Test apparatus and method for simulating hydraulic fracture of concrete under high water pressure

A technology of hydraulic splitting and testing equipment, which is applied in the direction of measuring equipment, using stable tension/pressure to test material strength, and preparation of test samples, etc. It can solve the problems of cumbersome sample pouring, unsynchronized data collection, and high-pressure water sealing. The problem has not been well solved and other problems, to achieve the effect of convenient concrete sample and convenient test data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

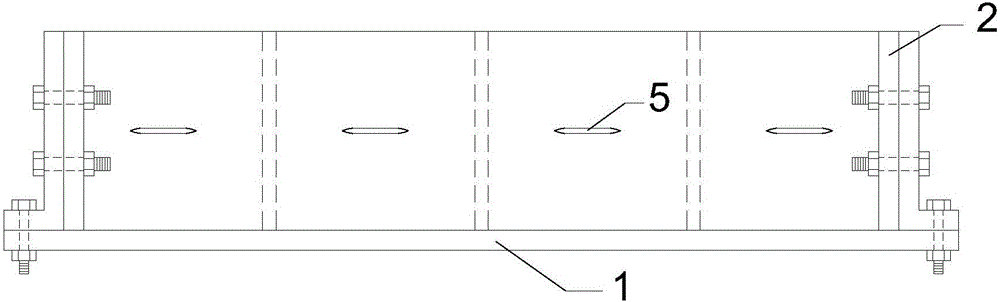

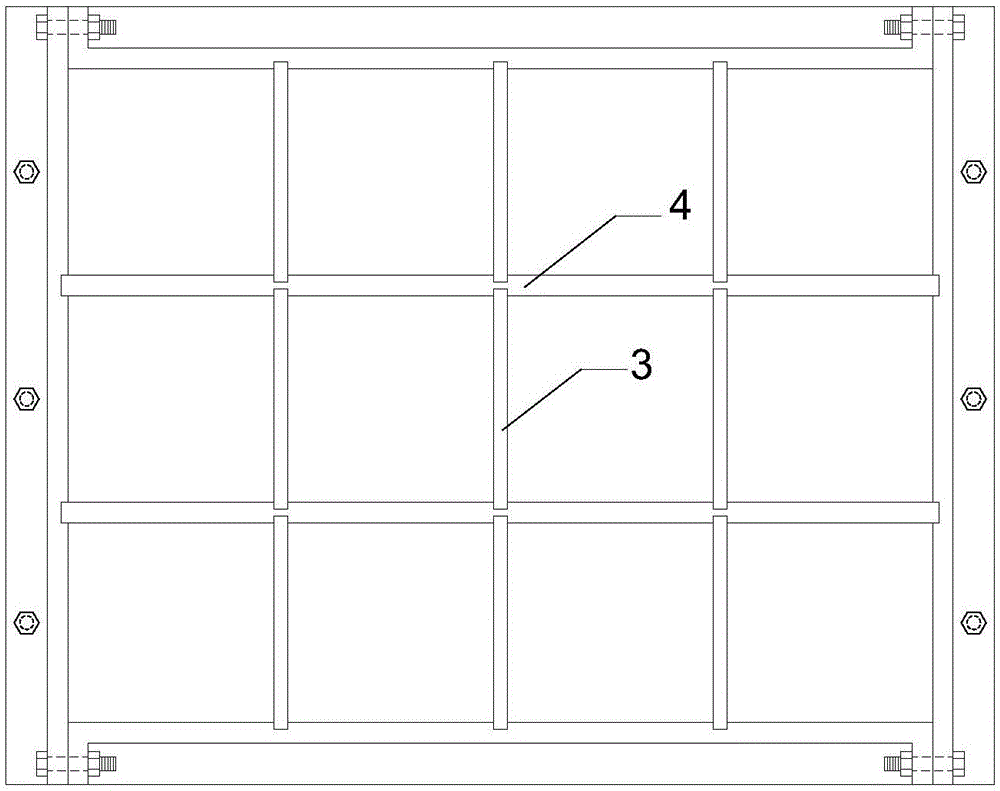

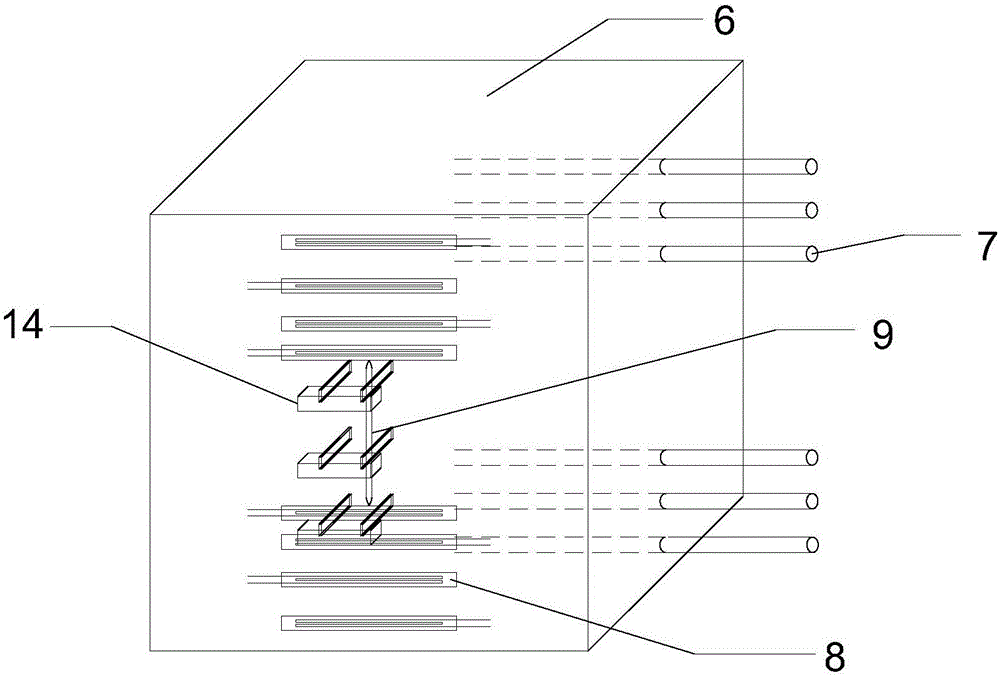

[0038] As can be seen in conjunction with the accompanying drawings, the test device for simulating concrete hydraulic splitting under high water pressure includes a concrete sample 6, a hydraulic supply system and a data acquisition system. Water is transported in 9 to form high pressure in the concrete sample 6 until the concrete sample 6 is split, and the hydraulic pressure data and deformation data of the concrete sample 6 during the splitting process are collected through the data acquisition system for easy analysis.

[0039] The concrete sample 6 is in the shape of a rectangular body, and the concrete sample 6 is preset with a crack 9, and the crack 9 penetrates from one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com