Patents

Literature

238results about How to "Increase melting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

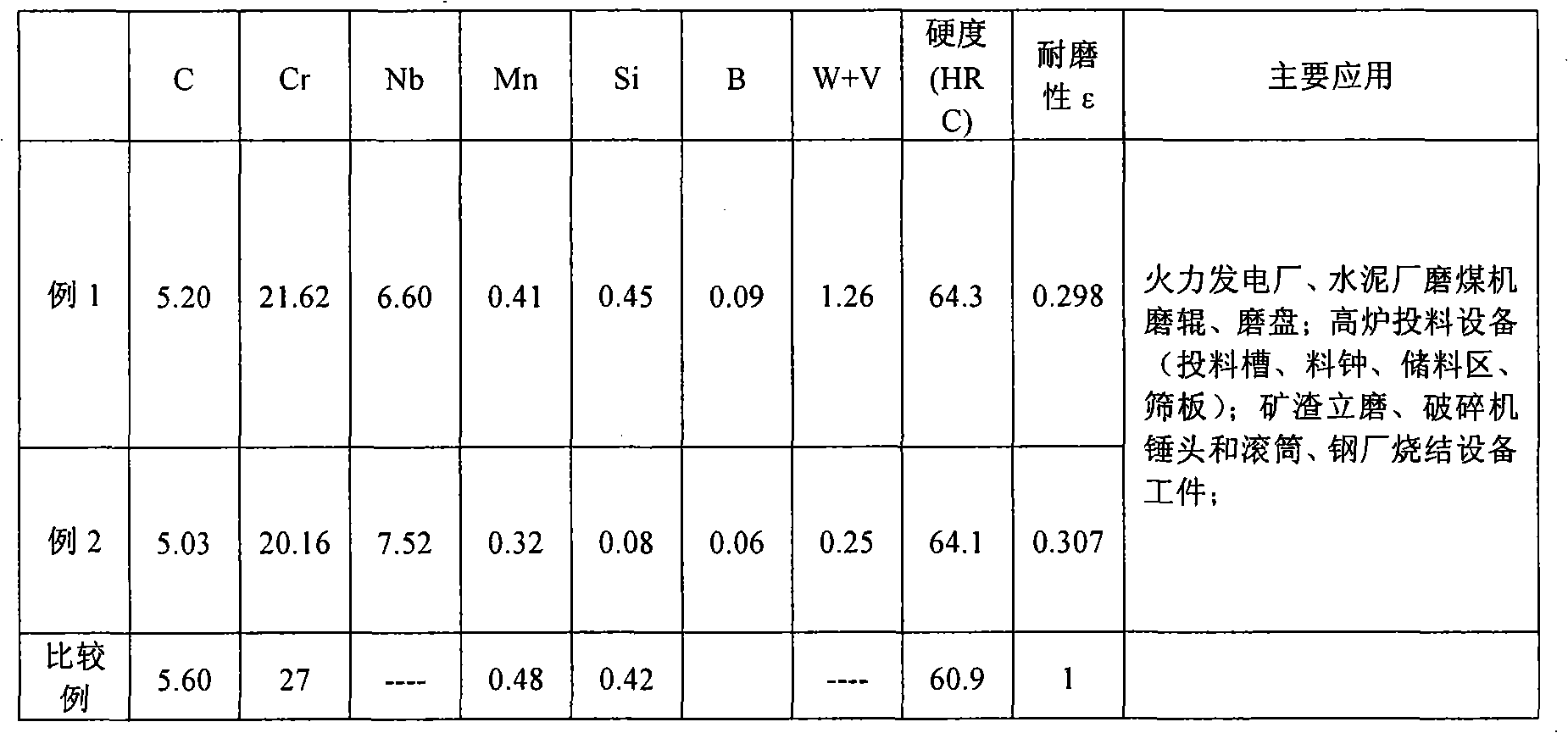

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

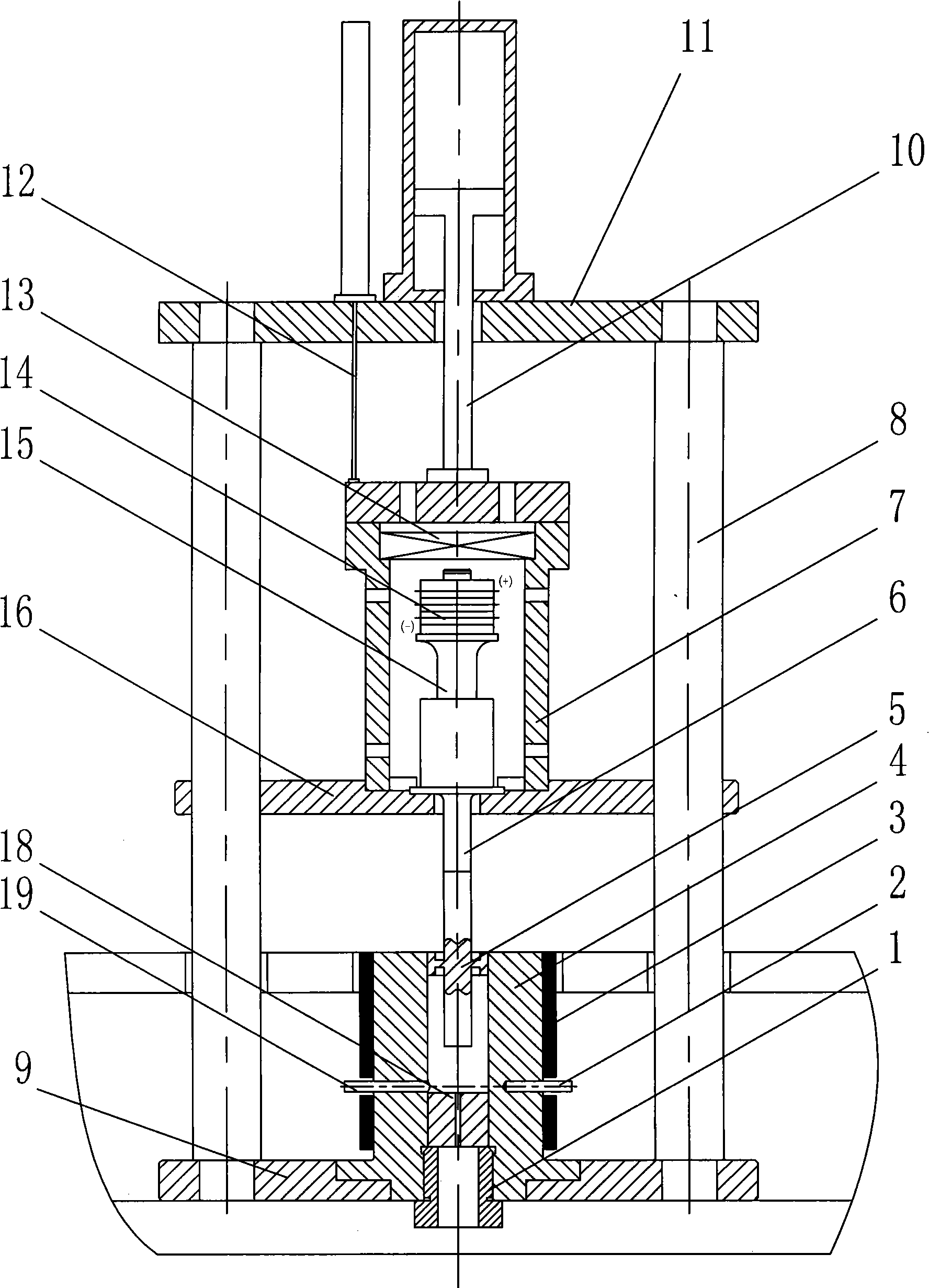

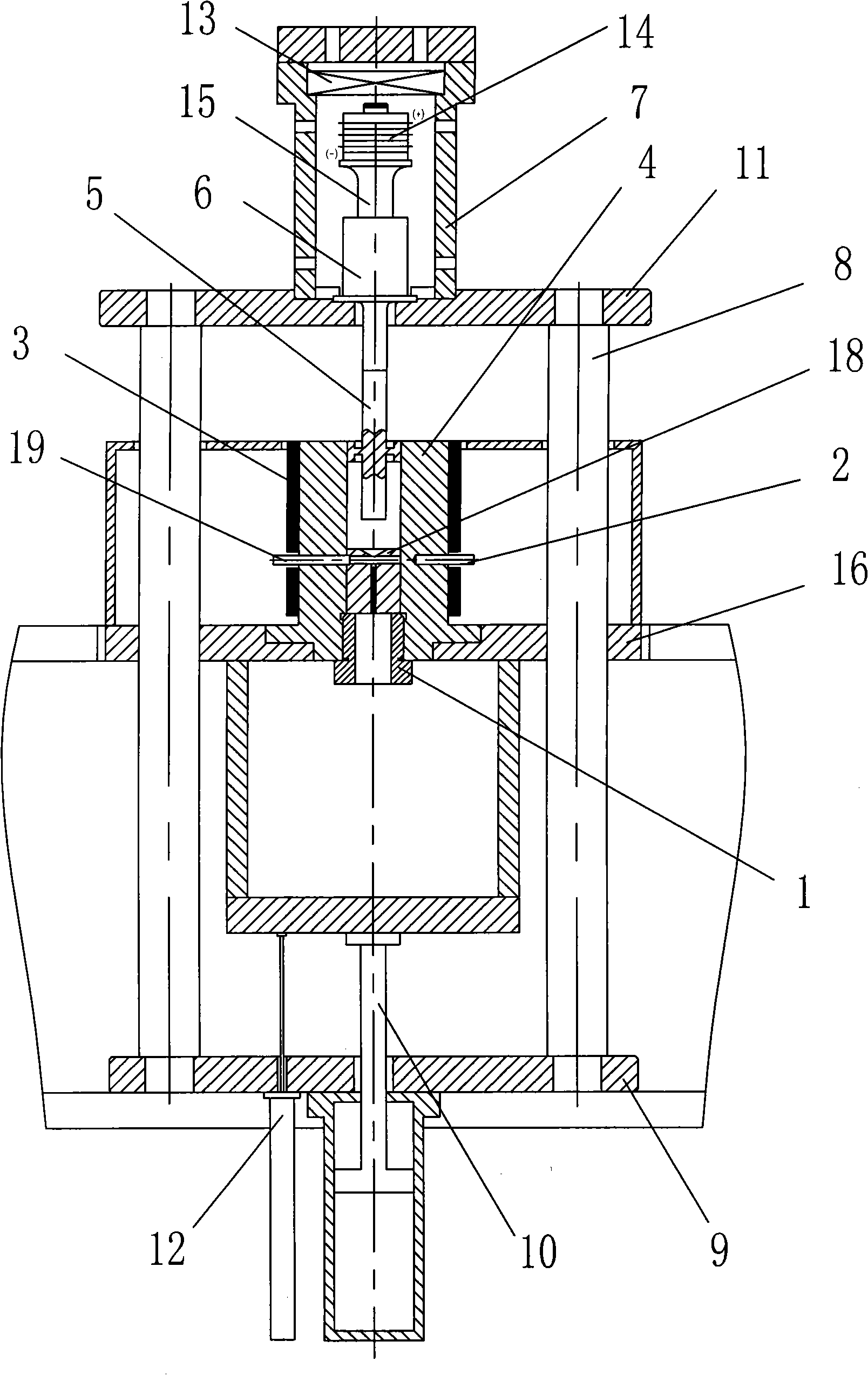

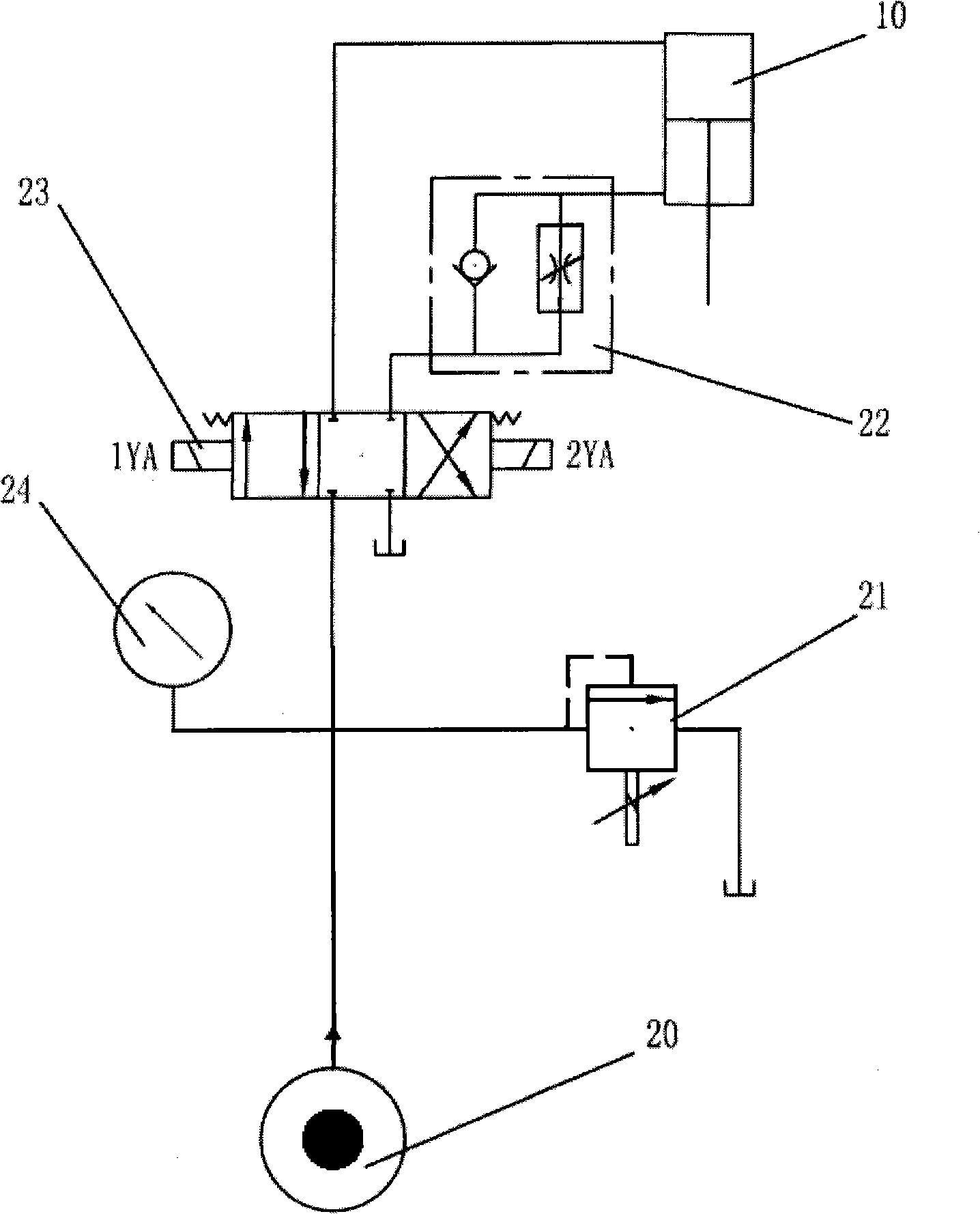

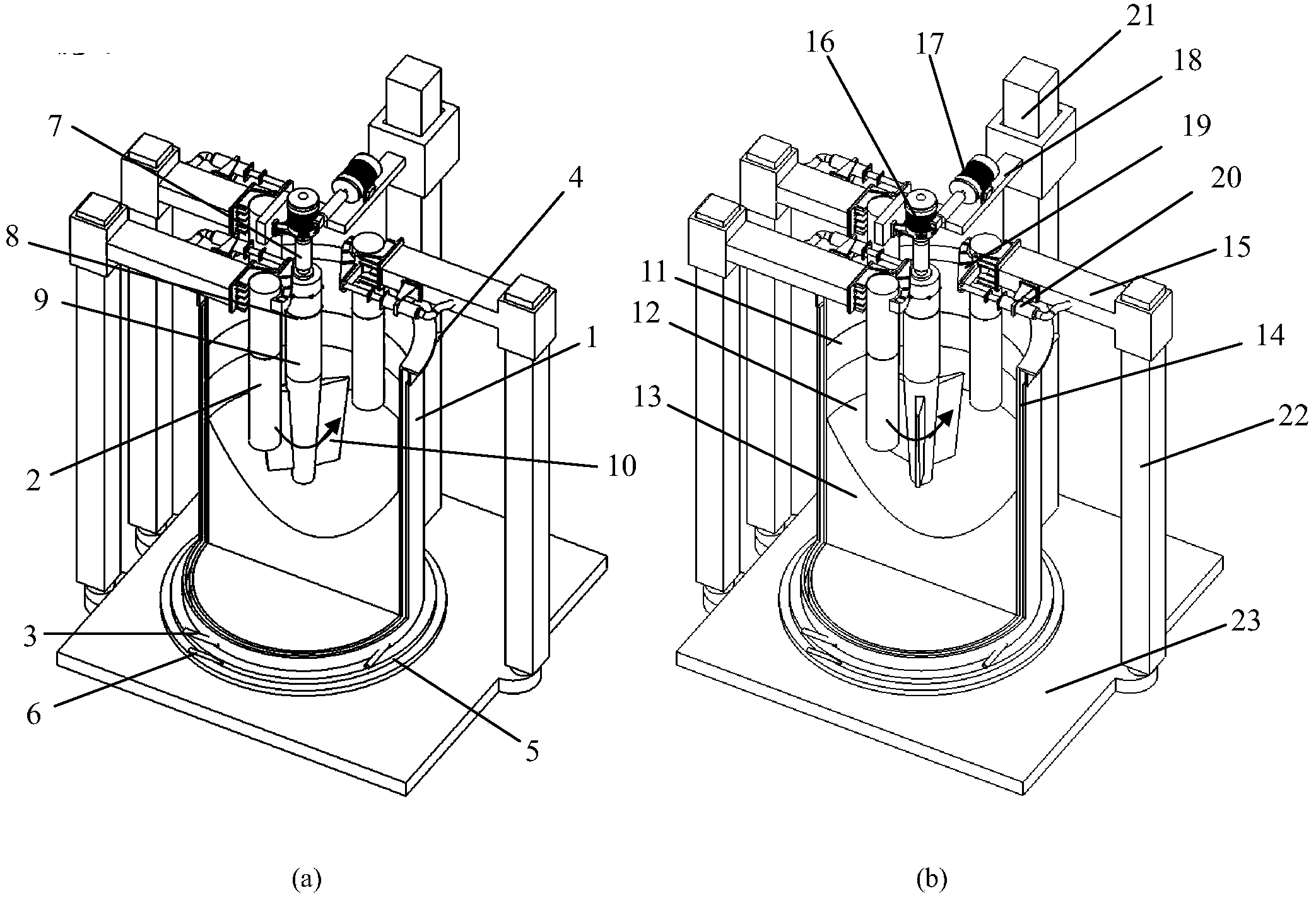

Test device for accomplishing polymer melting plasticization using superaudio vibration

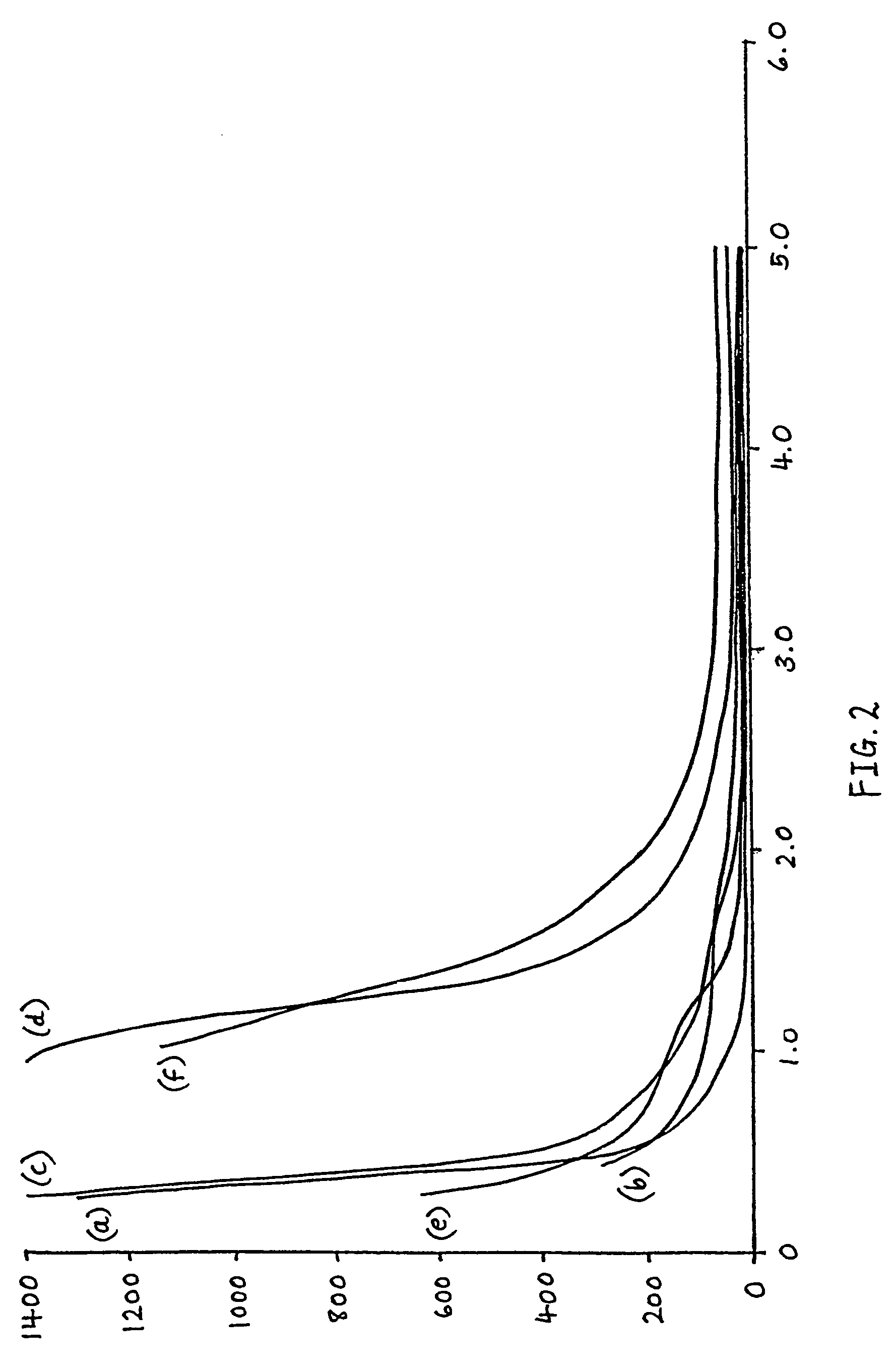

InactiveCN101261266AConstant pressureRealize melt plasticizationMaterial testing goodsData acquisitionEngineering

The invention discloses a testing device that realizes the melting and plasticizing of polymers by utilizing ultrasonic frequency vibration, wherein, a material cylinder (4) is arranged on a stand (9); a capillary orifice mode (18), a tool head (5), a thermocouple (2), a heating ring (3) and a high temperature melt temperature pressure sensor (19) are arranged in the material cylinder (4); the lower end of a guide pillar (8) is arranged on the stand (9), the upper end of the guide pillar (8) is provided with a frame(11), the frame(11) is provided with a hydraulic transmission and control system, a guide bracket (16) is glidingly arranged on the guide pillar (8), the guide bracket (16) is provided with an ultrasonic vibration system, the tool head (5) is connected with the ultrasonic vibration system by a way of transmission, the ultrasonic vibration system is connected with the hydraulic transmission and control system by a way of transmission, the ultrasonic vibration system is provided with a displacement sensor (12), and the high temperature melt temperature pressure sensor (19) and the displacement sensor (12) are electronically connected with a computer data acquisition system. In terms of function, the testing device of the invention not only can simultaneously realize the melting and plasticizing of polymer materials by utilizing ultrasonic frequency vibration and detect the formability of ultrasonic plasticizing, but also can satisfy the needs of conventional processability test for the polymers.

Owner:CENT SOUTH UNIV

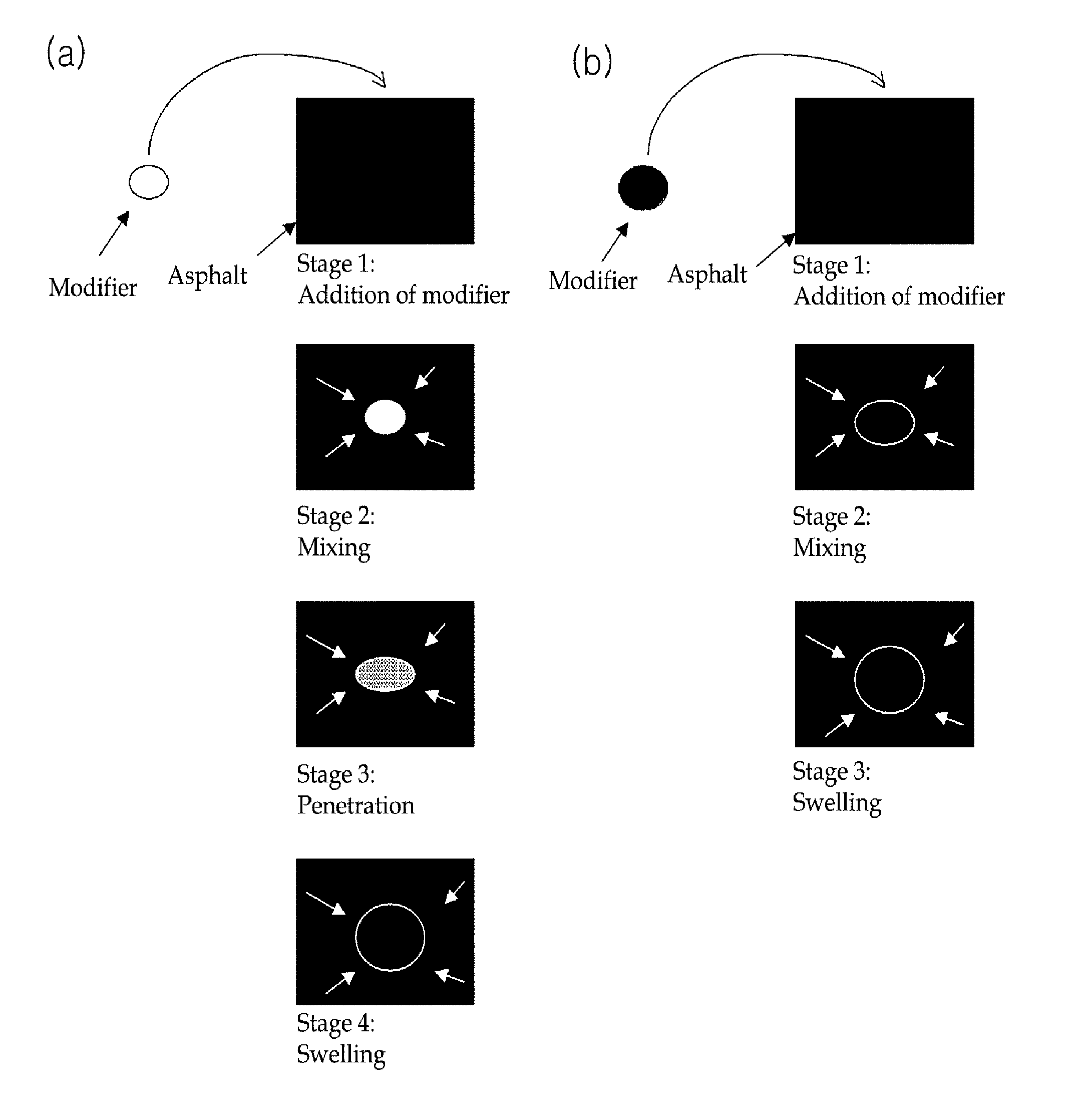

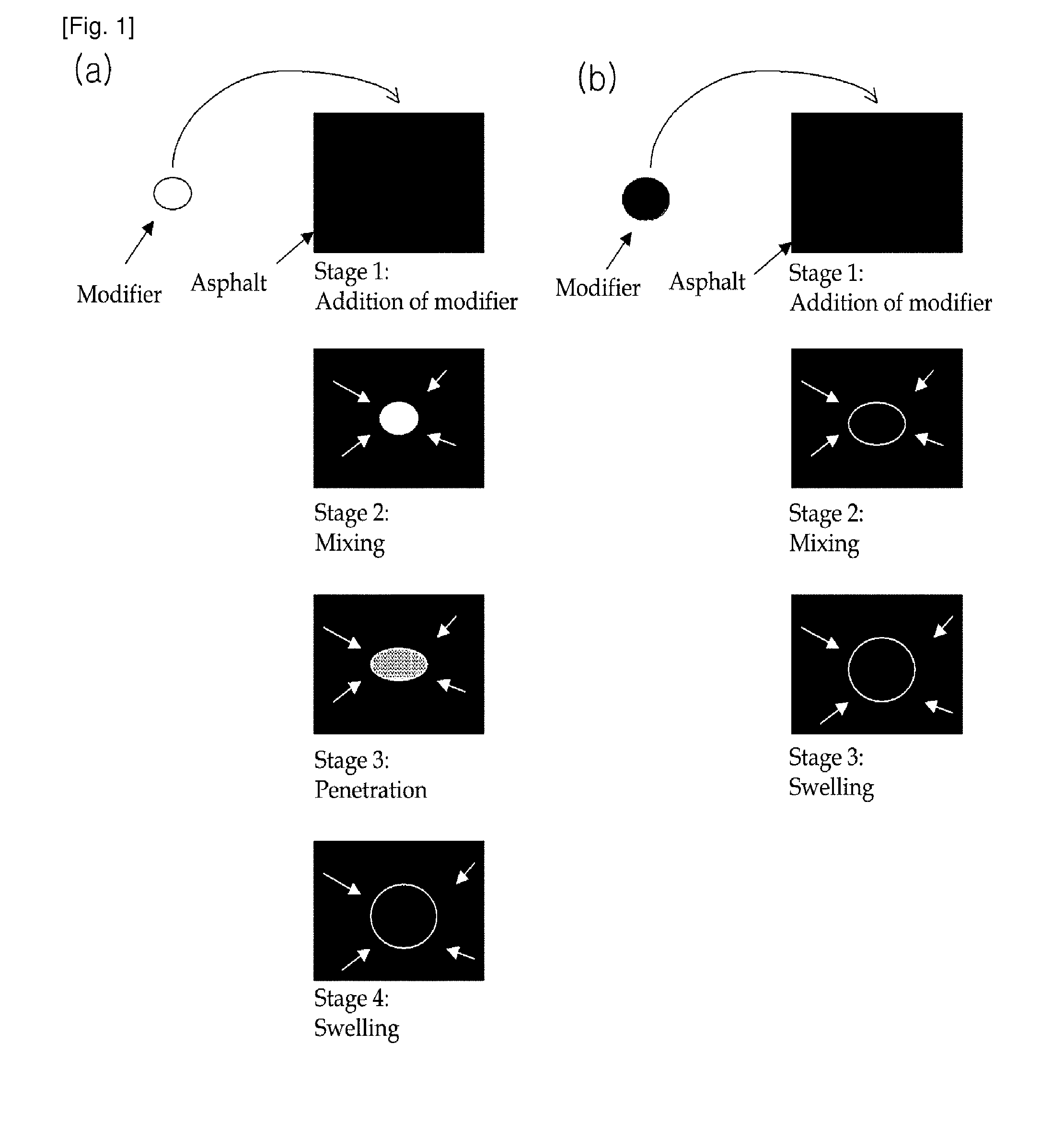

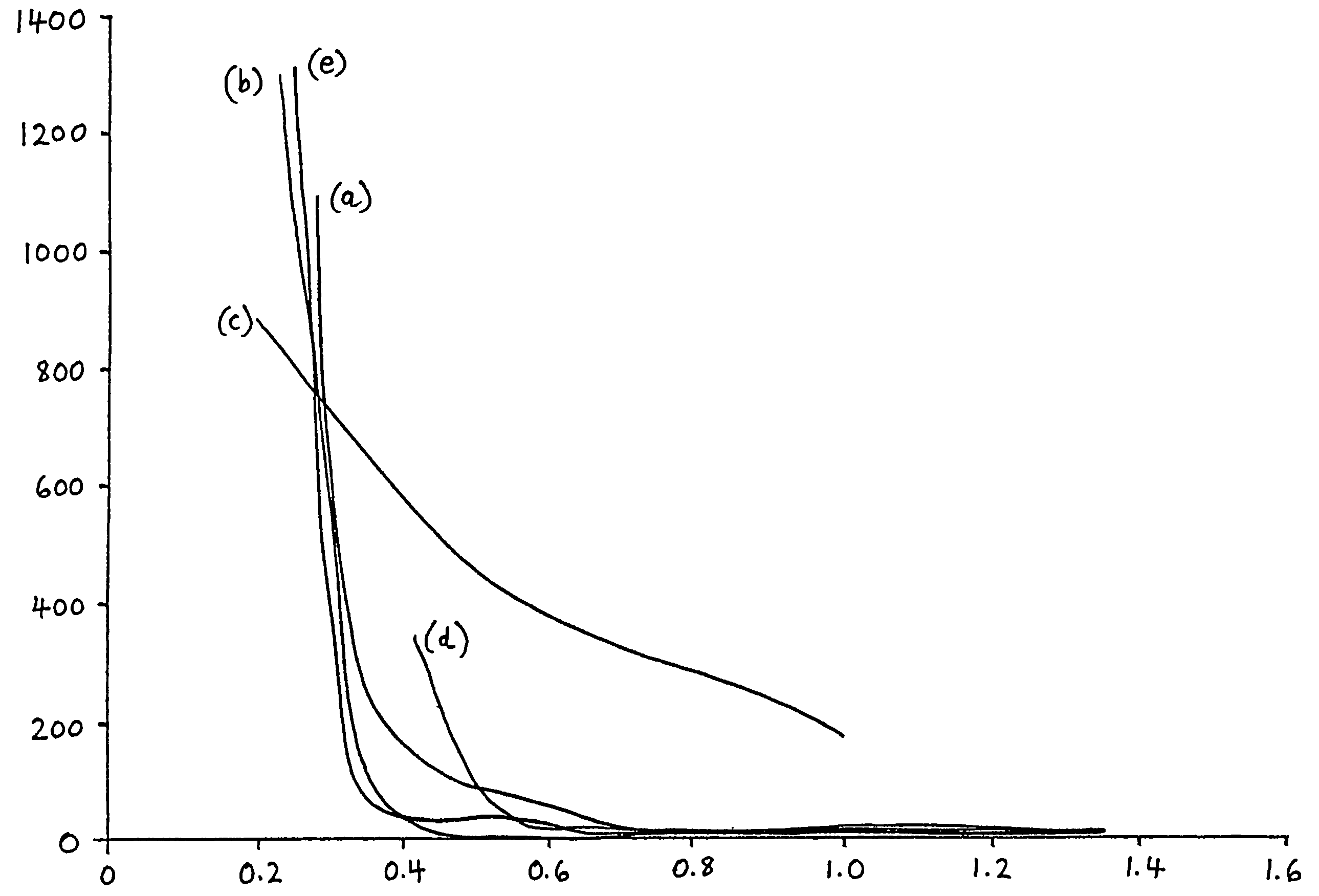

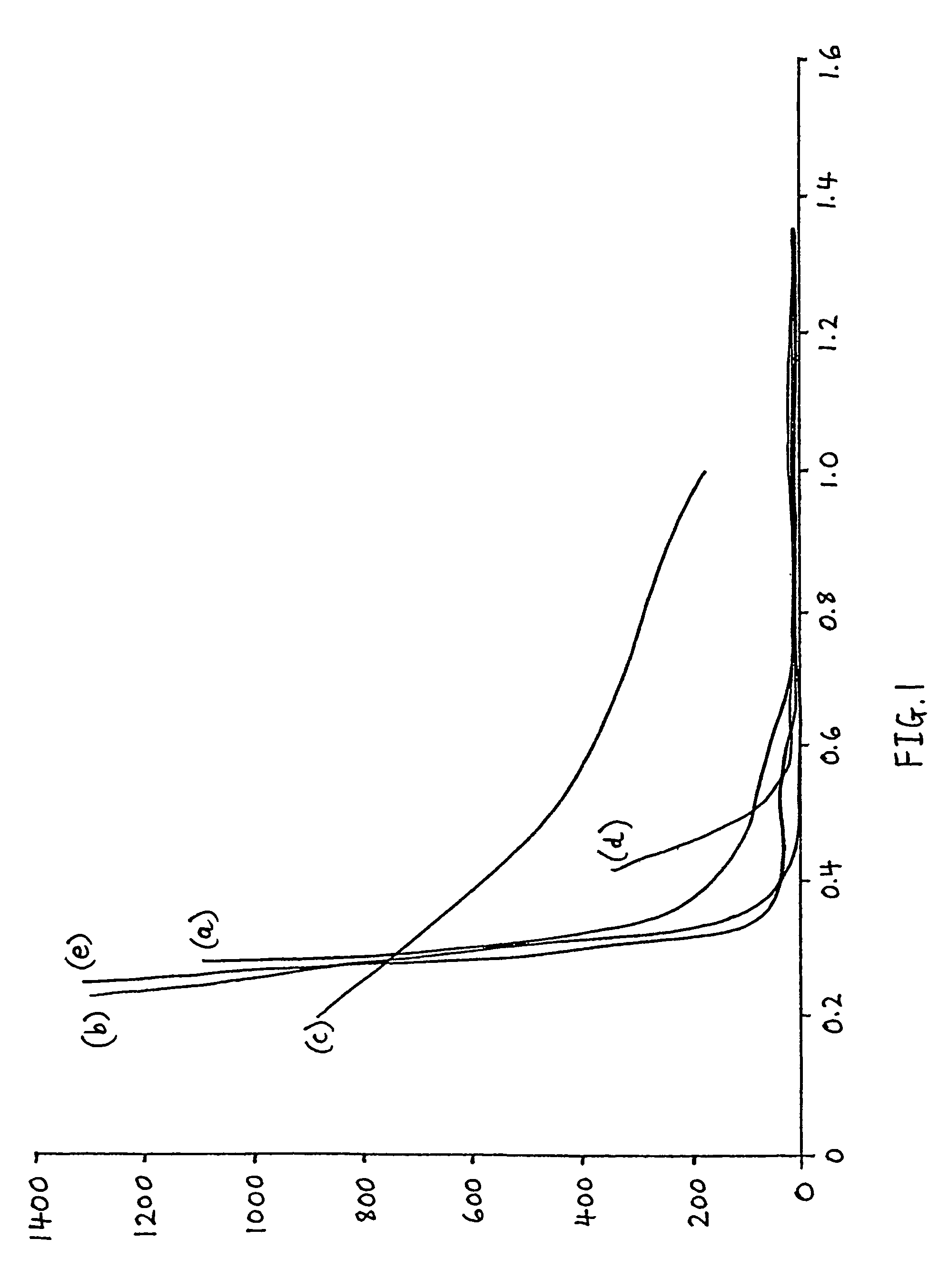

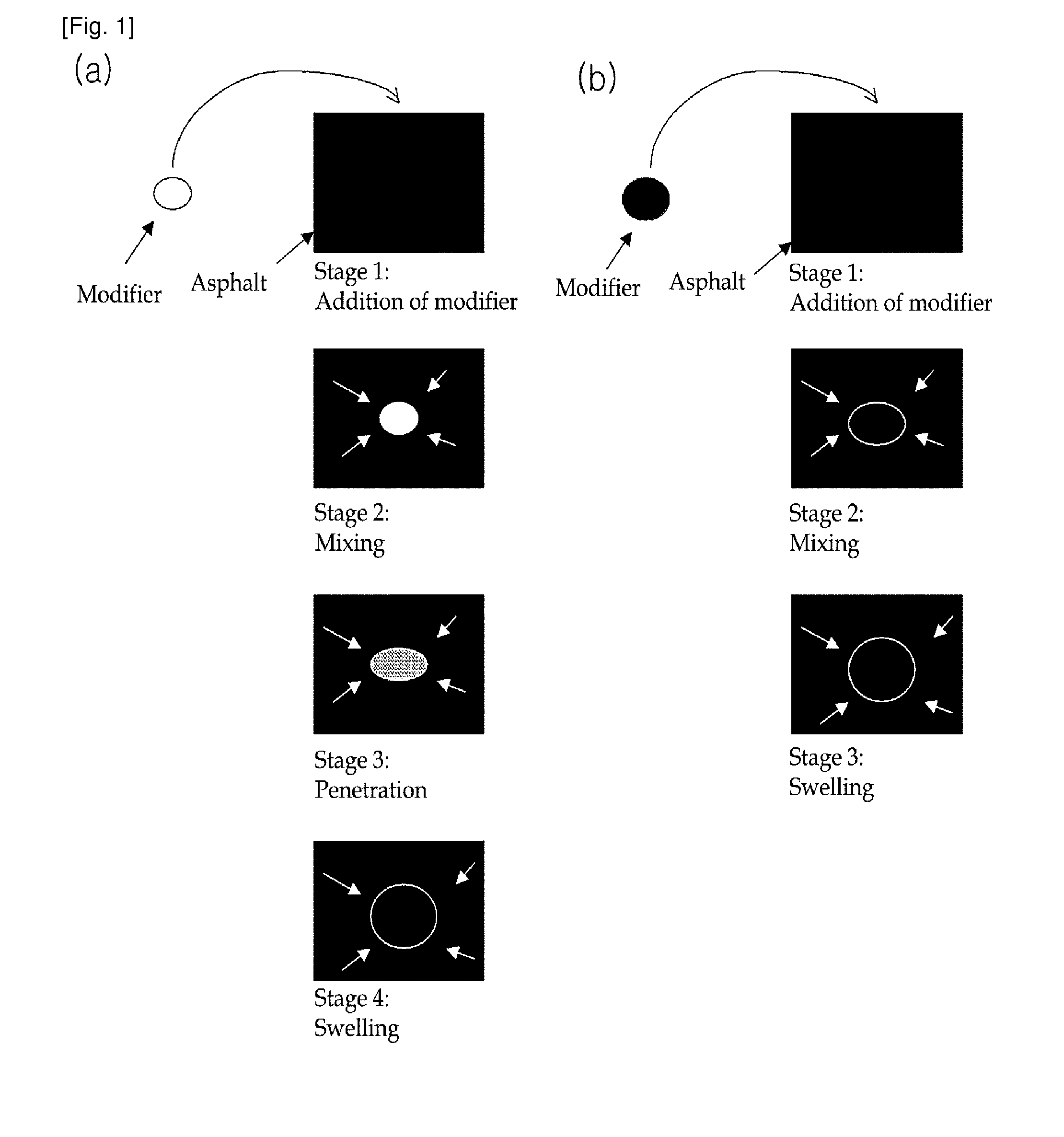

Asphalt modifier compositions with an improved melting rate and modified asphalt prepared using the same

ActiveUS20100273915A1Increase melting rateShorten melting timeBuilding insulationsProduction rateButadiene-styrene rubber

The present invention relates to a pellet type SBS-asphalt master batch modifier composition comprising styrene-butadiene-styrene (SBS) block copolymer and asphalt, and modified asphalt prepared by melting and mixing the pellet type SBS-asphalt master batch modifier composition with asphalt. The modified asphalt prepared thereof has advantages that deterioration of physical properties and thermal oxidation can be prevented while productivity can be improved due to reduced melting time of modifier.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

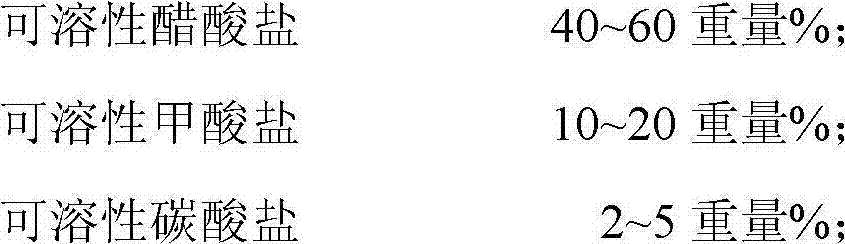

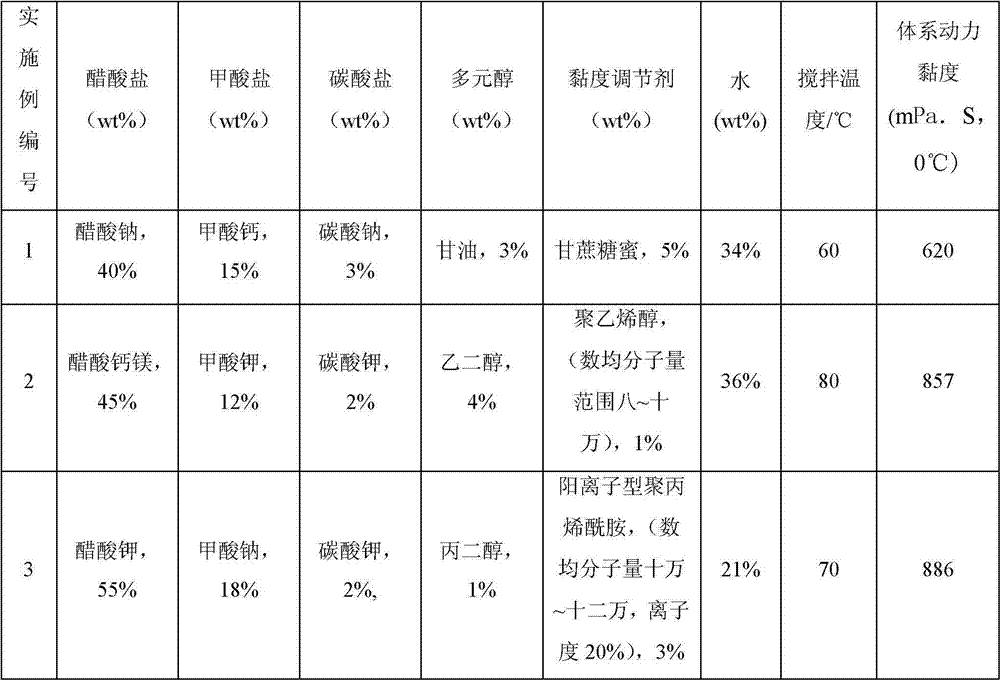

Green environment-friendly snow-melting liquid and preparation method thereof

InactiveCN102899004AFast melting rateNo pollution in the processOther chemical processesFormateMetallic materials

The invention relates to a green environment-friendly snow-melting liquid and a preparation method thereof. The liquid contains the following components: 40-60 wt% of a soluble acetate; 10-20 wt% of a soluble formate; 2-5 wt% of a soluble carbonate; 1-5 wt% of a polyol; 1-5 wt% of a viscosity modifier; and 20-40 wt% of water. The green environment-friendly snow-melting liquid provided in the invention is free of chloride ions, has a fast snow-melting rate, has no corrosion on metal materials such as steel bars, and has no pollution on soil and water bodies, thus being green and environment-friendly. The snow-melting liquid is convenient for storage and transportation, and has wide application. Compared with most of existing solid snow-melting materials, the snow-melting liquid has the characteristics of fully mechanized spreading way, uniform spreading, labor cost reduction, and spreading time reduction, etc.

Owner:HUBEI PROVINCE FREEWAY IND DEV +1

Core/shell polymer

InactiveUS20070117935A1Increase melt viscosityGood extrudabilityFibre treatmentCoatingsPolymer chemistryPolymer

Owner:THE CHEMOURS CO FC LLC

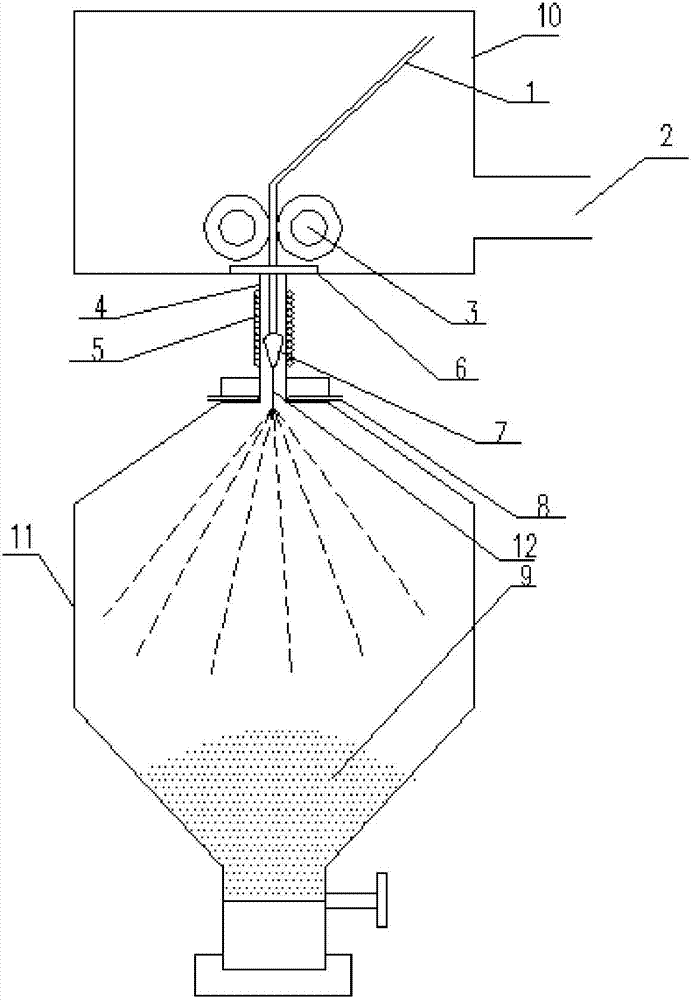

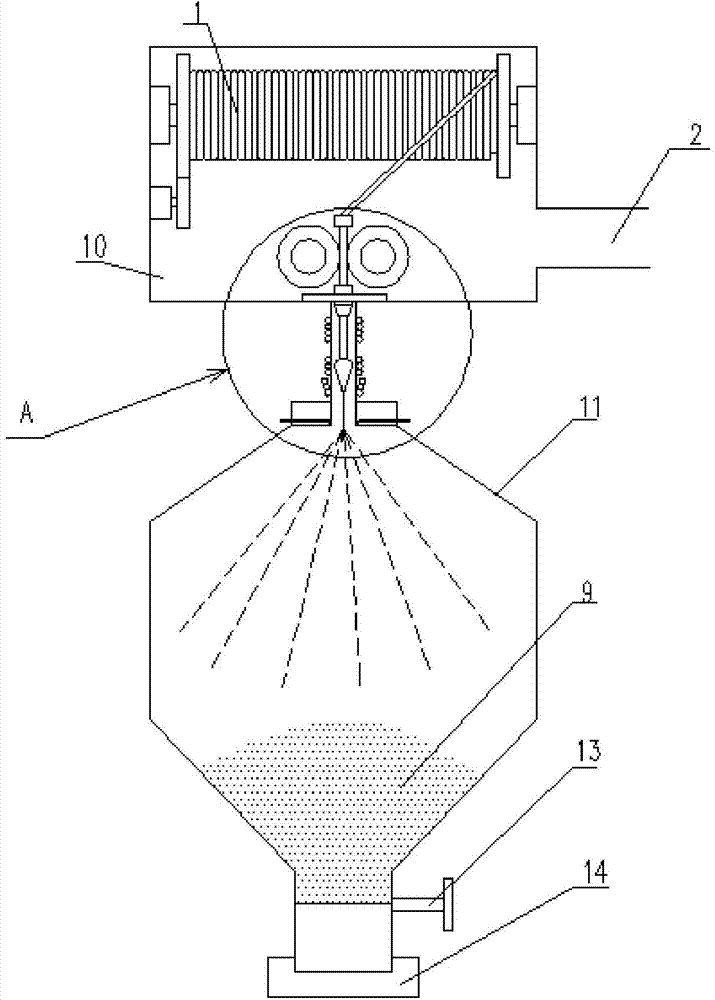

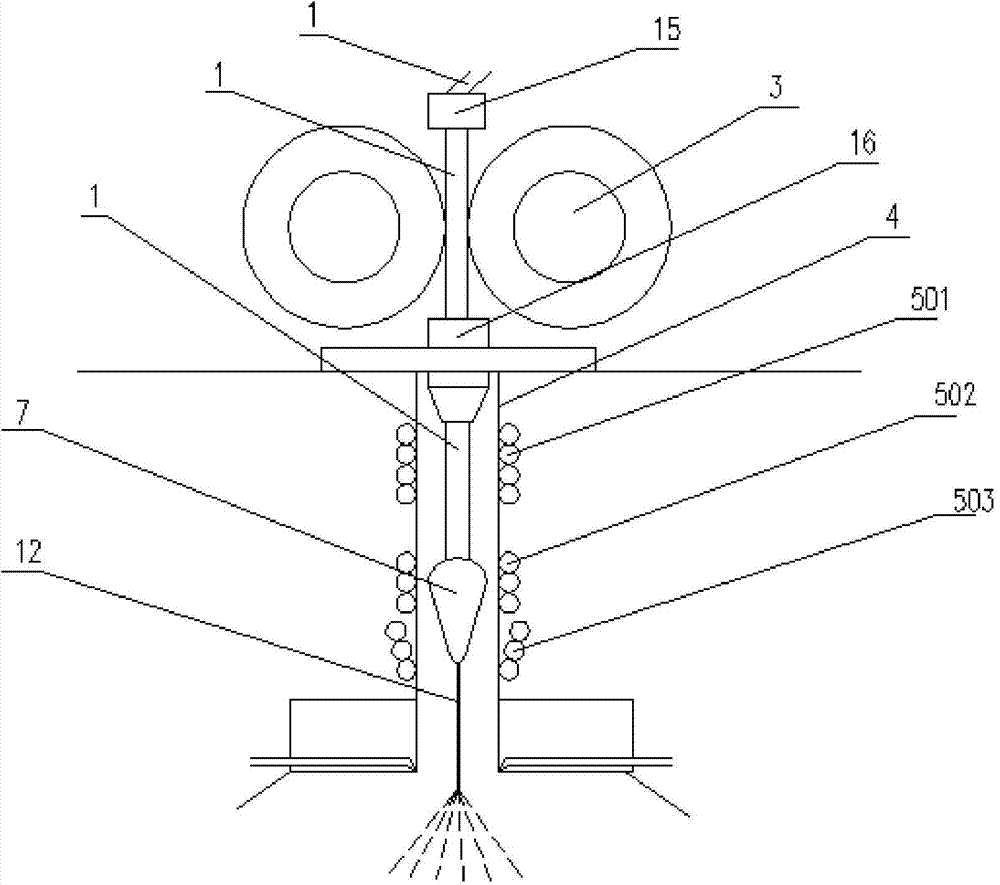

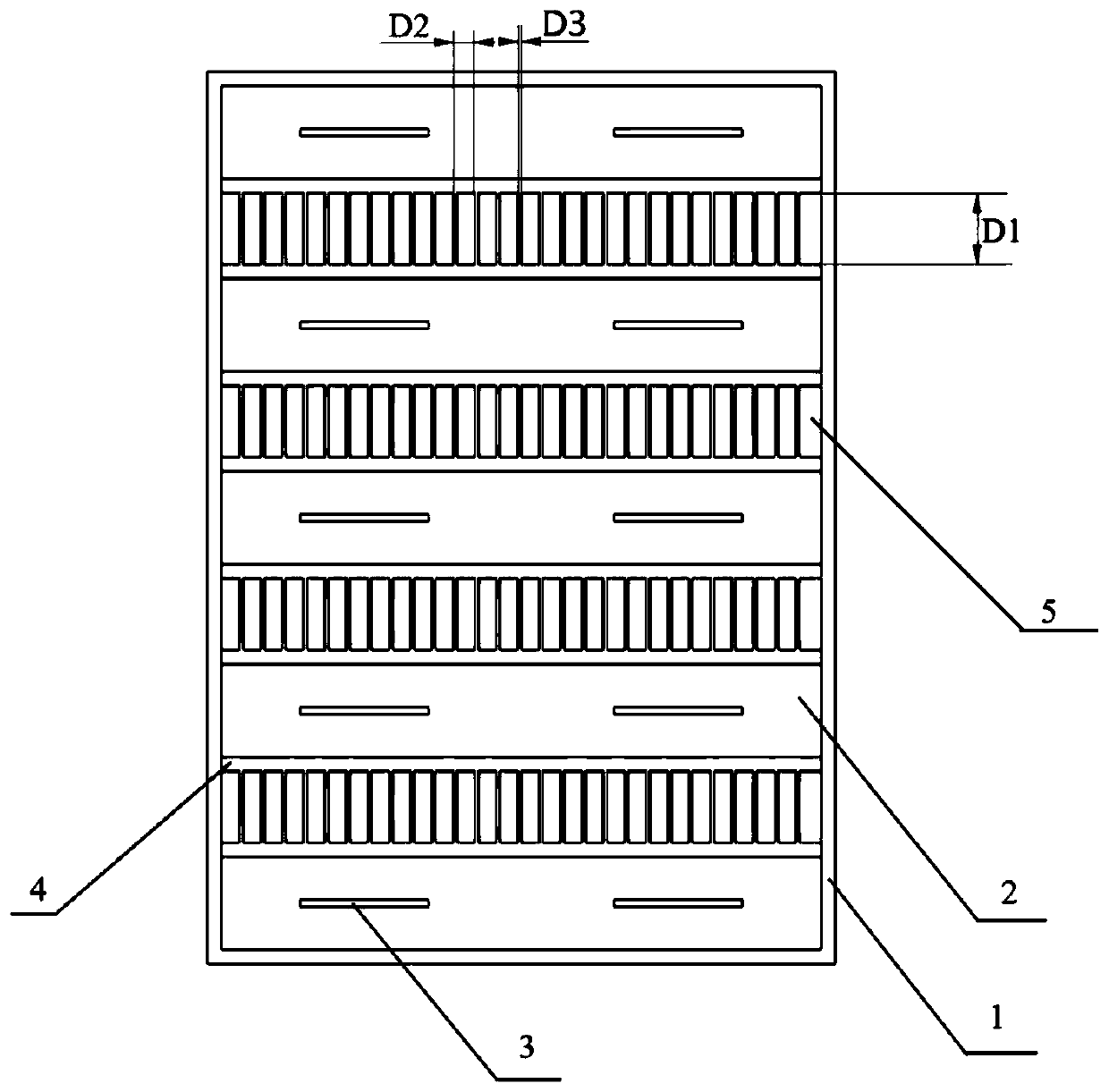

Method and device for metal powder preparation based on controllable magnetic levitation melting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

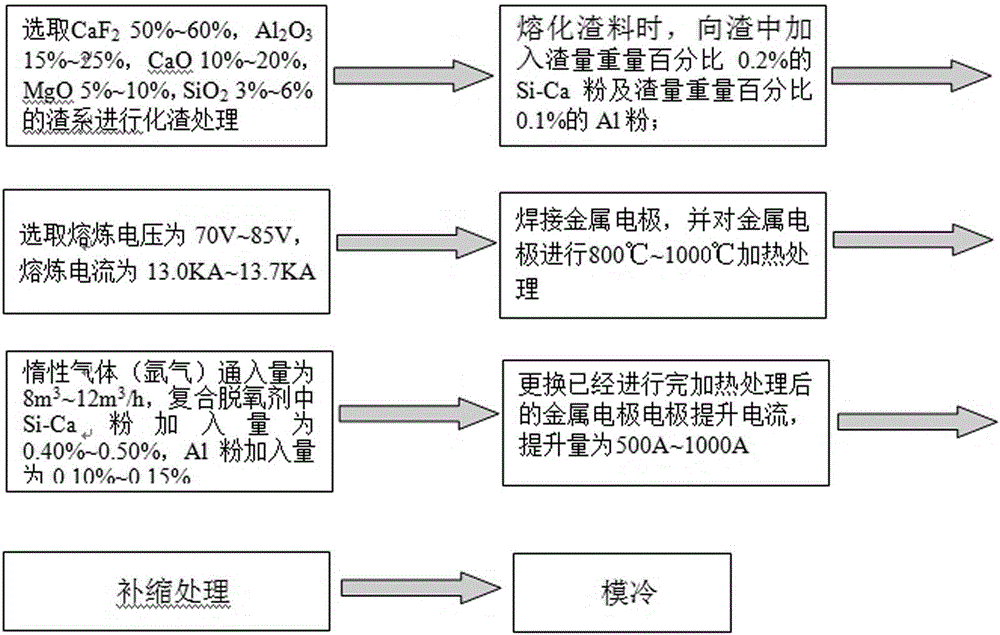

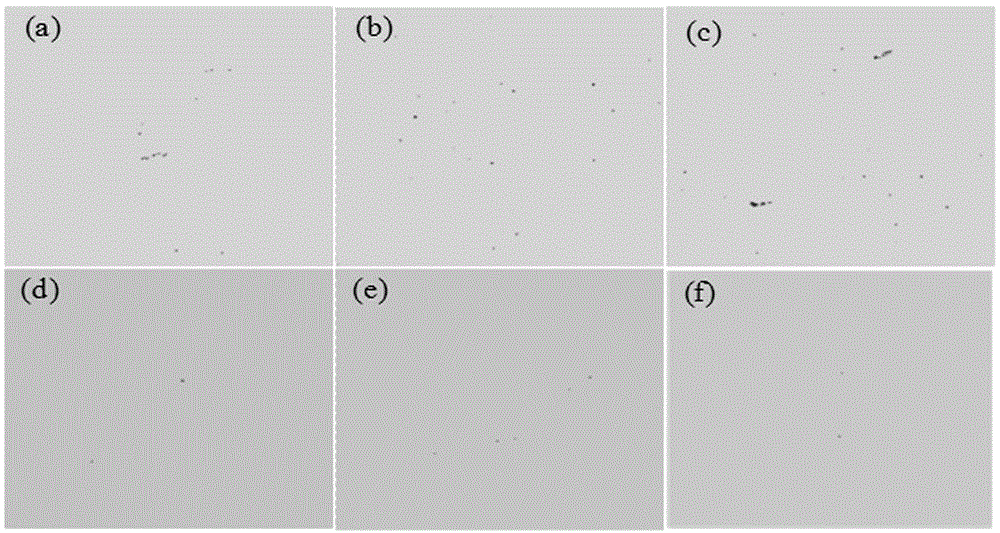

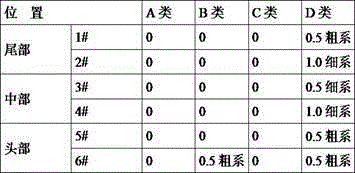

Electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power

The invention discloses an electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power. The method comprises the following steps: (1) selecting a cylindrical metal electrode for electroslag; (2) treating the metal electrode by adopting a machining method; (3) carrying out welding treatment and heating treatment on the metal electrode and a stainless-steel false electrode for the electroslag; (4) carrying out slag melting treatment by selecting a slag system which contains 50%-60% (by weight) of CaF2, 15%-25% (by weight) of Al2O3, 10%-20% (by weight) of CaO, 5%-10% (by weight) of MgO and 3%-6% (by weight) of SiO2; (6) carrying out feeding treatment; (7) carrying out die cooling. According to the austenite nitrogenous stainless steel prepared by the method, the forming of a steel ingot surface is good, and the inclusion content is low and can reach that the inclusion content of a coarse series of a class A is not higher than 0.5, the inclusion content of a fine series of the class A is not higher than 0.5, the inclusion content of a coarse series of a class B is not higher than 0.5, the inclusion content of a fine series of the class B is not higher than 0.5, the inclusion content of a coarse series of a class C is not higher than 0.5, the inclusion content of a fine series of the class C is not higher than 0.5, the inclusion content of a coarse series of a class D is not higher than 0.5, and the inclusion content of a fine series of the class D is not higher than 1.0.

Owner:沈阳科金特种材料有限公司

Fluxing apparatus of LCD glass melting furnace

InactiveCN101381197AHigh clarification temperatureClarification temperature is goodGlass furnace apparatusGlass productionViscosityGlass production

The invention relates to a liquid-crystal glass tank furnace fluxing device and a method for solving the difficult problems that liquid-crystal glass is high in melting temperature, high in high temperature viscosity, low in melting rate and high in volatility when melting. A tank bottom between a charging opening and a bubble of a tank furnace is provided with a row of electrodes; the tank bottom in a clarification area close to a liquid flow hole is provided with a row of electrodes as well; and a pure oxygen burner jetting flame into the furnace is arranged on the tank furnace. The device aids in melting through a plurality of fluxing modes, homogenizes the temperature of molten glass, raises the internal temperature of the molten glass, speeds up convection, accelerates glass clarification process, reduces crystallization tendency, and can obtain the glass with higher quality. Therefore, the device is especially applicable to the liquid-crystal glass production harsh in requirement on glass quality.

Owner:HENAN ANFEI ELECTRONICS GLASS

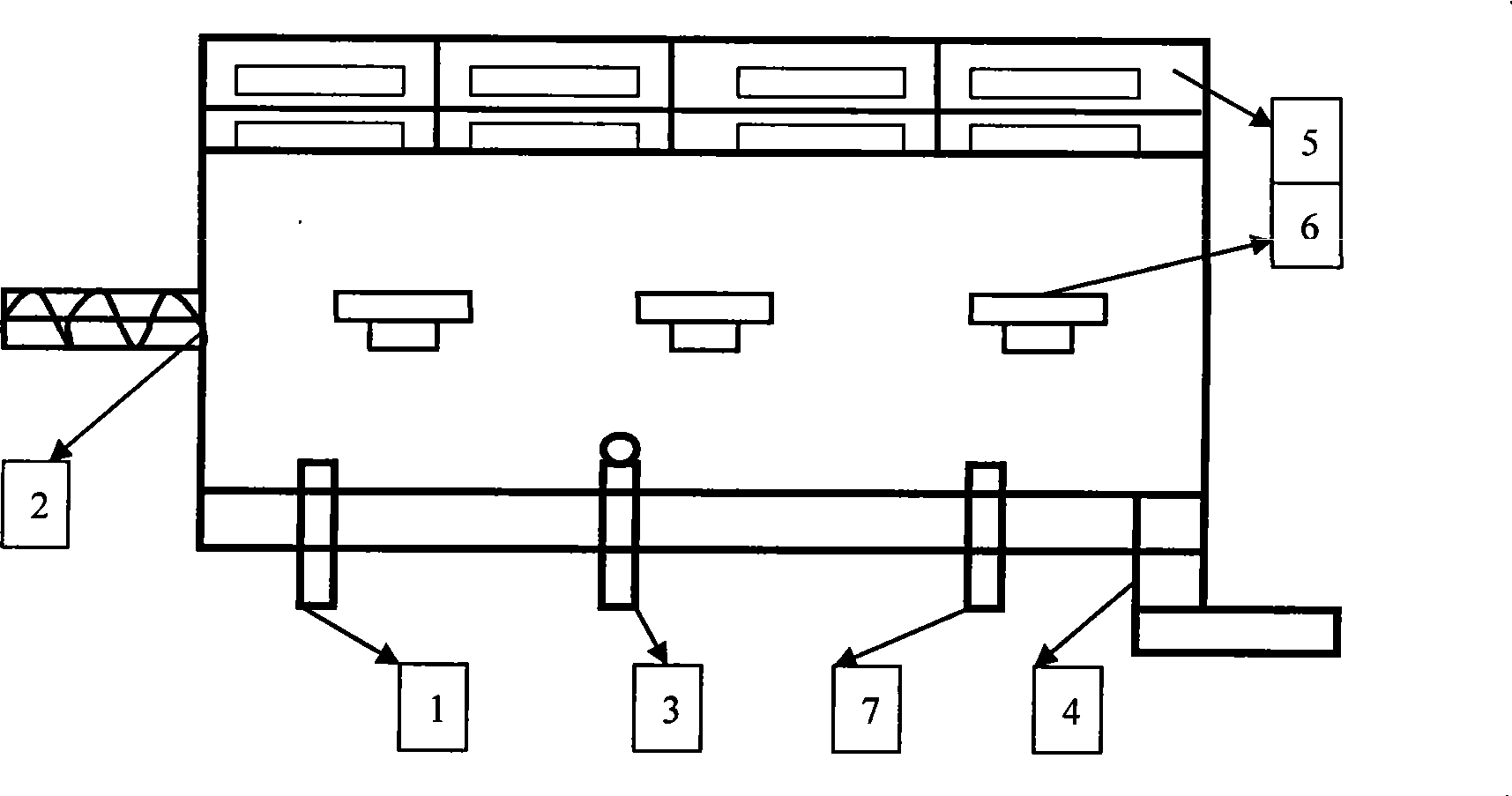

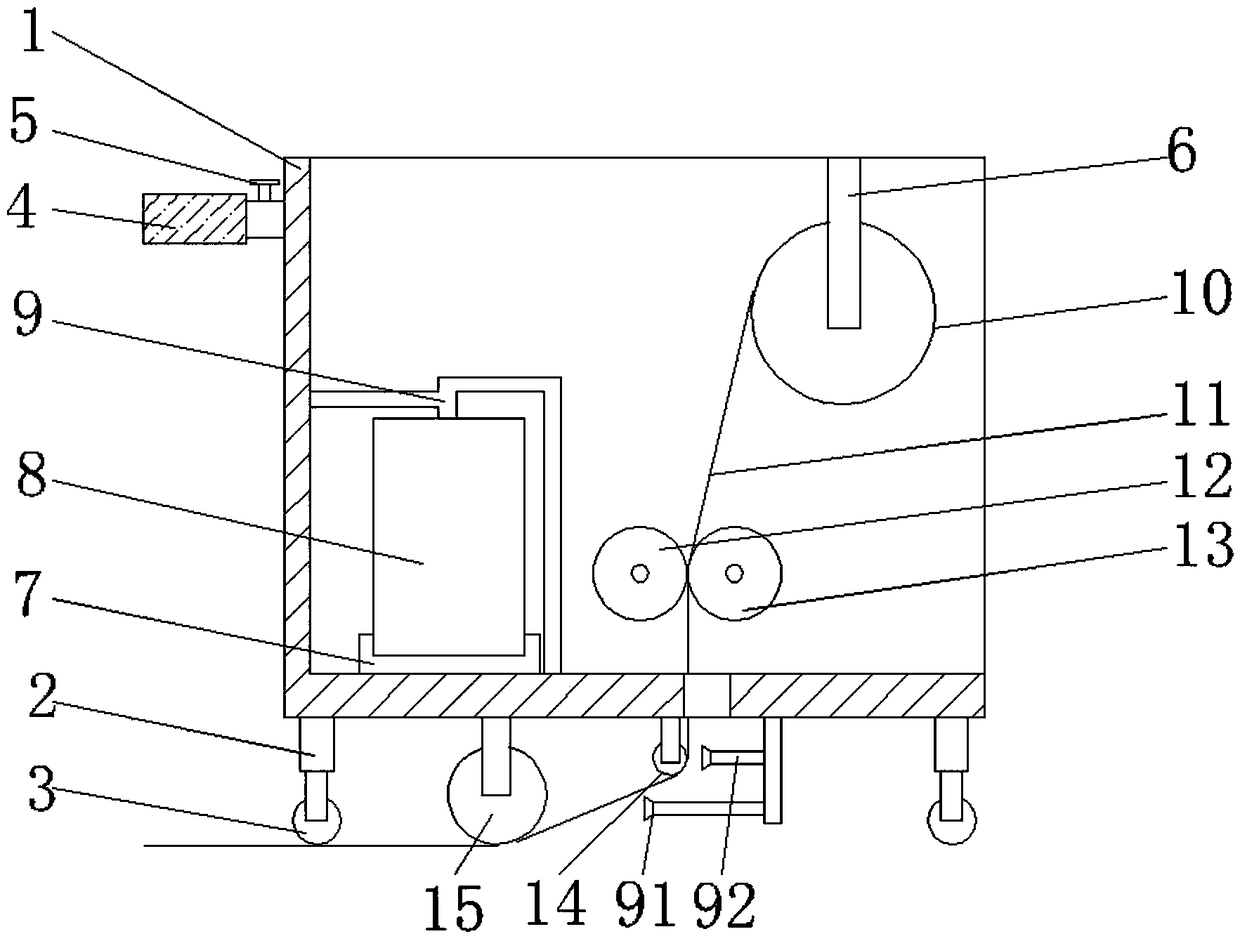

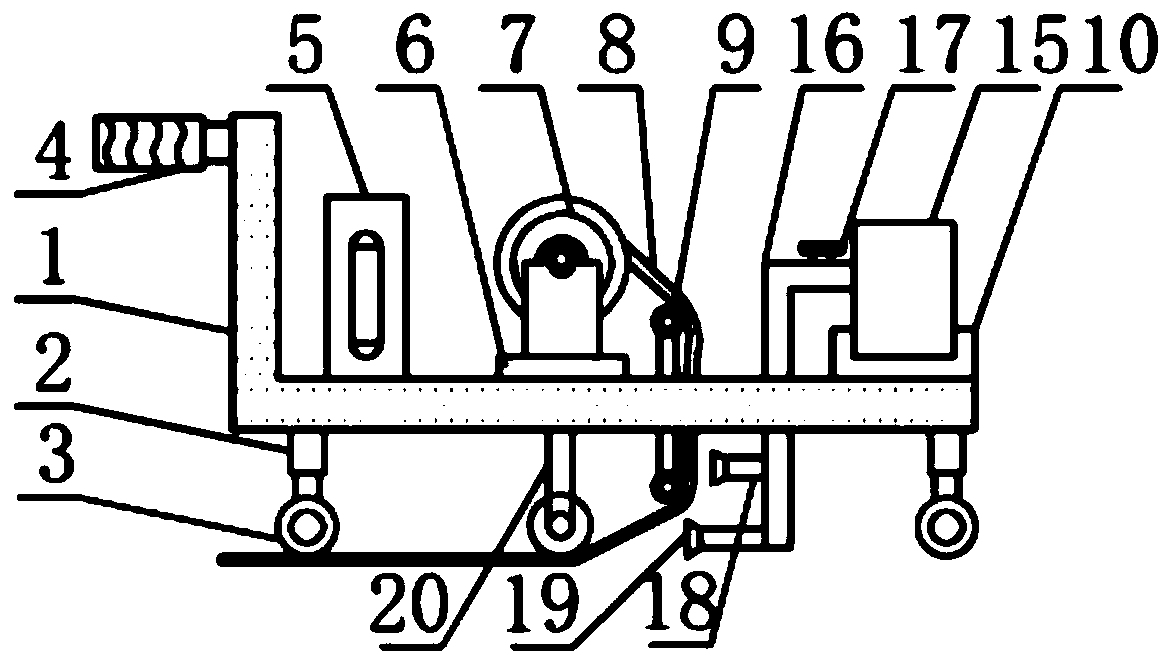

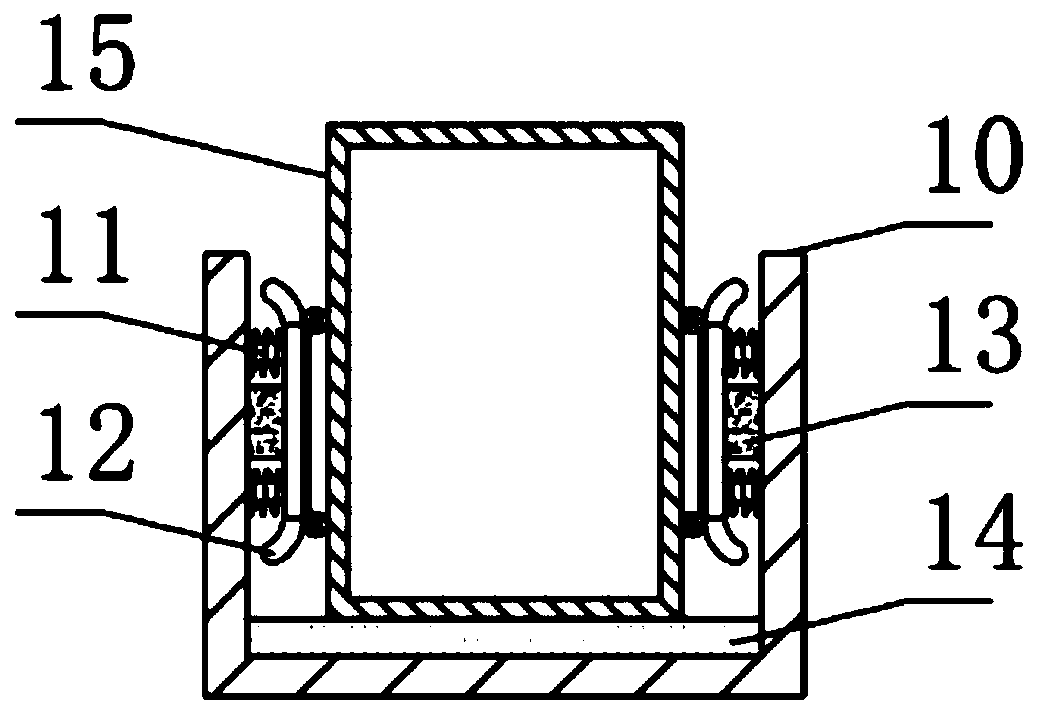

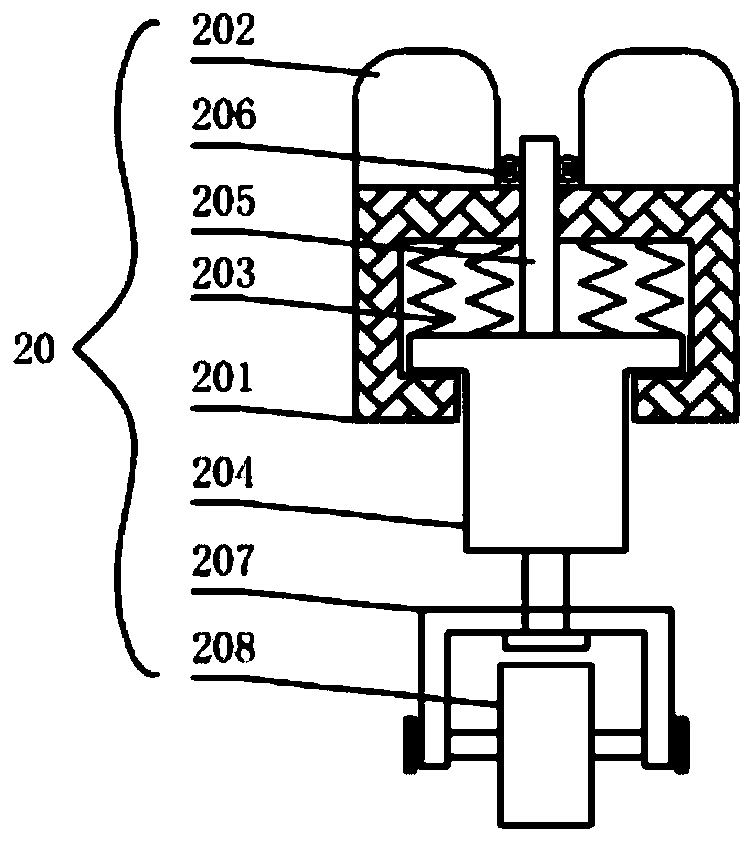

Laying device for waterproof coiled material

The invention discloses a laying device for a waterproof coiled material. The laying device comprises a box body, a heating device and a laying pressing device; damping rods are mounted at the four corners of the bottom end of the box body, sliding wheels are mounted at the bottom ends of the damping rods, a handle is arranged at the upper end of the outer wall of the left side of the box body, and an adjusting valve is arranged on the handle; sliding grooves are symmetrically formed in the front inner wall and the rear inner wall of the box body; the heating device comprises a U-shaped base,a fuel gas tank and a fuel gas pipeline; the U-shaped base is fixed to a bottom plate of the box body, the fuel gas pipeline stretches out of the fuel gas tank, one end of the fuel gas pipeline is connected with the adjusting valve, and the other end of the fuel gas pipeline stretches out of the bottom plate of the box body and is provided with a preheating spraying nozzle and a heating spraying nozzle; and the laying pressing device comprises a first winding roller, the waterproof coiled material, a second winding roller, a third winding roller, a flat-laying roller and a pressing roller. Thelaying device has the advantages that the stability of the laying device is good, the pasting effect of the waterproof coiled material is good, construction manpower is reduced, and the constructionefficiency is improved.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Free flowing glass batch

InactiveUS7494948B2Improve melting propertiesImprove uniformityCharging furnaceGlass productionGlass meltingChemistry

A process for preparing and storing moist glass-making batch is disclosed, comprising incorporating a surfactant in moist batch so that when the batch is either: a) stored at a temperature below 35° C., it remains free flowing without setting, or b) pre-heated at, or above, 100° C. before supply to a glass melting furnace, it remains free flowing without setting. The moist batch includes from 2% to 10% by weight free water and from 0.0001% to 5% by weight surfactant, which is preferably a soluble soap (for example a carboxylate having from 4 to 22 carbon atoms in its chain) that is incorporated into the batch as it is mixed. The moist batch can be stored for at least 24 hours, and it can be pre-heated to at least 150° C., and remain free flowing without setting.

Owner:PILKINGTON GROUP LTD

Method for smelting crude lead in oxygen-enriched side-blowing smelting furnace

InactiveCN102776383AEmission reductionSimplify the melting processProcess efficiency improvementLead smeltingPhysical chemistry

The invention relates to a method for smelting crude lead in an oxygen-enriched side-blowing smelting furnace, belonging to the technical field of lead smelting. The method comprises the process steps of: 1) crude lead material preparation: proportioning lead-containing materials, quartz stones and limestone flux according to silicate degree being 0.9-1.3 percent, evenly mixing and crushing the lead-containing materials and the flux to grain size being less than or equal to 40mm; 2) crude lead smelting preparation: melting partial crude lead materials to a depth of 300-400mm in the oxygen-enriched side-blowing smelting furnace; and 3) crude lead smelting: continuously feeding the crude lead materials into a hearth and then controlling smelting air-coal ratio, temperature and high-pressure oxygen-enriched air supply, wherein molten lead sinks down and automatically flows into a furnace bed for heat preservation and storage through a siphon port, the molten lead automatically flows into a casting mold to form ingots when the depth of the stored molten lead reaches an overflow port, and the accumulated floating lean slag is discharged and is introduced into the crude lead material preparation process. The method for smelting crude lead in the oxygen-enriched side-blowing smelting furnace has the advantages that the investment is small, the smelting efficiency is high, the energy consumption is low, the arrangement is facilitated, the treatment capacity is high, the method is suitable for mass production, the materials are not required to be granulated, bricked, dried and stored, and the quantity of flue dust is small.

Owner:杨龙安

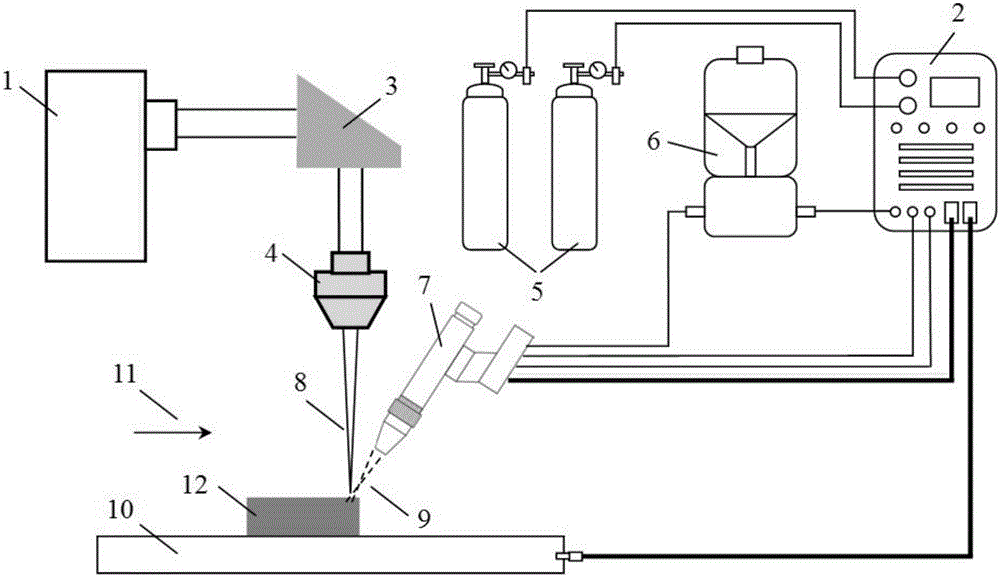

Laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying

ActiveCN105834428AIncrease energy densityLow heat inputAdditive manufacturing apparatusIncreasing energy efficiencyArc stabilityOptoelectronics

The invention discloses a laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying. By means of the method, flow carrying and synchronous powder sending of powder are achieved by means of a micro-beam plasma arc, and main energy needed for forming a metal structure is provided by means of a pulse laser heat source. The powder sending precision of powder materials is improved by means of the good arc stability and stiffness of the micro-beam plasma arc; and by means of the characteristic that the energy function of the micro-beam plasma arc is concentrated is utilized, so that the melting rate and the deposition rate of the powder are increased, and the heat absorbing rate of the powder materials and a forming area on the energy of the laser heat source is increased. The main arc current of the micro-beam plasma arc in the method is 30 A-50 A, the pulse peak power of a pulse laser beam is 4 kW-10 kW, and three-dimensional fast forming and manufacturing of metal materials and the structure are achieved by adjusting the relative position relation between the laser beam and the powder carrying flow of the micro-beam plasma arc, the beam spot coinciding ratio and the output energy of the micro-beam plasma arc and the laser beam. The laser three-dimensional fast forming and manufacturing method has the beneficial effects of being high in forming efficiency, high in precision, little in deformation, high in technical adaptability and the like.

Owner:CHONGQING UNIV OF TECH

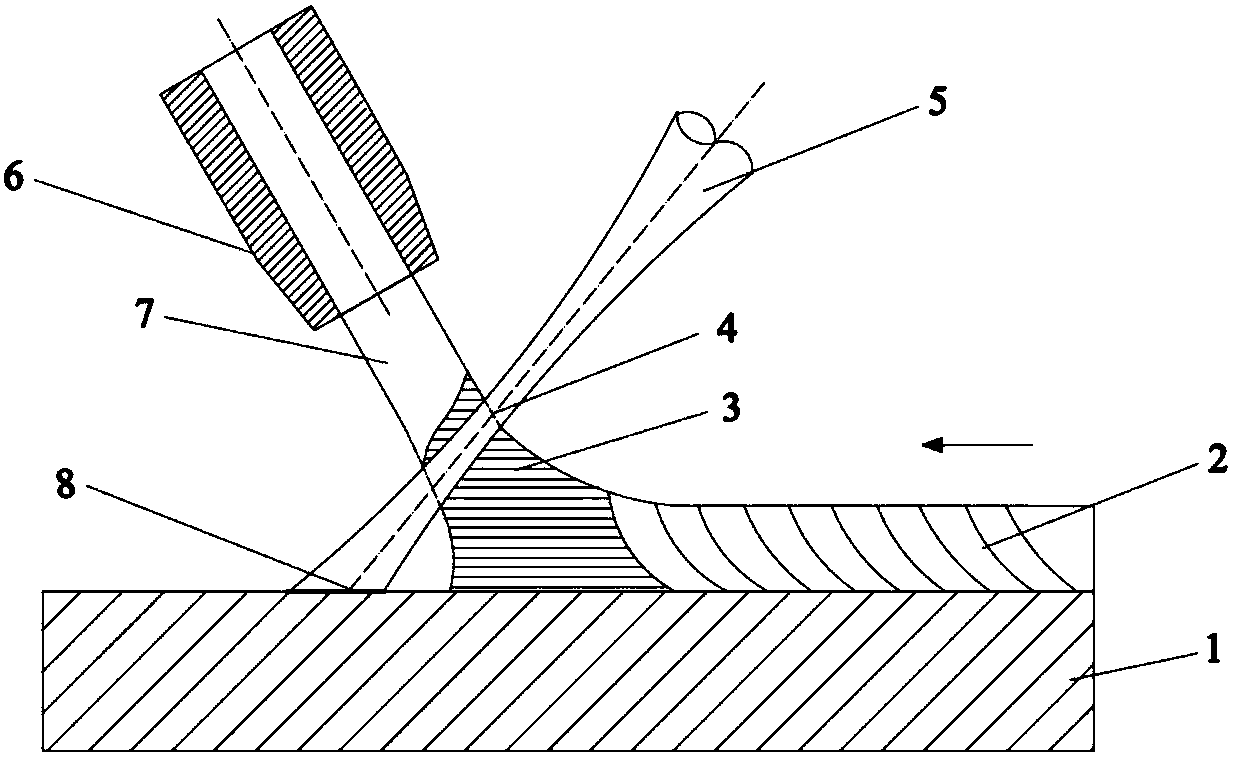

Wire feeding type laser material increase manufacturing method

ActiveCN108188581AIncrease melting rateImprove forming efficiencyAdditive manufacturing apparatusLaser beam welding apparatusThermal conductivityEngineering

The invention provides a wire feeding type laser material increase manufacturing method and a system applying the same, wherein a welding wire and a laser beam are arranged on the two sides of a normal line of a substrate at a certain angle; the laser beam is acted on the welding wire to generate a deep penetration small hole; the welding wire absorbs laser energy in a deep penetration mode to beheated and melted and is transited onto the surface of the substrate to form a cladding layer; and the laser beam, after penetrating through a wire, irradiates the surface of the substrate to preheatthe surface of the substrate in a thermal conductivity mode. According to the wire feeding type laser material increase manufacturing method, the formation efficiency of wire feeding type laser material increase manufacturing can be improved, and the welding wire melting rate is greatly increased by utilizing the deep penetration mode to heat and melt the welding wire; and a workpiece is heated and melted in the thermal conductivity mode, and the defects of small hole type air holes and the like can be effectively avoided from being generated.

Owner:BEIJING UNIV OF TECH

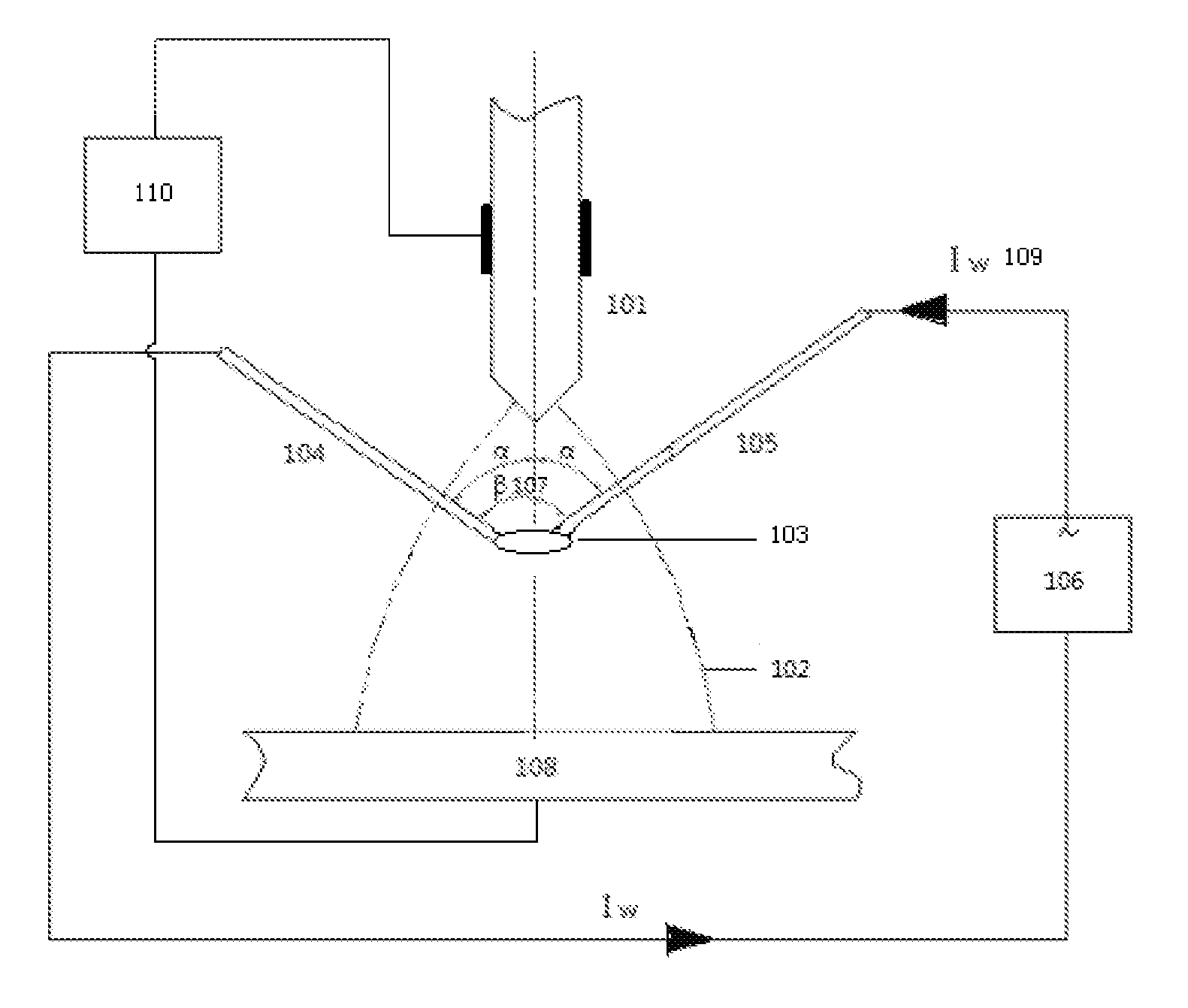

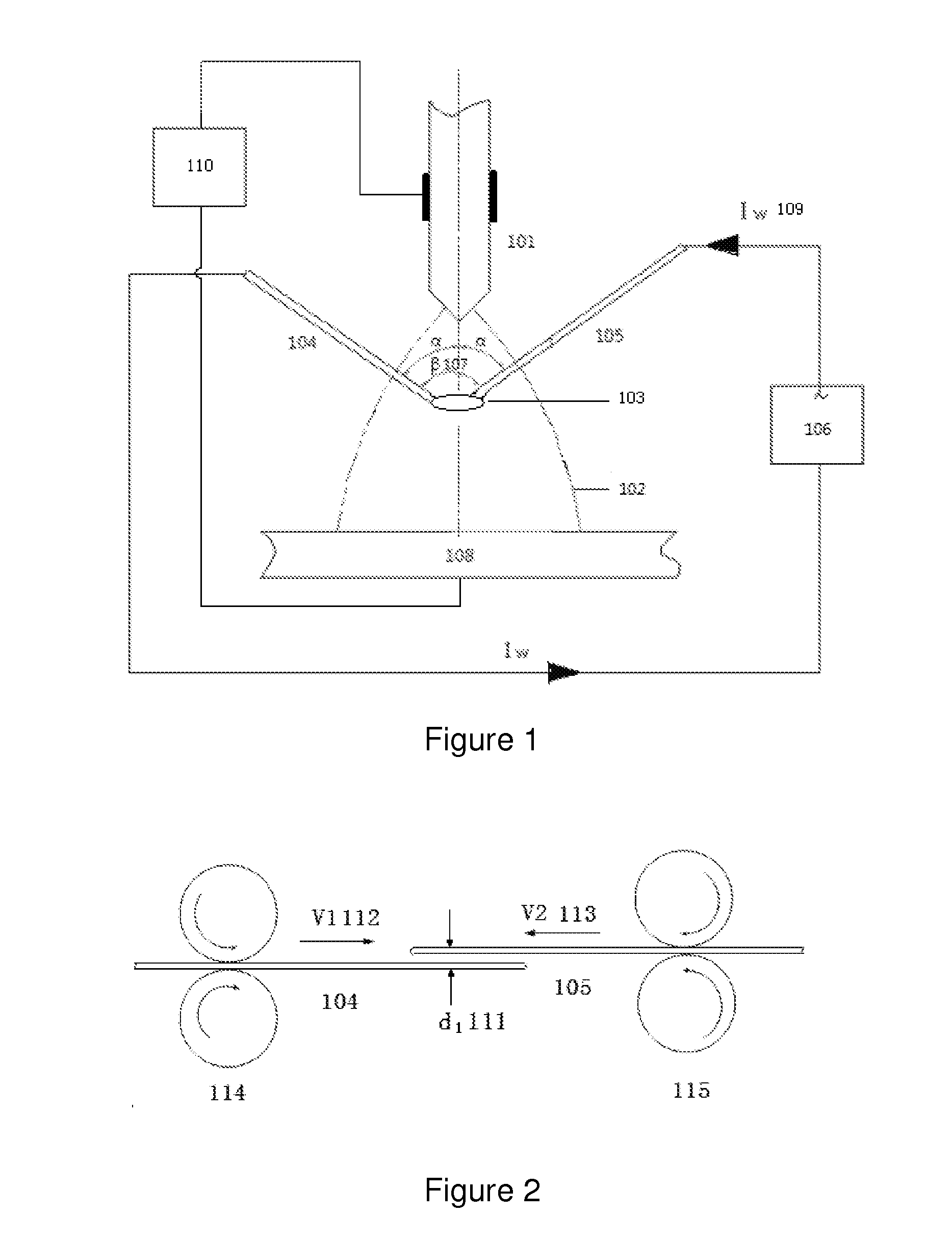

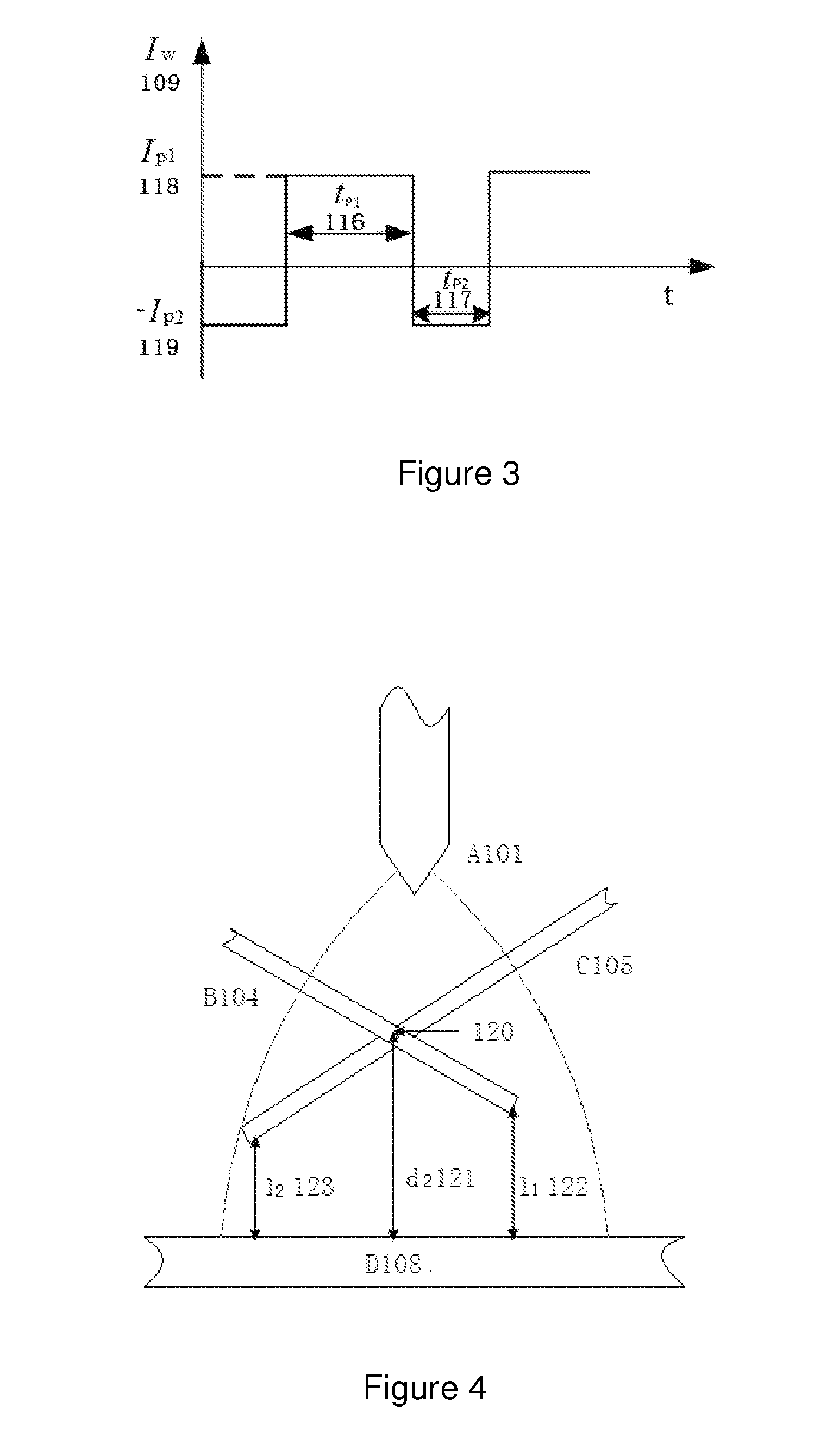

Gas tungsten arc welding with cross ac arcing twin wires

ActiveUS20140291297A1High depositionLow heat inputArc welding apparatusPlasma welding apparatusSide effectGas tungsten arc welding

Gas metal arc welding (GMAW) is a widely used process for joining metals. Its main advantage over its competition gas tungsten arc welding (GTAW) is its high productivity in depositing metals. However, to melt metal from the wire to deposit into the work-piece, additional heat is consumed and applied to the work-piece with an uncontrolled fixed proportion to the effective heat that melts the wire. Such additional heat is often in excess of the needed heat input for the work-piece. The side-effects include a waste of the energy, an increased distortion, and possible materials property degradation. This invention is to device a method to transfer this part of heat to melt the wire by adding two wires, which form a pair of arc spots, under a tungsten arc. It also devices a method to assure the arc between the two wires be maintained stable such that the transfer be successfully continuous. The successful continuous transfer improves the energy efficiency, eliminates the adverse effects on the distortion and materials property, and decouples the controls on mass input and heat input on the work-piece.

Owner:BEIJING UNIV OF TECH

Blast furnace-intermediate frequency furnace duplexing smelting short process production technology

The invention provides a short flow manufacturing technique for the duplex smelting of a blast furnace-intermediate frequency furnace, relating to the blast furnace-intermediate frequency sensing electric stove smelting technique. The short flow manufacturing technique is characterized in that the liquid iron produced by an ironmaking blast furnace is directly added into the intermediate frequency sensing electric stove, the temperature is increased to adjust materials, and a cast piece is poured. In the material adjusting process, a liquid iron nucleating agent is added to accelerate the crystallization. The nucleating agent comprises the compositions in weight percentage: 65 to 70 percent of silicon, 0.5 to 2.5 percent of calcium, 0.0 to 6.0 percent of barium, 0.2 to 2.0 percent of aluminum, 0.05 to 0.2 percent of bismuth, and the balancing being iron. The short flow manufacturing technique has the advantages that the process of melting iron ingot for the second time is saved, the overheating efficiency of the sensing electric stove is high, the adjustment of components and the control of the temperature are convenient, the high temperature liquid iron which has good quality and meets the requirement for the cast piece is obtained; and the technique can be applied to spheroidal graphite casting to produce parts of an automobile, parts of wind power equipment, engineering plant cast pieces and other cast pieces, the product quality is improved, the energy is saved, the production efficiency and the production benefits are improved, and the environmental pollution is reduced.

Owner:LINZHOU HEXIN CASTING CO LTD

On-line hot preparation method of glass batch

InactiveCN101913752AImprove thermal conductivityIncrease the reaction areaCharging furnaceGlass productionAdhesiveRefractory

The invention discloses an on-line hot preparation method of a glass batch. The method comprises the following steps of: adding a proper quantity of adhesives to a traditional glass batch and pressing the mixture into a block material; preheating to decompose the molded block material in a firing kiln to form a sintered block consisting of silicate and silicon dioxide, immediately pulverizing the block into granules in the hot state; conveying and uniformly scattering the granules into a filling pocket; and pushing into a glass kiln for melting. The on-line hot preparation method of the glass batch can greatly improve the heat conductivity coefficient of the batch, improve the melting rate of the glass kiln, increase the glass capacity and achieve the purpose of saving energy. The compacted glass batch block reduces flying dust in the glass kiln, prolongs the service life of refractory materials, prevents the blockage of a regenerative chamber, purifies the operating environment, reduces the flying loss of the batch and stabilizes the glass component. The method ensures that the melting rate can be improved by 20-30 percent. Compared with a traditional method, the method ensures that the fuel consumed for producing the same quantity of glass can be saved by 10-20 percent.

Owner:杭州蓝星新材料技术有限公司

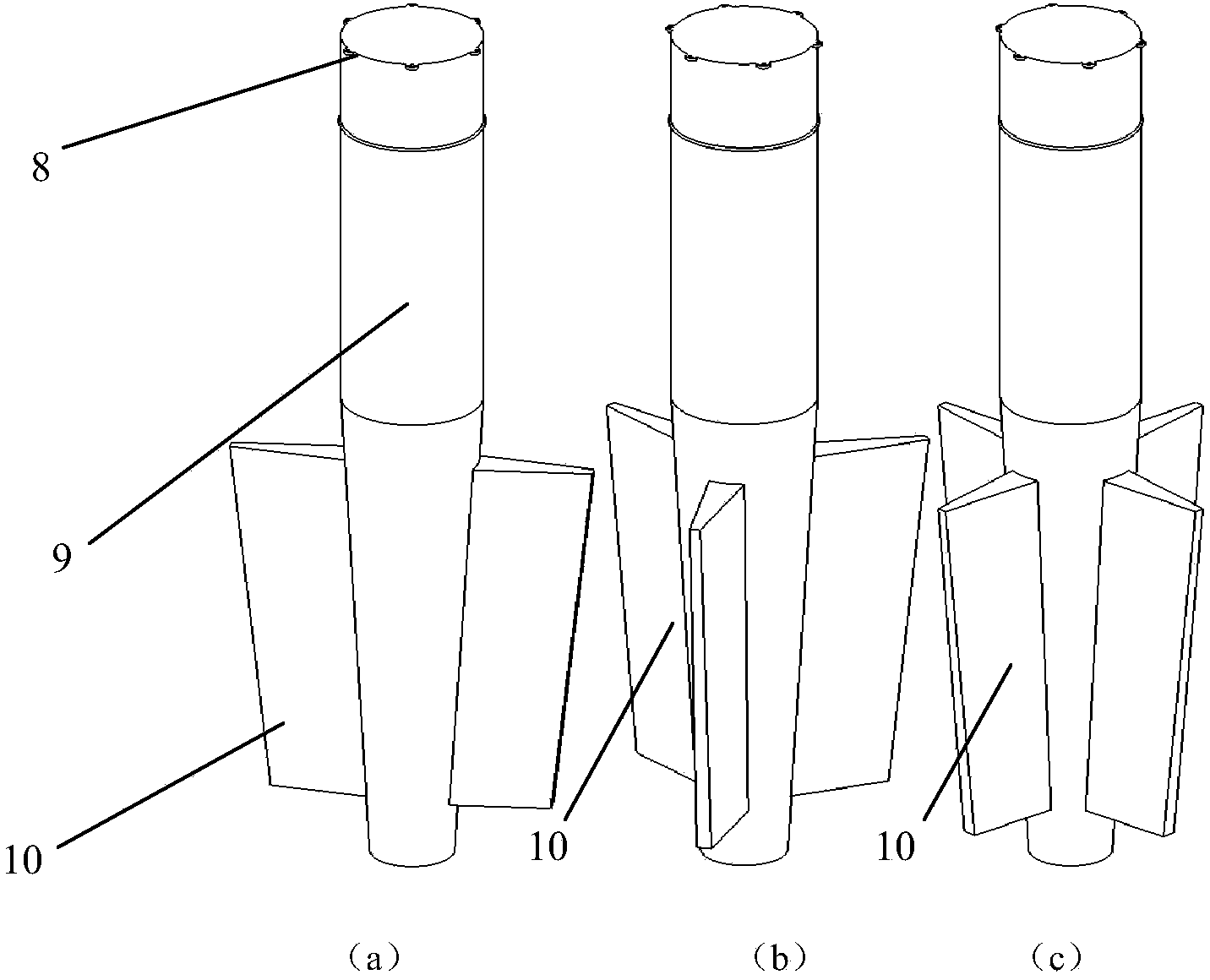

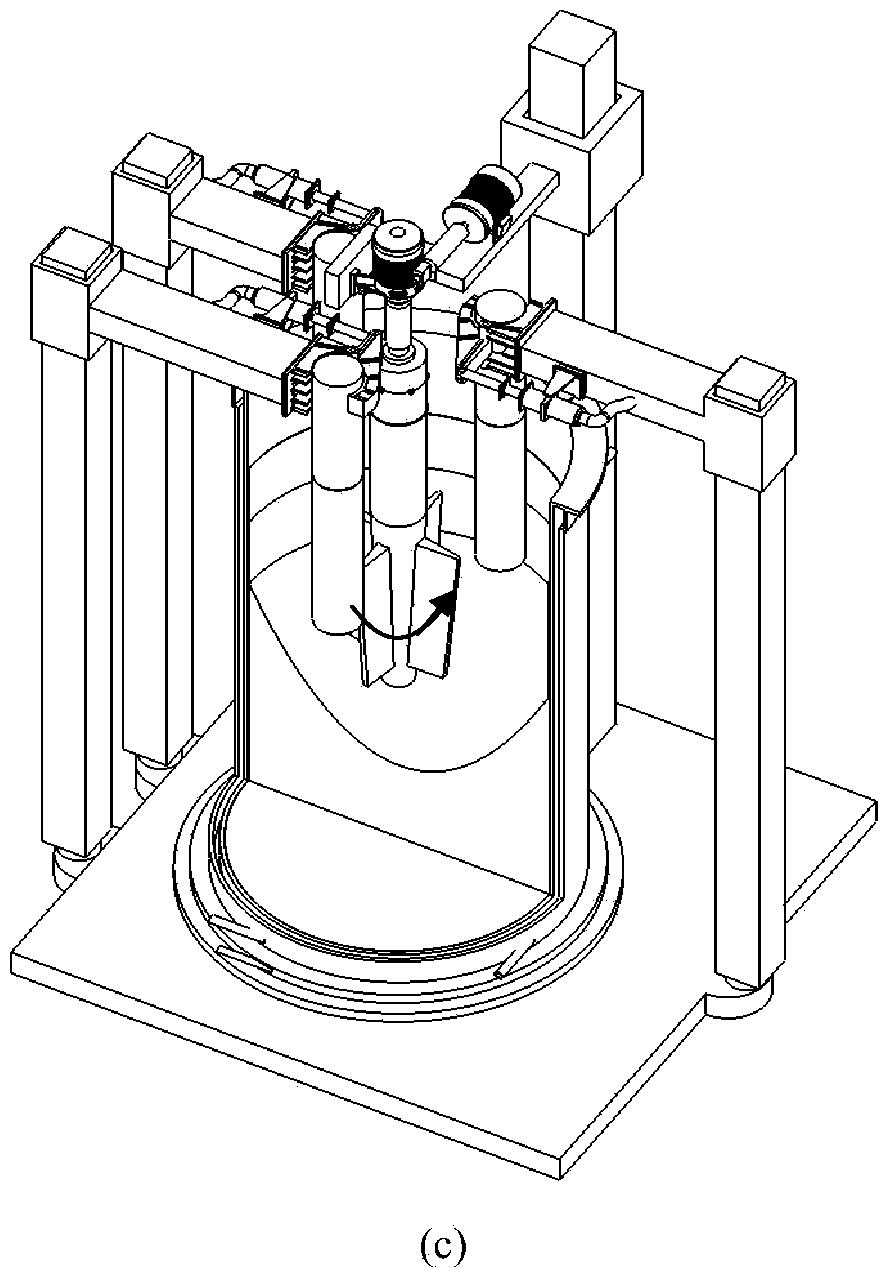

Consumable stirrer added device and method for producing large homogeneous electro-slag re-melting steel ingots

InactiveCN103406520ASpeed up cooling and heat transferShorten the setting timeSlagWater circulation

The invention discloses a consumable stirrer added device and method for producing large homogeneous electro-slag re-melting steel ingots. The device comprises a crystallizer, consumable electrodes, a cooling water circulation system, a lifting cross arm, an electronic control unit, a consumable electrode control unit and a consumable stirrer. The consumable stirrer comprises a stirring shaft and stirring blades which are fixedly connected onto the stirring shaft, and materials of the stirrer are identical to materials of the finally produced large homogeneous electro-slag re-melting steel ingot finished products. The stirring shaft is connected with an output shaft of a speed reducer through a coupling unit, the stirring blades are in sheet structures which thicken from the tops of the blades to the roots of the blades, the stirring blades are fixedly connected onto the stirring shaft in a single-layer multi-sheet mode, and the consumable stirring is controlled by the lifting cross arm to enter and exit the crystallizer. According to the device and the method, rotary flow of molten steel of the steel ingot solidification front is driven by the rotation of the consumable stirrer, so that primary dendrites of the solidification front are fractured to enter melts to form novel crystal nucleuses, the structure compactness is enhanced, and segregation of metal elements are restrained.

Owner:NORTHEASTERN UNIV

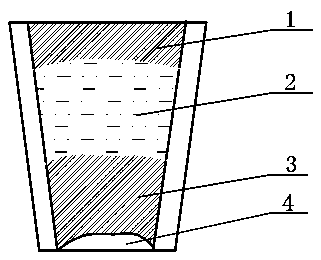

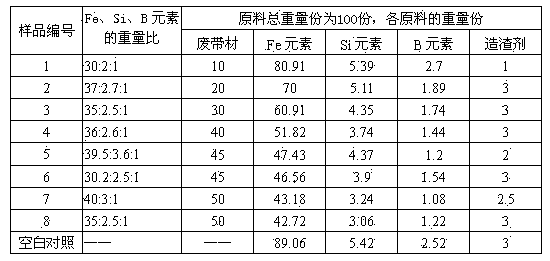

Method for smelting iron-based amorphous master alloy with waste strips

The invention belongs to the technical field of smelting of master alloys for amorphous materials and in particular relates to a method for smelting an iron-based amorphous master alloy with waste strips. The following raw materials are adopted: waste strips, a slag former, pure iron, ferroboron and industrial silicon. The smelting method comprises the following steps: I. firstly adding part of pure iron, all ferroboron and all industrial silicon to an induction furnace and heating the materials; II. after the materials in the induction furnace are chemically cleaned for the first time, adding all the waste strips; III. after the materials in the induction furnace are chemically cleaned for the second time, adding part of the slag former for slag forming and beating; then adding the residual pure iron; IV. when the materials in the induction furnace are chemically cleaned for the third time, introducing argon and adding the slag former for slag forming and beating; V. pouring the product into the master alloy in the required shape. The iron-based amorphous waste strips can be re-smelted by the method, and the prepared iron-based amorphous master alloy achieves the aims of saving resources and reducing the production cost.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

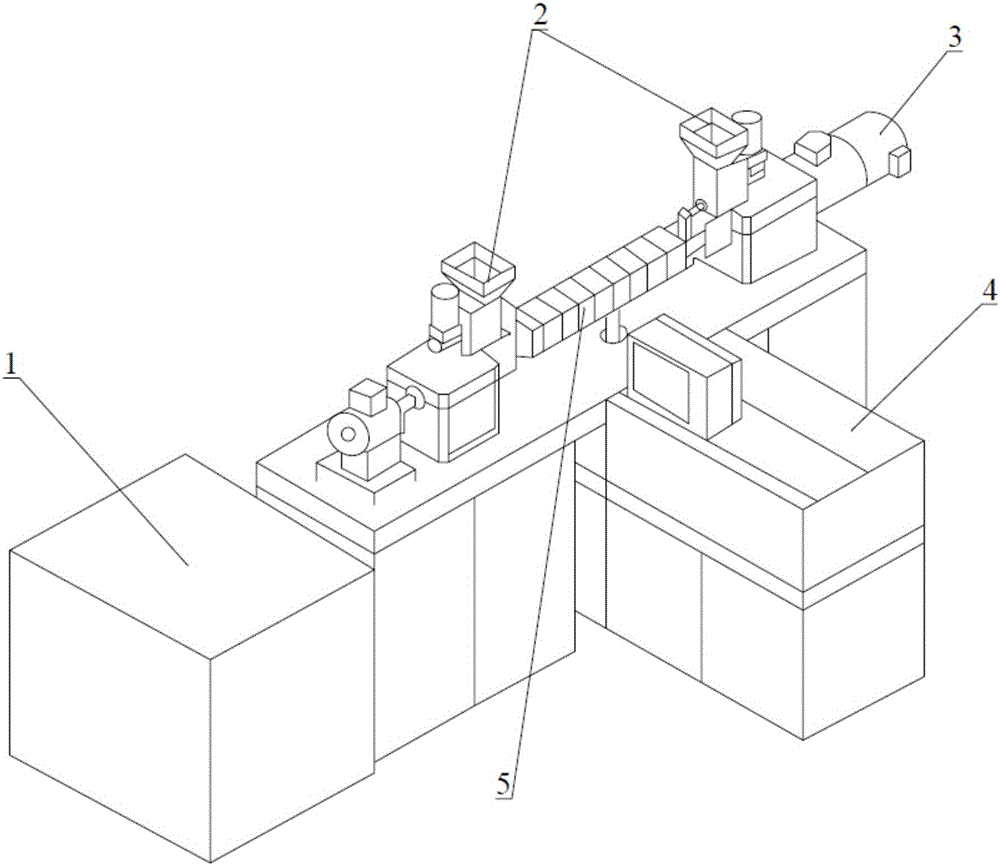

Balanced type triple-screw vibrating force field reinforced plasticizing mixing extrusion method and equipment

ActiveCN105856530AGood plasticizing and mixing effectReduce energy consumptionScrew systemEngineering

The invention discloses balanced type triple-screw vibrating force field reinforced plasticizing mixing extrusion method and equipment. According to the method, an axial vibrating force field is added on a main screw of a triple-screw system, meanwhile, a bidirectional feeding manner is adopted, so that when the triple-screw system rotates, the main screw axially vibrates, and the material suffers from the shearing action and the axial vibrating extrusion grinding action at the same time in the triple-screw system, and thus increasing the mixing effect of the material. The equipment comprises a hydraulic excitation device, a triple-screw system, a measuring and control device, a driving motor and feeding hoppers, wherein two ends of the triple-screw system are respectively provided with the feeding hoppers, two ends of the main screw of the triple-screw system are respectively connected with the hydraulic excitation device and the driving motor, the measuring and control device is arranged at one side of the triple-screw system, and the driving motor and the hydraulic excitation device are respectively in electric connection with the measuring and control device. According to the invention, a conventional plasticizing mixing method is broken through, the vibrating force field is increased, and the plasticizing mixing effect of the material during conveying can be enhanced; and since bidirectional feeding is adopted, the axial resistance of the vibrating force field is eliminated.

Owner:SOUTH CHINA UNIV OF TECH +1

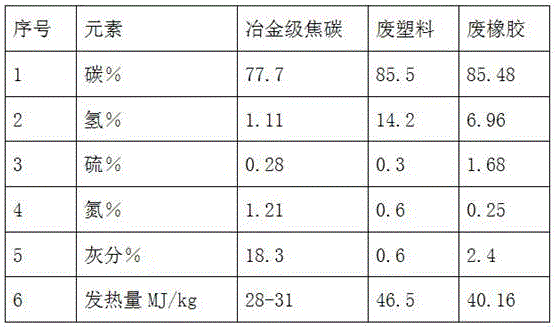

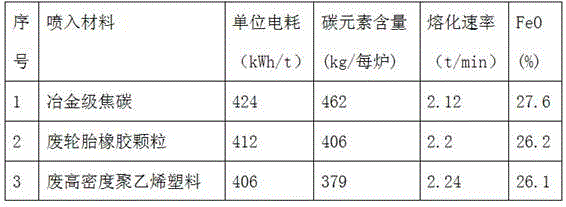

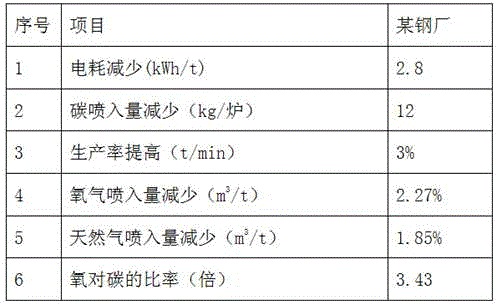

Method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber

ActiveCN106350635ASolve pollutionReduce pollutionElectric furnaceProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber, wherein the steps are as follows: The waste plastic and the waste rubber are to be crushed. When the temperature of the slag reaches 1600-1650oC and the limestone is completely dissolved, the pulverized waste plastic and waste rubber and metallurgical grade coke are injected into the slag. At this time, there is a large amount of FeO in the slag layer, and then FeO is reduced by waste plastics and waste rubber and C in metallurgical grade coke to produce Fe and CO gas, and CO gas is trapped by slag to form foam slag. In order to produce a large amount of foaming slag, oxygen-enriched operation is carried out for feeding oxygen. When the O2 content in the slag exceeds the CO equilibrium curve, excessive CO gas is generated. After the CO gas is captured by the slag, a large amount of foam slag is formed. By mixing the waste plastics, waste rubber and metallurgical grade coke, the foaming slag is characterized by improvement of the electric arc furnace steelmaking efficiency, cost reduction of electric arc furnace steel and less environmental pollution.

Owner:HENAN TAIHANG QUANLI HEAVY IND

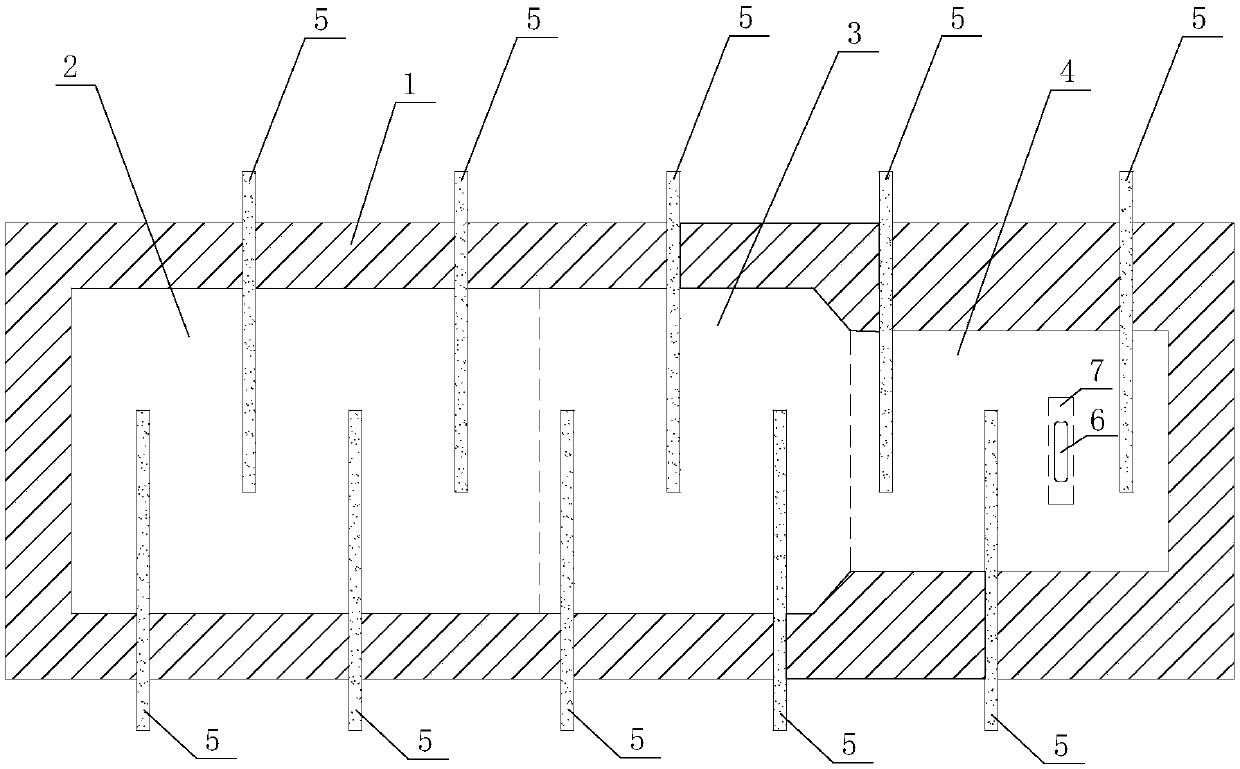

Gas-electric kiln for producing basalt continuous fiber

PendingCN107857462AUniform temperatureUniform compositionGlass furnace apparatusElectric furnaceFiberCombustor

The invention provides a gas-electric kiln for producing basalt continuous fiber. A cavity in a kiln body comprises a melting region, a clarification homogenizing region and a work region; two long high side walls of the melting region, two long high side walls of the clarification homogenizing region and two long high side walls of the work region are each provided with at least one electrode; all electrodes on the two long high side walls of the kiln body are distributed in a staggered mode in the length direction of the kiln body; combustors are arranged on the two long high side walls of the melting region, the two long high side walls of the clarification homogenizing region and the two long high side walls of the work region; the electrified electrodes are immersed in basalt molten liquid, and a heating mode belongs to internal heating; the combustors conduct heating above the basalt molten liquid, and a heating mode belongs to external radiation heating; the two heating modes are combined to form internal and external integrated heating, so that a thermal field in the kiln is more uniform, the melting rate of basalt stone is increased, the temperature and components of the basalt molten liquid are more uniform, the yield and quality of the basalt continuous fiber produced by the single kiln are improved, and the kiln is more beneficial to achieving large-scale industrialproduction of the basalt continuous fiber.

Owner:山东聚源玄武岩纤维股份有限公司

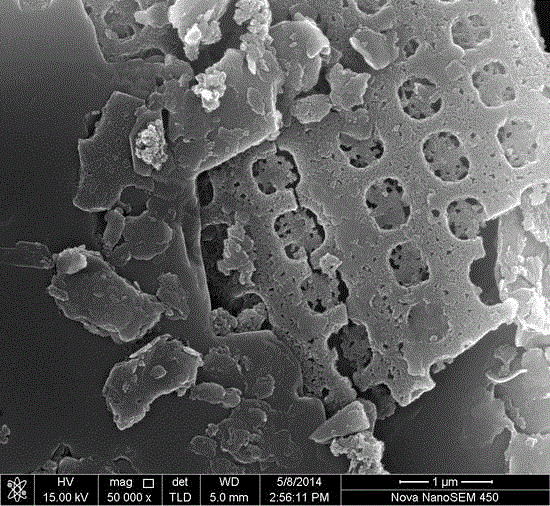

Method for preparing medicinal brown bottle by using cullet

The invention relates to a method for preparing a medical brown bottle by using broken glass, and belongs to the technical field of production technology of glass. The method is characterized in that the brown bottle consists of the following oxide chemical components by weight percentage: 70 to 73 percent of SiO2, 1.8 to 2.2 percent of Al2O3, 0.2 to 0.4 percent of Fe2O3, 7.8 to 8.1 percent of CaO, 2.0 to 2.5 percent of MgO, 14 to 15 percent of R2O, and 0.25 to 0.33 percent of BaO, wherein R is Na or K; and the raw materials contain the broken glass accounting for 10 to 20 percent of the total weight of the raw materials. Through limiting granularity and mixing evenness of the broken glass, the method solves the problem of homogenization of the raw materials, and improves quality of the glass to facilitate medicine packing.

Owner:SHANDONG PHARMA GLASS

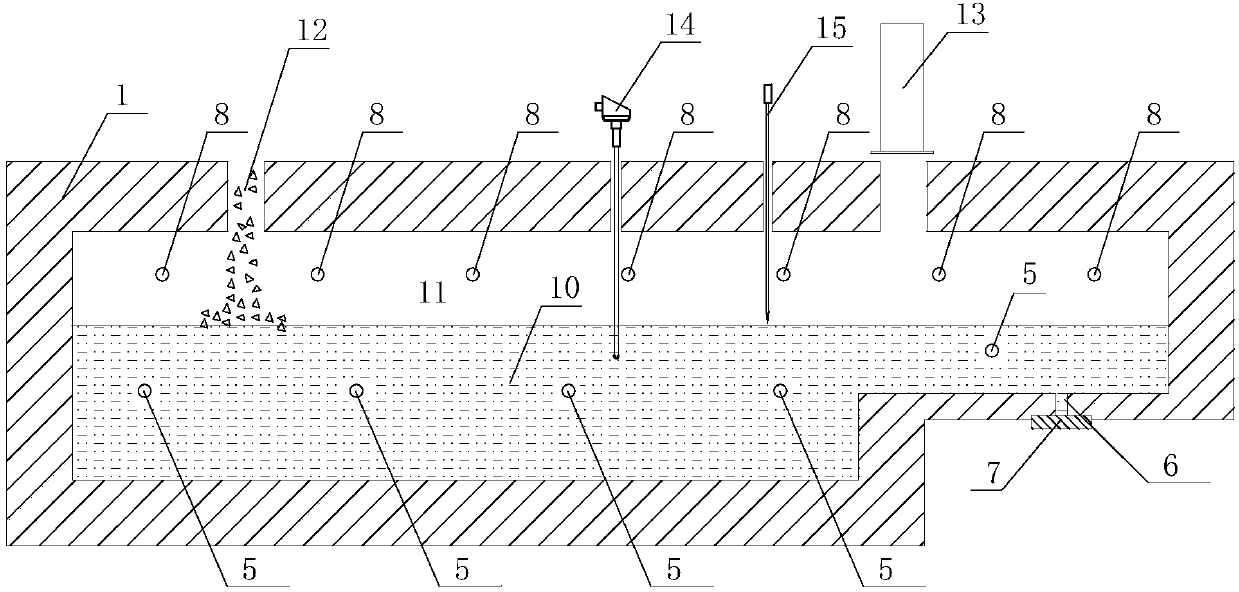

Method for processing and manufacturing aluminum ingot by utilizing and recovering waste aluminum powder

InactiveCN107893163AHigh recovery rateIncrease melting rateProcess efficiency improvementIngotImpurity

The invention relates to the technical field of waste aluminum recovery and utilization and discloses a method for processing and manufacturing aluminum ingot by utilizing and recovering waste aluminum powder. According to the method, the waste aluminum powder and the like are melted again, in the melting process, degassing, deslagging, modifying and refining are carried out, finally casting is carried out, the ingot is formed, the influence of technological parameters like the waste aluminum powder melting time, the refining temperature, the casting speed, the flux ratio and the flux additionamount to quality of the regenerated aluminum ingot is studied, the set technological parameters enable the gas content and the impurity content in a melted aluminum alloy to be minimum, different fluxes are added according to the different purification effects on melt by the fluxes, a covering agent and a refining agent are used, melting impurity can be improved to increase the metal recovery rate, and the metal melting rate can be increased to save fuel and reduce the burning loss. The method solves the problems of some defects like pin holes, looseness, inclusion and air holes occurring inand on the surface of the regenerated aluminum ingot.

Owner:安徽玉成光华铝业有限公司

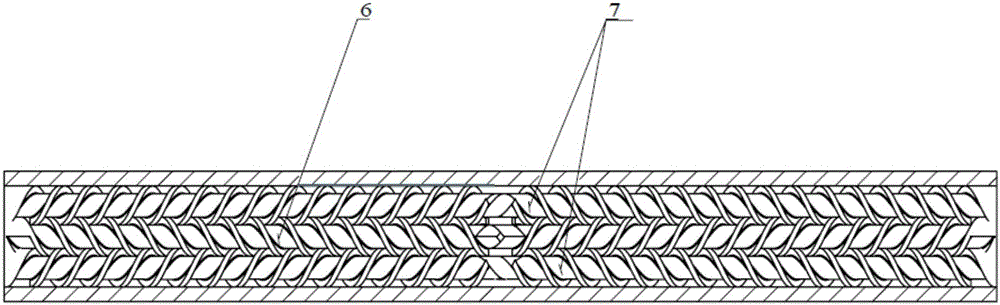

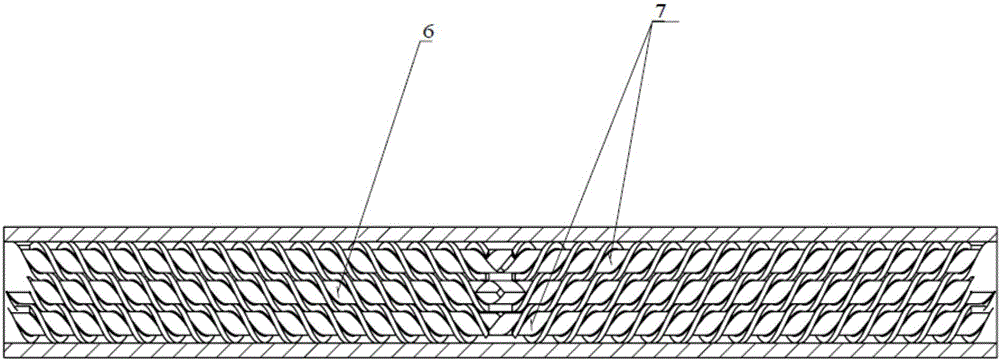

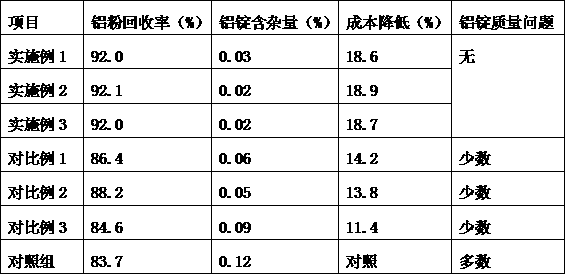

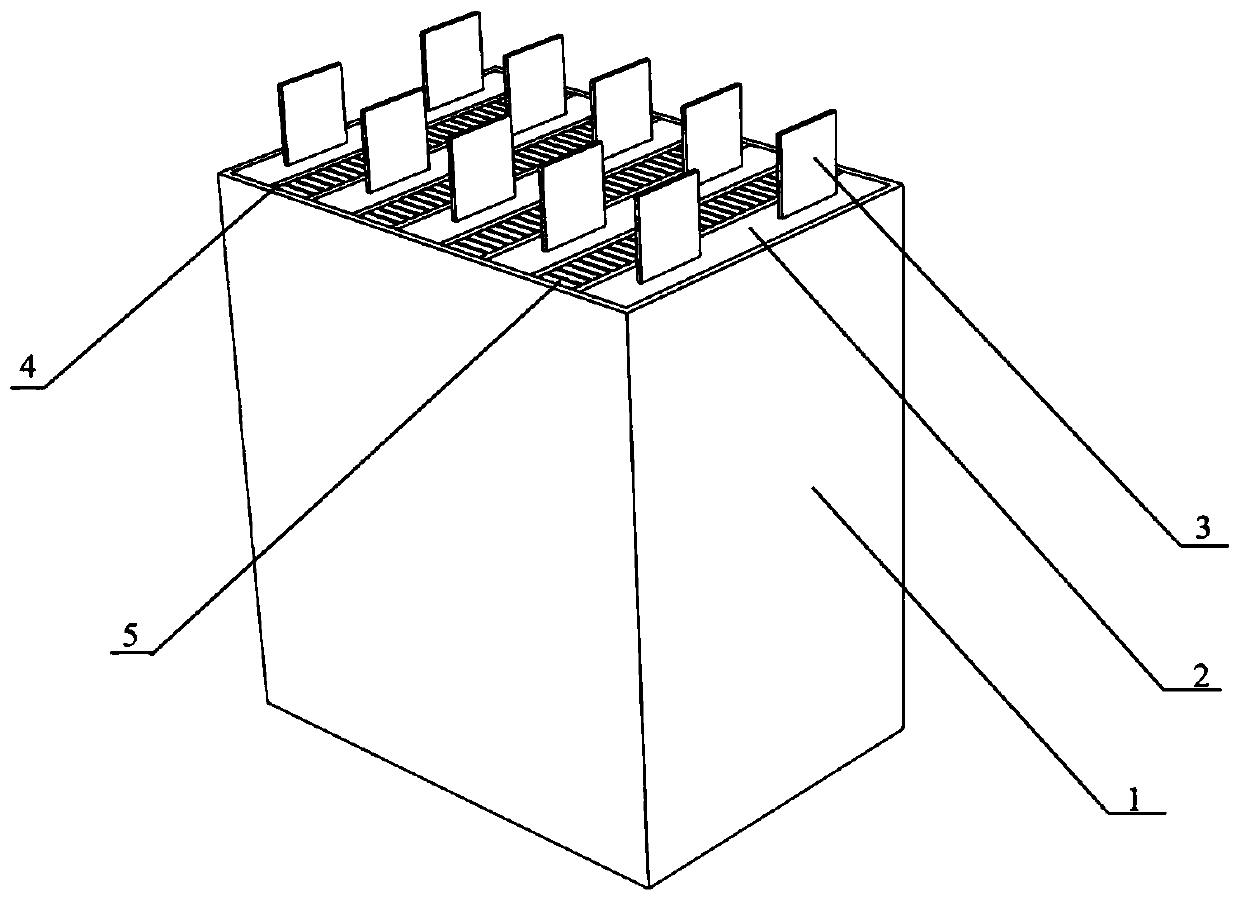

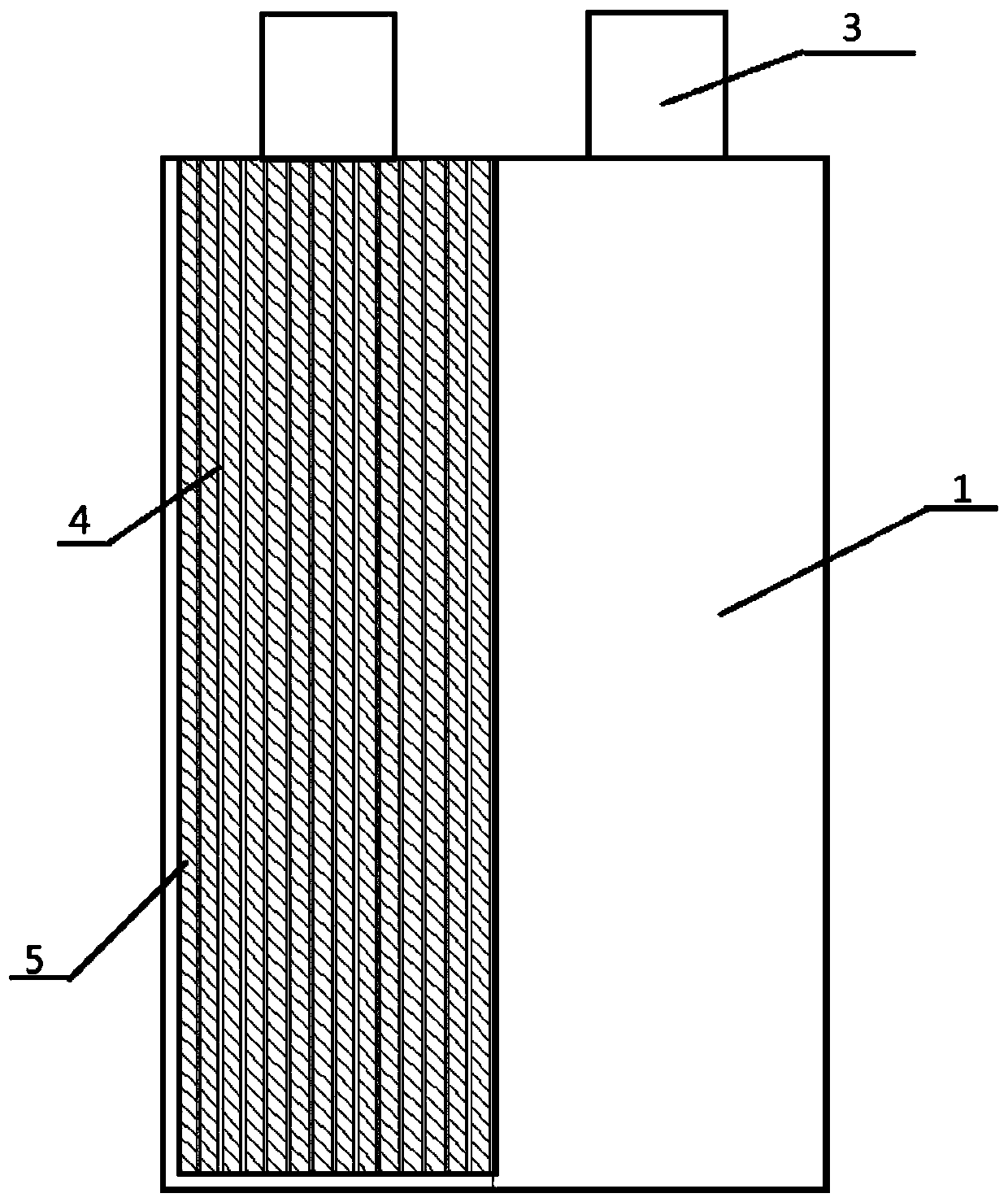

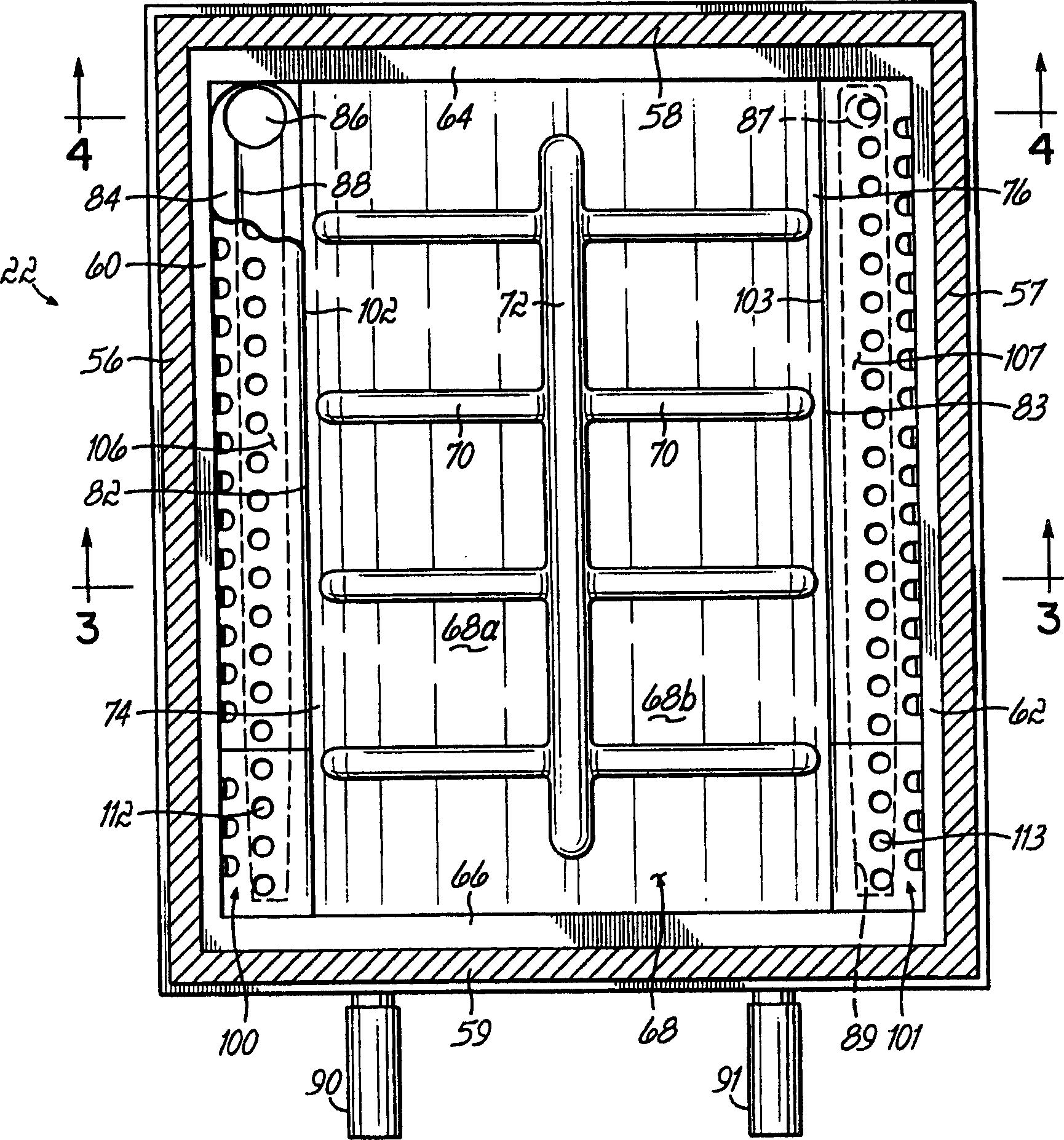

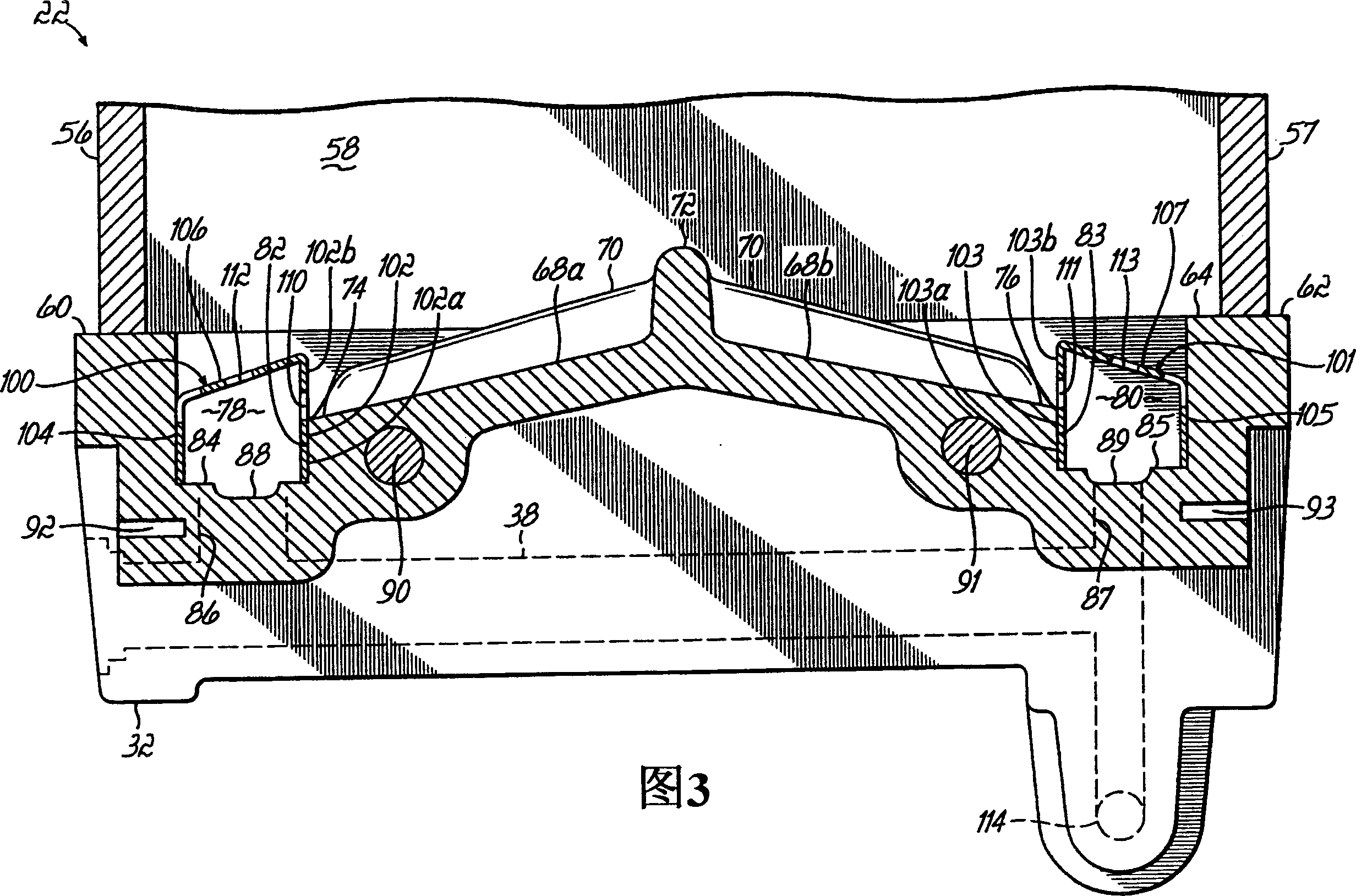

Lithium ion battery module thermal management system based on phase change material- fin composite structure

InactiveCN109768194AGuaranteed temperature uniformityIncrease the heat exchange areaSecondary cellsCell component detailsHeat transfer efficiencyWork performance

The present invention discloses a lithium ion battery module thermal management system based on a phase change material- fin composite structure, pertaining to the field of lithium ion battery thermalmanagement systems. The system comprises an aluminum battery box, and a plurality of square ferric phosphate lithium battery modules and heat-dissipation structures are fixed in the aluminum batterybox, wherein the square ferric phosphate lithium battery modules and heat-dissipation structures are alternately arranged. The upper surface of each ferric phosphate lithium battery module is fixed with ferric phosphate lithium battery tabs. Each heat-dissipation structure consists of a pair of substrates and a plurality of heat-dissipation fins, wherein the heat-dissipation fins are arranged between a pair of substrates, and each two adjacent heat-dissipation fins are filled with a phase change material. According to the thermal management system, the disadvantages of the conventional thermalmanagement system, such as small heat transfer area, low phase change material thermal conductivity and low heat transfer efficiency between the phase change materials and the batteries, are overcome; and the heat conduction and the thermal convection of the phase change materials are improved via the fin structures, so that the battery heating rate is lowered, the battery module temperature gradient is reduced, and the safety, the working performance and the durability of the batteries are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Asphalt modifier compositions with an improved melting rate and modified asphalt prepared using the same

ActiveUS8173725B2Increase melting rateShorten melting timeBuilding insulationsProduction rateAsphalt

The present invention relates to a pellet type SBS-asphalt master batch modifier composition comprising styrene-butadiene-styrene (SBS) block copolymer and asphalt, and modified asphalt prepared by melting and mixing the pellet type SBS-asphalt master batch modifier composition with asphalt. The modified asphalt prepared thereof has advantages that deterioration of physical properties and thermal oxidation can be prevented while productivity can be improved due to reduced melting time of modifier.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Preparation method of anti-freezing asphalt material

The invention discloses a preparation method of an anti-freezing asphalt material. The preparation method comprises the following steps of: heating 20-50 parts by weight of raw material asphalt in a temperature control furnace till the raw material asphalt is molten, then, adding 5-50 parts by weight of an anti-freezing filler and 5-50 parts by weight of quartz powder into the molten asphalt, and uniformly stirring; and pouring a sticky mixture into a pre-heated aluminium-made mould to naturally level while the sticky mixture is hot, cooling to room temperature, and polishing the surface of a sample by using metallographical abrasive paper with certain meshes so as to obtain the anti-freezing asphalt material. The preparation method of the anti-freezing asphalt material disclosed by the invention is simple; the use amount of sodium chloride in the traditional salt deicing method can be greatly reduced; the anti-freezing asphalt material has the anti-freezing effect on water droplets with super-cooled surfaces in the range of 0-8 DEG C; even frozen at a lower temperature (such as -15 DEG C), the ice melting rate is rapider than that of the common surface; the asphalt material disclosed by the invention can be used for paving highway pavement and is capable of preventing the highway pavement from freezing in the range of 0-8 DEG C; and therefore, traffic accidents are reduced.

Owner:JIANGXI GANYUE EXPRESSWAY

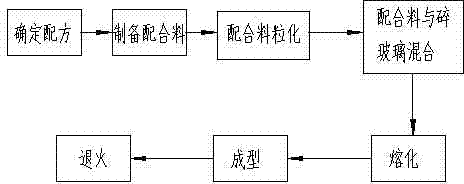

Porcelain white glass and production technique thereof

The invention relates to a porcelain white glass and a production technique thereof. The production technique comprises the following steps: (1) preparation of mixture; (2) melting: melting the mixture and glass cullet in a kiln; (3) forming: forming in a glass forming device; and (4) annealing: annealing in an annealing kiln. The porcelain white glass is prepared from the following raw materials in percentage by weight: 60-90% of mixture and 10-40% of glass cullet. The mixture comprises the following components in parts by weight: 50-60 parts of quartz sand, 13.5-16 parts of soda ash, 10-12 parts of aluminum hydroxide, 9-11 parts of sodium fluosilicate, 5-7 parts of fluorite, 0-1.5 parts of barium sulfate, 0.5-2 parts of sodium nitrate, 0-3 parts of calcite and 0.3-0.7 part of composite clarifier. The porcelain white glass with high-whiteness porcelain appearance effect can be obtained by finely regulating and controlling the raw material formula and technological parameters.

Owner:吴江光华玻璃厂

Waterproof coiled material paving device with good stability

The invention discloses a waterproof coiled material paving device with good stability, and belongs to the technical field of waterproof coiled material paving. The device comprises an L-shaped supporting plate, damping rods are arranged on the four corners of the bottom of the supporting plate, a fire extinguisher, a waterproof coiled material shaft support, a flat paving roller and a U-shaped base are arranged on the top plane of the supporting plate from left to right in sequence, the device is high in stability, the four corners of the bottom of the supporting plate are provided with the damping rods, the stability of the device can be effectively improved, a buffer spring and a guide plate are arranged on the inner wall of the U-shaped base, a gas tank can be conveniently stored, thegas tank stability can be effectively improved, shaking of the gas tank during work can be avoided, a preheating flame nozzle and a heating flame nozzle are formed in the bottom end of a gas conveyingpipe, the melting rate of the waterproof coiled material can be effectively improved, a compression spring achieves the buffer and pressure reduction effect on a press roller on the bottom of a T movable rod, break of the just-molten waterproof coiled material due to the too large pressure can be avoided, and the work efficiency is not affected.

Owner:江苏中岩岩土工程有限公司

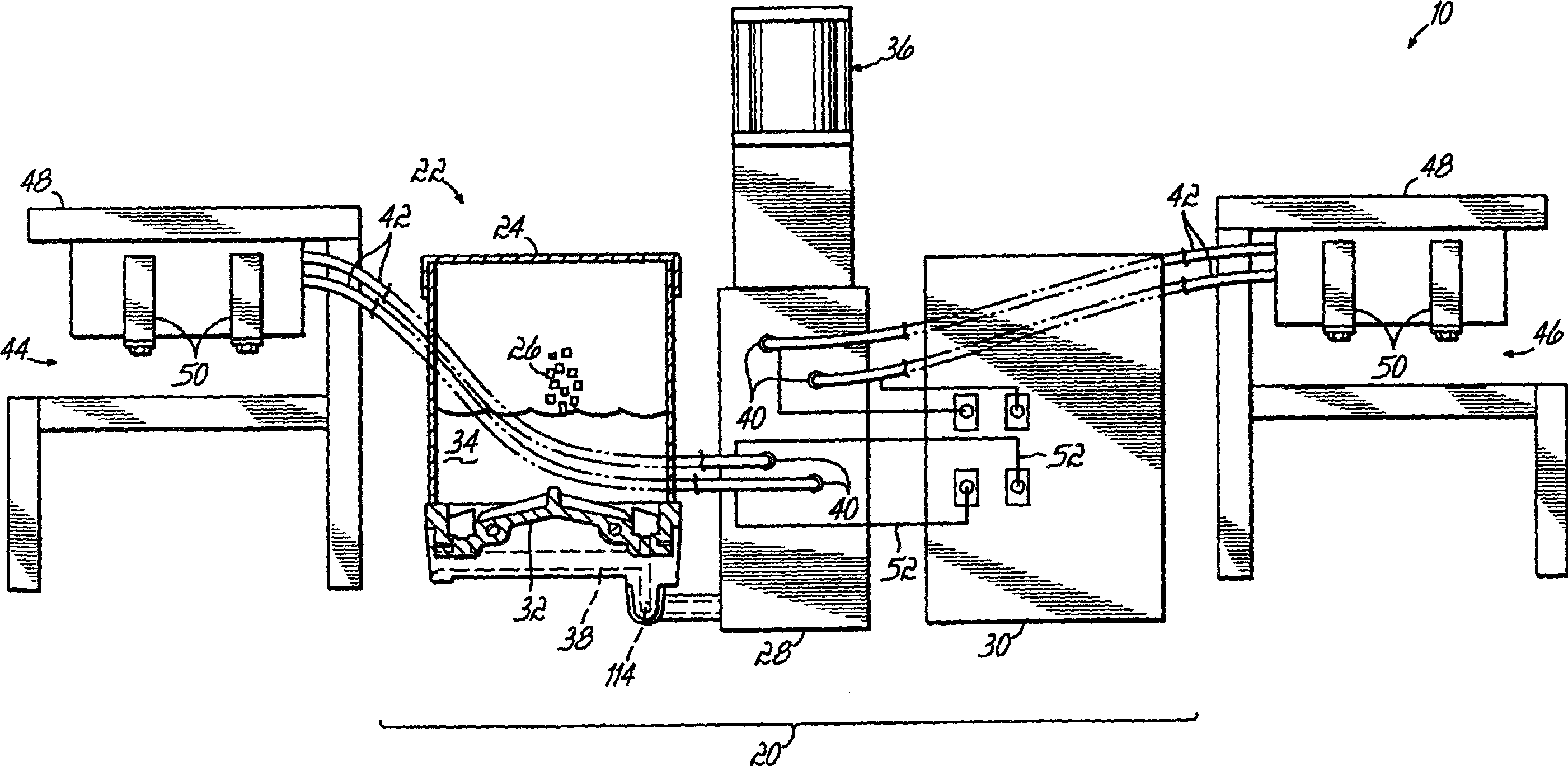

Apparatus and method for melting and supplying thermoplastic material to a dispenser

InactiveCN1775377AIncrease melting rateIncrease productionLiquid surface applicatorsCoatingsSemi solidEngineering

Apparatus and methods for melting and supplying thermoplastic material to a dispenser. The apparatus includes a tank having at least one side wall for receiving a solid or semi-solid thermoplastic material and a base member supporting the at least one side wall, the base member for heating and melting the thermoplastic material. The base member has a heated upper surface sloping downwardly toward the one or more side walls for directing the flow of molten material and is configured to provide a collection for receiving molten material groove. A filter element is positioned above this collection trough to filter the molten material. The filter is adapted to support remaining solid or partially cured thermoplastic material over a portion of the heated upper surface and provide a less restricted flow path for the molten material to the collection tank.

Owner:NORDSON CORP

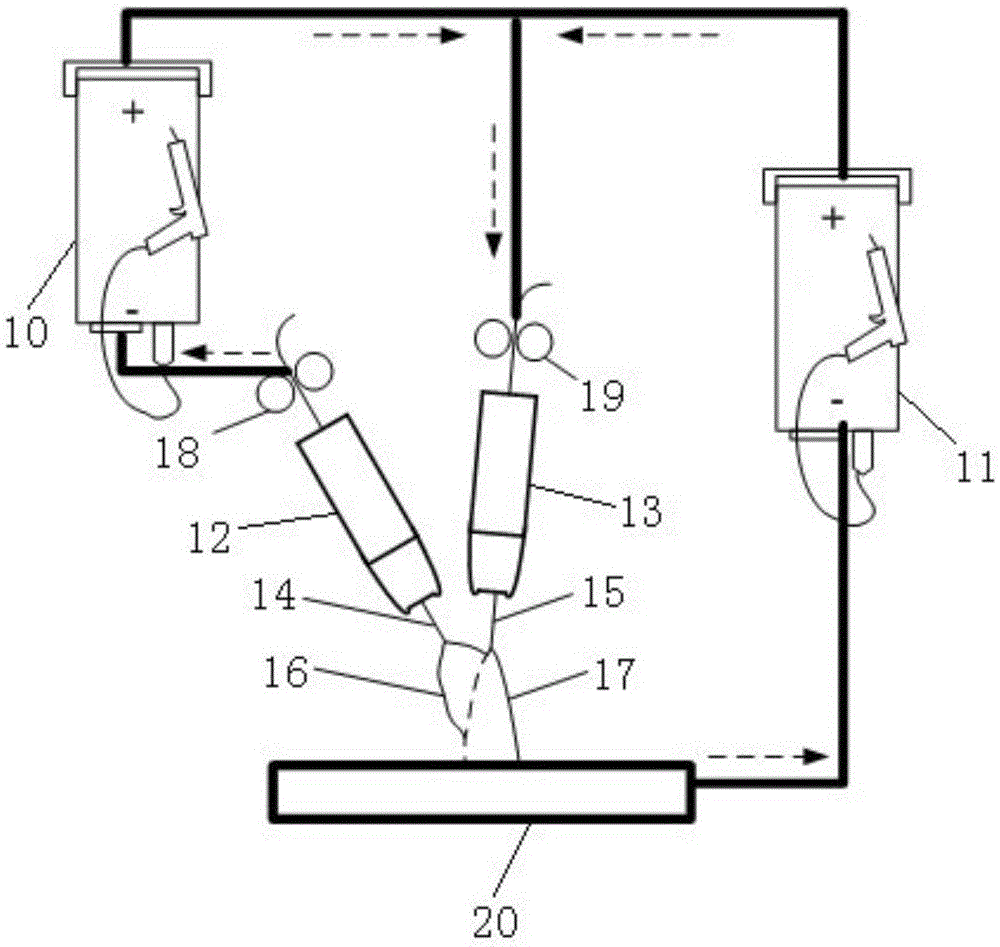

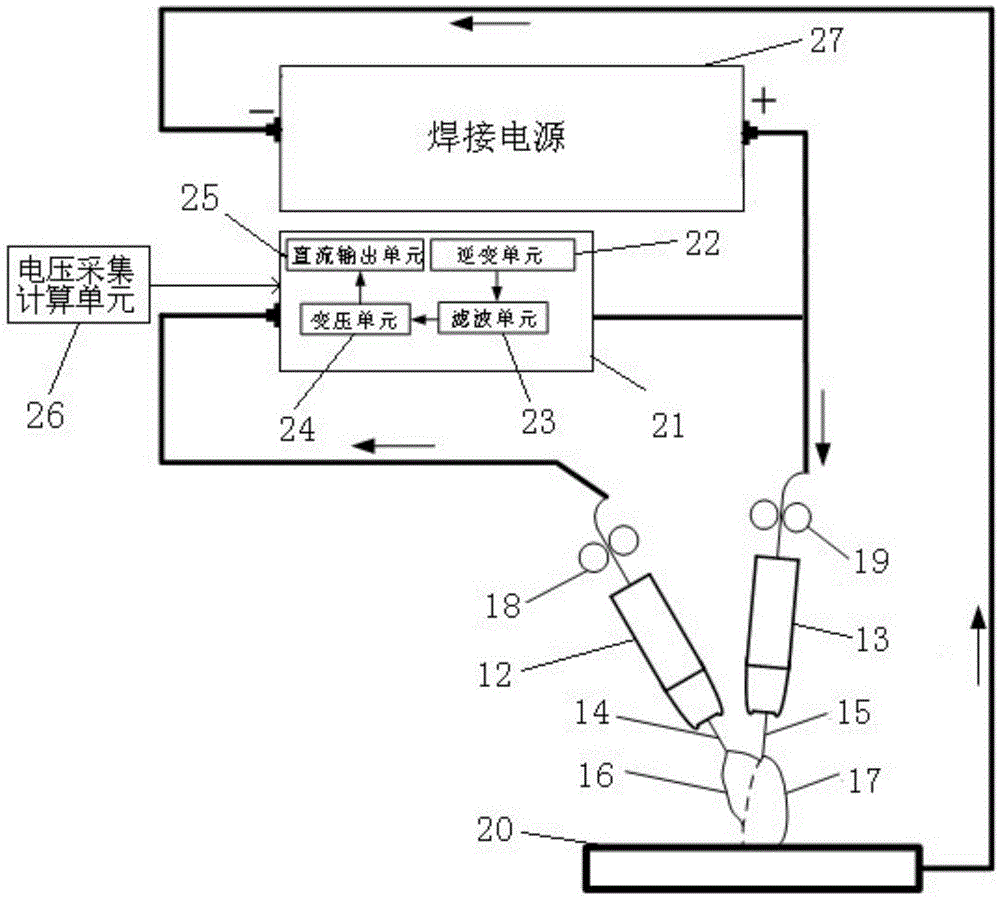

Twin-wire bypass coupled arc efficient metal-inert gas (MIG) welding system

InactiveCN105562897AGuaranteed stable combustionImprove welding qualityArc welding apparatusSystem structureElectric arc

The invention belongs to the technical field of welding and provides a novel twin-wire bypass coupled arc efficient metal-inert gas (MIG) welding system. By the adoption of the twin-wire bypass coupled arc efficient MIG welding system, the problems that an existing twin-wire bypass coupled arc efficient MIG welding system is complex in structure and high in cost are solved. The twin-wire bypass coupled arc efficient MIG welding system comprises a welding power source and a dynamic voltage adjusting device. The dynamic voltage adjusting device comprises an invert unit, a filtering unit, a voltage transformation unit and a direct-current output unit. The invert unit is used for inverting direct currents output by the positive electrode of the welding power source into alternating currents. The filtering unit is used for filtering current higher harmonics output by the invert unit in the inverting process. The voltage transformation unit is used for converting the output voltage of the invert unit into the voltage equivalent to the compensation amount of the bypass voltage. The direct-current output unit is used for rectifying the alternating currents output by the voltage transformation unit into the direct currents and outputting the direct currents. Due to the fact that the welding system comprises the welding power source, the system structure is simplified, and the welding cost is reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com