Folding and ironing method of garment pocket

A pocket and clothing technology, applied in clothing, clothing, washing devices and other directions, can solve the problems of poor button ironing effect, burnt hands of workers, low efficiency, etc., to avoid poor ironing effect, fast ironing, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

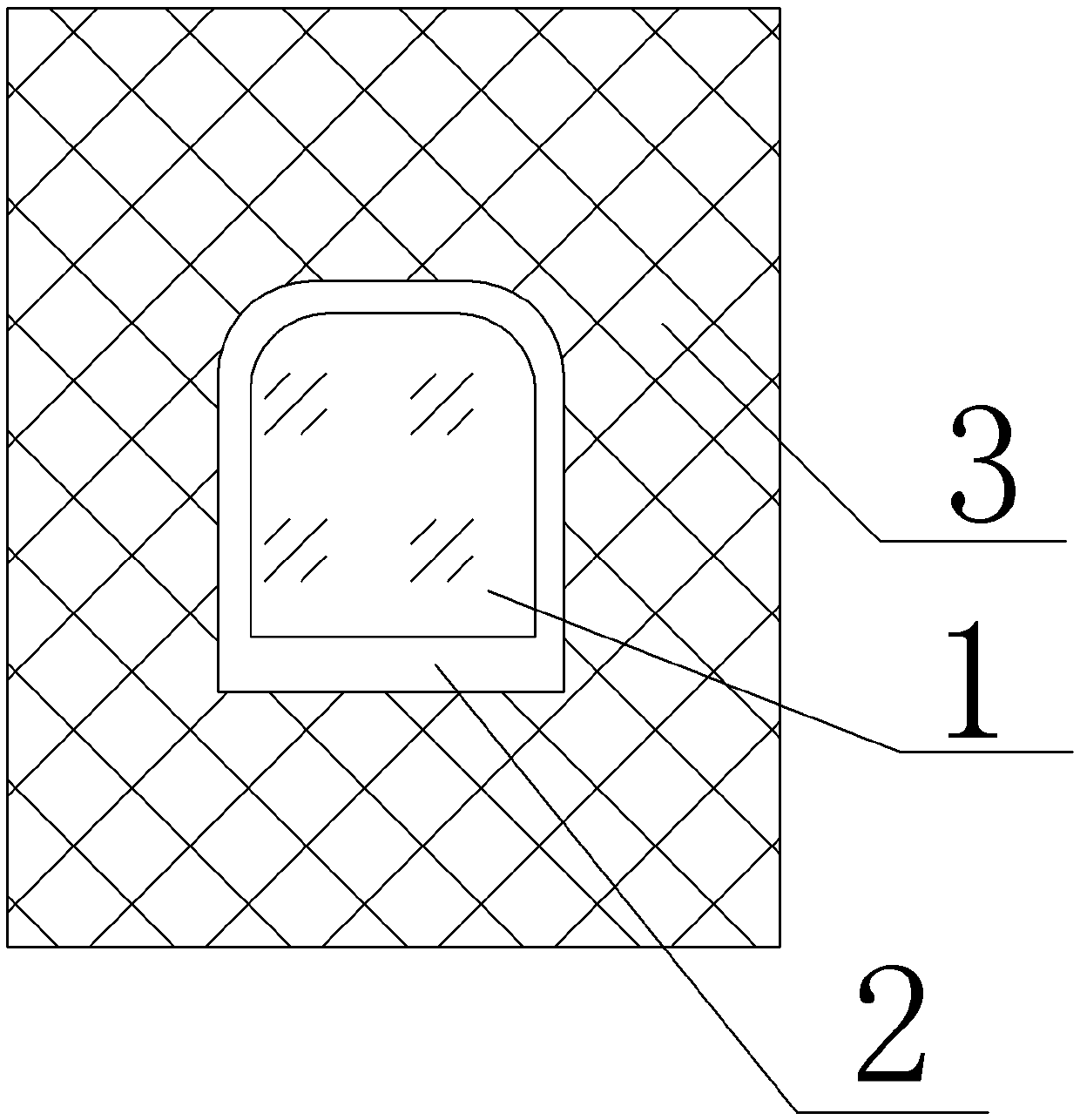

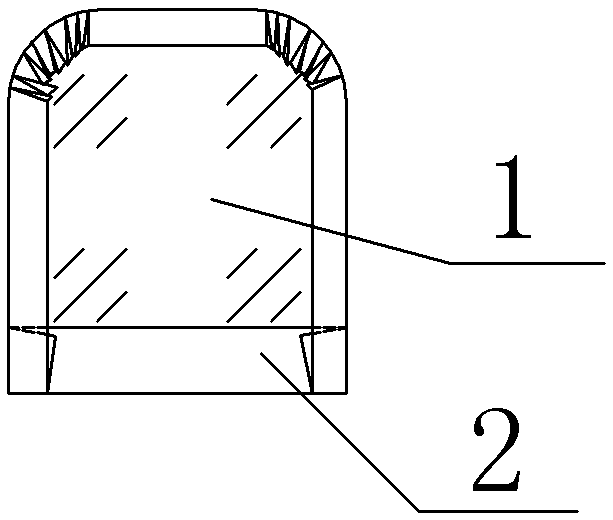

[0024] Example 1: Taking the pocket shape with rounded edges as an example, see figure 1 , figure 2 , image 3 , a buckle ironing method for garment pockets, comprising the following steps:

[0025] (1) Make the gusset: Cut the hard cardboard with a thickness of 3mm into a gusset 1 with the same shape as the required pocket and a distance of 3mm between the edge and the actual edge of the pocket;

[0026] (2) Stacking: such as figure 1 As shown, first lay a layer of rectangular bottom interlining 3 that is four times the size of the gusset plate on the workbench, then lay the pocket cloth piece 2 to be ironed on the center of the bottom interlining 3, and then place the The gusset 1 is laid on the pocket cloth sheet 2, and the center is aligned; the bottom interlining cloth 3 is elastic gauze cloth;

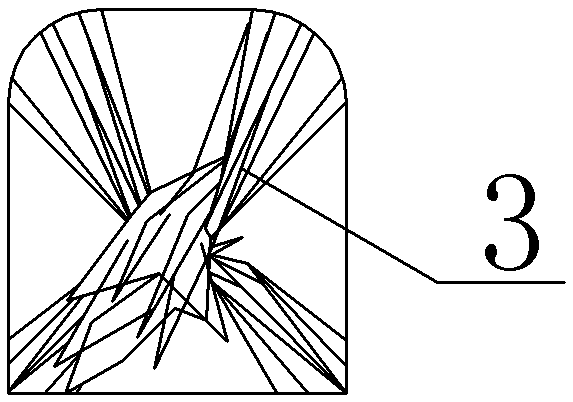

[0027] (3) Hemming: first fold and fix one side of the pocket cloth 2 along the gusset 1, then gather up the edge of the bottom interlining 3 and tighten it so that the othe...

Embodiment 2

[0029] Embodiment 2: A buckle ironing method for clothing pockets. The difference from Example 1 is that in step (1), the gusset 1 is cut from a plastic plate with a thickness of 2mm, and the edge of the gusset 1 is in contact with the pocket. The actual edge is 2mm apart;

Embodiment 3

[0030] Embodiment 3: A buckle ironing method for garment pockets. The difference from Example 1 is that in step (1), the gusset 1 is cut from a steel plate with a thickness of 1mm, and the edge of the gusset 1 is in line with the actual pocket. Edges are 1mm apart;

[0031] The tools and equipment involved in the above embodiments are conventional tools and equipment unless otherwise specified.

[0032] Concrete mode of operation of the present invention is as follows:

[0033] When making the gusset 1, cut the hard material into the same shape as the required pocket. Since the gusset 1 itself has a certain thickness, the size of the gusset should be slightly smaller than the actual size of the pocket, that is, the size of the gusset 1. The distance between the edge and the edge of the actual pocket size should be equal to the thickness of the gusset, so that after the pocket piece 2 is folded along the edge of the gusset and ironed, the border line of the ironed pocket piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com