in percentage by weight: 30-40% of demulsifier and 60-70% of water. The waterproof coating overcomes the shortcomings of a common elastomer, such as quick aging in a high-stress state for a long time, stretching fatigue and the like, and always keeps good viscosity and re-bonding ability; the problem of internal stress of a waterproof layer is thoroughly solved, so that the waterproof layer has the characteristics of strong sustained bonding ability, high elongation and low-temperature flexibility; the material has good adhesive property, good heat resistance and good low-temperature flexibility, and the creep property in a shear state can exceed 0.1N / mm.

Owner:浙江鲁班建筑防水有限公司

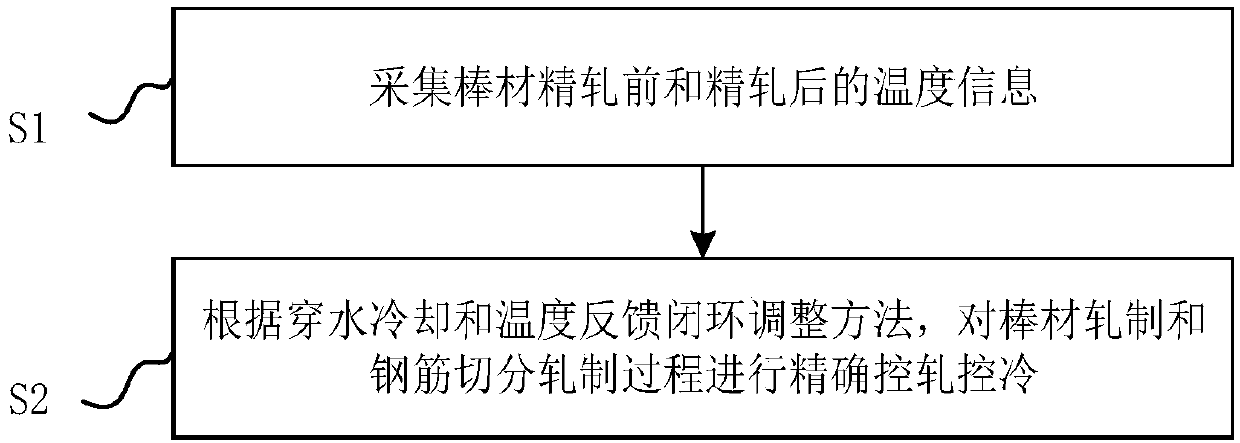

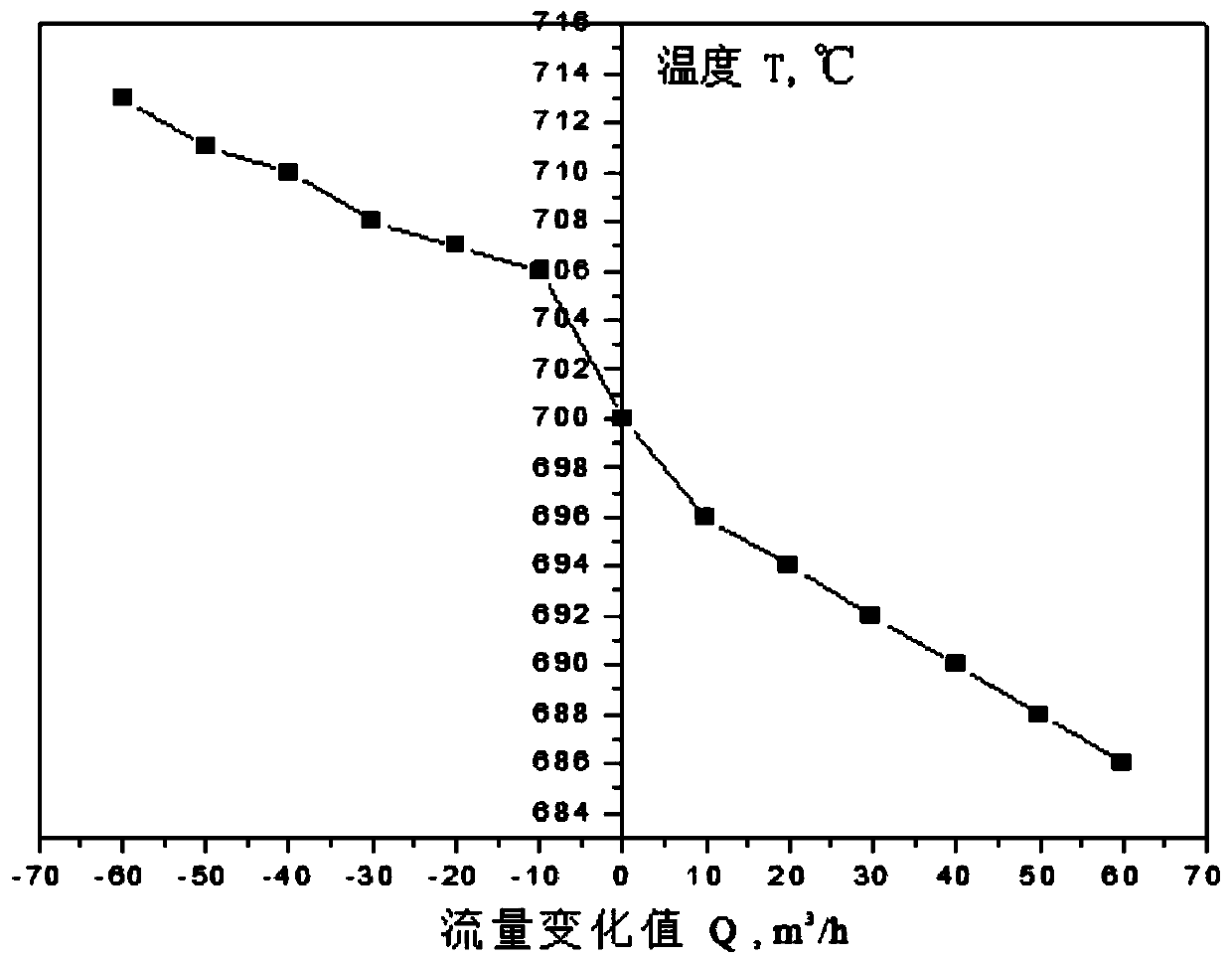

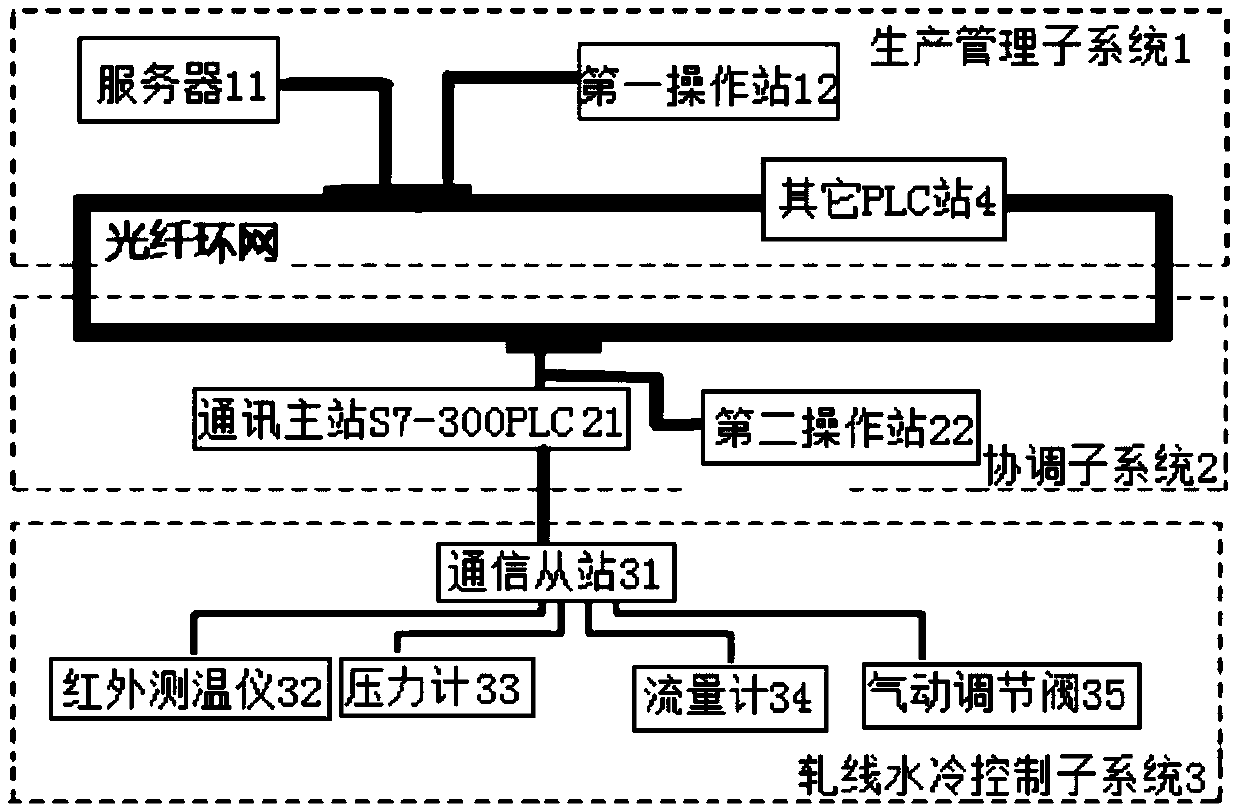

Water-cooling closed-loop control technological method and control system of stick materials

ActiveCN109675933AAchieving staged coolingReduce manufacturing costTemperature control deviceLoop controlControl system

The invention relates to a water-cooling closed-loop control technological method and control system of stick materials. The water-cooling closed-loop control technological method of stick materials comprises the following steps of collecting temperature information before finish rolling and after finish rolling of the stick materials; and according to through water cooling and a temperature feedback closed-loop regulating method, performing accurate rolling control and cooling control in the stick material rolling and reinforcing bar splitting rolling process. Through the adoption of the stick material water-cooling closed-loop control technological method disclosed by the invention, the stability of rolling control temperature and the stability of the cooling control technology can be realized, and the alloy usage quantity of the stick materials is reduced; the problems that the water cooling black circle tissue is generated on the surfaces of the stick materials and core surface hardness is poor caused by through water cooling are solved; and increasing the production benefits of a steel mill is facilitated. The method disclosed by the invention provides a technical thought foraccurately controlling a cooling technology for cooling the special steel stick materials including gears and the like after rolling, the problems of coarse crystal grains and cracking during cold shearing caused by unstable cooling technology of the special steel stick materials after rolling can be solved; and under the premise that the production cost of the stick materials of the steel mill isreduced, improving the product quality is facilitated, and the smooth operation of the production is promoted.

Owner:北京勤泽鸿翔冶金科技有限公司

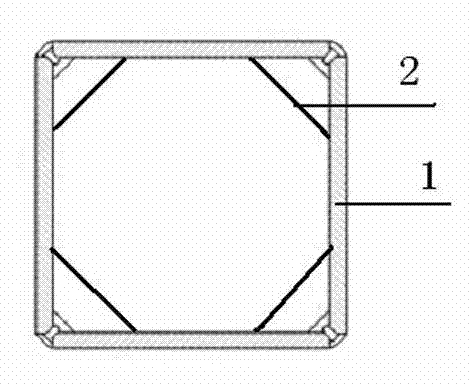

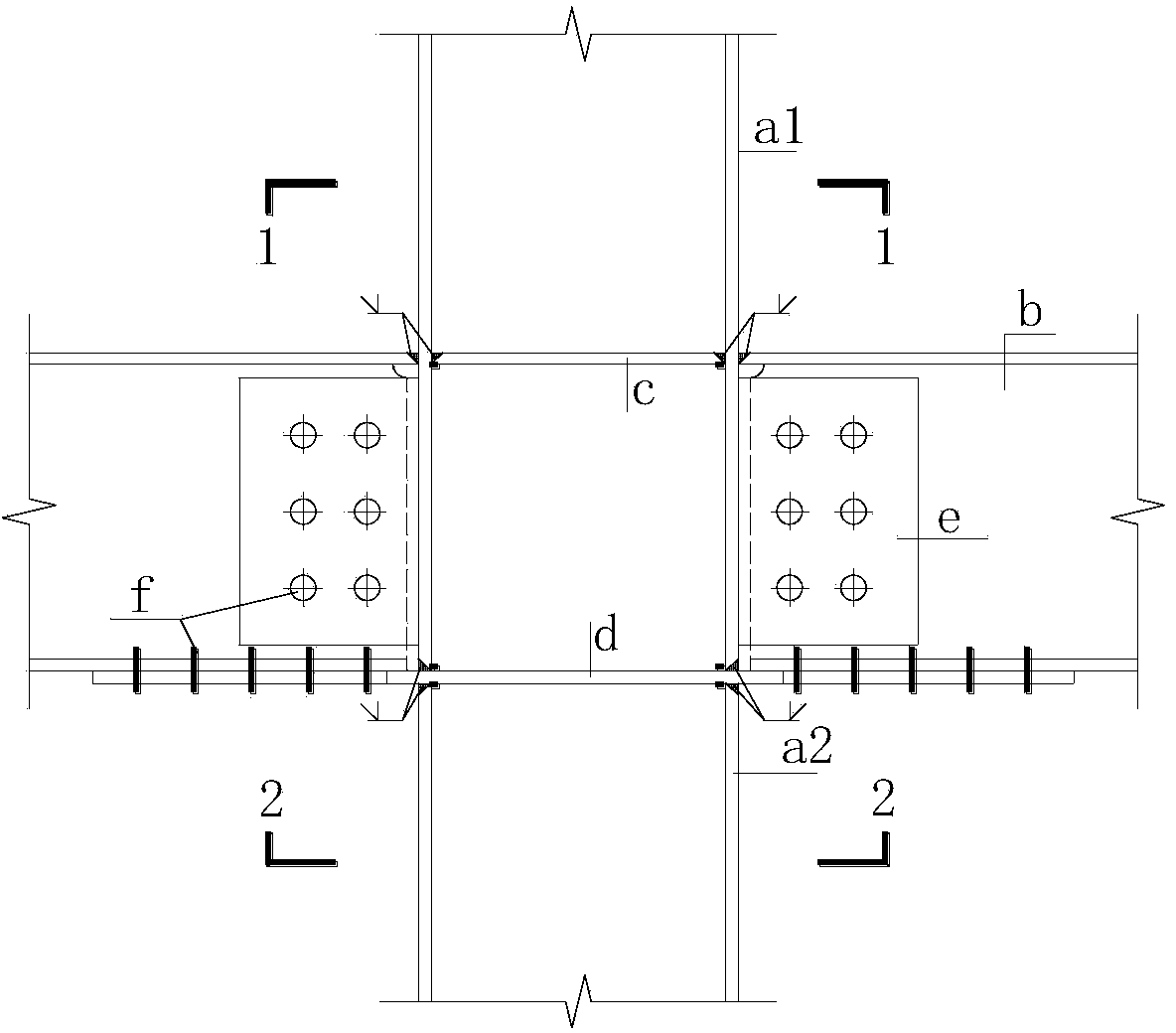

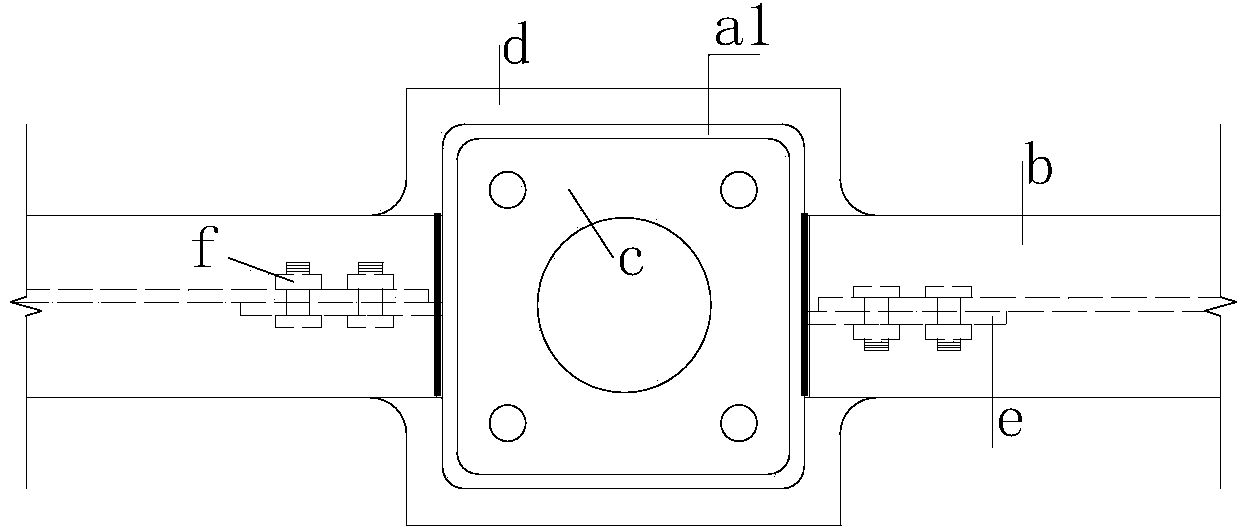

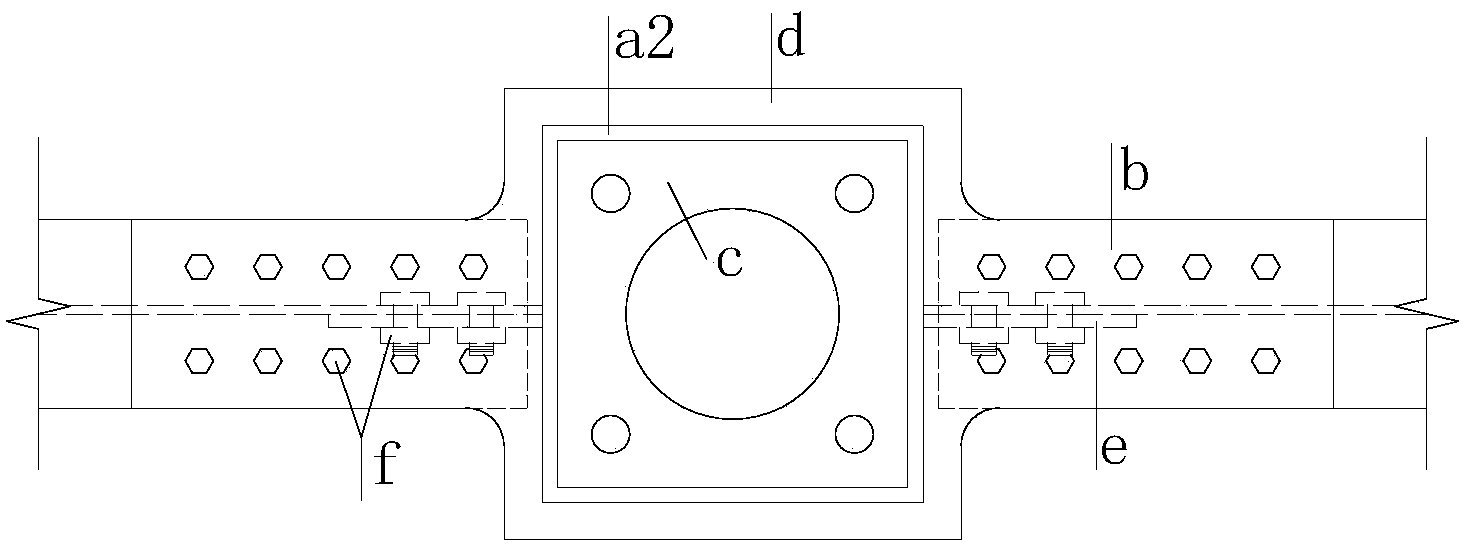

Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

InactiveCN103967133AAddress stressImprove prefabrication rateBuilding constructionsArchitectural engineeringEngineering

The invention discloses a stud welding mixed connection node of a rectangular concrete filled steel tubular column and an H-shaped steel girder. The H-shaped steel girder comprises an upper flange, a web and a lower flange, wherein the upper flange, the web and the lower flange are formed together. The rectangular concrete filled steel tubular column comprises an upper steel tube and a lower steel tube which are vertically arranged adjacently. The node comprises an inner separating board welded to the bottom in the upper steel tube, a through separating board welded to the bottom end of the upper steel tube and a vertical connecting board welded to the side of the bottom of the upper steel tube. The top end of the lower steel tube is welded to the lower surface of the through separating board. The upper flange is opposite to the inner separating board and welded to the upper steel tube. The web is connected with the vertical connecting board through high strength bolts. The lower flange is fixedly connected with the through separating board. According to the node, stud welding mixed connection is adopted, the node can be fast installed in the position in a field, a construction period can be obviously shortened, and the assembly process is facilitated. Meanwhile, due to the arrangement of the through separating board, a girder-end plastic hinge is moved outwards, the steel girder is damaged before the node, and safety of the node is guaranteed.

Owner:TIANJIN UNIV

Comprehensive bituminous-mixture low-temperature-performance detection device

ActiveCN105973717AExclude the effect of coolingAddress stressMaterial strength using tensile/compressive forcesMaterial thermal analysisControl systemEngineering

The invention discloses a comprehensive bituminous-mixture low-temperature-performance detection device, and relates to a comprehensive detection device. A low-temperature shrinkage test, a low-temperature stress relaxation test and a freezing breaking test need to be carried out through different devices, the problems that as the universality of the devices is poor, test cost is high, and meanwhile the accuracy of the detection result of a bituminous-mixture testing piece is low exist. The comprehensive bituminous-mixture low-temperature-performance detection device comprises an environmental box, a counterforce frame, a displacement measuring system, a data collecting control system, a micro-data collecting system and a heating system. The environmental box is arranged in the counterforce frame, a digital speckle camera faces to a visible window of the environmental box, a bituminous-mixture testing piece is arranged in the environmental box, one end of the bituminous-mixture testing piece is connected with a motor sequentially through a dowel steel and a transmission device, the other end of the bituminous-mixture testing piece is connected with a stress sensor through the other dowel steel, and the displacement measuring system is arranged outside the environmental box and connected with the counterforce frame. The comprehensive bituminous-mixture low-temperature-performance detection device is used for detecting the low-temperature performance of bitumen.

Owner:黑龙江省工研院资产经营管理有限公司

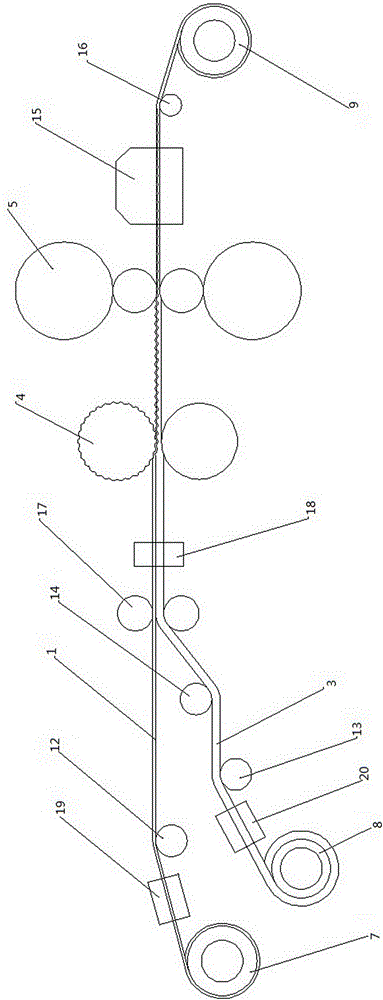

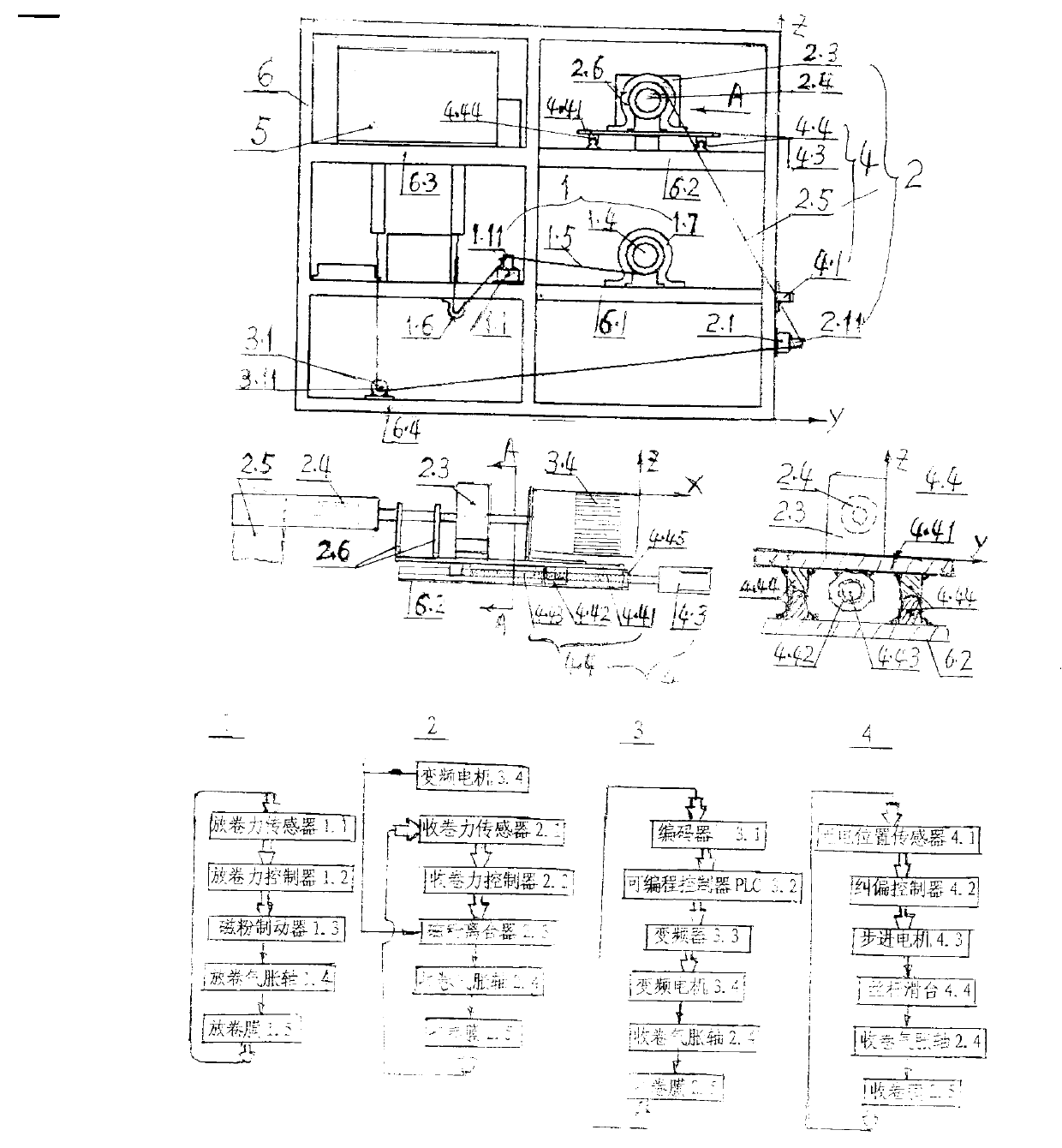

Automatic-deviation-rectification, constant-speed and constant-tension rewinding machine

The invention relates to an automatic-deviation-rectification, constant-speed and constant-tension rewinding machine. A magnetic powder brake and a cantilever unwinding inflation shaft are mounted on a rack; an unwinding membrane passes through an unwinding force sensor roll and an unwinding guide roll, and is delivered into a membrane processing device to form an unwinding tension control device; a screw rod sliding table and a stepping motor are fixed on the rack; a variable frequency motor, a magnetic powder clutch and a cantilever winding inflation shaft are fixed on the surface of the screw rod sliding table; a winding membrane sequentially passes through a photoelectric position sensor, a winding force sensor roll and an encoder roll, and finally passes into the membrane processing device to form a device for controlling winding tension, winding speed, deviation rectification and the like; and an unwinding force, winding force and deviation rectification controller with a program-controlled preset value is utilized to control constant tension of the membrane, and to rectify deviation automatically. The programmable logic controller (PLC), a frequency converter and the variable frequency motor are arranged to control the transmission of the membrane at the constant speed. The machine achieves multifunctional control, solves the problems of high stress deformation, non-uniform viscosity, the deviation and the like, is high in quality and efficiency, simple, reasonable in design, and convenient to operate and maintain, and is particularly applicable to rewinding of a polytetrafluoroethylene adhesive tape coil.

Owner:SICHUAN UNIV

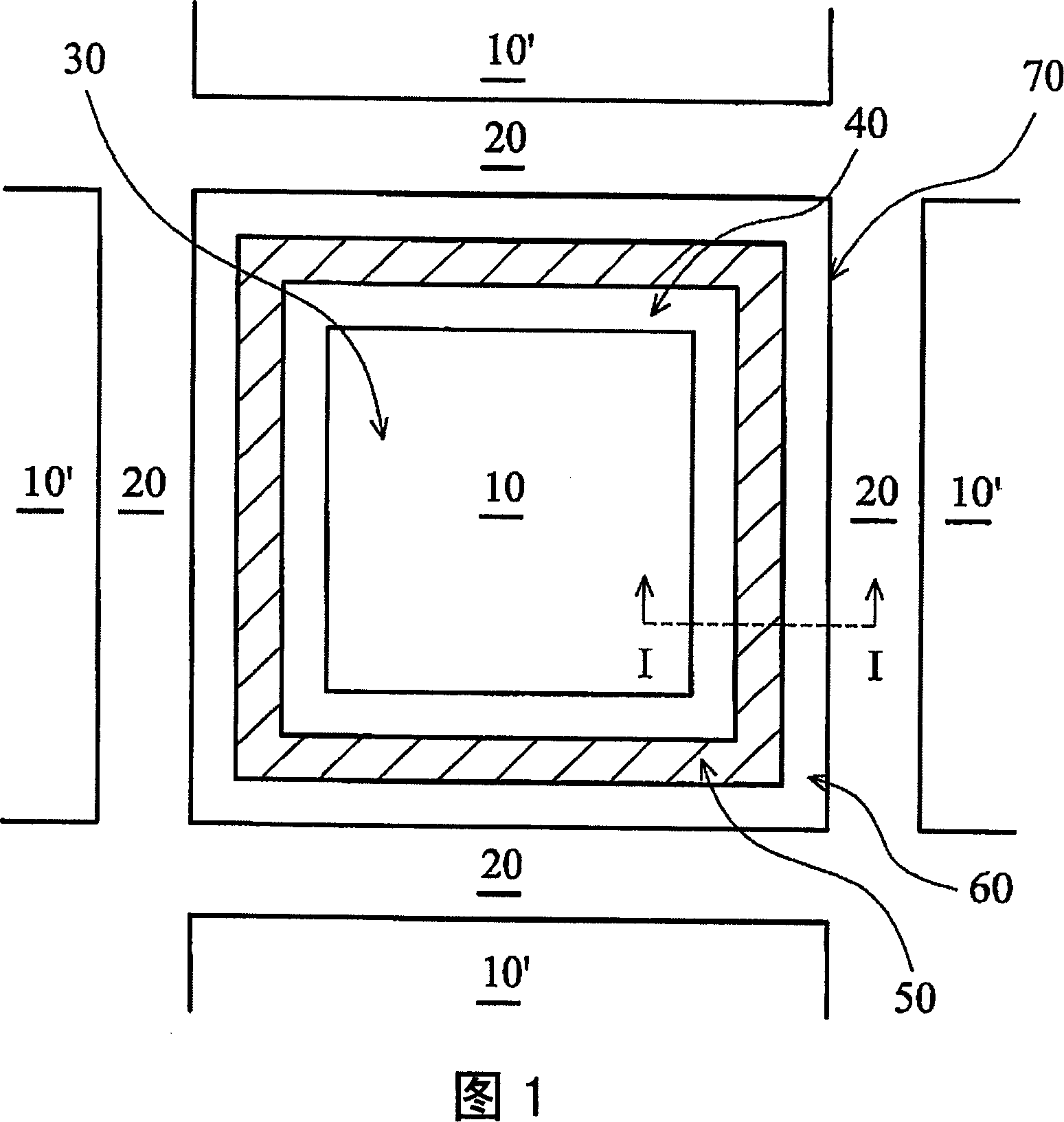

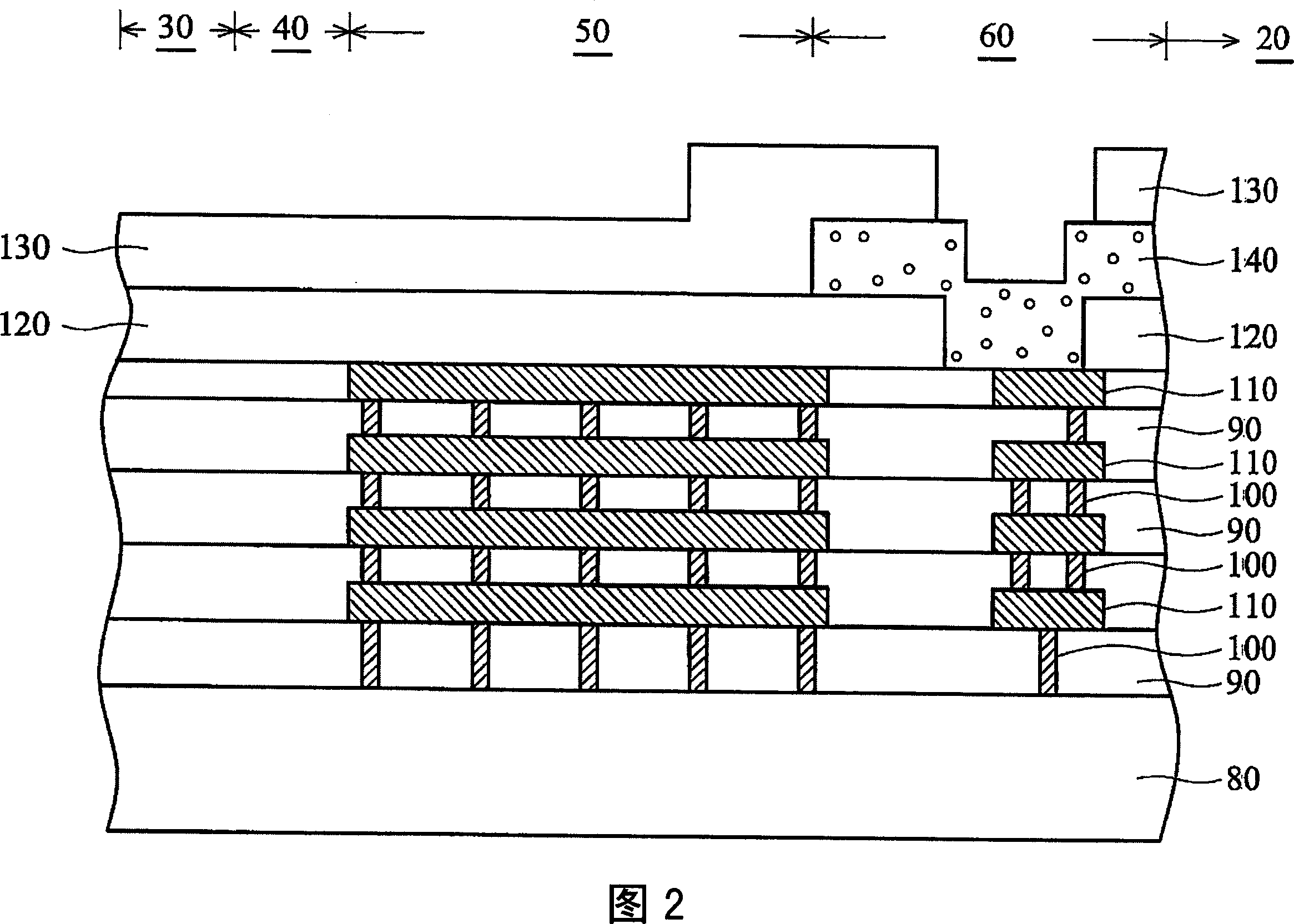

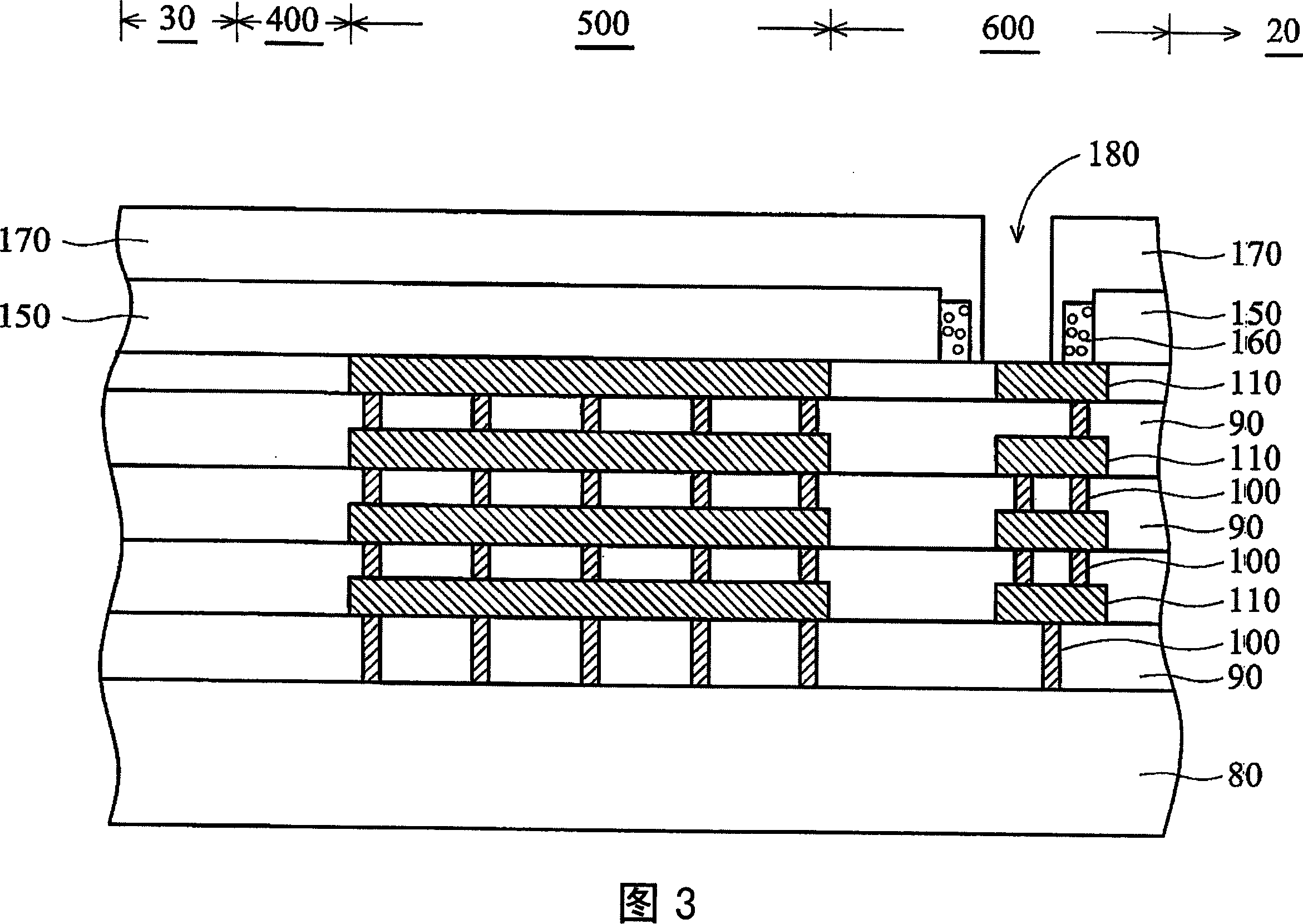

Semiconductor assembly, seal ring structure and forming method thereof

ActiveCN101000909AAvoid damageAddress stressSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerEngineering

A seal ring structure between an integrated circuit region and a scribe line is provided. In one embodiment, the seal ring structure comprises a substrate; a plurality of layers of metal lines formed overlying the substrate; a plurality of via plugs through intermetal dielectric layers between the layers of metal lines and wherein the via plugs interconnect the metal lines; a first passivation layer formed over the plurality of layers of metal lines, the first passivation layer having an opening therein exposing a portion of a top metal line; residual metal pad layers formed proximal the opening of the first passivation layer; and a second passivation layer formed over the first passivation layer, the second passivation layer enveloping the exposed residual metal pad or metal redistribution layers and further having a trench above the top metal line.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com