Patents

Literature

44results about How to "Beautiful weld bead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

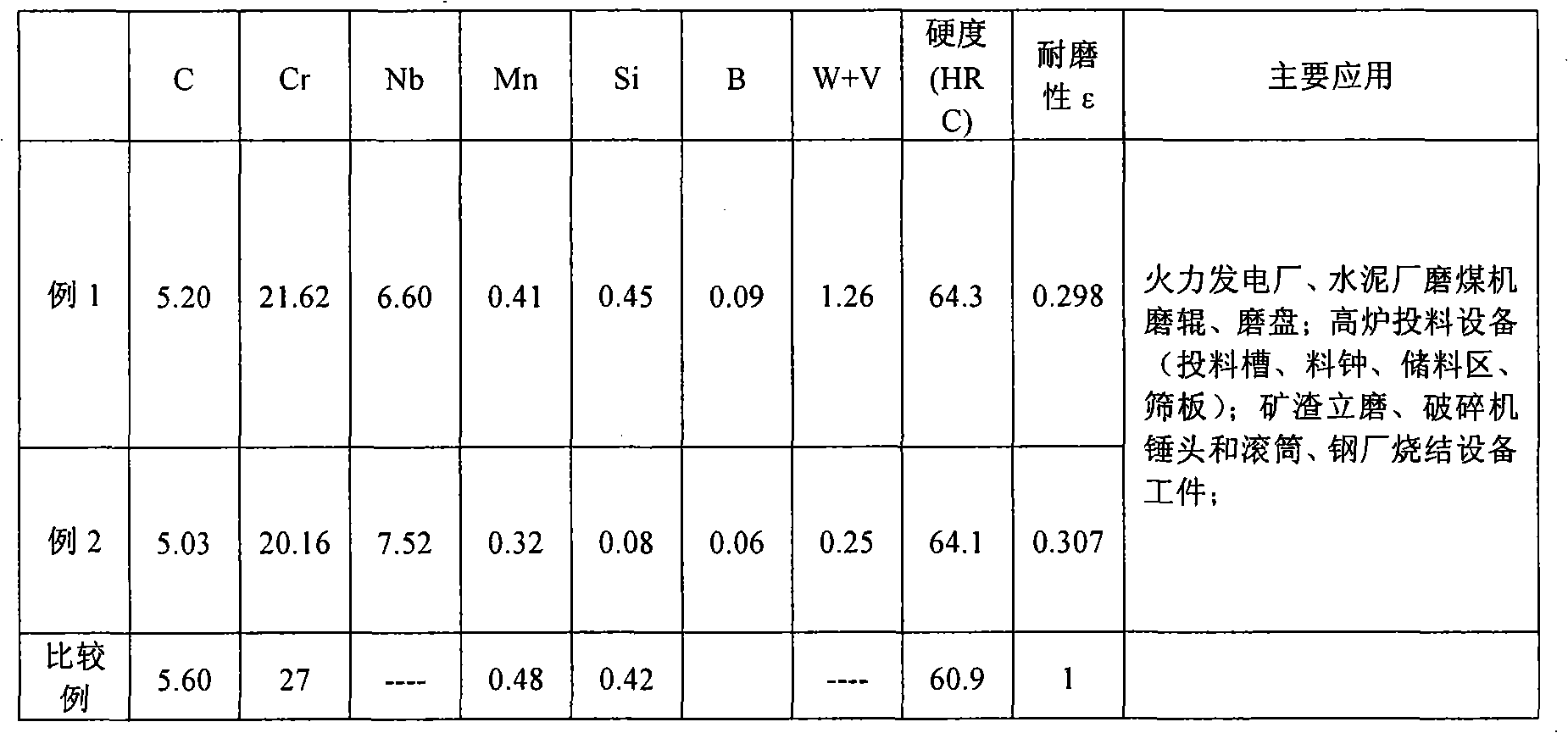

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

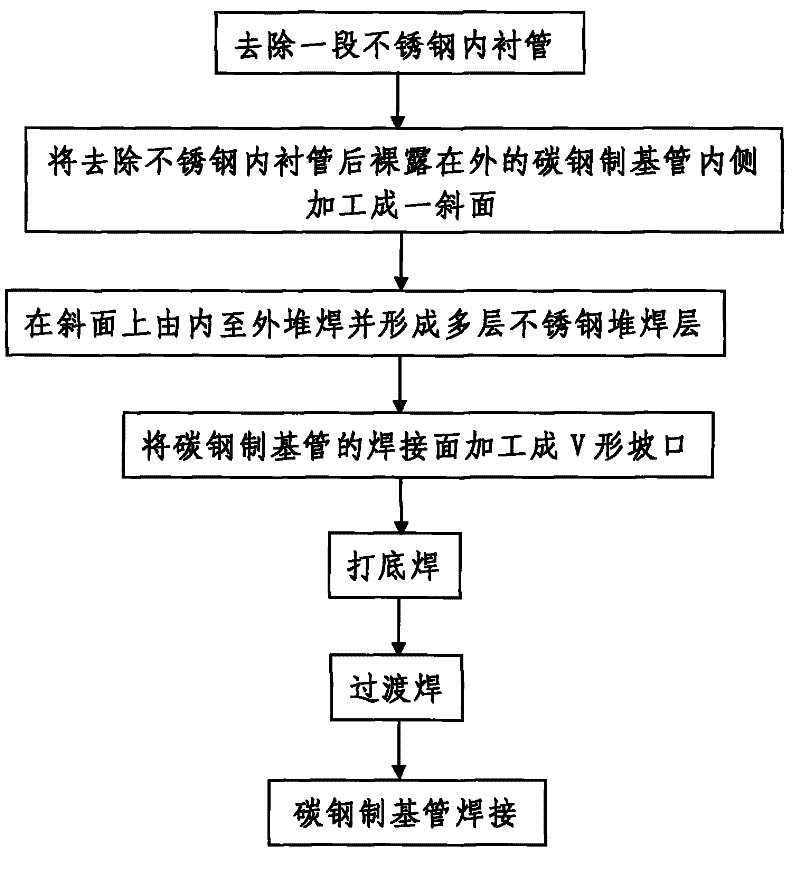

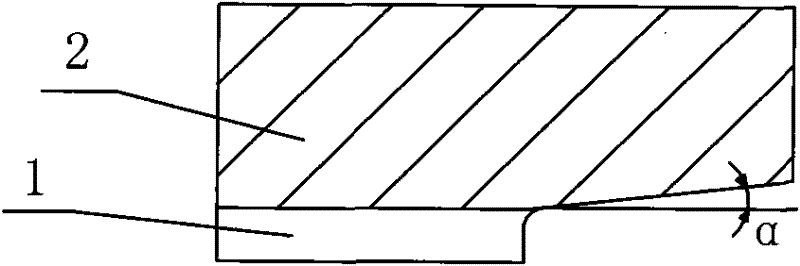

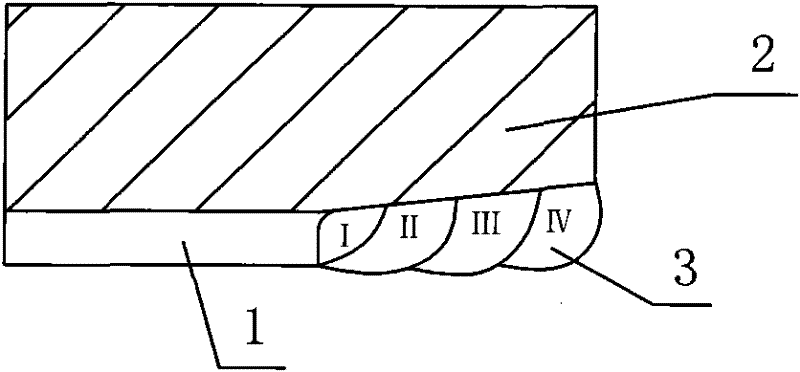

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/cutting media/materialsCarbon steelArc welding

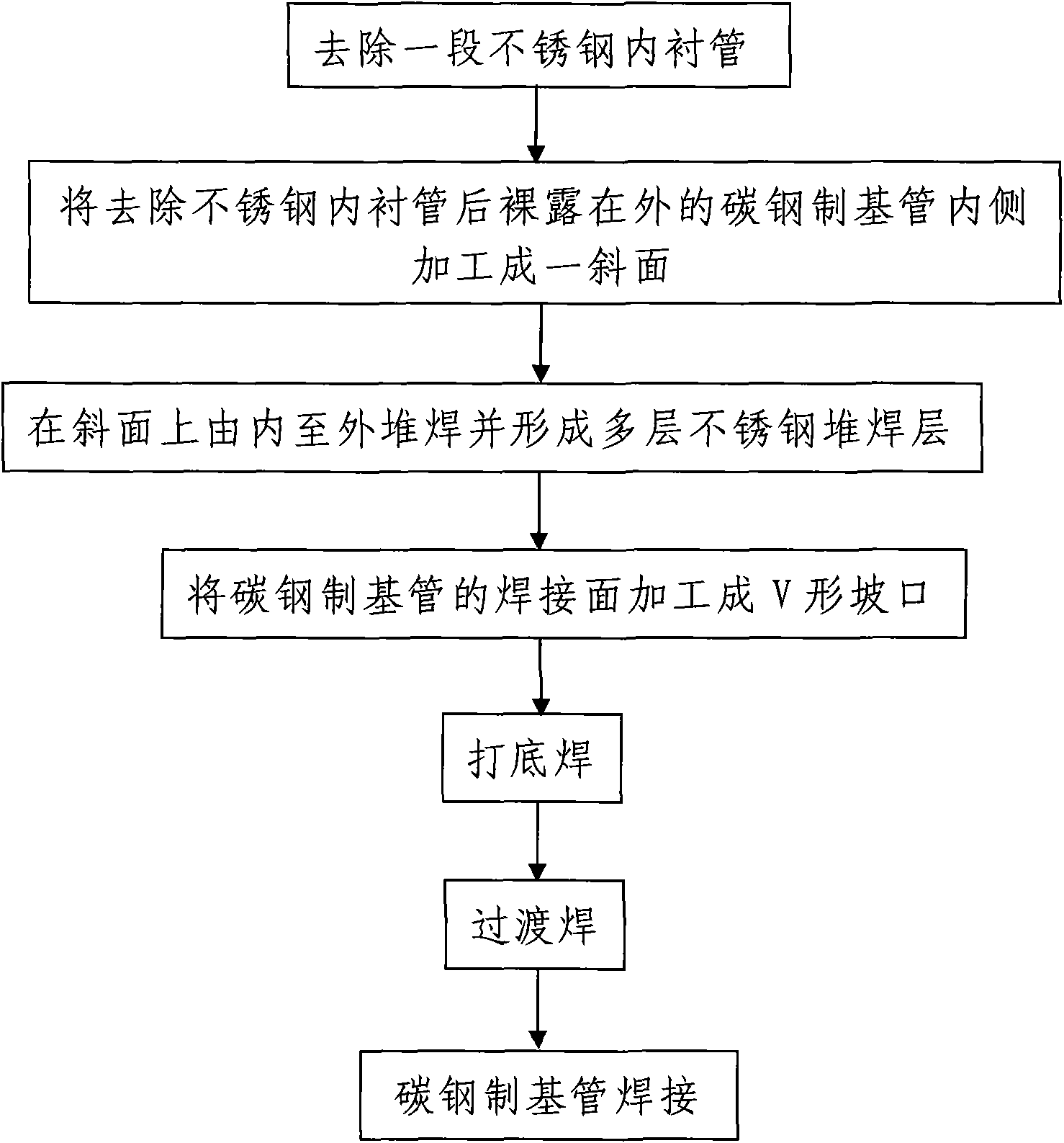

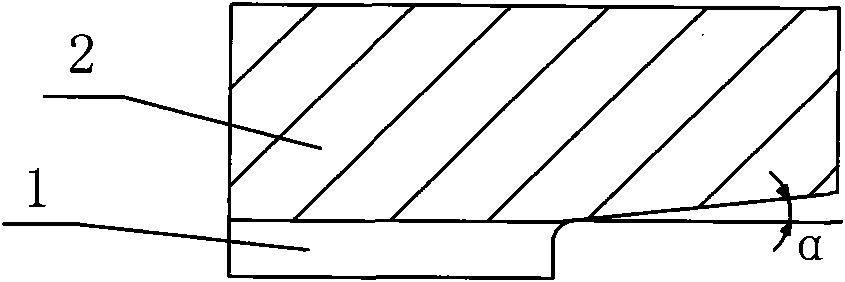

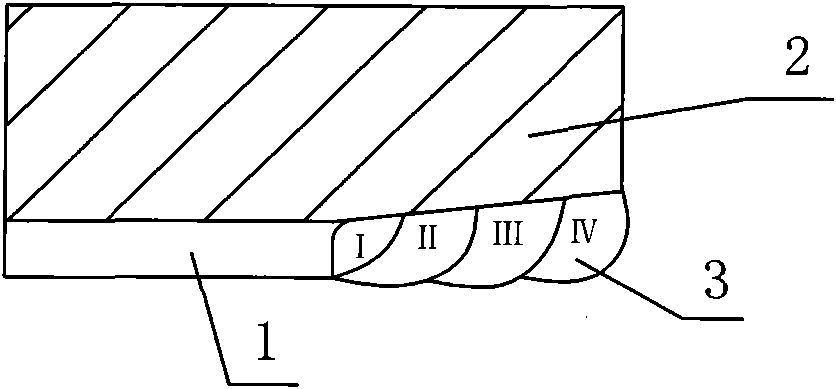

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows:removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclinedinwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

Self-protecting flux-cored wire for overlaying welding and use thereof

ActiveCN101081467AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaChromium carbideFerrosilicon

The present invention belongs to the field of composite material producing technology, and is especially one kind of self-protecting flux cored welding wire for build-up welding and its use. The flux core of the welding wire is mixture of alloy powder and mineral powder, and consists of chromium carbide 50-80 wt%, Mn 4-10 wt%, 75# ferrosilicon 2-6 wt%, Zr-Si-Fe 1-3 wt%, graphite 3-6 wt%, dolomite 1-3 wt%, natural rutile 0.1-3 wt%, Mo 1-6 wt%, Nb 3-6 wt%, V 2-8 wt%, W 0.1-2 wt%, Na2SiF6 0.1-3 wt%, ZrO2 1-3 wt%, and NaF0.1-2 wt%. The self-protecting flux cored welding wire for build-up welding has no need of adding protecting gas and flux, stable arc, fewer spattering and other advantages. It is applied mainly for build-up welding of grinding roll, grinding disc, antiwear plate, etc.

Owner:李淑华 +1

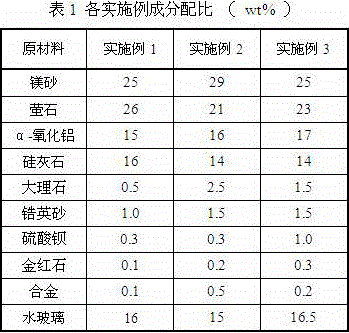

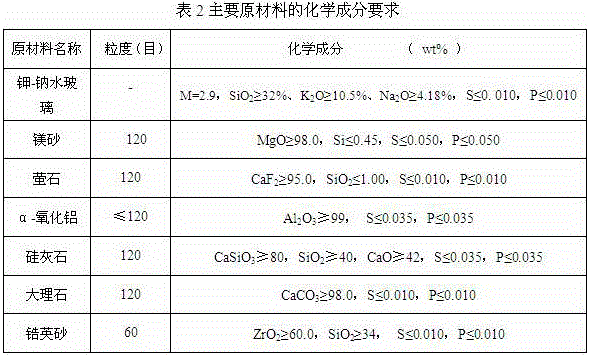

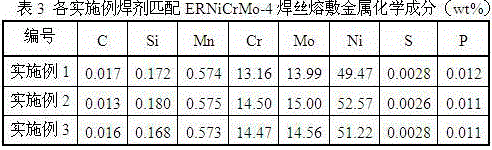

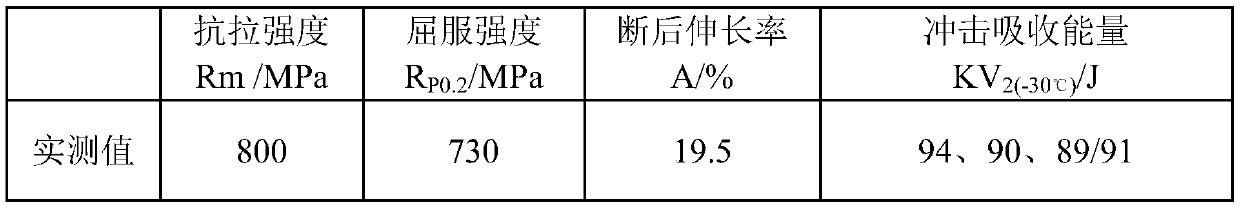

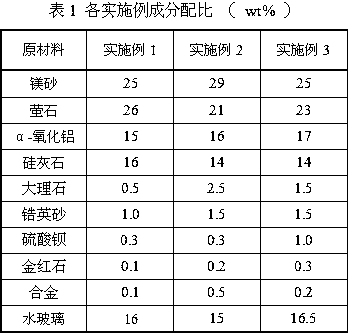

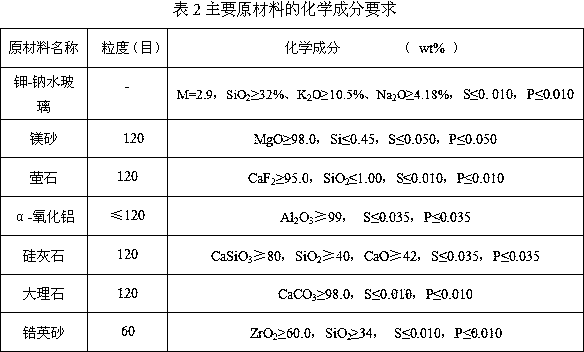

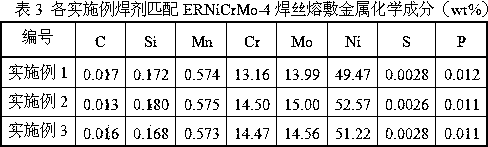

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

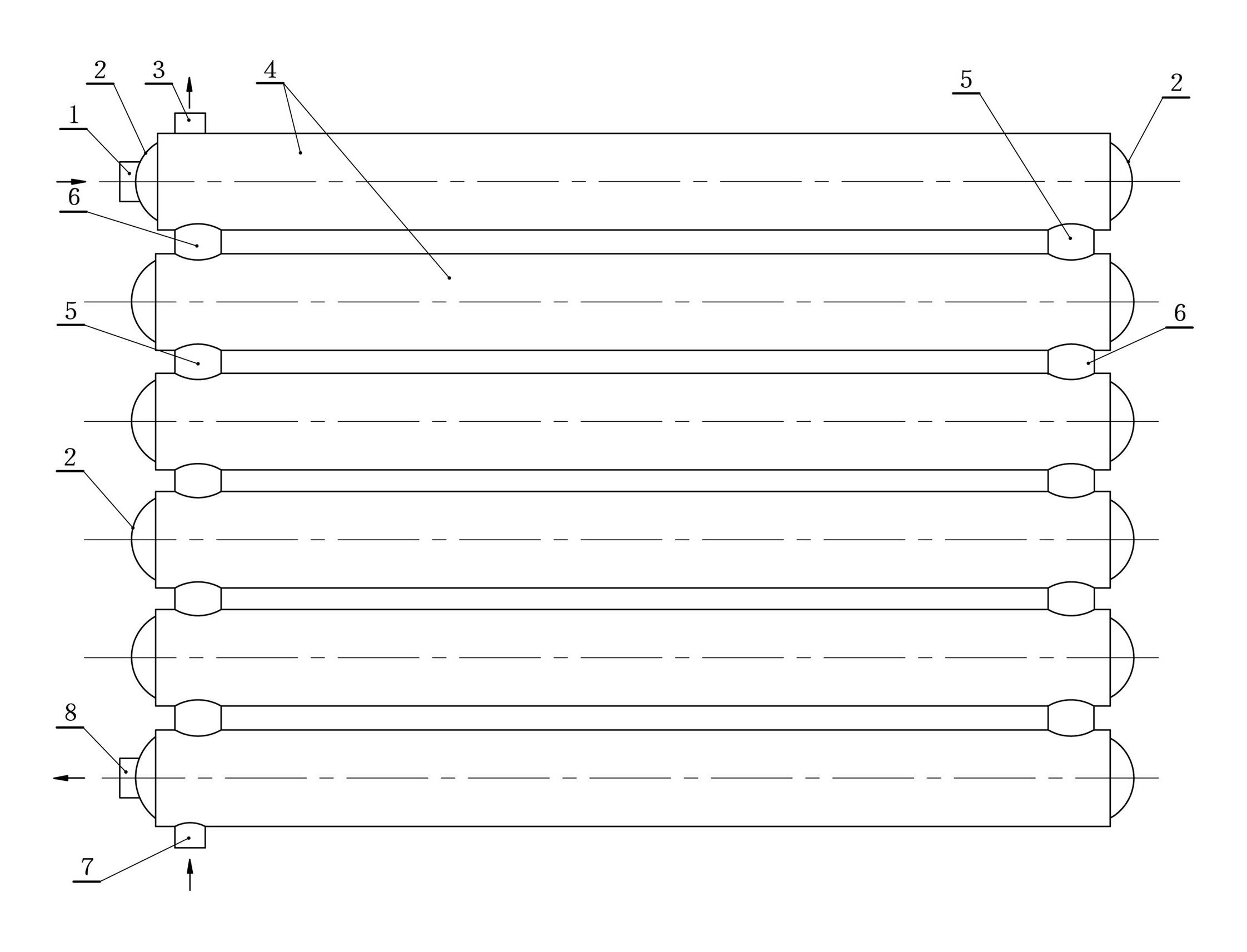

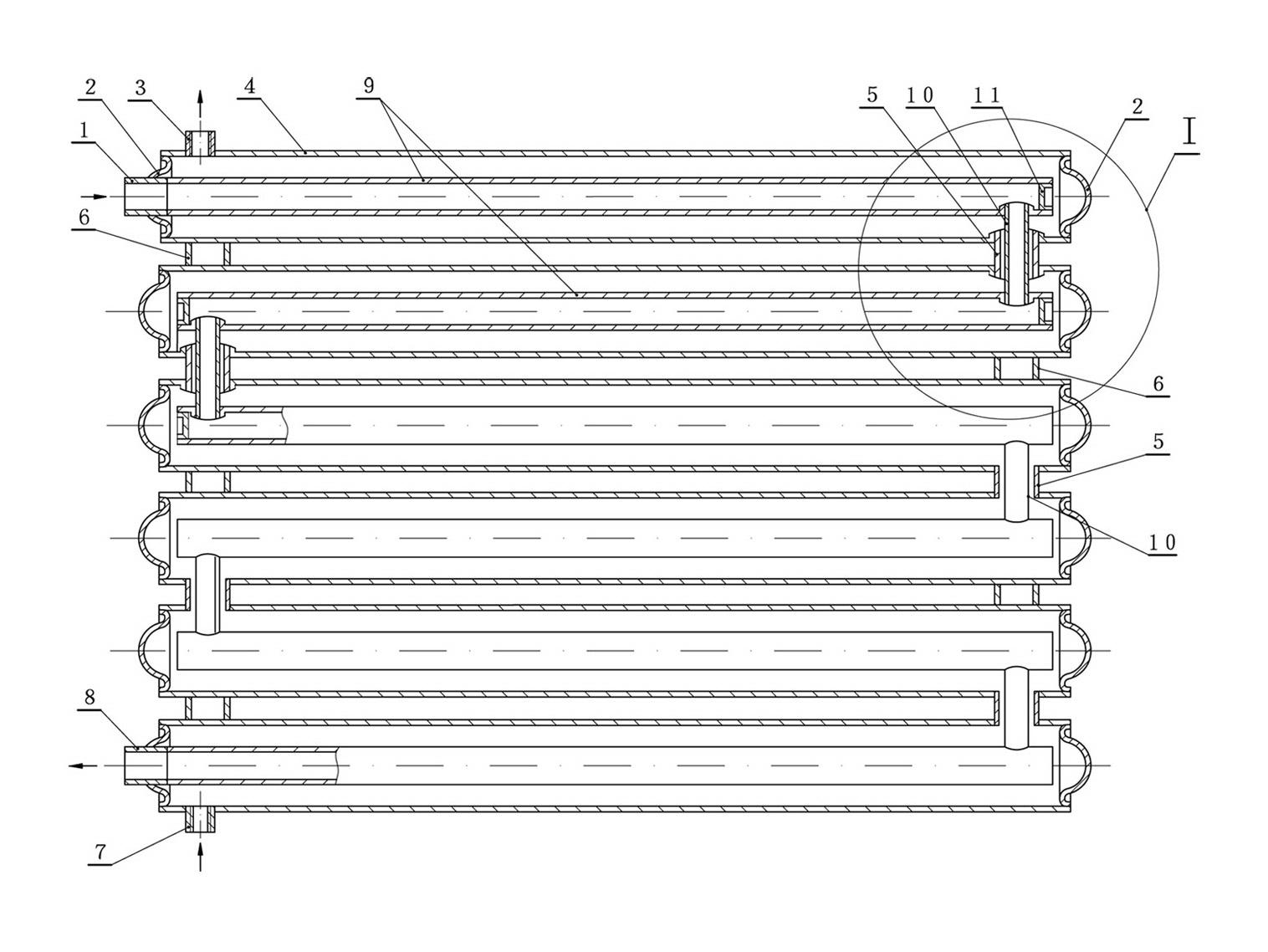

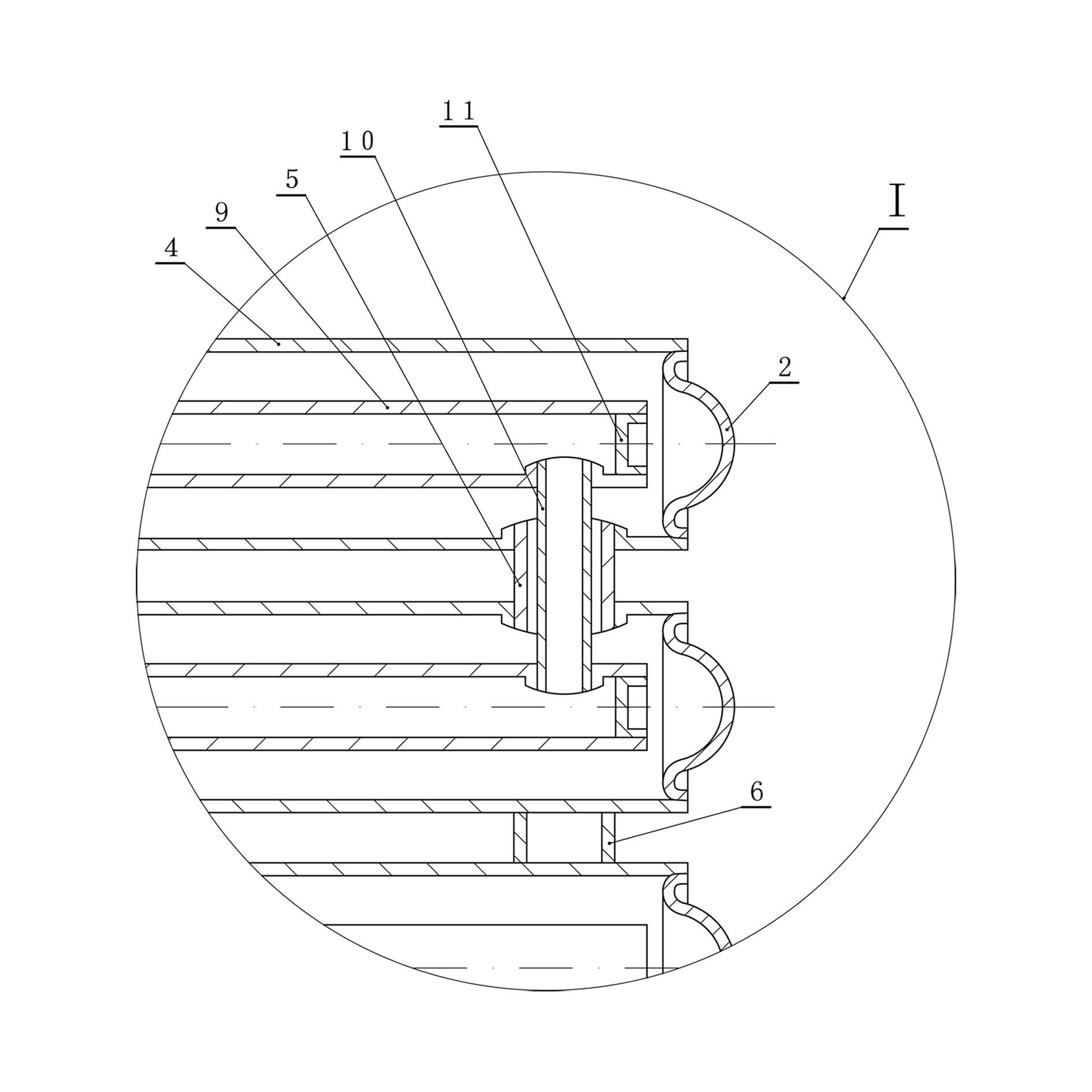

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

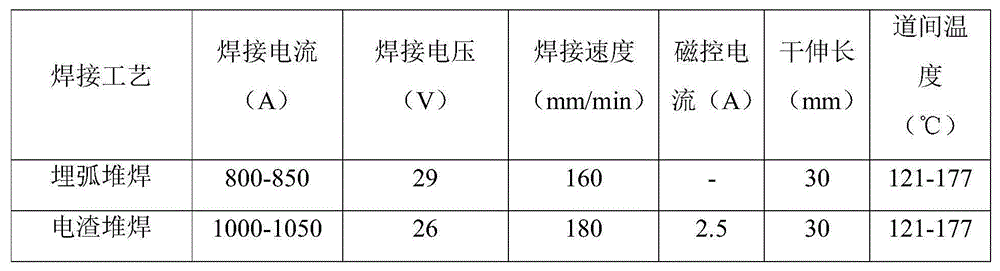

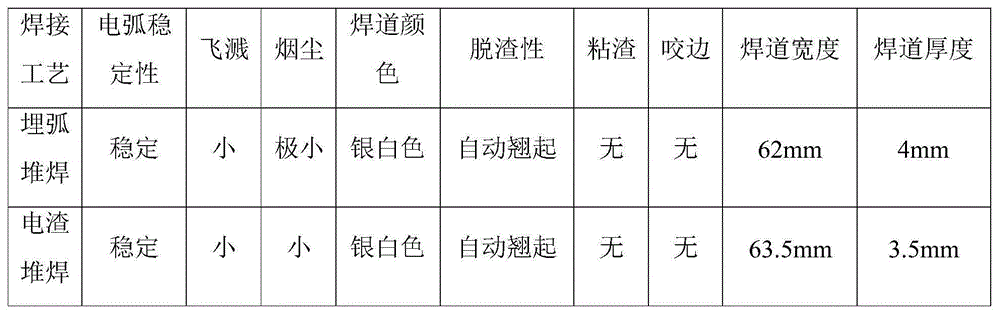

Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and welding method

InactiveCN105215571AImprove deposition efficiencyLow dilution rateWelding/cutting media/materialsSoldering mediaCrack resistanceNuclear power

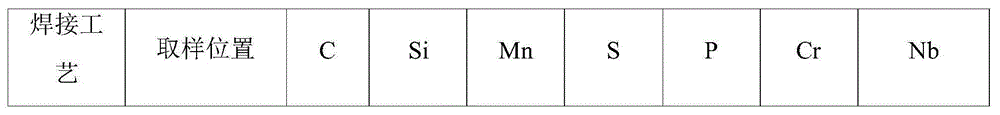

The invention provides a Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and a welding method and belongs to NiCrFe nickel base alloy solder strips. The solder strip is composed of, by weight, less than 0.04% of C, less than 0.50% of Si, less than 5.0% of Mn, less than 0.015% of S, less than 0.020% of P, 28.0-31.5% of Cr, 7.0-12.0% of Fe, less than 2.5% of Nb, less than 0.30% of Cu, less than 0.50% of Al, less than 0.50% of Ti, and the balance nickel. The Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power can be applicable to a submerged arc overlay welding process and an electroslag surfacing process and can also be applicable to manufacturing of key components of a nuclear island of a nuclear power plant by being matched with corresponding soldering flux, the Mn element and the Nb element are added in the solder strip and improve the performance of resistance to high temperature plasticity-losing cracks of surfacing deposited metal, the surfacing deposited metal has high crystallization crack resistance and stress corrosion cracking resistance, the excellent corrosion resistance is achieved and integrated mechanical performance is good. By being matched with the soldering flux for surfacing, a weld pass is attractive in formation, corrugations are compact, deslagging is easy and welding defects are avoided.

Owner:HARBIN WELDING INST LTD +2

Weather-resistant submerged arc welding wire for free-coating weather-resistant steel bridge

ActiveCN106001987AGood weld formabilityImprove metallurgical qualityArc welding apparatusWelding/cutting media/materialsChemical compositionAtmospheric corrosion

The invention discloses a weather-resistant submerged arc welding wire for a free-coating weather-resistant steel bridge, and belongs to the field of welding materials. According to the technical scheme, the weather-resistant submerged arc welding wire for the free-coating weather-resistant steel bridge comprises a basic chemical component Fe and the following chemical components in percentage by mass: 0.03 to 0.10% of C, 0.10 to 0.28% of Si, 1.15 to 1.55% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.25 to 0.55% of Cr, 0.25 to 0.55% of Ni, 0.20 to 0.50% of Cu, 0.005 to 0.025% of Ca, and 0.005 to 0.05% of Re. The welding wire is applied to the welding of Q345qENH-Q460qENH serial weather-resistant bridge steel, and is outstanding in atmospheric corrosion resistance, high in process performance, stable in quality, and suitable for large-scale popularization and application.

Owner:YANSHAN UNIV

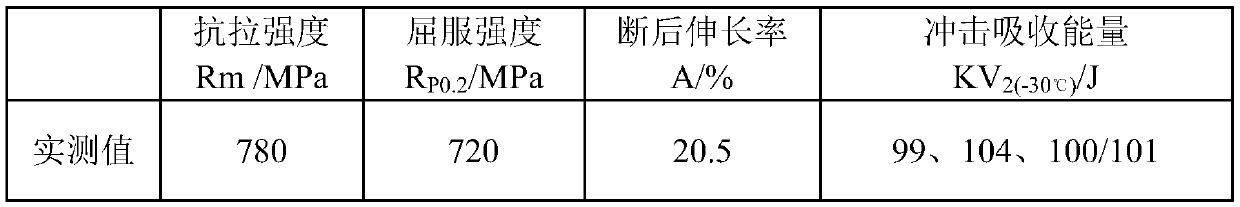

Sintered flux for LPG ship welding and preparation method and application thereof

ActiveCN108581270AImprove performanceGood workmanshipWelding/cutting media/materialsSoldering mediaMetal alloyRare earth

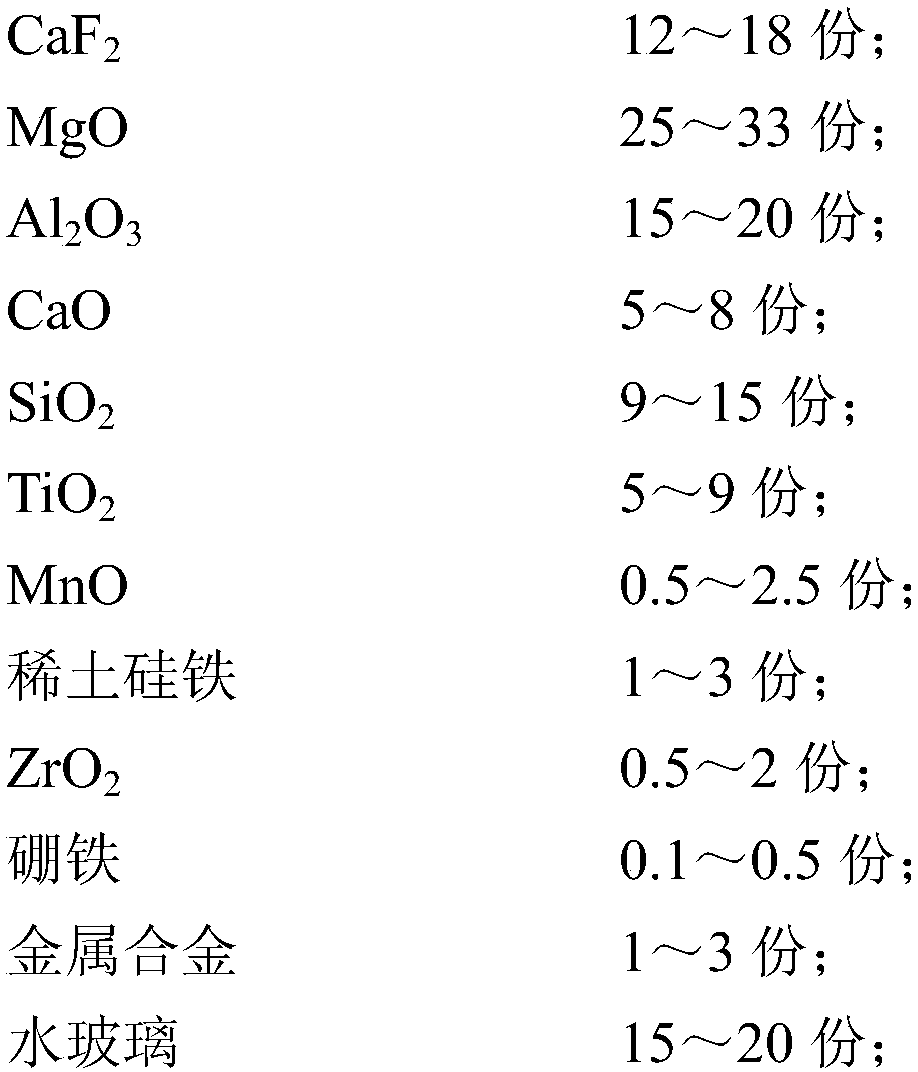

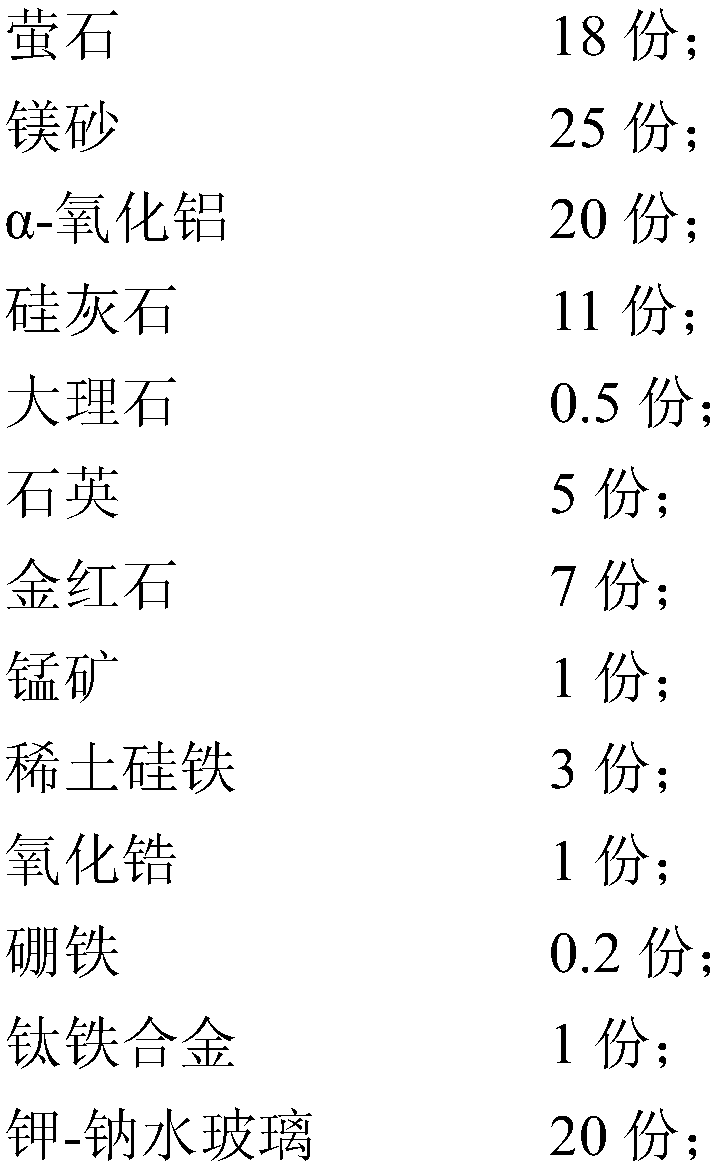

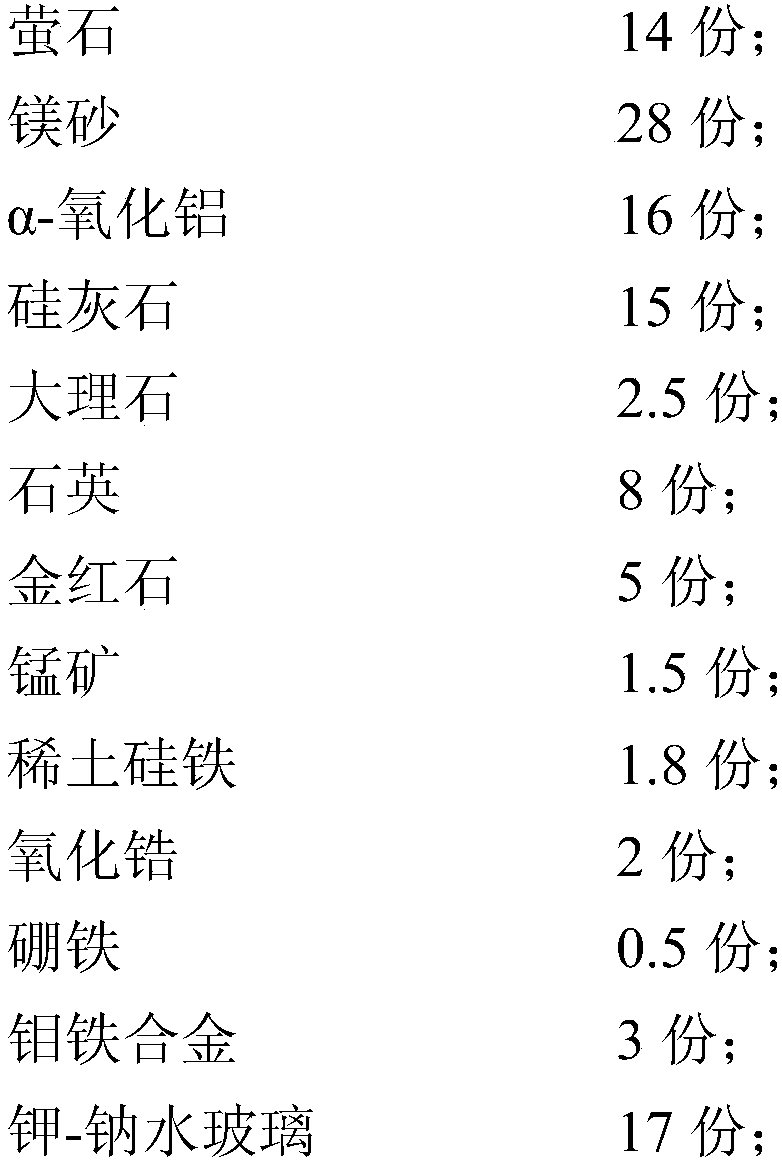

The invention belongs to the technical field of welding materials, and in particular relates to sintered flux for LPG ship welding and a preparation method and application thereof. The sintered flux for LPG ship welding is fluorine alkaline sintered flux which is prepared from the following components in parts by mass: 12-18 parts of GaF2, 25-33 parts of MgO, 15-20 parts of Al2O3, 5-8 parts of CaO, 9-15 parts of SiO2, 5-9 parts of TiO2, 0.5-2.5 parts of MnO, 1-3 parts of rare earth ferrosilicon, 0.5-2 parts of ZrO2, 0.1-0.5 part of ferroboron, 1-3 parts of metal alloy and 15-20 parts of waterglass. The flux is matched with an EH14 welding wire for submerged-arc welding, is relatively good in manufacturability, excellent in low temperature toughness, suitable for high heat input welding ofLPG ship construction, high in low temperature toughness, good in crack sensitivity and relative low in cost, and has a relatively good market promotional prospect and a good economic benefit.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

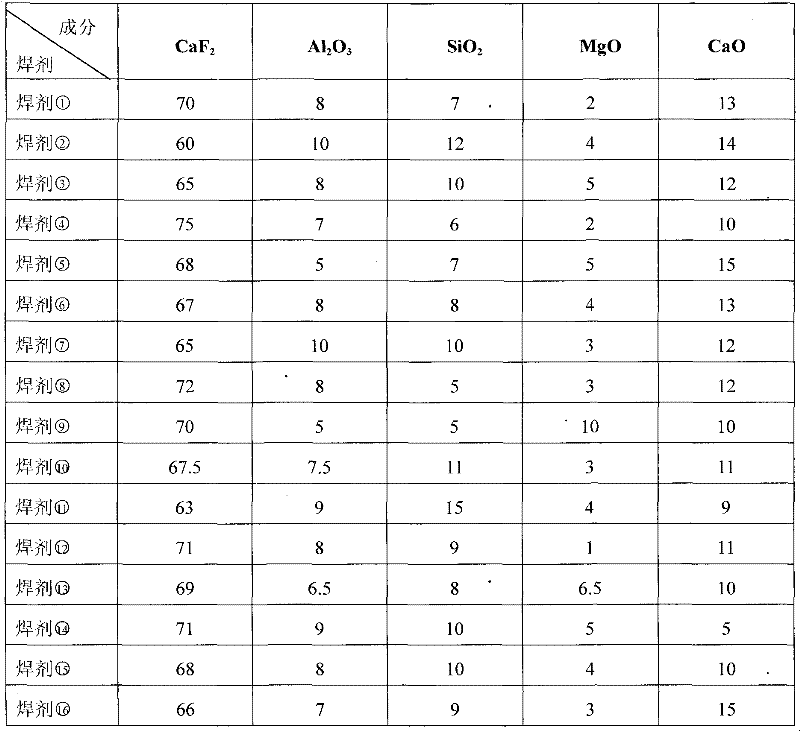

Stainless steel band electrode electroslag surfacing welding strip and welding flux

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

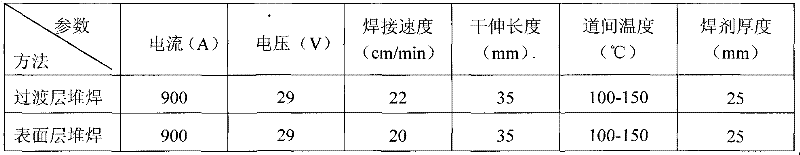

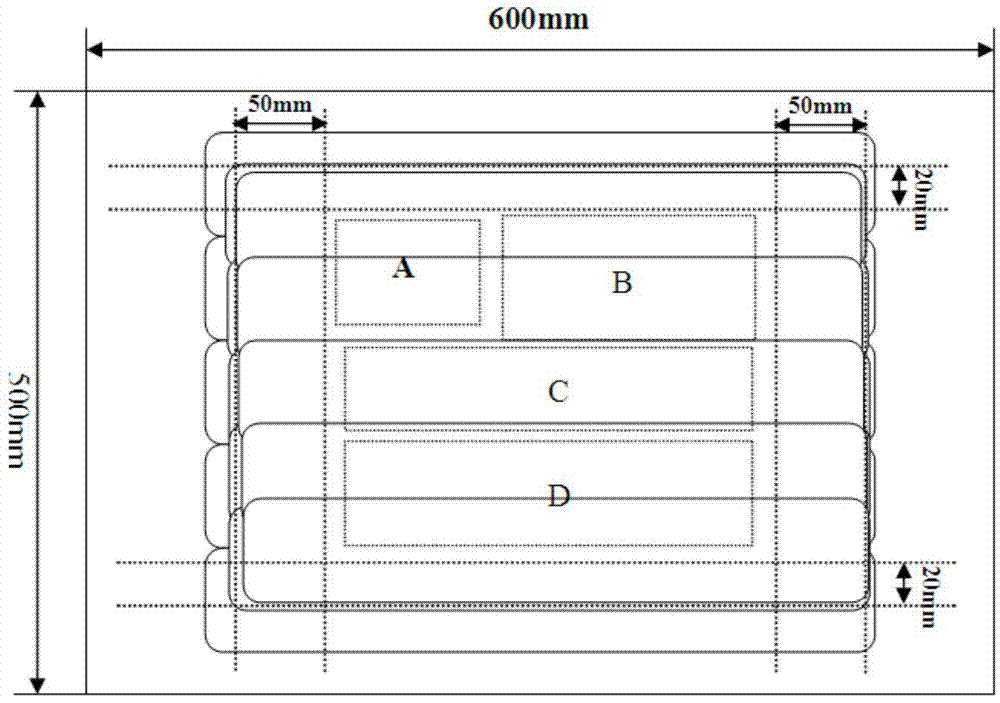

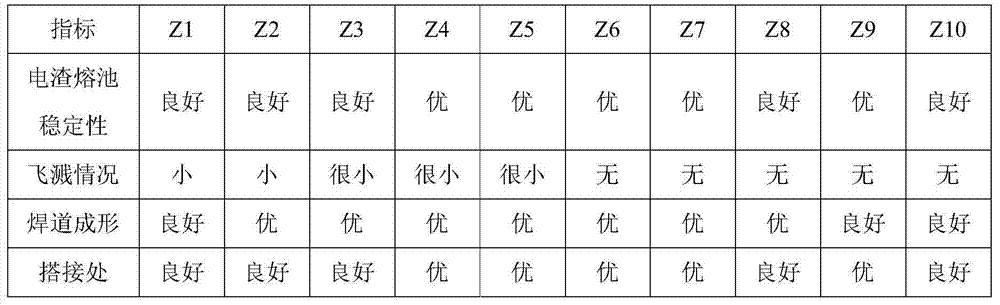

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

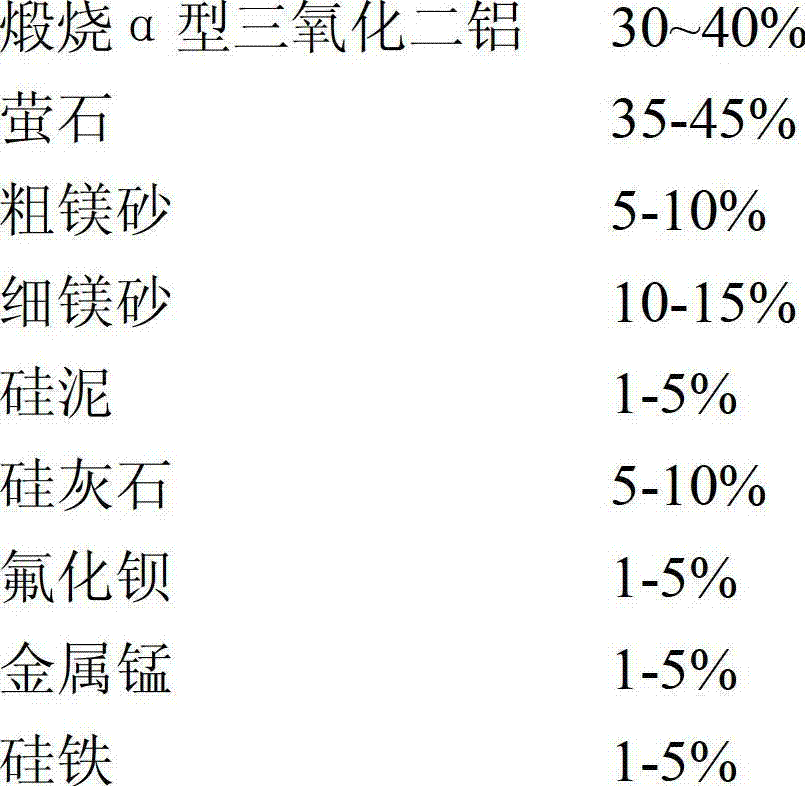

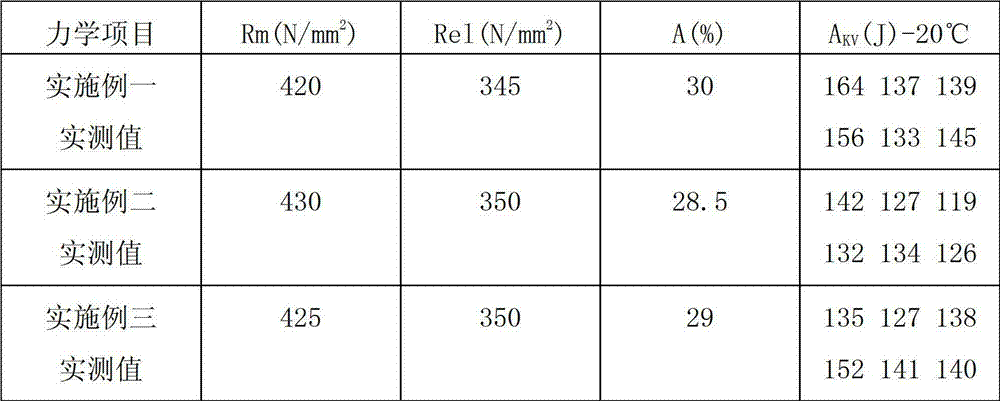

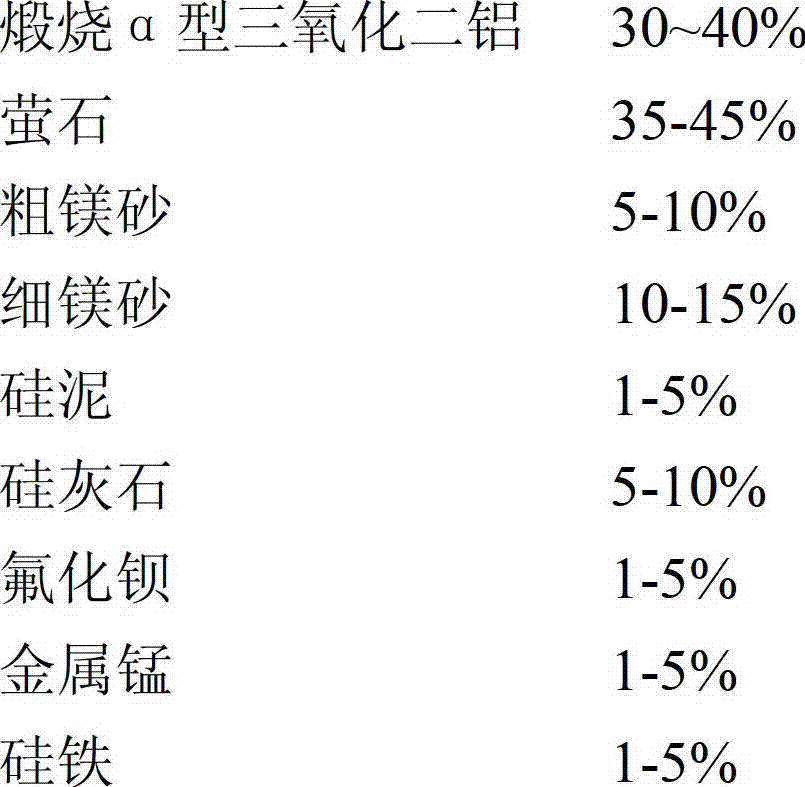

High-speed submerged-arc welding agent for thin plates

ActiveCN102922176ASolve puzzlesIncrease productivityArc welding apparatusWelding/cutting media/materialsSesquioxideManganese

The invention discloses a high-speed submerged-arc welding agent for thin plates, which comprises the following components by weight percent: 30 to 40 percent of calcined Alpha type aluminum sesquioxide, 35 to 45 percent of fluorite, 5 to 10 percent of coarse magnesia, 10 to 15 percent of fine magnesia, 1 to 5 percent of siliceous ooze, 5 to 10 percent of wollastonite, 1 to 5 percent of barium fluoride, 1 to 5 percent of manganese metal and 1 to 5 percent of ferrosilicon, wherein the total weight percent of all the components is 100 percent. The high-speed submerged-arc welding agent has the advantages that the production efficiency is high; the comprehensive cost is low; the welding quality is good; difficulty in submerged-arc welding of the thin plates is reduced; the welding property and the mechanical property are superior; the formation of a welding bead is beautiful; and residue removing is very easy.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Gas shielded welding wire for automatic welding of 07MnMoVR spherical tank

InactiveCN106425159ASimple welding processImprove low temperature impact toughnessArc welding apparatusWelding/cutting media/materialsFriction weldingTrace element

The invention discloses a gas shielded welding wire for automatic welding of a 07MnMoVR spherical tank. The welding wire is a low alloy steel welding wire, the welding wire is prepared from, by weight, 0.12% or less of C, 1.3-2.0% of Mn, 0.30-1.0% of Si, 0.01% or less of S, 0.02% or less of P, 0.5% or less of Cr, 0.5-1.5% of Ni, 0.1-0.6% of Mo, 0.5% of Cu and 0.02-0.1% of Ti. The gas shielded welding wire has the advantages that the formula proportion is reasonable, welding technological performance is good, and by adding a proper amount of trace elements and a certain amount of Mn, Ni, Mo and other alloy elements, the properties of a welded metal on a flat position, a horizontal position, an vertical position and an supine position can meet requirements, and the welding wire can be applied to all-position welding.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

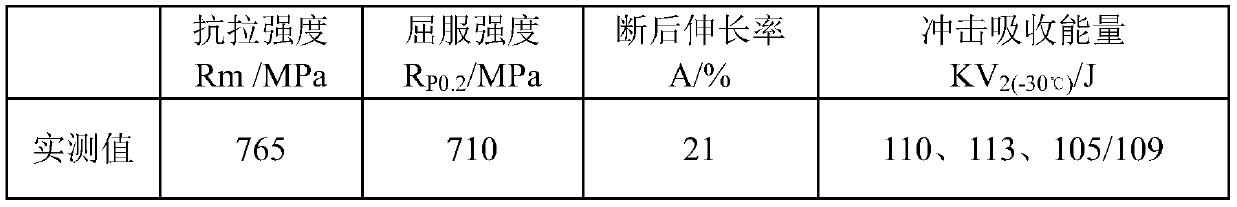

All position welding low hydrogen type electrode excellent in low temperature impact toughness and for SA-508Gr.4N steel

InactiveCN110369908AExcellent all-position welding process performanceEvenly meltedWelding/cutting media/materialsSoldering mediaOperabilityYttrium

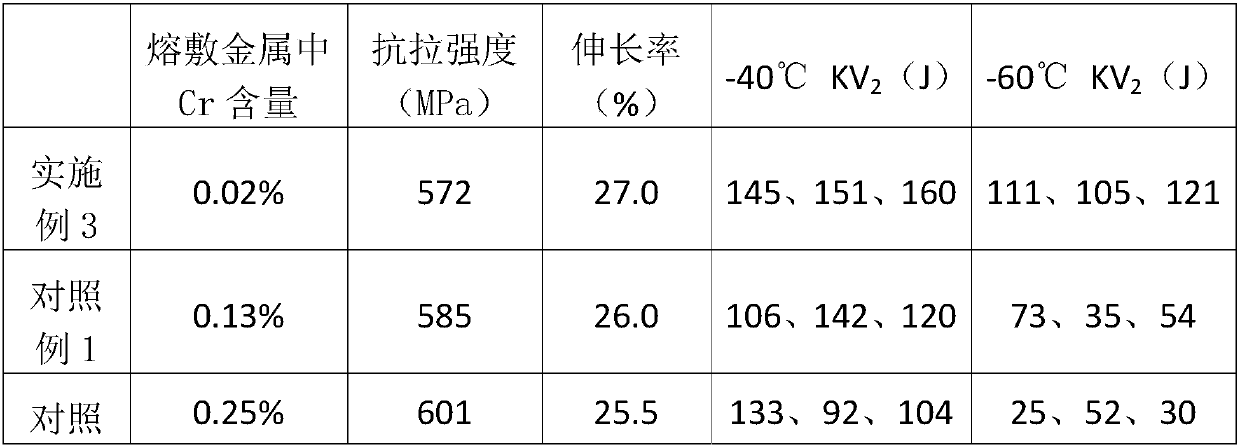

The invention discloses an all position welding low hydrogen type electrode excellent in low temperature impact toughness and for SA-508Gr.4N steel, and relates to the weld material technology field.The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel solves the problems that an existing low hydrogen type electrode for the SA-508Gr.4N steel is poor in low temperature impact toughness and unsuitable for all position welding. The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel comprises a core wire and a coating, wherein the core wire consists of C, Si, Mn, S, P and the balance Fe, the coating consists of a powder material and a binding agent, and the power material consists of marble, fluorite, strontium carbonate, titanium dioxide, quartz, yttrium-based silicon iron, ferrotitanium, electrolytic manganese, mid-carbon ferromanganese, nickel powder, sodium carbonate and potassium alginate. The all position welding low hydrogen type electrode excellent in low temperature impact toughness and for the SA-508Gr.4N steel has excellent allposition welding technology performance, and is stable in electric arc, small in splashing amount and moderate in sleeving especially in vertical welding and overhead welding, melts the coating evenly, enables a weld pass to be beautiful in shaping, achieves good operability for welding operators, and has ideal mechanical performance. The all position welding low hydrogen type electrode excellentin low temperature impact toughness and for the SA-508Gr.4N steel is suitable for the all position welding of the SA-508Gr.4N steel.

Owner:HARBIN WELL WELDING CO LTD +1

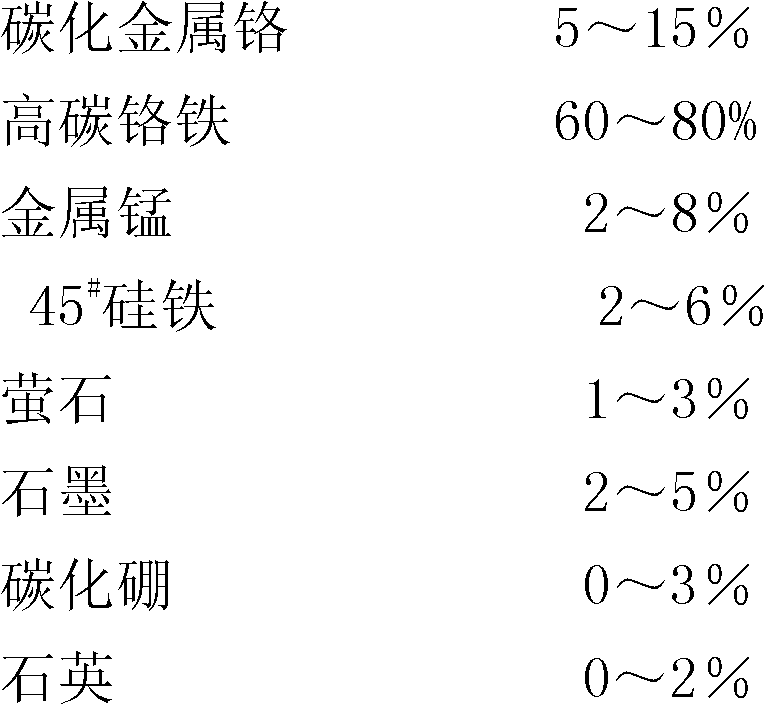

Slag-free surfacing welding rod

ActiveCN102416531AImprove deposition efficiencyEasy arc startWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

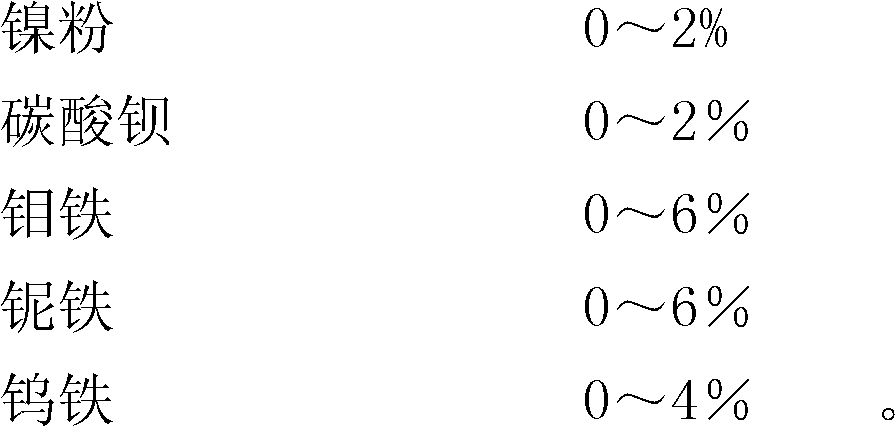

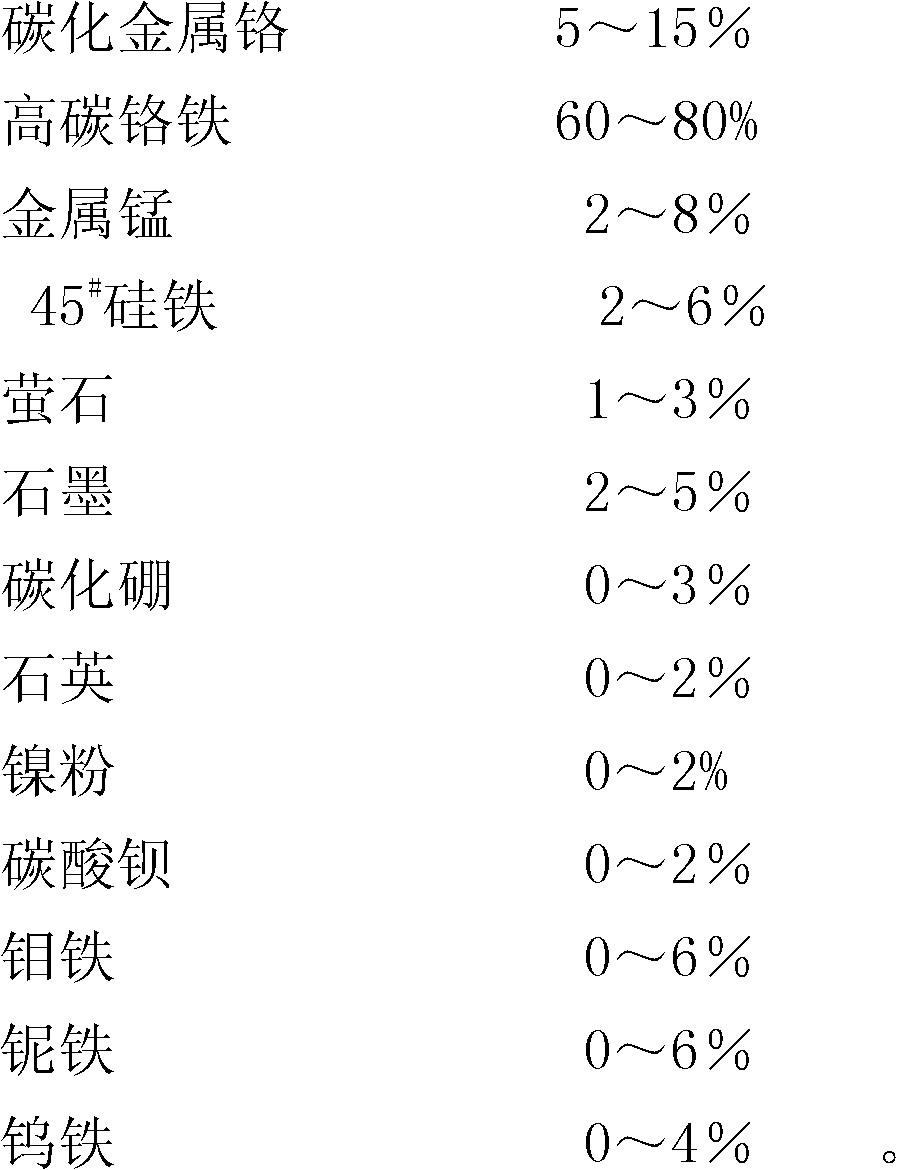

The invention relates to a slag-free surfacing welding rod, which comprises a welding core (using an H08A welding core) and a coating. Powdered raw materials, including carbonized chromium, high carbon ferrochrome, manganese, No. 45 ferrosilicon, fluorspar, graphite, boron carbide, quartz, nickel powder, barium carbonate, molybdenum iron, niobium iron and tungsten iron are mixed to obtain the coating; potassium-sodium water glass with the weight being 5 percent of the weight of the coating powder and the modulus being 45 is slowly added into the prepared coating powder and then mixed; the coating is uniformly and concentrically extruded on the H08A welding core with the diameter being 4.0mm to obtain the surfacing welding rod according to a mass ratio of the coating which is added with the water glass: the welding core being 2:1. . When the slag-free surfacing welding rod with high wear resistance is applied in surfacing, continuous surfacing can be realized with no need to knock off slag, the deposition efficiency is high, arcs can be easily formed, no red tails can be formed in the continuous surfacing, and the hardness of deposited metal can reach above HRc65. The slag-free surfacing welding rod can be applied in composite manufacturing and repair of various products subject to intermediate and low stress and serious abrasive wear.

Owner:中机焊业科技(福建)有限公司

High-toughness titanium type flux-cored wire for weathering steel

ActiveCN109623196AImprove low temperature impact toughnessImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaPotassiumRare earth

The invention provides a high-toughness titanium type flux-cored wire for weathering steel, comprising a core and a sheath, the core comprising the following components in parts by weight: 300-500 parts of rutile, 15-35 parts of sodium fluoride, 2-15 parts of rare earth fluoride, 25-50 parts of potassium silicon titanate, 100-180 parts of silicomanganese alloy, 5-16 parts of medium carbon ferromanganese, 20-50 parts of manganese metal, 25-60 parts of magnesium powder, 40-100 parts of nickel powder, 10-30 parts of copper powder, 10-30 parts of ferrotitanium, 1-5 parts of ferro-boron, and 80-400parts of iron powder; the flux-cored wire welding metal satisfies that Cr is smaller than 0.10%. The present invention provides the high-toughness titanium type flux-cored wire for weathering steel,which can improve the low-temperature impact toughness on the basis of satisfying the weather resistance, and can be widely applied in weathering steel projects requiring impact toughness at -60 DEG C.

Owner:TIANJIN YONGCHANG WELDING WIRES +1

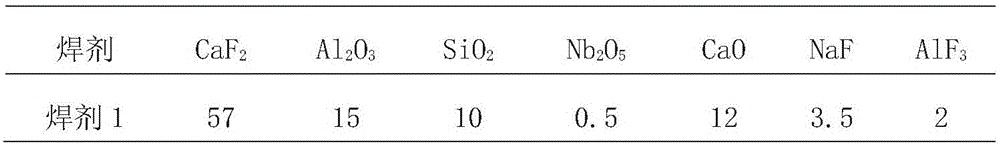

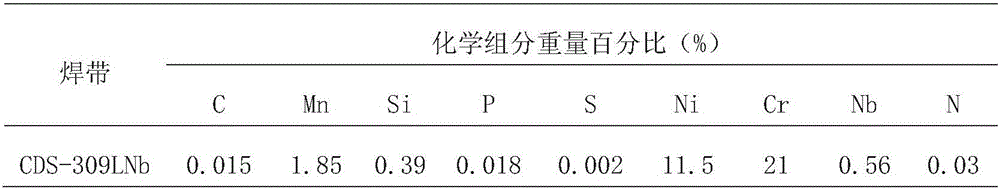

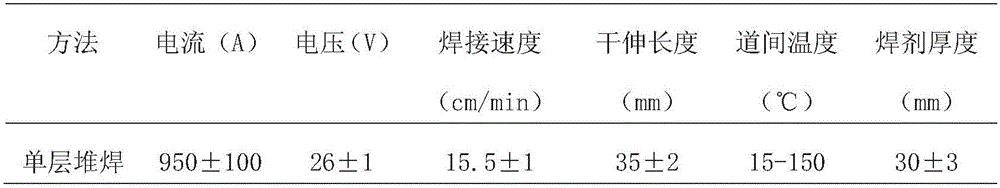

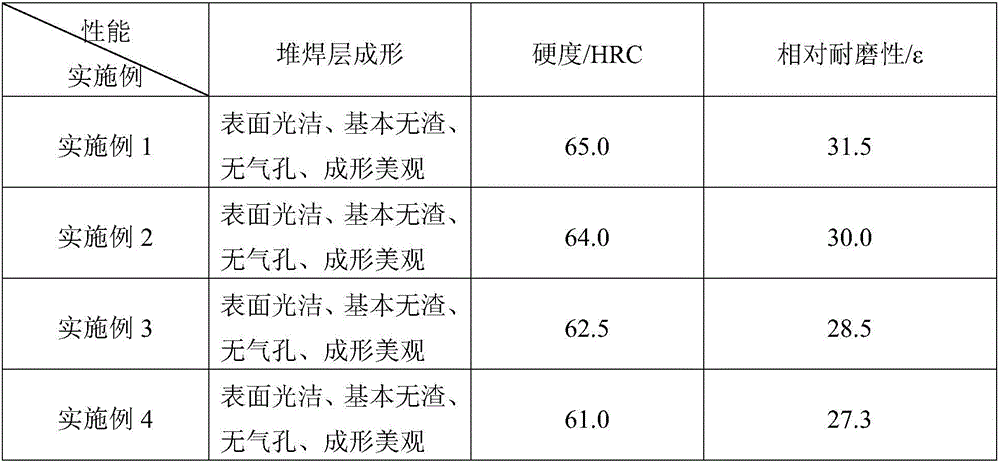

Nb-containing stainless steel soldering strip and soldering flux for monolayer strip electro-slag surfacing

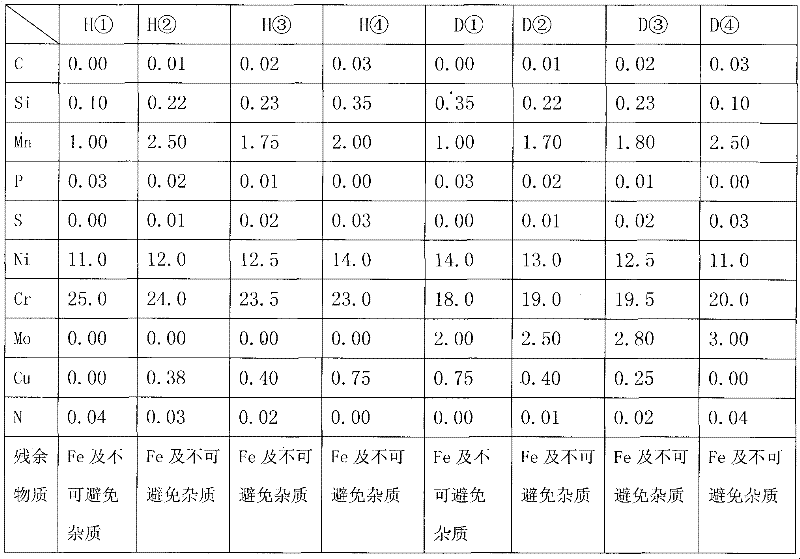

InactiveCN106425166AWeight percent optimizationGood surfacing processWelding/cutting media/materialsSoldering mediaSlagSoldering

The invention discloses an Nb-containing stainless steel soldering strip and soldering flux for monolayer strip electro-slag surfacing. The soldering strip comprises, by weight, 0-0.03% of C, 0.1-0.5% of Si, 1-2.5% of Mn, 0-0.03% of P, 0-0.03% of S, 9-14% of Ni, 21-25% of Cr, 0.4-0.8% of Nb, 0-0.05% of N and the balance Fe and other inevitable impurities. The soldering flux comprises, by weight, 55-70% of CaF2, 8-15% of Al2O3, 5-10% of SiO2, 0.2-1.5% of Nb2O5, 5-15% of CaO, 1-5% of NaF and 1-5% of AlF3. By regulating and controlling the chemical components of the soldering strip and the soldering flux, deslagging is easy in the welding process, a formed weld pass is attractive, and the excellent intergranular corrosion resistance is achieved, and no cracks occur during surfacing bending.

Owner:KUSN GINTUNE WELDING

Low-alloy steel welding rod capable of achieving postweld heat treatment

ActiveCN107088719AImprove stabilitySolve crackingWelding/cutting media/materialsSoldering mediaManganesePotassium/sodium ratio

The invention provides a low-alloy steel welding rod capable of achieving postweld heat treatment. An H08E carbon steel welding core is used as a welding core. A flux cover comprises, by weight, 42-55 parts of marble, 18-24 parts of fluorite, 0,5-2 parts of rutile, 3-9 parts of quartz, 0.3-0.8 part of sodium carbonate, 0.3-0.8 part of CMC, 0.2-0.5 part of graphite, 3-9 parts of silicon iron, 3-9 parts of manganese, 9-18 parts of alloy, and 20-25 parts of water glass. Alloy powder comprises, by weight, 25-35 parts of nickel powder, 5-15 parts of ferromolybdenum, 5-15 parts of ferrotitanium and 90-110 parts of iron powder. Potassium-sodium water glass with the modulus M being 3.4 and the potassium-sodium ratio being 1 / 2-3 / 4 is adopted to serve as the water glass. According to the low-alloy steel welding rod capable of achieving postweld heat treatment, the manufacturability is good; and under the wide technological specification, electric arcs are stable, deslagging is easy, and weld beads are formed uniformly and are attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Flux-cored wire capable of enhancing welding partition continuous self-protection effect and preparation method thereof

ActiveCN106001994AGood deoxidation self-protection abilityBeautiful shapeWelding/cutting media/materialsSoldering mediaHigh carbonFerrochrome

The invention discloses a flux-cored wire capable of enhancing the welding partition continuous self-protection effect and a preparation method thereof. A low-carbon steel strip serves as a skin. A flux core is prepared from 70-85wt% of high-carbon ferrochrome, 1-3.5wt% of ferroboron, 8.5-18.5wt% of a deoxidizing agent, 1-5wt% of an arc stabilizing agent and the balance ferrous powder. By the total weight of the flux core, the deoxidizing agent is prepared from 3-6wt% of 230-mesh silicomanganese alloy, 3-6wt% of 50-mesh graphite, 2-4.5wt% of 50-mesh aluminum powder and 0.5-2wt% of 50-mesh magnesium powder. The arc stabilizing agent is a mechanical mixture formed by sodium potassium silicate and sodium carbonate, and the flux core accounts for 54-59wt% of the mass of the wire. The wire can effectively enhance the self-protection effect of various partitions (at the melting stage, the globular transfer stage and the molten pool stage) of the wire, an arc is stable, the manufacturability is good, and a surfacing layer is attractive in shape, high in hardness and good in wear resistance.

Owner:JIANGSU UNIV OF SCI & TECH

Fused flux used for welding 9Ni steel and preparation method of fused flux

ActiveCN110102933AGood moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassiumMoisture absorption

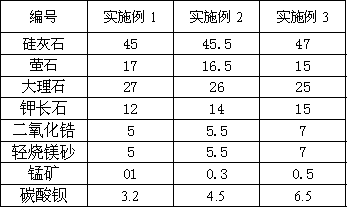

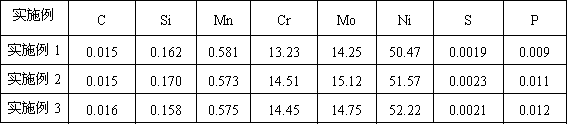

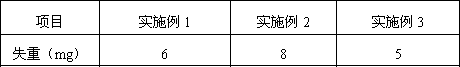

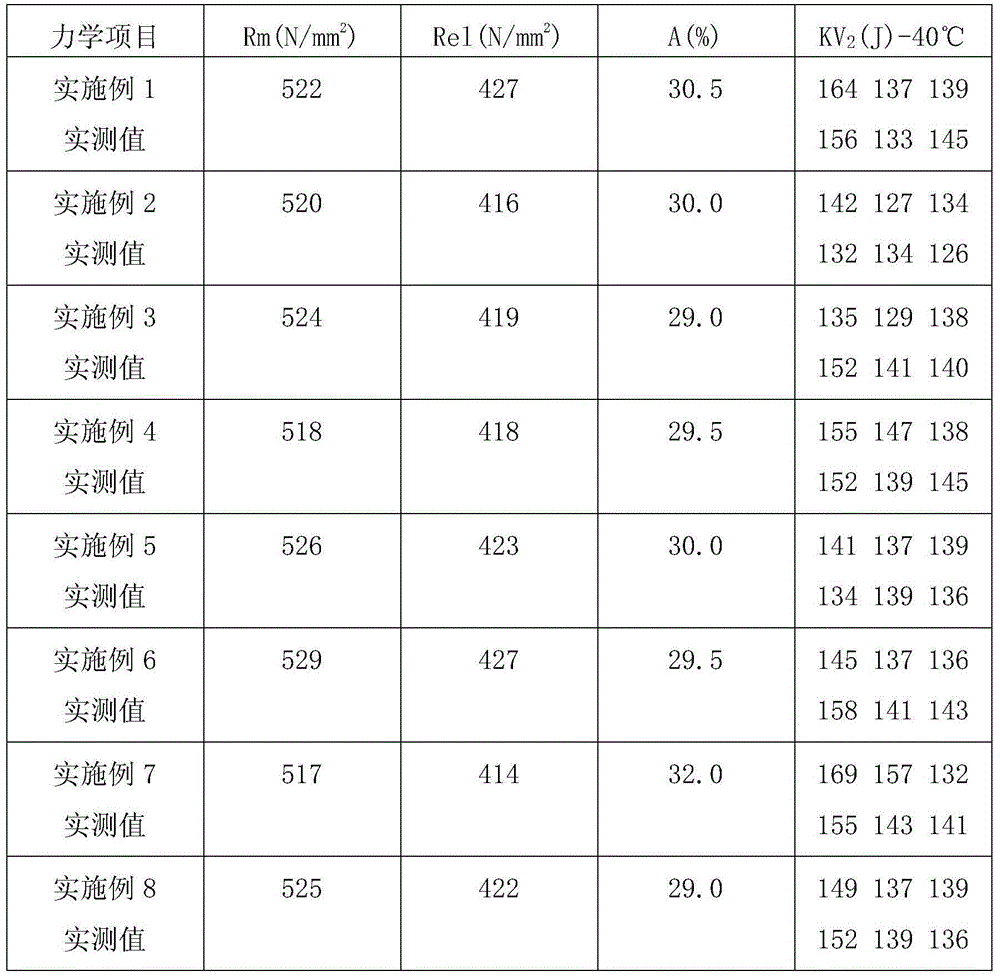

The invention relates to a fused flux used for welding 9Ni steel and a preparation method of the fused flux, and belongs to the field of welding materials. The fused flux comprises, by weight, 45-47 parts of wollastonite, 15-17 parts of CaF2, 25-27 parts of marble, 12-15 parts of potassium feldspar, 5-7 parts of ZrO2, 5-7 parts of MgO, 0.1-0.5 part of manganese ore, and 2.5-5 parts of BaO. The preparation method comprises the steps of material preparation, smelting, pelletizing, crushing and screening, drying, and packaging, wherein the granularity of the fused flux is 10-80 meshes. The fusedflux has the characteristic of good moisture-absorption resistance and is used in cooperation with an ERNiCrMO-4 nickel-based welding wire according with ASMEIISFA-5.14, the weldability and the mechanical performance of weld joints are good, the tenacity of weld metal at an ultralow temperature is stable and good, and the anti-heat-crack sensitivity is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Efficient welding method for E690 high strength steel cylinder

InactiveCN107234318AIncrease productivityPrevent intrusionArc welding apparatusWelding/soldering/cutting articlesThermal insulationSlag

The invention discloses an efficient welding method for an E690 high strength steel cylinder. The efficient welding method includes the following steps that through two steps of selecting of welding materials and a welding technology, and efficient welding of the E690 high strength steel cylinder is completed; because submerged-arc welding acts as slag protection, welding flux and welding slag can prevent air from intruding a molten pool, thermal insulation can further be achieved, cooling speed of a welding joint is reduced, and the mechanical properties of junctions are ensured; welding parameters are preset, the stability of the welding parameters is ensured, electric arcs are stable, deslagging is easy, the surface of the welding joint is bright and clean, forming of a welding bead is beautiful, and compositions of the welding joint are further uniform; and according to the efficient welding method for the E690 high strength steel cylinder, requirements for welders are low, and the qualified rate of X ray inspection reaches above 99%.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Efficient welding method for 4130 high-pressure pipe

InactiveCN107378207AArc stabilizationReduce splashArc welding apparatusHigh pressureMaterial selection

The invention discloses an efficient welding method for a 4130 high-pressure pipe. Efficient welding of the 4130 high-pressure pipe is finished through the technology steps of welding material selection, gas selection and welding control. According to the efficient welding method, flux-cored wire gas shielded welding is used, efficient continuous welding can be achieved, the deposition rate of flux-cored wire gas shielded welding is 3 times of the deposition rate of original manual welding stick electric arc welding, the speed of manual welding stick electric arc welding is 1.5 kg / h, the speed of flux-cored wire CO2 gas shielded welding is 4.5 kg / h, the deposition efficiency of a flux-cored wire reaches 90%, and the deposition efficiency of a manual welding stick is only 65%.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Flux for narrow-gap submerged arc welding

ActiveCN104384754AIncrease productivityLow costArc welding apparatusWelding/cutting media/materialsSlagFerrosilicon

The invention discloses a flux for narrow-gap submerged arc welding. The flux consists of the following raw materials in part by weight: 10 to 30 parts of calcined alpha aluminium oxide, 20 to 45 parts of fluorite, 15 to 30 parts of coarse magnesia, 10 to 25 parts of fine magnesia, 10 to 25 parts of bauxite, 5 to 15 parts of wollastonite, 1 to 15 parts of rutile, 1 to 10 parts of manganese metal and 1 to 10 parts of silicon iron. The flux has the beneficial effects that 1, the flux has the characteristics of high production efficiency, low composite cost, good welding quality and the like; 2, the problem of a narrow gap in submerged arc welding is solved, the flux has good welding technological properties and mechanical properties, a weld beam is formed attractively, and slag is easy to detach.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

A weather-resistant gas-shielded welding wire for a coating-free weather-resistant steel bridge

ActiveCN105798481BGuaranteed StrengthGuaranteed weather resistanceWelding/cutting media/materialsSoldering mediaChemical compositionAtmosphere

The invention provides a weather-proof gas protection welding wire for a coating-free weather-proof steel bridge, and belongs to the field of welding materials. According to the technical scheme, in the weather-proof gas protection welding wire for the coating-free weather-proof steel bridge, chemical components comprise the basic component Fe, and the welding wire is further prepared from, by mass percent, 0.03%-0.10% of C, 0.30%-0.50% of Si, 1.20%-1.60% of Mn, not larger than 0.012% of P, not larger than 0.005% of S, 0.30%-0.60% of Cr, 0.20%-0.50% of Ni, 0.20%-0.50% of Cu, 0.005%-0.025% of Ca and 0.005%-0.05% of Re. The welding wire is used for welding of weather-proof bridge steel, the strength of extension of deposited metal is high, the yield strength is high, the elongation is larger than or equal to 24%, and the low temperature impact resisting performance and the atmosphere corrosion resisting performance are excellent; and the welding wire is easy to manufacture and suitable for being popularized on a large scale.

Owner:YANSHAN UNIV

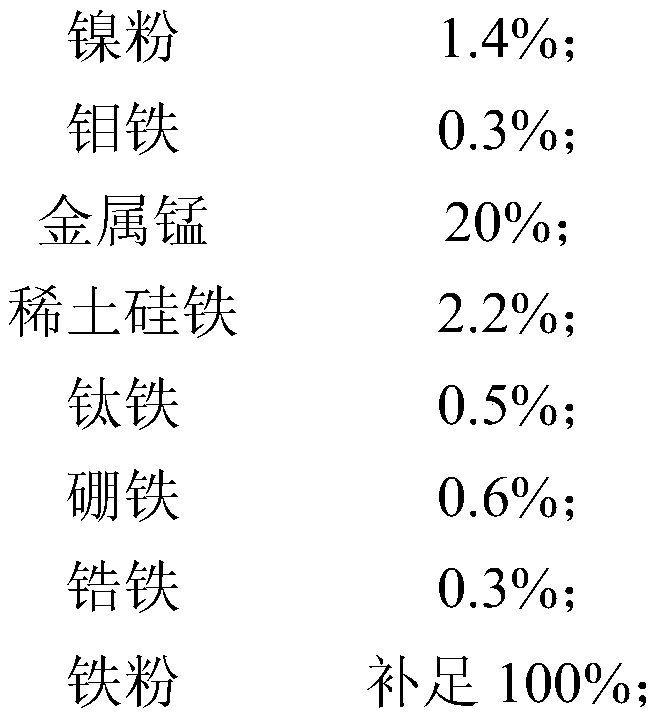

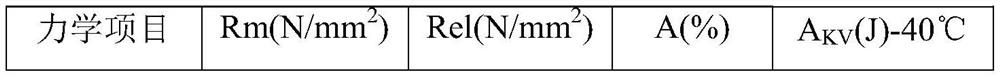

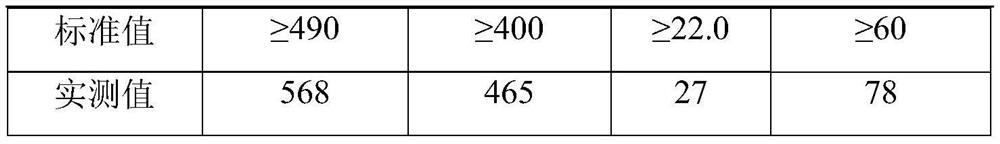

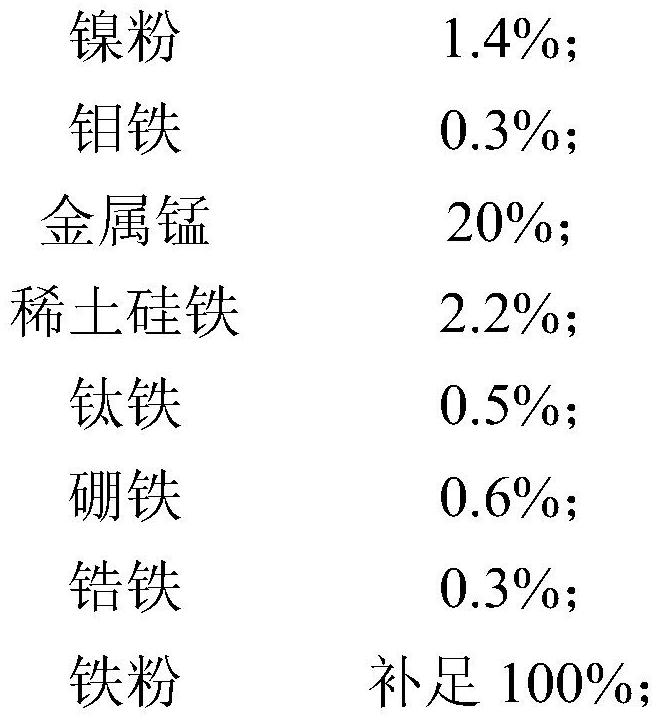

Seamless flux-cored powder and submerged arc welding wire for LPG ship welding and preparation and application

ActiveCN108788515AStrong resistance to moisture absorptionLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

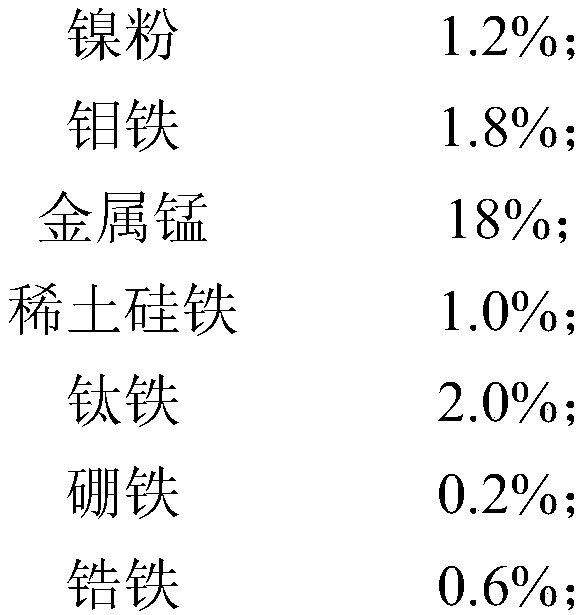

The invention belongs to the technical field of welding materials, and particularly relates to a seamless flux-cored powder and submerged arc welding wire for LPG ship welding and preparation and application. The seamless flux-cored powder for LPG ship welding comprises the following compositions of, by mass, 1.2-4.5% of metallic nickel, 0.3-1.8% of ferromolybdenum, 14-20 % of metallic manganese,1-3% of rare earth ferrosilicon, 0.5-2% of titanium iron, 0.2-0.6% of boron iron, 0.2-0.6% of zirconium iron and the balance metallic iron. The invention further provides the submerged arc welding wire comprising the flux-cored powder. The welding wire is matched and combined with F7A(P)8 flux conforming to ASME II SFA-5.17, the characteristics of good moisture absorption resistance, stable electric arc and beautiful welding line formation are achieved, the technology capability is good, low temperature toughness of welding line metal is good, the anti-crack sensitivity is good, high heat input welding for LPG ship construction is suitable, and great market promotion prospects and good economic benefits are achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855BSimple welding processImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsBond interfaceSpot welding

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows: removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclined inwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Self-protecting flux-cored wire for overlaying welding and use thereof

ActiveCN100462188CArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The present invention belongs to the field of composite material producing technology, and is especially one kind of self-protecting flux cored welding wire for build-up welding and its use. The flux core of the welding wire is mixture of alloy powder and mineral powder, and consists of chromium carbide 50-80 wt%, Mn 4-10 wt%, 75# ferrosilicon 2-6 wt%, Zr-Si-Fe 1-3 wt%, graphite 3-6 wt%, dolomite 1-3 wt%, natural rutile 0.1-3 wt%, Mo 1-6 wt%, Nb 3-6 wt%, V 2-8 wt%, W 0.1-2 wt%, Na2SiF6 0.1-3 wt%, ZrO2 1-3 wt%, and NaF0.1-2 wt%. The self-protecting flux cored welding wire for build-up welding has no need of adding protecting gas and flux, stable arc, fewer spattering and other advantages. It is applied mainly for build-up welding of grinding roll, grinding disc, antiwear plate, etc.

Owner:李淑华 +1

A kind of corrosion-resistant high-strength high-toughness submerged arc welding flux and its application

ActiveCN109664051BImprove corrosion resistanceImprove crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceFluoride

The invention provides a corrosion-resistant, high-strength, high-toughness submerged arc welding flux and its application. The submerged arc welding flux comprises the following components in parts by weight: 5-11 parts of acidic oxide, 48-61 parts of basic oxide, fluoride 30-40 parts, 0.1-0.5 parts of yttrium-based rare earth. The corrosion-resistant, high-strength and high-toughness submerged arc welding flux and its application in the present invention can improve corrosion resistance and crack resistance, and can be used for welding bridge steels resistant to marine atmospheric corrosion.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

A kind of seamless flux core powder, submerged arc welding wire for lpg ship welding and its preparation and application

ActiveCN108788515BGood workmanshipArc stabilizationWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention belongs to the technical field of welding materials, and particularly relates to a seamless flux-cored powder and submerged arc welding wire for LPG ship welding and preparation and application. The seamless flux-cored powder for LPG ship welding comprises the following compositions of, by mass, 1.2-4.5% of metallic nickel, 0.3-1.8% of ferromolybdenum, 14-20 % of metallic manganese,1-3% of rare earth ferrosilicon, 0.5-2% of titanium iron, 0.2-0.6% of boron iron, 0.2-0.6% of zirconium iron and the balance metallic iron. The invention further provides the submerged arc welding wire comprising the flux-cored powder. The welding wire is matched and combined with F7A(P)8 flux conforming to ASME II SFA-5.17, the characteristics of good moisture absorption resistance, stable electric arc and beautiful welding line formation are achieved, the technology capability is good, low temperature toughness of welding line metal is good, the anti-crack sensitivity is good, high heat input welding for LPG ship construction is suitable, and great market promotion prospects and good economic benefits are achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A kind of sintered flux for 9ni steel welding and preparation method thereof

ActiveCN106238965BImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Flux-cored welding wire for enhancing continuous self-protection effect of welding zone and preparation method thereof

ActiveCN106001994BGood deoxidation self-protection abilityBeautiful shapeWelding/cutting media/materialsSoldering mediaMelting tankHigh carbon

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com