Rapid ironing and shaping mechanism acting on knitted garment products

A shaping mechanism and clothing technology, applied in the field of knitted fabric processing, can solve the problems of clothing shape differences, clothing ironing time inconsistencies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

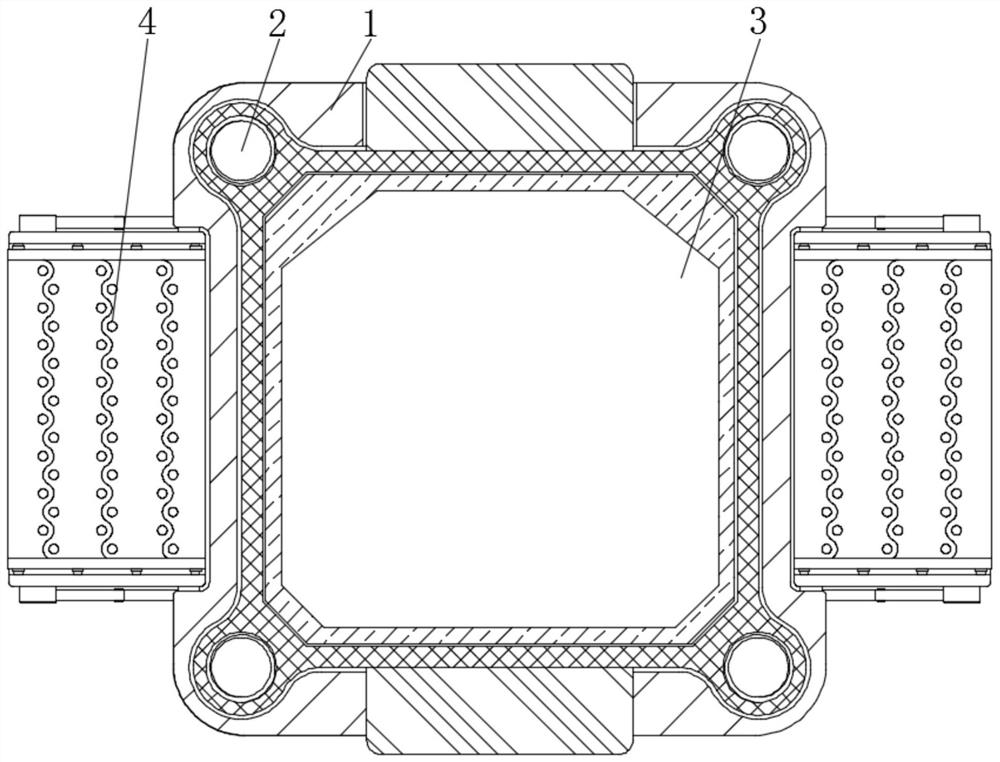

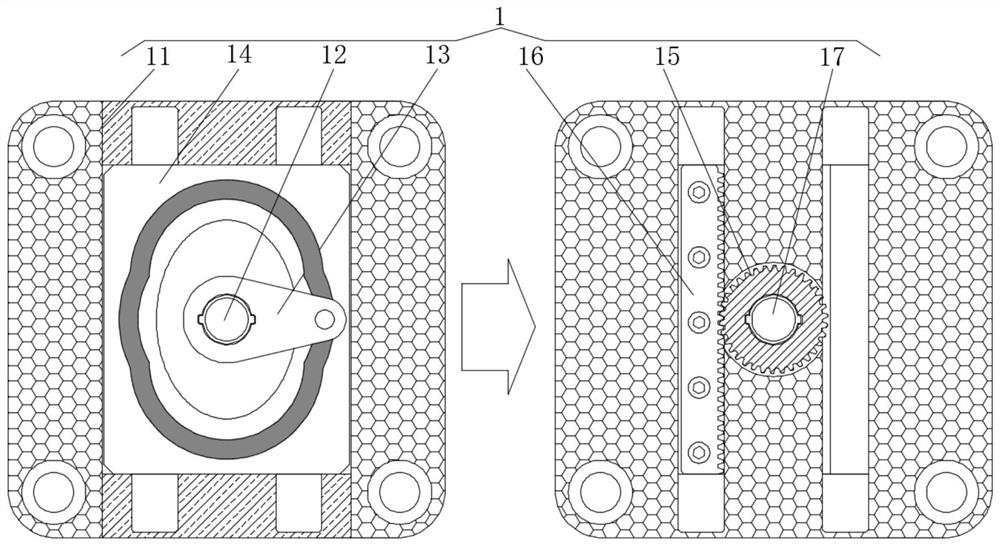

[0025] see Figure 1-3 , a rapid ironing and shaping mechanism acting on knitted garment products, comprising a switching mechanism 1, the switching mechanism 1 comprising a switching frame 11, the bottom of the switching frame 11 is rotatably connected to a driving shaft 12, and the outer side of the driving shaft 12 is fixedly connected to a switching lever 13. The bottom of the switching rack 11 is slidably connected with a switching slide plate 14, and the bottom of the switching slide plate 14 is provided with an arc-shaped chute, which is adapted to the rotating shaft connected to the inside of the switching lever 13, and the two sides of the switching slide plate 14 are provided with The rectangular chute adapted to the switching frame 11, the top of the switching slide plate 14 is fixedly connected with a rectangular slide rail adapted to the switching frame 11, the top of the switching frame 11 is rotatably connected to a connecting shaft 17, and the outside of the con...

Embodiment 2

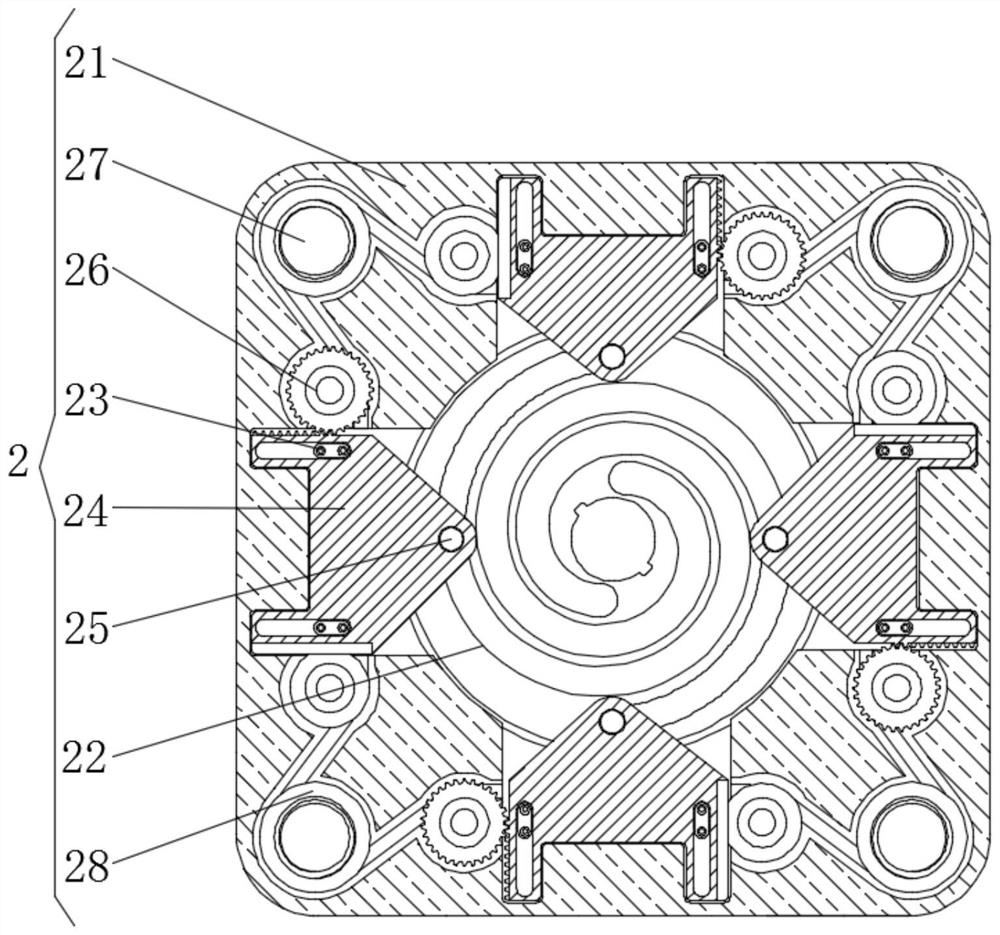

[0028] see figure 1 and Figure 4-5 , a rapid ironing and setting mechanism for knitted garment products, which also includes an ironing mechanism 3, the ironing mechanism 3 includes a lifting plate 31, and the inside of the lifting plate 31 is provided with a rectangular groove adapted to the humidifying frame 33, and the lifting plate 31 is rotatably connected with the lifting shaft 27, the inside of the lifting plate 31 is provided with a threaded hole adapted to the pressure gear 37, the inside of the lifting plate 31 is slidably connected with a support guide post 32, and the top of the support guide post 32 is fixedly connected with a humidifying frame 33. The bottom of the humidifying frame 33 is rotatably connected with a support rod 34, the interior of the lifting plate 31 is fixedly connected with a sliding guide post 36, the outer side of the sliding guide post 36 is slidably connected with a sliding block 35, and the inside of the humidifying frame 33 is rotatably ...

Embodiment 3

[0031] see Figure 1-5, a rapid ironing and shaping mechanism acting on knitted garment products, comprising a switching mechanism 1, the switching mechanism 1 comprising a switching frame 11, the bottom of the switching frame 11 is rotatably connected to a driving shaft 12, and the outer side of the driving shaft 12 is fixedly connected to a switching lever 13. The bottom of the switching rack 11 is slidably connected with a switching slide plate 14, and the bottom of the switching slide plate 14 is provided with an arc-shaped chute, which is adapted to the rotating shaft connected to the inside of the switching lever 13, and the two sides of the switching slide plate 14 are provided with The rectangular chute adapted to the switching frame 11, the top of the switching slide plate 14 is fixedly connected with a rectangular slide rail adapted to the switching frame 11, the top of the switching frame 11 is rotatably connected to a connecting shaft 17, and the outside of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com