Patents

Literature

1151results about "Conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

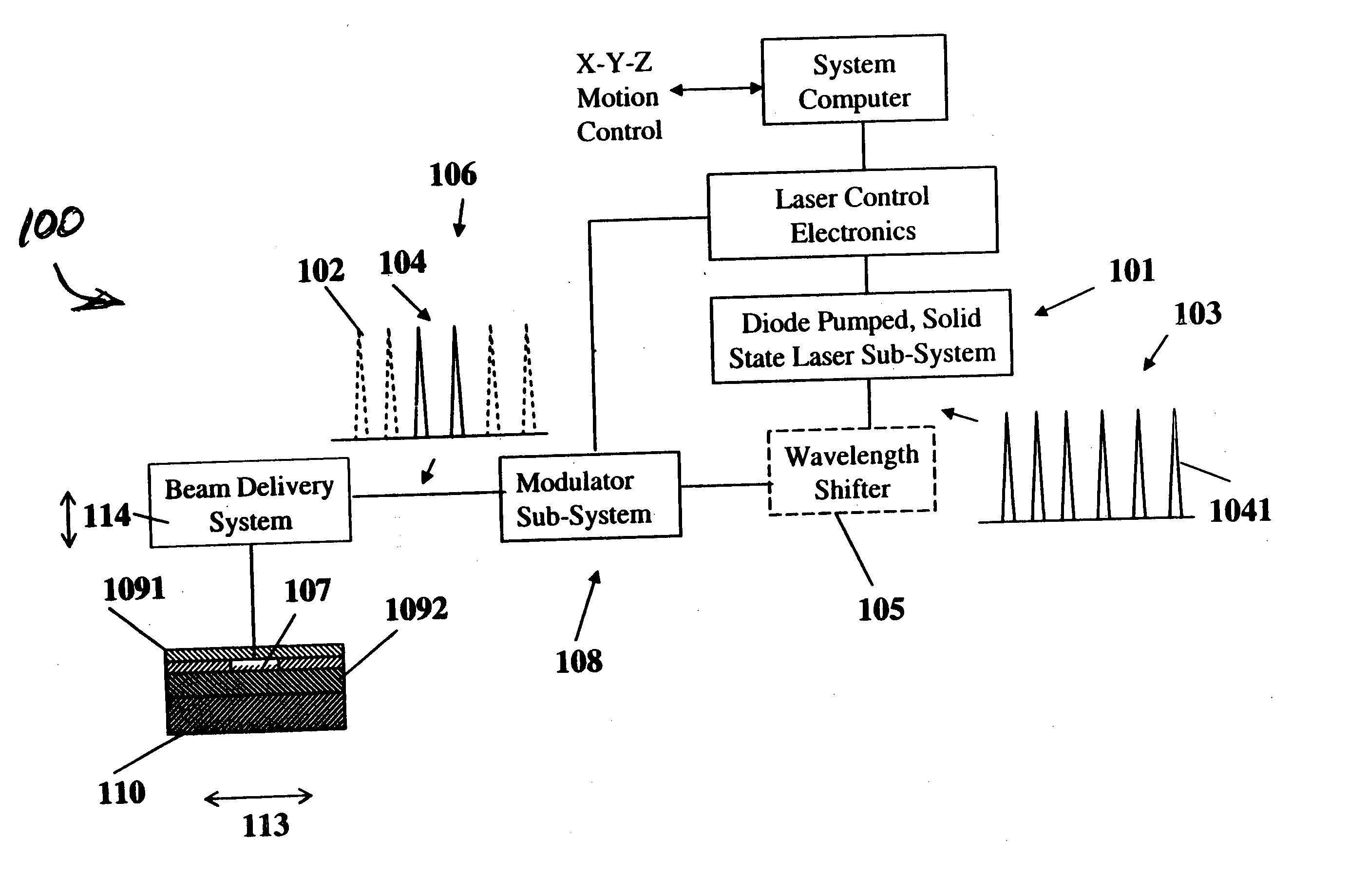

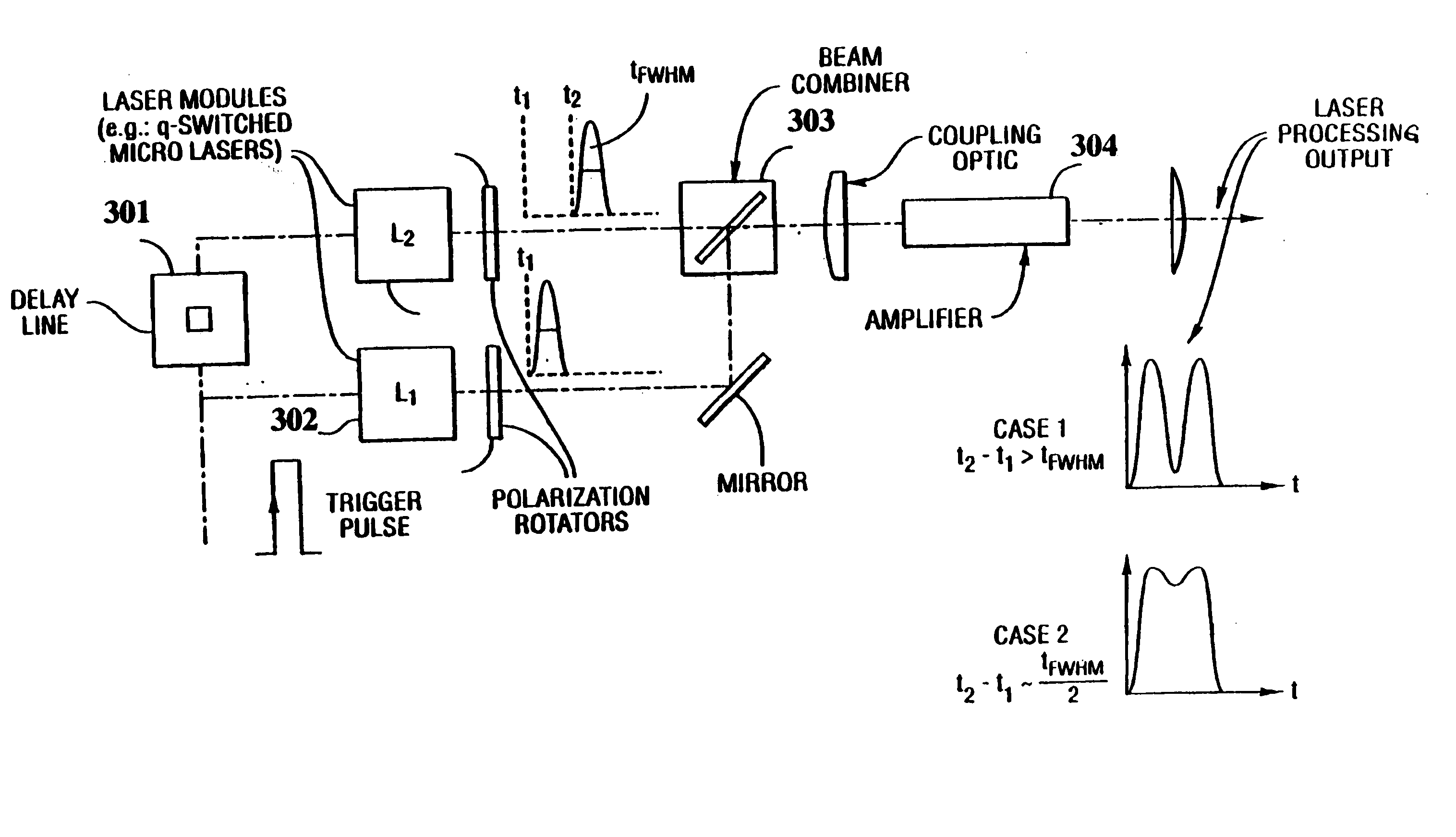

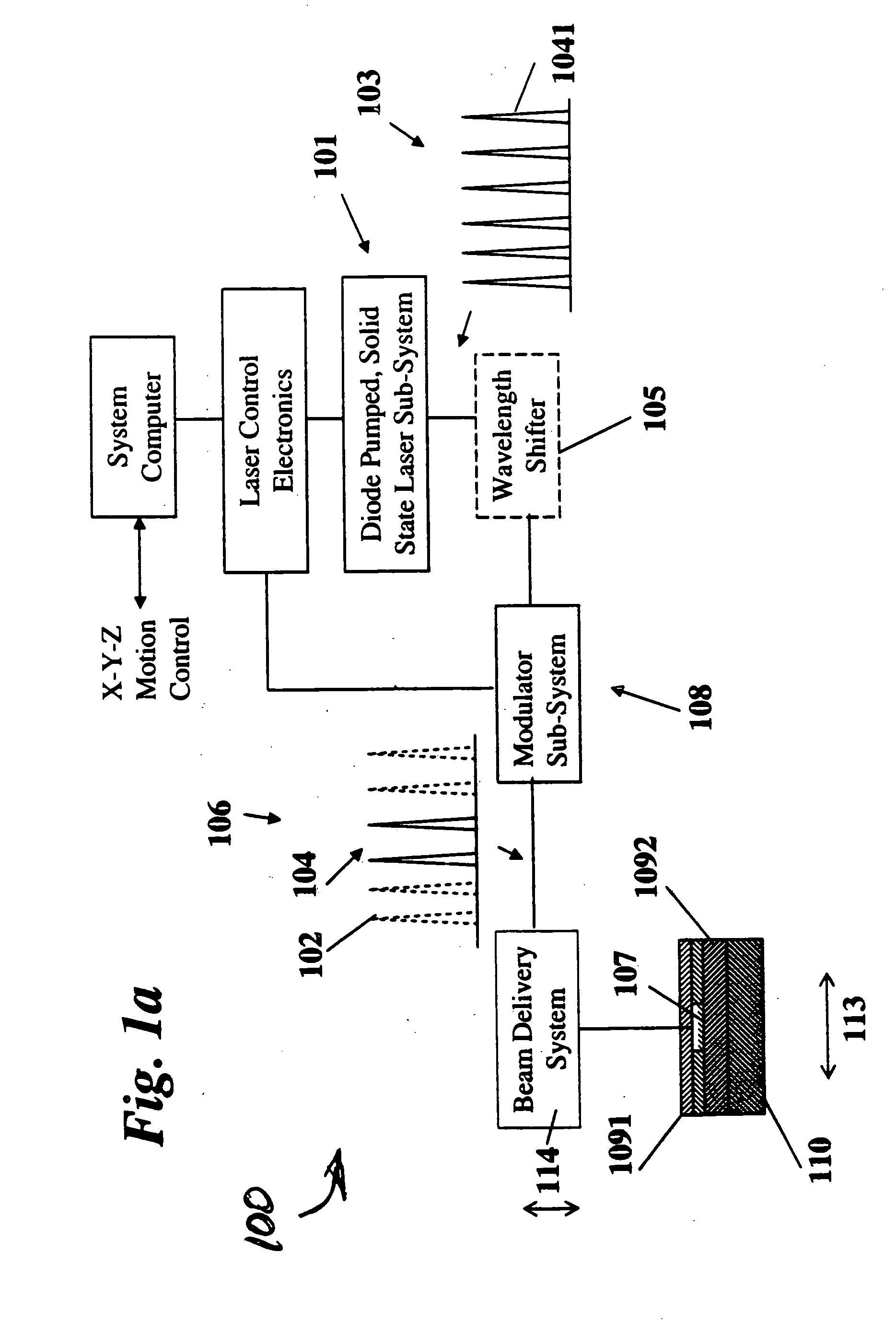

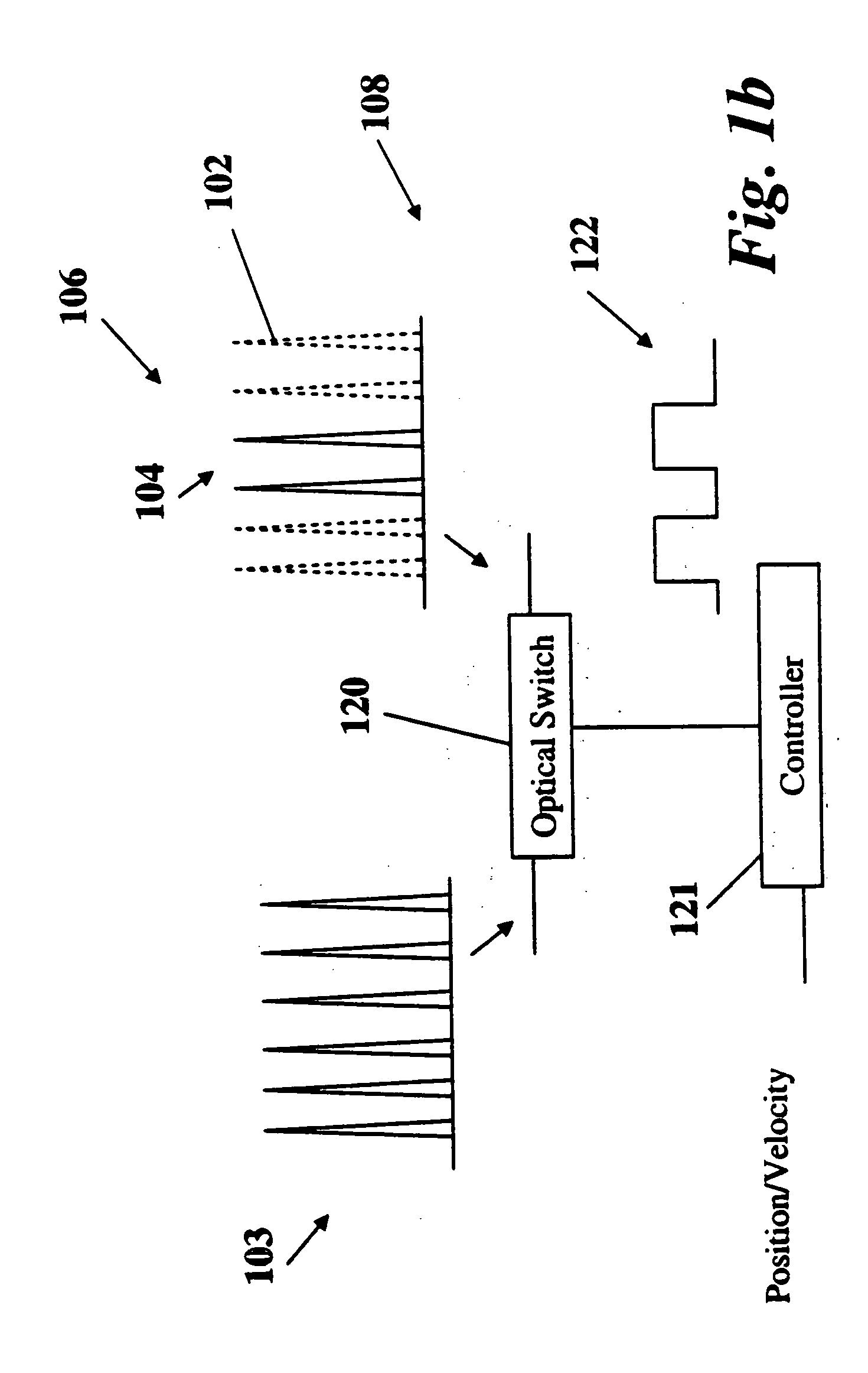

Laser-based system for memory link processing with picosecond lasers

InactiveUS20040134894A1Quality improvementReduce reflectivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserMicroscopic scale

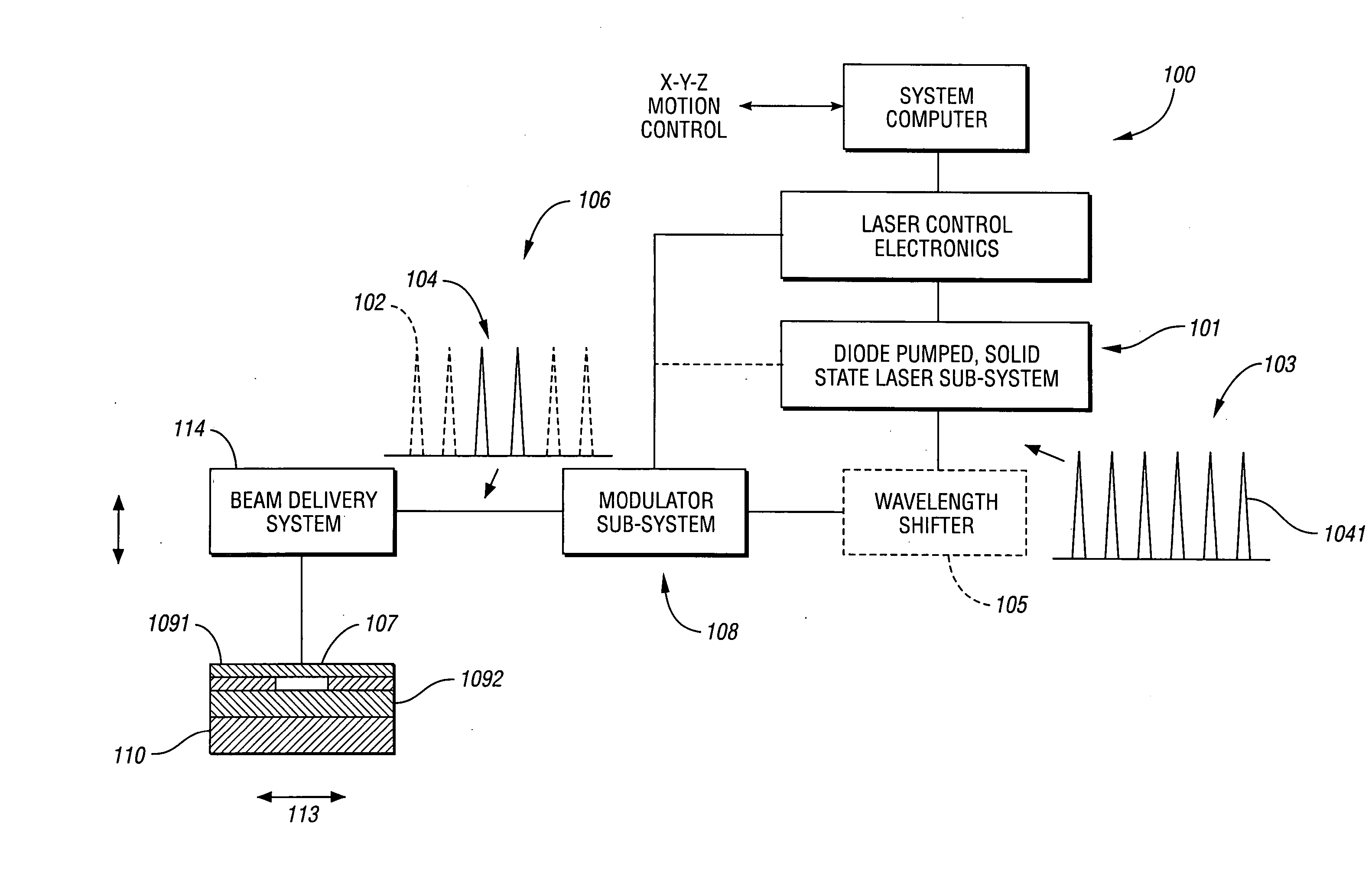

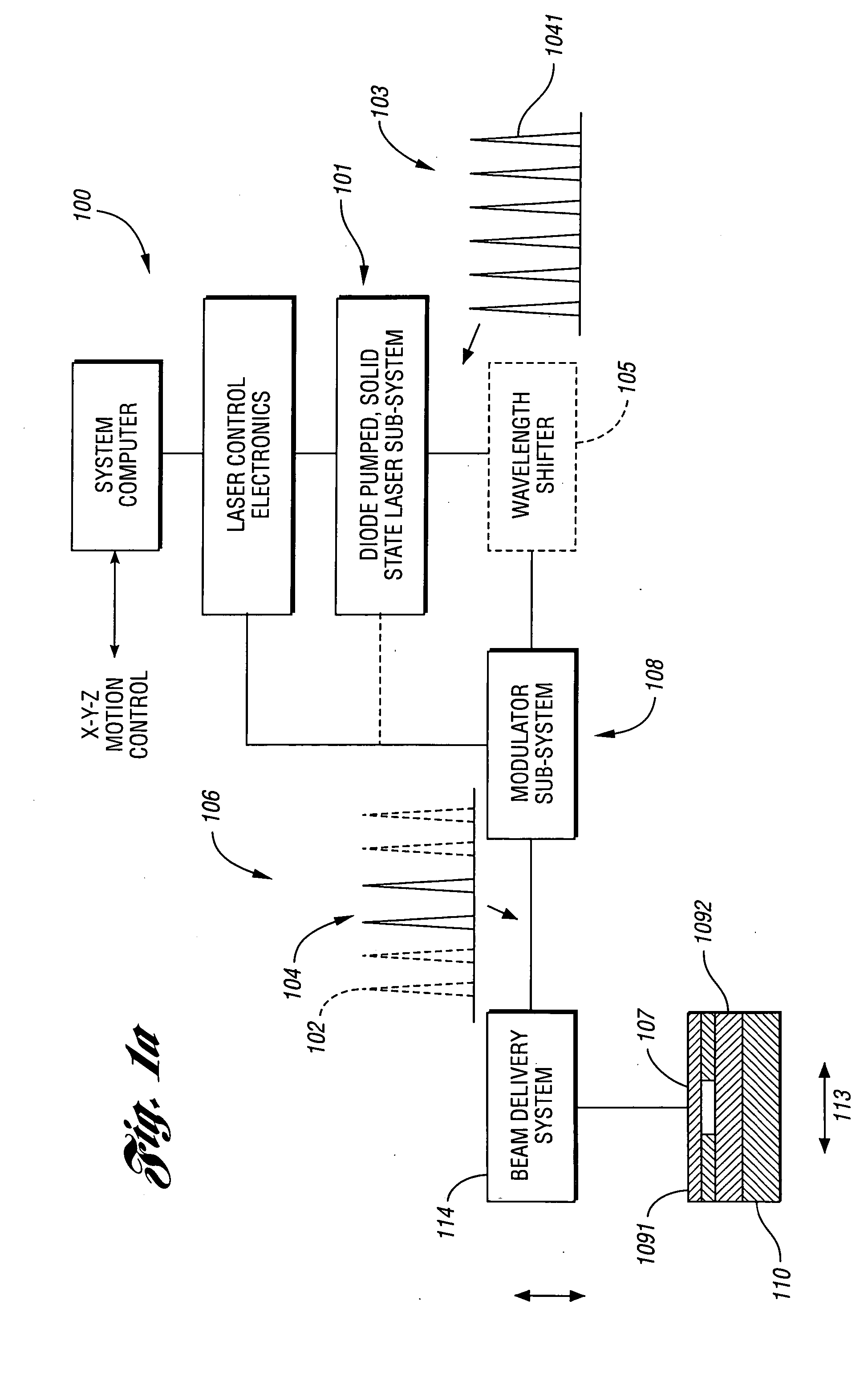

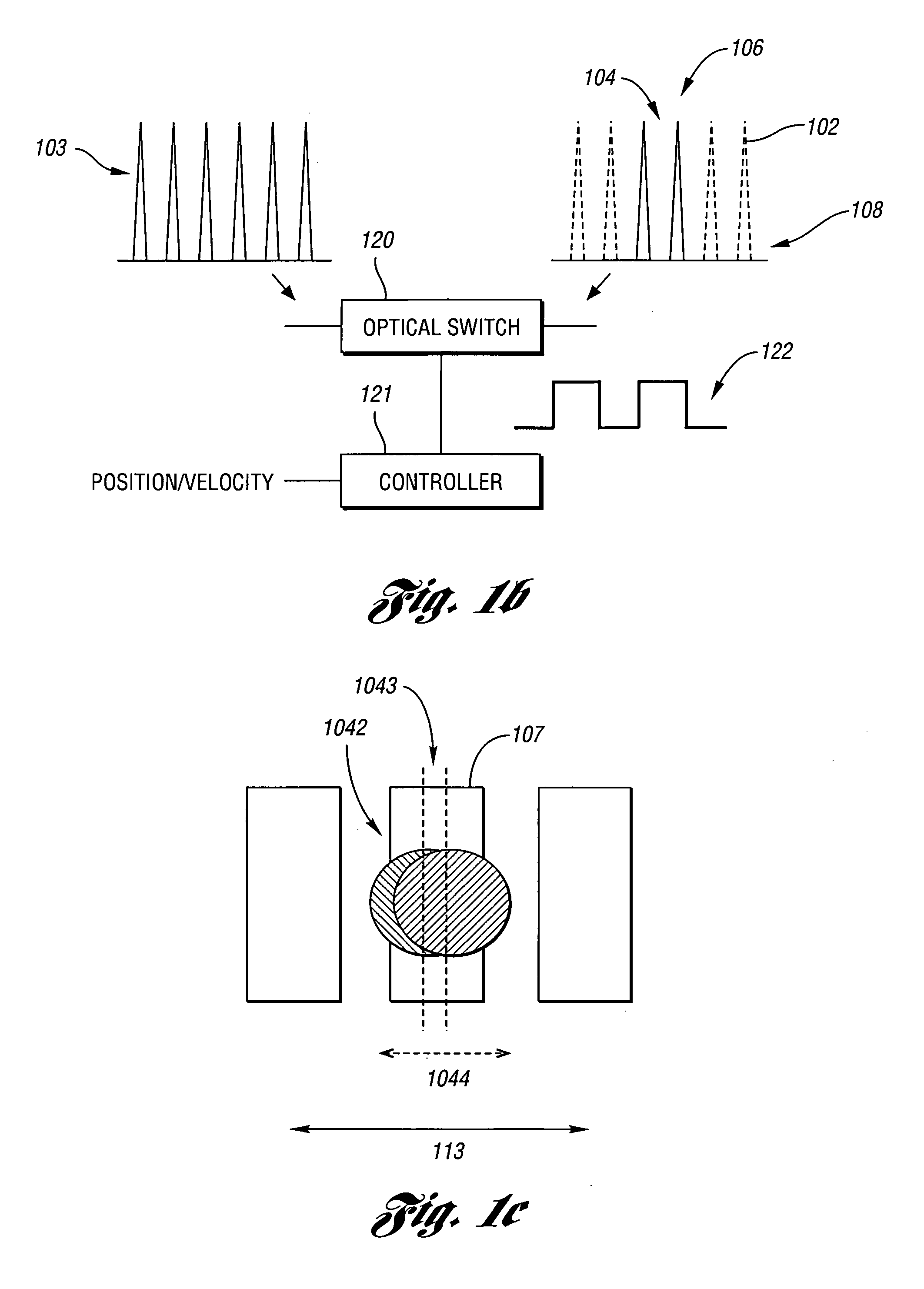

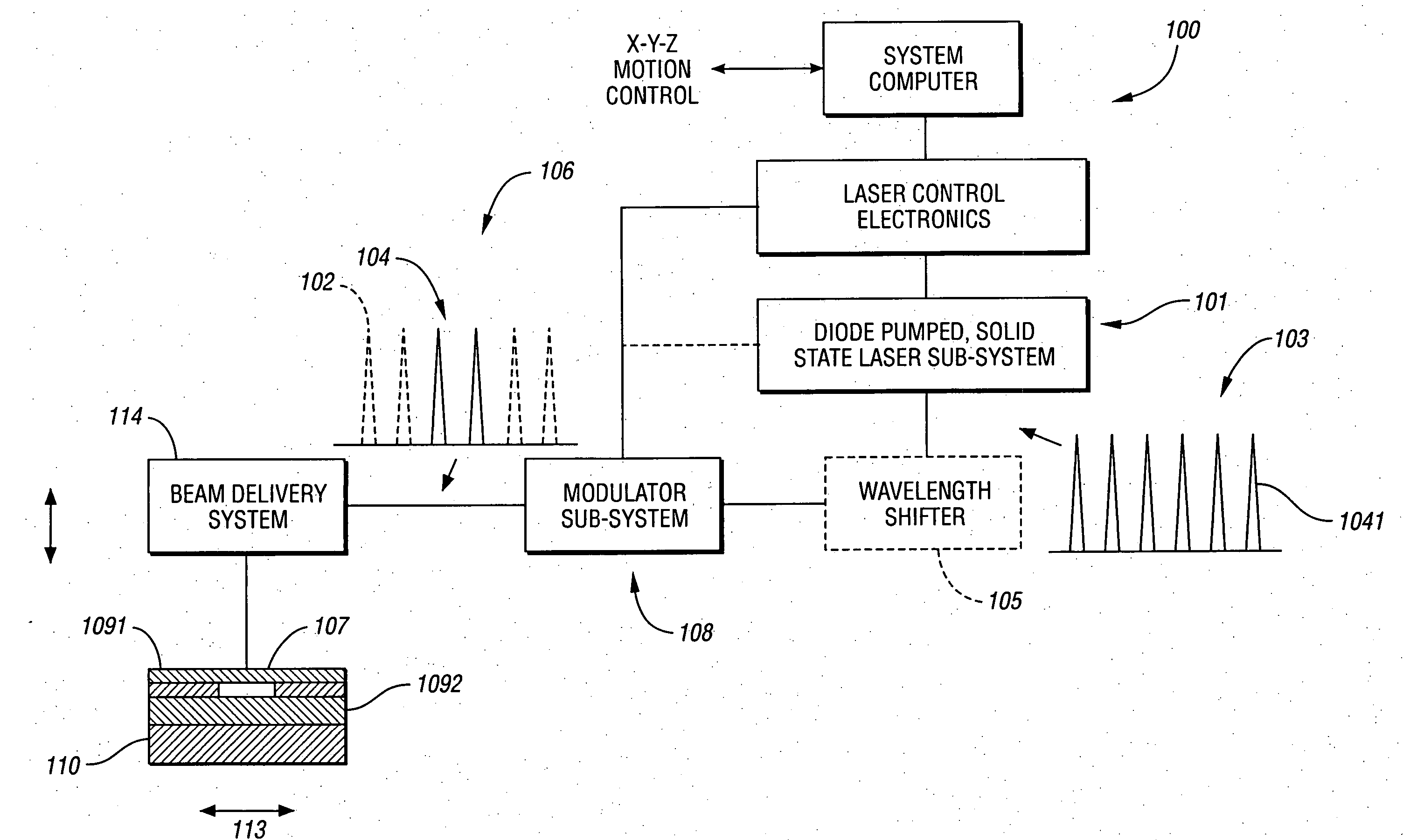

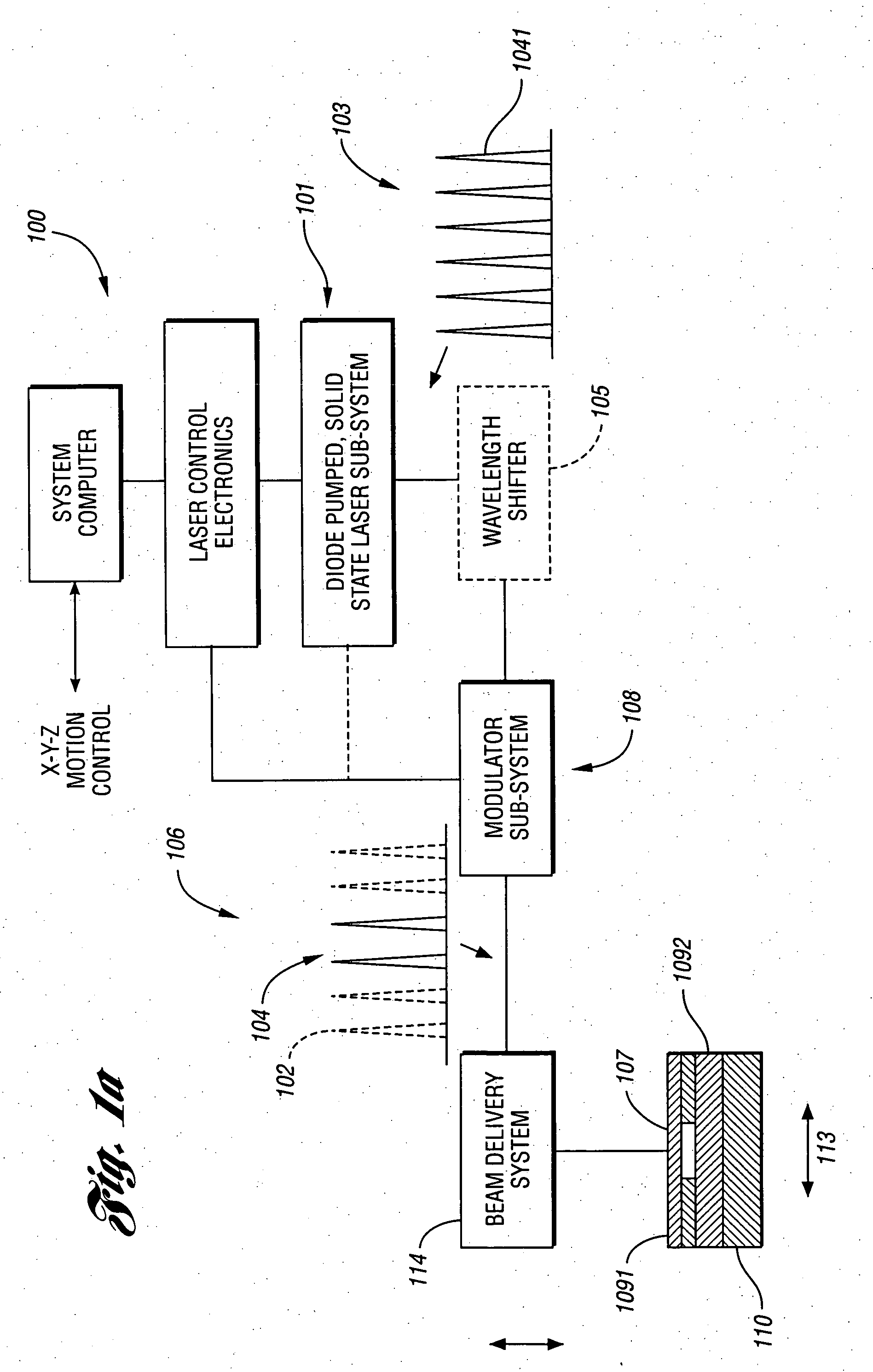

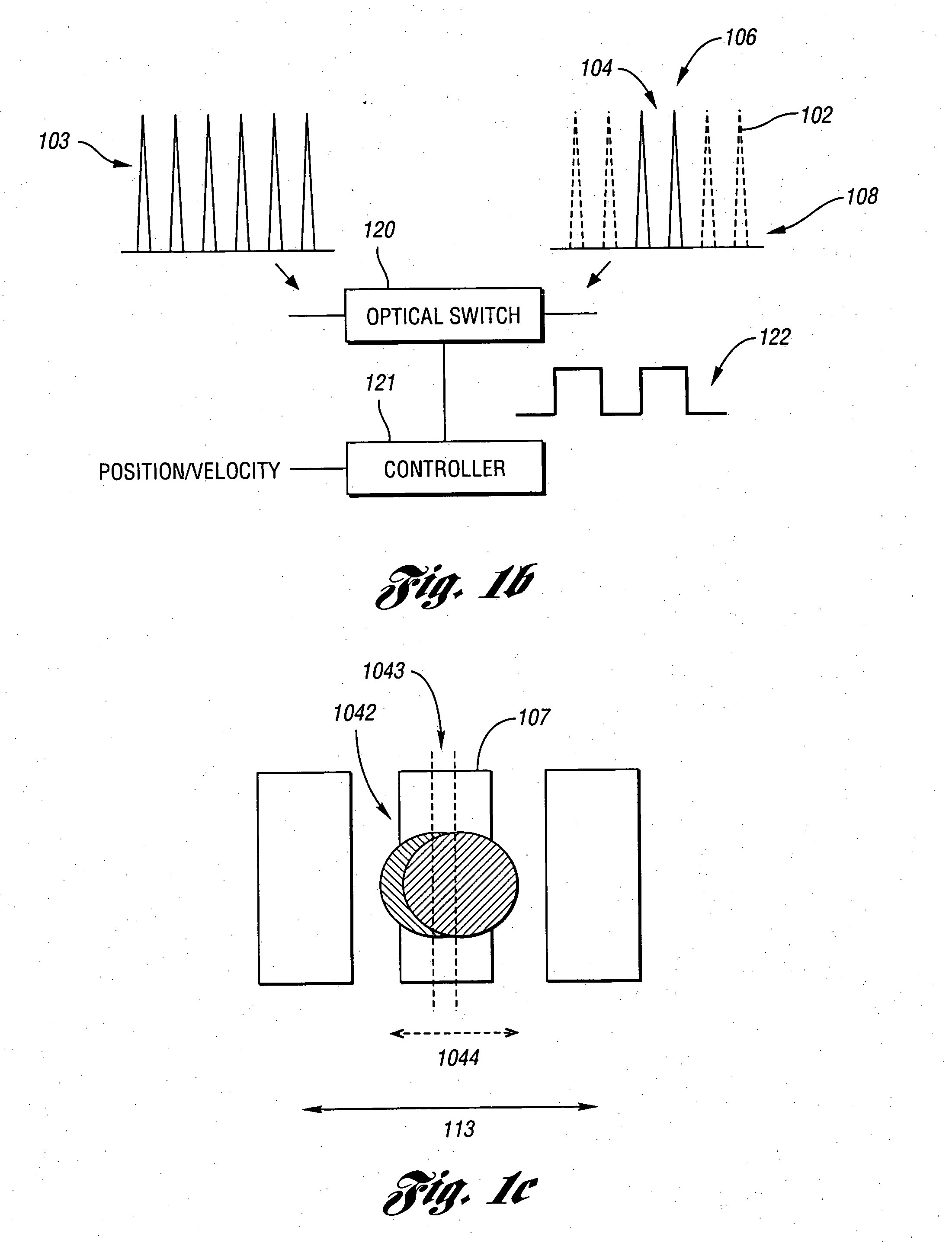

A laser-based system for processing target material within a microscopic region without causing undesirable changes in electrical or physical characteristics of at least one material surrounding the target material, the system includes a seed laser, an optical amplifier, and a beam delivery system. The seed laser for generating a sequence of laser pulses having a first pre-determined wavelength. The optical amplifier for amplifying at least a portion of the sequence of pulses to obtain an amplified sequence of output pulses. The beam delivery system for delivering and focusing at least one pulse of the amplified sequence of pulses onto the target material. The at least one output pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond. The pulse duration being within a thermal processing range. The at least one focused output pulse having sufficient power density at a location within the target material to reduce the reflectivity of the target material and efficiently couple the focused output into the target material to remove the target material.

Owner:GSI LUMONICS CORP

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20040134896A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserNanosecond

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:ELECTRO SCI IND INC

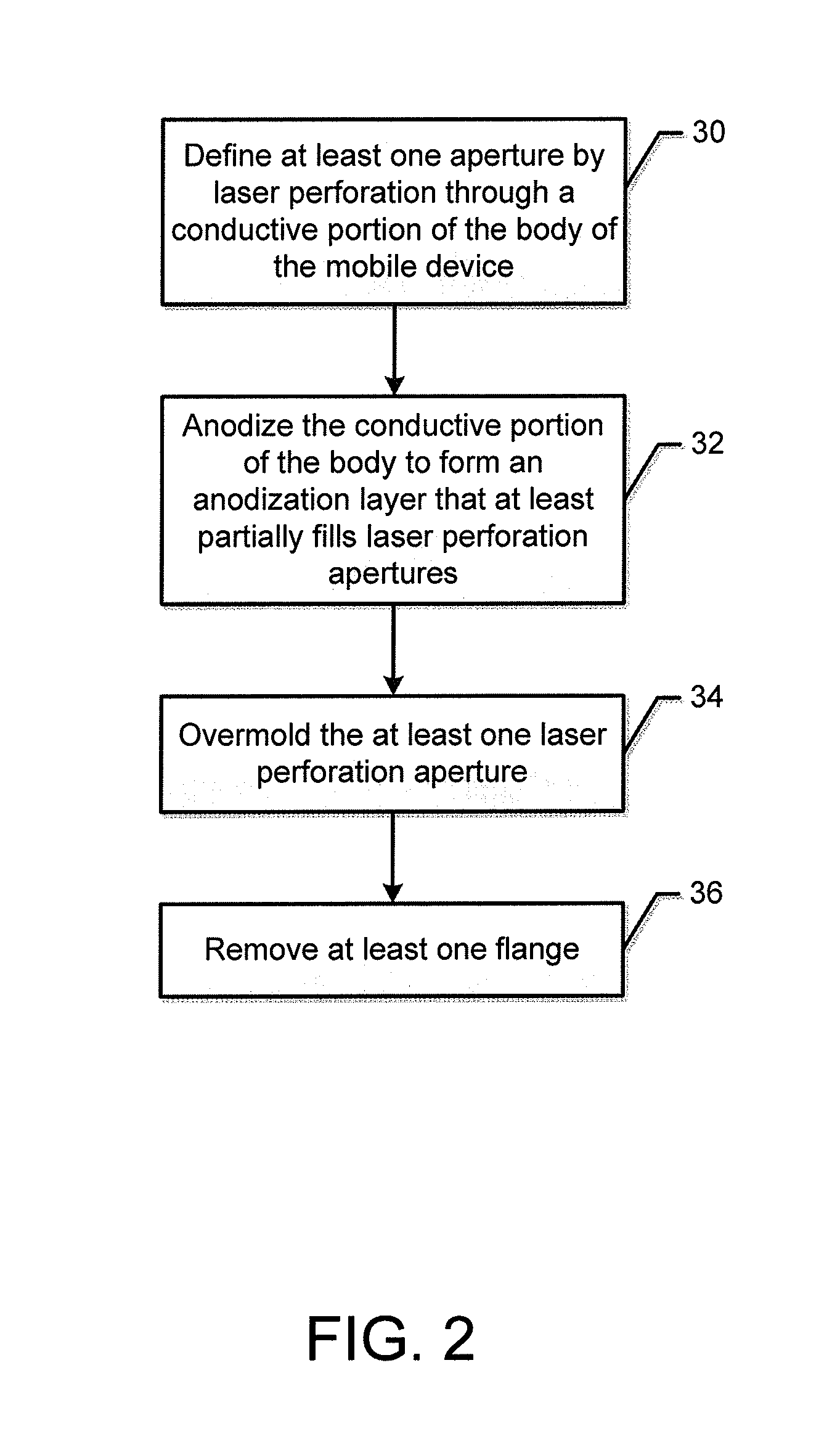

Portable electronic device body having laser perforation apertures and associated fabrication method

ActiveUS20140126172A1Reduce lossLow dielectric constantCasings/cabinets/drawers detailsSubstation equipmentRadio frequency signalMaterial Perforation

A method of fabricating the body of the portable electronic device as well as the resulting portable electronic device and its body are provided to facilitate the transmission of radio frequency signals through the body of the portable electronic device. In the context of a method, at least one aperture and, in some instances, a plurality of apertures are defined by laser perforation through a conductive portion of the body of the portable electronic device. The method may also anodize the conductive portion including at least partially filling the at least one aperture with an anodization layer. As such, the conductive portion of the body of the portable electronic device has a relatively consistent, metallic appearance, even though laser perforation apertures are defined therein for supporting the transmission of radio frequency signals.

Owner:NOKIA TECHNOLOGLES OY

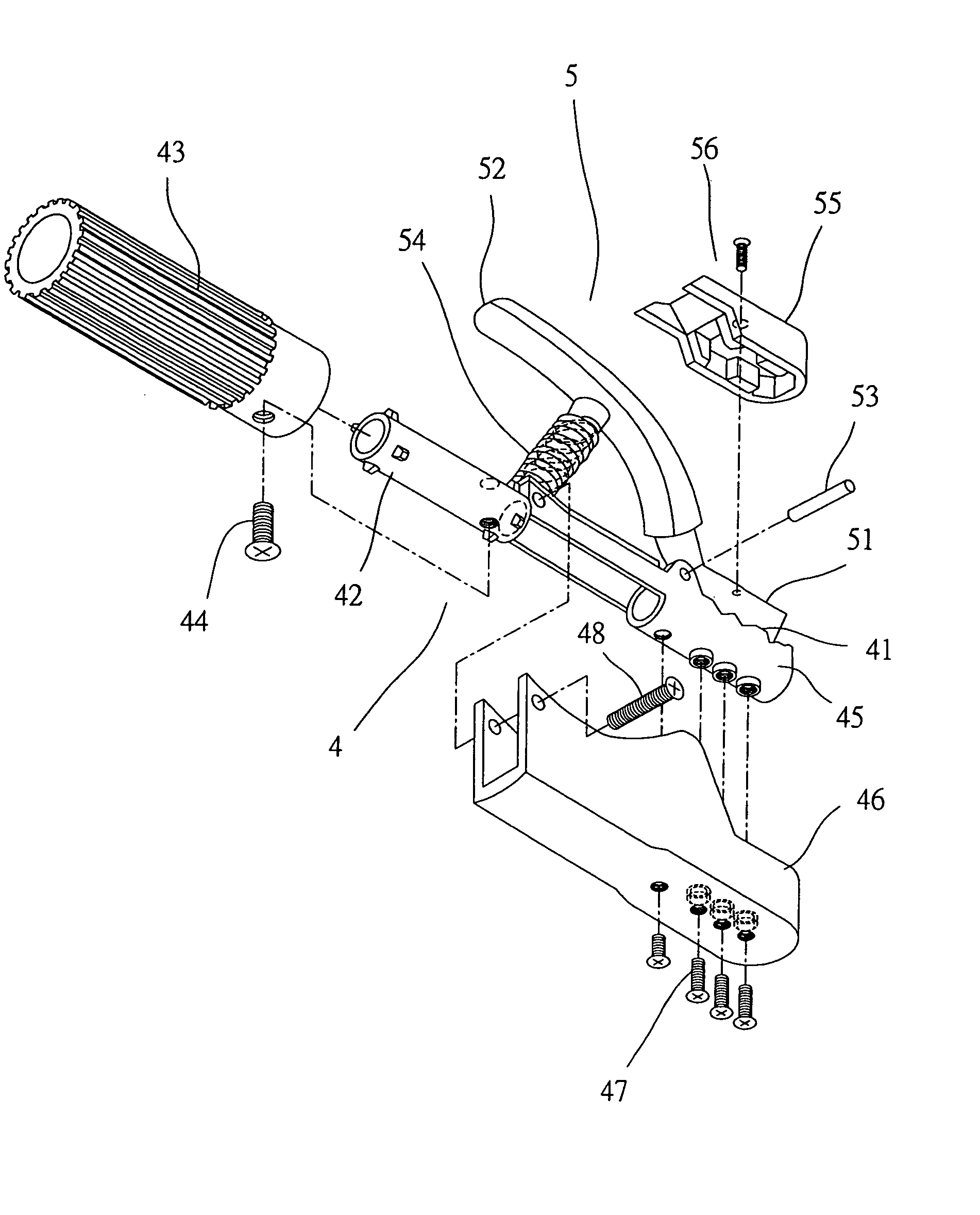

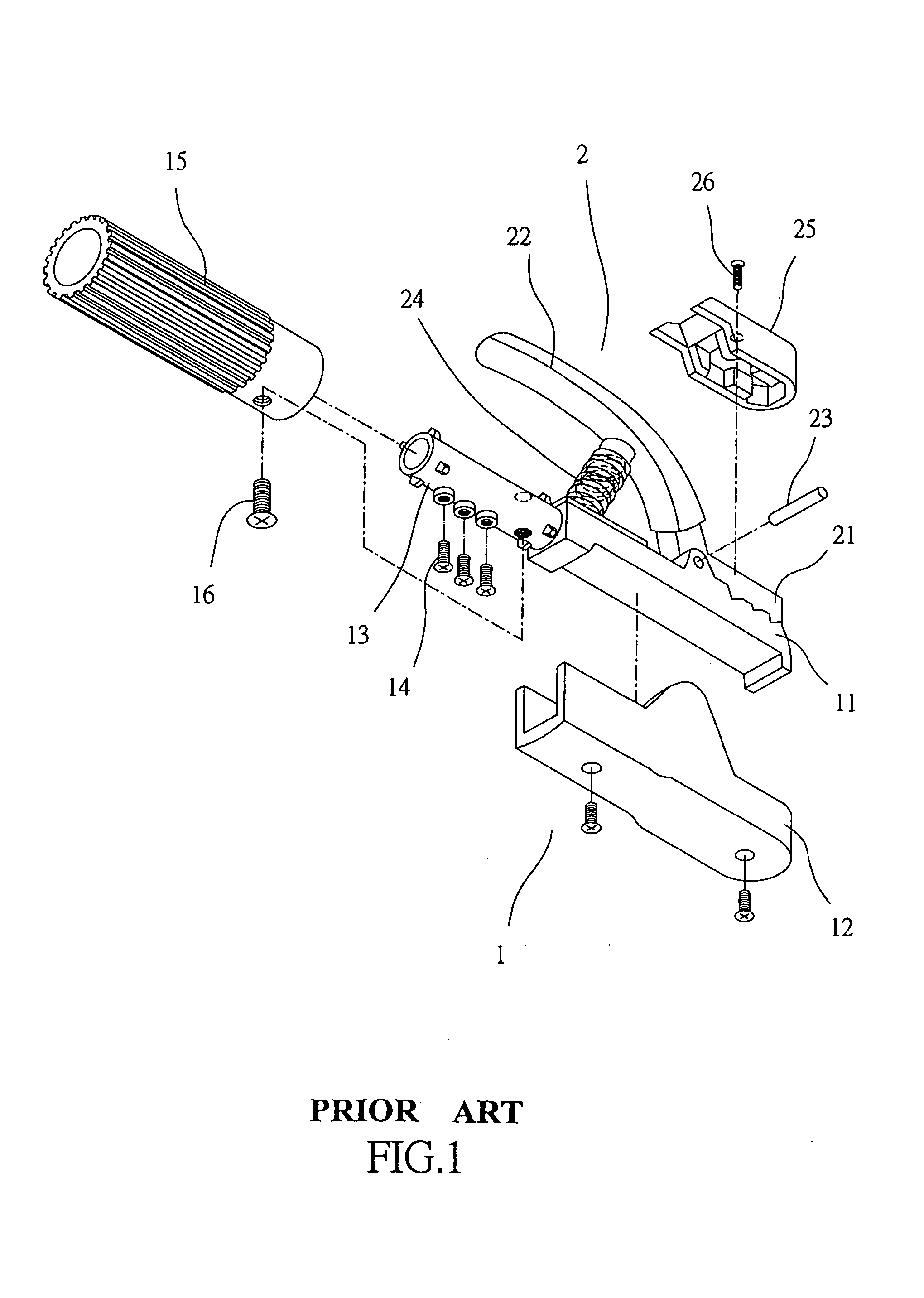

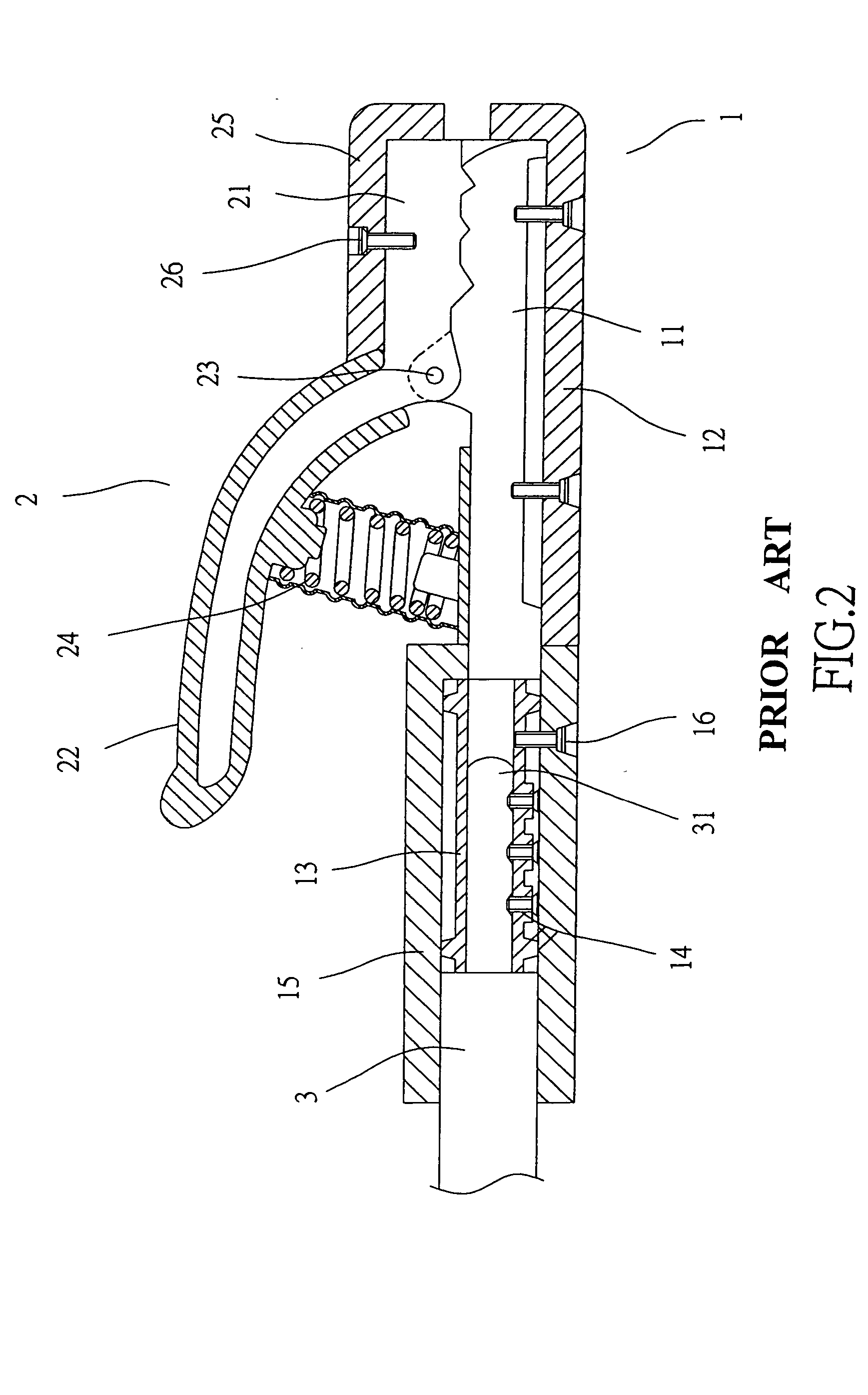

Electrode holder

InactiveUS20050189336A1Achieve normal workElectric discharge heatingWelding/cutting auxillary devicesEngineeringMachine press

An electrode holder comprised of a press and a clamp has at the bottom of the clamp adapted with a cylindrical base to allow one end of an electrode lead to pass through; the lead end being fastened in place by a bolt in conjunction with a protection pad covering up the cylindrical base so that in the course of welding, the point of heat conduction being kept farthest as from the hand gripping the holder to achieve working comfort.

Owner:KU JU CHING

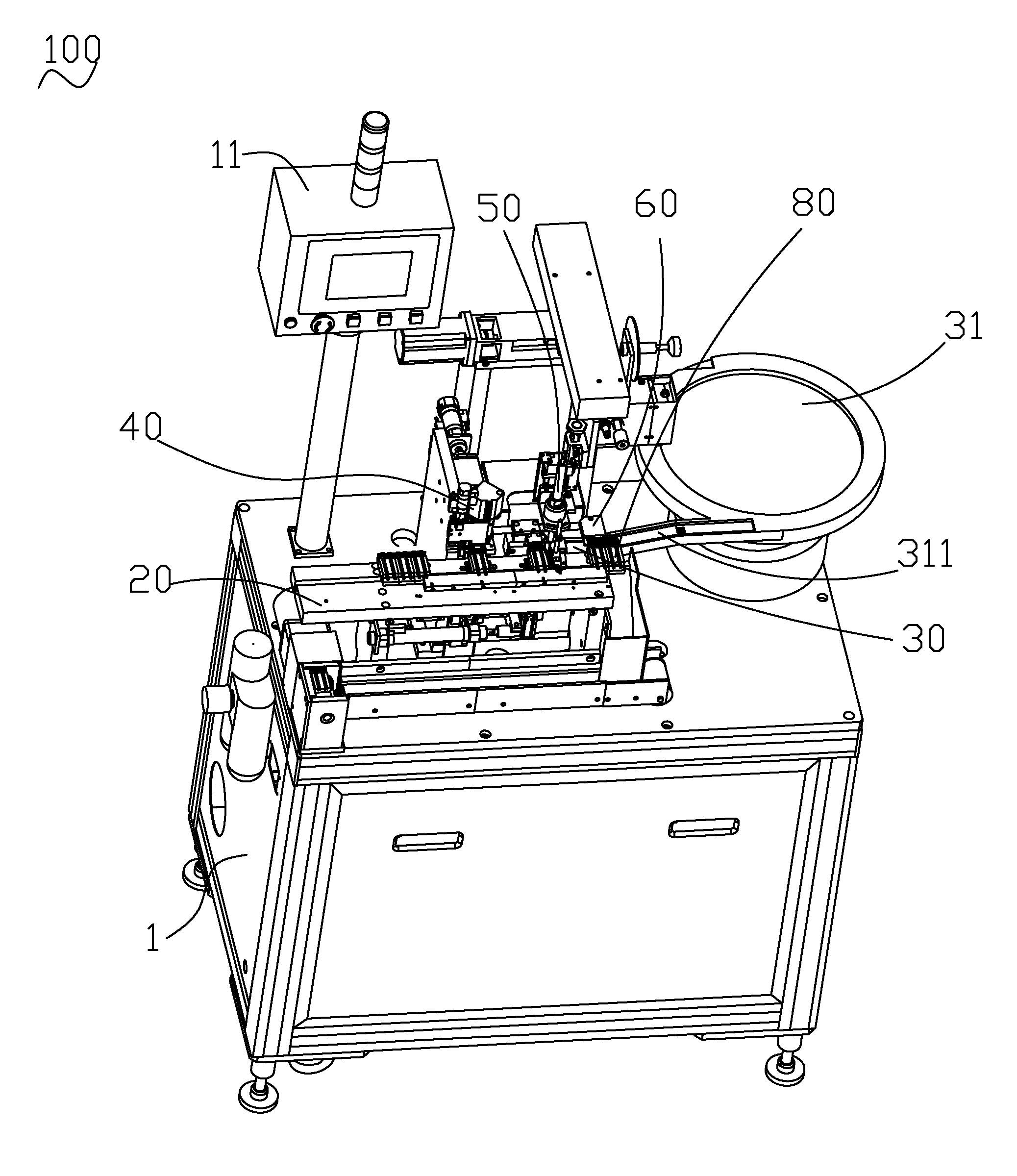

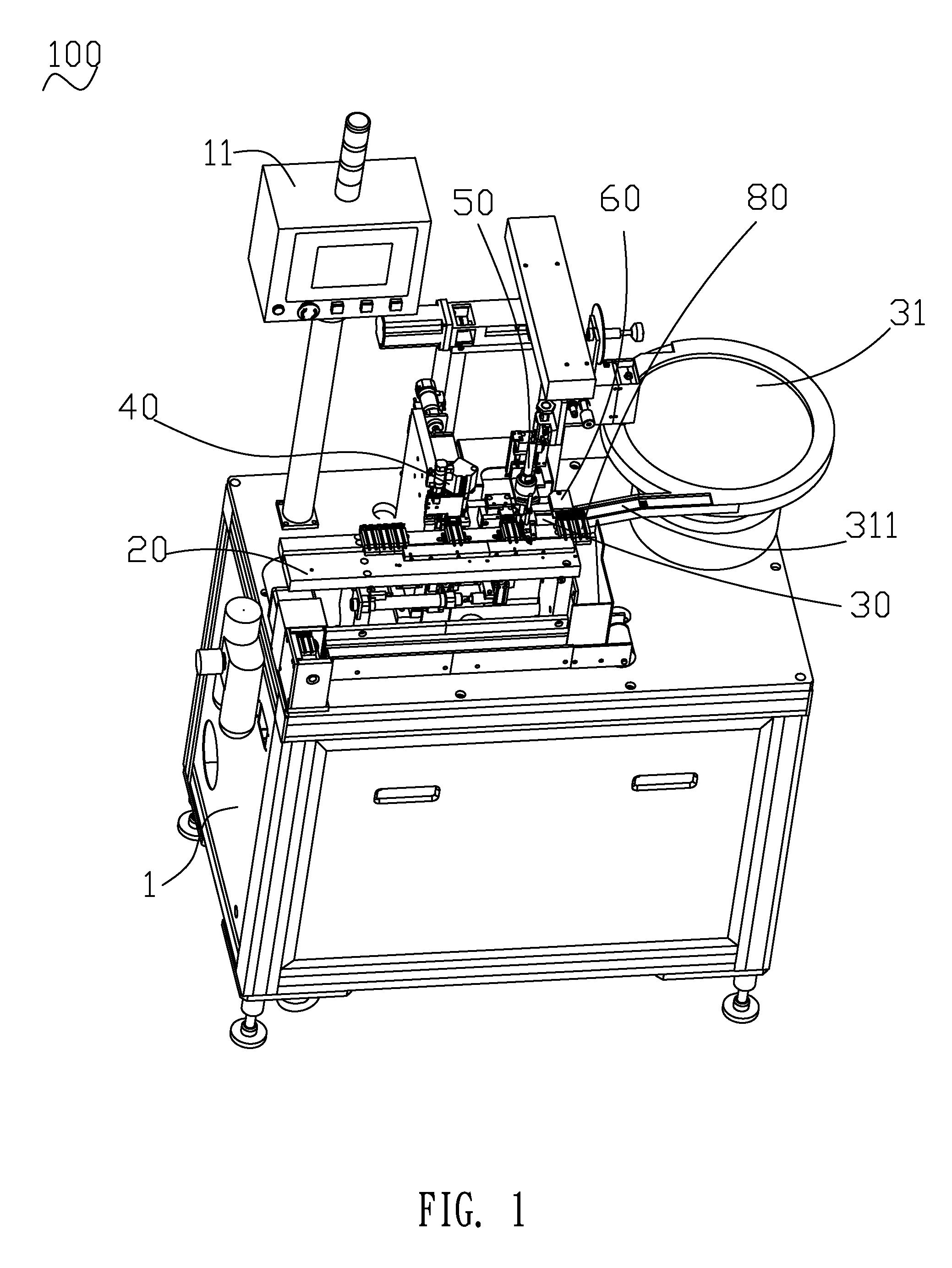

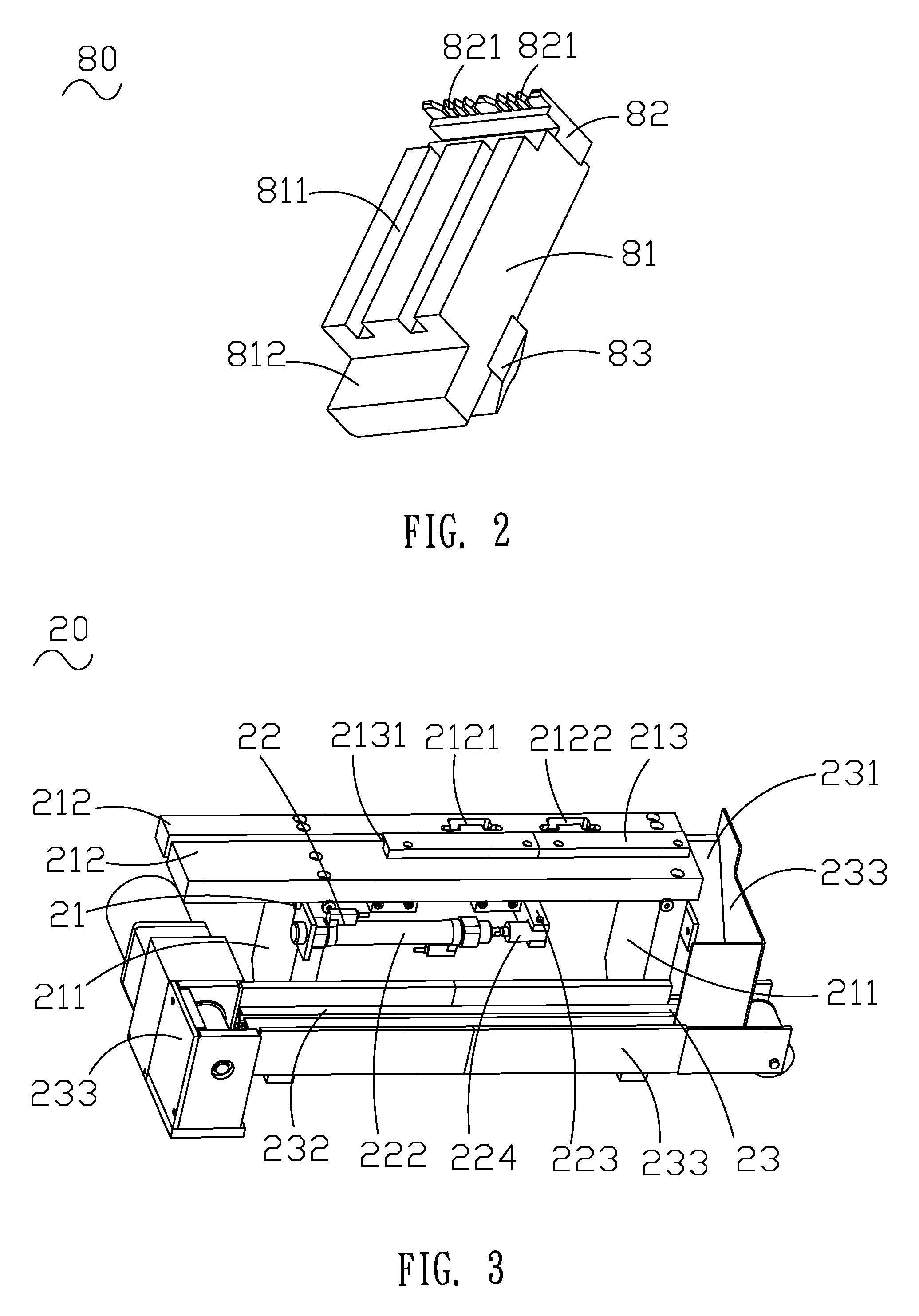

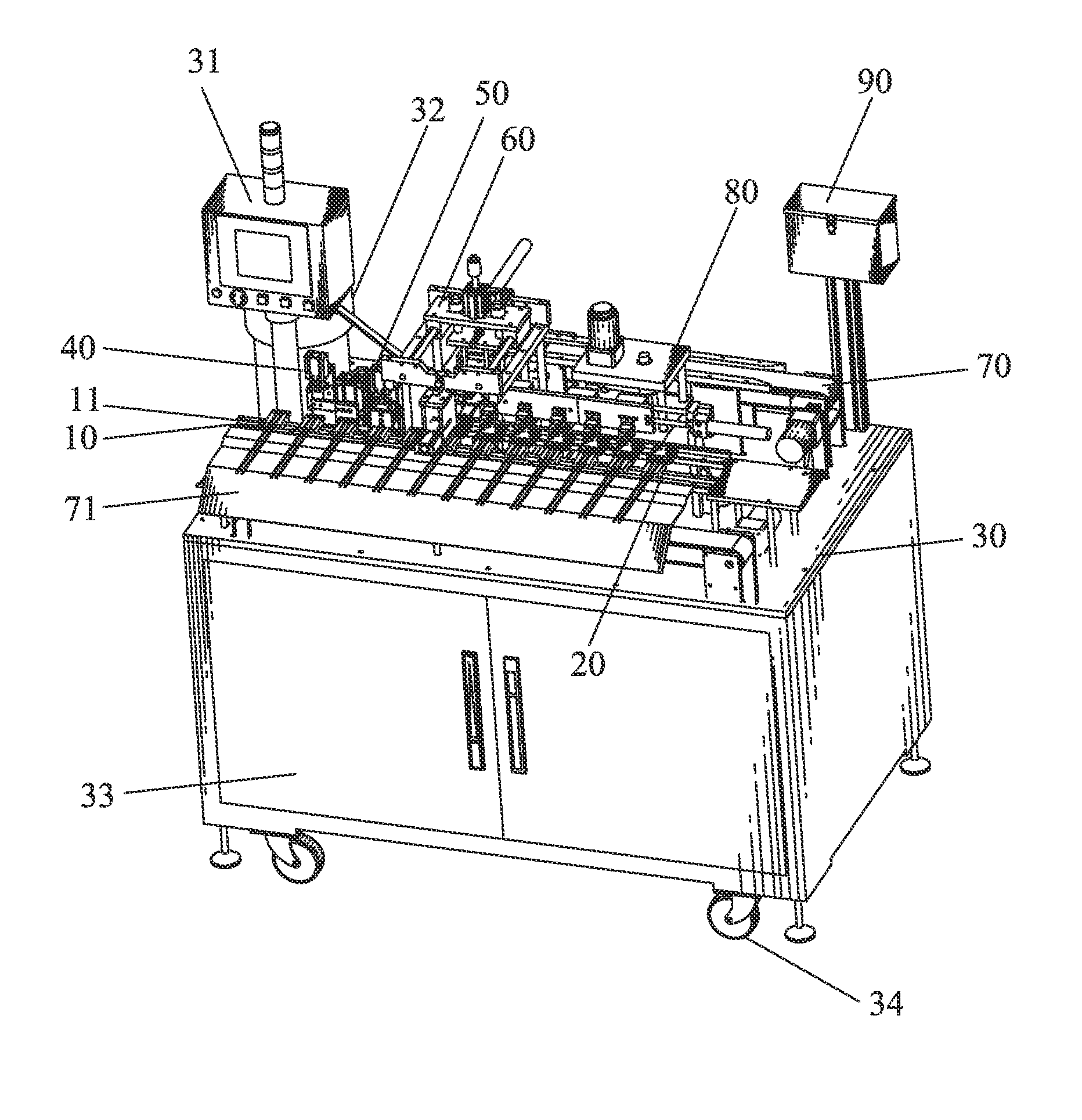

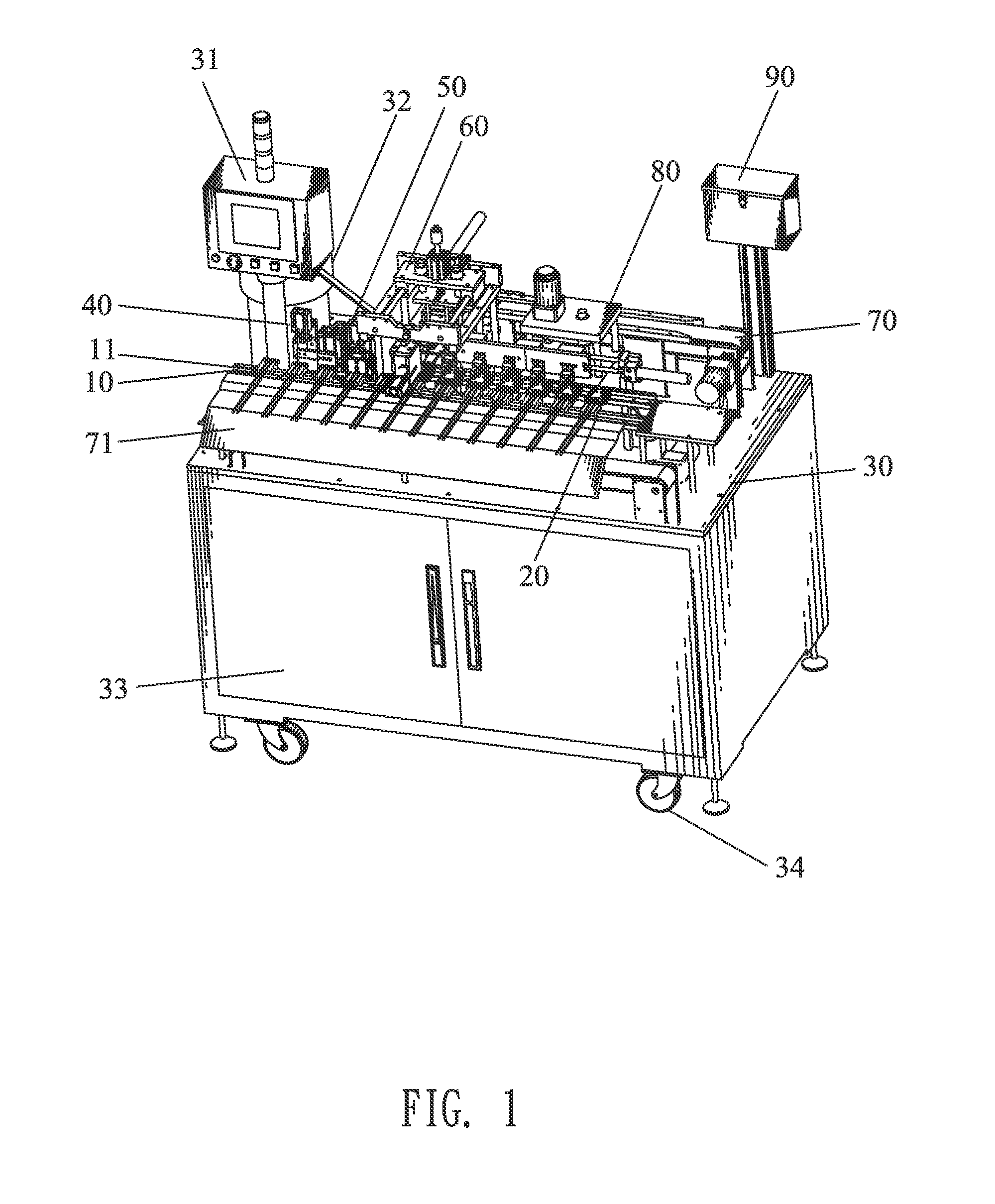

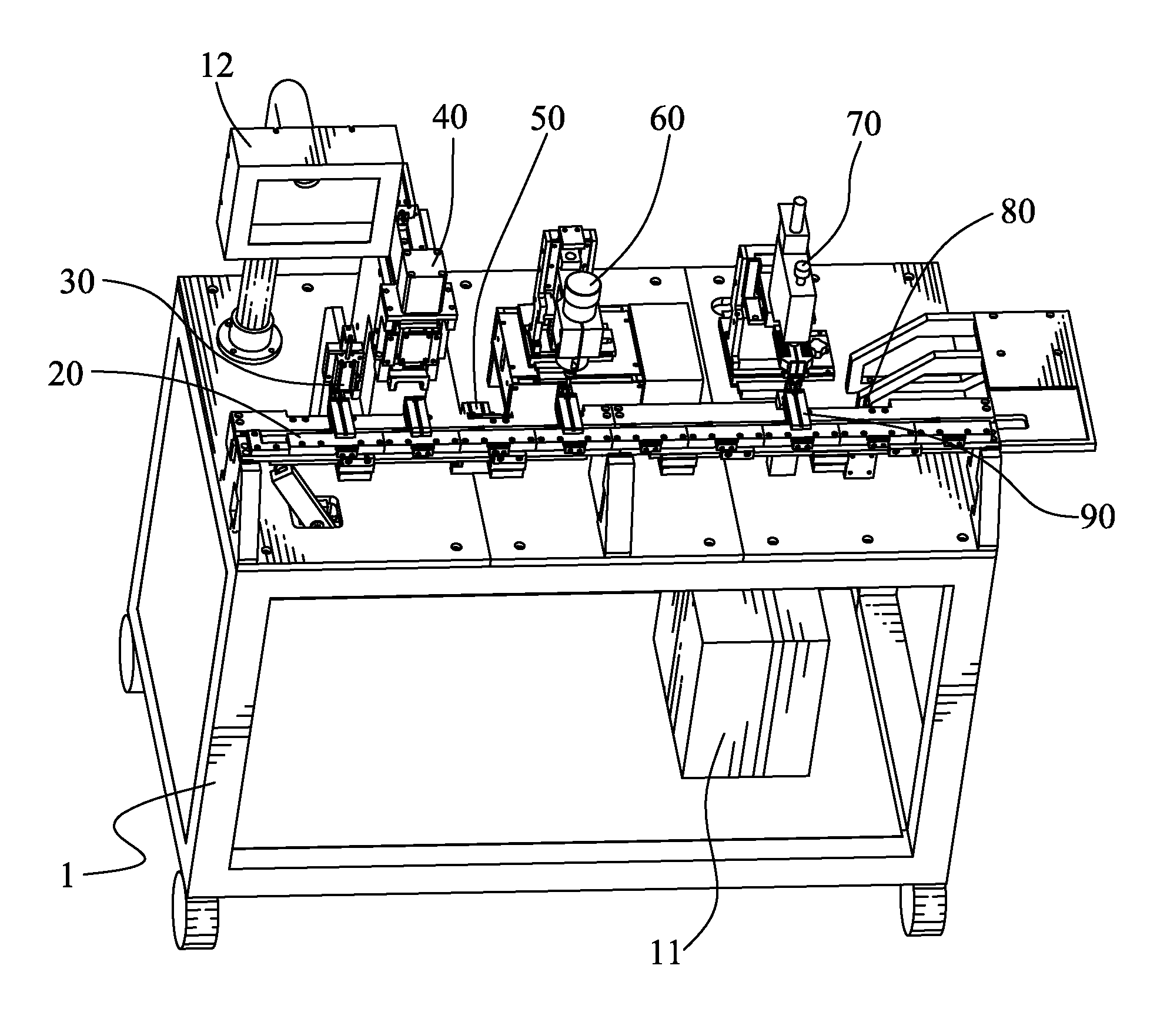

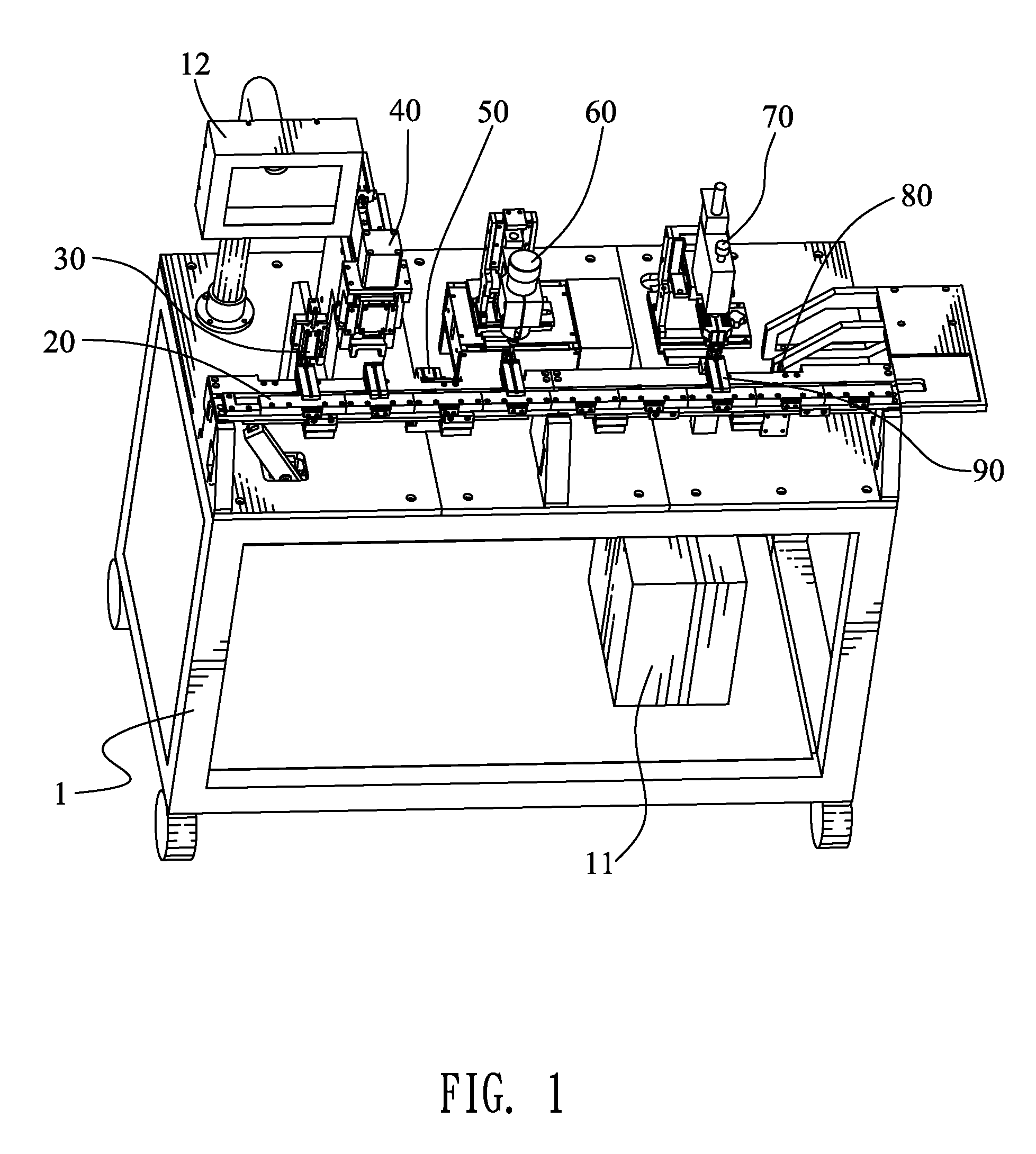

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

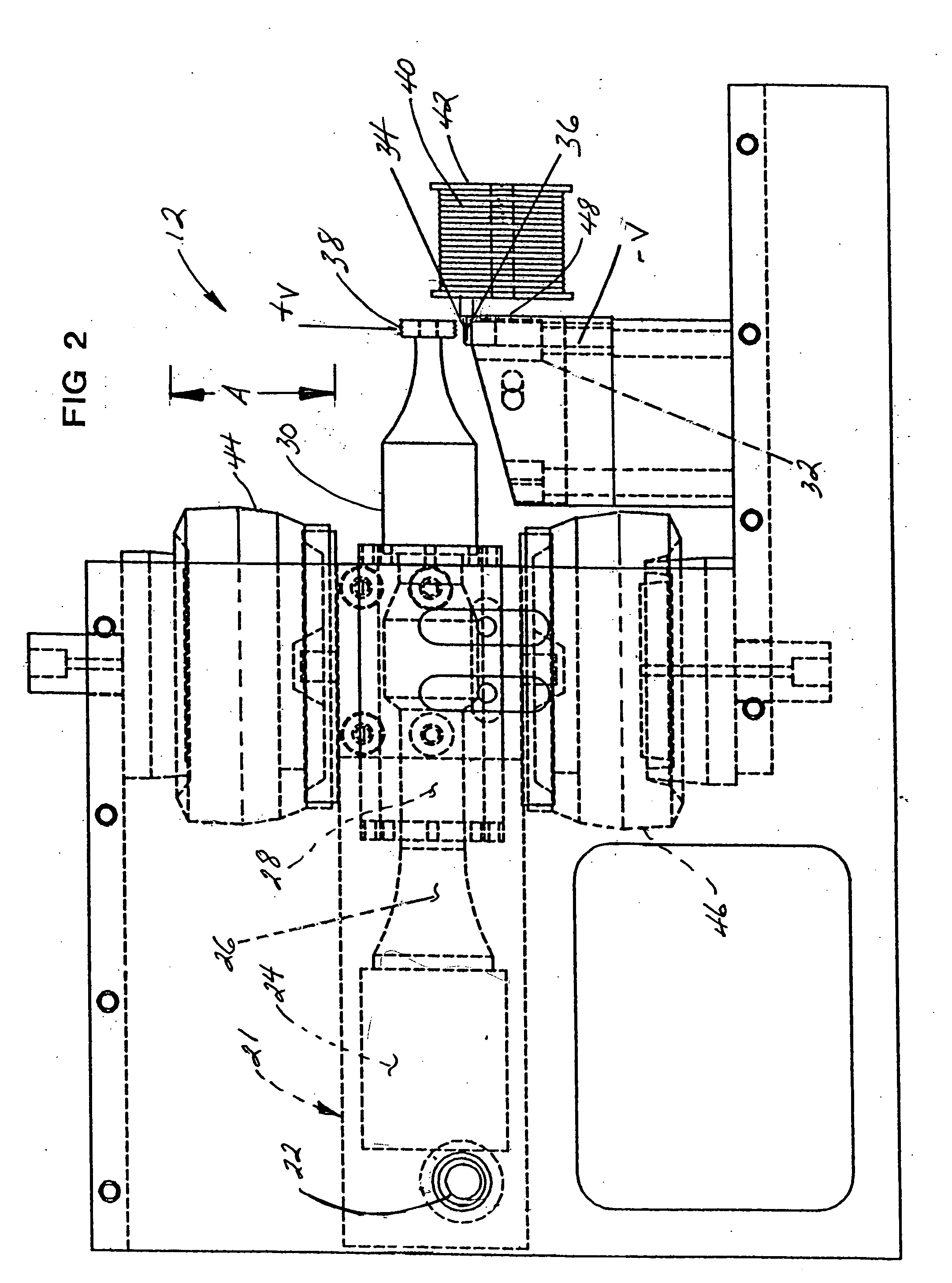

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

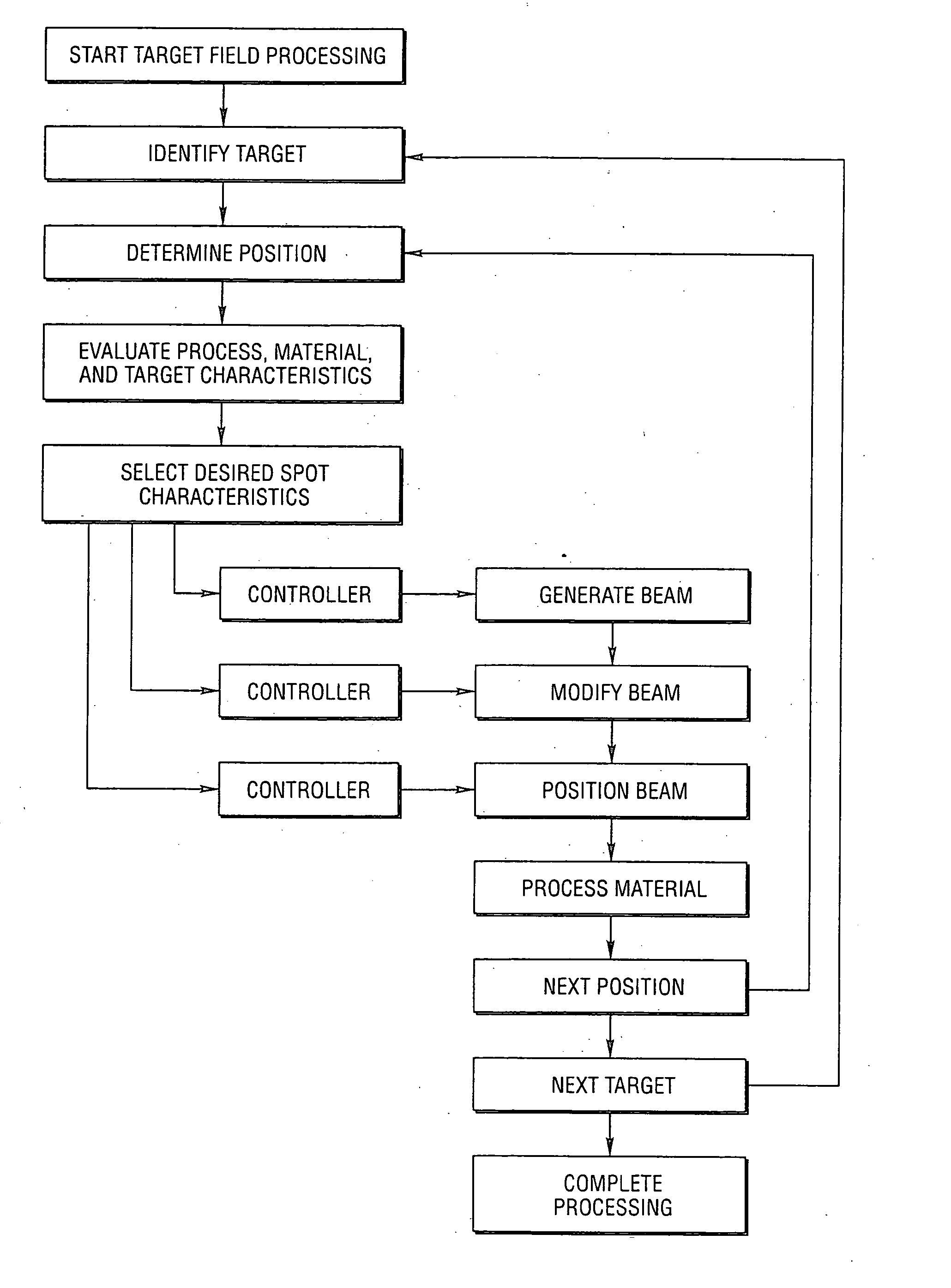

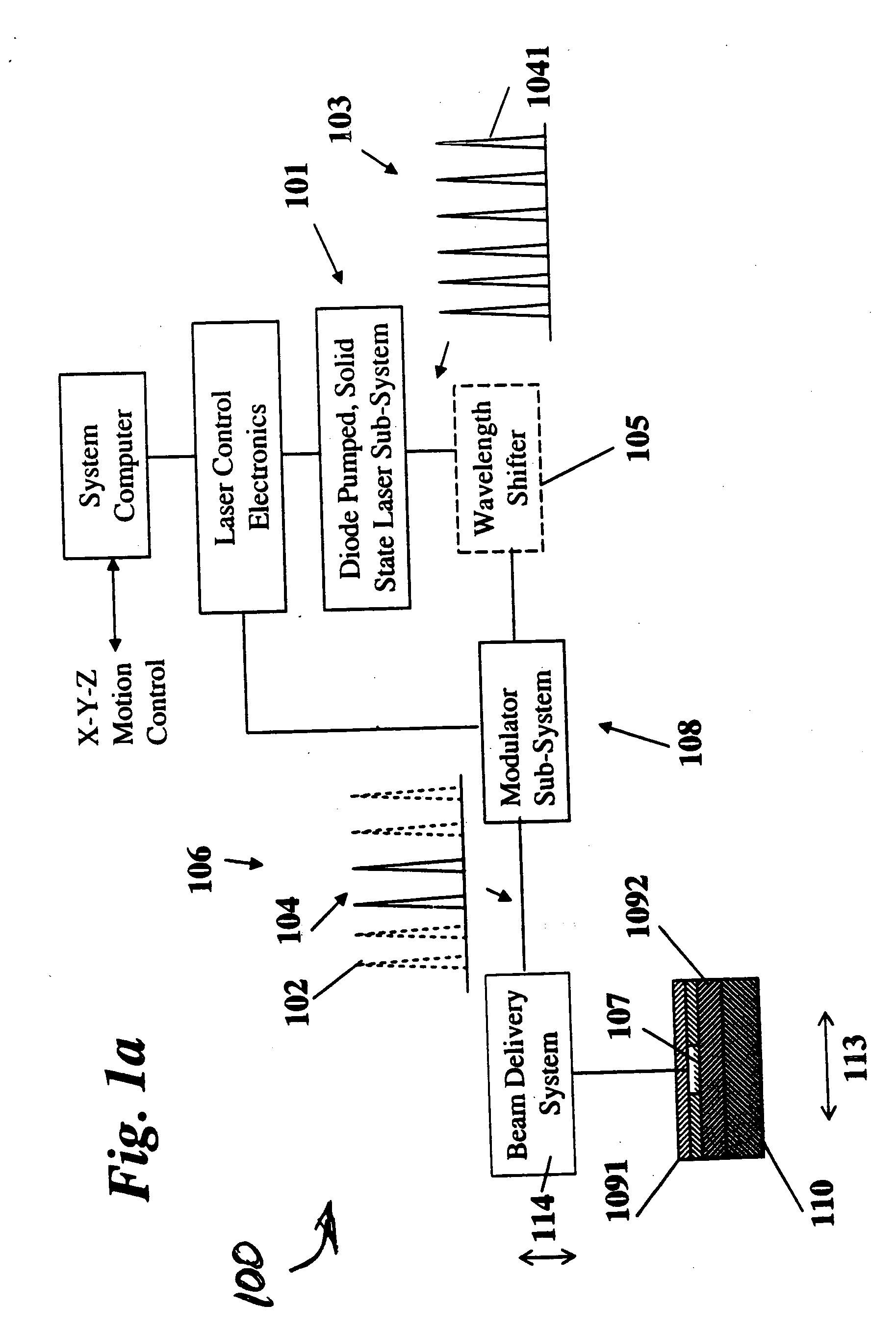

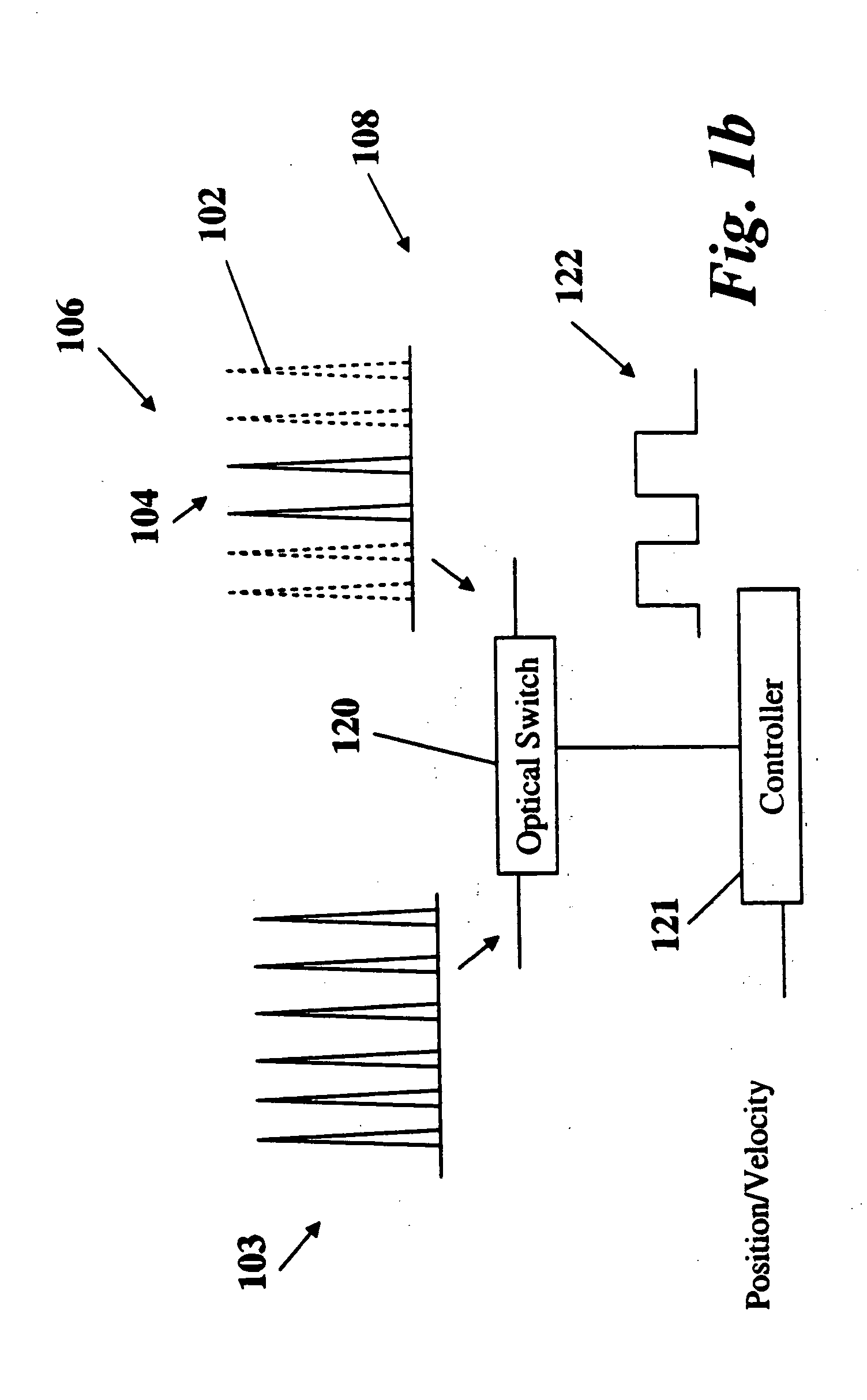

High-speed, precision, laser-based method and system for processing material of one or more targets within a field

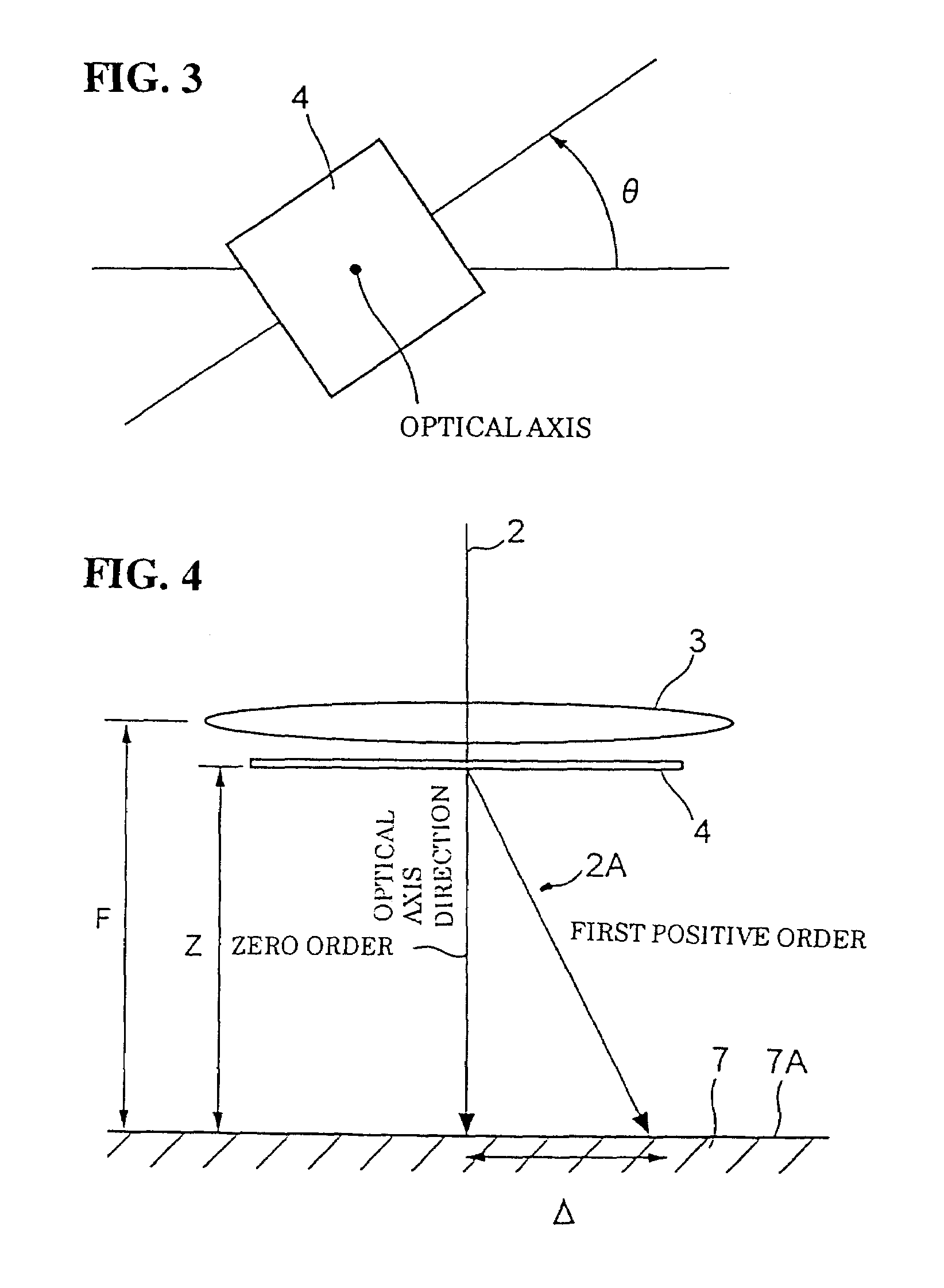

InactiveUS20050017156A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsIlluminanceOptical axis

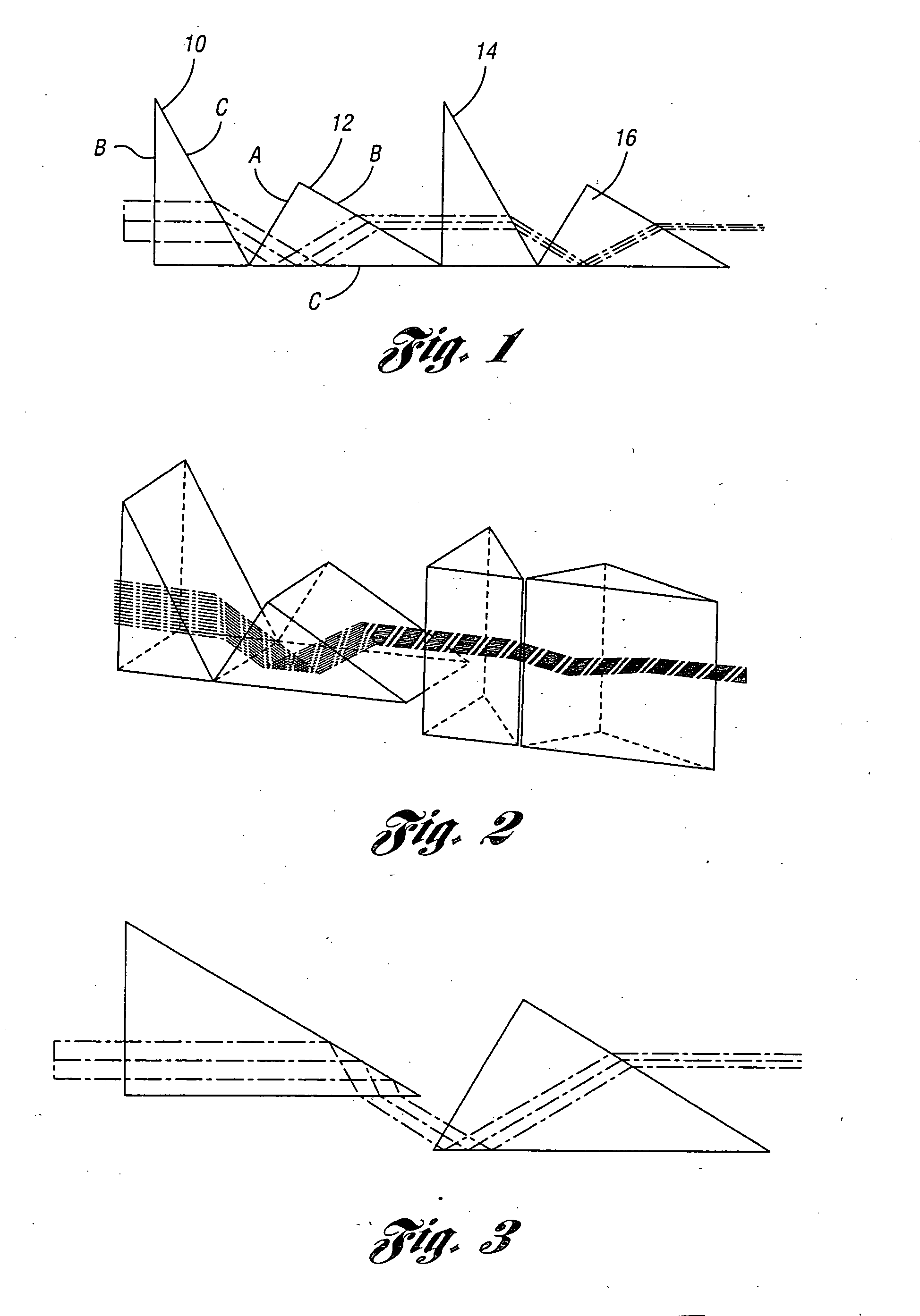

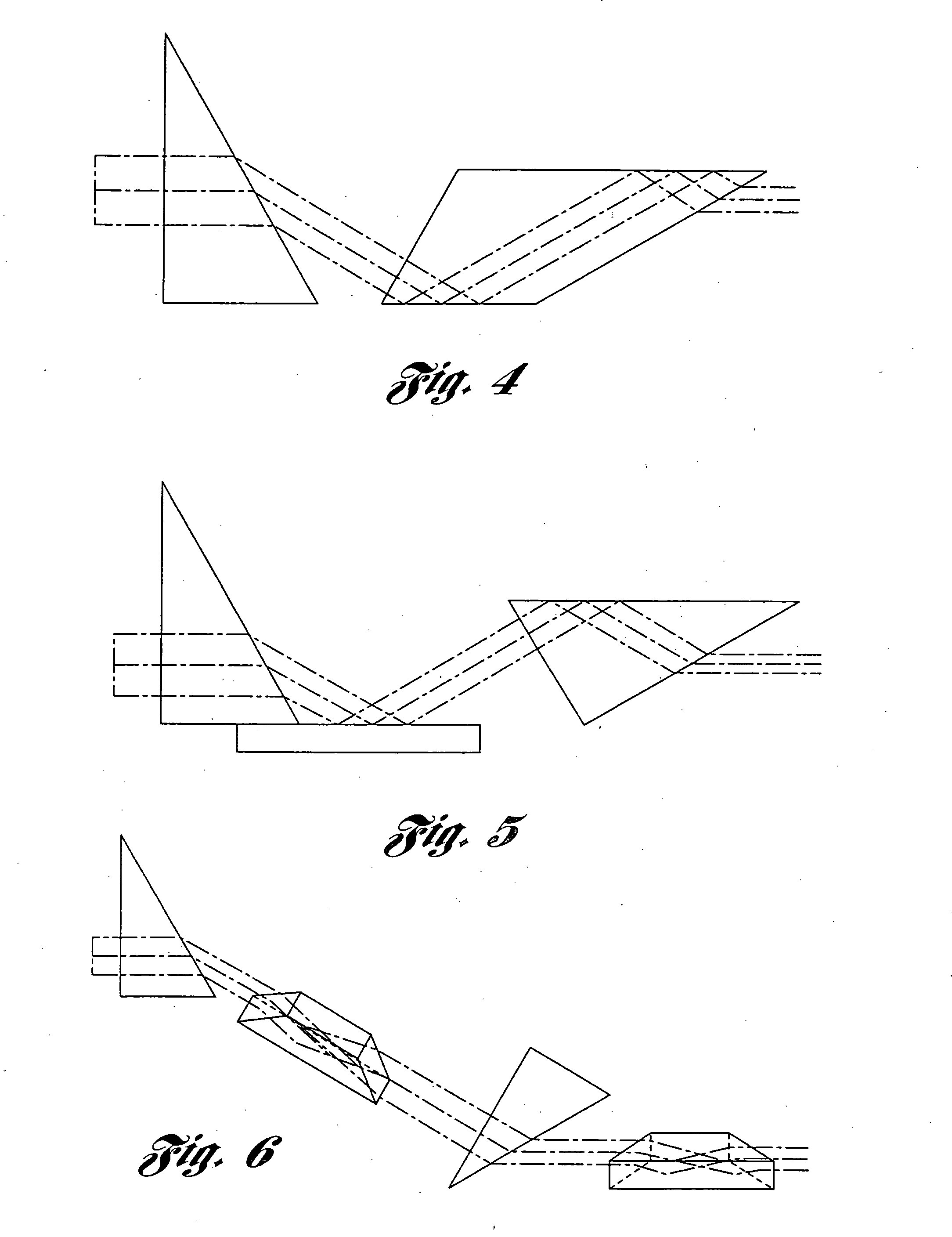

A precision, laser-based method and system for high-speed, sequential processing of material of targets within a field are disclosed that control the irradiation distribution pattern of imaged spots. For each spot, a laser beam is incident on a first anamorphic optical device and a second anamorphic optical device so that the beam is controllably modified into an elliptical irradiance pattern. The modified beam is propagated through a scanning optical system with an objective lens to image a controlled elliptical spot on the target. In one embodiment, the relative orientations of the devices along an optical axis are controlled to modify the beam irradiance pattern to obtain an elliptical shape while the absolute orientation of the devices controls the orientation of the elliptical spot.

Owner:ELECTRO SCI IND INC

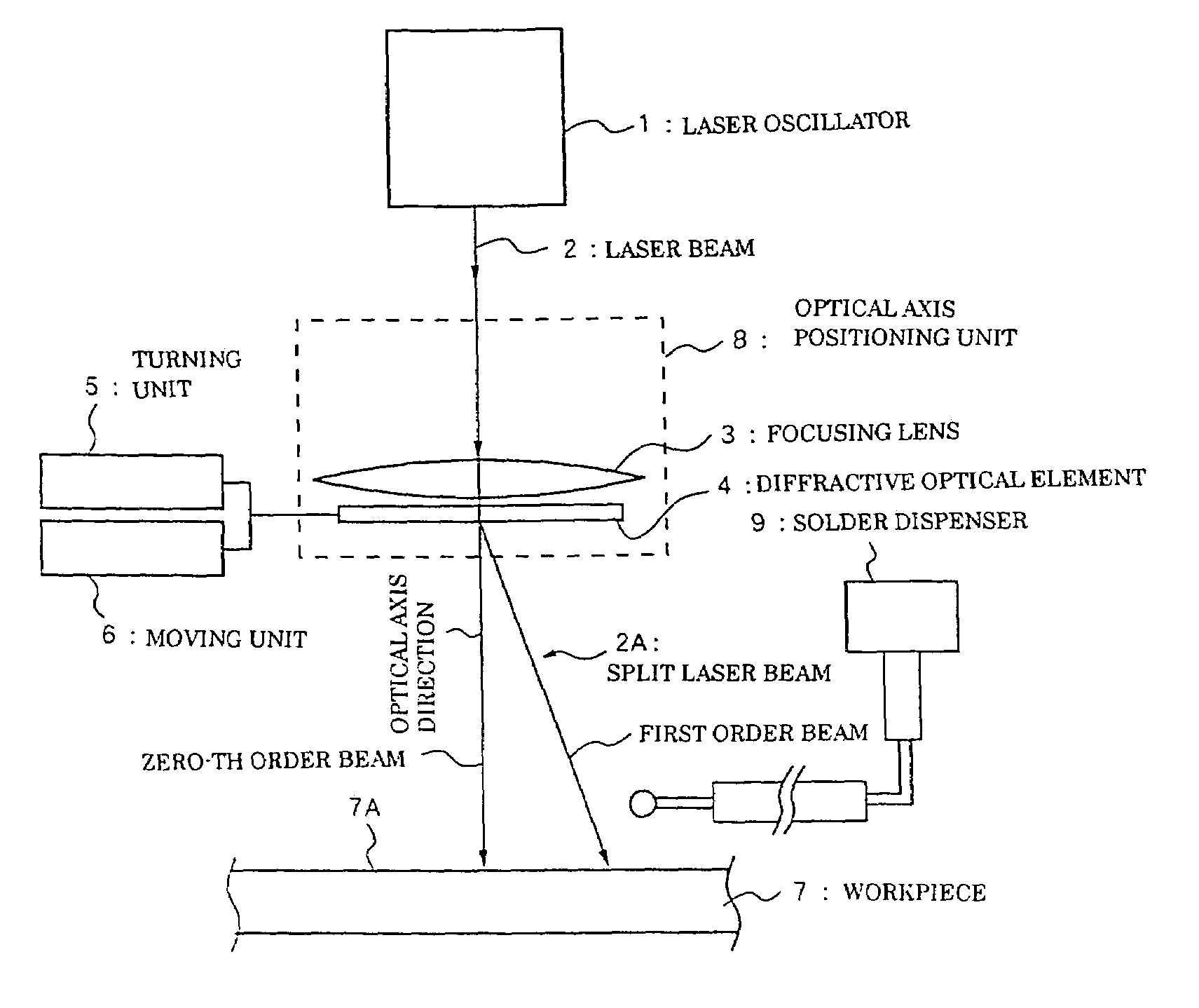

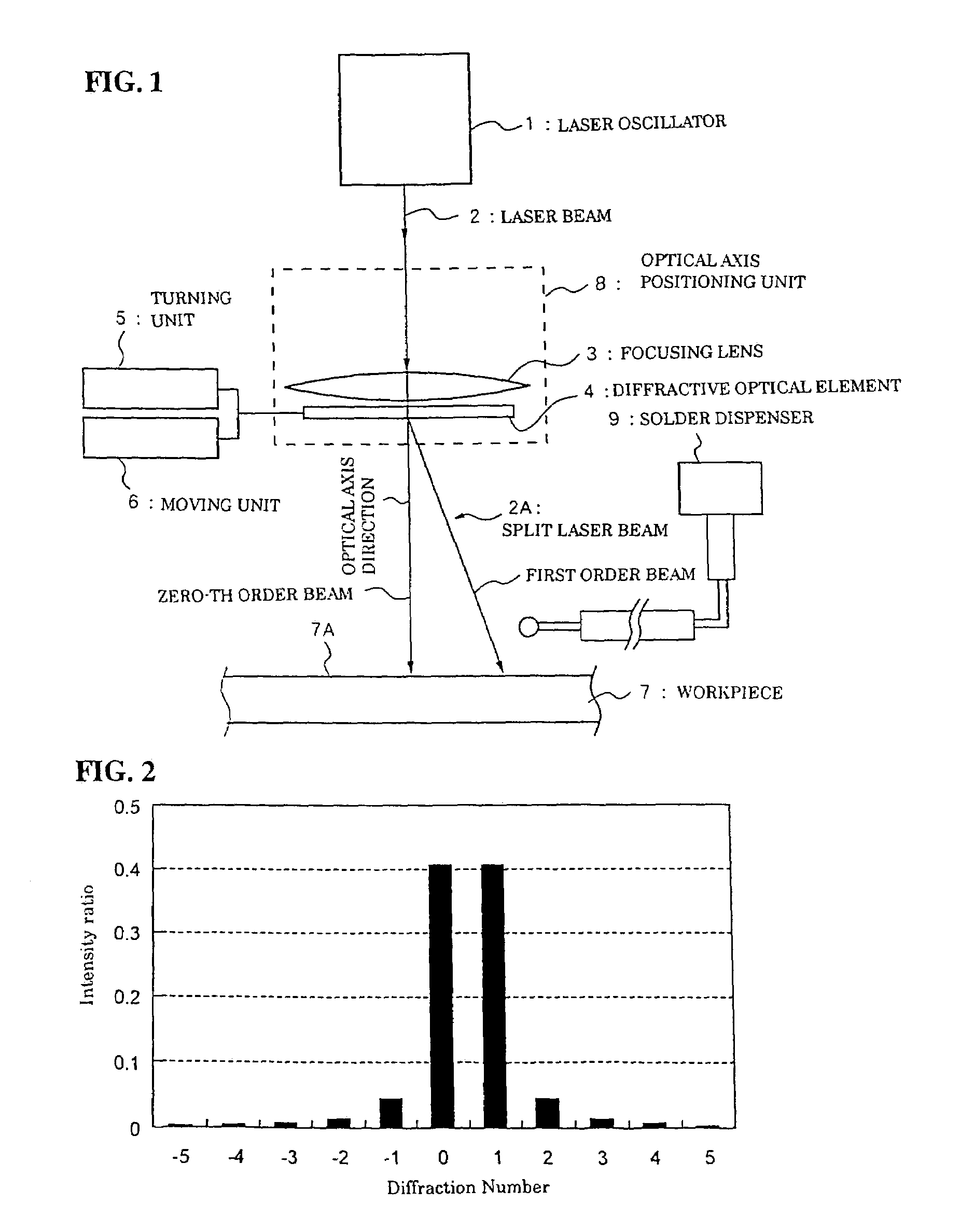

Laser processing method, laser welding method, and laser processing apparatus

ActiveUS7009138B2High energy laserImprove energy efficiencyPrinted circuit assemblingSoldering apparatusLaser processingLight beam

A processing method including steps for splitting a single beam into a plurality of beams including a zero-order diffracted beam, by diffracting the single beam by a diffractive element, for turning an array of focused beam spots obtained from the plurality of beams about the center of the zero-order diffracted beam according to the direction of an array of welding points where parts mounted on a circuit board are welded to the board, for causing a spot interval between focused beam spots in the array to agree with the interval between the plurality of welding points by adjusting the distance from the diffractive element to the board, and for increasing the intensity of the plurality of beams, to a welding intensity, and connecting the parts by simultaneously irradiating the welding points with the focused beam spots in the array having the determined direction and spot interval.

Owner:SEIKO EPSON CORP

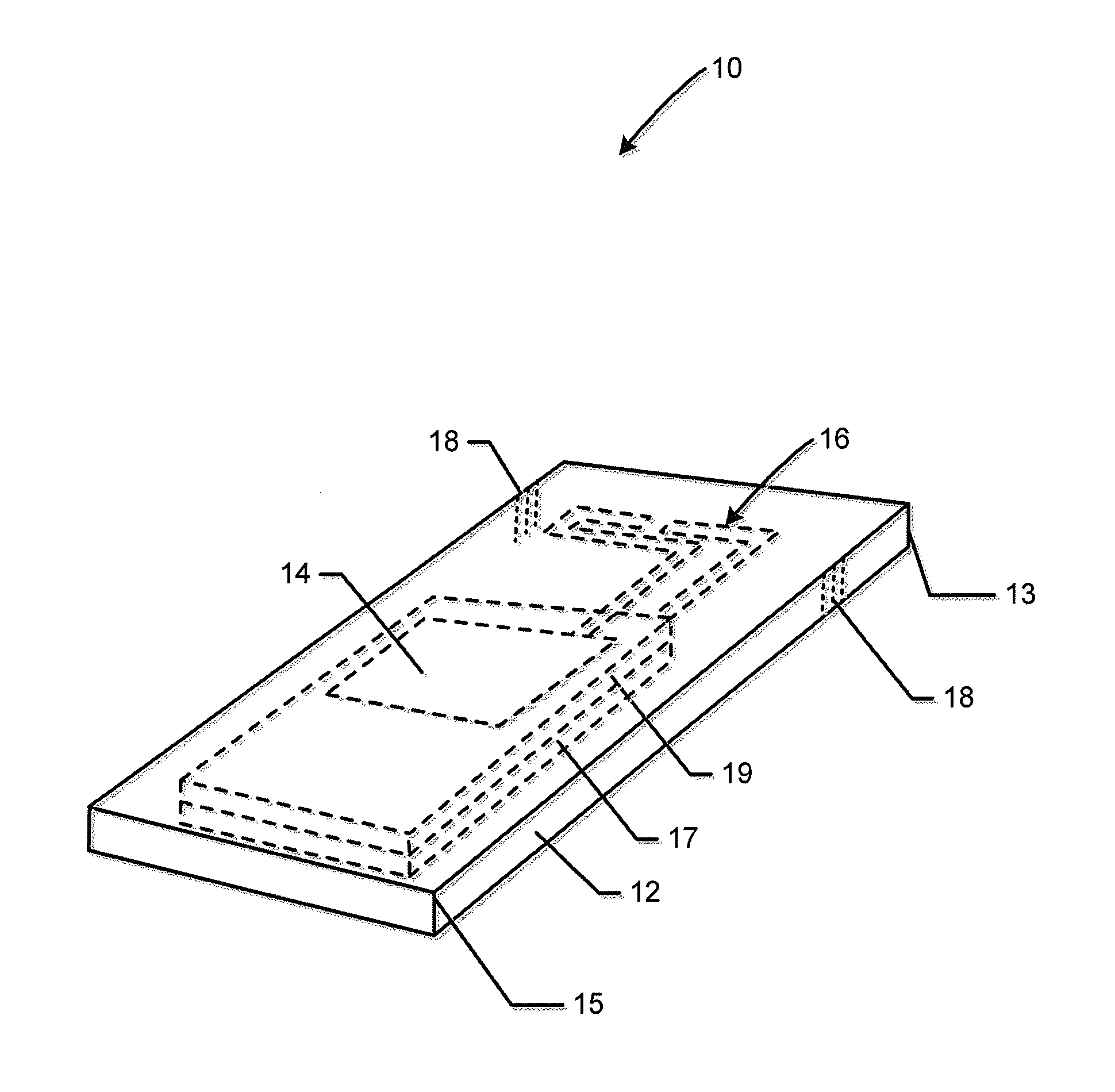

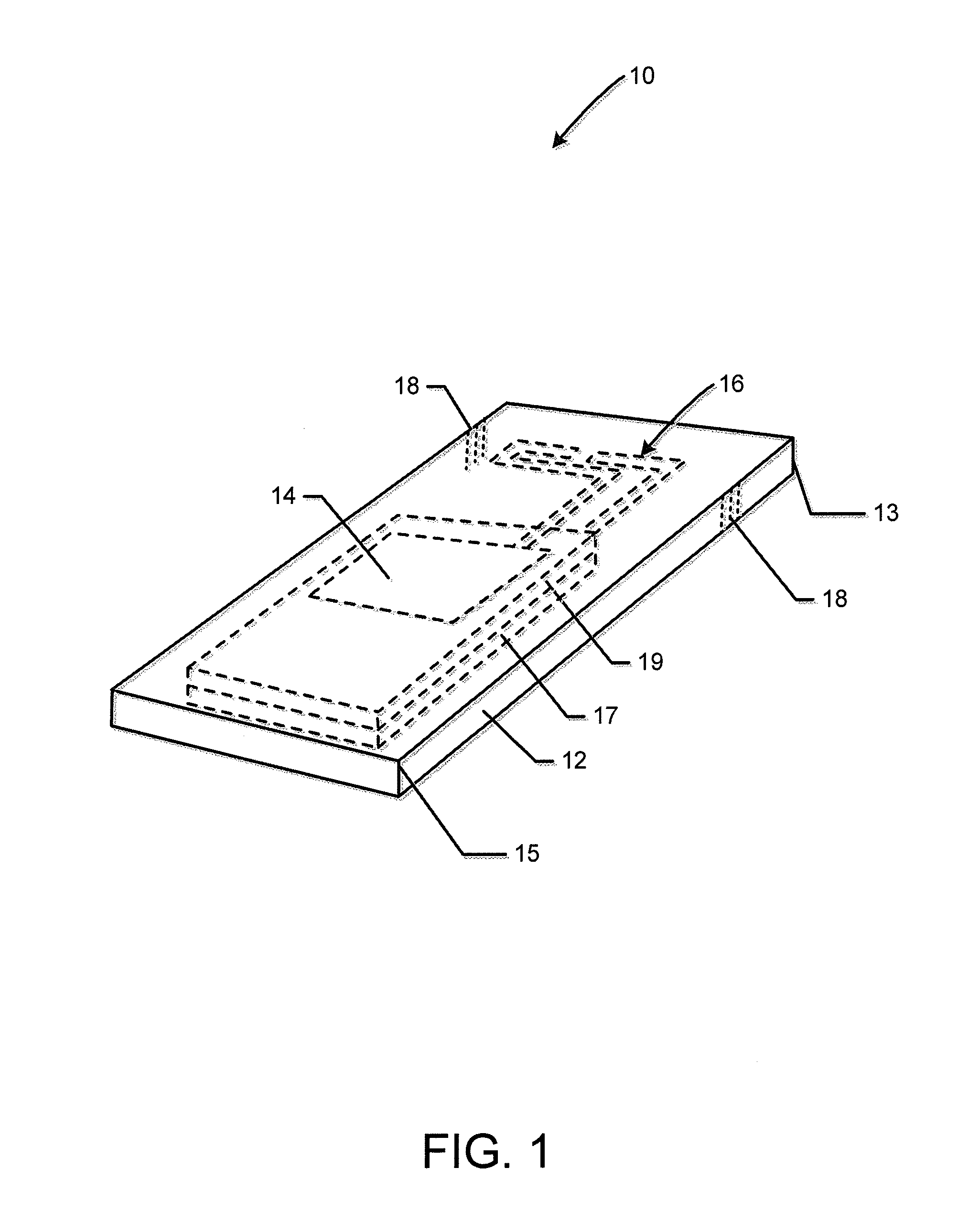

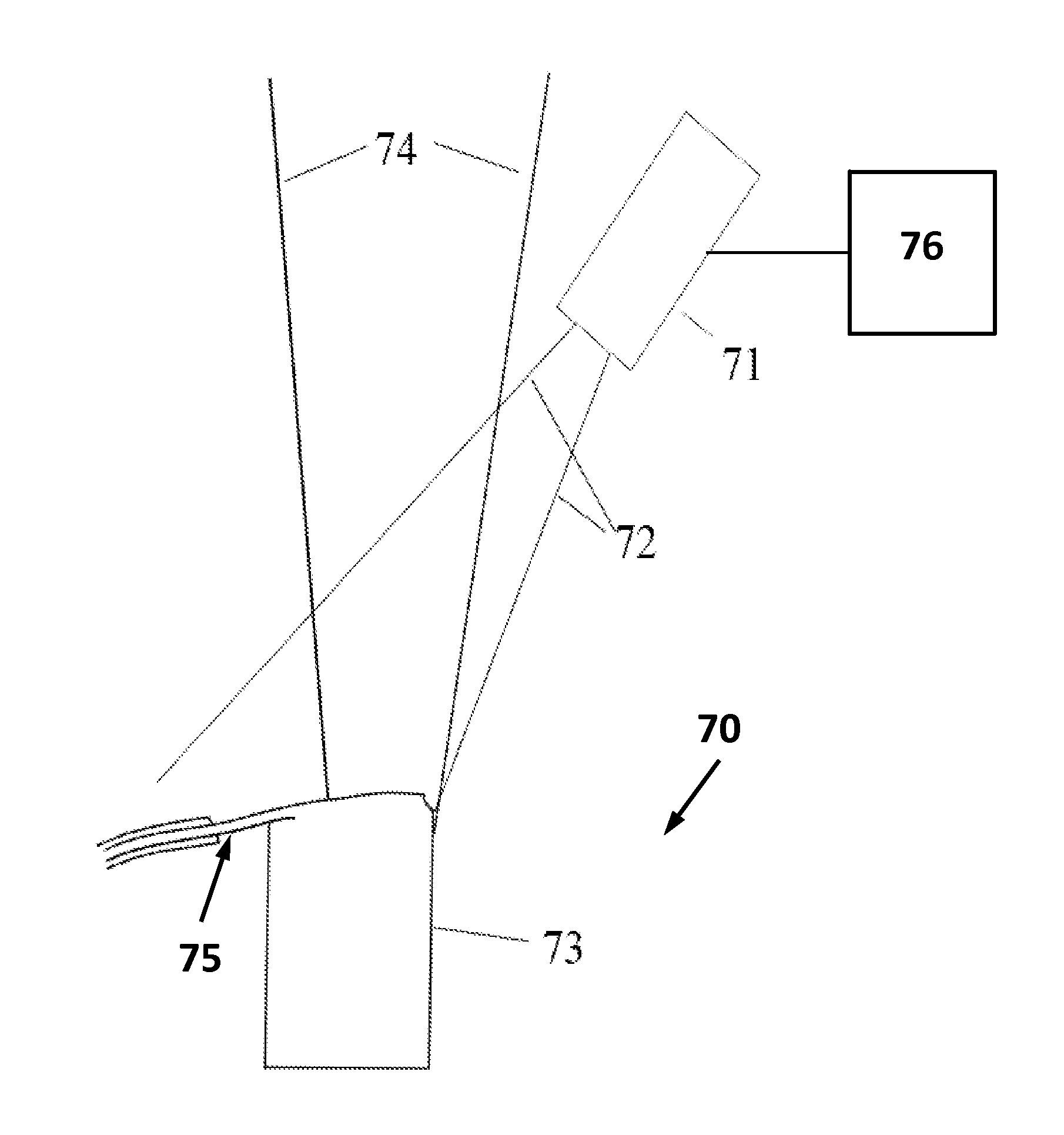

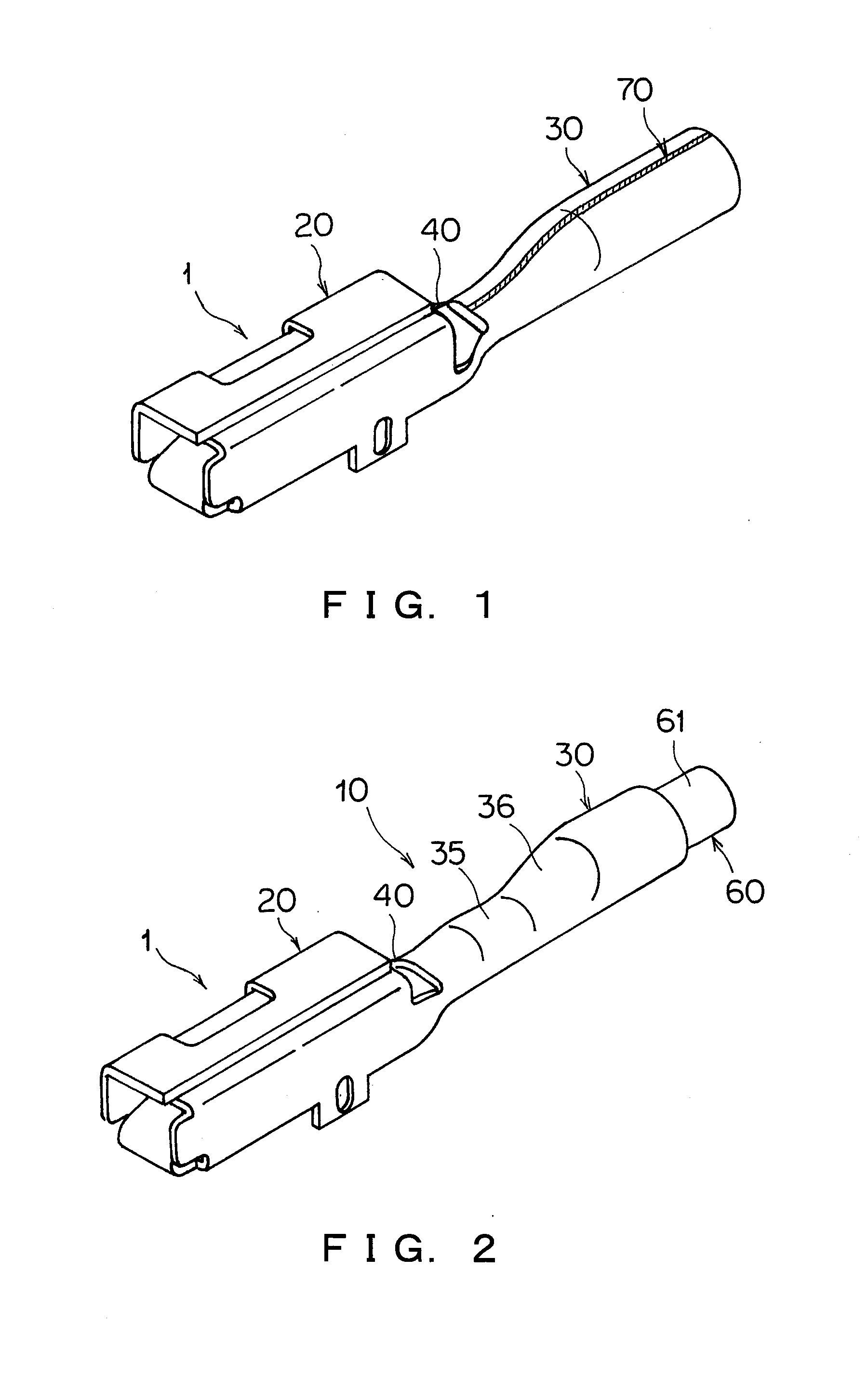

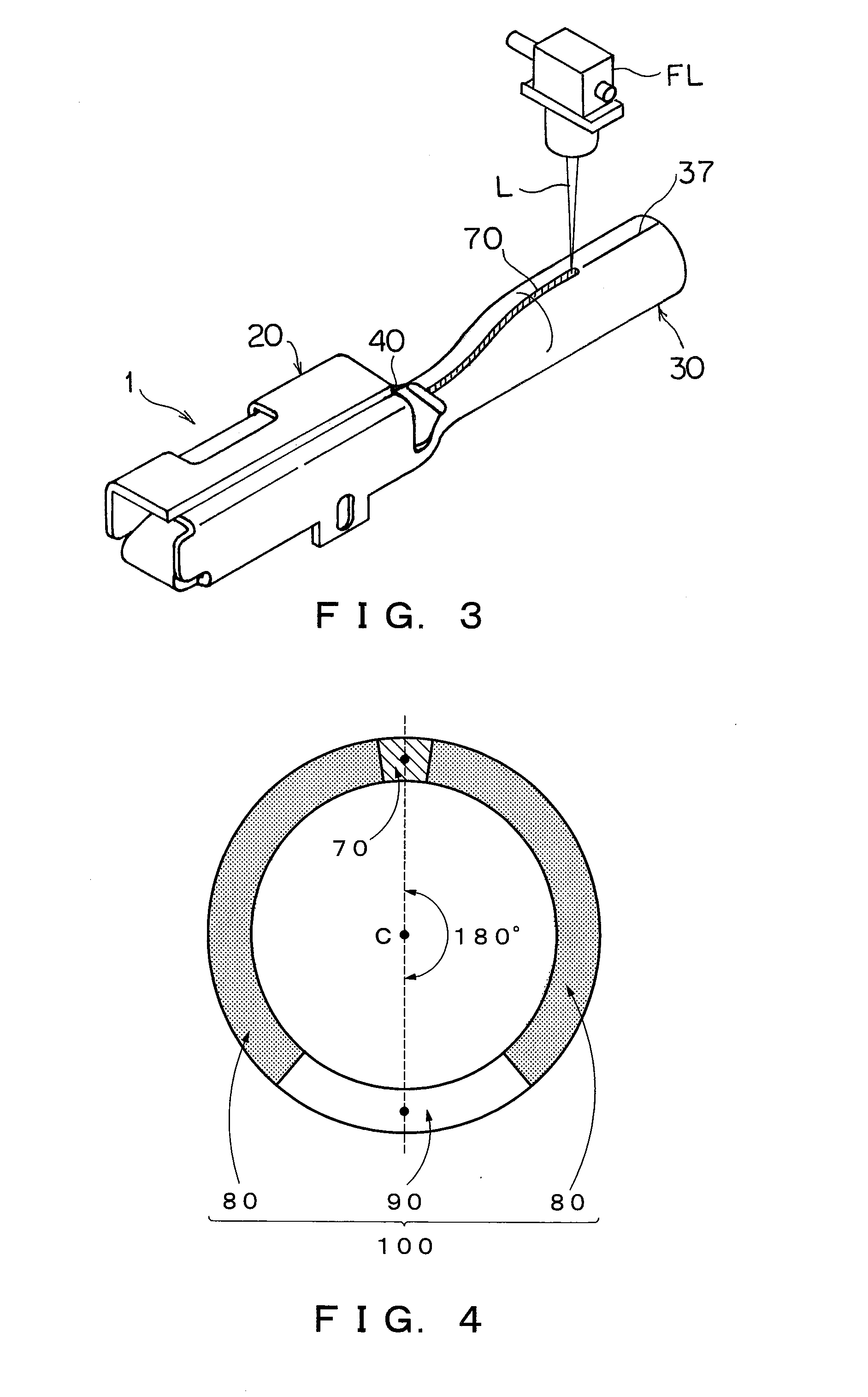

System, apparatus and method for hybrid function micro welding

An apparatus, system and method for micro welding, wherein insulated object, such as a wire, that includes a metallic conductor that is at least partially covered by one or more layers of insulation, is positioned across a termination point. A laser beam may be applied to an area of the insulated object overlapping the termination point, wherein the applied laser beam is configured to substantially simultaneously (i) ablate the one or more layers of insulation in a first region of the area, (ii) weld the metallic conductor to the termination point in a second region of the area, and (iii) detach a portion of the object from the termination point in a third region of the area.

Owner:JABIL INC

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20050092720A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserLaser processing

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:GSI LUMONICS CORP

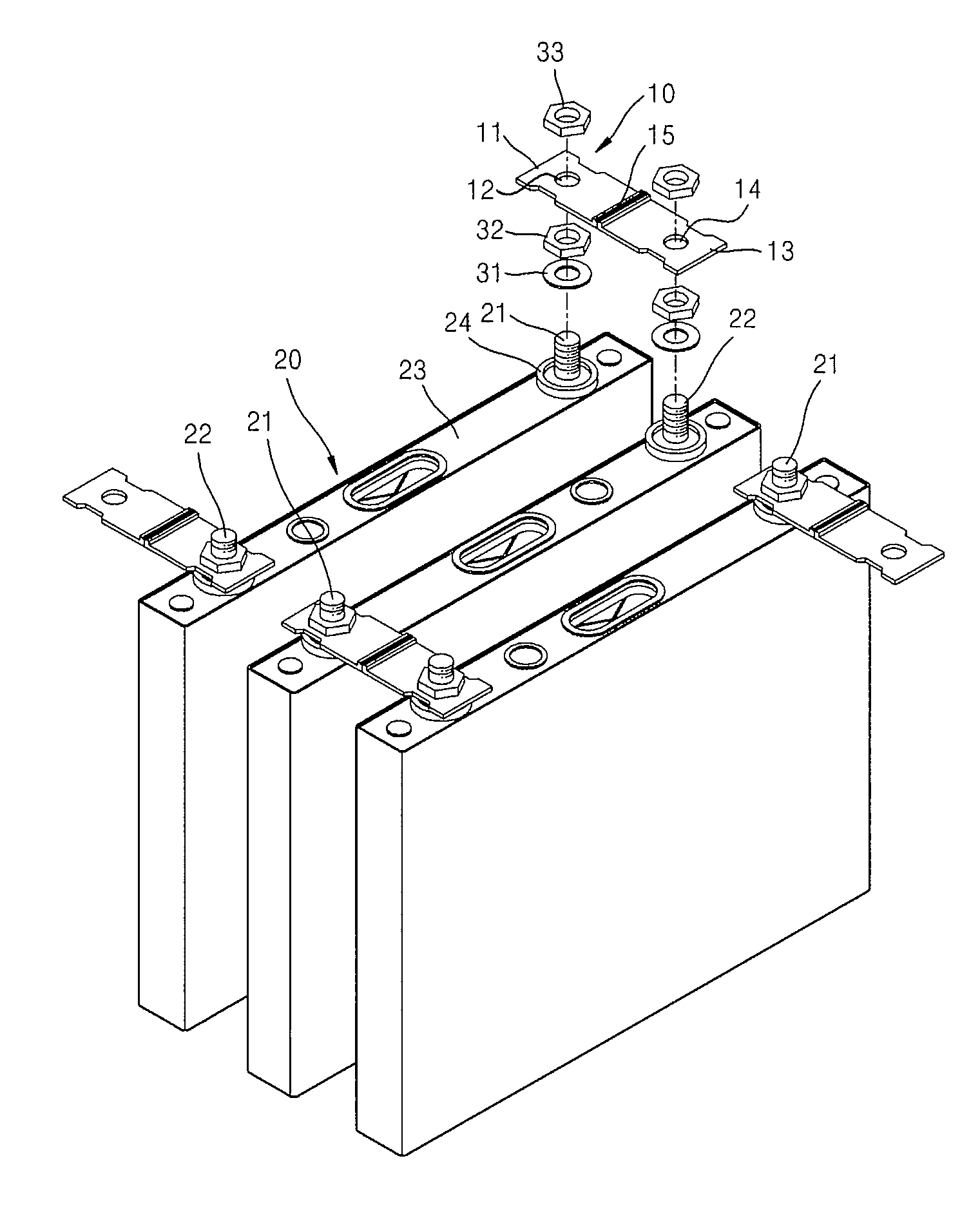

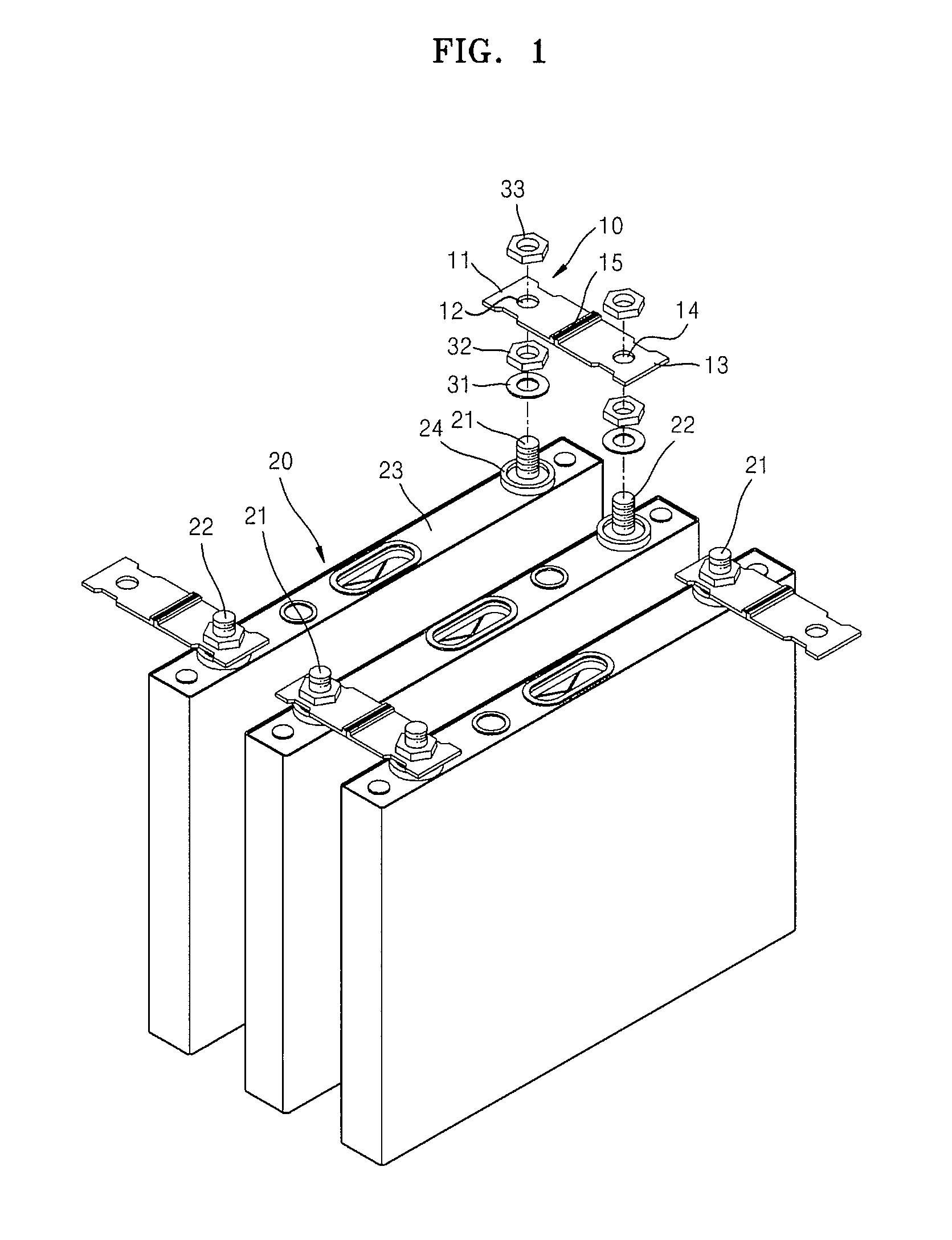

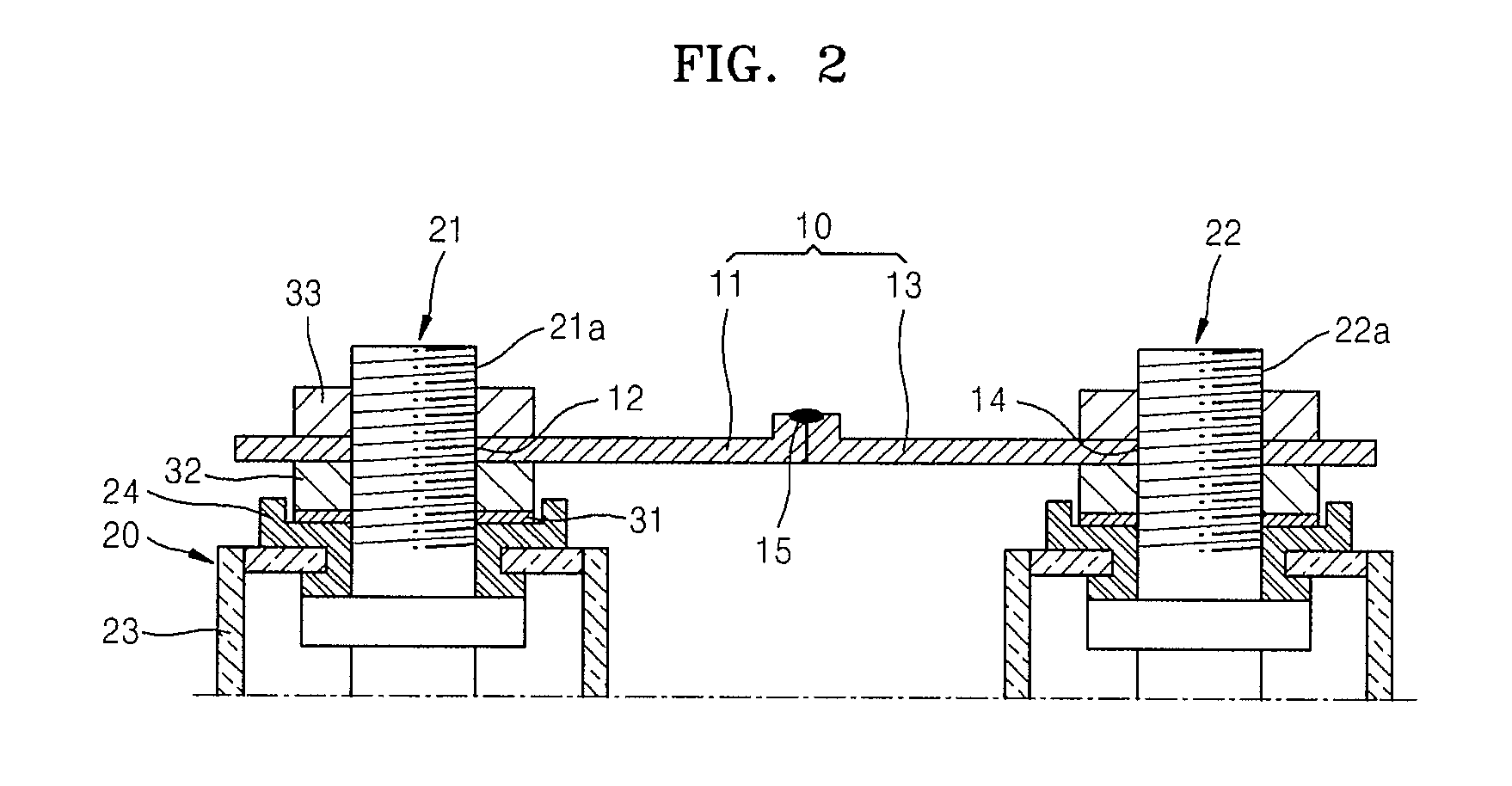

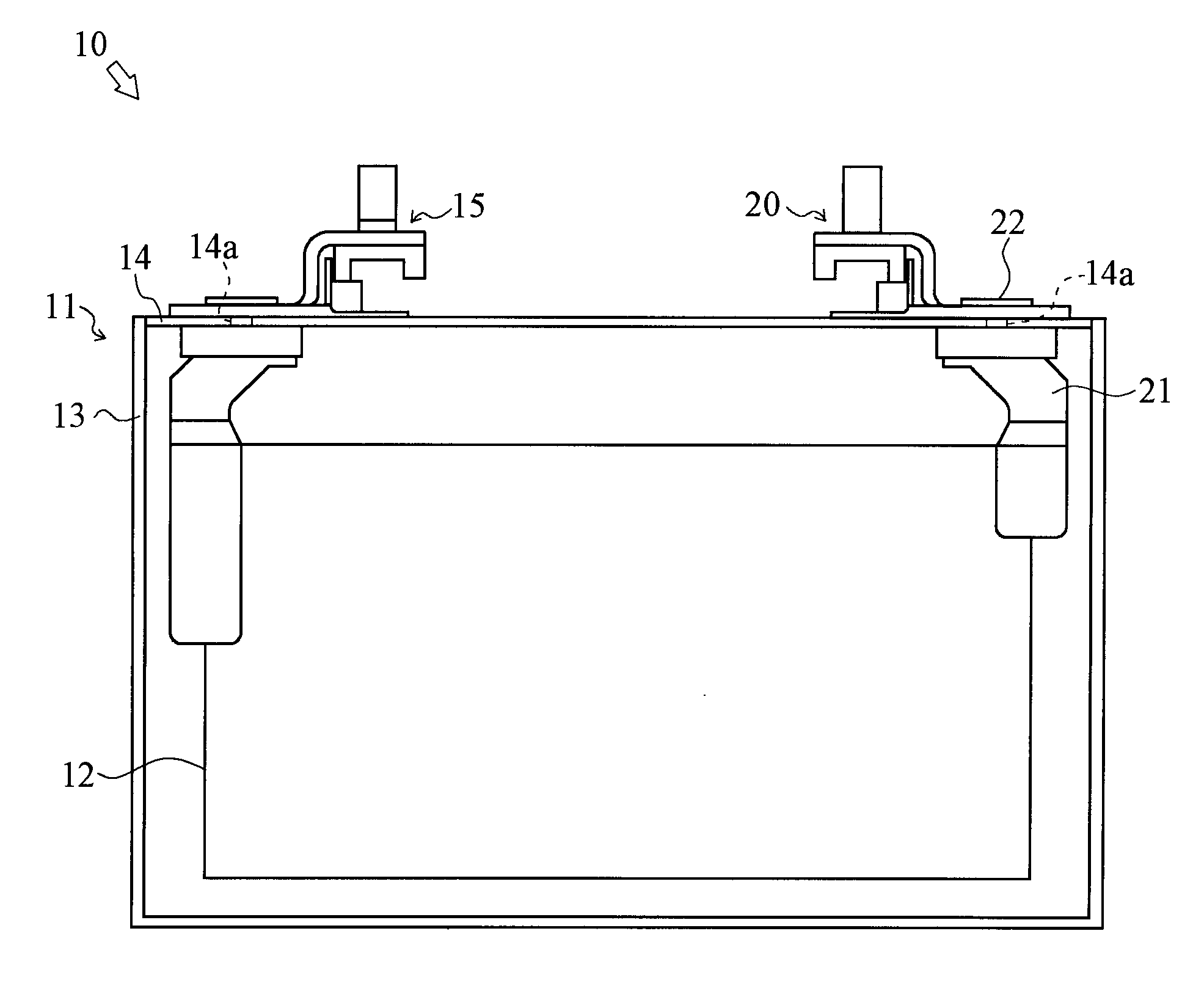

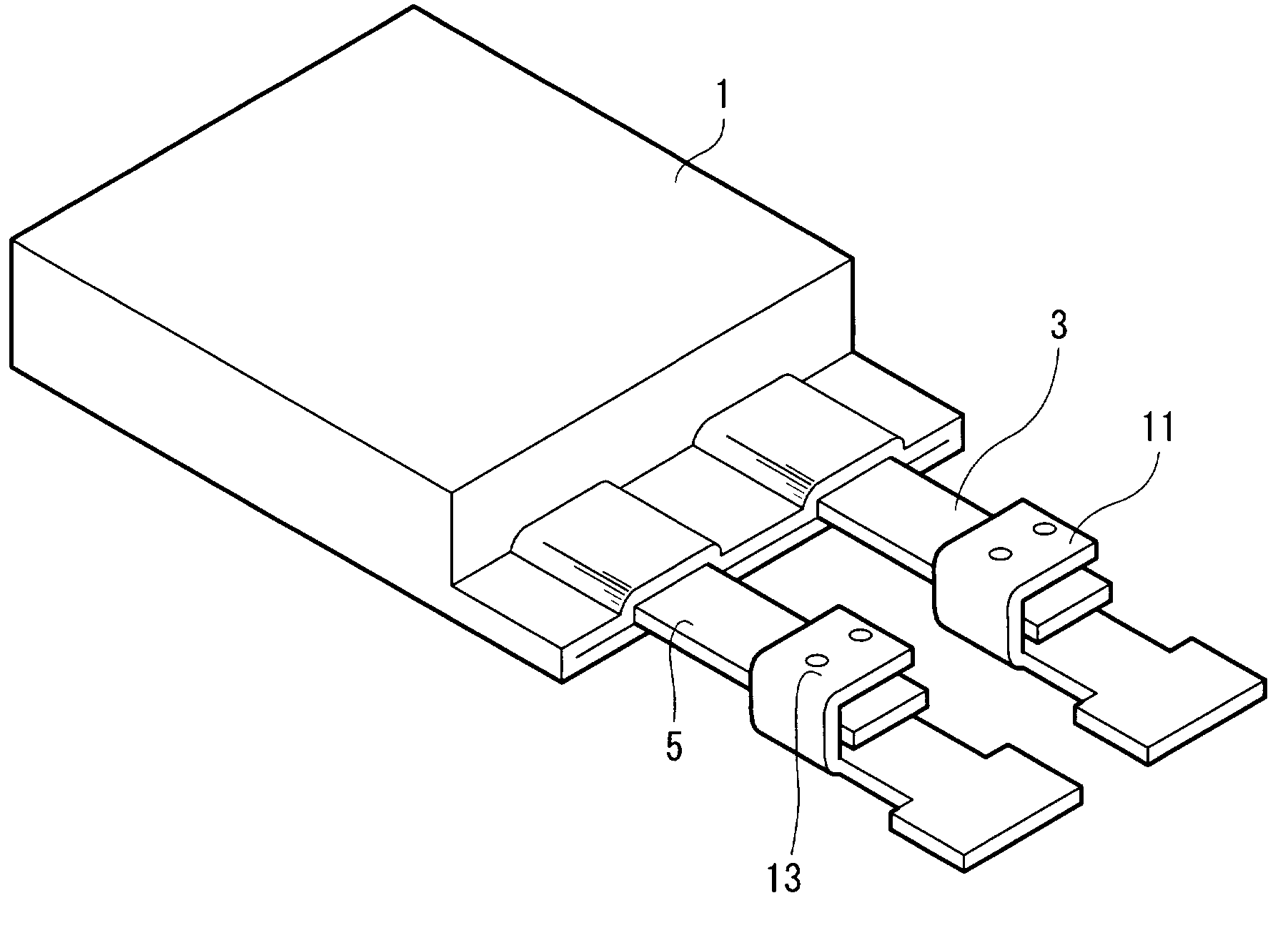

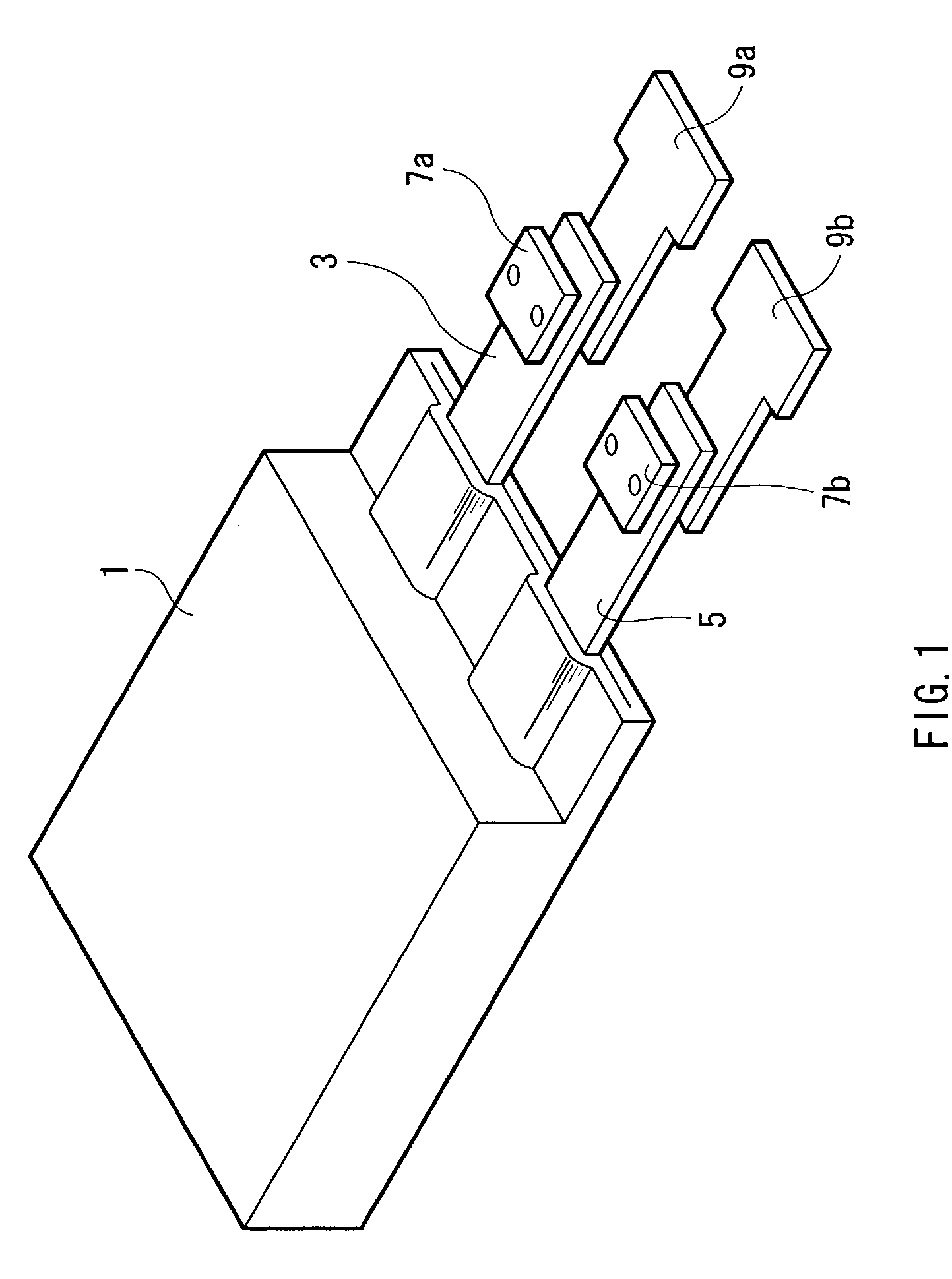

Bus bar and battery module including the same

InactiveUS20110117420A1Contact electrical resistance can be reducedReduce contactPrimary cell to battery groupingActive material electrodesElectrical batteryEngineering

A battery module includes a plurality of secondary batteries, each of the secondary batteries having a first terminal and a second terminal comprising different metals; and a plurality of bus bars, each of the bus bars including a first connecting portion comprising a first metal and connected to the first terminal of one of the secondary batteries, and a first end portion, and a second connecting portion comprising a second metal different from the first metal and connected to the second terminal of another one of the secondary batteries adjacent to the one secondary battery, and a second end portion, wherein the first end portion is connected to the second end portion by a weld.

Owner:ROBERT BOSCH GMBH +1

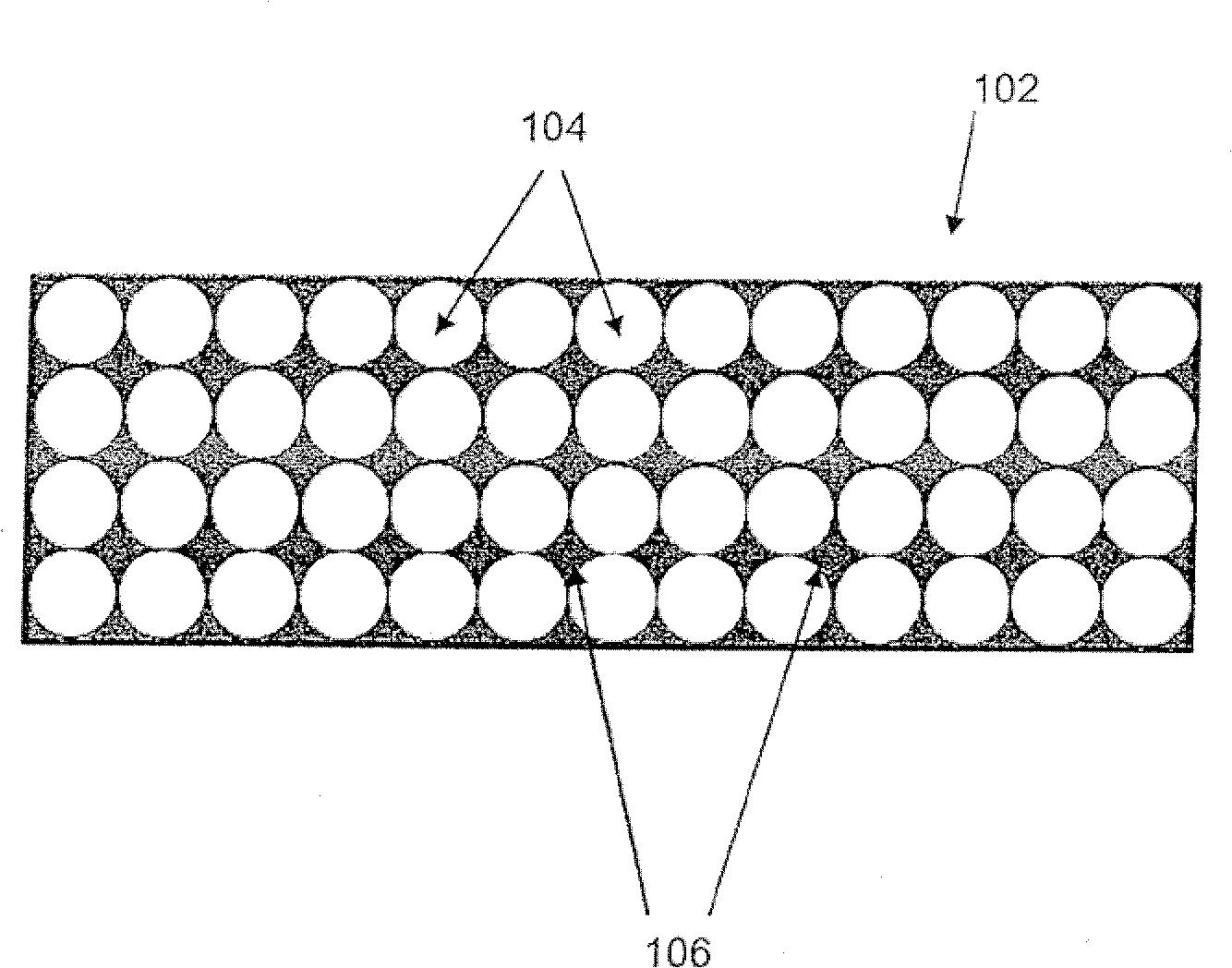

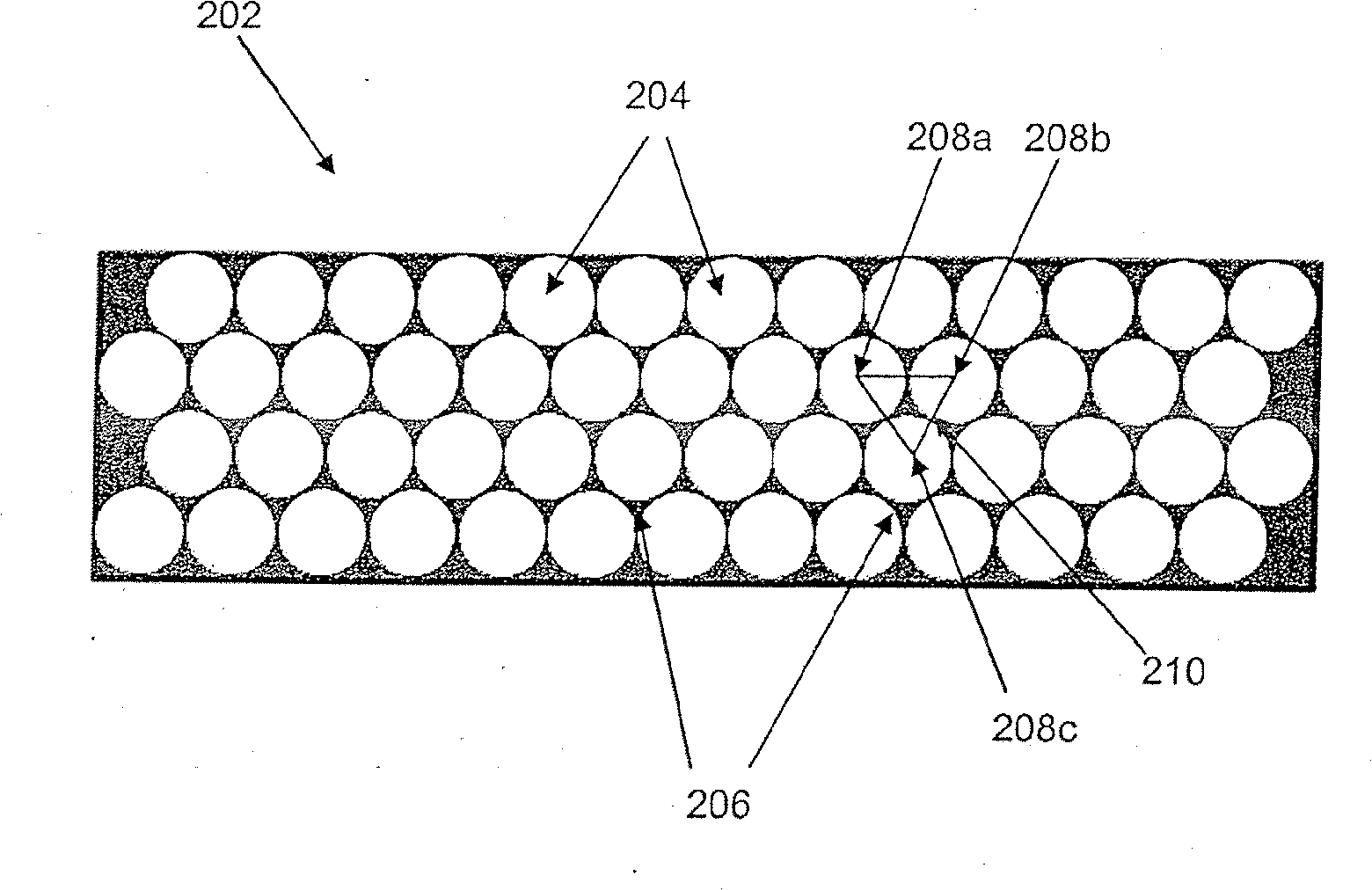

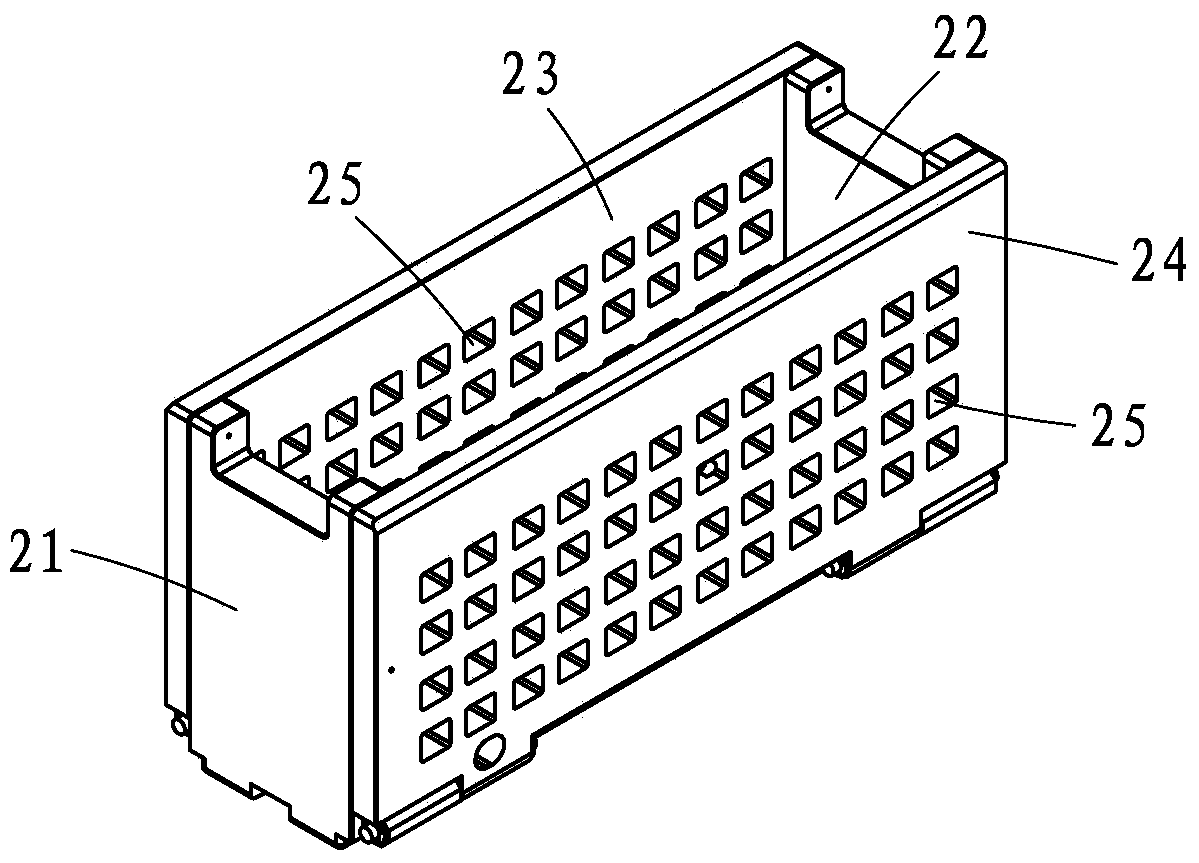

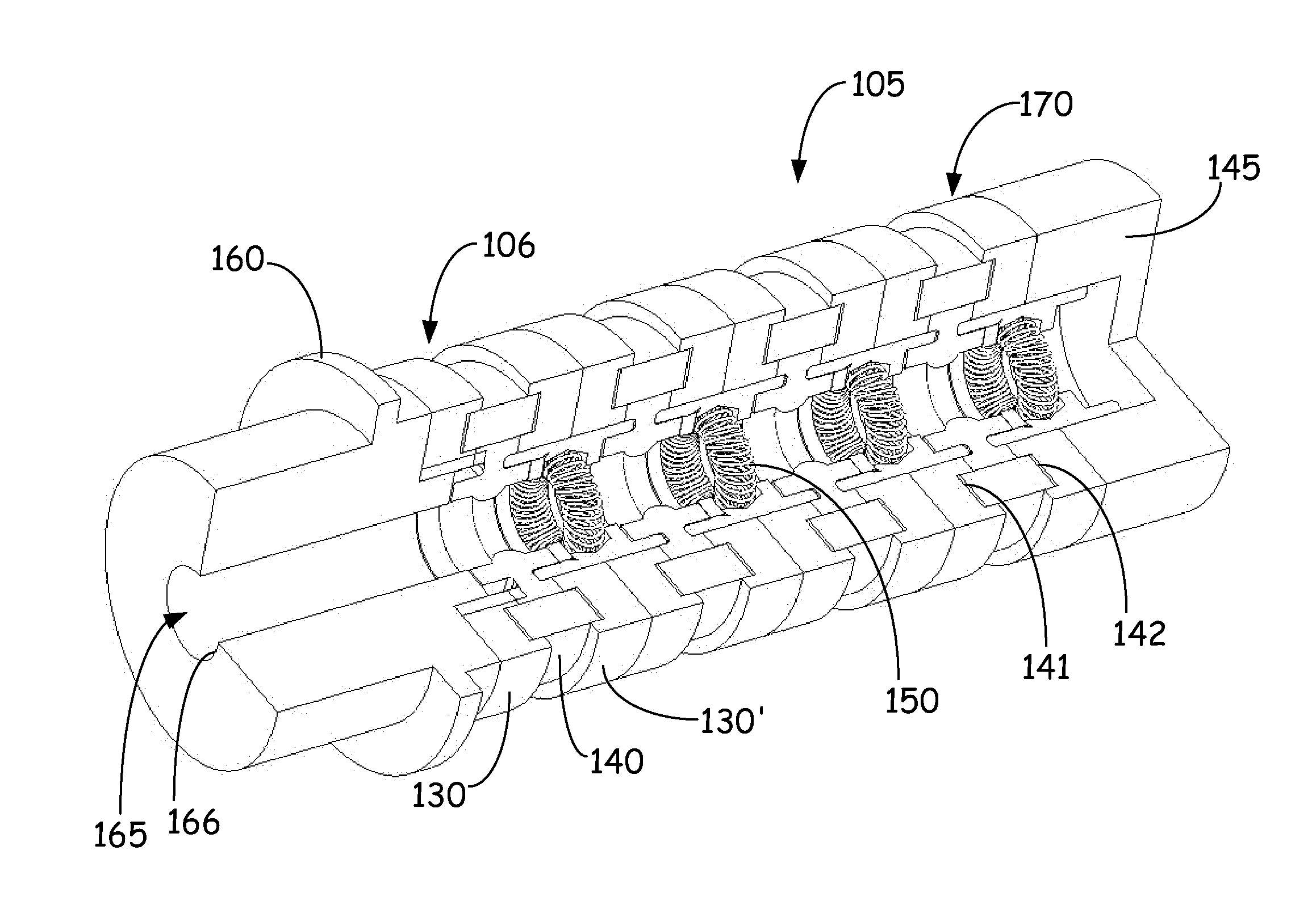

Flexible voltage nested battery module design

ActiveCN102057519ASafe and compact fuse designCurrent conducting connectionsSmall-sized cells cases/jacketsLithiumIsoetes triquetra

Exemplary embodiments of the present invention provide flexible, multi-voltage battery modules having multiple cells that are nested together. The cells can be, for example, cylindrical lithium ion cells. To increase cell package density, the cells can be disposed in a nested configuration so that adjacent cell centers form equilateral triangles. The cells can be placed in a housing or case with interlocking tabs that allow multiple modules to be connected together. Within a module, the cells can be connected in different configurations by buss bars at the top and the bottom of the battery cells. The different configurations may provide different voltages for the module.

Owner:A123 SYSTEMS LLC

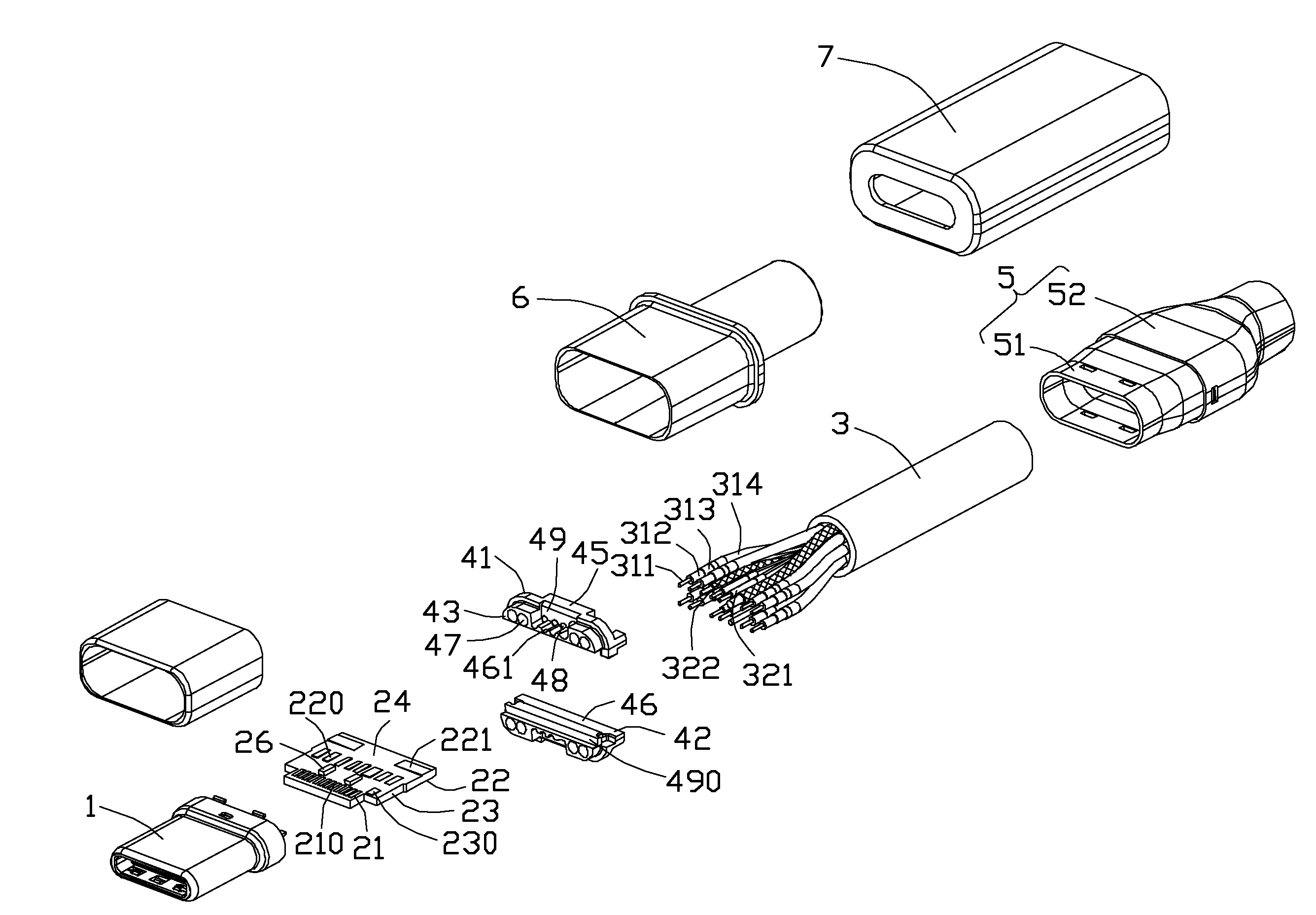

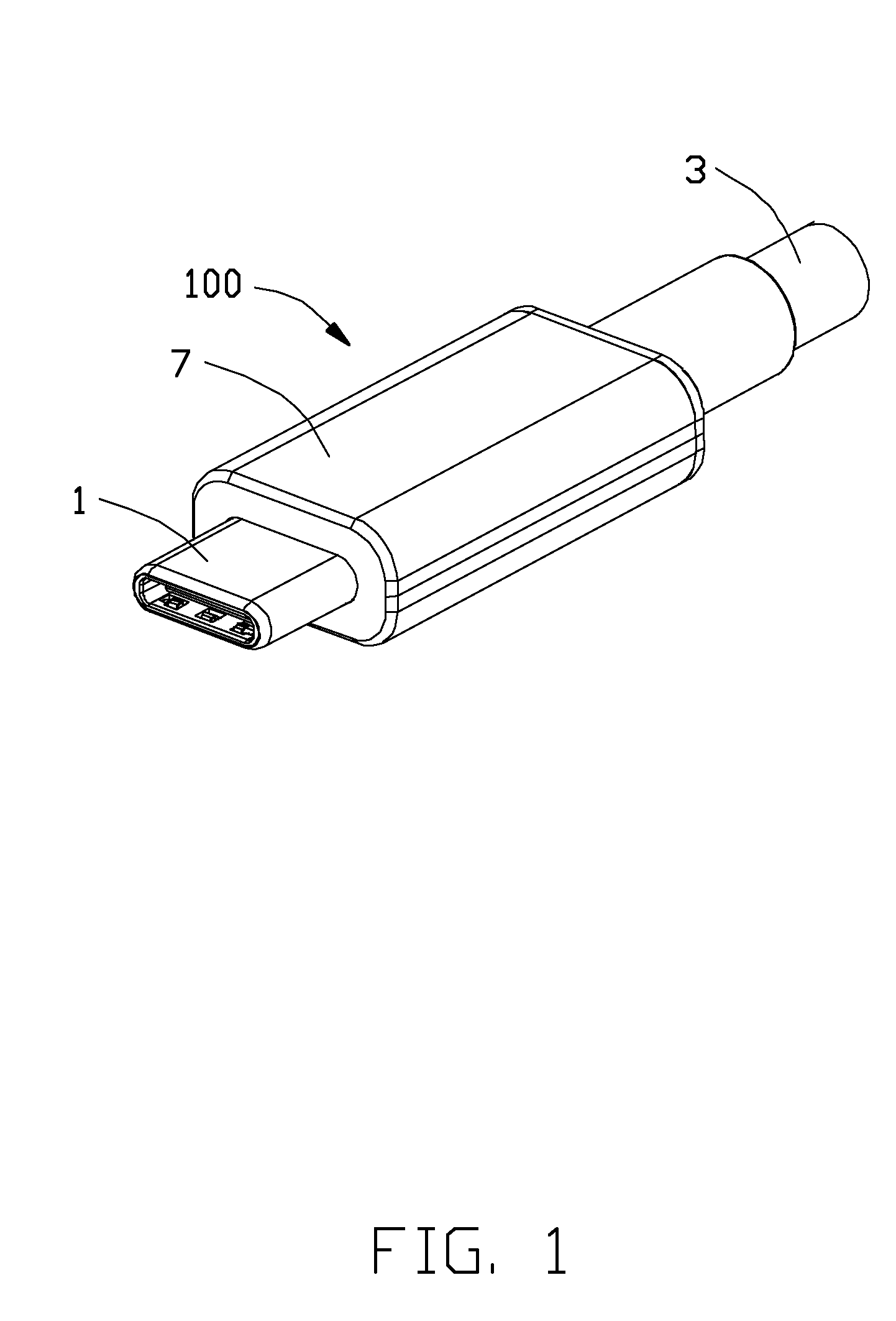

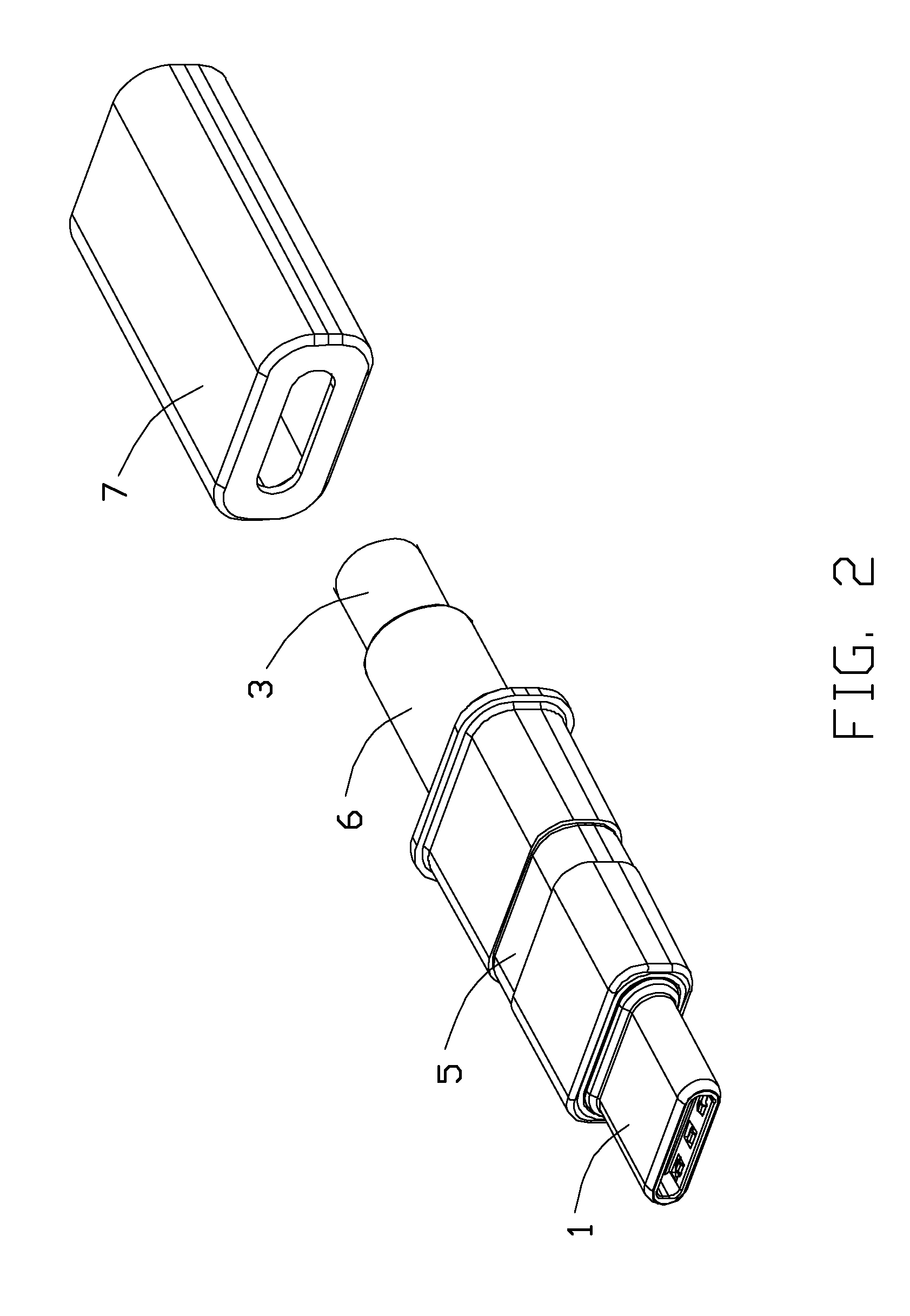

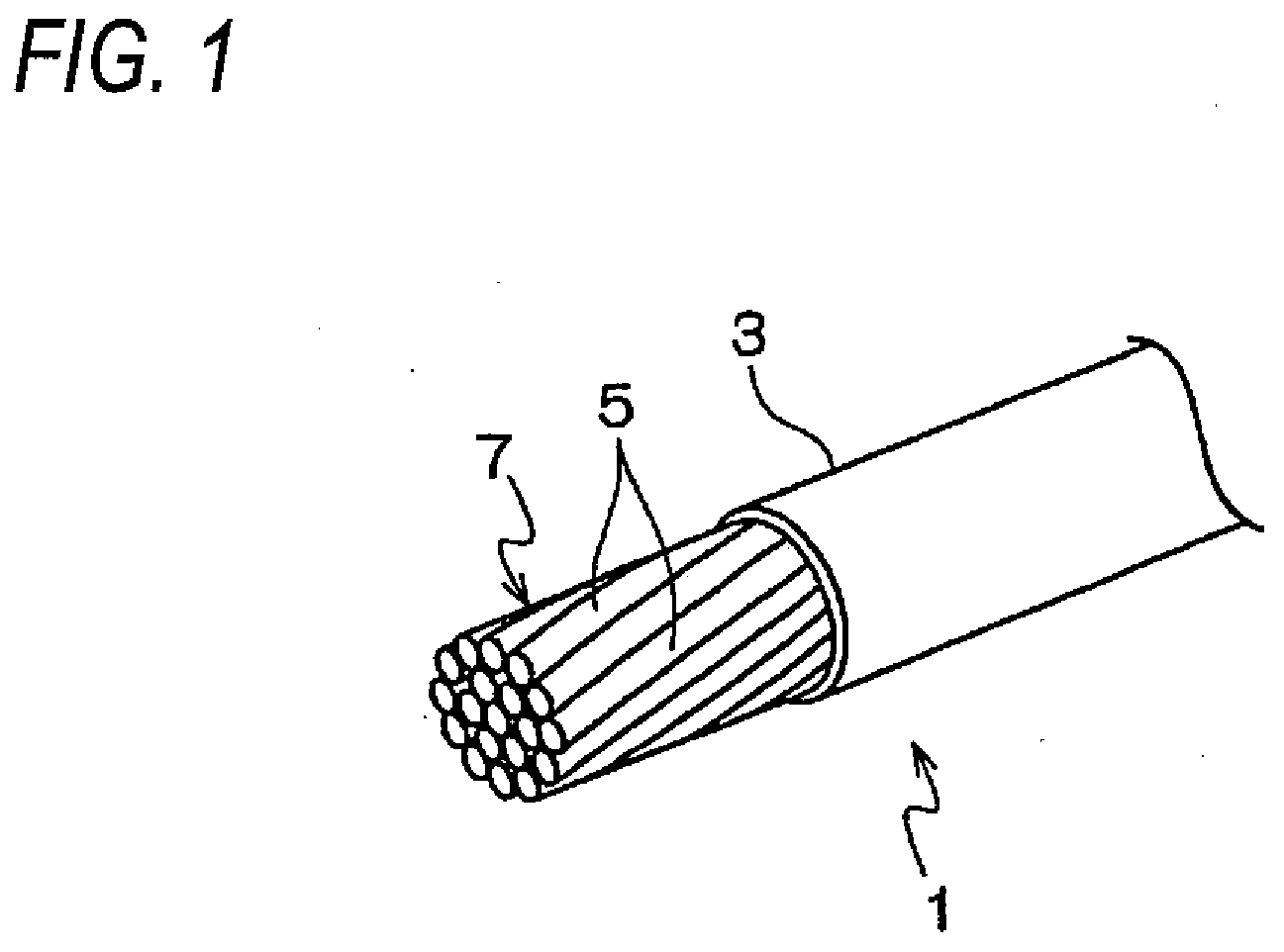

Cable connector assembly with cable wires made of heat-resisting material

ActiveUS20160079689A1Avoid damageAvoid wire damageLine/current collector detailsElectrically conductive connectionsElectrical conductorCoaxial line

A cable connector assembly includes a PCB defining some second conductive pads disposed on a rear end portion of the PCB and some third conductive pads disposed behind the second conductive pads, a cable defining a number of coaxial wires and single wires, and a housing. Each coaxial wire has a first inner conductor, an inner insulative layer enclosing the first inner conductor, a metal braided layer soldered to the corresponding third conductive pads, and an outer insulative layer. Part of the coaxial wires and single wires adjacent to the coaxial wires are disposed on at least one surface of the PCB. Each single wire has a second conductor, a first insulative layer, and a second insulative layer. The first insulative layer is made of heat-resisting material to prevent the adjacent single wires from being damaged when soldering the metal braided layer of the coaxial wires.

Owner:FOXCONN INTERCONNECT TECH LTD

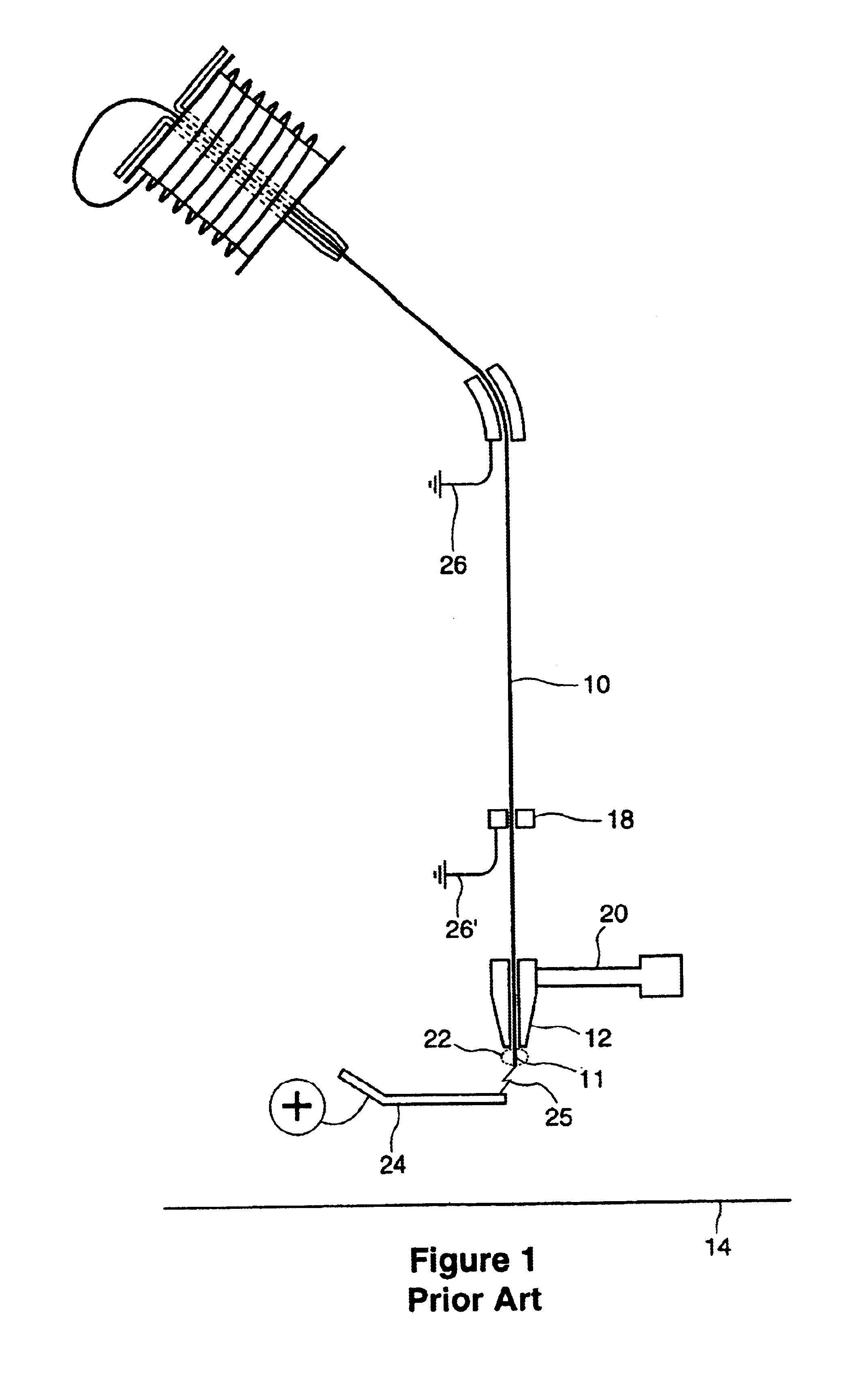

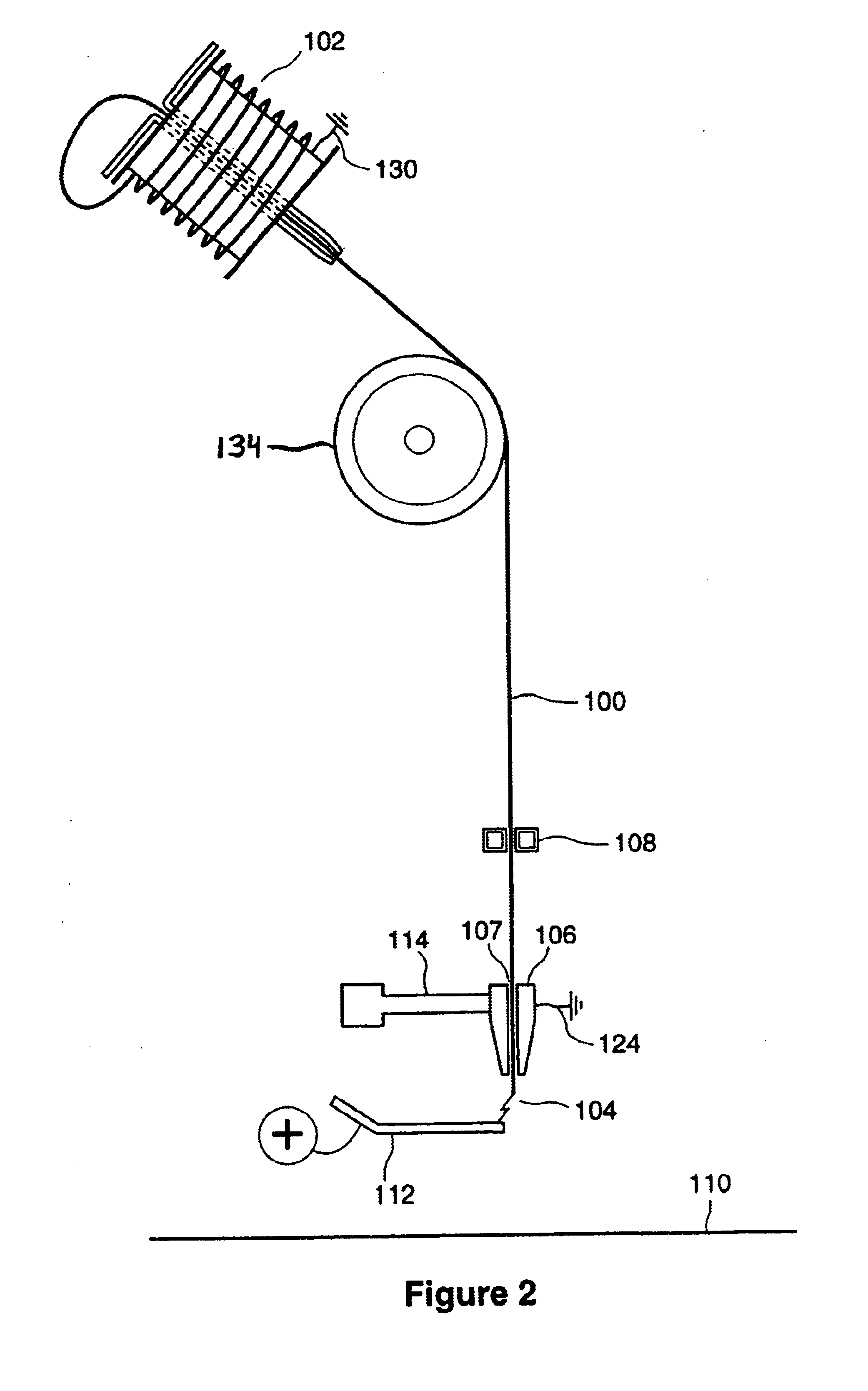

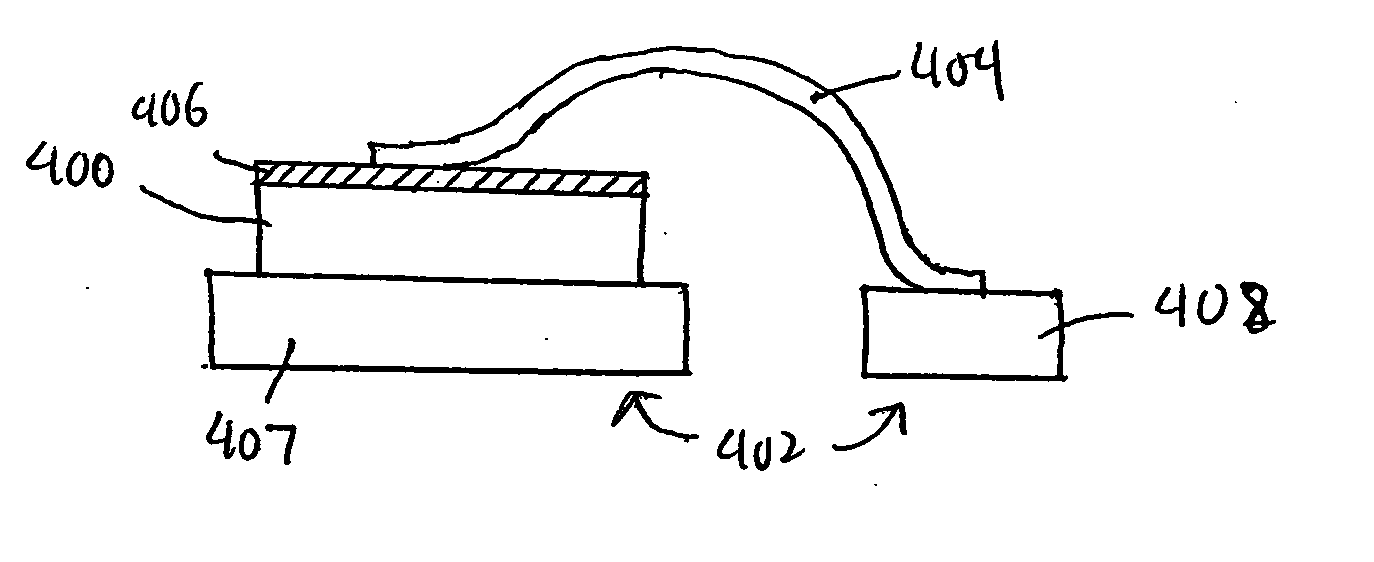

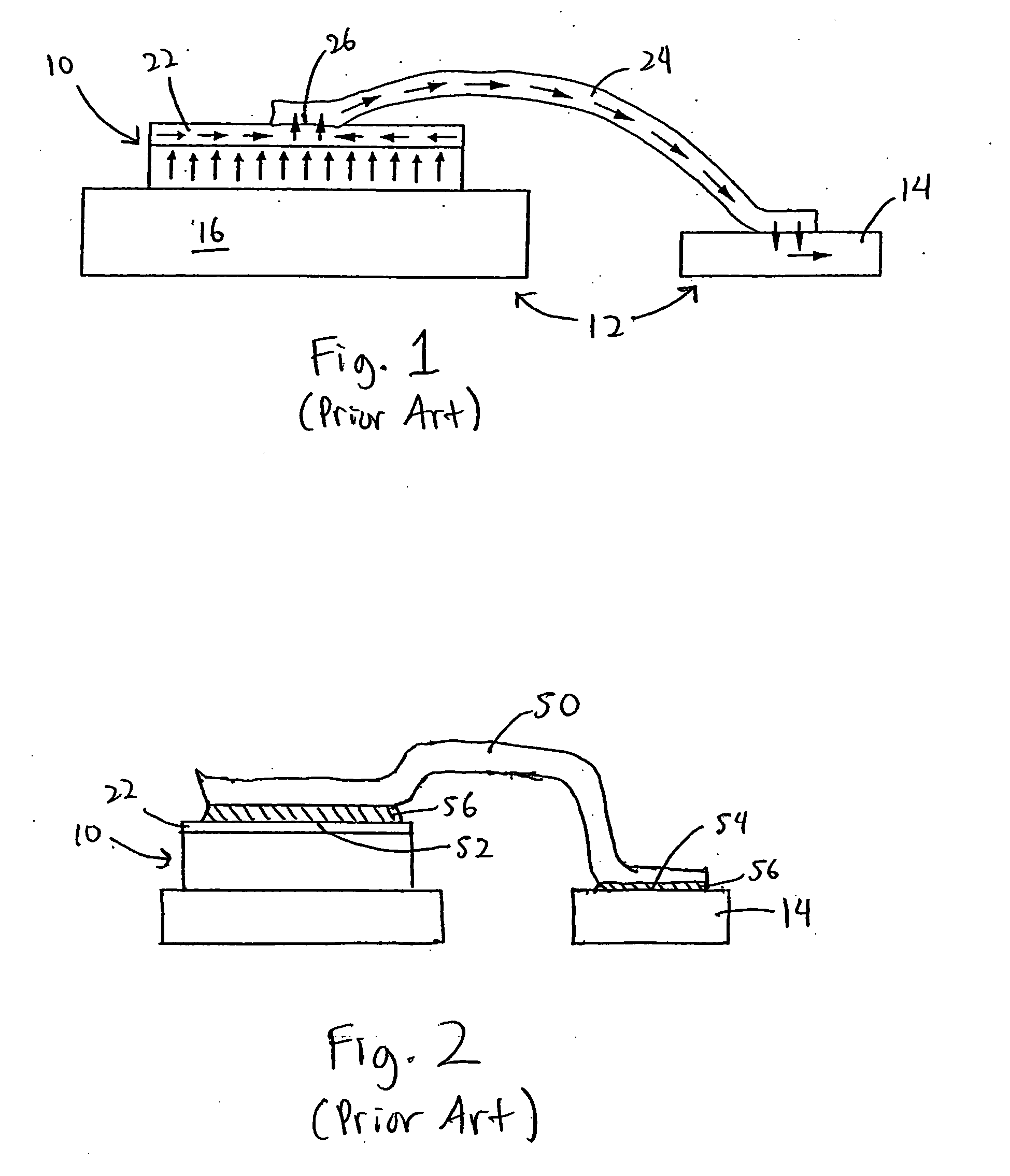

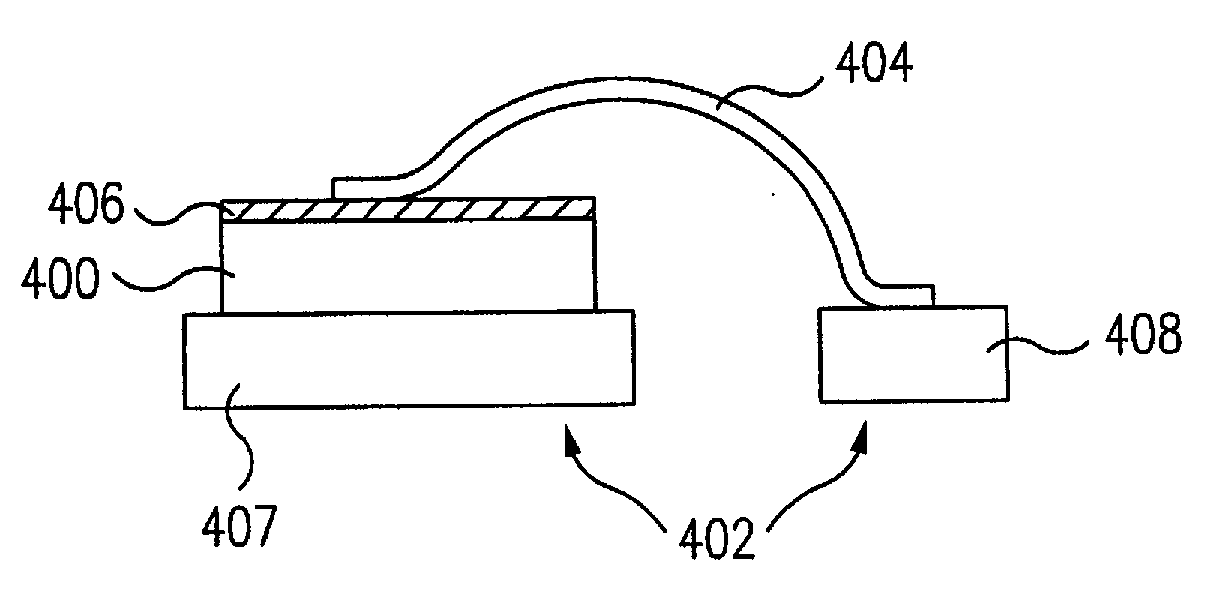

Wire bonder for ball bonding insulated wire and method of using same

InactiveUS6896170B2Easy to integrate into existing equipmentEasy to installSemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A wire bonder for bonding an insulated wire to a surface is disclosed. The bonder includes a bond head, having a bonding position adjacent to said surface and a wire preparation position spaced apart from the surface. There is a wire holder on the bond head, the wire holder being sized and shaped to permit a free end of the insulated wire to extend from the wire holder when the bond head is in the spaced apart position. A source of insulated wire for said bond head is provided as well as an electrical discharge wand positioned adjacent to said bond head when the bond head is in the spaced apart position. The wand directs sufficient electricity at the extending free end of the insulated wire to form a bond ball on the free end. A ground associated with the insulated wire, is provided the ground being sized and positioned to conduct electrical energy away from the insulated bond wire to prevent the insulation on the bond wire remote from the free end from being damaged.

Owner:MICROBONDS INC

Automatic soldering machine

InactiveUS8517245B1Solve low manufacturing efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMan machineEngineering

An automatic soldering machine adapted for soldering cables with electronic products includes a main frame module, a man-machine control interface, a sliding tray located in front of the man-machine control interface, a loading tool slidably disposed in the sliding tray, a feeding module close to a bottom of the sliding tray, a removing module located between the man-machine control interface and a reforming module, a container, a loading tool combination module located above the sliding tray, a spraying module located in rear of the sliding tray, and a loading tool reflow module mounted on a rear of the main frame module. The man-machine control interface is connected with and controls the loading tool, the feeding module, the removing module, the reforming module, the loading tool combination module, the spraying module and the loading tool reflow module for realizing an automatic soldering process of the electronic products and the cables.

Owner:CHENG UEI PRECISION IND CO LTD

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20050115936A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserLaser processing

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:GSI LUMONICS CORP

Soldering apparatus and soldering method

InactiveUS7845541B1Simplify the welding processImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectronic componentSolder paste

A soldering apparatus has a fixture receiving an electronic component and a conducting wire, with a free end of the conducting wire superimposed on the soldering area of the electronic component, a convey mechanism capable of transmitting the fixture downstream, a daubing device, and a soldering device. The daubing device has a level movable element capable of moving along a convey direction of the convey mechanism, and a vertical movable element mounted on the level movable element and capable of moving along an upward and downward direction. A carrier mounted to the vertical movable element has a solder paste can for loading the solder paste, and an output portion for dispensing the solder paste to the soldering area. The soldering device has a soldering head heating the solder paste for shrinking the insulator, with the core wire exposing and connected to the soldering area by the cool solder paste.

Owner:CHENG UEI PRECISION IND CO LTD

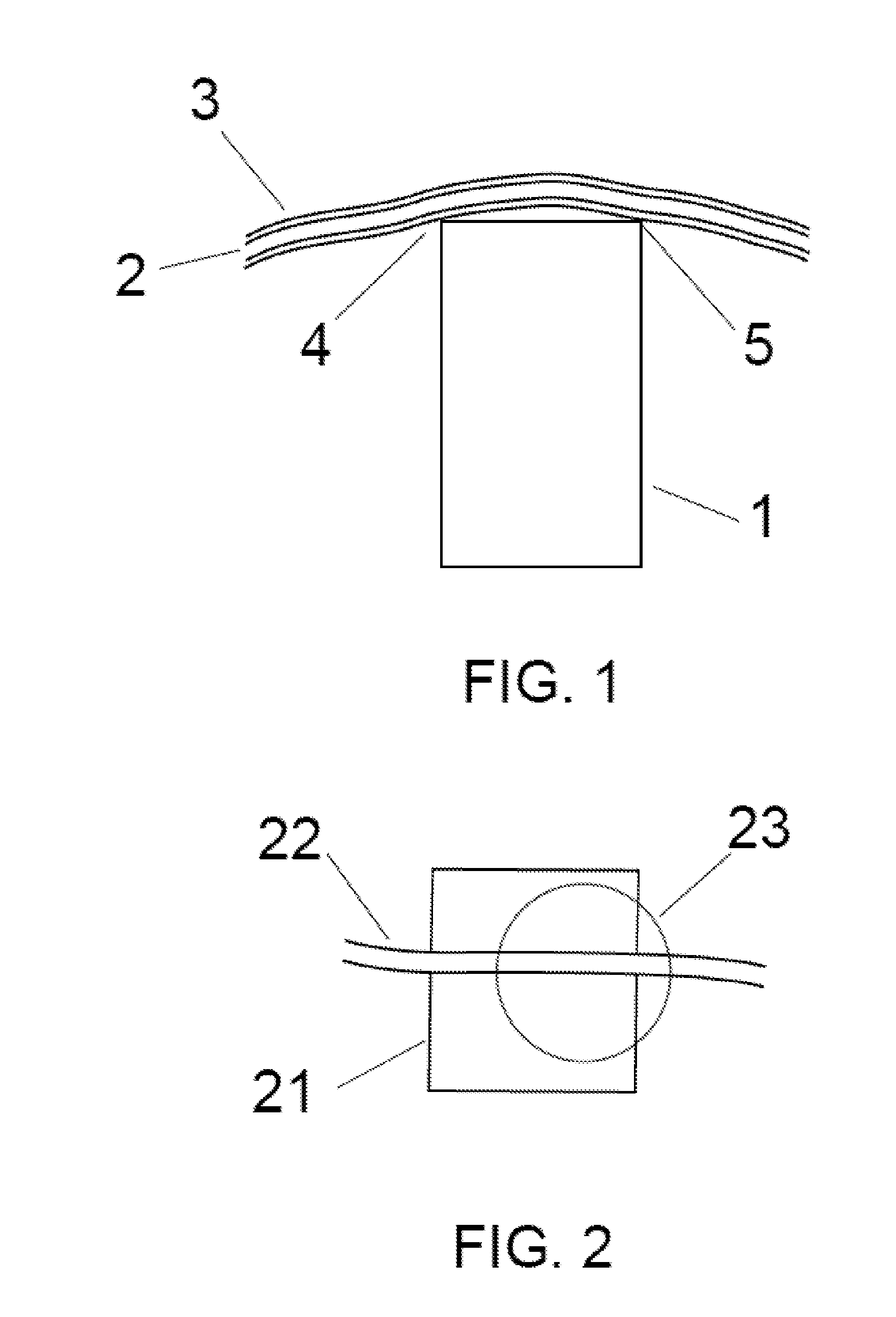

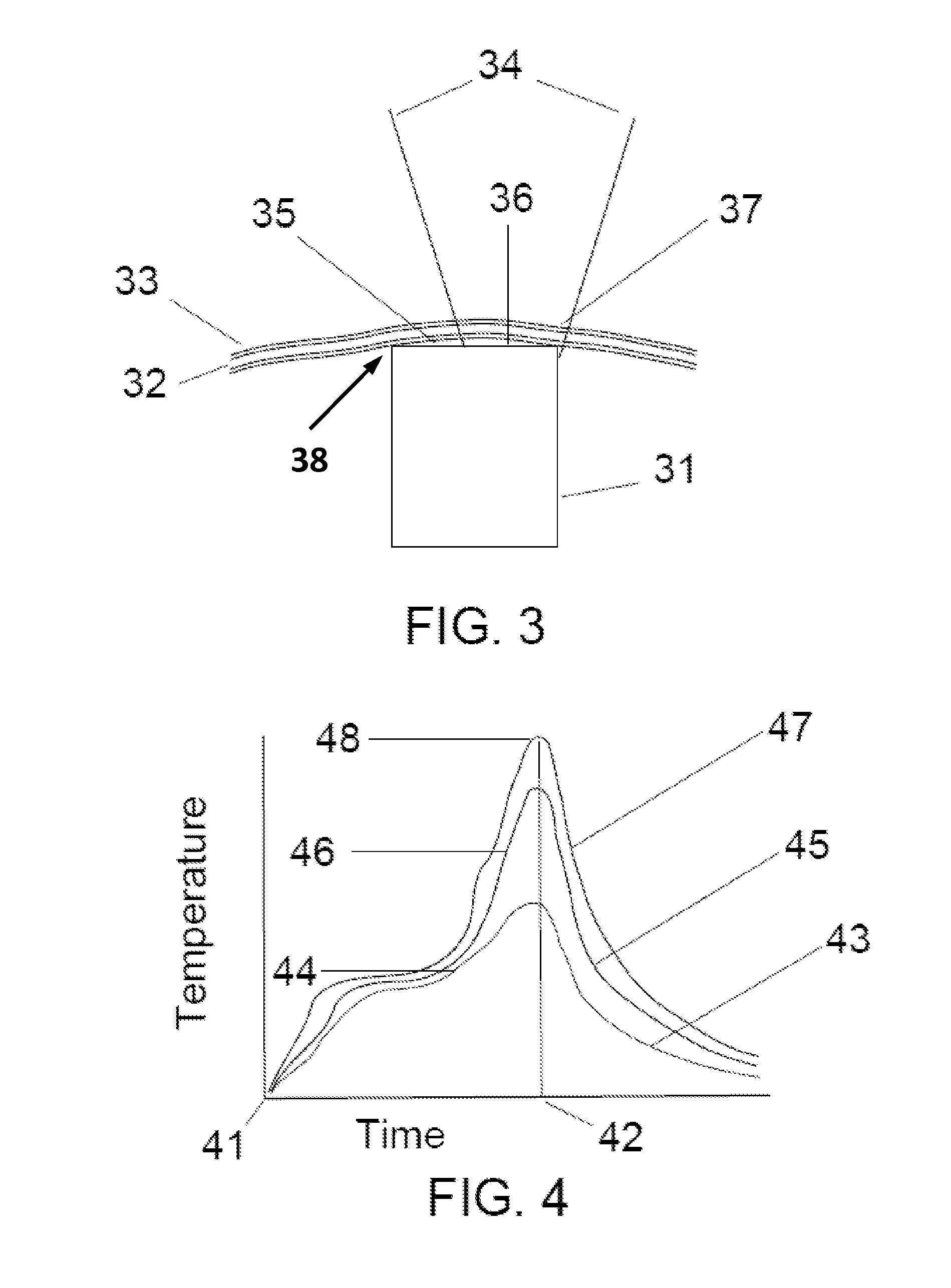

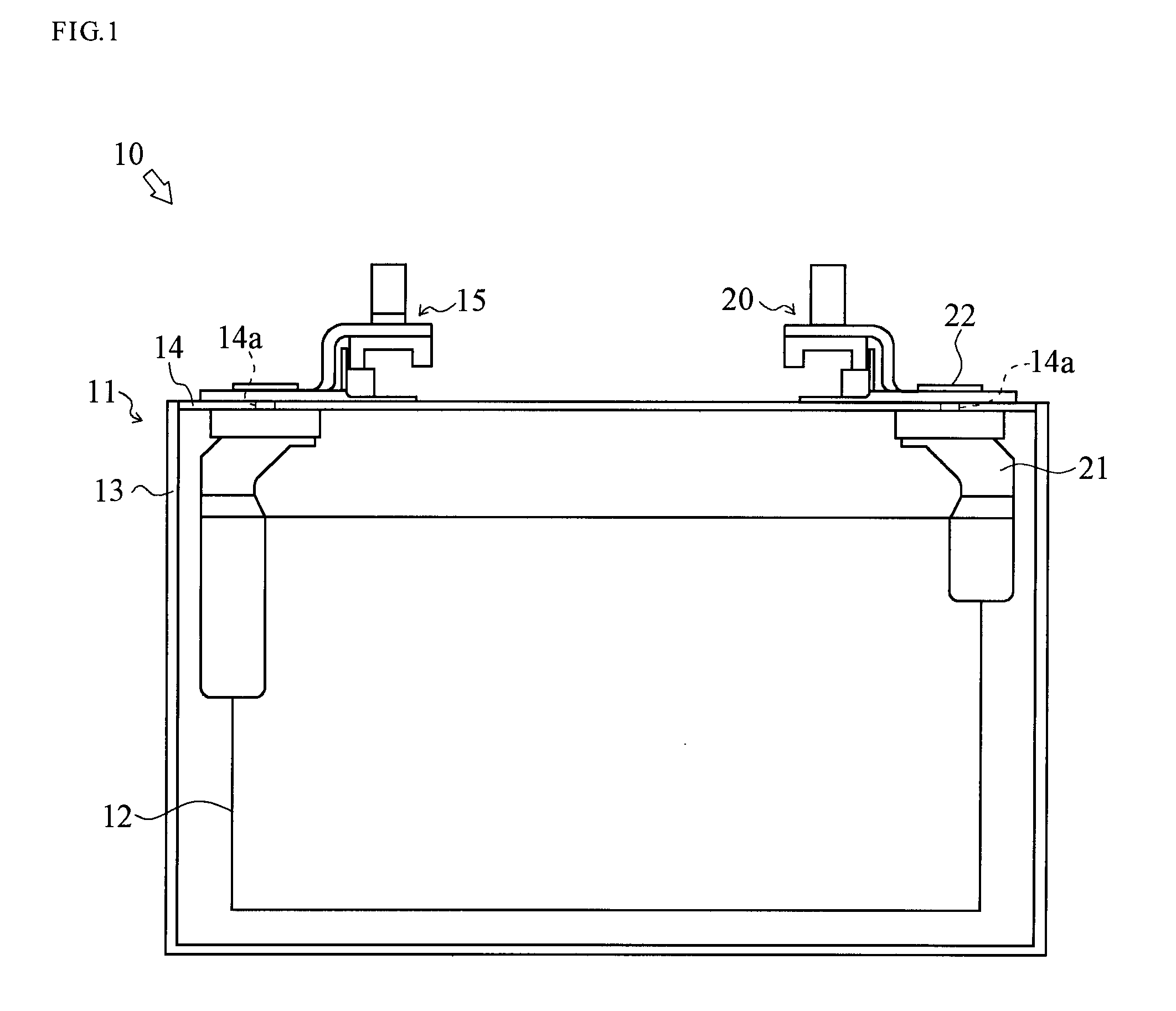

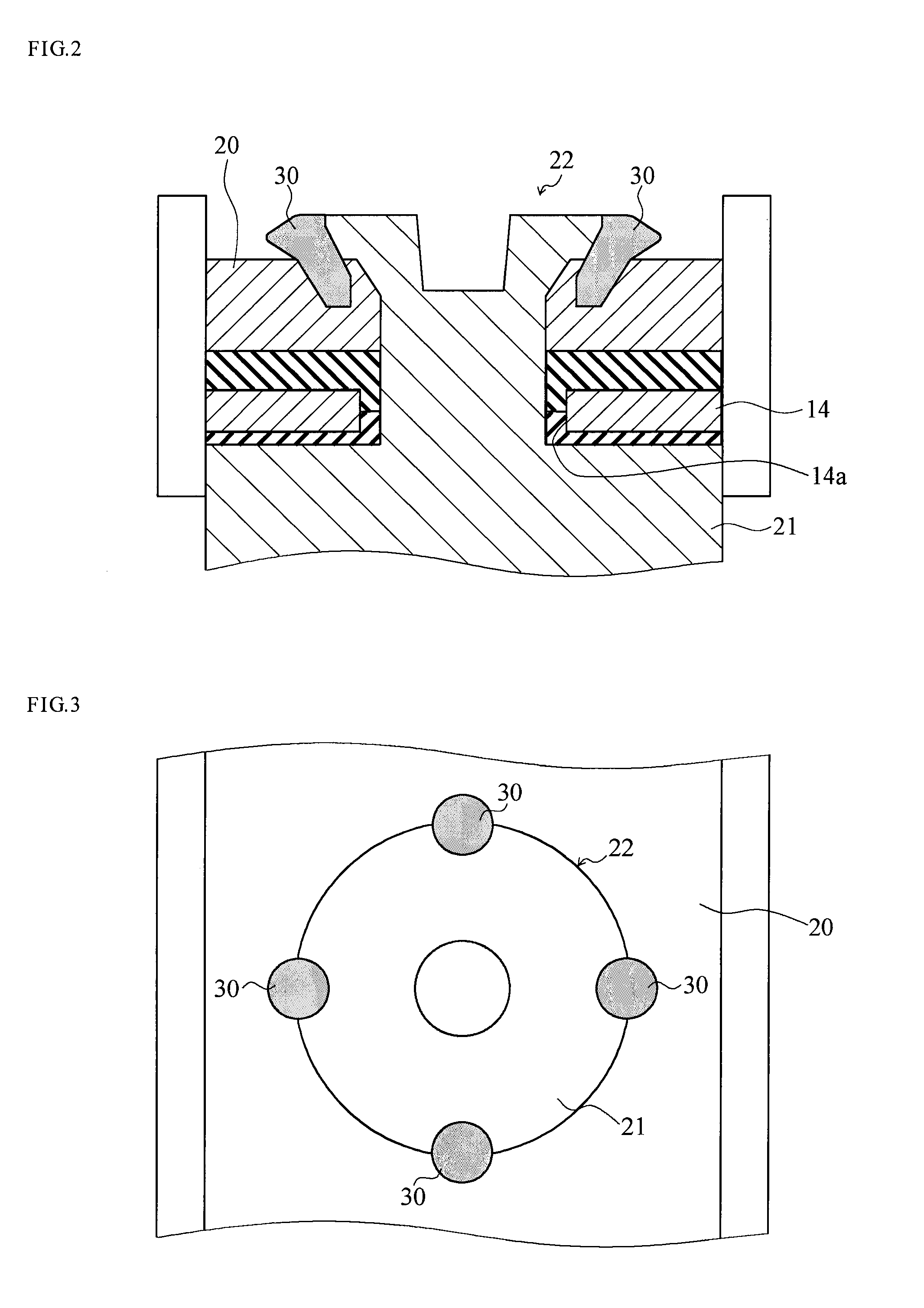

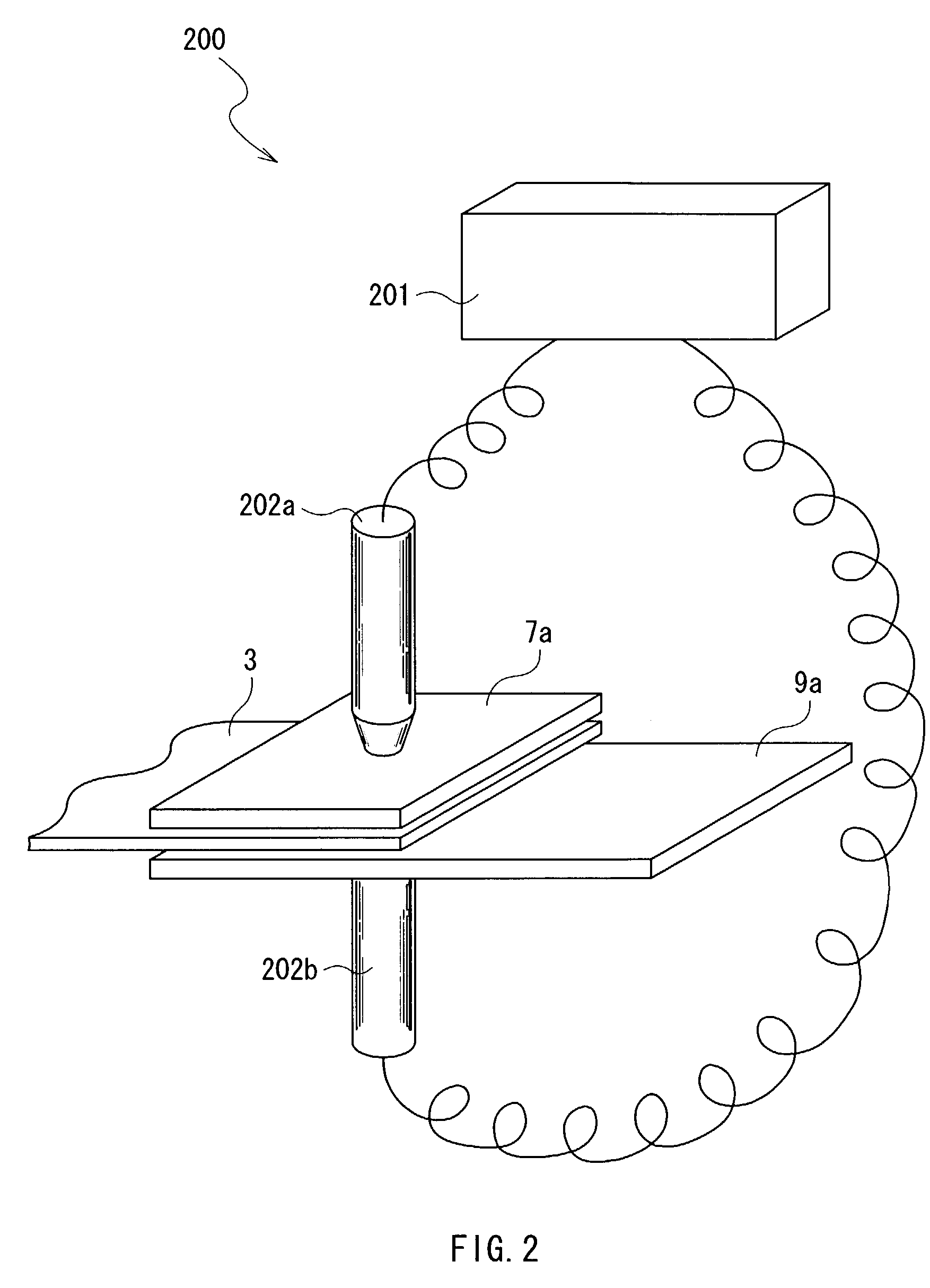

Method of laser-welding and method of manufacturing battery including the same

InactiveUS20120055909A1Final product manufactureSmall-sized cells cases/jacketsLaser processingLaser light

Provided is a method of laser-welding that can achieve uniform welding of a member with large laser reflectance on a surface thereof A laser welding step (S1) includes a surface roughening step (S11) in which a first laser processing device irradiates laser light to a surface (each welding portion (31)) of a welding section (30, 30, 30, 30) between a negative electrode terminal (20) (a first member) and a negative electrode lead (21) (a second member) and carries out roughening, thereby forming a laser marker (32) on the surface; and a welding step (S12) in which a second laser processing device irradiates laser light to each welding portion (31) roughened in the surface roughening step (S11) and melts each welding portion (31), thereby carrying out the laser-welding of the negative electrode terminal (20) to the negative electrode lead (21).

Owner:TOYOTA JIDOSHA KK

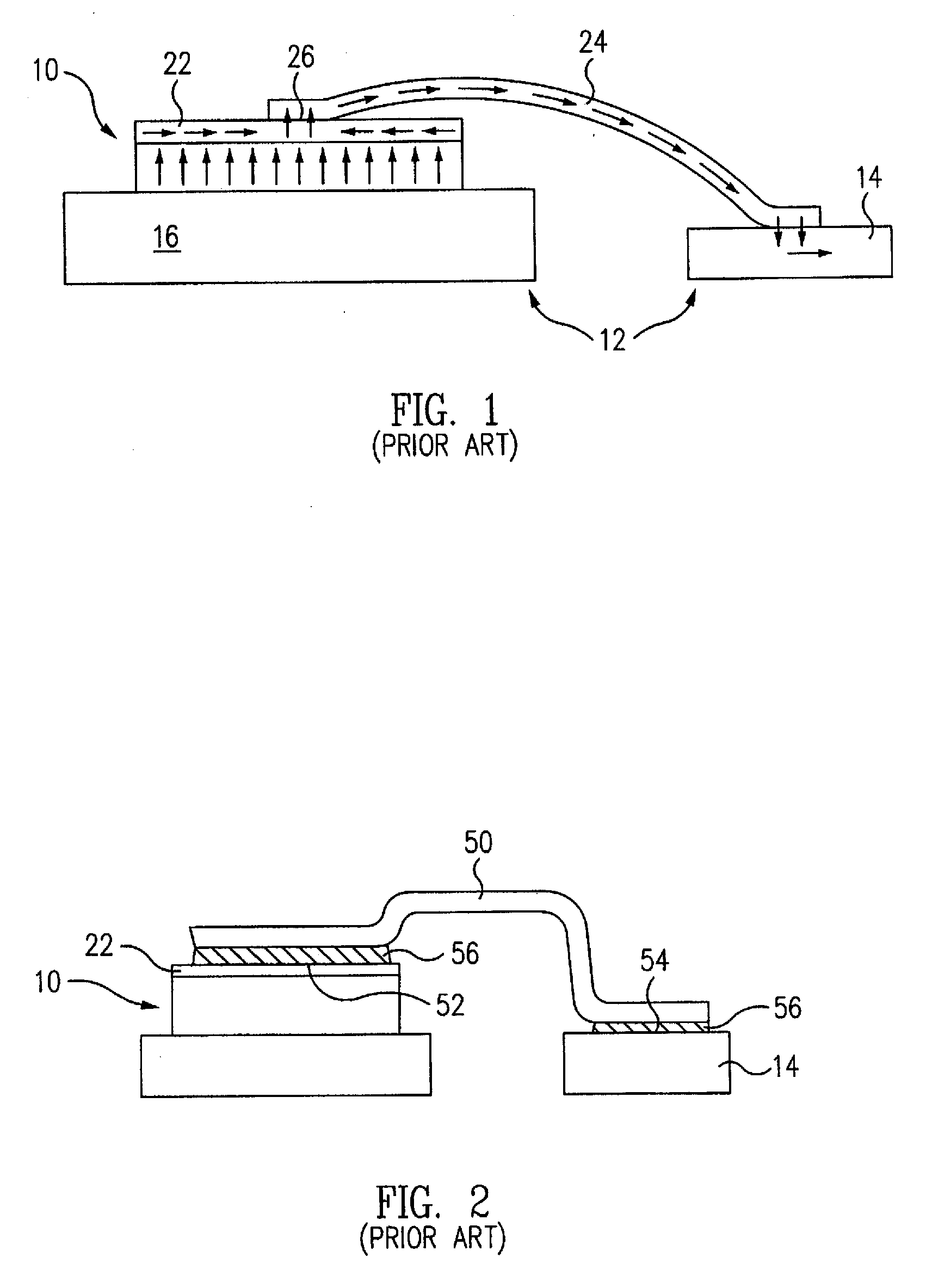

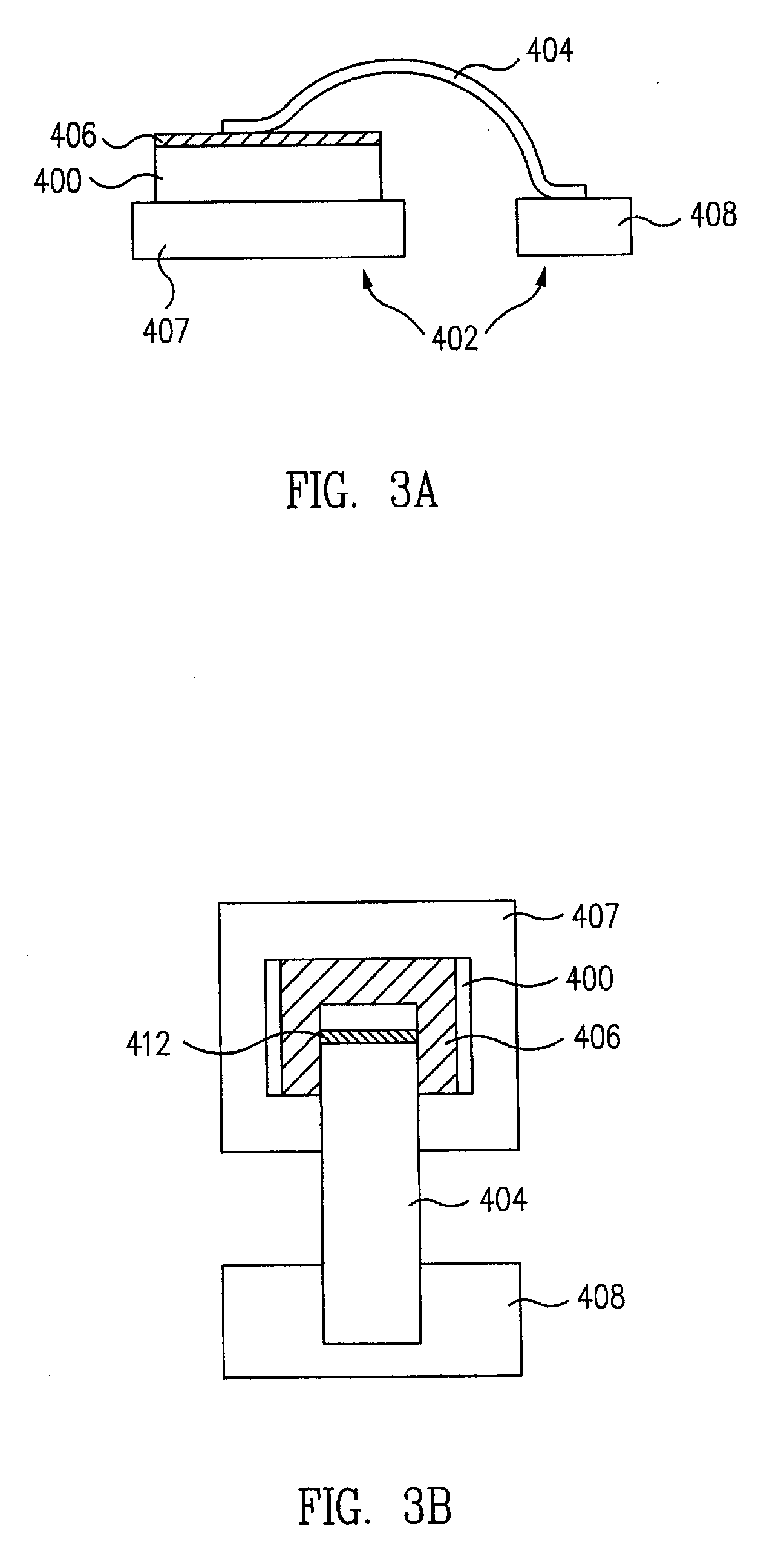

Ribbon bonding in an electronic package

InactiveUS20050269694A1Increase the areaIncrease the sectionSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceEngineering

A flexible conductive ribbon is ultrasonically bonded to the surface of a die and terminals from a lead frame of a package. Multiple ribbons and / or multiple bonded areas provide various benefits, such as high current capability, reduced spreading resistance, reliable bonds due to large contact areas, lower cost and higher throughput due to less areas to bond and test.

Owner:LUECHINGER CHRISTOPH B

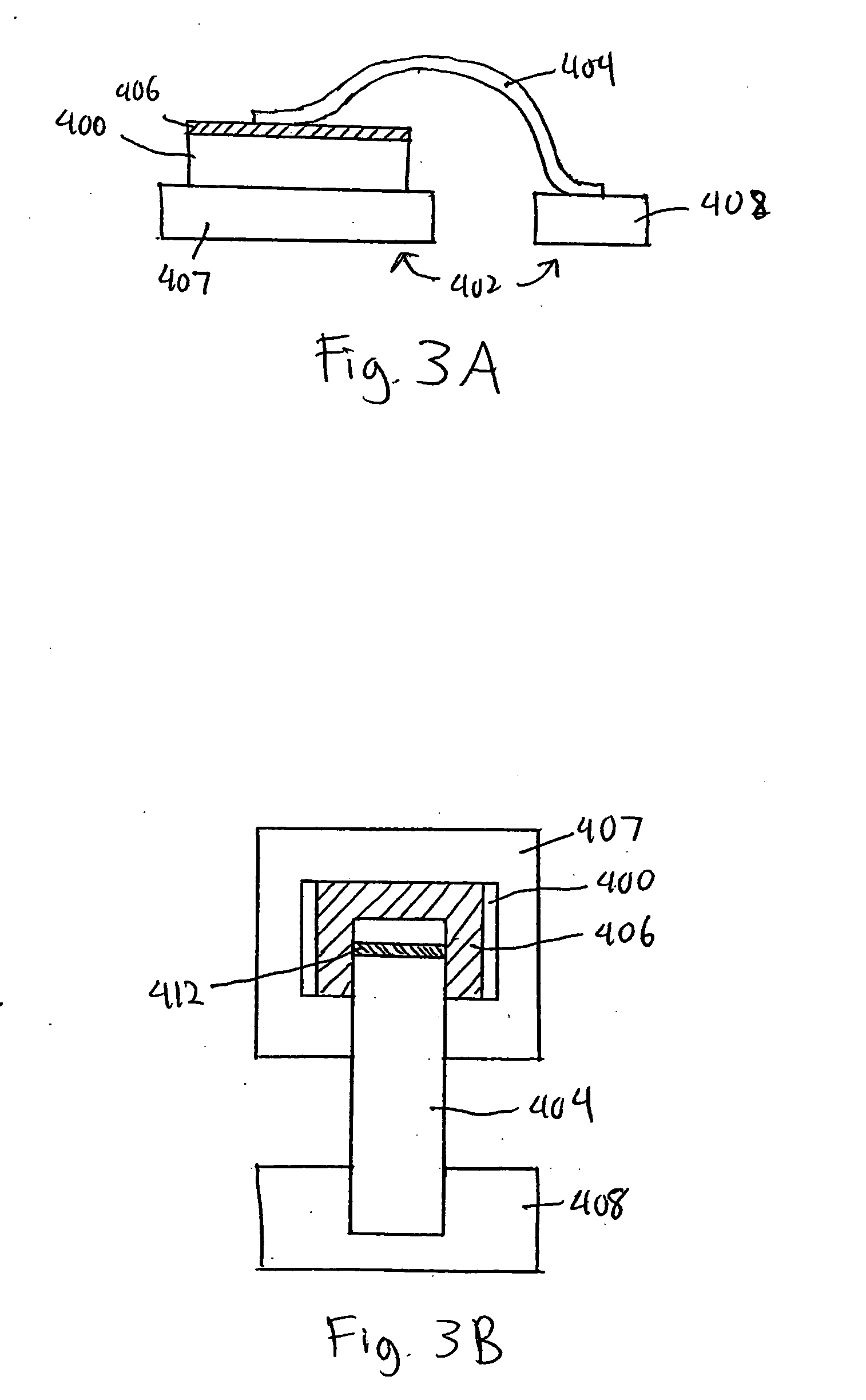

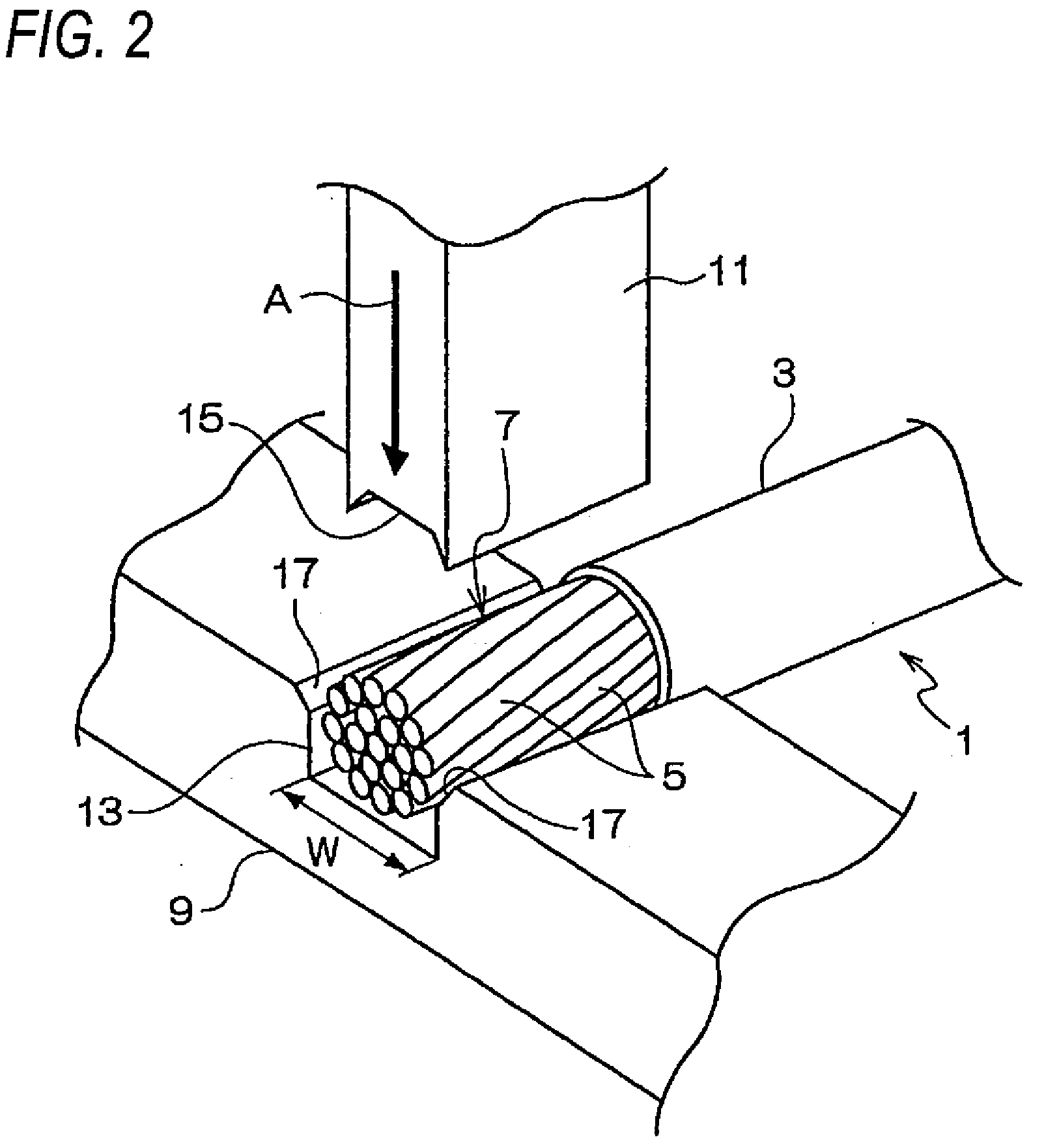

Ultrasonic bonding method of electric wire

ActiveUS20110062218A1Thin thicknessSwelling can be suppressedElectrically conductive connectionsSoldering apparatusElectrical conductorEngineering

In an ultrasonic bonding method of an electric wire in which the electric wire 1 in which a conductor end 7 made of plural core wires is exposed and a metallic connection terminal 19 formed by erecting two side walls 27 from a bottom surface are prepared and the conductor end is bonded to the connection terminal by applying ultrasonic vibration while the conductor end of the electric wire is positioned in the bottom surface between the two side walls of the connection terminal and is pushed, a cross section of the conductor end of the electric wire is made by being molded by press so that a thickness of a width direction between the side walls becomes thin toward at least one of the side positioned in the bottom surface of the connection terminal and the side to which the ultrasonic vibration is applied.

Owner:YAZAKI CORP

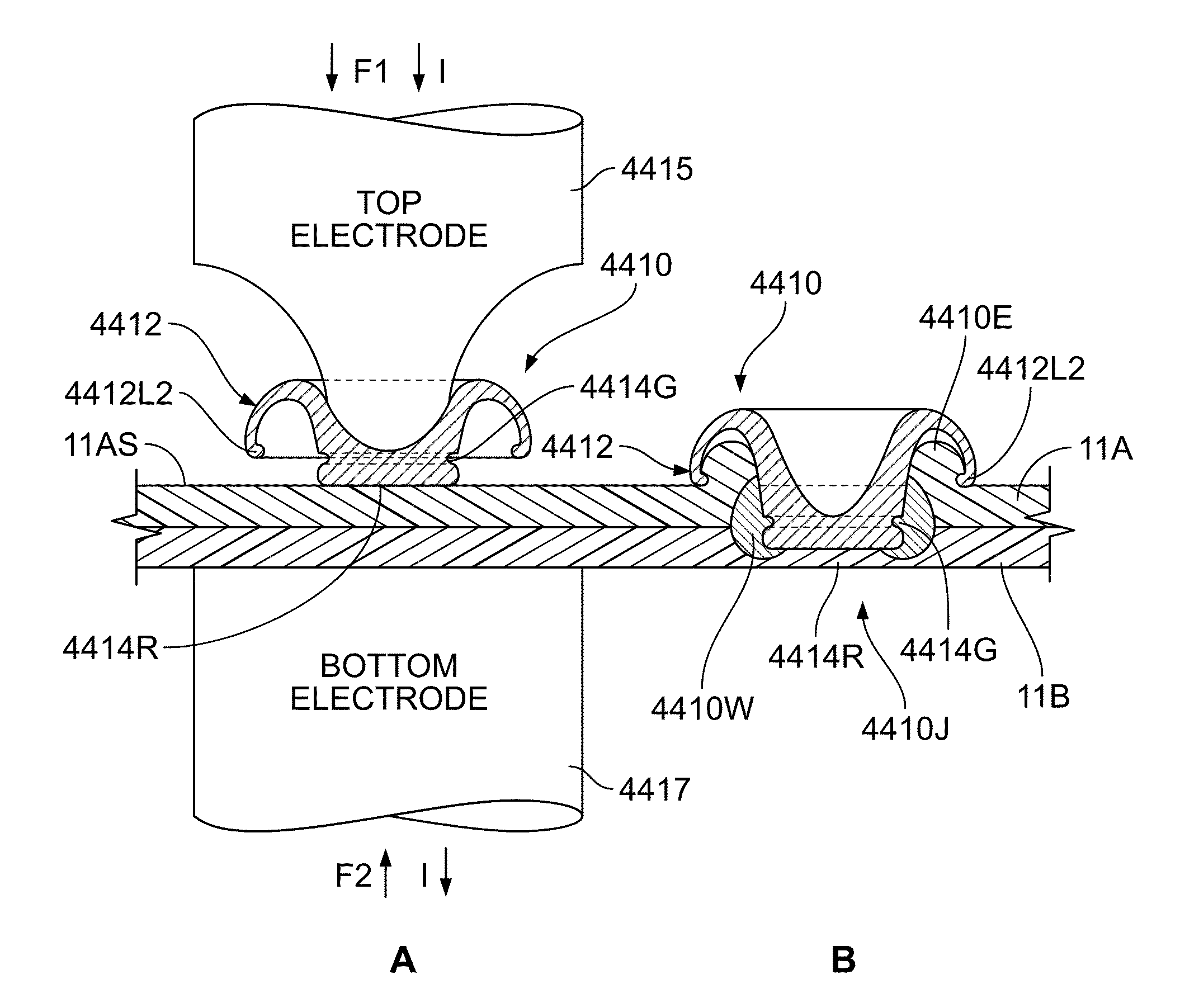

Resistance welding fastener, apparatus and methods for joining similar and dissimilar materials

ActiveUS20160167158A1Improve the immunitySheet joiningWelding/cutting media/materialsConductive materialsAlloy

An apparatus and method for fastening layers of non-ferrous alloys, like aluminum, magnesium and copper utilizes a steel fastener and a spot welding machine. The fastener and metals are stacked and the heat from the welder's electric current softens the lower melting point aluminum allowing the fastener to penetrate the aluminum. A weld zone between the fastener and the various layers creates an internal weld. The fastener has a rough shaft that is coated by the molten weld zone and is hard to withdraw on solidification. Layers of non-conductive materials like plastics and ceramics may also be affixed to a conductive layer using a fastener made from a compatible material that extends through a pilot hole and welds to or penetrates a conductive layer. The fastener may have projections that initially reduce contact area with the stack.

Owner:HOWMET AEROSPACE INC

Cell, cell production method, welded article production method and pedestal

InactiveUS7037621B2Easy to weldImprove reliabilityFinal product manufactureActive material electrodesLithiumElectrical resistance and conductance

Owner:MURATA MFG CO LTD

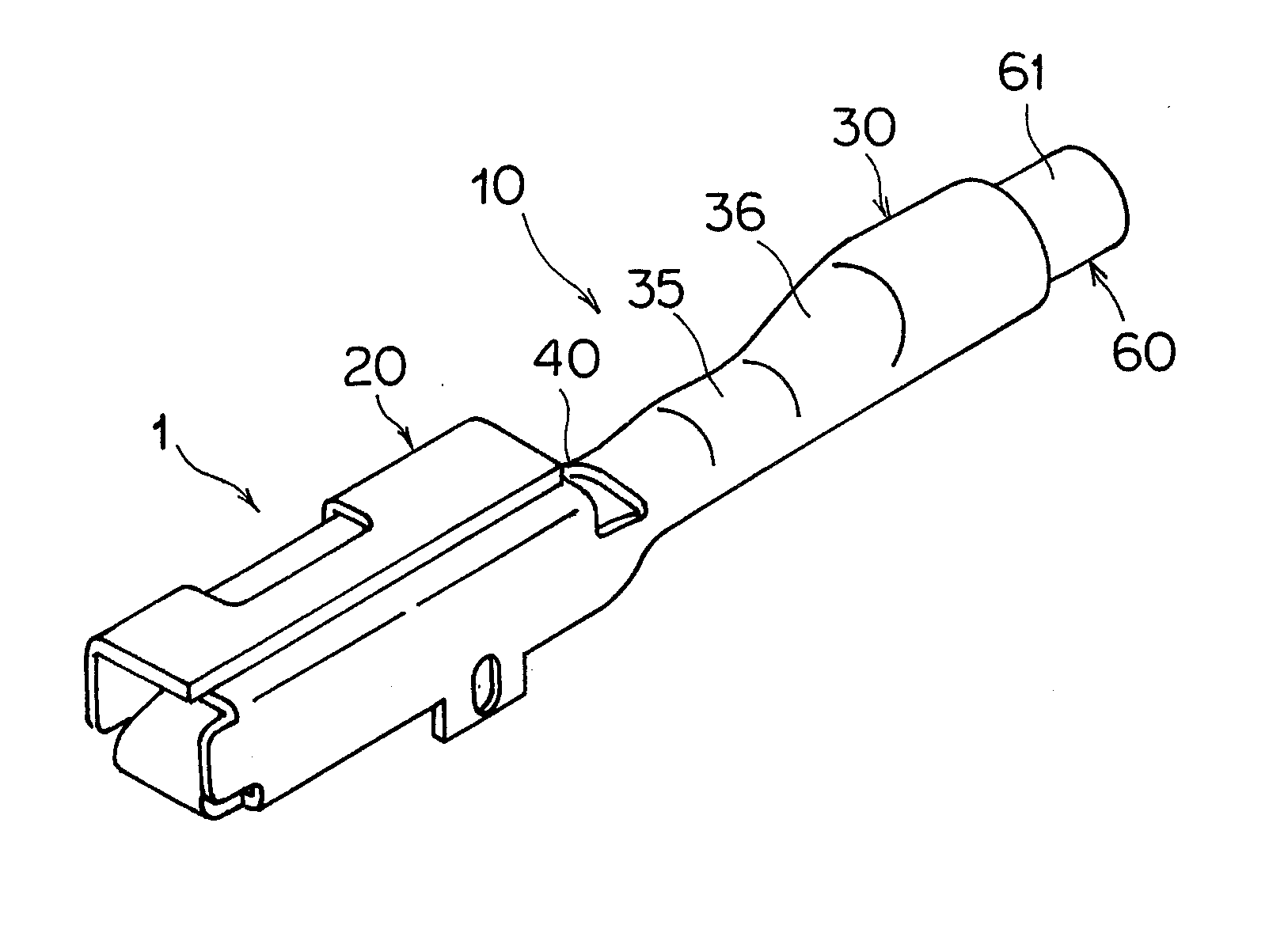

Terminal, Method of Manufacturing Terminal, and Termination Connection Structure of Electric Wire

ActiveUS20140273667A1Improve anti-corrosion performanceLow costContact member manufacturingConnections effected by permanent deformationMetallic substrateElectric wire

A terminal includes a tubular crimp portion that crimp connects with an electric wire. The tubular crimp portion is composed of a metal member. The tubular crimp portion includes a non-weld portion and a weld portion, the weld portion being formed by welding. A metal base material constituting the metal member of the non-weld portion includes a normal portion and an annealed portion.

Owner:FURUKAWA ELECTRIC CO LTD +1

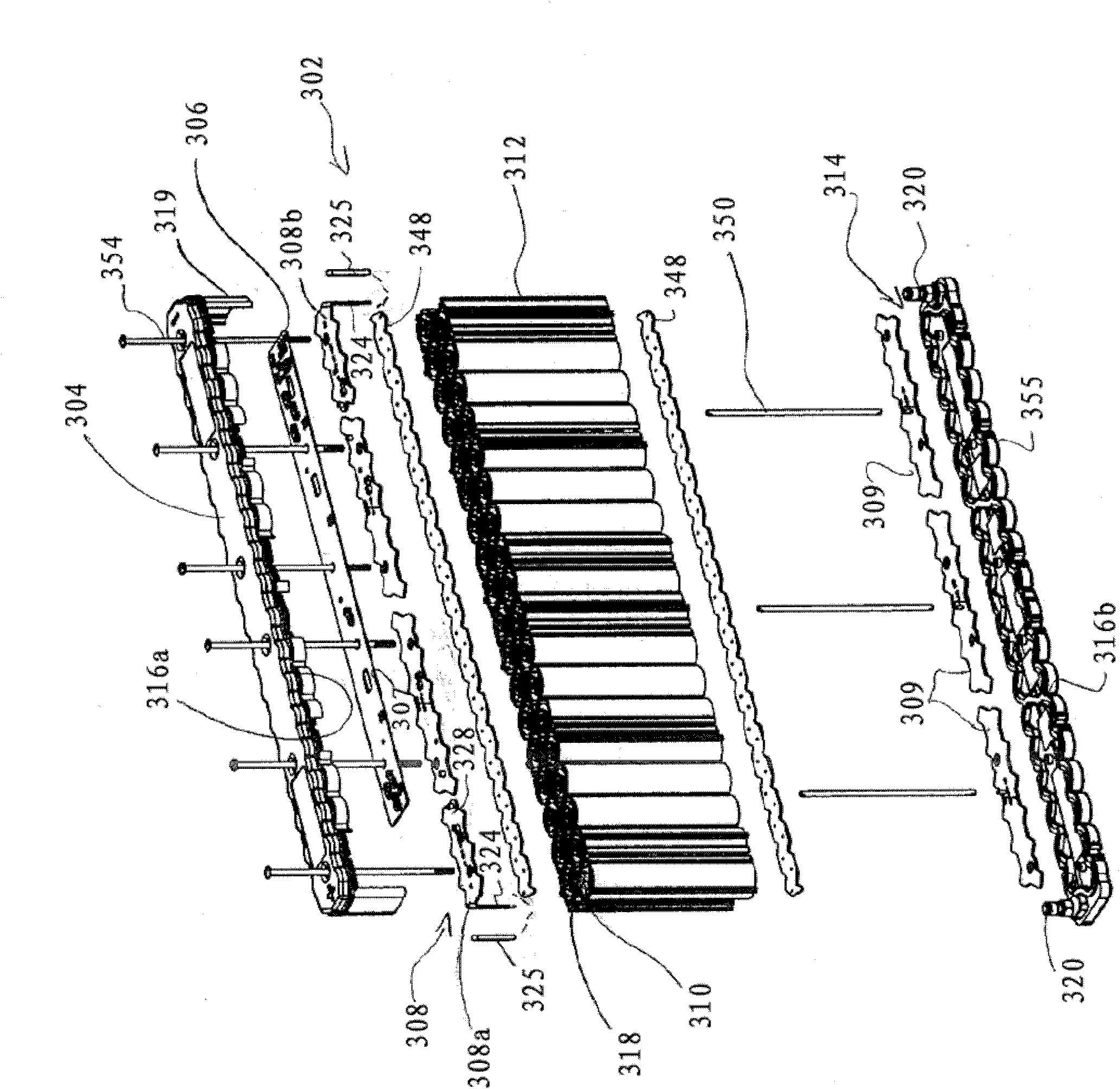

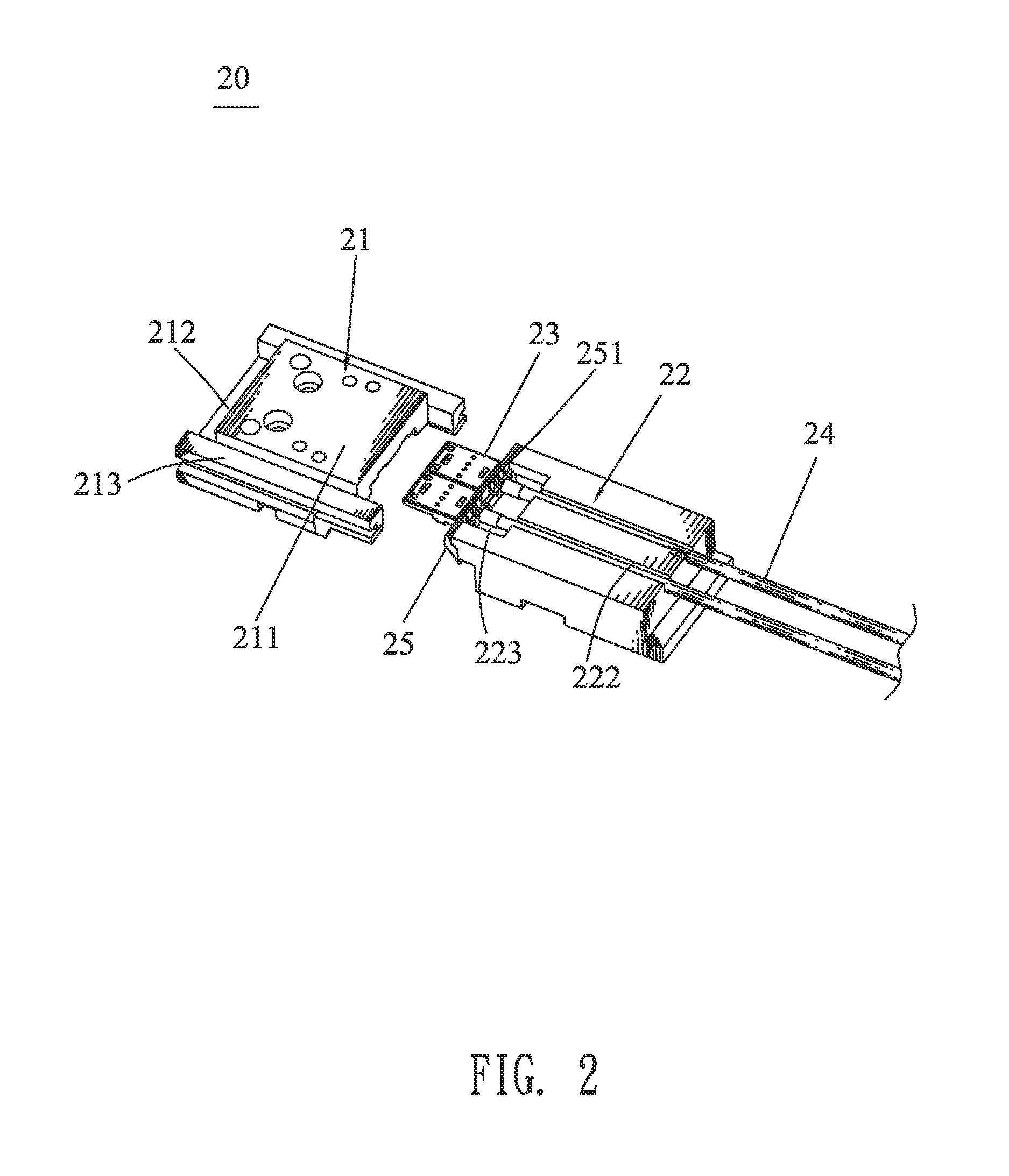

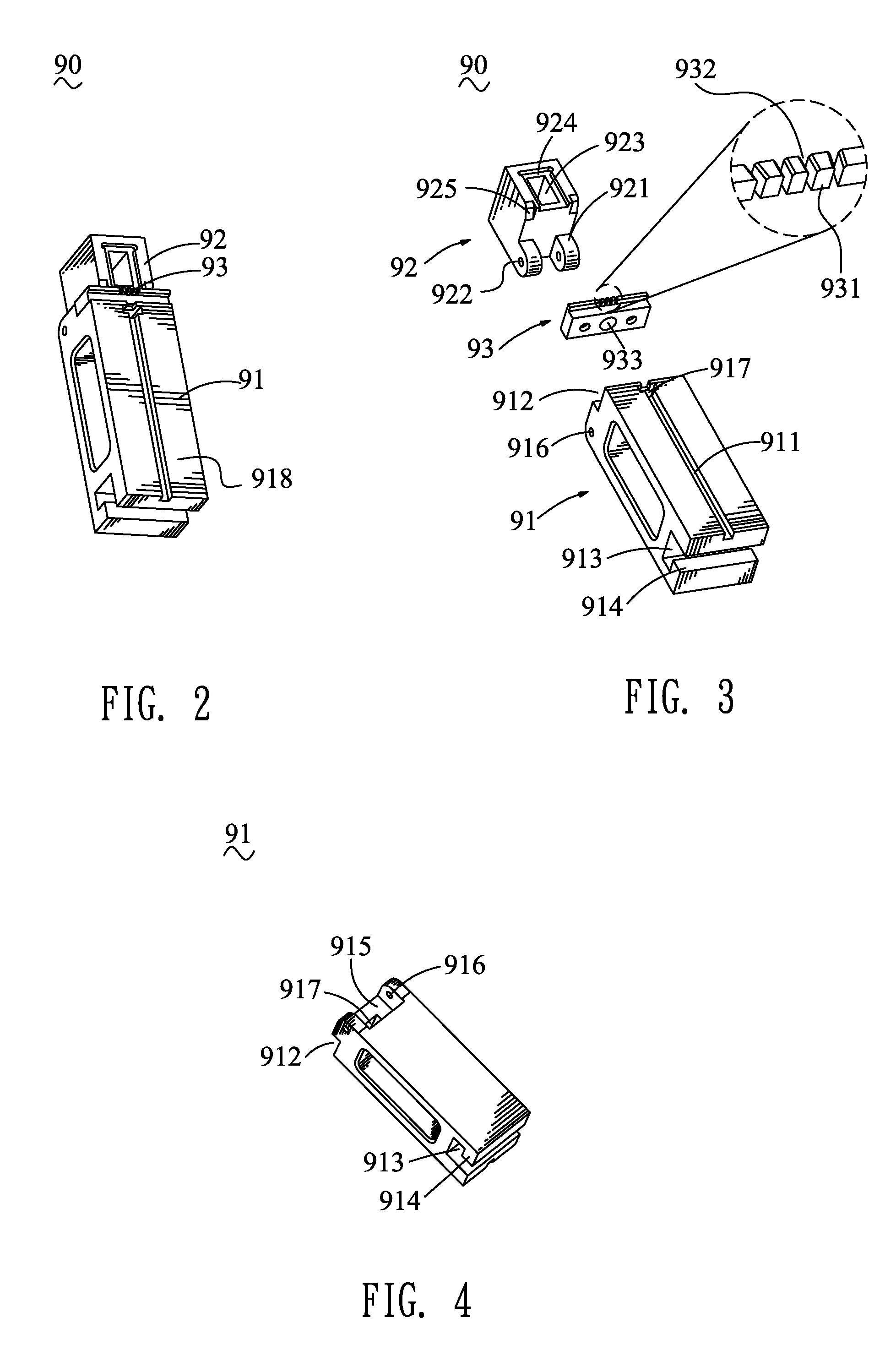

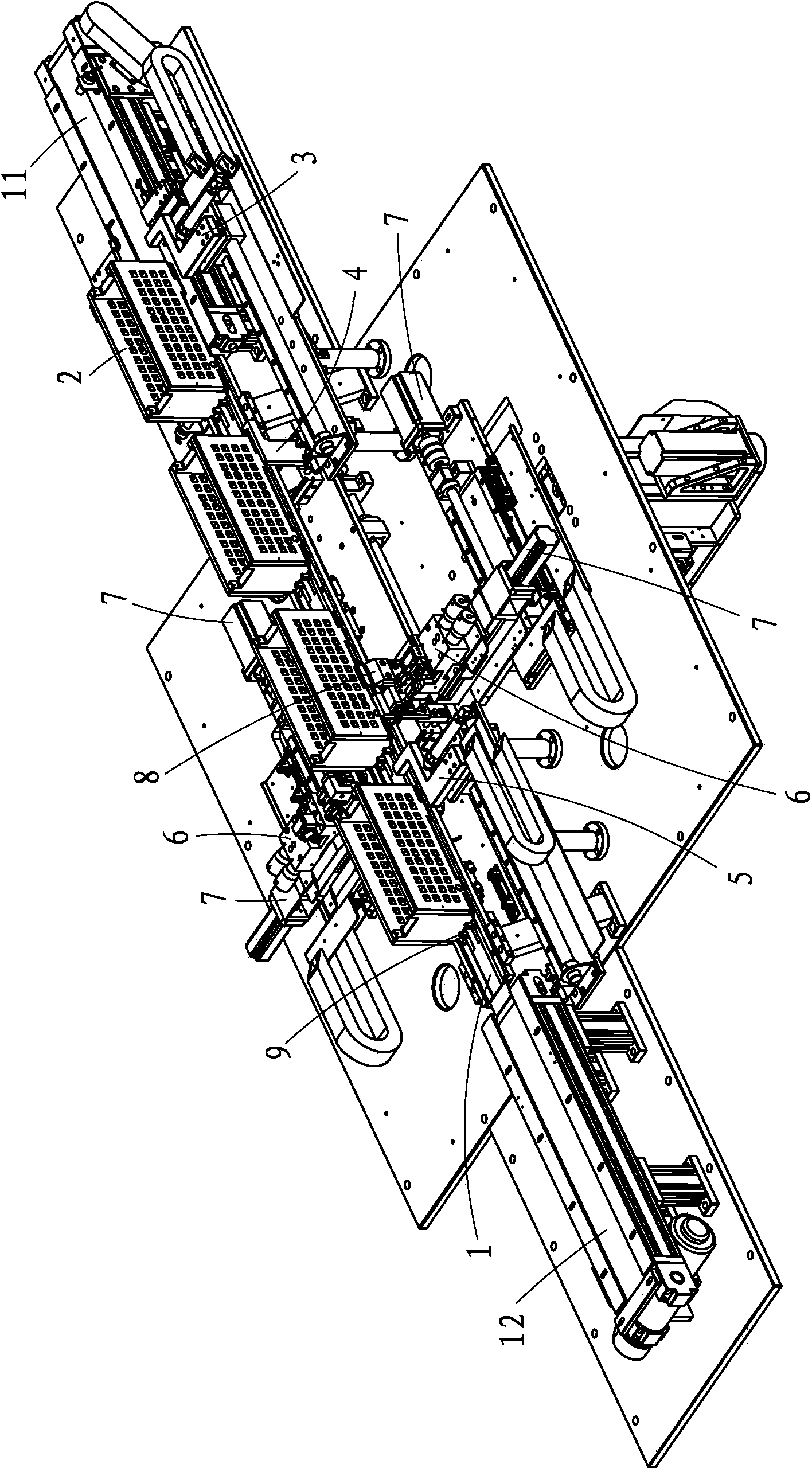

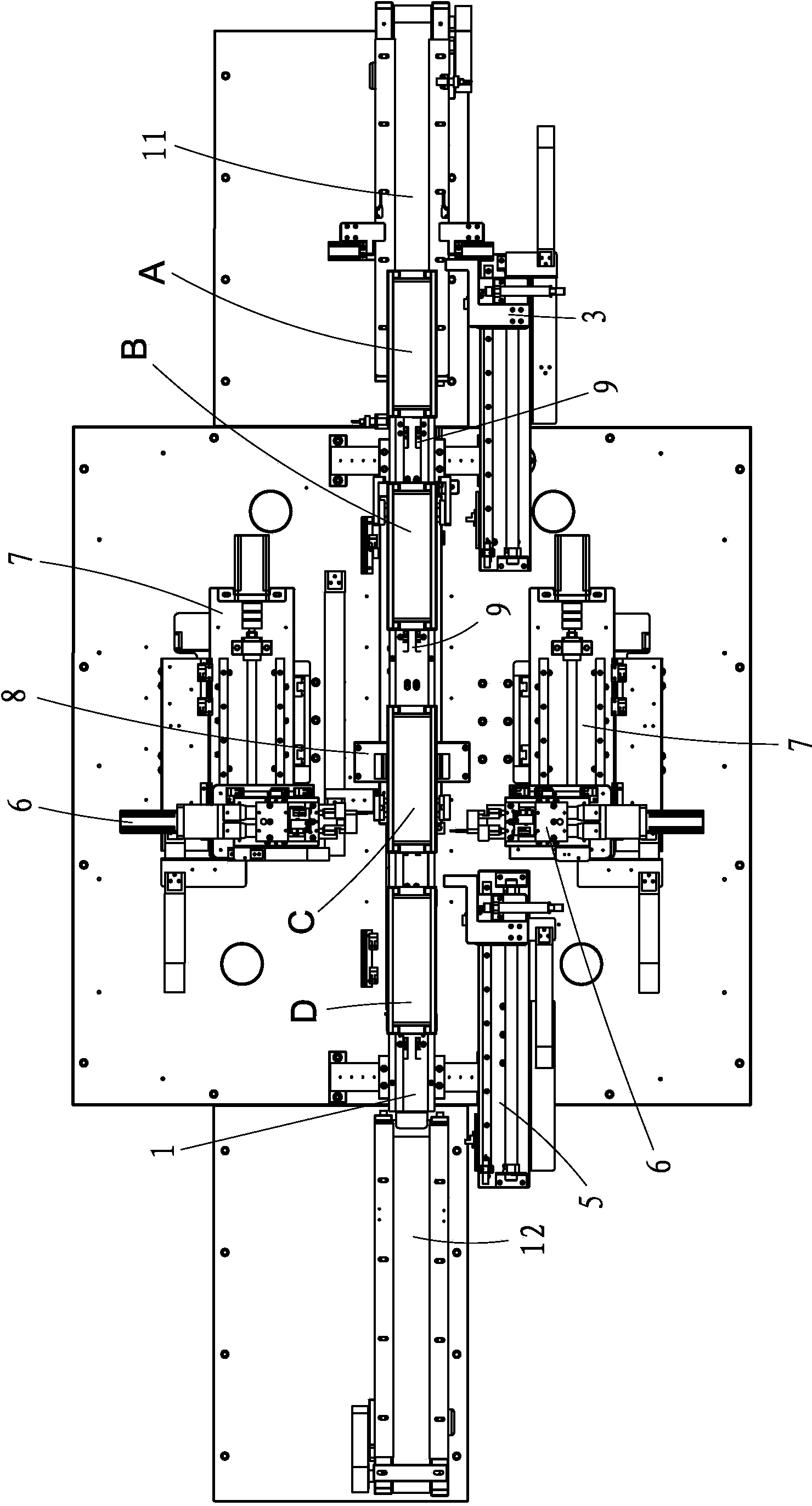

Full-automatic spot welding machine for power battery pack electrode slice

ActiveCN103934605ASpacing wide range adjustmentAdaptableWelding/cutting auxillary devicesAuxillary welding devicesPower batteryAssembly line

The invention provides a full-automatic spot welding machine for a power battery pack electrode slice. The full-automatic spot welding machine comprises a rail, a plurality of jigs, a jig pushing-in mechanism, a jig transfer guide mechanism, a jig pushing-out mechanism, two spot welding heads, two three-axis motion mechanisms and a positioning clamping mechanism. The power battery pack electrode slice on which spot welding is about to be conducted is placed on the jigs to intermittently move forwards. The two spot welding heads are located on the two sides of the rail respectively and controlled by the three-axis motion mechanisms to move along three axes. The jigs are pushed in by the jig pushing-in mechanism for feeding, the fed jigs are pushed to spot welding positions one by one through the jig transfer guide mechanism and then are clamped through the positioning clamping mechanism, and then the jigs are pushed out through the jig pushing-out mechanism after spot welding is conducted through the spot welding heads. The intelligent user-related assembly line type full-automatic spot welding machine for the power battery pack electrode slice is high in efficiency, low in consumption, high in welding quality, and easy to link.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

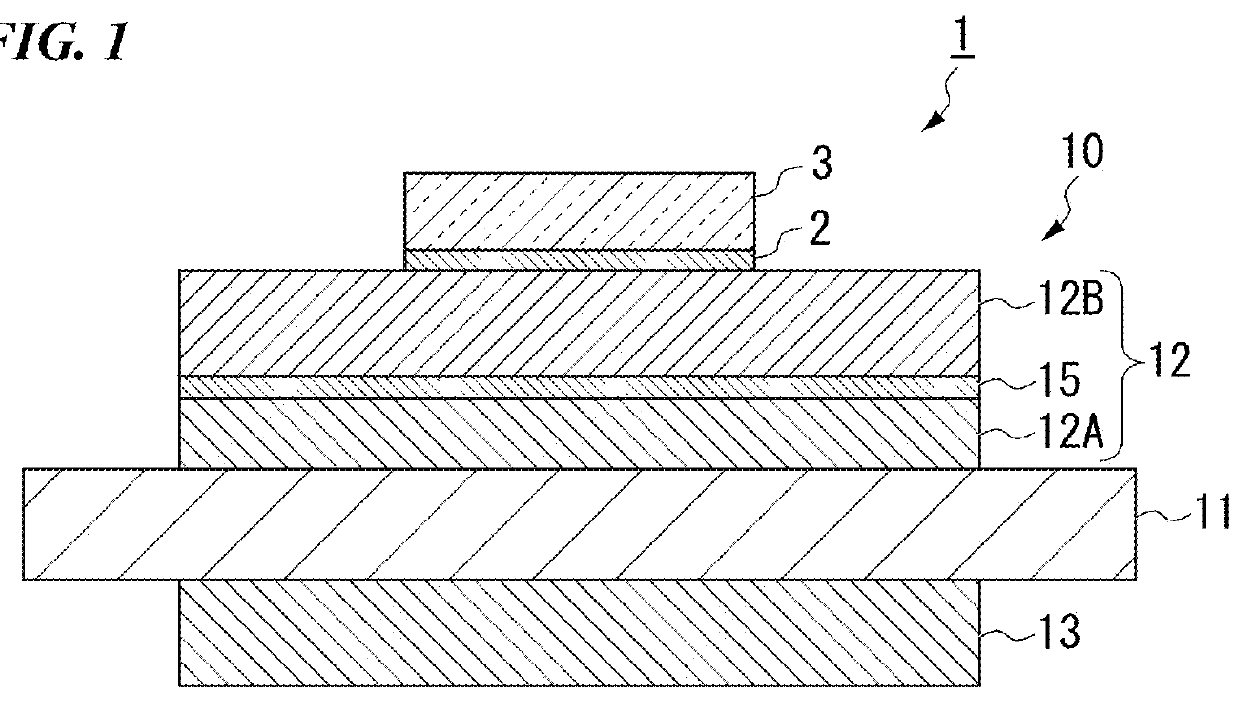

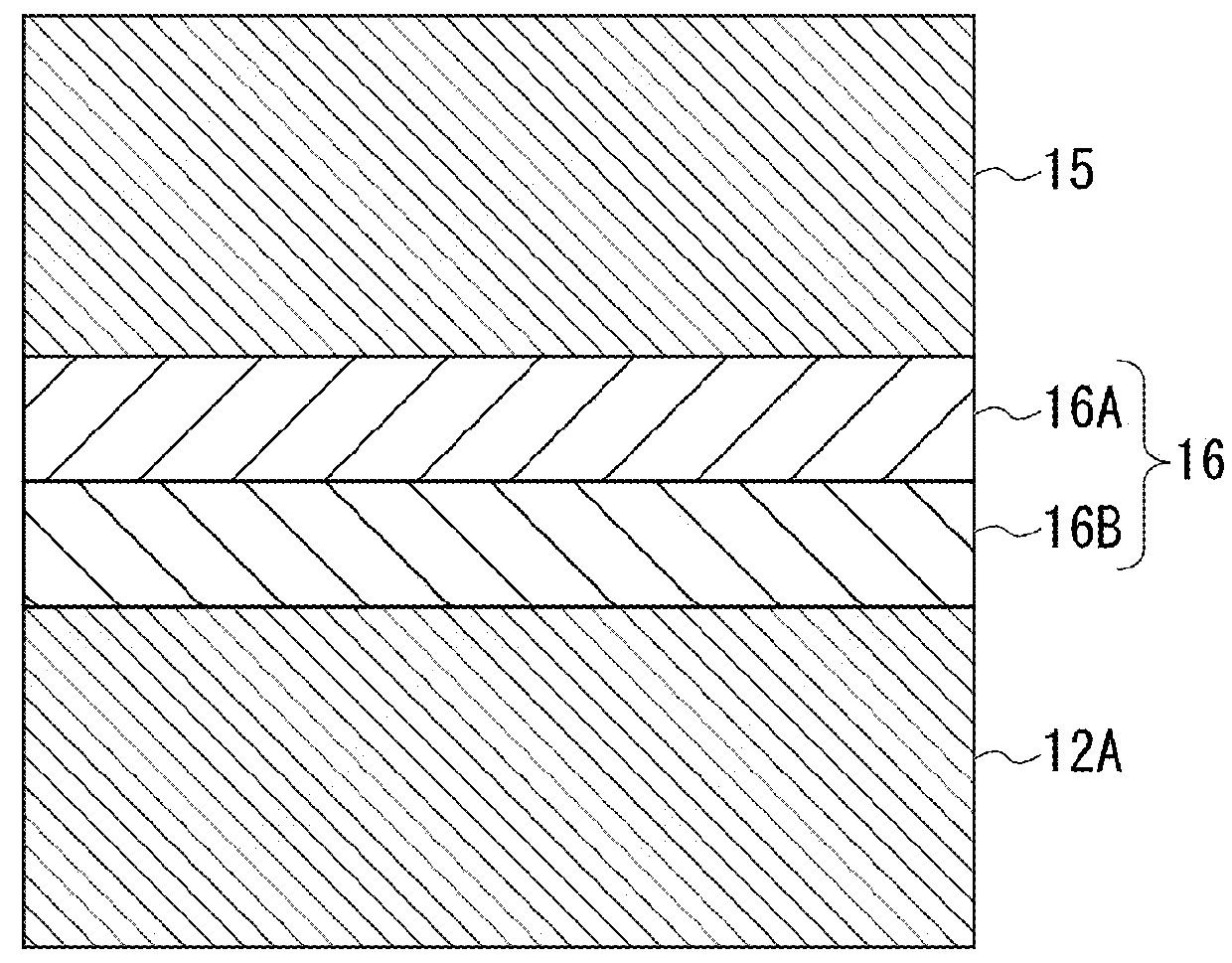

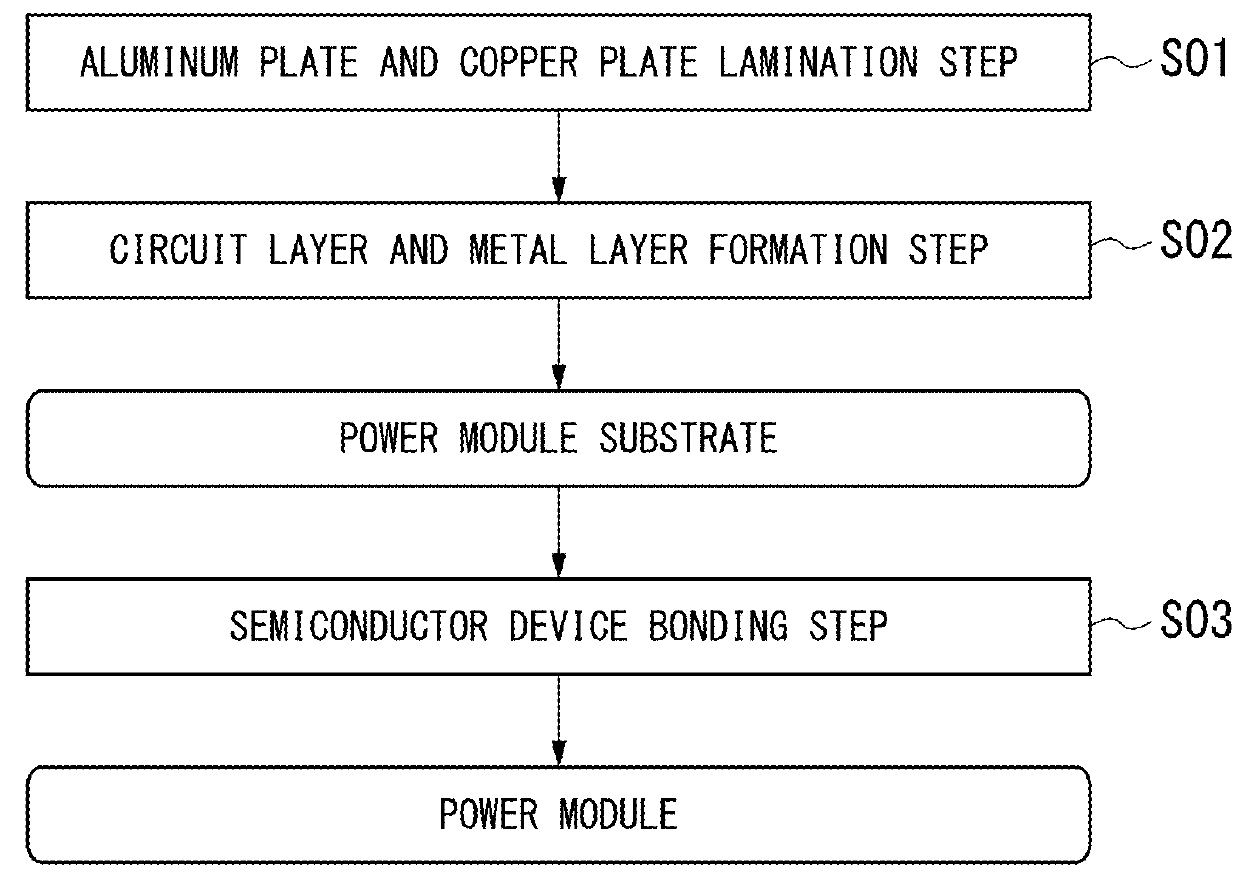

Bonding body, power module substrate, and heat-sink-attached power module substrate

ActiveUS20160035660A1Improve bond reliabilityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesBond interfaceCopper

A bonding body includes: an aluminum member composed of aluminum; and a metal member composed of any one of copper, nickel, and silver, wherein the aluminum member and the metal member are bonded together. In a bonding interface between the aluminum member and the metal member, a Ti layer and an Al—Ti—Si layer are formed, the Ti layer being disposed at the metal member side in the bonding interface, and the Al—Ti—Si layer being disposed between the Ti layer the aluminum member and containing Si which is solid-solubilized into Al3Ti. The Al—Ti—Si layer includes: a first Al—Ti—Si layer formed at the Ti layer side; and a second Al—Ti—Si layer formed at the aluminum member side and a Si concentration of which is lower than a Si concentration of the first Al—Ti—Si layer.

Owner:MITSUBISHI MATERIALS CORP

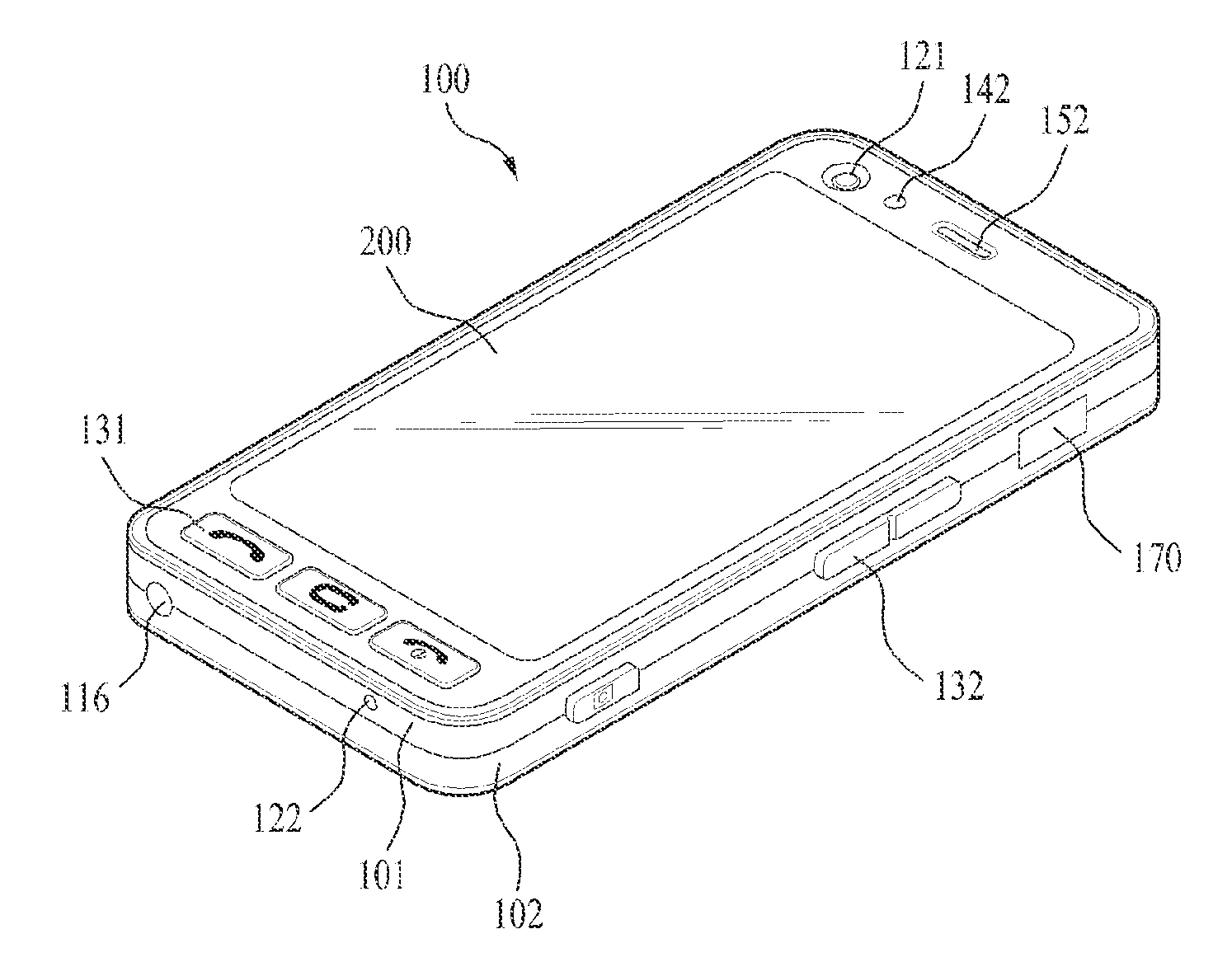

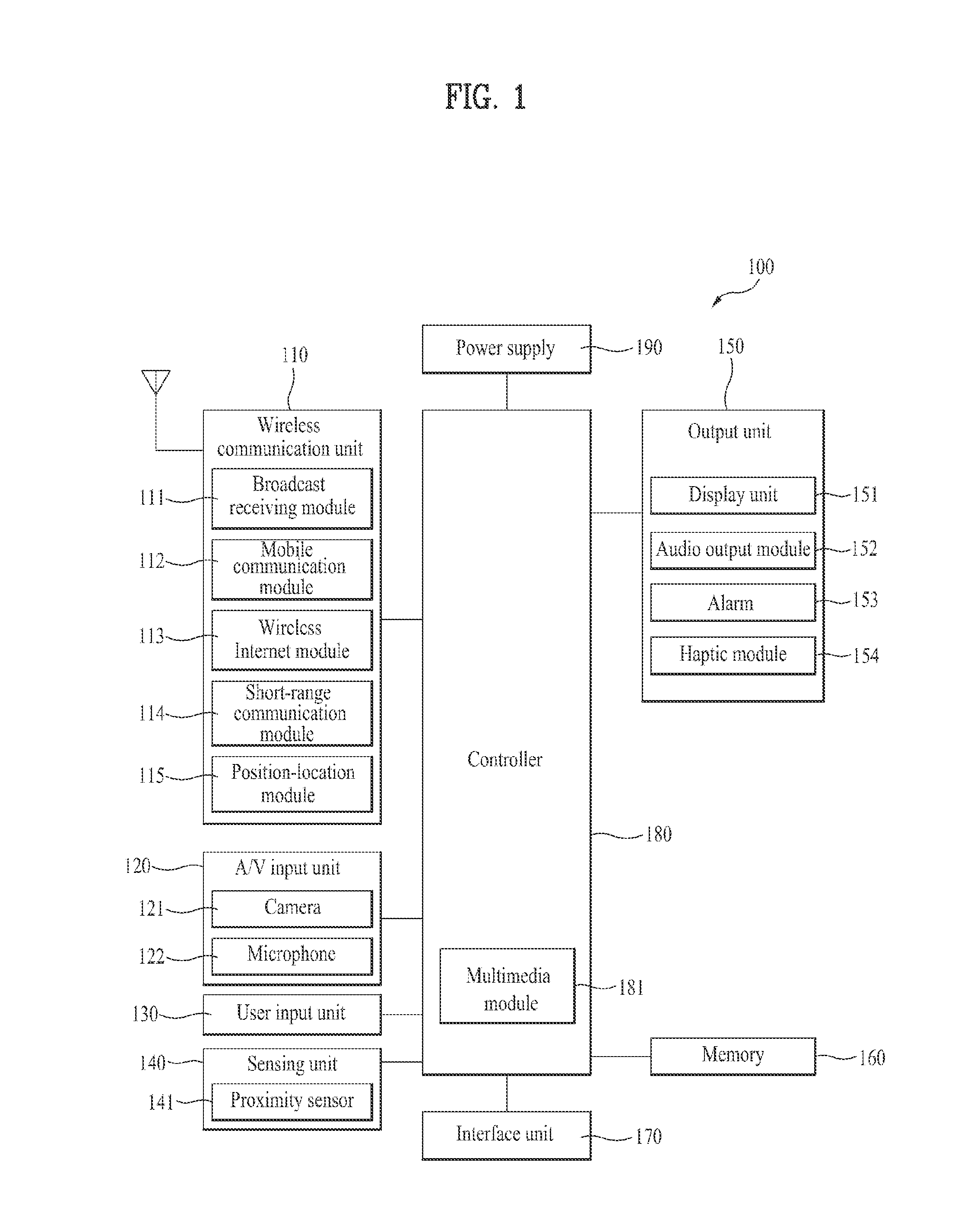

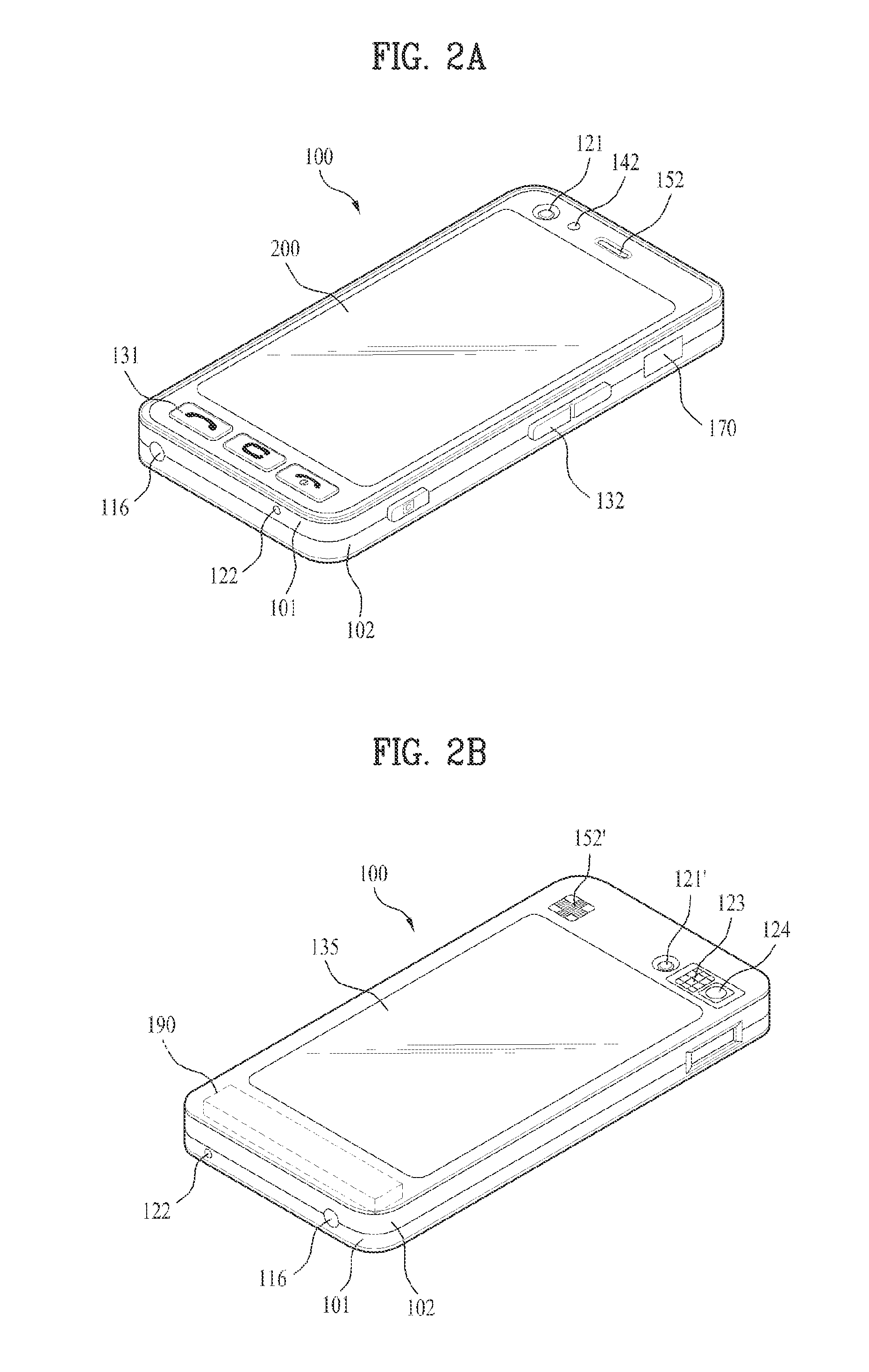

Mobile terminal and manufacturing method thereof

ActiveUS20120236587A1Reduce manufacturing costHigh color reproductionMechanical apparatusGlass reforming apparatusDisplay deviceQuantum dot

A mobile terminal and manufacturing method thereof are disclosed, by which color reproducibility of a display and the expected life span of a display can be enhanced using quantum dots. The present invention may include a display panel, a plurality of light source units spaced apart from each other, and a quantum dot filter unit provided to a light emitting surface of the light source unit to enable a light provided by the light source unit to pass through. And, the quantum dot filter unit may include a light transmissive hollow pipe member having one end opening or both end openings, quantum dots provided within the light transmissive hollow pipe member, and a sealing member configured to seal the one end opening or the both end openings, the sealing member formed of a same material of the light transmissive hollow pipe member.

Owner:LG ELECTRONICS INC

Ribbon bonding in an electronic package

InactiveUS20070141755A1Increase the areaIncrease the sectionSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceLead frame

Owner:ORTHODYNE ELECTRONICS

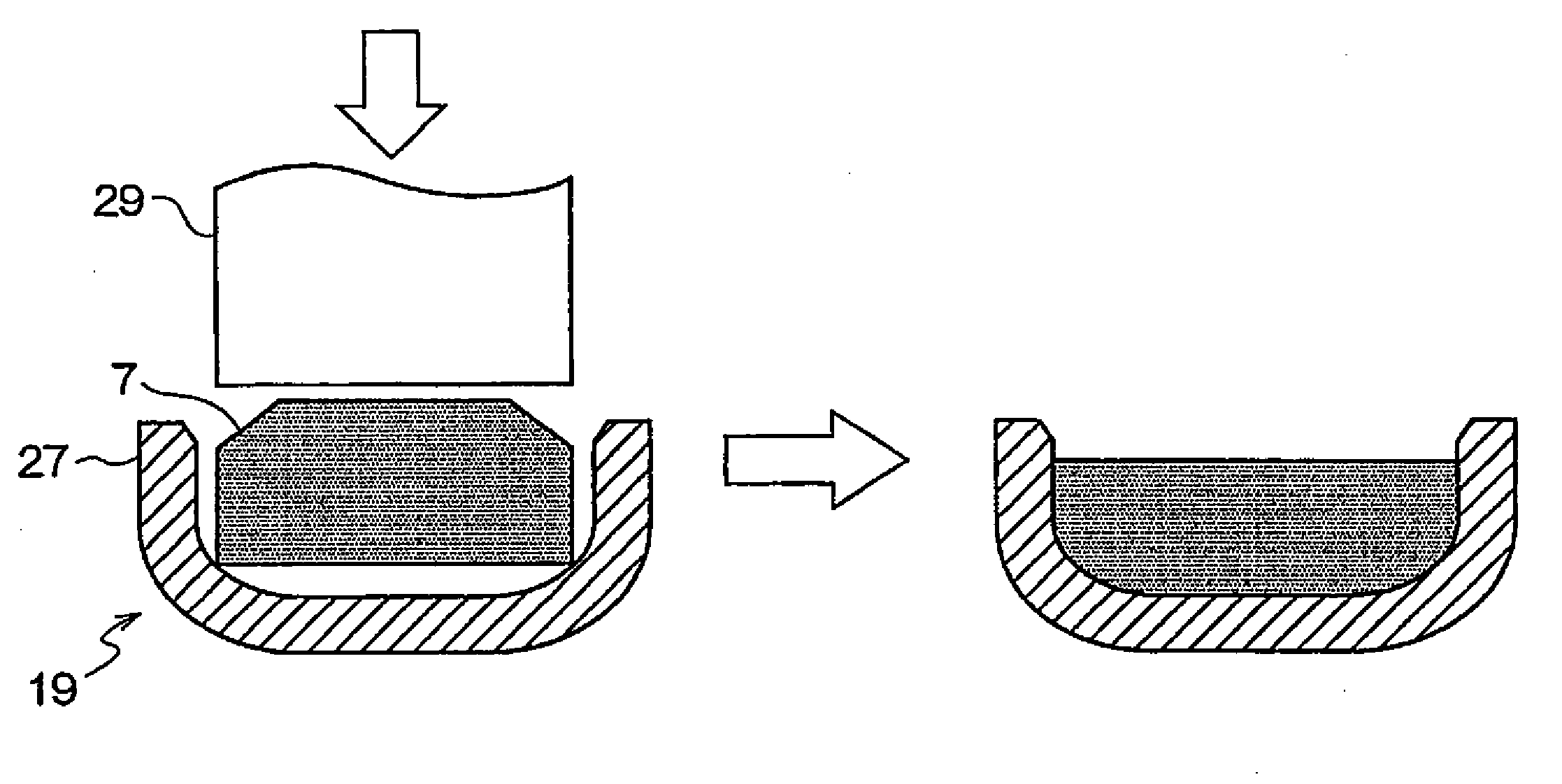

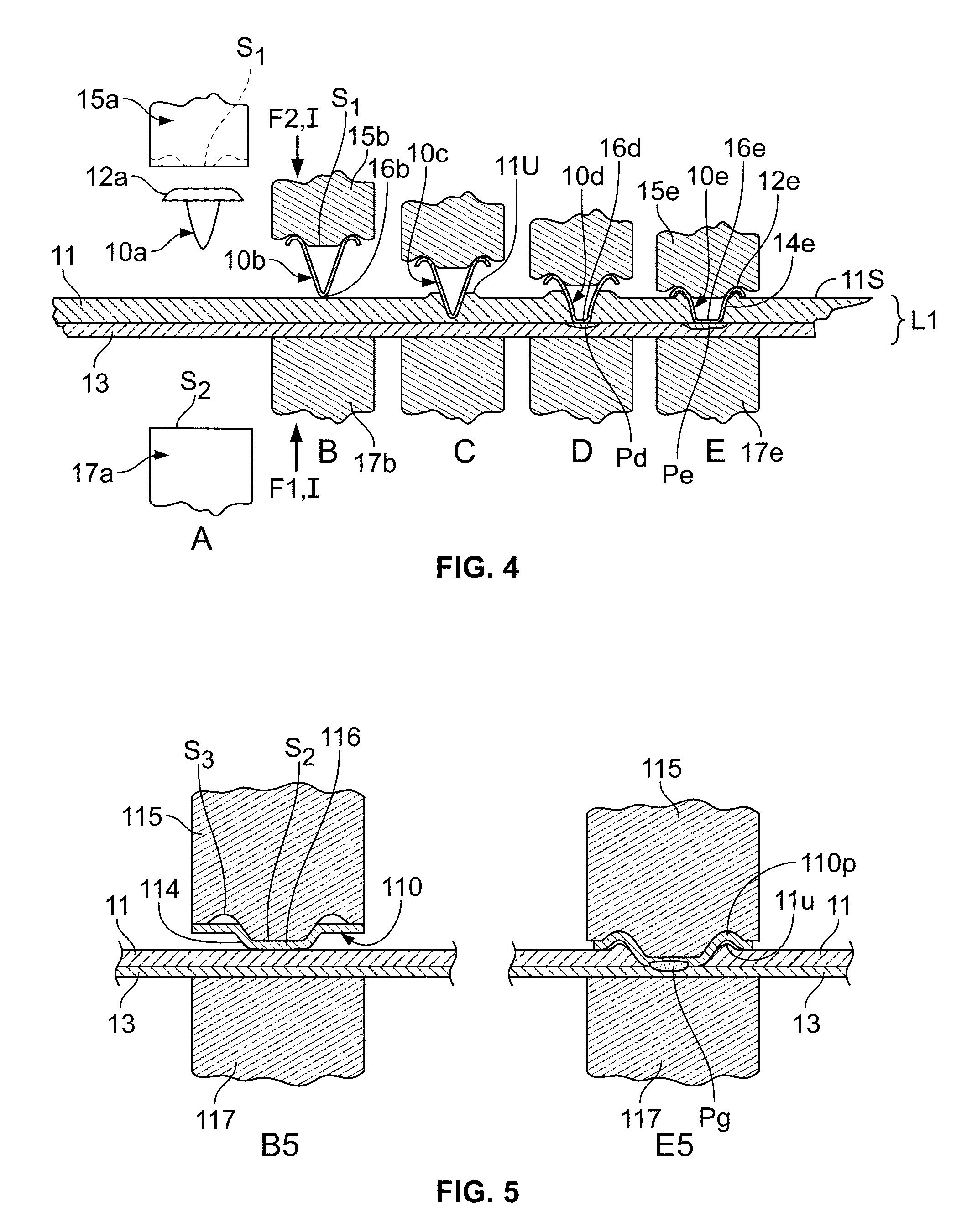

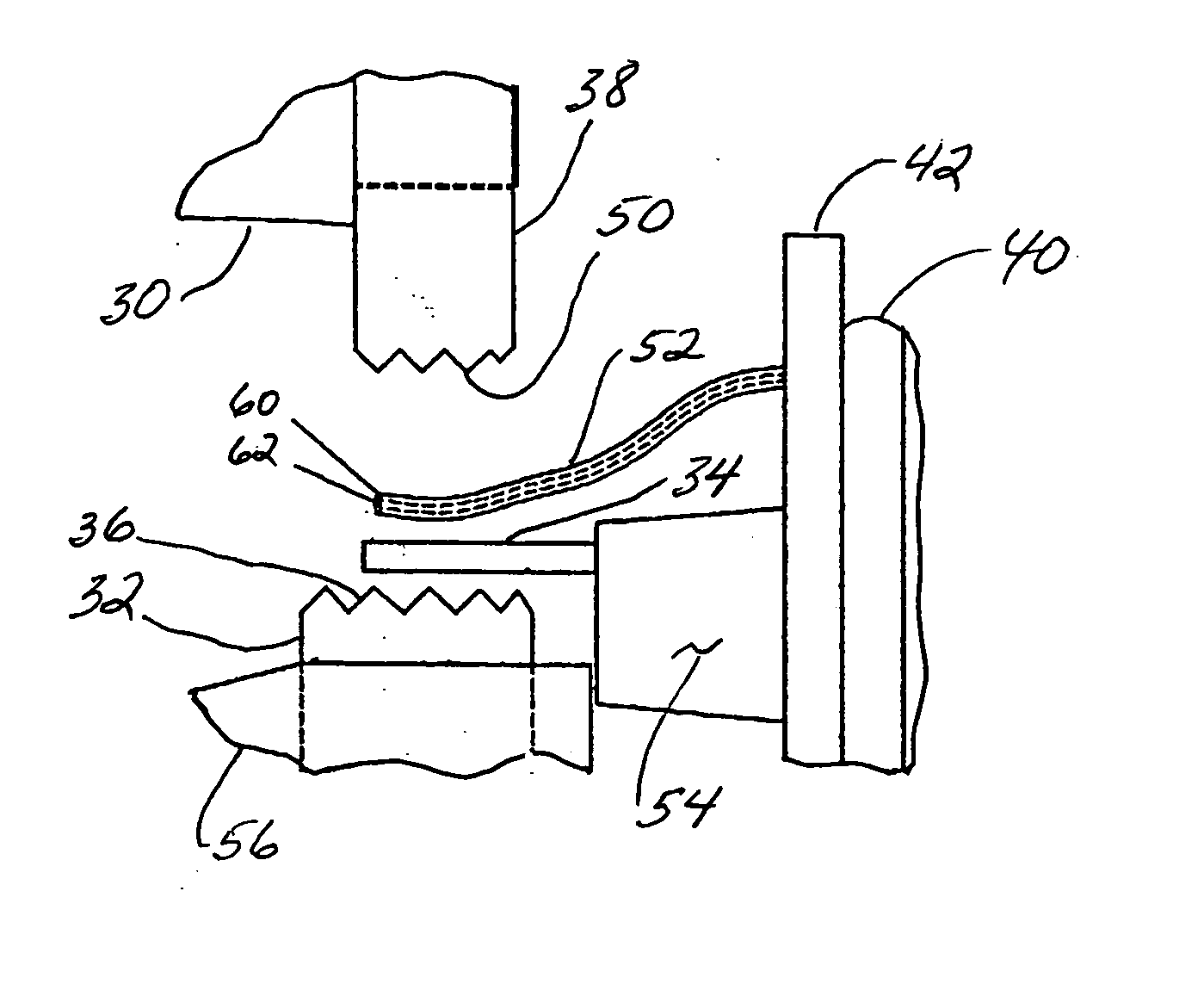

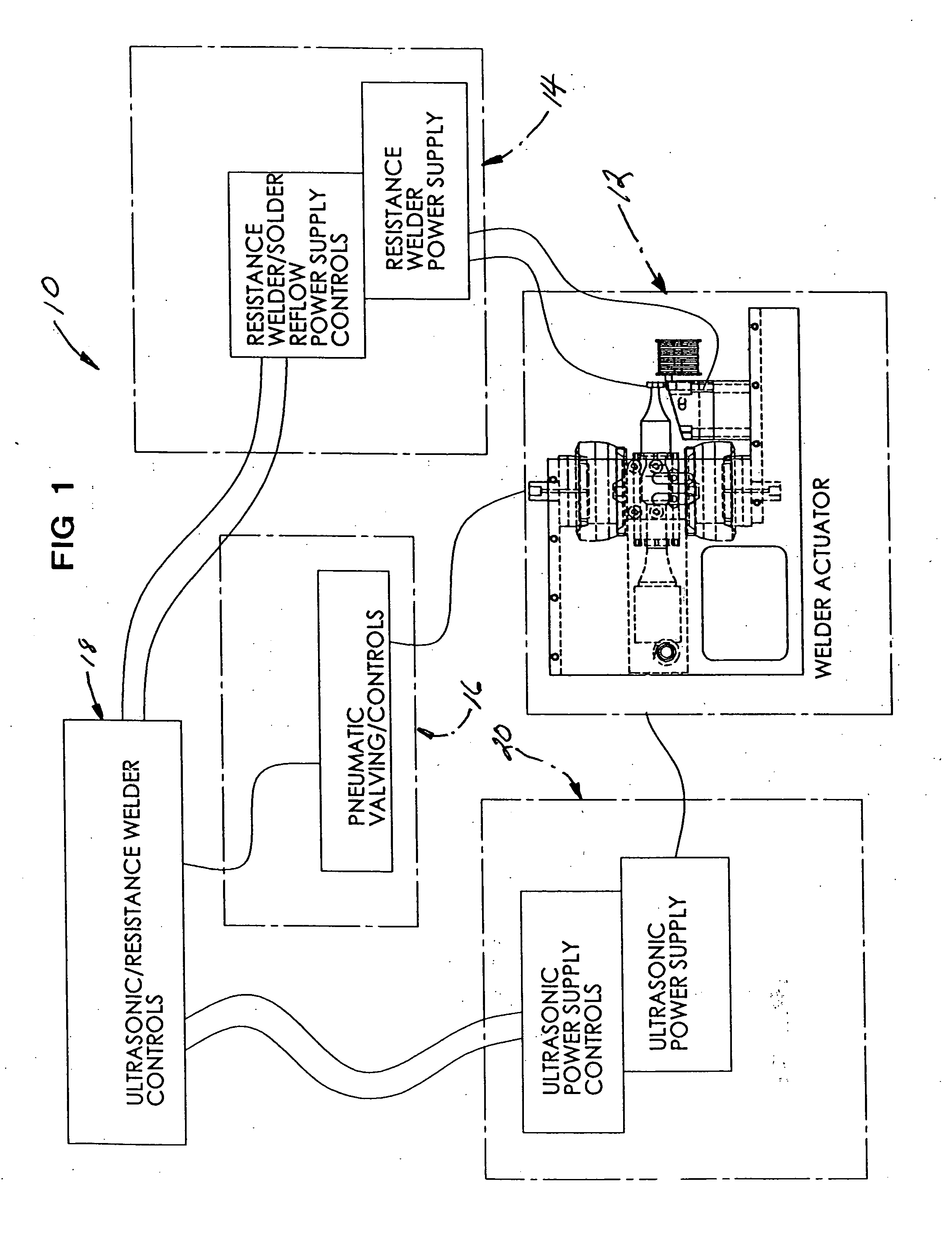

Apparatus and method for connecting coated wires

InactiveUS20060208033A1Strong weldmentWelding/cutting auxillary devicesAuxillary welding devicesElectrical resistance and conductanceWire rod

An apparatus and method of connecting a covered wire to a wire terminal which incorporates ultrasonic and resistance welding in sequence. The method includes (a) positioning the wire terminal against an anvil; (b) positioning the covered wire against the terminal; (c) positioning a tip of an ultrasonic welder in clamped engagement with the wire terminal and the covered wire together against the anvil; (d) ultrasonically vibrating the tip for a time sufficient for the covering against the terminal to be displaced and electrical contact established between the tip and the anvil through the wire and the terminal; and (e) applying sufficient electric current between the tip and the anvil to resistance weld the wire and the terminal together.

Owner:WELTER CURTIS L

Magnetic Pulse Welding and Forming for Plates

ActiveUS20130086961A1High frequency current welding apparatusConductorsElectrical conductorMagnetic pulse welding

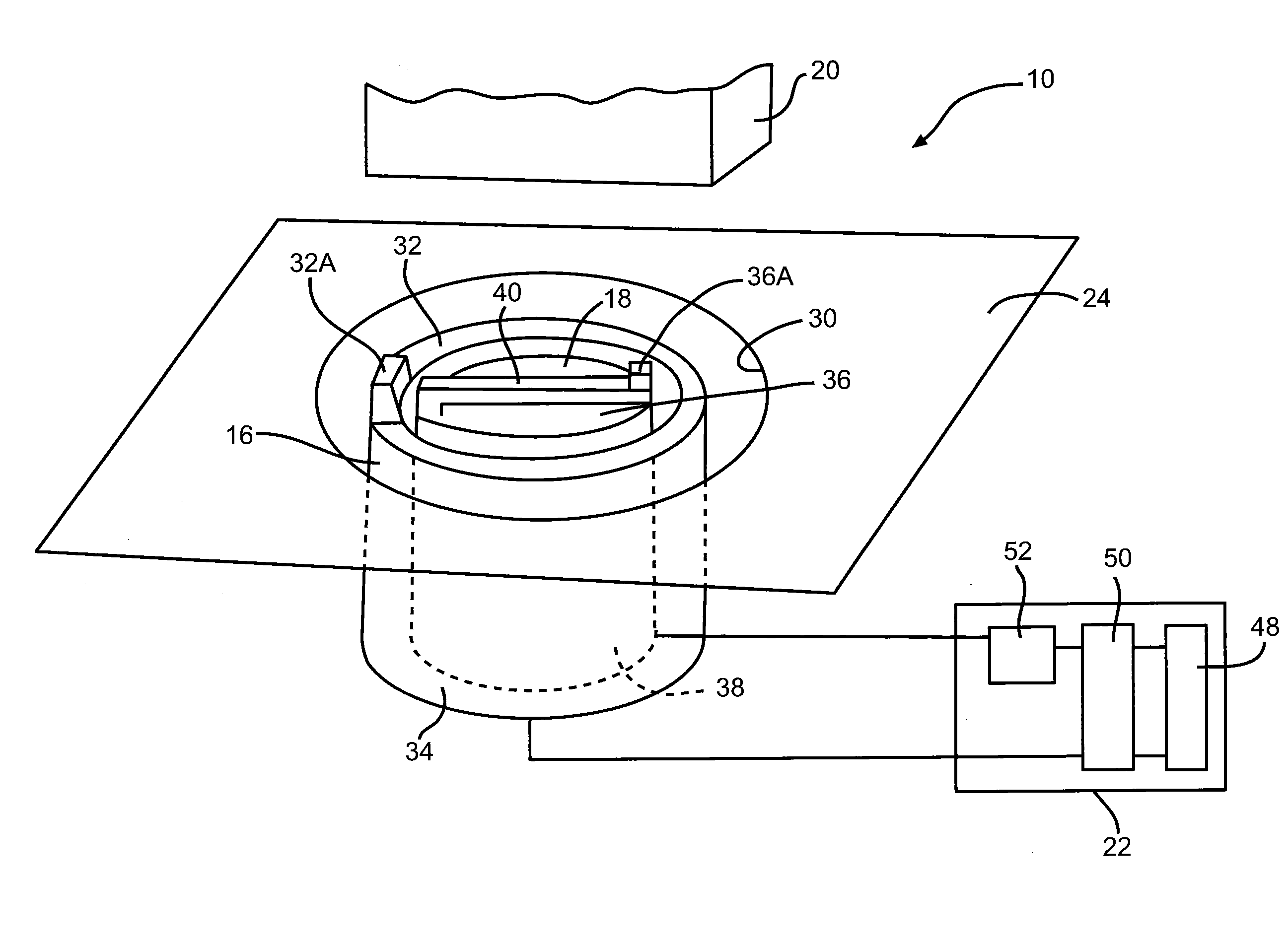

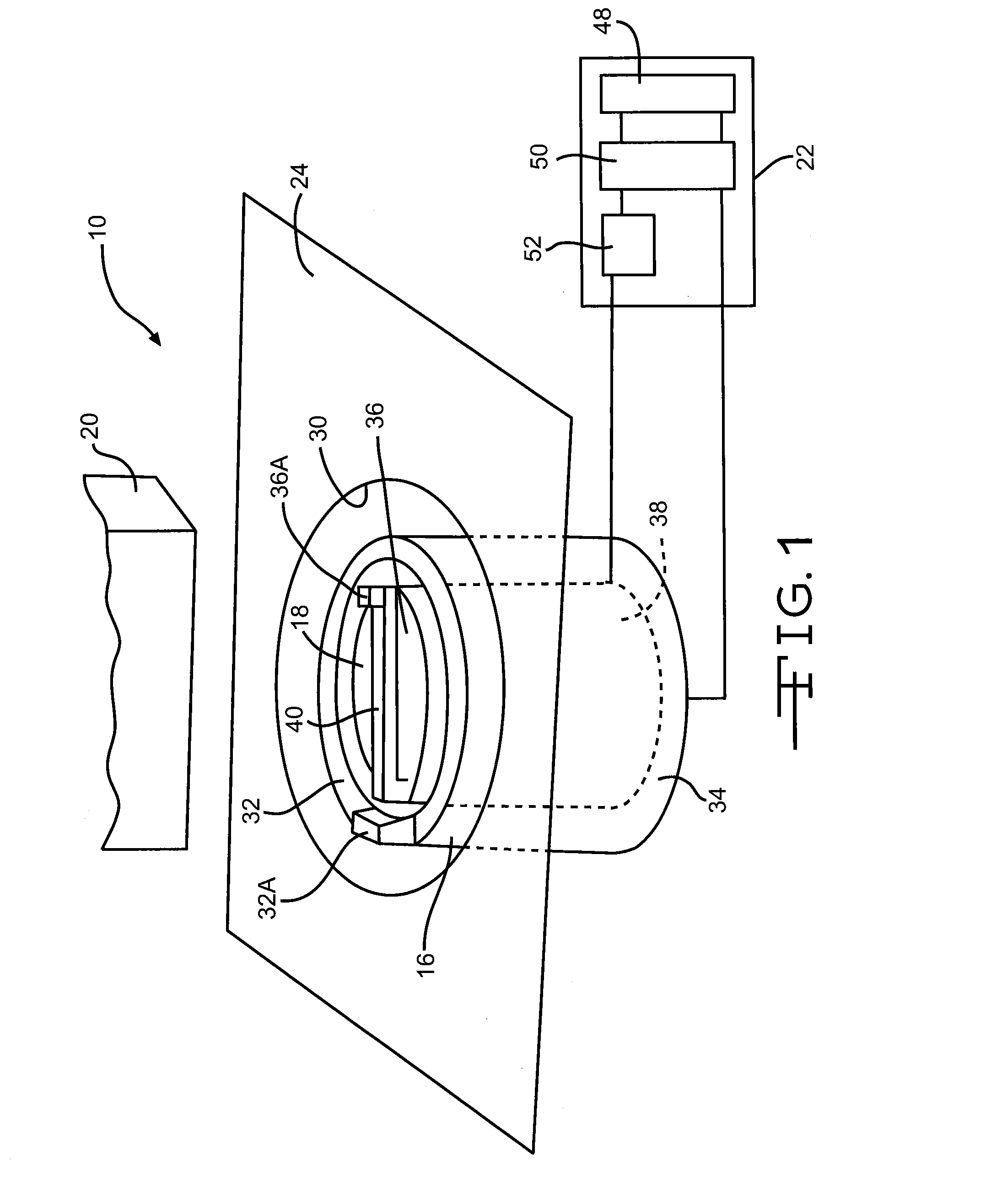

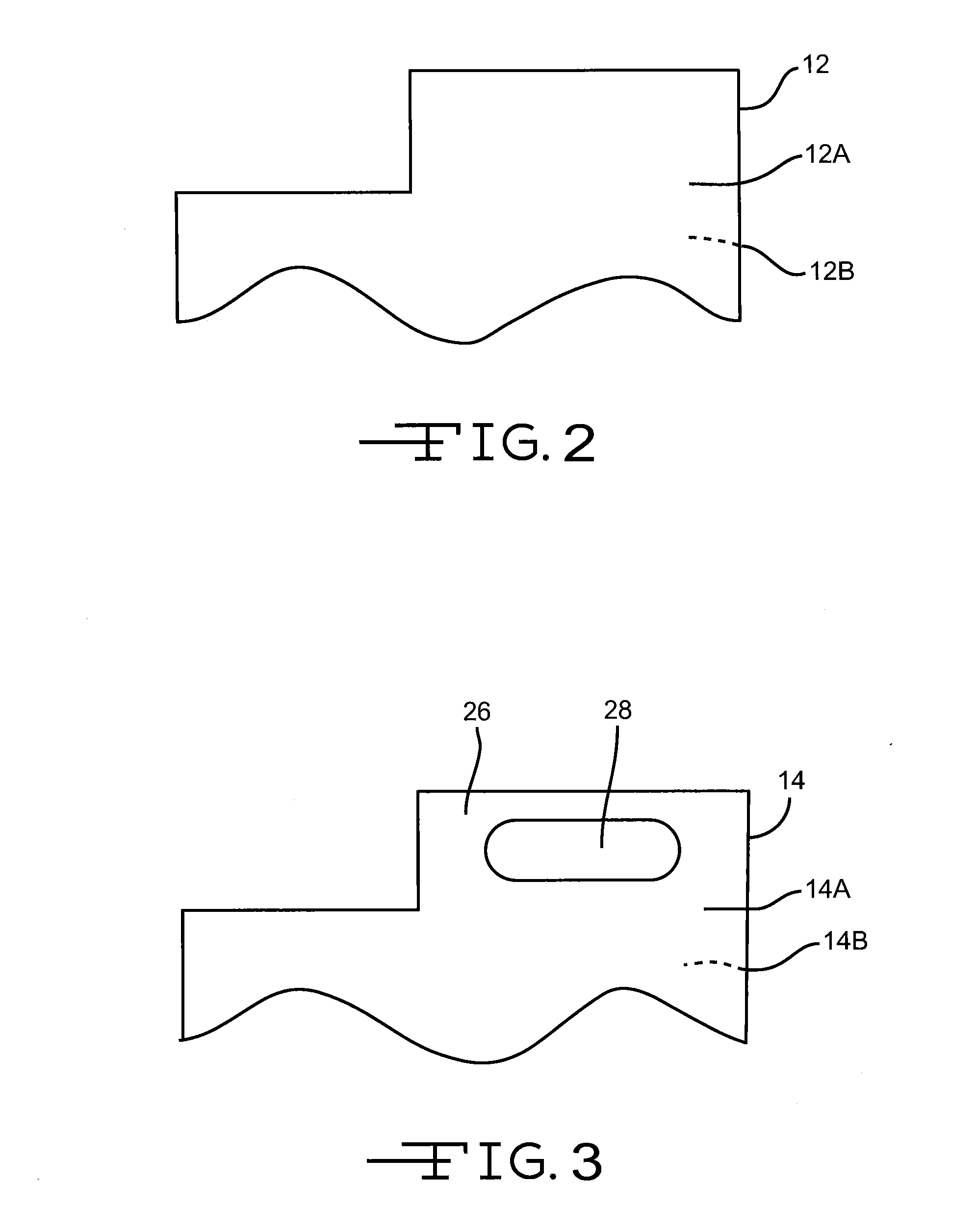

A method of welding two workpieces together is described. A conductor in electrical communication with a pulse circuit is provided. A portion of the second workpiece is located adjacent the conductor. The two workpieces are also located together. A portion, or all, of one workpiece is welded to the other by applying a pulse current to one of the workpieces. A method of forming a workpiece is disclosed using a pulse current to move the workpiece into a desired shape.

Owner:DANA AUTOMOTIVE SYST GRP LLC

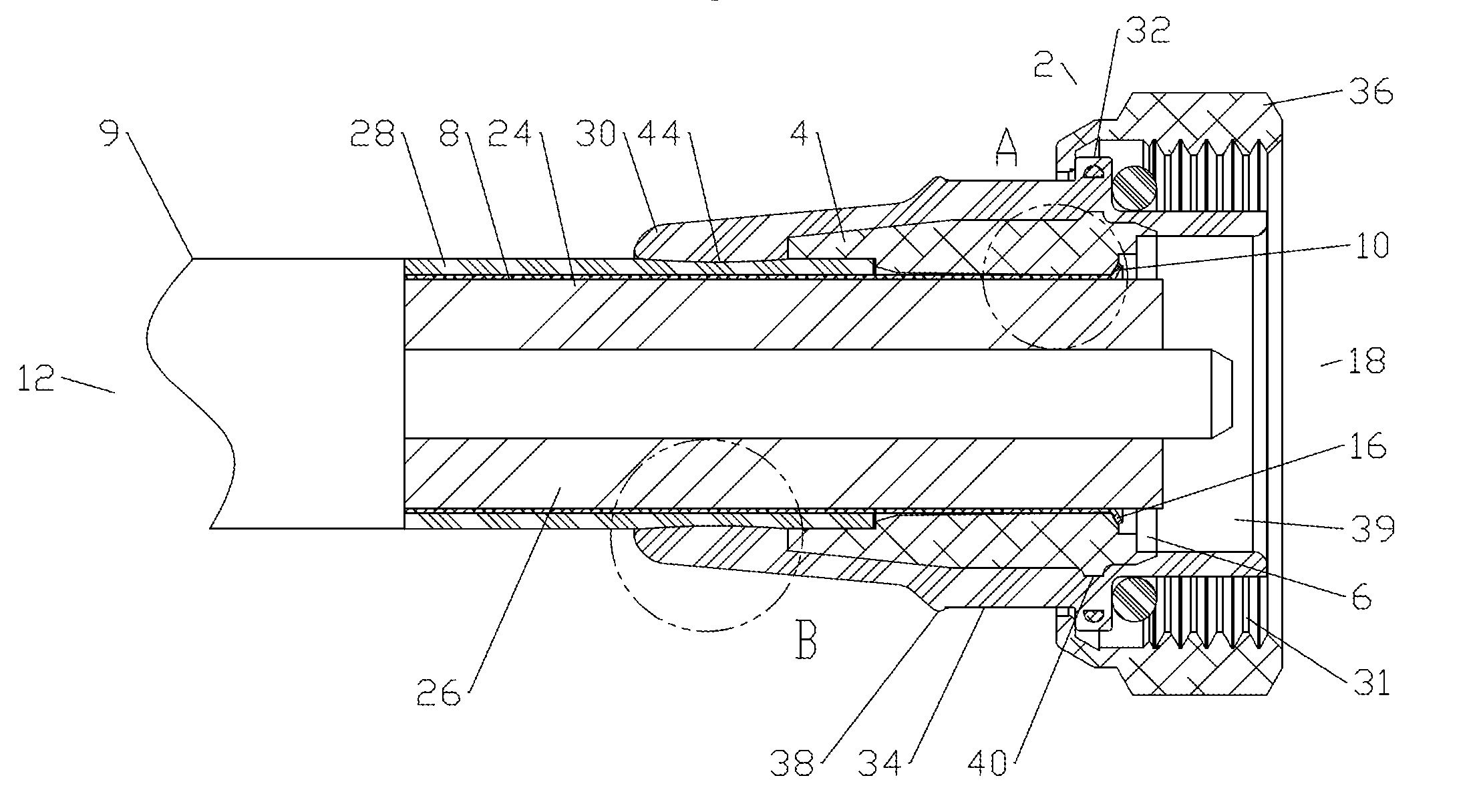

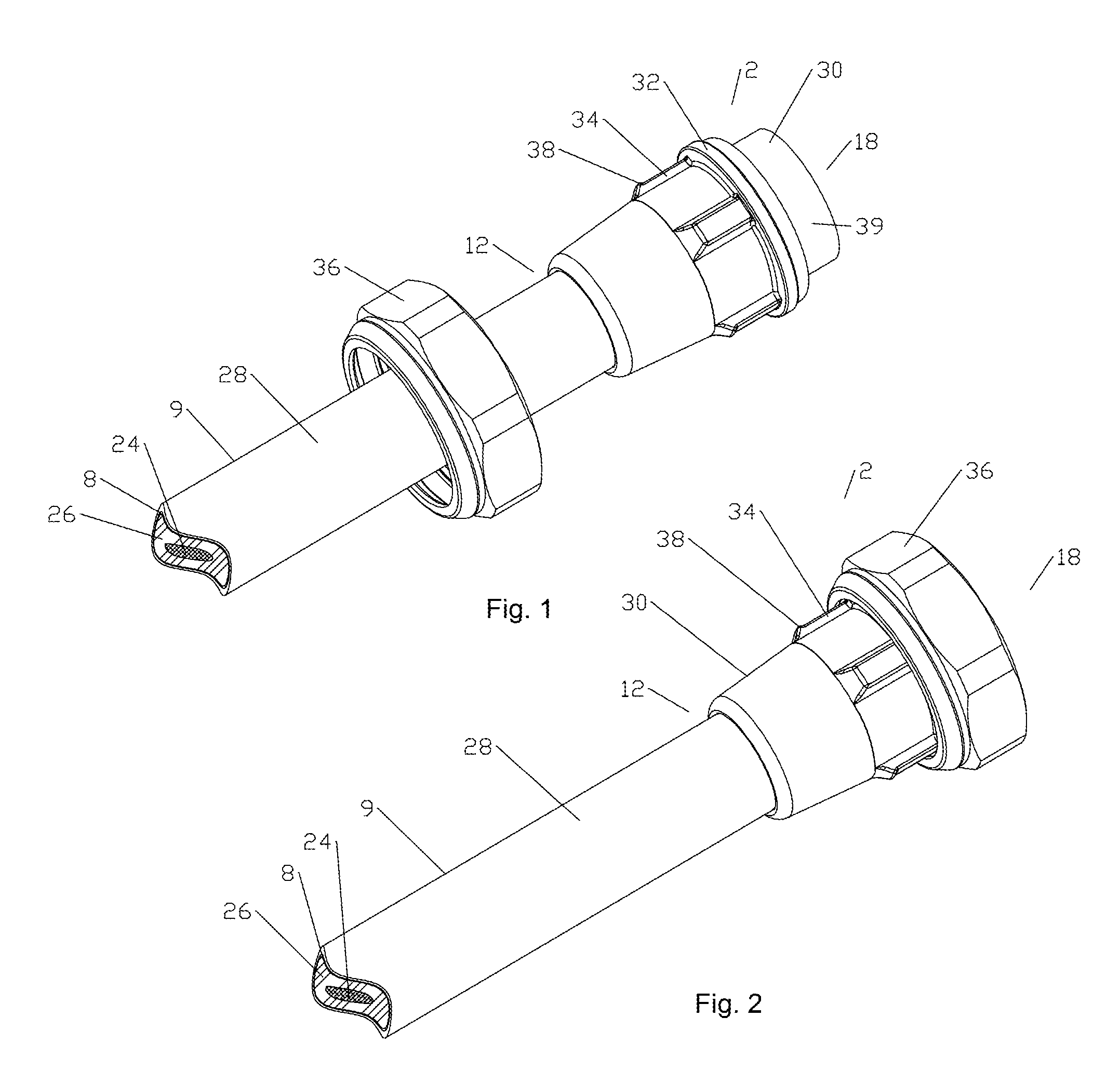

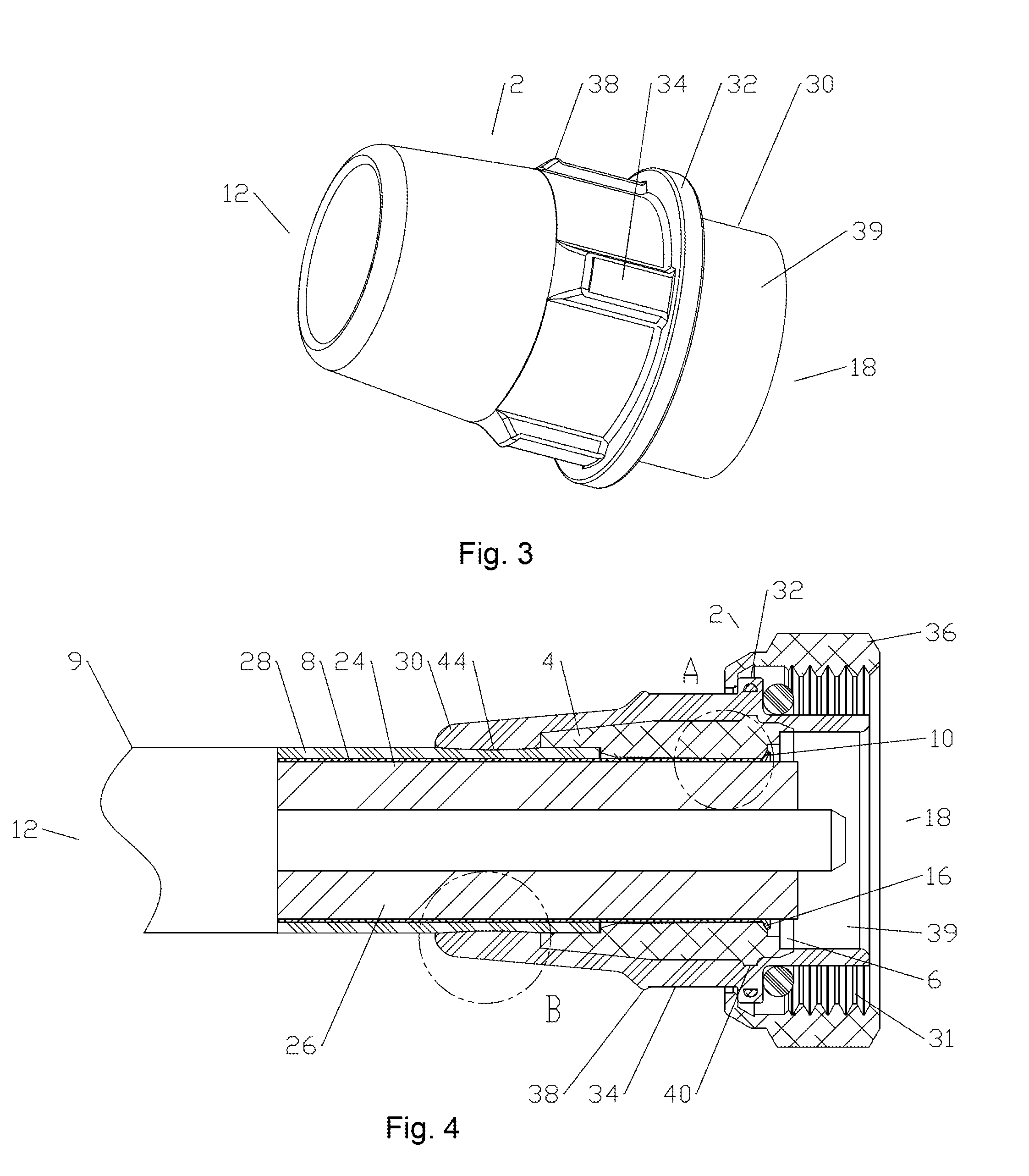

Ultrasonic weld coaxial connector and interconnection method

InactiveUS20120129390A1Cost-effectiveSignificant material cost efficiencyElectrically conductive connectionsContact member assembly/disassemblyCoaxial cableElectrical conductor

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by ultrasonic welding is provided with a monolithic connector body with a bore. An annular flare seat is angled radially outward from the bore toward a connector end of the connector; the annular flare seat open to the connector end of the connector. The flare seat may be provided with an annular flare seat corrugation.

Owner:COMMSCOPE TECH LLC

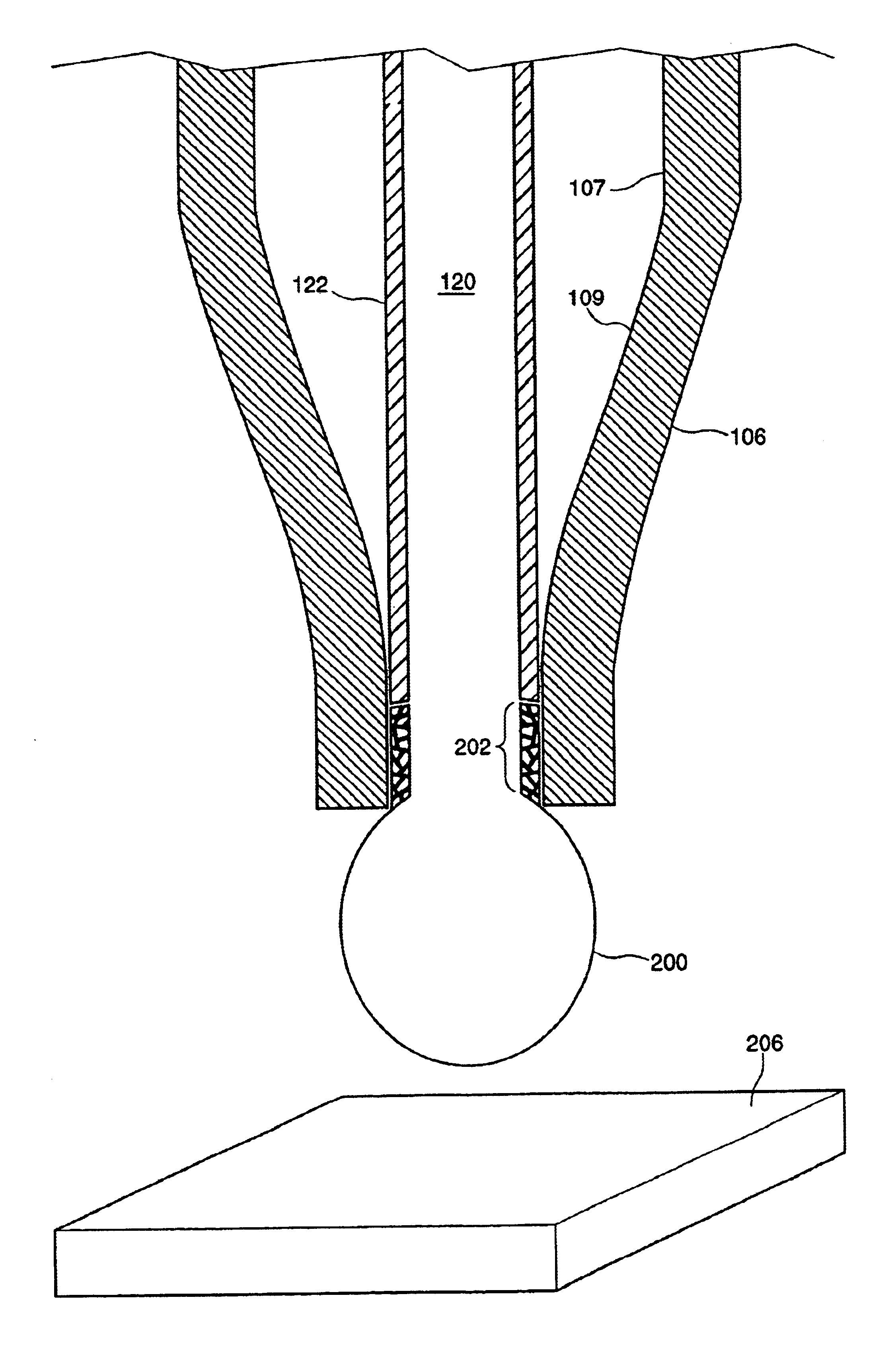

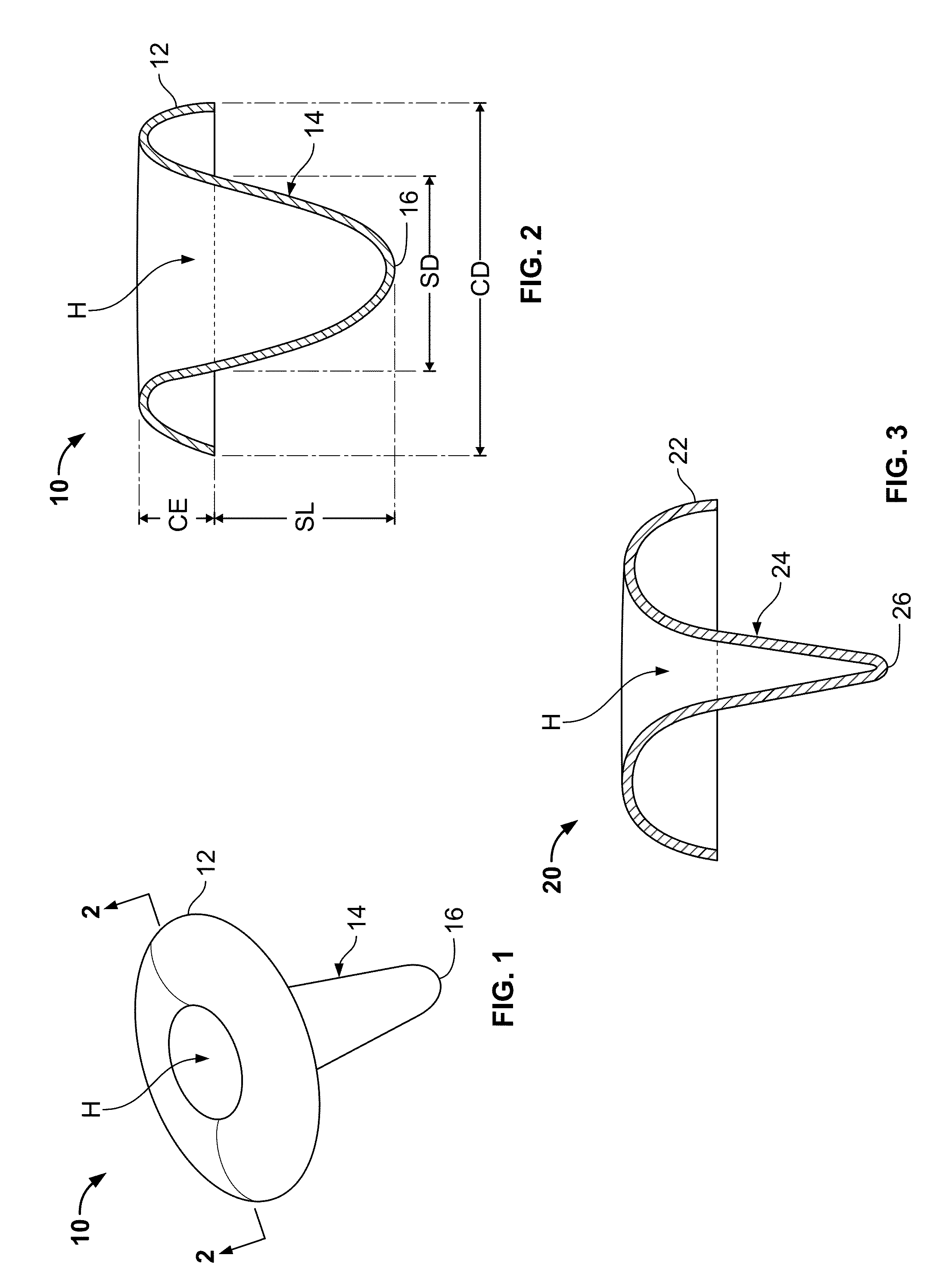

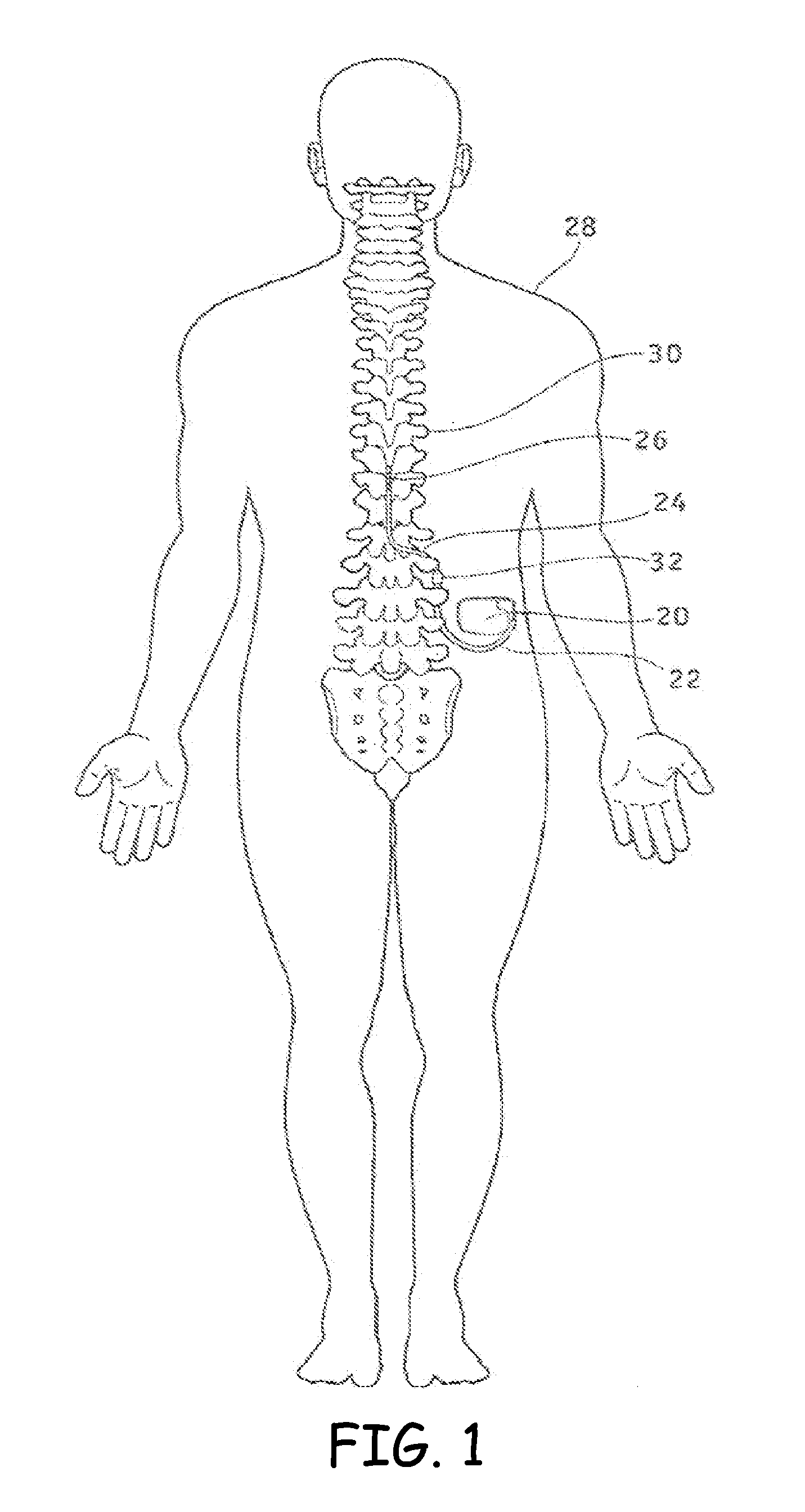

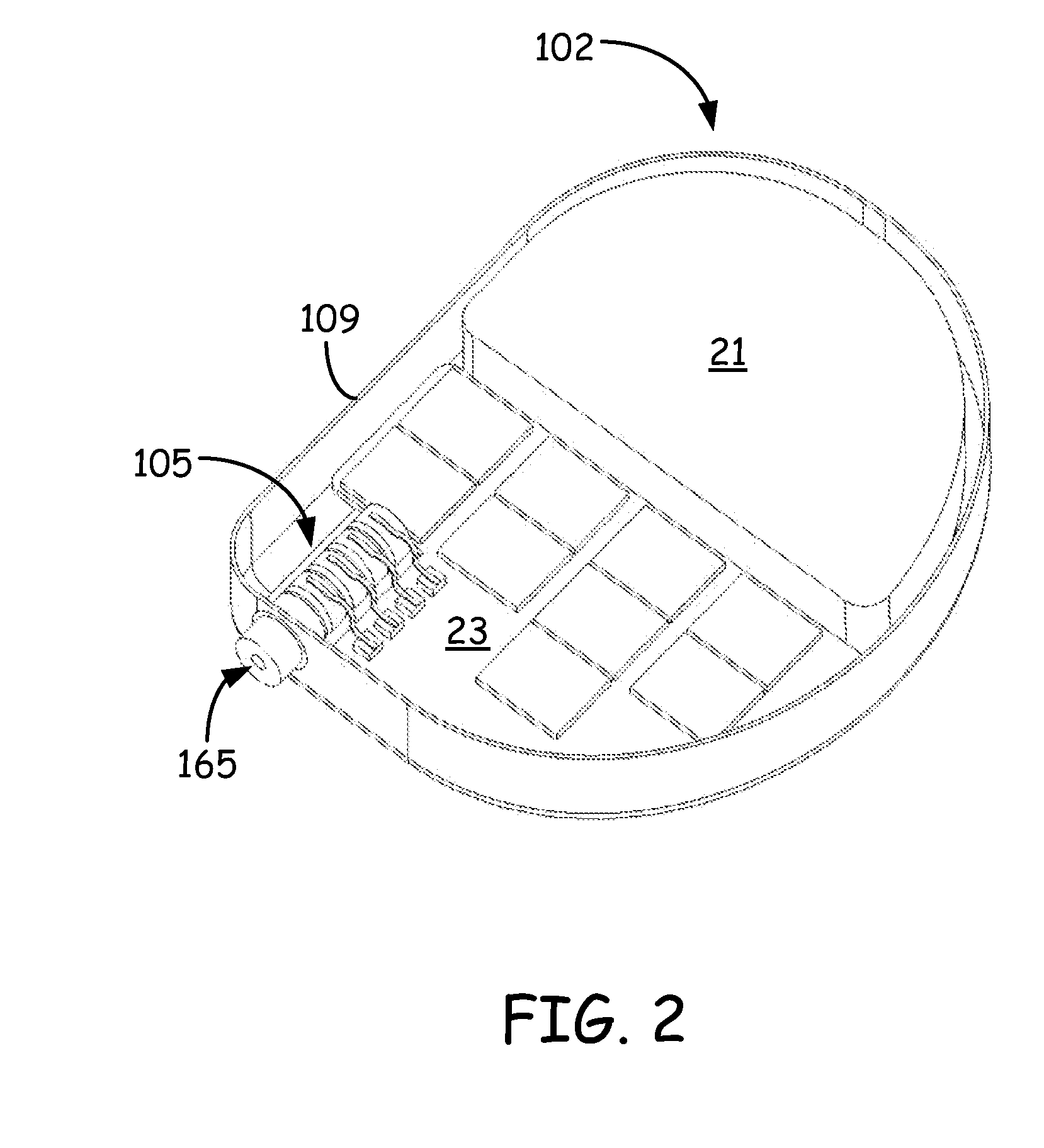

Diffusion bonded lead connector

A medical device lead connector includes electrically conducting contact rings spaced apart by an electrically insulating ring and in axial alignment. The electrically conducting contact ring and the insulating ring having an interface bond on an atomic level.

Owner:MEDTRONIC INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com