Slide bar type tensile limiting-displacement vibration isolation support

A seismic isolation bearing and sliding rod technology, which can be used in earthquake resistance, building components, building structures, etc., can solve problems such as damage to rubber bearings, restrict the development and destruction of high-rise building projects, and achieve resistance to horizontal shear and vertical The ability of tensile deformation is strong, the effect of solving the tensile stress exceeding the limit of the isolation bearing and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

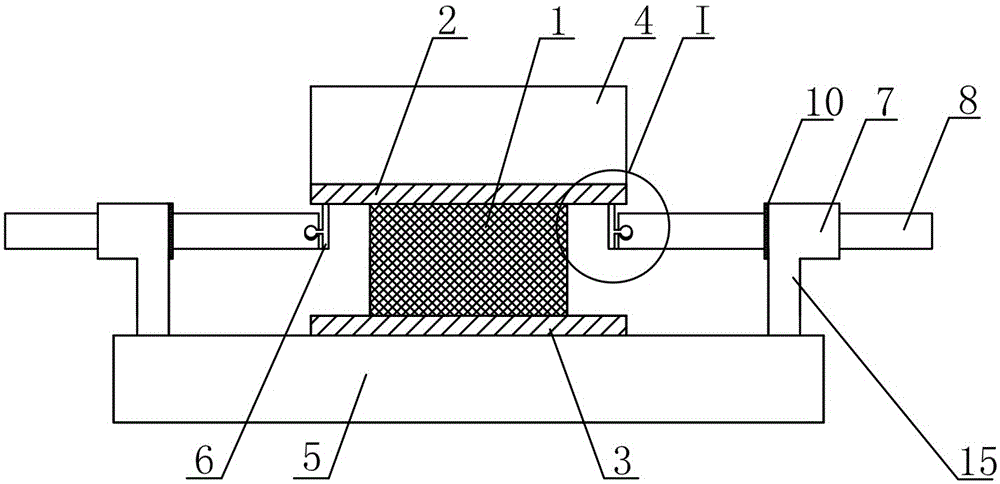

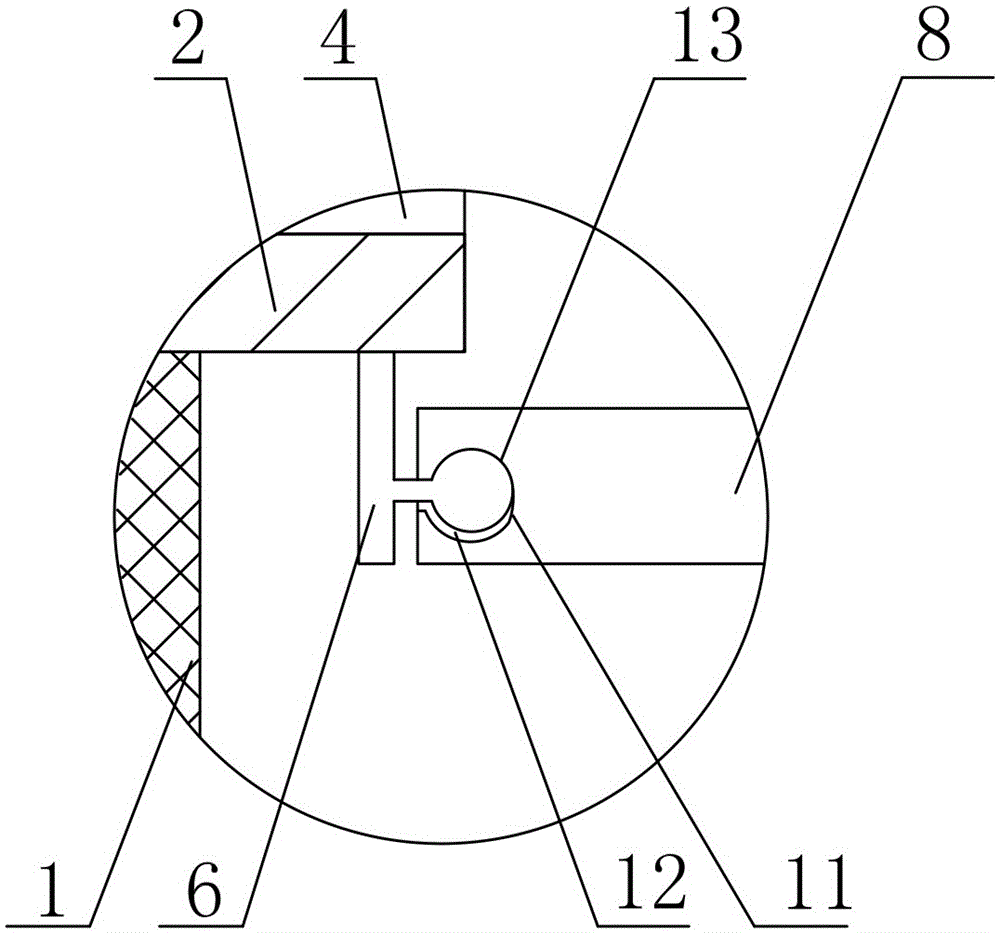

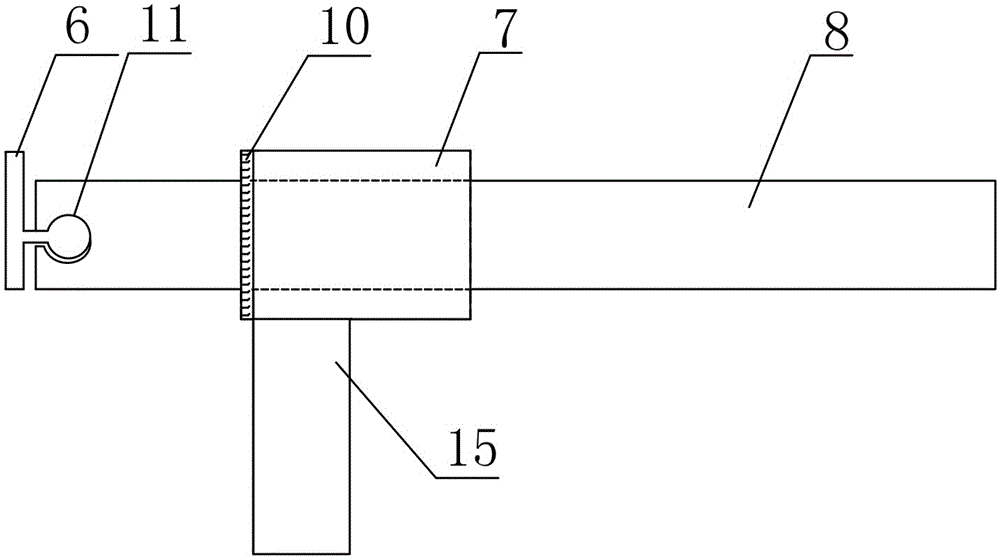

[0018] See attached Figure 4 , the present invention is four tension-limiting mechanisms that are controlled by the limbs. The slide bars 6 are arranged symmetrically in pairs along the bottom periphery of the upper support steel plate 2. The slide bars 6 are welded to the upper support steel plates 2, and it is guaranteed that they will not affect The horizontal shear deformation of the vibration-isolation rubber pad 1 within the allowable range of the current code. The sleeve 7 is reliably anchored by the base 15 and the lower structure 5. The sleeve 7 needs to ensure that the pull rod 8 is inserted just right, and oil the contact surface to ensure that the pull rod 8 can slide freely in the sleeve 7. The position of the sleeve 7 needs to be Ensure that the horizontal deformation of the shock-absorbing rubber pad 1 will not be hindered within the allowable range of the current code, and at the same time, a damping pad 10 is provided on the side of the sleeve 7 and the shock...

Embodiment 2

[0022] See attached Figure 7 , the present invention is two tension-limiting mechanisms set by the limb control type, the slide bar 6 is arranged symmetrically along both sides of the bottom of the upper support steel plate 2, and the two ends of the slide bar 6 are provided with baffles 14 . When the shock-absorbing rubber pad 1 produces horizontal shear deformation in the horizontal direction, the sliding rod 6 and the chute 11 slide relative to each other, so that the pull rod 8 and the sleeve 7 also slide relative to each other to adapt to the shock-absorbing rubber pad 1. The horizontal shear deformation until the chute 11 contacts the baffle 14 resists and limits the further expansion of the horizontal shear deformation of the vibration-isolation rubber pad 1, thereby limiting the horizontal shear deformation of the vibration-isolation support within the allowable range of the current specification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com