Fluxing apparatus of LCD glass melting furnace

A technology of liquid crystal glass and pool furnace, applied in glass furnace equipment, glass production, glass manufacturing equipment, etc., can solve the problems of unable to meet the production requirements of liquid crystal glass, high melting temperature of liquid crystal glass, and inability to produce liquid crystal glass, etc., to achieve uniformity of clarification , It is beneficial to melting and accelerating the effect of melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

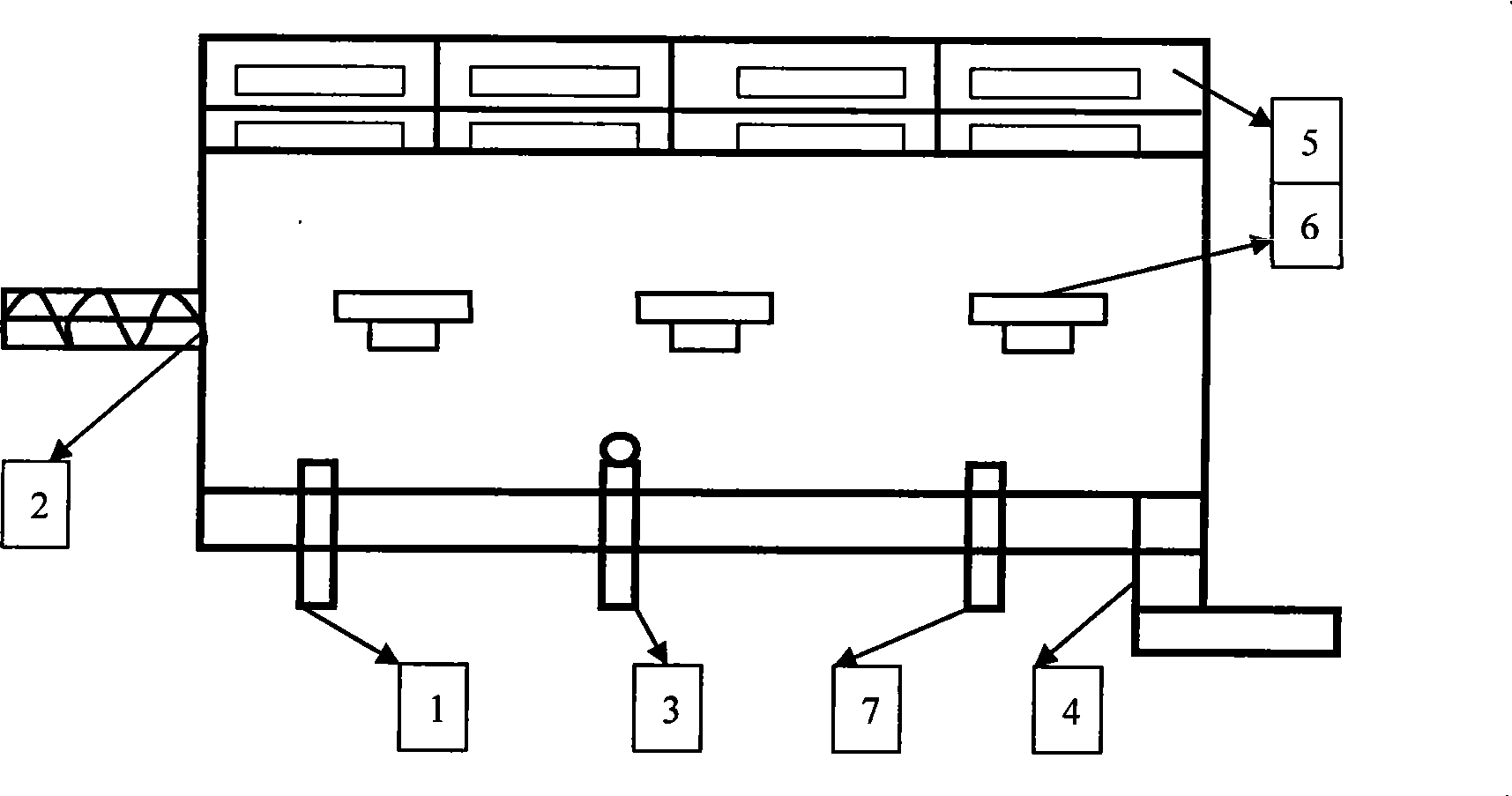

[0031] Embodiment: As shown in the figure, the present invention installs a row of electrodes 1 on the bottom of the pool between the feed port 2 and the bubble 3 of the pool furnace, and installs a row of electrodes 7 on the bottom of the pool near the flow hole 4 in the clarification area. The pure oxygen burner 6 which injects the flame into the furnace is installed on the pool furnace. The roof tile 5 used in the upper part of the pool furnace is the brick surface that transmits heat to the glass surface by radiation into the roof tile 5 of the inner arc. The radian of the crown brick 5 is about 60° with the angle between the inner surface of the brick. The electrode 1 is located at the bottom of the pool close to the feeding port 2 and two-thirds away from the bubble 3 .

[0032] A method for boosting a liquid crystal glass pool furnace, characterized in that:

[0033] 1) Feed the batch material into the pool furnace from the feeding port 2, and install a row of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com