Thermo-couple composite protective sleeve and making method thereof

A technology for protecting sleeves and thermocouples, used in thermometers that use electrical/magnetic components directly sensitive to heat, measuring heat, and using electrical devices, etc., can solve the problem of corrosion resistance, thermal shock resistance and mechanical properties. Strength problems, affecting the stable control of the production process, unable to meet the actual needs and other problems, to achieve the effect of excellent high temperature oxidation resistance and liquid metal corrosion resistance, anti-stripping performance, and good Zn-Al corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

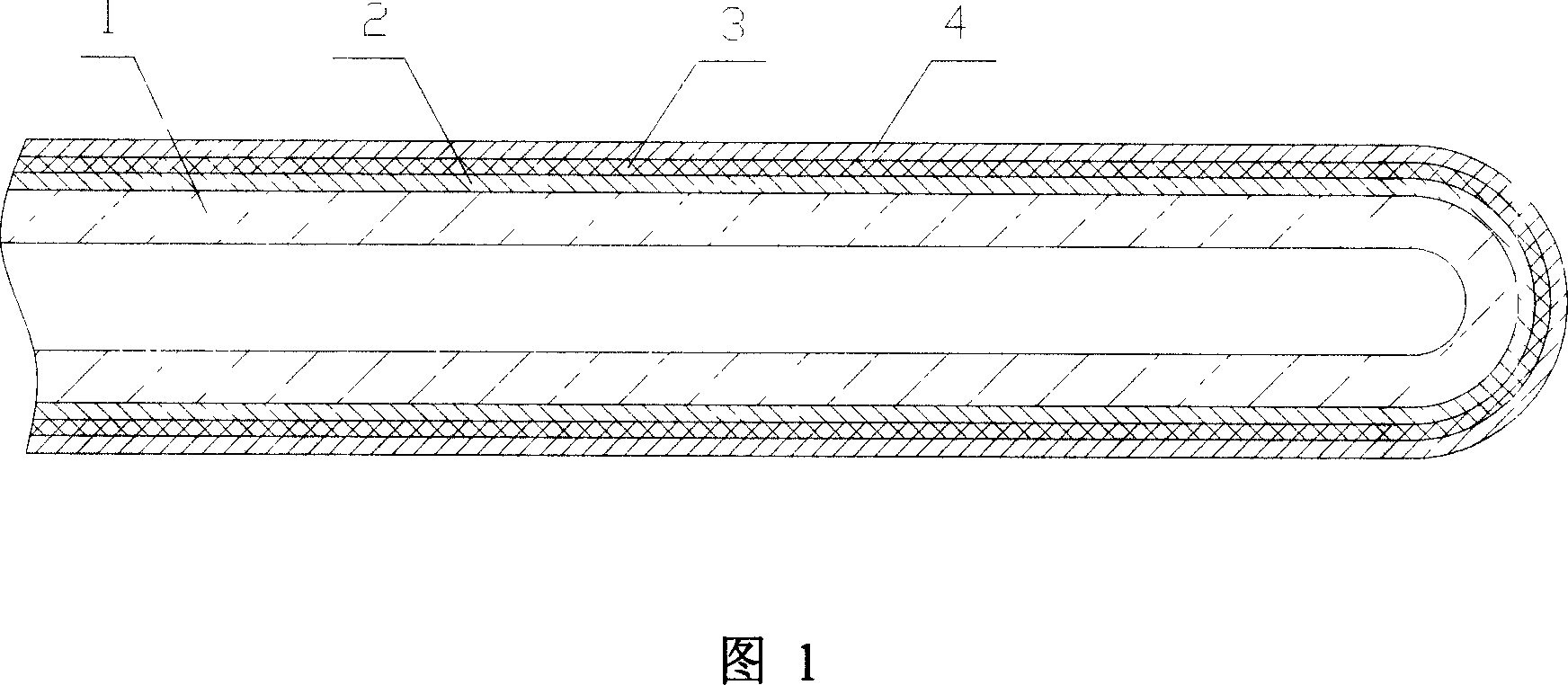

[0028] 316L stainless steel material is used to process and make a thermocouple protection sleeve cylinder with a diameter of 22×450mm and a wall thickness of ≥5mm. Before spraying, use an organic cleaning agent to remove possible oil stains on the surface of the substrate to be sprayed, and use 20 mesh brown corundum sand on the metal cylinder. The body is roughened to make the surface reach an appropriate roughness, and then spray Cr with a thickness of about 0.10mm 3 C 2 -NiCr and 0.15mm MoB / CrCo metal bonded underlayer and 0.20mm composite (MoB / CrCo-Al 2 o 3 ) gradient transition layer, and finally spray 0.15mm of Al 2 o 3 Protective coating.

Embodiment 2

[0030] Use corrosion-resistant gray cast iron alloy material to process and make thermocouple protection casing cylinder body with φ28×450mm and wall thickness ≥8mm. Before spraying, use organic cleaning agent to remove the surface of the substrate to be sprayed, and roughen the metal cylinder body with brown corundum sand. chemical treatment, followed by spraying a MoB / CrCo metal bonding primer with a thickness of about 0.20mm and a composite (MoB / CrCo-Al 2 o 3 ) gradient transition layer, and finally spray 0.20mm Al 2 o 3 Protective coating.

[0031] The above-mentioned thermocouple composite protective sleeve is actually applied to the hot-dip galvanized aluminum production line, and the continuous service life exceeds one month, or even more than two months, which greatly exceeds the 5-day service life of the original thermocouple.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com