Patents

Literature

314results about How to "Fast laying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

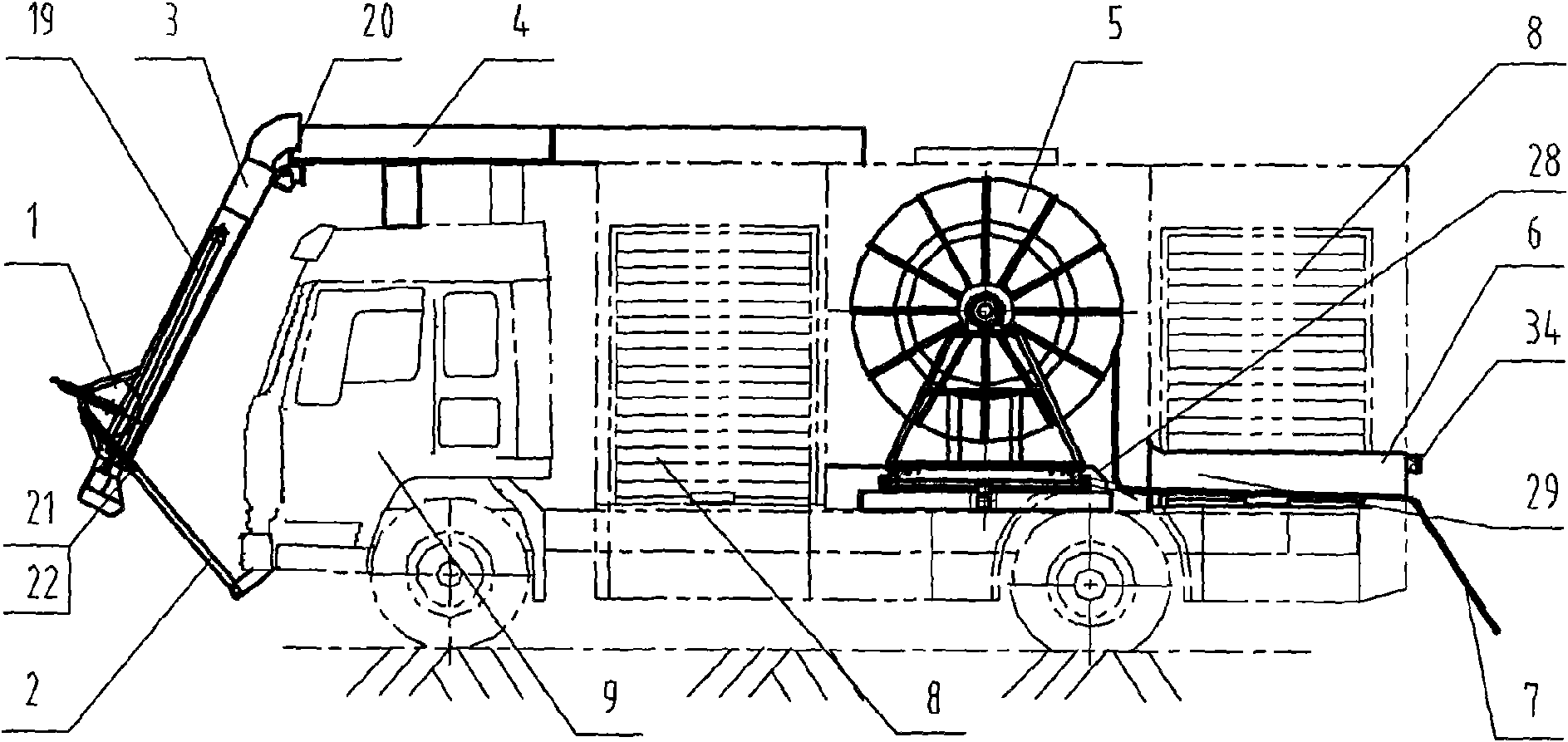

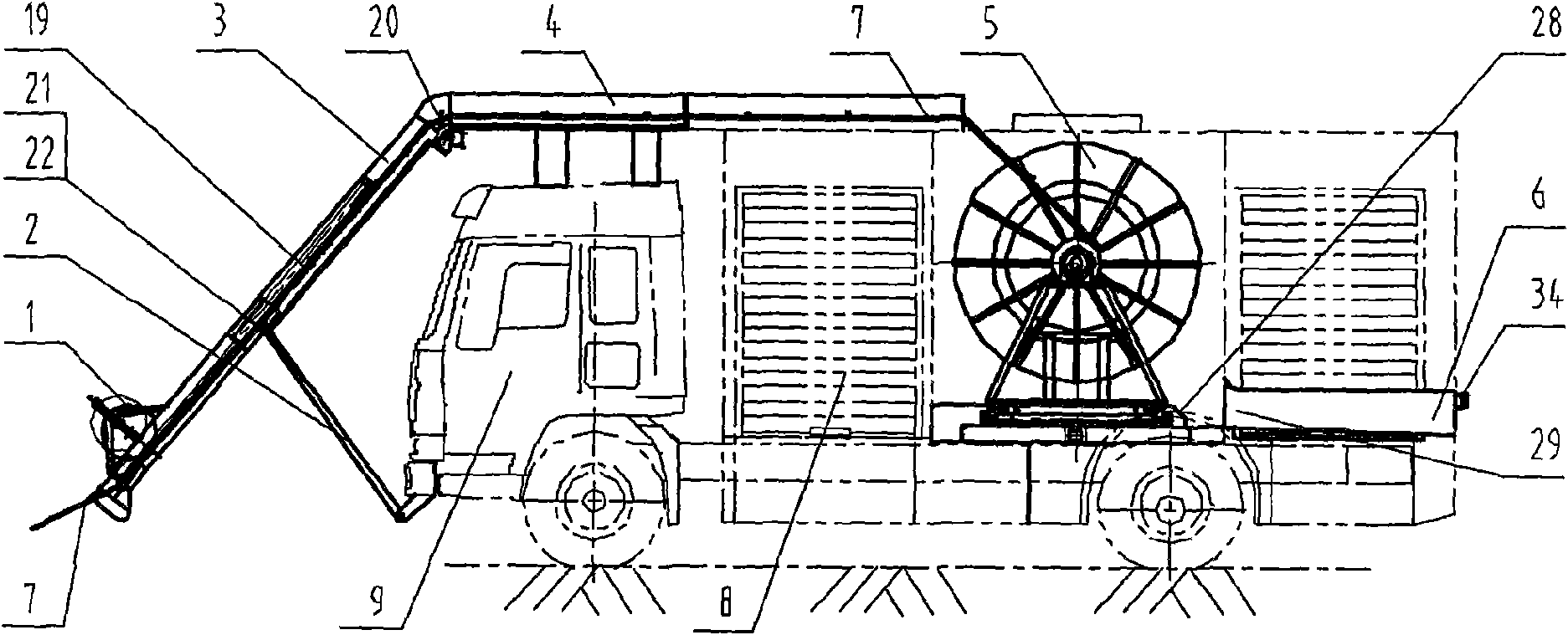

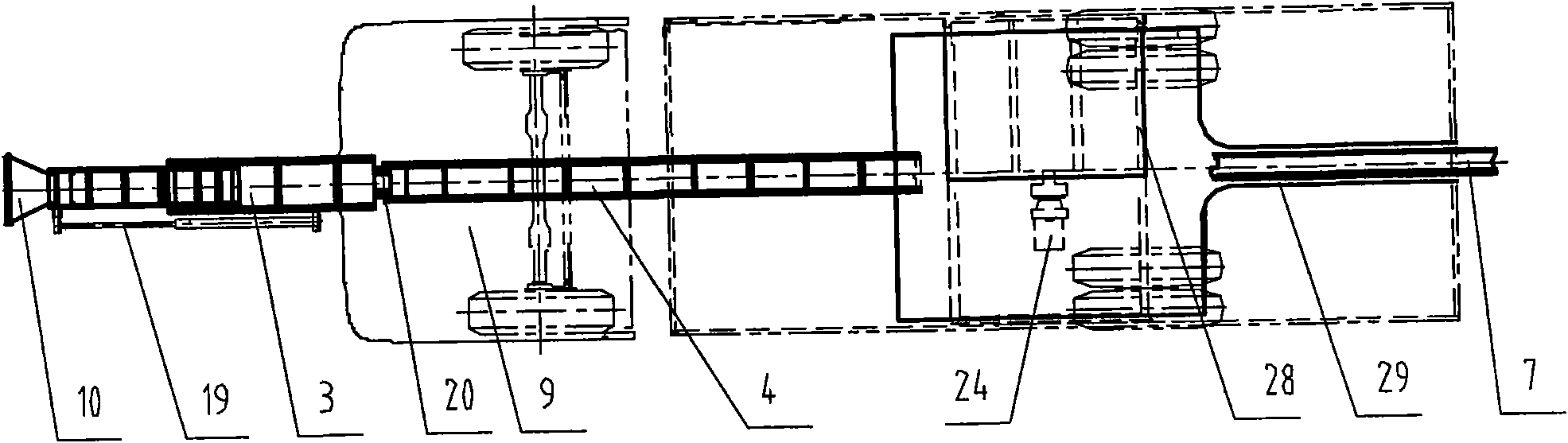

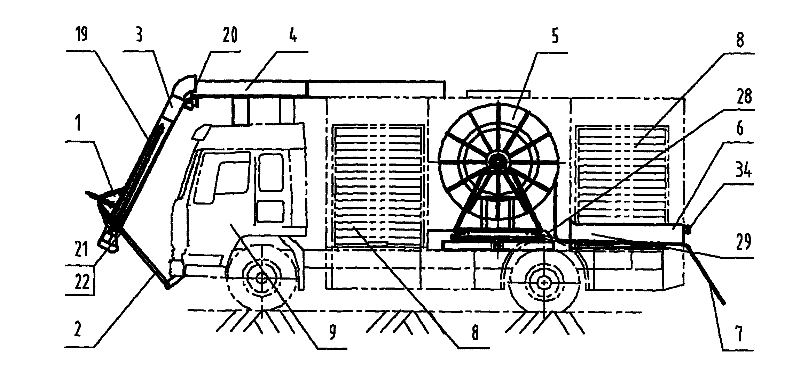

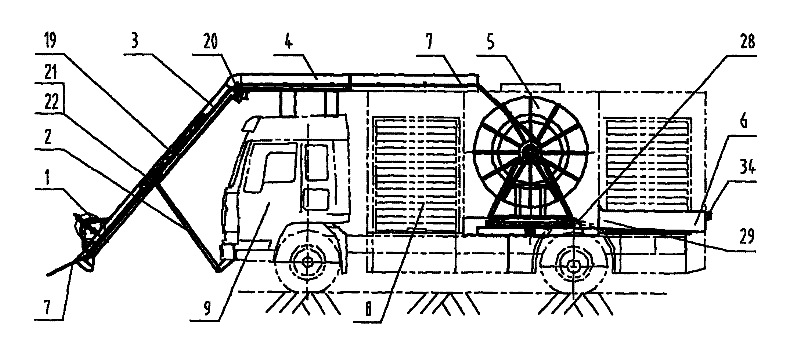

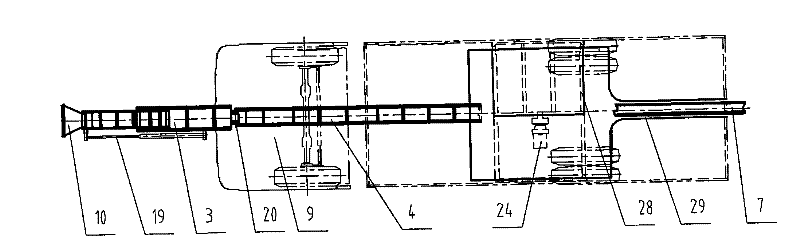

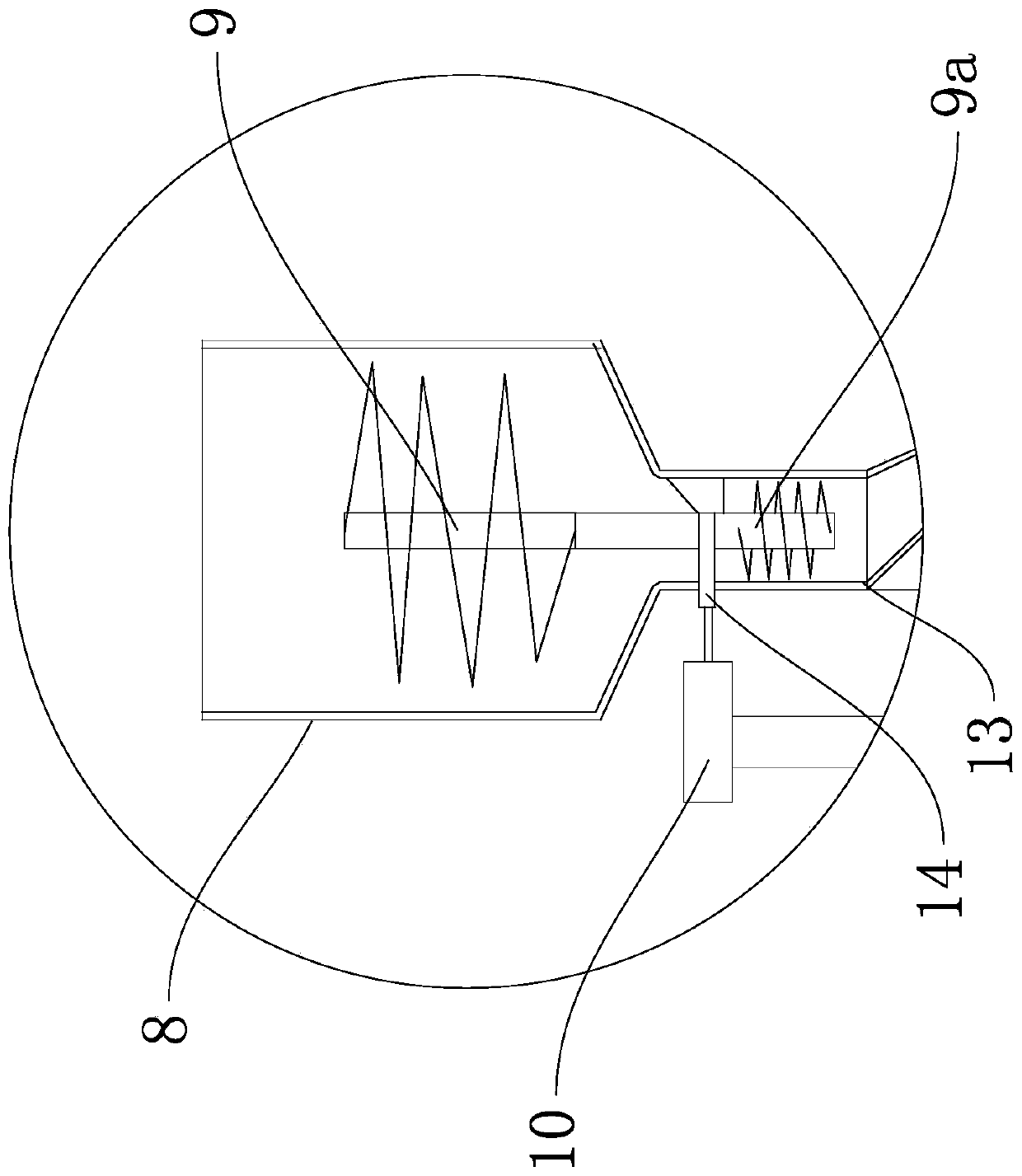

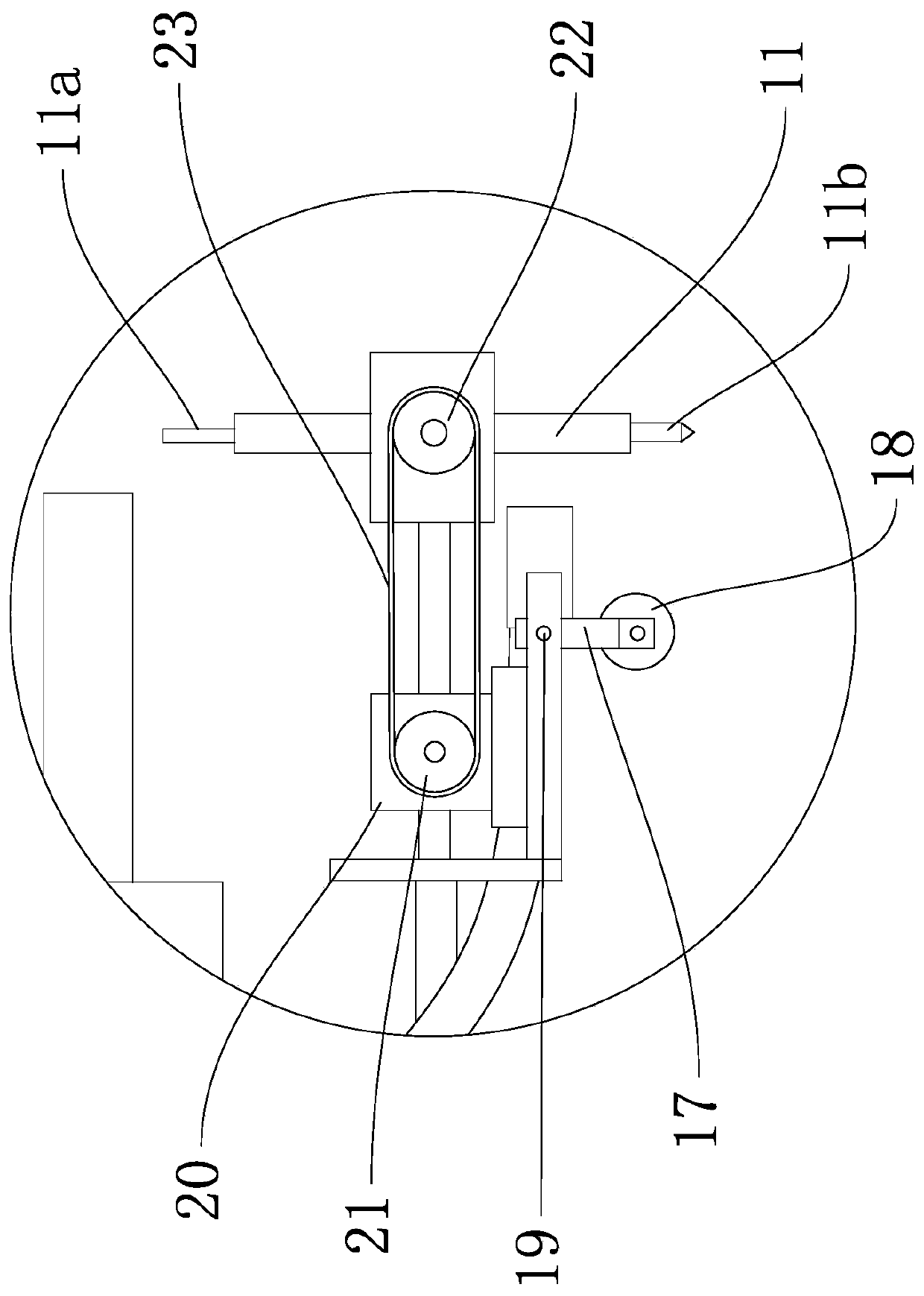

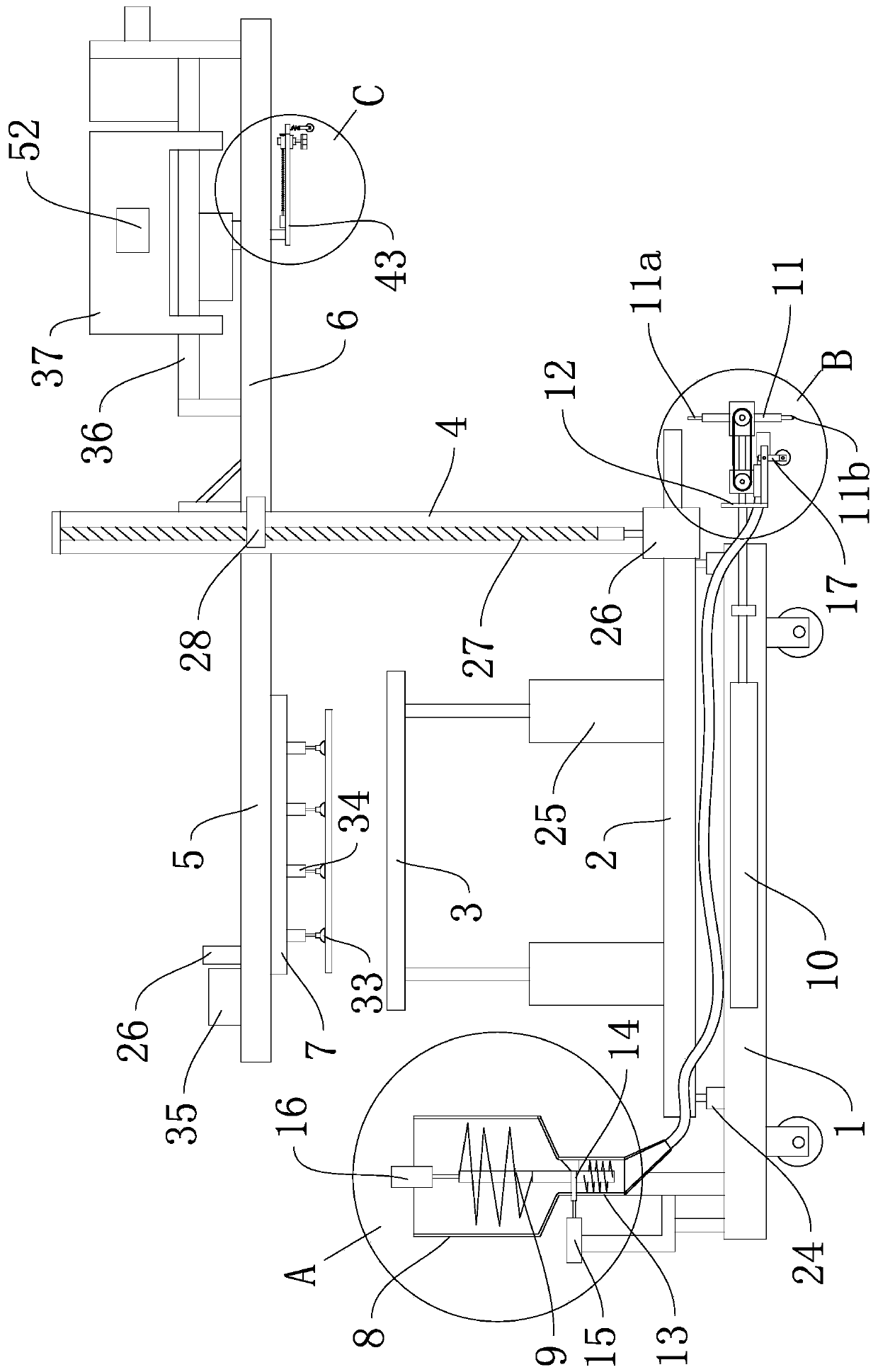

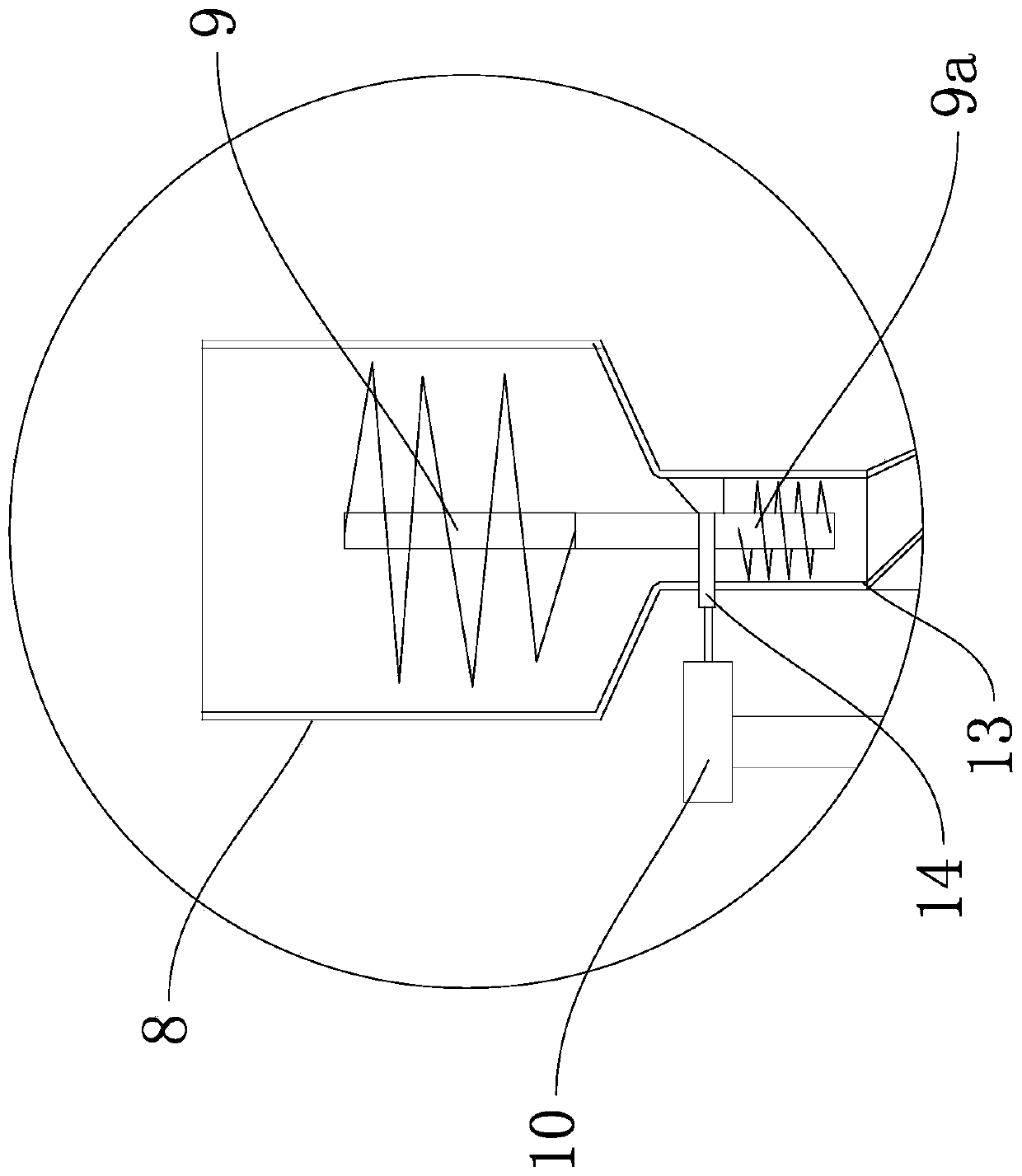

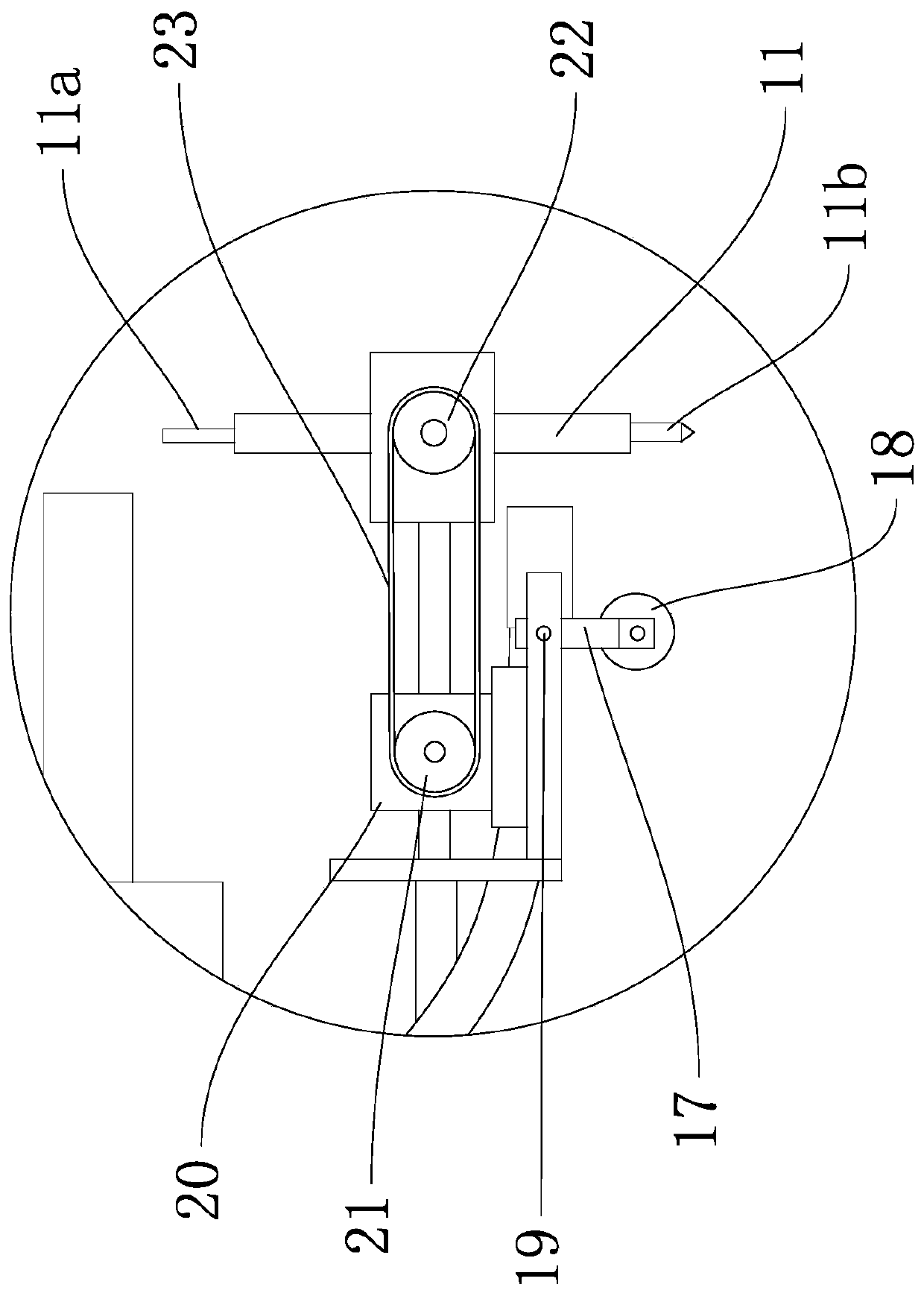

Fire service equipment vehicle with fire-hose laying and picking device

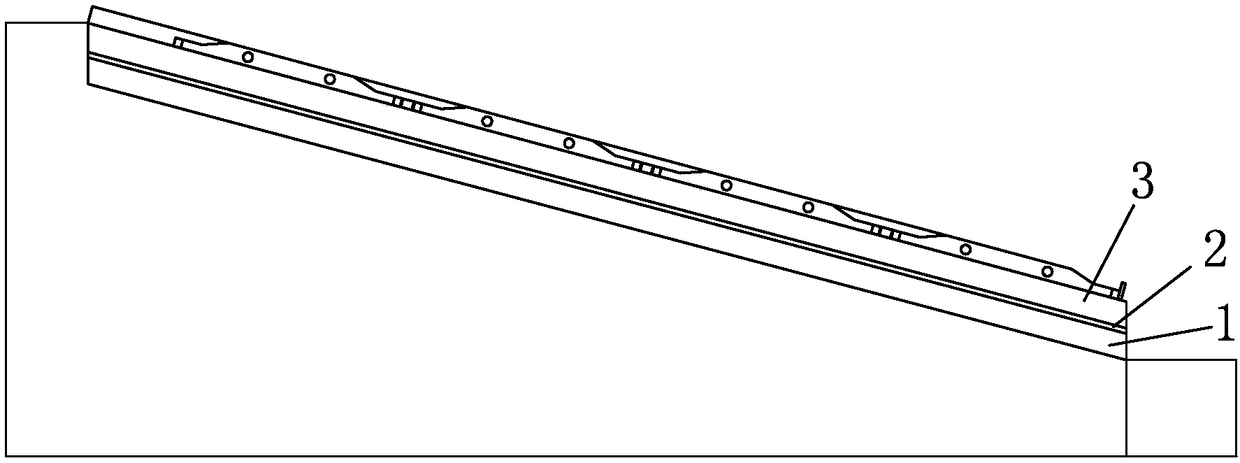

A fire service equipment vehicle with a fire-hose laying and picking device comprises a vehicle body (9) and is characterized in that a reel device (5) which can collect and release water hoses is arranged on the middle rear part of the vehicle body (9); the front part of the reel device is provided with an upper chute (4) and a lower chute (3) which are connected together by an articulating structure (20), and a picker (1) which is arranged on the front end part of the lower chute, extrudes and shapes the water hoses; and a laying device (6) which sends the water hoses out is arranged on the rear part of the reel device. The implementation of the invention can realize the fast and long distance laying and picking of the water hoses which are jointly controlled by machinery, electricity and liquid, solves the problem of getting water from water sources far from fire disaster fields; afterwards, the water hoses can be taken back to the fire service equipment vehicle with less effort by depending the fire-hose laying and picking device.

Owner:ZHENGZHOU YUTONG HEAVY IND

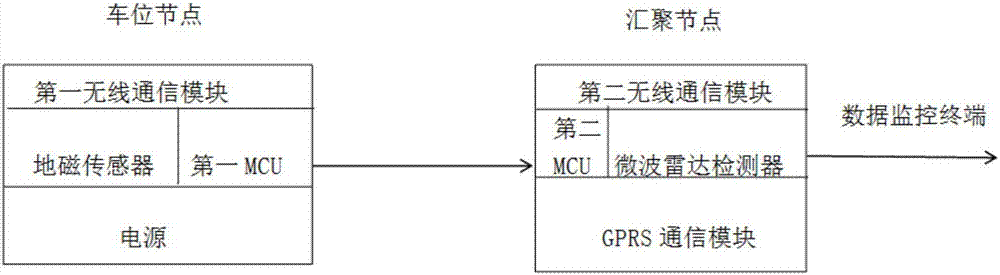

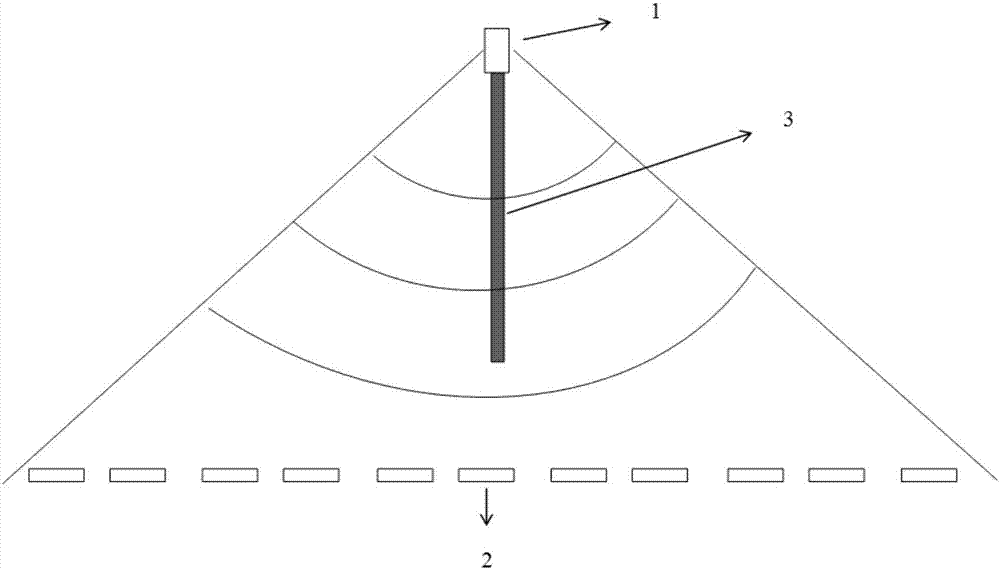

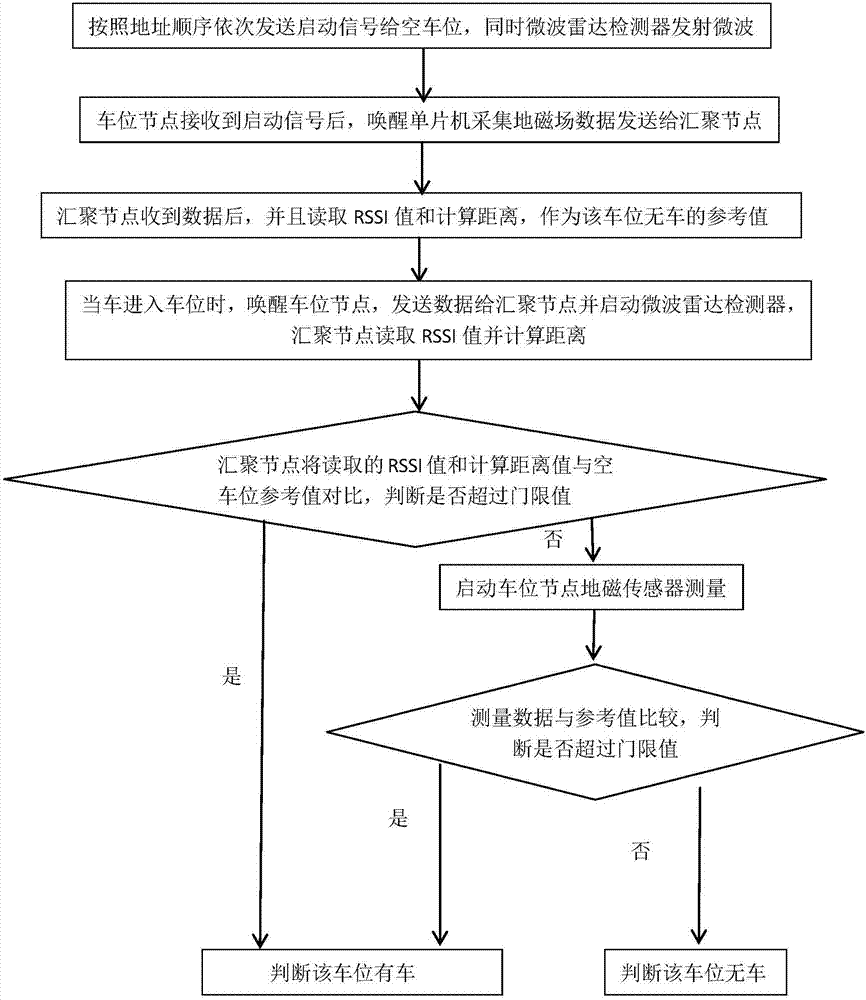

Multi-sensor low power consumption vehicle detection system and method based on adaptive environment

ActiveCN106875733AReduce volumeEasy to installIndication of parksing free spacesEngineeringVehicle detection

The invention relates to a multi-sensor low power consumption vehicle detection system and method based on an adaptive environment. A parking space node is installed in each parking space, when a vehicle enters or leaves the parking space, the geomagnetic field size of the parking space is changed obviously, a parking space node in a dormant state is woken, a parking space number and a parking space state are sent to a sink node, the sink node receives related data and read a Received Signal Strength Indication (RSSI) value, at the same time a microwave radar detector on the sink node of the area is started, the parking space which is calibrated in advance subjected to distance measurement again, and the state of the parking space at that time is determined when the vehicle enters or leaves. When the parking space information can not be detected by the RSSI value due to external factors such as a parking lot parking space environment or weather, a geomagnetic sensor is started as an auxiliary detection mode, and the reliability and accuracy of the method are improved.

Owner:NANJING UNIV OF SCI & TECH

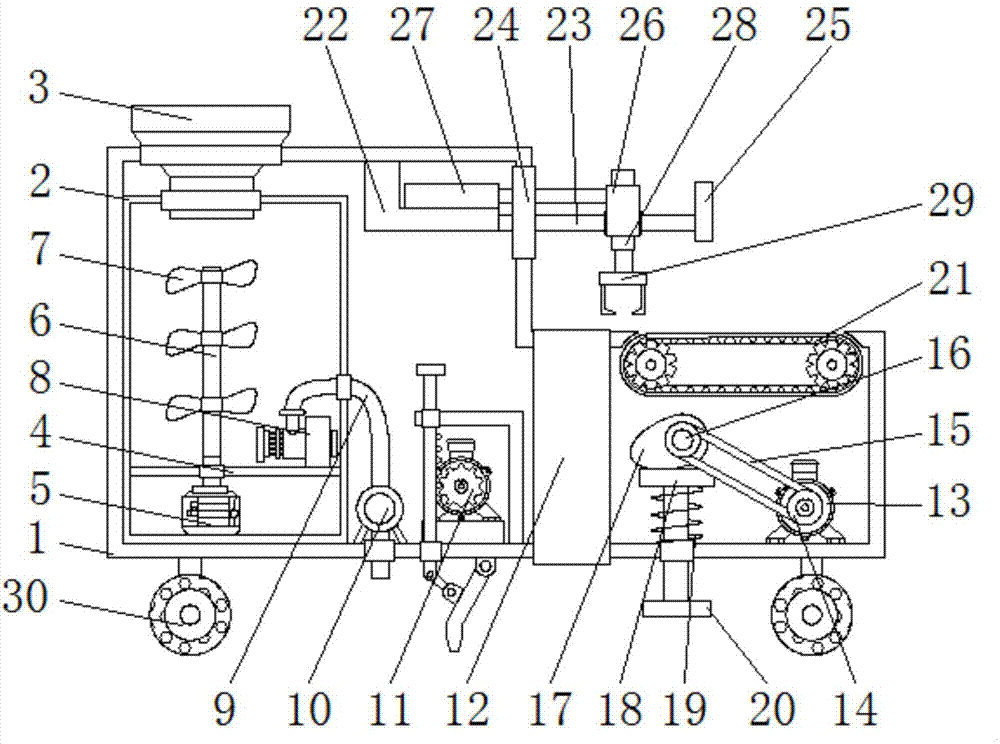

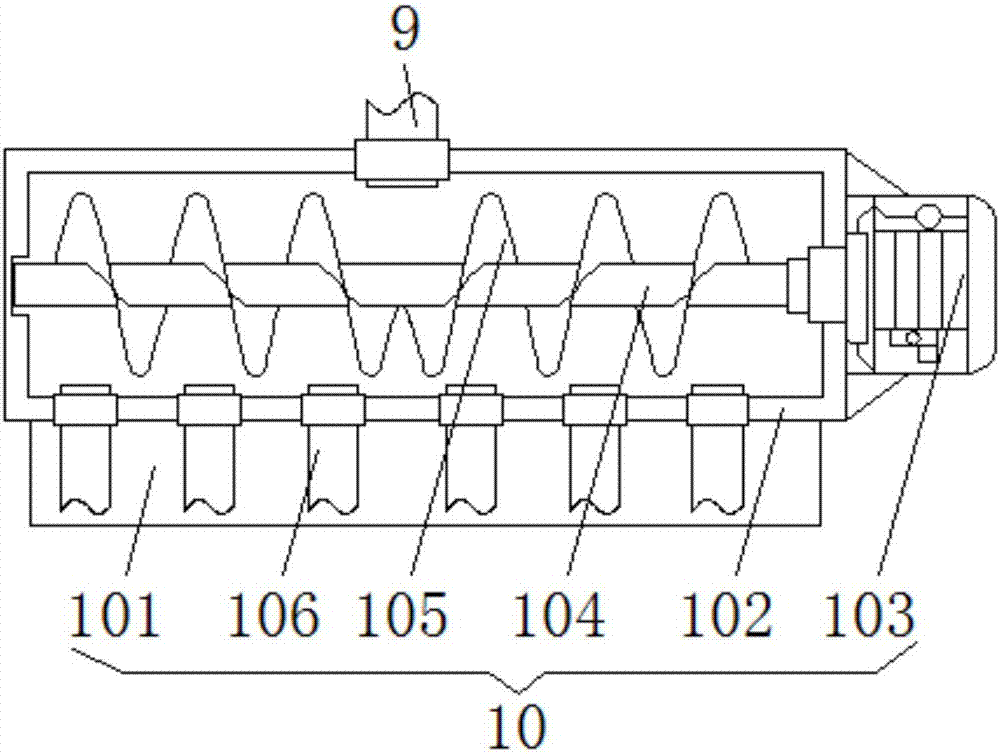

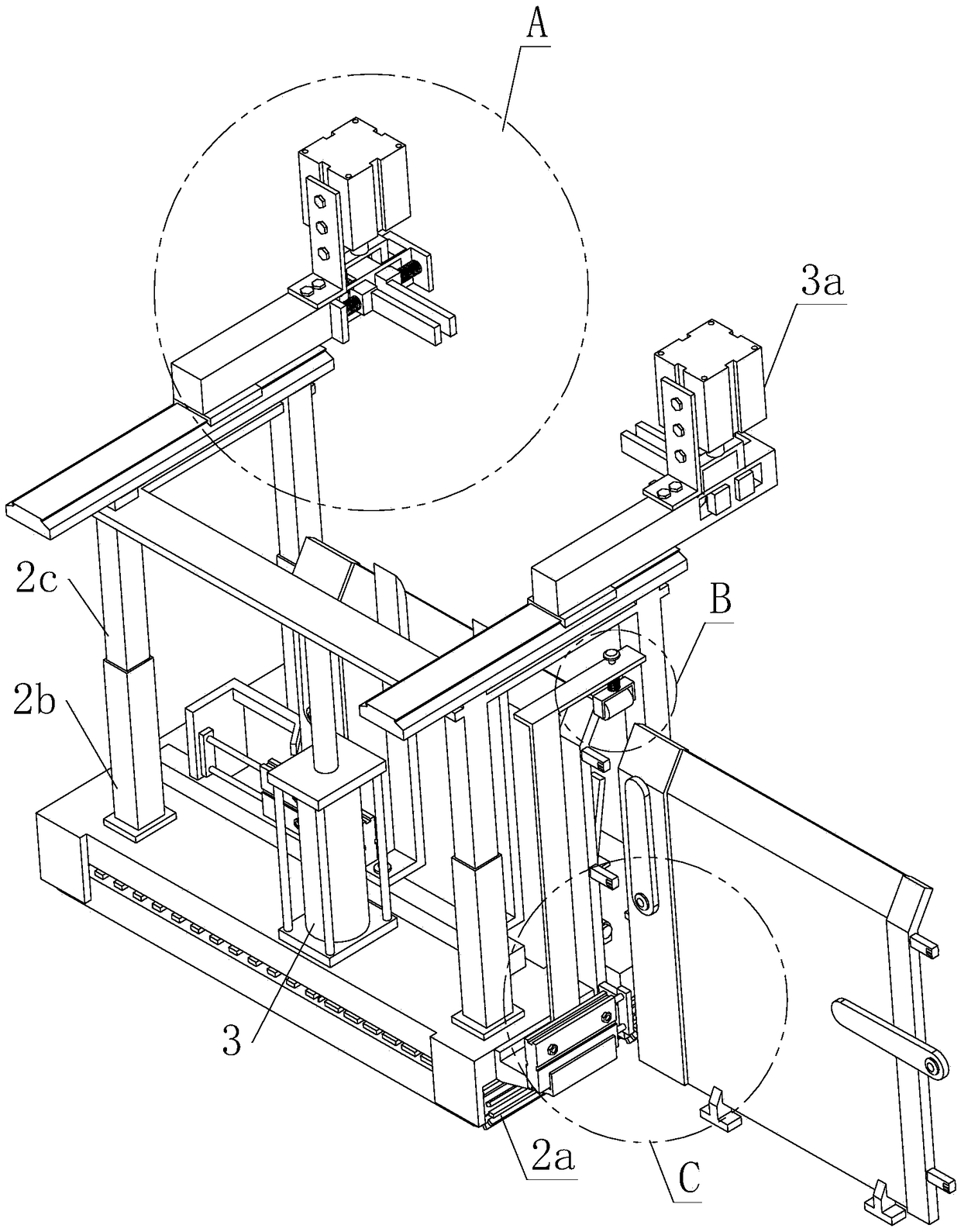

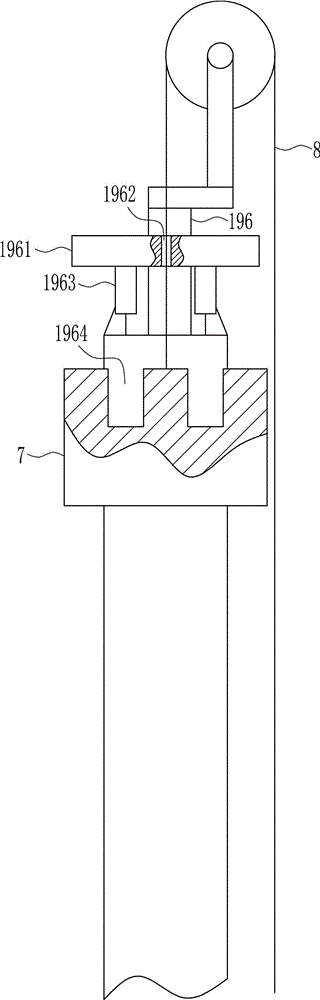

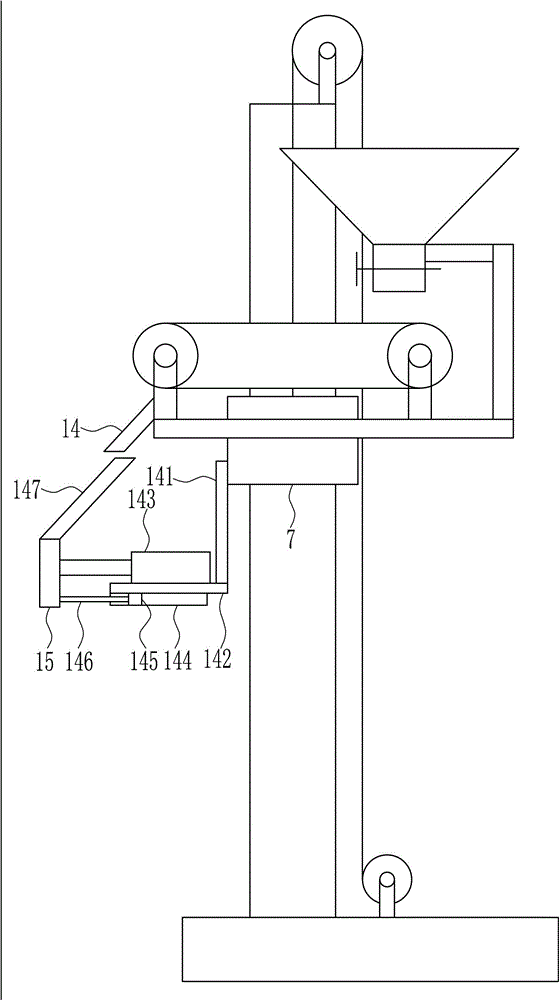

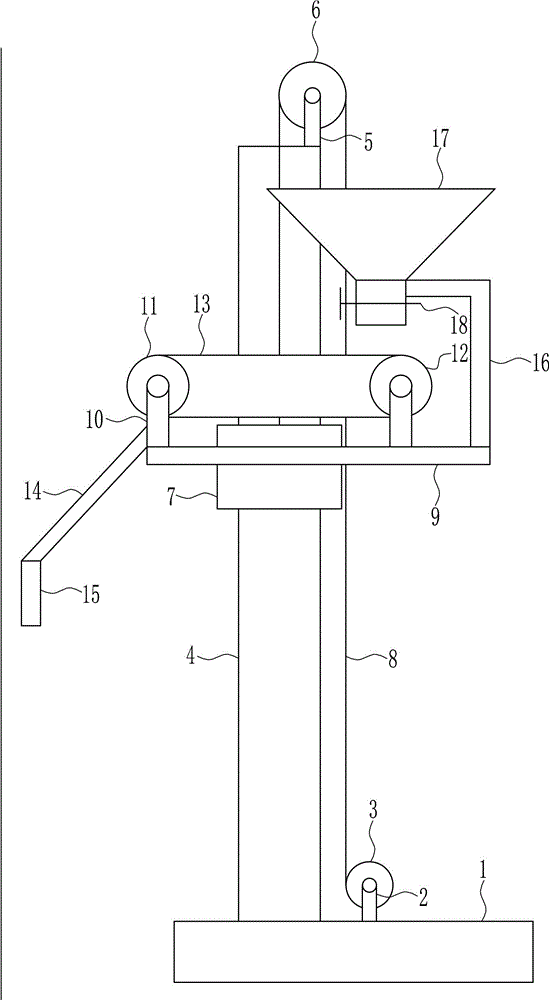

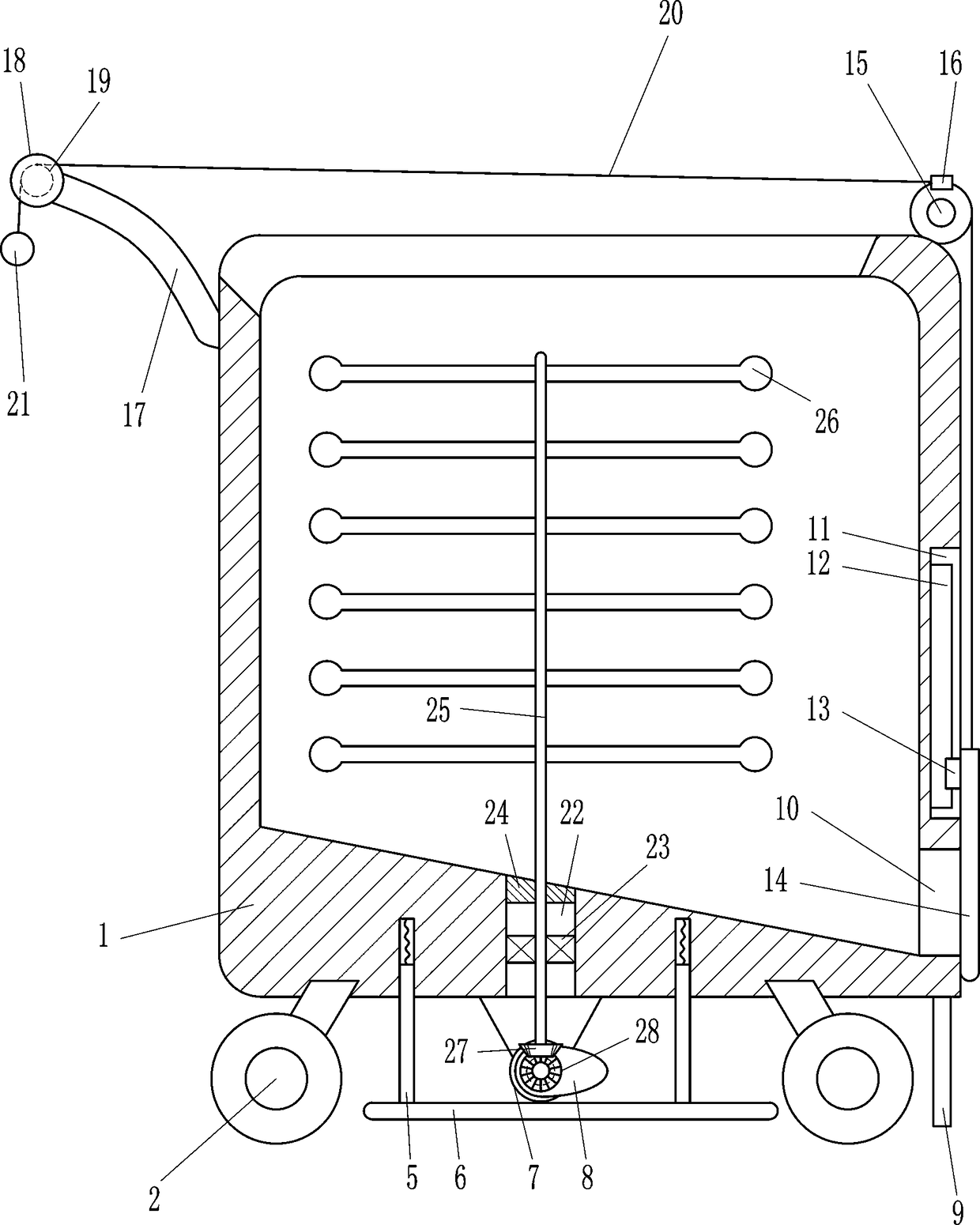

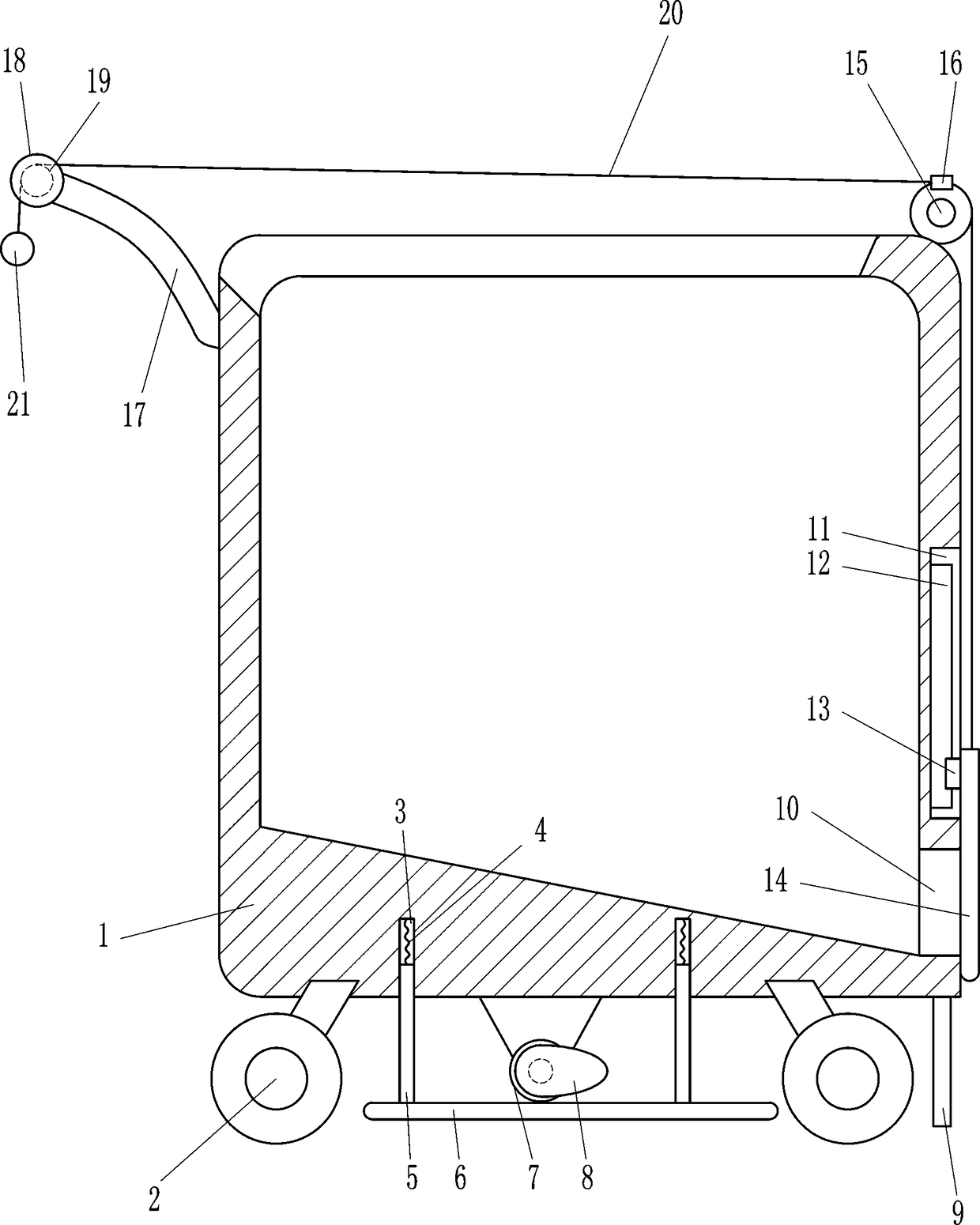

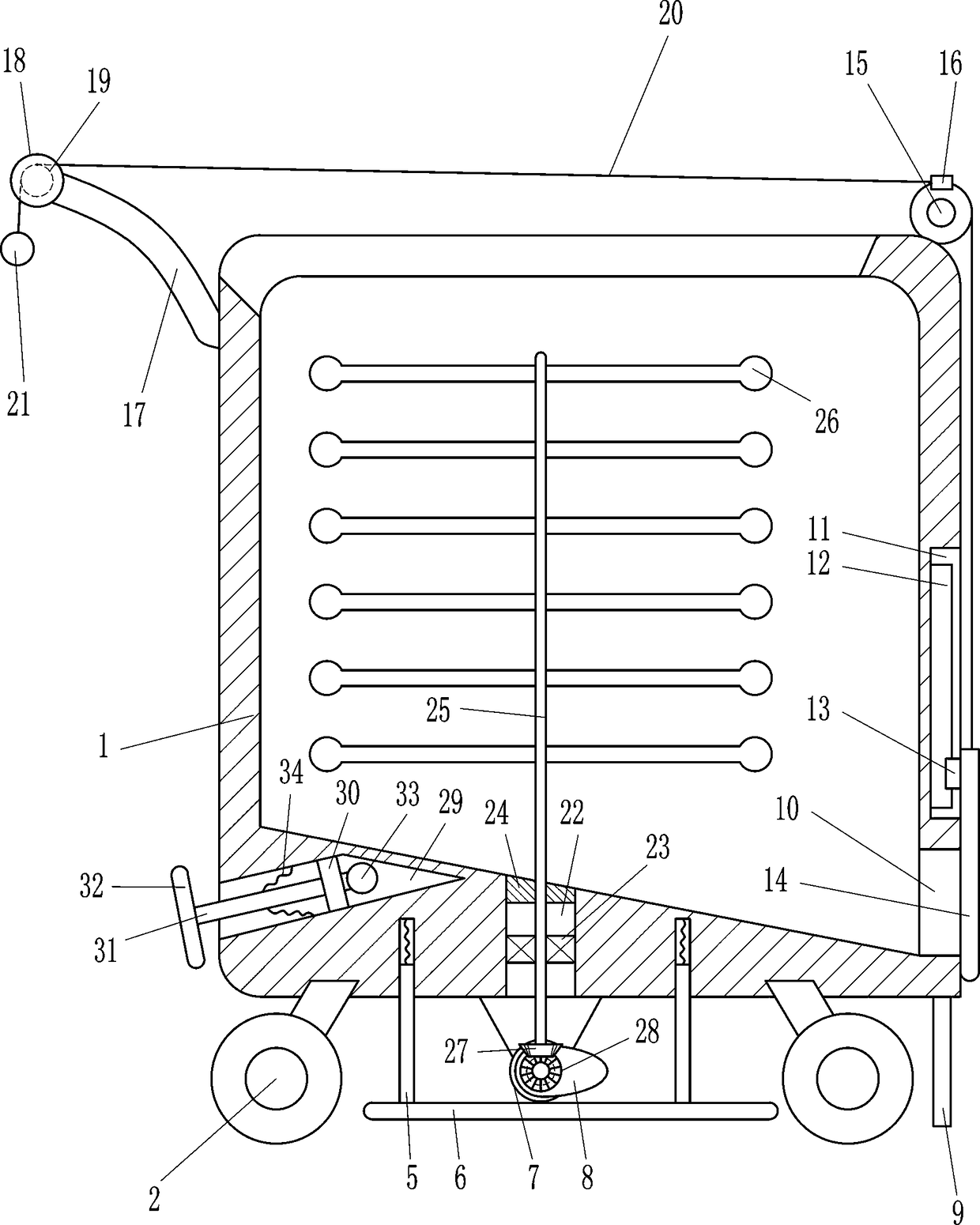

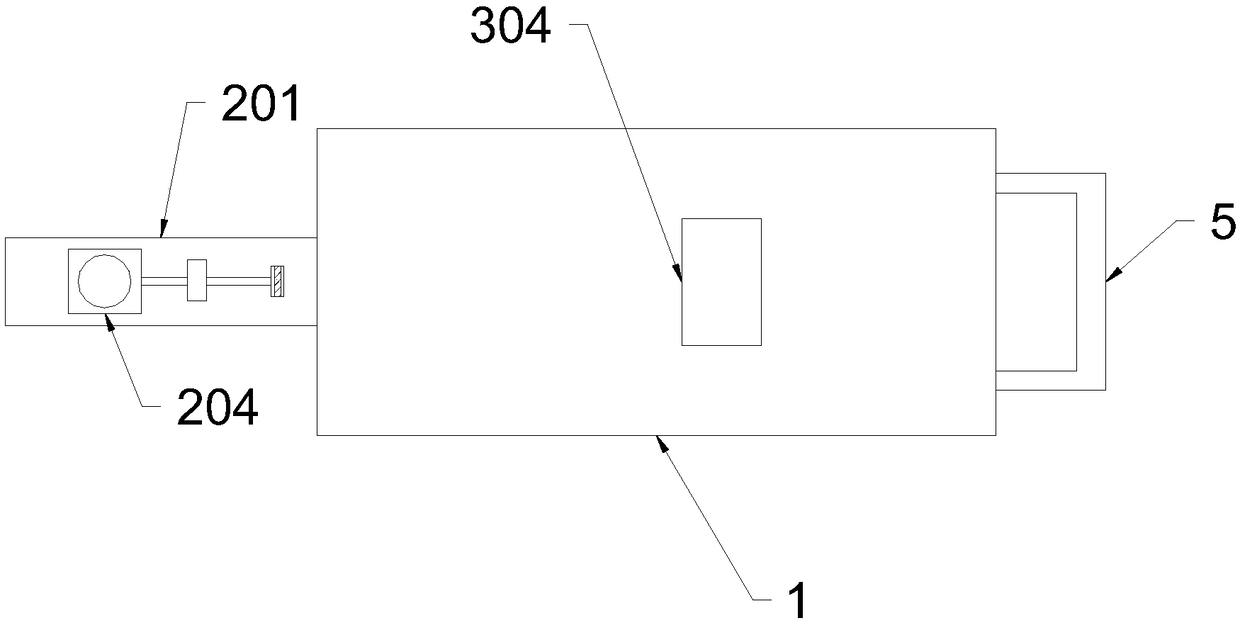

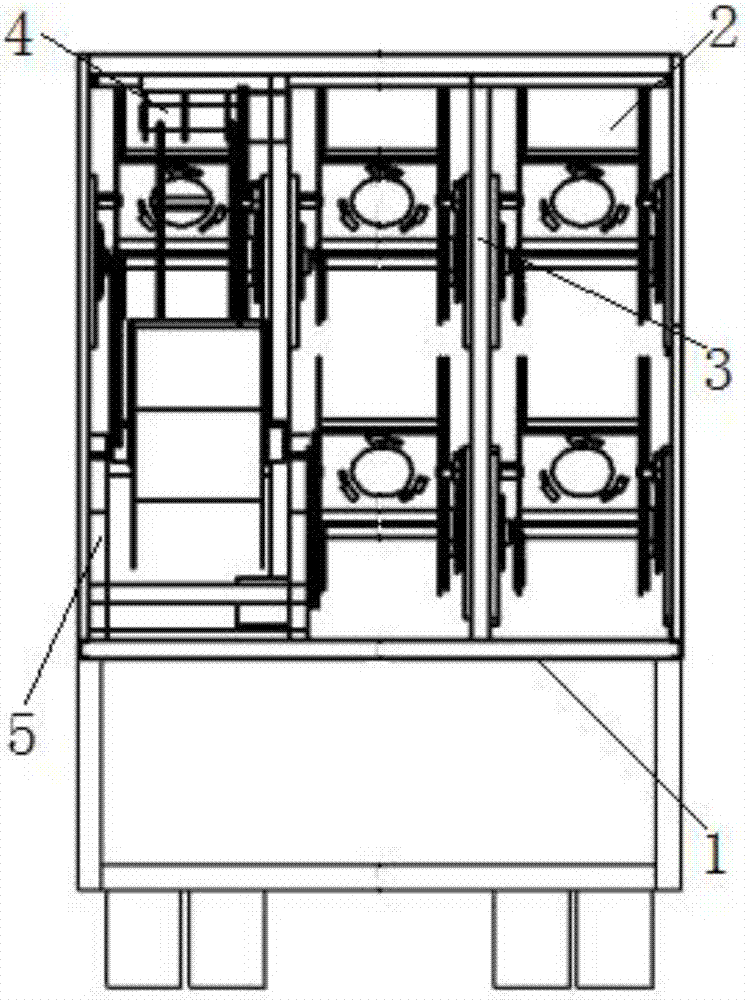

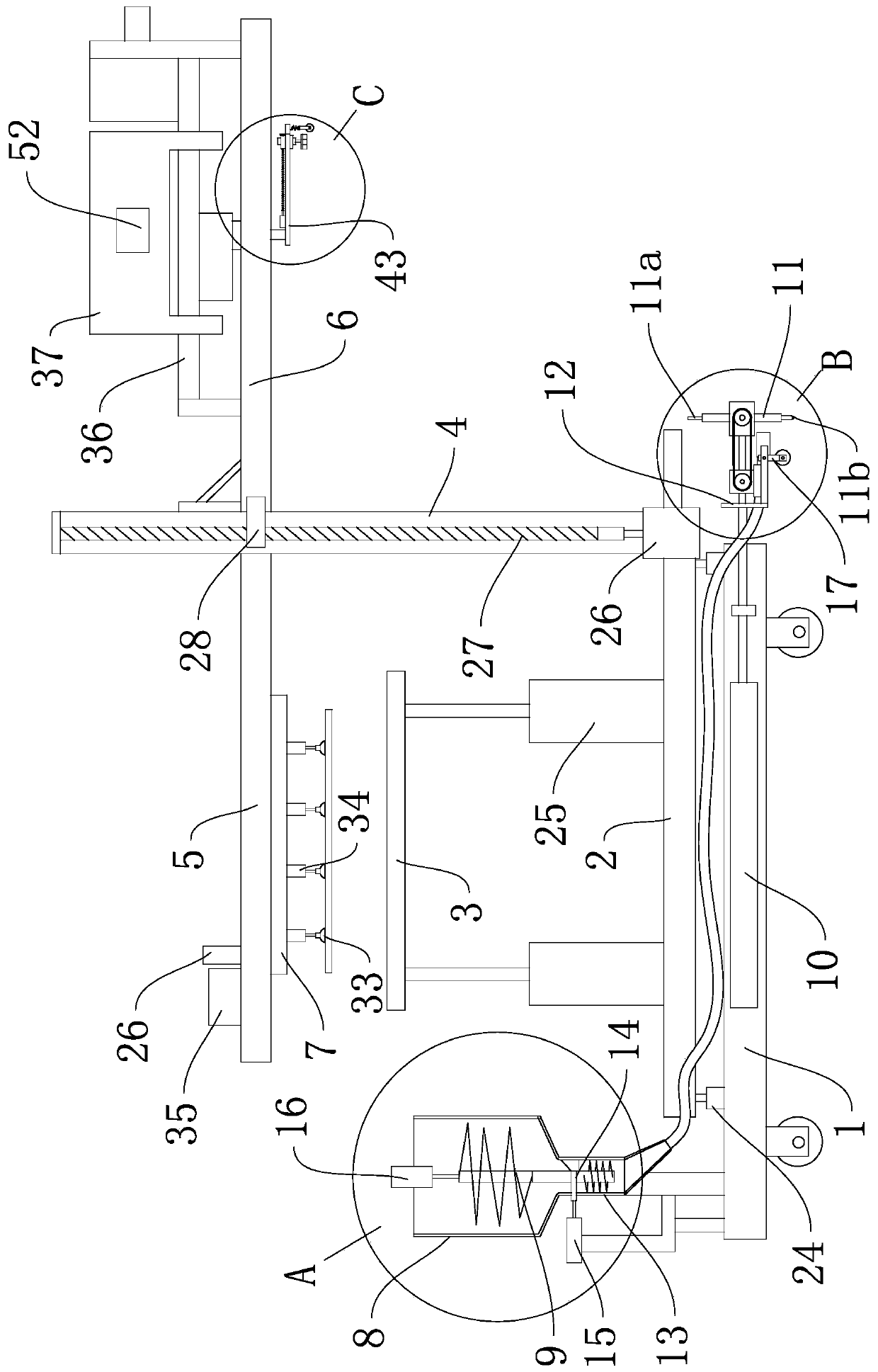

Brick paving device for sidewalks of municipal buildings

InactiveCN107513928ANo manual laying requiredReduce manual laborRoads maintainenceFixed frameArchitectural engineering

The invention discloses a brick paving device for sidewalks of municipal buildings. The brick paving device comprises a tank body, wherein a stirring tank is fixed at one side of the inner wall of the tank body, a partition board is fixed between two sides of the inner wall of the stirring tank, and a material pump is fixed at the top of the partition board; a material falling device is fixed at the bottom of the inner wall of the tank body, and a discharging hole of the material pump is communicated with the material falling device through a flexible pipe; a material smearing device is fixed at the bottom of the inner wall of the tank body, and a brick paving channel is formed in the right side of the material smearing device; a fixing frame is fixed at the top of the inner wall of the tank body, and a brick clamping device is mounted on the fixing frame; and a crawler belt conveying device is fixed on the inner wall of the tank body, and a brick smoothening plate is mounted below the crawler belt conveying device. The invention relates to the technical field of municipal constructions. The brick paving device can be used for uniformly paving cement and brickworks and is integrated with stirring and paving functions, and the manual paving is omitted, so that the use of labor force is saved, and the construction efficiency of a project is greatly improved.

Owner:陈杨平

Fire service equipment vehicle with fire-hose laying and picking device

Owner:ZHENGZHOU YUTONG HEAVY IND

APF (advanced polarizer film) self-adhesive waterproof coiled material construction method

The invention discloses an APF (advanced polarizer film) self-adhesive waterproof coiled material construction method which includes a step of plane construction and a step of facade construction. The step of plane construction includes base layer cleaning, base face line snapping, polymer cement mortar preparing, node processing, reinforcing layer and internal and external corner adding, APF self-adhesive waterproof coiled material layer pre-paving, polymer cement mortar coating and scraping, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing, and the step of facade construction includes facade base layer cleaning, facade base face coiled material positioning and line snapping, base layer treating agent coating and scraping, node processing, APF self-adhesive waterproof coiled material layer paving, lapping, rolling, head recovering and organizing for acceptance testing. The polymer cement mortar is utilized as a bonding layer, so that the bonding layer can be quickly paved on a humid concrete base layer and can also be directly paved on a dry concrete face.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

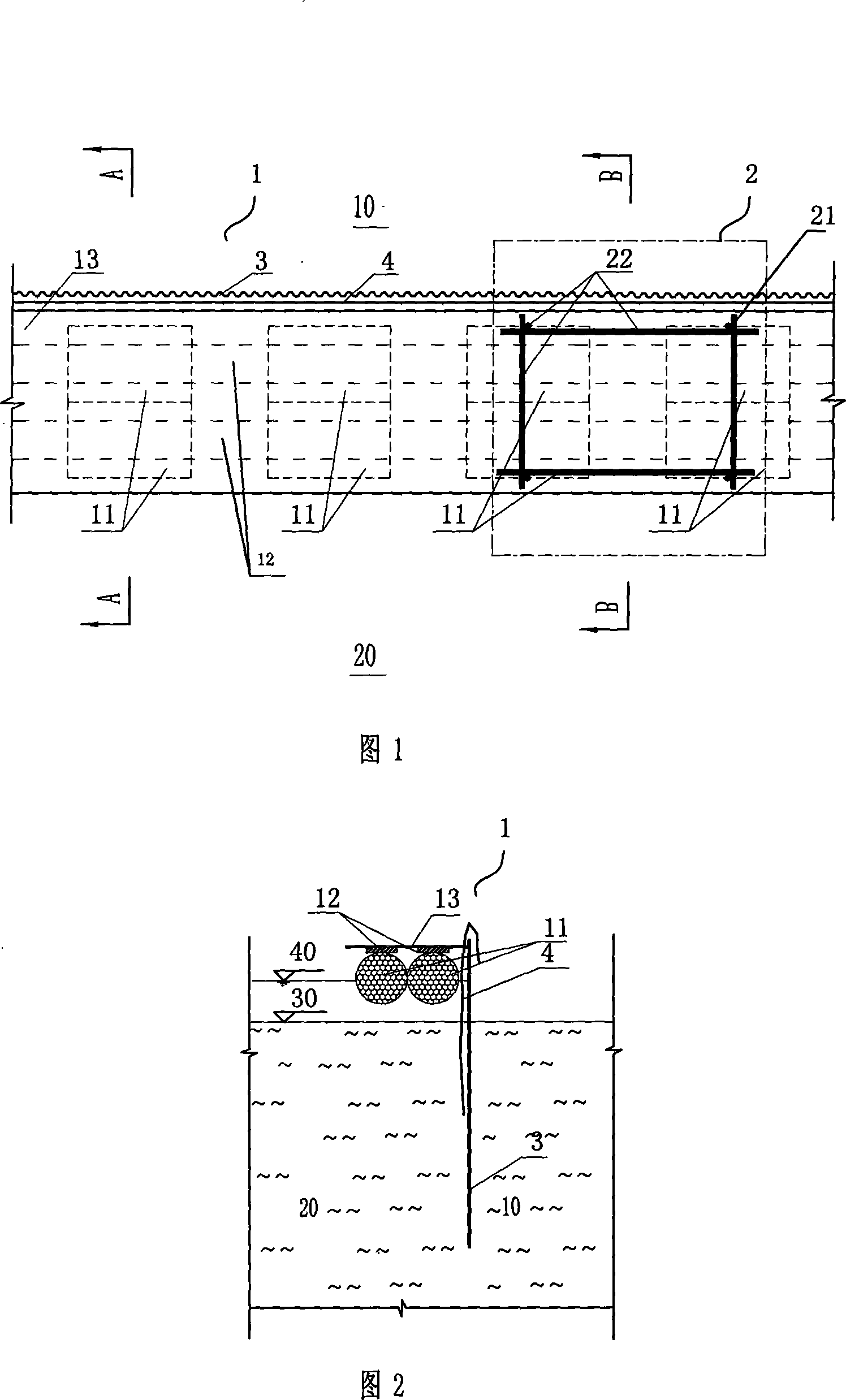

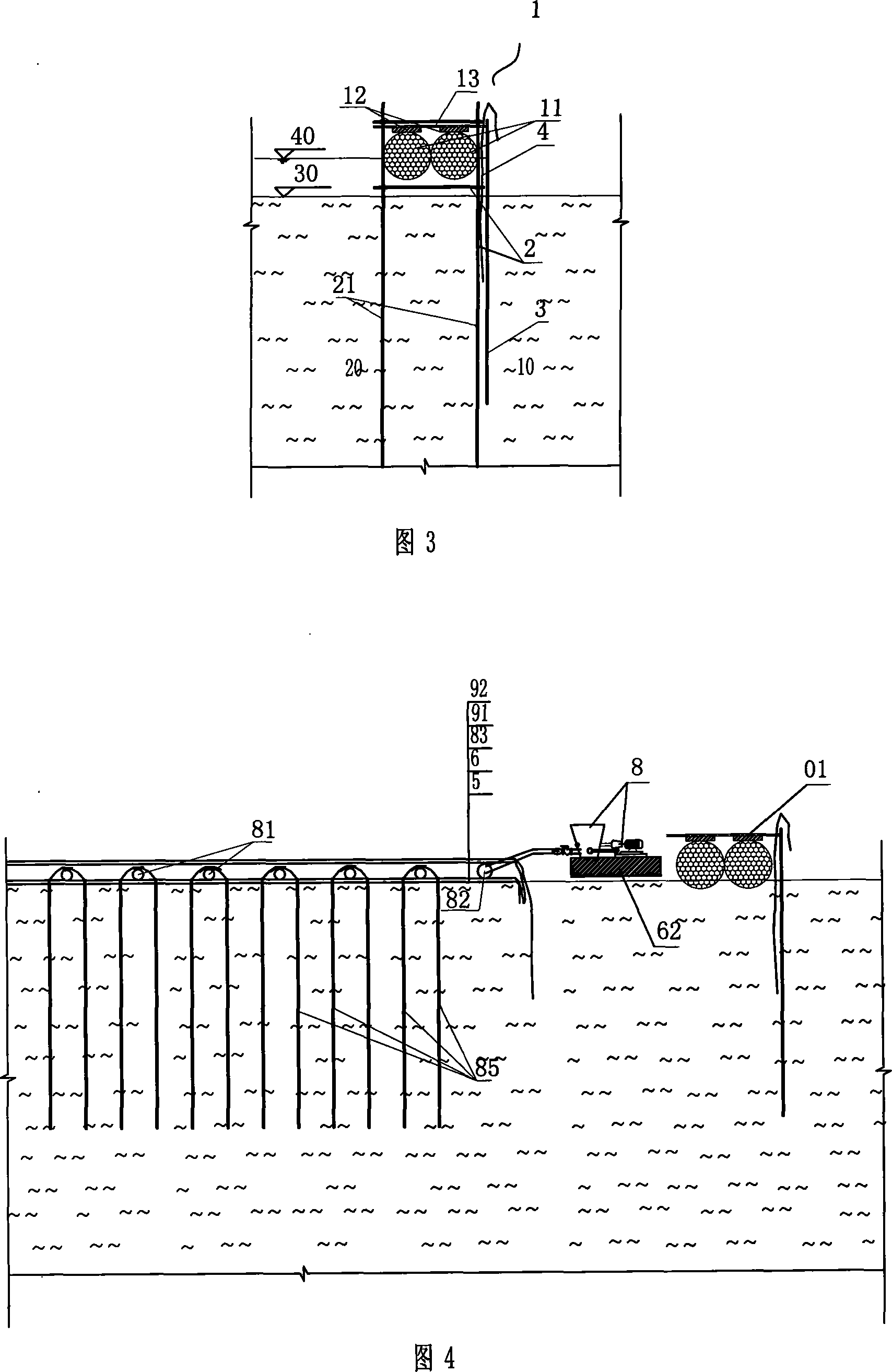

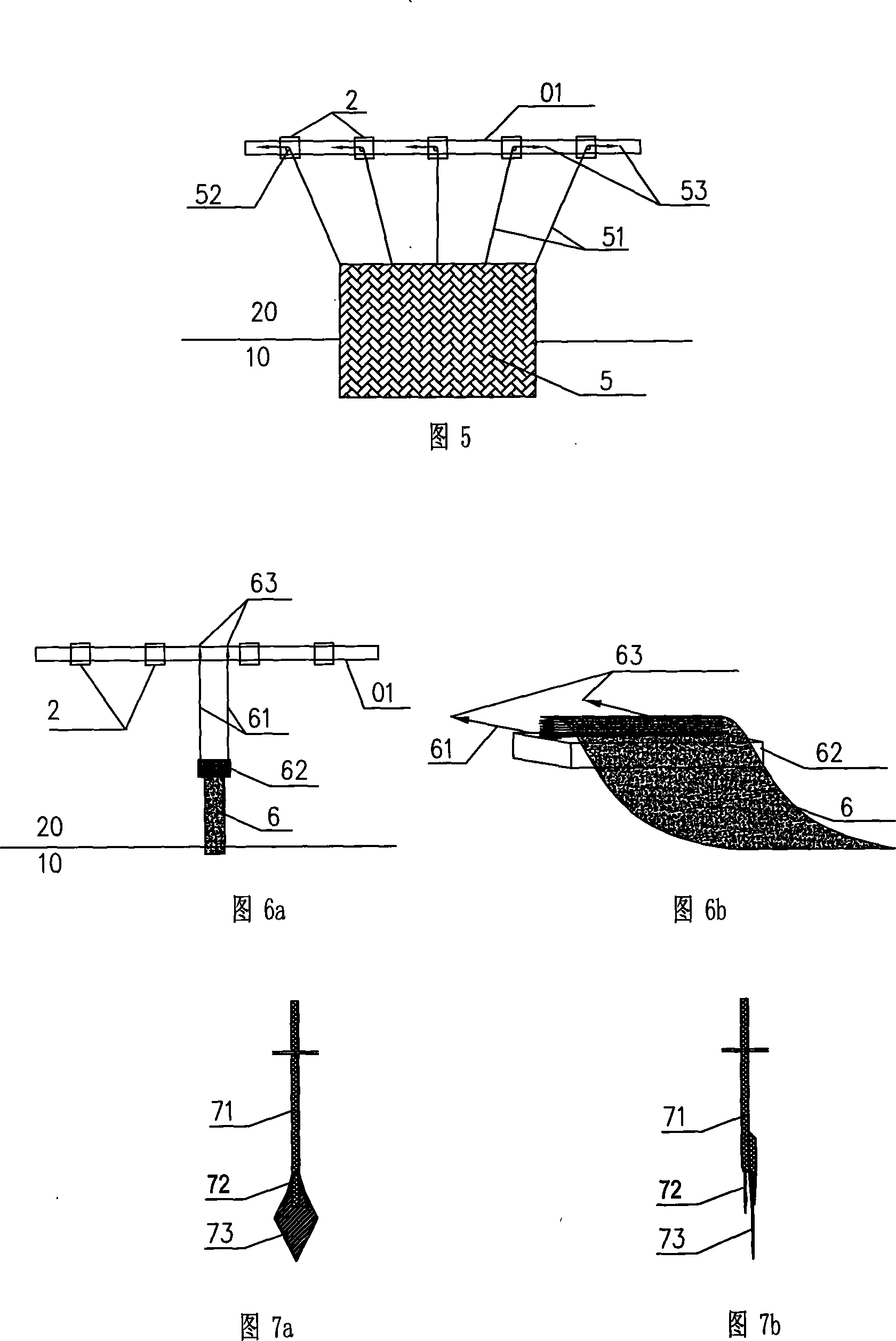

Method for rapidly reinforcing ultra-soft soil superficial zone and packaged technology

The invention discloses a fast strengthening method for ultra-soft earth, comprising the following steps: (1) arranging the separation curtains to divide a plurality of construction areas in the area of waiting for strengthening; pouring water at the field; using the device of artificial inserting plate to insert and arrange the short plastic drainage plate; arranging the horizontal drainage pipeline and then paving a layer of sealing film on the pipeline; forming the strengthening device for shallow layer of ultra-soft earth through the vacuum pumping equipment connected with the pipeline; (2) vacuuming the strengthening device for shallow layer of ultra-soft earth; (3) integrally strengthening the foundation of the device. The fast strengthening method for ultra-soft earth has the advantages that the method can rapidly and effectively solve the problem of strengthening the ultra-soft foundation on the shallow layer, so as to supply the favorable conditions for the construction, such as drainage sand cushion, plastic drainage board or bag sand-well, and supply an advanced art used for strengthening rapidly the foundation on silt or ultra-soft foundation on the filled silt with saving costs greatly.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

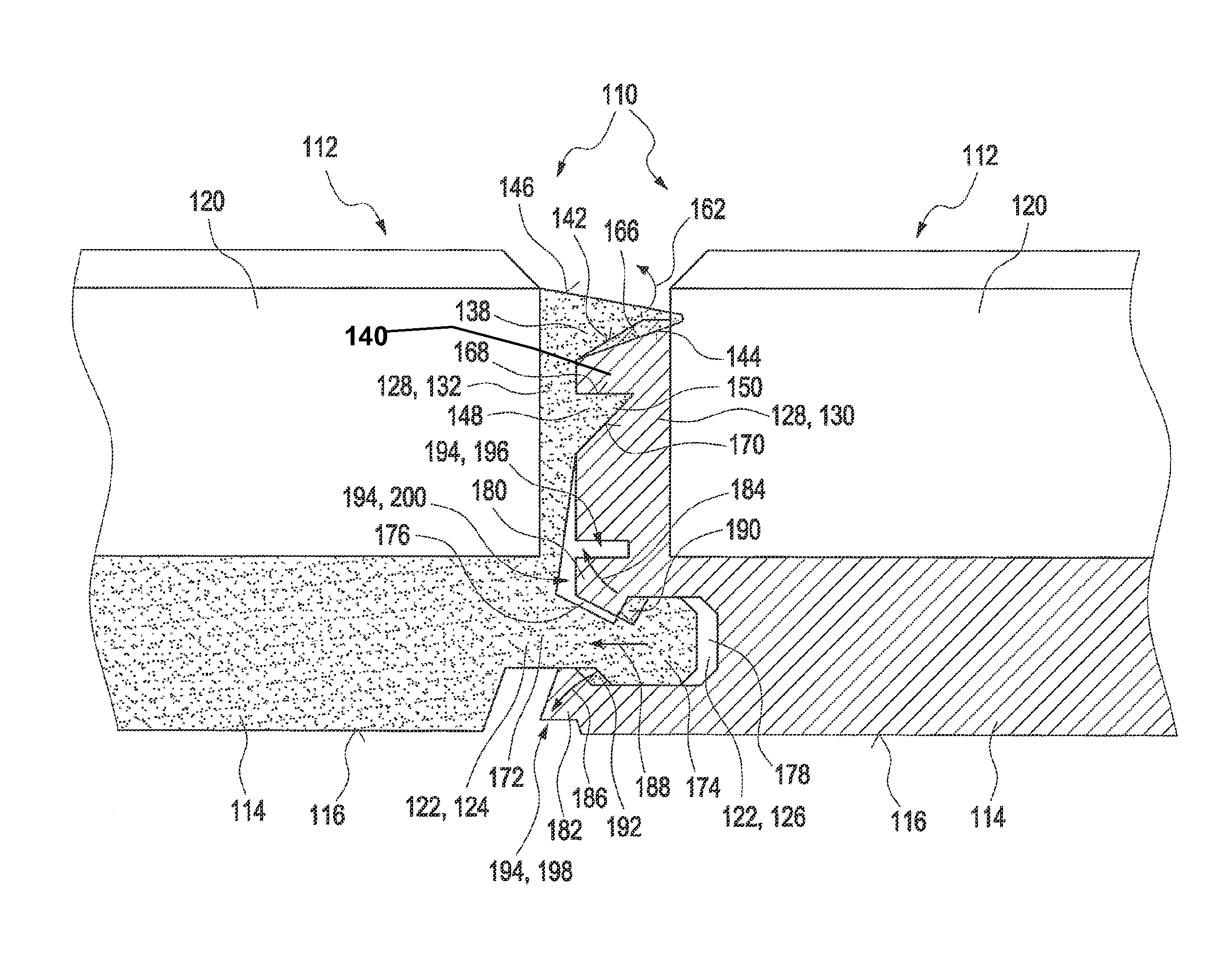

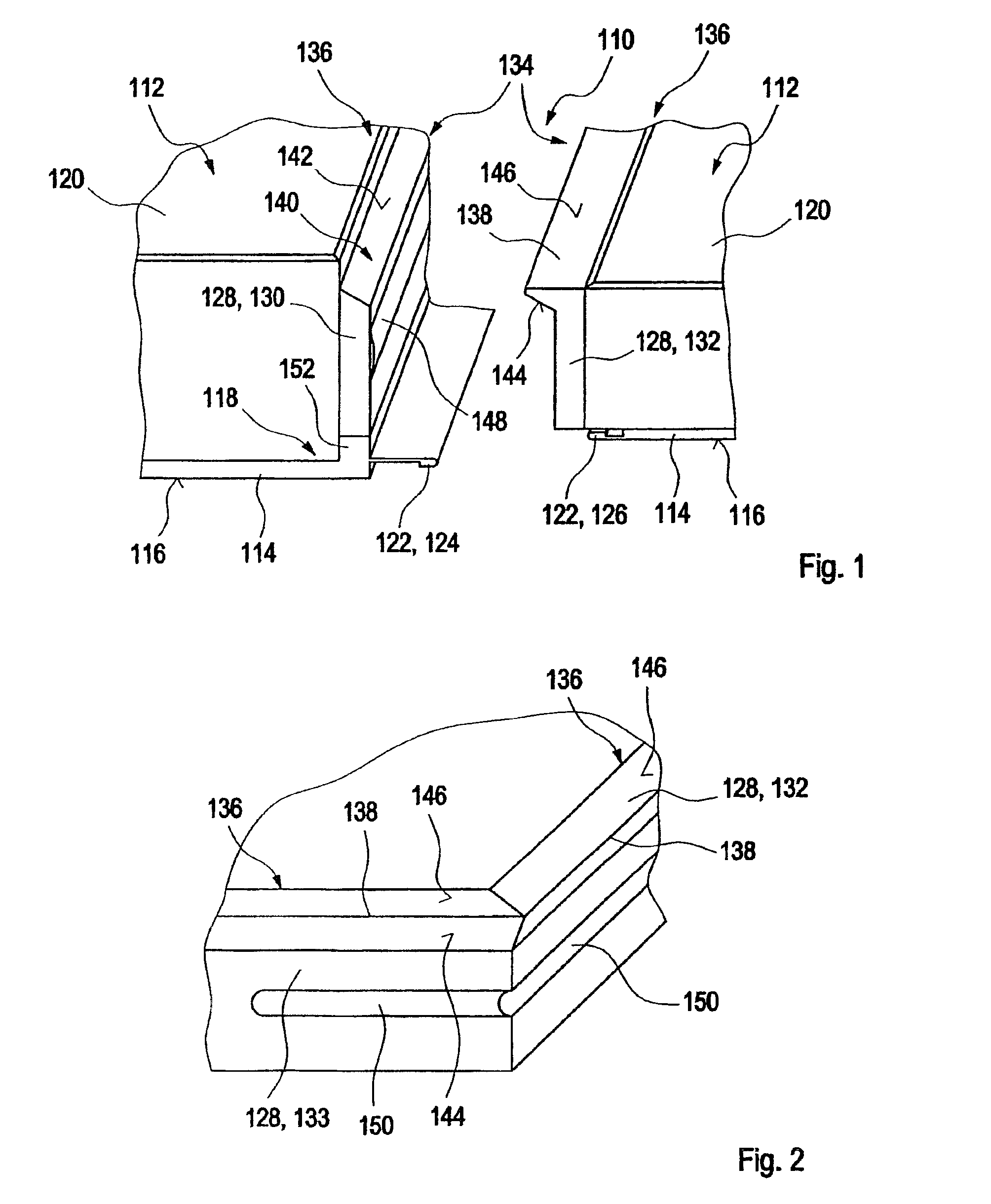

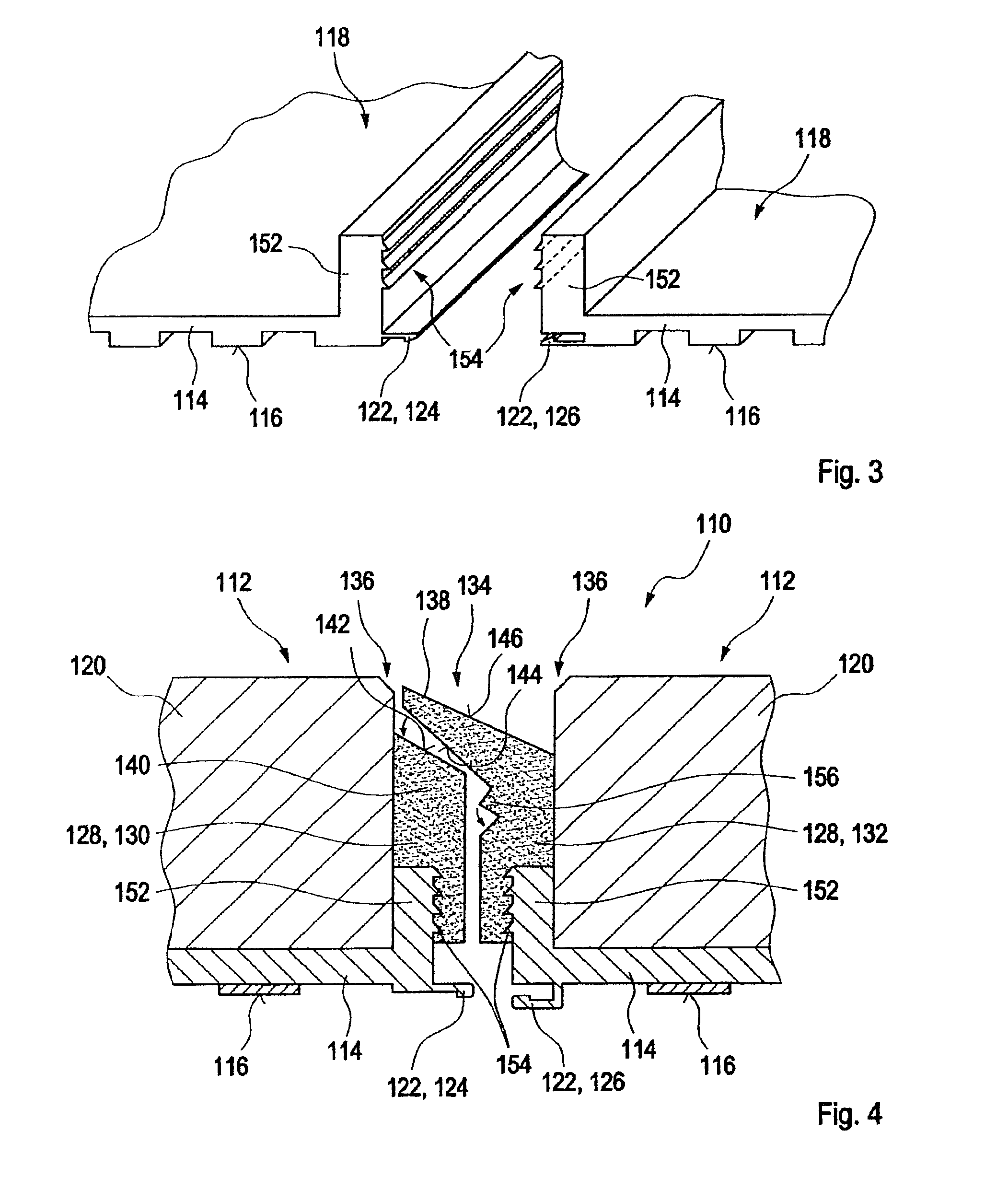

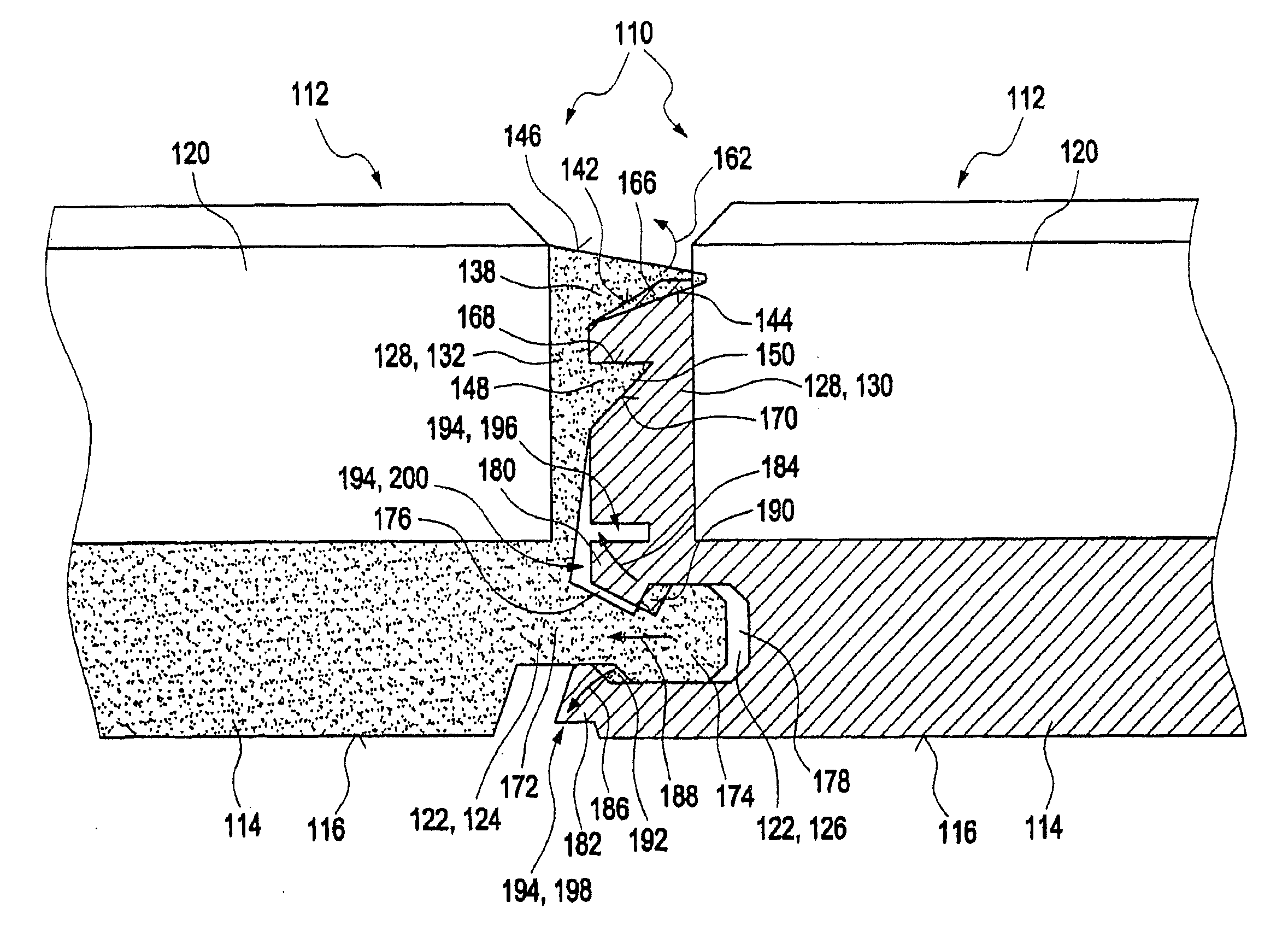

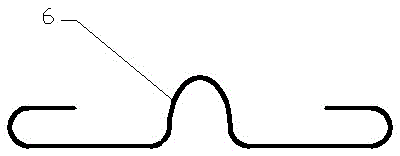

Surface covering system

InactiveUS8640418B2Improve sealingImprove mechanical stabilityCovering/liningsWallsCovering systemBiomedical engineering

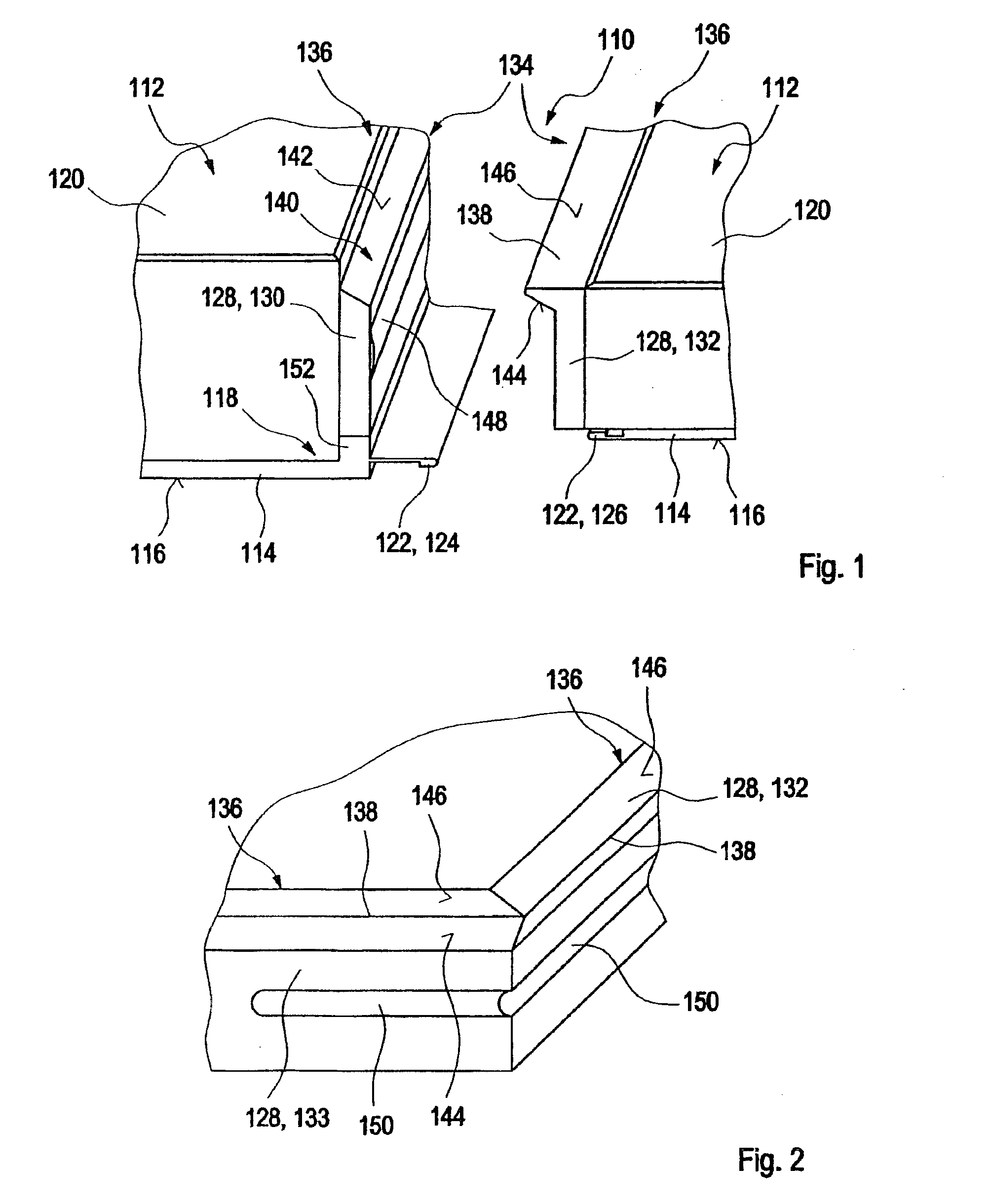

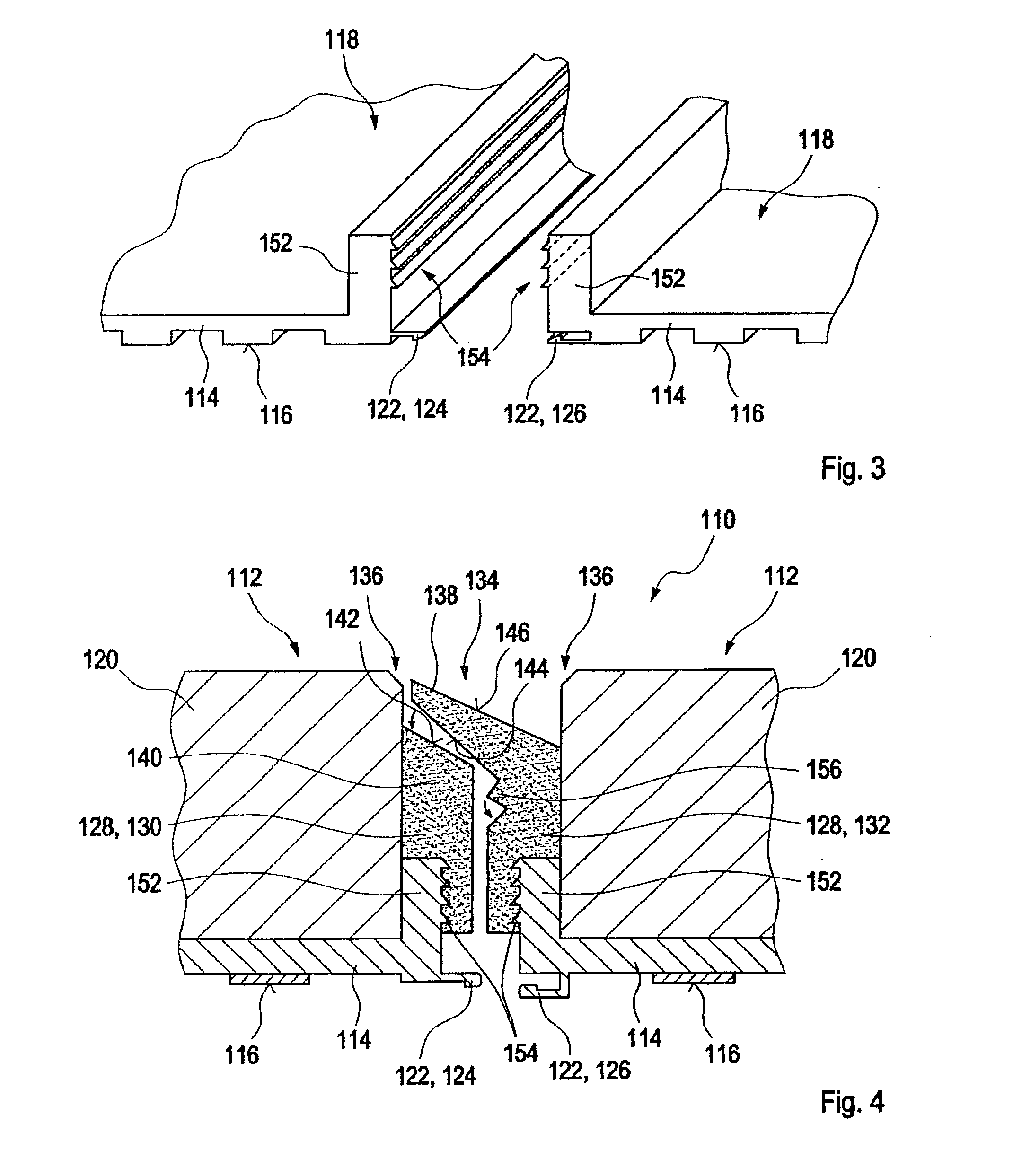

A surface covering system for covering surfaces with a covering material, particularly for covering wall surfaces or floor surfaces with tile material. The surface covering system includes at least two covering modules, which can be placed on the surface so as to adjoin each other. A first covering module has at least one first sealing profile, and a second covering profile has at least one second sealing profile. The sealing profiles are designed to engage each other in a positioned state of the covering modules and form a common seal.

Owner:GIANOLI GABRIELLA

Surface covering system

InactiveUS20110179735A1Avoid disadvantagesAesthetically pleasingConstruction materialCovering/liningsCovering systemBiomedical engineering

A surface covering system for covering surfaces with a covering material, particularly for covering wall surfaces or floor surfaces with tile material. The surface covering system includes at least two covering modules, which can be placed on the surface so as to adjoin each other. A first covering module has at least one first sealing profile, and a second covering profile has at least one second sealing profile. The sealing profiles are designed to engage each other in a positioned state of the covering modules and form a common seal.

Owner:GIANOLI GABRIELLA

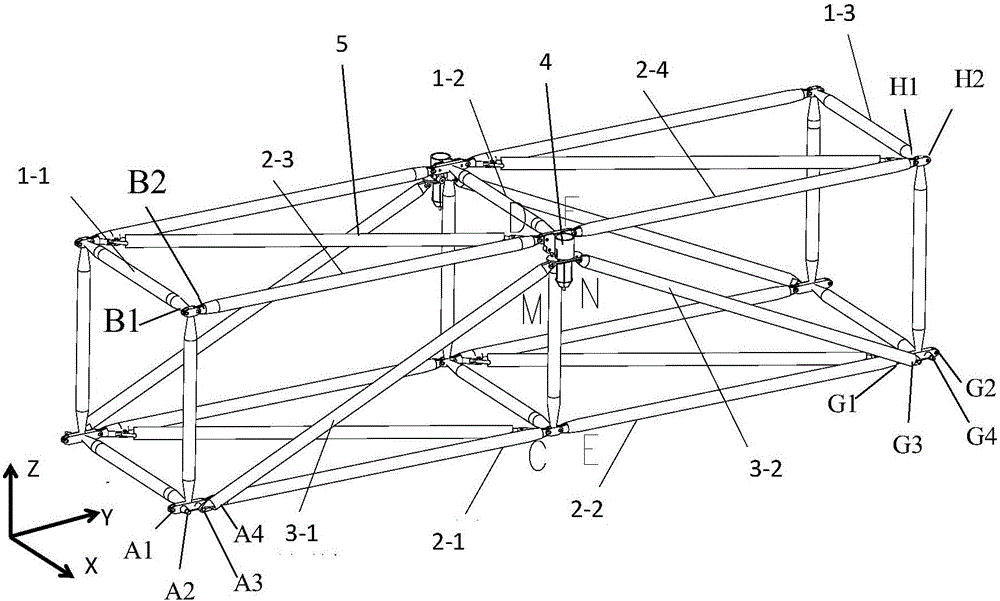

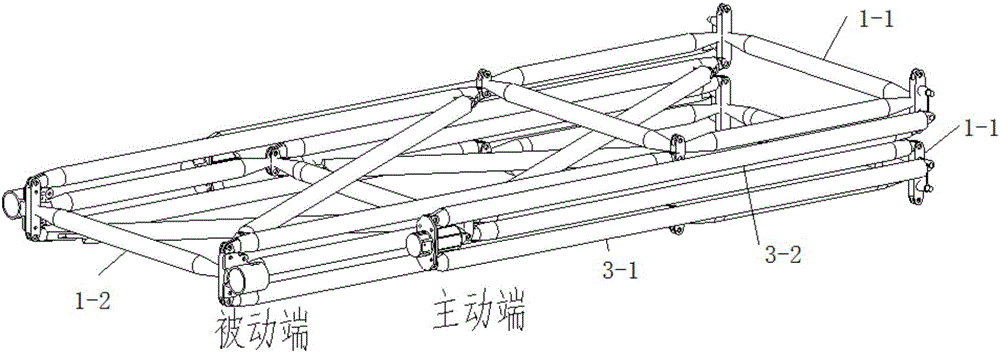

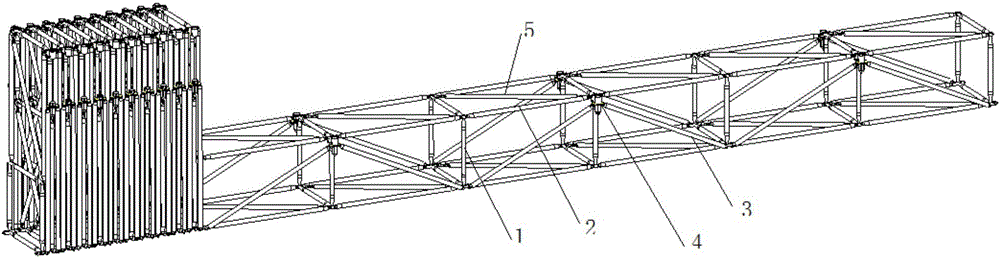

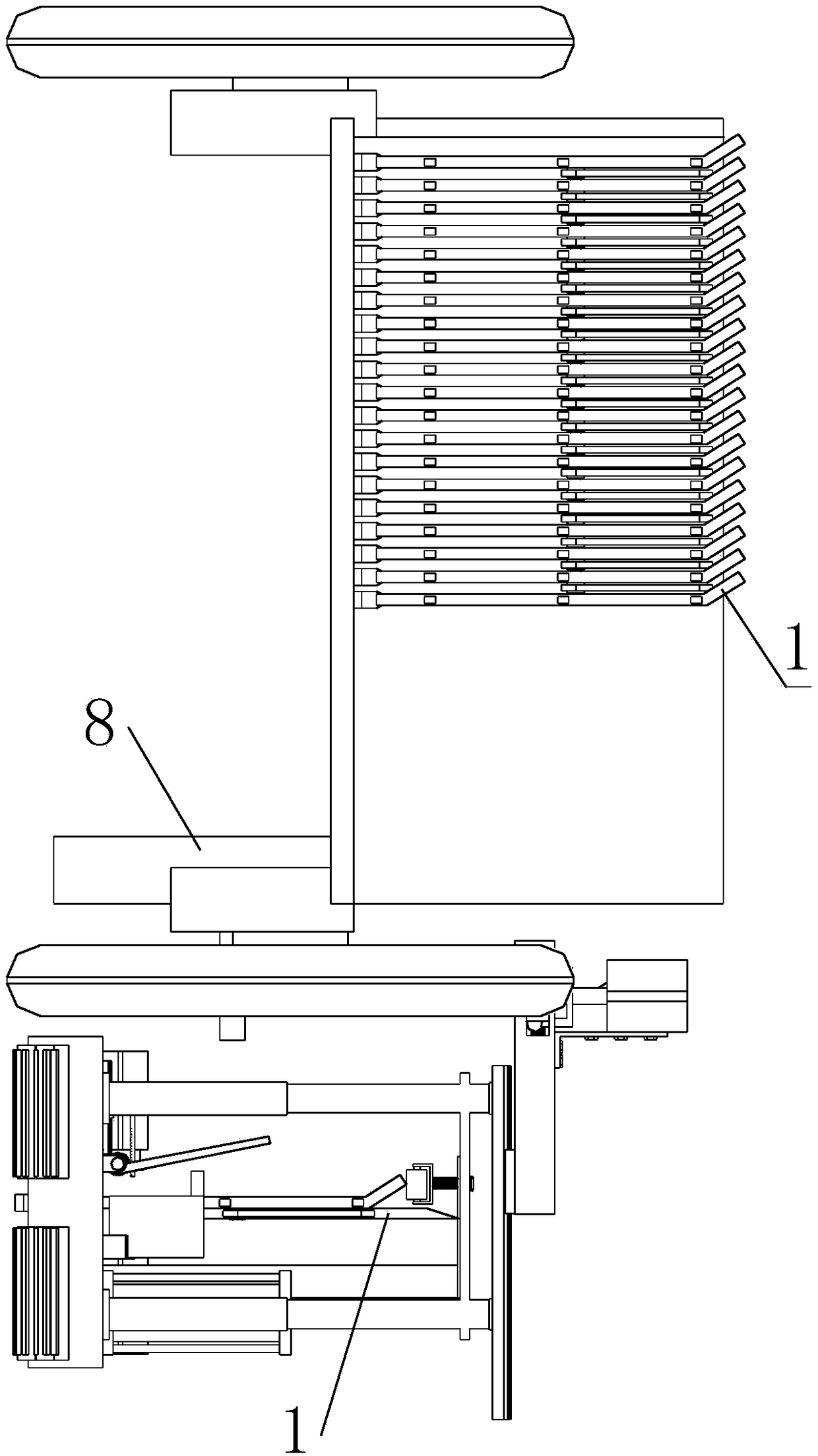

Repeatable folding and unfolding truss structure and cell element thereof

ActiveCN105923170AIncrease stiffnessImprove carrying capacityArtificial satellitesGirdersLocking mechanismRigid frame

The invention relates to a truss structure, and specifically relates to a repeatable folding and unfolding truss structure and a cell element thereof. The truss cell element of the repeatable folding and unfolding truss structure comprises three rigid frames (1), a cross rod (2), a diagonal member (3) and a locking mechanism (4). The truss cell element can form a linear beam truss cell element or a round beam truss cell element according to different geometrical parameters of the rigid frames (1), the cross rod (2), and the diagonal member (3). The truss cell elements are hinged in sequence along a length direction, to form a repeatable folding and unfolding truss. The cell elements provide continuous unfolding of truss girders in a plurality of structures, including a linear type, round and other continuous shapes, and unfolding tracks are very simple and are lines. The cell elements simplify an unfolding process and improve unfolding efficiency.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

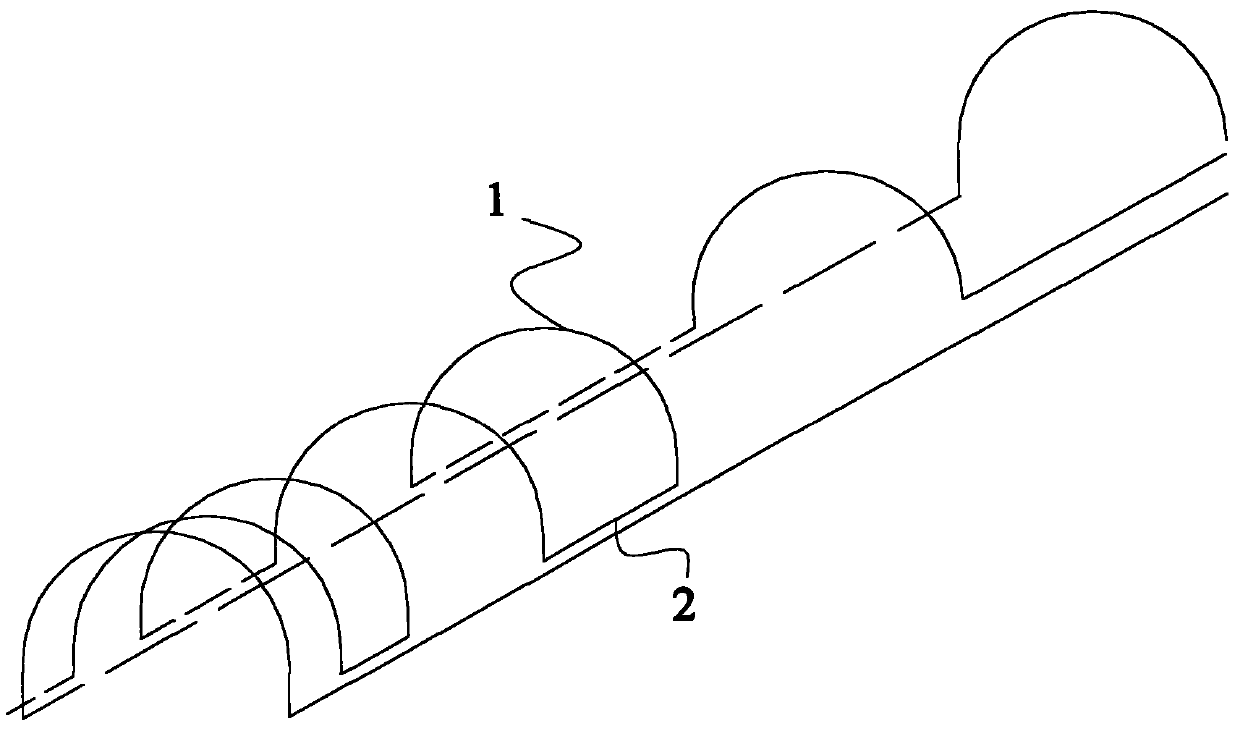

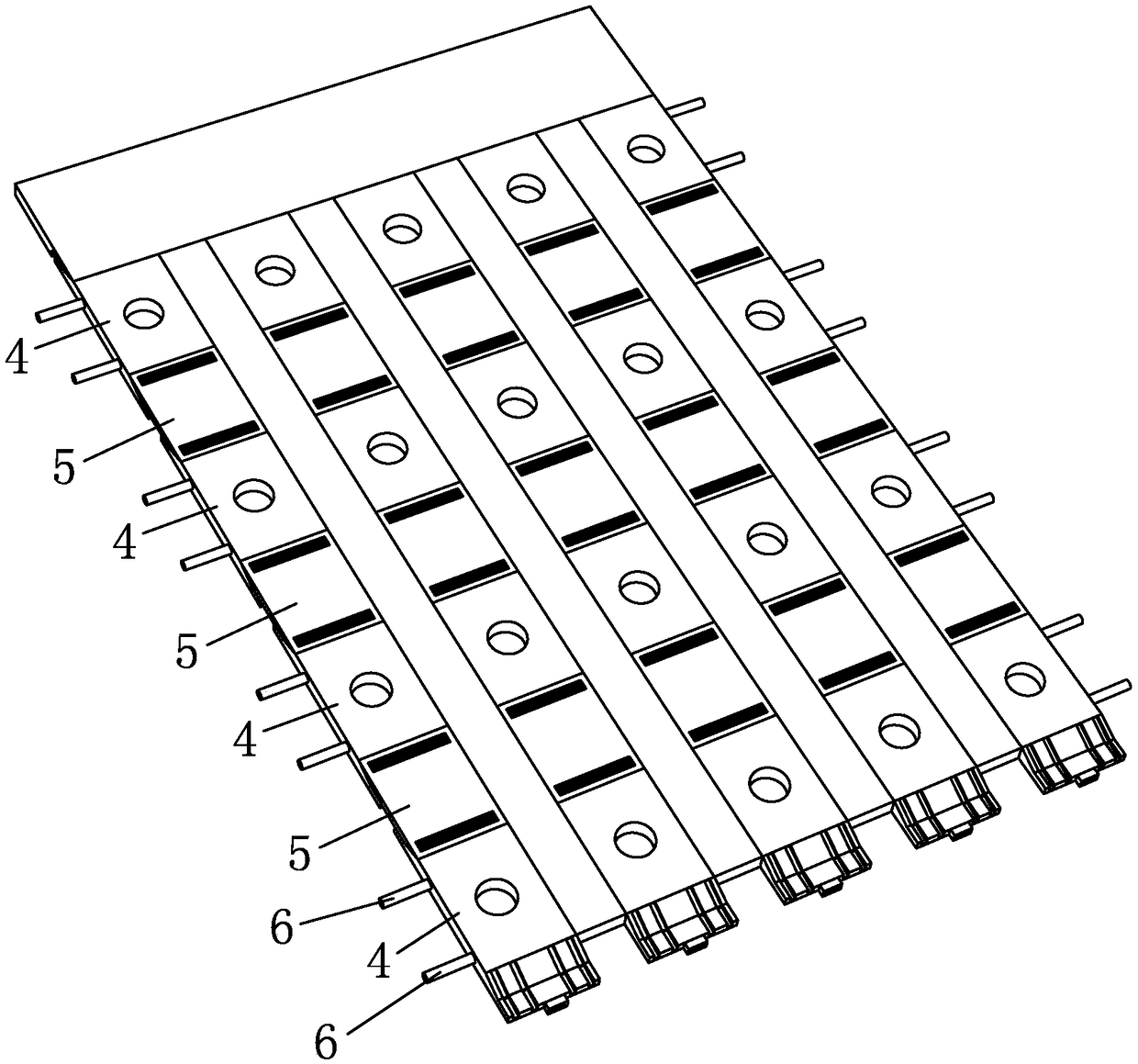

Method for paving internal concrete distributed sensing fibers

InactiveCN101738693AFast layingSolving the Difficulties of Embedding Inside ConcreteOptical fibre/cable installationThermometers using physical/chemical changesFiberStructural monitoring

The invention discloses a method for paving internal concrete distributed sensing fibers, which comprises the following steps: A) checking and cleaning a fiber conduit embedded in the concrete; B) blowing the sensing fibers into the fiber conduit through a fiber gas blowing port; C) selecting a grouting section, injecting slurry into a grouting port of the grouting section, closing a slurry outlet of the grouting section after the slurry is full of the grouting section, and keeping the slurry in the grouting section for 3 to 5 minutes under the pressure of between 1.0 and 1.5MPa so as to fix the sensing fibers in the fiber conduit; and D) circularly operating the step C) till the grouting of all the grouting sections is finished. The method achieves quick and lossless pavement for the long-distance distributed sensing fibers, solves the difficult problem that the structure monitoring field cannot embed the distributed sensing fibers into the concrete, ensures the distributed fiber sensing technology to monitor the structural strain and temperature more effectively, and realizes structural long-term and stable healthy survey.

Owner:ZHEJIANG UNIV

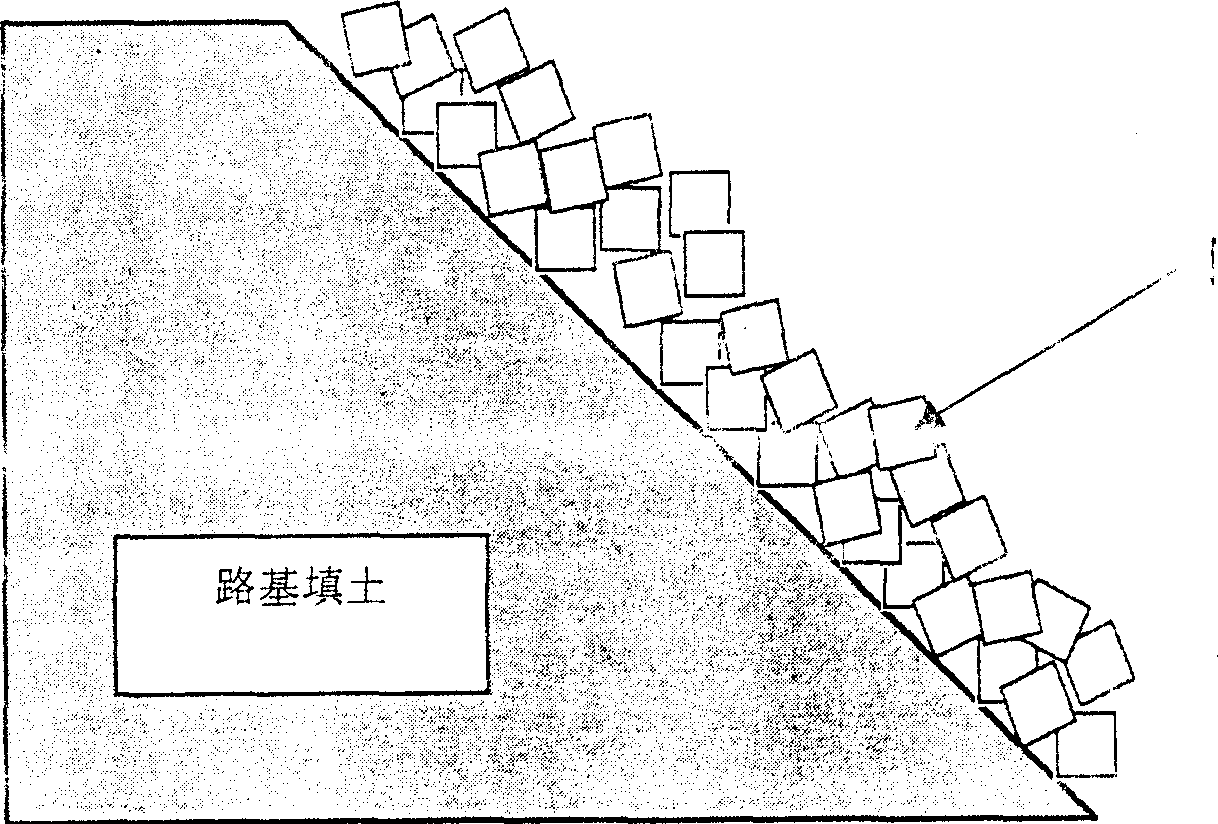

Construction method of ecological revetment for river bank protection

ActiveCN108442318AQuick changeExtend the life cycleClimate change adaptationCoastlines protectionRevetmentCatchwater

The invention discloses a construction method of an ecological revetment for river bank protection. The construction method comprises the following steps of a, paving a gravel material cushion layer;b, paving geotechnical cloth; c, backfilling a soil layer with the depth of 20-30 cm on the geotechnical cloth, and compacting the soil layer; d, constructing the ecological revetment; and e, placingsoil into ecological planting holes of ecological building blocks, and then growing plants. According to the construction method, the ecological building blocks after construction cannot fall off, sothat the overall performance of the whole ecological revetment is improved, and the flood prevention effect, the ecological effect, the landscape effect and the self-cleaning effect of the ecologicalrevetment are enhanced; and meanwhile, accumulated water on the construction site can flow into the inclined surface parts of the ecological building blocks through filter plates used for lapping withthe building blocks, and the water on the inclined surface parts of the ecological building blocks are discharged into the soil through drainage grooves, so that the earthwork of the construction area which is not paved with the ecological building blocks is prevented from being subjected to micro-amplitude sedimentation phenomenon, the flatness of the excavated earthwork is guaranteed, the ecological building blocks can be conveniently and quickly laid, moreover, the ecological building blocks can be quickly replaced, and the service period of the ecological revetment can be prolonged.

Owner:浙江丰茂盛业建设有限公司

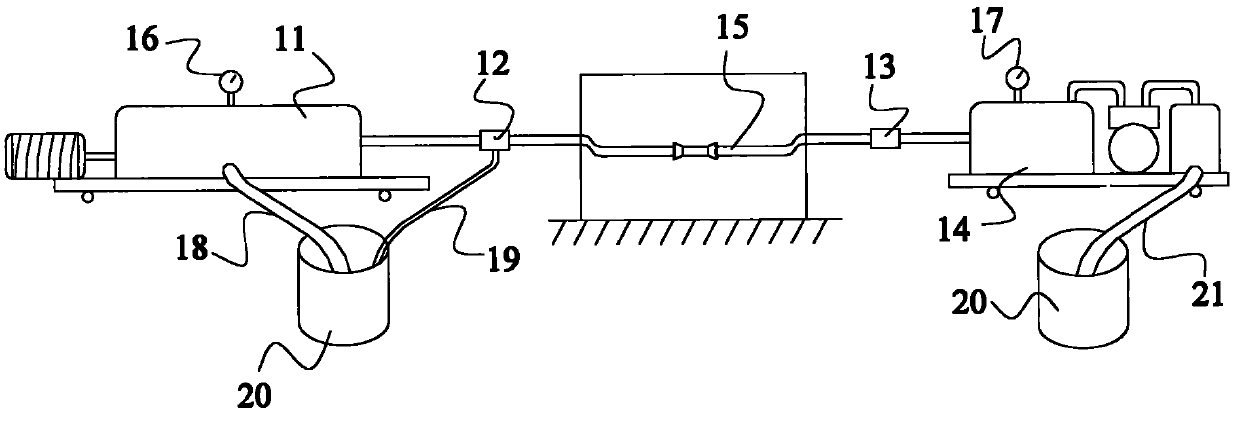

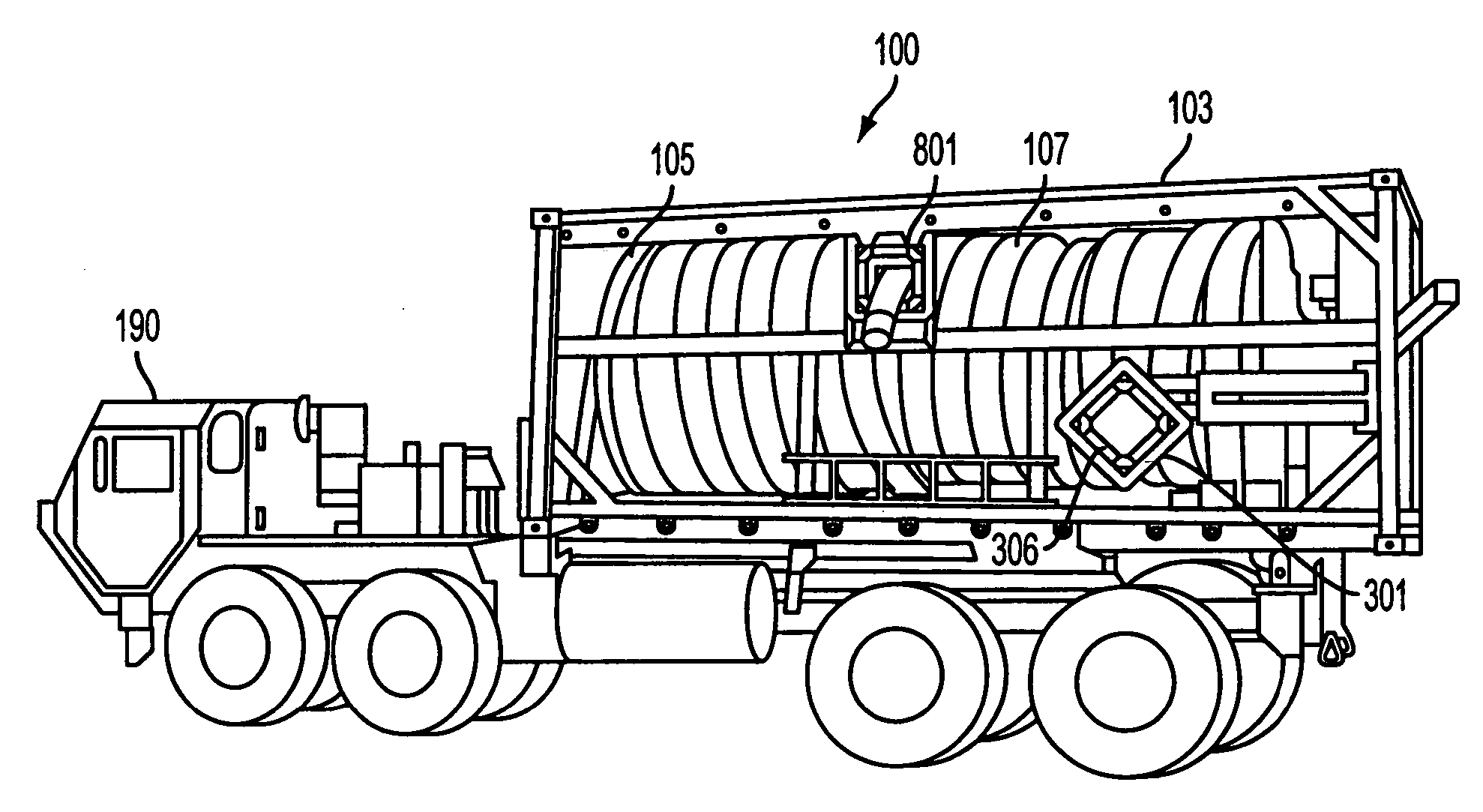

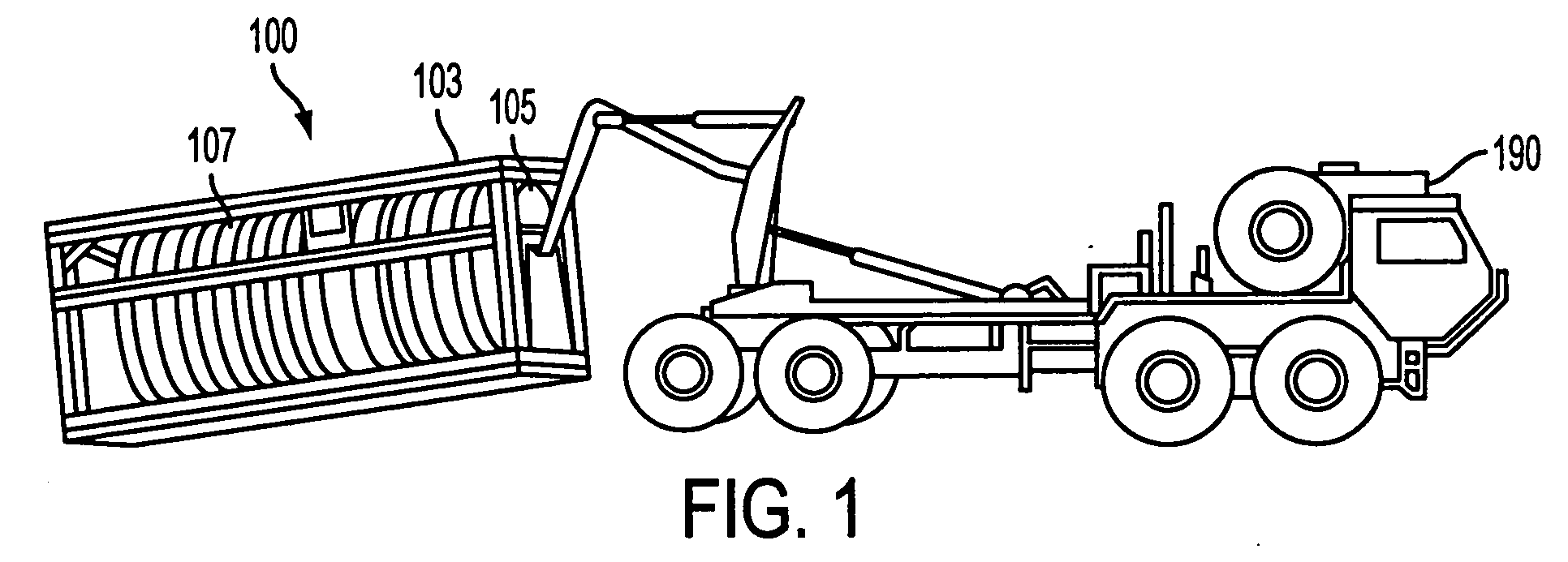

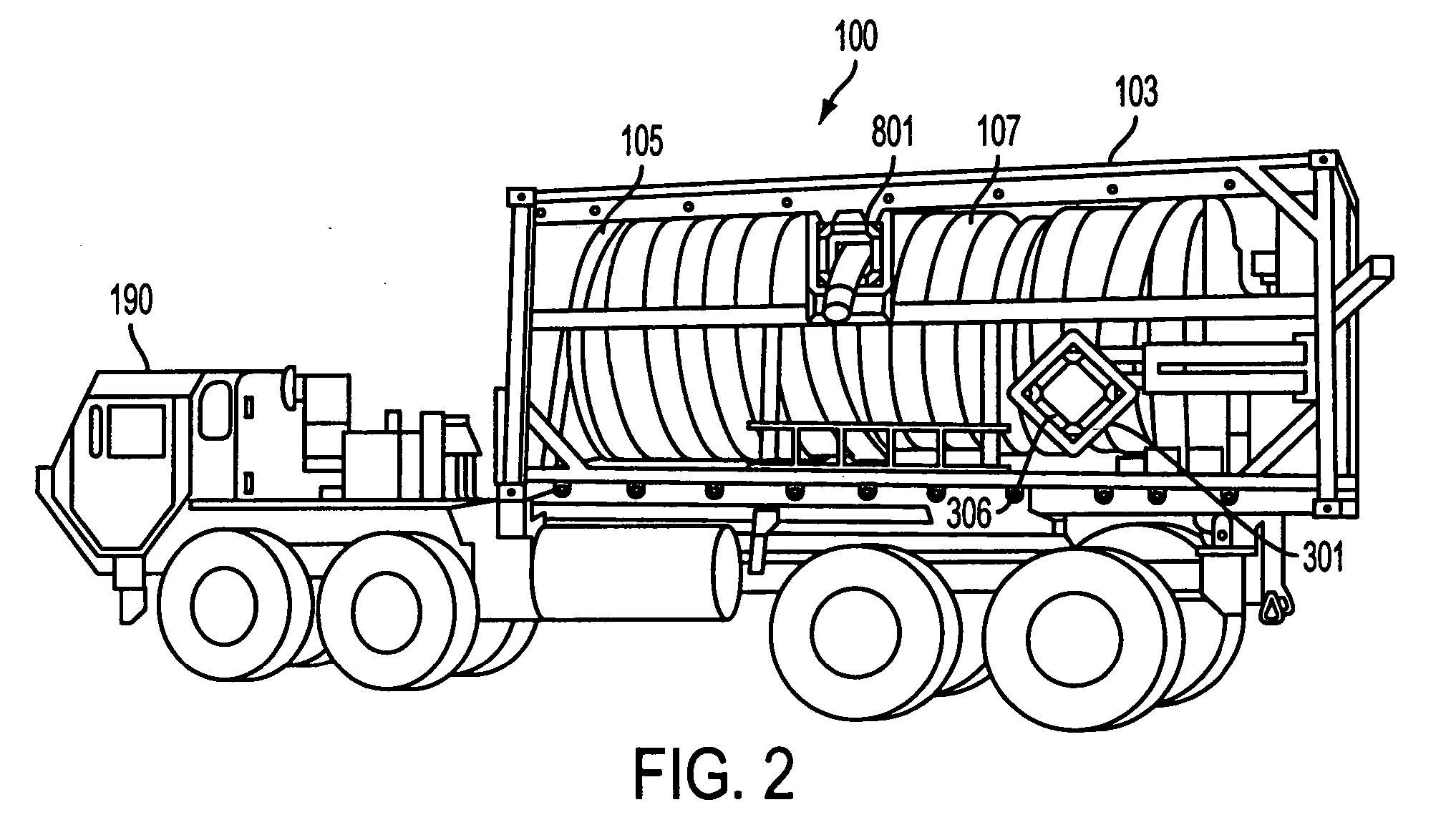

Systems and methods for the rapid deployment of piping

ActiveUS20050109870A1Fast layingIncrease speedPipe laying and repairWaterborne vesselsPipeline transportEngineering

A piping transport structure for use with a deployment vehicle to provide for improved efficiencies in laying temporary or semi-permanent piping structures. There is also a system for having one or more deployment vehicles smoothly lay piping and to allow for long pipe lays to be carried out in less time.

Owner:DRS SUSTAINMENT SYST

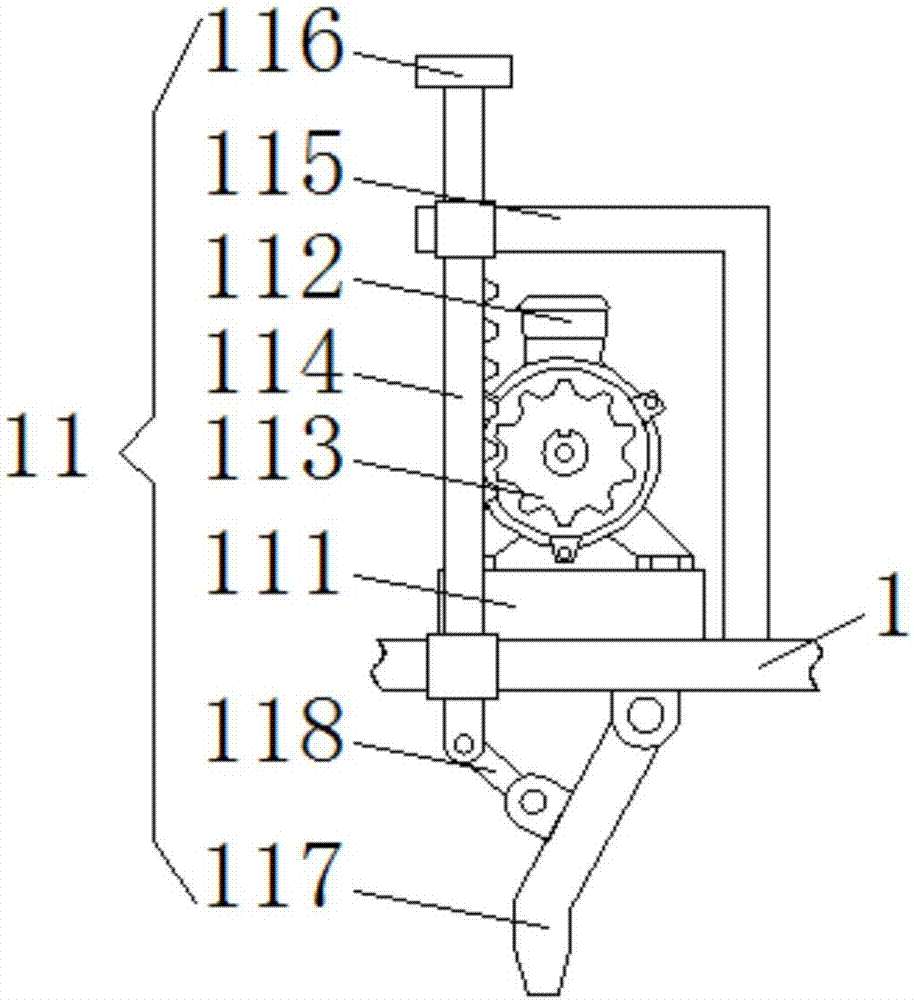

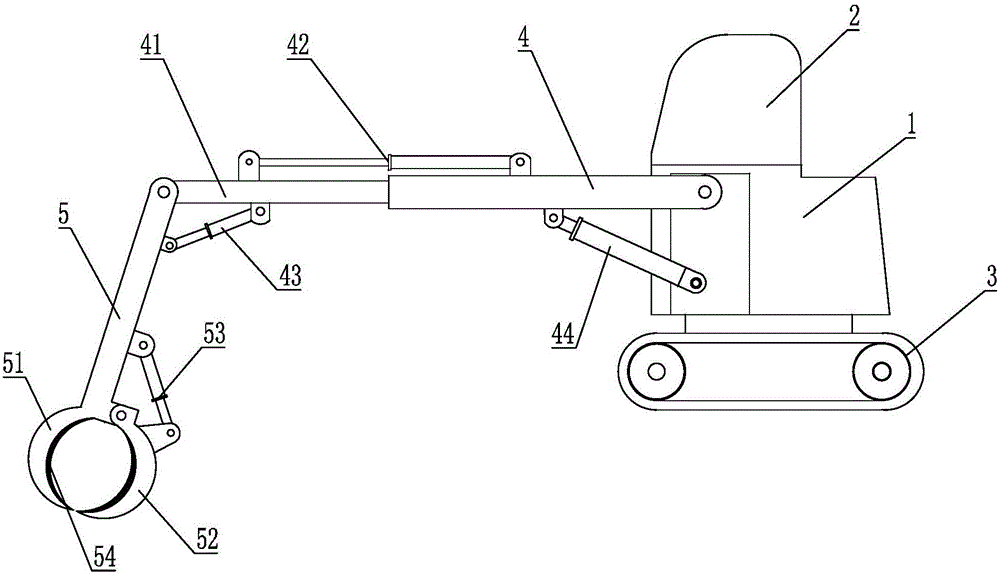

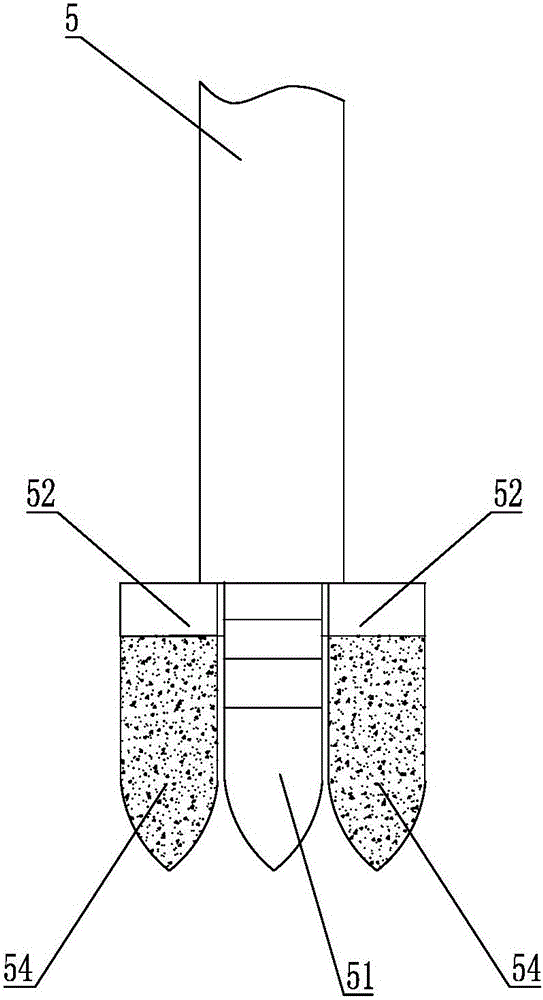

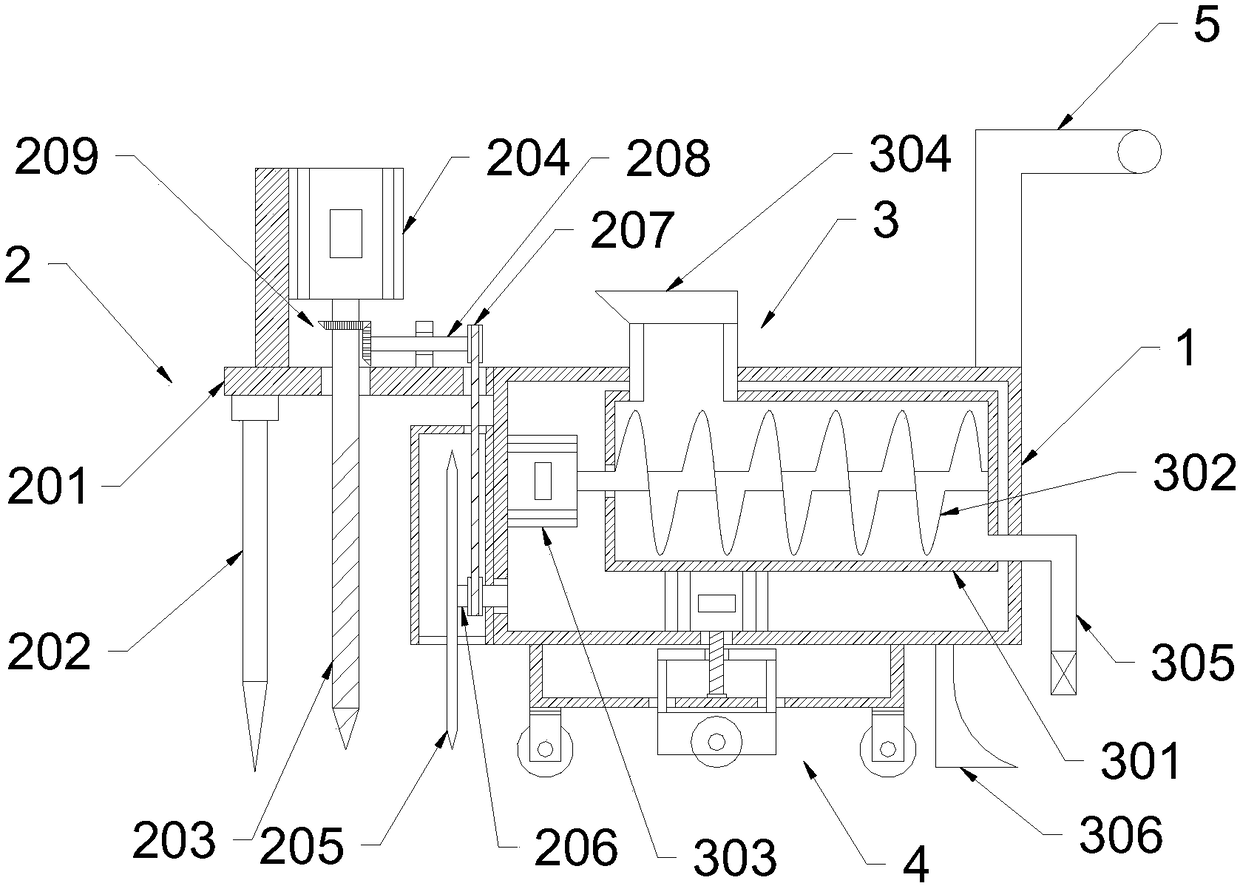

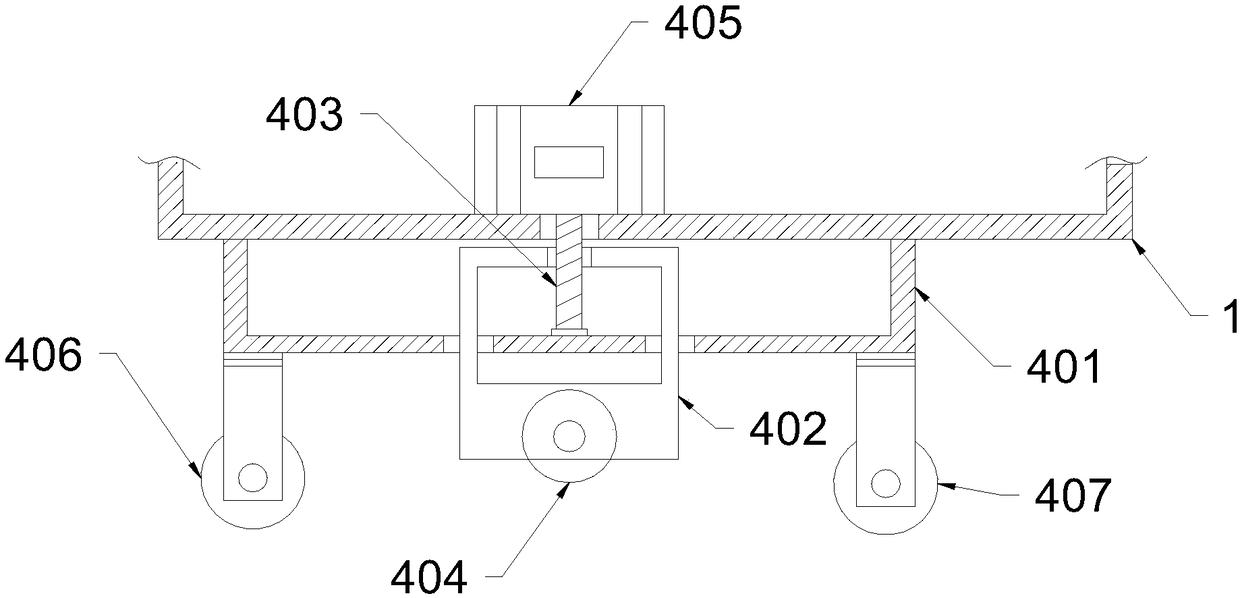

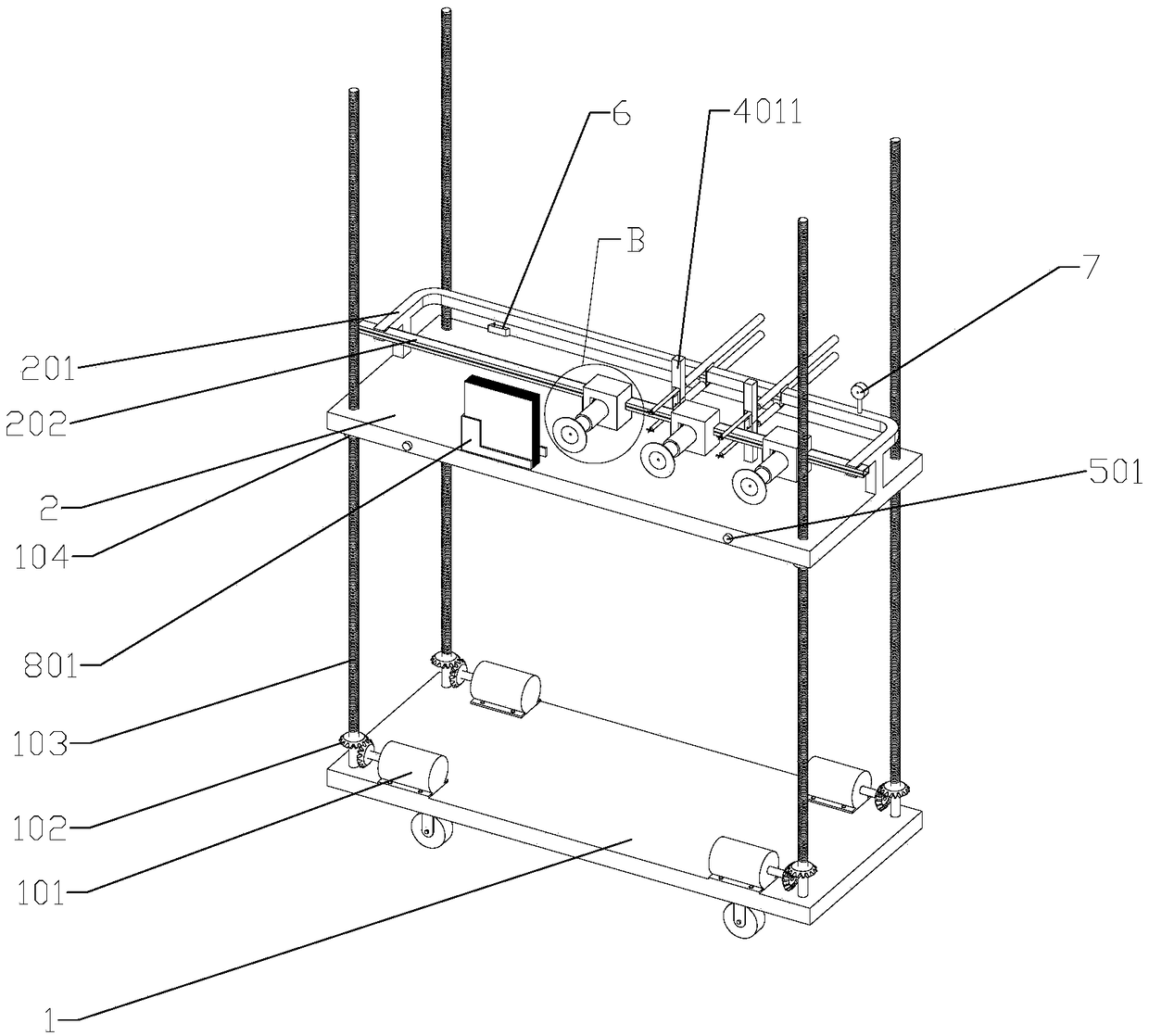

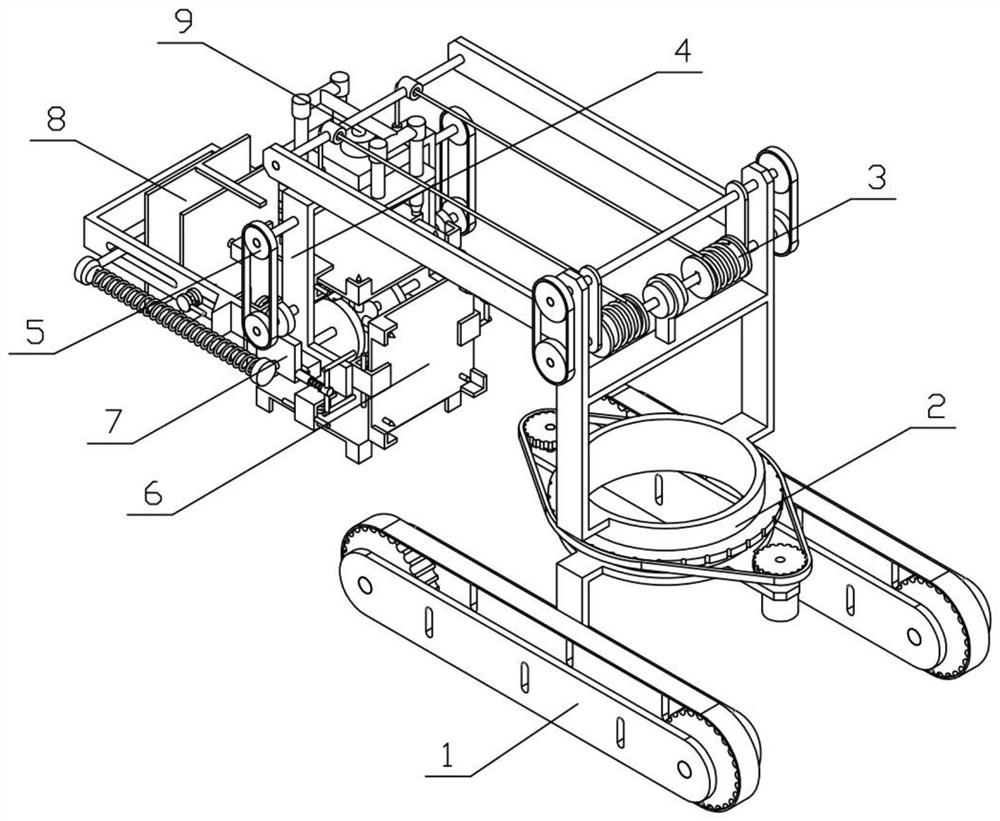

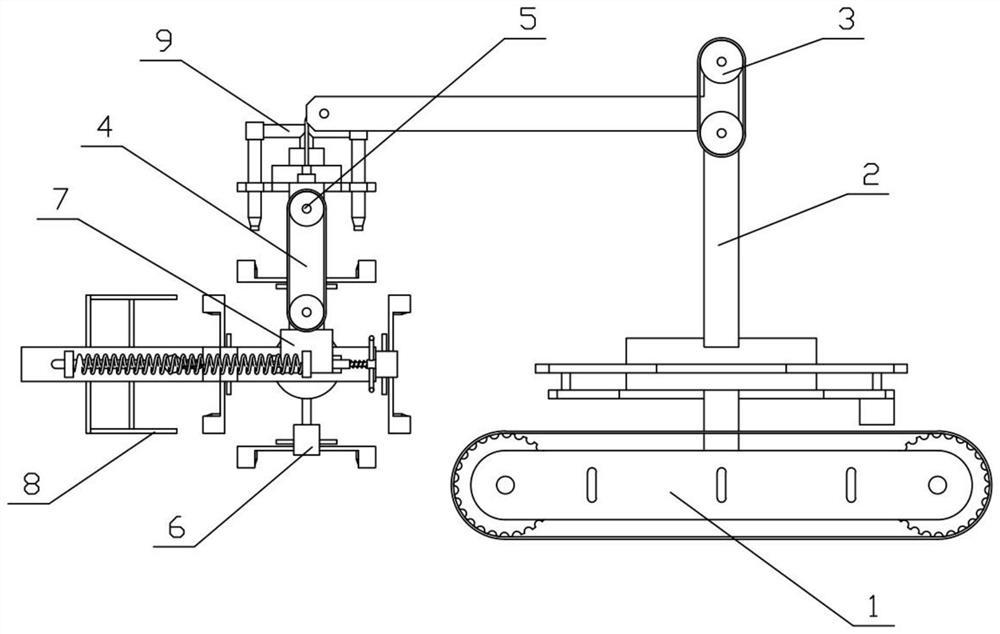

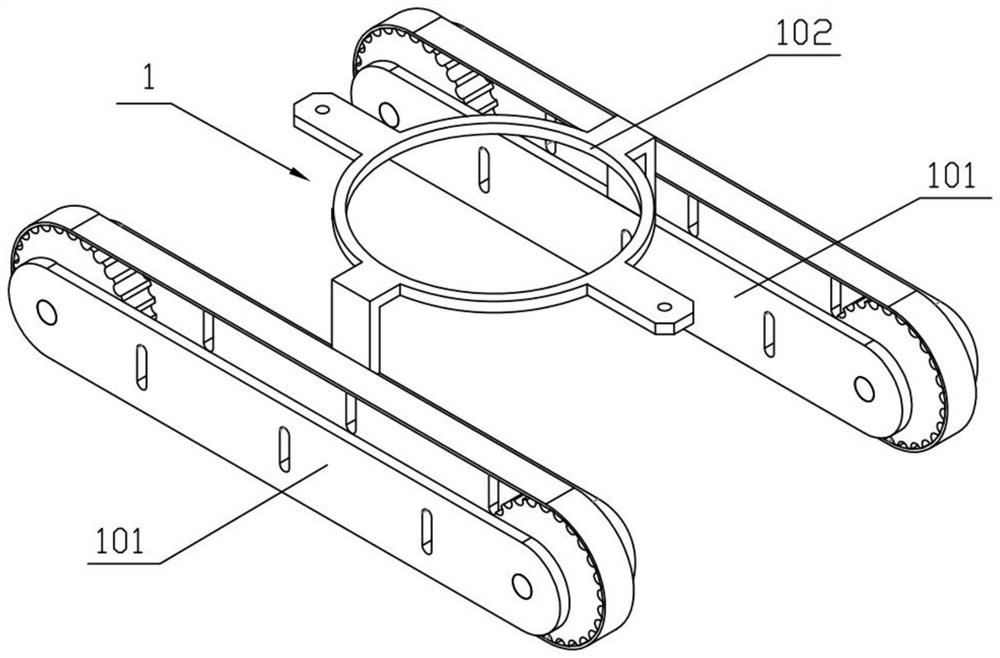

Electric power tube laying working vehicle

InactiveCN105114697AFast layingEasy to adjustPipe laying and repairEndless track vehiclesControl systemElectric power system

The invention discloses an electric power tube laying working vehicle which comprises a vehicle body. A power device and a hydraulic system are arranged on the vehicle body. A control system is further arranged on the vehicle body. The power device and the hydraulic system are connected with the control system. A walking device in transmission connection with the power device is arranged at the bottom end of the vehicle body. Operating arms are hinged to the two sides of the vehicle body respectively, and hydraulic lifting devices are arranged between the operating arms and the vehicle body. Holding claws are arranged at the ends of the operating arms, hydraulic locating and adjusting devices are arranged between the holding claws and the operating arms, and the hydraulic lifting devices and the hydraulic locating and adjusting devices are connected with the hydraulic system. The electric power tube laying working vehicle is convenient to operate, the influence of the electric power tube laying working environment is small, and electric power tube laying is fast.

Owner:国网山东五莲县供电公司 +1

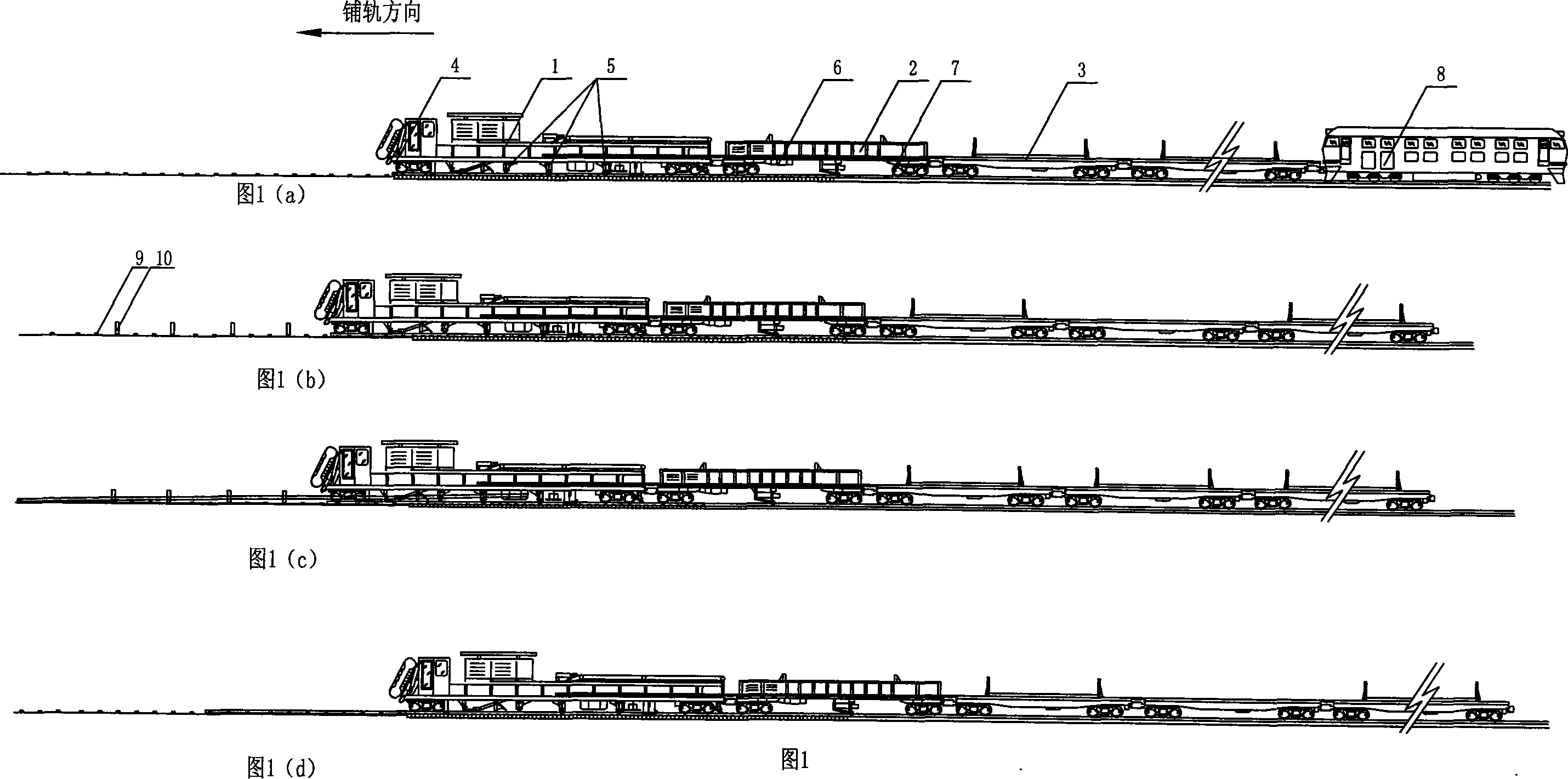

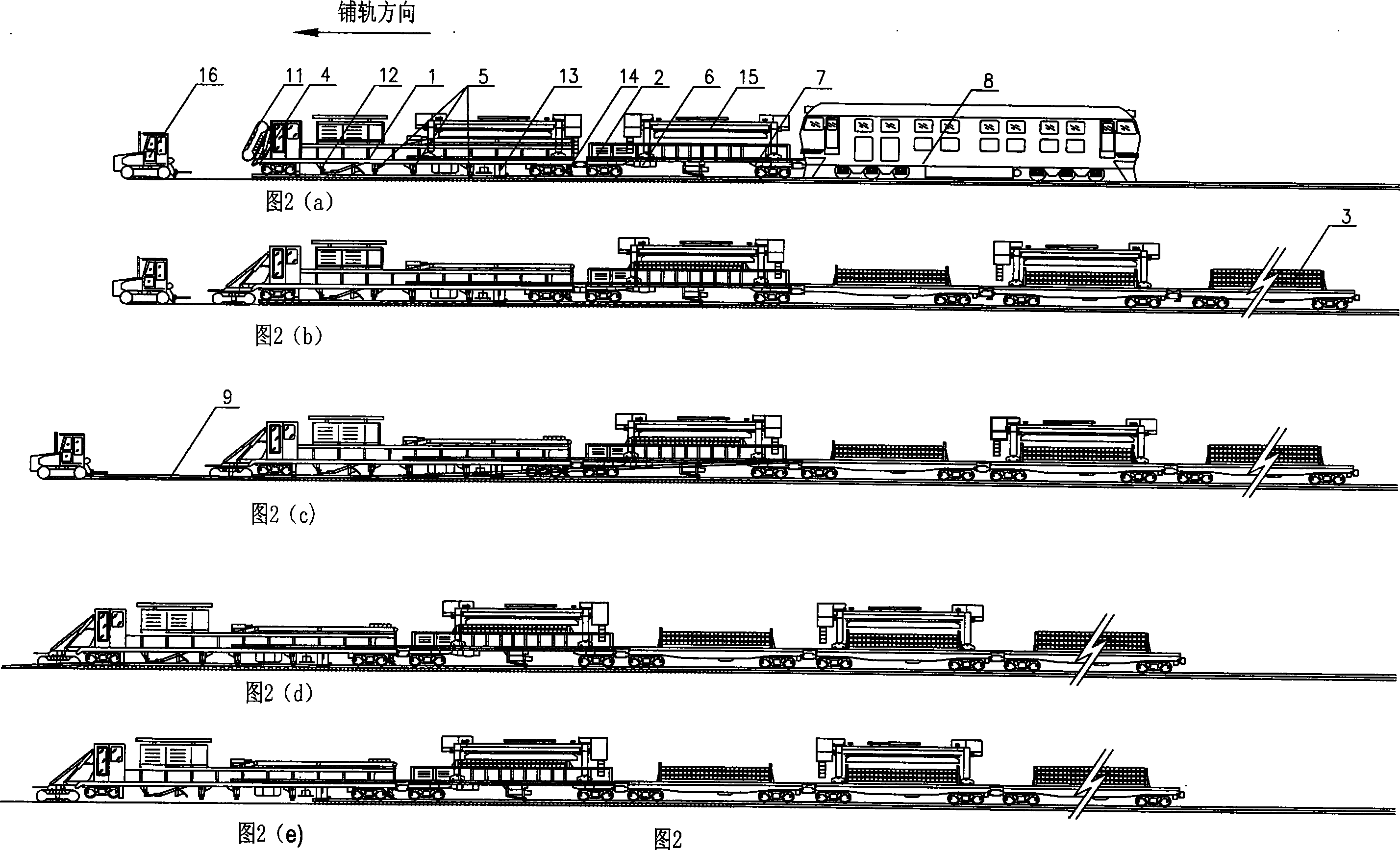

Constructing method for laying seamless line track of CPG 500 type seamless line long rail laying machine set

ActiveCN101050615AOne-time laying is smoothFast layingRailway track constructionIndustrial engineeringBuilding construction

The present invention relates to a construction method for laying seamless line rail track by using CPG 500 seamless line long rail string track-laying machine unit. It is characterized by that it utilizes CPG 500 model seamless line long rail string track-laying machine unit to lay long rail track with 500 m by means of one-step operation, and has no need of other equipment, and its working efficiency is high and laying quality is good.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

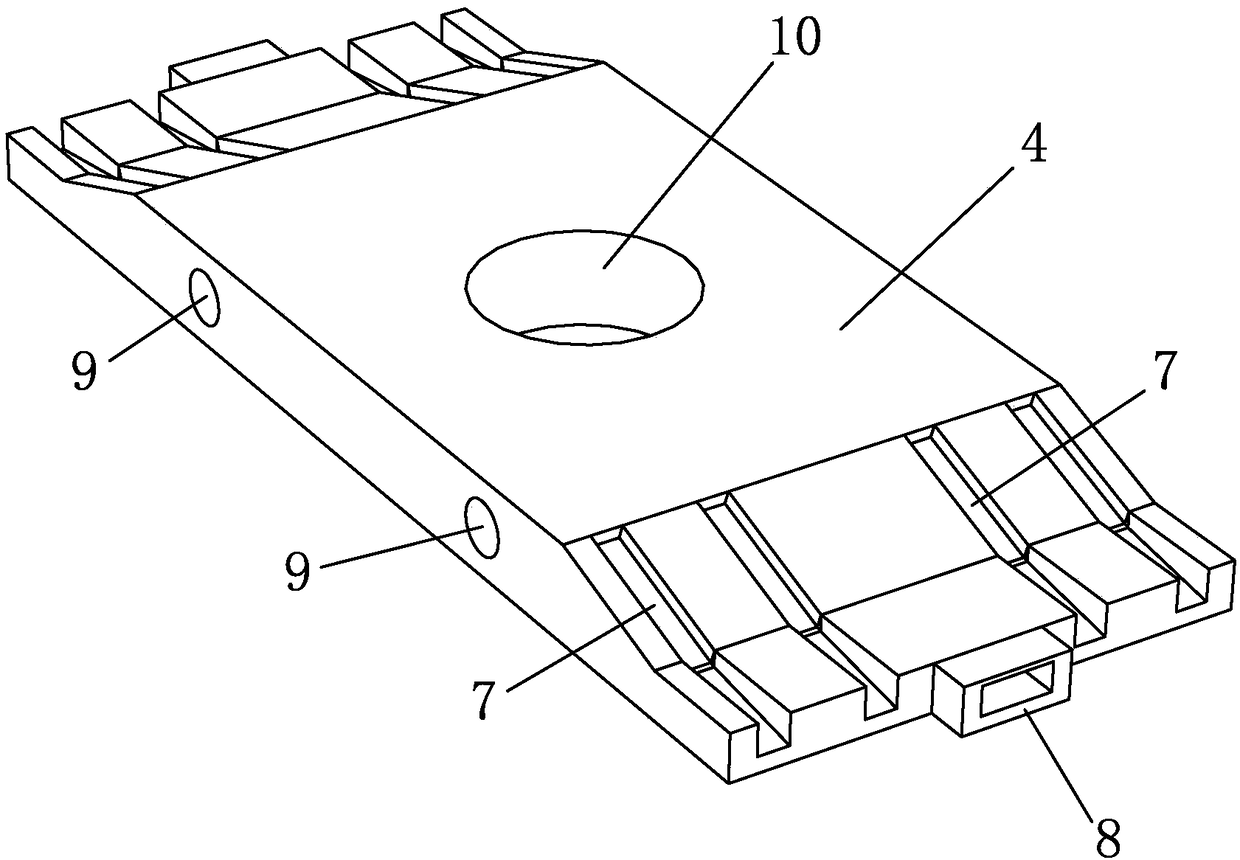

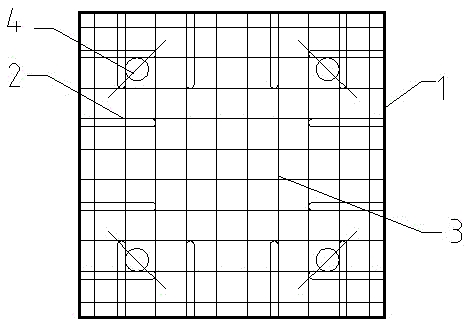

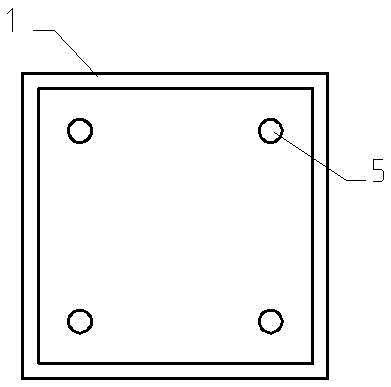

Manufacturing process for environment-friendly construction modularization tool type temporary road plate block

InactiveCN105563640AIncrease profitGuaranteed load capacityCeramic shaping apparatusTemporary pavingsArchitectural engineeringSteel frame

The invention discloses a manufacturing process for an environment-friendly construction modularization tool type temporary road plate block. The specific manufacturing process comprises the steps of 1, surveying and lining; 2, manufacturing of U-steel frames; 3, welding of frame reinforced reinforcing steel bars; 4, assembling of reinforcing steel bars; 5, pre-burying and installing of lifting rings; 6, installing of lifting ring hole die sleeves; 7, concrete pouring; and 8, maintenance. The environment-friendly construction modularization tool type temporary road plate block applying the manufacturing process comprises the U-steel frames, the frame reinforced reinforcing steel bars, the inside assembling reinforcing steel bars, the lifting rings and pouring concrete plate block bodies. According to the manufacturing process for the environment-friendly construction modularization tool type temporary road plate block, U-steel cantilever beams used for cantilever scaffolds in former projects are adopted as frame materials, and the advantage of environmental protection is achieved; the process of double-layer reinforcement distribution is adopted, and thus the bearing capacity of the road plate block is ensured; laying of the modularization tool type temporary road plate block is flexible through factory-like manufacturing, and the temporary road plate block can be laid or folded according to the requirements of an engineering site and are widely applied; the temporary road plate block can be reused for many times, so that environmental pollution is reduced, the effects of energy conservation and environmental protection are achieved, and the purpose of environment-friendly construction is achieved.

Owner:江海燕

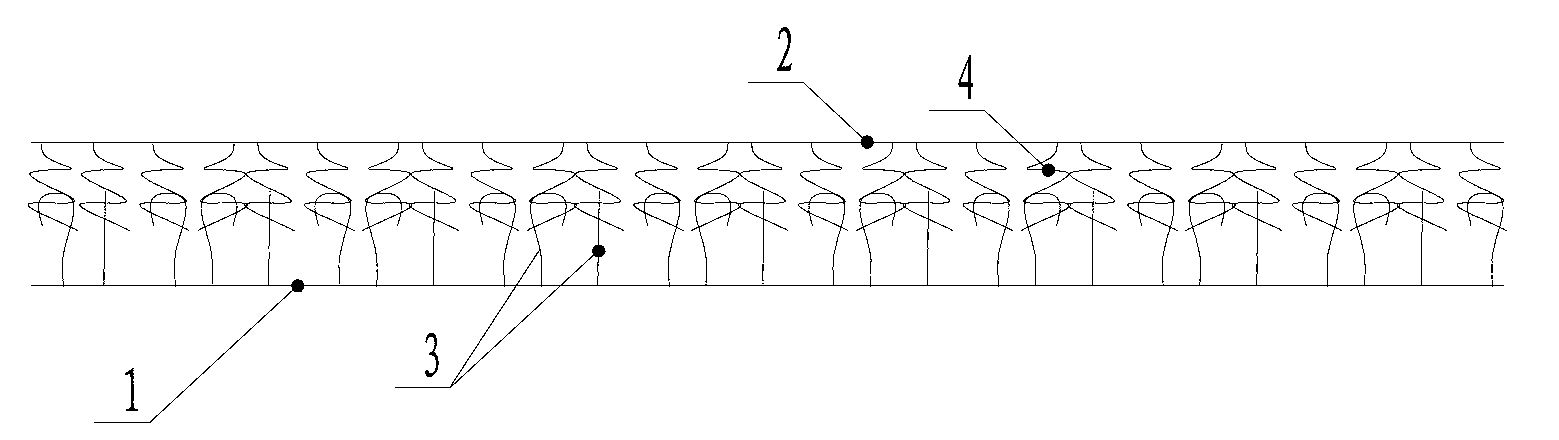

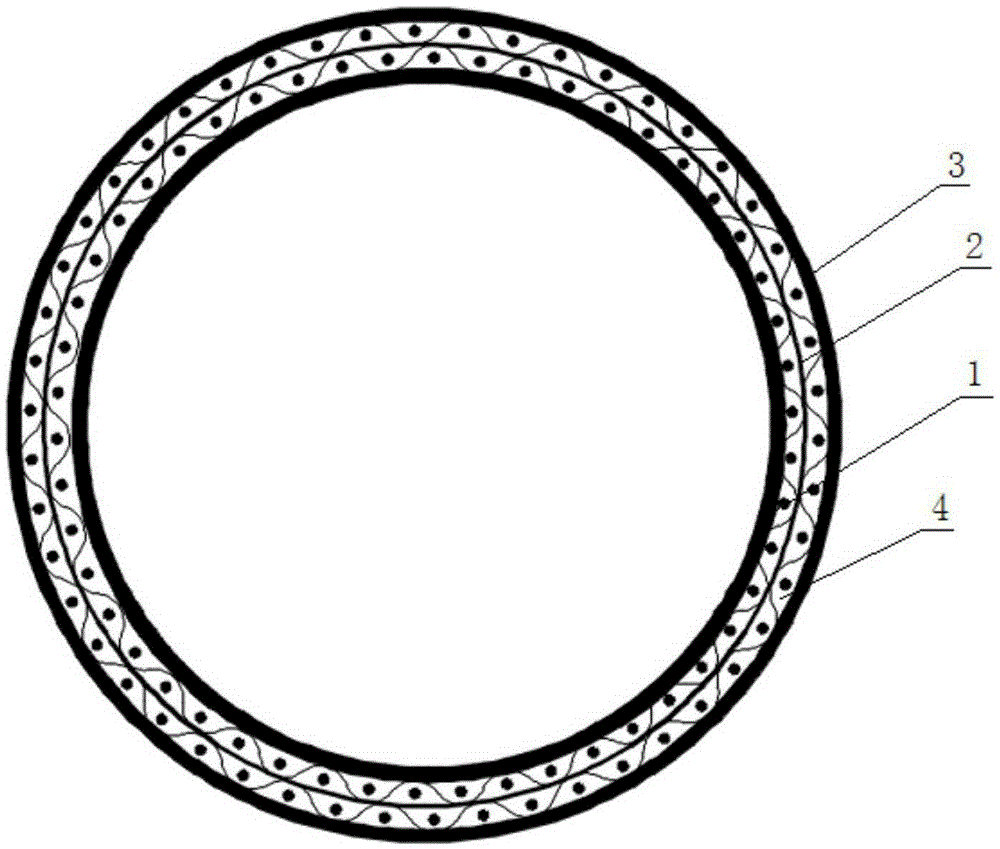

Hand-flapping automatic laid and hung type tunnel waterproof board

The invention discloses a hand-flapping automatic laid and hung type tunnel waterproof board; the tunnel waterproof board mainly comprises a waterproof board (2) and a geotechnical cloth (1), which are laminated with each other, wherein adhesive hooks (3) are uniformly distributed on one surface of the geotechnical cloth (1) laminated with the waterproof board (2); adhesive wires (4) are uniformly distributed on one surface of the waterproof board (2) laminated with the geotechnical cloth (1); and the geotechnical cloth (1) and the waterproof board (2) are combined together in an adhesive way through the adhesive hooks and the adhesive wires. According to the invention, the waterproof board has a plurality of fixing and connecting points, and a purpose that the waterproof board is stably fixed without sinking is achieved. Through the designing of the adhesive hooks and the adhesive wires, convenience for connecting and laying is achieved, an effect of enhancing water seepage capacity of the back of the waterproof board without hot melt welding can be also achieved, environment friendliness is achieved and resources are saved. The hand-flapping automatic laid and hung type tunnel waterproof board disclosed by the invention has the advantages of simple structure and easiness in factory machining production; construction quality and environmental protection can be guaranteed; construction efficiency is increased; and cost is saved.

Owner:中铁隧道局集团建设有限公司

Wall cement laying equipment used in construction site

The invention relates to cement laying equipment, in particular to cement laying equipment used in a construction site. The cement laying equipment achieves the purposes that the cement sheds little when laid, the laying process saves both time and labor, dangerousness to a worker is small and the contamination of the clothes of the worker is small. The cement laying equipment comprises a base plate, a first supporting leg, an electric wire winding wheel, a guide rail, a second supporting leg, a fixed pulley, a guide sleeve, a pulling line, a placing board, a third supporting leg, a driving wheel, a driven wheel and the like. The upper side of the base plate is provided with the first supporting leg in a welding mode, and the electric wire winding wheel is rotatably connected to the first supporting leg. According to the wall cement laying equipment used in the construction site, the effects that the cement sheds little when laid, the laying process saves both time and labor, dangerousness to the worker is small and the contamination of the clothes of the worker is small are achieved.

Owner:广东龙越建筑工程有限公司

Cement floor paving equipment used for building construction

The invention relates to floor paving equipment, in particular to cement floor paving equipment used for building construction, and aims to provide the cement floor paving equipment used for buildingconstruction which can rapid pave cement floor and is low in labor intensity. Through the technical scheme, the cement floor paving equipment used for building construction comprises a frame body, wheels, first springs, a guide rod, a pressure plate, a motor, a cam, a push plate, a sliding rail, a sliding block, a baffle plate, a fixed pulley, a clamping block, a connecting rod and the like; the wheels are mounted at the bottom of the frame body, guide grooves are formed in the left and right sides of the bottom of the frame body, and the upper inner walls of the guide grooves in the left andright sides are connected with the first springs respectively. Through the arrangement of the push plate, a cement paste can be pushed easily when the equipment is pushed by people, and the pressure plate can be used for rapidly paving cement on the ground due to the cooperation of the cam and the pressure plate, so that the working strength of workers is reduced.

Owner:黄玉发

Rotary pavement repairing device

InactiveCN108103914AImprove efficiencyGuaranteed laying effectRoads maintainenceVehicle frameRoad surface

The invention discloses a rotary pavement repairing device. The device comprises a frame and a stirring tank, wherein a crushing device is arranged on the left side of the frame, a stirring and pouring device is arranged in the frame, and a moving device is arranged below the frame. A lifting wheel and a fixing rod are arranged, so that the frame can move circumferentially, and a cutting wheel cuts out circular slits on the ground to ensure the laying effect of a joint; meanwhile, the pavement on the inner side of the slits is crushed by a drill stem, a columnar groove is formed, and the edgecutting and grooving efficiency is improved. The stirring tank is arranged, raw materials are poured into the opened columnar groove through a pouring pipe, laying is completed rapidly, and operationefficiency is improved.

Owner:屈大忠

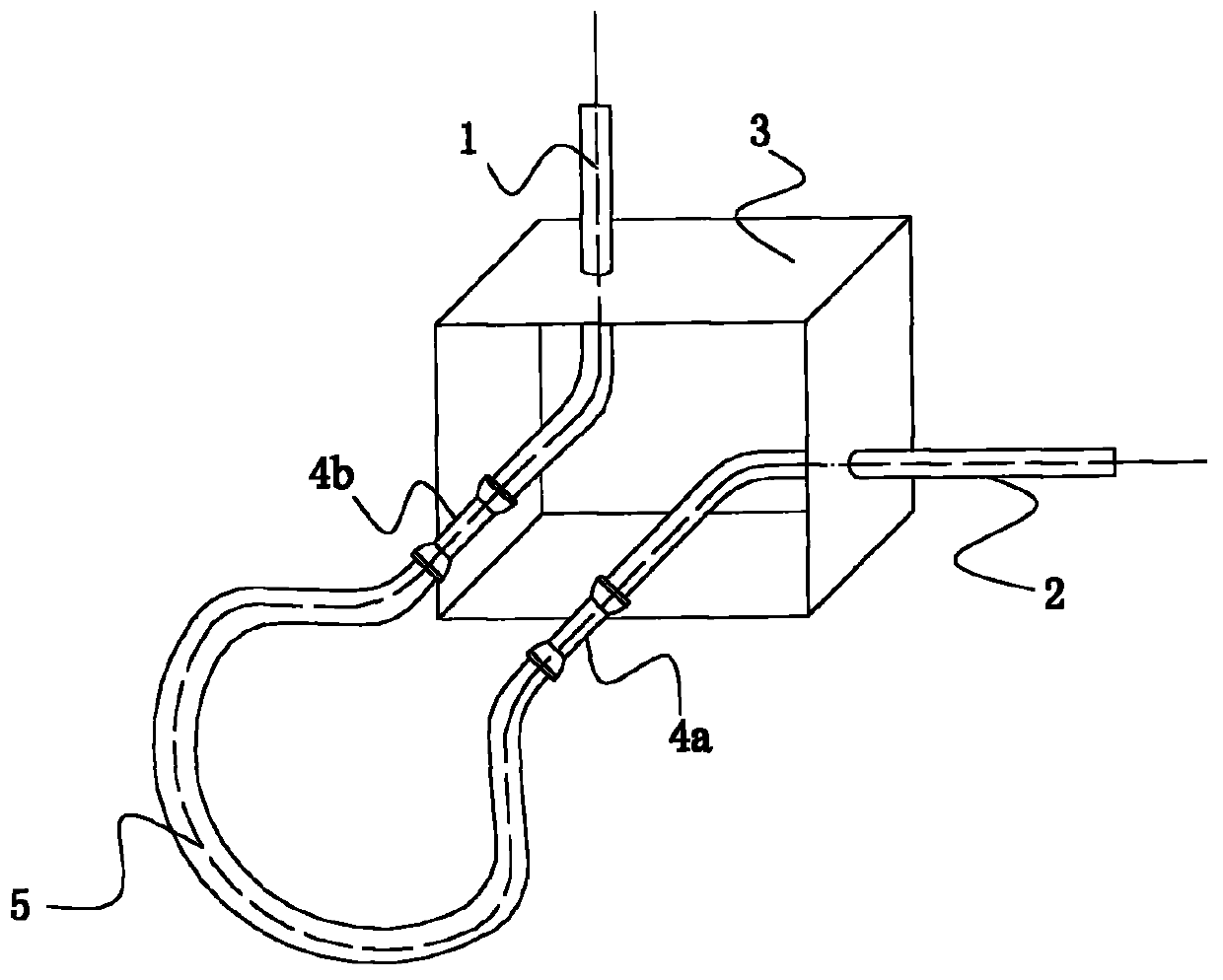

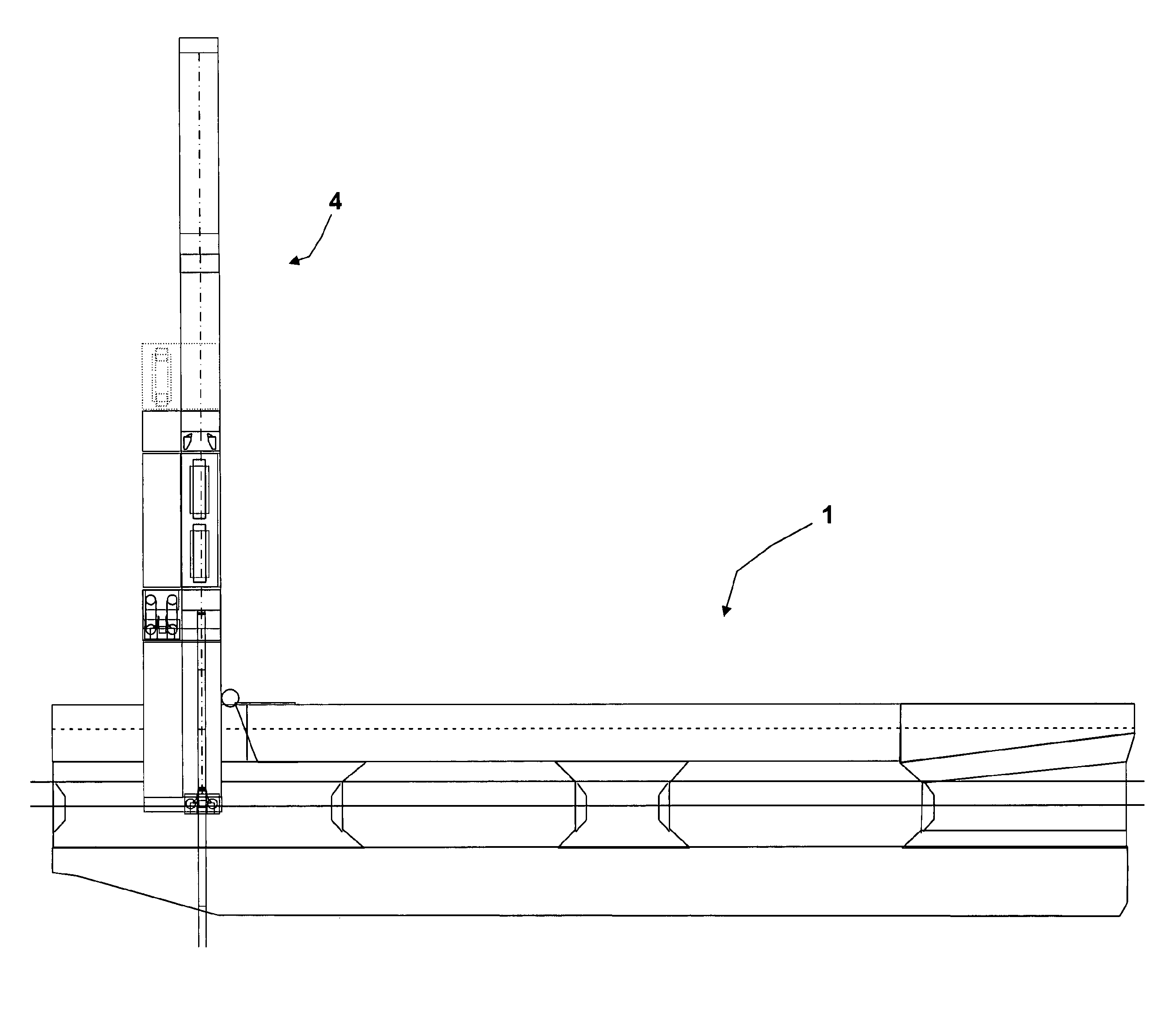

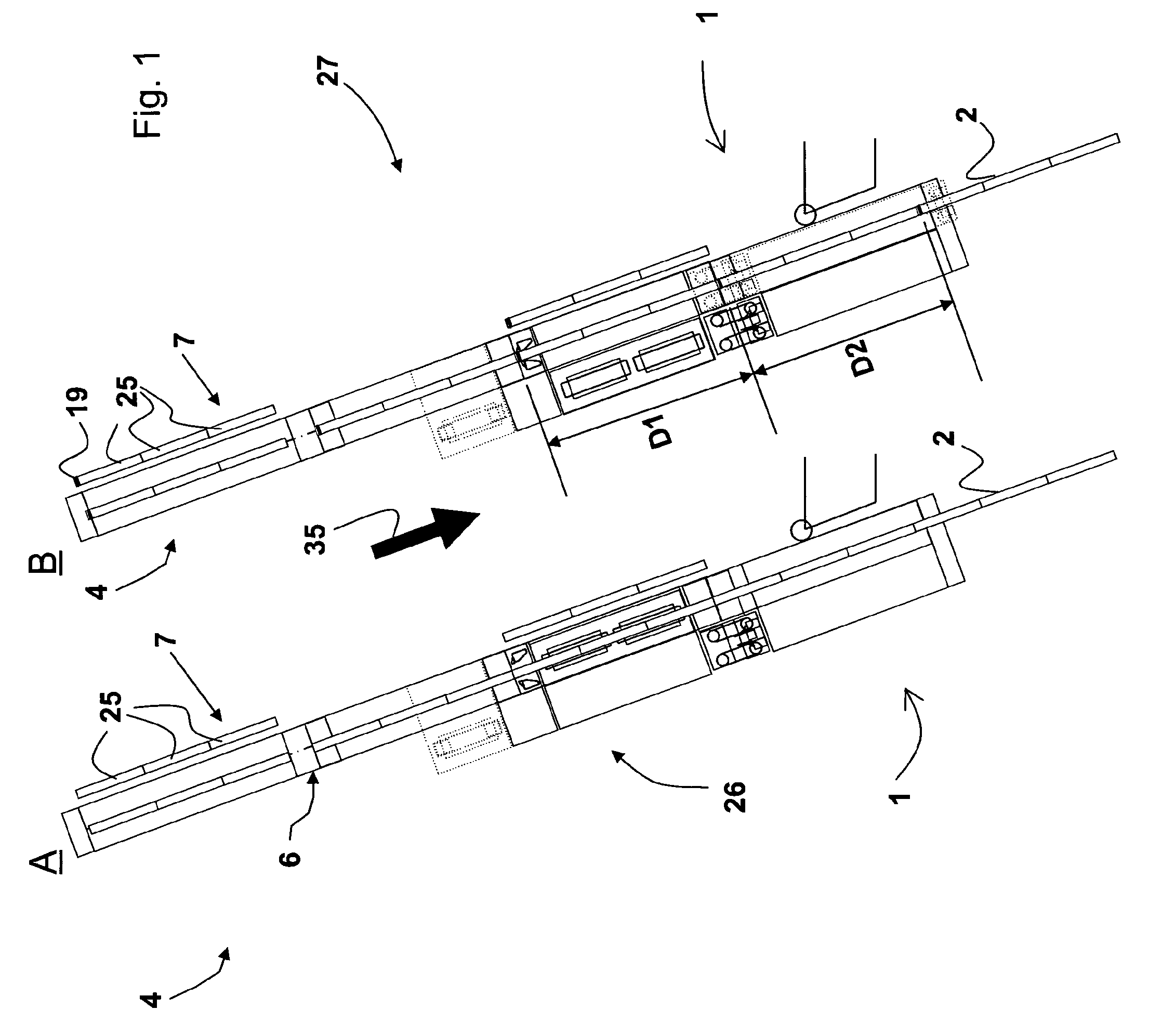

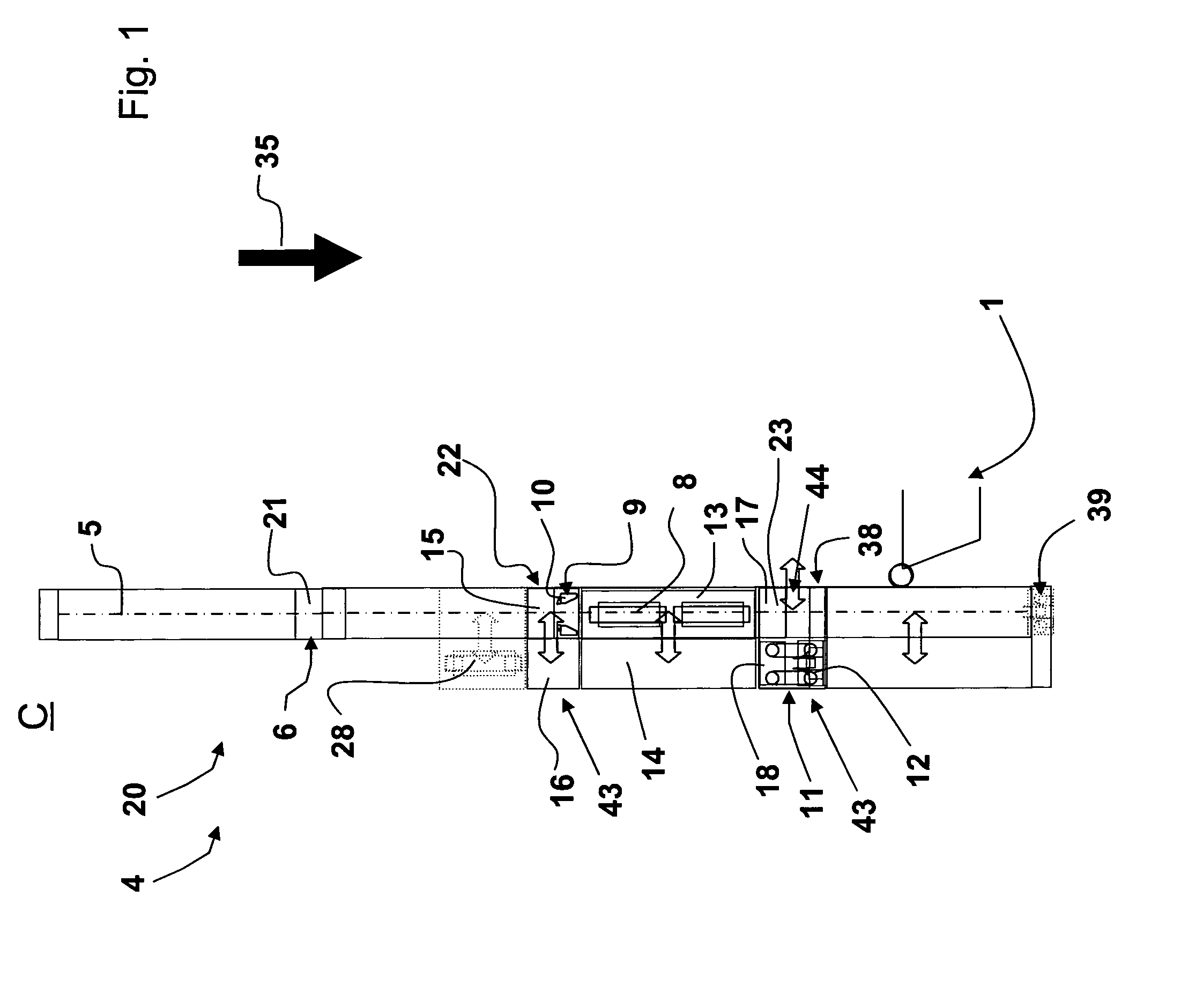

Pipeline laying vessel and method of laying a pipeline

The invention relates to a pipeline laying vessel (1) for laying a pipeline (2) at a seabed (3) and comprising a tower (4) comprising a firing line (5) along which in use the pipeline is laid and at least one work station (6) for connecting a pipe section (7) to a suspended pipeline and a method of laying pipeline at a sea bed with such a pipe laying vessel.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND SE

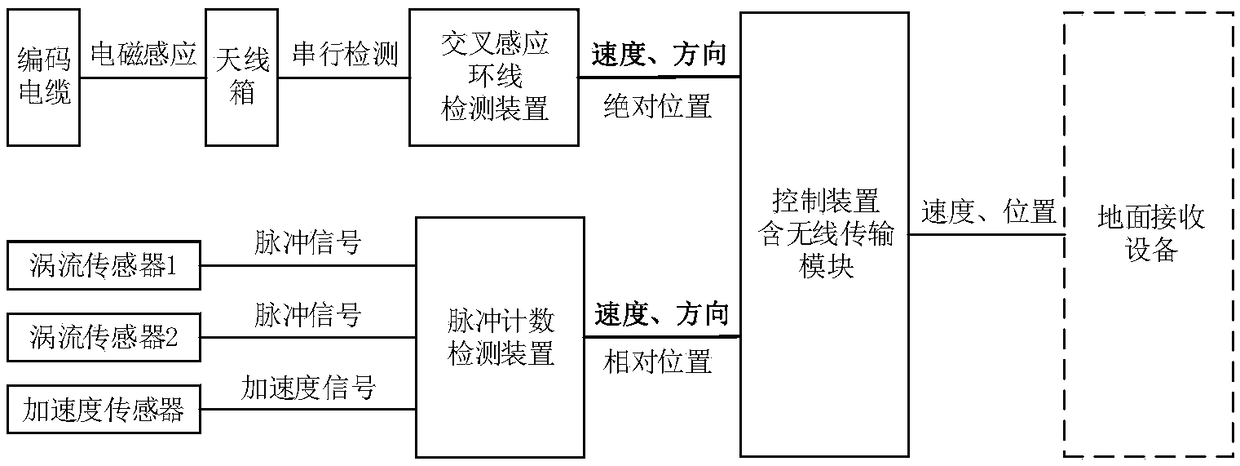

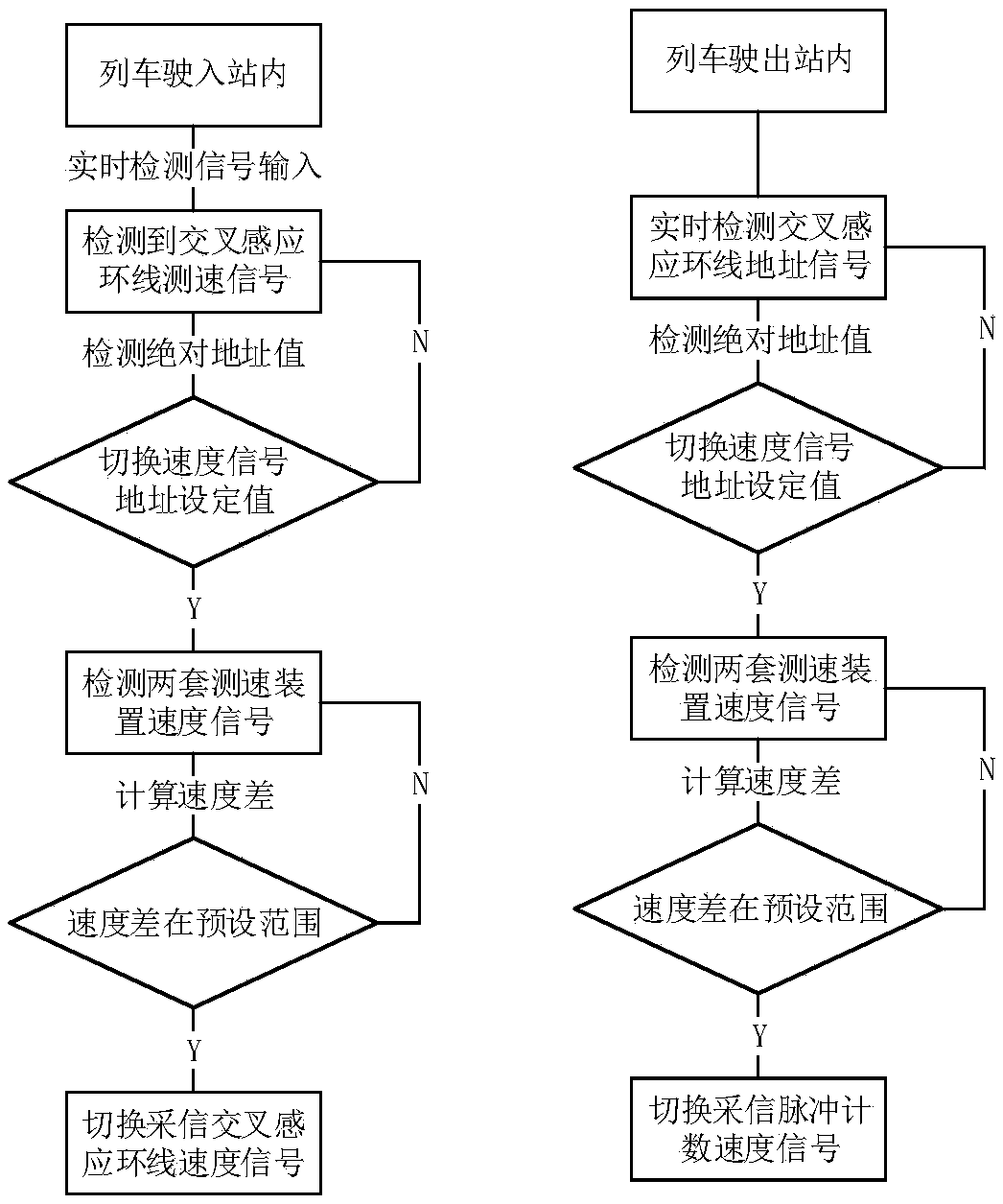

A maglev train speed measurement and positioning system and method

InactiveCN108891448AGuaranteed control accuracy requirementsMeet speed measurement accuracyRailway signalling and safetyWireless transmissionOn board

The invention discloses a speed measuring and positioning system and a method for a maglev train, comprising two sets of speed measuring devices, one set of cross induction loop speed measuring deviceis used for a track line area with high precision requirement in a station, and the other set of pulse counting speed measuring device is used for a track line area with low precision requirement outside the station. The speed measuring and positioning system also includes a set of control devices, By connecting with two sets of speed measuring devices, Receiving the data sent by the two sets ofspeed measuring devices, according to the vehicle position and the speed and direction information fed back by the two sets of speed measuring devices, automatically adjusting the vehicle speed, position and direction information according to the current demand through the corresponding algorithm, and sending the train current speed, position and direction to the vehicle under the vehicle throughthe wireless transmission module of the on-board controller. The invention satisfies the requirements of speed measurement accuracy and position feedback by adopting different speed measurement positioning in different areas.

Owner:中铁磁浮科技(成都)有限公司 +1

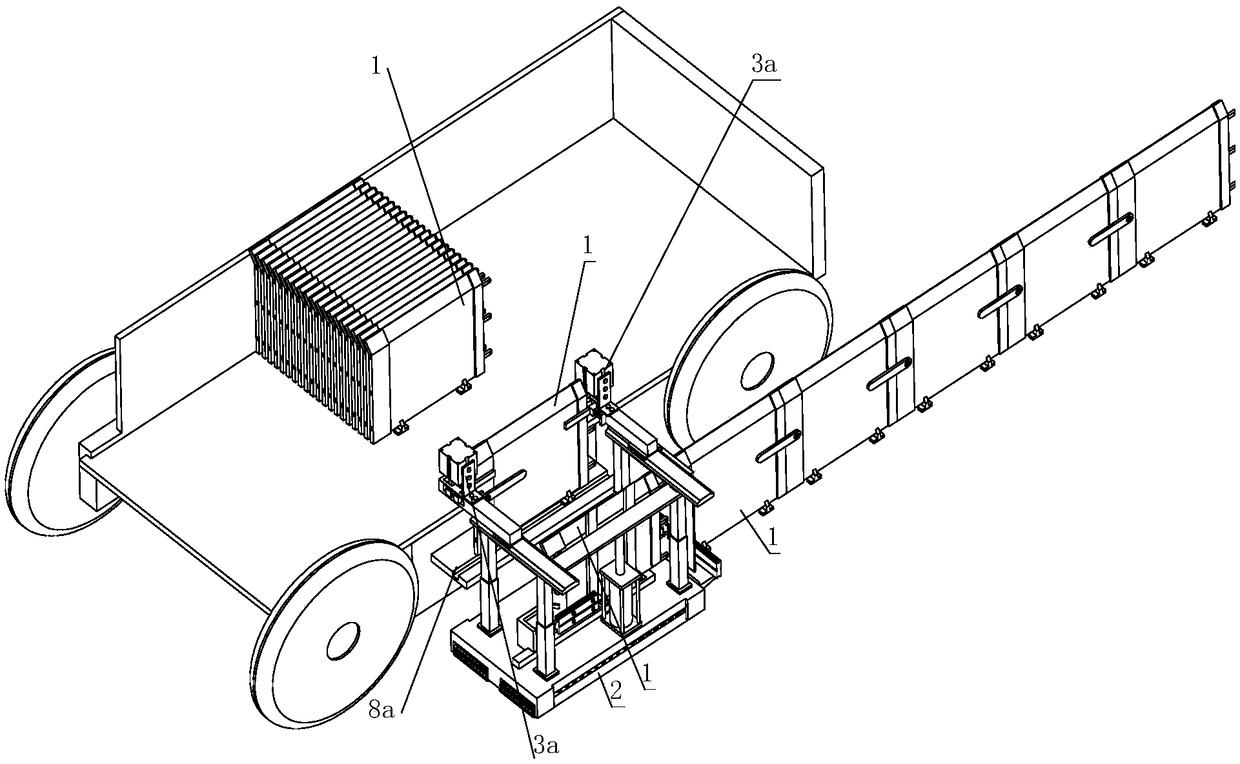

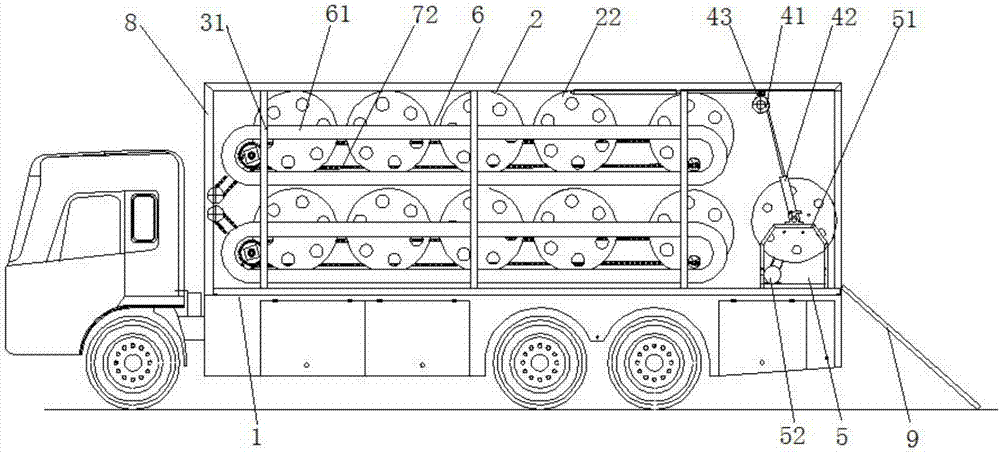

Water hose distribution vehicle

The invention provides a water hose distribution vehicle. The water hose distribution vehicle comprises an automobile chassis, a reel mechanism, a reel bearing mechanism, a hoisting mechanism and a reel winding mechanism. The reel bearing mechanism and the reel winding mechanism are arranged on the automobile chassis. The reel bearing mechanism is used for bearing the reel mechanism, and the reel winding mechanism is used for driving the reel mechanism to rotate. The reel mechanism comprises a reel shaft and a reel, wherein the reel is arranged on the reel shaft in a sleeving manner and is in linkage with the reel shaft. The hoisting mechanism can hoist the reel mechanism back and forth between the reel bearing mechanism and the reel winding mechanism. The water hose distribution vehicle has the beneficial effects that when the hose distribution vehicle works, a water hose can be rapidly laid and recovered, the number of stored water hoses is large, the water hose is used in cooperation with the vehicle, the working radius of the water supplying and draining can be increased, the mechanical degree is high, the working intensity of manual water hose carrying can be relieved, and the situation that the service life is shortened as the water hose is abraded and leaks water due to manual dragging and laying can be prevented.

Owner:FUJIAN QIAOLONG EMERGENCY EQUIP CO LTD

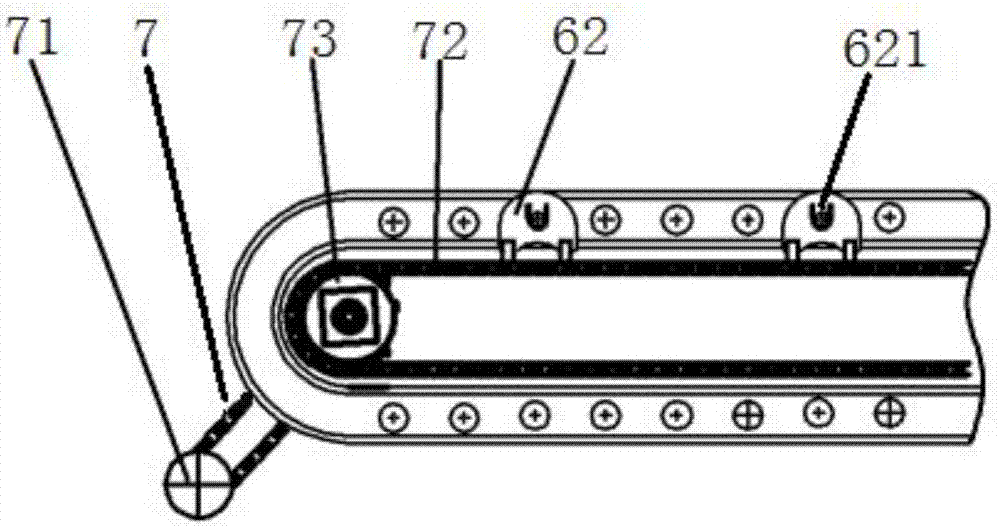

Fast tile attaching machine for building construction

InactiveCN109083381AFast layingAccurate and standard layingBuilding constructionsLaser sensorMechanical engineering

The invention discloses a fast tile attaching machine for building construction. The fast tile attaching machine comprises a vehicle body, an operation platform, a sucker device, multiple seam clamping device conveying mechanisms, a distance setting device and a controller; the seam clamping device conveying mechanisms are arranged at the rear portion of a guide rail, each seam clamping device conveying mechanism comprises a storage clamp and two air cylinders II vertically arranged on a crossbar of a U-shaped support frame, and the front ends of piston rods of the air cylinders II are provided with clamping parts; each storage clamp comprises two identical clamp bodies, each clamp body is internally provided with a cavity, positioning slots are symmetrically formed in both sides of each cavity, positioning plates are disposed above the positioning slots, and gaps are reserved between the positioning plates and the positioning slots and used for seam clamping devices to slide out; thedistance setting device includes two laser sensors arranged in the front of the operation platform and a laser source arranged outside the vehicle body; an infrared emitter, an audible and visual alarm and a tile placement frame are arranged on the operation platform. The fast tile attaching machine can suck multiple tiles at the same time, the laying precision is high, the tiles can be attached automatically, and the seam clamping devices are placed at the same time.

Owner:湖北屹峡峰建设工程有限公司

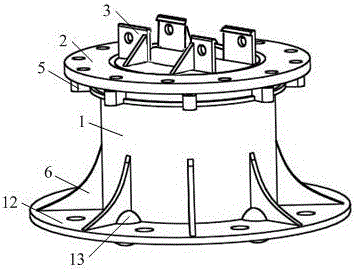

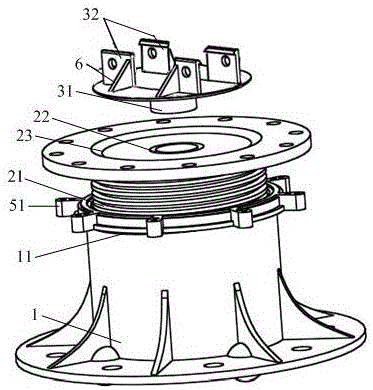

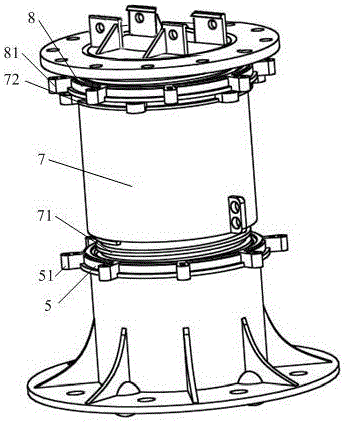

Supporting system special for outdoor floors and outdoor floor paving method

The invention discloses a supporting system special for outdoor floors. The supporting system comprises struts, keels and keel covers; the struts are vertically arranged on the ground; the keels are horizontally supported at the upper ends of the struts; and the keel covers are arranged the two ends of the keels and used for connecting the different keels. Each strut comprises a base, a supporting platform and joggling pieces. Each keel is a hollow long-strip-shaped rod, two of side surfaces of each keel are provided with clamping grooves, and hooks can be buckles with the clamping grooves. One end of each keel cover is a keel port connection part for being engaged with the end of the corresponding keel, and the other end of the keel cover is a keel clamping connection part for being connected with the corresponding clamping groove of the keel. The invention further discloses an outdoor floor paving method. By adopting the supporting system special for the outdoor floors and the outdoor floor paving method, the distance between each base and the corresponding supporting platform can be quickly adjusted so that the required supporting height can be obtained; and the joggling pieces can horizontally rotate relative to the supporting platforms, keel clamping can be facilitated, the paving difficulty is lowered, and the paving speed is increased.

Owner:MEXYTECH

Hollow concrete block for protecting perenial frozen soil road bed and slope

The hollow concrete block for protecting perennial frozen soil road bed and slope consists of plant stalks, cement, sand and soil, and is hollow cube with outer side length of 30-200 mm and wall thickness of 10-50 mm. It may be also hollow sphere, hollow cuboid or hollow cylinder. The present invention is simple in construction, low in cost, easy in maintenance, and has the merits of both sun shield and ballast revetment. Hollow blocks of different shapes are combined in certain thickness to reach excellent sun shielding effect and excellent ventilation and temperature lowering effect for protecting perennial frozen soil road bed and slope positively.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

High-pressure hose and production method thereof

InactiveCN105387291AImprove environmental adaptabilityGood flexibilityFlexible pipesWoven fabricsVulcanizationEngineering

The invention discloses a high-pressure hose and a production method thereof. The high-pressure hose comprises an inner rubber layer, a reinforcing layer and an outer rubber layer which are sequentially arranged from inside to outside. The reinforcing layer is composed of two layers of circularly-woven pipe blanks woven from warp and weft. The two layers of circularly-woven pipe blanks are sewn into a whole through lifting warp arranged in a reciprocating crossed manner and are of a plain weave structure. The circularly-woven pipe blanks are made of high-strength synthetic fibers. The inner rubber layer and the outer rubber layer are made of polyurethane. The production method of the high-pressure hose includes the steps that the reinforcing layer is woven from the high-strength synthetic fibers through a circular weaving machine, the outer side of the reinforcing layer is coated with the polyurethane through a thermal coating method, and the inner side of the reinforcing layer is coated with the polyurethane through an inner rubber layer steam vulcanization method. The high-pressure hose has the advantages that the pressure-bearing strength is remarkably improved and the hose can be used for conveyance under the high-pressure condition; and the soft hose is good in flexibility, capable of being flatly wound, convenient to operate, high in laying and reeling speed, flexible, high in environmental adaptability and the like.

Owner:BEIJING SIHAI FUTONG ENERGY TECH

Building external wall insulation board laying device

The invention relates to an insulation board laying device, in particular to a building external wall insulation board laying device. The device comprises a moving mechanism, a rotating mechanism, a retracting and releasing mechanism, a laying support, a power mechanism, a material changing mechanism, a material pushing mechanism, a feeding mechanism and a spraying mechanism, wherein the device can be driven to move by means of the moving mechanism, the rotating mechanism is used for adjusting the position of the laying support, the retracting and releasing mechanism is used for retracting andreleasing the laying support, the power mechanism drives the material changing mechanism and the material pushing mechanism to move, the material changing mechanism conveys insulation boards to the laying position, the material pushing mechanism drives the material changing mechanism and the feeding mechanism to move, the insulation boards on the feeding mechanism are thus pushed into the material changing mechanism, insulation boards in the material changing mechanism are attached to a wall, the spraying mechanism can spray an adhesive on the insulation boards to enable the insulation boardsto be adhered to the wall, and the laying support is continuously put down under cooperation of the retracting and releasing mechanism, so that the insulation boards are rapidly laid outside the wall.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Tile laying structure in full-automatic ground tile laying device

The invention provides a tile laying structure in a full-automatic ground tile laying device and belongs to the technical field of buildings. The tile laying structure solves the problem that the existing tile pasting efficiency is low. The tile laying structure in the full-automatic ground tile laying device comprises a base; a moving device capable of moving the base is arranged on the base; anadjusting table is arranged on the base; a stacking table for stacking ground piles is arranged on the adjusting table; the adjustable table is further fixedly provided with a vertical guide rail; theupper end of the guide rail is fixedly provided with a first rail and a second rail capable of ascending and descending, wherein the first rail can be in butt joint with the second rail; the guide rail is fixedly provided with a lifting mechanism driving the second rail to ascend and descend; a sliding frame is arranged on the first rail; and the sliding frame can slide to the second rail from the first rail. The tile laying structure has the beneficial effect that the tile pasting efficiency is high.

Owner:海宁百丽丝染整有限责任公司

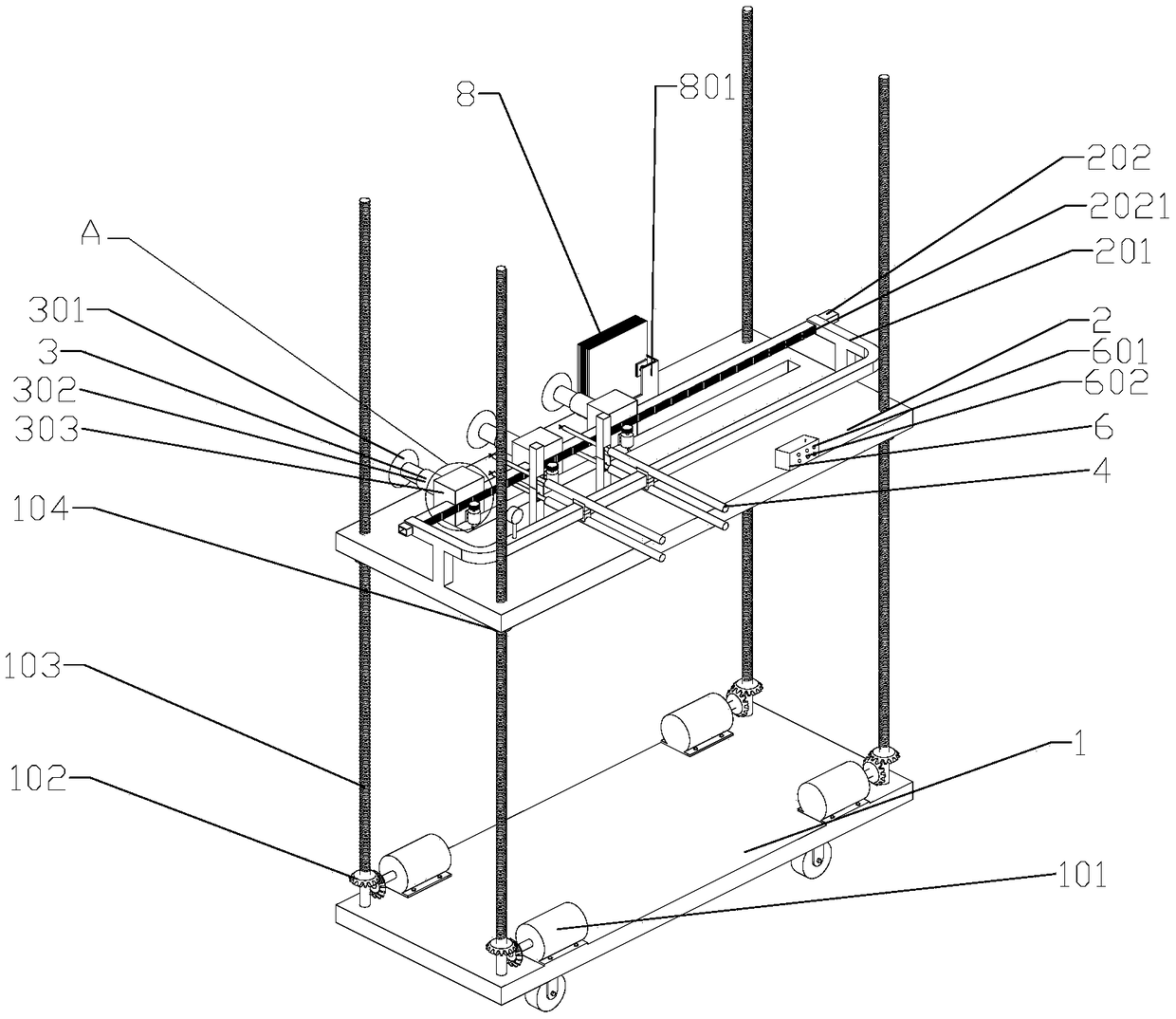

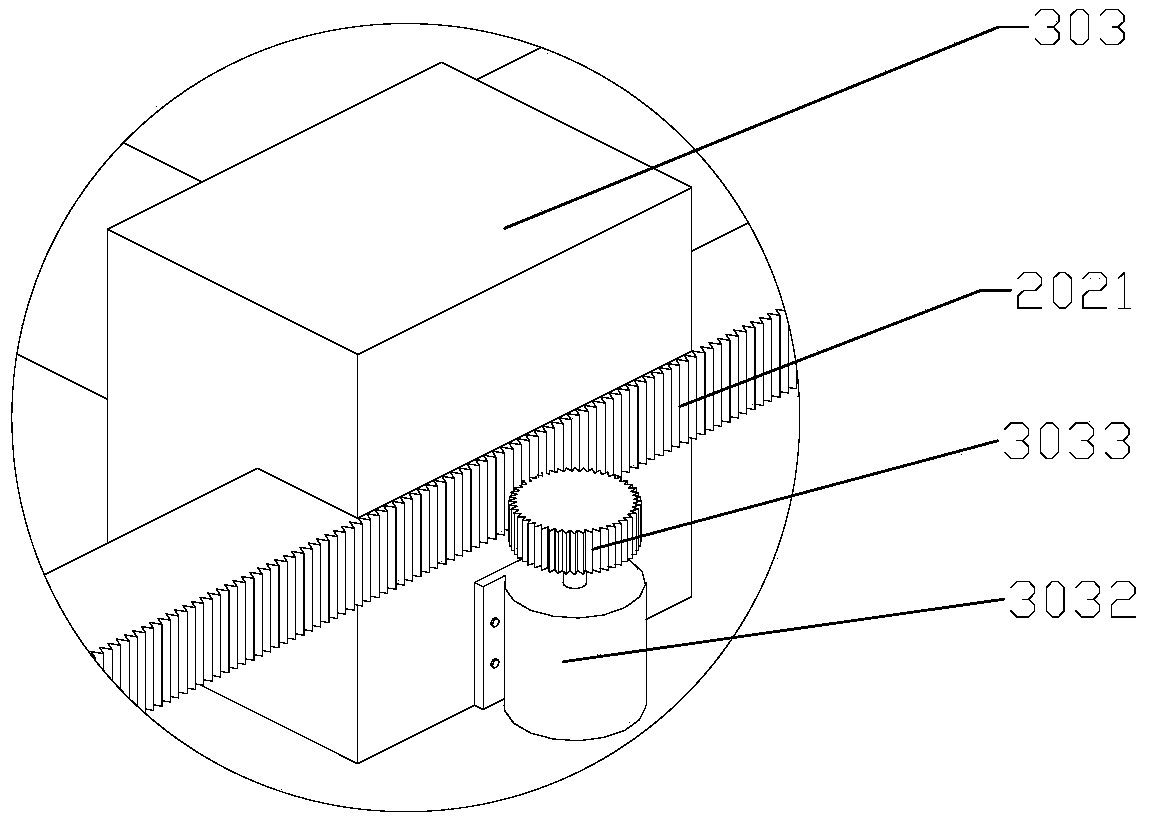

Full-automatic floor tile pavement equipment

The invention provides full-automatic floor tile pavement equipment, belongs to the technical field of construction, and solves such technical problems as slow tile pavement efficiency in the prior art. The full-automatic floor tile pavement equipment comprises a base; the base is provided with a moving device for enabling the base to move; the base is provided with a stirring and paving mechanismfor stirring cement and uniformly paving the cement on the floor; the base is provided with an adjusting table; multiple adjusting modules are arranged between the adjusting base and the base; the adjusting modules can maintain the adjusting table in a horizontal state; a stacking table for stacking floor tiles is arranged on the adjusting table; a vertical guide rail is fixed on the adjusting table; a first rail and a second rail capable of lifting up and down are fixed at the upper end of the guide rail; the first rail can be in butt joint with the second rail; a lifting mechanism for driving the second rail to lift is fixed on the guide rail; and a slide frame is arranged on the first rail. The full-automatic floor tile pavement equipment has the advantage of high tile pavement efficiency.

Owner:WENLING SHENLONG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com