Patents

Literature

410results about How to "Guaranteed tidy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent express delivery distribution vehicle and use method thereof

ActiveCN105539248AGuaranteed tidyEasy loadingLoad securingItem transportation vehiclesButt jointHanging basket

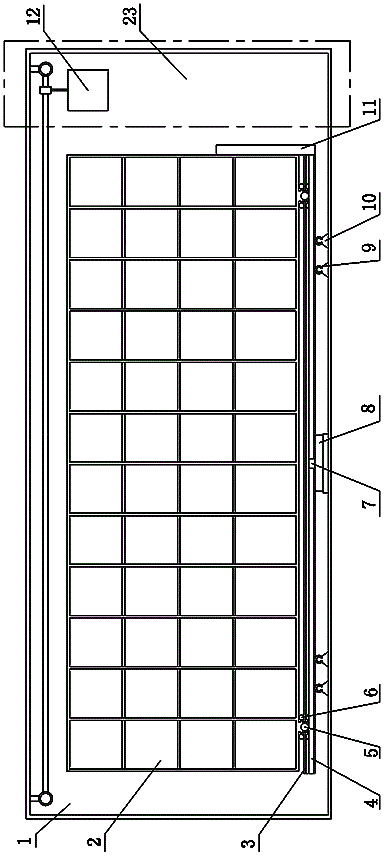

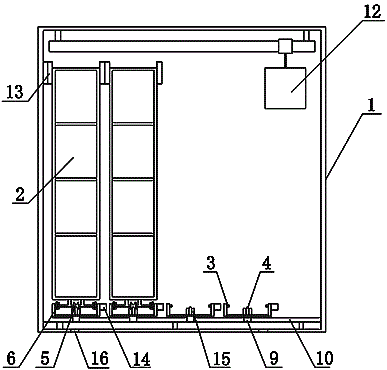

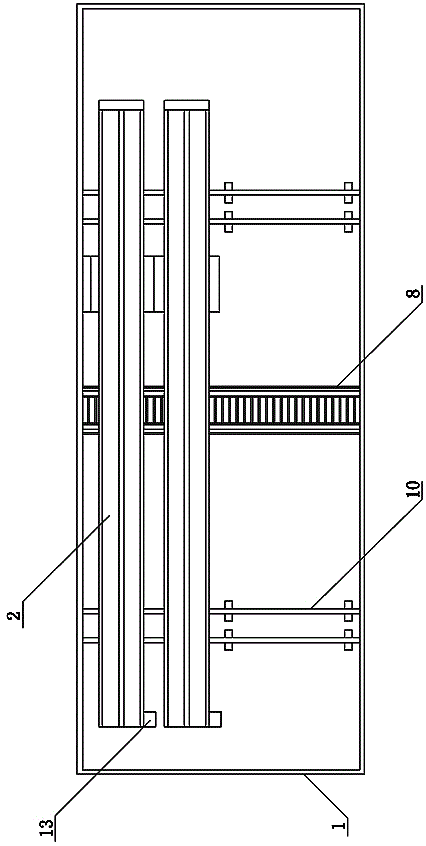

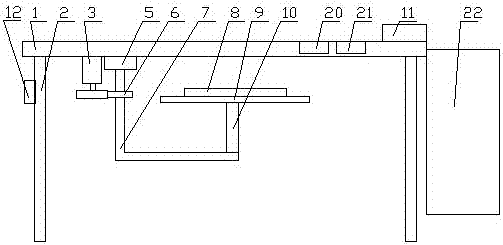

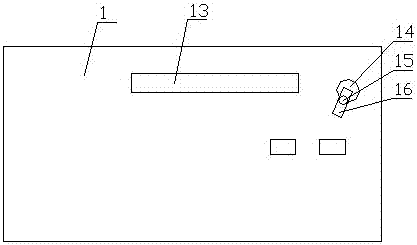

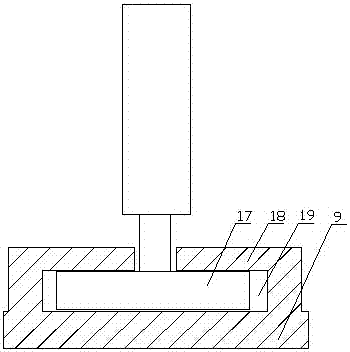

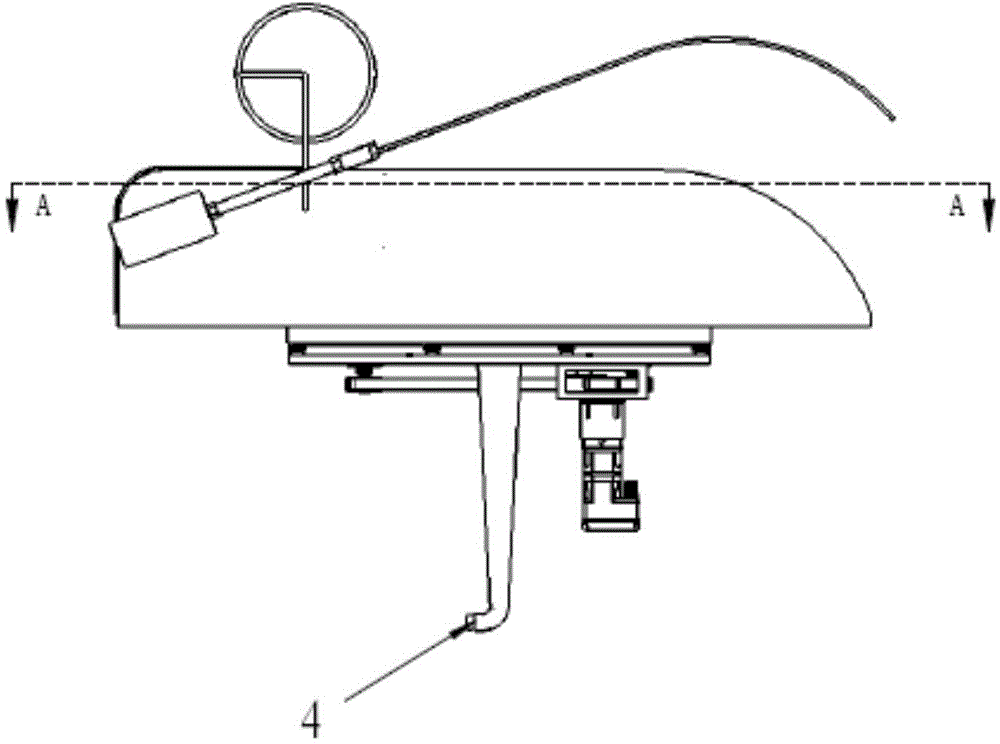

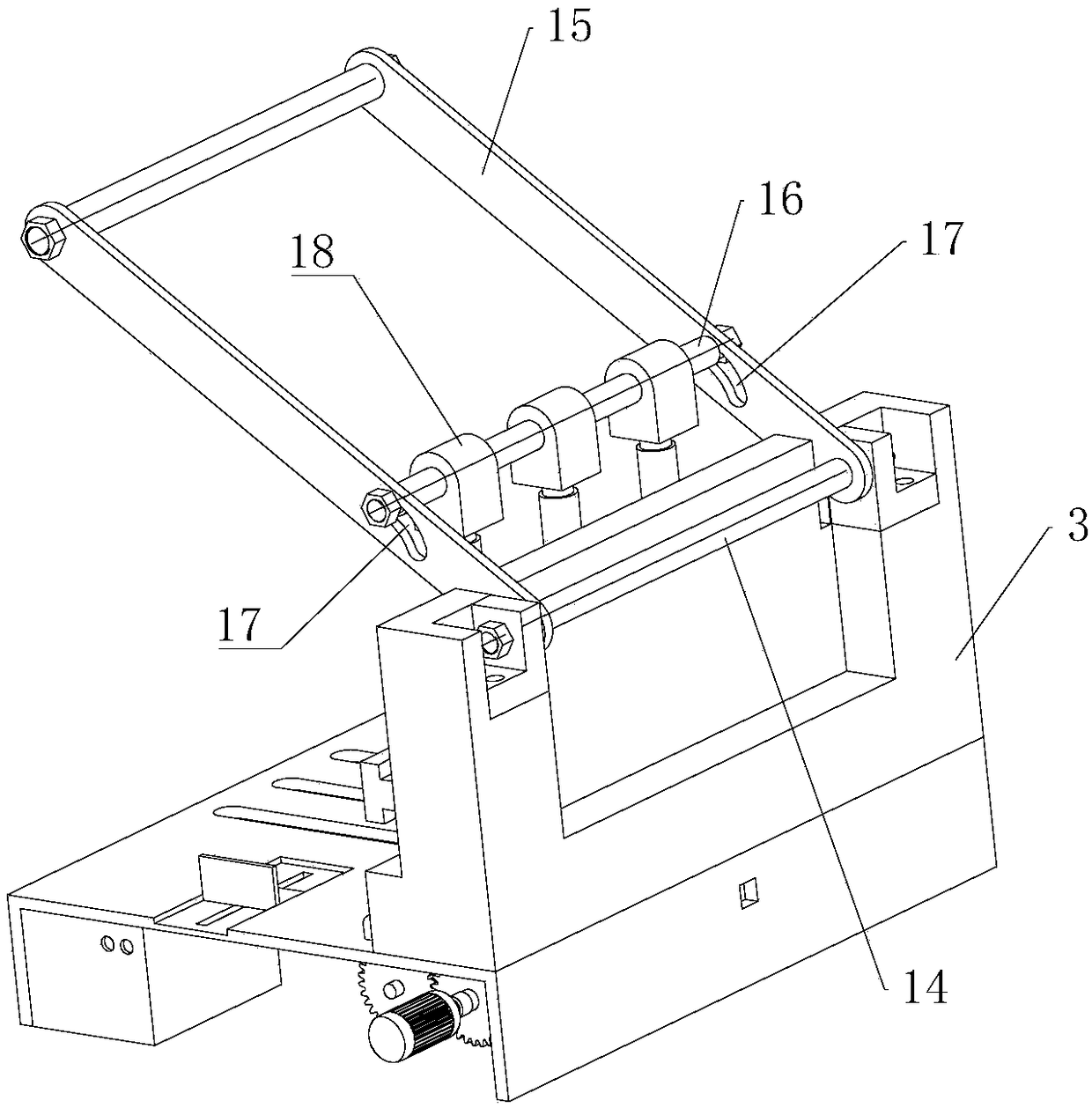

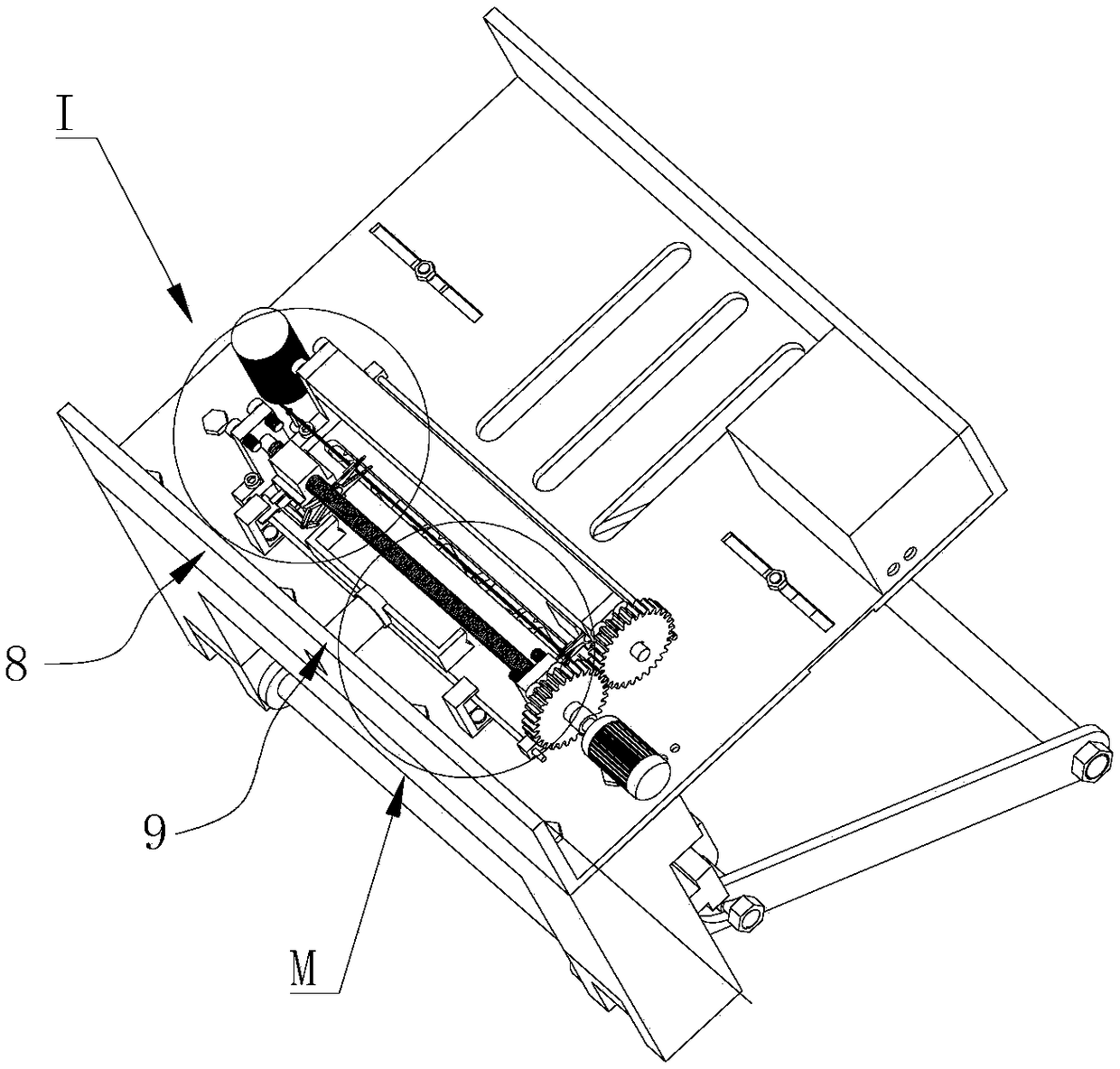

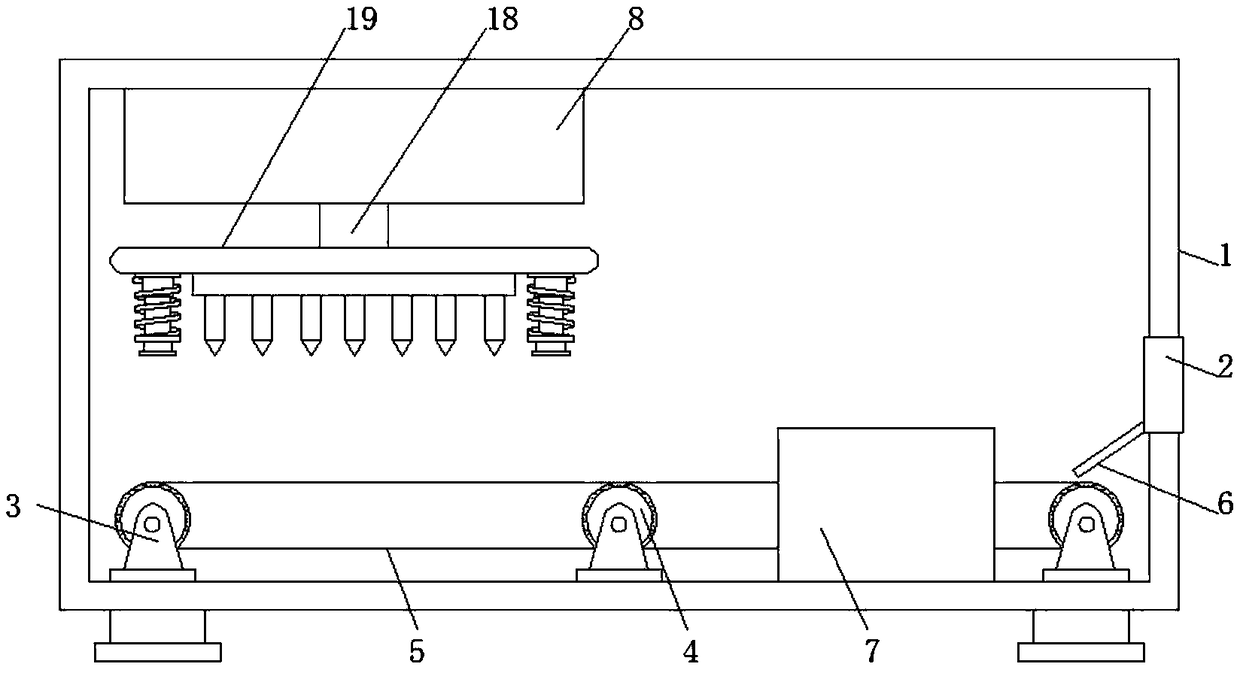

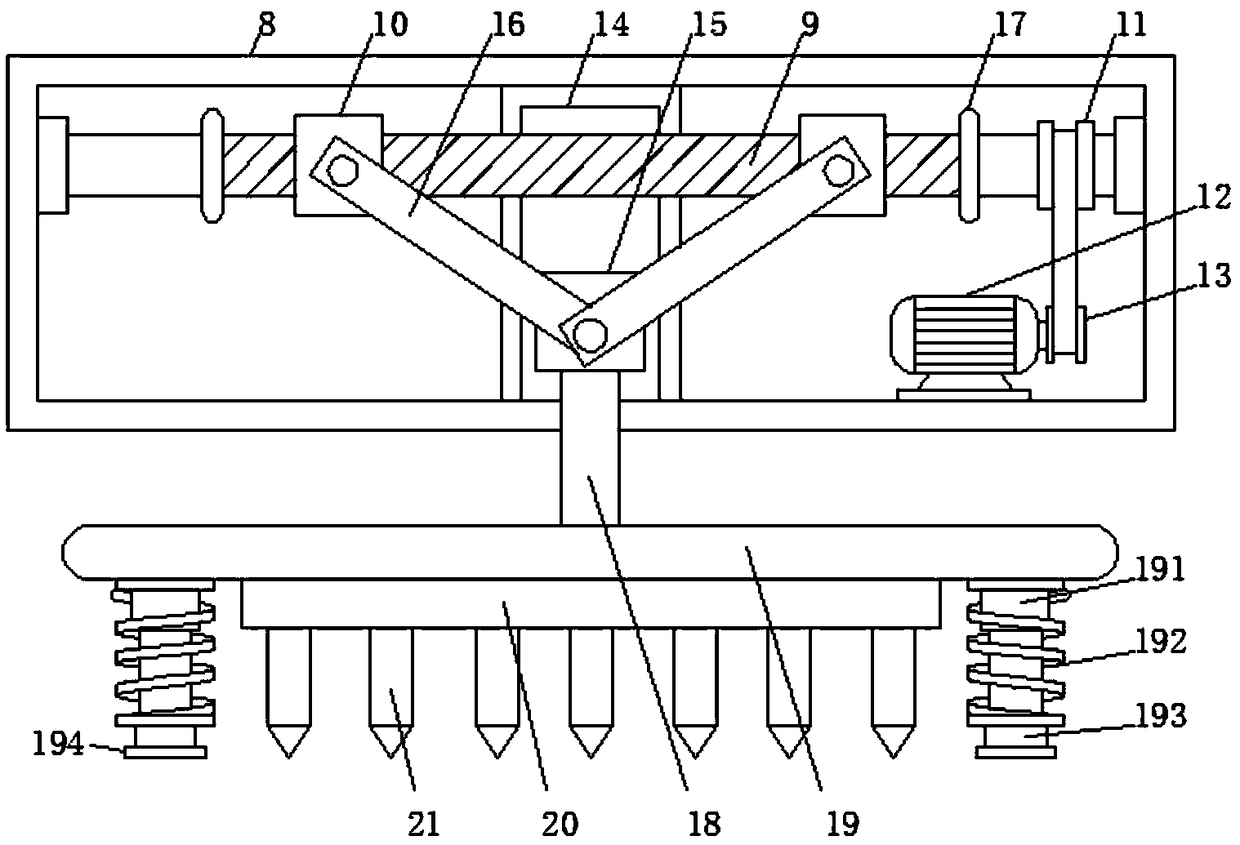

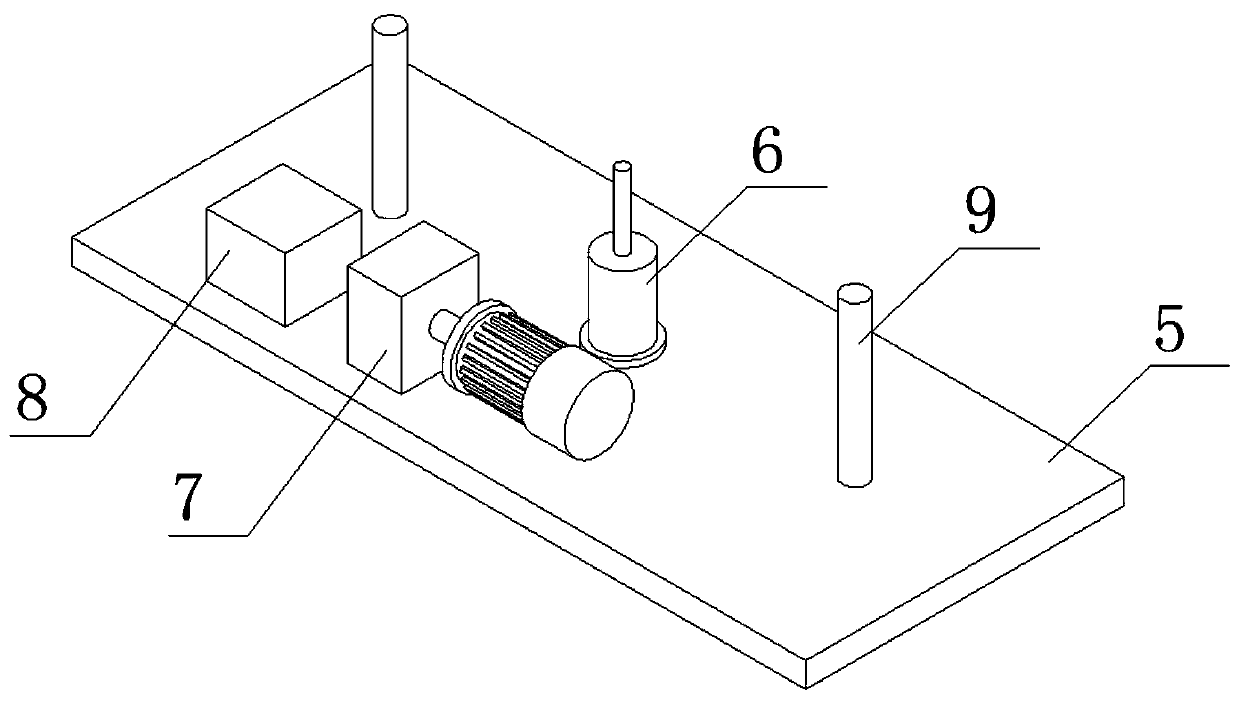

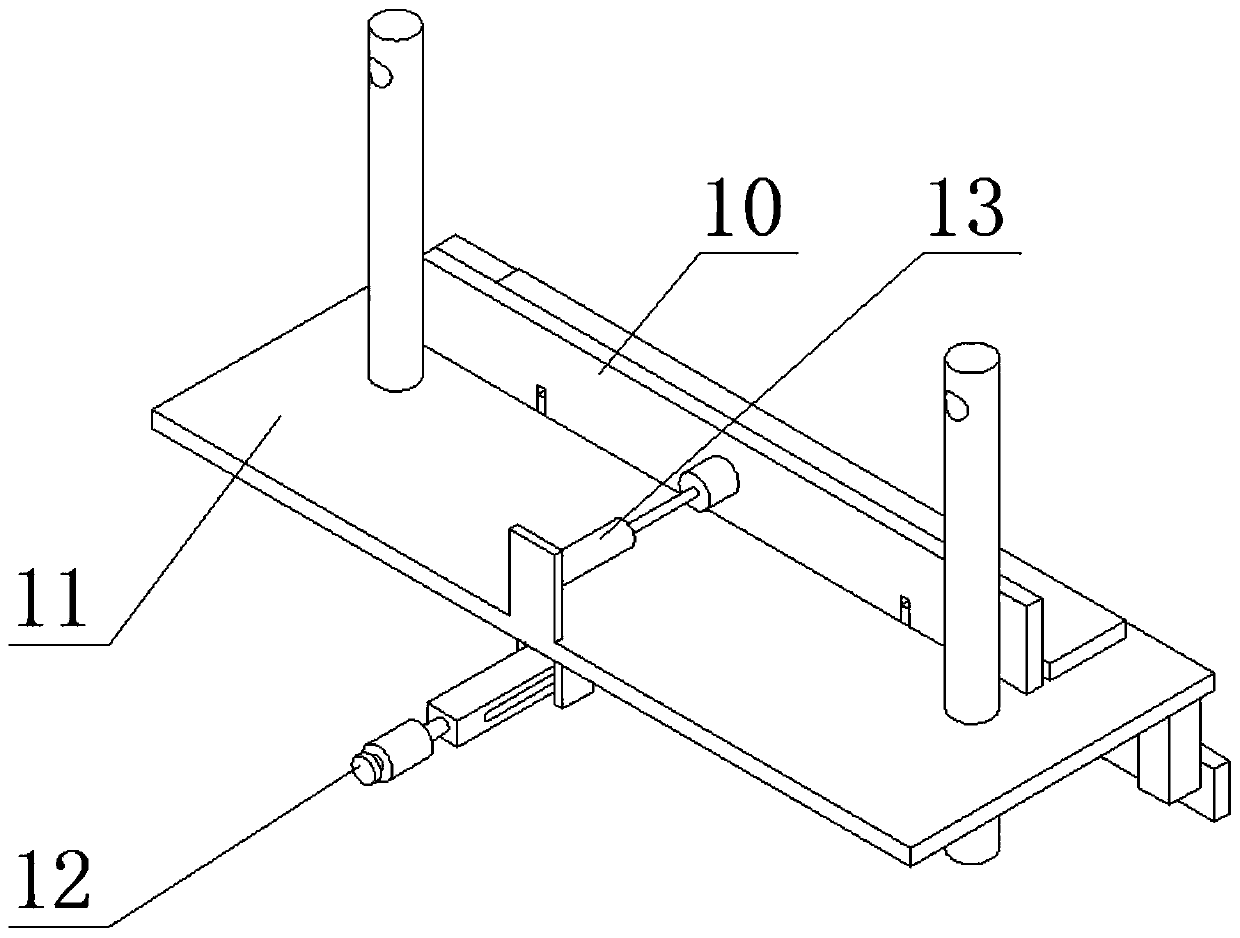

The invention relates to an intelligent express delivery distribution vehicle which comprises a carriage (1), a goods cabinet, a bottom moving mechanism and a hanging basket moving mechanism (12). The carriage (1) is of a hollow cuboid structure. The bottom moving mechanism is arranged on the bottom face of the inner side of the carriage (1). The goods cabinet is installed on the bottom moving mechanism in a matched manner. A hanging basket stop region (23) is arranged in the portion, on one side of the goods cabinet, of the carriage (1). The hanging basket moving mechanism (12) is installed above the hanging basket stop region (23). A ferry vehicle butt-joint module (16) is further arranged at the bottom of the carriage (1). The bottom moving mechanism comprises a load bearing sliding rail (4), a linear motor (8), transverse moving sliding blocks (9), transverse moving guide rails (10) and a bottom frame (11). The goods cabinet comprises drawer frames, multiple storage drawers (2) and magnetic seats (13) and load bearing idler wheels (5) are installed at the bottoms of the drawer frames. The intelligent express delivery distribution vehicle has the beneficial effects that the intelligence degree is high, loading is convenient, the distribution process is simple, and time and labor are saved.

Owner:SOUTHWEST PETROLEUM UNIV

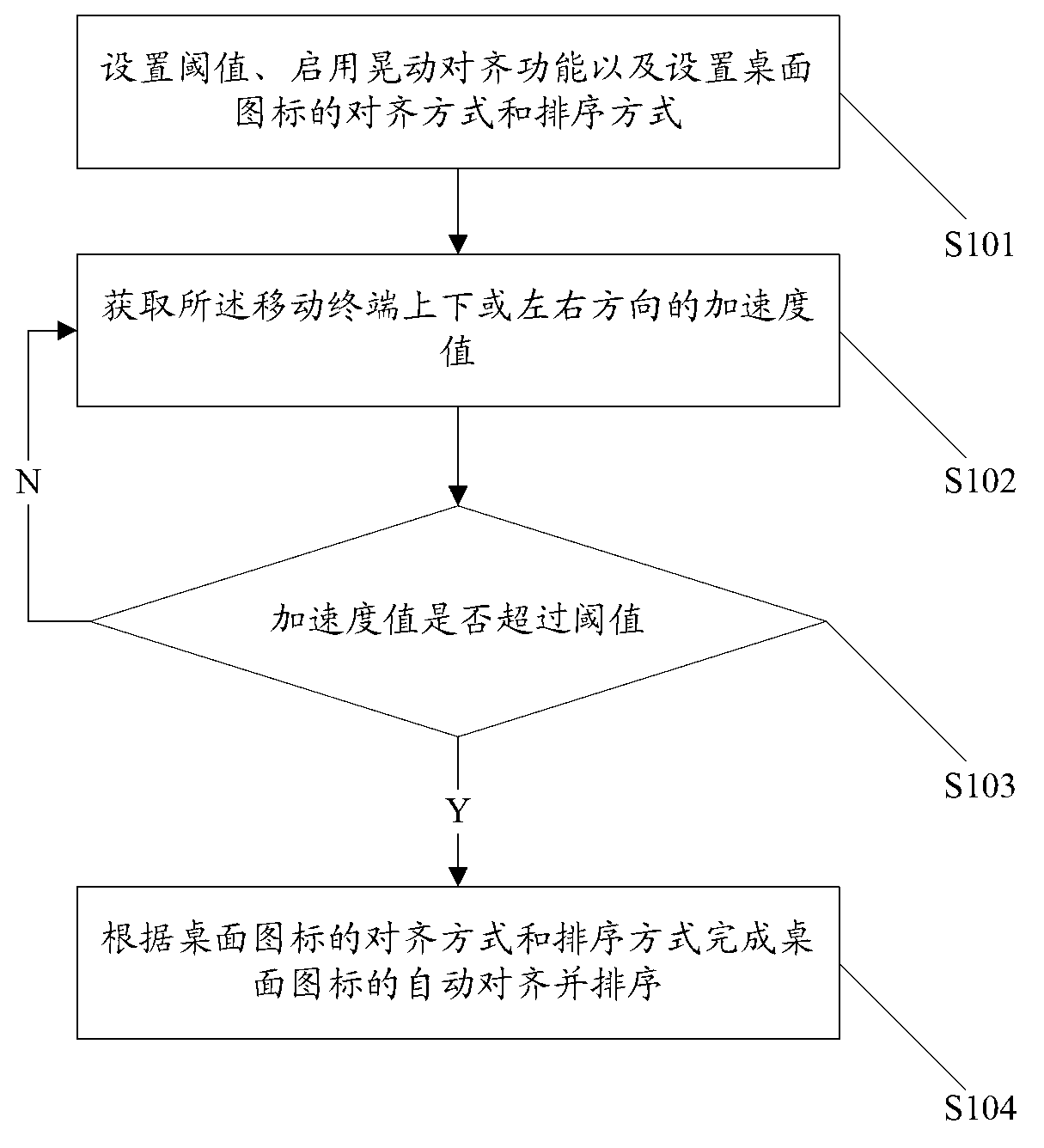

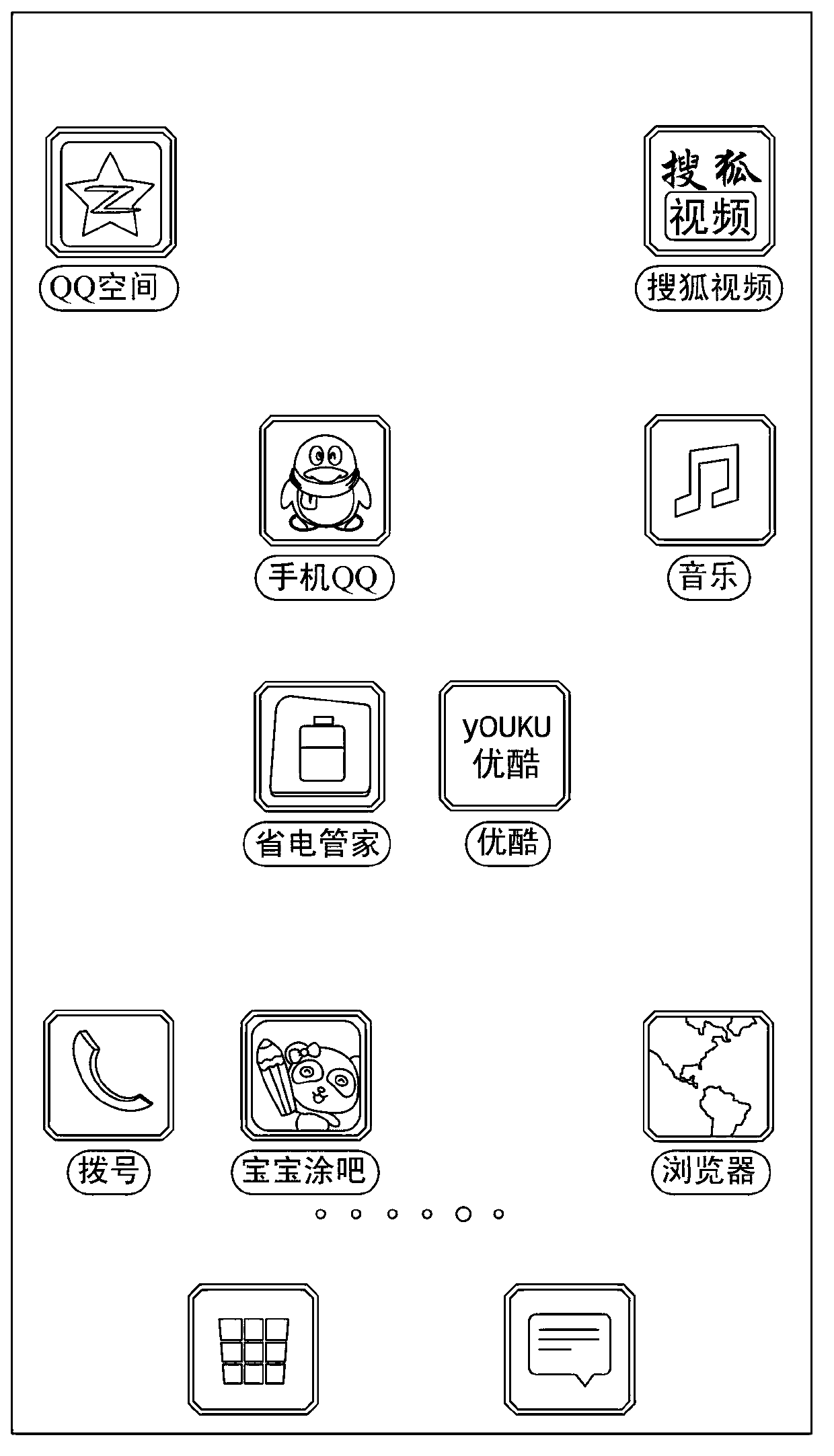

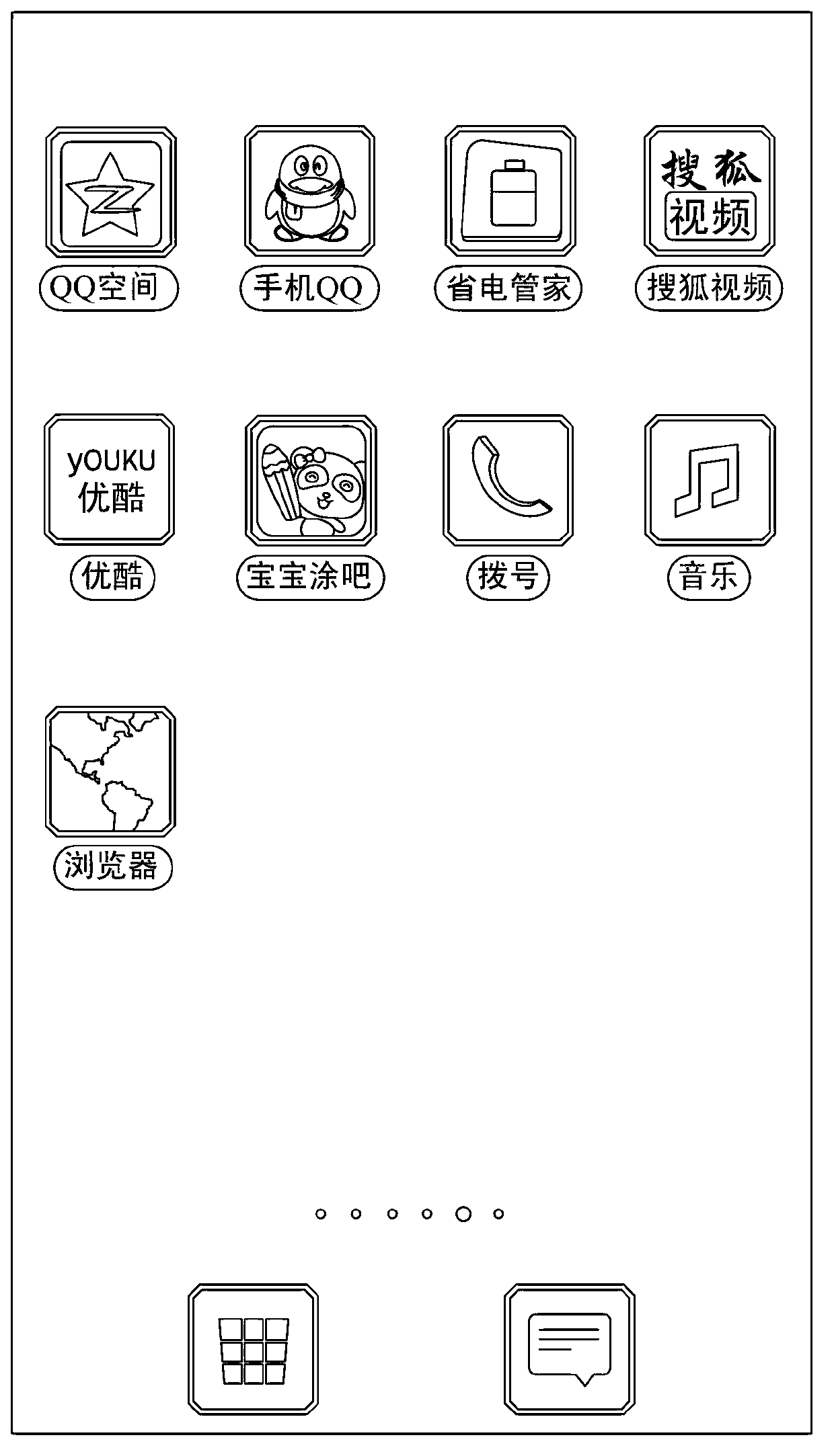

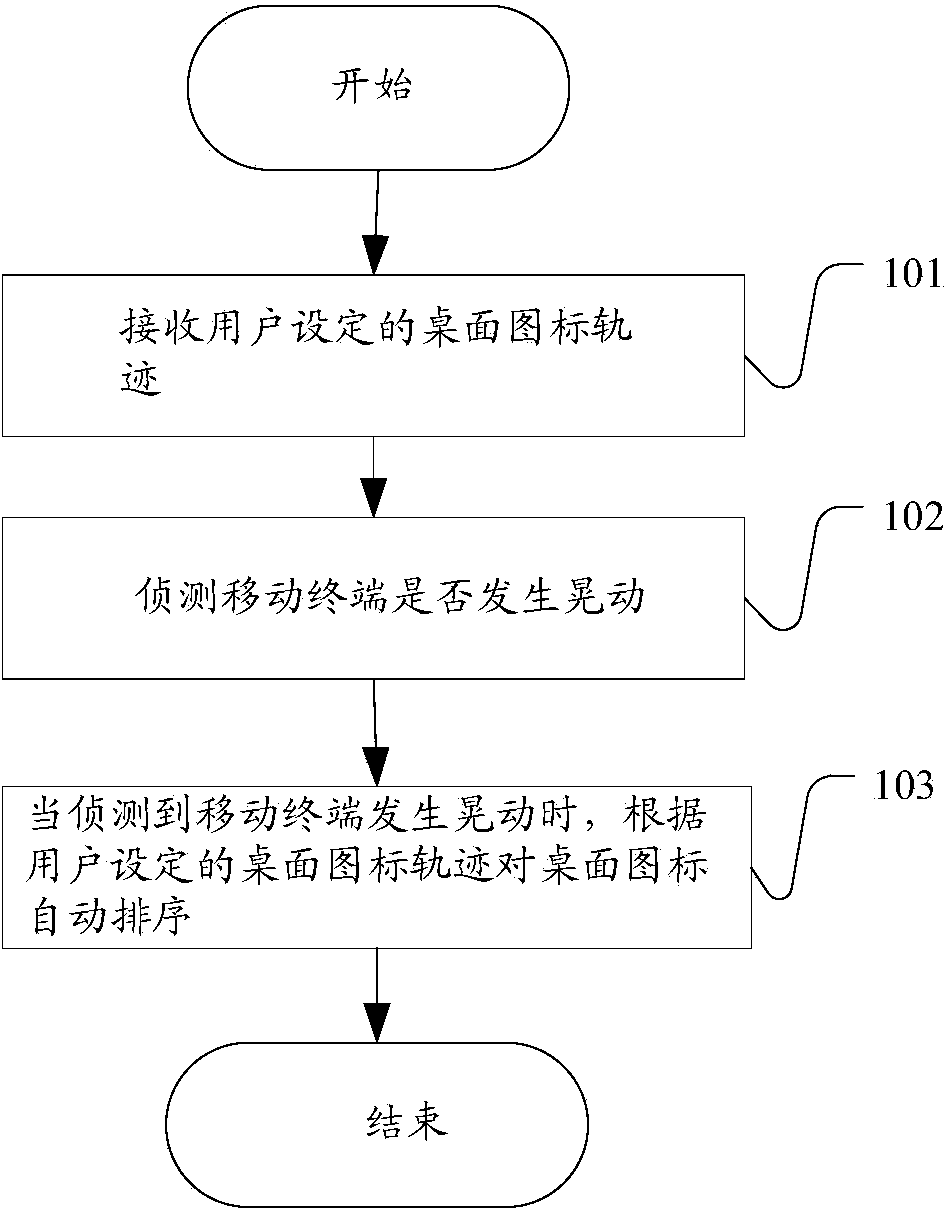

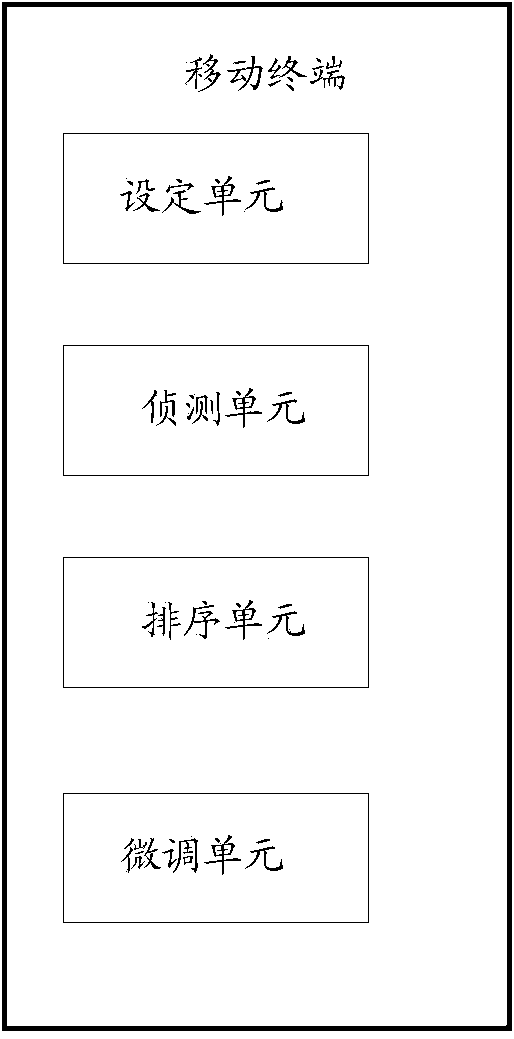

Method and mobile terminal for realizing automatic alignment and sorting of desktop icons by shaking

InactiveCN102968247AKeep tidyImprove user experienceInput/output processes for data processingComputer engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

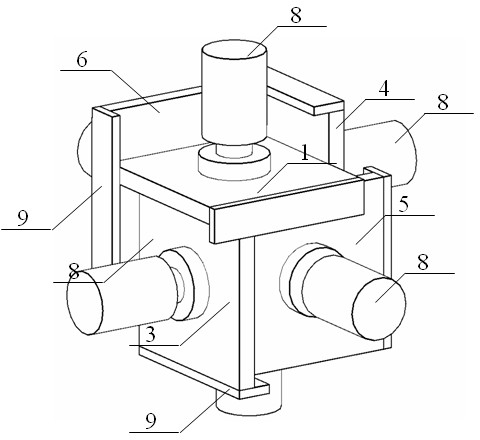

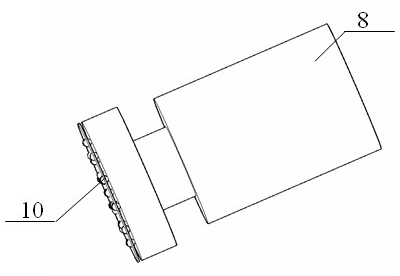

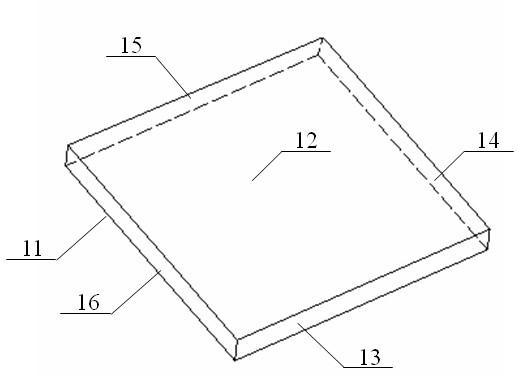

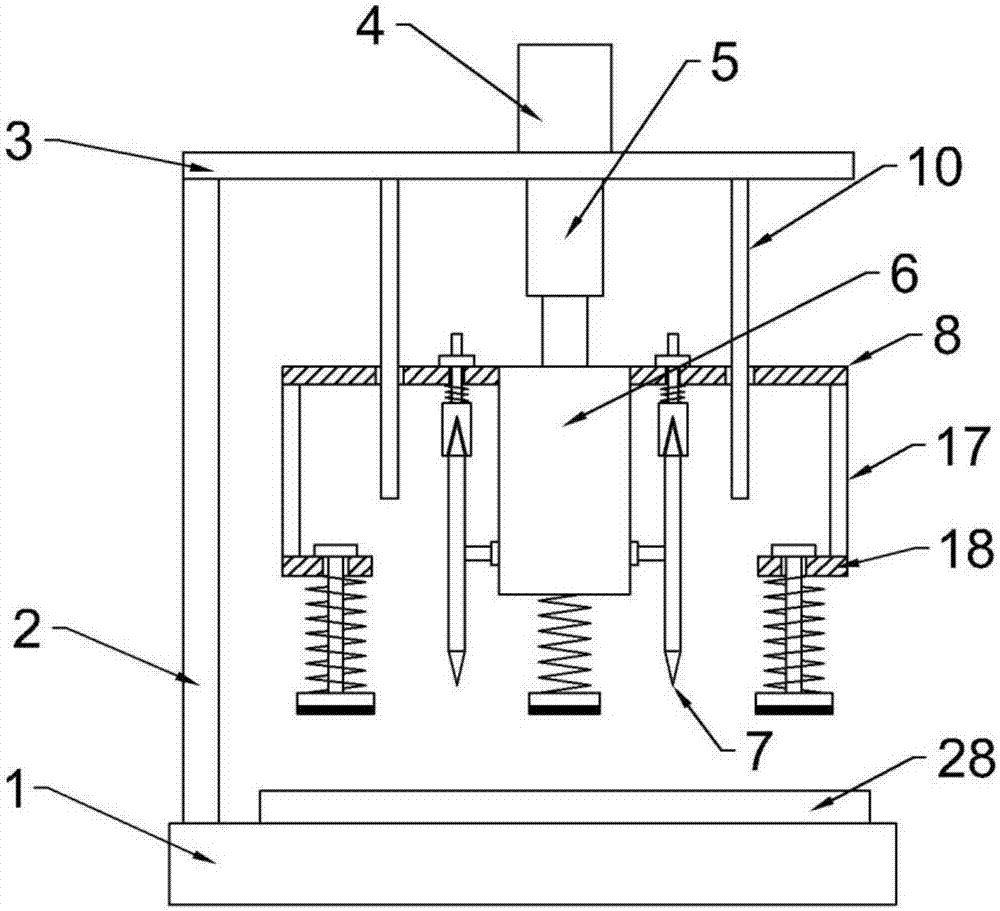

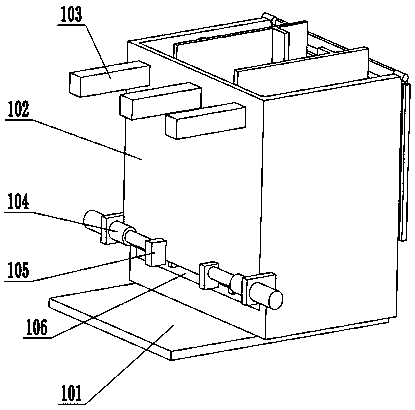

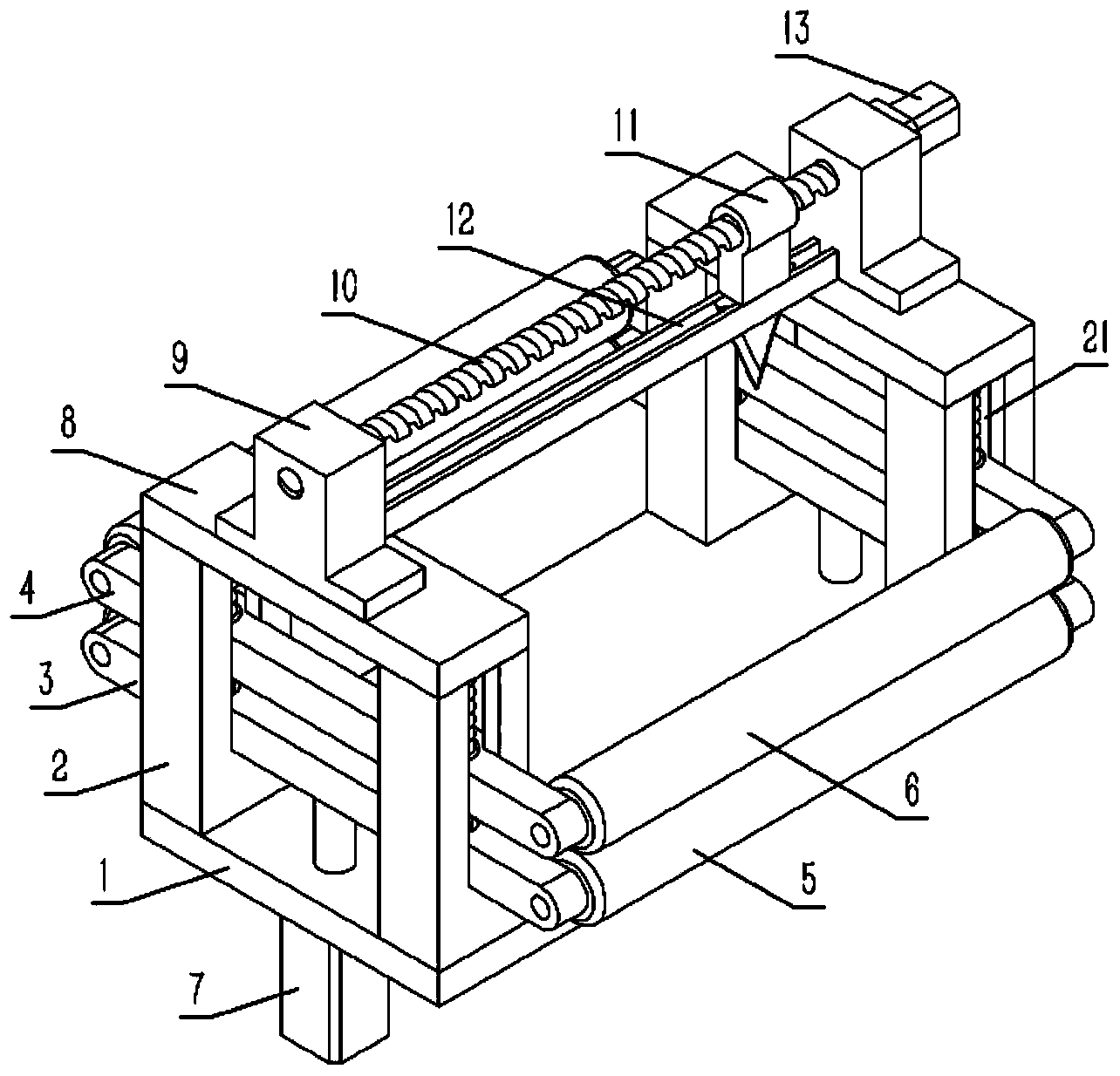

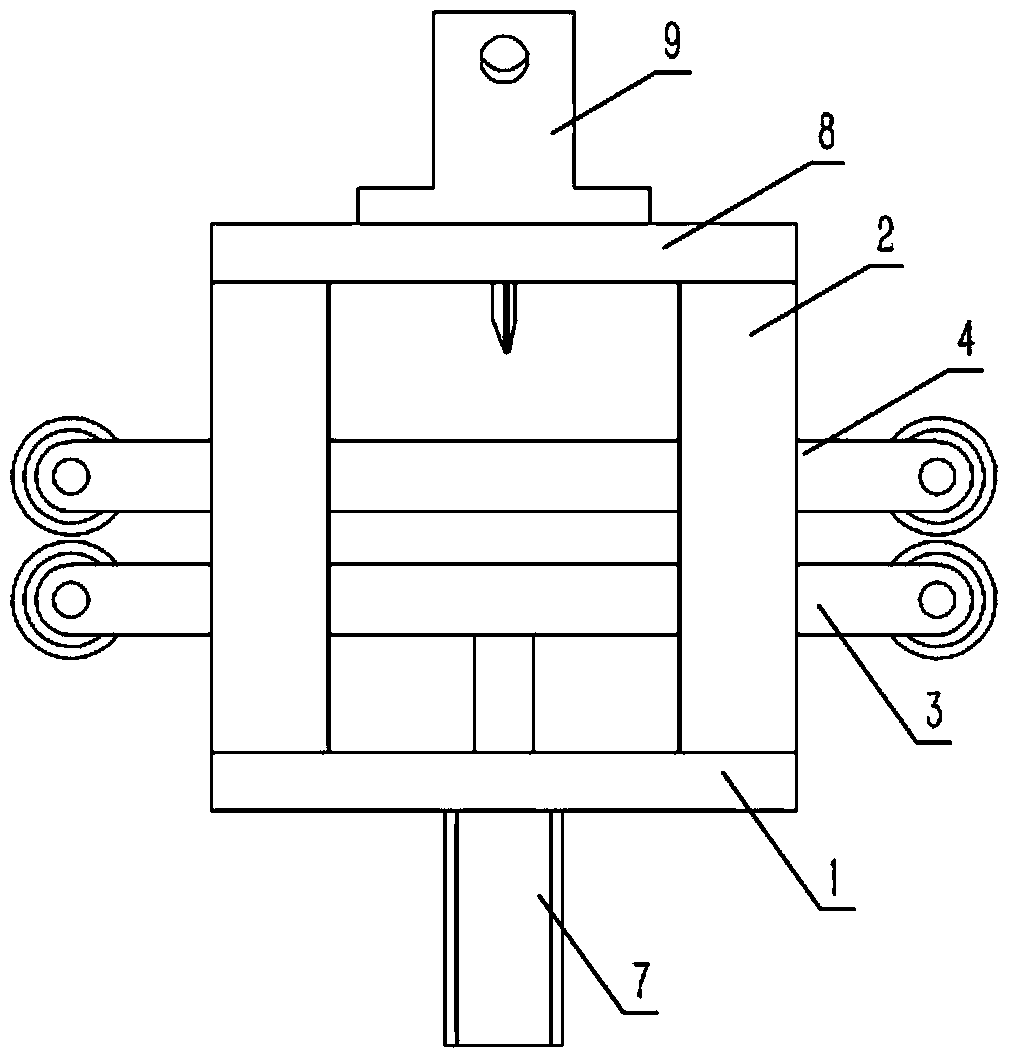

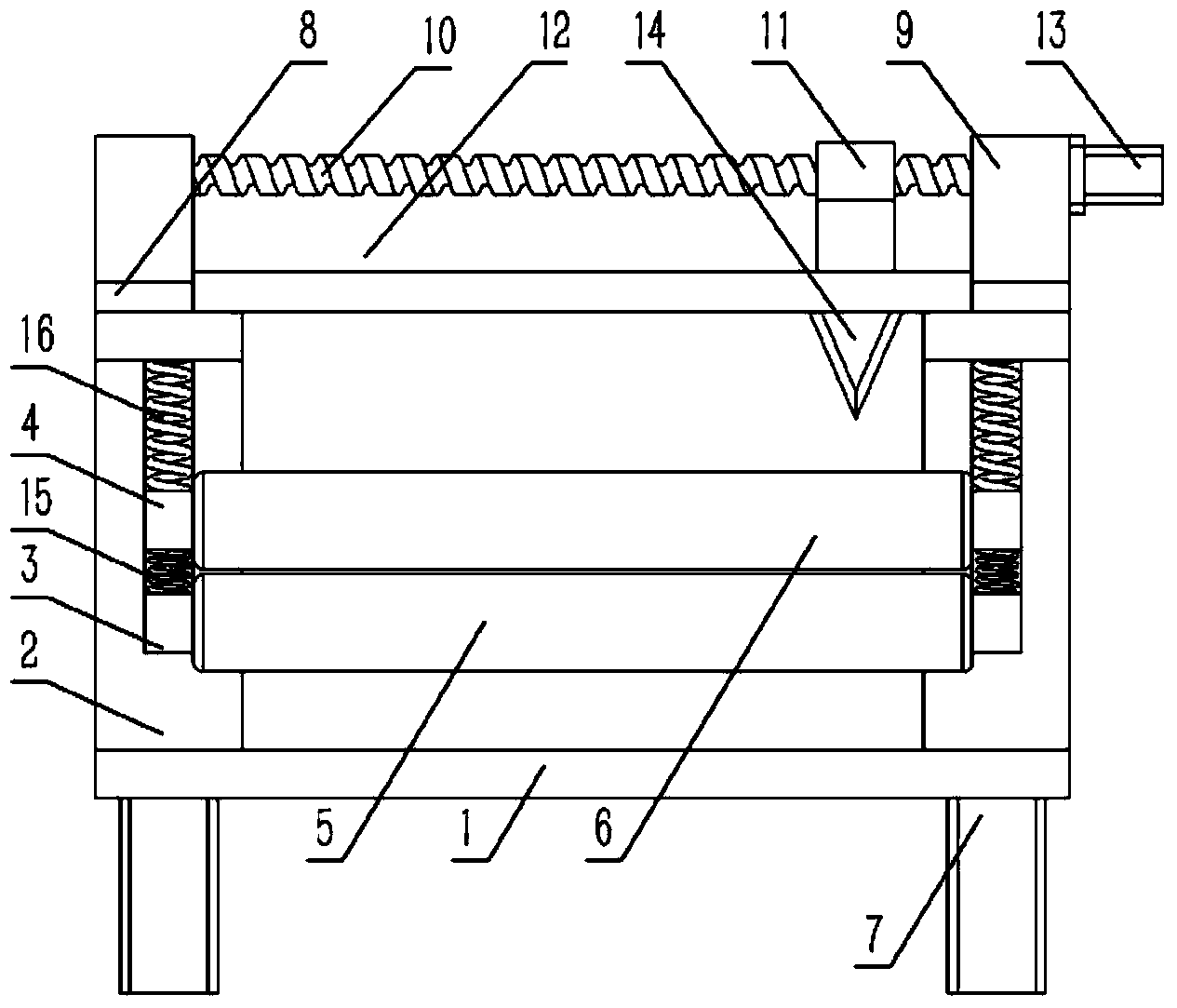

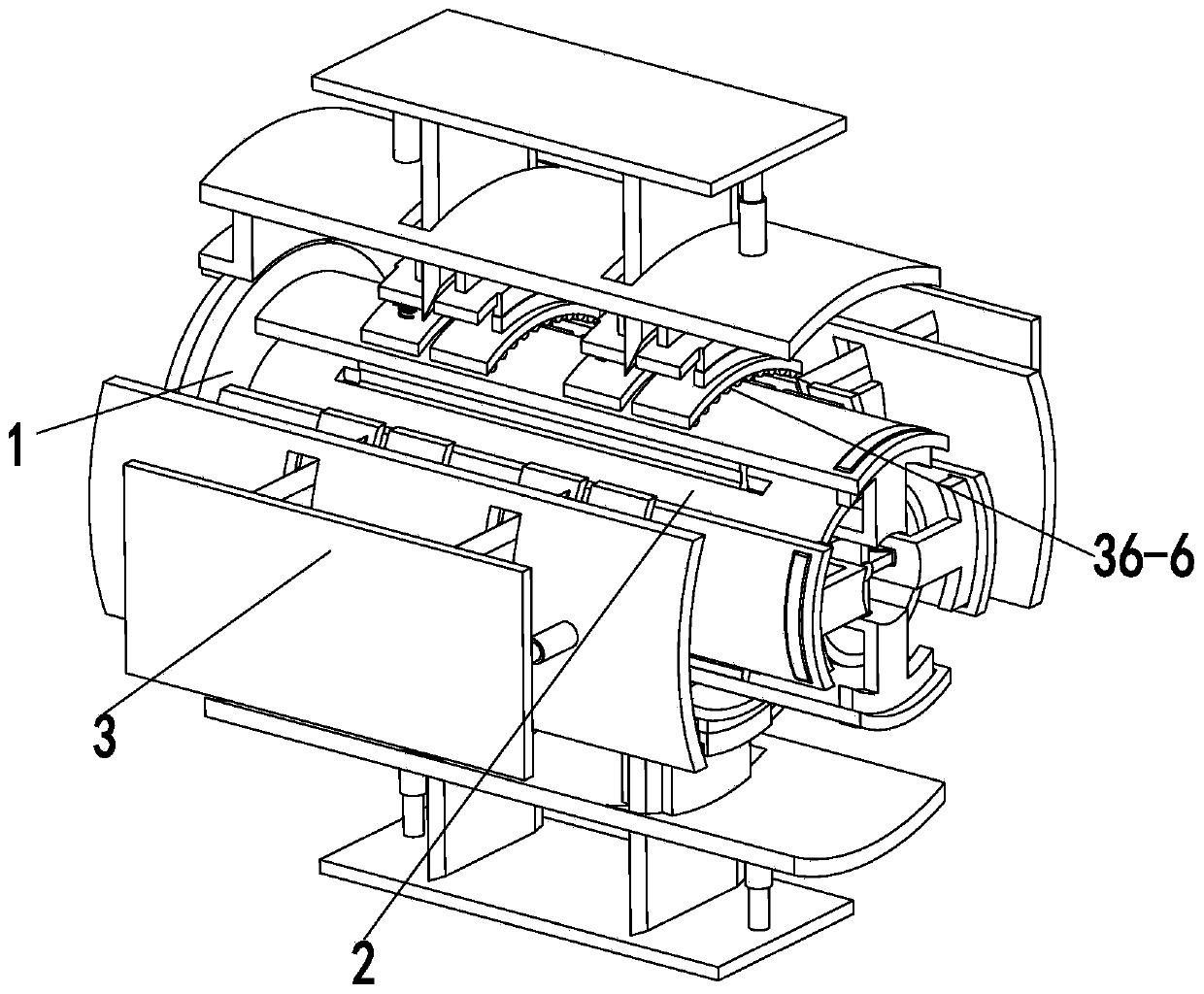

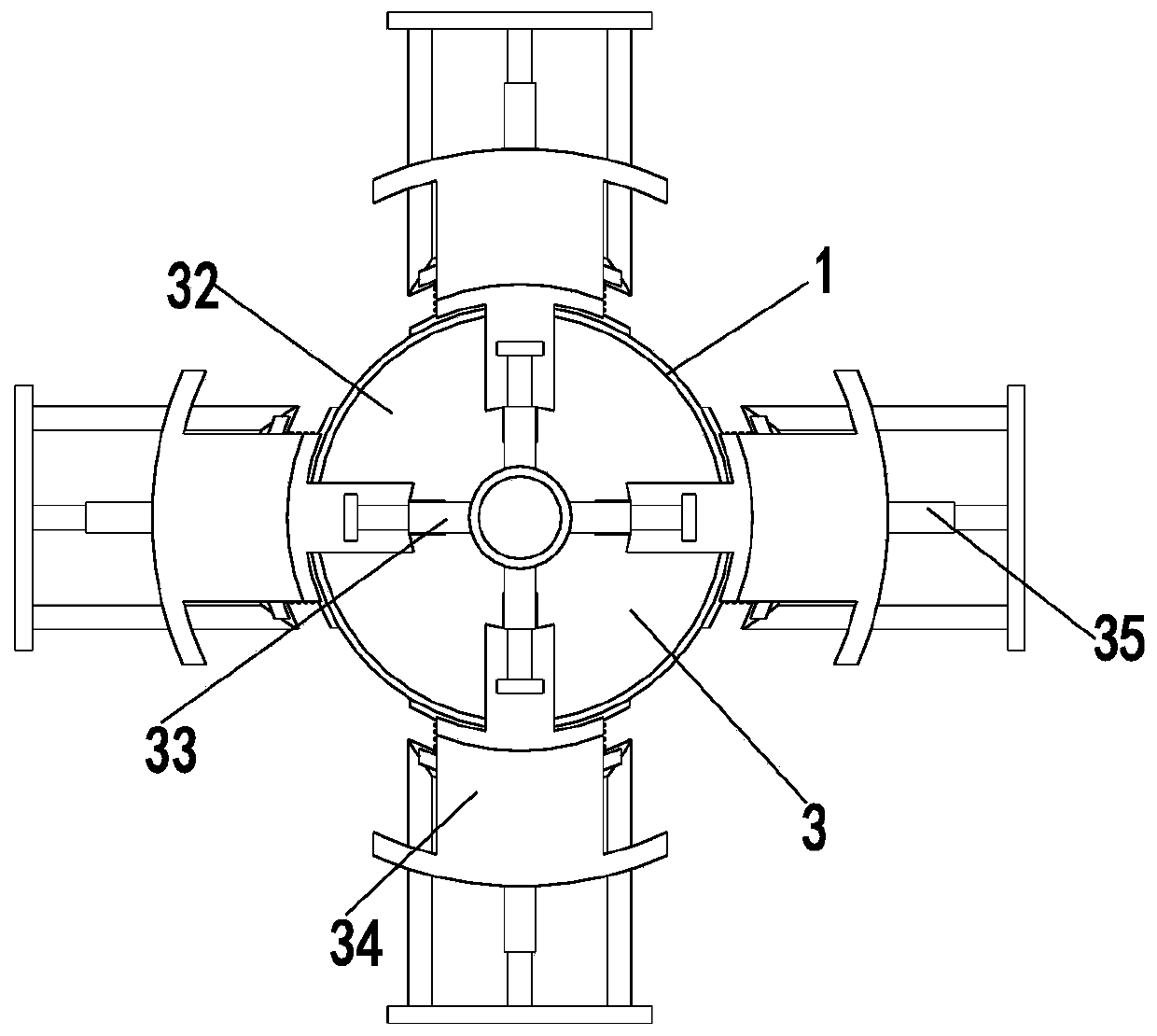

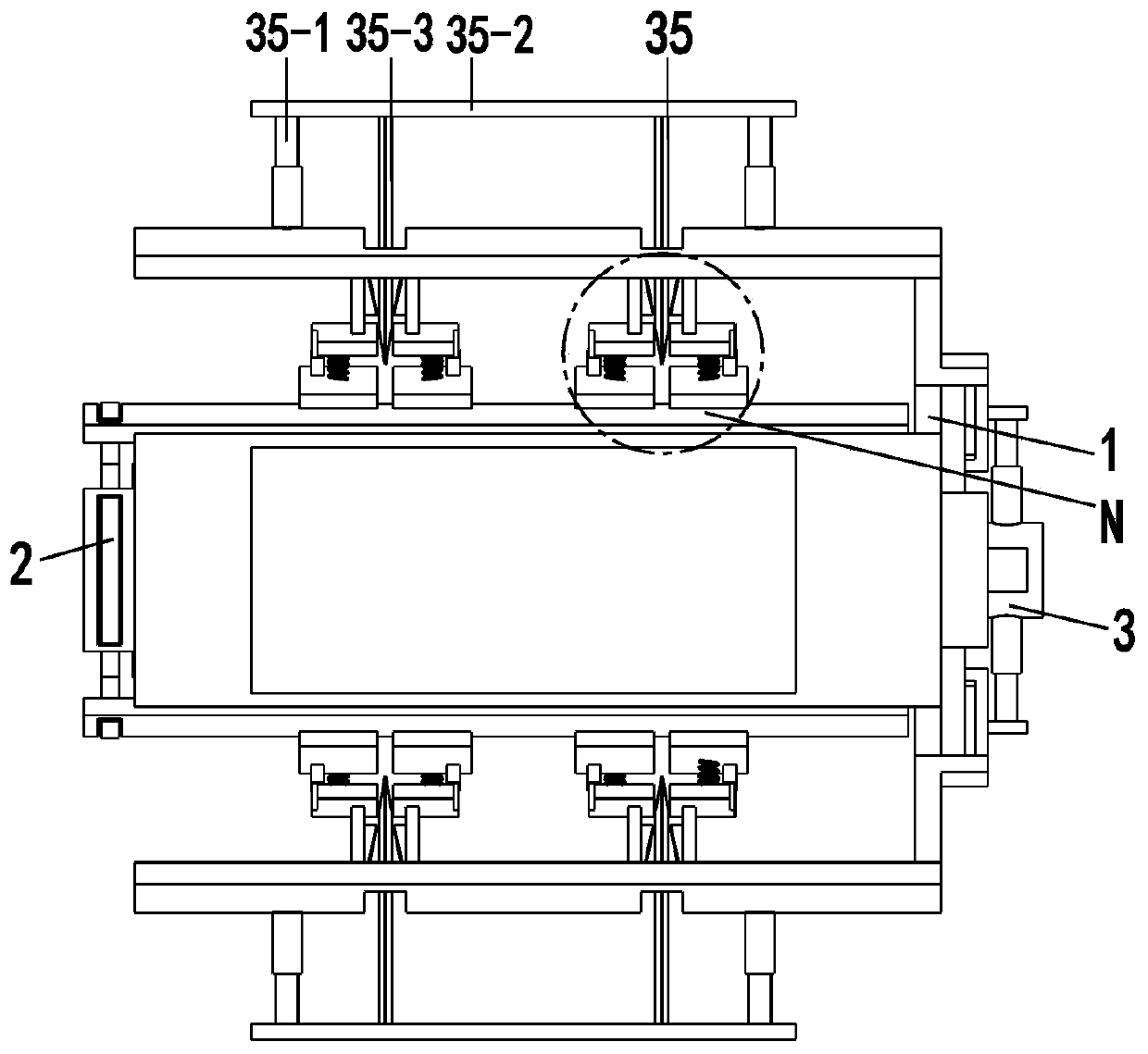

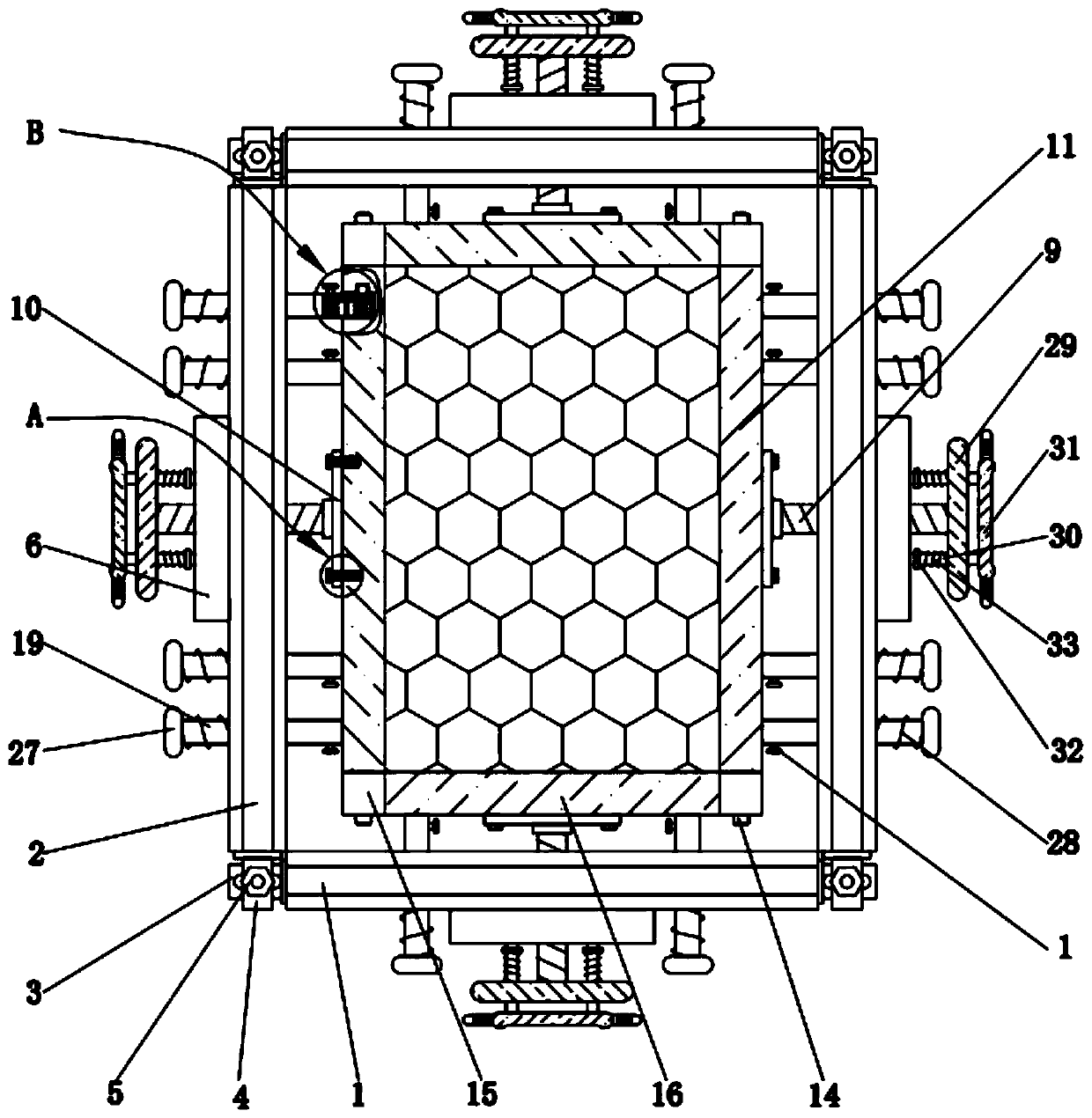

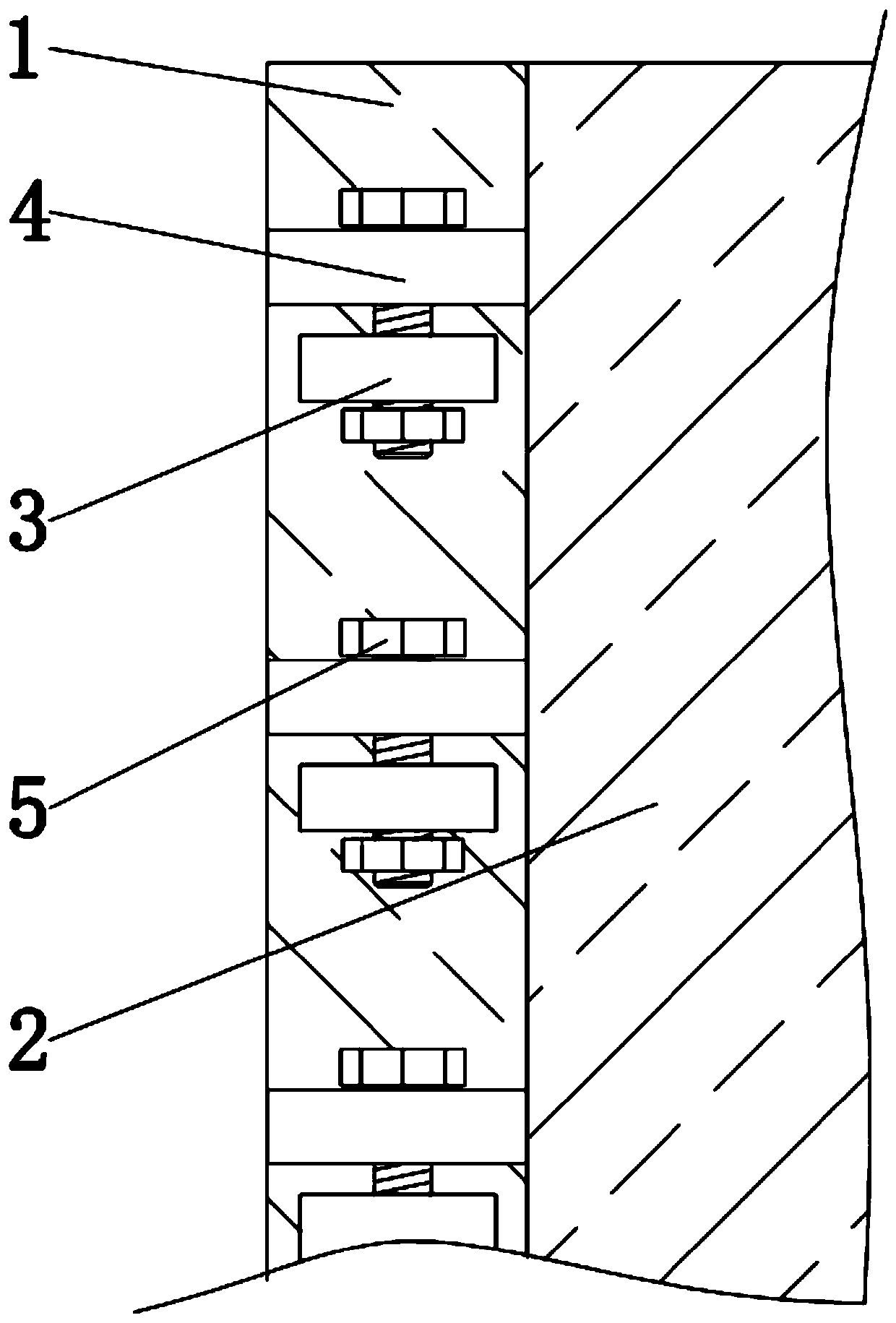

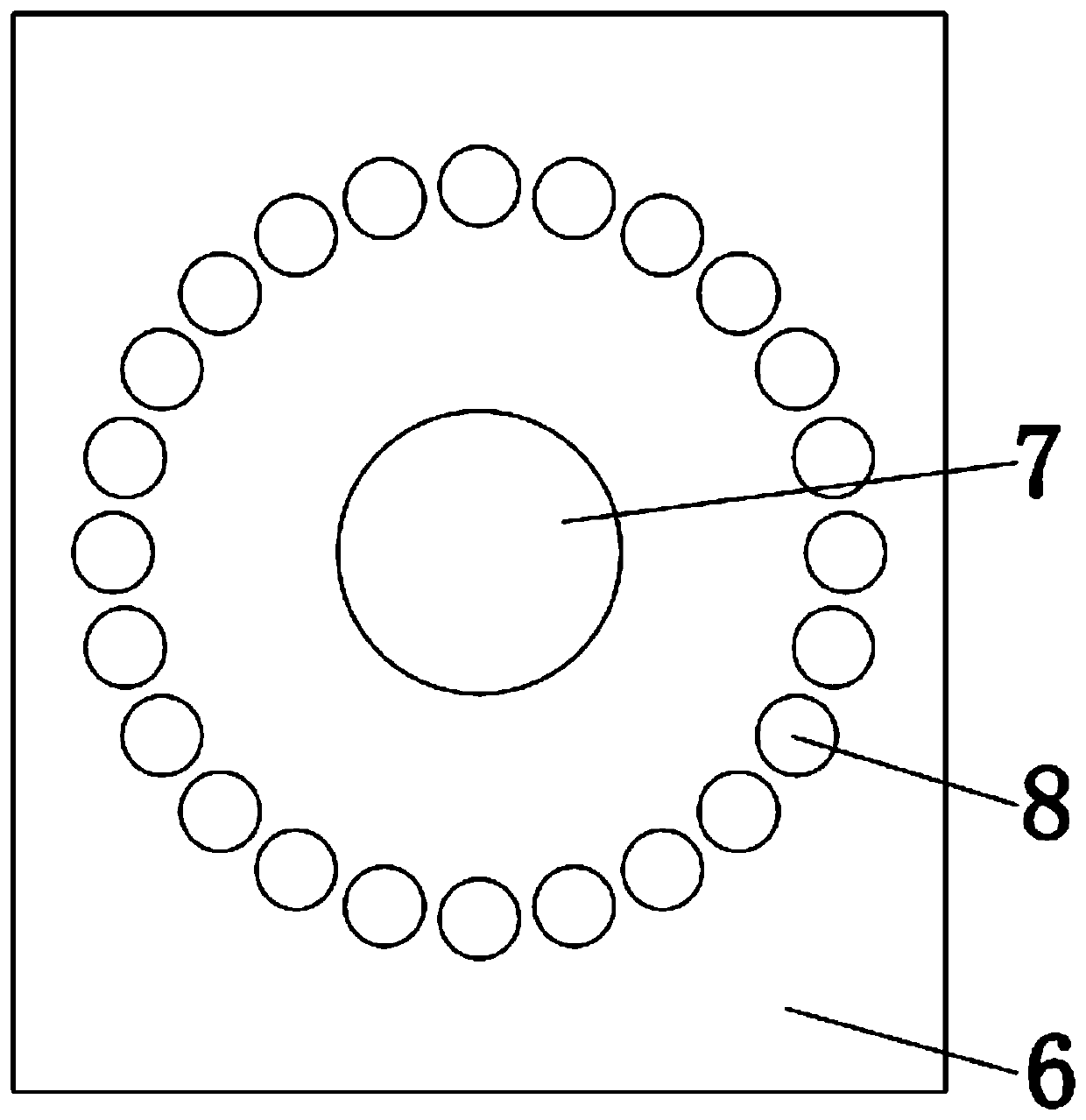

True three-dimensional sliding variable dimension loading box device used for geomechanical model test

InactiveCN102621001AResolve interfering issuesAchieve multi-purposeMaterial strength using tensile/compressive forcesModel testMechanical engineering

The invention discloses a true three-dimensional sliding variable dimension loading box device used for a geomechanical model test, comprising a true three-dimensional loading box and jacks. The true three-dimensional sliding variable dimension loading box device is characterized in that the true three-dimensional sliding variable dimension loading box is composed of six bearing plates, each bearing plate is provided with an inner surface, an outer surface and four sides, the jack is arranged on the outer surface of each bearing plate, a first side and a second side of each bearing plate are respectively arranged on the inner surfaces of two adjacent bearing plates, and the first side and the second side are adjacent. The true three-dimensional sliding variable dimension loading box device disclosed by the invention can be widely applied to geomechanical model test research in the fields of hydroelectric power, transportation, energy source, resource and national defense and can effectively guide and optimize design and construction of underground engineering; and a three-dimensional geomechanical model test can be effectively guaranteed to be carried out at high quality.

Owner:HOHAI UNIV

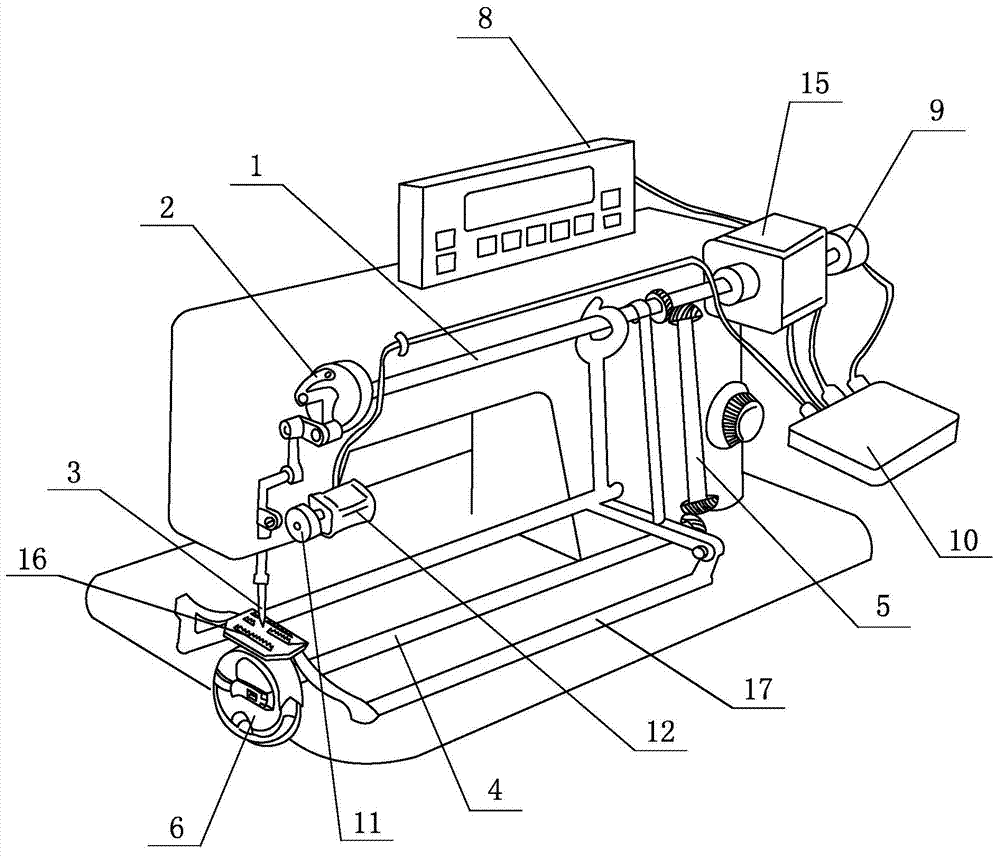

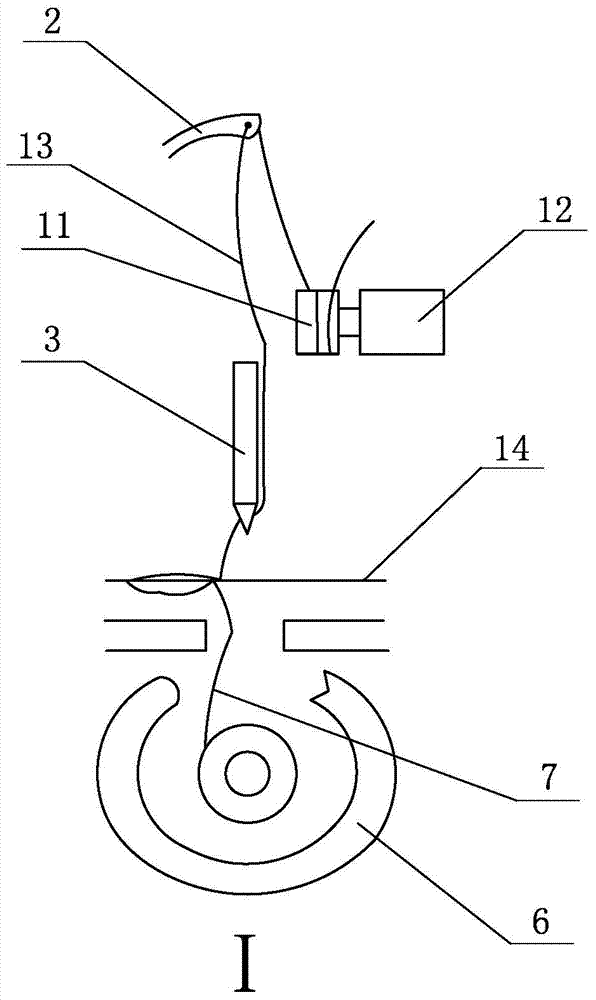

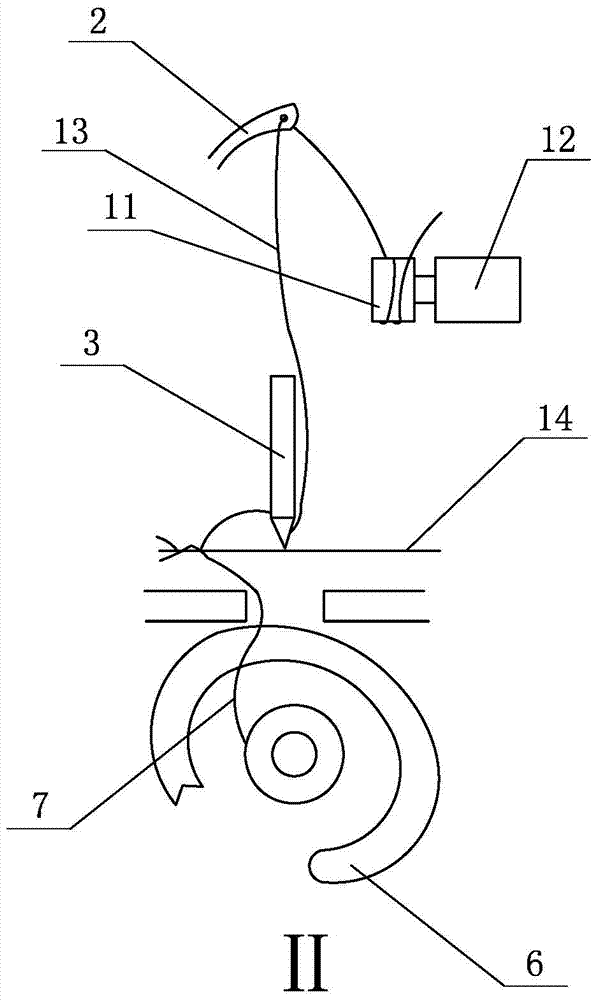

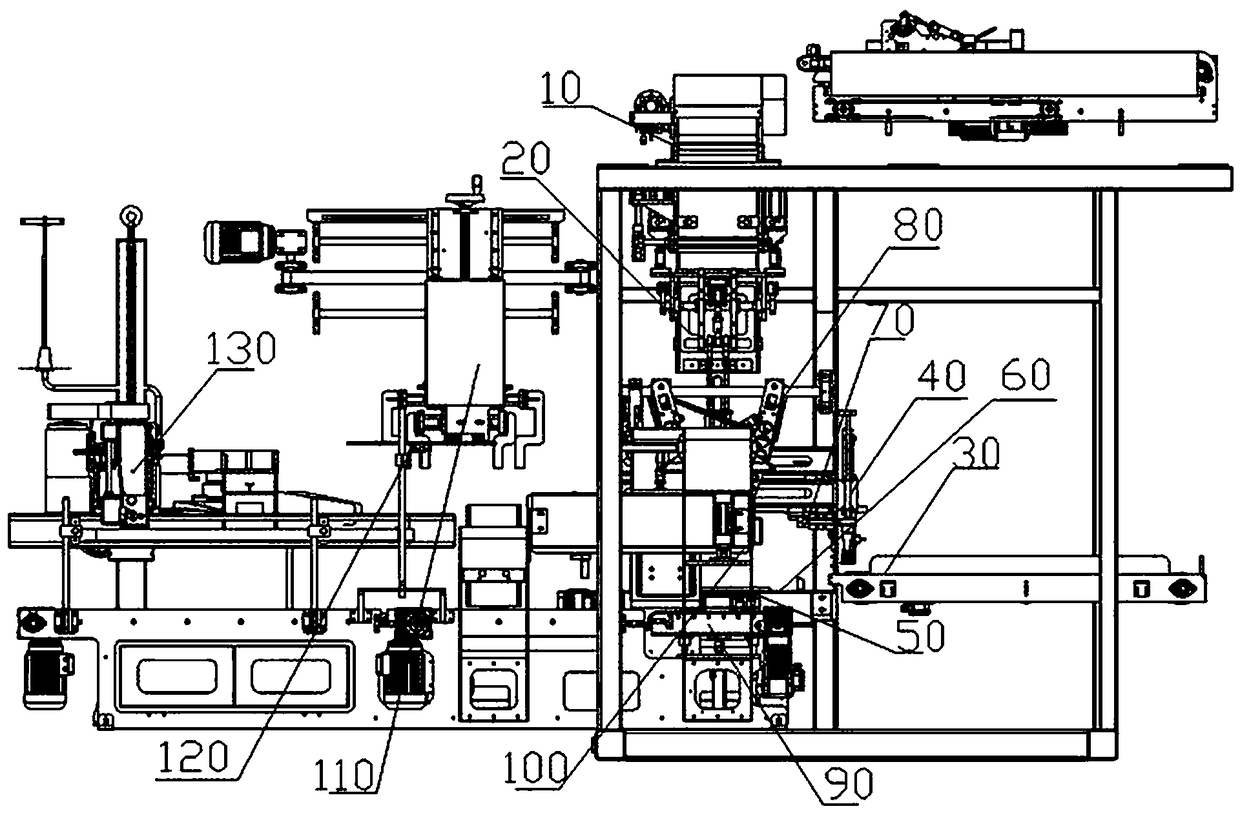

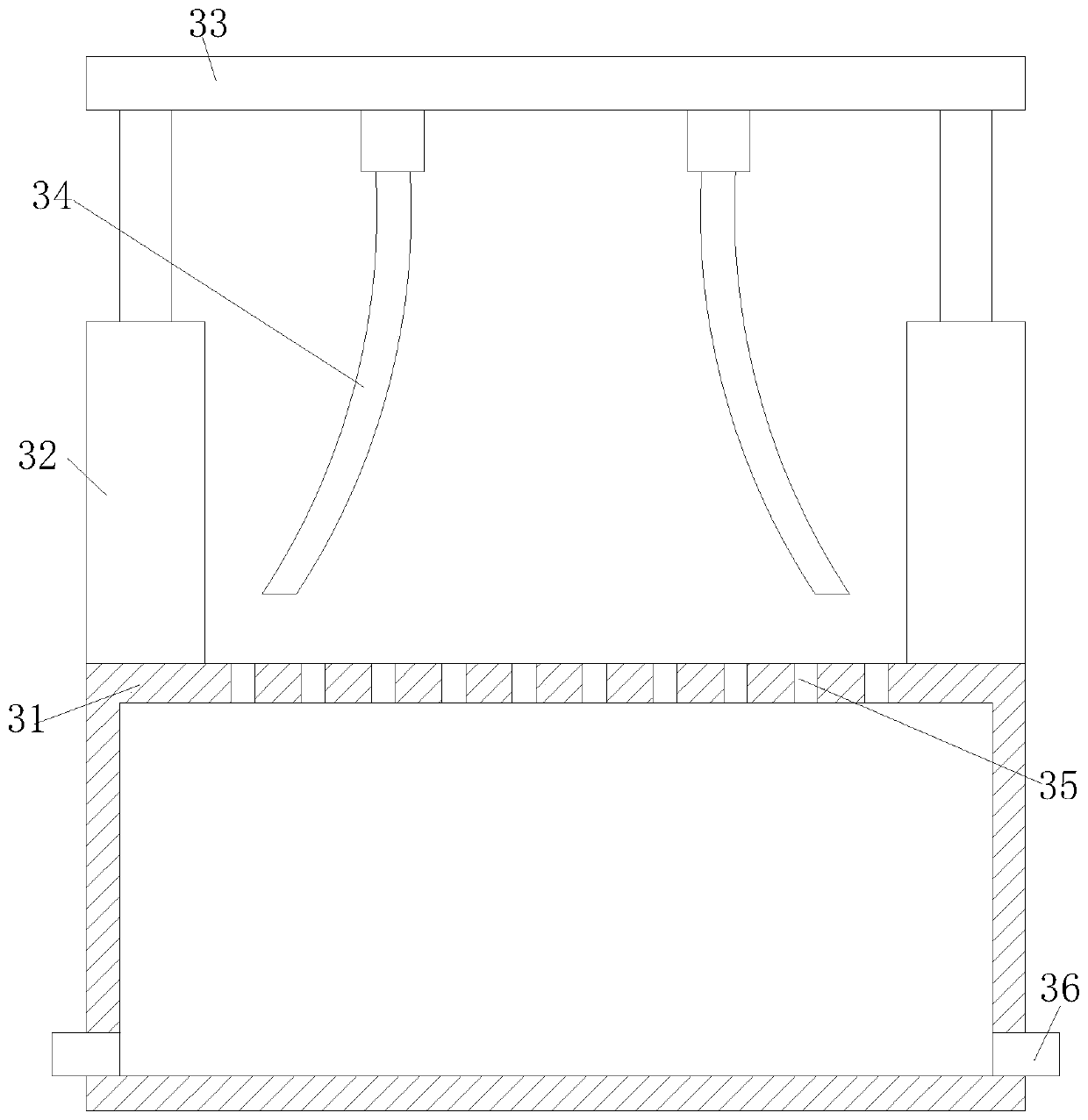

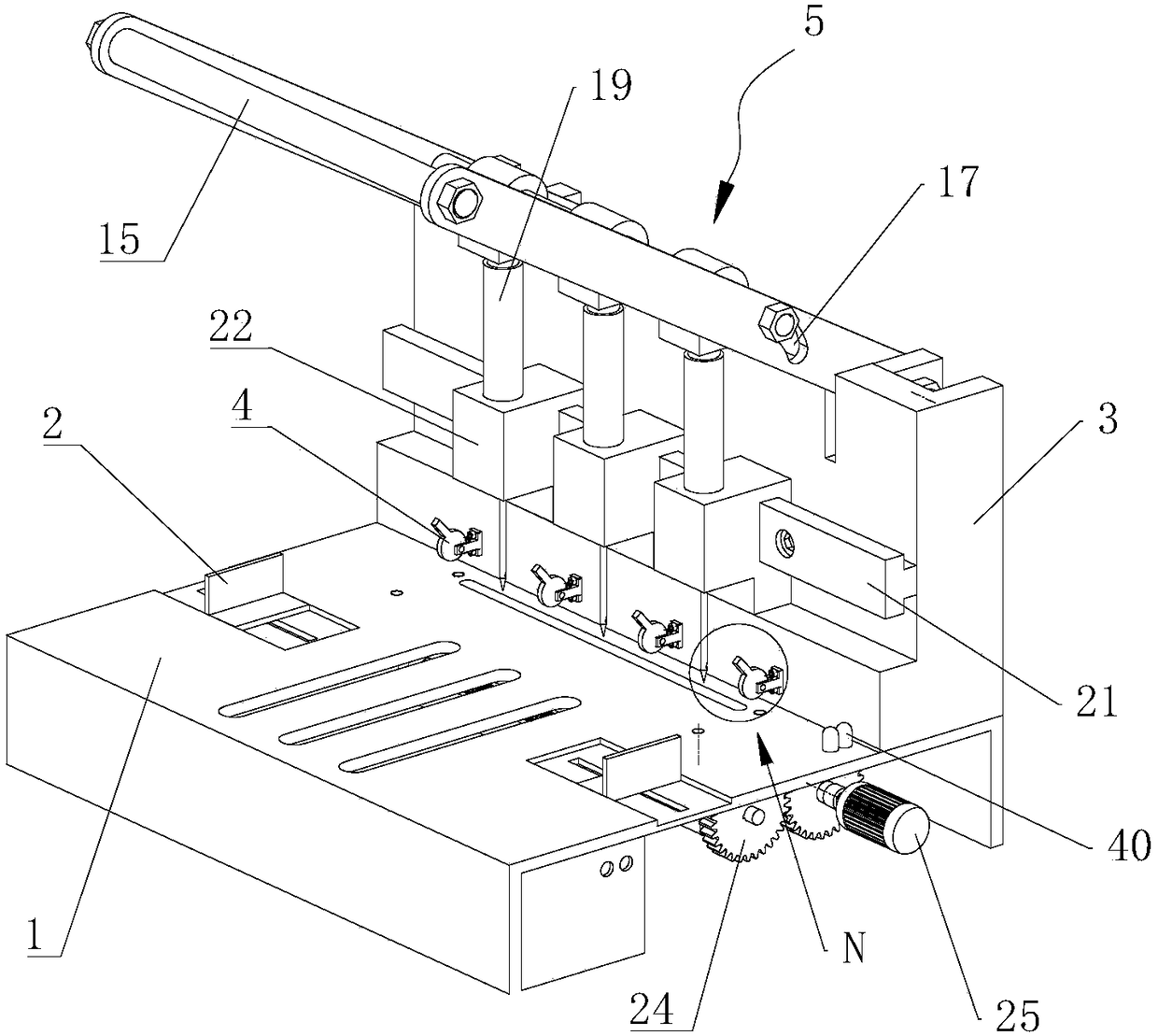

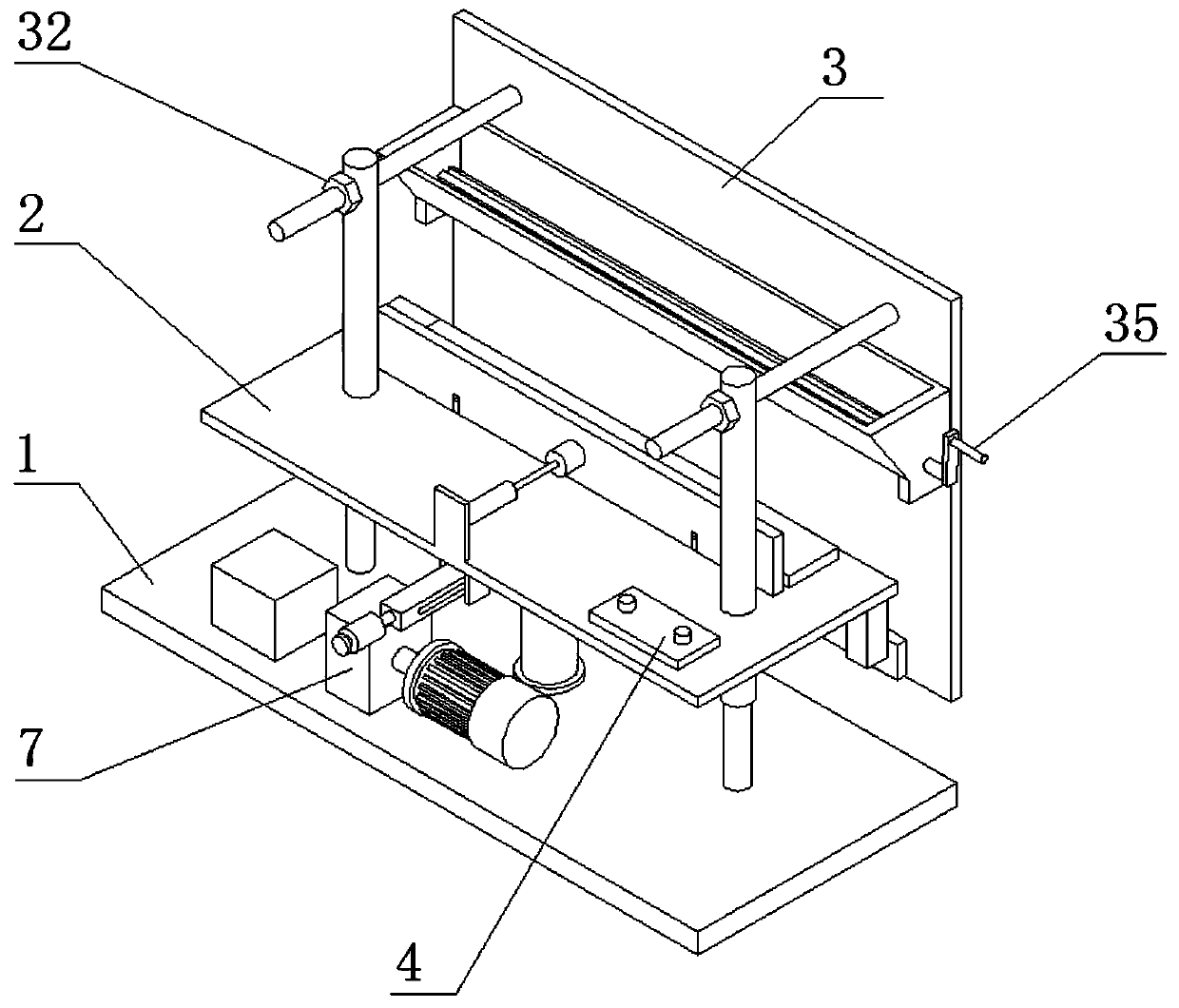

Automatic thread feeding system of sewing machine and control method thereof

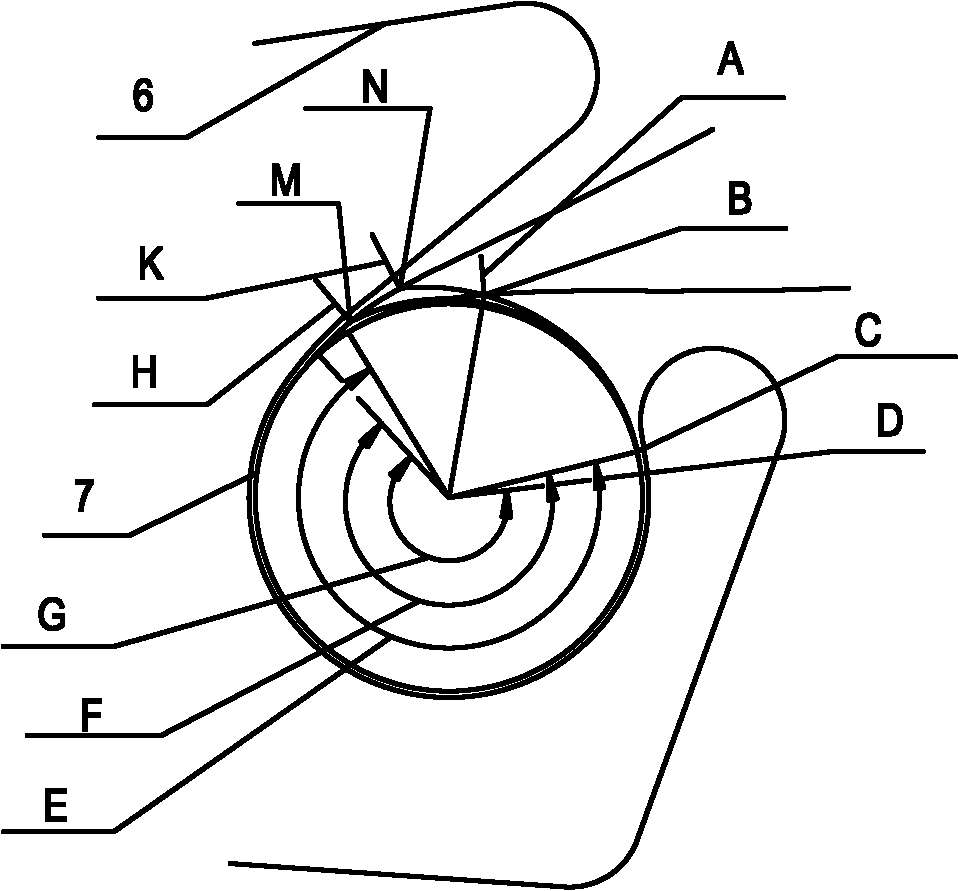

InactiveCN104120547AConsistent outputConsistent pitchProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftElectric machinery

The invention discloses an automatic thread feeding system of a sewing machine. The automatic thread feeding system comprises an upper shaft, a lower shaft, a control device, a cloth feeding system and a sewing thread tension adjusting device. One end of the upper shaft is connected with a sewing machine driving mechanism, and the other end of the upper shaft is connected with a thread take-up lever and a sewing needle; one end of the lower shaft is connected with the upper shaft through a transmission shaft, and a rotating shuttle is arranged at the other end of the lower shaft and wound with a sewing bottom thread. The automatic thread feeding system is characterized in that the sewing thread tension adjusting device comprises a rotating body and a stepping motor, the rotating body is connected with an output end of the stepping motor, the sewing machine driving mechanism and a control end of the stepping motor are connected with the control device, the rotating body is wound with a sewing upper thread, and the sewing upper thread penetrates through the thread take-up lever and is connected with the sewing needle. The control method includes the steps of parameter setting, sewing needle sewing, rotating body taking up, cloth moving and rotating body paying off. The sewn stitches are in order, and sewing quality is high.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

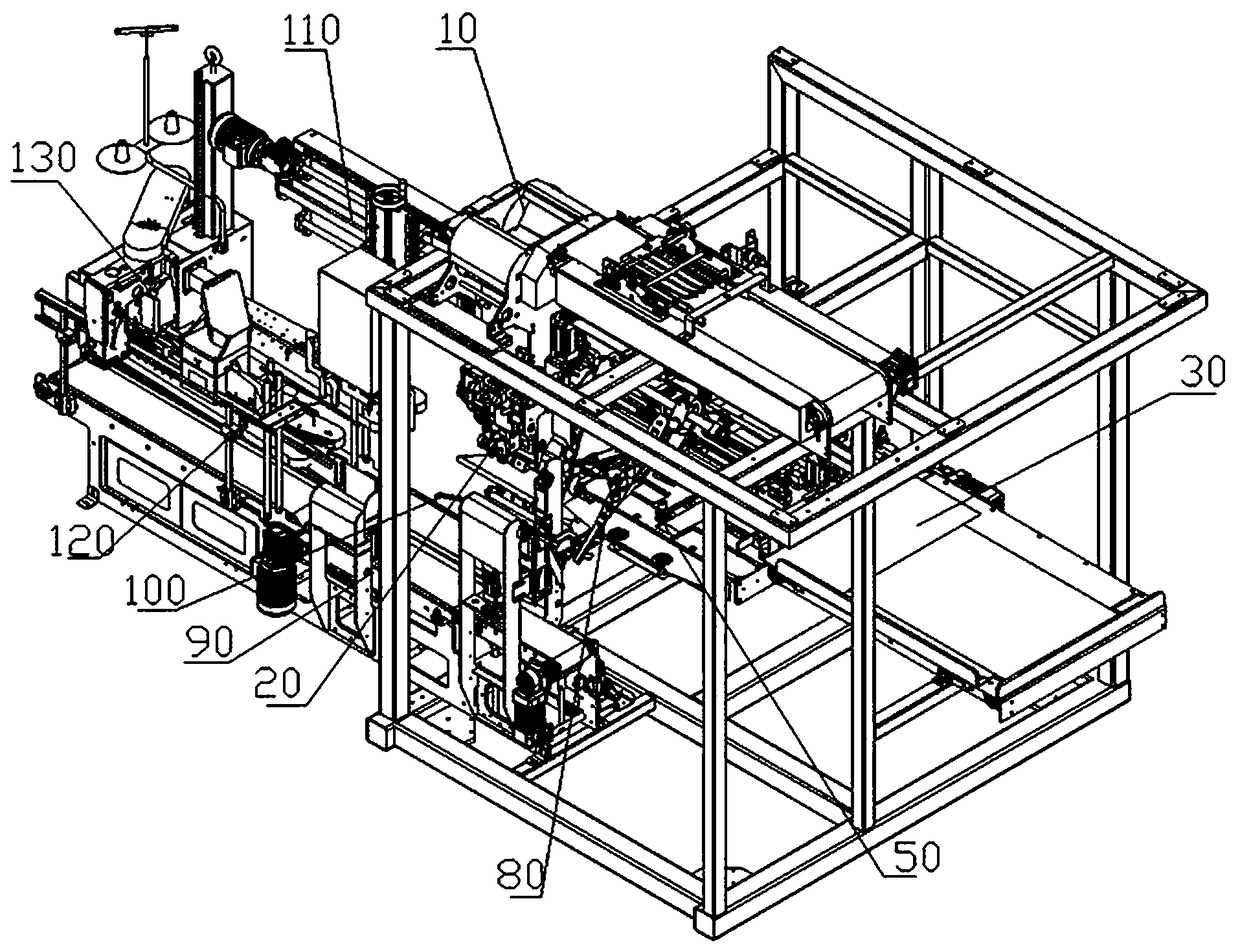

Automatic bagging machine

PendingCN108820273APrevent the bag from fallingEasy to stackWrapper twisting/gatheringSolid materialEngineeringMechanical engineering

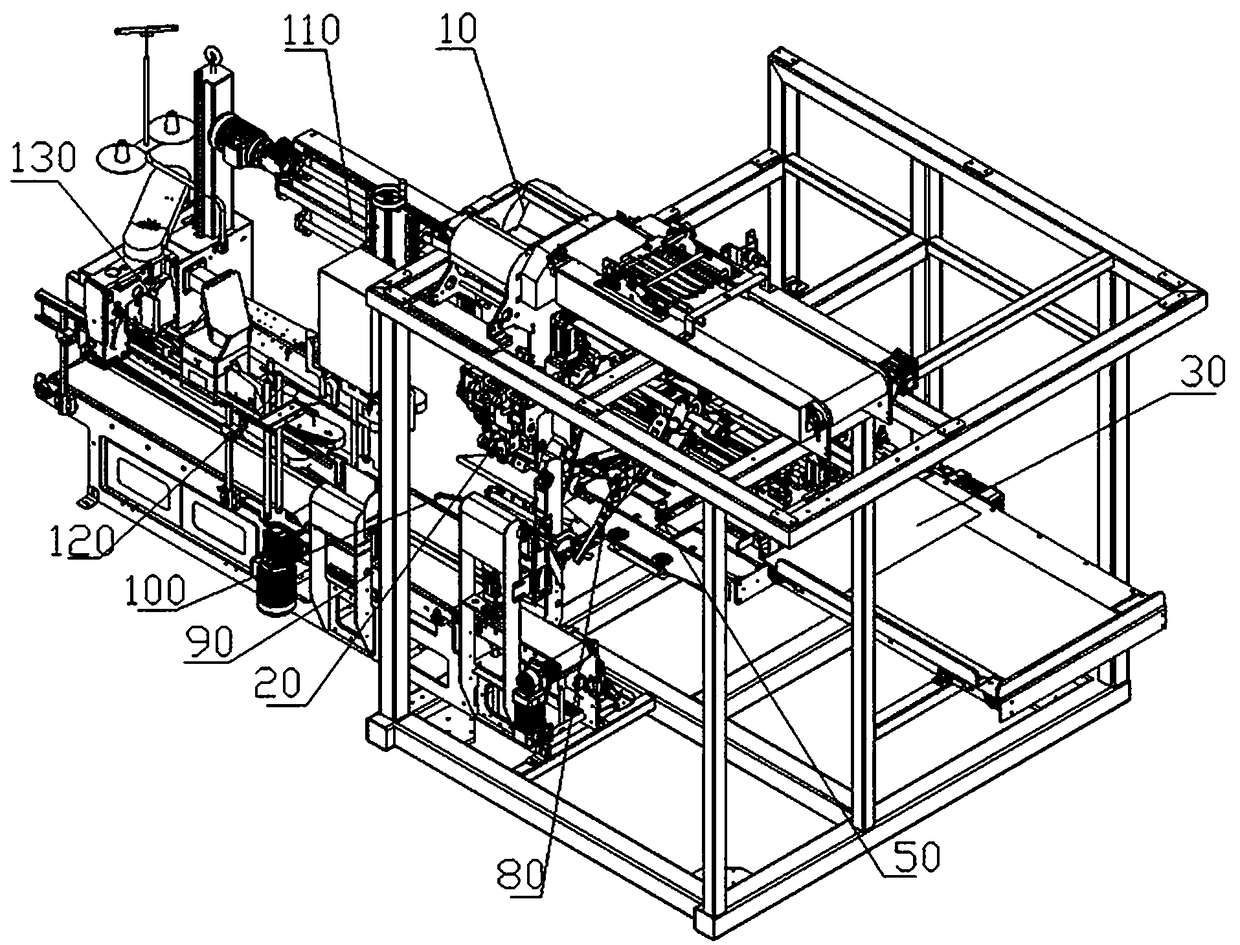

The invention discloses an automatic bagging machine, and relates to the technical field of packaging machinery. The automatic bagging machine comprises a bag receiving bin mechanism, a bag clamping mechanism, a bag storage, a bag taking mechanism, a bag opening mechanism, a bagging mechanism, a bag shaking mechanism, a bag holding mechanism, a bag opening arranging mechanism, a bag opening guidemechanism and a bag sewing mechanism, wherein the bag shaking mechanism comprise a bag shaking platform which moves up and down in a reciprocating manner and flaps the bottoms of packaging bags sleeving on the bag clamping mechanism, the bag holding mechanism is arranged on one side of the bag shaking mechanism, the bag opening arranging mechanism is used for sorting the bag opening of each packaging bag, and the bag opening of each packaging bag enters the bag sewing mechanism under the guide of the bag opening guide mechanism to be sealed. According to the automatic bagging machine, in the bagging process, bag pouring of the packaging bags can be effectively prevented, the bag opening of each packaging bag is folded into an M shape through the bag opening arranging mechanism when the packaging bag is sealed, so that the opening of the sealing bag forms an end surface, and therefore material loosening of salt bags in the packaging bags cannot be caused in the transportation process.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

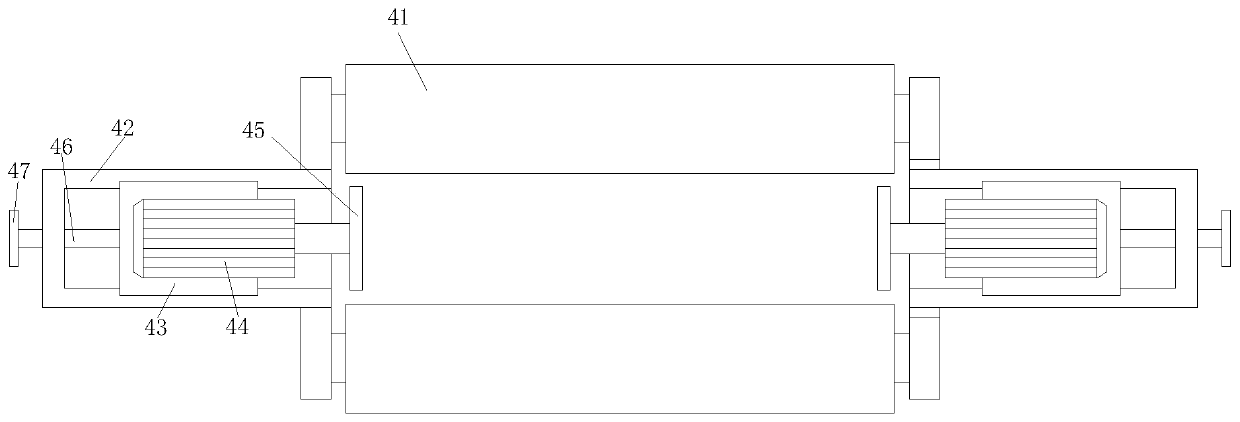

Double-cutter cutting device for packing plates

ActiveCN107876855ASame speedGuaranteed sharpMachine tool componentsShearing machinesDrive shaftCoupling

The invention discloses a double-cutter cutting device for packing plates. The double-cutter cutting device comprises a base, a supporting column, a transverse plate, a first motor, a feed mechanism,a cutting mechanism and an extension plate, and the cutting mechanism comprises a shell, a second motor, a driving shaft, a driving bevel gear, a driven bevel gear, a rotating shaft, a coupling and aconnecting shaft; cutting wheels are mounted at the end, away from the coupling, of the connecting shaft, and mounting holes are formed in the side, close to the shell, on the extension plate; threaded columns are arranged in the mounting holes, and friction blocks are mounted at the lower ends of the threaded columns; and a first spring is further arranged on each threaded column in a sleeving mode, and the first springs are located between the extension plate and the friction blocks. According to the double-cutter cutting device for the packing plates, single power is adopted to drive the double cutting wheels, the same rotational speed of the two cutting wheels can be achieved, neat cutting is ensured, by arranging the friction blocks, the cutting wheels can be grinded while being cut,so that the cutting wheels is ensured to be sharp, the plates can be pressed and fixed while feeding of the cutting mechanism is conducted by arranging pressing blocks, and a separate control fixtureis not required to be arranged.

Owner:宣城大天新材料科技股份有限公司

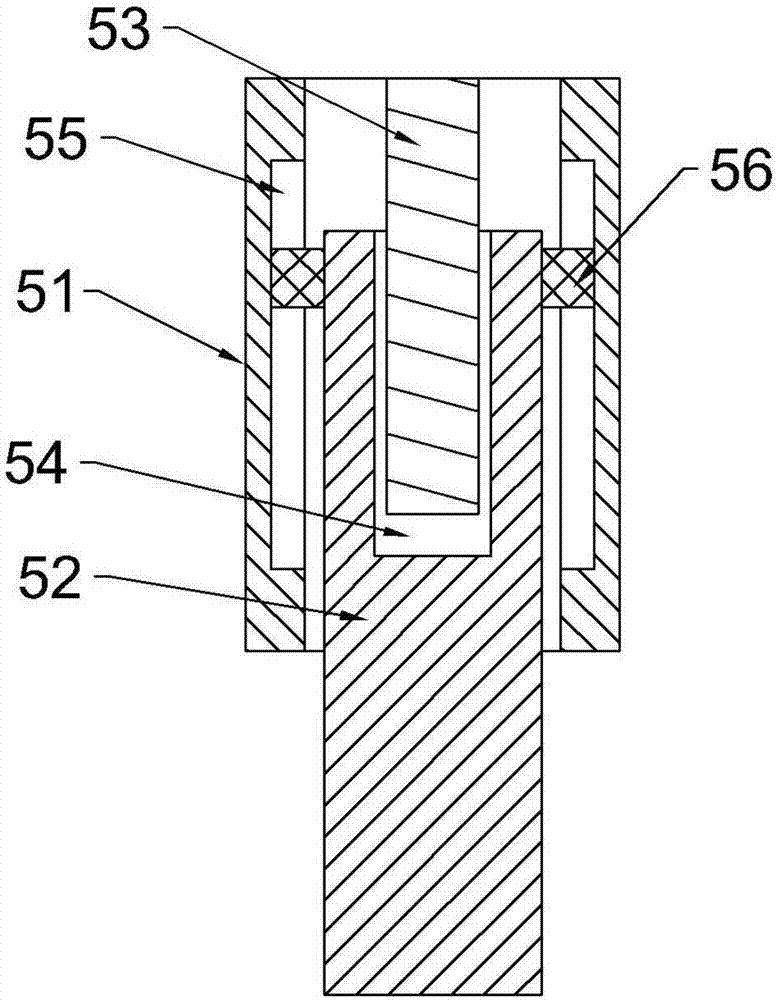

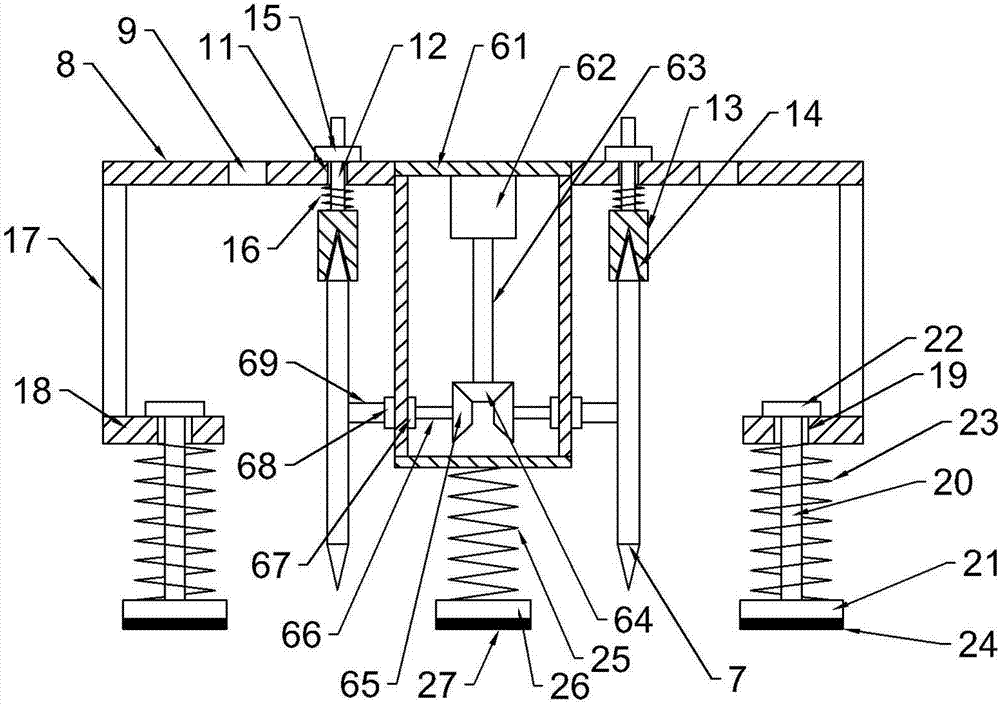

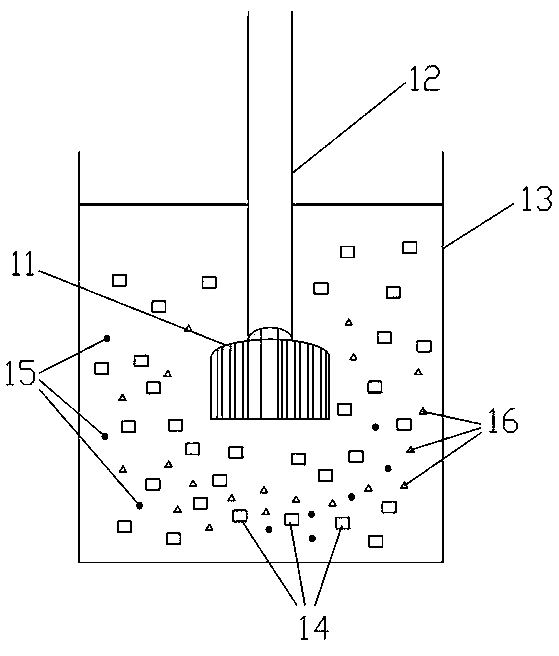

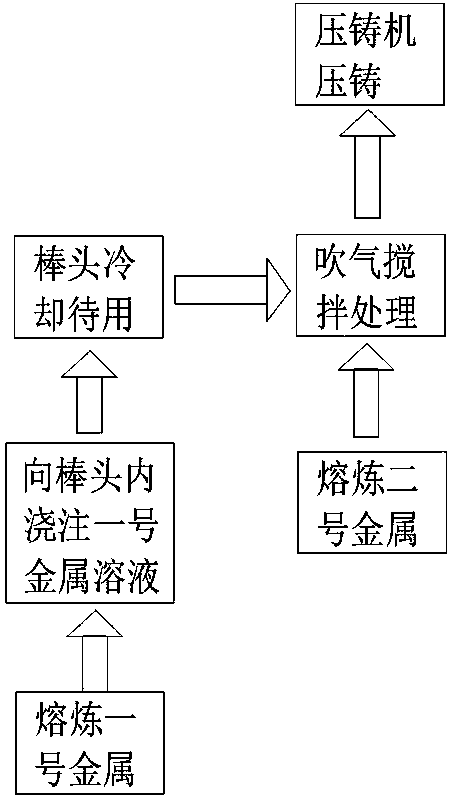

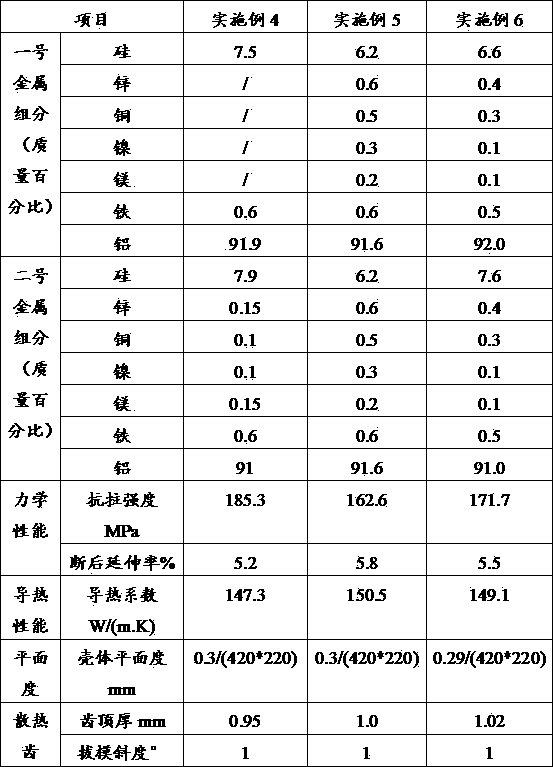

Aluminum-silicon alloy for rheo-diecasting radiating shell and preparation method of aluminum-silicon alloy

The invention discloses an aluminum-silicon alloy for a rheo-diecasting radiating shell. The aluminum-silicon alloy comprises components in percentage by mass as follows: 5.5%-8.0% of silicone, 0.1%-1.5% of copper, 0.1%-2.0% of zinc, 0.1%-2.0% of nickel, 0.1%-0.8% of magnesium, 0.1%-1.0% of iron and the balance of aluminum and inevitable trace impurities. The invention further discloses a preparation method of the aluminum-silicon alloy for the rheo-diecasting radiating shell. According to the preparation method, NO.1 solid metal is fed into No.2 liquid metal by a rod head, and slurry in a ladle is rapidly, efficiently and uniformly mixed under the action of blowing and stirring. The aluminum-silicon alloy has the advantages of high heat conductivity coefficient, good liquid liquidity and applicability to semi-solid state rheo-diecasting of the radiating shell. The preparation method is simple and easy to operate, the aluminum-silicon alloy has higher uniformity and liquidity by means of the prepared method, and the rheo-diecasting radiating shell is convenient to prepare.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL +1

Method for sorting desktop icons of mobile terminal and mobile terminal

ActiveCN103927088ASpeed up the search applicationGuaranteed aestheticsInput/output processes for data processingApplication softwareComputer engineering

Owner:NUBIA TECHNOLOGY CO LTD

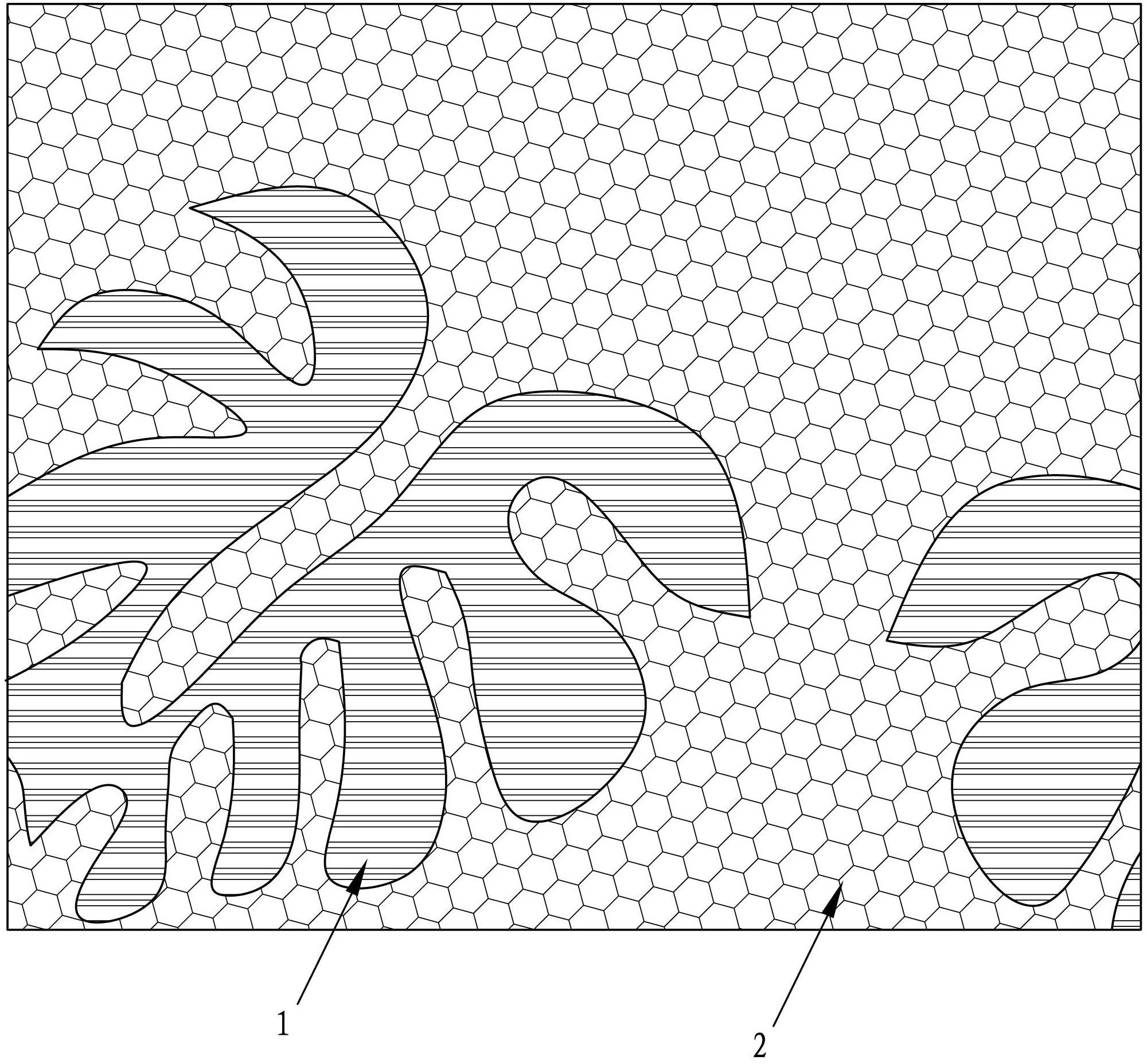

Three-dimensional transversely-wrinkled fuzzing towel and weaving process thereof

ActiveCN102660824AGuaranteed uptimeStrong three-dimensional senseHeating/cooling textile fabricsWoven fabricsEngineeringPolymer science

Owner:SUNVIM GROUP

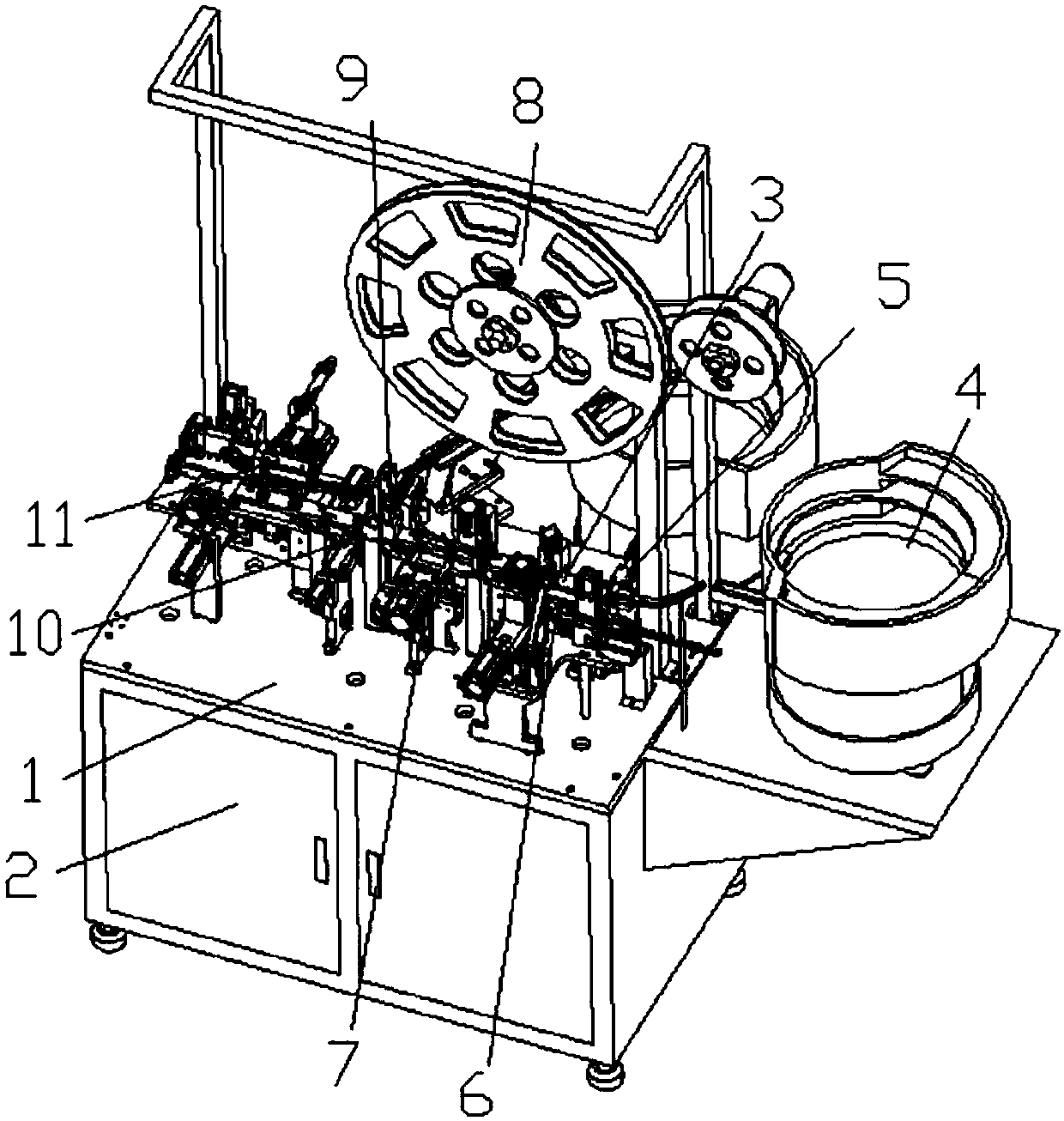

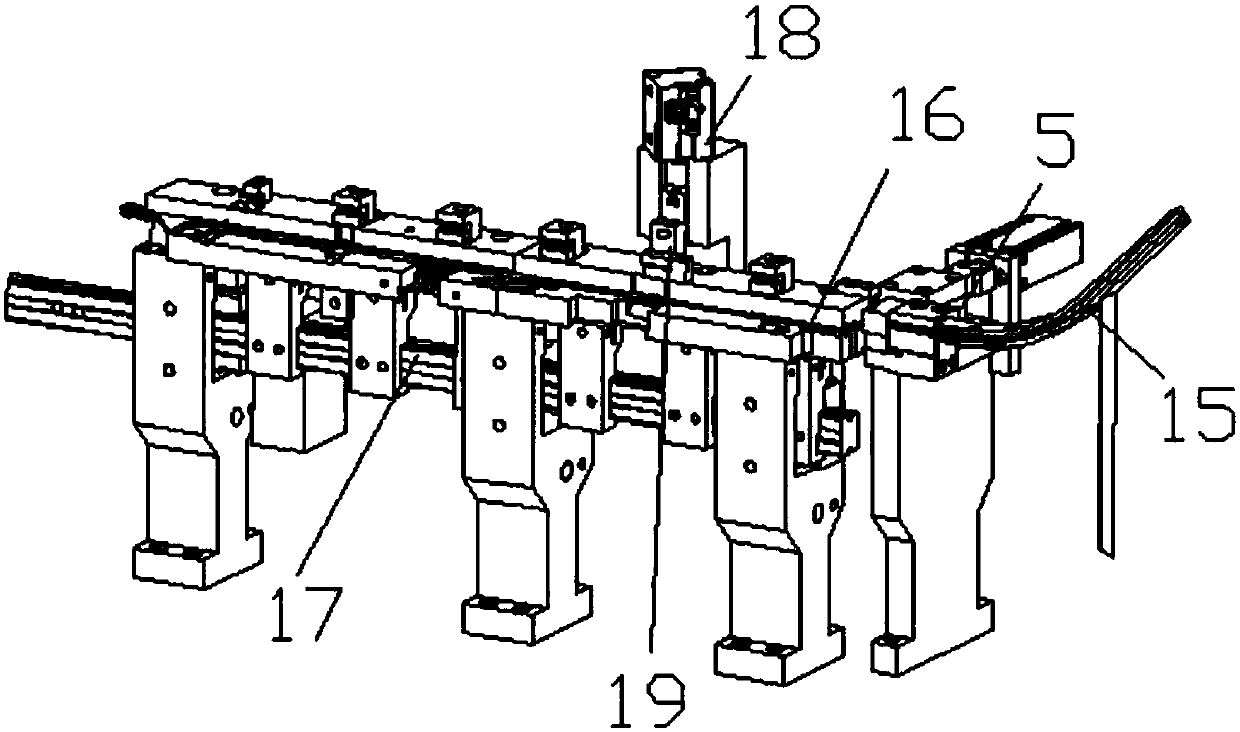

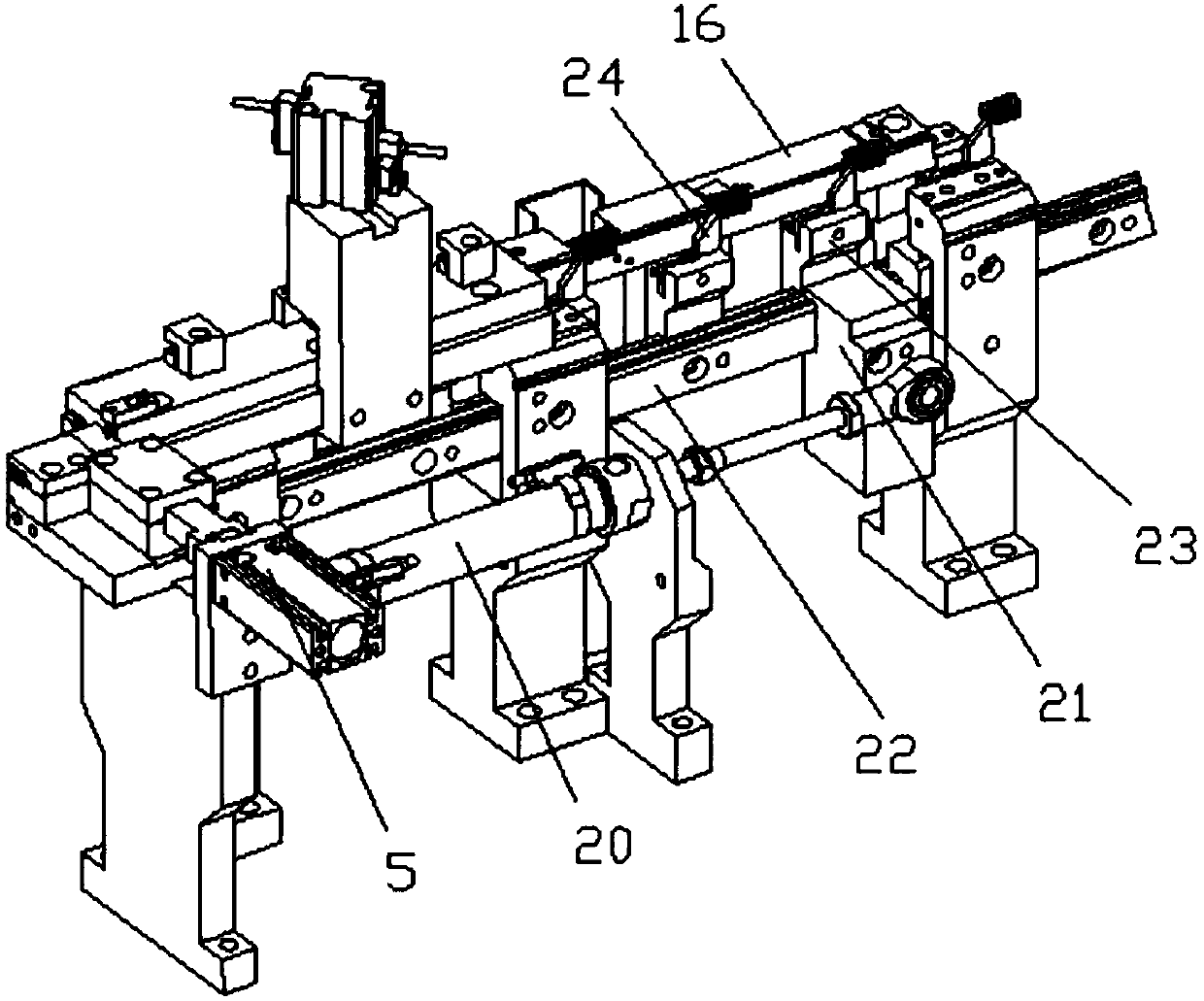

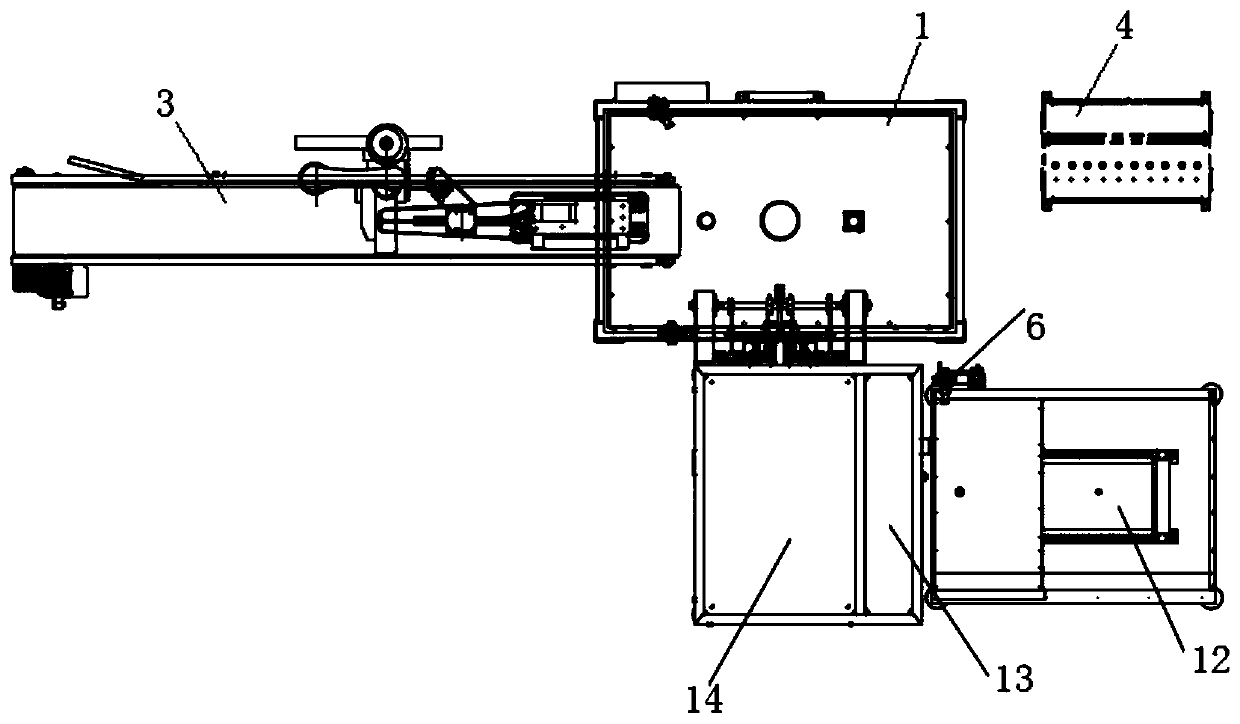

Automatic assembling machine for connector

ActiveCN107553085AAccurate jackingRealize automated assemblyOther manufacturing equipments/toolsMetal working apparatusMechanical engineering

The invention relates to an automatic assembling machine for a connector. A rack is provided with a rubber core conveying device and a shell conveying groove; a shell feeding device is arranged on theupper portion of the shell conveying groove, a shell material feeding device is matched with the right side of the shell conveying groove, and a rubber core ejecting-in port is formed in the front side of the shell conveying groove and is matched with a rubber core ejecting-in device; the shell material feeding device is connected with a shell vibration material feeding disk through a shell material feeding groove; the shell feeding device comprises a shell feeding lifting cylinder which is connected with a shell reciprocating feeding pull rod; the shell reciprocating feeding pull rod is connected with a shell feeding block; and feeding grooves matched with the left and right length of the shell are uniformly formed in the lower portion of the shell feeding block. According to the automatic assembling machine for the connector, by means of the shell feeding device in fixed distance feeding guarantees the fixed distance feeding of a shell, the fixed rubber core ejecting-in port is formed in the shell conveying groove, it is guaranteed that a rubber core is accurately ejected in from the rubber core ejecting-in port, automatic assembling of the connector rubber core and the shell isachieved, meanwhile the positioning and assembling structure is simplified, and the work efficiency is improved.

Owner:TONGXIANG YAORUN ELECTRONICS

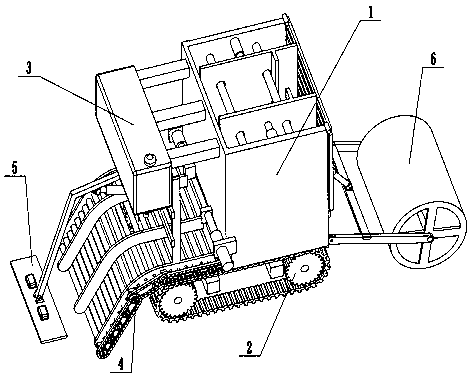

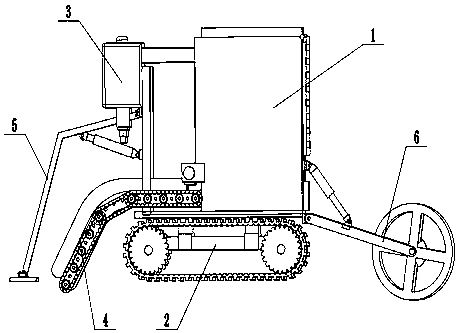

Automatic road floor tile laying equipment

InactiveCN110485241AImprove efficiencyFast layingRoads maintainenceMechanical engineeringWater spray

Owner:陈达

Intelligent special table for accounting

InactiveCN106923500AMeet the use requirementsDoes not affect the legsOffice tablesVariable height tablesDisplay deviceIndustrial engineering

The invention discloses an intelligent special table for accounting. The special table comprises a table body, wherein a lifting bracket is arranged at the lower side of the table body; a lifting groove is formed in the table body; a display rotary lifting mechanism is arranged at the lower side of the lifting groove; a human face height recognition mechanism is arranged on the table body; a seal storage module and a cash counting sponge module are additionally arranged on the table body; an automatic ink jet mechanism is arranged in the seal storage module; an automatic humidifying mechanism is arranged in the cash counting sponge module; a bill storage mechanism is arranged at one side of the table body; and the display rotary lifting mechanism, the lifting bracket, the human face height recognition mechanism, the automatic ink jet mechanism, the automatic humidifying mechanism and the bill storage mechanism are connected to a controller. According to the intelligent special table for accounting provided by the invention, human face height of a user can be automatically adjusted in accordance with heights of the table body and a display, so that the user can operate a computer and can view the display conveniently; and seals, bills and cash-counting sponge can be kept in a classified mode, so that the surface of the table body is kept tidy.

Owner:上海立信会计金融学院

Method for bagging of materials

ActiveCN108839828AConvenient reverseInhibit sheddingWrapper twisting/gatheringSolid materialEngineering

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

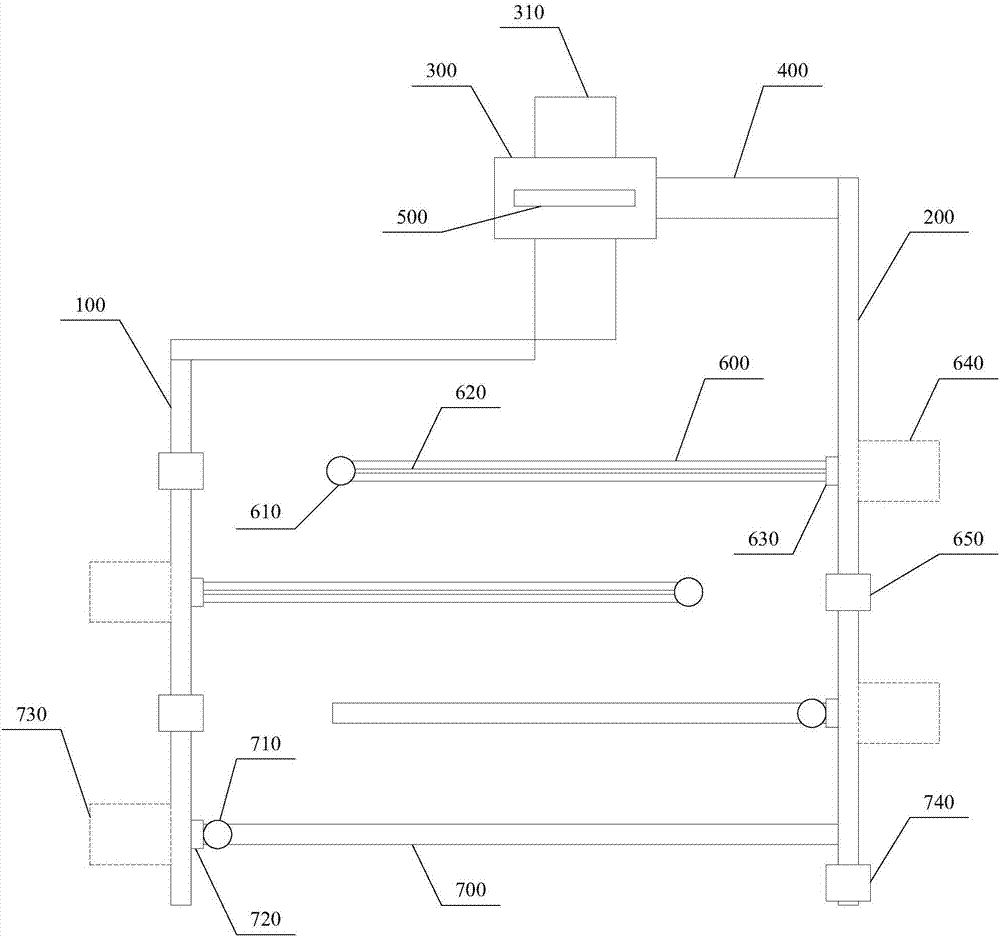

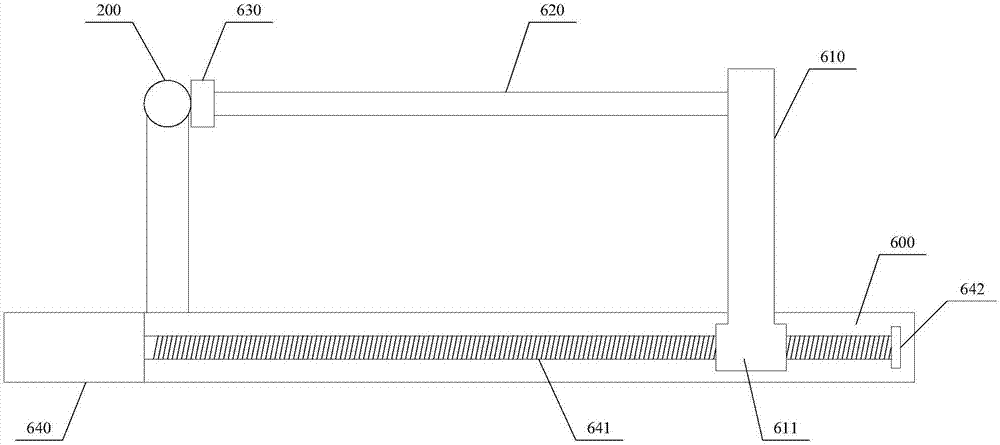

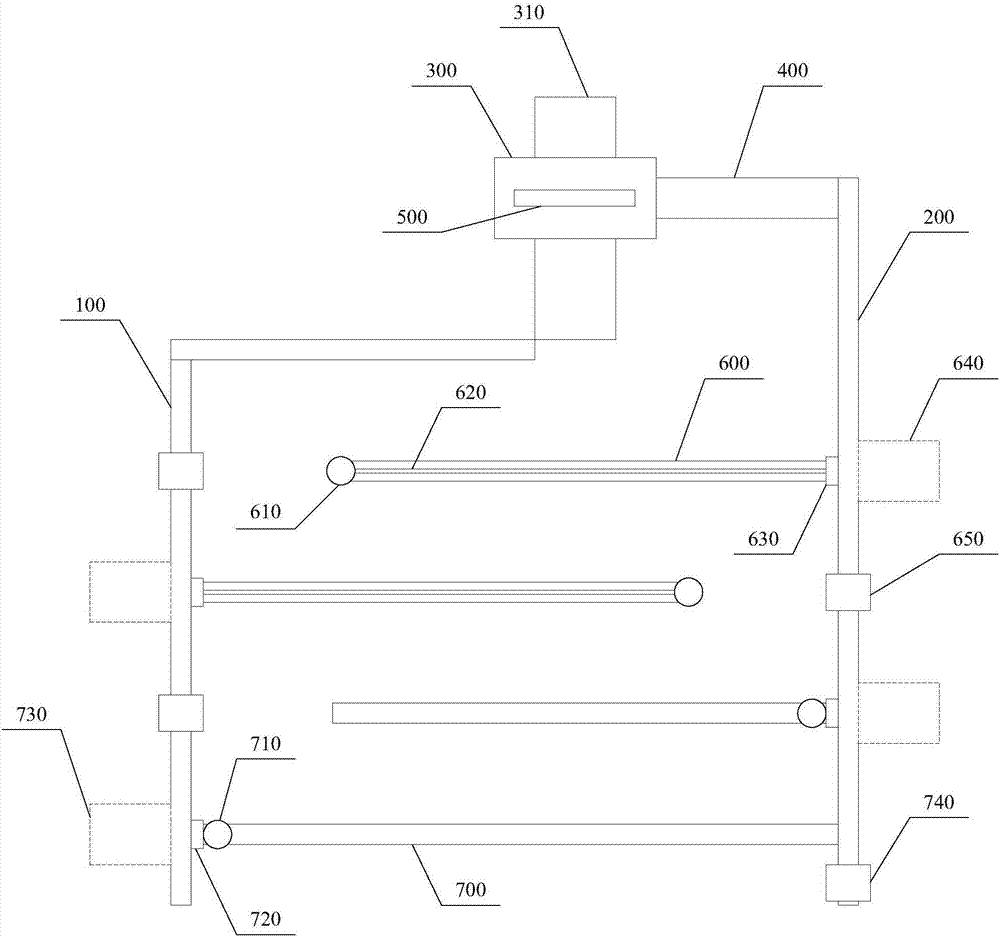

Food water cutting device and food water cutting method

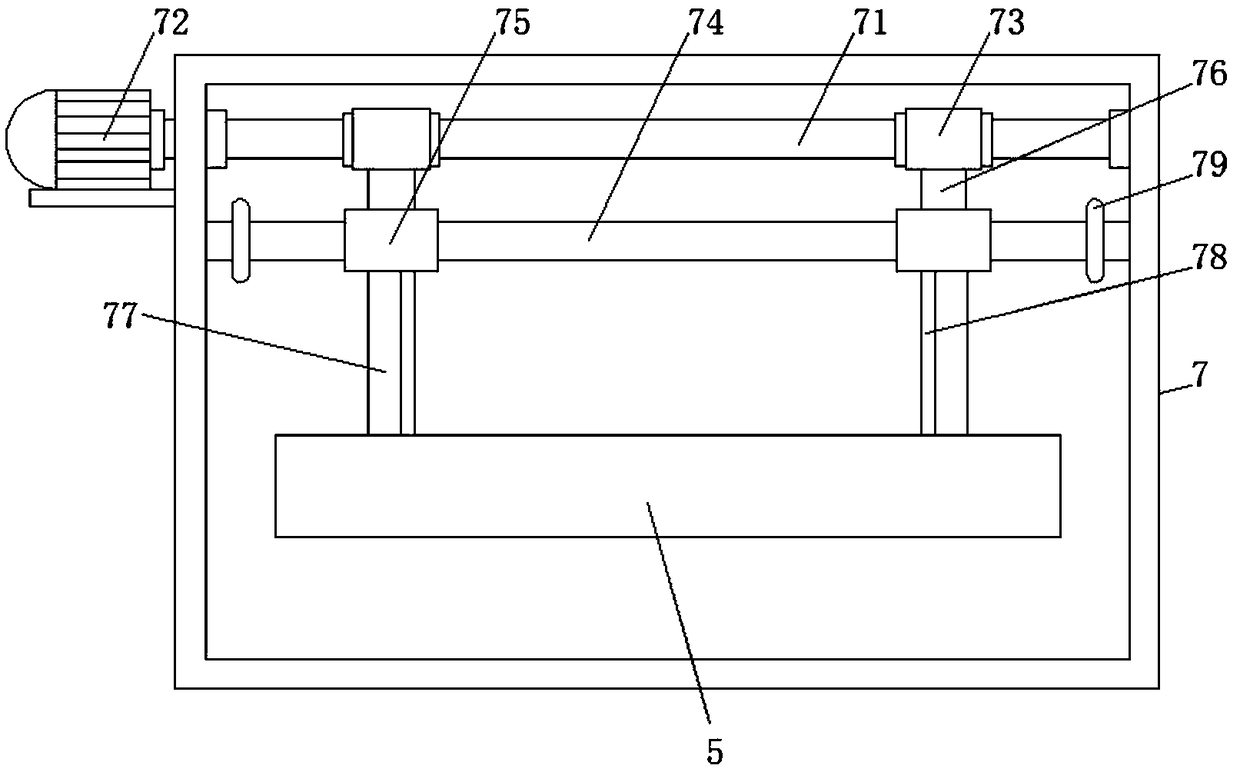

The invention discloses a food water cutting device and a food water cutting method. A cutting head moving device is used for driving a water cutter head to move; a cutting platform comprises a food table facet and a food table facet moving device; the food table facet is arranged under the water cutter head; the food table facet moving device is used for driving the food table facet to move; a negative pressure cleaning system comprises a collector, a vacuum device and an absorbing pipeline connected on the vacuum device; the collector is arranged on the lower side of the cutting platform and is used for cleaning food debris generated during the cutting process. The food water cutting method comprises the following steps: putting to-be-cut food on the food table facet; driving the cutter head to move along the horizontal direction of the cutting platform by the cutting head moving device; driving the food table facet to move along the longitudinal direction of the cutting platform by the food table facet moving device or driving the food table facet to rotate by a food table facet rotating device. The food water cutting device can realize the diversity of cut patterns; food is not stuck to a water cutter; cutting edges are effectively kept tidy.

Owner:DARDI INT CORP

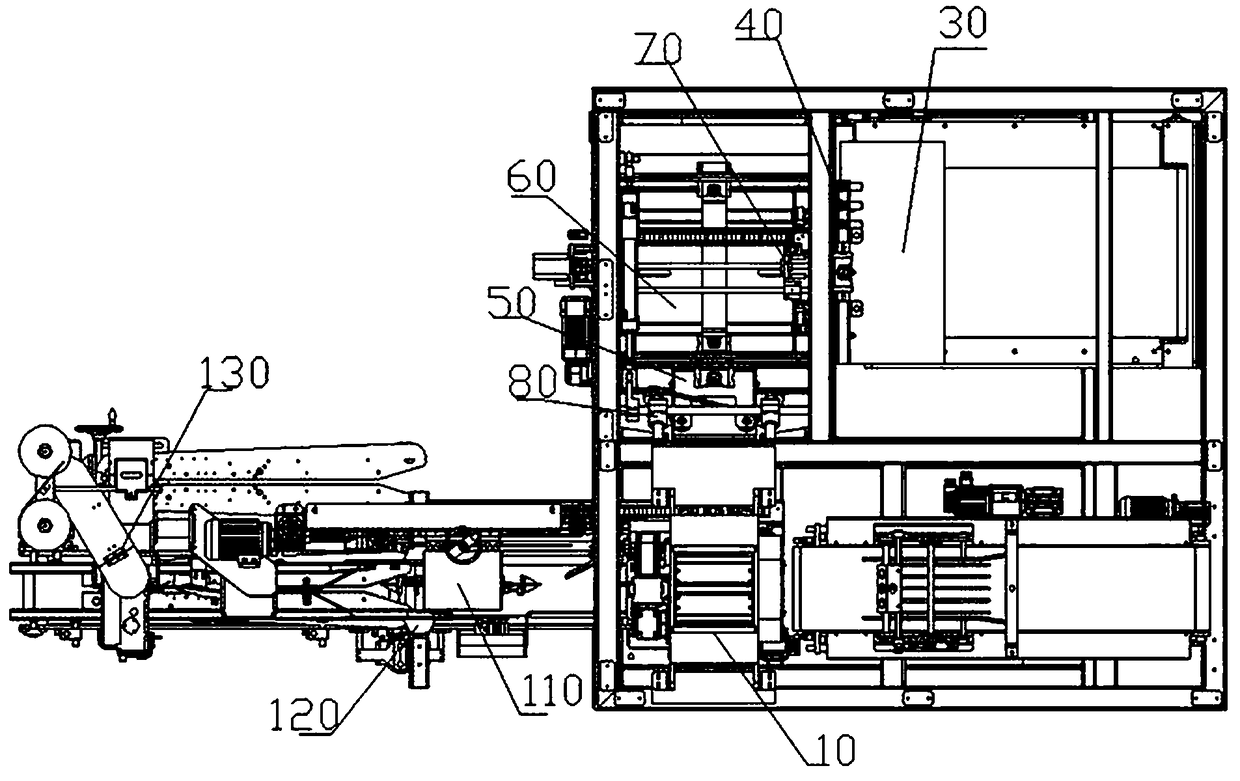

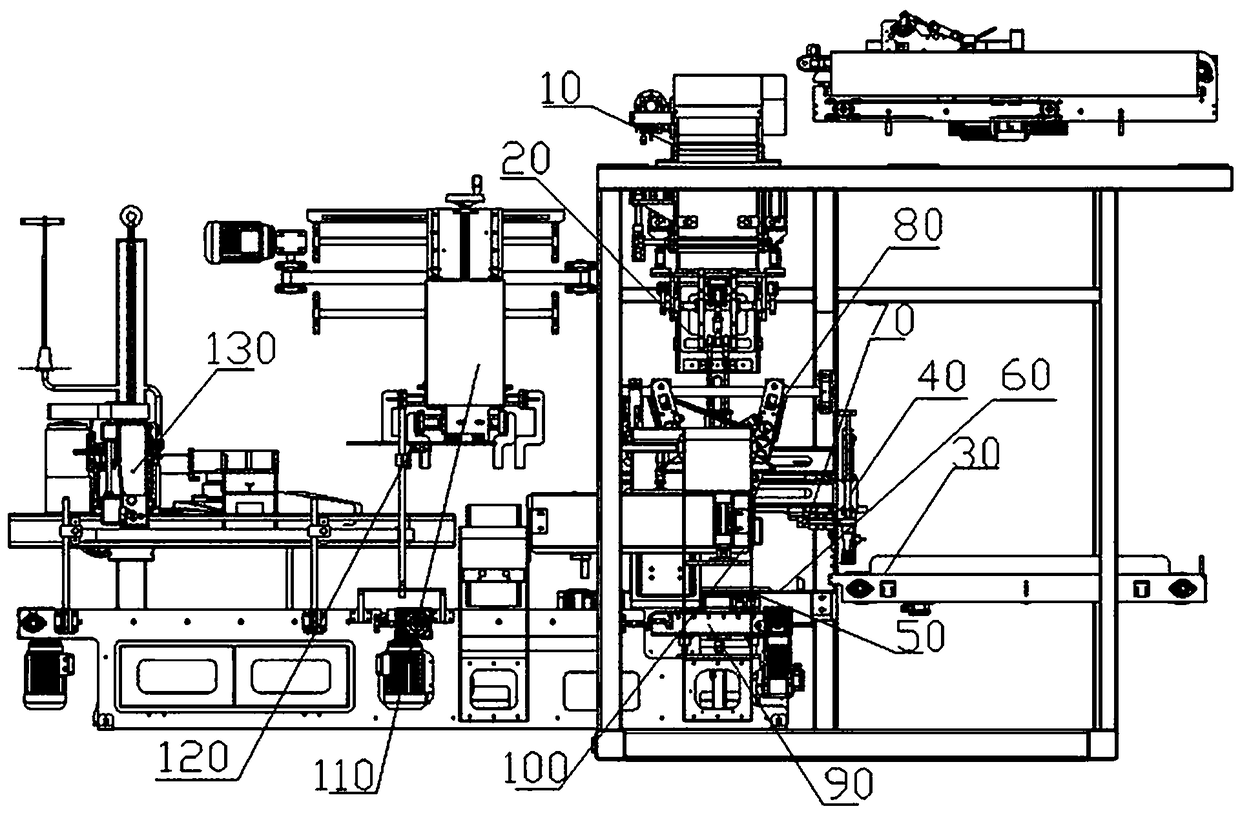

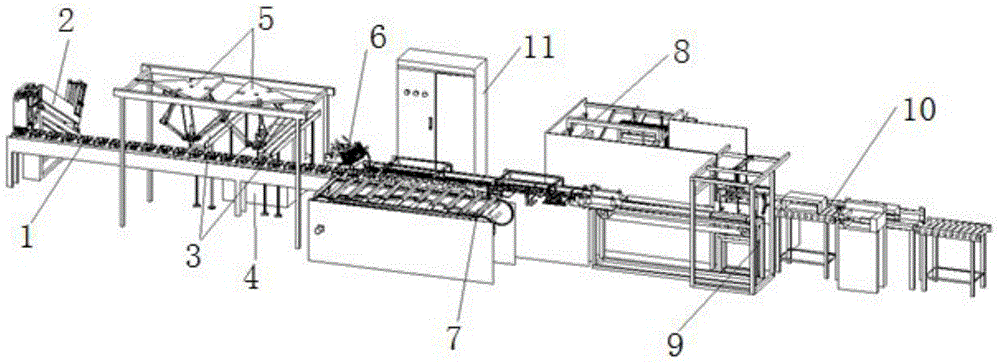

Packaging production line used for multi-product collective packaging

InactiveCN104875912AReferred to separation efficiencyFully automatedFinal package aspectsIndividual articlesProduction lineControl system

The invention relates to a packaging production line used for multi-product collective packaging. The packaging production line comprises a main conveying belt, a plastic demounting support machine, a feeding conveying belt, a coding machine, a feeding manipulator, a box demounting machine, a box packing and sealing machine, a box unpacking machine, an integral code layer box filling machine, a box sealing machine and a control cabinet. The packaging production line is characterized in that the plastic demounting support machine, the feeding manipulator, the box unpacking machine and the box packing and sealing machine are sequentially connected via the main conveying belt, the coding machine is mounted on the lower portion of the feeding conveying belt, the feeding manipulator is arranged right above the main conveying belt and higher than the feeding conveying belt, and the main conveying belt, the plastic demounting support machine, the feeding conveying belt, the coding machine, the feeding manipulator, the box demounting machine, the box packing and sealing machine, the box unpacking machine, the integral code layer box filling machine and the box sealing machine are electrically connected with a control system in the control cabinet.

Owner:HEBEI UNIV OF TECH

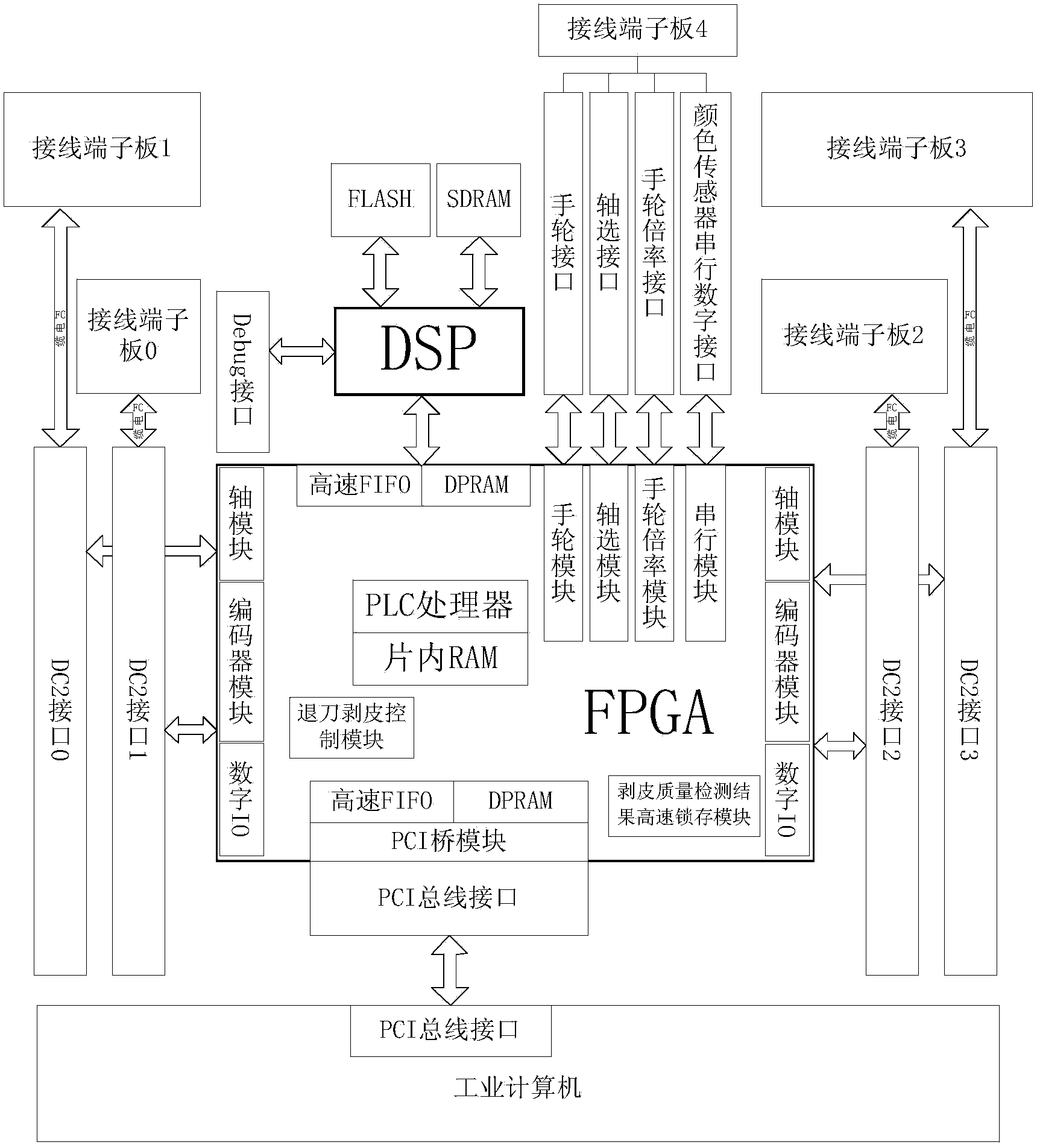

Full-automatic single-ended and double-ended tangent wire stripping terminal pressure welding machine control system

The invention discloses a full-automatic single-ended and double-ended tangent wire stripping terminal pressure welding machine control system. The system comprises an industrial computer, a PLC+MC integrated controller and terminal boards. The industrial computer is connected with the PLC+MC integrated controller through a PCI bus interface, and the controller is connected with the terminal boards through DC2 interfaces. The high-performance embedded control technology is introduced to the harness processing field, so that the high-performance control system for harness processing is achieved; coordinated synchronization of mechanical control and mechanical motion is achieved by adopting multiple control modes; the PLC process is integrated with motion control, and high-speed and high-precision smooth processing is achieved through parameter optimization matching of processing technologies, motion control based on speed modes and the like.

Owner:SOUTH CHINA UNIV OF TECH

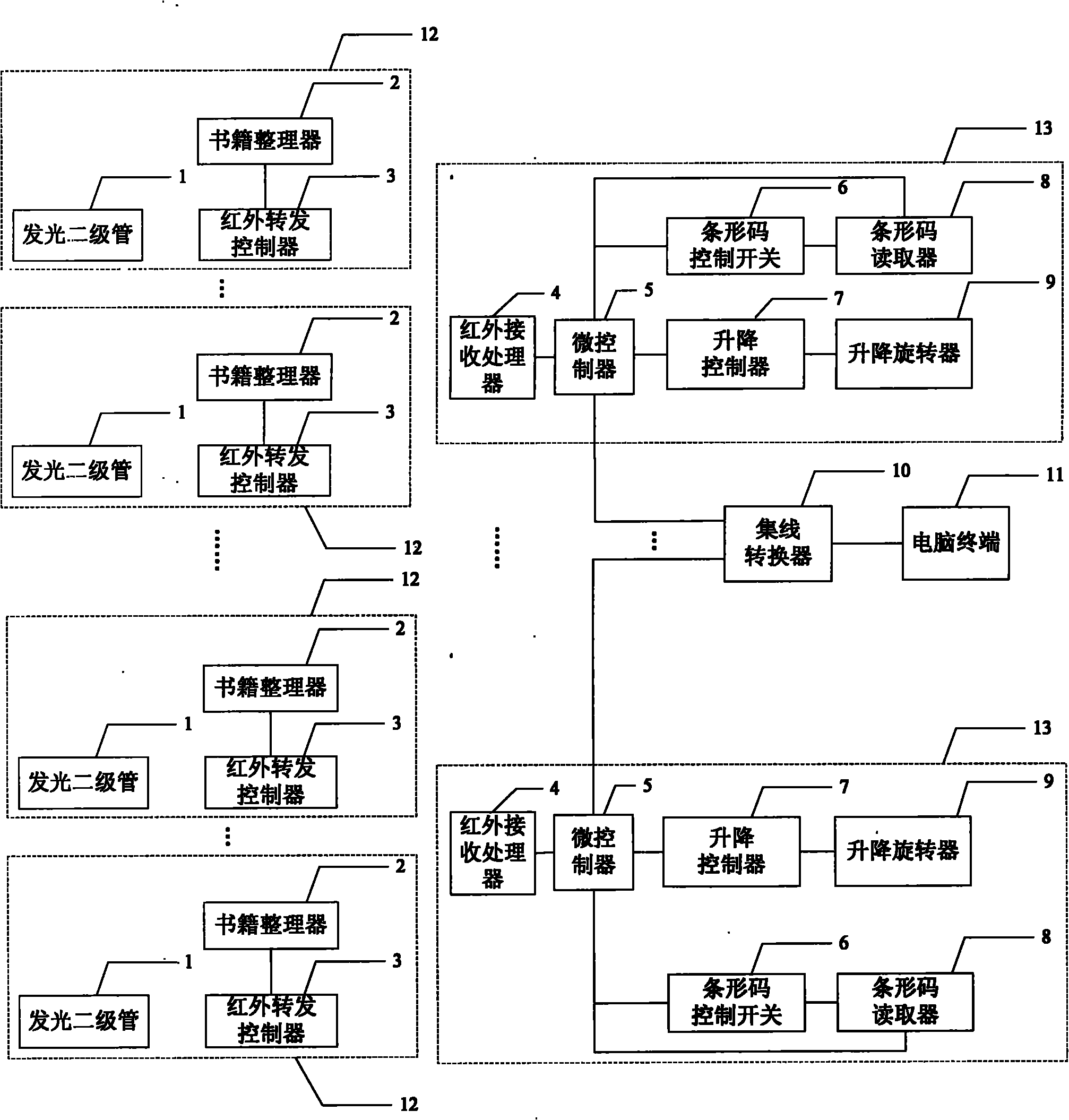

Self-service error-detecting arrangement device for library

InactiveCN101779864ASolve manual error checkingSolve the problem of low efficiency of manual error checkingBook-troughsMicrocontrollerEngineering

The invention discloses a self-service error-detecting arrangement device for a library, and belongs to the technical field of library arrangement automation. The self-service error-detecting arrangement device comprises an induction arrangement system, a control scanning system and a computer terminal, wherein the induction arrangement system comprises a book collator, a light-emitting diode and an infrared forwarding controller; the control scanning system comprises a lifting rotator, an infrared receiving processor, a microcontroller, a barcode reader and the like; the light-emitting diode sends infrared light to the infrared forwarding controller; if a person takes or puts a book, the infrared light is cut off, a book taking signal is forwarded to the infrared receiving processor, and a book collator is started; and the microcontroller receives the book taking signal of the infrared receiving processor, outputs the book taking signal to the lifting controller so as to control the lifting rotator to carry the barcode reader to lift together, outputs the book taking signal to a barcode control switch to start the barcode reader to rotationally scan bar codes of the whole layer of books, receives barcode data, and judges a book arrangement error to transmit to the computer terminal. The self-service error-detecting arrangement device detects wrongly arranged books in real time, and simultaneously ensures the neatness of the front surface of a bookshelf when the sizes of the books are different.

Owner:SHANDONG UNIV

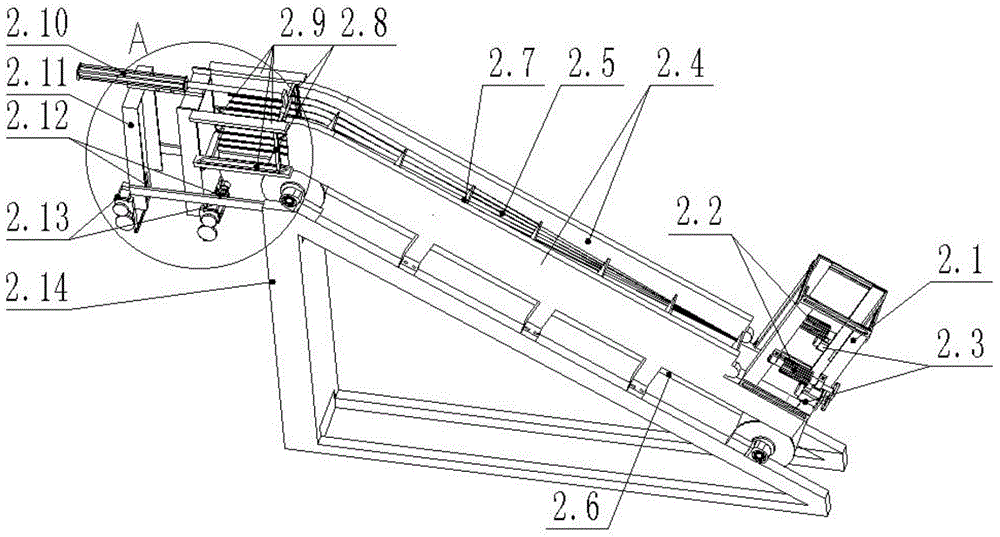

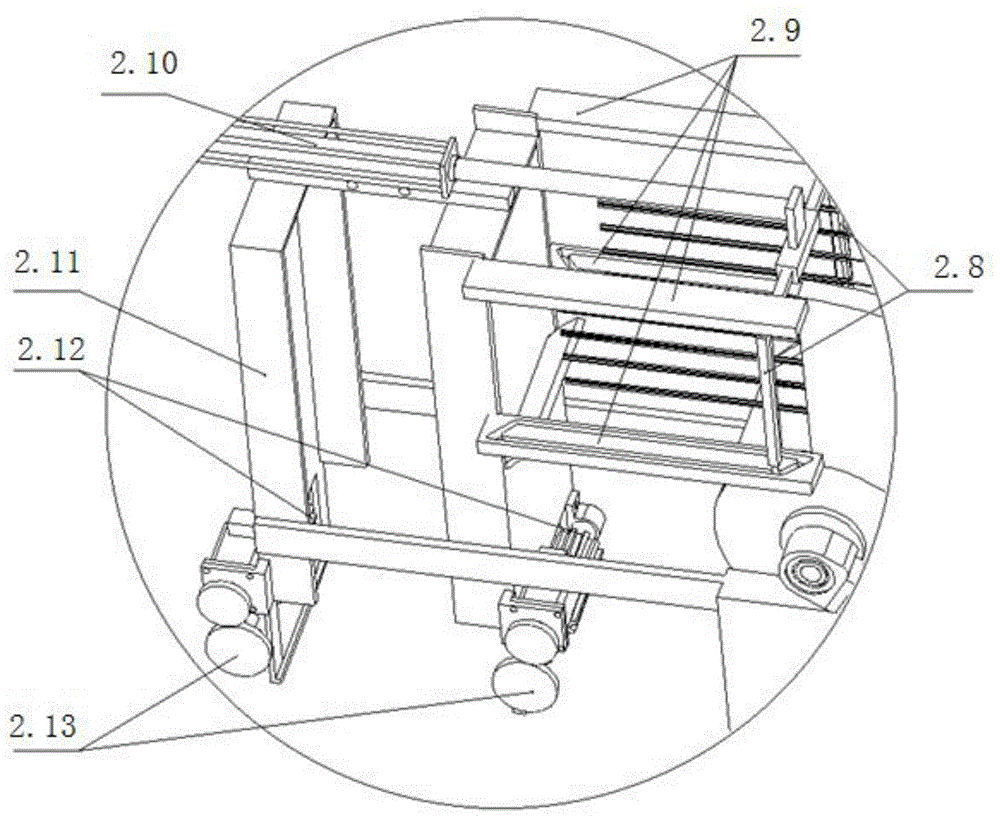

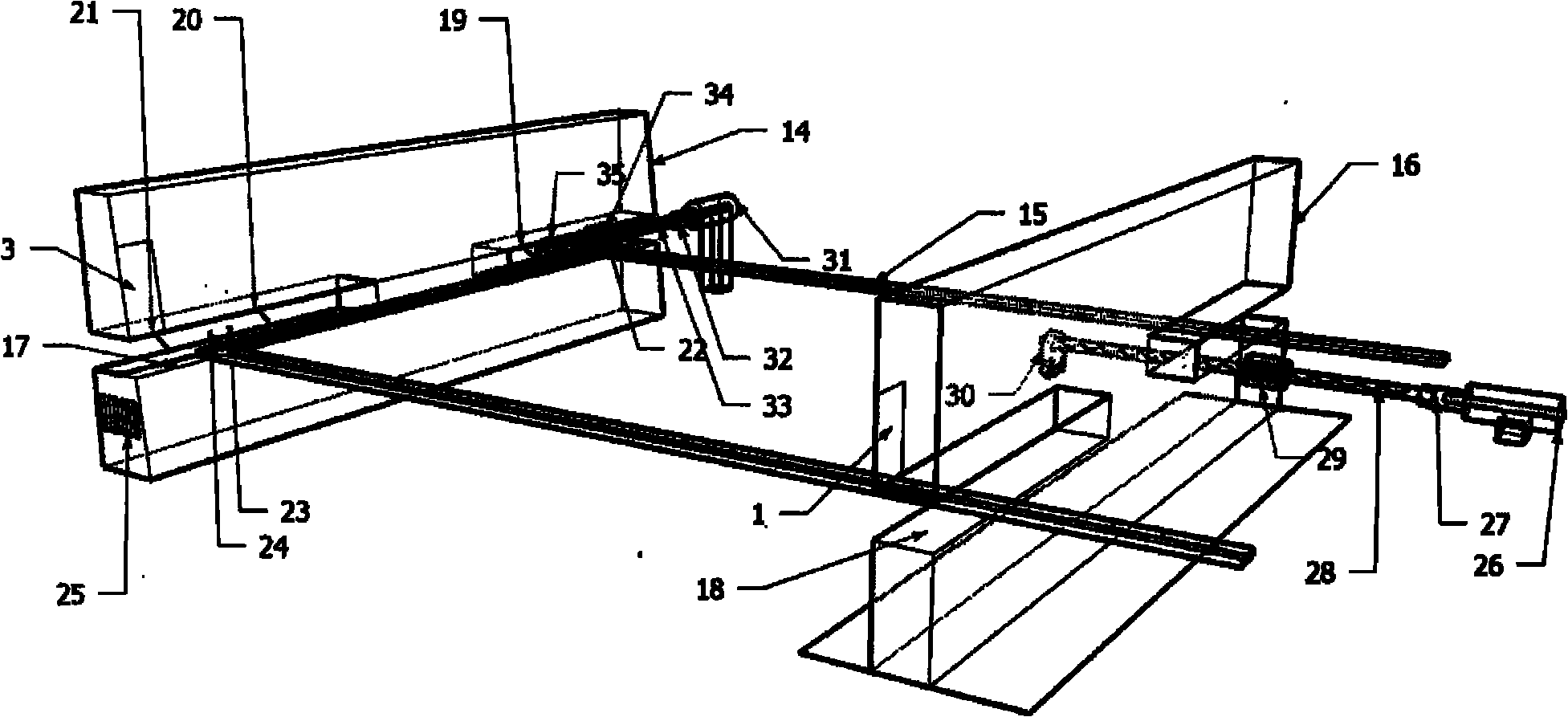

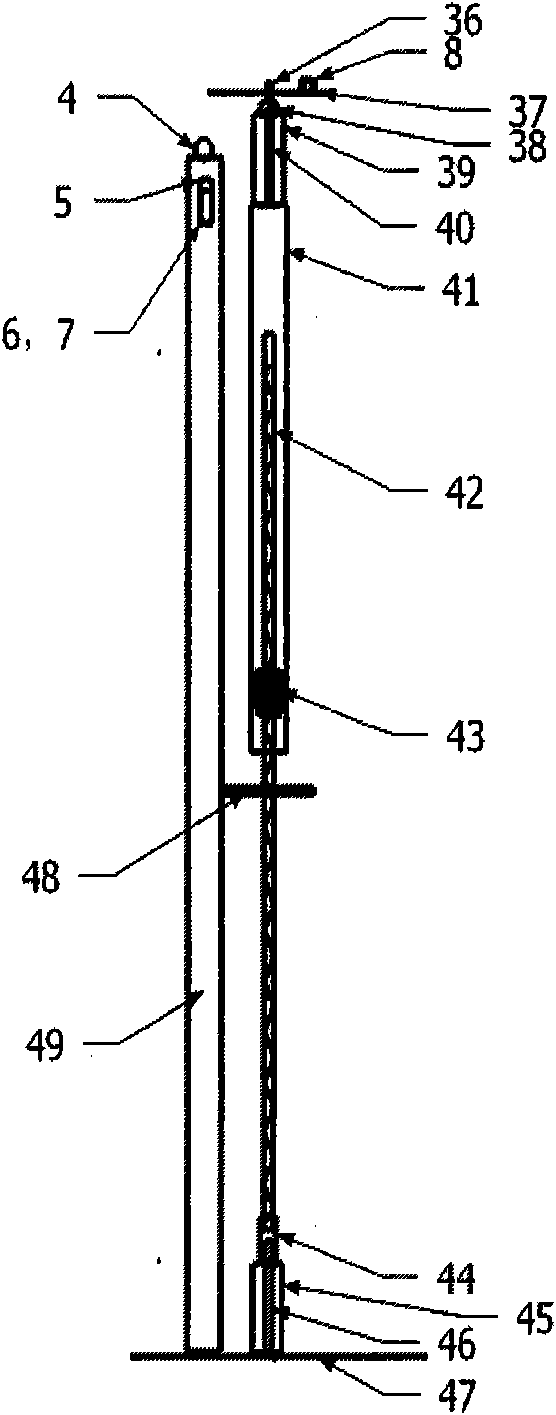

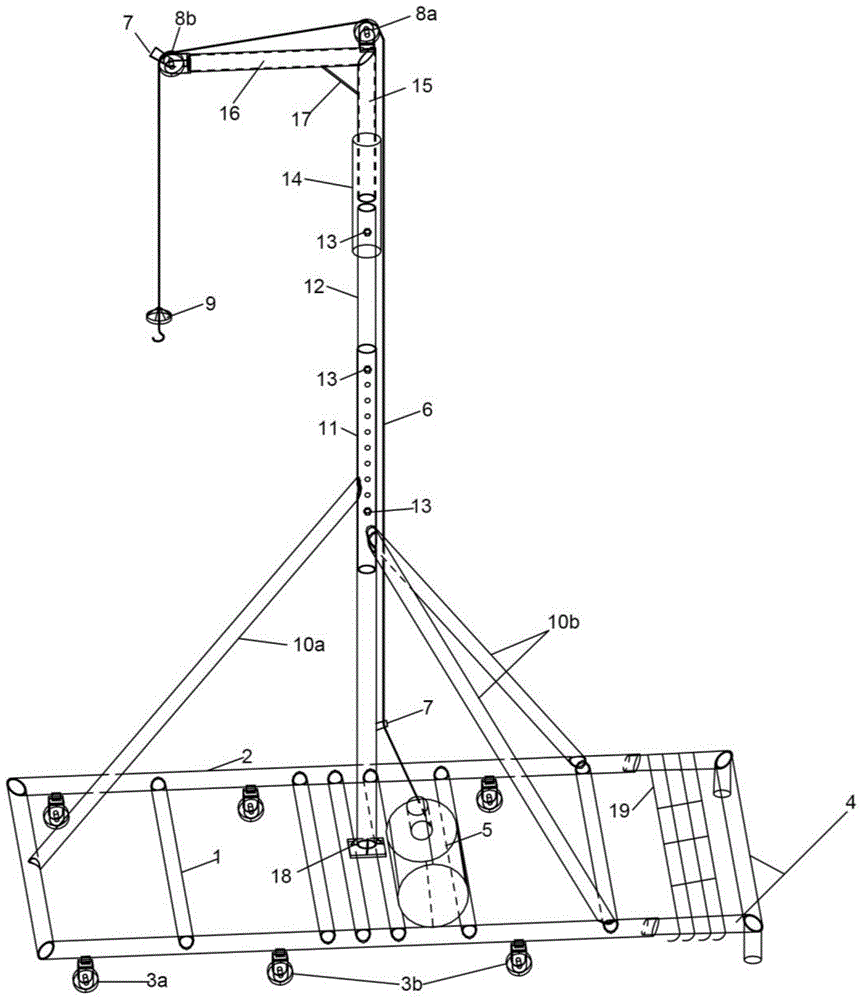

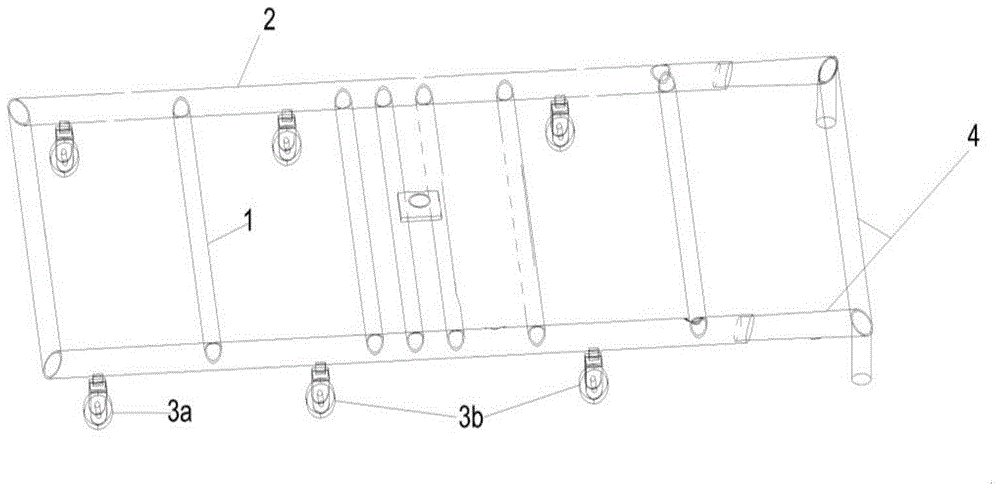

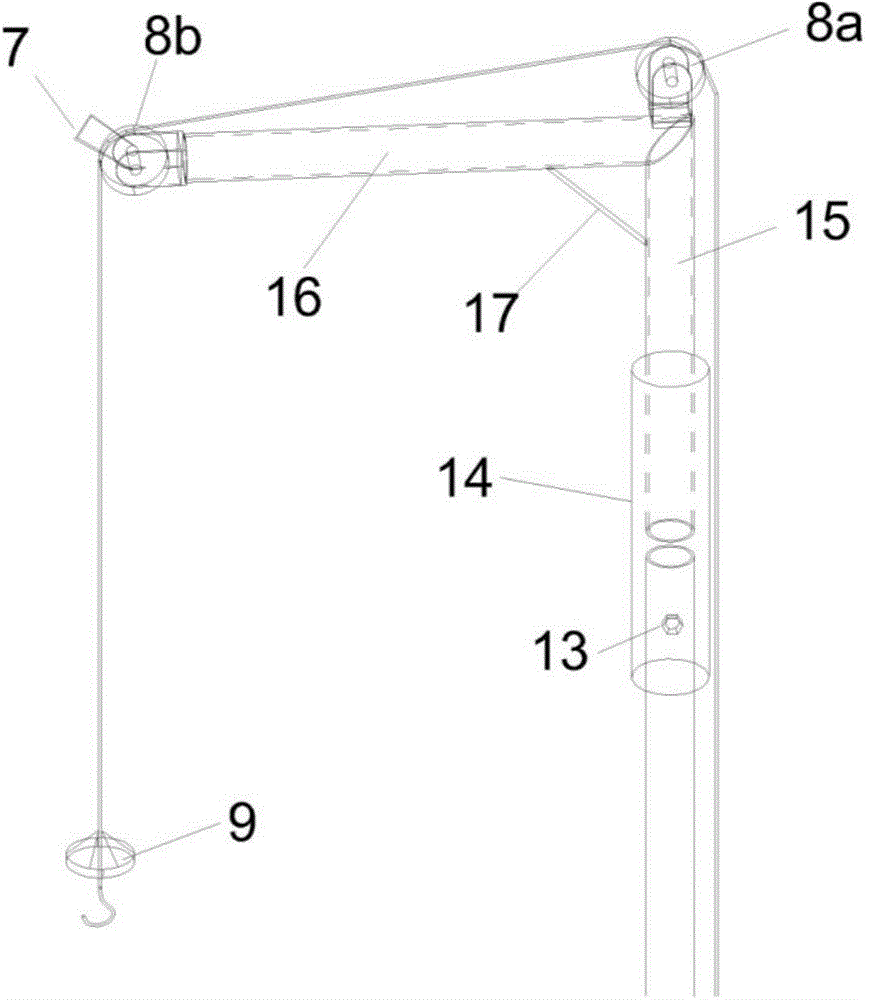

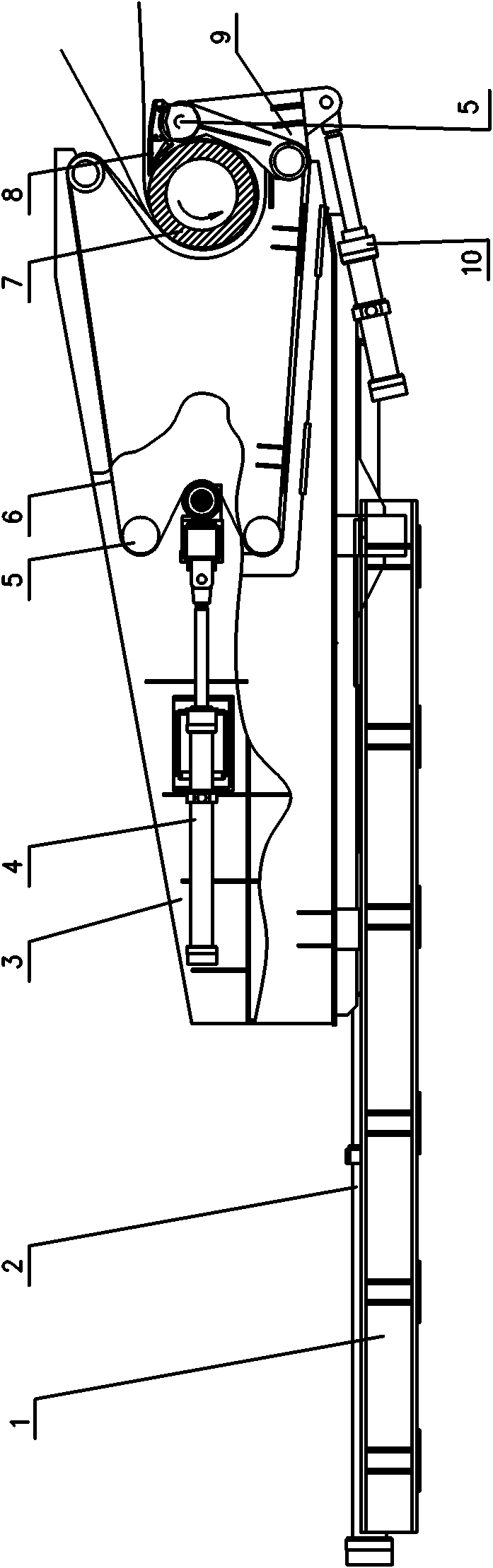

Vertical transport device for construction material between building block layers

InactiveCN104860211AGuaranteed integrityGuaranteed tidyCargo handling apparatusPassenger handling apparatusEngineeringMaterial transport

The invention discloses a vertical transport device for a construction material between building block layers. The vertical transport device comprises a horizontal base, a main mast, a telescopic mast, a rotary sleeve, a rotary mast, a horizontal hanger rod, a first fixed pulley and a winding engine, wherein the main mast is vertically fixed on the horizontal base; the lower end of the telescopic mast is inserted into the upper end in the main mast; the upper end of the telescopic mast is inserted into the lower end in the rotary sleeve; the upper end of the rotary sleeve is inserted into the rotary mast; the top of the rotary mast is vertically and fixedly connected with one end of the horizontal hanger rod; two ends of the horizontal hanger rod are respectively connected with the first fixed pulley and a second fixed pulley to form a pulley; a lifting hook is arranged at one end, which winds the first fixed pulley, of a steel wire rope; one end, which winds the second fixed pulley, of the steel wire rope, is connected with the winding engine; the winding engine is fixedly arranged on the horizontal base. The problem that the building blocks for secondary structure construction of a large-floor height structure is difficult to vertically transport is solved; the vertical transport device has the advantages of being simple, efficient, safe, low in equipment cost, and easy to operate and maintain; the material transportation efficiency and the construction efficiency of a worker are improved; the construction labor intensity is alleviated.

Owner:WUHAN CONSTR ENG

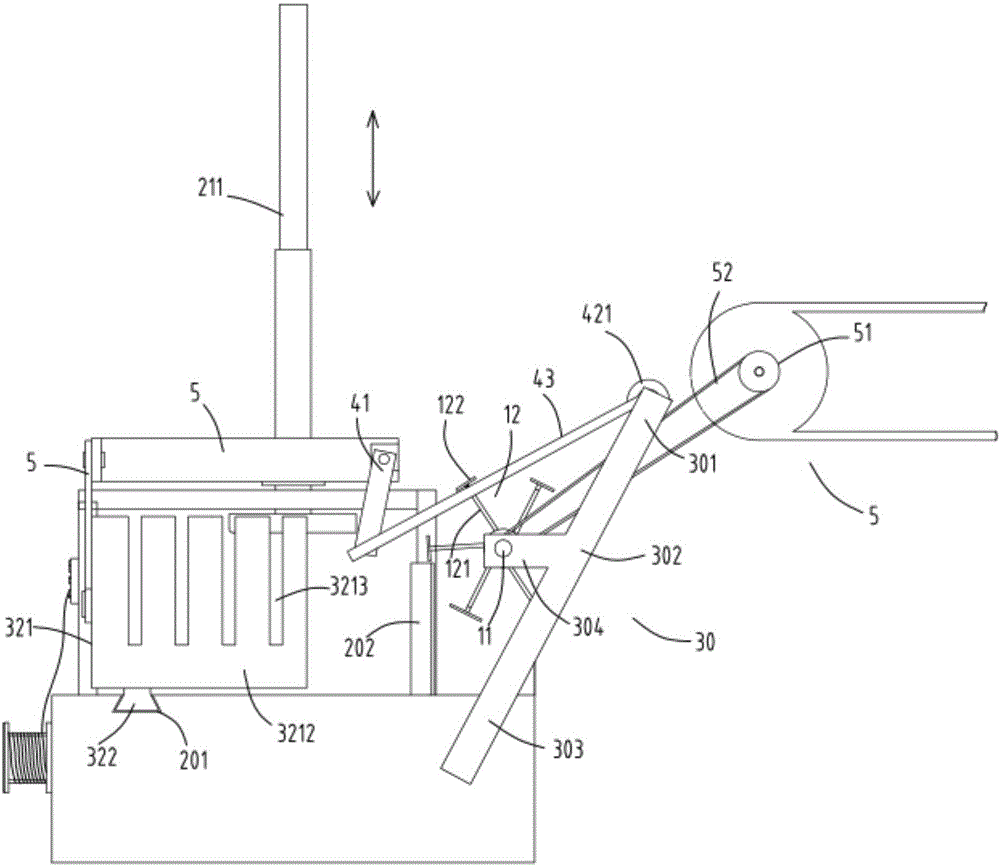

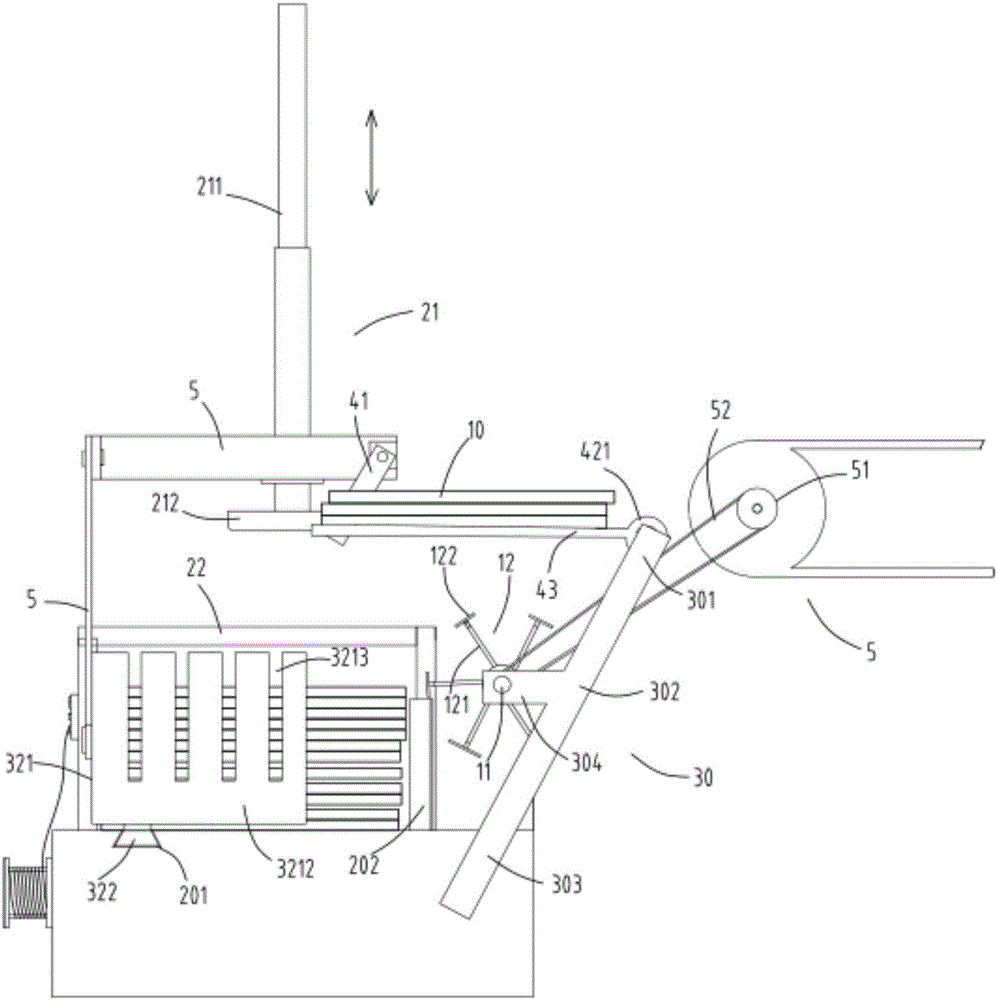

Arrangement equipment for packaging with supporting and sending device

ActiveCN106672288AEnhanced binding effectWork well togetherBundling machine detailsInstabilityCarton

The invention relates to arrangement equipment for packaging with a supporting and sending device. The arrangement equipment comprises the supporting and sending device, a pressing and packaging part, a pushing and arranging part and a bearing part; the supporting and sending device is composed of a rotary shaft and a plurality of supporting units fixedly arranged in the circumferential direction of the rotary shaft; each supporting unit is composed of a supporting rod and a supporting plate fixed at the end part of the supporting rod; the pressing and packaging part is composed of a pressing device and a packaging device; the pressing device is composed of a lifting rod and a pressure plate fixed at the end part of the lifting rod; the pushing and arranging part is composed of a transmission part driven by the lifting rod and a baffle part which slides along a workbench driven by the transmission part; the bearing part is composed of moving rod driven by the lifting rod and a bearing plate which rotates around a fixing shaft arranged at the upper section part of a bracket driven by the moving rod; and a through groove through which the supporting and sending device rotates is formed in the bearing plate. According to the arrangement equipment, the problems of untidy piling of paper boxes before packaging, infirmness in loose packaging, large equipment operation noise, instability in whole transmission of cached and piled paper boxes and up and down irregularity are overcome

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

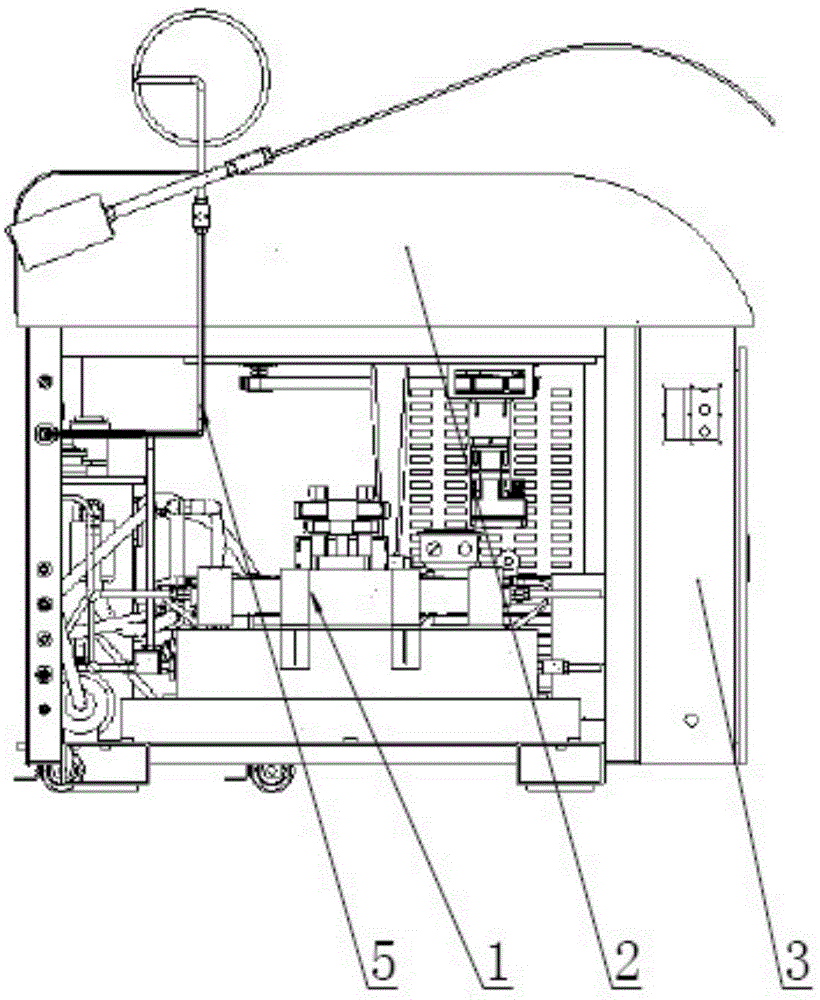

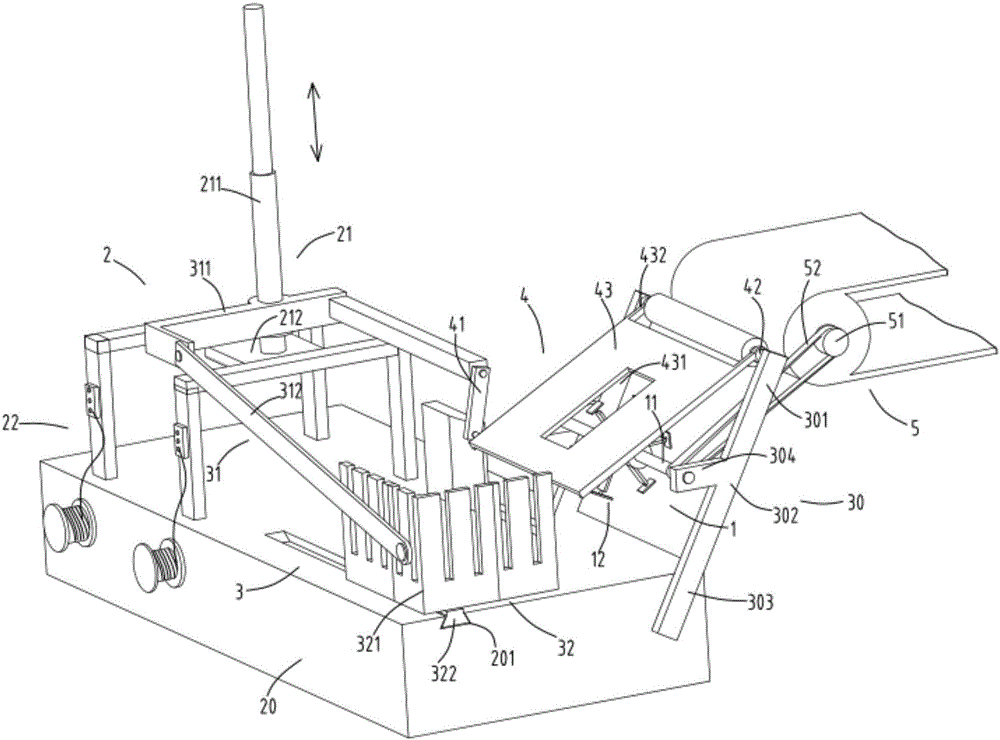

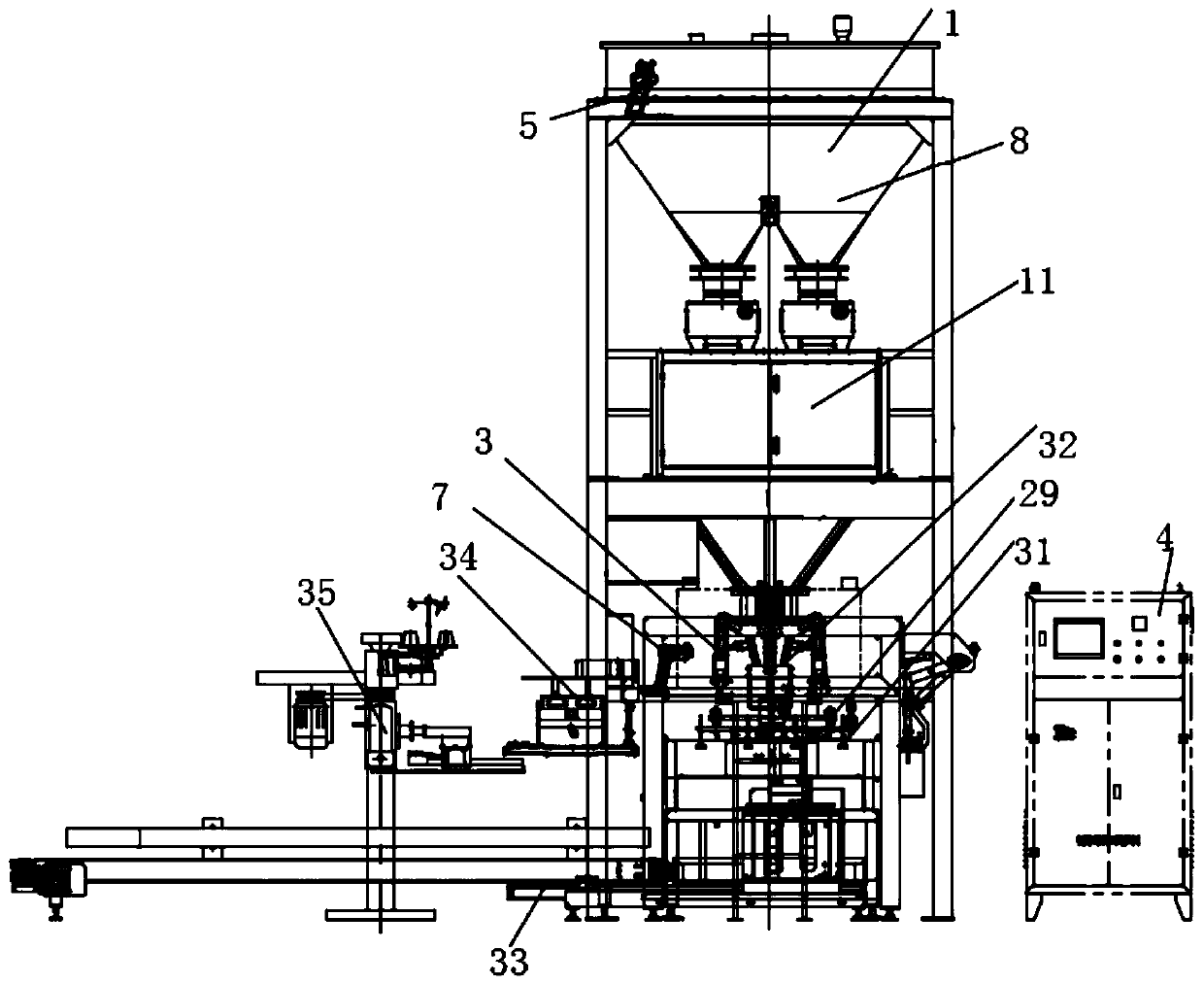

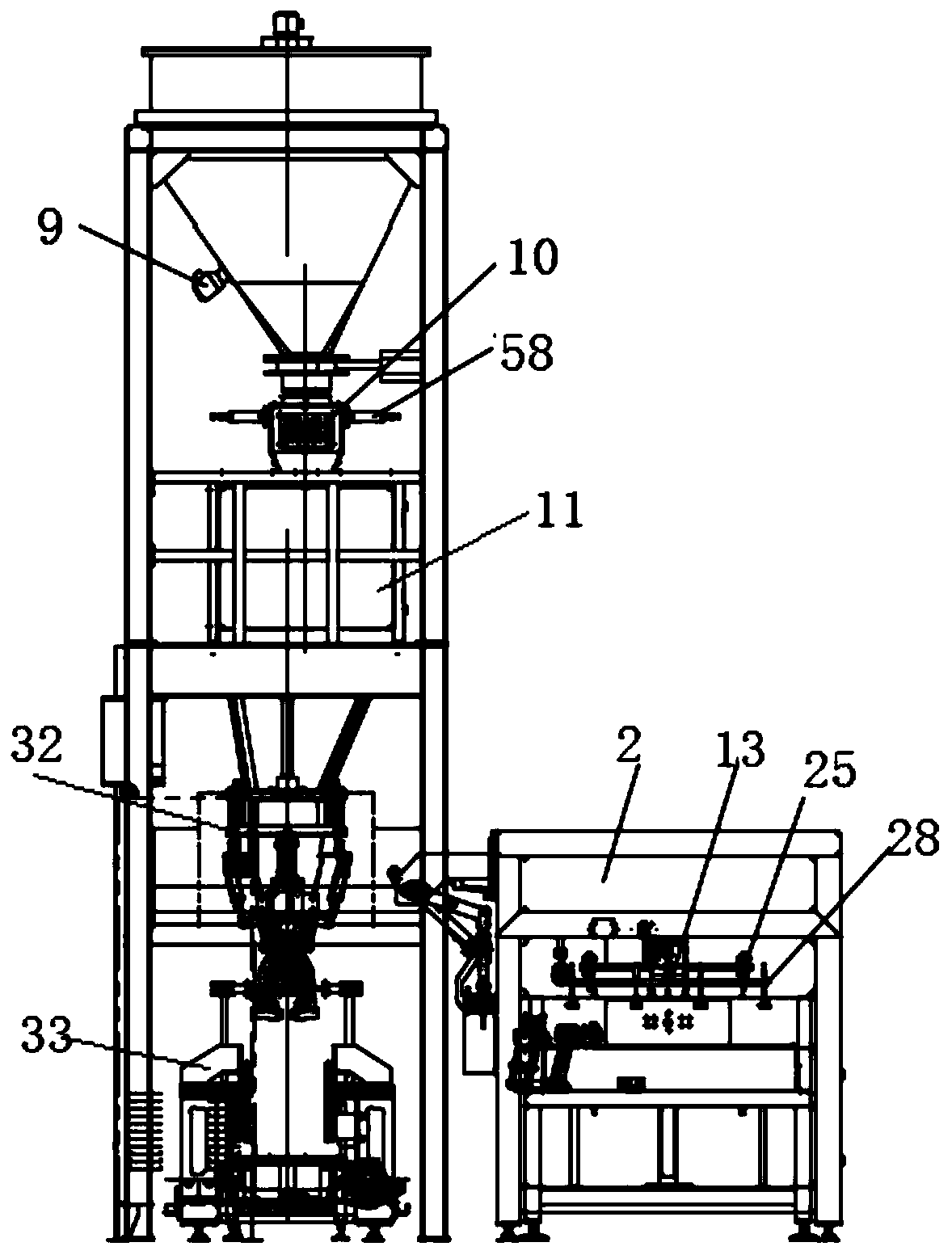

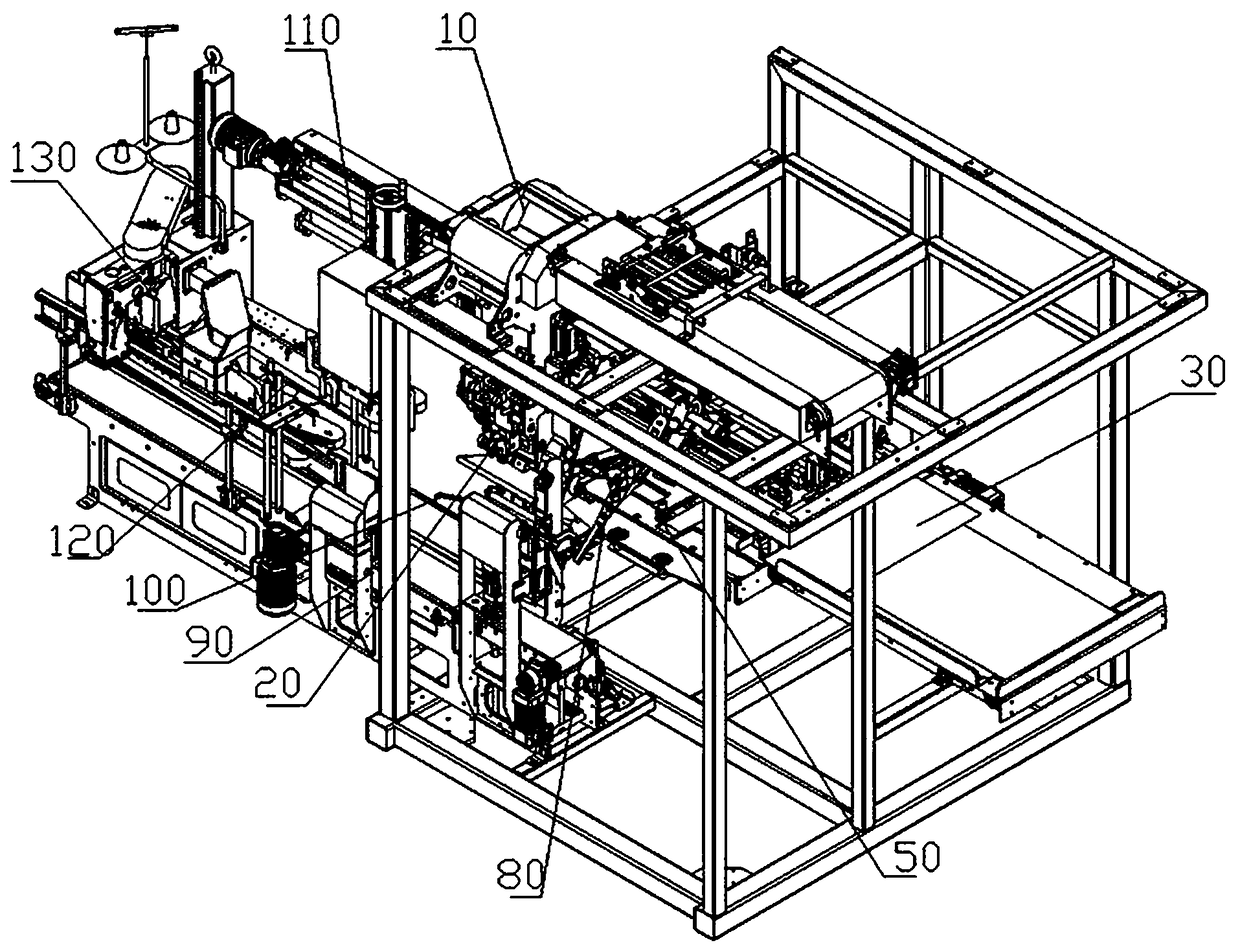

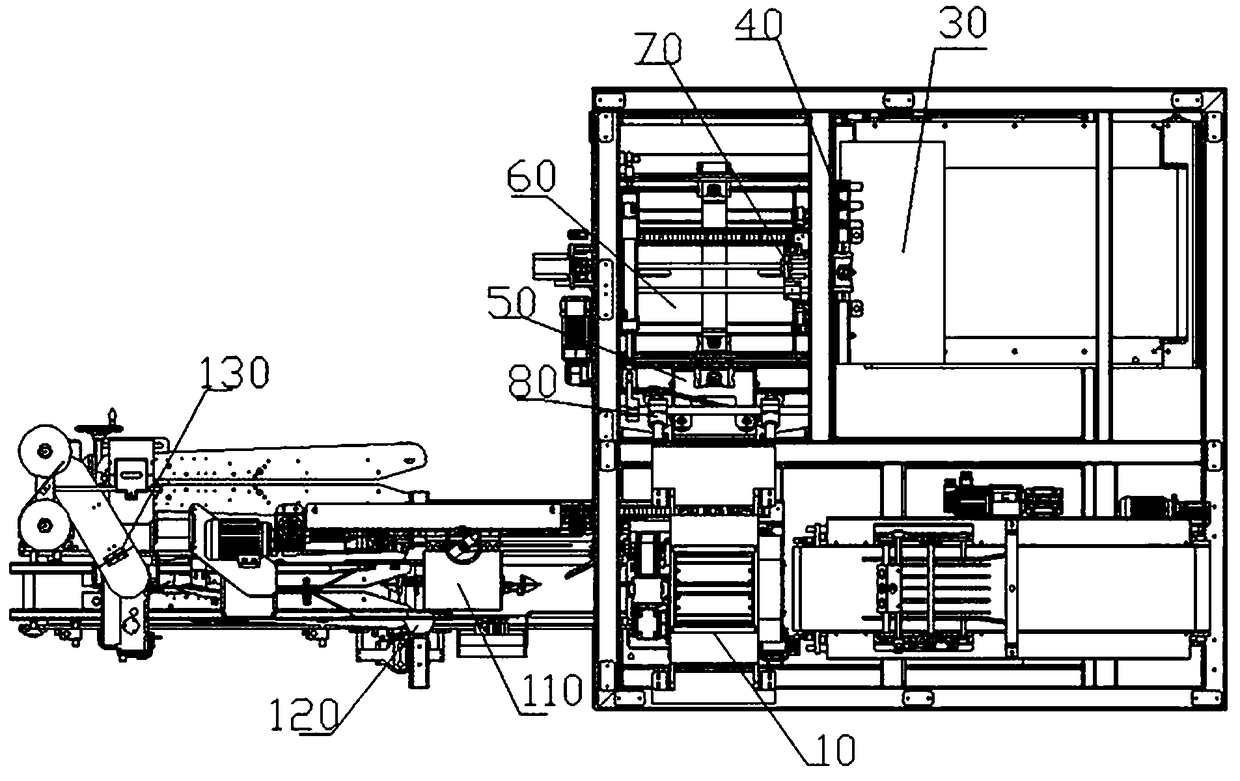

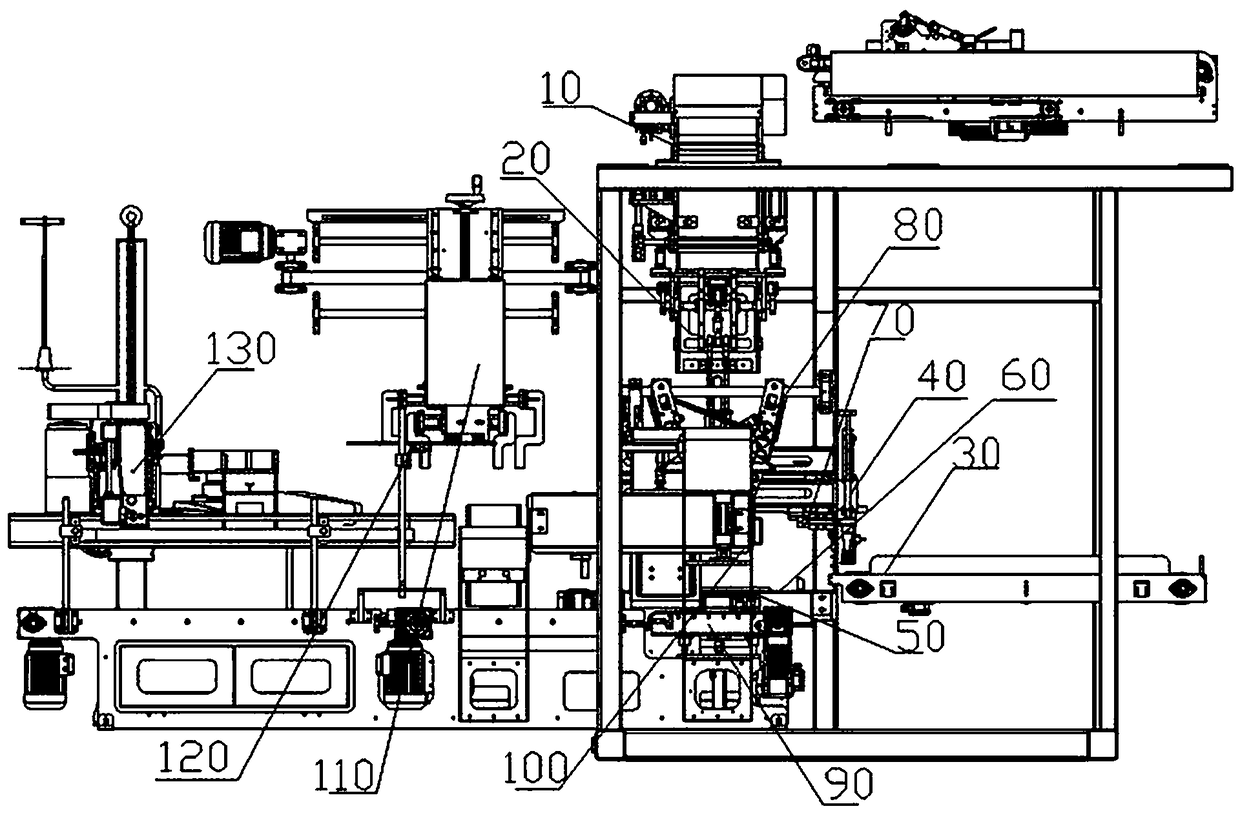

Full-automatic bagging, metering and packaging system based on vision detection

ActiveCN110803345AAdjustable bag widthWill not affect the bagSolid materialEngineeringComputer vision

The invention discloses a full-automatic bagging, metering and packaging system based on vision detection. The system comprises a full-automatic quantitative metering unit for feeding and metering, afull-automatic bagging unit for supplying bags, replacing and bagging, a full-automatic packaging unit for clamping the bags, transferring and conveying the bags and sewing the bags and an electric control device for controlling the full-automatic quantitative metering unit, the full-automatic bagging unit and the full-automatic packaging unit. A vision detection mechanism I is mounted on the full-automatic quantitative metering unit, a vision detection mechanism II and a vision detection mechanism III are separately mounted on the full-automatic bagging unit, and the vision detection mechanism I, the vision detection mechanism II and the vision detection mechanism III are in communication connection to the electric control device. A bagging sucking disc mechanism is matched with vision detection in a bag taking process to detect the degree of to-be-settled packaging bags, to detect whether the packaging bags are in a mess or not and to detect the opening conditions of the bag mouths after the bags are taken on a bag supporting plate without finding abnormality manually, so that accurate data images are provided for analysis and use by a system.

Owner:合肥伟特机电装备制造有限公司

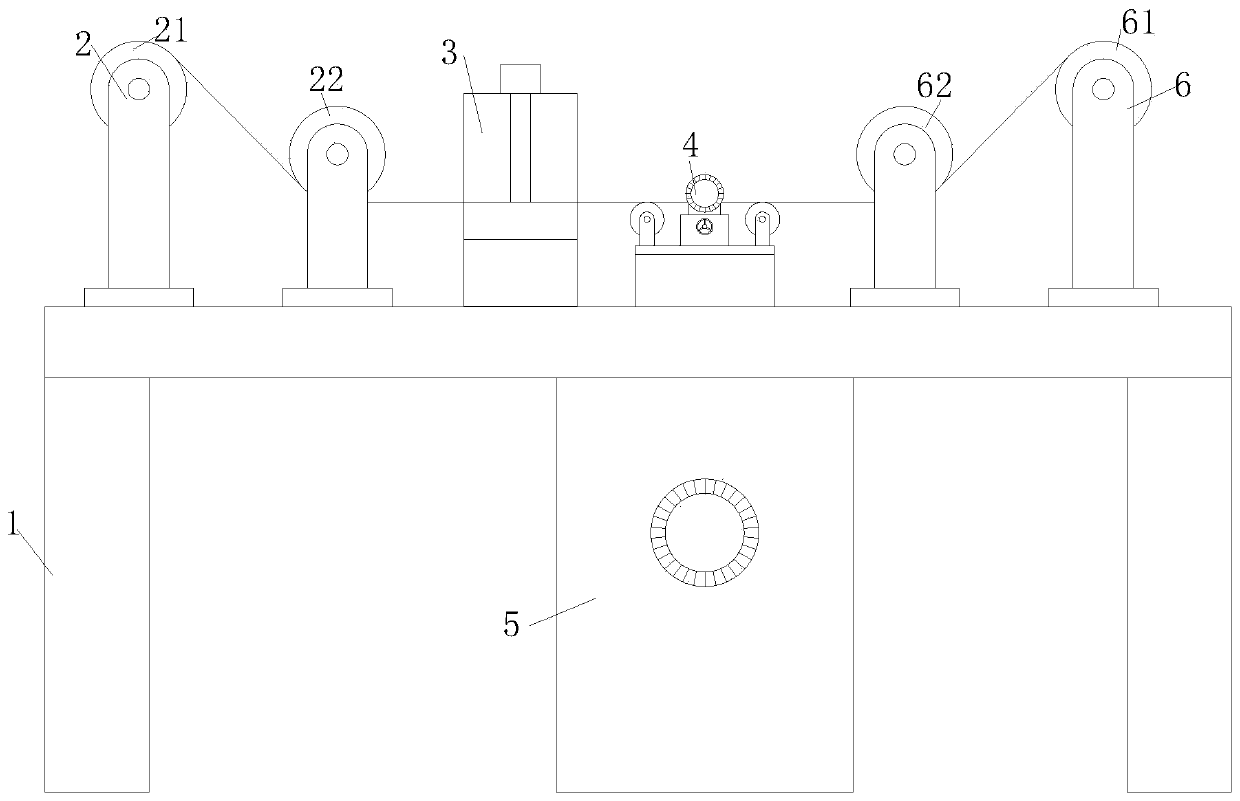

Cloth trimming and recycling device

InactiveCN110965307AGuaranteed tidyAvoid wastingSevering textilesStructural engineeringMechanical engineering

The invention discloses a cloth trimming and recycling device, which comprises a rack, wherein an unwinding component is arranged on one side of the rack; a flattening component is arranged at one side of the unwinding component; a trimming component is arranged on one side, away from the unwinding component, of the flattening component; a recycling component is arranged below the trimming component; and a winding component is arranged on one side, away from the flattening component, of the trimming component. Through the arrangement of the flattening component, the flattening component is used for flattening the wrinkles of the cloth from the middle to the outward, so that the neatness of cloth trimming is guaranteed, the burrs of the flattened cloth are cut by the trimming component, andthe cut burrs are recycled by the recycling component; and furthermore, a winding roller is detachably arranged in the middle of a recycling bin, so that subsequent unified collection and utilizationare facilitated, and waste of resources is avoided.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

Cloth cutting device of textile machine

ActiveCN103950766AGuaranteed tidyImprove work efficiencyWebs handlingArchitectural engineeringTextile

The invention discloses a cloth cutting device of a textile machine. The cloth cutting device of the textile machine comprises an upper reed beam, a lower reed beam, upright columns and reed teeth of a steel reed, wherein the reed teeth are uniformly distributed between the upper reed beam and the lower reed beam; linear guide rails are fixed on the upper end surface of the upper reed beam and the lower end surface of the lower reed beam and are sleeved with linear bearings; the linear bearings are fixed on the inner bottom surface of an n-shaped bracket; a clamping strip is fixedly connected to the inner side wall of the bracket through a bolt; the bolt is sleeved with a rubber strip; two side surfaces of the rubber strip are respectively propped against the clamping strip and the bracket; the end surface of one side of the rubber strip is propped against the inner end surface of the upper reed beam or the lower reed beam, and the other end of the rubber strip is exposed from the bottom surface of the bracket. According to the cloth cutting device of the textile machine, contact between a reeding cutter and the reed beams of the steel reed is avoided, and meanwhile, abrasion of the reeding cutter can be reduced due to frictional contact between the reeding cutter and the rubber strip, so that the abrasion of the reeding cutter and the steel reed is reduced, and the service lives of the reeding cutter and the steel reed are prolonged.

Owner:苏州盛泽科技创业园发展有限公司

Automatic punching and threading binding machine

The invention provides an automatic punching and threading binding machine which solves the problems of low efficiency and cumbersome operation. The automatic punching and threading binding machine comprises a paper placing platform, a rear support platform, a cord wheel, a cord sending and shearing mechanism and a cord pushing mechanism, wherein the upper surface of the paper placing platform ishorizontally arranged, and a paper baffle plate is arranged on the paper placing platform; the rear support platform is fixed on the paper placing platform, a paper pressing mechanism used for fixingpaper on the paper placing platform is arranged on the rear support platform, and a pin pressing mechanism used for punching the fixed paper is arranged on the rear support platform; the cord wheel isarranged on one side of the paper placing platform and is wound with a bookbinding cord; the cord sending and shearing mechanism is arranged under the paper placing platform and is used for sending out and shearing off the bookbinding cord on the cord wheel; and the cord pushing mechanism is arranged on one side of the bookbinding cord and is used for pushing the sent bookbinding cord to the pinpressing mechanism. The automatic punching and threading binding machine has the advantages of simple structure and convenience in operation, can greatly improve the paper binding efficiency and reduce labor intensity, and has good practicality.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Design drawing binding equipment for industrial design

InactiveCN109050038AImprove aestheticsEvenly spacedBook making processesSheet bindingPunchingElectric machinery

The invention relates to the technical field of industrial design, in particular to design drawing binding equipment for industrial design. The invention aims to solve the technical problem that whena design drawing is punched and bound, binding holes are not uniform and are not on the same straight line. The design drawing binding equipment for industrial design comprises a binding box, whereinan entrance is formed in the right side of the binding box, the bottom of the inner wall of the binding box is connected with three supporting seats, and transmission rollers are rotationally connected to the tops of the three supporting seats. According to the design drawing binding equipment, the forward and reverse rotation of a rotating motor enables a first threaded rod drives two threaded sleeves to move oppositely, a sliding block is enabled to move up and down in a sliding rail through connecting rods, and a push rod drives the whole binding to perform punching for the drawing, so thata traditional manual operation mode is replaced, the binding holes are located on the same straight line are uniform at intervals, and the attractiveness of the bound drawing is improved.

Owner:芜湖文青机械设备设计有限公司

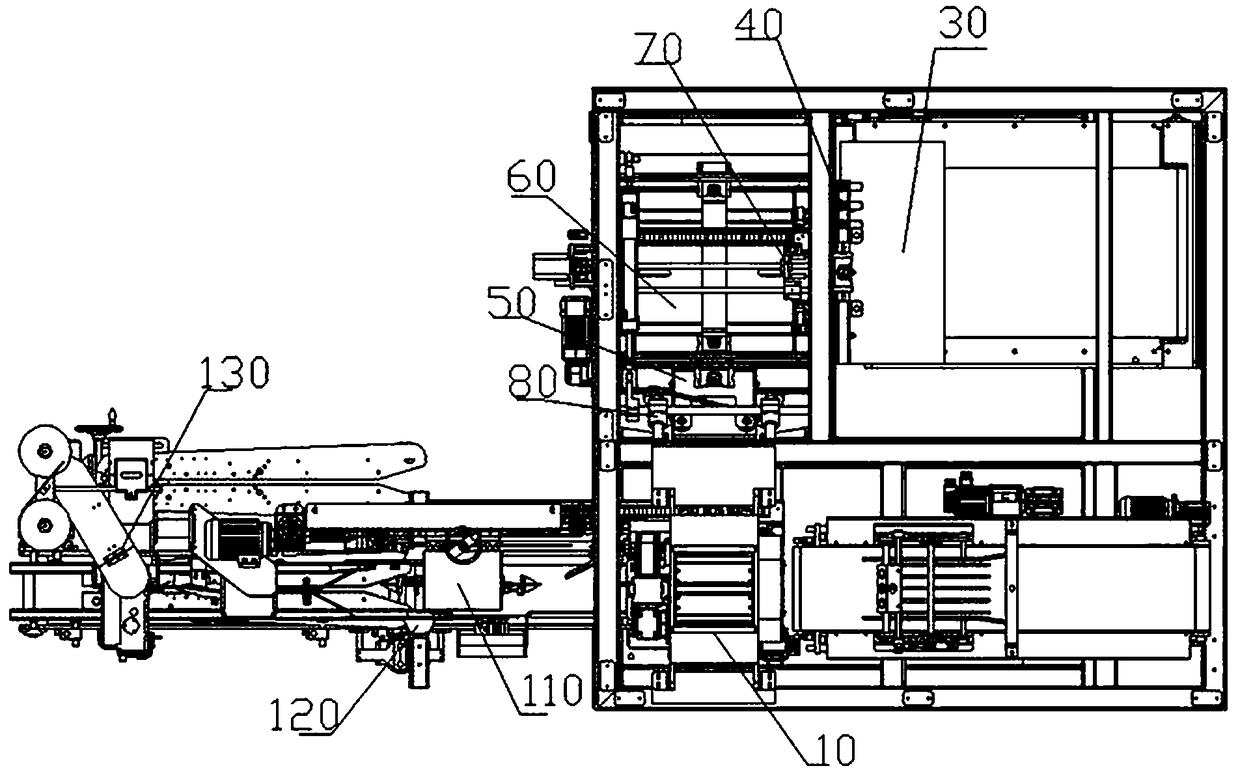

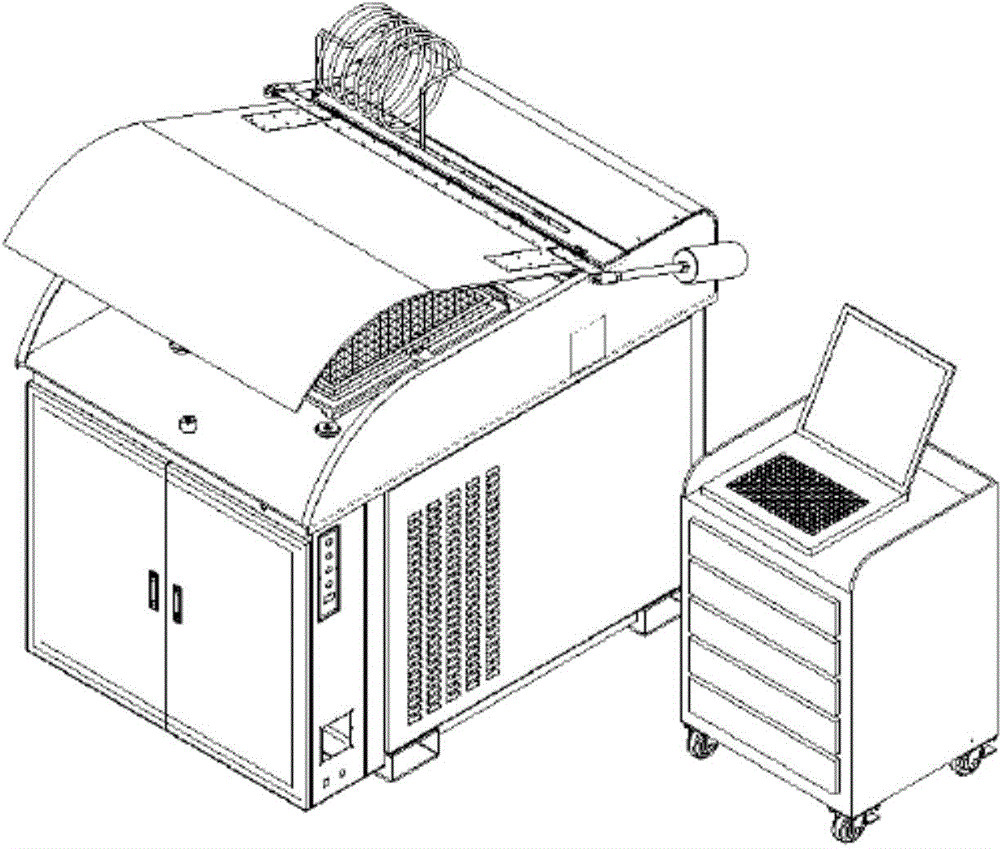

Bag feeding type packaging machine

PendingCN108820274AInhibit sheddingThe way it moves horizontally is stableWrapper twisting/gatheringSolid materialEngineeringPackaging machine

The invention discloses a bag feeding type packaging machine and relates to the technical field of packaging machines. The bag feeding type packaging machine comprises a material receiving station, abagging station, a bag preparing station, a bag fetching station, a bag opening station, a bag opening arranging station, a bag sewing station, a bag shaking mechanism and a bag holding mechanism. Thebag shaking mechanism comprises a bag shaking platform which moves up and down in a reciprocating manner to beat the bottom of a packaging bag arranged on the bagging station in a sleeving manner. The bag holding mechanism is arranged on one side of the bag shaking mechanism. The bag opening arranging station arranges a bag opening of the packaging bag located below the bag opening arranging station. The arranged packaging bag enters the bag sewing station to be sealed. According to the bag feeding type packaging machine, in the bagging process, the packaging bag can be effectively preventedfrom toppling, when the packaging bag is sealed, the bag opening arranging mechanism enables the bag opening of the packaging bag to be folded into one end face, one end face is formed at the positionof the bag opening of the sealed packaging bag, and scattering of salt packets in the packaging bag is avoided in the transportation process.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Efficient blister film slitting device and slitting method thereof

The invention relates to an efficient blister film slitting device and a slitting method thereof. The slitting device comprise a fixing plate, a tube core supporting mechanism and a slitting mechanism, wherein the tube core supporting mechanism is arranged at the front end of the fixing plate; the slitting mechanism is arranged outside the tube core supporting mechanism; the slitting mechanism isarranged at the rear end of the fixing plate; the tube core supporting mechanism comprises a fixing cylinder, a telescopic plate, a supporting plate, an anti-sliding plate and a limiting branched chain; the slitting mechanism comprises a rotary motor, a rotary plate, an adjusting cylinder, an adjusting frame, a slitting tool rest and a protective branched chain; the limiting branched chain comprises an installation plate, a regulating cylinder, a limiting block and a limiting frame; and the protective branched chain comprises a sliding plate, a connecting block, a working plate, a buffer spring, a protective plate and a rolling column. According to the slitting device and the slitting method thereof, the problems of poor flatness of the cut, easy extrusion deformation of the tube core, potential safety hazard in manual blanking and the like in existing slitting process of a blister film roll are solved.

Owner:安徽润宇医用包装材料有限公司

Energy-saving environment-friendly building bricklaying device

ActiveCN110374343AMake sure the tiles are neatPrevent cement leakage from polluting the environmentBuilding material handlingHydraulic pressureBrick

The invention discloses an energy-saving environment-friendly building bricklaying device. The device comprises a bearing base, a lifting disc combination, a positioning plate combination and a control box. The bearing base is composed of a bottom plate, a bearing oil cylinder, a hydraulic pup and a hydraulic oil tank. The bearing oil cylinder is mounted on the side wall of the top of the bottom plate through a bolt, and guide cylinders are welded to the positions, on the two sides of the bearing oil cylinder, of the top side wall of the bottom plate. Outer bricks can be manually and evenly placed on a supporting pressing plate in a brick arranging combination, a bricklaying oil cylinder pushing stroke pushes the bricks to a limiting plate on the positioning plate combination in order, animpact sleeve on the vibration position is manually held and exerts force to the left side, the supporting pressing plate rotates clockwises, the bricks slide to the pre-laid cement in order, a bricklaying oil cylinder is adjusted, one side of the supporting pressing plate falls on the bricks, the impact sleeve is manually held, and carries out circular impact on a T column, a connecting frame drives the supporting pressing plate to frequently impact the bricks, the bricks are flat, and in-batch bricklaying operated by a single person can be achieved.

Owner:中乐建业集团有限公司

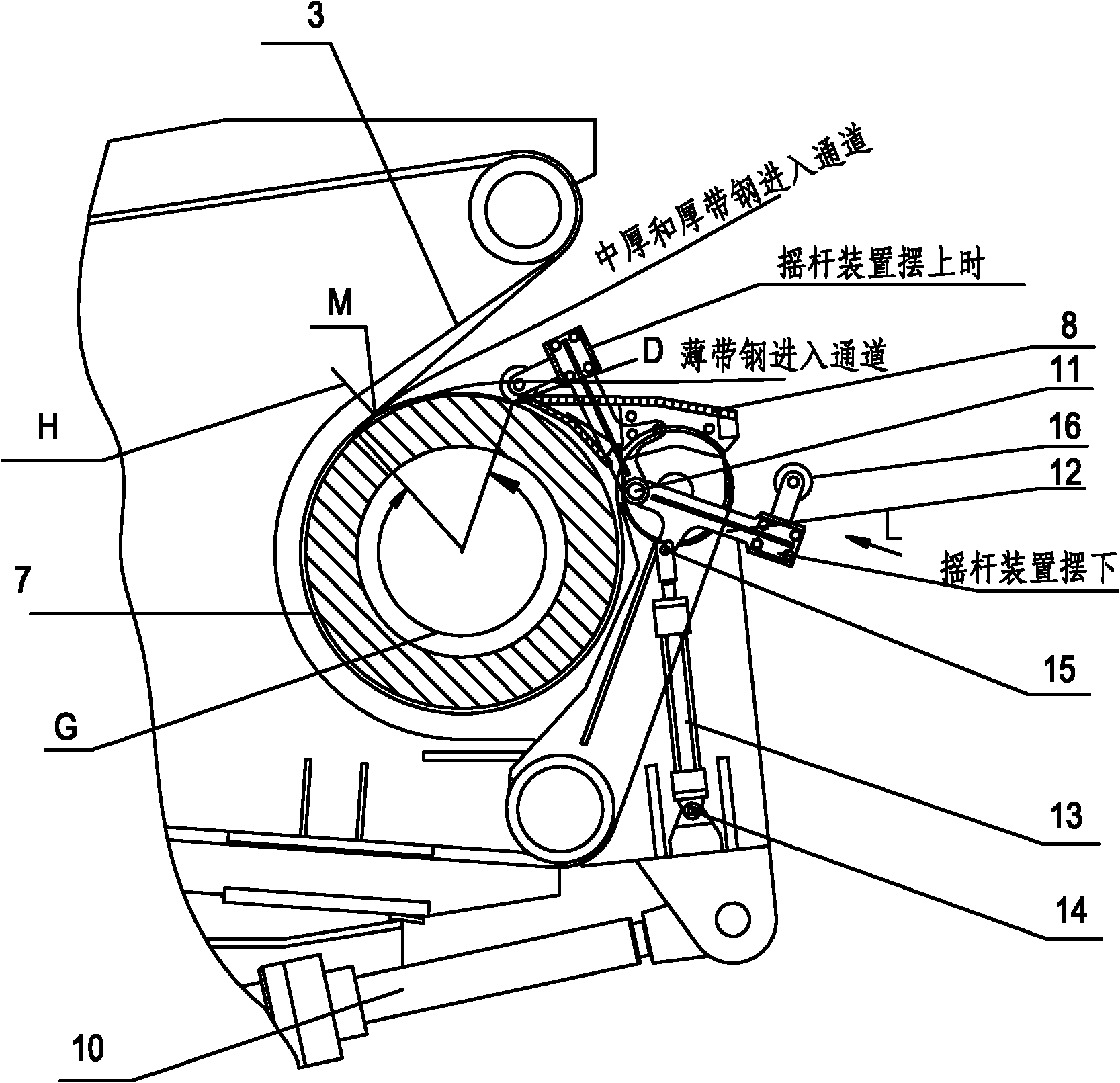

Belt winding aid and method for aiding in cold steel strip winding by using same

The invention relates to a belt winding aid and a method for aiding in cold steel strip winding by using same. The trolley of the belt winding aid is connected with a first hydraulic cylinder and slides horizontally along a base under the push of the first hydraulic cylinder, and a turning arm, of which the initial positions are below, is arranged on the two sides of the end part of the trolley parallelly and connected with a second hydraulic cylinder movably and can rotate upward under the push of the second hydraulic cylinder; a guide plate is arranged above the turning arm and keeps a fixed distance from a winding drum; a belt is tensioned or loosened by a third hydraulic cylinder, and the turning arm drives the belt to be wound on or released from the winding drum through a belt wheel arranged on the turning arm; and the upper end of the turning arm is provided with a rocker which can rock up and down, and a roller is arranged on the end part of the rocker. When the device and the method are adopted, an aid is provided for the winding of a thick steel strip, the steel strip can effectively wind on the winding drum, and the edge of a steel coil is ordered; and the device and the method are applicable to various planishers and the thickness range of cold steel strips to be wound with aid is enlarged considerably.

Owner:WISDRI ENG & RES INC LTD

Train/ metro station security system

The invention discloses a train / metro station security system and relates to the technical field of public safety management. The train / metro station security system is characterized in that the train / metro station security system comprises a left guardrail, right guardrail, a security inspection instrument, a security inspection door which are installed at the entrance; the left guardrail andright guardrail are parallel to each other; the security inspection door is installed on one side of the security inspection instrument; the left guardrail, right guardrail, security inspection instrument and security inspection door in a circle form an entrance area; a plurality of diversion devices are mounted in the entrance area; a drive motor in the diversion device drives a diversion bar tomove in a diversion mounting slot under the control of a driver so that automatic control is completely achieved, and the trouble of manual handling is eliminated. Furthermore, the fixed diversion mounting slot enables the diversion bar to be fixed on the ground when the diversion bar is stationary, and a diversion channel guaranteed to be neat, which provides a strong guarantee for the safety ofrailway stations or subway stations.

Owner:柴葳崴

Casting mold plate device capable of easily and conveniently disassembling and demolding

InactiveCN109707163AHigh precisionLabor savingAuxillary members of forms/shuttering/falseworksForm treatmentEngineeringCasting mold

The invention provides a casting mold plate device capable of easily and conveniently disassembling and demolding. The casting mold plate device capable of easily and conveniently disassembling and demolding comprises horizontal plates and vertical plates, a plurality of first connecting blocks, a plurality of second connecting blocks, and auxiliary plates, wherein the multiple first connecting blocks are evenly arranged on the two sides of the horizontal plates; the multiple second connecting blocks are evenly arranged on one sides of the vertical plates and the other sides of the vertical plates; and the right sides of the auxiliary plates are fixed to left threaded rods of the vertical plates, and the threaded rods are arranged on the left sides of the auxiliary plates. According to thecasting mold plate device capable of easily and conveniently disassembling and demolding, the accuracy of rotation of the threaded rods is improved, disassembly and assembly of mold plates are more convenient and lightweight, meanwhile, a great deal of labor force is saved, operation is easy and convenient, stability of movement and installation of the mold plates is improved, tidiness and stability of casting are ensured, thus disassembly of the mold plates is programmed, stability of the mold plates after being installed is ensured, and meanwhile, the convenience of removal of the mold plates is improved.

Owner:ZHONGHANG CONSTR ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com