Patents

Literature

33results about How to "Guaranteed laying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

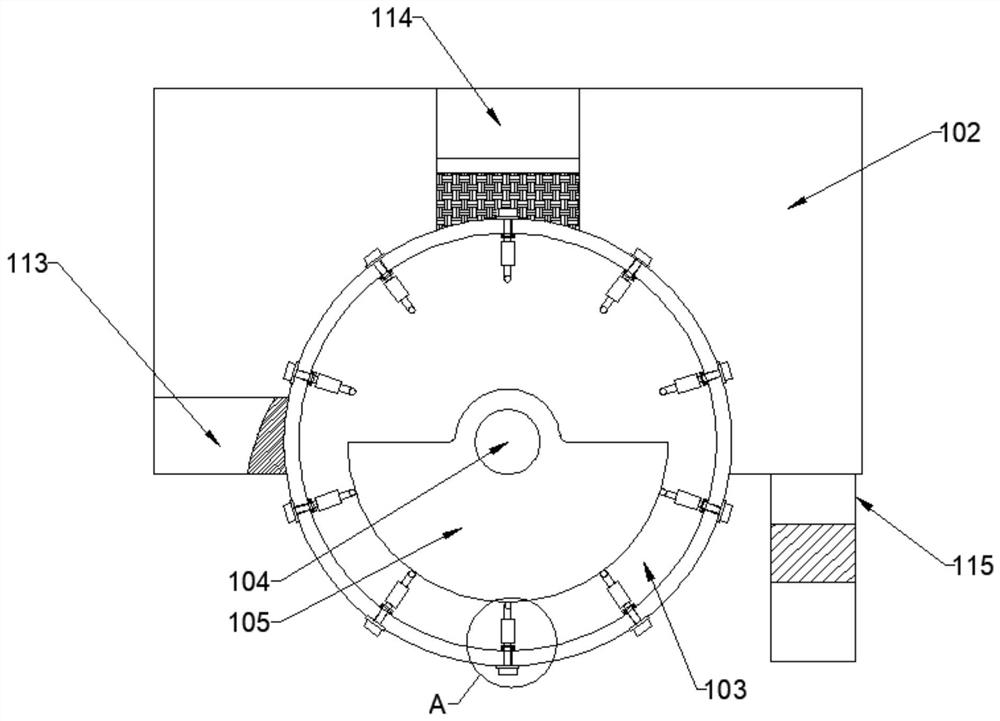

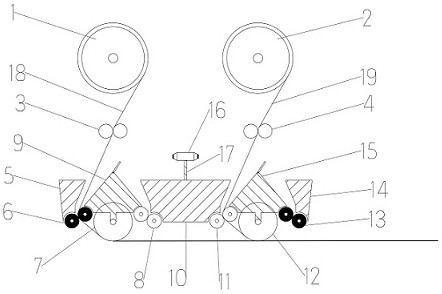

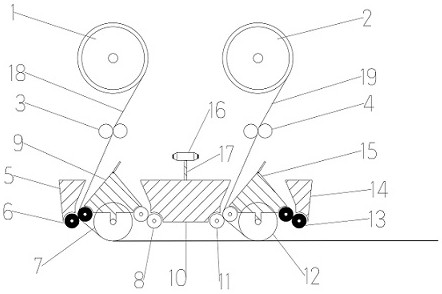

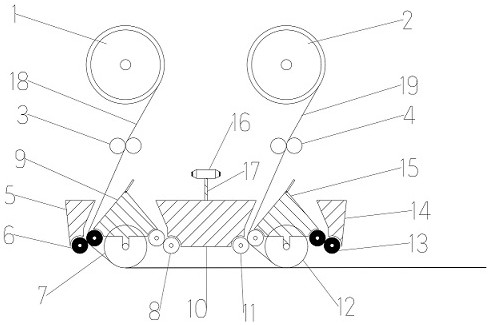

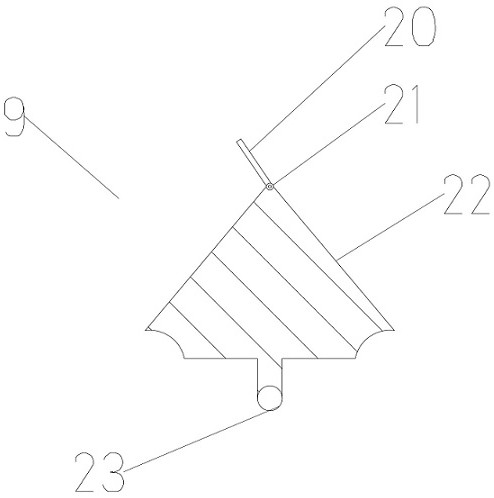

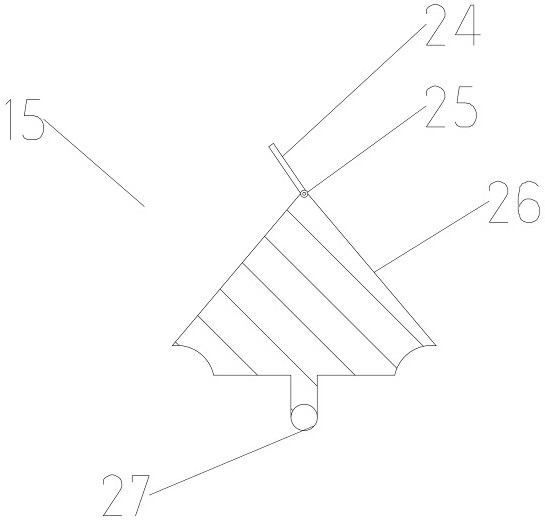

Waterproof and seepage-proofing coiled material paving equipment

ActiveCN104775571AGuaranteed laying effectGuaranteed compression effectRoof toolsRoads maintainenceEngineering

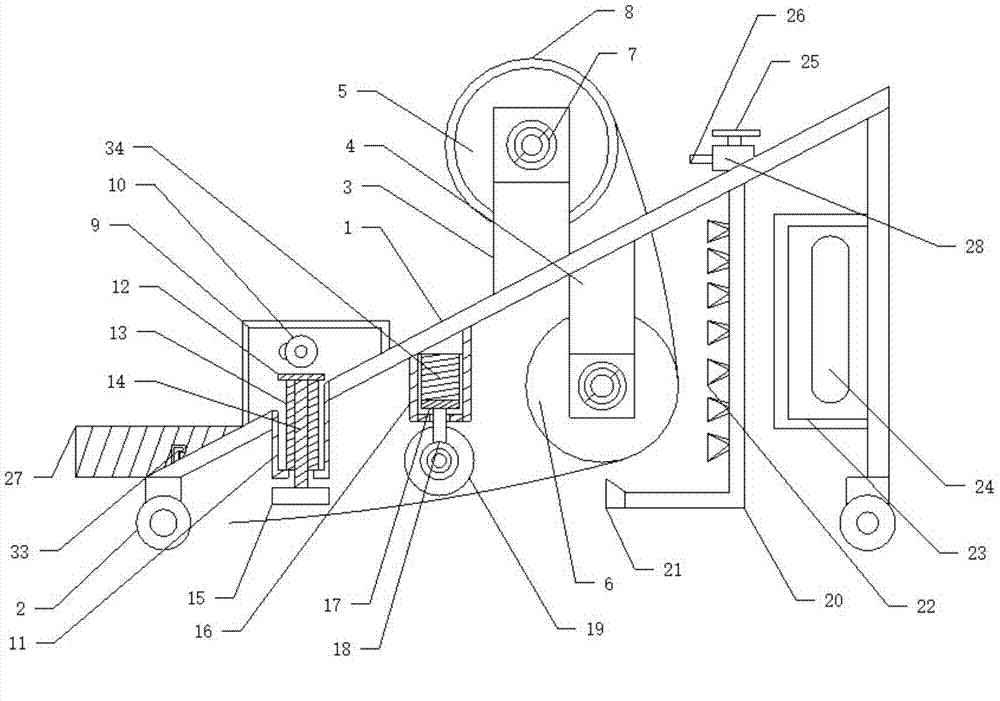

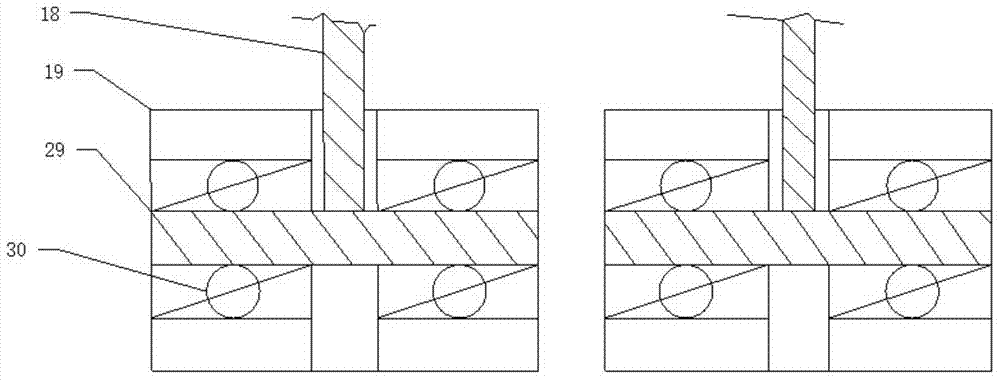

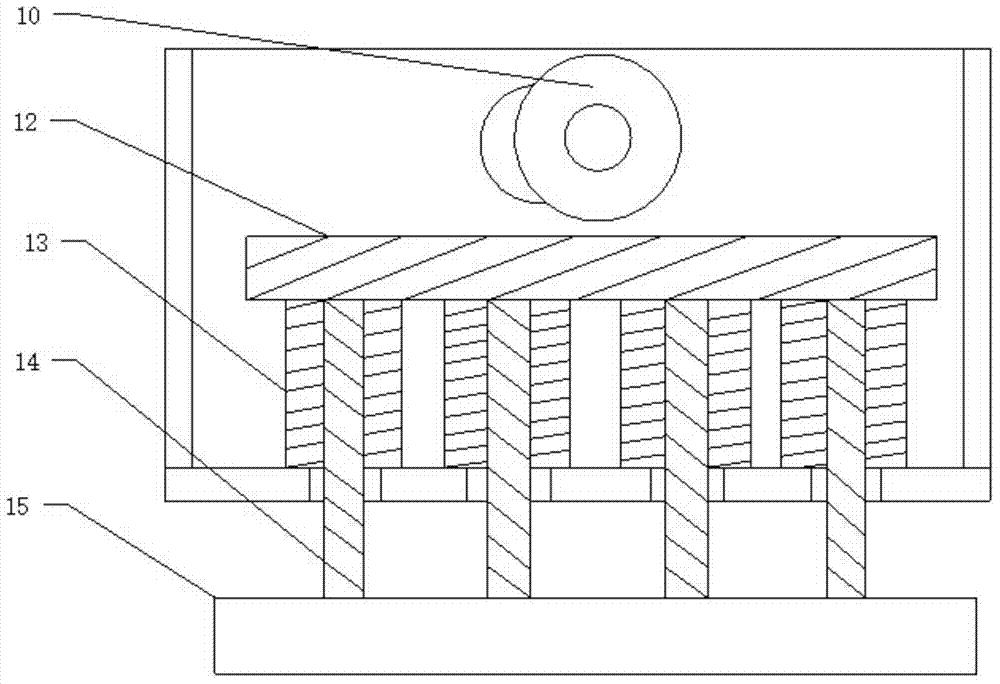

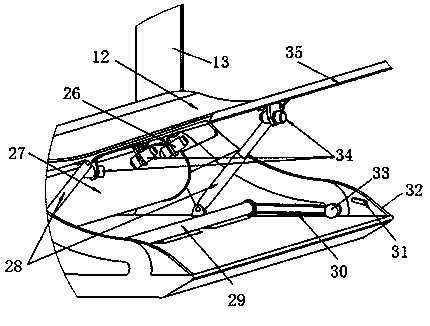

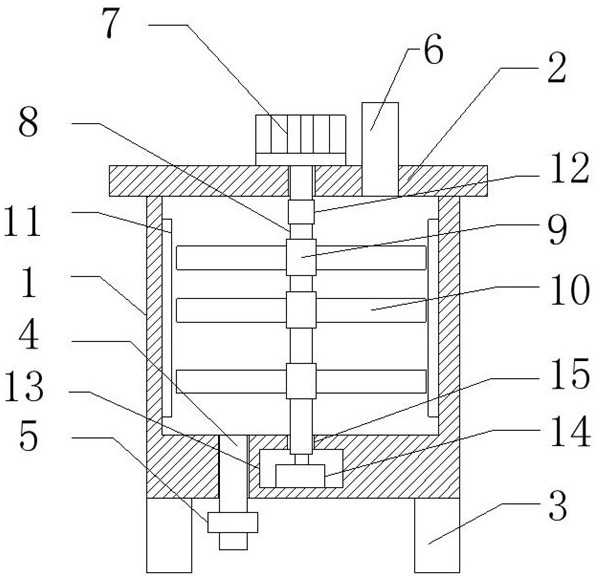

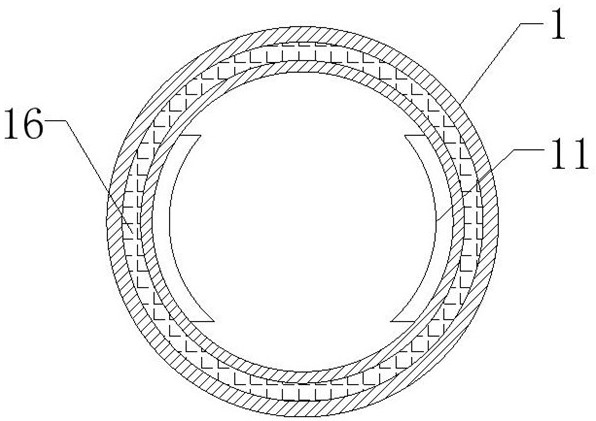

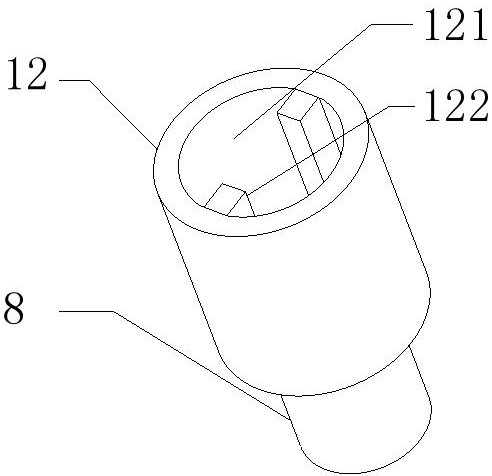

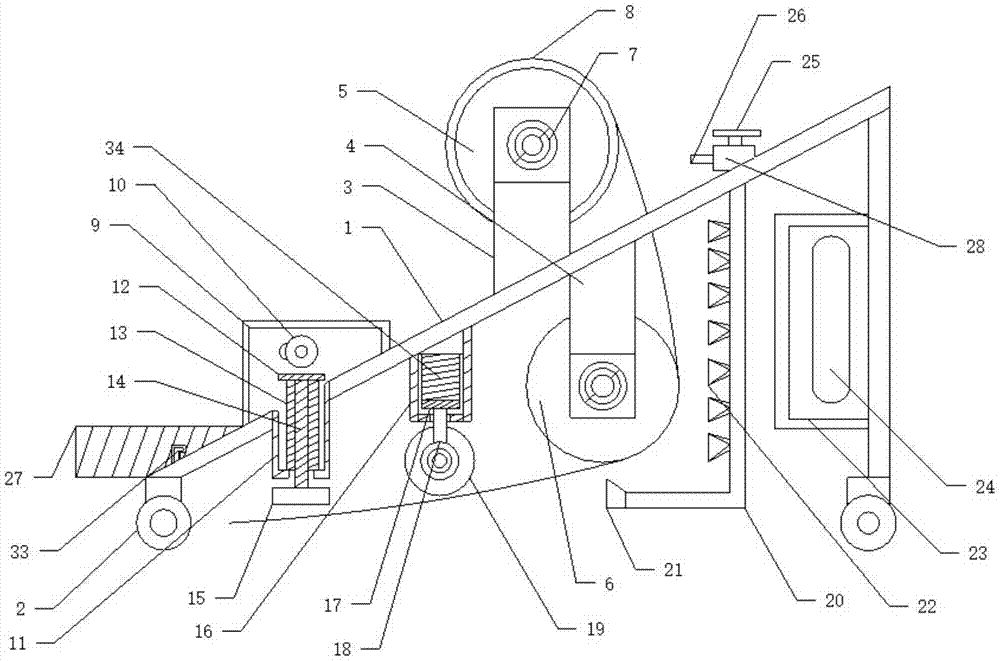

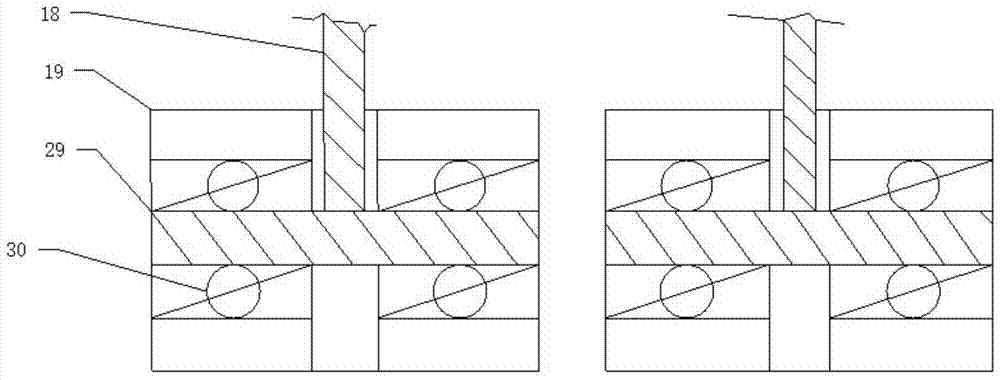

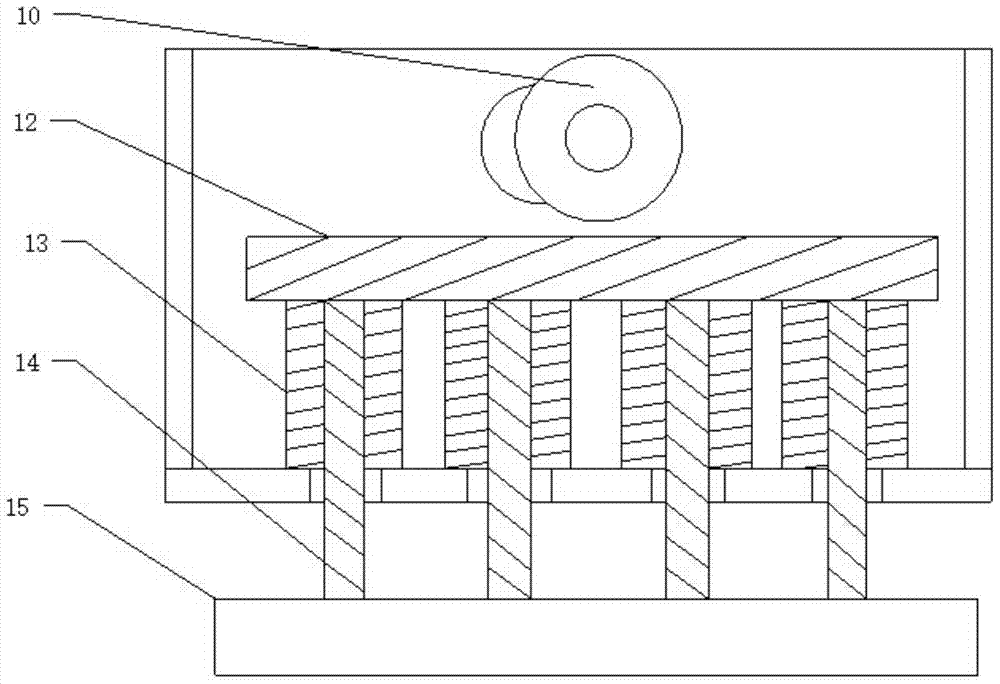

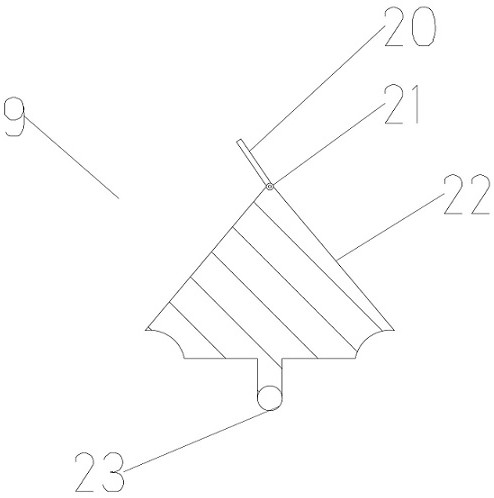

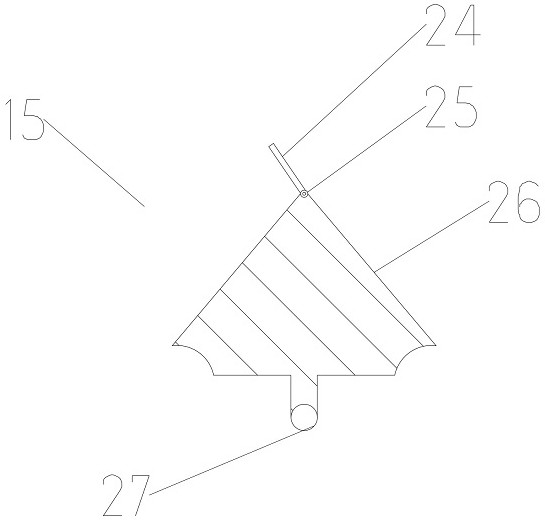

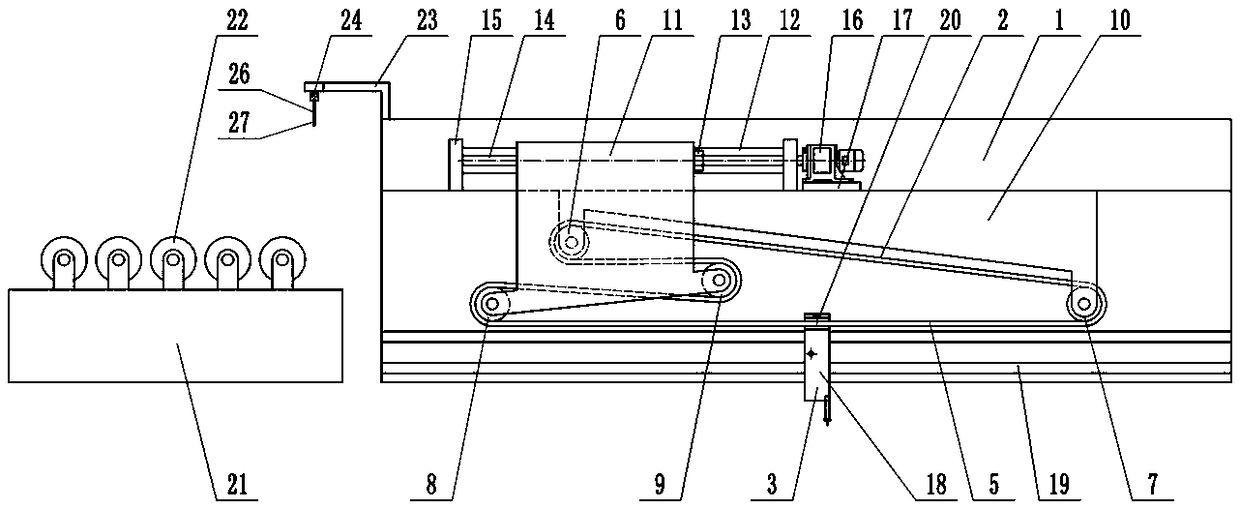

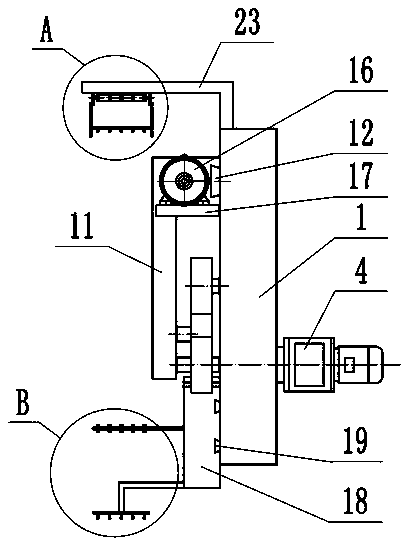

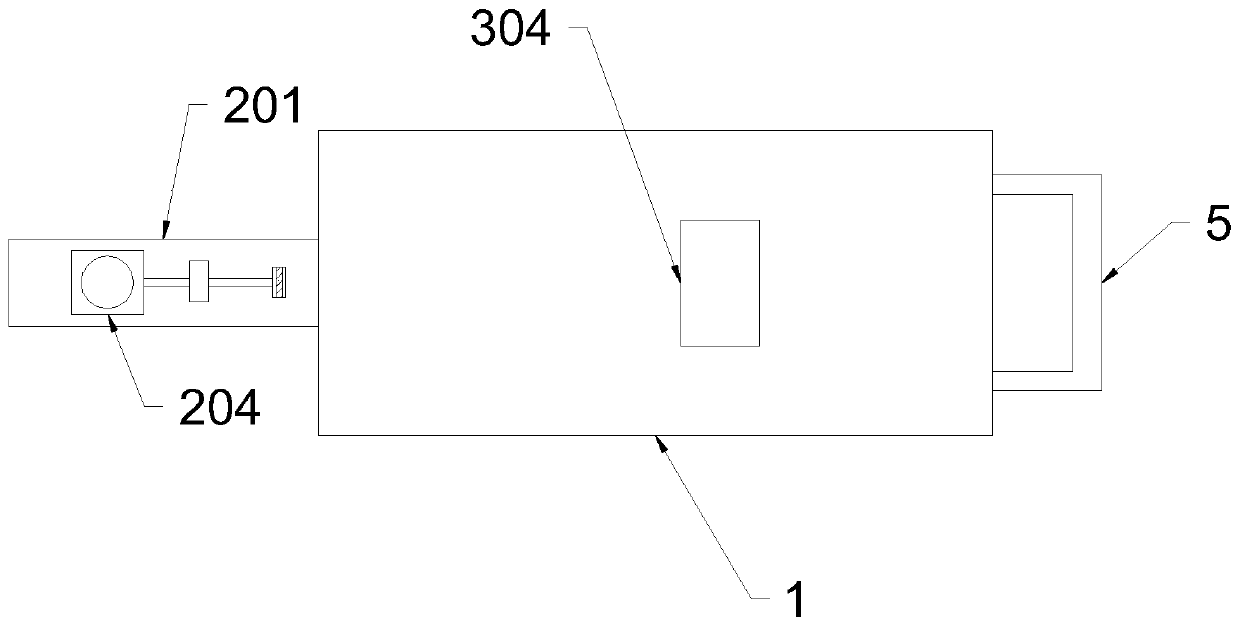

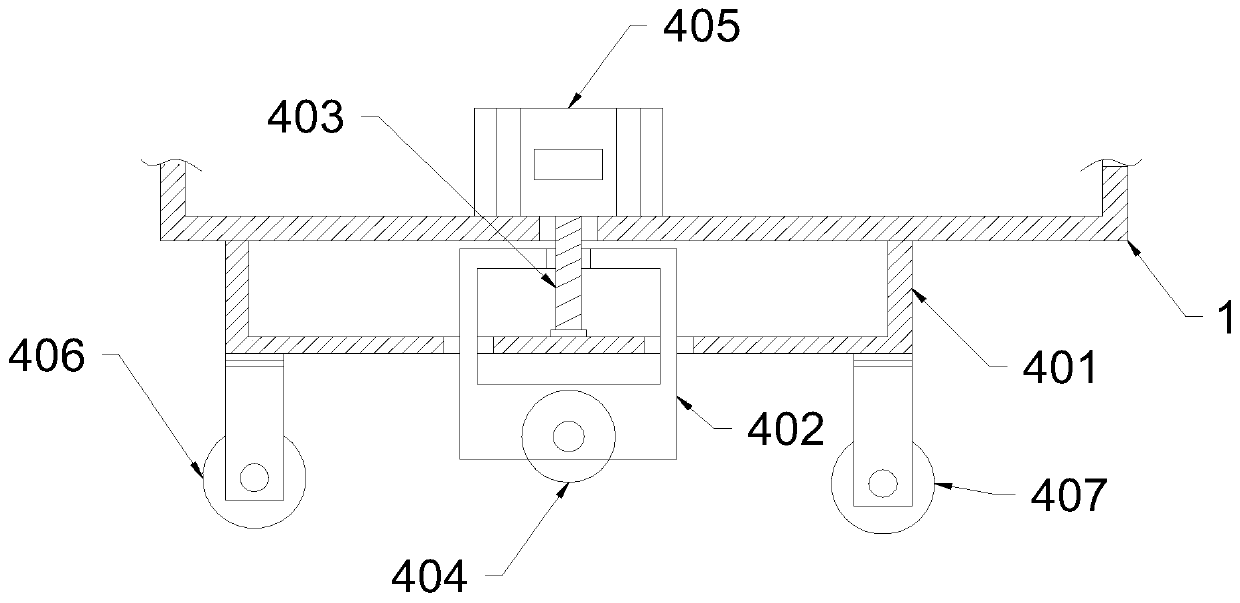

The invention discloses waterproof and seepage-proofing coiled material paving equipment, which comprises a machine body, an upper support frame and a lower support frame, wherein the upper support frame is arranged at two sides of the machine body, the lower support frame is arranged at two sides of the machine body and corresponds to the upper support frame, a coiled material rolling wheel is arranged on the upper support frame arranged at two sides, and a guide wheel is arranged on the lower support frame arranged at the two sides; a press wheel groove is also formed in the machine body, a second spring and a press wheel press plate elastically pressed by the second spring are respectively arranged in the press wheel groove, a propping rod passing through a through hole formed in the press wheel groove is formed in the press wheel press plate, the end part of the propping rod is connected with a press wheel, the press wheel corresponds to the guide wheel, and the waterproof and seepage-proofing coiled material paving equipment also comprises a main flame spray head and a preheating flame head corresponding to waterproof coiled materials. The waterproof and seepage-proofing coiled material paving equipment has the advantages that the structure is simple, the preheating flame head arranged on the machine body can be used for preheating the waterproof coiled materials, and the heating melting is enabled to be more sufficient in the heating melting process by using the main flame spraying head, the waterproof coiled material paving efficiency is high, in addition, the paving quality is good, and the waterproof effect is better.

Owner:河南景美环保工程有限公司

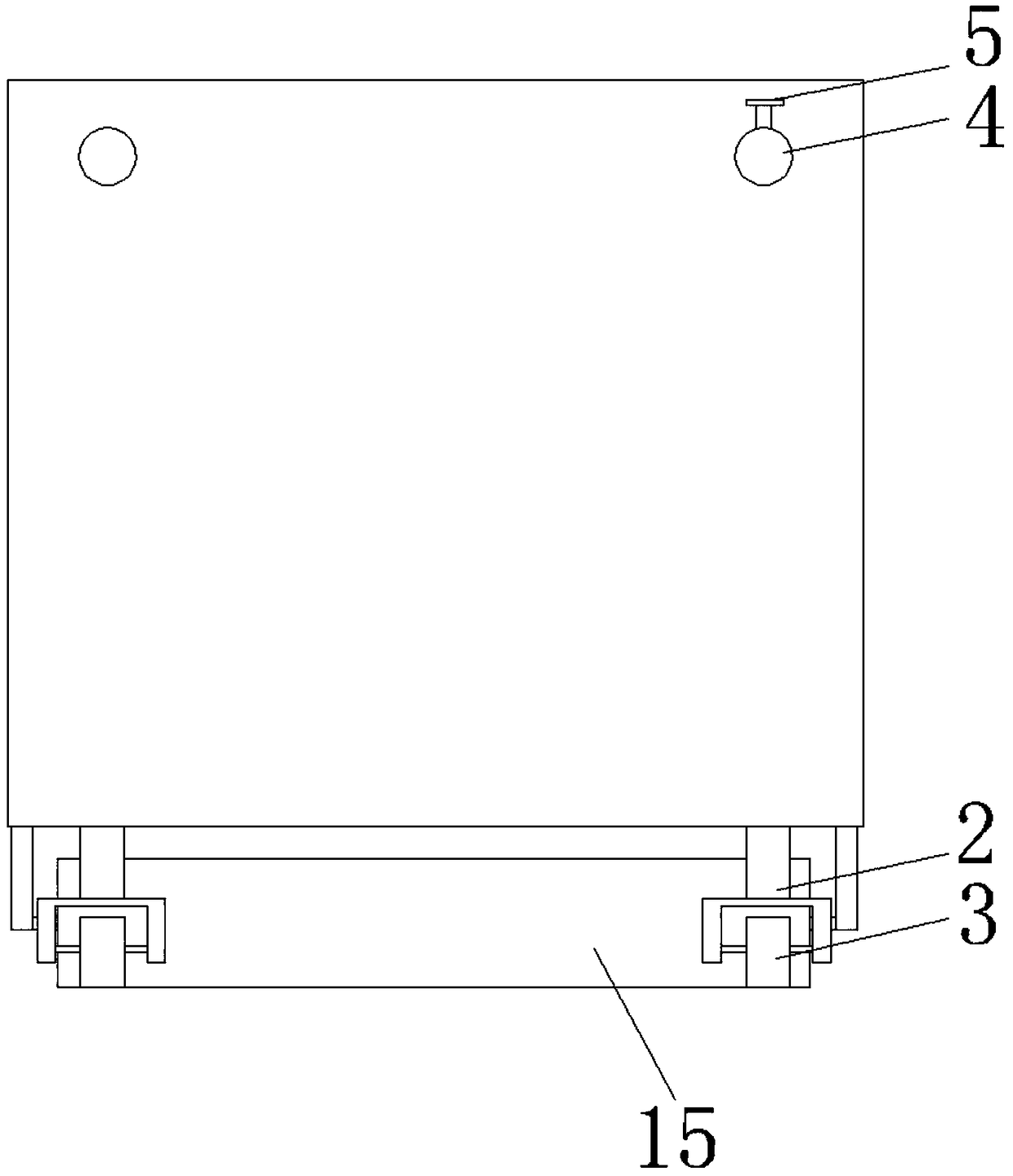

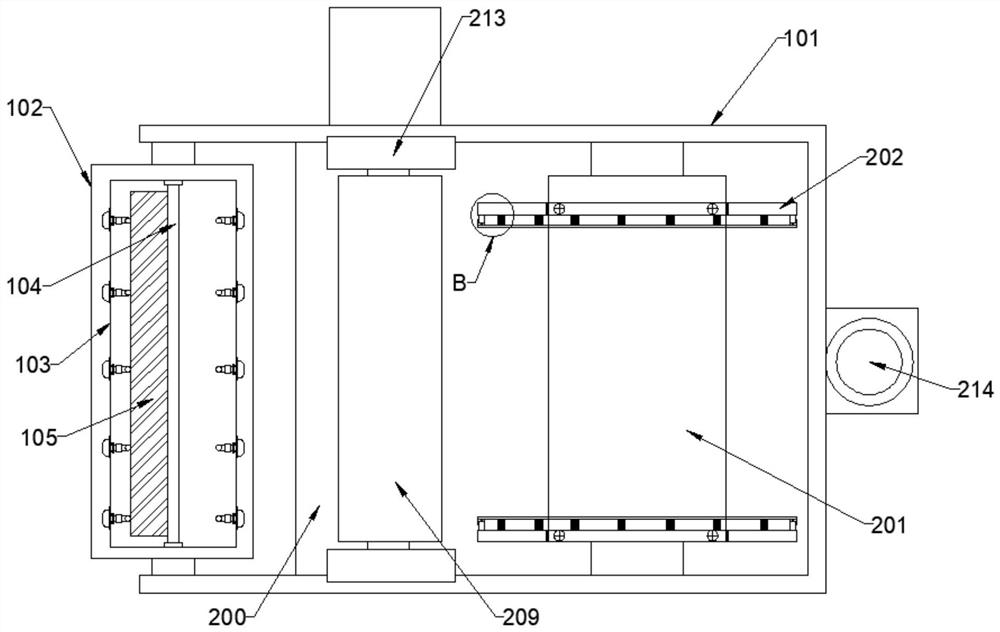

Laying device for waterproof coiled material

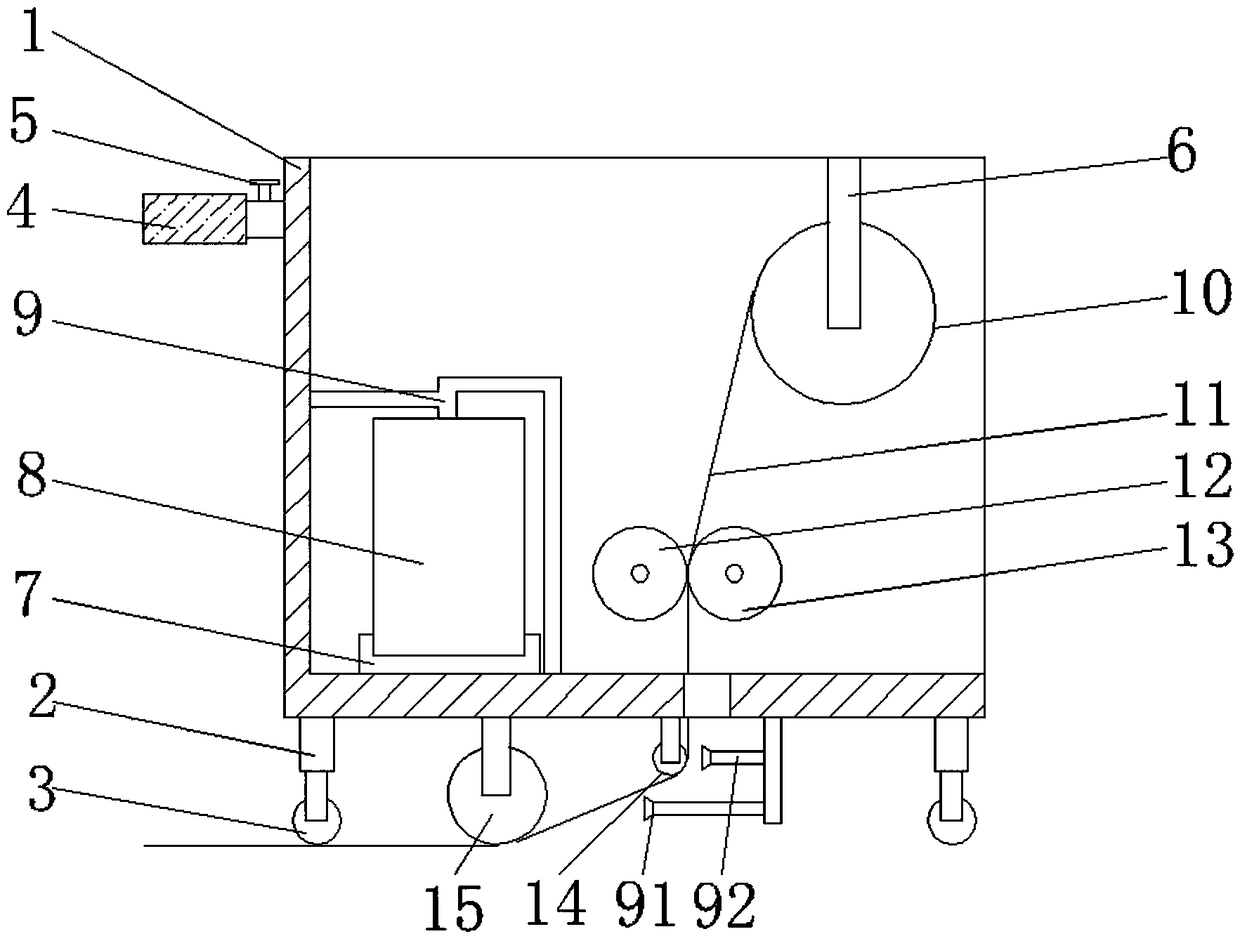

The invention discloses a laying device for a waterproof coiled material. The laying device comprises a box body, a heating device and a laying pressing device; damping rods are mounted at the four corners of the bottom end of the box body, sliding wheels are mounted at the bottom ends of the damping rods, a handle is arranged at the upper end of the outer wall of the left side of the box body, and an adjusting valve is arranged on the handle; sliding grooves are symmetrically formed in the front inner wall and the rear inner wall of the box body; the heating device comprises a U-shaped base,a fuel gas tank and a fuel gas pipeline; the U-shaped base is fixed to a bottom plate of the box body, the fuel gas pipeline stretches out of the fuel gas tank, one end of the fuel gas pipeline is connected with the adjusting valve, and the other end of the fuel gas pipeline stretches out of the bottom plate of the box body and is provided with a preheating spraying nozzle and a heating spraying nozzle; and the laying pressing device comprises a first winding roller, the waterproof coiled material, a second winding roller, a third winding roller, a flat-laying roller and a pressing roller. Thelaying device has the advantages that the stability of the laying device is good, the pasting effect of the waterproof coiled material is good, construction manpower is reduced, and the constructionefficiency is improved.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

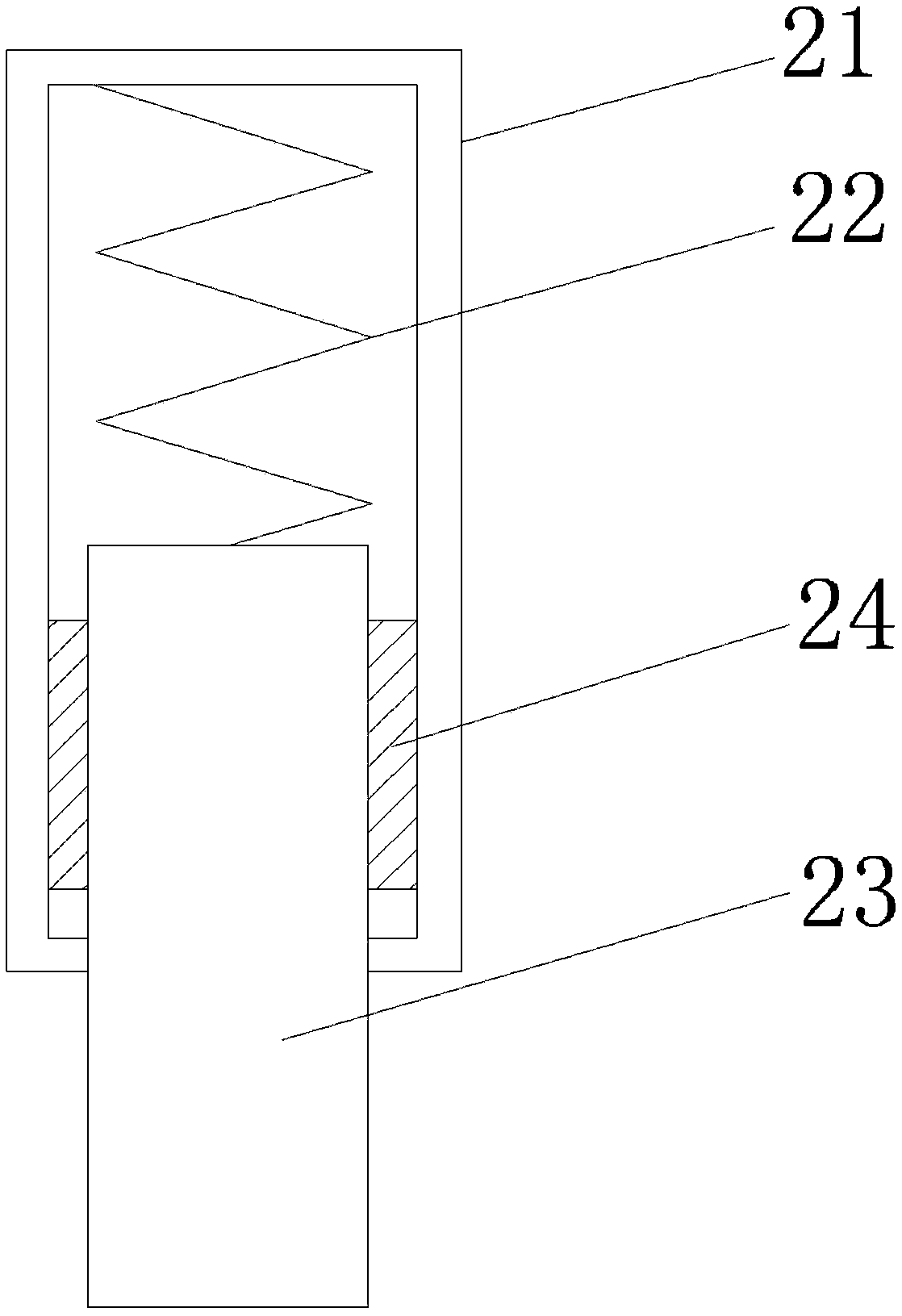

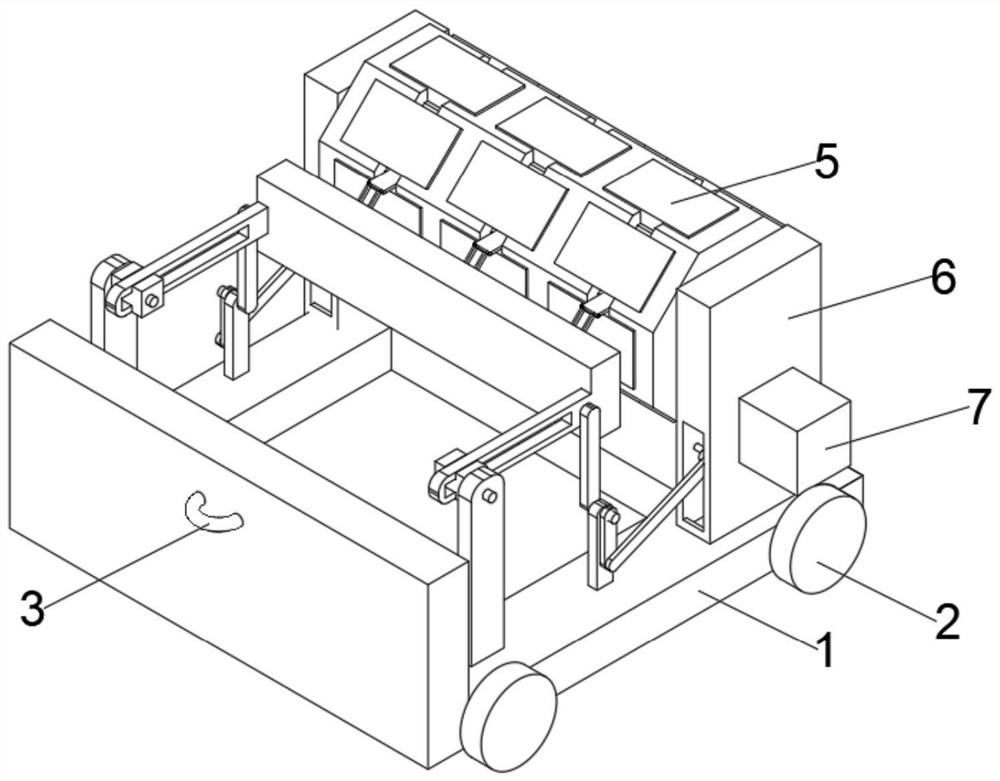

Rotary pavement repairing device

InactiveCN108103914AImprove efficiencyGuaranteed laying effectRoads maintainenceVehicle frameRoad surface

The invention discloses a rotary pavement repairing device. The device comprises a frame and a stirring tank, wherein a crushing device is arranged on the left side of the frame, a stirring and pouring device is arranged in the frame, and a moving device is arranged below the frame. A lifting wheel and a fixing rod are arranged, so that the frame can move circumferentially, and a cutting wheel cuts out circular slits on the ground to ensure the laying effect of a joint; meanwhile, the pavement on the inner side of the slits is crushed by a drill stem, a columnar groove is formed, and the edgecutting and grooving efficiency is improved. The stirring tank is arranged, raw materials are poured into the opened columnar groove through a pouring pipe, laying is completed rapidly, and operationefficiency is improved.

Owner:屈大忠

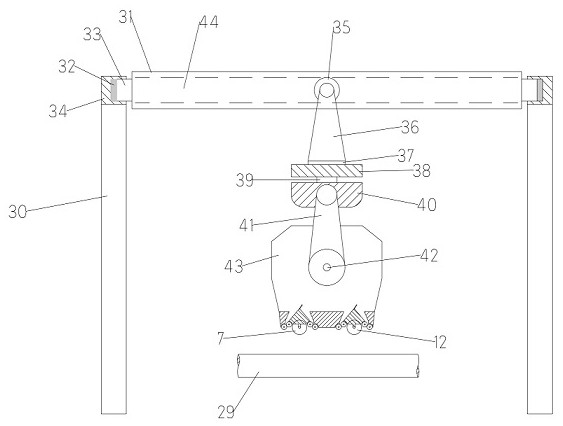

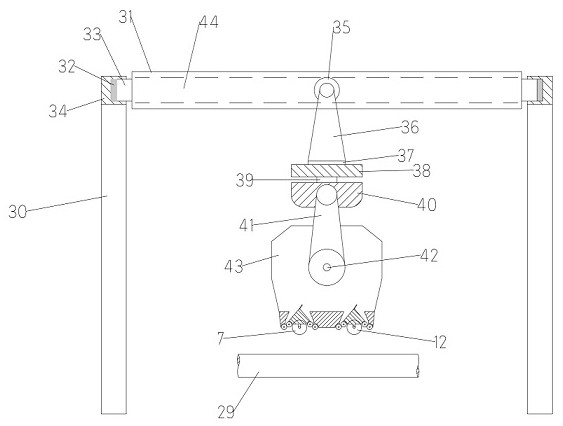

Cable laying device for cable trench

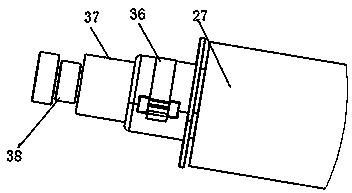

ActiveCN112103842AImprove laying efficiencyReduce labor intensityFilament handlingApparatus for laying cablesElectric machineryPortal frame

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Batch brick paving device for municipal engineering

The invention discloses a batch brick paving device for municipal engineering, and belongs to the technical field of municipal engineering. The batch brick paving device for municipal engineering comprises an L-shaped moving plate, the upper side of the interior of a mechanical box is rotationally connected with an intermittent wheel through a rotating shaft, the inner end of the rotating shaft of the intermittent wheel penetrates through the inner wall of the mechanical box, extends to the outside and is sleeved with an octagonal rotating block, a plurality of brick clamping grooves are linearly formed in the surface of the octagonal rotating block at equal intervals, a machine box is arranged on the outer side of the mechanical box located on the right side, a rocker arm is fixedly arranged on one side of a notched disc, the octagonal rotating block and the intermittent wheel are correspondingly arranged, so that the intermittent wheel can intermittently rotate, a clamping plate can take down a plurality of bricks from a brick clamping groove while intermittent rotation is conducted, then the action is changed, and downward laying is conducted; and at the moment, the octagonal rotating block performs the transposition of the brick clamping groove. According to the brick paving device, the equipment is small, the brick paving amount is guaranteed, the time interval is reduced, continuous paving can be achieved, and the paving efficiency is improved.

Owner:贾方赞

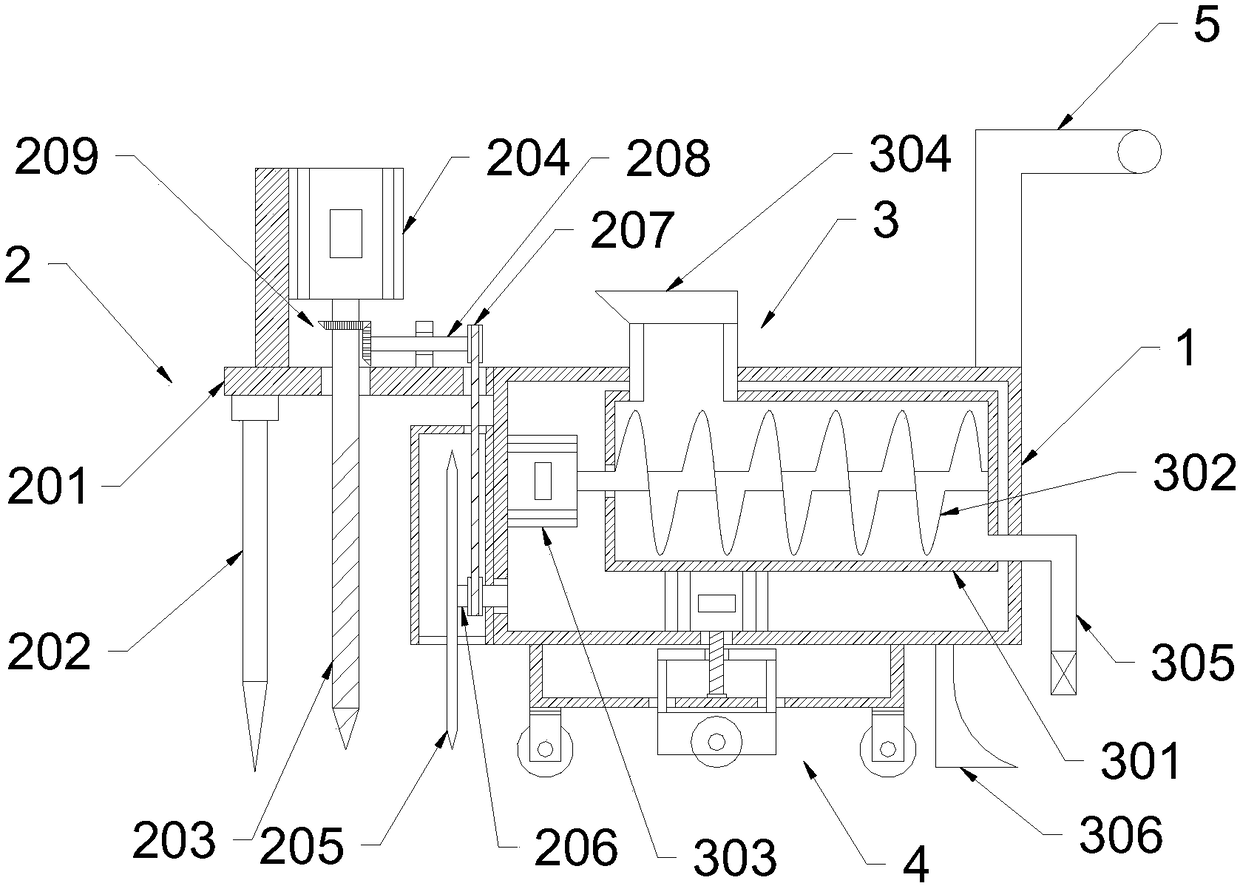

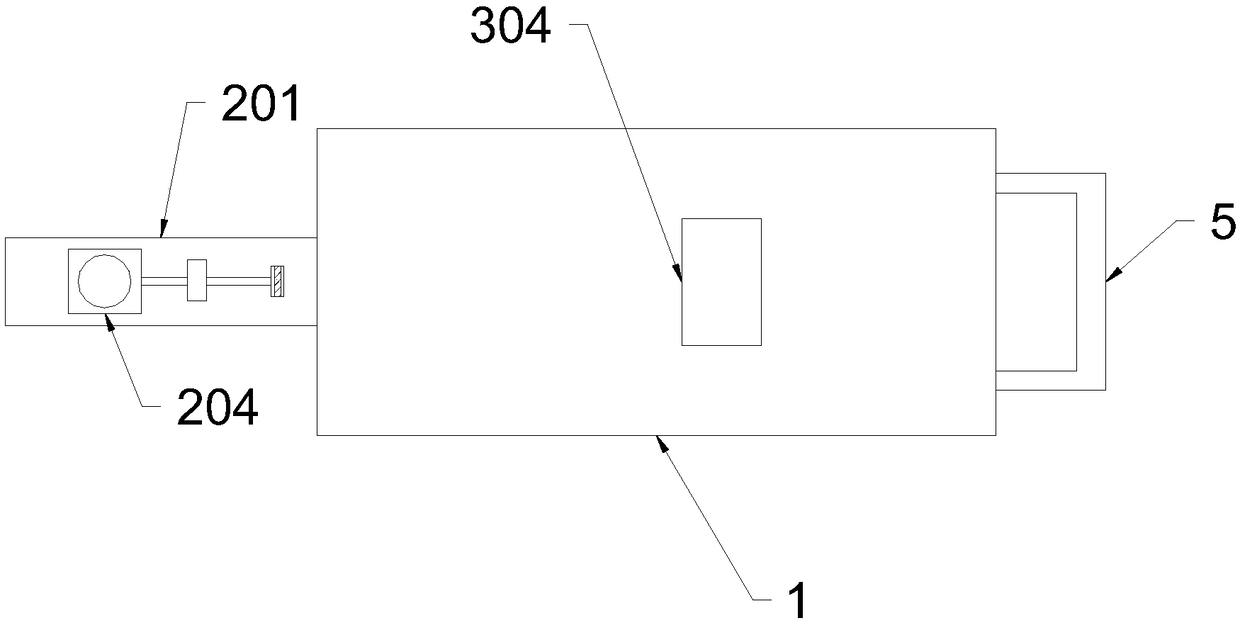

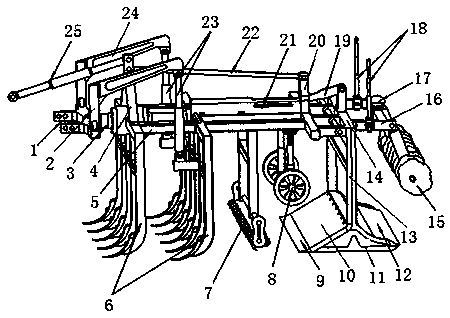

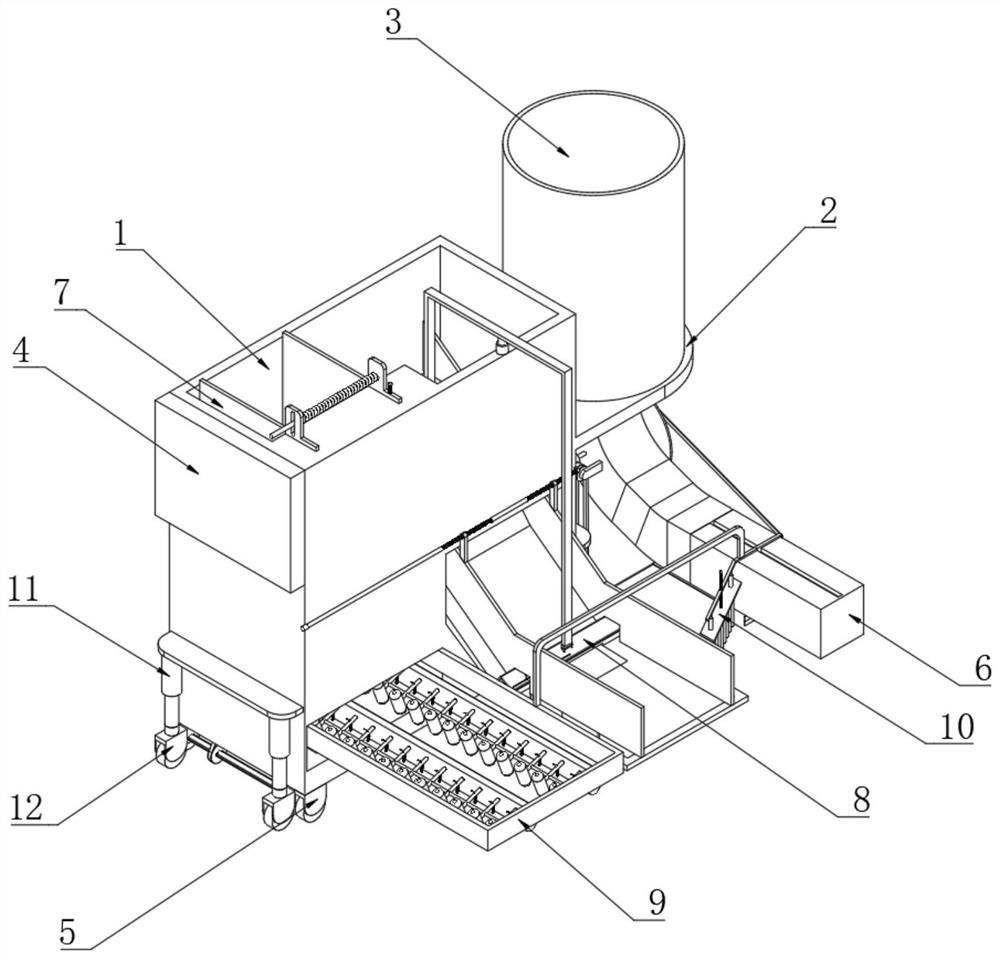

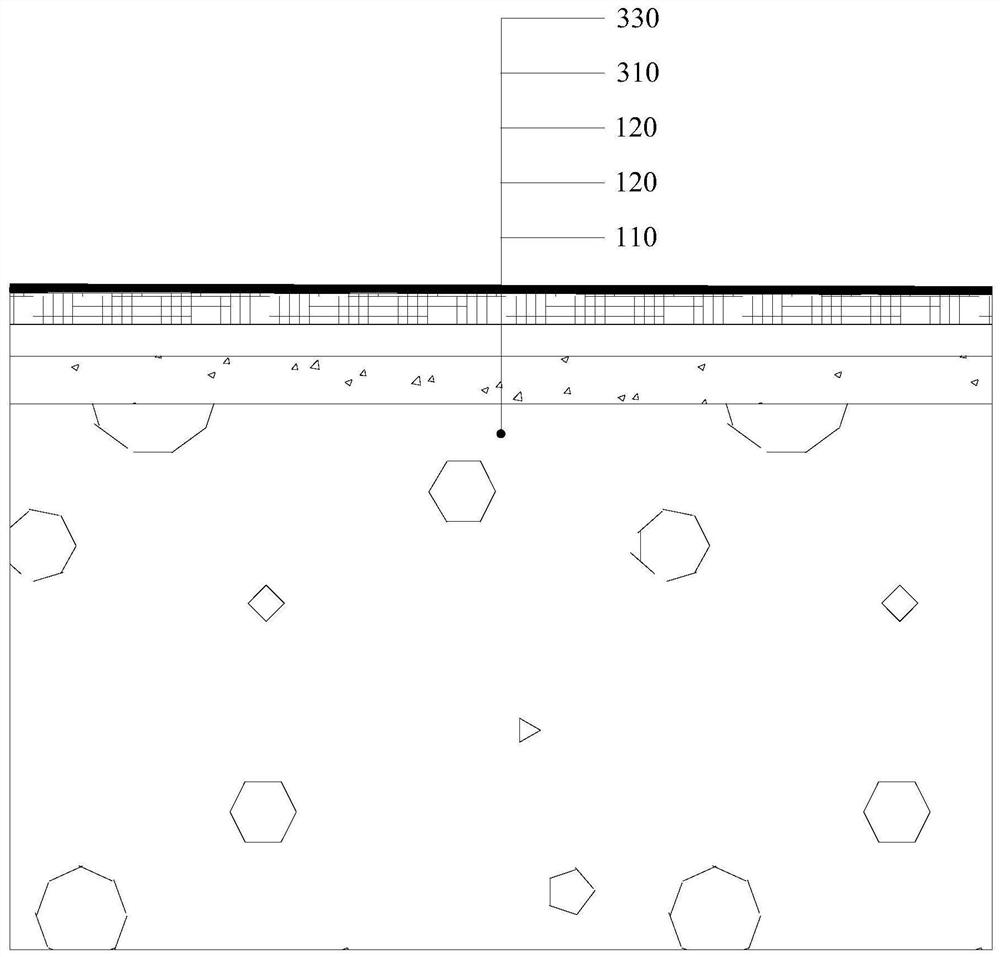

Machine for laying salt-resisting mulching film under plough layer of coastal saline-alkali land and use method of machine

PendingCN108541495ASuppression of groundwater salt sourcesGuaranteed laying effectSpadesPloughsAlkali soilIntegrated operations

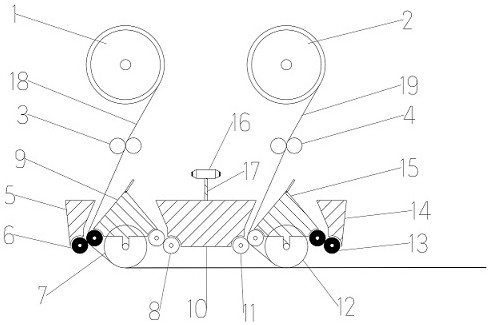

The invention relates to a machine for laying salt-resisting mulching film under a plough layer of coastal saline-alkali land and a use method of the machine. The machine comprises a rack, a film laying device is arranged below the rack and comprises a soil digging inclined surface, the two sides of the top edges of the soil digging inclined surface are fixed to the rack through columns separately, a film laying bottom plate extends backwards at the bottom edge of the soil digging inclined surface in the horizontal direction, and the top edges of the soil digging inclined surface are rotatablyconnected with a film laying shielding plate capable of covering the rear edge of the film laying bottom plate; supporting plates defining the soil digging inclined surface, the film laying bottom plate and the film laying shielding plate into a film laying cavity extend upwards at the two sides of the film laying bottom plate respectively, a film mounting roller, a film pressing roller and a film spreading roller are rotatably connected to the portion, between the supporting plates, in the film laying cavity from front to back in sequence, the film pressing roller is driven by a driving device electrically connected with a controller, and the two ends of the film pressing roller are in transmission connection with the two ends of the film spreading roller through belts respectively. Themachine achieves the integrated operation of soil loosening, sol breaking, film laying and flat raking, the film laying depth and the inclined angle can be adjusted according to actual planning requirements, and the machine is easy to popularize.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

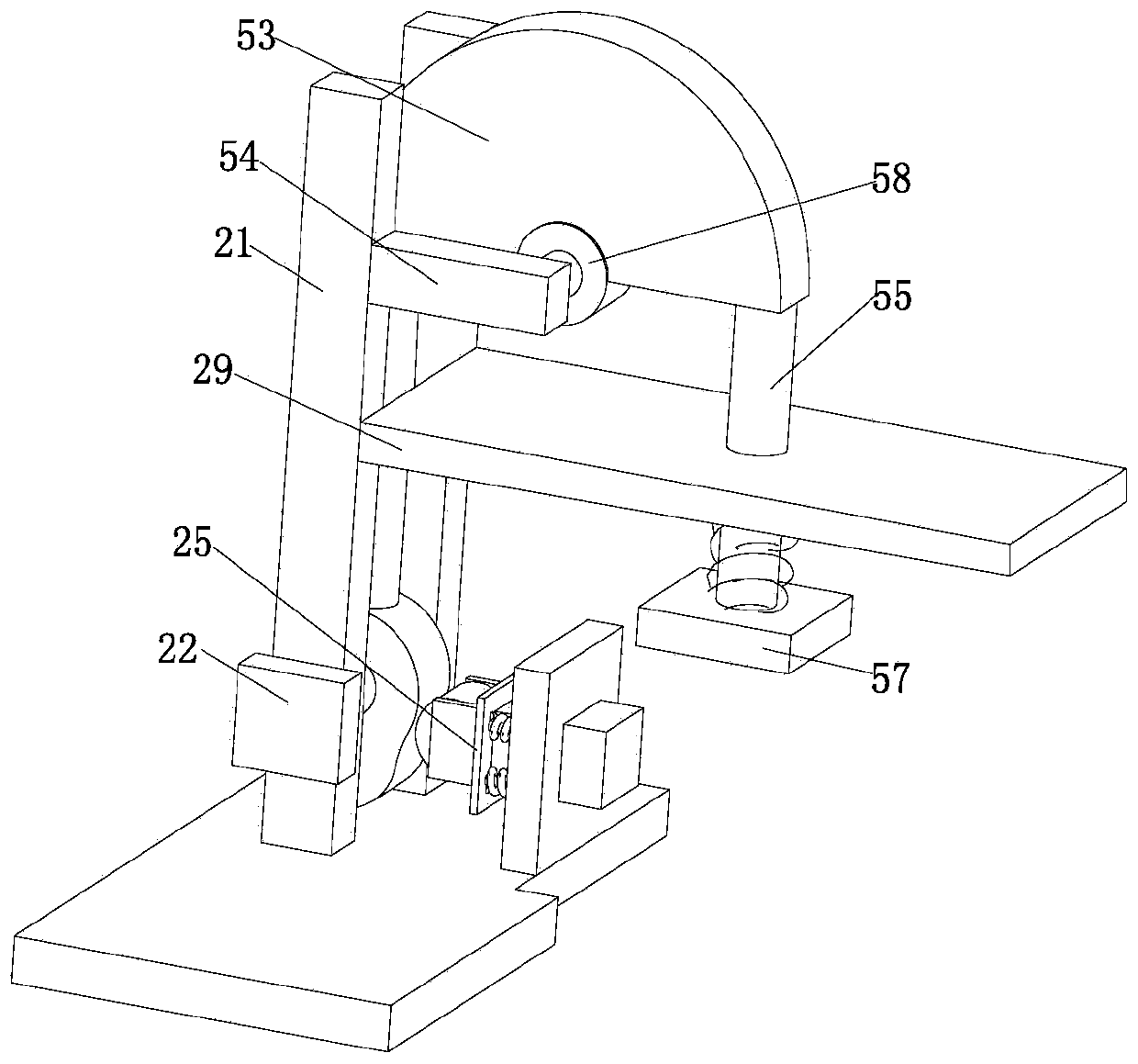

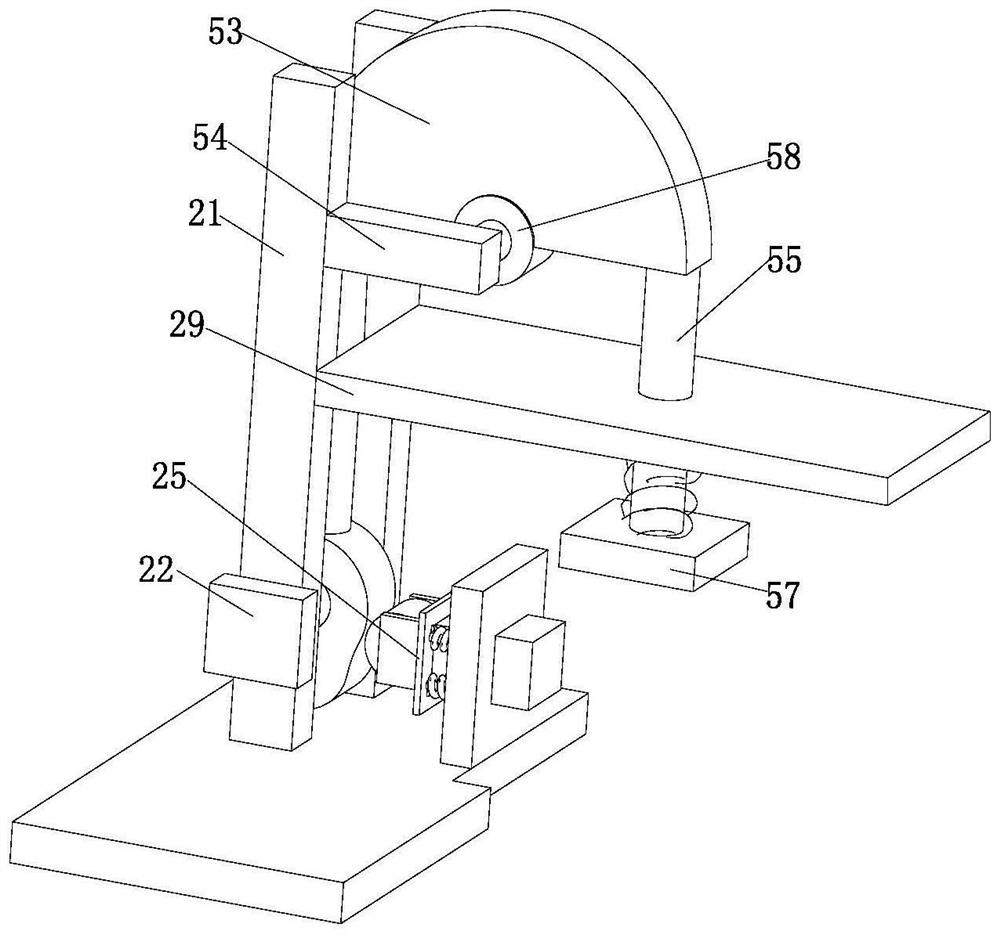

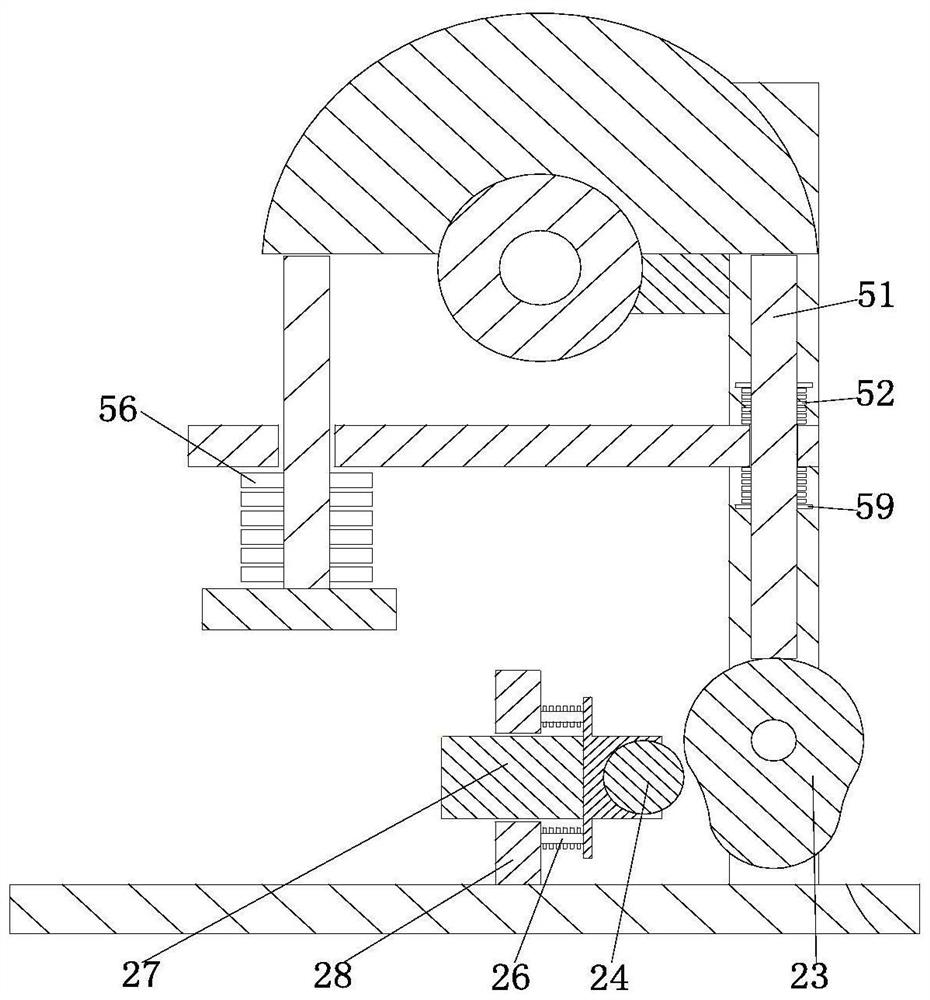

Auxiliary machine for river channel revetment construction

The invention relates to an auxiliary machine for river channel revetment construction. The auxiliary machine comprises a bottom plate, a tapping device, a positioning device and an alignment device,the left side of the front end of the bottom plate is provided with the alignment device, the rear end of the bottom plate is provided with the tapping device, and the tapping device is provided withthe positioning device. According to the auxiliary machine, the following problems, existing during existing hexagonal hollow brick laying, that firstly, skilled hollow hexagonal brick laying workersare in shortage day by day, the workers bend down to work on hollow hexagonal brick laying operation for a long time, so that occupational diseases such as the lumbar vertebra disease and the cervicalvertebra disease are prone to be caused, and the physical and psychological health of human bodies is not facilitated; and secondly, the laying workers have different experience, the laying level isvaried, for the same laying site, the laying results of the different workers are different, the overall effect is influenced, the laying cost is high, the laying speed is slow, the laying efficiencyis low, and a large amount of labor is occupied can be solved.

Owner:雷州市奇丰农业生态科技有限公司

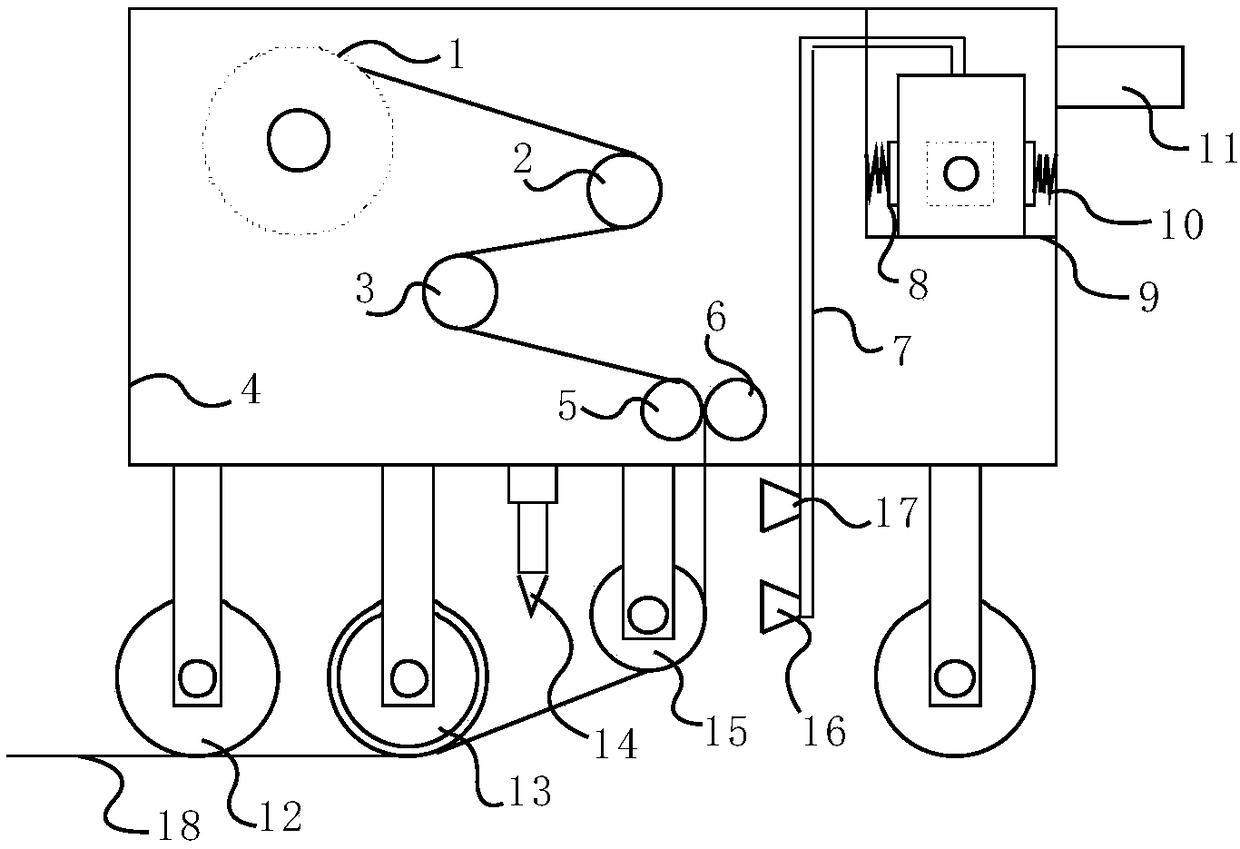

Device for laying waterproof coiled material

PendingCN108915172AGuaranteed heating effectGuaranteed heating speedUnderground chambersRoof toolsFuel tankSpray nozzle

The invention relates to a device for laying a waterproof coiled material. The device comprises a transmission box, a transmission mechanism, a hot-pressing roller arranged at the bottom of the transmission box, and a baking device. The baking device comprises a fuel tank, a set of main spraying nozzles facing a baking roller and a set of preheating spraying nozzles arranged above the main spraying nozzles. The baking device comprises the two rows of spraying nozzles which are arranged perpendicularly, thus the waterproof coiled material can be pre-heated through the preheating spraying nozzles in the using process, and accordingly the heating melting effect and the heating speed of the main spraying nozzles are ensured, and the melting speed can also be ensured while the melting effect isensured; and in addition, the waterproof coiled material penetrates through the bottom of the transmission box, is heated and molten through the baking roller and then transmitted to the hot-pressingroller with the controllable temperature, the coiled material is further hot-molten through the hot-pressing roller, the heated and molten waterproof coiled material is compressed on the ground, andthus the laying effect is further ensured.

Owner:天津欣辰湖建材有限公司

Floor tile laying device for building construction

PendingCN113585684AScientific and reasonable structureSafe to useBuilding constructionsCement MaterialArchitectural engineering

The invention discloses a floor tile laying device for building construction. The floor tile laying device comprises a loading box, a rectangular plate is installed at one end of the loading box through screws, a feeding cylinder is fixedly installed at the top end of the rectangular plate, a storage battery is fixedly installed at one end of the loading box, and directional wheels are evenly installed at the bottom end of the loading box; a continuous synchronous type discharging and paving assembly is installed at the bottom end of the feeding cylinder and is formed by combining a leveling plate, a sealing plate, a first belt transmission mechanism used for driving the leveling plate, a driving rod, a rectangular rod, a rotating blade with a discharging blocking function, a driving plate and a blocking plate. According to the floor tile laying device for building construction, cement can be guided and conveyed in the walking process, the problems that a large amount of cement falls off and too much cement is accumulated are solved, discharging is conducted through movement of the floor tile laying device for building construction, cement discharging continuity is achieved, floor tiles can be better attached, and the purpose that cement laying is stopped immediately is achieved; the cement laying effect is guaranteed, and meanwhile cement waste can be avoided.

Owner:田静

Agricultural multifunctional integrated mulching film laying device

PendingCN113557897AImprove work efficiencySave time on manual fillingSpadesPloughsCartAgricultural engineering

The invention discloses an agricultural multifunctional integrated mulching film laying device which comprises a cart, a notch is formed in one side of the top end of the cart, a placement roller is clamped to the middle of the inner wall of the notch, a controller is fixedly installed on the edge of one side of the top end of the cart, a storage battery is fixedly installed in the middle of the top end of the cart, integrated ditching assembly mechanisms are symmetrically installed on the two sides of the bottom end of the cart, and each integrated ditching assembly mechanism comprises a press-fit electric telescopic rod, a press-fit frame, an arc spring, a soil collecting plate, a movable electric push rod, a movable frame, a double-face sawtooth strip, a driving gear, a connecting gear, an arc insection strip and a rotary cover plate. Through the integrated ditching assembly mechanisms, horizontal ditching can be conveniently conducted on soil, the ditching difficulty of workers is reduced, meanwhile, mulching films in horizontal ditches can be extruded, so that the mulching films and the plane are connected more stably, and the problem that workers need to spend time carrying out ditching in the prior art is solved.

Owner:蓝柱平

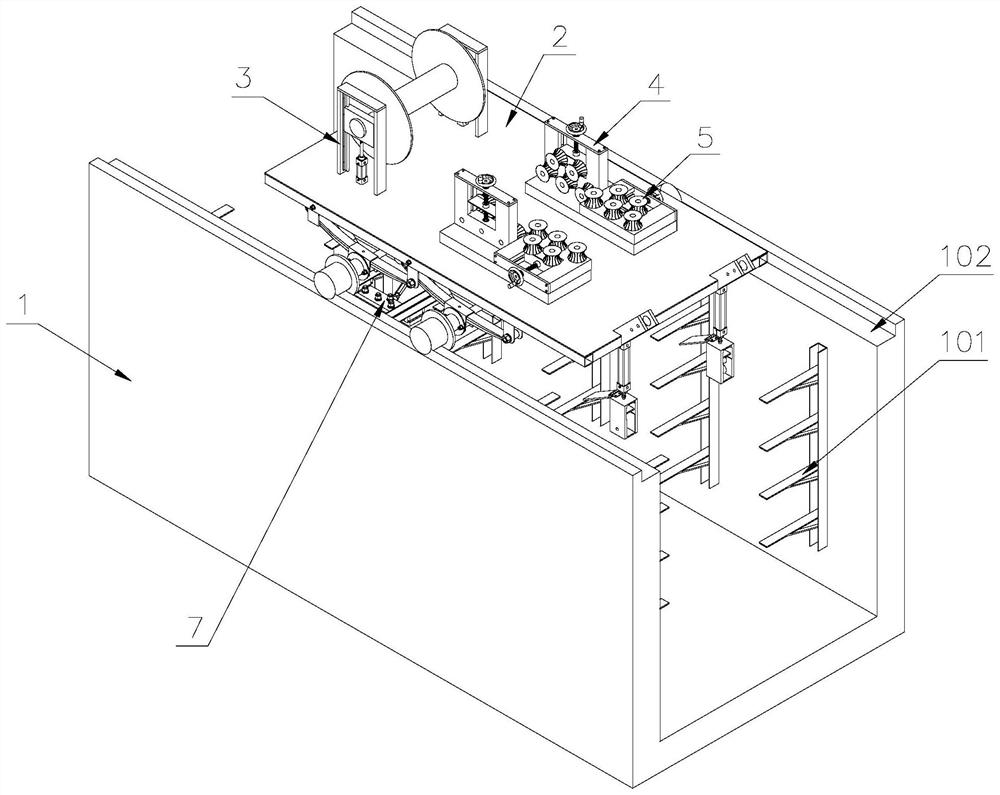

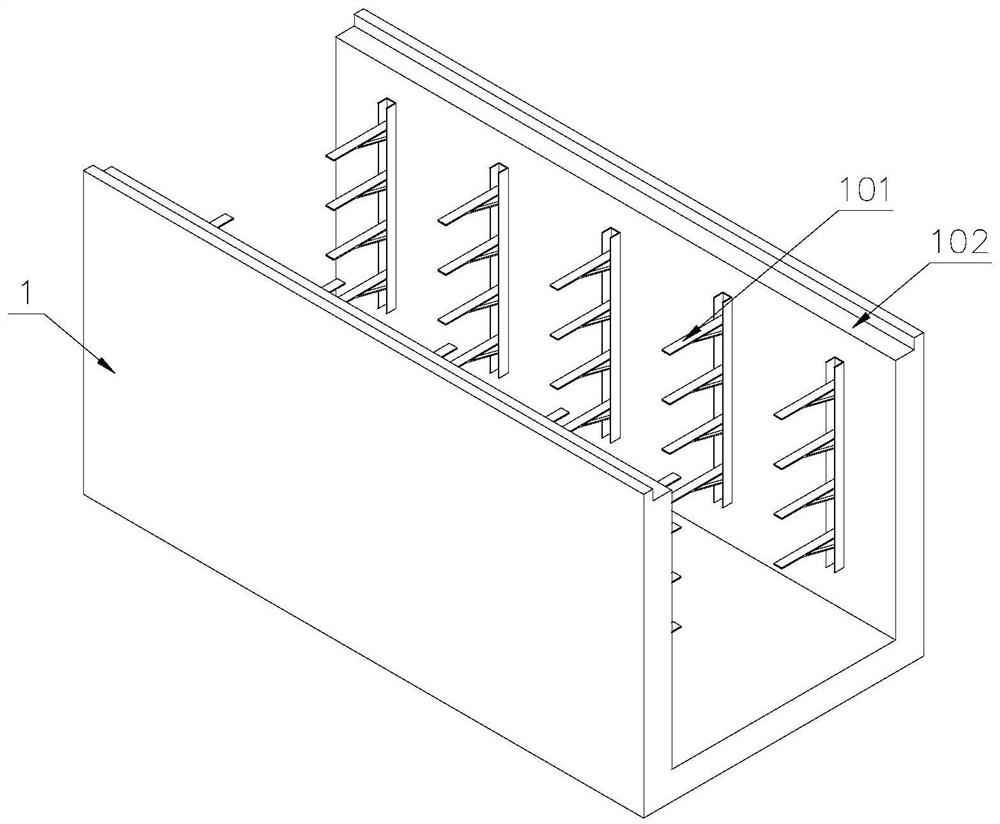

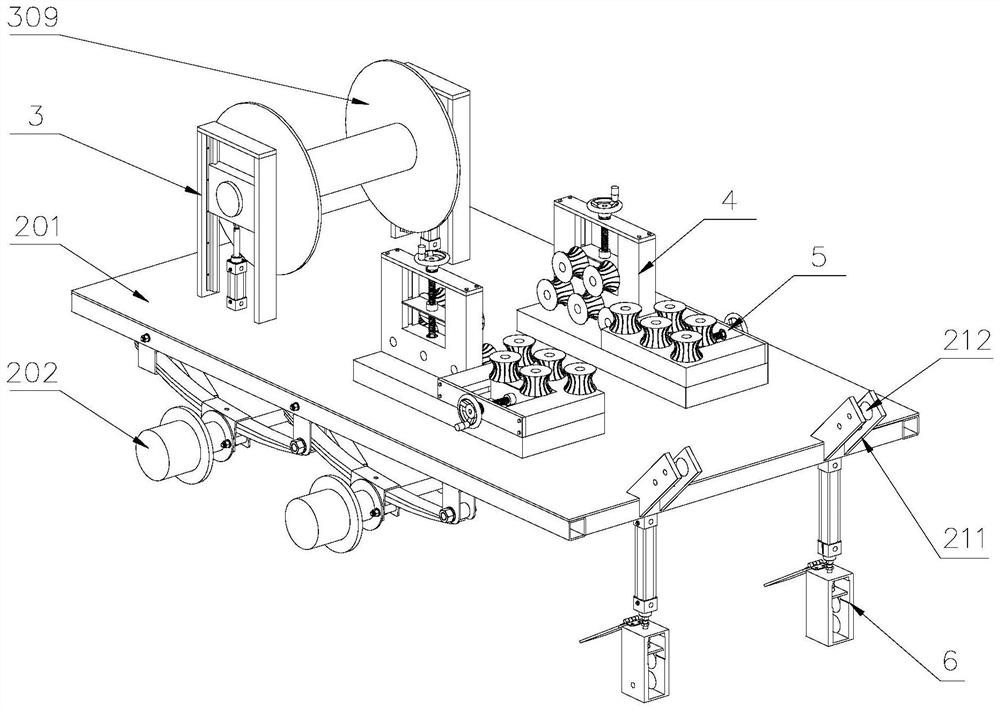

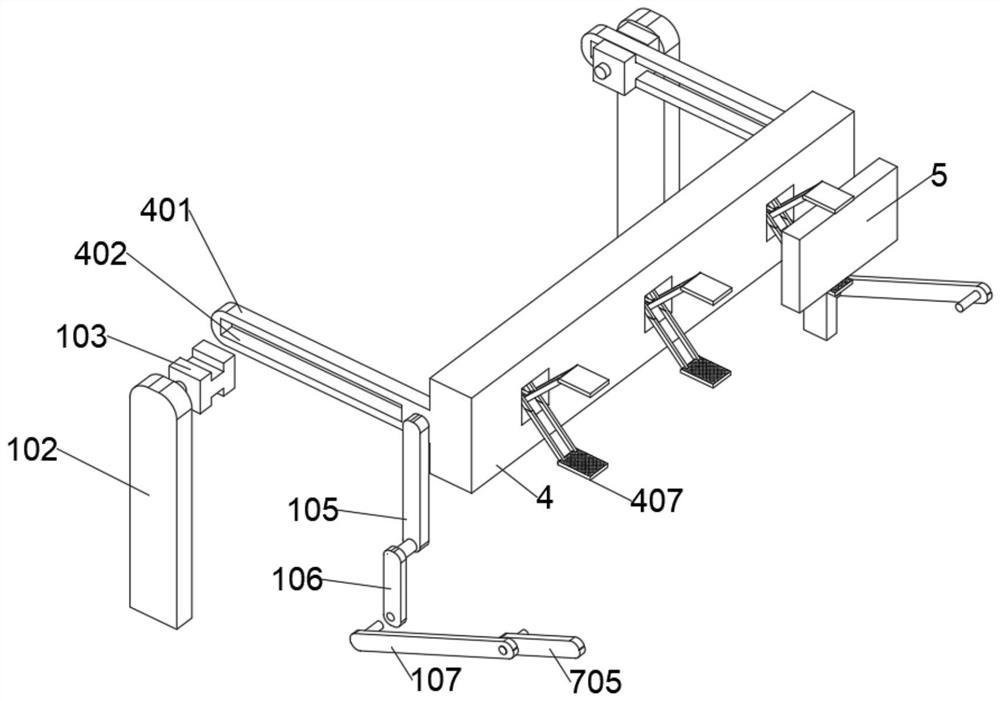

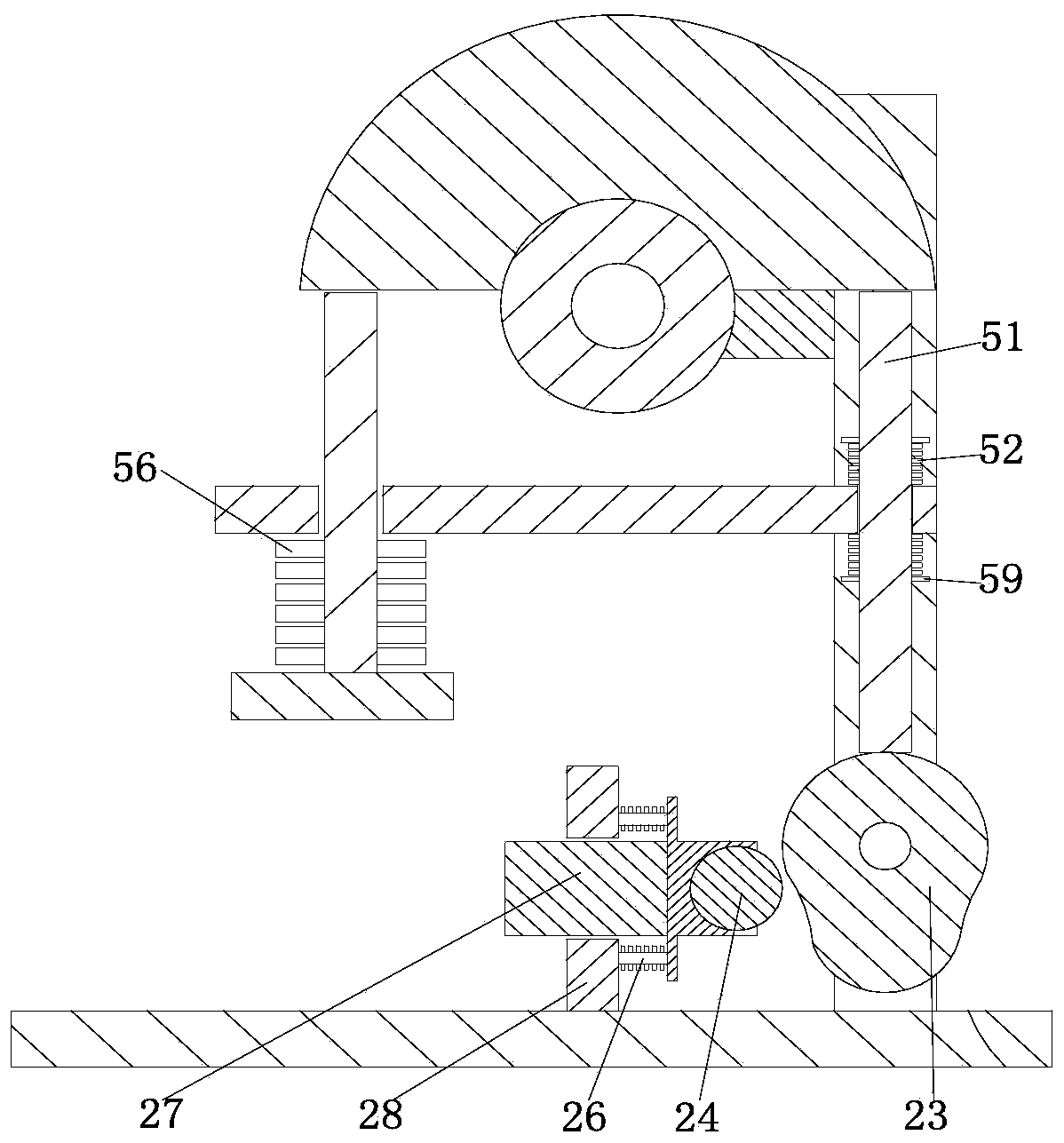

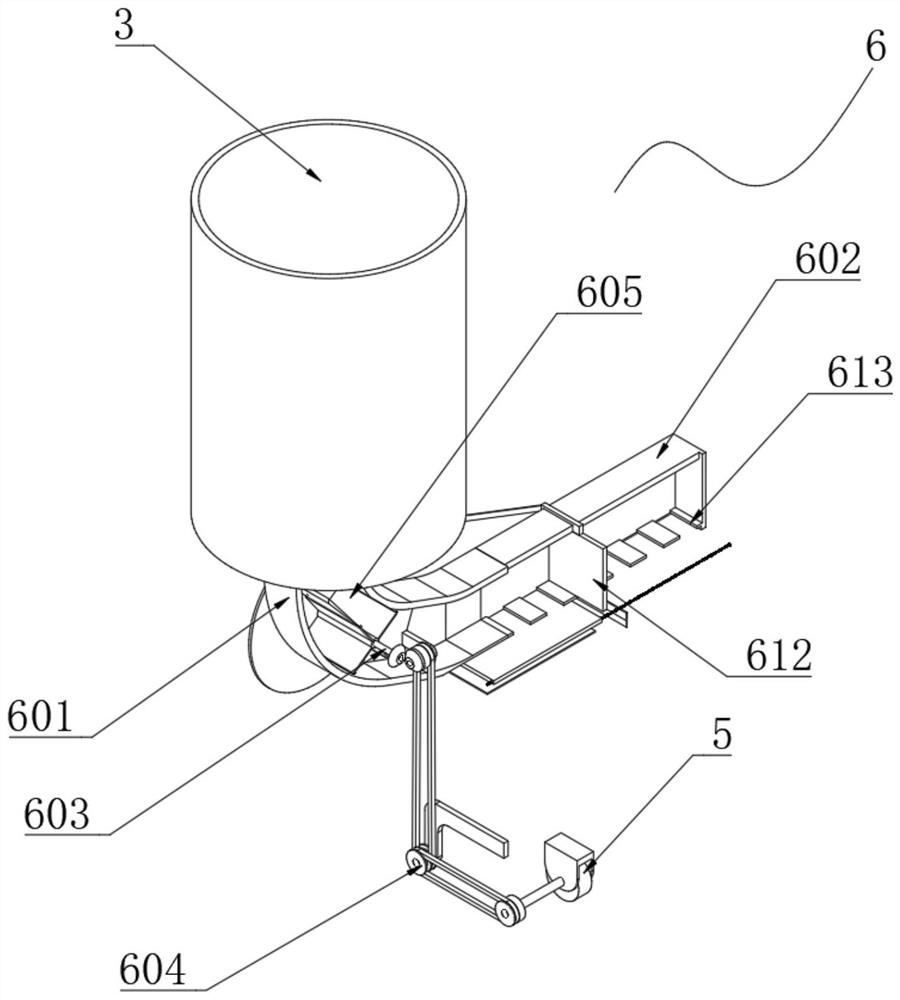

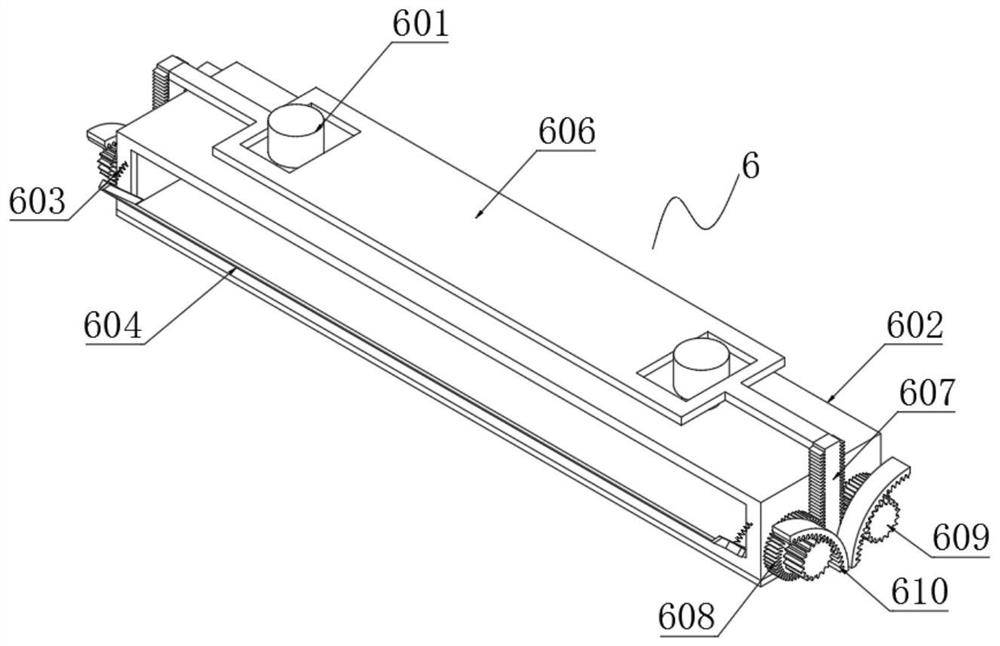

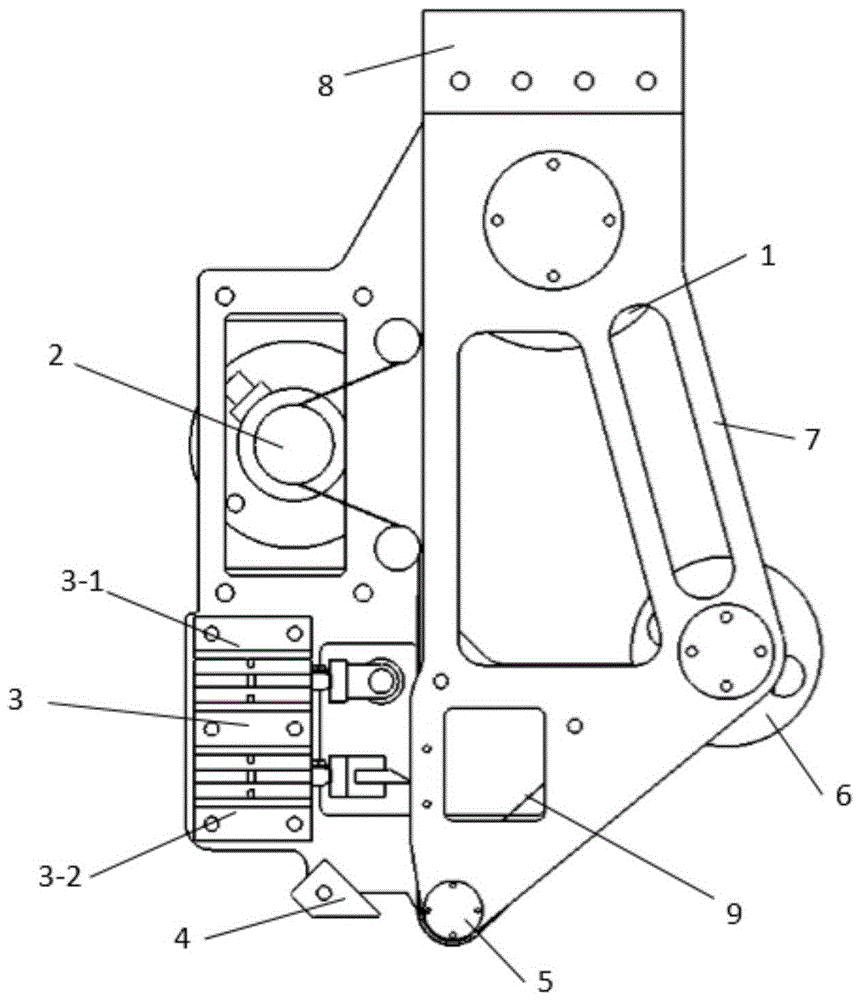

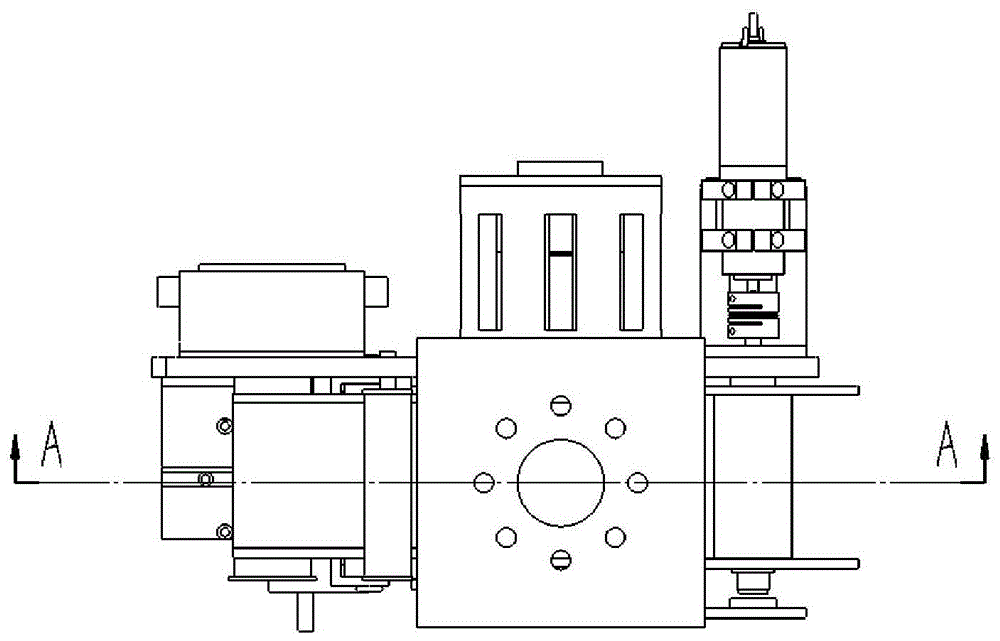

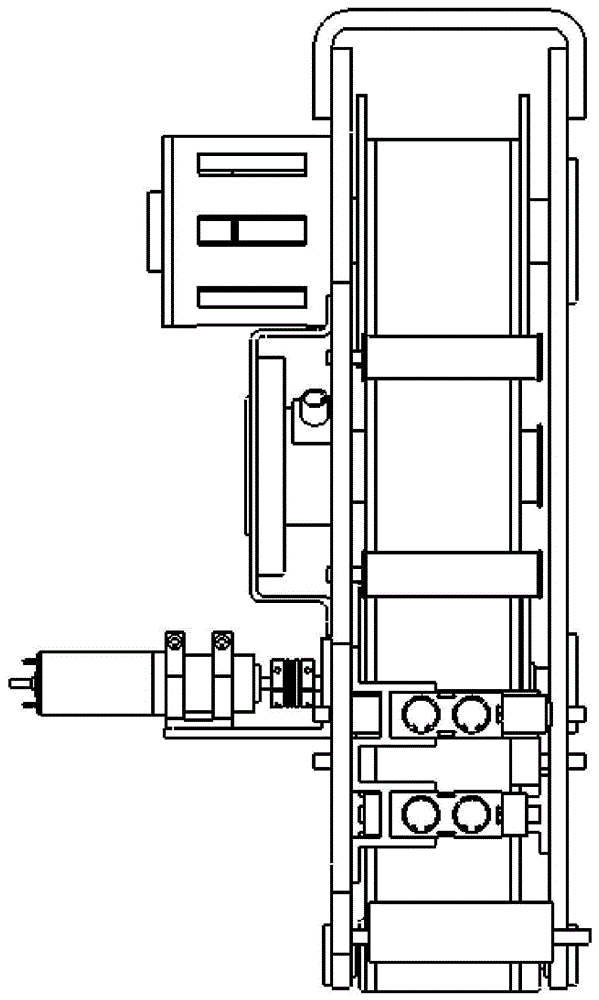

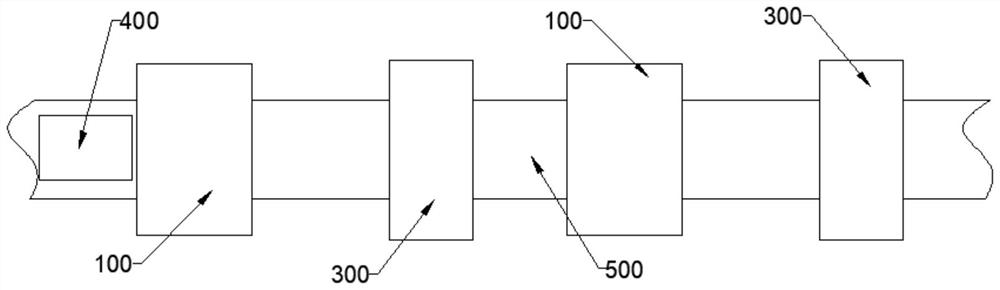

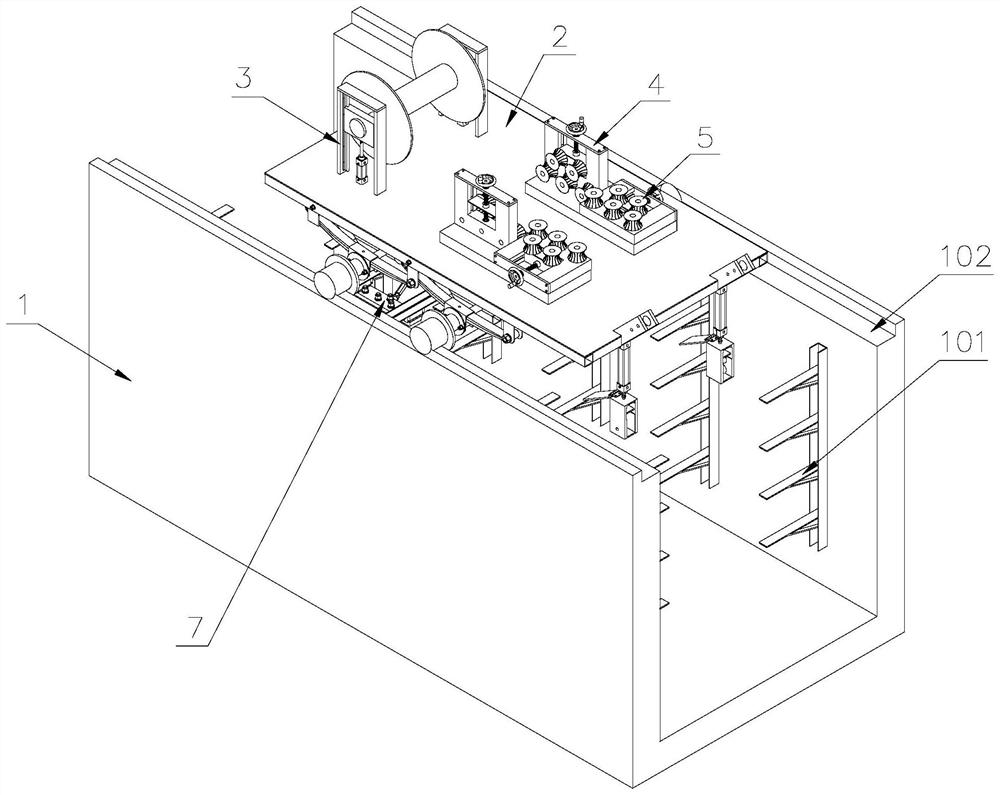

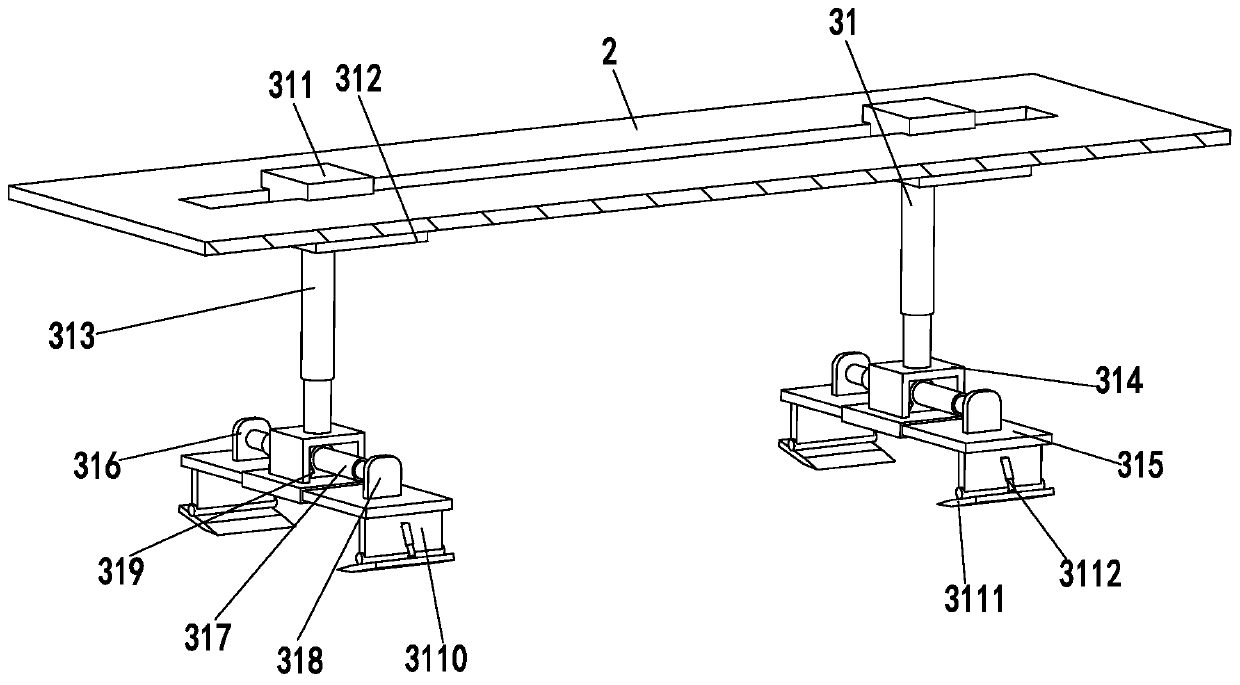

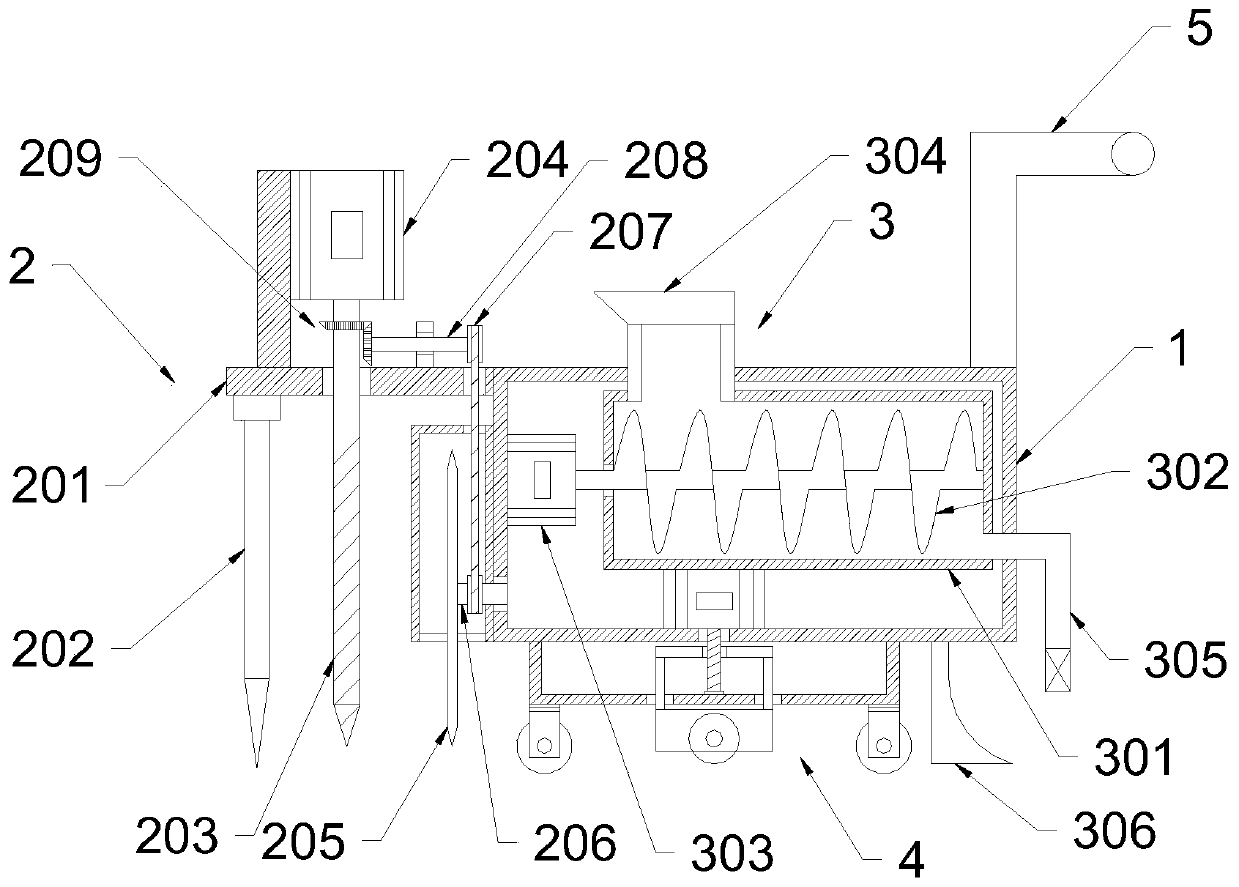

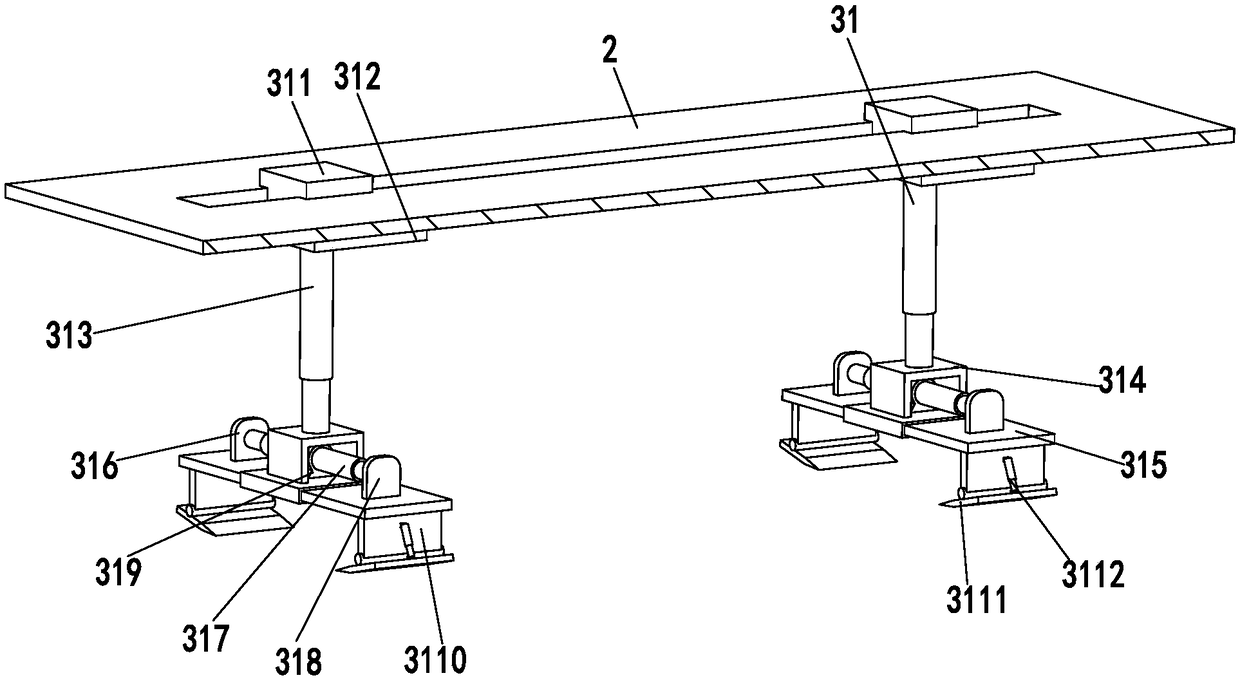

A kind of automatic tape laying device and method based on six-axis robot

The invention discloses a six-shaft robot based type automatic tape paving device and a six-shaft robot based type automatic tape paving method. The device is applied to the field of automatic manufacturing equipment for paving a composite material fiber tape. The device comprises a belt releasing device (1), a tension detection device (2), a pressing and shearing device (3), an infrared heating device (4), a pressing mechanism (5), a lining paper collecting device (6), a rack (7) and a connection mechanism (8). The device has the function of automatically paving a composite material prepreg tape, breaks through the block of a foreign technology, and meets the requirements on manufacturing of composite materials by aerospace and aviation industries.

Owner:WUHAN UNIV

Heating and heat preservation device for asphalt pavement

PendingCN112482132AImprove the heating effectSolve the effect of uneven heatingRoads maintainenceElectric machineryHeat conservation

The invention relates to the technical field of asphalt pavement, and discloses a heating and heat preservation device for asphalt pavement. The device comprises a device shell, a mounting plate is fixedly mounted at the top end of the device shell, supporting seats are fixedly mounted on the two sides of the bottom end of the device shell, and a discharging pipeline fixedly communicates with oneside of the bottom end of the device shell. And a control valve is fixedly mounted on the outer surface of the discharging pipeline, and a feeding port is formed in one side of the top end of the mounting plate. According to the heating and heat preservation device for asphalt pavement, through the arrangement of the structures such as a driving motor, a heating mechanism, a mounting sleeve, a stirring shaft, stirring blades, a clamping sleeve and a lifting air cylinder, up-down reciprocating stirring of asphalt can be achieved through mutual cooperation of the structures such as the driving motor and the lifting air cylinder while the asphalt is heated; and thus the uniform heating of asphalt is realized. Meanwhile, the clamping sleeve has the advantages of being convenient to install, simple in structure, good in heating effect and the like, and the problem that existing heating is uneven is solved.

Owner:寿县永固新型建材科技有限公司

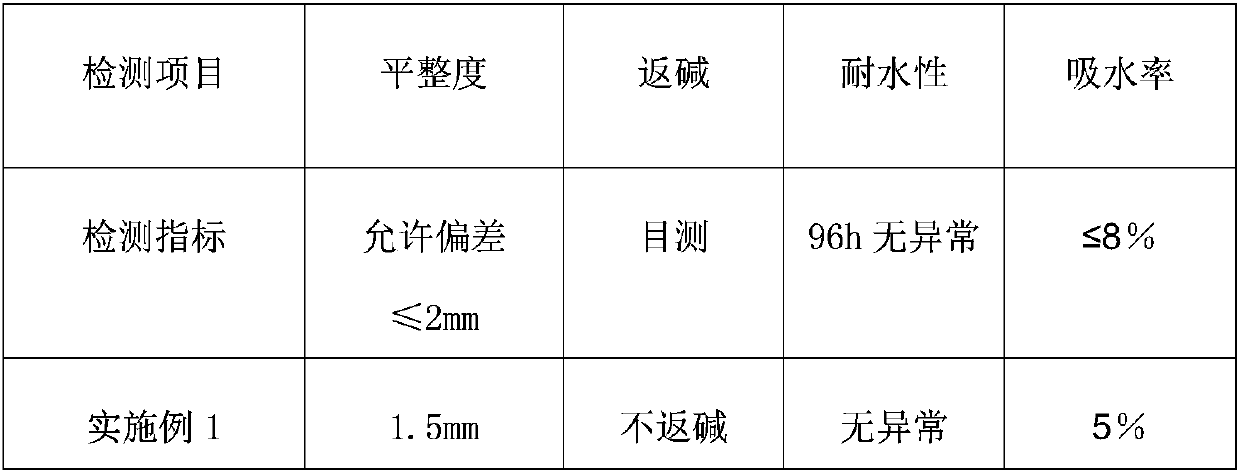

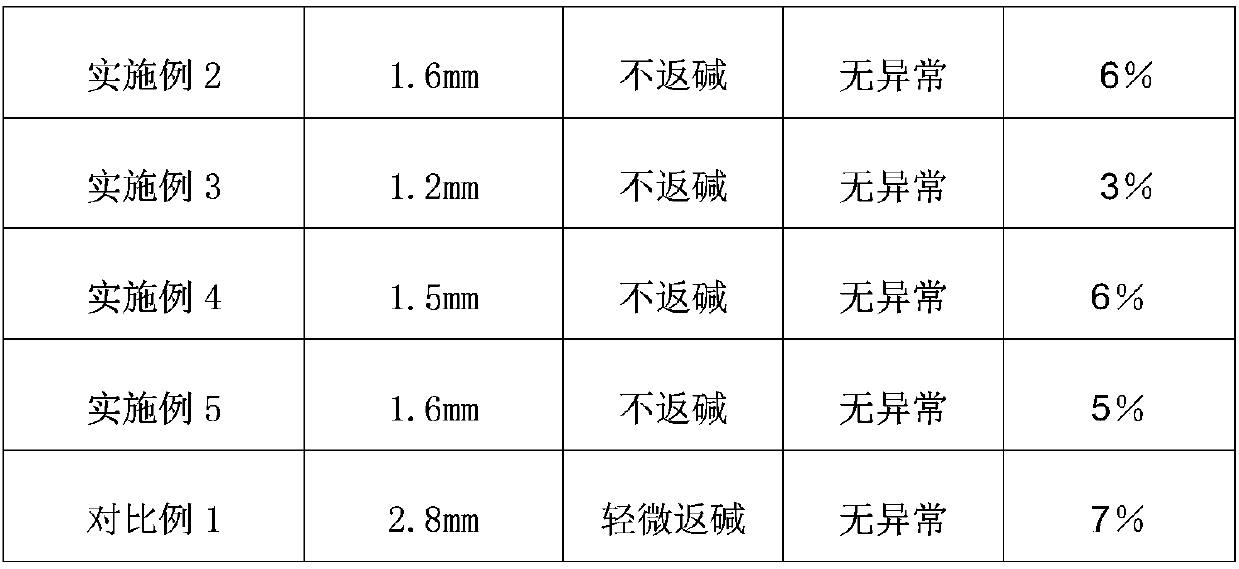

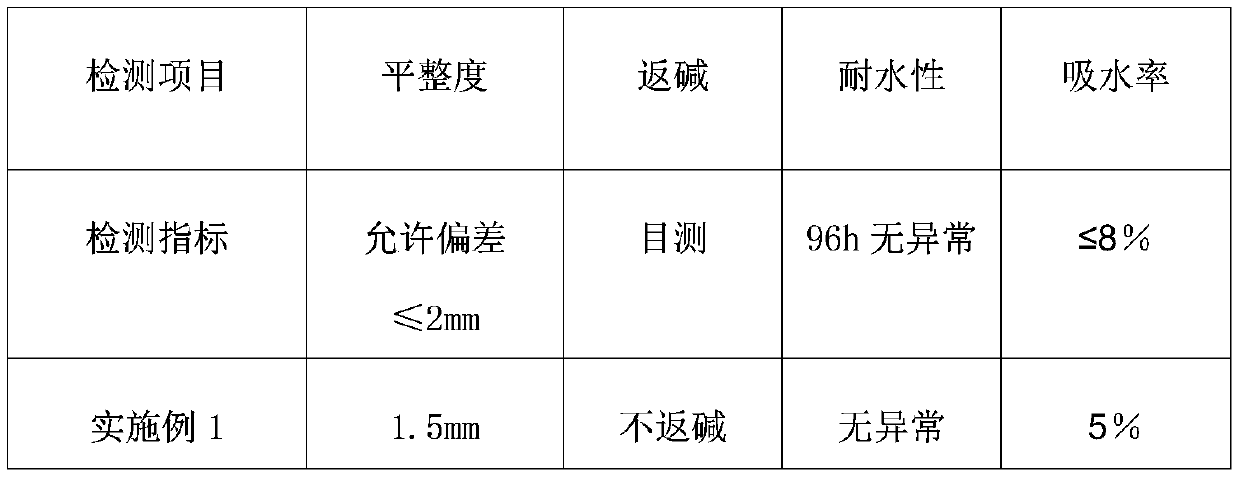

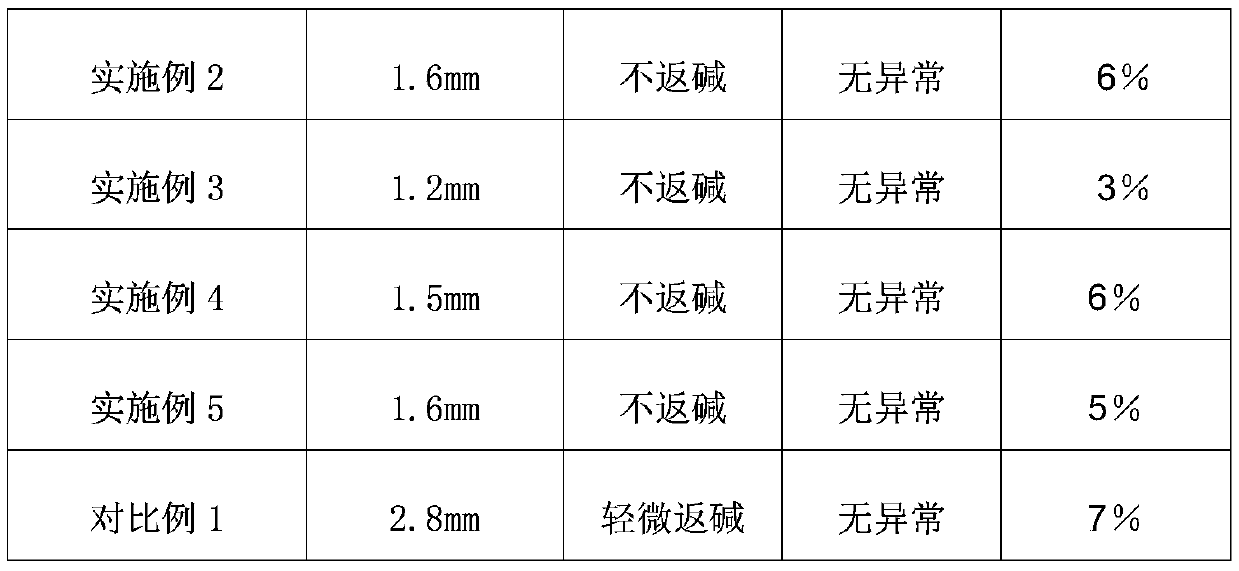

Construction technology for paving graceful soft rock to indoor floor decoration

The invention provides a construction technology for paving graceful soft rock to indoor floor decoration and belongs to the technical field of construction. The construction technology comprises thefollowing steps: pre-treating a base layer, namely firstly sweeping dust and impurities and then using the leveling putty for locally repairing; treating the base layer, namely using the special puttyfor twice constructing the pre-treated base layer and then using a sand paper above 80# for sanding; maintaining: spraying water for maintaining for at least two times; paving, namely using special adhesive mortar for paving till the graceful soft rock is compactly and smoothly paved and meets the requirement; and jointing and cleaning, namely using jointing agent for jointing and then cleaning the paved surface of the graceful soft rock after the jointing agent is solidified. The pavement of the graceful soft rock according to the construction technology provided by the invention has the advantage that the paved graceful soft rock is smooth, is free from alkali reappearing and is high in construction speed.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Thermal-insulation fireproof cement composite board and manufacturing process thereof

PendingCN113650153AWell laidGuaranteed embeddingAuxillary shaping apparatusHeat proofingManufacturing technologyCement composites

The invention discloses a thermal-insulation fireproof cement composite board and a manufacturing process thereof. The manufacturing process comprises the following steps of step A, manufacturing a mold; B, placing the mold; C, using manufacturing equipment for manufacturing a lower fabric layer with a lower mesh layer; D, placing a core material; E, manufacturing an upper fabric layer with an upper surface layer by using manufacturing equipment; F, stacking and standing; and G, demolding a finished product. Through the arrangement of the manufacturing equipment, gridding cloth can be conveniently laid, clamping connection between the gridding cloth and a laying roller is prevented, meanwhile, the gridding cloth can be conveniently embedded into cement mortar, the uneven wrinkle phenomenon of the laid gridding cloth is prevented, the heat preservation effect of the gridding cloth is guaranteed, meanwhile, the gridding cloth is conveniently cut, the cut gridding cloth is fixed, the phenomena of shaking and displacement of the laid gridding cloth during cutting are prevented, and then the laying effect of the gridding cloth is guaranteed.

Owner:BEIJING ZHONGXING NINGHAO NEW BUILDING MATERIALS CO LTD

A waterproof and anti-seepage membrane laying equipment

ActiveCN104775571BGuaranteed laying effectGuaranteed compression effectRoof toolsRoads maintainencePulp and paper industryTorch

The invention discloses a waterproof and anti-seepage coiled material laying equipment, comprising a body, upper brackets arranged on both sides of the body and lower brackets arranged on both sides of the body corresponding to the upper brackets, the upper brackets on both sides are provided with There is a coil roller, and guide wheels are provided on the lower brackets on both sides; a pinch wheel groove is also set on the body, and a second spring and a pinch wheel platen pressed by the second spring are respectively arranged in the pinch wheel groove , the pressure roller plate is provided with a push rod passing through the through hole set in the pressure roller groove, the end of the push rod is connected with a pressure roller, the pressure roller corresponds to the guide wheel, and also includes a The preheating flame head and the main flame nozzle corresponding to the waterproof coiled material, the present invention has a simple structure, and can use the preheated flame head arranged on the machine body to preheat the waterproof coiled material, so as to further ensure that the main nozzle The heating and melting process of the flame head is more sufficient, so that the efficiency of laying the waterproof membrane is high, the laying quality is good, and the waterproof effect is better.

Owner:河南景美环保工程有限公司

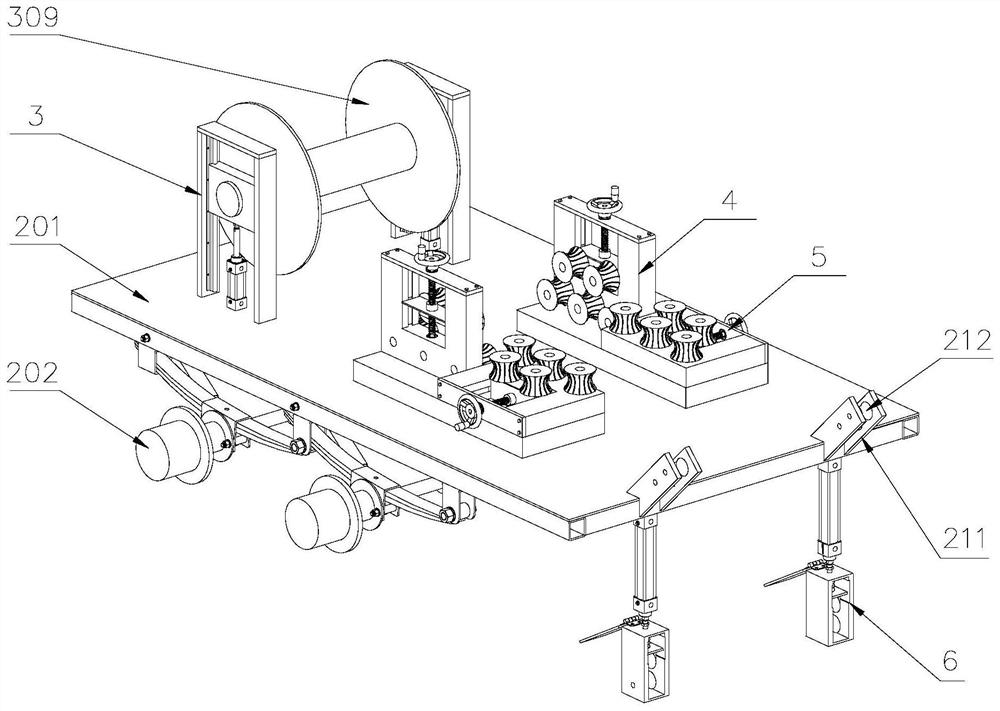

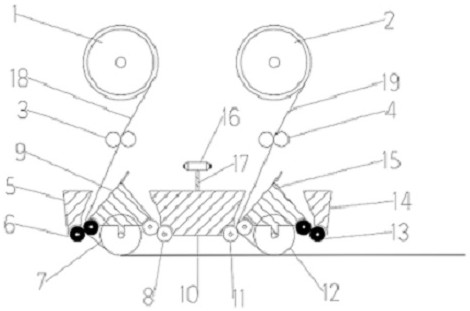

Automatic prepreg tape laying device

ActiveCN113352646AImprove adhesionIncrease productivityFinal product manufactureLaser beam welding apparatusLaser cuttingIndustrial engineering

The invention discloses an automatic prepreg tape laying device. The device comprises a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, and the feeding mechanism comprises a left tape coil, a right tape coil, a first clamping roller pair, a second clamping roller pair, a first prepreg tape and a second prepreg tape. The laying mechanism comprises a first heating roller pair, a first pressing roller, a first laying roller pair, a second laying roller pair, a second pressing roller and a second heating roller pair, the guiding mechanism comprises a first guiding mechanism, a third guiding mechanism and a second guiding mechanism, and the cutting mechanism comprises a double-head laser cutter and a supporting frame. The reversing mechanism comprises a first reversing mechanism and a second reversing mechanism. According to the automatic prepreg tape laying device, single laying layer by layer is not needed, the production efficiency is greatly improved, meanwhile, idle stroke returing or turning around is not needed, and the laying time is saved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

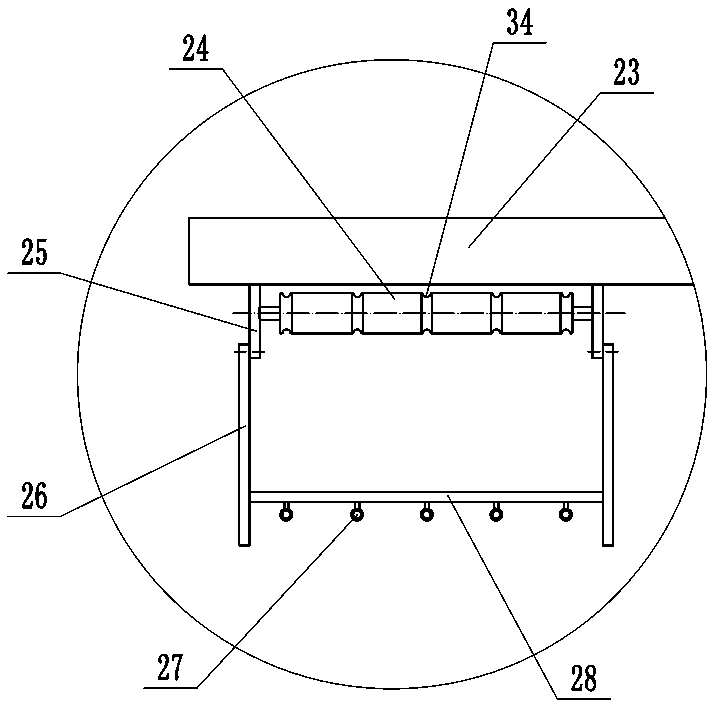

Adjustable weft repeated laying device

The invention provides an adjustable weft repeated laying device and belongs to the field of glass fiber cloth weaving. The adjustable weft repeated laying device comprises a laying distance adjustingcomponent and a laying component, wherein a first laying wheel and a second laying wheel of the laying distance adjusting component are rotatablely arranged on a fixed laying wheel support; both a third laying wheel and a fourth laying wheel can be rotatablely arranged on a movable laying wheel support; a laying belt is arranged on the first laying wheel, the second laying wheel, the third layingwheel and the fourth laying wheel in a surrounding manner; a laying support for the laying component is mounted on the laying belt; yarn guiding wheels are rotatablely arranged on a yarn guiding wheel fulcrum shaft at equal intervals; laying pull rings are arranged on a laying pull ring rack at equal intervals; a fixing yarn guiding rod is rotatablely arranged on a fixing yarn guiding rod support; the upper end of a swinging yarn guiding rack is hinged to the lower end of the fixing yarn guiding rod support; and swinging yarn guiding rings are mounted on a swinging yarn guiding ring support at equal intervals. According to the adjustable weft repeated laying device provided by the invention, on the premise of not changing the laying belt, broadwise distance adjustment in weft laying can be achieved.

Owner:桐乡市安港新材料有限公司

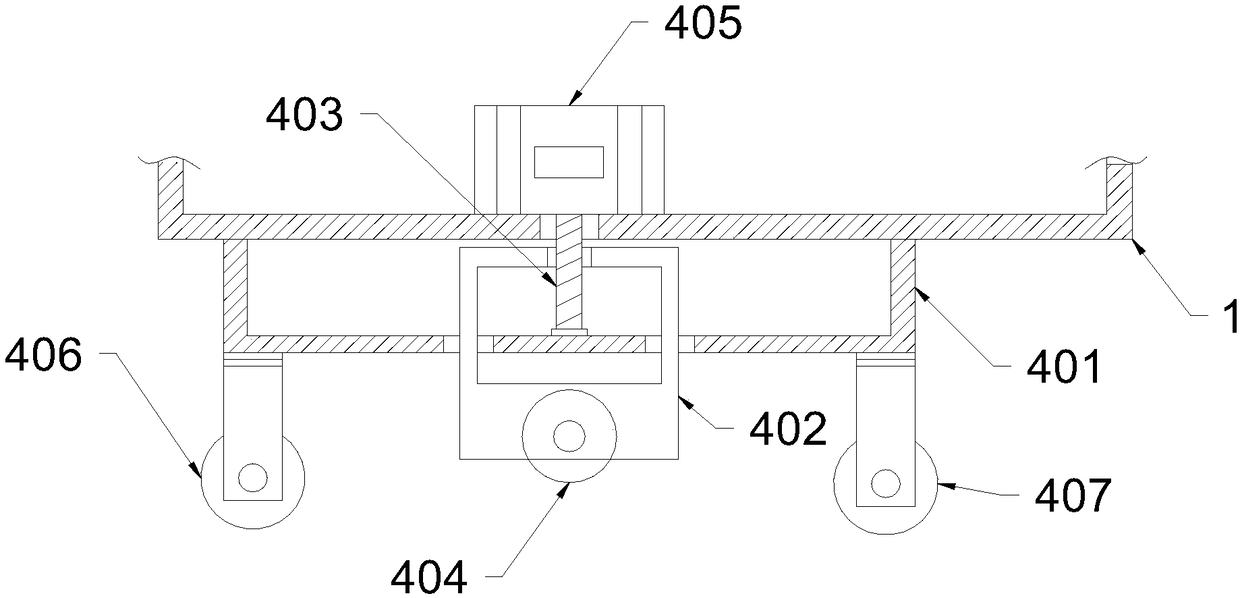

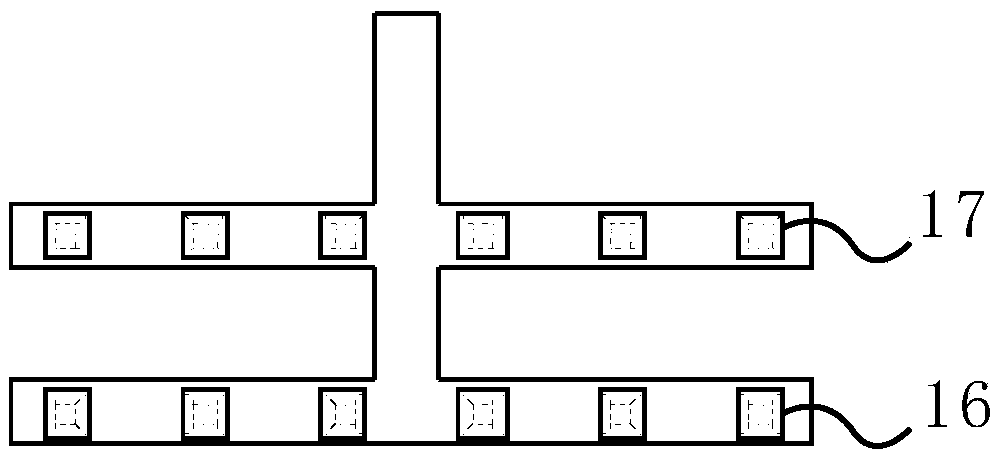

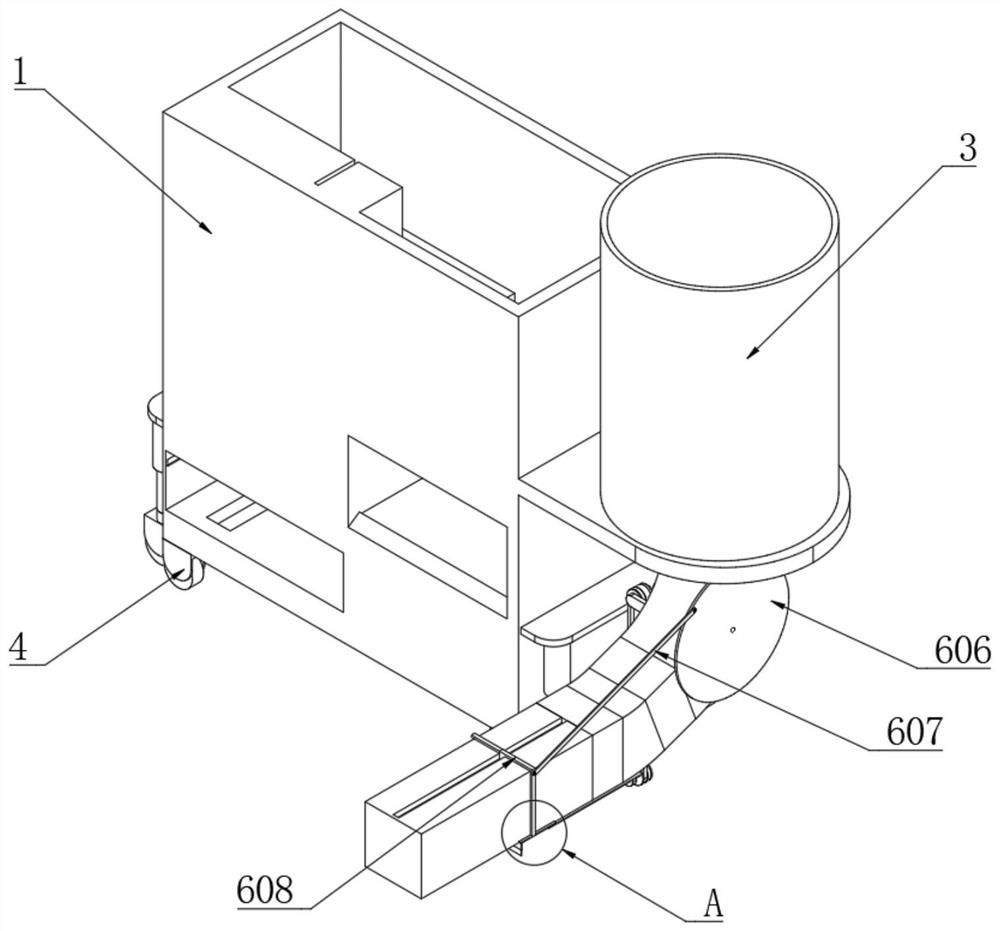

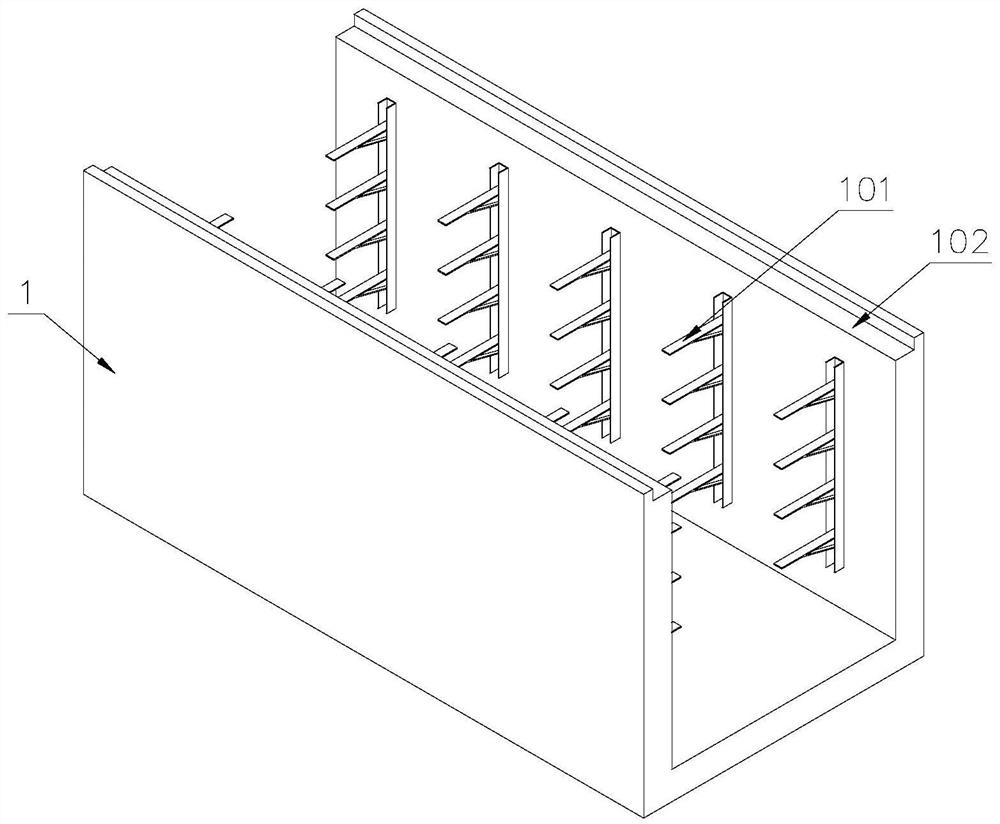

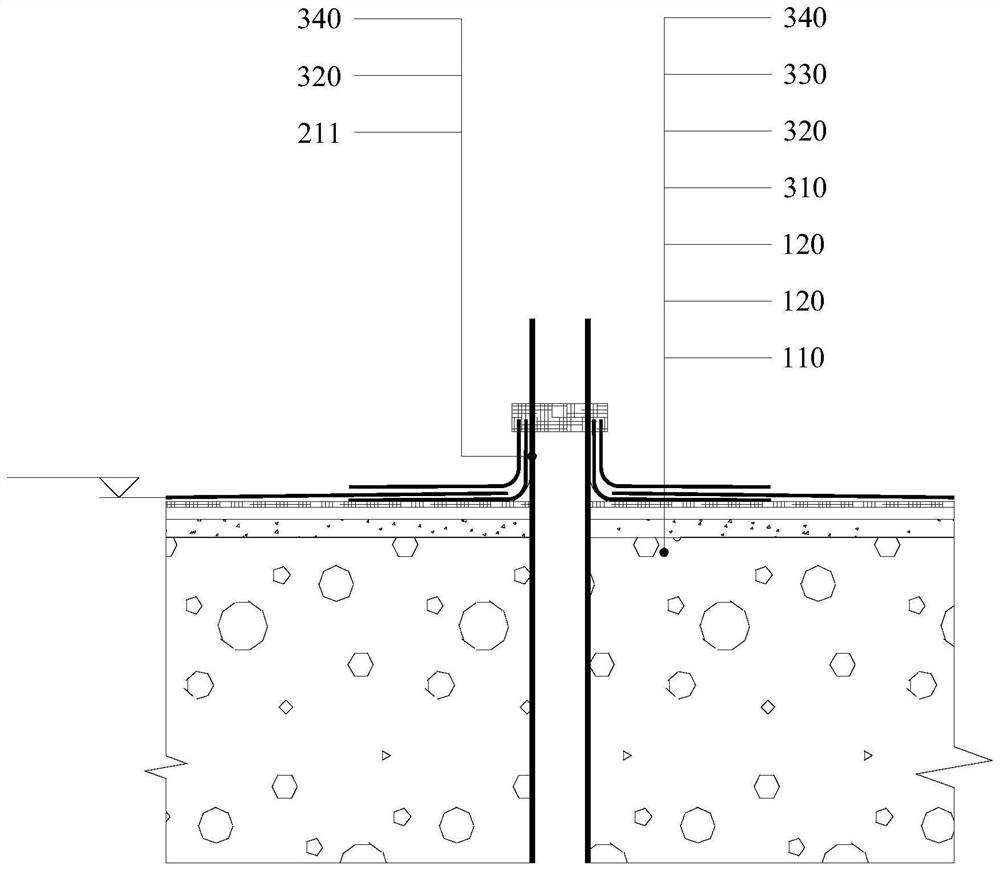

A cable laying device for cable trench

ActiveCN112103842BImprove laying efficiencyReduce labor intensityFilament handlingApparatus for laying cablesElectric machineryStructural engineering

The invention discloses a cable laying device for a cable trench, which comprises a cable trench, a mobile vehicle arranged on the cable trench, a wire-laying device arranged on the upper side of the rear part of the mobile vehicle, and a laying device arranged on the lower side of the front part of the mobile vehicle. Wire device, the mobile car includes a car body, a wheel shaft arranged at the lower part of the car body, moving wheels arranged at both ends of the wheel shaft, and a motor arranged at the lower part of the car body; The support plate on the frame; the wire laying device includes a threading frame arranged on the upper part of the cable, a supporting wheel arranged inside the threading frame, and a crimping wheel arranged on the upper part of the supporting wheel. In the present invention, a wire-laying device is provided on the upper side of the mobile vehicle, and a wire-laying device is provided on the lower side of the mobile vehicle. When the mobile vehicle moves on the cable trench, the wire-laying device releases the cables. Laying on the cable rack improves the efficiency of cable laying and reduces the labor intensity of workers.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

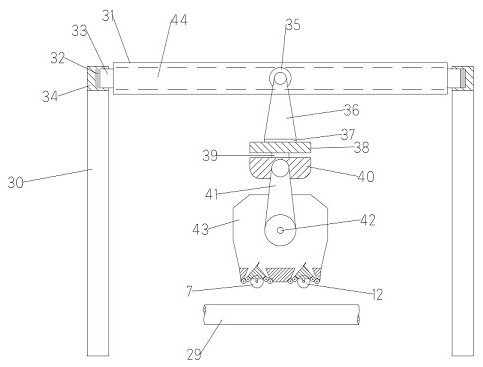

A prepreg tape automatic placement head and guide rail bracket

ActiveCN113276447BImprove adhesionIncrease productivityWeight reductionStructural engineeringMechanical engineering

A prepreg tape automatic laying head and a guide rail bracket, the guide rail bracket includes two U-shaped support columns, a rolling beam and a laying head fixing device, and the two U-shaped support columns are symmetrically arranged on the prepreg tape. On both sides of the automatic placement head, the top of the U-shaped support column is provided with a bracket guide rail, and the rolling beam is fixed to the first rolling wheel through the first connecting shaft, and the first rolling wheel can be installed on the bracket guide rail. In the middle rolling, the rolling beam is provided with a beam guide inside, the prepreg tape automatic laying head is provided with a cover outside, and the cover is connected to the rolling beam through the laying head fixing device, and the prepreg tape automatic laying head Including feeding mechanism, laying mechanism, cutting mechanism, guiding mechanism and reversing mechanism. The automatic laying head of the prepreg tape does not need to be laid layer by layer, which greatly improves the production efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

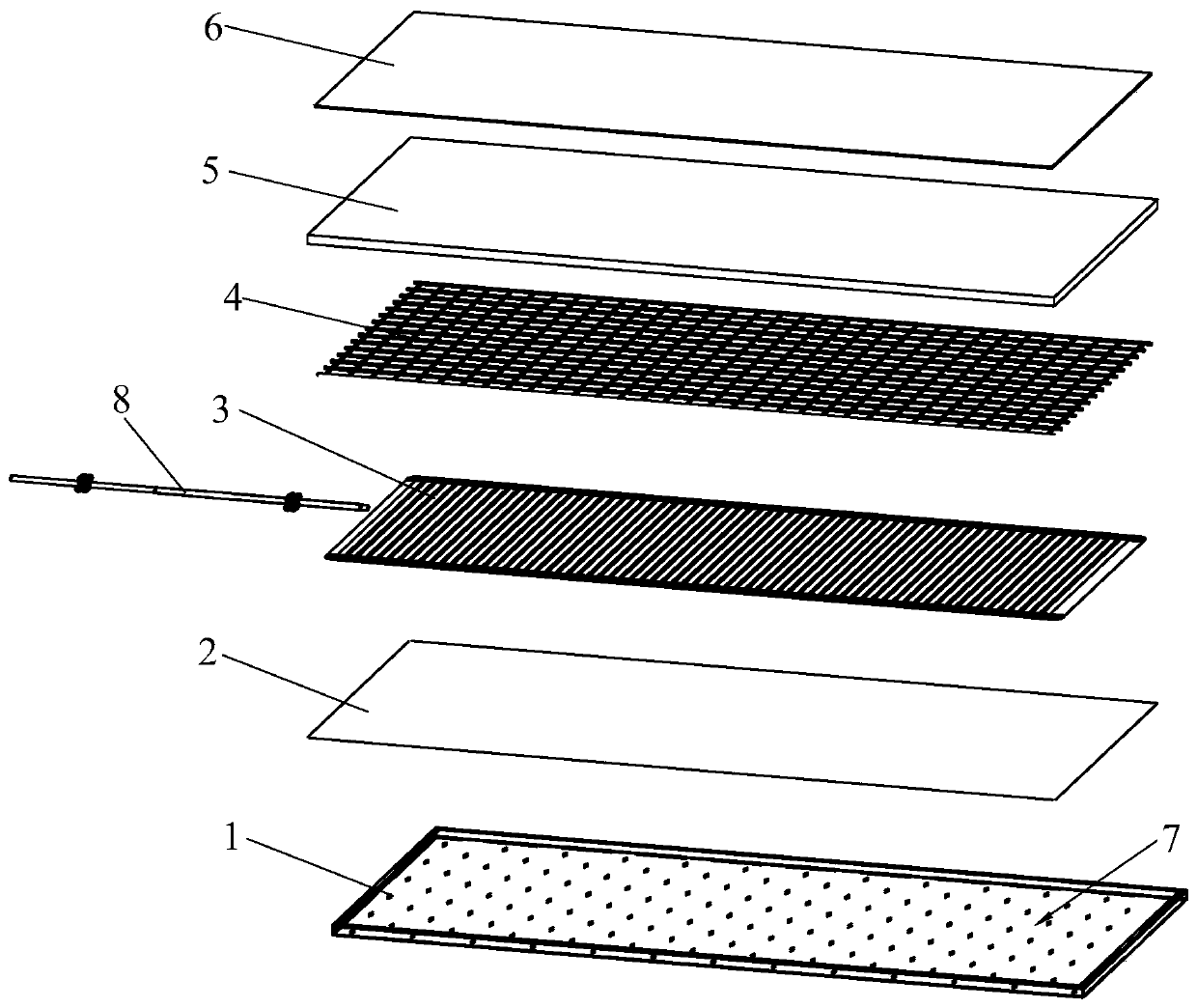

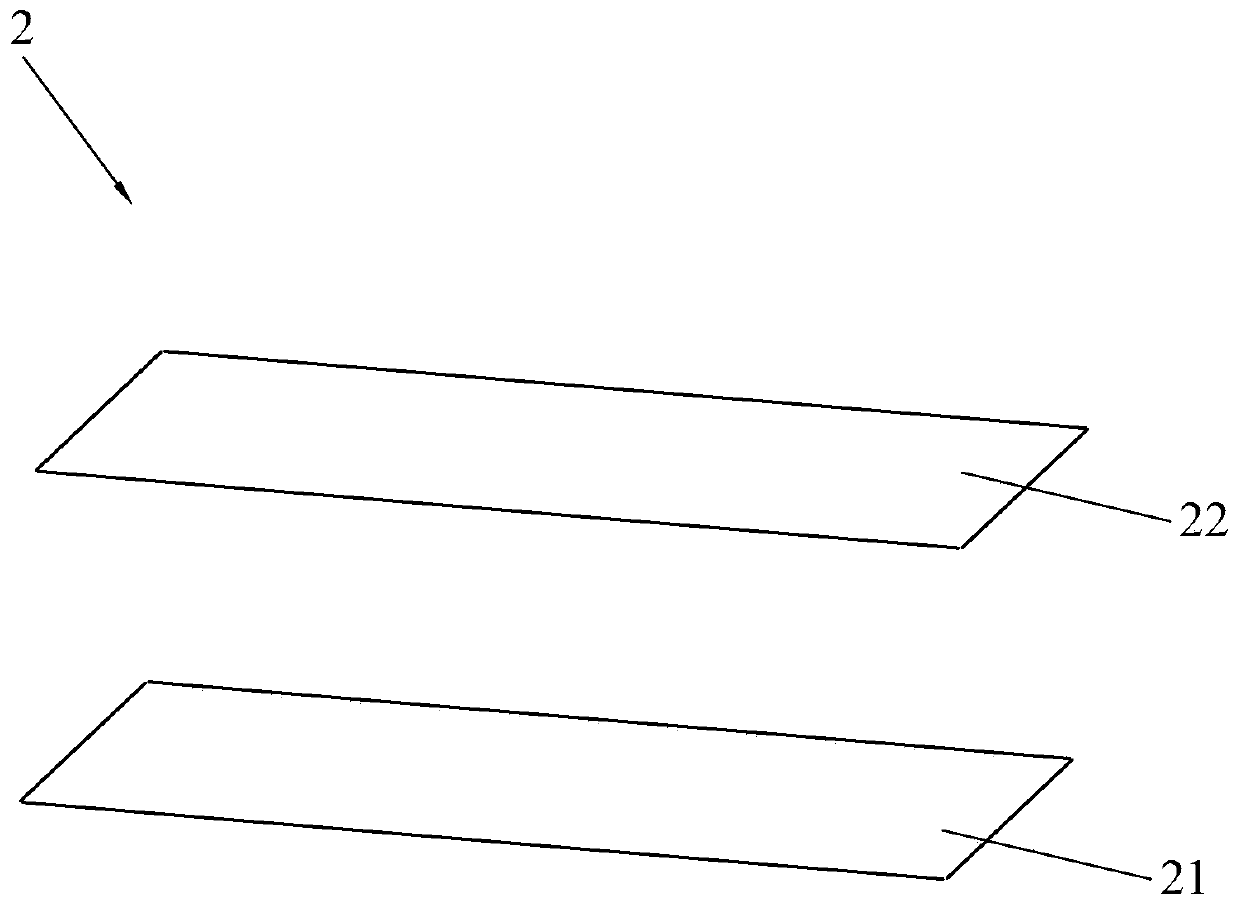

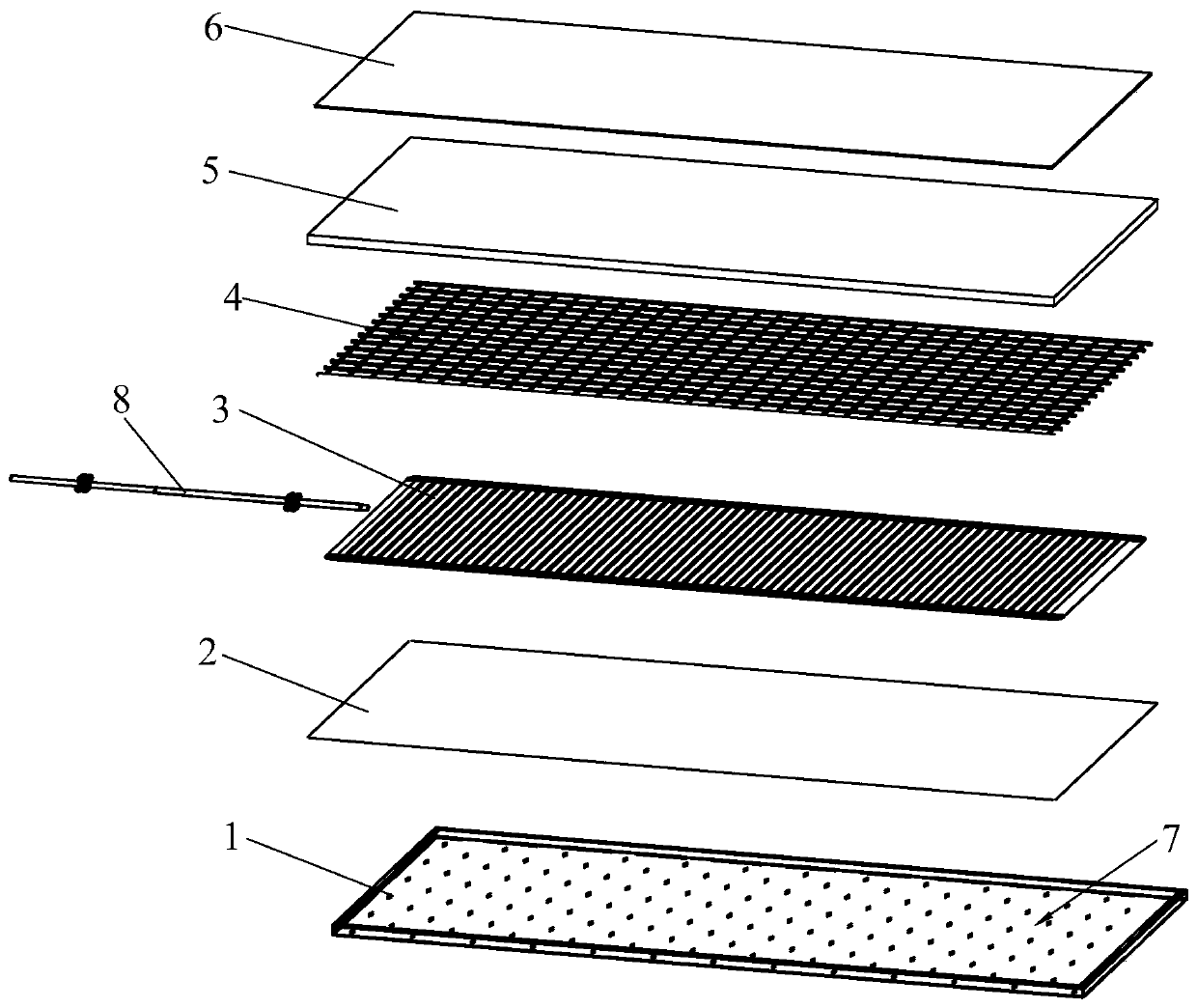

Ground heating film buckle plate module

PendingCN109714839ASafe and keep workingPlay a role in heat preservationLighting and heating apparatusElectric heating systemCapacitancePower flow

The invention discloses a ground heating film buckle plate module. The module comprises a lower housing, a distributed capacitive current absorbing layer, an electric heating film, an anti-twisting structure layer, a polyurethane heat-preservation flame-retardant layer and an upper cover, wherein the upper cover and the lower housing are fixedly combined into a body, and an accommodation cavity isformed between the upper cover and the lower housing. The distributed capacitive current absorbing layer, the electric heating film, the anti-twisting structure layer and the polyurethane heat-preservation flame-retardant layer are sequentially stacked in the accommodation cavity from bottom to top. The module can lead a leakage current, generated by the electric heating film to a ground distributed capacitor, back to a loop, thereby improving the reliability of the product. The arrangement of the polyurethane heat-preservation flame-retardant layer enables the ground heating film buckle plate module to achieve the heat preservation effect, so that a special heat preservation material layer does not need to be laid in the actual construction process, the construction efficiency is improved, and the laying effect is also ensured. In addition, the ground heating film buckle plate module is easy to produce, is safe to use and is convenient to store, transport and install on site.

Owner:广东暖丰电热科技有限公司

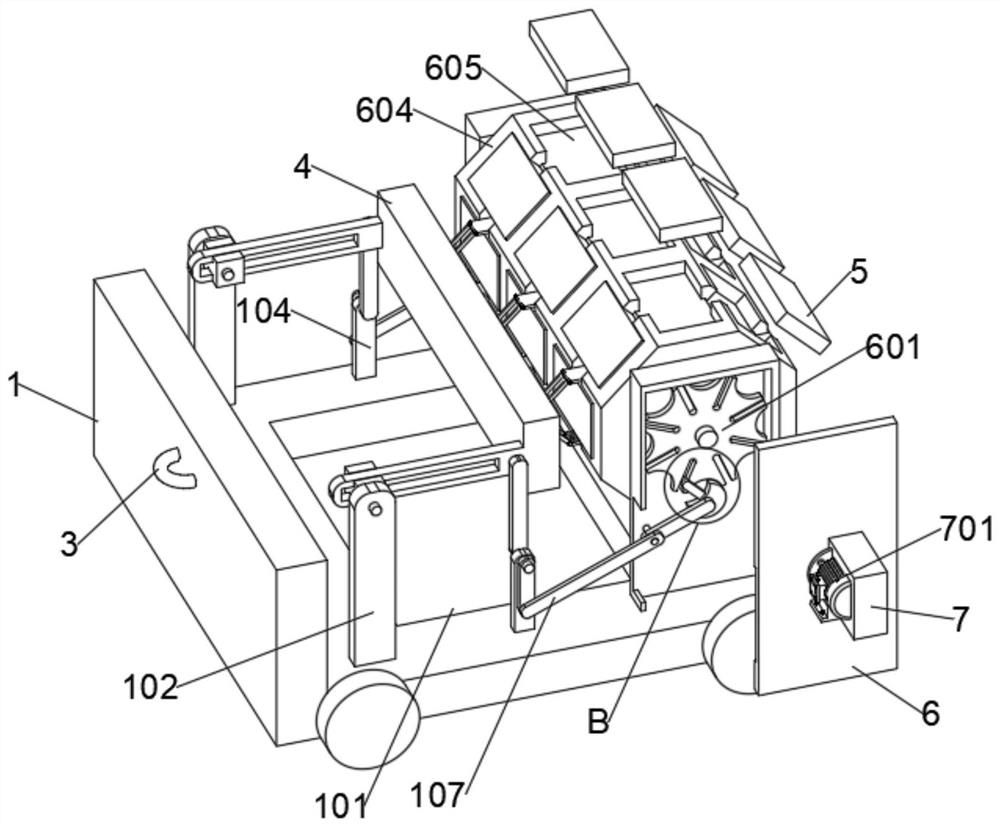

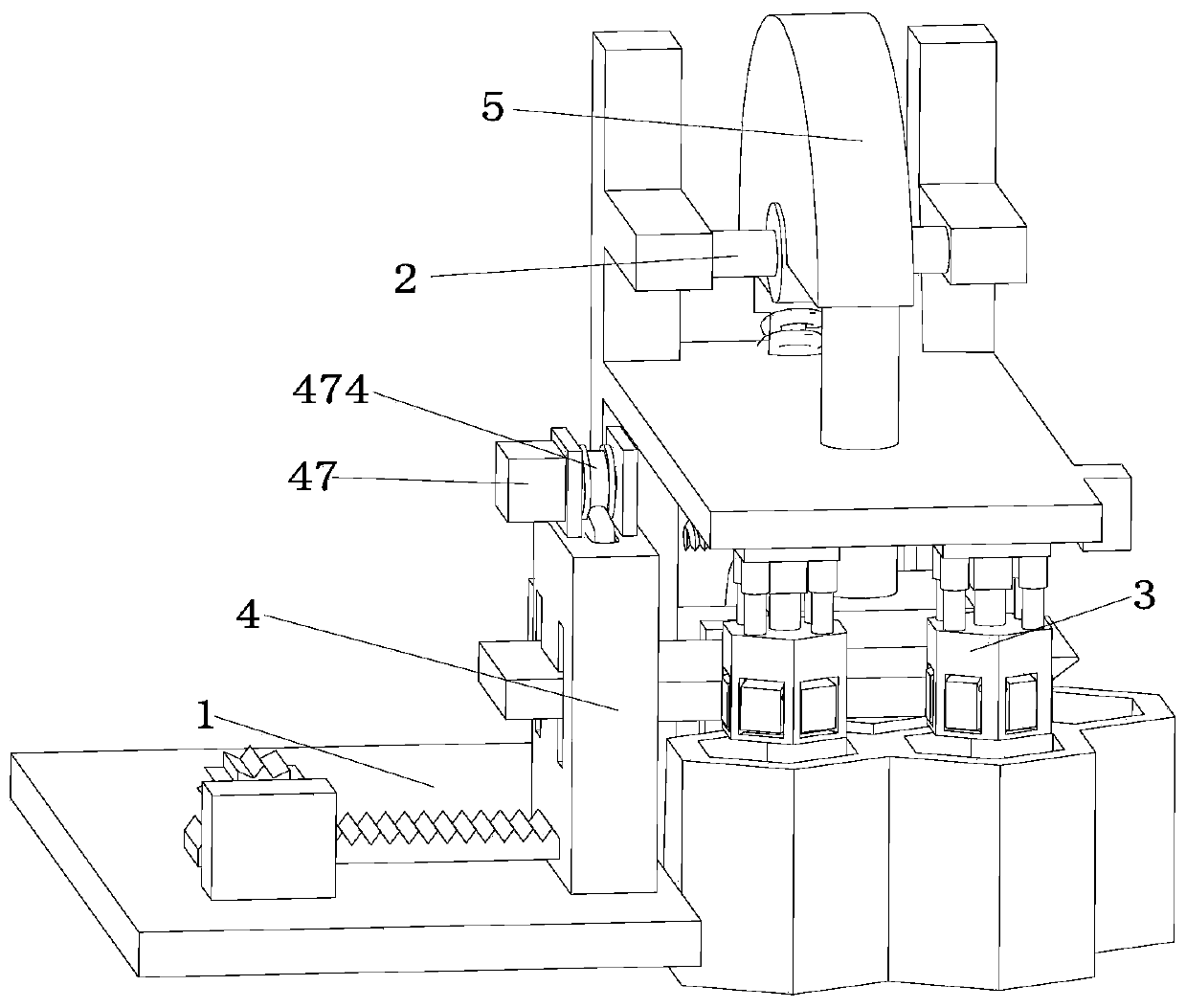

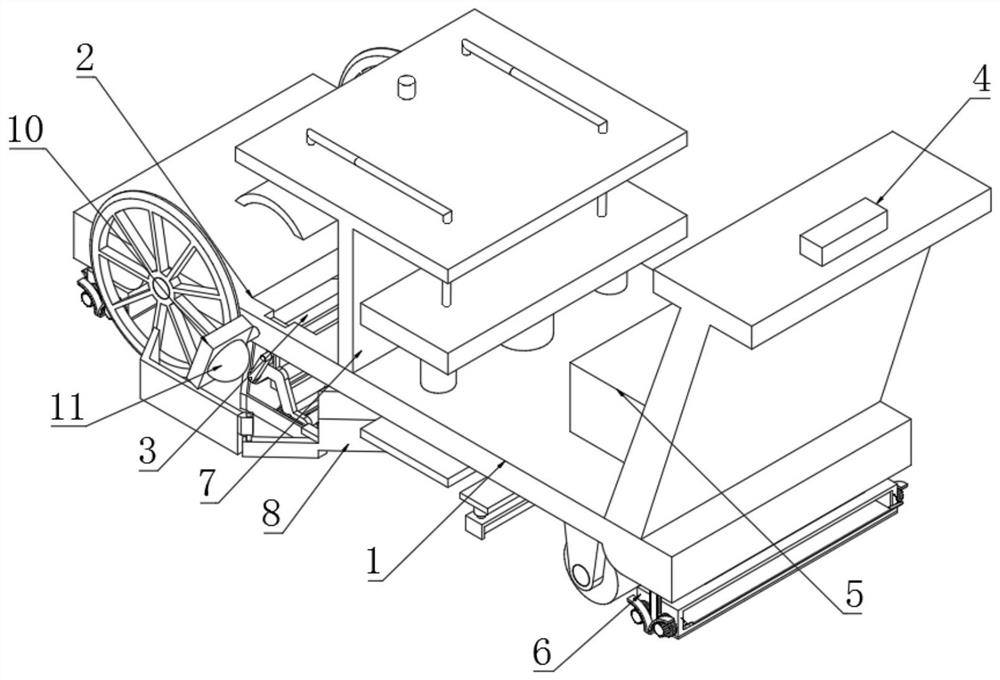

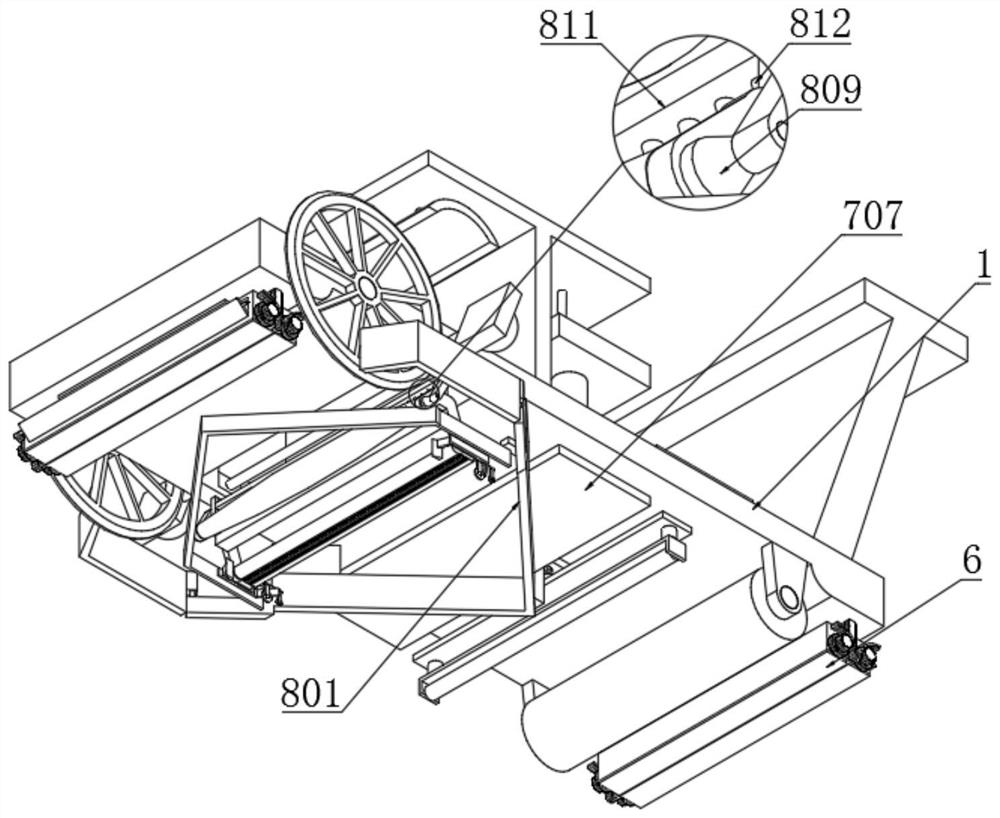

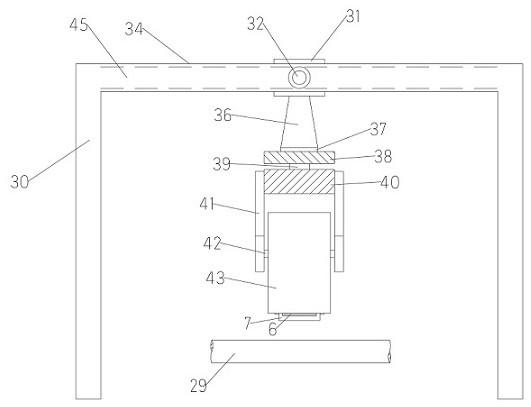

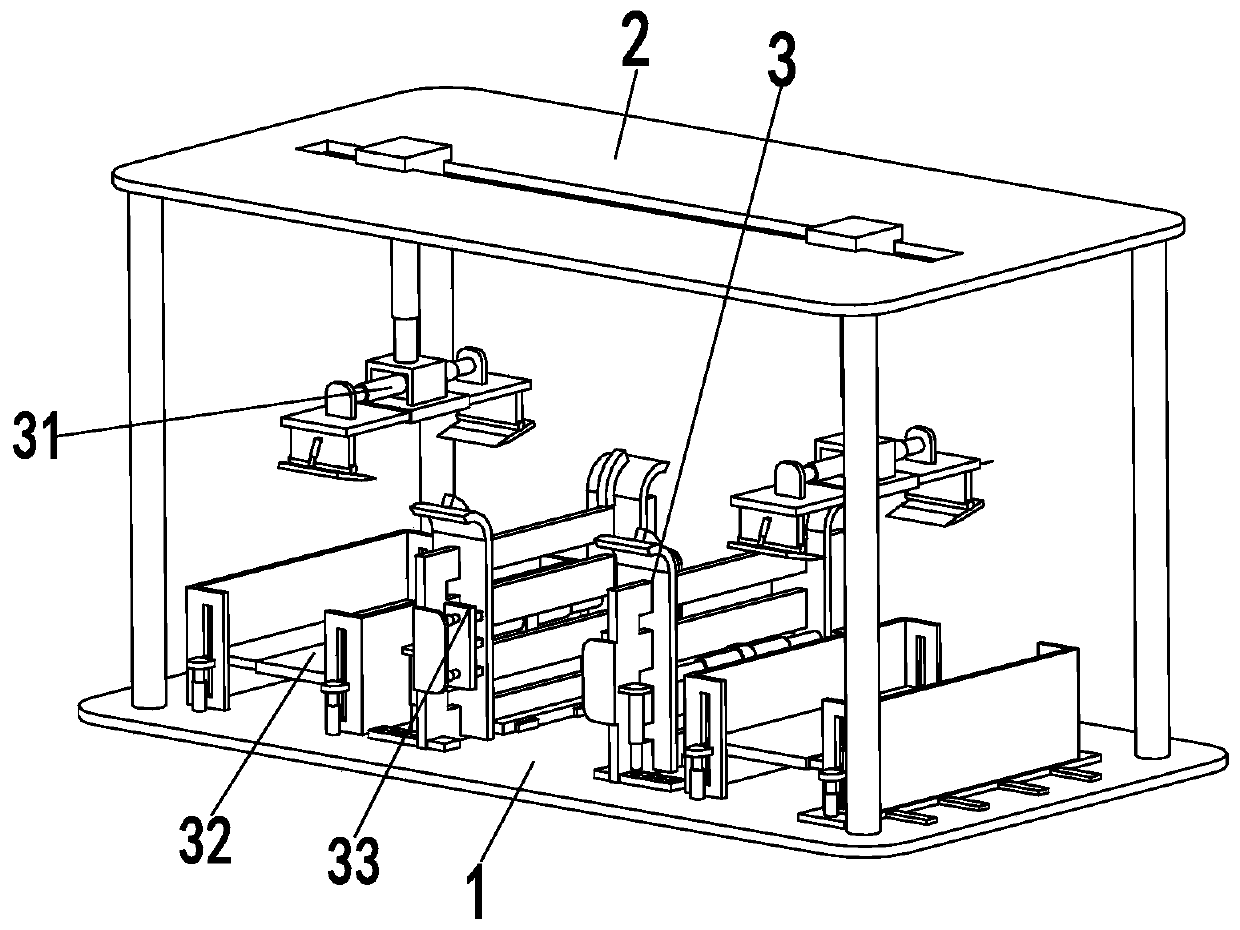

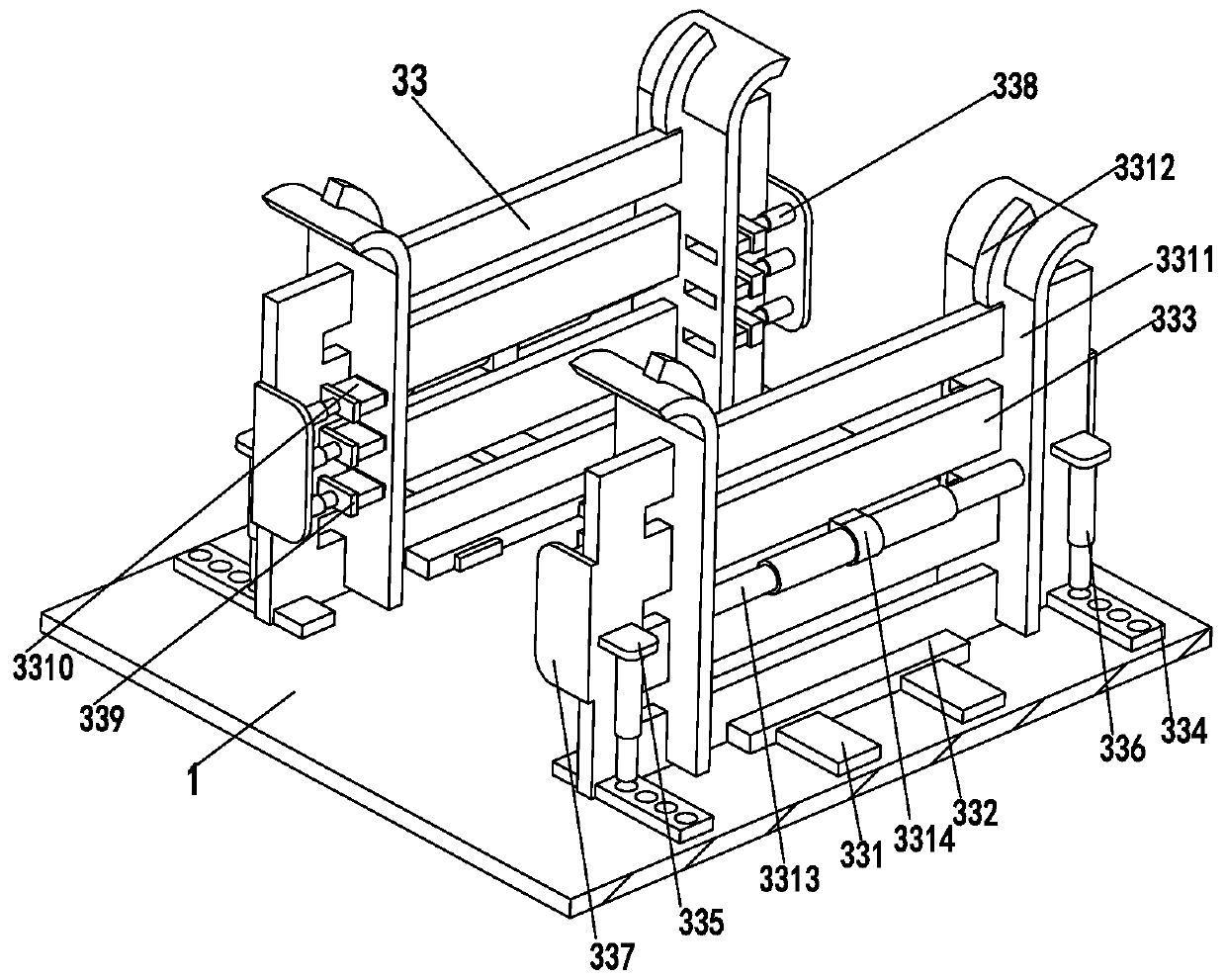

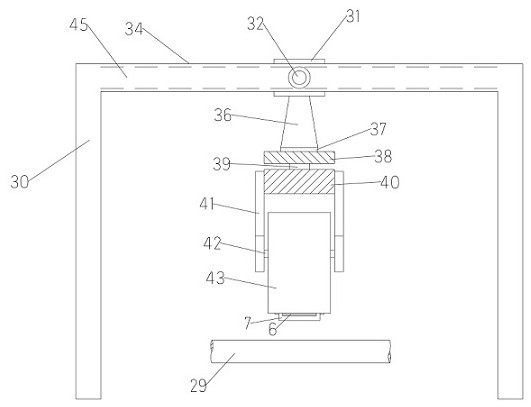

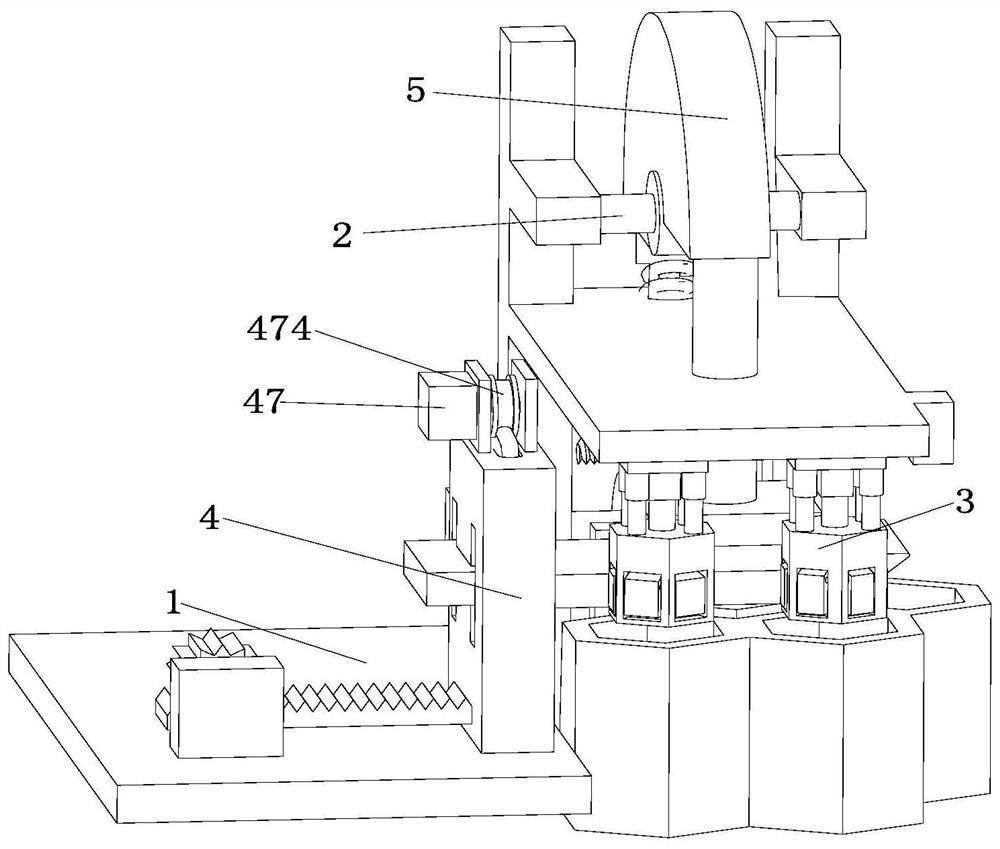

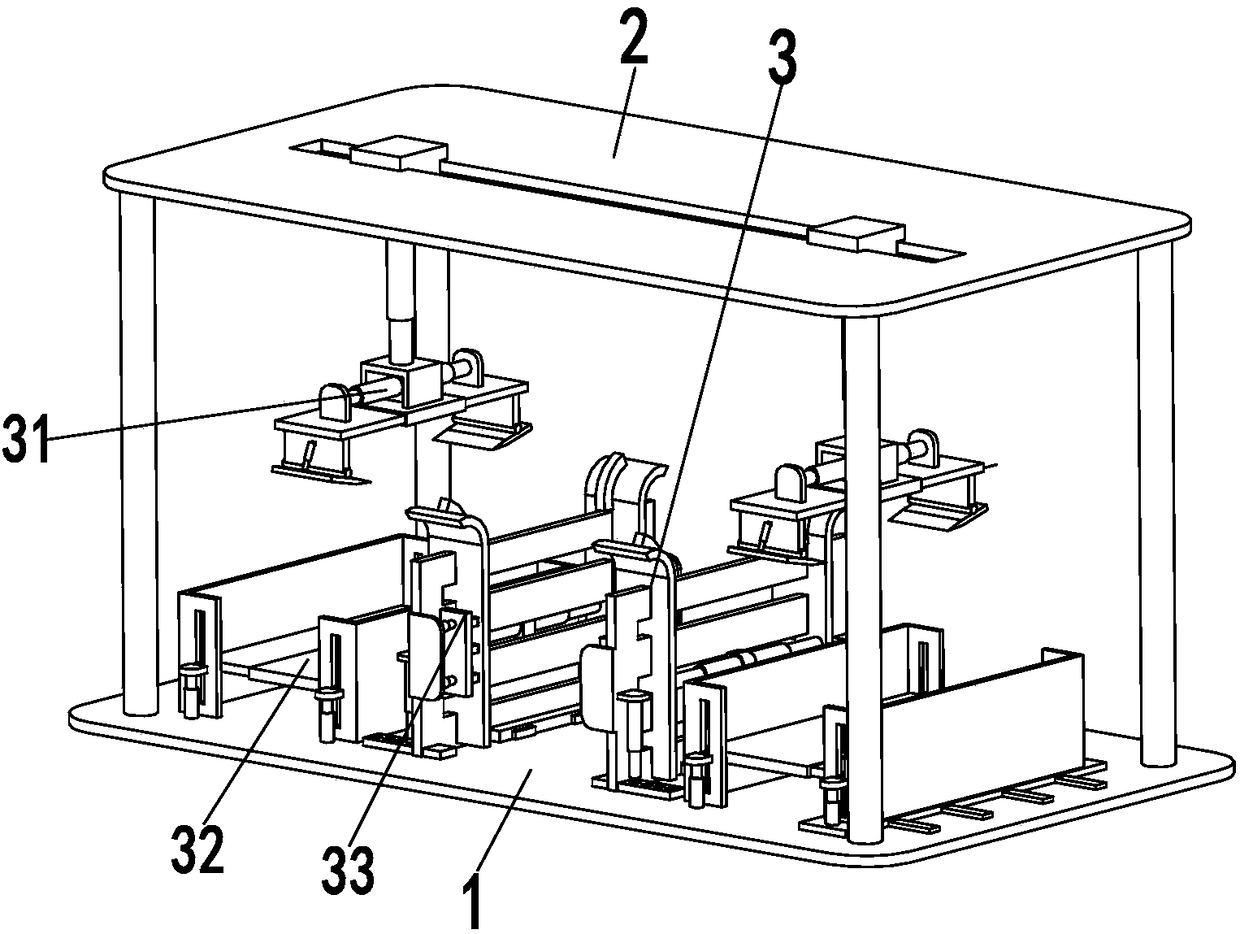

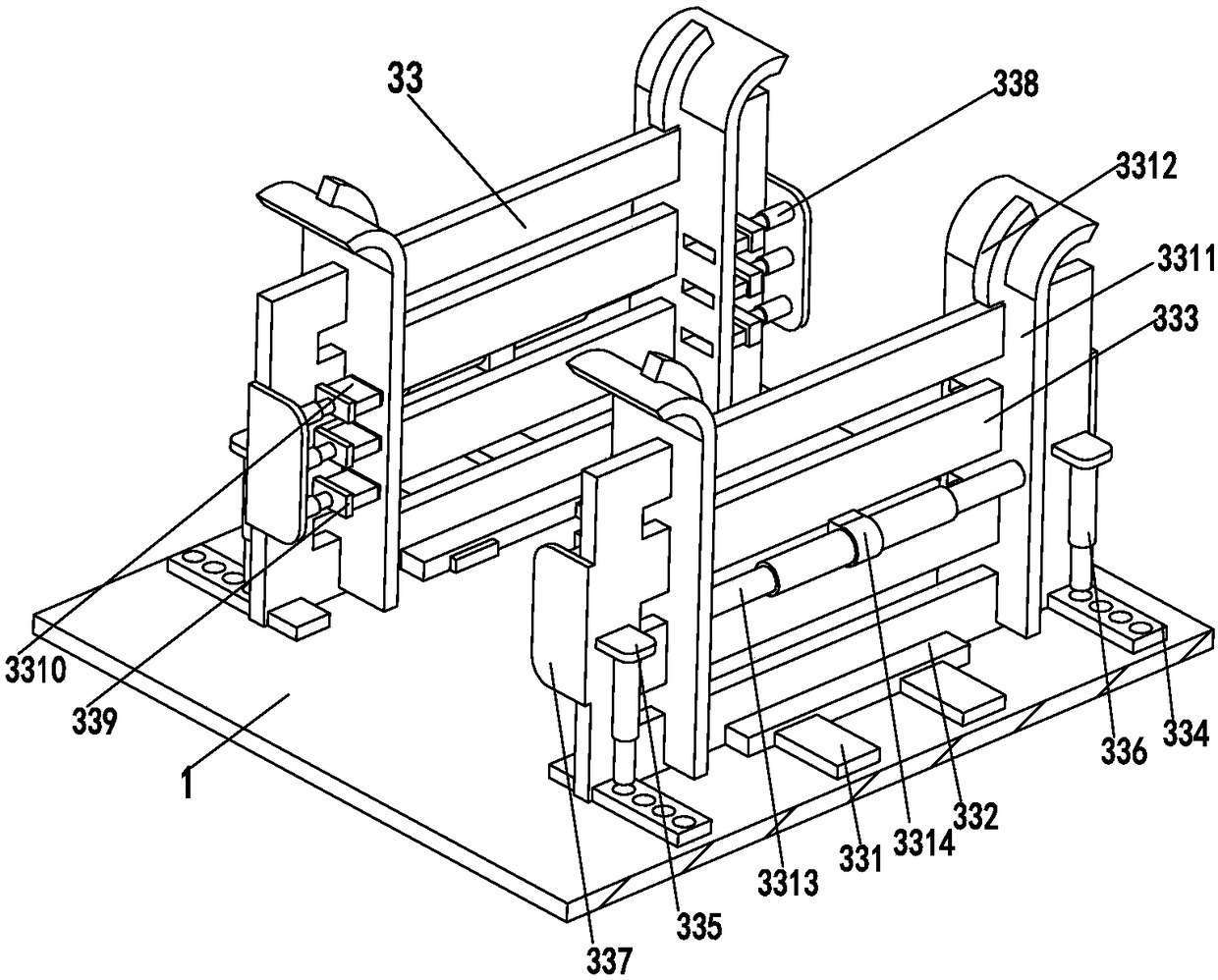

An environmentally friendly power component laying machine

ActiveCN108538770BIncrease labor costReduce labor intensityFinal product manufactureSemiconductor/solid-state device manufacturingAgricultural engineeringStructural engineering

The invention relates to an environmental protection electric power assembly laying machine. The environmental protection electric power assembly laying machine comprises a base plate, a mounting frame, two grabbing mechanisms, loading boxes and stacking mechanisms, wherein the mounting frame is arranged on the base plate; a sliding groove is formed in the upper end of the mounting frame; the grabbing mechanisms are arranged in the sliding groove in a sliding fitting mode; the two grabbing mechanisms are symmetrically arranged at the front and back ends of the sliding groove; the loading boxesare arranged on the base plate; the two loading boxes are symmetrically arranged at the front and back ends of the base plate; the stacking mechanisms are arranged at the middle of the base plate, and the two stacking mechanisms are arranged symmetrically; each component of a photovoltaic module are taken out from the loading boxes by the grabbing mechanisms, and then the grabbing mechanisms putthe components into the stacking mechanisms; and under the action of the stacking mechanisms, each component is stacked neatly without manual stacking, so that the laying effect is guaranteed. The environmental protection electric power assembly laying machine can realize the function of automatically laying the photovoltaic module, and has the advantages of low labor cost, low labor intensity, high work efficiency, neat laying and the like.

Owner:金华美诺机电有限公司

Automatic prepreg tape laying head and guide rail bracket

ActiveCN113276447AImprove adhesionIncrease productivityWeight reductionStructural engineeringMechanical engineering

The invention relates to an automatic prepreg tape laying head and a guide rail bracket. The guide rail bracket comprises two U-shaped supporting columns, a rolling cross beam and a laying head fixing device; the two U-shaped supporting columns are symmetrically arranged on the two sides of the automatic prepreg tape laying head; a bracket guide rail is arranged in the top of each U-shaped supporting column; the rolling cross beam is fixed to a first rolling wheel through a first connecting shaft; the first rolling wheel can roll in the bracket guide rail; a cross beam guide rail is arranged in the rolling cross beam; an outer cover is arranged on the outer side of the automatic prepreg tape laying head and connected with the rolling cross beam through a laying head fixing device; and the automatic prepreg tape laying head comprises a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism. The automatic prepreg tape laying head does not need to be placed layer by layer in a single time, so that the production efficiency is greatly improved, and meanwhile, idle stroke return stroke or turning around is not needed, so that the laying time is saved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Auxiliary machinery for river slope protection construction

InactiveCN110616671BHigh cost of layingLaying speed is slowCoastlines protectionHuman bodyAgricultural science

The invention relates to an auxiliary machine for river slope protection construction, which includes a bottom plate, a tapping device, a positioning device and an alignment device. Installed with a positioning device, the present invention can solve the following problems in the laying of existing hexagonal hollow bricks. 1. Skilled laying workers of hollow hexagonal bricks are in short supply day by day. Occupational diseases are not conducive to the physical and mental health of the human body; 2. The experience of laying workers is different, and the laying level is uneven. For the same laying site, different workers have different laying results, which affects the overall effect, high laying cost, slow laying speed, low laying efficiency and Take up a lot of labor.

Owner:雷州市奇丰农业生态科技有限公司

A rotary pavement repairing device

InactiveCN108103914BImprove efficiencyGuaranteed laying effectRoads maintainenceVehicle frameRoad surface

The invention discloses a rotary pavement repairing device. The device comprises a frame and a stirring tank, wherein a crushing device is arranged on the left side of the frame, a stirring and pouring device is arranged in the frame, and a moving device is arranged below the frame. A lifting wheel and a fixing rod are arranged, so that the frame can move circumferentially, and a cutting wheel cuts out circular slits on the ground to ensure the laying effect of a joint; meanwhile, the pavement on the inner side of the slits is crushed by a drill stem, a columnar groove is formed, and the edgecutting and grooving efficiency is improved. The stirring tank is arranged, raw materials are poured into the opened columnar groove through a pouring pipe, laying is completed rapidly, and operationefficiency is improved.

Owner:屈大忠

A construction technique of soft and soft stone pasted in indoor floor decoration

ActiveCN107663053BGuaranteed laying effectImprove laying effectFlooringArchitectural engineeringRockdust

The invention provides a construction technology for paving graceful soft rock to indoor floor decoration and belongs to the technical field of construction. The construction technology comprises thefollowing steps: pre-treating a base layer, namely firstly sweeping dust and impurities and then using the leveling putty for locally repairing; treating the base layer, namely using the special puttyfor twice constructing the pre-treated base layer and then using a sand paper above 80# for sanding; maintaining: spraying water for maintaining for at least two times; paving, namely using special adhesive mortar for paving till the graceful soft rock is compactly and smoothly paved and meets the requirement; and jointing and cleaning, namely using jointing agent for jointing and then cleaning the paved surface of the graceful soft rock after the jointing agent is solidified. The pavement of the graceful soft rock according to the construction technology provided by the invention has the advantage that the paved graceful soft rock is smooth, is free from alkali reappearing and is high in construction speed.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

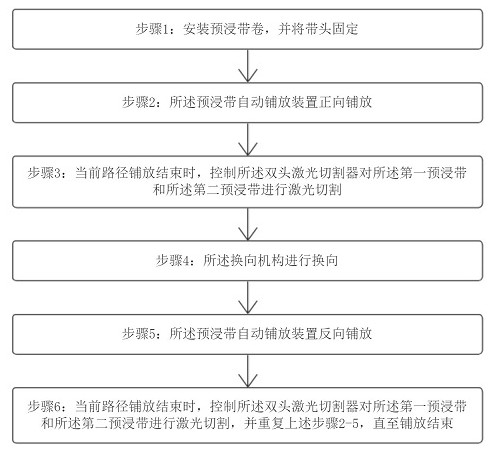

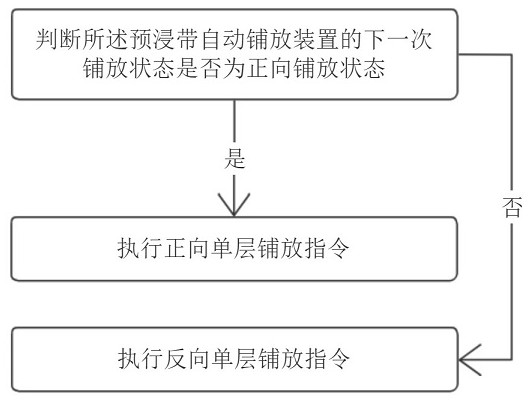

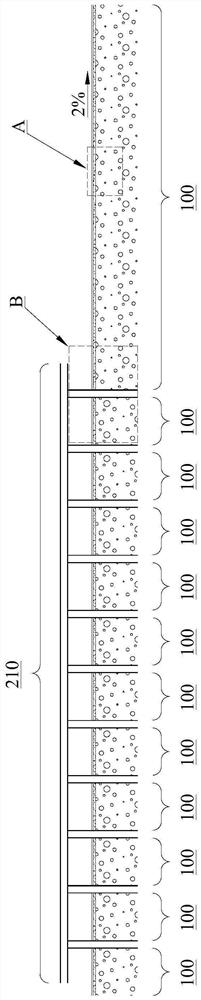

A double-layer two-way laying method of prepreg tape automatic laying device

ActiveCN113320188BImprove adhesionIncrease productivityWeight reductionStructural engineeringMechanical engineering

A double-layer bidirectional laying method of a prepreg tape automatic laying device. The prepreg tape automatic laying device includes a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism. The two-way laying method includes the first laying mechanism laying the first layer, and the second laying mechanism at a distance behind the first laying mechanism then laying the second layer, so that two layers of prepreg tapes can be laid simultaneously, and the Reversing the direction of the mechanism, respectively guiding the first prepreg tape and the second prepreg tape to be conveyed to the first pressing roller and the second pressing roller in the opposite direction to the previous laying process, and the next laying process can be carried out. Realize two-way laying. The double-layer two-way laying method does not need to lay one by one layer by layer, which greatly improves the production efficiency, and at the same time, it does not need to return or turn around in an empty way, which saves the laying time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A waterproof repair method for a roof with a large-area steel frame structure

ActiveCN111456485BSolve the problem of water leakage and water seepageImprove stabilityRoof covering using flexible materialsBuilding repairsArchitectural engineeringSteel frame

The invention discloses a waterproof repair method for a roof with a large-area steel frame structure. Through the overall analysis of the roof structure, it is determined to adopt the overall repair method to carry out waterproof repair on the roof to solve the problem of difficult investigation of water leakage and water seepage on large and complex roofs. The roof structure is classified in the way of partial crossing, the flat roof is divided into flat type as a whole, and the part of the flat roof close to the steel frame structure is classified into the corner type including the steel frame structure, which realizes the unity of overall and partial repair, which is beneficial Improve the stability of the repaired structure, thereby increasing its service life.

Owner:科顺建筑修缮技术有限公司

Environmental protection electric power assembly laying machine

ActiveCN108538770AIncrease labor costReduce labor intensityFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringFront and back ends

The invention relates to an environmental protection electric power assembly laying machine. The environmental protection electric power assembly laying machine comprises a base plate, a mounting frame, two grabbing mechanisms, loading boxes and stacking mechanisms, wherein the mounting frame is arranged on the base plate; a sliding groove is formed in the upper end of the mounting frame; the grabbing mechanisms are arranged in the sliding groove in a sliding fitting mode; the two grabbing mechanisms are symmetrically arranged at the front and back ends of the sliding groove; the loading boxesare arranged on the base plate; the two loading boxes are symmetrically arranged at the front and back ends of the base plate; the stacking mechanisms are arranged at the middle of the base plate, and the two stacking mechanisms are arranged symmetrically; each component of a photovoltaic module are taken out from the loading boxes by the grabbing mechanisms, and then the grabbing mechanisms putthe components into the stacking mechanisms; and under the action of the stacking mechanisms, each component is stacked neatly without manual stacking, so that the laying effect is guaranteed. The environmental protection electric power assembly laying machine can realize the function of automatically laying the photovoltaic module, and has the advantages of low labor cost, low labor intensity, high work efficiency, neat laying and the like.

Owner:金华美诺机电有限公司

A prepreg tape automatic laying device

ActiveCN113352646BImprove adhesionIncrease productivityFinal product manufactureLaser beam welding apparatusLaser cuttingIndustrial engineering

An automatic prepreg tape laying device, comprising a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, the feeding mechanism comprises a left tape roll, a right tape roll, a first pair of clamping rollers, a Two pairs of nip rollers, a first prepreg tape and a second prepreg tape, the laying mechanism includes a first pair of heating rolls, a first pressing roll, a first pair of rolls for laying, a second pair of rolls for laying, a second pair of rolls for laying Two pressing rollers and a second pair of heating rollers, the guiding mechanism includes a first guiding mechanism, a third guiding mechanism and a second guiding mechanism, the cutting mechanism includes a double-head laser cutter and a support frame, the The reversing mechanism includes a first reversing mechanism and a second reversing mechanism. The prepreg tape automatic laying device does not need to be laid layer by layer at a time, which greatly improves the production efficiency, and at the same time, it does not need to return or turn around in an empty way, which saves the laying time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

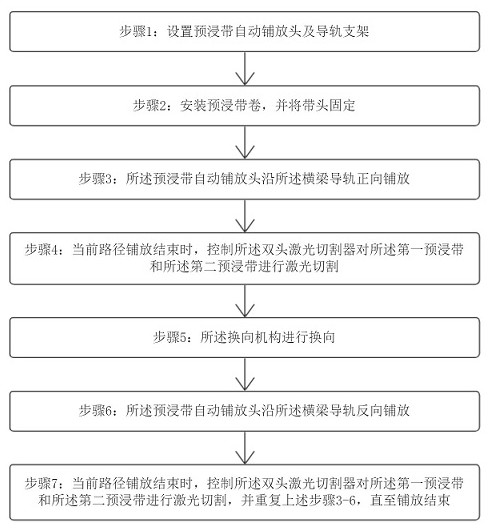

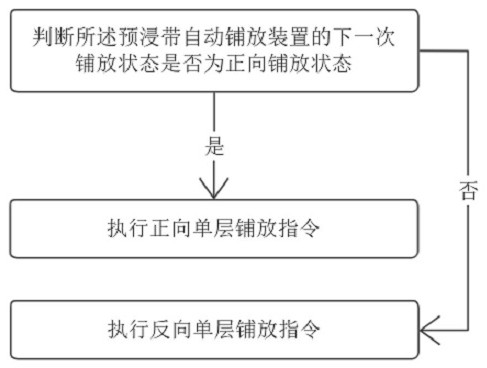

An automatic laying method

ActiveCN113276448BImprove adhesionIncrease productivityWeight reductionEngineeringStructural engineering

An automatic laying method includes the following steps: step 1: setting an automatic laying head and a guide rail bracket for a prepreg tape, step 2: installing a prepreg tape roll and fixing the tape head, step 3: automatically laying the prepreg tape The laying head is placed along the beam guide in the forward direction, step 4: when the laying of the current path is completed, the double-head laser cutter is controlled to perform laser cutting on the first prepreg tape and the second prepreg tape, Step 5: The reversing mechanism performs reversing, Step 6: The automatic prepreg tape laying head is reversely laid along the beam guide rail, Step 7: When the laying of the current path is completed, the double-head laser is controlled The cutter performs laser cutting on the first prepreg tape and the second prepreg tape, and repeats the above steps 2-5 until the laying is completed. The automatic laying method does not require single layer-by-layer laying, which greatly improves the production efficiency, and at the same time does not need to return or turn around in an empty way, which saves the laying time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com