Patents

Literature

324results about How to "Evenly melted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

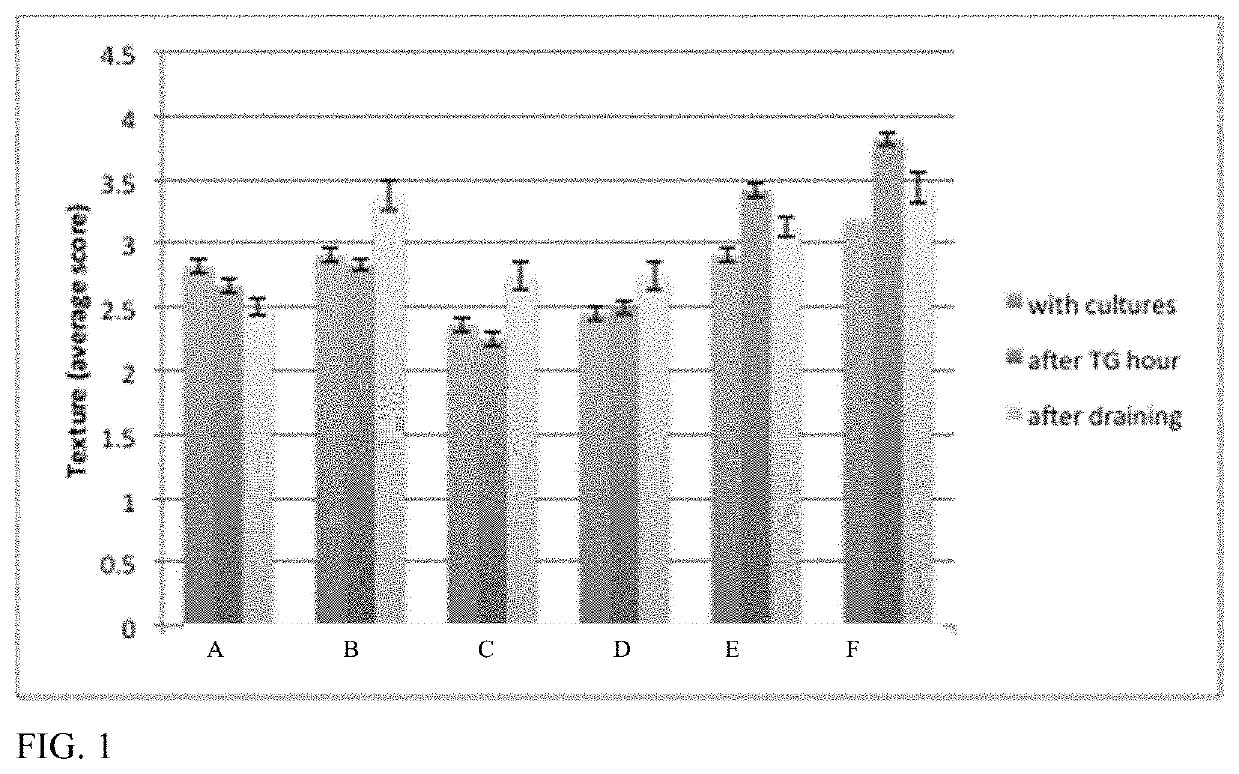

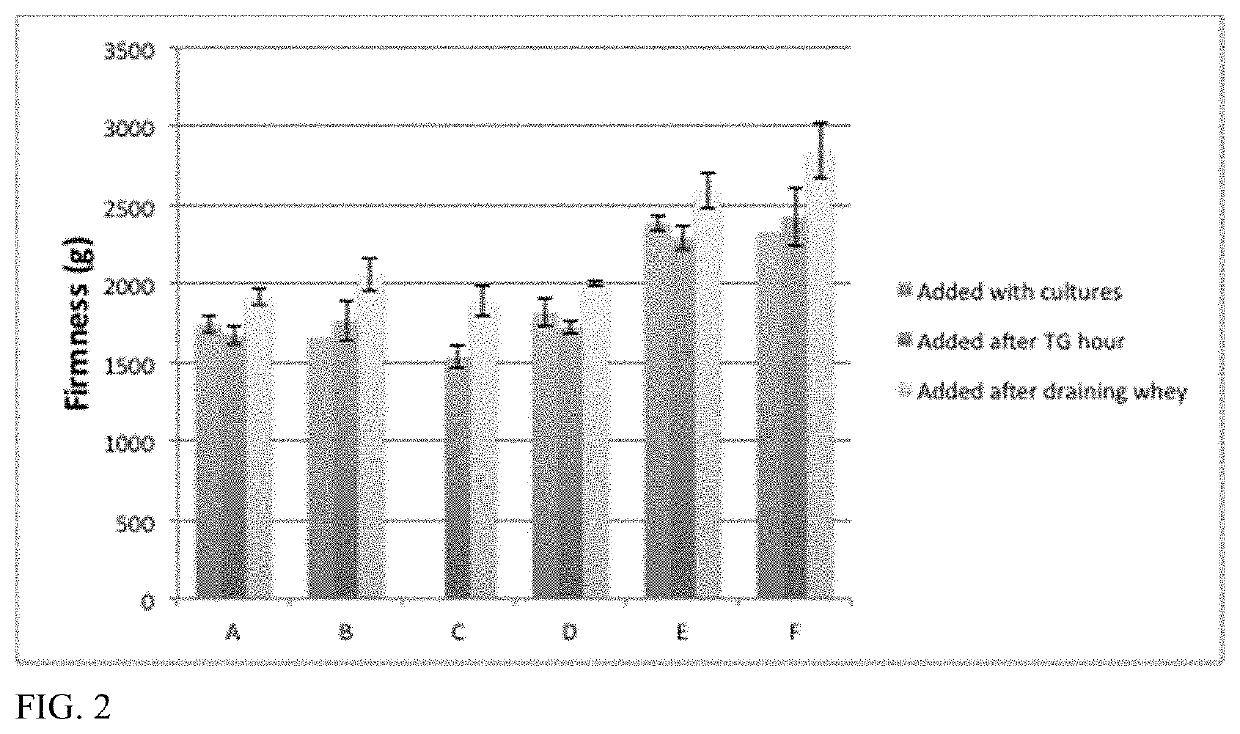

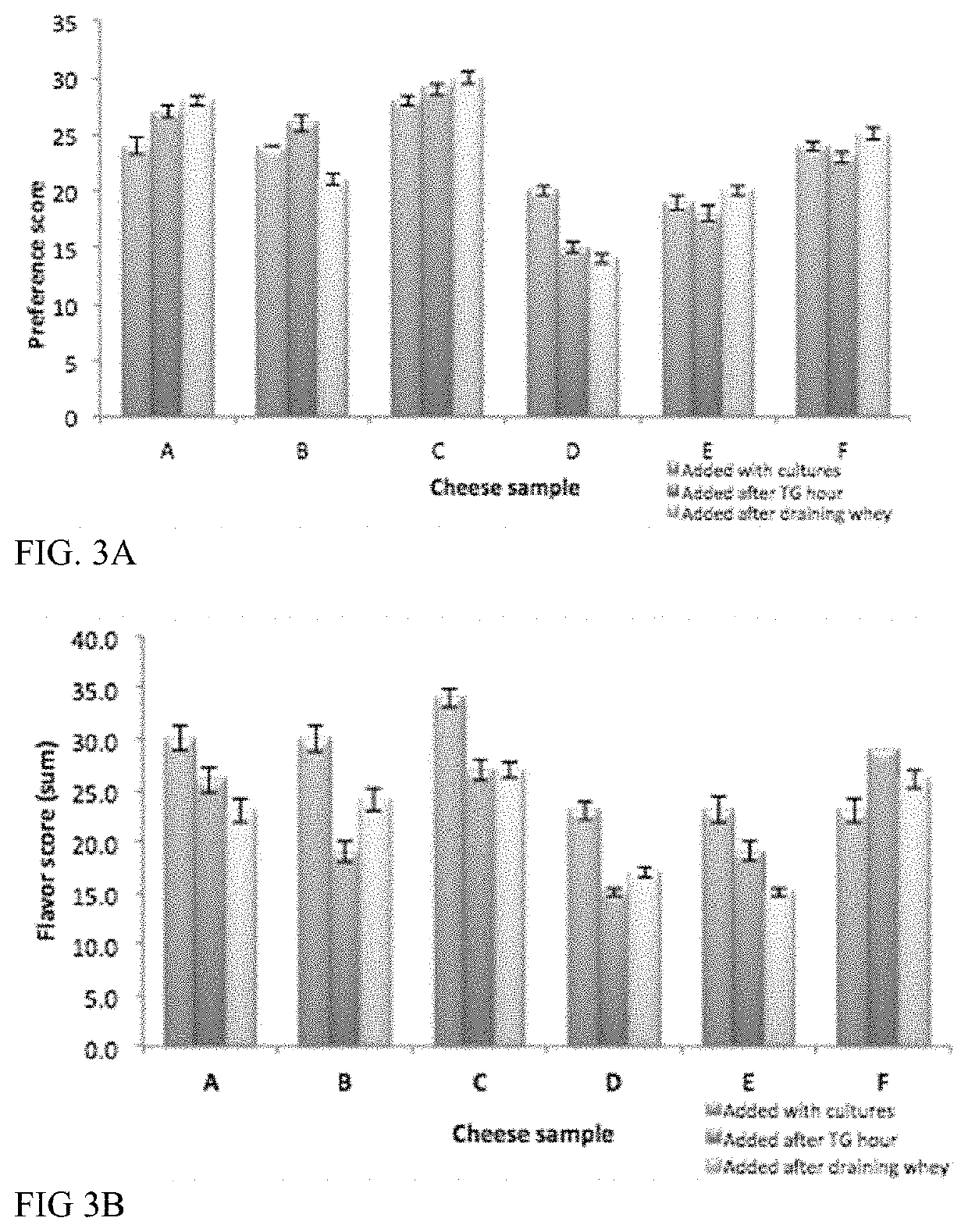

Methods and compositions for consumables

ActiveUS20150305361A1Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyMilk preparationCheese manufactureBiotechnologyConsumables

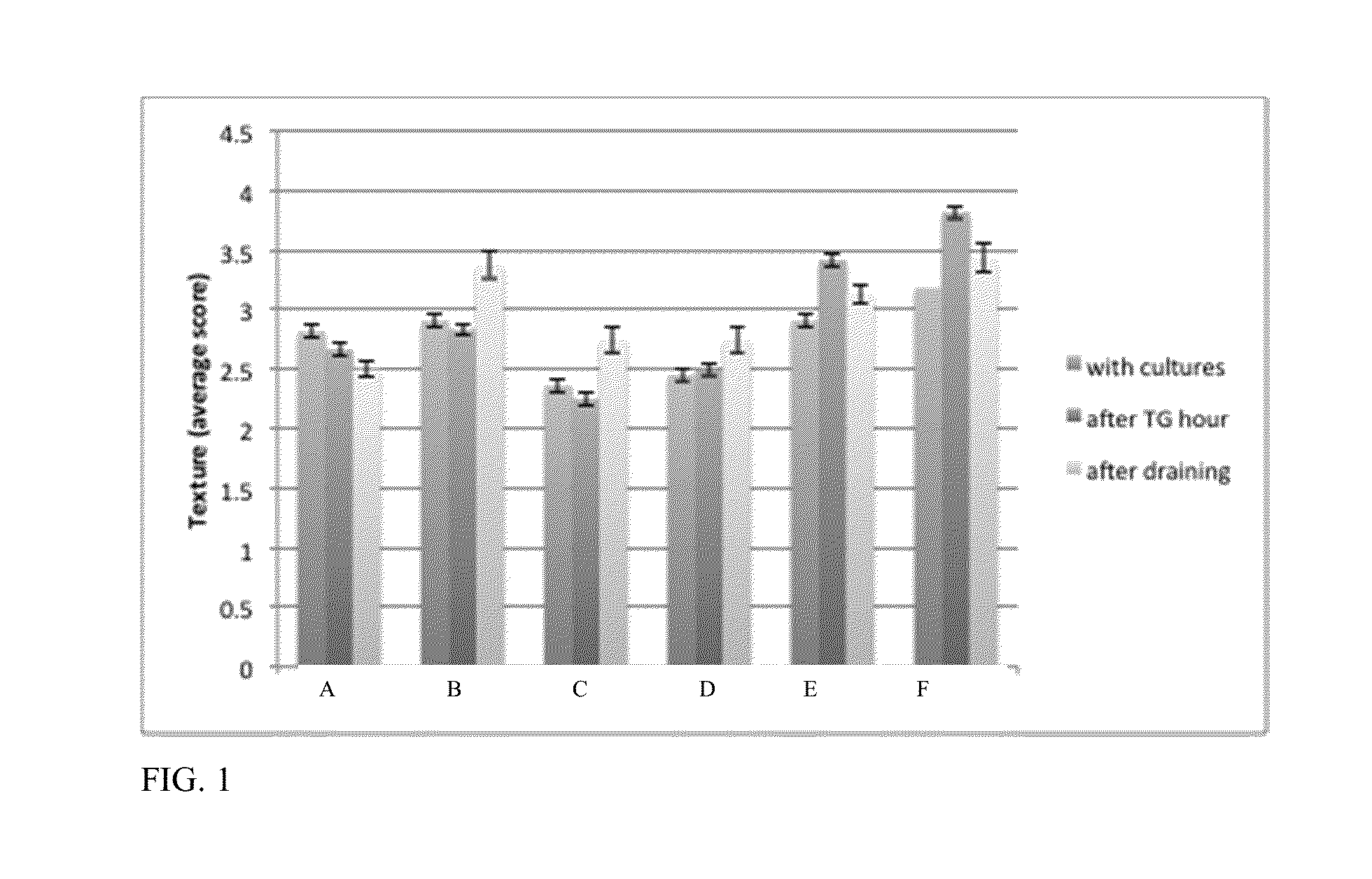

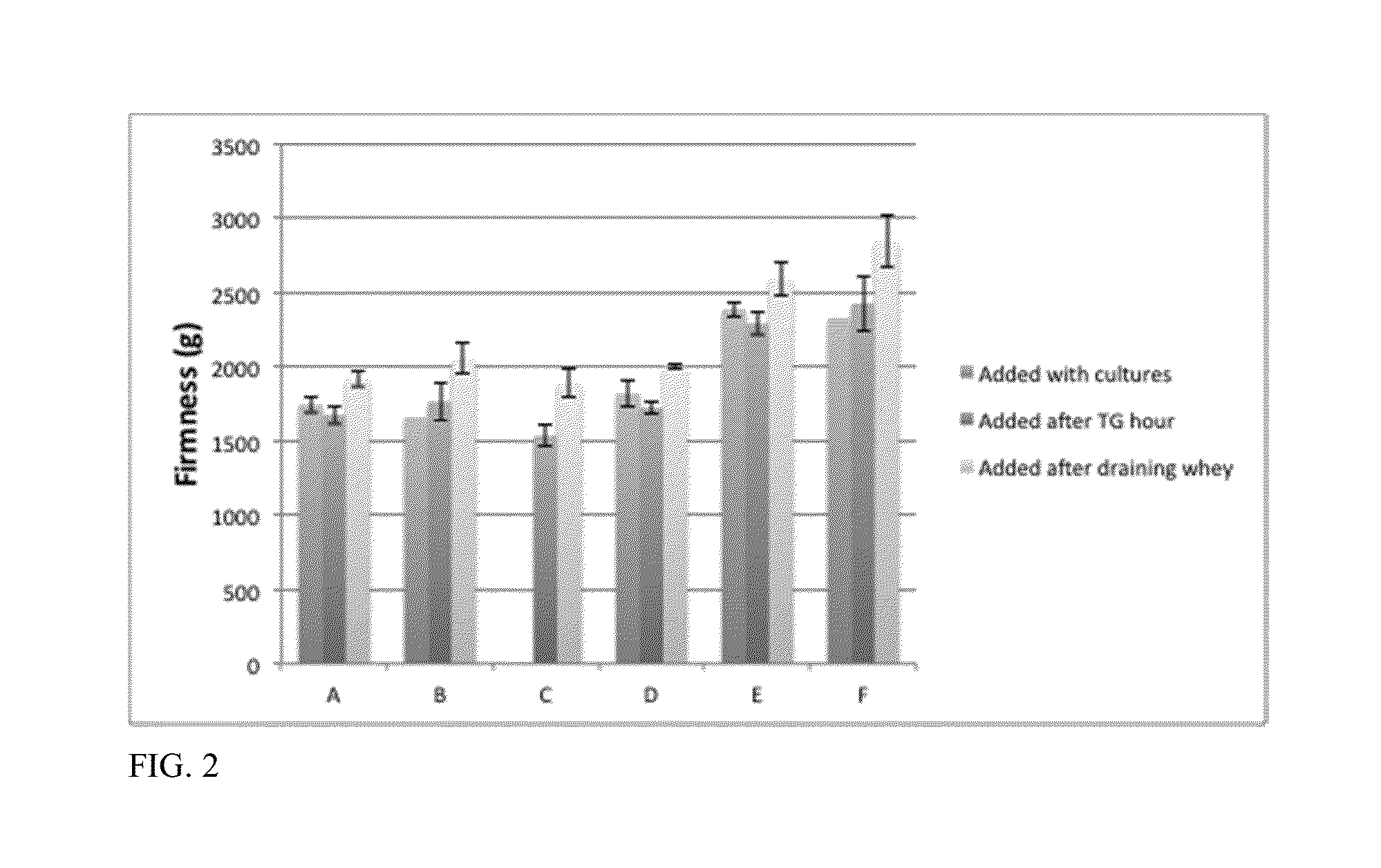

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

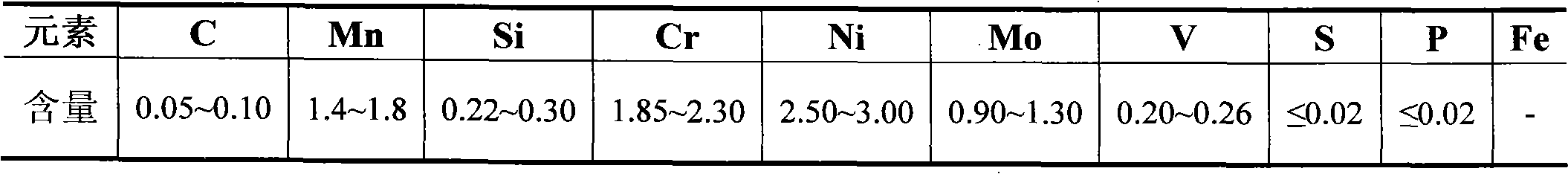

Manufactring method for smelting stainless steel containing N biphase

InactiveCN1563463AGood decarburization effectCarbon content is not limitedElectric arc furnaceDouble phase

A method for smelting double-phase with N stain less steel characterizes 1. carrying out the primary smelting according to the return oxygen blowing wethod 2. smelting qualified double stainless steel with N in composition and purity (1) blown temperature is higher than or equal to 1540deg,c (2) carbon elimination: blowing N2, O2 mixed gas for decarbonization and increasing N2 and process the increased temperature O2 / N2=4, sampling to regulated the components: when c=0.10%, stop blowing O2 but Ar instead, adding prerecovered stags for 7min, total sample analysis including all stags and adding recovery stags (3) recovery: blowing Ar and forcing to eliminate O, blowing N to increase N, sample analysis, fine adjustment to the composition to get the cast ingot.

Owner:宝钢特钢有限公司

Fluorine-free environment-friendly type continuous casting protecting slag for the blast furnace slag containing titanium and the manufacturing process of the same

The present invention relates to steel-making crystallizer protecting dregs, and is environment protecting fluoride-free protecting dregs suitable for continuous casting of plate billet and square billet. The protecting dregs consist of sintering base material, titanium-containing blast slag, manganese ore powder, bentone, carbon black, clay shaped graphite, etc. Its production process includes the synthesis of base material and the compounding of protecting dregs. The protecting dregs may be molten in the crystallizer homogeneously to produce cast billet lubricating and heat insulating effect and has no corrosion to casting machine and no pollution to water.

Owner:CHONGQING UNIV

Boron-containing titanium-based amorphous solder for braze welding Si3N4 ceramic and preparation method thereof

The invention relates to braze welding Si3N4 ceramics containing the boron Ti-based amorphous solder and the preparation method thereof, and belongs to the brazing material in the field of amorphous state and metallurgy. The ingredients of the brazing material consist of the following according to the mass percent: Zr of 12.0-28.0 percent, Ni of 12.0-28.0 percent, Cu of 12.0-28.0 percent, and B of 0.05-0.5 percent, and the remains is Ti. The melting scope of the brazing material ranges 1,150K to 1,250K, and the brazing temperature is from 1,273K to 1,373K. The Ti-Zr-Ni-Cu-B amorphous braze vacuum braze welding Si3N4 ceramics, which is produced by the rapid solidification technology, has superior high-temperature performance to Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder. The tie-in high-temperature bend strength reaches 145MPa under 673K DEG,108MPa under 773K DEG, and still 93MPa under 873K DEG.

Owner:JIANGSU UNIV OF SCI & TECH

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Middle-temperature sharp-quenching aluminum solder and method of producing the same

InactiveCN101134273AFlat surfaceGood workmanshipWelding/cutting media/materialsSoldering media6063 aluminium alloyMelt temperature

The present invention belongs to the field of aluminum and aluminum alloy connecting material, relates to aluminum brazing material, and is especially one kind of fast cooled Al-Si-Cu-Zn brazing material for brazing aluminum and aluminum alloy and its preparation process. The Al-Si-Cu-Zn brazing material consists of Si 5.0-12.5 wt%, Cu 15.0-30.0 wt%, Zn 2.5-7.5 wt%, Sr 0.001-0.5 wt% and Al for the rest. The Al-Si-Cu-Zn brazing material is prepared through one single roll and fast cooling process. It has melting temperature of 500-525 deg.c and brazing temperature of 530-570 deg.c, and is suitable for brazing aluminum and aluminum alloy with solidus temperature over 530 deg.c.

Owner:JIANGSU UNIV OF SCI & TECH

Titanium group high temperature amorphous solder of hard solder Si*N* ceramic and method for producing the same

The invention discloses braze welding Si3N4 porcelain Ti base high temperature non-crystalline brazing filler metal and the preparing method thereof, in particular to Ti-Zr-Ni-Cu high temperature active non-crystalline brazing filler metal and the preparing method thereof, and pertains to the braze welding material of non-crystalline state and metallurgy field. The brazing filler metal has the ingredients and the contents (matching according to the quality percentage) as follows: Ti of 30.0 to 45.0 percent, Zr of 22.0 to 26.0 percent, Ni of 12.0 to 16.0 percent, and Cu of 15.0 to 30.0 percent. The melting temperature range of the brazing filler metal is 1100 to 1170 K; the braze welding temperature is 1223 to 1323 K. Compared with the brazing filler metal prepared by normal melting technique with the same component, the Ti-Zr-Ni-Cu high temperature active non-crystalline brazing filler metal leaf obtained by the rapid solidifying technique has favorable wetting property and tie-in dynam performance; adopting the non-crystalline brazing filler metal to vacuum braze weld Si3N4 porcelain, the tie-in chamber temperature bending intensity is 160 MPa; when the temperature is 673 K, the tie-in high temperature bending intensity is 126 MPa; when the temperature is 773 K, the high temperature bending intensity is 83 MPa.

Owner:JIANGSU UNIV OF SCI & TECH

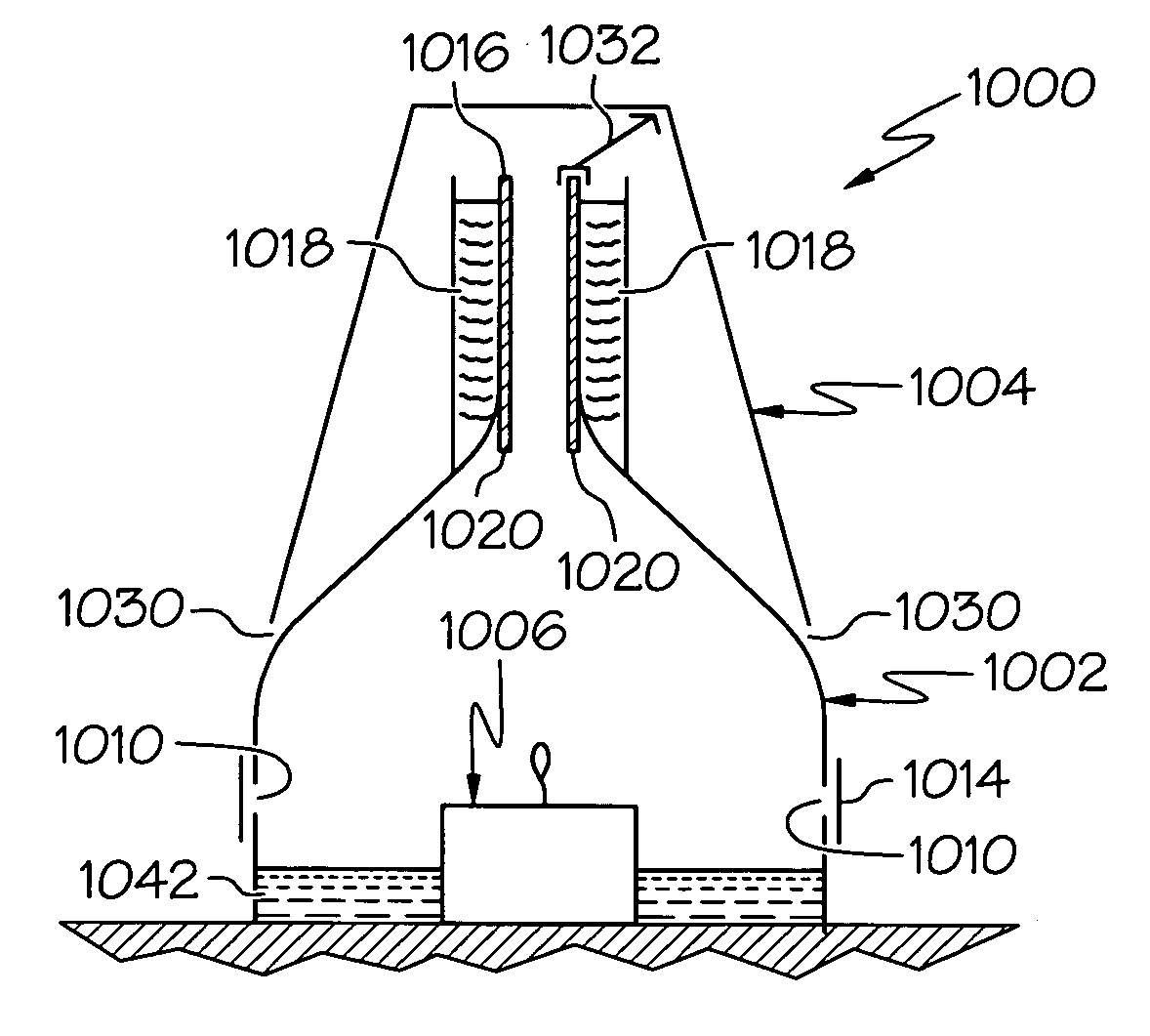

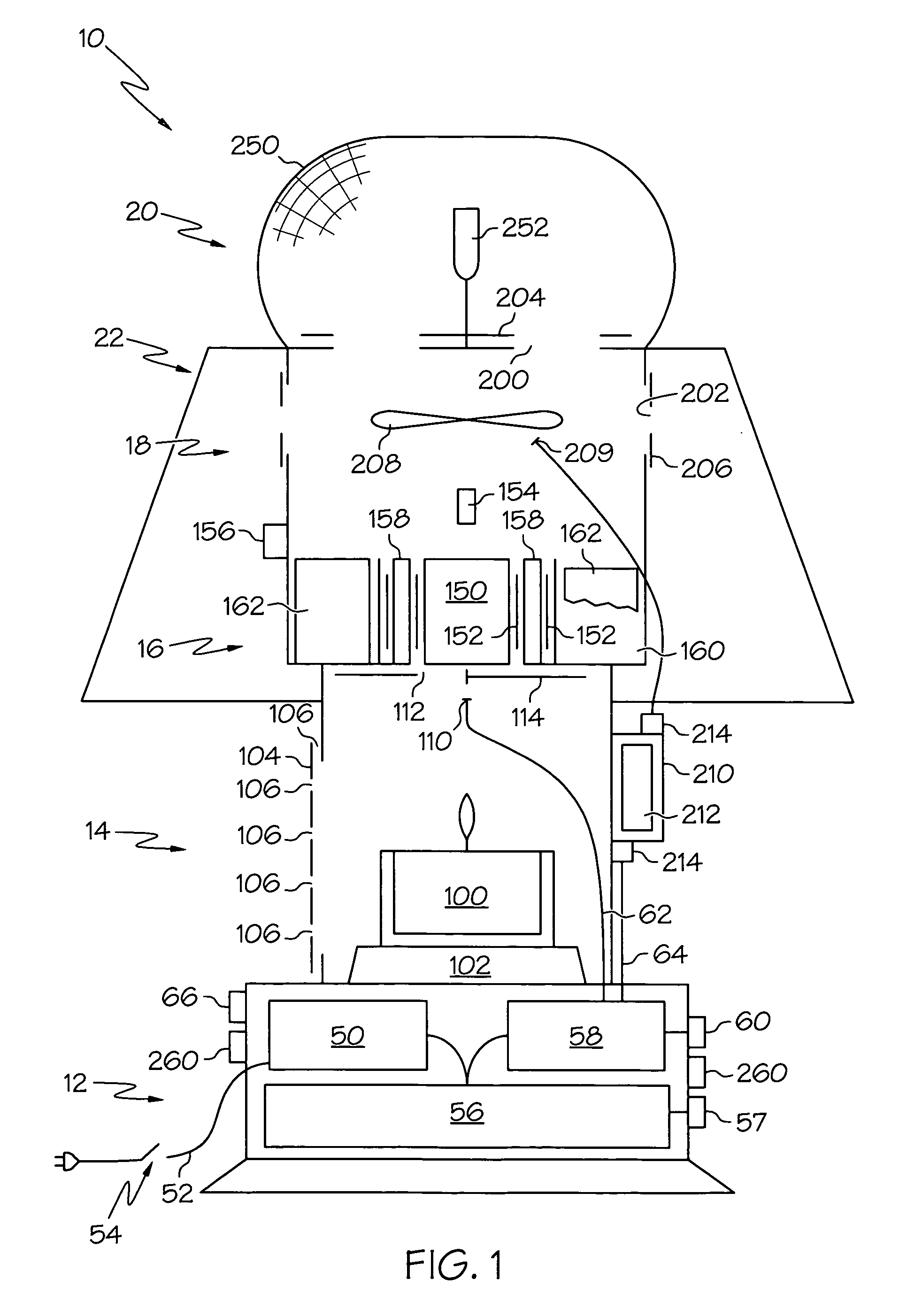

Lamp with protected combustion chamber

InactiveUS20060123694A1Prevents the candle from being blown outEffective distributionElectric shock equipmentsInsect catchers and killersCombustion chamberCooling chamber

A lamp includes a combustion chamber having a neck that defines a combustion chamber air outlet. A candle is disposed in the combustion chamber and, when burned, creates an upward flow of air and combustion products through the neck. A reservoir is disposed around a portion of the neck with a material to be heated disposed in the reservoir. In one configuration, the material is a candle fuel that is wicked by the neck and drips into the candle to refuel the candle. In another configuration, the material is a scented material that evaporates when heated to distribute the scent. A cooling chamber may be disposed above the combustion chamber with the outlet of the cooling chamber being disposed below the outlet of the neck. Another configuration allows the height of the flame to be adjusted by varying the volume of air allowed to be drawn into the unit.

Owner:WELCH TOMMY D

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

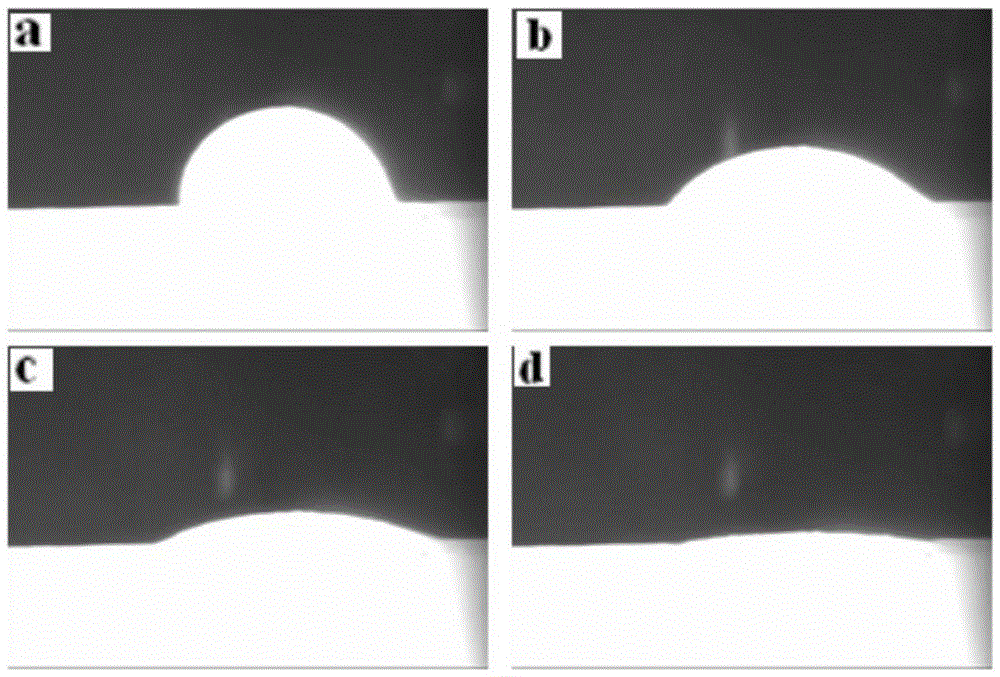

Pulsed laser welding method for high-pressure sealed valve body component

InactiveCN102653034AIncrease productivityHigh precisionLaser beam welding apparatusPeak valueHigh pressure

The invention discloses a pulsed laser welding method for a high-pressure sealed valve body component and aims at providing a processing method for forming a continuous compact weld bead, which has the advantages of stable quality, higher efficiency, appropriate fusion depth of a joint after welding, regular weld joint, bright joint, uniform melting and mutually overlapped laser spots. The method disclosed by the invention is realized through the following technical scheme comprising the following steps of: (a) removing oxides on the surface of a weld and washing a joint part by a washing agent; (b) enabling a valve seat to be tightly close to a sealing gasket through a clamp, clamping on a three-jaw chuck, tilting a rotating table for 45 degrees and melting an angle joint of the valve body component; and (c) setting single pulse energy according to the characteristics of material and enabling a pulse waveform to be steep at the front and gentle at the back, thereby rapidly increasing laser energy to a peak value, rapidly heating, improving absorbability, then slowly lowering the temperature, maintaining the temperature for heating continuously, avoiding violent splashing, simultaneously increasing the fusion depth, melting the angle joint into a whole, matching with reasonable welding speed and pulse frequency, and enabling the laser spots to be mutually overlapped for forming the continuous compact weld bead.

Owner:成都泛华航空仪表电器有限公司

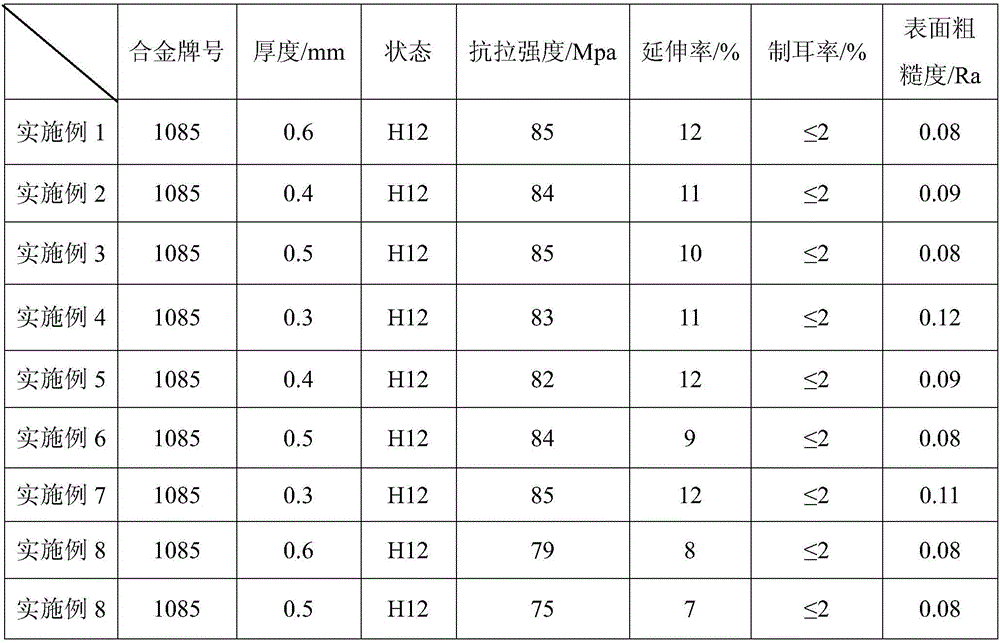

Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

ActiveCN106319292ASolve the shortcomings of uneven online refinementEvenly meltedSmelting processDistribution system

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

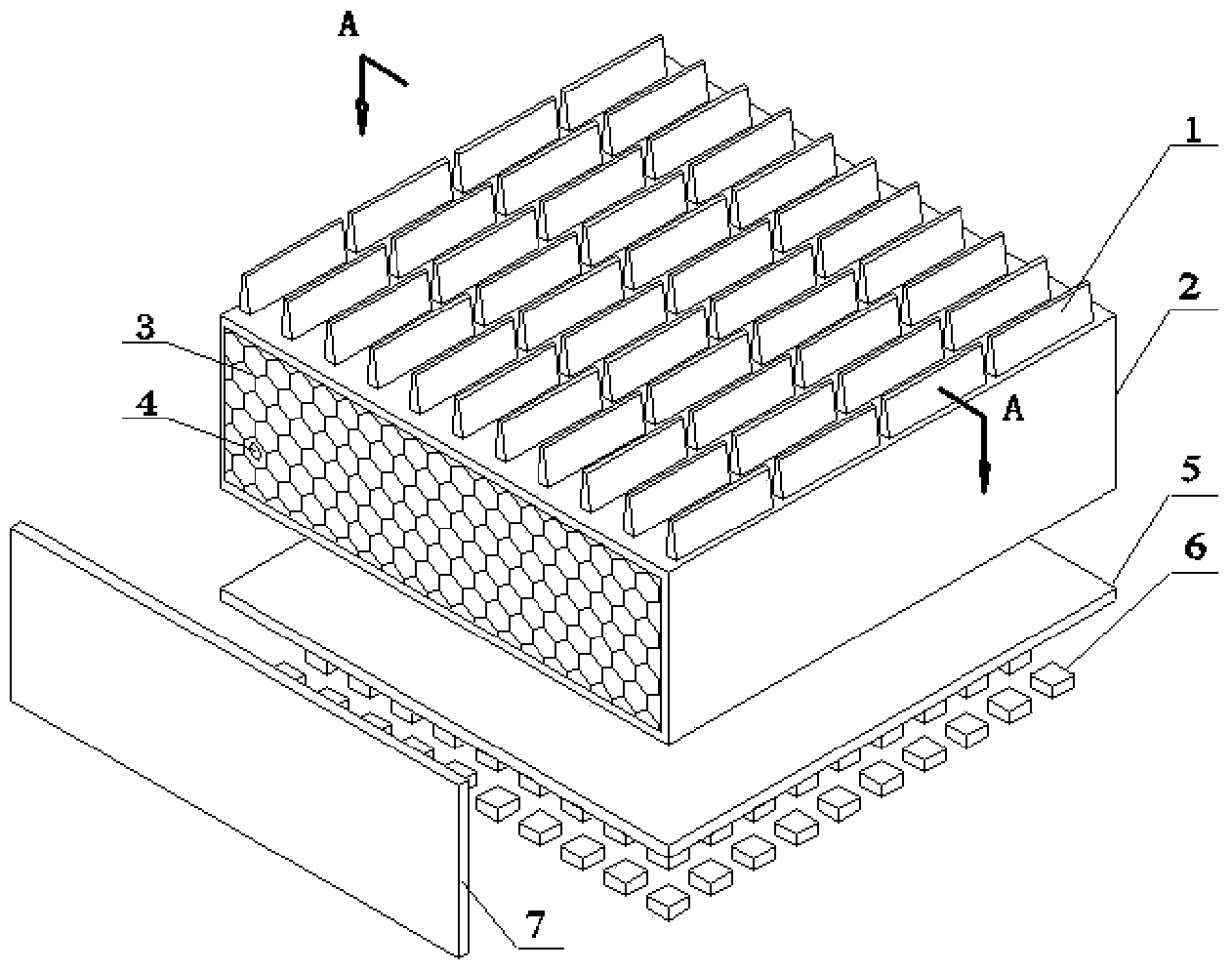

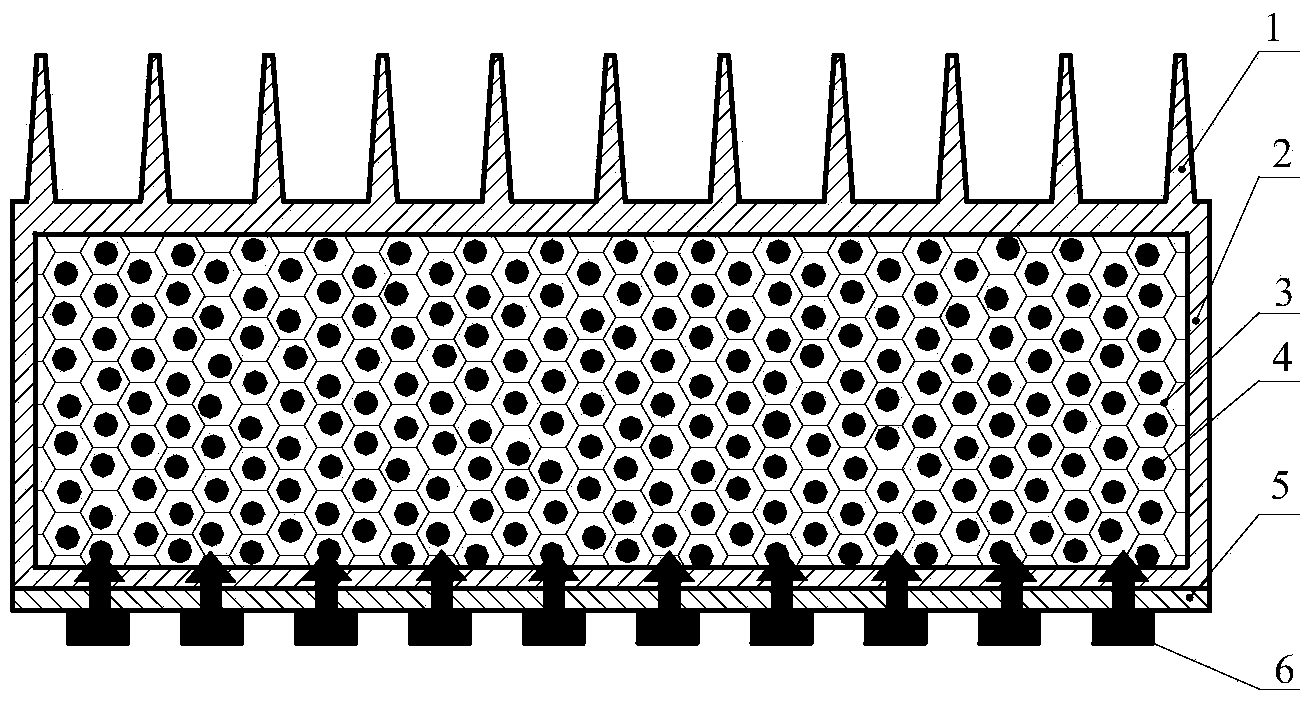

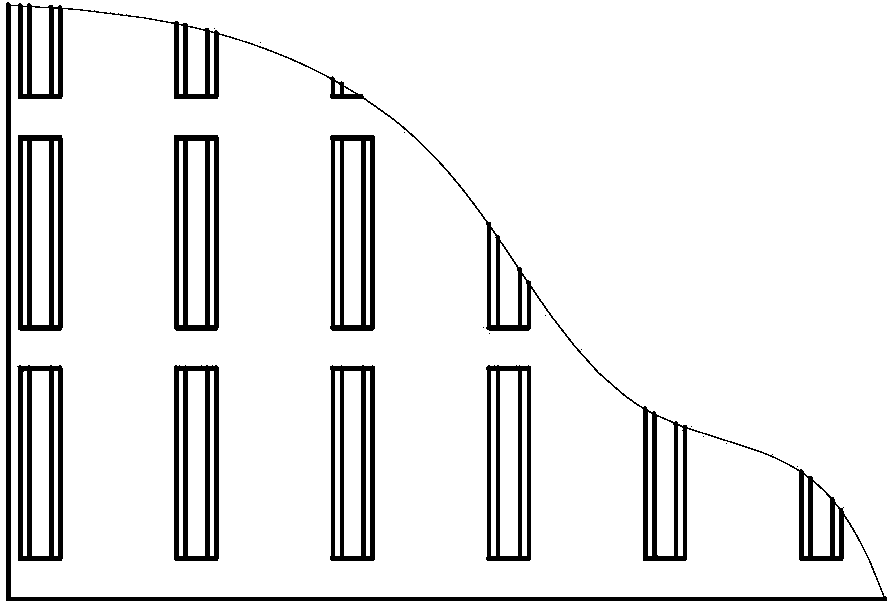

High-power LED multi-hole phase-changing heat sink structure

InactiveCN104241513AReduce dependenceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesExternal energyWorking temperature

A high-power LED multi-hole phase-changing heat sink structure comprises a radiator inner cavity. A plurality of radiator fins are arranged on the top face of the radiator inner cavity. A metal multi-hole structure is arranged in the radiator inner cavity in a sintering mode. Holes of the metal multi-hole structure are filled with phase-changing materials. An LED electronic chip is arranged on the bottom face of the radiator inner cavity. The melting point of the phase-changing materials is lower than the normal working temperature of the LED electronic chip. The response speed of phase-changing latent heat storing can be increased, the weight and the cost of an LED radiating structure are lowered, a part of heat emitted by the chip during LED working is dissipated in a natural-convection mode, a large part is stored by latent heat absorbed during a phase-changing material melting process, meanwhile, the temperature of the LED chip is controlled through the melting point of the phase-changing materials, and radiating performance is improved. The high-power LED multi-hole phase-changing heat sink structure has the advantages of being simple in structure, light in weight, small in size, good in adjusting performance, good in radiating effect, long in service life, free from external energy loss and environment pollution and the like.

Owner:XI AN JIAOTONG UNIV

Brazing filler metal for brazing W-Cu composite and Fe-based alloy, method and brazing technique

ActiveCN105081597AModerate melting temperatureFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal for brazing a W-Cu composite and Fe-based alloy, a method and a brazing technique. The brazing filler metal is in a foil piece strip shape. The thickness of the brazing filler metal ranges from 50 micrometers to 100 micrometers. The brazing filler metal comprises, by weight, 6.0%-9.0% of Mn, 3.5%-5% of Co, 0.3%-1.7% of Ni, 2.0%-5.0% of Zr, 1.2%-2.8% of Ti, and the balance Cu. The brazing temperature of the brazing filler metal ranges from 1000 DEG C to 1050 DEG C, the melting temperature of the brazing filler metal is moderate, and the brazing filler metal is uniformly melted; diffusion and the interface reaction of alloy elements in the brazed connection process can be promoted through a brazing filler metal foil piece, and the wetting and spreading capacity of the brazing filler metal on the surfaces of the W-Cu composite and the Fe-based sintered alloy is improved; crystal particles are refined, residual stress is reduced, and the mechanical performance of joints is improved; the brazing technique for connecting the W-Cu composite and the Fe-based sintered alloy through the brazing filler metal is stable and reliable, vacuum brazed connection is used, a component is in a vacuum state in the heating process, the whole component does not deform, the defects such as microscopic cracks, air holes and inclusions are avoided, and the wetting and spreading capacity of the surface of the brazing filler metal is good.

Owner:JIANGSU UNIV OF SCI & TECH

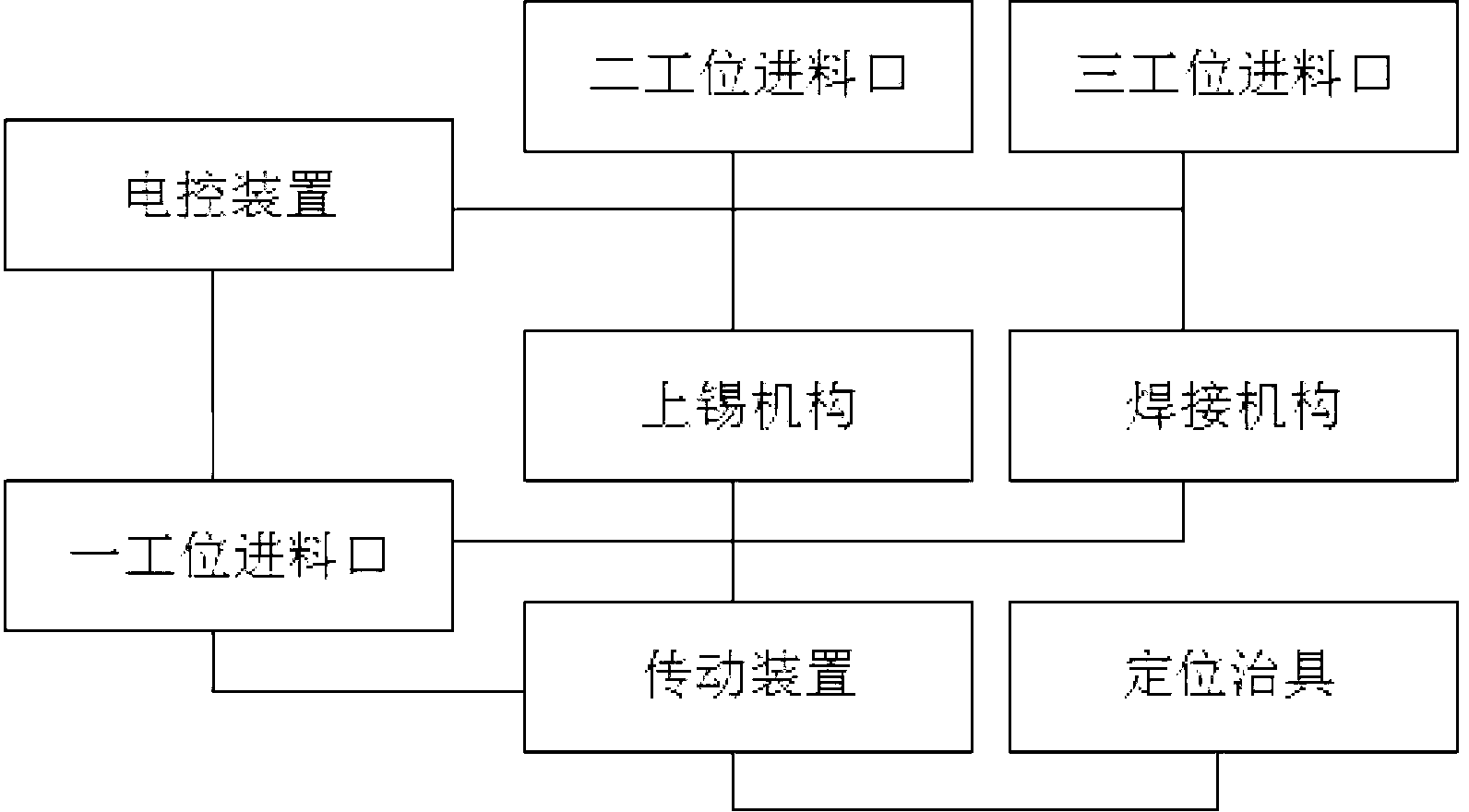

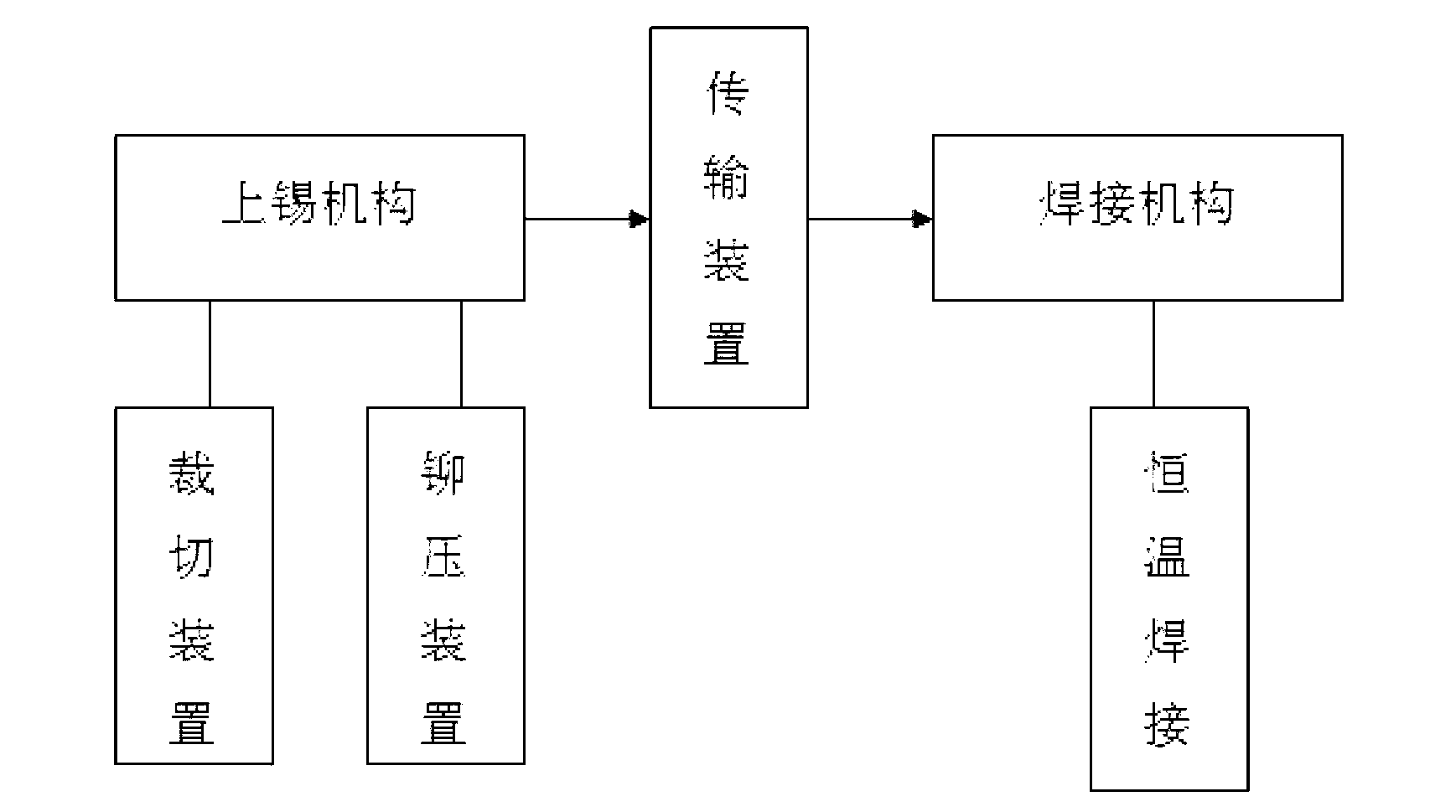

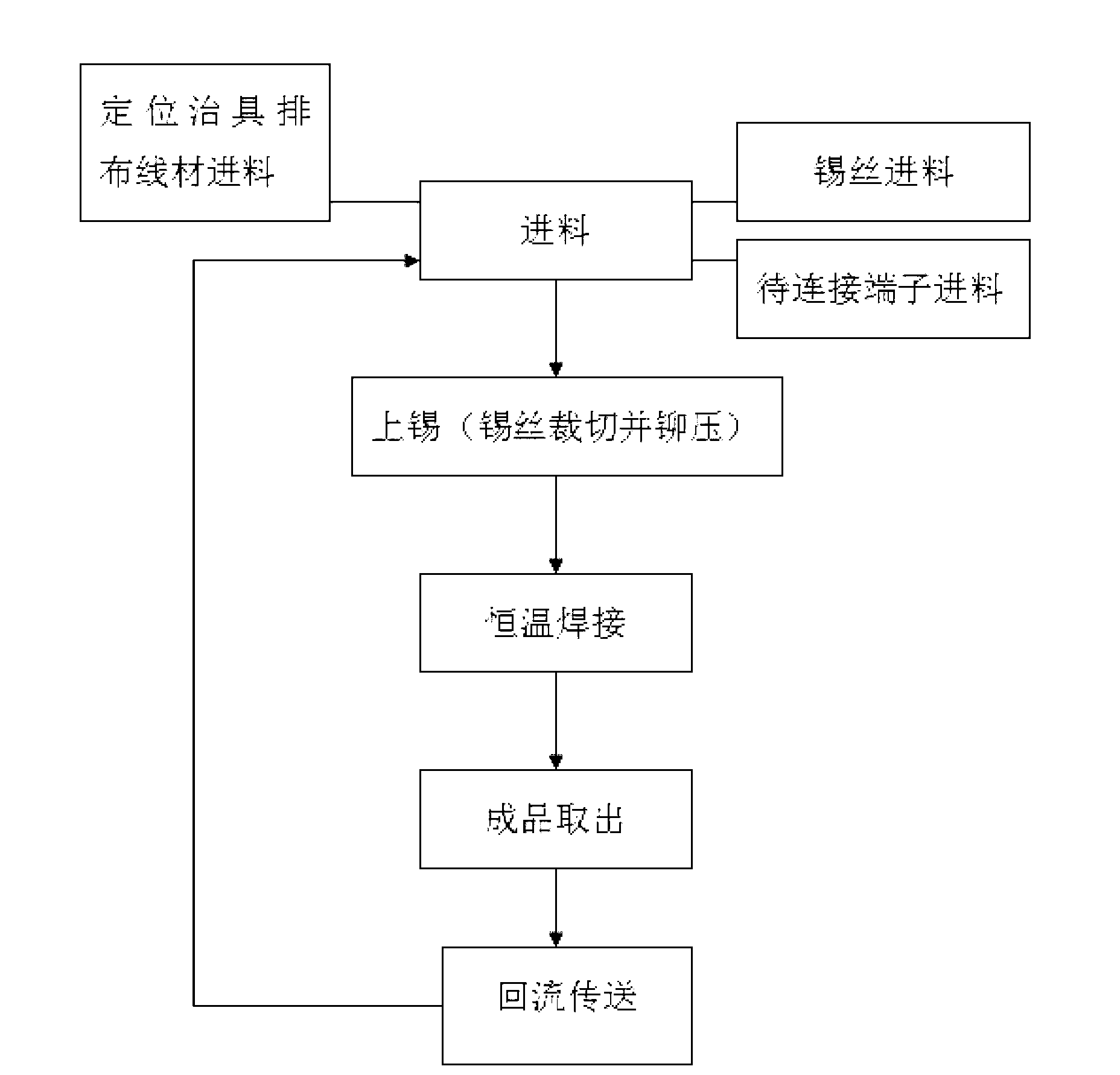

Automatic wire welding process and automatic wire welding machine

ActiveCN103252551AEvenly meltedRegular and beautiful appearanceLine/current collector detailsConductorsEngineeringTin

The invention discloses an automatic wire welding process. A first station feed inlet of a feed processing device guides a to-be-welded wire which is subjected to peeling and cutting at a cutting station into a positioning jig of a transmission device. A second station feed inlet guide a tin wire into a tinning mechanism. A third station feed inlet guide a to-be-connected terminal into a welding structure. The tinning mechanism flattens and cuts the tin wire to form a tin sheet, and the tin sheet is riveted by means of casting and wrapped at the connection of the wire and the terminal. The welding structure guides the positioning jig for fixing the to-be-welded wire to a welding station and performs constant-temperature welding of the wire and the terminal after accurate positioning of the wire and the to-be-connected terminal. By the automatic wire welding process, automatic wire welding is achieved, tin wire welding totally covers wire heads, crack and dropping are less easily, and product service life is prolonged. The invention further provides an automatic wire welding machine for realizing the process.

Owner:东莞市恒仓智能机械设备厂

High-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as preparation method and welding method

InactiveCN104858570AEvenly meltedImprove wettingWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMechanical property

The invention discloses high-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as a preparation method and a welding method. The high-temperature Zr-based brazing filler metal comprises the following elements by weight: 10 to 12 percent of V, 3.0 to 9.0 percent of Nb, 3.0 to 4.0 percent of Si, 8.0 to 16 percent of Cu, 9.0 to 12 percent of Ni, 11 to 14 percent of Cr, 3.0 to 5.0 percent of Sn, and the balance of Zr. The brazing temperature of the brazing filler metal is 1010 to 1090 DEG C and moderate, so that the brazing filler metal is uniformly melted; tinsel made of the brazing filler metal can accelerate atomic diffusion and interface reaction in a high-temperature connection process, so that the wetting and spreading capabilities of the brazing filler metal are improved, the residual stress in a joint is reduced, and the mechanical property of the joint is improved. Through the adoption of the preparation method of the brazing filler metal, the preparation of the brazing filler metal can be reproduced repeatedly, so as to facilitate popularization and application; through the adoption of the brazing technology provided by the invention, sample pieces are connected through vacuum brazing, wherein the sample pieces are in a vacuum atmosphere while being heated, so that problems such as oxidation and pollution are solved, the surface wetting and spreading capabilities are relatively high, convenience is brought for filling of a brazing seam, the strength of the joint is improved, and the obtained welded joint can be stable and reliable.

Owner:江门市新会区华科电器制品有限公司

Seamless solid metal calcium cored wire for steelmaking and deoxidation and preparation method thereof

The invention discloses a seamless solid metal calcium cored wire for steelmaking and deoxidation and a preparation method thereof. The seamless solid metal calcium cored wire consists of an outer-layer steel tube, a middle coating layer and an inner core, wherein the inner core is a solid metal calcium (pure calcium) wire. The seamless solid metal calcium cored wire disclosed by the utility model has the beneficial effects that vapor pressure and the gasification rate of metal calcium can be reduced, the depth of the seamless solid metal calcium cored wire inserted in molten steel is increased, the boiling of the molten steel is reduced, the time that the metal calcium is adsorbed by metal is reduced, the boiling phenomenon of the existing seamed solid calcium cored wire inserted in the molten steel is overcome, the phenomenon that the wire feeding is affected due to hollow powder calcium cored wire and non-uniform core powder weigh is reduced, and the bring-in of harmful elements (S, P, C and Si) in the powder calcium cored wire is avoided, so that the yield and the stability of metal calcium are greatly improved.

Owner:周海涛 +1

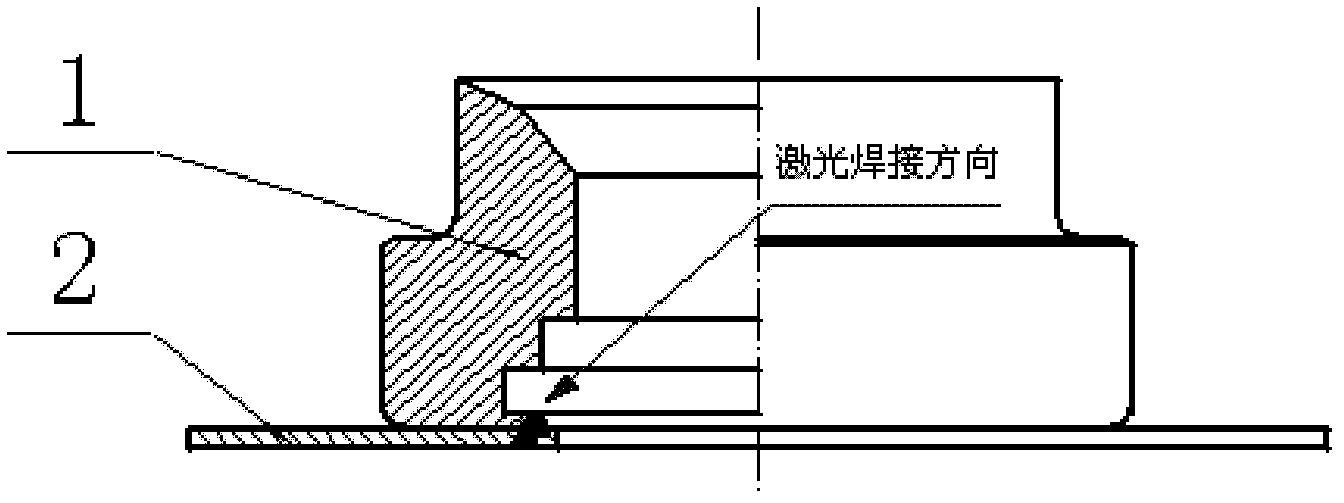

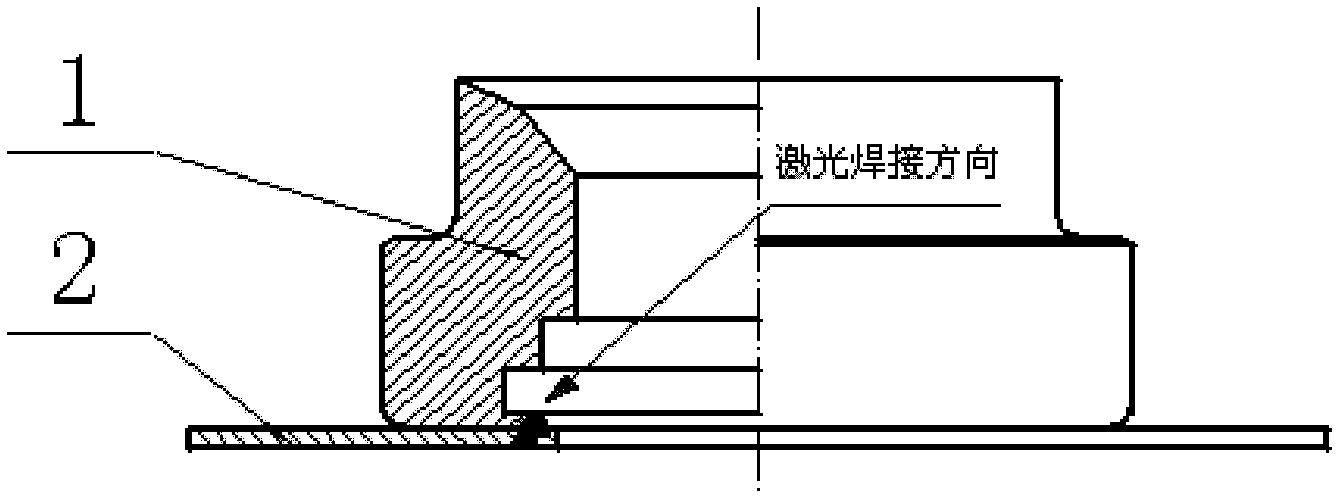

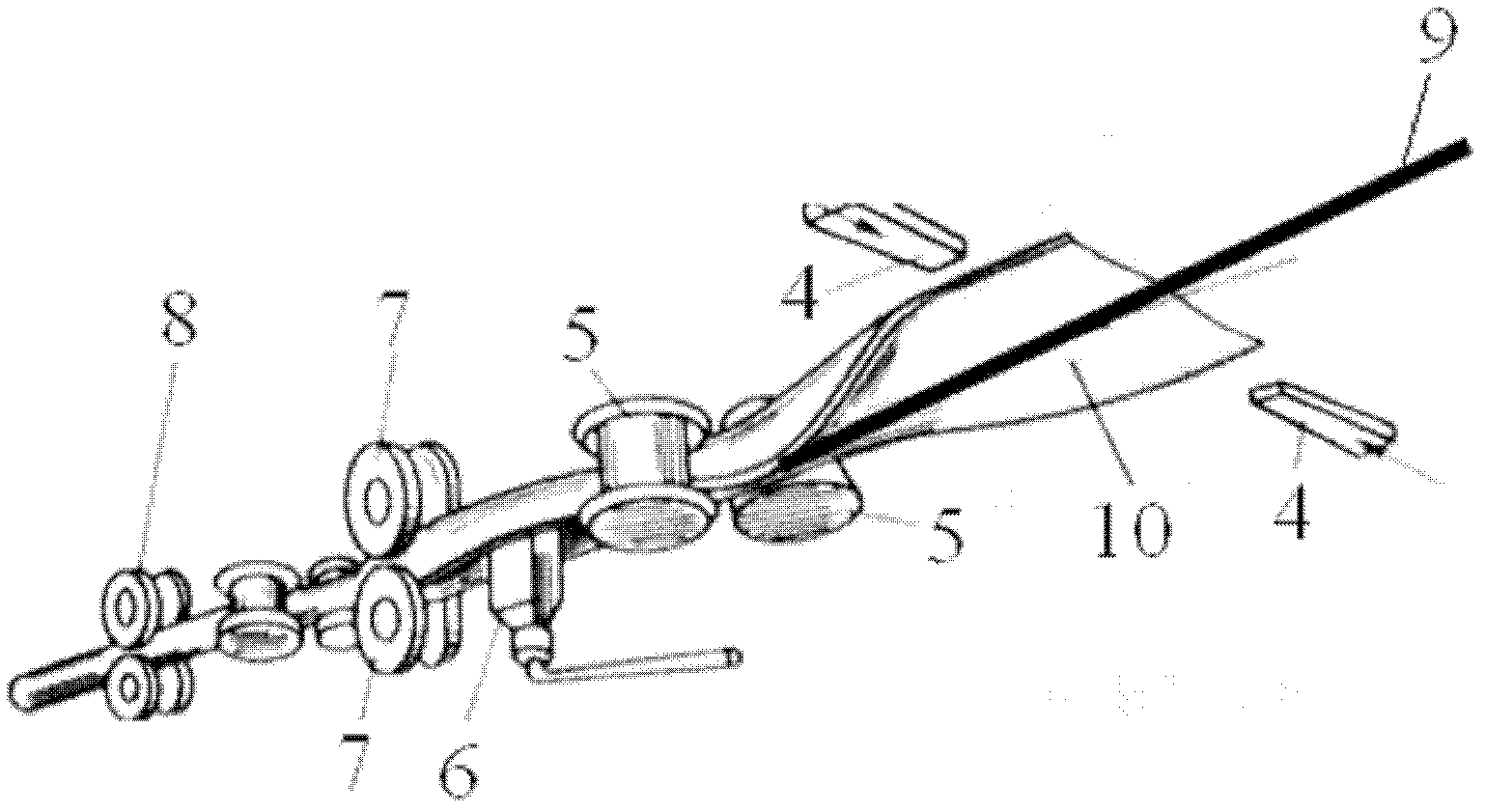

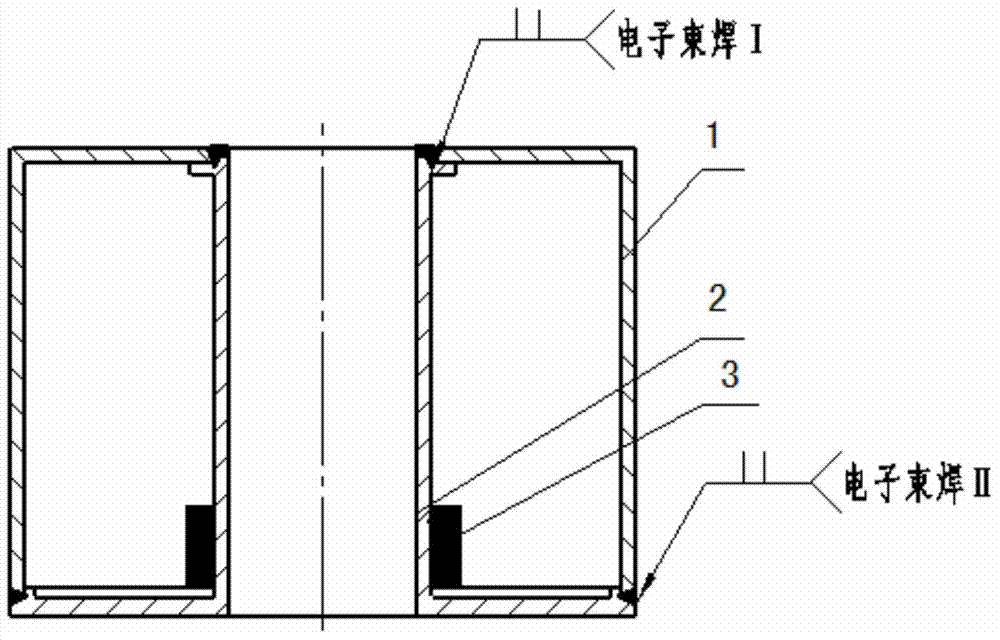

Method for welding thin-walled cylinder with magnet sleeved inside in seal housing component

ActiveCN103537788ASimple and fast operationQuality improvementElectron beam welding apparatusSteam pressureEngineering

The invention provides a method for welding a thin-walled cylinder with a magnet sleeved inside in a seal housing component. The welding efficiency of the aluminum alloy thin-walled seal housing component can be obviously improved through the method, quality is stable, a connector is bright, fusion is even, and continuous and compact welding beads can be formed. According to the technical scheme, the method comprises the following steps that the butt joint positions of inner and outer housing welding joints are closely attached through a clamp, and annular welding joint pulse electron beam tack welding is carried out on the circumferential seam crossing of an assembled component; a deflection distance occurring to an electron beam caused by Lorentz force is compensated by an electron beam deflection angle; the total heat input amount of the electron beam is controlled with the impulse waveform of the pulse electron beam, the impulse waveform is steep in the front and gentle in the back, and welding is carried out through heat generated when beam flow ascends and descends; under the condition that small pulse power is set and steam pressure is reduced, a pulse back edge is prolonged by 3-5s, slow reduction is carried out, the focal position of the electron beam is adjusted to be within the range 0.55mm below the surface of a workpiece, the surface of a connector to be welded is melted and integrally welded, and the continuous welding beads are formed.

Owner:四川泛华航空仪表电器有限公司

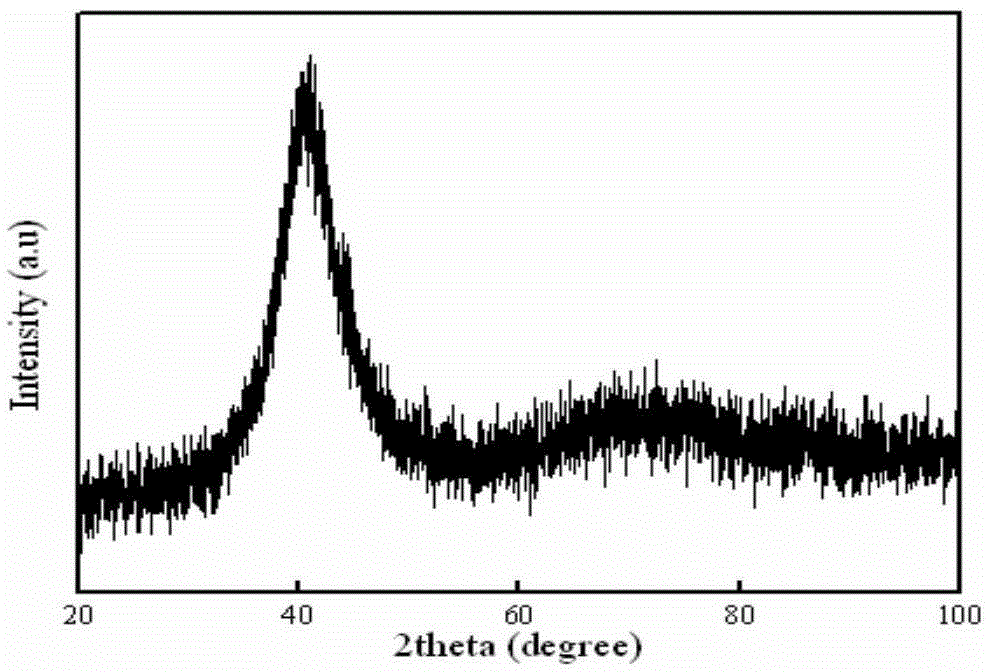

Aluminum powder for 3D (three-dimensional) printing and preparation method of aluminum powder

ActiveCN104668552ALower melting temperatureEvenly meltedTransportation and packagingMetal-working apparatus3D printingAluminium oxides

The invention provides aluminum powder for 3D (three-dimensional) printing. In the aluminum powder, white carbon black serves as a carrier. A preparation method of the aluminum powder comprises the following steps of fusing aluminum at the temperature of 680 DEG C in a vacuum environment; staying the fused aluminum in gaps of the white carbon black; and performing argon protecting grinding on the fused aluminum to form spherical aluminum powder of which the average grain diameter is 50-100 nanometers and the degree of sphericity is above 0.75. Monomers wrap the surface of the aluminum powder in a gathered manner, so that the oxygen content of the spherical aluminum powder is reduced; and influences of aluminum oxide on fusion of the aluminum are avoided, the fusing temperature of the obtained aluminum powder is low, the aluminum powder is fused uniformly, tissues in metal are uniform when the aluminum powder is used for 3D printing, the forming precision of products is improved, and the aluminum powder can be used for preparing precise metal products of complicated components.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

Methods and compositions for consumables

ActiveUS10986848B2Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyCheese manufactureFood scienceBiotechnologyConsumables

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

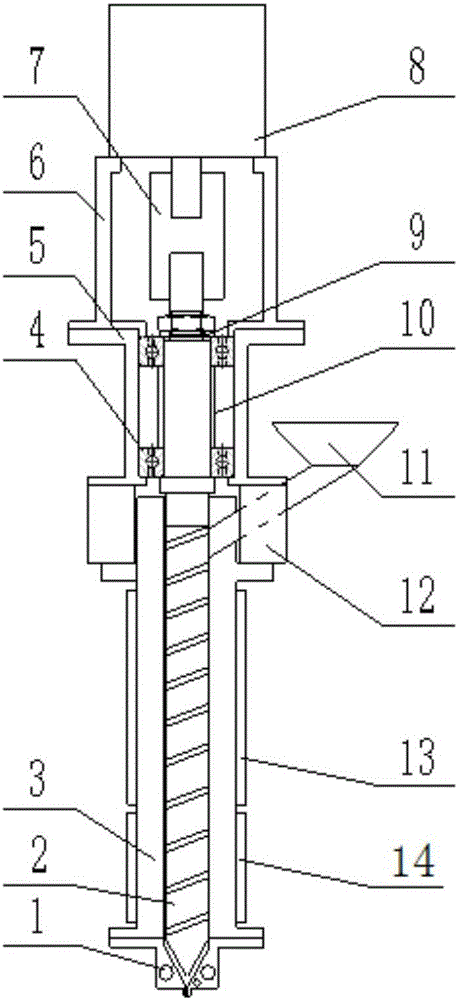

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-alkalinity crystallizer covering slag prepared from building waste clay

The invention discloses low-alkalinity crystallizer covering slag prepared from building waste clay. The low-alkalinity crystallizer covering slag comprises the following raw material components in percentage by mass: 30 to 55 percent of clay, 8 to 15 percent of fluorite, 15 to 30 percent of lime stone, 8 to 15 percent of sodium carbonate, 1 to 3 percent of magnesium oxide, 2 to 4 percent of carbon black, 5 to 15 percent of graphite and 1 to 3 percent of binder. The covering slag prepared from the clay serving as a main material can maintain the complete granules of the hollow covering slag, has good heat-preserving effect in the using process and is melted uniformly without caking so as to guarantee to introduce molten slag uniformly and smoothly, effectively control the heat transfer ofa crystallizer, avoid the caking of the crystallizer and a blank shell and improve the external quality of cast blanks.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Slab 430 stainless steel continuous casting crystallizer casting powder

The invention provides slab 430 stainless steel continuous casting crystallizer casting powder. The chemical components of the slab 430 stainless steel continuous casting crystallizer casting powder include, by mass, 0.8-1.2 percent of Li2O, 0.5-1.5 percent of MnO, 4.5-5.5 percent of F-, 3.5-4.5 percent of free carbon, 28-33 percent of SiO2, 25.5-32.0 percent of CaO, 9.0-12 percent of Al2O3, 10-15 percent of Na2O, 1.2-1.8 percent of MgO, 1.2-2.0 percent of Fe2O3 and 1.0 percent of k2O<, and the binary basicity (CaO / SiO2) is 0.7-1.0. The slab 430 stainless steel continuous casting crystallizer casting powder can be melted uniformly with a few slag rims, the thickness of liquid casting powder is 10-12 mm at the normal pull rate, the consumption quantity per ton of steel is 0.40-0.60 Kg, and the non-cleaning rate of the surfaces of casting blanks can reach up to 98 percent.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP +1

High-temperature amorphous solder for soldering Si3N4 ceramics

InactiveCN101823188AGood flexibilityImprove wettabilityWelding/cutting media/materialsSoldering mediaRoom temperatureFlexural strength

The invention discloses high-temperature amorphous solder for soldering Si3N4 ceramics, belonging to the technical field of soldering materials. The high-temperature amorphous solder of the invention for soldering the Si3N4 ceramics comprises the following components by weight percent: 35.0% to 45.0% of Ti, 20% to 30% of Zr, 0.1% to 0.3% of B and Cu in balancing amount, wherein the melting temperature of the solder ranges from 1,100K to 1,200K, and the soldering temperature thereof is 1,223K to 1,373K. The Si3N4 ceramics is prepared by vacuum-soldering the Ti-Zr-Cu-B high-temperature active amorphous solder on the basis of the rapid solidification technology, and the maximal room-temperature strength of the Si3N4 ceramics reaches 245MPa; and the high-temperature performance thereof is much higher than that of the Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder, particularly, the high-temperature bending strength of the ceramic connector is 165.5MPa at the testing temperature of 673K.

Owner:JIANGSU UNIV OF SCI & TECH

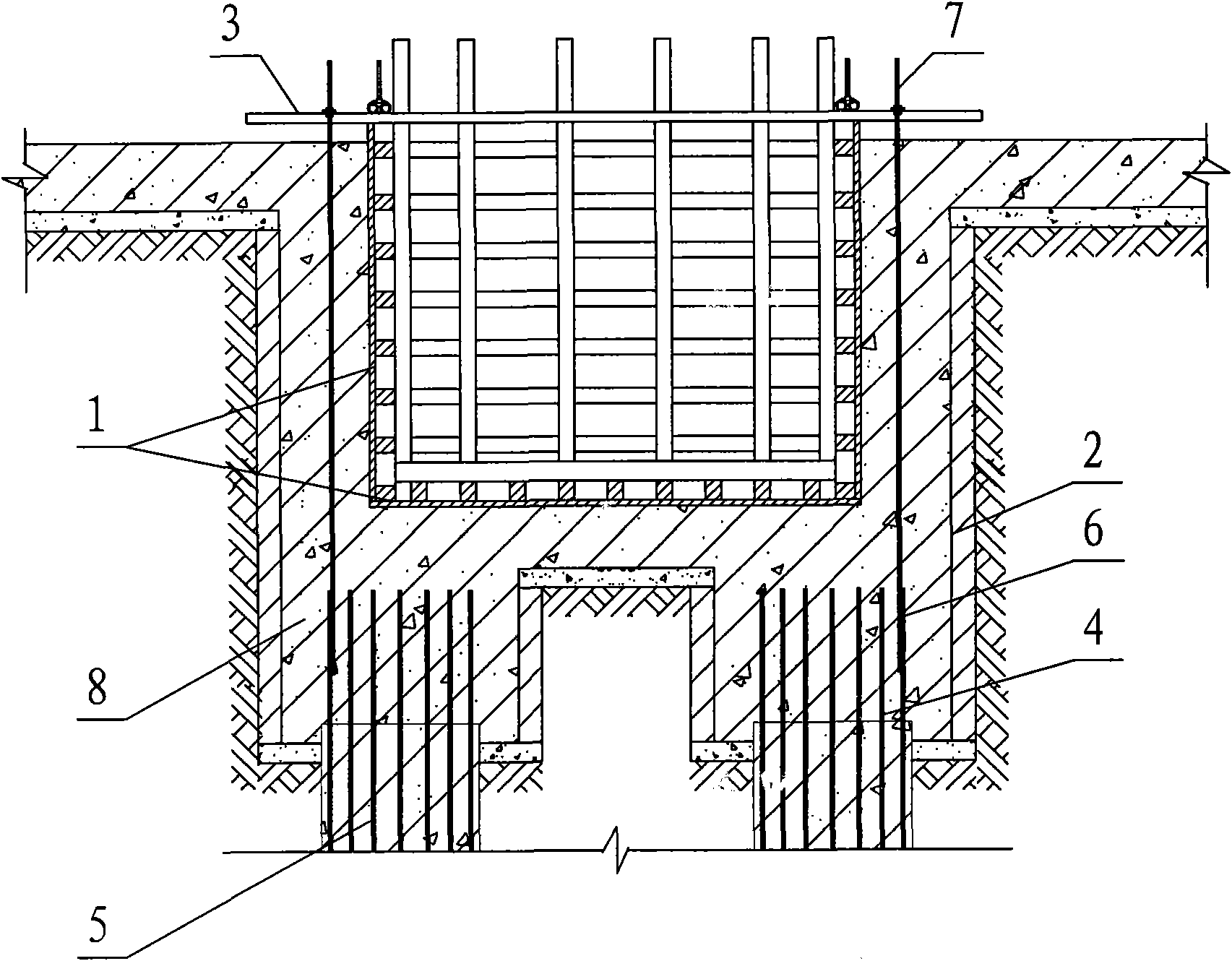

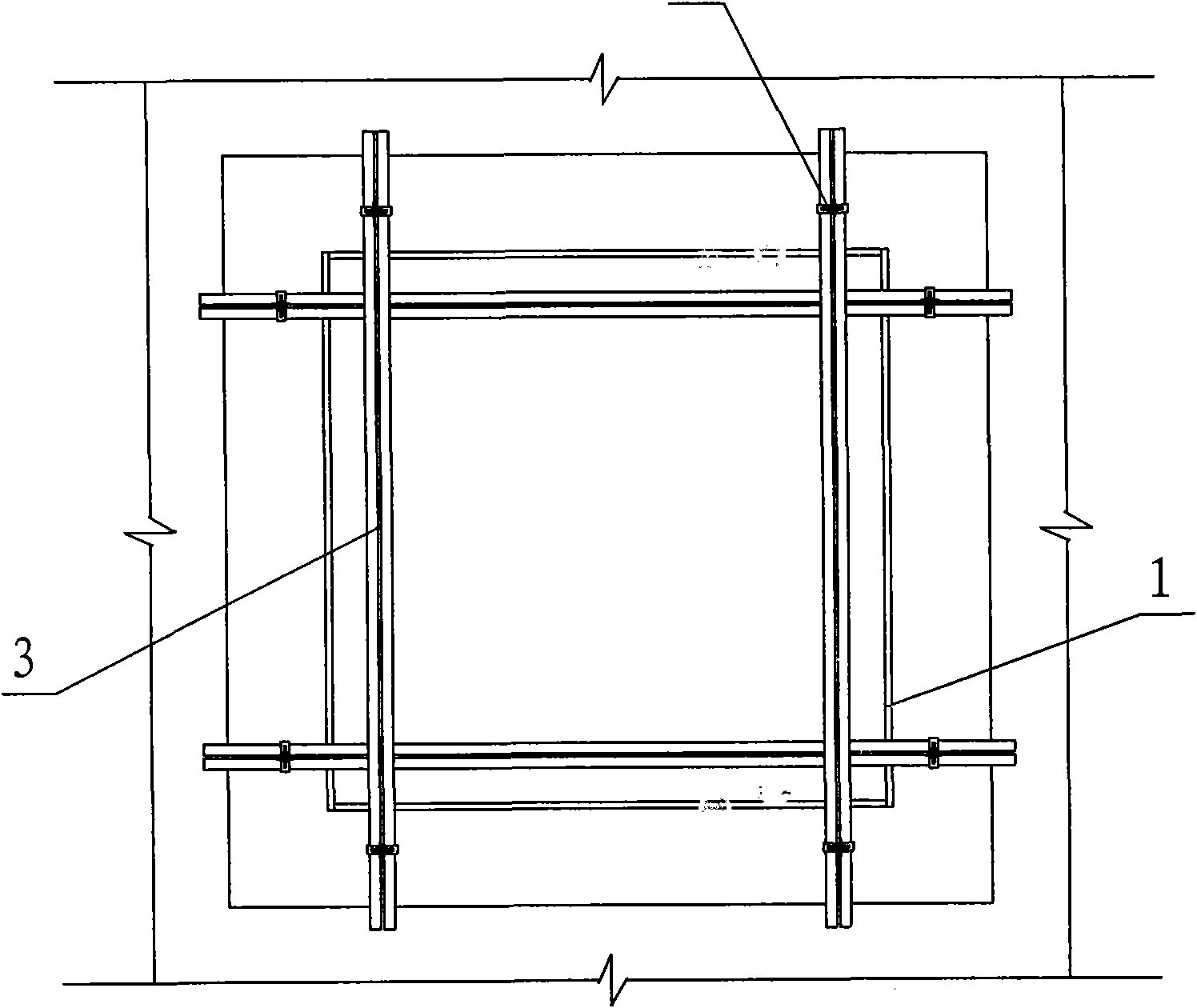

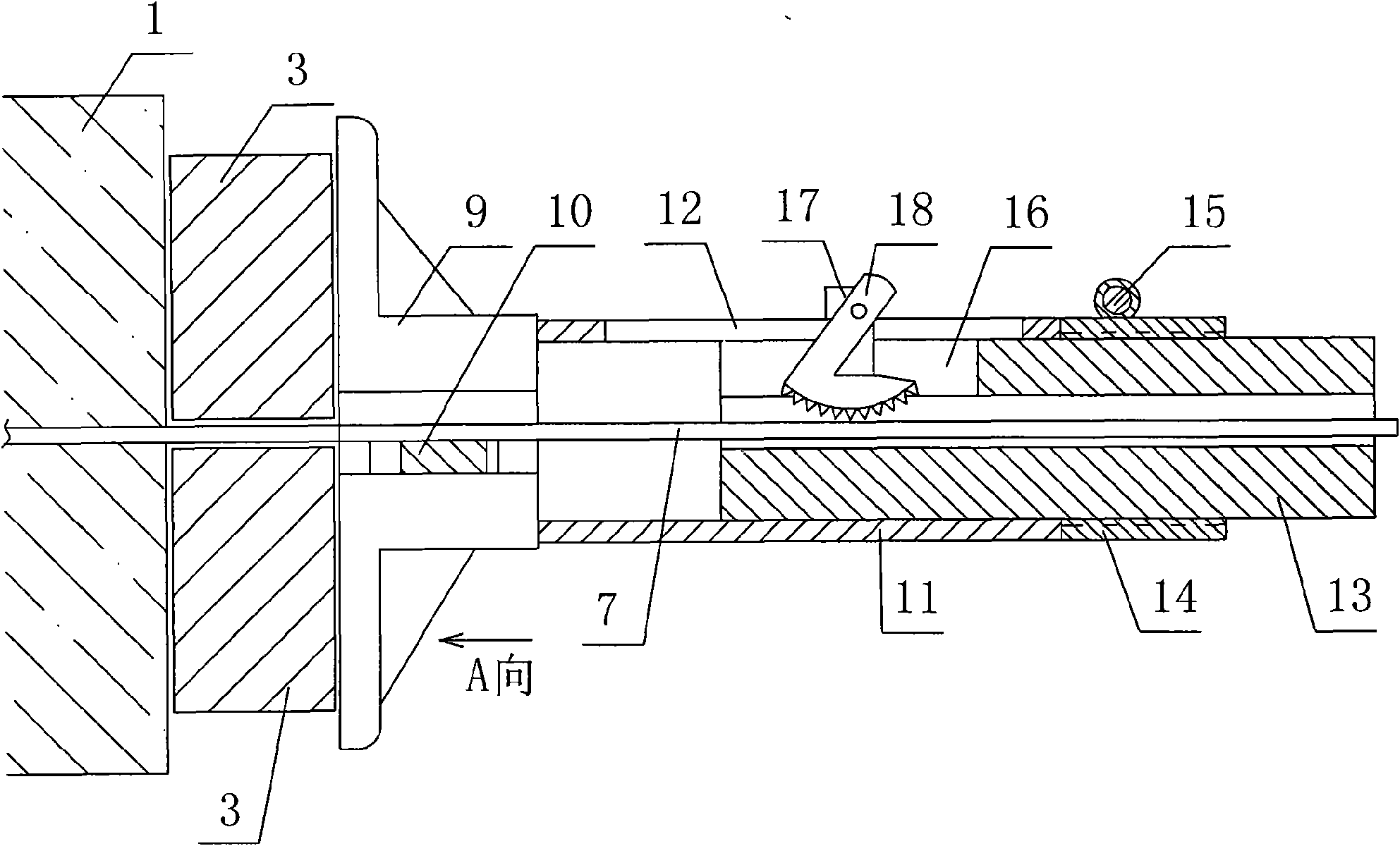

Construction method for resisting uplift in internal mold of concrete box

The invention provides a construction method for resisting the uplift in the internal mold of a concrete box. The method comprises the following steps: welding the longitudinal reinforcing steel bars on the box wall of the concrete box to be cast with the main reinforcing steel bars of a pile foundation at the bottom of a foundation pit; embedding an internal mold in the foundation pit and arranging a batten or a support tube at the top of the internal mold; tensioning the longitudinal reinforcing steel bars of the box wall, which are welded with the main reinforcing steel bars of the pile foundation, and then, fixedly connecting the upper ends of the longitudinal reinforcing steel bars of the box wall with the batten or the support tube; and casting the concrete and resisting the buoyant force of the concrete applying on the bottom plate of the box mold by the reaction force generated by the welded longitudinal reinforcing steel bars of the box wall and the batten or the support tube, so that the internal mold can be pressed by the support tube to prevent the internal mold from going up. The invention is suitable for resisting the buoyant force in the internal mold of a small-size concrete box and has the characteristics of reliable buoyancy resistance and easily guaranteed construction quality; and compared with the conventional method, the invention does not need secondary transport with high labor consumption, economizes on human resources and improves the production efficiency.

Owner:HUNAN SUNPEAK CONSTR

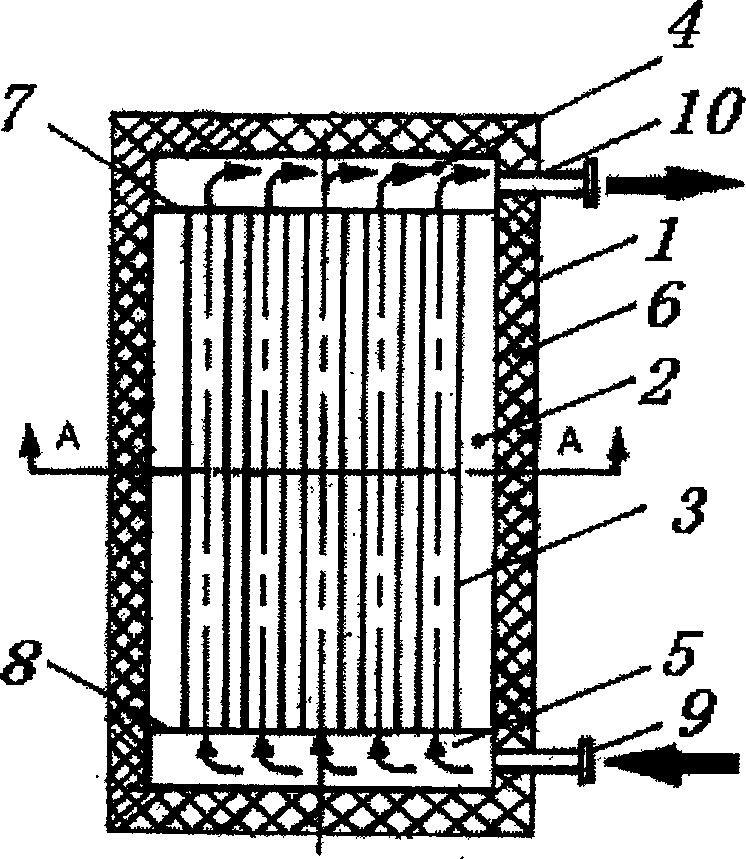

Phase-change cold-storage device for air conditioner

InactiveCN1731034AImprove heat transfer performanceReduce heat transfer resistanceDomestic cooling apparatusLighting and heating apparatusEngineeringPhase change

The phase change cold accumulator includes cold accumulator barrel with one set of heat exchange pipe with coolant, phase change cold accumulating material, upper liquid collecting chamber located in and communicated to the upper end of the heat exchange pipe, and lower liquid collecting chamber located in and communicated to the lower end of the heat exchange pipe. The cold accumulator barrel is provided with coolant inlet communicated with the lower liquid collecting chamber and coolant outlet communicated with the upper liquid collecting chamber, and the phase change cold accumulating material is sealed inside the cavity comprising the cold accumulator barrel, the heat exchange pipe, the upper end plate and the lower end plate. The present invention has small heat transfer resistance, small flow resistance, high cold accumulating and releasing efficiency, and homogeneous solidification and melting of the phase change cold accumulating material, and is suitable for various cooling air conditioners.

Owner:NANJING UNIV

Glass Fiber Composition, Glass Fiber, and Glass Fiber Containing Composition Material

ActiveUS20090312171A1Reduce yieldReduce solubilityGlass making apparatusPrinted circuitsGlass fiberBoron

An object is to provide a readily fusible glass fiber composition that can alleviate environmental problem and reduce raw material cost by decreasing boron content, and that can facilitate the manufacturing of fine-count glass filament. A glass fiber composition of the present invention is an oxide glass composition, and has compositions of 0.01 to 3% of P2O5, 52 to 62% of SiO2, 10 to 16% of Al2O3, 0 to 8% of B2O3, 0 to 5% of MgO, 16 to 30% of CaO, and 0 to 2% of R2O(R═Li+N+K), which are in terms of oxide represented in mass percentage.

Owner:NIPPON ELECTRIC GLASS CO LTD

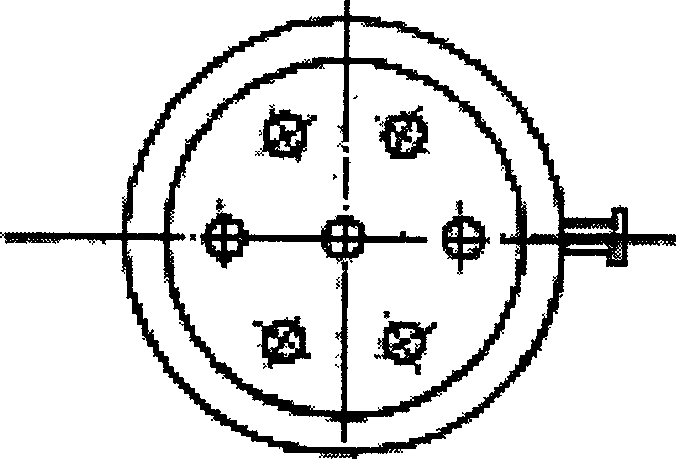

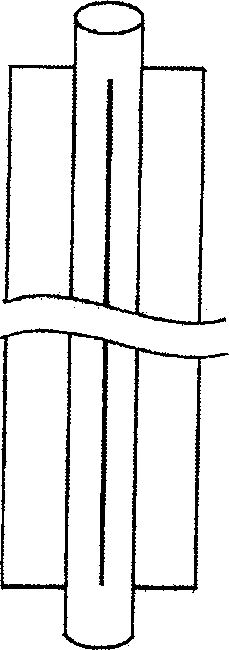

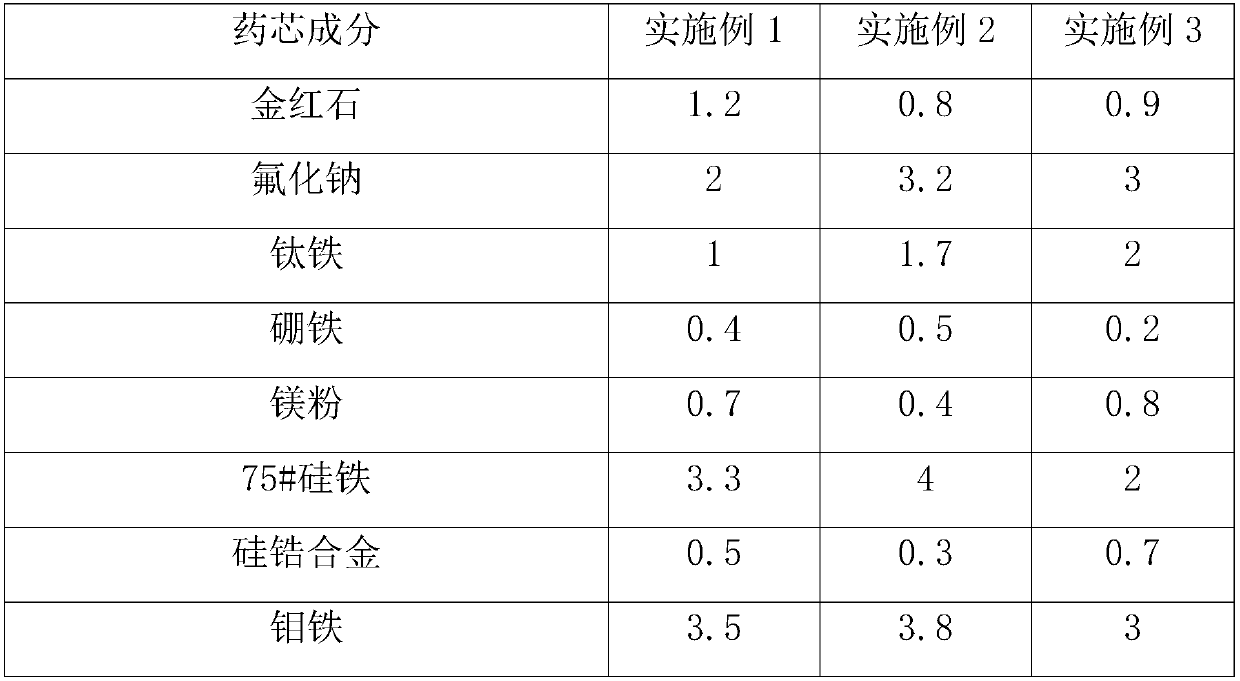

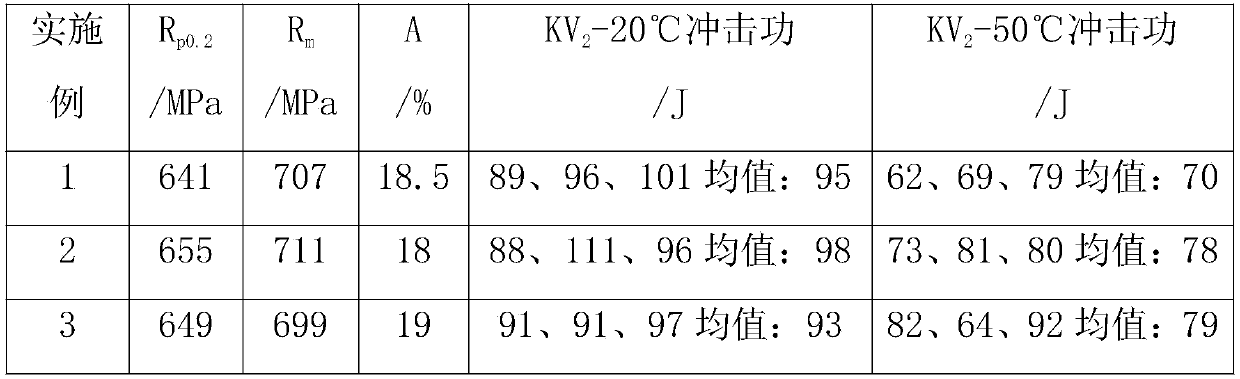

Metal powder core type flux-cored wire for additive manufacturing and welding method thereof

ActiveCN108672977AReduce oxygen contentImprove crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceArc stability

The invention provides a metal powder core type flux-cored wire for additive manufacturing. The metal powder core type flux-cored wire for additive manufacturing comprises carbon steel outer skin anda flux core arranged in the carbon steel outer skin. The flux core comprises the following components in percentage by mass based on total mass: 0.8-1.2% of rutile, 2-3.2% of sodium fluoride, 1-2% offerrotitanium, 0.2-0.5% of ferroboron, 0.4-0.8% of magnesium powder, 2-4% of 75# atomized ferrosilicon, 0.3-0.7% of a silicon-zirconium alloy, 3-3.8% of ferromolybdenum, 25-30% of nickel powder, 0.4-1.1% of anhydrous feldspar, 0.2-0.6% of rare earth fluoride, 2.2-3.1% of electrolytic manganese and the balance iron powder. According to the flux-cored wire, the oxygen content of a weld joint is reduced by way of combined deoxygenation of Mn-Mg-Si-Ti-Zr, and meanwhile, by adding a proper amount of minerals, the weld joint forming and arc stability is improved; by adding the iron powder, the deposition efficiency of the flux-cored wire is improved; by adding the rare earth alloy, the S content in weld joint metal is reduced and the shape of the occluded foreign substances is changed, so that the low-temperature toughness is improved, and therefore, the flux-cored wire is stable in mechanical property of melted metal, good in crack resistance and excellent in low-temperature toughness at 50DEG C below zero.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Solder for brazing red copper and graphite and brazing method

InactiveCN106392367AEvenly meltedImprove wettabilityWelding/cutting media/materialsSoldering mediaElemental compositionGraphite

The invention discloses solder for brazing red copper and graphite and a brazing method. The solder comprises the following elemental compositions in percent by weight: 20-25 percent of Ag, 10-15 percent of Cu, 10-15 percent of Ti and the balance of Al. The brazing temperature of the Al-based Ag-Cu-Ti lead-free solder is 950-1,030 DEG C, and the melting temperature of the solder is moderate; through addition of related beneficial elements, graphite is wetted and spread well by the solder; an obtained brazed joint is high in strength and high in corrosion resistance, can be completely applied in a complex environment, and is economic solder with high comprehensive performance; the brazing process is simple and reasonable; by adoption of a vacuum furnace brazing method, brazing flux is not required and other protection measures are not taken during the brazing process; and a high vacuum environment cooperates with setting of reasonable technological parameters, so that the whole component is free from deformation, micro cracks, air holes and impurities, and the brazed joint with high mechanical property is beneficial for being obtained.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

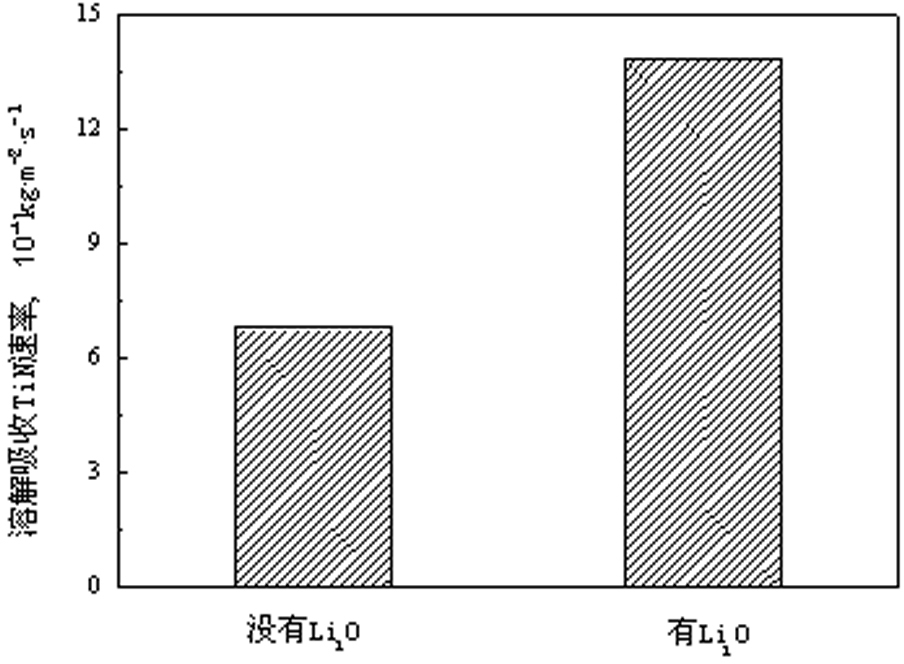

Continuous casting mold powder for ferrite stainless steel and preparation method thereof

The invention discloses continuous casting mold powder for ferrite stainless steel and a preparation method thereof. The mold powder comprises the following components in percentage by weight: 20-40% CaO, 30-50% of SiO2, 35-10% of Al2O, 1-5% of MgO, 1-15% of Na2O, 1-10% of CaF2, 1-5% of Li2O and 2-8% of C, wherein the particle size is 0.5-1.5 millimeters. The preparation method comprises the following steps: (1) crushing and uniformly mixing carbon material, wollastonite, waste ash, limestone, soda ash and cryolite, and adding lithium hydroxide into the mixture to obtain a lithium-doped material; (2) adding water and stirring to obtain slurry; and (3) drying the slurry and preparing powdery continuous casting mold powder for ferrite stainless steel; or making the slurry into particles by a spraying granulation method, and roasting to obtain the continuous casting mold powder for ferrite stainless steel. According to the invention, the viscosity, melting temperature, crystallization rate and dissolution and absorption rate of TiN of the continuous casting mold powder meet the requirements of continuous casting; and the continuous casting mold powder has the characteristics of low preparation cost, simple process and the like and has a good application prospect.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com