Liquid crystal composition and display unit containing the same

A technology of liquid crystal composition and display unit, applied in liquid crystal materials, optics, instruments, etc., can solve problems such as low birefringence and viscosity, and achieve good refractive anisotropy, good low-temperature storage, and good dielectric anisotropy The effect of the opposite sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

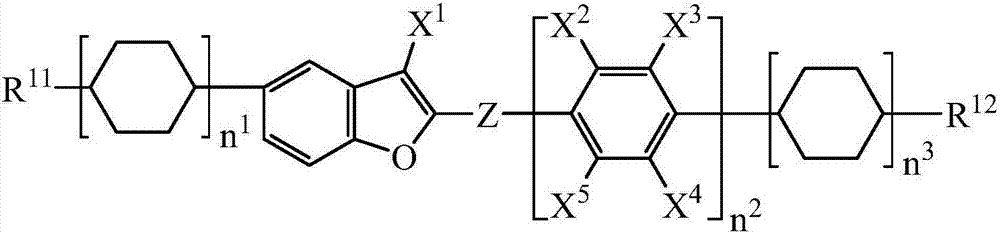

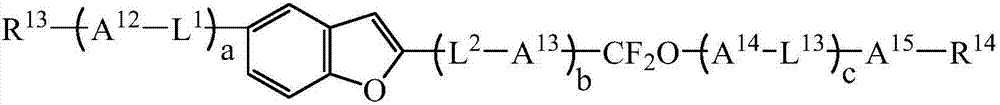

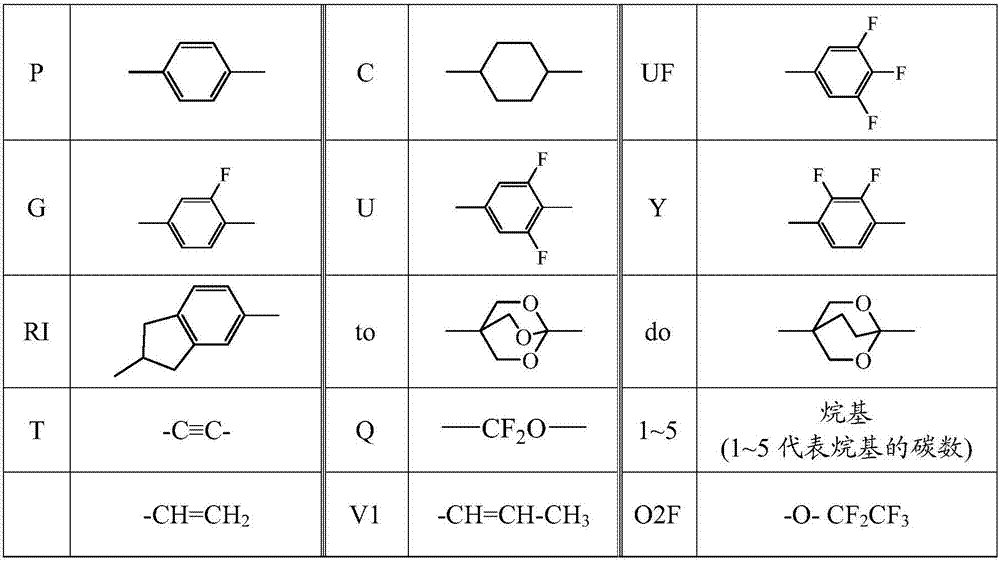

Method used

Image

Examples

Embodiment 1

[0071] The liquid crystal compositions of Example 1, Example 2 and Comparative Example 1 were mixed at 25° C. to obtain liquid crystal compositions according to the composition and content of the compounds shown in Table 2 below. The liquid crystal compositions of Example 1, Example 2 and Comparative Example 1 were respectively tested according to the following test methods, and the results obtained are summarized in Table 2 below.

[0072] [testing method]

[0073] 1. Clarification point temperature (T ni , ℃): Using a differential scanning calorimeter (DSC) system, place the liquid crystal composition on an aluminum pan and accurately weigh 0.5 to 10 mg. The starting point to determine the phase change temperature. The expression of the phase change is: the crystalline phase is marked as C, the smectic phase is marked as S, the nematic phase is marked as N, and the liquid is marked as I. Among them, the phase transition temperature from the nematic phase to the liquid is ...

Embodiment 3

[0083] The liquid crystal compositions of Example 3 and Comparative Example 2 were mixed at 25° C. according to the composition and content of the compounds in Table 3 below to obtain liquid crystal compositions. The liquid crystal compositions of Example 3 and Comparative Example 2 were respectively tested according to the aforementioned test methods, and the results obtained are summarized in Table 3 below.

[0084] table 3

[0085]

[0086] As can be seen from the results in Table 3, the liquid crystal composition of Example 3 can have a higher T because it contains the compound shown in the chemical formula 2. ni , better Δε, Δn and K 11 , and good low temperature storage.

Embodiment 4、5

[0087] [Example 4, 5 and Comparative Examples 3 and 4]

[0088] The liquid crystal compositions of Examples 4 and 5 and Comparative Examples 3 and 4 were mixed at 25° C. according to the composition and content of the compounds in Table 4 below to obtain liquid crystal compositions. The liquid crystal compositions of Examples 4 and 5 and Comparative Examples 3 and 4 were respectively tested according to the aforementioned testing methods, and the results obtained are summarized in Table 4 below.

[0089] Table 4

[0090]

[0091] Comparing the results of Example 4, Example 5 and Comparative Example 3, it can be found that the Δn of the liquid crystal composition of Comparative Example 3 is low and does not have low-temperature storage properties, which proves that when the liquid crystal composition is not added to the liquid crystal composition shown in Chemical Formula 2 When the compound is used, it will not be able to store at low temperature.

[0092] Comparing the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com