Patents

Literature

125 results about "Magnetic pulse welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

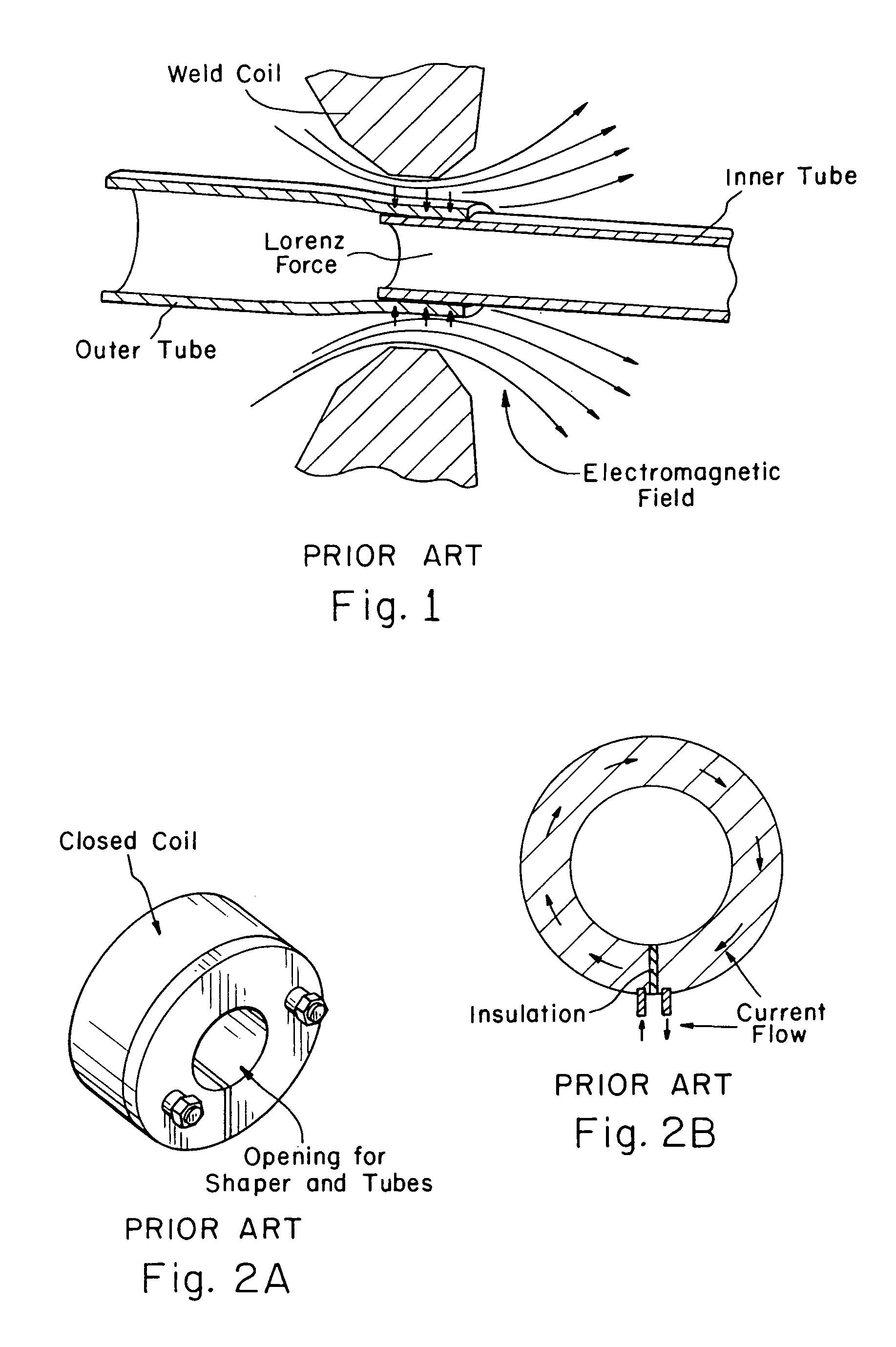

Magnetic pulse welding (MPW) is a solid state welding process that uses magnetic forces to weld two workpieces together. The welding mechanism is most similar to that of explosion welding. Magnetic pulse welding started in the early 1970s, when the automotive industry began to use solid state welding. The biggest advantage using magnetic pulse welding is that the formation of brittle intermetallic phases is avoided. Therefore, dissimilar metals can be welded, which cannot be joined by fusion welding. With magnetic pulse welding high quality welds in similar and dissimilar metals can be made in microseconds without the need for shielding gases or welding consumables.

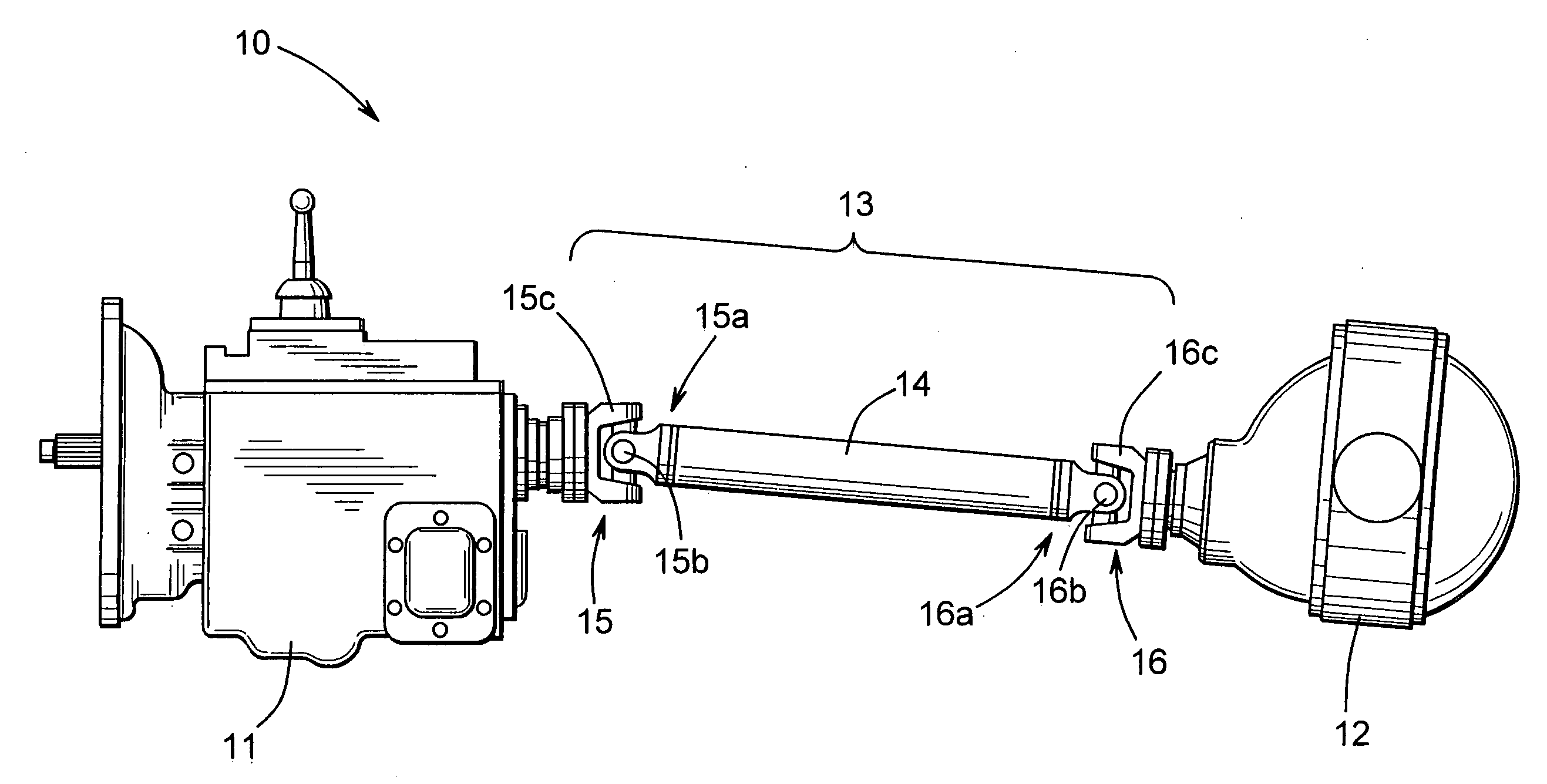

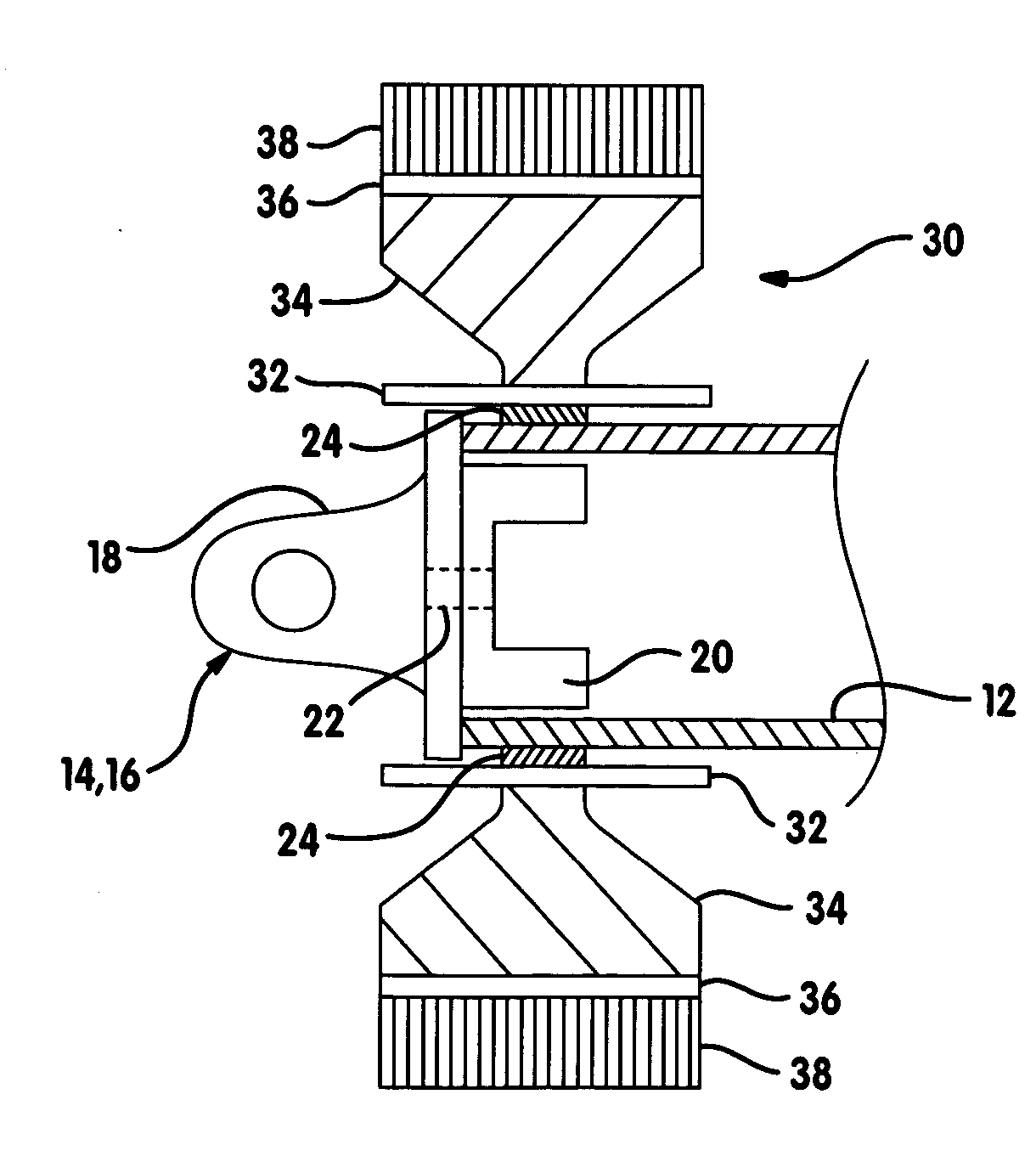

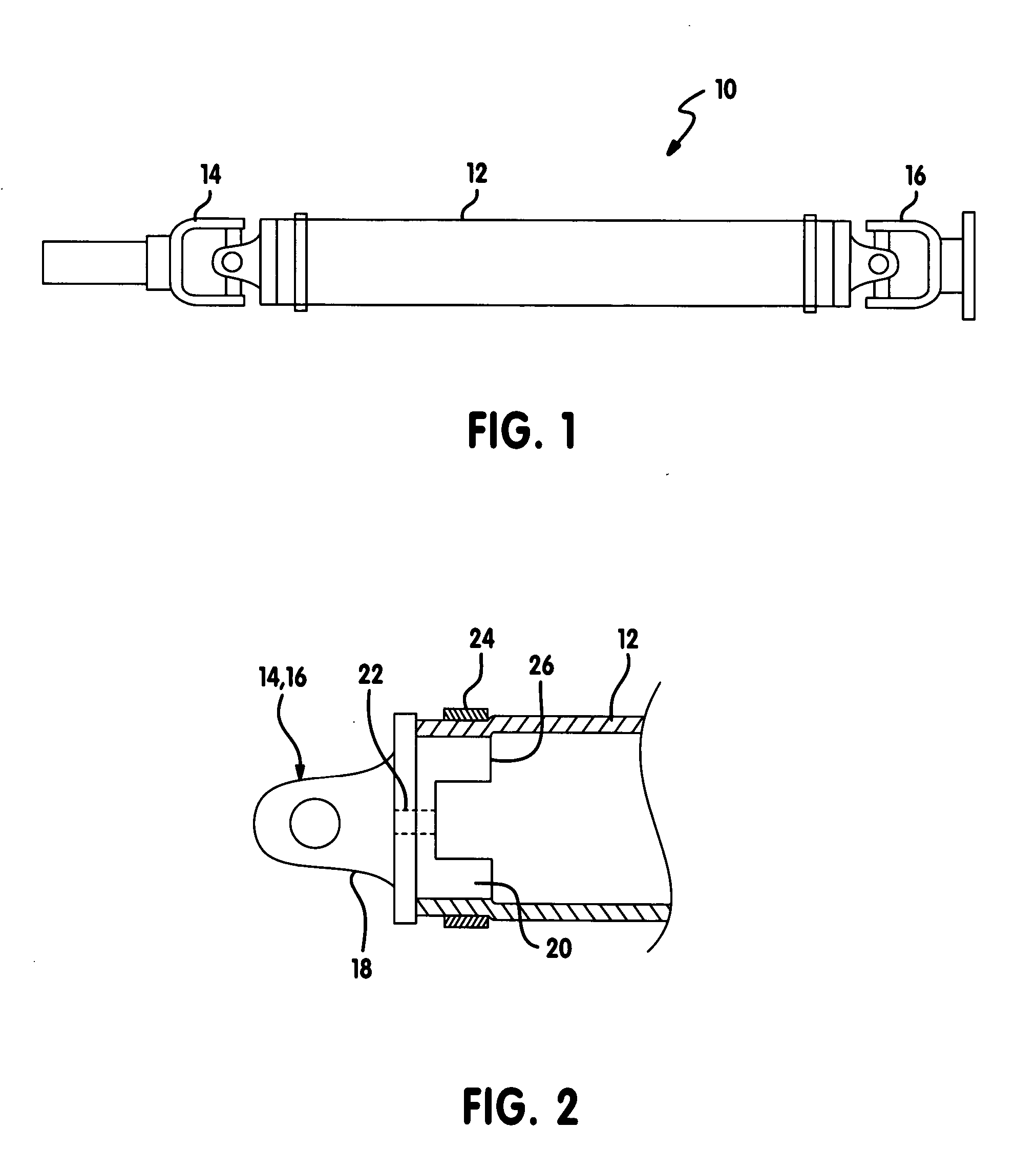

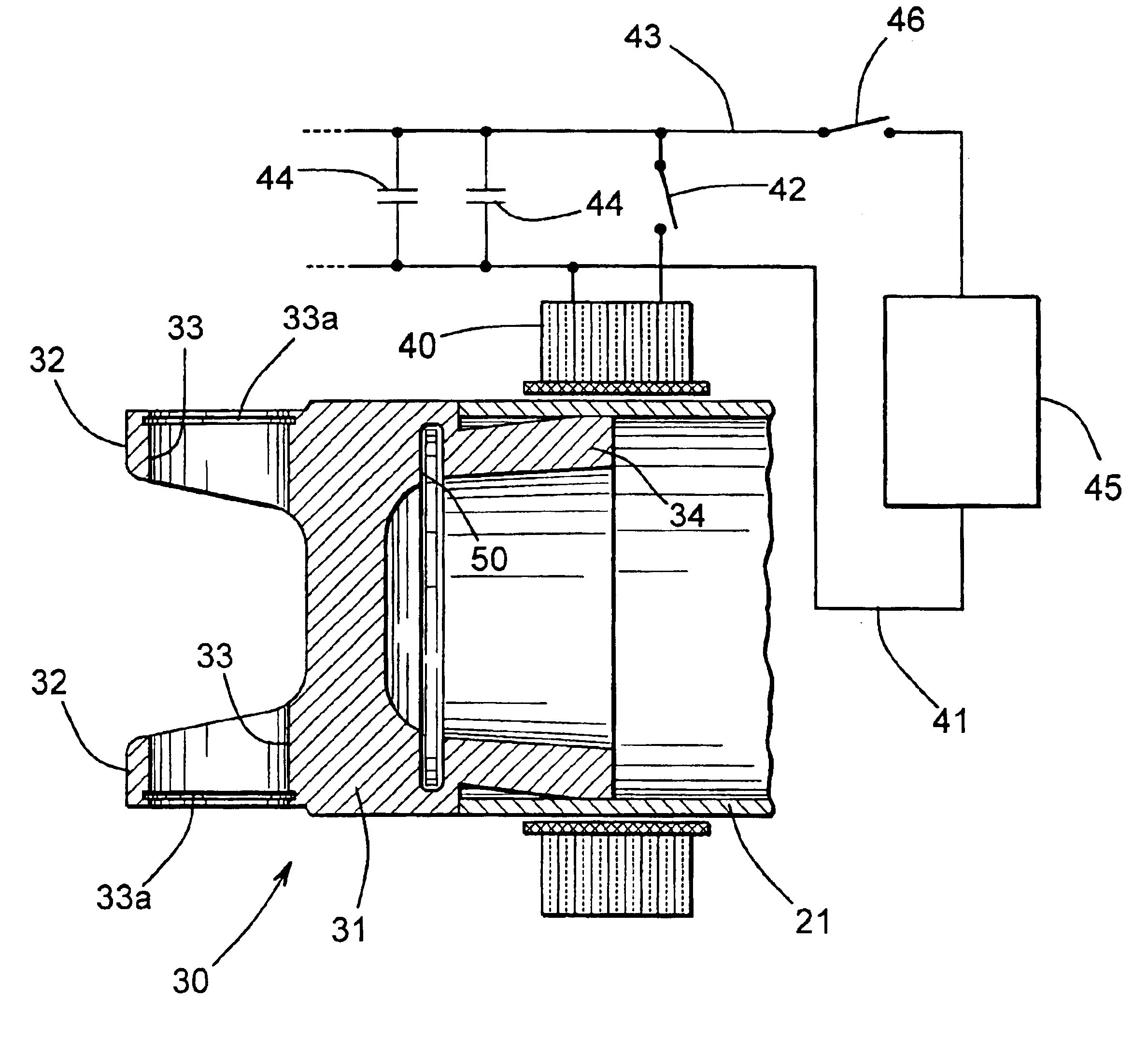

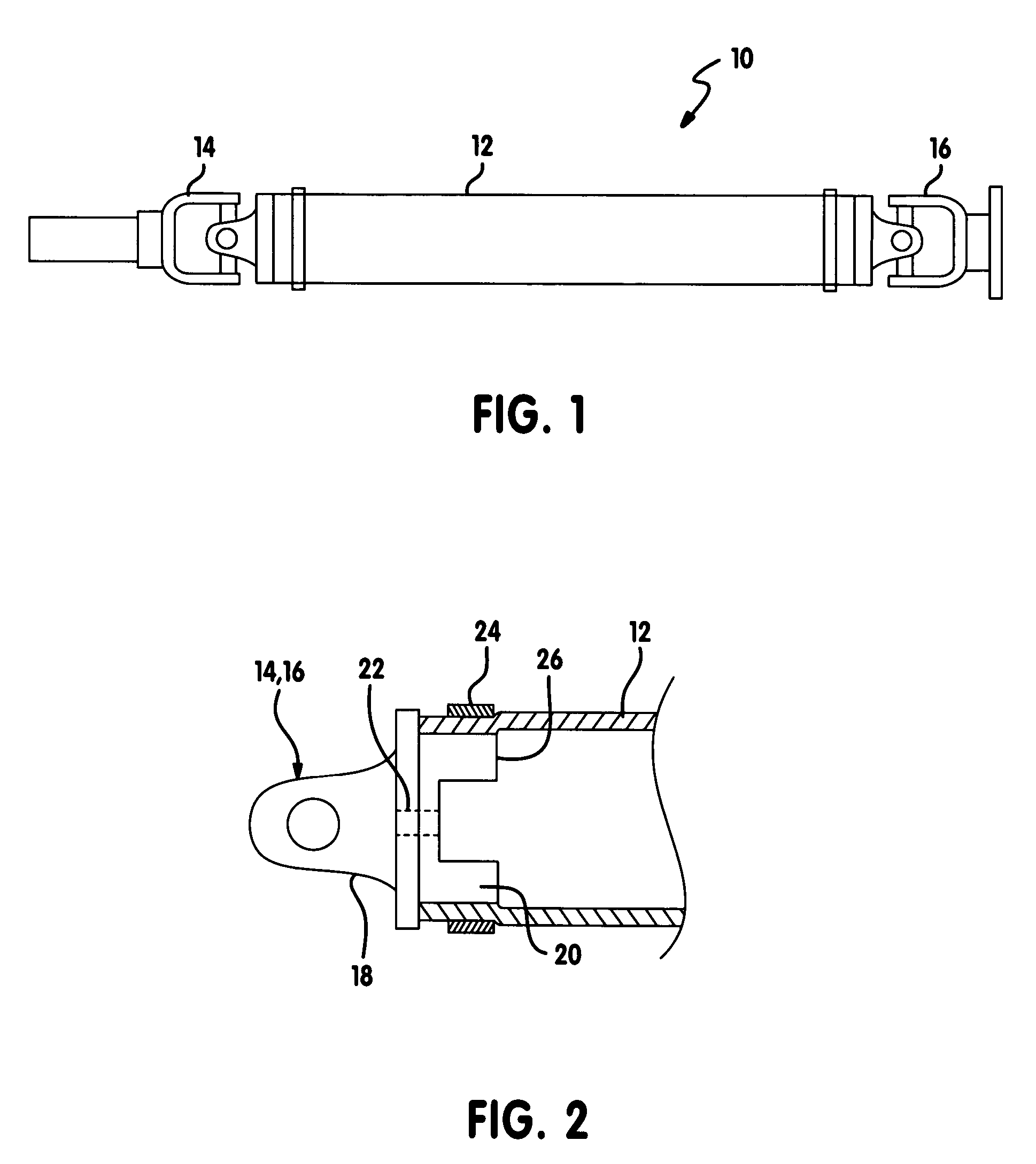

Driveshaft assembly and method of manufacturing same

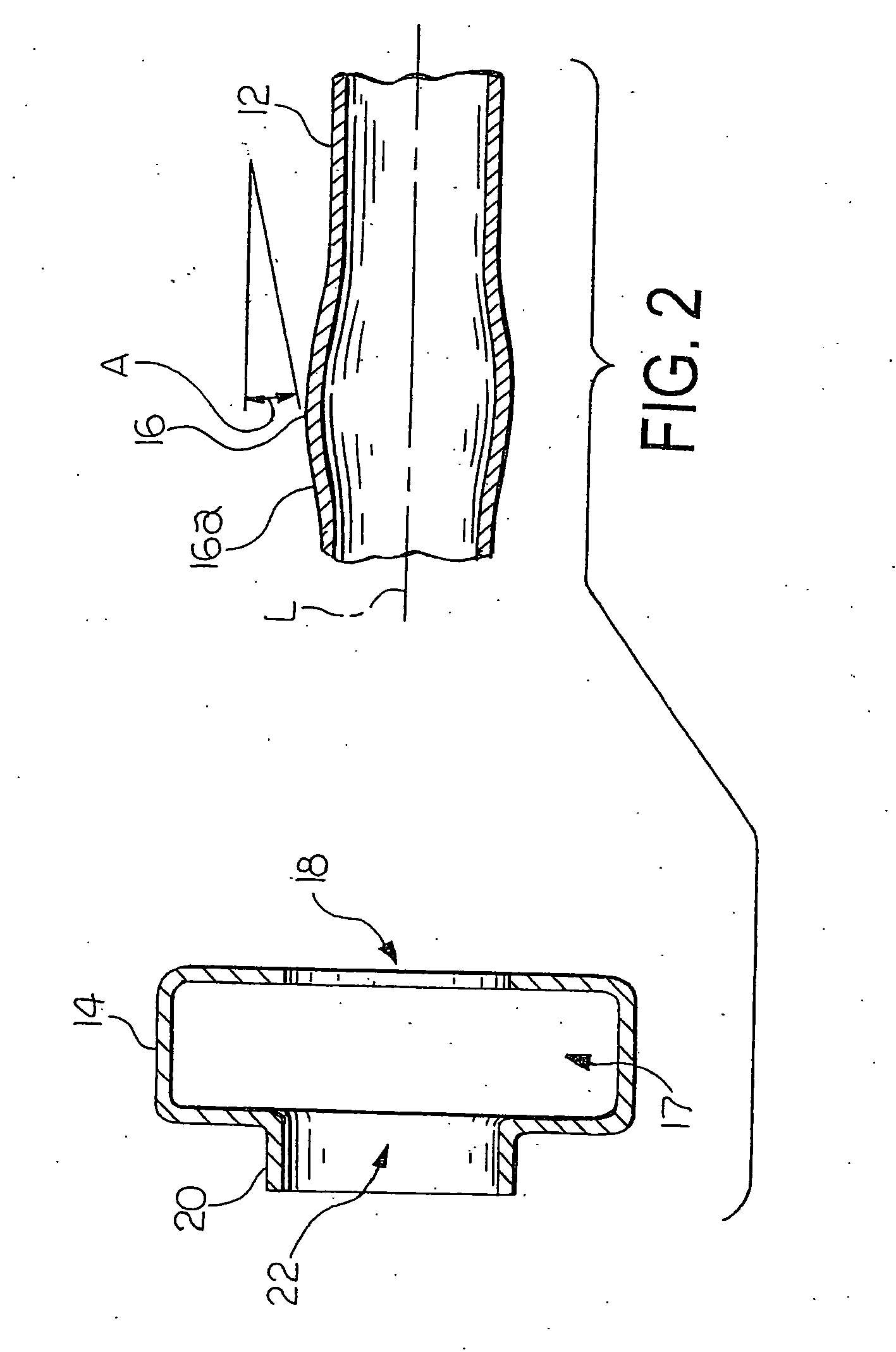

InactiveUS20070066406A1Protection from damageSimple structureClutchesYielding couplingEngineeringMagnetic pulse welding

A driveshaft assembly includes a yoke including a body portion, a pair of opposed yoke arms that extends generally in a first axial direction from the body portion, and a neck portion that extends generally in a second axial direction from the body portion. A driveshaft tube is secured to the neck portion of the yoke, such as by magnetic pulse welding. A ring is secured to the body portion of the yoke, such as by press fitting, and a balance weight is secured to the ring, such as by welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

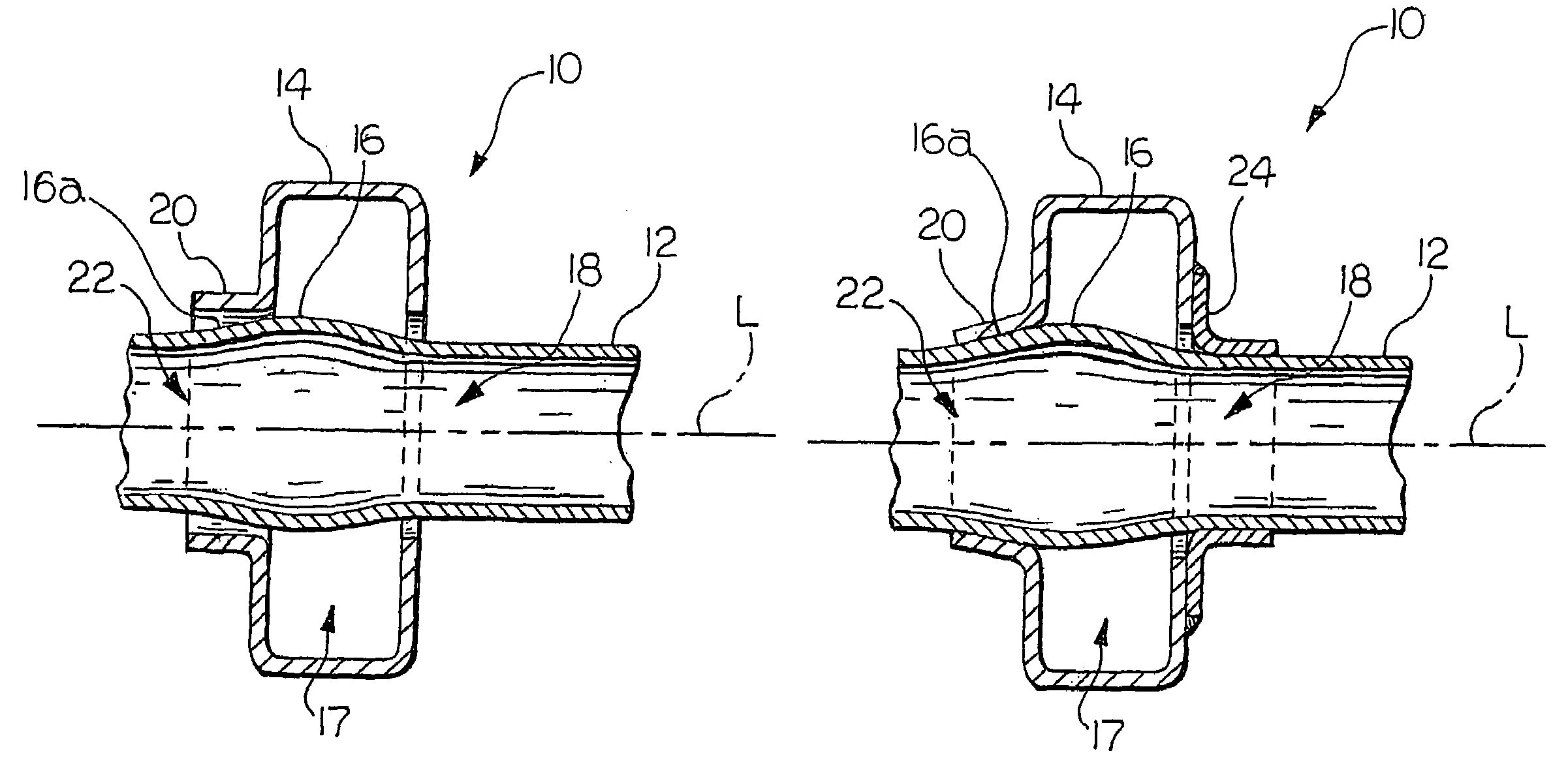

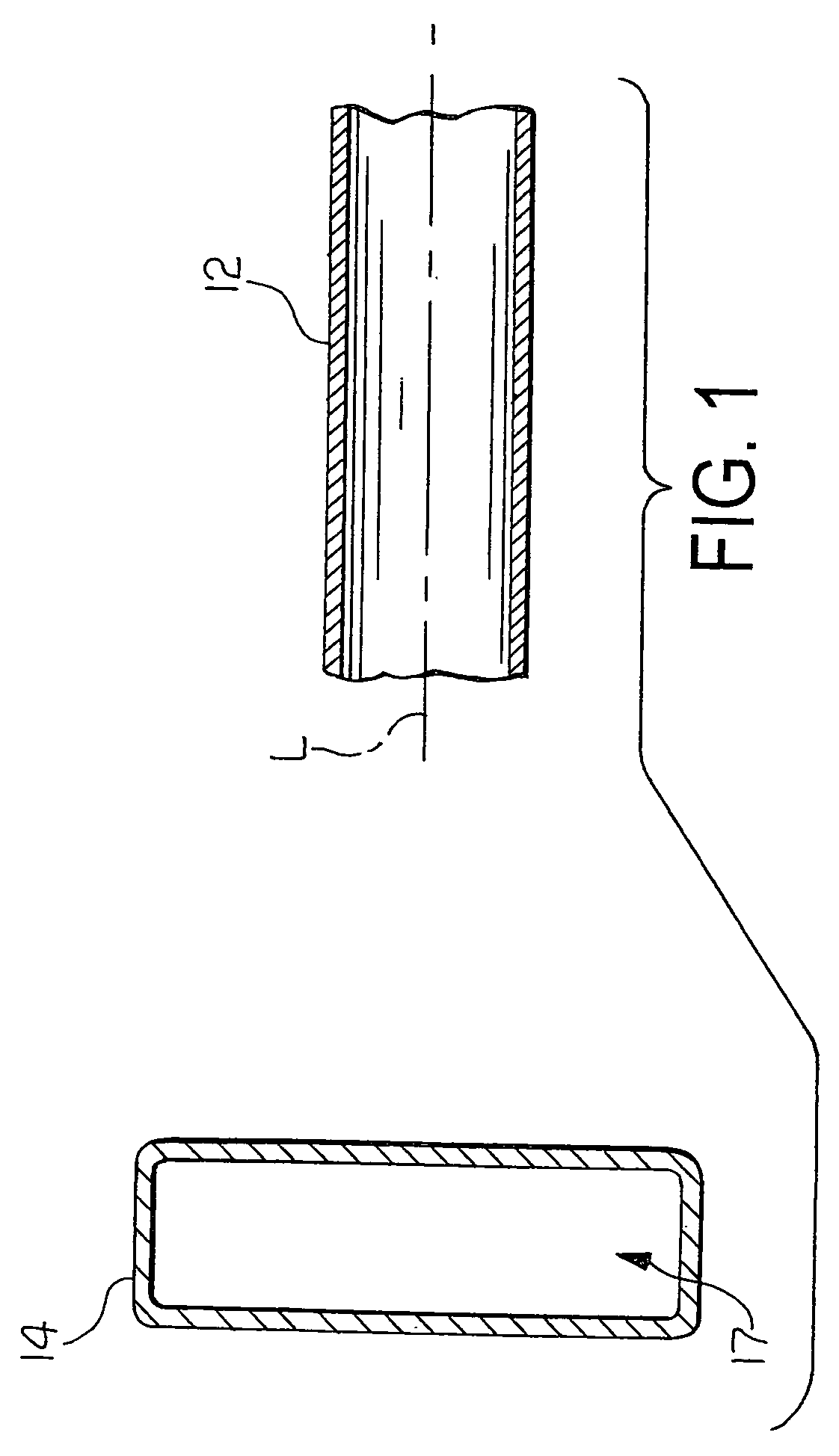

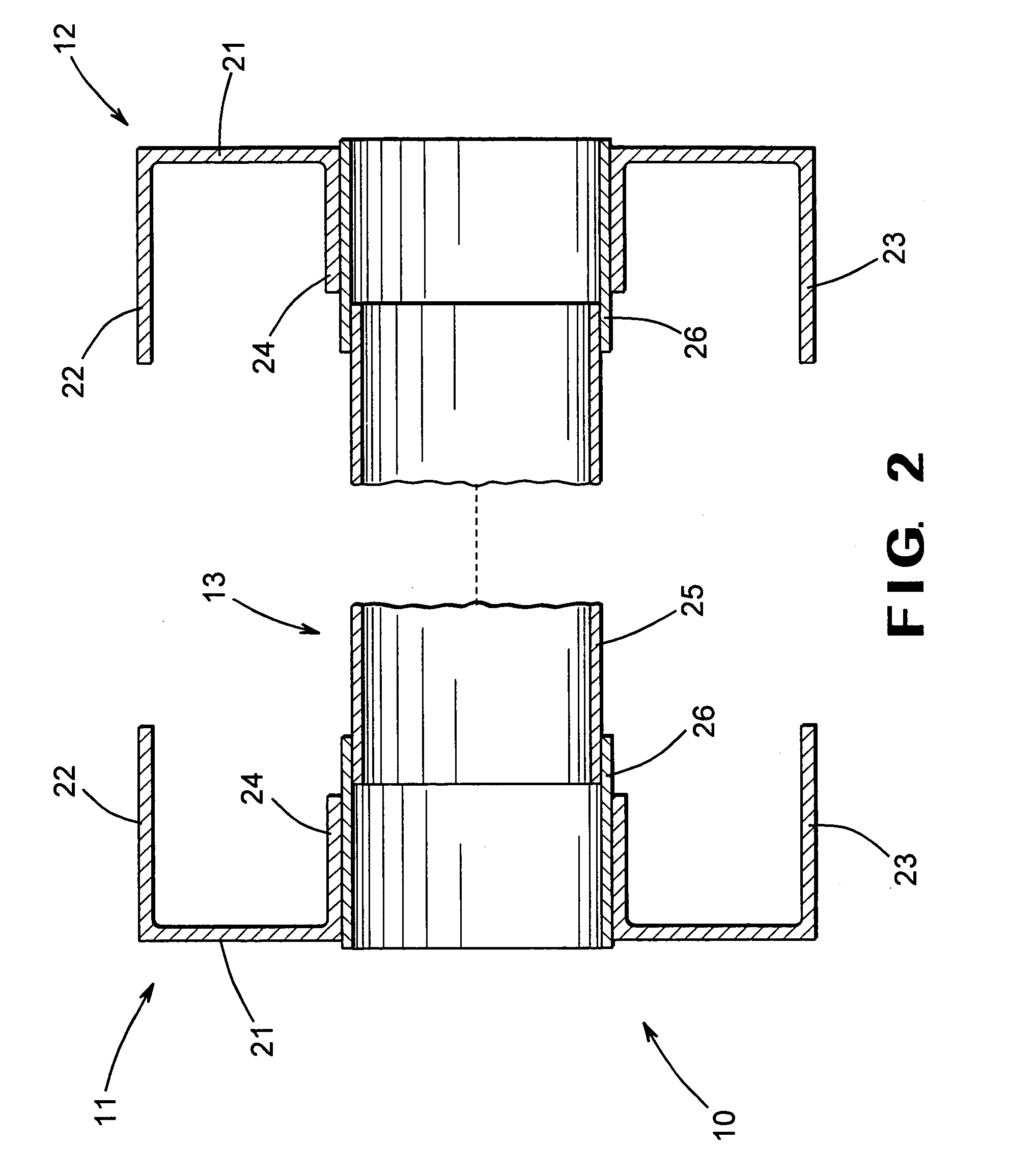

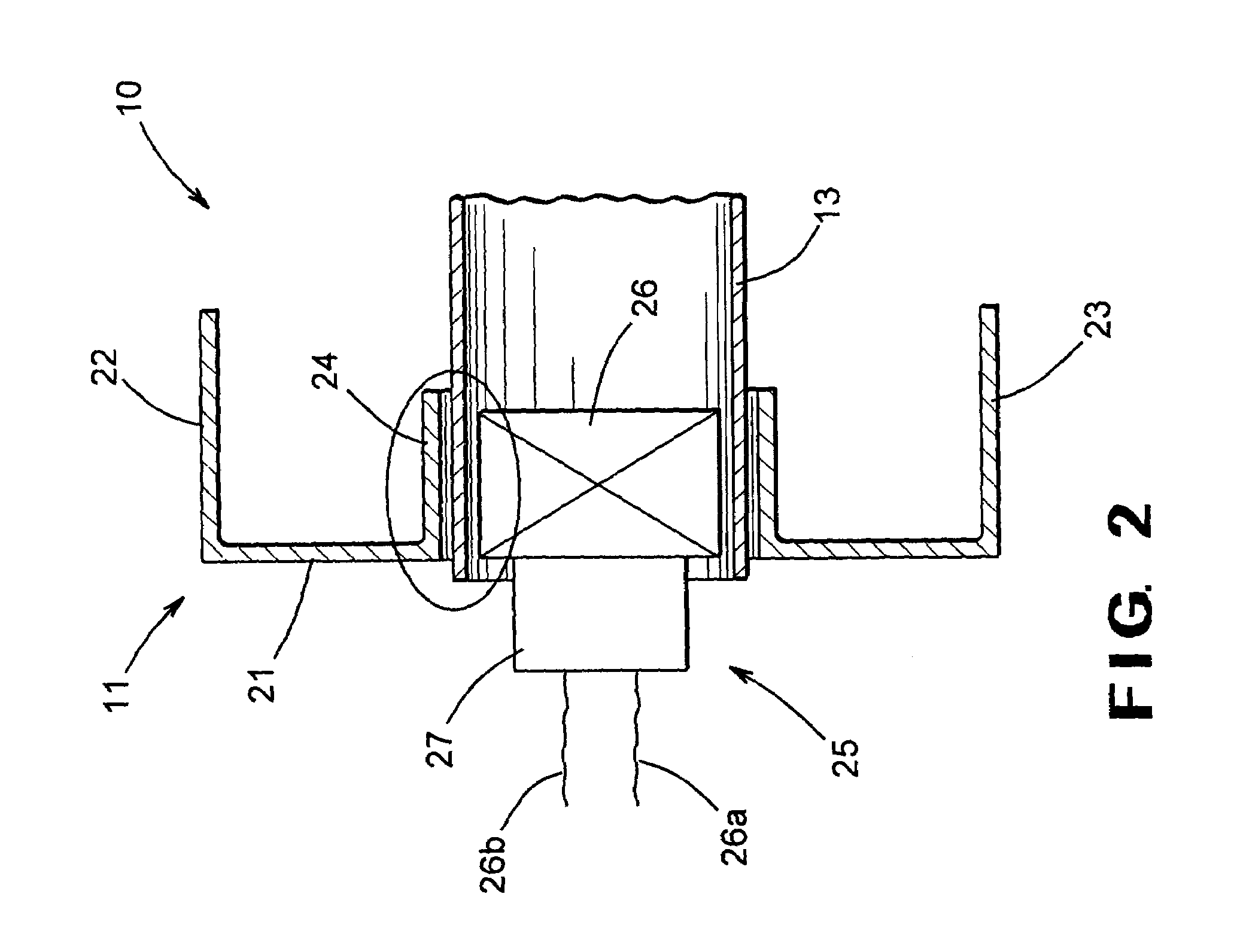

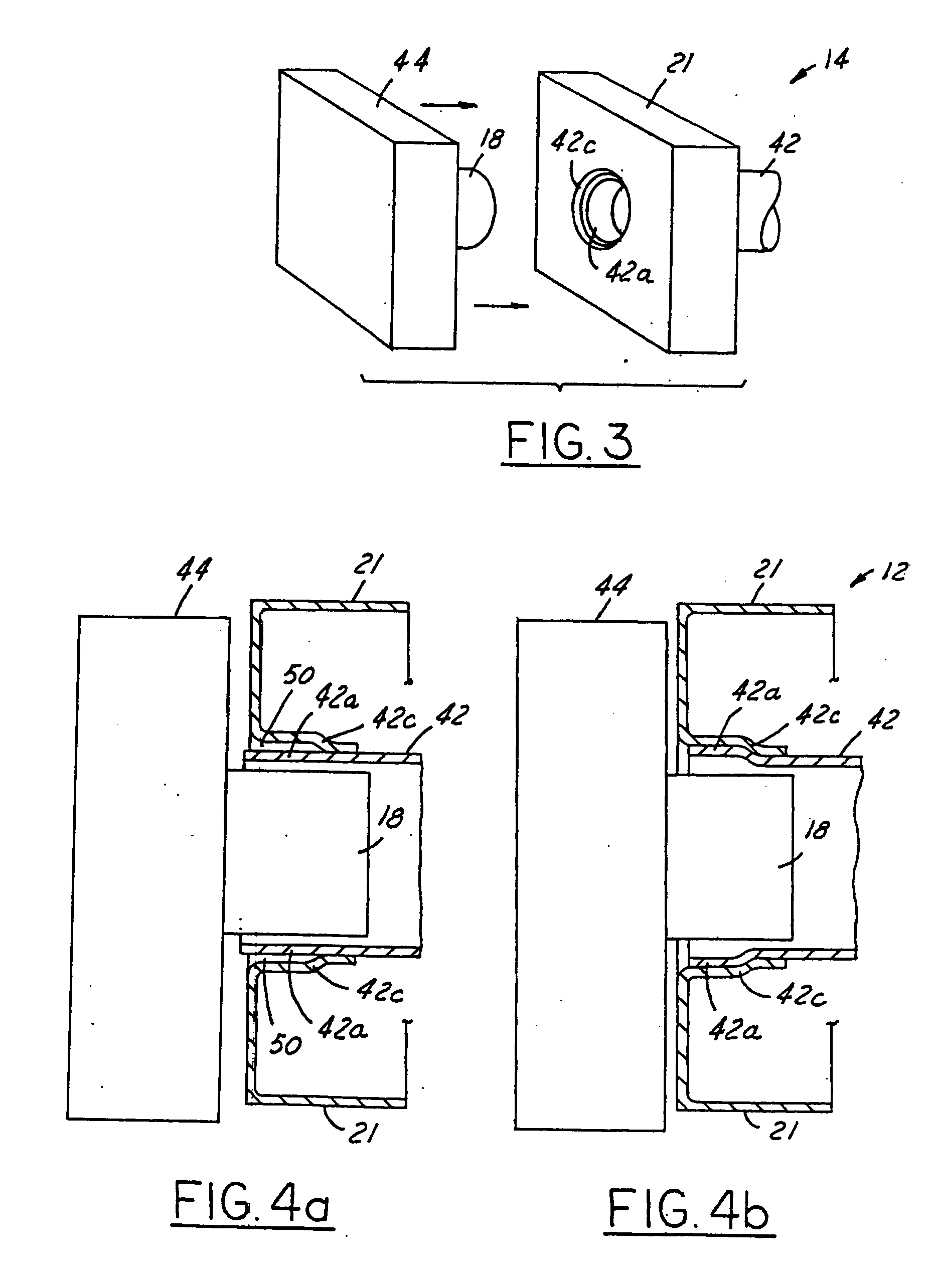

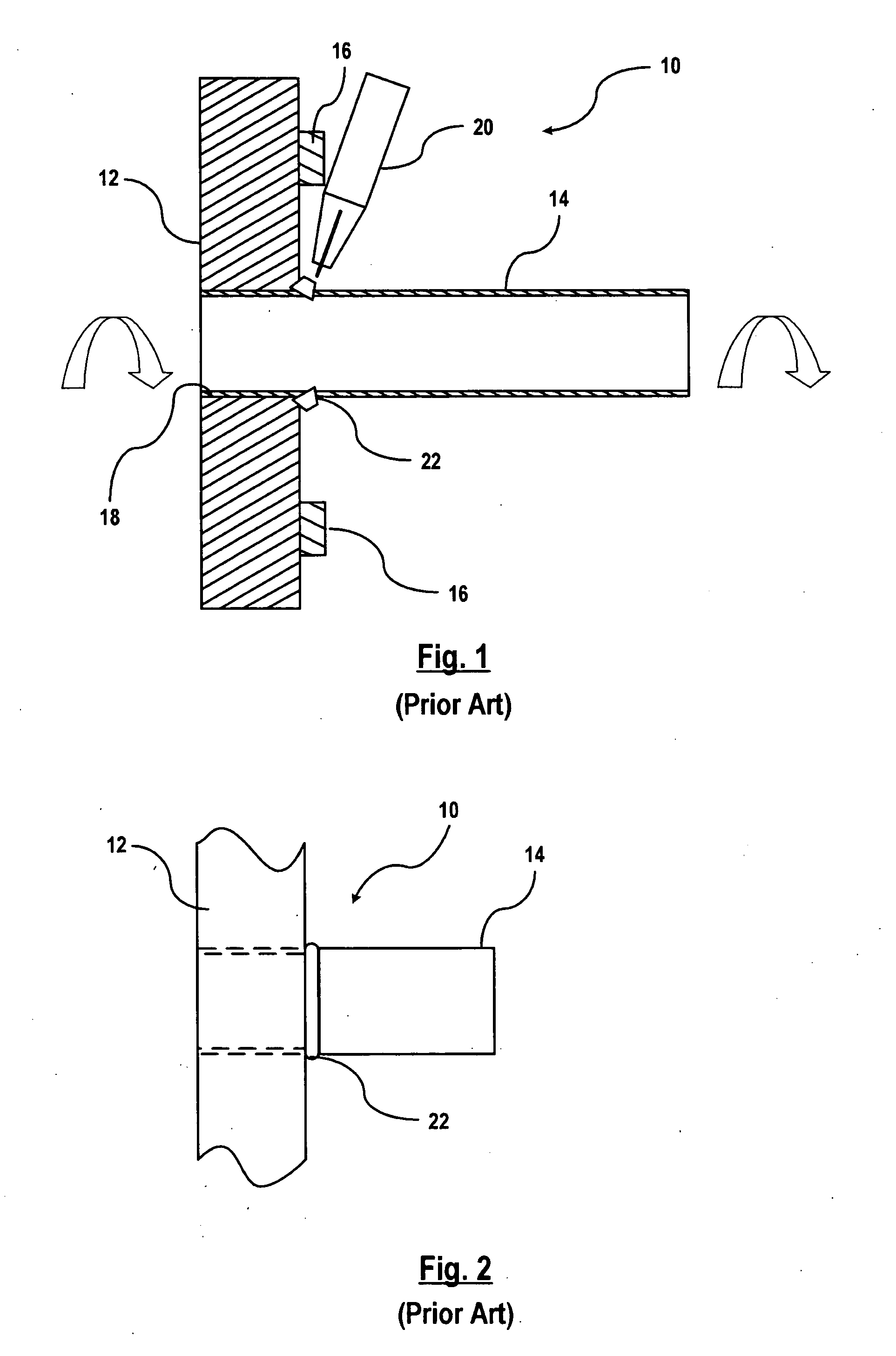

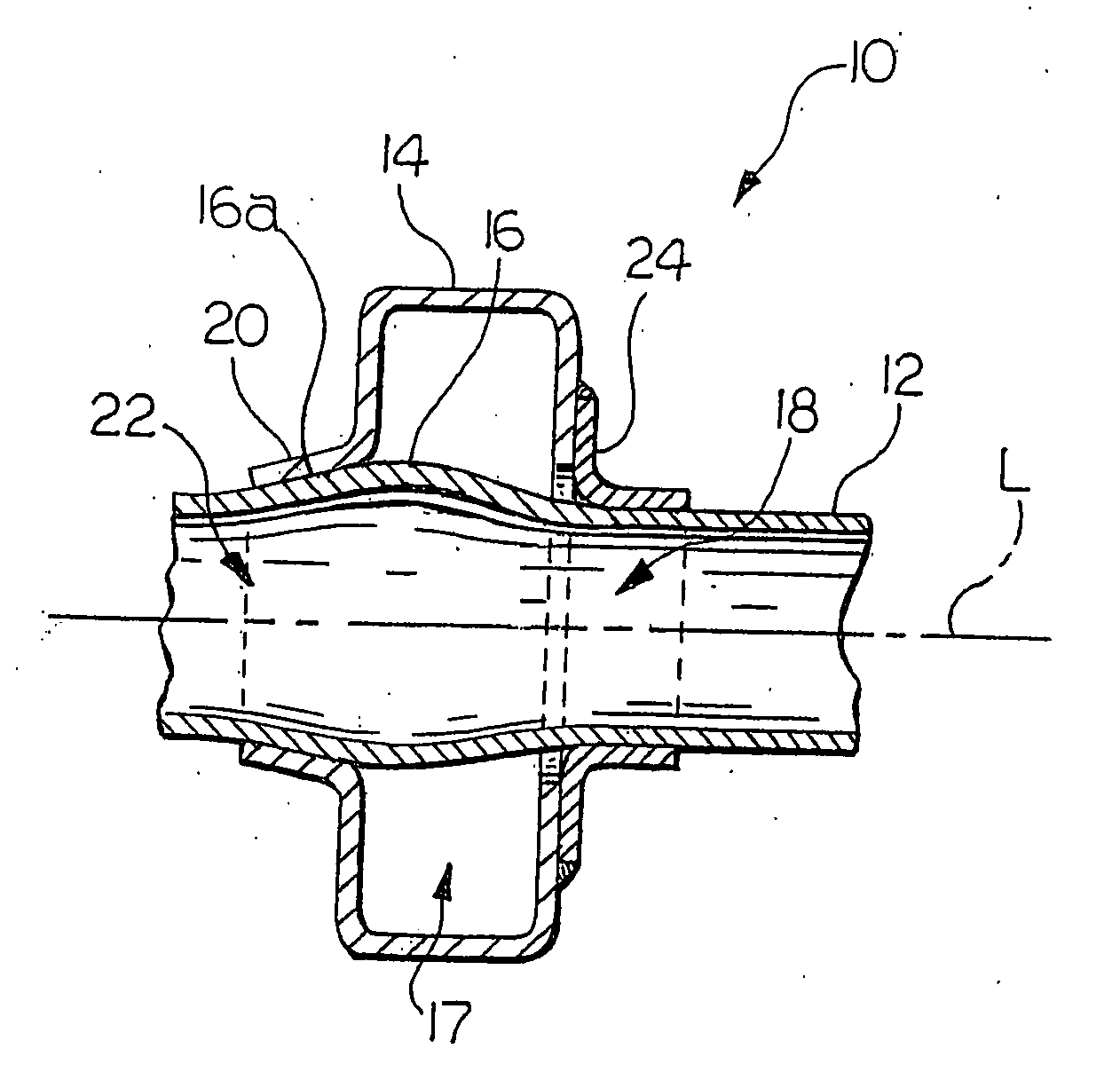

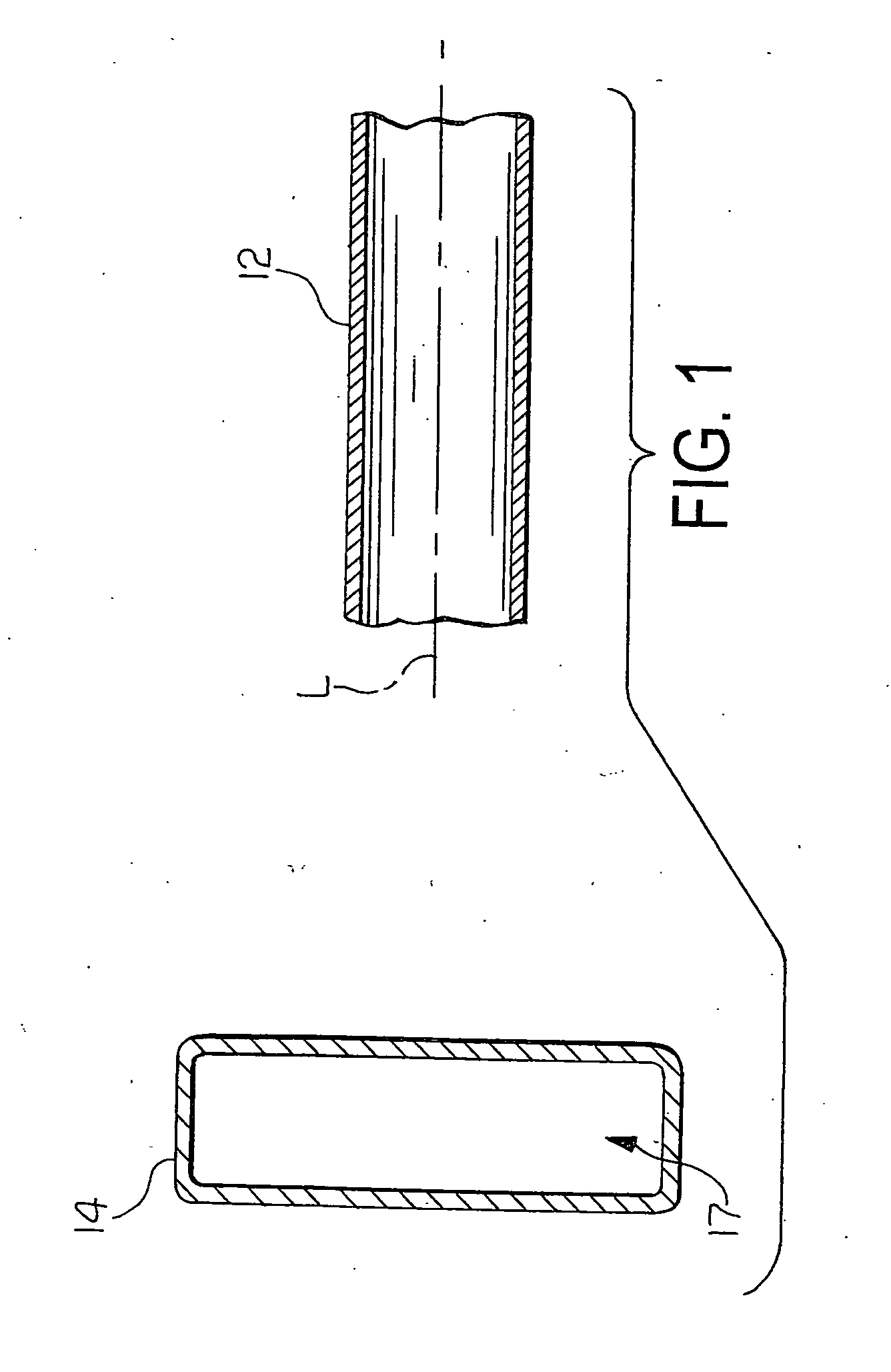

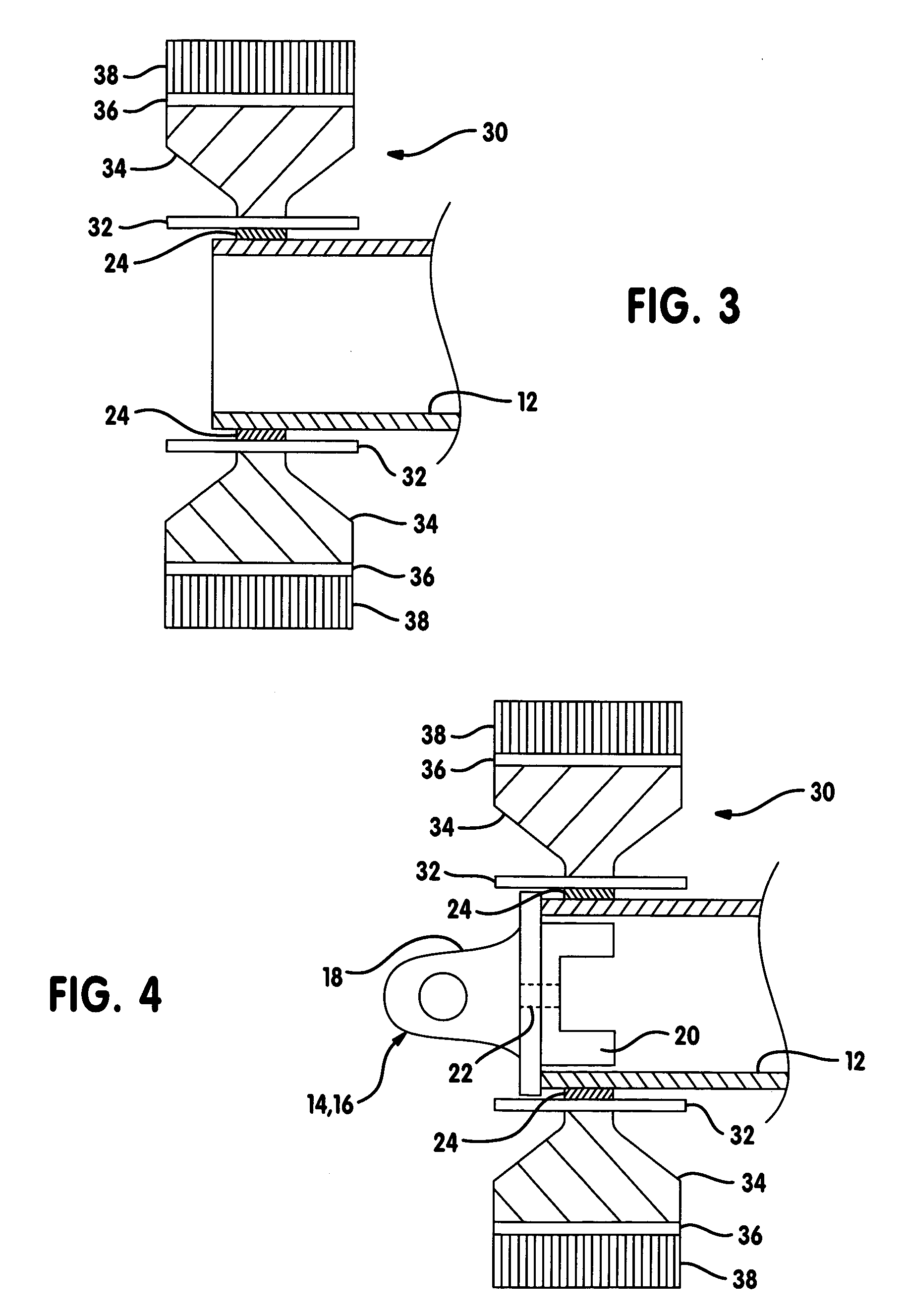

Method of permanently joining first and second metallic components

InactiveUS7127816B2Ropes and cables for vehicles/pulleyArc welding apparatusMagnetic pulse weldingFlange

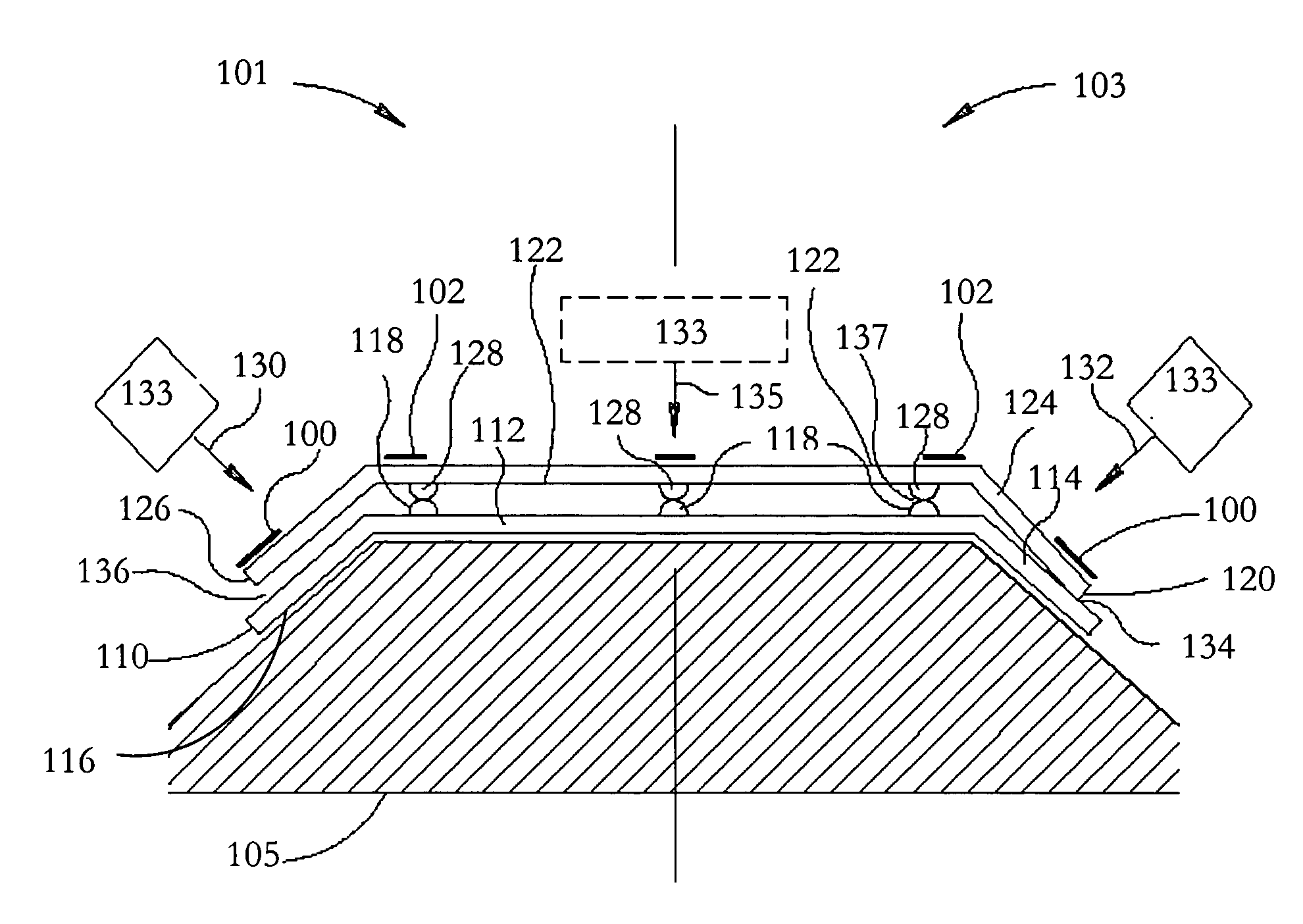

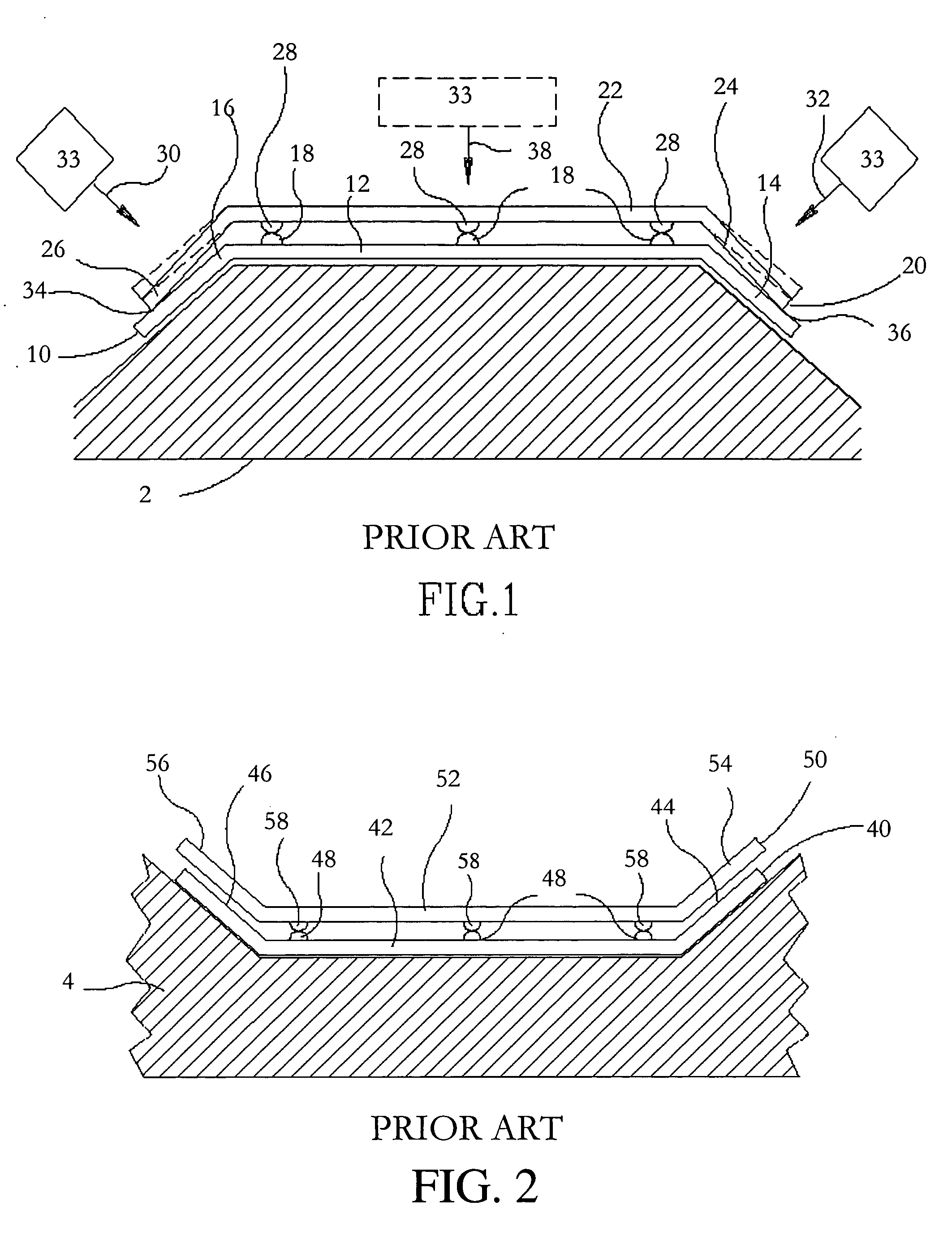

A pair of metallic components, such as a pair of metallic structural components for a vehicular body and frame assembly, are permanently joined using a magnetic pulse welding process. Initially, a first metallic component is provided having a first aperture that is formed through a first side and a second aperture having a hollow cylindrical flange portion that is formed through a second side. A second metallic component is provided having a surface that extends at an angle relative to the flange portion. The angled surface may be provided in the form of either an enlarged region or a reduced region on the second metallic component. The first and second metallic components are arranged such that the flange portion of the first metallic component overlaps the surface of the second metallic component. A magnetic pulse welding process is performed to cause the flange portion of the first metallic component and the angled surface of the second metallic component to engage one another and become permanently joined.

Owner:METALSA SA DE CV

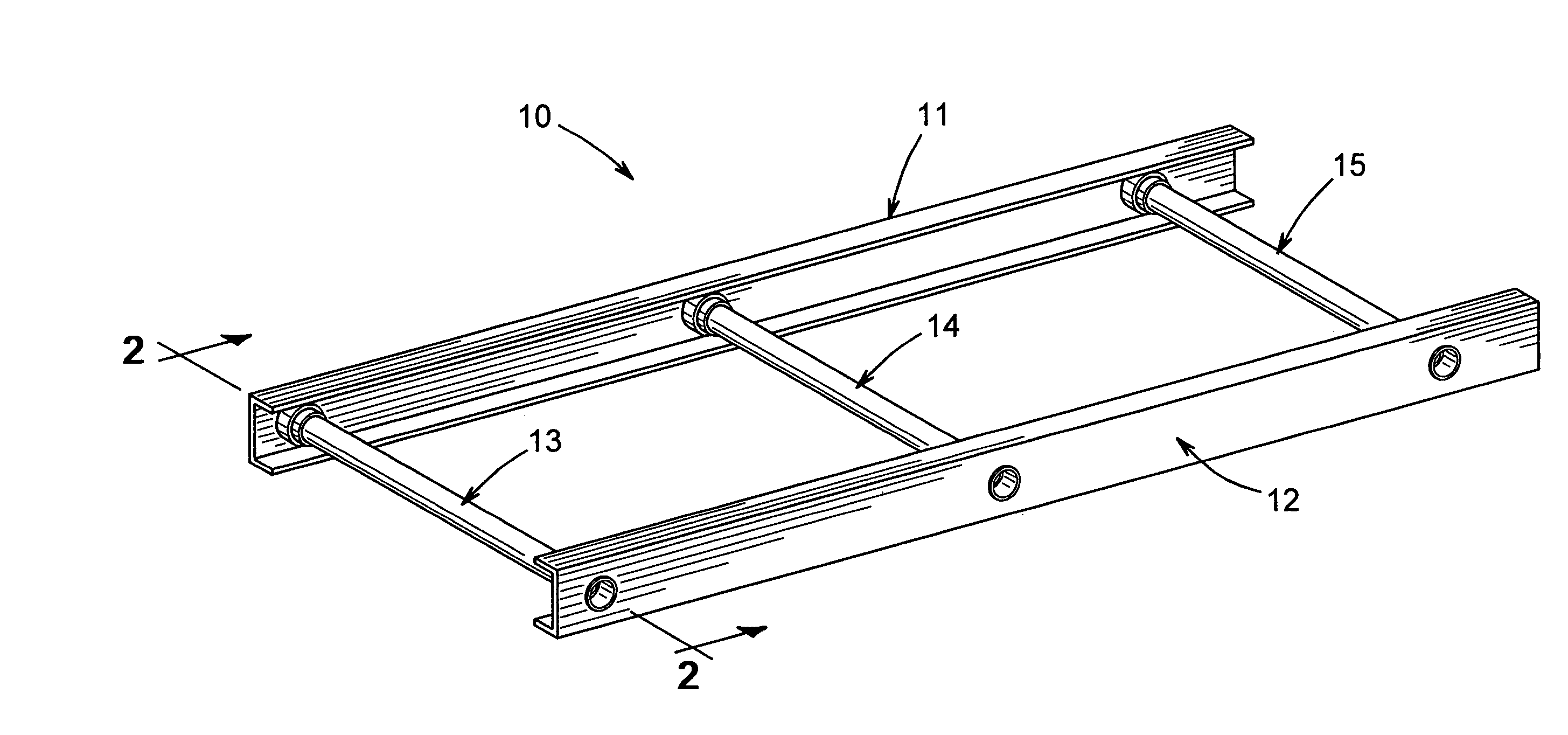

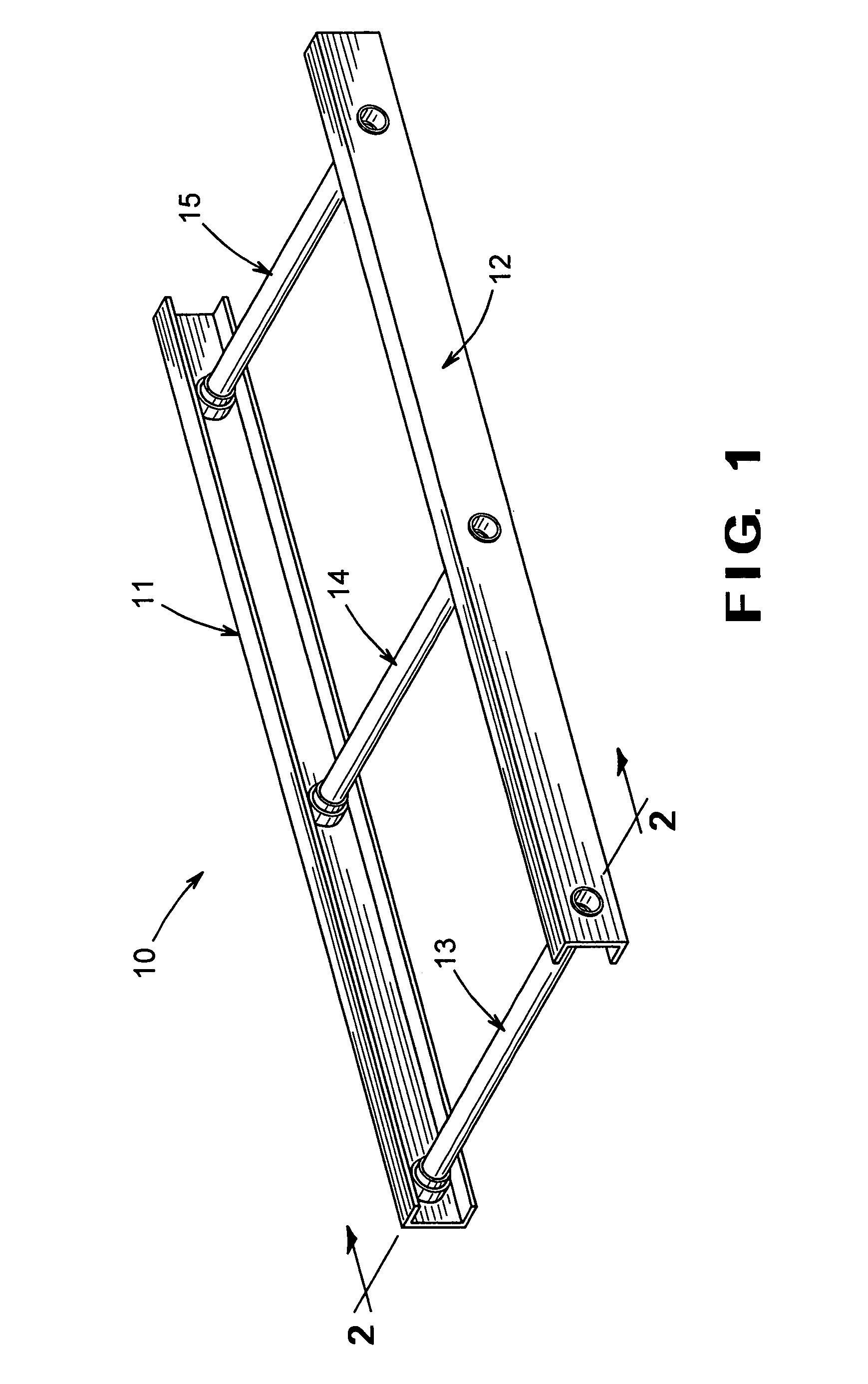

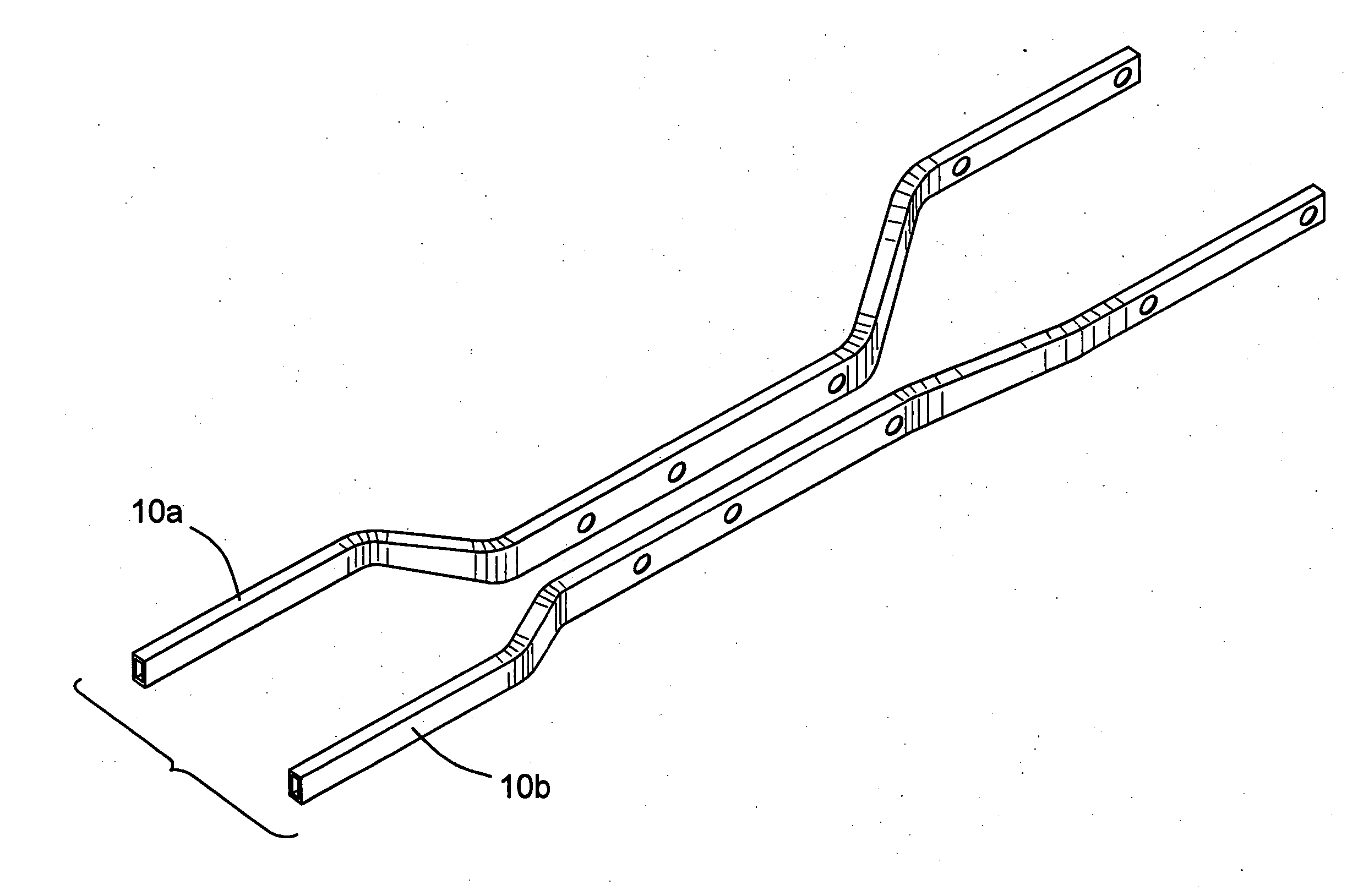

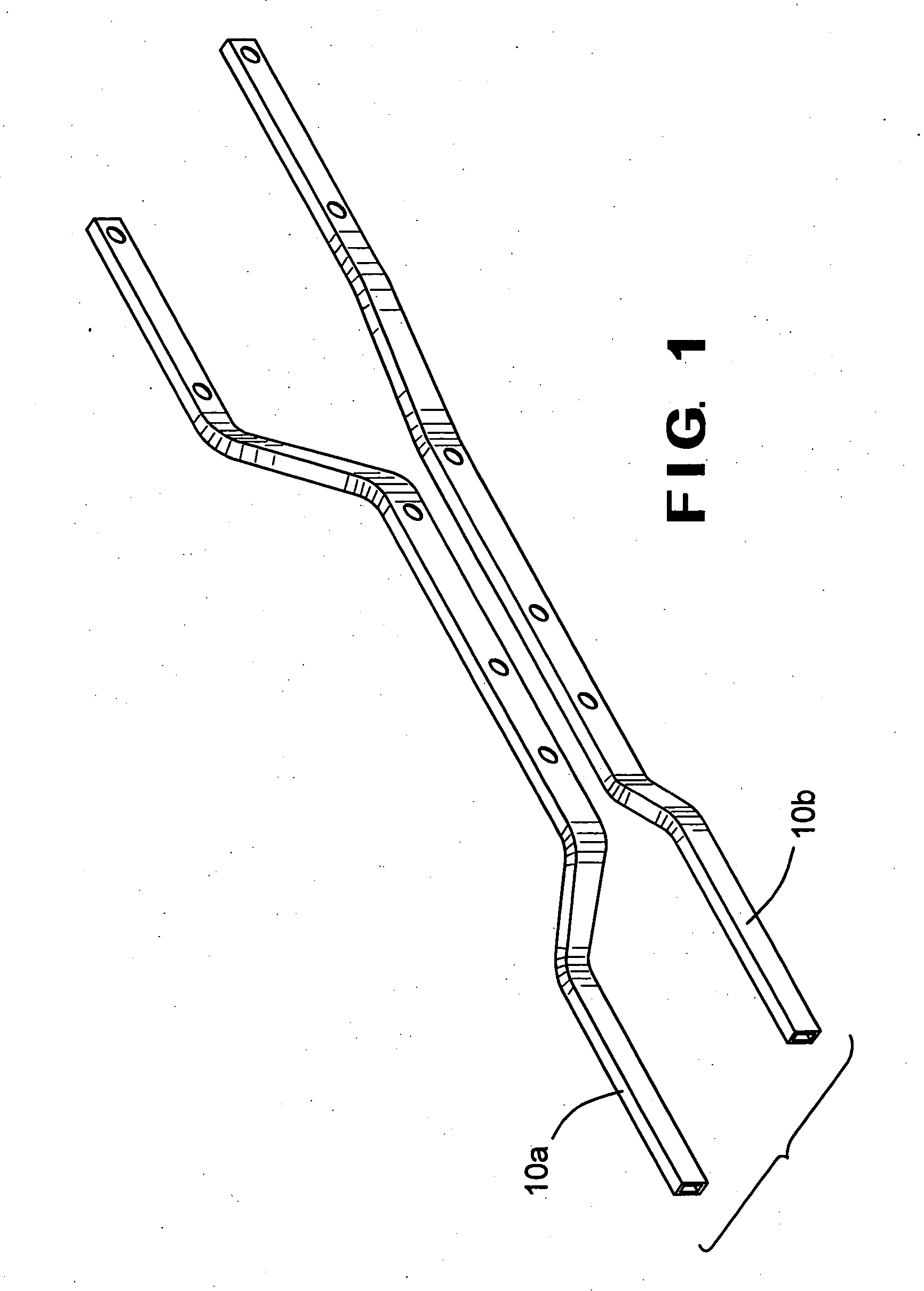

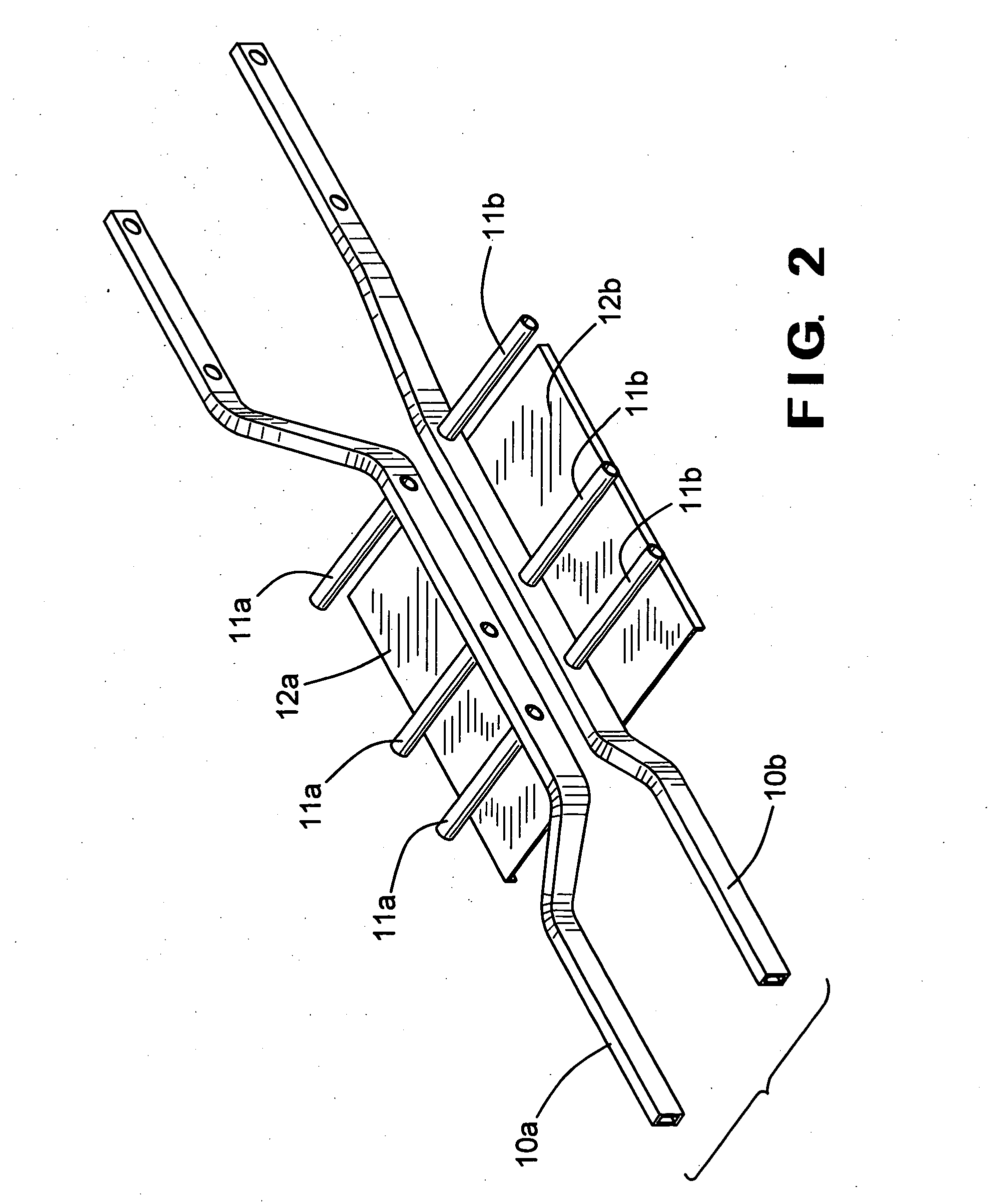

Bi-metallic structural component for vehicle frame assembly

ActiveUS7144040B2Simple structureVehicle seatsVehicle body-frame connectionsVehicle frameClassical mechanics

A vehicle body and frame assembly includes a pair of longitudinally extending side rails having a plurality of transverse cross members extending therebetween. The cross member is a multiple piece structure, including a central portion having a pair of end portions secured thereto. The central portion of the cross member is preferably formed from a first metallic material, while the end portions are preferably both formed from a second metallic material. The end portions of the cross member are preferably formed from the same metallic material as the respective side rails to which they are secured. The end portions of the cross member can be secured to the ends of the central portion by any desired process, such as by magnetic pulse welding. Similarly, the cross member can be secured to the side rails by any desired process, such as by magnetic pulse welding or by conventional welding. The end portions of the cross member can extend either partially or completely through the respective side rails. If desired, a reinforcing and positioning collar can be secured to the end portions of the cross member adjacent to each of the side rails.

Owner:METALSA SA DE CV

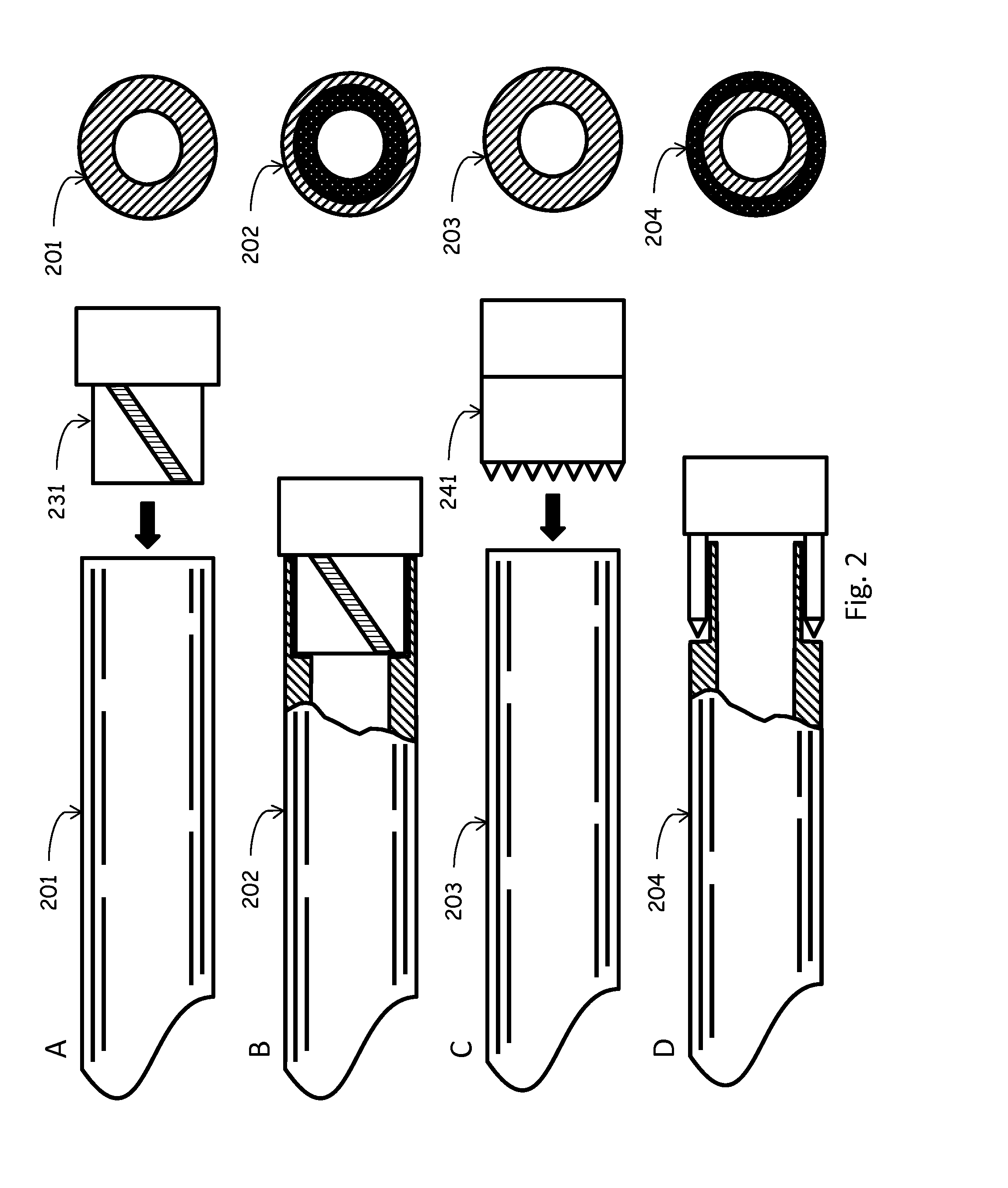

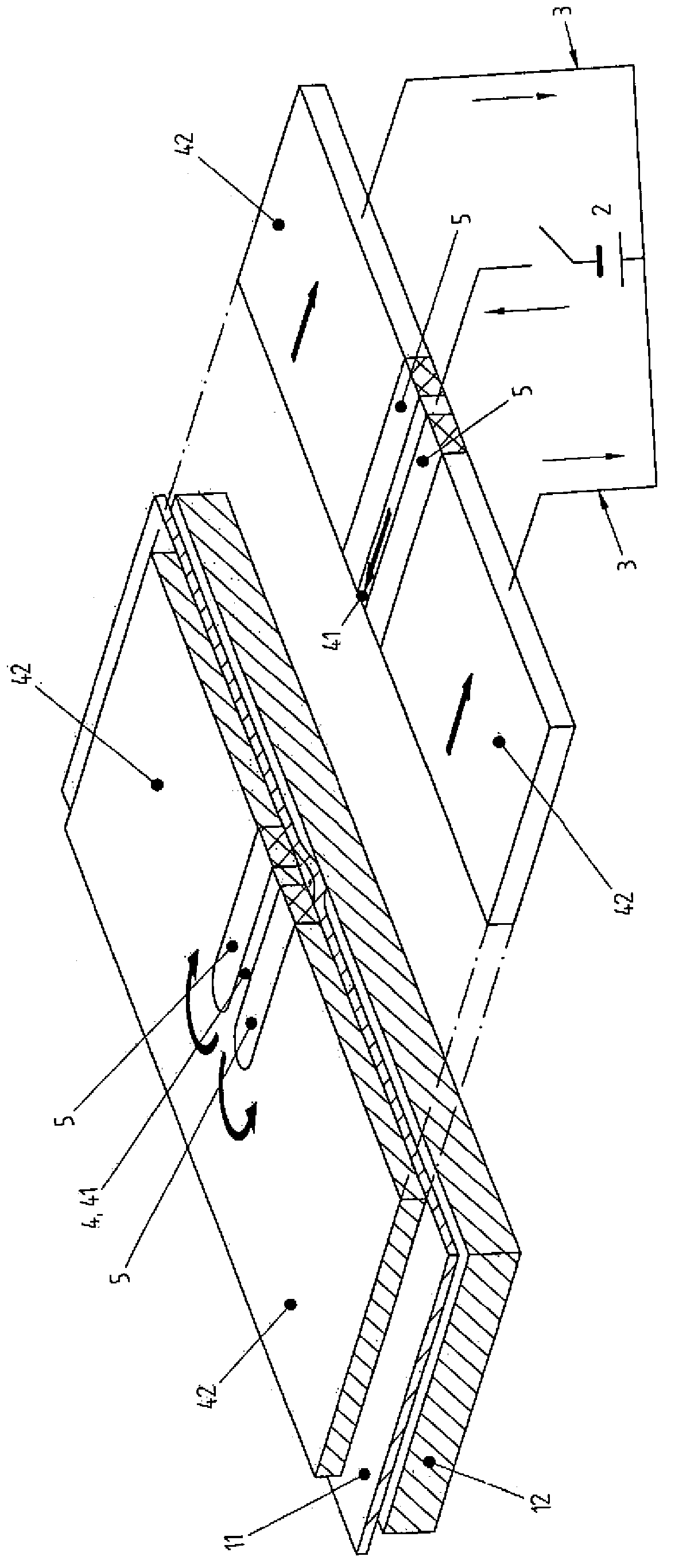

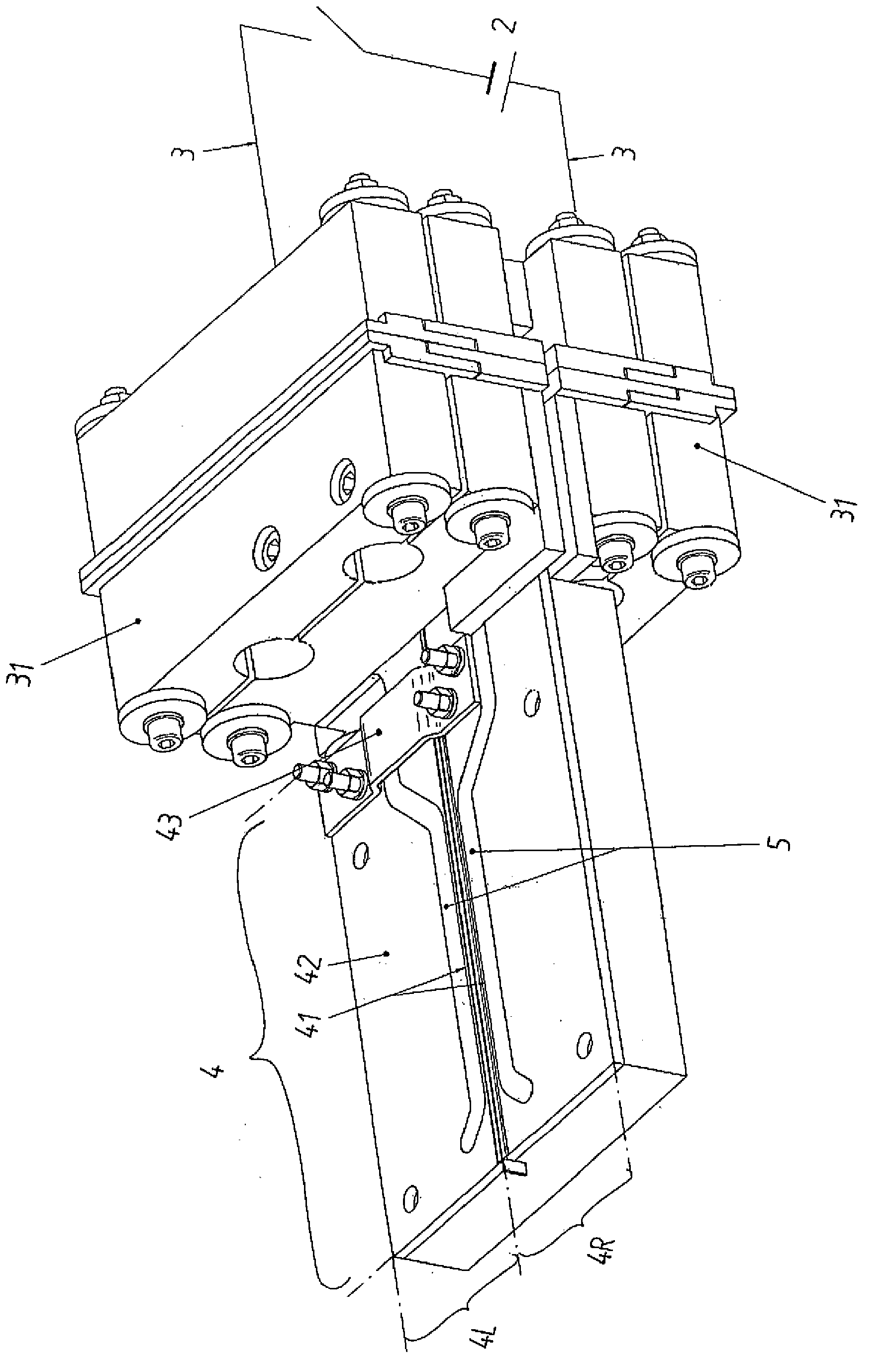

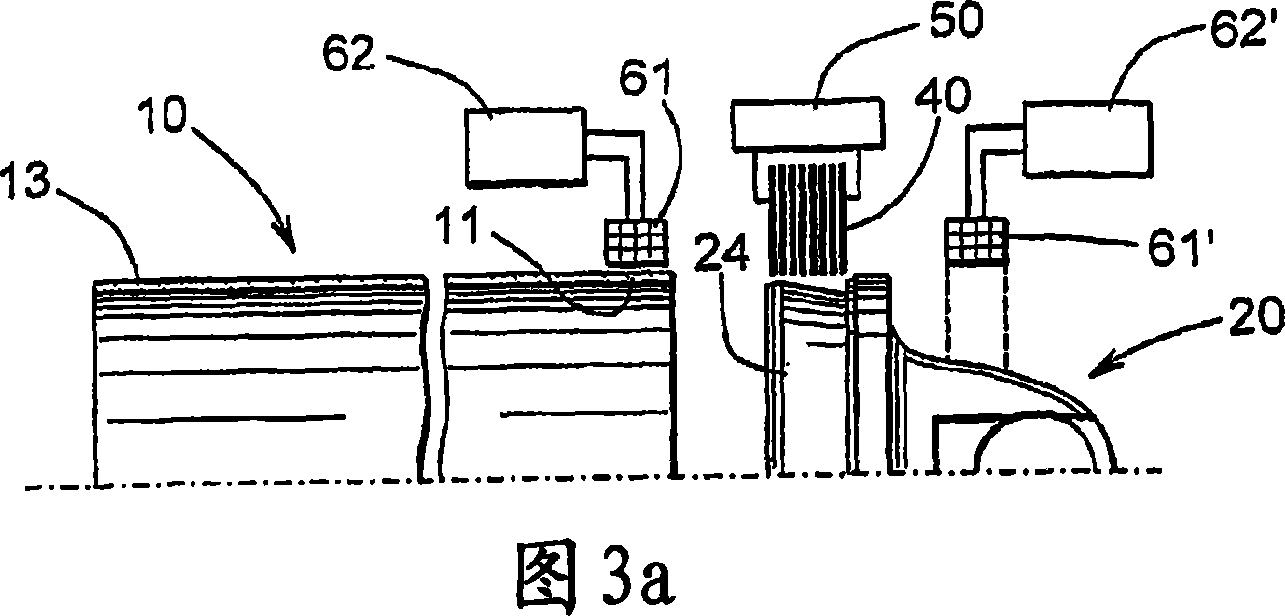

Magnetic Pulse Welding and Forming for Plates

ActiveUS20130086961A1High frequency current welding apparatusConductorsElectrical conductorMagnetic pulse welding

A method of welding two workpieces together is described. A conductor in electrical communication with a pulse circuit is provided. A portion of the second workpiece is located adjacent the conductor. The two workpieces are also located together. A portion, or all, of one workpiece is welded to the other by applying a pulse current to one of the workpieces. A method of forming a workpiece is disclosed using a pulse current to move the workpiece into a desired shape.

Owner:DANA AUTOMOTIVE SYST GRP LLC

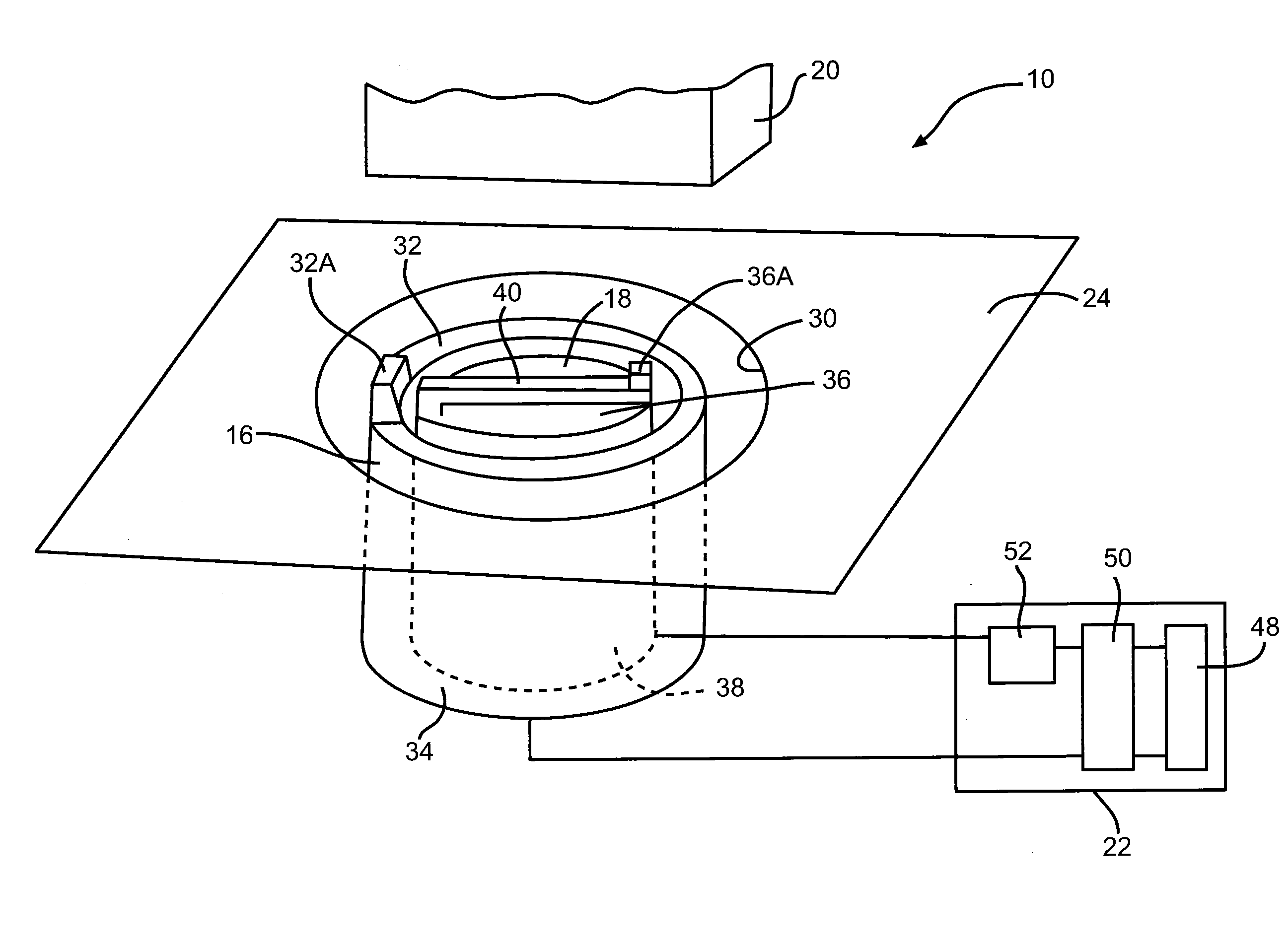

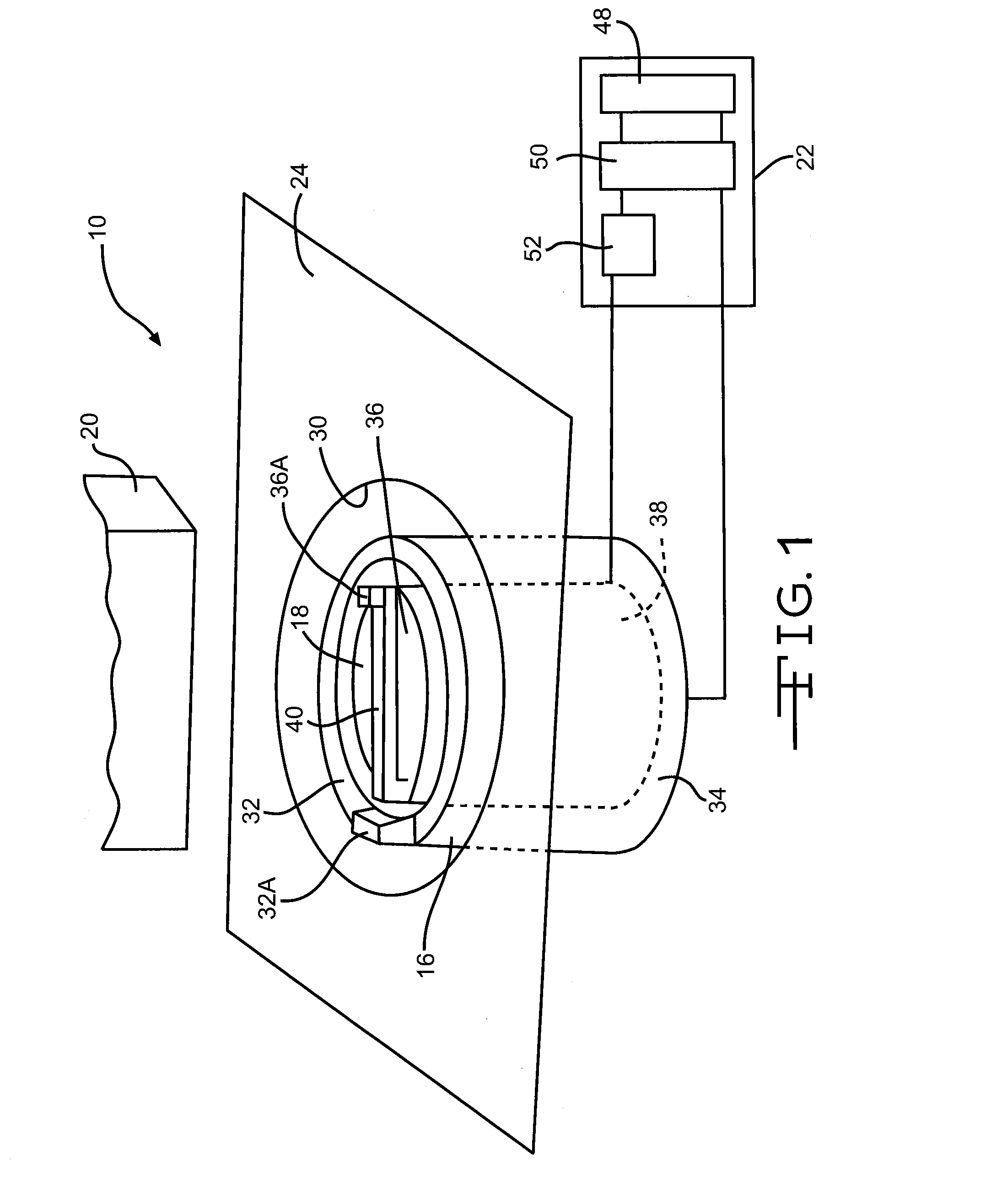

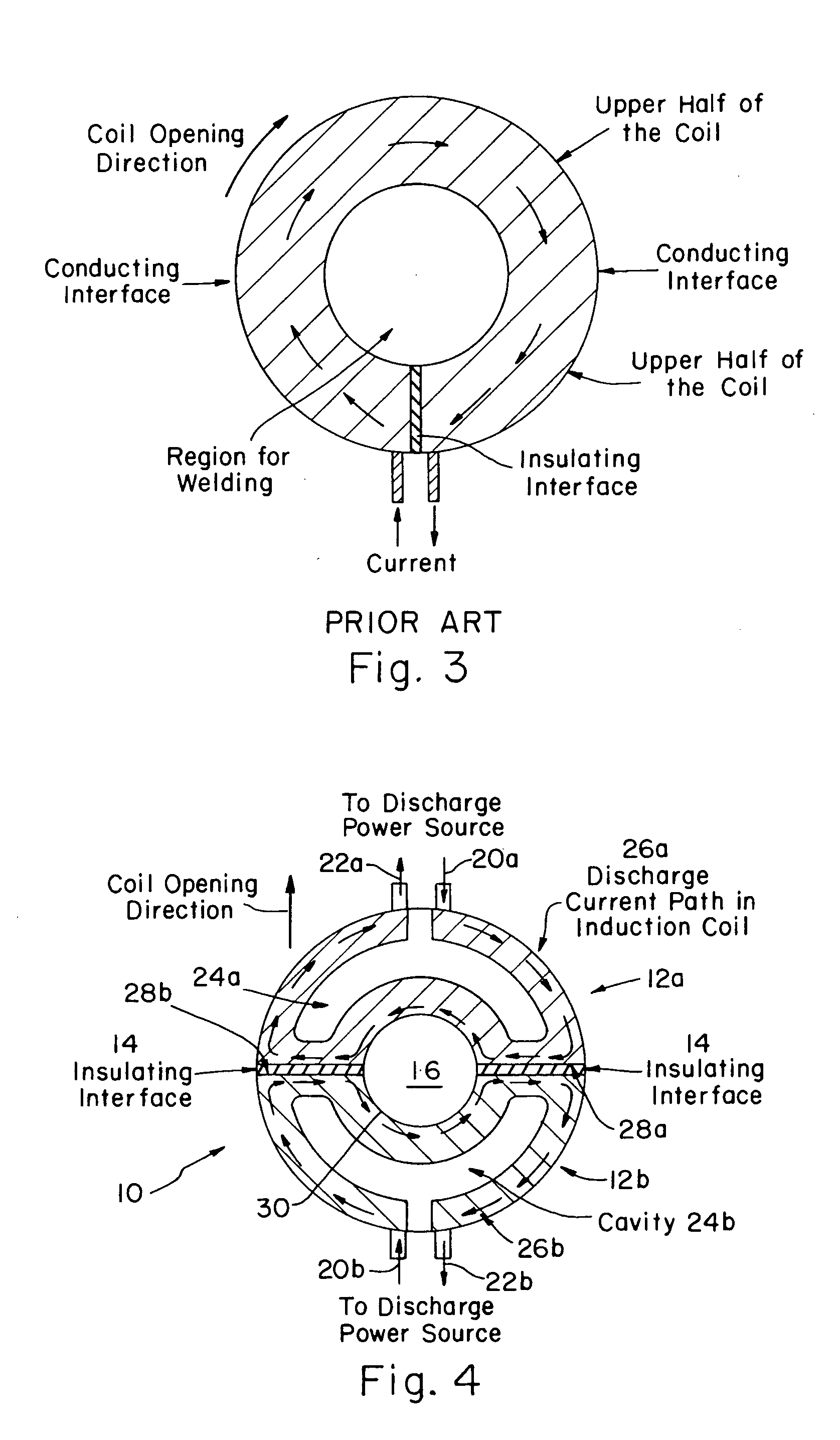

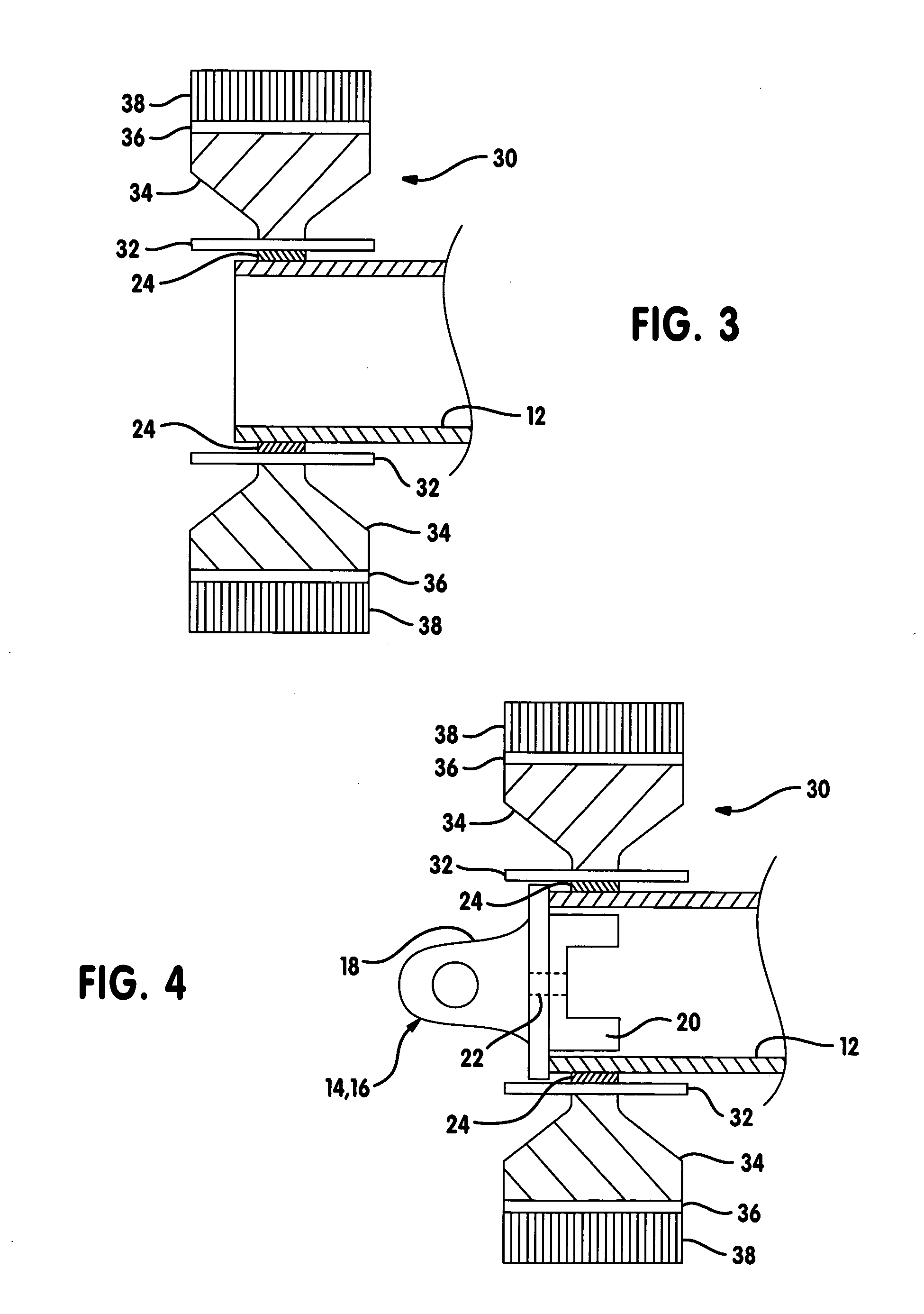

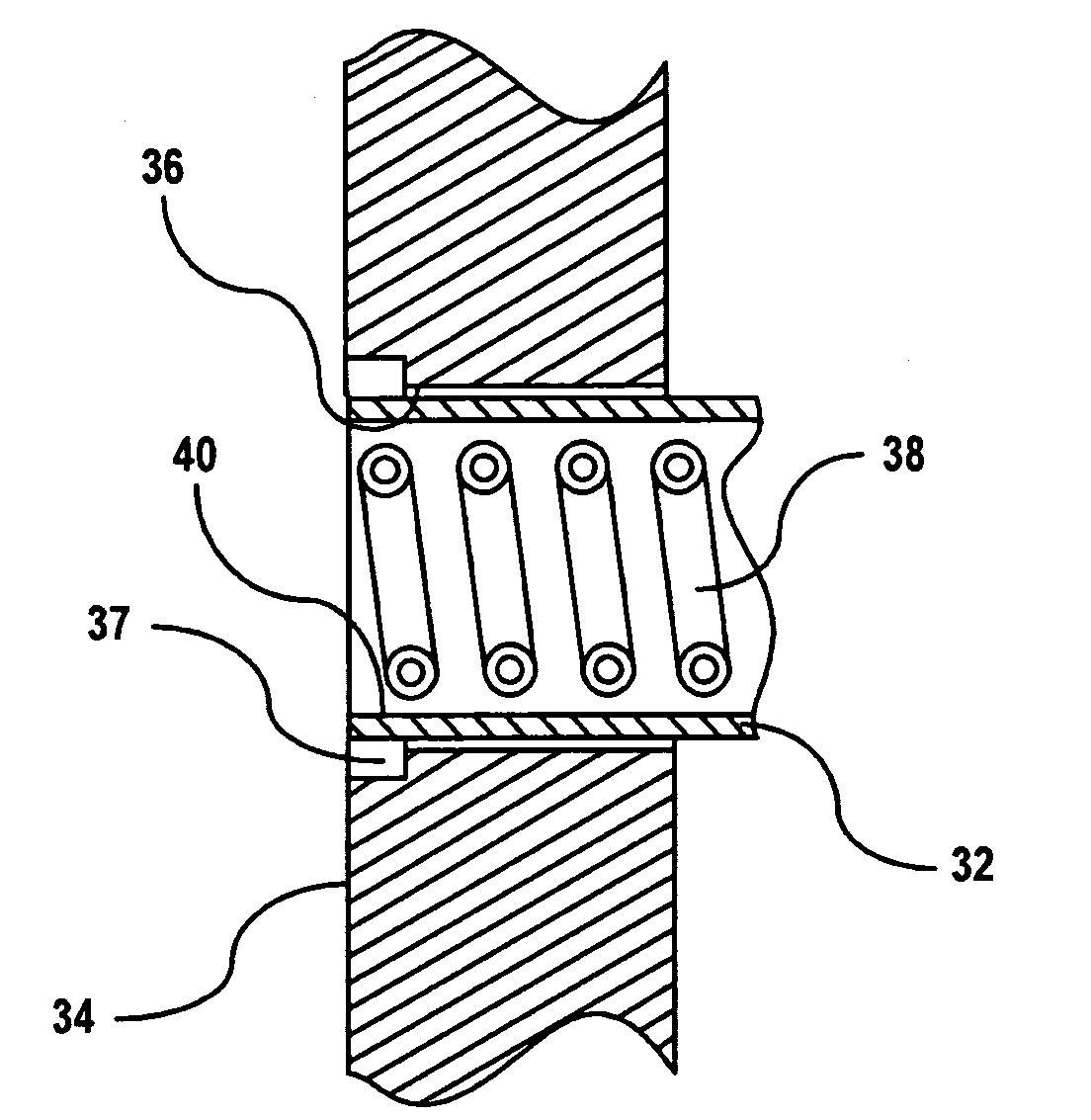

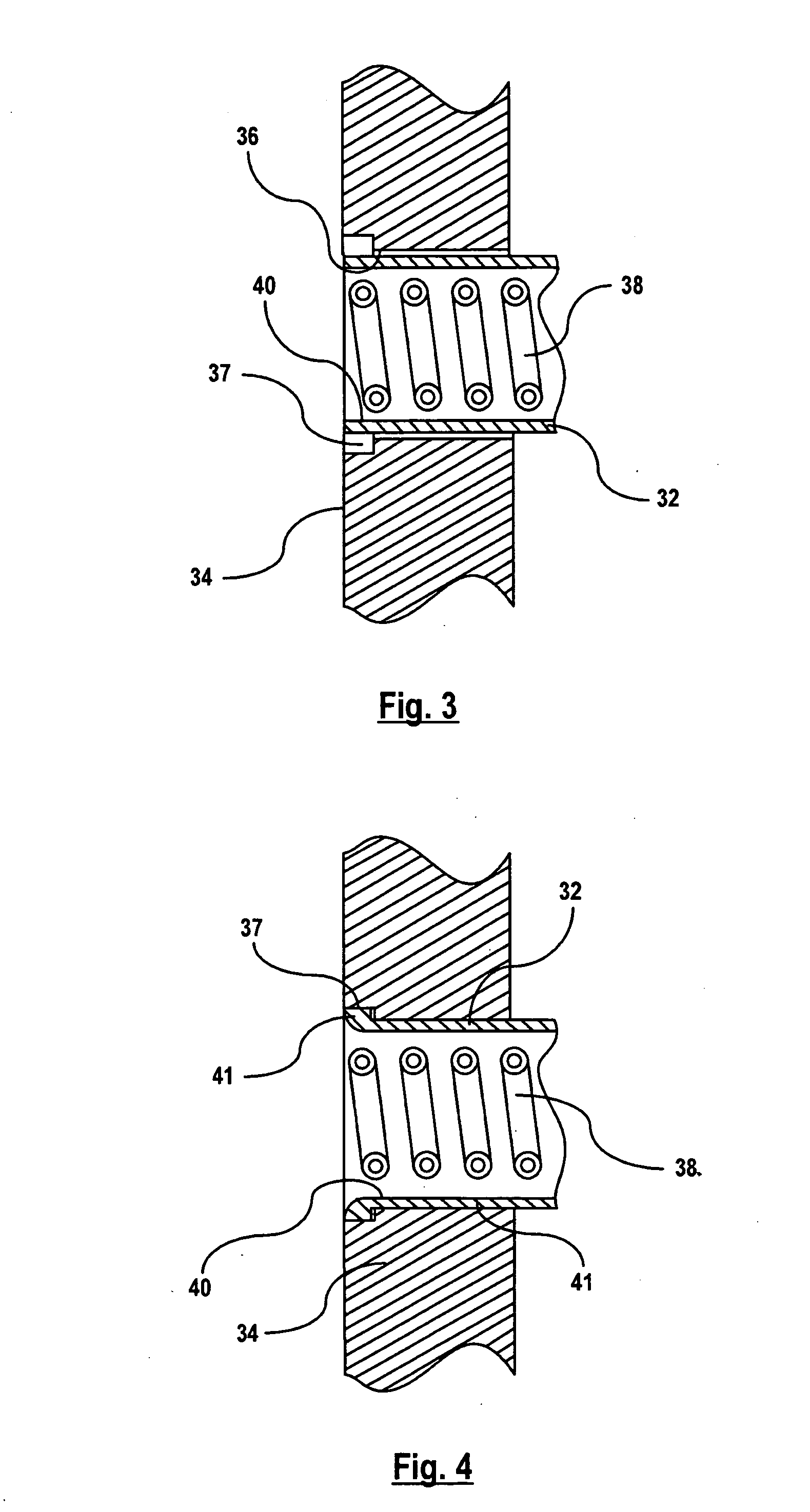

Coil design for magnetic pulse welding and forming

InactiveUS20050205553A1Quickly opened/closedReduce mechanical wearCoil arrangementsHigh frequency current welding apparatusEngineeringMagnetic pulse welding

A magnetic pulse welding (MPW) or forming (MPF) device is provided having a split coil design, thereby facilitating the opening and closing thereof. As such, part / workpieces can be readily loaded and unloaded with respect thereto. This ability to easily load and unload parts is considered critical to the successful application of MPW technology to mass production environments. The open / split coil design includes a plurality of independent induction coil sections, allowing the device to be quickly opened / closed for loading / unloading of workpieces therewithin.

Owner:ENG MECHANICS OF COLU

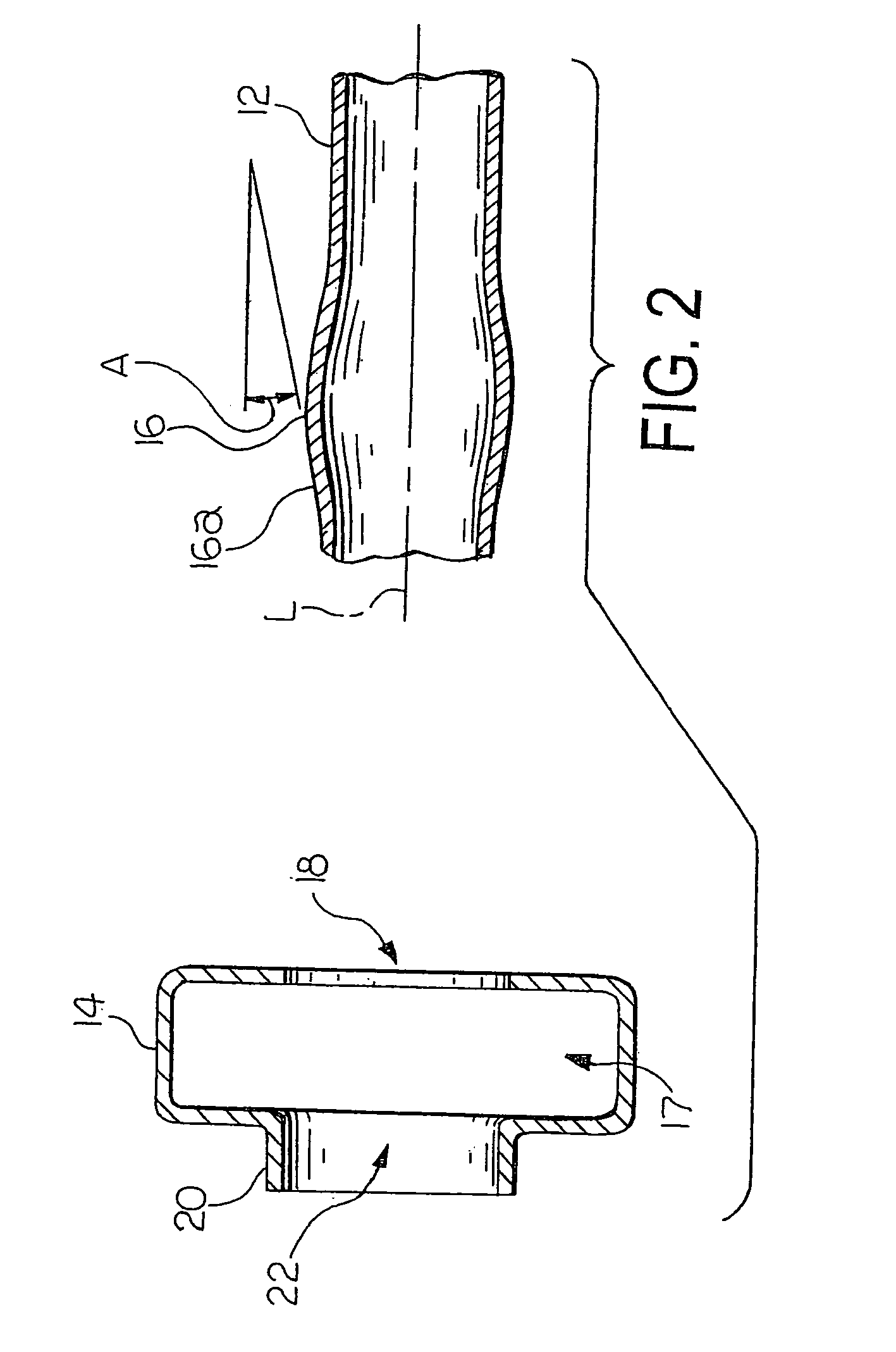

Method and apparatus for performing a magnetic pulse welding operation

InactiveUS6921013B1Small intensityFacilitate subsequent performanceMetal working apparatusTubular articlesInductorEngineering

A pair of metallic components are co-axially aligned prior to full energization of the magnetic pulse welding inductor to provide for improved control of the magnetic pulse welding process. To accomplish this, either or both of the components are supported in a floating manner. An electromagnetic coil is then energized so as to generate a magnetic field of relatively small intensity within or about one of the components. This relatively small intensity magnetic field exerts a relatively small force on the two components, causing them to move to a co-axially aligned position relative to one another and to the coil. Then, while the components are co-axially aligned, they are subjected to a magnetic field of relatively large intensity for the purpose of permanently joining such components together. This relatively large intensity magnetic field exerts a large pressure on one of the two components, causing it to deform toward the other of the two components at a high velocity. The high velocity impact of these two components, as well as the large pressures exerted thereon, caused the two components to become permanently joined together.

Owner:METALSA SA DE CV

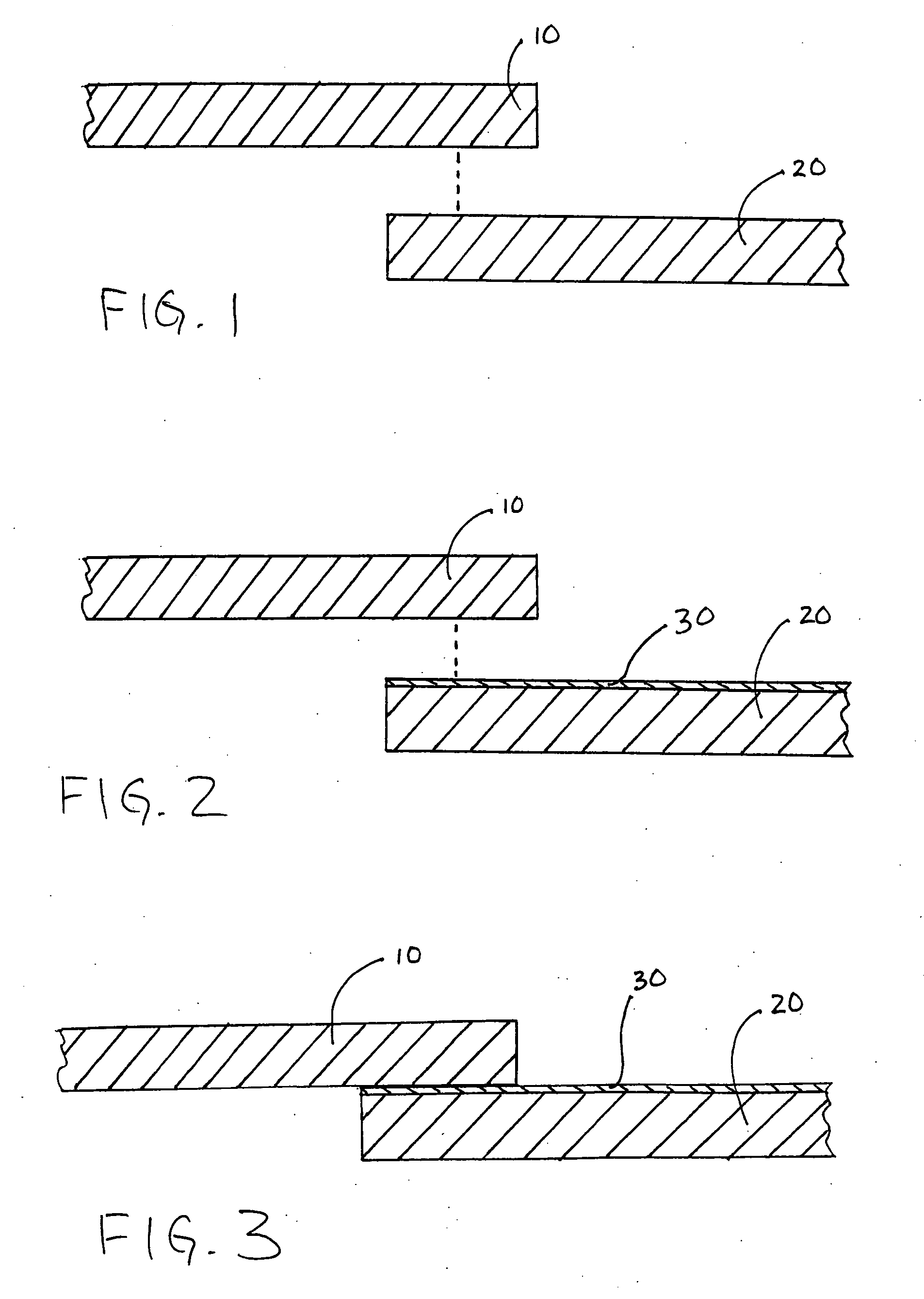

Method of permanently joining components formed from metallic materials

A method is provided for permanently joining a first metallic component that is formed from a 5000 series aluminum alloy material and a second metallic component that is formed from a steel alloy material. One of the first and second components is provided with a layer of an aluminum alloy material that is different from the 5000 series aluminum alloy material used to form the first and second metallic components, such as a layer of a 6000 series aluminum alloy material. The layer of the 6000 series aluminum alloy material can be provided as a coating on the selected one of the first and second components or in solid form. After the layer of the 6000 series aluminum alloy material can be provided on the selected one of the first and second components, the first and second components are secured together without the application of heat, such as by magnetic pulse welding, friction welding, and the like.

Owner:DANA AUTOMOTIVE SYST GRP LLC

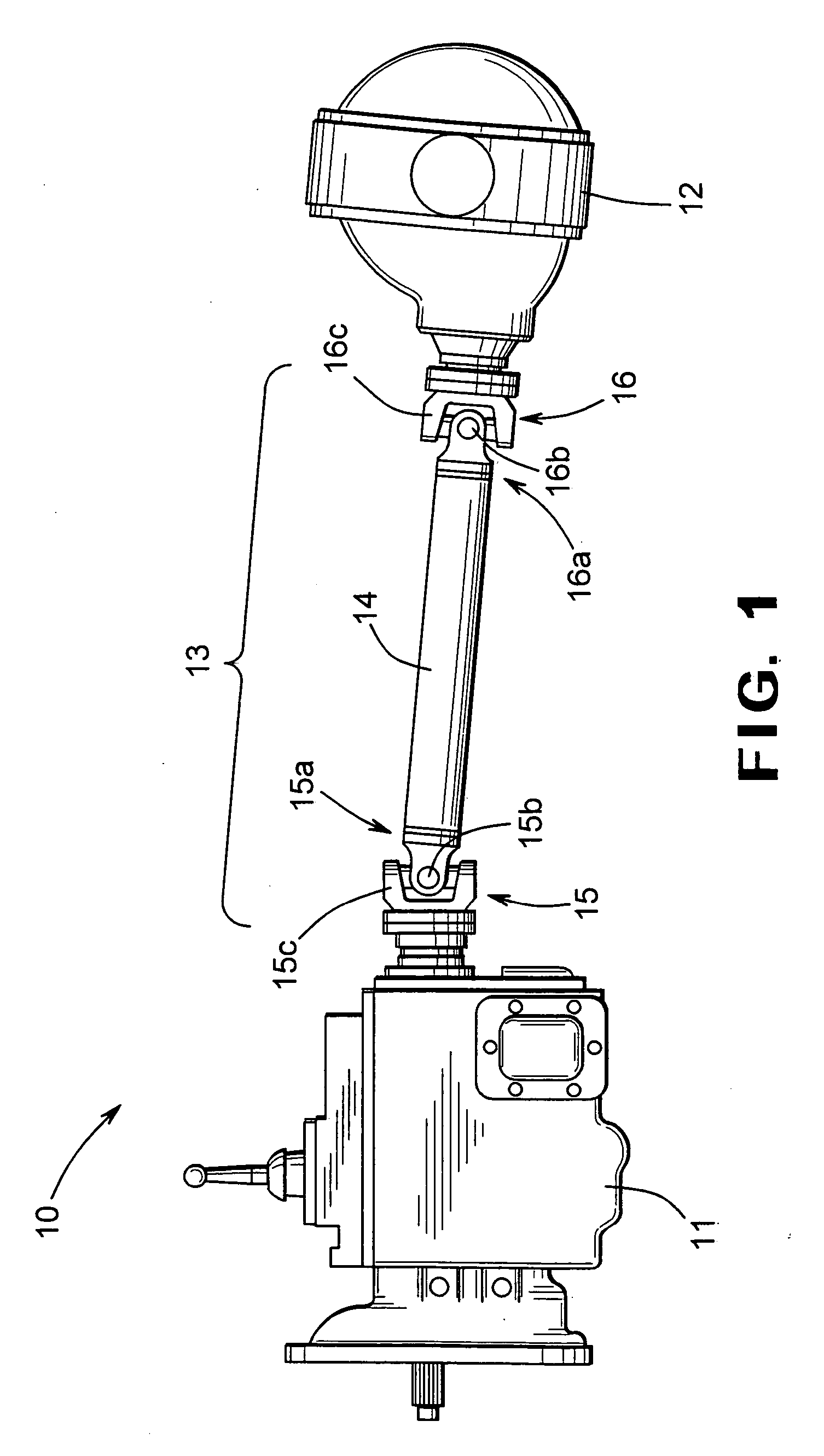

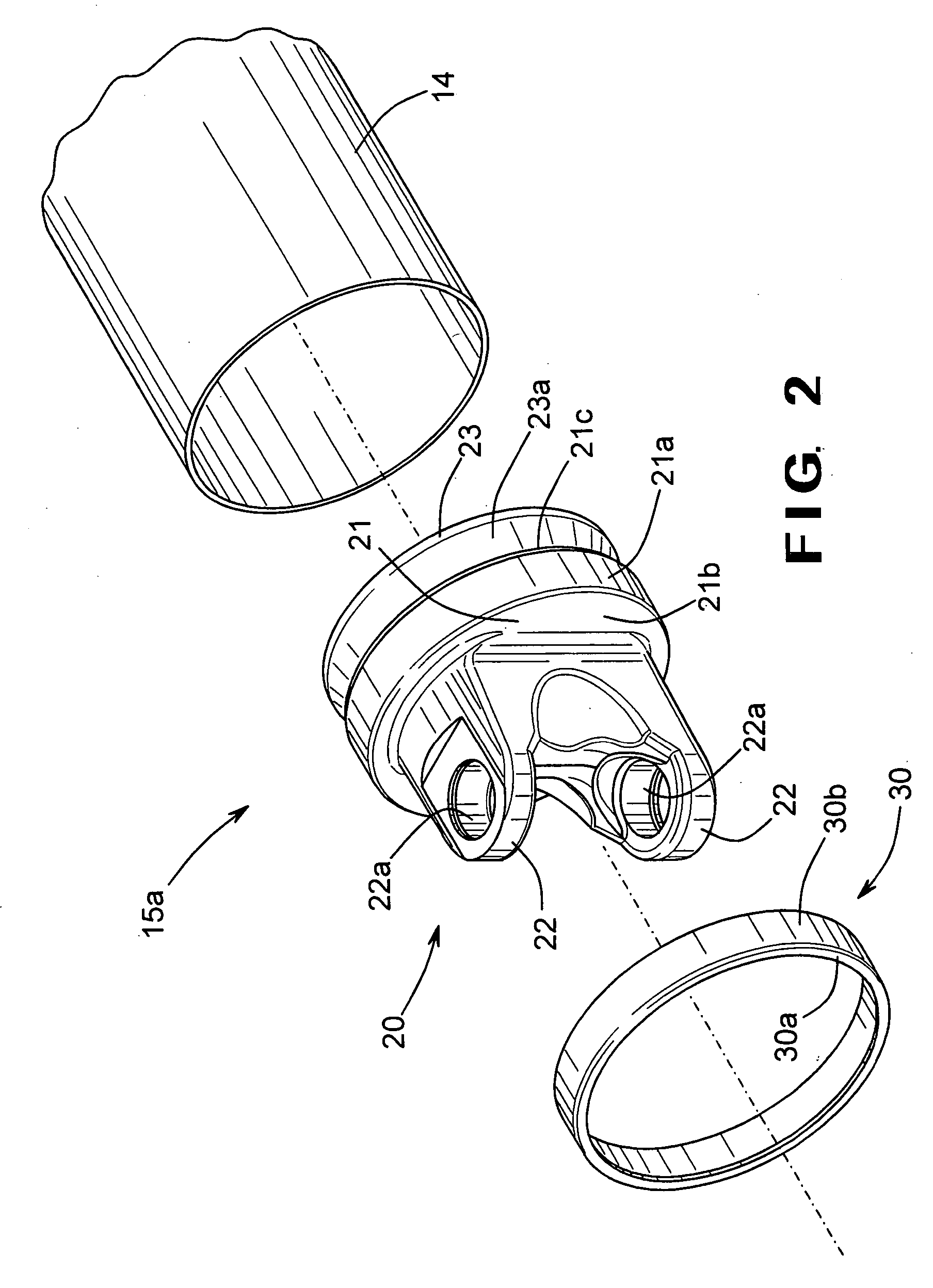

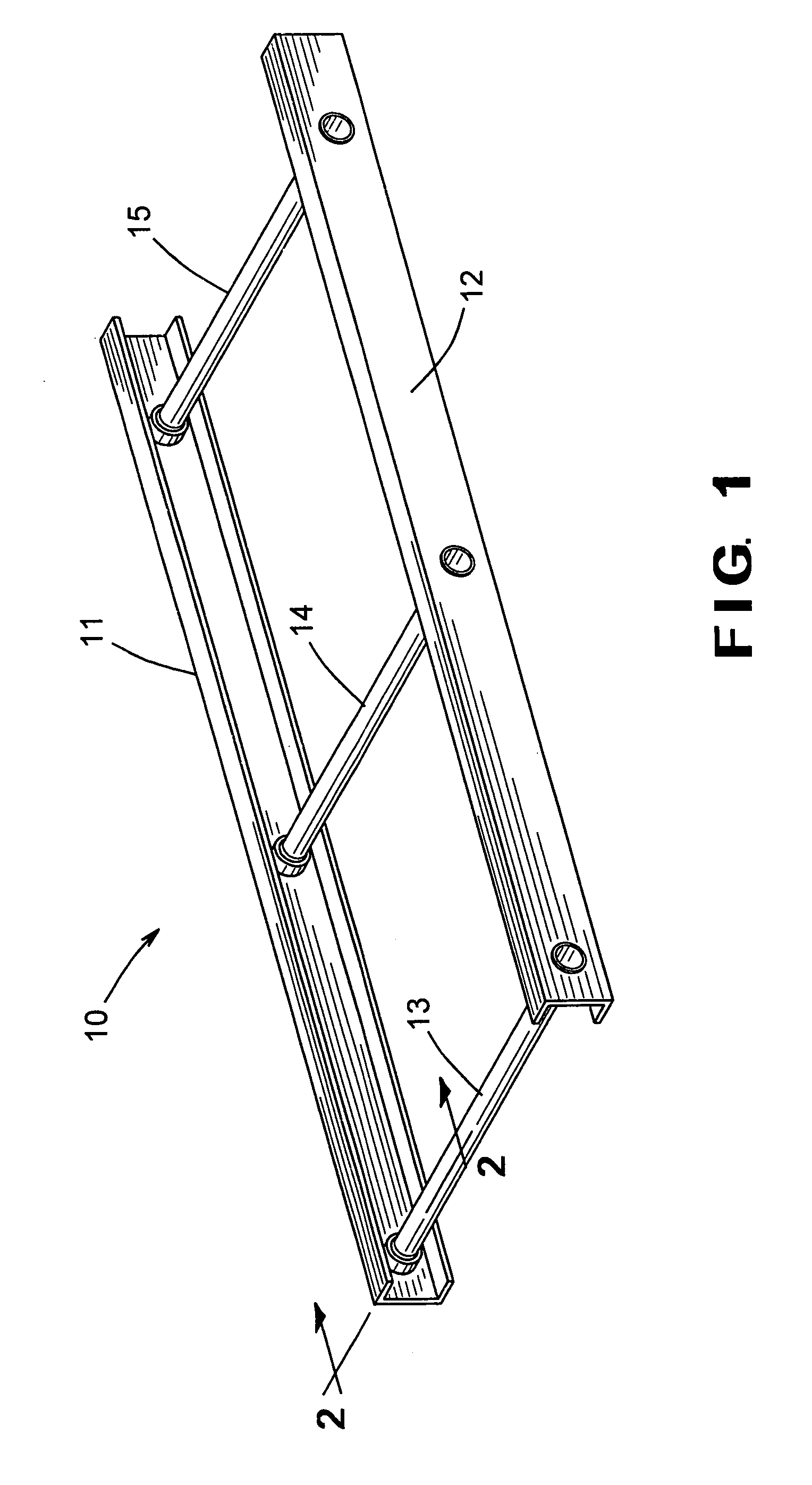

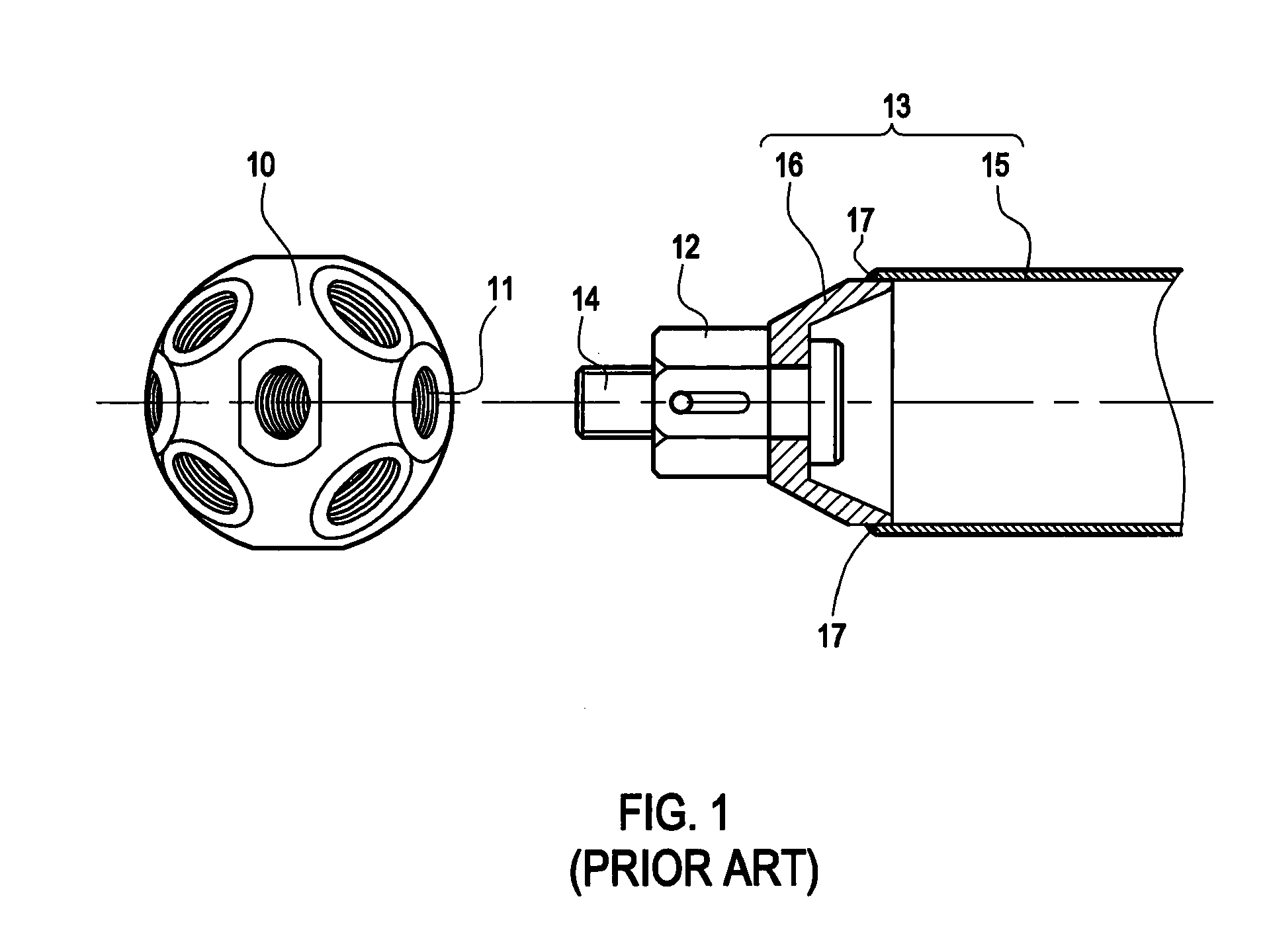

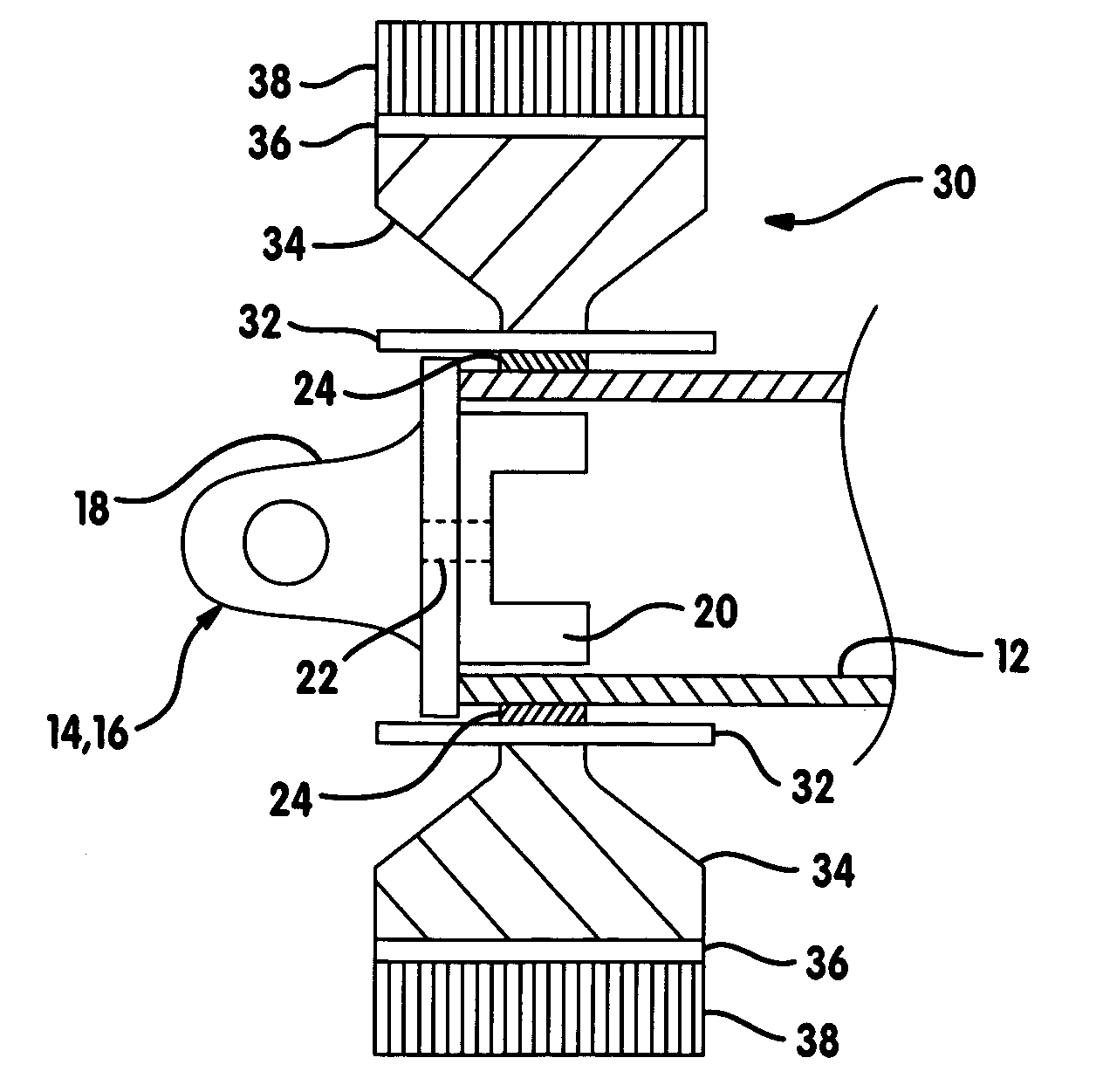

Method for securing a yoke to a tube using magnetic pulse welding techniques

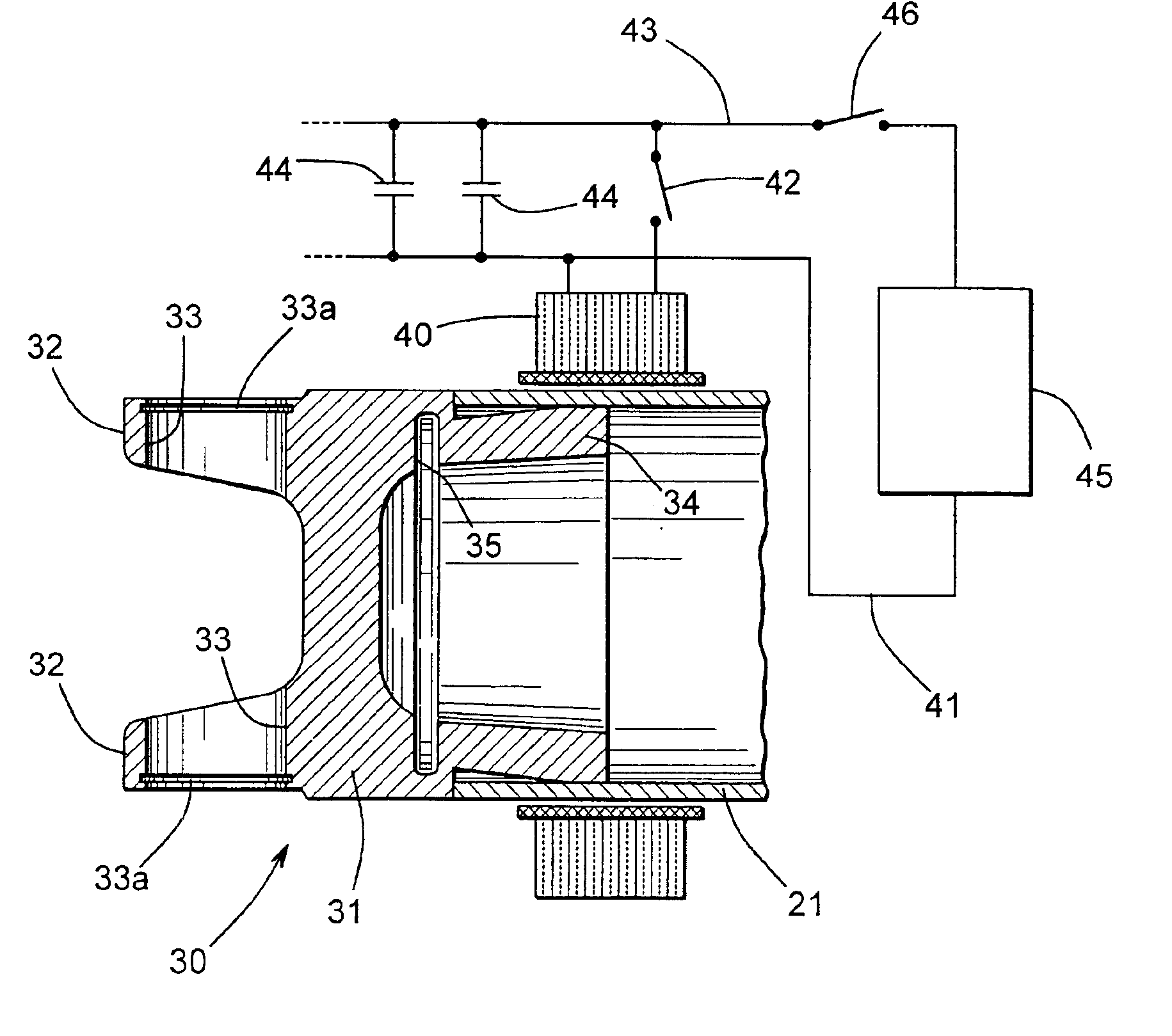

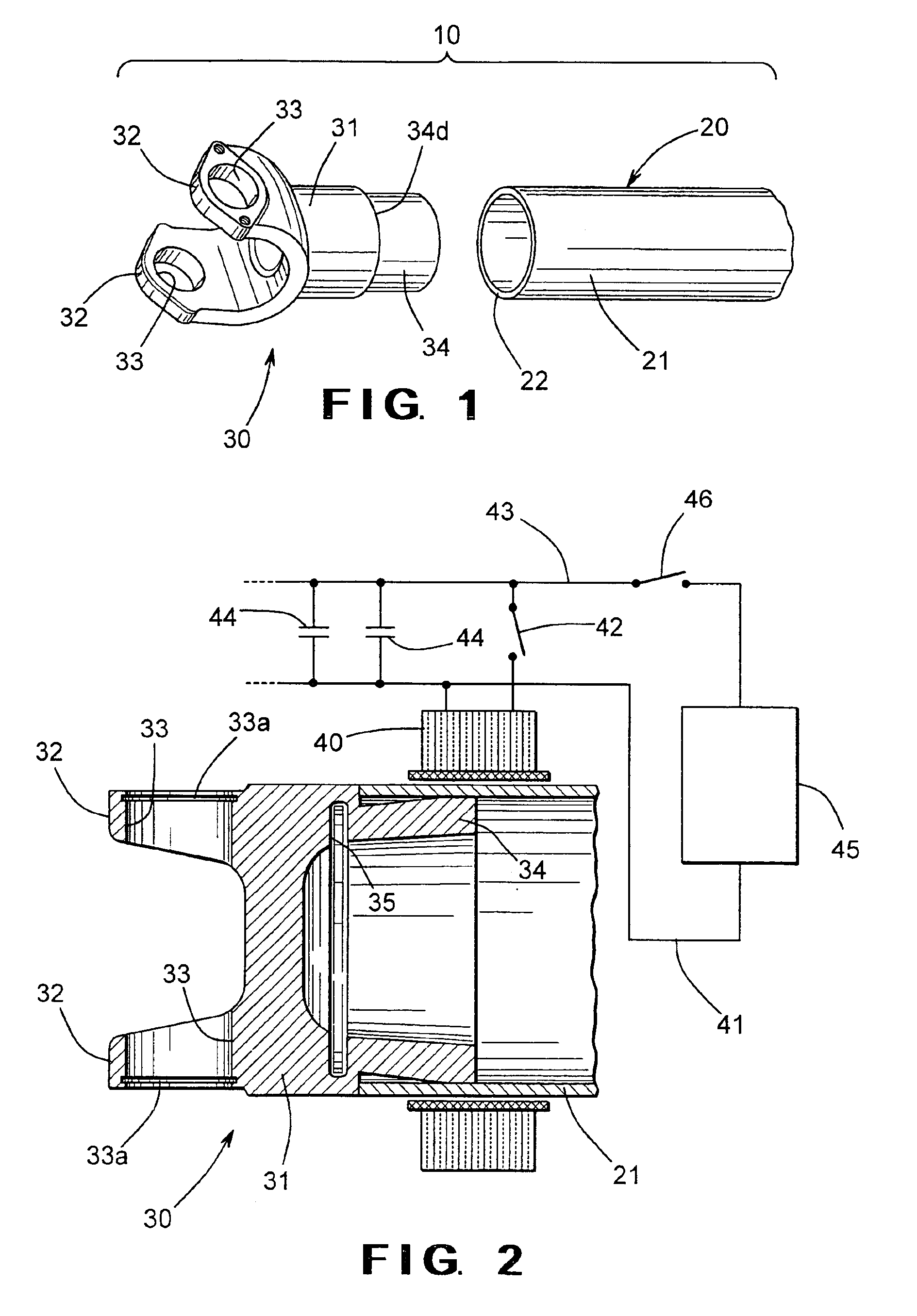

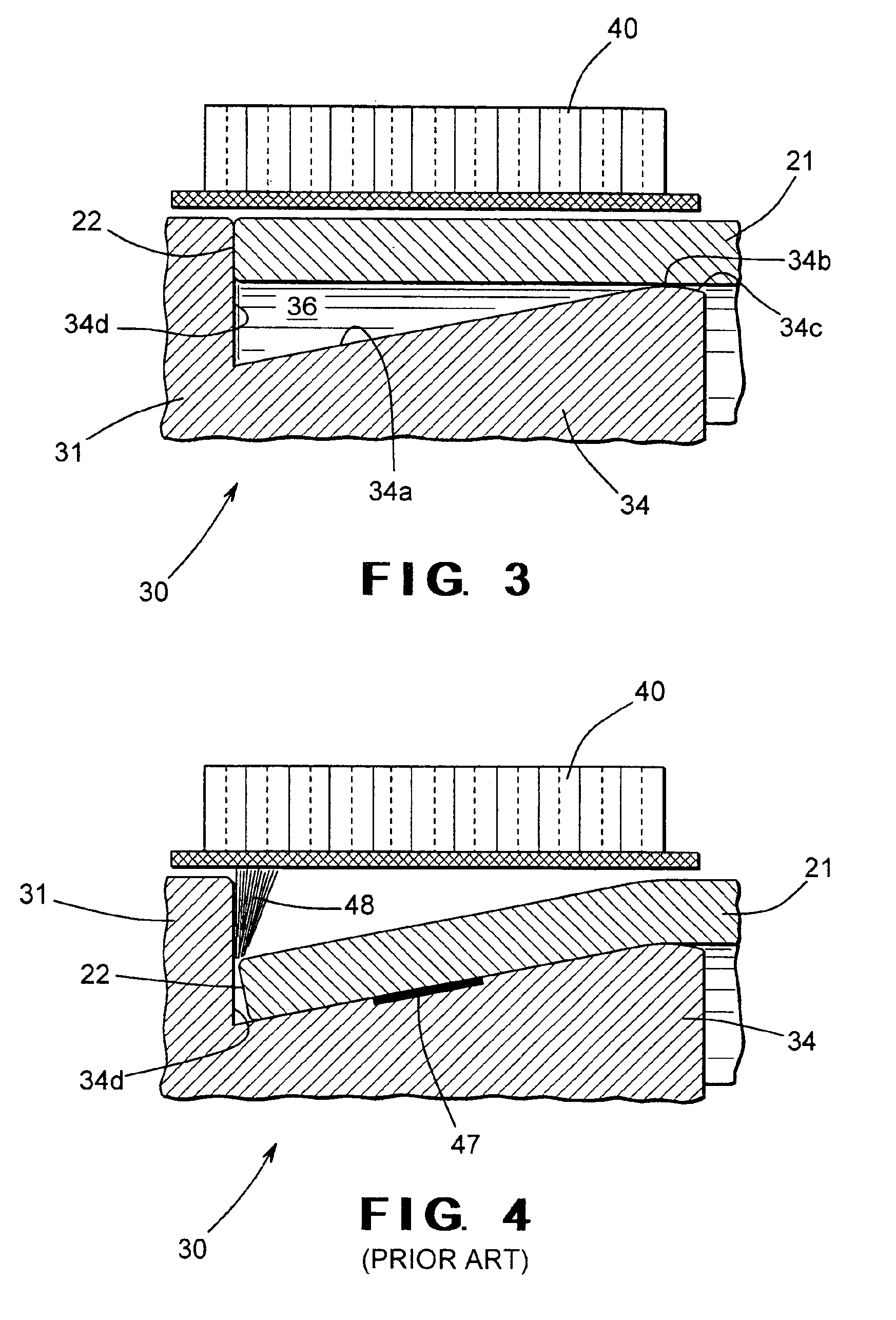

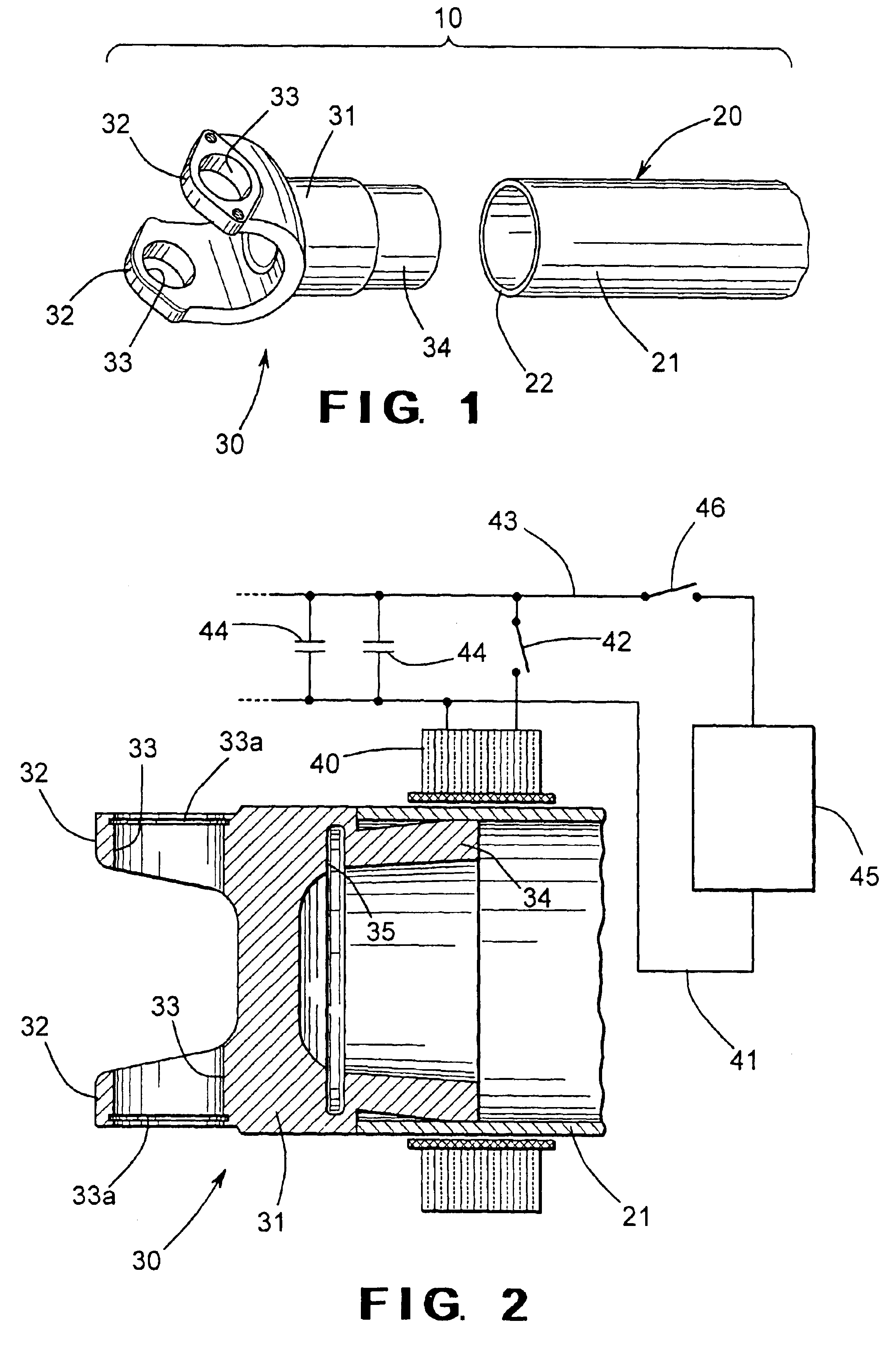

InactiveUS6910617B2Potential damageSoldering apparatusHigh frequency current welding apparatusInductorMagnetic pulse welding

A magnetic pulse welding operation is performed to secure first and second metallic components together, such as a yoke and a driveshaft tube in a vehicular driveshaft assembly. The yoke includes a first portion, such as a body portion, and a second portion, such as a pair of opposed yoke arms. The end of the driveshaft tube is disposed co-axially about the body portion of the yoke. An inductor axially is positioned co-axially about the overlapping portions of the end of the driveshaft tube and the body portion of the yoke. The inductor is energized to perform a magnetic pulse welding operation to secure the end of the driveshaft tube to the body portion of the yoke without generating a significant flow of air toward the inductor.

Owner:DANA AUTOMOTIVE SYST GRP LLC

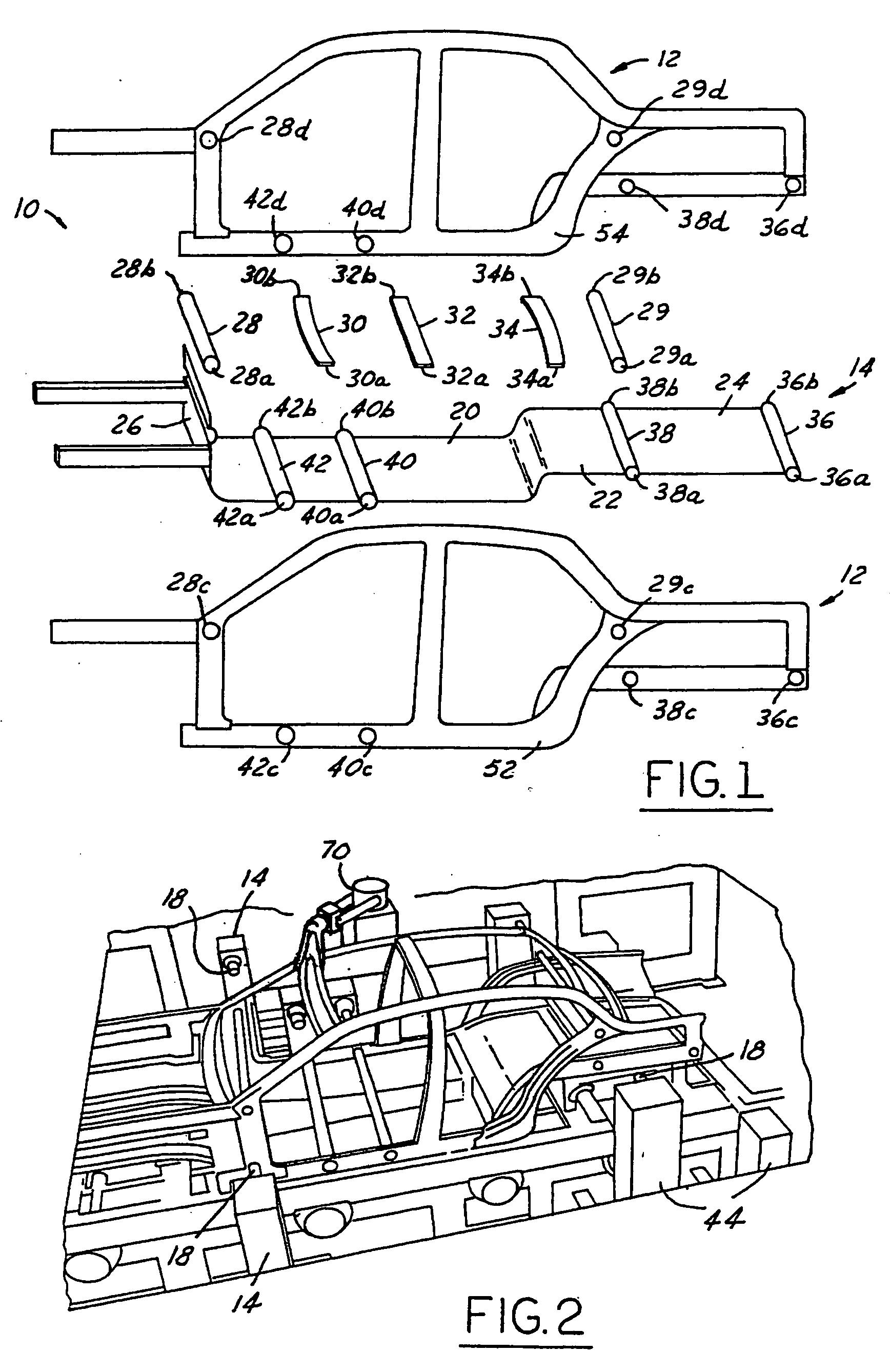

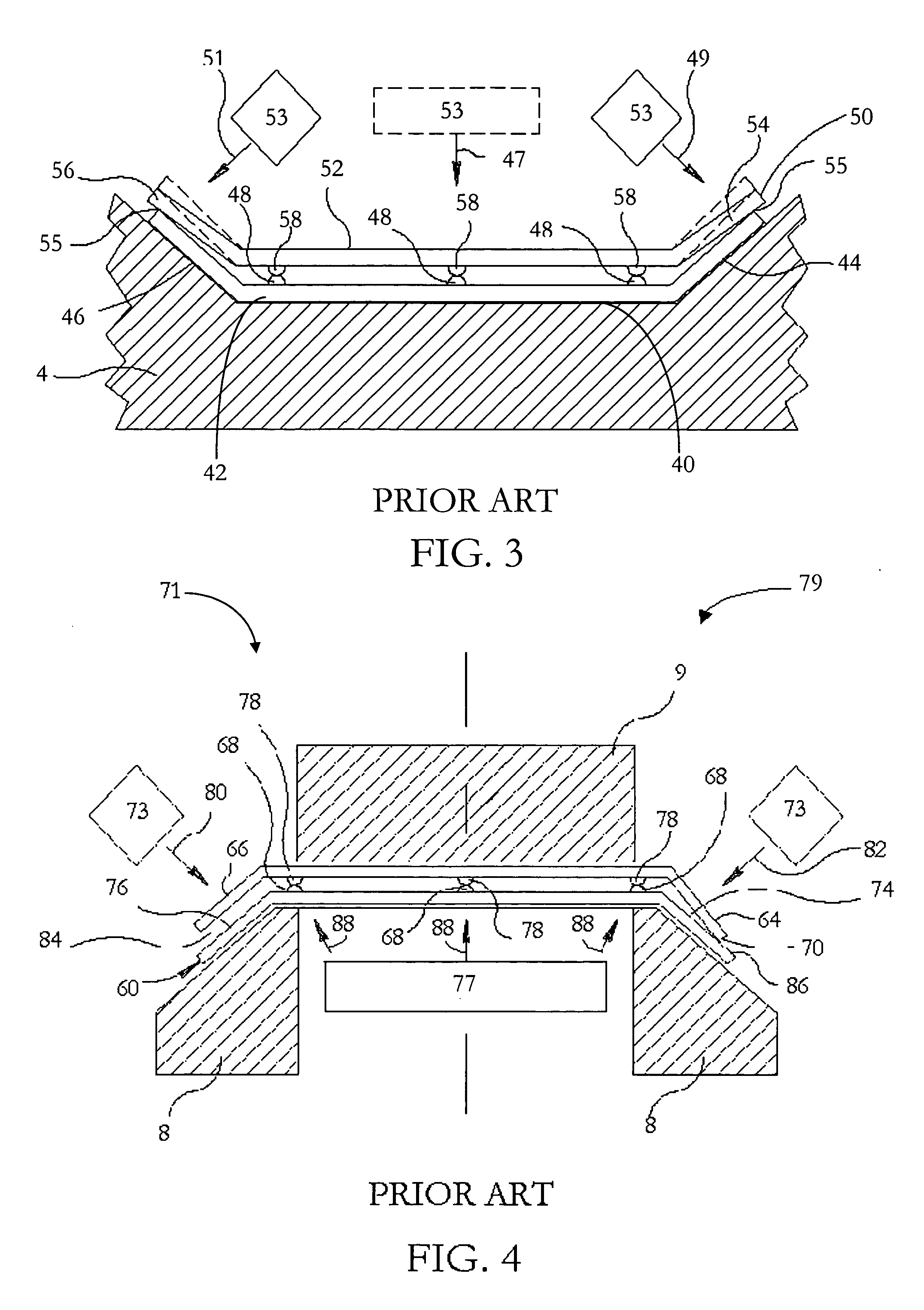

Magnetically pulse welded underbody

InactiveUS20050035586A1Reduced overall vehicle structure weight and costHigh strengthVehicle body-frame connectionsWelding/cutting auxillary devicesVehicle frameEngineering

A vehicle frame assembly for an automotive vehicle comprises an underbody structural member including a generally planar floor portion, and one or more cross members. A plurality of metallic structural members includes body side structures wherein the body side structures are secured to the aluminum underbody structural member by magnetic pulse welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

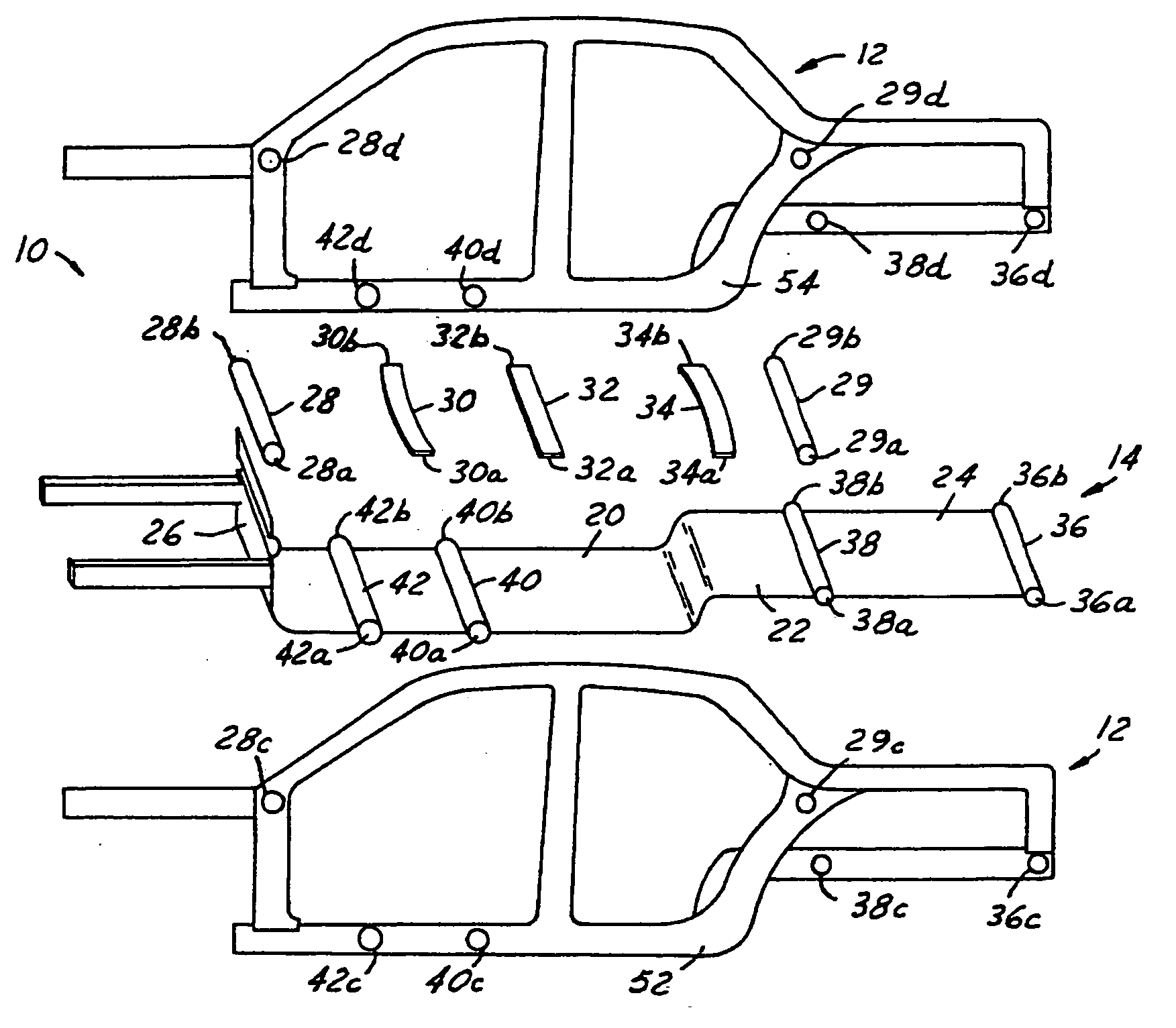

Method of manufacturing a frame assembly

InactiveUS20050116460A1Easy to manufactureCompromising stylingVehicle body-frame connectionsUnderstructuresEngineeringMagnetic pulse welding

A method of manufacturing a frame assembly includes the steps of providing an underbody assembly including a plurality of structural components that are secured together so as to be generally planar in shape; providing first and second sidebody assemblies that each include a plurality of structural components that are secured together so as to be generally planar in shape; and securing the underbody assembly to the first and second sidebody assemblies to form a frame assembly. The underbody assembly can be formed by securing first and second longitudinally extending, closed channel beams to a plurality of closed channel cross members. Each of the sidebody assemblies can be formed by securing a closed channel lower rocker rail and closed channel upper roof rail to a plurality of pillars. Each of the pillars can be formed by initially securing a first stamping to the lower rocker rail and the upper roof rail, then securing a second stamping to each of the first stampings. The underbody assembly can be secured to the first and second sidebody assemblies by magnetic pulse welding to form the frame assembly.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Manufacturing method for rod member of three-dimensional statically indeterminate truss structure

InactiveUS20110100979A1Reduce power consumptionHigh bonding strengthHigh frequency current welding apparatusNon-electric welding apparatusStatically indeterminateCoupling

A manufacturing method for a rod member of a three-dimensional statically indeterminate truss structure is provided, which includes the following steps. A first conical connection element is provided, which has a guide slot and a coupling portion on a front and a rear end respectively. A first screw connection is made to penetrate from the coupling portion of the first conical connection element, such that a screw portion of the first screw connection penetrates out of the guide slot, and a head portion of the first screw connection is confined within the first conical connection element. The coupling portion of the first conical connection element is aligned and engaged with a first end opening of a tube member, and the first end opening of the tube member is joined to an engaging portion in the coupling portion of the first conical connection element by applying a magnetic pulse welding technique.

Owner:METAL INDS RES & DEV CENT

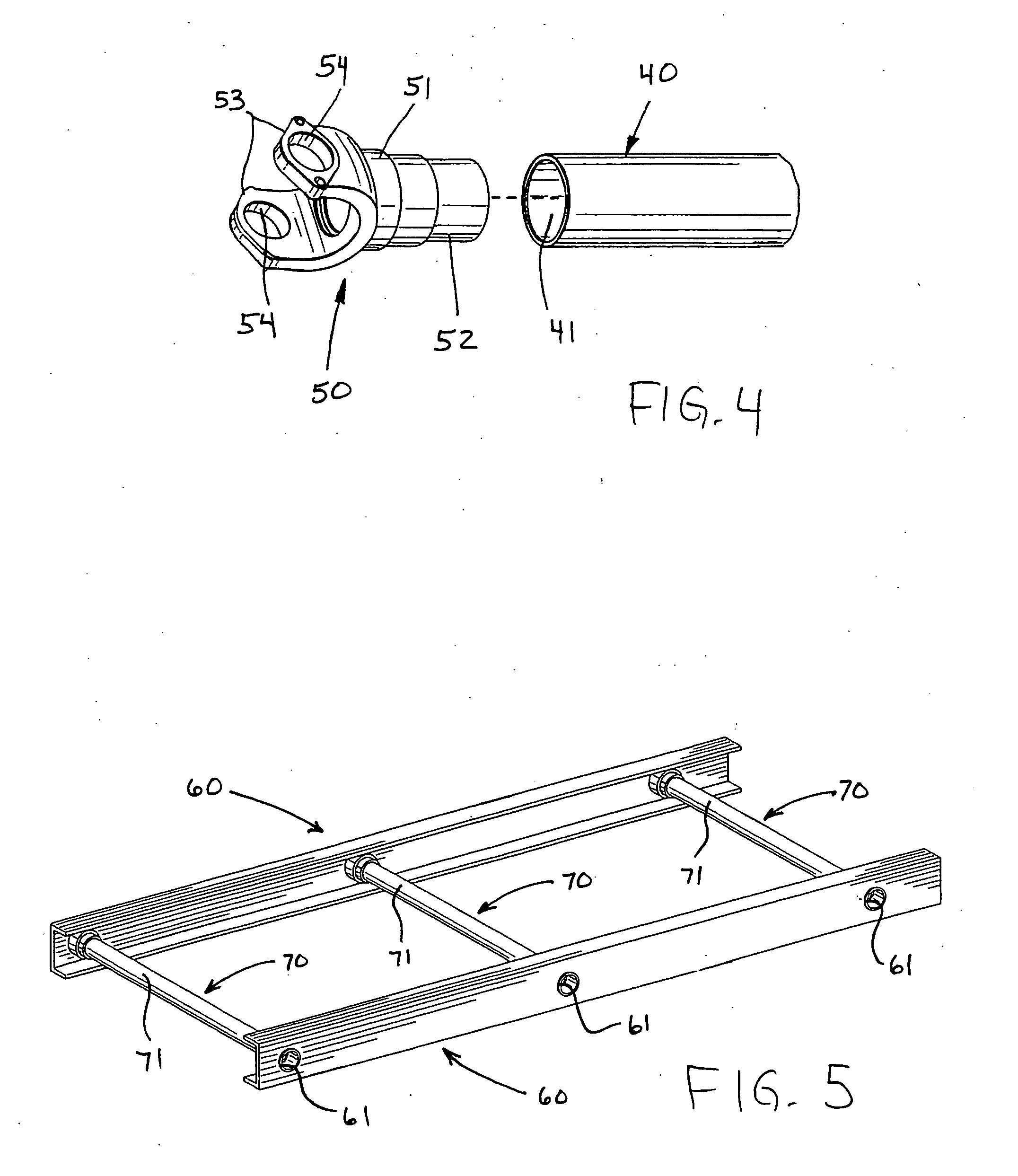

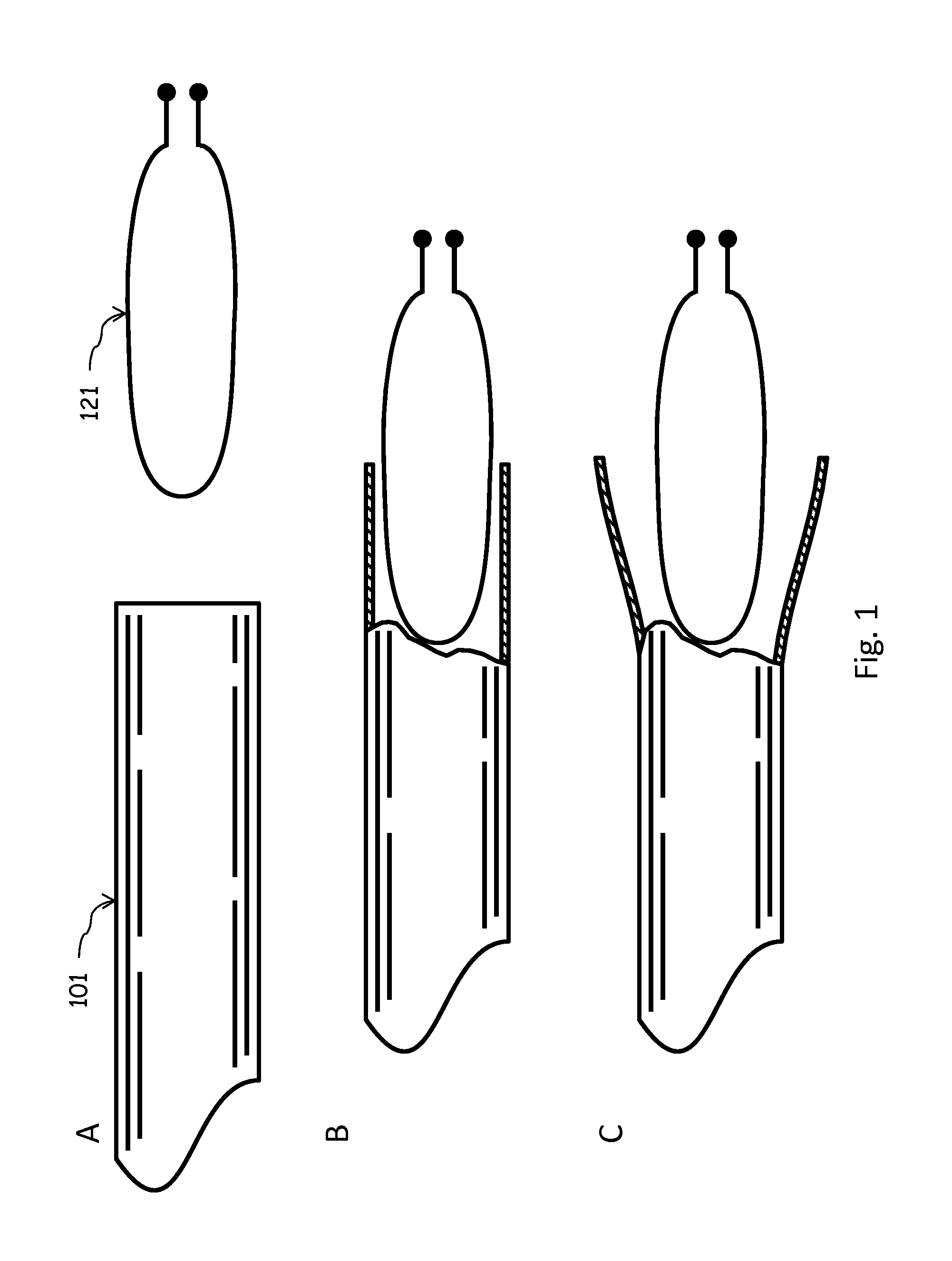

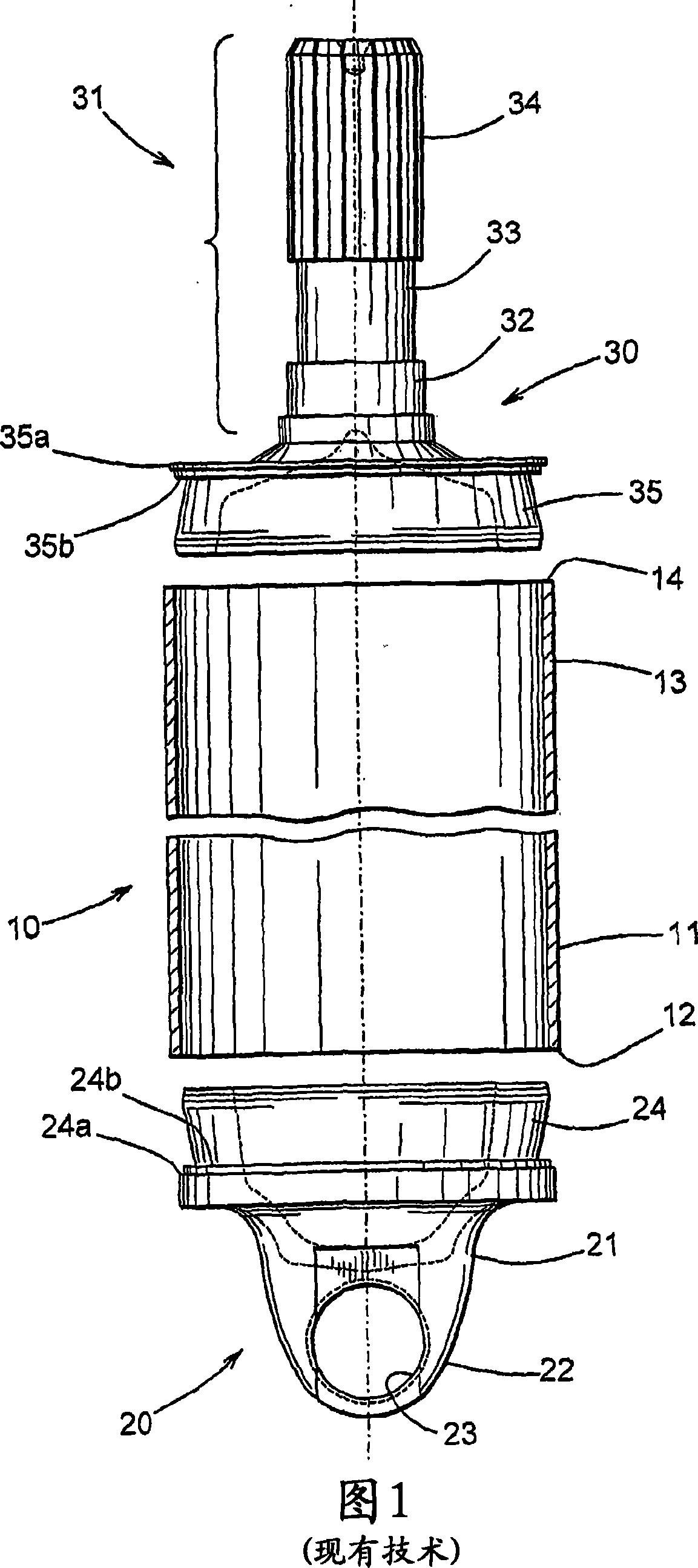

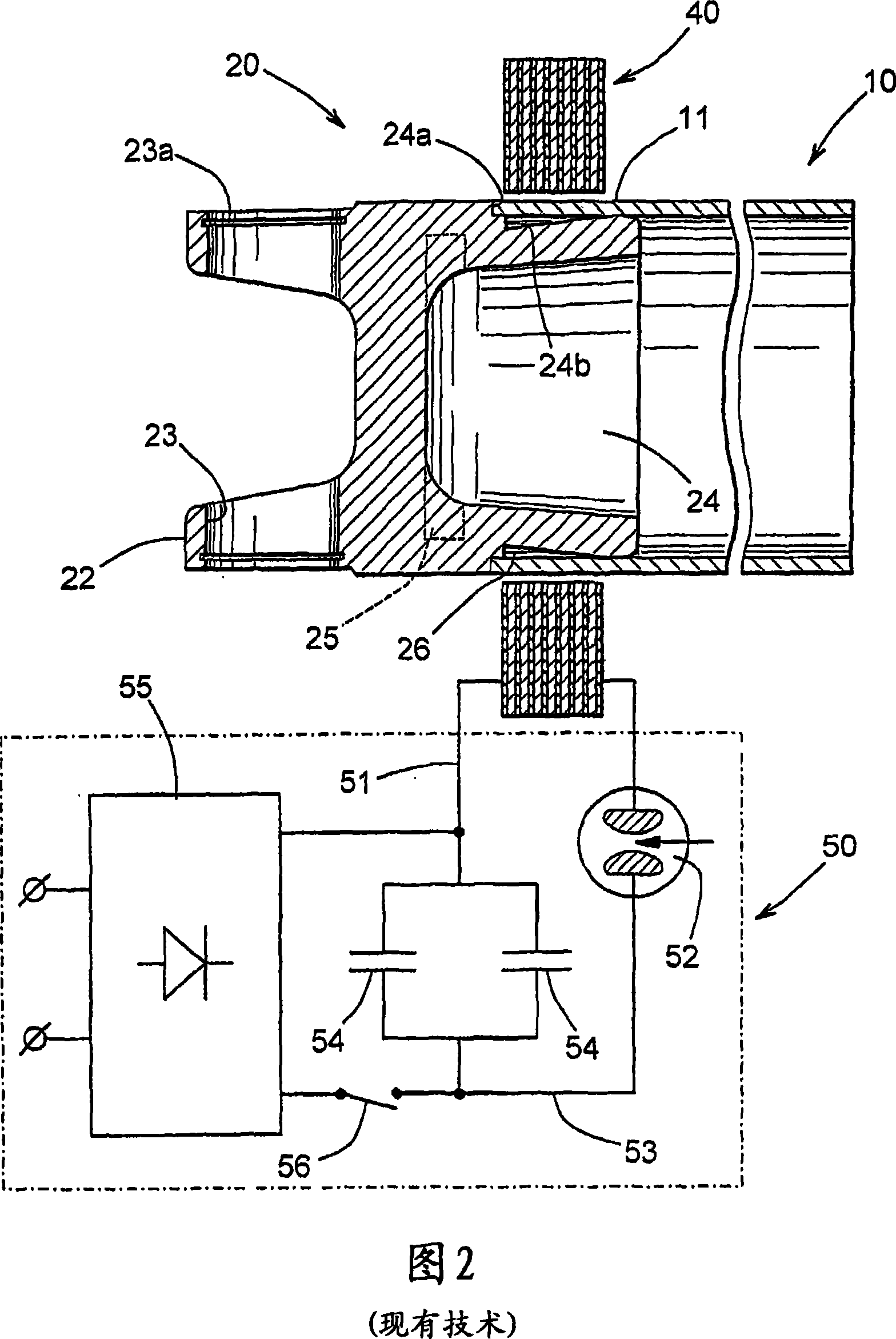

Magnetic pulse welding of steel propshafts

ActiveUS20060081684A1Improve conductivityHigh frequency current welding apparatusVehicle componentsDrive shaftInductor

A method of magnetically welding an end fitting to a metal tube includes assembling a driver ring over an end of the tube and inserting a length of the end fitting into a bore of the tube. An overlap region of the tube, the driver ring and the cylinder are encompassed by an inductor assembly of a magnetic pulse welding apparatus and the tube is welded to the end fitting using the magnetic welding apparatus.

Owner:AMERICAN AXLE & MFG

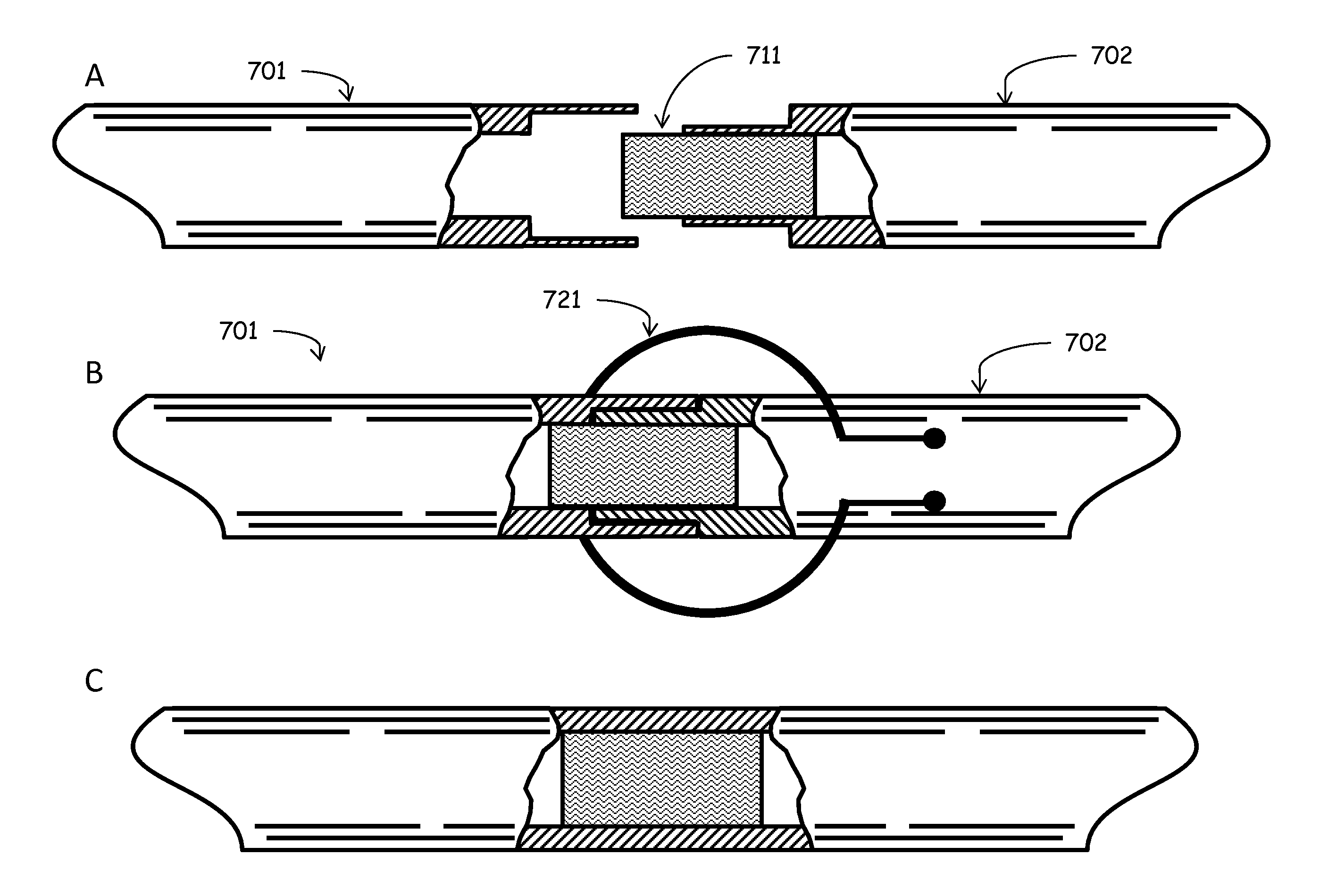

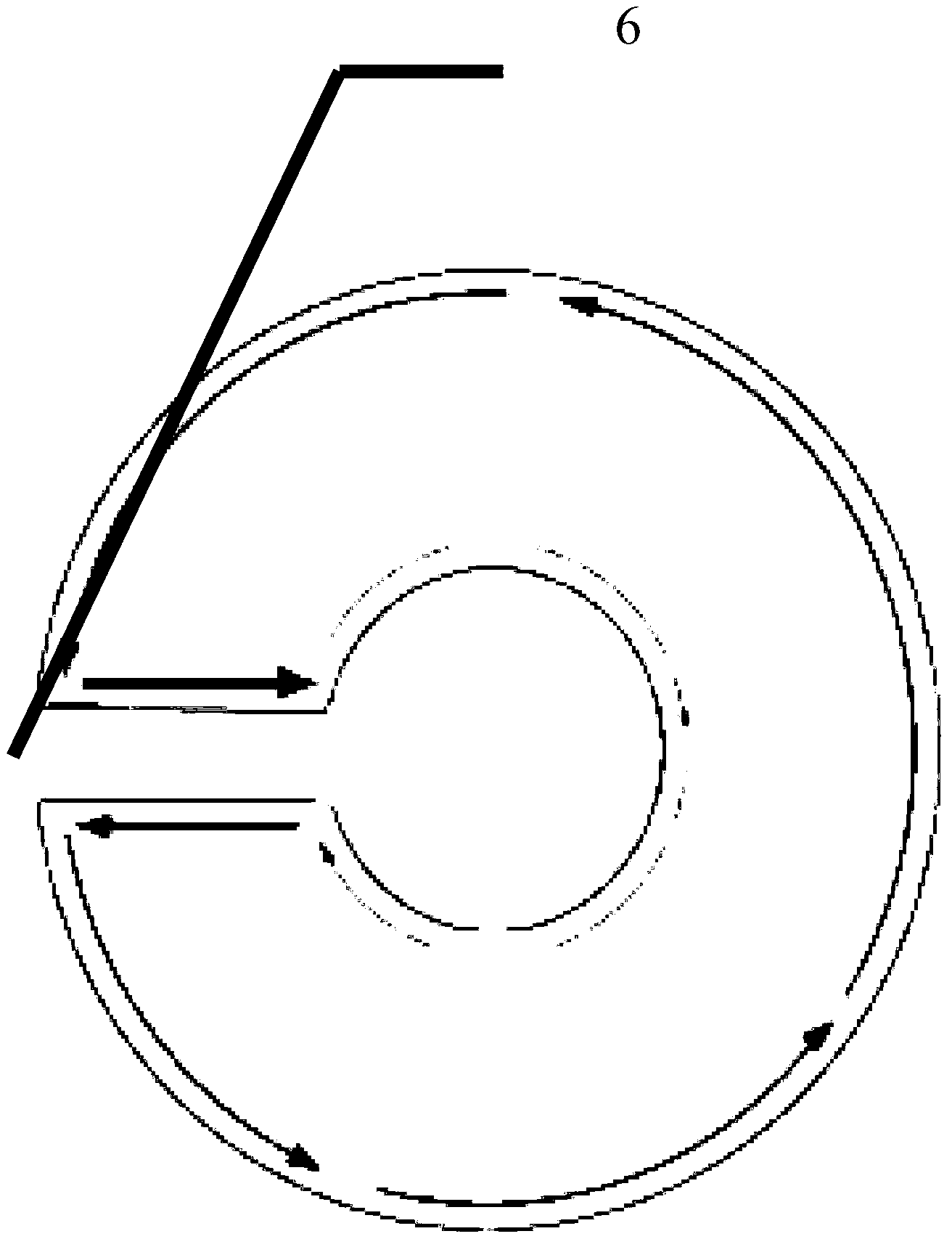

Coiled tubing lap welds by magnetic pulse welding

InactiveUS20150328712A1High strengthLittle and no loss of CT integrityPipeline systemsHigh frequency current welding apparatusCoiled tubingMagnetic pulse welding

A method for joining coiled tubing is described. Coiled tubing joints using a magnetic pulse welder are described that retain the strength of the original tubing. This type of joint is useful for joining multiple coiled tubing sections or for removing and repairing damaged coiled tubing. Because the joint is as strong as the original tubing, these types of joints may be used when placing tubing in the well.

Owner:CONOCOPHILLIPS CO

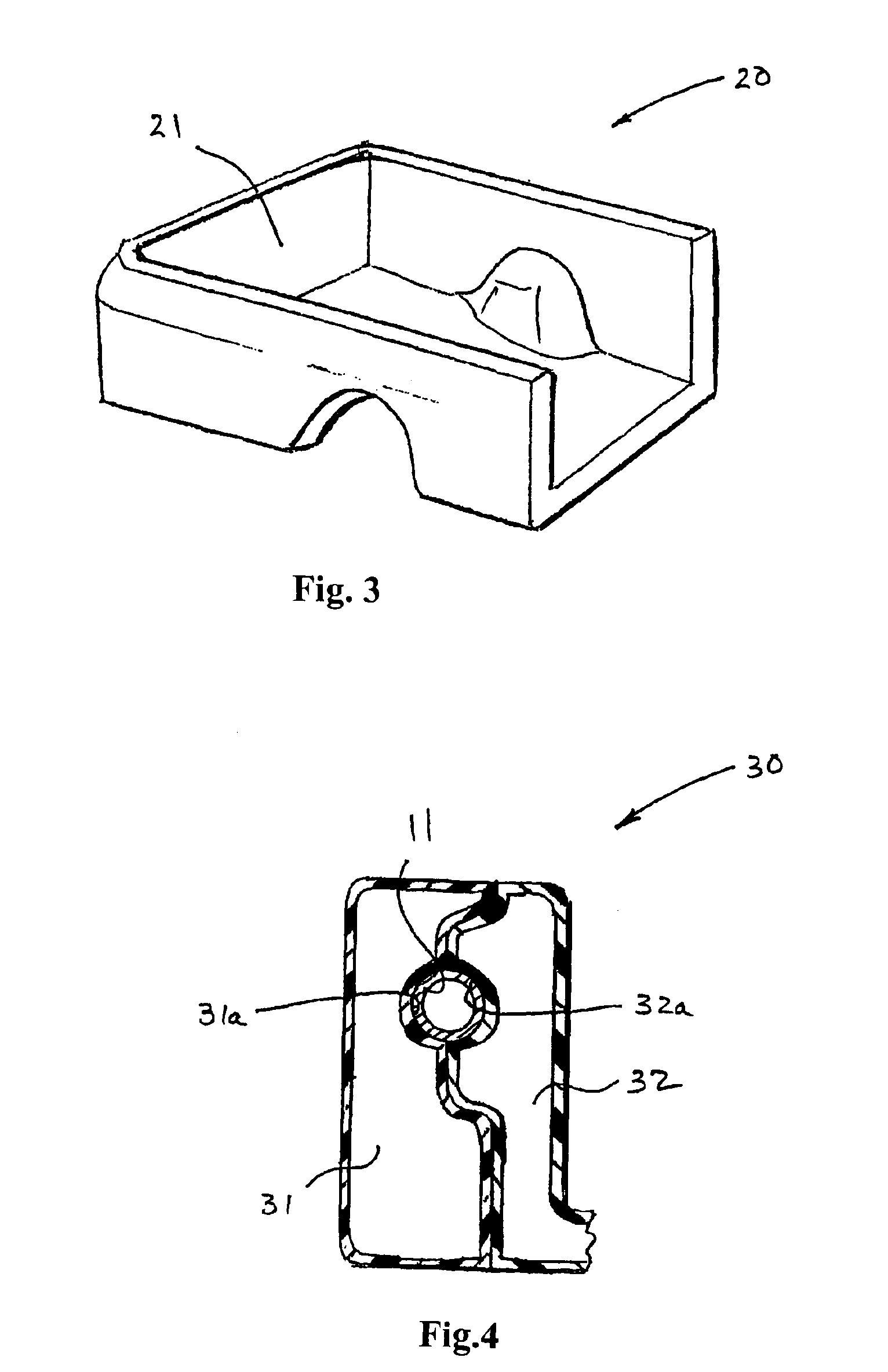

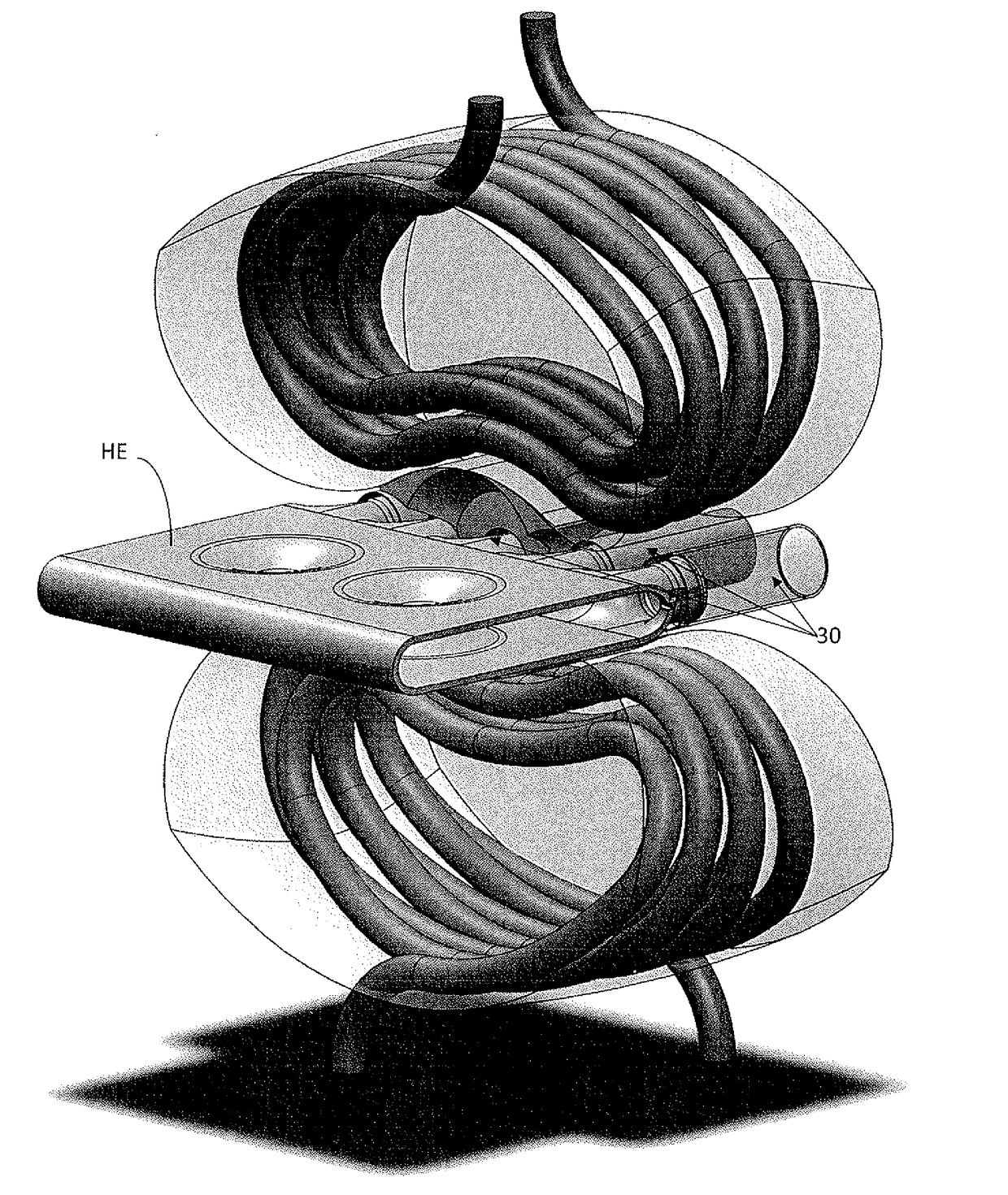

Method for forming a heat exchanger stack

InactiveUS20050092474A1Resistance to electromagnetic impulse weldingMetal working apparatusWelding apparatusEngineeringElectromagnetic pulse

A heat exchanger stack includes two or more nestable plates formed of a plate material being substantially unresponsive to electromagnetic impulse welding, and wherein each plate includes a generally flat central portion having a plurality of protrusions protruding from one or more surfaces thereof and one or more pairs of edge portions generally formed non-coplanar relative to the generally flat central portion. The two or more plates are arranged in a nesting arrangement and spaced apart by the protrusions so as to define therebetween a space through which a heat exchange medium may flow. Further, two or more plates are affixed together by electromagnetic pulse welds at a plurality of welding locations which include the protrusions and one or more pairs of edge portions. Also, the two or more plates are mutually connected at the welding locations via a facilitator substrate, which is highly responsive to electromagnetic impulse welding, and which is disposed on one or more of the two plates.

Owner:SEIDEL PESSACH

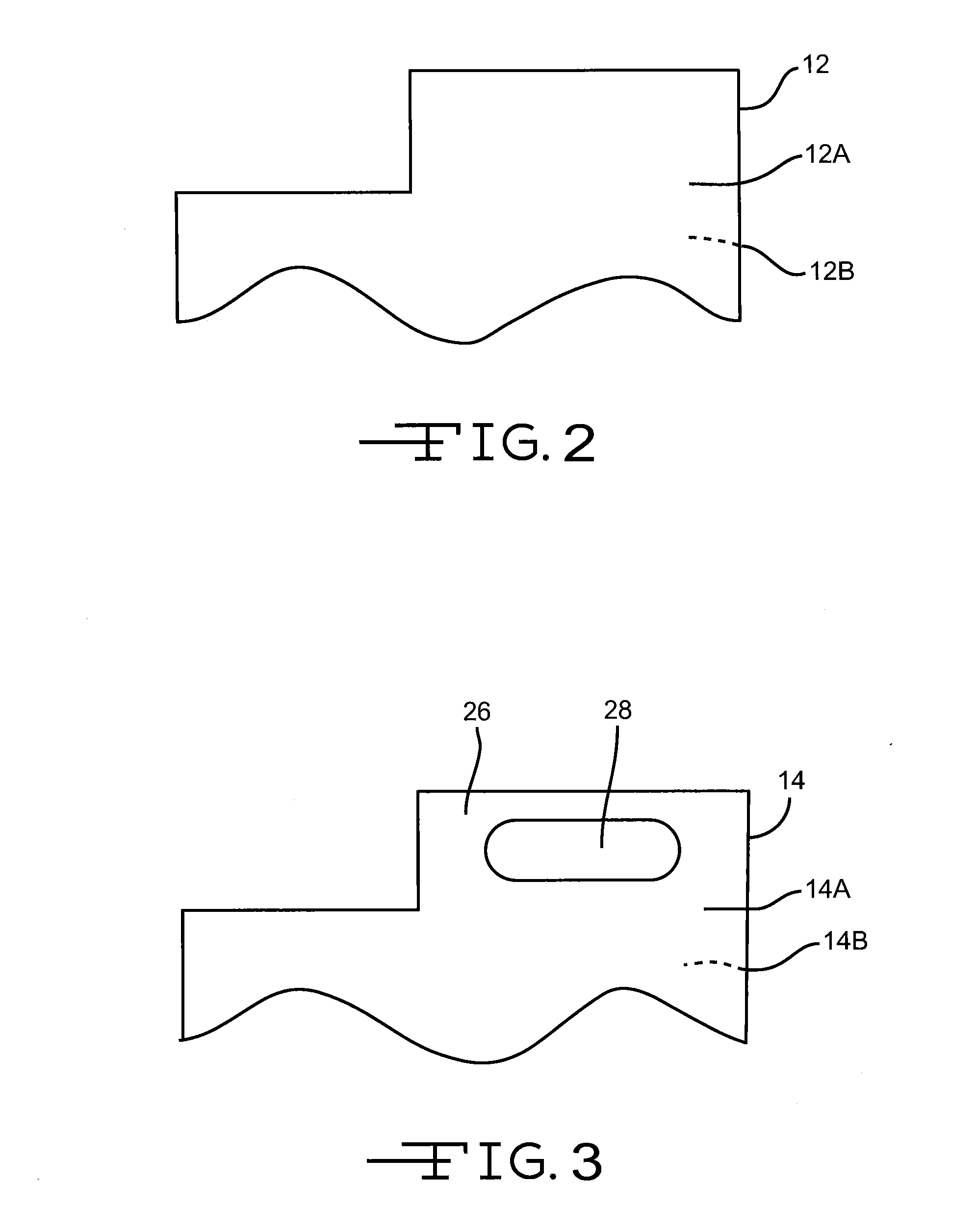

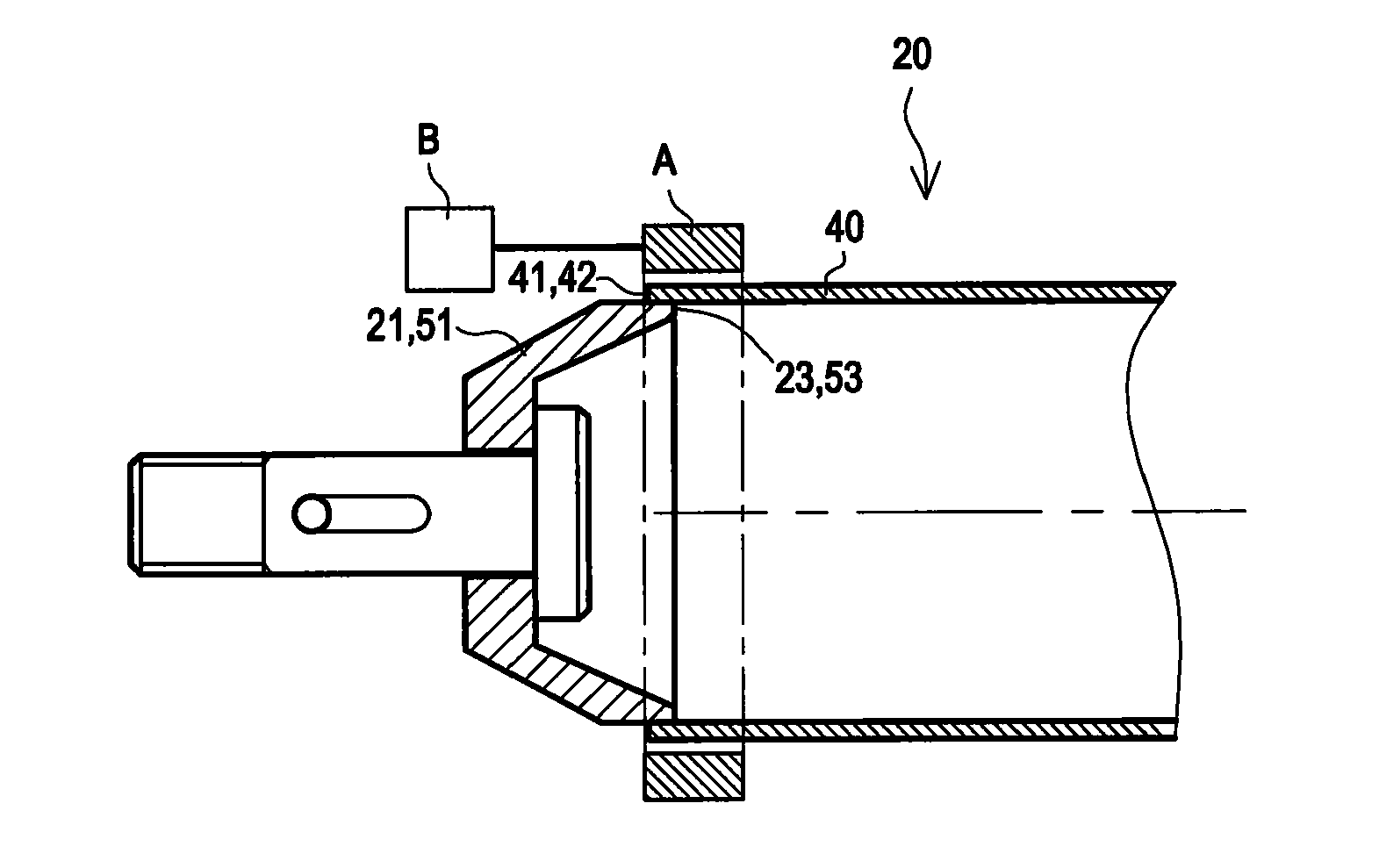

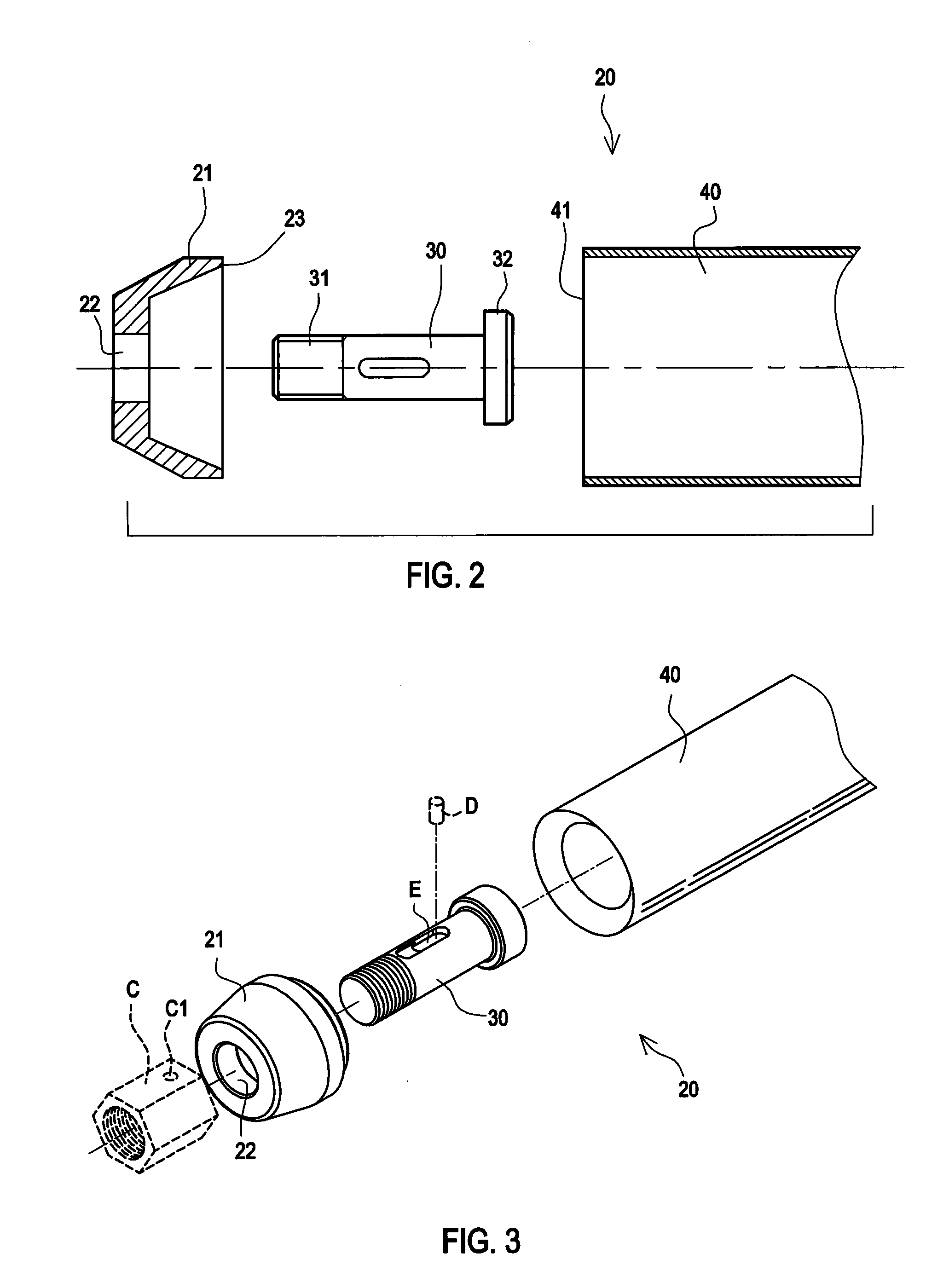

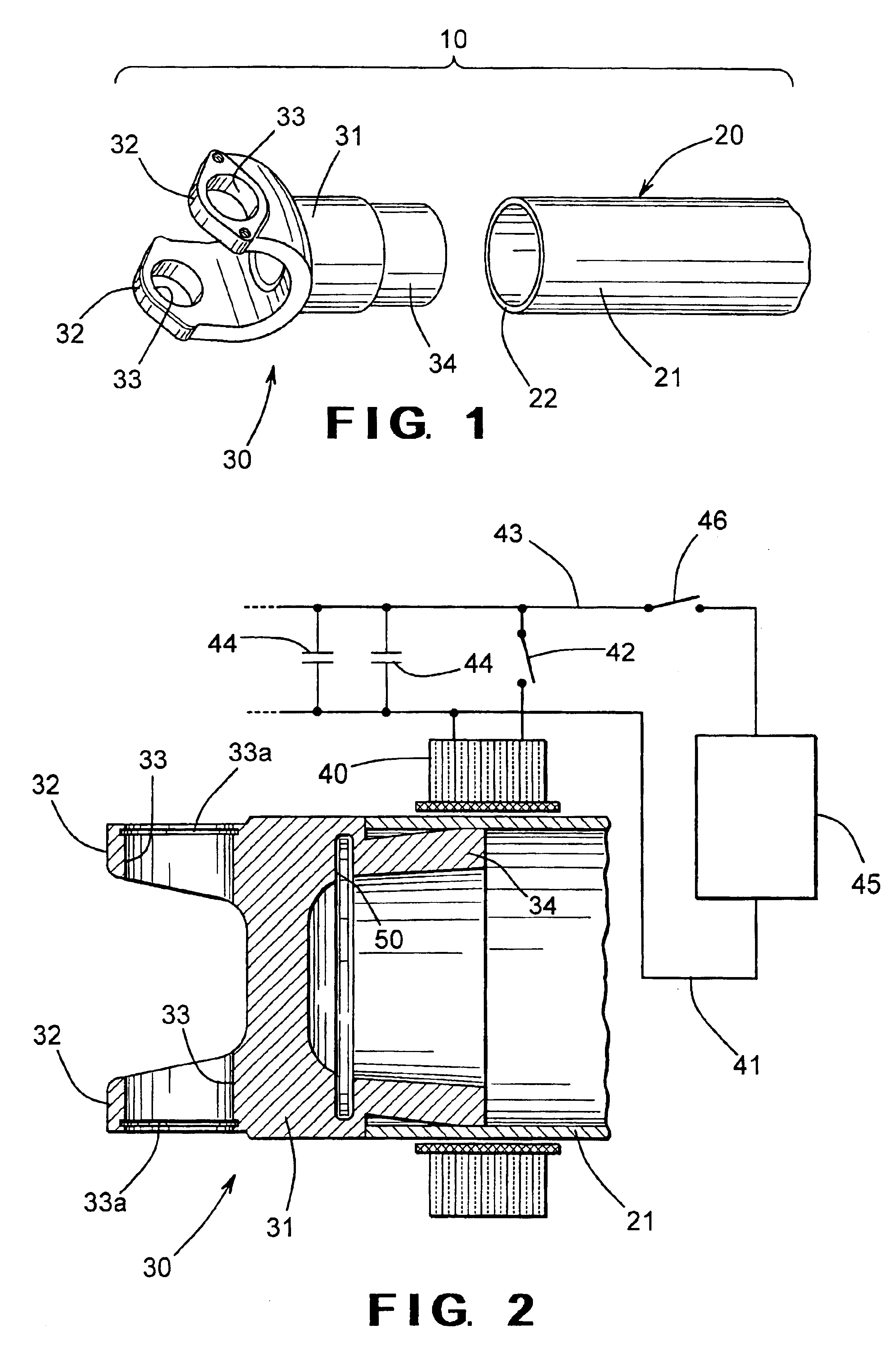

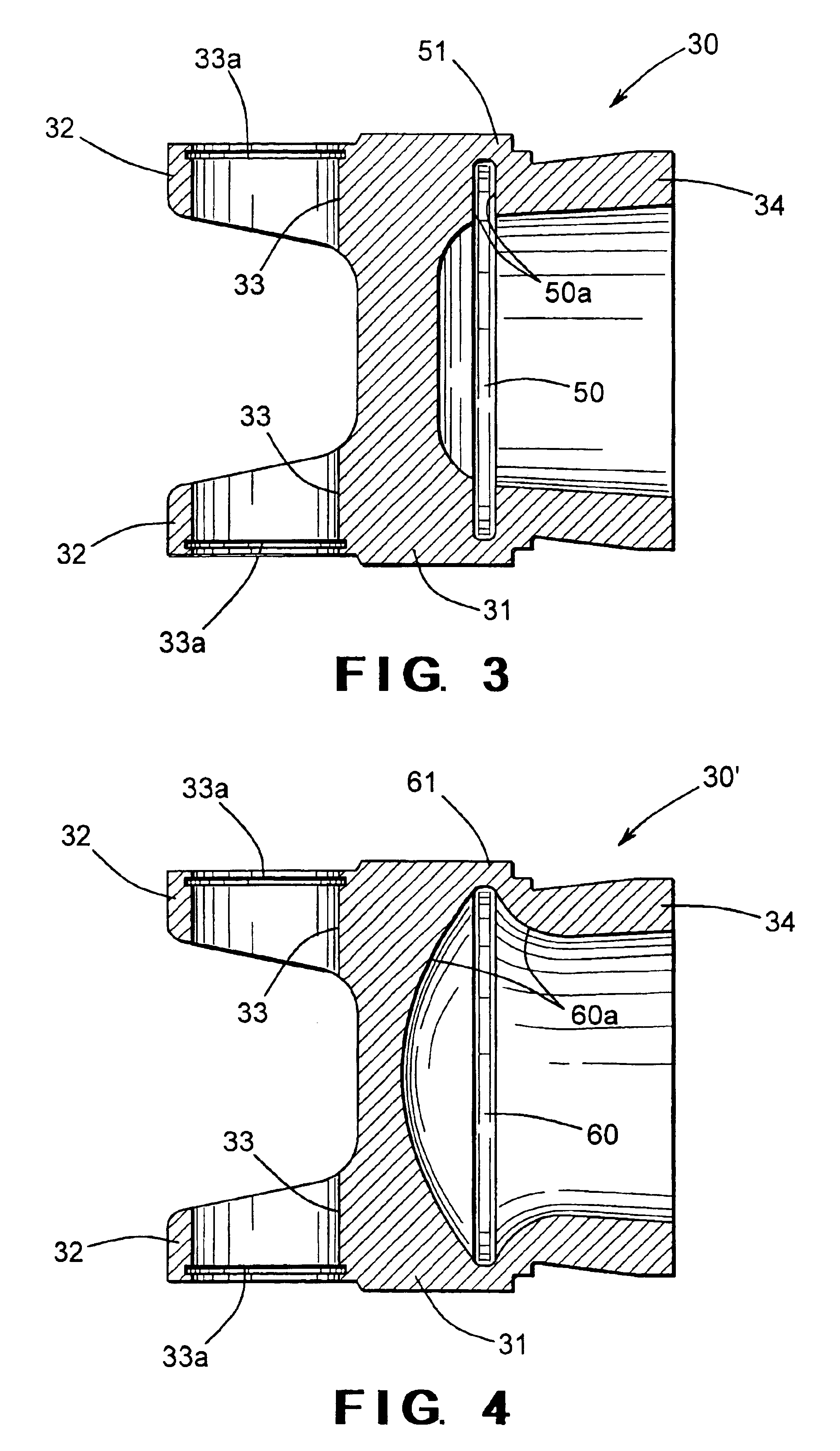

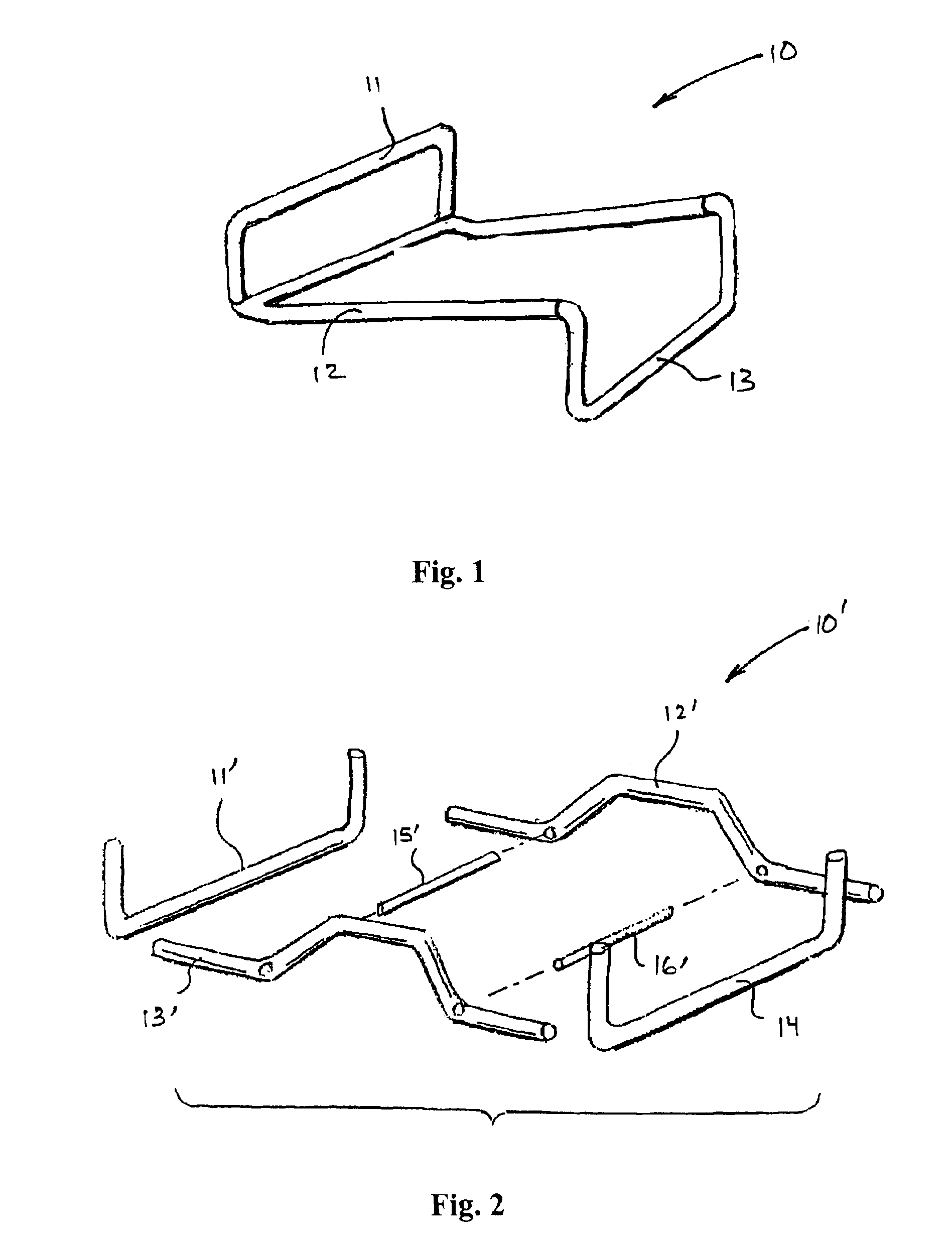

Yoke structure that is adapted to be secured to a tube using magnetic pulse welding techniques

InactiveUS6892929B2Quantity minimizationRestrict propagationBearing assemblySoldering apparatusShock waveDrive shaft

A magnetic pulse welding operation is performed to secure first and second metallic components together, such as a yoke and a driveshaft tube in a vehicular driveshaft assembly. The yoke includes a first portion, such as a body portion, and a second portion, such as a pair of opposed yoke arms, that are separated by a bridge portion. The end of the driveshaft tube is disposed co-axially about the body portion of the yoke, and a magnetic pulse welding operation is performed to secure the end of the driveshaft tube to the body portion of the yoke. The bridge portion can be defined by a groove formed in either the outer surface or the inner surface of the yoke. The groove may have side portions that extend either generally perpendicular or are angled or tapered relative to an axis of rotation of the yoke. If desired, a pair of opposed, semi-circular grooves may be formed in the yoke to define the bridge portion. The bridge portion allows the yoke arms to be elastically deformed and can also limit the propagation of shock waves through the yoke that can result from the performance of the magnetic pulse welding operation.

Owner:TORQUE TRACTION TECH INC

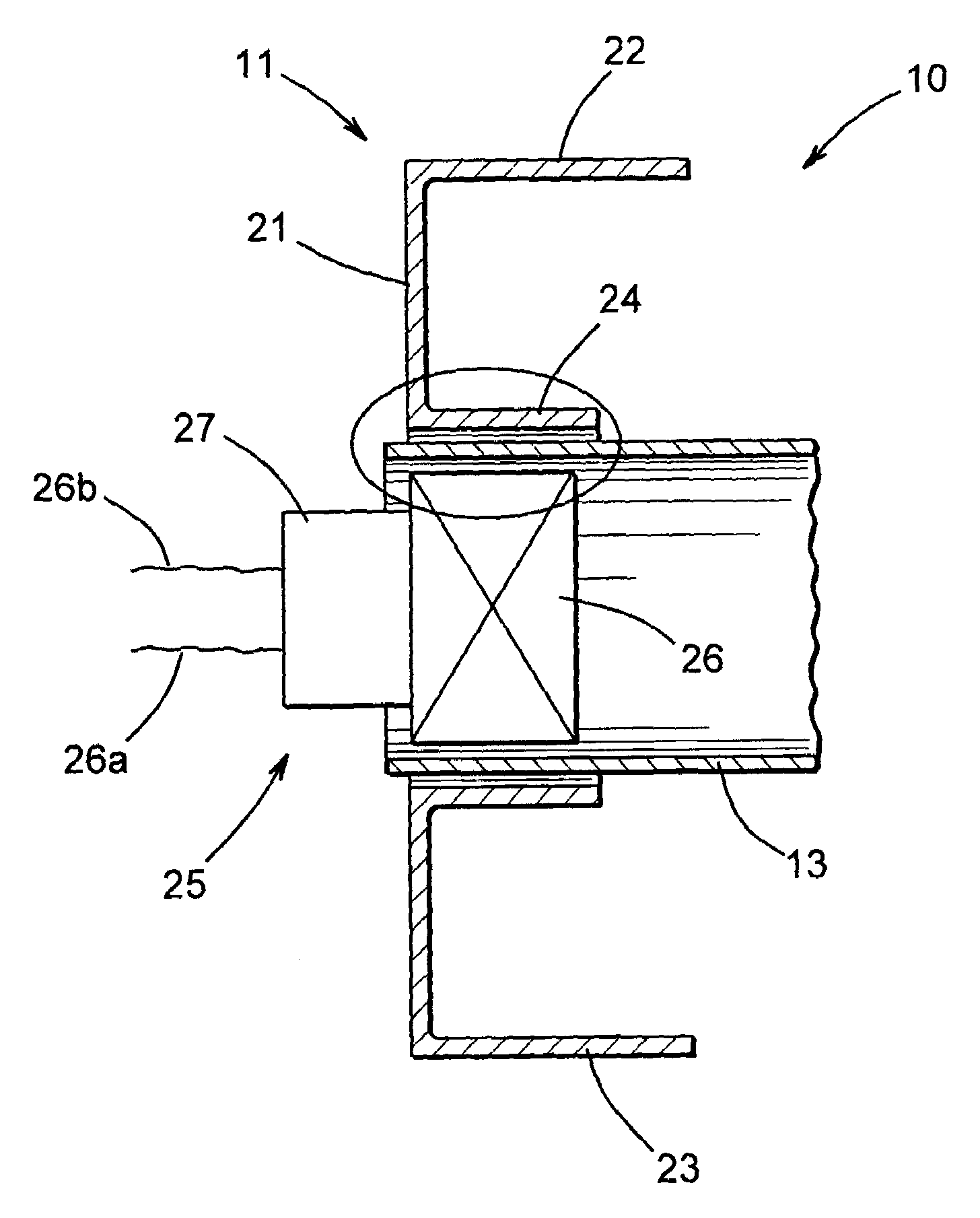

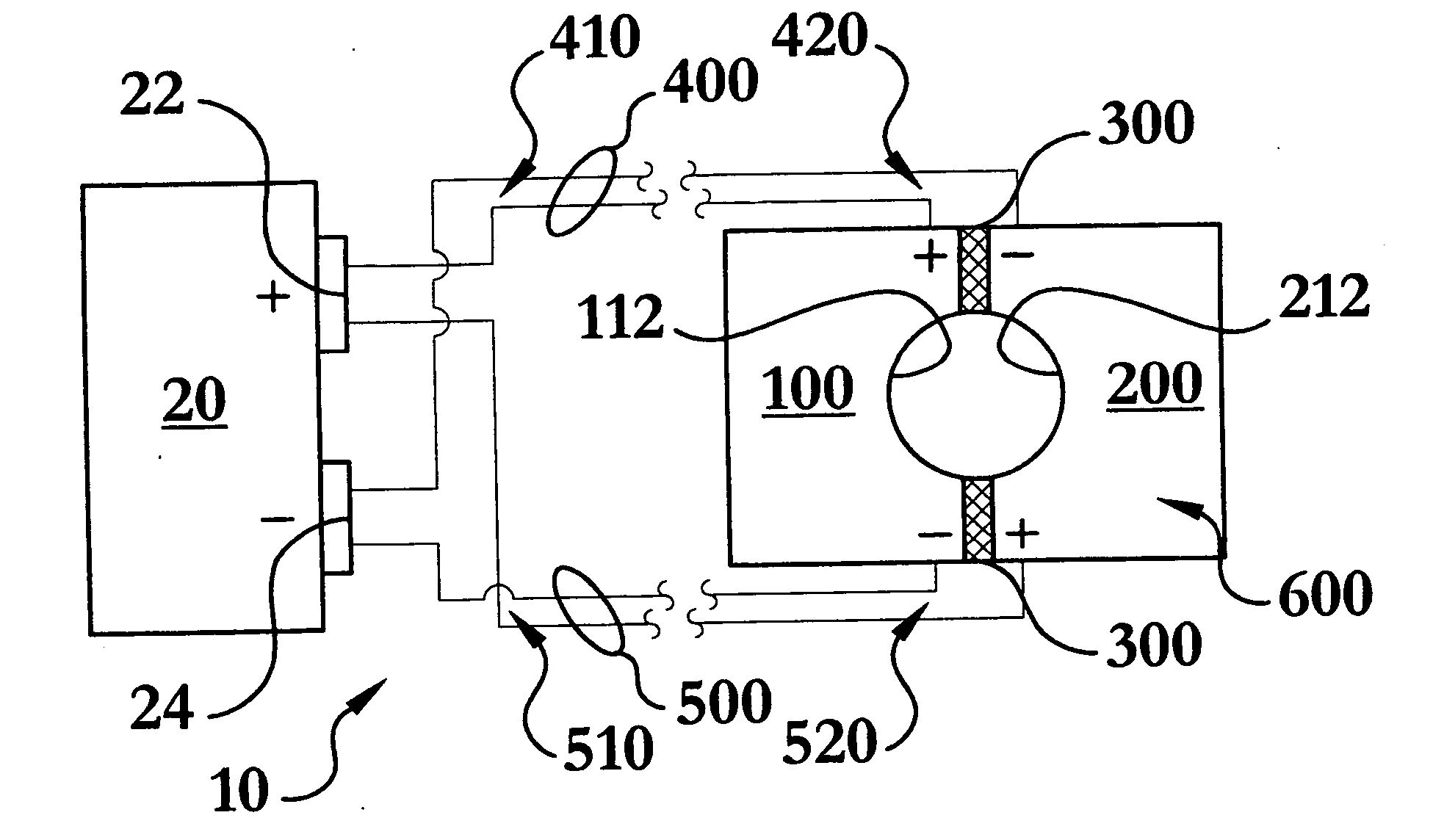

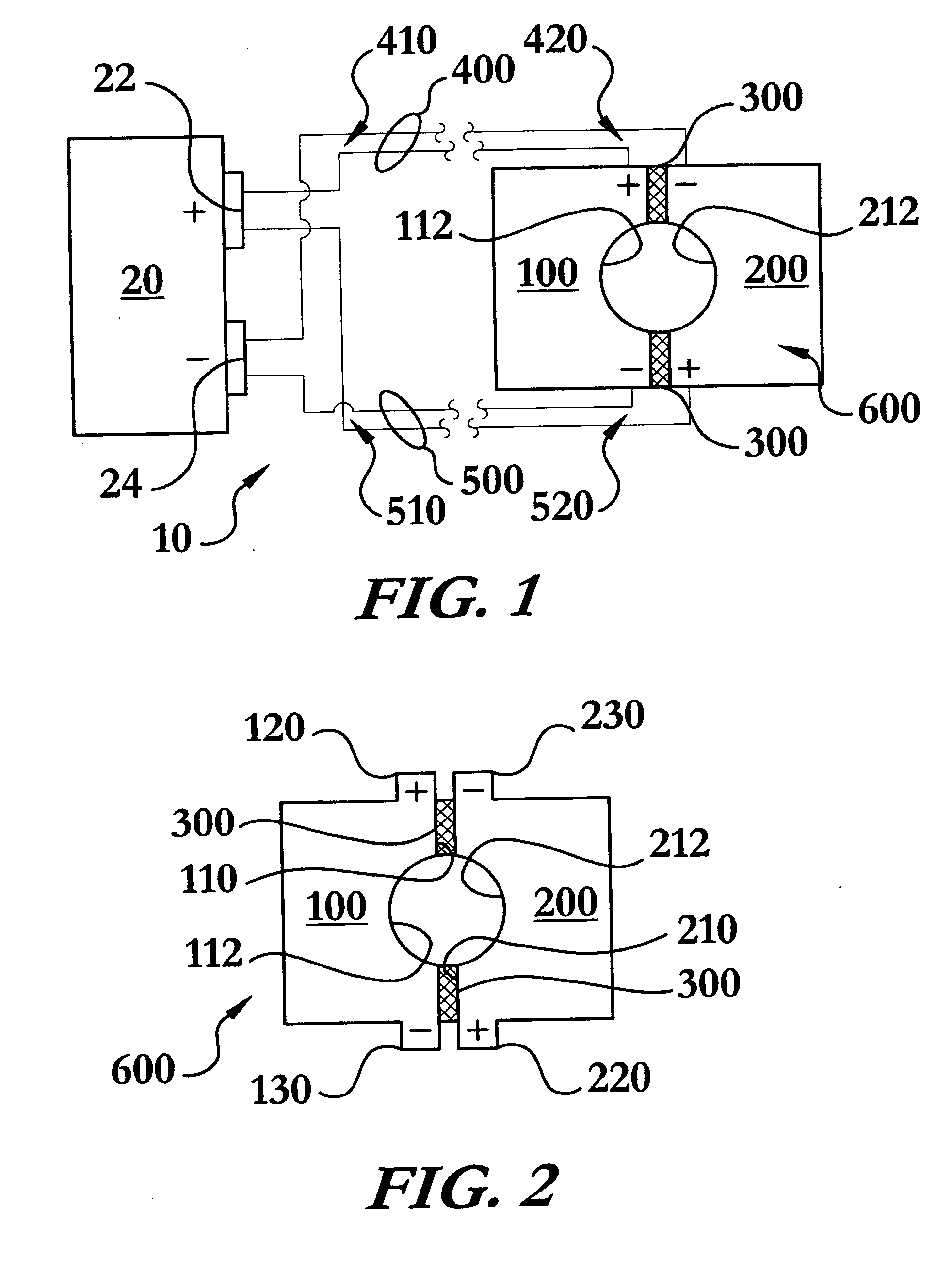

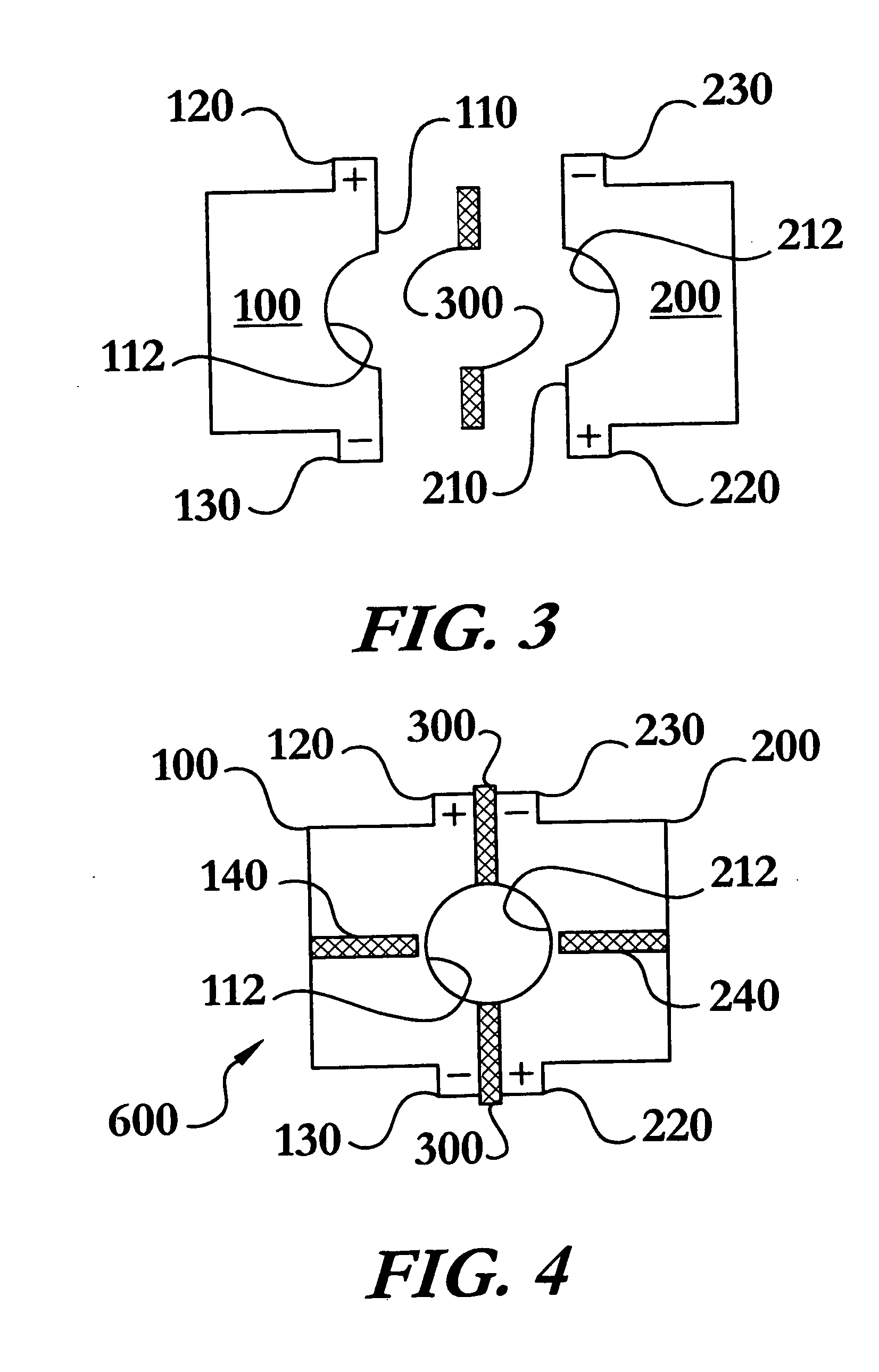

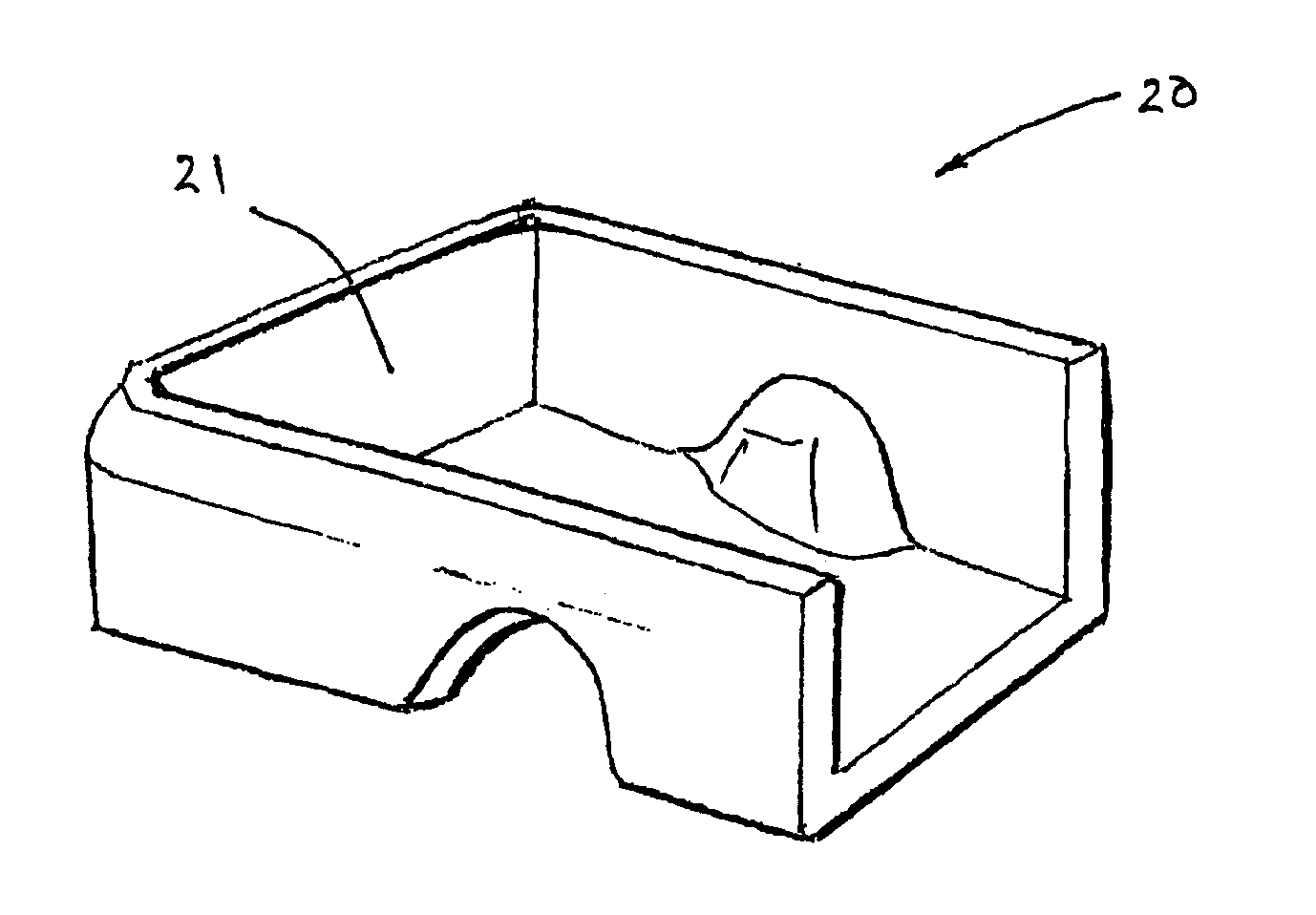

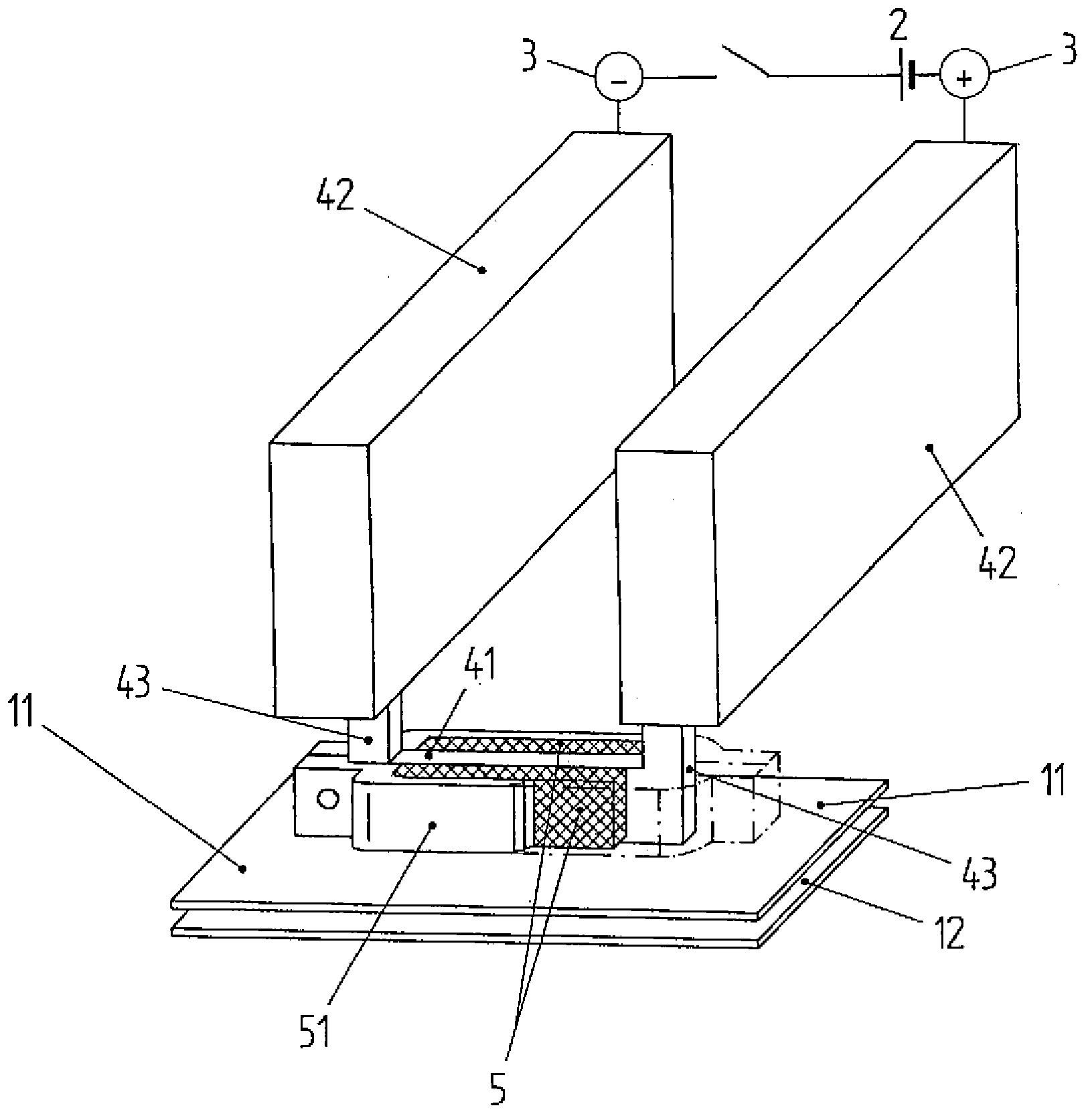

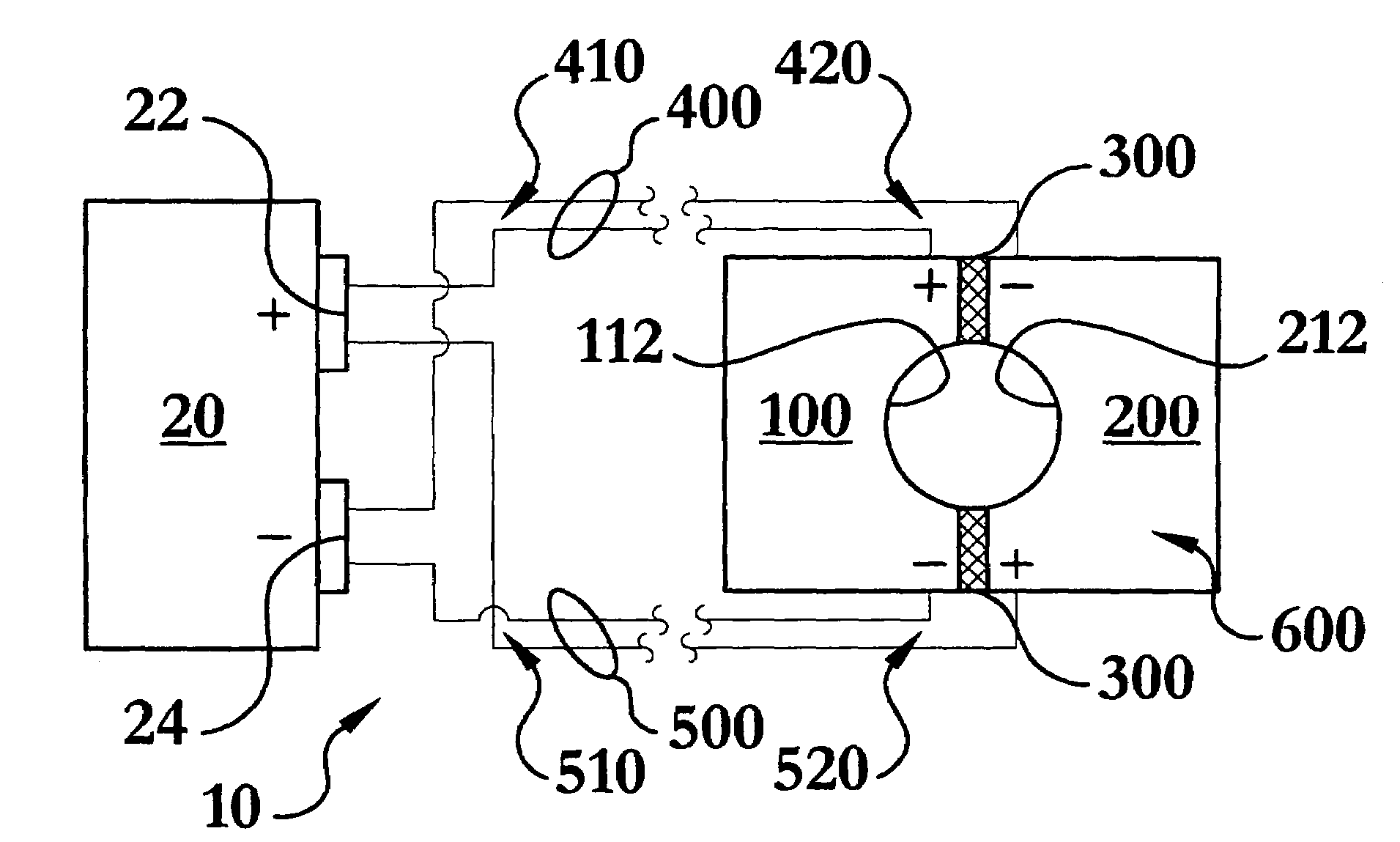

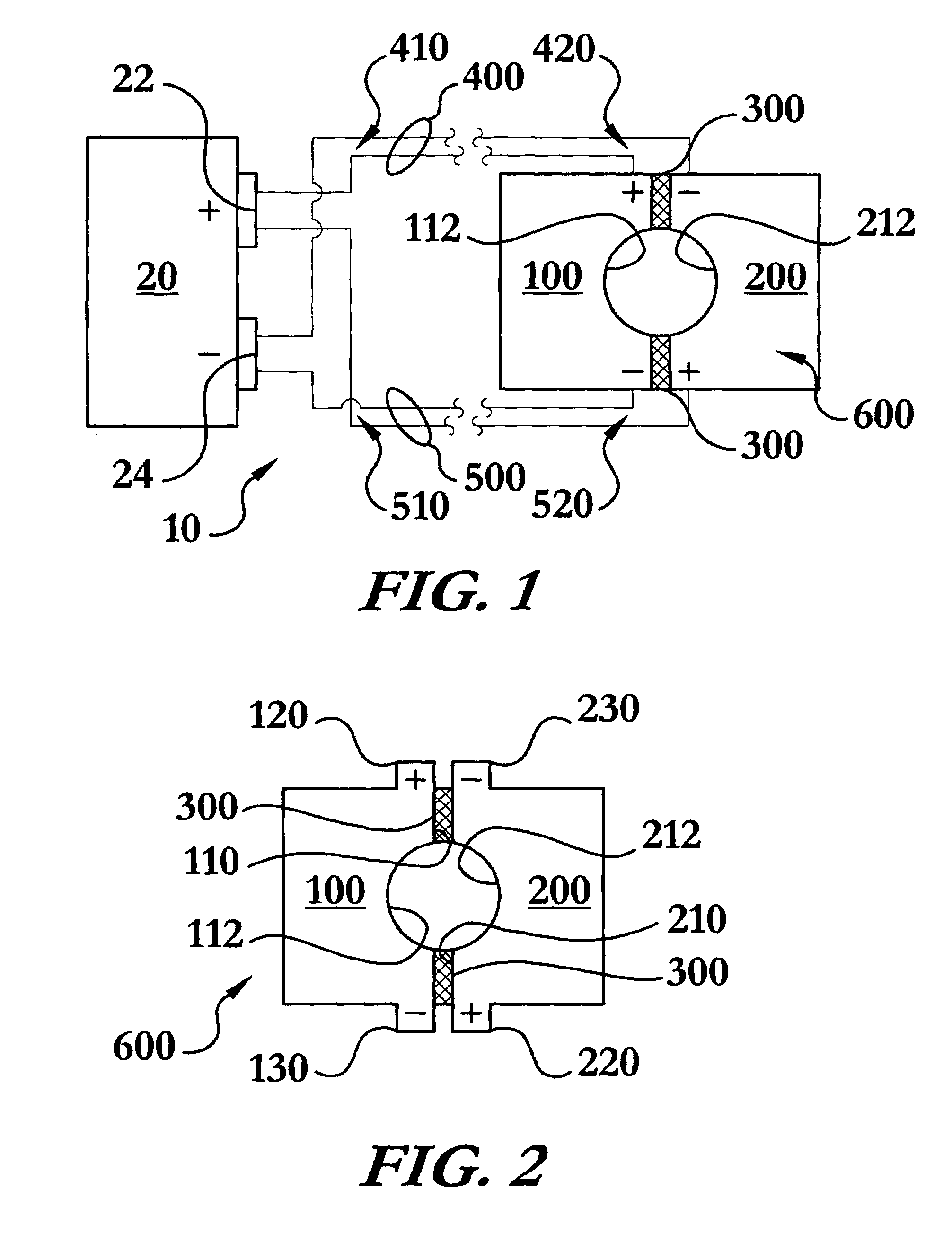

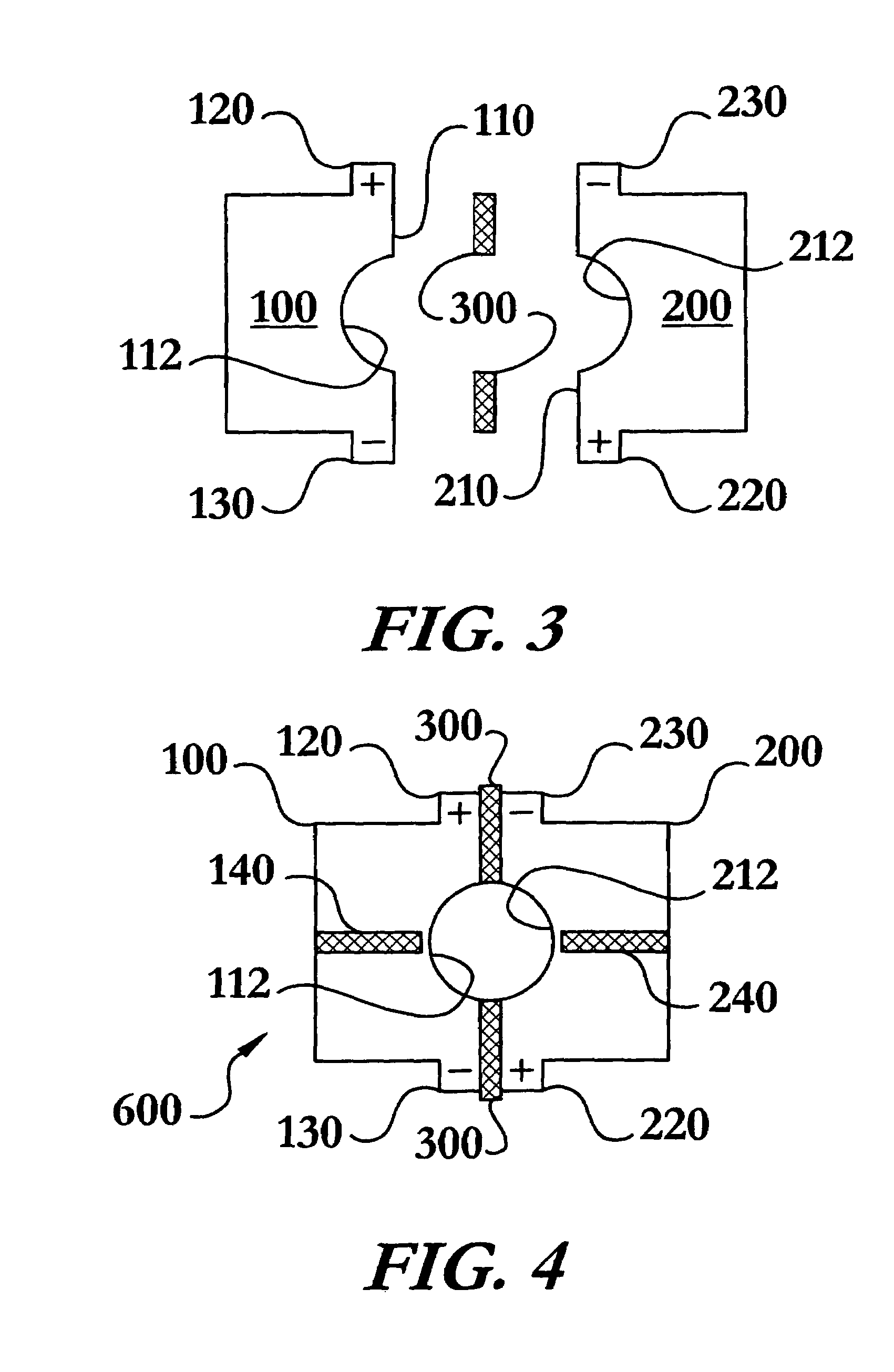

Opposed current flow magnetic pulse forming and joining system

ActiveUS20060185412A1Reduce inductanceMinimize their inductancePower hammersHammer drivesElectricityElectrical conductor

An opposed current flow magnetic pulse forming and joining system in electrical communication with a magnetic pulse power supply having a positive connection and a negative connection. The system may be used in forming individual workpieces or joining multiple workpieces, including joining by magnetic pulse welding. The system includes a first section, a second section, an insulator, and a first and a second pair of conductors. The first and second sections cooperate to enclose the workpiece(s) and function to create an electromagnetic force similar to that produced by a single closed coil. The system is configured to achieve desirable current flow by minimizing inductance, inductive reactance, and impedance in the conductors. The pairs of conductors may incorporate closely spaced individual conductors, braided conductors, and coaxial conductors. The current flow in the individual conductors of each pair of conductors is opposed, as is the current flow through the sections.

Owner:EDISON WELDING INSTITUTE INC

Storage box for a pickup truck formed from metallic and composite materials

InactiveUS6945591B2Light weightSimple structureVehicle seatsSupplementary fittingsPickup truckEngineering

A storage box for a pickup truck or similar vehicle is formed from a combination of metallic and composite materials. The storage box includes an internal storage box frame that is formed from a plurality of metallic tubular components that are secured together, such as by magnetic pulse welding techniques. The metallic tubular pieces can be formed from steel, aluminum, and the like, or any combination thereof. The storage box further includes one or more panels that are formed from composite materials, such as urethane, that are secured to the metallic storage box frame. The composite panels may secured to the metallic storage frame box by molding the composite material directly about the metallic storage box frame. Alternatively, the composite panels may be formed as separate pieces that are connected to the metallic storage box frame. The combination of the internal metallic storage box frame and the external composite storage box panels provides a relatively light weight storage box that is resistant to dents and other deformations during use.

Owner:METALSA SA DE CV

Vehicle exhaust component assembly using magnetic pulse welding

InactiveUS20080072584A1Add supportExhaust apparatusSilencing apparatusMagnetic pulse weldingElectrical and Electronics engineering

A vehicle exhaust system is provided that includes a first exhaust member having an end that includes an enlarged section. A second exhaust member is sized to receive a portion of the first exhaust member. The enlarged section of the first exhaust member has an outer diameter that is larger than an inner diameter of at least one section of the second exhaust member for creating an interference condition between the first and second exhaust member to prevent axial movement of the first exhaust member in at least one axial direction. The first exhaust member is secured to the second exhaust member by magnetic pulse welding.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

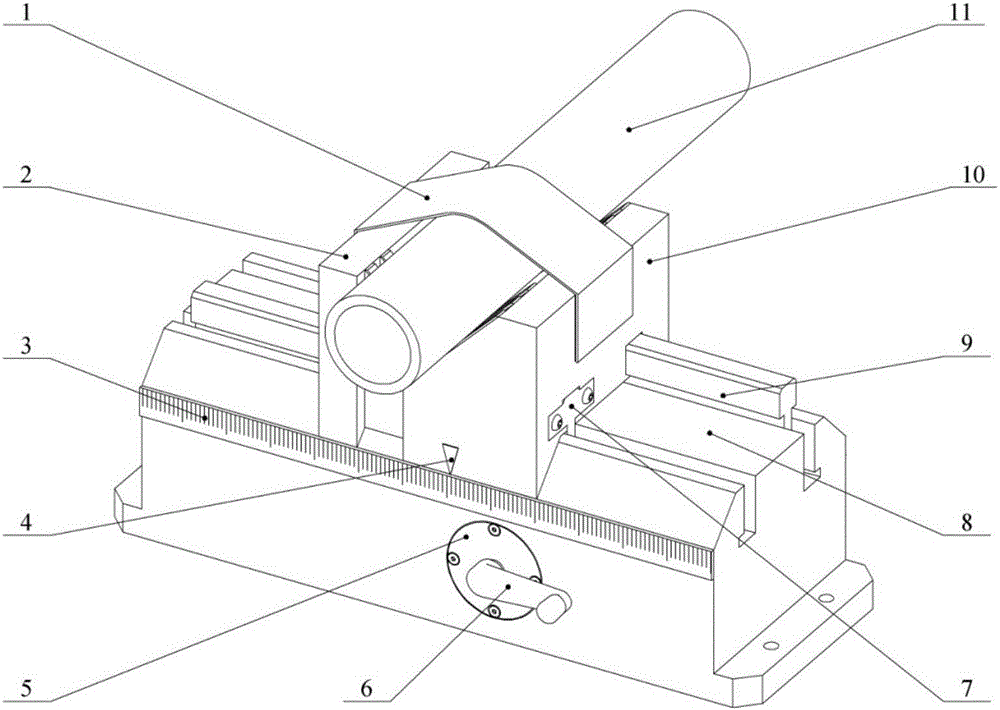

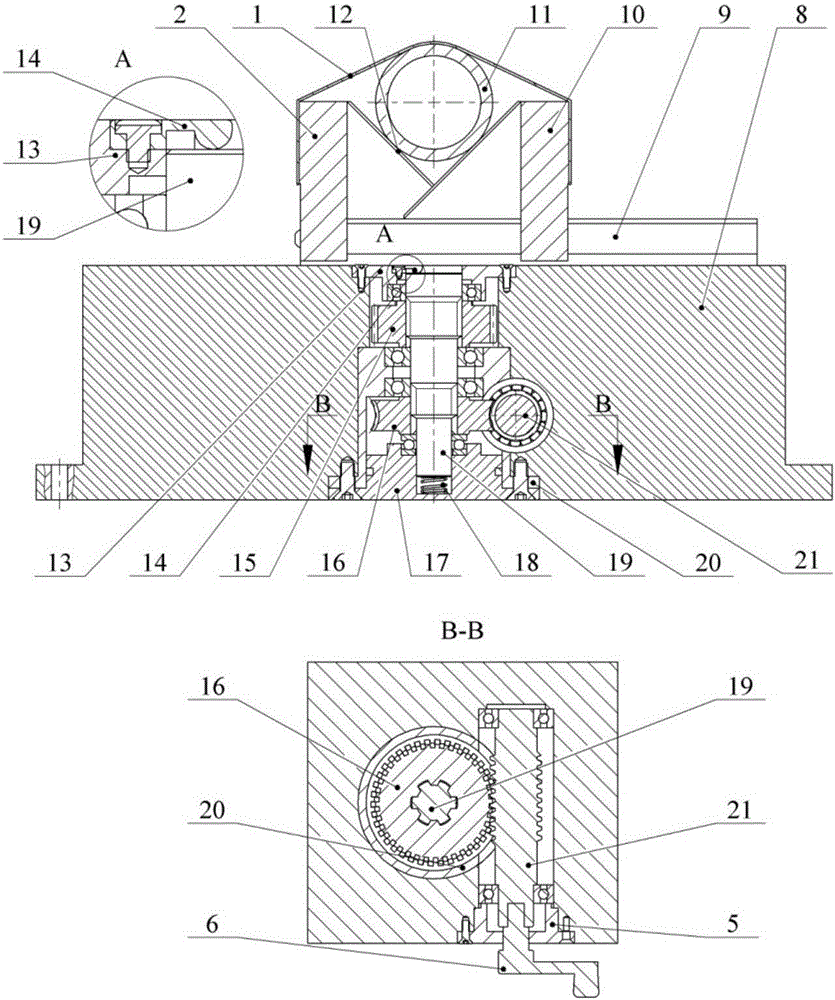

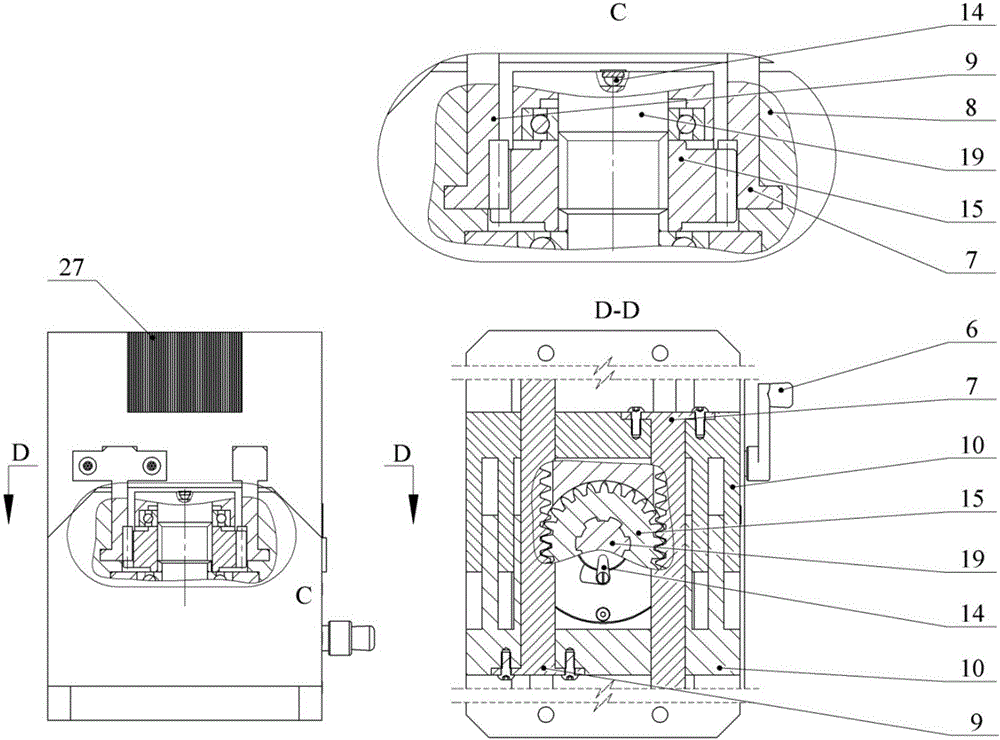

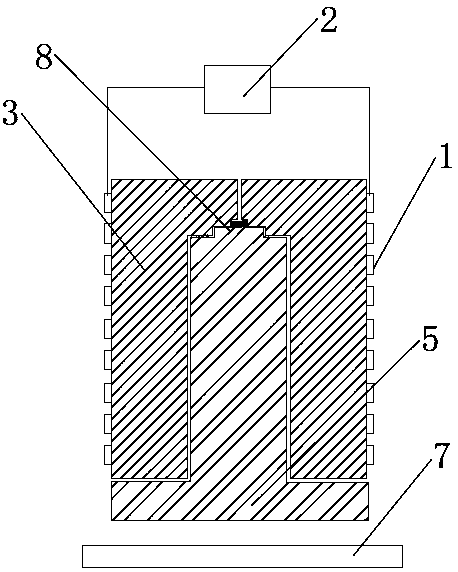

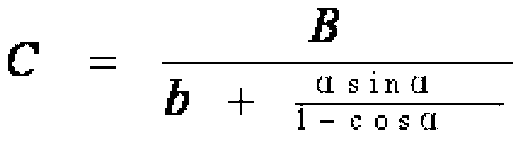

Circular tube centering flexible clamp for magnetic pulse welding

InactiveCN105710591AHow to use it in detailExplain how to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMagnetic pulse welding

The invention relates to a circular tube centering flexible clamp for magnetic pulse welding. The circular tube centering flexible clamp comprises an adjusting mechanism and a workpiece fixing mechanism, wherein the adjusting mechanism comprises a base (8), a worm shaft system and a center shaft system; and the structure of the workpiece fixing mechanism is used for containing circular tube workpieces in different sizes, and the circular tube workpieces are fixed in a manner of connection through hook and loop fasteners. The invention further provides a computational formula of the adjusting distance of the circular tube workpieces, the using method of the clamp is described in detail, and the circular tube centering flexible clamp is simple, reliable and convenient to operate.

Owner:HUNAN UNIV

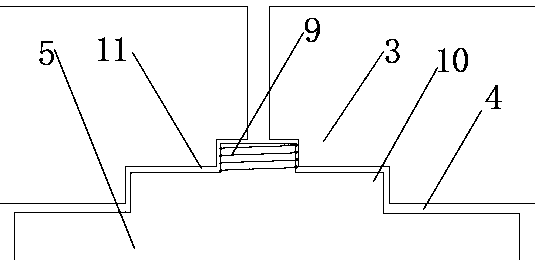

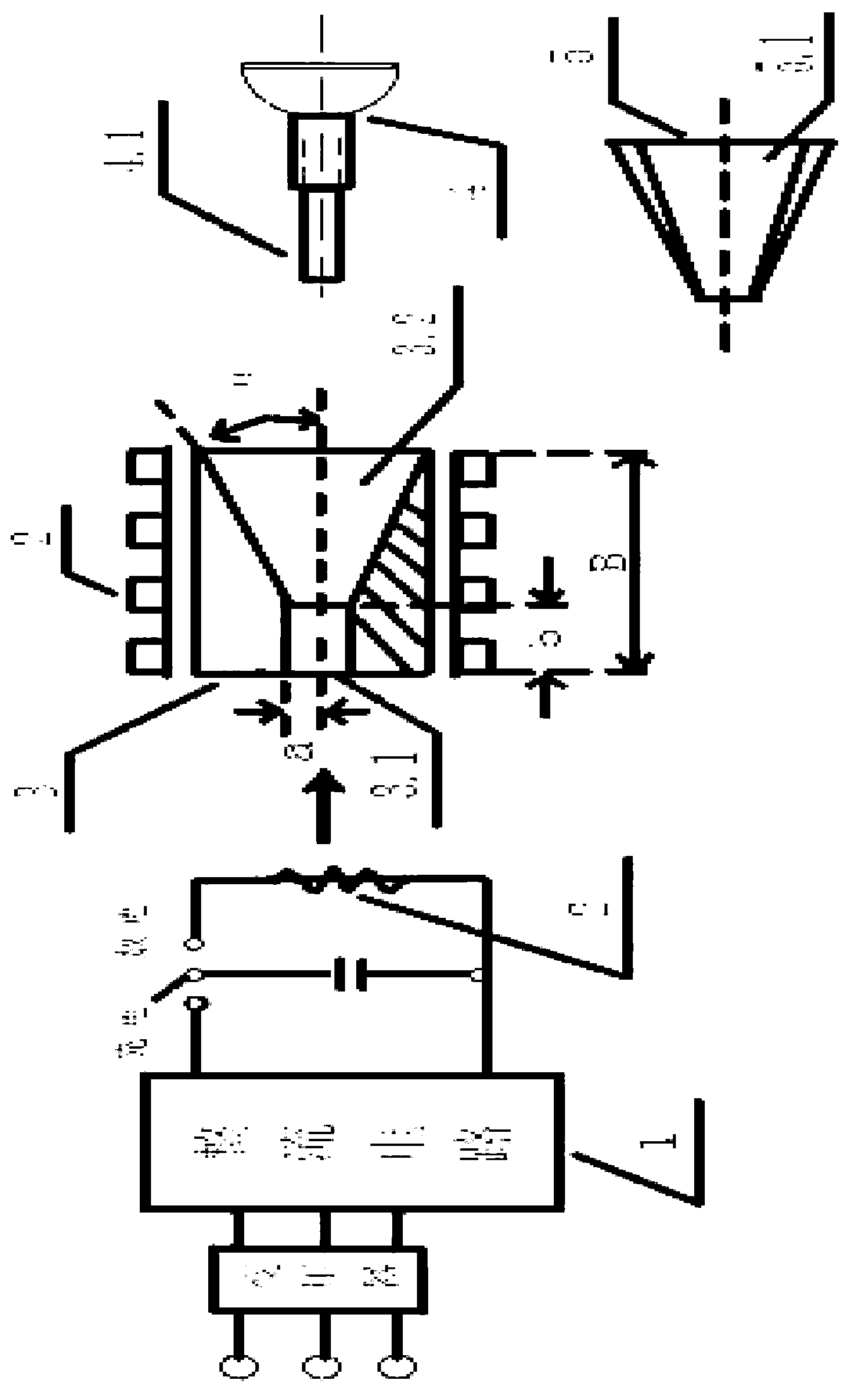

Electromagnetic pulse welding device for welding metal sheets using cooling insulator

ActiveCN103347640AHeat dissipation fastImprove microstructureCoil arrangementsHigh frequency current welding apparatusElectrical conductorMetal sheet

The invention relates to an electromagnetic pulse-welding device for joining a metal sheet to a metal part, consisting of an electric energy source which is connected to a coil by means of a current conductor, the active part of said coil being in the direct proximity of the metal sheet, said metal sheet being at a distance from the metal part. The passive part of the coil has a larger cross-section than the active part and said active part borders on one part of the surface in a positive fit, to a cooling insulator, the material having a relatively high thermal conductivity and a relatively low magnetic and electric conductivity compared to the material of the coil.

Owner:PST PRODS

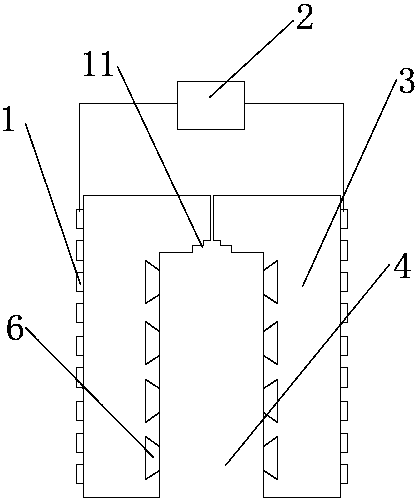

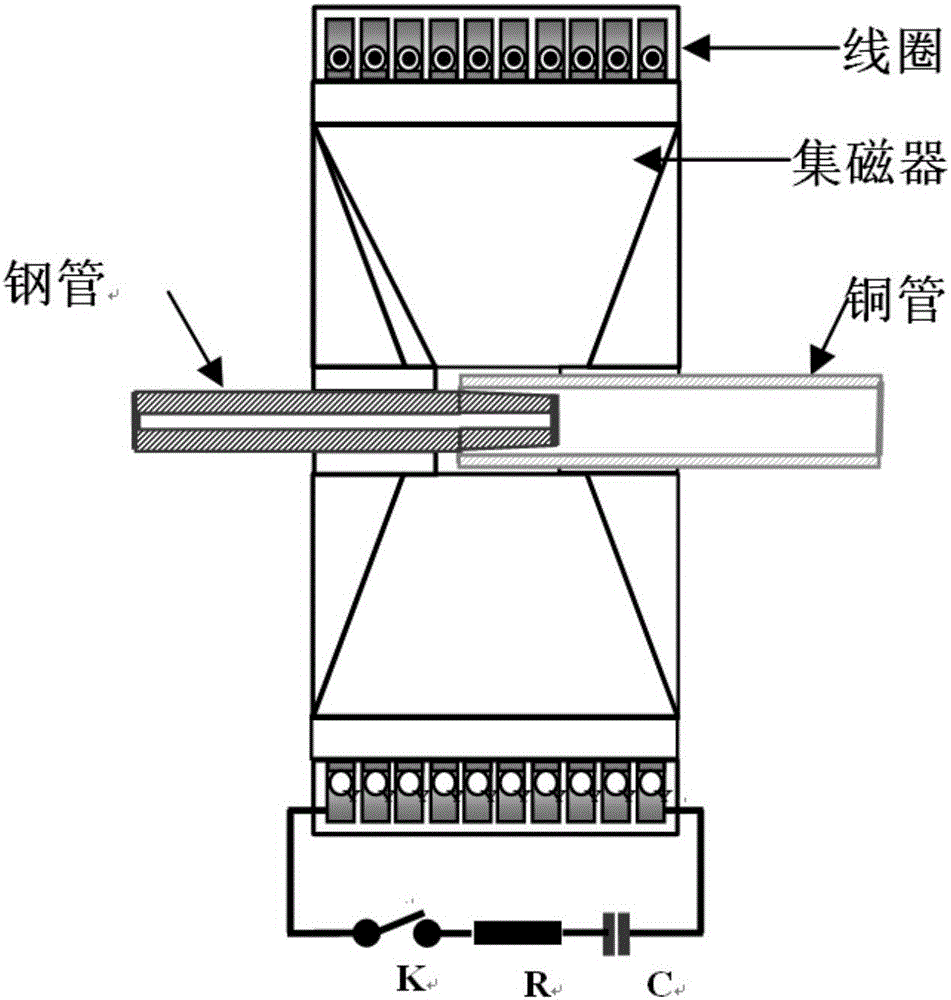

Combined magnetic collector for electromagnetic pulsation welding

ActiveCN109807449AAchieve weldingIncrease profitWelding/cutting auxillary devicesAuxillary welding devicesConvex structureMagnetic pulse welding

The invention discloses a combined magnetic collector for electromagnetic pulsation welding. The combined magnetic collector comprises a coil, a power supply and a magnetic collector body, wherein thecoil is wound around the outer side of the magnetic collector body, and the coil is connected with the power supply through wires. When tubular workpieces are welded, the magnetic collector body comprises a first component, wherein the outside of the first component is a cylinder, and a central groove is formed in the axial direction of the first component; the cross section of the first component is a U shape, and the coil is uniformly distributed on the outer surface of the first component; and when plate-shaped workpieces are welded, the magnetic collector body further comprises a second component, wherein the second component is of a convex structure matched with a central groove of the first component in use and is provided a T-shaped cross section, and the top end of the convex partof the second component is further provided with a conducting device, so that the first component and the second component are fixed. According to the combined magnetic collector, the method of combining the first component and the second component is adopted, when two workpieces in different shapes are welded, different special magnetic collectors do not need to be replaced, and welding of the tubular workpieces and the plate-shaped workpieces can be realized only by using the first component alone or by combining the first component and the second component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for performing a magnetic pulse welding operation to secure first and second metallic components with a preheating step for softening a first part of the first member

Owner:DANA AUTOMOTIVE SYST GRP LLC

Magnetic pulse asymmetric magnetic collection device for special-shaped pipe fitting

InactiveCN103231165AIncreased durabilityReduce mechanical stressNon-electric welding apparatusPipe fittingEngineering

A magnetic pulse asymmetric magnetic collection device for a special-shaped pipe fitting belongs to the tooling design field of special type welding. The magnetic pulse asymmetric magnetic collection device for the special-shaped pipe fitting is characterized in that the shape of the special-shaped is a whole which is formed by connecting a cylindrical pipe fitting with an umbrella-shaped structure; the magnetic pulse asymmetric magnetic collection device utilizes a cylinder as an original material, a small cylinder is formed on one side of the cylinder, a truncated cone is formed on the other side of the cylinder, and the bottom surface of the small cylinder is the upper bottom surface of the truncated cone; the small cylinder, the truncated cone and the cylinder as the original material are coaxial; and the cylinder is also provided with a guide groove which is formed by cutting through the cylinder from the outer surface to the axis in the axial direction of the cylinder. By means of the energy conversion fundamental principle during a magnetic pulse welding process, the magnetic pulse welding process can be completed instantly, energy can be precisely controlled, and good repeatability is obtained, so that mechanization and automation can be achieved easily. Welding pieces with good quality can be obtained and environmental friendliness is achieved.

Owner:BEIJING UNIV OF TECH

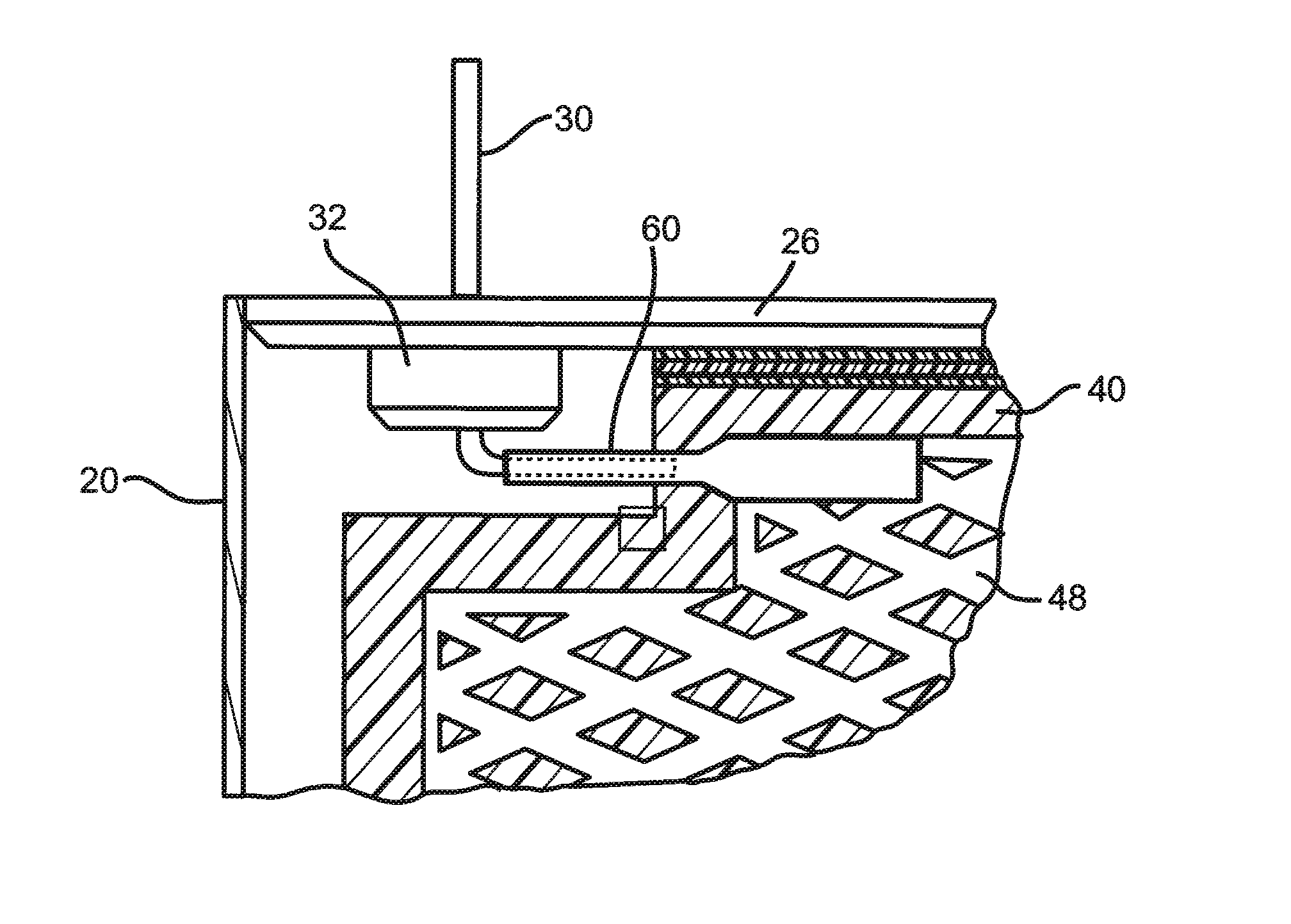

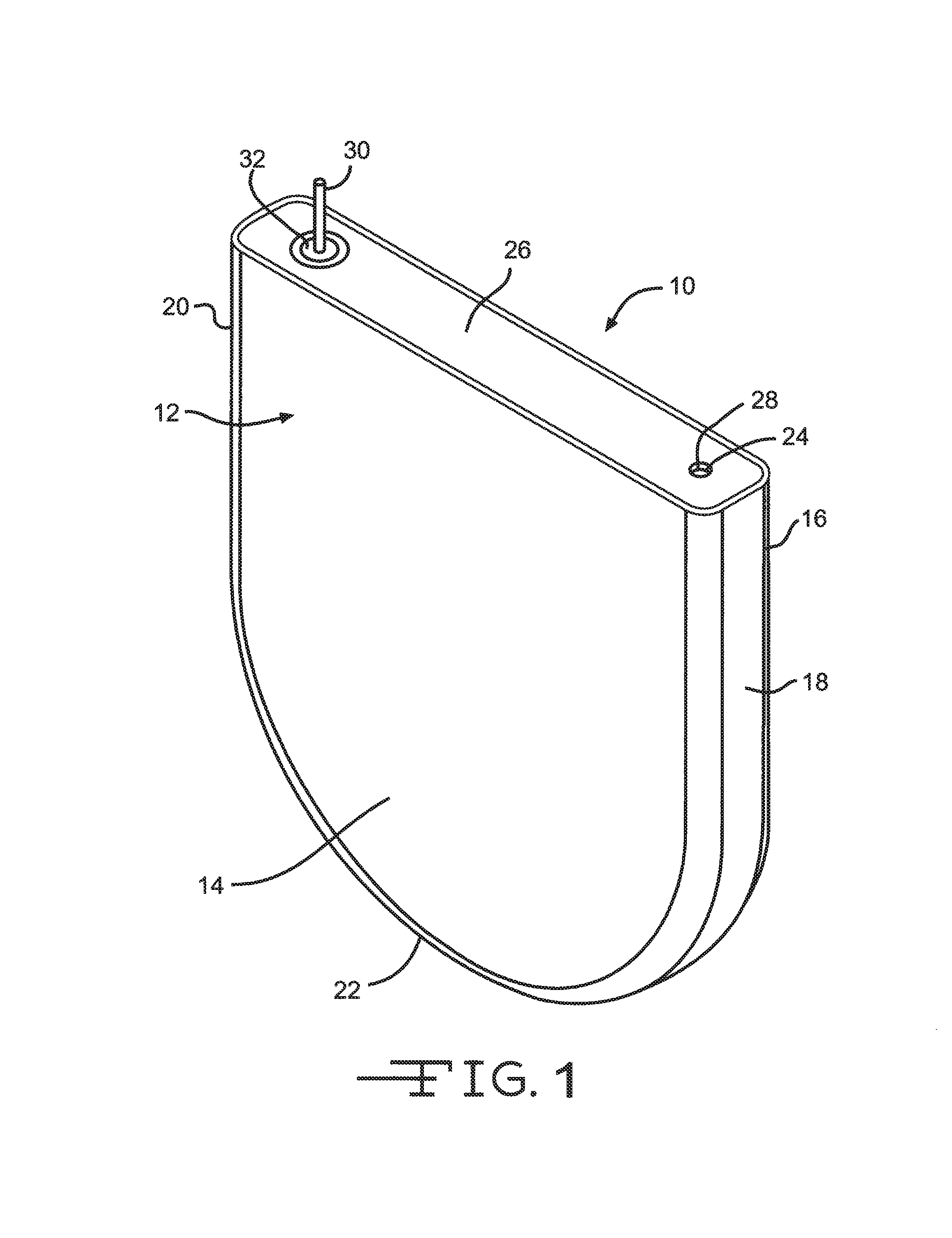

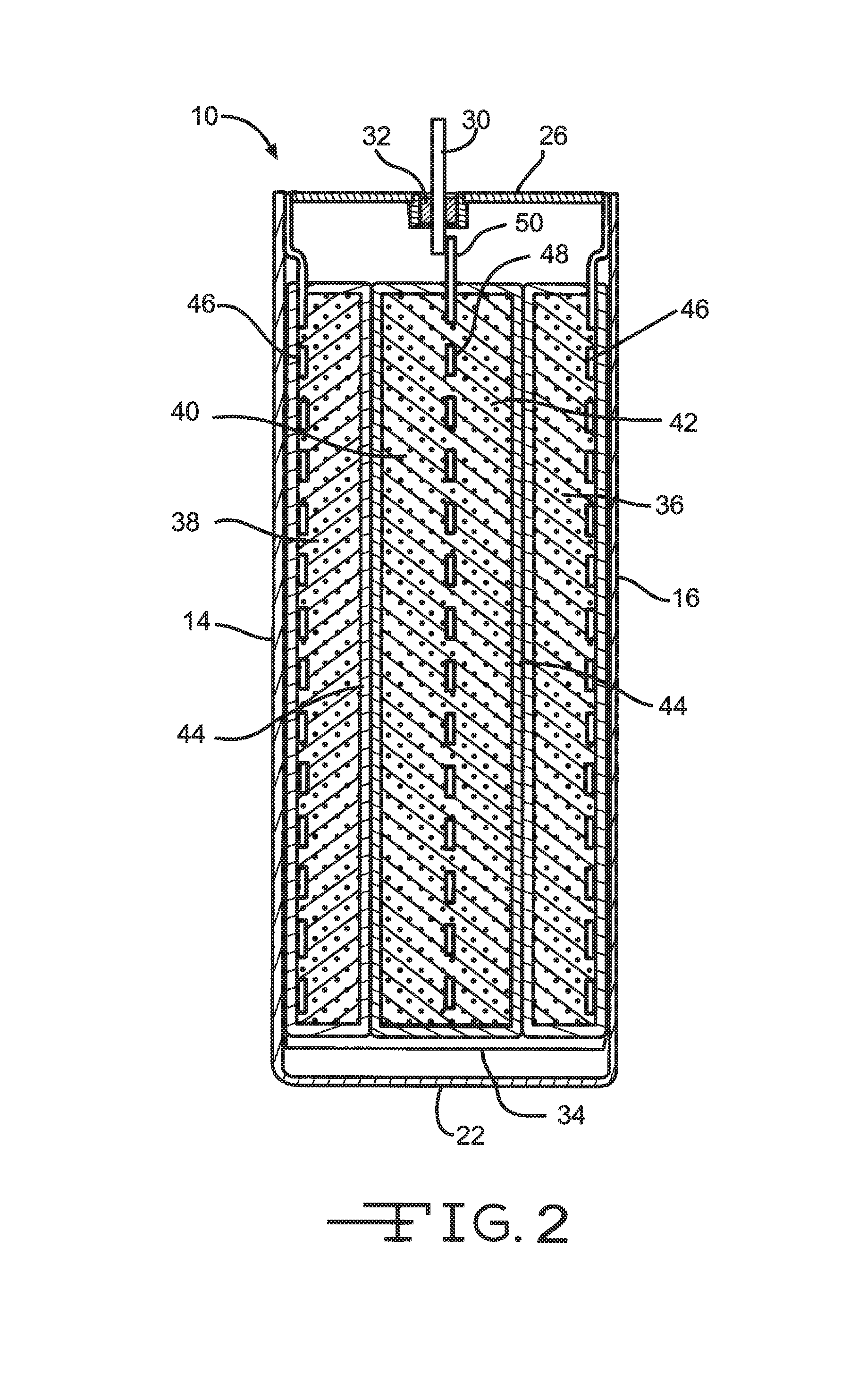

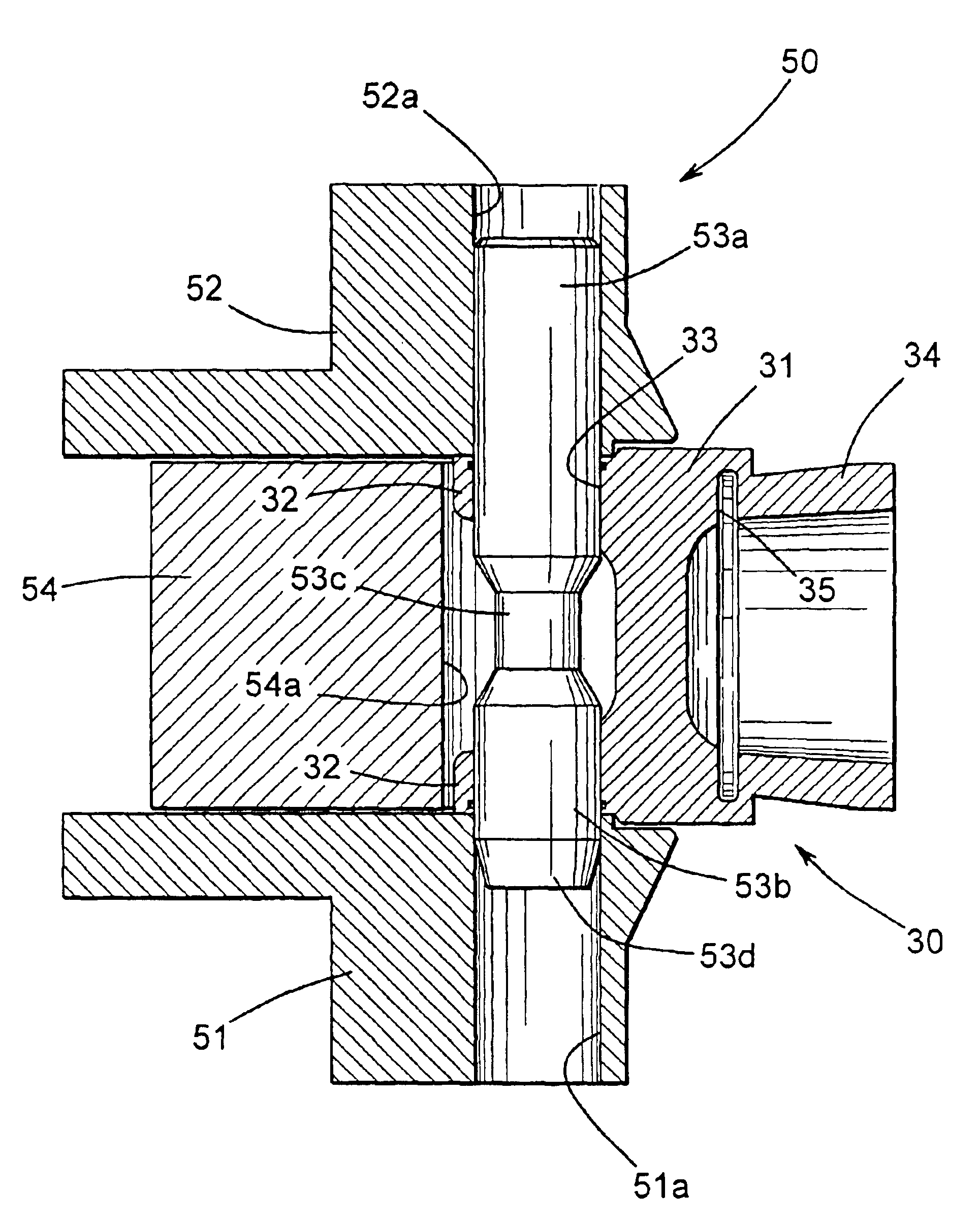

Magnetic pulse welding in medical power manufacturing

InactiveUS9553296B1Minimizing extensive inter diffusionFormation of intermetallic bonds is minimizedCell electrodesElectric connector introductionElectrical batteryPulsed DC

A magnetic pulse welding process for joining a current collector to a terminal pin in the construction of electrochemical cells is described. The magnetic pulse welding process utilizes a pulsed direct current and an electrically conductive coil to generate an electro-magnetic force that causes two work pieces to collide with each other and form a bond therebetween. Preferably, the method is used to bond the terminal pin to the cathode current collector. This method of attachment is suitable for either primary or secondary cells, particularly those powering implantable biomedical devices.

Owner:WILSON GREATBATCH LTD

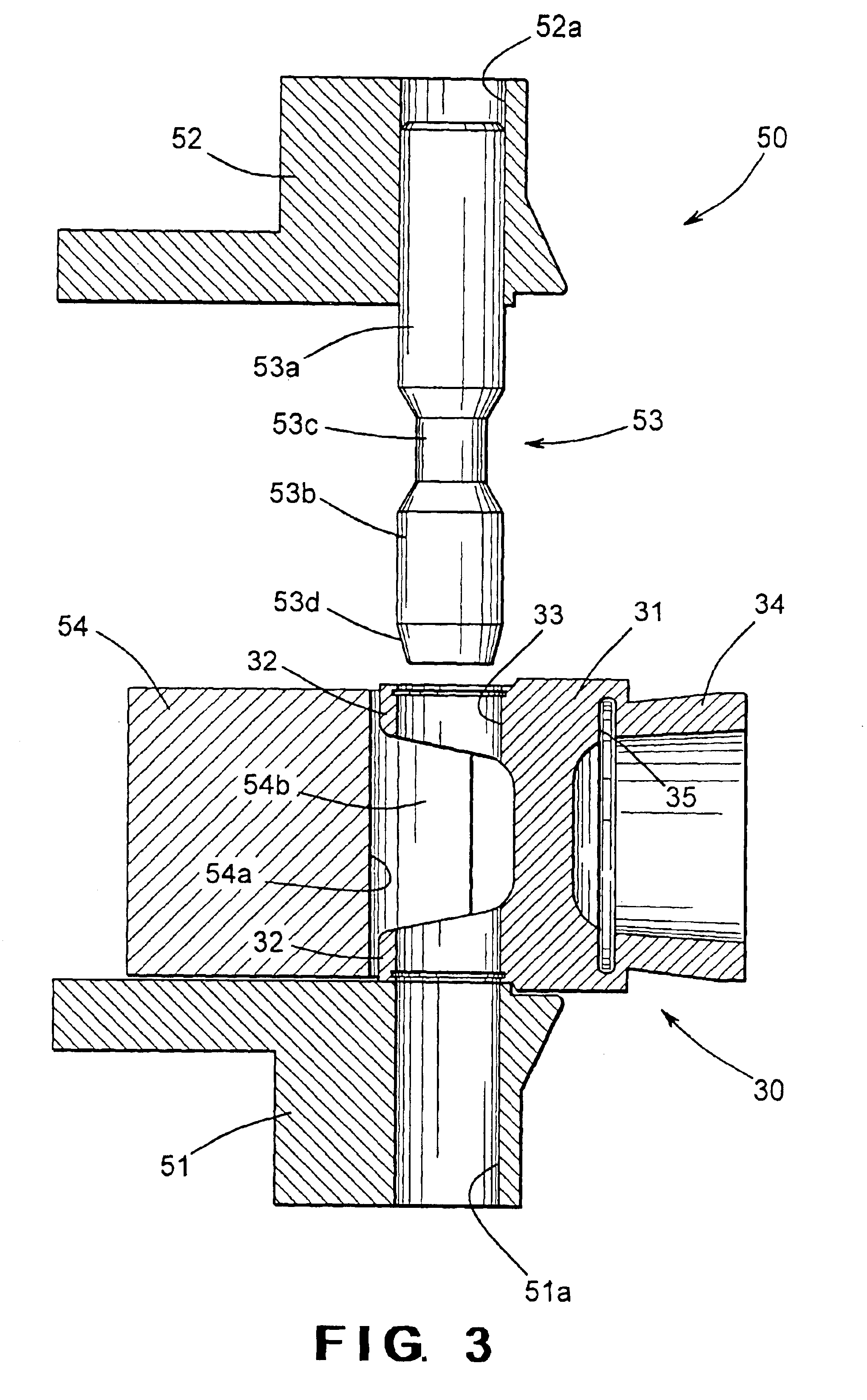

Apparatus for securing a yoke to a tube using magnetic pulse welding techniques

InactiveUS6908023B2Quantity minimizationAvoid deformationHigh frequency current welding apparatusNon-electric welding apparatusShock waveMagnetic pulse welding

An apparatus for supporting a workpiece, such as a yoke having a body portion and a pair of opposed yoke arms, during a magnetic pulse welding operation includes a lower jaw, an upper jaw, and a support pin extending therebetween. During the magnetic pulse welding operation, the lower and upper jaws of the support apparatus engage the opposed yoke arms, and the support pin extends through respective openings formed through the opposed yoke arms. The support apparatus can also include a counter die that is disposed between the lower jaw and the upper jaw and has an arcuate recess formed therein that receives the outer portions of the opposed yoke arms therein. Lastly, the support apparatus can further include a pair of positioning rails that engage the body portion of the yoke. As a result, the support apparatus prevents deformation of the opposed yoke arms and absorbs shock waves that can be propagated through the yoke during the magnetic pulse welding operation.

Owner:TORQUE TRACTION TECH INC

Method of permanently joining first and second metallic components

InactiveUS20050193545A1Improve performanceRopes and cables for vehicles/pulleyArc welding apparatusEngineeringMagnetic pulse welding

A pair of metallic components, such as a pair of metallic structural components for a vehicular body and frame assembly, are permanently joined using a magnetic pulse welding process. Initially, a first metallic component is provided having a first aperture that is formed through a first side and a second aperture having a hollow cylindrical flange portion that is formed through a second side. A second metallic component is provide having a surface that extends at an angle relative to the flange portion. The angled surface may be provided in the form of either an enlarged region or a reduced region on the second metallic component. The first and second metallic components are arranged such that the flange portion of the first metallic component overlaps the surface of the second metallic component. A magnetic pulse welding process is performed to cause the flange portion of the first metallic component and the angled surface of the second metallic component to engage one another and become permanently joined.

Owner:METALSA SA DE CV

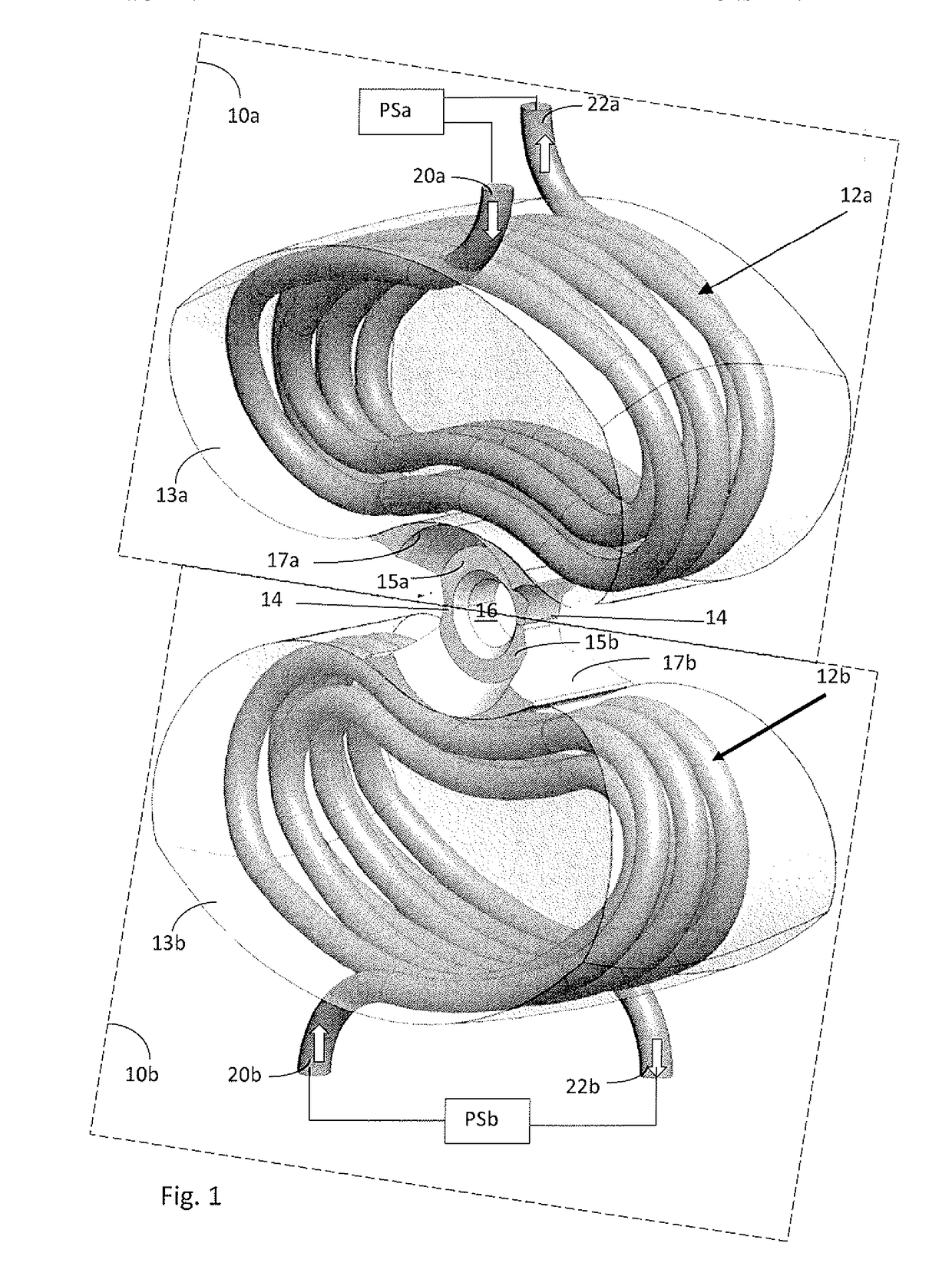

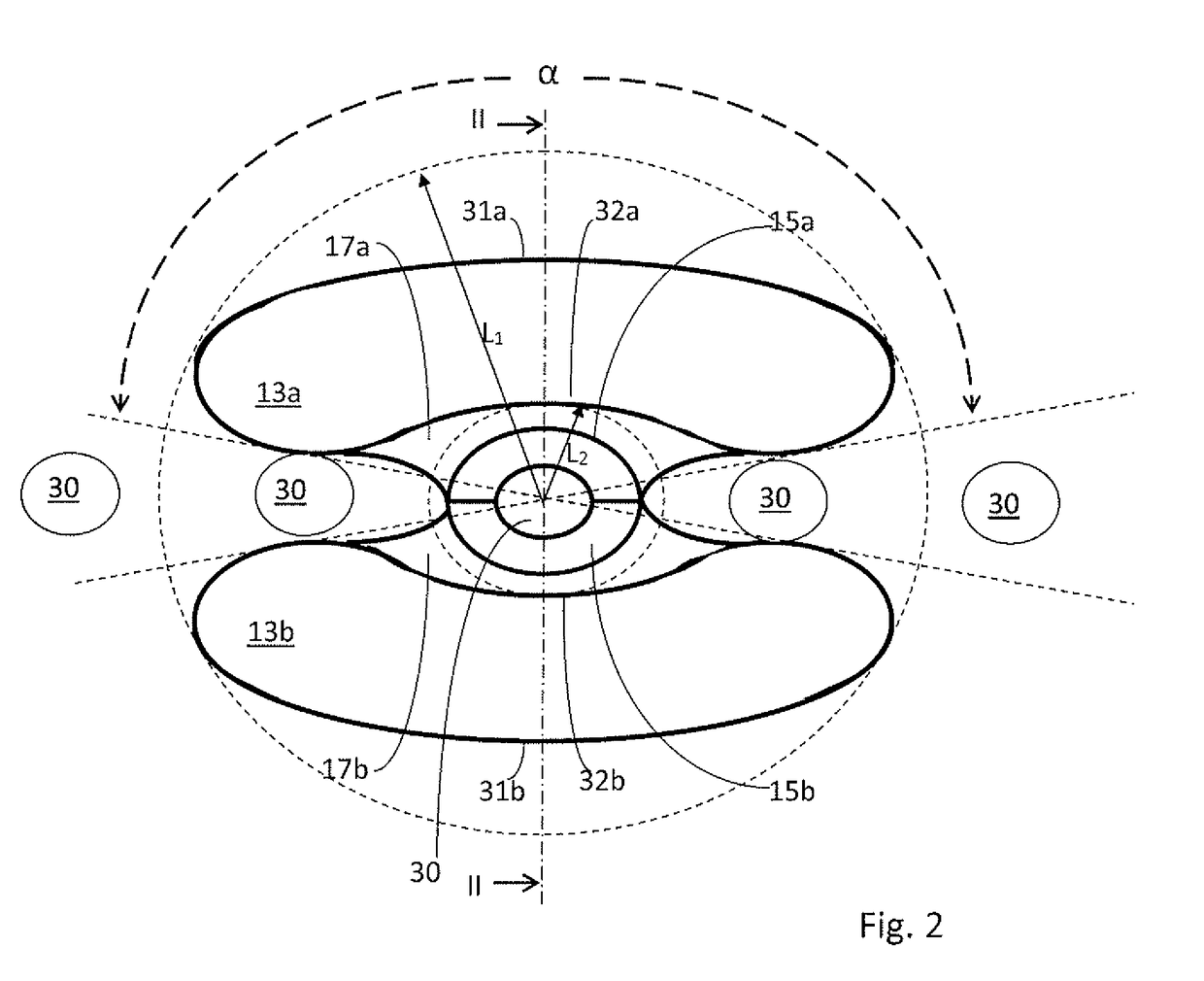

Welding head for magnetic pulse welding of tubular profiles to a cylindrical inner member

InactiveUS20170266752A1Open fastClose fastCoil arrangementsHeat exchange apparatusMagnetic pulse weldingMechanical engineering

The invention relates to a welding head for magnetic pulse welding of hollow thin-walled profile to an inner member having a complementary outer form to said hollow thin-walled profile. The weld head comprises two movable weld head halves (10a,10b) forming said weld head wherein each half has at least one individual induction coil (12a,12b) connected to a power source independently from the other weld head half, with coils wound in a kidney-shape. The work piece is clamped between shapers (15a,15b) integrated with each half. With this weld head could for example work pieces such as tubular thin-walled profiles be welded, even if they are integrated in a closed tubular design, as the weld head could be closed quickly over the welding position and opened for release of the work piece without experiencing arching in clamping area.

Owner:VALMET AB

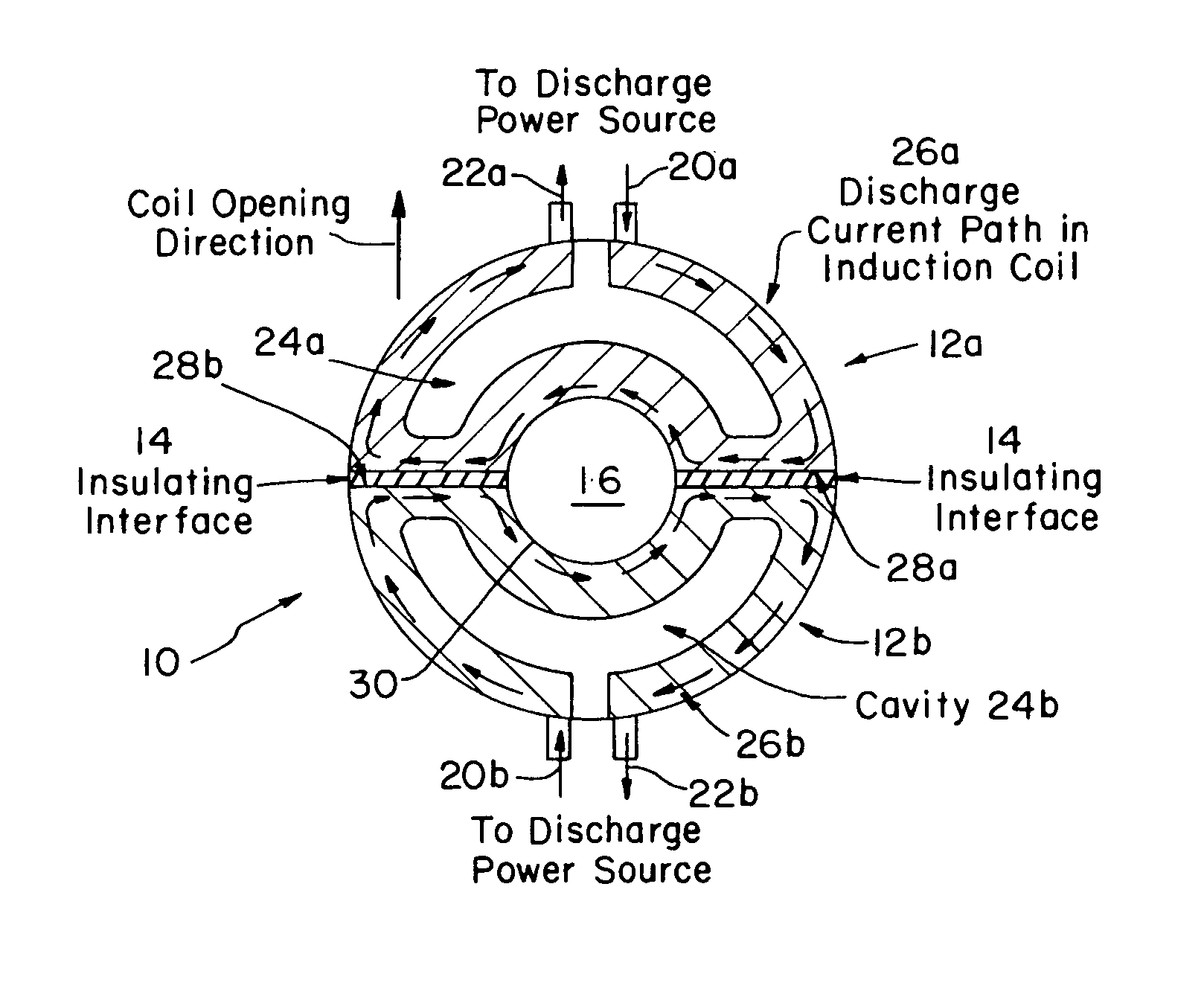

Opposed current flow magnetic pulse forming and joining system

ActiveUS7395597B2Quality improvementImprove reliabilityPower hammersHammer drivesElectricityElectrical conductor

An opposed current flow magnetic pulse forming and joining system in electrical communication with a magnetic pulse power supply having a positive connection and a negative connection. The system may be used in forming individual workpieces or joining multiple workpieces, including joining by magnetic pulse welding. The system includes a first section, a second section, an insulator, and a first and a second pair of conductors. The first and second sections cooperate to enclose the workpiece(s) and function to create an electromagnetic force similar to that produced by a single closed coil. The system is configured to achieve desirable current flow by minimizing inductance, inductive reactance, and impedance in the conductors. The pairs of conductors may incorporate closely spaced individual conductors, braided conductors, and coaxial conductors. The current flow in the individual conductors of each pair of conductors is opposed, as is the current flow through the sections.

Owner:EDISON WELDING INSTITUTE INC

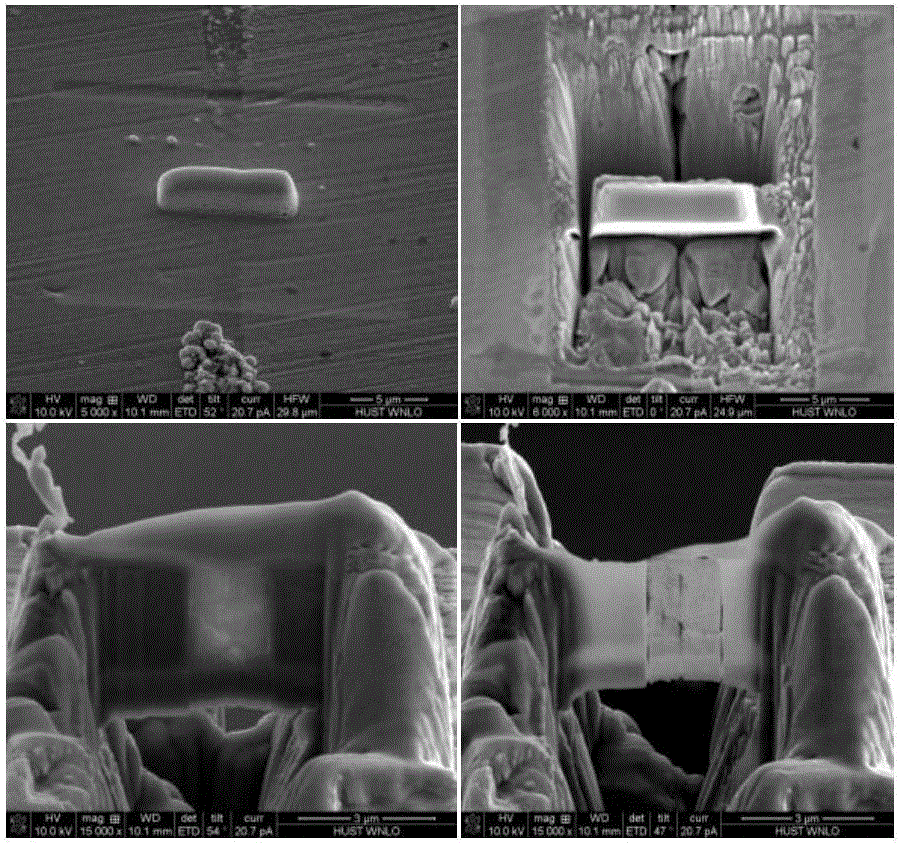

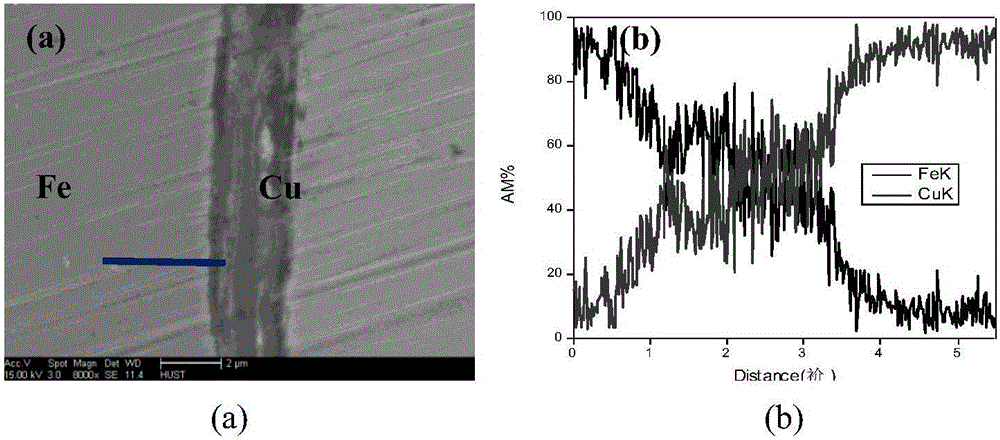

Positive mixing enthalpy dissimilar metal material welding method

InactiveCN106271016AImprove energy efficiencyShort cycleWelding/soldering/cutting articlesNon-electric welding apparatusMetallic materialsElectromagnetic forming

The invention discloses a positive mixing enthalpy dissimilar metal material welding method. The method includes the first step of welding material pretreatment, wherein two positive mixing enthalpy dissimilar metal materials are subjected to annealing to eliminate machining-induced residual stress, the metal materials are mechanically ground and mechanically polished by means of diamond polishing paste, and then the polished metal materials are subjected to solution corrosion so as to finish representation on an optical microscope or crystal grain morphological detection; the second step of magnetic pulse welding, wherein the two to-be-welded positive mixing enthalpy dissimilar metal materials are placed in an electromagnetic forming system, a coil in the powered-on electromagnetic forming system generates a pulsed high magnetic field by means of high-amplitude instantaneous current, the outer surface of a magnetic collector in the electromagnetic forming system simultaneously generates induced current under the action of the pulsed high magnetic field, so the first dissimilar metal material obtains impact kinetic energy instantaneously and impacts the second dissimilar metal material at high speed, and accordingly welding of the two dissimilar metal materials is achieved. By means of the method, metallurgical welding of positive mixing enthalpy dissimilar metal can be achieved, and accordingly welding products which are good in welding performance and have no obvious structural defects on joints are prepared and formed.

Owner:HUAZHONG UNIV OF SCI & TECH

Magnetic pulse welding of steel propshafts

A method of magnetically welding an end fitting to a metal tube includes assembling a driver ring over an end of the tube and inserting a length of the end fitting into a bore of the tube. An overlap region of the tube, the driver ring and the cylinder are encompassed by an inductor assembly of a magnetic pulse welding apparatus and the tube is welded to the end fitting using the magnetic welding apparatus.

Owner:AMERICAN AXLE & MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com