Full-automatic spot welding machine for power battery pack electrode slice

A technology for power battery packs and electrode sheets, which is applied in resistance welding equipment, circuits, welding equipment, etc., can solve the problems of high investment in special spot welding power sources, increased equipment costs, and low welding efficiency, and is conducive to the transformation and upgrading of production lines. , Easy installation and replacement, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

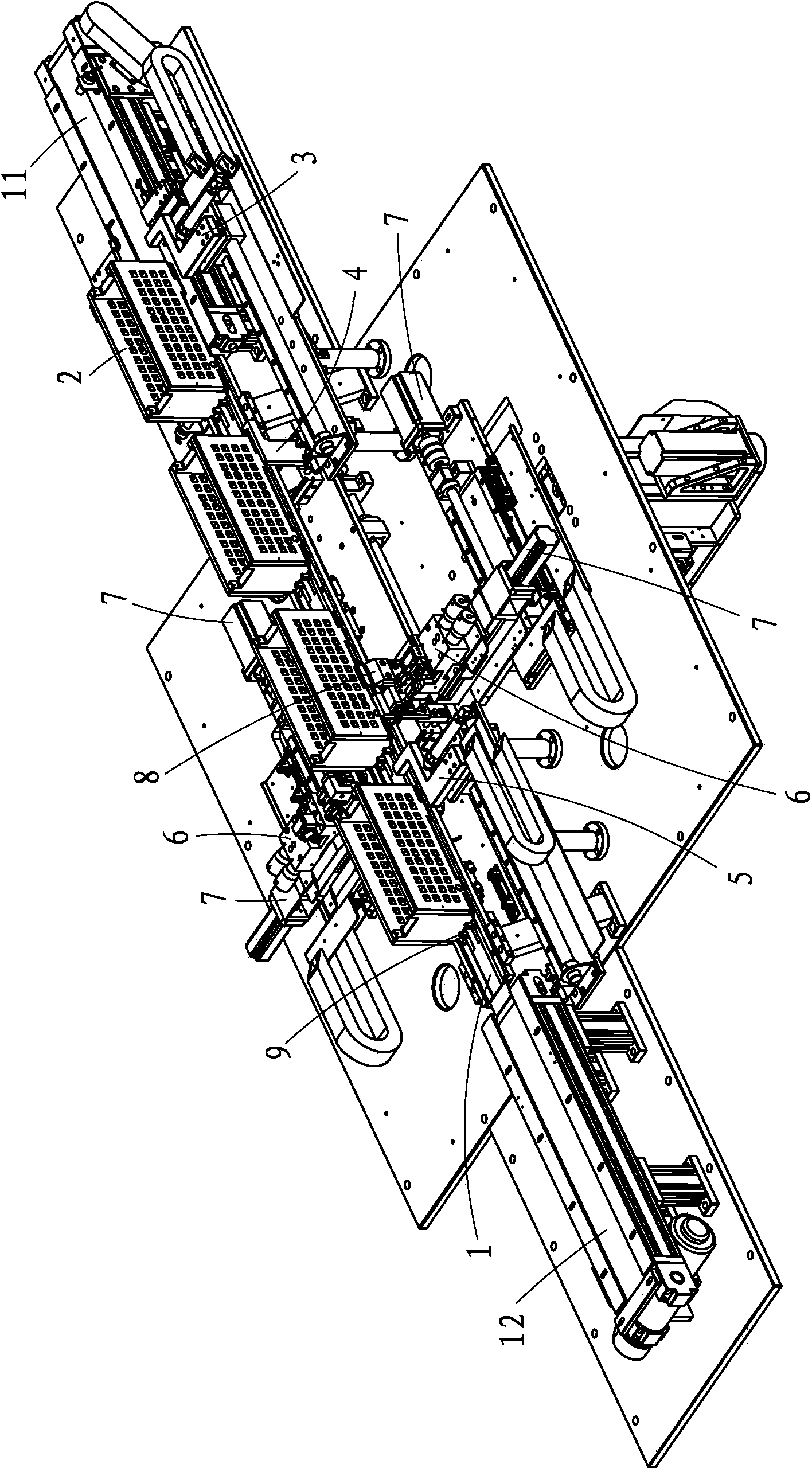

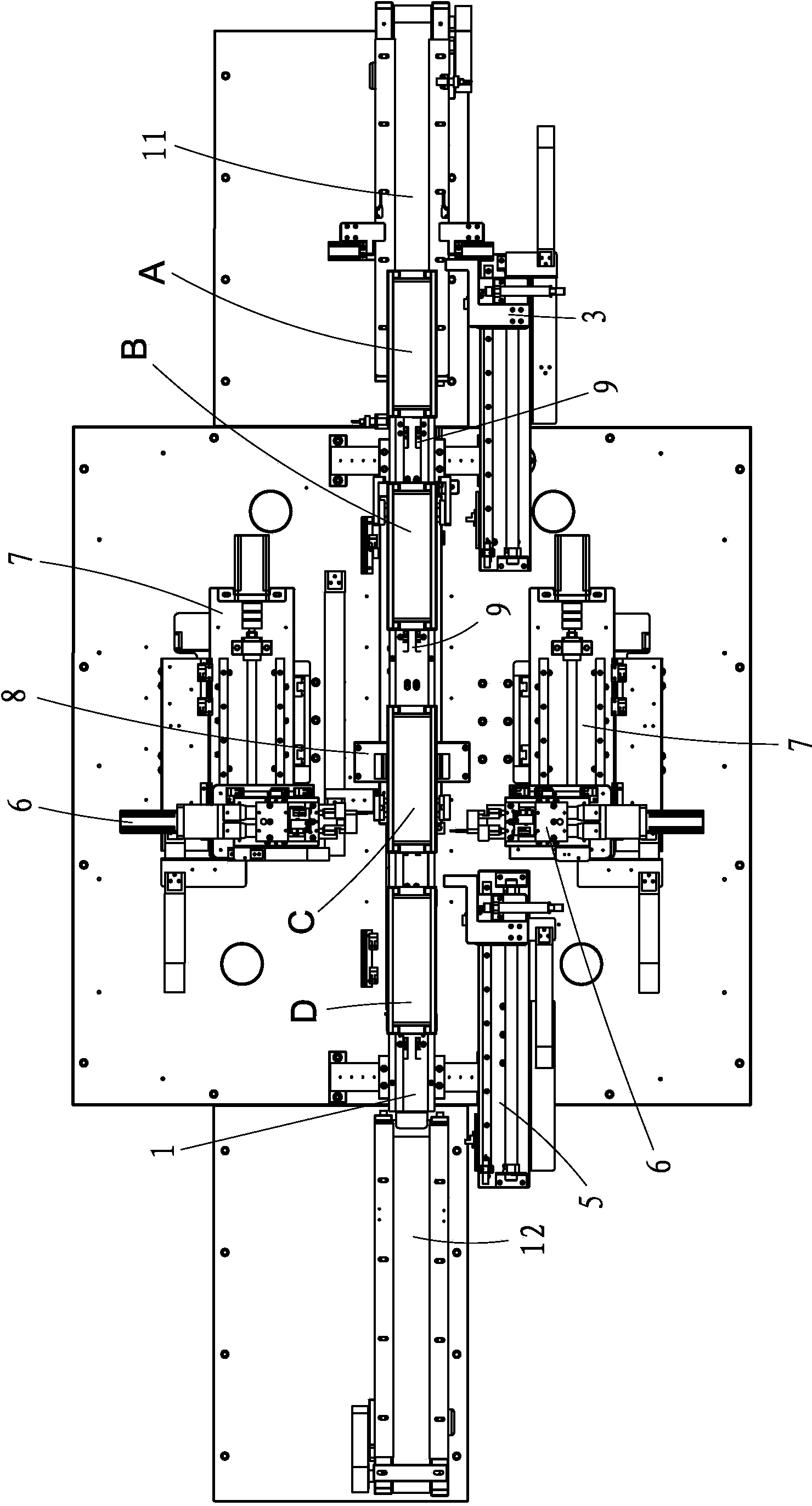

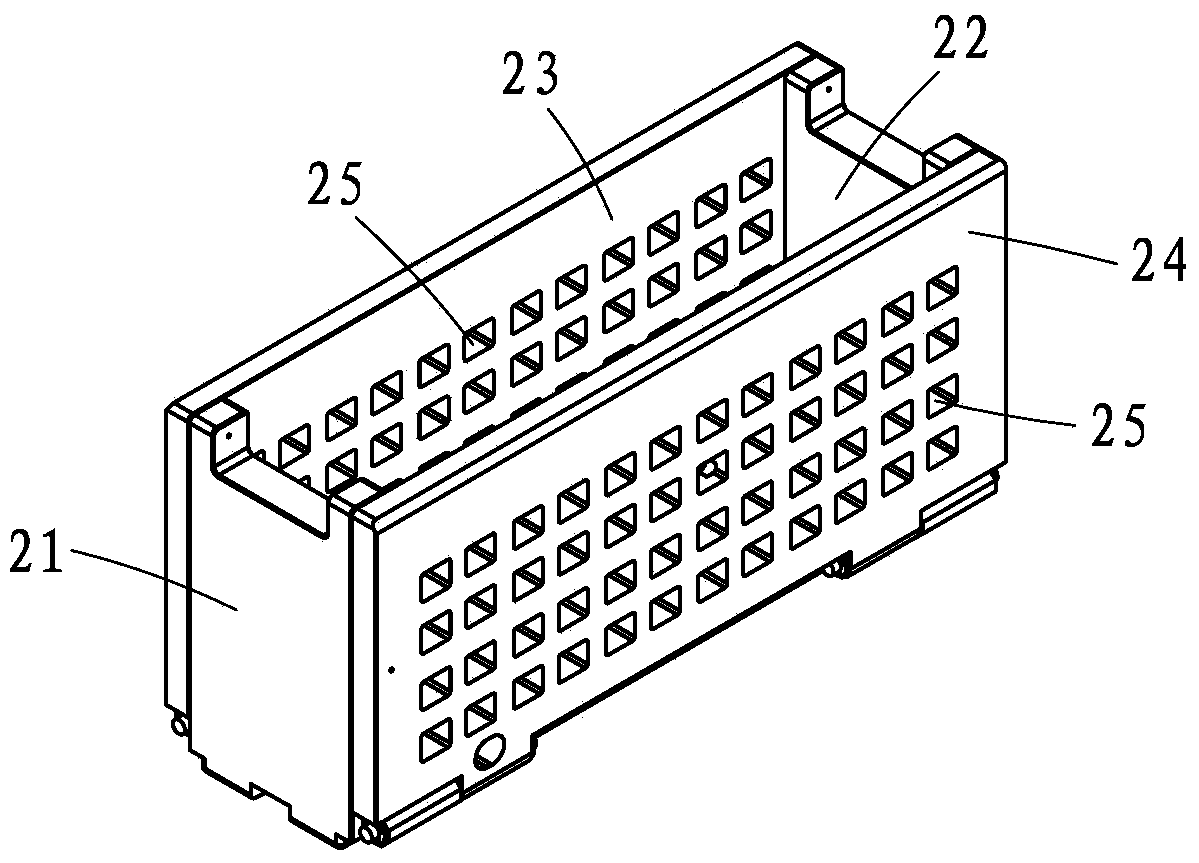

[0032] Such as Figure 1 to Figure 9 As shown, the fully automatic spot welding machine of the present invention comprises a track 1, a plurality of jigs 2, a jig advancing mechanism 3, a jig transfer guiding mechanism 4, a jig pushing out mechanism 5, two spot welding head 6, two three-axis motion mechanisms 7, and a positioning and clamping mechanism 8; the electrode sheet of the power battery pack to be spot-welded (not shown) is placed on the jig 2, and the jig 2 is Advance intermittently on track 1; Described two spot welding heads 6 are positioned at the both sides of track 1 respectively and are respectively arranged on a described three-axis motion mechanism 7, and control spot welding head 6 along three axes by this three axis motion mechanism 7 shaft movement; the jig propulsion mechanism 3 and the jig push-out mechanism 5 are respectively arranged on the feed end 11 and the discharge end 12 of the track 1, and the jig transfer guide mechanism 4 is arranged on the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com