Patents

Literature

241results about How to "Solve the flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

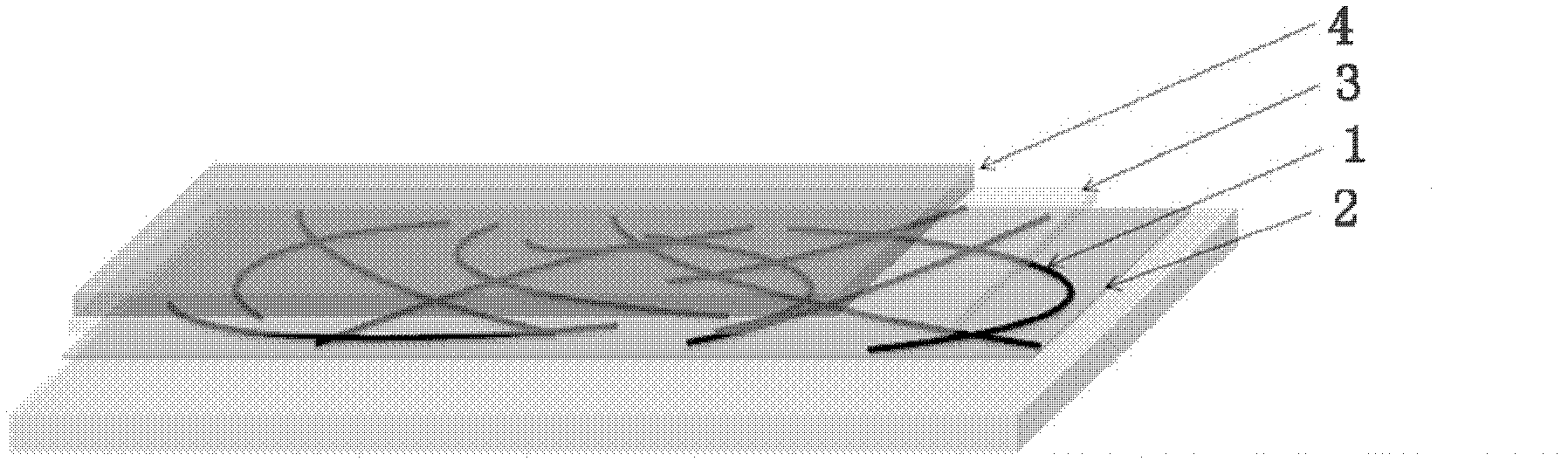

Automatic wire arranging device and method

ActiveCN103662967ASolve the problem of changing direction in timeSolve the flatnessFilament handlingManufacturing technologyEngineering

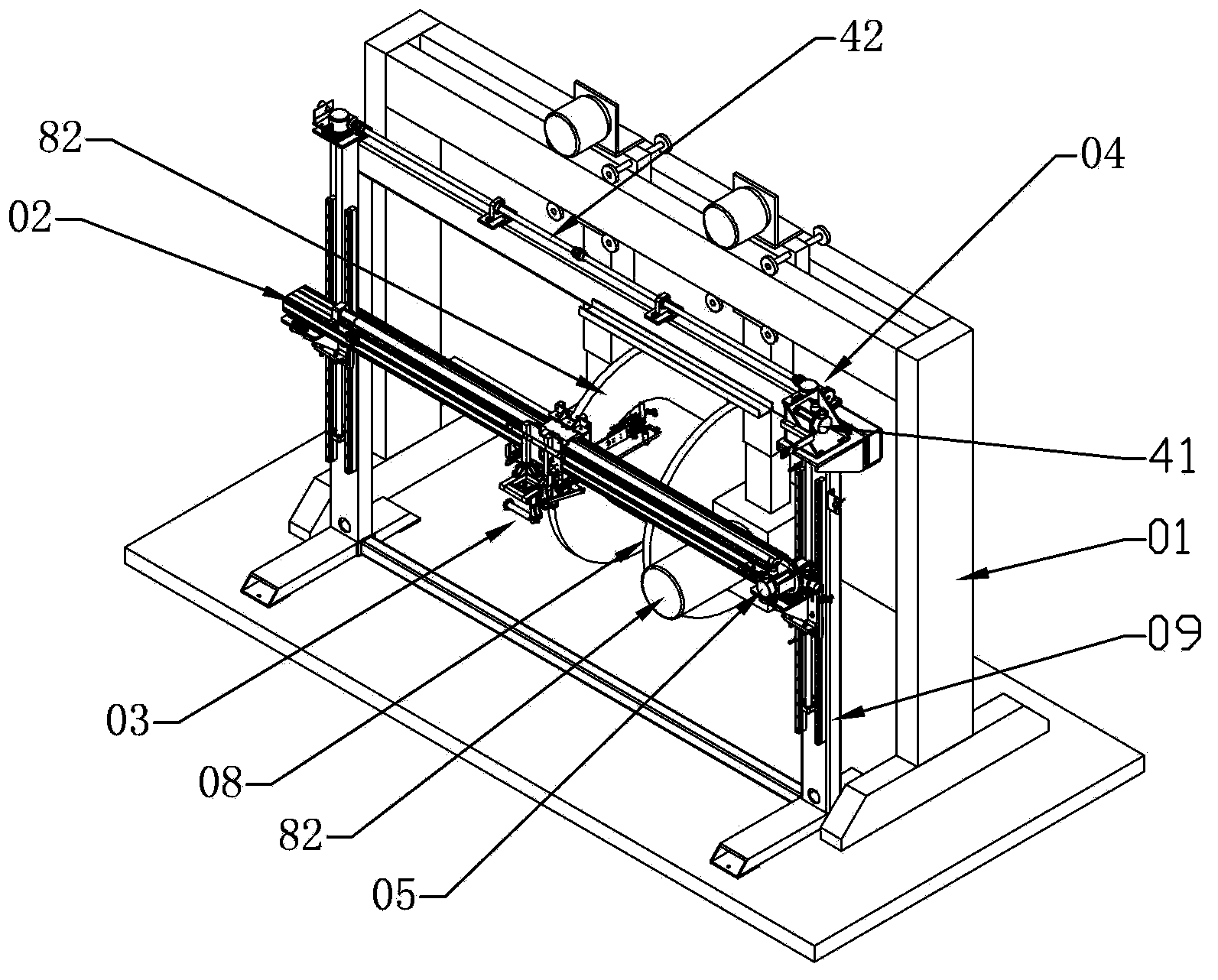

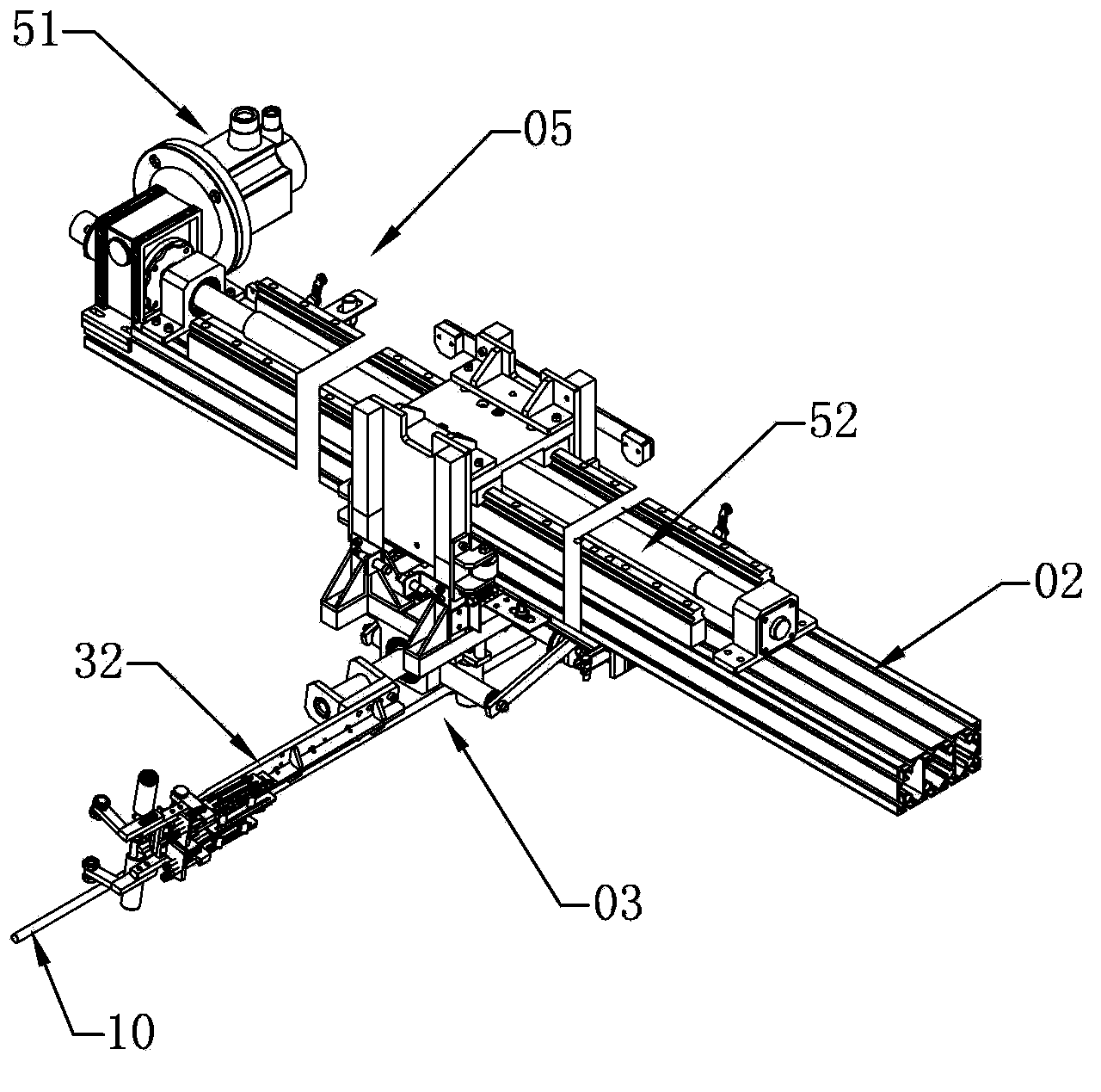

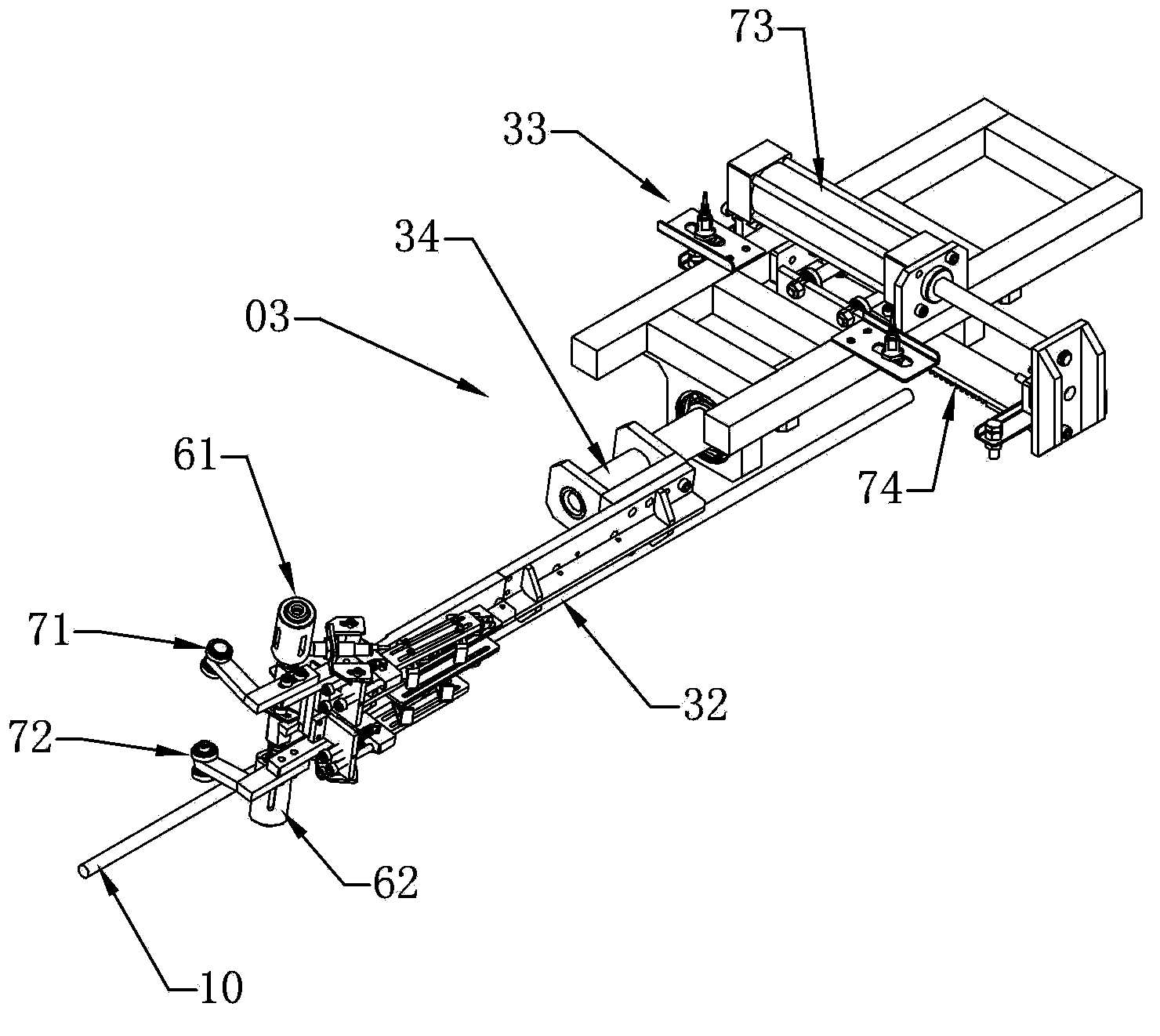

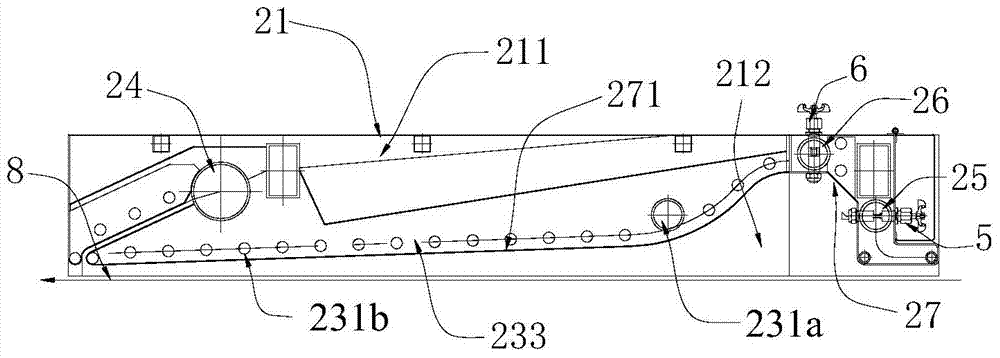

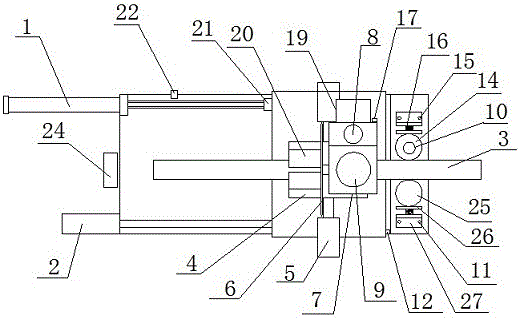

The invention discloses an automatic wire arranging device and belongs to the technical field of cable manufacturing. The existing wire arranging method is prone to notches, wire accumulation and wire jumping. The device comprises a portal frame, a transverse moving platform, a mechanical arm, a lifting mechanism, a horizontal moving mechanism, a dynamic complementing mechanism, an automatic reversing mechanism, a wire winding mechanism, a portal auxiliary frame, a controller and an encoder. Wire arranging is conducted according to a set pitch, in a wire arranging process, the wire arranging device can conduct position complementing control according to actual production conditions, a sheathed line and a designed mechanism structure are arranged in a set angle range, and the conditions of notches and wire jumping during wire arranging can not happen.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

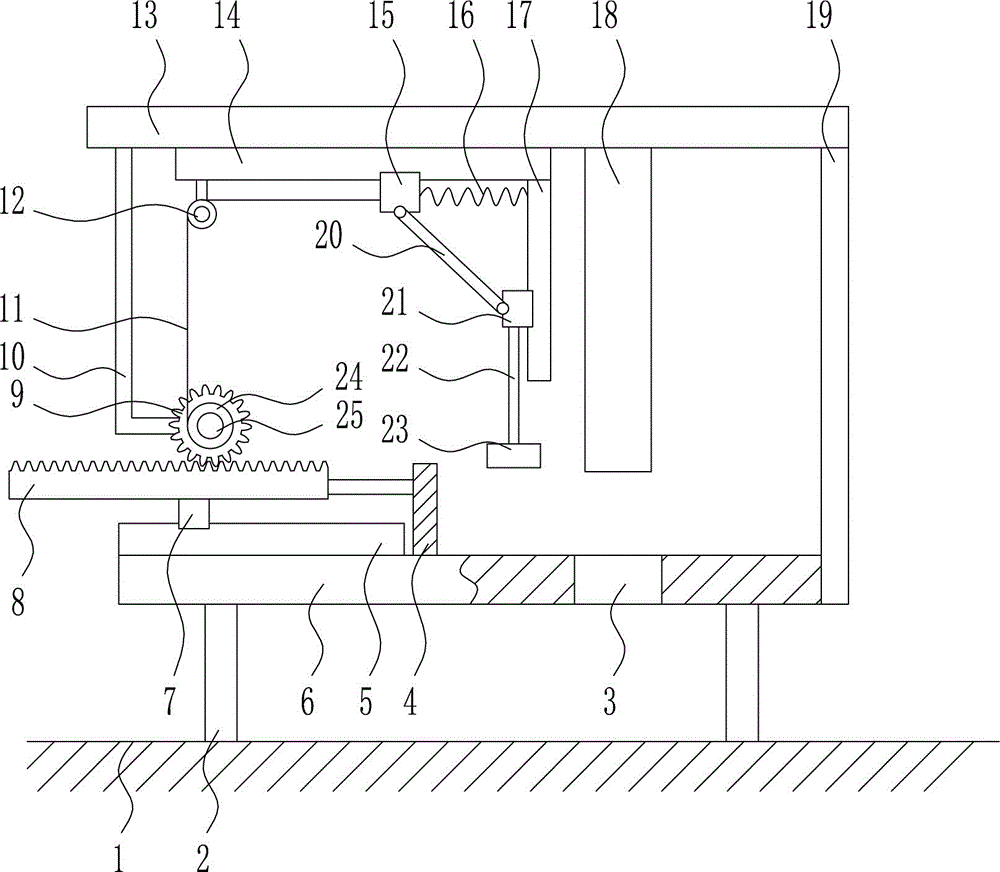

Efficient wood cutting device for construction site

ActiveCN106827097AEasy to cutIntegrity guaranteedProfiling/shaping machinesArchitectural engineeringWood cutting

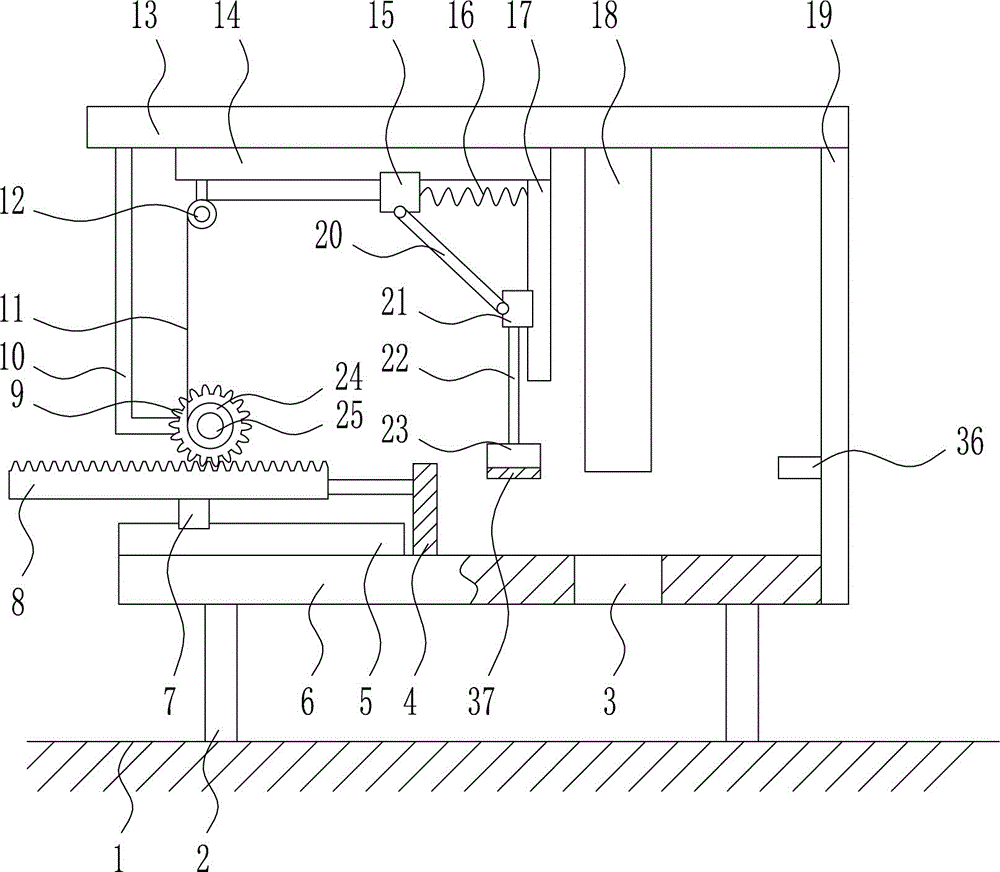

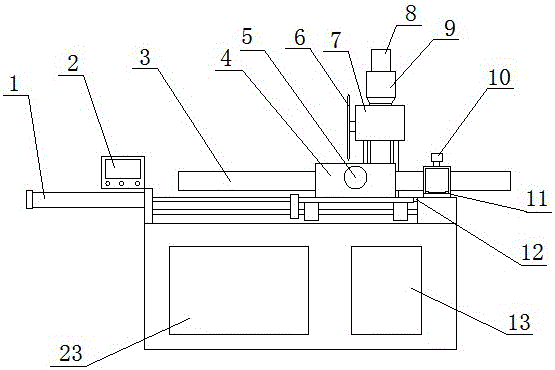

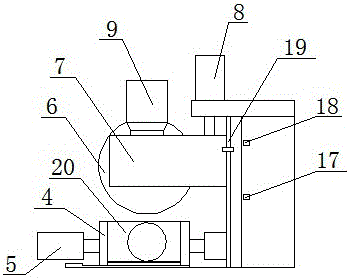

The invention relates to a cutting device, in particular to an efficient wood cutting device for a construction site, and aims to provide an efficient wood cutting device with high wood cutting efficiency for a construction site. The efficient wood cutting device for the construction site comprises a support rod, a push block, a first slide rail, a cutting table, a first slide block, a rack, a gear, a connecting rod, a stay cord, a fixed pulley, a top plate, a second slide rail, a second slide block and the like, wherein the cutting table is arranged at the top end of the support rod; the cutting table is provided with a through hole; the left side of the top of the cutting table is provided with the first slide rail; the first slide rail is provided with the first slide block; the top of the first slide block is provided with the rack. By adopting the efficient wood cutting device, the aim of rapidly cutting wood for the construction site is fulfilled; meanwhile, the problems of waste in time and force, low cutting efficiency and uneven cutting caused by manual wood cutting are solved through an electric cutting wheel.

Owner:XUZHOU CAMRY WOOD CO LTD

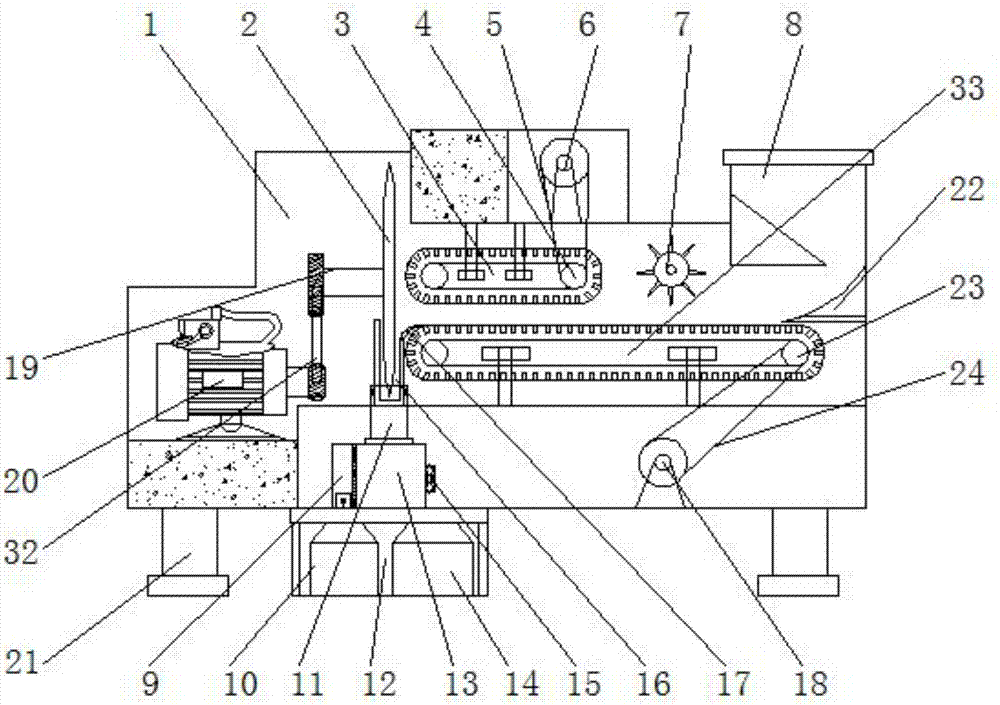

Traditional Chinese medicine slicing machine capable of conduct fast dust removing and efficient classified collecting

The invention discloses a traditional Chinese medicine slicing machine capable of conducting fast dust removing and efficient classified collecting. The traditional Chinese medicine slicing machine comprises a machine body, a tool disc, a second conveying chain, a dust removing bin and a first conveying chain. The tool disc is installed at the middle position of the interior of the machine body. The first conveying chain is arranged at the upper end, away from one side of a first motor and in the machine body, of the tool disc. The output end of a fourth motor is provided with a rotating flattening wheel. A slicing chamber is arranged at the position, below the tool disc, in the machine body. The dust removing bin is installed at the position, on one side of the slicing chamber, of the interior of the machine body. A first filtering net and a second filtering net are installed above a screening device. By means of the traditional Chinese medicine slicing machine, integrated machining functions of automatic flat slicing, fast dust removing and efficient classified collecting of traditional Chinese medicines are achieved, and the traditional Chinese medicine slicing machine has the beneficial effects that the automation degree is high, the slicing technology operation efficiency is high, slicing force applying is even, the slicing thickness is uniform, the slicing flatness is good, classified collecting can be automatically conducted according to sizes, and slicing powder and dust on the surfaces of traditional Chinese medicine slices can be automatically removed.

Owner:安徽健诚中药饮片有限公司

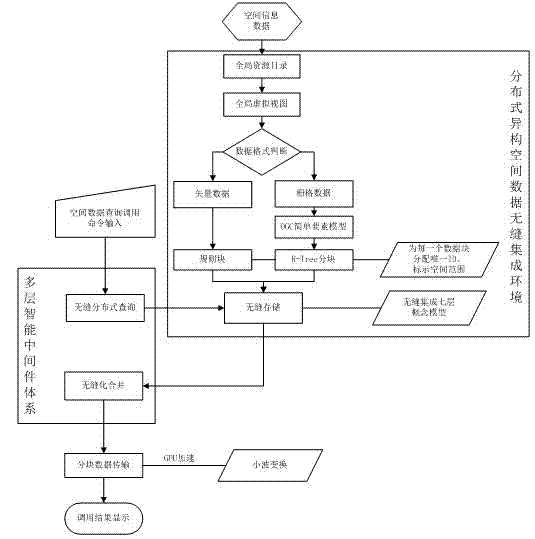

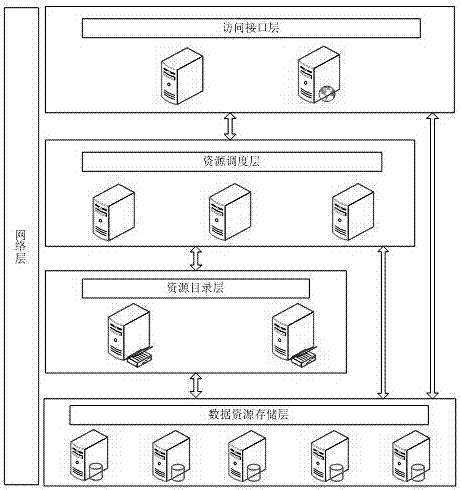

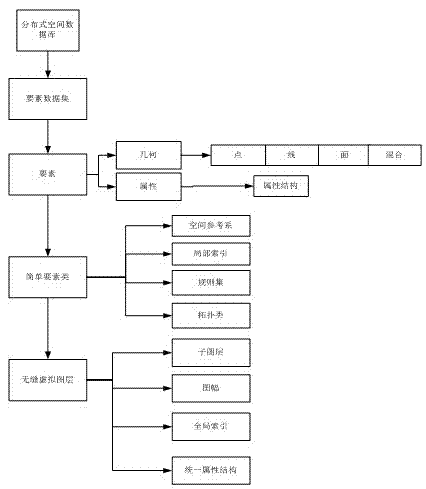

Mass multisource heterogeneous spatial information data seamless integration management method

InactiveCN102902782AEfficient integrationFacilitate geographic information sharingSpecial data processing applicationsGeographic information systemInformation resource

The invention discloses a mass multisource heterogeneous spatial information data seamless integration management method. The method comprises the steps of: building a distributed seamless integration conceptual model, and under the distributed heterogeneous spatial data seamless integration environment, using a multi-layer intelligent middleware system to build a cross-platform, exchangeable, safe and reliable spatial data management system which supports a heterogeneous database, the distributed computation and the cooperative services. According to the method provided by the invention, normalized sharing and low-level integration of the geographic information resource are realized, the data utilization rate is increased, and further the information timeliness and the working efficiency are improved.

Owner:ZHEJIANG UNIV +1

Terahertz absorption layer of carbon nano tube and metamaterial composite structure and preparation method of terahertz absorption layer

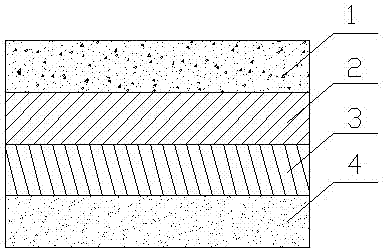

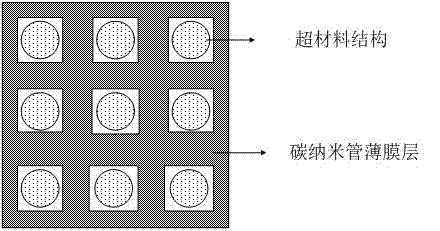

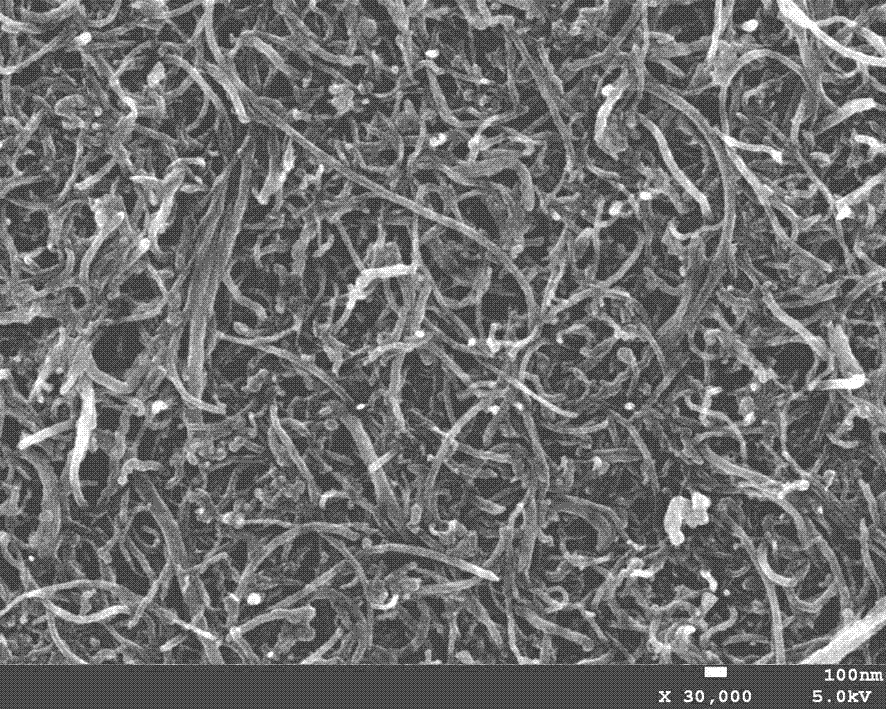

InactiveCN103489943ASolve the flatnessSolve the adhesionFinal product manufacturePhotometryTerahertz radiationCarbon nanotube

The invention discloses a terahertz absorption layer of a carbon nano tube and metamaterial composite structure and a preparation method of the terahertz absorption layer. The terahertz absorption layer sequentially comprises a top absorption layer, a dielectric layer, a metal reflection layer and a carbon nano tube film layer from top to bottom. According to special optical properties of the carbon nano tube film and the absorption rate close to 100 percent of the metamaterial composite structure on terahertz radiation, the absorption rate of a detection unit on terahertz waveband radiation is obviously enhanced, and the terahertz detection performance of a detector is improved. Meanwhile, because the carbon nano tube has high thermal conductivity, the absorbed heat energy can be rapidly transmitted to the detection unit, and the response speed of the detector is improved.

Owner:成都市金草阳科技有限公司 +1

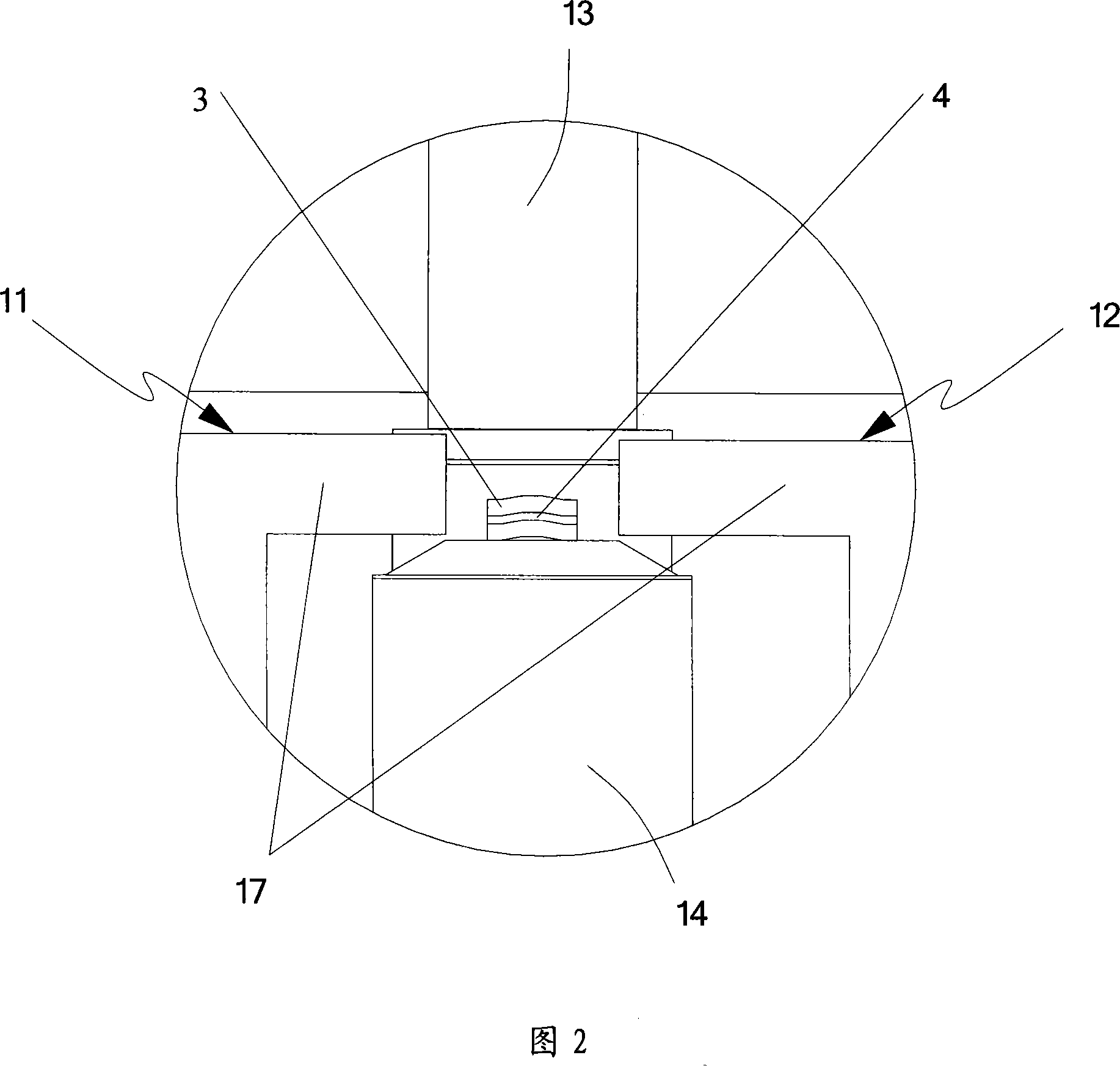

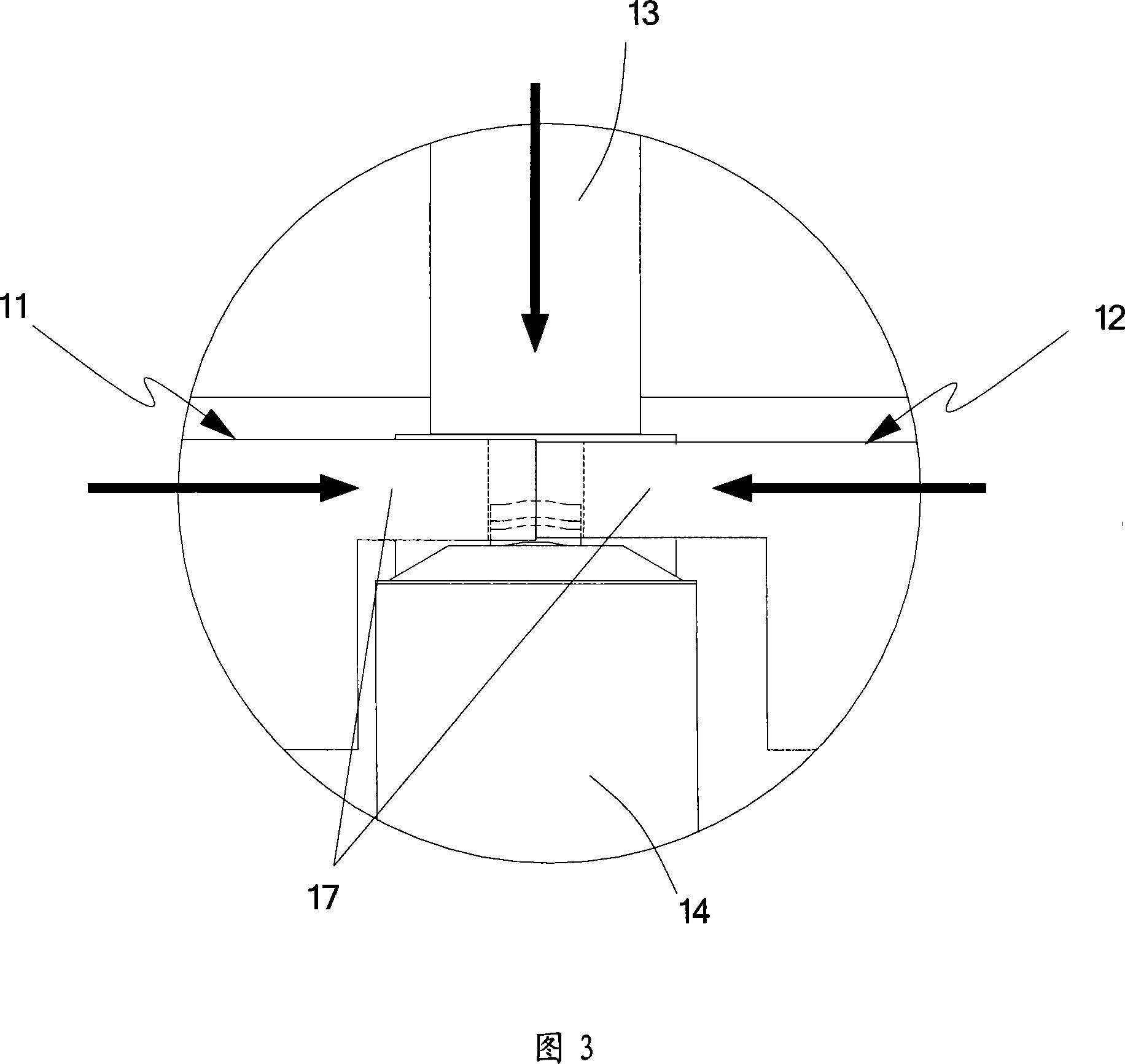

Lens module production device and method of manufacture thereof

InactiveCN101105570ASolve the problem of eccentricitySolve lens skewGlass pressing apparatusMountingsCushioningCamera lens

The invention relates to a lens module manufacture device and the manufacture method thereof; the lens module manufacture device comprises a lens (a separating cushion piece can be selected to match with the lens), a forming mould and moulding processes; wherein the lens can be the lenses in various catalogs; the separating cushion piece is equipped between the lenses; the forming mould comprises a mould cavity; the mould cavity consists of an upper film kernel, a lower film kernel, a left sliding block film kernel and a right sliding block film kernel (or the film kernel in other direction); cushioning devices can be equipped on the film kernel and under the film kernel; the cushioning devices are used to cushion the lens and the separating cushion piece and regulate the tolerances of the lens and the separating cushion piece; stop sliding blocks can be equipped on the front ends of the left and the right sliding block film kernels, which avoids the migration or the transplacement of the center line of the lens when the lens module is formed. The invention makes at least one lens and more than one separating cushion piece selected to match with the lens pass through a thermohardening or a thermoplastic forming mould and be processed into the lens module through an integral forming processing procedure.

Owner:HORNIX OPTICAL TECH

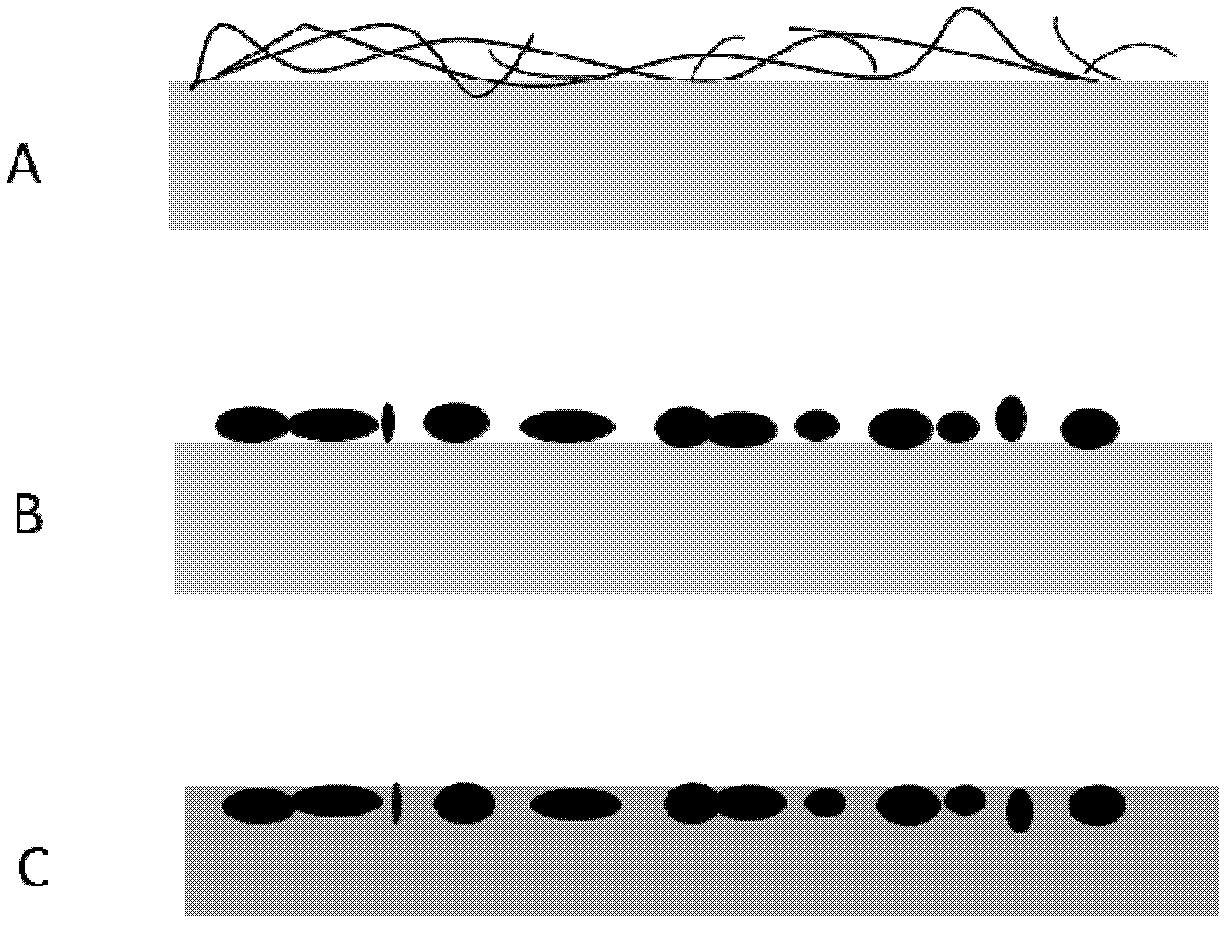

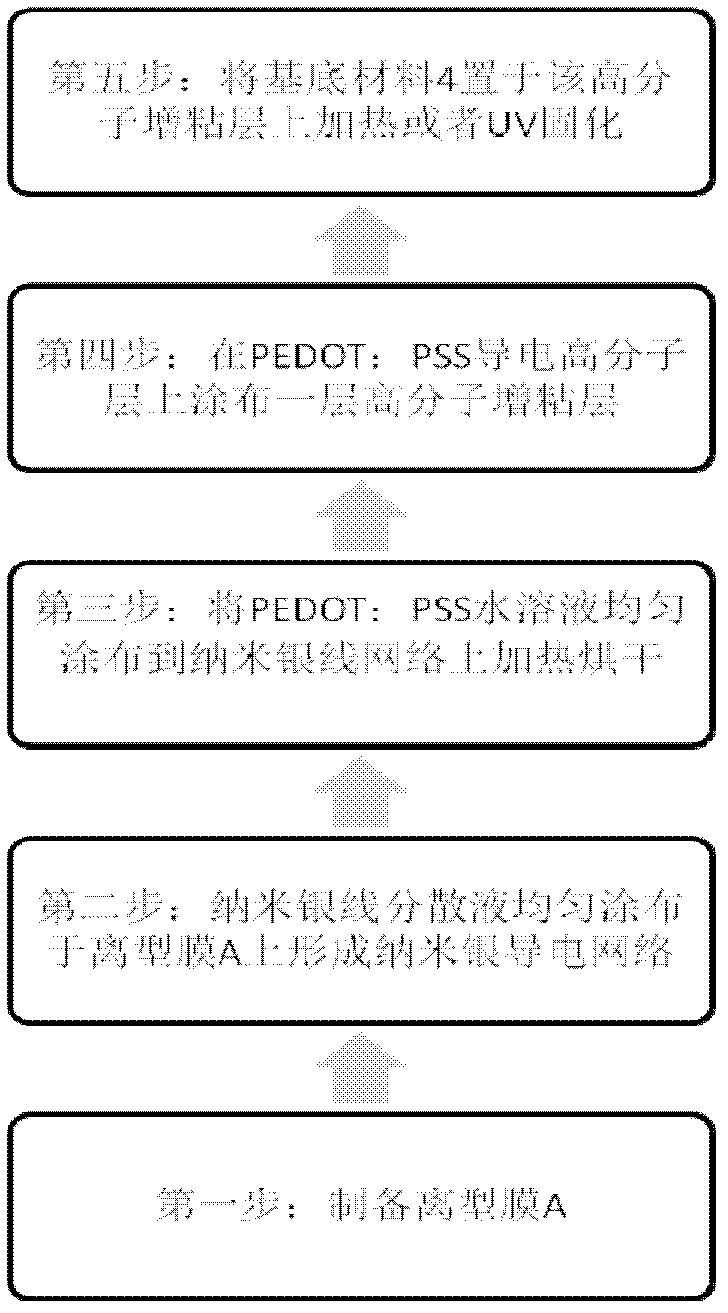

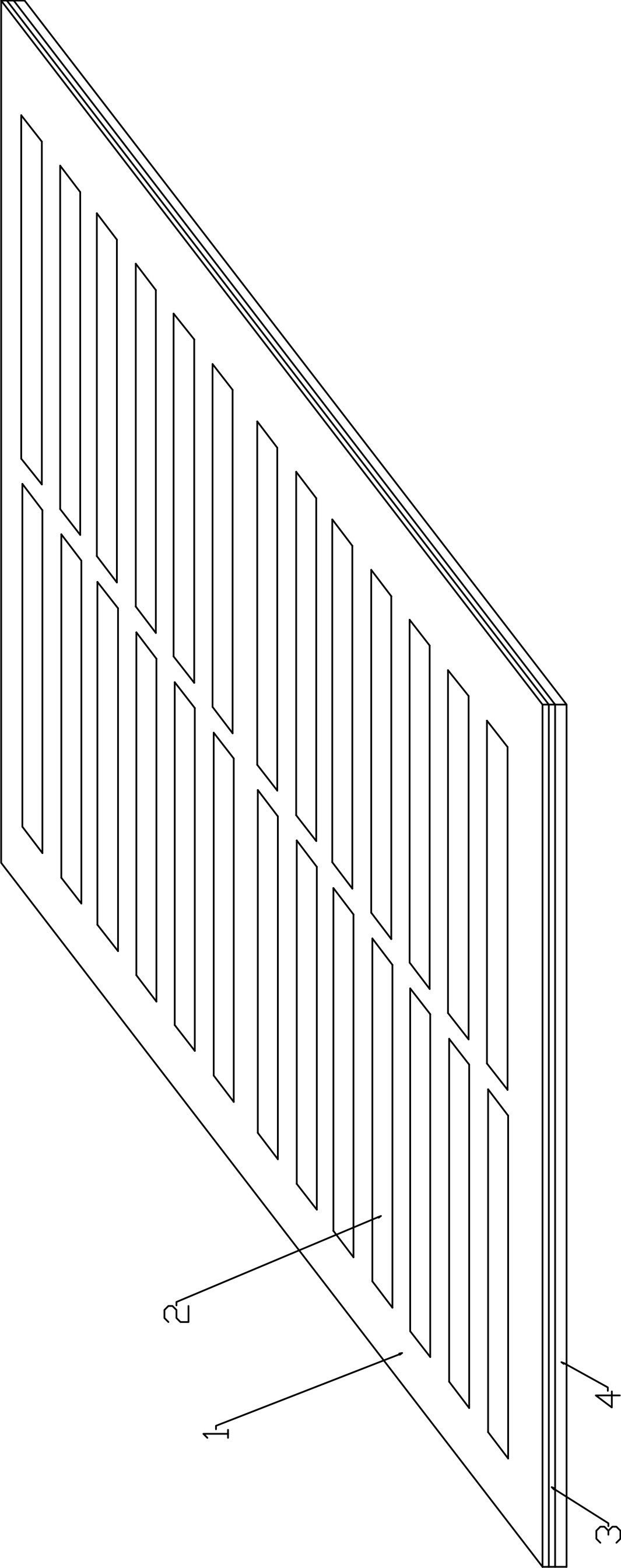

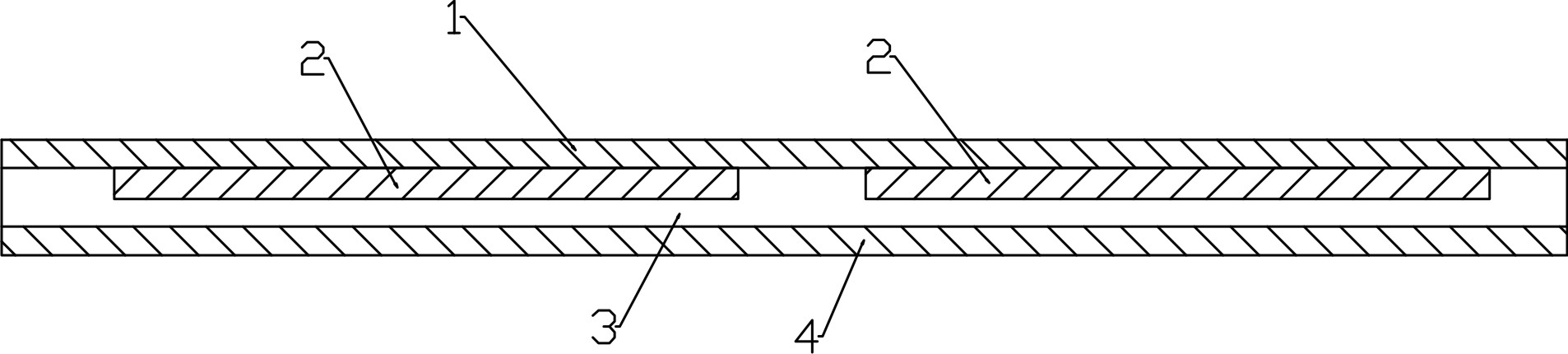

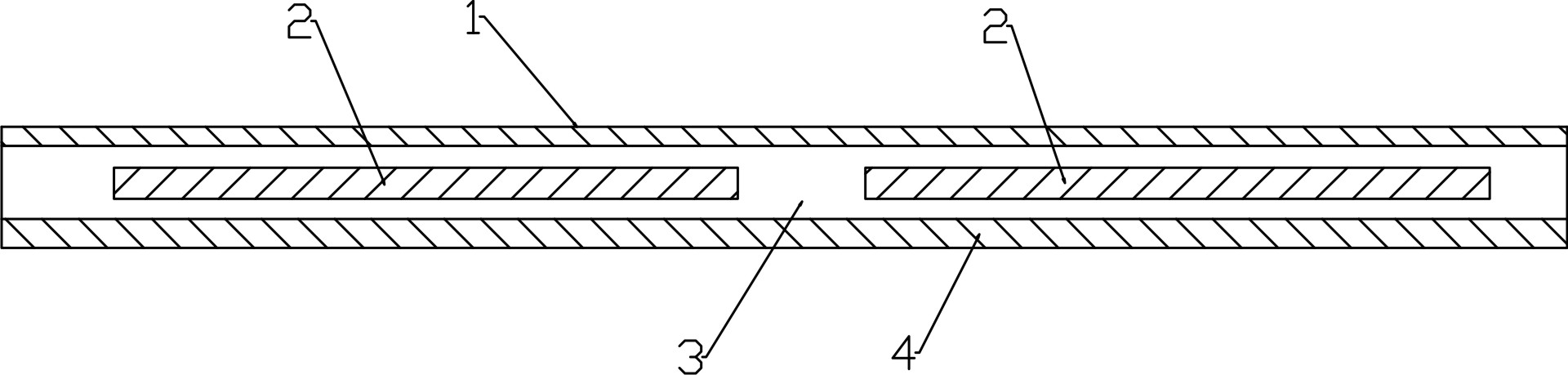

Nanometer silver transparent electrode material and preparation method thereof

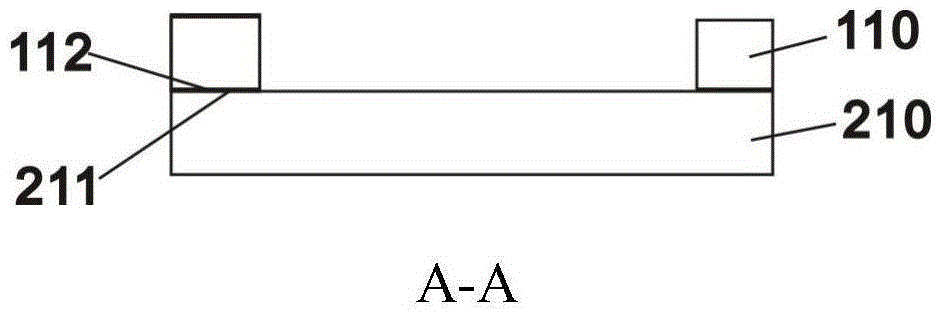

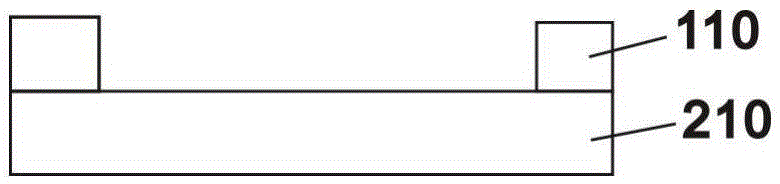

ActiveCN102522145BImplement mosaicSolve the flatnessConductive layers on insulating-supportsCable/conductor manufactureHigh volume manufacturingMolecular materials

The invention discloses a nanometer silver transparent electrode material and a preparation method thereof. The nanometer silver transparent electrode material comprises the following four layers of structures: 1 a nanometer silver wire network, 2 poly(3,4-ethylenedioxythiophene) (PEDOT): an electricity conductive high molecular layer formed by evenly coating PSS aqueous solution, 3 a high molecular material tackifying layer and 4 a substrate. The nanometer silver wire transparent electrode is high in light transmitting rate, low in resistance, good in adhesion between the electricity conductive layer and the substrate, high in surface flatness degree, simple in preparation process and convenient for large-scale production and overcomes the shortcomings of being complex in a process for preparing the nanometer silver wire transparent electrode through a transfer method and not suitable for large-scale production.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Antibacterial ceramic tile and preparation method thereof

ActiveCN110698227AGood antibacterial effectImprove bindingClaywaresAnti bacterialAntibacterial agent

The invention discloses an antibacterial ceramic tile. The antibacterial ceramic tile comprises an antibacterial glaze layer arranged on the upper surface of a ceramic tile; the antibacterial glaze layer is composed of a basic transparent glaze and a zirconium phosphate loaded composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent comprises a zirconium phosphate carrier and a composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent is accumulated at the upper part of the antibacterial glaze layer, and antibacterial effective components of the composite antibacterial agent are antibacterial oxides and antibacterial ions. According to a preparation method, zirconium phosphate is introduced into the antibacterial glaze layer on the surface of the ceramic tile; by utilizing the characteristic of low density of zirconium phosphate, zirconium phosphate is accumulated at the upper part of the glaze layer after being sintered at a high temperature to form a surface with a porous structure, so that the zirconium phosphate is used as a carrier to which the composite antibacterial agent is attached, the binding force of antibacterial materials and the ceramic tile is enhanced, the ceramic tile is endowed with long-acting and excellent antibacterial performance, and meanwhile, the surface appearance decoration effect of the ceramic tile is not influenced. The invention further discloses a preparation process of the antibacterial ceramic tile, and the preparation process is simple in step, high in controllability and beneficial to large-scale industrial production.

Owner:FOSHAN OCEANO CERAMICS

Solar panel and encapsulation process

ActiveCN101916788ASolve the flatnessSolve the bubblesFinal product manufacturePhotovoltaic energy generationWhole bodyHot melt

The invention relates to a solar panel and an encapsulation process. The solar panel comprises a silicon wafer, wherein the back of the silicon wafer is adhered to a printed circuit board (PCB) board; a polythylene terephthalate (PET) material light-transmitting layer is arranged on the upside of the silicon wafer; and the PCB board is provided with anode and cathode printed coils which are connected with the anode and cathode of the silicon wafer. The encapsulation process of the solar panel comprises the following steps of: firstly, clamping the silicon wafer and flake-like ethylene vinyl acetate (EVA) hot melt glue between the PCB board and the PET material light-transmitting layer and placing the whole body in a vacuum laminating machine; secondly, vacuumizing the vacuum laminating machine and then heating materials to be processed in the vacuum laminating machine; and finally charging air into air bags in the vacuum laminating machine for pressurization.

Owner:HANGZHOU SOLAR PHOTOELECTRICITY

Self-adaption laser shot blasting shape correcting device based on large data platform and method

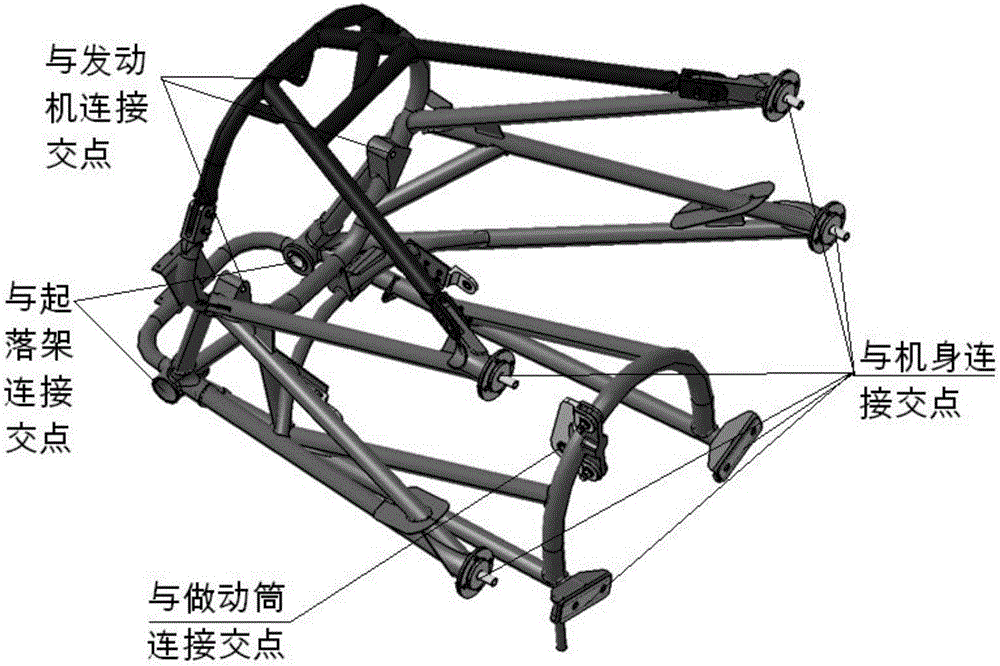

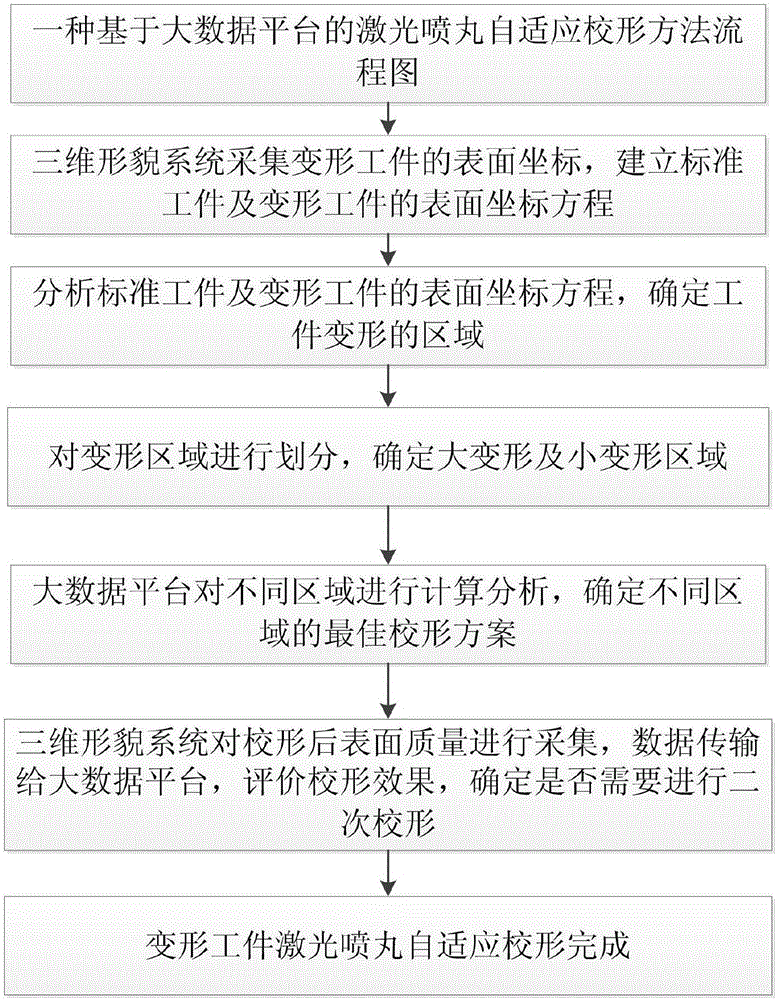

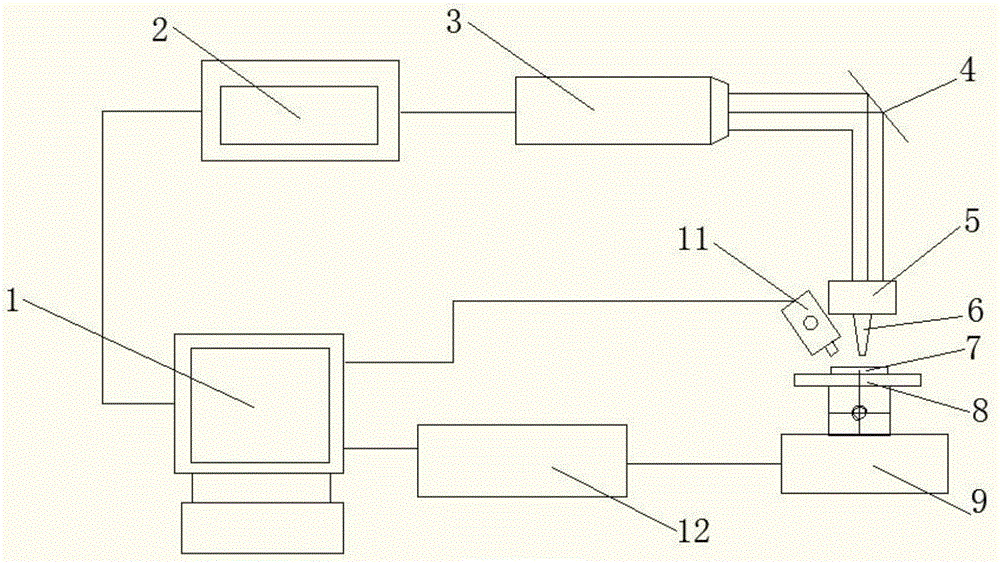

InactiveCN106216843ASolve the flatnessAddress stressLaser beam welding apparatusThree dimensional shapeData entry

The invention discloses a self-adaption laser shot blasting shape correcting device based on a large data platform and a method. The method comprises the following steps: (1) surface curvature data of a calibrated workpiece and a workpiece needing to be corrected the shape is input to respectively build three-dimensional curvature models; (2) an optimal shape correcting scheme is calculated through a laser shot blasting shape correcting large data platform in a self-adaption manner; (3) the shapes of the workpieces are corrected according to the optimal shape correcting scheme; the surface curvature detection is performed for the shape-corrected workpieces through a three-dimensional shape measurer; and data is input in the large data platform; and (4) the shape correcting effect is estimated through the large data platform to determine if secondary shape correction is needed; and if so, the steps (1-3) are repeated until the final machining requirements are reached, so that the self-adaption laser shot blasting shape correction of the workpieces is realized.

Owner:GUANGDONG UNIV OF TECH

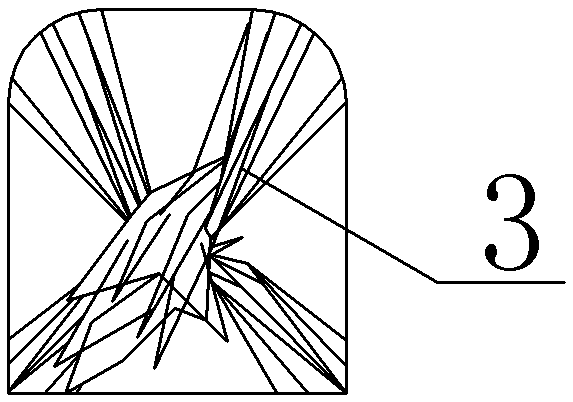

Incompletely-fused glass group and making method thereof

InactiveCN105565647AHave diversitySolve the flatnessGlass reforming apparatusFracture zoneFused glass

The invention provides an incompletely-fused glass group and a making method thereof. The incompletely-fused glass group comprises at least two pieces of glass, wherein the surface smoothness of the glass is less than 10 nanometers; the at least two pieces of glass are jointed together; a fused fracture zone is formed between every two pieces of glass. The making method comprises the following steps: cleaning the surfaces of the two pieces of glass; making the surfaces of the two pieces of the glass come into contact with each other; applying force to the glass group to make contact parts form Van der Waals force joint; heating the glass group in a backing way at the temperature of 240-600 DEG C for 0.5-48 hours; watching the glass group state of the fused fracture zone, namely, the incompletely-fused glass group, under a microscope. In the incompletely-fused glass group, no jointing medium is used, so that the diversity of glass can be met, and the machining quality of the glass is ensured.

Owner:XIAMEN BOENSI APPL MATERIAL SCI & TECH

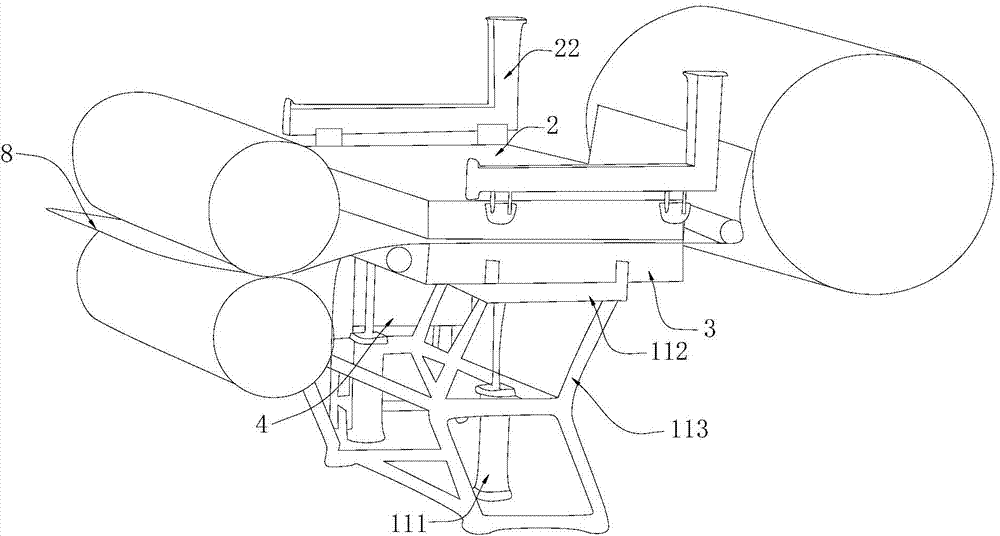

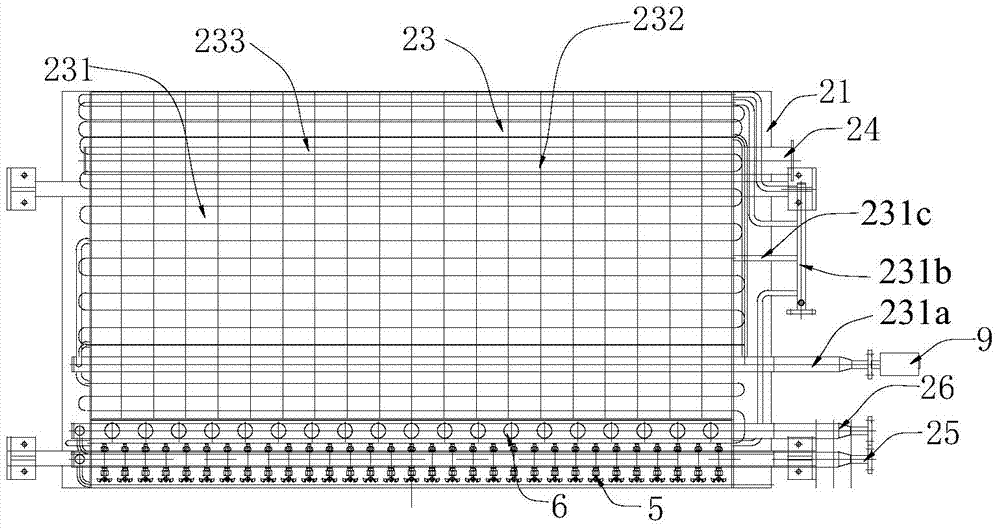

Paper humidifying device on paper making machine

ActiveCN103938483ARaise the partition temperatureEnhanced HumidificationDamping devicesNozzleHeat exchanger

The invention relates to the field of paper making devices, in particular to a paper humidifying device on a paper making machine. The paper humidifying device comprises an upper humidifying box. The upper humidifying box comprises a box body, a heat exchanger, a separation plate and a steam pipeline. The heat exchanger, the separation plate and the steam pipeline are arranged in the box body. The heat exchanger comprises a steam inlet and a steam outlet. The steam pipeline is communicated with the steam outlet in the heat exchanger, the box body is arranged on paper conveyed by a roll shaft, the separation plate divides the box body into an upper part and a lower part, an installation room is arranged in the upper part, and a humidifying room is arranged between the separation plate and the paper. The heat exchanger and the steam pipeline both are arranged in the installation room, the heat exchanger is connected with the separation plate through heat conduction, a steam valve is arranged on the steam pipeline, and a nozzle on the steam valve is located in the humidifying room. The surface density and the printing effect of paper processed by the paper humidifying device on the paper making machine are greatly improved, and smoothness is achieved, and warping is avoided.

Owner:浙江汉普新材料技术有限公司

Fixed-size saw cutting device for plastic-steel composite pressure pipe

InactiveCN105935802AGuaranteed sawing accuracyRealize automatic collectionMetal sawing devicesAutomatic control devicesReducerElectric control

A fixed-size saw cutting device for a plastic-steel composite pressure pipe comprises a length measuring mechanism, a saw cutting operating mechanism, a hydraulic power system and an electric control mechanism. The length measuring mechanism comprises counting wheels arranged on the two sides of an inlet pipe opening, a coded disc and an adjusting wheel. The saw cutting operating mechanism comprises a sliding system, a saw cutting system, a clamping system and a returning system. The saw cutting system comprises an executing mechanism and an induction mechanism. The executing mechanism comprises a lifting oil cylinder, a motor, a speed reducer and a low-rotation-speed saw blade, all of which are sequentially connected. The induction mechanism comprises a photoelectric limiting part I and a photoelectric limiting part II which are used for controlling ascending and descending of the low-rotation-speed saw blade. According to the fixed-size saw cutting device, through adjustment of the length measuring mechanism and the saw cutting mechanism, the saw cutting precision of the plastic-steel composite pressure pipe is guaranteed, and the fixed-size saw cutting device is suitable for conducting saw cutting operation on plastic-steel composite pressure pipes with different diameters and wall thicknesses.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Real leather or leather processing technology

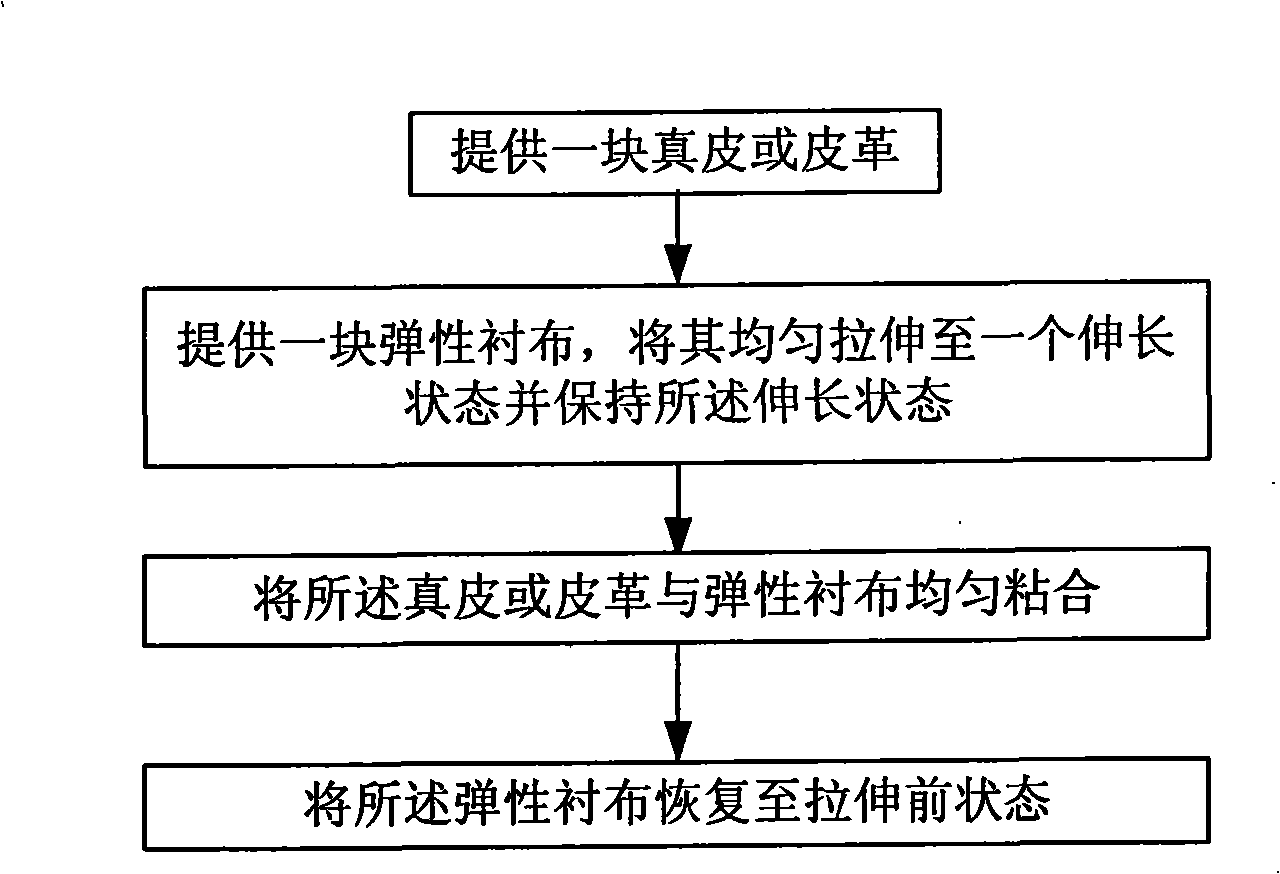

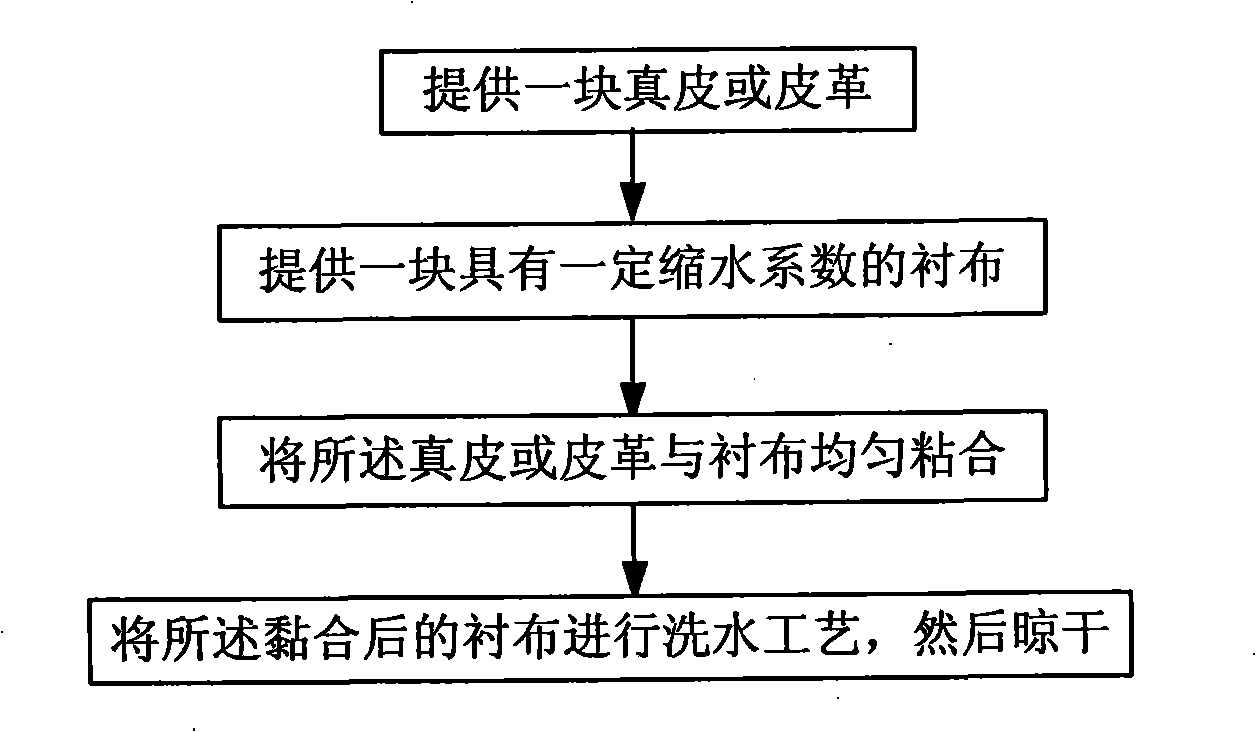

InactiveCN101348024AElasticNatural shrinkageLamination ancillary operationsLaminationInterliningComputer science

The invention provides a real leather or leather processing technology, which comprises the following steps: providing a piece of real leather or leather; providing a piece of elastic interlining, uniformly stretching the elastic interlining into an extension state and maintaining the extension state; uniformly adhering the real leather or the leather with the elastic interlining; restoring the elastic interlining to the state before stretching. The invention further provides a real leather or leather processing technology, which comprises the following steps: providing a piece of real leather or leather; providing a piece of interlining with certain shrinking coefficient; uniformly adhering the real leather or the leather with the elastic interlining; carrying out washing technology to the adhered interlining and drying. By adhering the pre-stretched elastic technological interlining or the technological interlining with large shrinking coefficient to the real leather or the leather, the technology can ensure that the real leather or the leather generates uniform and natural shrinking and has elasticity.

Owner:珠海港丽鞋业有限公司

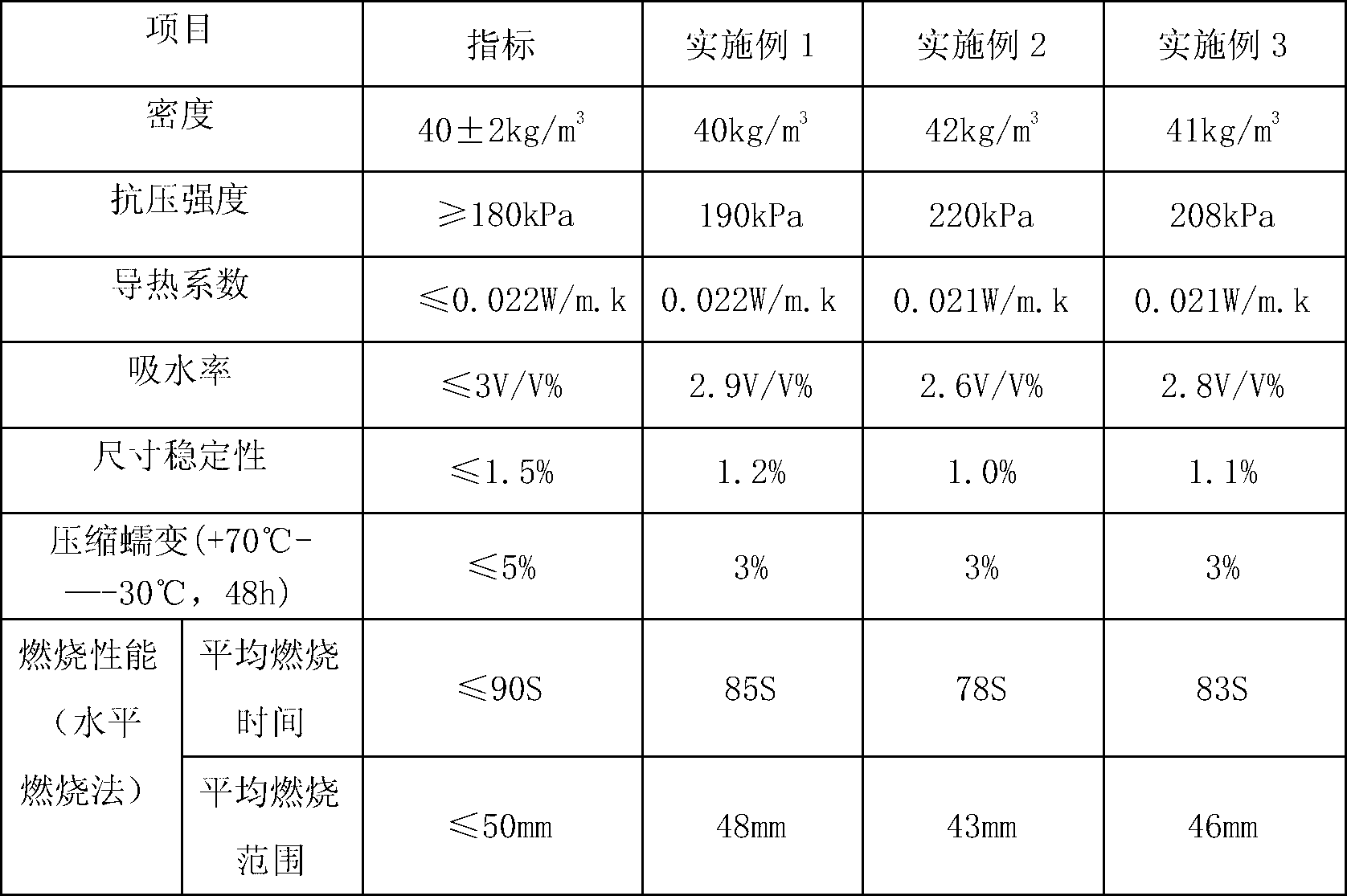

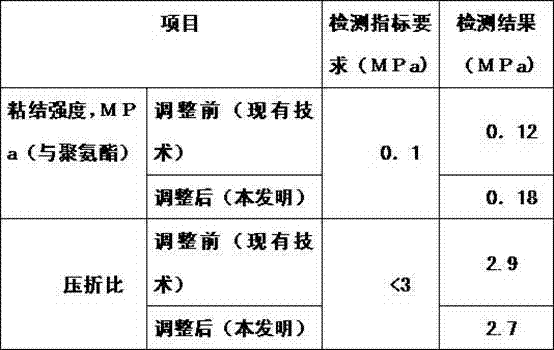

Combination material of insulation boards for producing building outer walls and preparation method thereof

The invention relates to a combination material of polyurethane insulation boards for producing building outer walls by using a continuous method and a preparation method thereof. The combination material is composed of a component A and a component B, a weight ratio of the component A to the component B is 1:1-1.3, wherein the component A is composed of the following components, by weight, of 20-40% of polyether polyol A, 15-35% of polyether polyol B, 10-20% of polyether polyol C, 1.0-3.0% of foam stabilizer, 1.0-3.0% of chemical foaming agent, 10-20% of physical foaming agent, 0.5-3.5% of catalytic agent and 10-20% of fire retardant, and the component B is polymethyl polyphenyl polyisocyanates. The preparation method of the combination material comprises stirring and mixing all components in the component A in proportion, and then mixing the component A with the component B. Polyurethane foams made of the combination material are low in heat conductivity coefficient, good in leakproofness, excellent in flame retardant property, good in product stability and capable of completely meeting requirements for polyurethane outer wall boards.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

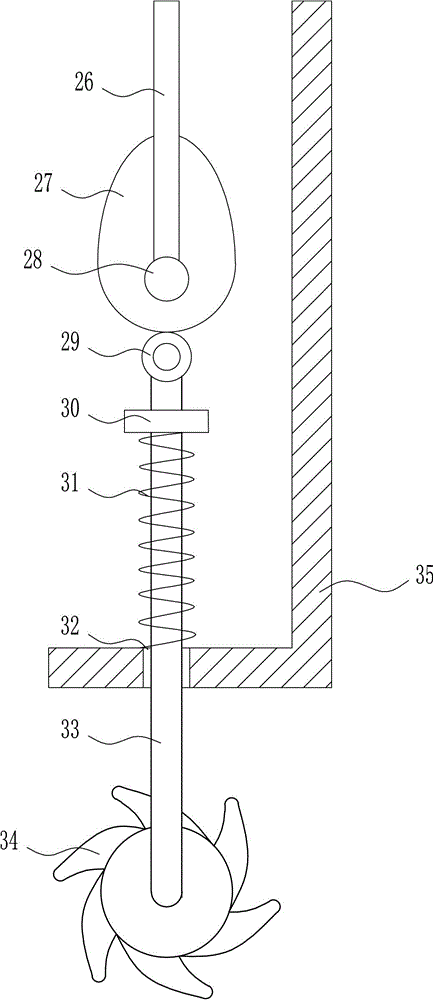

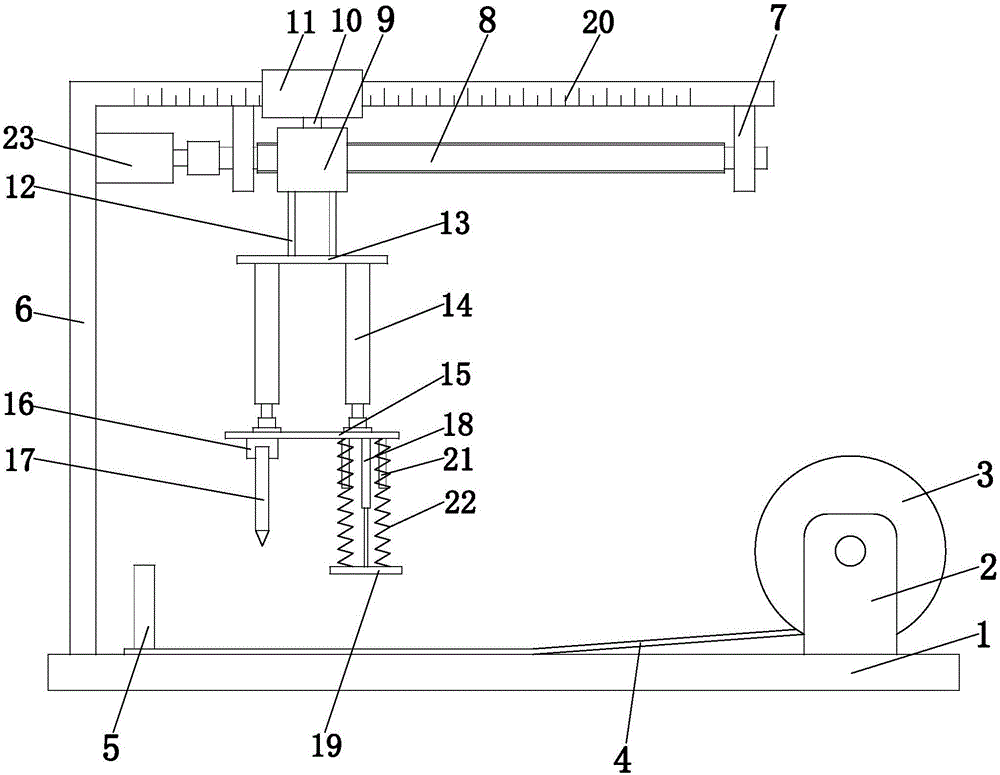

Accurate heat preservation cotton cutting mechanism

ActiveCN106498692ASolve the speed problemSolve the flatnessIroning machinesSevering textilesCouplingEngineering

The invention relates to an accurate heat preservation cotton cutting mechanism which comprises a base plate. Two lifting lugs are symmetrically arranged on the upper end face of the base plate, a winding wheel is installed between the two lifting lugs through a hinge pin and is wound with cotton, the starting end of the cotton always extends to the left side of the upper end face of the base plate, and a magnet is attracted to the starting end of the cotton. An L-shaped support is arranged on the left side of the upper end face of the base plate, two installing lugs are arranged on the lower side of the upper end face of the L-shaped support, a lead screw is installed between the two installing lugs through a bearing, a driving motor is installed at the left end of the lead screw through a coupler, and the bottom end of the driving motor is installed on the L-shaped support through a motor seat. The problems of low cutting speed, uneven cutting, inaccurate cutting size, low working efficiency and the like existing in a manual heat preservation cotton cutting mode can be solved, a rapid and accurate heat preservation cotton cutting function can be achieved, and the accurate heat preservation cotton cutting mechanism has the advantages of being high in cutting speed, flat in cutting, accurate in cutting size, high in working efficiency and the like.

Owner:广东加美堡保温材料有限公司

Surface mortar for outer wall external insulation system using sprayed rigid foam polyurethane

InactiveCN102351471AAvoid crackingGood flexibilitySolid waste managementCrack resistanceThermal insulation

The invention relates to a surface mortar for an outer wall external insulation system using sprayed rigid foam polyurethane. The surface motor is prepared by mixing the following materials in proportion (mass): 40 to 58% of cement, 20 to 35% of a lightweight insulation material, 0.1 to 0.2% of an anti-cracking agent, 0.4 to 1% of redispersible rubber powder, 0.2 to 0.3% of a water-retaining agent and 0 to 0.5% of slow-drying agent, with the balance being a filler. The surface mortar provided in the invention has good flexibility and crack resistance, can compensate for temperature strain caused by difference among expansion coefficients of materials and avoids the cracking of the external insulation system, thereby thoroughly overcoming the difficulty in leveling and the problem of proneness to cracking in the prior art. Simultaneously, a conventional process for leveling of insulation mortar and rendering of crack resistant mortar is simplified in the invention; the surface mortar provided in the invention has both the functions of leveling and rendering and has excellent leveling and filling performance and a light weight, providing reliable guarantee for the security of the system. Low cost and substantially reduced construction cost are achieved in the invention.

Owner:江苏百代节能建材有限公司

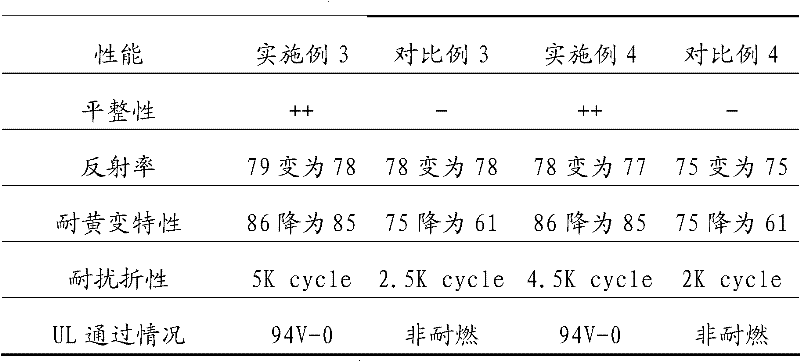

White covering film for flexible circuit board as well as preparation method and application for same

InactiveCN102501499ASolve the flatnessHigh reflective brightnessLamination ancillary operationsSynthetic resin layered productsSurface brightnessFlexible circuits

The invention provides a white covering film for a flexible circuit board, comprising an outmost white ink layer, a middle polyimide layer, an inner adhesive layer and release paper on a bottom layer. The invention further provides a method for preparing a flexible circuit board by using the white covering film, comprising the following steps of: removing the release paper on the bottom layer of the white covering film, thermally bonding the adhesive layer of the white covering film on a pre-treated flexible copper-clad plate primarily, pressing-fitting by a hot press, and finally roasting. The flexible circuit board prepared by using the white covering film provided by the invention is good in smoothness, remarkably increased in the reflecting brightness of LED (light-emitting diode), excellent in anti-yellowing characteristic, great in flexibility, as well as good in surface brightness and reflectivity.

Owner:欣兴同泰科技(昆山)有限公司

Highly protective polyimide flame-retardant garment fabric and heat setting method thereof

InactiveCN106585026AImprove flame retardant performanceImprove antibacterial propertiesWeft knittingSynthetic resin layered productsYarnEngineering

The invention provides a highly protective polyimide flame-retardant garment fabric and a heat setting method thereof and relates to the technical field of flame-retardant fabrics. The highly protective polyimide flame-retardant garment fabric is prepared from an inner layer and an outer layer through sewing. The inner layer is prepared from polyimide fiber yarn and flame-retardant filaments through weaving. The outer layer is a cloth surface with raised grids and is prepared from polyimide fiber yarn and flame-retardant filaments through weaving. The highly protective polyimide flame-retardant garment fabric has good fire resistance and heat-insulating functions, can be used at a high temperature for a long time, is comfortable, and reduces hair slip. Through heat setting, the fabric is smooth and flat and size stability.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

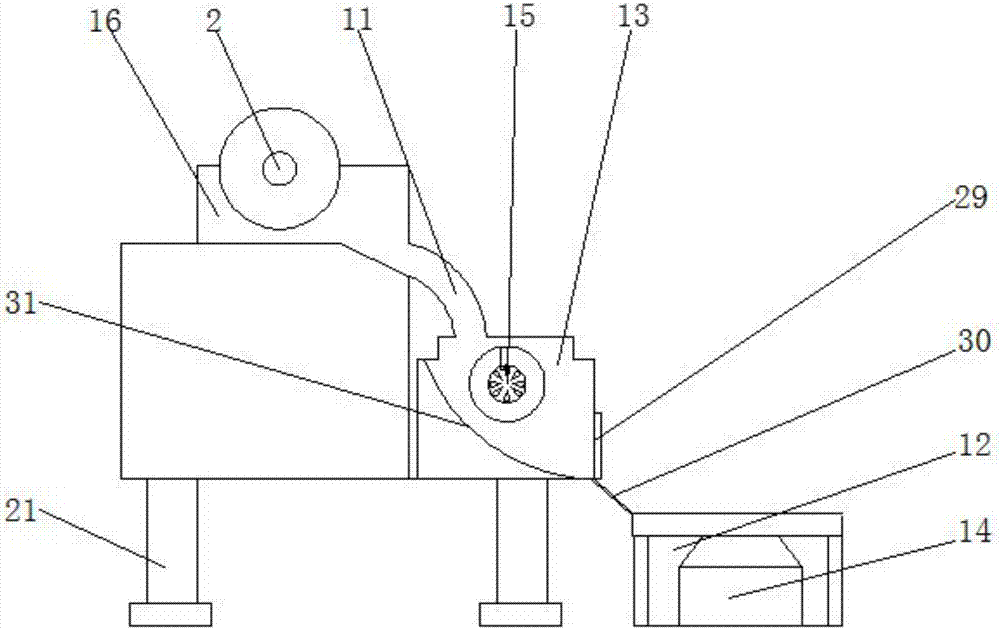

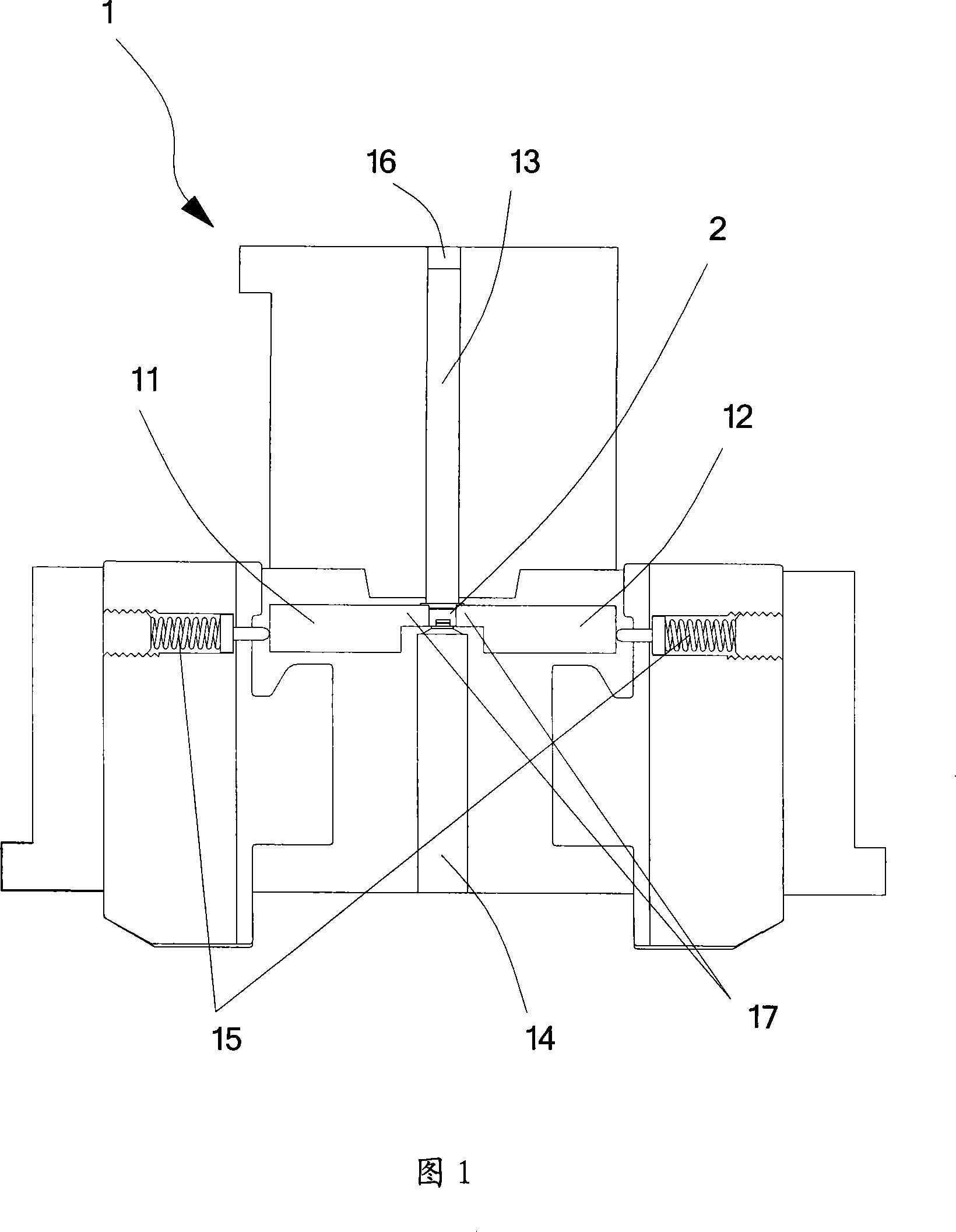

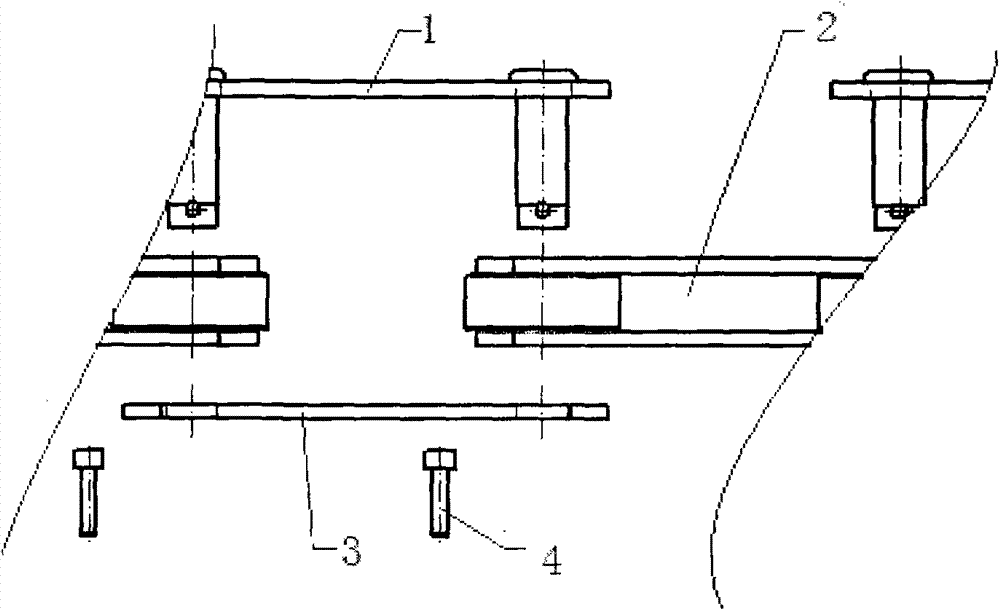

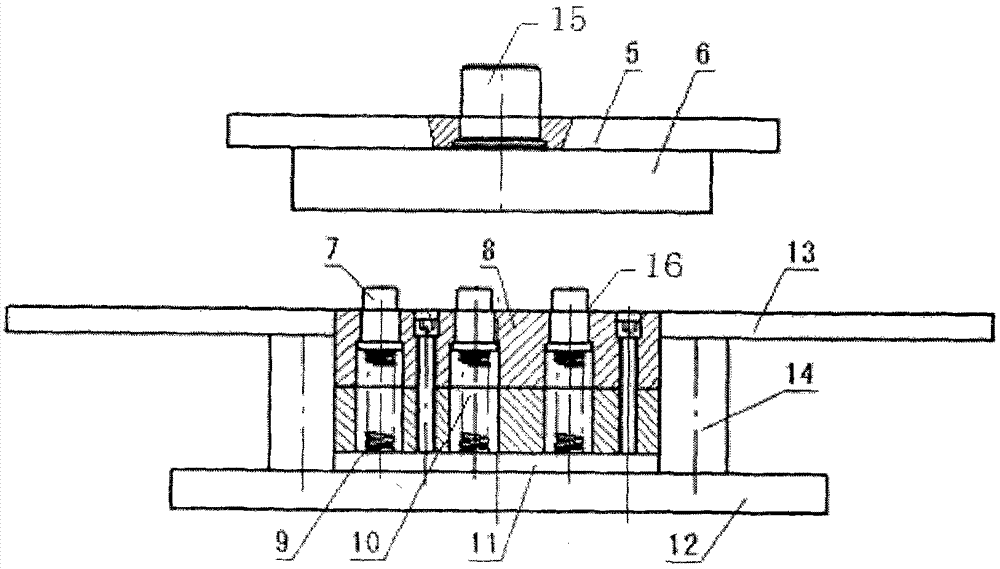

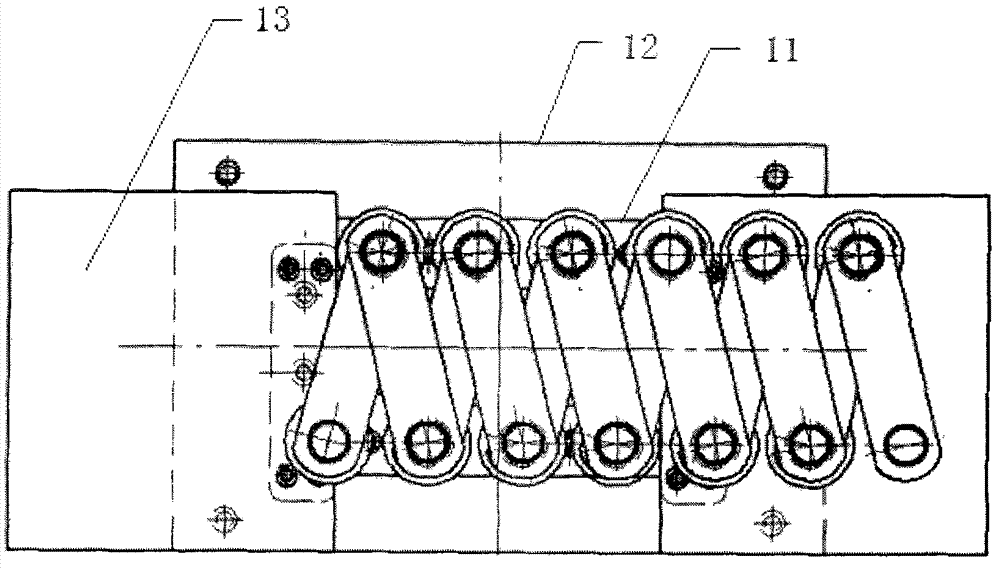

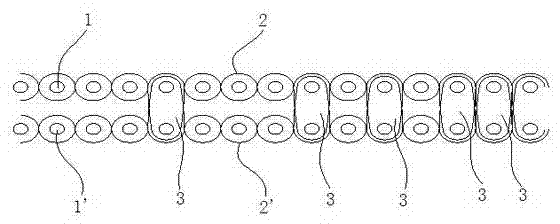

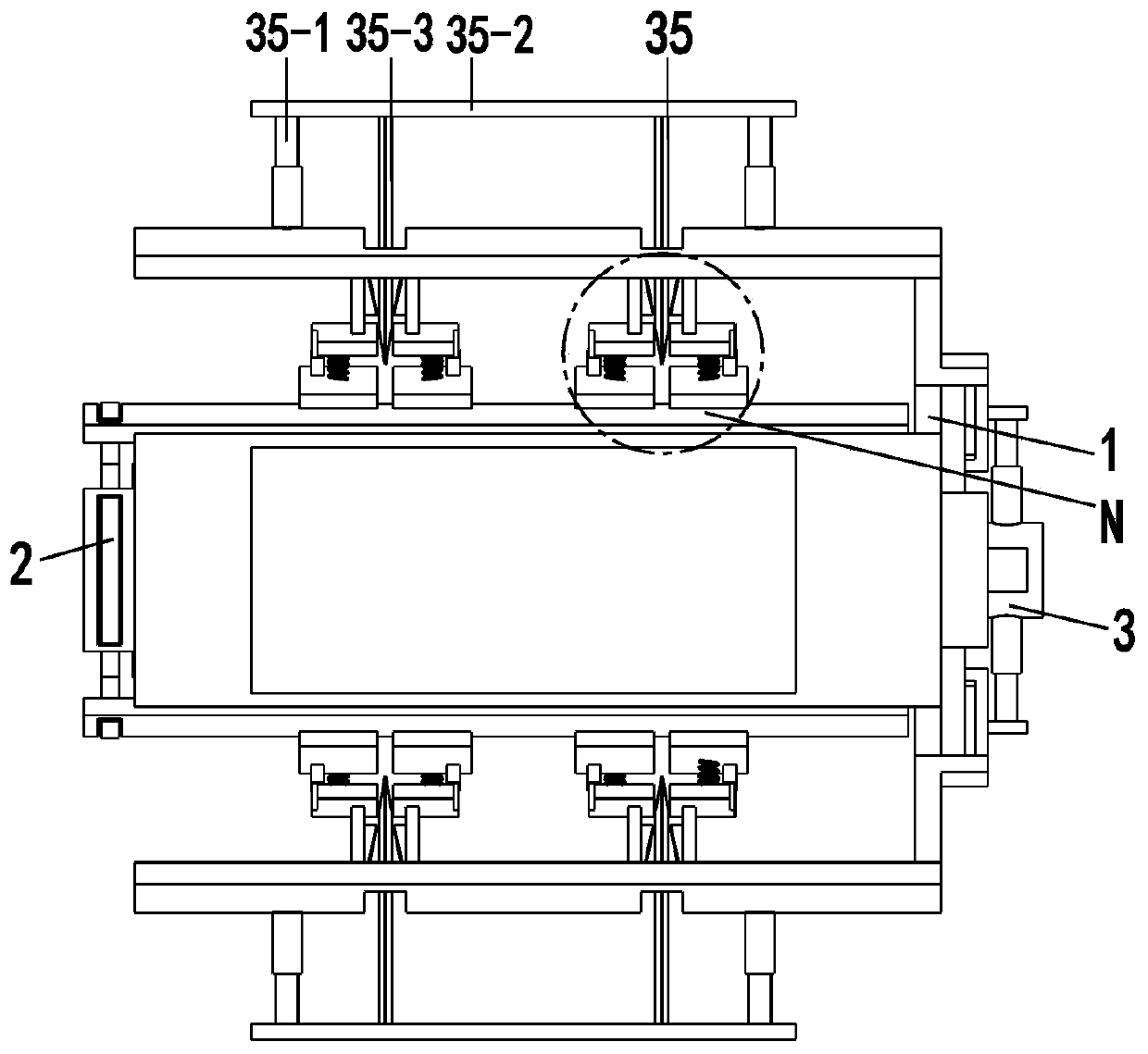

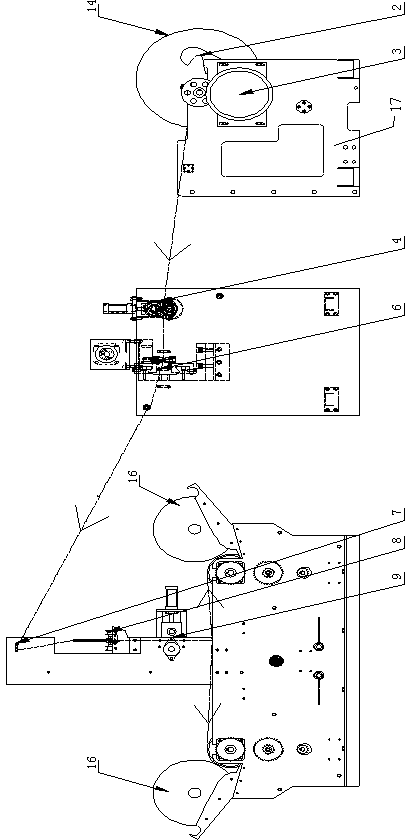

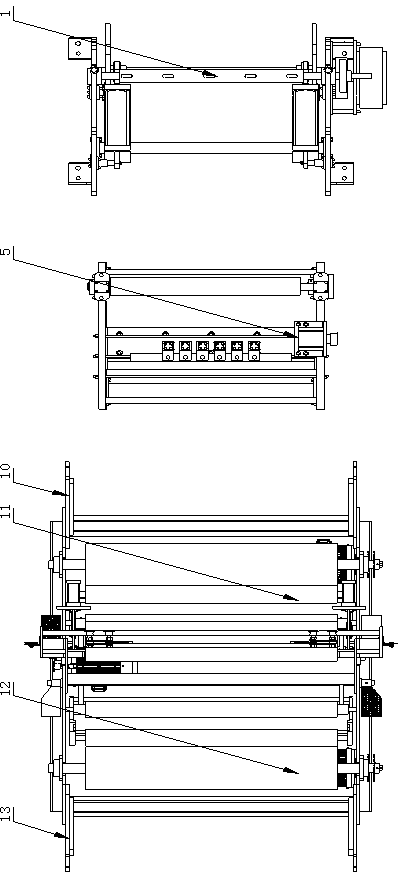

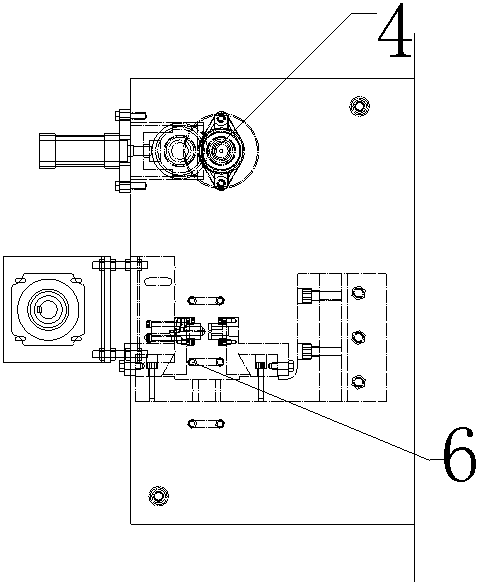

Device and method for assembling chain integrally

ActiveCN103934409ASimple and efficient operationGood controllabilityMetal chainsBolsterControllability

The invention discloses a device and method for assembling a chain integrally. The device comprises a hydraulic machine, a hydraulic machine work panel, an upper template, an upper die and a bottom board. The top face of the upper template is fixed to the bottom of a hydraulic rod of the hydraulic machine and the bottom of the upper template is fixed to the upper die. The bottom board is fixed to the upper side of the hydraulic machine work panel. A lower bolster is installed above the bottom board. A left supporting block cushion block, a right supporting block cushion block, a left supporting block and a right supporting block are arranged at the two sides of the lower bolster, wherein the left supporting block cushion block, the right supporting block cushion block, the left supporting block and the right supporting block are perpendicular to the bottom board. A core base is installed between the left supporting block cushion block and the right supporting block cushion block. Multiple locating holes are formed in the core base at intervals. Each locating hole is provided with a core base cushion block and a spring. The top end of each spring is provided with a mandrel. The method comprises the steps that firstly, localization is conducted simultaneously through the mandrels; secondly, half outer links to be assembled are arranged in located inner link sleeve holes; thirdly, hinge pins are pressed downwards; finally, the hinge pins bounce up. According to the device and method for assembling the chain integrally, operation is simple, controllability is good, and safety performance is high.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

Preparation process for ultrathin ceramic brick

The invention discloses a preparation process for an ultrathin ceramic brick. Blank raw materials comprise the following components in percentage by weight: 35-40% of clay, 25-30% of feldspar, 8-13% of lithium chinastone, 5-10% of aluminum ore and 15-20% of white sand; the preparation process comprises the following steps: preparing materials, pulping, preparing powder, forming and drying, biscuiting, glazing and printing, carrying out glaze firing, carrying out fine trimming and packaging. Through the adoption of the preparation process disclosed by the invention, the dosage of raw materials is reduced, the ball-milling time and sintering time are shortened to some extent, and the sintering temperature is reduced to some extent, so that sewage discharge, exhaust emission and consumption of energy and raw materials are reduced greatly and manpower resources are saved greatly.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

Ceramic slurry for LED (light-emitting diode) metal substrate and preparation method of LED (light-emitting diode) metal substrate

ActiveCN104600182AImprove thermal conductivityImprove insulation performanceSemiconductor devicesScreen printingSilver paste

The invention discloses ceramic slurry for an LED (light-emitting diode) metal substrate and a preparation method of the LED (light-emitting diode) metal substrate. The ceramic slurry consists of ceramic powder, solution, surface active agent and moistening agent. The preparation method of the LED metal substrate includes: 1) selecting a metal plate, burnishing and polishing a printing surface of the metal plate, cleaning and drying it; 2) coating the slurry on the printing surface of the metal plate, sintering and cooling to the room temperature, and forming an insulation layer; 3) coating weldable silver slurry to the surface of the insulation layer, sintering and cooling to the room temperature, and forming a circuit layer; 4) coating solder resist ink at a non-electrode part, mark out positive and negative poles, and then solidify ink. The insulation layer of the ceramic slurry for the LED metal substrate is high in heat conductivity coefficient and good in insulation performance; the insulation layer is coated by the method of silk-screen printing and sintered under medium temperature; the insulation layer at the surface of the metal plate is compact, uniform and smooth; the circuit layer is coated by the method of silk-screen printing and sintered under medium temperature; thus the ceramic slurry is green and environmental-friendly.

Owner:广州市尤特新材料有限公司

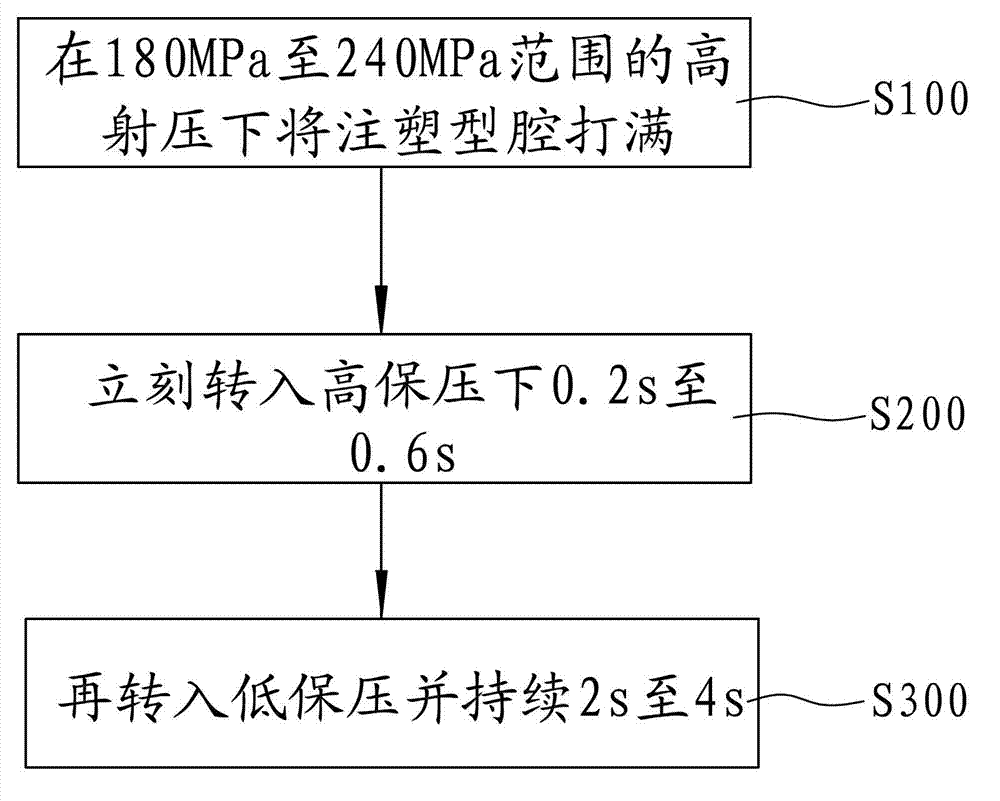

Injection molding production technique of IML (In Mold Labelling) ultrathin workpieces

ActiveCN102848518ASolve the problem of concave deformation and flatnessSolve the flatnessCoatingsComposite materialHigh pressure

The invention discloses an injection molding production technique of IML (In Mold Labelling) ultrathin workpieces, and the technique comprises the following steps: fulfilling an injection molding die cavity at a high injection pressure of 180-240MPa, immediately performing high pressure maintaining on the injection molding die cavity for 0.2-0.6s, transferring to low pressure maintaining operation and keeping for 2-4s. Compared with the prior art, the injection molding production technique disclosed by the invention overcomes the technology prejudice of immediately performing high pressure maintaining for 0.2-0.6s after fulfilling the injection molding die cavity and transferring to the low pressure maintaining operation for 2-4s, so that the concave deformation and smoothness problems of the IML products can be solved when forming IML products smaller than 1.0mm, and qualified IML products are formed.

Owner:通达(石狮)科技有限公司

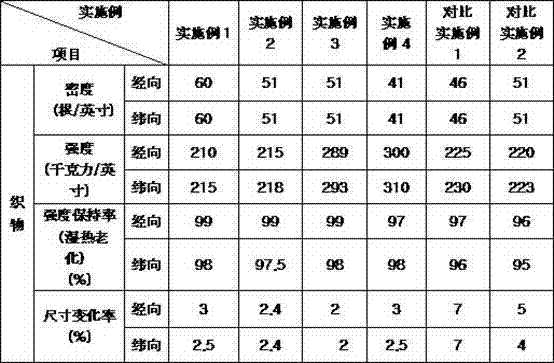

Fabric for airbag, fully moulded airbag as well as manufacturing method thereof

ActiveCN103541224ALow costGood technical effectFibre typesPedestrian/occupant safety arrangementPolyamidePolyester

The invention relates to a fabric for an airbag, wherein the warps and wefts of the fabric consist of polyamide or polyester fibers. The fabric is characterized in that the dry and wet hot shrinking percentages of the polyamide or polyester fibers are below 5%, and the size rate of change of the fabric for the airbag after hot water and hot wind treatment as well as coating of 35-115g / m<2> silica gel resin on the surface of the fabric is less than 3%. The invention further relates to a fully moulded airbag comprising the fabric for the airbag as well as a manufacturing method thereof. On the basis of lowering the cost, the invention solves the problems of size stability, smoothness, air impermeability, high strength, ageing resistance and the like of existing fully moulded airbags.

Owner:KOLON NANJING SPECIAL TEXTILE

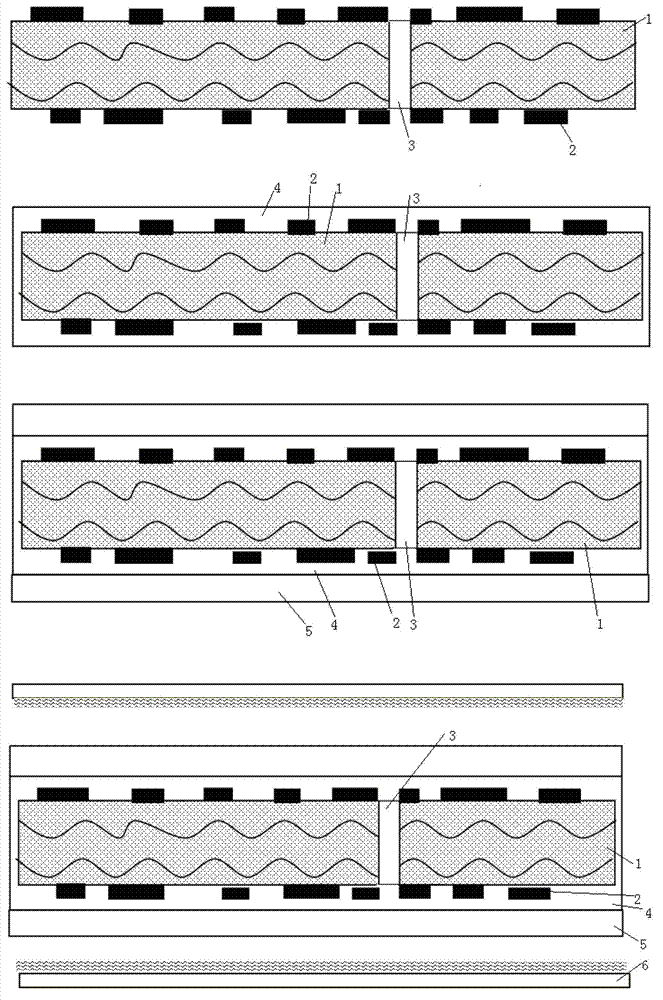

Production method of multilayer printed circuit board

InactiveCN103118507AImprove manufacturing yieldImprove uniformityMultilayer circuit manufactureFine lineEpoxy

The invention discloses a production method of a multilayer printed circuit board. Two copper foil wire layers are disposed on upper and lower surfaces of a copper-clad substrate or insulating plate respectively, and circuit through holes by which the upper and lower surface are communicated are established between the layers. After wiring on the copper-clad substrate or insulating plate is complete, oxidation is performed and the copper-clad substrate or insulating plate is placed in an epoxy resin glue cell for cycle control of temperature, humidity and solid-content ratio. The copper-clad substrate or insulating plate is coated with an epoxy resin glue layer. After the epoxy resin glue layer fully solidifies, an epoxy resin thin glue layer is applied to the copper-clad substrate or insulating plate and is baked to semi-solid state. Multiple copper-clad substrates or insulating plates are stacked. After copper foils are spread to the top and bottom of the stack, the stack is subjected to high-temperature press-fitting. The press-fitted copper-clad substrates or insulating plates are subjected to surface circuit treatment, and circuit through holes are established between the plates to allow for communication of circuits in all layers. Flatness of the inner layer of the printed circuit board is improved, inner buried holes are smoothed, manufacturing yield of fine lines and uniformity of line width are improved, and bending and warping degree of the printed circuit board is lowered.

Owner:明光瑞智电子科技有限公司

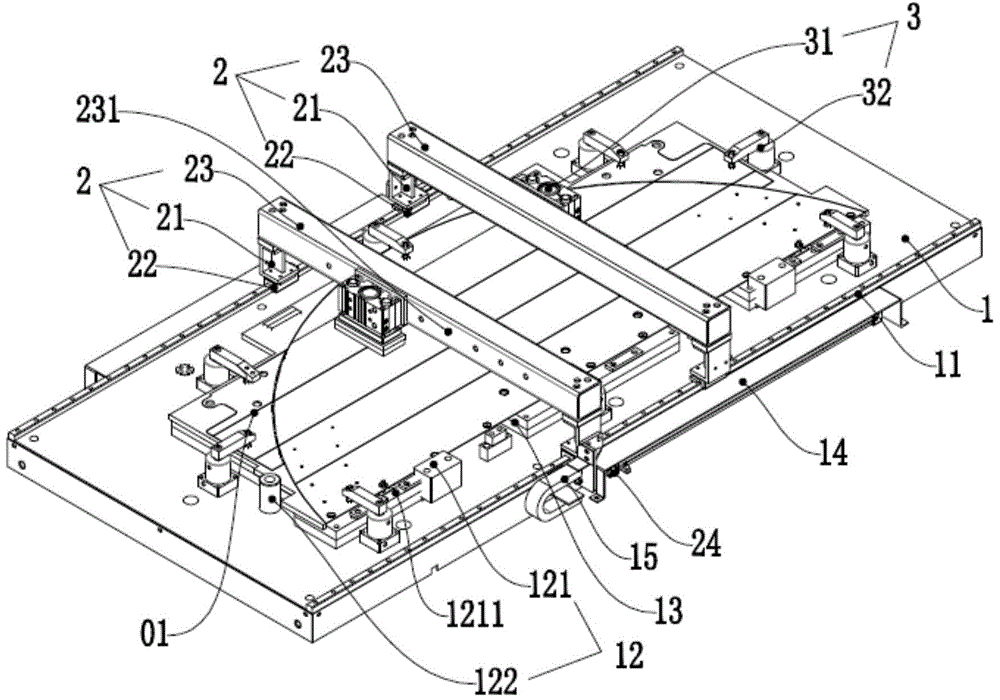

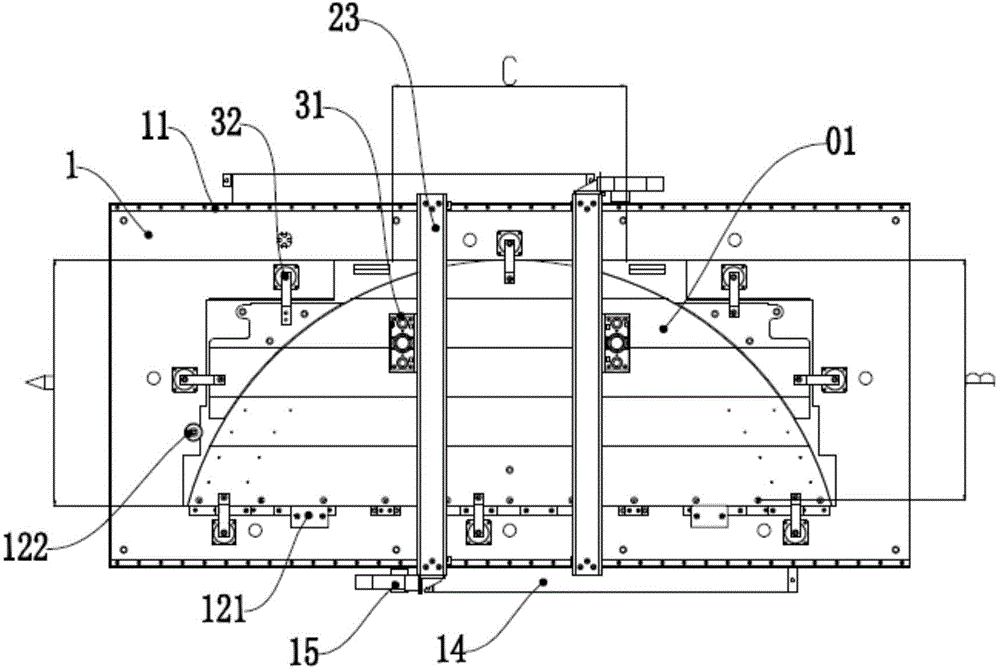

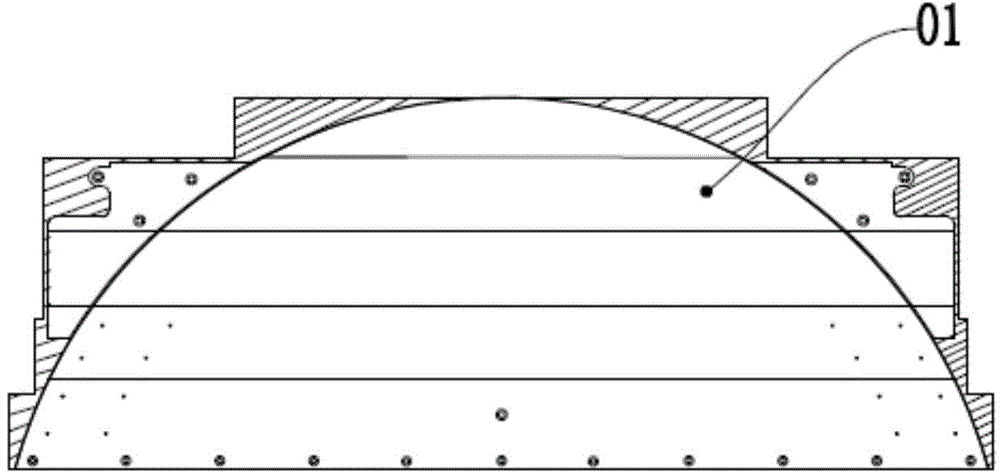

Clamp for elongated workpiece with outer contour needing to be milled

ActiveCN104875043AAvoid offsetGuaranteed stabilityWork clamping meansMilling equipment detailsControl systemEngineering

The invention discloses a clamp for an elongated workpiece with an outer contour needing to be milled. The clamp comprises a base, a moving gantry device, a positioning device and a control system, wherein a transverse guide rail is mounted at each of the upper and lower edges of the base; limiting devices used for limiting a workpiece blank are arranged on the upper surface of the base at intervals according to the shape of the outer contour of the workpiece blank needing to be machined; a gantry frame structure moves along the transverse guide rails under the control of a gantry frame cylinder; the positioning device comprises a pressing-down positioning device used for pressing down the middle of the workpiece blank and a plurality of rotatable angle positioning devices used for pressing down the outer contour of the workpiece blank; the control system controls the movement of the moving gantry device according to the machining movement locus of a tool and controls the loosening of one or more positioning devices in the positioning devices to avoid a tool path. The invention provides the clamp for the elongated workpiece with the outer contour needing to be milled, the machining efficiency is improved, the machining path of the tool is avoided, the operation safety is improved, and the machining precision is high.

Owner:FOSHAN PRATIC CNC SCI & TECH

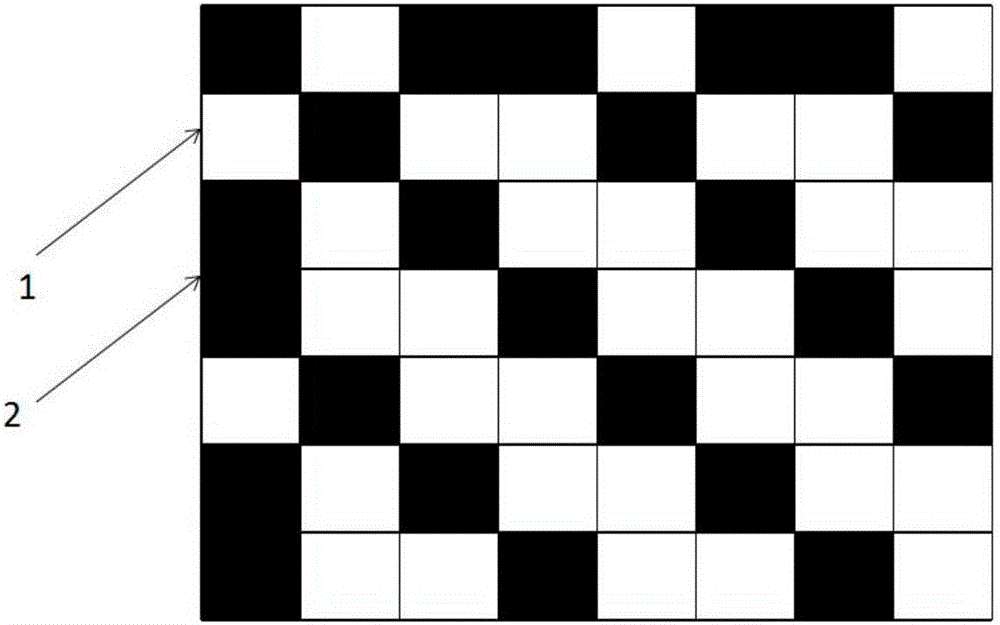

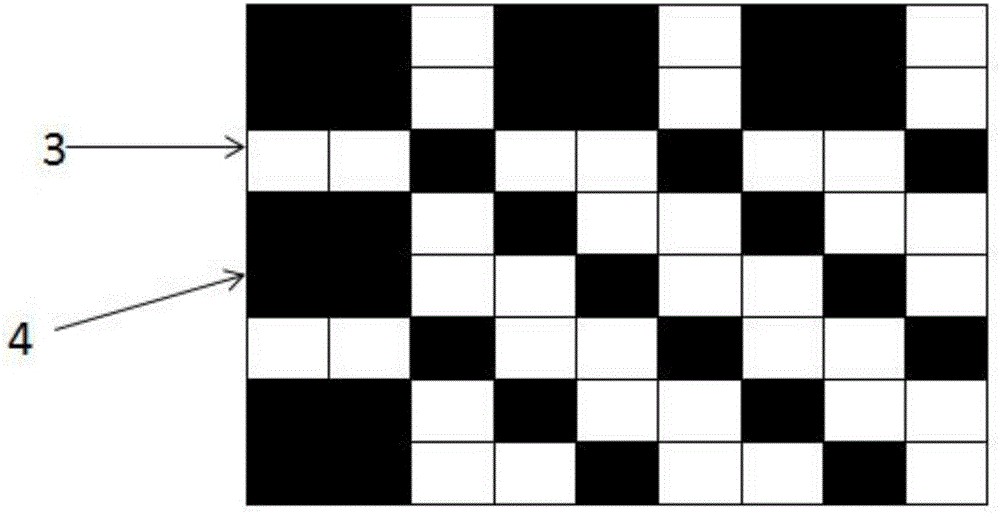

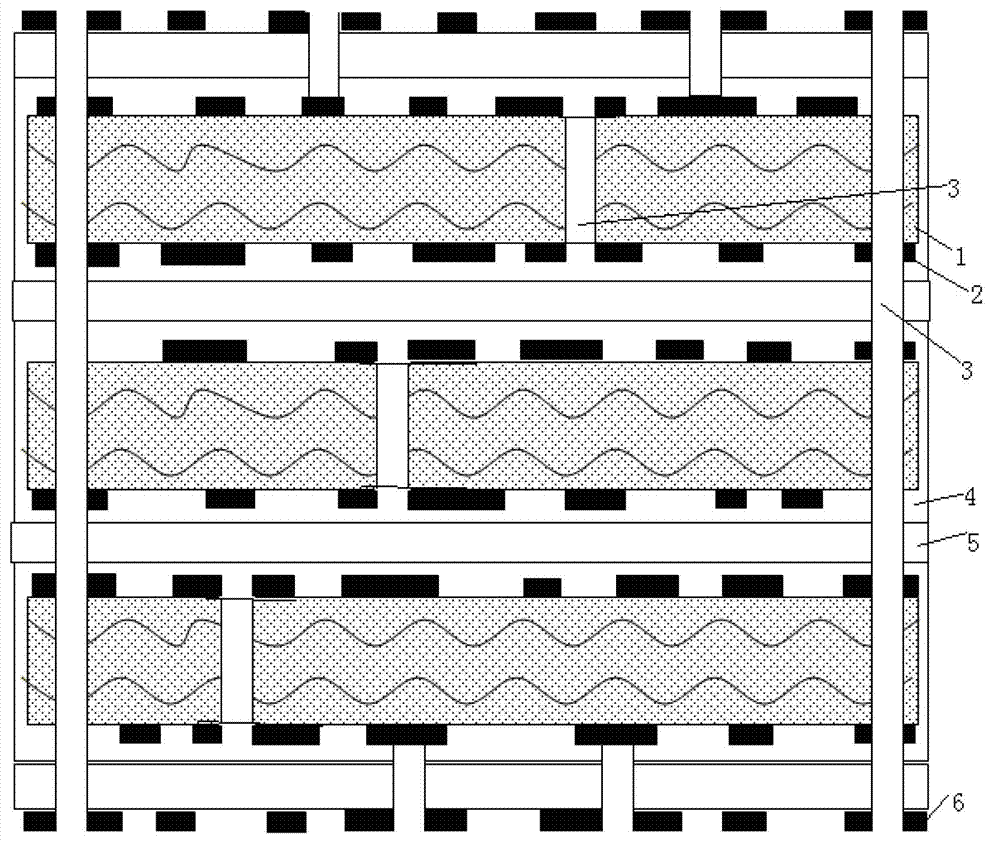

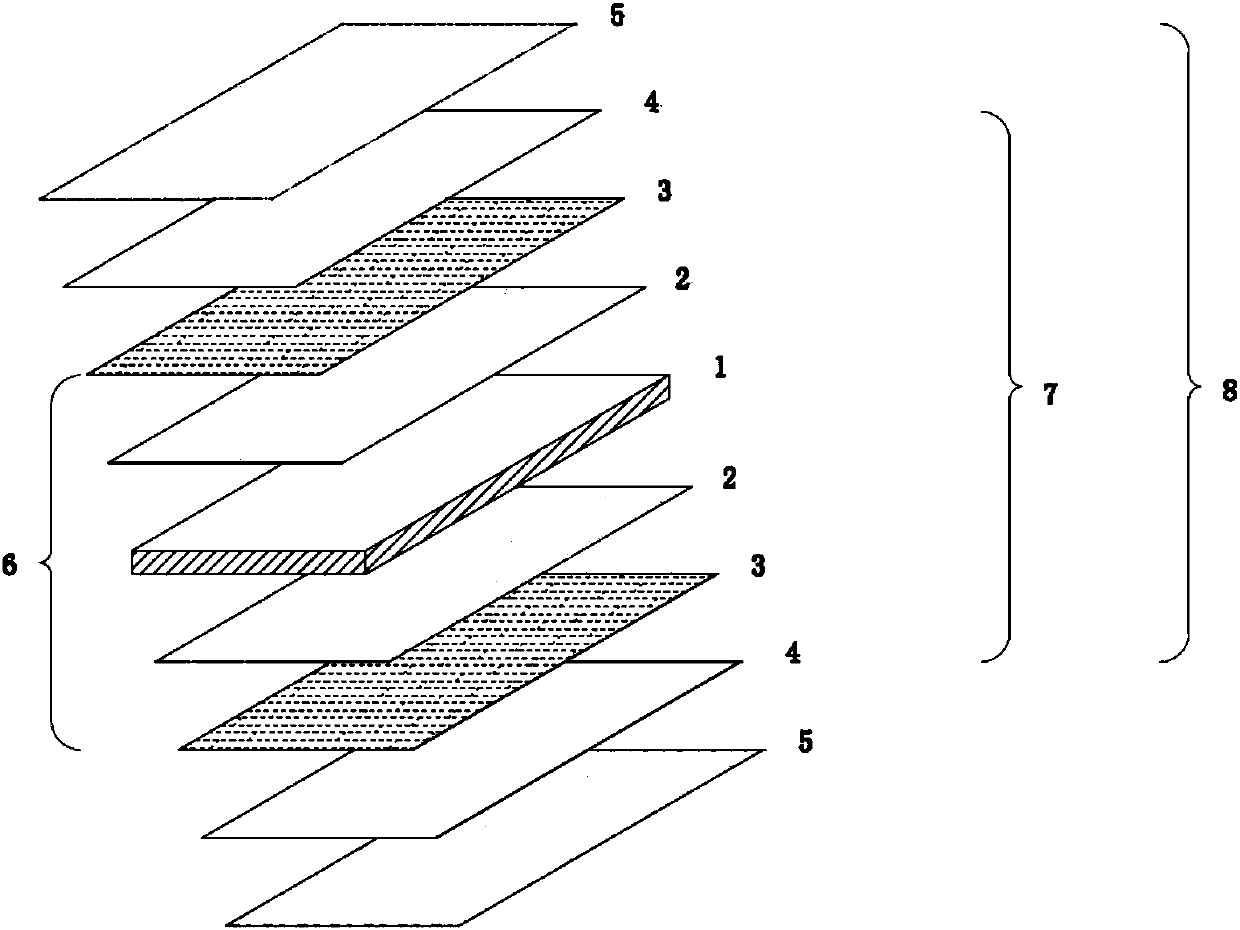

Formaldehyde-free paint-free water-based fiberboard and preparation process thereof

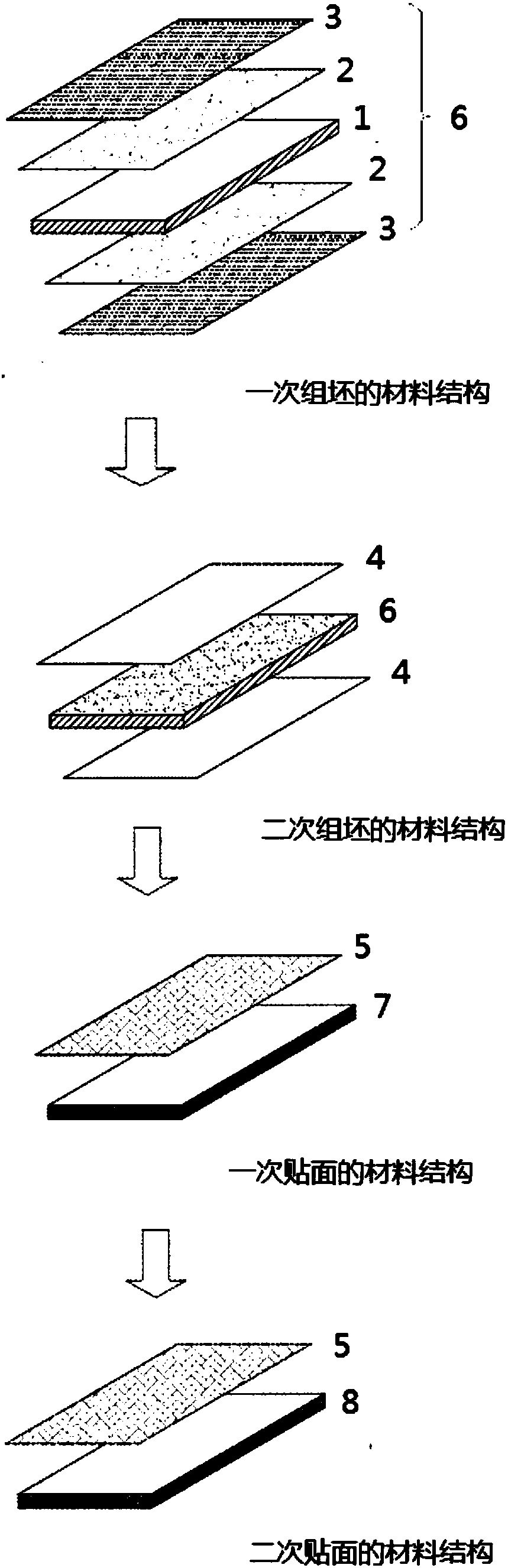

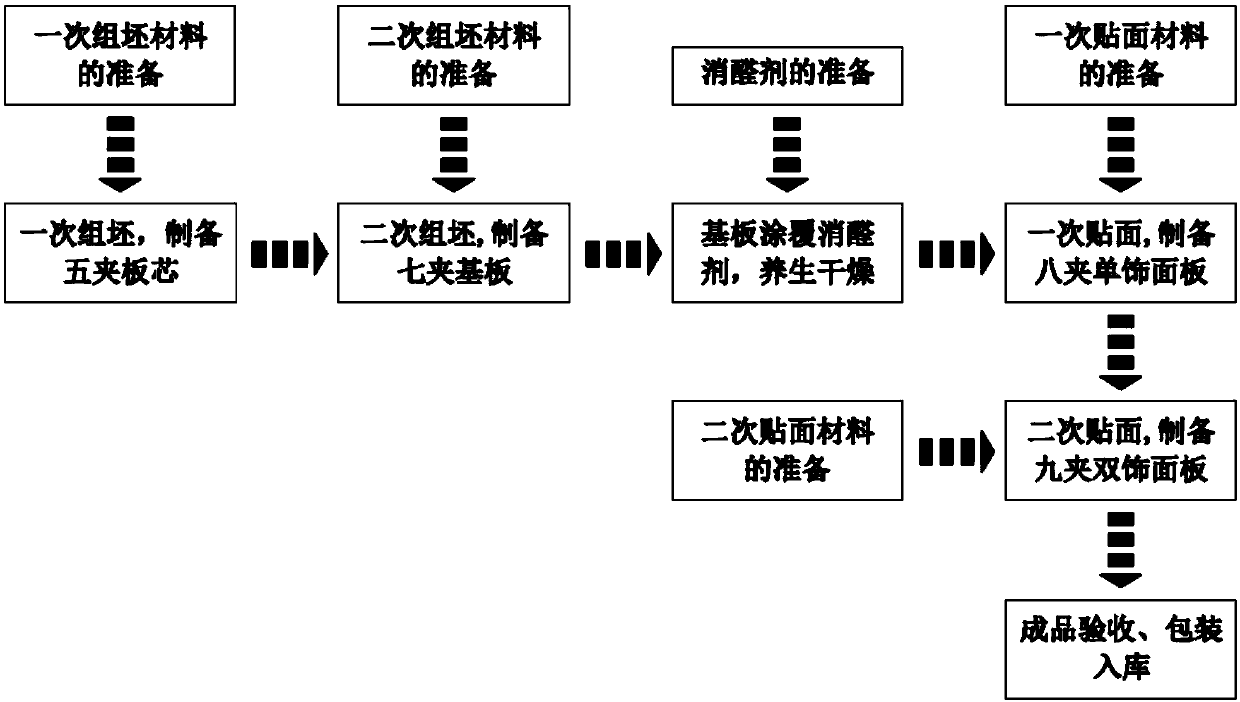

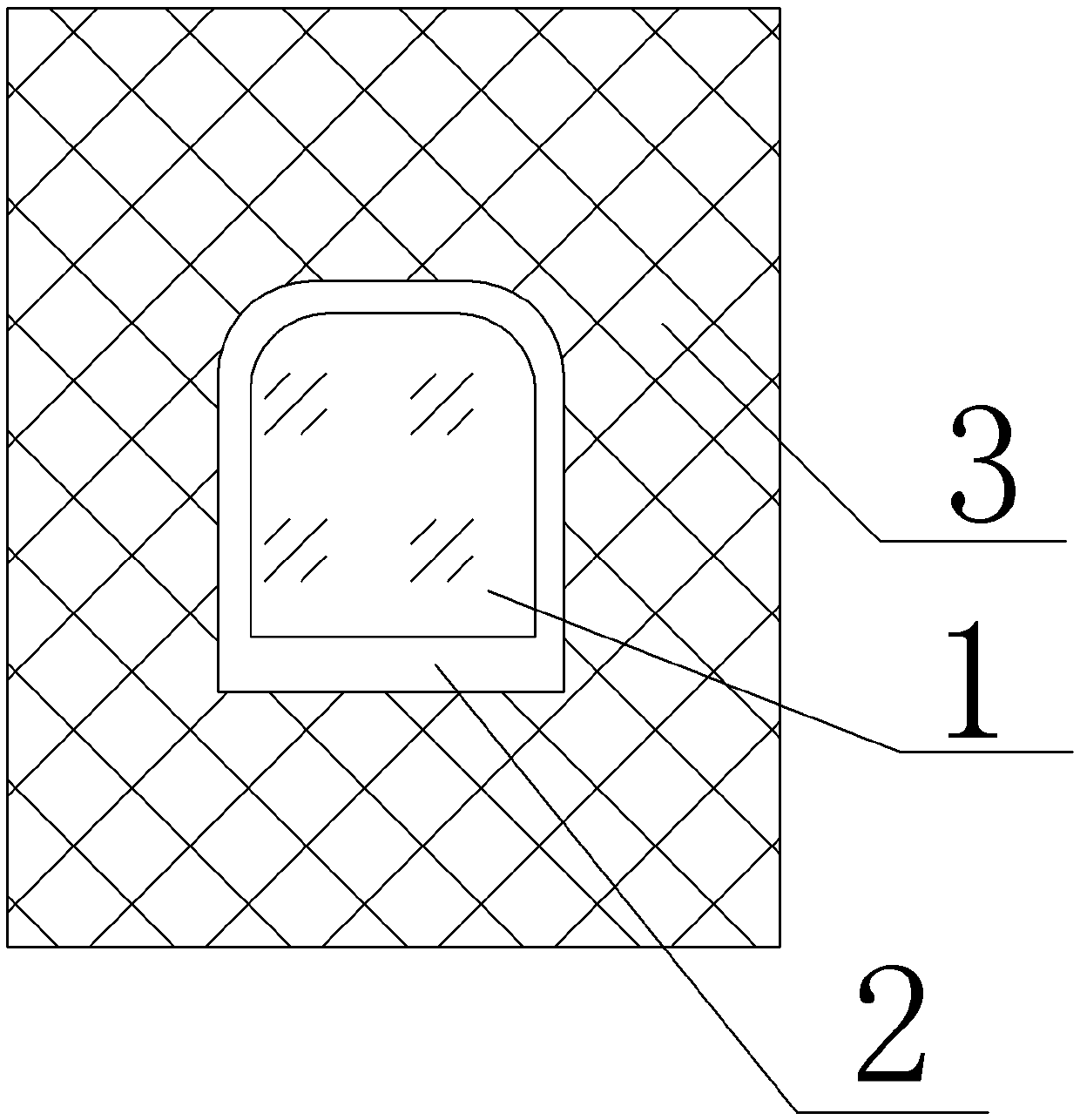

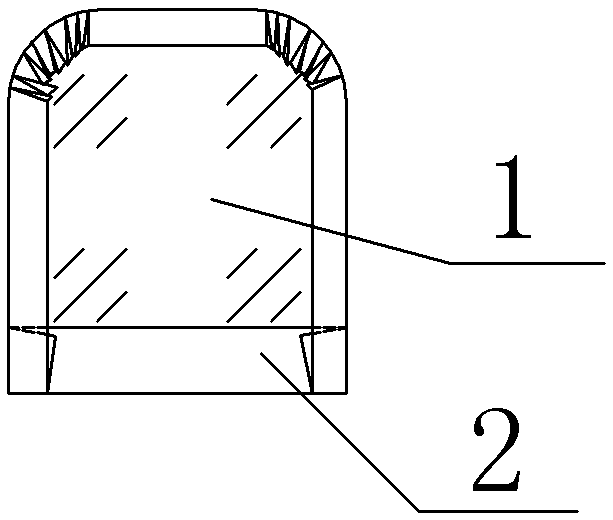

InactiveCN107599077AImprove flatnessReduce the number of layersLaminationLamination apparatusCentral layerEngineering

The invention discloses a formaldehyde-free paint-free water-based fiberboard. The fiberboard is characterized by being of a multi-layer plywood structure, and is provided with a central layer 1, longmiddle plate layers 2, short middle plate layers 3, balance buffer layers 4 and decorative paper layers 5, wherein the long middle plate layers 2, the short middle plate layers 3, the balance bufferlayers 4 and the decorative paper layers 5 are sequentially laminated from the central layer 1 to outer layers; the center layer 1 is a radiata pine integrally-spliced long middle plate with the thickness of 7 mm; and the thickness of the formaldehyde-free paint-free water-based fiberboard of the multi-layer plywood structure is 17.0mm + / - 0.1 mm, and formaldehyde content is 0. According to the formaldehyde-free paint-free water-based fiberboard and the preparation process thereof, special material selection and a special processing technology are adopted, so that a novel formaldehyde-free paint-free water-based fiberboard of the multi-layer plywood structure is provided, and therefore the purpose of reducing cost is achieved on the premise that product quality is guaranteed not to be reduced.

Owner:兰州科天水性科技有限公司

Efficient blister film slitting device and slitting method thereof

The invention relates to an efficient blister film slitting device and a slitting method thereof. The slitting device comprise a fixing plate, a tube core supporting mechanism and a slitting mechanism, wherein the tube core supporting mechanism is arranged at the front end of the fixing plate; the slitting mechanism is arranged outside the tube core supporting mechanism; the slitting mechanism isarranged at the rear end of the fixing plate; the tube core supporting mechanism comprises a fixing cylinder, a telescopic plate, a supporting plate, an anti-sliding plate and a limiting branched chain; the slitting mechanism comprises a rotary motor, a rotary plate, an adjusting cylinder, an adjusting frame, a slitting tool rest and a protective branched chain; the limiting branched chain comprises an installation plate, a regulating cylinder, a limiting block and a limiting frame; and the protective branched chain comprises a sliding plate, a connecting block, a working plate, a buffer spring, a protective plate and a rolling column. According to the slitting device and the slitting method thereof, the problems of poor flatness of the cut, easy extrusion deformation of the tube core, potential safety hazard in manual blanking and the like in existing slitting process of a blister film roll are solved.

Owner:安徽润宇医用包装材料有限公司

Polyethylene film on-line perforating machine

ActiveCN104016180ARemove thickeningSolve the flatnessArticle deliveryWebs handlingPunchingOperability

The invention provides a polyethylene film on-line perforating machine. The perforating machine comprises a feeding device, a punching device and a coiling mechanism and is controlled through a PLC, a coiled film roll is arranged on an inflatable shaft, a polyethylene film is driven to move forwards by an upper and lower glue press roll mechanism through a roll to penetrate through the punching mechanism comprising a plurality of upper milling heads and a plurality of lower milling heads corresponding to the upper milling heads in position, the polyethylene film penetrates through the space between the upper milling heads and the lower milling heads to be punched, the punched polyethylene film moves forwards to be conveyed to the coiling mechanism comprising a bridge crossing roll through which the punched polyethylene film penetrates, and the polyethylene film is cut through a left and right double-cutter mechanism, the left part of the polyethylene film is coiled by a left coiling block, and the right part of the polyethylene film is coiled by a right coiling block. The perforating machine is simple in structure, reasonable in design, high in operability and capable of effectively overcoming the defects of an existing laser punching machine, improves work efficiency and increases economical benefits of enterprises.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

Folding and ironing method of garment pocket

Owner:郑州湧秀服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com