Solar panel and encapsulation process

A technology for solar panels and packaging technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of uneven packaging, high rejection rate, air bubbles, etc., and achieve the effect of closed flat, low rejection rate, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

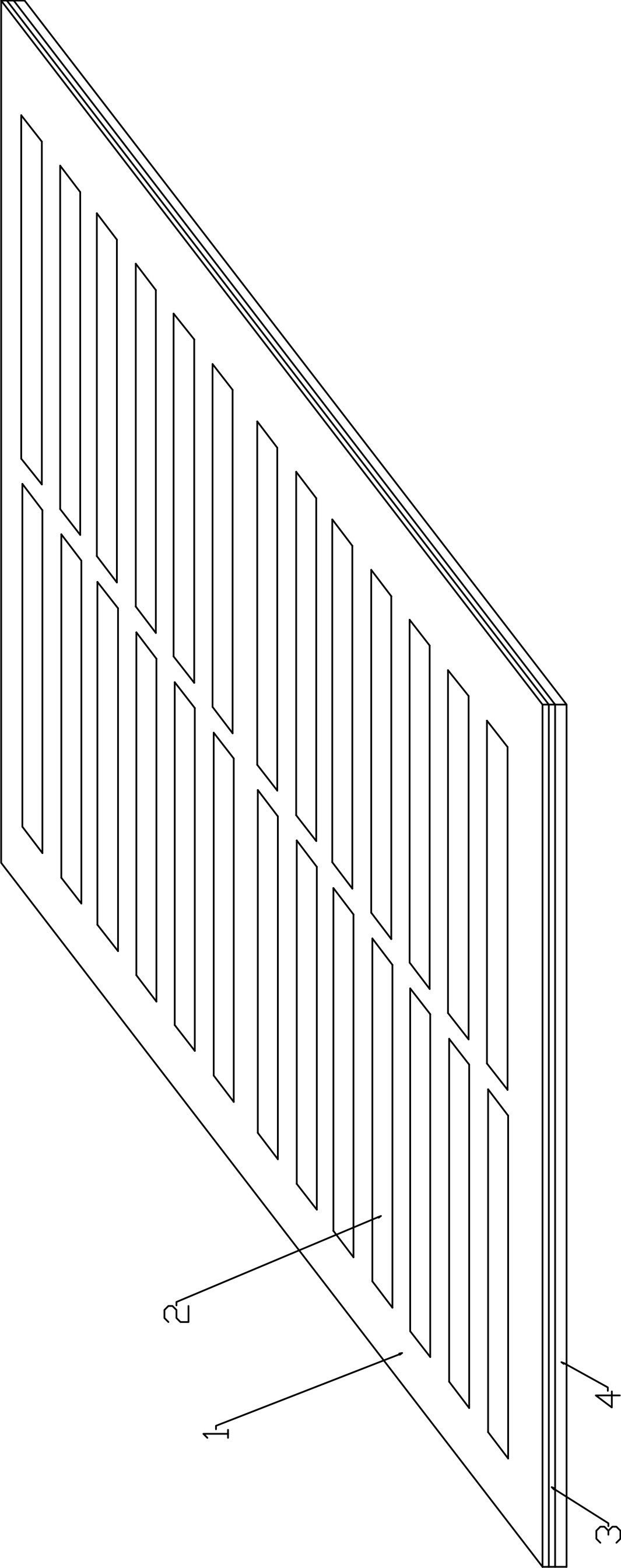

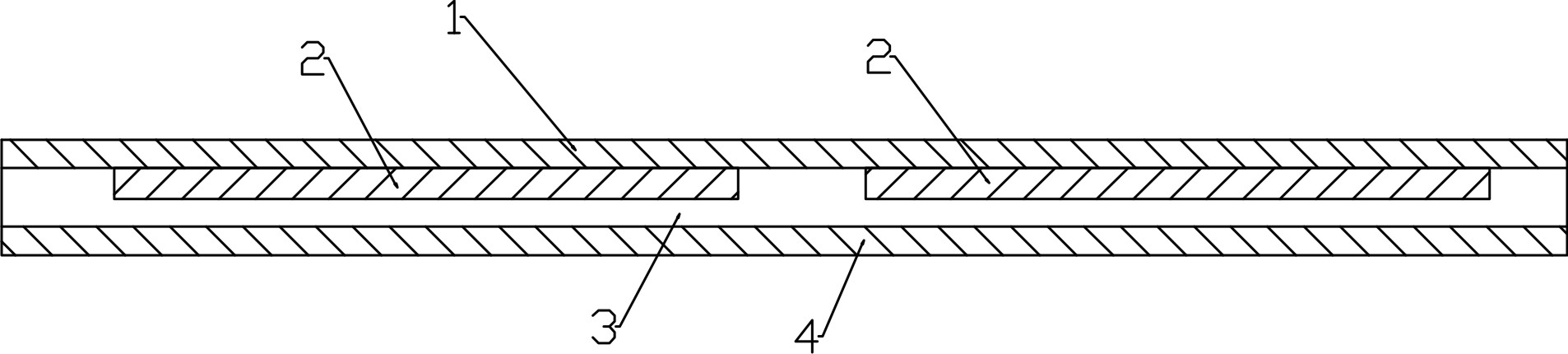

[0032] Such as figure 1 , figure 2 As shown, the present invention is a solar cell panel, including a silicon wafer 2, the silicon wafer is embedded in a layer of EVA glue layer 3, and the EVA glue layer is respectively connected with the PCB board 4 and the transparent layer of PET material 1 phase bonding. The front, rear, left, and lower sides of the silicon wafer are arranged in the EVA glue layer, the thickness of the EVA glue layer is 0.3-0.5mm, and the upper side of the silicon wafer is attached to the lower side of the light-transmitting layer of PET material. The PCB board is provided with positive and negative electrode printed lines connected with the positive and negative electrodes of the silicon chip.

[0033] The solar panel is manufactured through the following process, including the following steps:

[0034] The first step is to arrange the light-transmitting layers of PCB board, sheet EVA hot melt adhesive, silicon wafer, sheet EVA hot melt adhesive, and PET mat...

Embodiment 2

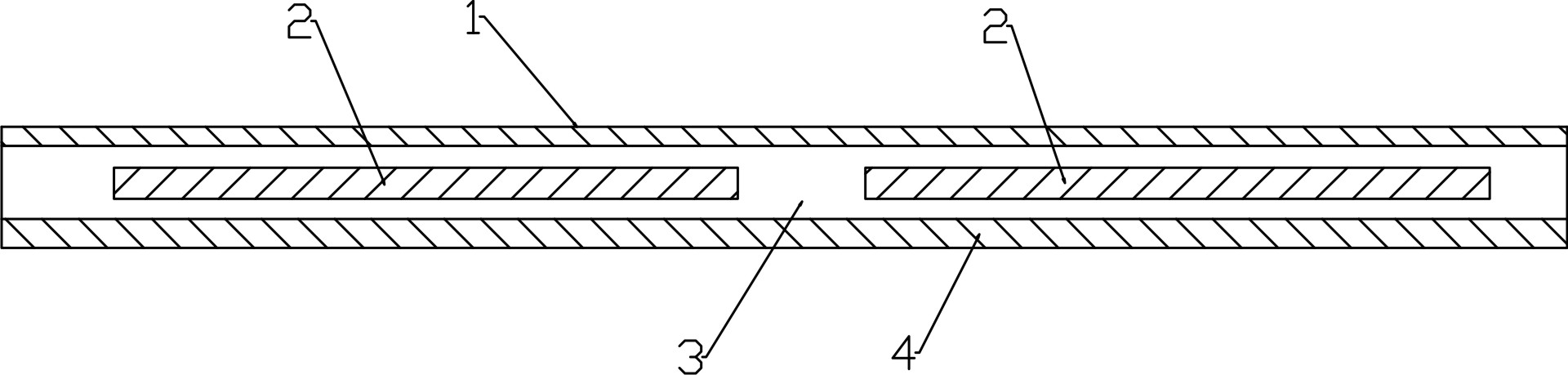

[0042] Such as image 3 As shown, the present invention is a solar cell panel, including a silicon wafer 2, the silicon wafer is embedded in a layer of EVA glue layer 3, and the EVA glue layer is respectively connected with the PCB board 4 and the transparent layer of PET material 1 phase bonding. The front, rear, left, and lower sides of the silicon wafer are arranged in the EVA glue layer, the thickness of the EVA glue layer is 0.3-0.5mm, and the upper side of the silicon wafer is attached to the lower side of the light-transmitting layer of PET material. The PCB board is provided with positive and negative electrode printed lines connected with the positive and negative electrodes of the silicon chip.

[0043] The solar panel is manufactured through the following process, including the following steps:

[0044] The first step is to arrange the light-transmitting layers of PCB board, sheet EVA hot melt adhesive, silicon wafer, sheet EVA hot melt adhesive, and PET material from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com